Patents

Literature

5414 results about "Lithium iron phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium iron phosphate (LFP) is an inorganic compound with the formula LiFePO₄. It is a gray, red-grey, brown or black solid that is insoluble in water. The material has attracted attention as a component of lithium iron phosphate batteries, a type of Li-ion battery. This battery chemistry is targeted for use in power tools, electric vehicles, and solar energy installations. It is also used in OLPC XO education laptops.

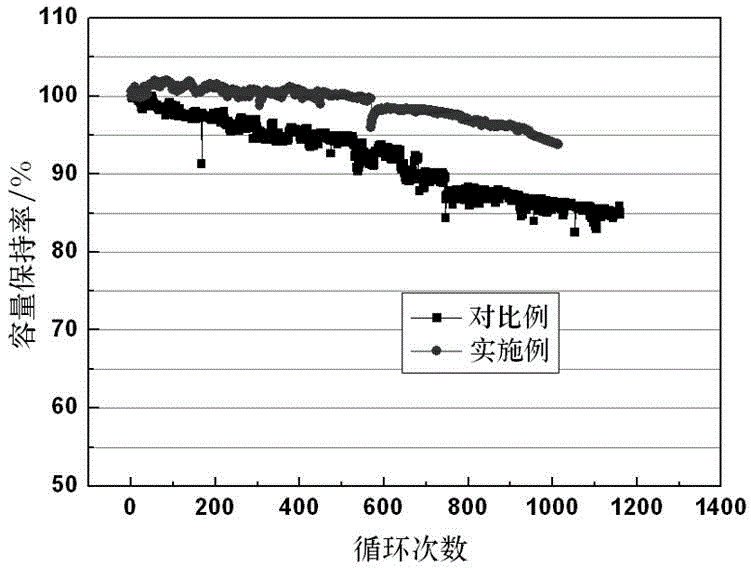

Graphite alkene iron lithium phosphate positive active material, preparing method thereof, and lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material

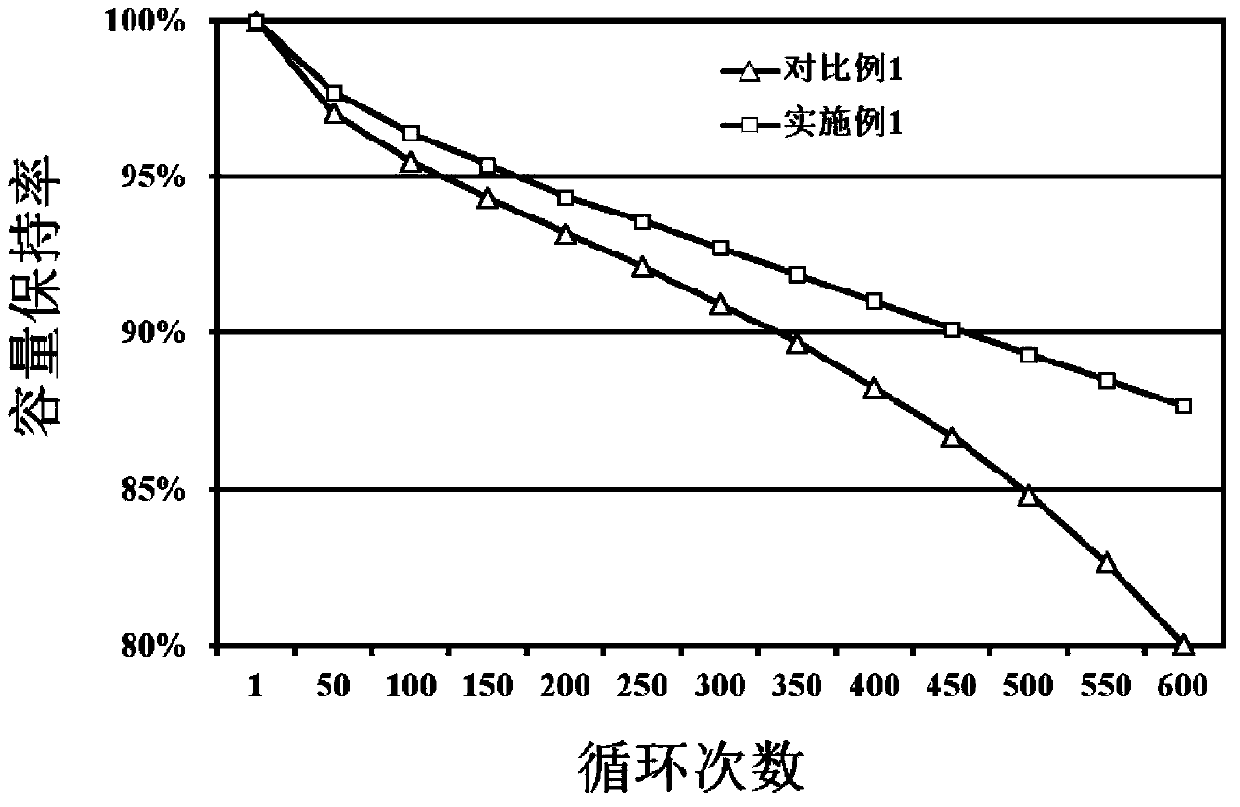

InactiveCN101752561AImprove conductivityImprove cycle stabilityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

The present invention relates to graphite alkene iron lithium phosphate positive active material, a preparing method thereof, and a lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material. Graphite alkene and iron lithium phosphate are dispersed into water solution to be mixed evenly by stirring and ultra audible sound, then, are dried to obtain iron lithium phosphate material compounded by the graphite alkene and the iron lithium phosphate to be annealed by high temperature, and finally, the graphite alkene modified iron lithium phosphate positive active material is obtained. Compared with traditional carbon coated and conductive polymeric adulteration modified lithium batteries, the lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material has the advantages of high battery capacity, good charging-discharging circulating performance, long life and high circulating stability, and has great utility value.

Owner:宁波艾能锂电材料科技股份有限公司

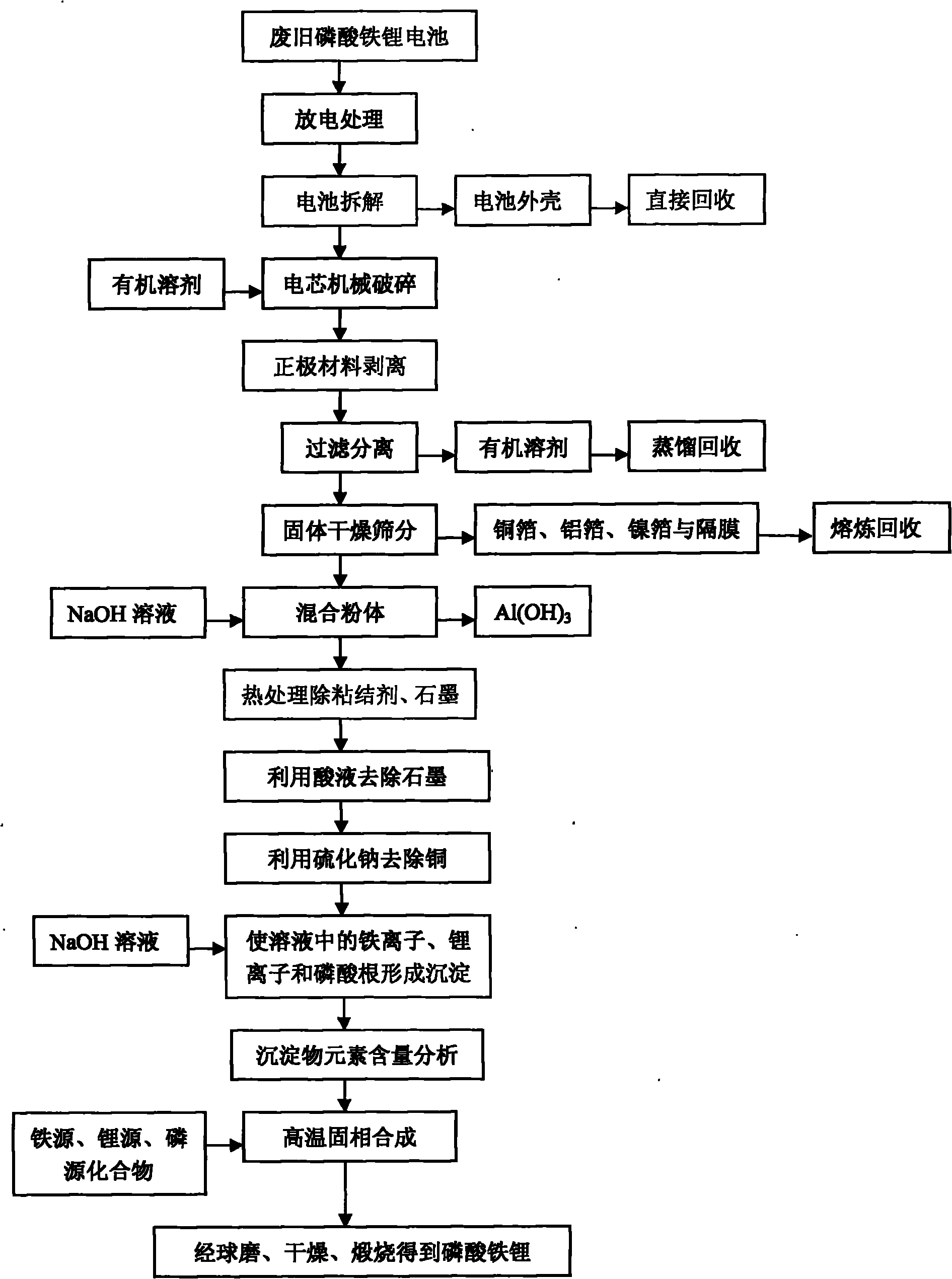

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

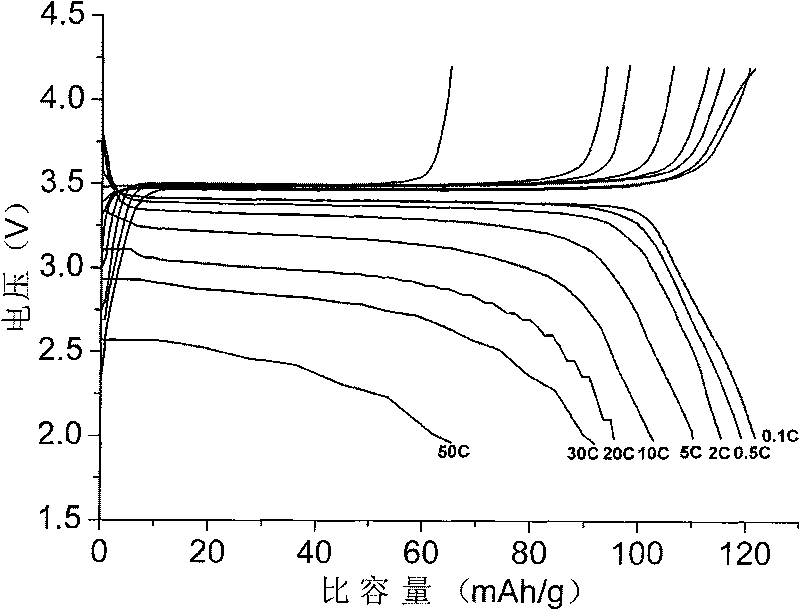

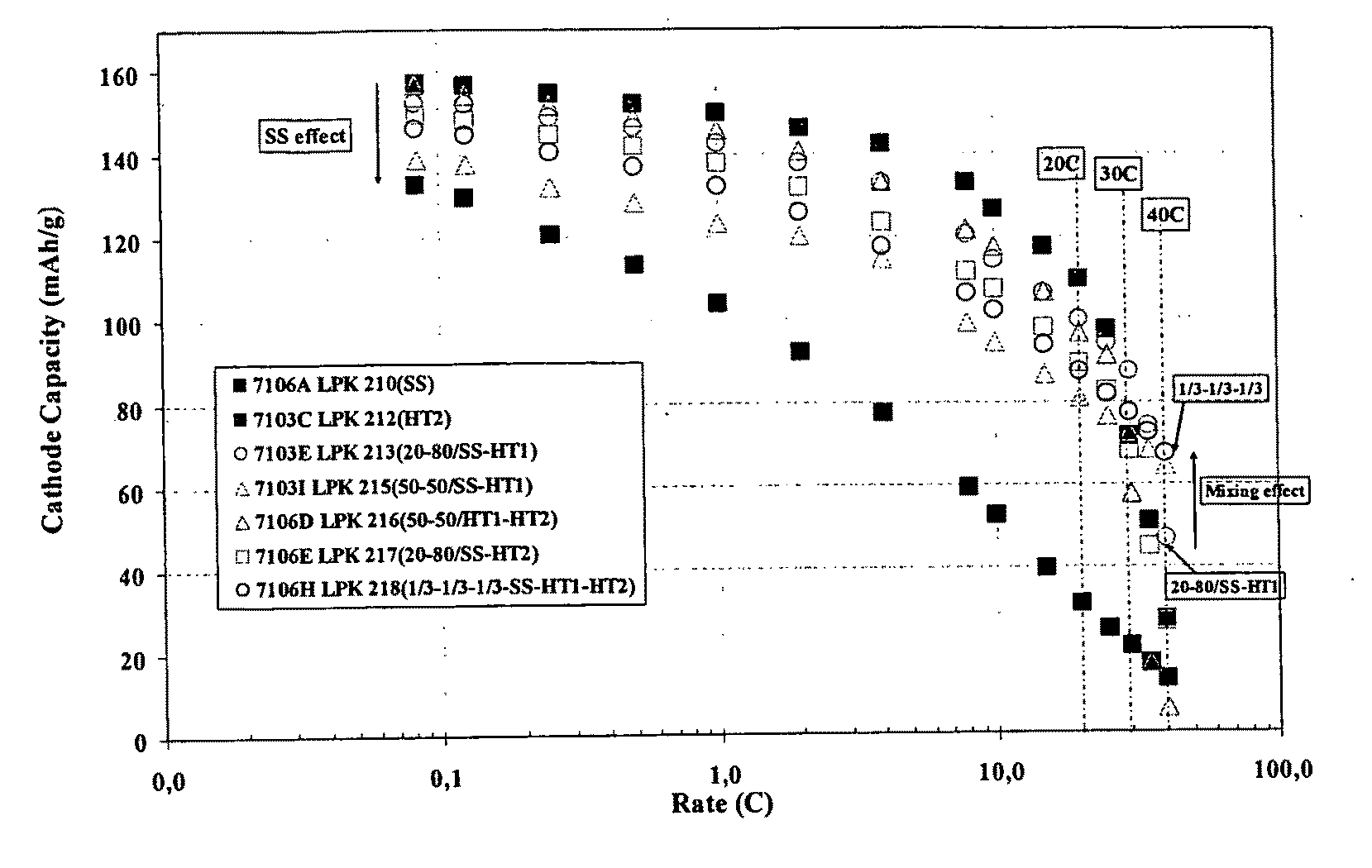

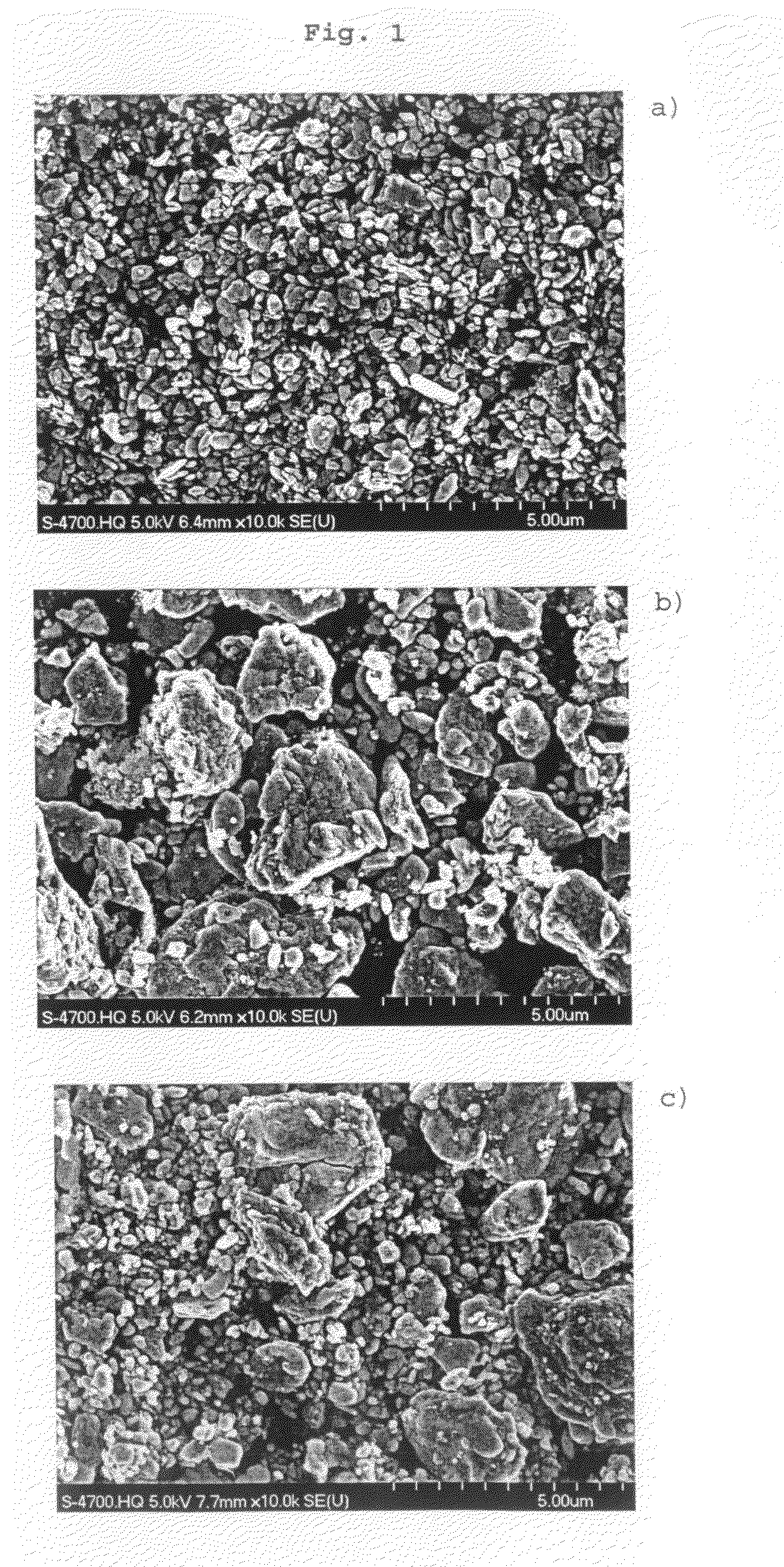

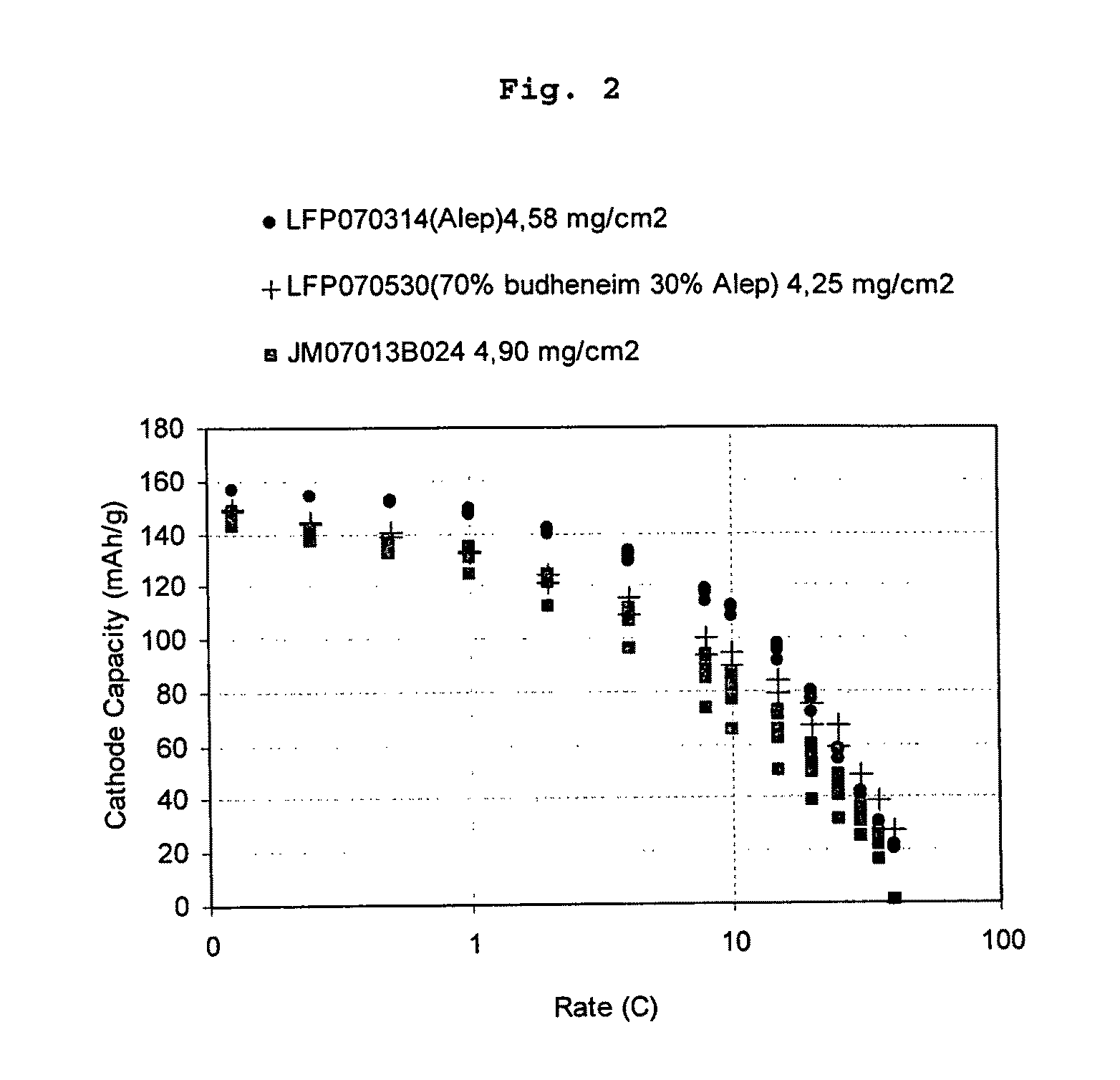

Lithium iron phosphate cathode materials with enhanced energy density and power performance

