Patents

Literature

317 results about "Carbonitriding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonitriding is a metallurgical surface modification technique that is used to increase the surface hardness of a metal, thereby reducing wear. During the process, atoms of carbon and nitrogen diffuse interstitially into the metal, creating barriers to slip, increasing the hardness and modulus near the surface. Carbonitriding is often applied to inexpensive, easily machined low carbon steel to impart the surface properties of more expensive and difficult to work grades of steel. Surface hardness of carbonitrided parts ranges from 55 to 62 HRC.

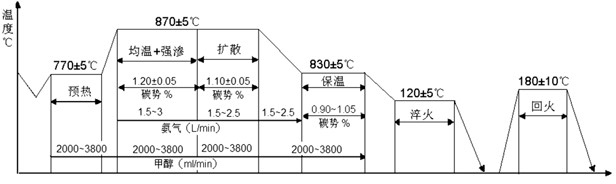

Medium-deep-layer carburization or carbonitriding thermal processing technology for bearings or clutch parts

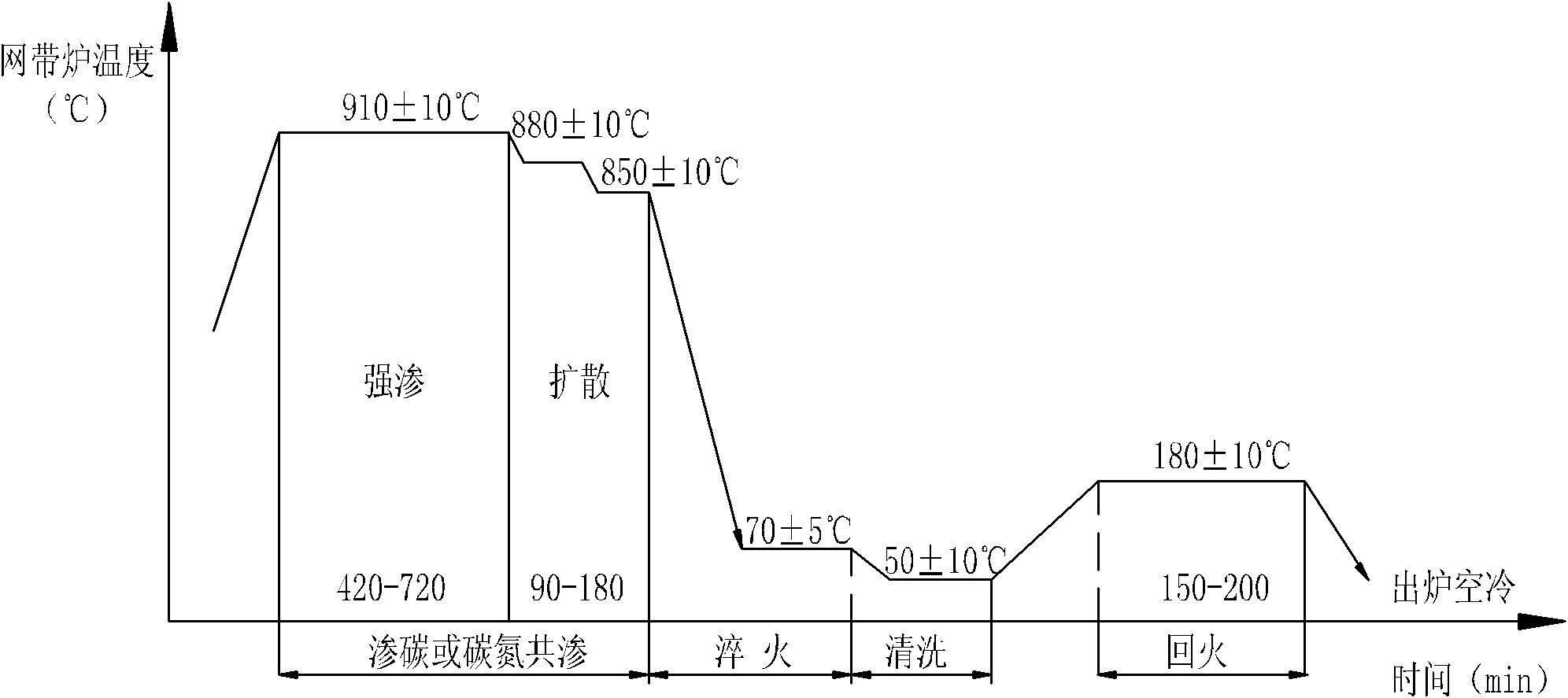

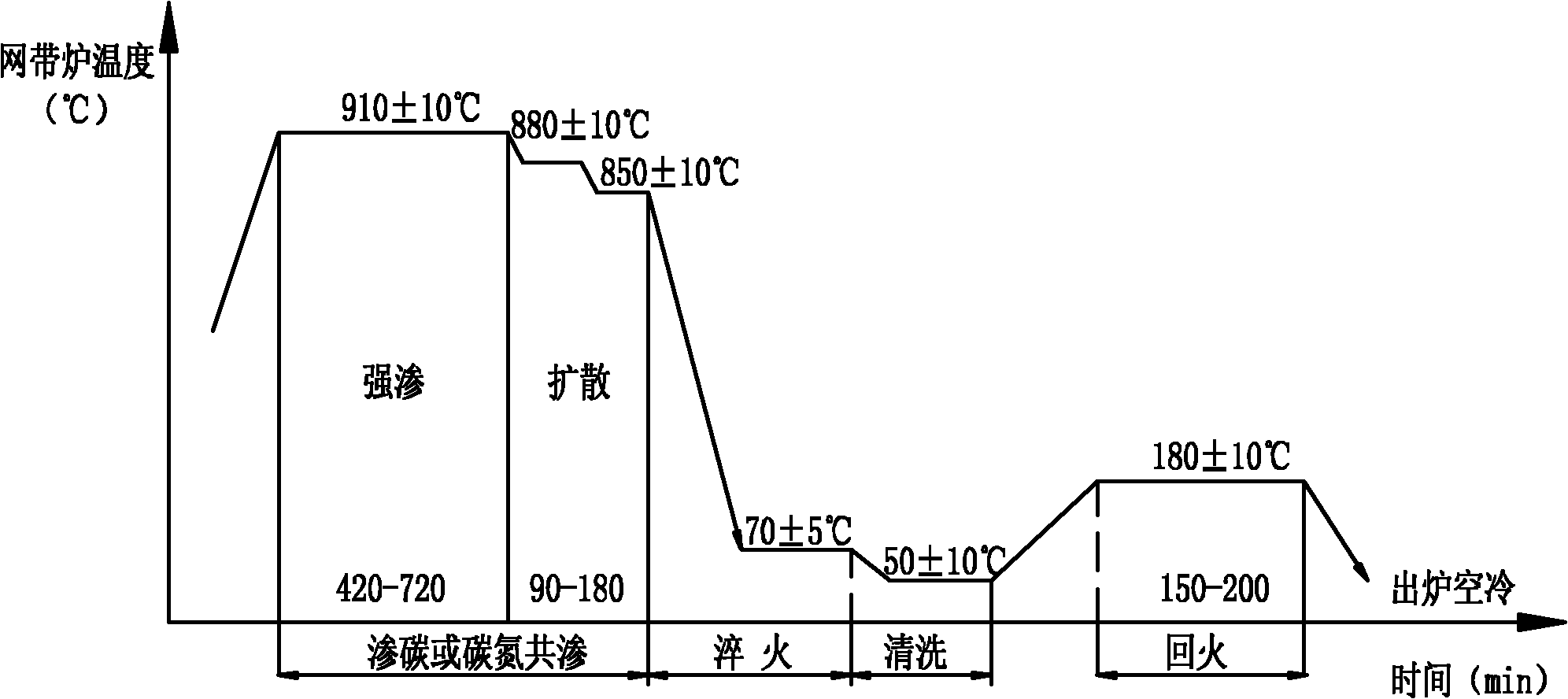

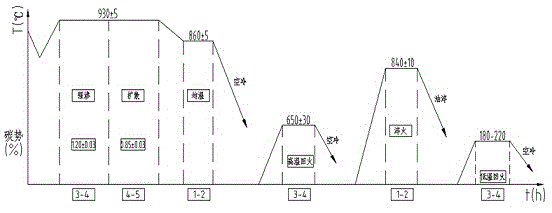

ActiveCN102154652ALess often openLess closing actionSolid state diffusion coatingFurnace typesProduction lineCarbon potential

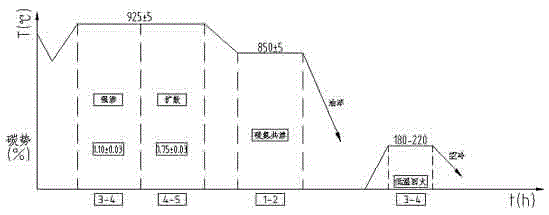

The invention relates to a medium-deep-layer carburization or carbonitriding thermal processing technology for bearings or clutch parts. In the invention, the carburization or carbonitriding is carried on parts by utilizing a continuous production line of a carrier roller type mesh belt furnace with a controllable atmosphere, and the technology comprises the following steps in sequence: strong permeation, diffusion, quenching, cleaning, low-temperature tempering, discharging and air cooling. In the invention, the continuous production line of the carrier roller type mesh belt furnace with the controllable atmosphere is used for carrying out the medium-deep-layer carburization or carbonitriding, thus continuous production is realized, the production efficiency is improved, the productivity is increased, frequent opening and closing actions of a gap furnace can be reduced, non-oxidization treatment is realized, and the labor intensity is reduced; and in addition, carbon potentials in all areas of the mesh belt furnace are respectively controlled so as to guarantee the quality stability.

Owner:JIANG SU NAN FANG BEARING CO LTD

High carbon chromium bearing parts surface chemical heat-treatment process

ActiveCN1804128AHigh surface hardnessIncrease compressive stressSolid state diffusion coatingFurnace typesHigh carbonIn vehicle

The disclosed surface chemical thermal treatment technique for a high-C-Cr bearing comprises: setting parameters, front cleaning, pre-oxidizing, heating, carbonitriding, cooling to diffuse, quenching, and tempering. This invention uses the treatment device in vehicle and motor cycle gear process to form one layer with special tissue and improve contact fatigue strength and surface hardness.

Owner:CHONGQING CHANGJIANG BEARING

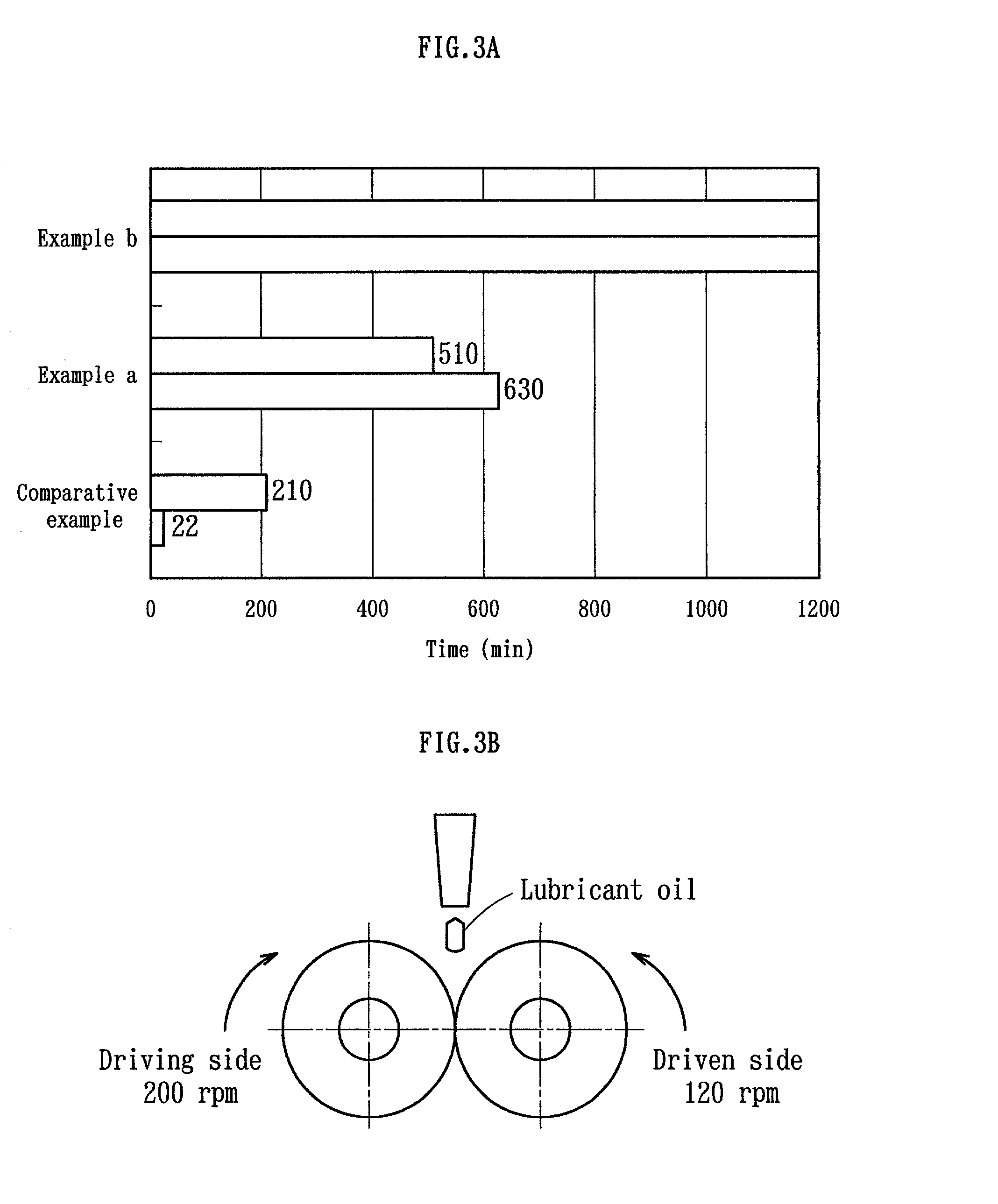

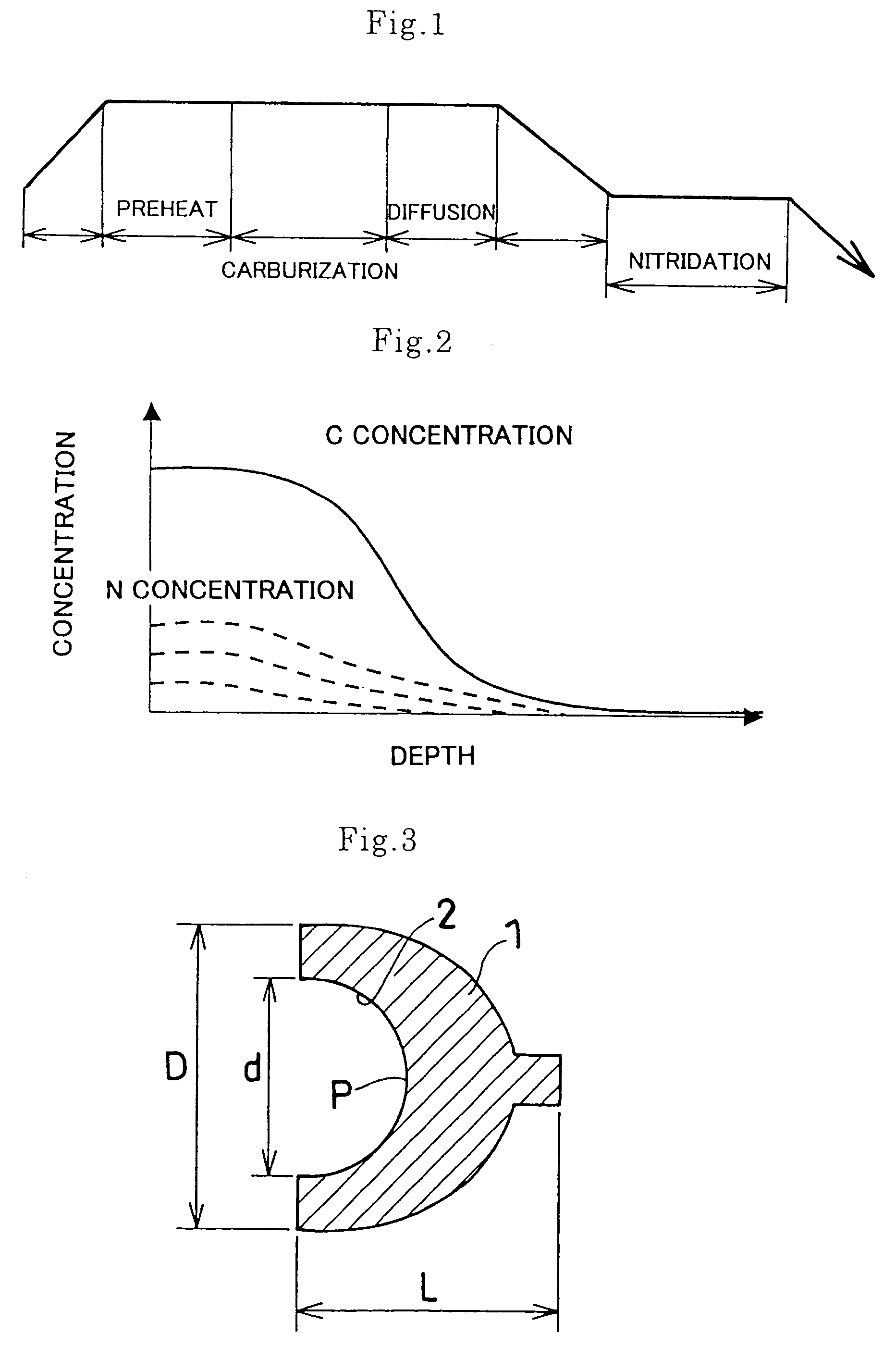

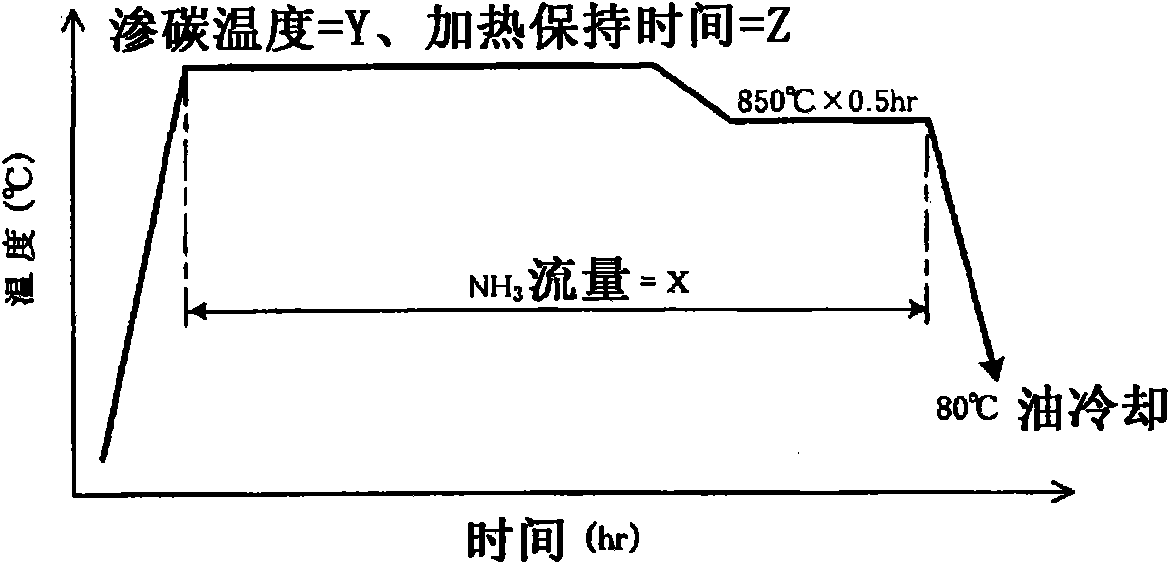

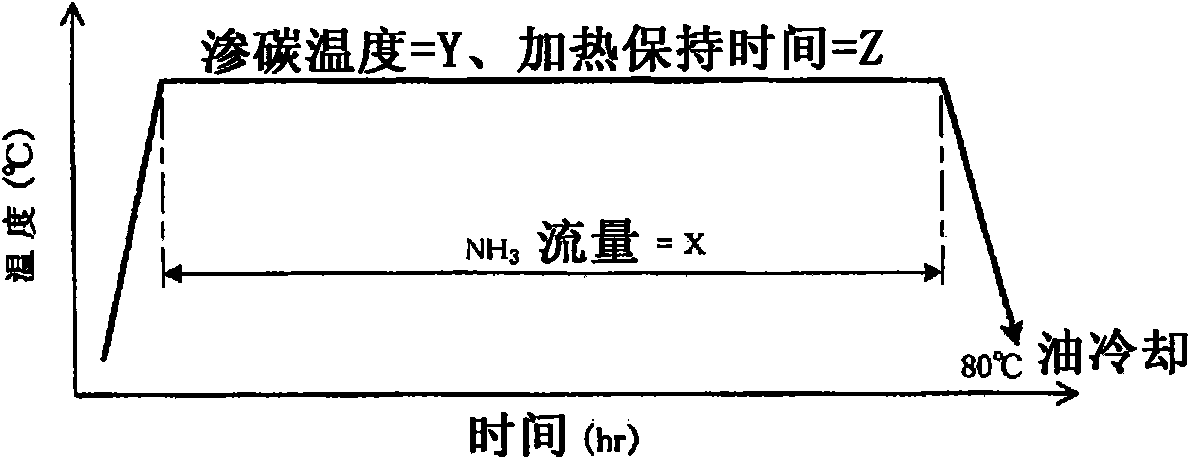

Carbonitriding method, machinery component fabrication method, and machinery component

ActiveUS20100154937A1Improves nitrogen permeating rateReduce manufacturing costBearing componentsSolid state diffusion coatingNitrogenEngineering

