Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

A lithium iron phosphate battery, lithium iron phosphate technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problem of low lithium recovery rate, achieve improved electrochemical performance, simple process, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take the waste lithium iron phosphate power battery of model A123, disassemble it, peel off the battery casing, and then soak it in deionized water, that is, separate the positive electrode sheet, negative electrode sheet, separator, electrolyte and conductive parts except the battery casing. Put the agent into deionized water together, perform ultrasonic 0.5h and mechanical stirring for 0.5h alternately, repeat 8 times in total, that is, ultrasonic and mechanical stirring are carried out for a total of 8h, until the positive and negative powders are separated from the pole piece, take out the aluminum foil and copper foil and Diaphragm, and the rest is a mixed solution. In the A123 lithium iron phosphate power battery, the aluminum foil is used as the positive electrode substrate, and the copper foil is used as the negative electrode substrate;

[0047] Evaporate part of the water from the mixed solution, put it into a planetary ball mill and mill it at a speed of 400r / ...

Embodiment 2

[0052] Take 1 kg of recycled material prepared in Example 1 and then add 100 g of starch and 0.0816 mol of manganese acetate to perform high-energy ball milling at a speed of 2000 r / min for 3 hours. The mass ratio is 8:1, and spray drying is adopted after high-energy ball milling. The solid-solid ratio of the feed liquid (solvent is water) in spray drying is 38%, and the recovered waste pre-burned material is obtained; among them, the particle size after high-energy ball milling is mainly Concentrated at 0.9mm±0.2mm, pH is 8.2;

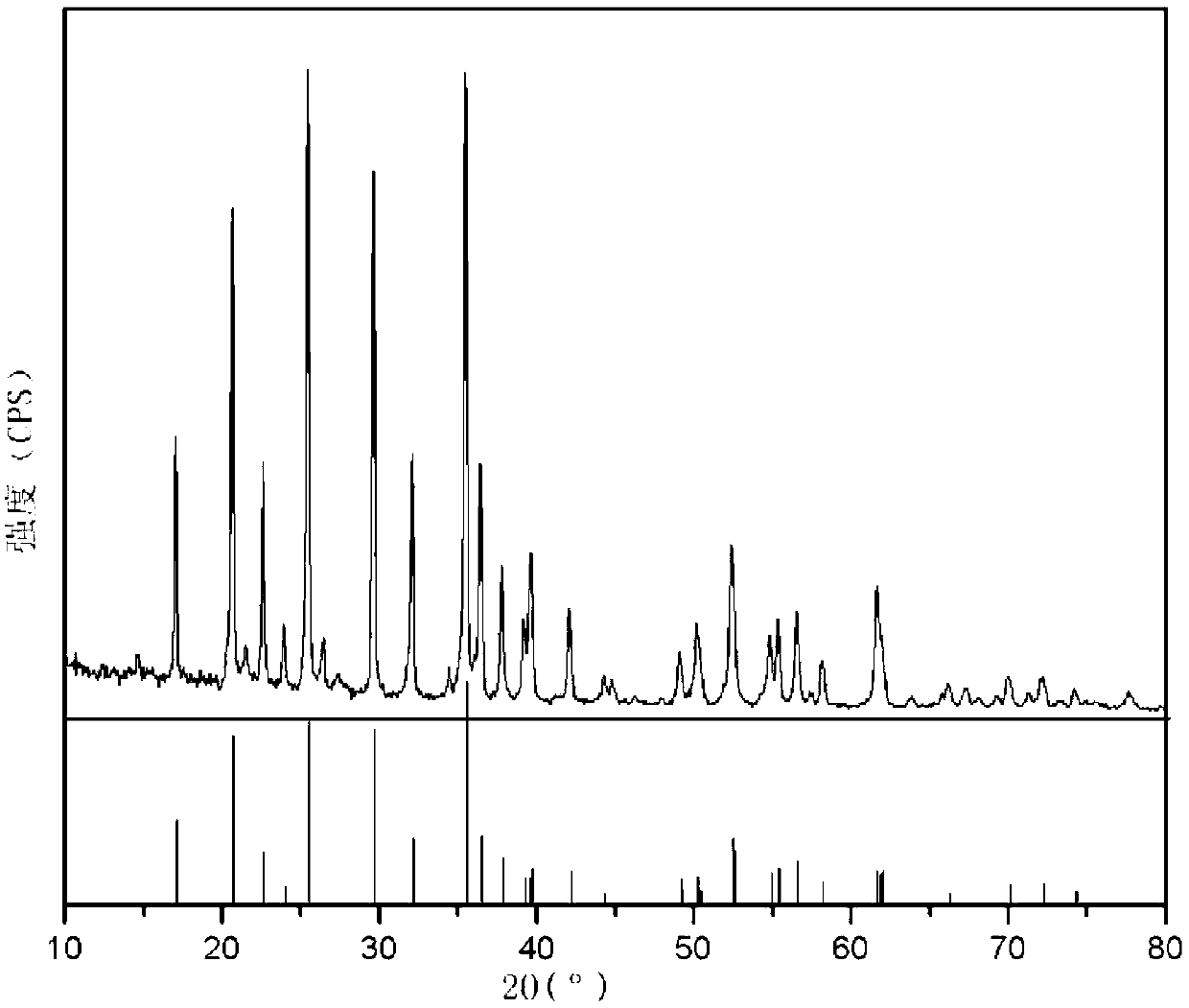

[0053] The recycled waste pre-sintered material was solid-phase sintered in a nitrogen protective atmosphere at 600°C for 8 hours to obtain a lithium iron phosphate product. The X-ray diffraction (XRD) diffraction pattern of the lithium iron phosphate product is as follows Figure 4 As shown, the molar ratio of Li:Fe:P in the lithium iron phosphate product obtained through ICP analysis is 1:1:1.

