Patents

Literature

121results about How to "Improve high rate charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

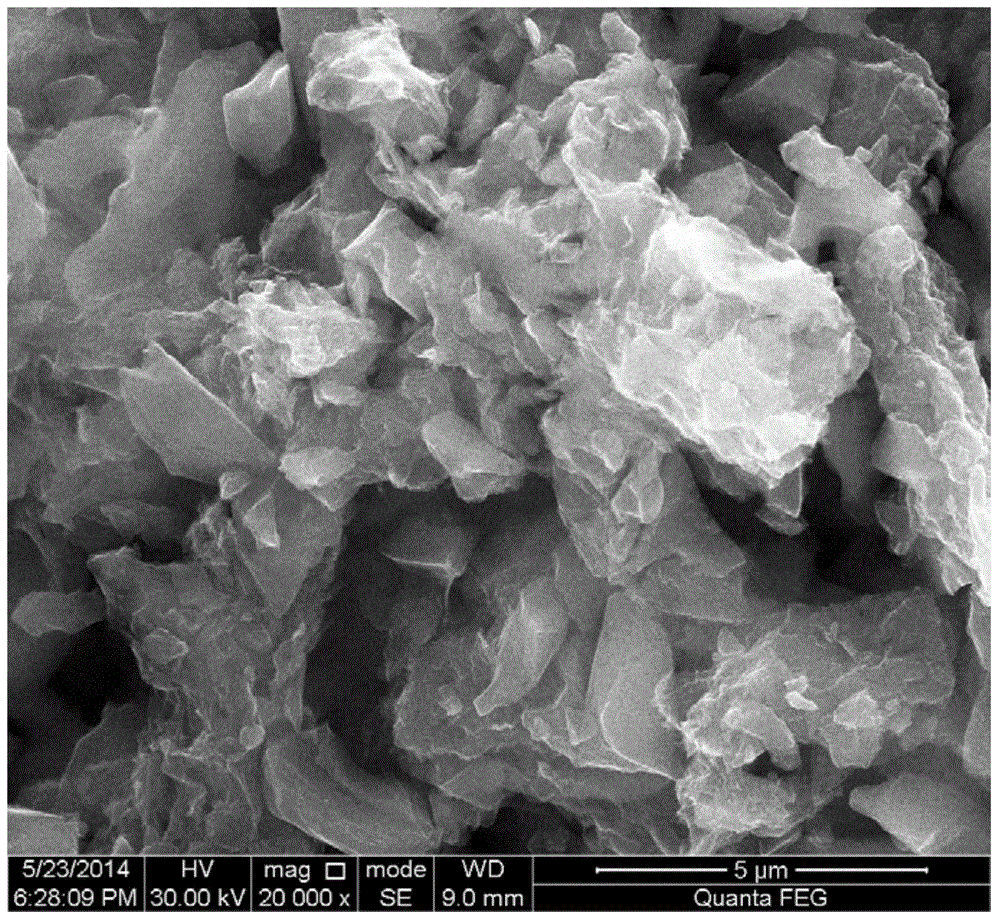

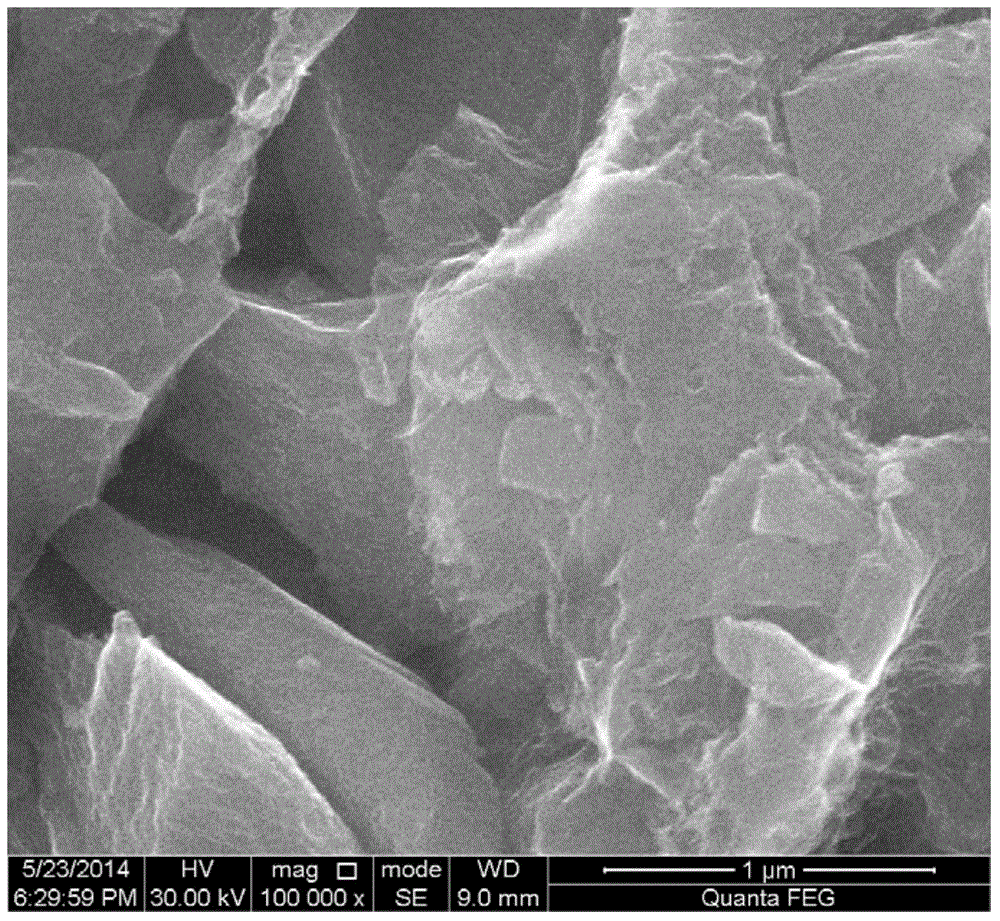

Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

ActiveCN103560235AUnique hierarchical core-shell structureIncrease contentCell electrodesHigh ratePorous carbon

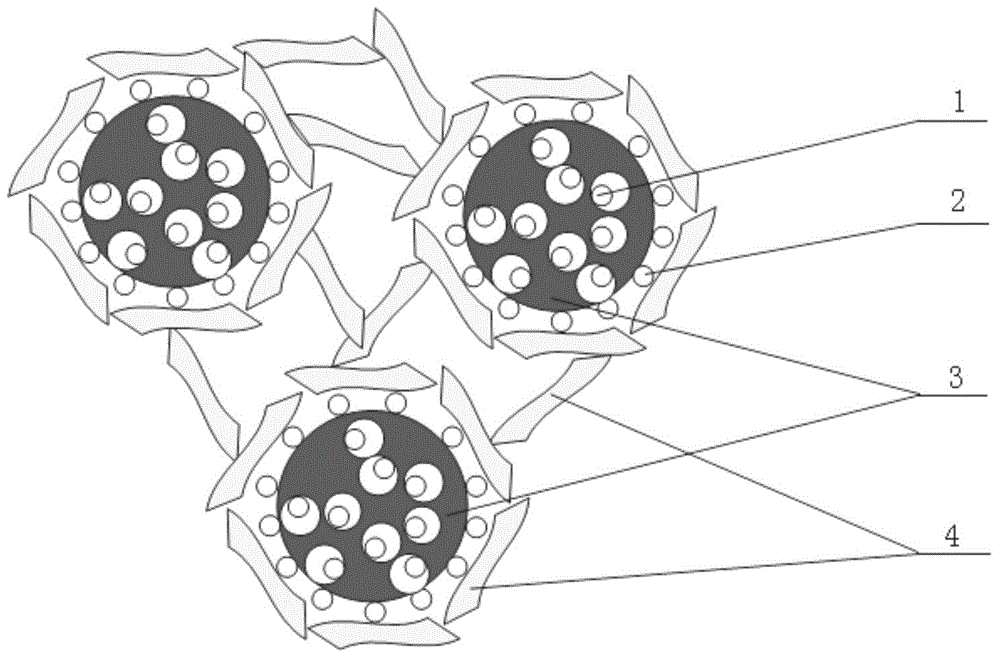

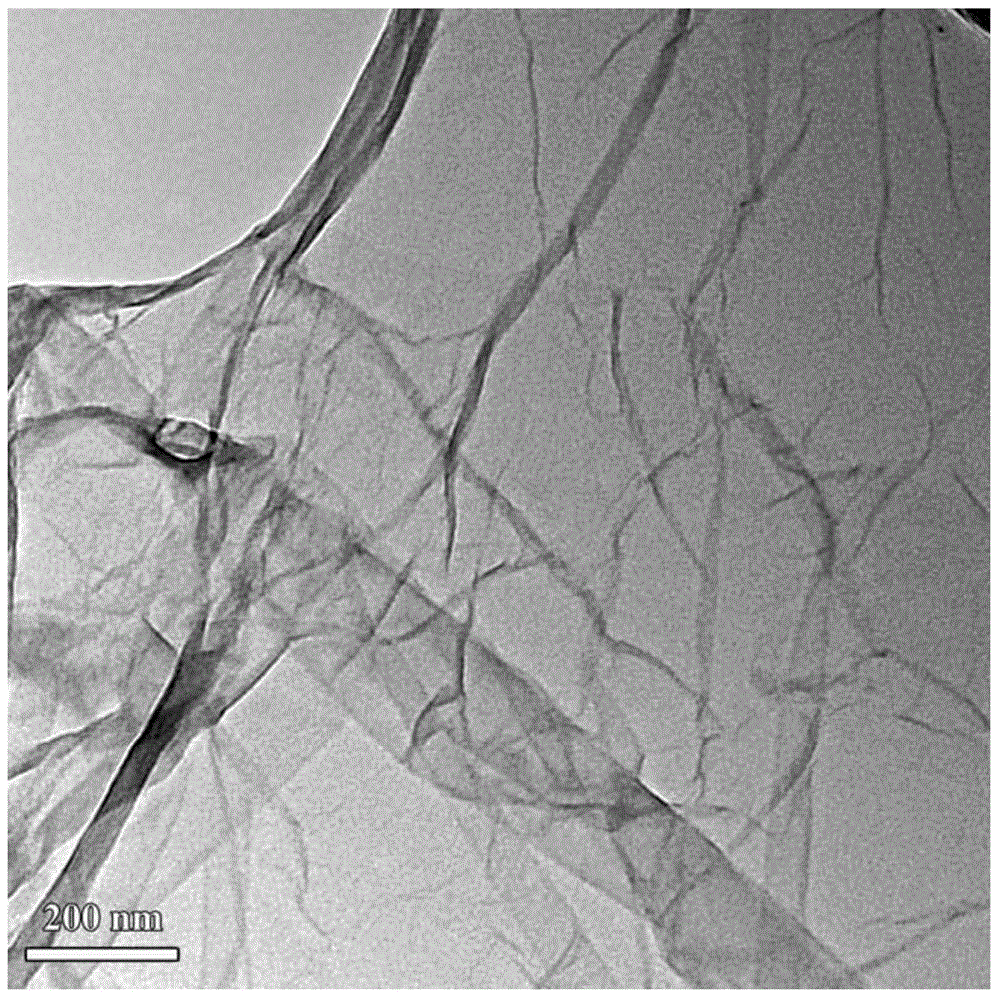

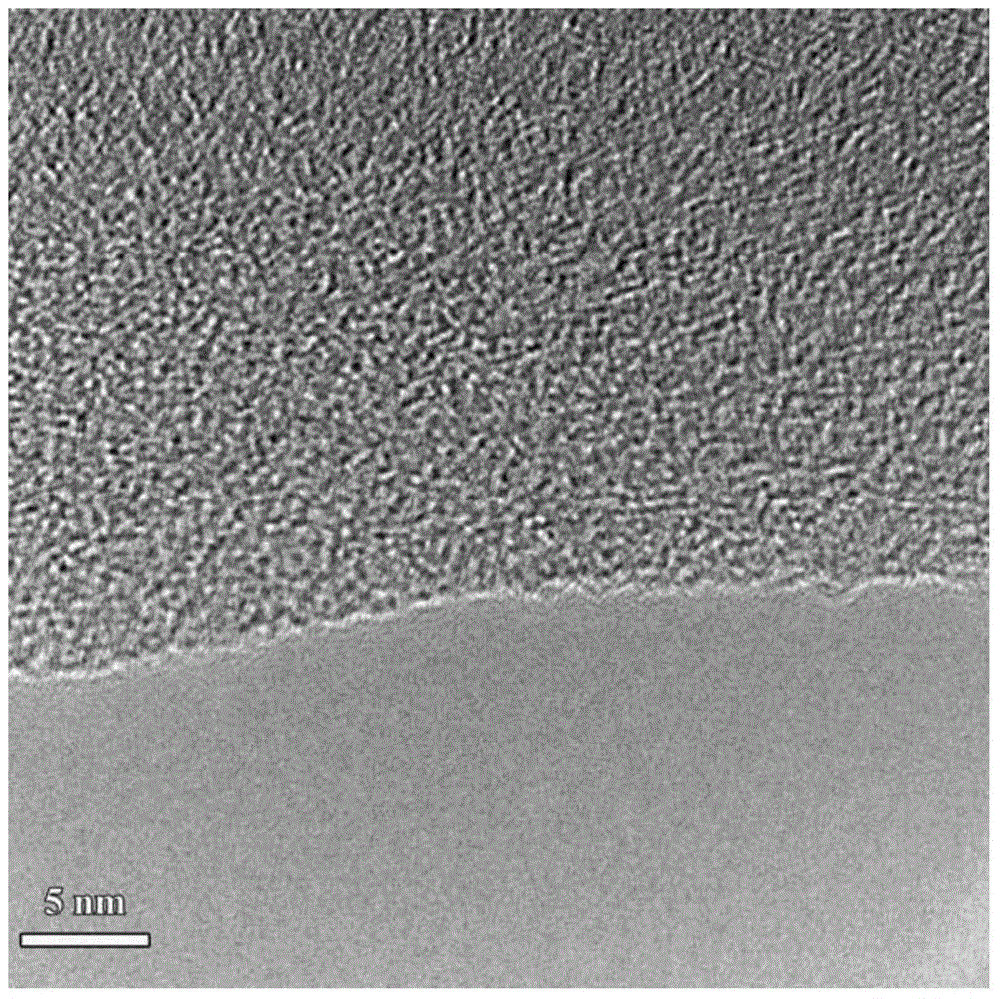

The invention provides a grapheme-coated sulfur / porous carbon composite material and a preparation method thereof, and relates to a grapheme-coated sulfur / porous carbon composite material used as the positive electrode material of a lithium-sulfur secondary battery and a preparation method thereof. The grapheme-coated sulfur / porous carbon composite positive electrode material provided by the invention can be used for solving the technical problem that the existing grapheme-coated sulfur-containing composite material used as the positive electrode material of a lithium-sulfur battery is low in electrochemical properties. The external surface of each of the particles of the grapheme-coated sulfur / porous carbon composite material provided by the invention is evenly covered with a graphene sheet, and a graphene conductive network is formed between the particles; the obtained grapheme-coated sulfur / porous carbon composite material has a hierarchical core-shell structure. The preparation method of the grapheme-coated sulfur / porous carbon composite material is obtained by adding a sulfur / porous carbon composite material to graphene slurry which is stable for a long time and in which graphene sheets are highly dispersed in water for mixing and coating. The positive electrode material has high specific capacity, long cycle life and excellent high-rate performance. Besides, the grapheme-coated sulfur / porous carbon composite material can be used as the positive electrode material of a lithium secondary battery.

Owner:HARBIN INST OF TECH

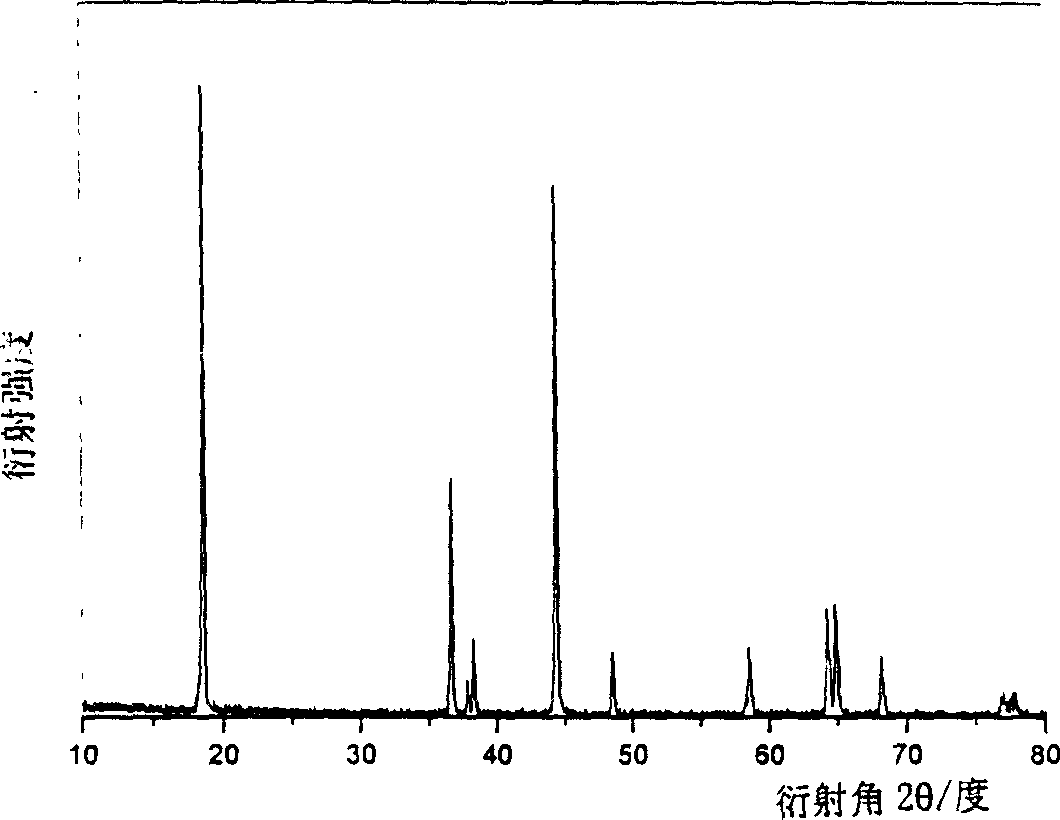

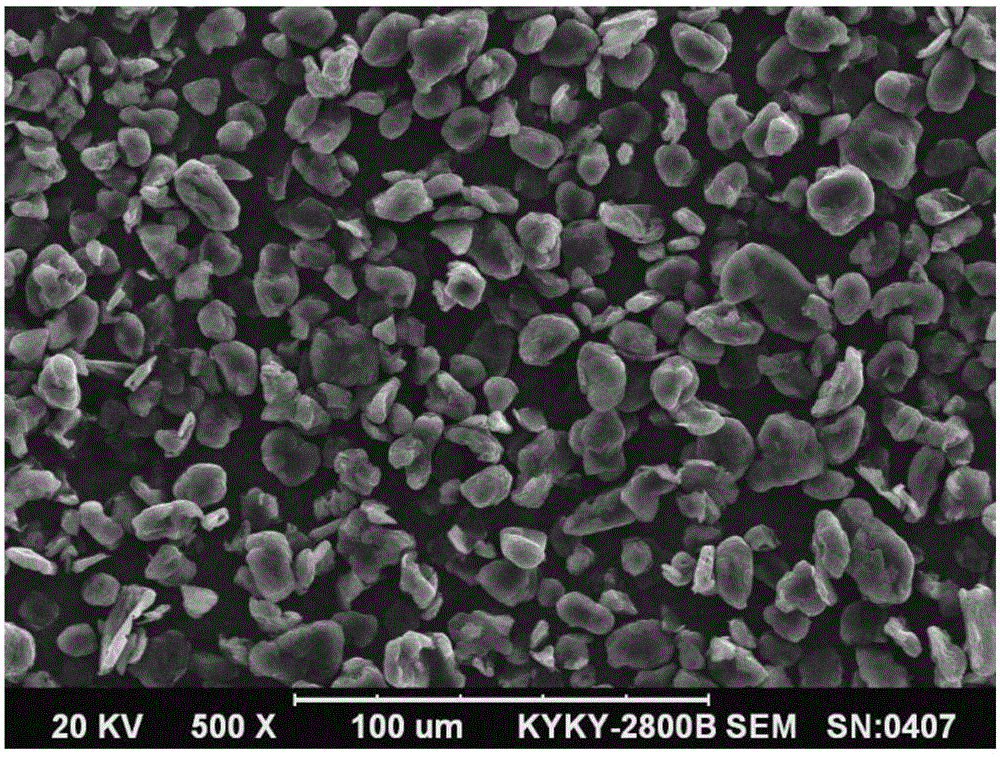

High-performance lithium ion battery cathode material and preparation method thereof

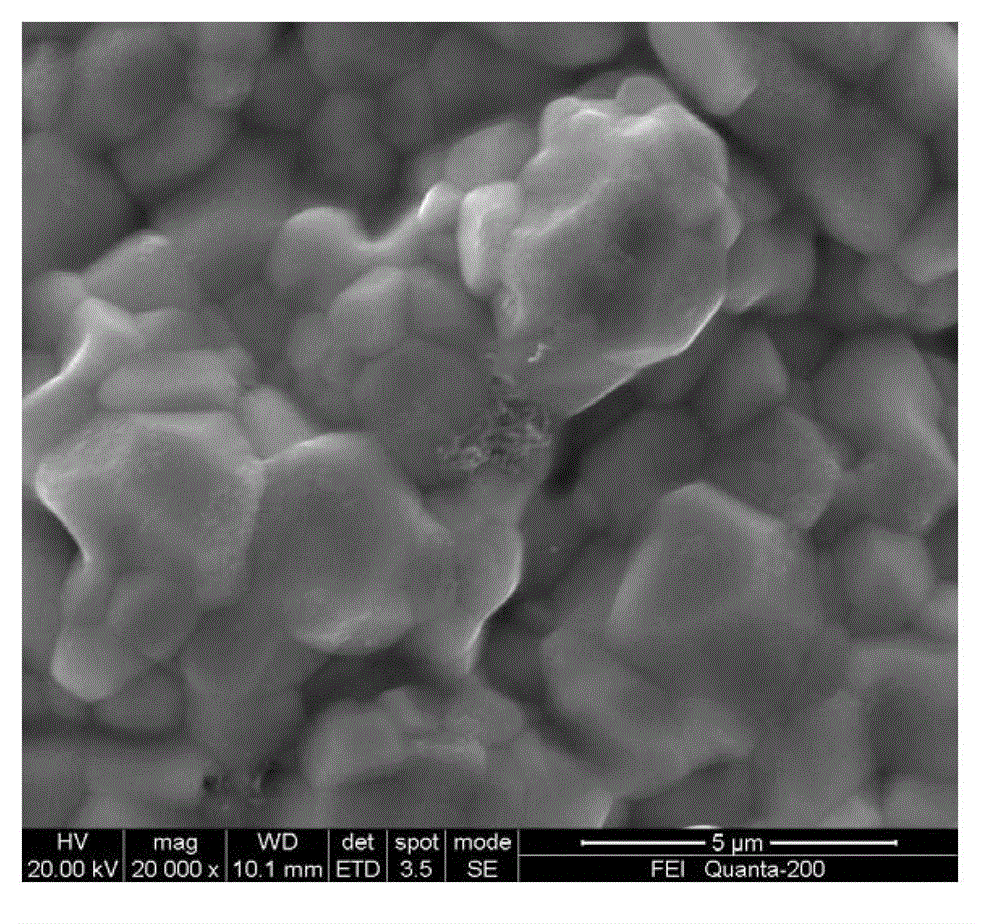

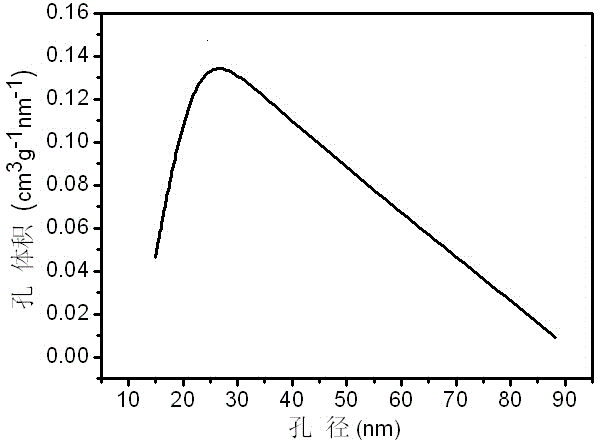

InactiveCN101847722AHigh tap densityImprove electrode processing performanceElectrode manufacturing processesNickel oxides/hydroxidesSingle crystalCobalt

