Patents

Literature

114 results about "Beech" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beech (Fagus) is a genus of deciduous trees in the family Fagaceae, native to temperate Europe, Asia, and North America. Recent classification systems of the genus recognize 10 to 13 species in two distinct subgenera, Engleriana and Fagus. The Engleriana subgenus is found only in East Asia, and is notably distinct from the Fagus subgenus in that these beeches are low-branching trees, often made up of several major trunks with yellowish bark. Further differentiating characteristics include the whitish bloom on the underside of the leaves, the visible tertiary leaf veins, and a long, smooth cupule-peduncle. Fagus japonica, Fagus engleriana, and the species F. okamotoi, proposed by the botanist Chung-Fu Shen in 1992, comprise this subgenus. The better known Fagus subgenus beeches are high-branching with tall, stout trunks and smooth silver-grey bark. This group includes Fagus sylvatica, Fagus grandifolia, Fagus crenata, Fagus lucida, Fagus longipetiolata, and Fagus hayatae. The classification of the European beech, Fagus sylvatica is complex, with a variety of different names proposed for different species and subspecies within this region (for example Fagus taurica, Fagus orientalis, and Fagus moesica). Research suggests that beeches in Eurasia differentiated fairly late in evolutionary history, during the Miocene. The populations in this area represent a range of often overlapping morphotypes, though genetic analysis does not clearly support separate species.

