Patents

Literature

273 results about "Phosphate product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

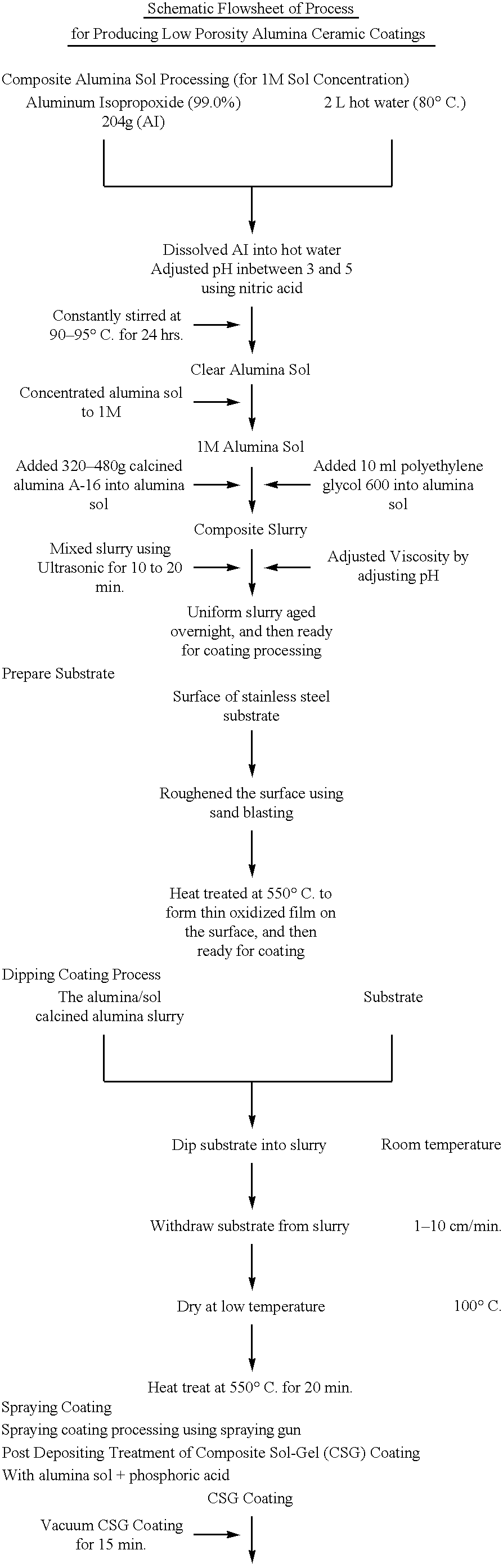

Process for making chemically bonded sol-gel ceramics

InactiveUS6284682B1Liquid/solution decomposition chemical coatingSuperimposed coating processPorosityCeramic coating

This invention relates to a novel method of decreasing porosity of ceramics produced by sol-gel processing. The process of preparing chemically bonded sol-gel ceramics comprises phosphating a sol-gel derived oxide or hydrated oxide and polymerizing the phosphated product with heat treatment. Such combined sol-gel / chemical bonding process can be used to fabricate dense, thick ceramics or ceramic coatings for a variety of applications, including high temperature corrosion protection, wear resistance, dielectric properties, non-sticky surfaces, bio-active ceramics, thermal barrier ceramics, non-wetted surfaces, and others.

Owner:THE UNIV OF BRITISH COLUMBIA

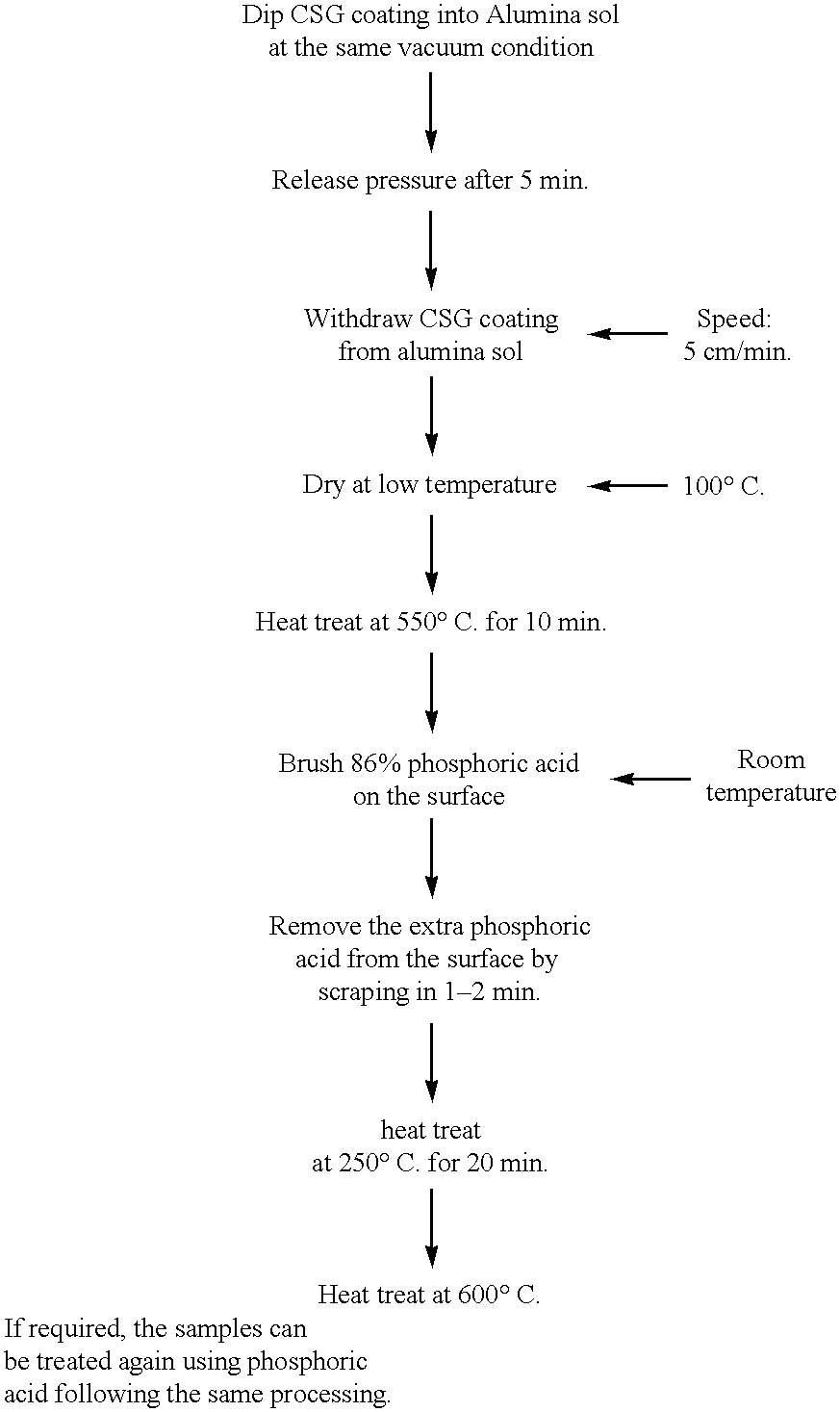

Production method for monoammonium phosphate

InactiveCN104016323AReduce energy consumptionReduce manufacturing costPhosphatesWater insolubleDecomposition

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for monoammonium phosphate. A monoammonium phosphate product is prepared by directly subjecting high pure urea phosphate and ammonia to a double decomposition reaction and reacting for 20-60 min with stirring by controlling a reaction temperature at 40-80 DEG C and a pH value at a reaction endpoint being 4.2-4.6, and through the steps of cooling for crystallization; separating by centrifugation and drying. Measurements of physical and chemical indexes of the produced product show that the physical and chemical indexes of the produced monoammonium phosphate product meet an industrial first level standard. Specifically, the total nutrient content of monoammonium phosphate is higher than 73%; the content of total nitrogen is 12.01-12.23%; the content of phosphorus pentoxide is 61.05-61.25%; the content of moisture is 0.35-0.52%; a pH value is 4.2-4.6; the content of water insoluble materials is 0.090-0.096%; and the content of fluoride is 0.15-0.19%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

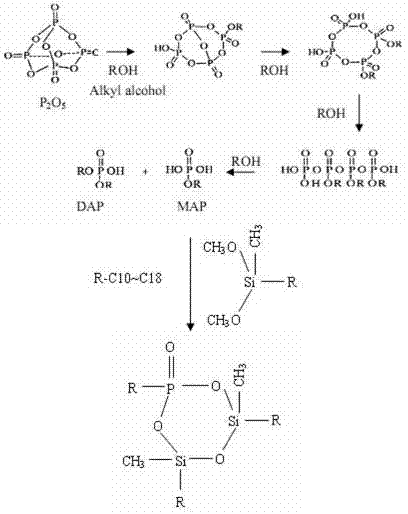

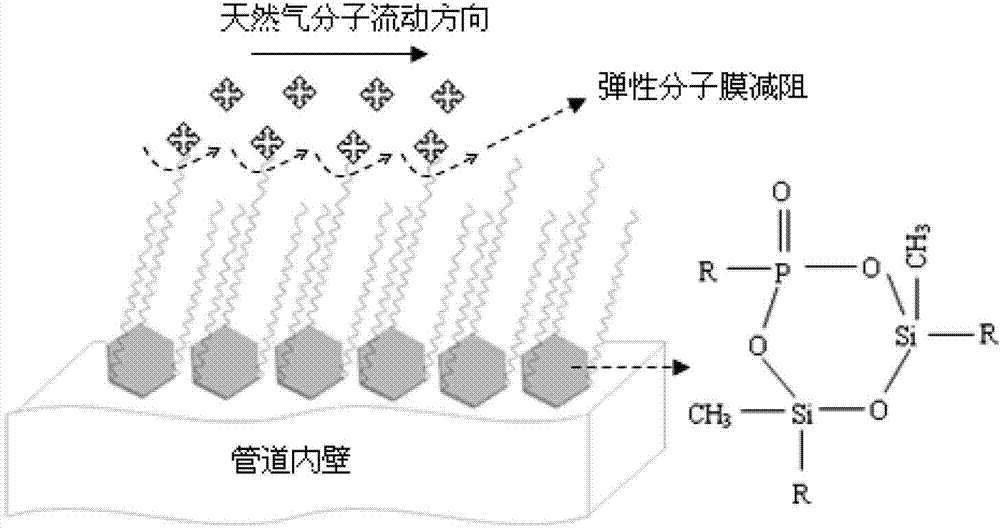

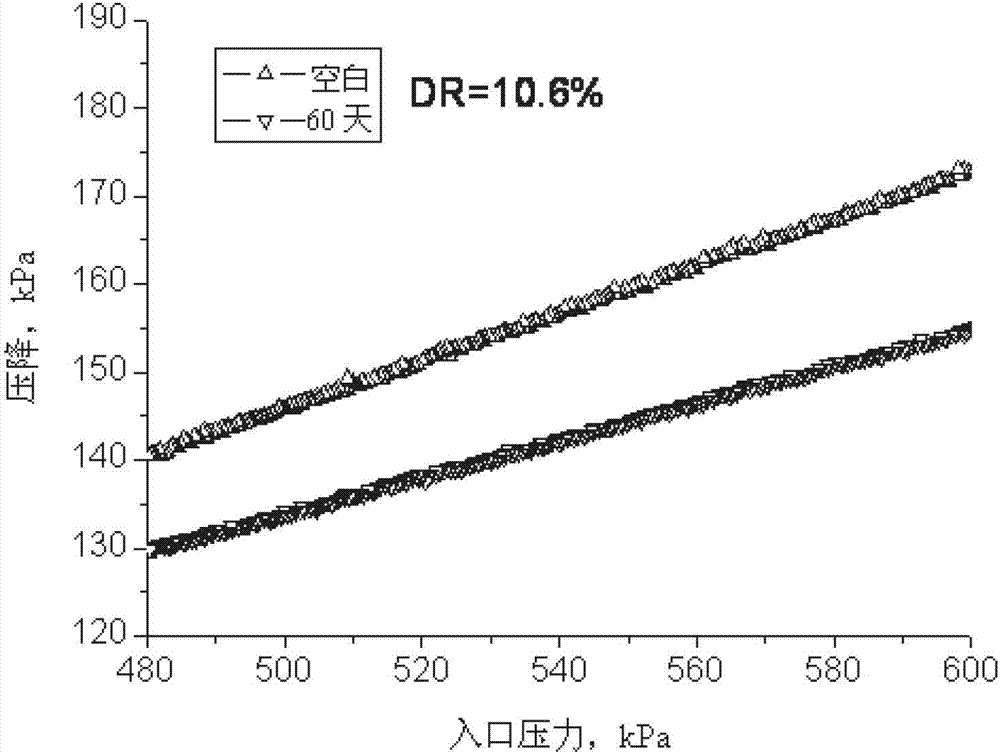

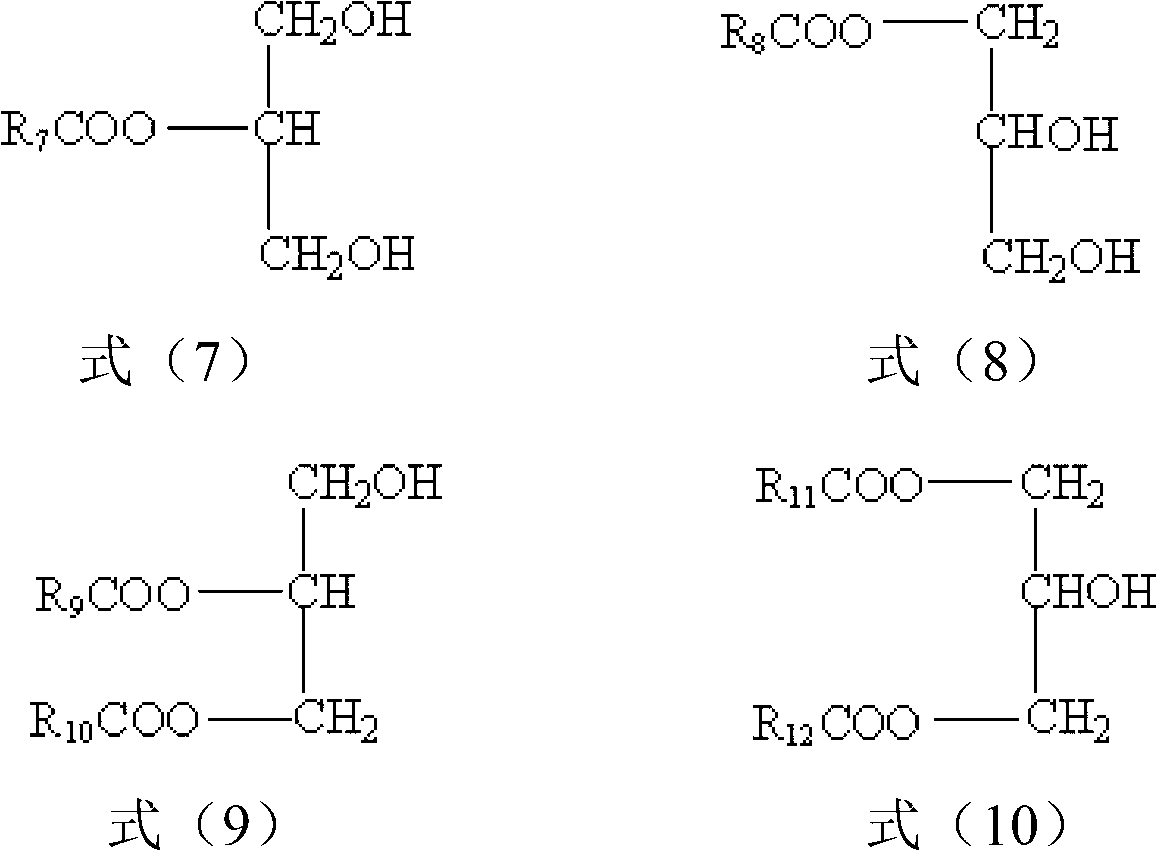

Hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer and preparation method thereof

The invention relates to a hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer and a preparation method thereof. The preparation method comprises the following steps: reacting raw materials phosphorus pentoxide and long-chain alkyl alcohol in a mol ratio of 2:1-4:1 to generate the product mainly comprising long-chain monoalkyl phosphate (MAP); reacting long-chain alkylmethyl dimethoxysilane and the MAP product in a mol ratio of 2:1-2.5:1 to generate an alkylsiloxane-phosphate product mixture, wherein the content of the hexatomic-ring long alkylsiloxane-phosphate is 80-85 wt.%, and the content of the linear alkylsiloxane-phosphate is 15-20 wt.%; and dissolving the obtained alkylsiloxane-phosphate product mixture in n-heptane to form a 30-50 wt.% solution, thereby obtaining the hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer. The invention has the advantages of high corrosion inhibition efficiency, high drag reduction rate and long effective period.