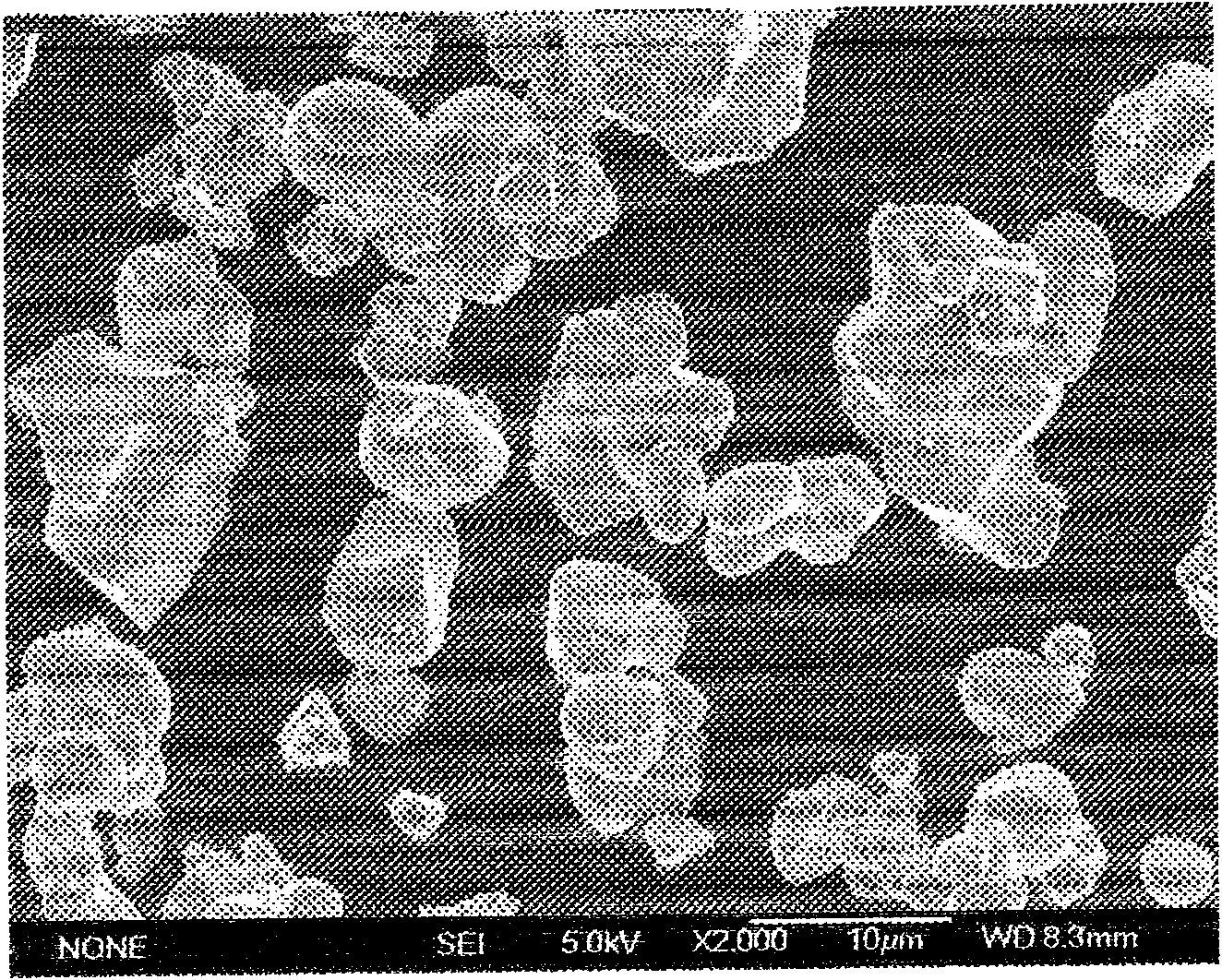

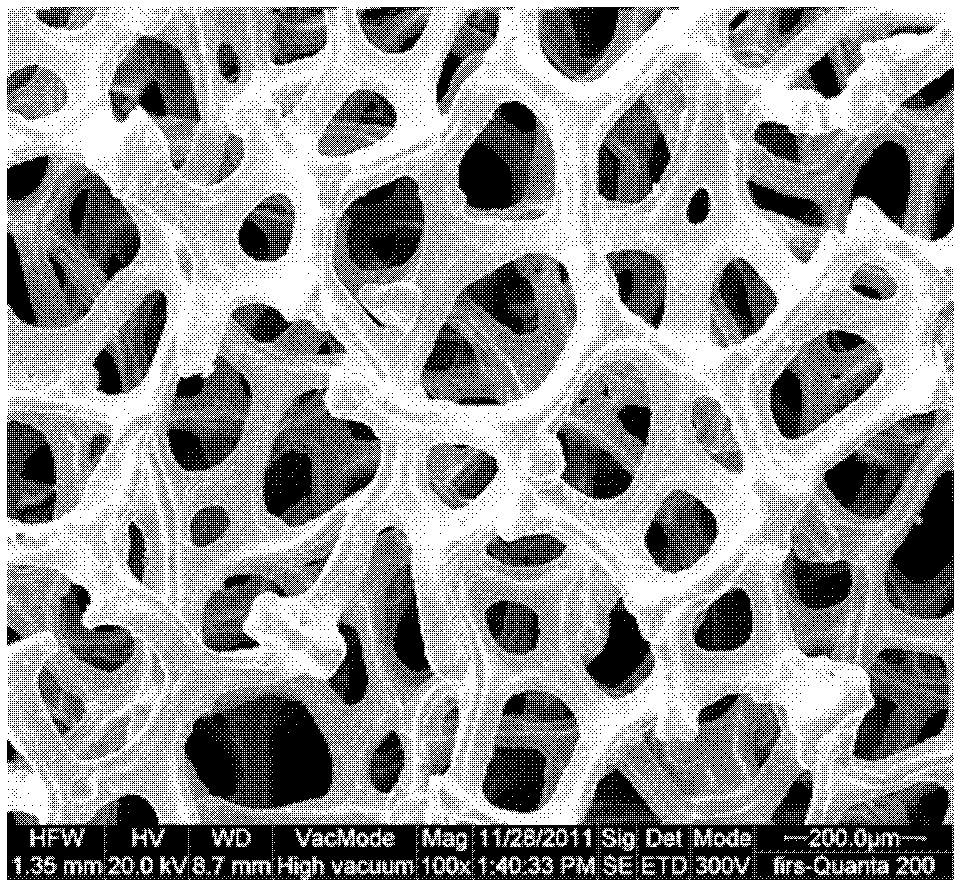

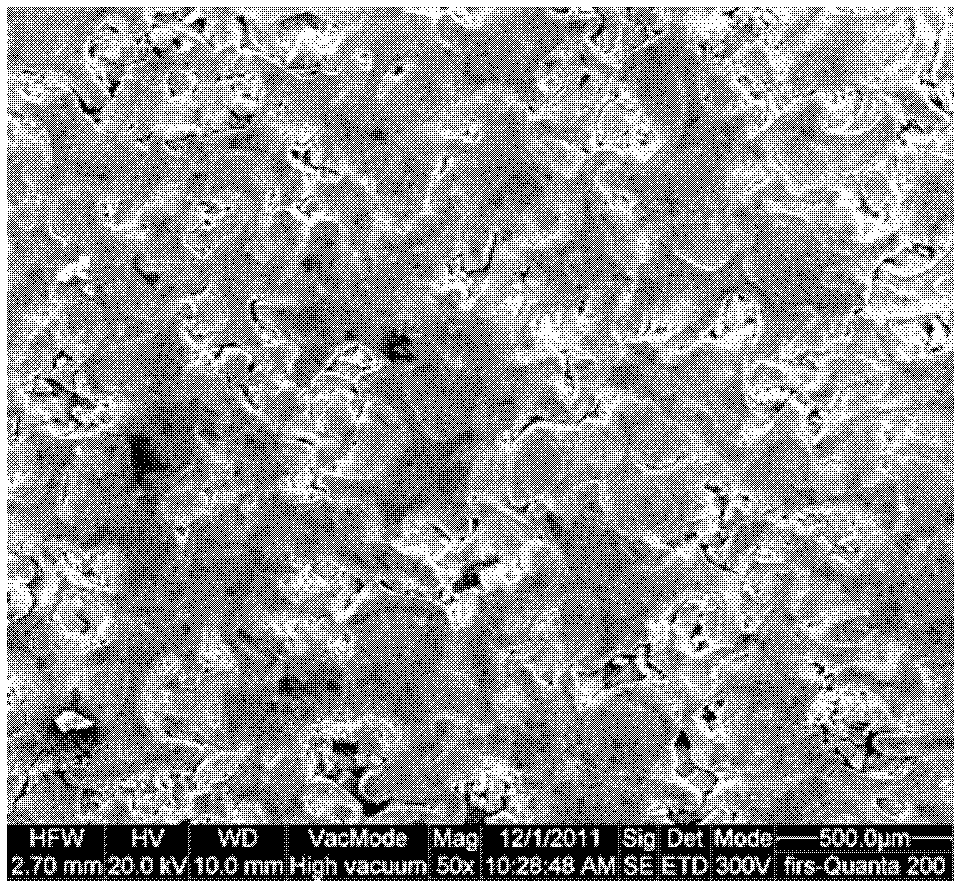

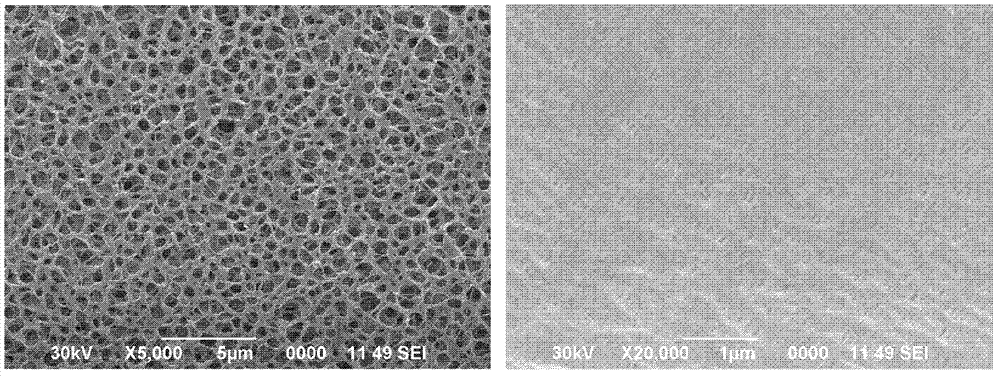

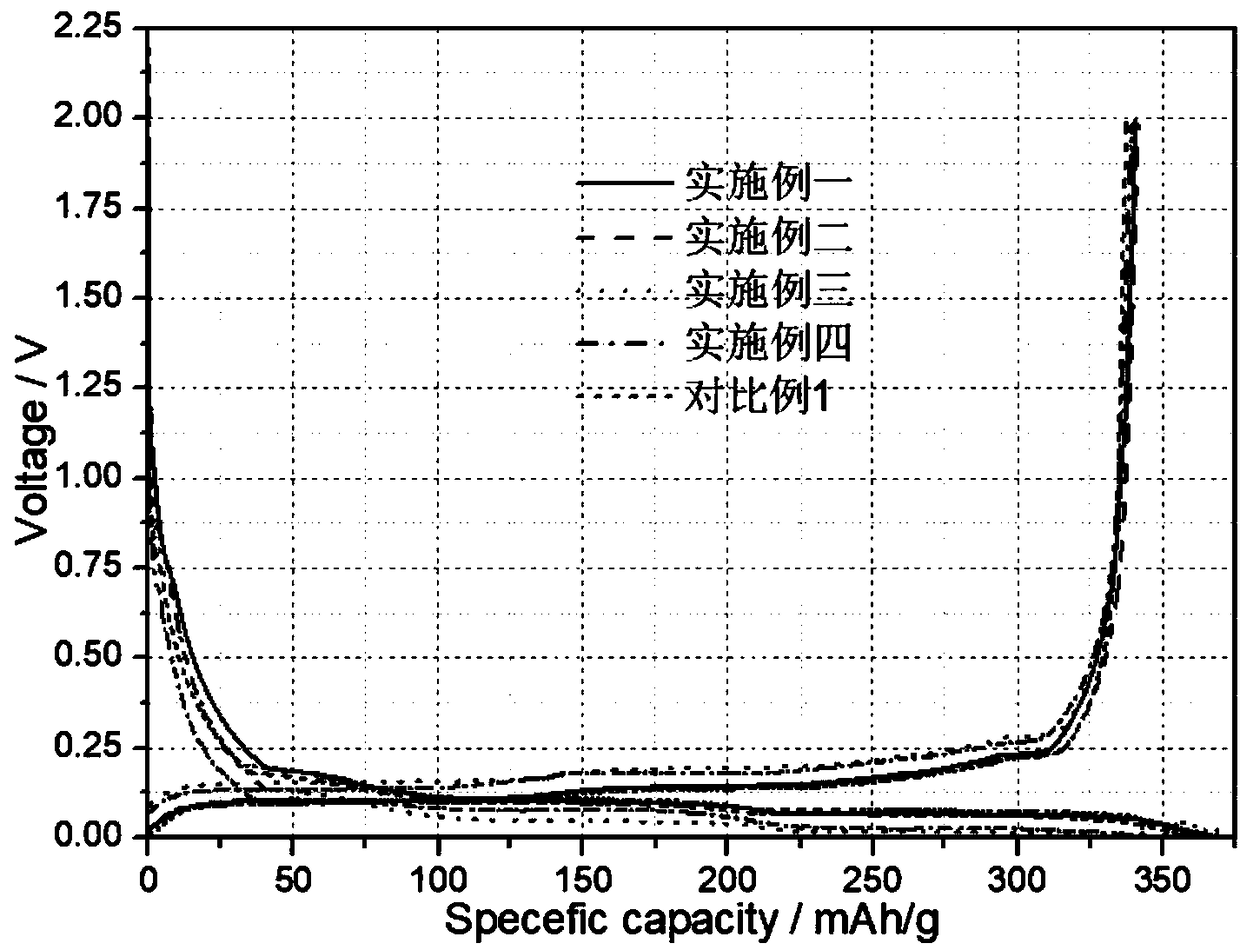

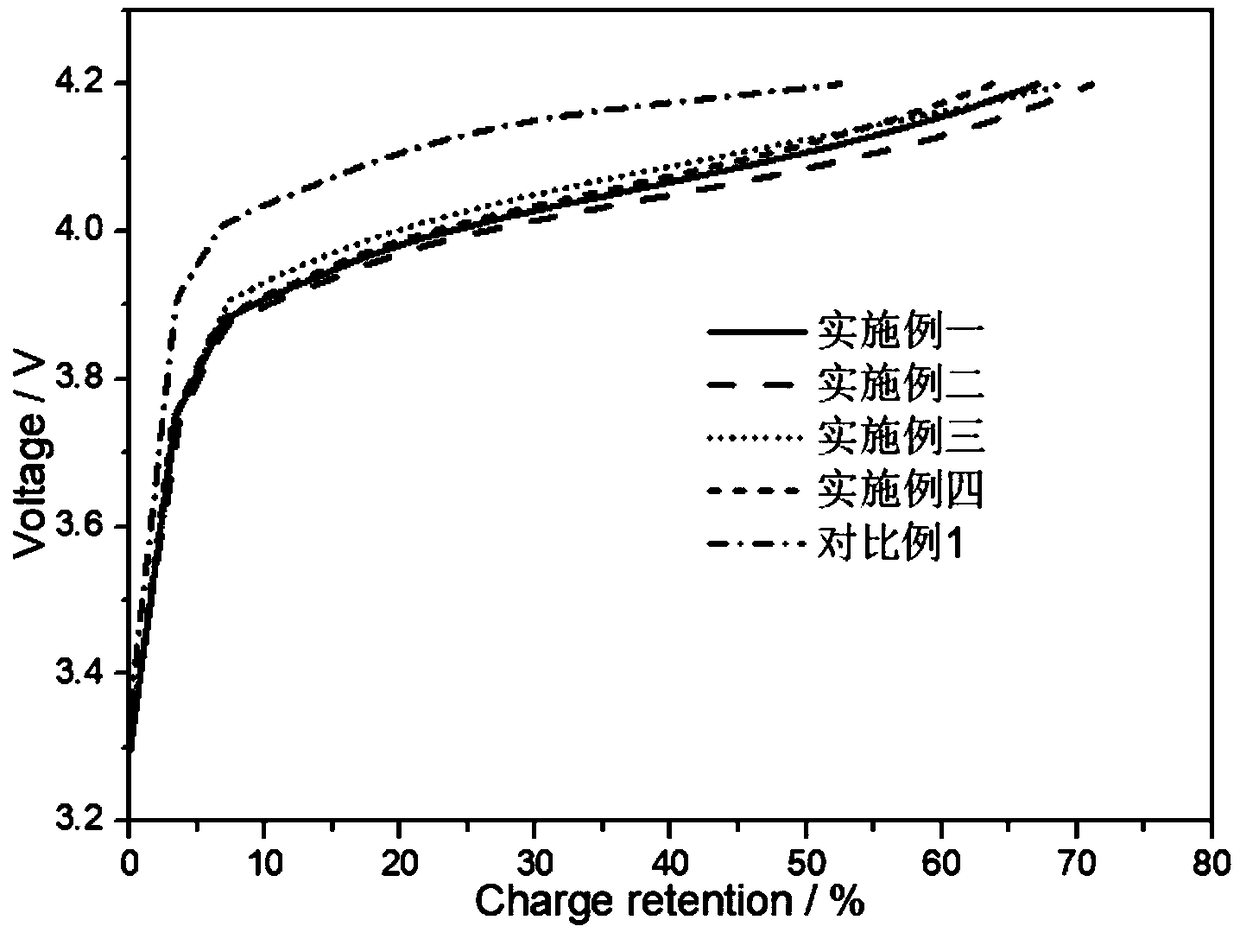

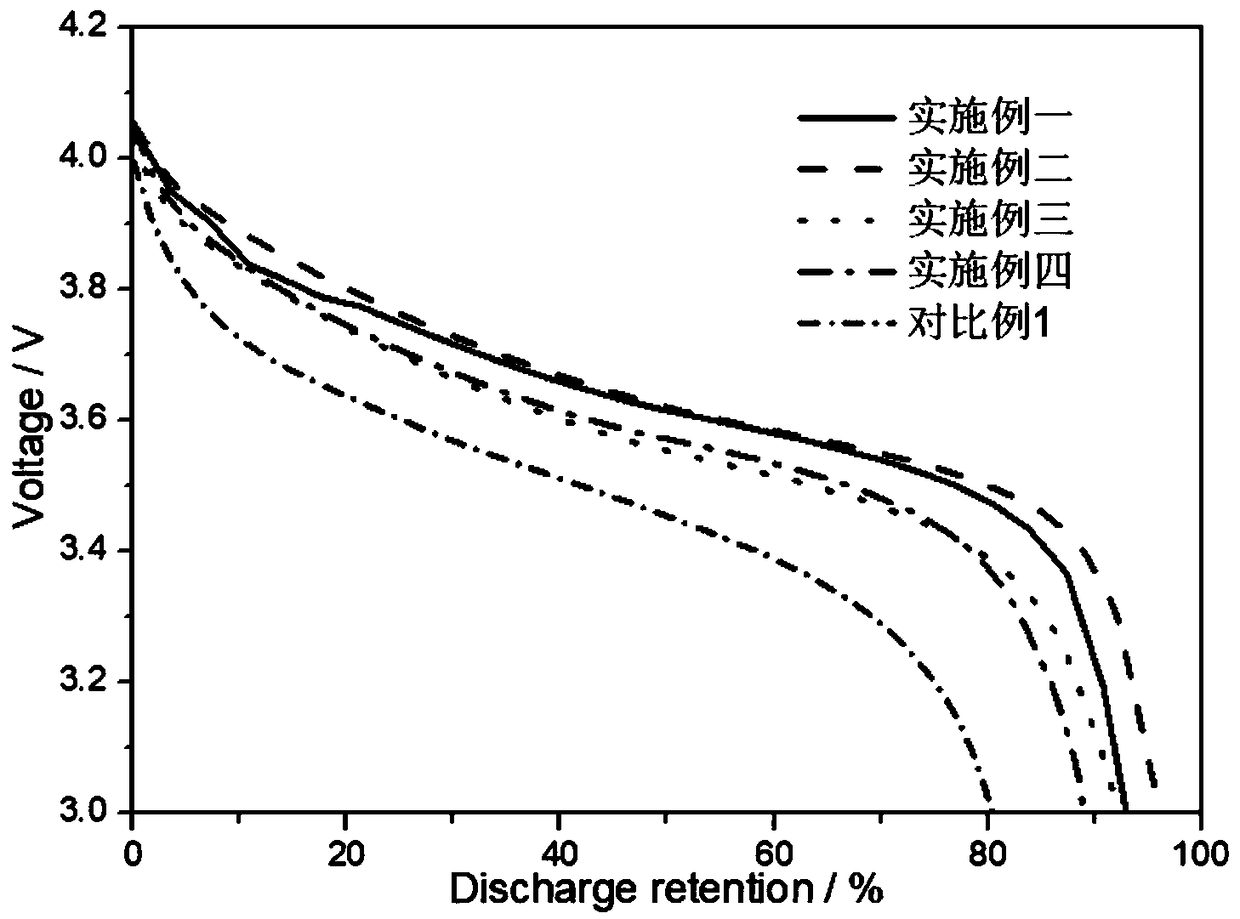

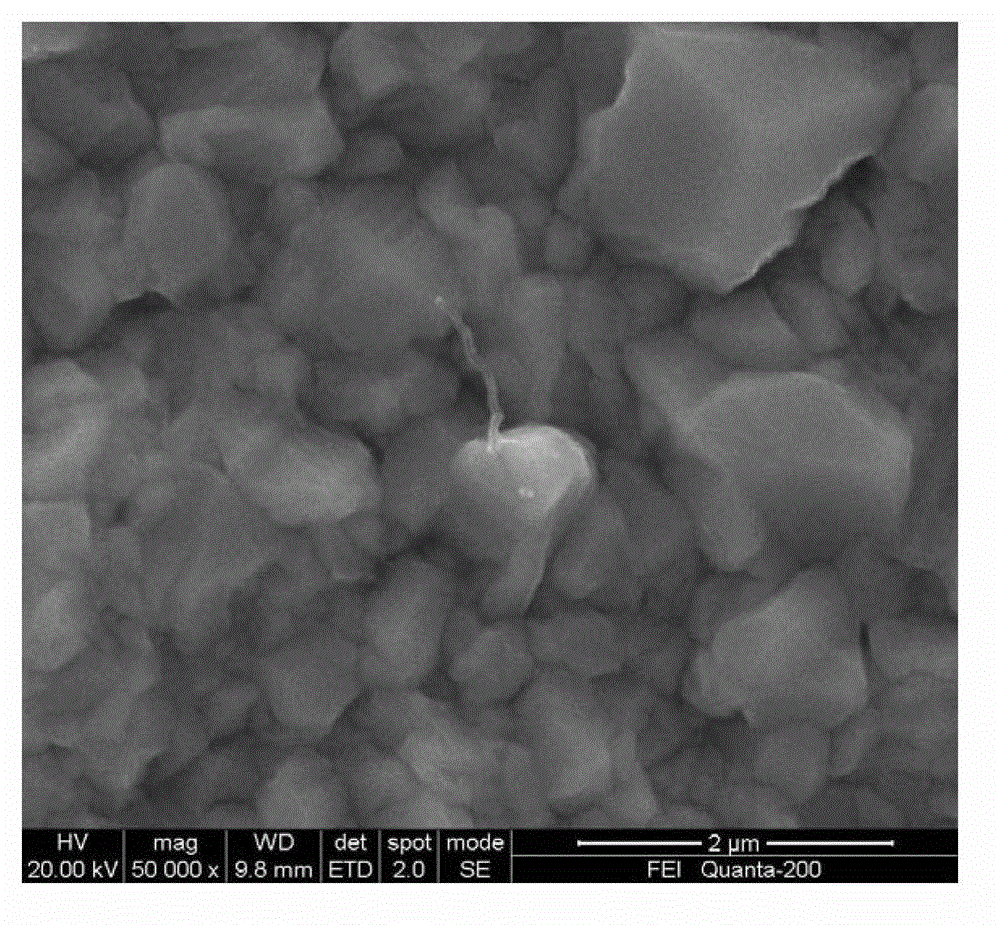

The invention relates to a lithium ion battery cathode material LiNixCoyM1-x-yO2 prepared from micron-sized single crystal particles and a preparation method thereof, wherein x is greater than 0 and is not more than 0.8, y is greater than 0 and is not more than 0.5, and M is one or two of Li, Mn, Al and Mg. The invention is characterized in that (1) composite oxide or hydroxide of transition metal nickel, transition metal cobalt and modified metal M is used as a raw material, the composite oxide or hydroxide is porous aggregate comprising nanocrystals, the average size of the aggregate is 2-50 micrometers, and the specific surface area of the aggregate is greater than 15m<2> / g (measured by BET method); (2) the composite metal oxide or hydroxide and lithium salts are milled in a ball mill, the micron-sized composite metal oxide or hydroxide is converted into nanocrystal particles to obtain a nano-sized mixed precursor of the composite metal oxide or hydroxide and the lithium salts, and the mixed precursor is sintered at uniform temperature to obtain the required lithium ion battery cathode material; and (3) the prepared lithium ion battery cathode material LiNixCoyM1-x-yO2 is basically prepared from micron-sized single crystal particles, and the average size of the single crystal particles is 2-20 micrometers. In addition, the product has excellent physical and electrochemical properties, such as ultra-low specific surface area, reasonable particle size distribution, good electrode processing properties, ultra-long cycle life, excellent rate capability, obvious high and low temperature cycling and storing properties and excellent safety; and the product can be widely used as a high-performance lithium ion battery cathode material. The invention provides the high-performance lithium ion battery cathode material and the preparation method thereof.