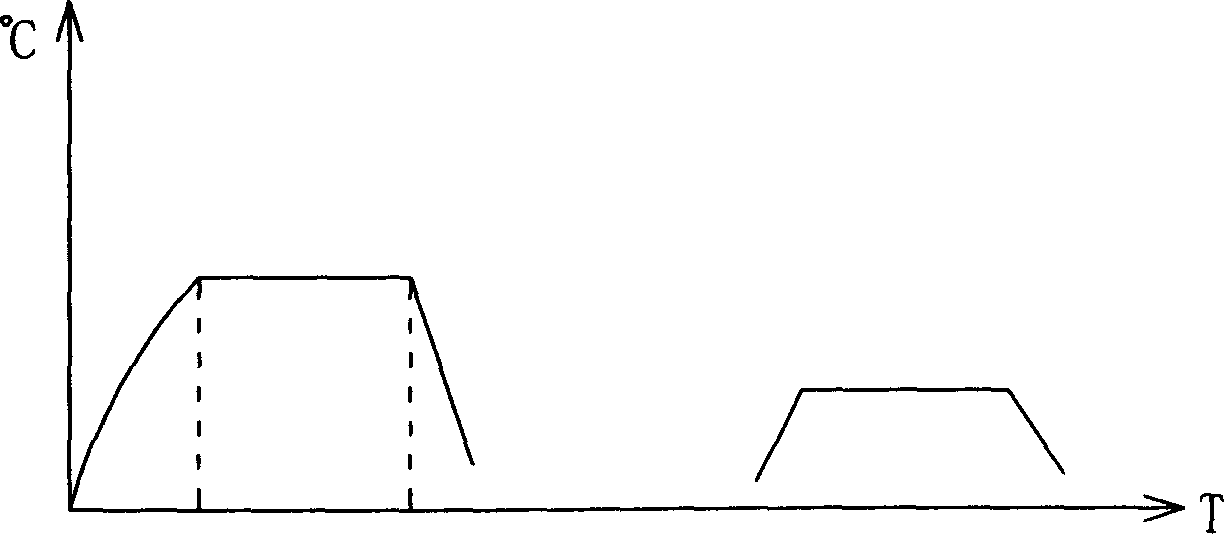

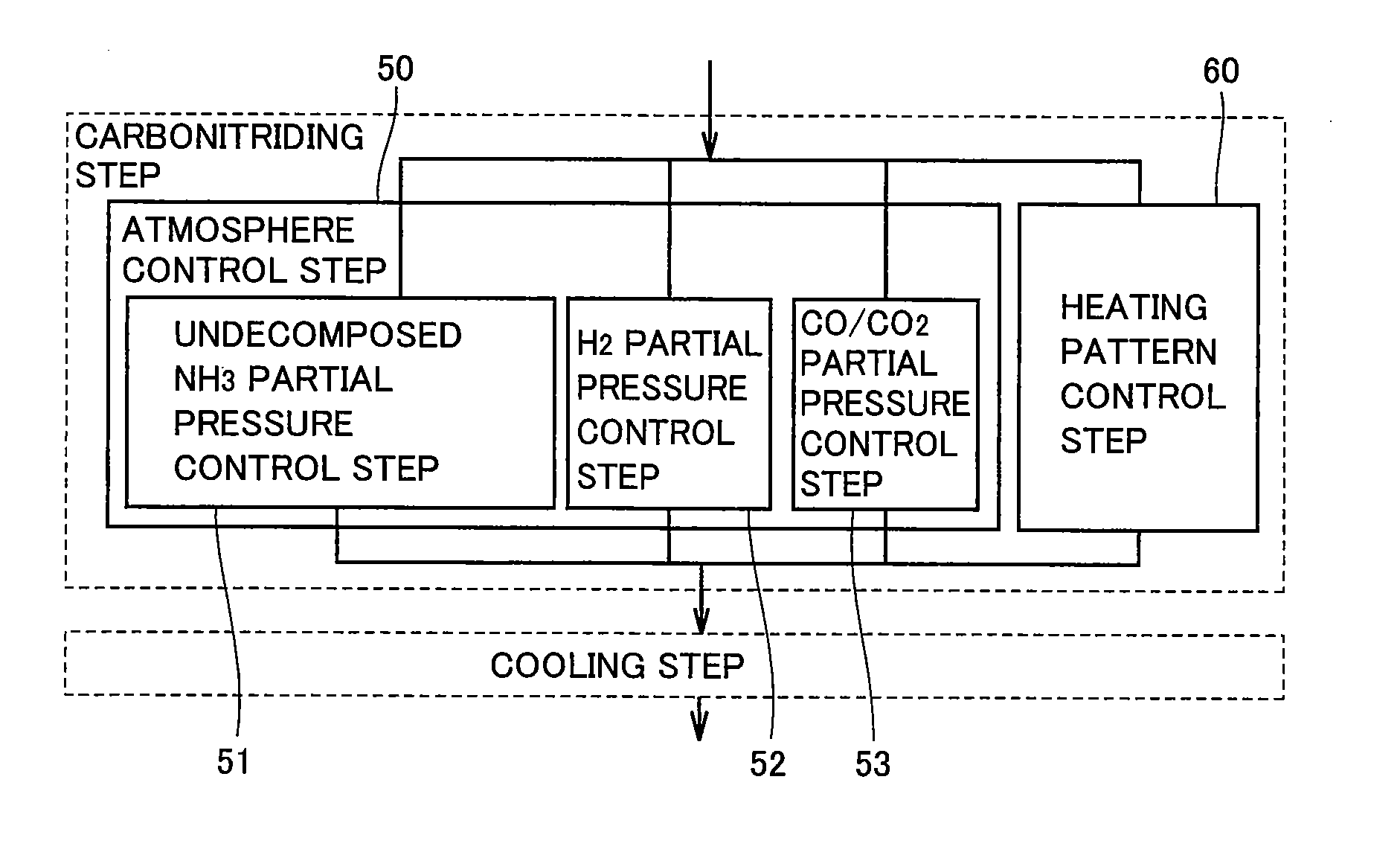

A carbonitriding method that can improve the nitrogen permeating rate to render the carbonitriding process effective includes an atmosphere control step (50), and a heating pattern control step (60). The atmosphere control step (50) includes an undecomposed NH3 partial pressure control step (51), and a CO / CO2 partial pressure control step (53). The undecomposed NH3 partial pressure control step (51) and the CO / CO2 partial pressure control step (53) are carried out in the atmosphere control step (50) such that ac* defined by the following equation (1) is at least 0.88 and not more than 1.27, and α defined by equation (2) is at least 0.012 and not more than 0.020, where PN is the undecomposed ammonia partial pressure and PH is the hydrogen partial pressure in the heat treatment furnace, whereinac*=(Pco)2K×Pco2(1)PCO: partial pressure of carbon dioxide (atm), PCO<sub2>2< / sub2>: partial pressure of carbon dioxide (atm)K: equlibrium constant at <C>+CO22COα=PN0.006×(PH)32×(1.877-1.055×ac*)100(2)