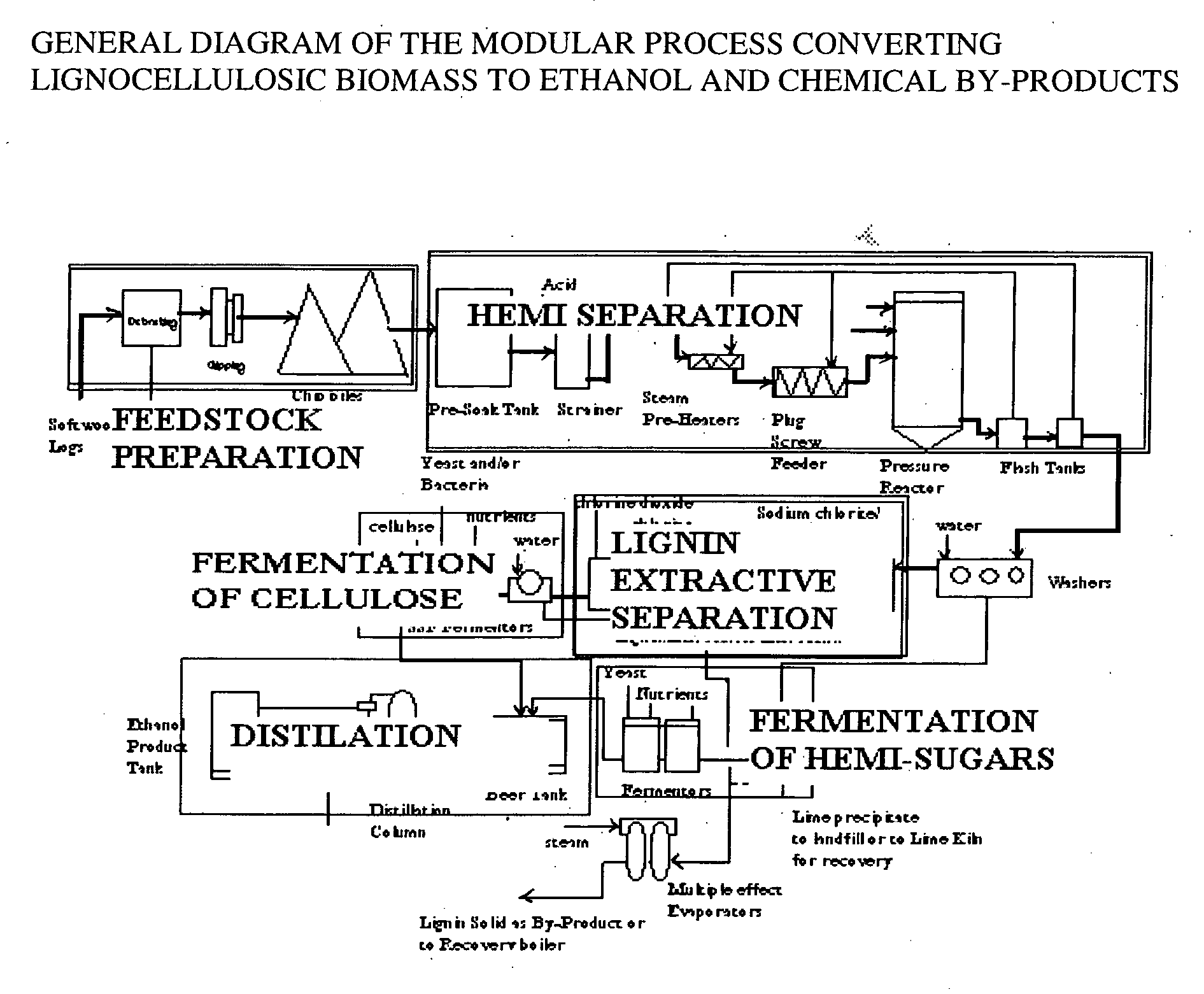

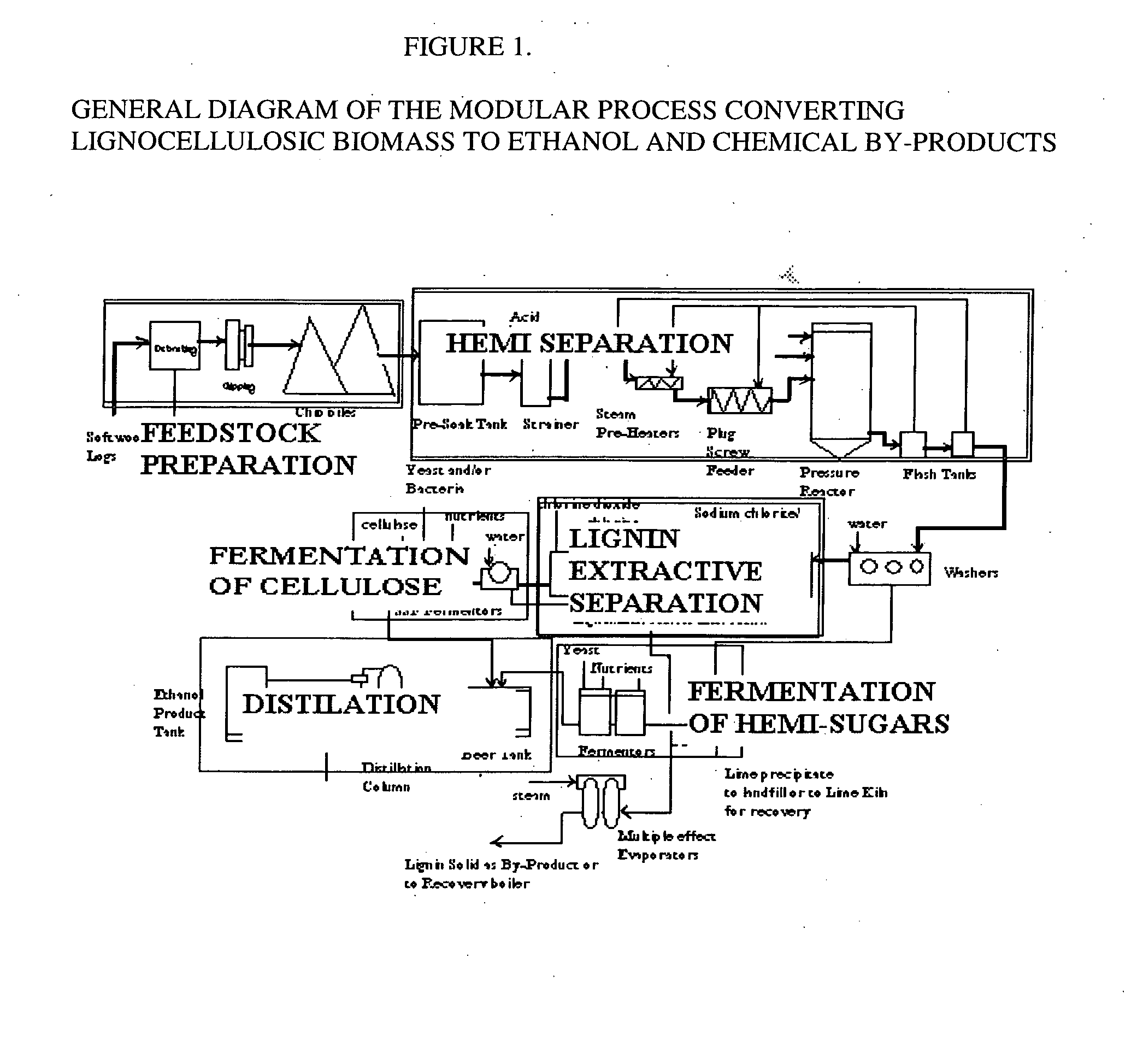

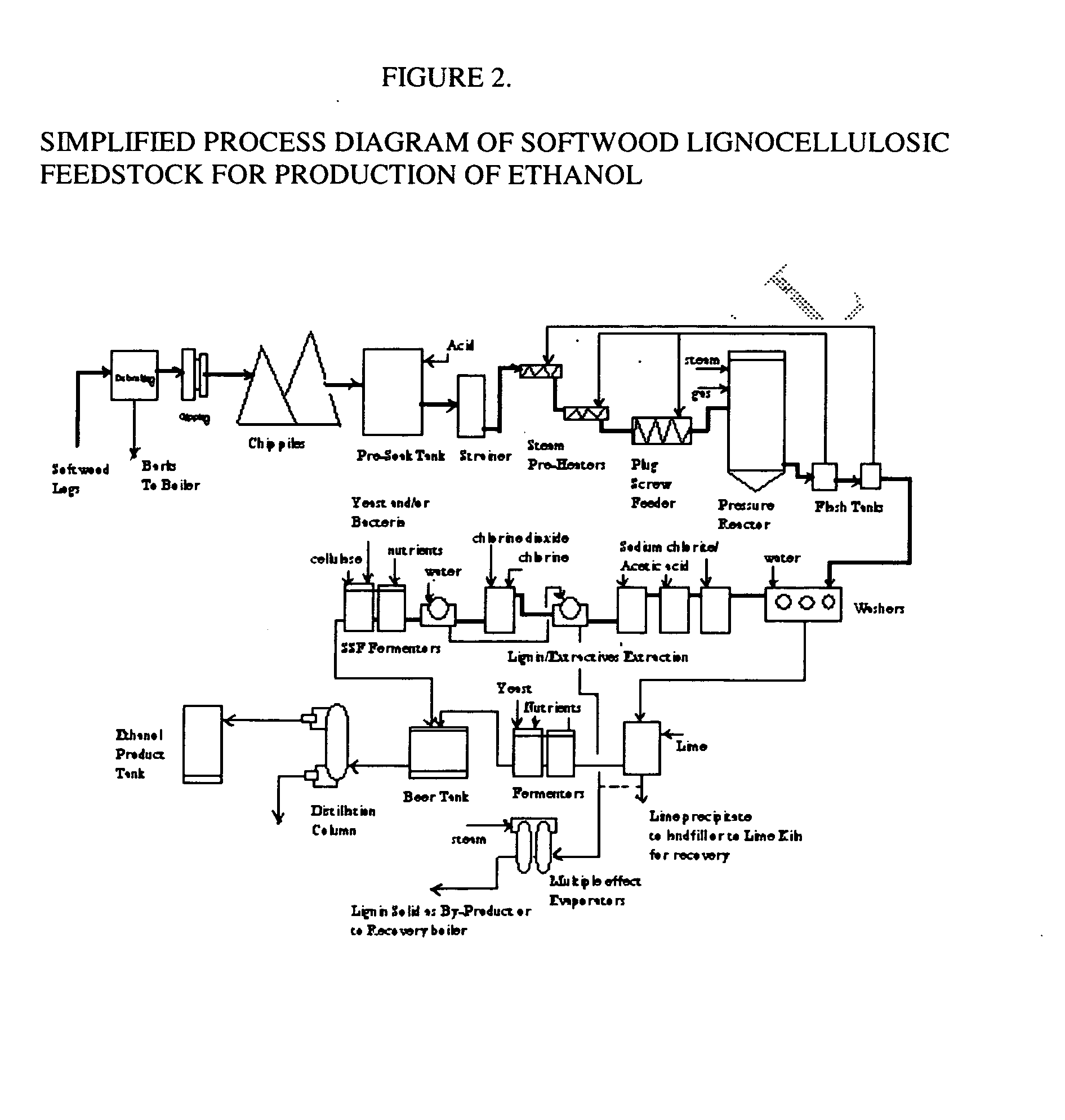

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

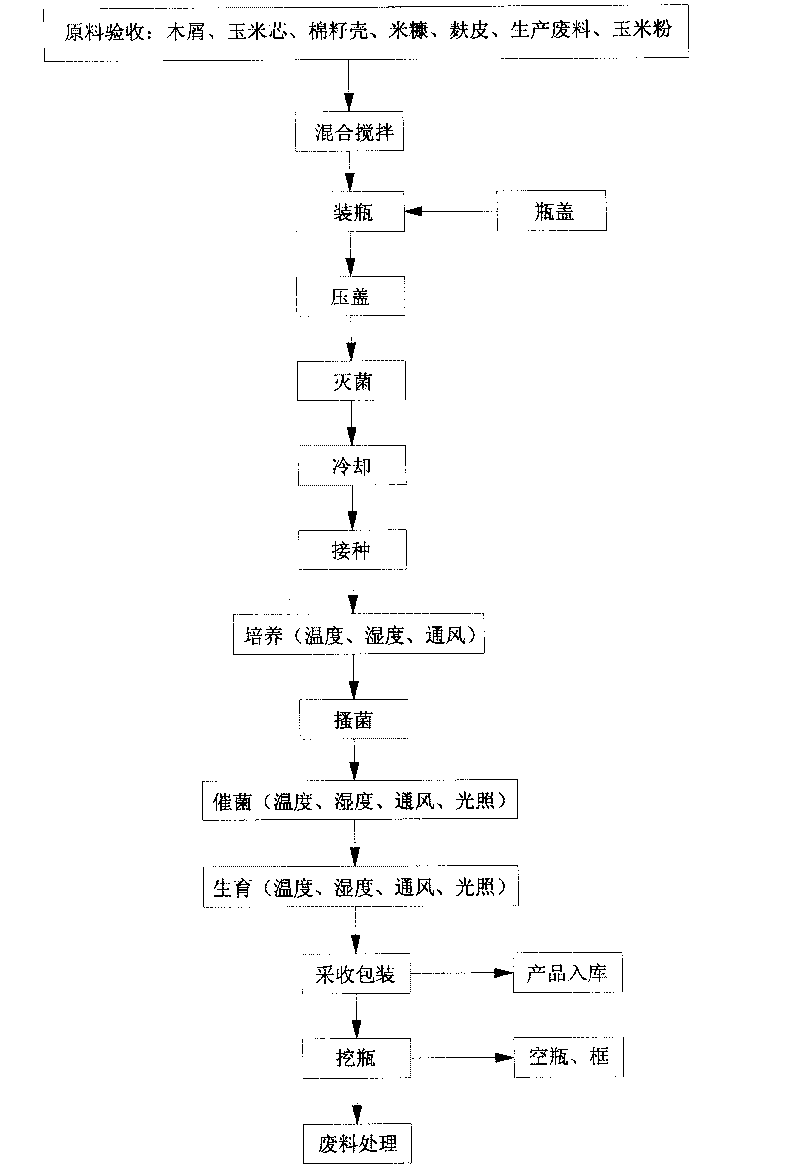

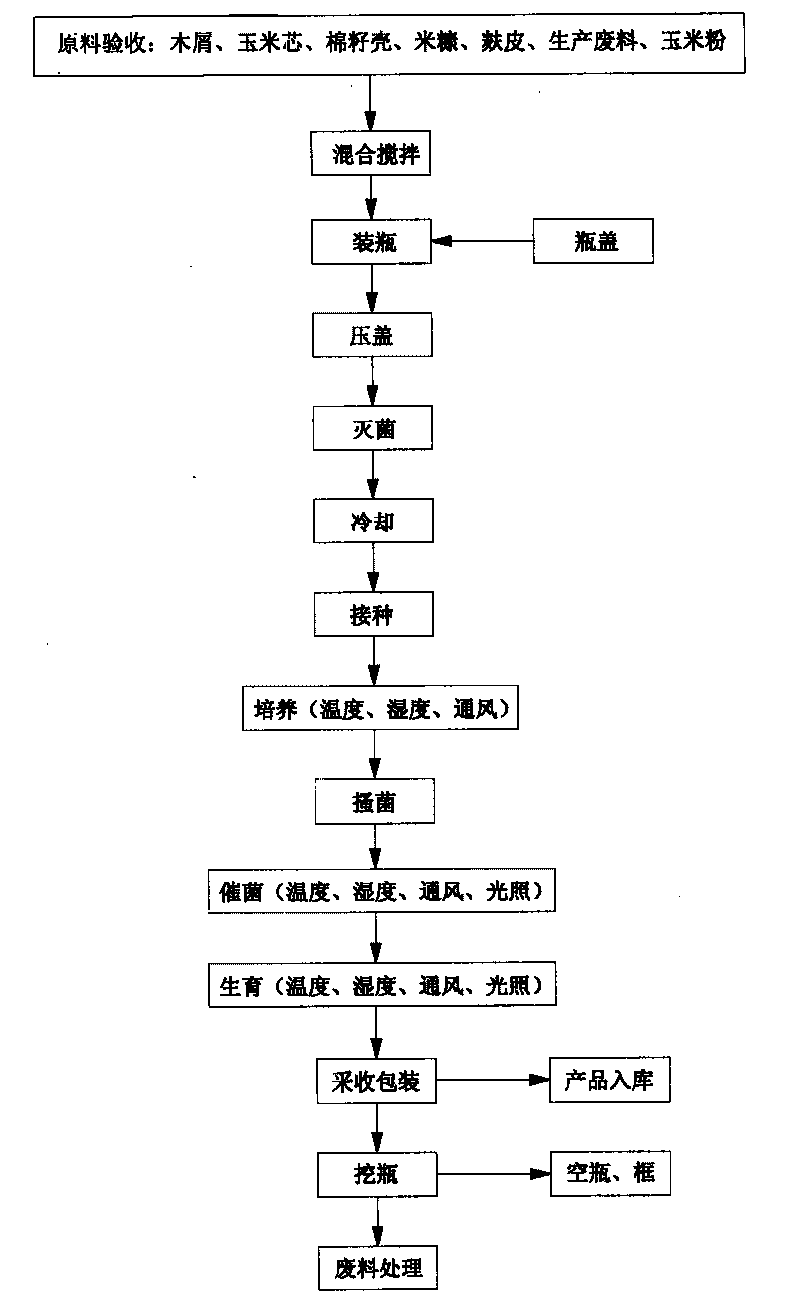

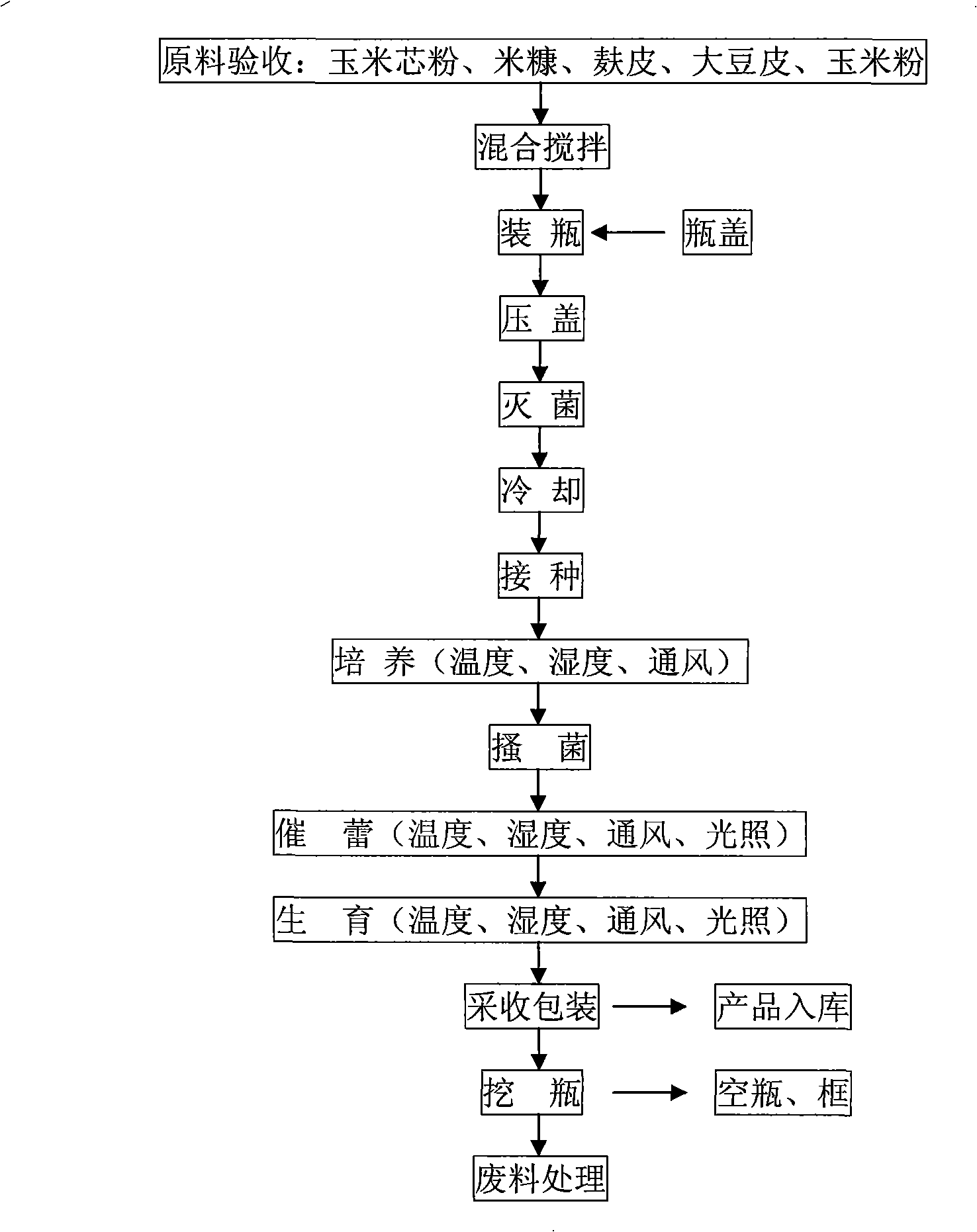

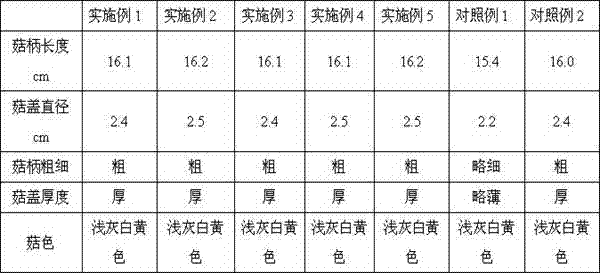

Formula of culture medium for high yield beech mushrooms and production process

The invention relates to a formula of a culture medium for high yield beech mushrooms and a production process. The invention relates to the technical field of biological fungus cultivation, in particular to the formula of the culture medium for high yield beech mushrooms and a production process. The production process comprises the following steps: removing lignin, semi lignin, cellulose and thelike in wood chips and corn cobs by using a microbial corrosion catalyst; releasing contents of the wood chip and the corn cobs through biological fermentation to provide sufficient nutrients for thegrowth and development of the beech mushrooms; and fully degrading and releasing nutritional compositions of raw materials which constitute the culture medium through microbial degradation, and providing with matched environmental factors such as light, temperature, humidity, air and the like which are suitable for the growth and development of the beech mushrooms so as to improve the yield and the quality of a single bottle.

Owner:STARWAY FOOD TECH DONG GUAN +1

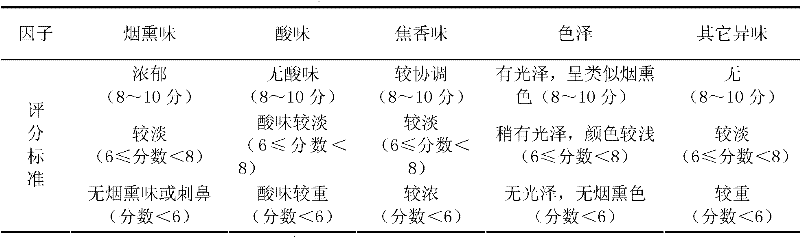

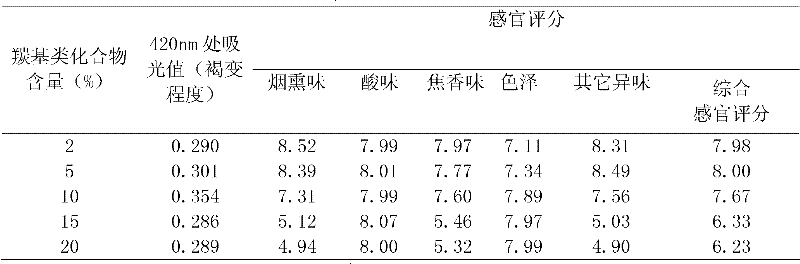

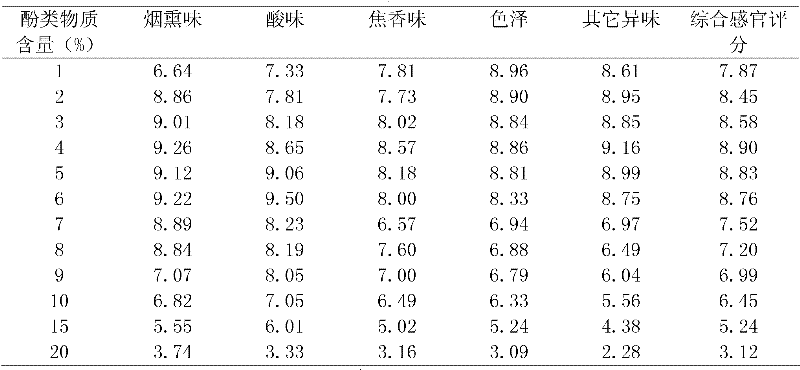

A color-flavor safe three-effect food smoking liquid and its preparation method

The invention discloses a color, flavor and safety three-effect food fumeol and its preparation method. The fumeol provided by the invention contains the following main components of: a phenol substance, a carbonyl compound, an organic acid substance, an ester matter, ethanol, reducing sugar, amino acid, an emulsifier, sodium polyacrylat, B vitamins, sodium erythorbate and water. In addition, oneor more components selected from a group consisting of a tea tree extract product, a beech extract product, a cypress branch extract product and a fruit tree extract product can also be added. The preparation method of the fumeol is simple, is easy to operate in batch production, and has good repeatability; the preparation process requires no smoke, is safe and protects the environment; and smoked products prepared by the use of the fumeol has a good local flavor as well as good color. Therefore, the food fumeol provided by the invention has an extensive application prospect.

