A method for preparing an inexpensive ultrafiltration membrane that can be used in the treatment of oil production wastewater

A technology for oil extraction wastewater and ultrafiltration membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of harsh operating conditions, a large amount of scum, and high energy consumption, and achieves low preparation costs and operating costs. Small, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

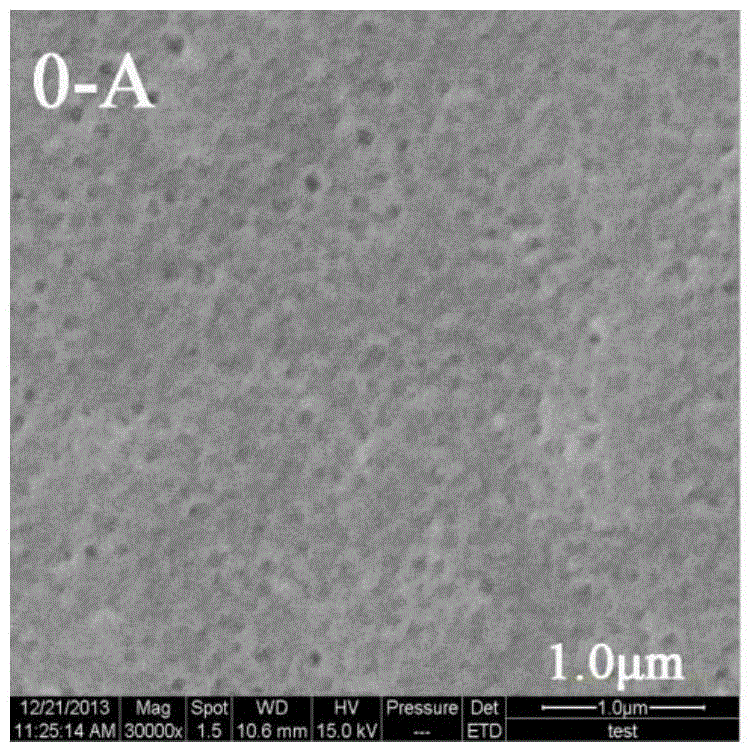

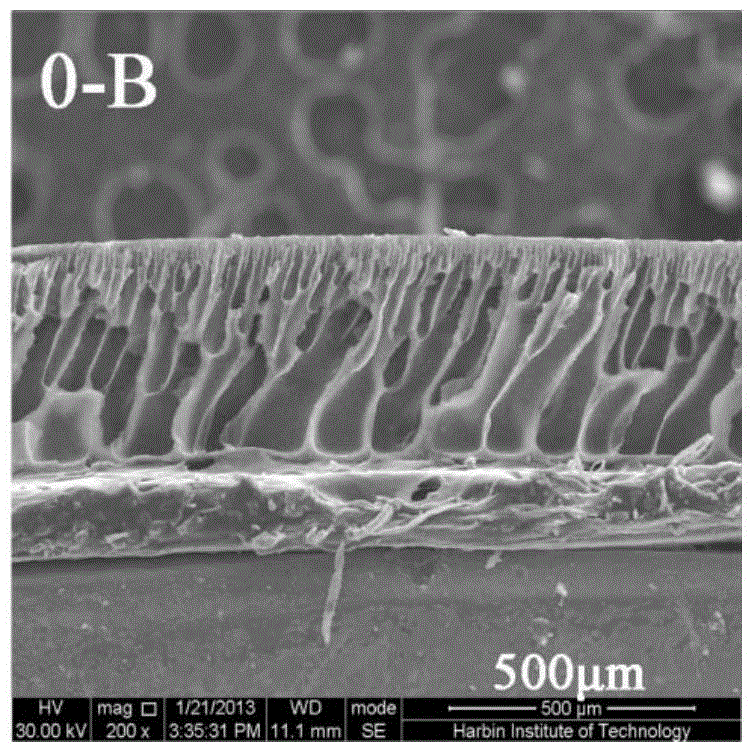

[0039] Dissolve 3g of nano-silica in 159g of N-N dimethylacetamide solvent (DMAc), and disperse under ultrasonic conditions for 30min, then mix 12g of polyvinylpyrrolidone, 2g of Tween 80, and 24g of polyvinyl chloride resin powder Add them to the nanoparticle suspension in turn under stirring, and stir evenly in a water bath at 30° C. for 24 hours. After it was completely dissolved, it was placed in a vacuum drying oven at 30°C (vacuum degree: 0.08MPa) and allowed to stand for defoaming for more than 12 hours. Then, use the L-S phase inversion method to form a film with a scraper machine in an environment with a temperature of 25°C and a humidity of 65%. After volatilizing for 15 seconds, put it into a 30% DMAc coagulation solution. After the film is automatically peeled off, the newborn Put the diaphragm into pure water and fully soak it for 48 hours to obtain a nano-silica modified polyvinyl chloride flat separation membrane.

