Patents

Literature

2380 results about "Xylanase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xylanase (EC 3.2.1.8) is any of a class of enzymes that degrade the linear polysaccharide xylan into xylose, thus breaking down hemicellulose, one of the major components of plant cell walls. As such, it plays a major role in micro-organisms thriving on plant sources for the degradation of plant matter into usable nutrients. Xylanases are produced by fungi, bacteria, yeast, marine algae, protozoans, snails, crustaceans, insect, seeds, etc.; mammals do not produce xylanases. However, the principal commercial source of xylanases is filamentous fungi.

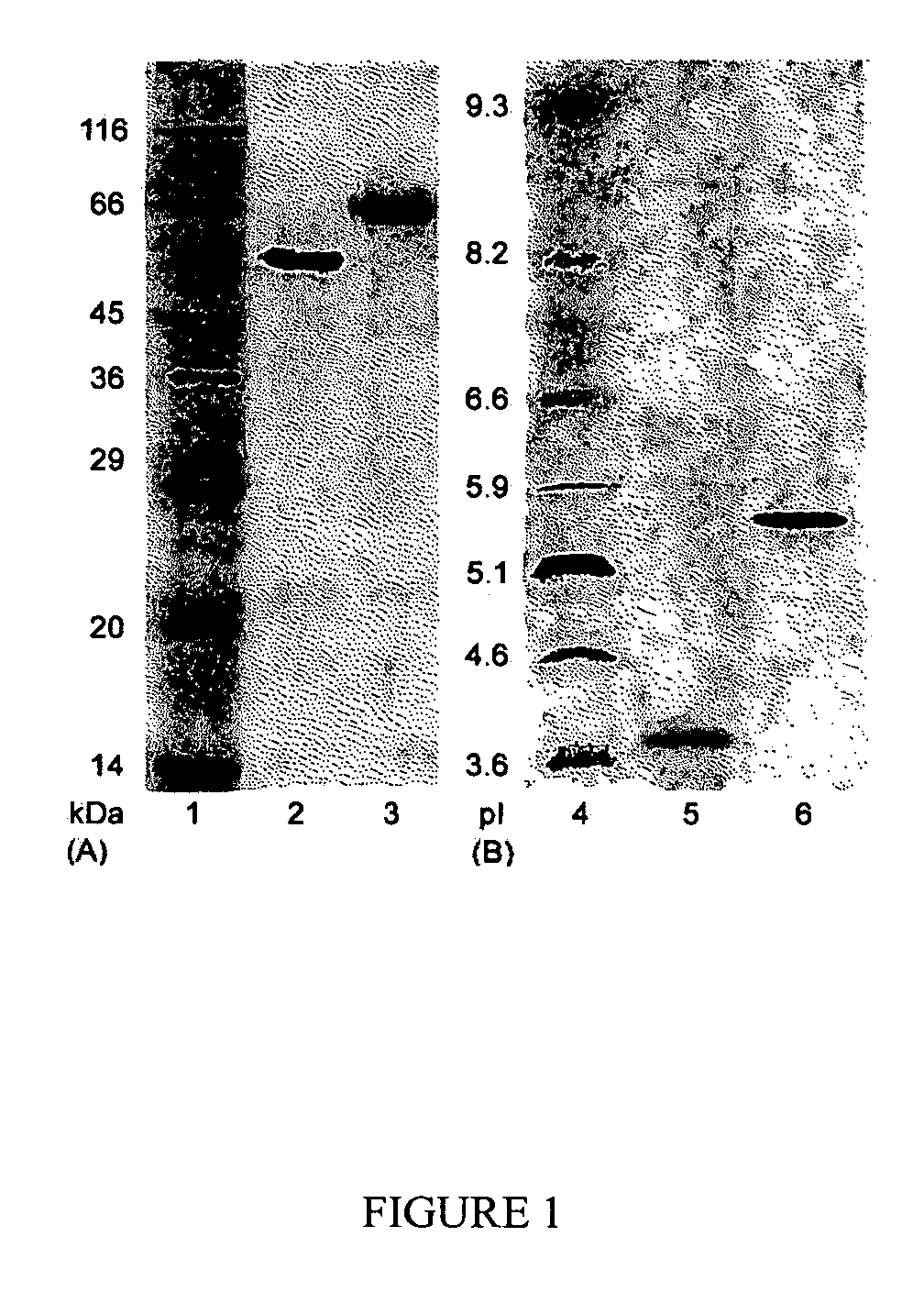

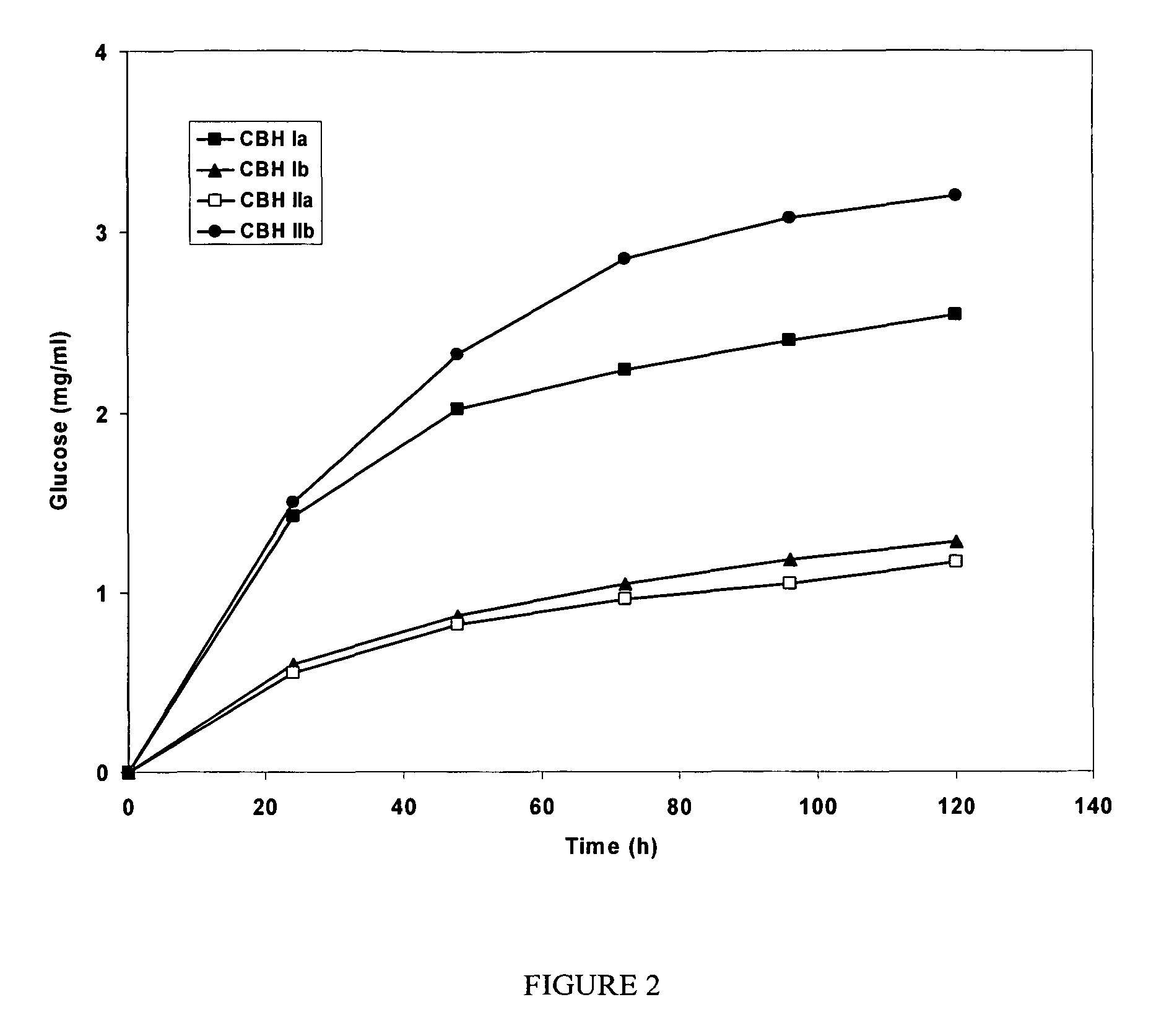

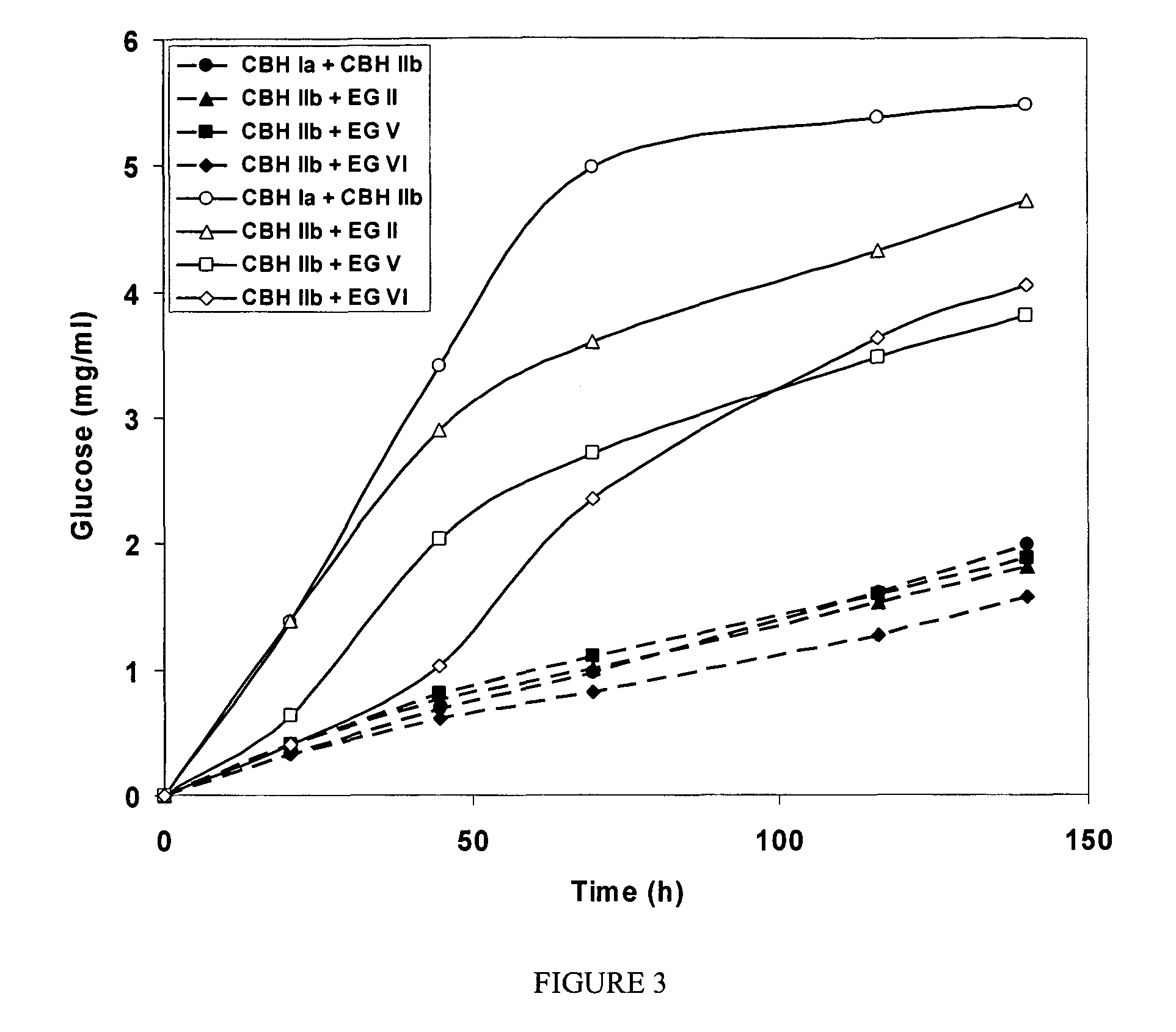

Construction of highly efficient cellulase compositions for enzymatic hydrolysis of cellulose