Owner:郭秀云

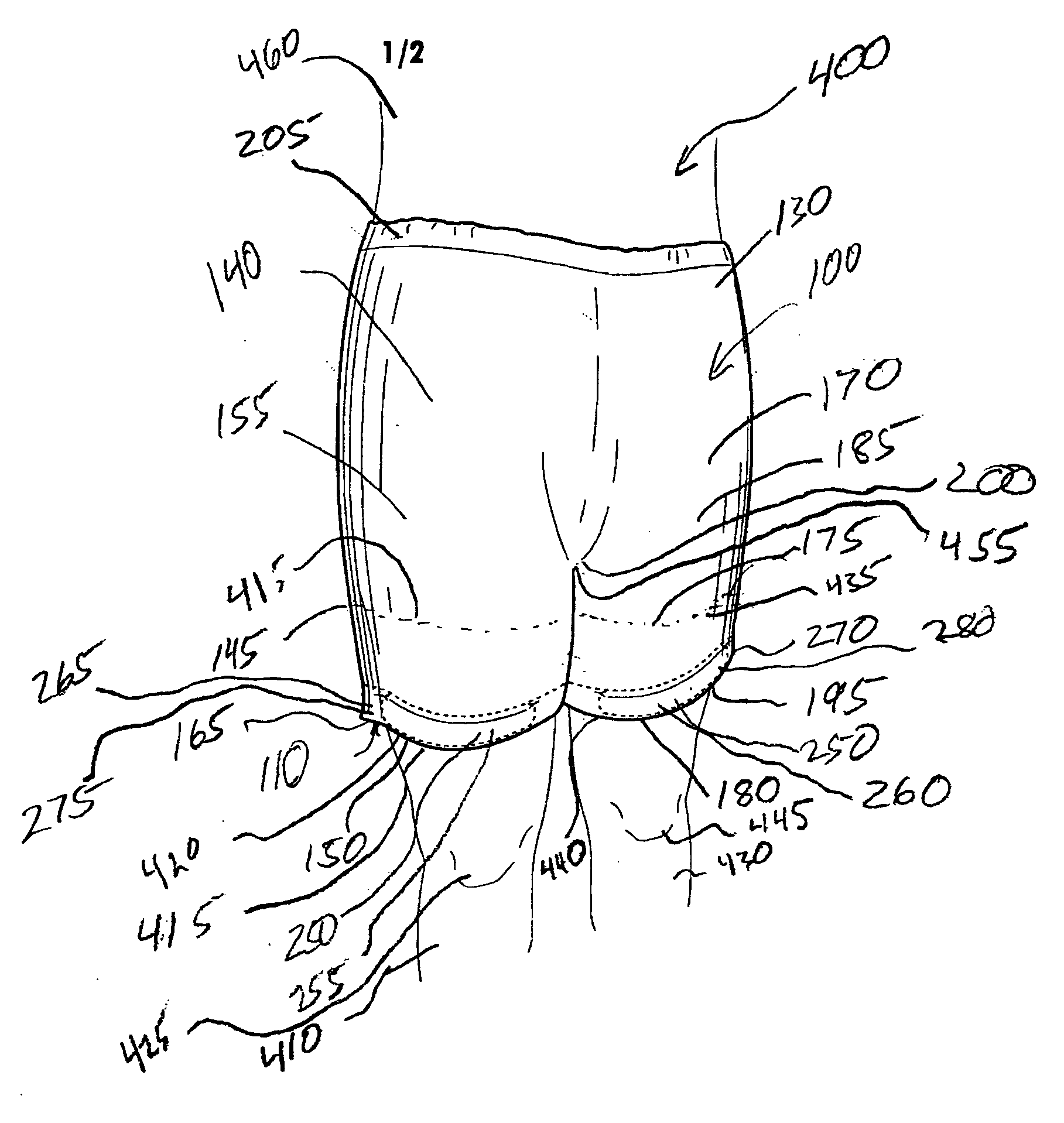

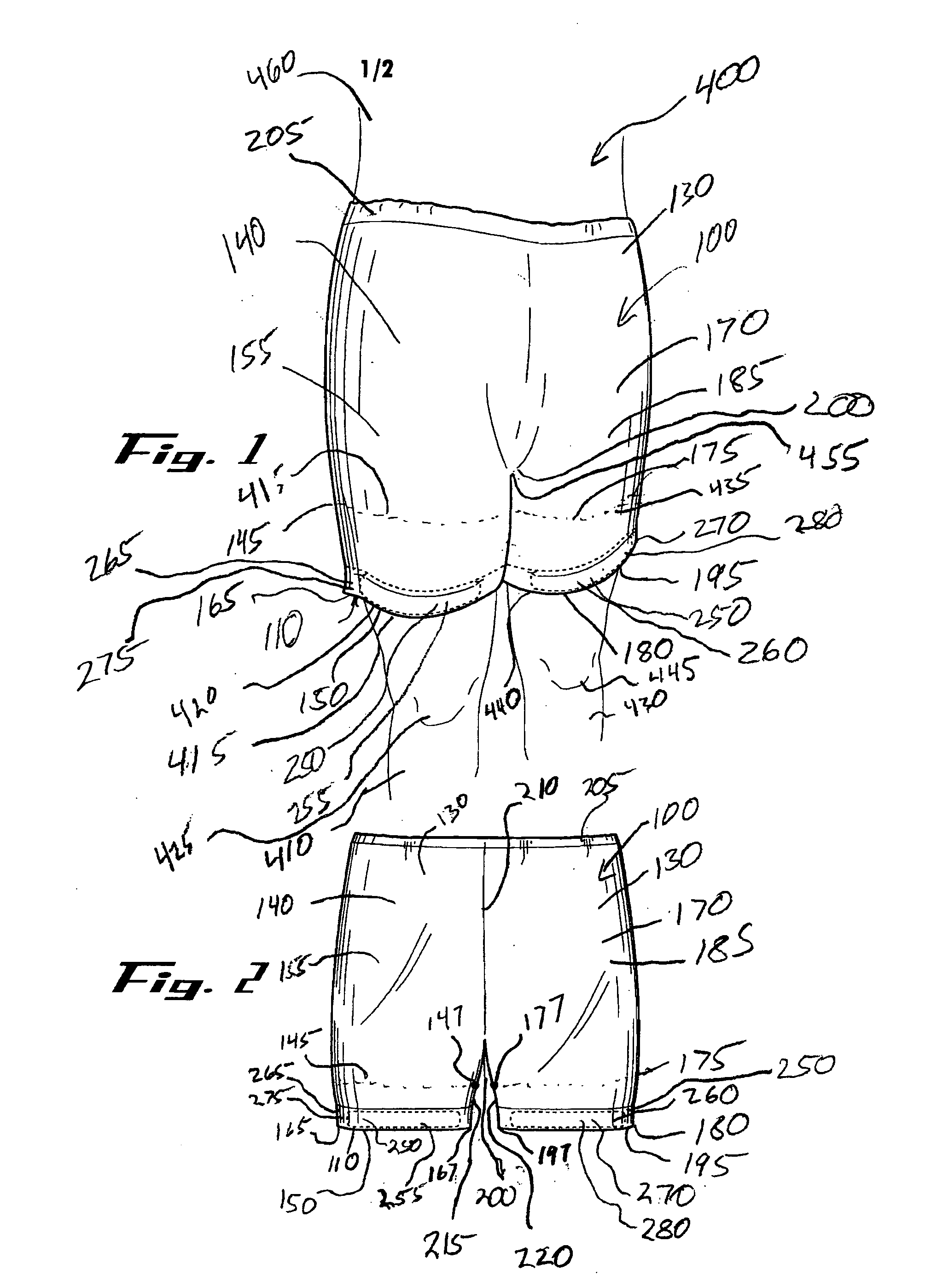

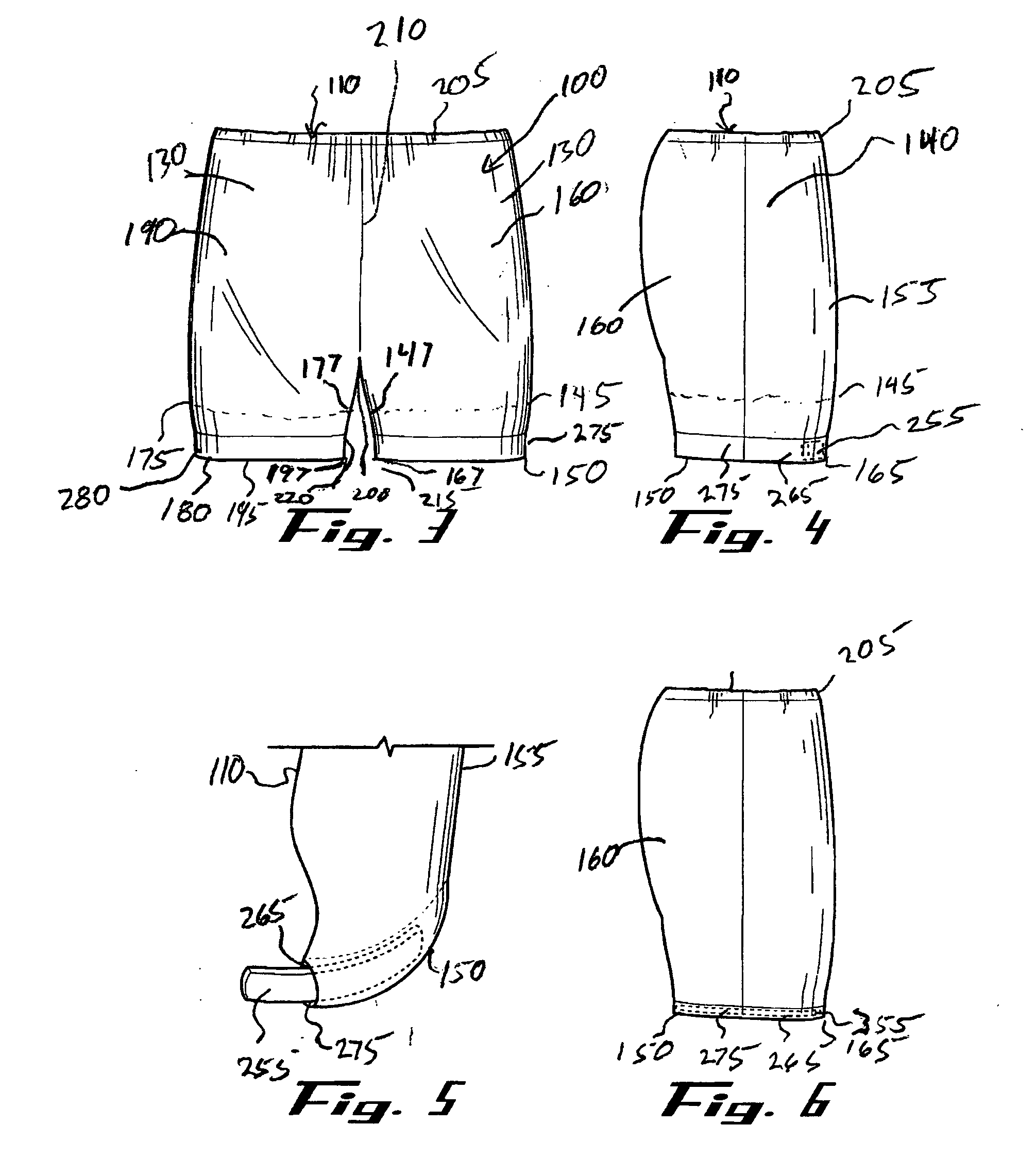

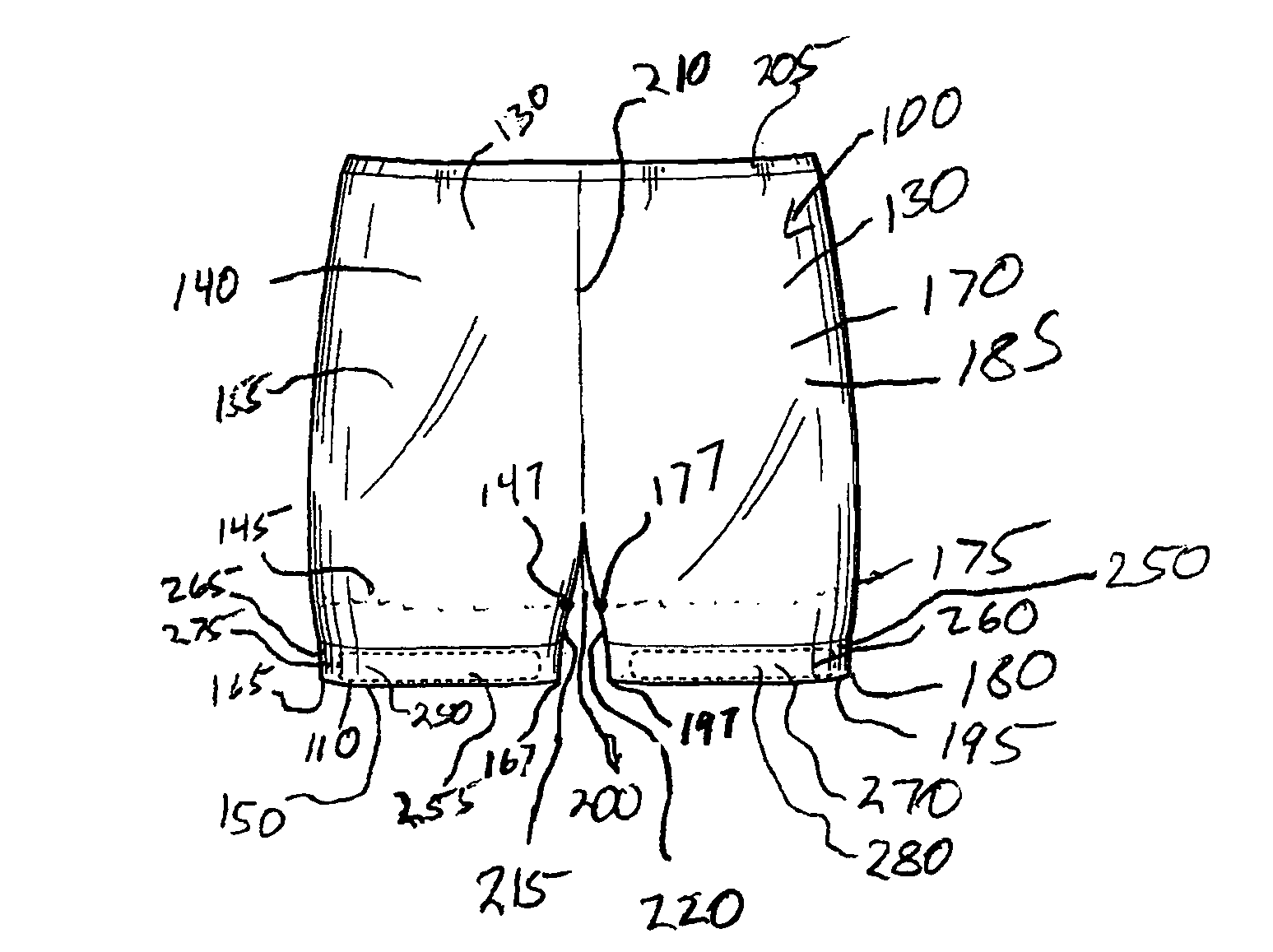

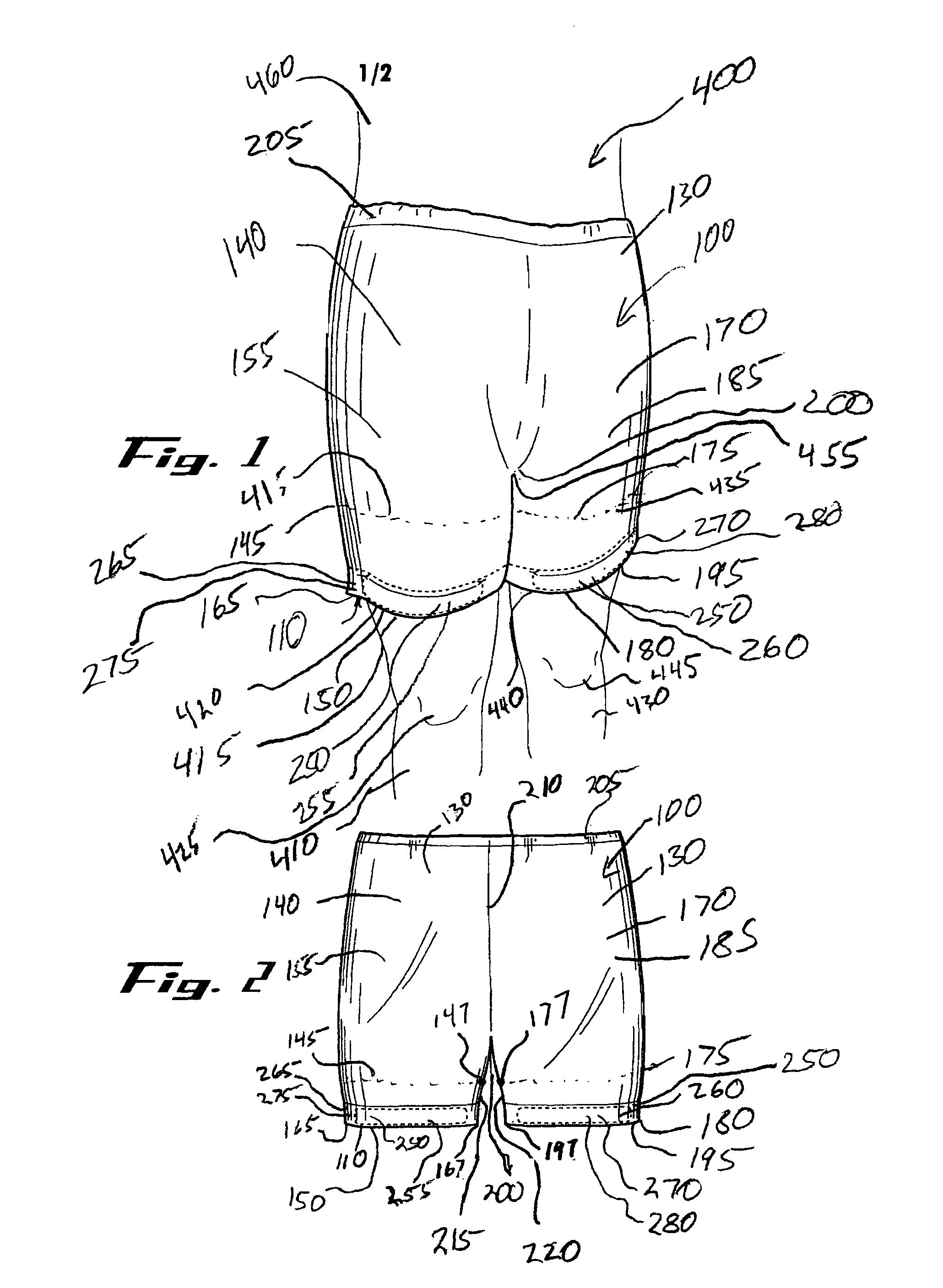

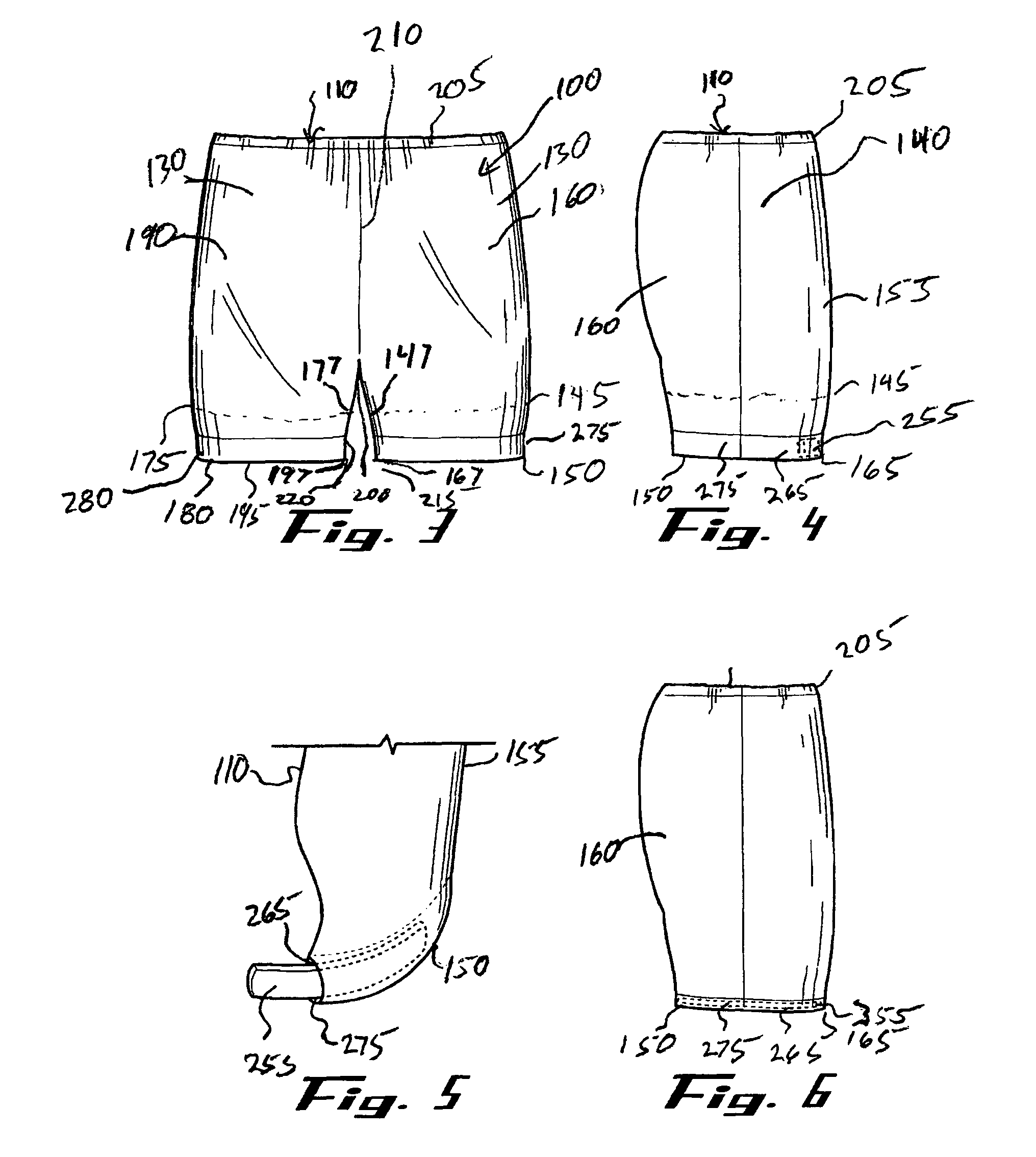

Weighted undergarment

InactiveUS20090025124A1Prevents leg chafingWicks away moistureGarment suspendersGirdlesBeechEngineering

The invention prevents leg chafing, and keeps the garment from riding up in the wearer's crotch area, by disposing weights on the garment. If the garment is an undergarment, then Modal® fabric, a bio-based fiber made by spinning reconstituted cellulose from beech trees, is especially preferred, as it is extremely soft, and wicks away moisture in an effective manner. It is an object of the invention to reduce leg chafing. It is a further object of the invention to teach a method of preventing garments from riding up into the wearer's crotch area.

Owner:GEARHART ELIZABETH

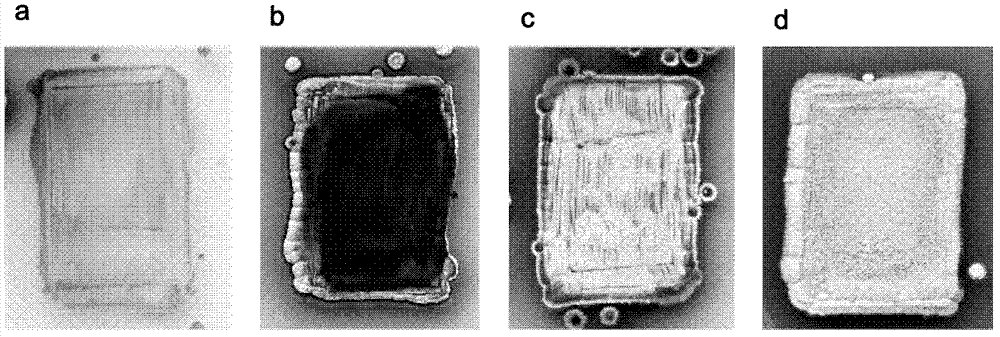

Cultivation method of white beech mushroom

The invention relates to a cultivation method of white beech mushroom, comprising the steps of preparing a culture medium, cooling, inoculating, cultivating, scratching, injecting water, planting and harvesting. The culture medium comprises the following components in percentage by weight: 15-25 percent of bits of wood, 10-20 percent of corn cob, 20-30 percent of rice bran, 10-20 percent of bran, 5 percent of corn powder, 15-25 percent of production waste and 5 percent of cottonseed hull, wherein the water content of the culture medium is 64-66 percent, the pH value of the culture medium is 6-7, and the culture medium is uniformly stirred, bottled and sterilized at high pressure. The invention provides the cultivation method which takes the bits of wood and production waste as main raw materials and has low cost, thereby effectively shortening the production period, reducing the production cost, ensuring the stable quality and obtaining better economic benefits.

Owner:SHANGHAI FINC BIO TECH INC

Bamboo-wood straw and manufacturing method

The invention provides a bamboo-wood straw and a manufacturing method. A bamboo-wood straw main body is of a straight-strip tubular structure with a uniform wall thickness, one end of the bamboo-woodstraw main body is cut into a flat cut to serve as a drinking port, the other end of the bamboo-wood straw main body is cut into an inclined cut to serve as a puncturing port, raw materials of the bamboo-wood straw are ripe bamboo or wood which is uniform and consistent in texture, and include sandalwood, beech, oak, phoebe zhennan, ormosia henryi and the like. According to the bamboo-wood straw,a new structure suitable for combination and processing is adopted, requirements for natural formation of the raw materials are small, common materials can be directly adopted, the requirements for selecting materials are small, and the material cost is greatly reduced; the raw materials are environment-friendly, easy to recycle and recyclable, and the bamboo and the wood have the characteristic of environmental protection, and can be conveniently reused in many fields after being used as disposable straws; the processing method is suitable for large-scale production; and the requirements of the raw materials are relatively low, standardized production can be realized, and the quality of products is stable and controllable.

Owner:林仙珠

Anti-aging essence composition and preparation method thereof

ActiveCN102657592AProtect the environmentIn line with health principlesCosmetic preparationsToilet preparationsCaprylyl GlycolBeta-glucan

The invention provides an anti-aging essence composition and a preparation method thereof. The composition comprises the following component A and component B in percentage by weight: in component A, 80 to 85 percent of plant water, 2 to 8 percent glycerol, 0.01 to 0.2 percent of hyaluronic acid, and 2 to 5 percent of beta-glucan; and in component B, 2 to 5 percent of organic cotton thistle extract, 2 to 5 percent of organic beech extract, 2 to 5 percent of organic apple extract, and 0.3 to 0.7 percent of 1,2hexanediol and caprylyl glycol mixture. The method comprises the following steps: 1) heating the component A to 80-85 DEG C, and stirring so as to completely dissolve the component A; 2) cooling to 40-45 DEG C, and adding the component B; and 3) discharging to prepare the organic anti-aging essence. The invention has the beneficial effects that the essence has the functions of enhancing the skin elasticity and resisting aging; and the whole process of processing, producing and packaging is in accordance with the environmentally-friendly and healthy principle, and the anti-aging product is safer and environmentally-friendly.