Owner:NTN CORP

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

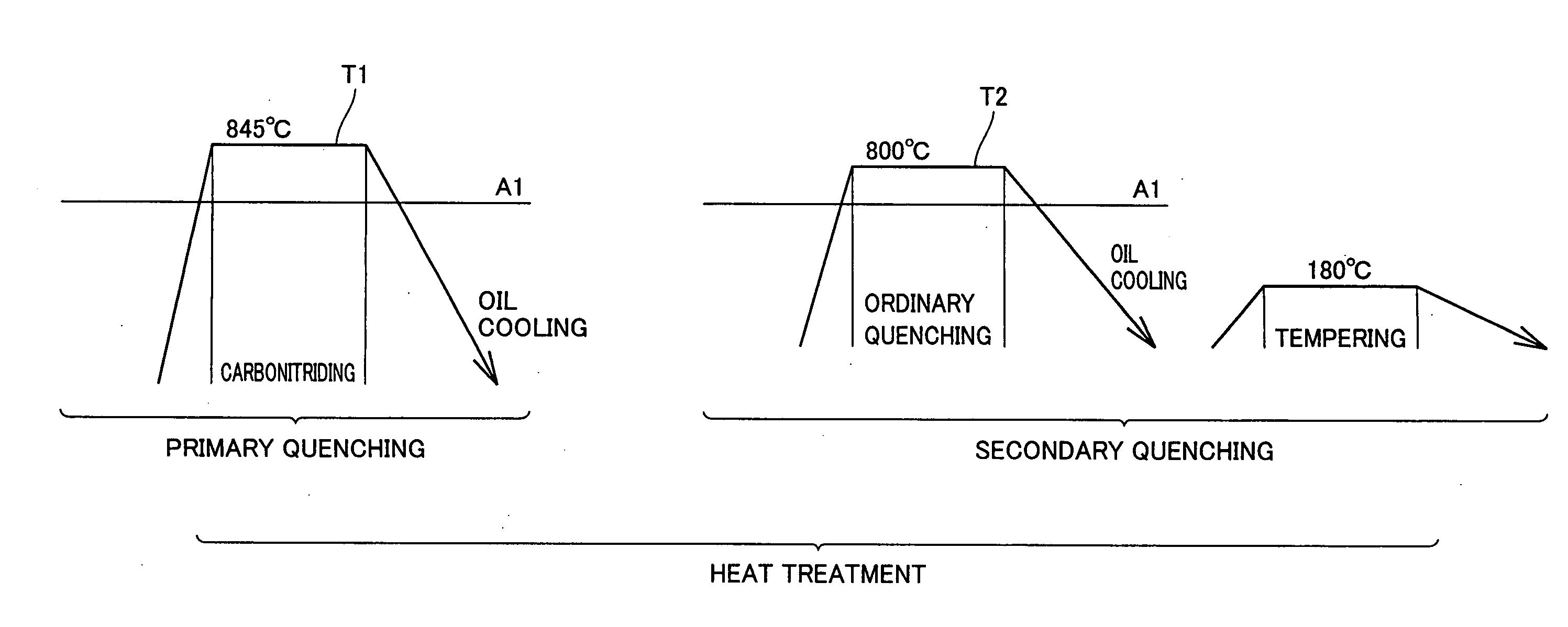

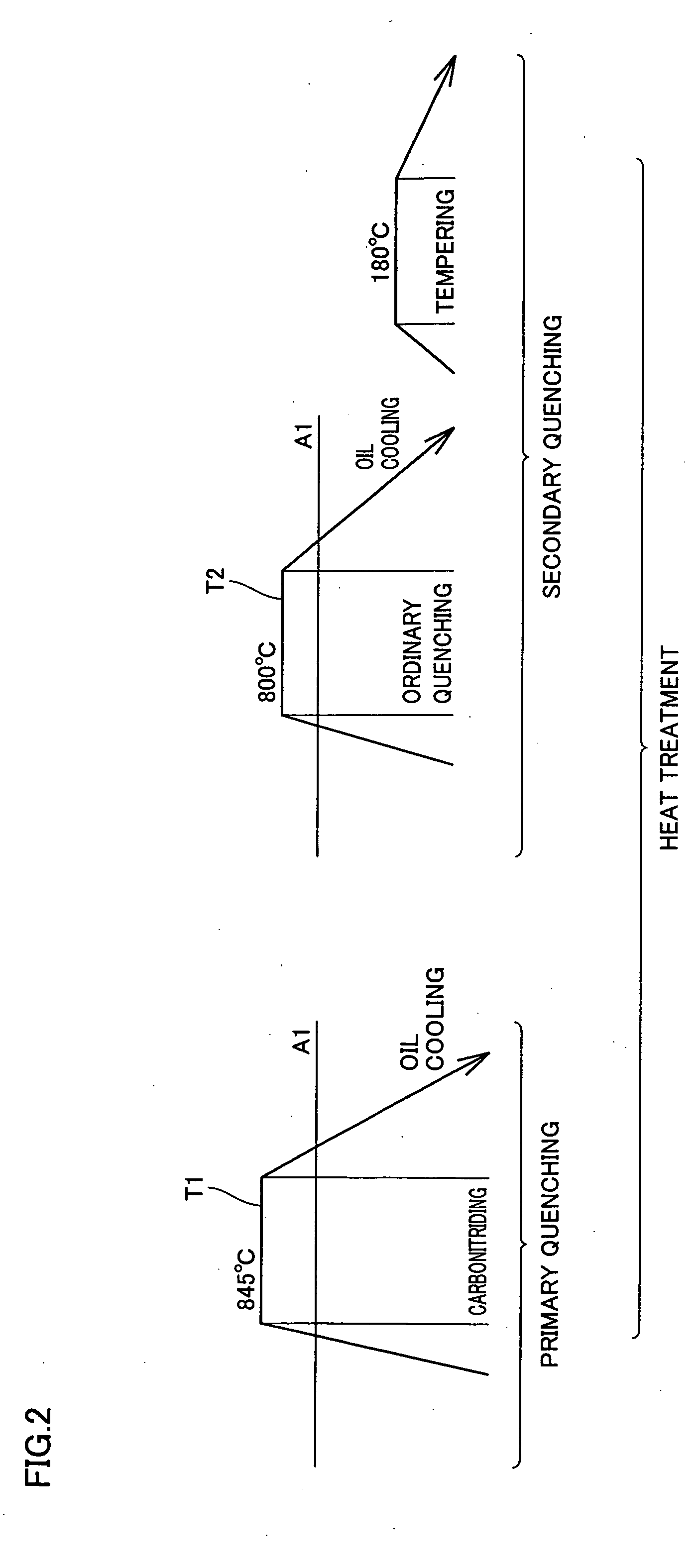

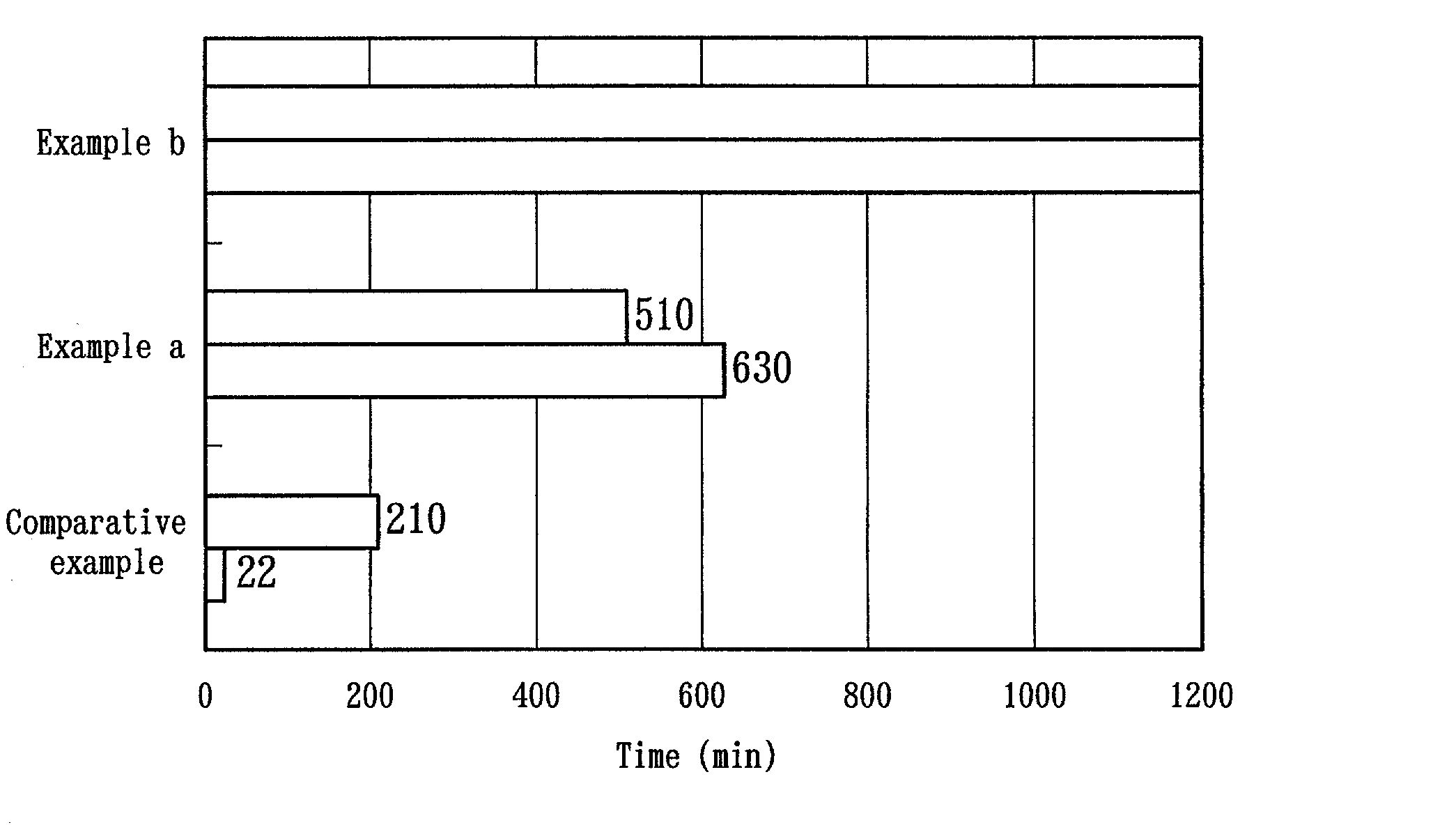

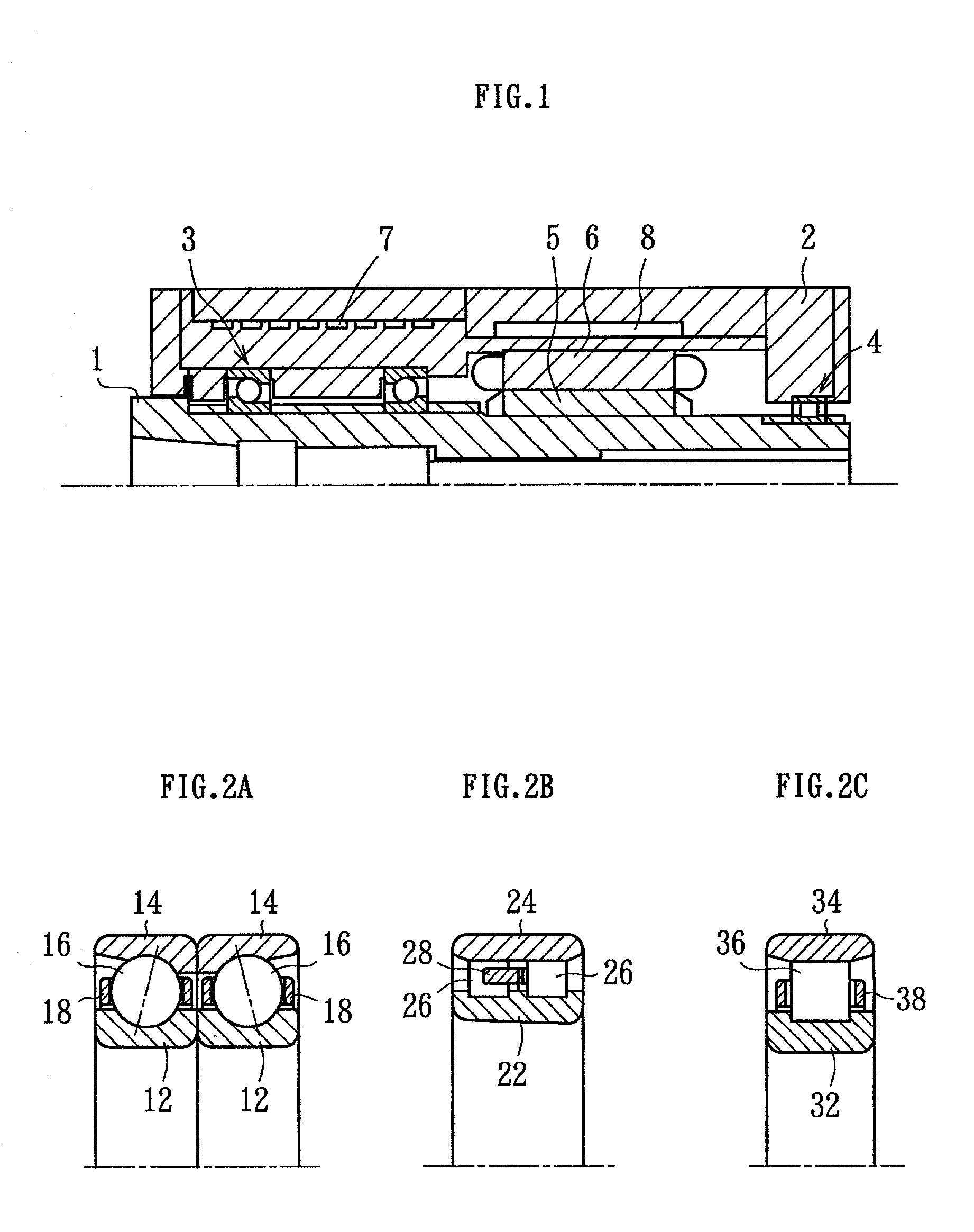

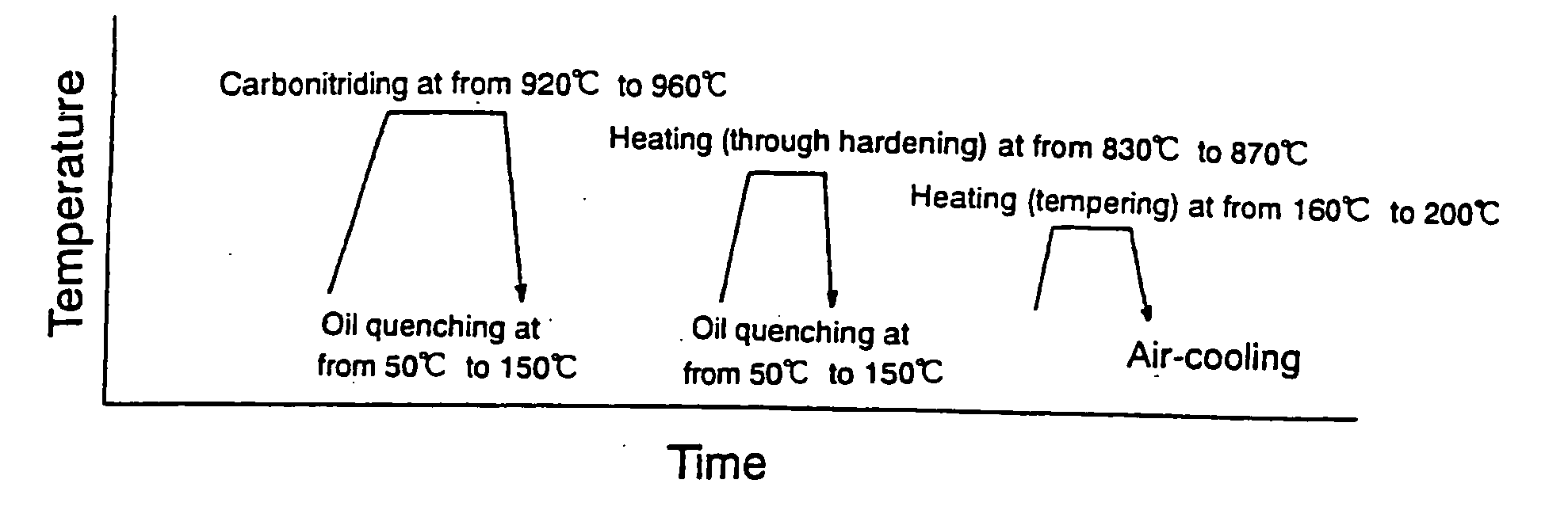

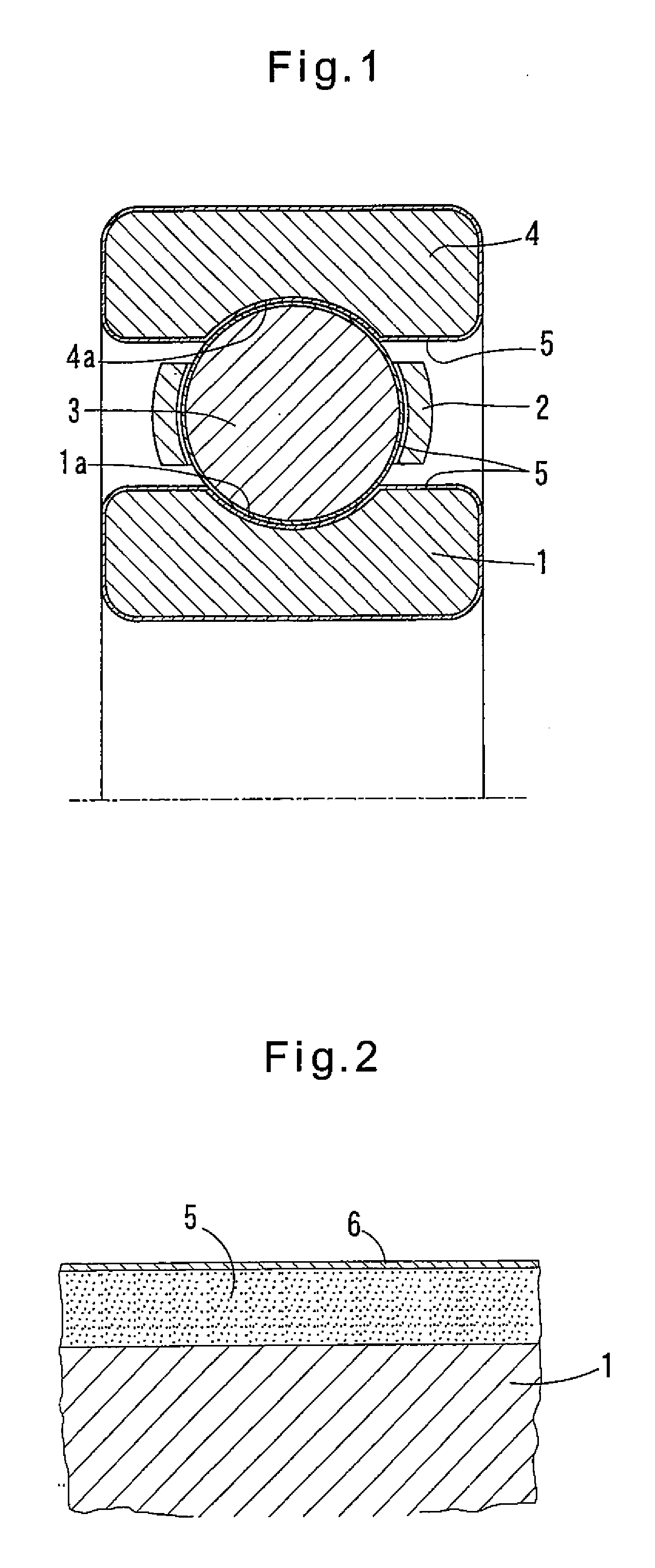

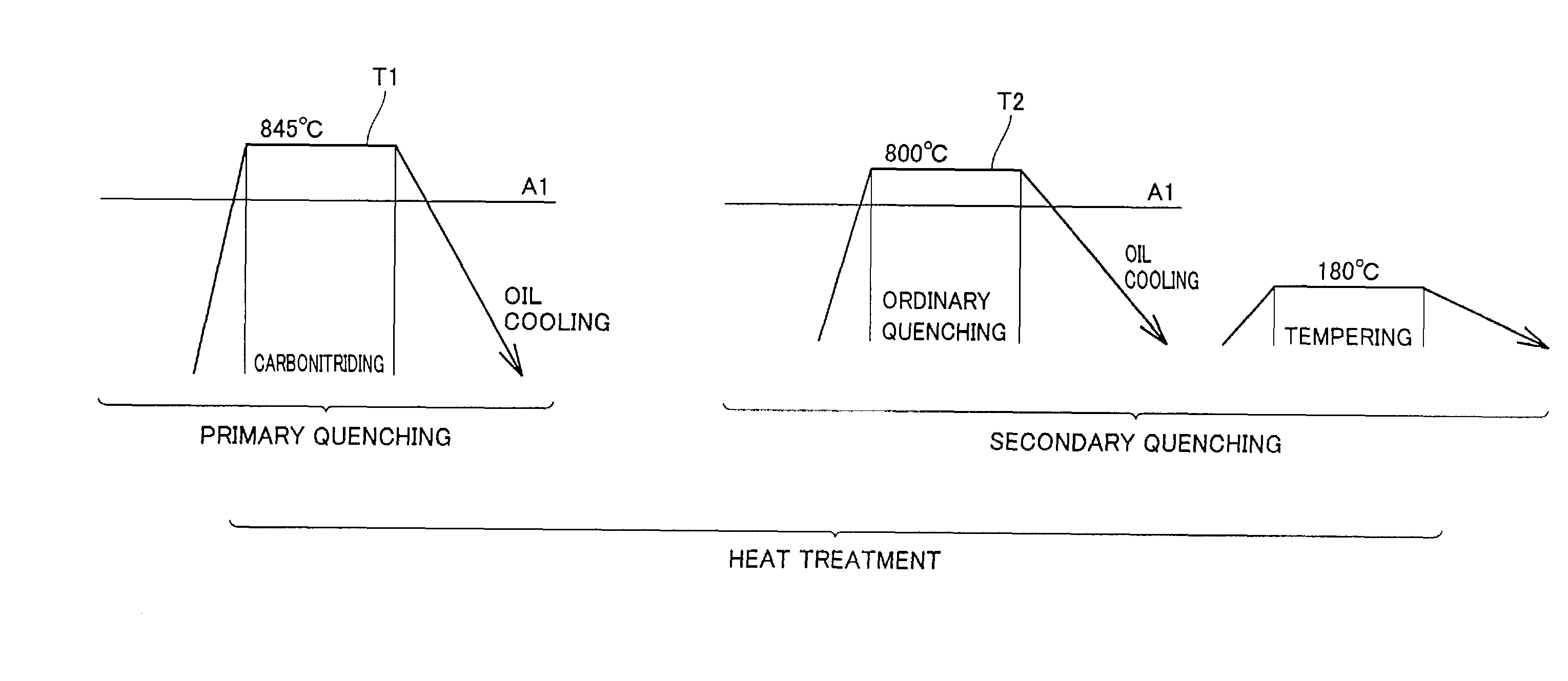

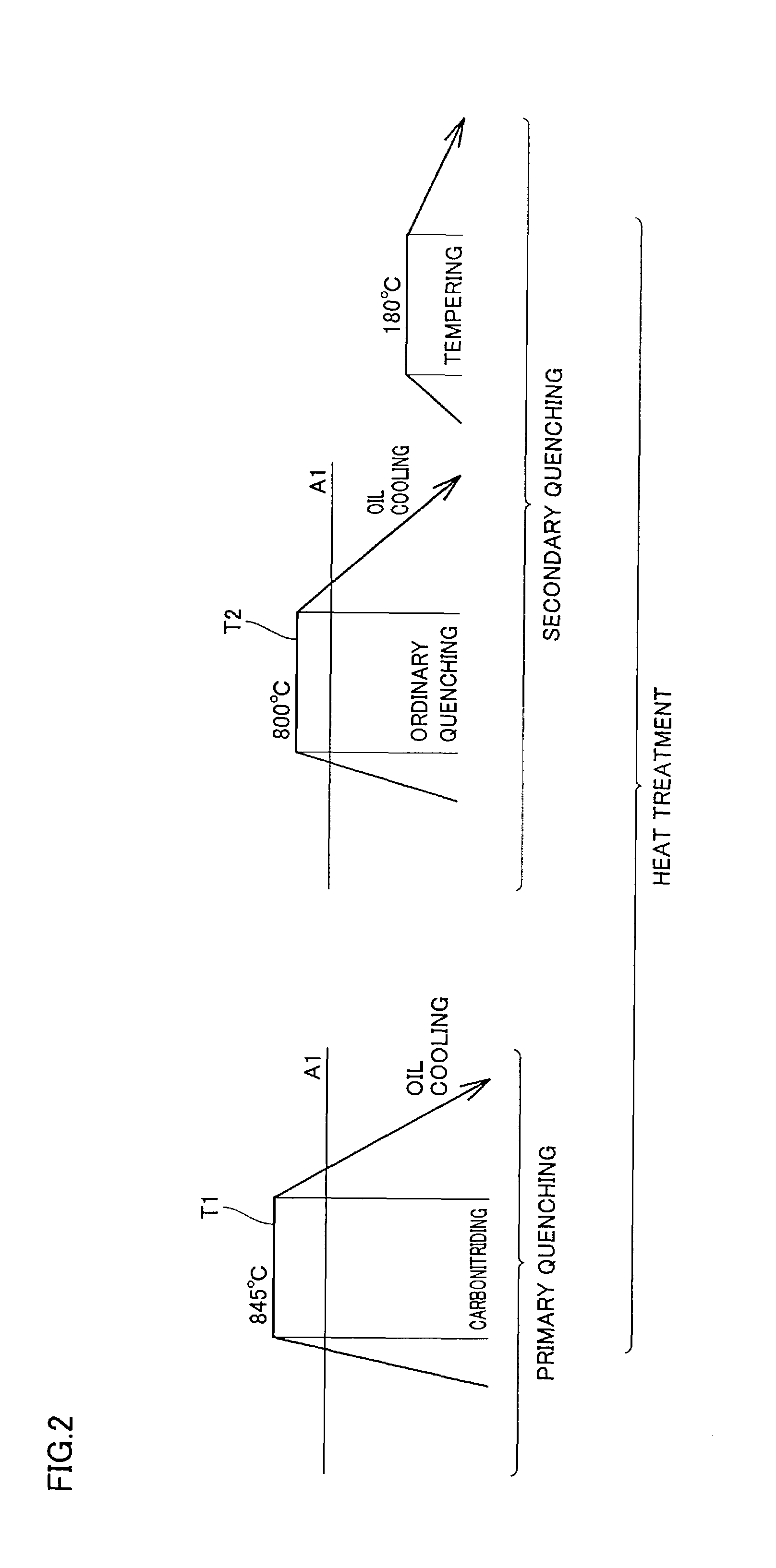

Bearing's component, heat treatment method thereof, heat treatment apparatus, and rolling bearing