InactiveUS20090155689A1Powerful performanceHigh discharge ratePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiberPhosphate

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:PHOSTECH LITHIUM

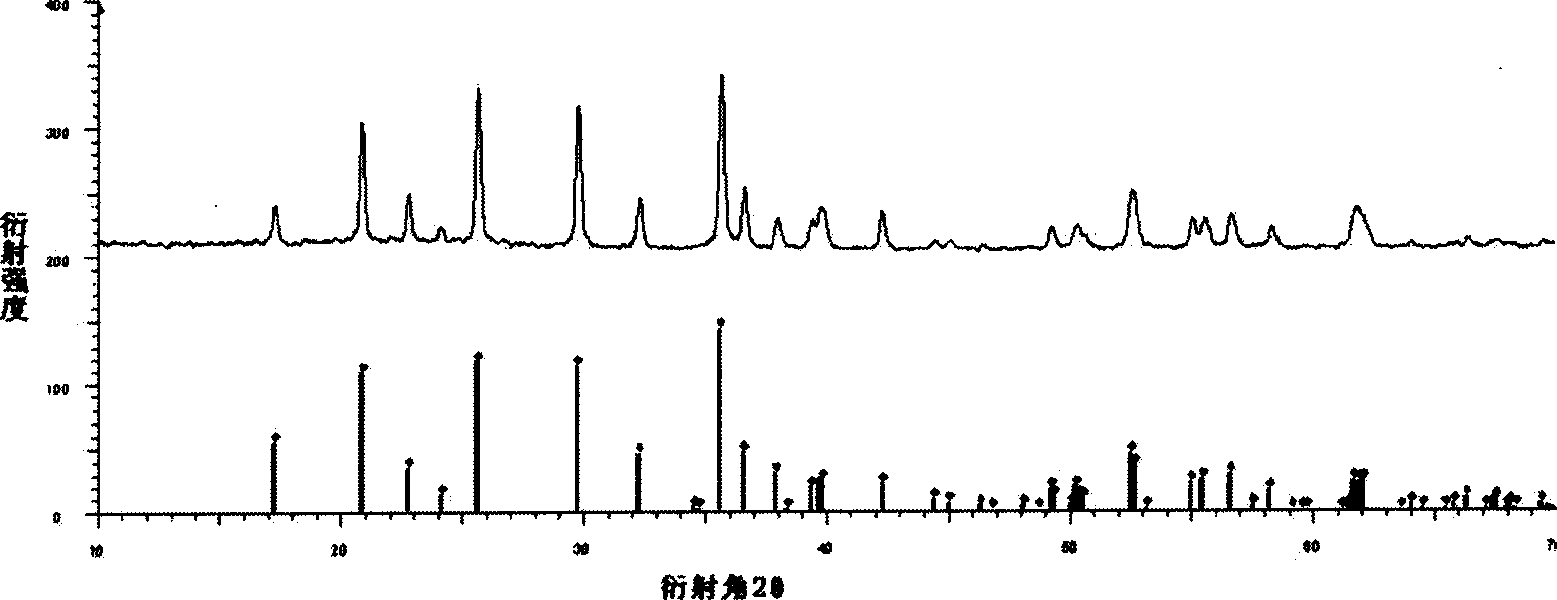

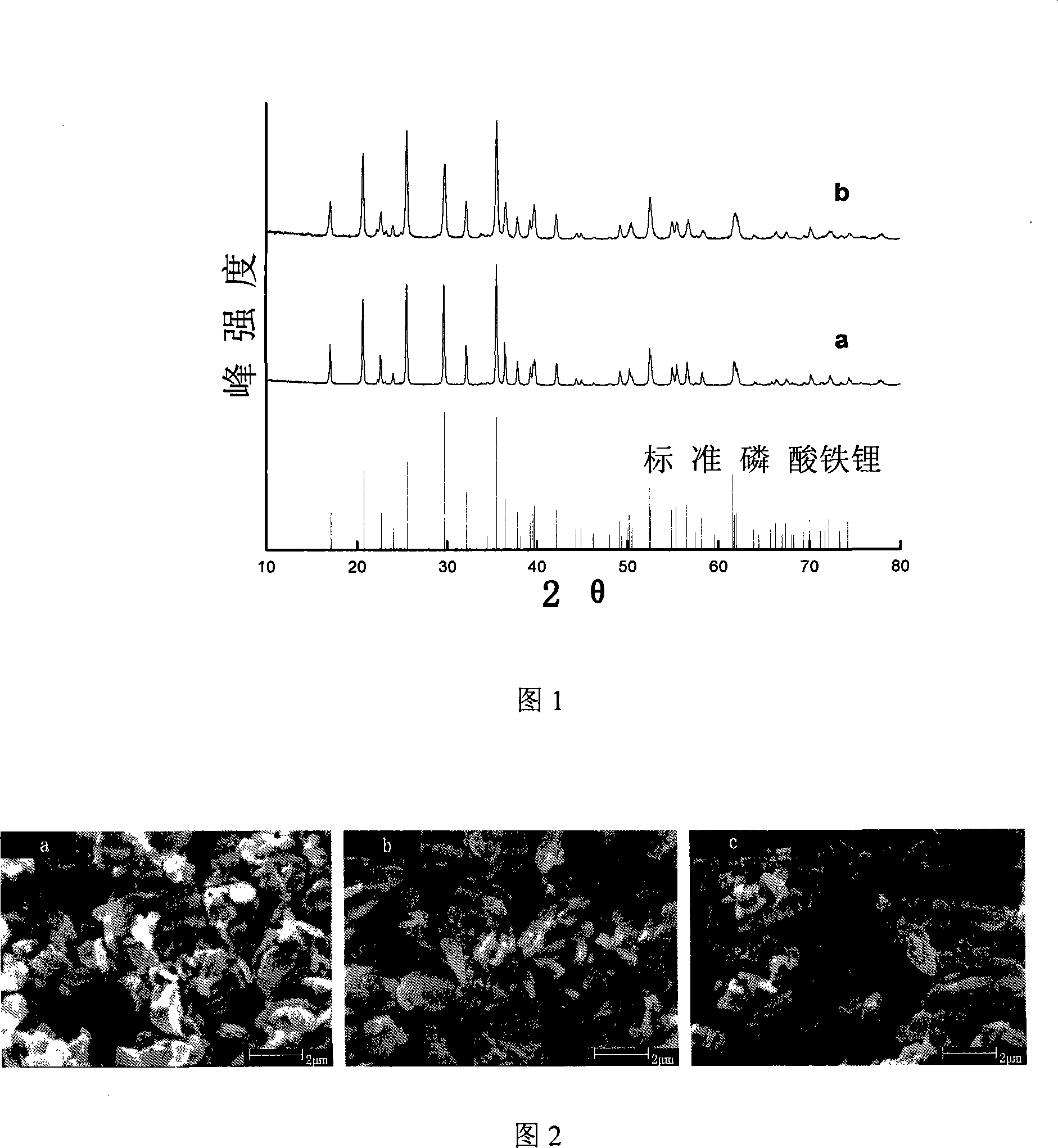

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

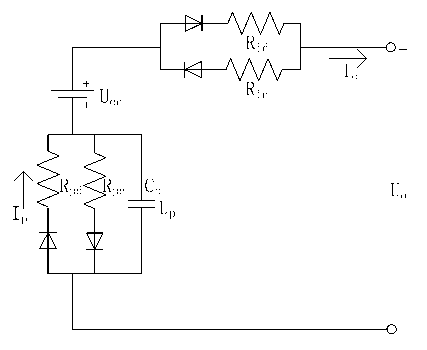

SOC (State of Charge) and SOH (State of Health) prediction method of electric vehicle-mounted lithium iron phosphate battery

InactiveCN103020445APrediction is accurateJudgment performanceSecondary cells servicing/maintenanceSpecial data processing applicationsLithium iron phosphateElectrical battery

The invention discloses an SOC (State of Charge) and SOH (State of Health) prediction method of an electric vehicle-mounted lithium iron phosphate battery, which comprises the following steps of: (a) improving a Thevenin cell equivalent model; (b) determining the state equation and the output equation of a system; (c) identifying battery model parameters; (d) using a Kalman filter algorithm to iterate the state variables of the system, so that the predictive value of SOC is closer to the actual value; and (e) using a dual-channel Kalman filter algorithm to carry out the online predication of an internal resistance and capacity of the lithium iron phosphate battery, and simultaneously predicating the SOH of the battery according to the changes in the internal resistance and the capacity value of the battery in the current state and the initial state. With the method, the predication precision of SOH of the battery is effectively improved, the decline in battery performance can be determined more accurately, and the internal resistance and capacity information of the battery is combined to provide a basis for making the battery management strategy and maintaining and replacing the battery.

Owner:SOUTHWEST JIAOTONG UNIV +1

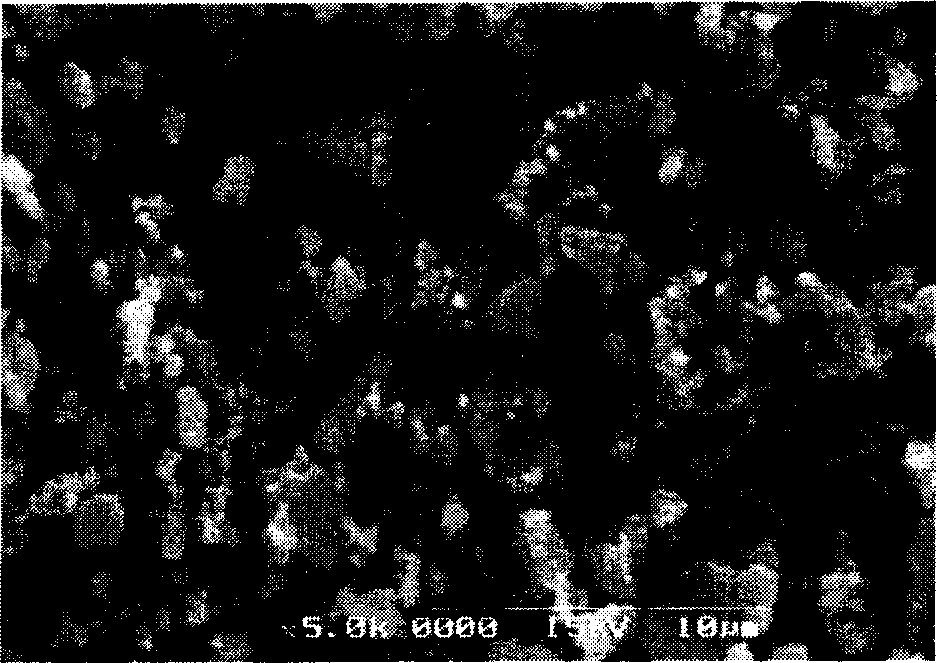

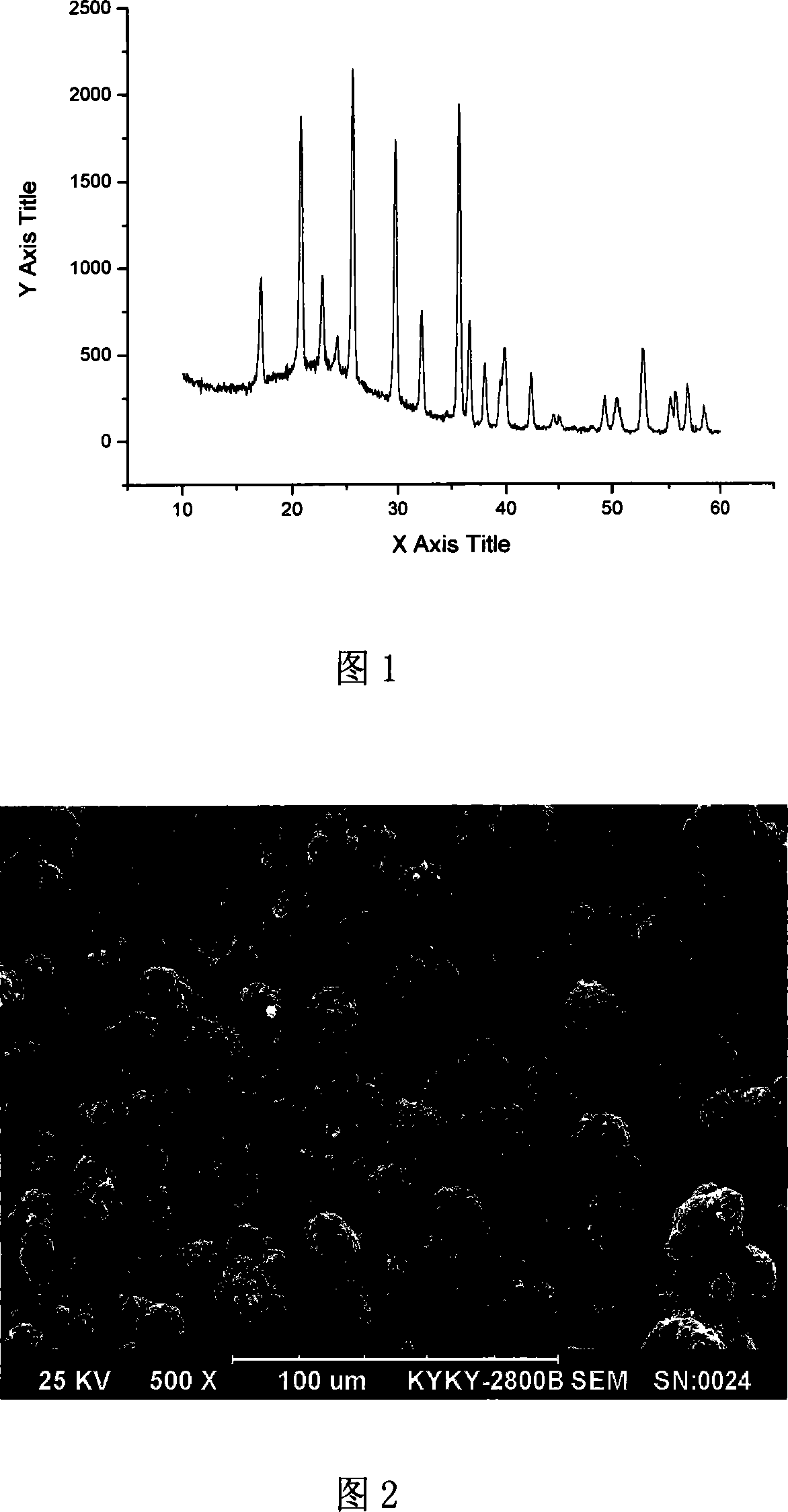

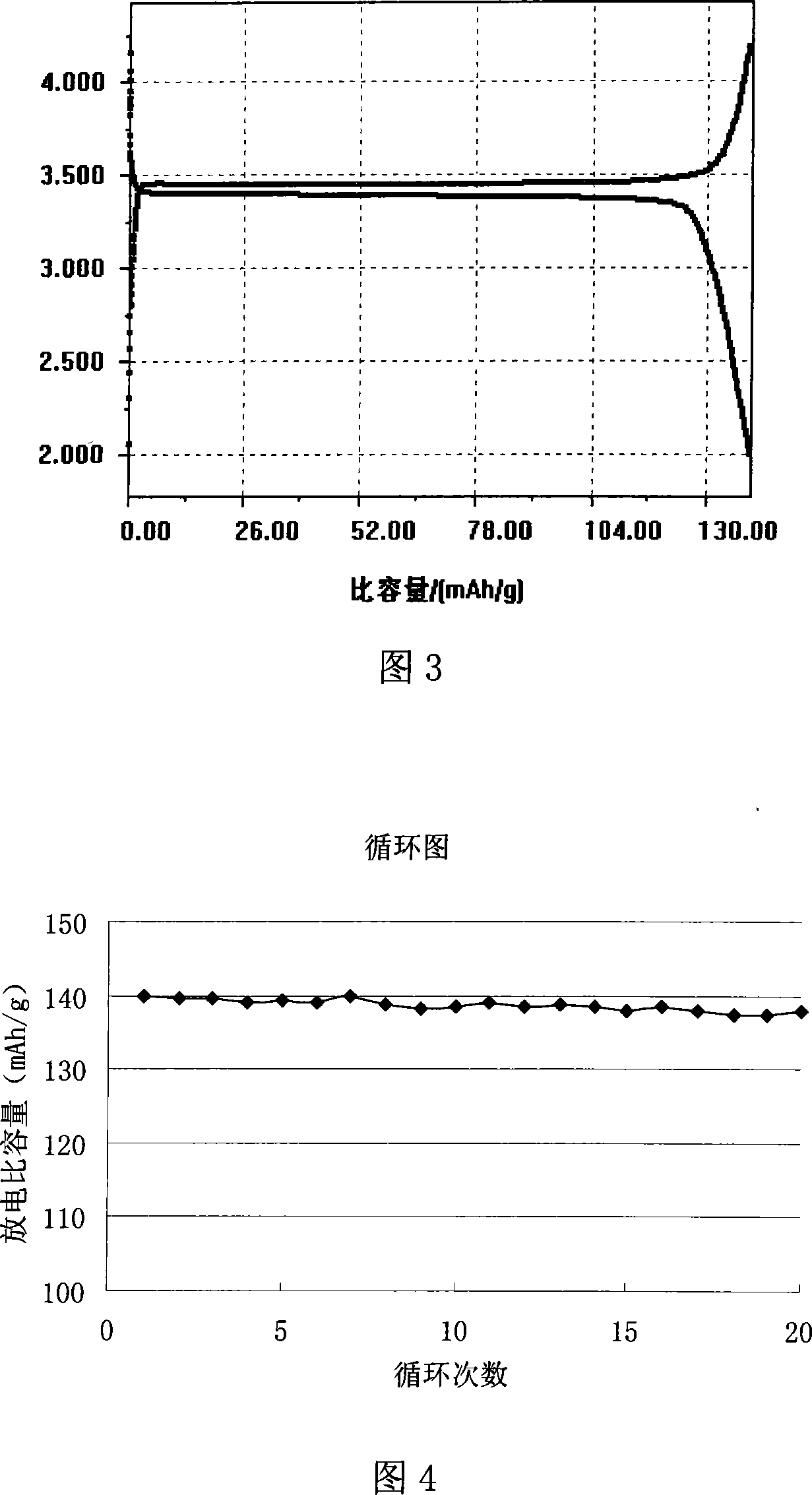

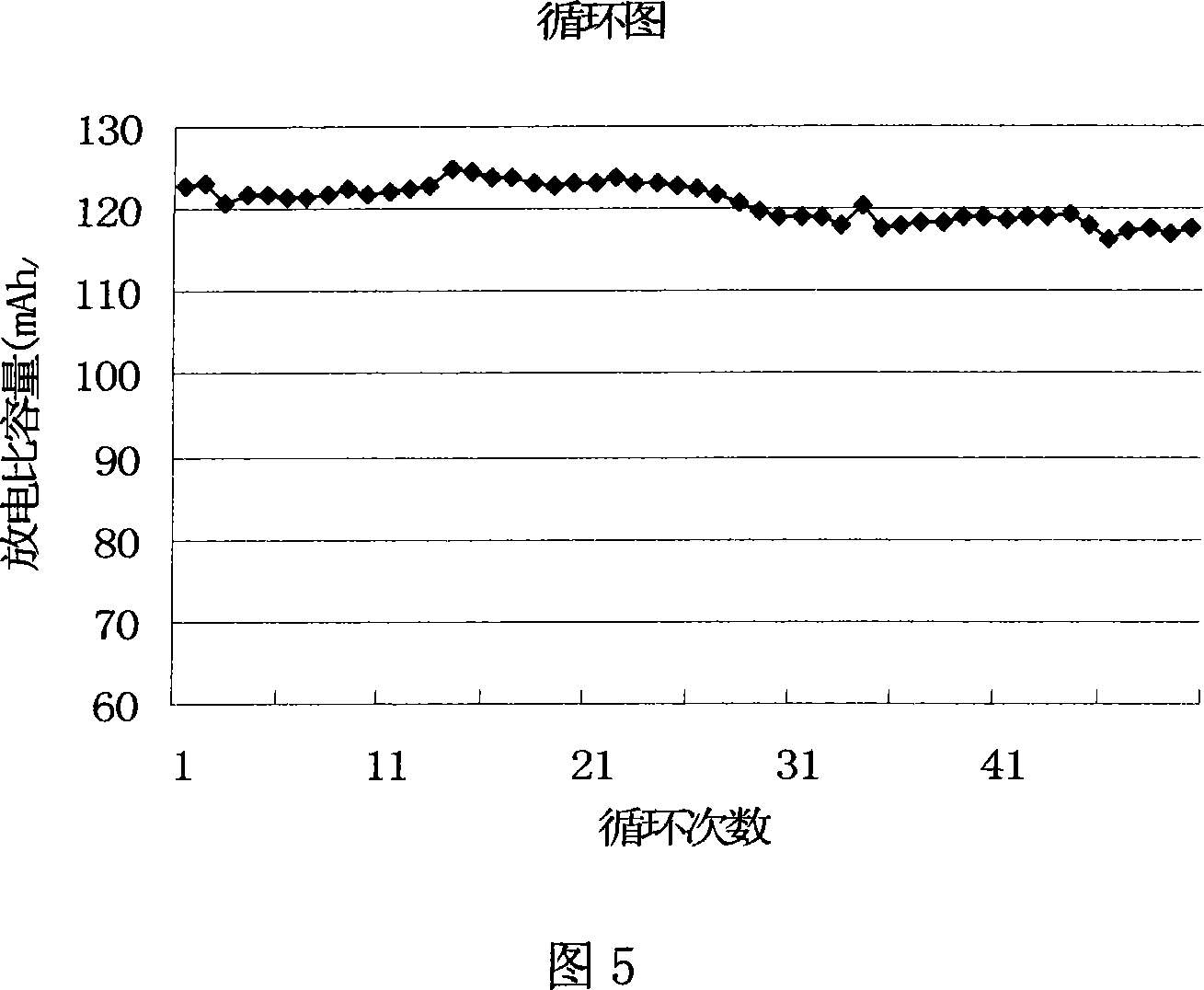

Method for preparing nanometer ferrous phosphate lithium /carbon composite material

