Patents

Literature

10493 results about "By-product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A by-product or byproduct is a secondary product derived from a production process, manufacturing process or chemical reaction; it is not the primary product or service being produced. A by-product can be useful and marketable or it can be considered waste: for example, bran, which is a byproduct of the milling of wheat into refined flour, is sometimes composted or burned for disposal, but in other cases, it can be used as a nutritious ingredient in human food or animal feed. Gasoline was once a byproduct of oil refining that later became a desirable commodity as motor fuel. The plastic used in plastic shopping bags also started as a by-product of oil refining.

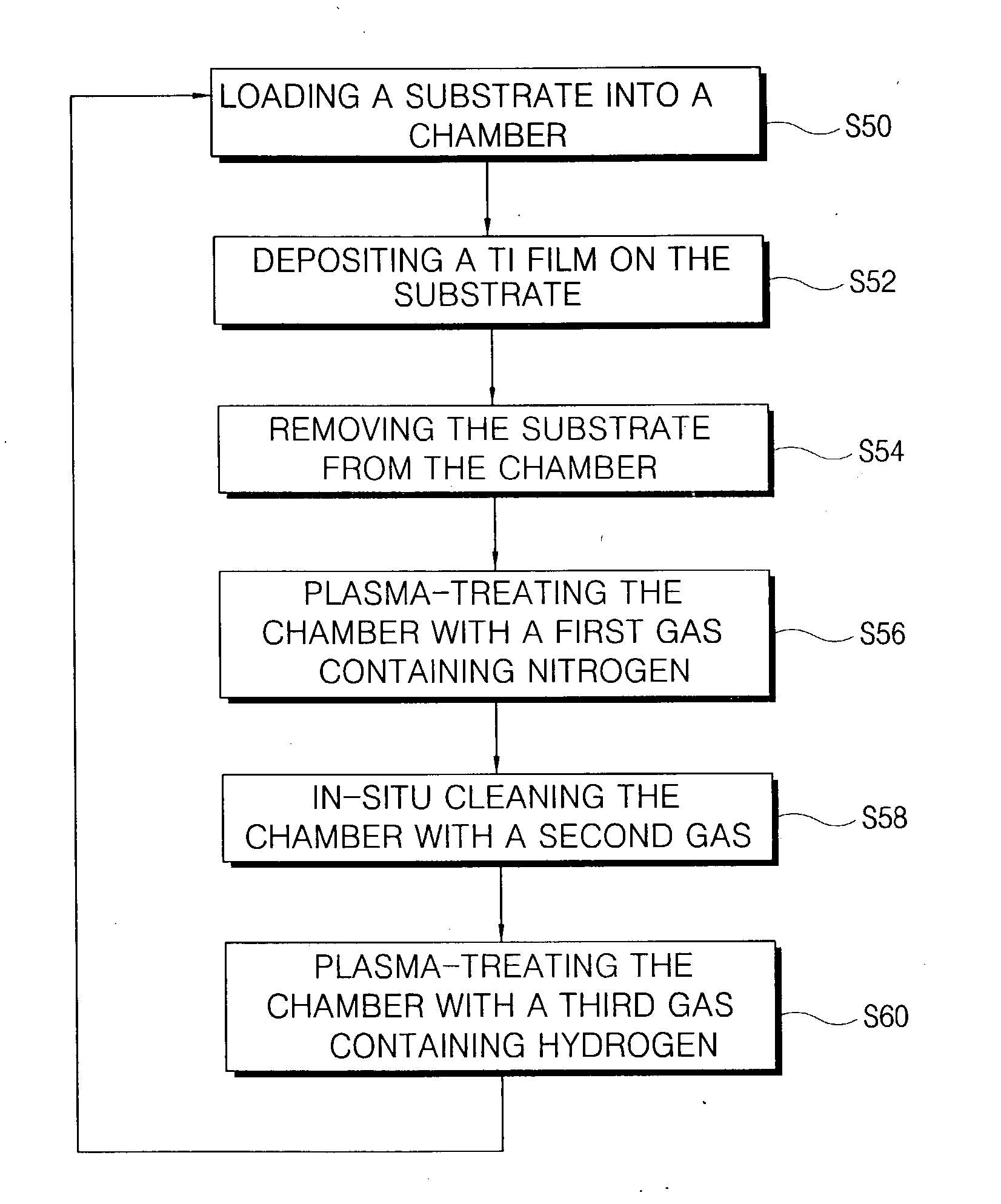

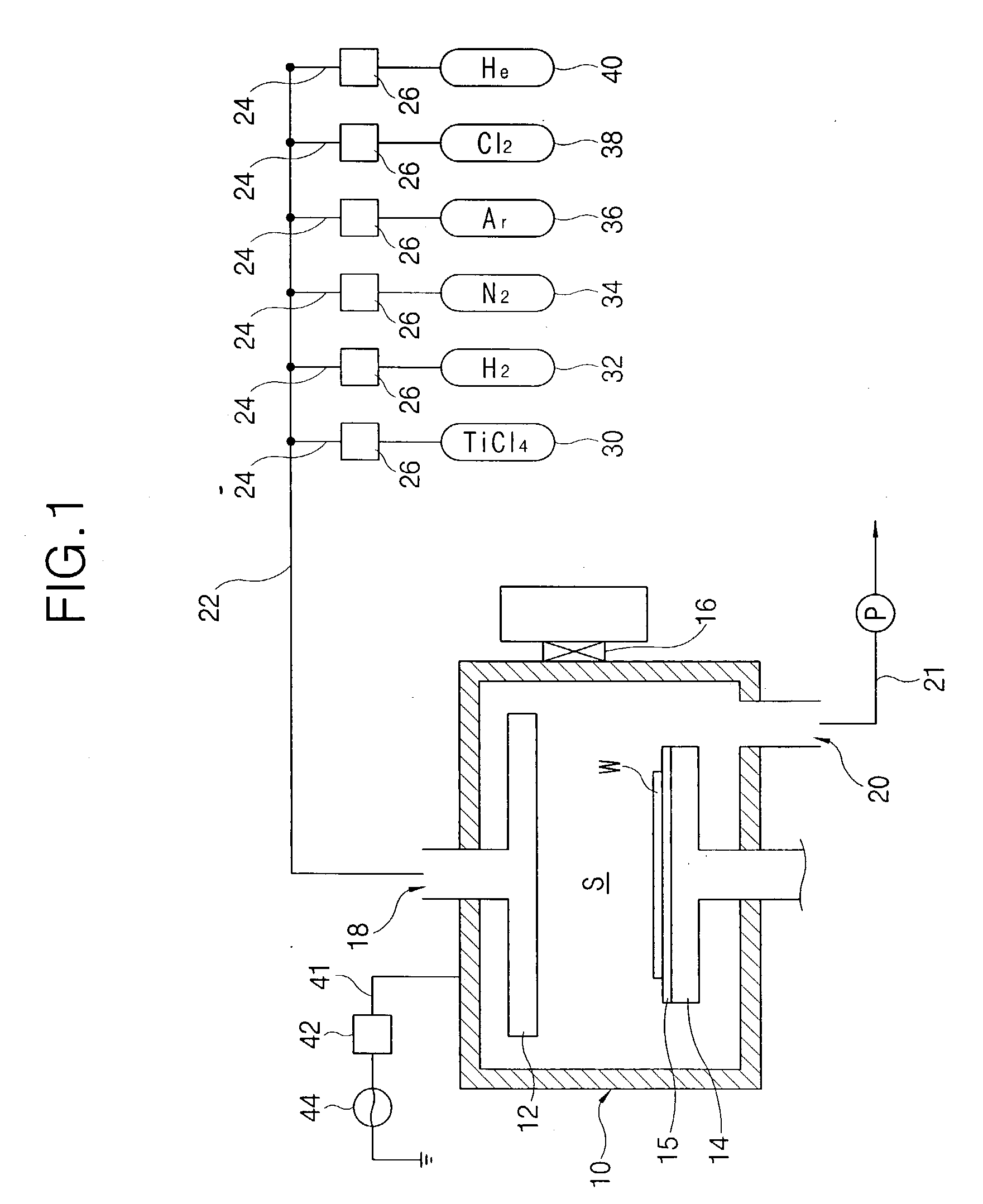

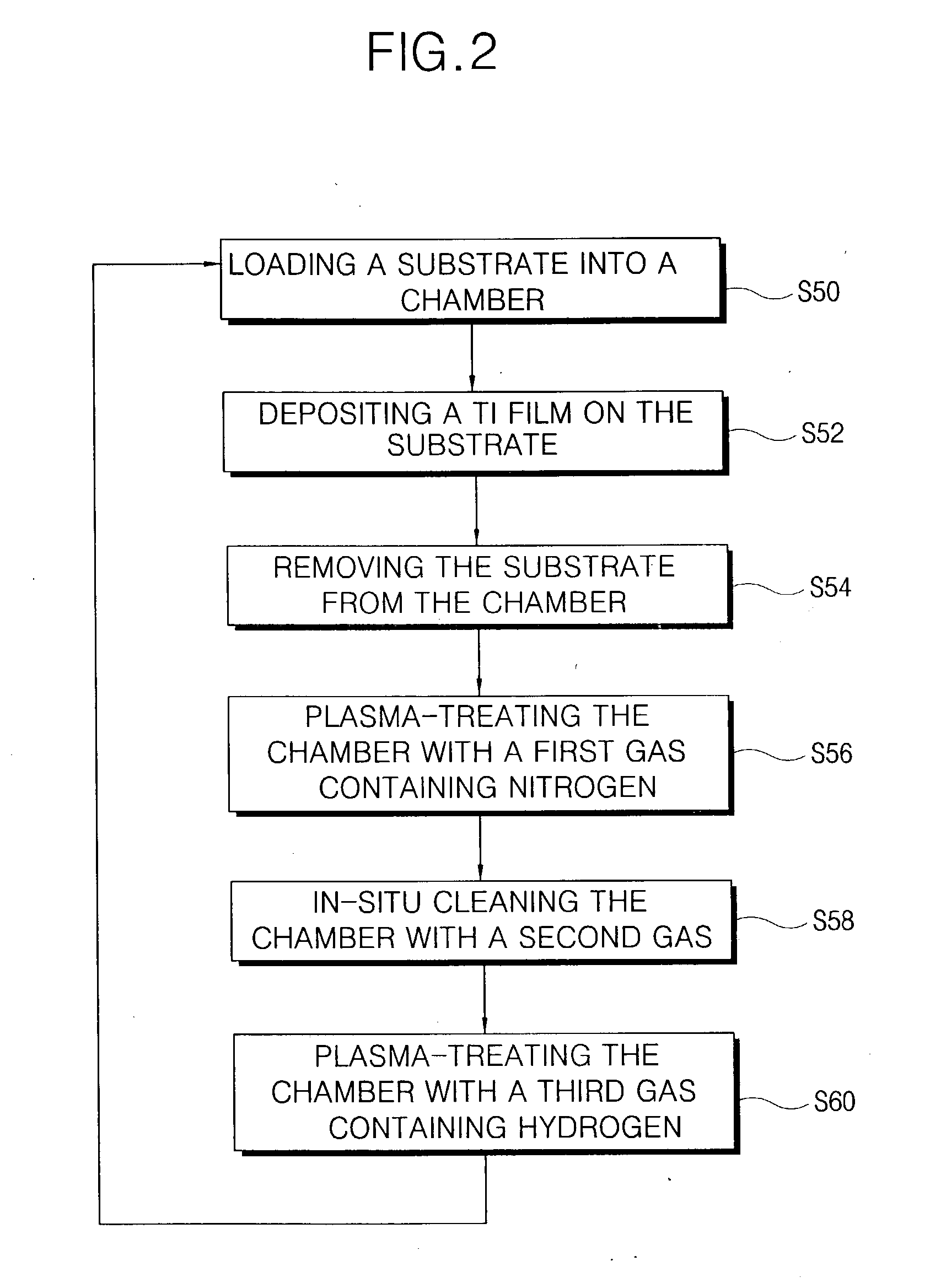

Method of cleaning a chemical vapor deposition chamber

InactiveUS20040013818A1Reduce the amount requiredIncrease resistanceHollow article cleaningElectrostatic cleaningHydrogenNitrogen

After a processing chamber is used to deposit a refractory metal film on a substrate, the chamber is plasma-treated with a gas including either nitrogen and / or hydrogen and in-situ cleaned. By plasma-treating the chamber with a gas including nitrogen, the refractory metal film that forms on interior surfaces of the chamber during substrate processing is nitrided. The nitrided refractory metal film can be removed from the chamber during the in-situ cleaning. By plasma-treating the chamber with a gas including hydrogen, reaction by-products generated in the chamber is diluted and removed. The chamber may be plasma-treated in a gas ambient including both nitrogen and hydrogen. Also, the plasma treatment may be performed before and after the in-situ cleaning.

Owner:SAMSUNG ELECTRONICS CO LTD

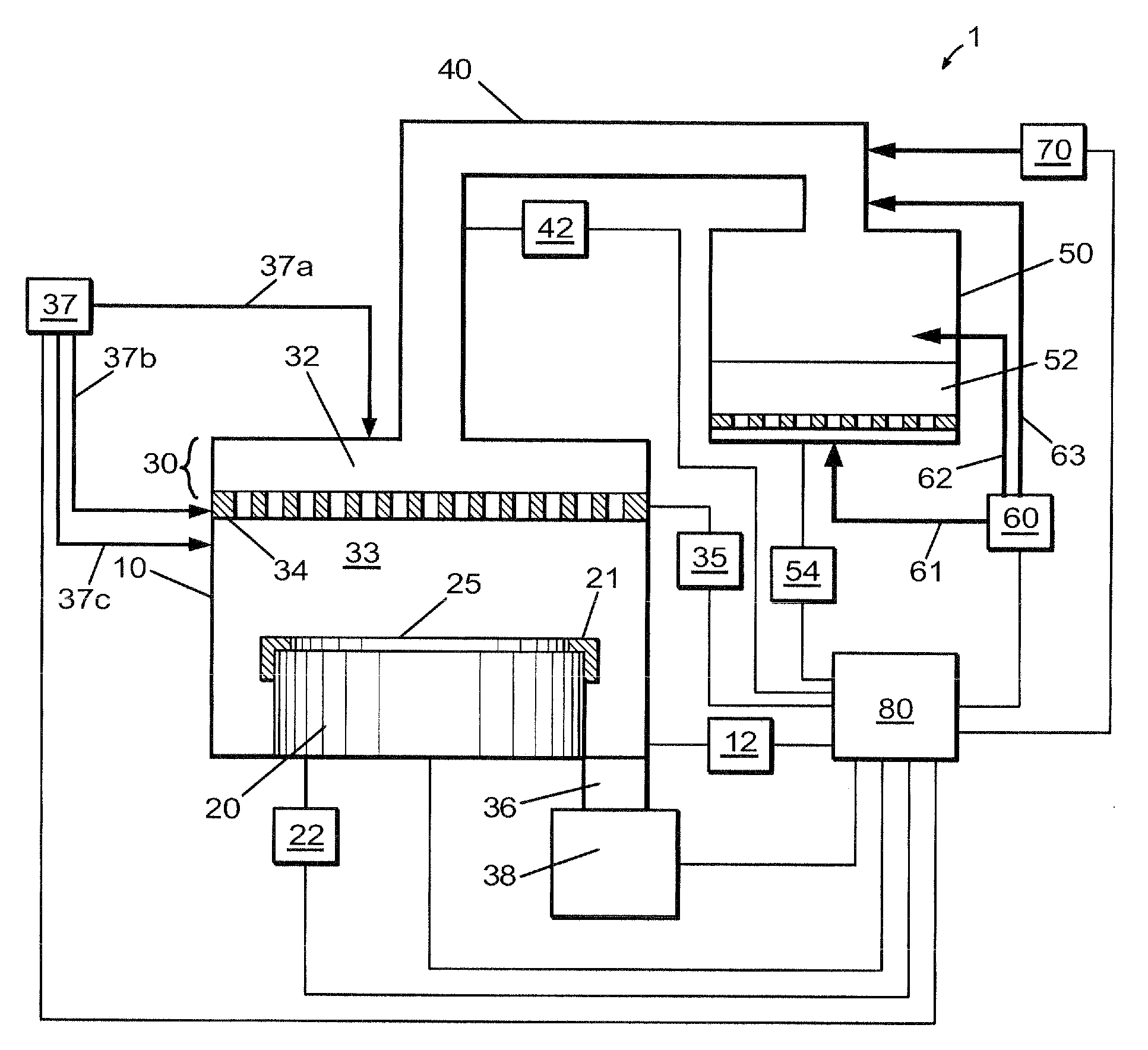

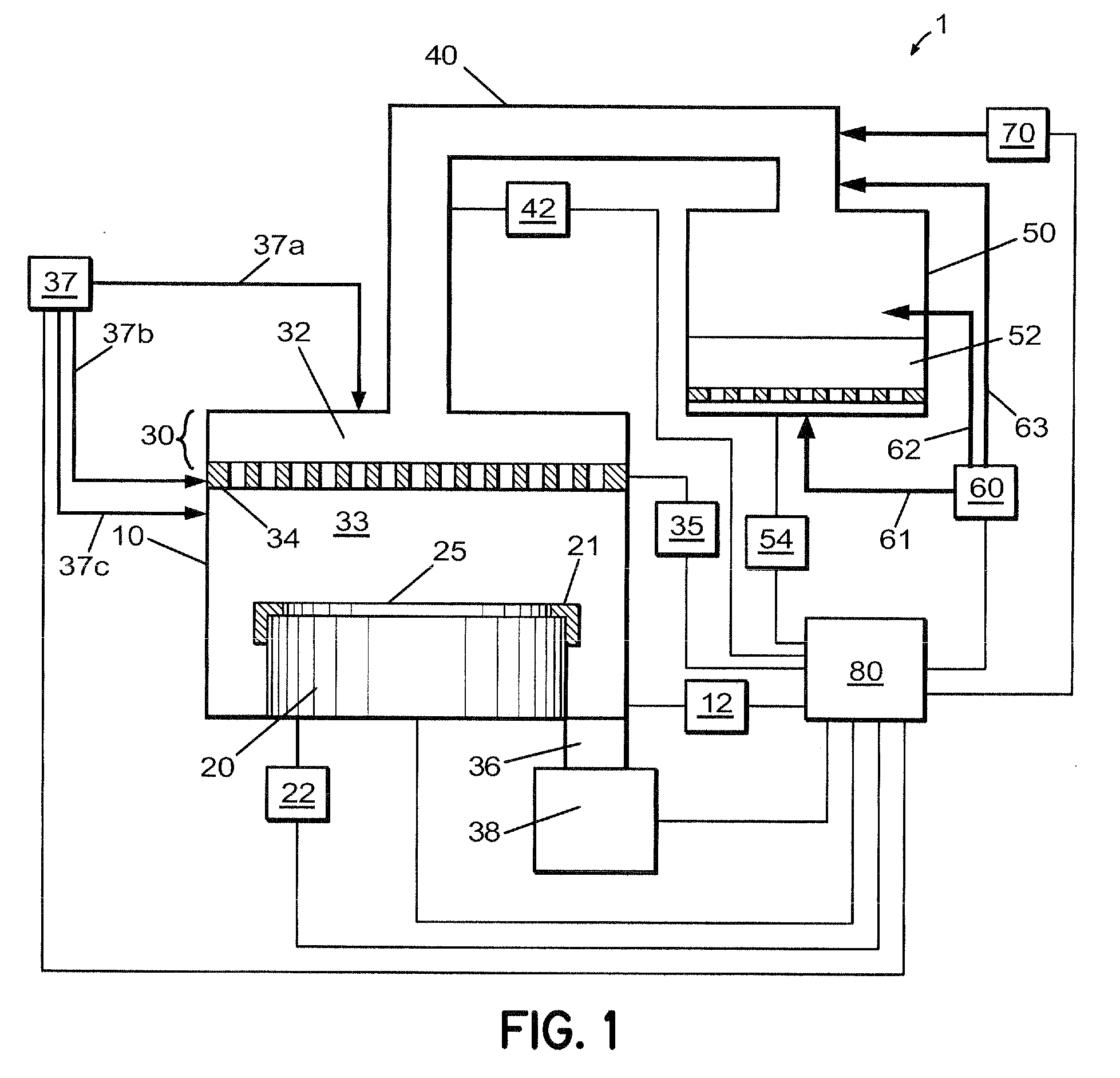

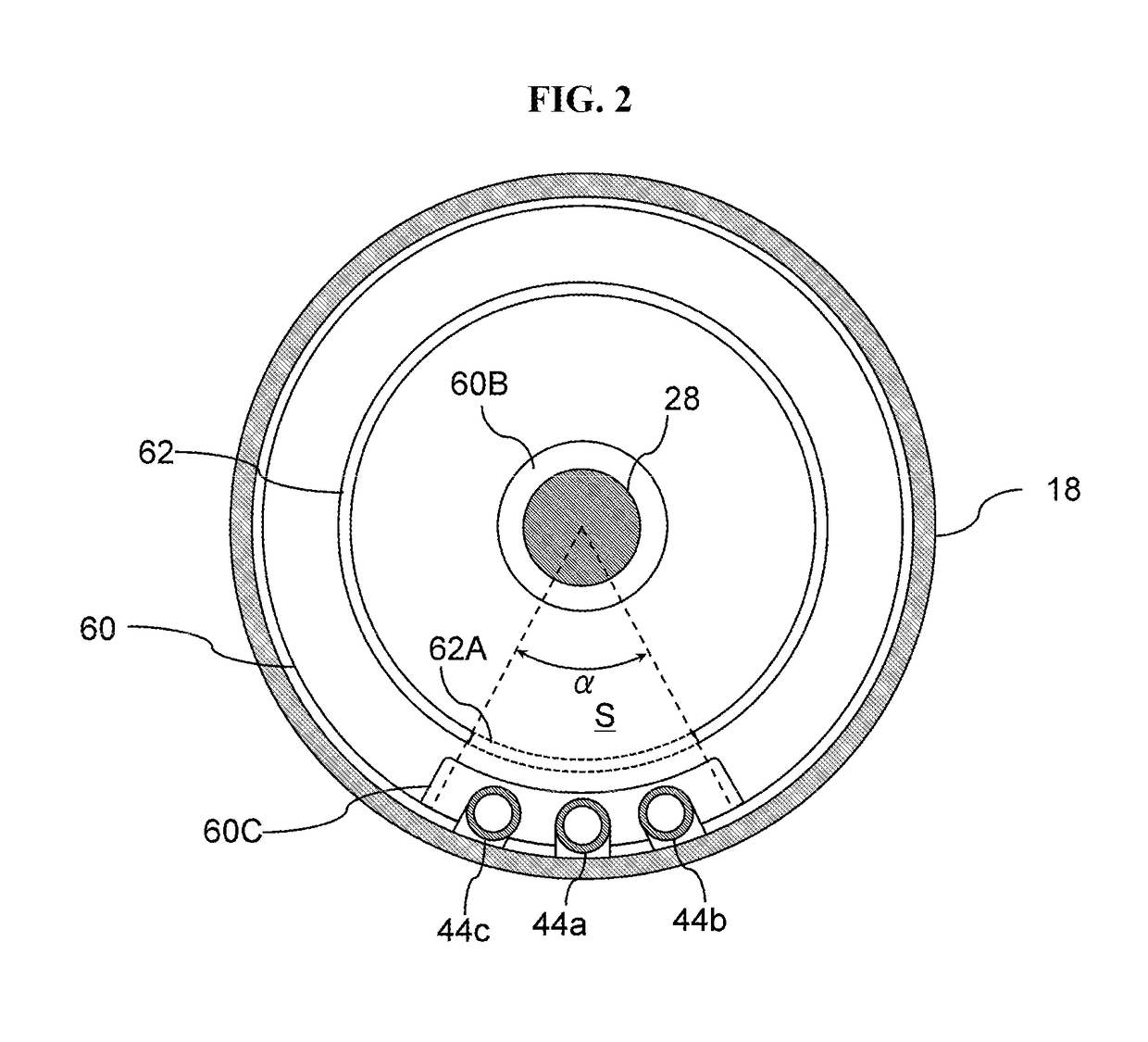

Method and apparatus for reducing carbon monoxide poisoning at the peripheral edge of a substrate in a thin film deposition system

InactiveUS20070234955A1Reduce CO poisoningSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCO poisoningOptoelectronics

A method and apparatus is described for reducing CO poisoning of a thin metal film formed on a substrate using a metal carbonyl precursor. The thin metal film is formed on the substrate resting on a substrate holder in a thin film deposition system. The substrate holder comprises a shield ring positioned on a peripheral edge of the substrate holder and configured to surround the peripheral edge of the substrate, whereby the shield ring reduces the production of CO by-products at the peripheral edge of the substrate.

Owner:TOKYO ELECTRON LTD

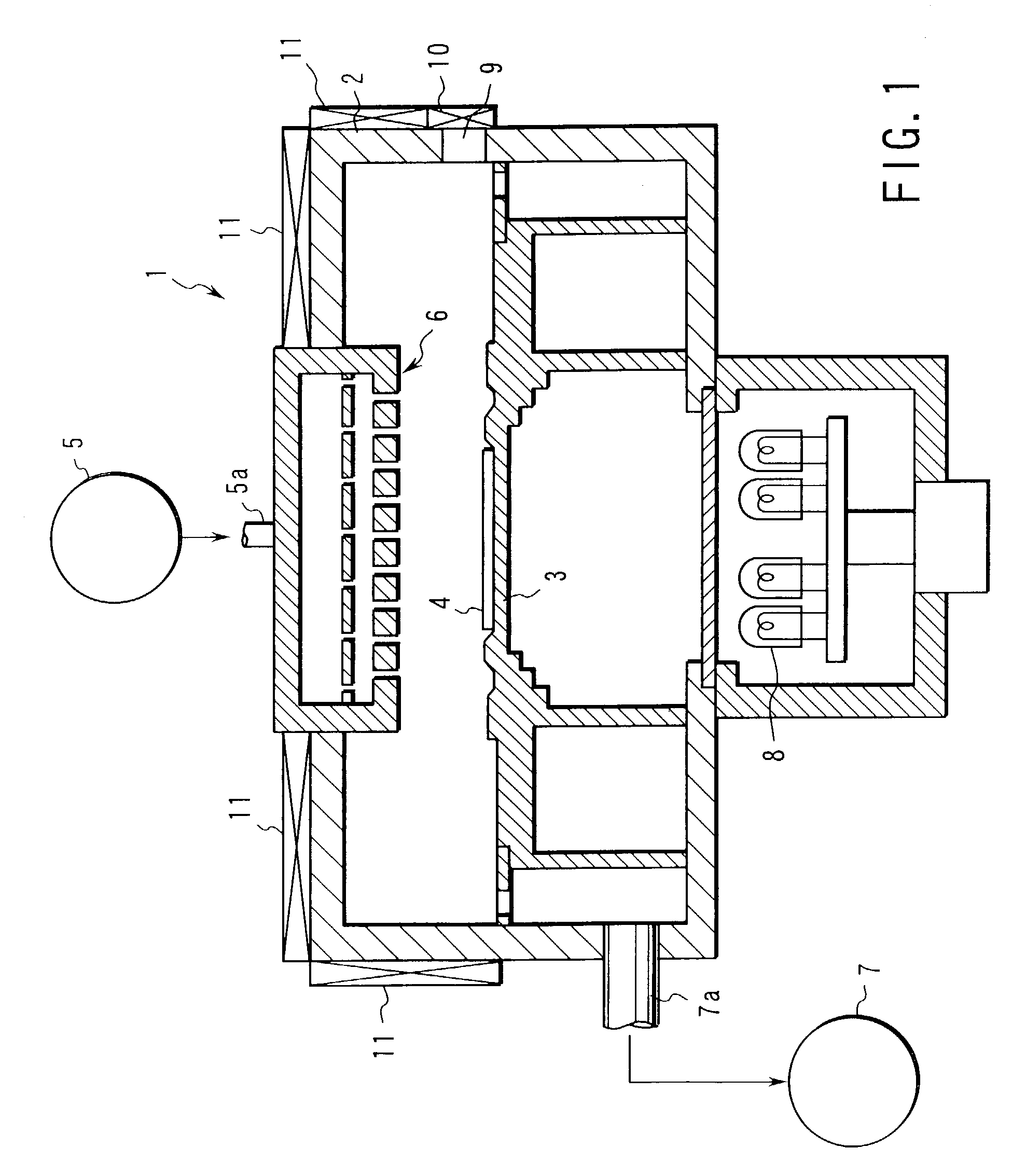

Substrate processing apparatus, lid cover and method of manufacturing semiconductor device

ActiveUS20180033645A1Avoid stickingElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasProcess engineering