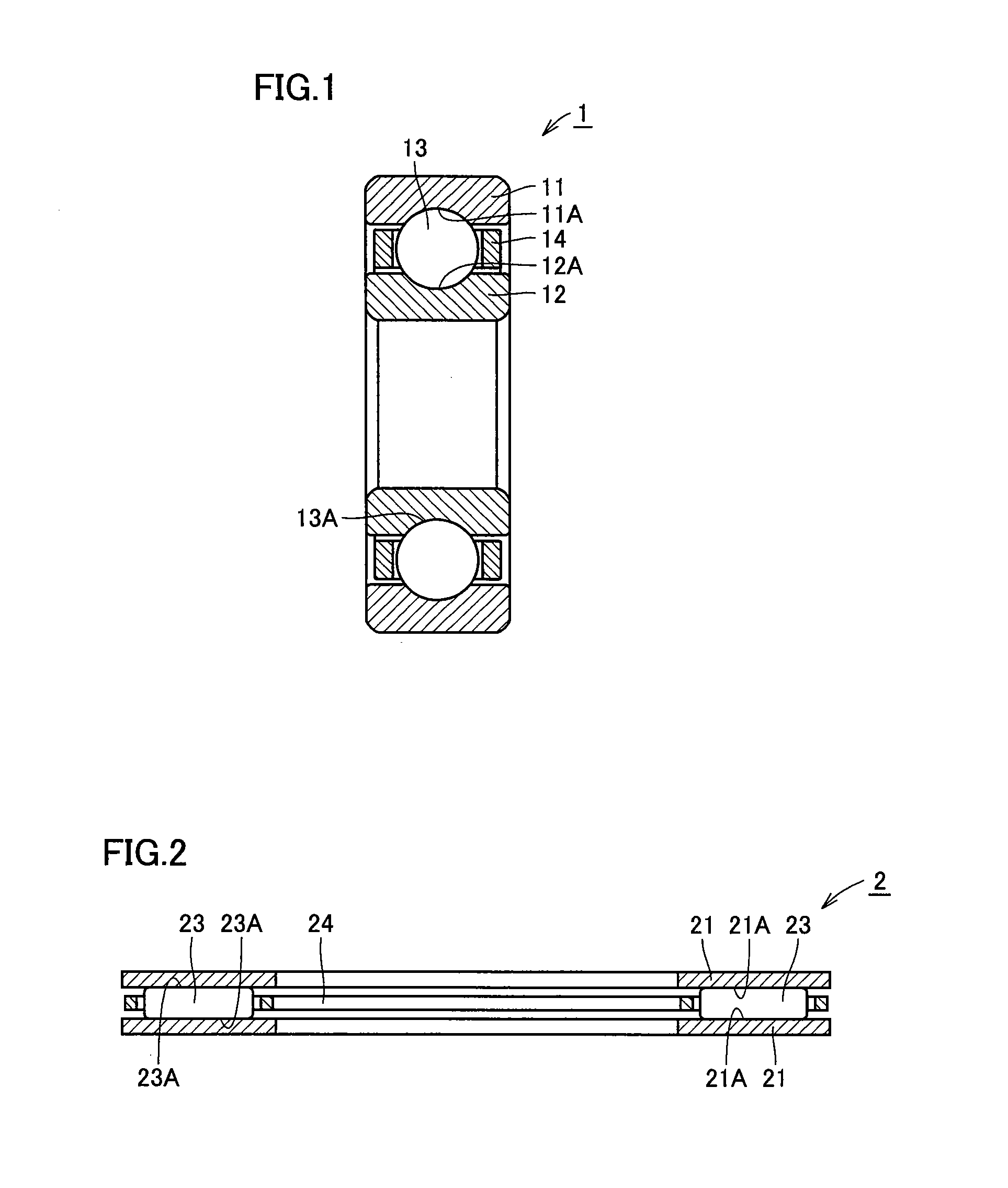

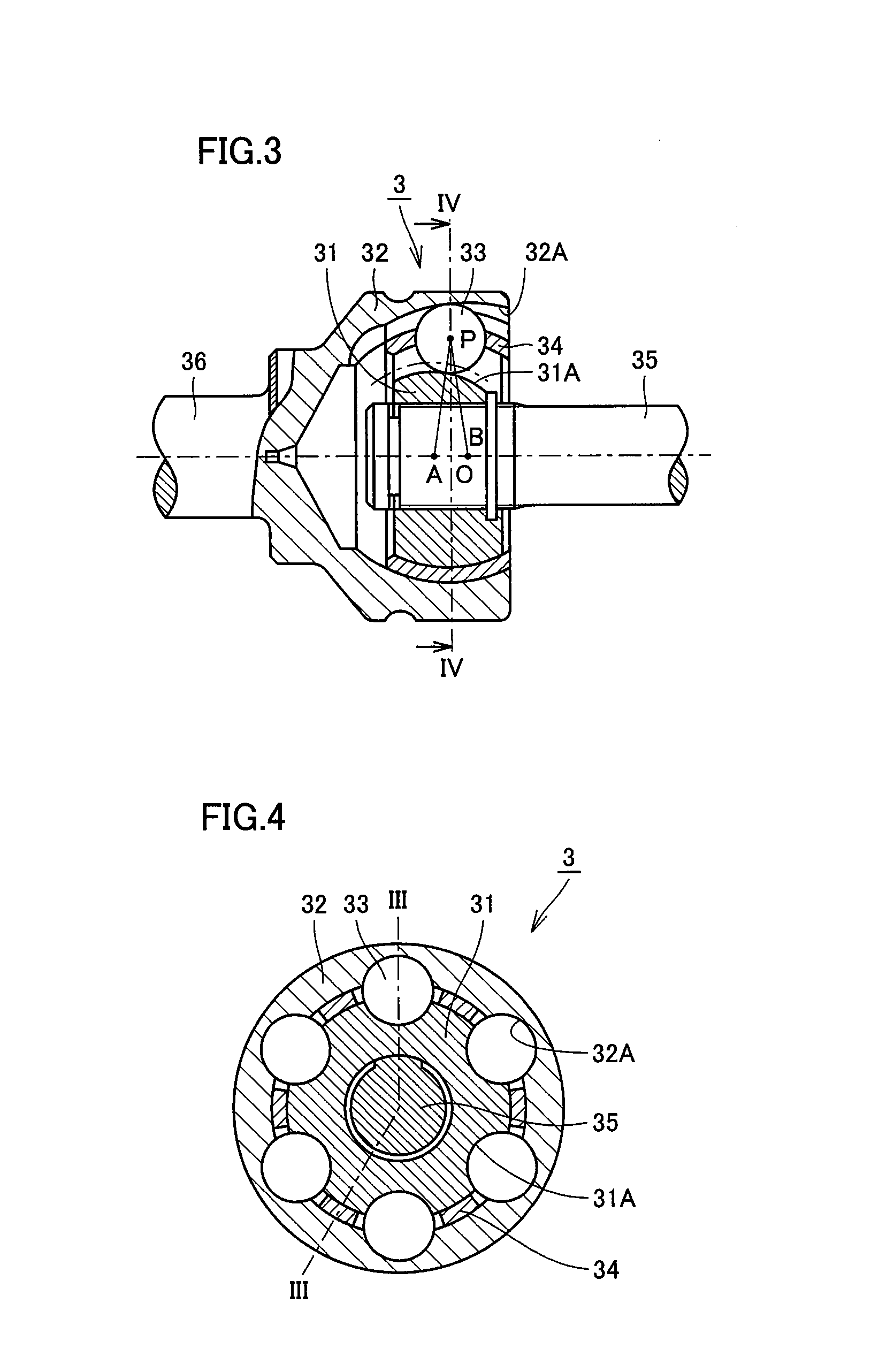

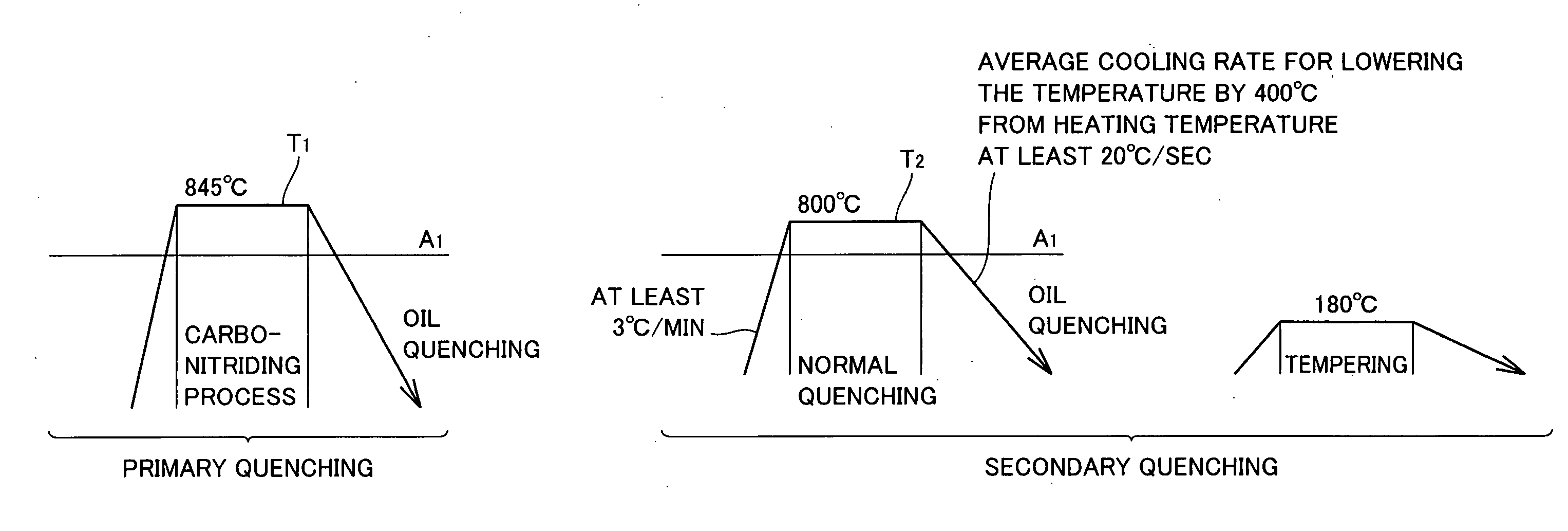

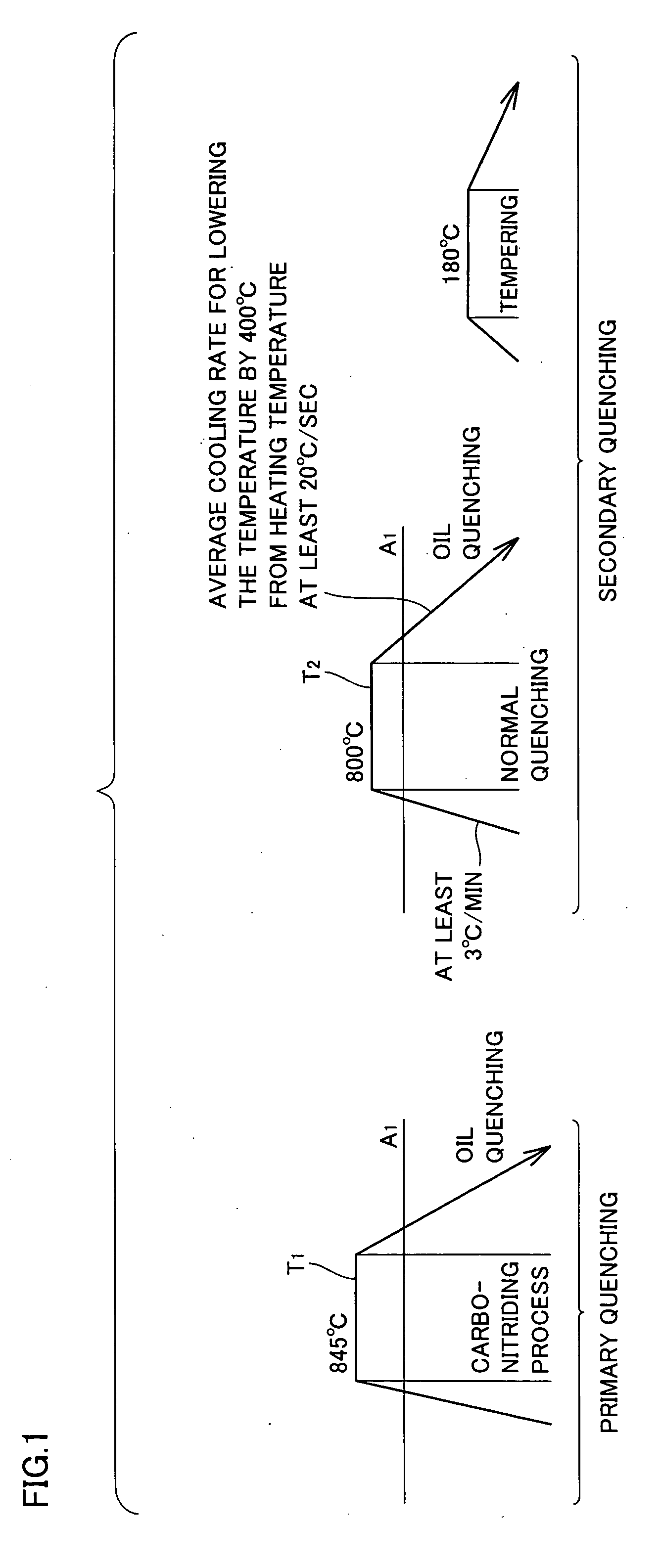

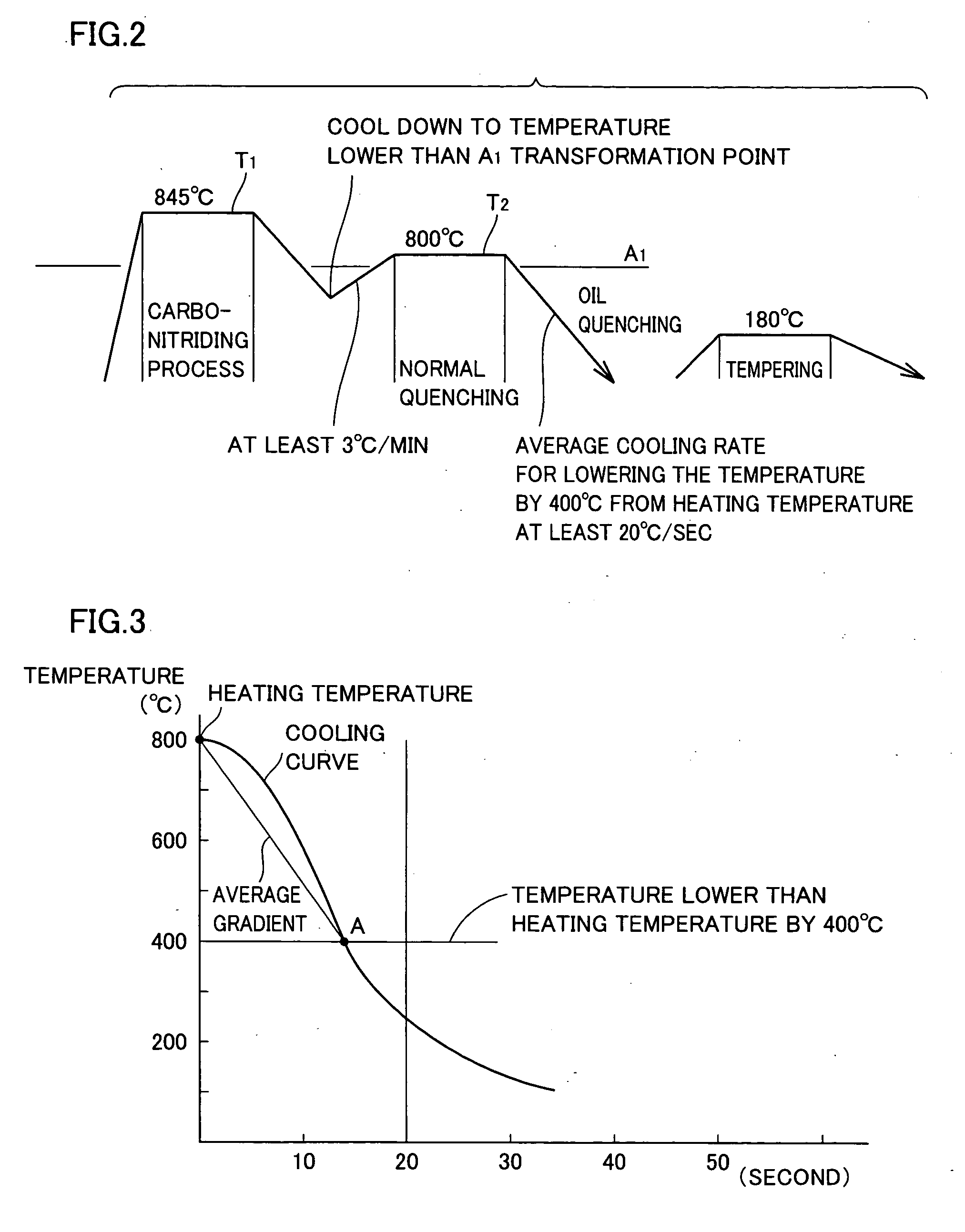

ActiveUS20050045247A1Improve cracking strengthReduced long-term dimensional variation rateShaftsBearing componentsRolling contact fatigueUltimate tensile strength

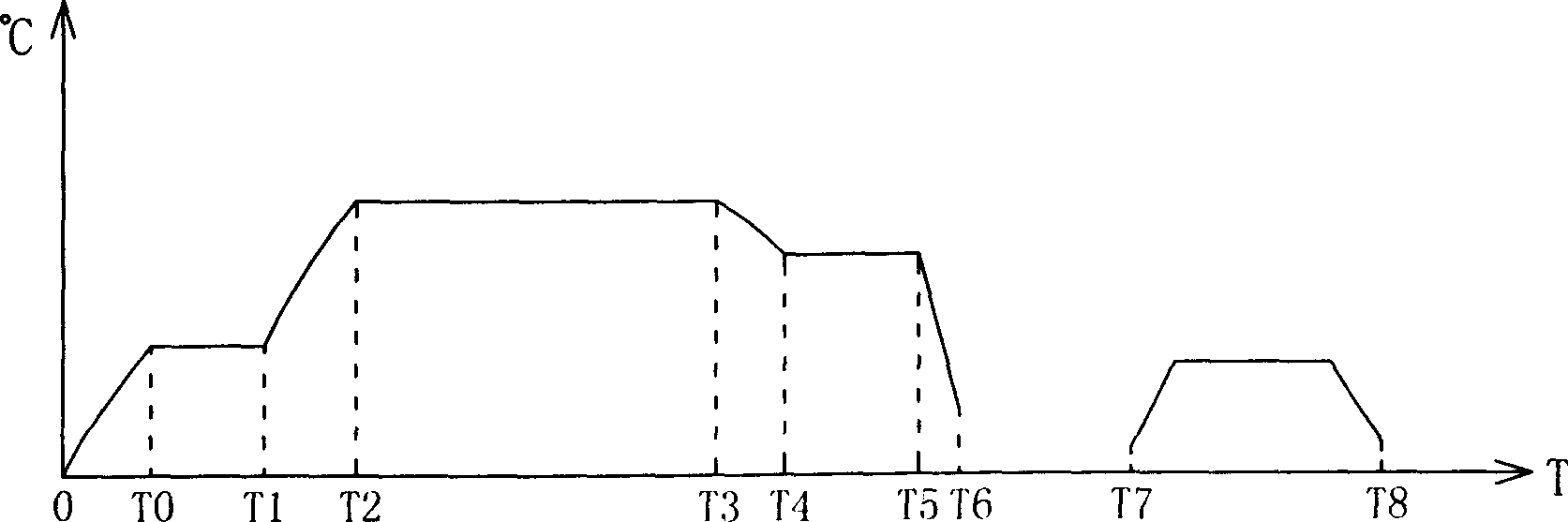

Obtain a bearing's component, a heat treatment method thereof, and a rolling bearing having a long life against rolling contact fatigue and high anti-crack strength, and suppressed long-term dimensional variation rate. The bearing's component is carbonitrided at a carbonitriding temperature higher than an A1 transformation point of steel for the bearing's component and then cooled to a temperature lower than the A1 transformation point, and subsequently, using a heat treatment apparatus that successively moves and heats each individual bearing's component, reheated to a range of quenching temperature of no less than the A1 transformation point and less than the carbonitriding temperature to be quenched.

Owner:NTN CORP

Bearing part, heat treatment method thereof, and rolling bearing

ActiveUS20050205163A1Solution to short lifeImprove cracking strengthShaftsBall bearingsQuenchingTransition temperature

A bearing part comprising steel subjected to carbonitriding at a carbonitriding temperature exceeding the A1 transformation temperature, and cooled to a temperature lower than the A1 transformation temperature. The steel is reheated to a temperature for quenching that is not lower than the A1 transformation temperature but lower than the carbonitriding temperature, and then quenched.

Owner:NTN CORP

Bearing for main spindle of machine tool

InactiveUS20020066502A1Excellent rolling fatigue resistanceReduce manufacturing costRoller bearingsBall bearingsHardnessMachine tool

A bearing for use in the main spindle of a machine tool is provide, in which at least the raceway of the bearing contains by mass, C: 0.6-1.3%, Si: 0.3-3.0%, Mn: 0.2-1.5%, P: 0.03% or less, S: 0.03% or less, Cr: 0.3-5.0%, Ni: 0.1-3.0%, Al: 0.050% or less, Ti: 0.003% or less, O: 0.0015% or less, N: 0.015% or less; and the rest is composed of Fe and unavoidable impurities. The raceway is tempered after either quenching or carbonitriding and its surface hardness presents at least HRC 58 after tempering.

Owner:NTN CORP

Heat treatment process of metal workpiece

ActiveCN102230151AHigh strengthSolve the problem of durable pitting wearSolid state diffusion coatingTemperingShielding gas

The invention provides a heat treatment process of a metal workpiece. The heat treatment process comprises the following steps: firstly preheating the workpiece to be treated in the presence of shielding gas; heating for carbonitriding; quenching; and tempering and cooling. The heat-treated workpiece has the advantages of high strength and good wear resistance; and a durability test and a main physiochemical performance test show that the workpiece meets technological requirements.

Owner:新大洲本田摩托(苏州)有限公司

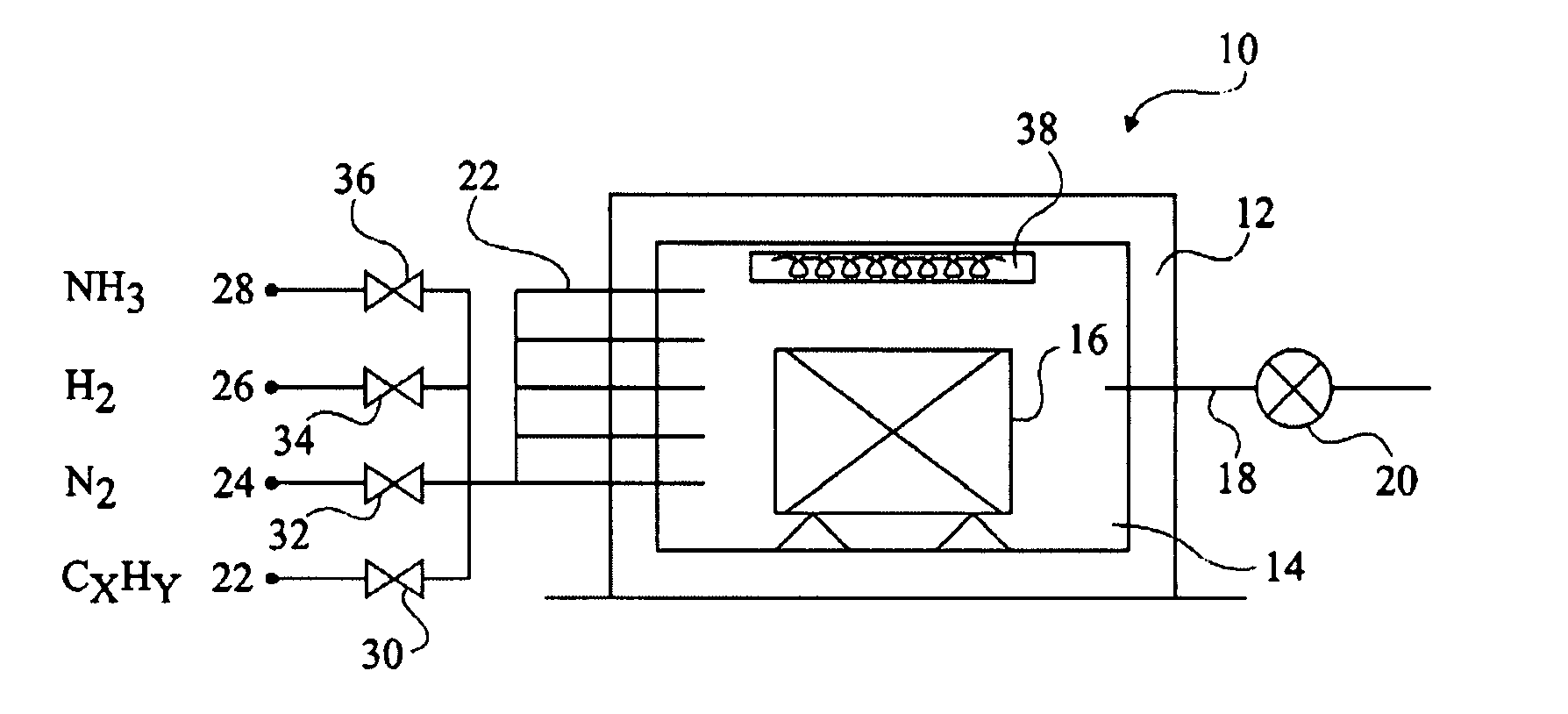

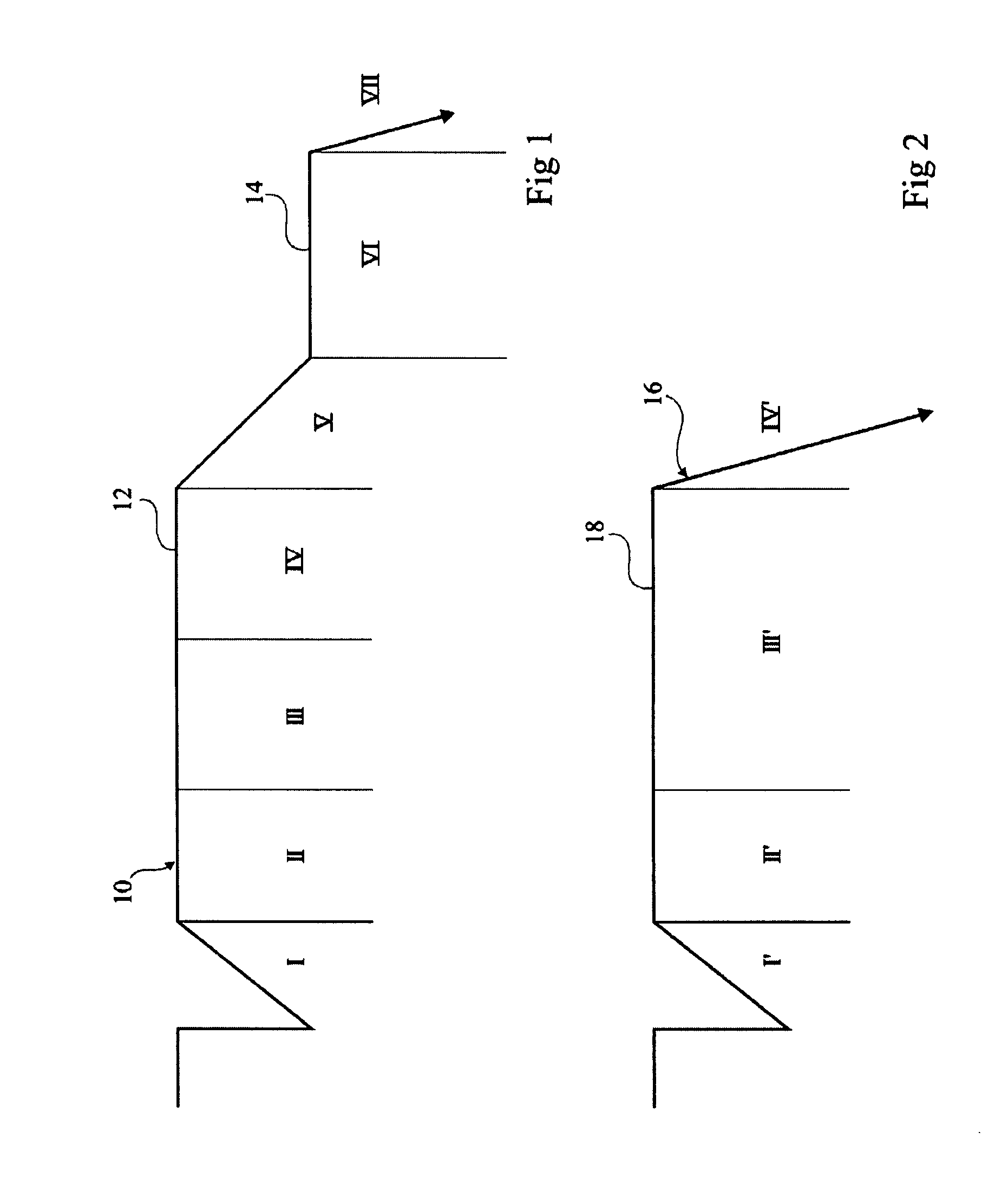

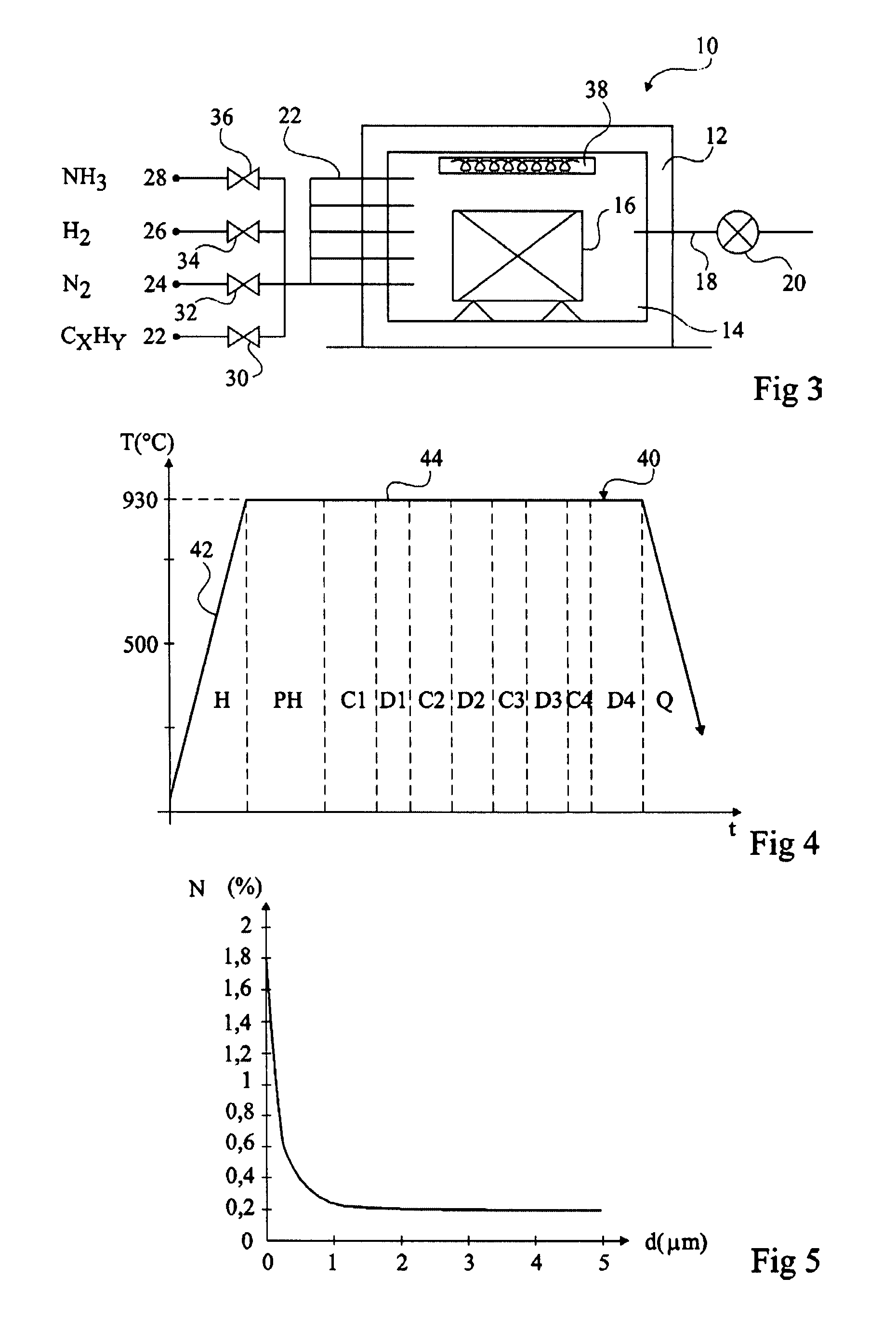

Low pressure carbonitriding method and device

ActiveUS20110036462A1Accurately and reproducibly obtainingSimple designLiquid surface applicatorsSolid state diffusion coatingInternal pressureNitrogen