Owner:PIPECHINA SOUTH CHINA CO

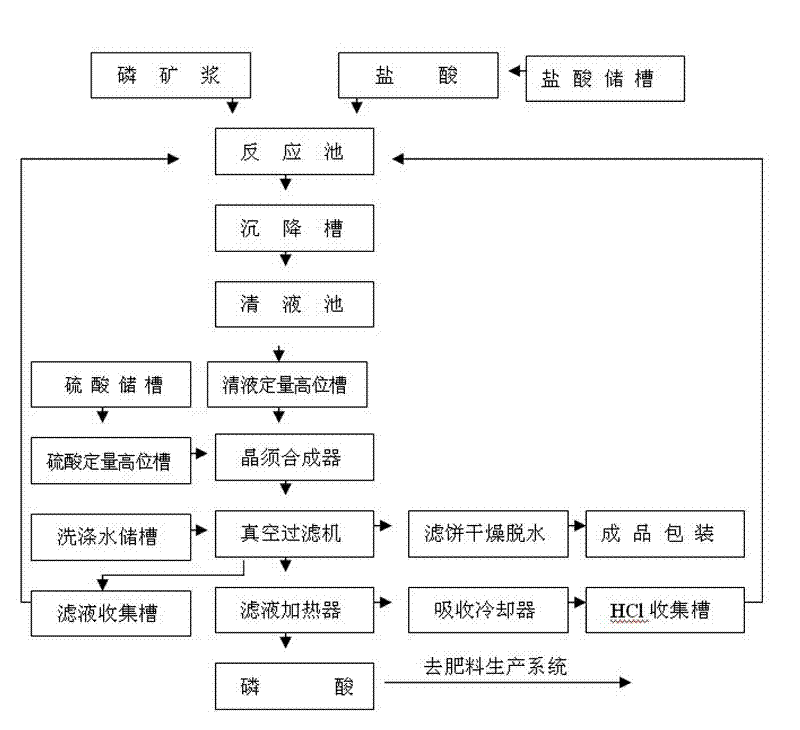

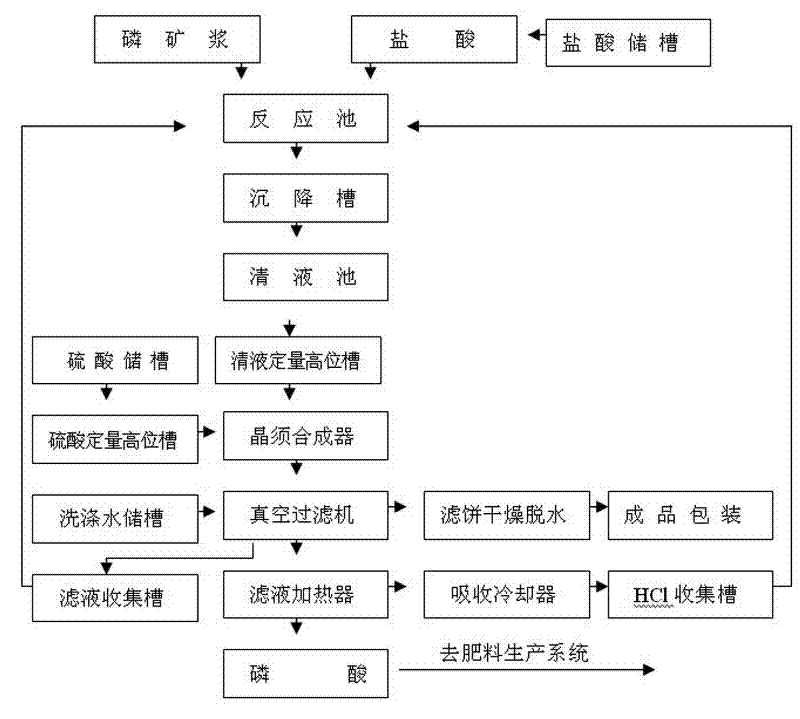

Method for producing phosphoric acid and gypsum whiskers by wet process

InactiveCN102303852ALarge specific surface areaTake advantage ofPolycrystalline material growthSingle crystal growth detailsPhosphate productChloride

The invention discloses a method for producing phosphoric acid and gypsum whiskers by a wet process, which is used in combination with a wet-process phosphoric acid production device. The method comprises: reacting hydrochloric acid with excessive phosphorus ore pulp to form calcium chloride solution containing hydrochloric acid; reacting the calcium chloride solution with solution of sulfuric acid to obtain a suspended matter; filtering, washing and obtaining dihydrate gypsum whiskers; and heating filtrate, cooling, and absorbing, wherein hydrogen chloride is circularly used, phosphoric acidis purified to be used for producing a phosphate product.

Owner:江苏瑞和化肥有限公司

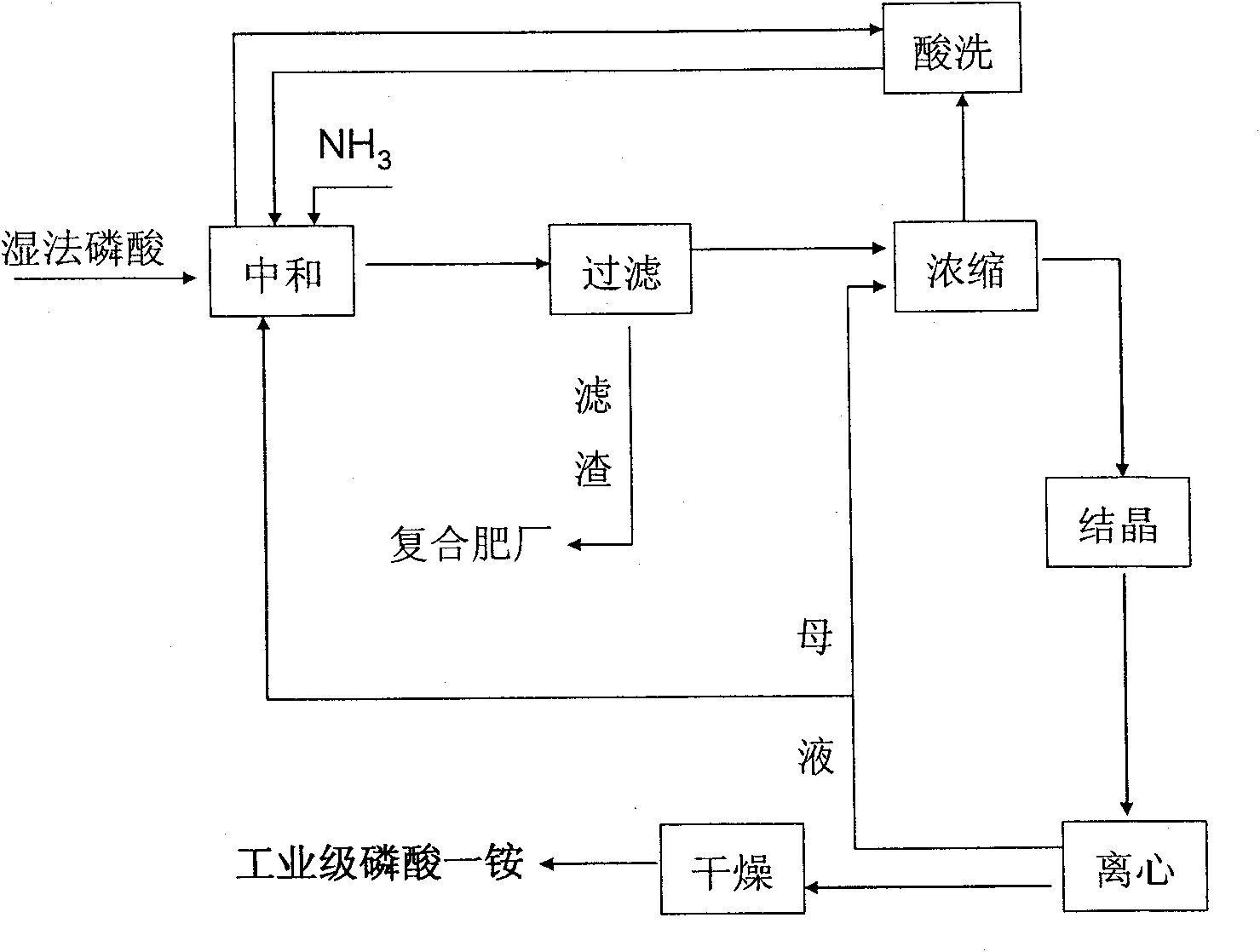

Method for preparing industrial grade monoammonium phosphate from wet-process phosphoric acid

InactiveCN101857211AReduce consumptionGuaranteed stabilityPhosphatesSocial benefitsPhosphate product

The invention discloses a method for preparing industrial grade monoammonium phosphate from wet-process phosphoric acid. In the method, the industrial grade monoammonium phosphate is prepared by neutralizing ammonia with low-cost wet-process phosphoric acid serving as raw materials; a pickling procedure is adopted, so that volatile gas materials are recycled, crystallization mother liquor is recycled or concentrated for recycling, the industrial grade monoammonium phosphate product is obtained, and the product yield is improved; meanwhile the by-products in the production process are used as compound fertilizer materials. The method has the advantages of greatly reducing the production cost of the industrial grade monoammonium phosphate, guaranteeing the stability of the product quality, and avoiding secondary pollution, along with low energy consumption and better economic benefit and social benefit.

Owner:广西利达磷化工有限公司

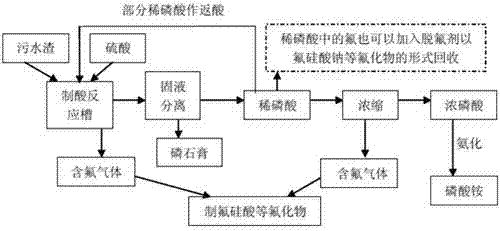

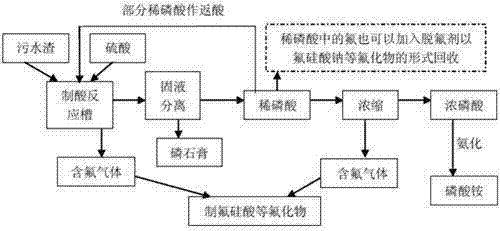

Method for recycling phosphorus and fluoride in sewage residue of phosphorus fertilizer plant

InactiveCN102502552AImprove use valueEffective way to usePhosphatesAlkali orthophosphate fertiliserO-Phosphoric AcidAgricultural engineering

The invention discloses a method for recycling phosphorus and fluoride in the sewage residue of a phosphorus fertilizer plant. According to the method, the sewage residue is decomposed by using sulfuric acid, the phosphorus and the fluoride in the sewage residue are extracted, calcium sulfate dihydrate crystal or calcium sulfate hemihydrate crystal and diluted phosphoric acid solution are generated, diluted phosphoric acid and phosphogypsum which is the by-product are obtained through solid-liquid separation, the diluted phosphoric acid is concentrated into concentrated phosphoric acid, the escaped fluorine containing gas is recycled in the process of concentrating the phosphoric acid and making acid and produced into the fluoride such as the fluosilicic acid and the like, or defluorination agent is added into the diluted phosphoric acid to recycle fluoride resources in the form of the fluoride such as the sodium fluosilicate and the like, and the obtained concentrated phosphoric acid can be used to prepare other phosphate products such as the ammonium phosphate and the like by using the traditional method. The method can be used to effectively recycle the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant so that the waste materials can be changed into the valuable materials and the recycling value of the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant can be improved. The method has good economic benefit and environment protection significance.

Owner:WENGFU (GRP) CO LTD

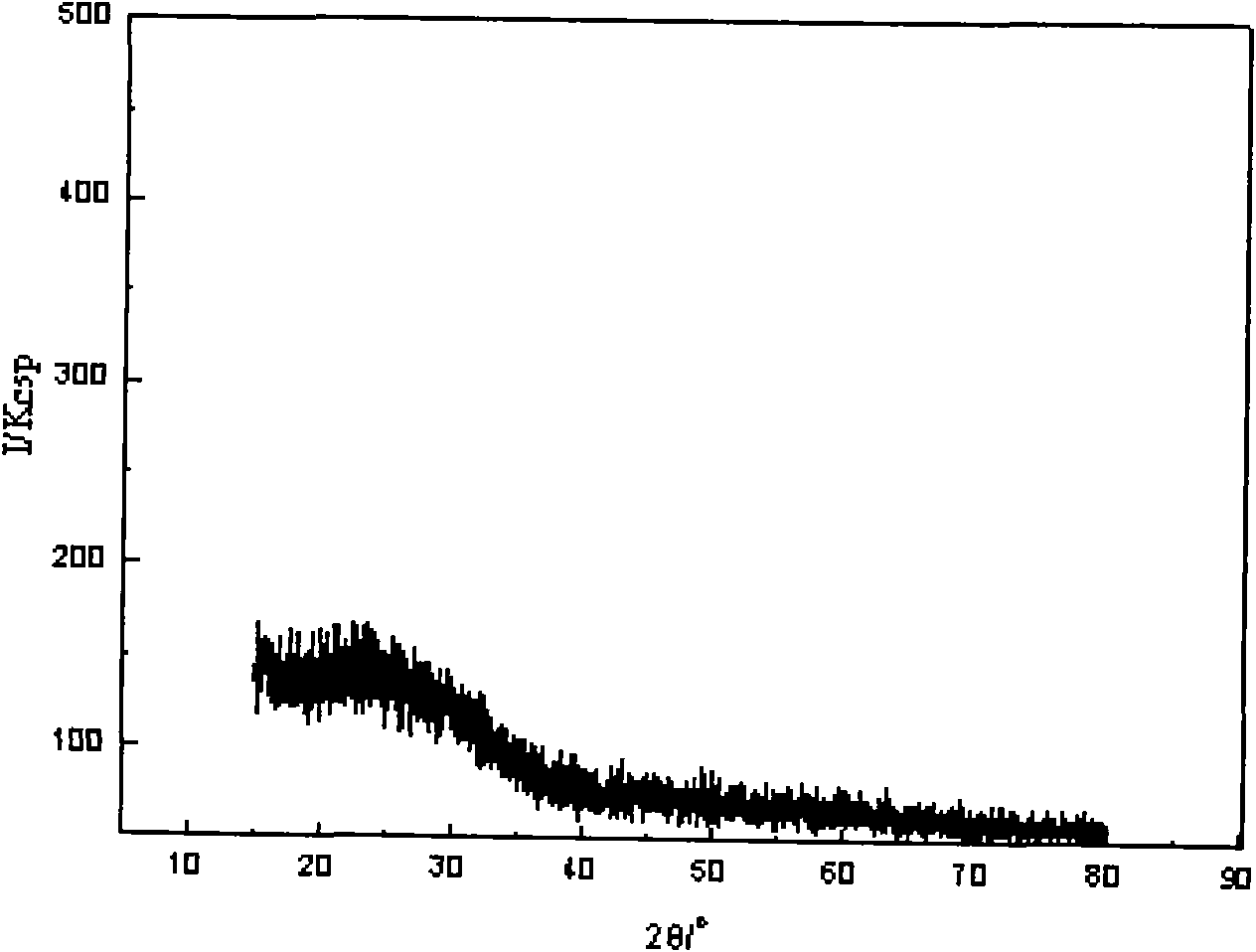

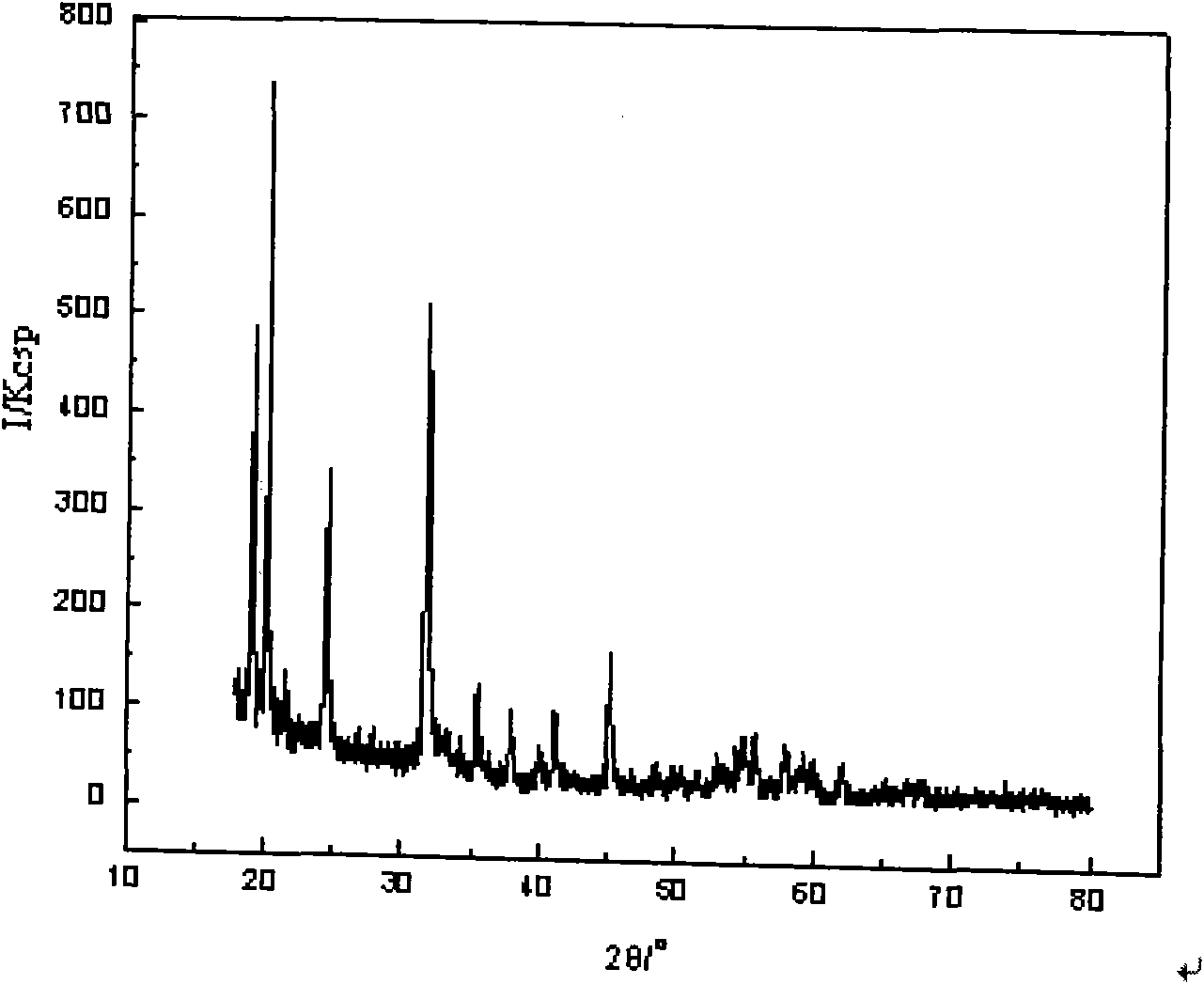

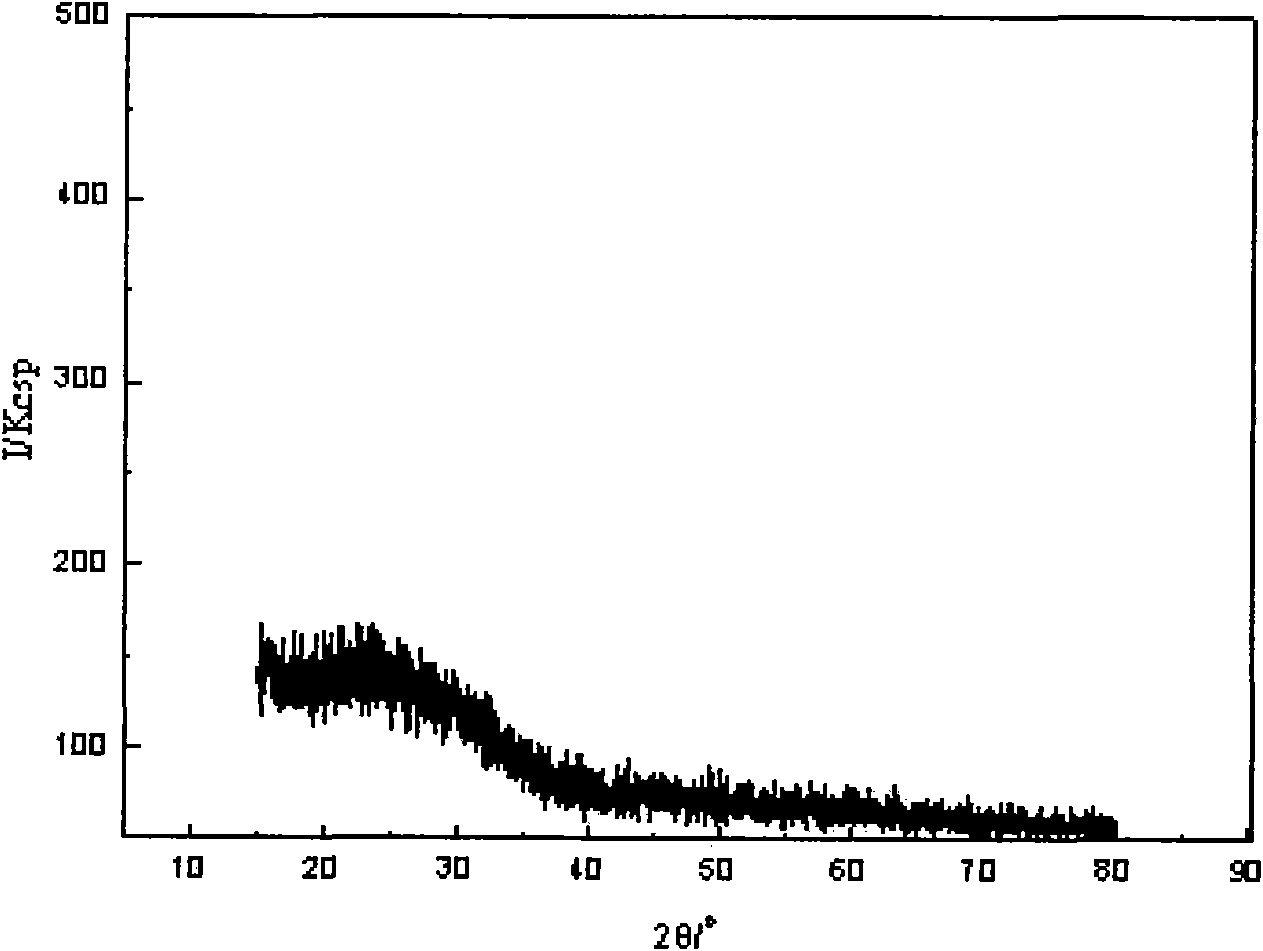

Preparation method of ferric phosphate and product thereof

ActiveCN101913586AImprove the operating environmentCell electrodesPhosphorus compoundsOrganic solventAmorphism

