Patents

Literature

2791 results about "Nano al2o3" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-woven media incorporating ultrafine or nanosize powders

InactiveUS20080026041A1Improve efficiencyLarge capacityMaterial nanotechnologyTreatment involving filtrationFiberActivated carbon

The invention is a fibrous structure for fluid streams that is a mixture of nano alumina fibers and second fibers arranged in a matrix to create asymmetrical pores and to which fine, ultrafine, or nanosize particles such as powdered activated carbon are attached without the use of binders. The fibrous structure containing powdered activated carbon intercepts contaminants from fluid streams. The invention is also a method of manufacturing and using the fibrous structure.

Owner:ARGONIDE CORP

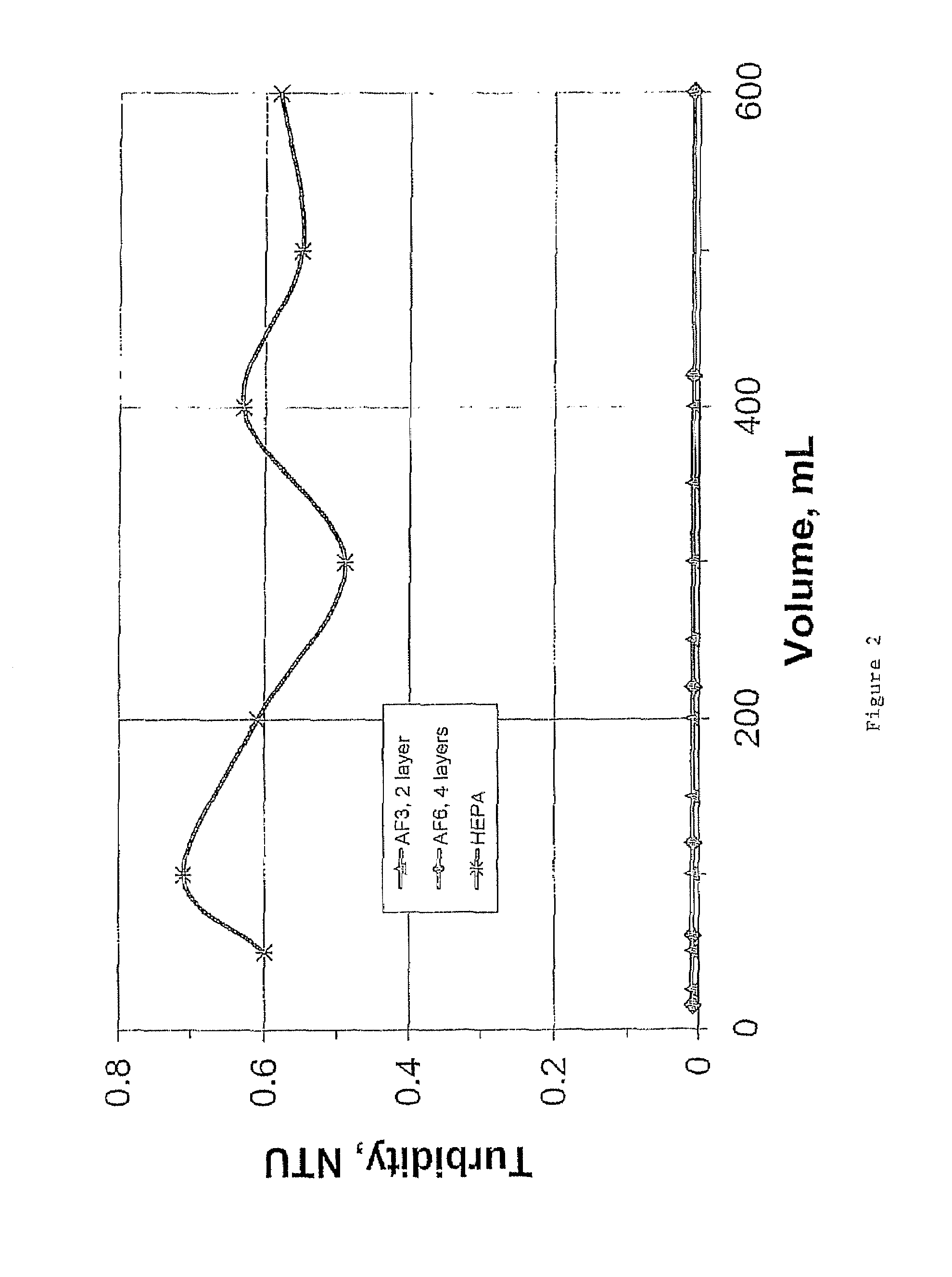

Drinking water filtration device

ActiveUS7390343B2Improve efficiencyLarge capacityMaterial nanotechnologyDispersed particle filtrationFiberHalogen

The invention is a device for purifying drinking water that has at least one fibrous structure. Preferably, there is an upstream and downstream fibrous structure. Each fibrous structure is a mixture of nano alumina fibers and second fibers arranged in a matrix to create asymmetric pores and to which fine, ultrafine, or nanosize particles are attached. Preferably, the device has an upstream antimicrobial for sterilization of retained microbes. The device is substantially more efficient at removing soluble contaminants such as halogens from a fluid stream than those previously available and is also able to retain turbidity, bacteria, and virus.

Owner:ARGONIDE CORP

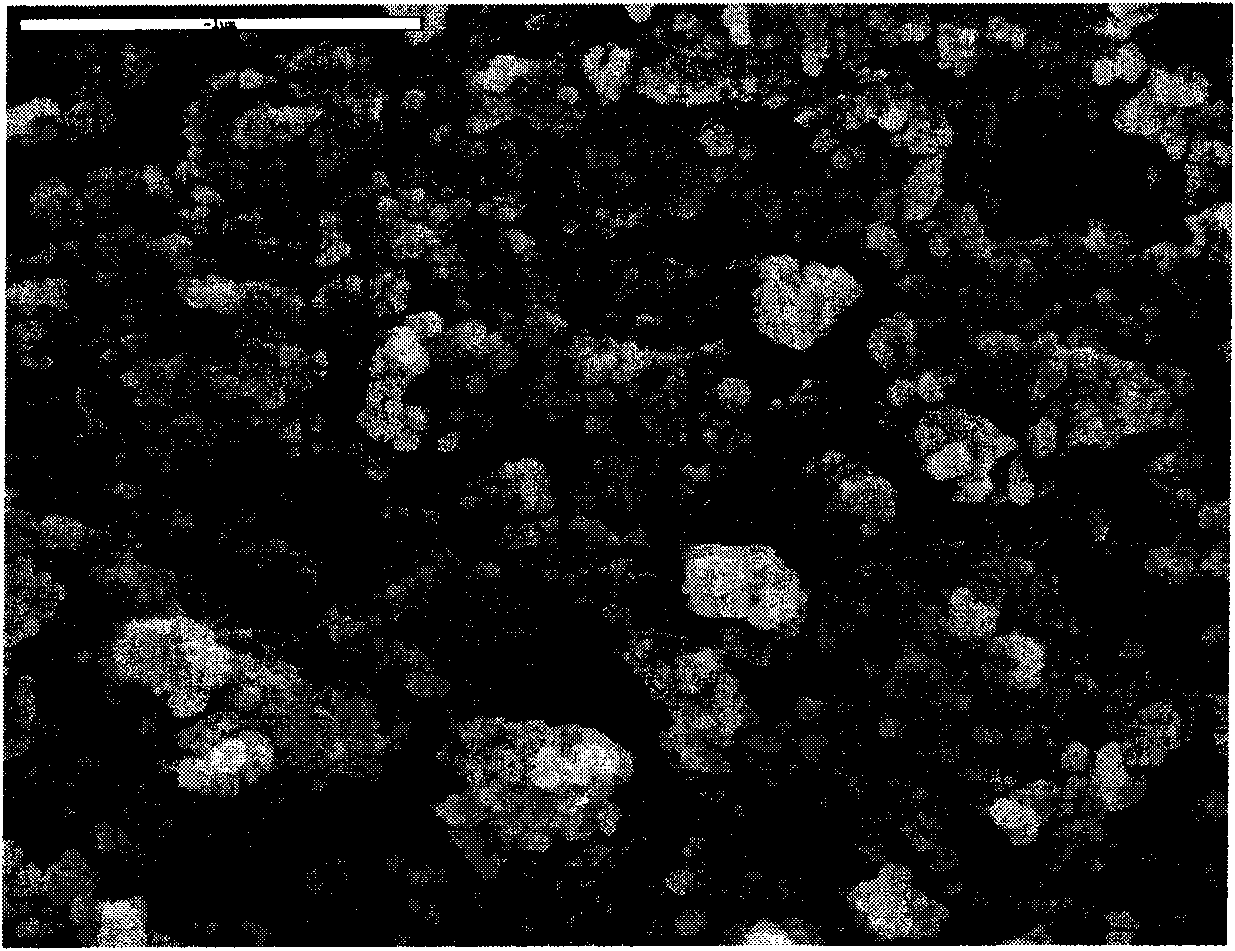

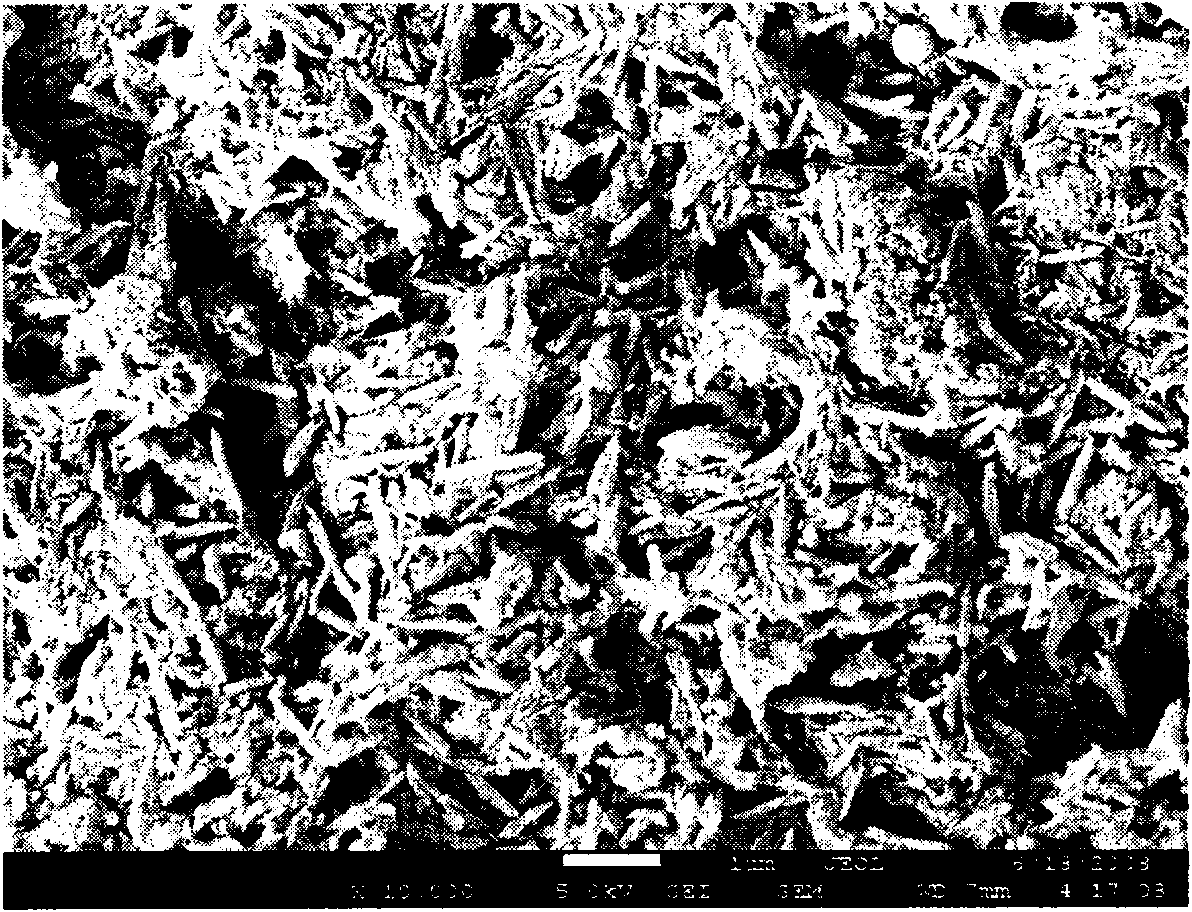

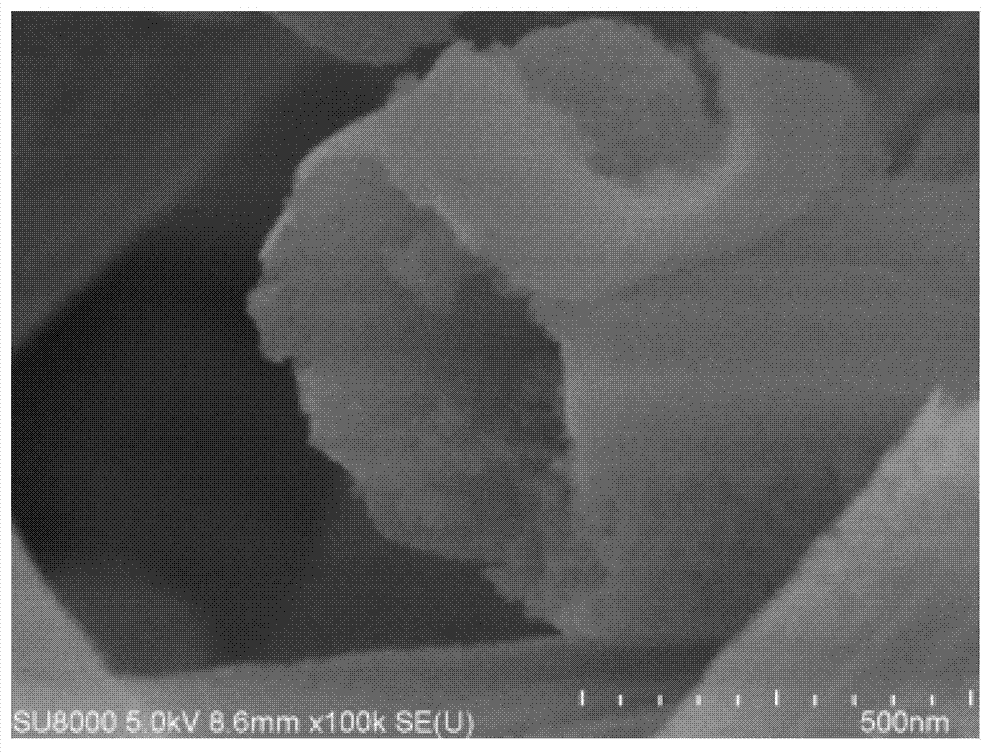

Alumina carrier and preparation method thereof

The invention discloses an alumina carrier and a preparation method thereof. In the alumina carrier, aluminum hydroxide gel prepared by a molten salt supersolubilizing micelle method is taken as a raw material. After a surfactant and a hydrocarbon component contained in the gel are molded and baked, nano-alumina particles formed by removing water from the polymerized aluminum hydroxide still have a basic rod-shaped structure and are piled up in an unordered way so as to form a frame structure. The alumina carrier has the characteristics of large pore volume, large pore diameter, high porosity, large orifice on the outer surface and high pore canal penetrability. In particular for macromolecules, the alumina carrier prevents catalyst inactivation caused by the blocking of an ink bottle-shaped orifice, so that impurity deposition is increased, and the running period of a catalyst is prolonged. The alumina carrier can be applied to a catalytic reaction which contains a macromolecule reactant or a macromolecule product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing nickel-coated alumina powder

The invention relates to a preparation method of nickel-coated alumina oxide powder, in particular to the preparation method of nickel-coated aluminum oxide powder for thermal spraying in aviation, aerospace and military fields. The invention is characterized in that: a suspension is made from a mixing liquid of nano-aluminum oxide and dispersant, stirred and added with nickel salt solution at the same time, and the obtained mixture liquid is dropped with ammonium water after being fully stirred, added with distilled water, when dark blue mixing solution C of nickel ammonia complex ([Ni (NH3)) 2+and alumina oxide is obtained; the mixing solution C is aged by water, filtered, washed and dried, and a green middle coated product is obtained; the green middle coated product is further reduced and roasted, finally, black nickel-coated aluminum oxide powder is prepared. The nickel-coated aluminum oxide powder prepared through the invention has uniform granularity, with average size less than or equal to 1.0Mum, and can enhance the application performance of nano-alumina and expand the application of nano-aluminum oxide; the product is mainly used for aviation, aerospace and military materials and other high-tech fields. The method of the invention is simple, reproducible and easy to be industrialized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

Heavy metals absorbent and method of use

InactiveUS20050029198A1Improved resistance to physical degradationAvoid easy cloggingOther chemical processesWater contaminantsFiberSorbent

A media for removal of heavy metals from an aqueous system comprising a mixture of nano alumina fibers and a ferric or manganic compound selected from the group consisting of hydroxides, oxyhydroxides, oxides and hydroxyoxides and mixtures thereof. The nano alumina is preferably produced by hydrothermal digestion of aluminum hydroxide, is treated with alkaline, followed by the addition of a ferric or manganic salt to form a gel like mass that is dried, heat treated, ground and sieved to form the sorbent. Alternatively a non-woven media is formed by adding mineral fiber such as microglass to the hydrothermal step. The resulting mulch is treated with alkaline and subsequently an iron and / or manganic compound, wet laid and dried to form the fibrous sorbent. Removal of heavy metals from the aqueous system is readily accomplished by contacting the aqueous system with the media until the heavy metal is substantially removed from the aqueous system.