Owner:广州泰润合投资有限公司

Method for producing handicraft picture frame

InactiveCN102805511AAvoid deformationImprove product qualityPicture framesDomestic mirrorsPaulowniaEngineering

A method for producing a handicraft picture frame mainly comprises the steps of using high-quality wood plates such as paulownia wood, beech, China fir and pine, preferably the paulownia wood, as raw materials; soaking and drying the raw materials; manufacturing the raw materials into frame strip blanks; sanding and cutting the frame strip blanks; manufacturing the frame strip blanks into an inner frame; sanding the inner frame; wrapping canvas on the inner frame; trimming off residual canvas edges so as to form the finished handicraft picture frame; and finally packaging the handicraft picture frame. Because the wood frame strips of the handicraft picture frame produced by the method are processed uniformly, flatly and smoothly, and the manufactured inner frame is flat and not easy to deform, the quality of the handicraft picture frame can be increased effectively. In addition, the picture frame is light, is easy to carry, and has a good market prospect.

Owner:KAIFENG JINXU PAINTING MATERIALS

Marine streptomyces viridochromogenes strain for producing alkali-tolerant and salt-tolerant xylanase and application of marine streptomyces viridochromogenes strain

InactiveCN102586134AGreat application potentialGood colorBacteriaMicroorganism based processesHigh concentrationFiber

A marine streptomyces viridochromogenes strain for producing alkali-tolerant and salt-tolerant xylanase and application of the marine streptomyces viridochromogenes strain belong to the field of biotechnology. The strain is collected in the China General Microbiological Culture Collection Center, and the collection number is 5565. The strain can normally grow under the extreme alkaline environment of pH11, shows a good oligotrophy-tolerant characteristic, can degrade a variety of hemicellulose-containing biomasses including corn straws, rice straws, Jerusalem artichoke straws, kelp fibers andthe like, and has a broad application prospect in utilizing cheap biomass resources to produce bio-based chemicals. The strain can produce xylanase under optimum conditions, and the enzymatic activity of the xylanase can be as high as 68.9U / ml. The produced xylanase has the following properties: the optimum pH value is 6.0, the optimum temperature is 70 DEG C, the optimum substrate is beech xylan, and the produced xylanase does not have cellulase activity, has high pH stability and thermal stability, and can tolerate high-concentration NaCl. As an enzyme preparation coming from the ocean, thexylanase can be widely used in papermaking, food, feed, wine making, energy and other industries.

Owner:DALIAN UNIV OF TECH

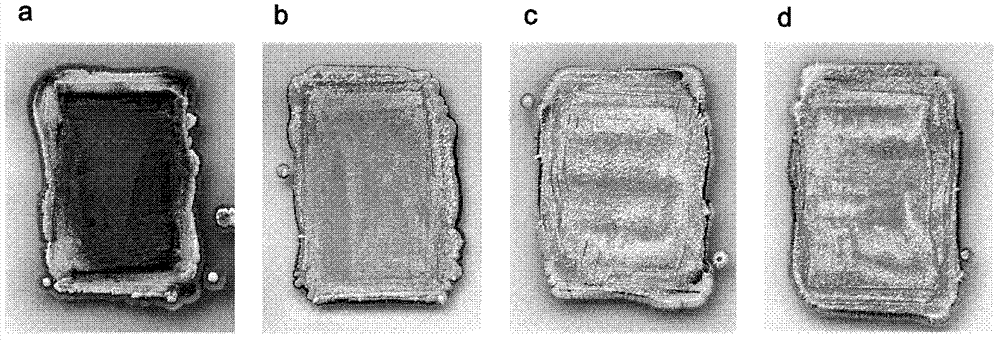

High yield cultivation method for brown crab flavour mushroom

The invention provides a high yield cultivating method for brown beech mushroom. By adopting the method, the brown beech mushroom can be cultivated in large scale through industrializing facilities and the growth period can be effectively shortened, thus reducing costs. A fully automatic production line is adopted for completing the whole course of stirring, bottling, disinfection, inoculation, cultivation, mushroom loosening and digging, and the temperature, humidity, ventilation and illumination of cultivation are adjusted manually, thus the best cultivation requirements can be met and the best yield and quality can be obtained. In the cultivating method of brown beech mushroom, soybean skin and corn cob are adopted as cultivation medium to replace wood dust completely, which solves the difficulty of raw material purchase due to the lack of wood dusts. The cultivation of the brown beech mushroom by industrializing facilities can meet the optimal cultivation requirements of the brown beech mushroom; compared with the prior art, the cultivation period is shortened, while the yield is increased.