The invention discloses a preparation method of ferric phosphate and a product thereof. The preparation method comprises the following steps of: (1) introducing a ferric iron source solution into an acid resistant reaction kettle by using a metering pump, and then adding a certain dosage of phosphoric acid solution and stirring for 1h; (b) adding a certain dosage of organic solvent to the acid resistant reaction kettle, and preserving heat at 15-98 DEG C and aging for 0.5-24h; and (c) carrying out washing, filtering and spray drying on the obtained ferric phosphate slurry to obtain a final ferric phosphate product, wherein the proportion by weight of the water to the iron to the phosphoric acid to the organic solvent is 100:1-20:1-30:1-500. In the method, the traditional alkali is replaced by the organic solvent to prepare the ferric phosphate; and because the organic solvent has milder property and no harm to the human body, and the operating environment is beneficially improved after mass production. The ferric phosphate of two different crystal forms of amorphism and orthorhombic systems can be prepared by adopting the method.

Owner:铜陵纳源材料科技有限公司

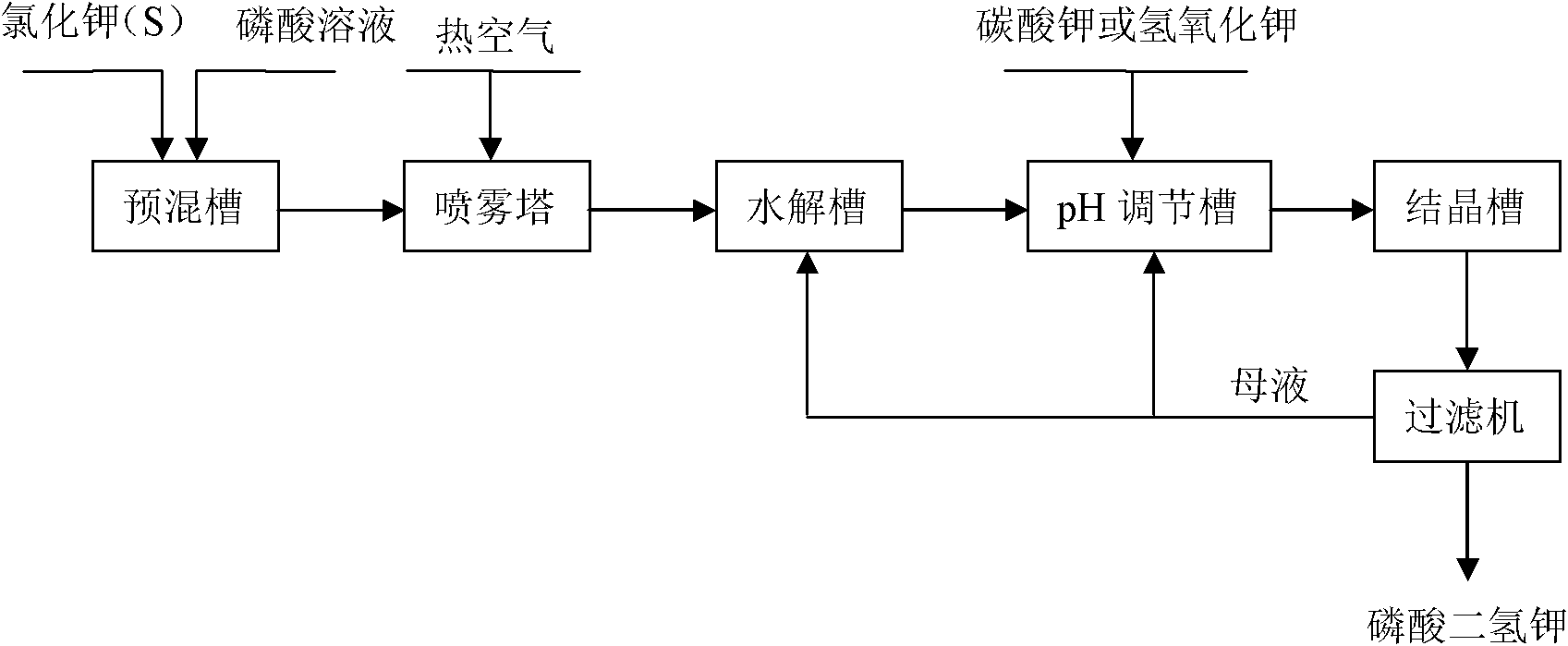

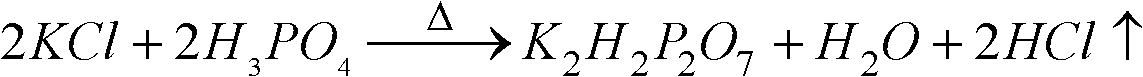

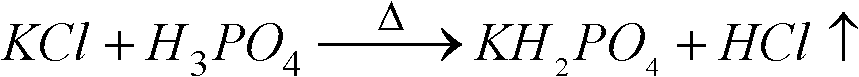

Method for producing potassium dihydrogen phosphate with double decomposition method

ActiveCN101857214AIncrease concentrationReduce concentrationPhosphorus compoundsDecompositionPhosphate product

The invention relates to a method for producing potassium dihydrogen phosphates, in particular to a method for producing potassium dihydrogen phosphate with a double decomposition method. The invention is characterized by further improving the quality of a potassium dihydrogen phosphate product and enhancing the concentration of byproduct hydrochloric acid on the basis of the work of the previous period. The method comprises the following steps of: mixing potassium chloride powder with a phosphoric acid solution, carrying out double decomposition reaction in a spray tower, dissipating hydrogen chloride gas generated by the reaction along with hot air for preparing hydrochloric acid or chlorate; and hydrolyzing, neutralizing and crystallizing double decomposition reaction materials after the hydrogen chloride gas is dissipated to prepare a potassium dihydrogen phosphate product. By adopting the method, it is unnecessary to dissolve potassium chloride into phosphoric acid, it is only necessary for adequately mixing the potassium chloride solid powder with phosphoric acid, therefore, the reaction time is shortened, the production energy consumption is reduced, the production efficiency is improved, and the conversion rate is higher up to more than 99%; meanwhile, the concentration of by-product hydrochloric acid can reach above 25%, and can reach as high as 33%, and the recycling value is greater.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Method for preparing battery-level ferric phosphate using pyrite cinders

InactiveCN102730659ARealize resource utilizationReduce manufacturing costSolid waste disposalPhosphorus compoundsResource utilizationPhosphate product

A method for preparing battery-level ferric phosphate using pyrite cinders uses pyrite cinders as raw materials. The dissolution of iron element in the pyrite cinders is improved by using a composite acidic medium, a soluble organic-acid ferric-salt is extracted and separated synchronously and selectively, and a high-purity ferric phosphate is obtained through replacement in situ under a weak-acid condition, so that the pyrite cinders are transformed into a high-additional ferric phosphate product, thereby realizing the resource utilization of bulk industry solid-wastes in a more economical manner. The ferric phosphate materials prepared by using the method have advantages of a controlled iron-phosphorus ratio, a low impurity content and a high reaction activity, thereby being favorable to insert lithium ion in a subsequent sintering process to form a lithium ferric phosphate crystal suitable for a lithium ion battery positive material.

Owner:LVLING CHEM GRP CO LTD JIANGSU +1

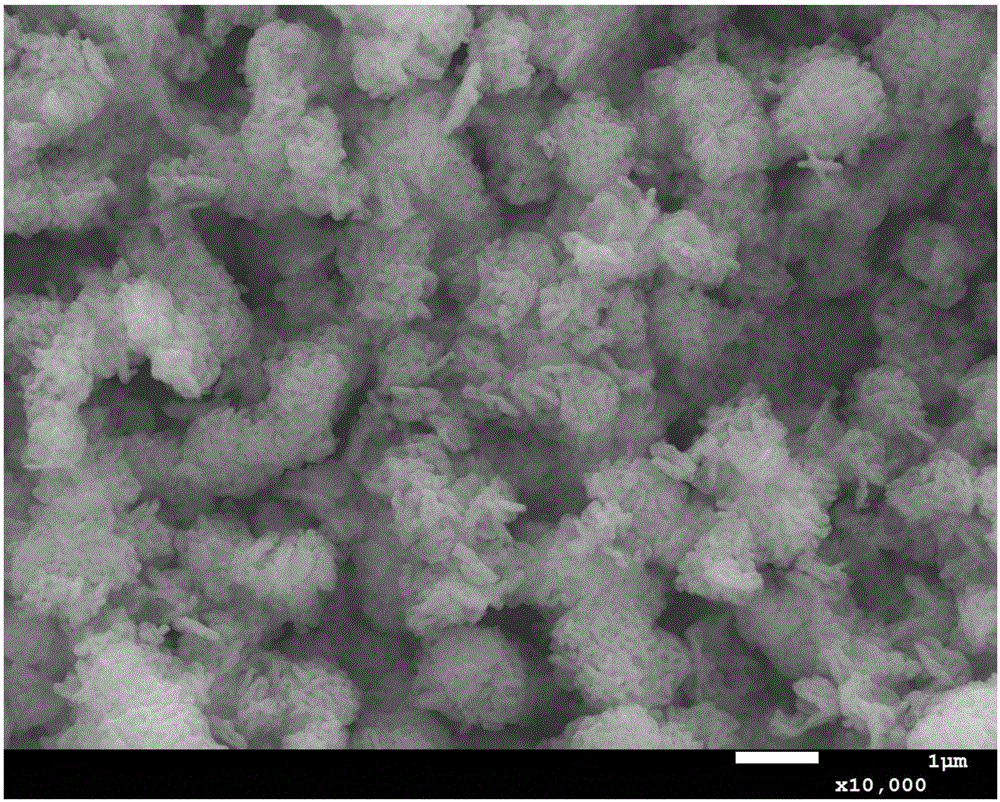

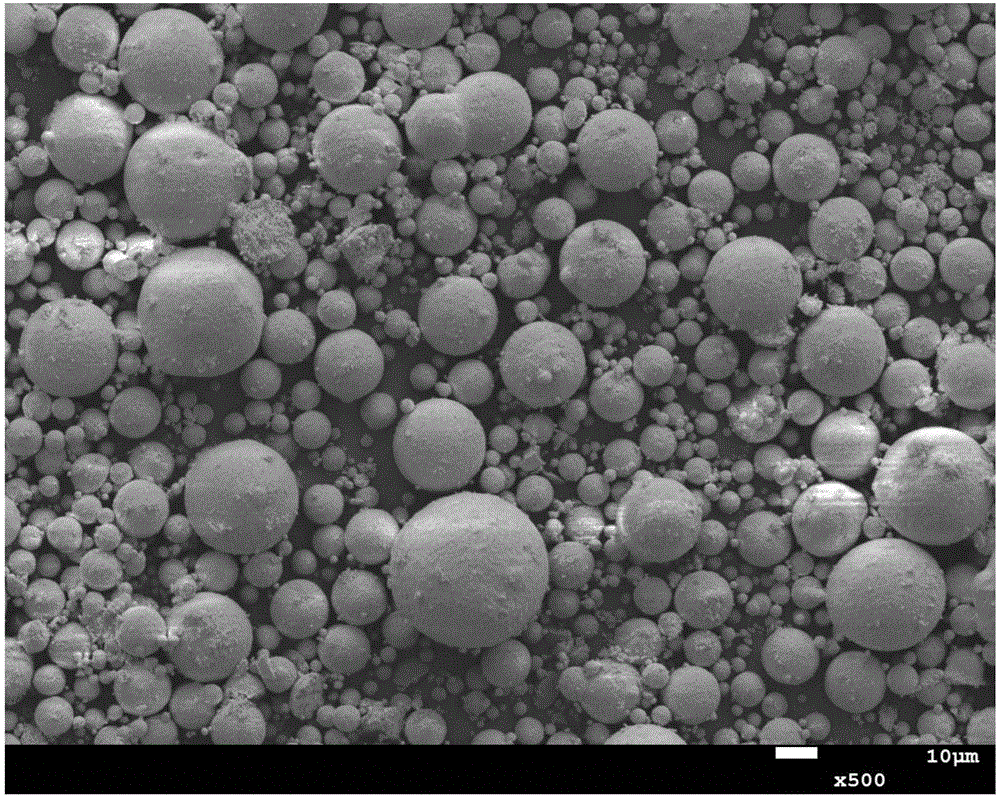

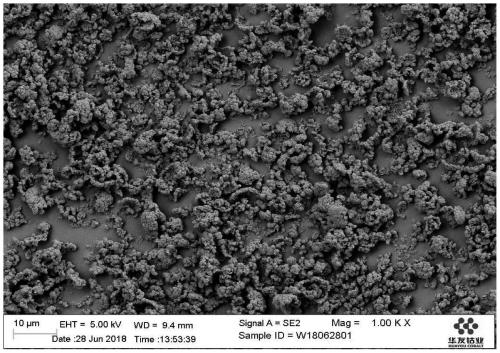

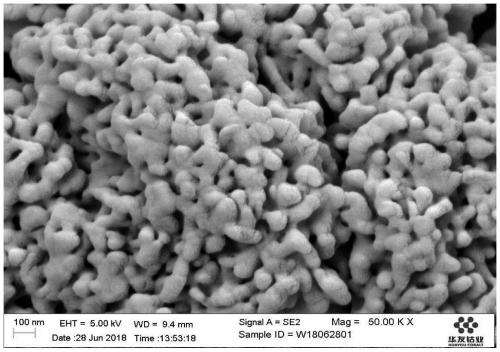

Preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and lithium battery

ActiveCN107522188AControllable particle sizeUniform particle size distributionCell electrodesNanotechnologyPhosphate productLithium-ion battery

The invention discloses a preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and a lithium battery. The method comprises the following steps: mixing: dropwise adding a mixed solution consisting of a phosphorus source compound solution and an oxidant solution into a soluble ferrous compound solution, adding a nano spherical control agent, and stirring and mixing; reacting: stirring at 50 to 100 DEG C under a refluxing condition, and reacting for 5 to 10 h; filtering: magnetically filtering the mixed solution after the reaction by adopting a high magnetic filter, press filtering the filtered solution, and obtaining a ferric phosphate crude product; and calcining: calcining for 24h at 650 to 850 DEG C under the protection of inert gas, and cooling to obtain a final ferric phosphate product. By adopting the method, the morphology of the ferric phosphate product can be controlled, and the performance of the lithium ferric phosphate can be improved.

