A kind of preparation method of the lithium-ion battery of conductive polymer coating positive electrode

A conductive polymer, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation methods, poor performance, and difficulty in industrialization, and achieve a simple manufacturing process and high-rate charge and discharge. The effect of improved performance and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

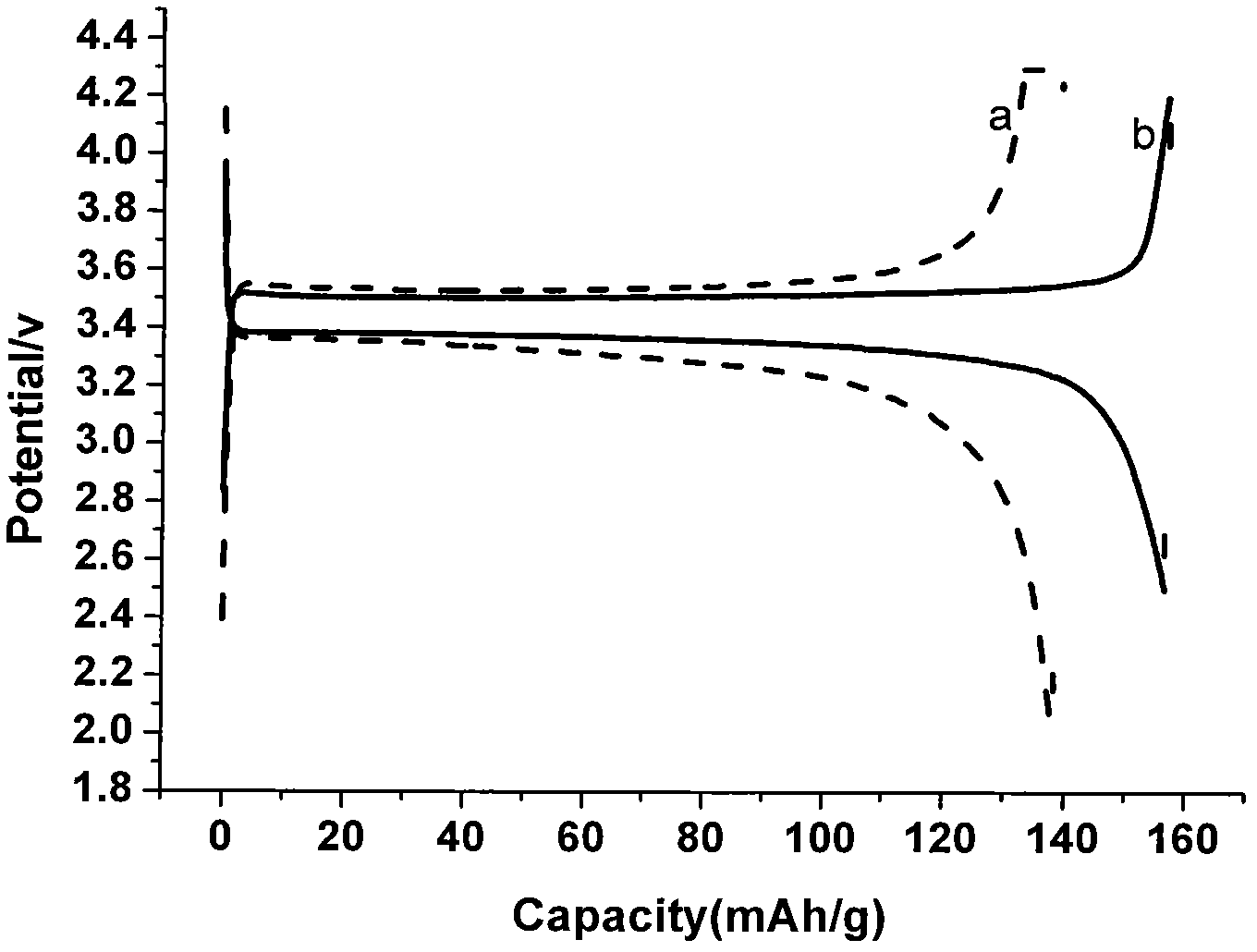

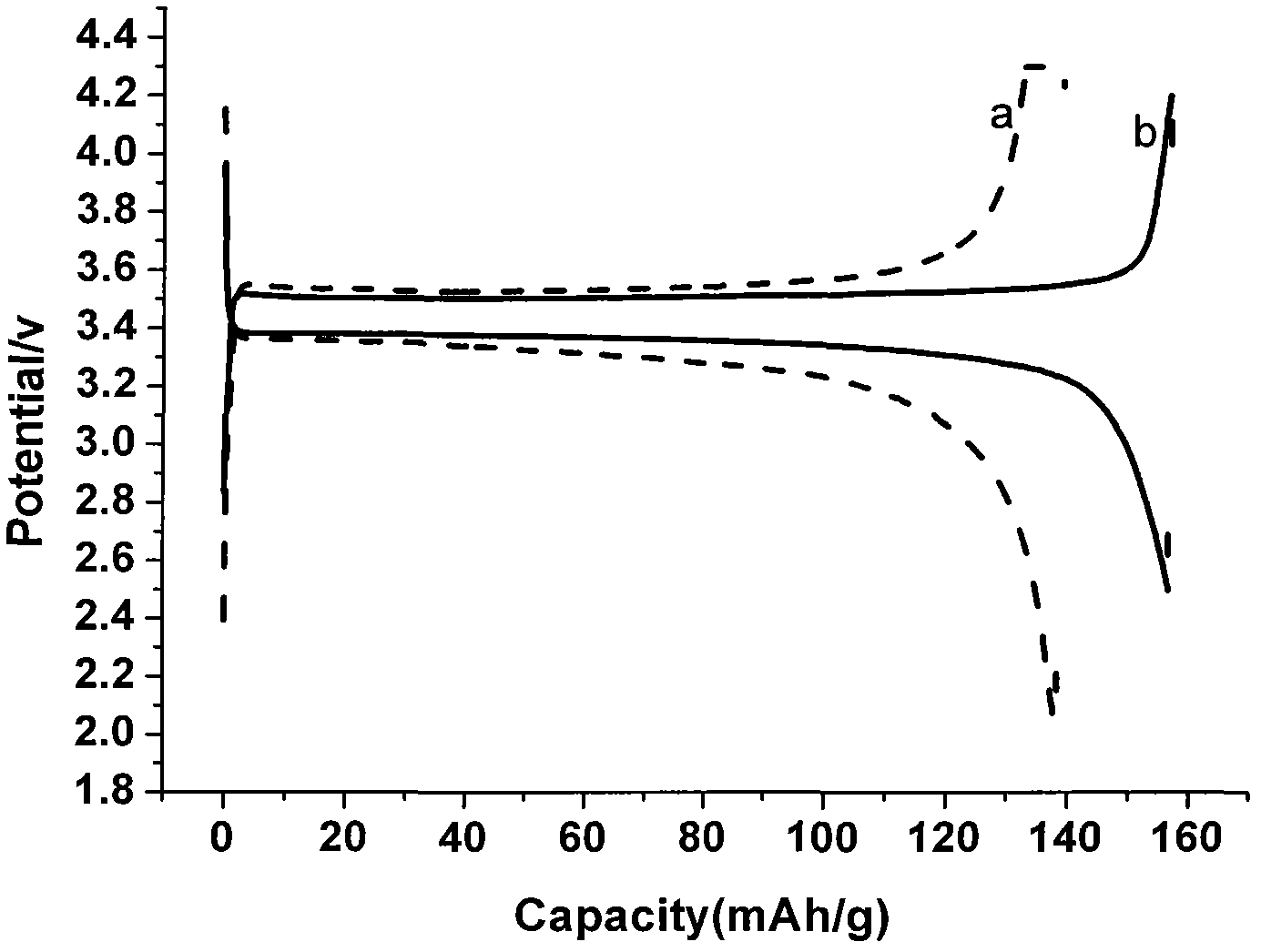

Embodiment 1

[0020] Lithium iron phosphate 77.5%, conductive agent acetylene black 4.5%, positive electrode binder polyvinylidene fluoride 7.5%, aniline or polyaniline 10.5%, mixed grinding, drying, and then adding solvent N-methylpyrrolidone 100% for stirring, Prepare positive electrode slurry. The slurry was coated on both sides of the aluminum foil, dried at 110° C., and rolled to obtain a positive electrode sheet. 93% of graphite, 3.5% of sodium carboxymethylcellulose, 3.5% of negative electrode binder LA132, and 80% of deionized water are used to make negative electrode slurry, and the negative electrode slurry is evenly coated on both sides of copper foil. After drying at 110°C, it was rolled to obtain a negative electrode sheet. Separate the above-mentioned positive electrode sheet and negative electrode sheet with a PP composite film, inject electrolyte, and the electrolyte is LiPF 6 -Dimethyl carbonate, propylene carbonate, its mass ratio is 1: 1, obtain battery after sealing, b...

Embodiment 2