Owner:SHANGHAI FINC BIO TECH INC

Weighted undergarment

InactiveUS8024819B2Prevents leg chafingWicks away moistureGarment suspendersTrousersBeechEngineering

Owner:GEARHART ELIZABETH

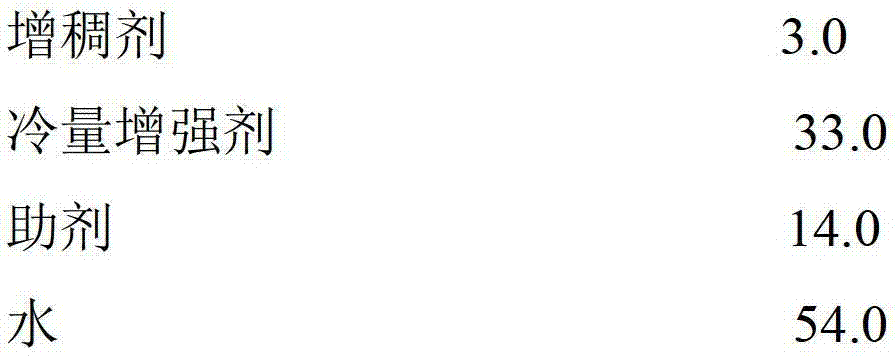

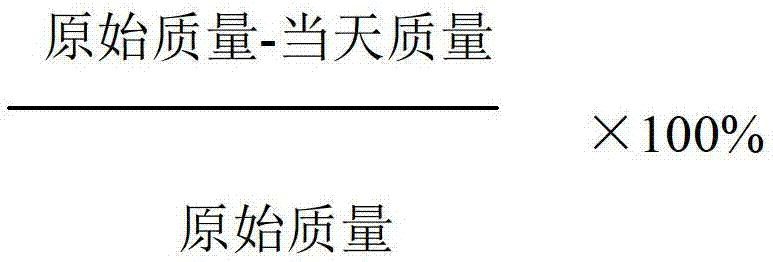

Brown beech mushroom refrigeration cold-insulation agent and preparation method thereof

InactiveCN103194178ALow freezing pointLowering the freezing pointHeat-exchange elementsFruits/vegetable preservation by freezing/coolingGlycerolBeech

The invention discloses a brown beech mushroom refrigeration cold-insulation agent and a preparation method thereof, wherein the cold-insulation agent is formed by combining a thickening agent formed from soluble chitosan and soluble starch with a cooling capacity reinforcing agent formed from ethanol and glycerol by adding auxiliaries formed from soluble amine or amine salt and soluble acetate and water. The brown beech mushroom refrigeration cold-insulation agent disclosed by the invention is not iced at low temperature; the limited space of a packaging box can be effectively utilized; the transportation cost is reduced; a better effect is played in a long time; good flowability is still kept at minus 30 DEG C; due to addition of the auxiliaries, the cooling capacity storage amount is further increased; the cold-insulation agent disclosed by the invention is low in use amount and also has the advantages of being low in corrosivity and environmental influence; and in addition, if packaging is leaked, effective components of the cold-insulation agent have good effects on fresh keeping and growth of products.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Forestation method improving fir wood property

InactiveCN108040804AImprove wood performanceIncrease competitionClimate change adaptationAfforestationLiriodendronBeech

The invention discloses a forestation method improving the fir wood property. The method comprises the following steps of high-quality seedling cultivation, land preparation and fertilization, tree species arrangement and planting and tending management. By conducting mixed plantation between plants or mixed plantation by rows on fir and one or more of pinus massoniana, phoebe bournei, steamed beech, liriodendron chinese and schima superba, competition between the fir and other tree species is increased, broad leaves of the phoebe bournei, the steamed beech, the schima superba, the liriodendron chinese and the like are likely to rot to form humus compared with Chinese fir leaves, multiple mineral nutrition is contained, the mineral nutrition is absorbed by the fir and then accumulated in wood of the trunk, and the wood property of the fir is improved.

Owner:HUNAN ACAD OF FORESTRY

Longevity mushroom edible fungus soup and method for producing the same

The invention discloses bowling mushroom edible fungi soup and a production method thereof; the method is mainly characterized in that bowling mushroom, golden mushroom, beech mushroom and Bailing mushroom are first cleaned and sorted; and then pork loin, beef ribs and a duck are boiled into soup; pre-treated edible fungi and mushroom are weighed by the capacity of every package; the boiled soup is added in, and the product is sealed; high-pressure sterilization is conducted to the sealed packaged product, and then the product is coded, packaged after being cooled and put into a warehouse. The bowling mushroom edible fungi soup produced by the method is incomparably fresh and fragrant, not only has the unique freshness of mushrooms but also has the freshness of animal meat and bone; the mushrooms are tender, tasty, refreshing, nutritious, delicious, fresh and fragrant, have the function of health care, and are rare excellent products in food.

Owner:MAANSHAN ANKANG FUNGUS IND

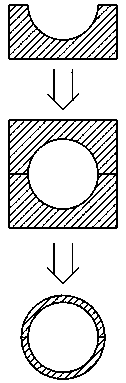

Method for preparing insect-resistant damp-proof wood veneer

InactiveCN109135179AIncrease elasticityImprove toughnessPlastic/resin/waxes insulatorsWood treatment detailsAdhesiveNano al2o3

The invention discloses a method for preparing insect-resistant damp-proof wood veneer. The method includes steps of A, grinding pine bark to obtain pine powder; B, grinding beech shavings to obtain beech powder; C, placing the pine powder and the beech powder into stirring barrels, uniformly mixing the pine powder and the beech powder with each other to obtain first mixtures, adding distilled water into the first mixtures, stirring the distilled water and the first mixtures, and sequentially adding camphor wood powder, mica powder, nanometer aluminum oxide powder and glass fibers into the distilled water and the first mixtures in stirring procedures to obtain second mixtures; D, sequentially adding flame retardants, adhesive and drying agents into the stirring barrels, stirring the flameretardants, the adhesive, the drying agents and the second mixtures and filling the stirring barrels with nitrogen in stirring procedures; E, pouring materials obtained at the step D into molds, carrying out compression molding by the aid of molding machines and carrying out mold release to obtain wood veneer semi-finished products; F, placing the wood veneer semi-finished products obtained at thestep E into drying ovens and carrying out drying treatment to obtain wood veneer finished products. The method has the advantage that excellent insect-resistant effects and excellent damp-proof effects can be realized by the insect-resistant damp-proof wood veneer prepared by the aid of the method.

Owner:湖州韵高木业有限公司

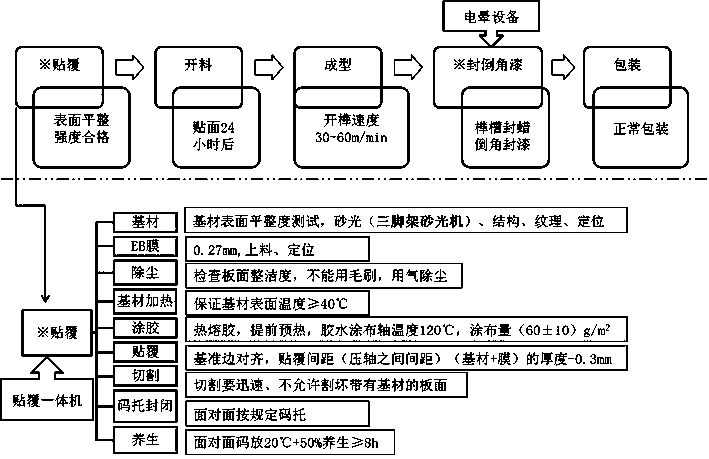

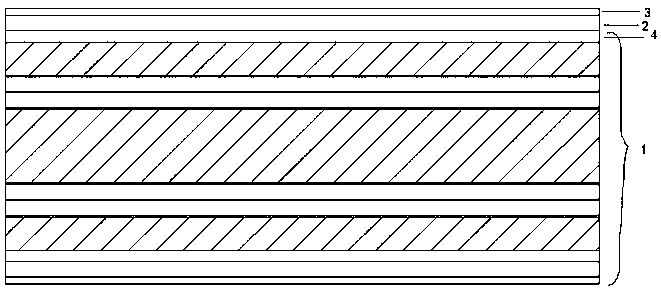

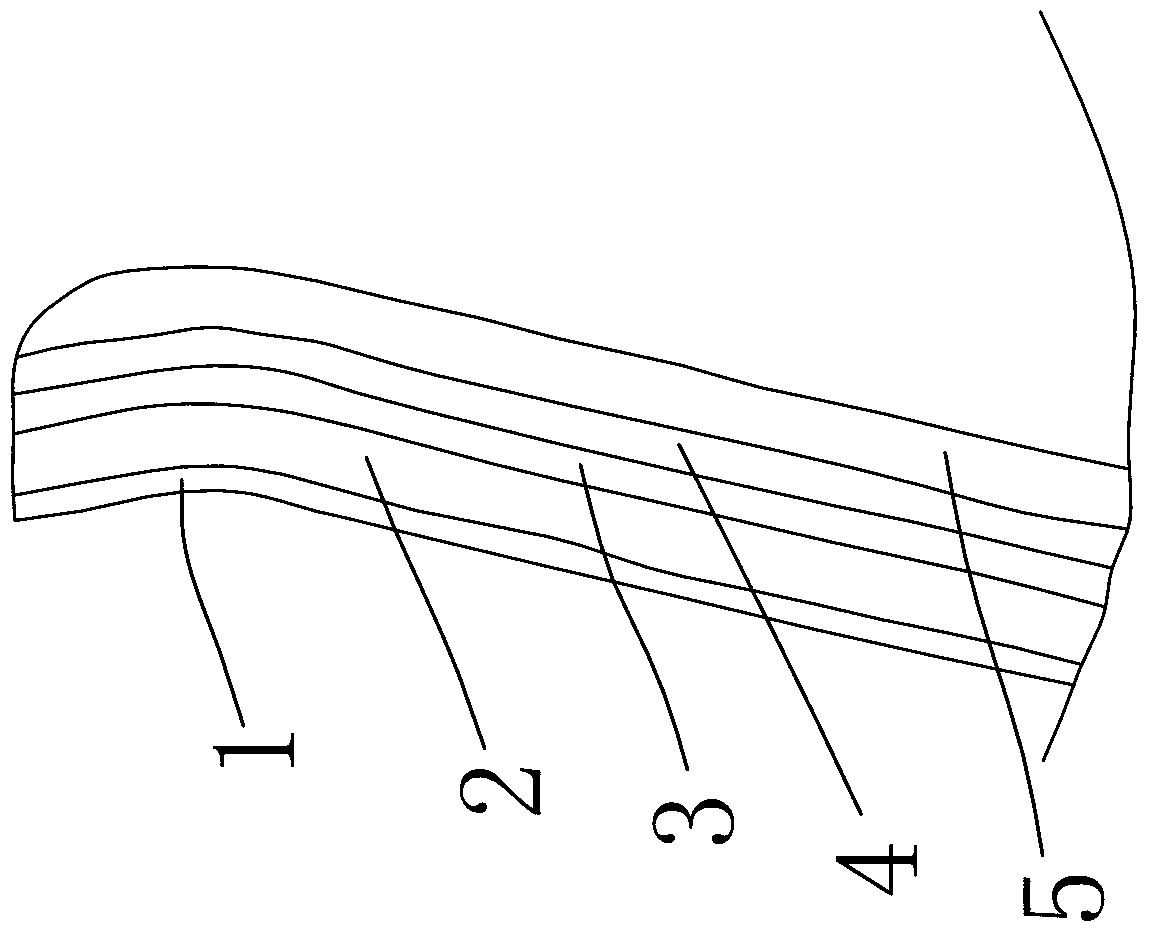

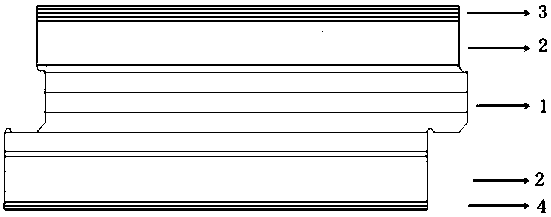

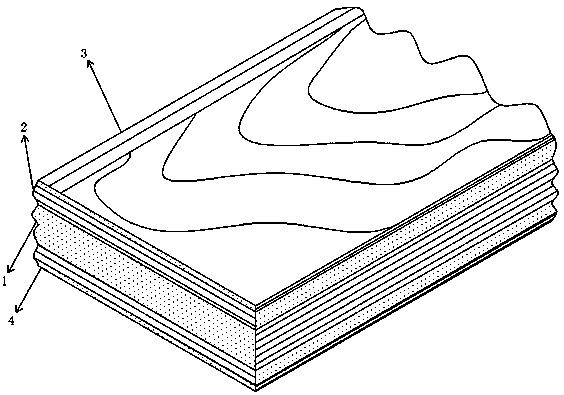

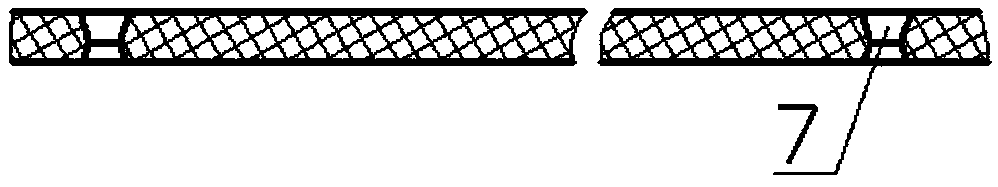

EB-cured polypropylene film facing multilayer composite floor and production process

PendingCN109537847AOvercome problems such as surface defectsHigh bonding strengthLamination ancillary operationsSynthetic resin layered productsSurface layerEngineering

The invention belongs to the technical field of ground paving materials and relates to an EB-cured polypropylene film facing multilayer composite floor. The floor comprises a floor substrate body anda surface layer attached to the floor substrate body, wherein the substrate body is a multilayer substrate, the thickness of the substrate body is 11.7-14.7 mm, the surface layer is formed by stickingan EB-cured polypropylene film to a polyurethane resin adhesive layer, the thickness of the surface layer is 0.22-0.32 mm, and wood texture of the surface layer of the substrate is parallel to the length direction of the EB-cured polypropylene film. The thickness of the EB-cured polypropylene film is about 0.22-0.32 mm; the thickness of the polyurethane resin adhesive layer is 0.1-0.2mm; the surface layer of the substrate is made of a beech tree or a birch tree and the other tree species with the thickness of greater than or equal to 0.8 mm. The invention also discloses a production process of the floor, and the production process alleviates the current deficiency of wood resources and reserves natural texture characteristics of wood. By using polyurethane resin, the EB film and the multilayer substrate are fitted and pressed at one time, and the surface of the floor does not need to be coated with ultraviolet curing UV paint. The floor has the advantages of being simple in productionprocess, small in environmental pollution, low in cost and high in comprehensive value.

Owner:圣象地板(句容)有限公司

Preparation method of culture medium for cultivating hypsizigus marmoreus

InactiveCN107056360AShorten the growth cycleIncrease productionCalcareous fertilisersAlkali orthophosphate fertiliserMinor elementHigh pressure

The invention discloses a preparation method of a culture medium for cultivating hypsizigus marmoreus, belonging to the technical field of edible fungus cultivation. The method comprises the following steps: 1. taking bagasse, peanut shells and bamboo sawdust, pulverizing to obtain powder of which the particle diameter is 1-2mm, and soaking in a NaOH solution to obtain swollen residues; 2. uniformly mixing fungus residues, rape seed cakes, chicken manure, wheat straws, beech wood cuttings, fly ash, Eichhornia crassipes, water and a fermentation inoculum with the swollen residues, and carrying out fermentation to obtain a fermented fertilizer; 3. mixing the fermented fertilizer with urea, potassium phosphate, lime powder, ammonium lignosulfonate, zeolite powder, humic acid and peach gum powder, regulating the pH value, and controlling the water content at 65-67%; and 4. carrying out high-pressure steam sterilization, cooling, and packaging in a fungus bag, thereby obtaining the culture medium. The hypsizigus marmoreus culture medium disclosed by the invention has balanced nutrition, contains multiple minor elements, and is capable of shortening the hypsizigus marmoreus growth period and enhancing the yield and quality of the hypsizigus marmoreus.