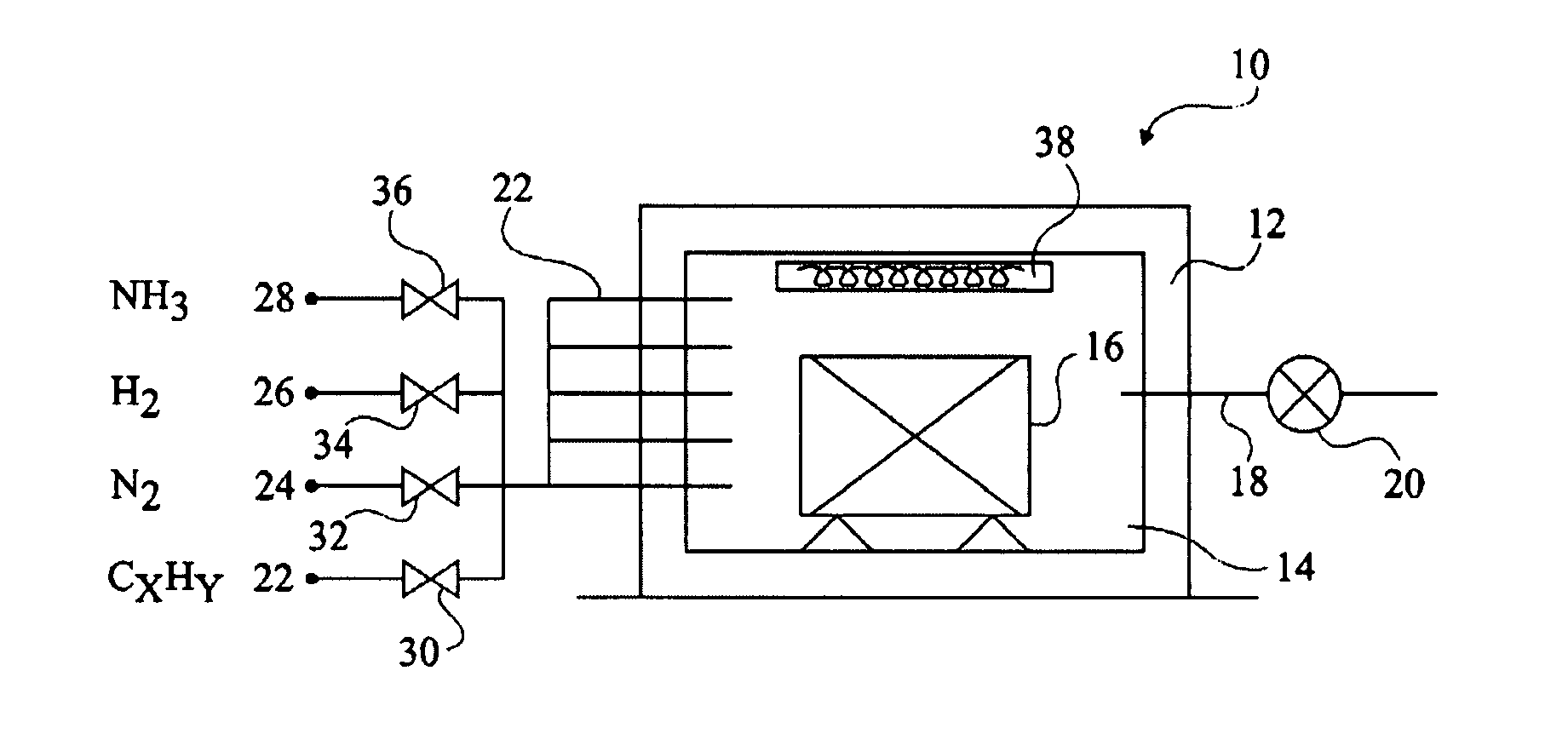

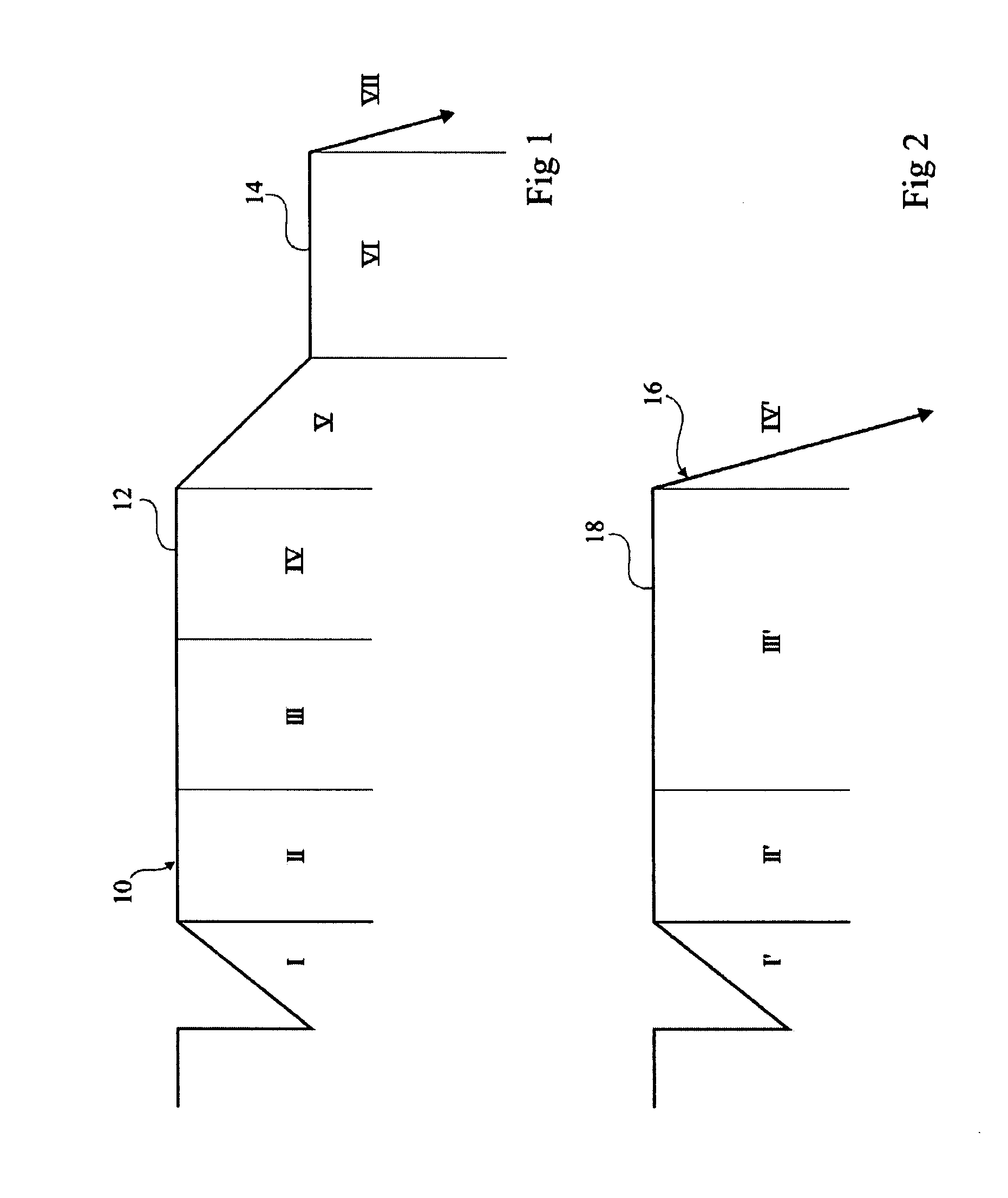

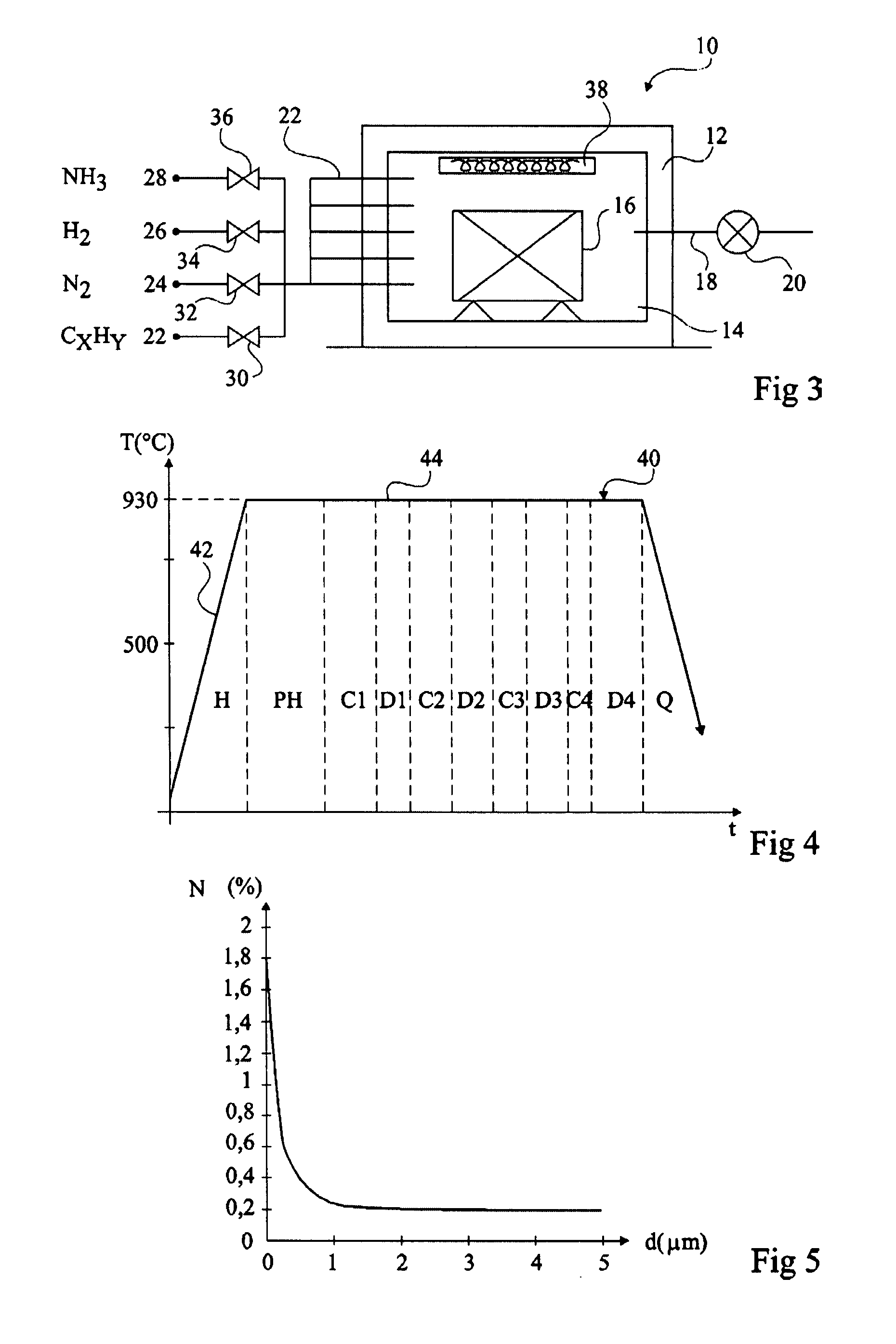

A method for carbonitriding a steel part arranged in an enclosure maintained at a reduced internal pressure, the part being maintained at a temperature level, comprising an alternation of first and second steps, a carburizing gas being injected into the enclosure during the first steps only and a nitriding gas being injected into the enclosure only during at least part of at least two second steps.

Owner:ECM TECHNOLOGY PTY LTD

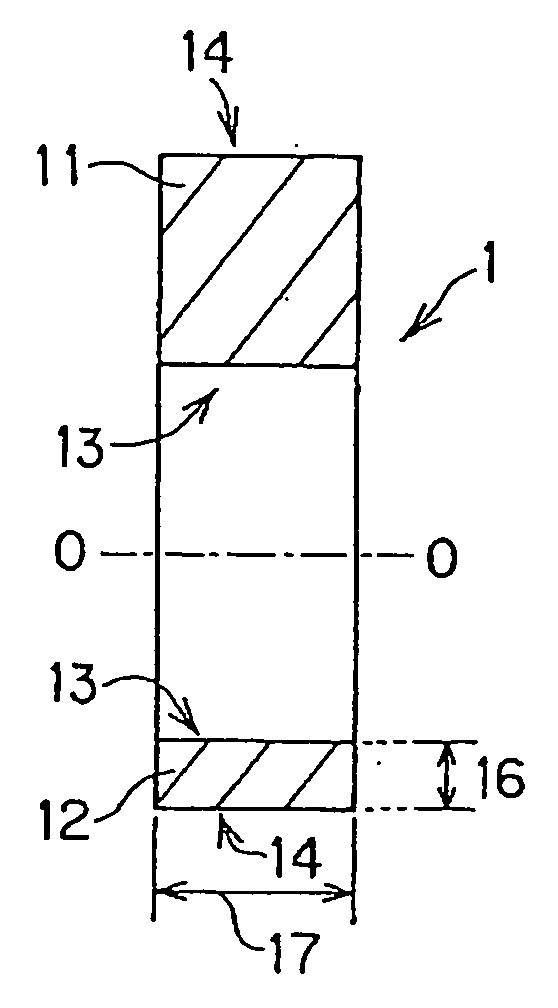

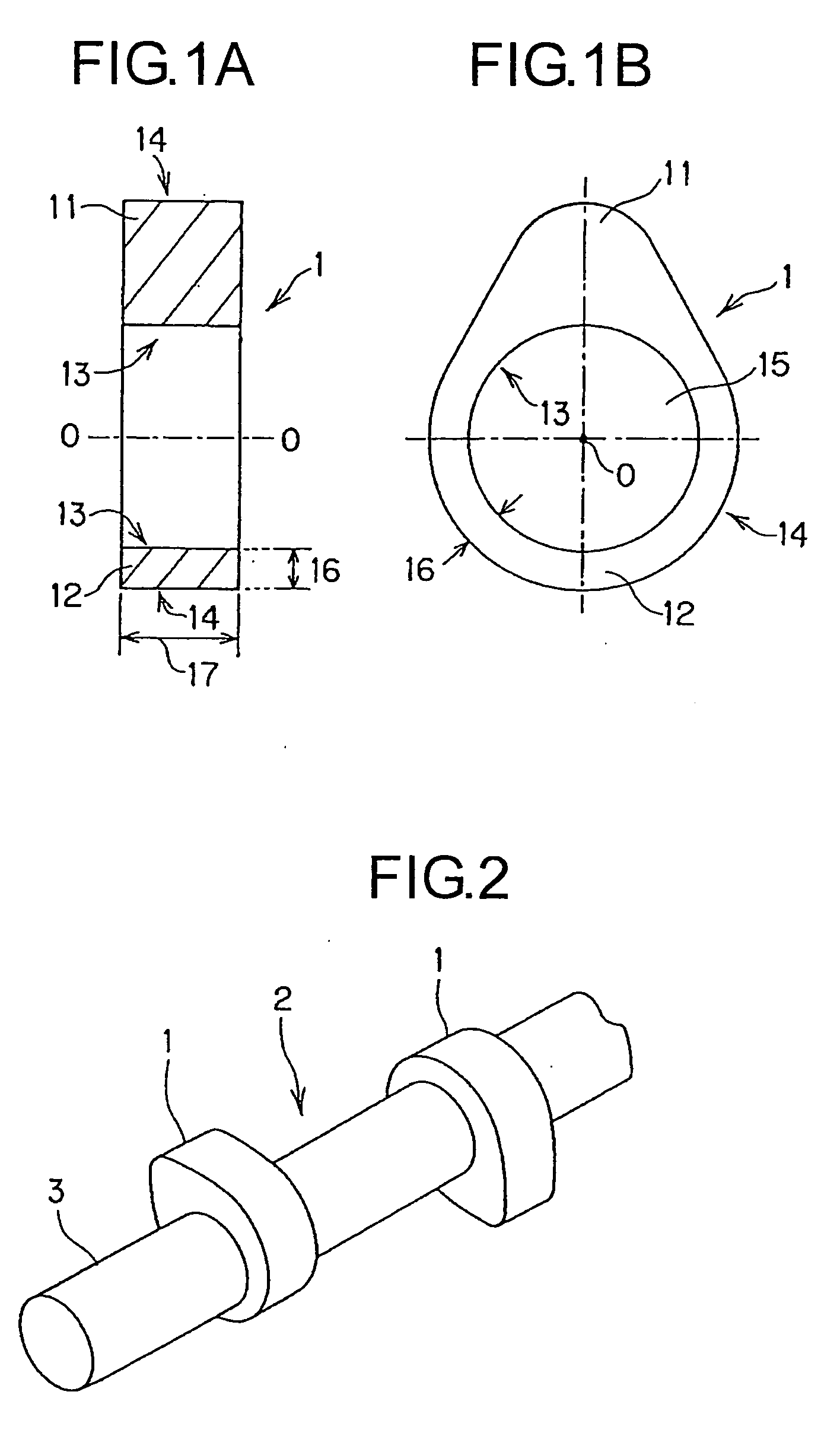

Method of Manufacturing Cam Shaft, Cam Shaft, and Cam Lobe Material Used in the Same

InactiveUS20080276753A1Expand allowanceReduce wall thicknessCamsValve drivesMetallurgyDegrees of freedom

A method of manufacturing a cam shaft that prevents cracks during the joining of a cam lobe to a shaft, and improves the degree of freedom of design of the cam lobe is provided.By a method of manufacturing a cam shaft that after an inner circumferential surface 13 of a cam lobe 1 is subjected to treatment for residual compressive stress addition treatment, the cam lob 1 is joined to a shaft, above problem is solved. It is preferred that the residual compressive stress on the inner circumferential surface 13 of the cam lobe 1 is not less than 100 MPa. In addition, an outer peripheral surface 14 of the cam lobe 1 can be also subjected to treatment for residual compressive stress addition treatment. As the treatment for residual compressive stress addition treatment, shot-peening treatment, induction hardening treatment, barrel polishing treatment, carburizing and quenching treatment or carbonitriding treatment is performed.