Owner:QINGDAO LNCM

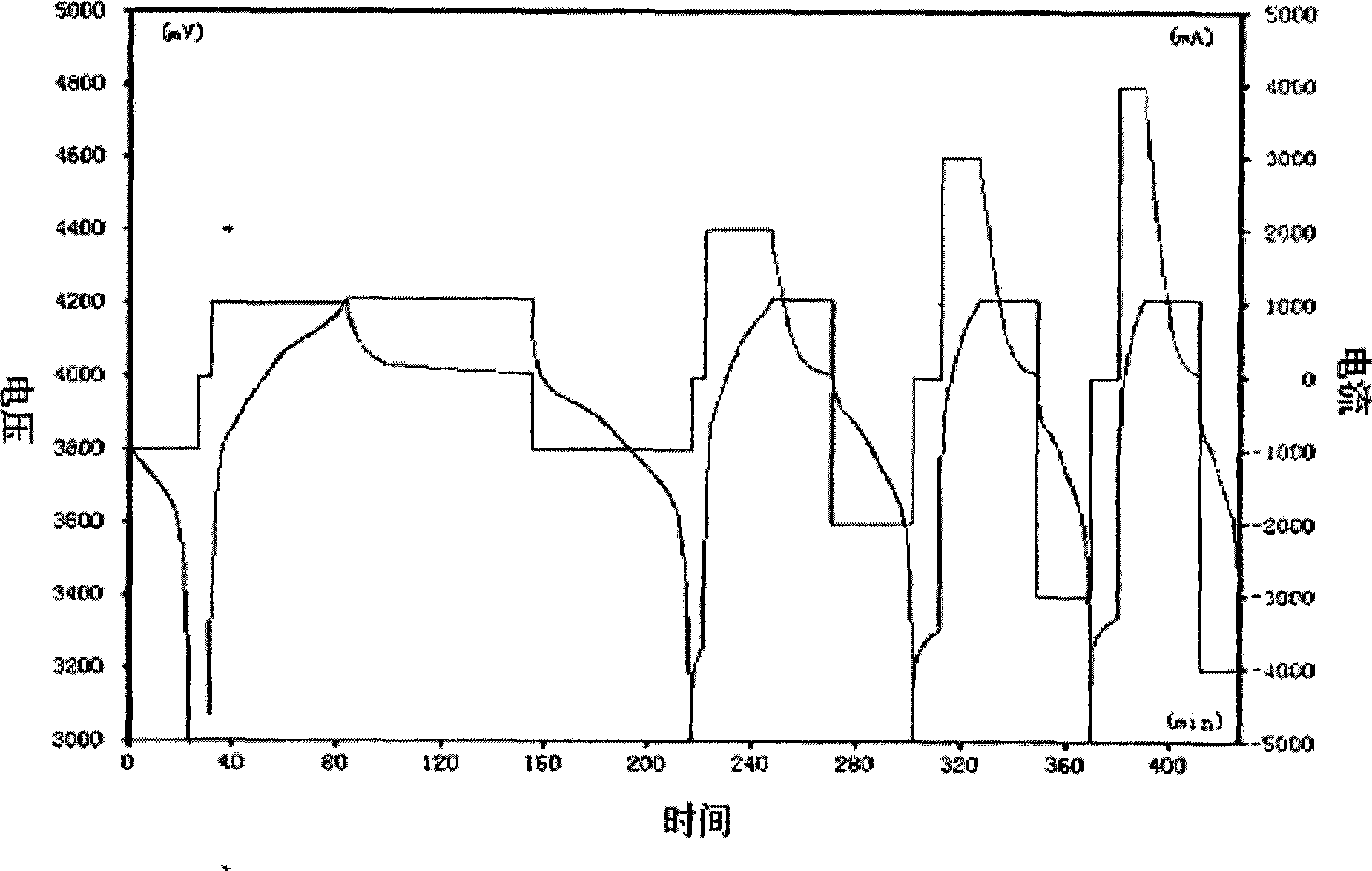

Multi-multiplying power charging-discharging lithium ion battery and method for producing the same

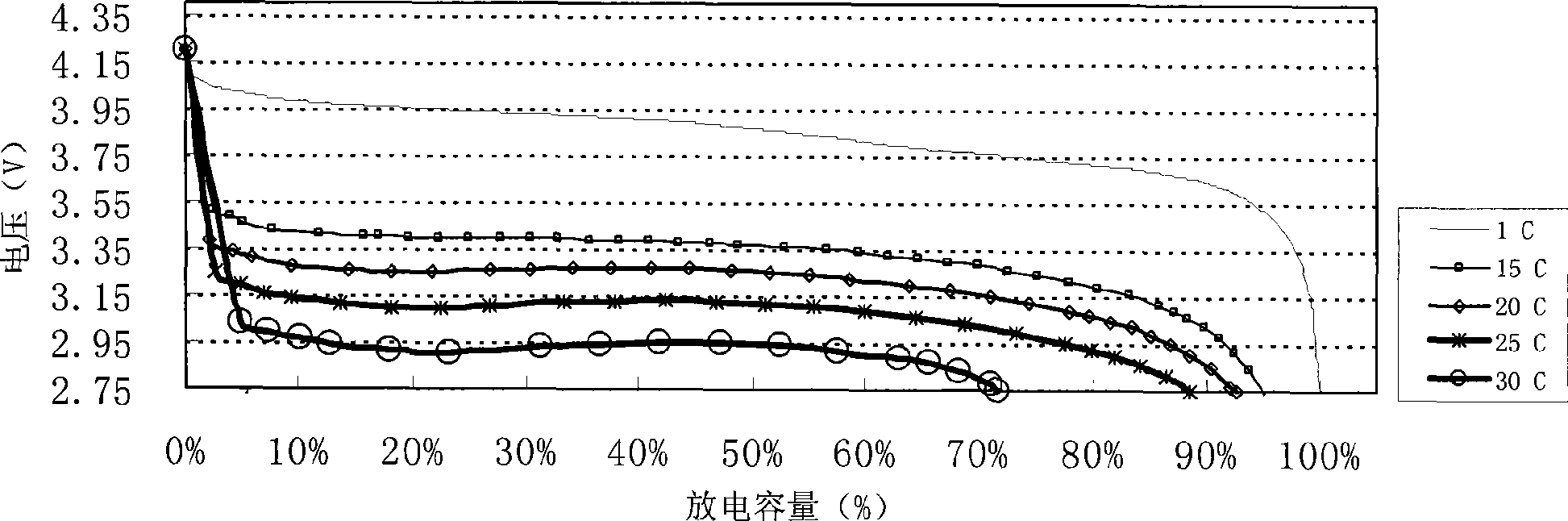

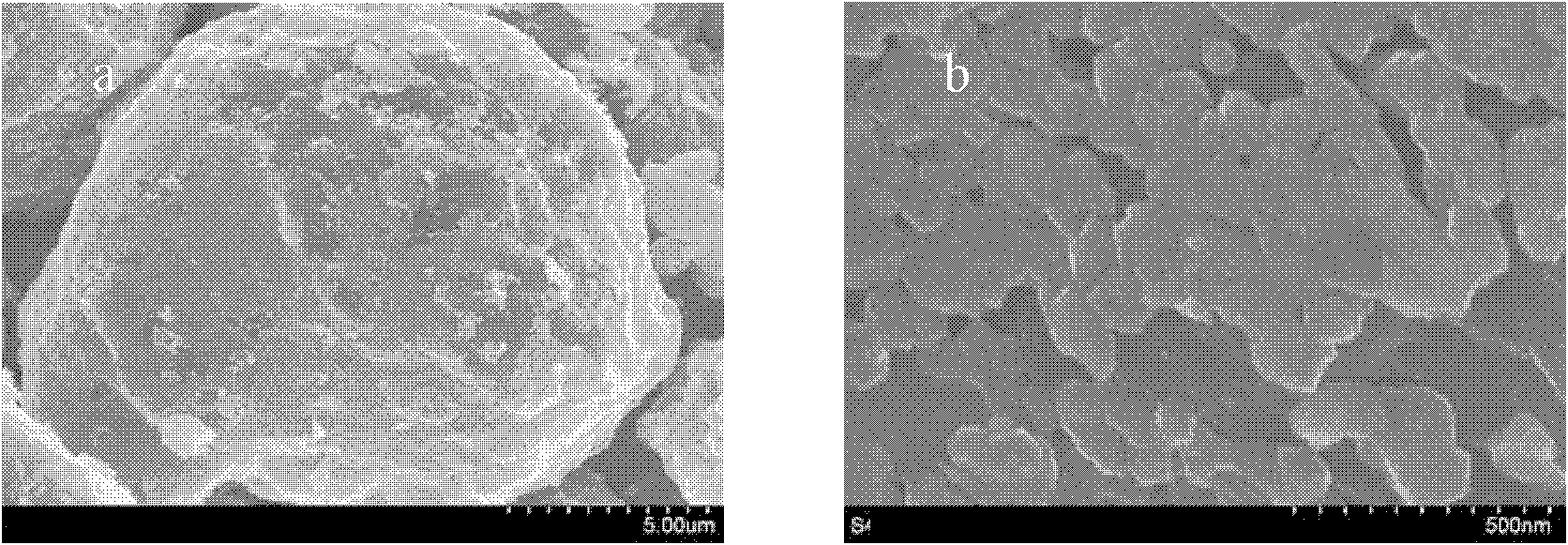

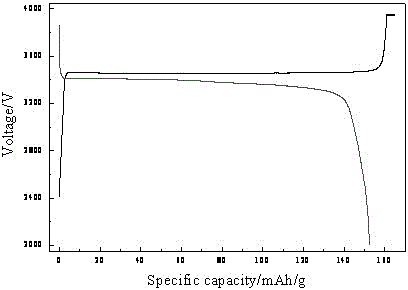

InactiveCN101499530AImprove high rate charge and discharge performanceImprove performanceElectrode manufacturing processesFinal product manufactureHigh rateMicrosphere

The invention provides a high-rate charge-discharge lithium-ion battery and a preparation method thereof. The anode active material of the lithium-ion battery is lithium manganate; the cathode active material is selected from one or more of mesocarbon microbeads, artificial graphite or natural graphite coated by mesophase pitch; a conductive agent is selected from one or more of conductive graphite, conductive carbon black, nano Ag, nano SiO2 or nano Al2O3. The preparation method of the lithium-ion battery comprises the preparation of the anode plate, the parathion of the cathode plate and the assembly of the battery. The lithium-ion battery has the advantages of high-rate charge-discharge performance, long cycle life, high capacity, safe use, environmental protection, low cost and the like. The preparation method has the advantage of simple and easy process operation, and is applicable to the mass production.

Owner:深圳市崧鼎实业有限公司

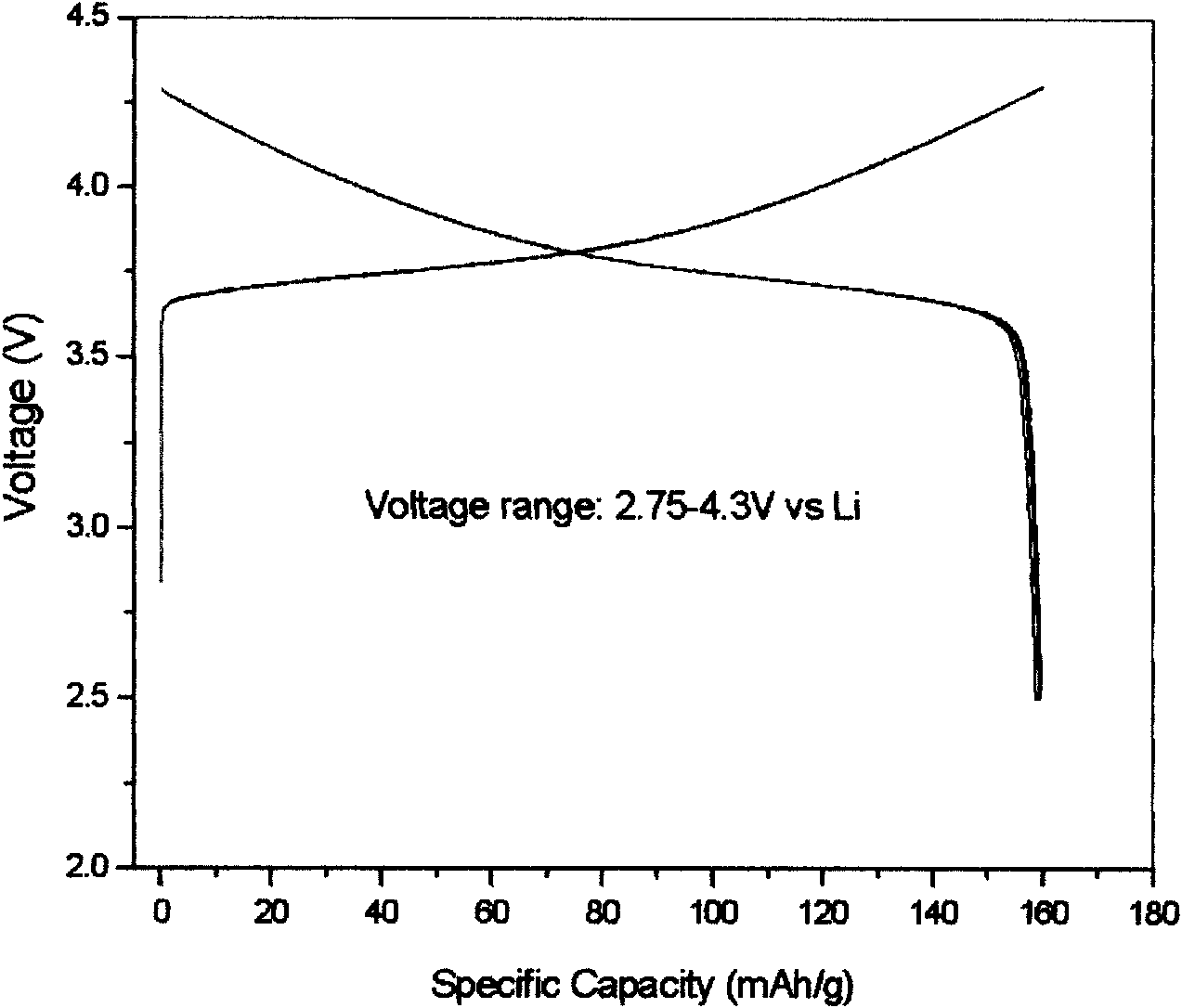

A positive electrode material for lithium secondary cell, and preparation and usage thereof

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Positive electrode material of manganese series, and preparation and usage thereof

InactiveCN1595689AIncrease energy densityIncrease powerElectrode manufacturing processesSecondary cellsManganeseThermal stability

The invention relates to manganese department positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn1-x-y NixMyO2(x is not less than 0.2 and not larger than 0.8, y is not less than 0 and not larger than 0.6, and x+y is not larger than 1.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Cr. The manufacturing method for manganese department positive electrode material of the lithium secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher 6 of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge .

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

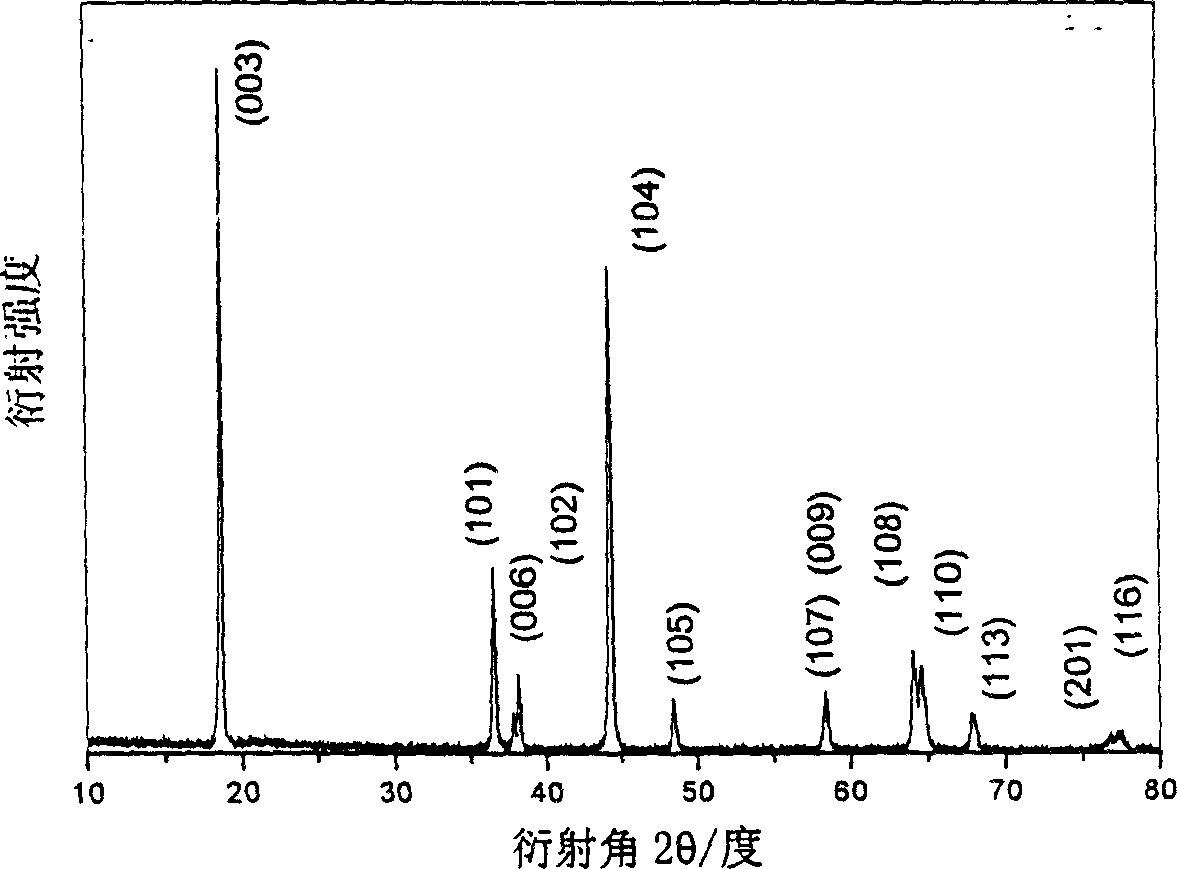

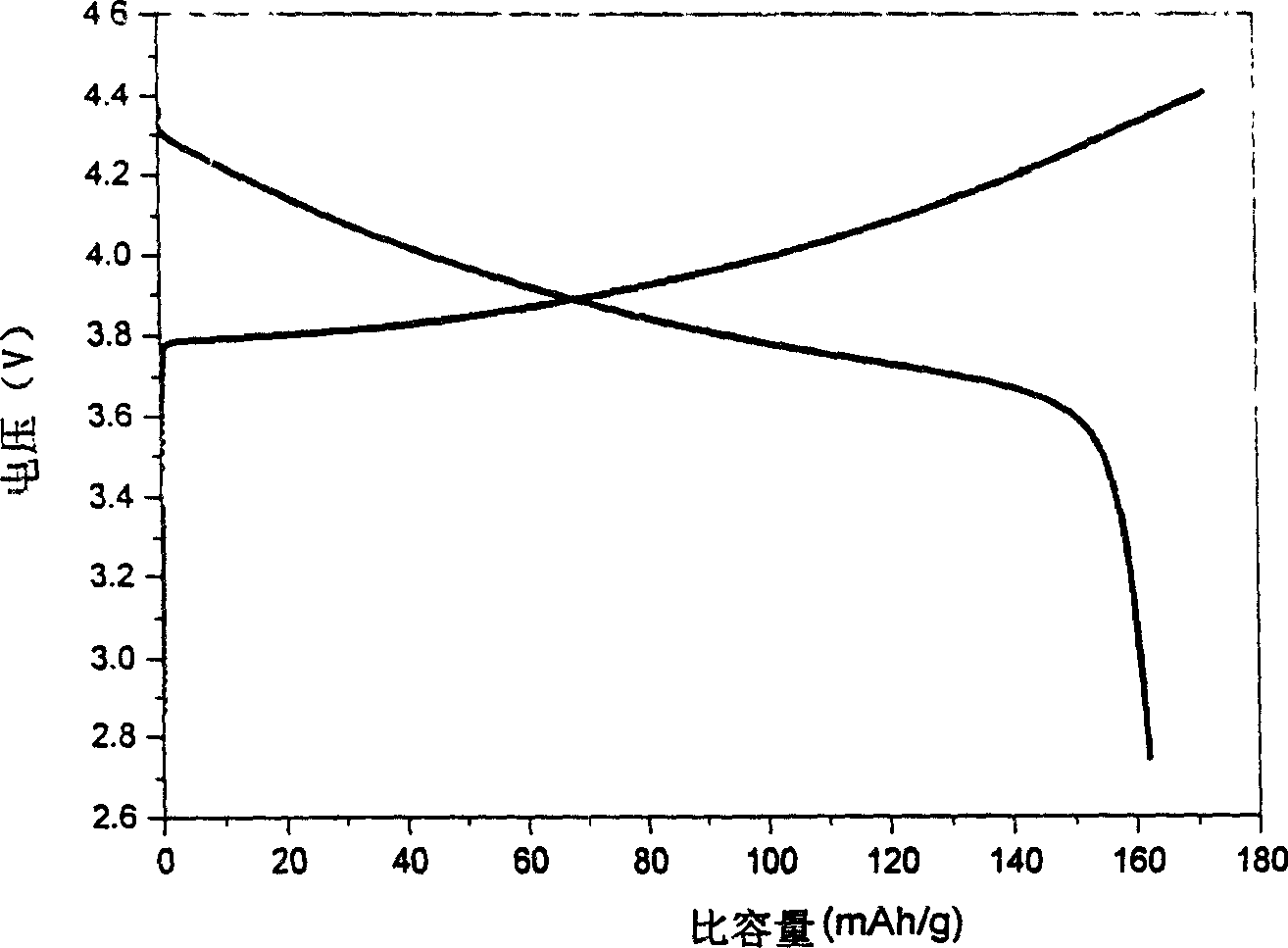

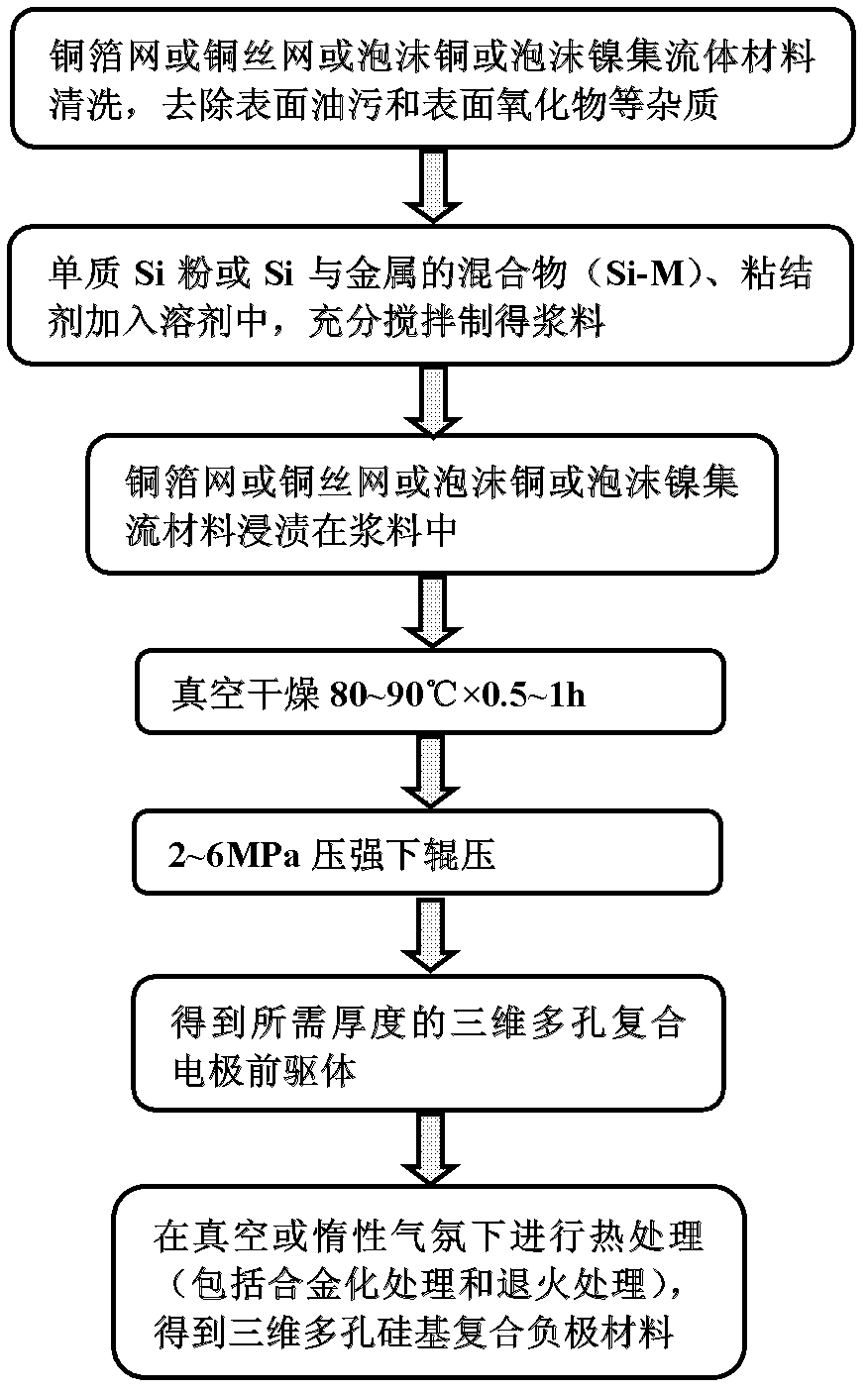

Three-dimensional porous silicon-based composite negative electrode material of lithium ion cell and preparation method thereof