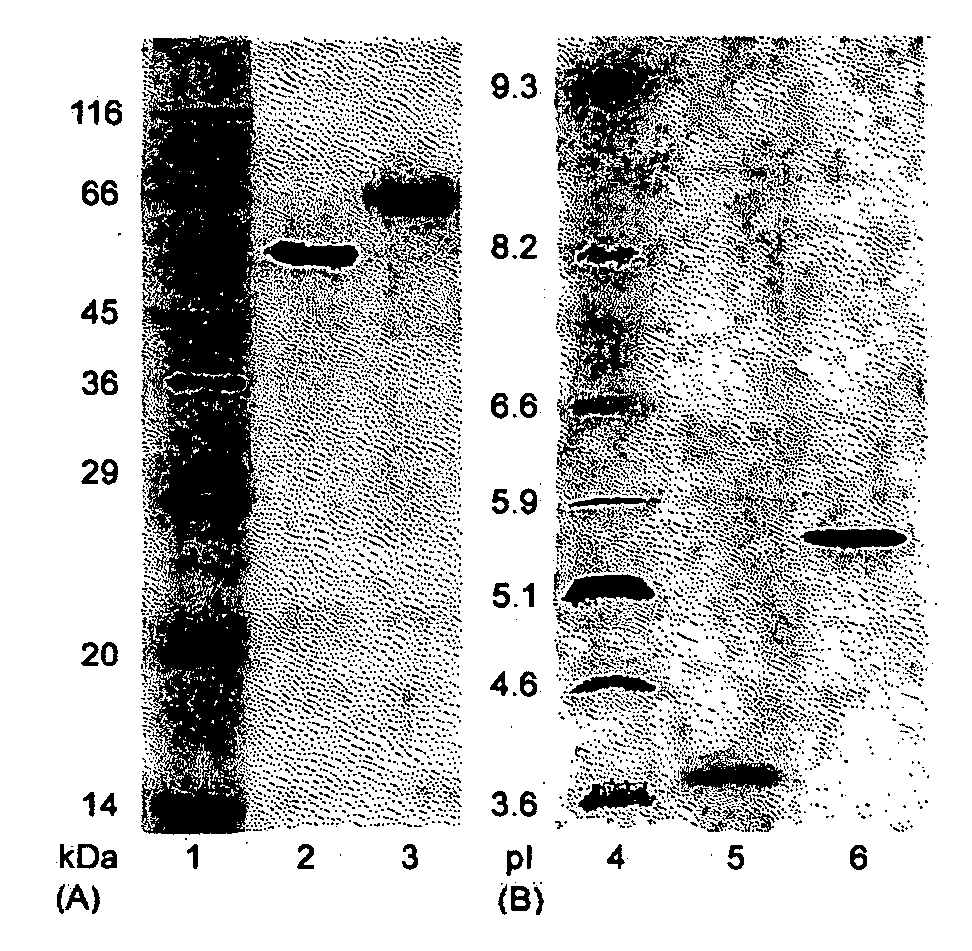

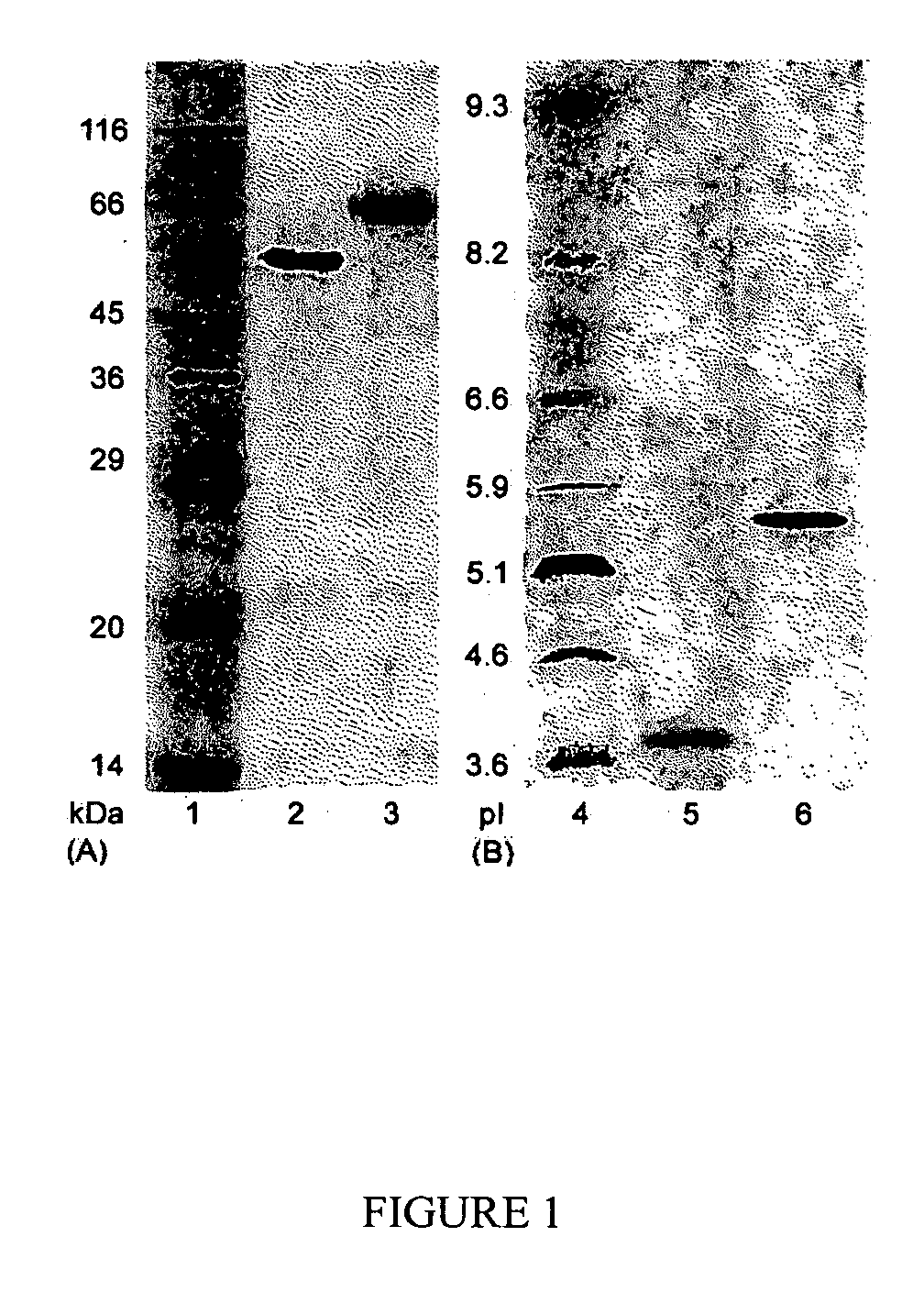

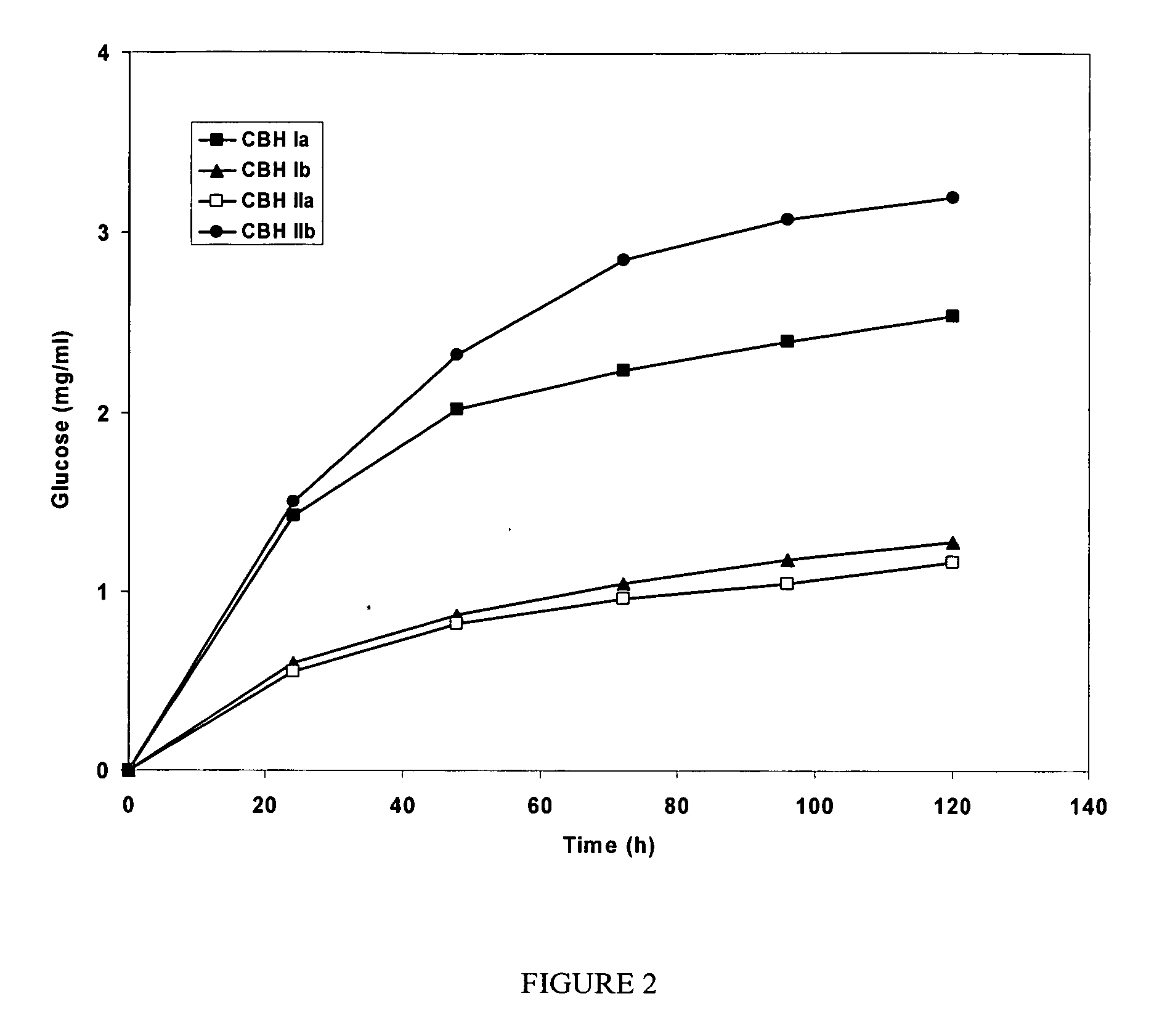

This invention provides novel enzyme compositions using newly identified and isolated C. lucknowense enzymes, including CBH Ib CBH IIb, EG II, EG VI, β-glucosidase, and xylanase II in conjunction with previously identified enzymes CBH Ia, CBH IIa (previously described as Endo 43), and EG V. These enzyme compositions demonstrate an extremely high ability to convert lignocellulosic biomass (e.g., Avicel, cotton, Douglas fir wood pretreated by organosolv) to glucose. CBH Ia and IIb, which both have a cellulose-binding module (CBM) displayed a pronounced synergism with three major endoglucanases (EG II, EG V, EG VI) from the same fungus in hydrolysis of cotton as well as a strong synergy with each other. The enzyme compositions are effective in hydrolysis of the lignocellulosic biomass.

