Patents

Literature

89results about How to "Improve filtration throughput" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

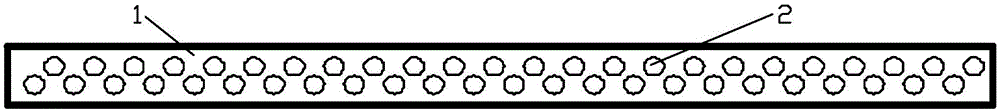

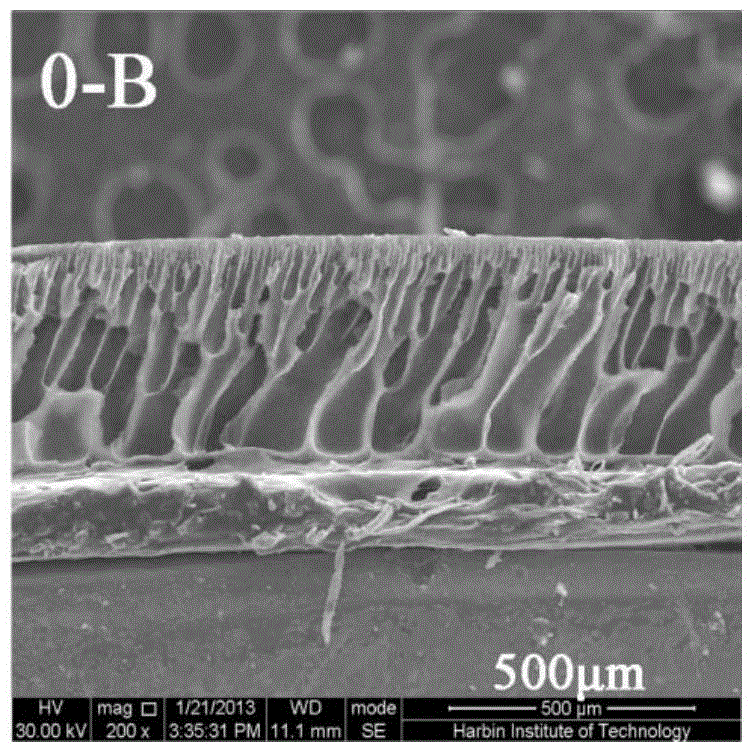

Silicon carbide ceramic support body and preparation method thereof

InactiveCN102389719AHigh strengthExtended service lifeSemi-permeable membranesHydrogen atmospherePlasticizer

The invention relates to a silicon carbide ceramic support body and a preparation method thereof. The raw material powder of the support body is mixed powder consisting of silicon carbide powder 1 and silicon carbide powder 2, wherein the silicon carbide powder 1 has a median particle diameter D50 of 25-45mu m, the silicon carbide powder 2 has a median particle diameter D50 of less than 5mu m, the ratio of the D50 of the silicon carbide powder 1 to the D50 of the silicon carbide powder 2 is not less than 6, and the consumption of the silicon carbide powder 2 is 0.5-13 percent of the weight of the used silicon carbide powder 1. The raw material powder is mixed with a solvent, an adhering agent, a plasticizer and a pore-forming agent to form pug, the pug is subjected to stamping to form a raw blank, the raw blank is dewatered and degreased to form a calcined product, and the calcined product is sintered in argon or hydrogen atmosphere or vacuum to form the support body of a recrystallized silicon carbide ceramic membrane. The support body of the recrystallized silicon carbide ceramic membrane has filtering flux and strength which are higher than those of the traditional commercial support body of an aluminum oxide ceramic membrane.

Owner:SANDA FILM SCI & TECH XIAMEN

Multi-layer oil-water separator and working method therefor

InactiveCN105016504AGood separation effectExtend your lifeFatty/oily/floating substances removal devicesWater contaminantsOil–water separatorFiltration

The invention provides a multi-layer oil-water separator and a working method therefor. The separator comprises a water inlet and a water outlet, wherein a plurality of layers of separating materials are arranged between the water inlet and the water outlet; separating holes are formed in the separating materials; a runner is formed among the separating layers by virtue of a grid; the two sides of the grid are sealed; and the hole diameter of the separating holes is gradually reduced layer by layer from the water inlet to the water outlet. The multi-layer oil-water separator adopts a layer-by-layer filter mode, has good separating effect and relatively high filtration flux, and has cleaning and back cleaning functions, so that the service life of the separator is prolonged. The separator is compact in mechanism, high in integration and convenient for automatic operation and large-scale amplification.

Owner:WUXI LVZHIXING ENVIRONMENTAL PROTECTION CO LTD

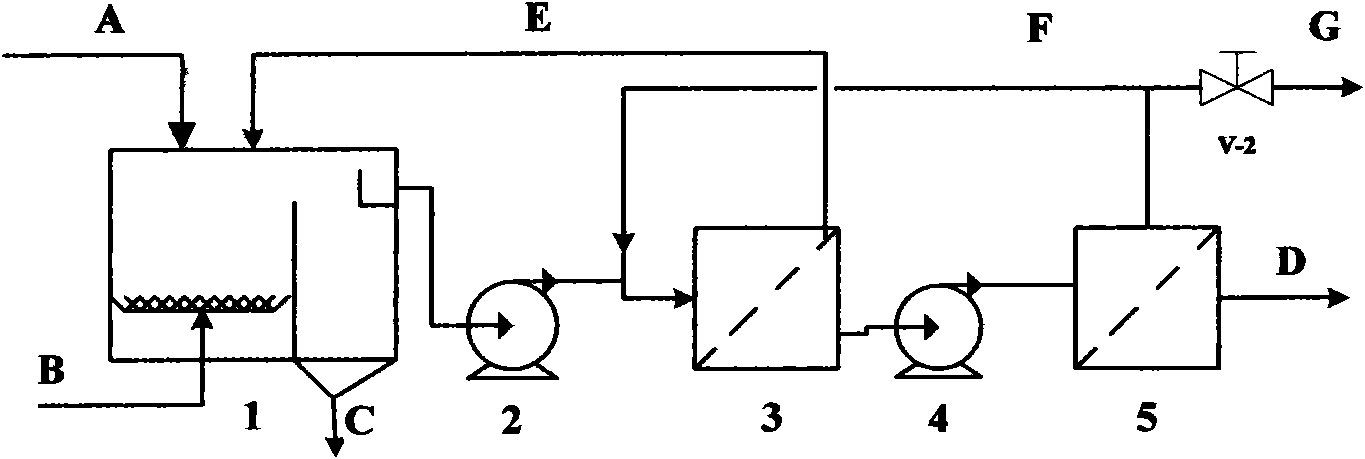

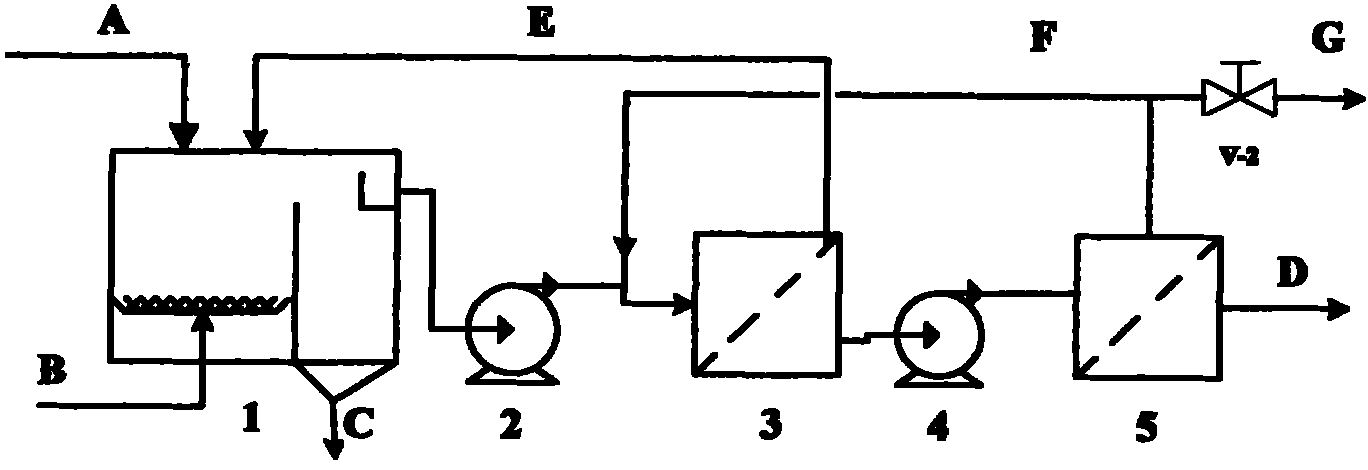

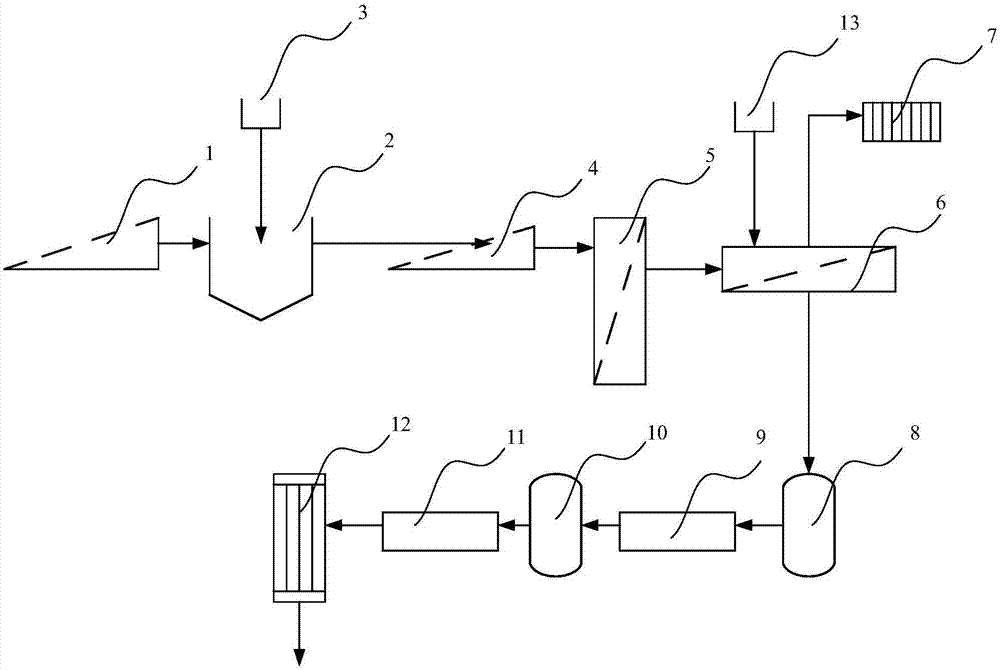

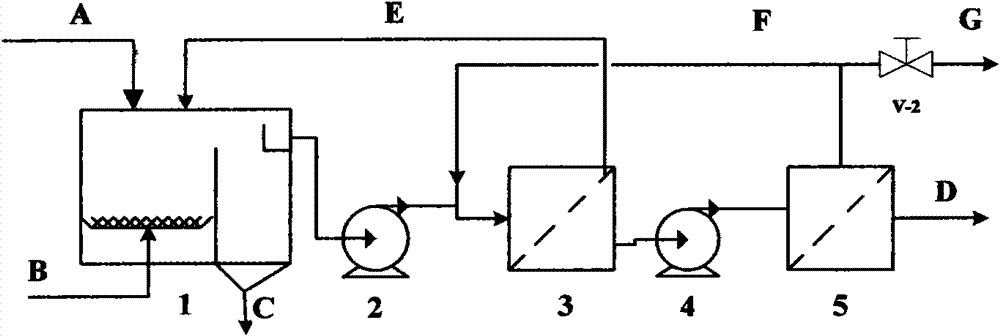

Method for high temperature wastewater treatment and reuse in MTO process

ActiveCN101962235AImprove filtration throughputHigh removal rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentThermal energyWastewater

The invention relates to a method for treating and reusing high-temperature stripping purified wastewater produced in the process of transferring oxygenated compounds into olefins by using a high-temperature separation membrane. The combination process can effectively remove the impurities such as metal ions and organic micro-molecules and the like in stripping purified water, and the treated purified water in a tower kettle can meet the quality requirements of makeup water for middle and low-pressure boilers or the quality requirements of the makeup water in the MTO process. The invention effectively overcomes the defects exiting in the method for treating and reusing the stripping purified water without condensation in the MTO process, and lowers or reduces the consumption of circulating cooling water in the process of cooling firstly and then treating, thereby saving a large amount of boiler water and recycling the thermal energy of produced high temperature wastewater, and providing a stable and efficient way for high temperature wastewater treatment and reuse of relevant enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

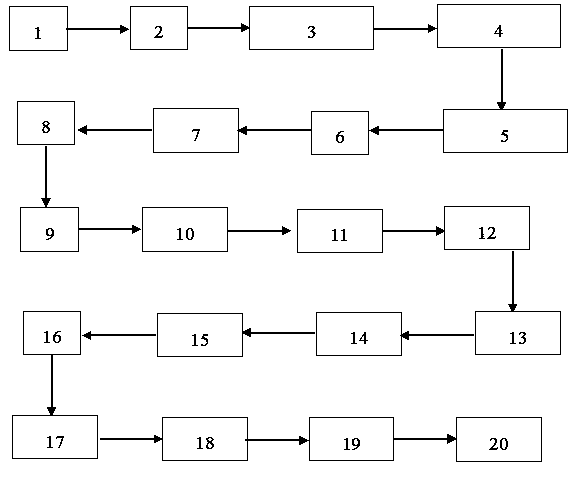

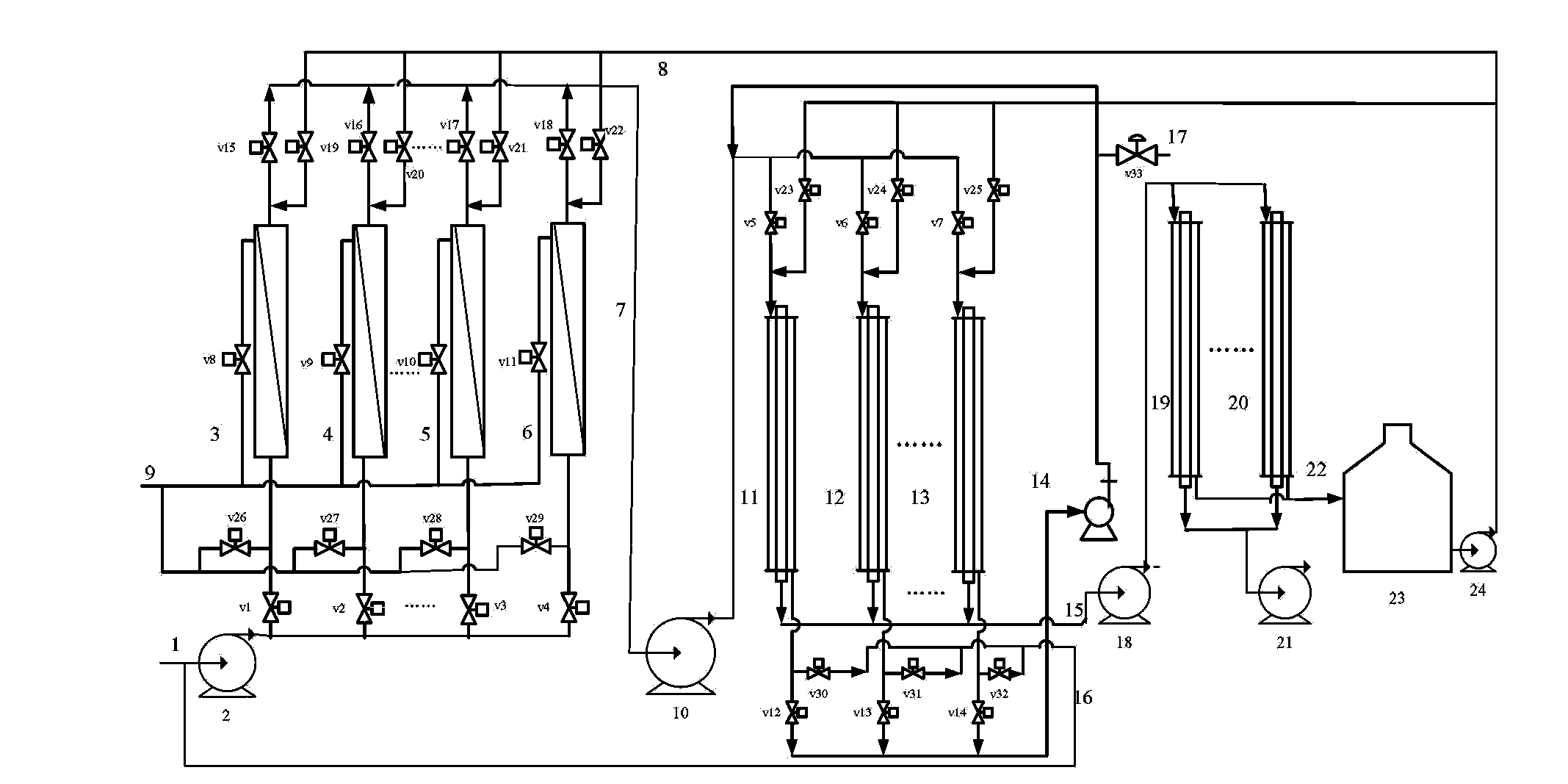

Preparation system of car urea

ActiveCN103933860ALarge specific surface areaImprove adsorption capacityDispersed particle separationActivated carbonDesalination

The invention discloses a preparation system of car urea. The preparation system comprises a raw water tank (1), a raw water pump (2), a gravel filter system (3), an active carbon filter system (4), an ion exchange softening device (5), a pressurizing pump (6), a micro filter device (7), an ultra-filtration device (8), a middle water tank (9), a high pressure pump (10), a primary reverse osmosis device (11), a secondary reverse osmosis device (12), an EDI (electronic data interchange) system (13), an urea water barrel (14), a material storage tank (15), a primary filter system (16), a homogenization system (17), a discoloring system (18), a purifying system (19) and a filling device (20) which are connected in sequence by a pipeline. The system is reasonable in structural design, wide in range of application, good in equipment mating performance, high in automation degree, high in operability, small in floor area, capable of removing various ions in water, capable of reaching a salt removing rate of over 99.5%, stable in operation and high in utilization rate.