ActiveCN102683655AEasy to operateReduce processing costsElectrode carriers/collectorsSecondary cellsCopper wireCopper foil

The invention discloses a three-dimensional porous silicon-based composite negative electrode material of a lithium ion cell and a preparation method thereof. A collection body material, such as a copper foil net or a copper wire net or foam copper or foam nickel, which has a three-dimensional net structure, enables electrode active substances to be uniformly dispersed in the material and the surface of the material, and has high temperature resistant characteristic and excellent conductivity, is adopted; and a sizing material containing simple substance silicon or a mixture of simple substance silicon and metal M is combined with the copper foil net or copper wire net or foam copper or foam nickel by a dipping method, and then the three-dimensional porous silicon-based composite negative electrode material is formed by a heat treatment (alloying and annealing treatment) manner. According to the invention, based on the three-dimensional porous structure, the forming of silicon metal alloy as well as excellent binding force between the negative electrode material and the three-dimensional porous collection body material, the cell prepared from the porous silicon-based composite negative electrode material has higher discharge specific capacity and first charge-discharge efficiency and excellent cycle performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

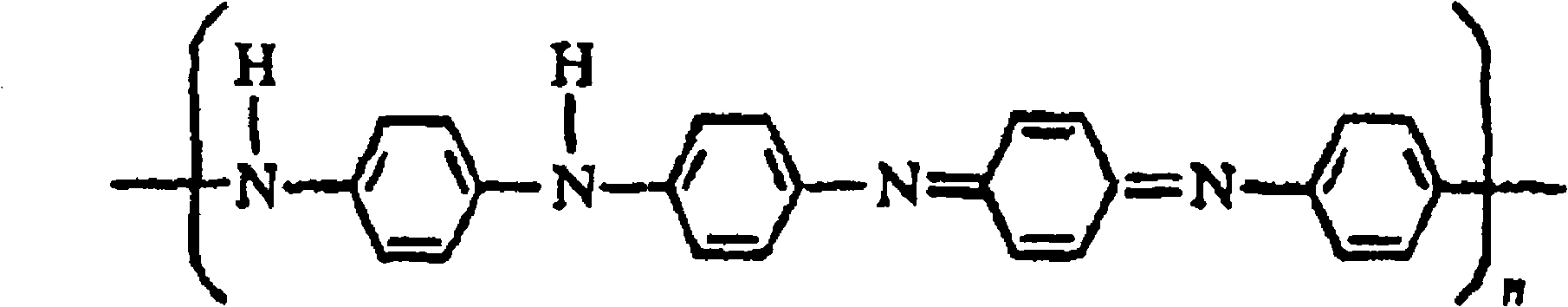

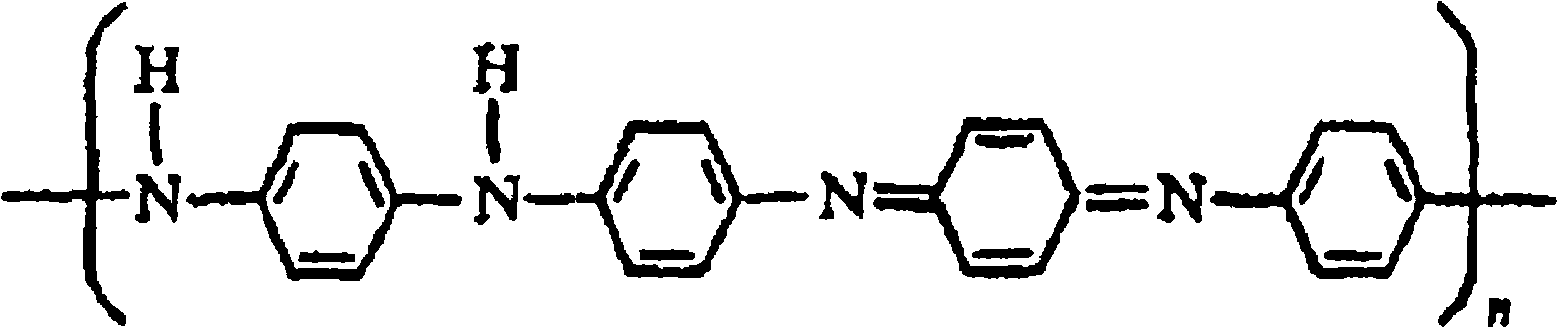

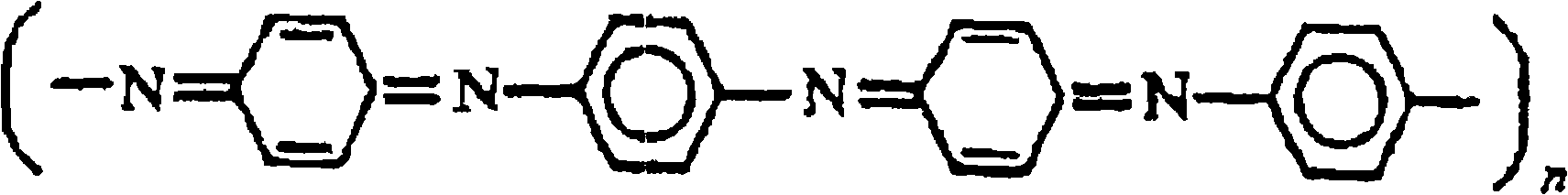

A kind of preparation method of the lithium-ion battery of conductive polymer coating positive electrode

InactiveCN102280656AImprove adhesionImprove conductivityCell electrodesSecondary cellsConductive polymerSlurry

The invention discloses a preparation method of a lithium-ion battery with a conductive polymer coated positive electrode. The positive electrode sheet is a positive electrode slurry made of a positive electrode material, a conductive agent, a positive electrode binder, a conductive polymer or a conductive polymer monomer, and a solvent. The negative electrode sheet is composed of negative electrode material, thickener, negative electrode binder, and solvent mixed into negative electrode slurry and negative electrode current collector. The specific capacity of the battery is increased by 10-20% by adding a conductive polymer or a conductive polymer monomer to the slurry for coating. The invention effectively improves the performance of the prepared positive electrode material, and because the method is simple, the product cost is reduced, the process is simplified, and the method is suitable for large-scale production.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