Owner:KOKUSA ELECTRIC CO LTD

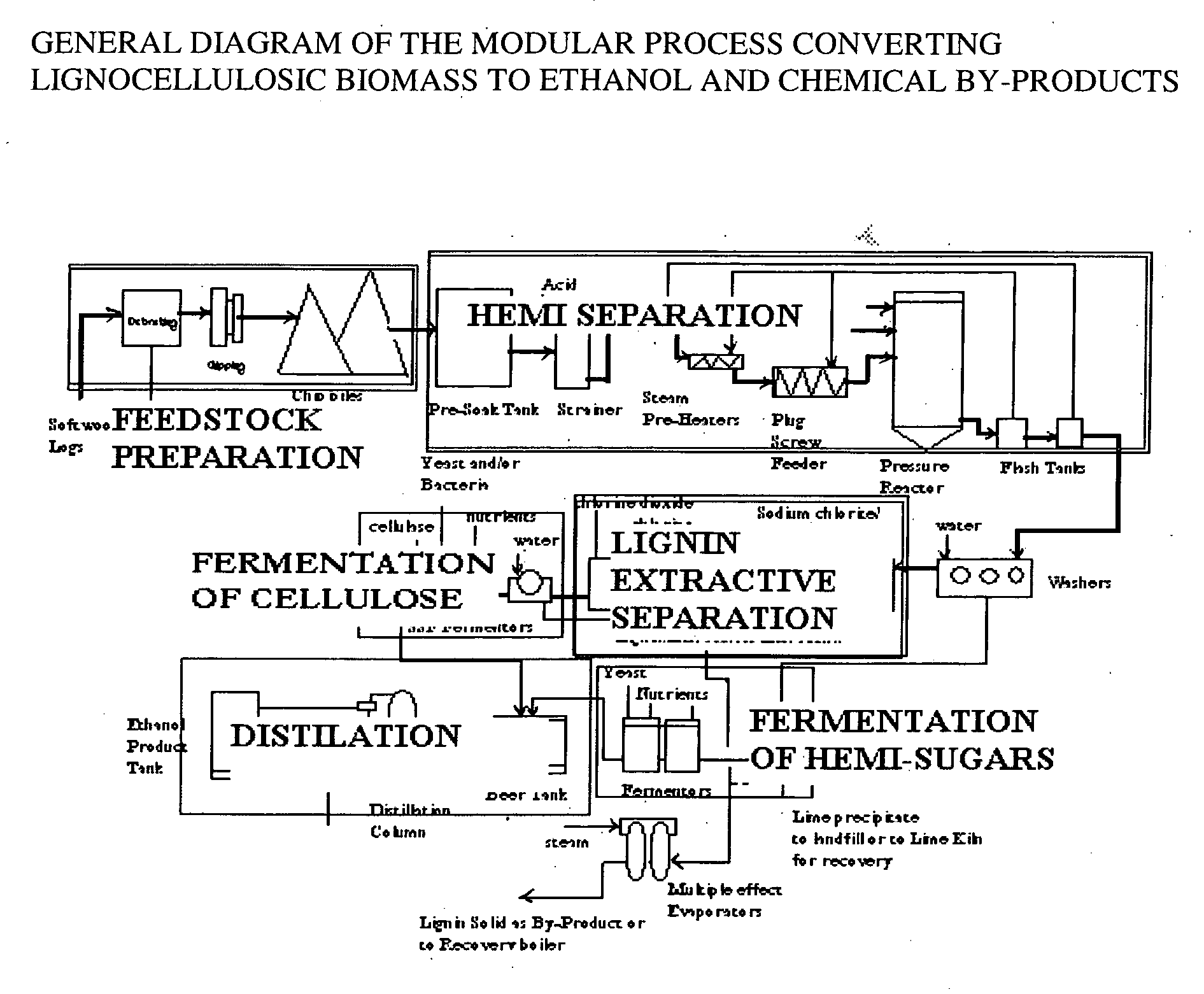

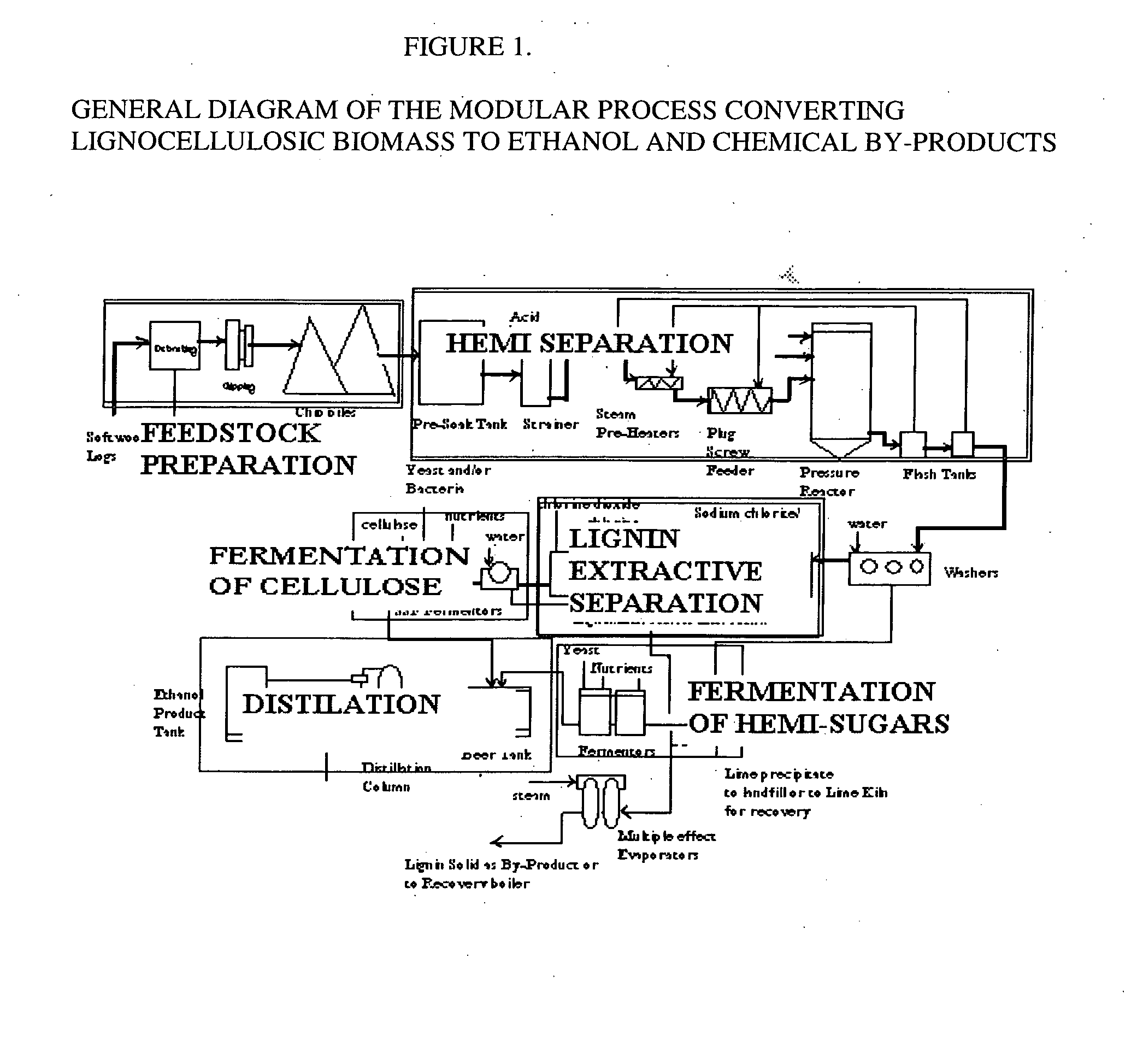

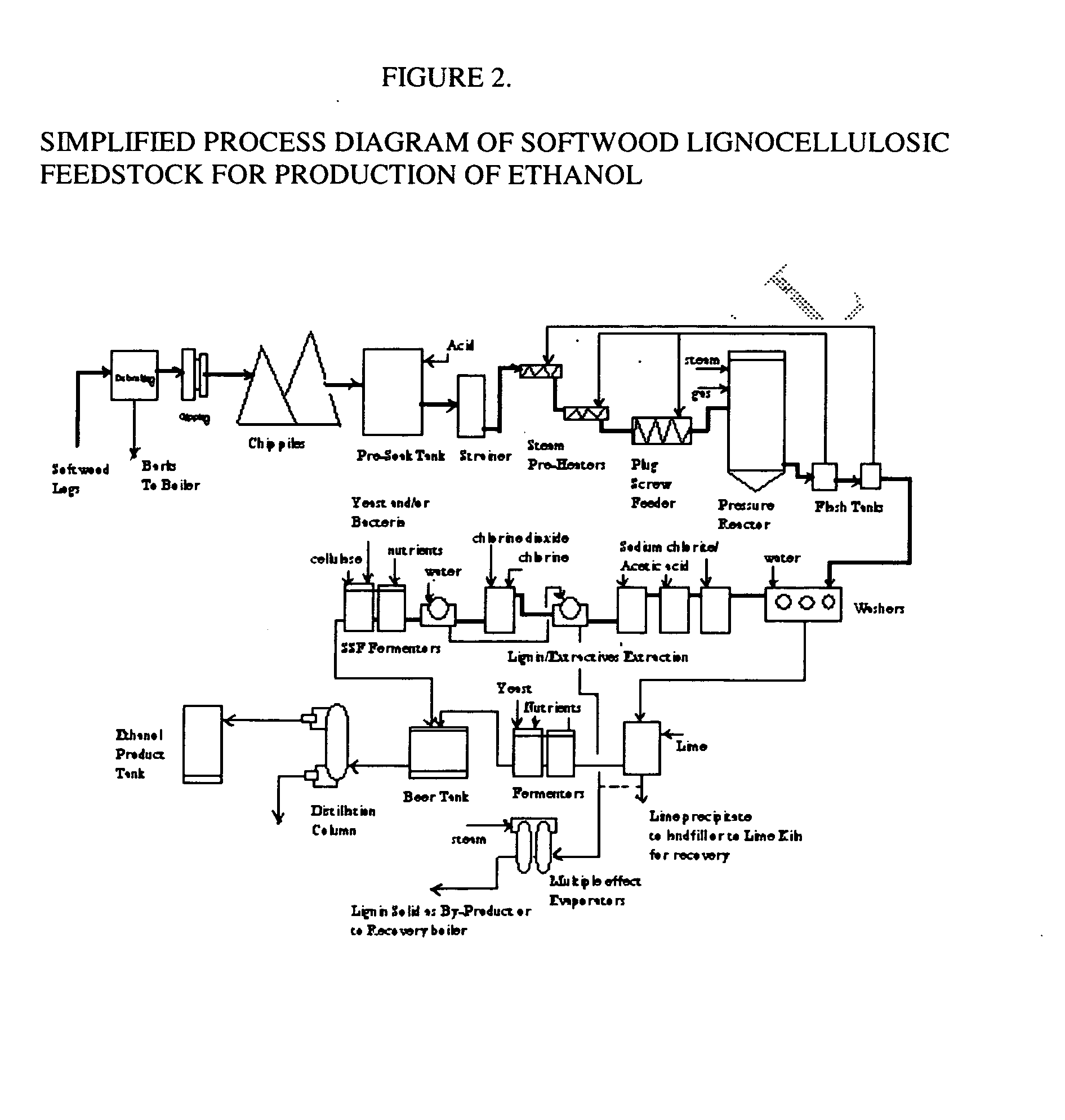

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

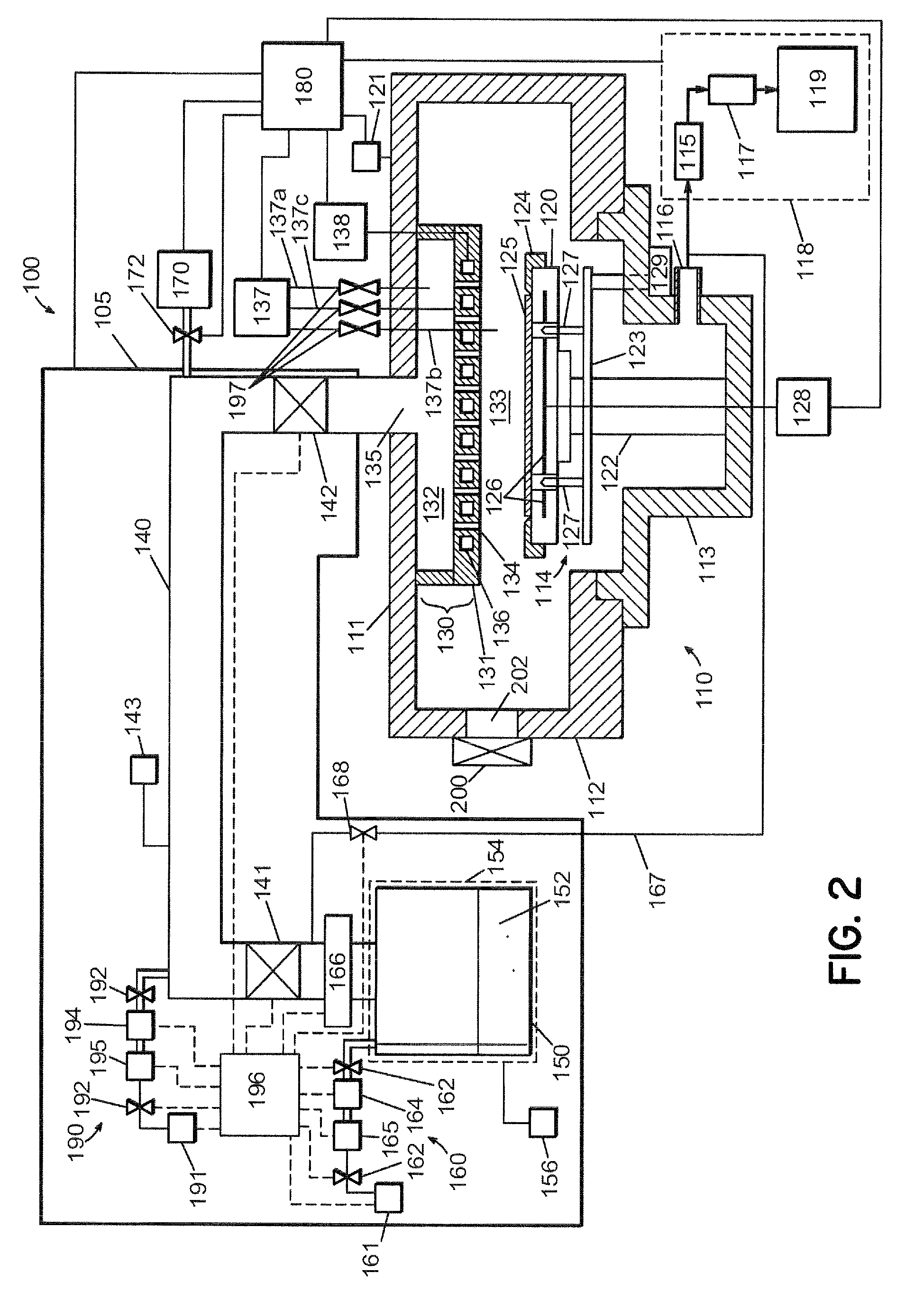

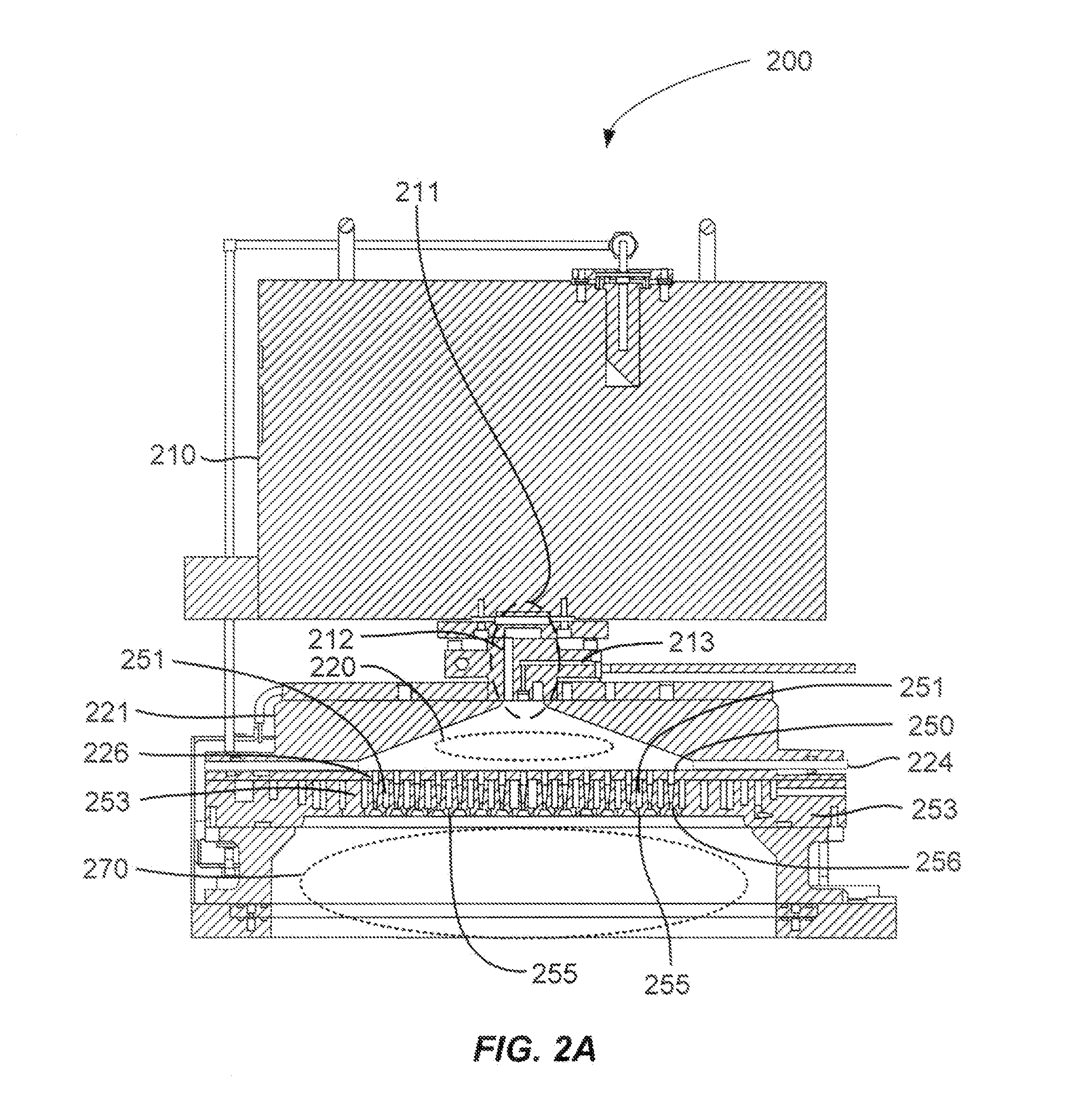

Apparatus and method for the deposition of silicon nitride films

InactiveUS20060102076A1Evenly distributedResidue reductionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCompound (substance)Process engineering

A method and apparatus for a chemical vapor deposition (CVD) chamber provides uniform heat distribution, uniform distribution of process chemicals in the CVD chamber, and minimization of by-product and condensate residue in the chamber. The improvements include a processing chamber comprising a chamber body, a base, and a chamber lid defining a processing region, a substrate support disposed in the processing region, a gas delivery system mounted on a chamber lid, the gas delivery system comprising an adapter ring and two blocker plates that define a gas mixing region, and a face plate fastened to the adapter ring, an exhaust system mounted at the base, a heating element positioned to heat the adapter ring; and a heating element positioned to heat a portion of the exhaust system.

Owner:APPLIED MATERIALS INC

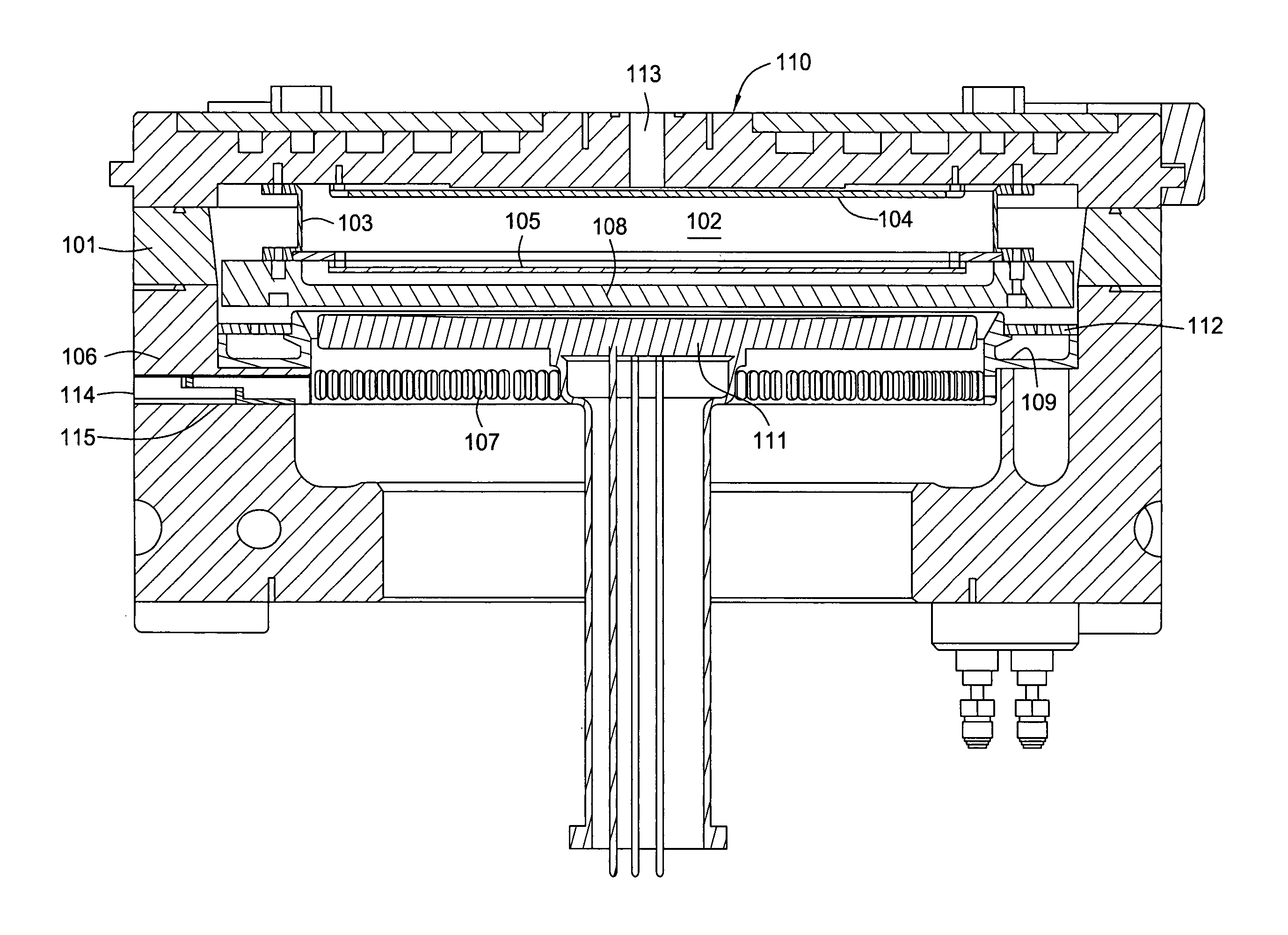

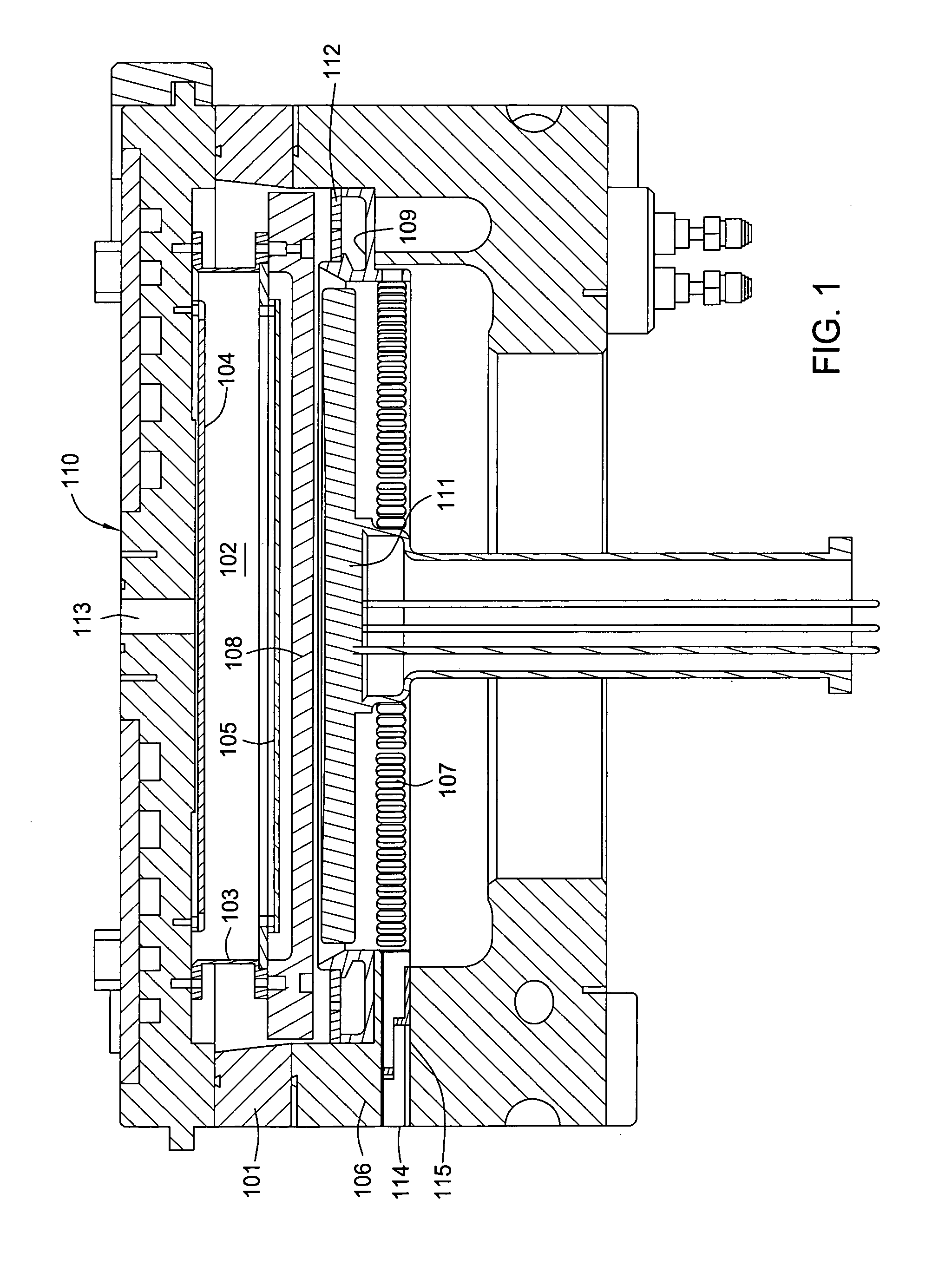

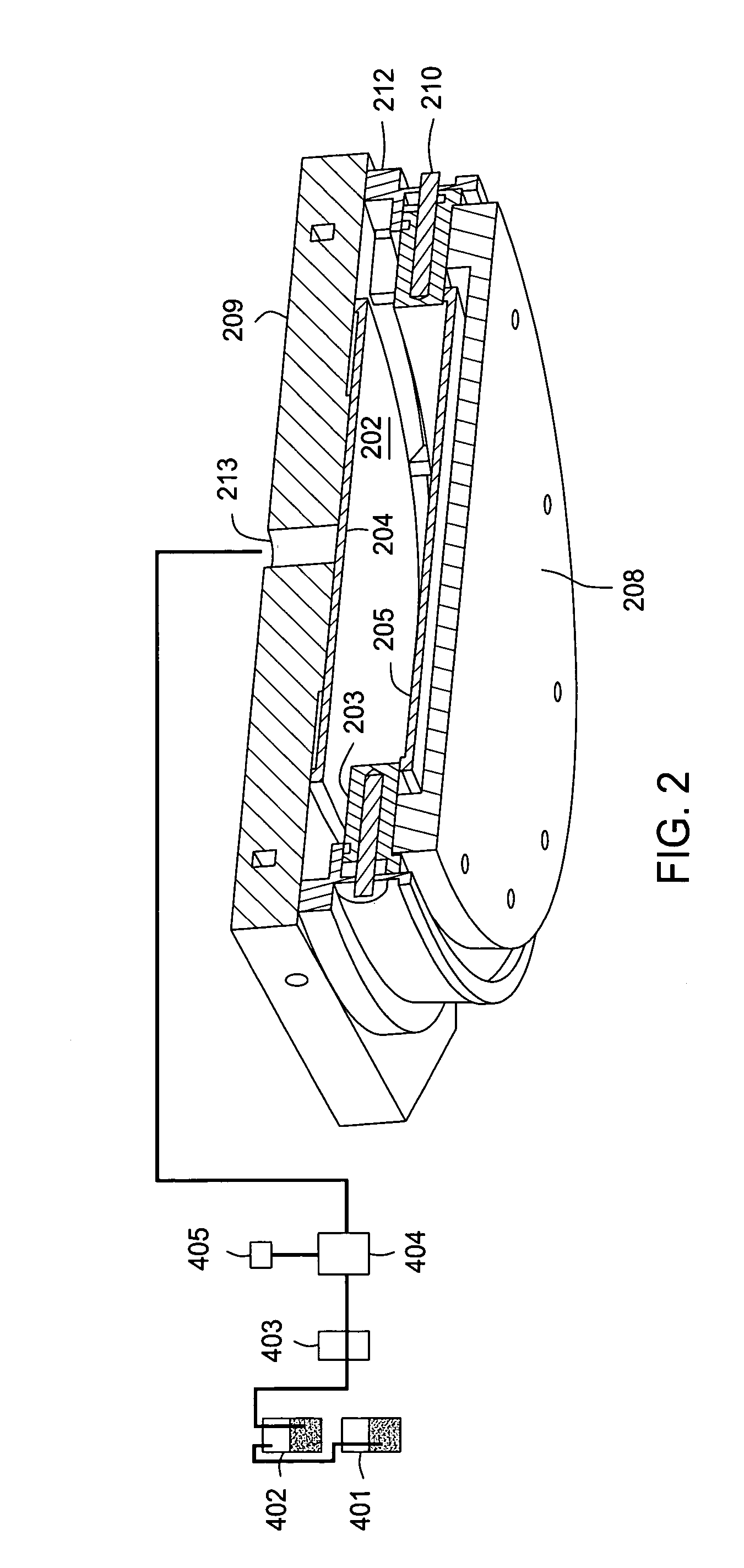

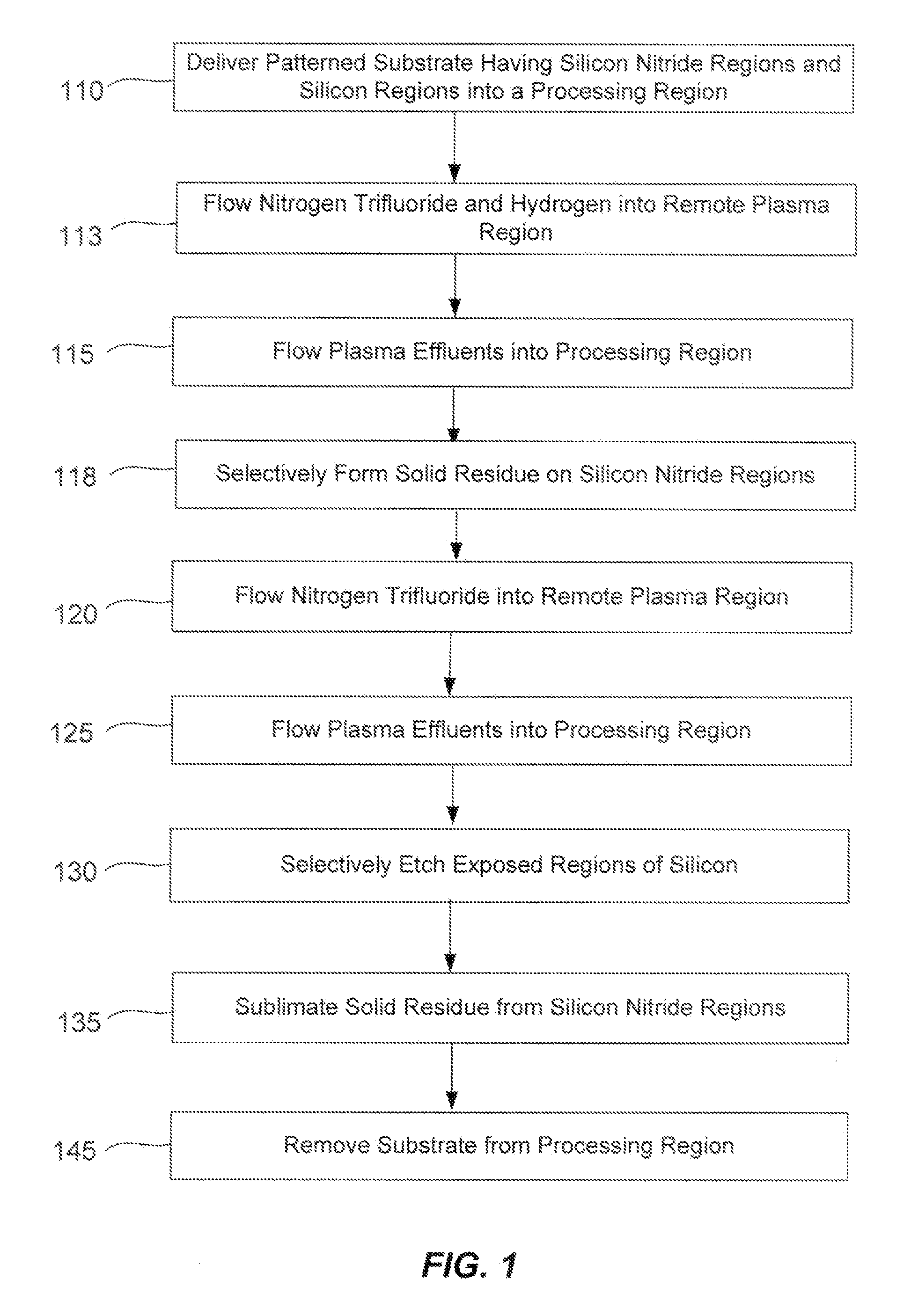

Selective suppression of dry-etch rate of materials containing both silicon and nitrogen