Owner:ARGONIDE CORP

Novel nano modified antimicrobial water-based woodware paint

InactiveCN103059669ANo pollution in the processNon-flammableAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

The invention discloses a novel nano modified antimicrobial water-based woodware paint which comprises acrylic resin emulsion, polyurethane resin emulsion, nano silica sol, nano aluminum oxide, nano titanium dioxide, nano silver, film-forming assistant, defoaming agent, wetting and dispersing agent, leveling agent, thickening agent, wax emulsion and pH regulator. The nano materials dispersed in the water-based paint enhance the hardness of the coated film, so that the coated film has excellent yellowing resistance, aging resistance and mold resistance.

Owner:高凡

Titanium silicon molecular sieve catalyst as well as preparation method and use thereof

ActiveCN101371989ALarge particle sizeHigh mechanical strengthOrganic chemistryMolecular sieve catalystsMolecular sieveNano al2o3

The invention relates to a titanium silicate molecular sieve catalyst and the preparation method and the application thereof. The catalyst comprises 25-65 percent of titanium silicate molecular sieve and 20-65 percent of nanometer alumina. The mechanical strength is 20-30N / cm<2>. Prepared by an extruded moulding method, the catalyst has the characteristics of high mechanical strength, high catalytic activity and selectivity, and the like, and is especially applied to catalyzing 3-chloropropene oxidation reaction to prepare epichlorohydrin.