[0022] Lithium vanadate 70%, conductive agent acetylene black 8%, positive electrode binder polytetrafluoroethylene 6.5%, pyrrole or polypyrrole 15.5%, mixed and ground, dried, then added, and then added solvent dimethylamide 120% to carry out Stir to make positive electrode slurry. The slurry was coated on both sides of the aluminum foil, dried at 110° C., and rolled to obtain a positive electrode sheet. Graphite 88%, sodium carboxymethyl cellulose 5.5%, negative electrode binder SBR 6.5%, deionized water 100%, make negative electrode slurry, and negative electrode slurry is evenly coated on both sides of copper foil. After drying at 110°C, it was rolled to obtain a negative electrode sheet. Separate the above-mentioned positive electrode sheet and negative electrode sheet with a PP composite film, inject electrolyte, and the electrolyte is LiPF 6-Dimethyl carbonate, propylene carbonate, its mass ratio is 1: 1, obtain battery after sealing, battery first discharge specific ...

Embodiment 3

[0024] Lithium cobaltate 73.5%, conductive agent acetylene black 6.5%, positive electrode binder polytetrafluoroethylene 6.5%, thiophene or polythiophene 14.5%, mixed and ground, dried, then added, and then added solvent dimethylamide 135% Stir to make positive electrode slurry. The slurry was coated on both sides of the aluminum foil, dried at 110°C, and rolled to obtain a positive electrode sheet. Graphite 86%, sodium carboxymethyl cellulose 6.5%, negative electrode binder SBR 7.5%, deionized water 110%, make negative electrode slurry, and negative electrode slurry is evenly coated on both sides of copper foil. After drying at 110°C, it was rolled to obtain a negative electrode sheet. Separate the above-mentioned positive electrode sheet and negative electrode sheet with a PP composite film, inject electrolyte, and the electrolyte is LiPF 6 -Dimethyl carbonate, propylene carbonate, its mass ratio is 1: 1, obtain battery after sealing, battery first discharge specific capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com