Owner:许星星

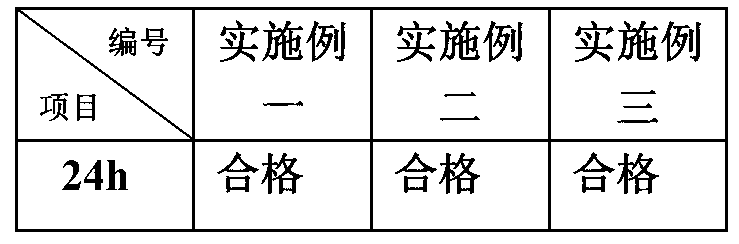

Automobile decorative sheet layer structure and layer structure processing technology

ActiveCN103318102AReasonable structure arrangementNice appearanceAnodisationLayered productsWalnut NutWax

The invention belongs to the technical field of automobile accessories and provides an automobile decorative sheet layer structure and the layer structure processing technology of the automobile decorative sheet layer. The automobile decorative sheet layer structure structurally comprises a non-woven layer, an aluminum part layer, a beech layer, a fiberboard layer and a walnut layer from inside to outside. The fiberboard layer is formed by wood fibers, a bonding formula, a flame-retarding formula and a waterproof formula. According to the processing technology, firstly, electrolytic oxidation is performed on the surface of the aluminum part layer, wax removing is performed before electrolytic oxidation, and a mixture of the flame-retarding formula, a gluing formula and the bonding formula is sprayed on the wood fibers which undergo hot grinding, and the fiberboard layer is formed through the procedures of drying, paving, hot pressing and sanding. The automobile decorative sheet layer structure and the layer structure processing technology of the automobile decorative sheet layer have the advantages that the technology processing process is green and safe and protects the environment; all the technology procedures are simple, therefore, yield is improved, a qualification rate is improved, production cost is reduced, and maintenance is easy; the layer structure after being processed is reasonable in layout, beautiful in appearance, and good in corrosion resistance, and the defects such as cracking and rusting are overcome; meanwhile, a high-quality film layer is formed on the outer surface of the layer structure, and therefore the corrosion resistance performance is enhanced.

Owner:宁波劳伦斯汽车内饰件有限公司

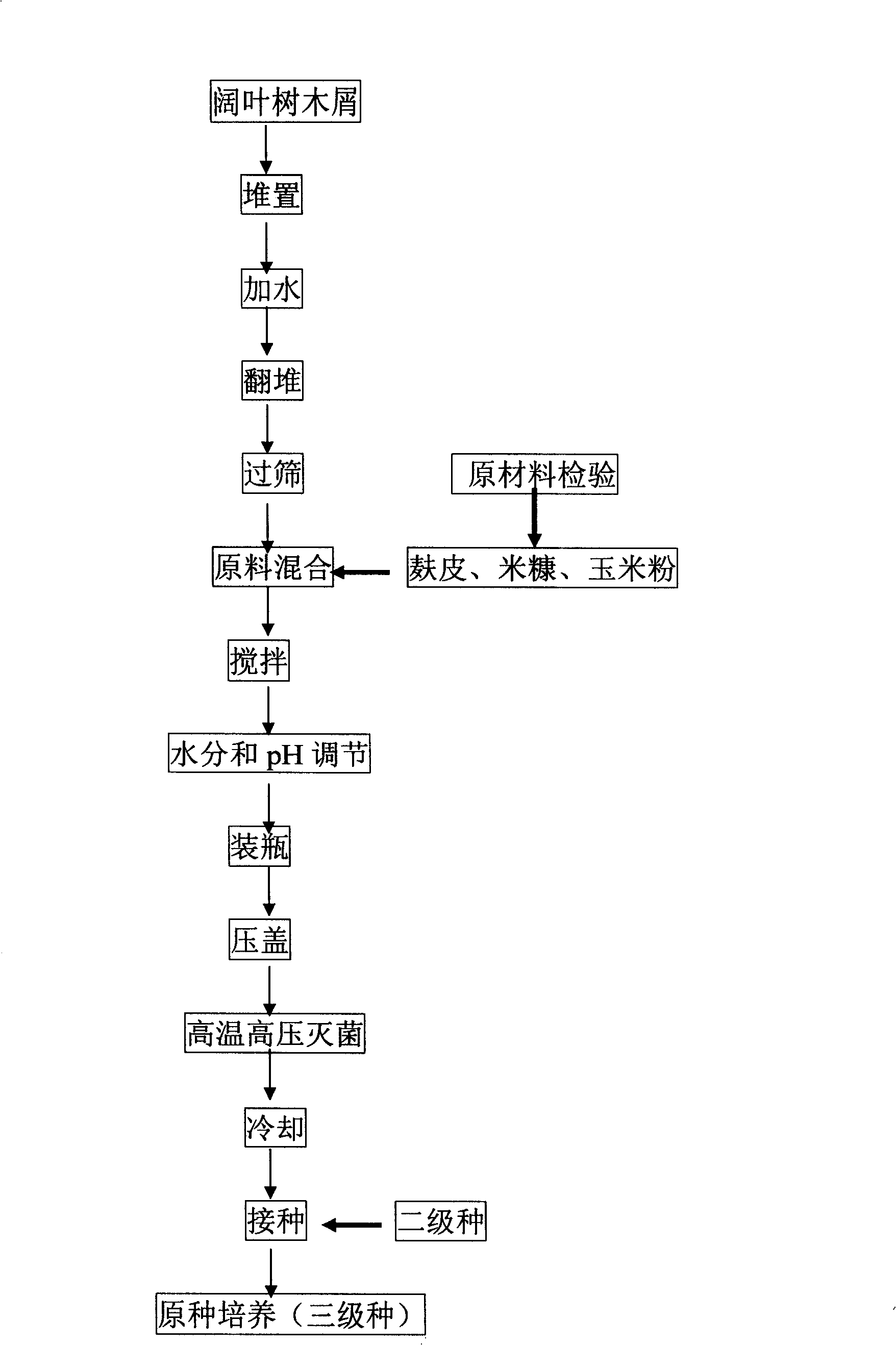

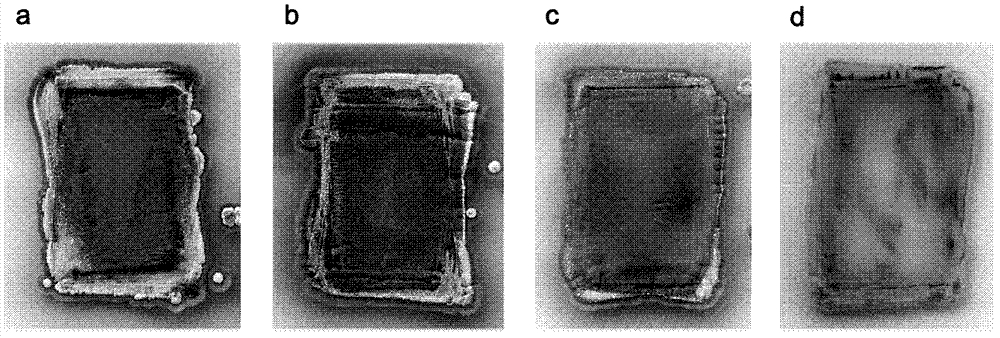

Process for preparing protospecies of white beech mushroom

The invention discloses a pedigree seed production method for white crab-taste mushroom, which is characterized in that sawdust, rice bran, wheat bran and maize powders are taken as cultivation raw material and poured into a mixing machine for uniform mixing in a dry way; water is then added into the mixing machine till the water content in the cultivating material reaches 60-62%; the operations of bottle mounting and cover pressing are carried out, and once sterilization under high temperature and high pressure is carried out; the bottles are arranged into a cooling chamber after the sterilization operation is completed; after the cooling operation, secondary seed is selected for inoculation; the pedigree seed bottle is sent to a pedigree seed cultivating chamber after the inoculation operation is completed; the temperature of the cultivating chamber is set to be 22-23 DEG C, the moisture thereof is 70-75%, the CO2 consistency thereof is controlled under 2000ppm; mycelium is filled in the whole bottle after being cultivated for 26-30 days and the pedigree seed can be used after being cultivated for 35-60 days; the selection operation is carried out thrice during the cultivation process when the bottles with slow spawn running, pollution or unusual situation are removed. The pedigree seed production method of the white crab-taste mushroom of the invention has quick spawn running speed and saves the cost; new compounding of the pedigree seed production does not affect the yield after inoculation and cultivation.

Owner:SHANGHAI FINC BIO TECH INC

Marine streptomyces viridochromogenes strain for producing alkali-tolerant and salt-tolerant xylanase and application of marine streptomyces viridochromogenes strain

InactiveCN102586134BPromote degradationGreat application potentialBacteriaMicroorganism based processesHigh concentrationFiber

A marine streptomyces viridochromogenes strain for producing alkali-tolerant and salt-tolerant xylanase and application of the marine streptomyces viridochromogenes strain belong to the field of biotechnology. The strain is collected in the China General Microbiological Culture Collection Center, and the collection number is 5565. The strain can normally grow under the extreme alkaline environment of pH11, shows a good oligotrophy-tolerant characteristic, can degrade a variety of hemicellulose-containing biomasses including corn straws, rice straws, Jerusalem artichoke straws, kelp fibers and the like, and has a broad application prospect in utilizing cheap biomass resources to produce bio-based chemicals. The strain can produce xylanase under optimum conditions, and the enzymatic activity of the xylanase can be as high as 68.9U / ml. The produced xylanase has the following properties: the optimum pH value is 6.0, the optimum temperature is 70 DEG C, the optimum substrate is beech xylan, and the produced xylanase does not have cellulase activity, has high pH stability and thermal stability, and can tolerate high-concentration NaCl. As an enzyme preparation coming from the ocean, the xylanase can be widely used in papermaking, food, feed, wine making, energy and other industries.

Owner:DALIAN UNIV OF TECH

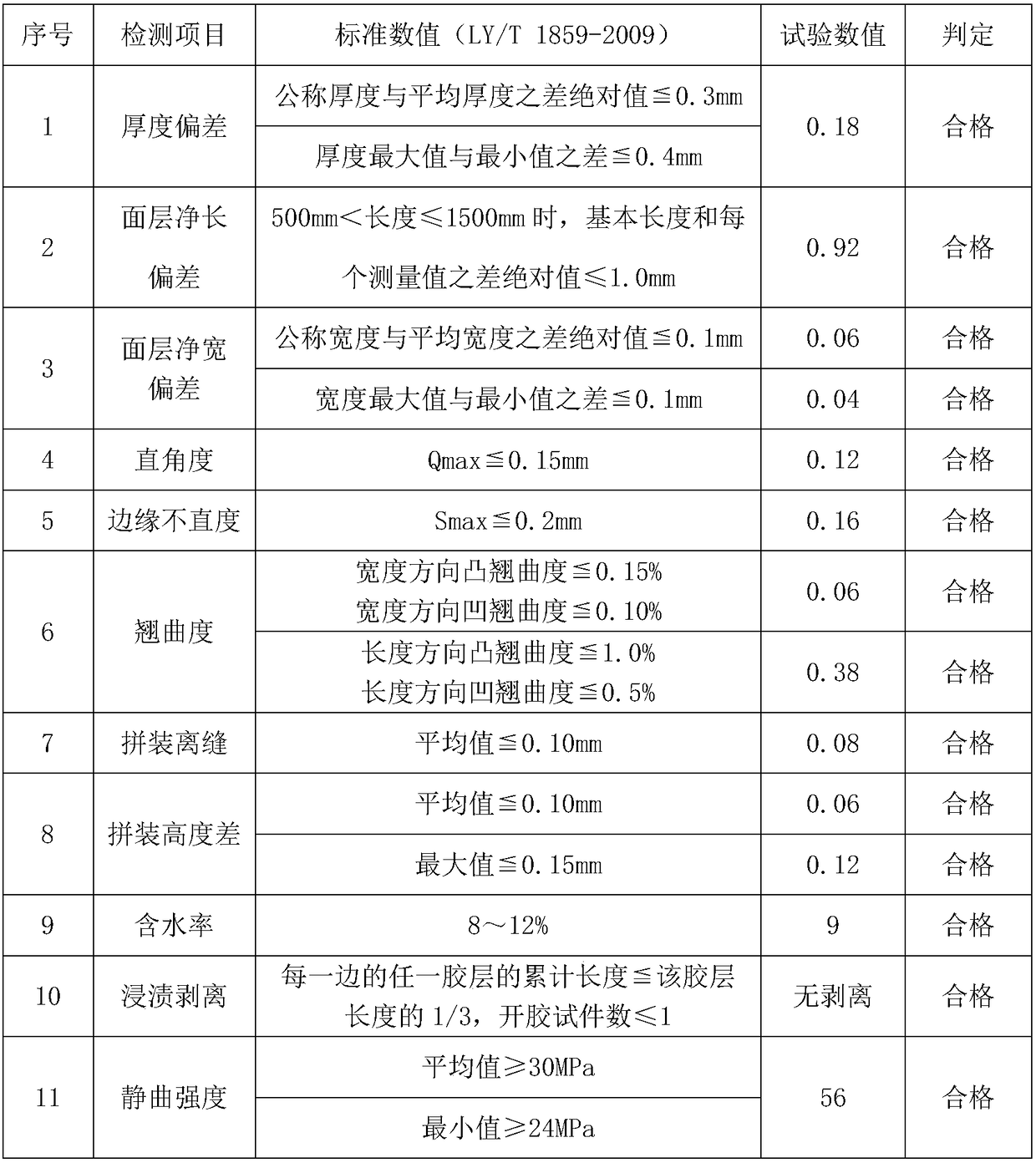

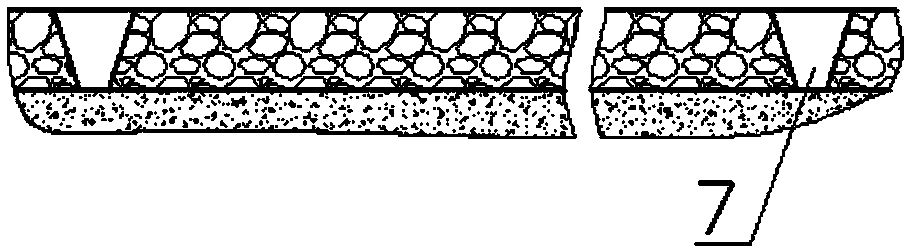

Wiredrawing solid wood composite floor of special structure and technique thereof

PendingCN108797936AHigh bonding strengthDimensional stabilityWood working apparatusFlat articlesWaxSolid wood

The invention belongs to the technical field of wood floors, relates to a solid wood composite floor, in particular to a wiredrawing solid wood composite floor of a special structure, and further discloses a production technique of the floor. The wiredrawing solid wood composite floor comprises a core layer, a surface layer and a bottom layer. Eucalyptus layers are arranged between the core layerand the surface layer as well as between the core layer and the bottom layer correspondingly. All the layers are arranged in a texture criss-cross mode and then subjected to gluing blank-assembling and hot-press gluing to form the wiredrawing solid wood composite floor. The surface of the surface layer is subjected to rough wiredrawing treatment, and the wiredrawing depth is 0.2-0.4 mm. Accordingto the wiredrawing solid wood composite floor of the special structure, original plywood layers are replaced with eucalyptus, beech serves as a bottom layer, a wiredrawing color register technique isadopted, the surface of the wiredrawing solid wood composite floor is coated with eight-bottom two-sided environment-friendly UV paint, and edge sealing treatment is conducted through waterproof wax with high performance and high environmental friendliness; coniferous pine wood, eucalyptus fast-growing wood and the like are effectively utilized, comprehensive utilization of the wood is maximized,and the cost is lowered; and the loss of equipment can further be effectively reduced, the physical and mechanical properties of the produced wiredrawing floor meet the requirements of the professional standard.