Micron single crystal granular anode material of lithium ion battery

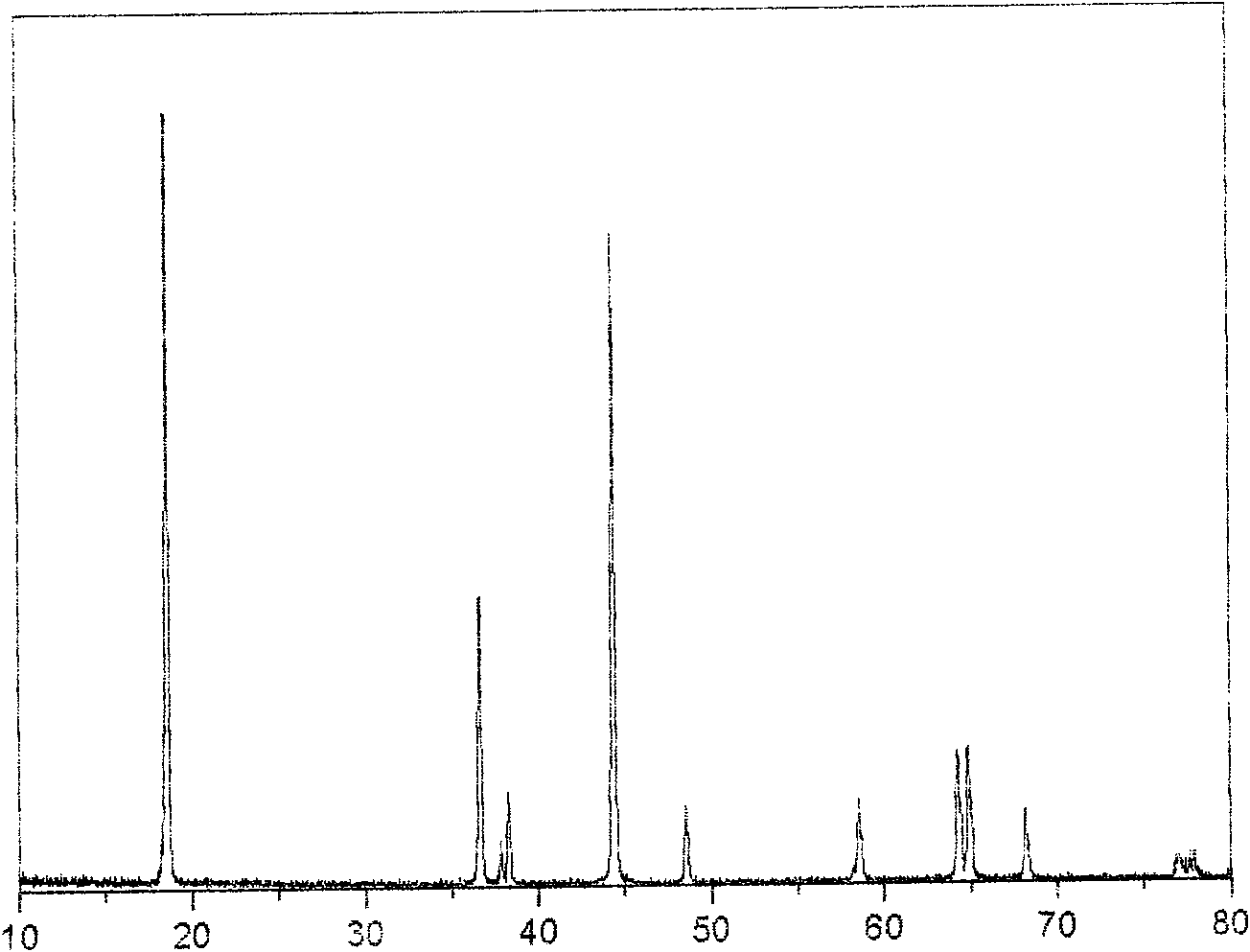

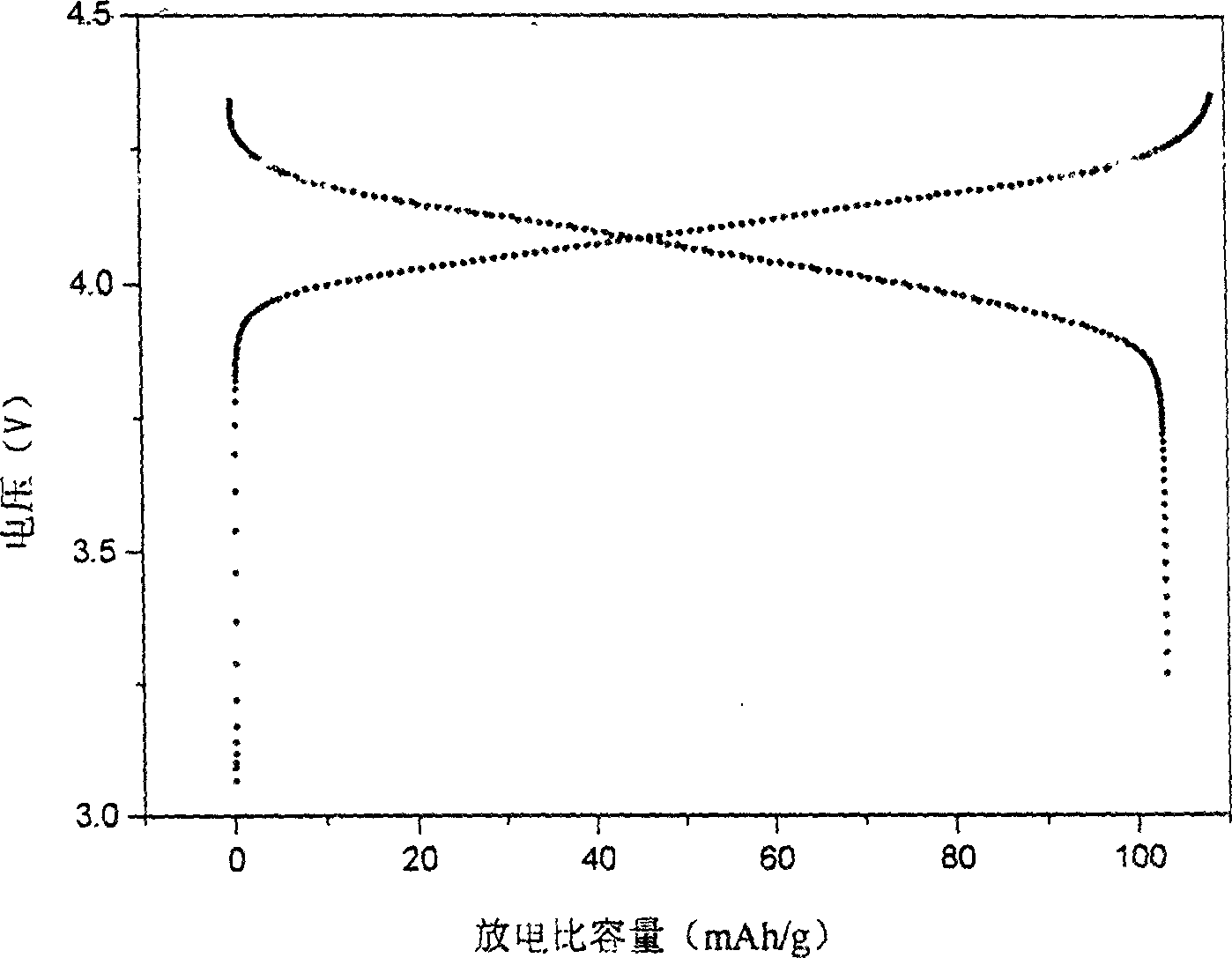

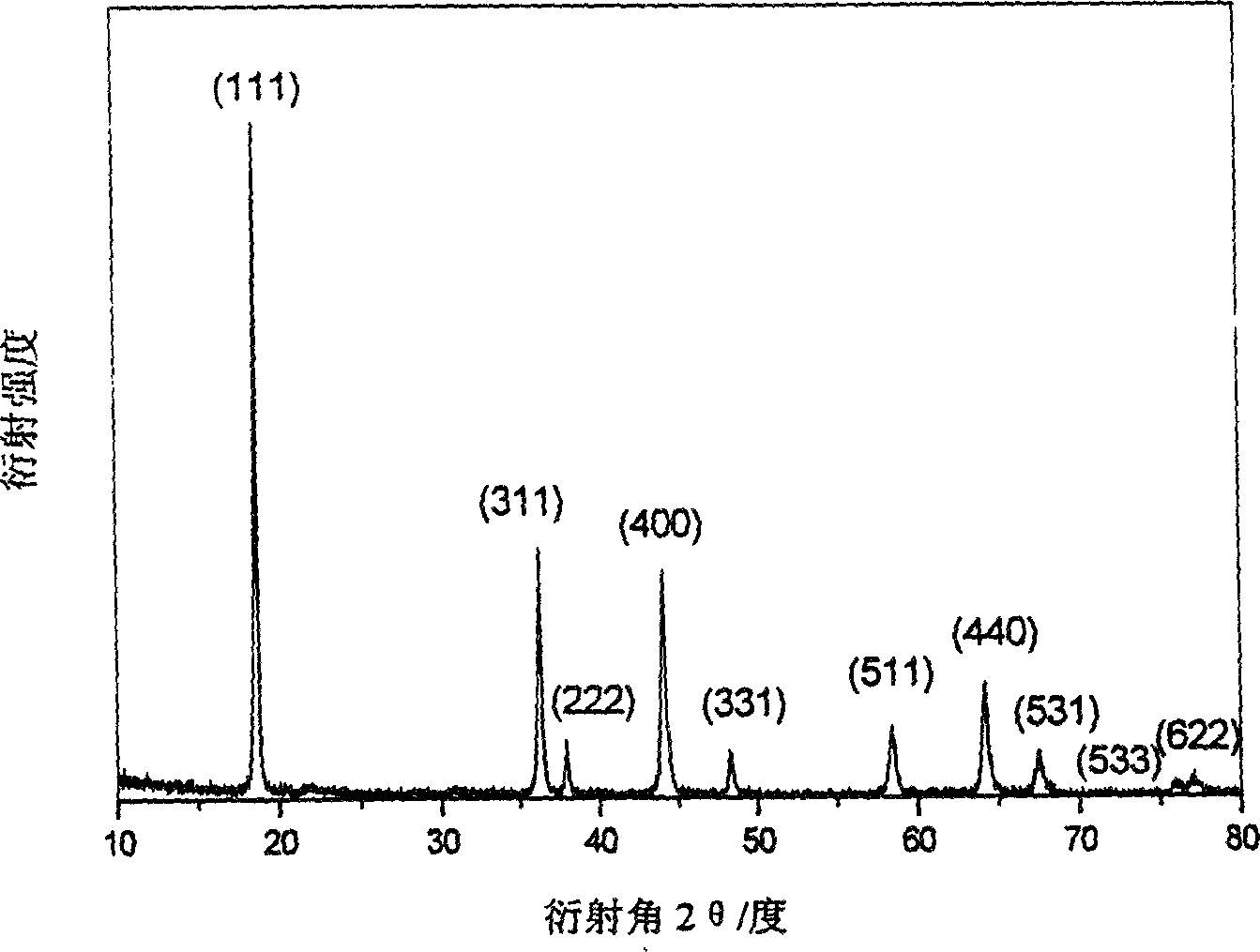

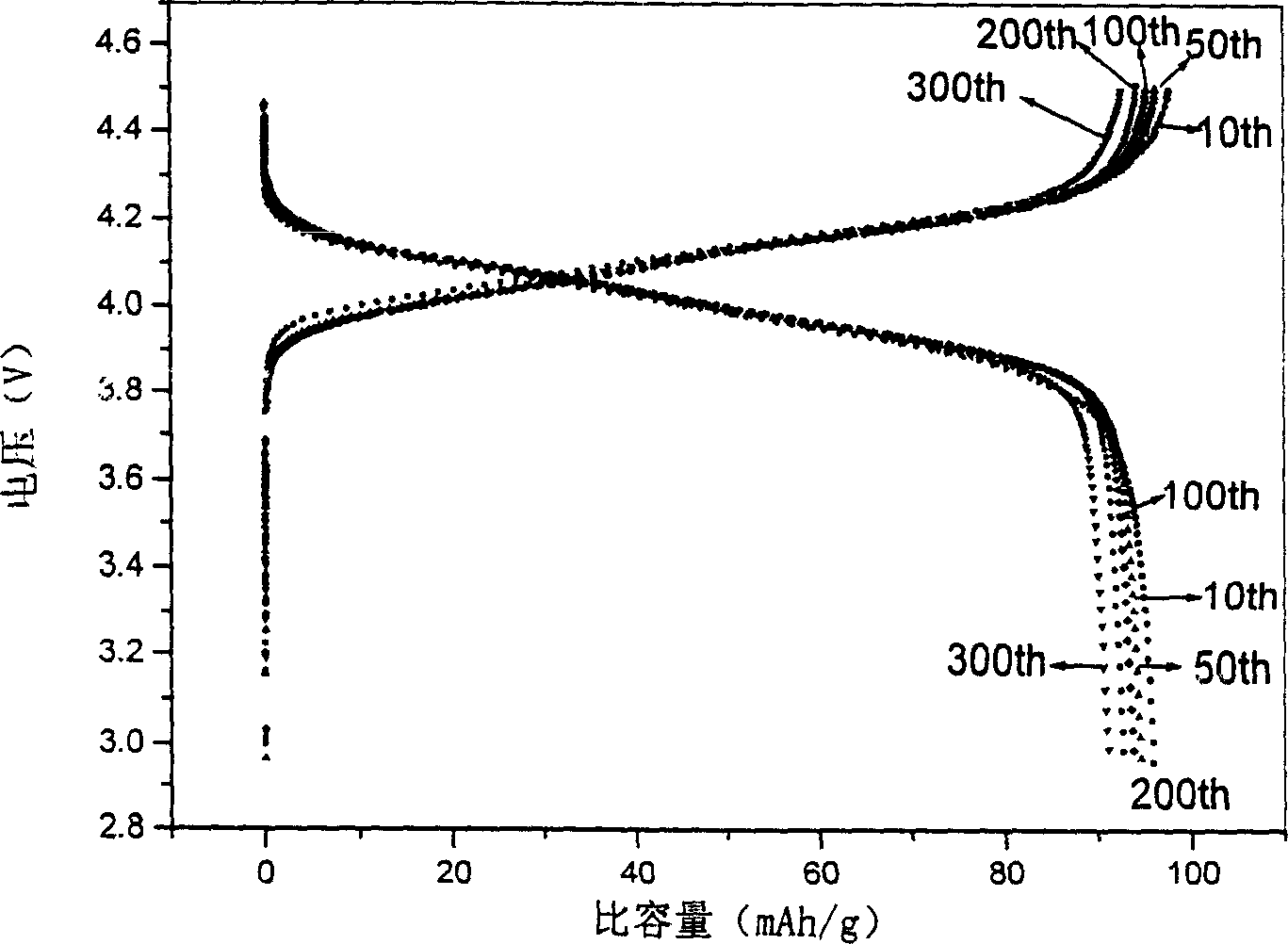

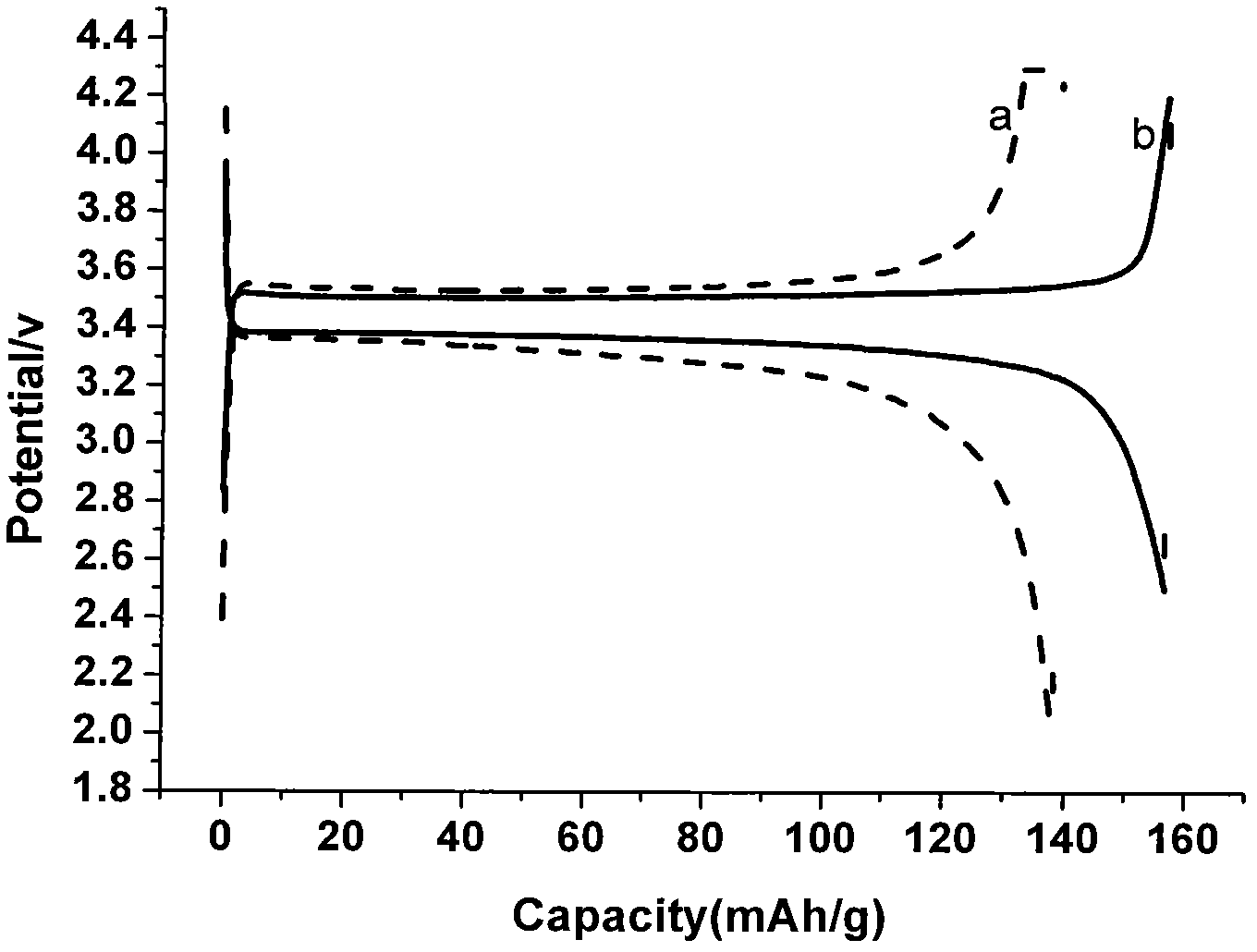

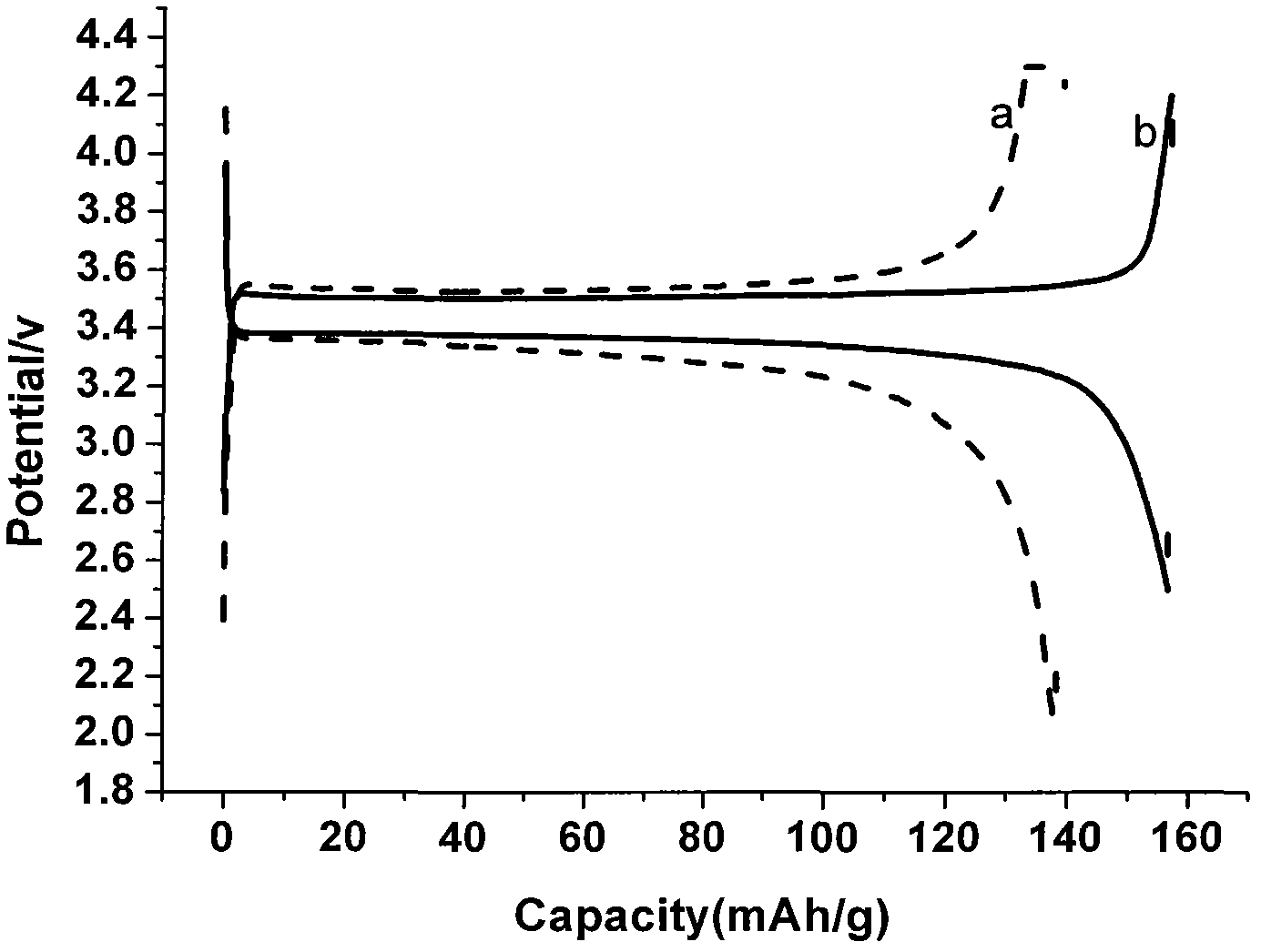

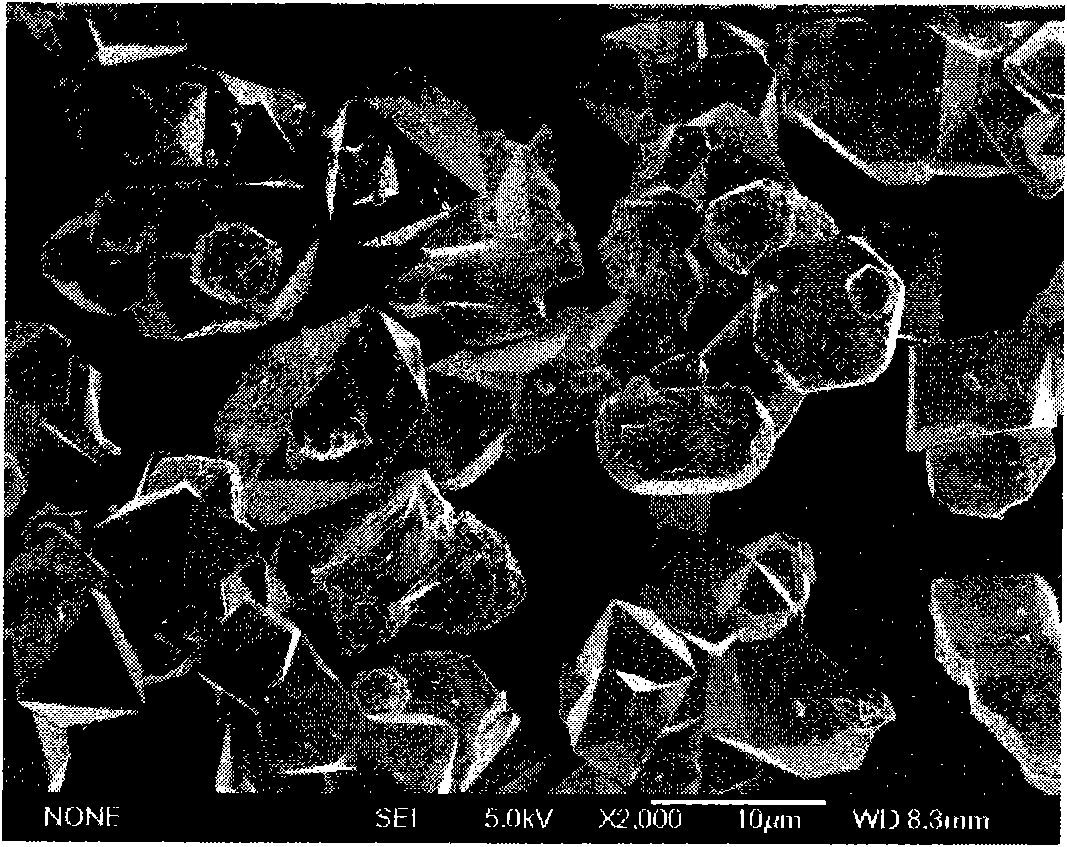

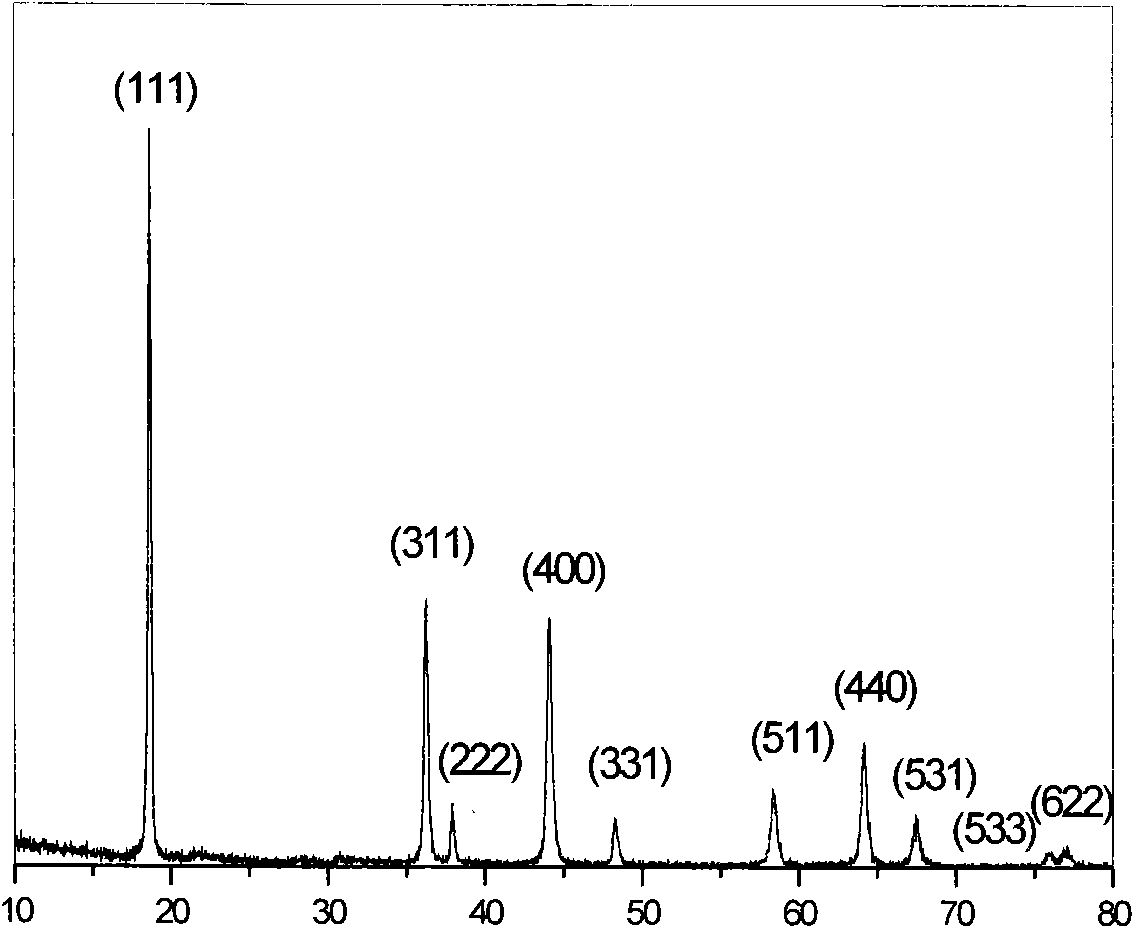

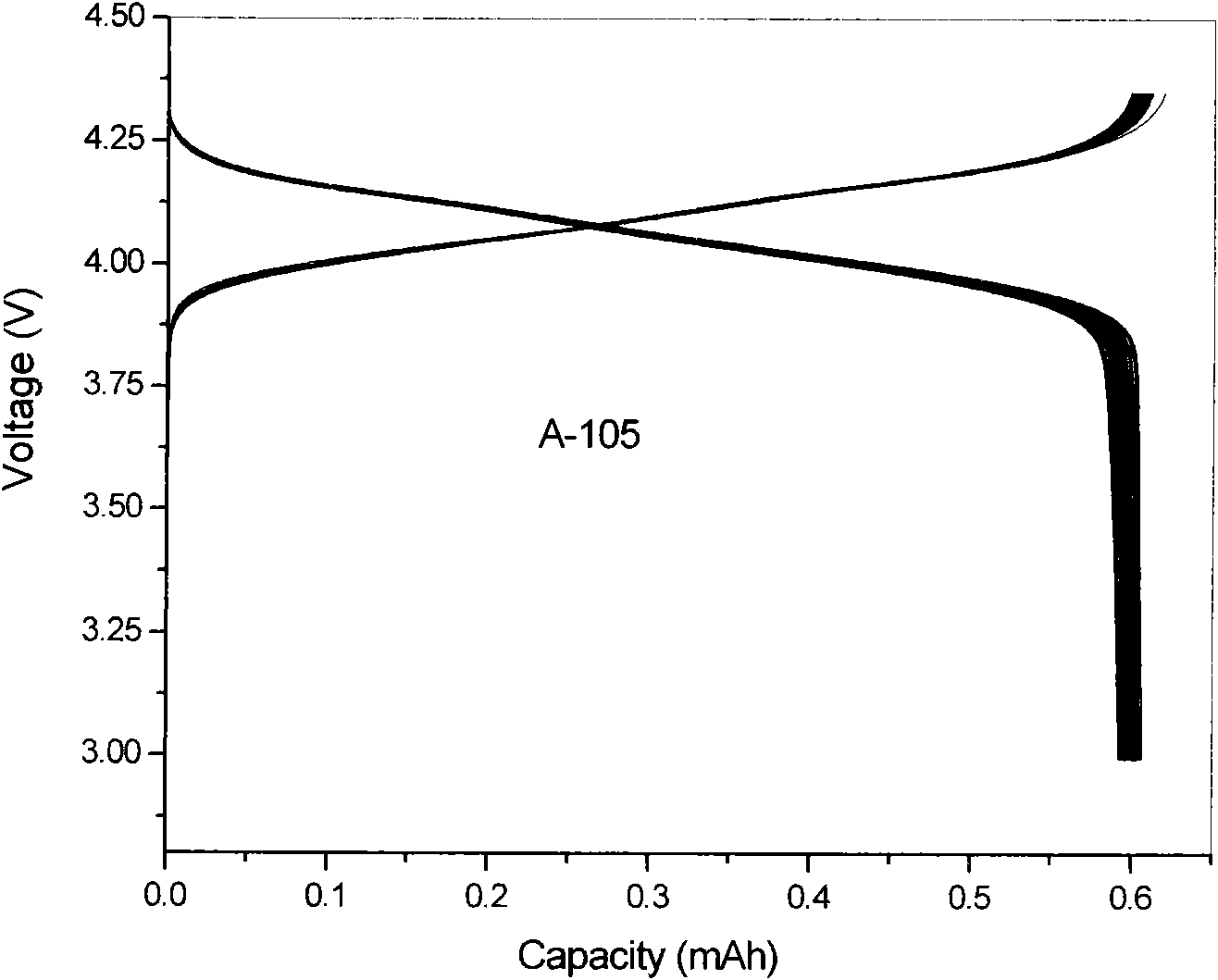

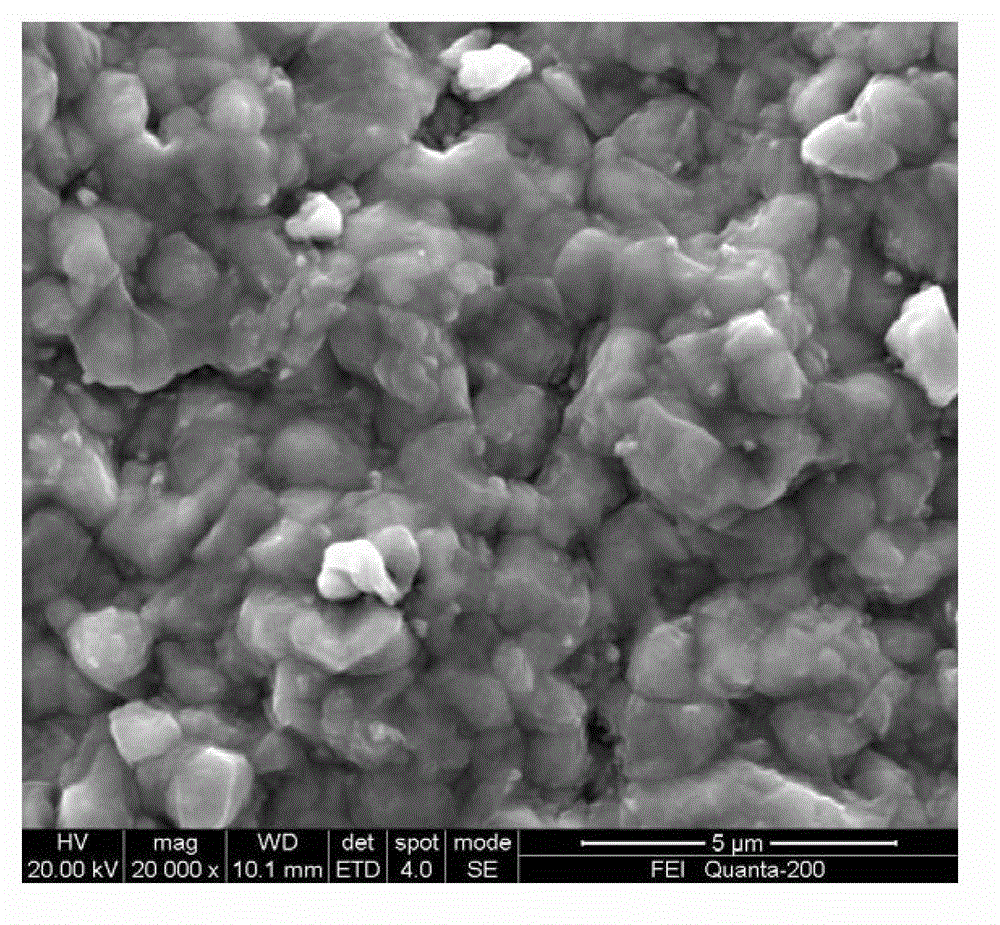

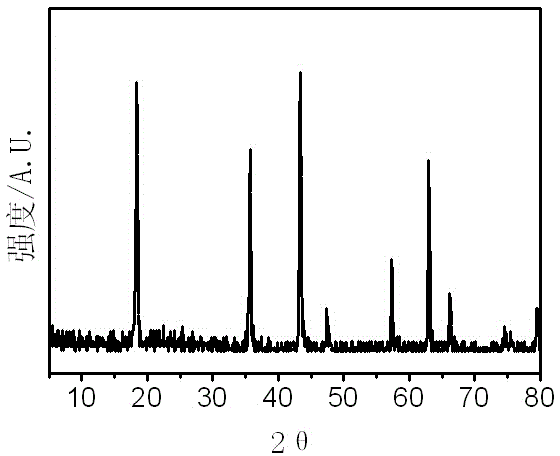

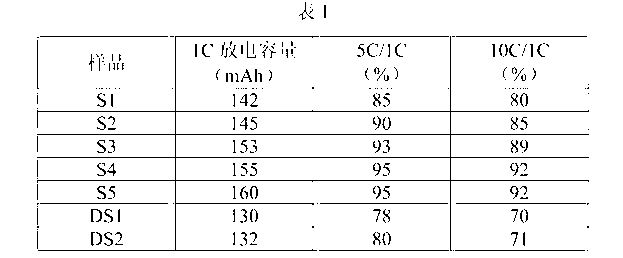

InactiveCN101587950AImprove high rate charge and discharge performanceImproved cycle life and high power output performanceAlkaline accumulatorsCell electrodesTemperature cyclingComposite oxide

The invention relates to a micron single crystal modified normal spinel lithium manganate LiMn(2-z)MzO4 and a preparation method thereof, wherein z is more than or equal to 0 and is less than or equal to 0.5. The preparation method is characterized in that firstly, composite oxides of manganese and modified metal M are used as raw materials of preparation, the composite oxides are porous aggregates consisting of nanometer microcrystal, the average size of the aggregates is between 5 micrometers and 20 micrometers, and the specific surface of the composite oxides powder is more than 20m / g (measured by a BET method); secondly, the prepared modified lithium manganate material basically consists of micro regular octahedron single crystal, the average size of the single crystal granular is between 5 micrometers and 20 micrometers, the specific surface is lower and is less than 0.5m / g. In addition, the product has excellent physical and electrochemical properties, such as ultralow specific surface, reasonable granular size distribution, better electrode processing property and ultralong circulation service life, excellent multiplying power property, remarkable high-low temperature cycling and storage properties, and best safety, and can be widely used as the materials of an anode of the lithium ion battery, especially a power lithium ion battery.