Owner:YOSHIHIRO COMM EQUIP GRP CO LTD

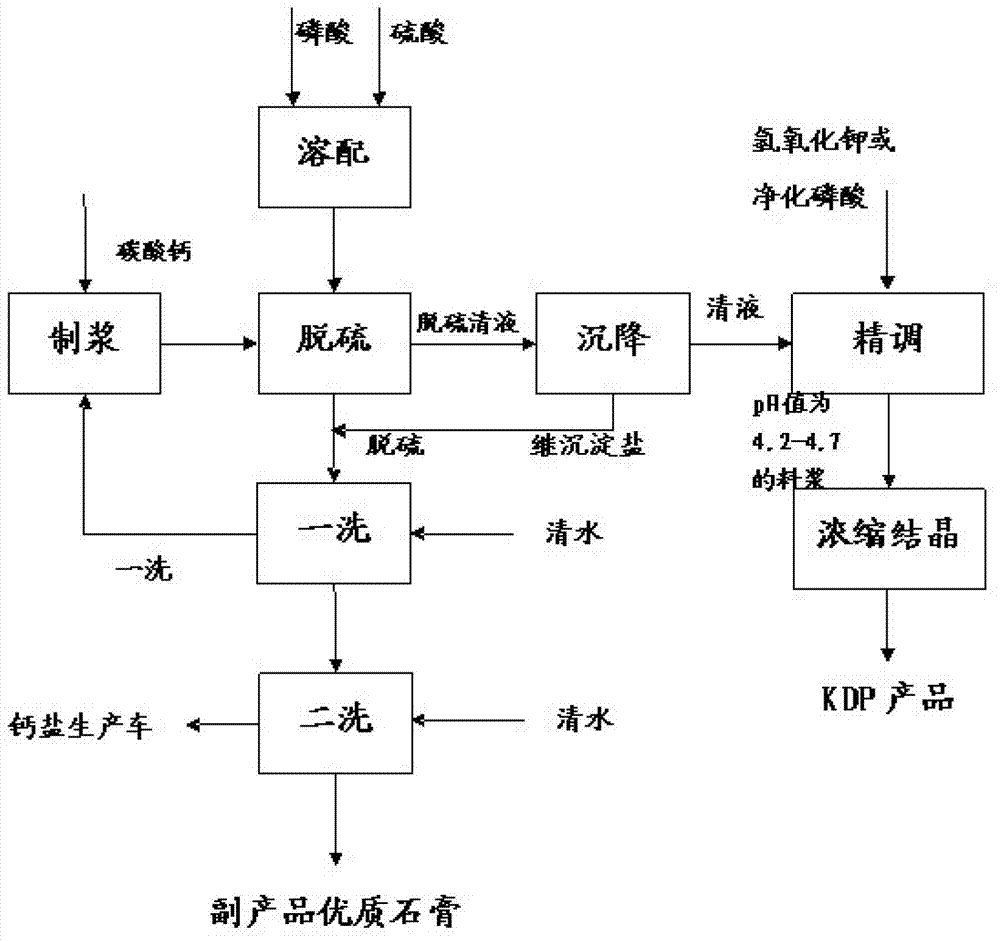

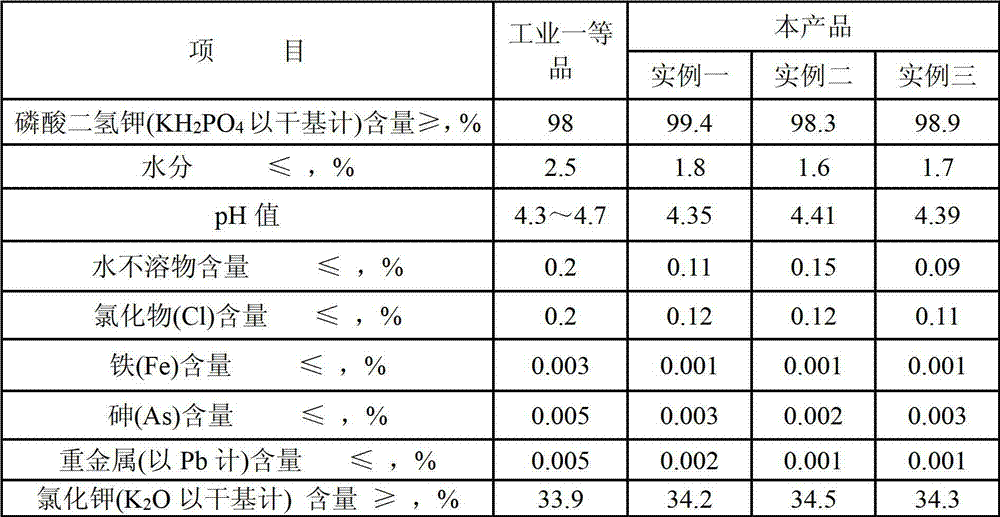

Method for producing industrial-grade potassium dihydrogen phosphate (KH2PO4) by wet method purified phosphoric acid and potassium sulfate

ActiveCN102963874AReduce lossesInhibition lossCalcium/strontium/barium sulfatesPhosphorus compoundsChemical industryReaction temperature

The invention discloses a method for producing industrial-grade potassium dihydrogen phosphate (KH2PO4) by wet method purified phosphoric acid and potassium sulfate, belonging to the field of phosphorus chemical industry. The method comprises the following steps: a. adding potassium sulfate in wet method purified phosphoric acid and fully dissolving potassium sulfate, wherein the addition amount of potassium sulfate based on mole ratio is that p:K is 0.6-1.2:1; b, adding calcium carbonate slurry with solid content of 50-90% in the solution obtained from the step a, stirring for reaction, wherein the reaction temperature is controlled to 60-90 DEG C, the addition amount of the calcium carbonate slurry based on mole ratio is that Ca:S is 0.6-1.2; c. filtering a mixed material system which is obtained by the reaction in the step b; and d. adjusting the pH value of the filtrate obtained from the step c to 4-5, and then concentrating and crystallizing, thus obtaining the potassium dihydrogen phosphate product. The method is simple in process, easy to control and industrially apply, low in cost and high in yield; and the yield of P2O5 can be up to over 96% and the yield of K2O can be up to over 98%.

Owner:GUIZHOU CHANHEN CHEM CO LTD

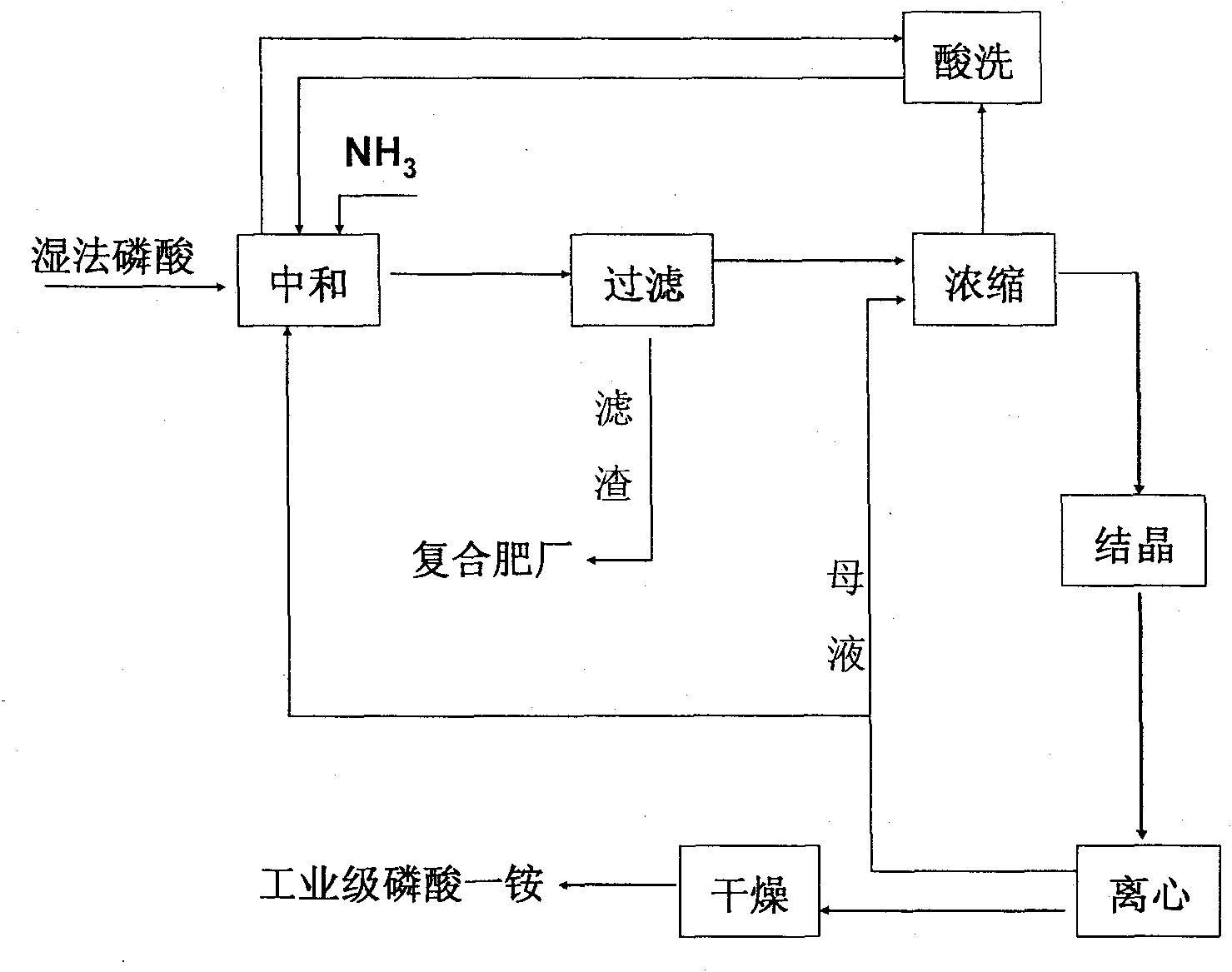

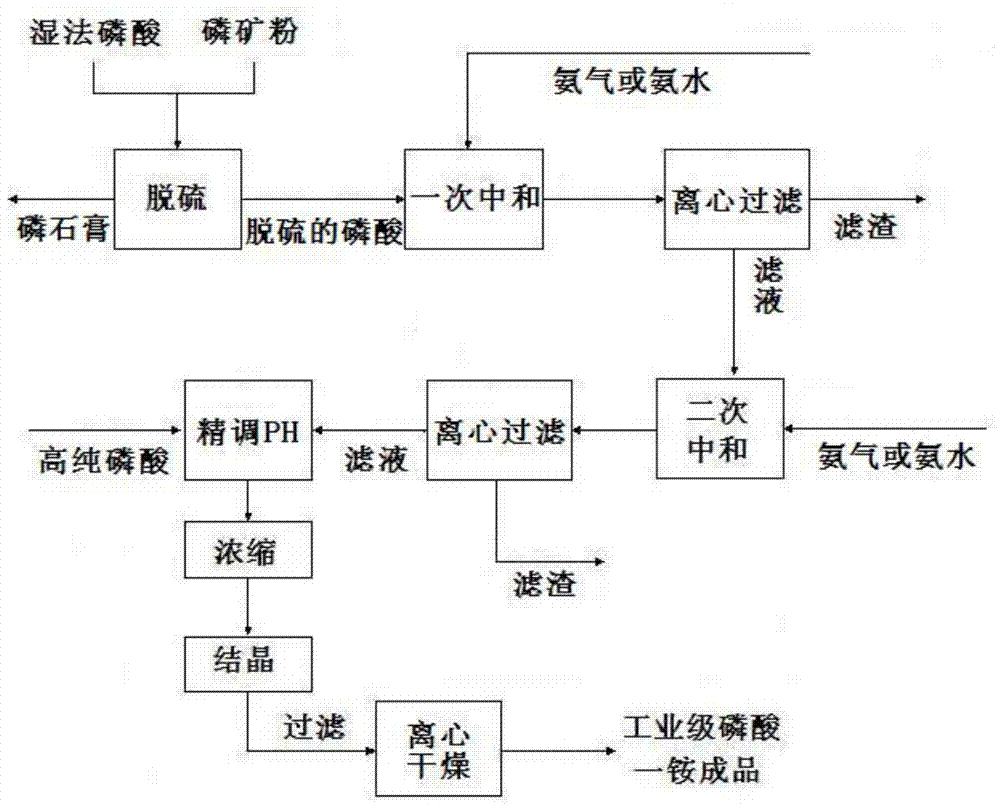

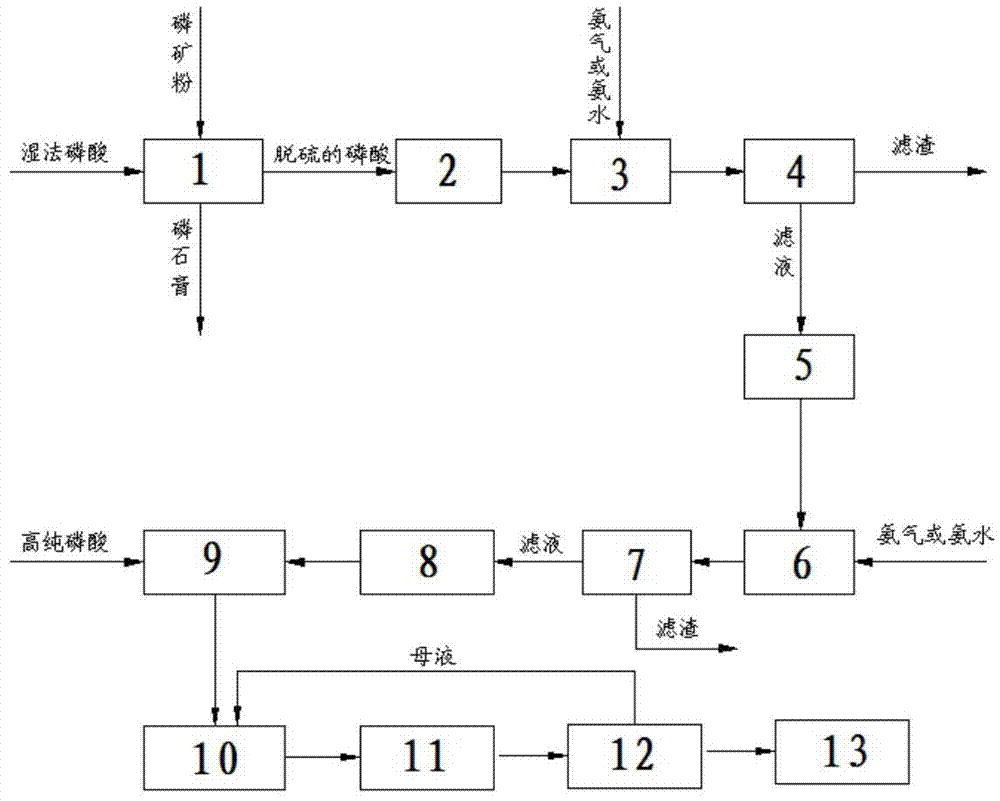

Method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid

The invention discloses a method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid. The method comprises the steps of performing neutralization reaction for two times on filtrate and ammonia gas or ammonia water to obtain ammonium phosphate slurry, wherein the filtrate is obtained by performing desulfurization reaction on phosphate rock powder and wet process phosphoric acid; performing concentration, crystallization and drying by using filtrate which is obtained by adjusting the pH value with high-purity phosphoric acid to obtain an industrial grade monoammonium phosphate product; removing most of impurity ions when the pH value is neutralized to 4.0-5.0 by the first neutralization reaction, then performing the second neutralization reaction to remove impurities in the wet process phosphoric acid, finely adjusting the pH value to 3.9-4.4 by using the high-purity phosphoric acid, and performing concentration and crystallization to obtain the industrial grade monoammonium phosphate. The method disclosed by the invention reduces the production cost and energy consumption and is environment-friendly and pollution-free; the obtained product is stable in quality, the process flow is short, the device construction investment is saved, the needed operators are less, the energy consumption is reduced, the pollution is reduced, and the quality of monoammonium phosphate is ensured through effective impurity removal, so that the method has a very good economic benefit.

Owner:GUIZHOU KAILIN GRP CO LTD

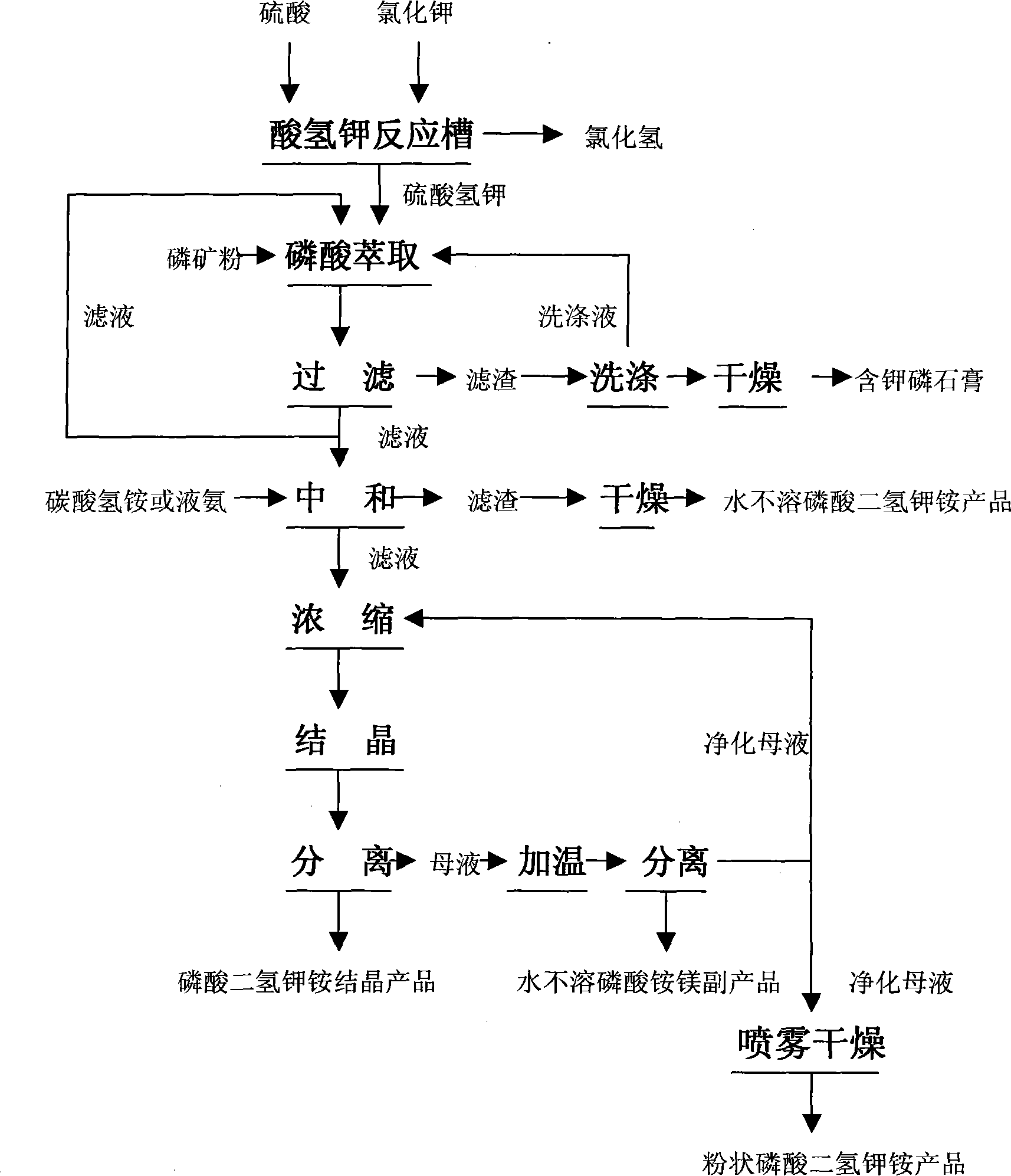

Preparation of ammonium potassium dihydrogen phosphate

ActiveCN101348244AIncrease profitReduce energy consumptionPhosphorus compoundsEvaporationPhosphate product

The invention provides a method for preparing potassium dihydrogen phosphate. In the method, phosphate ores, sulphuric acid and potassium chloride are taken as base materials and subjected to phosphoric acid extraction, filtering, neutralization and separation, concentration and crystallization to obtain a full water-soluble potassium dihydrogen phosphate product, and the potassium dihydrogen phosphate solution prepared is high in concentration, the solid content reaches 40 percent, thereby reducing the load of the concentration process; in particular, the method adopts a process of neutralization first and concentration second, so that the corrosivity of concentration liquids is small, the boiling point is low, and the conventional multi-effect concentration by evaporation can be performed by the common equipment, and the equipment investment and the energy consumption are greatly lowered; because in the phosphoric acid extraction process, the potassium bisulfate is added, thereby effectively lowering the emission of fluorine-containing exhaust gases and facilitating the environmental protection; adding with the development and the utilization of potassium-containing phosphogypsum, the method of the invention can avoid the environmental pollution caused by the phosphogypsum, improve the material utilization ratio and make the material utilization ratio reach 100 percent.

