Solution used for steel surface quick plasma electrolysis boro-carbonization and boro-carbonization method

A plasma, steel surface technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of large deformation of the workpiece, prone to cracks, high boronizing temperature, and improve the comprehensive service life, The effect of good wear resistance and high hardness of the infiltrated layer

Inactive Publication Date: 2014-11-05

BEIJING NORMAL UNIVERSITY

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Generally, three infiltration processes of solid phase, liquid phase and gas phase are used. The gas phase boronizing agent uses hydrogen as the carrier and boron trichloride (BCl 3 ) and diborane (B 2 h 6 ) as infiltration agents, they are expensive, highly toxic, and explosive, and must be equipped with special boronizing equipment, and the process is complicated

Powder solid boronizing is to bury the workpiece in a sealed boronizing powder or granular medium. The boronizing layer is formed at a slow rate, difficult to clean, and high in cost.

At present, various boronizing methods are carried out in the range of 900 ~ 950 ° C, the temperature of boronizing is high, the processing time is long, and the deformation of the workpiece is large.

On the other hand, although the boronizing layer has high hardness, it is brittle and prone to cracks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

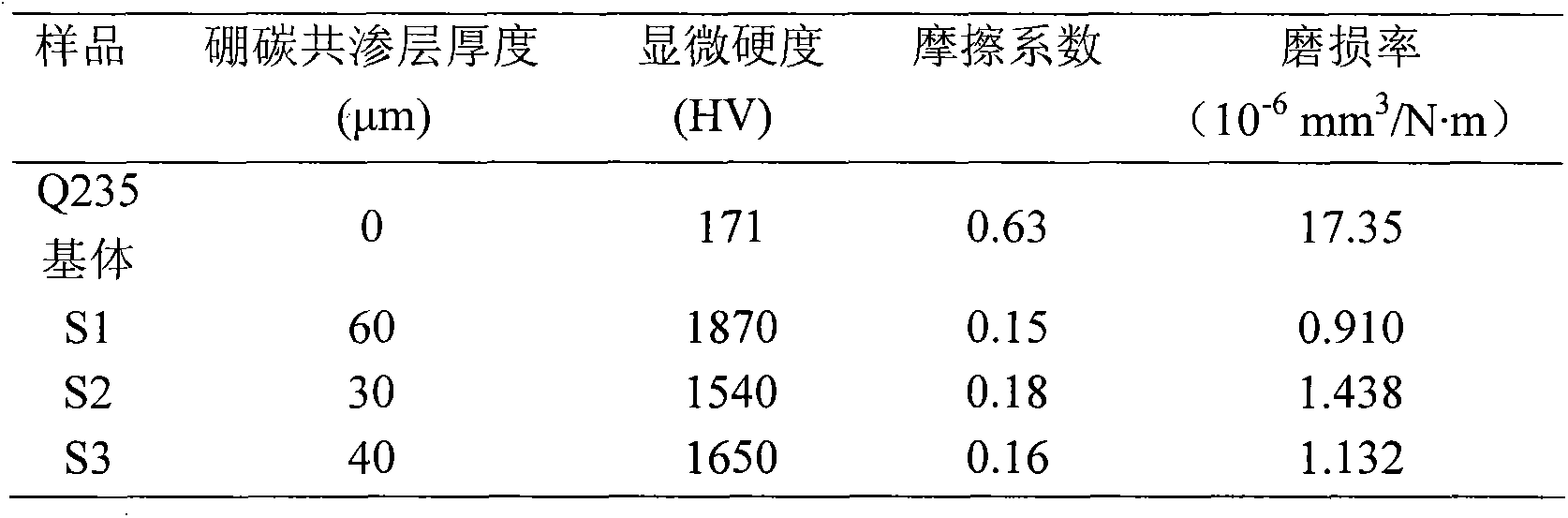

A solution used for steel surface quick plasma electrolysis boro-carbonization and a boro-carbonization method which belong to the technical field of steel surface treatment. The method is particularly a boron-carbon binary penetration method. Components of the solution, which is used as an electrolyte, include, by mass, 25-50% of borax, 10-30% of glycerin, 5-15% of sodium bicarbonate, 5-15% of sodium sulfate, 2-5 parts of potassium chloride and 20-50% of deionized water. A steel sample, being used as a cathode, is soaked in the solution and a graphite material is used as an anode. Under a room temperature condition, a 200-500V voltage is applied to the two electrodes and a boro-carbonization layer with a thickness being 15-80 [mu]m can be obtained after a treatment being carried out for 5-50 min, wherein a hardness of the boro-carbonization layer is 1500-2000 HV and is 8-12 times than a steel substrate. Meanwhile, a friction coefficient is reduced to 1 / 3-1 / 5 of the friction coefficient of the steel substrate and a wear rate is reduced to 1 / 12-1 / 20 of the wear rate of the steel substrate. By means of the plasma electrolysis boro-carbonization treatment, a frictional wearing resistant performance of steel is significantly improved. The method is free of post-treatment, is simple, is small in deformation of a workpiece and can reduce cost.

Description

technical field [0001] The invention relates to the technical field of iron and steel surface treatment, in particular to a solution and method for plasma electrolytic boron-carbon binary co-infiltration. The treated iron and steel materials can improve their wear resistance. Background technique [0002] Generally, steel materials, especially low carbon steel, have low hardness, large friction coefficient and poor wear resistance. Surface modification is an effective method to improve the wear resistance of steel. Common methods include surface heat treatment, thermal spraying, vapor deposition, carburizing, nitriding, and carbonitriding. Surface boronizing is a chemical heat treatment method for metal surface strengthening, by infiltrating boron elements into steel and alloys to obtain iron borides. The hardness of the boronizing layer is much higher than that of carburizing and nitriding layers, and the boronizing layer also has high corrosion resistance, which greatly i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C8/38

Inventor 薛文斌王彬吴杰金小越杜建成华铭

Owner BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com