Owner:DANISCO US INC

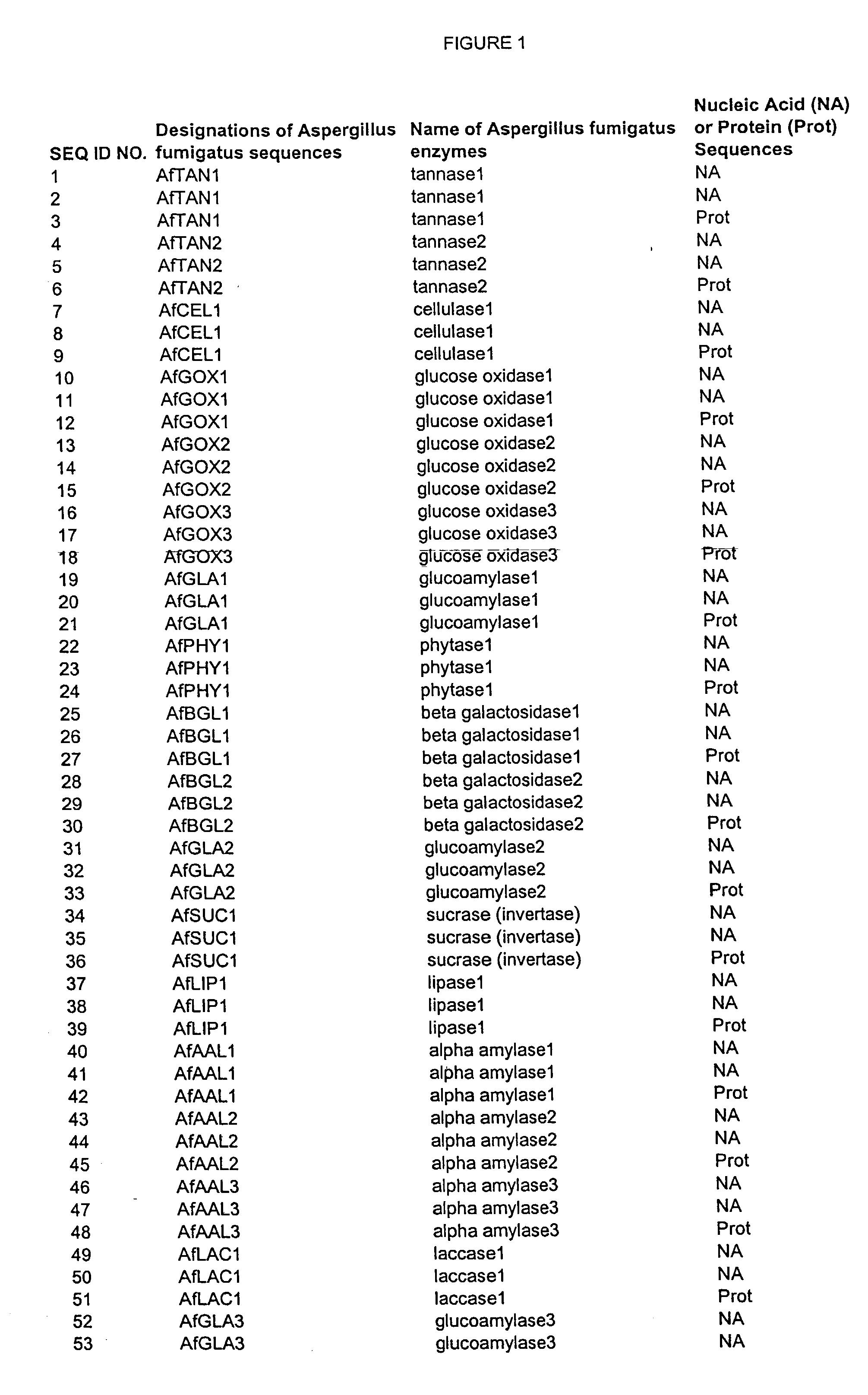

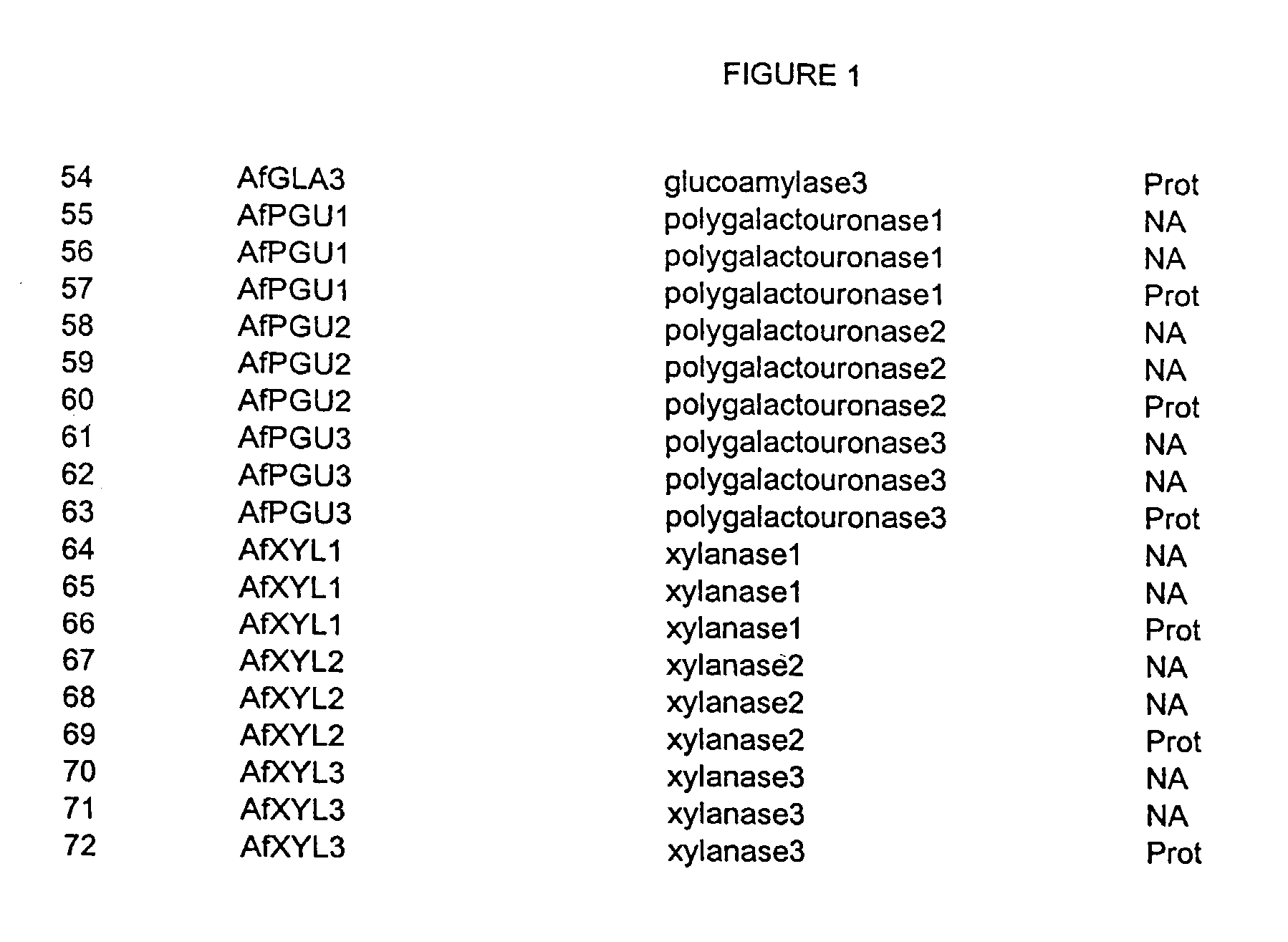

Nucleic acids of aspergillus fumigatus encoding industrial enzymes and methods of use

The present invention provides nucleotide sequences of Aspegillus fumigatus that encode proteins which exhibit enzyme activities. Vectors, expression constructs, and host cells comprising the nucleotide sequences of the enzyme genes are also provided. The invention further provides methods for producing the enzymes, and methods for modifying the enzymes in order to improve their desirable characteristics. The activities displayed by the enzymes of the invention include those of a tannase, cellulase, glucose oxidase, glucoamylase, phytase, beta-galactosidases, invertase, lipase, alpha-amylase, laccase, polygalacturonase or xylanase. The enzymes of the invention can be used in a variety of industrial processes. Enzymatically active compositions in various forms as well as antibodies to the enzymes and fragments thereof, are also provided.