Owner:昆明隆祥化工有限公司

Method for extracting ferric phosphate from phosphorized waste residues

The invention relates to a method for extracting ferric phosphate from phosphorized waste residues. The method comprises the following steps: adding water into powdery phosphorized waste residues, and uniformly stirring; then, slowly adding concentrated hydrochloric acid into a reaction device till the white solids are fully dissolved; filtering the solution and removing undissolved substances; slowly dropwise adding sodium hydroxide solution into the filtrate, controlling the pH of the solution to 1.0-2.0, reacting for 3+ / -0.5 hours, and filtering; washing with distilled water to neutral; and drying and smashing to obtain a battery-grade ferric pyrophosphate product. According to the process of recovering and purifying ferric phosphate provided by the invention, the recovery rate of ferric phosphate reaches 90%, the content of Fe<3+> in the ferric phosphate product is greater than or equal to 29% (dihydrate), and Fe / P is equal to 0.97-1.0. According to the method provided by the invention, waste is turned to wealth, the problem that waste residues are discharged to cause the environmental pollution is solved, and the ferric phosphate product with a wide market prospect is extracted from phosphorized waste residues.

Owner:CHONGQING ENERGY COLLEGE

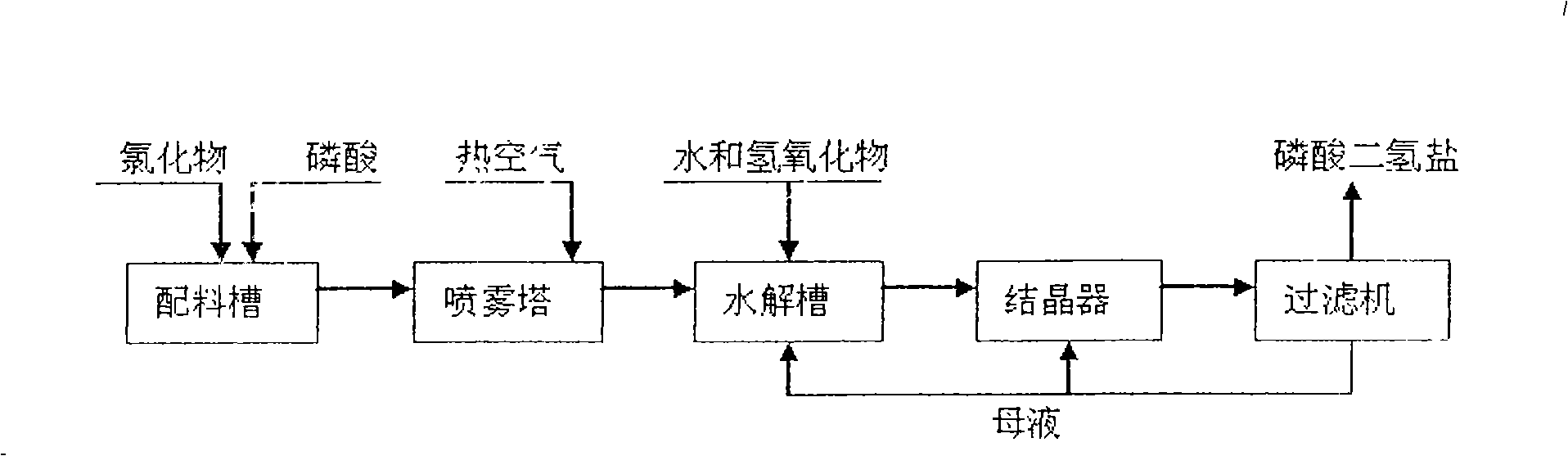

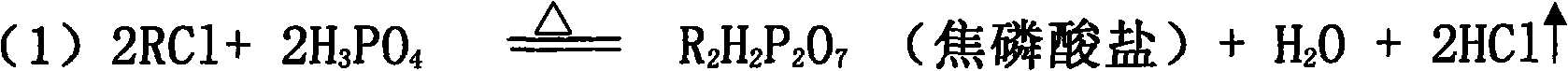

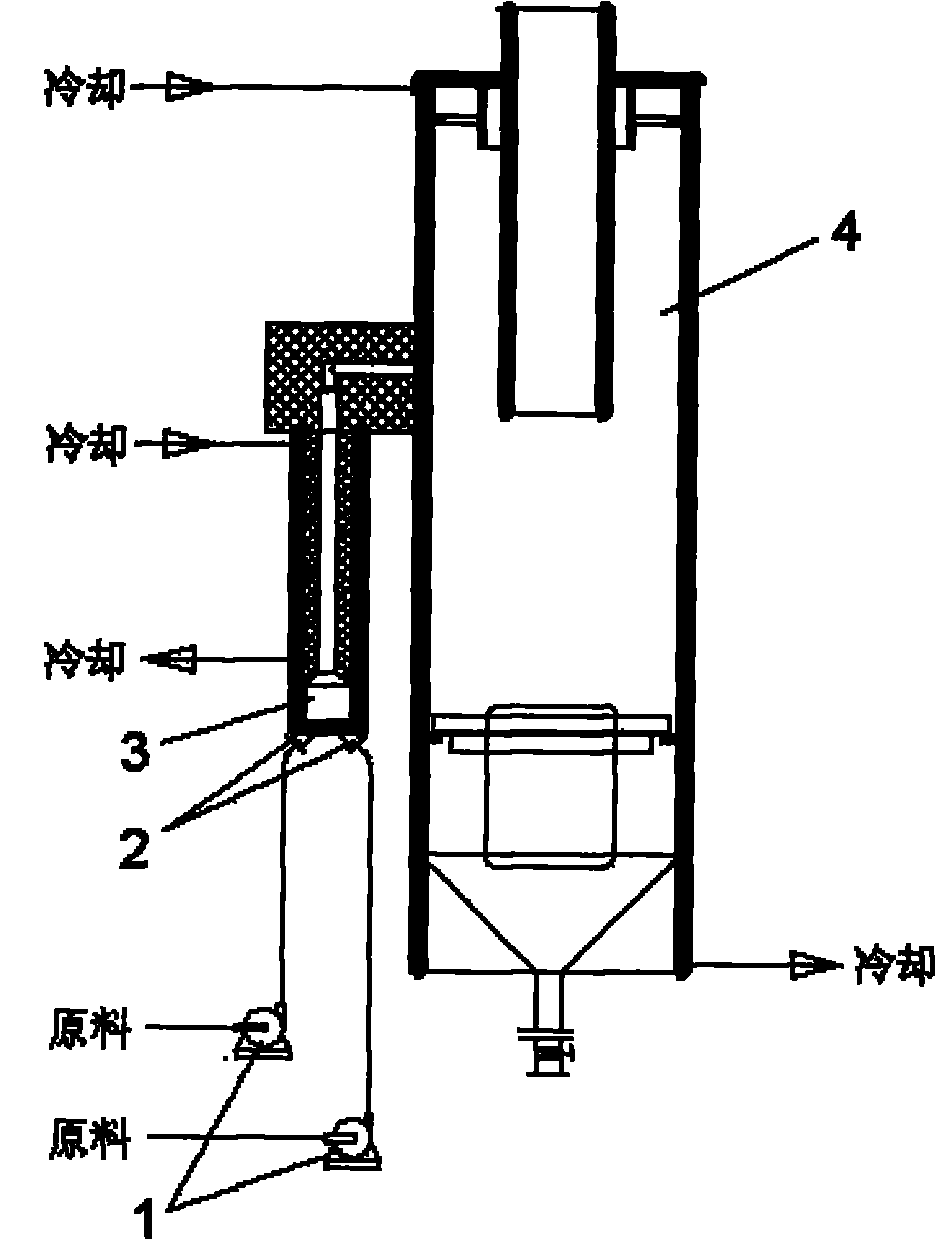

Method for preparing dihydric phosphate

ActiveCN101343052AReduce heat transfer rateLow mass transfer efficiencyPhosphatesSmall dropletDecomposition

The invention discloses a method of producing dihydric phosphate, which essentially comprises steps as follows: firstly, chloride is mixed with excessive phosphoric acid in order to obtain material liquid; secondly, the material liquid is added into the spray dryer to atomize into tiny droplets; thirdly, the droplets are instantaneously contacted and heated with as much hot air as is sufficient to enable double decomposition reaction between chloride and phosphoric acid to happen, so that hydrogen chloride gas escapes through the double decomposition reaction between chloride and phosphoric acid, and the remaining reaction products are hydrolyzed, the pH value thereof is regulated, and a dihydric phosphate product is obtained after cooling and crystallization. The production method has technical advantages that the shortcomings of prior art can be overcome, the spray dryer is adopted as a core reactor to atomize the material liquid into small droplets to be contacted with the high-temperature hot air, the specific surface area of evaporation is maximum, so that the escaping time of HCl and the water vapor is 3 to 8 seconds only, the reaction conversion rate reaches up to 97 percent, the cost of raw materials can be significantly reduced, the material liquid continues to be in and out, the reaction device is simple and practical, so that large-scale industrialization production can be achieved.

Owner:GUIZHOU CHANHEN CHEM CO LTD

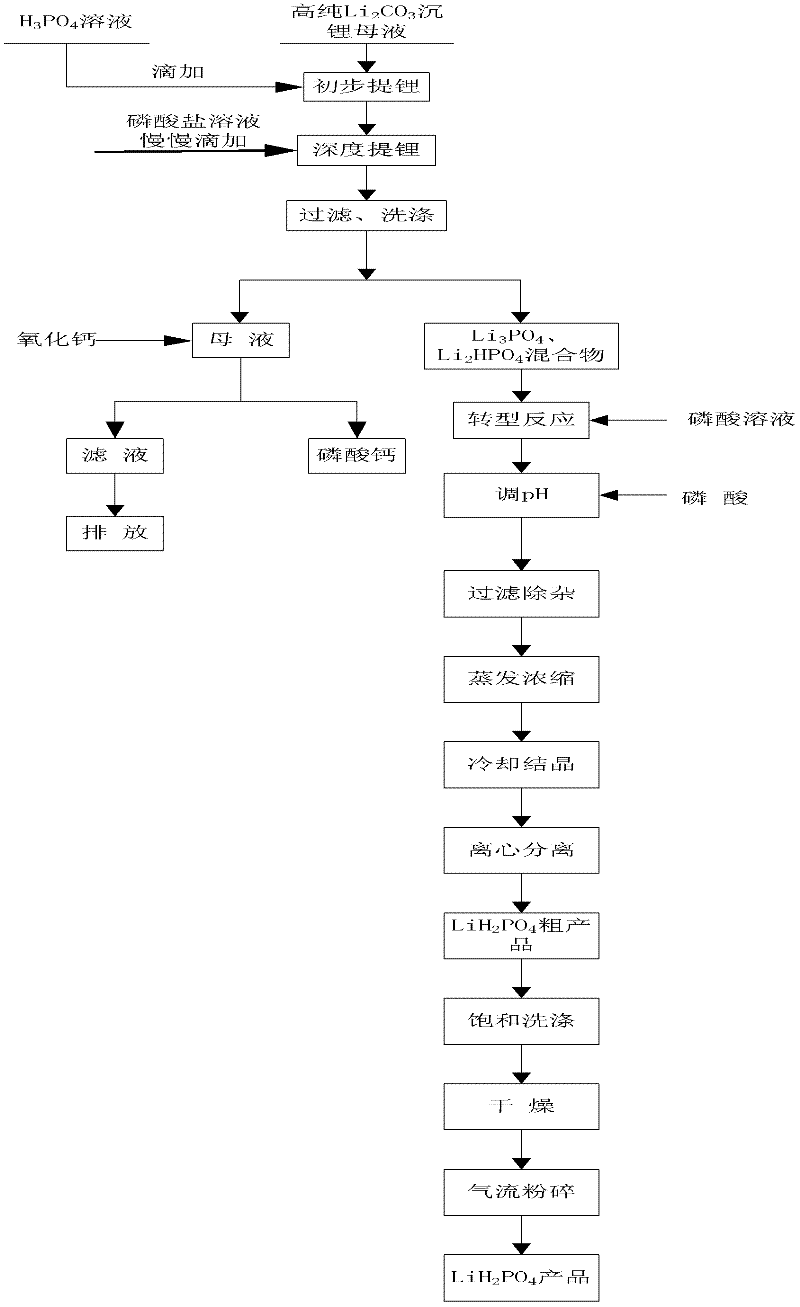

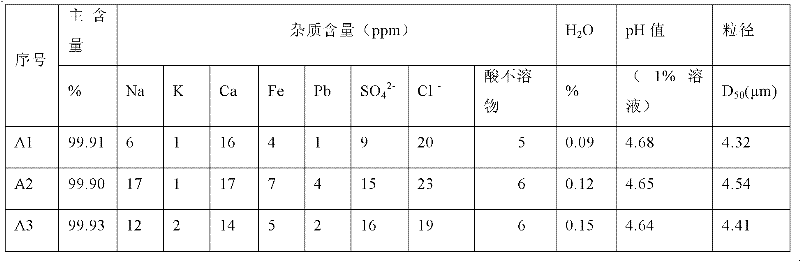

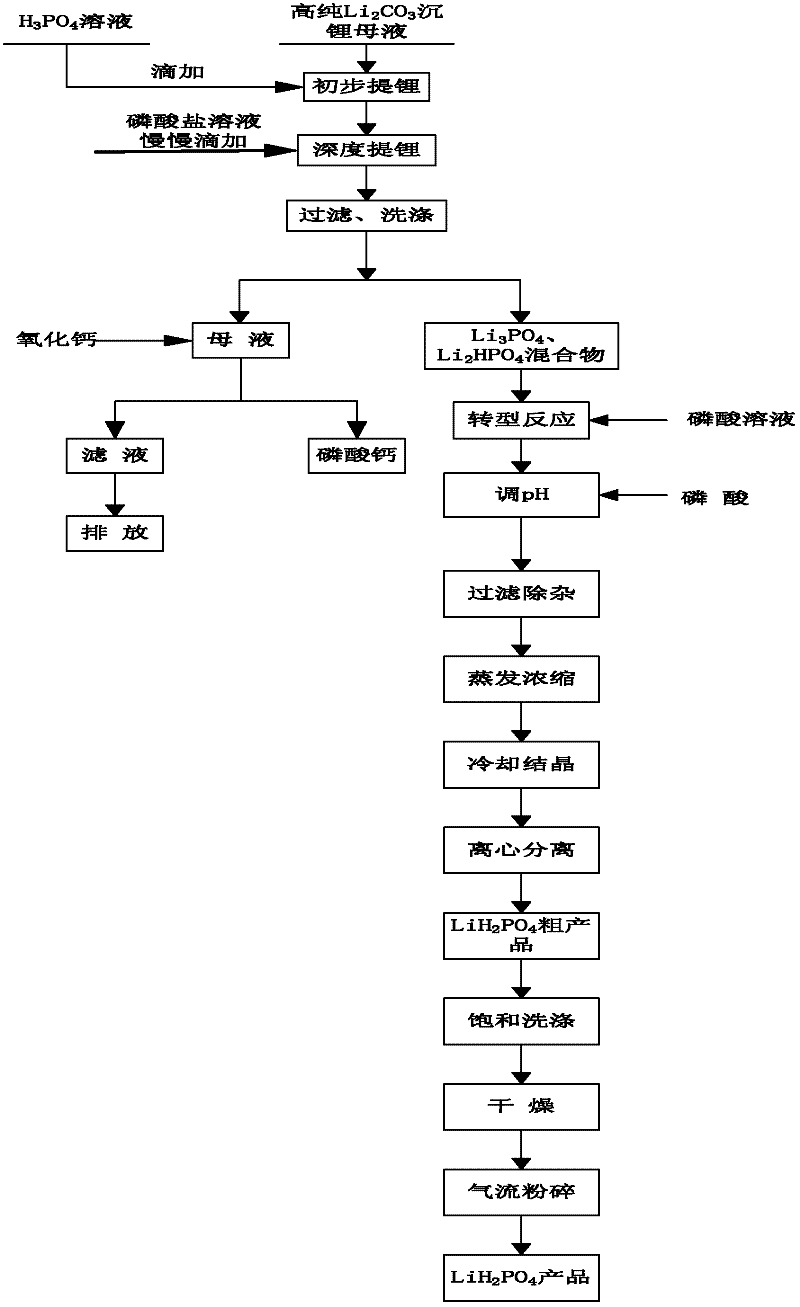

Method for preparing battery grade lithium dihydrogen phosphate with high-purity lithium carbonate lithium depositing mother solution

ActiveCN102351160AFine and uniformBright white colorPhosphorus compoundsPhosphate productEvaporation

The invention relates to a method for preparing battery grade lithium dihydrogen phosphate with a high-purity lithium carbonate lithium depositing mother solution. The method comprises the steps of: conducting preliminary lithium extraction and deep lithium extraction to a lithium carbonate lithium depositing mother solution with phosphoric acid and phosphate so as to obtain a mixture of lithium phosphate and dilithium hydrogen phosphate, reacting the mixture with phosphoric acid to generate a lithium dihydrogen phosphate solution, then carrying out concentration and evaporation, cooling and crystallization, centrifugation, saturation washing, drying, air-stream crushing and packaging, thus obtaining the battery grade lithium dihydrogen phosphate. The method of preparing battery grade lithium dihydrogen phosphate in the invention fully makes use of the mother solution generated during high-purity lithium carbonate production, and has the advantages of simple process, easy operation, low production cost, over 90% of lithium recovery rate, and stable quality of the obtained battery grade lithium dihydrogen phosphate product, and is also suitable for preparing the lithium ion battery positive material lithium iron phosphate. Therefore, the method provided in the invention boasts broad market prospects, as well as good economic and social benefits.