Owner:NANJING JIHONG ENVIRONMENTAL PROTECTION TECH

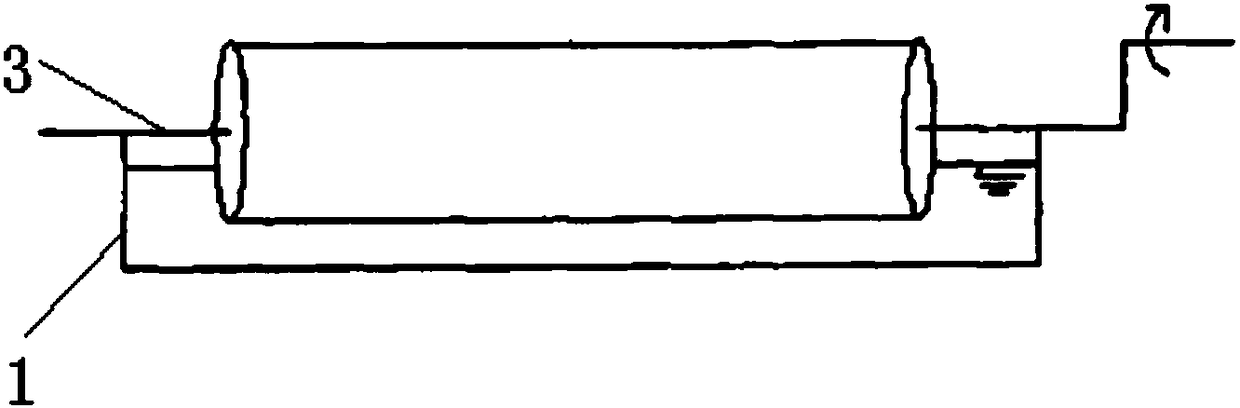

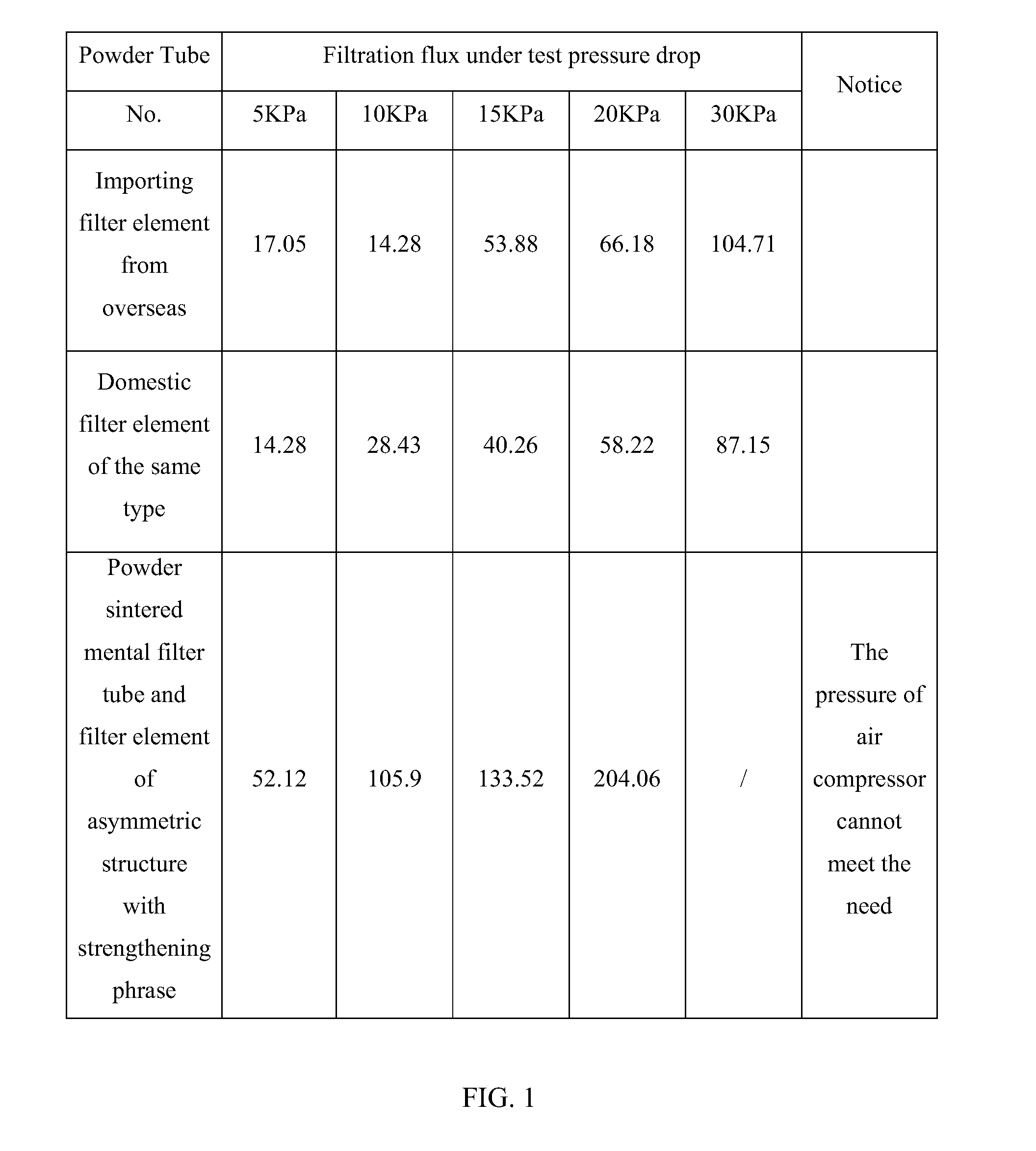

High-temperature gas-solid ceramic filter tube and preparation method

The invention provides improvement of ceramic filter tubes for high-temperature gas purification, and is characterized in that a high-temperature binder for sintering comprises two or more than two of magnesium oxide, strontium oxide, calcium oxide, potassium oxide-containing minerals, kaolin or clay, and trace rare earth, and mainly forms a liquid-phase silicate high-temperature binder above 1200 DEG C. The contradiction between binding strength of a filter tube support body and filtration flux and resistance drop is well coordinated and solved; the obtained filter tube support body not only meets the requirements for transport, installation, and using strength, but also has a high filtration flux and low filtration resistance. When the filter tube has rupture strength of not less than 26 MPa, and a filtration flux of 55 m3 / hm2, the resistance drop is 850-950 Pa or lower; the consistency for finished product batch production is good; and the performance difference is less than 10%.

Owner:宜兴市鑫帝豪高科陶瓷厂

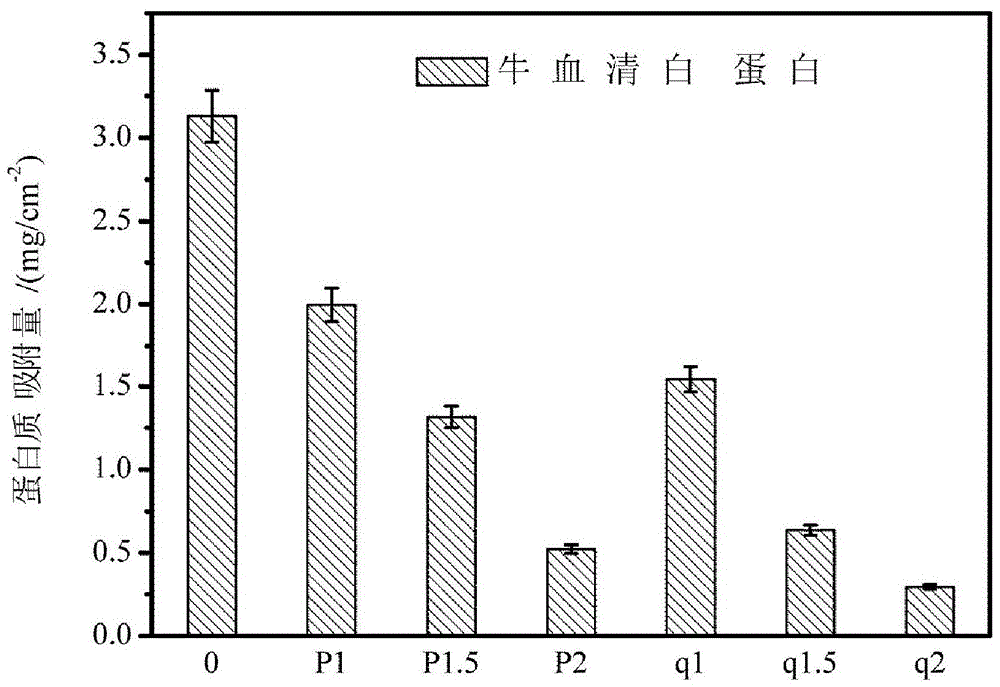

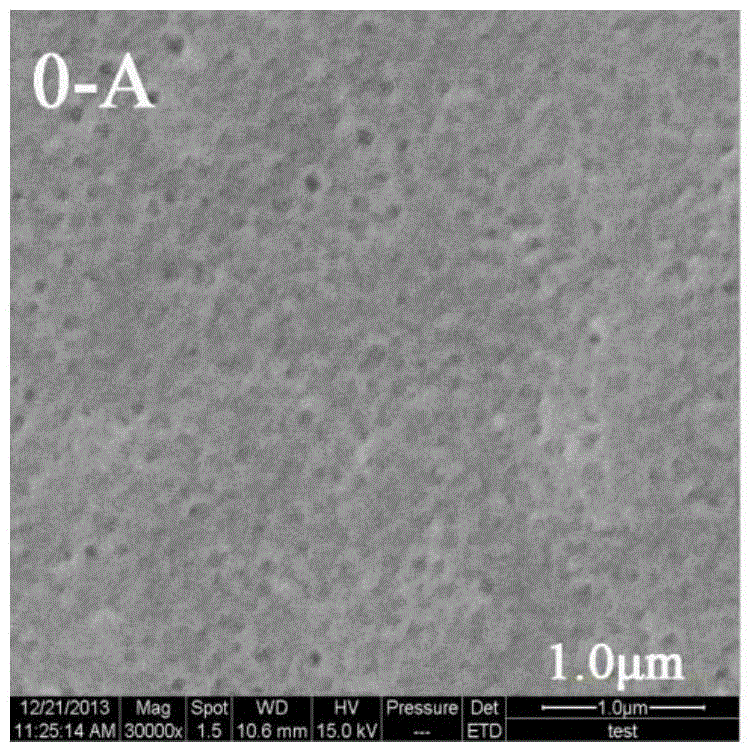

Preparation method of polyvinylidene fluoride/graphene oxide composite ultrafiltration membrane

InactiveCN105268333AImprove hydrophilic abilityImprove pollutionSemi-permeable membranesPhase conversionN-methylacetamide

The invention relates to a preparation method of a polyvinylidene fluoride / graphene oxide composite ultrafiltration membrane. The method comprises steps as follows: (1), graphene oxide with certain mass is weighed accurately, dispersed in an N,N-methyl acetamide solution and subjected to ultrasonic treatment for at least 10 h, and a fully stripped dispersion liquid is obtained; (2) polyvinylidene fluoride powder is stirred to be dissolved in the N,N-methyl acetamide solution at the temperature of 70 DEG C, the graphene oxide dispersion liquid and a polyvinylidene fluoride membrane casting liquid are mixed, stirred for 24 h and subjected to ultrasonic treatment for 2 h; (3) the membrane casting liquid is placed in a vacuum environment for full degasing, 200 mu m of the membrane casting liquid is accurately applied to a glass plate in certain size through a membrane scraper, the glass plate stays in the air for 20 s and is immersed in a coagulating bath which is deionized water at the temperature of 20 DEG C, and the phase conversion process is finished; (4) a prepared composite membrane is cleaned for removal of residual solvent. A polyvinylidene fluoride membrane material is modified, so that the application performance of the membrane is improved.

Owner:山西交控生态环境股份有限公司

Preparation method of nanometer TiO2-PA laminated film

InactiveCN103301756AGuaranteed stabilitySolve the problem of concentration reductionSemi-permeable membranesFiltrationNanotechnology

The invention discloses a preparation method of a nanometer TiO2-PA laminated film. According to the method, nanometer TiO2 particles are effectively scattered in the film through interfacial polymerization, so that the filtration flux of a PA film is effectively improved; moreover, the nanometer TiO2 particles can be effectively adhered to the PA film for a long time, so that the problem that the TiO2 particles easily drop off to cause the situation the TiO2 concentration of the film during the using process is reduced in the traditional preparation method is solved, and the stability of the nanometer TiO2-PA laminated film is ensured; and therefore, the preparation method has good application prospect and important research significance.

Owner:苏州瀚海高分子有限公司

Inorganic-organic composite film and preparation method thereof

The invention discloses an inorganic-organic composite film. A support is made of inorganic porous materials and comprises organic materials and cross-linking agents which sequentially coat the support, the thickness of the inorganic porous materials is 1mm-3mm, the thickness of the organic materials is 10-50 micrometers, and the pore diameter of the inorganic-organic composite film is 0.001-1 micrometer. The inorganic-organic composite film has high-strength, impact-resistant, high-precision and high-selectivity filtration performances, and is excellent in renewability. According to a preparation method of the inorganic-organic composite film, after prepared organic material casting solution and the cross-linking agents are poured into a tank, the surfaces of the inorganic porous materials are sequentially coated with the organic material and the cross-linking agents in a spin coating mode, film preparation procedures are finished, operation is simple and convenient, controllability is strong, and stability is high.

Owner:WESTERN BAODE TECH CO LTD

A novel metal filtration film and preparation method thereof

The invention relates to a metallic filter membrane which can be used in flat filtration, cylinder filtration and folded filtration, etc. Said preparing method uses following materials: nickel, titanium, chrome, stainless steel, molybdenum, cobalt, iron, and copper, etc, that using the powder of one said material or the alloy powder to be mixed with adhesive to be plated on the frameworks (alloy porous base band or spongy base band with same characters of powder) to be sintered. The invention can prepare the filter membrane whose diameter in 0.1 nanometers to 5 micrometers according to the different granularities of powder, with the characters of high-temperature resistance, acid alkali resistance, large flux, small volume, and long service life.

Owner:陈明波

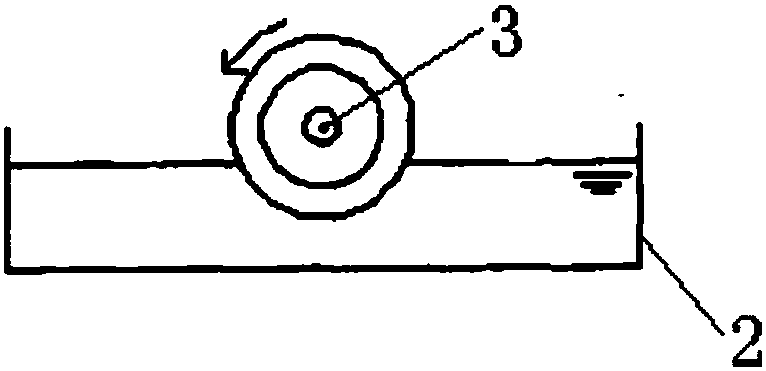

Preparation method of asymmetric plate ceramic nanofiltration membrane

PendingCN108079788ASolve for uniformitySolve the requestReverse osmosisCeramicwareWater basedEmulsion

The invention discloses a preparation method of an asymmetric plate ceramic nanofiltration membrane. According to the method, ceramic powder with different chemical composition and granular sizes is mixed with a water-based auxiliary, ceramic membrane slurry is prepared and printed on a plate ceramic membrane support body by a special porous emulsion roller, the support body is sintered at different temperatures, and the asymmetric plate ceramic nanofiltration membrane with different chemical composition and pore structures is formed on the surface of the support body. Density, diameter and depth of slurry adsorbing holes in the porous emulsion roller can be adjusted effectively with a laser drilling technology, so that thickness and uniformity of the ceramic membrane can be controlled precisely. The ceramic membrane with different thicknesses and surface pore size being 5-100 nm can be obtained with adoption of the porous emulsion roller with different pore density, pore diameter andpore depth. The asymmetric plate ceramic nanofiltration membrane is low in filtering resistance, high in filtering reflux, long in service life, energy-saving and environmentally friendly, and preparation cost is low.

Owner:肖汉宁

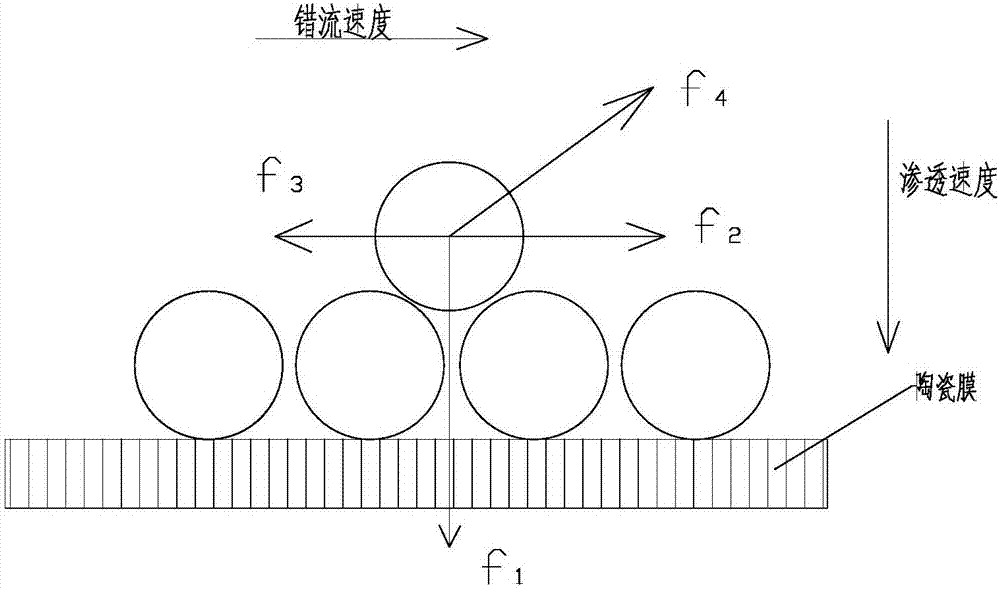

Treatment method and device of waste emulsion water

InactiveCN107473532AEfficient removalAvoid pollutionFatty/oily/floating substances removal devicesTreatment using aerobic processesFlocculationEmulsion

The invention relates to a treatment method and device of waste emulsion water, and belongs to the technical field of water treatment. The main process includes the steps of oil isolation on wobble plates, flocculation treatment, sediment through the wobble plates, coarse filtration, ceramic membrane filtration, biochemical treatment (anaerobic treatment, first-level aerobiotic treatment, oxygen deficit treatment, second-level aerobiotic treatment and MBR filtration), and acquirement of water produced after treatment. The treatment method of the waste emulsion water can effectively remove oil contaminants and particulate matter in the waste water, when a ceramic membrane is adopted for filtration, fine oil drops in emulsions can be removed, and meanwhile, a contamination process of the ceramic membrane is avoided by adopting a filter aid, so that filtration flux is increased; by adopting a ceramic membrane anti-blocking structure, the problem that particulate matter in the filter aid blocks a ceramic membrane pipe is solved.