Owner:CHINA PETROLEUM & CHEM CORP +1

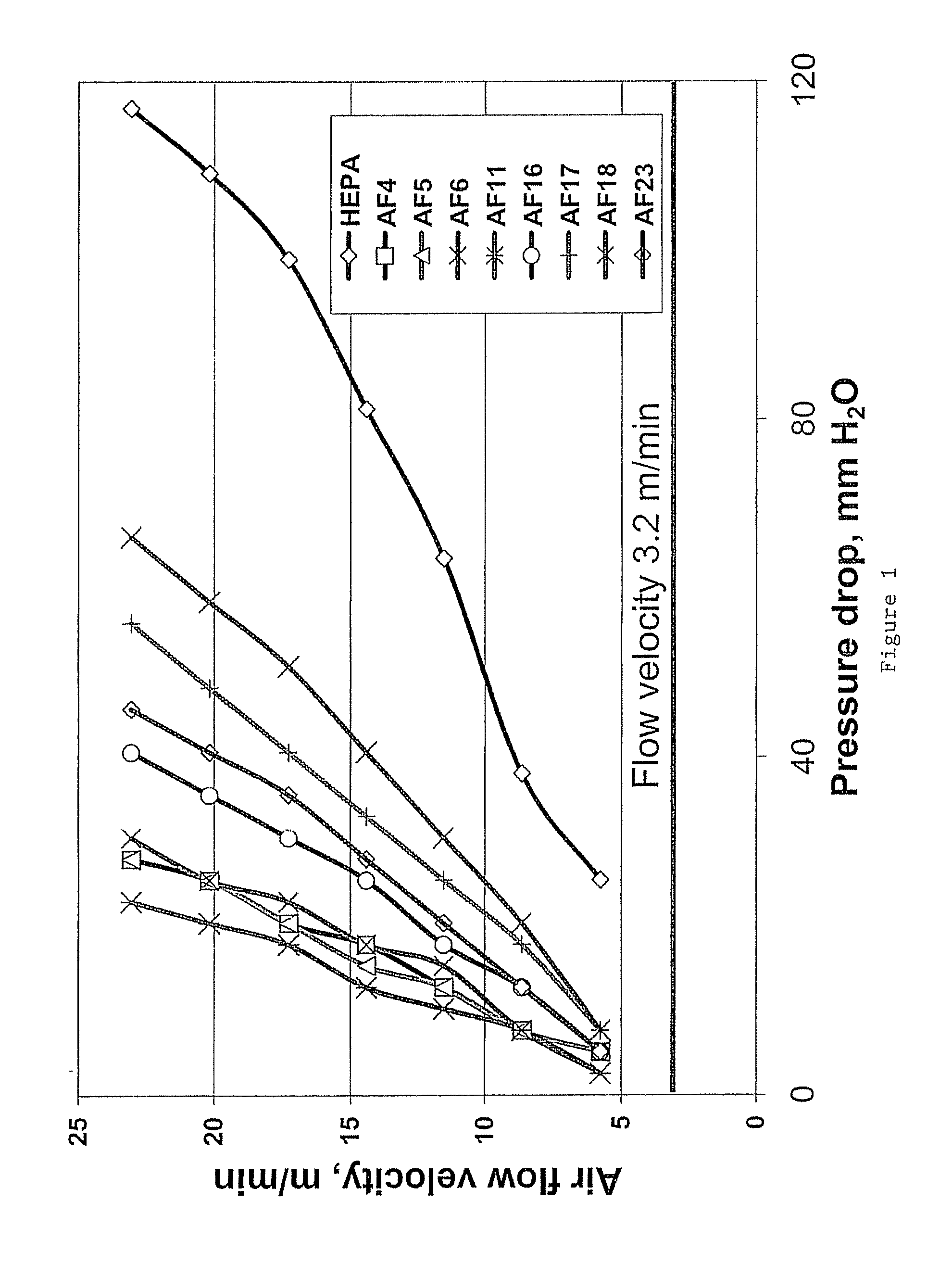

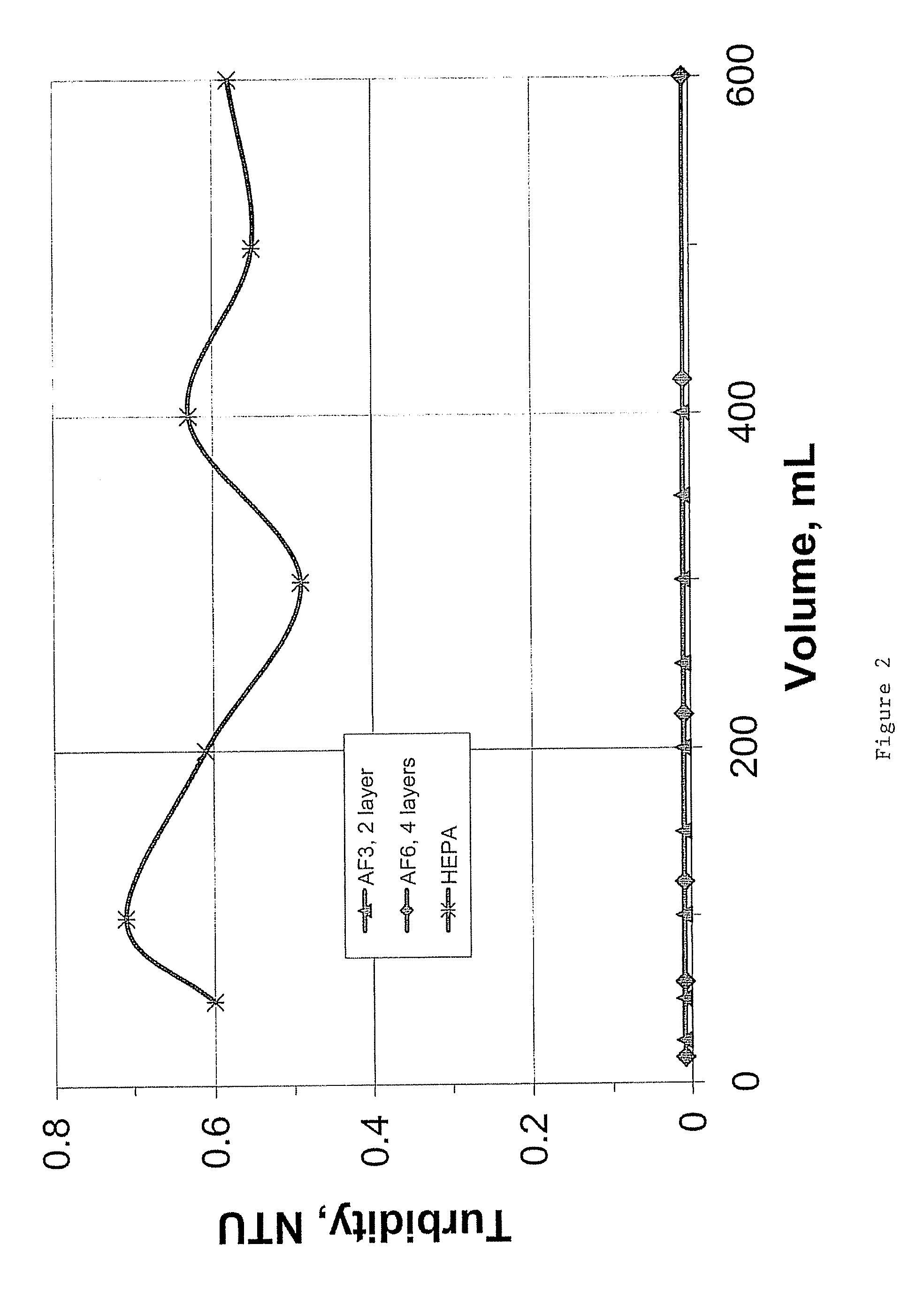

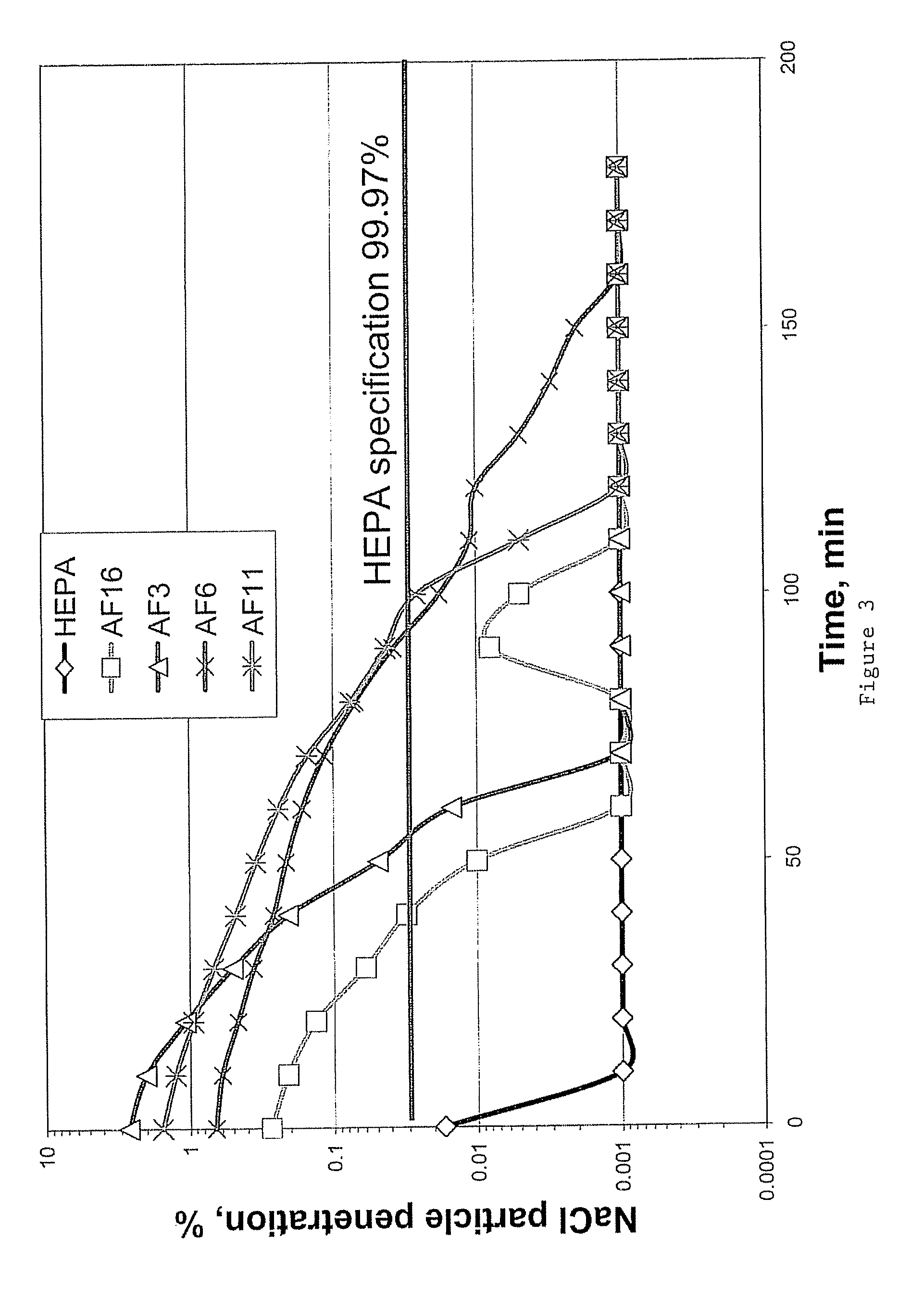

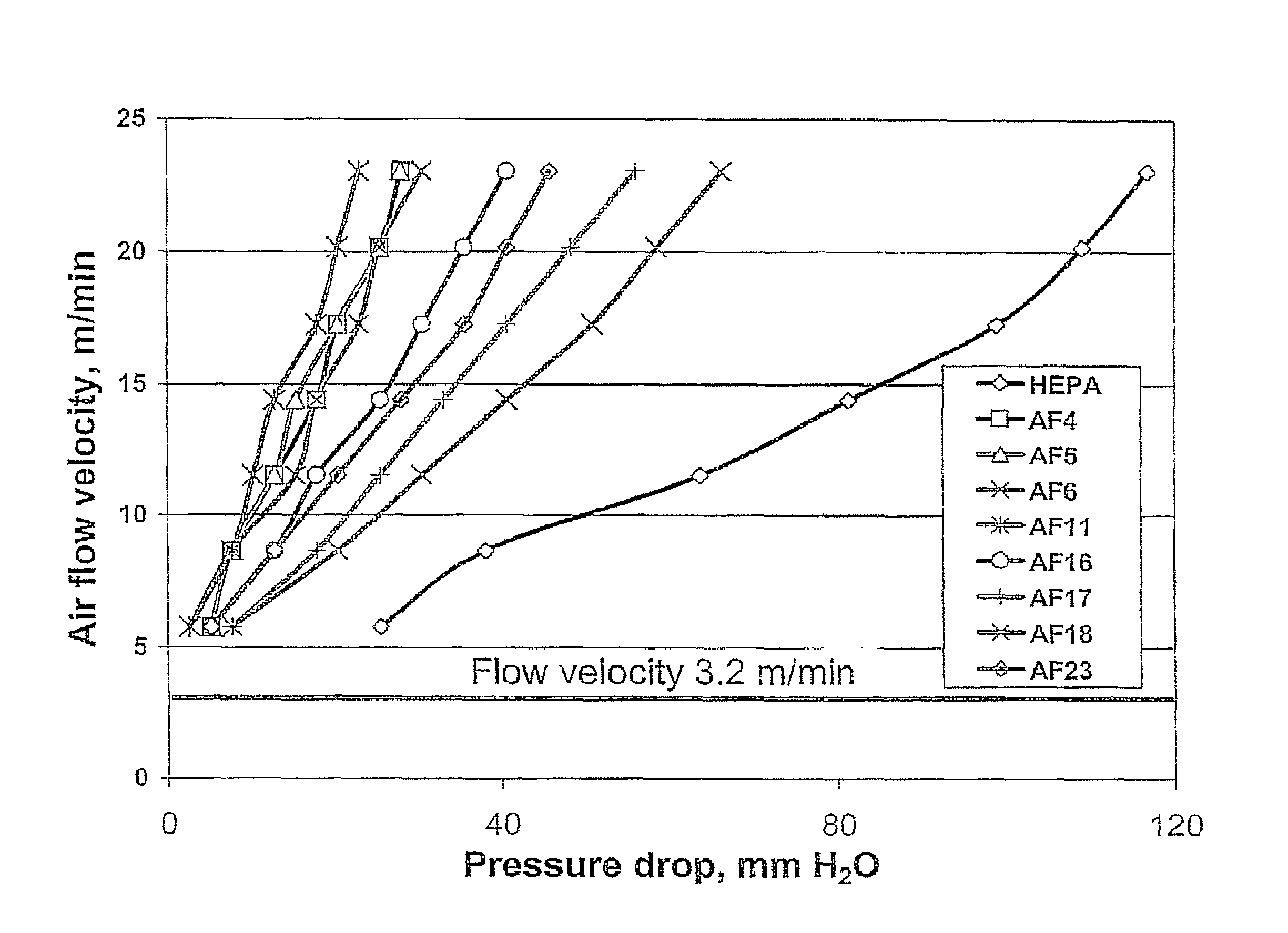

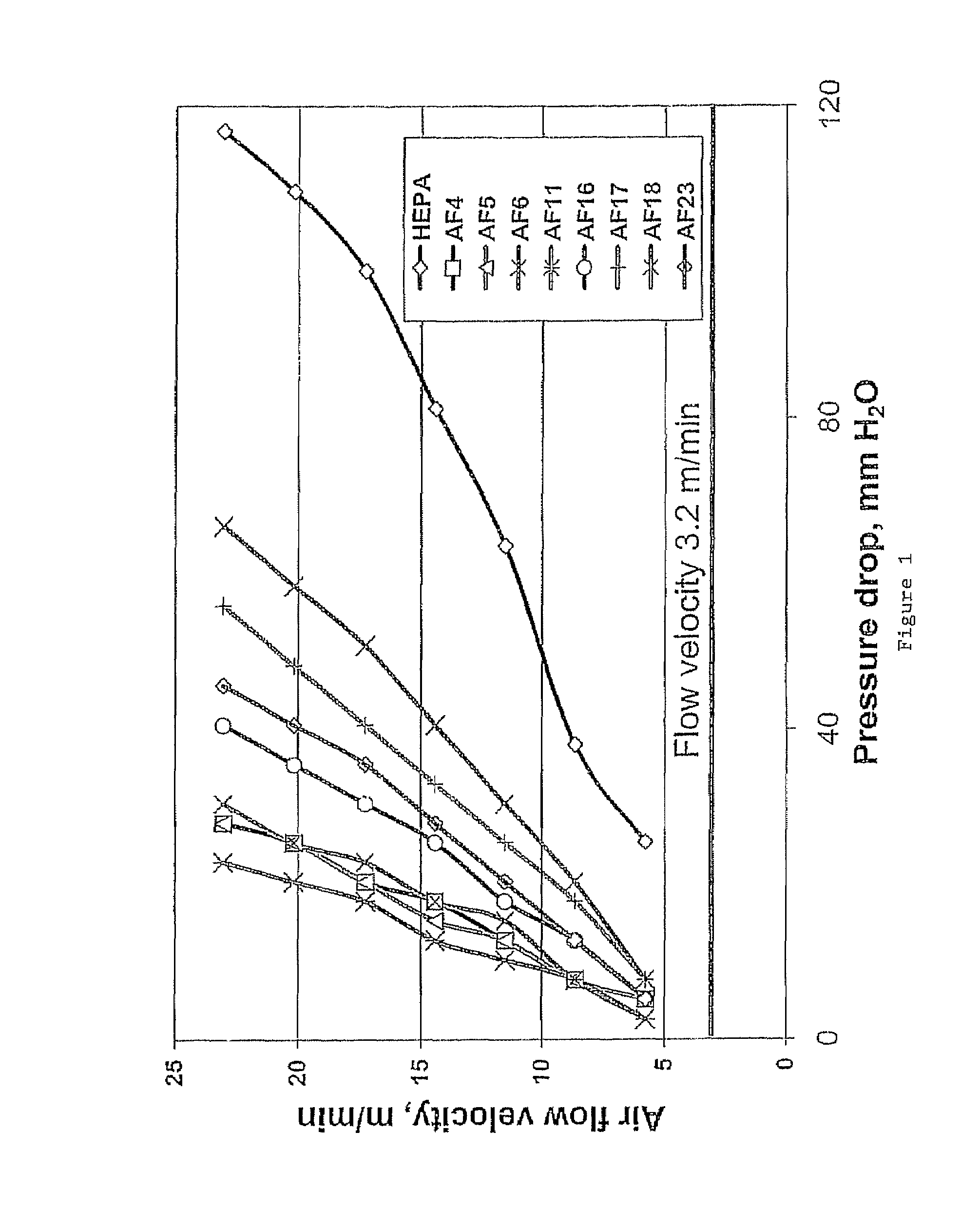

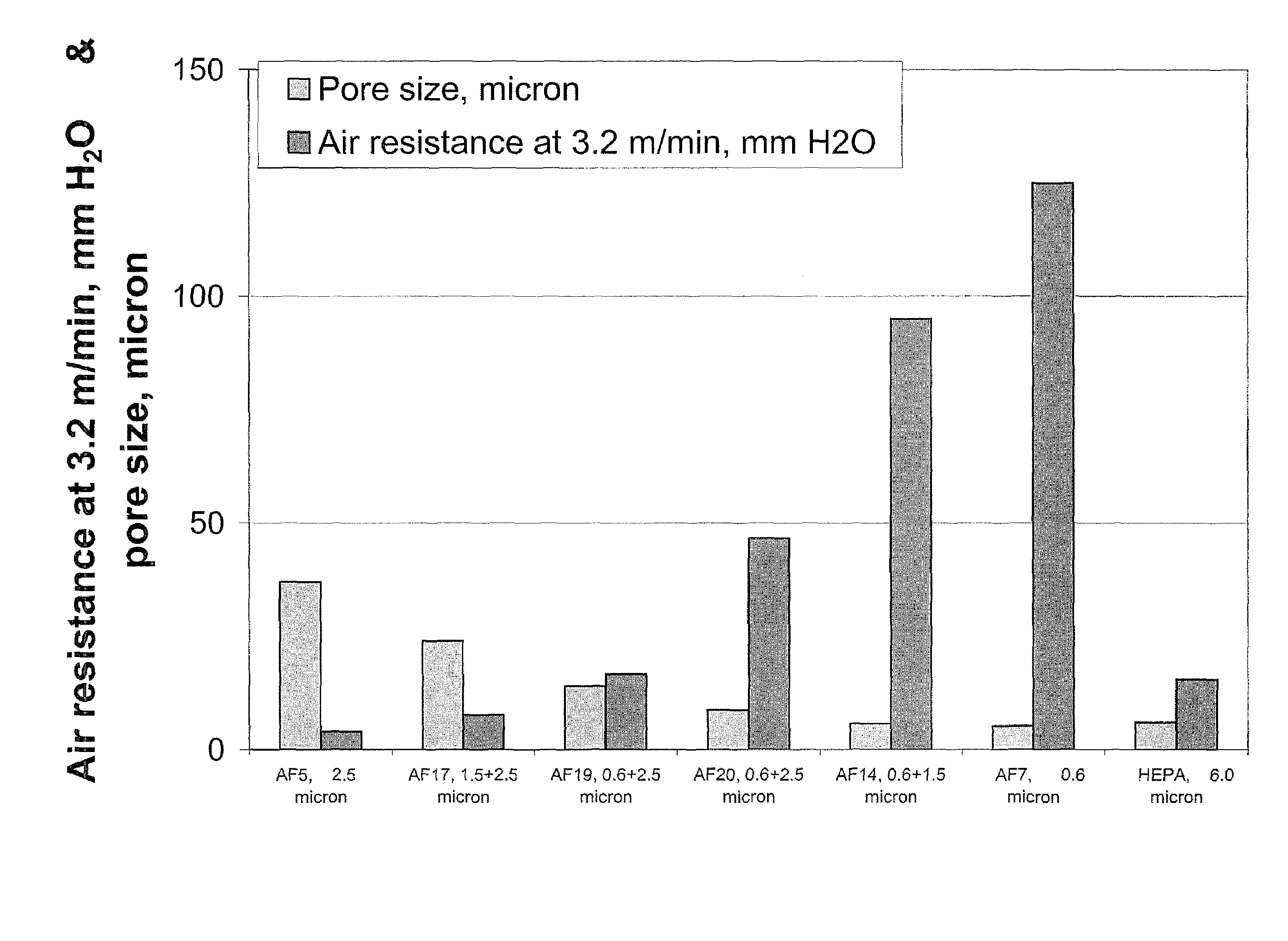

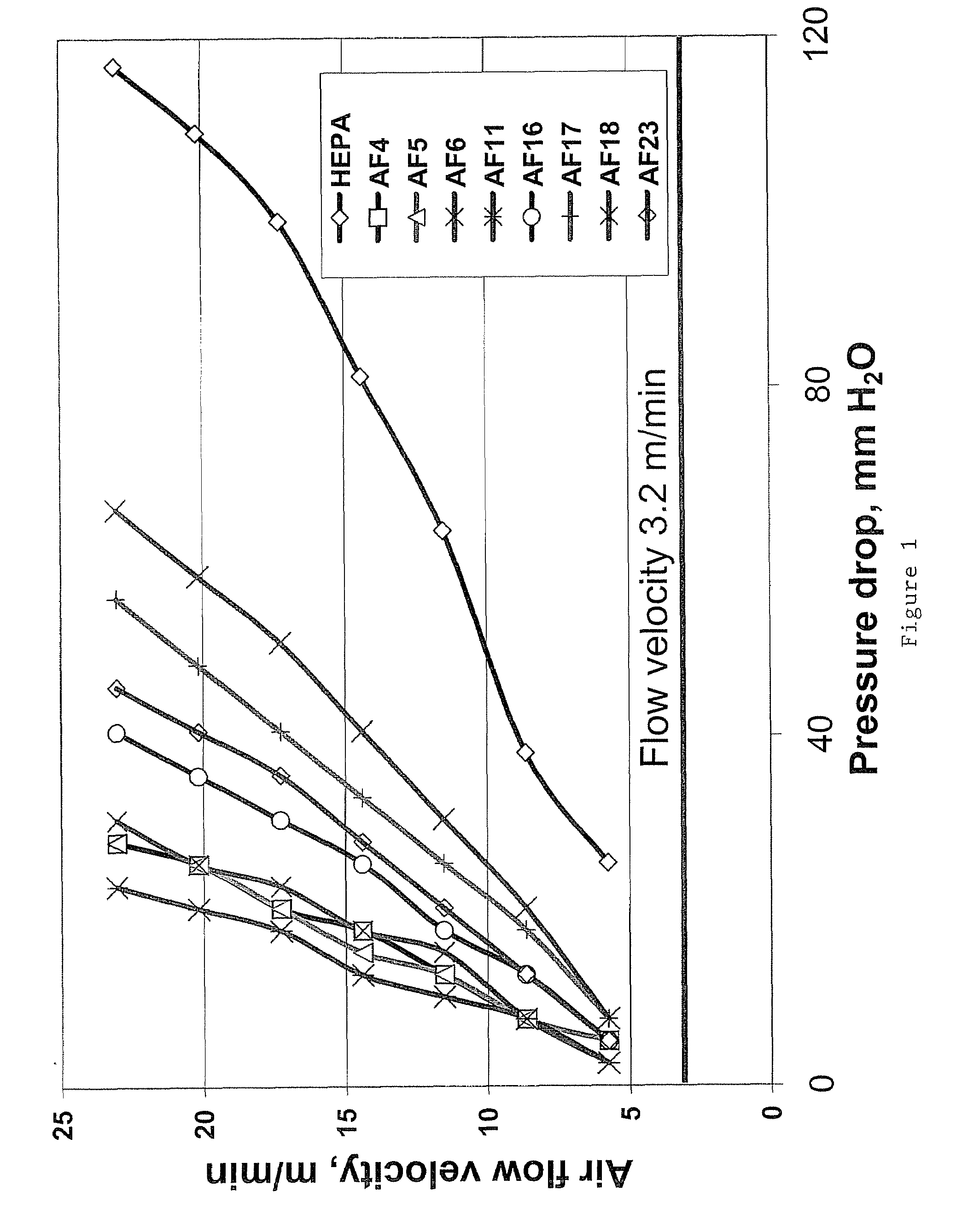

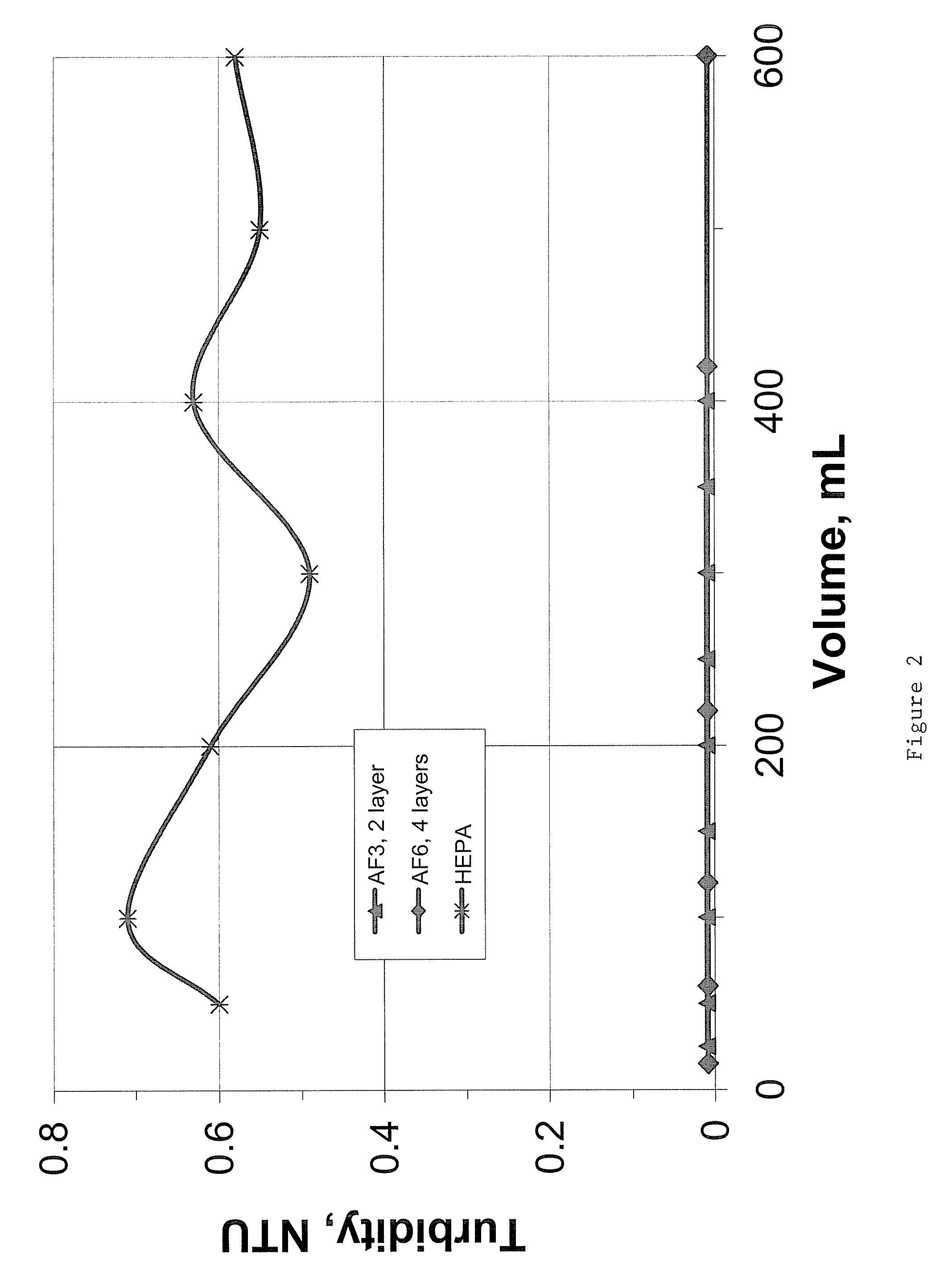

Electrostatic air filter

ActiveUS7311752B2Improve efficiencyLarge capacityDispersed particle filtrationSolid sorbent liquid separationSuspended particlesHEPA

The invention is a filter for gaseous media in which nano alumina fibers and second fibers are arranged in a matrix to create asymmetrical pores. The filter is a high efficiency, high capacity particulate filter that intercepts pathogens and other particulate matter from gaseous media, including vapor-suspended particles. The new filter has an improved retention of water-aerosolized particles as compared to conventional HEPA filters and may be used as a pre-filter that extends the life of HEPA filters by about five to ten times. The invention is also a method of manufacturing and using the filter.

Owner:ARGONIDE CORP

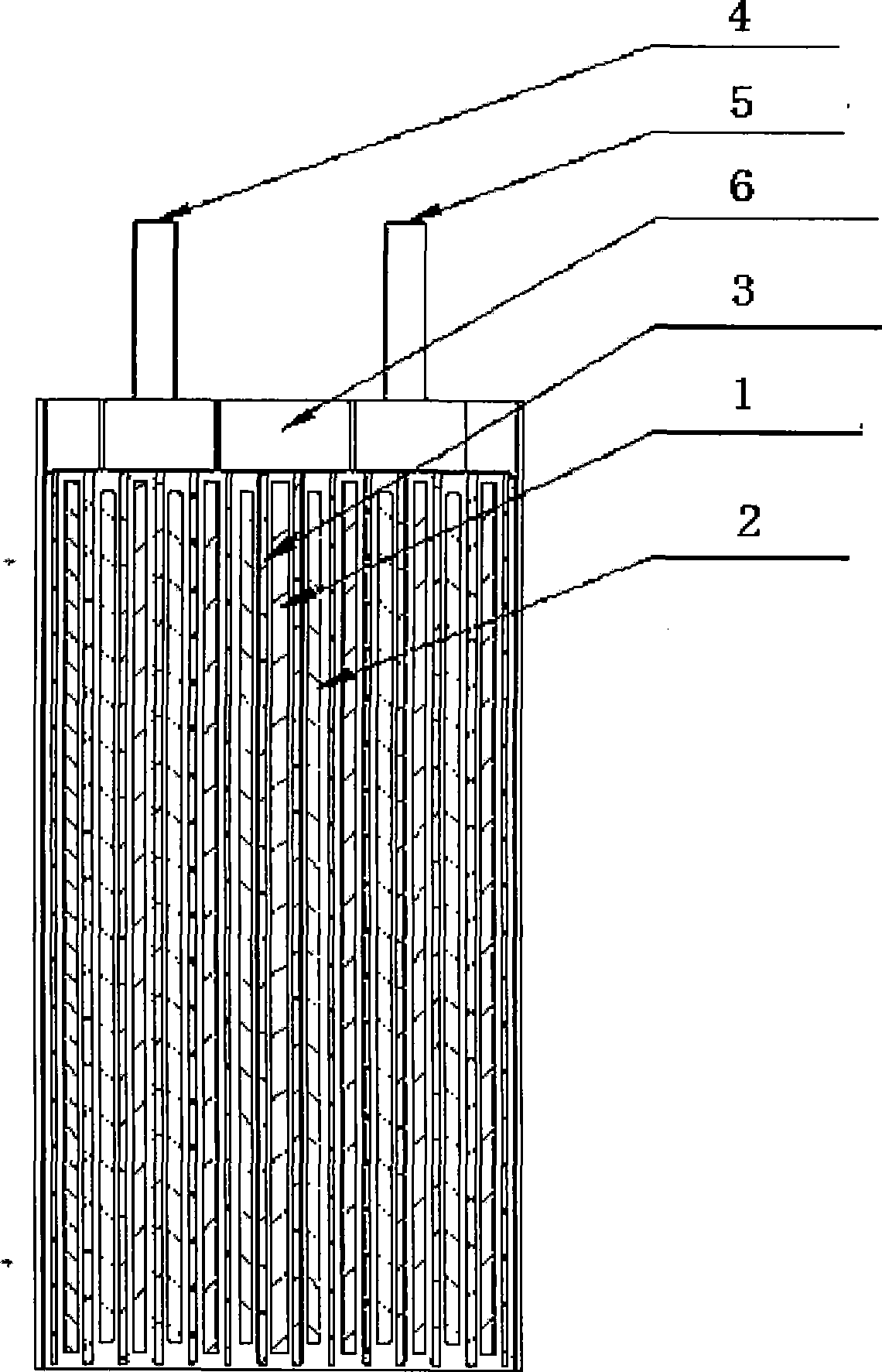

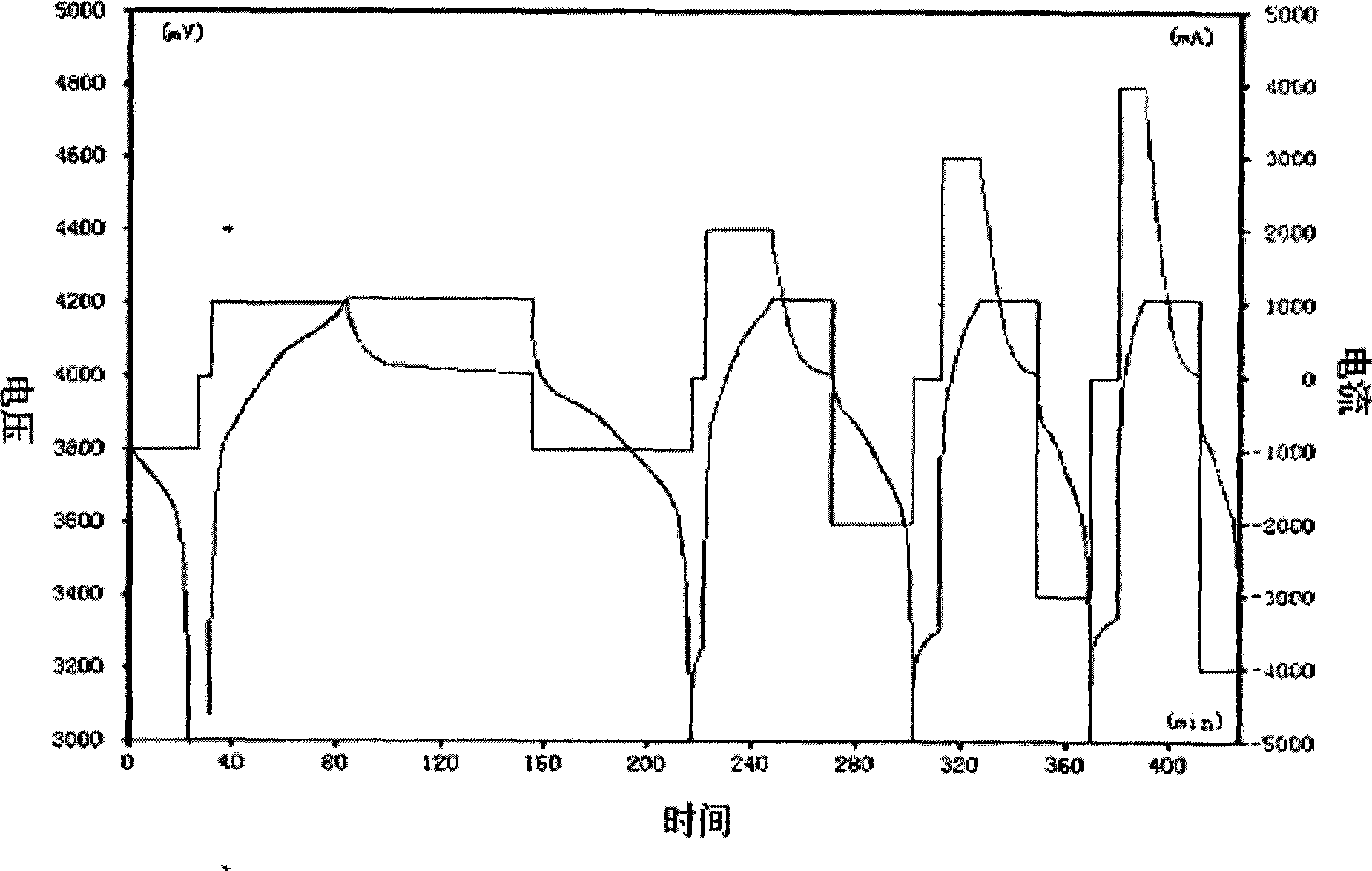