Owner:GANFENG LITHIUM CO LTD

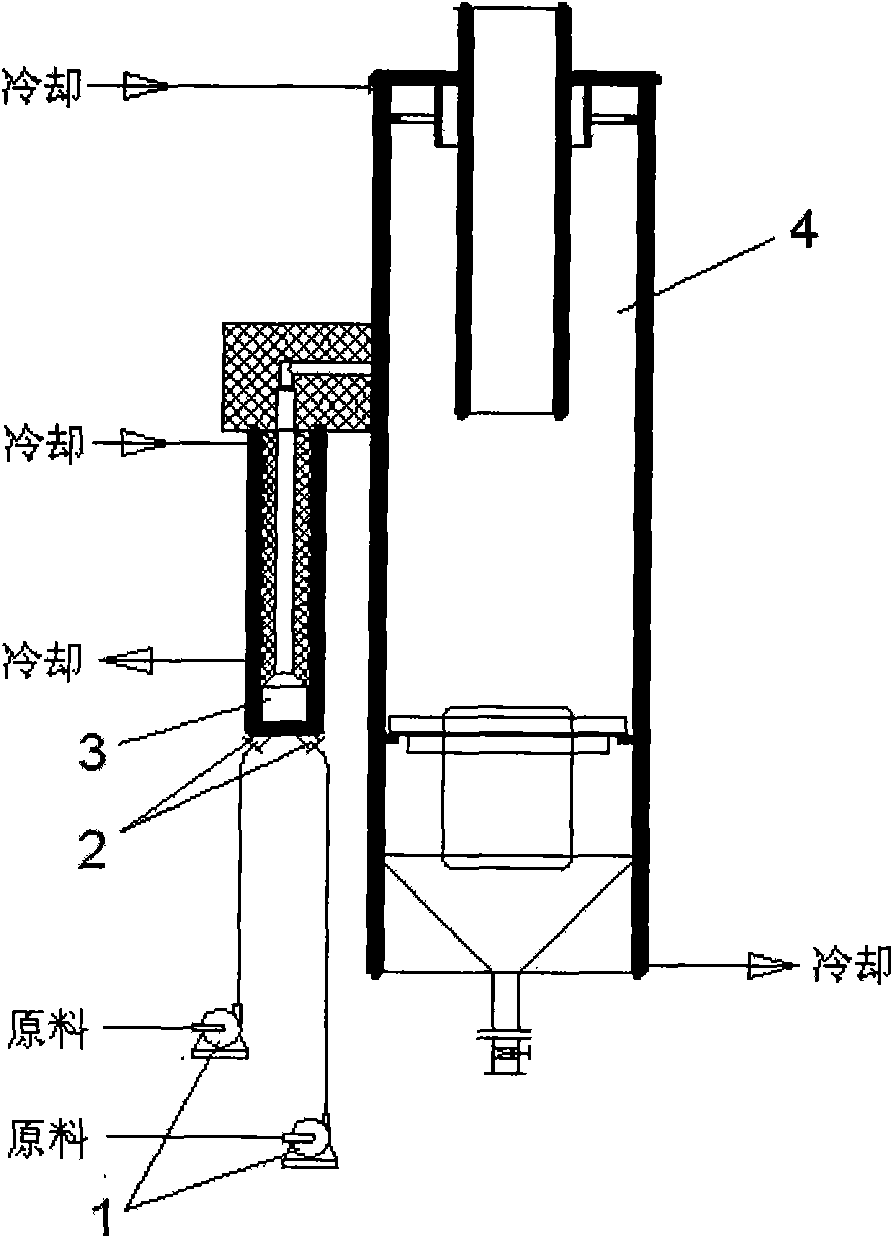

Production method of dimethyl phosphite

ActiveCN101870712AAvoid acidolysis side effectsImprove effective conversion rateGroup 5/15 element organic compoundsChemical/physical/physico-chemical nozzle-type rreactorsLiquid productCyclone

The invention relates to a production method of dimethyl phosphate, which takes phosphorus trichloride and methyl alcohol as raw materials for reaction. The method comprises the steps of: in a reaction chamber space having cross injection angle and the injection structures of the raw materials, respectively and continuously injecting and sending the phosphorus trichloride and the methyl alcohol which are based on the molar ratio of 1: (3.0-3.1) into the reaction chamber space through respective injection structures by corresponding pumping mechanisms for mixing together and reaction; then, introducing reaction material into a centrifugal cyclone separator with the pressure lower than that of the reaction chamber space along the tangential direction, and leading noncondensable gas and condensing liquid product to have centrifugal cyclone separation; and collecting the liquid dimethyl phosphate product descending along the inner wall of the centrifugal cyclone separator. The method can rapidly complete the reaction and the separation for products, effectively reduces the contact between HCl and the dimethyl phosphate, inhibits the occurrence of side reaction, improves the yield and the quality of the product, and greatly reduces the energy consumption.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD +1

Method for producing orthophosphate products from polyphosphates through hydrolysis

The invention mainly discloses a method for preparing orthophosphates from polyphosphates, and in particular relates to a method for preparing orthophosphate products from an orthophosphate-containing material recycled from phosphorus wastes as the raw material through hydrolysis.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

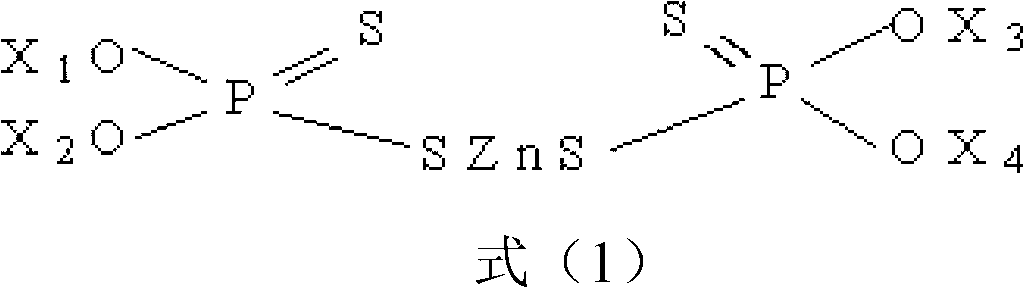

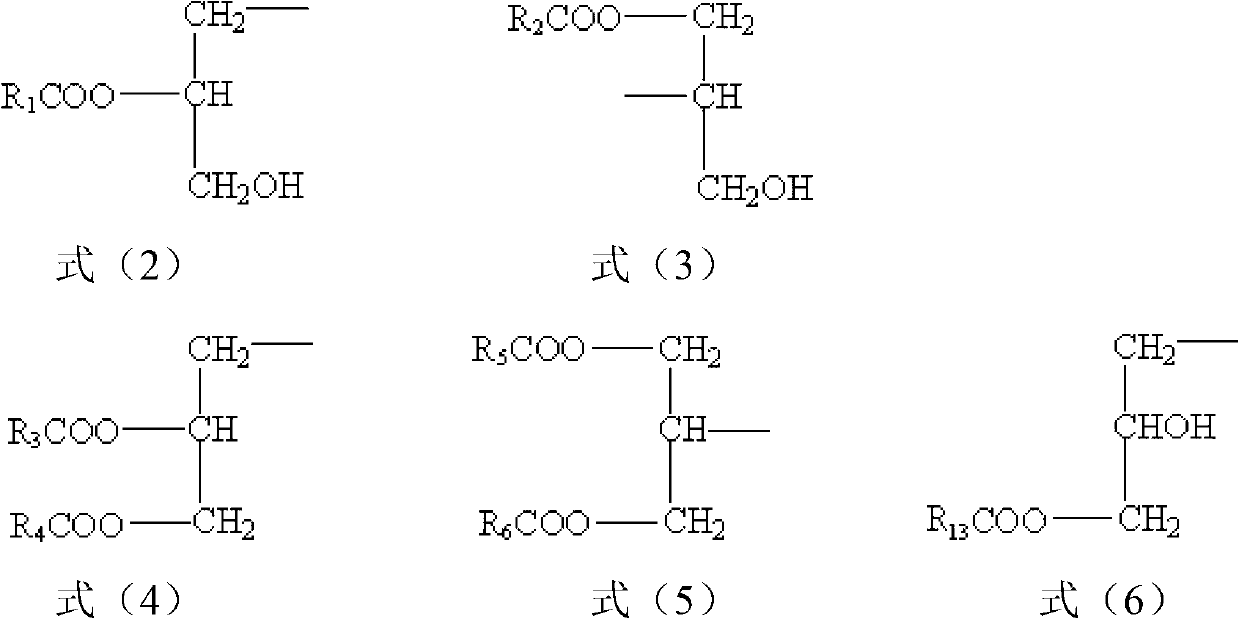

Extreme pressure antiwear agent and preparation method thereof and lubricating oil combination

Owner:CHINA PETROLEUM & CHEM CORP +1

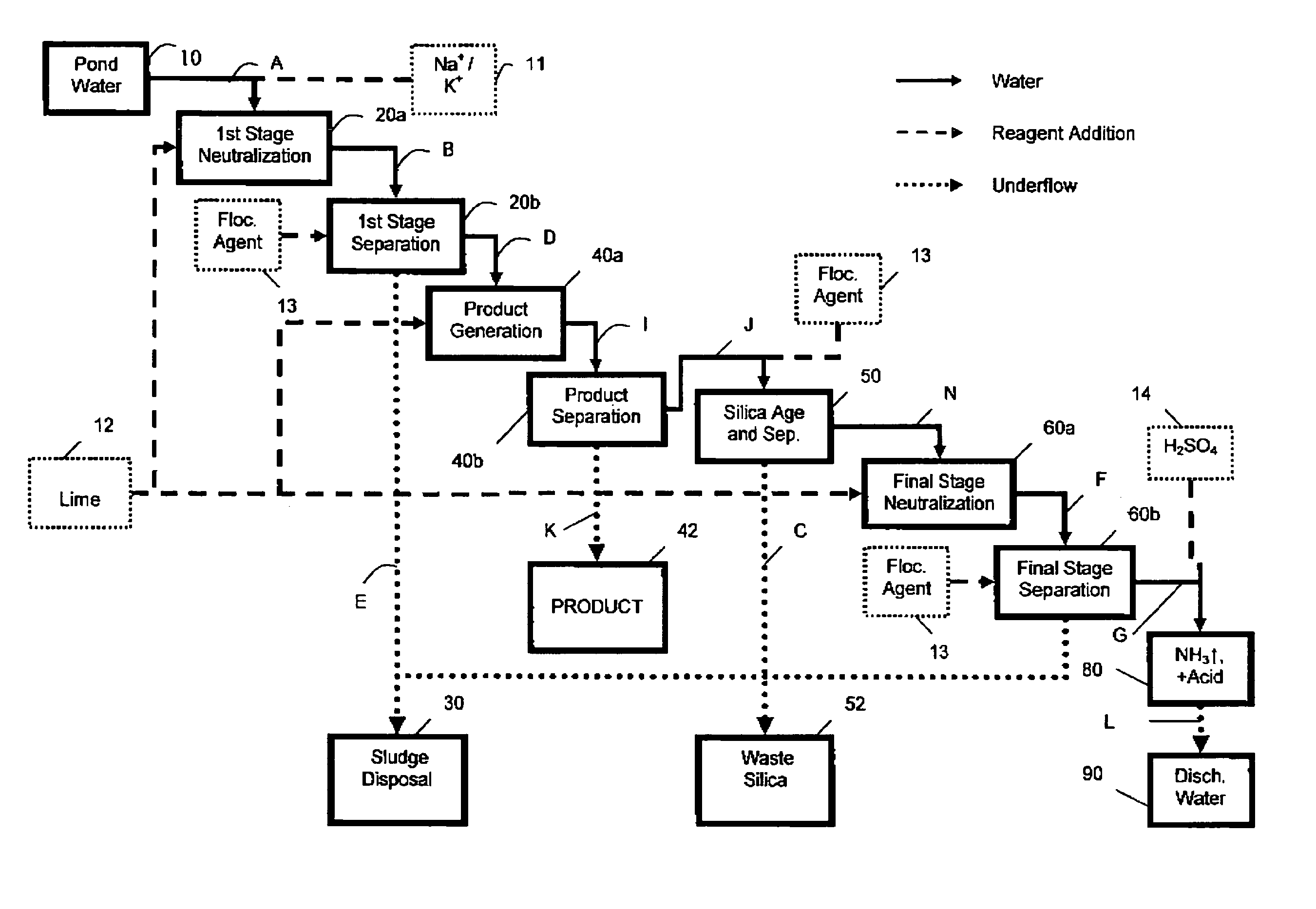

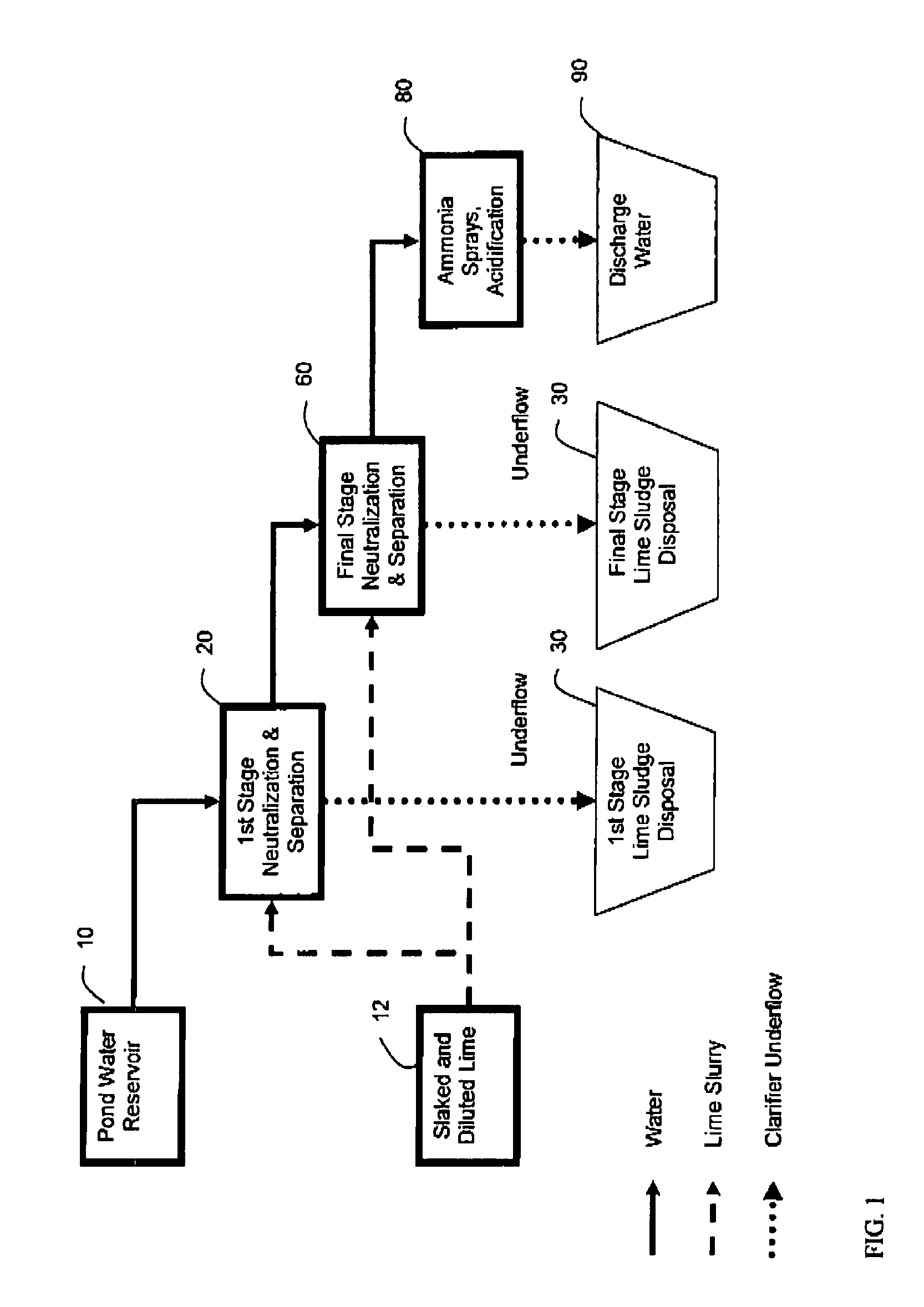

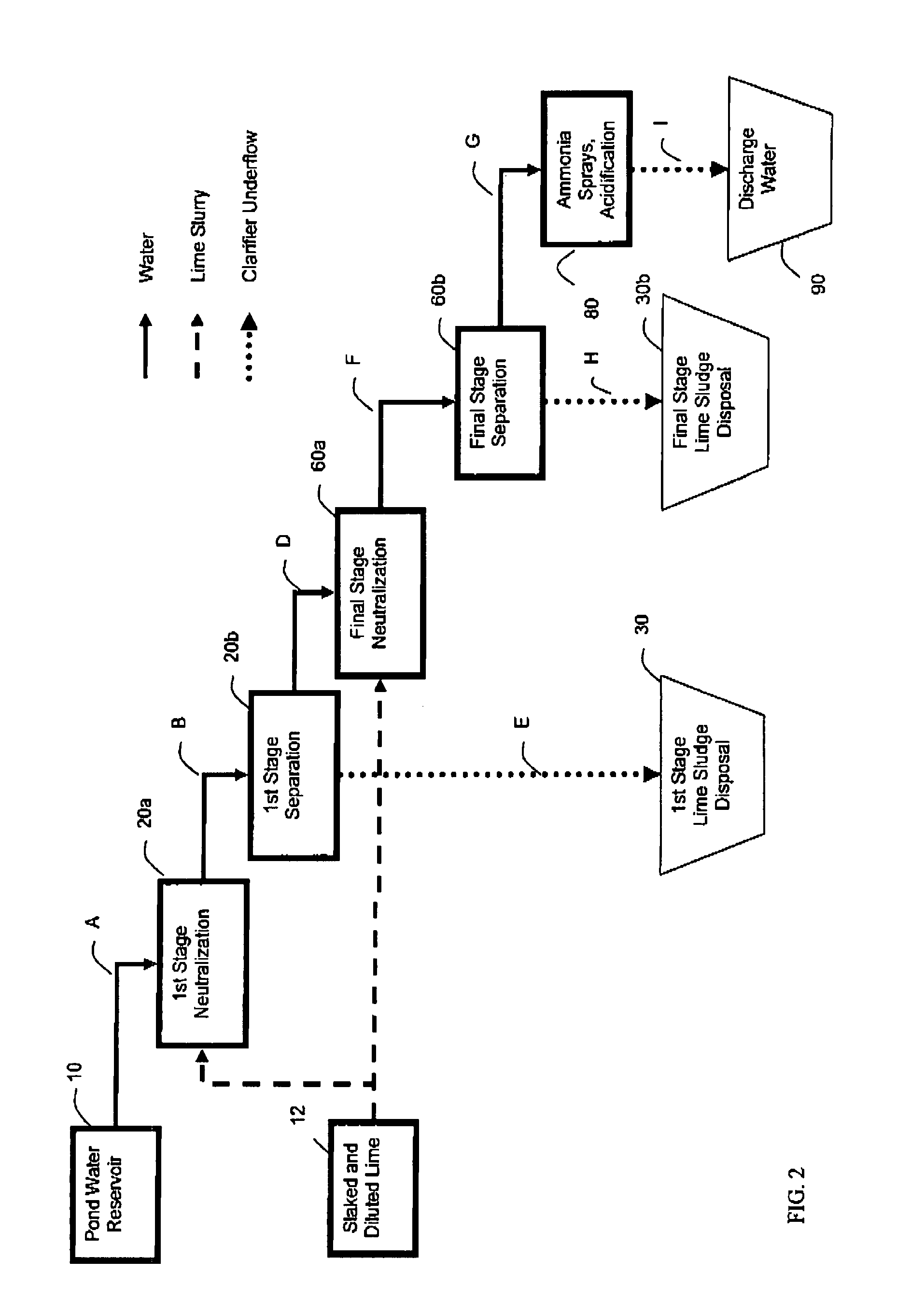

Process for treating pond water

ActiveUS7560031B1Promote recoveryLow fluoride valueWater contaminantsPhosphorus oxyacidsSludgePhosphate product