Owner:湛江市绿城环保再生资源有限公司

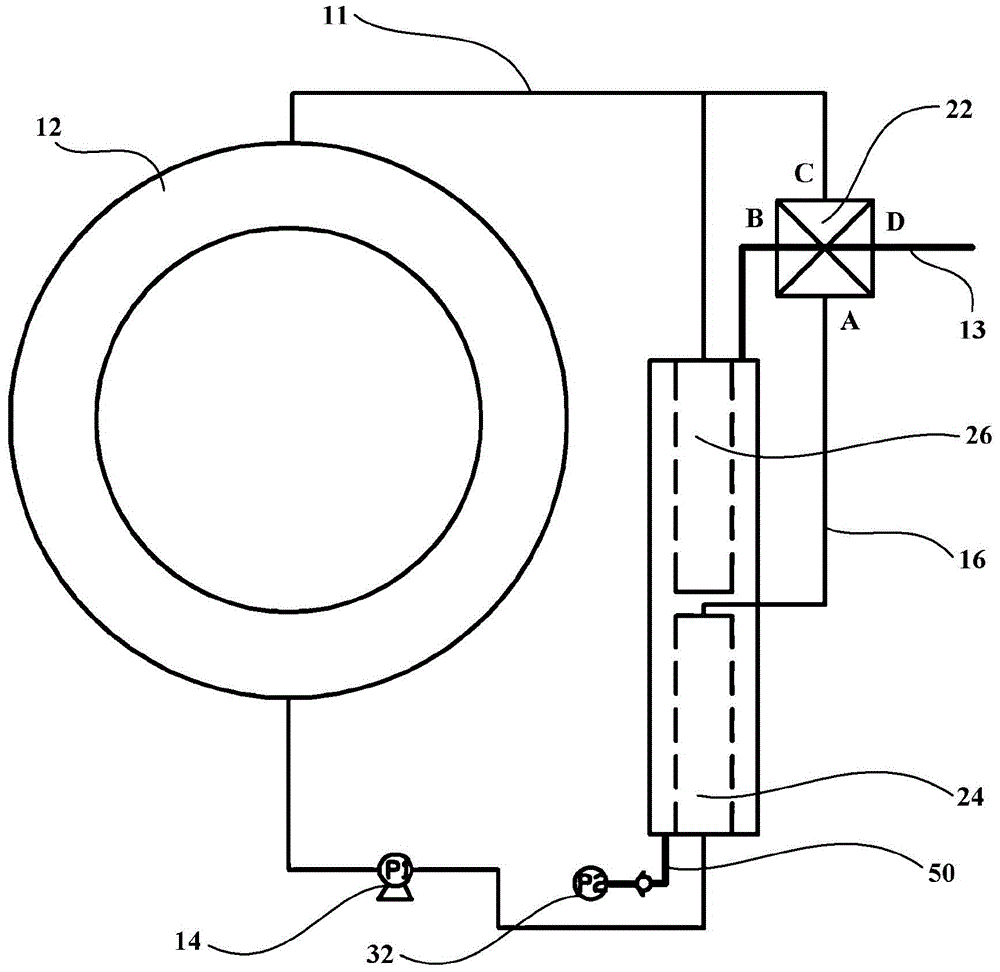

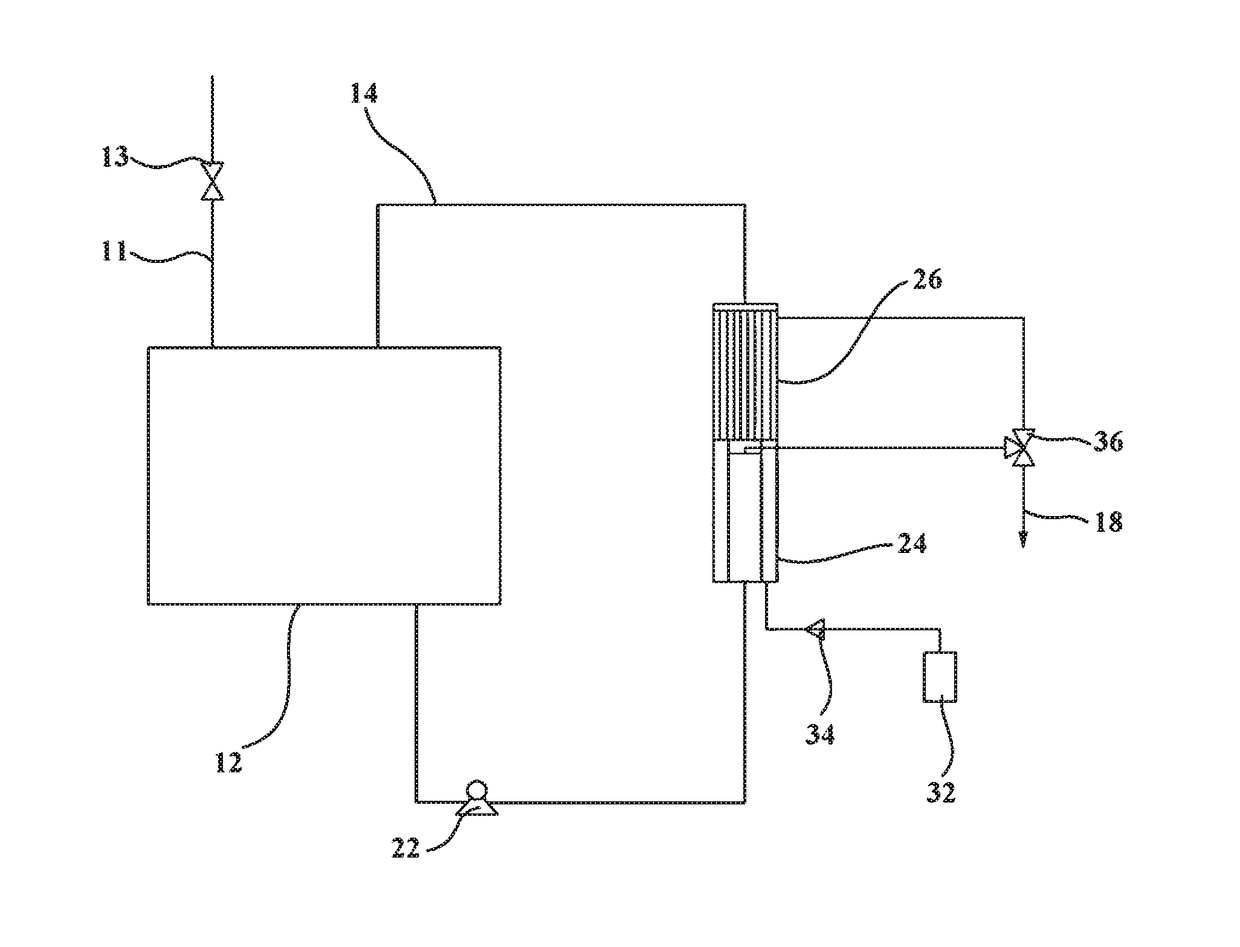

Washer

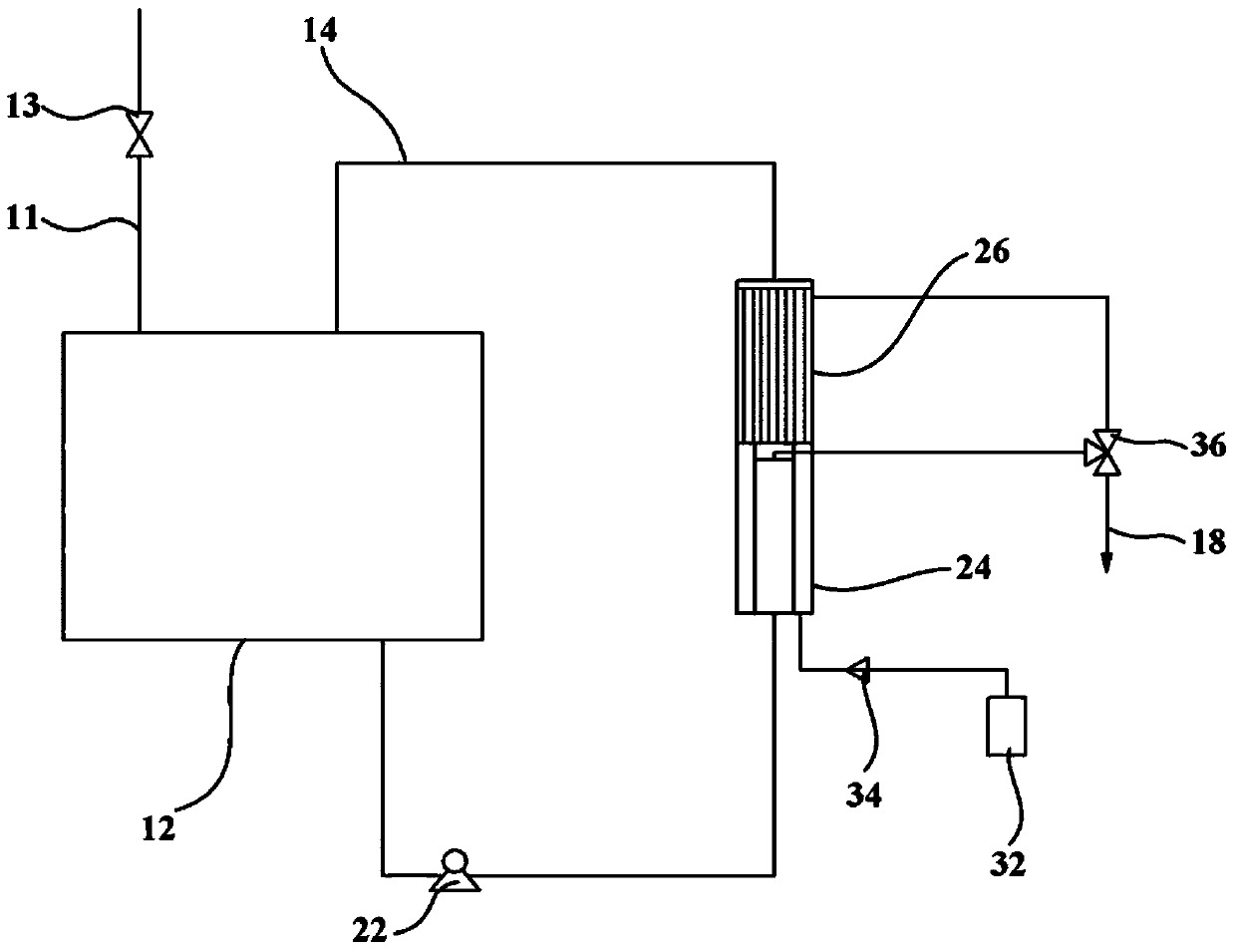

ActiveCN104805651AOptimize flow path layout and control methodsSimplify piping setupOther washing machinesTextiles and paperFiltrationWaste management

The invention provides a washer. The washer comprises filter components and a flow switching device, wherein the filter components in pairs are configured to filter water pumped by a washing cylinder of the washer, so as to circulate the water in the washing cylinder for reuse; the flow switching device is at least provided with a cleaning port for fluid to flow in and a discharge port for draining the fluid out of the washer; the flow switching device is configured to conduct or break over the cleaning port and the discharge port in a controlled way, so as to form a cleaning flow path when the cleaning port and the discharge port are conducted, and drain the cleaning fluid out of the washer after the filter components are washed. The washer provided by the invention has an optimized flow layout and a control way, the filter components in a circulating water filter system can be automatically cleaned by a cleaning flow path, the life of the filter components in the washer can be prolonged, and the higher filtration flux can be ensured all the time; furthermore, a dense drain flow path, a spraying flow path, a pure water washing flow path and the like can be provided to meet the demands of the washer in different operating processes.

Owner:HAIER GROUP TECHN R&D CENT +1

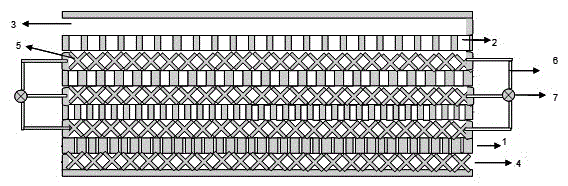

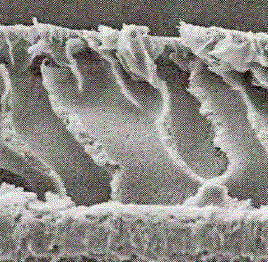

Method for producing composite filter tube and filter element made of multilayer metal mesh and metal powders

ActiveUS20150352469A1Low filtration resistanceLarge filtration fluxArc welding apparatusMembrane filtersMolding machineComposite filter

A method for producing a composite filter tube and filter element made of a multilayer metal mesh and metal powders, including: knitting to obtain metal meshes of different mesh numbers, obtaining a layered structure by means of a lamination method, then putting the layered structure in a vacuum furnace for sintering processing, sintering a metal composite layer to obtain a composite filter sheet and tube made of a multilayer metal mesh and metal powders with a multilayer metal mesh as a structure support layer and a metal powder sinter structure as a filter layer, then rolling the composite filter sheet and tube into a tubular filter element by using a shaping machine, and welding to obtain a composite filter tube and filter element product made of a multilayer metal mesh and metal powders.

