Low-temperature carbonitriding catalyst and carbonitriding method thereof

A carbonitriding, process method technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal material coating processes, etc., to achieve the effects of reducing co-infiltration temperature, easy control of process conditions, energy and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

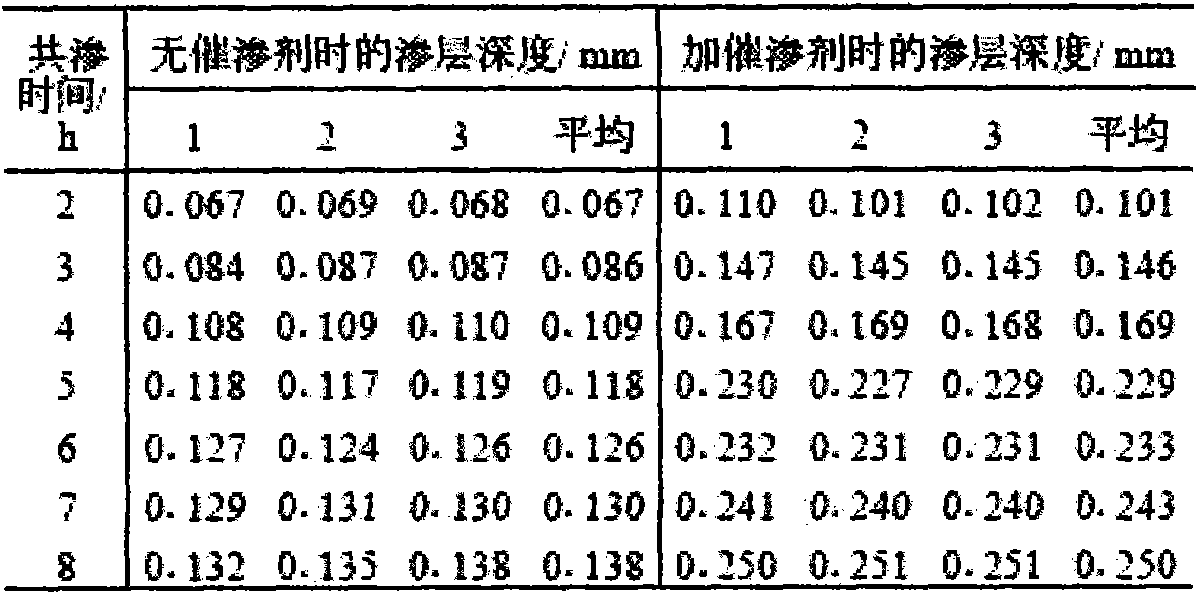

Embodiment 1

[0040]Using ammonium chloride, sponge titanium, rare earth, solid chromate, aluminum powder and quartz sand as raw materials, weigh each raw material in proportion, grind and mix them uniformly to form a catalyst, wherein the catalyst includes 10.6% by weight of chlorine ammonium chloride, 1.8% titanium sponge, 9% rare earth, 0.1% solid chromate, 0.01% aluminum powder, and the rest of the catalyst is quartz sand.

[0041] Mix the catalyst evenly and put it in a stainless steel container with the cleaned 3Cr2W8V steel test workpiece according to the specific gravity of 250:1 and put them into the bottom of the carburizing furnace for composite co-carburizing. It is carried out in the furnace, and the temperature control device is an electronic potentiometer. The test temperature is 500°C, and the test time is (2-8) h. The osmotic agent is [(NH2)2CO+C2H5OH] saturated solution + kerosene, and the amount of osmotic agent added is (70-80) drops / min. Finally, the product was coole...

Embodiment 2

[0047] Using ammonium chloride, sponge titanium, rare earth, solid chromate, aluminum powder and quartz sand as raw materials, weigh each raw material in proportion, grind and mix them uniformly to form a catalyst, wherein the catalyst includes 12% by weight of chlorine ammonium chloride, 2.5% titanium sponge, 10% rare earth, 1% solid chromate, 0.015% aluminum powder, and the rest of the catalyst is quartz sand.