Owner:QINGDAO LNCM

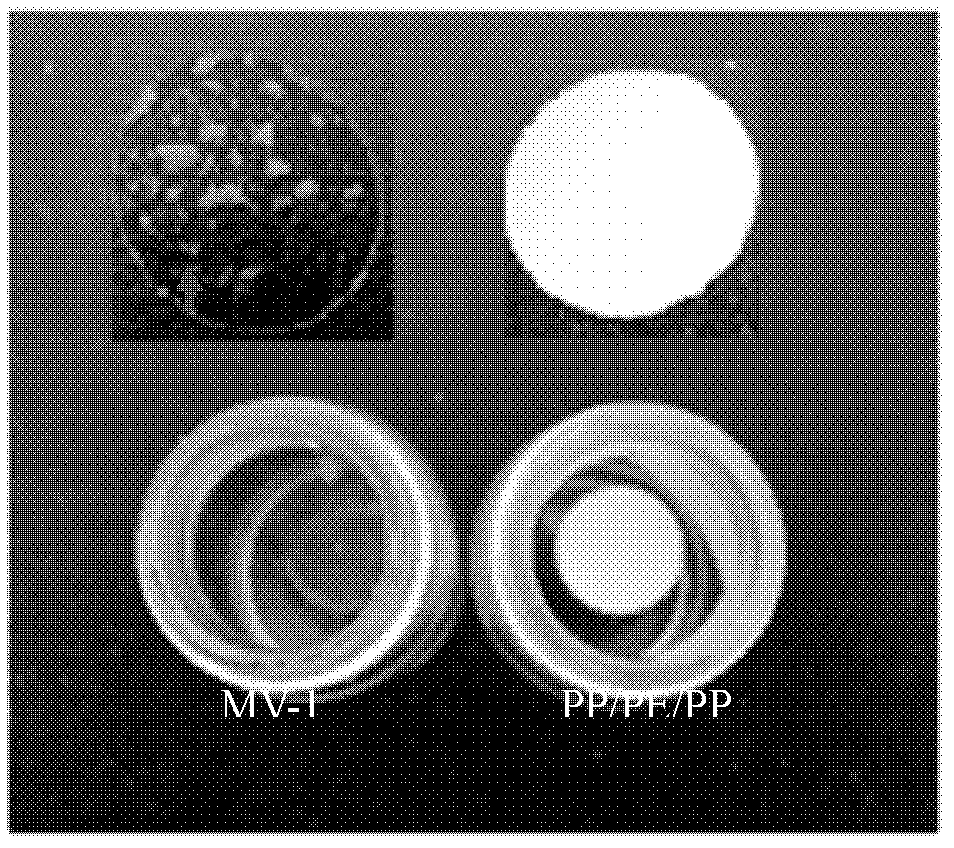

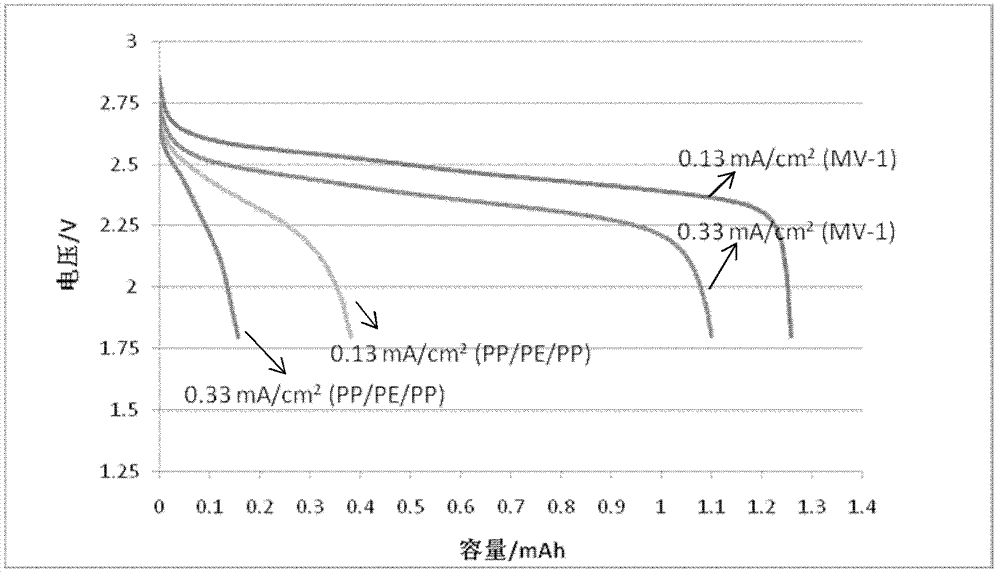

Lithium ion secondary battery containing ion liquid electrolyte

ActiveCN102903954AImprove performanceImprove cycle lifeCell seperators/membranes/diaphragms/spacersSecondary cellsLithiumHigh rate

Owner:MICROVAST POWER SYST CO LTD

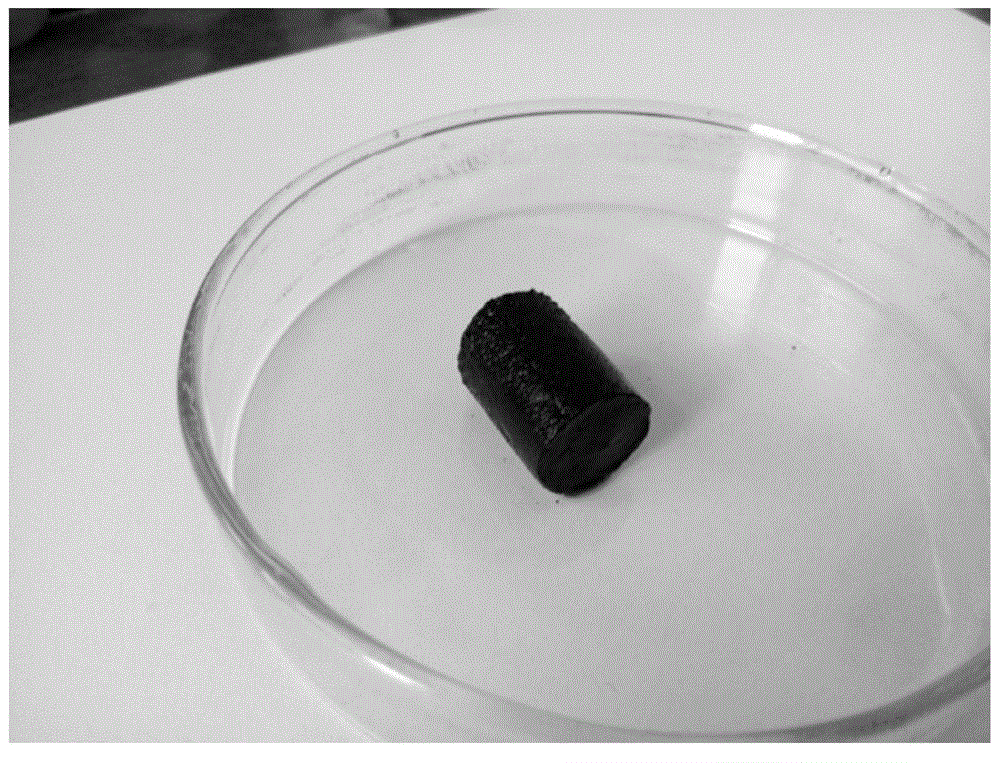

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

ActiveCN104064738AInhibition of dissolution lossPromote wettingCell electrodesSecondary cellsCvd grapheneGraphite oxide

The invention provides a hydrothermal preparation method of a graphene-coated sulfur / porous carbon composite material and relates to a preparation method of the graphene-coated sulfur / porous carbon composite material for a positive electrode material of a lithium-sulfur storage battery. The hydrothermal preparation method is used for solving the technical problem that the electrochemical property of the positive electrode material of an existing lithium-sulfur battery, namely a graphene-coated sulfur-containing composite material, is low. The hydrothermal preparation method comprises the steps of mixing and scattering the sulfur / porous carbon composite material with graphene slurry or oxidized graphene slurry, carrying out hydrothermal synthesis to prepare a hydrogel column, and drying to obtain the graphene-coated sulfur / porous carbon composite material. According to the graphene-coated sulfur / porous carbon composite material prepared by utilizing the hydrothermal preparation method, the outer surfaces of the graphene sheet layers are coated with sulfur / porous carbon composite material particles, a graphene conduction network is generated among the particles, and the obtained graphene-coated sulfur / porous carbon composite material is in a hierarchical core-shell structure; the positive electrode material has the high specific capacity, the long cycle life and the good rate capability; the composite positive electrode material can be used as a positive electrode material in a lithium secondary battery.

Owner:HARBIN INST OF TECH

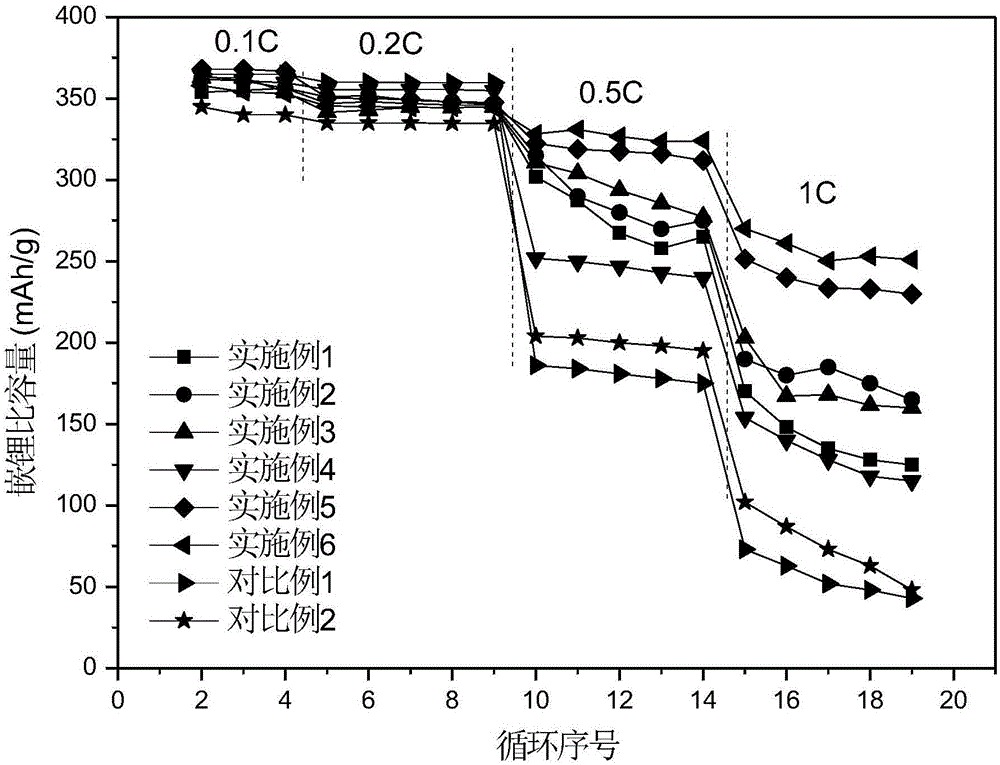

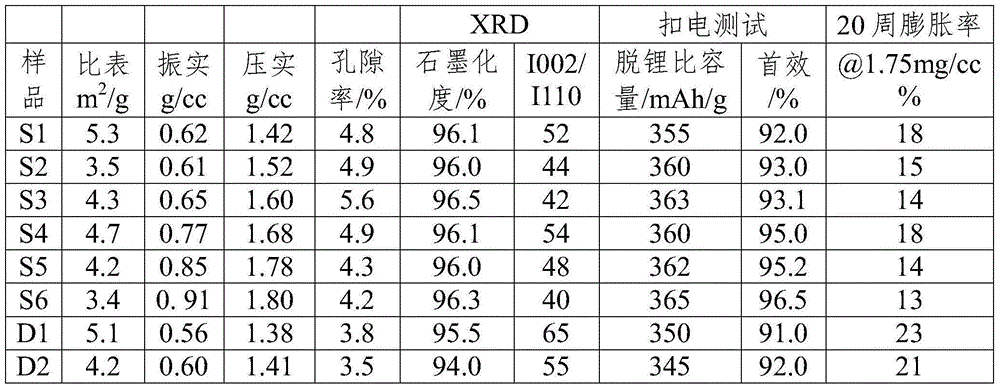

Preparation method of composite graphite, composite graphite and lithium ion battery

InactiveCN105098184ALow costHomogeneous catalytic effectCell electrodesSecondary cellsLithium electrodeGraphite

The invention provides a preparation method of composite graphite to overcome the problems that the composite graphite prepared by the method in the prior art is low in energy density, poor in high-rate charge and discharge properties and high in expansion rate in the charging and discharging processes. The preparation method comprises the following steps: (S1) providing ultrafine carbon powder, wherein the ultrafine carbon powder comprises green coke and / or mesophase carbon green microspheres; (S2) mixing the ultrafine carbon powder with a binder to obtain a mixture A, mixing the mixture A with a catalyst to obtain a mixture B, and then carrying out combined treatment on the mixture B to obtain a precursor; (S3) carrying out graphitizing treatment on the precursor to obtain a semi-finished product; and (S4) crushing, spheroidizing, wrapping and sieving the semi-finished product to obtain the composite graphite. Meanwhile, the invention further discloses the composite graphite prepared by the method and a lithium ion battery. The composite graphite provided by the invention is high in energy density, good in liquid absorption and retention properties, good in isotropic property, good in high-rate charge and discharge properties and low expansion rate in the charging and discharging processes.

Owner:BTR NEW MATERIAL GRP CO LTD

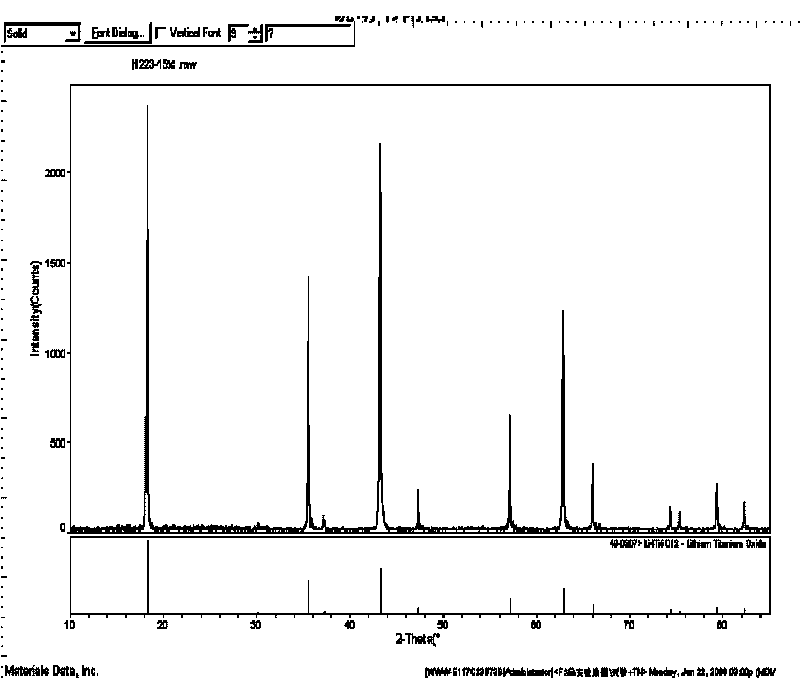

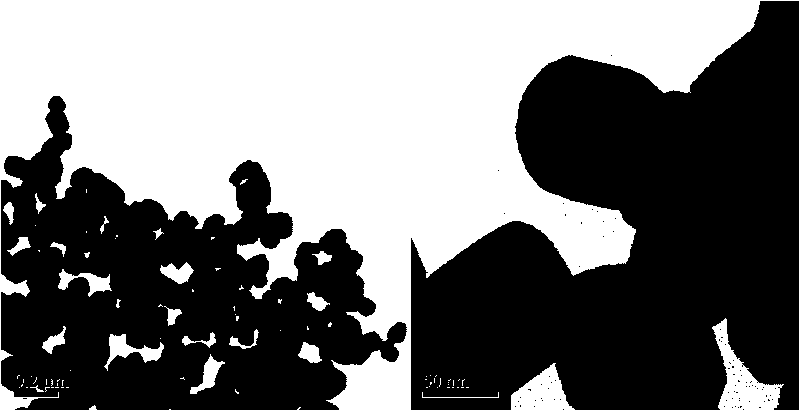

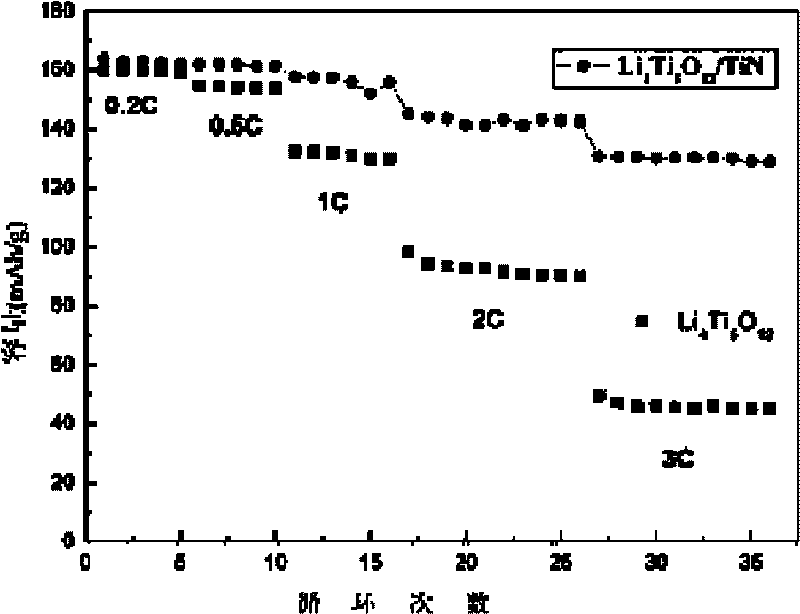

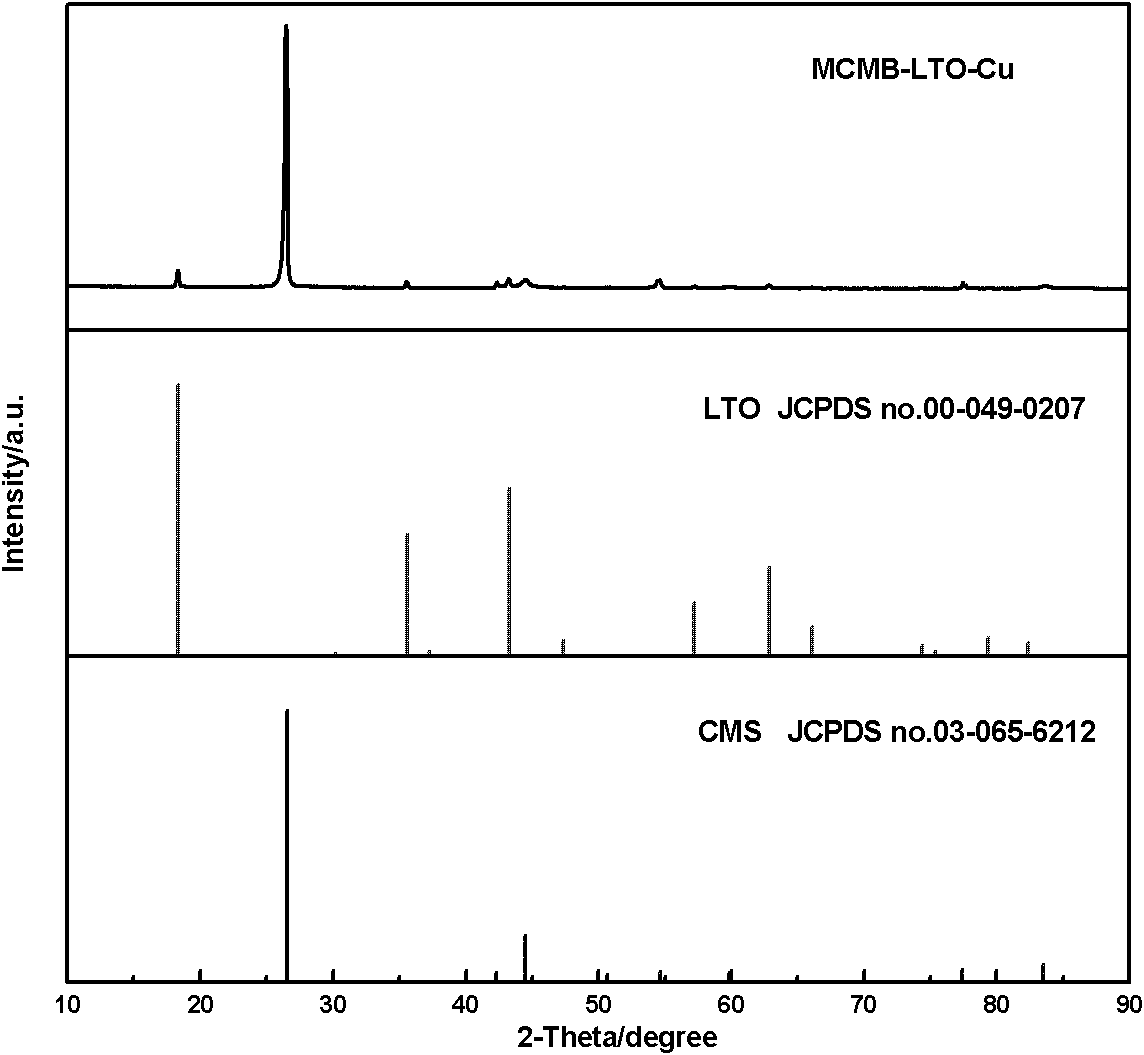

Method for preparing surface self-grown titanium nitride conducting film modified lithium titanate

The invention relates to a method for preparing a surface self-grown titanium nitride conducting film modified lithium titanate, which comprises the following steps of: uniformly mixing lithium titanate powder with solid nitrogen source in proportion in a dispersion medium in a mode of ultrasound or ball milling, drying the obtained slurry at the temperature of between70 and 120 DEG C, raising temperature to 600 to 900 DEG C in the inert protective atmosphere after grinding, preserving the heat for 10min to 1h, and then cooling together with a furnace to obtain the surface self-grown titanium nitride conducting film modified lithium titanate. Through heat nitrogen reaction, a layer of high-conductive film TiN is self-grown on the surface of the lithium titanate; the TiN film is firmly combined with the lithium titanate; and the prepared high-conductive Li4Ti5O12 / TiN material has high multiplying power of charge-discharge property and excellent circulating property. The preparation method has the advantages of low cost, simple operation and safety, and easy realization of mass production.

Owner:CENT SOUTH UNIV

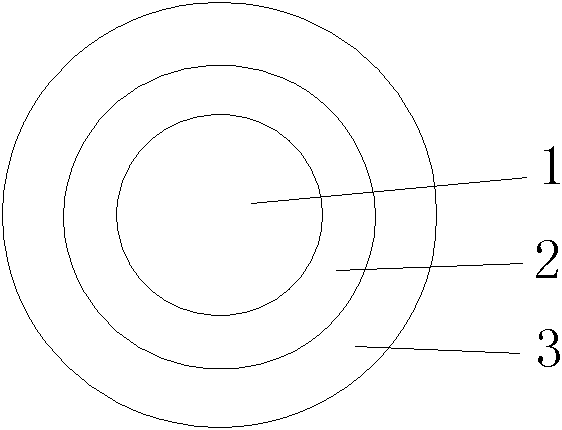

Composite carbon cathode material for lithium ion battery and preparation method thereof

InactiveCN102185142AInhibit growthImprove electrochemical performanceCell electrodesIonSpecific energy

The invention discloses a composite carbon cathode material for a lithium ion battery and a preparation method thereof, and relates to a cathode material for a lithium ion battery. The invention provides the composite carbon cathode material for the lithium ion battery and the preparation method thereof, wherein the composite carbon cathode material can reduce the influence of a solid electrolyte interface (SEI) film on the cyclical stability of the cathode material, partially prevent anode dissolved metal ions from being deposited on the surface of the cathode material to affect the cyclical performance of the cathode material and still provide high specific energy under the condition of high charging current. The composite carbon cathode material is provided with a nuclear shell layer structure of at least three layers, wherein the outer layer is a metal layer, an alloy layer or a carbon layer; the middle layer is a lithiated metal oxide layer or a metal oxide layer; and the inner layer is a carbon material layer. The preparation method comprises the following steps of: mixing and then drying a raw material for preparing a metal oxide and a carbon material; heating and sintering the dried raw materials under the protection of atmosphere to obtain a composite material of the lithiated metal oxide or metal oxide layer with nuclear shell structure and the carbon material; and plating a metal, alloy or carbon conductive layer with reversible mechanical ductility on the surface of the composite material to obtain a product.

Owner:XIAMEN UNIV

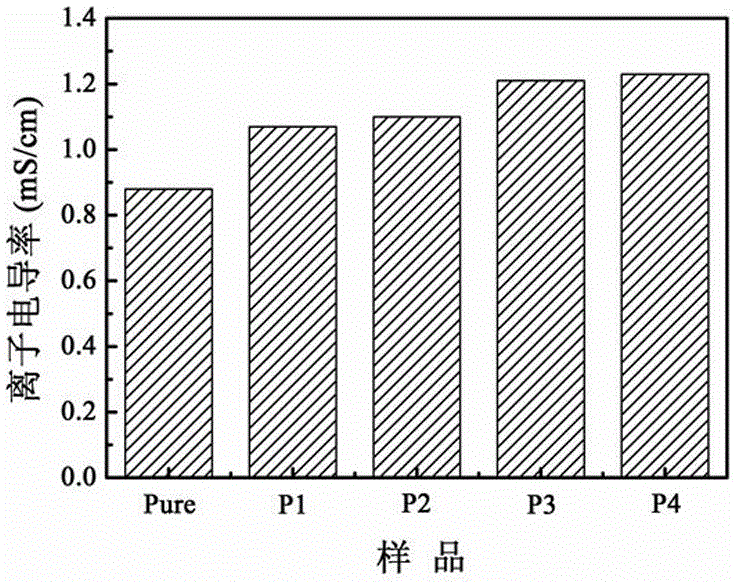

Porous lithium ion battery separator with interpenetrating polymer network structure, and preparation method and application for porous lithium ion battery separator

ActiveCN105932203AGood mechanical strengthGuaranteed ionic conductivityCell seperators/membranes/diaphragms/spacersSecondary cellsSolventPolyvinylidene fluoride

The invention discloses a porous lithium ion battery separator with an interpenetrating polymer network structure, and a preparation method and an application for the porous lithium ion battery separator. The preparation method specifically comprises the steps of uniformly mixing polyvinylidene fluoride-hexafluoropropylene, (methyl) acrylate monomers, octavinyl octa-silsesquioxane cross-linking agent and pore-forming auxiliary in a proper solvent to form porous gel polymer film with the interpenetrating polymer network structure through free radical polymerization, wherein the ion conductivity of the polymer film at a temperature of 25 DEG C can reach 1.0*10<-3>S / cm, the tensile strength can reach 7MPa, and excellent dimensional stability is realized; and on the basis, carrying out post processing on the gel polymer film to obtain the porous separator. By adoption of the lithium ion battery separator provided by the invention, the ionic conductivity can be greatly improved, and the high rate charging-discharging performance can be also obviously enhanced as well, so that the porous lithium ion battery separator is high in application potential.