Owner:WANG DONGWEI

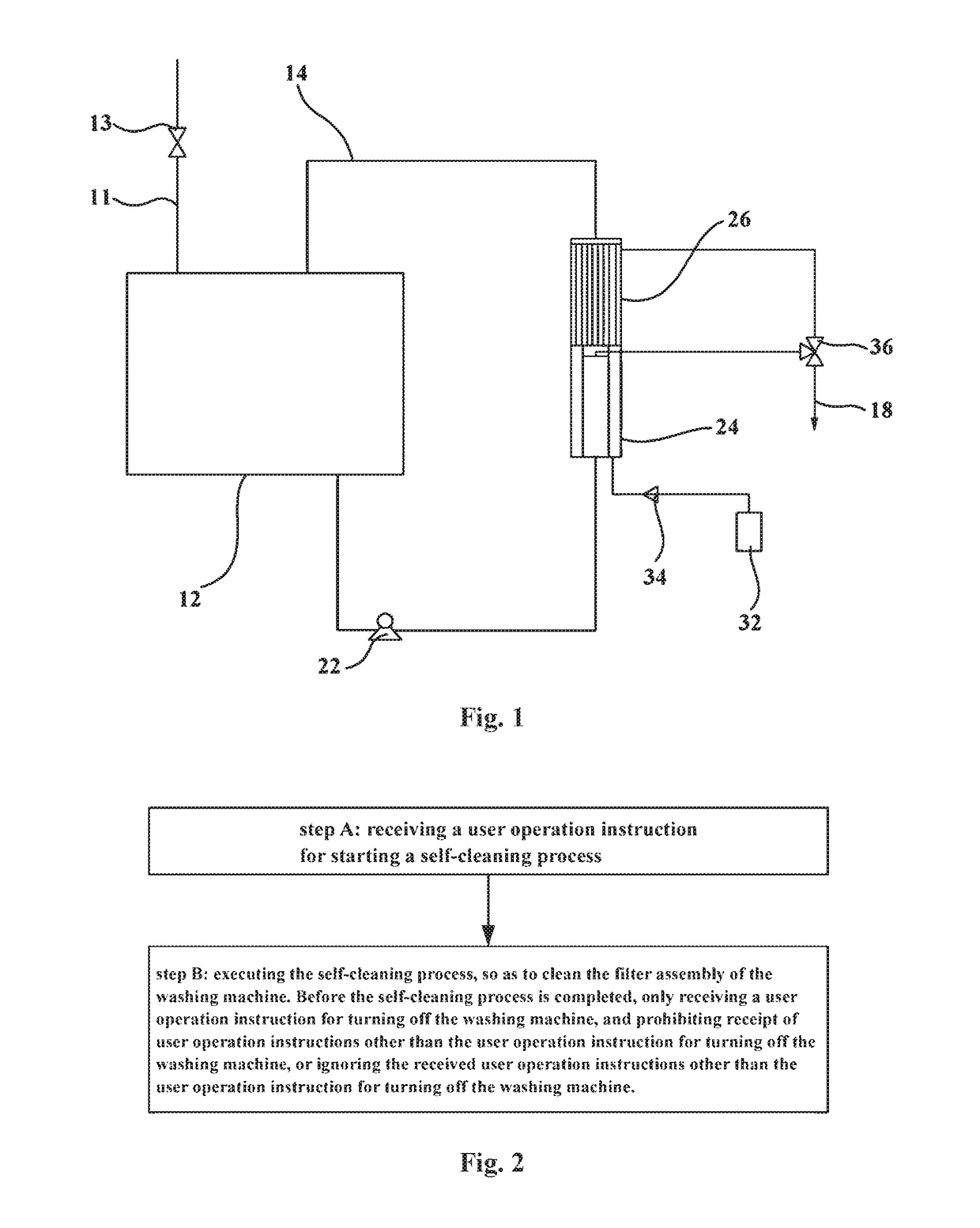

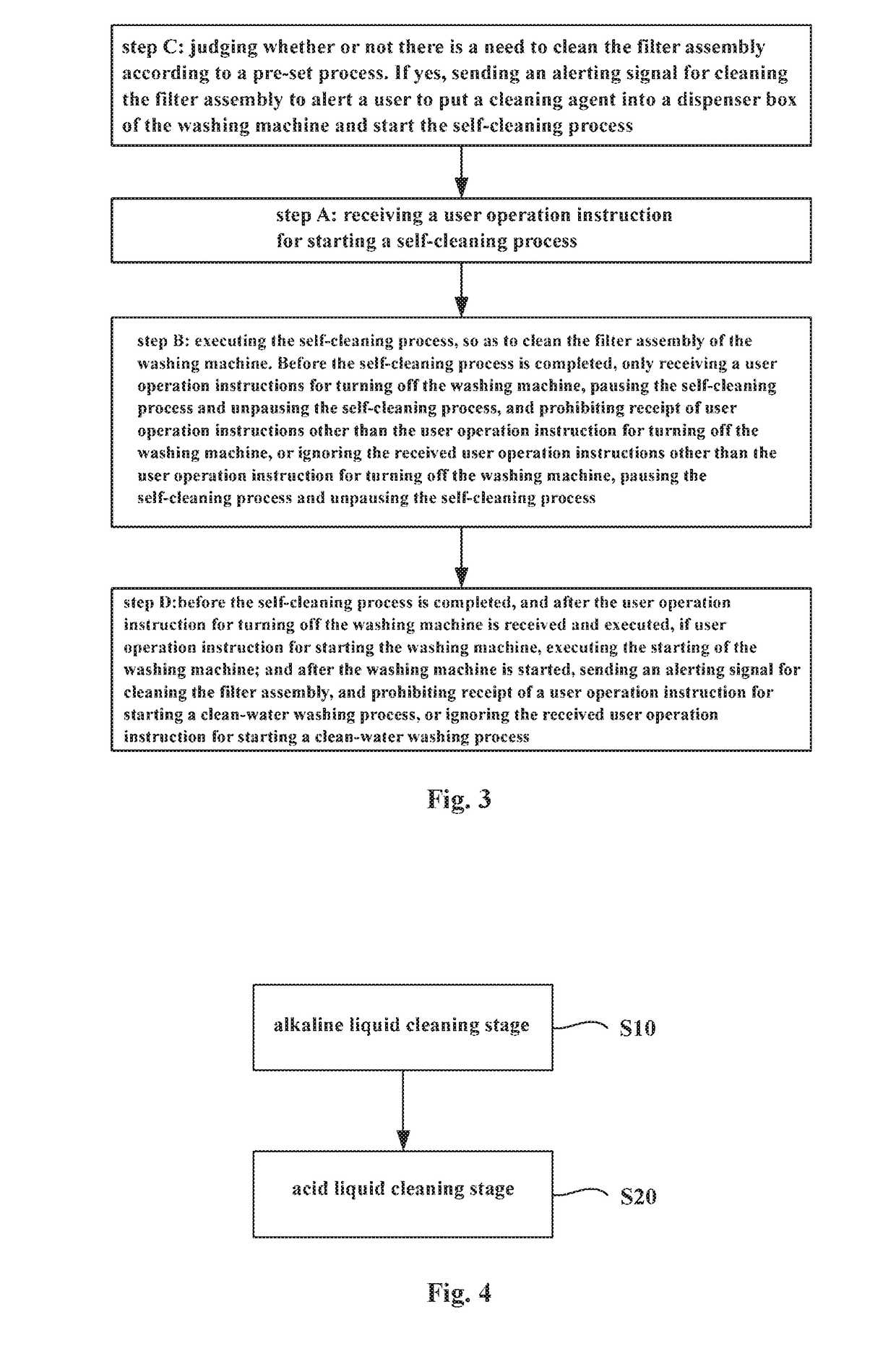

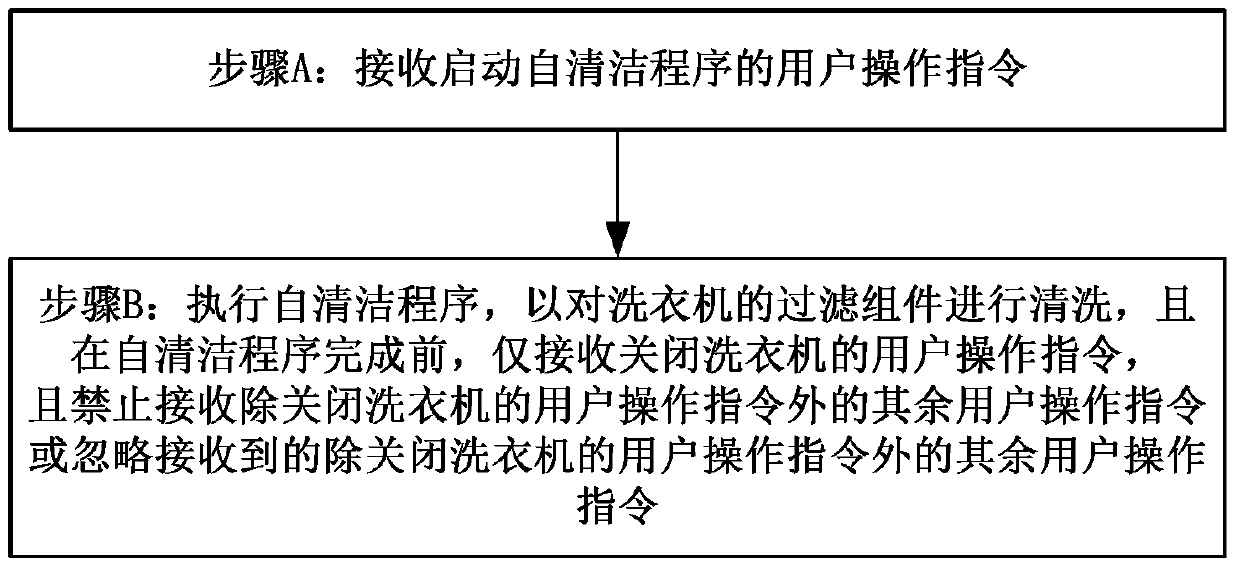

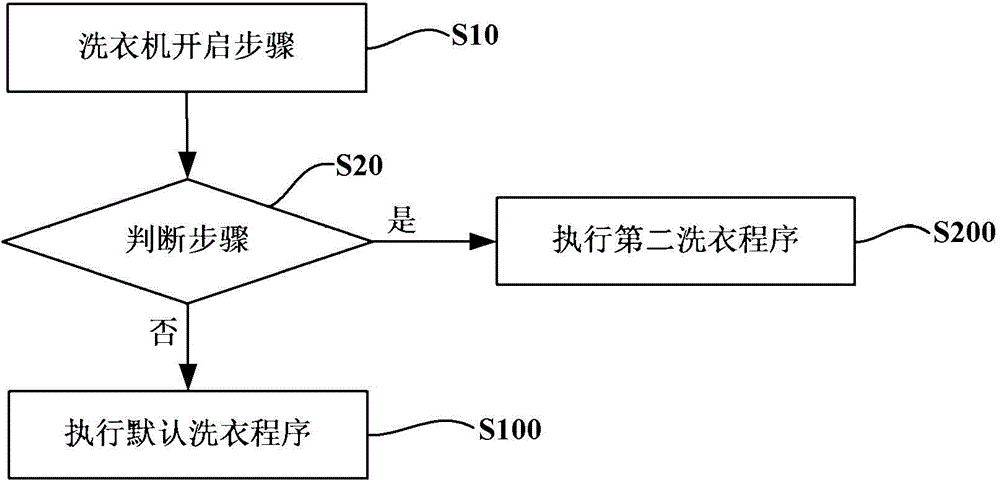

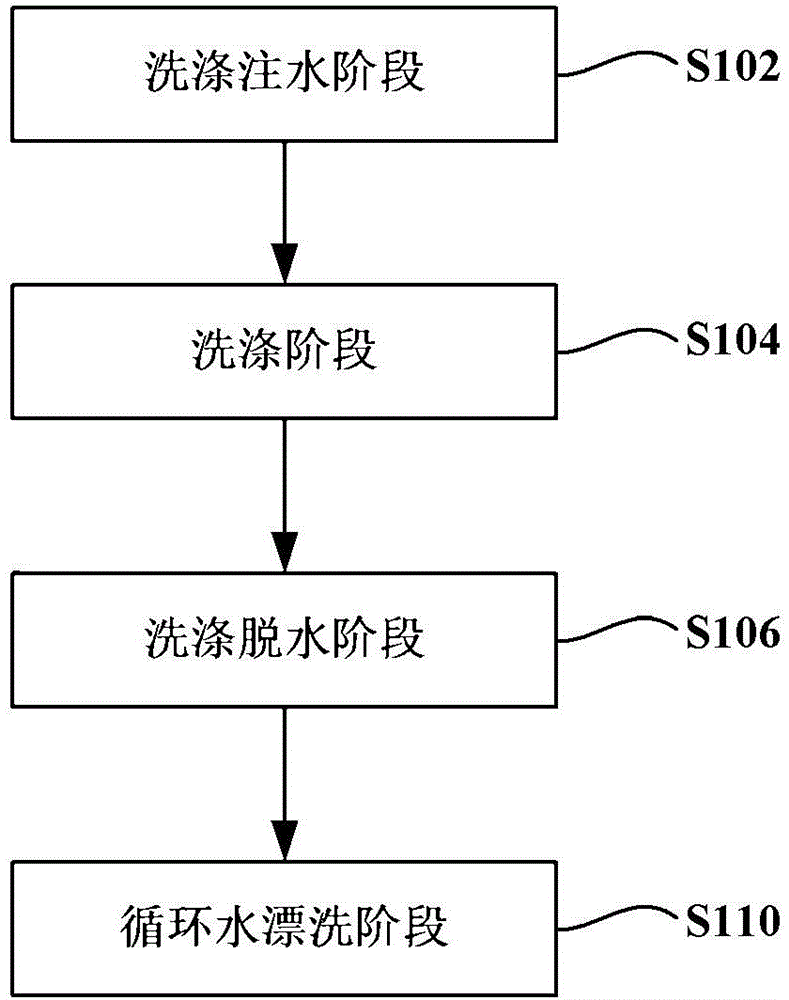

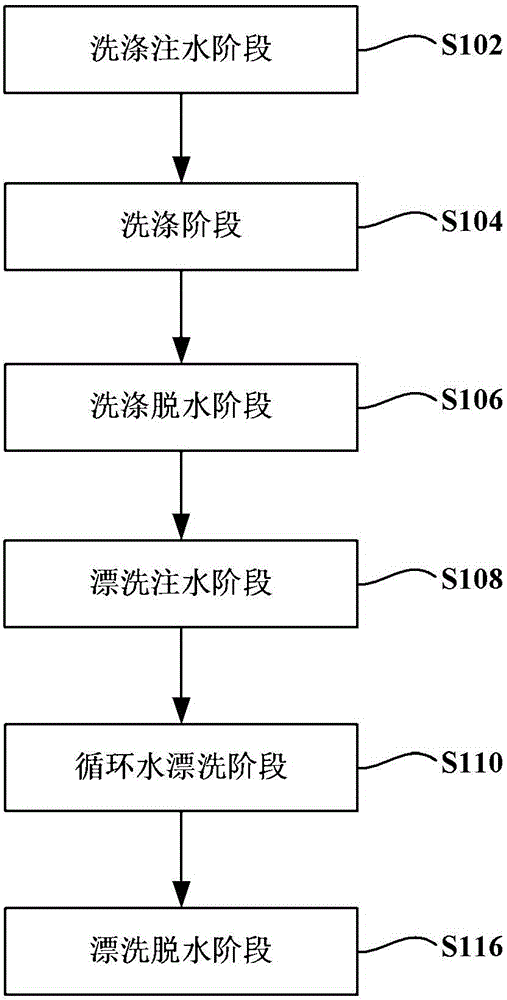

Self-cleaning method for filter assembly of washing machine

InactiveUS20170306544A1Extended service lifeImprove filtration throughputOther washing machinesControl devices for washing apparatusFiltrationProcess engineering

Provided is a self-cleaning method for a filter assembly of a washing machine, the method comprising: receiving a user operation instruction for starting a self-cleaning process; executing the self-cleaning process, so as to clean the filter assembly of the washing machine, and before the self-cleaning process is completed, only receiving user operation instructions for turning off the washing machine, pausing the self-cleaning process and unpausing the self-cleaning process, and prohibiting receipt of or ignoring the user operation instructions other than user operation instructions for turning off the washing machine, pausing the self-cleaning process and unpausing the self-cleaning process. According to the present invention, the filter assembly of the washing machine is thoroughly cleaned, prolonging the service life of the filter assembly in the washing machine and ensuring that the filter assembly always has a high filtration flux.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

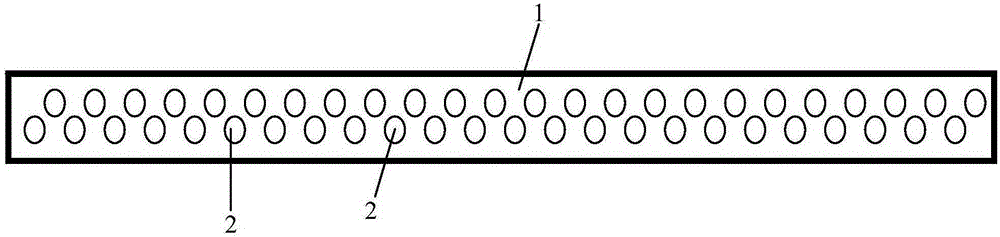

Multi-channel kaolin plate ceramic membrane support, preparation method and application thereof

The invention discloses a multi-channel kaolin plate ceramic membrane support, a preparation method and an application thereof. The preparation method includes the following steps: 1) mixing a kaolin ceramic aggregate, a pore forming agent, a dispersing agent and a gel-casting adhesive, ball-milling the mixture, adding RO water, heating the mixture to 40-85 DEG C and ball-milling the mixture for 4-20 h to obtain slurry; 2) maintaining the temperature of the slurry to be 40-85 DEG C, vacuum-defoaming the slurry, injecting the slurry into a moulding die, and performing in-situ moulding at 0-40 DEG C to obtain a wet blank; 3) demoulding the wet blank, shade-drying the wet blank at room temperature, drying the wet blank at 40-100 DEG C, and sintering the blank in air at 1000-1500 DEG C for 1-4 h with temperature maintained to obtain the multi-channel kaolin plate ceramic membrane support. The preparation method is carried out through the gel-casting process so that the method is wide in available range, is low in cost and is easy to control in processes. The blank body is high in strength, is low in organic substance content, can be sintered directly and is good in performance uniformity. The multi-channel kaolin plate ceramic membrane support has high total porosity and filtering flux, and is toxic-free and environment-friendly.