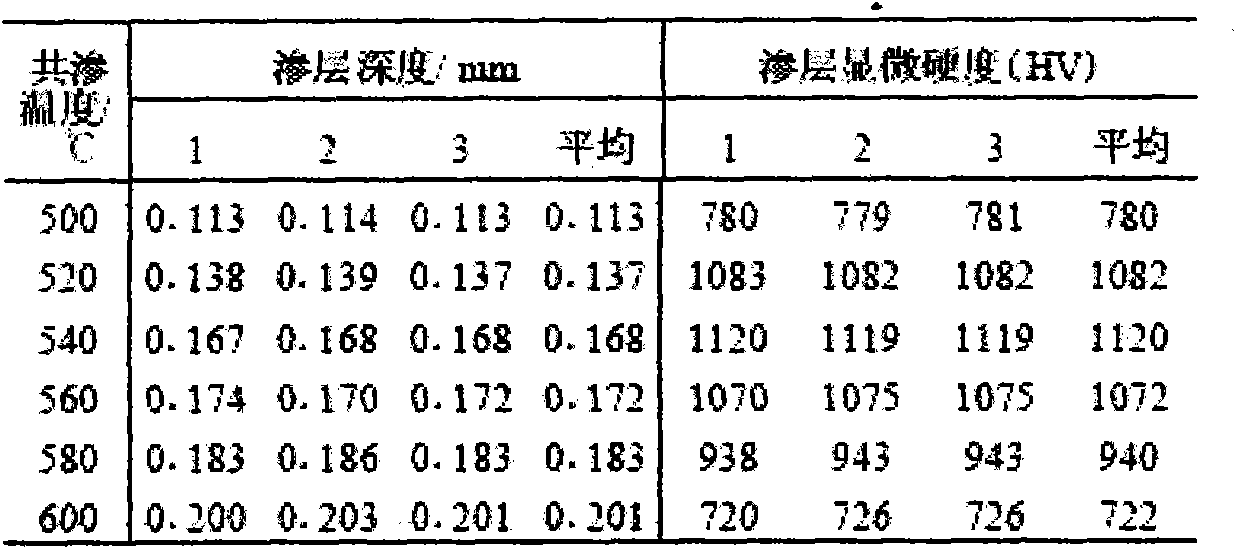

[0048] Mix the catalyst evenly and put it in a stainless steel container with the cleaned 3Cr2W8V steel test workpiece according to the specific gravity of 250:1 and put them into the bottom of the carburizing furnace for composite co-carburizing. It is carried out in the furnace, and the temperature control device is an electronic potentiometer. The test temperature is 500-600°C, and the co-infiltration time is 4 hours. The osmotic agent is [(NH2)2CO+C2H5OH] saturated solution + kerosene, and the amount of osmotic agent added is (70-80) drops / min. Finally, the pro...

Embodiment 3

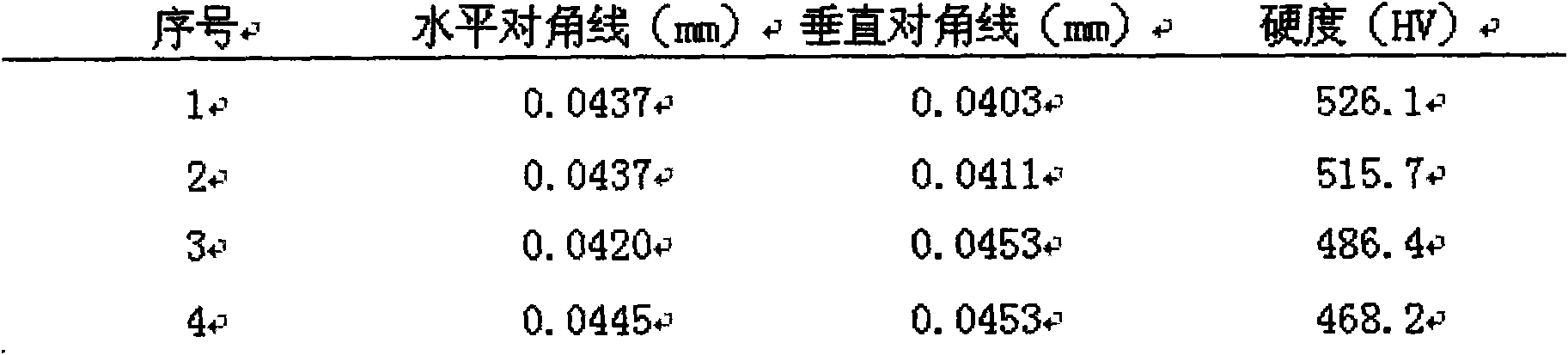

[0053] Using ammonium chloride, sponge titanium, rare earth, solid chromate, aluminum powder and quartz sand as raw materials, weigh each raw material in proportion, grind and mix them uniformly to form a catalyst, wherein the catalyst includes 10.6% by weight of chlorine ammonium chloride, 1.8% titanium sponge, 9% rare earth, 0.1% solid chromate, 0.01% aluminum powder, and the rest of the catalyst is quartz sand.

[0054] Mix the catalyst evenly and put it in a stainless steel container with the cleaned 20CrMnTi test workpiece according to the specific gravity of 250:1 and put it into the bottom of the carburizing furnace for composite co-carburizing. The temperature control device is an electronic potentiometer. The test temperature is 540°C, and the co-infiltration time is 4 hours. The osmotic agent is [(NH2)2CO+C2H5OH] saturated solution + kerosene, and the amount of osmotic agent added is (70-80) drops / min. Finally, the product was cooled to room temperature to complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com