InactiveCN101582498ARich sourcesLow priceElectrode manufacturing processesCapacitanceCarbon composites

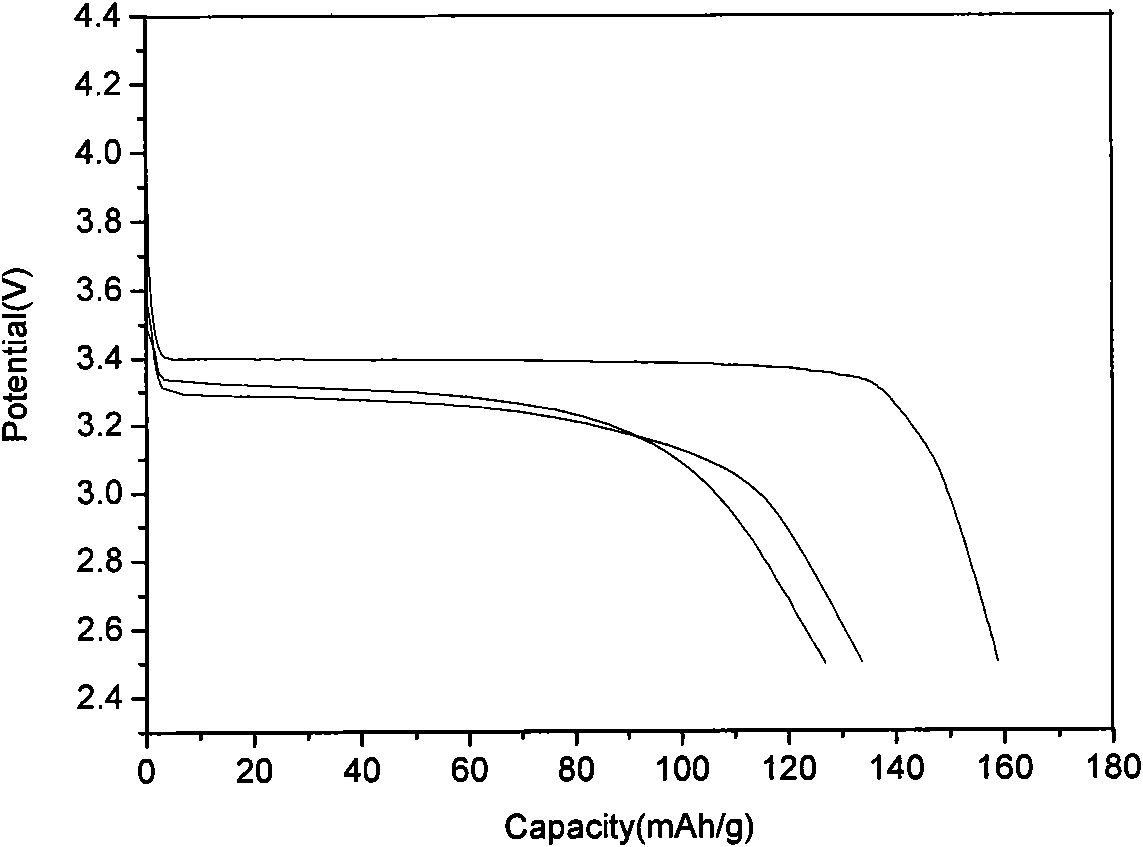

The invention belongs to energy materials, particularly relating to a method for preparing nanometer ferrous phosphate lithium / carbon composite material. In the invention, ferrous source, lithium source, phosphorus source are mixed with a small quantity of doped metal salt and organic macromolecular polymer carbon source according to certain ratio followed by the steps of ball milling, parching and calcining. High temperature sintering is carried out on the above mixture in the atmosphere of non-oxidation gas to obtain nanometer lithium iron phosphate LiMxFe(1-x)PO4 / C coated with carbon and LiFe(1-x)NxPO4 / C material, and the particle sizes of which are remarkably reduced and are less than 100nm. When the material is applied to battery assemble, 0.2C multiplying power discharge capacity can reach above 160mAh / g at room temperature, 1C multiplying power discharge capacity can be 140-155mAh / g, and 5C multiplying power discharge capacity is 130-150mAh / g. the initial capacity is 120-140mAh / g under the large multiplying power of 10C, and remains more than 90% through thousands of cycles, demonstrating good multiplying power and cycle properties. The invention features low cost, simple production process and fine safety. The prepared nanometer ferrous phosphate lithium / carbon composite material can be widely applied into manufacturing of convenient and fast equipment, electric vehicles and the like.

Owner:NORTHEAST NORMAL UNIVERSITY

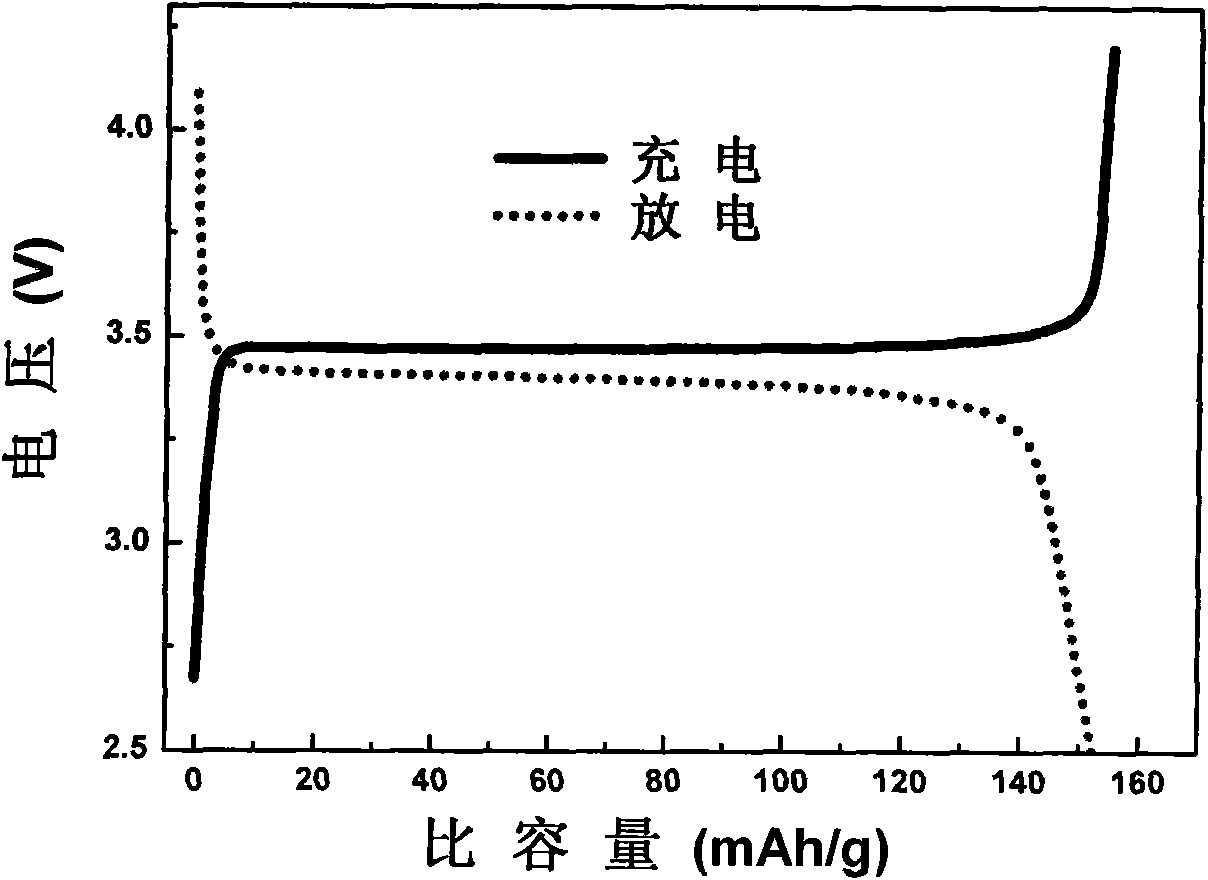

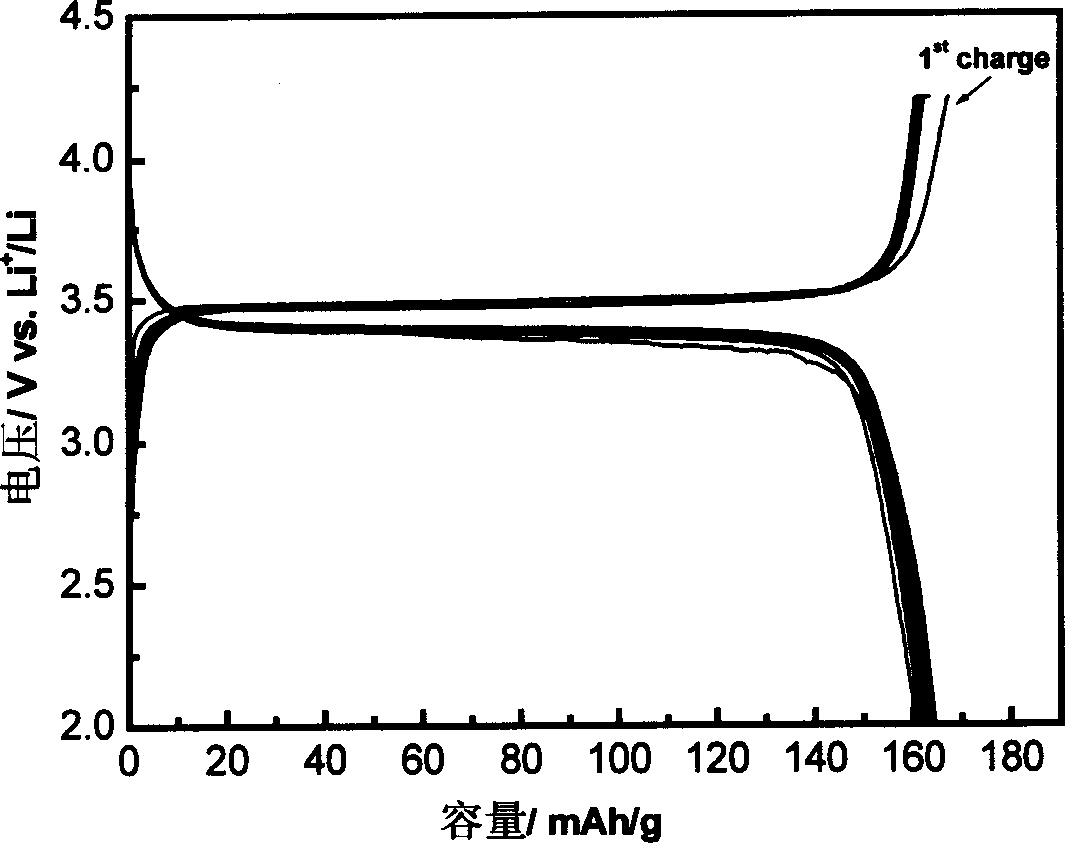

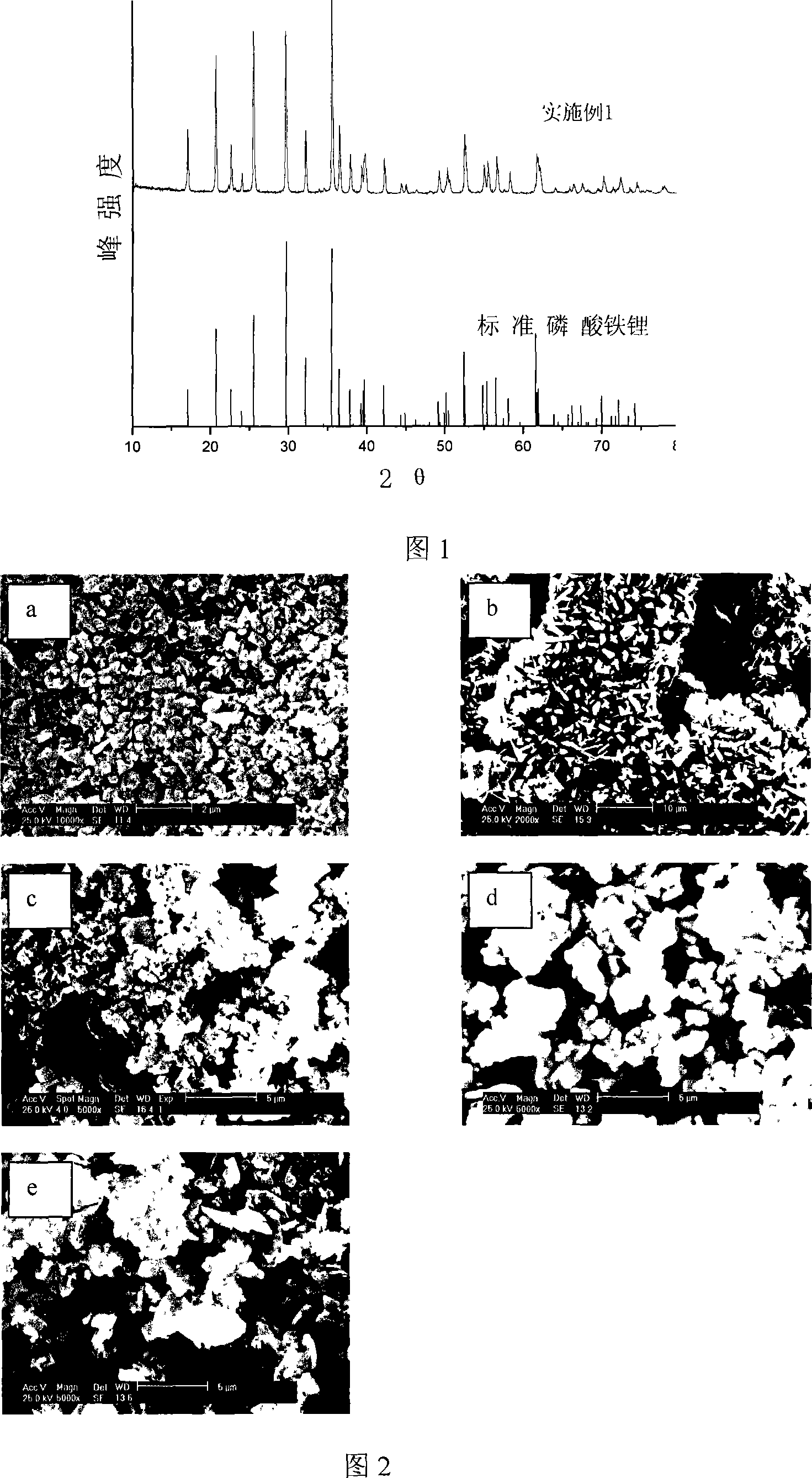

Preparation of multi-position doped lithium iron phosphate positive electrode material and application thereof

ActiveCN101339994AWide range of materialsIncrease base capacityElectrode manufacturing processesPhosphorus compoundsElectricityLithium iron phosphate

The invention discloses a preparation method of a multi-place doped lithium iron phosphate anode material and an application thereof, which belong to the technical field of the preparation of electrochemical power materials. The multi-place doped lithium iron phosphate anode material is expressed by the following formula: Li1-xAxFe1-yByP1-zCzO4Ddelta, wherein, at least two of x, y, x and delta can not be expressed zero at the same time. Multi-place doped anode material lithium iron phosphate powder which is used in a secondary lithium-ion battery and has good crystallization performance and even composition is prepared by adopting a solid phase method and a simple mixing and drying process; compared with the method doping in a certain crystal lattice place, the multi-place doped anode material lithium iron phosphate powder has wide doping material source, which can greatly improve the basic capacity and cycling electrical performance of matrix and is applied to a stable industrialized production and non-high-purity materials. The multi-place lithium iron phosphate of the invention is taken as the anode material and is usually used in the secondary lithium-ion battery and the secondary lithium-ion battery is taken as a power source.

Owner:甘肃大象能源科技有限公司

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

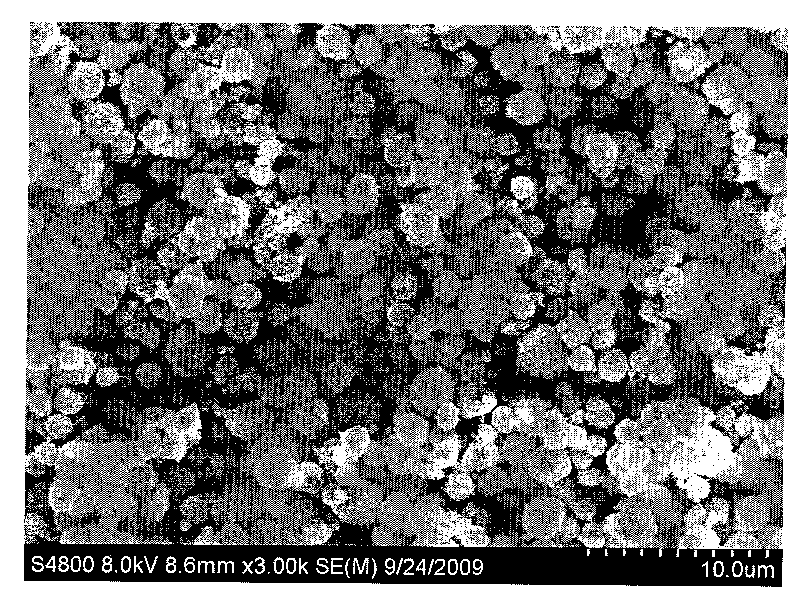

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

Method for preparing lithiumion cell positive material Iron-lithium phosphate

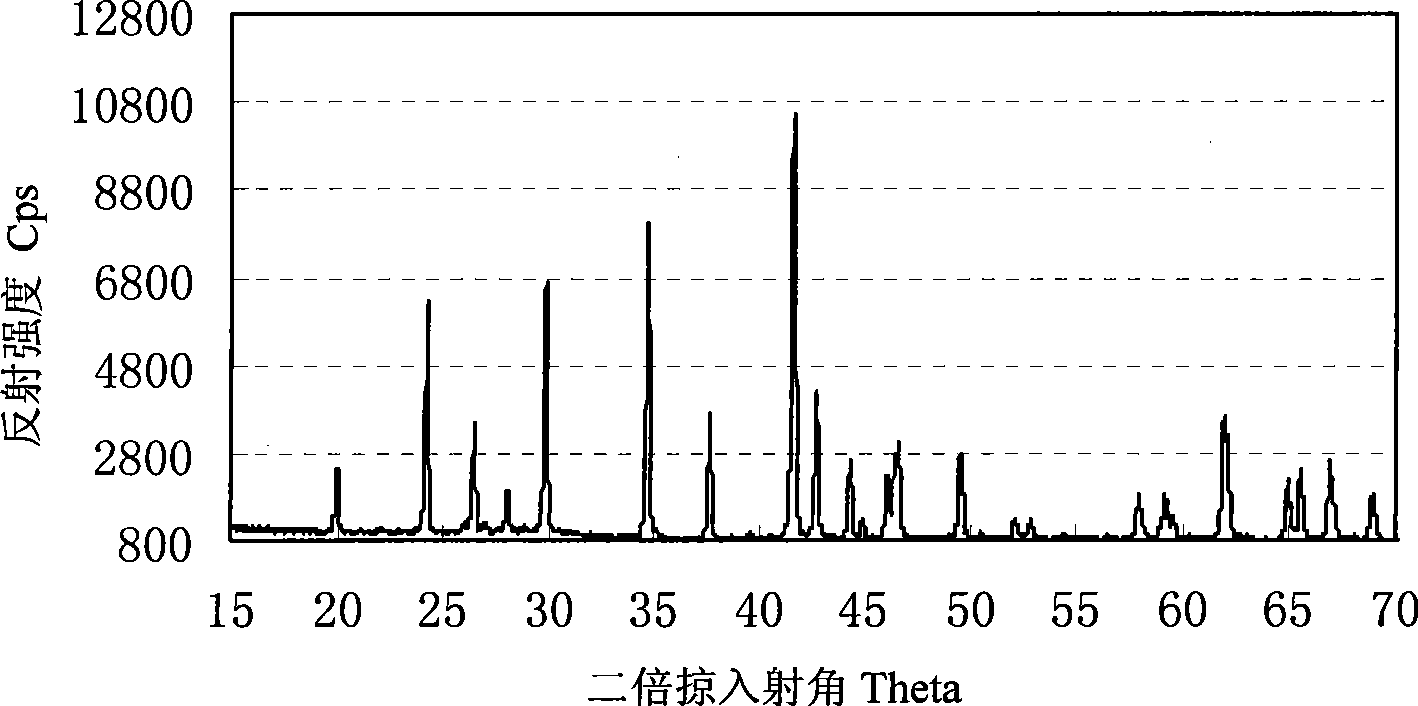

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

Wet chemistry method for preparing lithium iron phosphate

InactiveCN1431147AEasy to controlEvenly distributedElectrode thermal treatmentLi-accumulatorsChemical compositionLithium iron phosphate

A wet chemical process for preparing iron lithium phosphate includes mixing the solution or suspensions of Li source compound, Fe source compound, P source compound, doping element compound or electric conducting agent, and precipitant, reaction at 5-120 deg.C for 0.5-24 hr while stirring, filtering, washing, baking to obtain nano precursor, quickly heating to 500-800 deg.C in non-air or non-oxidizing atmosphere, calcining for 5-48 hr, and cooling. Its advantages are easy control, high uniformity and electric conductivity.