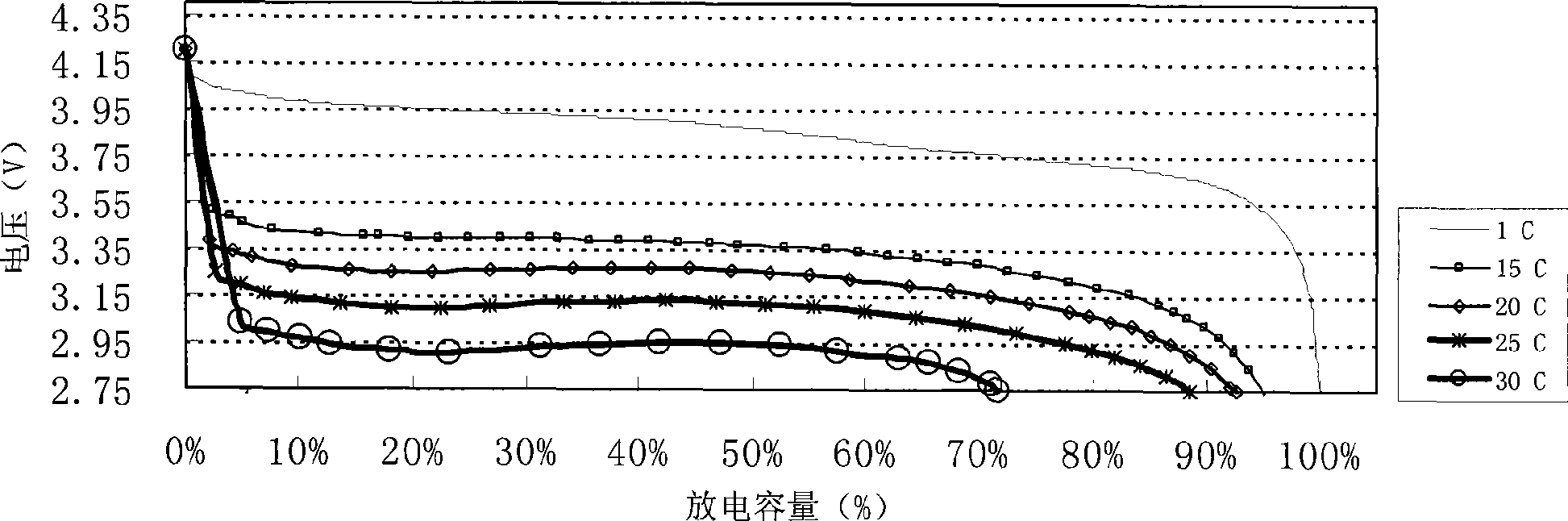

Multi-multiplying power charging-discharging lithium ion battery and method for producing the same

InactiveCN101499530AImprove high rate charge and discharge performanceImprove performanceElectrode manufacturing processesFinal product manufactureHigh rateMicrosphere

The invention provides a high-rate charge-discharge lithium-ion battery and a preparation method thereof. The anode active material of the lithium-ion battery is lithium manganate; the cathode active material is selected from one or more of mesocarbon microbeads, artificial graphite or natural graphite coated by mesophase pitch; a conductive agent is selected from one or more of conductive graphite, conductive carbon black, nano Ag, nano SiO2 or nano Al2O3. The preparation method of the lithium-ion battery comprises the preparation of the anode plate, the parathion of the cathode plate and the assembly of the battery. The lithium-ion battery has the advantages of high-rate charge-discharge performance, long cycle life, high capacity, safe use, environmental protection, low cost and the like. The preparation method has the advantage of simple and easy process operation, and is applicable to the mass production.