Owner:SANDA FILM SCI & TECH XIAMEN

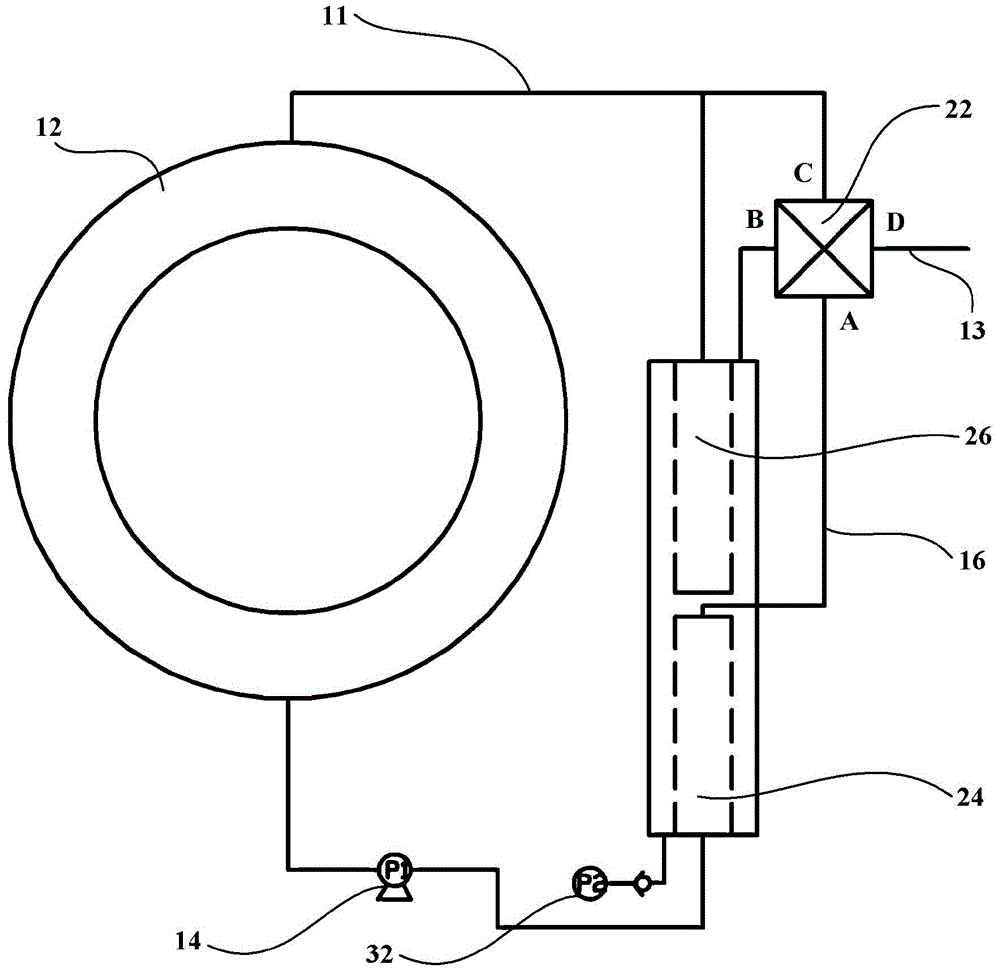

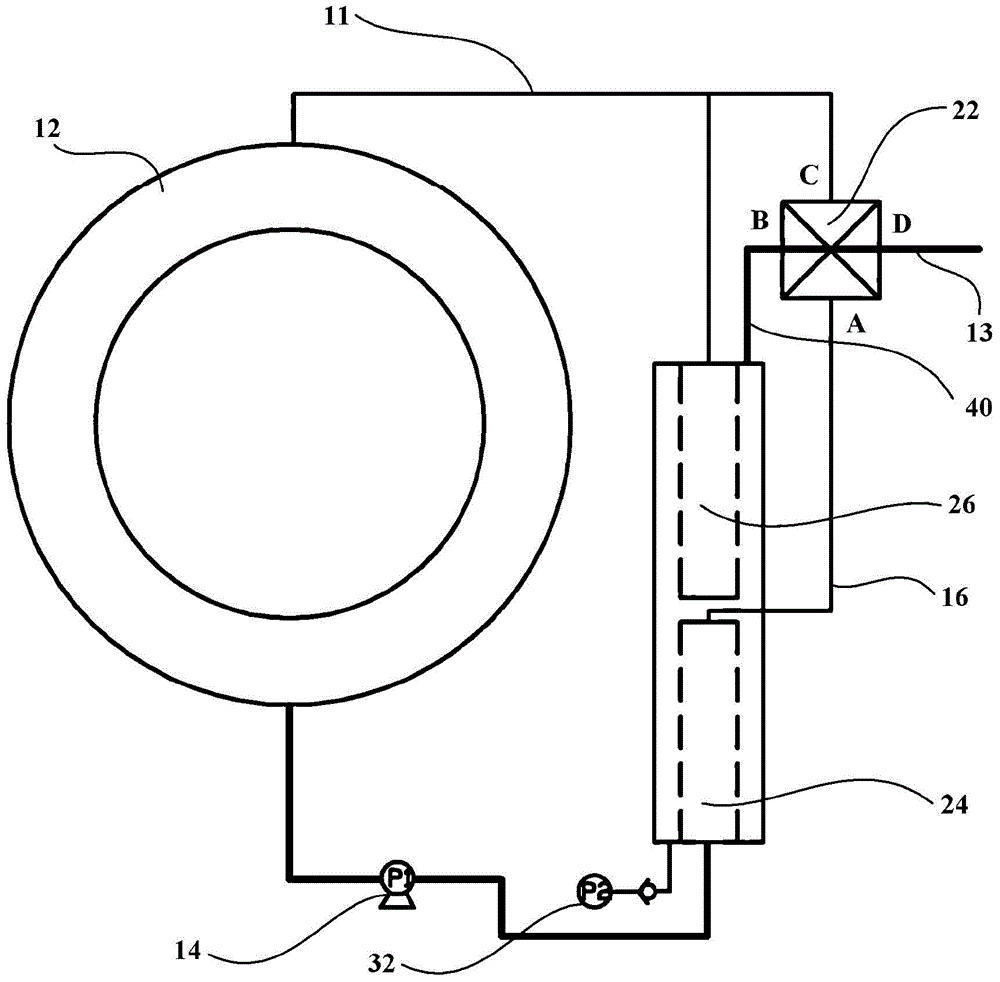

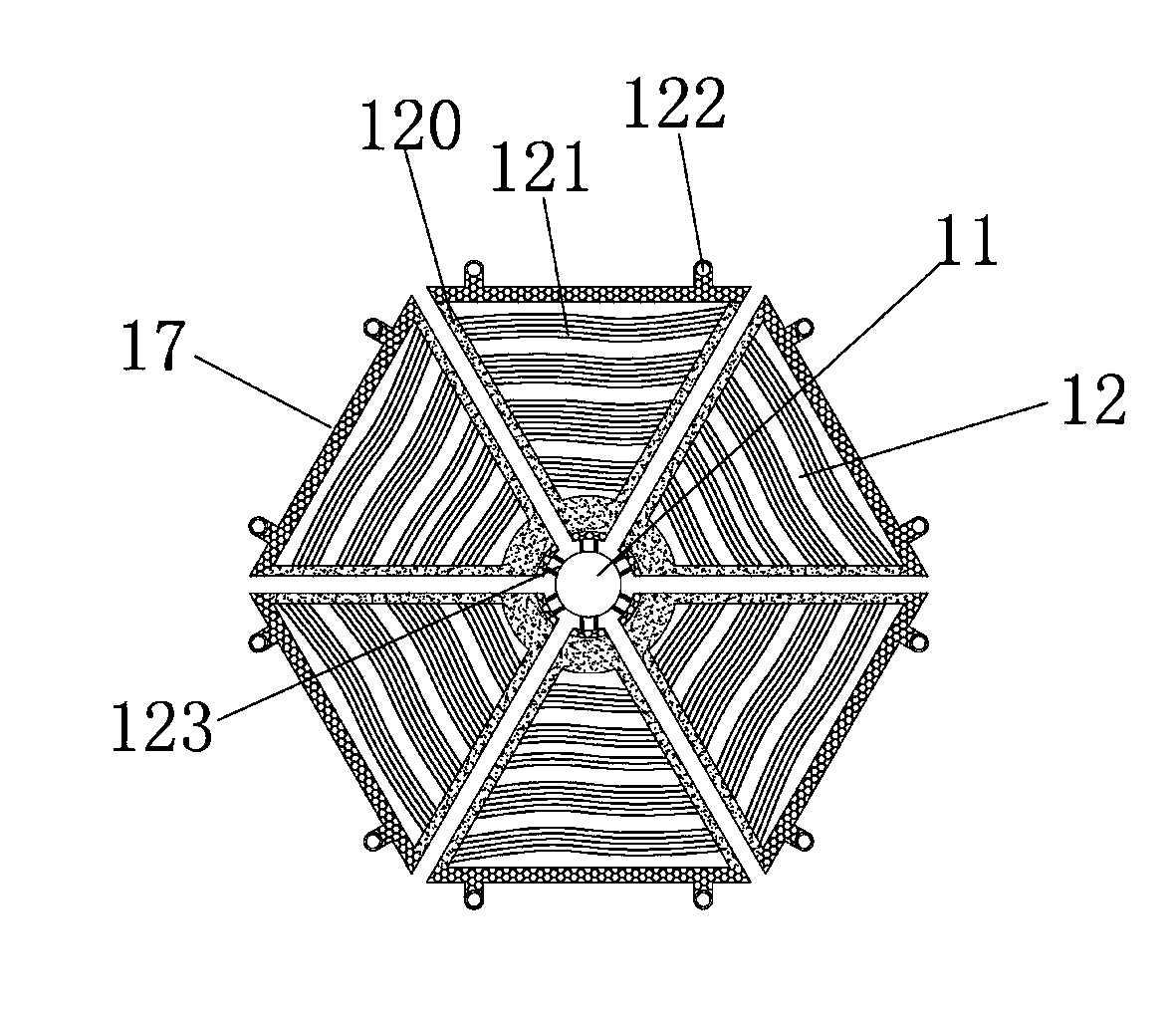

Fan-shaped rotary film separation device

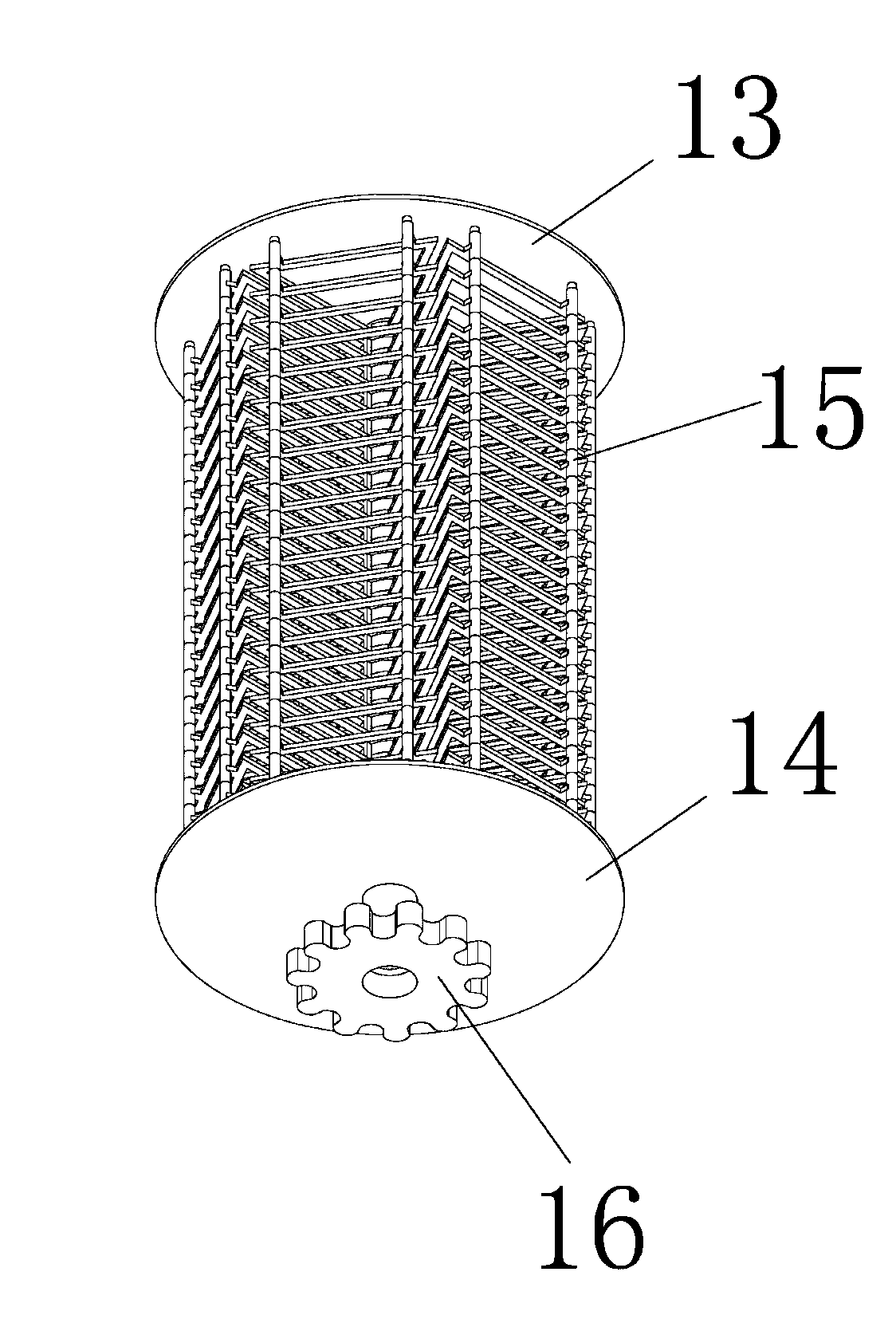

ActiveCN103316591AIncrease packing densityImprove filtration throughputSemi-permeable membranesPipingEngineering

The invention discloses a fan-shaped rotary film separation device which comprises a central water-collecting pipe, an upper tray and a lower tray, wherein a transmission gear is arranged at one end of the central water-collecting pipe; the fan-shaped rotary film separation device is characterized in that multiple turntables are distributed between the upper tray and the lower tray, each turntable consists of at least three fan-shaped film components; water collecting pipes are arranged on two sides and the inner sides of the fan-shaped film components; hollow fiber film filaments are filled in the fan-shaped film components; water outlets are formed in the inner sides of the fan-shaped film components; the water outlets are connected with the central water-collecting pipe; fixing holes are formed in the outer sides of the fan-shaped film components; multiple fixing posts are arranged on the outer circumferences of the upper tray and the lower tray; the fixing holes are fixedly formed in the fixing posts. Compared with other rotary film devices, the fan-shaped rotary film separation device has the advantages of high filling density, high filtration flux and the like; moreover, a film is conveniently replaced, and the aim of replacing the film can be fulfilled by replacing a fan-shaped film components only.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

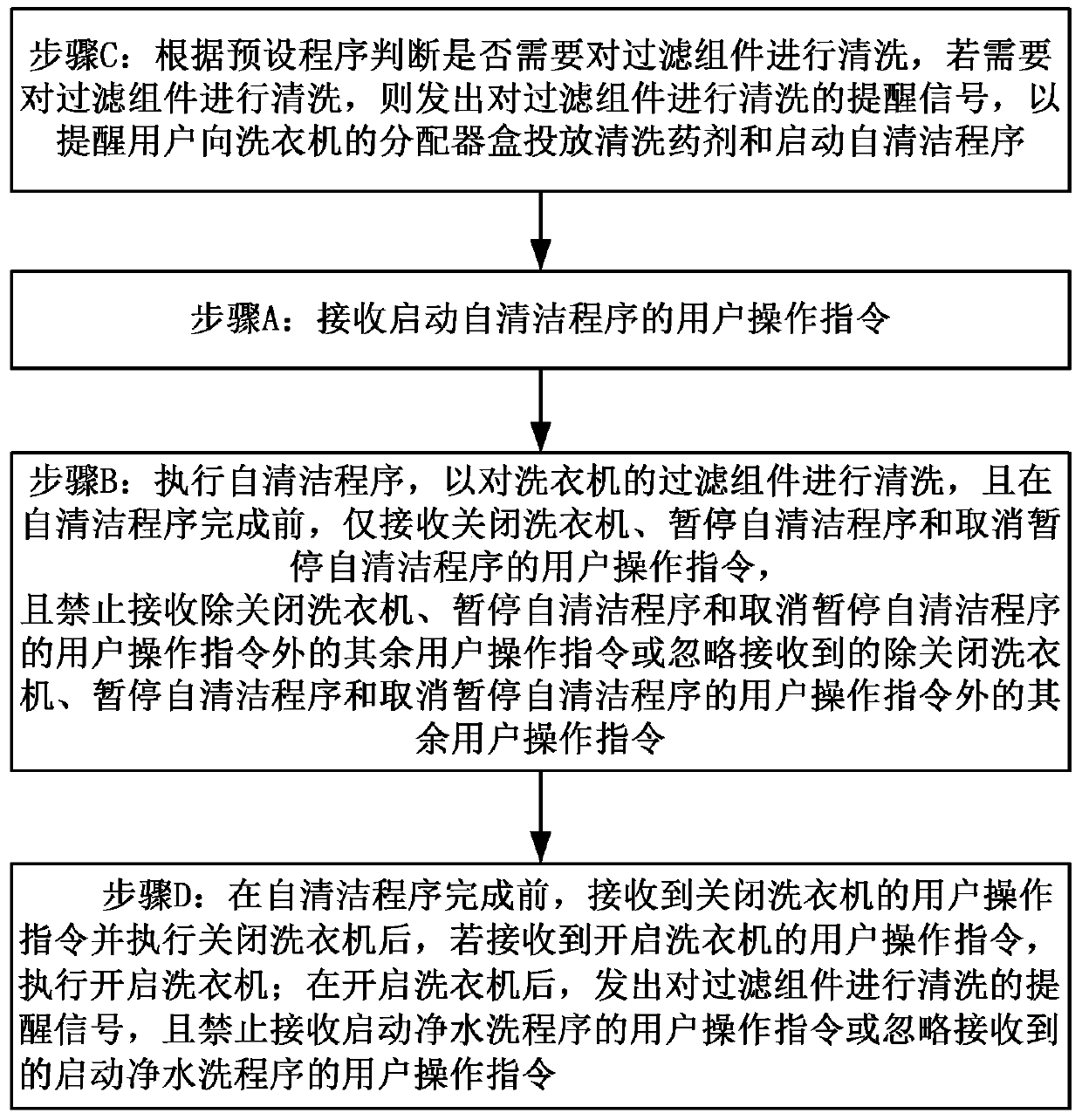

Washing machine filtering assembly self-cleaning method

ActiveCN105506934AAchieve cleaningExtend your lifeOther washing machinesControl devices for washing apparatusCleaning methodsComputer science

The invention provides a washing machine filtering assembly self-cleaning method comprising the following steps: receiving a user operation order used for starting a self-cleaning program; executing the self-cleaning program so as to clean a washing machine filtering assembly, and only receiving the following user operation orders before the self-cleaning program is finished: stopping the washing machine order, pausing the self-cleaning program order, and canceling the self-cleaning program pausing state order; other user operation orders besides the stopping washing machine order, pausing the self-cleaning program order, and canceling the self-cleaning program pausing state order are forbidden to receive or neglected. In a filtering assembly cleaning process of the self-cleaning program, the washing machine cannot receive or neglect other user operation orders besides the stopping washing machine order, pausing the self-cleaning program order, and canceling the self-cleaning program pausing state order, so the washing machine filtering assembly can be thoroughly cleaned, thus prolonging the filtering assembly life, and ensuring the filtering assembly to have a high filtering flux.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