Owner:NIPPON PISTONRING CO LTD

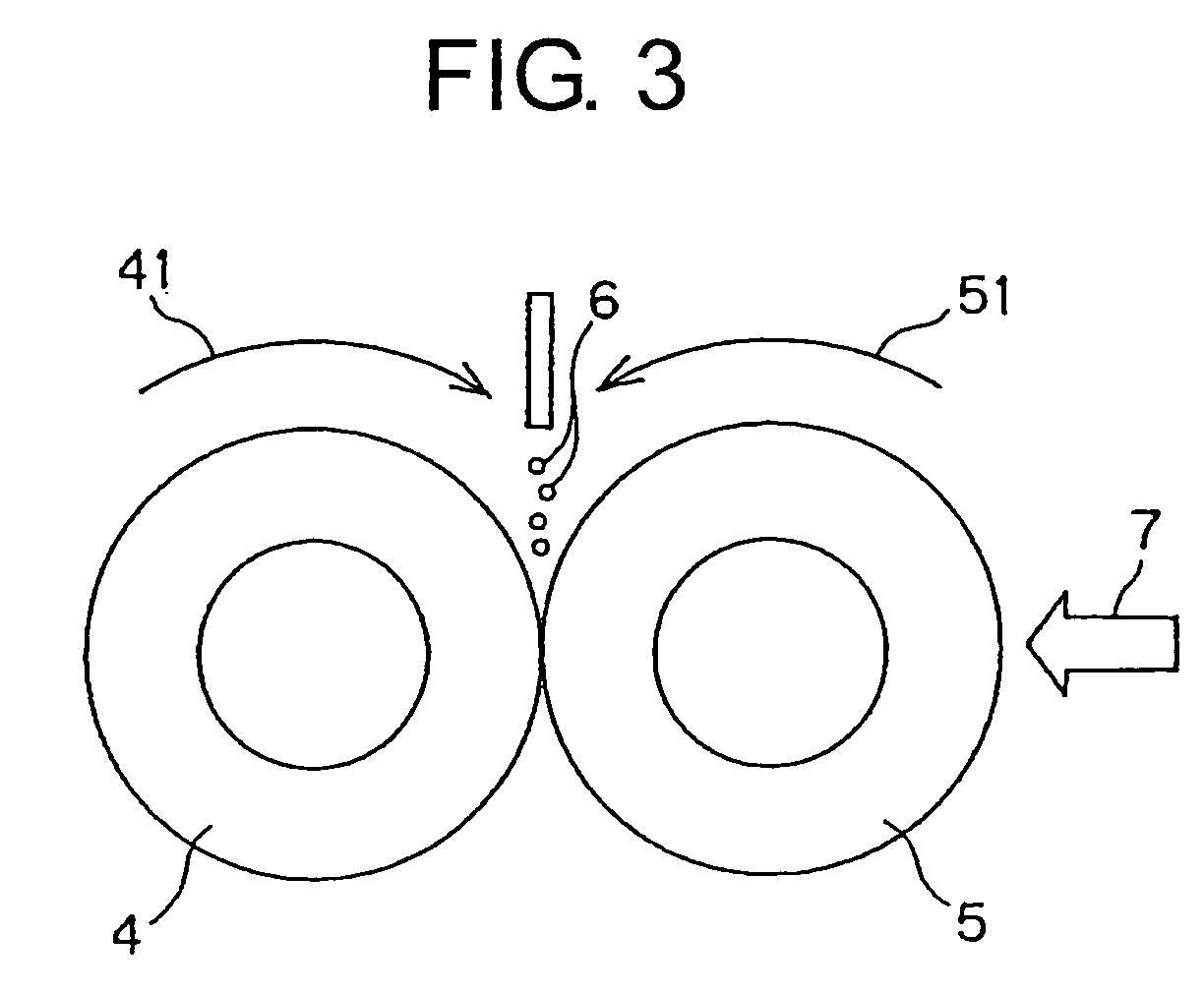

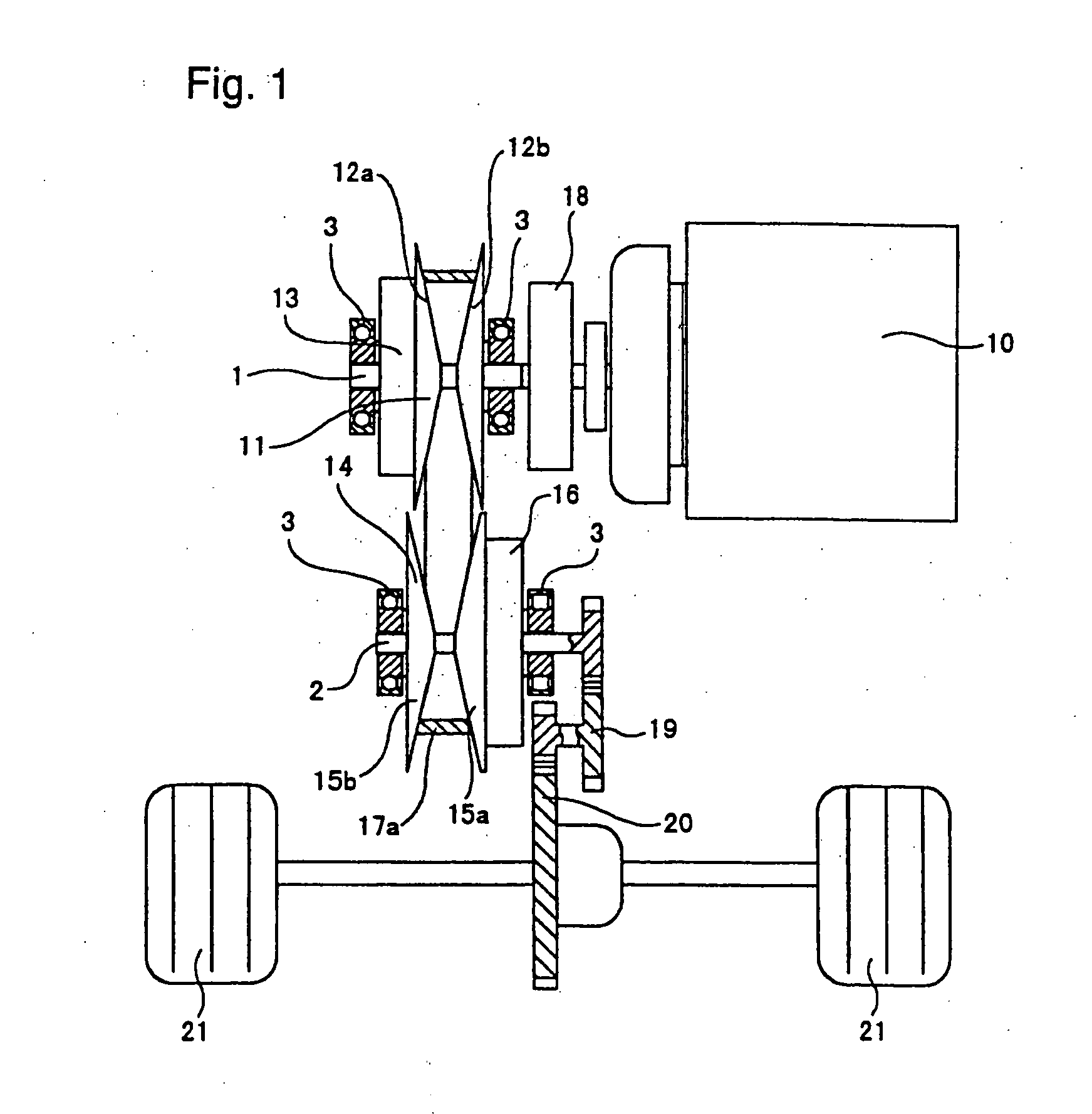

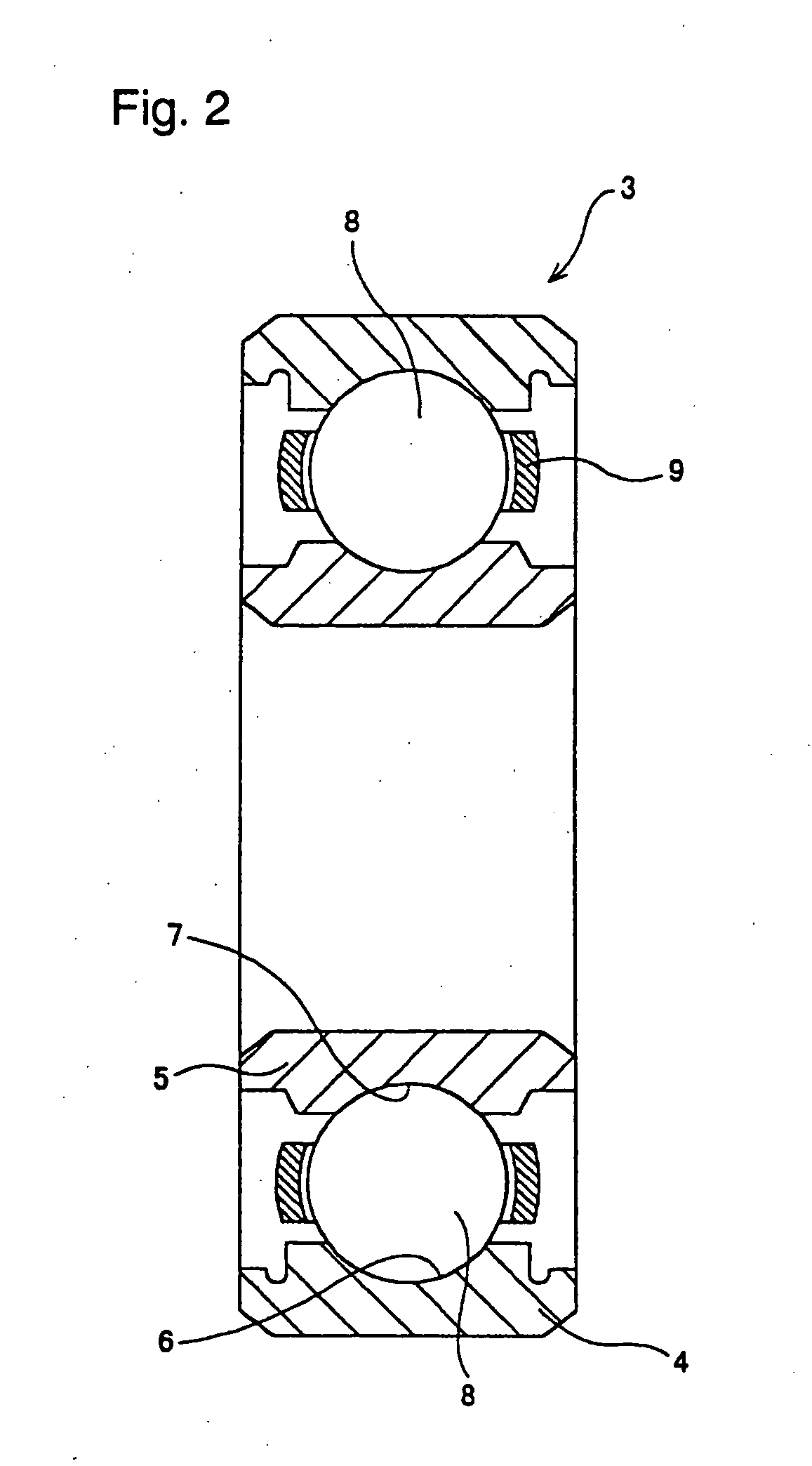

Rolling bearing for a belt-type continuously variable transmission

A bearing is provided to have sufficient durability even when CVT fluid having a low viscocity is used, with its flow rate kept small, so that the efficiency of the belt-type continuously variable transmission is improved. The material of the races including the outer race 4 is made of a iron-base alloy containing, by weight, C of from 0.15% to 0.5%, Si of 0.1% to 1.5%, Mn of 0.1% to 1.5%, and Cr of 0.5% to 3.0%. This material is subjected to carbonitriding, quenching, tempering and quenching finish. The surface portion of the outer raceway 6 on the inner peripheral surface of the outer race 4 is formed with a surface layer containing C of from 0.8 weight % to 1.2 weight % and N of from 0.05 weight % to 0.50 weight %.

Owner:NSK LTD

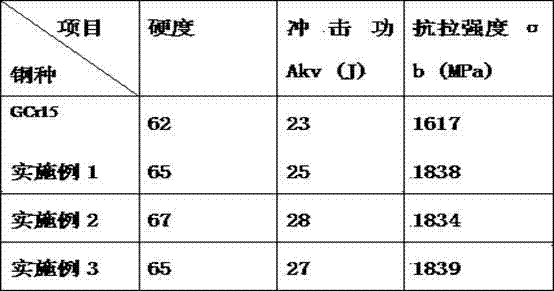

Wear-resistant bearing steel and heat treatment method thereof

The invention discloses wear-resistant bearing steel and a heat treatment method thereof. The wear-resistant bearing steel is high in hardness and good in wear resistance, and contains the following components in percentage by mass: 0.5-0.8% of C, 0.3-0.7% of Si, 0.95-1.3% of Mn, 1.2-1.9% of Cr, 0.5-0.8% of Mo, 0.15-0.5% of V, 0.0010-0.0045% of O, 0.0020-0.0060% of N, 0.020-0.15% of Ni, 0.05-0.15% of Ti, less than 0.025% of S, less than 0.025% of P, and the balance of iron. The heat treatment method for the wear-resistant bearing steel comprises the steps of common annealing, isothermal annealing, normalizing, high-temperature tempering, quenching, low-temperature tempering and carbonitriding.

Owner:牛加伟

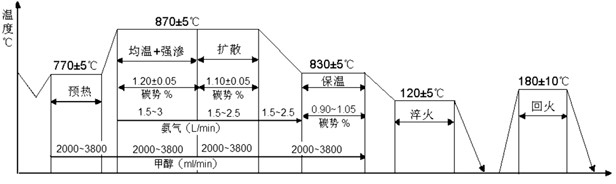

Carburizing and quenching heat treatment process of driven reverse gear used for transmissions

InactiveCN105177492AAdded co-infiltration stepHigh hardnessSolid state diffusion coatingFurnace typesAutomotive transmissionEnergy consumption

The invention provides a carburizing and quenching heat treatment process of a driven reverse gear used for transmissions. The process comprises the following steps: 1) carburizing; 2) carbonitriding; 3) quenching; 4) cleaning; and 5) tempering. The heat treatment process has the beneficial effects that the surface of the driven reverse gear is treated by carbonitriding; and carburizing and nitriding are combined, thus improving the quality of the surface of the driven reverse gear, improving the production efficiency, reducing the energy consumption and saving the production cost.

Owner:JIANGSU BAOJIE FORGING

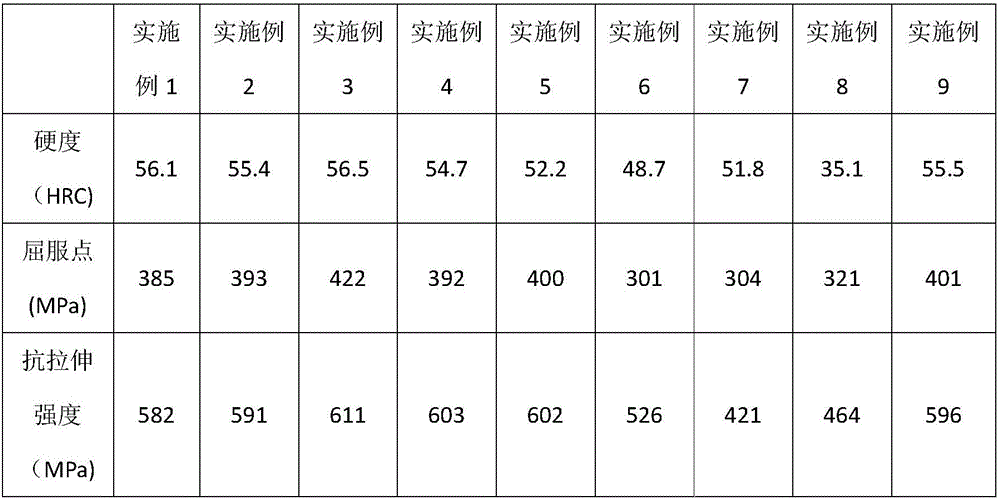

Preparation process of harmonic reducer flexible gear

ActiveCN106011621AHigh hardnessHigh tensile strengthTransportation and packagingMetal-working apparatusReduction driveHeat treated

The invention discloses a preparation process of a harmonic reducer flexible gear. The preparation process mainly comprises the following steps: (1) a low-carbon alloy steel basal material is molten as alloy soup in inert gas; (2) the alloy soup, prepared in the step (1), is poured in a harmonic reducer flexible gear casting mold for cooling molding, is molded through die-casting extrusion, and is thermally treated and annealed to form a harmonic reducer flexible gear blank; (3) the harmonic reducer flexible gear blank, manufactured by the step (2), is turned and punched as circular pieces; (4) the circular pieces, manufactured by the step (3) are spun at 400-450 DEG C, and are protected by inert gas to manufacture a harmonic reducer flexible gear prototype; and (5) the harmonic reducer flexible gear prototype is finished and polished to remove burrs on the surface; the laser heat treatment is performed for the surface layer to realize carbonitriding; the thickness of a carbonitriding layer is 0.08-0.12 mm; and the finished harmonic reducer flexible gear is manufactured. The manufactured harmonic reducer flexible gear is excellent in wear resistance and high in corrosion resistance and fatigue resistance.

Owner:广东本润机器人谐波科技有限公司

Automobile drive axle ring gear heat treatment process

InactiveCN102409151ALow percolation temperatureReduce heating distortionSolid state diffusion coatingFurnace typesNitrogenEngineering

The present invention discloses an automobile drive axle ring gear heat treatment process. The process comprises treatment steps of carbonitriding, quenching, cleaning, tempering, and correction and deformation, wherein the following step is performed after the low temperature carbonitriding process and before the quenching process: a mandrel for controlling ring gear deformation is immediately filled in the ring gear. The diameter size of the mandrel is 100.02-100.03% of the diameter size of the ring gear tip circle, wherein the ring gear is subjected to the low temperature carbonitriding treatment and the direct quenching treatment. The shaped teeth are processed on the mandrel excircle, such that the problems of out of roundness, deformation and oversize of the ring gear after the carburizing and quenching heat treatment are solved, the qualification rate of the heat treated product is improved, and the process is especially suitable for the heat treatment of the drive axle ring gear for the heavy truck.

Owner:SINO TRUK JINAN POWER

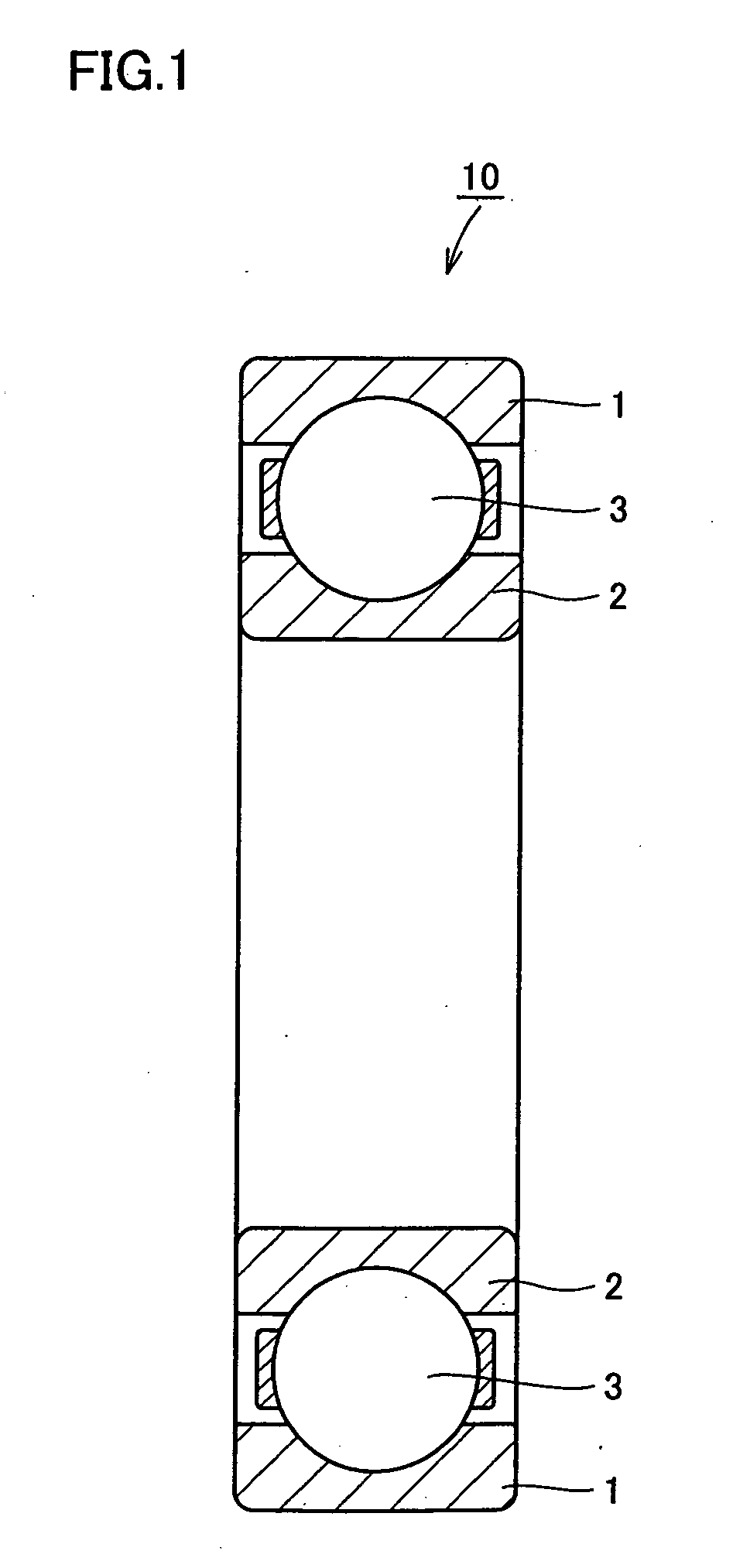

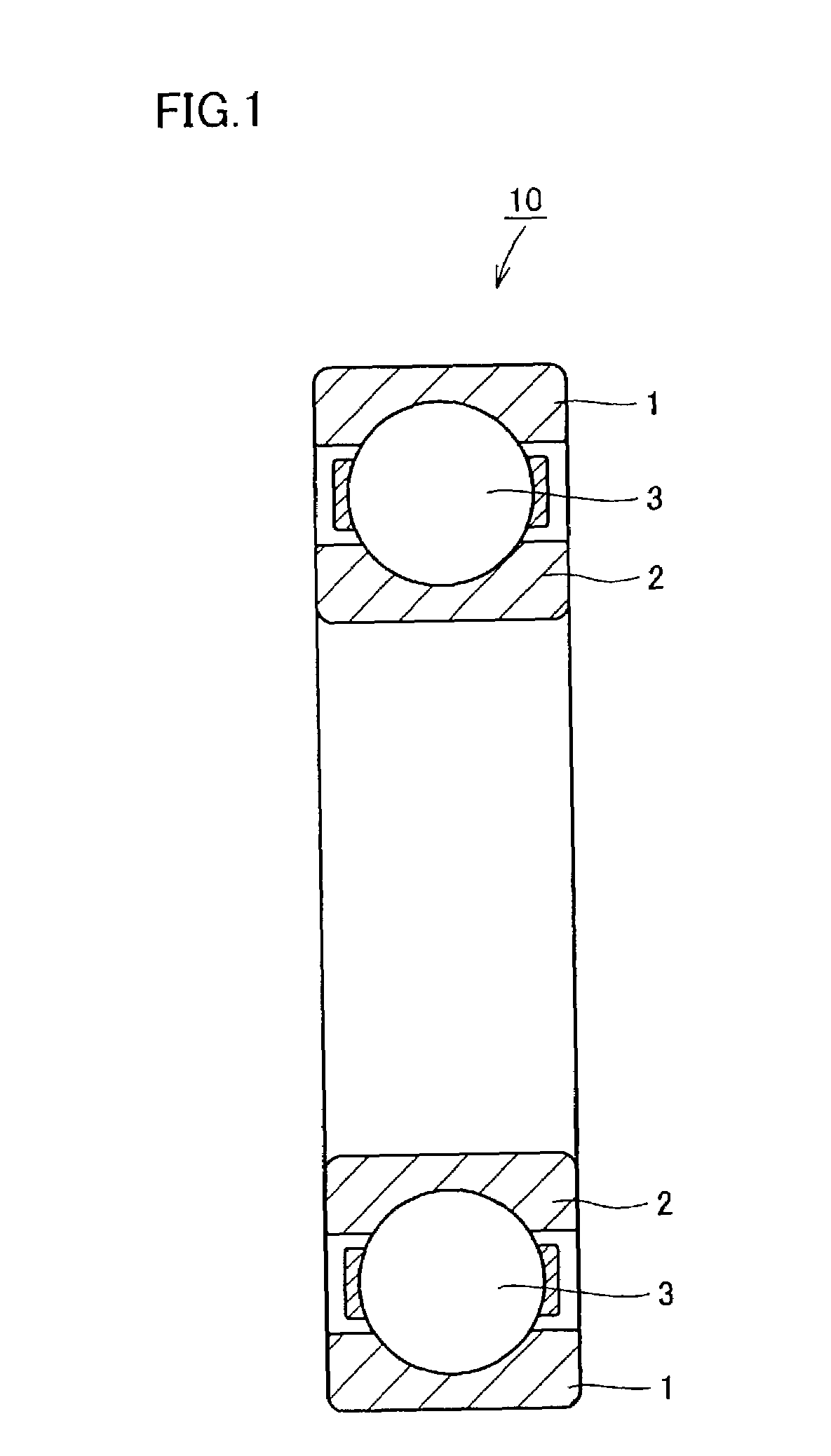

Rolling bearing

InactiveUS20130016938A1Reduces brittle flakingImprove toughnessShaftsBall bearingsForeign matterRolling-element bearing

A rolling bearing is disclosed of which the lifespan is increased by reducing brittle flaking and impression-induced flaking on the raceways of inner and outer races and the rolling elements. Steel containing 1.80-1.89% by weight of chrome (brittle flaking-resistant steel) is subjected to carbonitriding and then to hardening and tempering. The chrome reduces generation of white layers which are aggregates of carbon, thus reducing brittle flaking on e.g. the raceways (1a, 4a) due to the white layers. A residual austenite region (5) that forms when the steel is hardened and tempered increases toughness of the steel surface, thus reducing impression-induced flaking due to foreign matter such as wear dust. By reducing both brittle flaking and impression-induced flaking, it is possible to extend the lifespan of the bearing, and reduce maintenance cost such as the cost for changing lubricating oil.