Owner:深圳市崧鼎实业有限公司

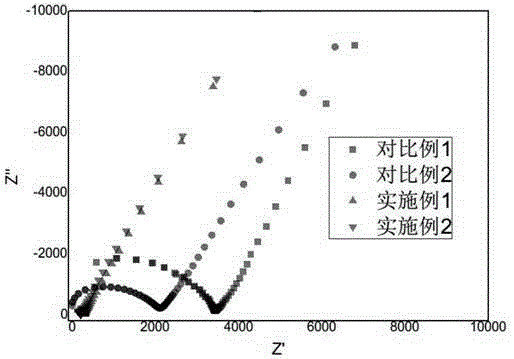

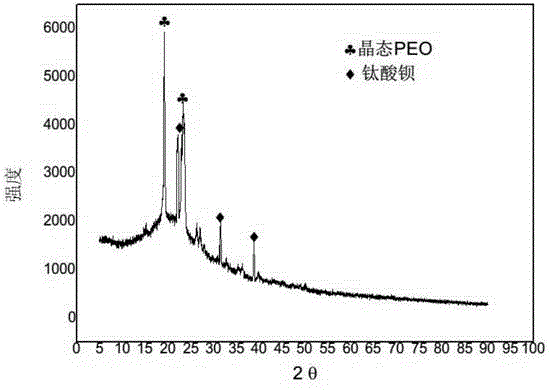

All-solid polymer electrolyte, and preparation method and application of all-solid polymer electrolyte

InactiveCN104538670AImprove conductivityHigh mechanical strengthSolid electrolytesFinal product manufacturePolyethylene oxideBarium titanate

The invention discloses an all-solid polymer electrolyte, and a preparation method and an application of the all-solid polymer electrolyte, and belongs to the field of lithium ion batteries. The all-solid polymer electrolyte comprises polyethylene oxide, lithium salt, inorganic nano particles and ion liquid, wherein a mass ratio of the lithium salt to polyethylene oxide is 0.1-0.5; the mass sum of the inorganic nano particles and the ion liquid is 10-30% of the mass of the all-solid polymer electrolyte; the lithium salt comprises one or several of bistrifluoromethane sulfonimide lithium salt, lithium tetrafluoroborate, lithium perchlorate, lithium hexafluorophosphate, lithium hexafluoroarsenate, lithium trifluoromethanesulfonate and lithium bis borate; and the inorganic nano particles comprise one or several of nano aluminum oxide, nano silicon oxide, nano zirconium oxide and nano barium titanate. The all-solid polymer electrolyte has better mechanical strength and higher ion conductivity. The method is simple in technology and low in cost; and raw materials are easy to obtain.

Owner:HUAZHONG UNIV OF SCI & TECH RES INST SHENZHEN

Negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and manufacturing method thereof

InactiveCN107083579AWith far infrared heating performanceAntibacterial and anti-mite effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and a manufacturing method thereof. The compound polyester fibers are added with a negative-ion additive, a far-infrared additive and an antibacterial and anti-mite additive, wherein the negative-ion additive, the far-infrared additive and the antibacterial and anti-mite additive respectively account for 2%, 5% and 6% by mass in the compound polyester fibers; the negative-ion additive comprises an additive carrier and tourmaline negative-ion powder; the far-infrared additive comprises an additive carrier, Tai Chi stone powder, ZrO2 nano-powder, nano-silicon dioxide, nano-aluminum oxide, nano-manganese oxide and nano-calcium oxide; the antibacterial and anti-mite additive comprises an additive carrier, nano-Cu-ZnO compound particles, nano-titanium dioxide, nano-zinc oxide and nano-silicon dioxide; and the additive carrier is TiO2 hollow spheres.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

Aluminium nitride ceramics material and preparation method thereof

ActiveCN101386539ADoes not significantly affect colloidal propertiesGood dispersion propertiesAluminium acetylacetonateNano al2o3

The invention discloses an aluminium nitride ceramic material and a preparation method thereof. The method is to add nano-alumina to raw materials in the prior preparation method for preparation according to the prior preparation process. In-situ growing nano-alumina can be obtained directly through adding the nano-alumina, or indirectly through adding organic aluminum, such as aluminium secondary butylate, aluminium isopropoxide or aluminium acetylacetonate, and by means of low-temperature decomposition of the organic alumina. The method can be applied to dry pressing and tape casting shaping, can obtain slurry with good dispersing characteristic and even mixing of the aluminium nitride and the nano-alumina by the ceramic preparation process, such as normal pressure, hot pressed sintering or the like, and is favorable for the improvement of sintering activity of materials, the reduction of sintering temperature, the improvement of luster uniformity, planeness and roughness for a ceramic substrate, and the reduction of production cost. The aluminium nitride ceramic material and the preparation method thereof can be widely applied to the field of aluminium nitride ceramic production.

Owner:无锡海古德新技术有限公司

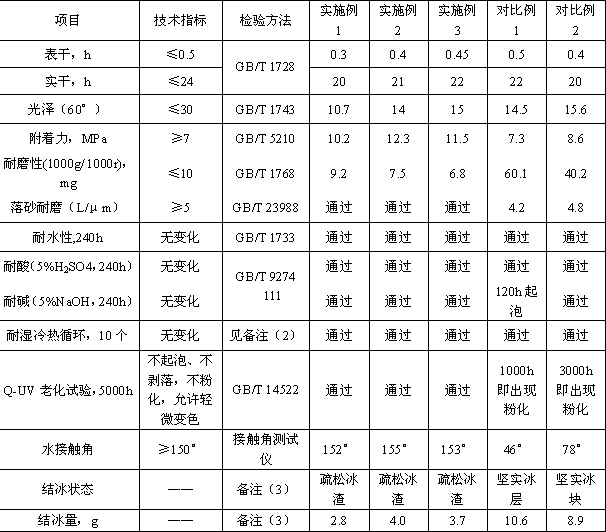

Super weather-resisting, wear-resisting and anti-icing wind-powered blade coating and preparation method thereof

ActiveCN103013316AGood weather resistanceImprove wear resistancePolyurea/polyurethane coatingsUltraviolet lightsSpray coating

The invention discloses a super weather-resisting, wear-resisting and anti-icing wind-powered blade coating and a preparation method thereof. A component A comprises the following compositions in percentage by mass: 27-44% of fluorocarbon resin, 10-25% of polyester resins, 0.5-2% of a silane coupling agent, 0.5-2% of a wetting dispersant, 0.5-2% of a thixotropic agent, 1-5% of nano titanium dioxide, 3-6% of nano alumina, 12-18% of a pigment, 5-10% of packing, 3-6% of extinction powder, 0.1-1% of an ultraviolet light absorber, 0.1-0.8% of a flatting agent, 0.01-0.4% of a defoaming agent and 5-10% of a diluent; and the component A and aliphatic isocyanate are proportioned according to a formula that -NCO / -OH = 1.05-1.2. The coating disclosed by the invention is outstanding in weather resistance and wear resistance, and can carry out long-acting protection on wind-powered blades and save the maintenance cost; the water contact angle is greater than or equal to 150 degrees, and the ice cover can be reduced by more than 50%; and the surface dry is implemented in 0.5 h, the hard dry is implemented in 24 h, and the coating can be subjected to brush coating, roll coating and spray coating, therefore, the coating is high in construction efficiency.

Owner:洛阳双瑞防腐工程技术有限公司

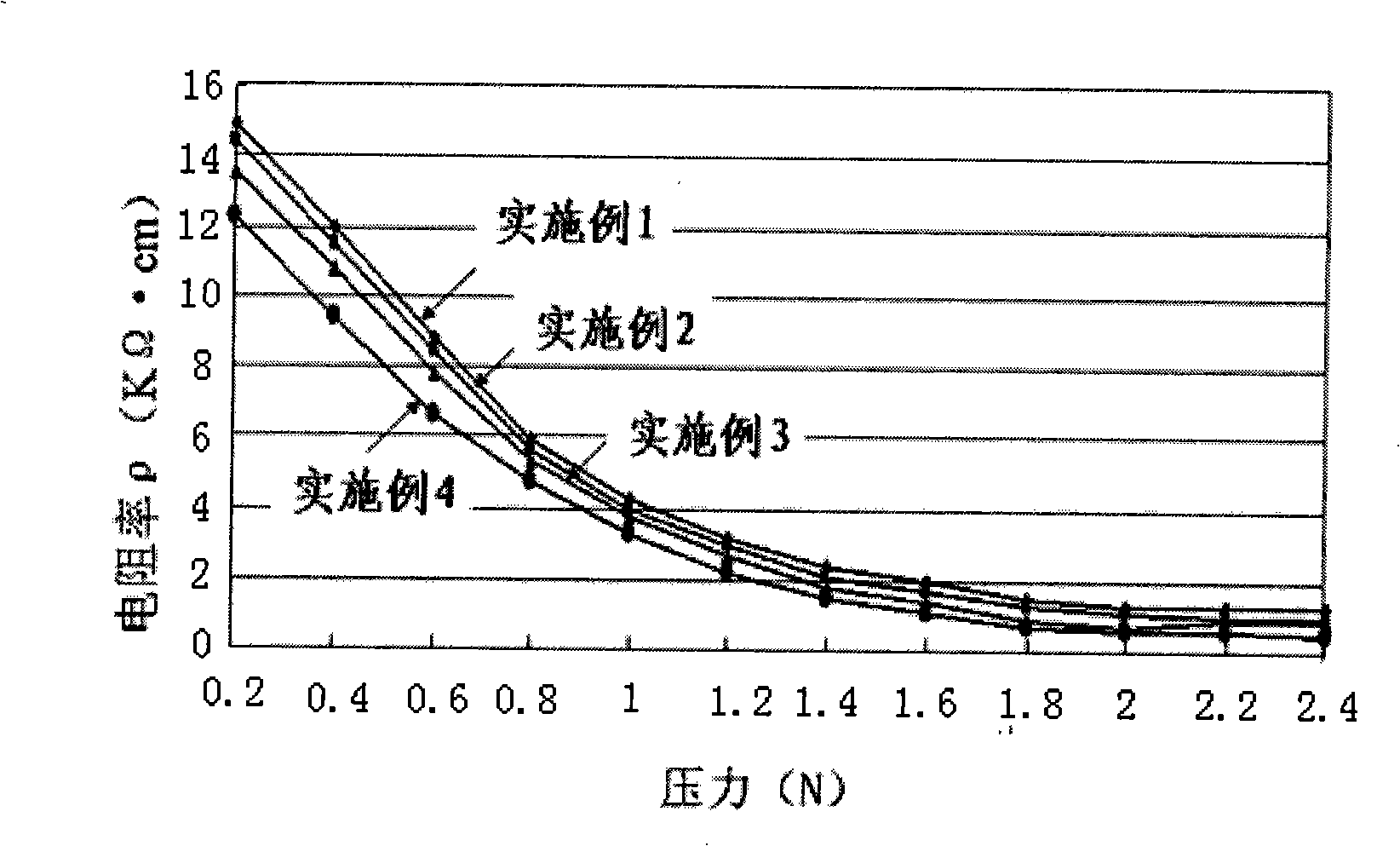

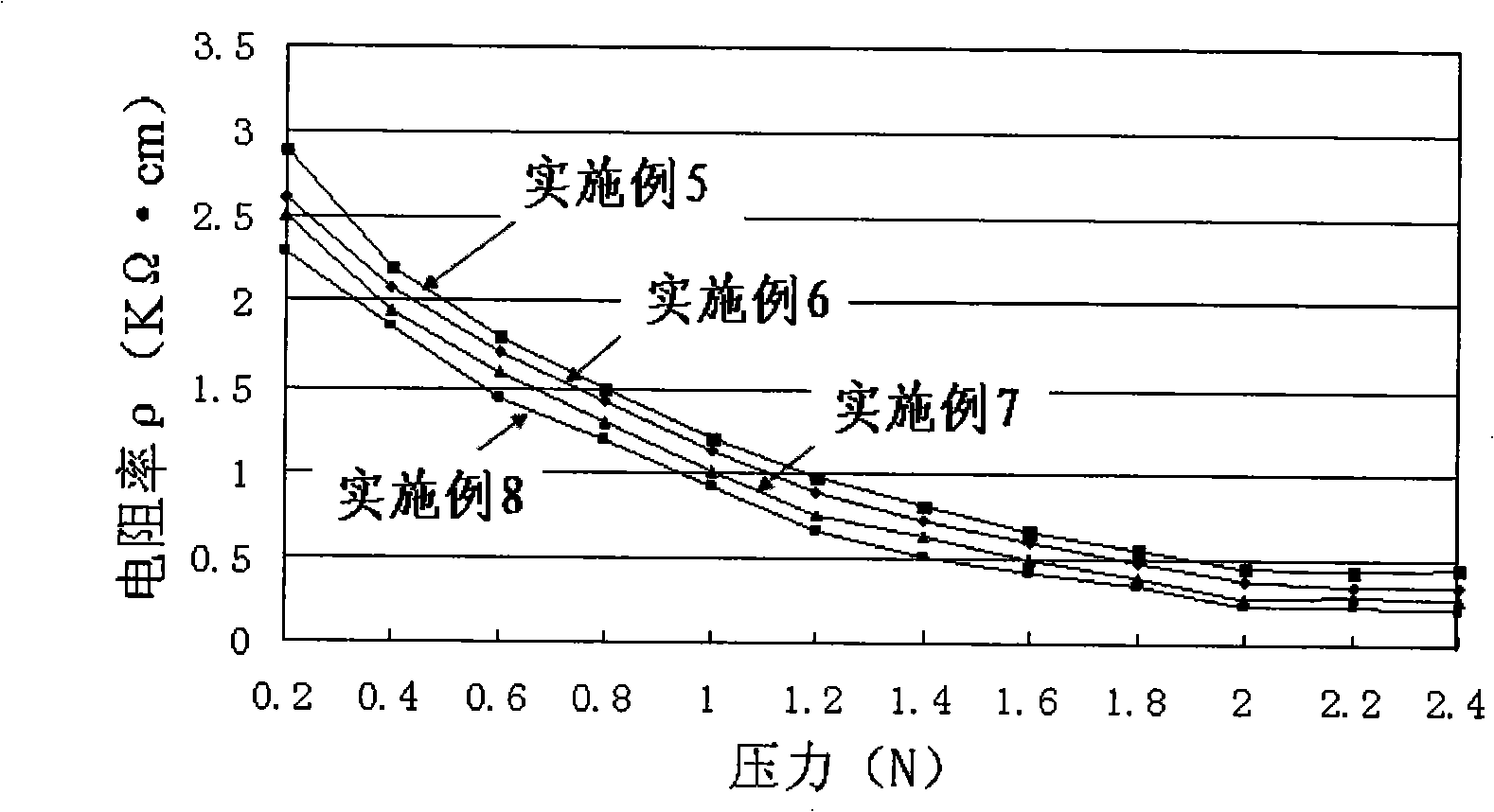

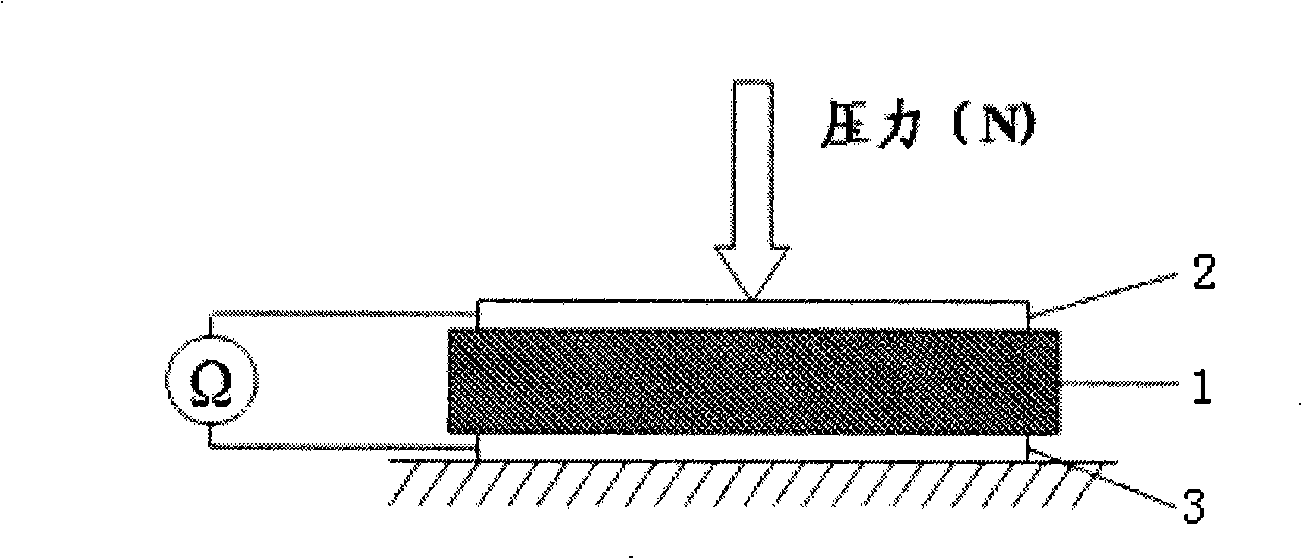

Pressure sensitive material used for flexible touch sensation sensor and preparation method thereof

InactiveCN101260237AImprove compatibilityGood flexibilityForce measurementSensor arrayTouch sensation

A pressure sensitive material used in a flexible touch sensor and a preparation method thereof are characterized in that: the material adopts carbon black, a silicon rubber composite system and added nano SiO2 or nano Al2O3 as raw materials; according to the preparation method, all raw materials are mixed in turn under normal temperature and normal pressure to obtain mixed solution which is injected into a touch sensor structural model, thereby curing forming is completed at room temperature. The pressure sensitive material, which has excellent touch sensing function and flexility, is suitable to be used in a touch sensor array structure designed at will; moreover, the preparation method has a simple process.