Owner:MERCK & CO INC

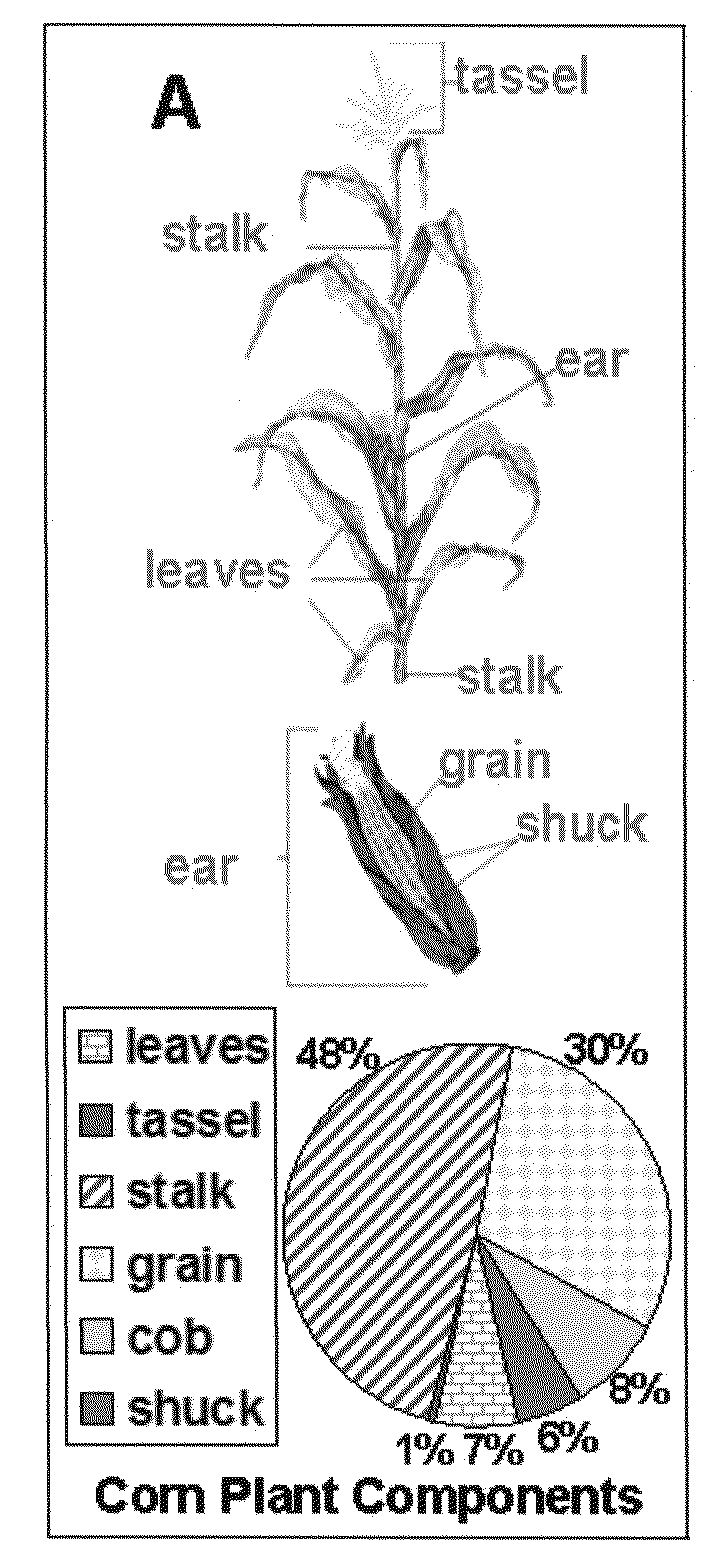

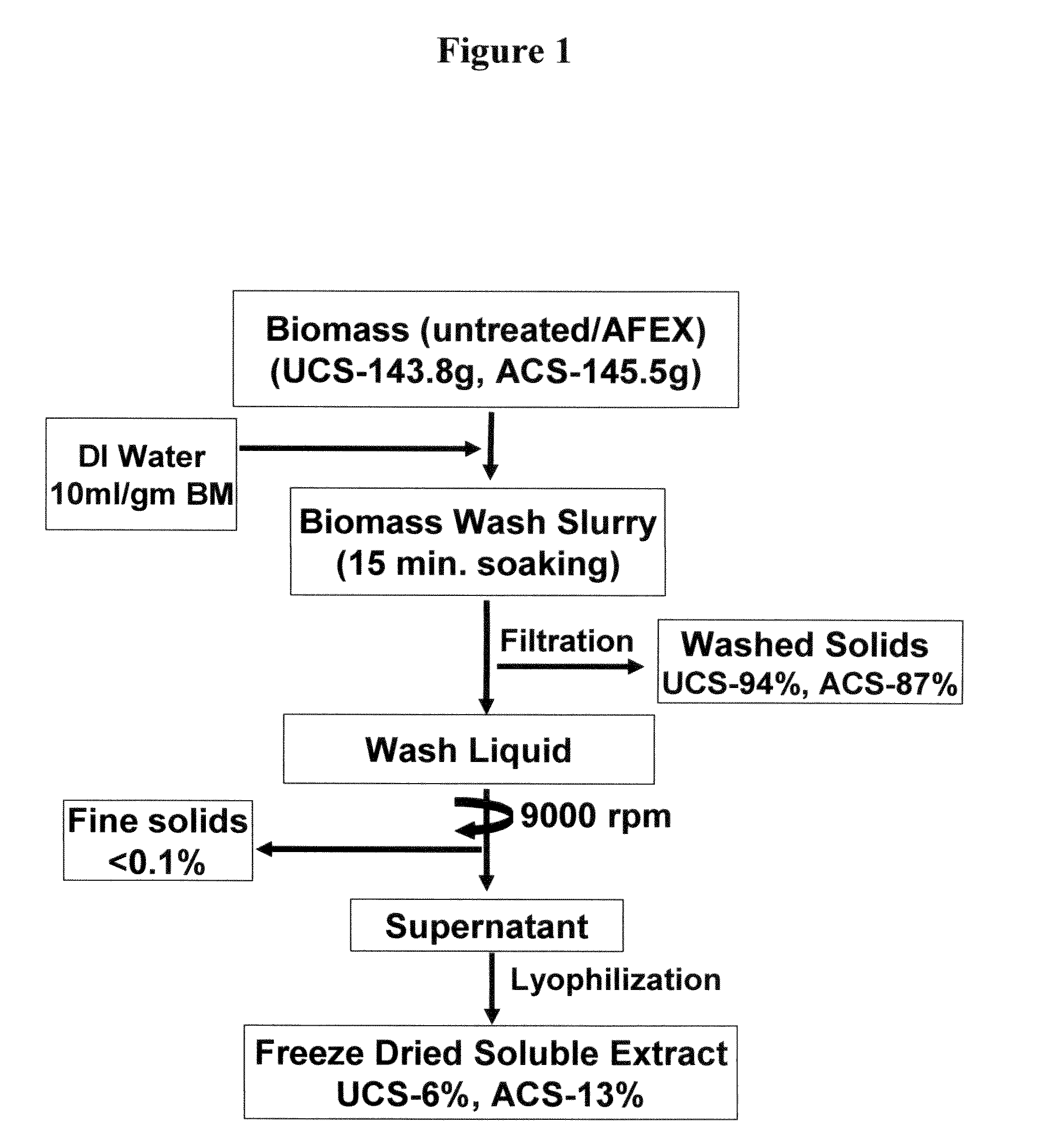

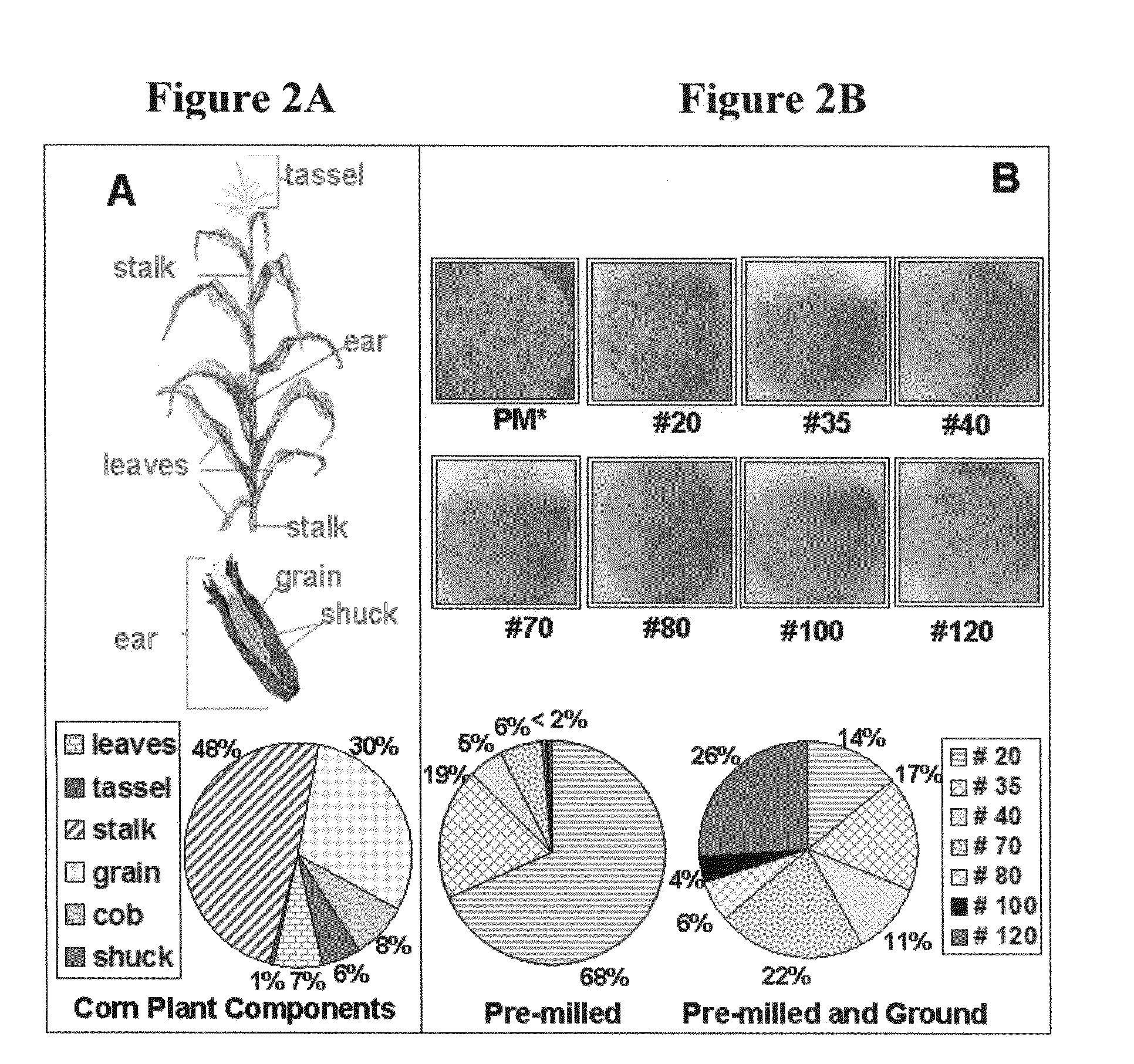

Process for enzymatically converting a plant biomass

The present invention describes a process for at least a 90% conversion of a plant biomass preferably by a reduction of the units of cellulase needed and by using a xylanase which acts synergistically with the cellulase to improve the yield of xylose and glucose as sugars. The process enables greater conversion of a lignocellulosic plant biomass to glucose and xylose for use as animal feeds and as fermentation as medium for producing ethanol.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