Owner:NTN CORP

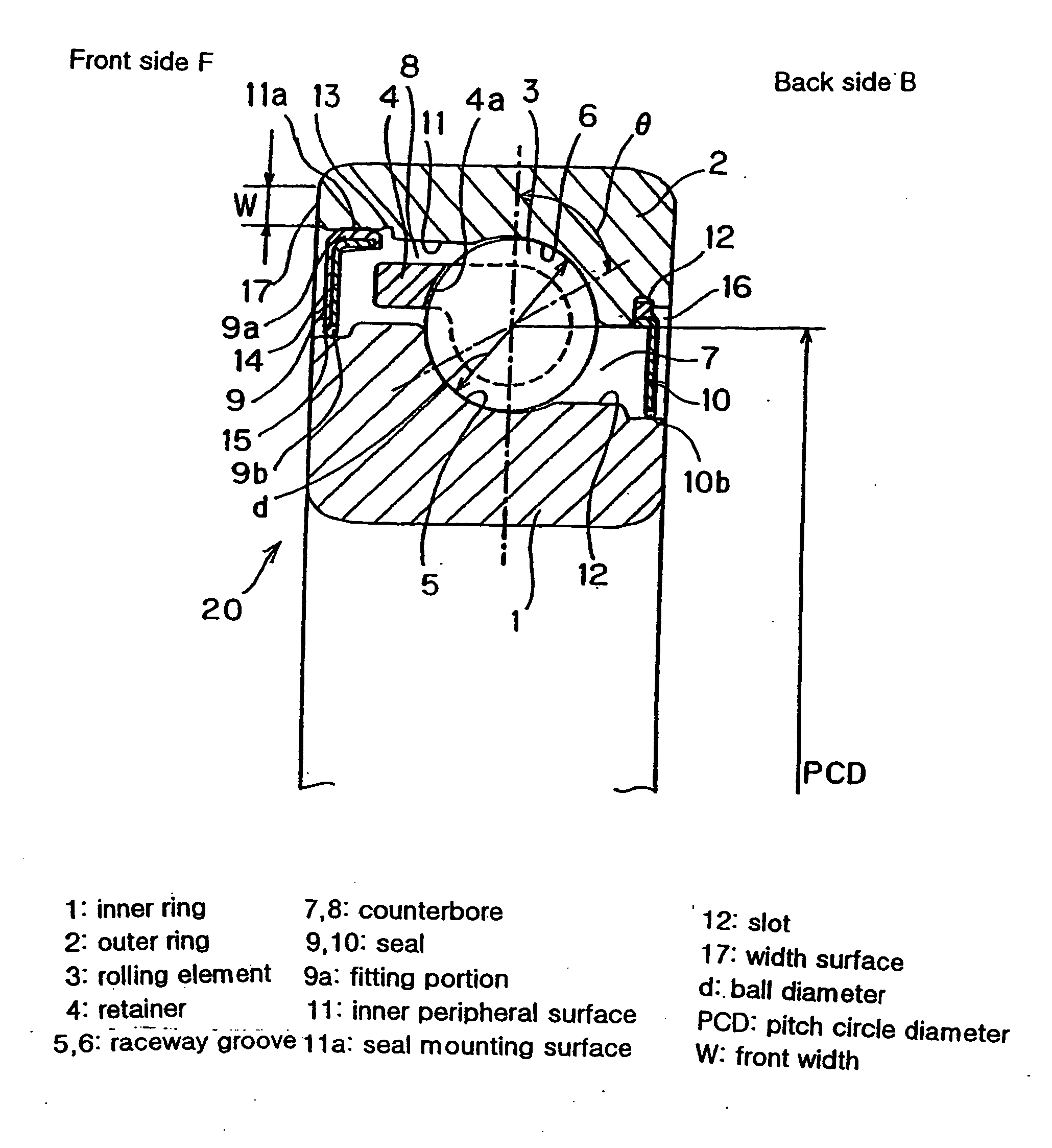

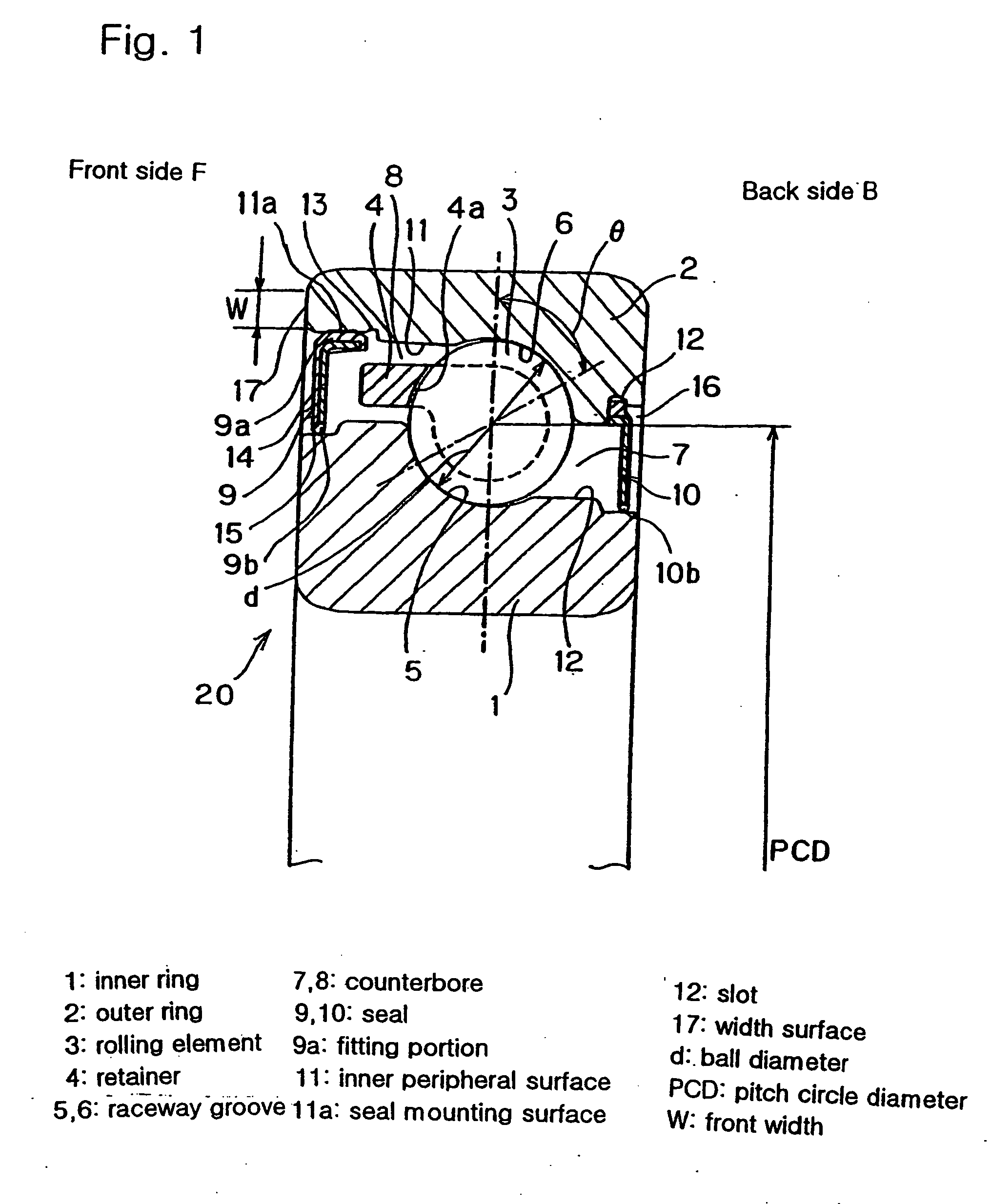

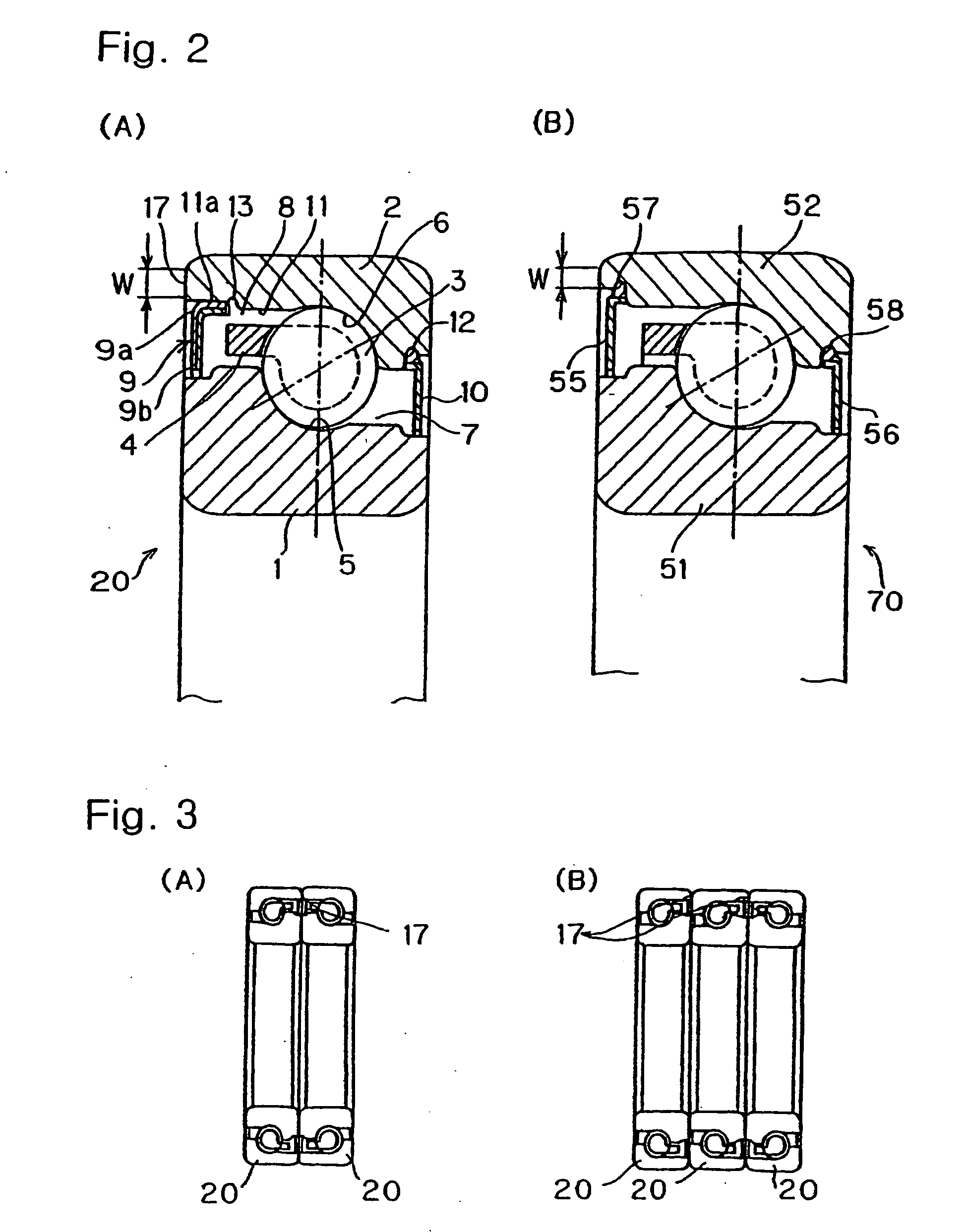

Angular ball bearing and rolling bearing

InactiveUS20060088235A1Increased durabilityImprove adhesionBall bearingsThickenersBall bearingRolling-element bearing

A rolling bearing is proposed in which even though a sealed type, no lowering of strength of the bearing rings or lowering of the front width will not occur for the convenience of mounting of a seal, and design of dimensions equivalent to a non-sealed type bearing and practicability can be achieved, and has fretting resistance. Rolling elements 3 are disposed between an inner ring 1 and an outer ring 2 with seals 9 and 10 provided. The seal 9 arranged on a counterbore 8 of the outer ring 2 is fitted in a pressed state on a peripheral surface portion of a cylindrical surface 11 forming the counterbore 8. By pressing, the seal 9 is mounted without forming a slot. The other seal 10 is fitted in a slot 12. The inner ring and the outer ring, or rolling elements of a bearing comprising the outer ring, inner ring, rolling elements and a retainer are subjected to carbonitriding and a grease using a urea compound as a thickening agent is sealed in the bearing.

Owner:UEDA KEIICHI

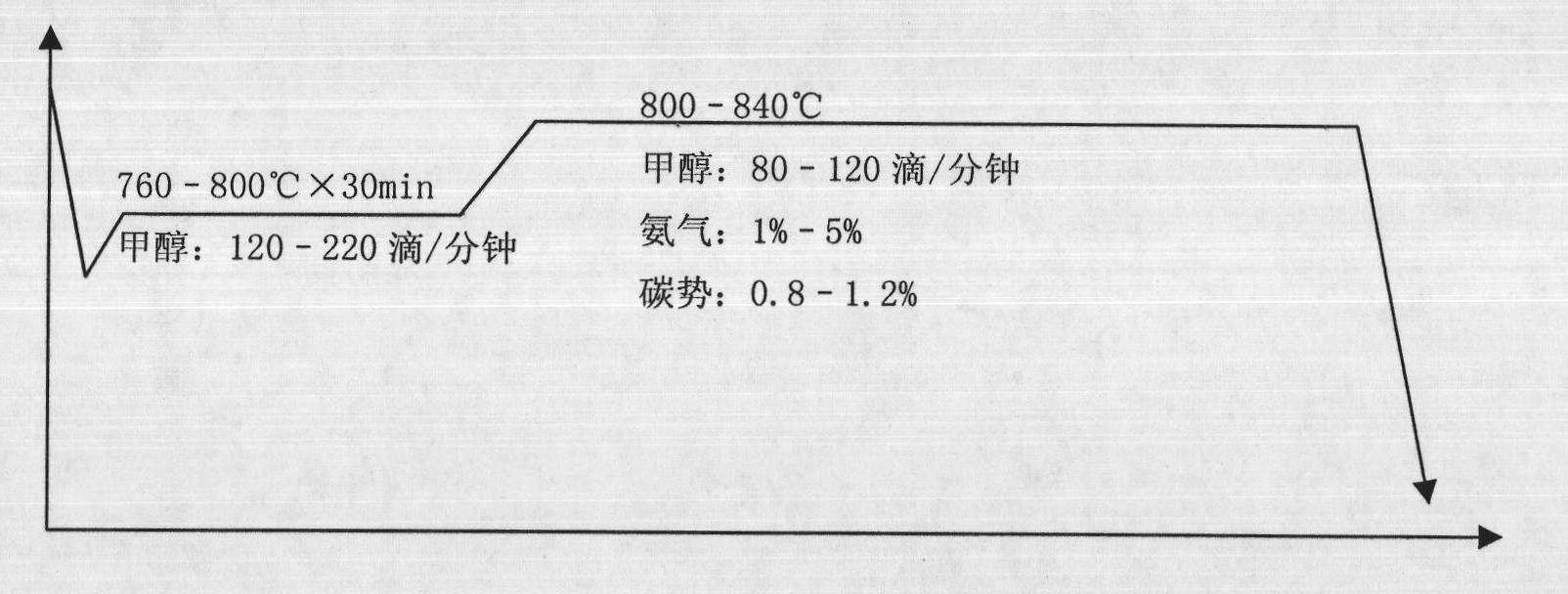

Process for strengthening nodular cast iron and finished product thereof

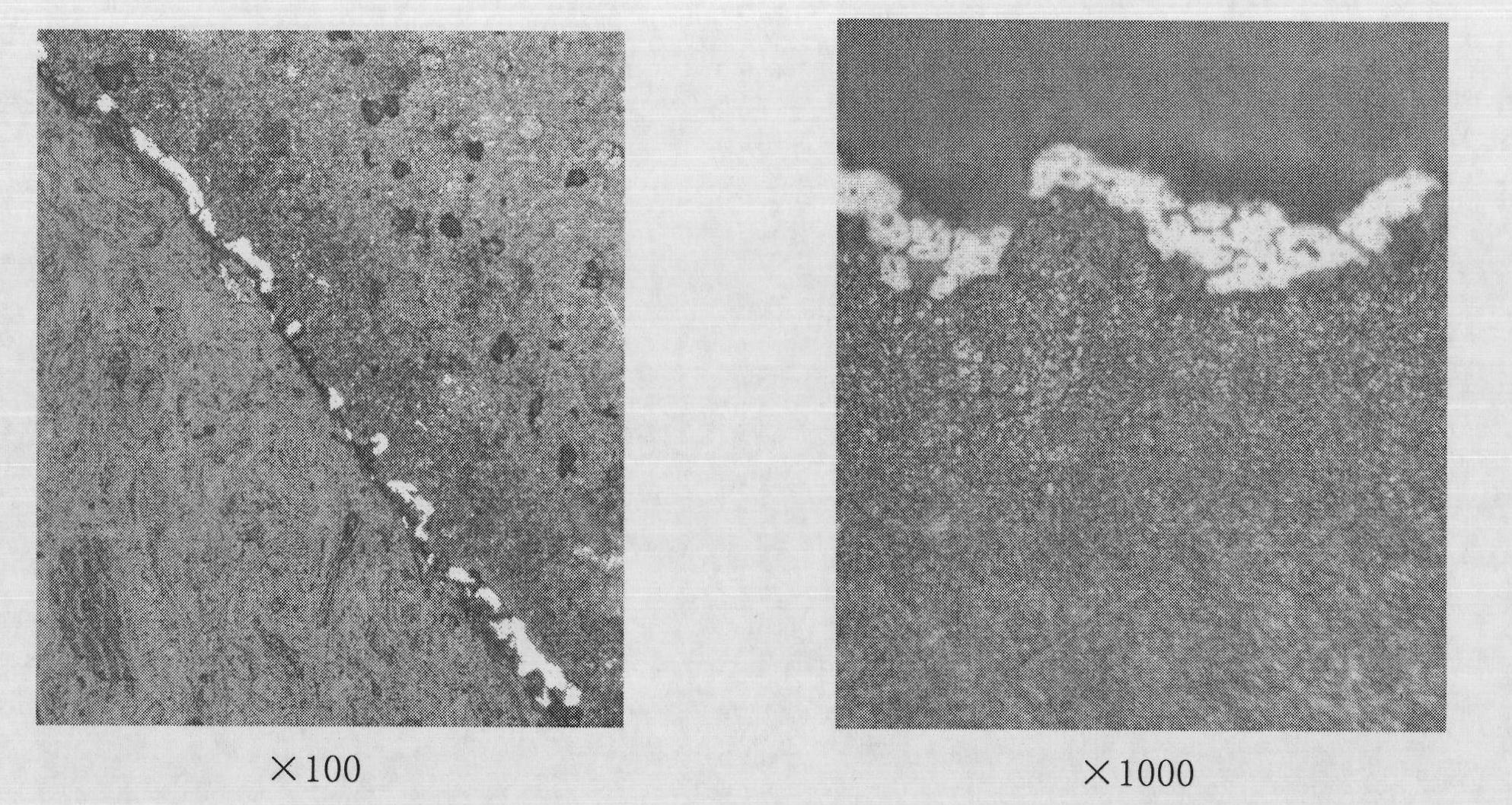

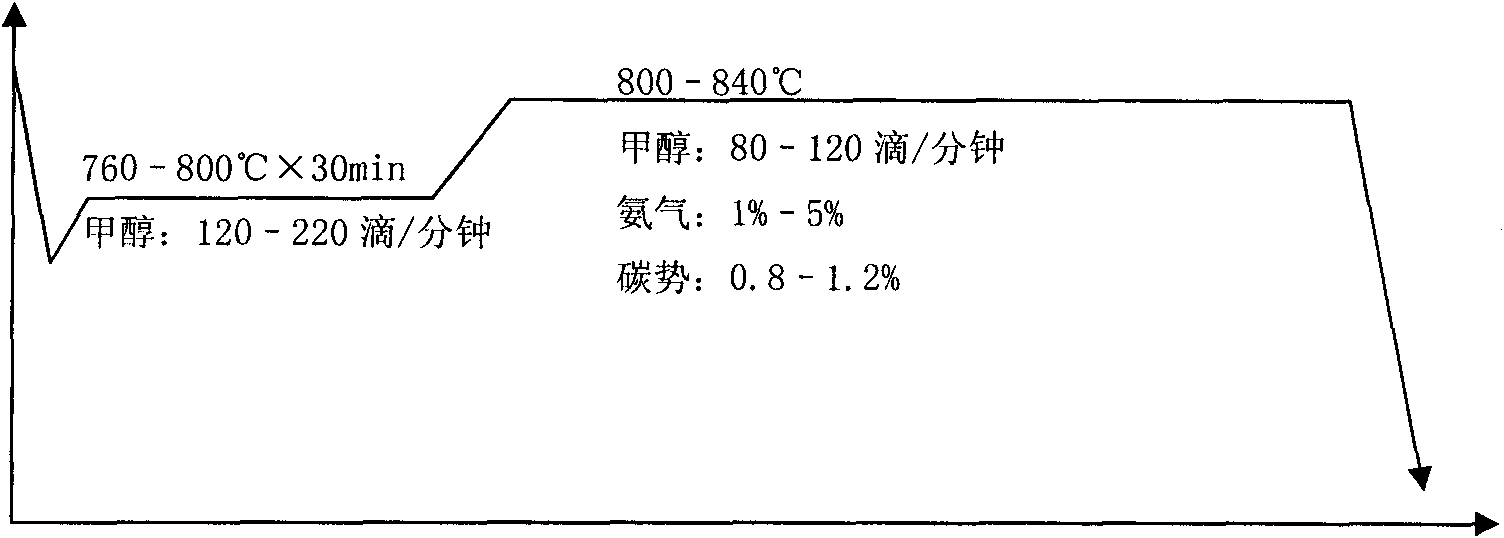

ActiveCN101851735AImprove abrasion resistanceImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialSurface layer

The invention discloses a process for strengthening nodular cast ion and a finished product thereof. The process comprises the following steps of: putting cleaned nodular cast iron parts into a carburizing furnace; performing carbonitriding, namely adding methanol and ammonia at the temperature of between 800 and 840 DEG C, wherein the addition of the methanol is 80-120 drops / minute, the adding volume of the ammonia is 1 to 5 percent of the volume of the methanol cracked gas, the carbon potential is maintained to between 0.8 and 1.2 percent, and the processing time is 2 to 4 hours; and performing quenching to obtain a part finished product. In the carbonitriding process, the decarbonization preventing technological measure is adopted, the metallographic structure of the finished product comprises a surface layer, a sublayer and a substrate in turn, the surface layer is a granular or continuously distributed compound layer, the sublayer is hidden needle-like nitrogenous martensite, retained austenite and graphite, and the substrate is thin needle-like martensite, retained austenite and graphite. The process can improve the scratch resistance, wear resistance and contact fatigue strength, can effectively prevent full decarbonization during carbonitriding of the nodular cast ion, and has the advantages of low process difficulty and low production cost.

Owner:DONGFENG MOTOR CORP HUBEI

Heat treatment method for steel pieces

InactiveCN101994118AImprove the level ofHigh surface hardnessSolid state diffusion coatingChemical treatmentHigh surface

The invention discloses a heat treatment method for steel pieces, and relates to improvement of a heat treatment method for surfaces of steel pieces. The heat treatment method makes the steel pieces improve the depth of an austenite nitriding / carbonitriding layer and reduce deformation, integrates and fully exerts the advantages of various processes, and overcomes respective disadvantages to complement one another so as to achieve excellent comprehensive usability. In the treatment method for compounding chemical heat treatment (such as carburizing or carbonitriding) and austenite nitriding or austenite carbonitriding technology, a workpiece is heated to be in an austenite state for carburizing or carbonitriding, a preset layer is obtained, and the temperature in the same furnace is reduced to the austenite nitriding temperature between 620 and 720 DEG C for nitriding or carbonitriding treatment, so that the nitrogen concentration on the surface of the workpiece reaches the nitrogen concentration of austenite and the level of the austenite nitriding layer is improved; and the workpiece is directly quenched and aged or directly subjected to isothermal quenching, so that the high-nitrogen austenite is decomposed and high surface hardness and wear resistance are achieved.

Owner:顾安民

Heat treatment process of high-carbon chromium bearing steel

The invention provides a heat treatment process of high-carbon chromium bearing steel and belongs to the technical field of steel materials and heat treatment. The heat treatment process comprises the steps of smelting, forging, incomplete annealing, normalizing, quenching and tempering, double-refining processing, carbonitriding and surface chromizing. According to the invention, repeated quenching, tempering and other heat treatment, surface carbonitriding and surface chromizing processes are mainly adopted to reinforce the hardness and strength and prolong the service life of a bearing, so that the finally produced bearing is higher in strength, stronger in hardness and longer in service life.

Owner:ANQING YINTAI BEARING

Low pressure carbonitriding method and device

ActiveUS8303731B2Accurately and reproducibly obtainingSimple designSolid state diffusion coatingInternal pressureNitrogen

A method for carbonitriding a steel part arranged in an enclosure maintained at a reduced internal pressure, the part being maintained at a temperature level, comprising an alternation of first and second steps, a carburizing gas being injected into the enclosure during the first steps only and a nitriding gas being injected into the enclosure only during at least part of at least two second steps.