Owner:HEFEI UNIV OF TECH

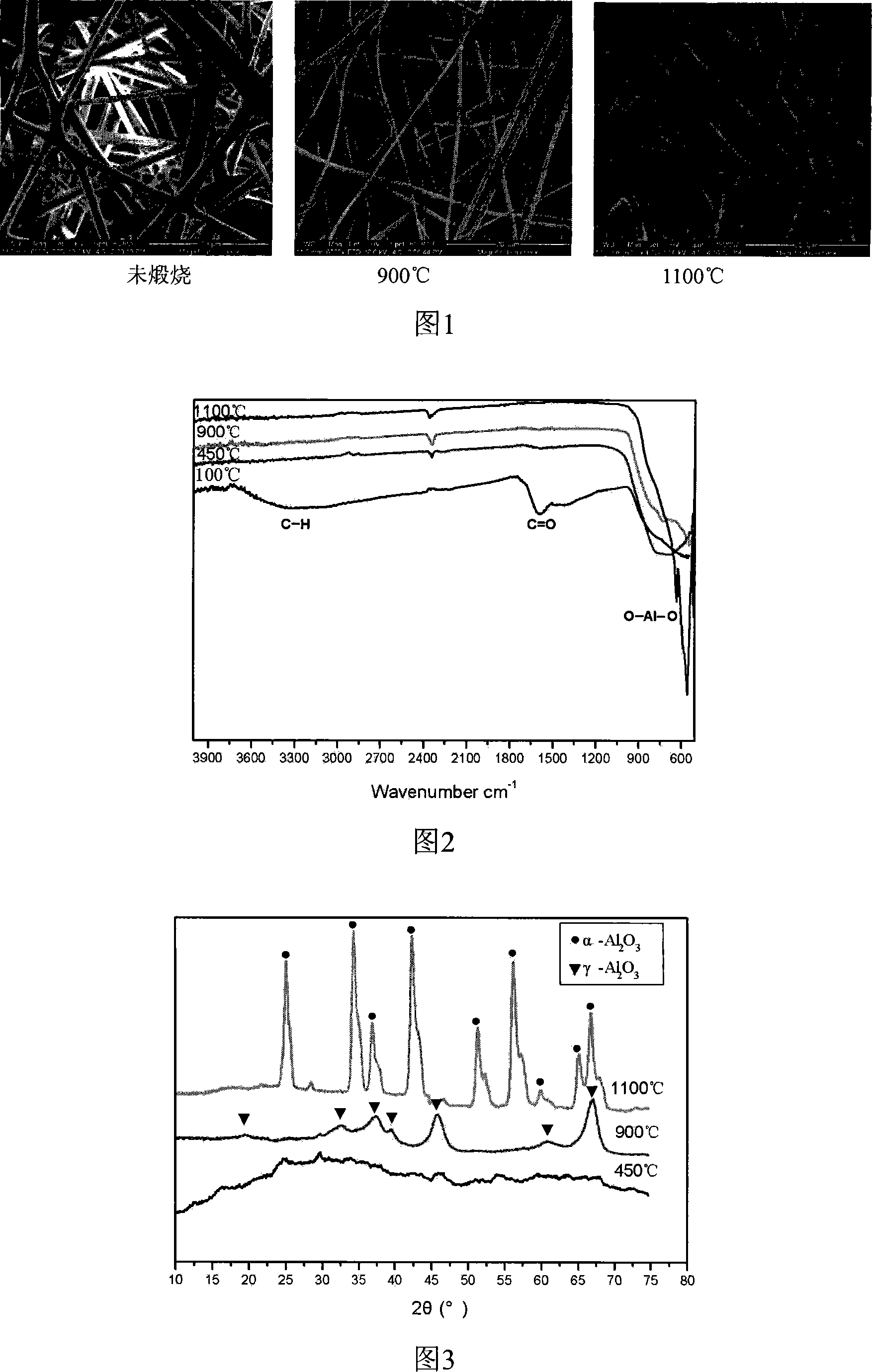

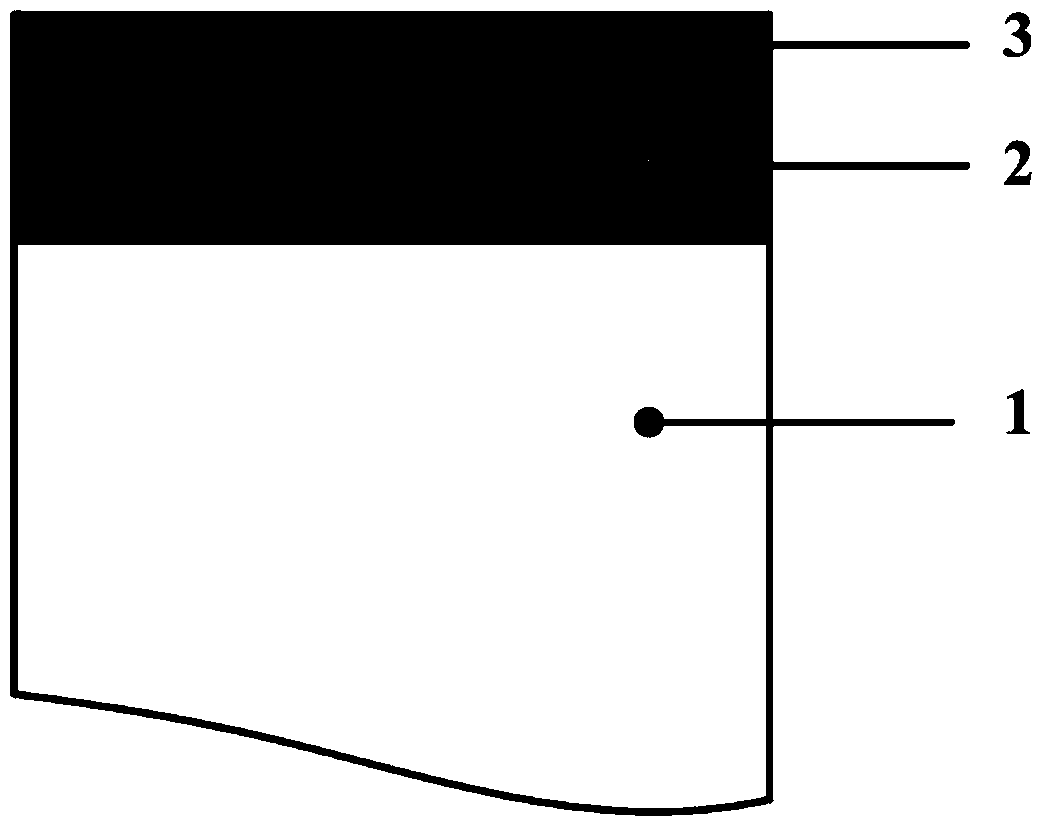

Method for preparing nano alumina fiber film material

The invention relates to a technology of preparing nano alumina fiber membrane material by electrostatic spinning, comprising: 1. the configuration of sol gel electrostatic spinning liquid. Pouring polyvinyl pyrrolidone into ethanol solvent and stirring thereof with high speed until completely dissolved; getting the polyvinyl pyrrolidone ethanol solution with the concentration of 5-8wt%, then, mixing the solution with the aluminum chloride solution with the concentration of 10-30wt%, wherein, the weight ratio between the polyvinyl pyrrolidone and the aluminum chloride is 3:1-1:1, stirring for one hour. 2. Electrostatic spinning. The prepared sol gel spinning liquid is injected into the electrostatic spinning device and electrostaticly spinning thereof is injected into aluminum chloride / polyvinyl pyrrolidone nano fiber membrane under the voltage of 25-35kv, the extrusion speed of 1-10ml / min and the reception distance of 10-20cm. 3. calcining. At last putting the prepared aluminum chloride / polyvinyl pyrrolidone nano fiber membrane into a muffle furnace and raising the temperature to 450-1100 DEG C with the speed of 50 DEG C / h, calcining for five hours and getting amorphous, Gamma type or Alpha type aluminum oxide fiber membrane. The nano aluminum oxide fiber membrane made by the invention is a catalyst and the carrier material of the catalyst and high temperature resistance filtration material with high specific surface area, good thermal stability and excellent mechanical properties. Furthermore, the material can be widely applied in fields such as the insulating materials and reinforced composites of space shuttle and high temperature boiler.

Owner:TIANJIN POLYTECHNIC UNIV

Efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry and its preparation method

Relateing to the field of antibacterial materials, the invention specifically provides an efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry obtained through compounding nano-magnesium oxide and other nano-inorganic materials and its preparation method. The nano-powder slurry takes nano-magnesium oxide as the main body, which is then compounded with one or more inorganic materials of nano-zinc oxide, nano-titanium oxide, nano-copper oxide, nano-cuprous oxide, nano-silver oxide, nano-zinc sulfide, nano-zirconium oxide, nano-yttrium oxide, nano-alumina, and nano-calcium oxide so as to form the nano-powder slurry, which comprises, by weight percent: 0.1-40% of nano-magnesium oxide, 0.01-40% of other inorganic materials, 0.5-12% of a polymeric dispersant, and the balance a solvent. In the method, a nano-inorganic material enters a solution composed of the polymeric dispersant and the solvent by means of high speed dispersion according to a predetermined proportion, and after ball milling, the composite nano-powder slurry can be obtained. The composite nano-powder slurry can be applied in antibacterial coatings, deodorants, textiles, paper products, plastics, rubbers, water treatment agents, ship protective agents, cosmetics and other aspects.

Owner:广东腐蚀科学与技术创新研究院

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652AImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

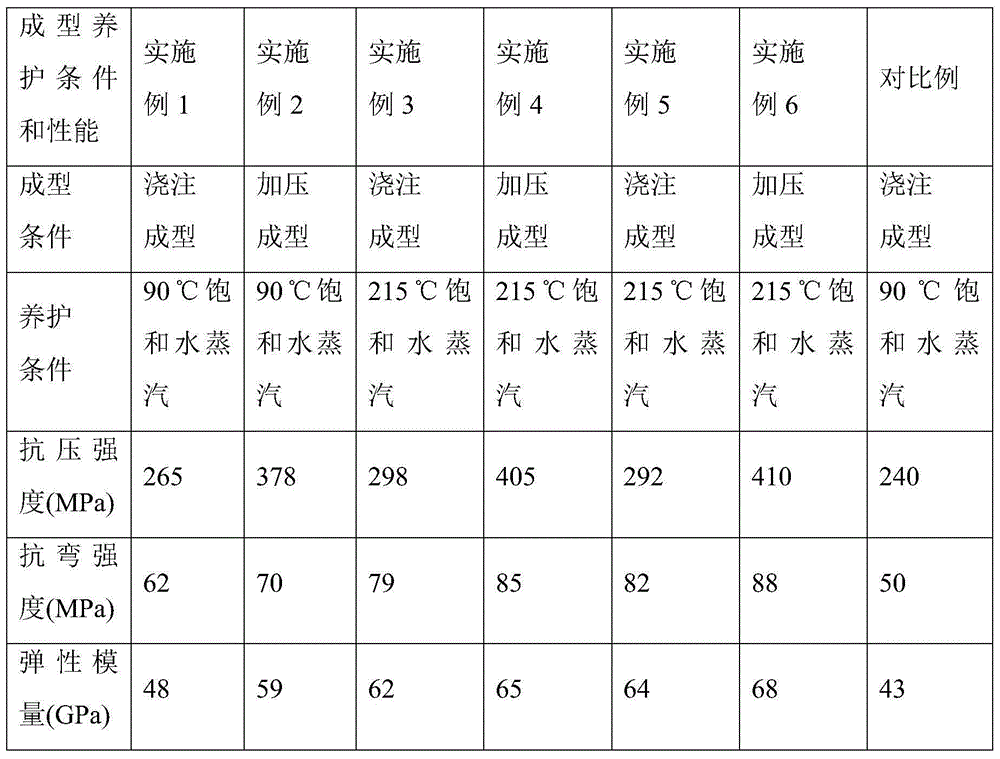

Cement-based nanocomposite material and preparation method thereof

The invention relates to an inorganic nanocomposite material and a preparation method thereof and in particular relates to a cement-based nanocomposite material and a preparation method thereof. The invention provides a cement-based nanocomposite material in order to improve the mechanical property of a cement-based material. The cement-based nanocomposite material comprises the following raw materials in parts by weight: 1 part of silicate cement, 0.15-0.25 part of silicon ash, 0.003-0.006 part of nano CaO, 0.01-0.02 part of nano CaCO3, 0.005-0.01 part of nano Al2O3, 0.01-0.02 part of fibrous nano calcium silicate or 0.001-0.002 part of carbon nanofibers, 0.3-0.4 part of 325-mesh quartz powder or glass powder, 0.45-0.55 part of quartz sand with a particle diameter of 0.4-0.6mm, 0.4-0.6 part of steel fiber, 0.015-0.025 part of a high-performance water reducer and 0.18-0.25 part of water. The mechanical property of the cement-based nanocomposite material is improved to a great extent.

Owner:HUNAN MINGXIANG TECH DEV

Thermostable white nano far-infrared ceramic powder and preparation method thereof

The invention discloses a thermostable white nano far-infrared ceramic powder and a preparation method thereof. The thermostable white nano far-infrared ceramic powder is prepared from the following components in percentage by weight: 20-30% of nano alumina, 3-8% of nano magnesia, 15-25% of nano monox, 10-20% of nano zirconia, 15-25% of nano zinc oxide, 7-10% of nano titanium oxide, 1-3% of nano rare earth oxide and 0.1-0.3% of nano precious metal oxide. In the invention, the nano rare earth oxide is one of yttrium oxide or lanthana or cerium oxide, and the nano precious metal oxide is one of platinum oxide or palladium oxide. The nano far-infrared ceramic powder can be subjected to subsequent processing at the high temperature of 1300-1450 DEG C, without reduction of radiance and radiation intensity, wherein the radiance can reach 0.90-0.94, and the nano far-infrared ceramic powder is white and can be widely applied to far-infrared household porcelain, wall and floor tiles, heating ceramic plates and high-temperature coating.