Owner:郑绵平

Recycling treatment method of waste and old lithium iron phosphate battery anode materials

InactiveCN102208706ANo pollution in the processEasy to operateSolid waste disposalWaste accumulators reclaimingLithium iron phosphateHigh energy

The invention discloses a recycling treatment method of waste and old lithium iron phosphate battery anode materials, which comprises the following steps of: firstly, scattering waste and old lithium iron phosphate batteries and stripping and collecting anode materials in the waste batteries; heating the collected anode materials at high temperature and removing carbon and an adhesion agent to obtain solid powder; adding a lithium source compound and a carbon source into the solid mixture; ball-milling the mixture through a high-energy wet method; and finally, charging the ball-milled powder into a non-oxide atmosphere and roasting at high temperature to obtain the qualified lithium iron phosphate anode materials. The recycling method disclosed by the invention has the advantages of simple process, convenience for operation and high recovery rate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

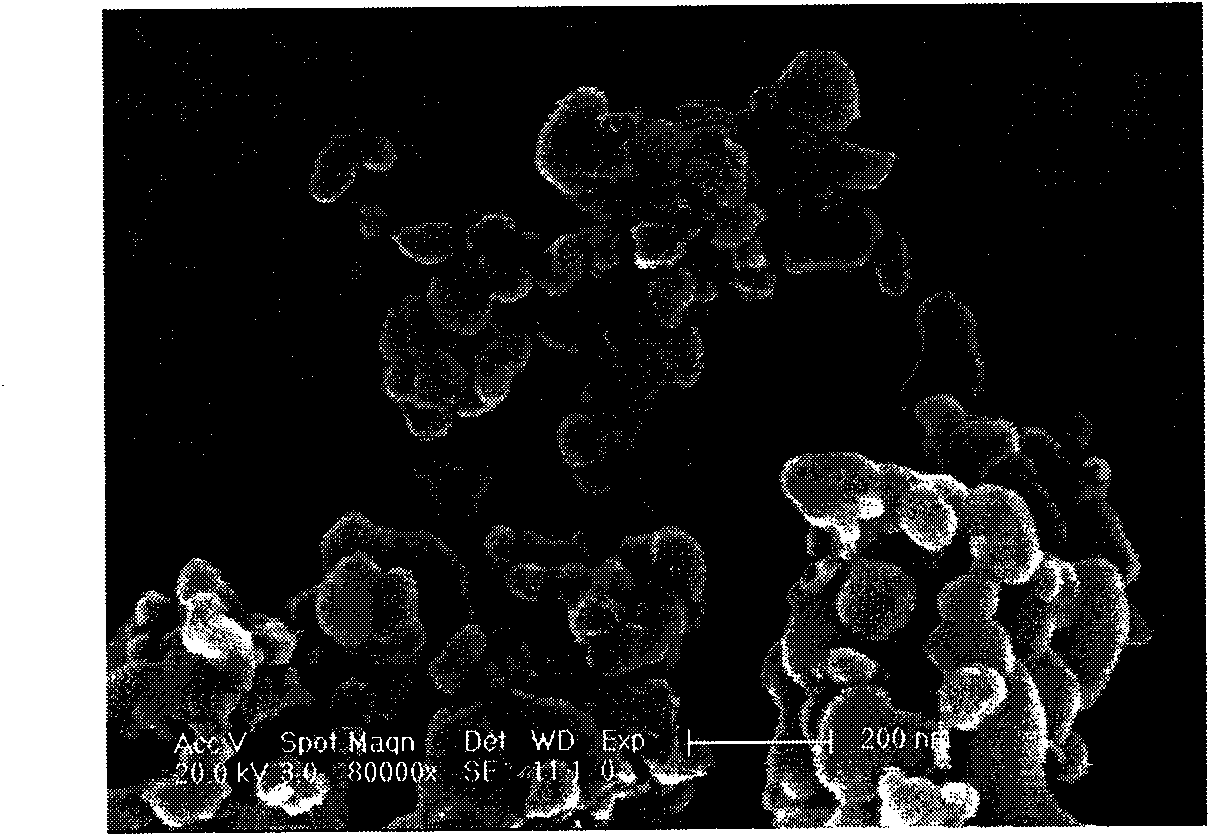

Method for preparing graphene-doped anode material for lithium-ion batteries

ActiveCN101800310AImprove conductivitySimple processing technologyCell electrodesLithium iron phosphateElectrical battery

The invention discloses a method for preparing a graphene-doped anode material for lithium-ion batteries. The main component of the anode material is lithium iron phosphate nanoparticles. The method comprises the following steps of: firstly preparing the graphene, graphene oxide, and intercalation graphene respectively; secondly, doping the mixture of the graphene, the graphene oxide and the intercalation graphene in the synthetic material of the lithium iron phosphate nanoparticles or directly mixing the lithium iron phosphate nanoparticles and the intercalation graphene, the graphene oxide,or chemically reduced graphene after the preparation of lithium iron phosphate nanoparticles; and finally, synthesizing the graphene or graphene oxide bridged or lithium iron phosphate nanoparticle-clad material after the treatment of drying, filtering, eluting, re-drying, and annealing. The lithium iron phosphate nanoparticles prepared by the method of the invention are characterized by the capability of greatly improving electron conductivity and providing the lithium-ion batteries anode material having the advantages of simple processing technique, low cost, high capacity and safety for lithium-ion batteries.

Owner:苏州格瑞丰纳米科技有限公司

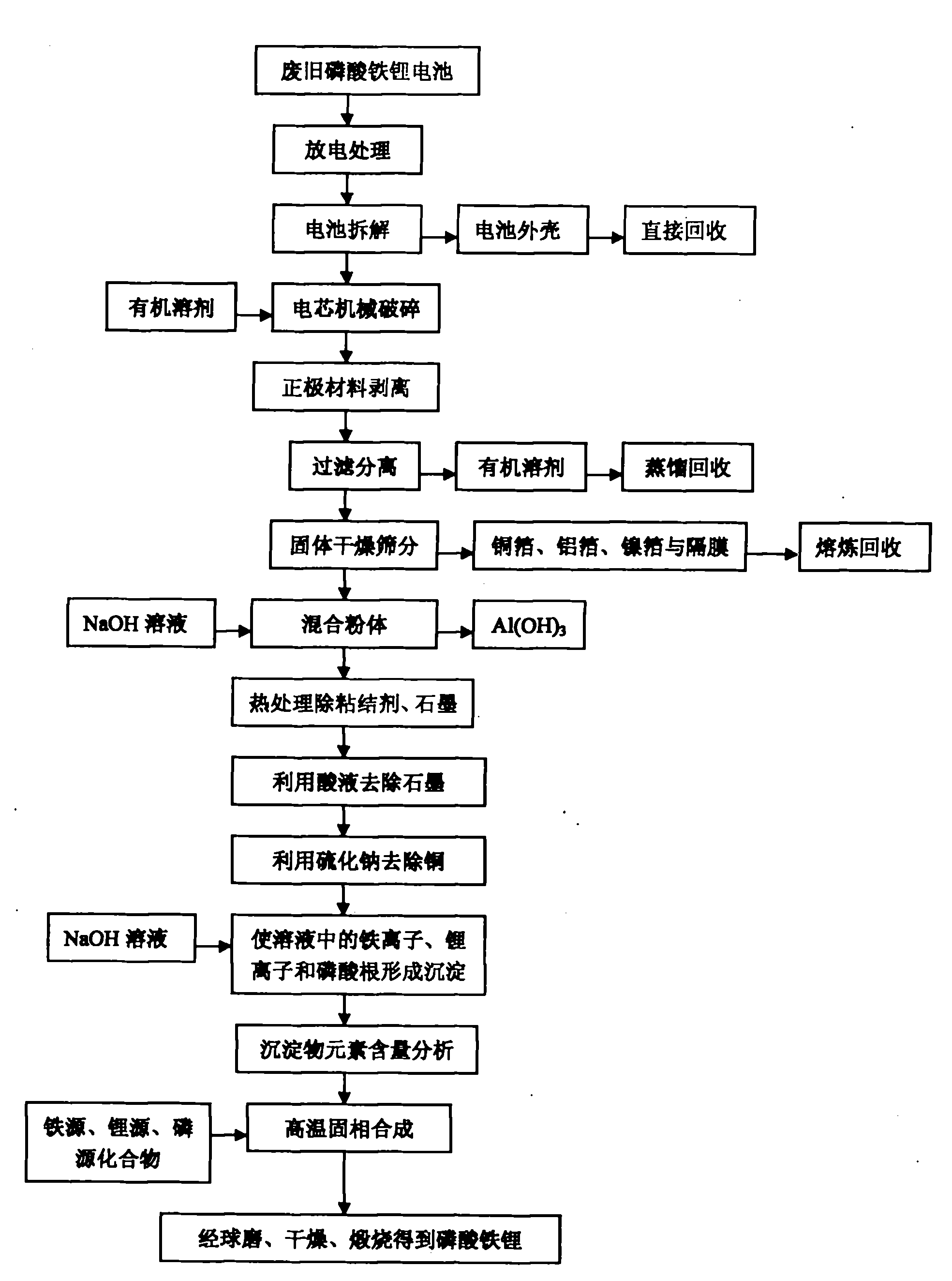

Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

ActiveCN102751548AEasy to separateImprove electrochemical performanceWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateHigh energy

The invention discloses a method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate batteries. The method comprises: 1) dismantling the recovered waste lithium iron phosphate batteries, stripping battery cases, immersing the batteries, separating the electrode plates from the powder material of positive and negative terminals through a method of alternation of ultrasonic and mechanical stirring, taking out the electrode plates and diaphragms, and obtaining mixed liquor; 2) performing a preliminary ball milling to the mixed liquor, and drying the uniformly mixed slurry obtained by the preliminary ball milling; 3) calcining the dried material in oxidizing atmosphere to obtain a recovered material, adding iron source, phosphorous source and optionally new lithium iron phosphate, then adding carbon source, high energy ball milling the obtained material, drying the material to obtain a pre-burning material of the recovered material; 4) microwave sintering or solid state sintering the pre-burning material of the recovered material in protective atmosphere to obtain the product of lithium iron phosphate. The preparation method has the advantages of environmental protection, no pollution, simpleness and practicality, high production utilization rate, simple

Owner:ZHEJIANG UNIV

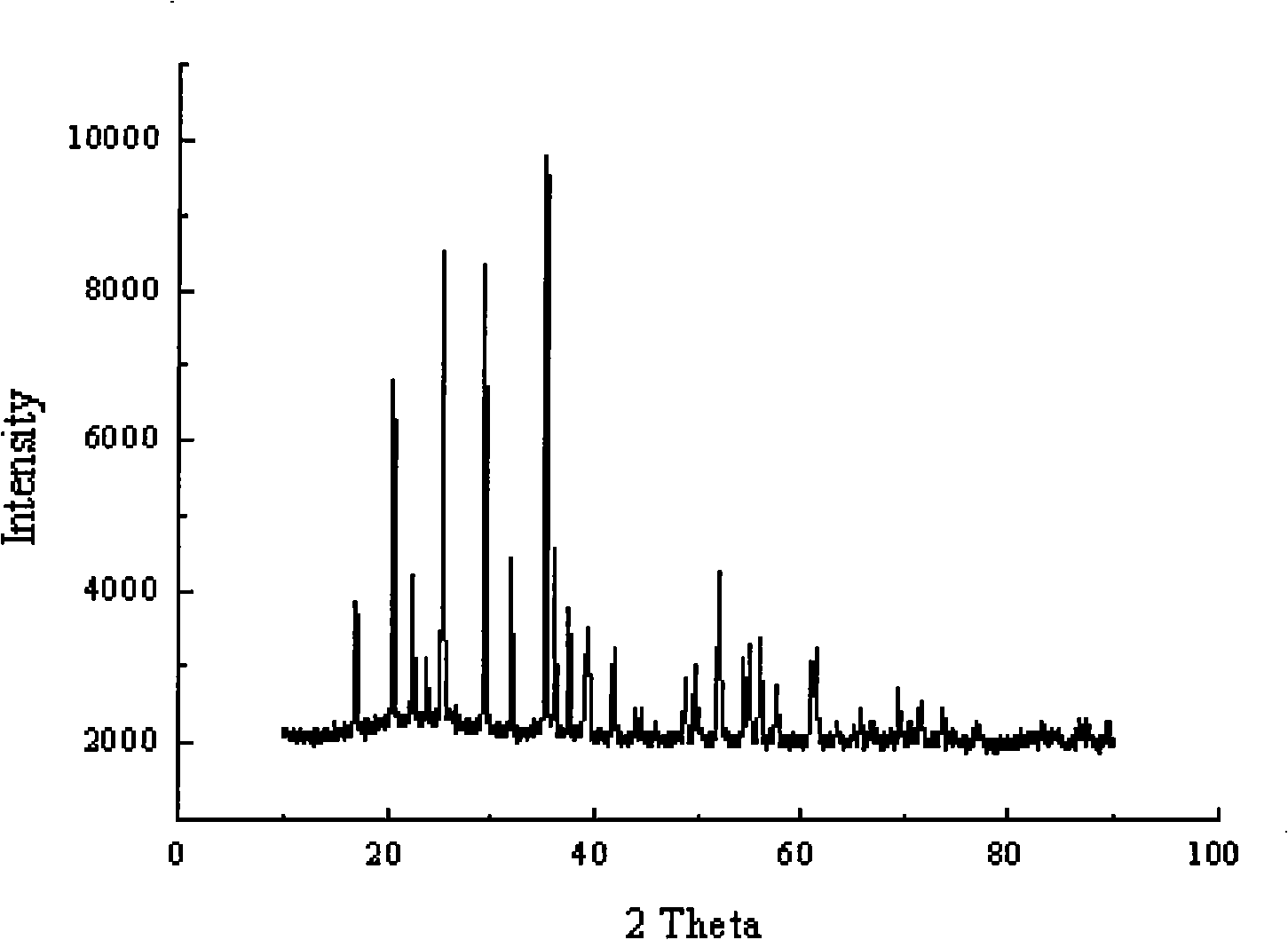

Method for preparing high-density spherical ferric lithium phosphate as anode material of lithium-ion battery

InactiveCN1635648AHigh bulk densityIncrease volume capacityElectrode manufacturing processesLithium compoundsPhosphateLithium-ion battery

This invention discloses the method for preparing high-density spherical lithium ferric phosphate used as the positive material of lithium ion cell, which contains synthesizing the ferric iron salt aqueous solution, phosphorus source aqueous solution and alkali aqueous solution to form spherical or spheroid ferric phosphate precursor, uniformly mixed with lithium source, carbon source and doped metal compound after being washed and dried, high temperature heat treating at 600-900 degree centigrade for 8-48 hr under inertia or reducing atmosphere protection to obtain lithium ferric phosphate with mean grain size of 7-12 micrometer,2.0-2.2g / cm3 of tap density, high buck density of 140-155mAh / g first discharge ratio capacity at normal temperature, and high volume ratio capacity.