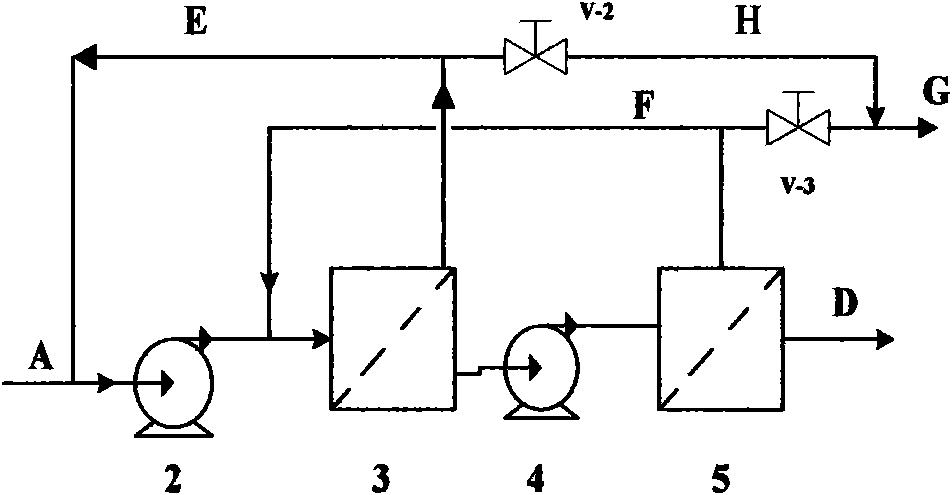

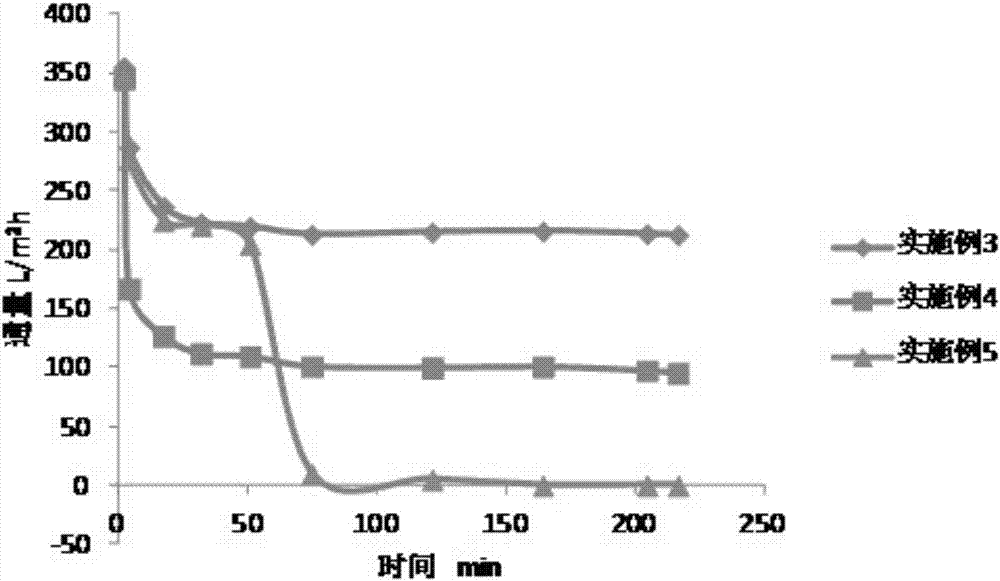

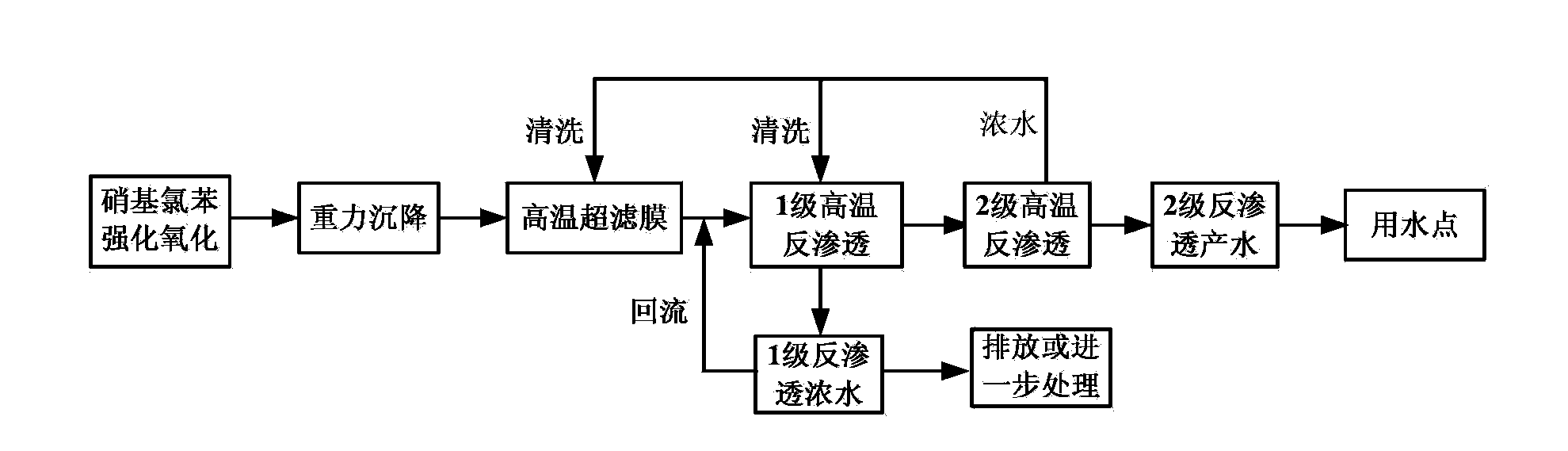

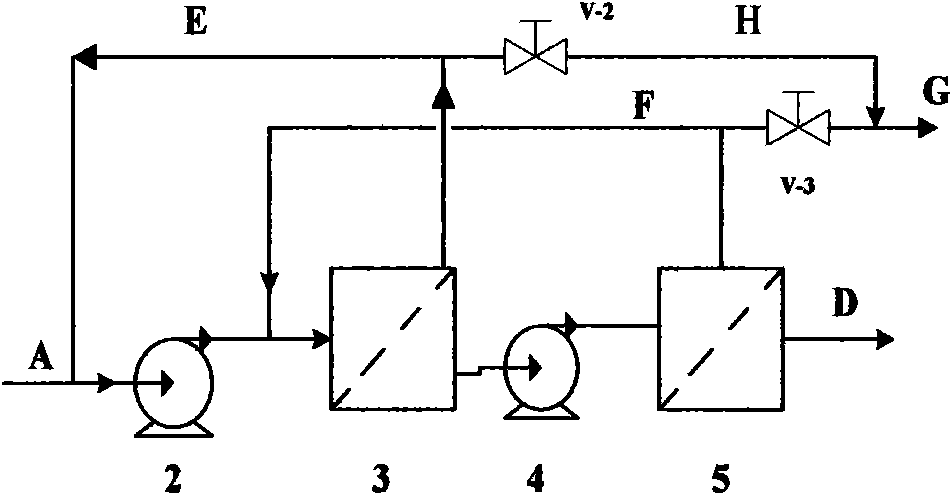

Advanced treatment and reuse method of high-temperature nitrochlorobenzene wastewater

ActiveCN103771562AImprove filtration throughputReduce operating pressureSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater filterFiltration

The invention relates to an advanced treatment and reuse method of high-temperature nitrochlorobenzene wastewater, and concretely relates to a method for treating high-temperature nitrochlorobenzene wastewater by utilizing a membrane separation technology. The method comprises the following steps: 1, directly filtering water obtained after the oxidation-gravity settlement of nitrochlorobenzene wastewater by an ultrafilter membrane filtration system; 2, carrying out primary pressurization of water obtained after the ultrafilter membrane filtration in step 1, and directly conveying the pressurized water to a primary reverse osmosis membrane system for filtration; and 3, carrying out secondary pressurization of water filtered in step 2, and directly conveying the filtered water obtained in step 2 to a secondary reverse osmosis membrane system for filtration, wherein water obtained after the secondary reverse osmosis is process reuse water. The finally obtained treated nitrochlorobenzene wastewater can satisfy quality requirements of make-up water for middle and low pressure boilers.

Owner:CHINA PETROLEUM & CHEM CORP +1

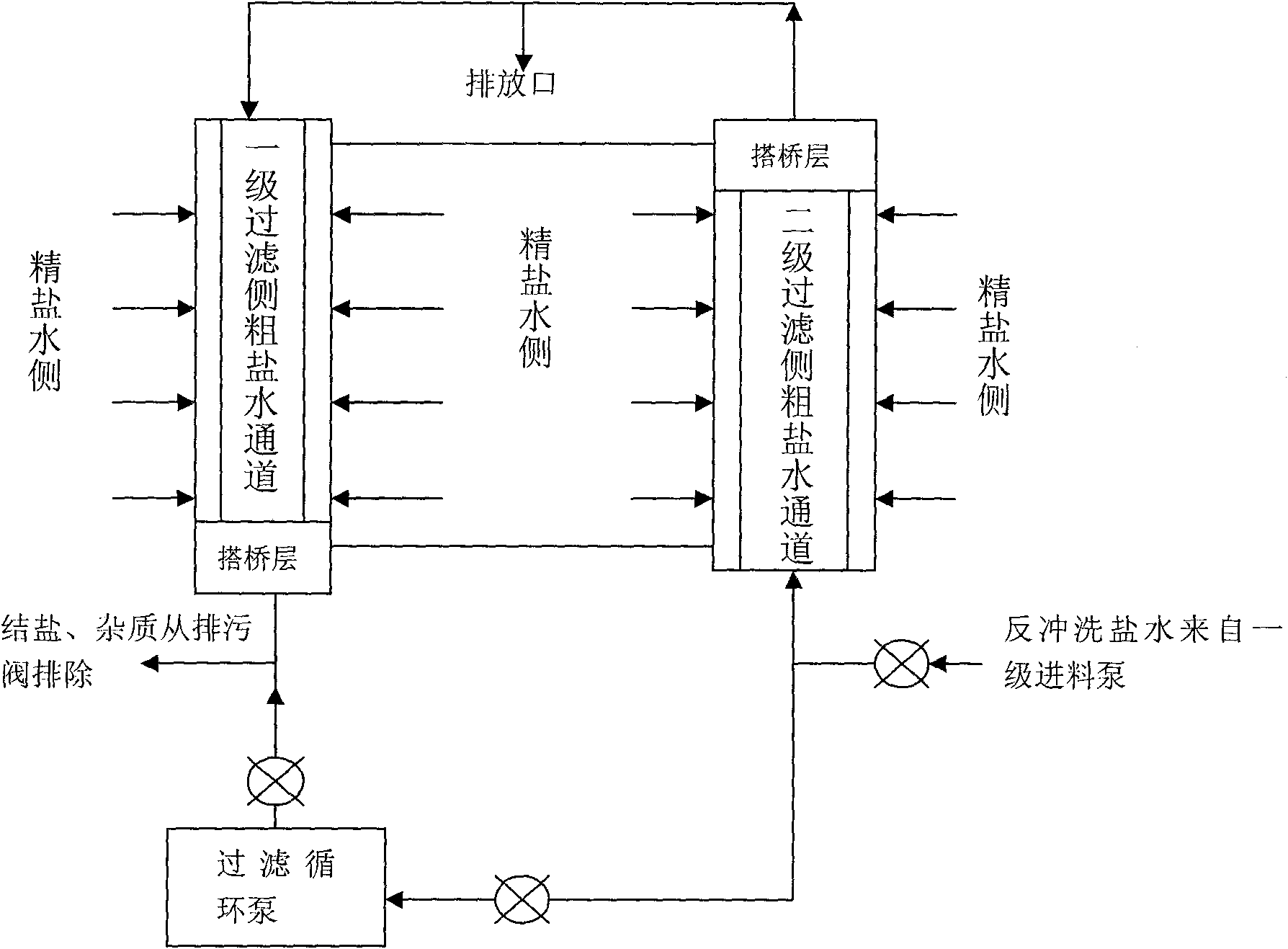

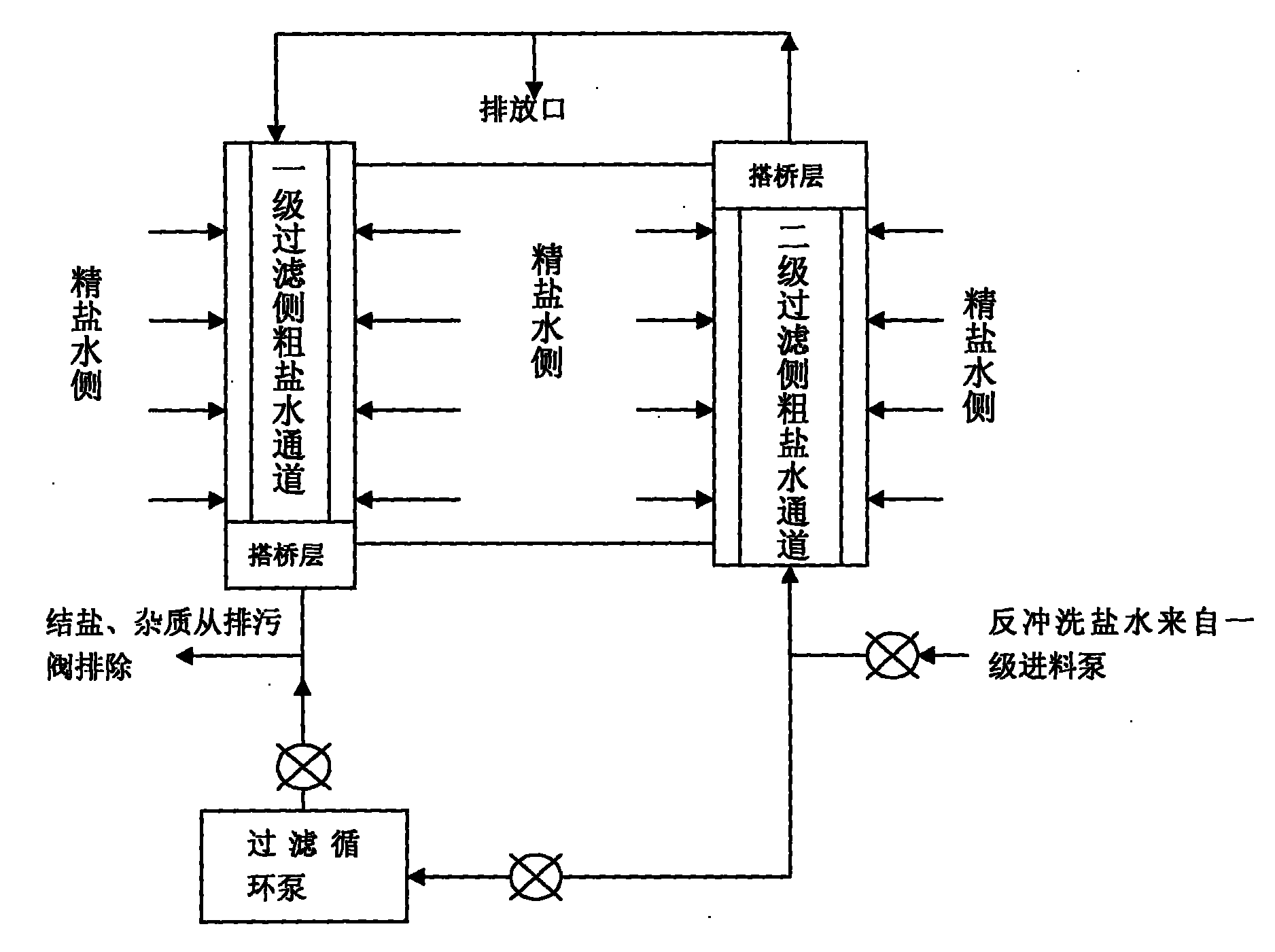

Back-washing regeneration method of ceramic membrane method brine refining process filter

InactiveCN101874949AMaintain high-throughput operation for a long timeExtended regenerative cleaning cycleAlkali metal chloridesStationary filtering element filtersFiberChemical industry

The invention relates to the technical field of chlor-alkali chemical industry production, in particular to a back-washing regeneration method of a ceramic membrane method brine refining process filter; the ceramic membrane method primary brine filtering refining process is a novel refined brine filtering production process in chlor-alkali industry brine refining process at home and abroad; at present, the process has the disadvantages of high back-washing frequency and unclean silt removal, and a primary filtering side membrane pipe is easy to block by bridging brine sludge in crude brine and fiber matters, so as to cause the primary filtering pressure to be raised to above 0.5MPa, stopping is needed to carry out regeneration cleaning, and the normal production is affected. In the invention, crude brine is adopted and flows backwards from two grades to one grade, and back-washing is carried out for a plurality of times forcibly at the refined brine side, one-grade filtering pressure of the filter can be reduced below 0.3MPa, normal production is restored, and the production running time can be increased.

Owner:河北盛华化工有限公司

Method for high temperature wastewater treatment and reuse in MTO process

ActiveCN101962235BImprove filtration throughputHigh removal rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentThermal energyWater quality

The invention relates to a method for treating and reusing high-temperature stripping purified wastewater produced in the process of transferring oxygenated compounds into olefins by using a high-temperature separation membrane. The combination process can effectively remove the impurities such as metal ions and organic micro-molecules and the like in stripping purified water, and the treated purified water in a tower kettle can meet the quality requirements of makeup water for middle and low-pressure boilers or the quality requirements of the makeup water in the MTO process. The invention effectively overcomes the defects exiting in the method for treating and reusing the stripping purified water without condensation in the MTO process, and lowers or reduces the consumption of circulating cooling water in the process of cooling firstly and then treating, thereby saving a large amount of boiler water and recycling the thermal energy of produced high temperature wastewater, and providing a stable and efficient way for high temperature wastewater treatment and reuse of relevant enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of concentrated juice

PendingCN110742218AHigh in nutrientsIncrease membrane filtration fluxNatural extract food ingredientsFood ingredient functionsChemistryPectinase

The invention belongs to the technical field of juice concentration and extraction, and discloses a processing method of concentrated juice. The processing method comprises the following steps: (1) juicing fresh fruits, and adding pectinase and cellulase for enzymolysis; (2) filtering enzymolysis pulp to obtain filter residues and a first filtrate, adding water to the filter residues, performing ultrasonic extraction and filtration to obtain a second filtrate, combining the second filtrate with the first filtrate, and performing filtration to obtain a coarse filtrate; (3) carrying out refinedfiltration on the coarse filtrate by using a nanofiltration membrane, and carrying out ultrafiltration treatment on the filtrate subjected to refined filtration by using a ceramic ultrafiltration membrane to obtain clarified juice; (4) concentrating the obtained clarified juice by using a reverse osmosis membrane to obtain concentrated juice; and (5) adding a stabilizer to the concentrated juice,fully stirring and uniformly mixing the concentrated juice, filling and sealing the uniformly mixed concentrated juice, and carrying out ultrahigh-pressure sterilization treatment and cooling to obtain the concentrated juice. The concentrated juice prepared by the method is fragrant and strong, can well retain nutritional ingredients and taste of the juice, and is stable in quality, simple and convenient in technological process and operation and low in investment and operation cost.