Owner:JINGDEZHEN BOZHI CERAMICS

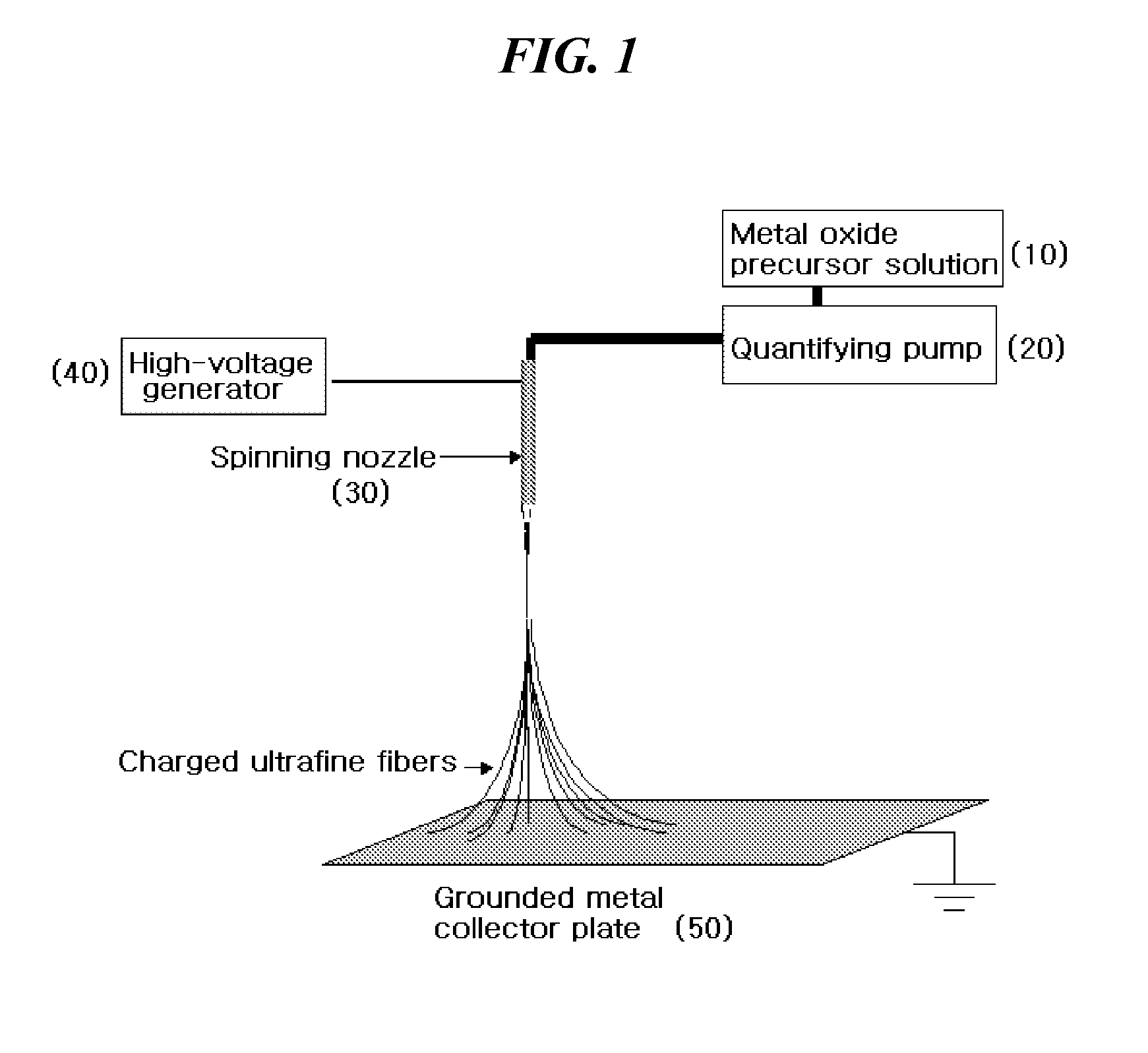

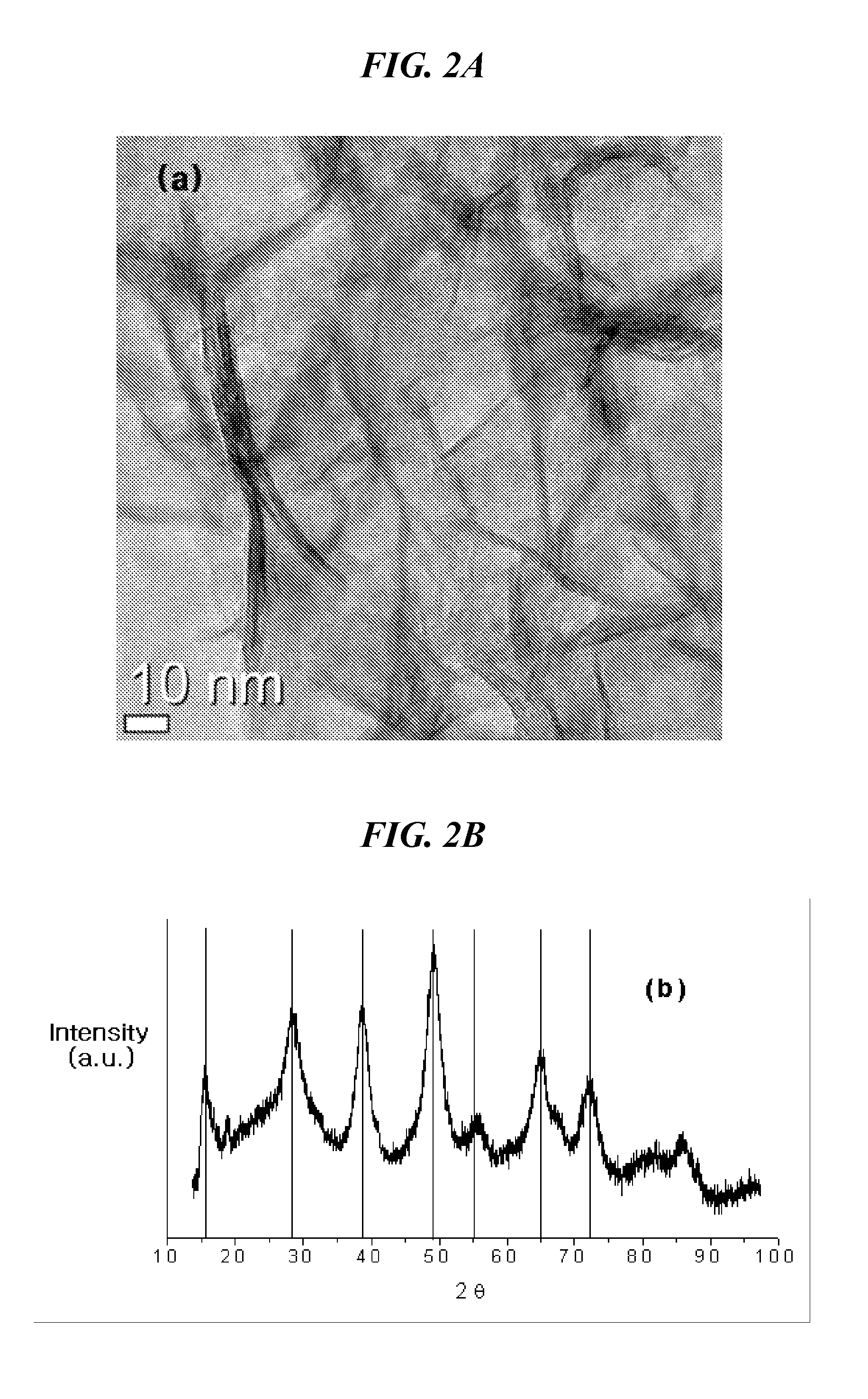

Ultrafine continuous fibrous ceramic filter and method of manufacturing same

InactiveUS20110266213A1Increase flow rateExtend your lifeMaterial nanotechnologySemi-permeable membranesPolymer resinSpinning

An ultrafine continuous fibrous ceramic filter, which comprises a filtering layer of a fibrous porous body, wherein the fibrous porous body comprises continuous ultrafine fibers of metal oxide which are randomly arranged and layered, and powdery nano-alumina incorporated into the ultrafine fibers or coated thereon, the ultrafine fibers being obtained by electrospinning a spinning solution comprising a metal oxide precursor sol-gel solution, and optionally, a polymer resin, and sintering the electrospun fibers, in which the ultrafine fibers have an average diameter of 10˜500 nm, and the fibrous porous body has a pore size of maximum frequency ranging from 0.05 to 2 μm, exhibits high filtration efficiency at a high flow rate, and can be regenerated.

Owner:KOREA INST OF SCI & TECH

Well Treatment Compositions and Methods Utilizing Nano-Particles

Disclosed embodiments relate to well treatment fluids and methods that utilize nano-particles. Exemplary nano-particles are selected from the group consisting of particulate nano-silica, nano-alumina, nano-zinc oxide, nano-boron, nano-iron oxide, and combinations thereof. Embodiments also relate to methods of cementing that include the use of nano-particles. An exemplary method of cementing comprises introducing a cement composition into a subterranean formation, wherein the cement composition comprises cement, water and a particulate nano-silica. Embodiments also relate to use of nano-particles in drilling fluids, completion fluids, stimulation fluids, and well clean-up fluids.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for preparing porous hollow nano-alumina fiber by static spinning

InactiveCN102776603ALow equipment requirementsImprove environmental friendlinessFilament/thread formingArtificial filament chemical after-treatmentPolymer dissolutionFiber

The invention relates to a method for preparing porous hollow nano-alumina fiber by static spinning. The method comprises the steps of: (1) dissolving metal salt and polymer into a cosolvent to obtain uniform or stably diffused spinning liquid, wherein the decomposing temperature of the metal salt is lower than that of the polymer, the vitrification transformation temperature of the polymer is lower than the decomposing temperature of the metal salt, and the diffusing rate of the oxide produced by decomposing the metal salt is less than the diffusing rate of the metal salt; (2) carrying out static spinning on the spinning liquid to obtain hybridized nanometer fiber; and (3) drying the hybridized nanometer fiber, and thermally processing to obtain the porous hollow nano-alumina fiber. According to the static spinning preparation method, the preparation technology is simple, and a special spinning needle head with an internal inserting pipe is not needed, and the requirement on equipment is low; and the obtained alumina fiber has the characteristics of high specific surface area, porous performance, and hollow performance and the like.

Owner:DONGHUA UNIV

Nano-aluminium oxide paste composition and its preparation method

InactiveCN1513924AGood monodispersityImprove efficiencyPigment treatment with macromolecular organic compoundsNano al2o3Slurry

A nano alumina slurry composition for ceramics, paint, ink, etc is prepared from nano alumina (150 nm), high-molecular disperser, and solvent through sequentially and proportionally adding said disperser and alumina to solvent, high-speed dispersing at 400-3000 rpm for 10-60 min, and grinding for 20 min-24 hr. Its advantages are high content of solid, low viscosity and high stability.

Owner:中科纳米涂料技术(苏州)有限公司

High-strength ceramic brick and preparation method thereof

The invention discloses a high-strength ceramic brick and a preparation method thereof. The ceramic brick is prepared from the following raw materials in parts by weight: 40-60 parts of yellow sand, 30-50 parts of barite, 15-25 parts of dolomite, 10-20 parts of volcanic rock, 20-30 parts of zirconite, 5-15 parts of mullite, 4-12 parts of blast furnace slag, 16-28 parts of modified clay, 7-14 parts of sea mud, 11-19 parts of a silica micro-powder, 8-16 parts of a waste brick powder, 3-9 parts of tricalcium phosphate, 4-8 parts of barium carbonate, 2-5 parts of nano silicon carbide, and 3-6 parts of nano alumina. The prepared ceramic brick has high strength, has the breaking strength of not less than 1050 N and the rupture modulus of not less than 30 MPa, is anti-knock, anti-cracking and non-friable, and enables the service life to be significantly improved.

Owner:安徽省亚欧陶瓷有限责任公司

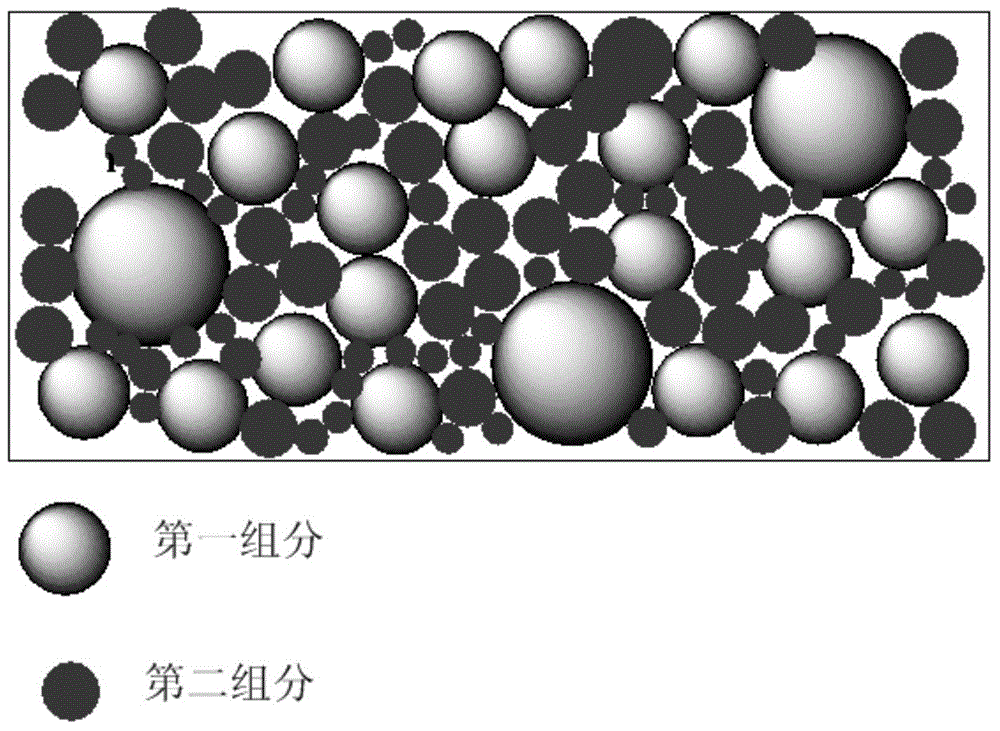

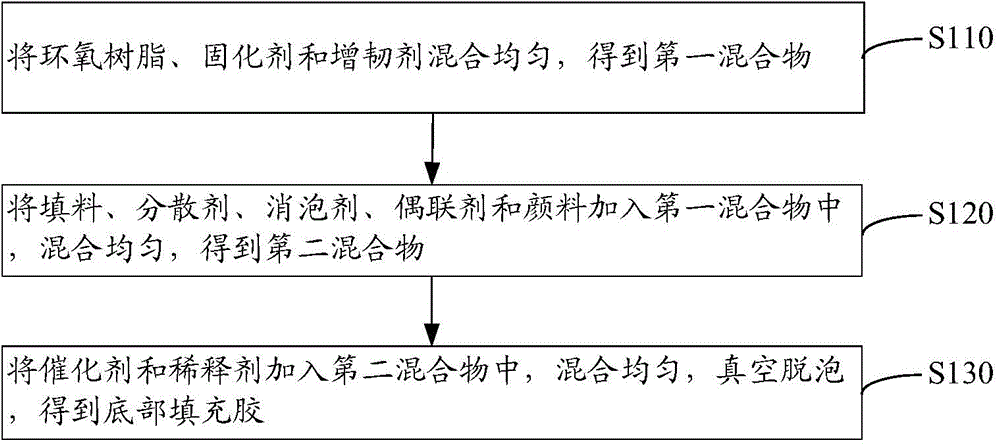

Underfill adhesive and preparation method thereof

ActiveCN104910845AImprove thermal conductivityHigh thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention relates to an underfill adhesive and a preparation method thereof. The underfill adhesive comprises the following ingredients by weight percent: 30 to 70 percent of filler, 10 to 50 percent of epoxy resin, 2 to 20 percent of curing agent, 0.1 to 0.5 percent of catalyst, 1 to 15 percent of flexibilizer, 1 to 25 percent of diluting agent, 0.1 to 3 percent of dispersing agent, 0.05 to 1 percent of defoaming agent, 0.1 to 1 percent of coupling agent and 0.1 to 0.5 percent of pigment; the filler comprises a first component and a second component, wherein the first component is spherical silicon dioxide, and the second component is selected from one of spherical nano aluminum oxide, spherical nano boron nitride, spherical nano aluminum nitride, spherical nano silicon carbide, spherical nano silicon nitride and spherical nano diamond powder. The filler comprises the first component and the second component, and a heat conduction channel can be formed in the underfill adhesive, so that the heat conduction coefficient can be increased; and the underfill adhesive has high heat conductivity and can be widely applied to high-density systematic encapsulation.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