Owner:TSINGHUA UNIV

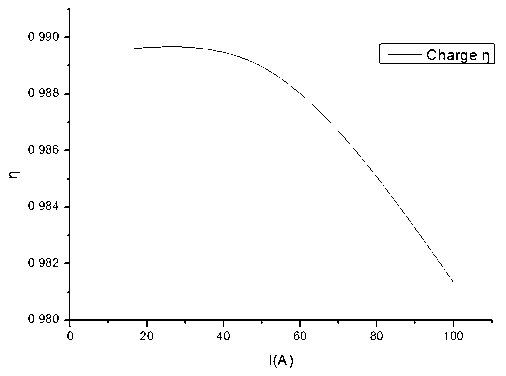

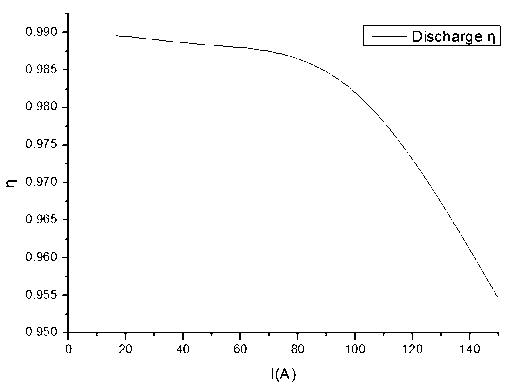

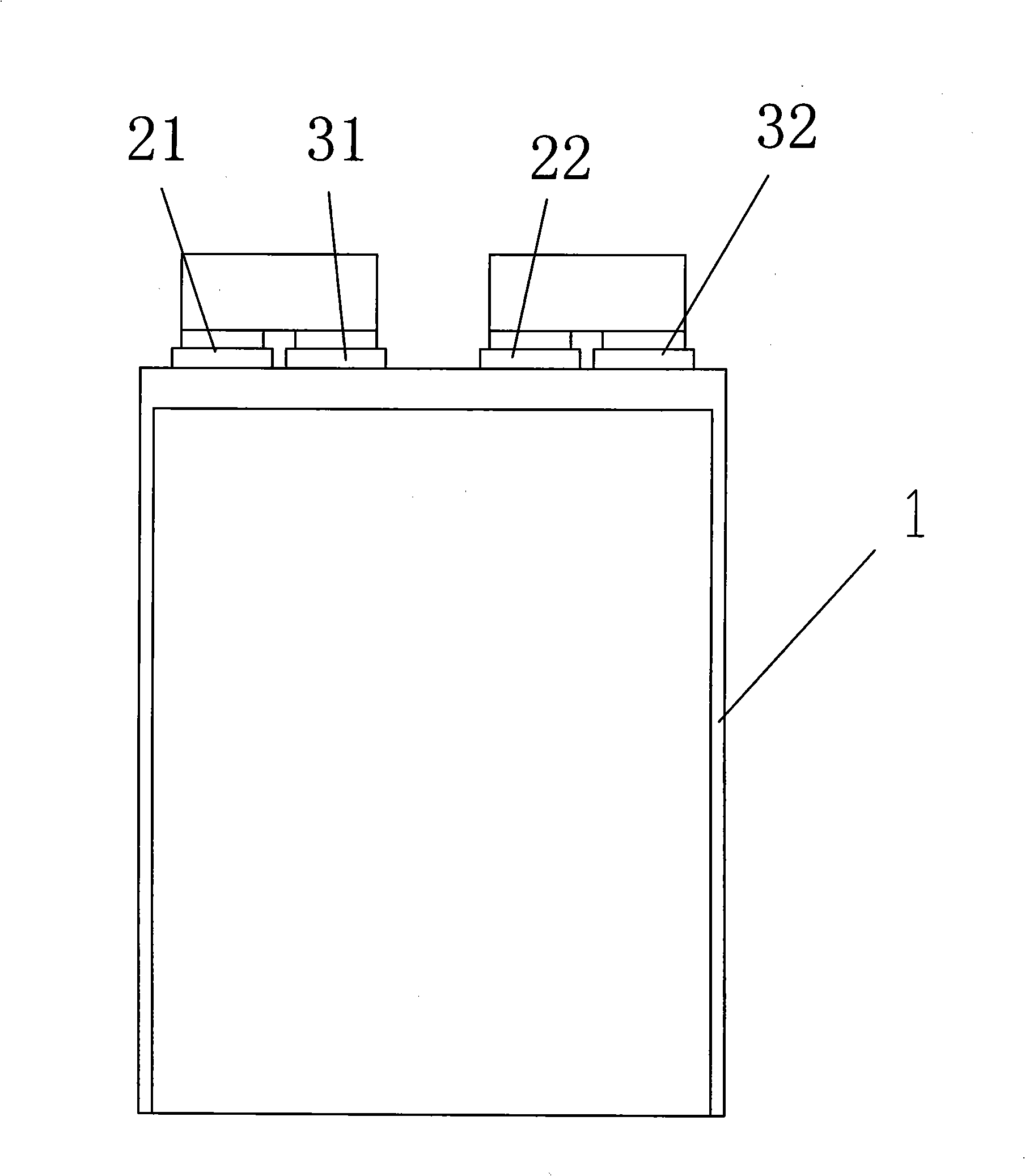

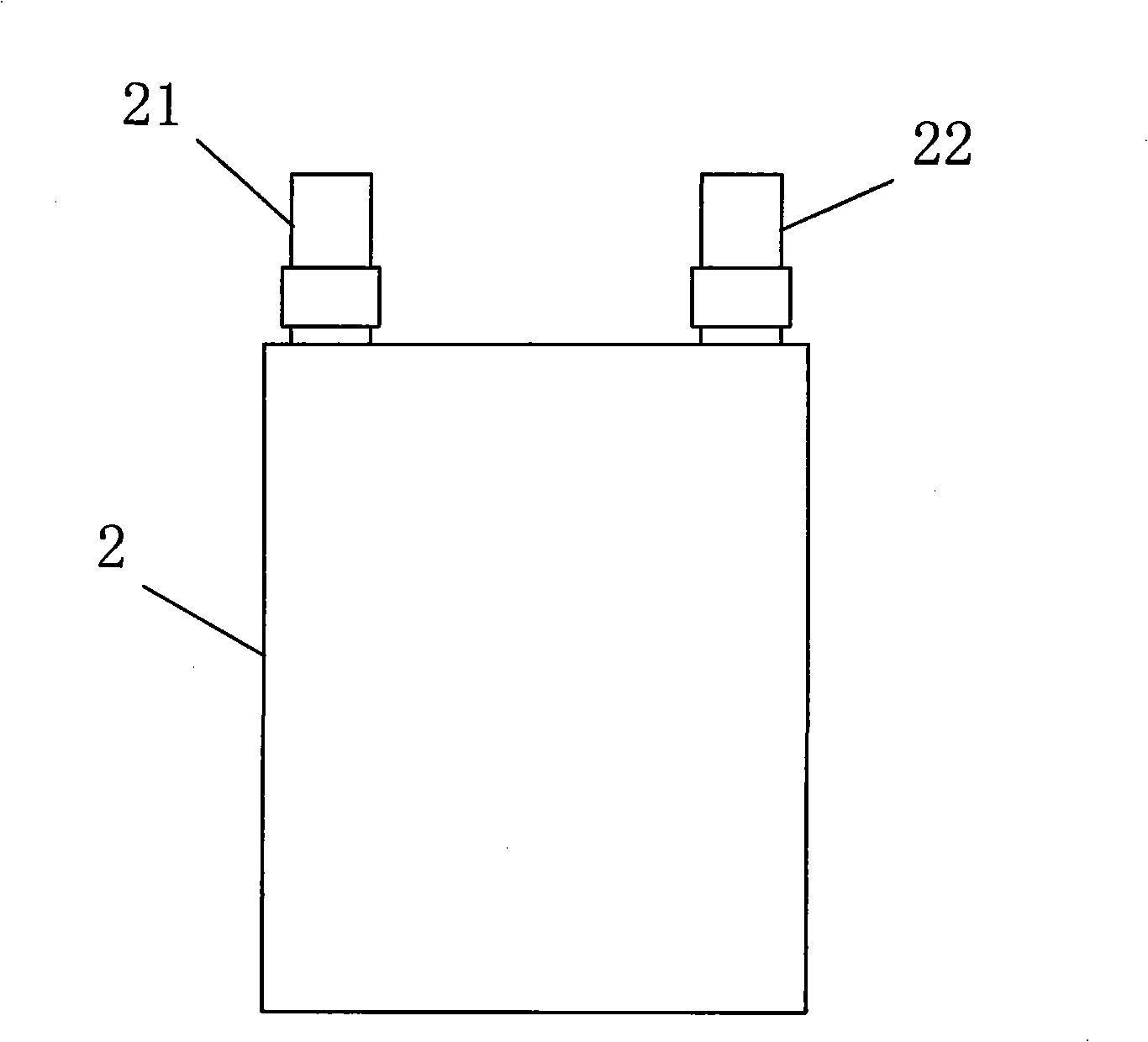

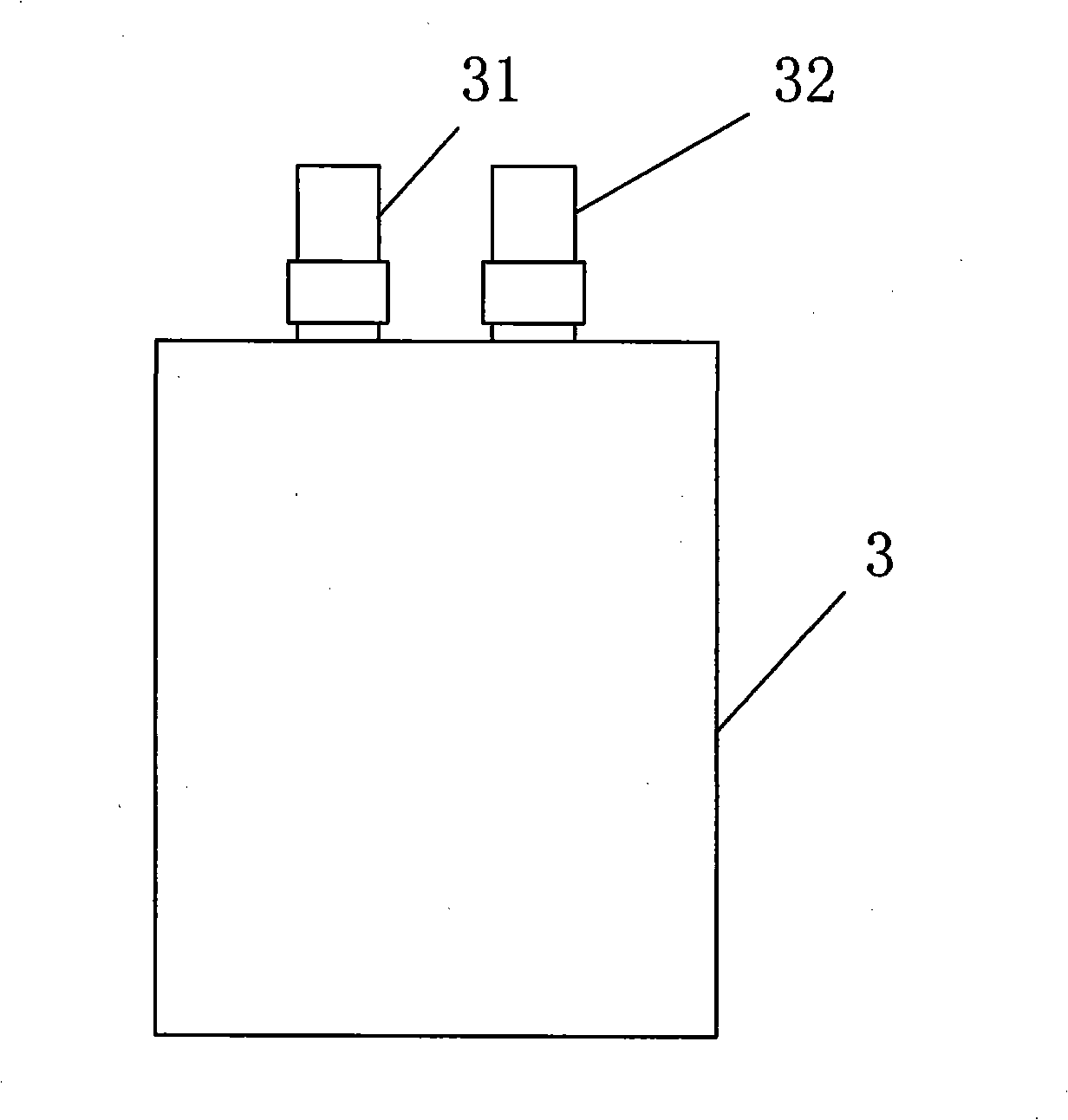

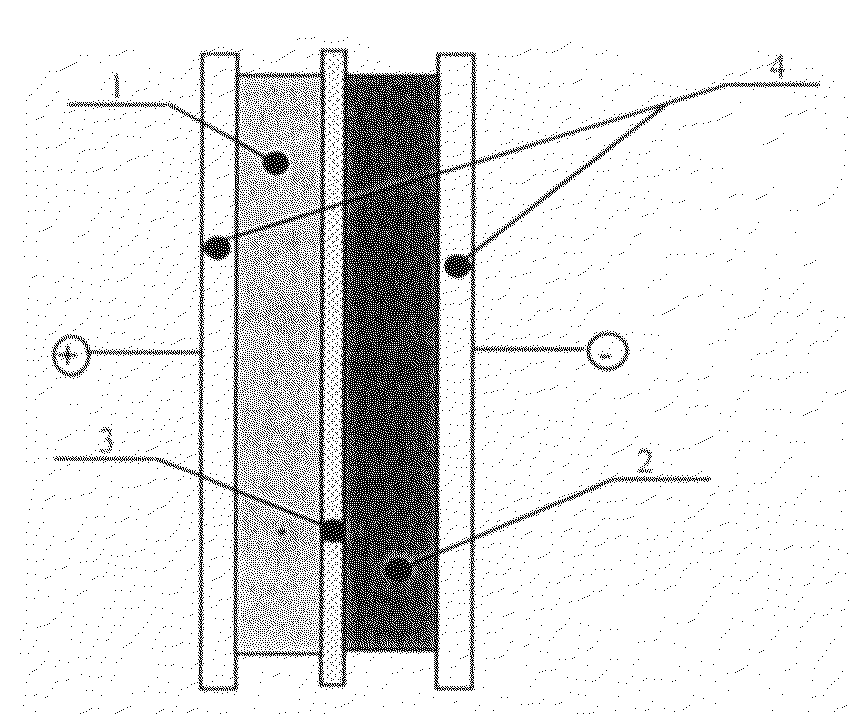

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

Asymmetric electrochemical supercapacitor and method of manufacture thereof

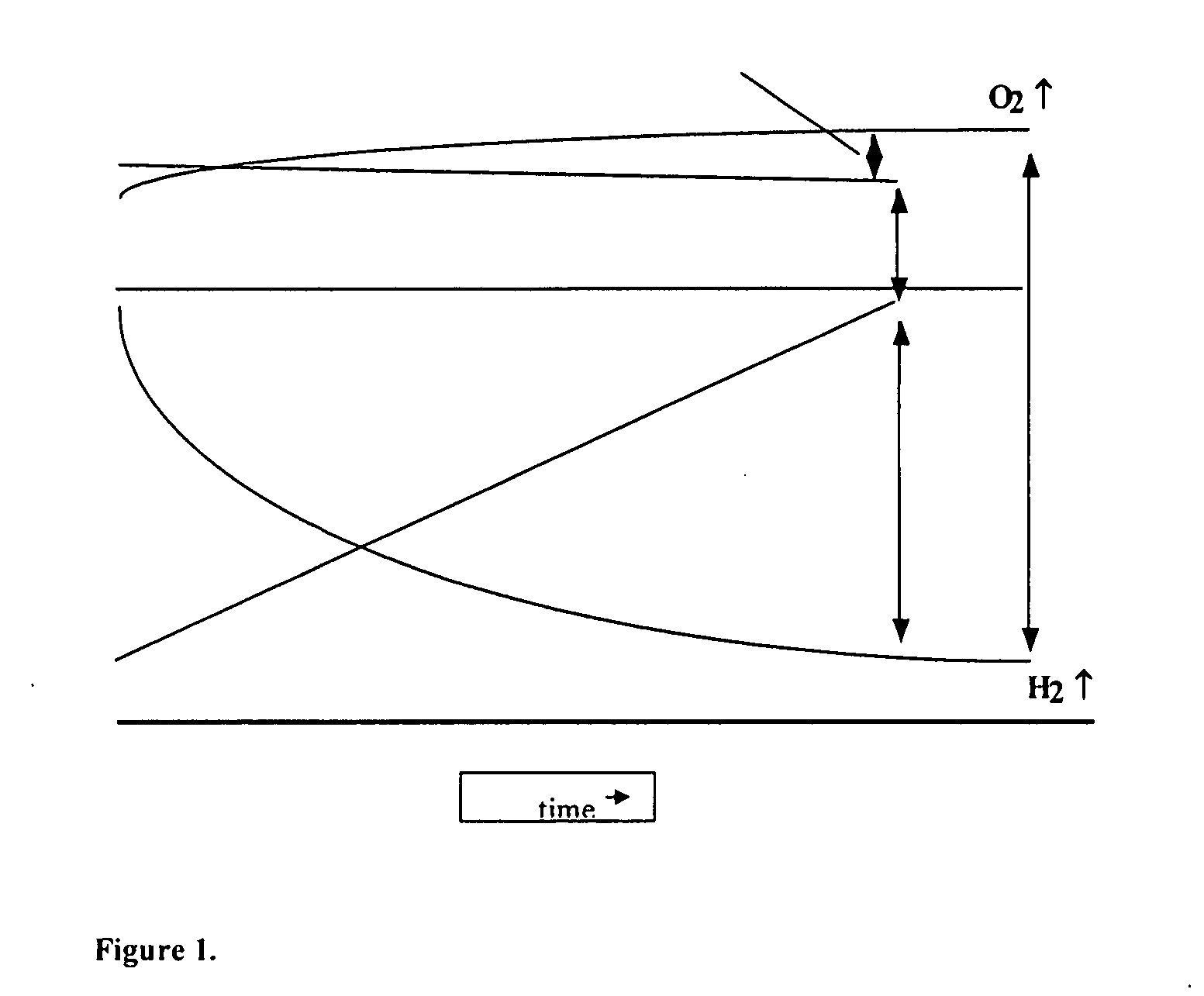

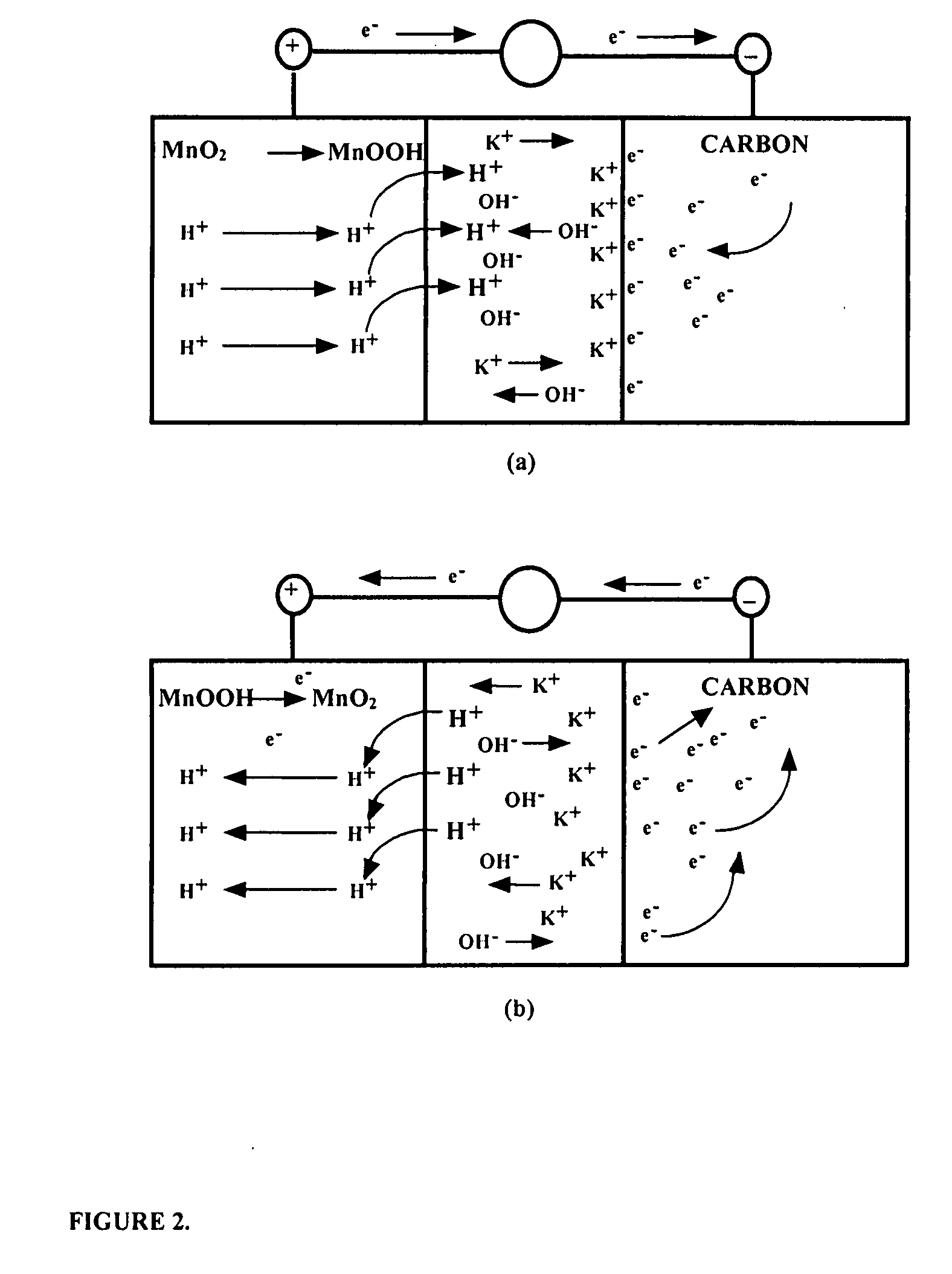

InactiveUS20080158778A1Increase energy densityImprove power densityHybrid capacitor electrodesLiquid electrolytic capacitorsAqueous electrolyteLithium manganese oxide

Asymmetric supercapacitors comprise: a positive electrode comprising a current collector and a first active material selected from the group consisting of manganese dioxide, silver oxide, iron sulfide, lithium manganese oxide, lithium cobalt oxide, lithium nickel oxide, lithium iron phosphate, and a combination comprising at least one of the foregoing active materials; a negative electrode comprising a carbonaceous active material; an aqueous electrolyte solution selected from the group consisting of aqueous solutions of hydroxides of alkali metals, aqueous solutions of carbonates of alkali metals, aqueous solutions of chlorides of alkali metals, aqueous solutions of sulfates of alkali metals, aqueous solutions of nitrates of alkali metals, and a combination comprising at least one of the foregoing aqueous solutions; and a separator plate. Alternatively, the electrolyte can be a non-aqueous ionic conducting electrolyte or a solid electrolyte.

Owner:U S NANOCORP

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

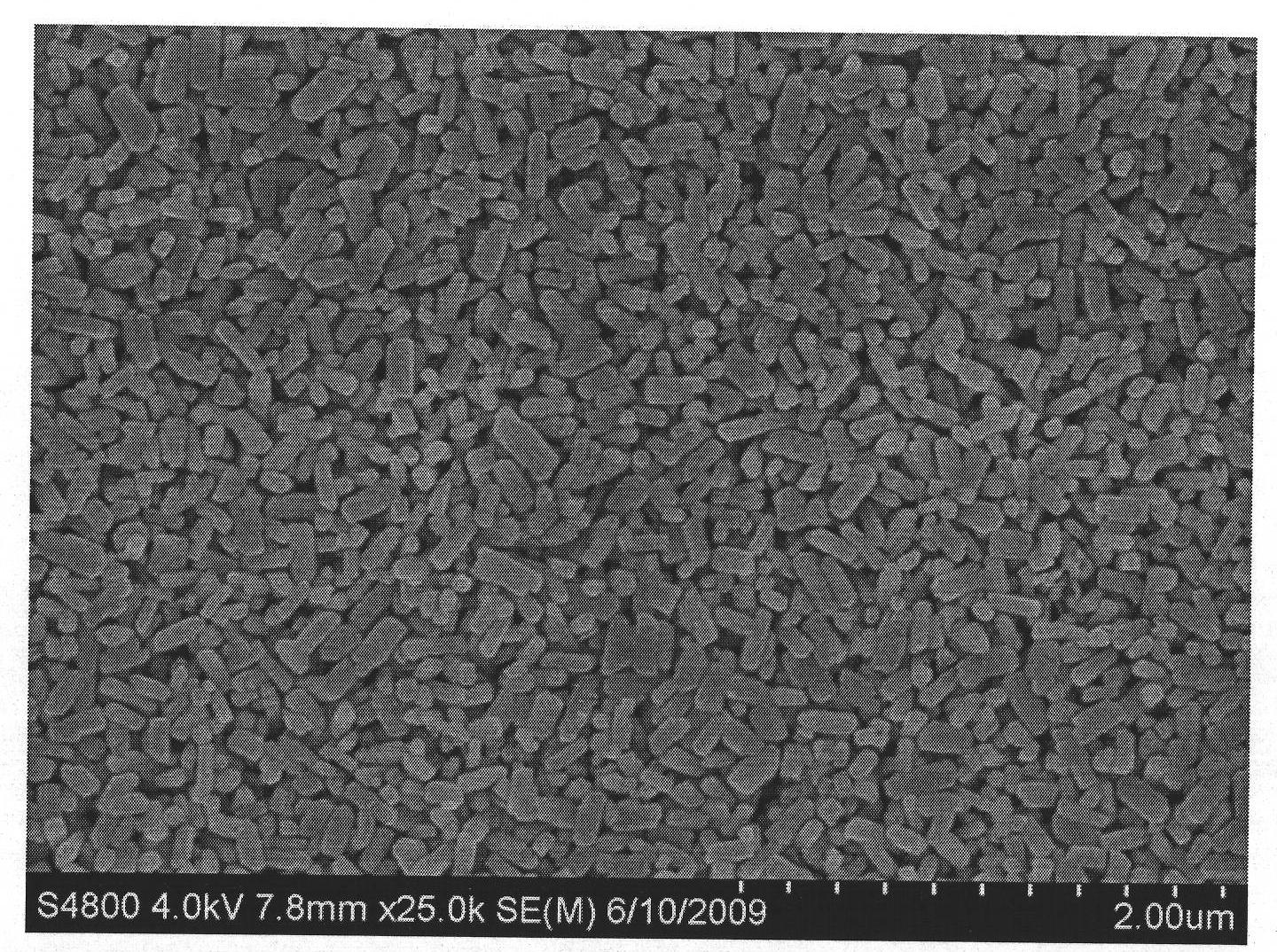

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

Method for recycling lithium iron phosphate anode material from lithium ionic cell waste

ActiveCN101359756AHigh tap densityIncrease capacityWaste accumulators reclaimingBattery recyclingRecovery methodLithium iron phosphate

The invention relates to a method for recovering a lithium iron phosphate anode material in lithium ion battery scraps, comprising: roasting the scraps in the atmosphere of inert gases at a temperature of between 450 and 600 DEG C for 2 to 5 hours, wherein, the method also includes: adding the powdered products into an ethanol solution of soluble ferric salt for mixing, drying the mixture, then roasting the mixture in the atmosphere of inert gases at a temperature of between 300 and 500 DEG C for 2 to 5 hours, and obtaining the lithium iron phosphate anode material through recovery. The recovery method can be used to obtain the lithium iron phosphate anode material with rather high tap density, so the lithium ion secondary battery made by adopting the anode material has rather high capacity.

