Lithium ion secondary battery containing ion liquid electrolyte

A secondary battery and ionic liquid technology, applied in the field of lithium-ion secondary batteries, can solve problems such as the inability to fundamentally eliminate safety hazards, the inability to reflect the advantages of ionic liquids, and the limited effect of electrolyte performance, so as to improve high-current performance and increase High current and high rate charge and discharge performance, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

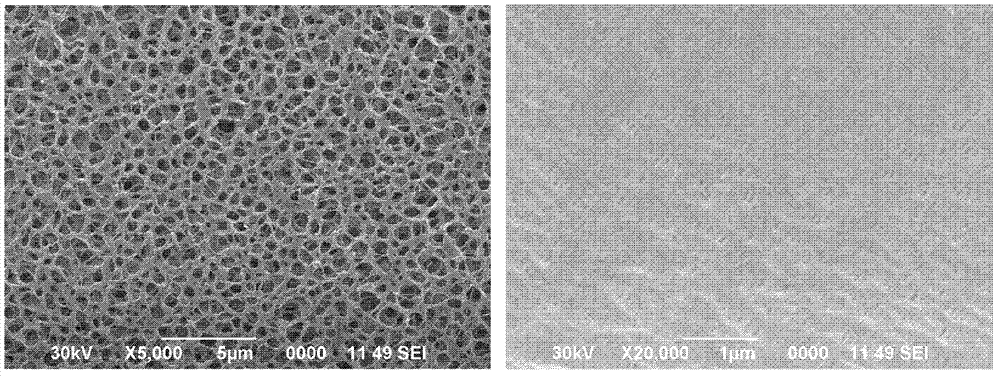

[0040] Example 1 Comparison of the wettability and liquid absorption of the polar porous diaphragm and the non-polar diaphragm to the ionic liquid electrolyte

[0041] Table 1 is a comparison of the physical properties of a certain polar porous separator and a PP / PE / PP three-layer separator.

[0042] Table 1

[0043]

Polar Porous Membrane MV-1

Polar Porous Membrane MV-2

PP / PE / PP diaphragm

Material

PVDF single layer

PVDF single layer

PP / PE / PP three-layer composite

thickness

22μm

25μm

20μm

internal structure

3D mesh

3D mesh

stretch hole

Air permeability*

150 seconds / 100CC

210 seconds / 100CC

400-500 seconds / 100CC

Porosity

60%

45%

43%

Aperture

0.1-1.0μm

0.1-1.0μm

0.1-0.2μm

[0044] *: Using ASTM D 737-2004 Test method for air permeability of textile fibers