A process for the treatment of phosphoric acid plant pond water facilitating the recovery of phosphorus values from the input pond water. In certain aspects the process recycles solids from a later stage neutralization and separation into the clarified liquid stream from an initial clarification and neutralization stage. A sufficient amount of solids are added to the clarified liquid stream to effect the pH-dependent precipitation of a phosphate product. In alternative aspects an intermediate pH-dependent precipitation of a phosphate product is achieved through the addition of a neutralizing agent. The phosphate product is further characterized by a low concentration of fluoride. In addition the phosphate product can be further processed to a high purity technical grade phosphoric acid. In certain aspects the process employs flocculating agents to enhance the formation of precipitates. In further aspects, methodologies taught herein facilitate the reduction of silica in the process streams. Processes according to the present invention are further characterized by an enhanced recovery of treated water, reduced sludge impoundment and reduced lime consumption when compared to conventional double liming processes.

Owner:VEOLIA WATER NORTH AMERICA OPERATING SERVICES

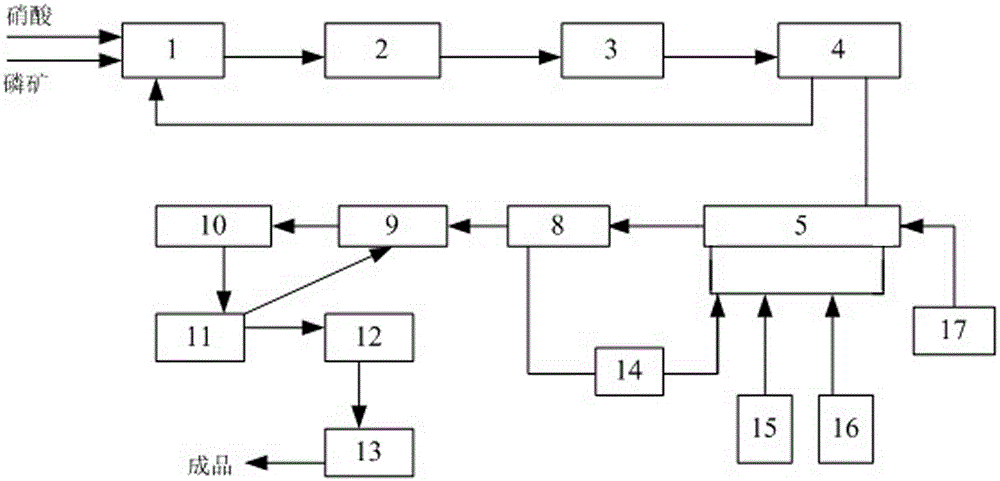

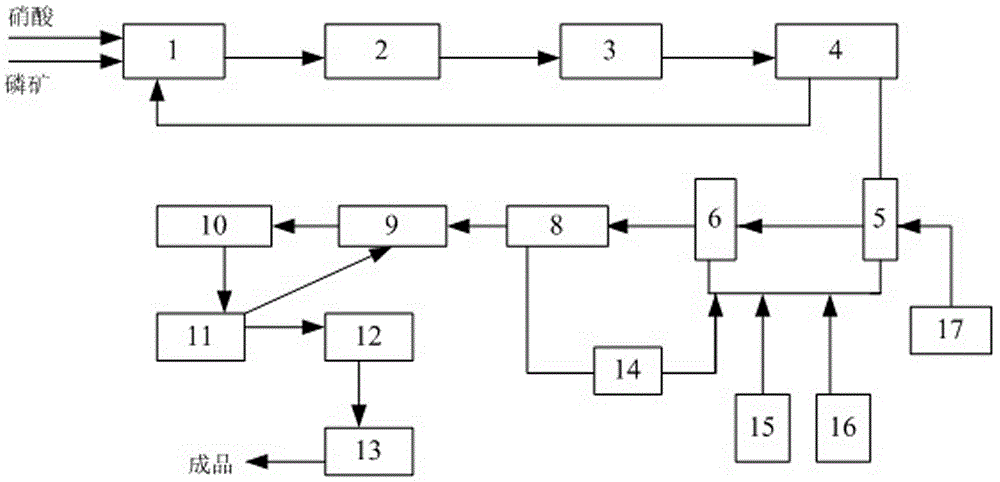

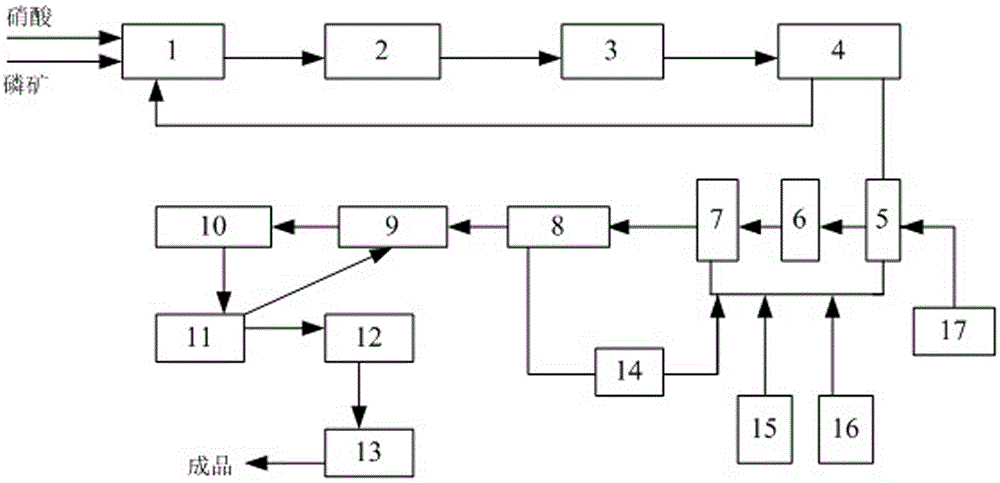

System and method for increasing nitric phosphate product P2O5 dissolvability in water

The invention discloses a system and a method for increasing a nitric phosphate product P2O5 dissolvability in water, belonging to the field of nitric phosphate production. Phosphorite is subjected to acidolysis, acid non-soluble substance separation, crystallization, filtering, neutralization, nitrogen and phosphorus evaporation, prilling, drying, screening, cooling and packing; mother liquor and potassium sulphate are added into a neutralizing tank according to a ratio, a small part of residual Ca<2+> are converted into calcium sulfate, generation of citric acid-soluble calcium hydrophosphate salt and insoluble phosphate is reduced, and K<+> is added in slurry. After the system is used, the production method is energy-saving and environment-friendly, a nutrient element kalium needed by plants is supplemented in a product while the dissolvability in water of a finished product P2O5 is increased, the material viscosity in a low temperature state in a neutralization process is reduced, and the quality of nitric phosphate is comprehensively improved.

Owner:TIANJI COAL CHEM IND GROUP

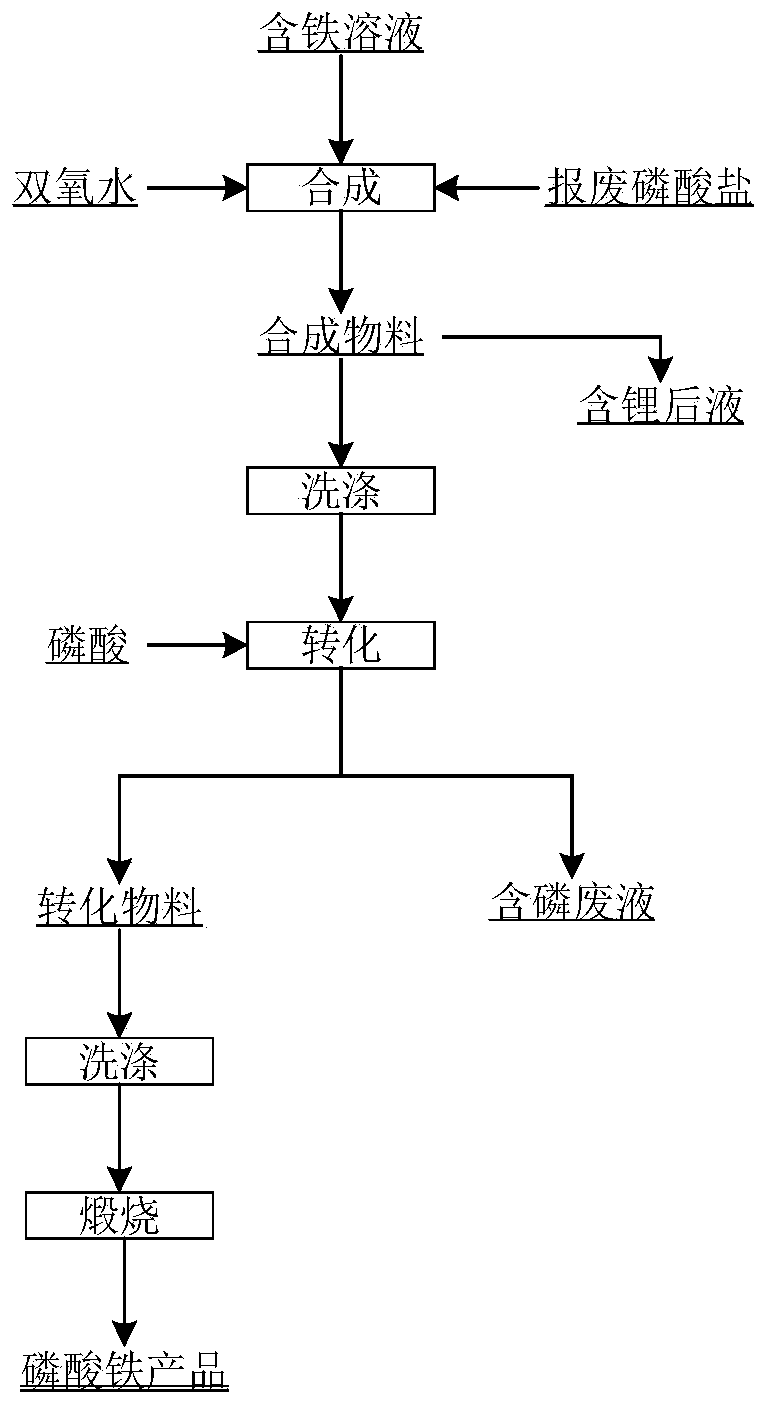

Method for synthesizing ferric phosphate by utilizing waste phosphate generated by precipitation of trace heavy metal

ActiveCN109809382ATo achieve the purpose of resource utilizationReduce manufacturing costPhosphorus compoundsFiltrationPhosphate product

The invention discloses a method for synthesizing ferric phosphate by utilizing waste phosphate generated by precipitation of trace heavy metal. The method is characterized by utilizing the waste phosphate as a phosphorus source, mixing the phosphorus source with an ferric-containing solution or mixing the phosphorus source with a ferrous solution and hydrogen peroxide after dissolving, synthesizing the ferric phosphate under a low-temperature condition, and filtering, thus obtaining filtrate and filter residue; recycling other valuable metal in the filtrate, adding phosphoric acid after washing and pulpifying the filter residue, converting under the condition that the temperature is 90 DE C, carrying out suction filtration after keeping warm, and drying free water in a suction filtrationmaterial, thus obtaining ferric phosphate dihydrate; calcining, thus preparing an anhydrous ferric phosphate product. The method for synthesizing the ferric phosphate by utilizing the waste phosphategenerated by precipitation of the trace heavy metal, disclosed by the invention, is simple in operation, a prepared ferric phosphate product can meet battery-grade standard requirements, the purpose of recycling phosphorus from the waste phosphate is realized, and the synthesis cost of the ferric phosphate can be obviously reduced; meanwhile, waste residue can be recycled, the additional value ofthe waste residue can be increased, and the problem of environment protection caused by the waste phosphate is also solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

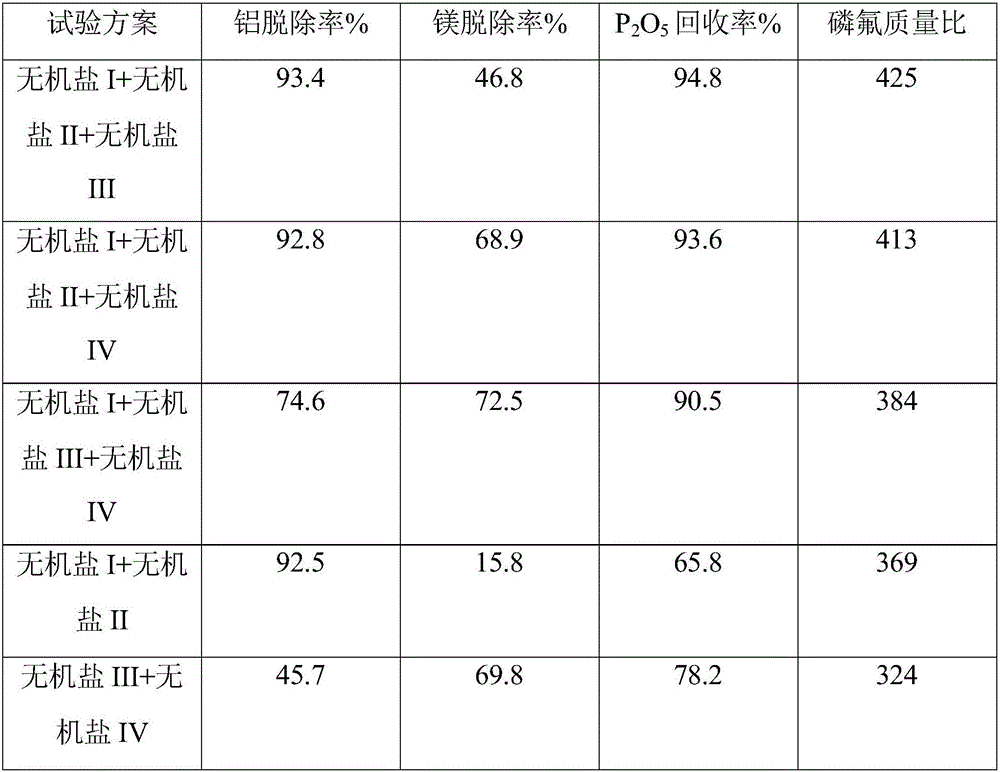

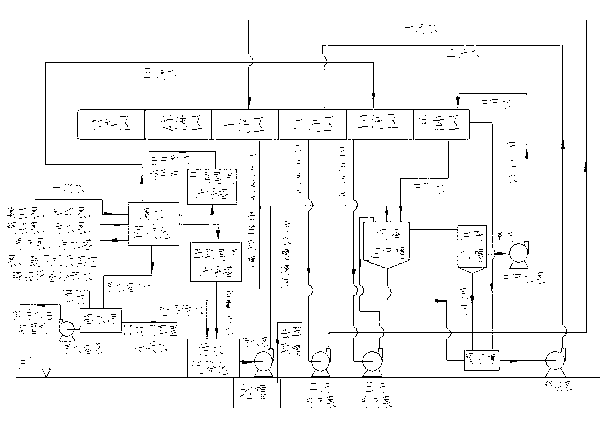

Deep purification method of feed-grade wet-process phosphoric acid

ActiveCN106185855ATo achieve the purpose of purificationReduce fluorine contentPhosphorus compoundsHigh concentrationInorganic salts

The invention discloses a deep purification method of feed-grade wet-process phosphoric acid. According to the deep purification method, inorganic salt I, inorganic salt II, inorganic salt III and inorganic salt IV are combined with aluminum and magnesium ions in wet-process phosphoric acid to generate indissolvable compound inorganic salt to be precipitated, aluminum and magnesium impurities are removed, and then fluorine is removed, thereby realizing the deep purification of wet-process phosphoric acid. According to a novel deep purification process of feed-grade wet-process phosphoric acid, aluminum, magnesium and fluorine can be removed from phosphoric acid by a wet process, so that the index requirements of raw material acid for producing feed calcium salt or high-concentration phosphatic fertilizers, soluble fertilizers and industrial grade phosphate products are met; and no new impurity ion is introduced into purified phosphate.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Closed cyclic utilization method for production water of monoammonium phosphate

ActiveCN103213961ASolve the amount of sewage waterEasy to handlePhosphatesPhosphate productEvaporation

A closed cyclic utilization method for production water of monoammonium phosphate, is suitable for a dihydrate pulp wet-process phosphoric acid technology and an ammonia neutralization fluidized drying phosphate fertilizer production system. A production water cyclic system mainly comprises a clear water recovery pond, a sewage settling basin, a settlement and overflow groove, a water flushing and distribution tank, a thick slurry groove, a round plate filter, an extraction tail gas washing tower, a dried tail gas washing tower. Multi stage closed cyclic utilization is preformed on sewage, and primary water consumed by per ton product is 2.5-2.8t, in order to supplement water entering into the product or phosphogypsum and lost by evaporation. The method provided by the invention resolves problems of a lot of sewage and difficult treatment, which puzzles a monoammonium phosphate production enterprise for a long time. The method has advantages of simple technology process, good sewage treating effect, small technology equipment and investment, low personnel labor intensity and high water utilization rate. The method can effectively save water resource, the water consumption of monoammonium phosphate product is reduced to 2.5-2.8t per ton product from 20t per ton product. The method implements closed cyclic utilization for production water of monoammonium phosphate, and zero discharge of sewage.