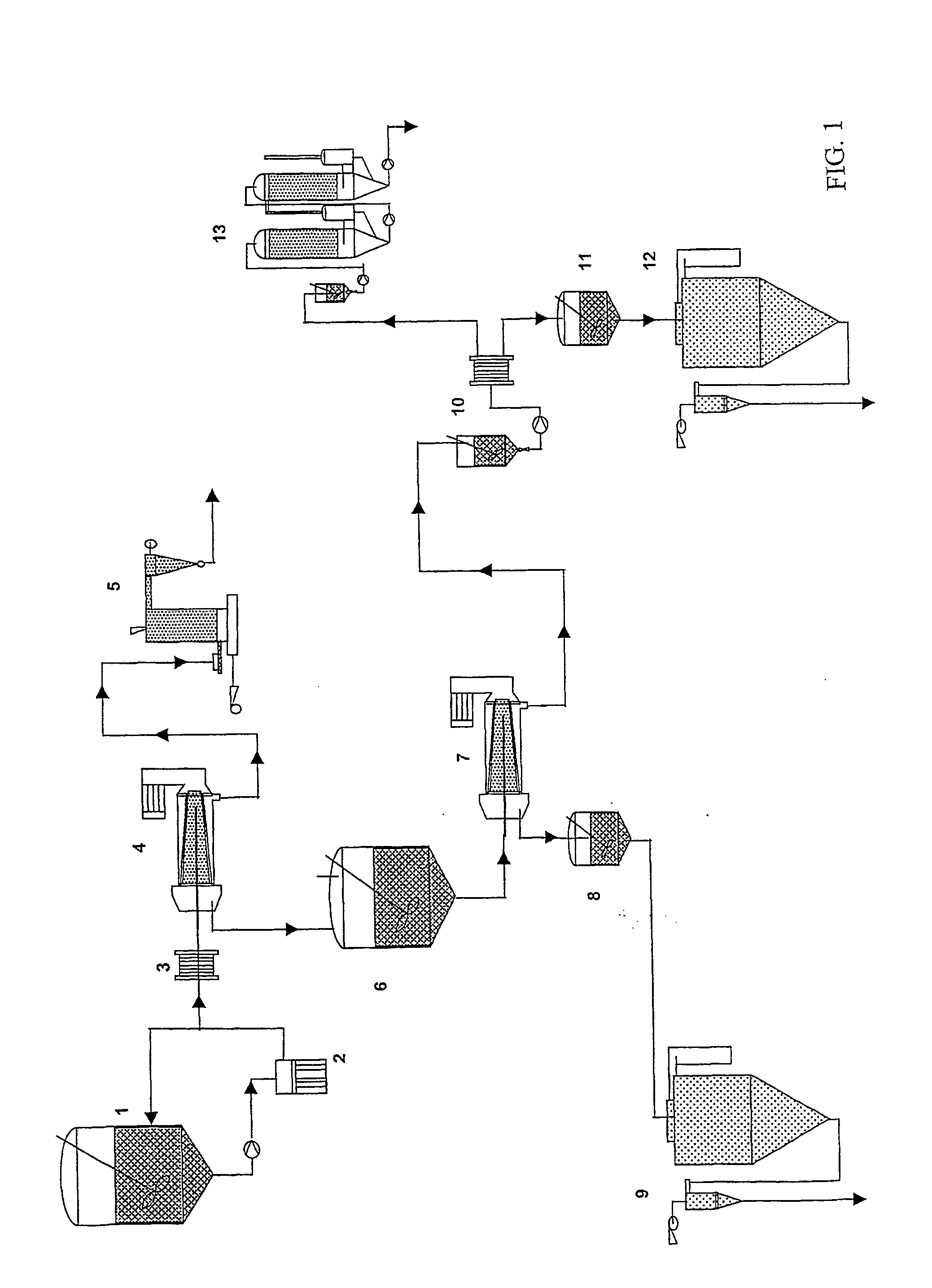

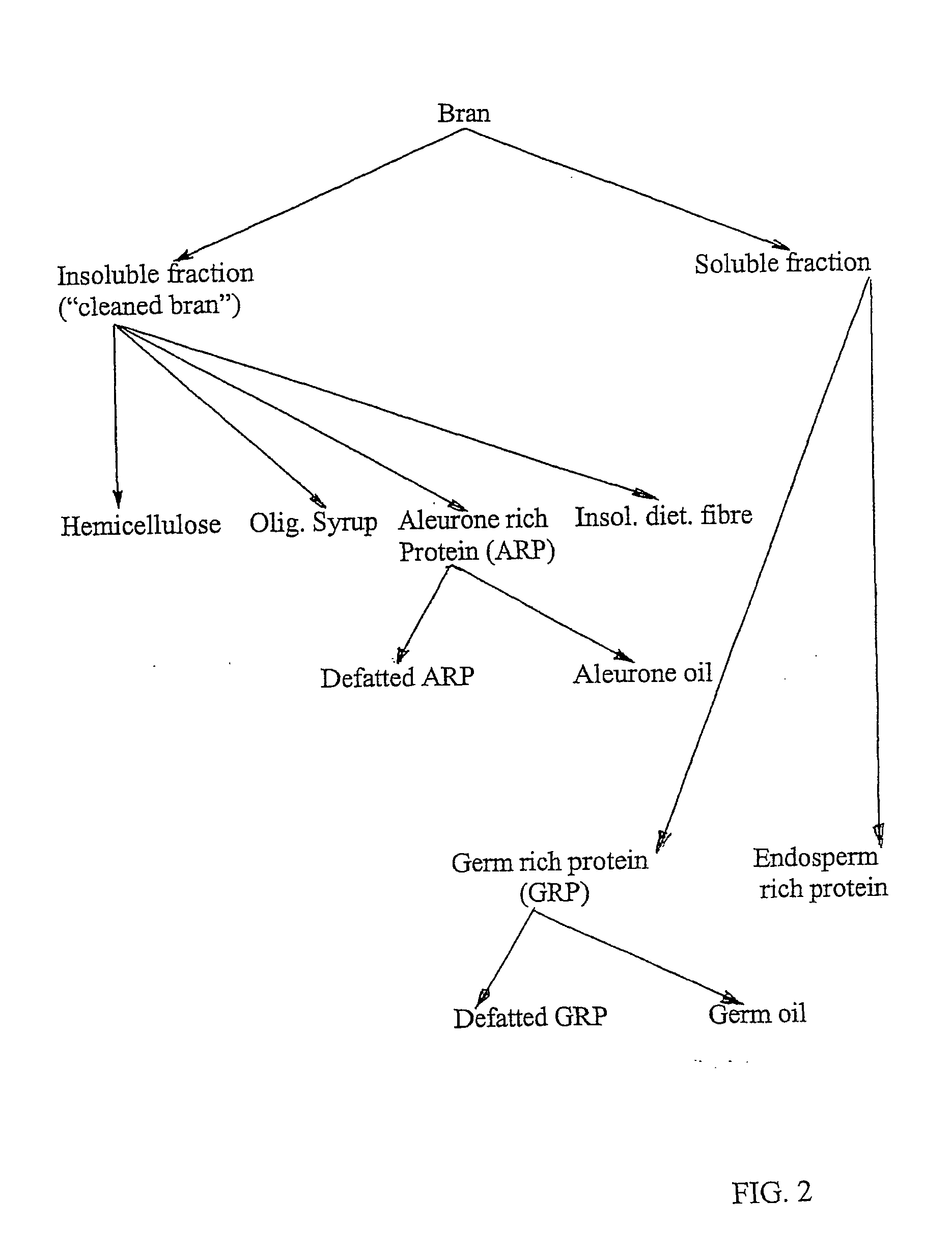

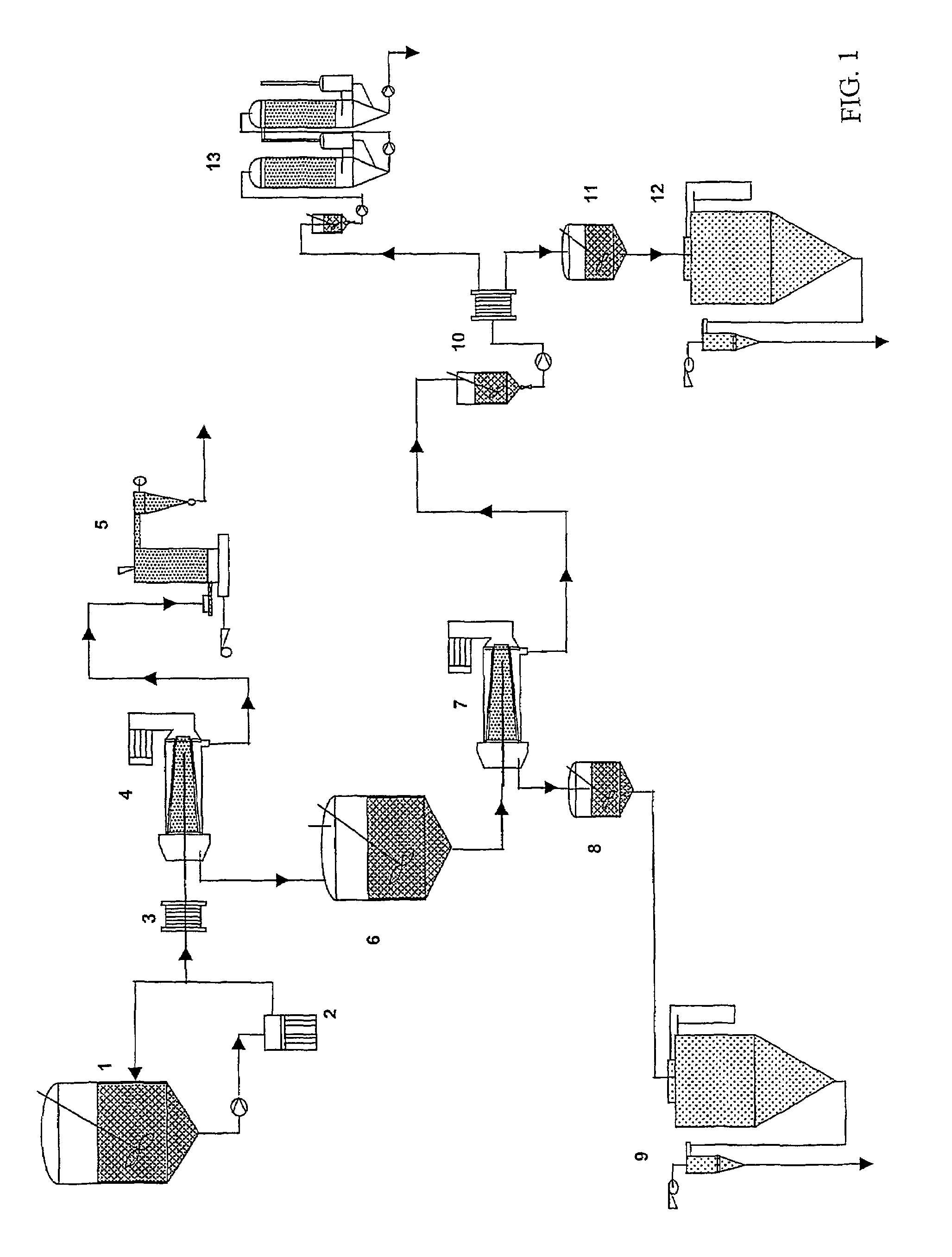

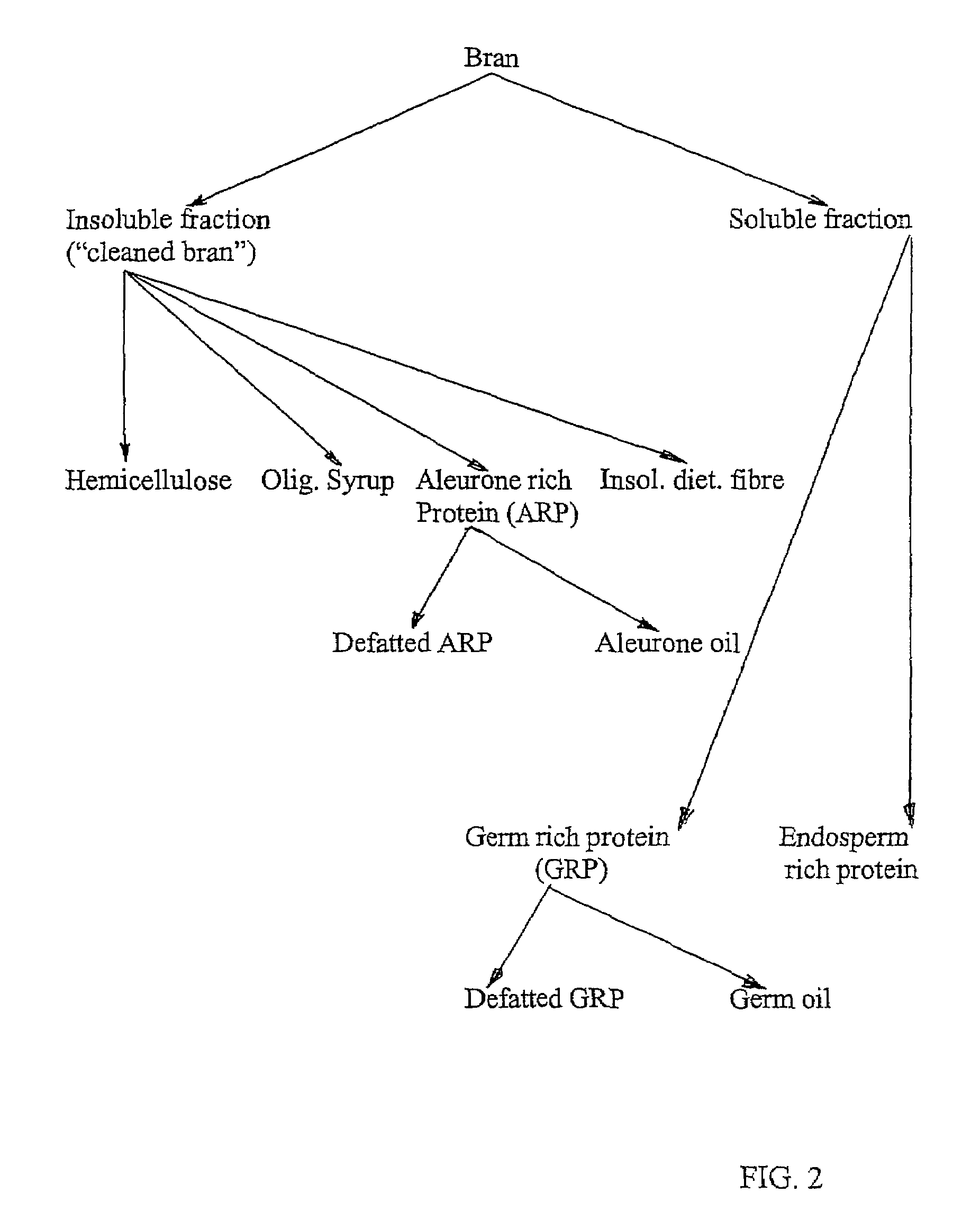

Process for the fractionation of cereal brans

InactiveUS20050089602A1Minimal contaminationImprove efficiencyTea extractionProtein composition from vegetable seedsUltrafiltrationHordeum vulgare