Owner:绵阳市安州区开创农业开发有限责任公司

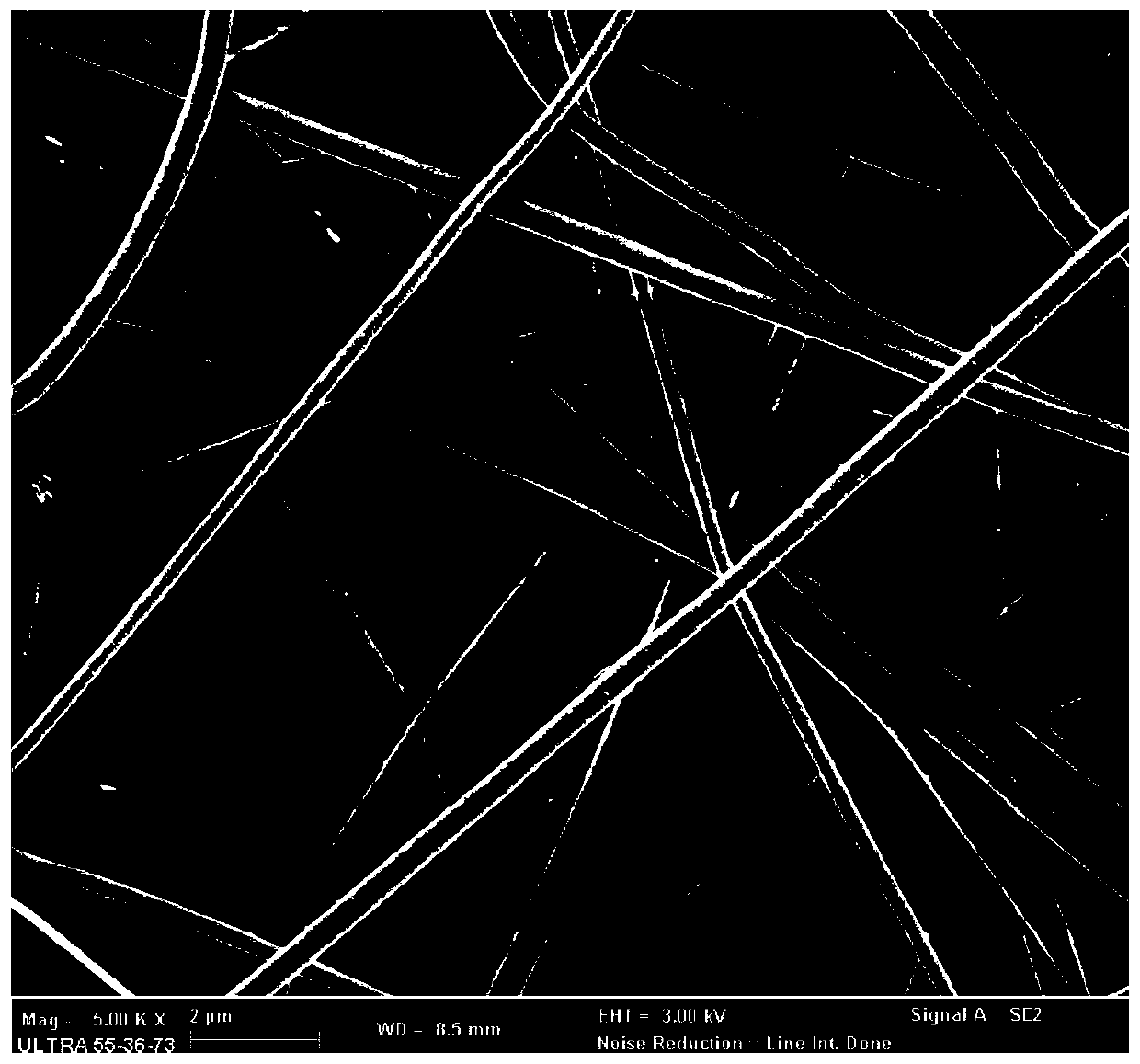

Ultrahigh-flux nanofiber filtering membrane and preparation method thereof

ActiveCN110935325AImprove mechanical propertiesImprove hydrophilicitySemi-permeable membranesMembranesPolymer scienceSpinning

The invention discloses an ultrahigh-flux nanofiber filtering membrane and a preparation method thereof, and relates to the technical field of nanofiber filtering membranes. The preparation method specifically comprises the following steps: adding an additive mixed solution into a spinning raw solution, and uniformly mixing to obtain a spinning solution; carrying out electrostatic spinning on thespinning solution to obtain a nanofiber filtering membrane crude product; and placing the nanofiber filtering membrane crude product in a stenter, and carrying out post-treatment to obtain the ultrahigh-flux nanofiber filtering membrane. According to the invention, the gas filtering flux of the ultrahigh-flux nanofiber filtering membrane prepared through the method is 2-3 times the gas filtering flux of the normally spun nanofiber filtering membrane, and the filtering efficiency reaches more than 99.5%.

Owner:HANGZHOU DEEFINE FILTRATION TECH

Preparation method and application of multi-channel cordierite plate ceramic membrane support

The invention discloses a preparation method and an application of a multi-channel cordierite plate ceramic membrane support. The preparation method includes the following steps: 1) weighing solid raw material components according to the following weight percentage ratio, and mixing the components, ball-milling the mixture, adding RO water, heating the mixture to 40-85 DEG C and ball-milling the mixture to obtain slurry; 2) maintaining the temperature of the slurry to be 40-85 DEG C, vacuum-defoaming the slurry, injecting the slurry into a plate-frame moulding die, and performing in-situ moulding at 0-40 DEG C to obtain a wet blank; 3) demoulding the wet blank, shade-drying the wet blank at room temperature, drying the wet blank at 40-100 DEG C, and sintering the blank in air at 1000-1400 DEG C with temperature maintained to obtain the multi-channel cordierite plate ceramic membrane support. The preparation method is carried out through the gel-casting process so that the method is wide in available range and is free of special demand on powders, and is low in cost, is easy to control in processes and achieves near-net-shape moulding to produce parts having complex shapes. The blank is high in strength, allows mechanical processing, is low in organic substance content, allows direct sintering and is free of individual gum removal. The blank and the sintered body have good performance uniformity.

Owner:SANDA FILM SCI & TECH XIAMEN

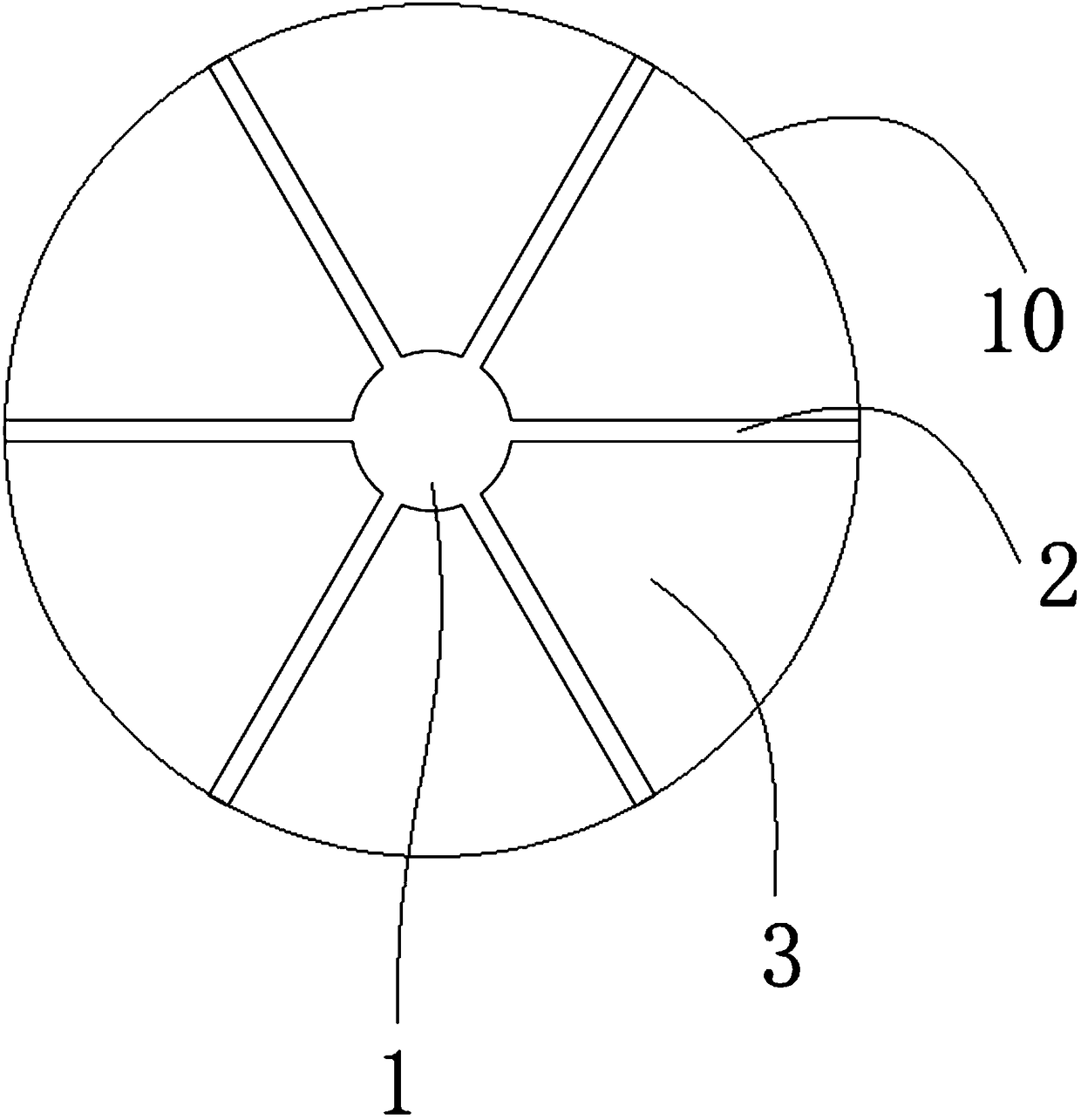

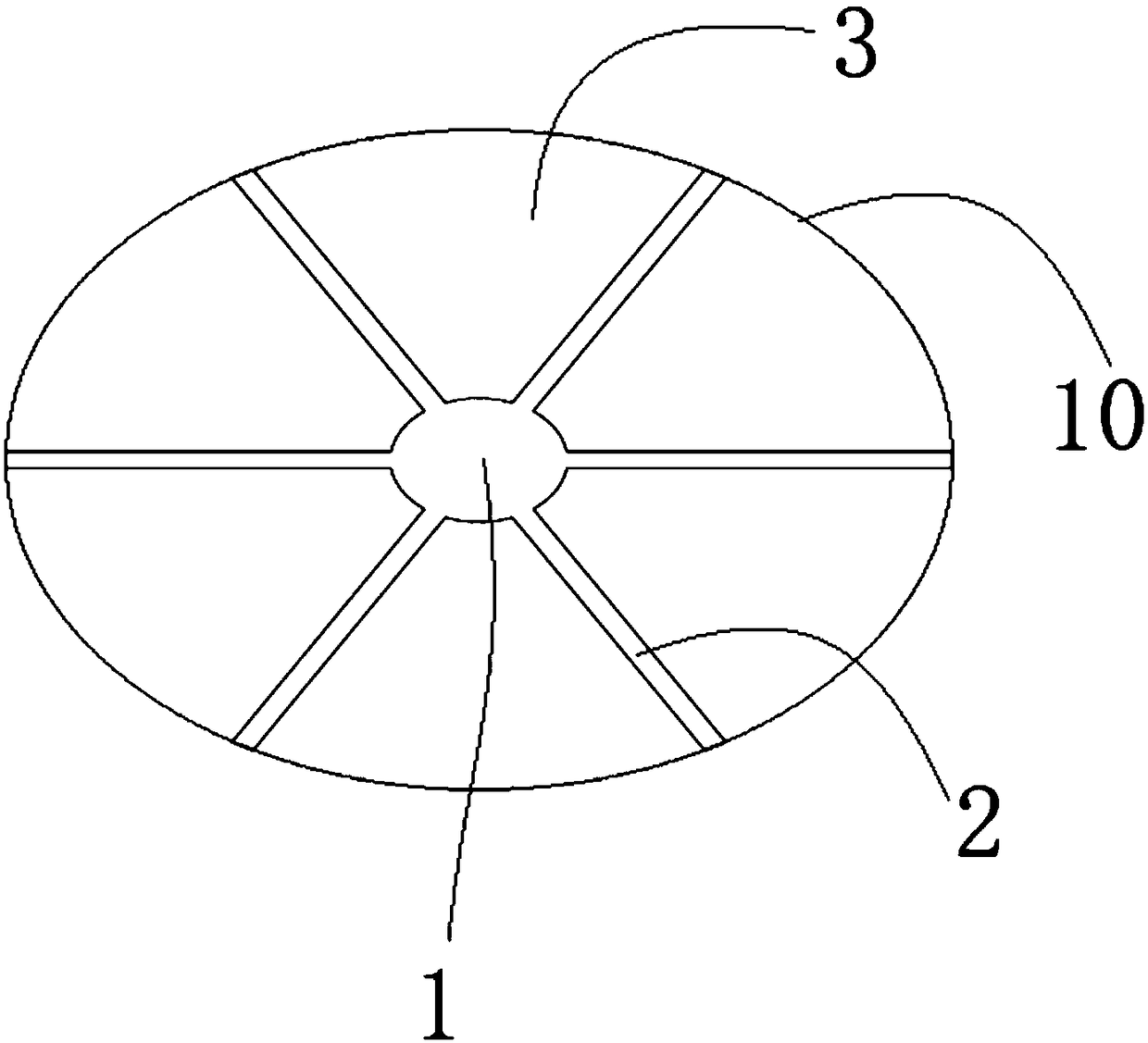

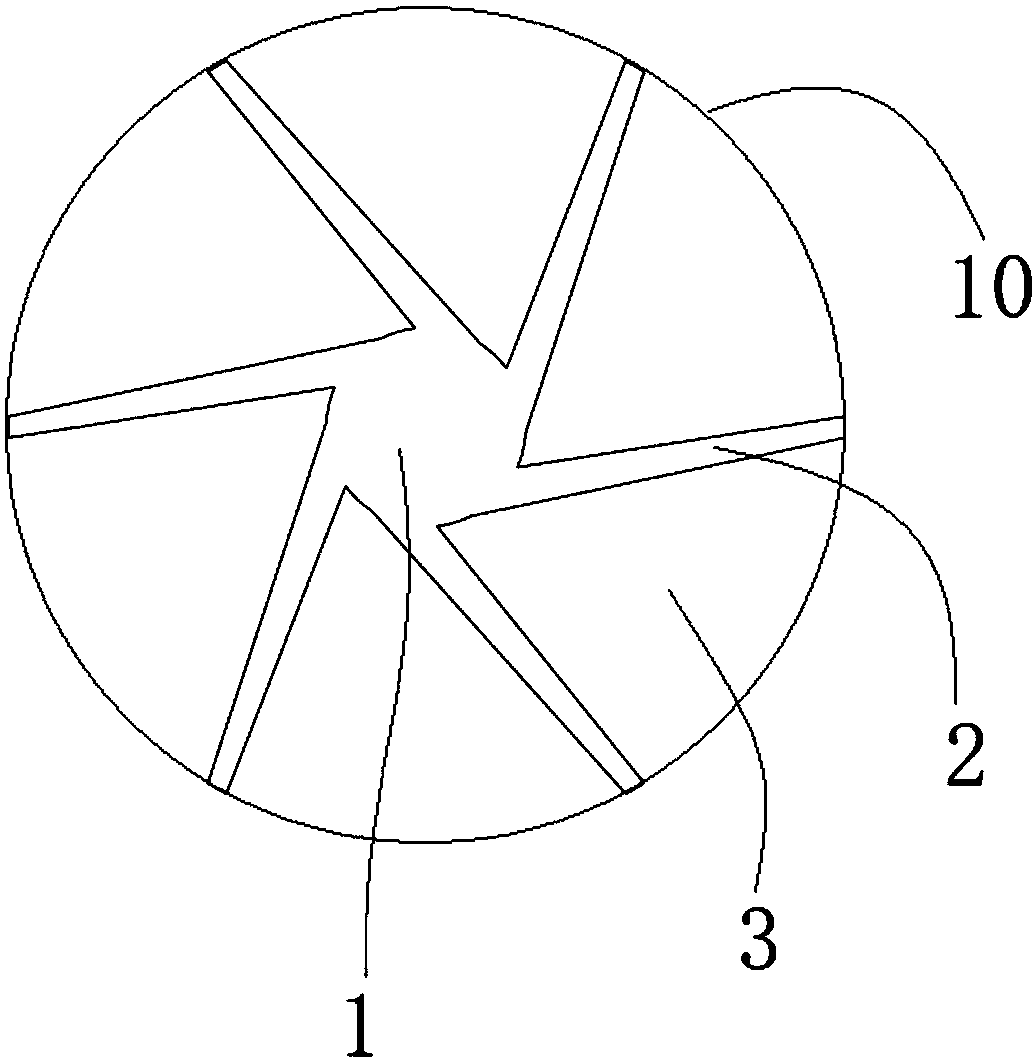

Petal-shaped inner supporting framework applied to tubular filtering membrane and application thereof

PendingCN108246116AImprove filtration efficiencyImprove filtration throughputSemi-permeable membranesMembranesPetalEngineering

The invention relates to a petal-shaped inner supporting framework applied to a tubular filtering membrane and application thereof. The supporting framework comprises a middle column and a plurality of supporting arms which are arranged around the outer side of the middle column, wherein the supporting arms extend in the axial direction of the middle column, and medium channels are formed every two adjacent supporting arms. The petal-shaped inner supporting framework has the beneficial effects that the structure can be once formed through equipment, and many times of processing is avoided; when the petal-shaped inner supporting framework is arranged in the tubular filtering membrane, the cross sections of the medium channels are expanded and optimized; thus, a filtering efficiency of the filtering membrane is improved, higher filtering membrane filtering flux is obtained, and a better filtering / separating effect is achieved.

