Composite modified A1203 ceramic microfiltering film

A ceramic microfiltration and modification technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems that it is difficult to take into account the permeability and acid and alkali corrosion resistance at the same time, and it is difficult to meet the actual requirements of the industry. Achieve excellent acid and alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

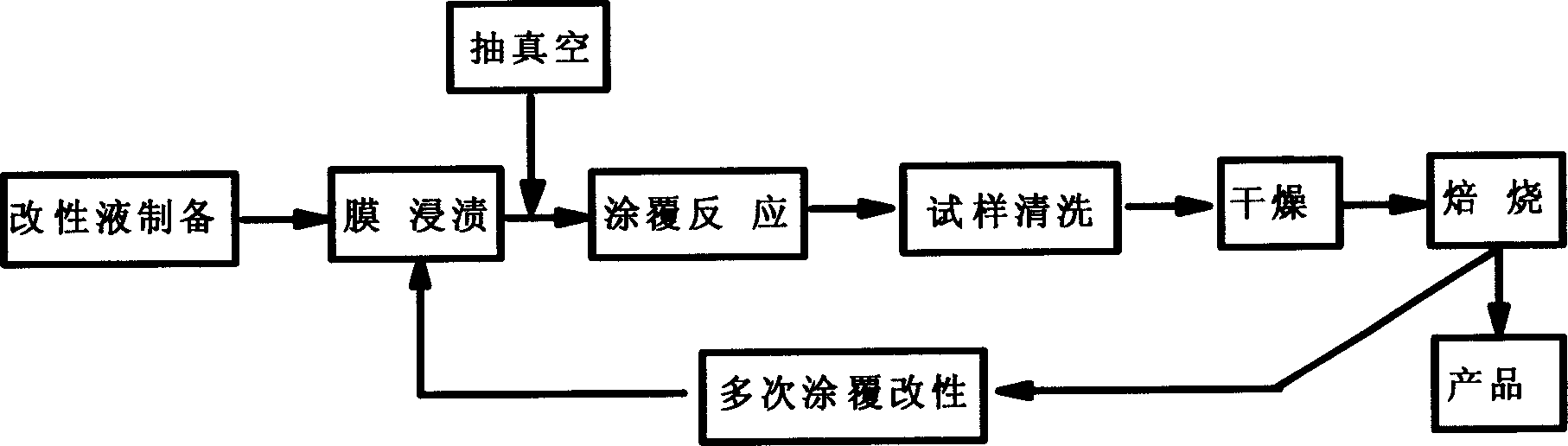

Method used

Image

Examples

Embodiment 1

[0013] (1) Preparation solution: ZnO modified layer coating solution preparation, zinc nitrate solution concentration is 0.3mol / L, Zn 2+ Add urea in / urea molar ratio 1:2, and fully stir, obtain zinc nitrate and urea mixed solution; ZrO 2 Modified layer coating liquid preparation, zirconium oxychloride is made into the solution of 0.3mol / L concentration, according to Zr 4+ The urea / urea molar ratio is 1:3, add urea, and fully stir to obtain a mixed solution of zirconium oxychloride and urea.

[0014] (2) First immerse the microfiltration membrane in the mixed solution of zinc nitrate and urea, then vacuumize it, react at 85°C for 4h, dry it and burn it at 950°C and keep it warm for 1h.

[0015] (3) Immerse the above-mentioned microfiltration membrane after being fired once in the mixed solution of zirconium oxychloride and urea, react at 90°C for 4h, dry and burn at 950°C and keep it warm for 1h to obtain ZnO·ZrO 2 Composite modified microfiltration membrane.

[0016] ...

Embodiment 2

[0018] (1) Preparation solution: ZnO modified layer coating solution preparation, zinc nitrate solution concentration is 0.3mol / L, Zn 2+ Add urea at a molar ratio of 1:2, and fully stir to obtain a mixed solution of zinc nitrate and urea; TiO 2 Modified layer coating solution preparation, titanium sulfate is made into a solution with a concentration of 0.2mol / L, according to Ti 4+ The urea / urea molar ratio is 1:3, add urea, and fully stir to obtain a mixed solution of titanium sulfate and urea.

[0019] (2) First immerse the microfiltration membrane in the mixed solution of zinc nitrate and urea, then vacuumize it, react at 85°C for 4h, dry it and burn it at 950°C and keep it warm for 1h.

[0020] (3) Immerse the above-mentioned microfiltration membrane after firing once in a mixed solution of titanium sulfate and urea, react at 95°C for 4h, dry it at 950°C and keep it warm for 1h to obtain ZnO·TiO 2 Composite modified microfiltration membrane.

[0021] Performance...

Embodiment 3

[0023] (1) Preparation solution: ZnO modified layer coating solution preparation, the concentration of zinc nitrate solution is 0.4mol / L, Zn 2+ Add urea in / urea molar ratio 1:2, and fully stir, obtain zinc nitrate and urea mixed solution; ZrO 2 Modified layer coating liquid preparation, zirconium oxychloride is made into the solution of 0.2mol / L concentration, according to Zr 4+ The urea / urea molar ratio is 1:3, add urea, and fully stir to obtain a mixed solution of zirconium oxychloride and urea.

[0024] (2) First immerse the microfiltration membrane in the mixed solution of zinc nitrate and urea, vacuumize it, react at 80°C for 4h, dry it and burn it at 1000°C and keep it warm for 1h.

[0025] (3) Then impregnate the above-mentioned microfiltration membrane after firing once in the mixed solution of zirconium oxychloride and urea, react at 95°C for 4h, dry and burn at 1000°C and keep it warm for 0.5h, and cool naturally to room temperature, Then the microfiltration membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com