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

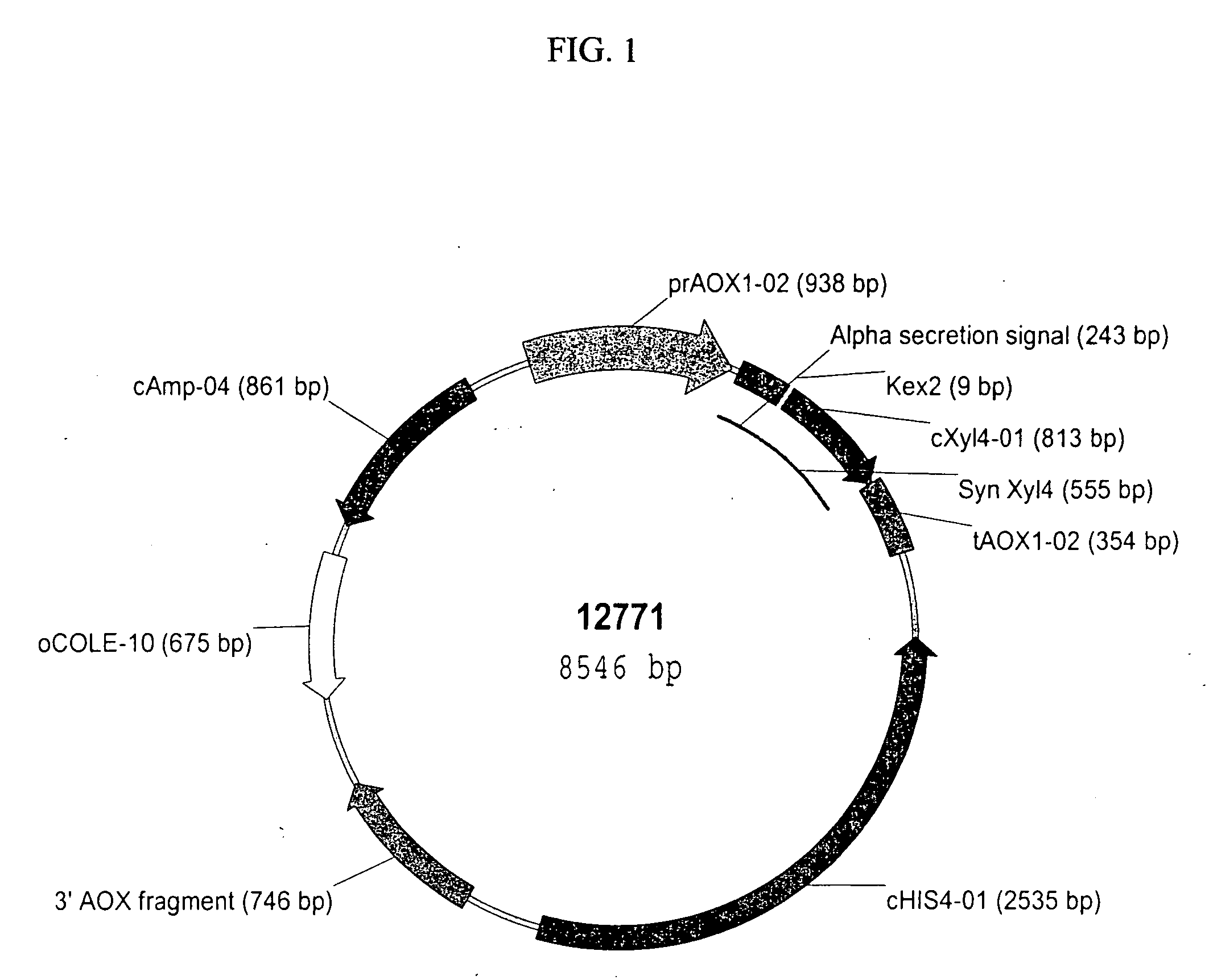

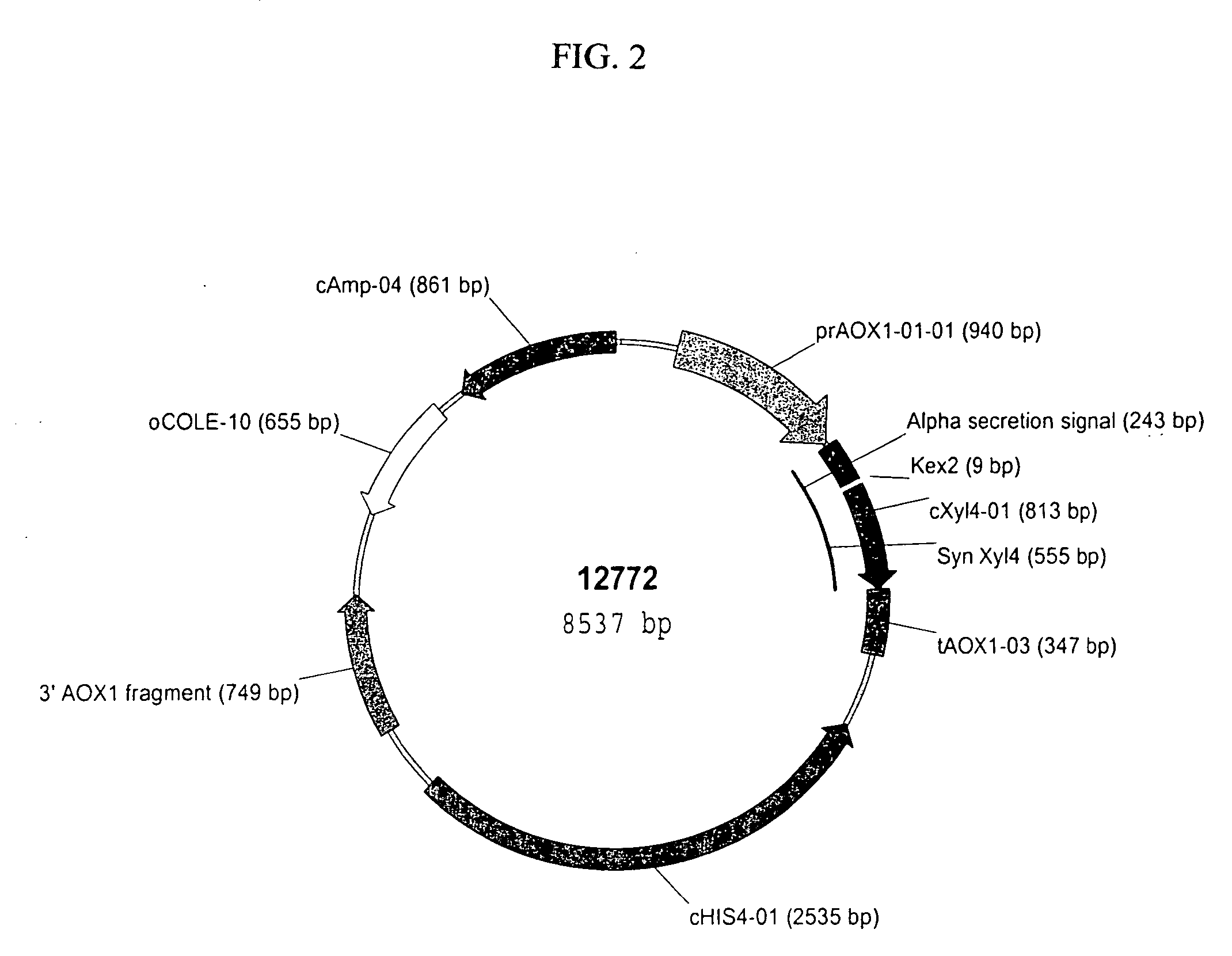

Microbially expressed xylanases and their use as feed additives and other uses

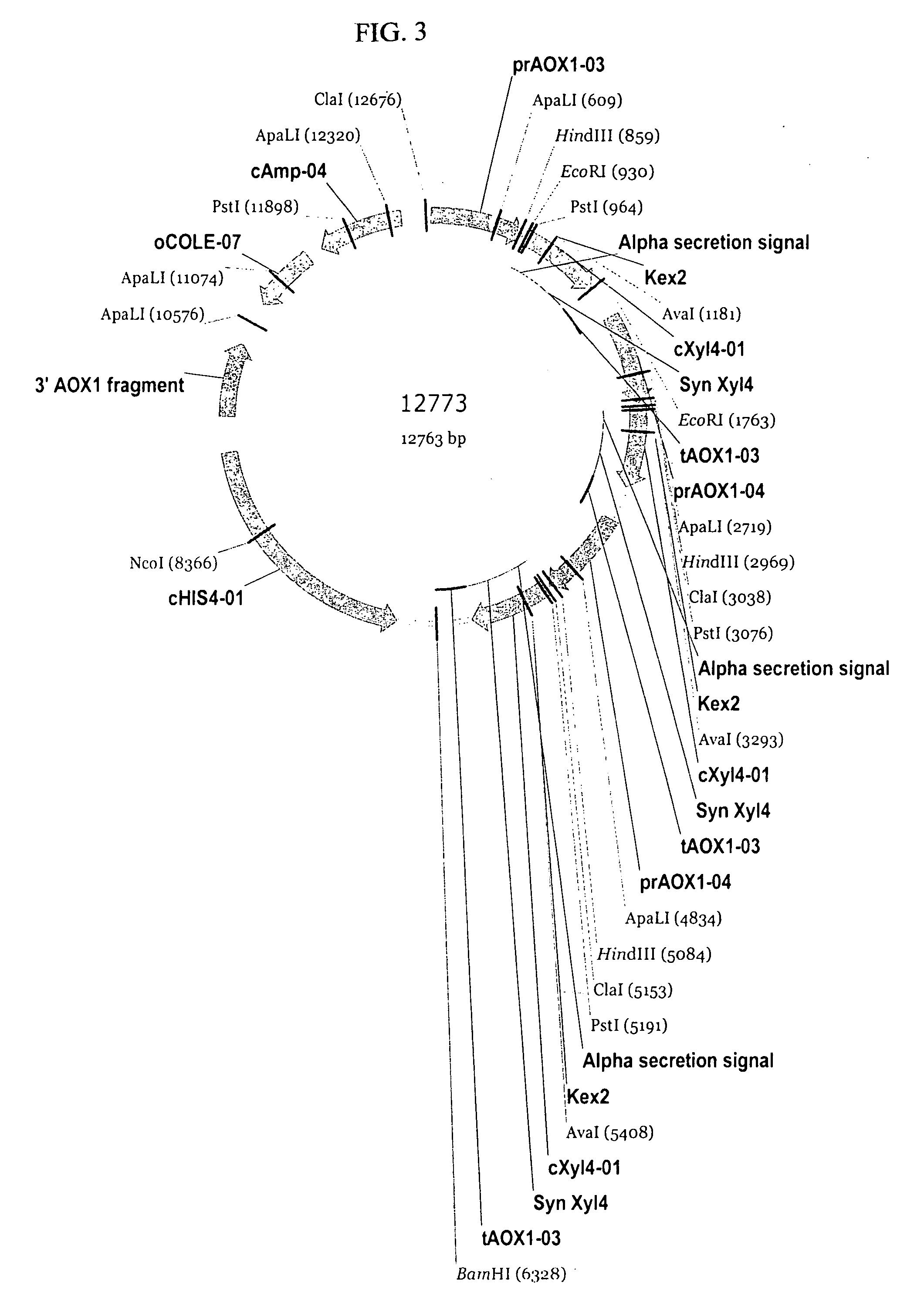

The present invention relates to codon-optimized xylanase coding sequences and the expression of xylanases in microbes and yeast. The invention further relates to using multiple copies of the xylanase expression construct for high levels of protein expression. The invention also relates to the use of xylanases as feed or food additives. The invention also relates to methods of expression of enzymes to increase thermotolerance by expressing them in organisms that glycosylate proteins compared to expression that the same enzyme without the