Owner:SHANGHAI MAITUO TECH DEV CO LTD

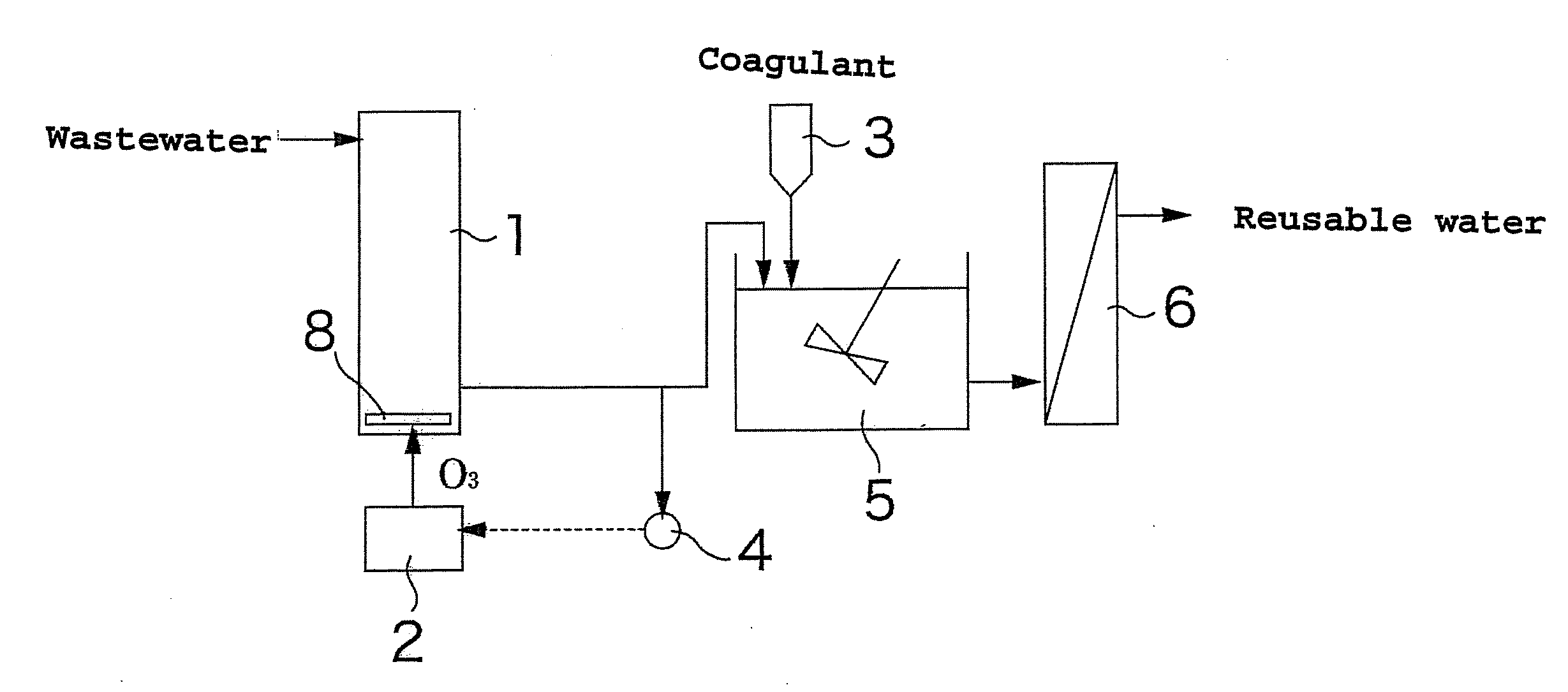

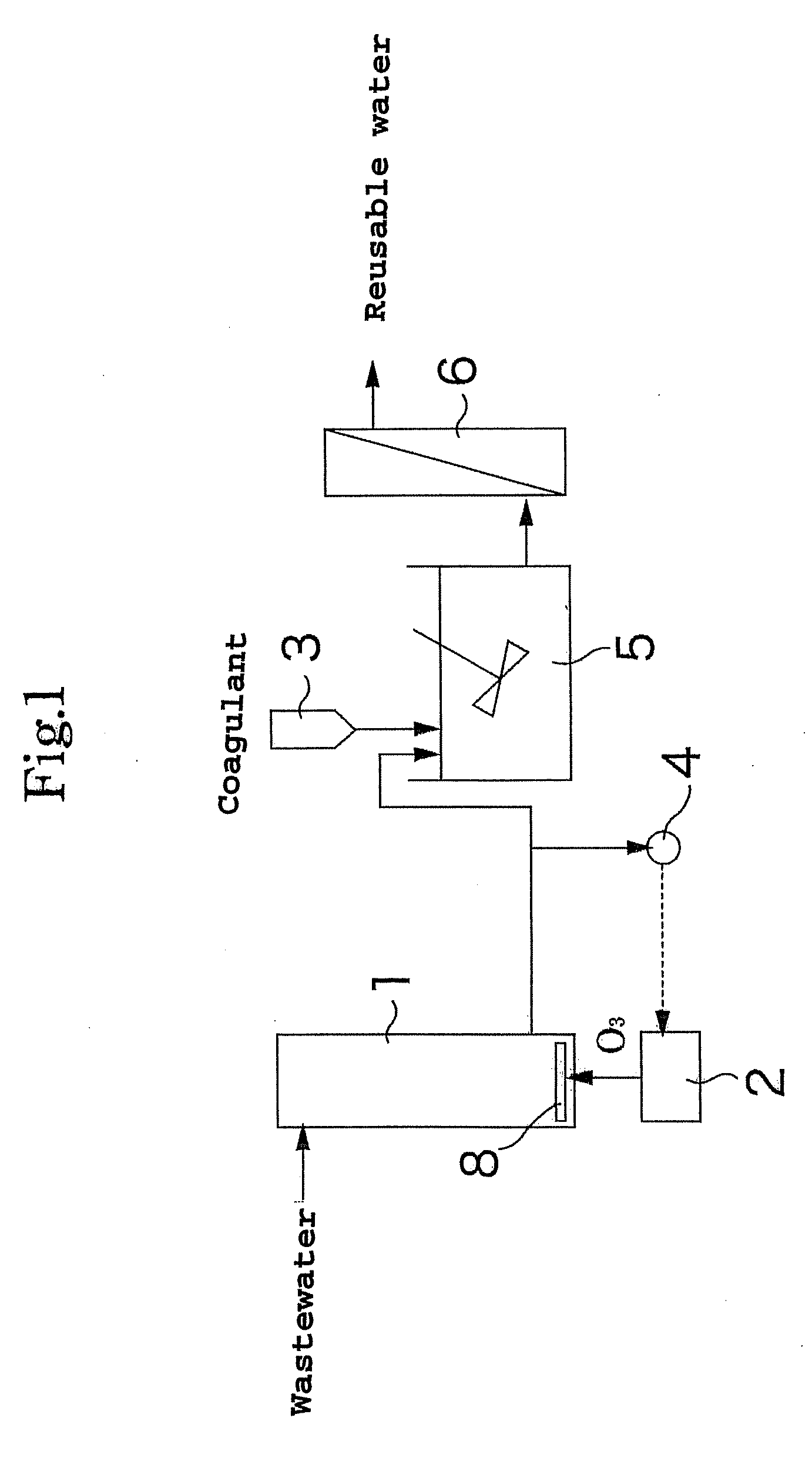

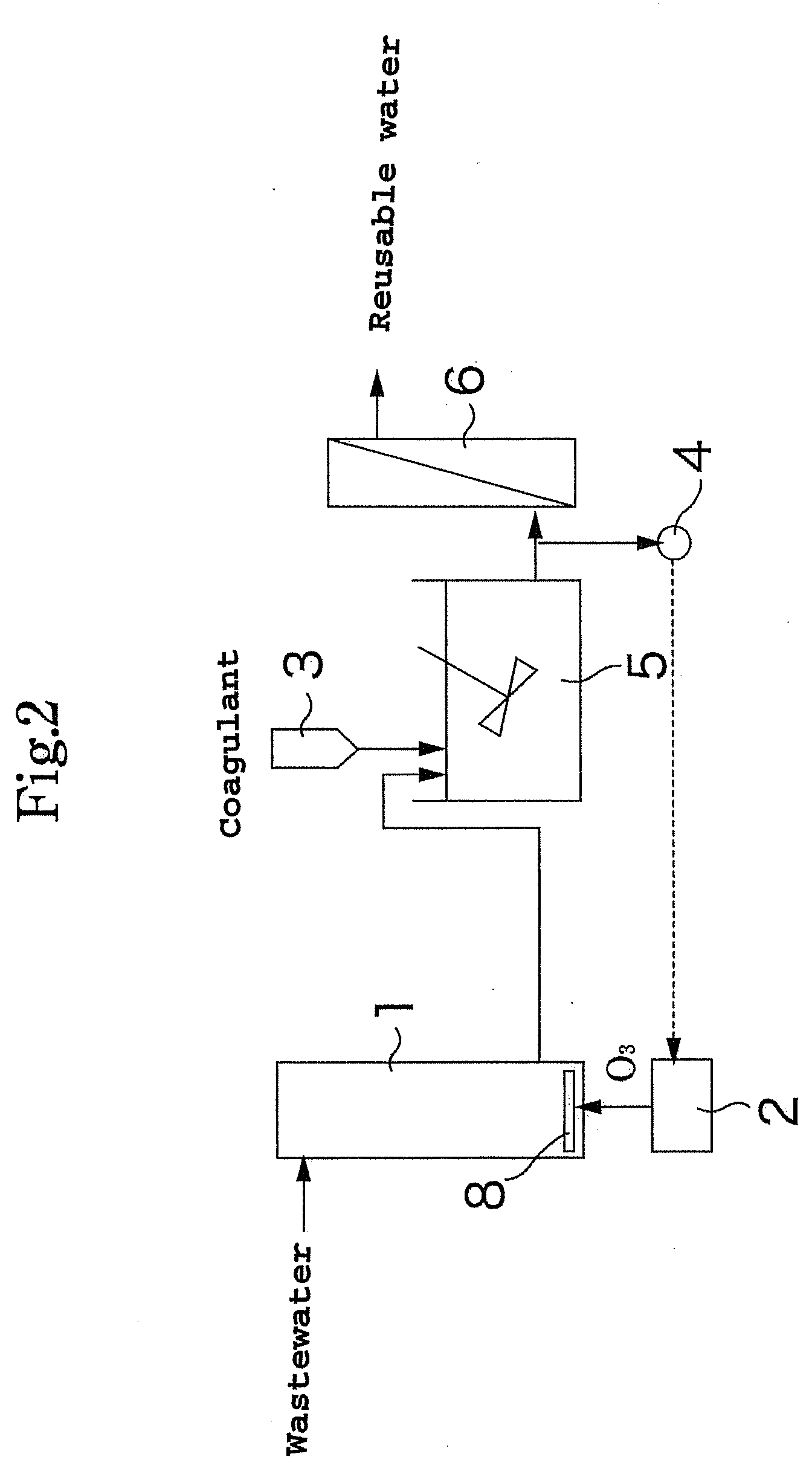

Method for recycling wastewater

ActiveUS20090127196A1Improve propertiesAvoid clogging the filterWater treatment parameter controlMembranesWastewaterSewage treatment

A method of wastewater reutilization by which reusable water can be stably obtained from a wastewater. Ozone is added to a wastewater, such as water resulting from sewage treatment, in such a small amount as to result in a residual ozone concentration as measured before membrane filtration of 0.01-1.0 mg / L. Ozone is thus brought into contact with fine solids contained in the wastewater to alter the surface properties of the fine solids so that the solids are easily to coagulate. Thereafter, a coagulant, e.g., PACl, is added from a coagulant addition device(3). The fine solids are coagulated in a coagulation tank(5) or a line mixer and the resultant water is subjected to membrane filtration with an ozone-resistant separation membrane(6) such as ceramic membrane. Thus, reusable water is obtained which has a residual ozone concentration, as measured after filtration through the membrane, less than 0.5 mg / L.

Owner:METAWATER CO LTD

High-temperature gas-solid ceramic filter tube and preparation method

The invention provides improvement of ceramic filter tubes for high-temperature gas purification, and is characterized in that a high-temperature binder for sintering comprises two or more than two of magnesium oxide, strontium oxide, calcium oxide, potassium oxide-containing minerals, kaolin or clay, and trace rare earth, and mainly forms a liquid-phase silicate high-temperature binder above 1200 DEG C. The contradiction between binding strength of a filter tube support body and filtration flux and resistance drop is well coordinated and solved; the obtained filter tube support body not only meets the requirements for transport, installation, and using strength, but also has a high filtration flux and low filtration resistance. When the filter tube has rupture strength of not less than 26 MPa, and a filtration flux of 55 m3 / hm2, the resistance drop is 850-950 Pa or lower; the consistency for finished product batch production is good; and the performance difference is less than 10%.

Owner:宜兴市鑫帝豪高科陶瓷厂

A method for preparing an inexpensive ultrafiltration membrane that can be used in the treatment of oil production wastewater

ActiveCN104258742BNo post-processingSimple processSemi-permeable membranesWater bathsFiltration membrane

The invention provides a preparation method of a cheap ultra-filtration membrane for treating oil producing wastewater. The preparation method comprises the following steps: dissolving nano silicon dioxide into a polyvinyl chloride dissolving solvent under ultrasonic condition to prepare a suspension solution of nano particles; then sequentially and slowly adding a pore-forming agent, a de-foaming agent and polyvinyl chloride into the suspension solution; continuously and mechanically agitating in a water bath of 30-40 DEG C for more than 24 hours until a homogeneous membrane casting solution is formed; sufficiently de-foaming the membrane casting solution in a vacuum drying box and scraping a membrane by using a membrane scraping machine; after volatilizing the scraped new membrane in the air for 15-60 seconds, slowly putting the scraped new membrane into a coagulating bath for coagulation; and after separating the membrane from a glass plate, sufficiently immersing the membrane in pure water for 48 hours to obtain a nano silicon dioxide modified polyvinyl chloride flat plate membrane. The preparation method of the cheap ultra-filtration membrane can be used for nano silicon dioxide polyvinyl chloride hollow fiber type ultra-filtration membranes and micro-filtration membranes, reverse osmosis membranes, nano-filtration membranes, pipe type membranes, capillary tube membranes or spiral-wound membranes.

Owner:HARBIN ENG UNIV

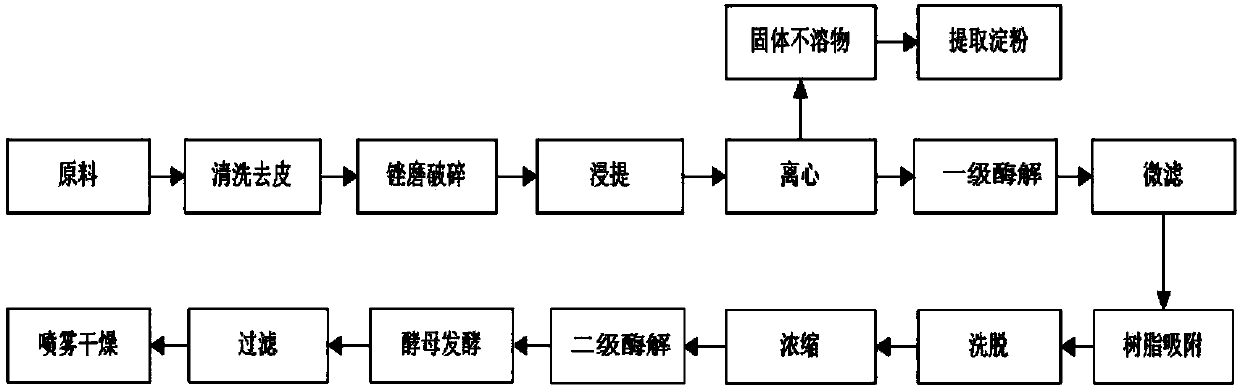

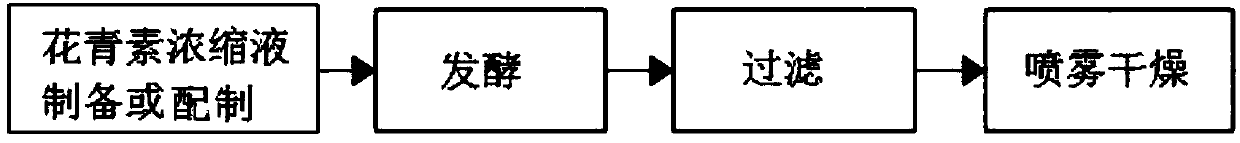

Extraction and purification method for high-purity purple sweet potato anthocyanin

InactiveCN107721964AReduce consumptionReduce extraction timeOrganic chemistryPectinaseHigh concentration

The invention aims to provide an extraction and purification method for high-purity purple sweet potato anthocyanin, in order to solve the problems of low extraction efficiency, easy polluted film filtration, low product purity, and the like, in the prior art. The method comprises the following steps: cleaning and peeling the raw materials; milling and crushing; extracting; centrifuging; performing first-level enzymolysis; absorbing resins; eluting; concentrating; performing second-level enzymolysis; performing yeast fermentation; filtering; performing spray drying, thus obtaining a high-concentration anthocyanin product. The purple sweet potato is milled and crushed after the cleaning and peeling process, so that the technology is capable of increasing the extraction rate of anthocyanin,reducing extraction time and reducing solvent consumption, namely, reducing the final handling capacity of the wastewater; the extracting solution is subjected to enzymolysis with pectinase, so that the flux of the membrane filtration is promoted and the membrane flux in the running process of the membrane is basically kept stable; yeast fermentation is adopted for removing the sugar from the anthocyanin resin purified solution, so that the product purity is greatly promoted.

Owner:安徽泰德康科技有限公司

Control method for washing machine with filtering water circulation system

ActiveCN104975460AExtend your lifeImprove filtration throughputOther washing machinesControl devices for washing apparatusWater filterWater flow

The invention provides a control method for a washing machine with a filtering water circulation system. More particularly, the control method comprises a first washing procedure which is set as a default washing procedure. The first washing procedure includes a phase for rinsing by circulating water, where rinsing water is used to rinse clothes in a washing tube. In the phase for rinsing by circulating water, the rinsing water runs into a circulating water filtering system and after filtering process, the circulation water flows back to the washing tube. In the default washing procedure, the rinsing water already filtered is used to circularly rinse washed clothes, which is beneficial for users to wash clothes in a water conserving manner, thus helping them nurture a good habit of saving water.

Owner:HAIER GROUP TECHN R&D CENT +1

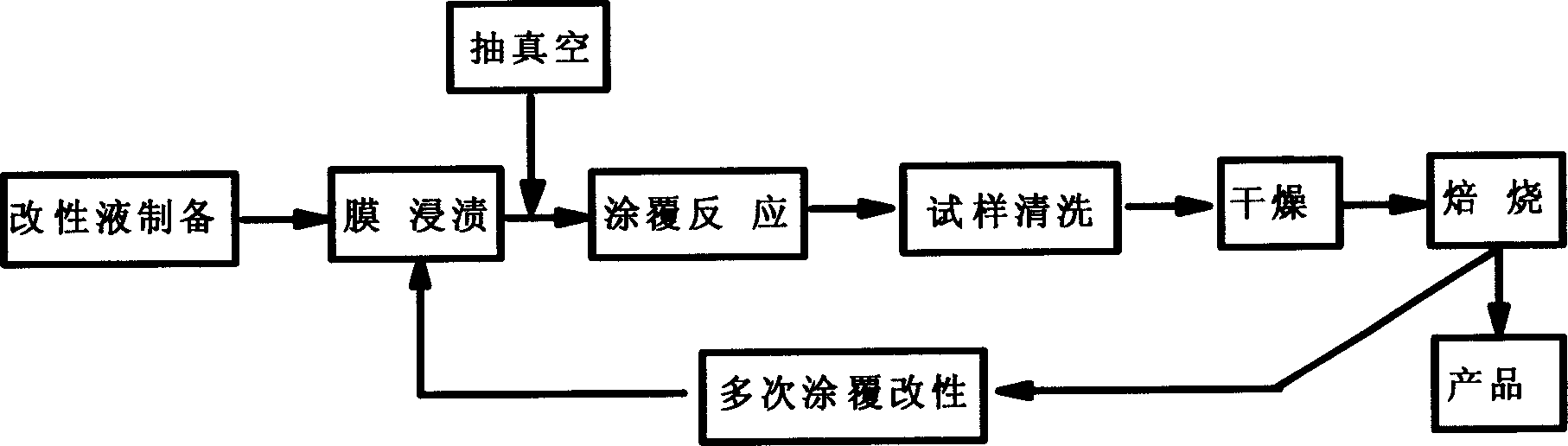

Composite modified A1203 ceramic microfiltering film

InactiveCN1879953AImprove filtration throughputStrong acid and alkali corrosion resistanceSemi-permeable membranesCeramicSemiconductor

The invention relates to a composite improved Al203 ceramic micro filter membrane, whose aperture is 200-500nm, wherein it is characterized in that: the inner surface of membrane hole is coated with two kinds of modified coats formed by semi conductive oxide, whose grain size is 5-20nm and thickness is 20-100nm. The invention reduces 17-30% aperture compared with former one, and improves 28% of filter reflux, with better acid alkali corrosion resistance.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com