Owner:圣象地板(句容)有限公司

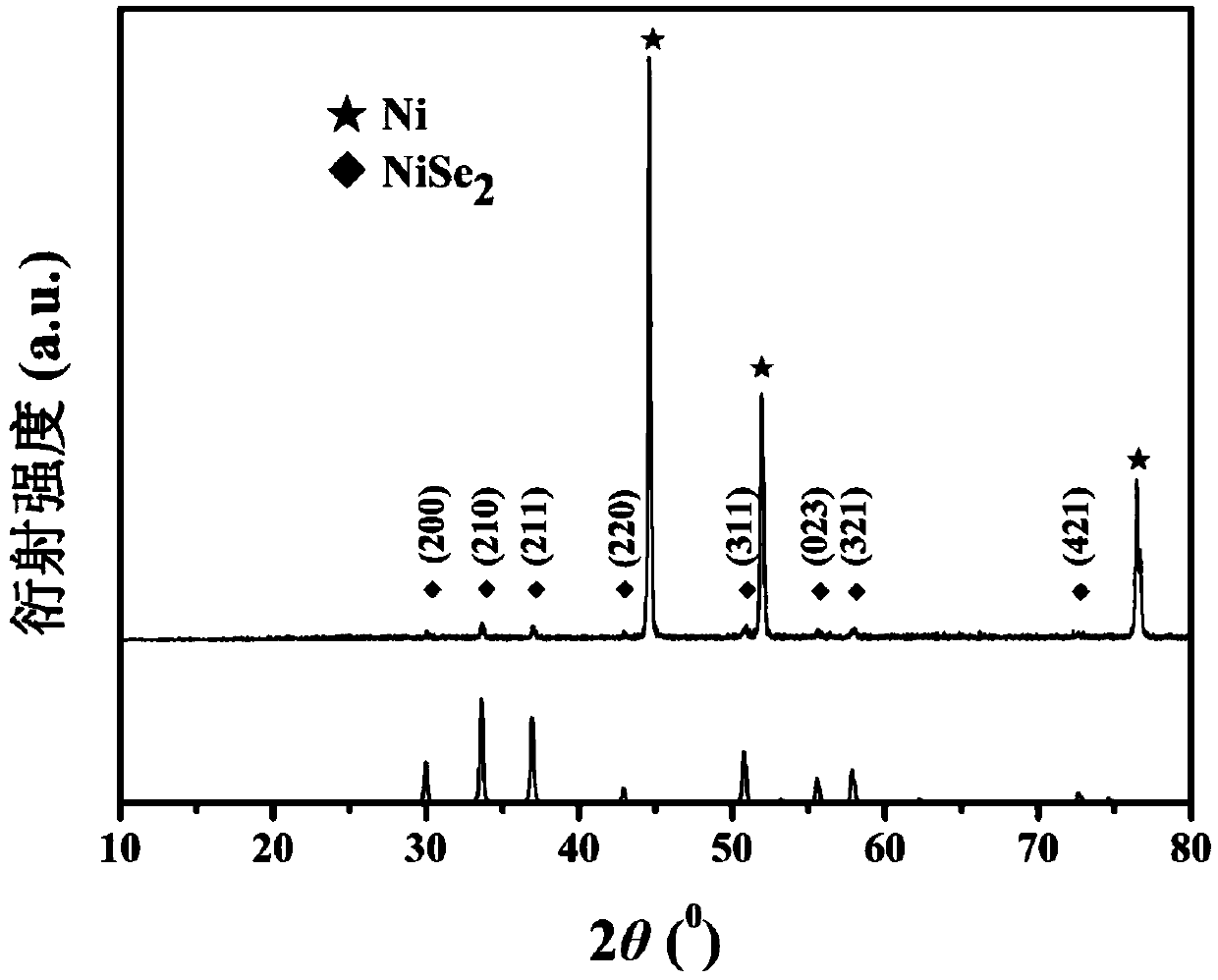

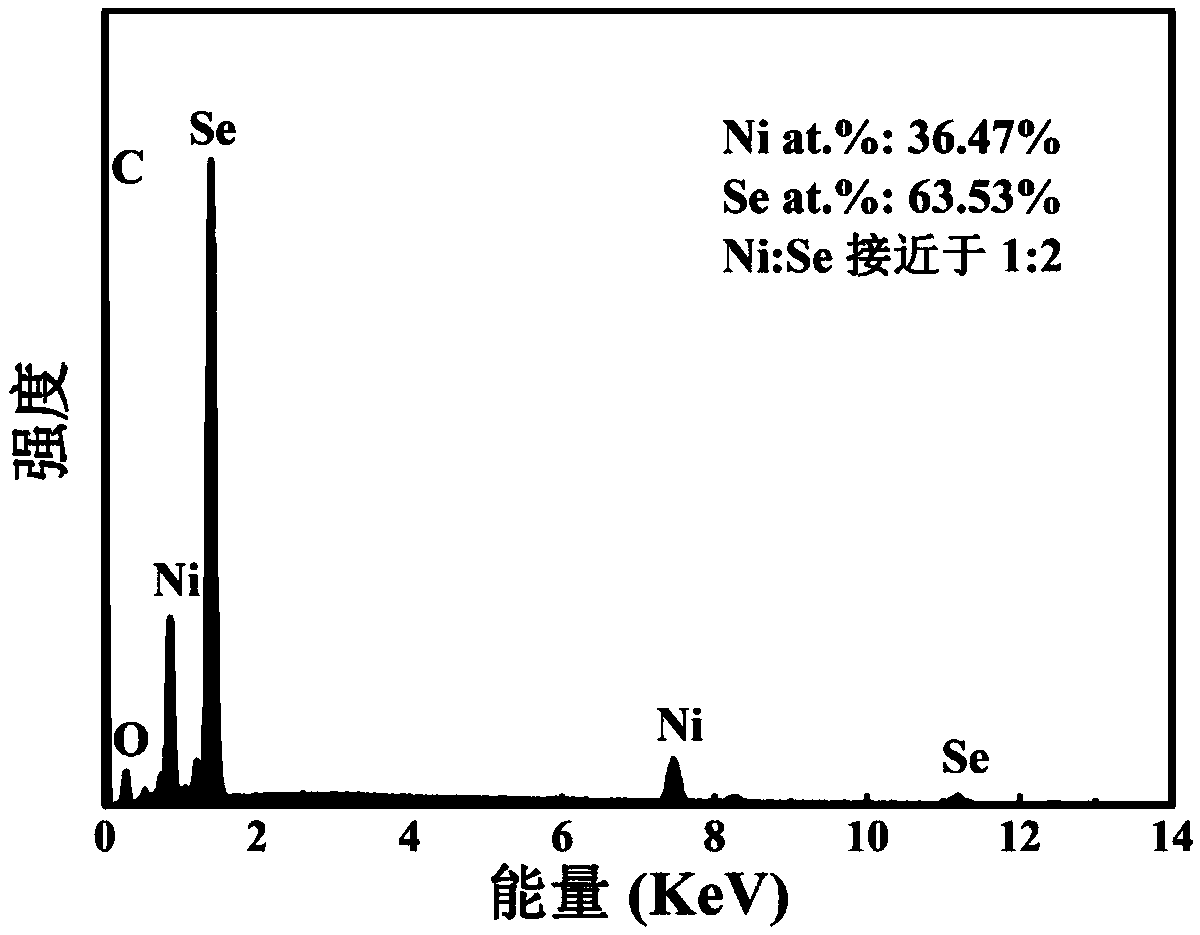

White-beech-mushroom-shaped nickel selenide 2 nano-array electrode material and preparation method thereof

ActiveCN109686592AEasy accessSave raw materialsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceReaction temperature

The invention discloses a white-beech-mushroom-shaped nickel selenide 2 nano-array electrode material and a preparation method thereof, and belongs to the technical field of supercapacitor electrode material preparation. The preparation method specifically comprises the following steps: a certain amount of selenium powder and a sodium hydroxide solution are mixed, hydro-thermal treatment is conducted in a reaction kettle with a polyphenylene liner, and thus a reaction solution is prepared; after the reaction solution is naturally cooled, pretreated foamed nickel is placed into the reaction solution for secondary hydro-thermal treatment; and the reaction temperature and time are controlled, and thus a white-beech-mushroom-shaped nickel selenide 2 nano-array can be obtained. The obtained electrode material has excellent electrochemical properties, the specific capacitance at the electric current density of 1.0 A / g can reach 2357 F / g, and the specific capacitance of the electrode materialcan still reach 1290 F / g even when the electric current density reach 5 A / g.

Owner:合肥九州龙腾科技成果转化有限公司

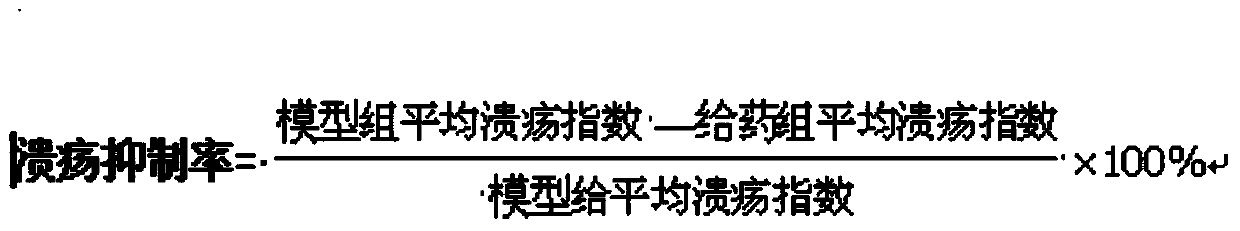

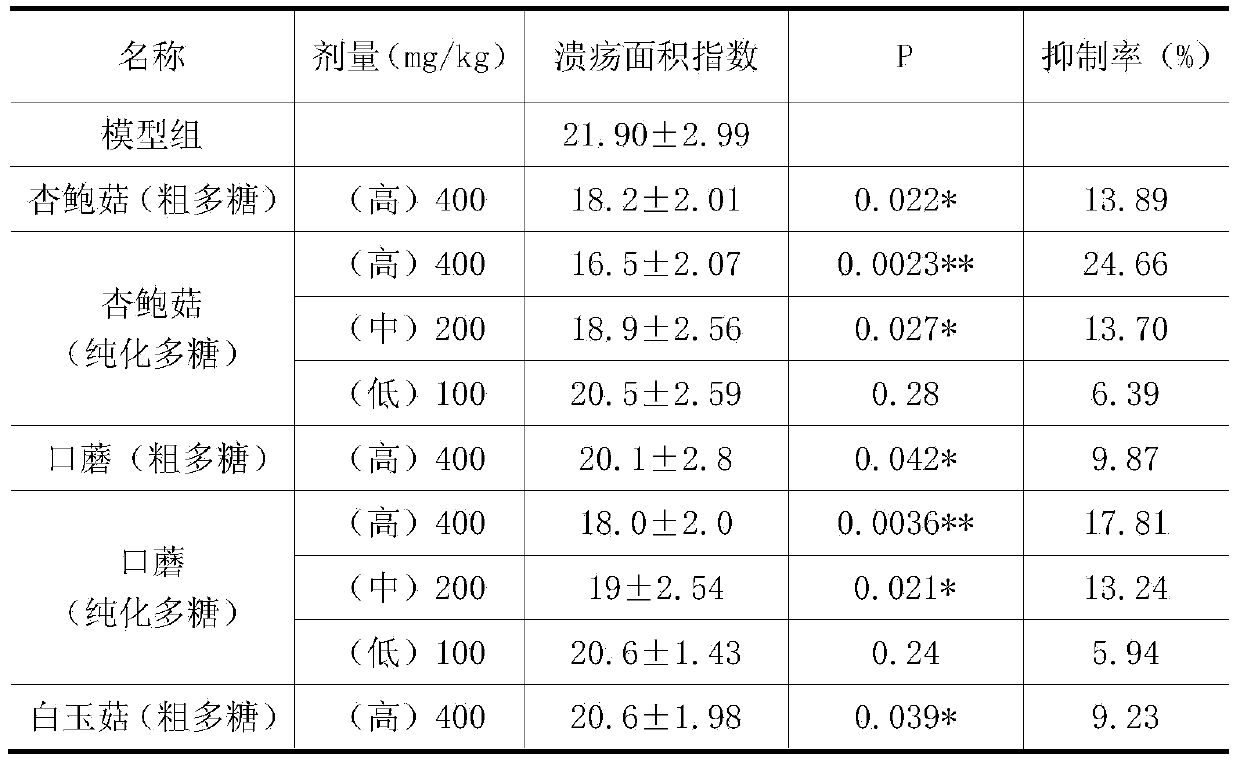

Fungal polysaccharide and composition thereof with anti-gastric ulcer effects

The invention relates to a fungal polysaccharide and a composition thereof with anti-gastric ulcer effects. According to the invention, a crude polysaccharide is obtained from fruiting bodies of pleurotus eryngii, white beech mushroom, calocybe gambosa, pleurotus citrinopileatus and hypsizygus mammoreus bigelow and the crude polysaccharide is purified with a purification method adopting a mixed pillar consisting of 717 cation exchange resin and 732 anion exchange resin; the anti-gastric ulcer effect of the purified fungal polysaccharide and the composition thereof is obviously strengthened; meanwhile, substances which possibly stimulate an immune system to generate allergy are removed, so that the fungal polysaccharide and the composition thereof are safer to use and are also beneficial to quality control of a product. According to the invention, the fungal polysaccharide and the composition thereof are proved to have obvious effects of preventing and treating gastric ulcer by experiments for the first time.

Owner:高其品

Red beech planting method

InactiveCN106069508ASmooth plantingPromote growthCultivating equipmentsHorticulture methodsBeechSeedling

The invention discloses a red beech planting method. The method sequentially includes the following steps of firstly, cultivating seedlings; secondly, transplanting the seedlings to a large field; thirdly, conducting field management, intertillage, dressing, and pruning and rectifying. By means of the method, it can be ensured that red beech can be smoothly planted and can smoothly grow; more importantly, a batch of plants which are the same in size, similar in shape and close in color can be provided, and therefore the arrangement and plantation of garden landscapes and potted landscapes can be conveniently conducted.