glycosylation. Further, the invention relates to methods of preparing feed, enzyme feed additives, and methods of reducing the feed conversion ration or increasing weight gain of animals.

Owner:SYNGENTA PARTICIPATIONS AG

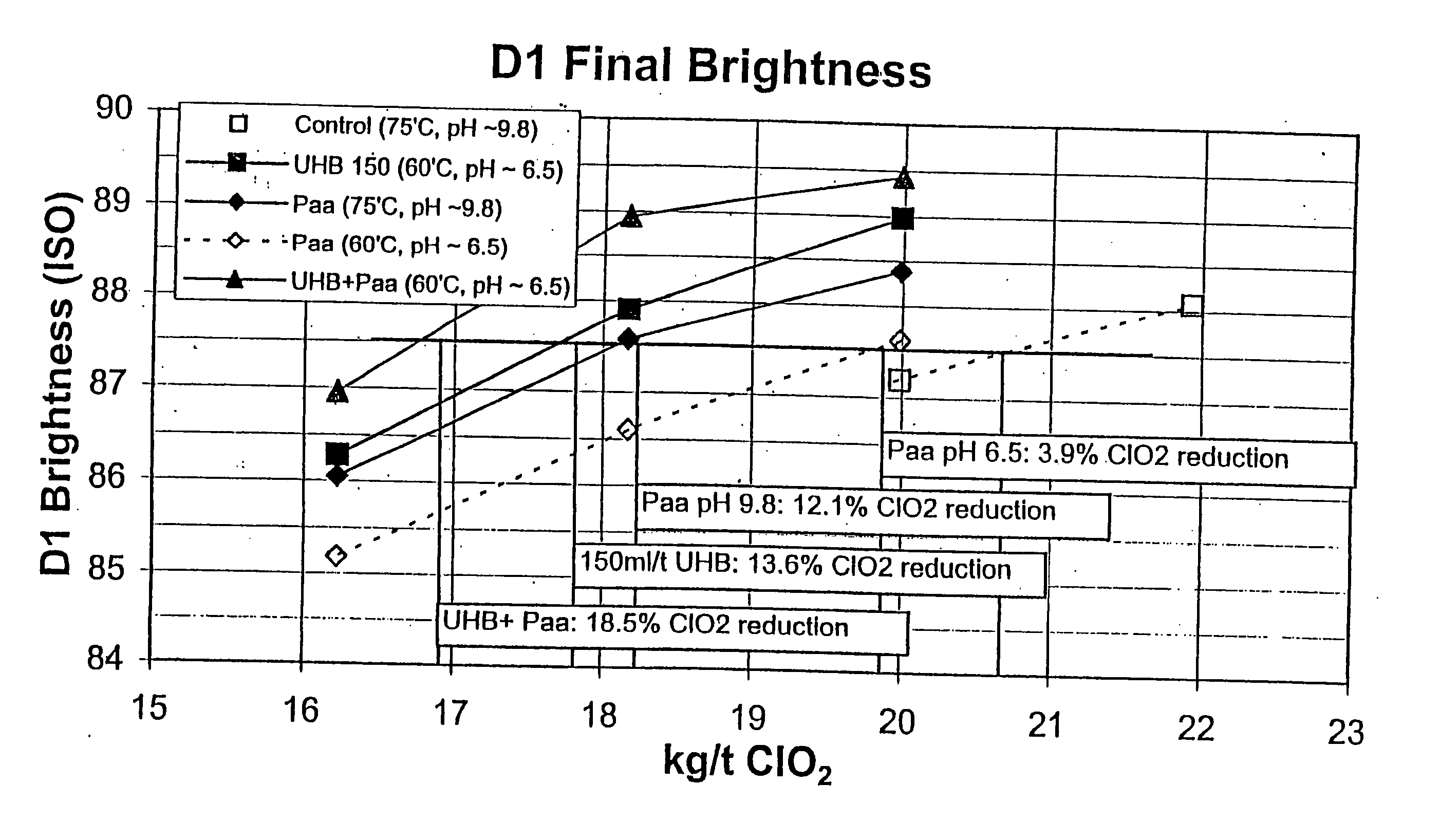

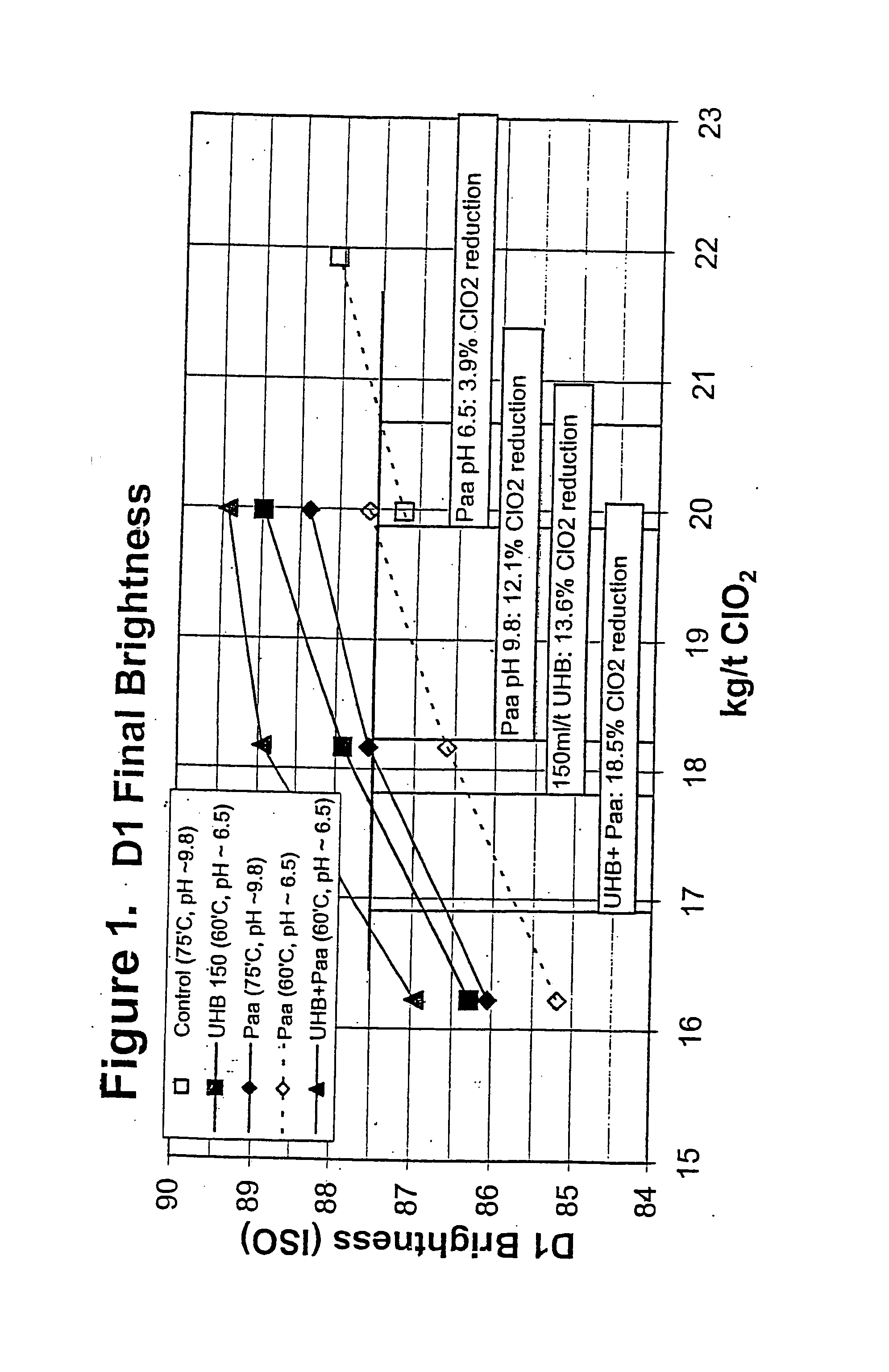

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

Xylanases, nucleic acids encoding them and methods for making and using them

InactiveUS20060003433A1Low viscosityIncrease profitBacteriaAntibody mimetics/scaffoldsXylanase YIncrease ph

The invention relates to xylanases and to polynucleotides encoding the xylanases. In addition, methods of designing new xylanases and methods of use thereof are also provided. The xylanases have increased activity and stability at increased pH and temperature.