InactiveUS20130059440A1Inhibit etch rateImprove etch selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

A method of suppressing the etch rate for exposed silicon-and-nitrogen-containing material on patterned heterogeneous structures is described and includes a two stage remote plasma etch. The etch selectivity of silicon relative to silicon nitride and other silicon-and-nitrogen-containing material is increased using the method. The first stage of the remote plasma etch reacts plasma effluents with the patterned heterogeneous structures to form protective solid by-product on the silicon-and-nitrogen-containing material. The plasma effluents of the first stage are formed from a remote plasma of a combination of precursors, including nitrogen trifluoride and hydrogen (H2). The second stage of the remote plasma etch also reacts plasma effluents with the patterned heterogeneous structures to selectively remove material which lacks the protective solid by-product. The plasma effluents of the second stage are formed from a remote plasma of a fluorine-containing precursor.

Owner:APPLIED MATERIALS INC

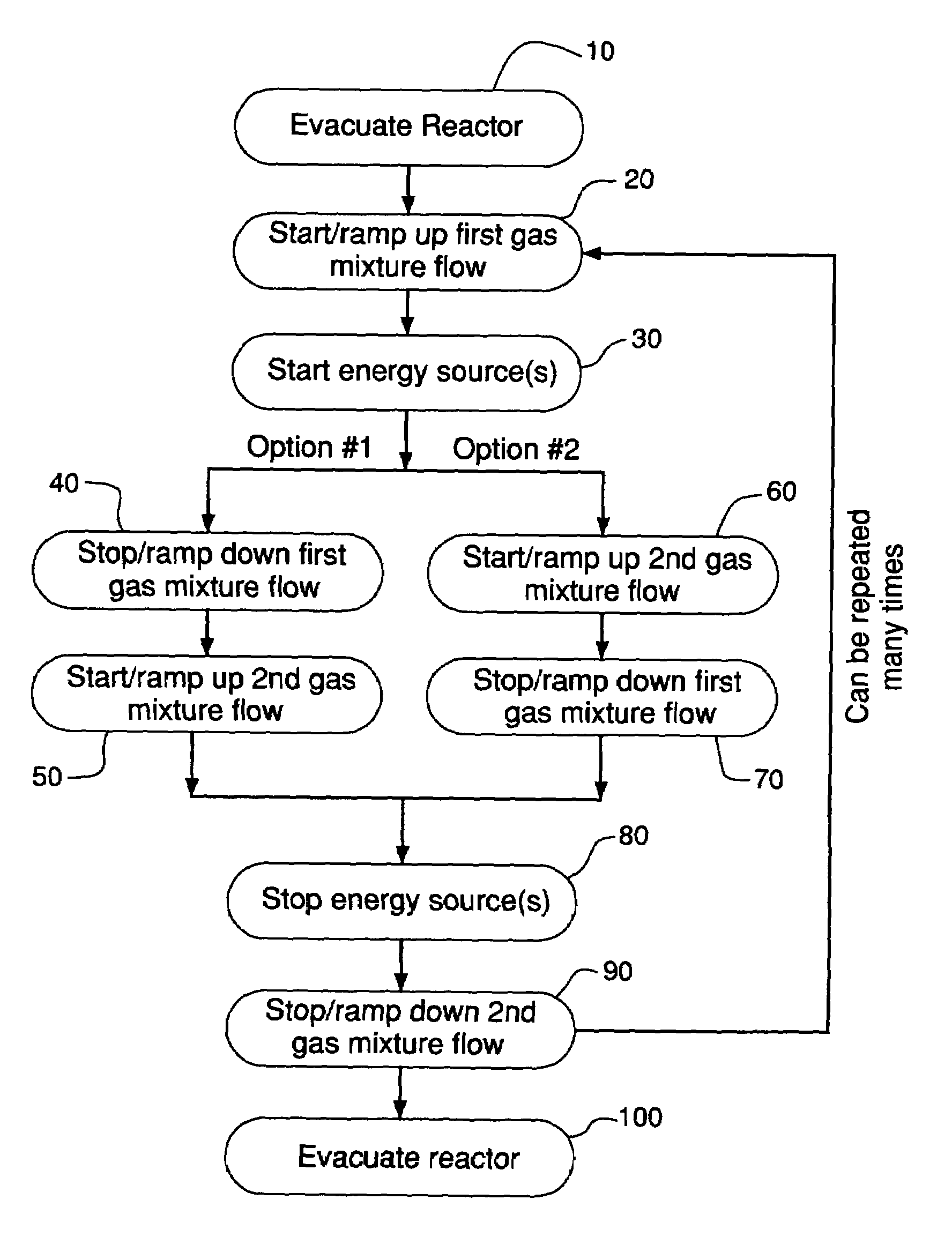

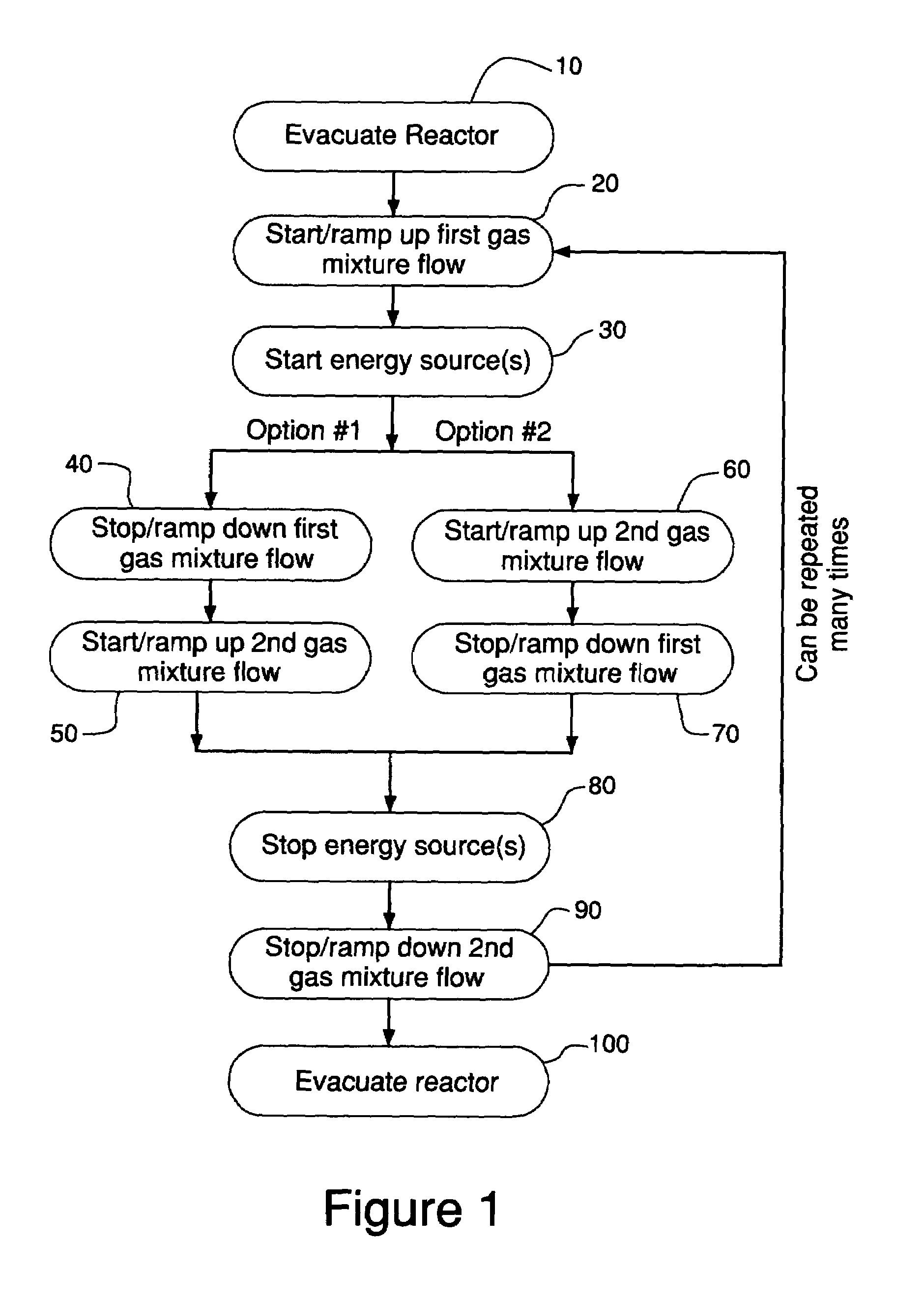

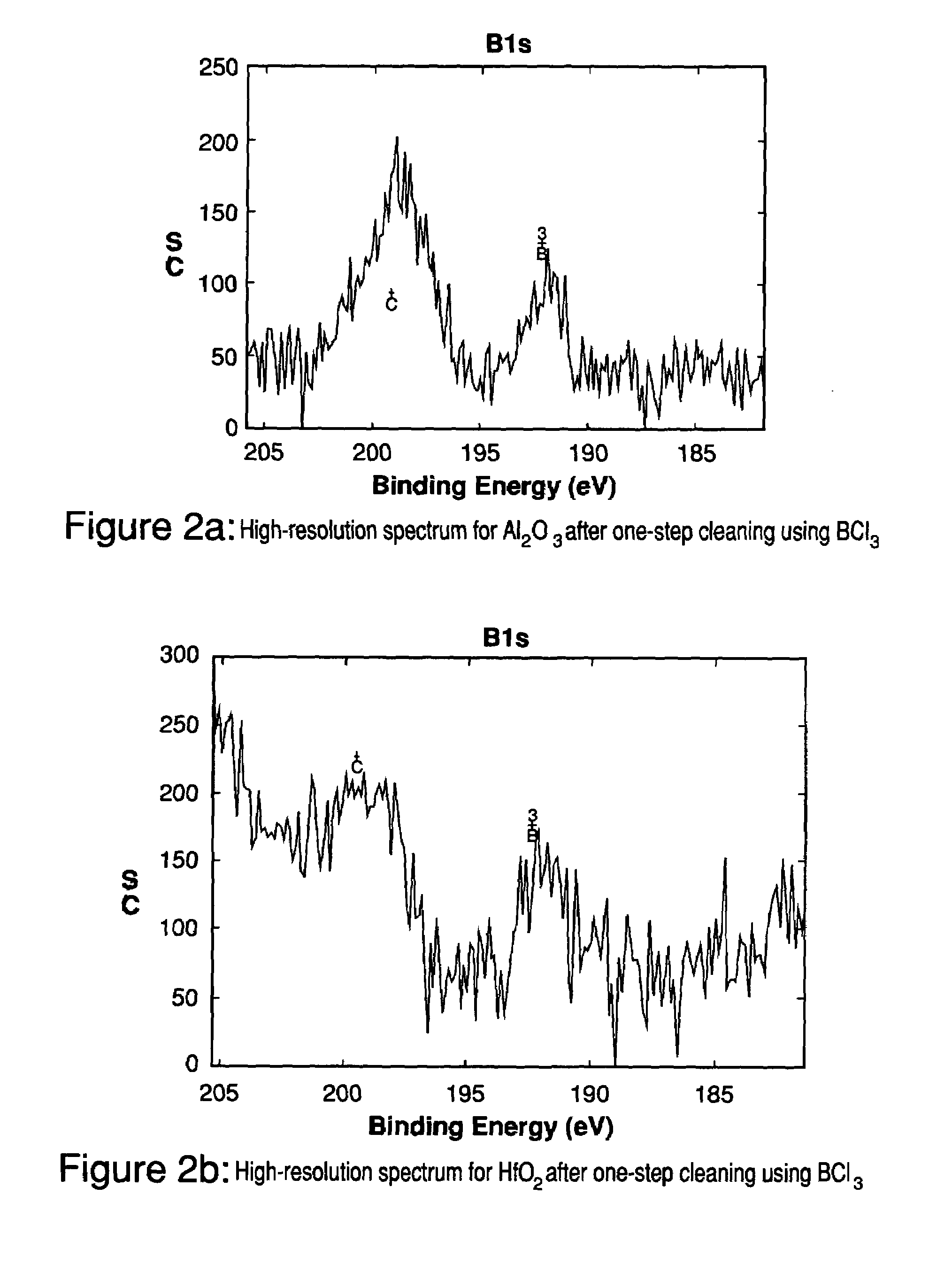

Method for cleaning deposition chambers for high dielectric constant materials

A method for dry etching and chamber cleaning high dielectric constant materials is disclosed herein. In one aspect of the present invention, there is provided a process for cleaning a substance comprising a dielectric constant greater than the dielectric constant of silicon dioxide from at least a portion of a surface of a reactor comprising: introducing a first gas mixture comprising a boron-containing reactive agent into the reactor wherein the first gas mixture reacts with the substance contained therein to provide a volatile product and a boron-containing by-product; introducing a second gas mixture comprising a fluorine-containing reactive agent into the reactor wherein the second gas mixture reacts with the boron-containing by-product contained therein to form the volatile product; and removing the volatile product from the reactor.

Owner:AIR PROD & CHEM INC

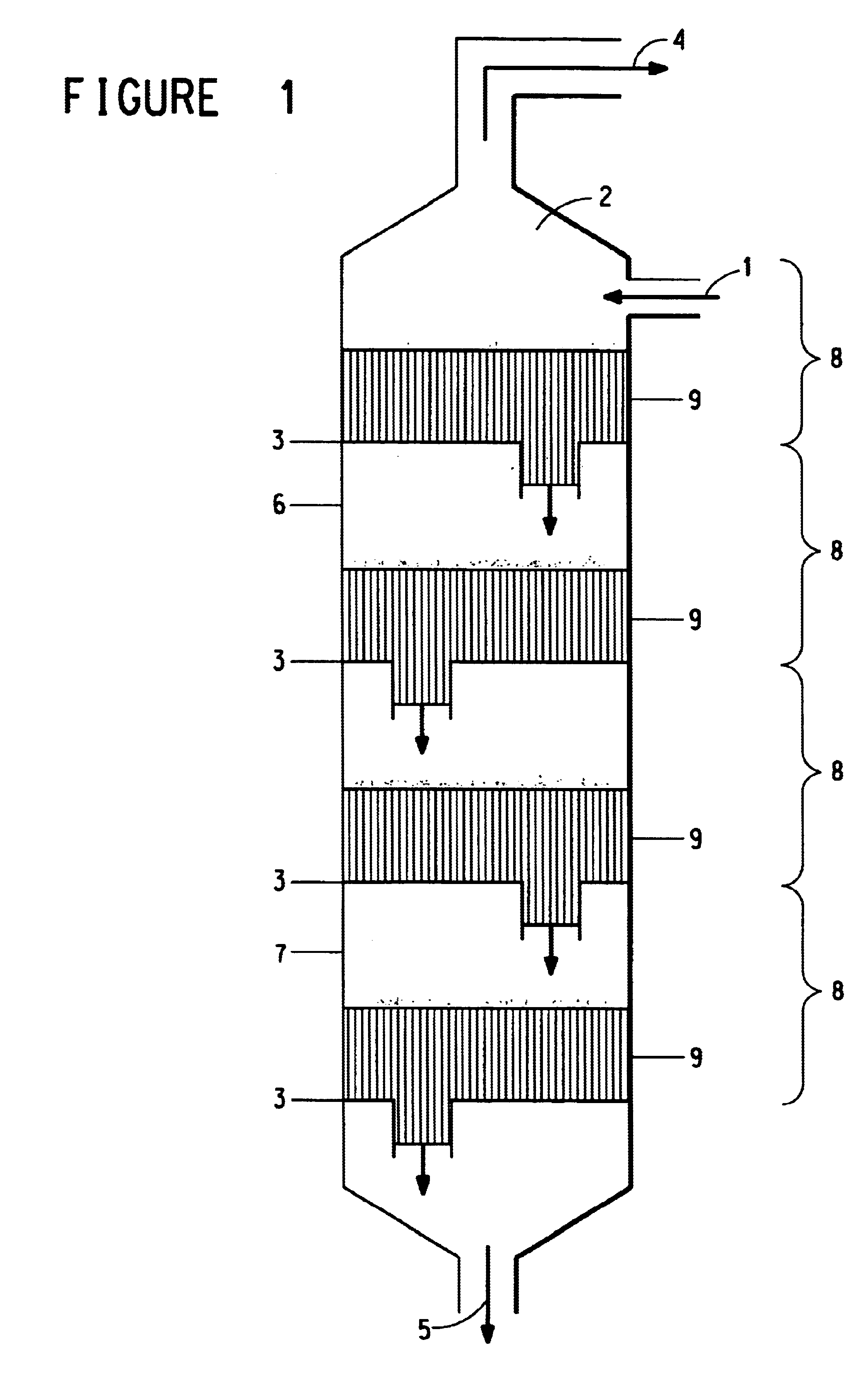

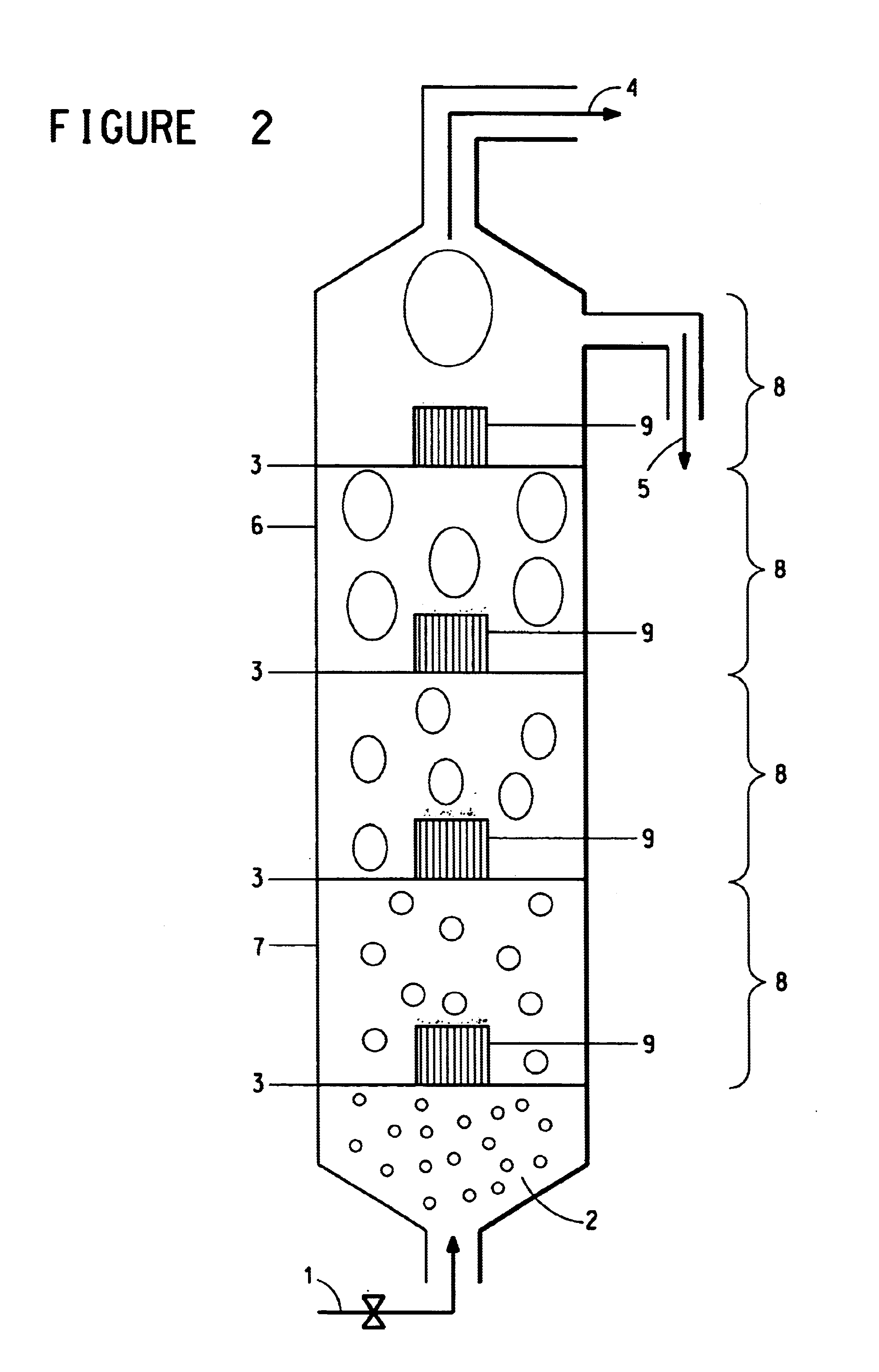

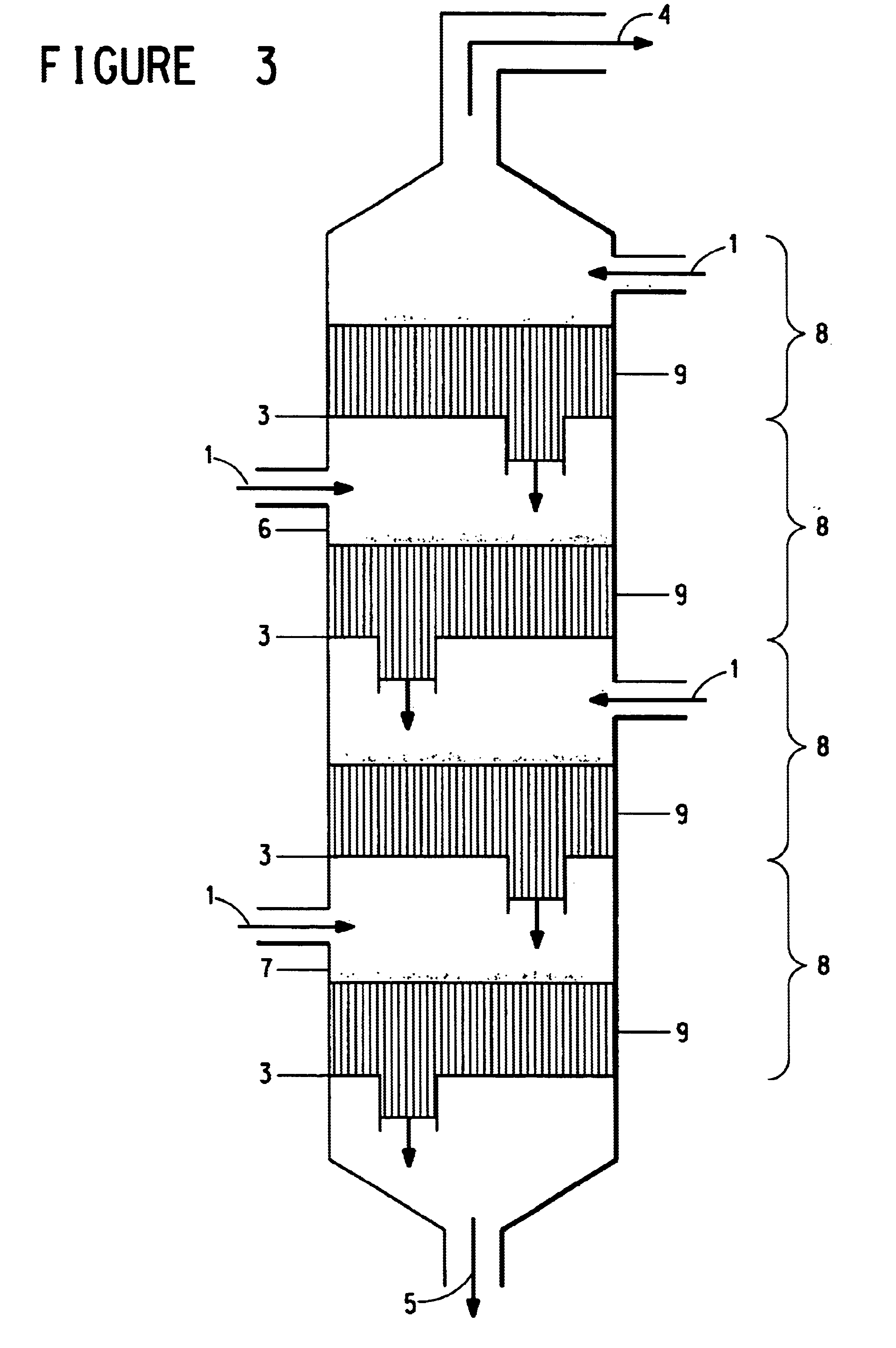

Continuous process for the preparation of polytrimethylene ether glycol

InactiveUS6720459B2Liquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseEther

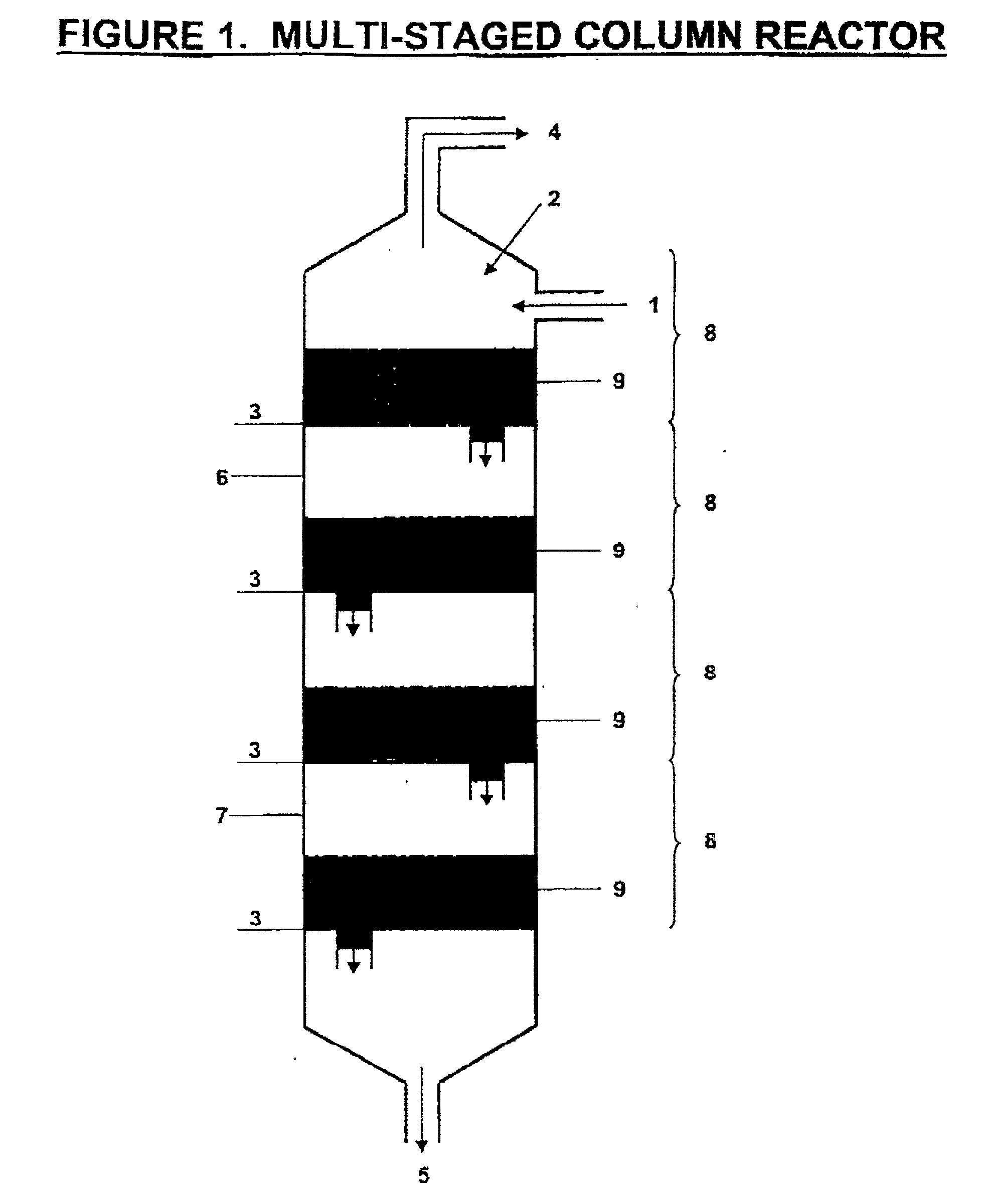

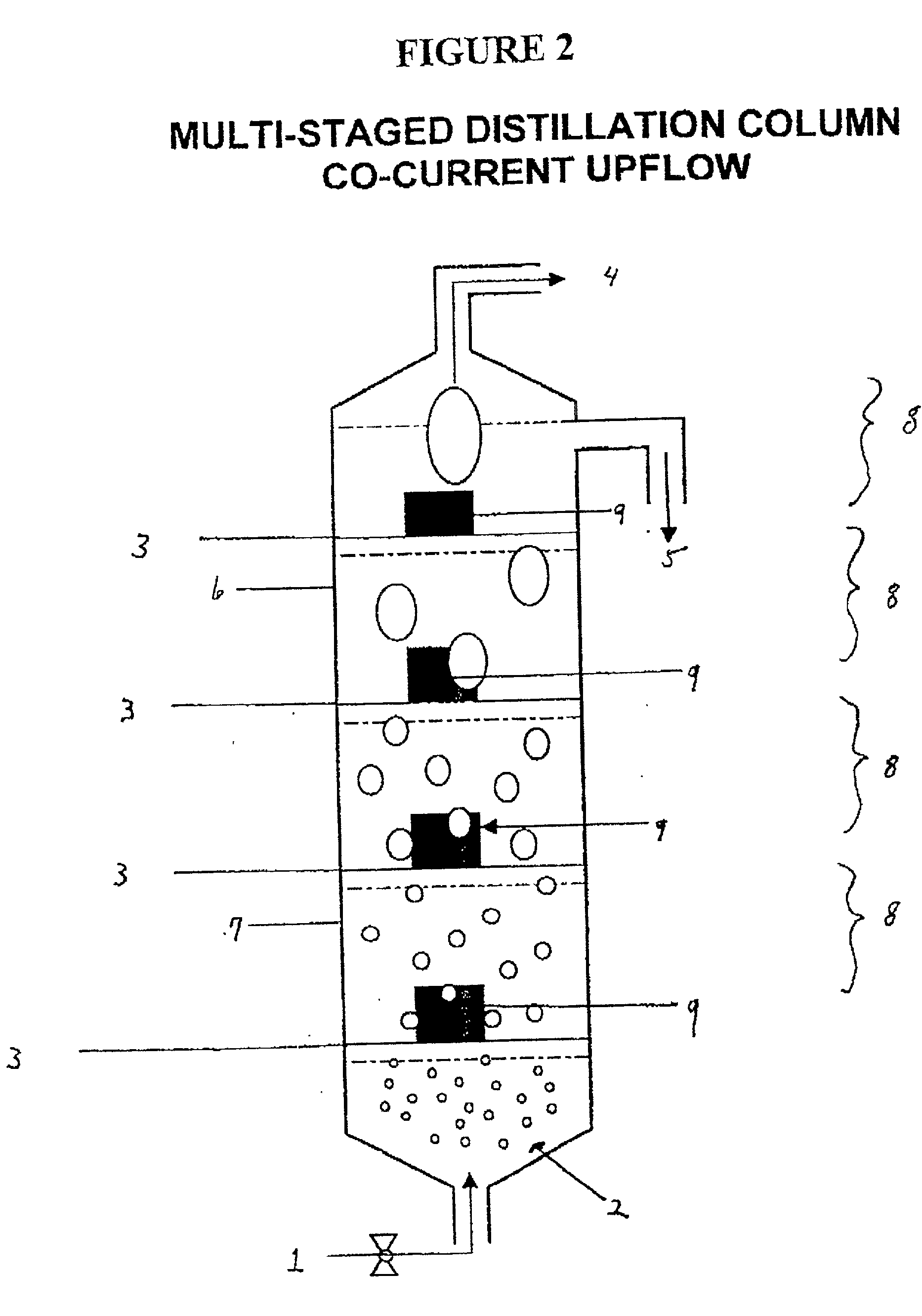

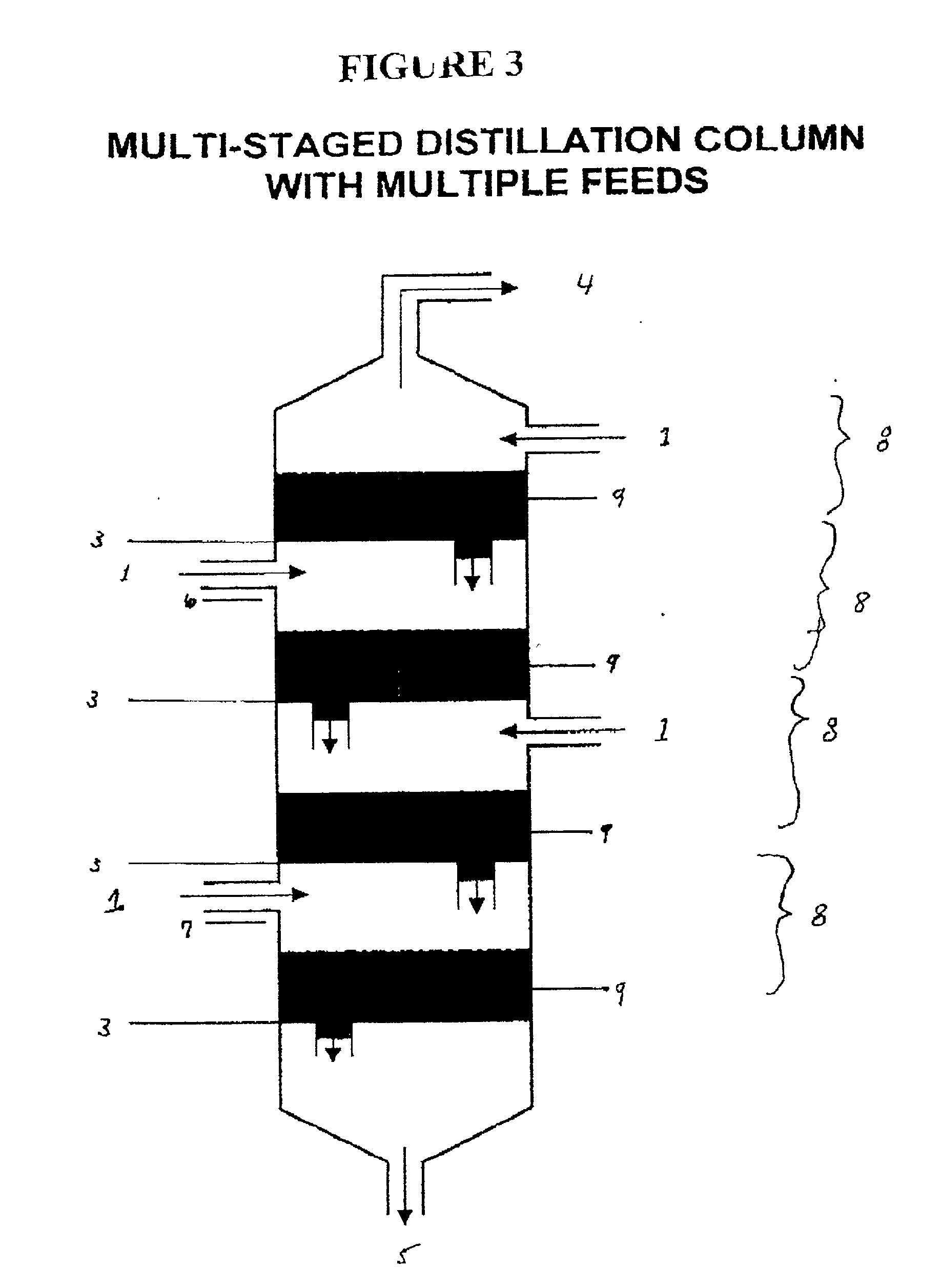

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

Acid coated sand for gravel pack and filter cake clean-up

InactiveUS20040055747A1Enhances filter cake removalSpeed up the flowCleaning apparatusFluid removalCarboxylic acidGlycollic acid

A method of the preparation and utilization of polymerized alpha-hydroxycarboxylic-acid-coated proppants for gravel pack and removal of filter cake that was deposited by reservoir drilling fluid. In a preferred example, polyglycolic-acid-coated sand is used to replace conventional gravel pack sand typically used for gravel packing. Under downhole conditions, the acidic by-product generated from the hydration of polyglycolic-acid-coated sand can break down acid-soluble and / or acid-breakable components embedded in the filter cake. This reaction enhances the filter cake removal and the flow of hydrocarbon from the producing formation. The polyglycolic-acid-coated sand may be produced by polymerizing a glycolic acid with a natural or synthetic proppant like 20-40 mesh commercial sand, at temperatures of about 210° F. or higher.

Owner:MI

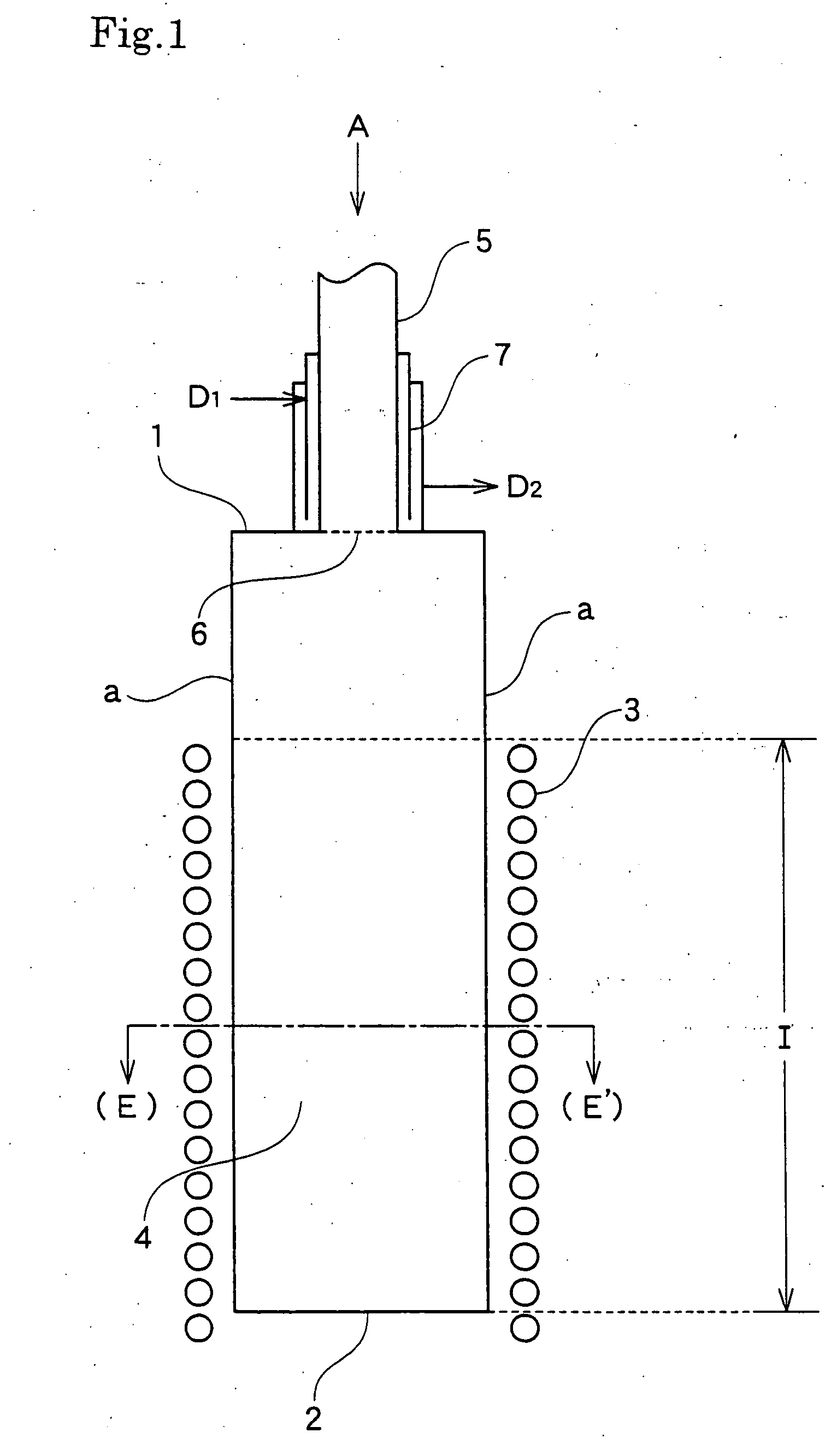

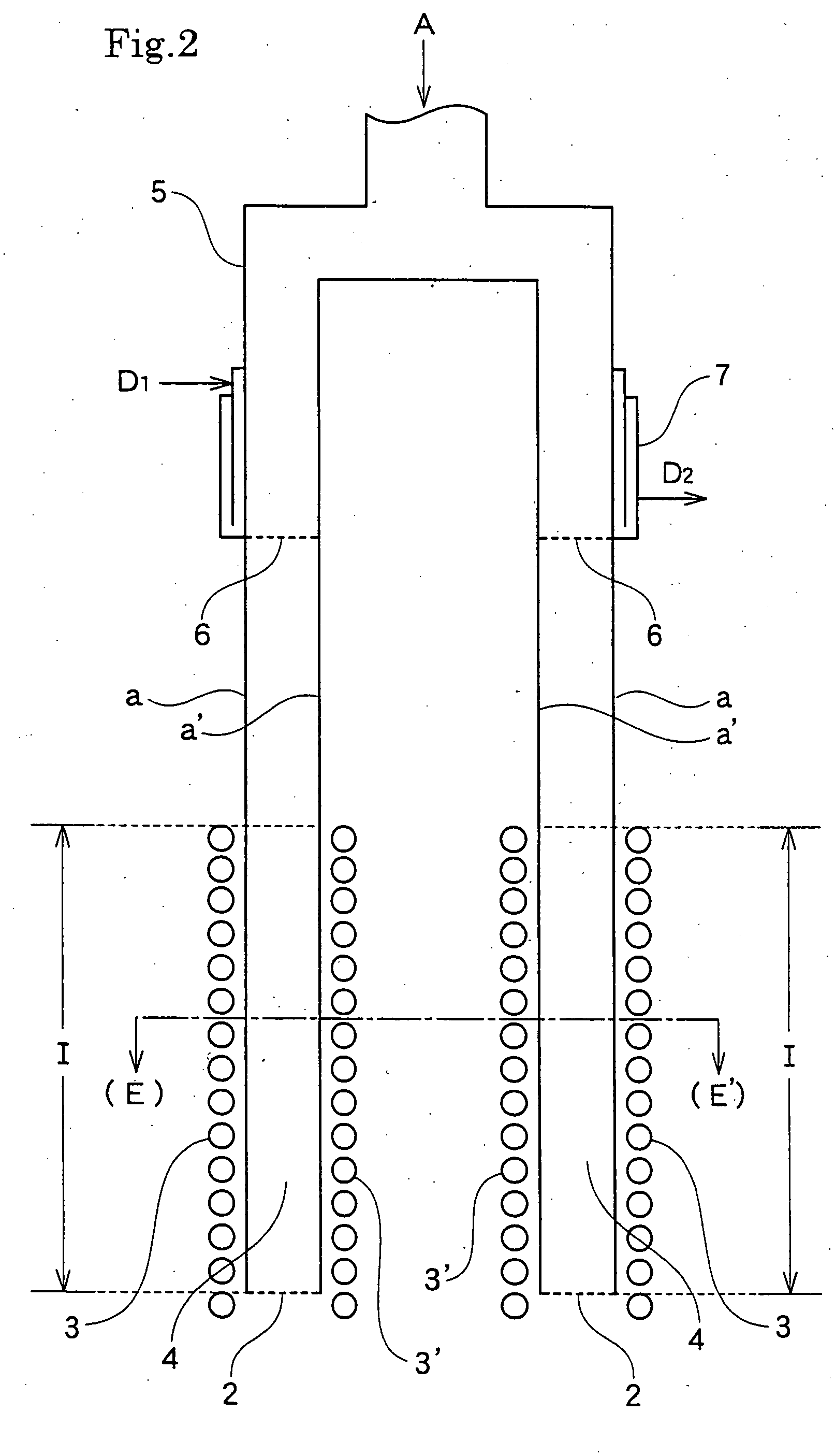

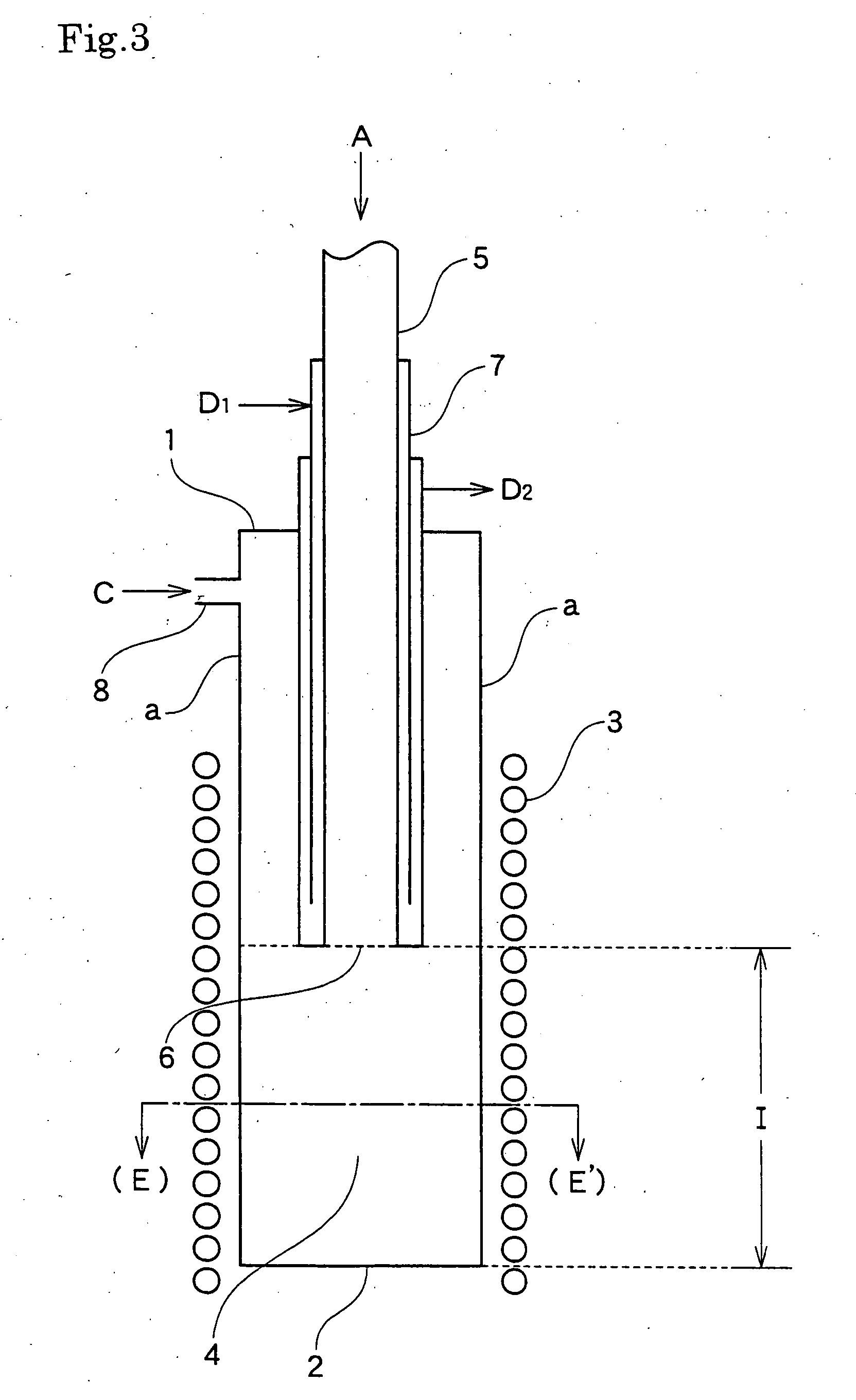

Reaction apparatus for producing silicon

ActiveUS20050201908A1Reduce spacingReduce distanceAfter-treatment apparatusSiliconProcess engineeringSilicon

A silicon production reactor comprising a reaction vessel and heating means, said reaction vessel comprising a vertically extending wall and a space surrounded by the wall, said heating means being capable of heating at least a part, including lower end portion, of the wall's surface facing the space to a temperature of not lower than the melting point of silicon, said silicon production reactor being adapted to flow raw gas for silicon deposition from an upper part of the space of the reaction vessel toward a lower part thereof, characterized in that the space of the reaction vessel is of slit form in cross-sectional view. This silicon production reactor is capable of attaining improvement with respect to problems encountered at apparatus scaleup, such as decrease of reactivity of raw gas and generation of by-products, thereby accomplishing a striking enhancement of production efficiency.

Owner:TOKUYAMA CORP

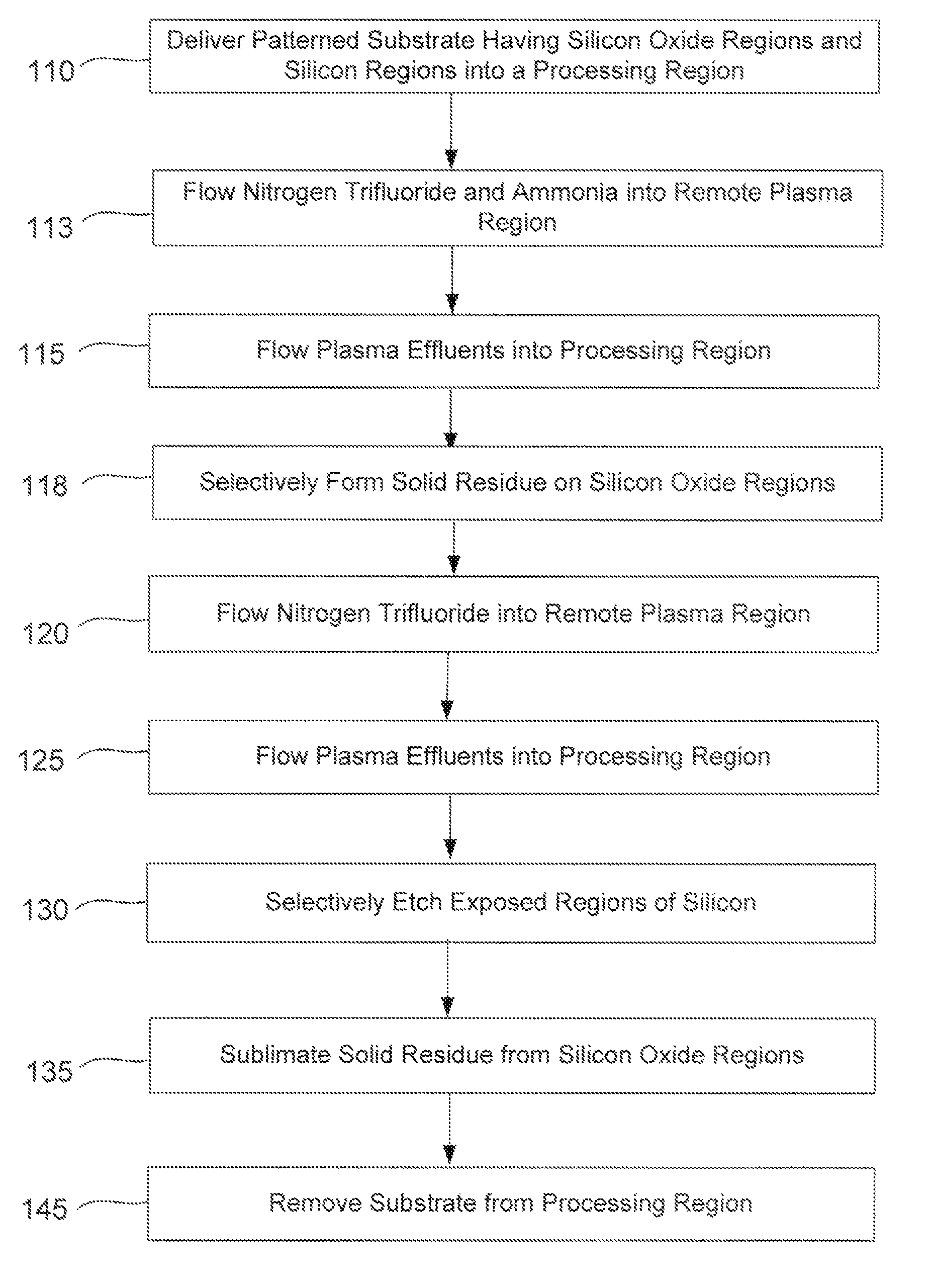

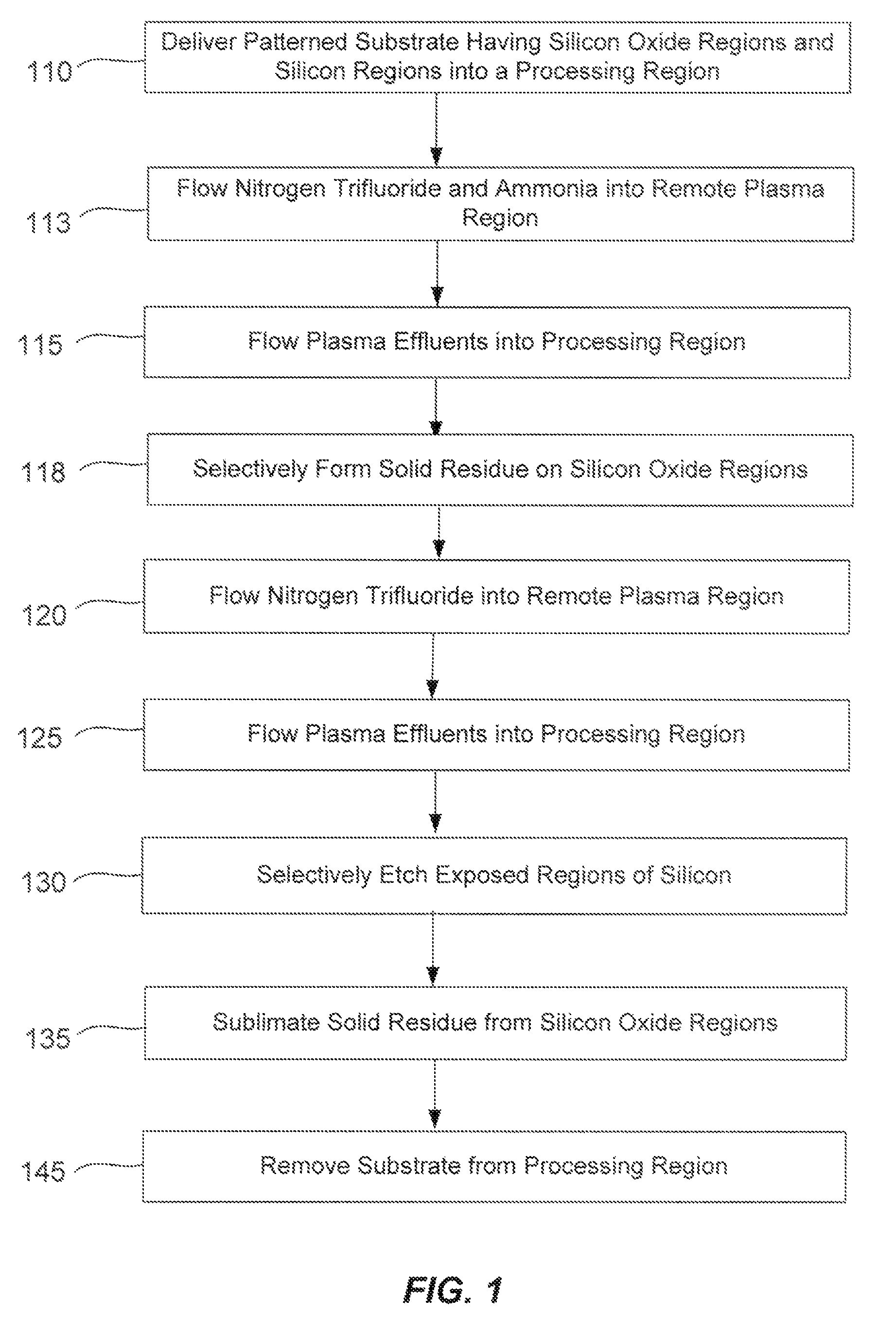

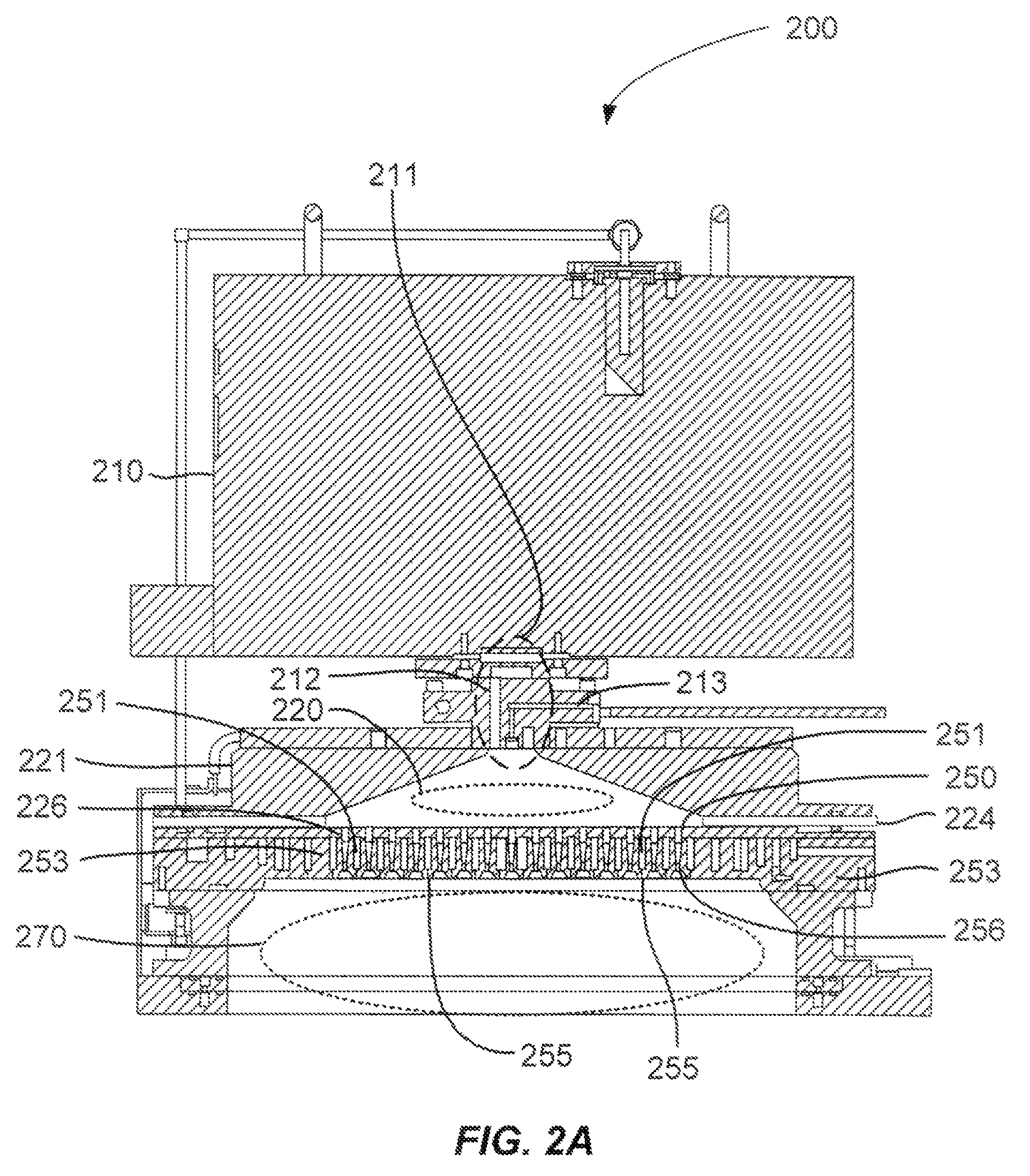

Selective suppression of dry-etch rate of materials containing both silicon and oxygen