Owner:安徽鸿基农业科技发展有限公司

White beech mushroom spent mushroom substrate fodder for feeding finishing pigs and production process thereof

InactiveCN106306409AEasy feedingNormal growthFood processingAnimal feeding stuffBiotechnologyCorn meal

The invention provides white beech mushroom spent mushroom substrate fodder for feeding finishing pigs and a production process thereof. The white beech mushroom spent mushroom substrate fodder comprises the following raw materials of 40-50% of white beech mushroom spent mushroom substrates, 20-30% of rice bran or bran, 5-6% of corn powder, 1.5-2.0% of brown sugar, 1.0-1.5% of compound vitamin, 22-30% of water and added cellulase accounting for 0.1-0.2% of the total quantity of the raw materials of the fodder; the prepared raw materials are mixed and loaded into a fermenting device, activated bacillus subtilis powder and saccharomycetes powder mixed bacterium liquor is added into the raw materials in an inoculated mode, and airtight fermenting is carried out; according to fermenting conditions, at the early stage of fermenting, temperature is 32-37 DEG C, time is 1-2d, at the later stage of fermenting, temperature is 25-30 DEG C, time is 3-5d, and the white beech mushroom spent mushroom substrate fodder can be used for feeding after fermenting is ended. The method is short in fermenting time, and the produced fodder is high in absorbing and utilizing rate of nutritive substances, has an obvious effect on weight increase of the fed finishing pigs, and is low in cost of raw materials.

Owner:LONGYAN UNIV

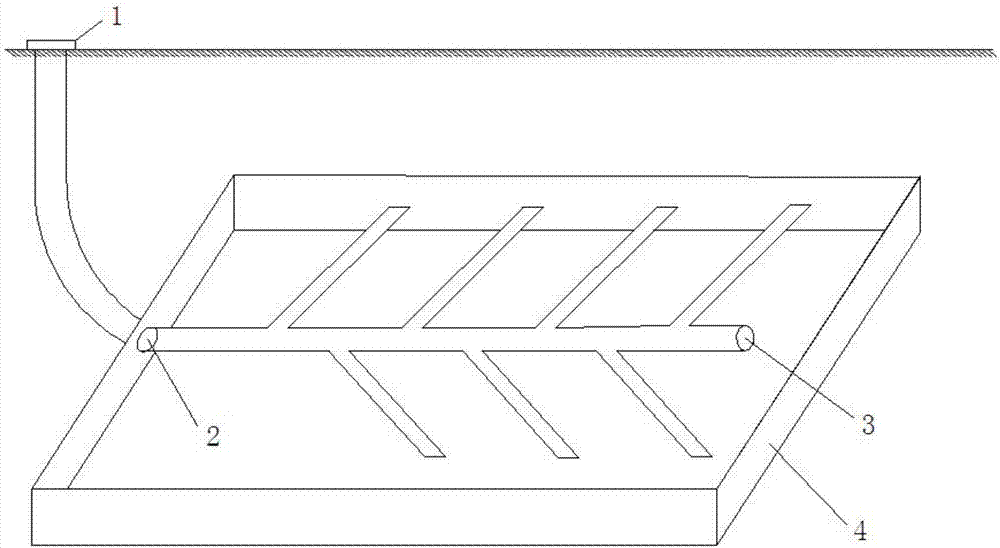

High-efficiency three-dimensional green intelligent mushroom cultivation room

PendingCN107646528ASimple methodEasy to operateCultivating equipmentsMushroom cultivationEcological environmentTricholoma

The invention provides a high-efficiency three-dimensional green intelligent mushroom cultivation room, and belongs to the field of three-dimensional intelligent mushroom cultivation in an original ecological environment under an imitating wild environment. A mushroom cultivation medium is spread on a mushroom support device in a thermal insulation cultivation room, and various fungus mushrooms oftoadstool, ycoperdon bovista, colorful mushroom, colorful lotus mushroom, shiitake, white beech mushroom, mushroom, drumstick mushroom, flammulina velutipes, red fir fungus, pleurotus cornucopiae, agrocybe cylindracea, ganoderma lucidum, hericium erinaceus, pleurotus ostreatus, tricholoma gambosum, pleurotus nebrodensis, pleurotus eryngii, flower mushroom, crab mushroom, and pleurotus geesteranusare cultivated through supplementing nutrition to the mushroom cultivation medium using the irrigation mode of infiltrating nutrient liquid from inside a nutrient supplying cavity to the outer side.The cultivation method of various mushrooms is simple and easy to operate, large-scale cultivation and industrialization are facilitated, a variety of mushrooms can be cultivated in four seasons, andthe supply of all kinds of mushrooms in the market in four seasons is ensured; the cultivated mushrooms are high in production yield, good in quality, and high in commercial value of industrialization; the mushroom cultivation medium can be repeatedly used for cultivating mushrooms, and the cost of mushroom cultivation is reduced.

Owner:黄为

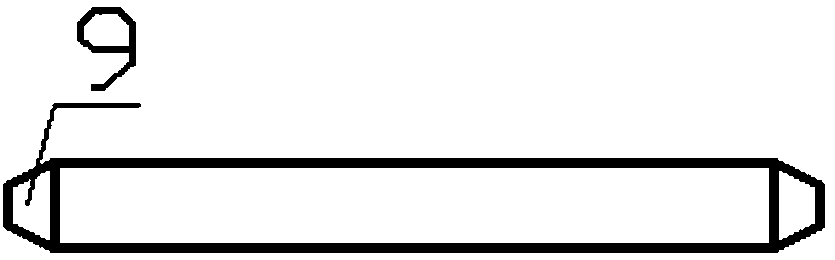

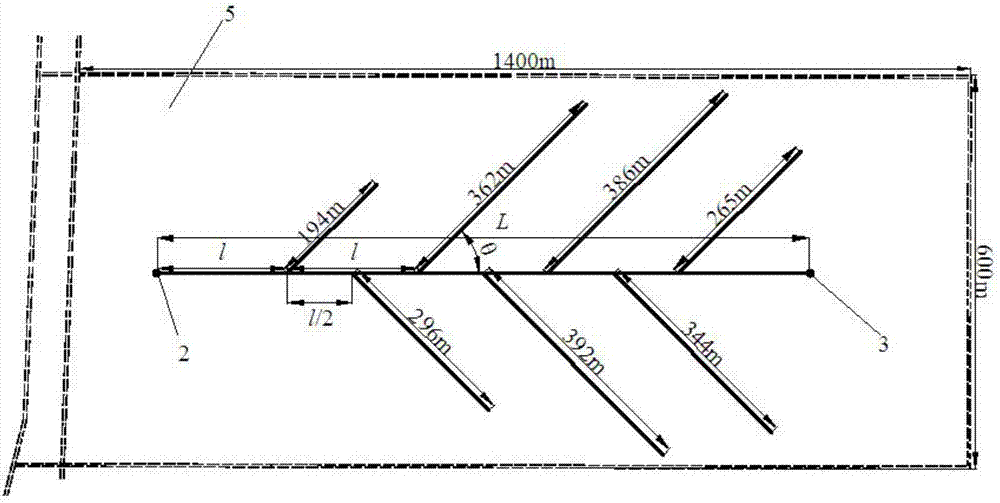

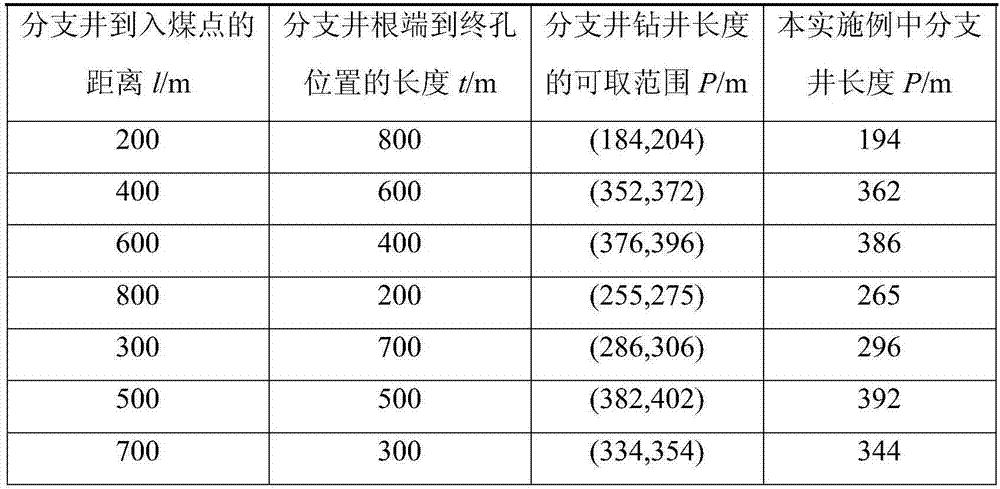

Well drilling arrangement method for extracting gas by imitating beech leaf vein structure

InactiveCN107339093ALess gushEliminate outstanding hazardsFluid removalGas removalWell drillingBeech

The invention provides a well drilling arrangement method for extracting gas by imitating a beech leaf vein structure, and relates to the technical field of mine gas harnessing and utilizing. The well drilling arrangement method for extracting the gas by imitating the beech leaf vein structure conducts arrangement on a gas extraction drill hole by imitating the arrangement mode of a beech leaf vein in a leaf blade and mainly comprises the following steps that 1, the position of a well mouth of well drilling is selected; 2, construction is conducted on a main well of gas extraction well drilling by imitating the beech leaf vein structure; and 3, construction is conducted on branched wells of gas extraction well drilling by imitating the beech leaf vein structure. According to the well drilling arrangement method for extracting the gas by imitating the beech leaf vein structure, the positions of the main well and the branched wells are arranged according to the beech leaf vein structure, the range met by the well drilling lengths of the branched wells is given, and the well drilling construction length is reasonably reduced; and high-efficiency outburst elimination on a low-permeability coal seam is achieved, the coal seam gas extraction efficiency is improved, the gas emission quantity of a working face is reduced, the dangerousness of a coal seam outburst is eliminated, and the coal mine production safety is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY +1

Production method of special highly-moisture-proof intermediate-density fiber board for office table

InactiveCN109129755ALow costTo achieve the purpose of sizing and water resistanceWood treatment detailsWood veneer joiningFiberThiourea

The invention discloses a production method of a special highly-moisture-proof intermediate-density fiber board for an office table. The method comprises the following steps: (1) preprocessing raw materials; (2) screening; (3) digesting to soften; (4) grinding; (5) applying glue, and drying; (6) pre-pressing; (7) thermally pressing; (8) sawing and sanding; (9) clinging to the surface, and thermally pressing; and (10) cutting the edge to obtain the special board for the office table. According to the method, eucalyptus bark, branches and waste leftovers in board manufacturing are treated as main raw materials; miscellaneous woods such as pine wood, basswood, briar wood, fraxinus mandshurica, beech wood, acer mono wood and lauan wood are added; the wastes are turned into treasures; and the wood resource is fully effectively utilized; hydrogenated rosin and thiourea are added to a moisture-proof urea resin adhering agent, so that the board has the advantages of being environmentally friendly, low in formaldehyde, and outstanding in moisture-proofing performance. The board is outstanding in moisture-proofing performance, high in water resistance, low in formaldehyde content, high in intensity, and high in durability, and is a safe and environmentally-friendly board.

Owner:广西横州丽冠环保材料有限公司

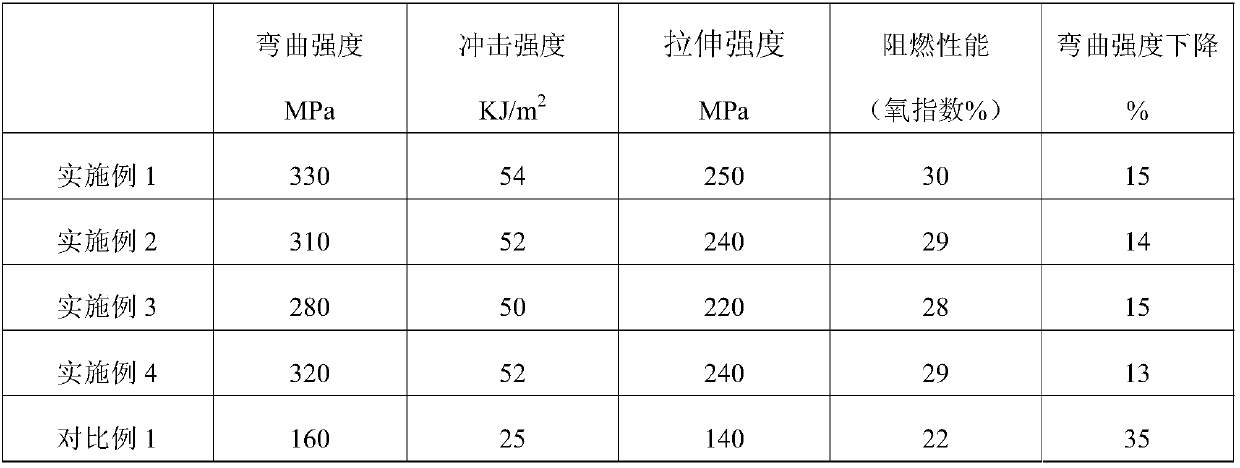

Wood plastic clothes rack and manufacturing process thereof

The invention provides a wood plastic clothes rack and a manufacturing process thereof, relating to the technical field of clothes rack processing. The wood plastic clothes rack comprises the following raw materials in parts by weight: 40-50 parts of beech powder, 10-20 parts of lignum cinnamomi camphorae powder, 20-40 parts of waste plastics, 5-20 parts of modified basalt fibers, 3-10 parts of glass fibers, 5-10 parts of magnesium hydroxide, 0.1-1 part of a heat stabilizer, 0.1-1 part of a lubricant, 0.1-1 part of a solubilizer and 1-5 parts of nano-zinc oxide. According to the wood plastic clothes rack provided by the invention, toughness, strength and flame retardance are improved, the rack has fragrance of lignum cinnamomi camphorae, damage caused by worms can be prevented, and air inthe wardrobe can be improved, so that the cost is further lowered, and forest resources are saved favorably.

Owner:广西荔浦安吉利木业有限公司

White beech mushroom cultivation technology

InactiveCN110192494AMaintain storabilityImprove yield and qualityCultivating equipmentsMushroom cultivationInsect pestPolypropylene

The invention discloses a white beech mushroom cultivation technology, and relates to the field of the edible mushroom cultivation and production process. According to the white beech mushroom cultivation technology, a medium comprises, by mass, 48% of cottonseed hull, 35% of wood dust, 10% of bran, 5% of corn flour, 1% of lime, 1% of soybean meal and 62% of water. The technology includes the following steps of S1, detecting a cultivation material, wherein it is ensured that the cultivation material is dry, fresh, free of mildew and insect pests, proper in grain size and uniform in thickness;S2, conducting bagging, wherein a polypropylene plastic bag with the specification of 18 cm*35 cm is used for cultivation, the bag is automatically filled with the material through a bagging machine,it is required that the bagging height is 18 cm, the bag weight is 1250+ / -50 g, the filling tightness is higher on the upper side and lower on the lower side and the material surface is level and freeof inclination, and a central hole is formed through an automatic hole forming bar. Through the white beech mushroom fungus strain running cultivation and fruiting management production process, reasonable harvesting at proper time is realized, and the uneven quality problems are solved that according to the white beech mushroom yield in part of factories, mushrooms become yellow and cannot be stored for a long time, tumor covers exist on mushroom caps and mushroom stalks are not uniform in thickness.

Owner:江苏友康生态科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com