Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

A technology of laser cladding and soft-hard composite, which is applied in coatings, chemical instruments and methods, metal material coating technology, etc., and can solve problems such as laser cladding soft-hard composite coatings that have not been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

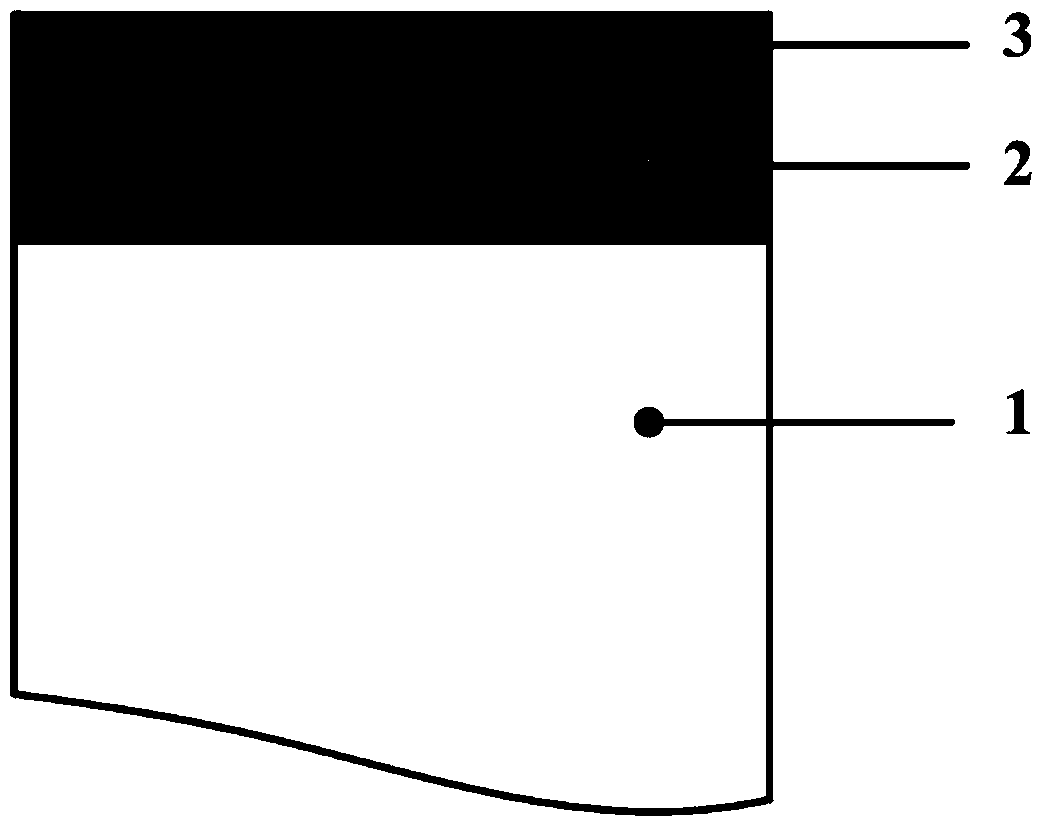

Image

Examples

example 1

[0018] A preparation method of laser cladding soft-hard composite coating self-lubricating tool, the base material is W18Cr4V high-speed steel tool; the surface self-lubricating soft coating material is nickel-coated MoS 2 , the hard coating material is nano-Al 2 o 3 Ceramic; cladding method is CO 2 Laser synchronous powder feeding method cladding. Its preparation method is as follows:

[0019] (1) Put the W18Cr4V high-speed steel tool in the alcohol and acetone solution for 20 minutes to ultrasonically clean it for degreasing treatment;

[0020] (2) Using CO with a wavelength of 10.6 μm 2 Laser, adjust the laser parameters as follows: laser power 600W, spot diameter 2mm, scanning speed 5mm / s, overlap rate Φ=25%.

[0021] (3) A with a particle size of 100-150nm 2 o 3 The ceramic powder is fully mixed, and its main component is 97%A 2 o 3 , 2%Ni and 1%Al; the prepared nano-Al 2 o 3 Ceramic powder is loaded into the powder feeder. Adjust the powder feeding rate of th...

example 2

[0026] A preparation method of self-lubricating tool with laser cladding soft-hard composite coating. The base material is W6Mo5Cr4V2 high-speed steel tool; the surface self-lubricating soft coating material is nickel-coated WS 2 , the hard coating material is ultrafine cemented carbide; the cladding method is CO 2 Laser synchronous powder feeding method cladding. Its preparation method is as follows:

[0027] (1) Put the W6Mo5Cr4V2 high-speed steel tool in the alcohol and acetone solution for 20 minutes and ultrasonically clean it for degreasing treatment;

[0028] (2) Using CO with a wavelength of 10.6 μm 2 Laser, adjust the laser parameters as follows: laser power 600W, spot diameter 3mm, scanning speed 4mm / s, overlap rate Φ=30%.

[0029] (3) Fully mix ultrafine cemented carbide powder with a particle size of 100-500nm, the main components of which are 80%WC, 10%Co, 5%W, 1.5%VC, 1%Cr 3 C 2 And 1%Ni, 1%Al and 0.5%Mo; put the prepared ultrafine cemented carbide powder in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com