Owner:贵州中伟资源循环产业发展有限公司

All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

ActiveCN103633329AImprove cycle lifeImprove discharge capacityCell electrodesSecondary cellsSolid state electrolyteTitanium disulfide

Embodiments of the present invention provide an all-solid state lithium ion battery composite positive electrode material, which comprises a positive electrode active material and a cladding layer arranged on the surface of the positive electrode active material, the positive electrode active material is one or a plurality of materials selected from a lithium cobalt oxide, lithium nickelate, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer material is one or a plurality of lithium-containing transition metal oxides. According to the present invention, with the cladding layer, formation of the space charge layer can be effectively inhibited, the electrode / inorganic solid state electrolyte interface can be improved, and the interface resistance of the all-solid state lithium ion battery can be easily reduced so as to improve cycle stability and durability of the all-solid state lithium ion battery. Embodiments of the present invention further provide a preparation method for the all-solid state lithium ion battery composite positive electrode material, and an all-solid state lithium ion battery containing the all-solid state lithium ion battery composite positive electrode material.

Owner:泰州市海通资产管理有限公司

Method for recovering waste lithium iron phosphate battery positive pieces

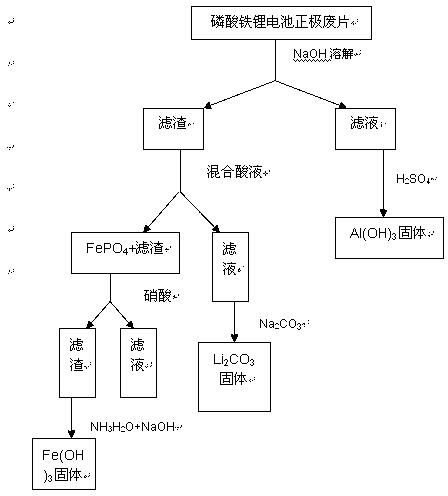

ActiveCN103280610AReduce pollutionWaste accumulators reclaimingProcess efficiency improvementPhosphoric acidImpurity

The invention discloses a method for recovering Al, Fe and Li in waste lithium iron phosphate battery positive pieces through an acid-alkali leaching process. The method comprises the following steps: dismounting the lithium iron phosphate battery positive pieces, dissolving the positive pieces by using an alkali, filtering, and dissolving obtained filter residues by a mixed acid solution for making Fe exist in an iron phosphate precipitate form and be separated from impurities comprising carbon black and the like and a lithium-containing solution; adding the lithium-containing solution to a 95DEG C saturated sodium carbonate solution for precipitation to obtain lithium carbonate; and adding an acid to obtain an iron-containing precipitate for leaching iron ions, and adding an alkaline solution to obtain Fe(OH)3. Al, Fe and Li in the waste lithium iron phosphate battery positive pieces are simply and effectively recovered through using low-concentration acids and alkalis and routine chemicals, and raw materials having economic benefits are recovered through using simple and effective equipment and the method.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

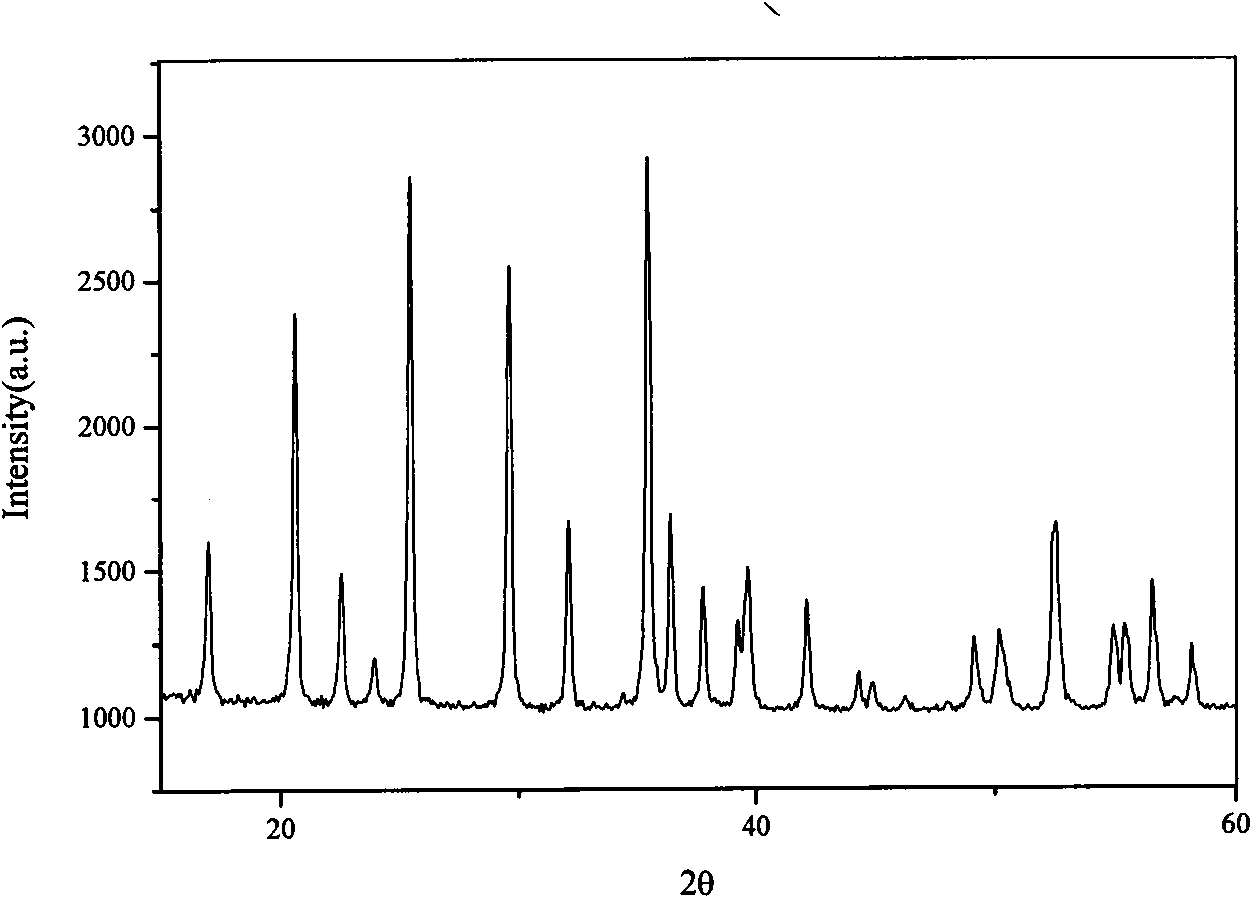

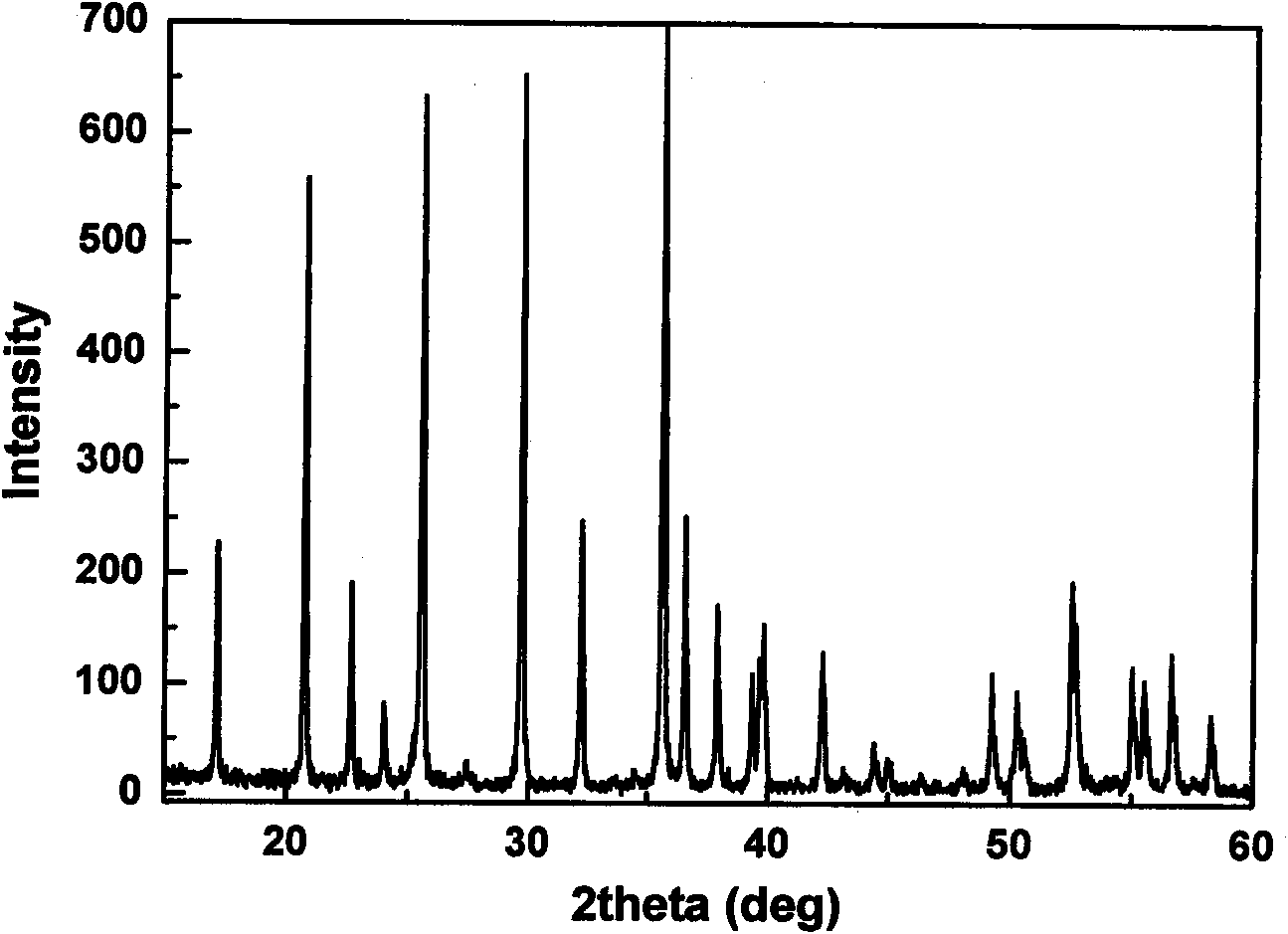

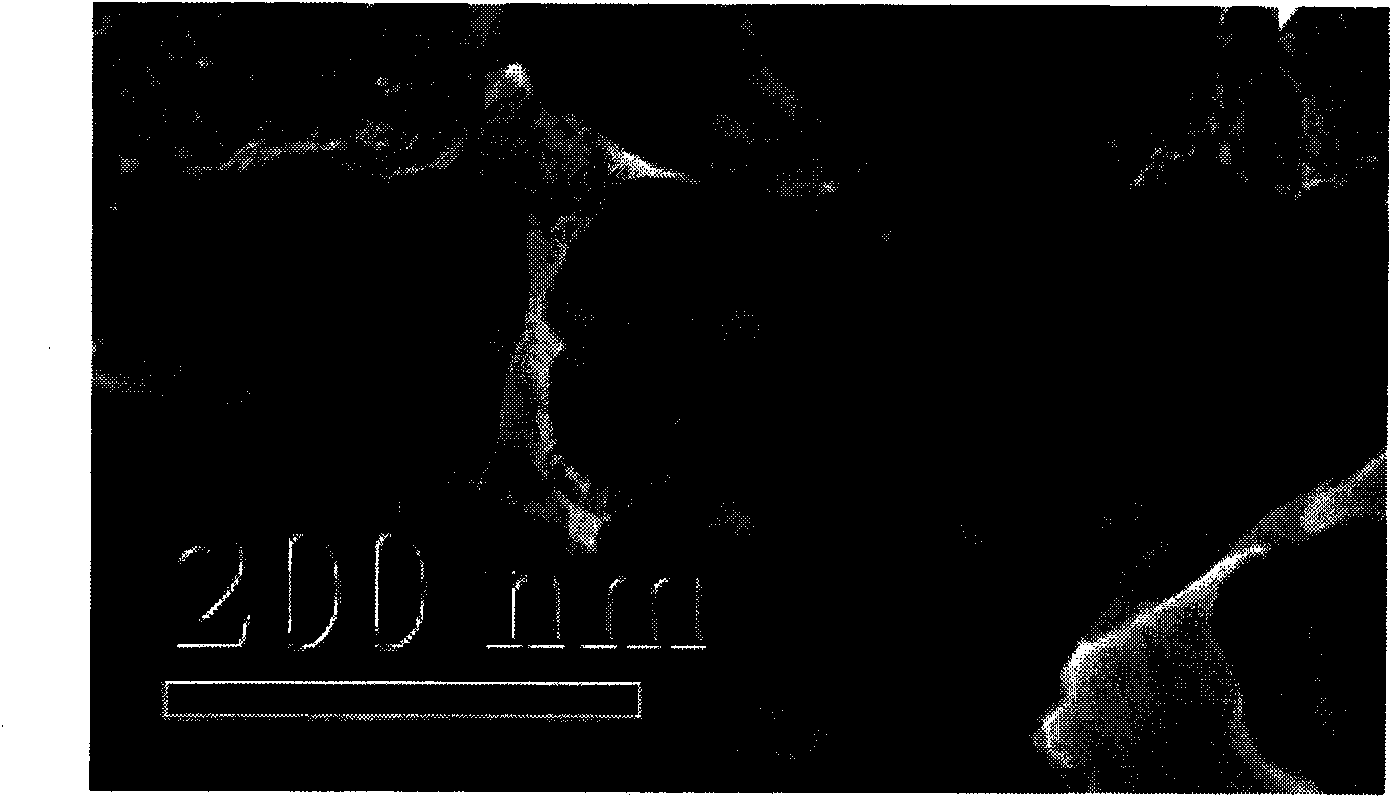

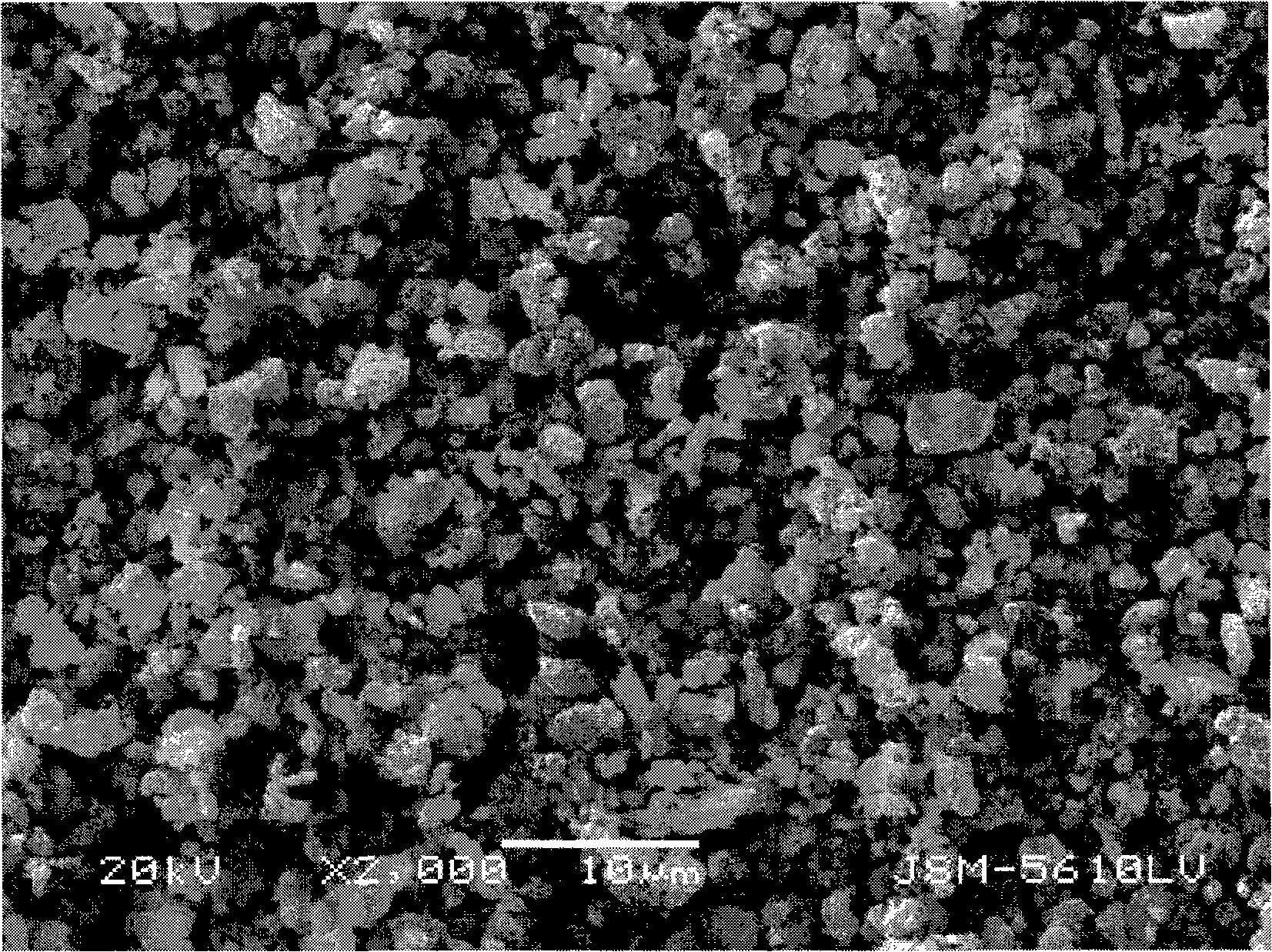

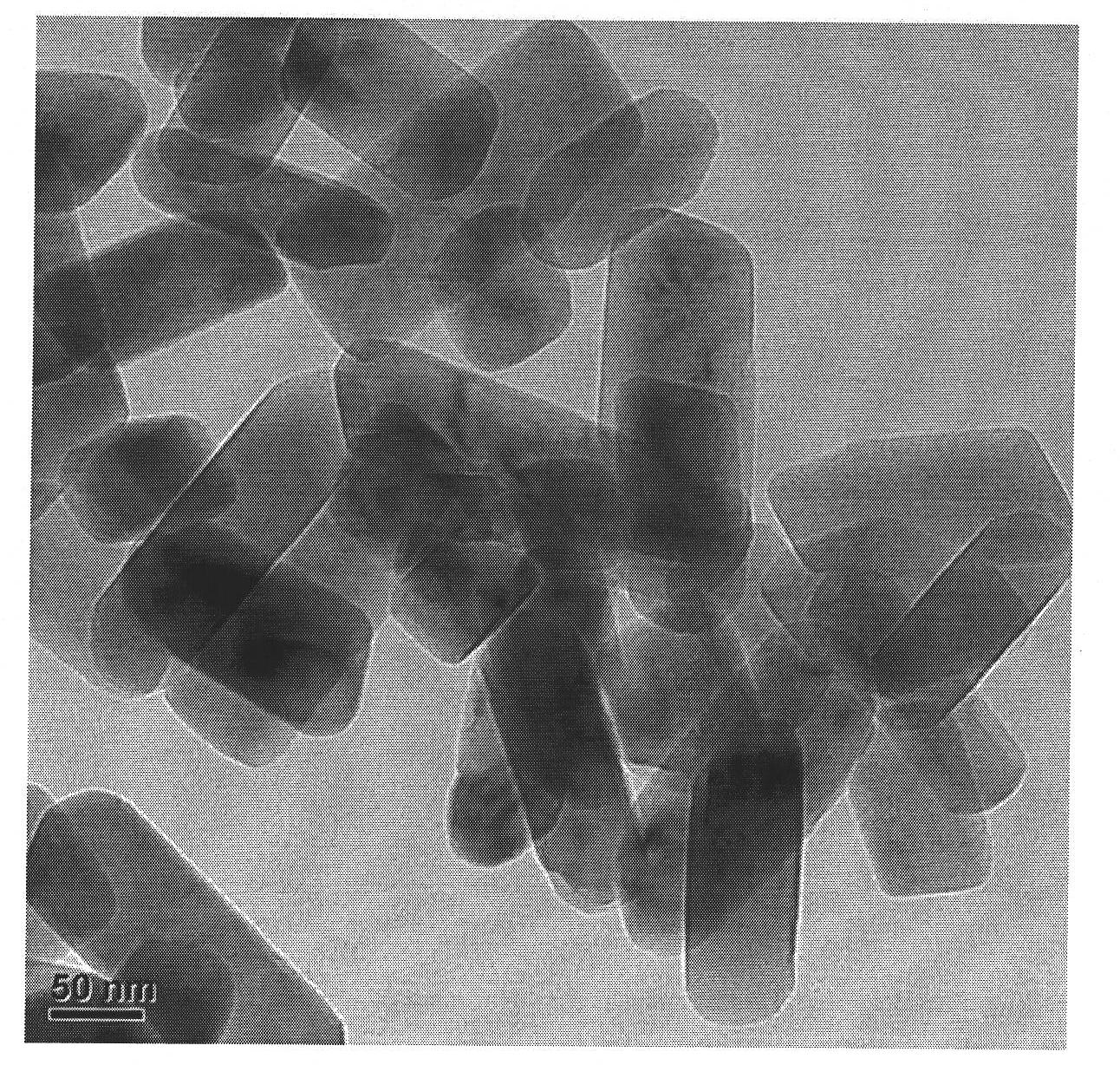

Preparation method of monodisperse lithium iron phosphate nanometer material and lithium-ion secondary battery