A method of suppressing the etch rate for exposed silicon-and-oxygen-containing material on patterned heterogeneous structures is described and includes a two stage remote plasma etch. Examples of materials whose selectivity is increased using this technique include silicon nitride and silicon. The first stage of the remote plasma etch reacts plasma effluents with the patterned heterogeneous structures to form protective solid by-product on the silicon-and-oxygen-containing material. The plasma effluents of the first stage are formed from a remote plasma of a combination of precursors, including a nitrogen-containing precursor and a hydrogen-containing precursor. The second stage of the remote plasma etch also reacts plasma effluents with the patterned heterogeneous structures to selectively remove material which lacks the protective solid by-product. The plasma effluents of the second stage are formed from a remote plasma of a fluorine-containing precursor.

Owner:APPLIED MATERIALS INC

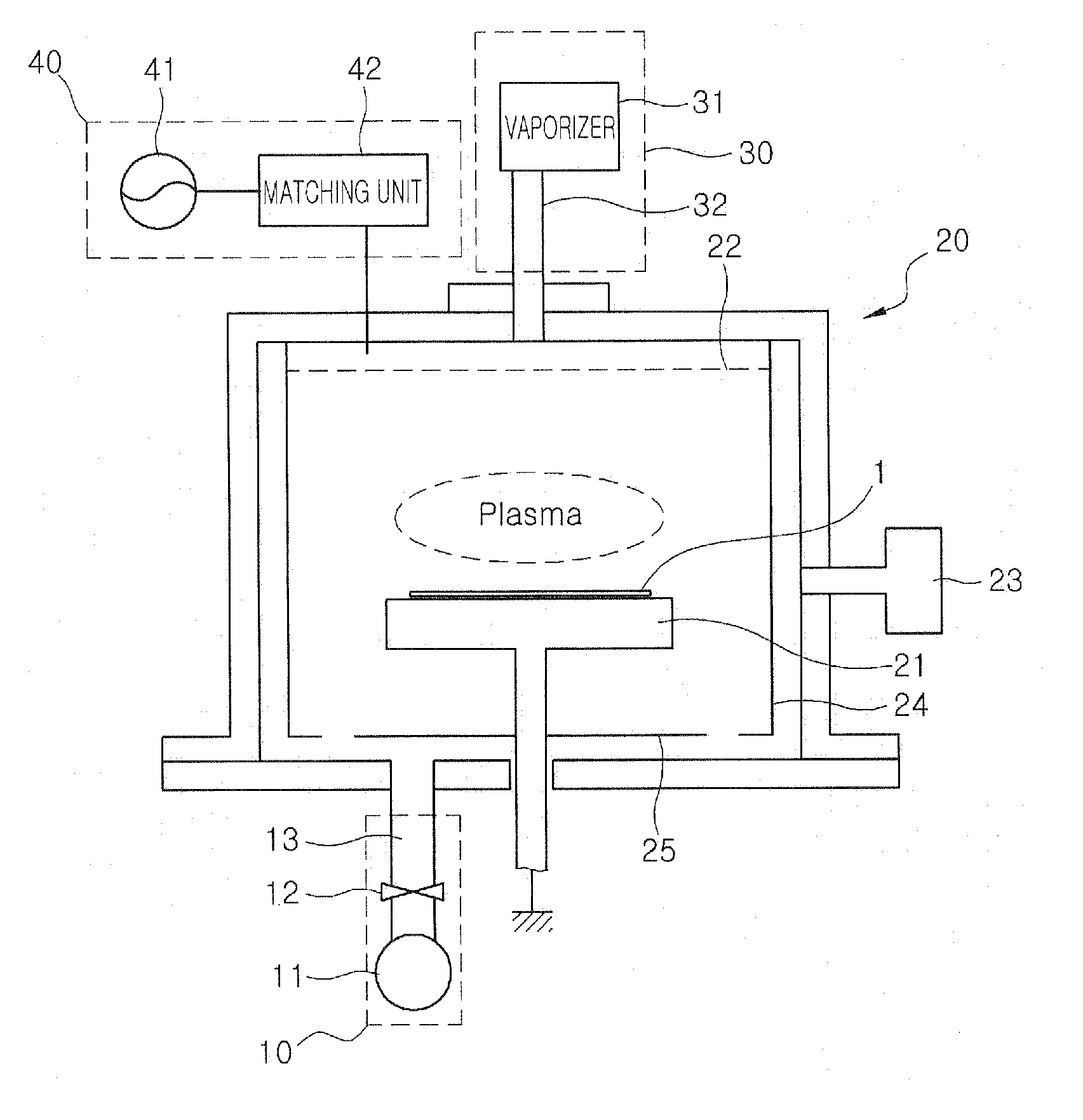

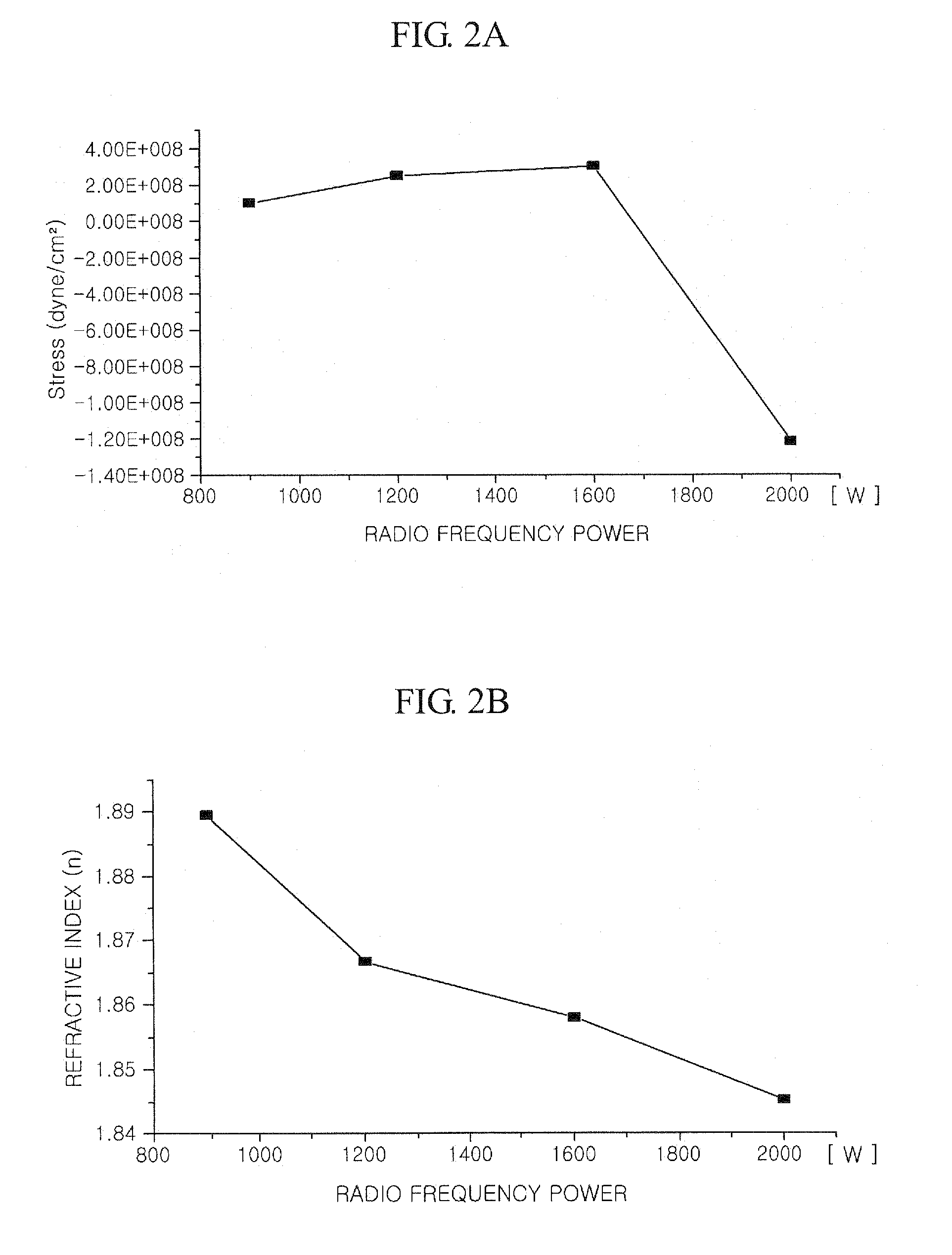

Method of forming amorphous carbon film and method of manufacturing semiconductor device using the same

InactiveUS20080293248A1Better controllableLight absorption coefficient is lowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRefractive indexDiffuse reflection

The present invention relates to a method of forming an amorphous carbon film and a method of manufacturing a semiconductor device using the method. An amorphous carbon film is formed on a substrate by vaporizing a liquid hydrocarbon compound, which has chain structure and one double bond, and supplying the compound to a chamber, and ionizing the compound. The amorphous carbon film is used as a hard mask film.It is possible to easily control characteristics of the amorphous carbon film, such as a deposition rate, an etching selectivity, a refractive index (n), a light absorption coefficient (k) and stress, so as to satisfy user's requirements. In particular, it is possible to lower the refractive index (n) and the light absorption coefficient (k). As a result, it is possible to perform a photolithography process without an antireflection film that prevents the diffuse reflection of a lower material layer.Further, a small amount of reaction by-product is generated during a deposition process, and it is possible to easily remove reaction by-products that are attached on the inner wall of a chamber. For this reason, it is possible to increase a cycle of a process for cleaning a chamber, and to increase parts changing cycles of a chamber. As a result, it is possible to save time and cost.

Owner:TES CO LTD

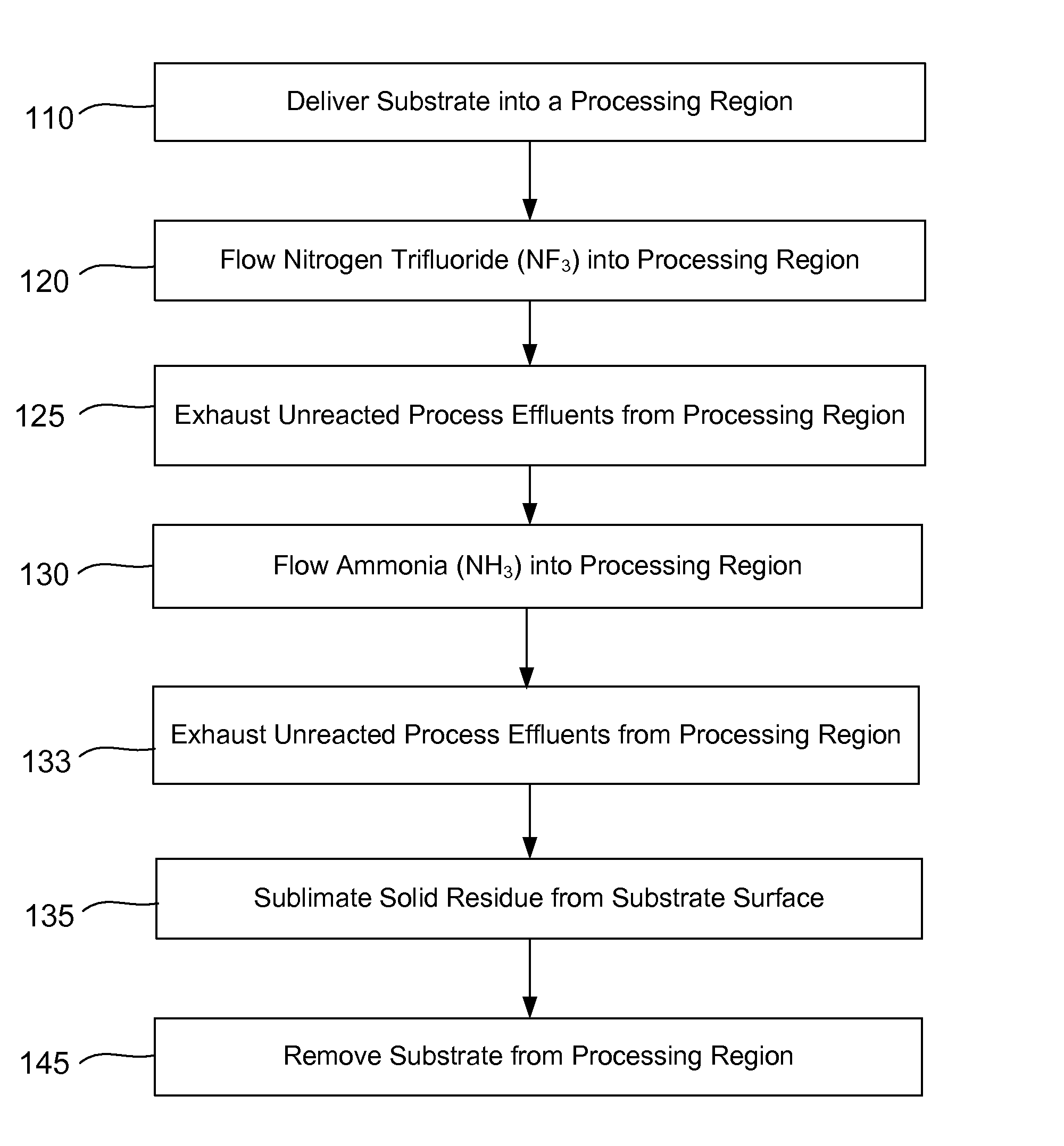

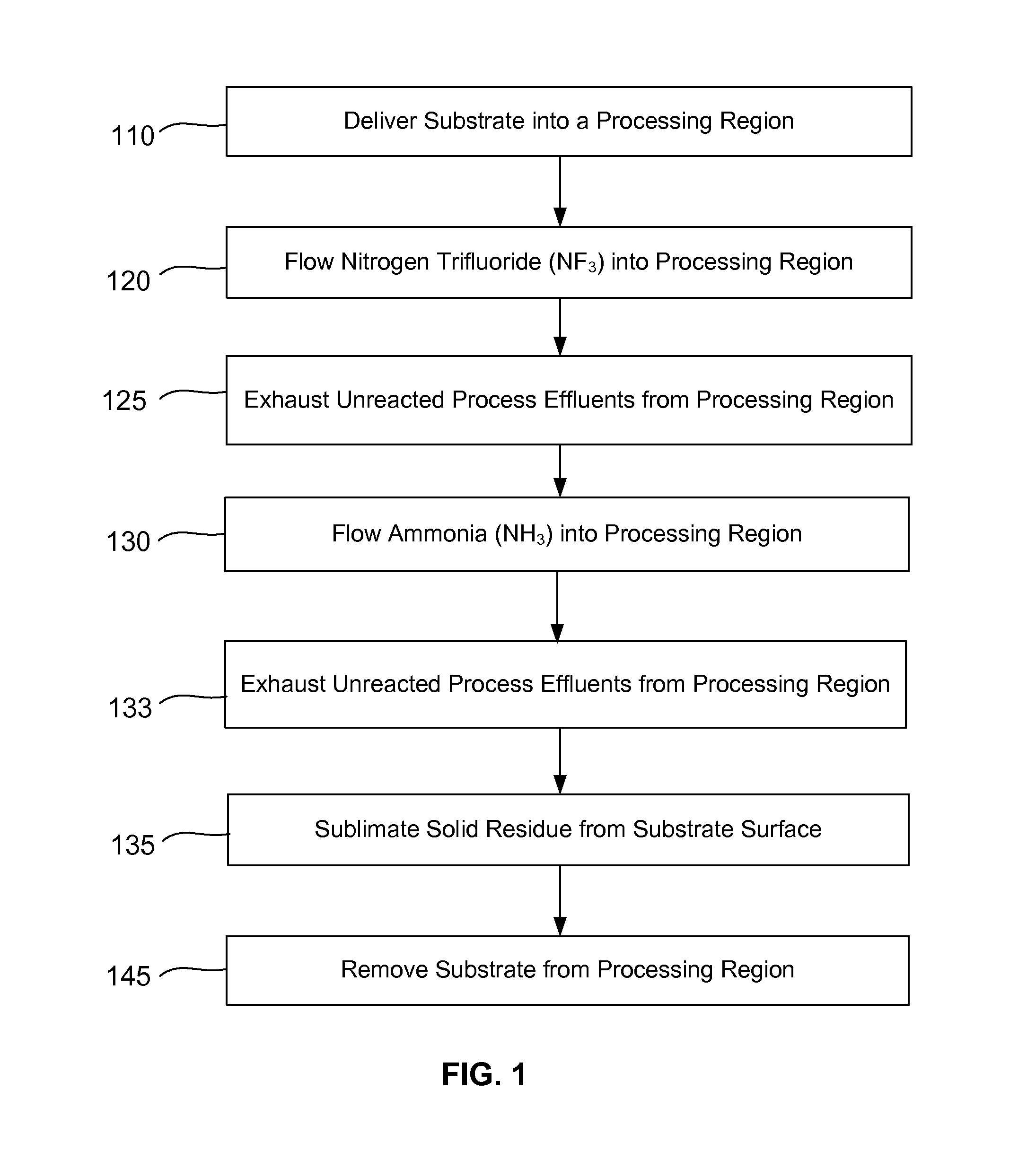

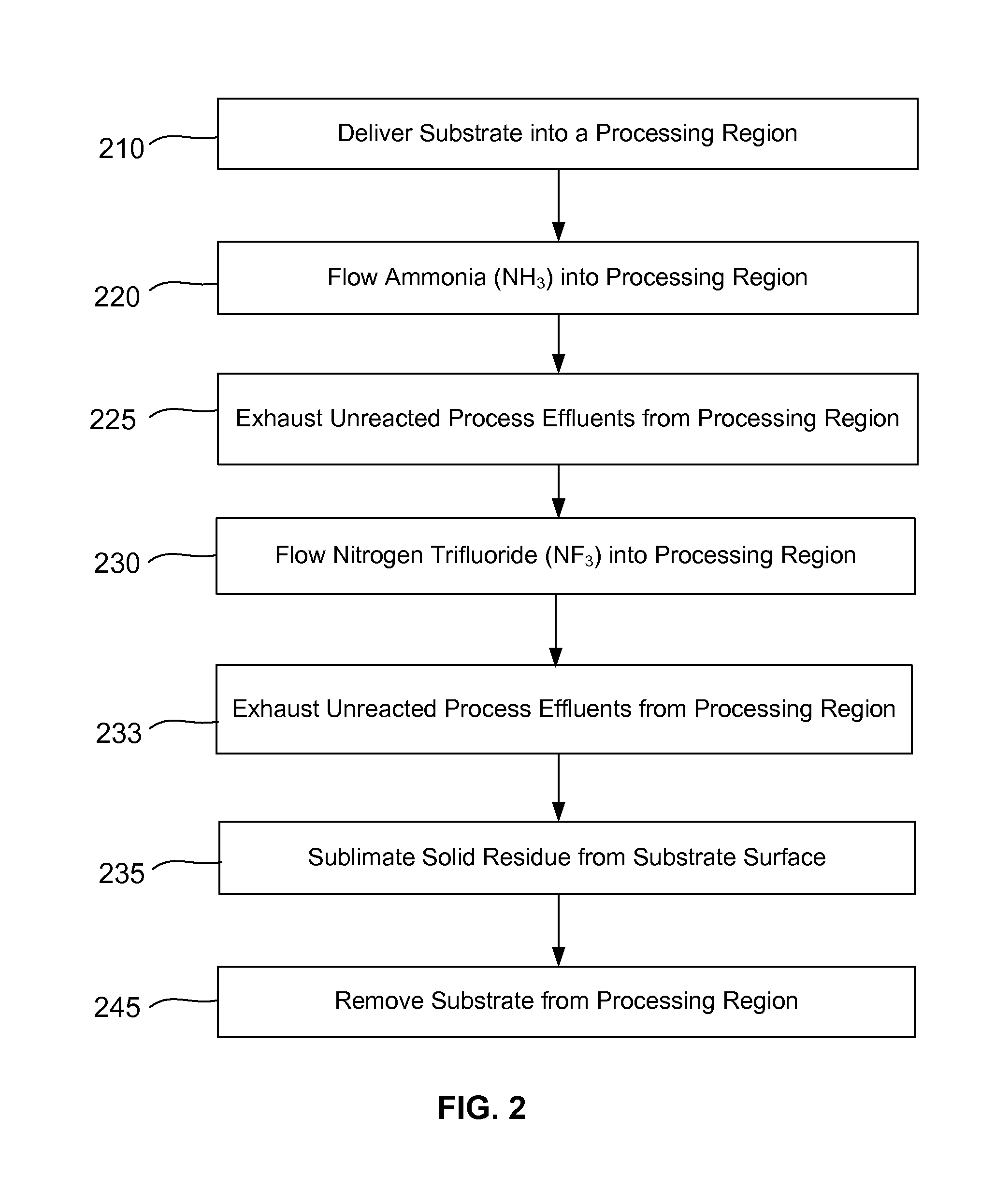

Conformal oxide dry etch

InactiveUS8801952B1Reduce the temperatureElectric discharge tubesDecorative surface effectsHydrogenSilicon oxide

A method of etching silicon oxide from a trench is described which allows more homogeneous etch rates up and down the sides of the trench. One disclosed method includes a sequential introduction of (1) a hydrogen-containing precursor and then (2) a fluorine-containing precursor into a substrate processing region. The temperature of the substrate is low during each of the two steps in order to allow the reaction to proceed and form solid residue by-product. A second disclosed method reverses the order of steps (1) and (2) but still forms solid residue by-product. The solid residue by-product is removed by raising the temperature in a subsequent sublimation step regardless of the order of the two steps.

Owner:APPLIED MATERIALS INC

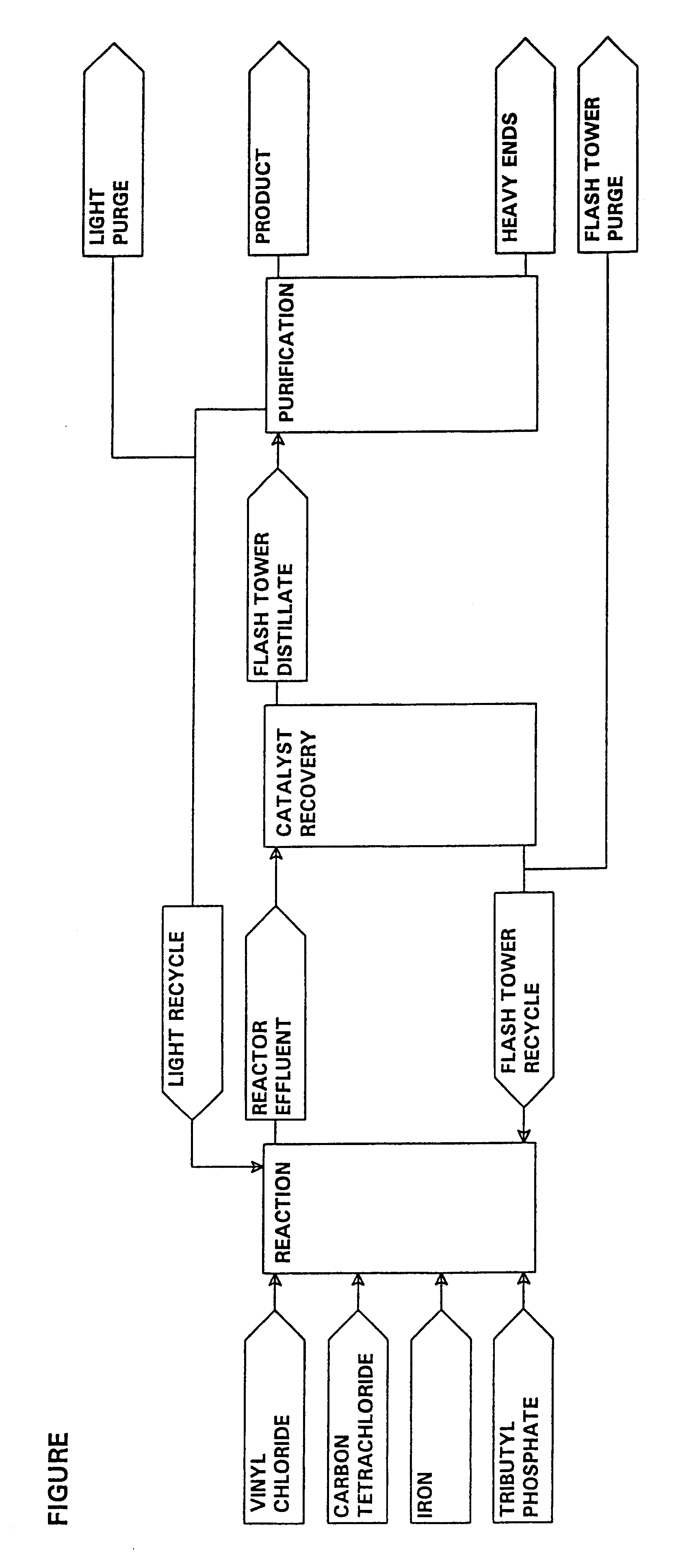

Process for the manufacture of 1, 1, 1, 3, 3-pentachloropropane

InactiveUS6313360B1Improve degradation rateShorten the timeOrganic chemistry methodsHalogenated hydrocarbon separation/purificationChlorideOrganic phosphates

A process is provided for the production of 1,1,1,3,3-pentachloropropane. The process comprises: (a) producing a product mixture in a reactor by reacting carbon tetrachloride and vinyl chloride in the presence of a catalyst mixture comprising organophosphate solvent, iron metal and ferric chloride under conditions sufficient to produce 1,1,1,3,3-pentachloropropane; (b) subjecting the 1,1,1,3,3-pentachloropropane containing product mixture from step (a) to evaporation such that a fraction enriched in 1,1,1,3,3-pentachloropropane is separated from the product mixture and a bottoms fraction results which comprises the iron metal / ferric chloride catalyst components and heavy end by-products; and (c) recycling at least a portion of the bottoms fraction from step (b) to the reactor.