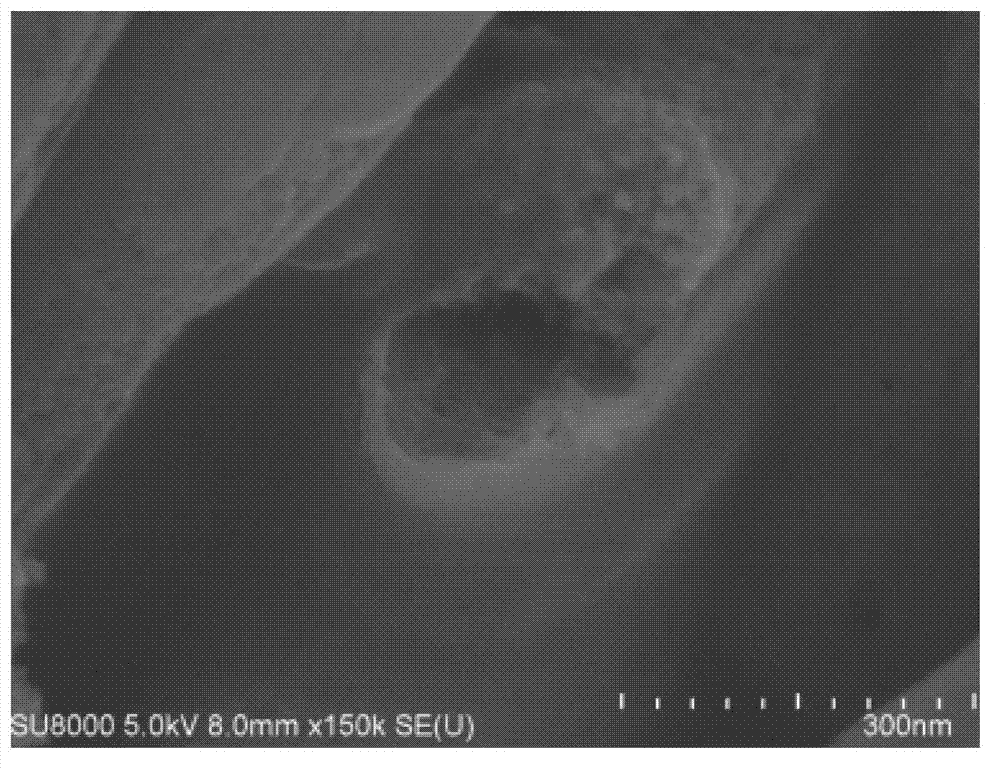

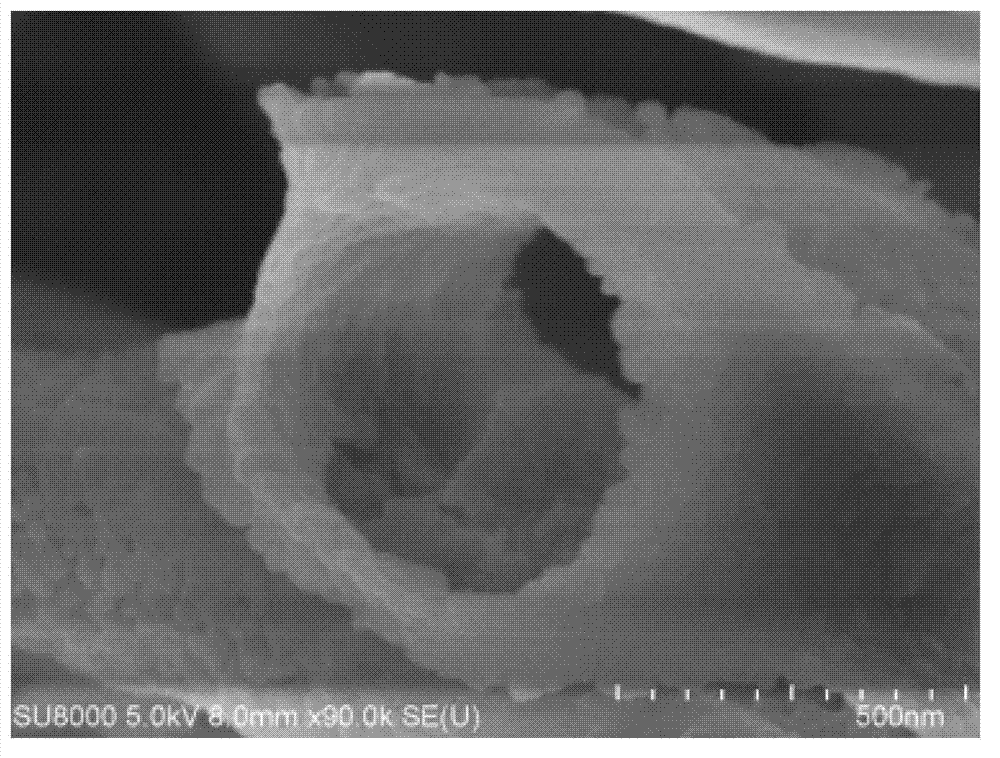

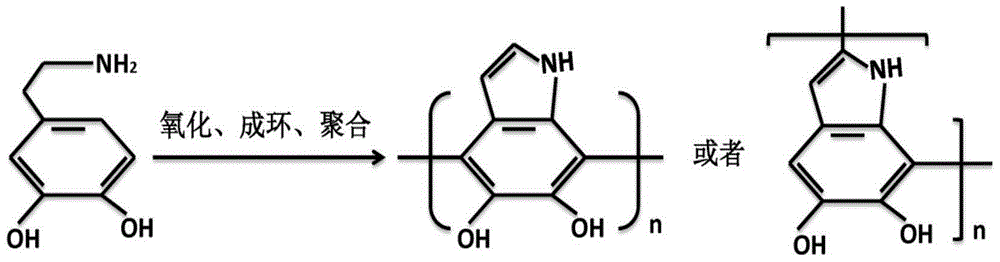

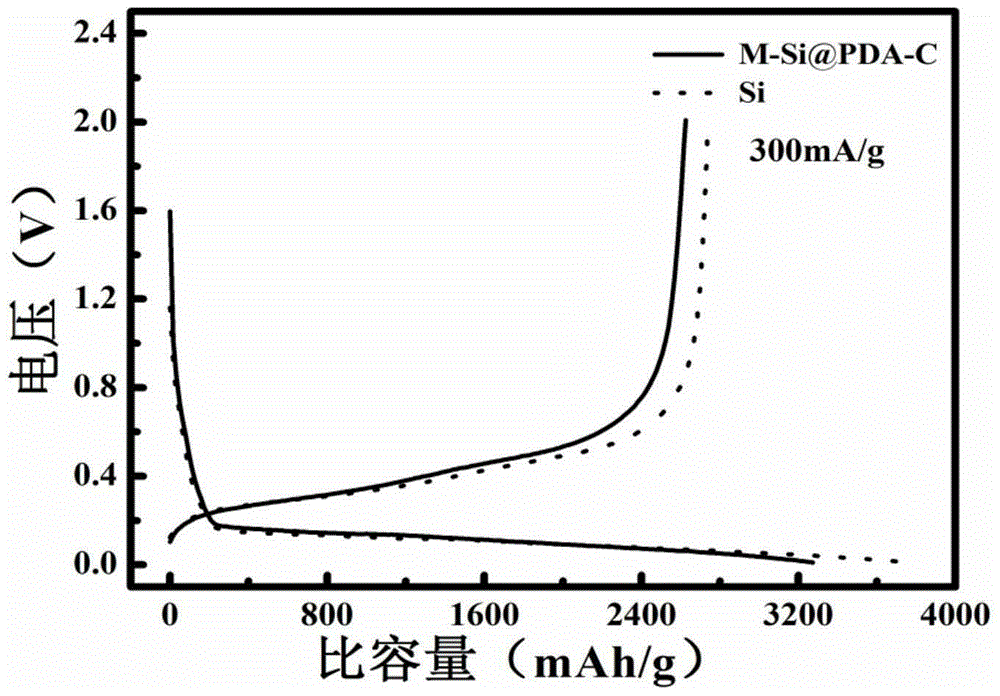

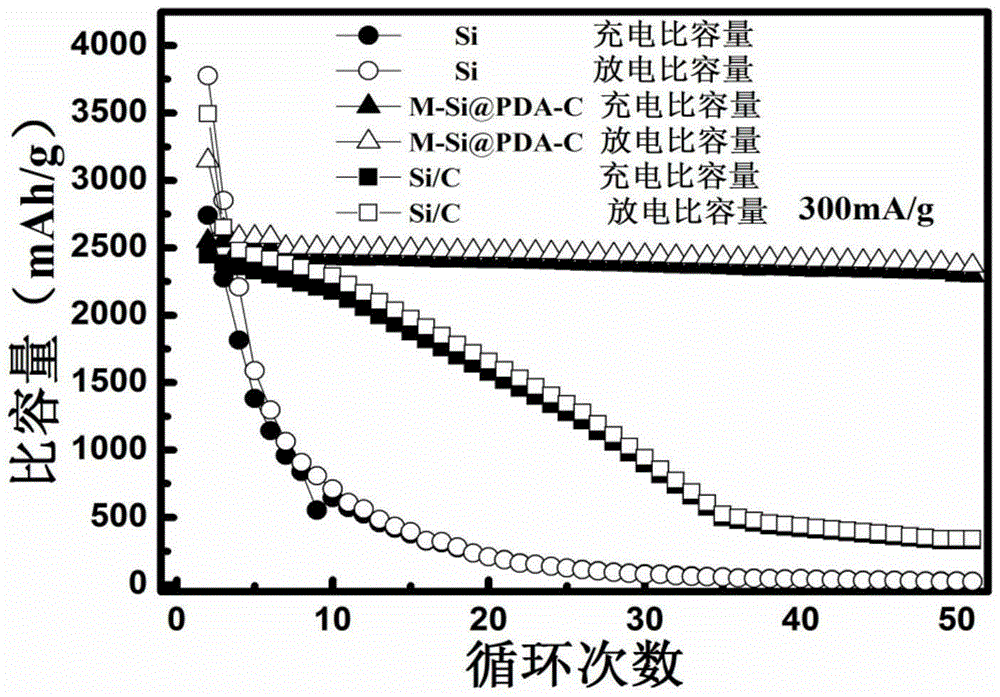

Preparation method of silicon-based anode material for lithium ion battery

The invention discloses a preparation method of a silicon-based anode material for a lithium ion battery. The preparation method comprises the following steps of using tetraethyl orthosilicate as a silicon source and nanometer aluminum oxide as a template agent to prepare a silicon dioxide coated nanometer aluminum oxide material, and then carrying out magnesiothermic reduction and acid treatment to obtain hollow porous silicon; coating the surface of the hollow porous silicon with a layer of polydopamine by means of self-polymerization of dopamine; and carrying out thermal treatment to prepare hollow porous silicon coated with a polydopamine pyrolytic carbon layer, namely the silicon-based anode material for the lithium ion battery. A porous silicon hollow structure can be used for providing a certain expansion space for volume changes during the charging and discharging process of silicon, a nitrogen-doped carbon layer formed after thermal treatment on the polydopamine has higher mechanical property and electrical conductivity than conventional carbon layers, thus, the silicon-based anode material disclosed by the invention has favorable cycle performance and rate performance, and the retention rate of the charge specific capacity of the silicon-based anode material is still kept 90% after 50 times of cycling.

Owner:CENT SOUTH UNIV

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Fluorinated polyurethane nanometer composite material and preparation method thereof

InactiveCN101585902AImprove hydrophobicityImprove hydrophobicity and oleophobicityPolyurea/polyurethane coatingsWear resistantNanoparticle

The invention relates to fluorinated polyurethane nanometer composite material and a preparation method thereof. The invention combines a polycondensation co-polymerization process and fluorine-introducing ultrasonic dispersion technology in the preparation process, nanometer aluminum oxide and nanometer silicon carbide are added and compounded in homogeneous phase in the polycondensation and the co-polymerization process, thereby obtaining nanometer particle reinforced fluorinated polyurethane nanometer composite material. A coating material with micron / nanometer dual structure surface and having hydro-oleophobic, wear resistant and erosion resistant functions, is obtained after film forming by spray coating on the base, drying and curing. The coating material prepared by the method has Hydro-oleophobic performance, and satisfies heat resisting, anticorrosion and wear resistant characteristics under hypergravity or high speed impact conditions.

Owner:HUNAN UNIV +1

Lithium titanate coated cathode and lithium ion battery using cathode

InactiveCN103050705ADoes not affect security featuresImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesHexafluoropropyleneNano al2o3

The invention discloses a lithium titanate coated cathode and a lithium ion battery using the cathode. The lithium titanate coated cathode comprises a cathode piece and a lithium titanate coating, wherein the lithium titanate coating comprises the following components by weight ratio: 90-97% of nanomaterial and 3-10% of adhesive agent; the nanomaterial is nano lithium titanate, or a combination of nano lithium titanate and nano alumina and / or nano aluminium nitride; the adhesive agent is one of a combination of SBR (Styrene Butadiene Rubber) and CMC (Carboxyl Methyl Cellulose), PVDF (Polyvinylidene Fluoride), PVDF-HFP (Polyvinylidene Fluoride-Hexafluoropropylene), and polyacrylate; pulp of the lithium titanate coating comprises a solvent; the solvent is one of deionized water and NMP (N-Methyl Pyrrolidone); the solid content of the pulp of the lithium titanate coating is 20-60%; and the two sides of the cathode piece are coated with the pulp of the lithium titanate coating. The lithium ion battery using the lithium titanate coated cathode has better electrolyte wettability on the premise that a safety feature of the battery is unaffected, and can form a fully contacted liquid-phase interface with a diaphragm, and the multiplying power performance and the cycle performance of the battery can be improved.

Owner:TIANJIN ENERGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com