ActiveCN101777648AUniform shapeSmall sizeCell electrodesSecondary cellsCarbon coatingOrganic solvent

The invention relates to a preparation method of a monodisperse lithium iron phosphate nanometer material, which is characterized by comprising the following steps of: dissolving a soluble lithium source compound, a ferrous source compound, a phosphorus source compound, a dopping element compound, a carbon source compound, and the like into water or a mixed solvent of the water and an organic solvent; sequentially adding to the organic solvent for stirring and mixing according to specific material mole ratio and order, and keeping the volume ratio of the organic solvent to the water to be within a certain range; transferring a mixture to a high-pressure reaction still for heating treatment; and processing a product through a plurality of steps of washing, drying, carbon coating, ball-milling, mixing, annealing, and the like to obtain the lithium iron phosphate anode active material which has high multiplying power circulation and property. The invention also discloses a relevant lithium-ion secondary battery. By adopting a hydrothermal / solvothermal method and using soluble materials as reactants, the invention enables ions to be uniformly mixed in the synthesizing process, thereby obtaining better crystal forms and very pure phases and further enhancing the property of batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing iron lithium phosphate by recovering water-system waste lithium-ion power battery

ActiveCN101916889AReduce manufacturing costSolving Recycling ProblemsWaste accumulators reclaimingBattery recyclingPower batteryIron salts

The invention discloses a method for preparing iron lithium phosphate by recovering water-system waste lithium-ion power batteries, comprising the following steps: 1) cutting and brushing a water-system waste lithium-ion power battery, processing by deionized water, sieving and drying to recover the mixture of an electrode material and a conductive agent; 2) adding inorganic acid to the dried mixture of the electrode material and the conductive agent to process, filtering to obtain acid solution containing Li+, Fe2+ and PO43-; 3) adding lithium salt or iron salt to the acid solution containing Li+, Fe2+ and PO43-, adding ascorbic acid and stirring, controlling the pH value to equal to 3-7, and filtering to obtain precipitation; and 4) adding the crude product LiFePO4 obtained in step 3) to a water solution of cane sugar for ball milling, drying and calcining to obtain a regenerative LiFePO4 material. The method has low cost, simple operation and no secondary pollution.

Owner:长春劲能科技集团有限公司

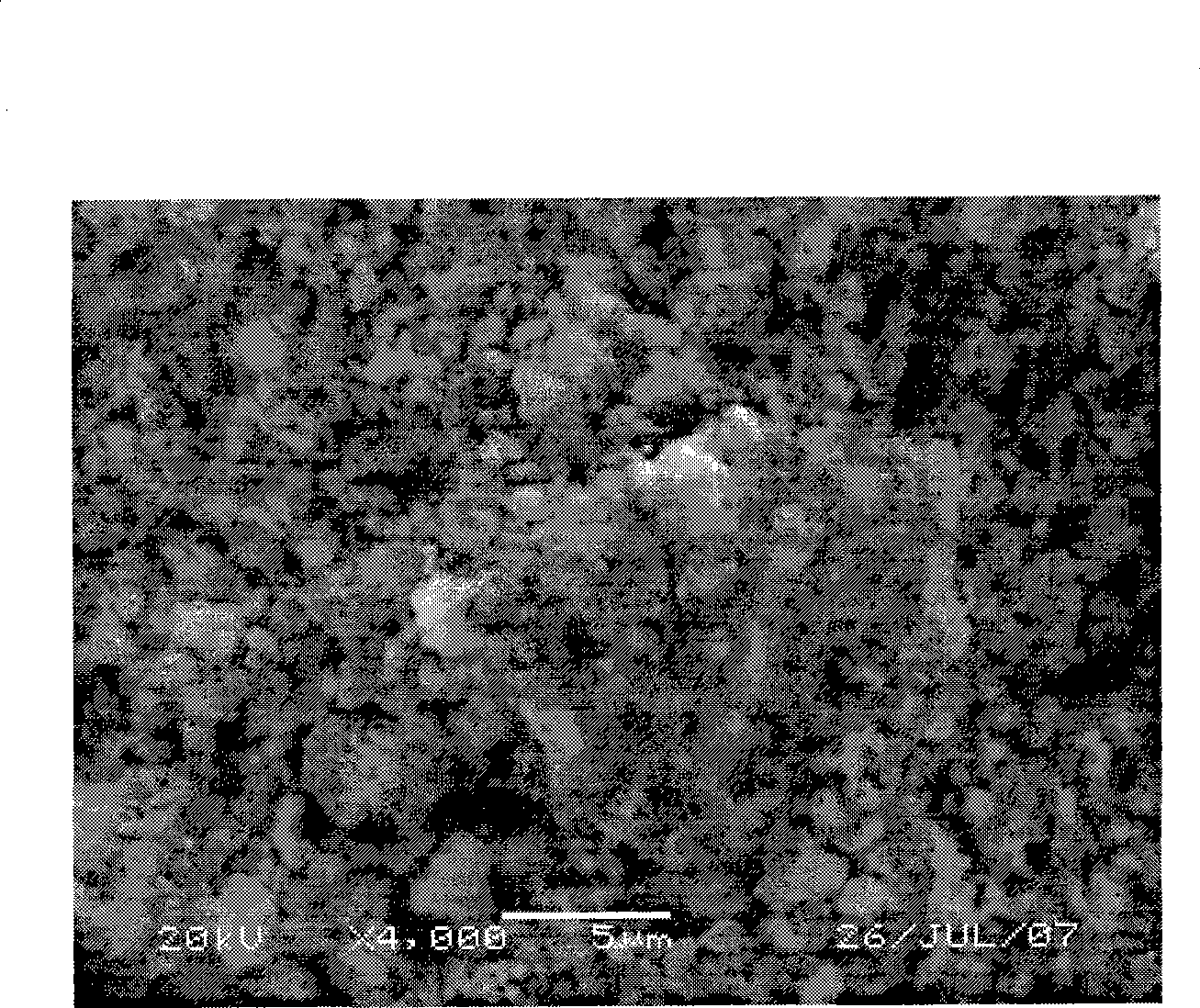

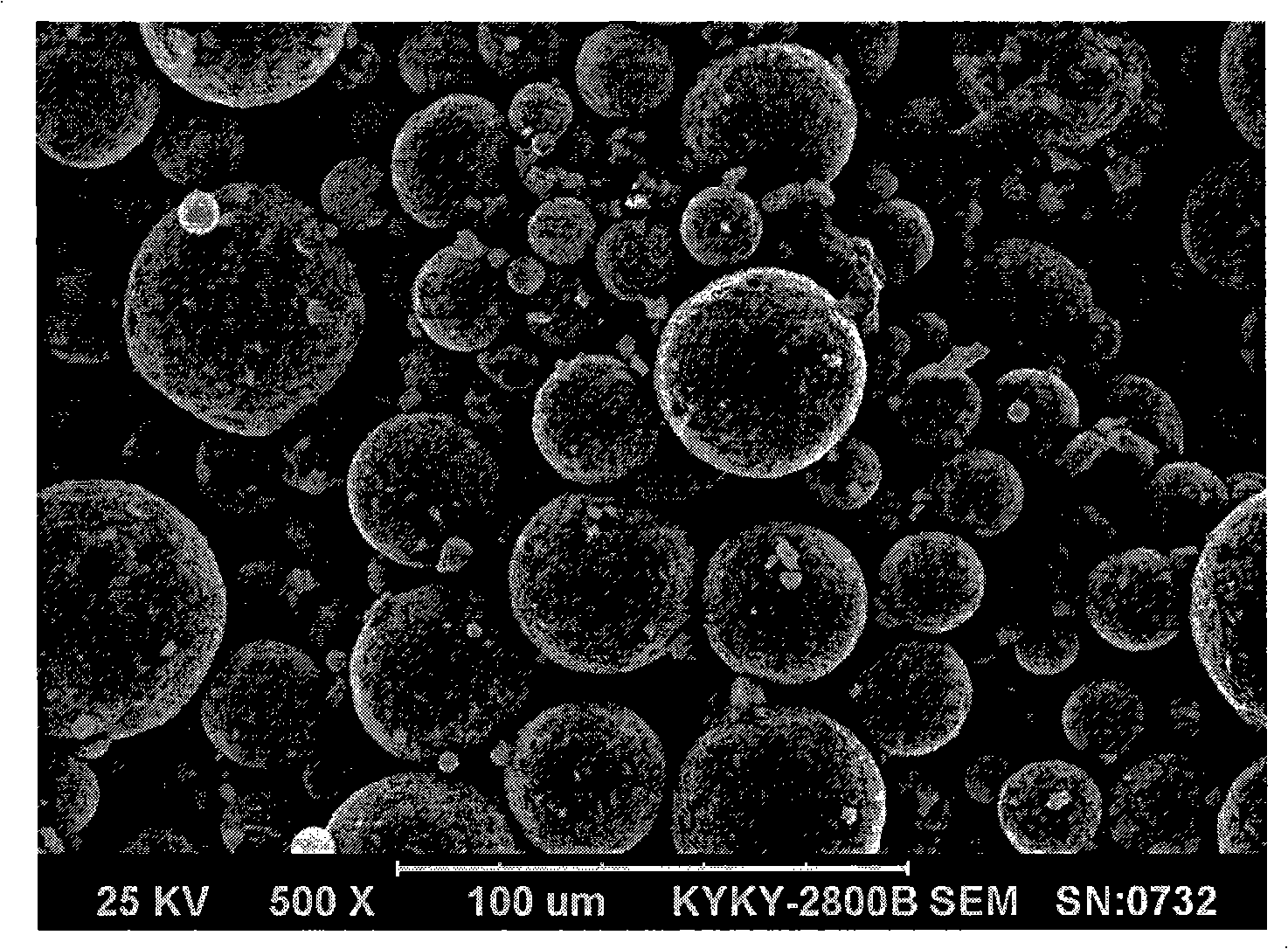

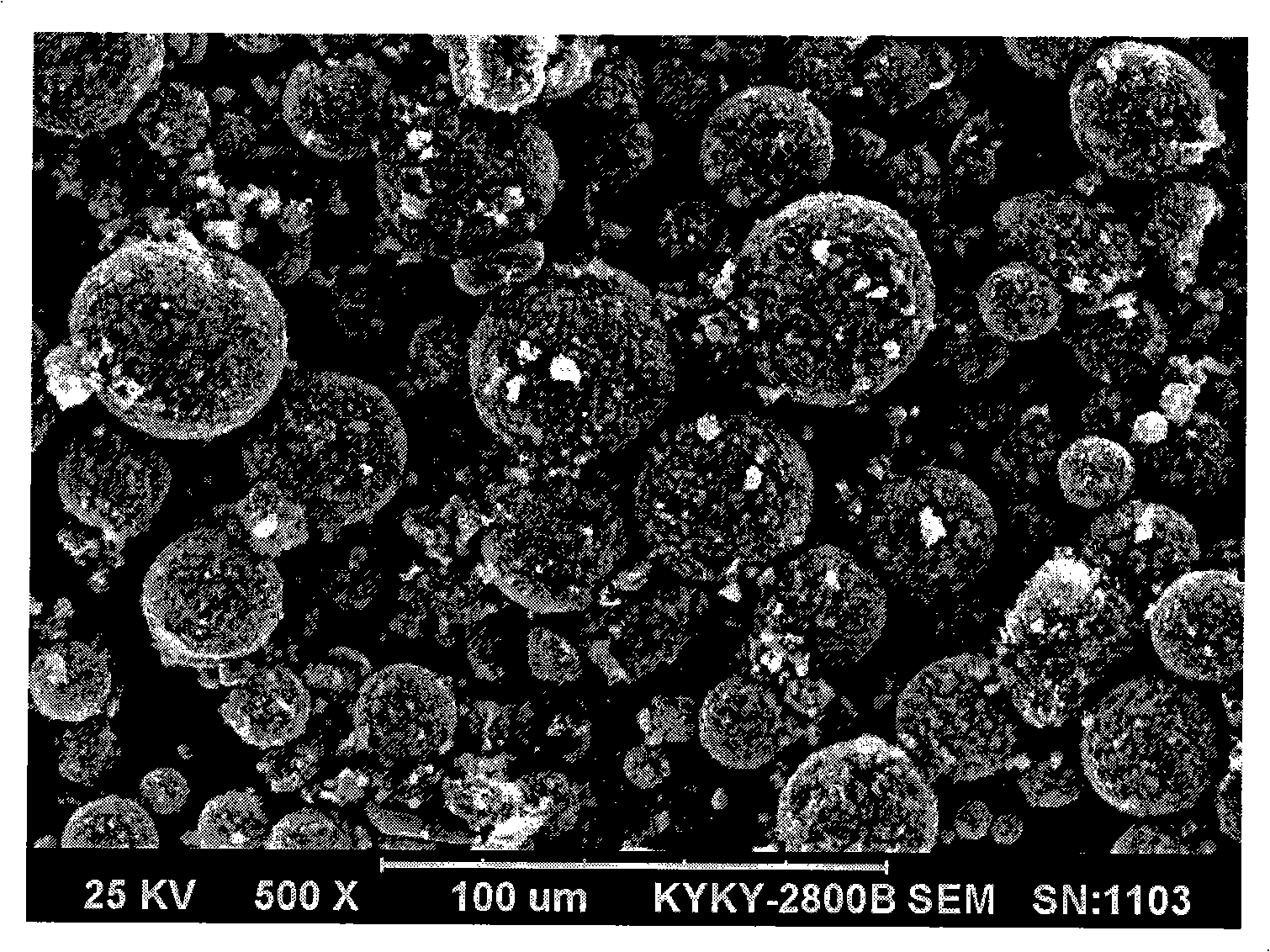

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

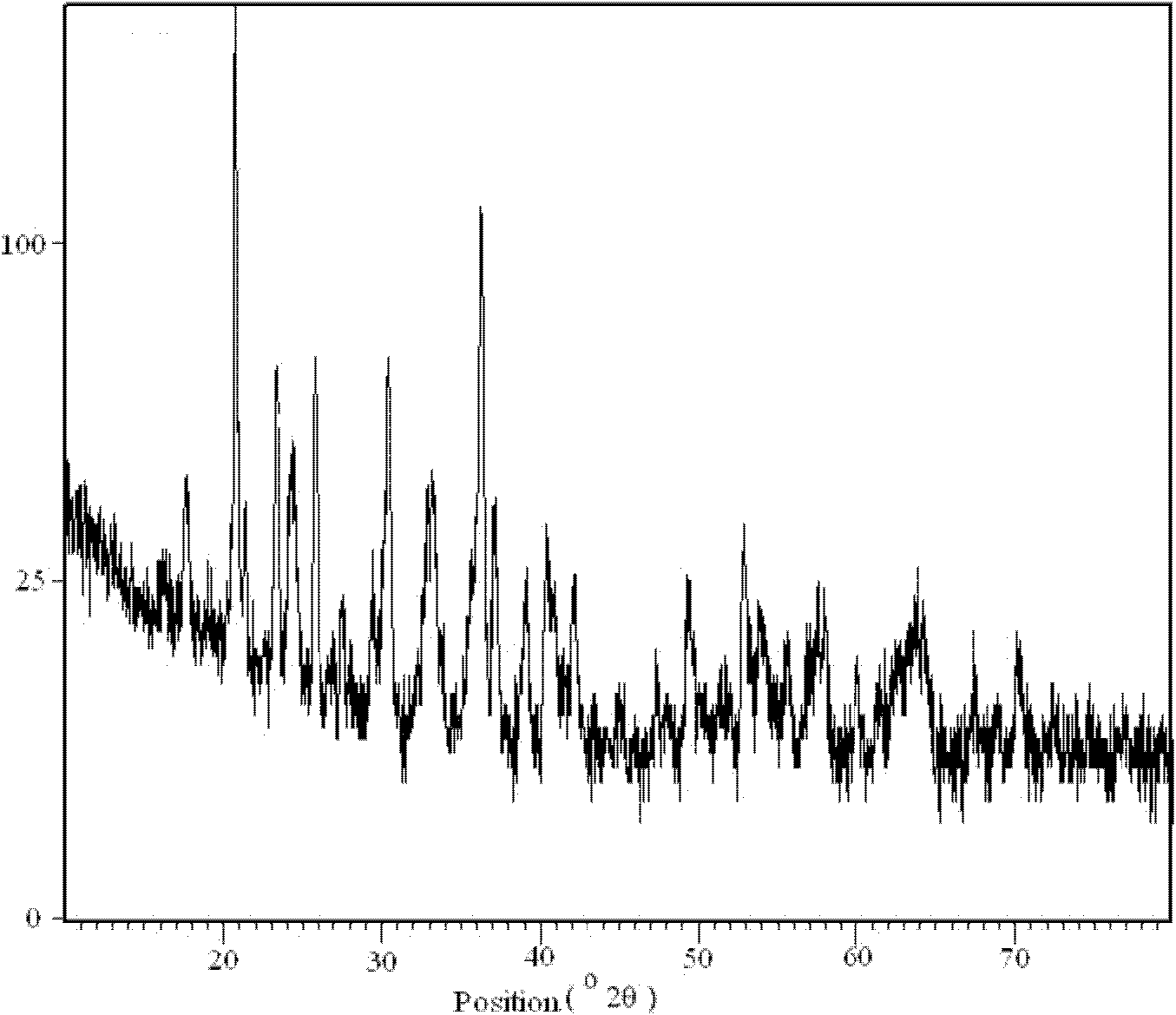

Method for repair and regeneration of waste lithium iron phosphate battery cathode material

ActiveCN102208707AReduce pollutionSave resourcesSolid waste disposalWaste accumulators reclaimingLithium iron phosphateEngineering

The invention discloses a method for repair and regeneration of waste lithium iron phosphate battery cathode materials, which allows a lithium-source solution or a suspension to react with a recovered waste lithium iron phosphate battery material by a hydrothermal reaction or a solvent-thermal reaction, or allows the recovered waste lithium iron phosphate battery material to be processed by solid-phase ball-milling and calcination with the lithium source, performs liquid-phase or solid-phase direct lithium-supplementing repair of delithiated waste lithium iron phosphate, and then performs pertinent repair and regeneration by coating conductive agents or coating conductive agents and doping metal ions. The invention adopts a direct repair and regeneration method; the repaired waste lithium iron phosphate battery cathode material has excellent performance, and the specific capacity can reach above 90% of the specific capacity before discard; the method not only can effectively reduce environmental pollution of waste batteries, but also can make full use of waste resources and changes waste into valuables.