Owner:OCCIDENTAL CHEM CORP

Acid coated sand for gravel pack and filter cake clean-up

InactiveUS6817414B2Speed up the flowGood removal effectCleaning apparatusFluid removalGlycollic acidCarboxylic acid

A method of the preparation and utilization of polymerized alpha-hydroxycarboxylic-acid-coated proppants for gravel pack and removal of filter cake that was deposited by reservoir drilling fluid. In a preferred example, polyglycolic-acid-coated sand is used to replace conventional gravel pack sand typically used for gravel packing. Under downhole conditions, the acidic by-product generated from the hydration of polyglycolic-acid-coated sand can break down acid-soluble and / or acid-breakable components embedded in the filter cake. This reaction enhances the filter cake removal and the flow of hydrocarbon from the producing formation. The polyglycolic-acid-coated sand may be produced by polymerizing a glycolic acid with a natural or synthetic proppant like 20-40 mesh commercial sand, at temperatures of about 210° F. or higher.

Owner:MI

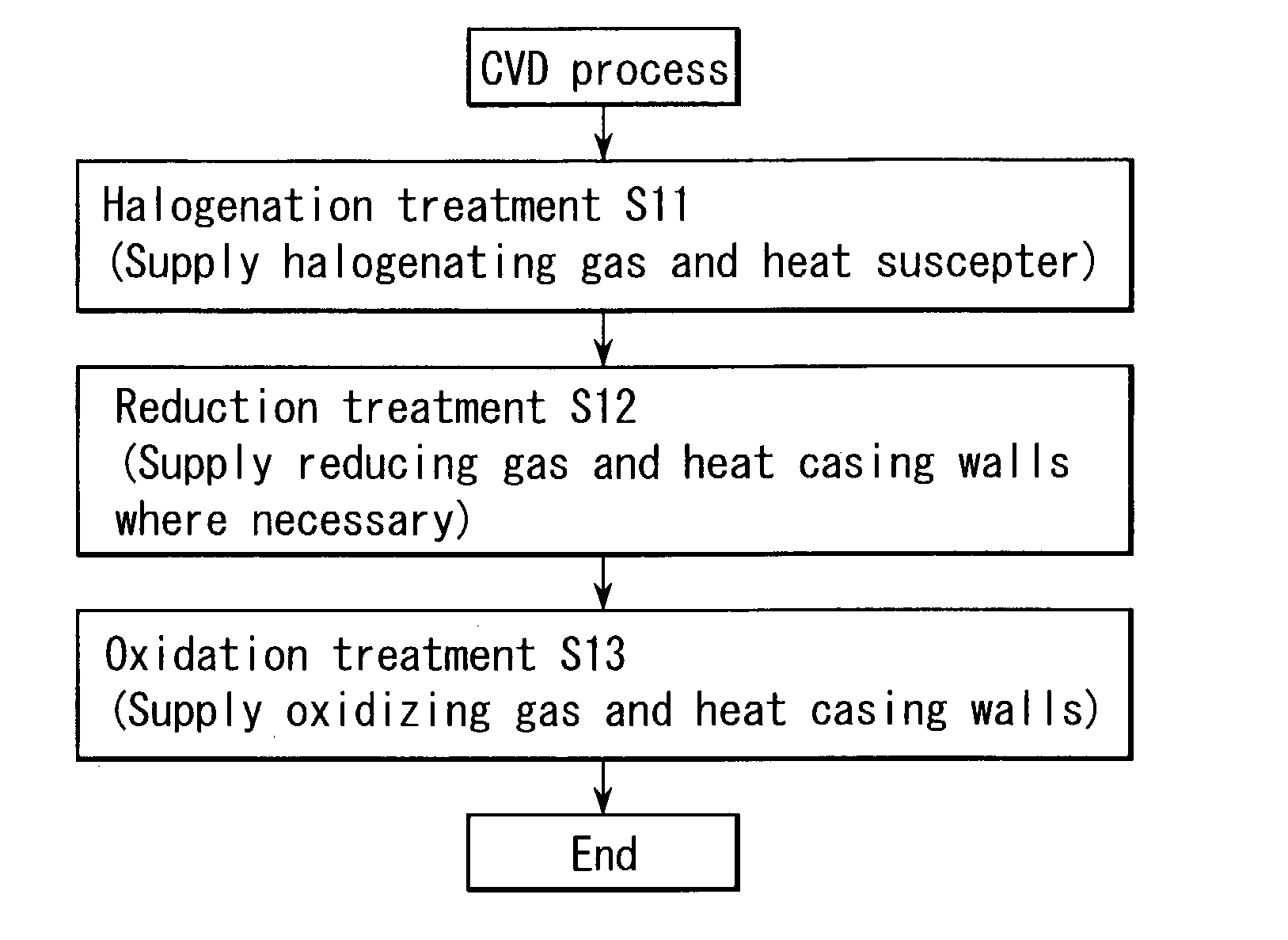

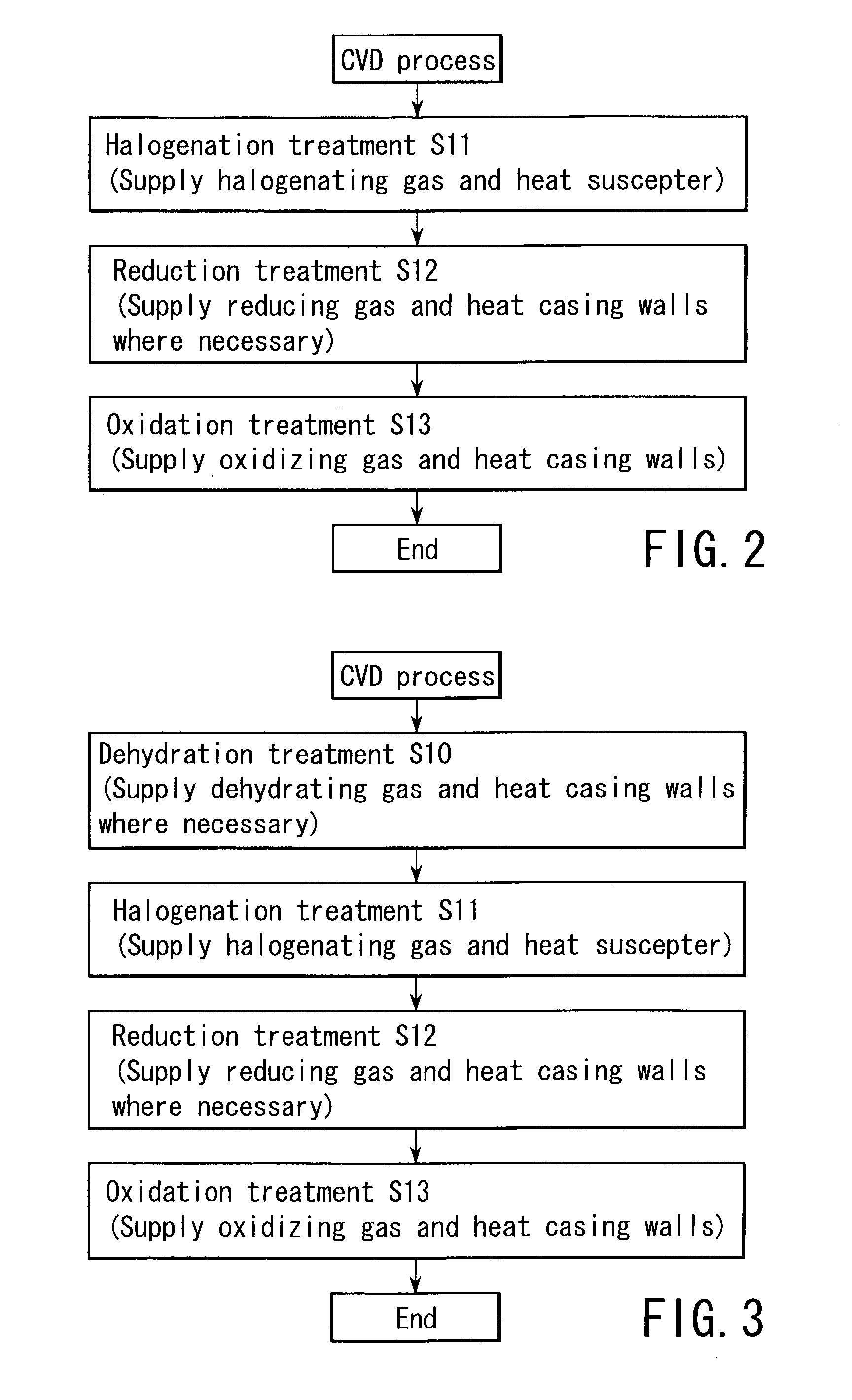

Method of cleaning processing chamber of semiconductor processing apparatus

InactiveUS20030205237A1Hollow article cleaningElectrostatic cleaningReduction treatmentSemiconductor

A method of cleaning the interior of a processing chamber first performs a halogenation treatment by supplying a treatment gas containing a halogenating gas into the processing chamber and heating a support member for a target substrate, thereby halogenating a metal element in a by-product film. A reduction treatment is then performed by supplying a treatment gas containing a reducing gas into the processing chamber, thereby reducing a halide of the metal element and liberating the metal element. An oxidation treatment is then performed by supplying a treatment gas containing an oxidizing gas into the processing chamber and heating the casing walls of the processing chamber, thereby passivating the liberated metal element by oxidation.

Owner:TOKYO ELECTRON LTD

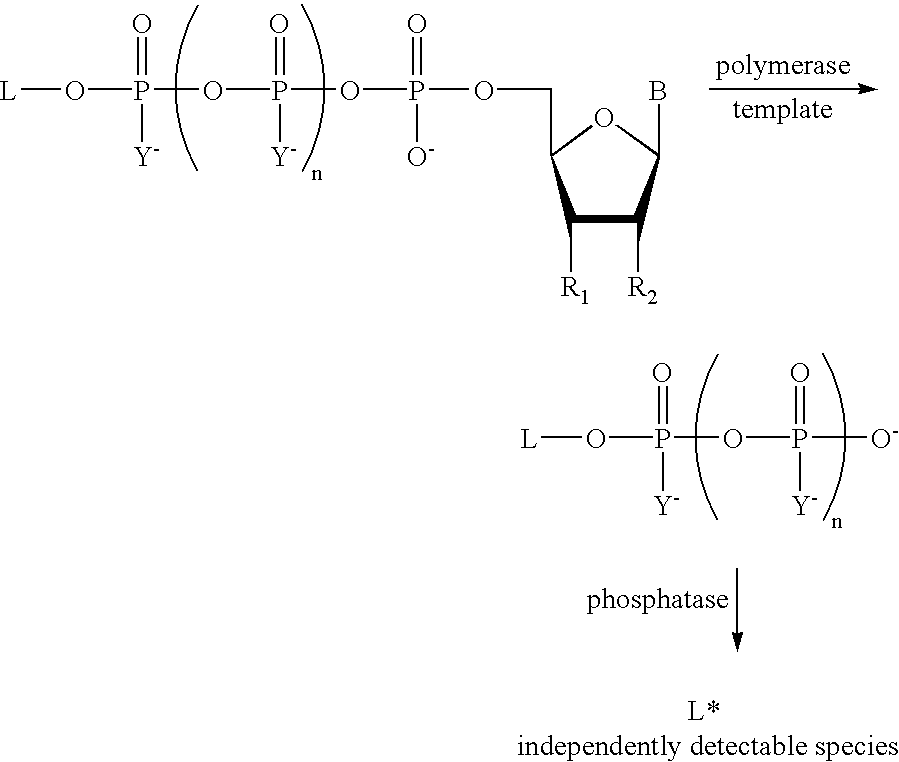

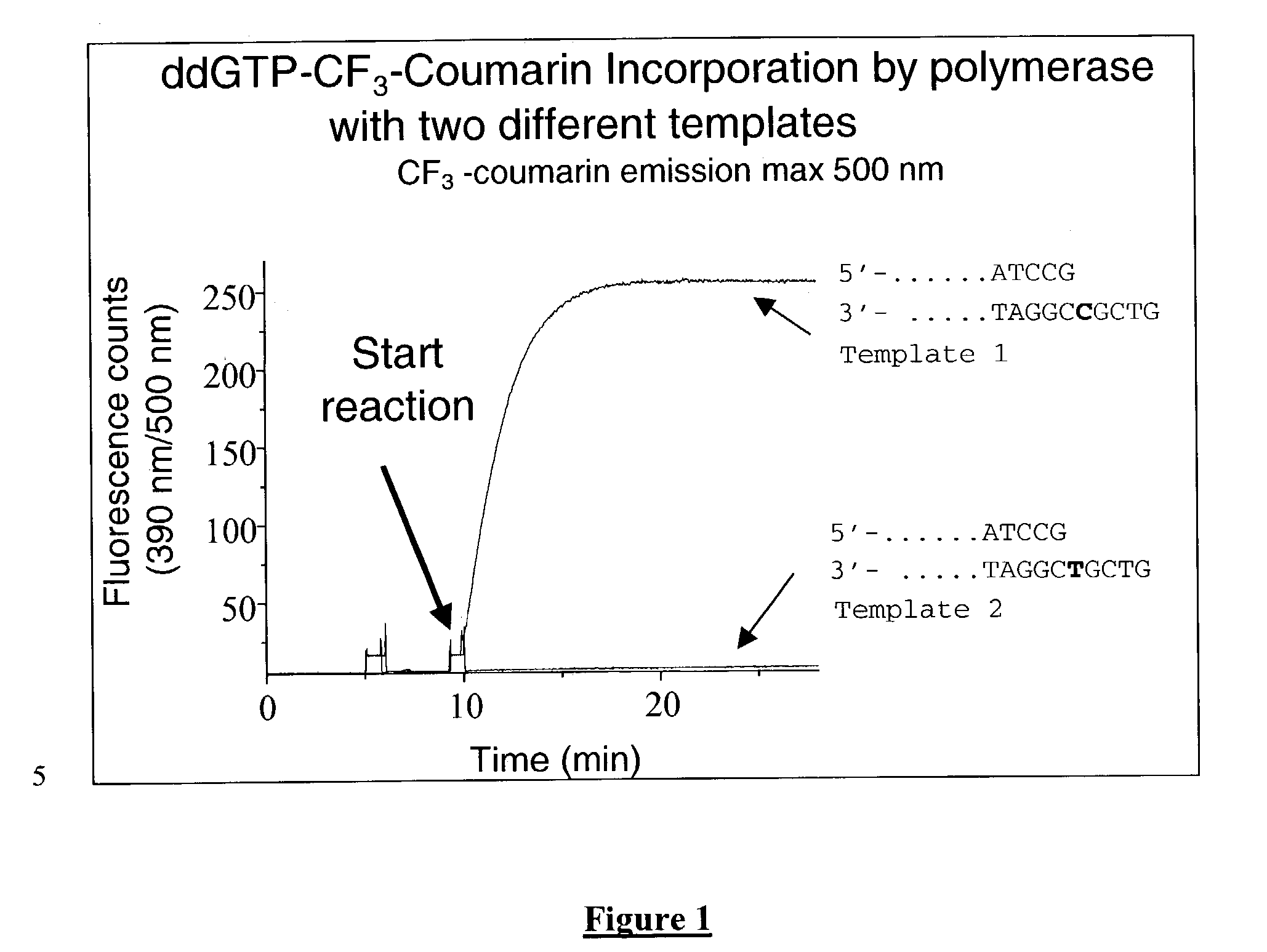

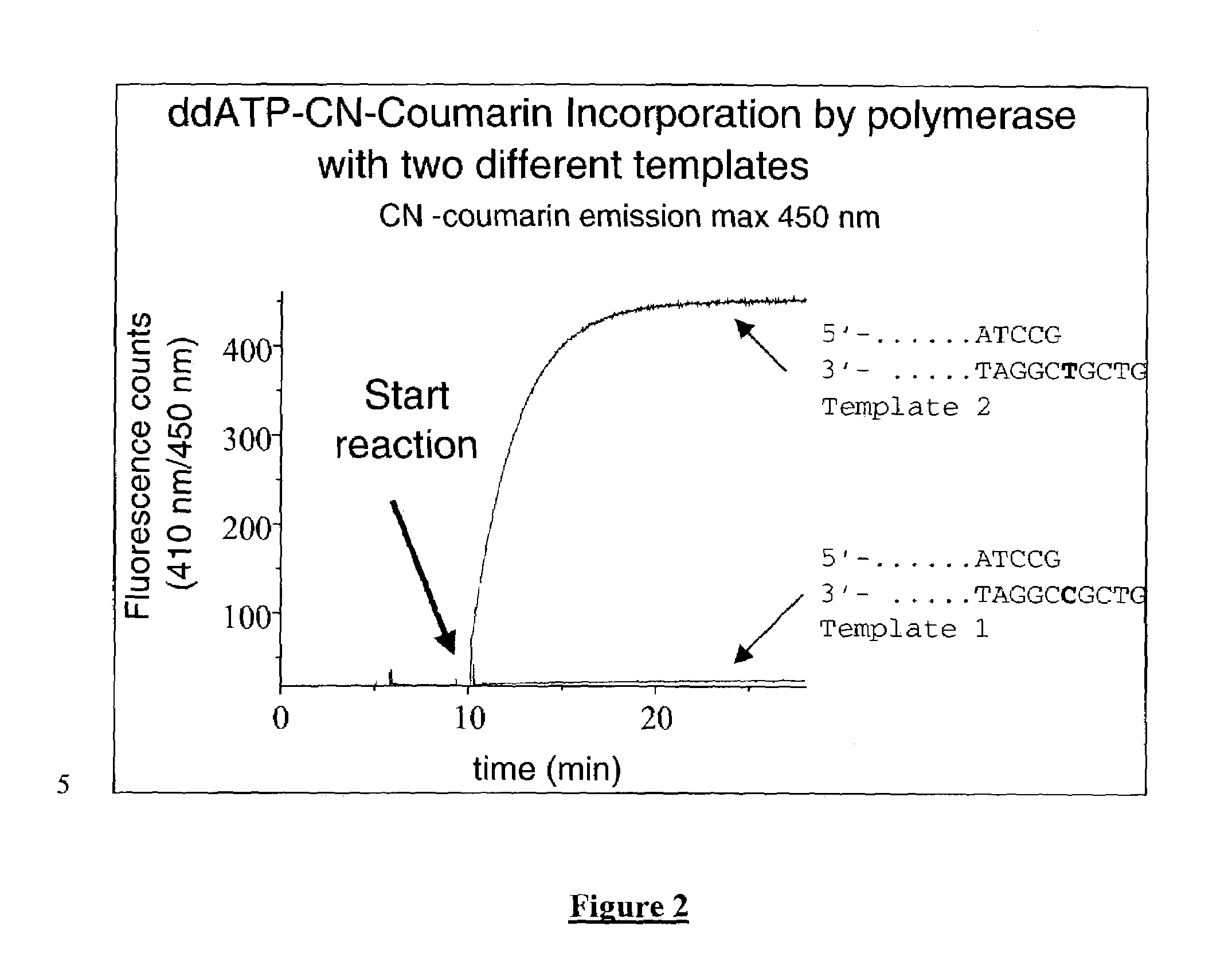

Labeled nucleoside polyphosphates

InactiveUS20030124576A1Sugar derivativesMaterial analysis by observing effect on chemical indicatorNucleic acid detectionFluorescence

The present invention describes new compositions of matter in the form of labeled nucleoside polyphosphates with four or more phosphates. In addition compositions of nucleoside polyphosphates with four or more phosphates that are substrates for nucleic acid polymerases with enhanced substrate properties and methods of using these nucleoside polyphosphates for nucleic acid detection, charcterization and quantification are described. The compositions provided by this invention include nucleoside polyphosphate, dideoxynucleoside polyphosphate, or deoxynucleoside polyphosphate analogues which have calorimetric, chemiluminescent, or fluorescent moieties, mass tags or an electrochemical tags attached to the terminal-phosphate. When a nucleic acid polymerase uses this analogue as a substrate, an enzyme-activatable label would be present on the inorganic polyphosphate by-product of phosphoryl transfer. Cleavage of the polyphosphate product of phosphoryl transfer via phosphatase leads to a detectable change in the label attached thereon. When the polymerase assay is performed in the presence of a phosphatase, there is provided a convenient method for real-time monitoring of DNA or RNA synthesis and detection of a target nucleic acid.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

Terminal-phosphate-labeled nucleotides and methods of use

The present invention describes methods of detecting a nucleic acid in a sample, based on the use of terminal-phosphate-labeled nucleotides as substrates for nucleic acid polymerases. The methods provided by this invention utilize a nucleoside polyphosphate, dideoxynucleoside polyphosphate, or deoxynucleoside polyphosphate analogue which has a colorimetric dye, chemiluminescent, or fluorescent moiety, a mass tag or an electrochemical tag attached to the terminal-phosphate. When a nucleic acid polymerase uses this analogue as a substrate, an enzyme-activatable label would be present on the inorganic polyphosphate by-product of phosphoryl transfer. Cleavage of the polyphosphate product of phosphoryl transfer via phosphatase leads to a detectable change in the label attached thereon. When the polymerase assay is performed in the presence of a phosphatase, there is provided a convenient method for real-time monitoring of DNA or RNA synthesis and detection of a target nucleic acid.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

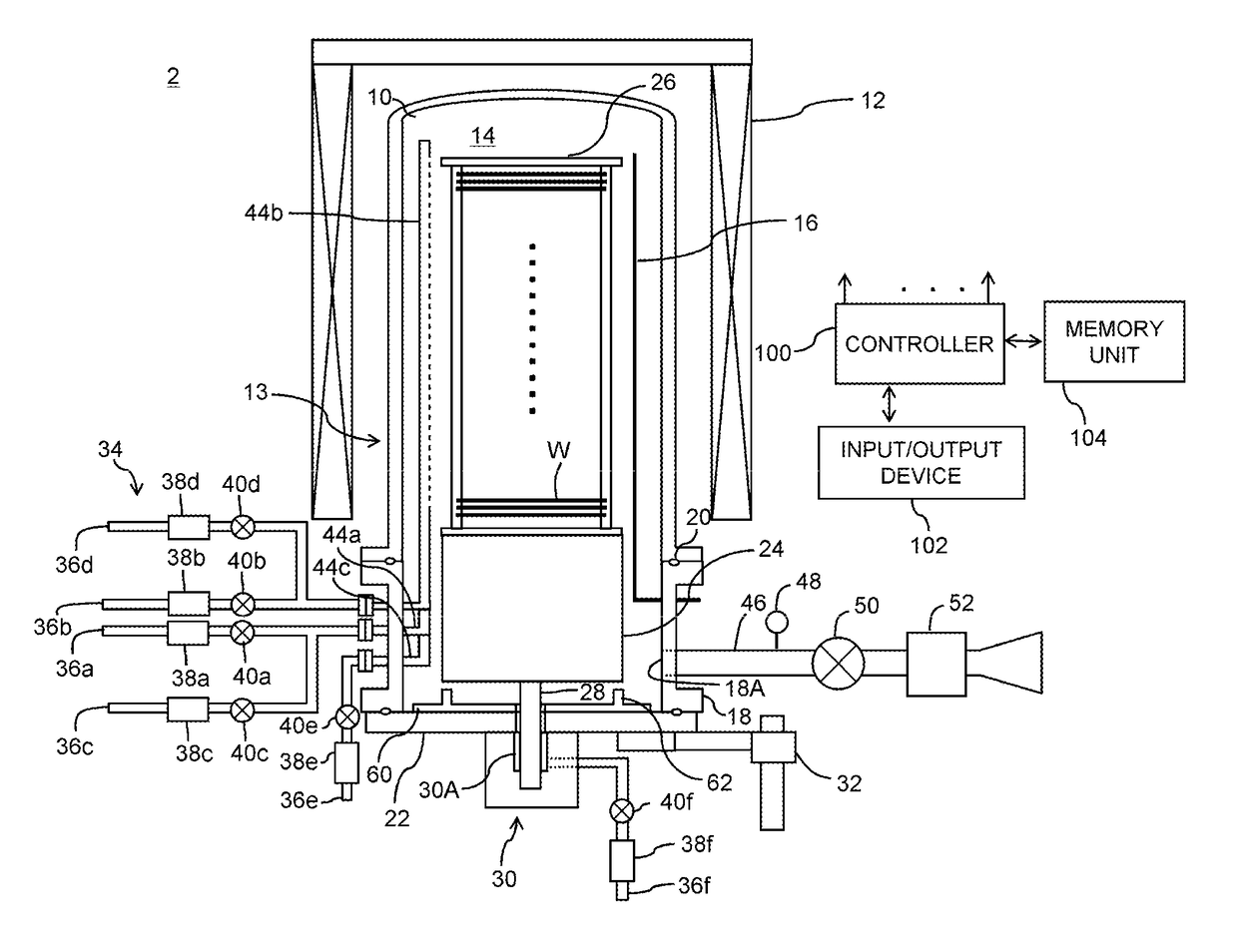

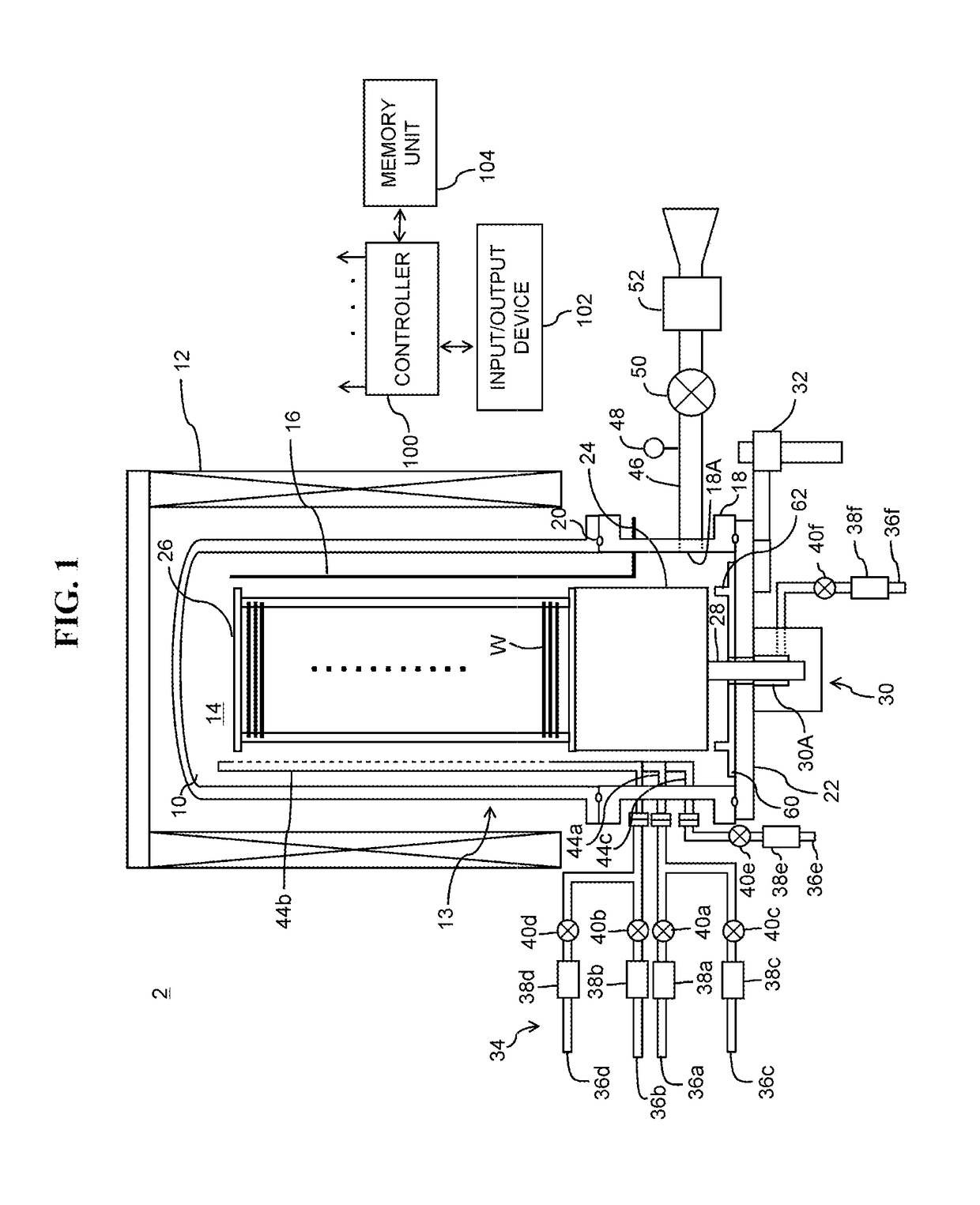

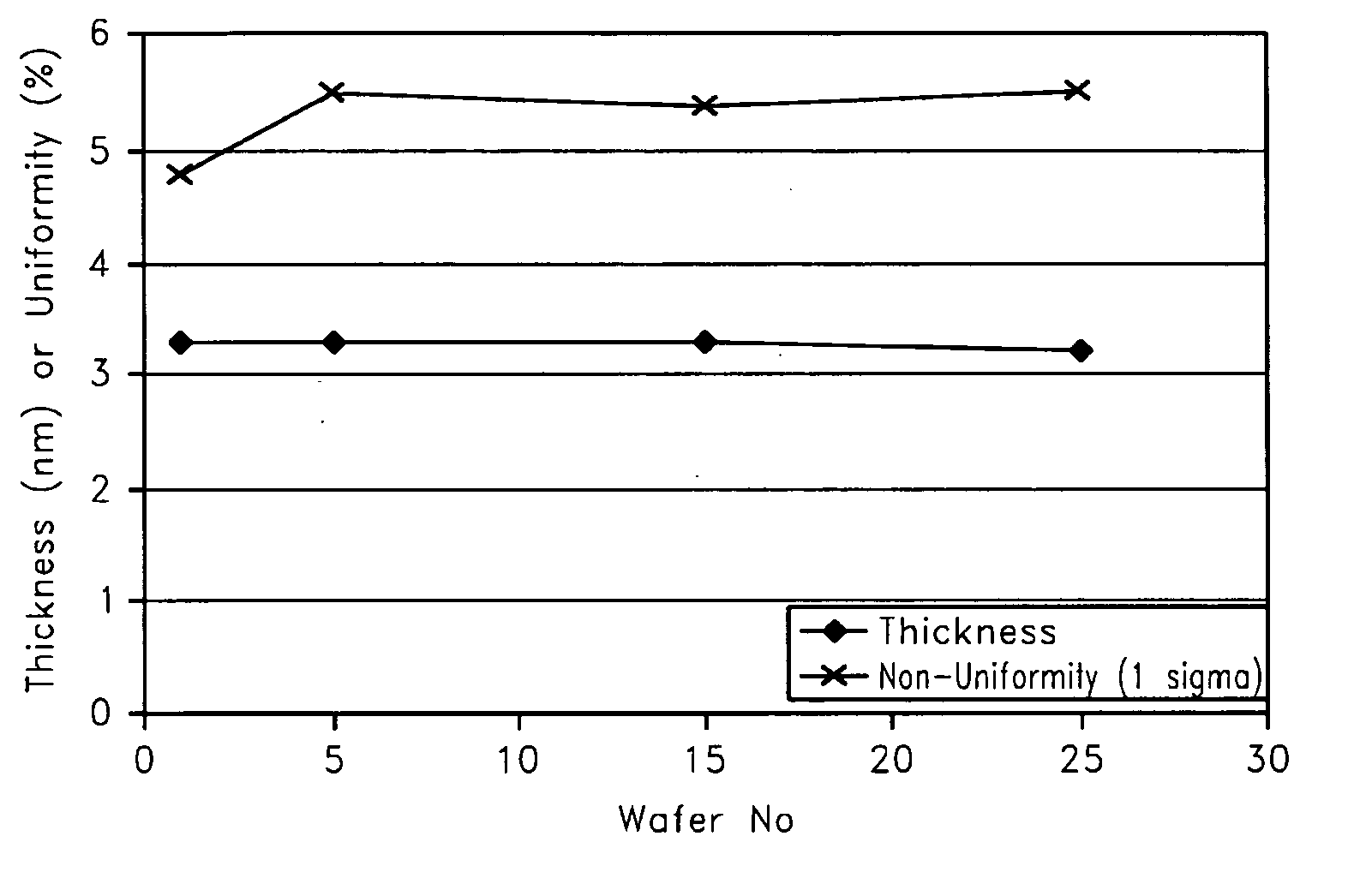

Method for the deposition of a film by CVD or ALD

ActiveUS20070123060A1Increase depositionImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseDeposition process

Methods and apparatus for deposition of a film on a substrate in a reaction chamber by an atomic layer deposition (ALD) or chemical vapor deposition (CVD) process include providing one or more reactants, and providing a volatile neutral coordinating ligand capable of coordinating at least one selected from the following: (i) one of the reactants; (ii) a reaction by-product formed during the deposition process. The neutral coordinating ligand thus improves volatility of either reactants and / or by-products, either in the gas phase or aiding in removal of species from reaction space surfaces. The neutral coordinating ligand is provided during the deposition process, either during or after reactant supply.