Owner:ECM TECHNOLOGY PTY LTD

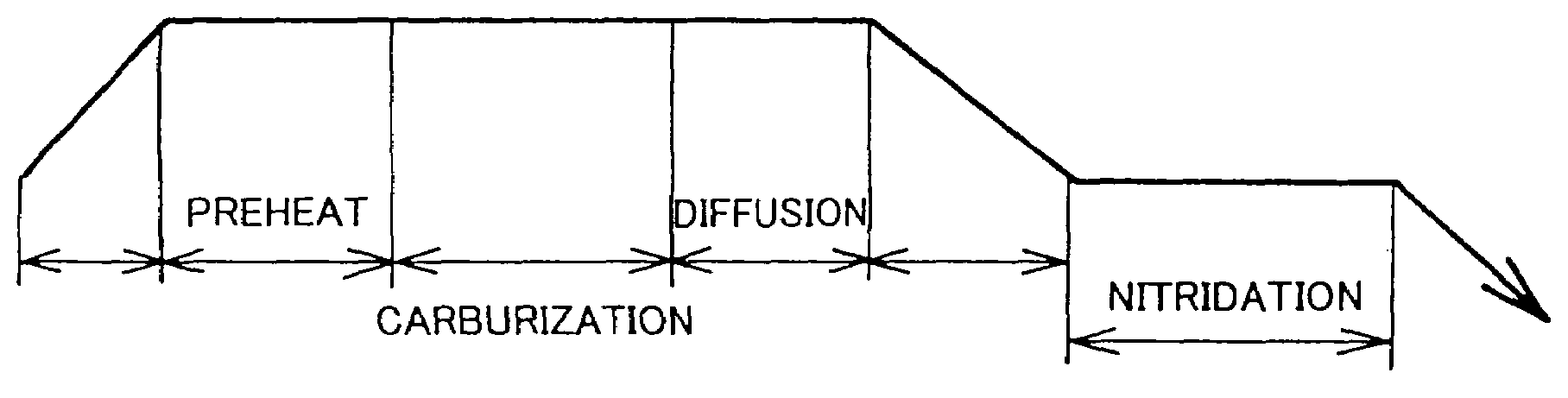

Vacuum carbo-nitriding method

InactiveUS7112248B2High surface hardnessIncrease effective case depthSolid state diffusion coatingEffective surfaceLower grade

A vacuum carbonitriding method includes: performing a vacuum carburizing process on an object to be treated (a workpiece) in a heat treating furnace under reduced pressures by supplying a carburizing gas into the furnace that has been heated to a predetermined carburizing temperature; stopping supply of the carburizing gas while keeping the carburizing temperature so as to diffuse carbon in the workpiece under reduced pressures; and performing a nitriding process on the workpiece by supplying a nitriding gas into the furnace under reduced pressures after lowering the furnace temperature. Required heat treatment qualities such as surface hardness, effective case depth, toughness and the like can be achieved in a short time with reproducibility even in a case of workpiece made of low-grade steel or case-hardened steel.

Owner:KOYO THERMO SYST CO LTD

Heat treatment process for surface hardening and carbonitriding of hydraulic parts

ActiveCN102534465AReasonable heating distributionReasonable heating distribution makes hydraulic parts heated reasonablySolid state diffusion coatingCarbon potentialNitrogen

The invention provides a heat treatment process for surface hardening and carbonitriding of hydraulic parts, which includes the following steps: a washing the hydraulic parts preparing for heat treatment to remove greasy dirt; b warming a carburizing multi-purpose furnace, and performing pre-carburizing treatment; c putting the hydraulic parts washed cleanly through the step a in the carburizing multi-purpose furnace, and performing strong carburizing; d adjusting carbon potential after the strong carburizing to perform diffusion; e putting the hydraulic parts after carbonitriding in the stepd in a quenching chamber of the carburizing multi-purpose furnace to be quenched, filtering oil and discharging from the furnace; and f washing the hydraulic parts of the step e, and putting the hydraulic parts in a tempering furnace to be tempered to obtain products.

Owner:SHANDONG CHANGLIN MACHINERY GRP

Low-temperature carbonitriding catalyst and carbonitriding method thereof

InactiveCN102125862AHigh surface hardnessImprove wear resistancePhysical/chemical process catalystsSolid state diffusion coatingRare earthTitanium

The invention provides a low-temperature catalyst and a carbonitriding method thereof. The catalyst comprises the following components in percent by weight: 10-15 percent of ammonium chloride, 1-5 percent of titanium sponge, 8-13 percent of rare earth, 0.1-2.5 percent of solid chromate, 0.01-1.5 percent of aluminum powder and the balance of quartz sand. The carbonitriding method comprises the following steps of: weighting the ammonium chloride, the titanium sponge, the rare earth, the solid chromate, the aluminum powder and the quartz sand as raw materials, grinding and mixing uniformly to form the catalyst; and mixing a cleaned workpiece with the catalyst uniformly and then charging into a furnace together for compound nitriding. The low-temperature catalyst and the carbonitriding method thereof are used for carrying out compound nitriding on a carbonitriding process by adopting the catalyst, and further improve surface hardness, wear resistance and corrosion resistance of a workpiece while reducing carbonitriding temperature and shortening carbonitriding time.

Owner:CENT SOUTH UNIV

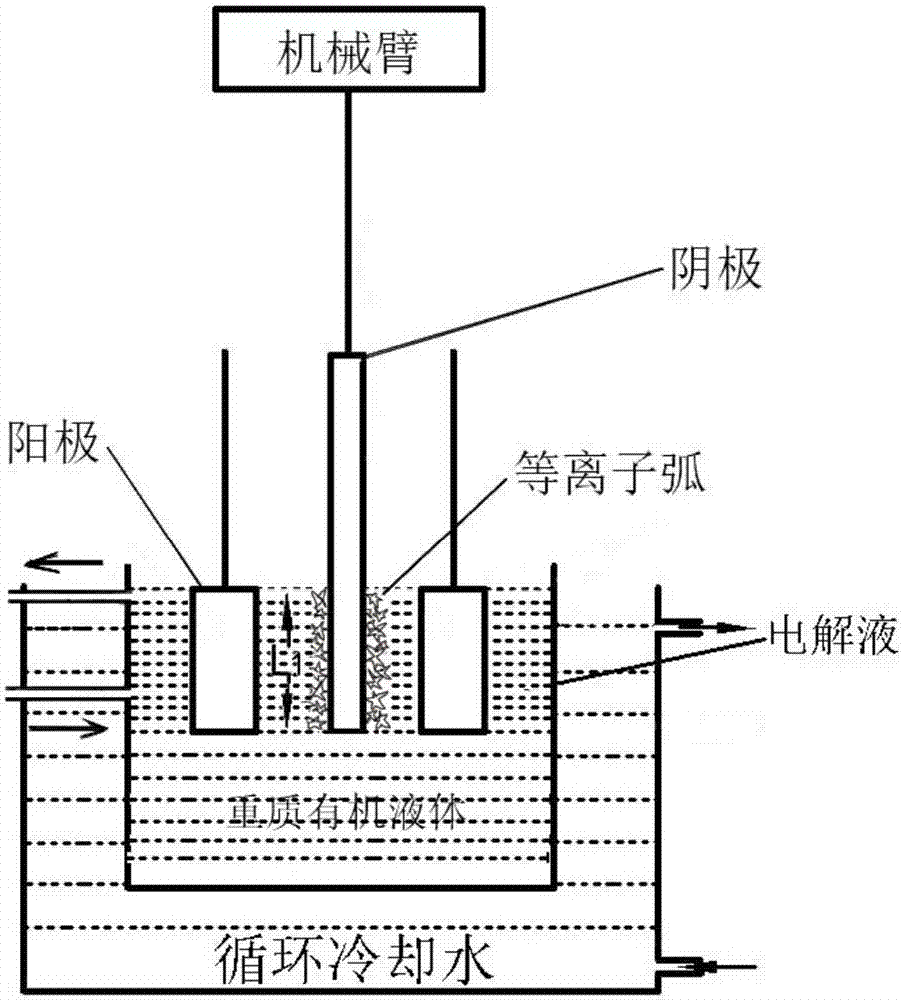

Coating large-area continuous deposition and surface modifying method

ActiveCN107385485AControl Surface RoughnessElectrolytic inorganic material coatingSurface reaction electrolytic coatingBorideComposite ceramic

The invention discloses a coating large-area continuous deposition and surface modifying method and belongs to the technical field of material surfaces. According to the method, cathode plasma electrolysis adopts electrolytic cell solutions with heavy organic liquid on the lower layer and an aqueous solution electrolyte on the upper layer. By controlling an electrode to be immersed into the electrolyte from the liquid surface, cathode metal is subjected to coating deposition or surface modifying treatment through plasma discharge in the aqueous solution electrolyte layer. By adjusting the area ratio of an anode to a cathode and applying the direct voltage or the pulse voltage to the cathode and the anode of an electrolytic cell, and in electrolytes of different components, oxides, carbides, borides and composite ceramic coatings can be deposited on the surface of the metal, and various metals such as nickel, copper, chromium and cadmium or metal composite coatings can be also deposited; and meanwhile, by introducing carbides and nitrides into the solutions, plasma nitriding, plasma carburizing or plasma carbonitriding of the metal cathode can be further achieved, besides, the material surface can be cleaned, oxides can be removed, and nanocrystallization of the material surface can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

Deep rare-earth boron carbonitriding agent

InactiveCN1827835AIncrease layer depthHigh hardnessSolid state diffusion coatingRare earthBoron carbide

The invention discloses the deep level rare earth boron-carbo-nitriding agent, comprising the following characters: 3-12 parts boron carbide, 2-9 parts potassium borofluoride, 2-9 parts rare earth chloride, 1-10 parts charcoal powder, 1-4 parts activated char, 1-4 parts fluorigard, 1-4 parts aquadrate and 48-89 parts carbofrax. The method comprises the following steps: adding rare earth chloride into agent to improve layer depth to 0.20-0.80mm; carrying out carbonitriding, improving the hard of buffer layer and width, reducing the hardness gradient, and avoiding boronization layer exfoliation; the rare earth entering into boronization layer, improving the boronization layer structure and property.

Owner:赵程

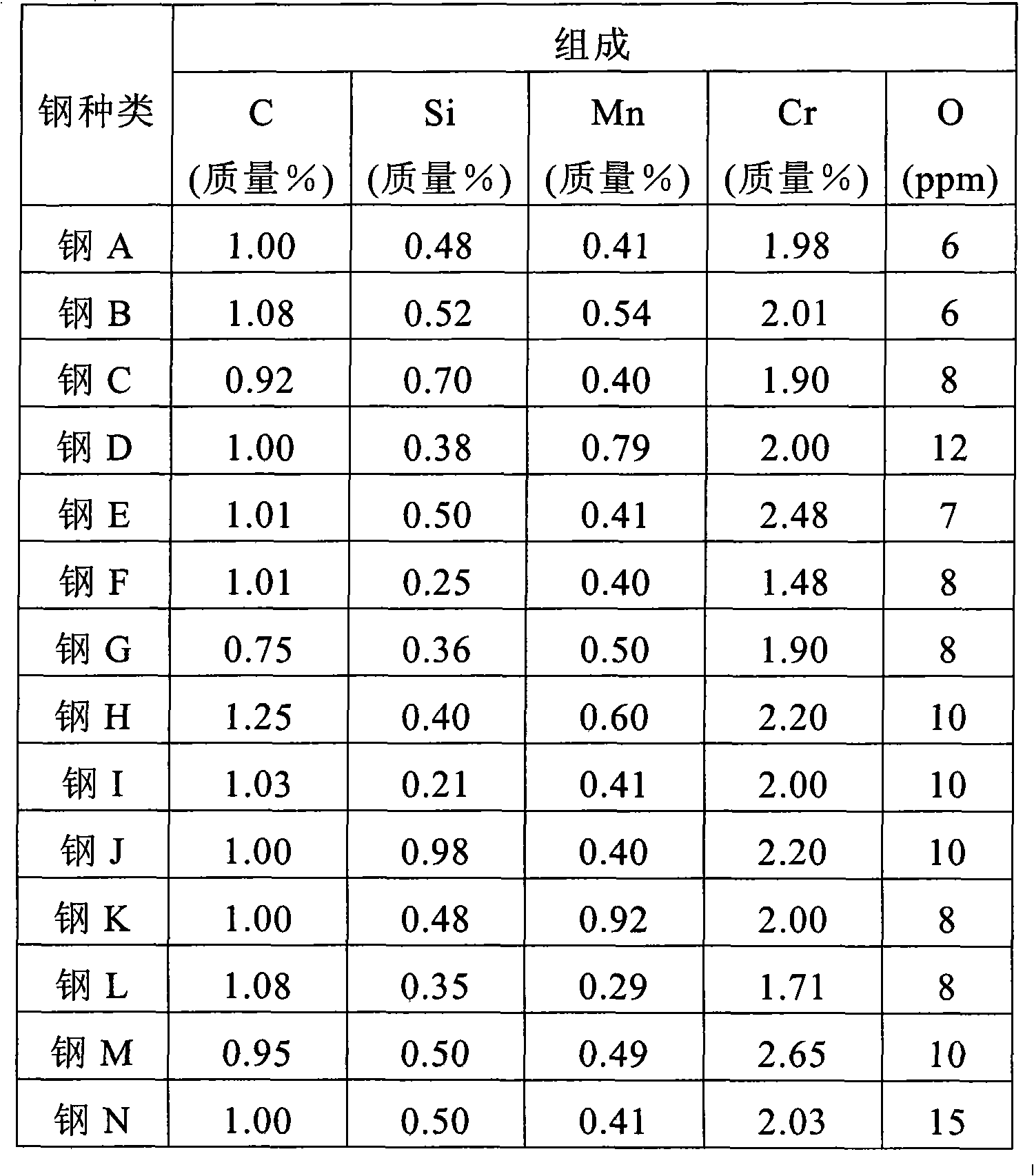

Rolling component and manufacturing method thereof

InactiveCN101970704ANo cost increaseExtend your lifeShaftsBearing componentsSquare MillimeterNitrogen

A rolling component formed by carrying out spheroidizing annealing, processing, carbonitriding, and finishing on steel material containing, by mass, 0.90% to 1.10% carbon, more than 0.35% and up to 0.70% silicon, less than 0.80% manganese, 1.85% to 2.50% chromium, and oxygen in the amount of 12 ppm or less. On the surface, the mean quantity of carbon is 1.20% to 1.50% by mass and the mean quantity of nitrogen is 0.10% to 0.60% by mass. There are at least 700,000 deposits with particle diameter of 0.1 [mu]m or more per square millimeter of the surface. Said deposits have a mean particle diameter of 0.6 [mu]m or less and a surface area ratio of 10% or more. The volume fraction of retained austenite on the surface is between 25% and 45%. The surface hardness is Hv 750 or more. The volume fraction of retained austenite inside the rolling component is 20% or less.

Owner:JTEKT CORP

Titanium carbonitride blast furnace protecting agent and preparation method thereof

InactiveCN101798234APlay the role of protecting the hearthBlast furnace componentsBlast furnace detailsBrickTitanium nitride

The invention discloses a titanium carbonitride blast furnace protecting agent and a preparation method thereof. The furnace protecting agent comprises the following components in percentage by weight: 50-74% of calcium carbonitride Ti (C, N), 17-40% of composition of CaO, MgO, SiO2 and AL2O3, greater than 1% of free carbon, greater than 3% of total iron TFe and less than 6% of titanium oxide. The preparation method comprises the following steps: selecting titanium concentrate, preparing carbon, mixing materials, forming, calcining, reducing, and carrying out carbonitriding of titanium, wherein the carbonitriding ratio of titanium is greater than 85%; the furnace wall at the corroded part of a furnace hearth is thinned, and the temperature of the corroded part is lower than the temperature of other regions, thereby forming a temperature gradient; and under the action of the temperature gradient, Ti(C, N) and attachments thereof are continuously accumulated and bonded in the corroded region until the temperature gradient relatively disappears. The invention overcomes the defects that in the prior art, the titanium content is unstable and the impurity content is high, the energy consumption is large, and the effective utilization ratio of titanium is lower than 30%; and the titanium carbonitride Ti (C, N) used as an effective component is directly formed in the molten iron of the furnace hearth and is deposited on the working surface of the corroded part of the furnace hearth or deposited in brick work joints to repair the corroded region, thereby performing the function of protecting the furnace hearth.

Owner:闫晓峰

Bearing part, heat treatment method thereof, and rolling bearing

InactiveUS7438477B2Improve cracking strengthAdd dimensionShaftsBall bearingsRolling-element bearingQuenching

A bearing part comprising steel subjected to carbonitriding at a carbonitriding temperature exceeding the A1 transformation temperature, and cooled to a temperature lower than the A1 transformation temperature. The steel is reheated to a temperature for quenching that is not lower than the A1 transformation temperature but lower than the carbonitriding temperature, and then quenched.

Owner:NTN CORP

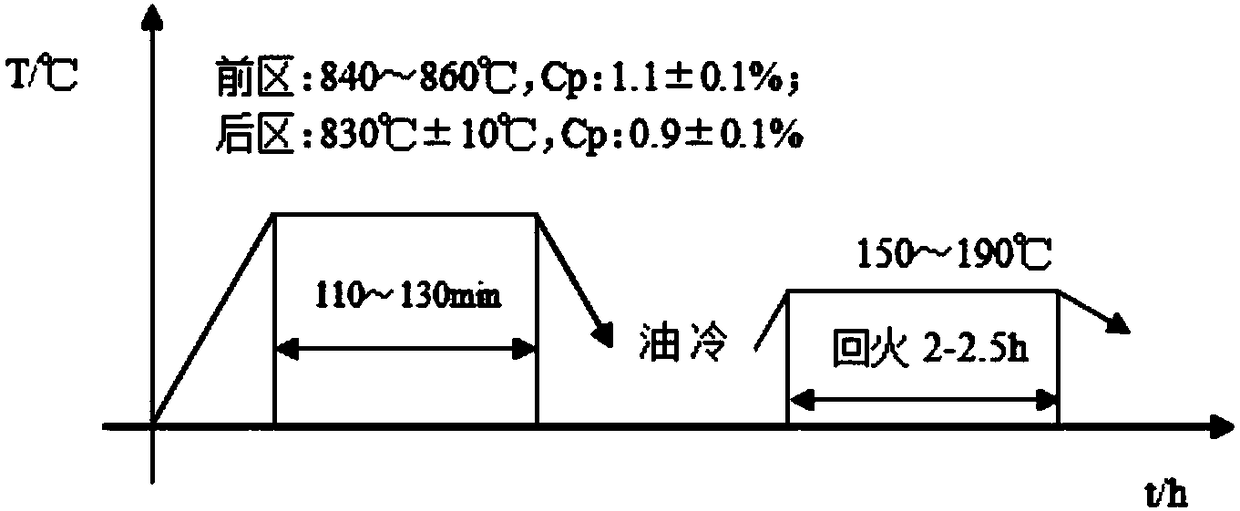

Medium carbon alloy steel chain pin shaft heat treatment method

InactiveCN108220541AImprove wear resistanceHigh hardnessSolid state diffusion coatingFurnace typesCarbon potentialQuenching

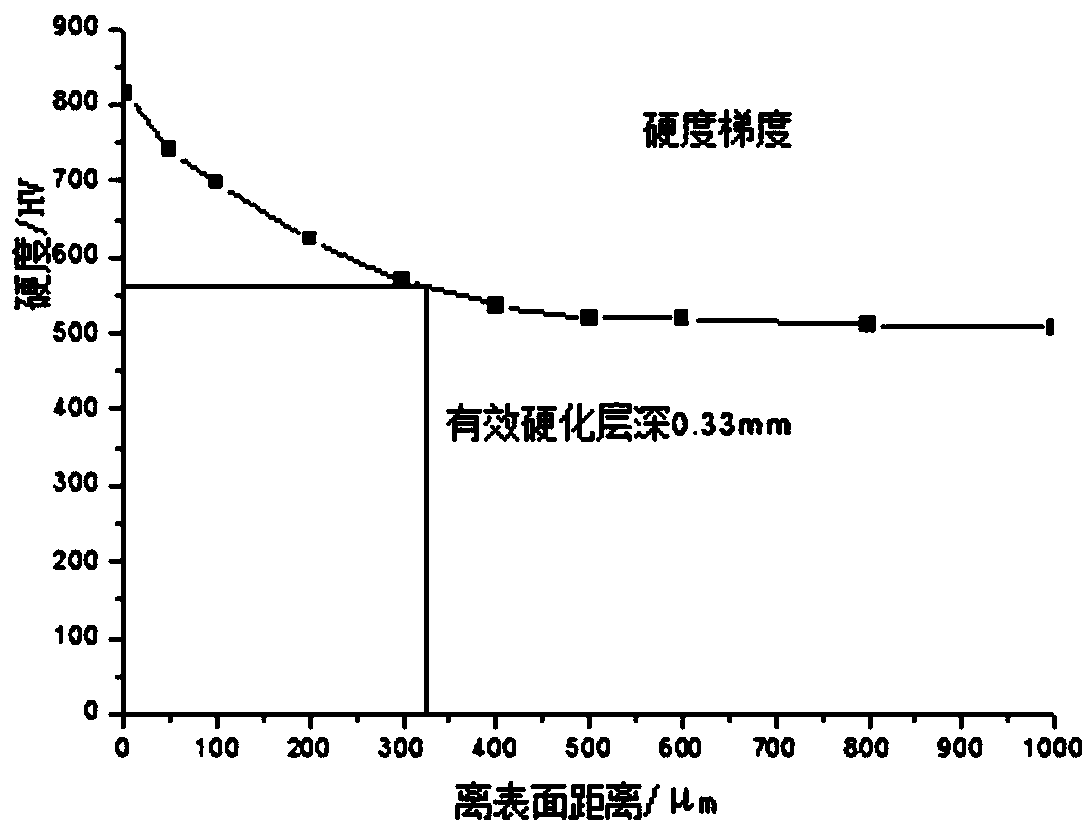

The invention discloses a medium carbon alloy steel chain pin shaft heat treatment method. A carbonitriding quenching and tempering treatment process with the front area and rear area of a meshbeltfurnace adjusting the temperature and carbon potential is adopted, a chain pin shaft with cold extrusion in place is enclosed into the meshbeltfurnace with controllable atmosphere, in the atmosphere protection environment, the front area heating temperature is set as 850 + / - 10 DEG C, the carbon potential (Cp) is set as (1.1 + / - 0.1)%, the rear area heating temperature is reduced to 830 + / - 10 DEG C,the carbon potential (Cp) is reduced to (0.9 + / - 0.1)%, the total heat preservation time of the front area and rear area is 110-130 minutes, then the chain pin shaft is subjected to tempering treatment after being quenched by quenching oil, the tempering temperature is 150-190 DEG C, and the tempering heat preservation time is 120-150 minutes. According to the medium carbon alloy steel chain pinshaft heat treatment method, by means of the manners that the different temperature of the front area and rear area of the meshbeltfurnace with the controllable atmosphere is adjusted, and long time heat preservation is performed, more nitrogen atoms are made to be infiltrated into the surface of the chain pin shaft, the infiltrating layer tissue with the pin shaft surface infiltrating layer hardness being high and the hardness gradient being low and gentle is obtained, and the wear resistance of the pin shaft is improved.

Owner:HANGZHOU ZIQIANG CHAIN DRIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com