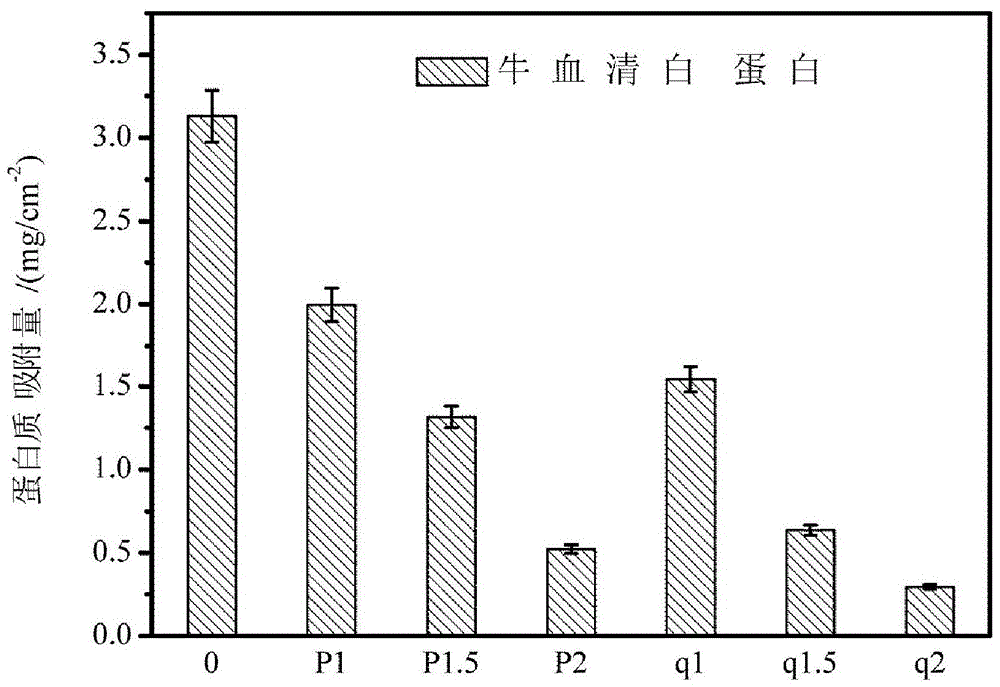

[0040] The characteristics of the flat membra...

Embodiment 2

[0042] Place the flat film made in Example 1 into an aqueous solution containing 30% glycerin and soak for 24 hours. After air-drying naturally, cut two diaphragms of the same size, and place the two diaphragms on several layers of plastic mesh with higher strength. Then seal its four sides into a U-shaped plexiglass frame, seal with epoxy resin, set a water outlet at one end of the diaphragm, and connect a pressure gauge and a peristaltic pump with a variable-diameter elbow. A nano-silica modified polyvinyl chloride flat membrane module is prepared.

[0043] The characteristics of the flat membrane module are: the membrane module is easy to assemble, and the materials are simple and easy to obtain. It is very suitable for use as a small test device in the experiment to simulate the process of ultrafiltration membrane treatment of a specific wastewater.

Embodiment 3

[0045] Dissolve 3g of nano-silica in 159g of N-N dimethylacetamide solvent (DMAc), and disperse under ultrasonic conditions for 30min, then mix 8g of polyvinylpyrrolidone, 2g of Tween 80, and 28g of polyvinyl chloride resin powder Add them to the nanoparticle suspension in turn under stirring, and stir evenly in a water bath at 30° C. for 24 hours. After it was completely dissolved, it was placed in a vacuum drying oven at 30°C (vacuum degree: 0.08MPa) and allowed to stand for defoaming for more than 12 hours. Then, use the L-S phase inversion method to form a film with a scraper machine in an environment with a temperature of 25°C and a humidity of 65%. After volatilizing for 1 min, put it into a coagulation bath containing pure water. After the film peels off automatically, the new film Put the sheet into pure water and fully soak for 48 hours to obtain a nano-silica modified polyvinyl chloride flat separation membrane.

[0046] The characteristics of the flat membrane are:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com