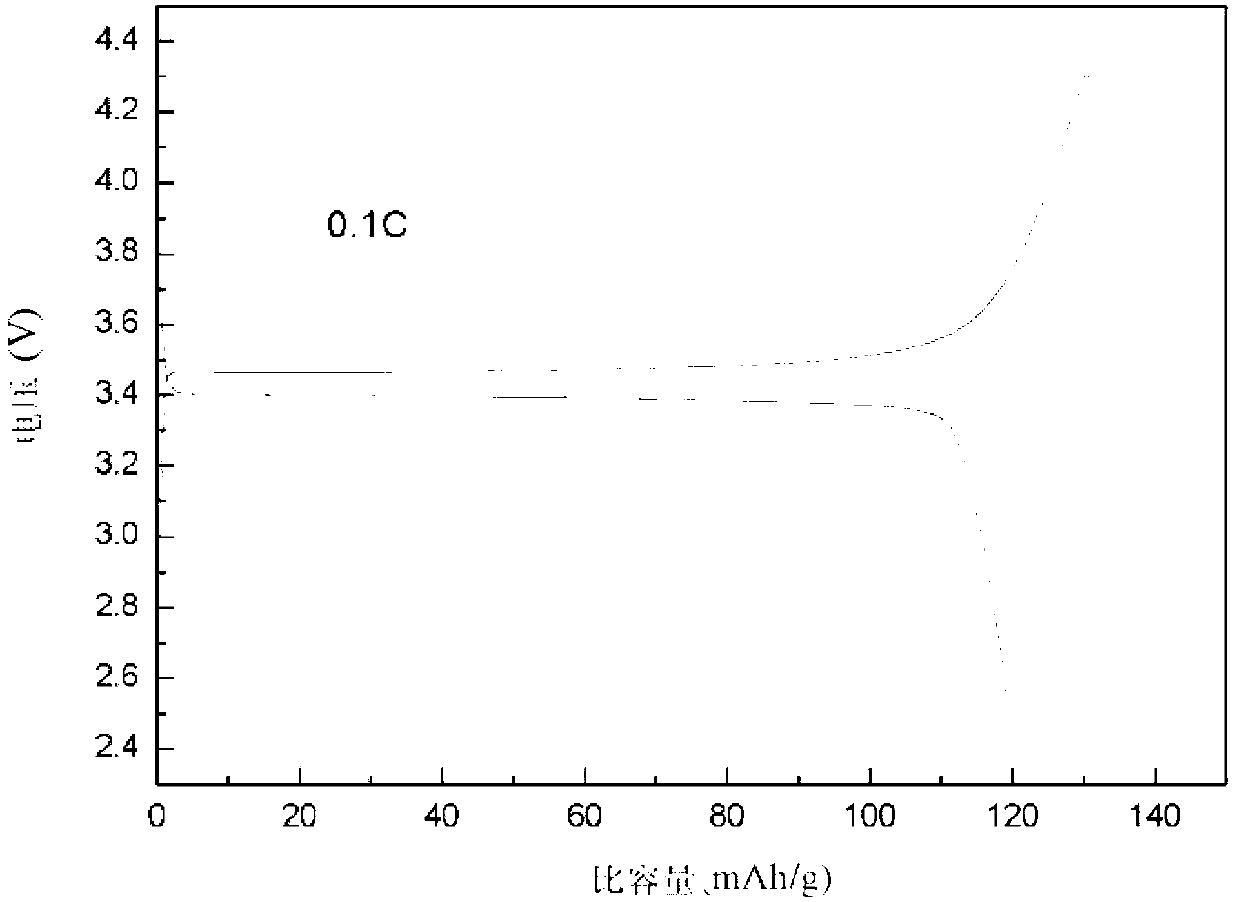

[0054] Mix and grind the lithium iron phosphate produ...

Embodiment 3

[0059] Take the waste lithium iron phosphate power battery of model A123, disassemble it, peel off the battery casing, and then soak it in acetone deionized water solution containing 20% by weight of acetone, that is, separate the positive plate from the part other than the battery casing , Negative plate, diaphragm, electrolyte and conductive agent are put together, ultrasonic 0.5h and mechanical stirring are carried out alternately for 0.5h, and repeated 4 times in total, that is, ultrasonic and mechanical stirring are carried out for a total of 4h until the positive and negative powders are separated from the pole piece , take out the aluminum foil, copper foil and diaphragm, and the rest is a mixed solution;

[0060] Evaporate part of the water from the mixed solution, put it into a planetary ball mill and mill it at a speed of 400r / min for 12 hours, take it out and dry it in an oven at 60°C for 12 hours, put the dried material into a tube sintering furnace under an oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com