Owner:襄阳泽东化工集团股份有限公司

Method for preparing diisopropyl phosphite

ActiveCN101250199AHeat dissipation fastLess side effectsGroup 5/15 element organic compoundsBenzenePhosphate product

The invention relates to a method for preparing diisopropyl phosphate via the esterification of phosphorus trichloride and isopropanol, which comprises adding phosphorus trichloride into benzene solvent to form a first mixture, adding benzene, isopropanol and weak alkaline organic catalyst into a reactor to form a second mixture, slowly adding the first mixture into the second mixture to form a reaction system, increasing and controlling temperature, reacting for 4.5-9h to obtain the mixture containing diisopropyl phosphate, deacidifying the mixture via pure alkali, filtering, distilling, depressurizing and distilling to obtain final diisopropyl phosphate product. The preparation method has low cost and high yield.

Owner:太仓市茜泾化工有限公司

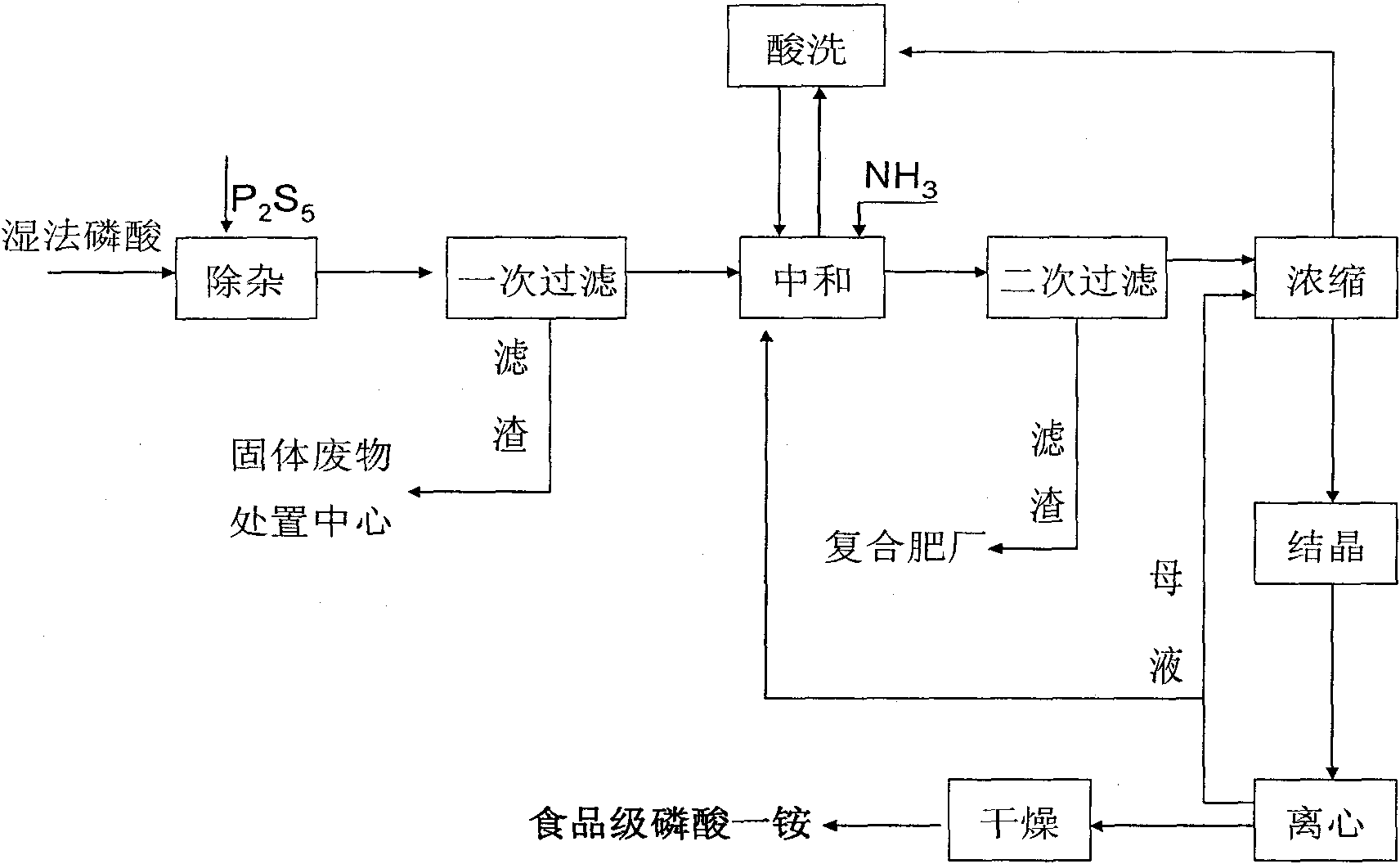

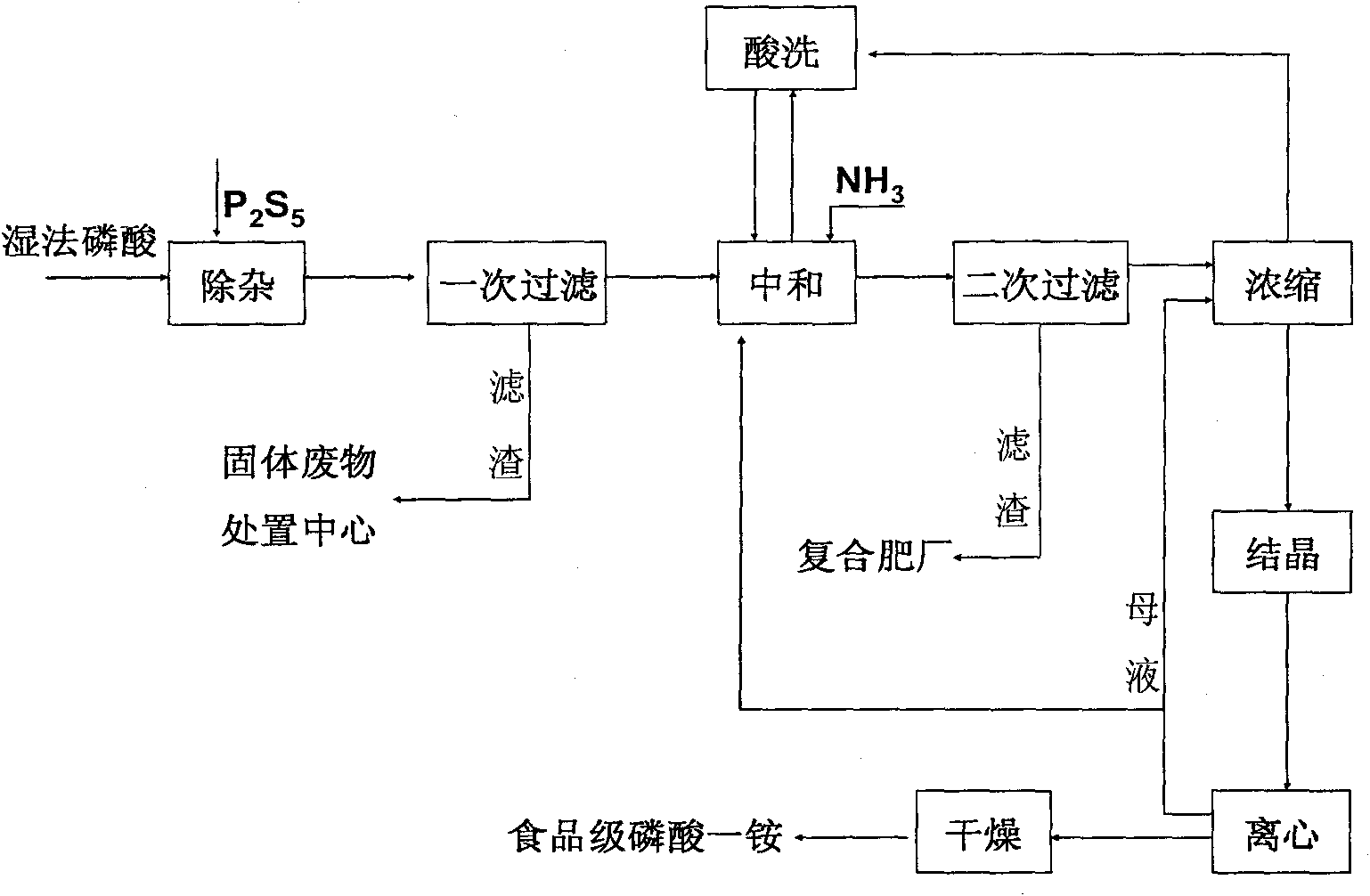

Method for preparing food-grade monoammonium phosphate from wet-process phosphoric acid

ActiveCN101857212AReduce consumptionGuaranteed stabilityPhosphatesFertilizer mixturesSocial benefitsPhosphate product

The invention discloses a method for producing food-grade monoammonium phosphate from wet-process phosphoric acid. The low-cost wet-process phosphoric acid is adopted as a raw material, is subjected to impurity removal and undergoes neutralization reaction with ammonia to prepare the food-grade monoammonium phosphate; a pickling procedure is adopted, so that volatile gas materials are recycled, crystallization mother liquor is recycled or concentrated for recycling, the food-grade monoammonium phosphate product is obtained, and the product yield is improved; meanwhile, byproducts in the production process are used as compound fertilizer materials. The method greatly reduces the production cost of the food-grade monoammonium phosphate, ensures the stability of product quality, avoids secondary pollution, and has low energy consumption and good economic and social benefits.

Owner:GUANGXI MINGLI CHEM

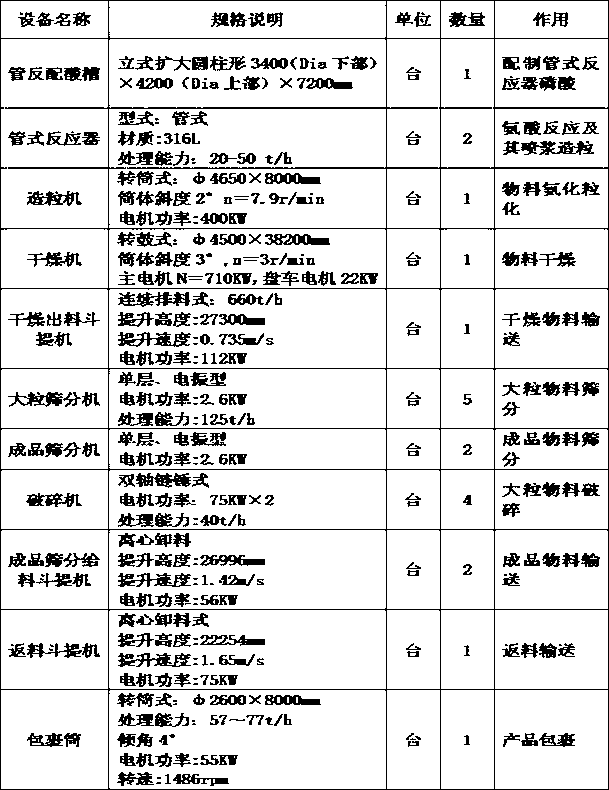

Equipment for producing high-nutrient monoammonium phosphate through double-tubular-reactor process

The invention discloses equipment for producing high-nutrient monoammonium phosphate through a double-tubular-reactor process. The equipment comprises a strong phosphoric acid clarifying tank, a tubular-reaction acid mixing tank, a granulator, tubular reactors, a drying machine, a bucket elevator, a screening machine, a crushing machine, a belt conveyor, a cooling fluidized bed, a wrapping barrel, a cyclone separator, a dust exhausting fan and a tail gas washing system. The equipment runs stably during the process switching and normal production period and can extract a granular monoammonium phosphate product with uniform grain size and nutrients and water meeting the standard through the main processes of mixing acid in a tubular-reaction manner, spraying and granulating, drying, screening and crushing (collecting returning charge), cooling and wrapping and the like; the product is high in water solubility, free from blocking and stable in performance in the air, contains available phosphorus (P2O5) more than 52% and nitrogen (N) more than 11%, is a high-quality base raw material for preparing an N, P and K three-element compound fertilizer and has strong market competitiveness.

Owner:WENGFU (GRP) CO LTD

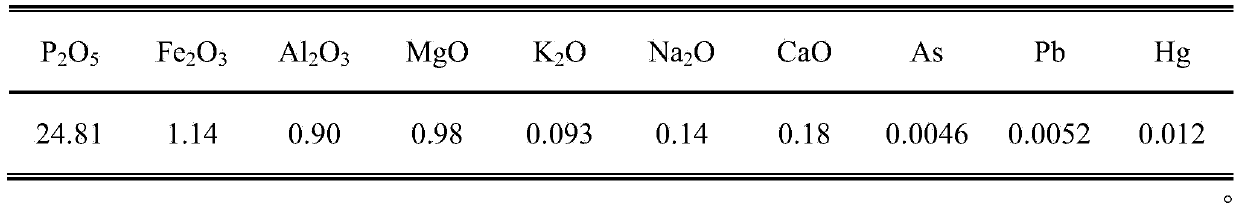

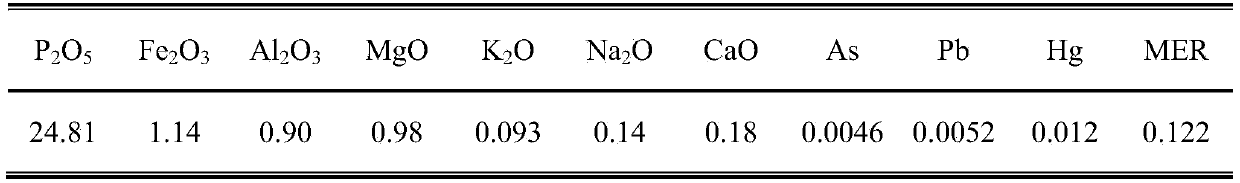

Wet process phosphoric acid purification technology of nonphosphate precipitation

ActiveCN105366654AMeet the concentrationWater soluble fertilizerPhosphorus compoundsChemical industryHigh concentration

The invention discloses a wet process phosphoric acid purification technology of nonphosphate precipitation and belongs to the field of phosphorus chemical industry. According to the wet process phosphoric acid purification technology of nonphosphate precipitation, an agent is combined with anions and cations in diluted phosphoric acid to generate an indissolvable double salt which is precipitated in a form of nonphosphate, so that a purpose of wet process phosphoric acid purification is achieved, thereby satisfying the demand of producing a high-concentration phosphate fertilizer, a water soluble fertilizer and an industrial phosphate product. The method can remove iron, magnesium, aluminum, arsenic, lead, sodium, potassium, sulfate radicals and the like stably in wet process phosphoric acid and has characteristics of being simple in reaction condition, short in a process flow, wide in an agent source, low in a treatment cost, high in a P2O5 recovery rate and the like, so that sesquioxide-removal, heavy metal removal and desulfuration by a one-step method are realized. The removal rates of iron, magnesium and aluminum in the treated wet process phosphoric acid separately reaches above 97%, 70% and 15%; arsenic and lead in diluted acid are less than 5 ppm; sodium (calculated by NaO) and potassium (calculated by K2O) are separately lower than 0.025% and 0.083%; sulfate radicals are lower than 0.16%; and the P2O5 recovery rate is higher than 98.5%.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Method for preparing lithium carbonate from lithium phosphate

InactiveCN106745099AReduce lossesHigh yieldPhosphorus compoundsLithium carbonates/bicarbonatesLithium carbonatePhosphate product

The invention provides a method for preparing lithium carbonate from lithium phosphate. According to the technical scheme, the method comprises steps as follows: cleaning, dissolution, impurity removal, lithium settlement, extraction of a phosphate product and recovery. During production, lithium elements are cyclically utilized, the loss is low, the yield is high, and the produced lithium carbonate has high purity and good quality and can reach the battery level. A large quantity of harmful chemical waste lithium phosphate can be utilized, and lithium carbonate urgently needed in the market can be produced.

Owner:天津二八科技股份有限公司

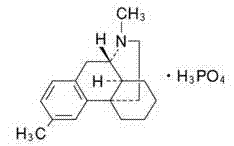

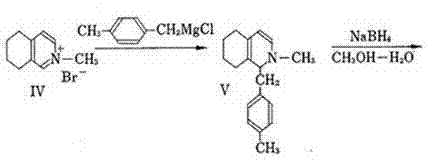

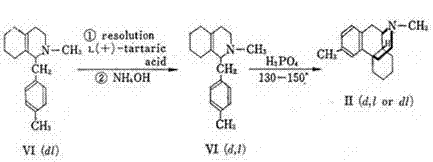

Preparation method of dimethylmorphinan phosphate used as cough medicine

InactiveCN102241630AReduction of chiral resolution processHigh yieldOrganic chemistryO-Phosphoric AcidIsoquinoline

The invention discloses a preparation method of dimethylmorphinan phosphate used as a cough medicine. The method comprises the following steps: removing L-mandelic acid from (S)-l-(4-methylbenzyl)-1,2,3,4,5,6,7,8-octahydroisoquinoline-L-mandelate to obtain (S)-l-(4-methylbenzyl)-1,2,3,4,5,6,7,8-octahydroisoquinoline, performing methylation by using the (S)-l-(4-methylbenzyl)-1,2,3,4,5,6,7,8-octahydroisoquinoline chiral material as a raw material, and then performing cyclization reaction together with phosphoric acid under the conditions of heating and decompression to obtain (9S,13S,14S)-3,17-dimethylmorphinan monophosphate with three chiral centers, namely dimethylmorphinan phosphate; and desalting, rectifying, crystallizing, salifying, drying, and packaging to obtain the refined dimethylmorphinan phosphate product. The method has the characteristics of simple process, low cost, high yield, high product purity, short production cycle and the like, thereby being a synthetic route suitable for industrial mass production.

Owner:HANGZHOU BAOLING GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com