Owner:ASM INTERNATIONAL

Integrated hydromethanation combined cycle process

InactiveUS20110062721A1Easy to understandCombustible gas catalytic treatmentHydrogen/synthetic gas productionHydrogenCombustible gas

The present invention relates to an integrated process for preparing combustible gaseous products via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen, a hydromethanation catalyst and optionally oxygen, and generating electrical power from those combustible gaseous products as well as a hydrogen and / or methane by-product stream.

Owner:SURE CHAMPION INVESTMENT LTD

Continuous process for the preparation of polytrimethylene ether glycol

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

Terminal-phosphate-labeled nucleotides and methods of use

The present invention relates to improved methods of detecting a target using a labeled substrate or substrate analog. The methods comprise reacting the substrate or substrate analog in an enzyme-catalyzed reaction which produces a labeled moiety with independently detectable signal only when such substrate or substrate analog reacts. The present invention, in particular, describes methods of detecting a nucleic acid in a sample, based on the use of terminal-phosphate-labeled nucleotides as substrates for nucleic acid polymerases. The methods provided by this invention utilize a nucleoside polyphosphate, dideoxynucleoside polyphosphate, or deoxynucleoside polyphosphate analogue which has a colorimetric dye, chemiluminescent, or fluorescent moiety, a mass tag or an electrochemical tag attached to the terminal-phosphate. When a nucleic acid polymerase uses this analogue as a substrate, an enzyme-activatable label would be present on the inorganic polyphosphate by-product of phosphoryl transfer. Cleavage of the polyphosphate product of phosphoryl transfer via phosphatase leads to a detectable change in the label attached thereon. When the polymerase assay is performed in the presence of a phosphatase, there is provided a convenient method for real-time monitoring of DNA or RNA synthesis and detection of a target nucleic acid.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

Method for producing hydrocarbons and oxygen-containing compounds from biomass

InactiveUS20050112739A1Improve direct utilizationImprove utilizationOrganic compound preparationHydrocarbon by hydrogenationChemical industryChemical reaction

The present invention generally relates to biochemical and chemical industry, and more particularly to a method which can be used in fermenting carbohydrate substrates of plant origin for producing C1-C5 alcohols, and for synthesis of higher alcohols, other oxygen-containing compounds and hydrocarbons as well as for the production of motor fuel components from biomass. Since C6 and higher alcohols, ethers, acetals, and higher hydrocarbons are not obtainable by a direct biochemical route, it is proposed to synthesize these using known chemical reactions, wherein by-products of fermentation are as raw materials for said synthesis.

Owner:SWEDISH BIOFUELS AB

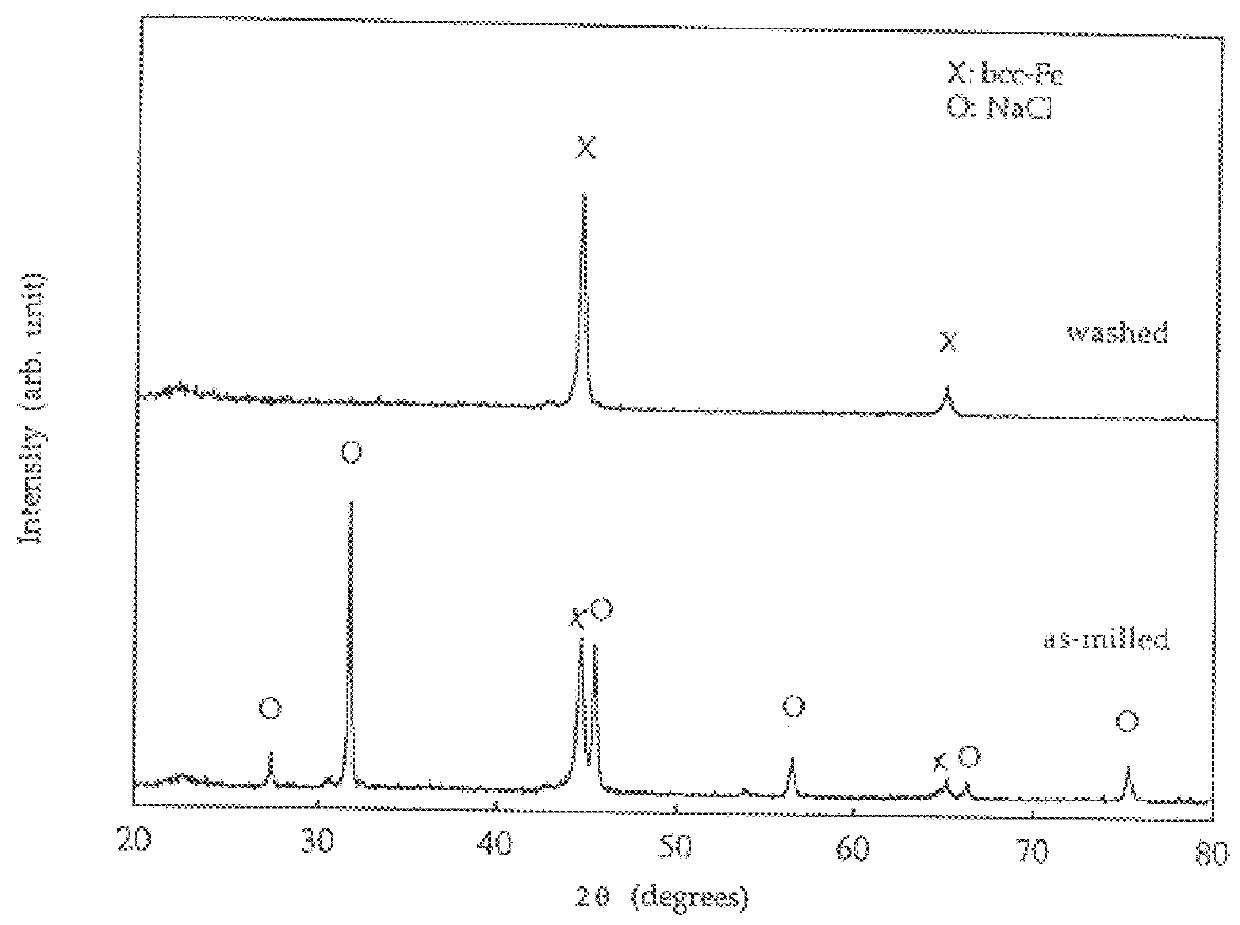

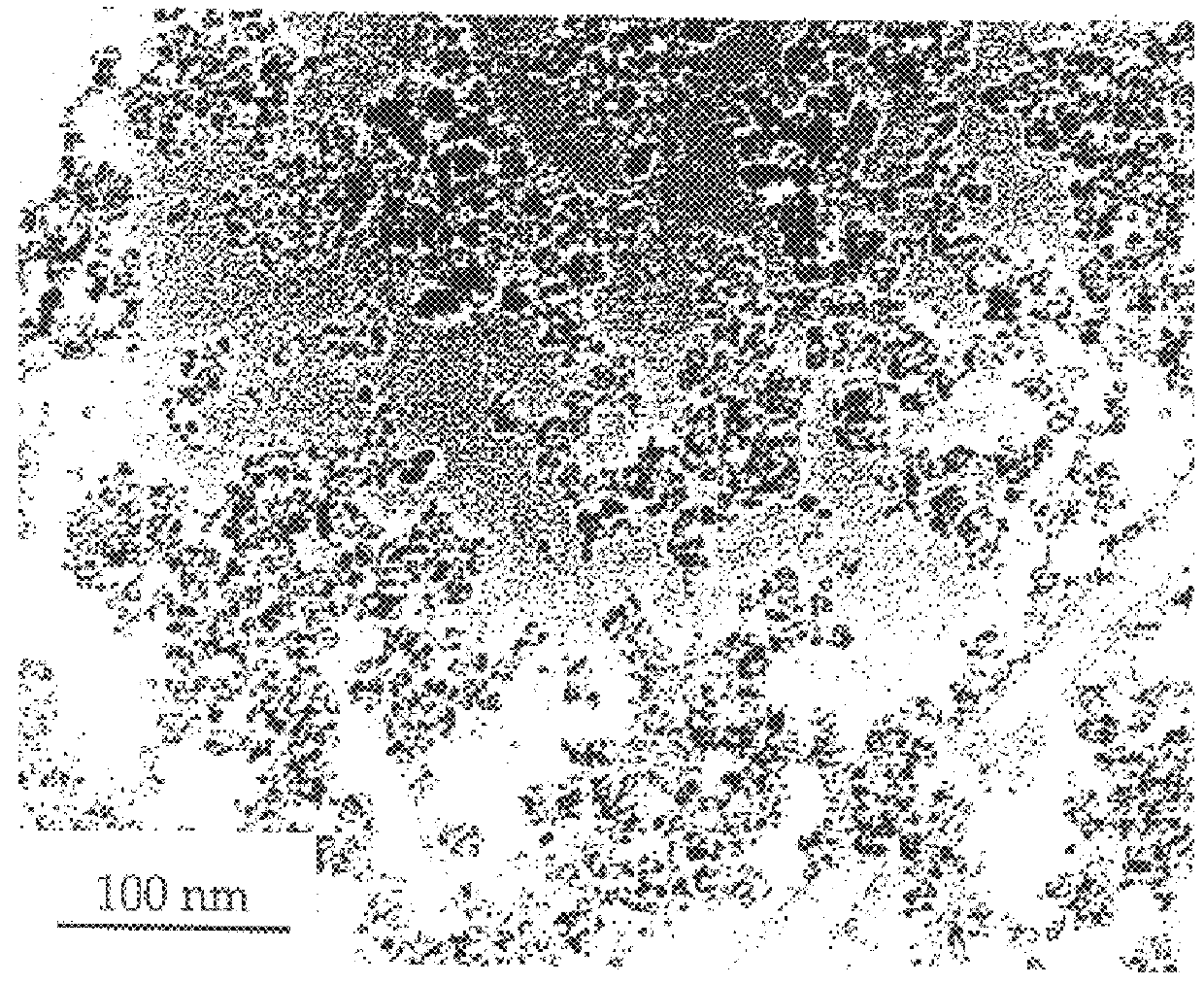

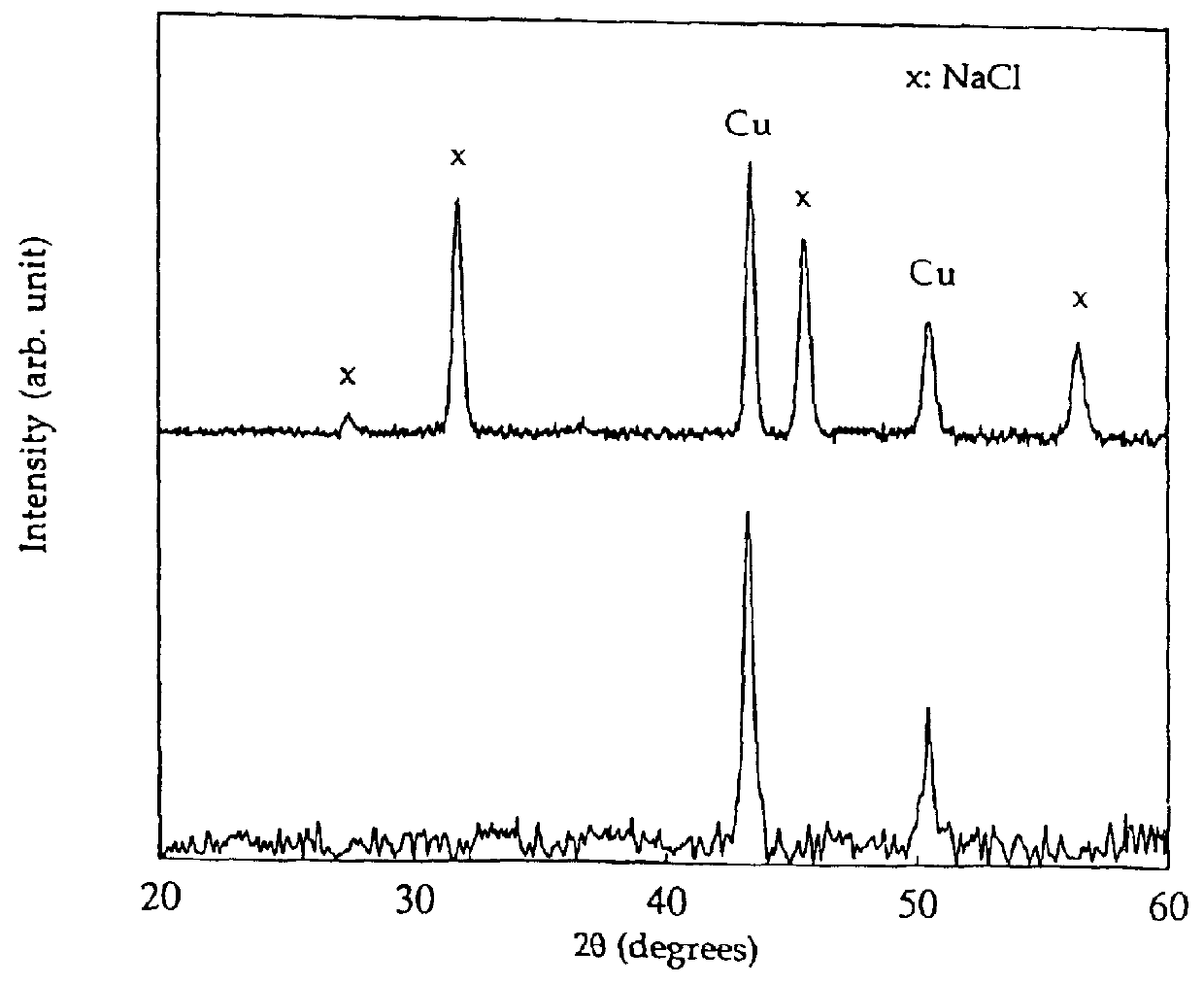

Process for the production of ultrafine particles

A new, cost effective process for the production of ultrafine particles which is based on mechanically activated chemical reaction of a metal compound with a suitable reagent. The process involves subjecting a mixture of a metal compound and a suitable reagent to mechanical activation to increase the chemical reactivity of the reactants and / or reaction kinetics such that a chemical reaction can occur which produces a solid nano-phase substance. Concomitantly, a by-product phase is also formed. This by-product phase is removed so that the solid nano-phase substance is left behind in the form of ultrafine particles. During mechanical activation a composite structure is formed which consists of an intimate mixture of nano-sized grains of the nano-phase substance and the reaction by-product phase. The step of removing the by-product phase, following mechanical activation, may involve subjecting the composite structure to a suitable solvent which dissolves the by-product phase, while not reacting with the solid nano-phase substance. The process according to the invention may be used to form ultrafine metal powders as well as ultrafine ceramic powders. Advantages of the process include a significant degree of control over the size and size distribution of the ultrafine particles, and over the nature of interfaces created between the solid nano-phase substance and the reaction by-product phase.

Owner:WESTERN AUSTRALIA UNIV OF THE

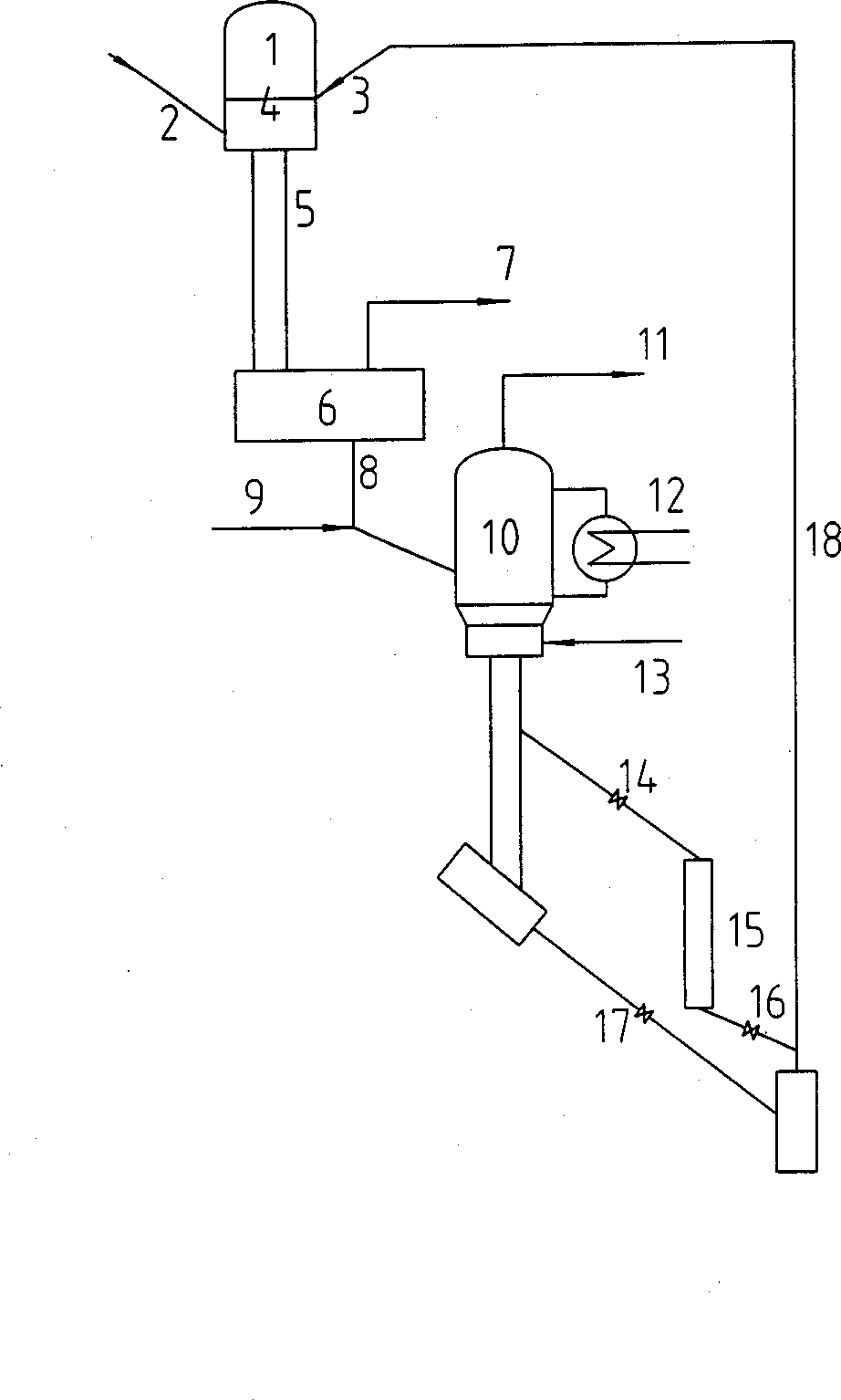

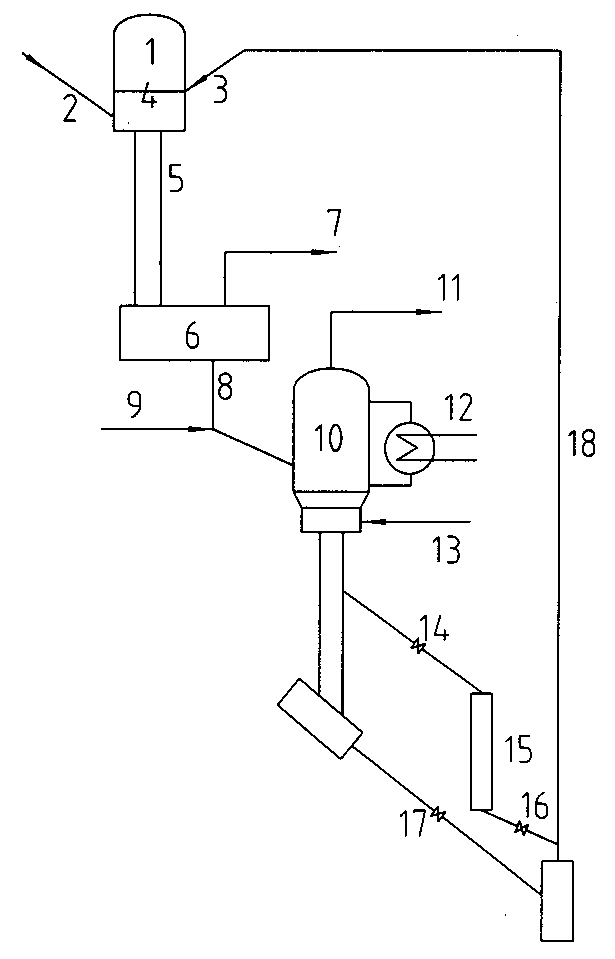

Process and system for preparing low-carbon olefin from methanol or dimethylether

InactiveCN1356299AReduce wearReduce aggregationHydrocarbon from oxygen organic compoundsChemical recyclingAlkaneGas solid

A process for preparing low-carbon olefin from methanol or dimethyl ether includes loading its raw material and silicon aluminium phosphate (SAPO34) molecular sieve as catalyst into gas-solid parallel down-flowing fluidized bed reactor, super-short contact, reaction, fast gas-solid separation to separating resultant from catalyst to prevent secondary reaction, and regerating catalyst for cyclic use. Its advantages include high output rate (93%), high conversion rate of raw material, and less by-product.

Owner:TSINGHUA UNIV

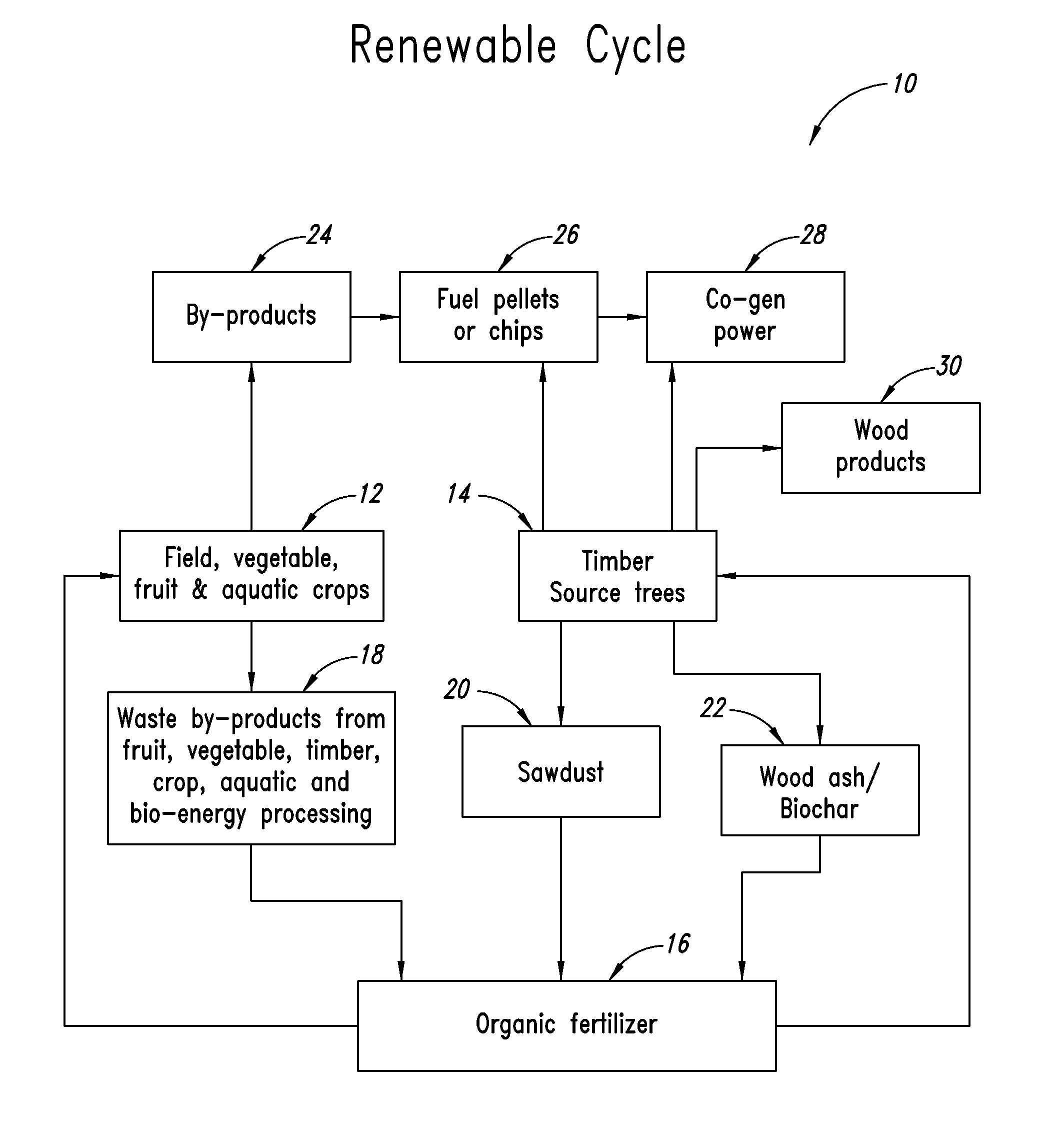

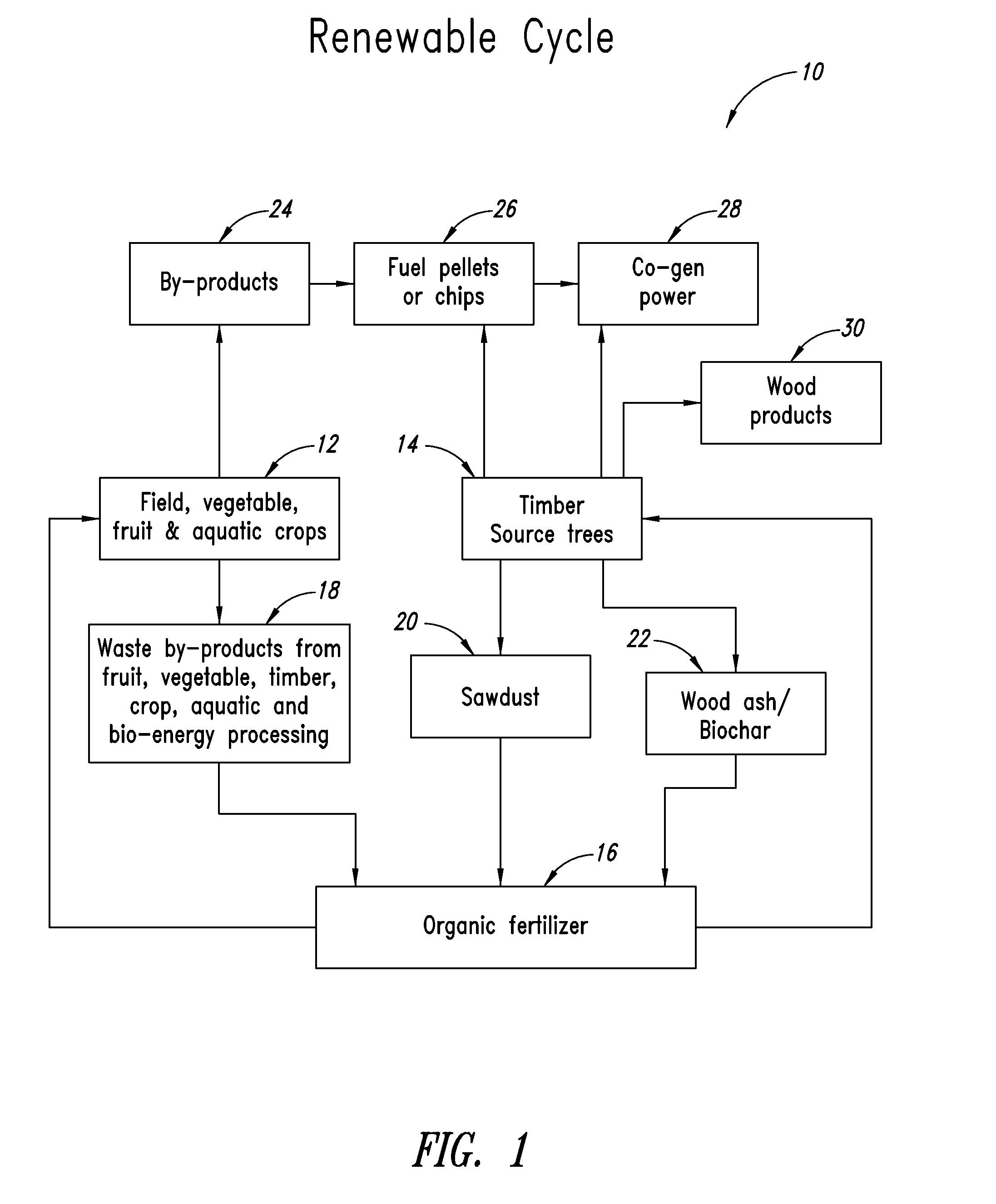

Organic soil treatment compound and method of making and using

InactiveUS20110023566A1Promote plant growthImprove scalabilityClimate change adaptationBioloigcal waste fertilisersParticulatesSoil treatment

A composition is provided that includes particulates from wood, chaff, hulls, crop compost, biochar, or waste residue, wood or crop ash and biochar, and a nitrogen source from waste residue from gasification processes, food processing waste water or other residual by-products of forest, aquatic, food or feed processing. Ideally, all of the components are environmentally friendly, from natural products, and free of manufactured chemicals.