Owner:HEFEI UNIV OF TECH

Core-shell composite anode material for lithium ion battery and preparation method thereof

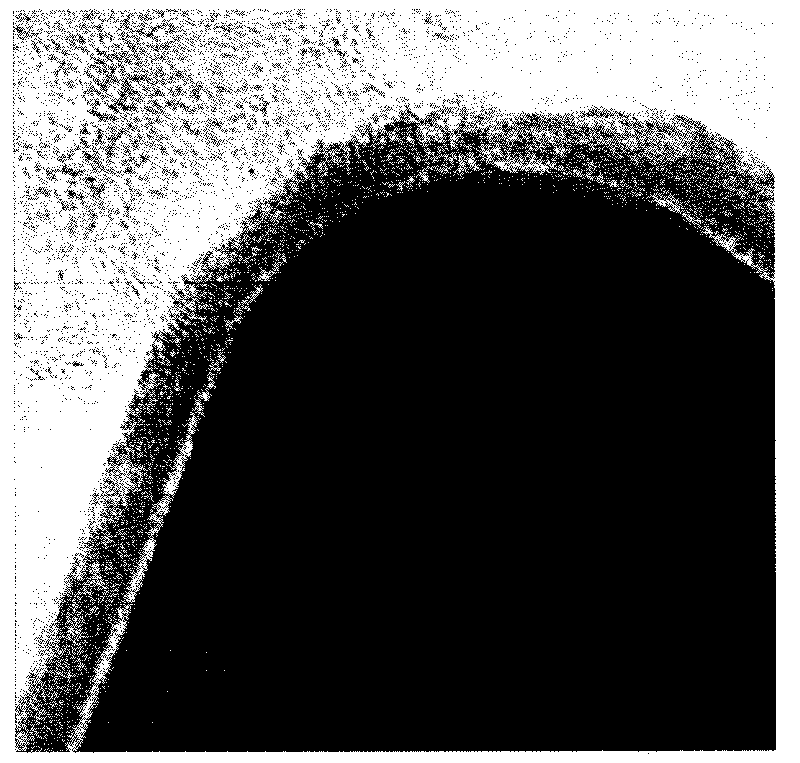

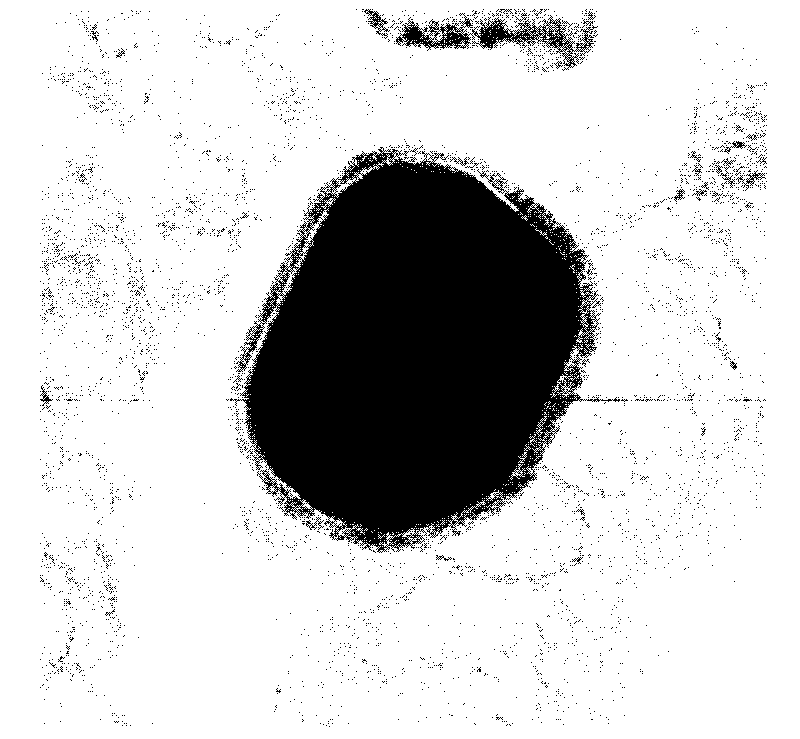

ActiveCN101740752AImprove conductivityHigh specific capacitySecondary cellsIron compoundsLithium iron phosphateElectrical battery

The invention discloses a core-shell composite anode material for a lithium ion battery. The composite anode material has a core-shell structure; the core-shell structure consists of a core-layer active material and a shell-layer active material; the core-layer active material is LiFePO4 or lithium manganate; the shell-layer active material is carbon-containing LiFePO4; the LiFePO4 has an Li1-XMXFePO4 or LiFe1-yMyPO4 structure; the lithium manganate has a LiMnO2 or LiMn2O4 structure; the carbon is selected from one or more of carbon nano tubes, superfine conductive black and an agraphitic carbon material; and the composite anode material comprises 65 to 99 mass percent of core-layer active material and 1 to 35 mass percent of shell-layer active material. The composite anode material of the invention has stable performance and excellent electrochemical properties; and the lithium ion battery manufactured by using the material has relatively high charge-discharge capacity and excellent cycle performance, can perform quick charging and large multiplying-factor discharging, can adapt to an ultra-low temperature working environment and is safe and stable.

Owner:SHENZHEN DYNANONIC

Novel detection method for self-discharge characteristics of lithium iron phosphate system power lithium ion batteries

ActiveCN104360284AStable self-discharge characteristicsExacerbated self-discharge trendElectrical testingCell fabricationEngineering

The invention discloses a novel detection method for self-discharge characteristics of lithium iron phosphate system power lithium ion batteries. The method comprises the following steps: step 1, charging and discharging batteries, and adjusting SOC (System On Chip) states of the batteries to be 20-40%; step 2, standing for a certain period of time at normal temperature, and measuring open-circuit voltage (OCV)1 of the batteries; step 3, performing high-temperature aging on the batteries; step 4, standing for a certain period of time at normal temperature, and then detecting OCV2 of the batteries; step 5, calculating a voltage drop deltaU of the batteries, wherein deltaU is equal to OCV1-OCV2; and step 6, calculating an average value and standard deviations of the voltage drops of the same group of batteries, determining a self-discharge detection standard of the batteries, and screening. The method for detecting the self-discharge characteristics of the batteries by virtue of voltage differences of the batteries disclosed by the invention can be used for well shielding interference of factors such as equipment, operations and environment temperature existing in a manufacturing process of the batteries in the self-discharge data acquisition accuracy of the batteries, so that the self-discharge characteristic data distortion of a single battery can be avoided, the matching reliability of the batteries can be effectively improved, and the cycle life of a battery pack can be prolonged.

Owner:SHANGHAI AEROSPACE POWER TECH +1

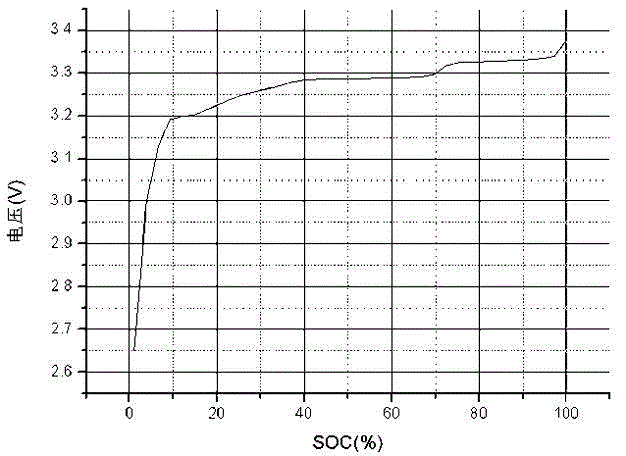

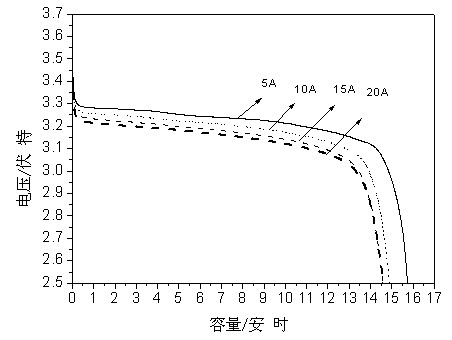

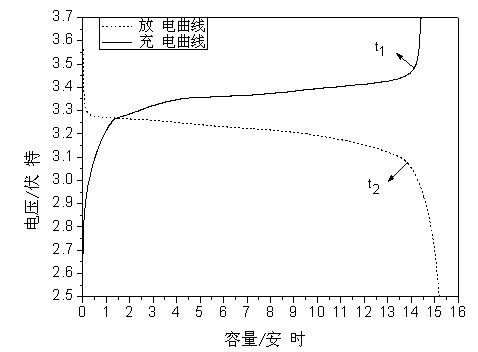

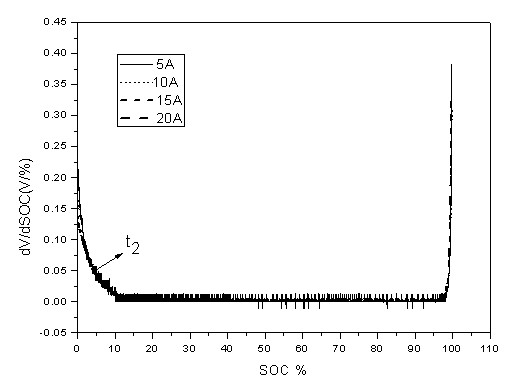

Self-correction method for remaining capacity estimation of lithium iron phosphate power battery

ActiveCN102540096AIncrease cumulative errorAvoid hard-to-define problemsElectrical testingPower batteryEnd stages

The invention discloses a self-correction method for remaining capacity estimation of a lithium iron phosphate power battery. The conventional method cannot meet national standard well. According to the self-correction method disclosed by the invention, compensation and correction are performed on the basis of estimating the remaining capacity of the lithium iron phosphate power battery by using an ampere-hour method; and according to the characteristic that voltage of the lithium iron phosphate power battery abruptly changes at the end stage of charging or discharging, the actual remaining capacity SOC (State Of Charge) is corrected when dV / dSOC' is detected to be greater than or equal to 0.05, so that accumulative estimation error existing during independent use of the ampere-hour method is reduced. The self-correction method is based on the ampere-hour method, is simple and easy and is easier to apply and generalize. Meanwhile, the invention also provides a calculation method of aging rate gamma. By continuously updating the aging rate, the error for estimation by using the ampere-hour method is reduced again.

Owner:ZHEJIANG UNIV

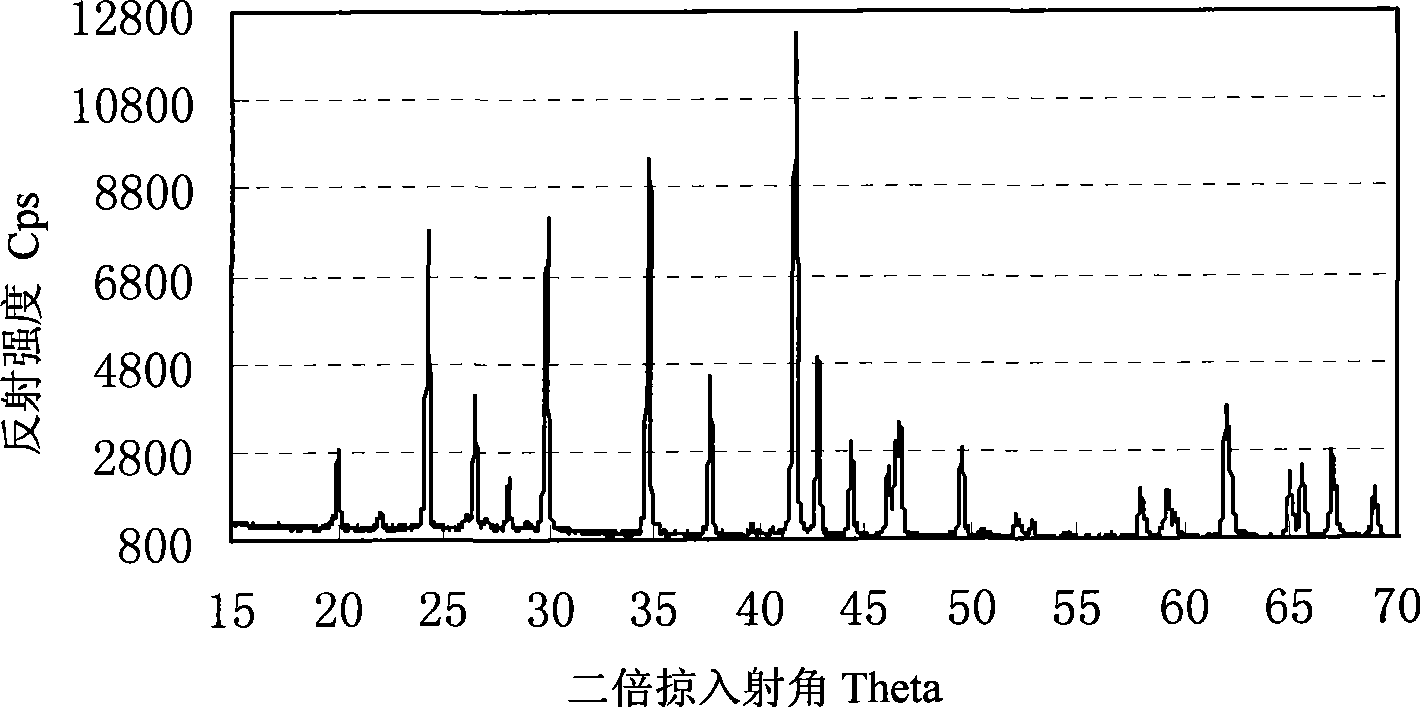

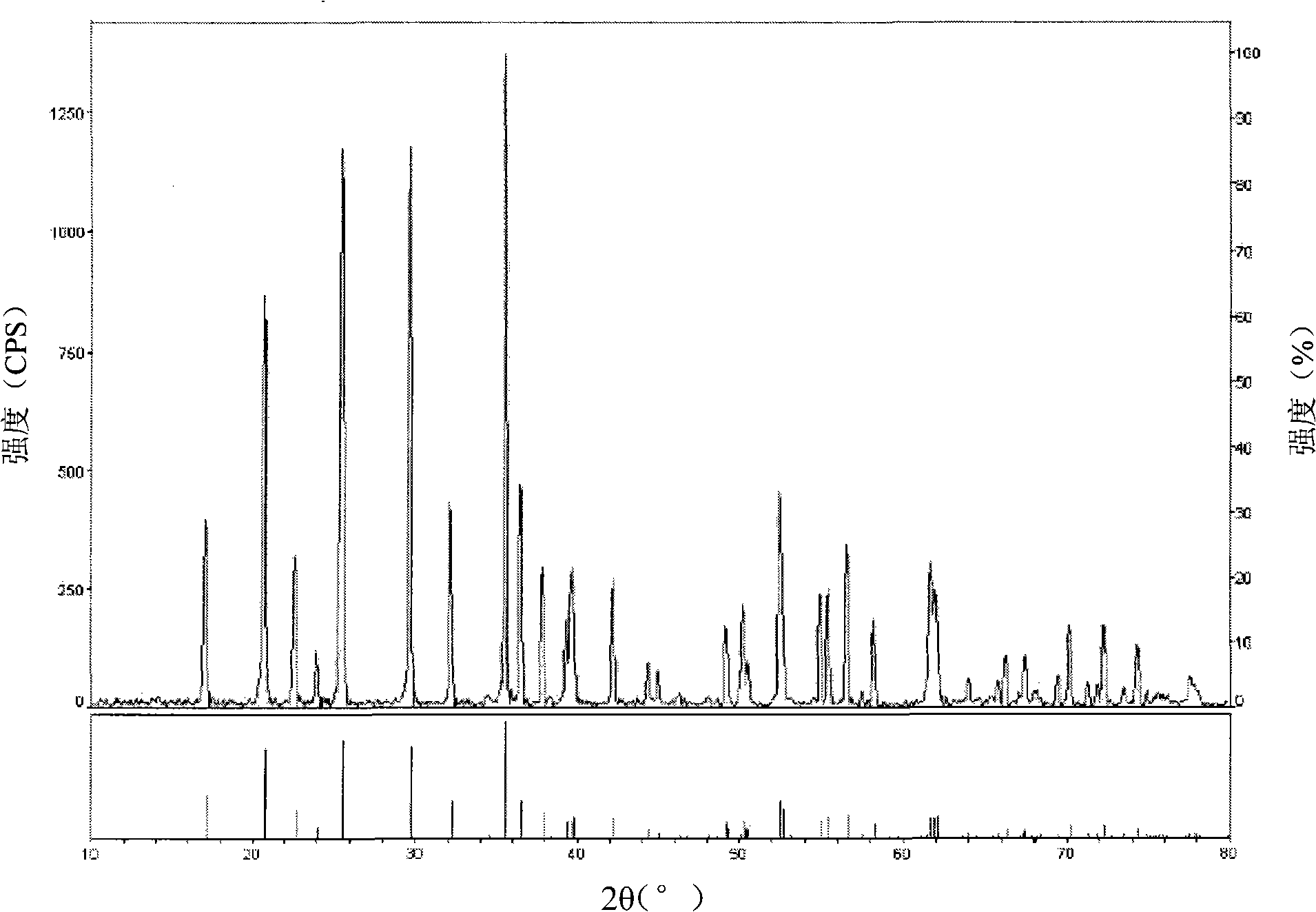

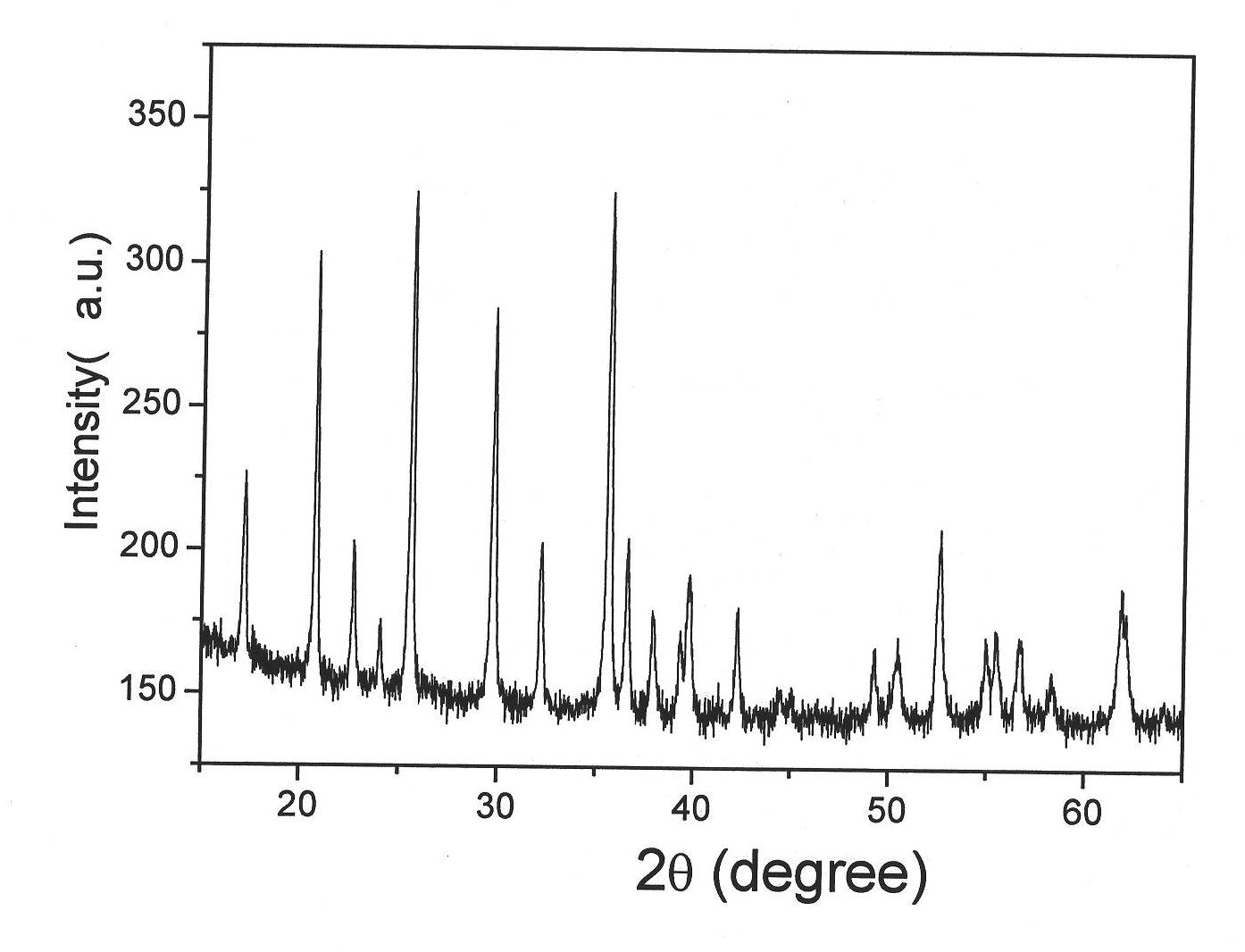

Hydro-thermal synthetic preparation method for lithium ion battery anode material lithium iron phosphate

InactiveCN101121509AImprove electrochemical performanceHigh purityCell electrodesPhosphorus compoundsPhosphateInlet valve

The present invention relates to a hydrothermal synthesis preparation method of a lithium iron phosphate of an anode material used by a lithium ion battery, concerning a phosphate containing two metals. The step is that a lithium source and a phosphor source are solubilized into the water or mixed with the water and then put into a high pressure kettle. After the air in the kettle is blown out by an inert gas, the high pressure kettle is sealed and heated to a temperature between 40 DEG C and 50 DEG C from a room temperature after being stirred. An inlet valve and a vent valve are opened and then a prepared divalent ferric salt liquor is added in. The high pressure kettle is sealed and the reaction time lasts from 200 minutes to 480minutes at the temperature between 140 DEG C and 170 DEG C. At the time, the inner pressure corresponding to the system is from 0.36 MPa to 0.85 MPa. The mixture rate of the added substance is Li: Fe: P and the mol ratio is 3.0-3.15: 1: 1.0-1.15. When the reaction starts, the reactant concentration is from mol / L 0.2 to 1.0mol / L, computed according to the concentration of the ferrous ion and then the resultant is filtrated, cleaned, dried and coated with the carbon. Finally the lithium iron phosphate product can be obtained. The present invention has the advantages of simple technology, good batch stability, good electrochemical performance and even distribution. The purity quotient can be more than 99 percent and the grain diameter D50 is between1.5Mu m and 2Mum.

Owner:HEBEI UNIV OF TECH

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com