Owner:SUZHOU UNIV

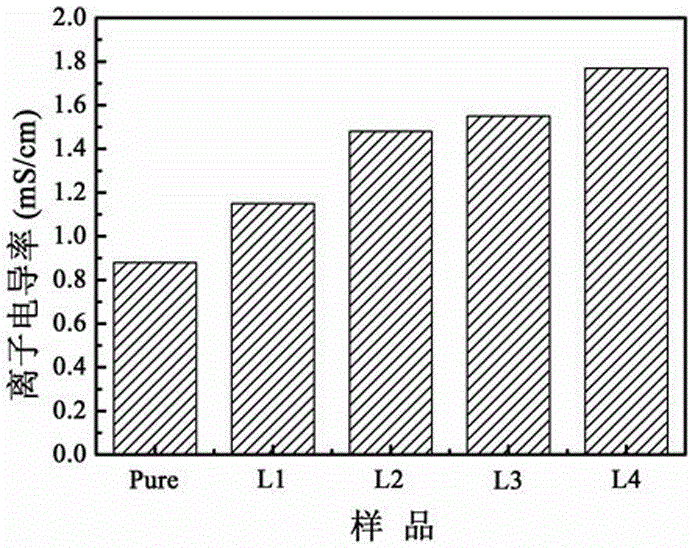

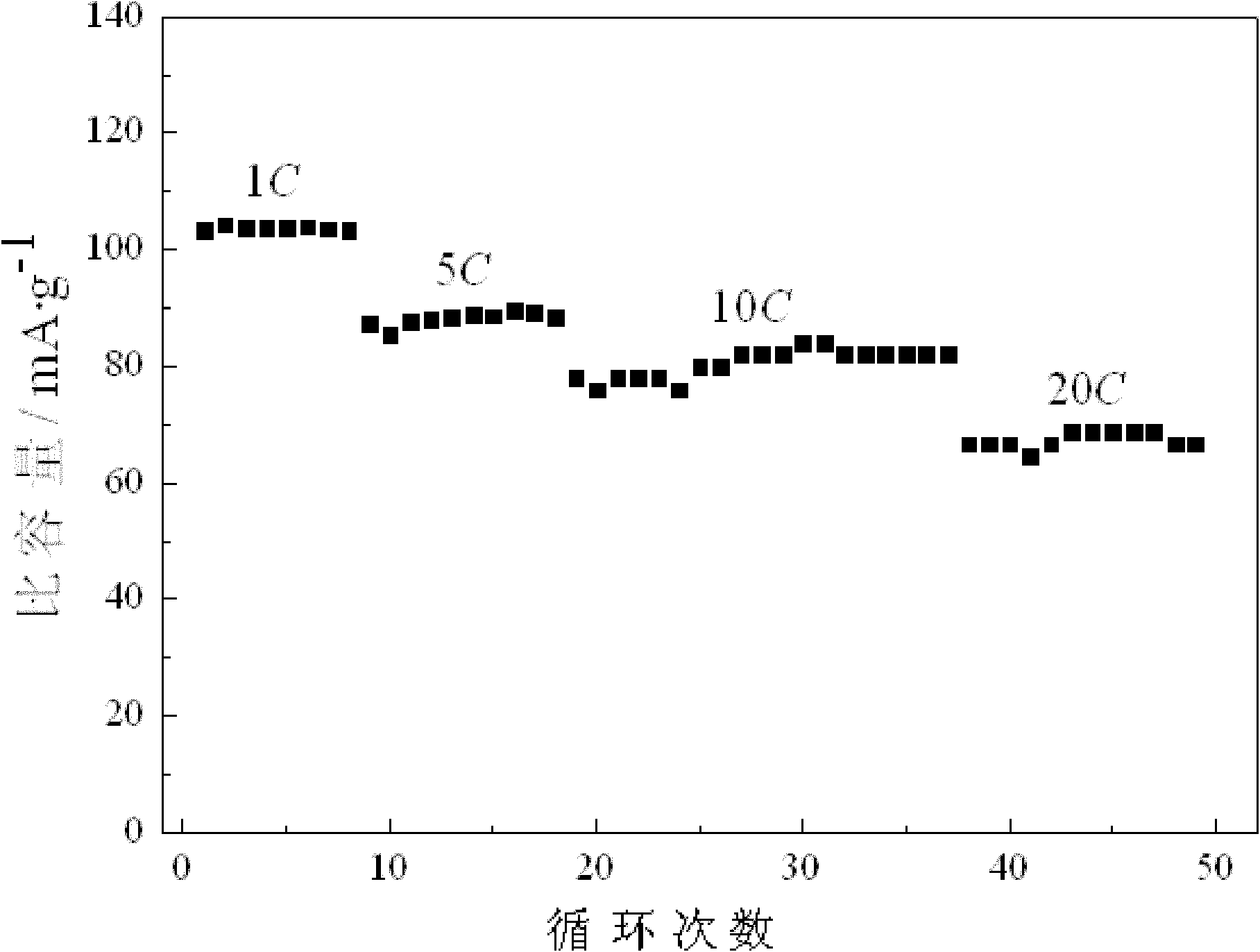

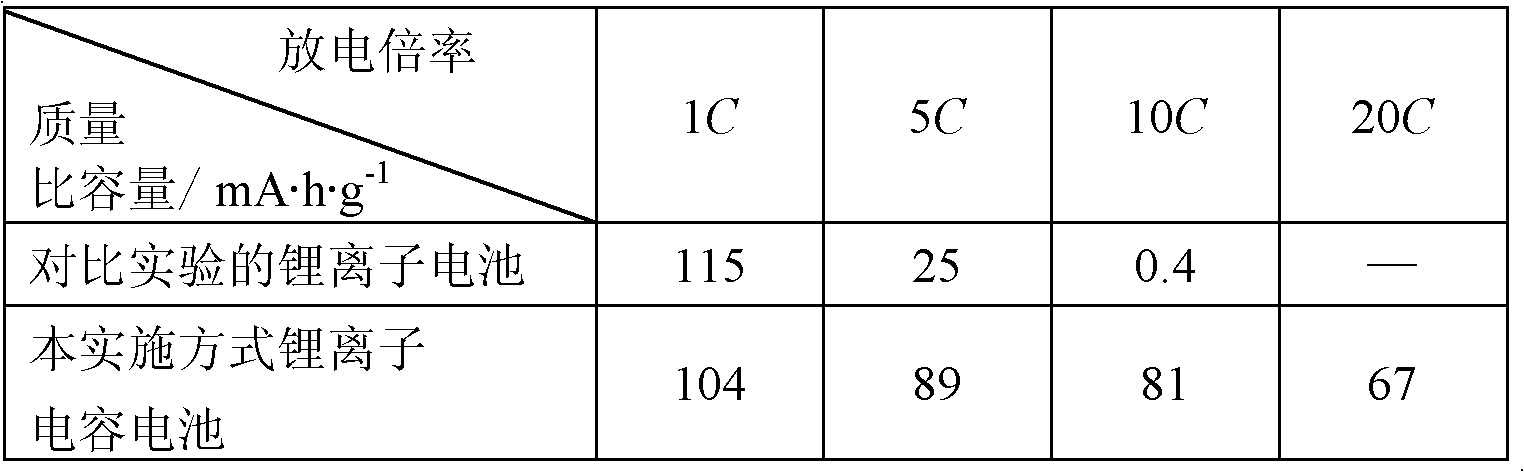

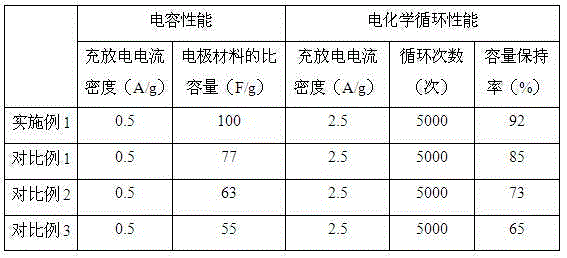

Capacitor carbon/lithium iron phosphate composite material, preparation method thereof and lithium-ion capacitor battery using same as cathode material

InactiveCN101944588AImprove high rate charge and discharge performanceIncrease surface areaElectrolytic capacitorsNon-aqueous electrolyte accumulator electrodesCapacitanceElectrical battery

The invention discloses a capacitor carbon / lithium iron phosphate composite material, a preparation method thereof and a lithium-ion capacitor battery using the same as a cathode material and relates to a lithium iron phosphate material, a preparation method and a lithium-ion capacitor battery using the lithium iron phosphate material as a cathode material, solving the problems of higher preparation cost of the traditional lithium iron phosphate and poor high-magnification charge / discharge properties of the lithium-ion batteries prepared from the traditional lithium iron phosphate. The composite material is formed by loading the lithium iron phosphate on activated carbon. The preparation method comprises the following steps of: preparing a lithium iron phosphate precursor by using a trivalent ferric salt, a phosphorus compound, a lithium source compound and an organic micromolecule carbon source as raw materials; and then mixing the precursor with the activated carbon and sintering. In the invention, the cathode sizing agent of the lithium-ion capacitor battery comprises the capacitor carbon / lithium iron phosphate composite material, a conductive agent and a bonding agent; the particle size distribution of the composite material is uniform; the trivalent ferric salt is used as a raw material, and the cost on the preparation is low; and the capacitor battery has good charge / discharge cycle performances and the mass specific capacity larger than 60mA.h.g<-1> under 20C magnification.

Owner:HARBIN INST OF TECH

Lithium ion secondary battery and preparation method thereof

InactiveCN101651233AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsHigh rateConductive polymer

The invention provides a lithium ion secondary battery. The lithium ion battery comprises a battery shell, a pole core and an electrolyte, wherein the pole core and the electrolyte are accommodated inthe battery shell; the pole core comprises a positive pole, a negative pole and a diaphragm positioned between the positive pole and the negative pole; the positive pole comprises a current collectorand positive materials; the positive materials comprise positive active substances, a conductive agent and a binder; the binder is provided with conductive performance; and the diaphragm is a porouspolyimide film. The invention also provides a preparation method for the lithium ion secondary battery. Due to the adoption of a conductive polymer serving as the positive binder and polyimide servingas the battery diaphragm, the lithium ion secondary battery provided by the invention significantly increases the capacity and the cycle performance of the battery, and significantly improves the high-rate charge and discharge performance.

Owner:BYD CO LTD

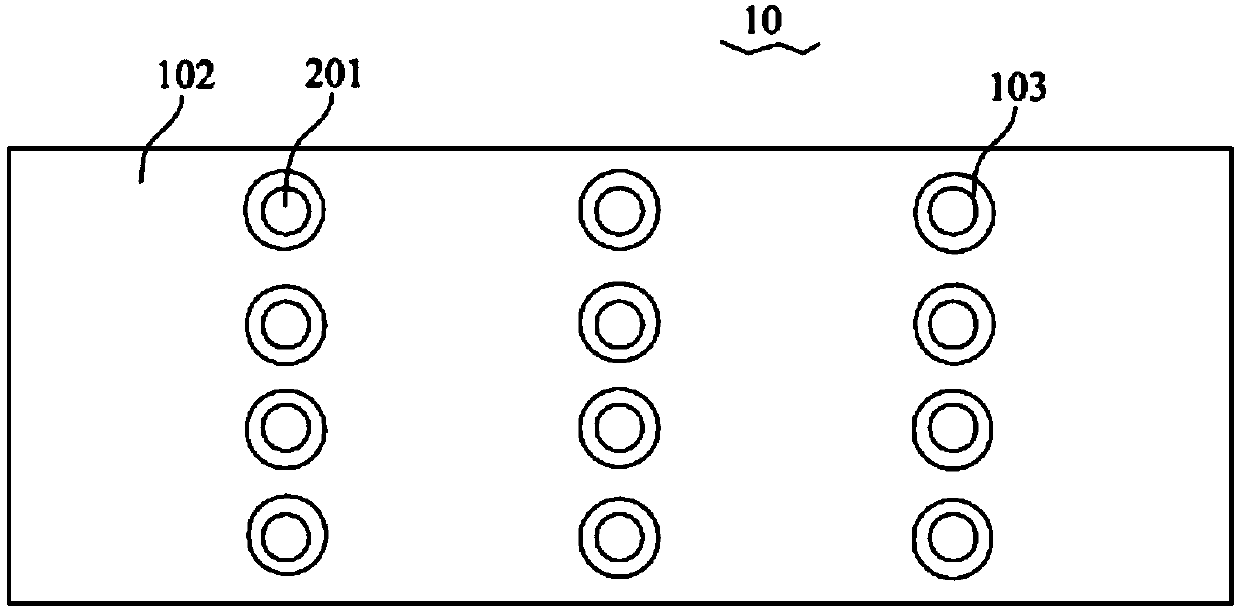

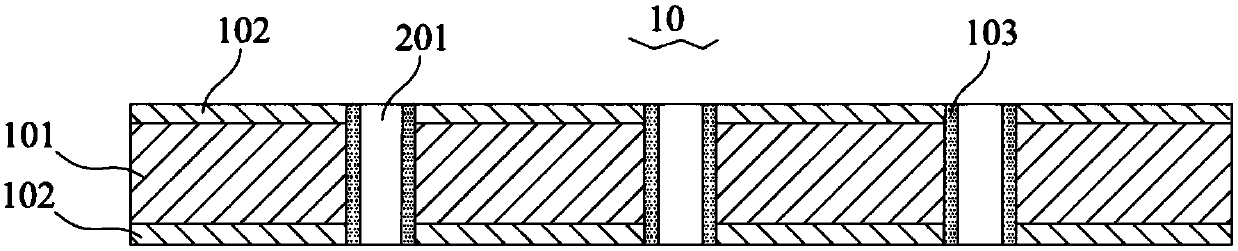

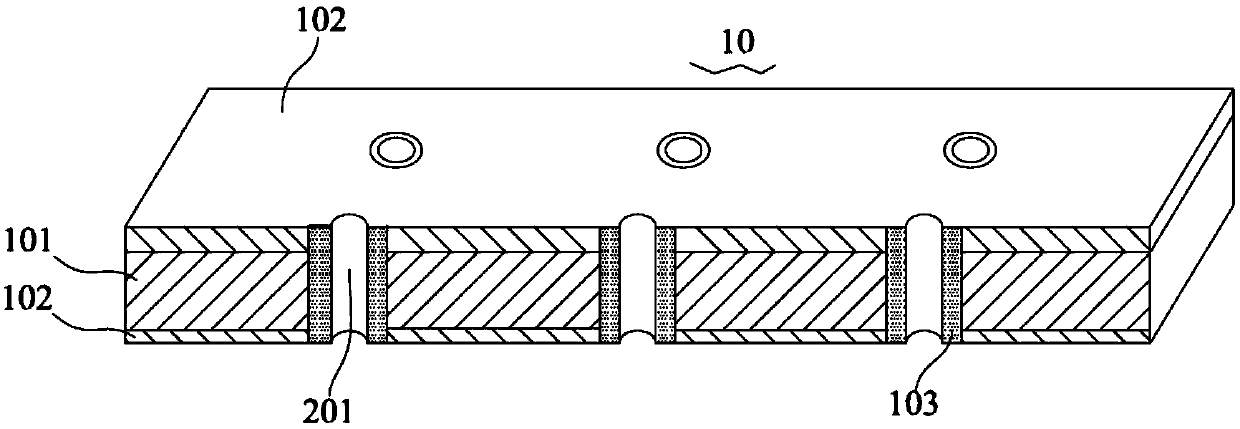

Current collector and pole plate thereof, and electrochemical device

InactiveCN110247056AImprove short circuit resistanceImprove securityElectrode carriers/collectorsSecondary cellsElectrical resistance and conductanceConductive materials

The present invention relates to the battery field, especially to a current collector. The current collector comprises a support layer, conductive layers and a conductive material, the conductive layers are located on the two surfaces of the support plate, the current collector is internally provided with a plurality of holes penetrating the support layer and the conductive layers, the holes are filled with the conductive material. The current collector can improve the short-circuit resistance of the battery in the case of short circuit under abnormal conditions, and can greatly reduce the short-circuit current. Therefore, the short-circuit heat generation amount can be greatly reduced, and the safety performance of the battery is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Graphene-cladded sulfur/microporous carbon sphere composite cathode material

InactiveCN104269543AGive full play to the advantagesImprove conductivityCell electrodesSecondary cellsComposite cathodeSulfur

The invention discloses a composite cathode material for secondary aluminum batteries. The composite cathode material is formed by compounding microporous carbon spheres, sulfur and graphene, has good electric conductivity and is capable of effectively suppressing that polysulfide dissolves in electrolyte to cause the shuttle effect. The preparation method of the composite cathode material comprises the following steps: firstly compounding the microporous carbon spheres and the sulfur, and then cladding the outer layer of the composition with a graphene sheet layer. The preparation method is simple in process and low in cost, toxic raw materials are not used, environment friendliness is achieved, the energy density is high, the utilization ratio of the sulfur is high, and the rate capability and the cycle performance of the secondary aluminum batteries are improved greatly.

Owner:NANJING ZHONGCHU NEW ENERGY

Carbon sulfur compound anode for secondary battery

InactiveCN104157879AHigh reactivityIncrease loadMaterial nanotechnologyNon-aqueous electrolyte accumulatorsCompound aElectricity

The invention discloses a carbon sulfur compound anode for a secondary battery. The anode is formed by compounding a carbon nanotube array, sulfur and graphene, is provided with a three-dimensional network conductive framework and is good in electrochemical performance. A preparation method of the anode comprises the following steps: compounding elemental sulfur in the carbon nanotube array at first and then wrapping an outer layer with few graphene sheet layers. The preparation method is simple in process, low in cost and environment-friendly due to nonuse of toxic raw materials; moreover, the compound anode does not need to be added with a conductive agent and a bonder, and is high in energy density and sulfur utilization rate, and the rate performance and the cycle performance of the secondary aluminum battery are greatly improved.

Owner:NANJING ZHONGCHU NEW ENERGY

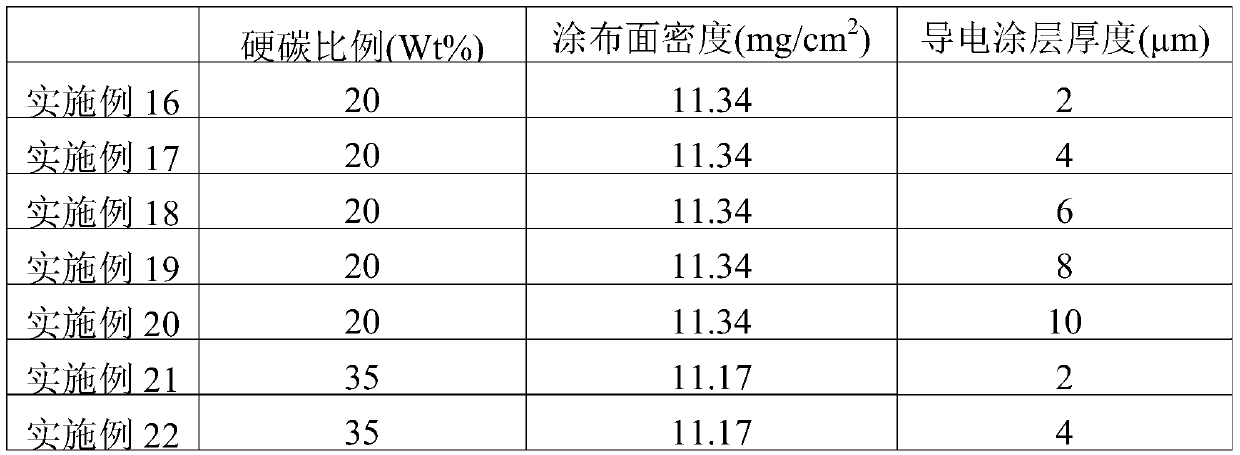

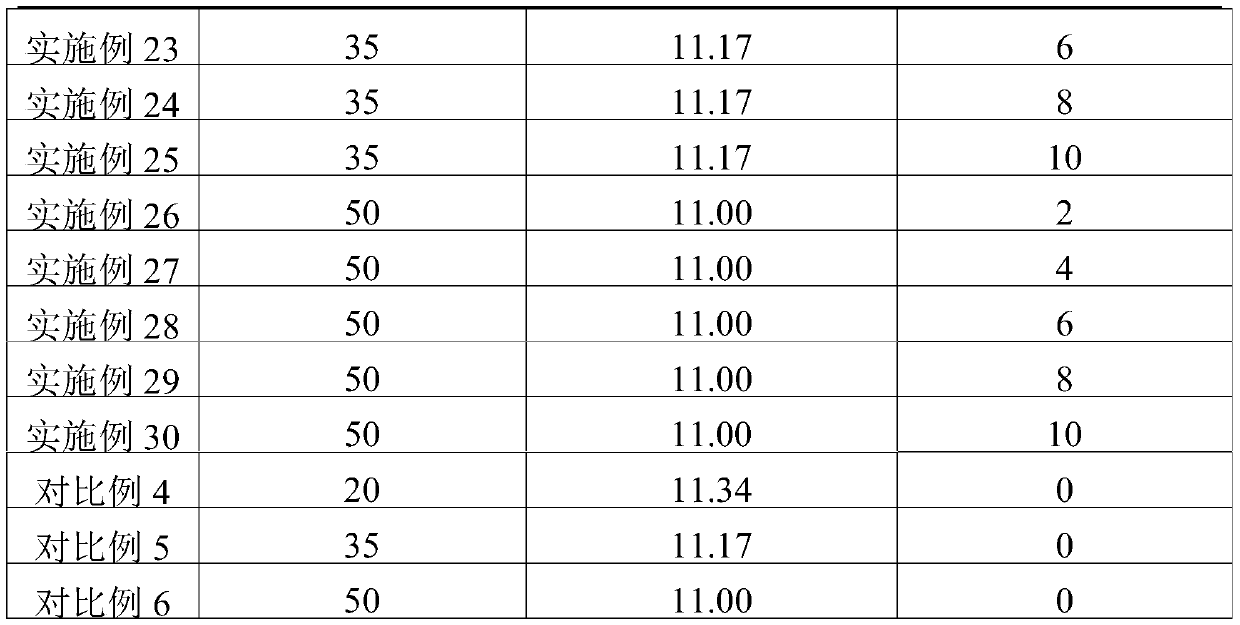

Lithium transition-metal oxide cell

ActiveCN105552306AImprove high rate charge and discharge performanceExtended service lifeFinal product manufactureCell electrodesHigh rateCharge discharge

The invention provides a lithium transition-metal oxide cell. The lithium transition-metal oxide cell comprises a negative plate and a positive plate. The negative plate comprises a negative active substance layer, negative current collector Cu foil and a negative conductive coating. The negative current collector Cu foil is coated with the negative conductive coating. The negative active substance layer is located on the negative conductive coating. The negative active substance layer comprises a mixture of graphite and hard carbon, a negative pole binder and a negative pole conductive agent. The positive plate comprises a positive active substance layer, positive current collector Al foil and a positive conductive coating. The positive current collector Al foil is coated with the positive conductive coating. The positive active substance layer is located on the positive conductive coating. The positive active substance layer comprises a lithium transition-metal oxide, a positive pole binder and a positive conductive agent. The lithium transition-metal oxide cell improves cell high-rate charge-discharge performances, prolongs a cell service life and can be used for electric bicycles, electric automobiles and energy storage power stations.