Owner:ECOTRAC ORGANICS

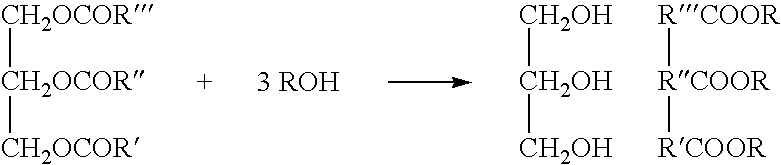

Environmentally benign anti-icing or deicing fluids employing triglyceride processing by-products

InactiveUS6890451B2Improve ice resistanceGreat tractionOther chemical processesTG - TriglycerideGlycerol

Deicing compositions comprised of glycerol-containing by-products of triglyceride processing processes are disclosed.

Owner:MLI ASSOC

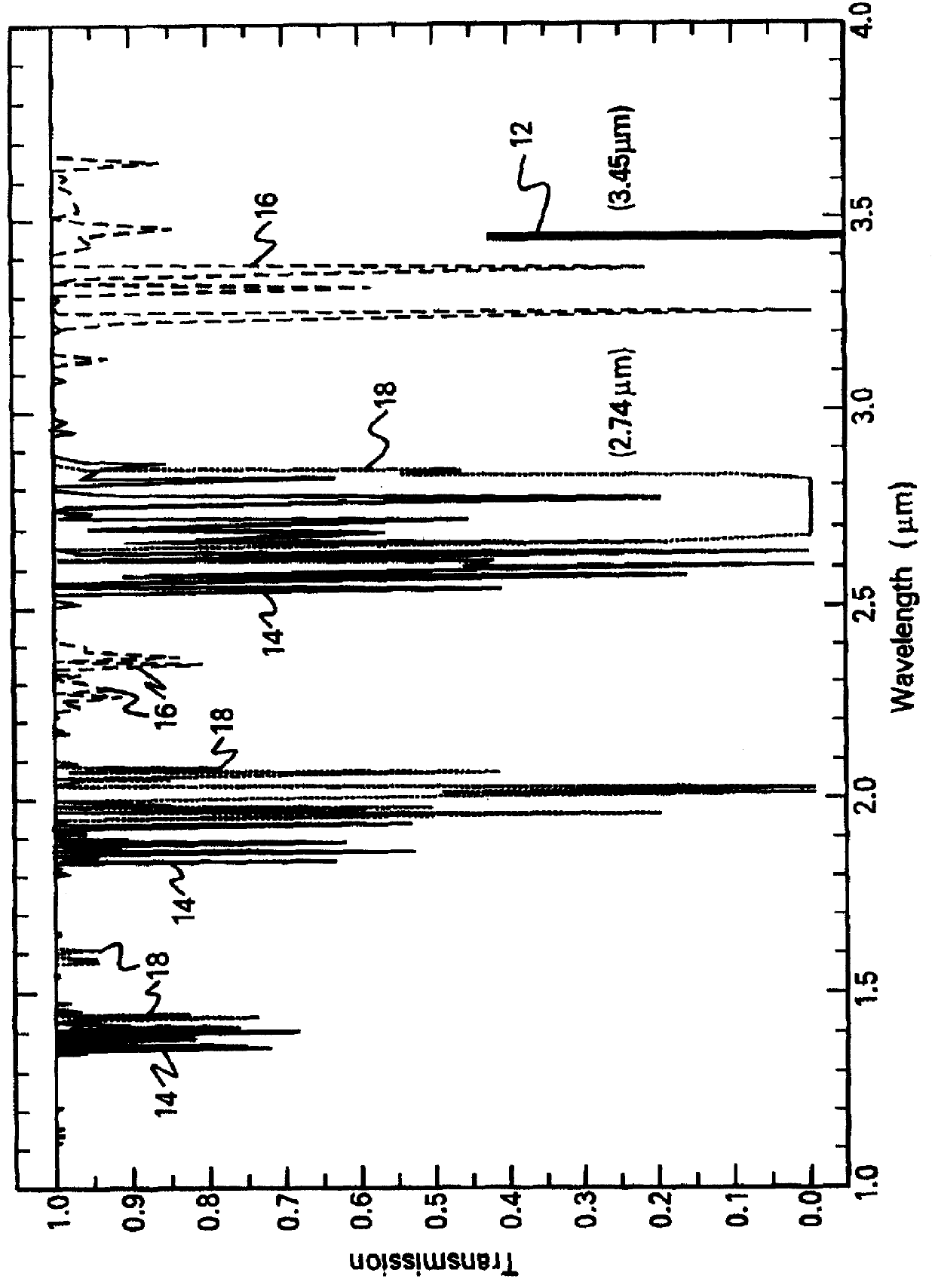

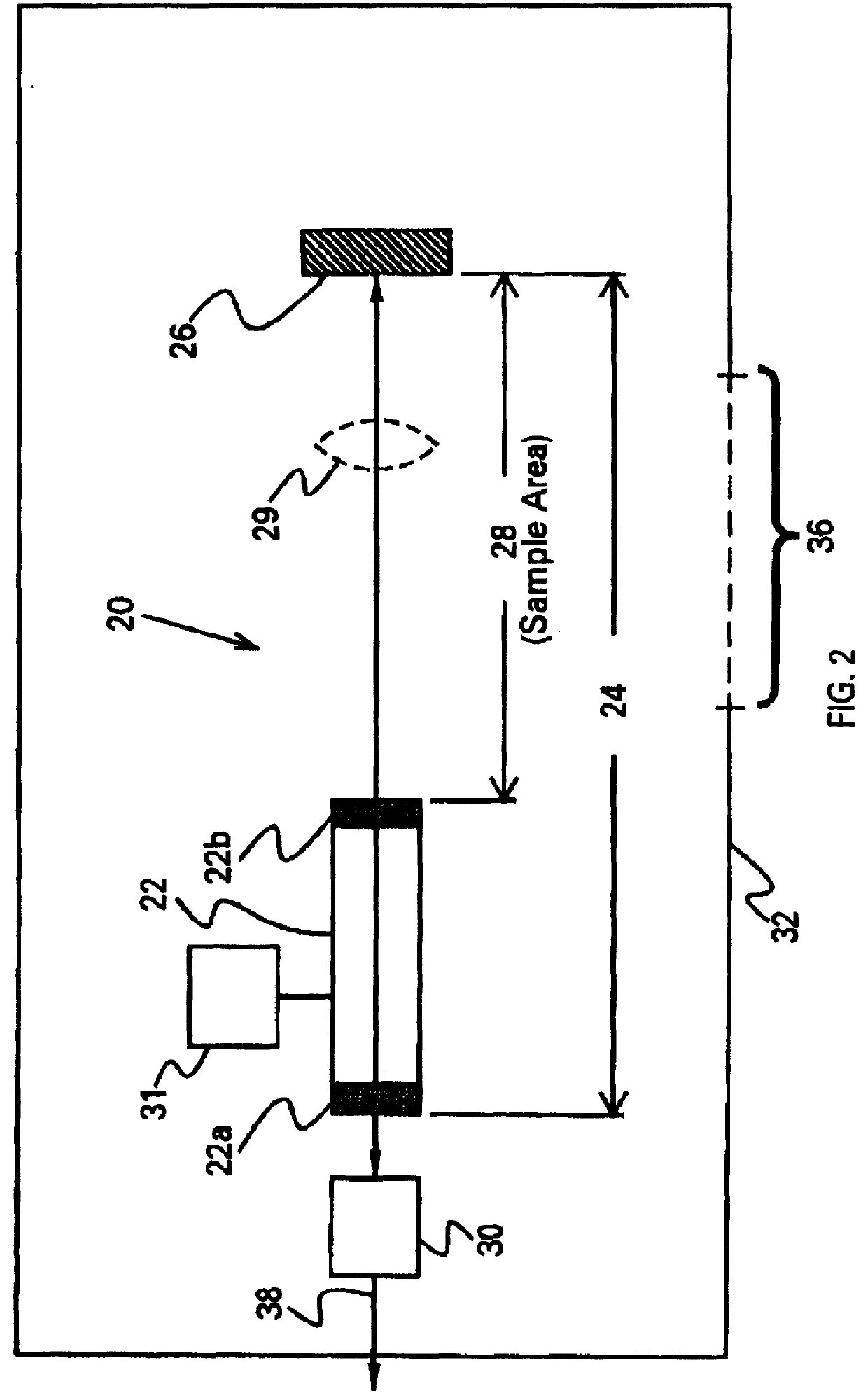

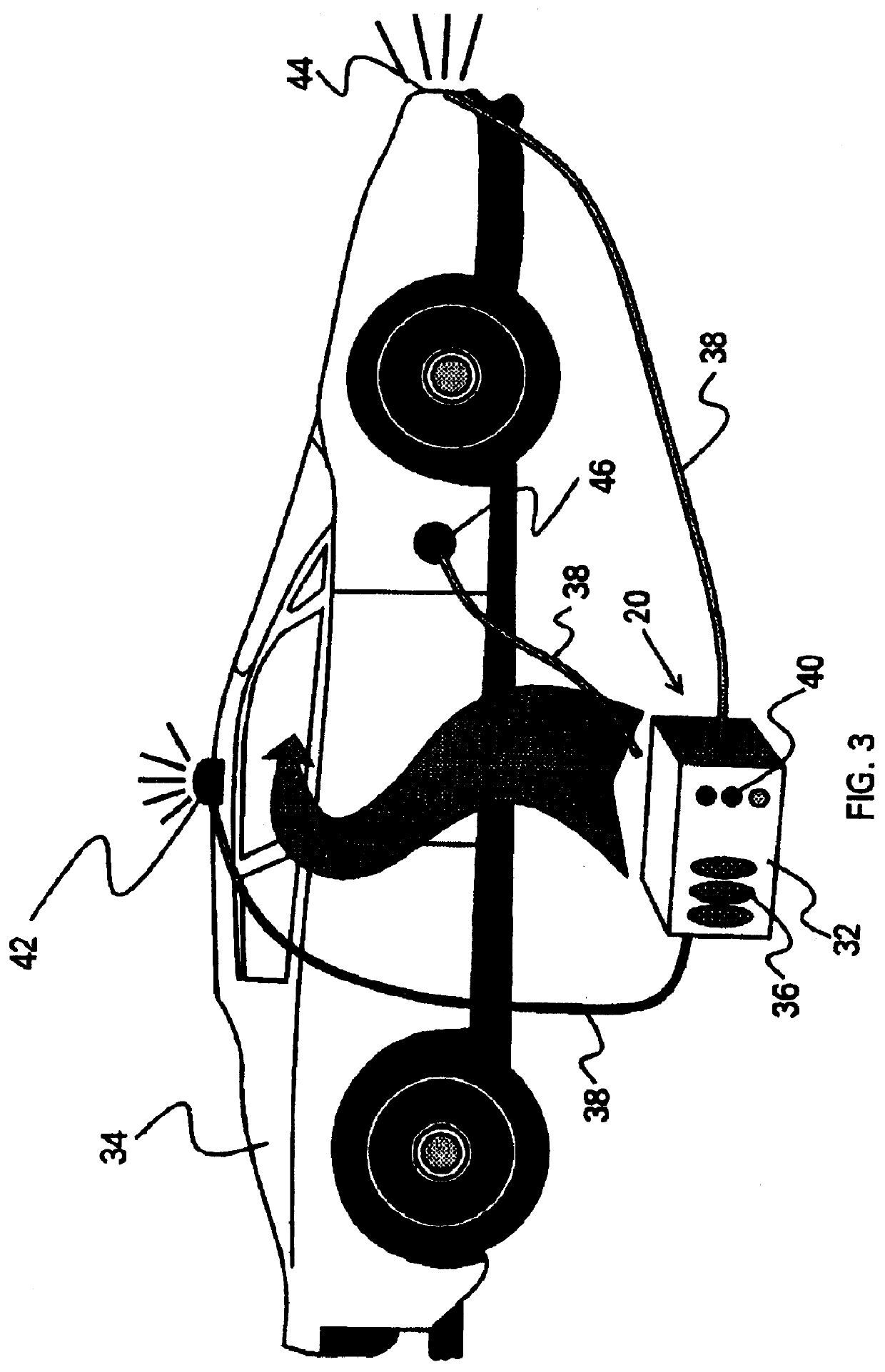

ILS sensors for drug detection within vehicles

On-board ILS sensors for detecting illegal drugs and based on intracavity laser spectroscopy (ILS) are provided for detecting the presence of drugs and their metabolized by-product vapors in an enclosed space, such as a vehicle. The sensor comprises: (a) a laser comprising a gain medium having two opposed facets within a laser resonator and functioning as an intracavity spectroscopic device having a first end and a second end, the first end operatively associated with a partially reflecting (i.e., partially transmitting) surface; (b) a reflective or dispersive optical element (e.g., a mirror or a diffraction grating) operatively associated with the second end to define a broadband wavelength laser resonator between the optical element and the first end and to thereby define an external cavity region between at least one facet of the gain medium and either the first end or the second end or both ends; (c) the external cavity region being exposed to air in the enclosed space to enable any drugs or their metabolized by-product molecules to enter thereinto; (d) a detector spaced from the first end; (e) appropriate electronics for measuring and analyzing the detector signal; (f) a housing for containing at least the laser, the partially reflecting surface, and the optical element, the housing being configured to prevent escape of stray radiation into the enclosed space and to permit air from the enclosed space to continuously circulate through the external cavity region for analysis; and (g) means for driving the laser (e.g., electrical or optical). A method is provided for measuring concentration of drug vapors and their metabolized by-product vapors in the vehicle or other enclosed space employing the on-board sensor. The method comprises: (1) sensing any drugs and their metabolized by-product vapors in the enclosed space by the on-board sensor; and (2) providing a signal indicative of presence of any drugs or metabolized vapors.

Owner:INNOVATIVE LASERS

Process for preparing halogenated alkanes

InactiveUS7094936B1High selectivityBig advantagePreparation by hydrogen halide split-offPreparation by halogen replacementAlkaneLewis acid catalysis

Methods and materials are provided for the production and purification of halogenated compounds and intermediates in the production of 1,1,1,3,3-pentafluoropropane. In a preferred embodiment, the process steps include: (1) reacting carbon tetrachloride with vinyl chloride to produce 1,1,1,3,3-pentachloropropane; (2) dehydrochlorinating the 1,1,1,3,3-pentachloropropane with a Lewis acid catalyst to produce 1,1,3,3-tetrachloropropene; (3) fluorinating the 1,1,3,3-tetrachloropropene to produce 1-chloro-3,3,3-trifluoropropene; (4) fluorinating the 1-chloro-3,3,3-trifluoropropene to produce a product mixture containing 1,1,1,3,3-pentafluoropropane; and (5) separating 1,1,1,3,3-pentafluoropropane from by-products.

Owner:EI DU PONT DE NEMOURS & CO

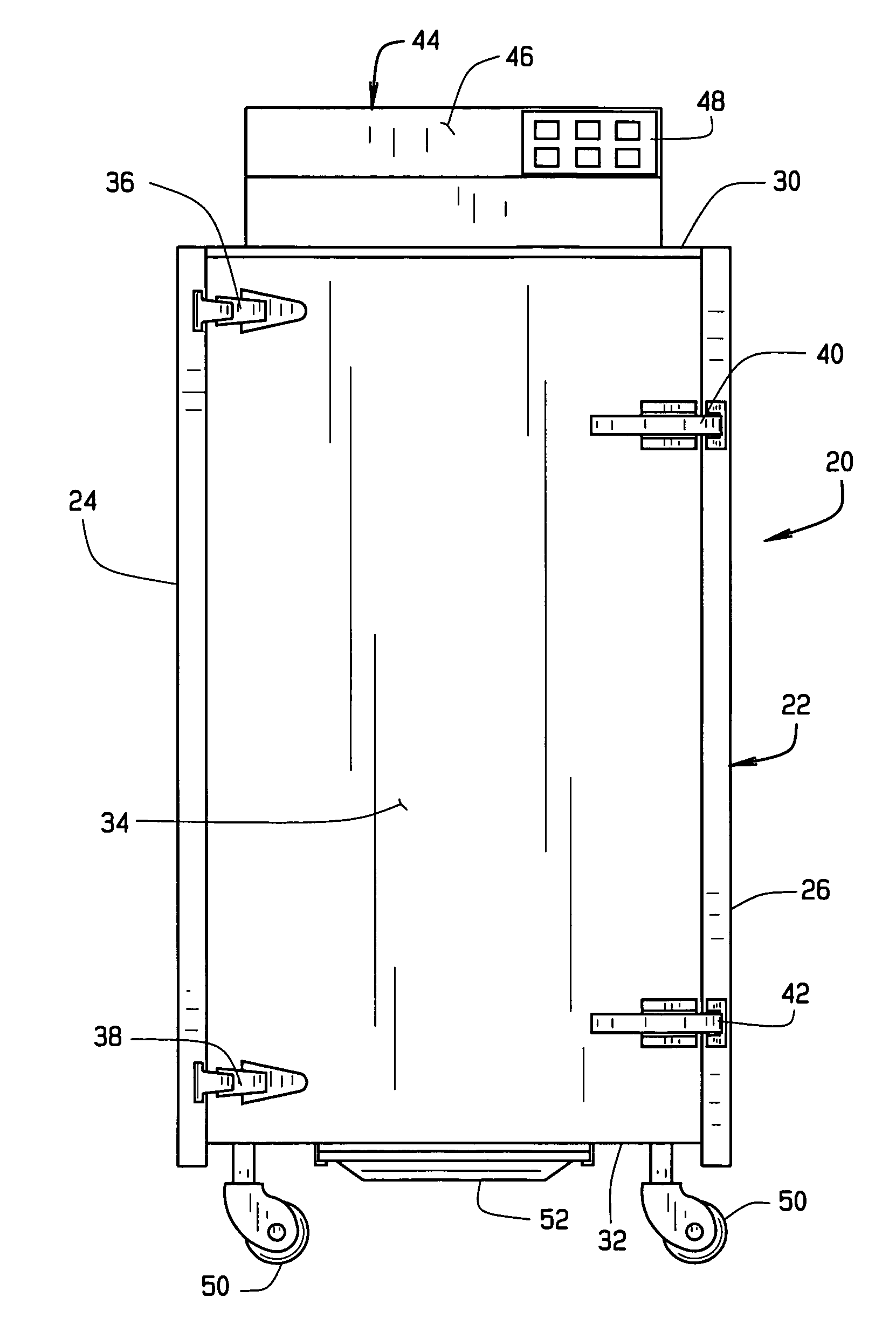

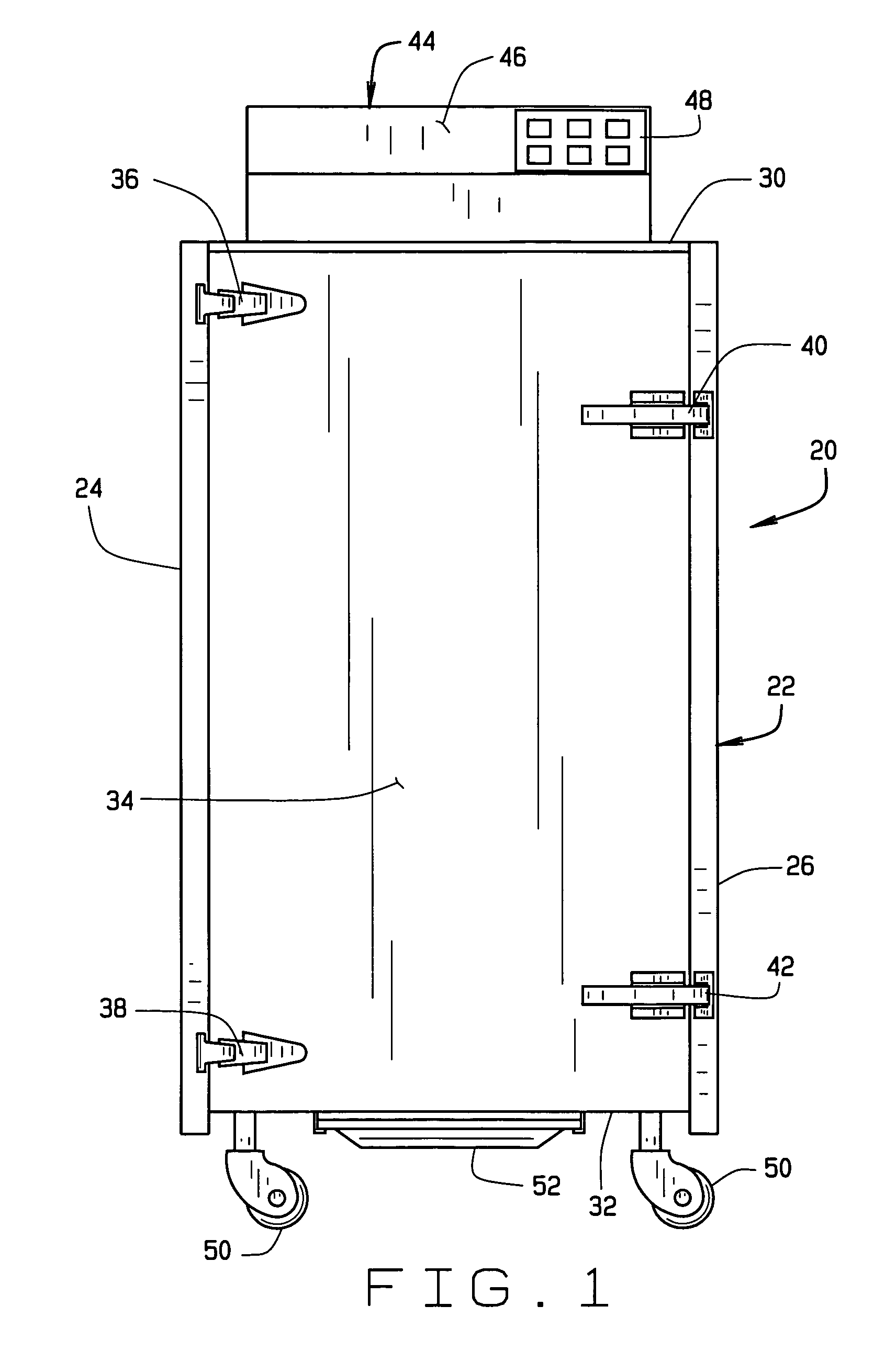

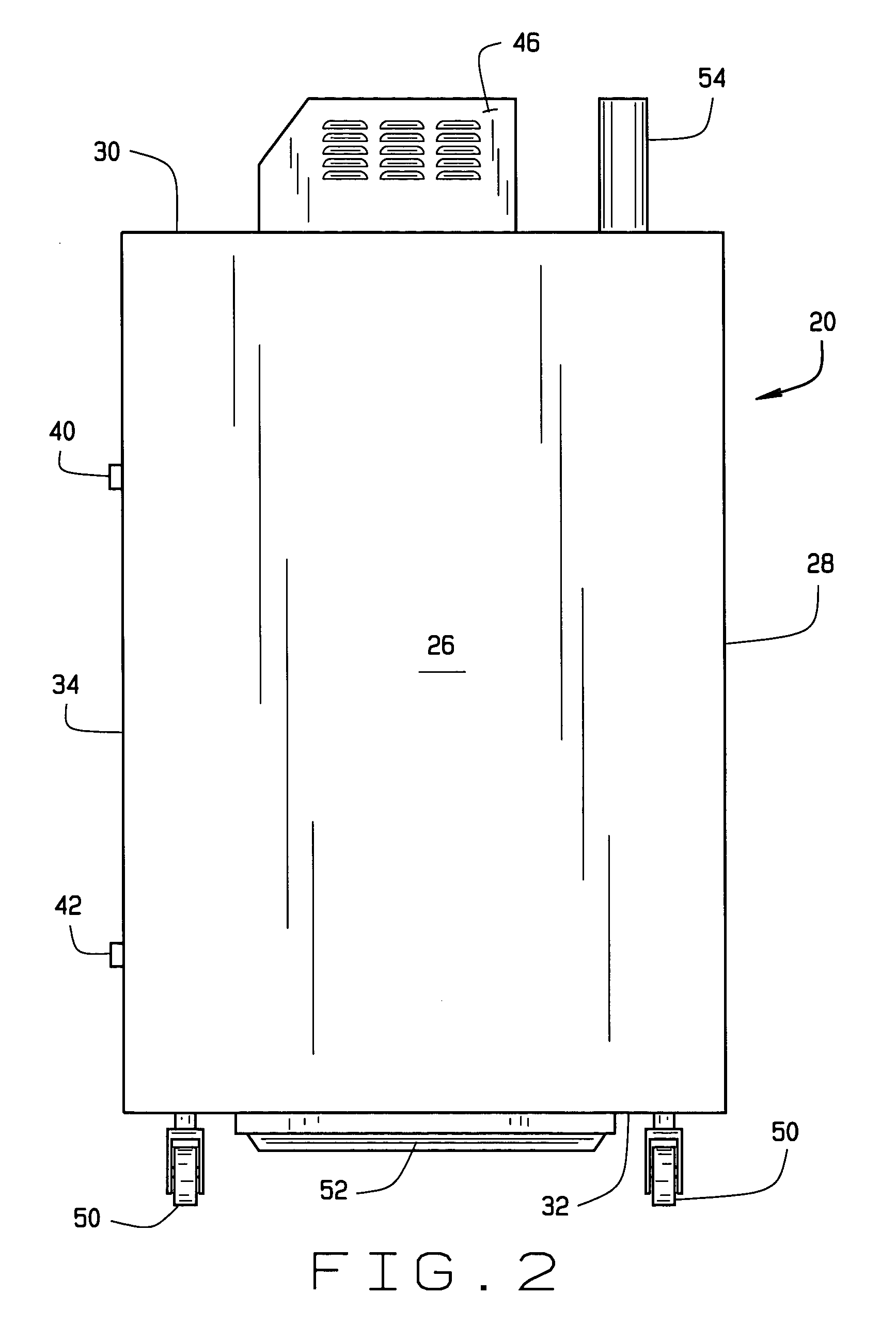

No waste cooking oven with multiple cooking functions

A multifunctional cooking oven for the preparation of food products including a cooking chamber, racks within the cooking chamber to support products to be prepared in the oven and a primary convection heat source. There is a drainable collection pan positioned below the racks to collect by-products rendered from the food products during preparation for later use. A steam source is positioned below the collection pan as well as a flavored smoke generator at the bottom of the preparation chamber. Airflow paths within the preparation chamber allow for the circulation of heat, steam and flavored smoke around the racks. The oven includes a programmable controller to control the primary heat source, the steam source and the flavored smoke generator that is programmed to operate any one of the heat source, the steam source and the flavor generator in any predetermined sequence, and for any predetermined duration of time to provide optimum preparation and flavoring of the products.

Owner:ROBERTSON MICHAEL L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com