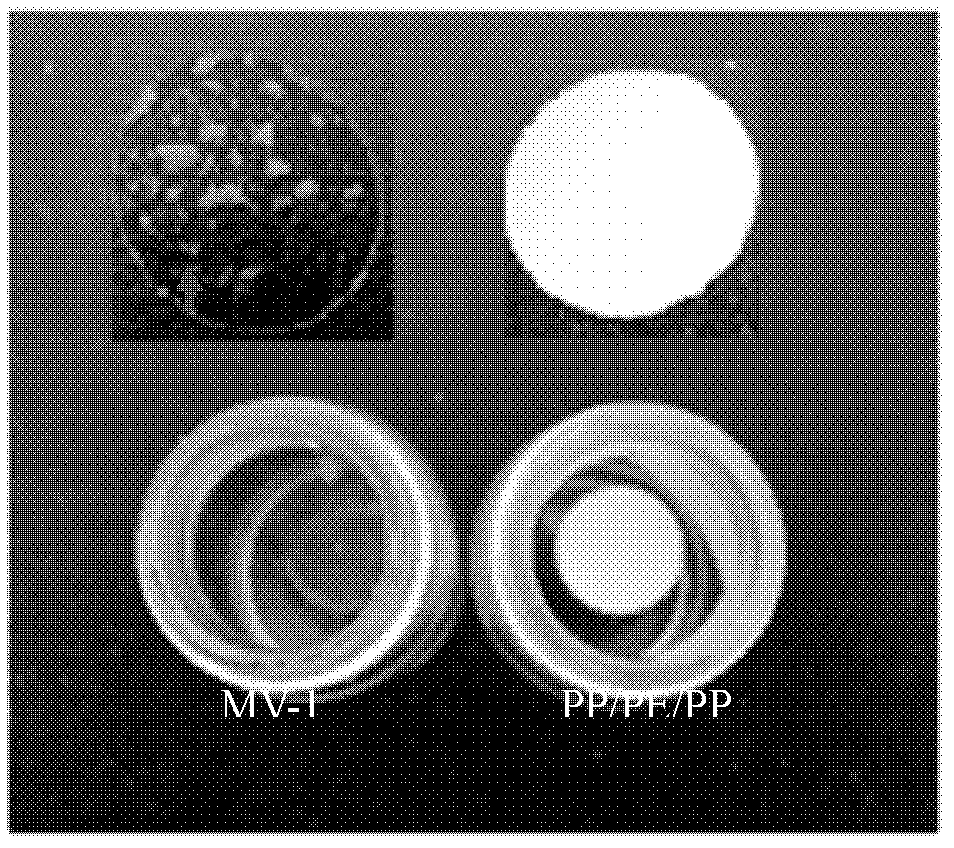

[0045] Cut the diaphragm in Table 1 with a cutter (the polar porous diaphra...

Embodiment 2

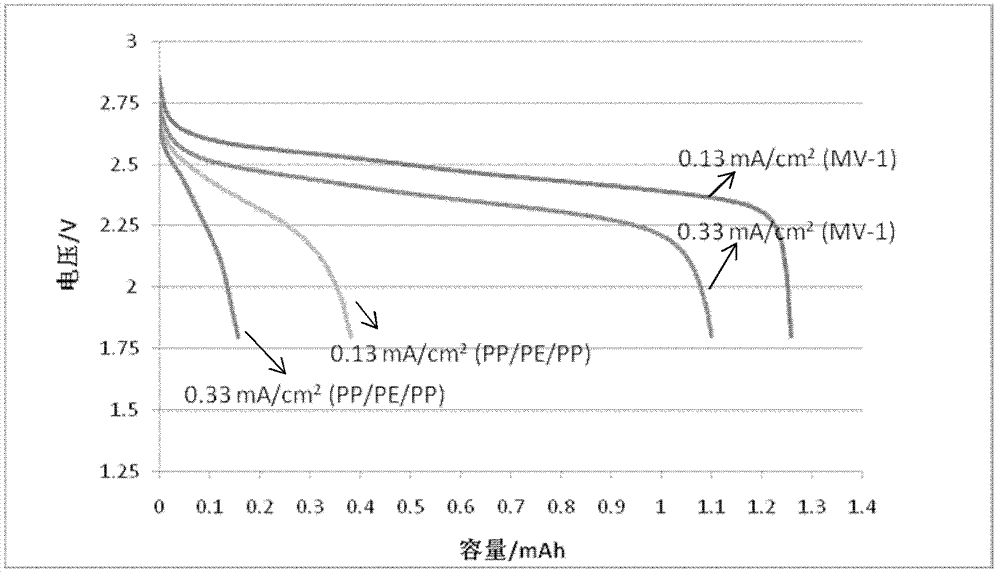

[0048] Example 2 Performance comparison of ionic liquid electrolytes combined with PP / PE / PP separators and polar porous separators applied to lithium-ion secondary batteries

[0049] The present invention does not limit the structure of the lithium-ion secondary battery, which may be cylindrical, square or button-shaped. In the embodiment of the present invention, a button-type lithium-ion secondary battery (CR2025) is used. The positive electrode material of the lithium-ion secondary battery is nickel-cobalt lithium manganate ternary material, and the negative electrode material is lithium titanate.

[0050] Take the active electrode material, conductive agent (conductive carbon black), and binder (PVDF) and mix uniformly according to a certain mass ratio, add solvent N-methylpyrrolidone, further mix uniformly, and prepare a slurry with a solid content of 60%. It is then coated on an Al foil current collector, rolled after drying, and punched into circular pole pieces (Φ=1.4c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com