Owner:TIANJIN ENERGIES

A boron doping modified hard carbon coating negative electrode material with high rate performance and a liquid phase preparation method thereof

ActiveCN109148847ASimple preparation processUnique preparation processCell electrodesSecondary cellsOxygen compoundAtomic radius

The invention relates to the field of lithium batteries, and discloses a boron doping modified hard carbon coating negative electrode material with high rate performance and a liquid phase preparationmethod thereof. A hard carbon carbon layer is formed on the surface of a negative electrode substrate after carbonization by a hard carbon carbon source, boron oxide is generated by decomposing a boron-oxygen compound at a high temperature, and a composite structure such as boron-carbon bond and boron-carbon-oxygen bond is formed on the surface of the negative electrode substrate at a high temperature. On the one hand, compared with other negative electrode materials, hard carbon has larger interlayer spacing and better rate charge-discharge performance. Through hard carbon coating, the highrate charge-discharge performance of negative electrode materials can be improved. On the other hand, by doping boron into the negative electrode material, the position of carbon atom in the crystal lattice of other negative electrode materials is replaced by boron atom, and the atomic radius of boron atom itself is larger than that of carbon atom, which leads to the increase of the interlayer spacing of the negative electrode material and the magnification performance of the material.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

Carbon-Cu6Sn5 alloy negative electrode materials and preparation method thereof

InactiveCN103066252AReduce the likelihood of sheddingIncrease migration rateElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

The invention discloses carbon-Cu6Sn5 alloy negative electrode materials and a preparation method thereof. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof combine carbon nanometer tubes and graphene into electrodes and add a Cu-CNTs connecting layer between active materials and current collectors. Therefore, cyclic perforce of an alloy negative electrode is improved greatly. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof use copper foils as the current collectors (electroplating substrates). The copper foils are plated by a Cu-CNTs composite plating and a composite plating of stannum-carbon nanometer tubes or stannum- graphene or stannum-carbon nanometer tubes- graphenes in sequence, wherein the thickness of the Cu-CNTs composite plating is 1-5 micrometers and the thickness of the composite plating of the stannum-carbon nanometer tubes or the stannum- graphene or the stannum-carbon nanometer tubes- graphene is 1-4 micrometers. The carbon-Cu6Sn5 alloy negative electrode materials can be obtained finally through thermal treatments. First specific discharge capacity of lithium ion battery alloy cathodes prepared by the method can achieve 613 m AH / g and specific capacity attenuation of the lithium ion battery alloy cathodes is only 4%-6% after 100 cycles. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof are simple in technique, good in prepared alloy cathode performance and suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

Carbon-coated nano lithium titanate composite material as well as preparation method and application thereof

ActiveCN104681804AImprove high rate charge and discharge performanceAvoid reunionMaterial nanotechnologyHybrid capacitor electrodesCarbon coatingElectrical battery

The invention discloses a carbon-coated nano lithium titanate composite material and a preparation method thereof. The preparation method comprises the following steps: 1, preparing nano lithium titanate, namely, respectively preparing micro emulsions of a lithium source and a titanium source, mixing the two types of micro emulsion, standing, centrifuging, alternatively washing with an organic solvent and water, drying, and performing high-temperature calcinations; 2, performing carbon coating on nano lithium titanate, namely, preparing a solution from an organic carbon source, adding lithium titanate granules prepared in the step 1 into the solution, performing ultrasonic dispersion, performing hydrothermal reaction, cooling after the reaction, alternatively washing with the organic solvent and water, filtering, and drying, thereby obtaining the carbon-coated nano lithium titanate composite material. Refining of lithium titanate can be achieved through a micro emulsion method, the solution can be prepared from the carbon source, and carbon coating of the nano lithium titanate can be achieved through hydrothermal reaction, so that a conductive carbon network which is uniform and dense in combination can be formed on the surface of lithium titanate, the conductivity and the large-power charge / discharge property of an electrode material are remarkably improved, and the carbon-coated nano lithium titanate composite material can be used for preparing lithium ion electric containers and lithium ion batteries.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for depositing silicon film at surface of lithium titanate cathode of lithium ion battery

InactiveCN101800305AImprove high rate charge and discharge performanceGood effectCell electrodesMuffle furnaceCopper foil

The invention belongs to the technical field of electrode material of lithium ion battery. The method is characterized in that the method comprises the following steps: dissolving titanium-containing precursor in absolute ethyl alcohol solution to obtain A solution; dissolving lithium-containing precursor in absolute ethyl alcohol to obtain B solution; and dropping the B solution in the A solution to form gel. The gel is dried, grinded and placed in a muffle furnace after aging for sintering to obtain Li4+xTi5+yO12; 70 parts of Li4+xTi5+yO12 and 17-23 parts of conductive black by weight are weighed and mixed and then grinded into a powder mixture; the mixture is poured in N-methyl pyrrolidone solution dissolved with 7-13 parts of bonder poly vinylidene fluoride by weight after being dried; the solution is coated on copper foil on standing at room temperature; and after drying, the lithium titanate cathode piece is obtained. The lithium titanate cathode piece as a deposition substrate is arranged rightly above the silicon source of a deposition cavity for deposition. The application of the method obviously improves high-powered charging and discharging performances of battery, and the improving effect is not influenced by specific technology for lithium titanate preparation; and the adaptability is very obvious.

Owner:FUJIAN NORMAL UNIV

Lithium iron phosphate composite cathode material and preparation method thereof

ActiveCN105514432AImprove electronic conductivityImprove high rate charge and discharge performanceCell electrodesSecondary cellsComposite cathodeGraphene

The invention provides a lithium iron phosphate composite cathode material and a preparation method thereof. A lithium iron phosphate material is wrapped by or doped with doping type graphene, wherein the wrapping amount or doping amount of doping type graphene is 6-10 wt%. By means of the technical scheme, after the lithium iron phosphate cathode material and doping type graphene are compounded, the electron conductivity of lithium iron phosphate is greatly improved; meanwhile, the lithium ion dispersion speed of the material is increased, and therefore the large-rate charging and discharging performance of lithium iron phosphate is improved, and the low-temperature charging and discharging performance of the material is improved; the material is simple in preparation process and suitable for industrial large-scale production.

Owner:李震祺 +1

Preparation method for high-activity material

InactiveCN106784702AReduce distanceSmall particle sizeCell electrodesSecondary cellsLithium iron phosphateUltra fine

Disclosed is a preparation method for a high-activity material. The preparation method comprises the following steps of weighing a lithium source, an iron source, a phosphorus source, a carbon source and an additive based on certain proportions, wherein the molar ratio of Li to Fe to P is 0.9-1.2 to 1 to 1, and the molar ratio of the additive to the lithium source is 0.001-0.05 to 1; adding the raw materials into an ultra-fine ball milling-grinder comprising a dispersing agent to be fully grinded to obtain uniformly dispersed slurry; conveying the slurry to a spray dryer to be subjected to drying and pelleting to obtain a lithium iron phosphate precursor; and performing sintering on the lithium iron phosphate precursor in an atmosphere furnace for one time, and cooling instantly, and then performing smashing and mechanical integrating to obtain a lithium iron phosphate product. The preparation method is simple in technological process, low in production cost and suitable for large-scale production.

Owner:德清崎辉机械科技有限公司

Preparation method of lithium titanate material, lithium titanate material, and lithium ion battery

InactiveCN102842706AImprove high rate charge and discharge performanceExcellent high rate charge and discharge performanceCell electrodesSecondary cellsPower batteryHigh rate

The invention provides a preparation method of a lithium titanate material, the lithium titanate material, and a lithium ion battery. The preparation method comprises the steps that: a mixture containing a lithium source and a nickel source is subjected to primary ball milling; the mixture is calcined, such that a precursor is obtained; the precursor is mixed with a titanium source, and the mixture is subjected to secondary ball milling; and the mixture is calcined in an inert or reductive atmosphere, such that the lithium titanate material is obtained. With the method, the prepared lithium titanate material has excellent rate discharge performance, and is especially suitable to be applied in fields such as power batteries which require high-rate charging and discharging.

Owner:BYD CO LTD

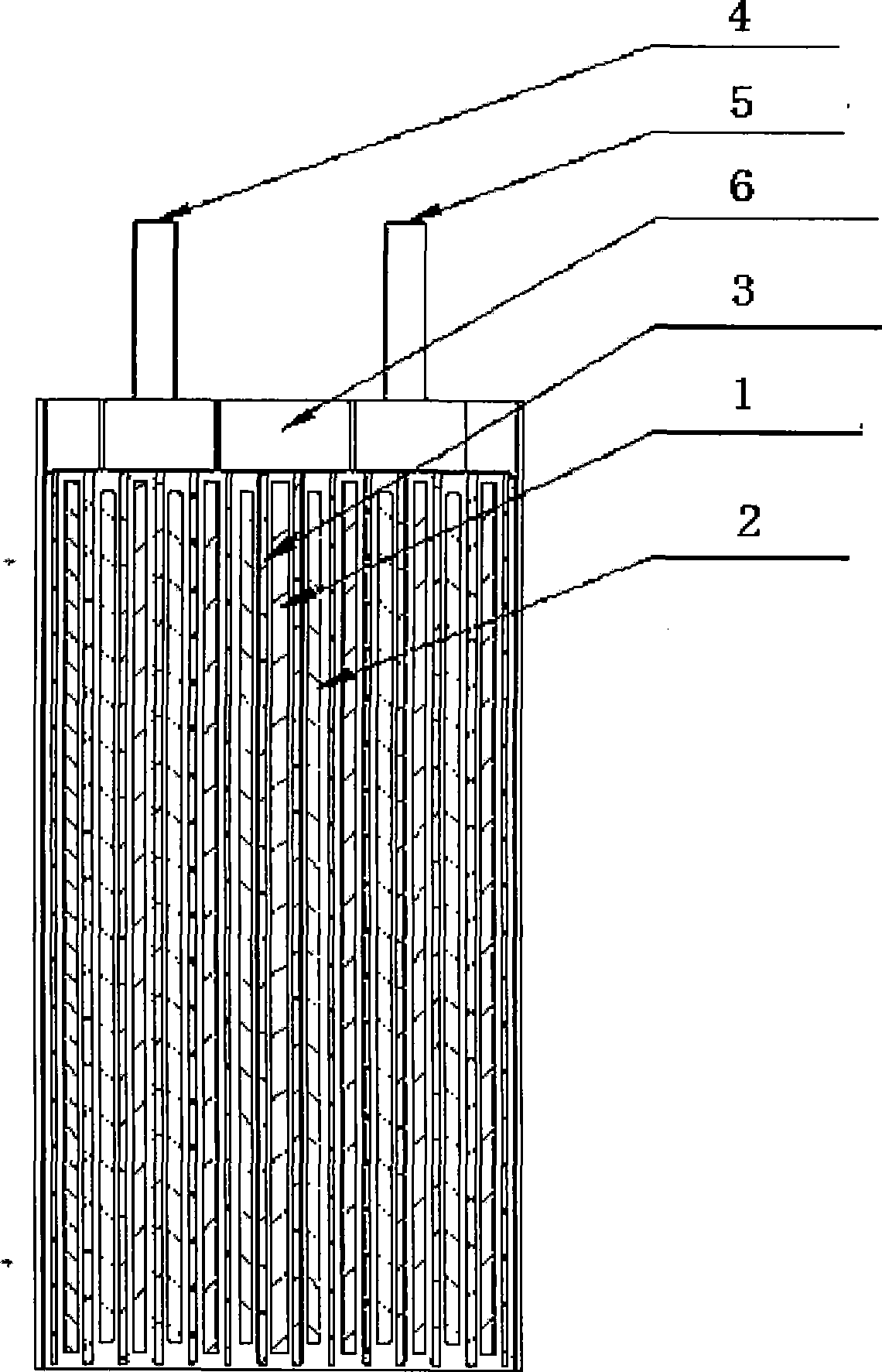

Lithium ion battery as well as preparation method thereof and lithium-ion battery pack

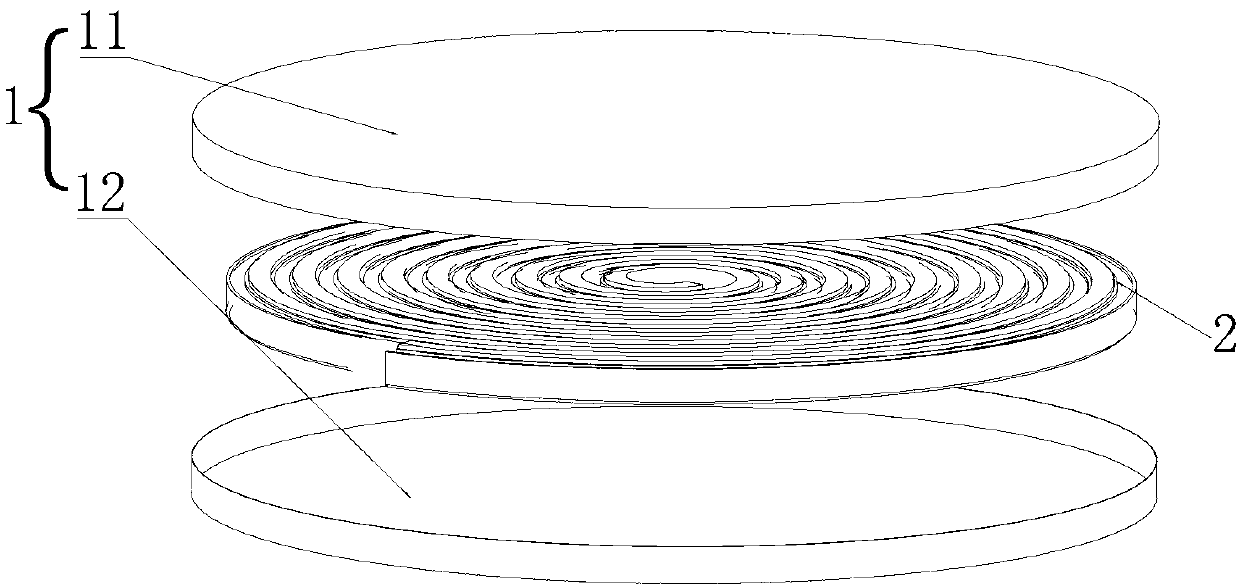

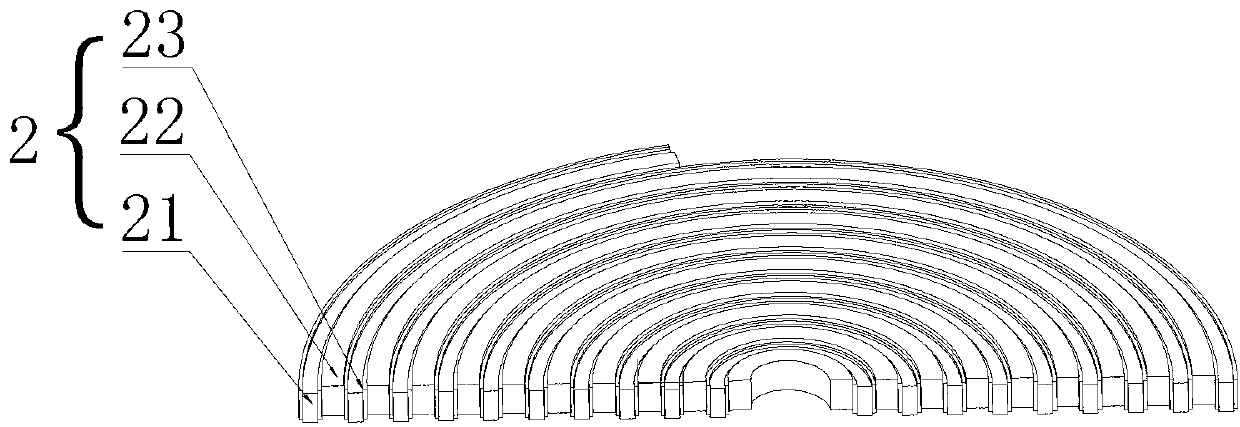

ActiveCN103346356ALower heat transfer coefficientImprove high rate charge and discharge performanceFinal product manufactureCell component detailsInsulation layerElectrical polarity

The invention relates to the technical field of batteries, and discloses a lithium ion battery. The lithium ion battery comprises a sealing device with a positive electrode and a negative electrode as well as a battery polar group which is arranged inside the sealing device, wherein the battery polar group comprises a positive plate, a negative plate and an insulation layer, and the positive plate and the negative plate are mutually coiled or laminated to form a flat structure; the insulation layer is arranged between the positive plate and the negative plate and used for separating the positive plate from the negative plate; on one end surface of the flat structure formed by coiling or laminating the positive plate and the negative plate, the positive plate is higher than the insulation layer, and the positive plate which is higher than the insulation layer is connected with the positive electrode on the sealing device through metal; on the other end surface of the flat structure formed by coiling or laminating the positive plate and the negative plate, the negative plate is higher than the insulation layer, and the negative plate which is higher than the insulation layer is connected with the negative electrode on the sealing device through the metal. The invention also discloses a preparation method of the lithium ion battery and a lithium-ion battery pack.

Owner:惠州市诺威新能源有限公司

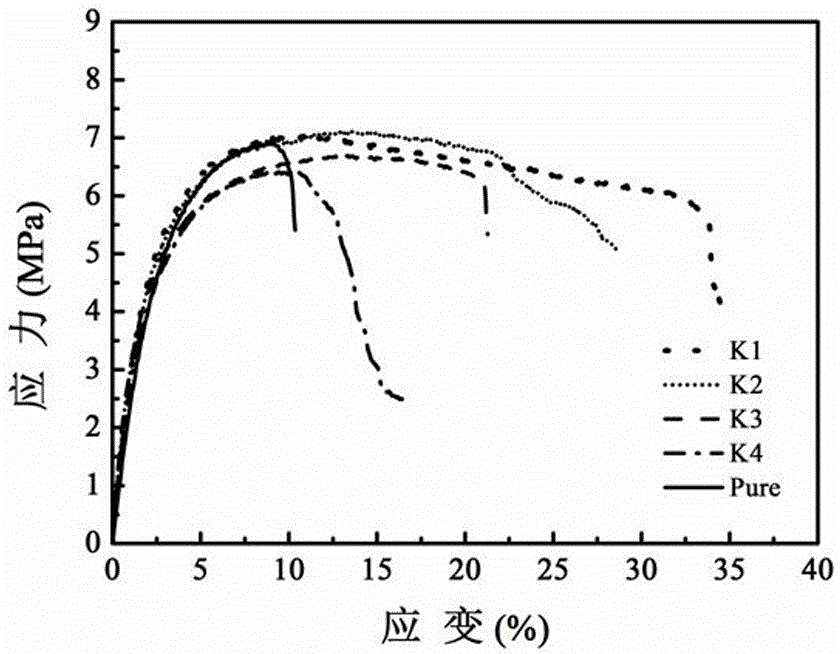

Porous lithium ion battery separator based on crosslinked and linear polymer and preparation method and application thereof

ActiveCN109119574AHigh mechanical strengthImprove thermal stabilityCell seperators/membranes/diaphragms/spacersSecondary cellsMeth-High rate

The invention discloses a porous lithium ion battery separator based on a crosslinked and linear polymer and a preparation method and application thereof. The specific preparation method comprises thefollow steps: polyvinylidene fluoride-hexafluoropropylene, (meth)acrylate monomer, octavinyl polyhedral oligomeric silsesquioxane crosslinking agent and nano-zinc oxide are uniformly mixed in a suitable solvent, and a gel polymer film with a crosslinkied structure is formed by free radical polymerization, and after a pore forming effect of nano-zinc oxide, the ionic conductivity of the gel polymer film is 1.4 * 10<-3> S / cm, the tensile strength is up to 16 MPa, and excellent dimensional stability is achieved. The lithium ion battery separator obtained by the invention can greatly improve theionic conductivity and the high rate charging and discharging performance, and has good application potential.

Owner:SUZHOU UNIV

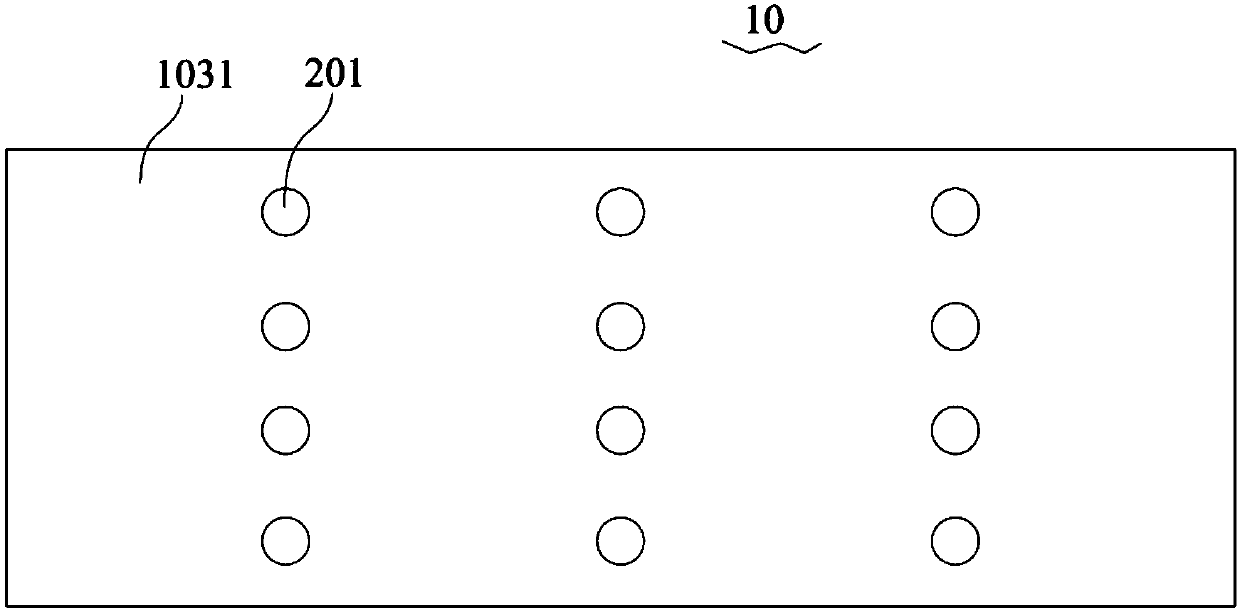

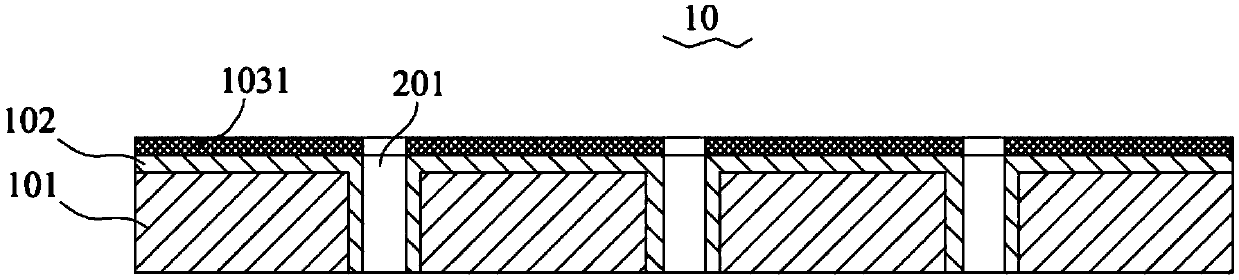

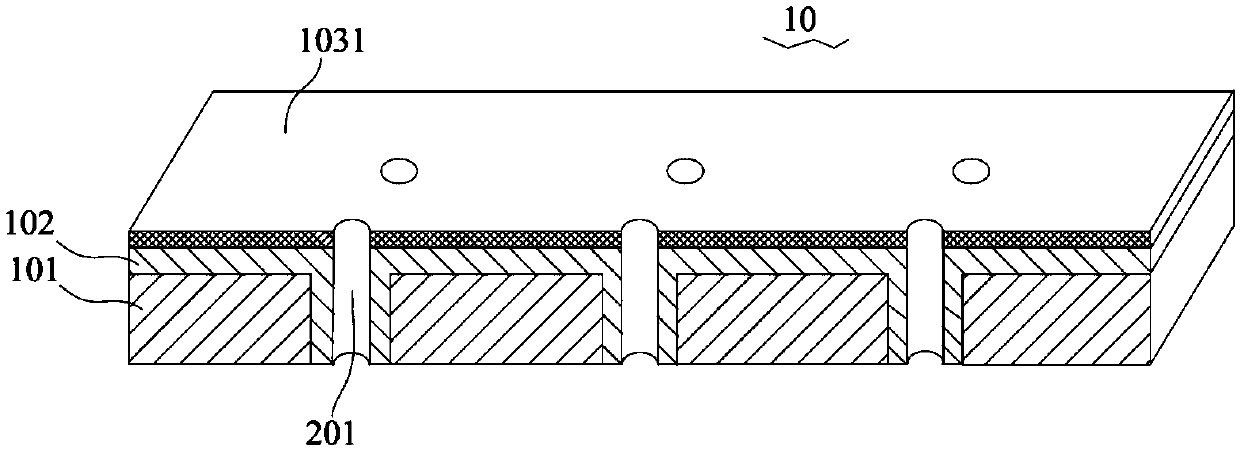

Current collector, pole sheet and electrochemical device

ActiveCN110661000AHigh mechanical strengthImprove securityElectrode carriers/collectorsSecondary cellsElectrolytic agentElectrical resistance and conductance

The application belongs to the field of batteries and relates to a current collector. The current collector includes an insulating layer and a conducting layer, wherein the conductive layer is positioned on at least one surface of the insulating layer; the current collector further comprises a first protective layer arranged on a surface, far away from the insulating layer, of the conducting layer; a plurality of holes penetrating through the insulating layer, the conducting layer and the first protective layer are formed in the current collector; and the first protective layer is a metal oxide protective layer. According to the current collector provided by the invention, short-circuit resistance during a short circuit under the abnormal condition of a battery can be improved, so that heat generated the short circuit can be greatly reduced, and therefore, the safety performance of the battery is improved; the mechanical strength of the conductive layer can be improved through the protective layer; the working stability of the current collector is improved; the service life of the current collector is prolonged; the plurality of holes penetrating through the insulating layer and the conductive layer can facilitate the passage of electrolyte, and therefore, the wettability of the electrolyte can be improved, and the electrochemical performance of the battery and the weight energy density of the battery can be improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com