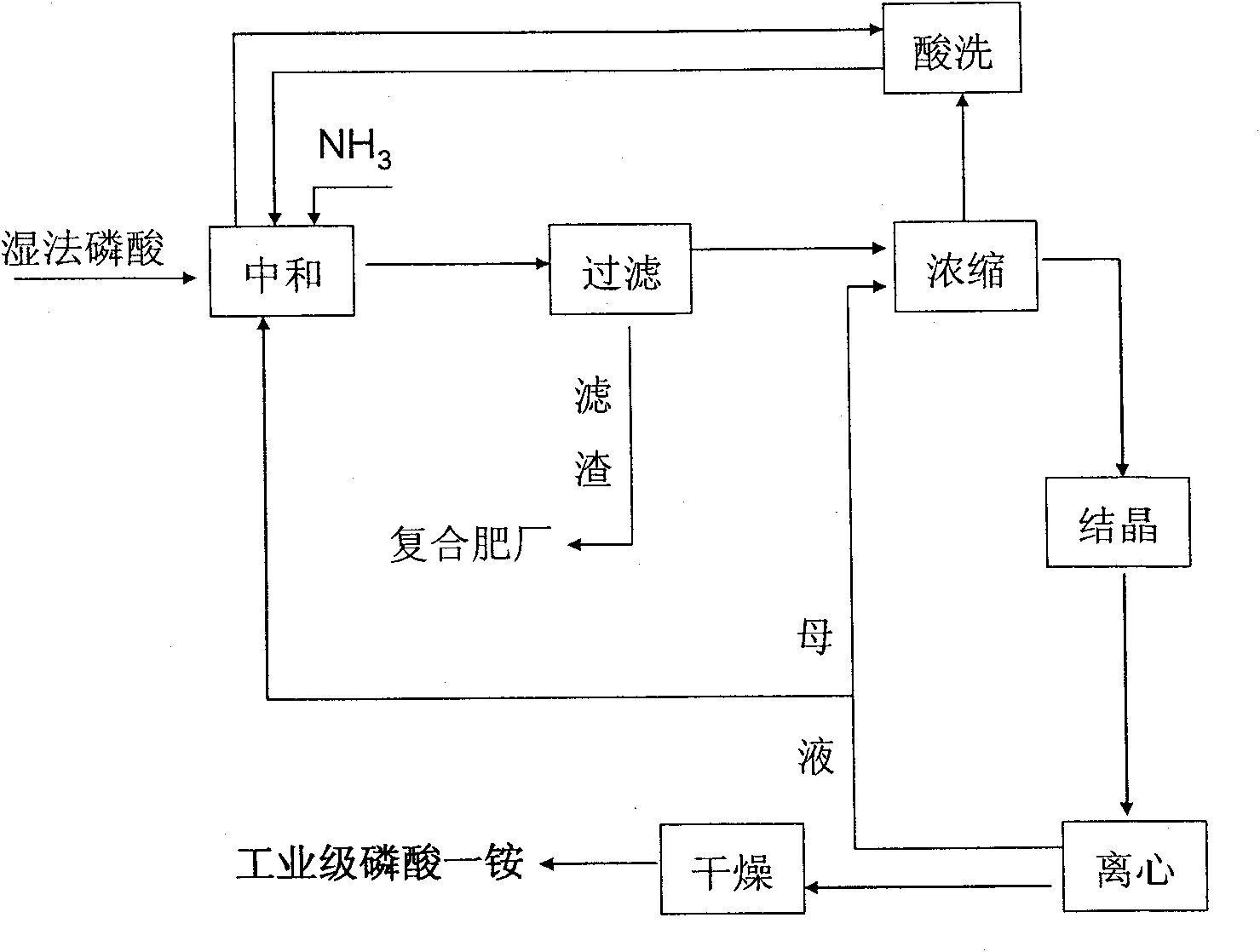

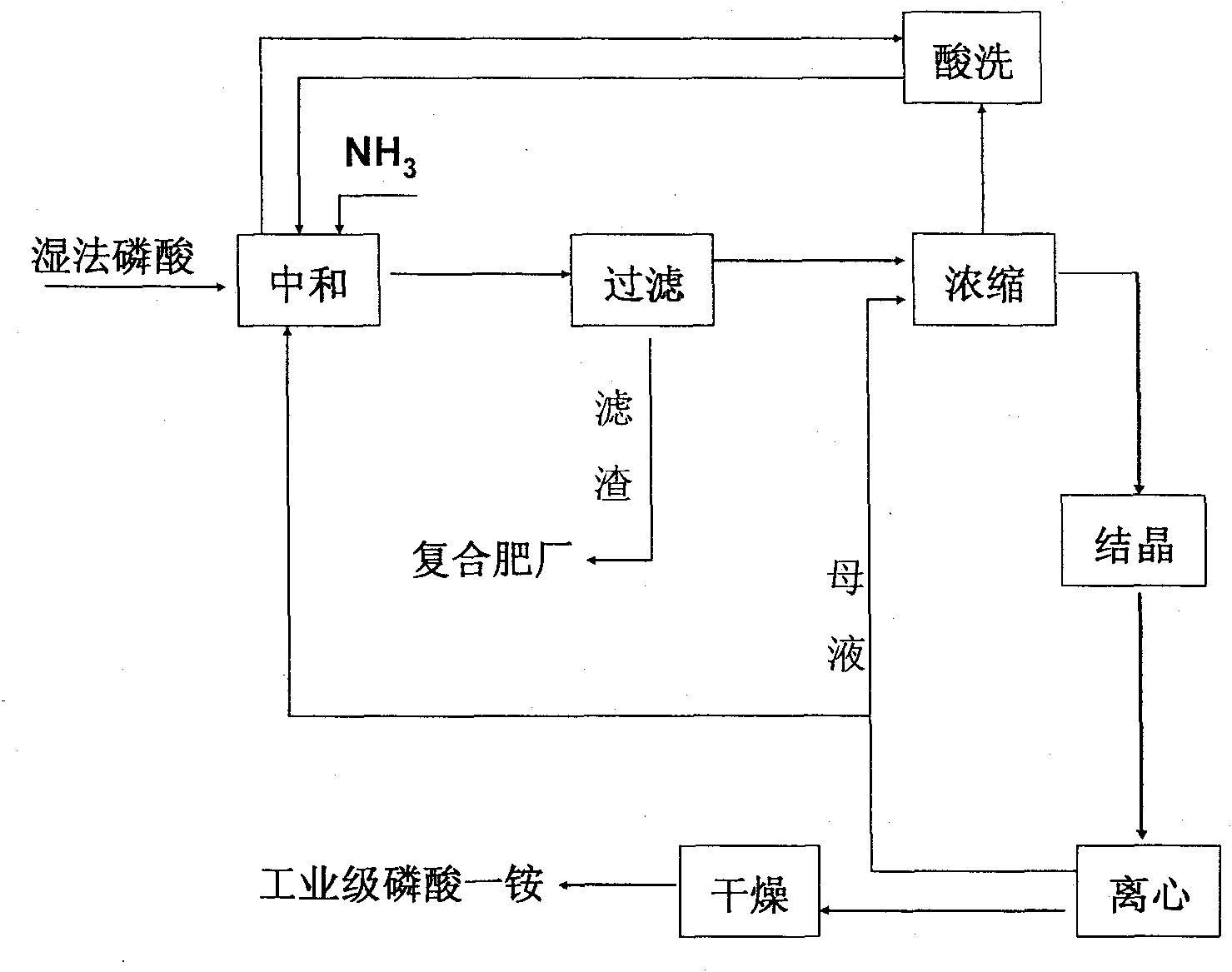

Method for preparing industrial grade monoammonium phosphate from wet-process phosphoric acid

A technology of monoammonium phosphate and wet-process phosphoric acid, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of complicated operation and long process flow, and achieve the effects of avoiding secondary pollution, reducing raw material consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the enamel reaction kettle, drop into the reclaimed crystallization mother liquor of 20% of the reaction kettle volume, start the agitator, then slowly add 40% P by weight concentration to the mother liquor 2 o 5 Wet-process phosphoric acid, and slowly feed ammonia gas, control PH=4.4 to carry out neutralization reaction at a temperature of 55°C, the volatilized ammonia gas is absorbed by the pickling bubbling absorption tower and then refluxed into the reactor, control PH=4.4 to At the end of the neutralization reaction, after stopping feeding, continue to stir for 20 minutes to obtain an industrial-grade monoammonium phosphate slurry; filter the obtained industrial-grade monoammonium phosphate slurry with a plate and frame filter press while it is hot to remove impurities, and send the filter cake to Compound fertilizer processing plant; send the obtained industrial-grade monoammonium phosphate solution to a vacuum concentrator for heating and concentration until a...

Embodiment 2

[0030] In the stainless steel reaction kettle, drop into the reclaimed crystallization mother liquor of 15% of the reaction kettle volume, start the agitator, then slowly add the weight concentration 38% P in the mother liquor 2 o 5 Wet-process phosphoric acid, and slowly feed ammonia gas, control pH = 4.6 to carry out neutralization reaction at a temperature of 70 ° C, the volatilized ammonia gas is absorbed by the pickling packed absorption tower and then refluxed into the reactor, control pH = 4.6 to neutralize and reaction end point, after stopping feeding, continue stirring for 30 minutes to obtain industrial-grade monoammonium phosphate slurry; filter the obtained industrial-grade monoammonium phosphate slurry with a plate and frame filter press while it is hot, remove impurities, and send the filter cake to compound Fertilizer processing plant; send the obtained industrial-grade monoammonium phosphate solution to a vacuum concentrator for heating and concentration until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com