Owner:BP CORP NORTH AMERICA INC

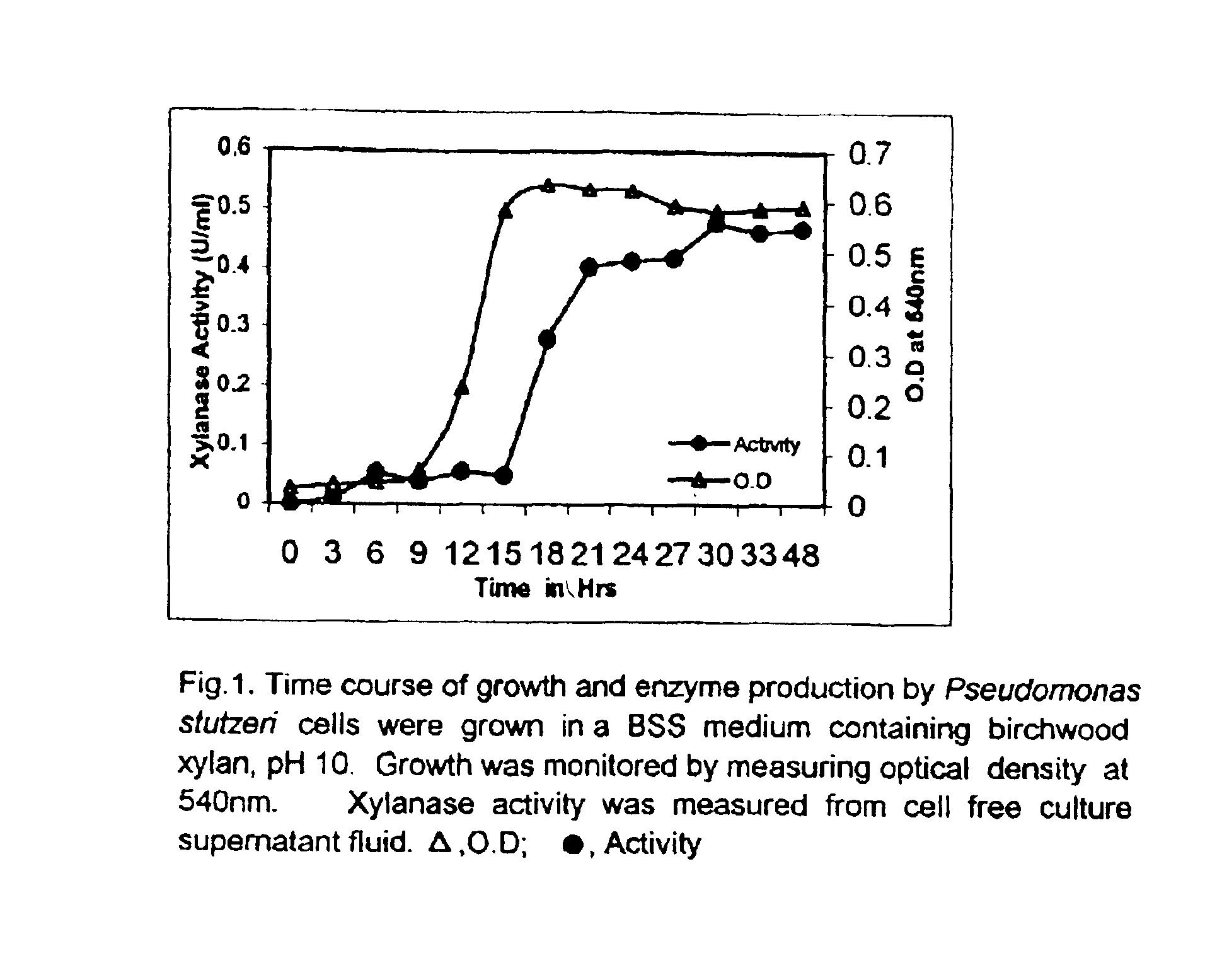

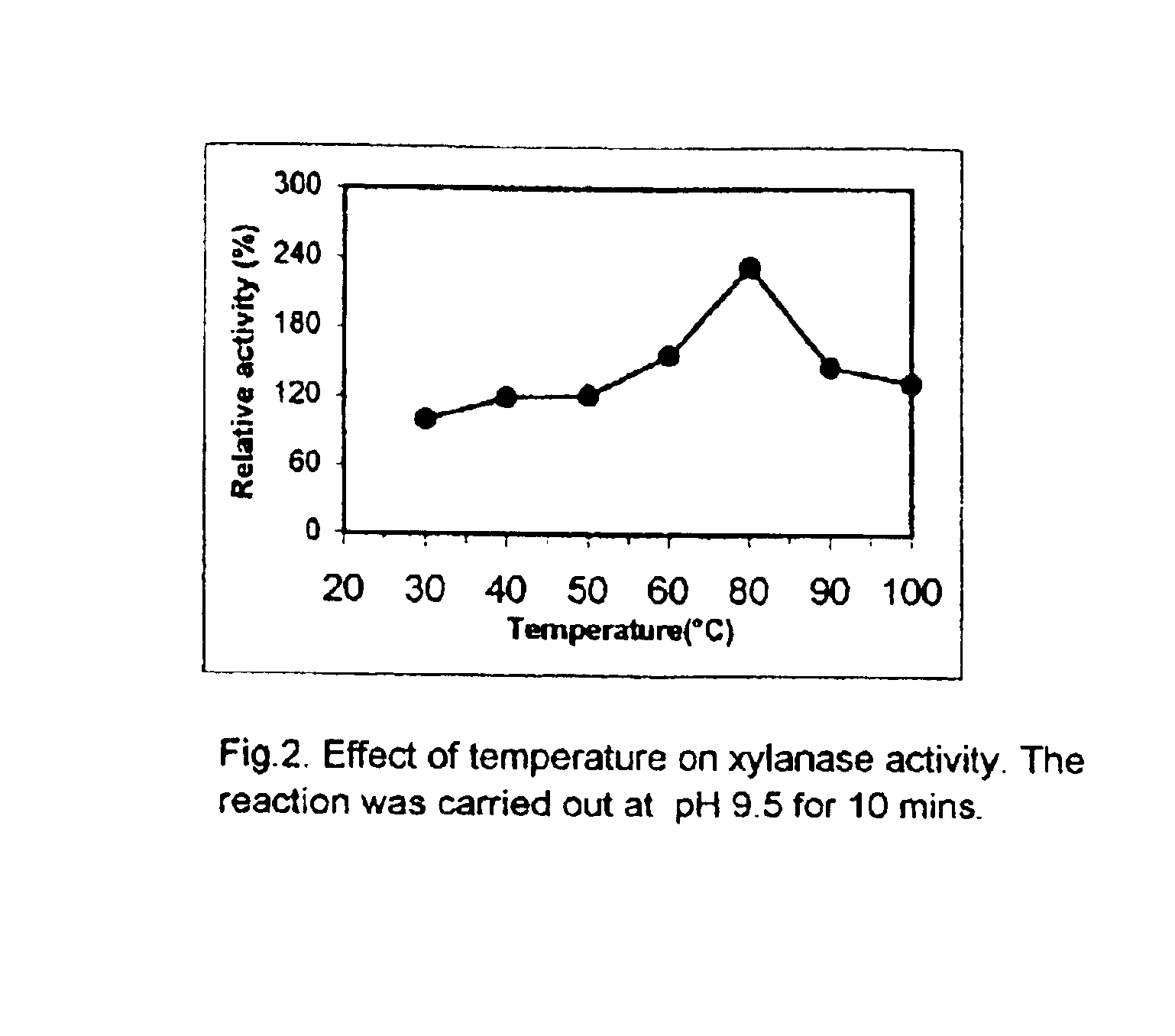

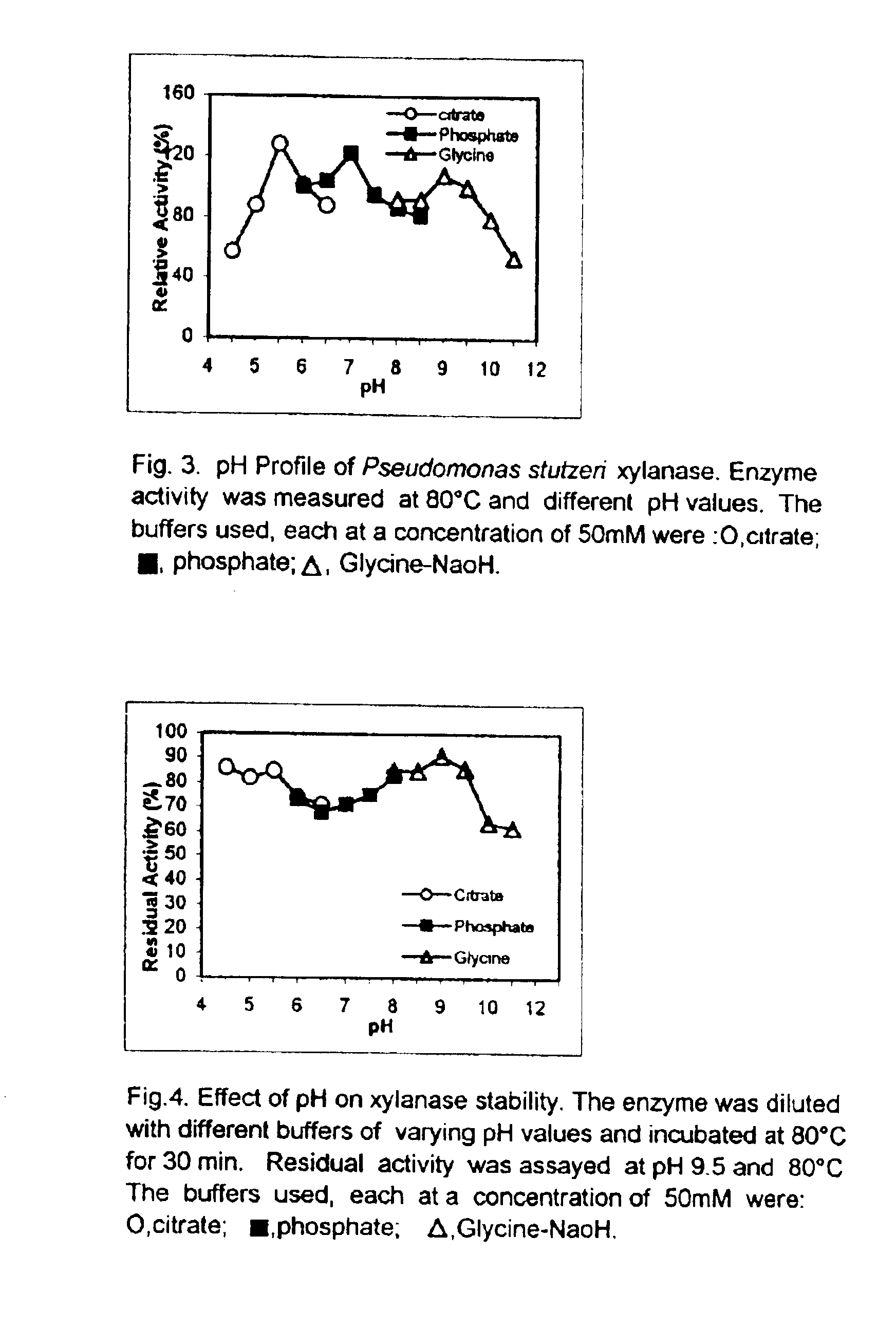

'Pseudomonas stutzeri' strain and process for preparation of xylanase

Owner:COUNCIL OF SCI & IND RES

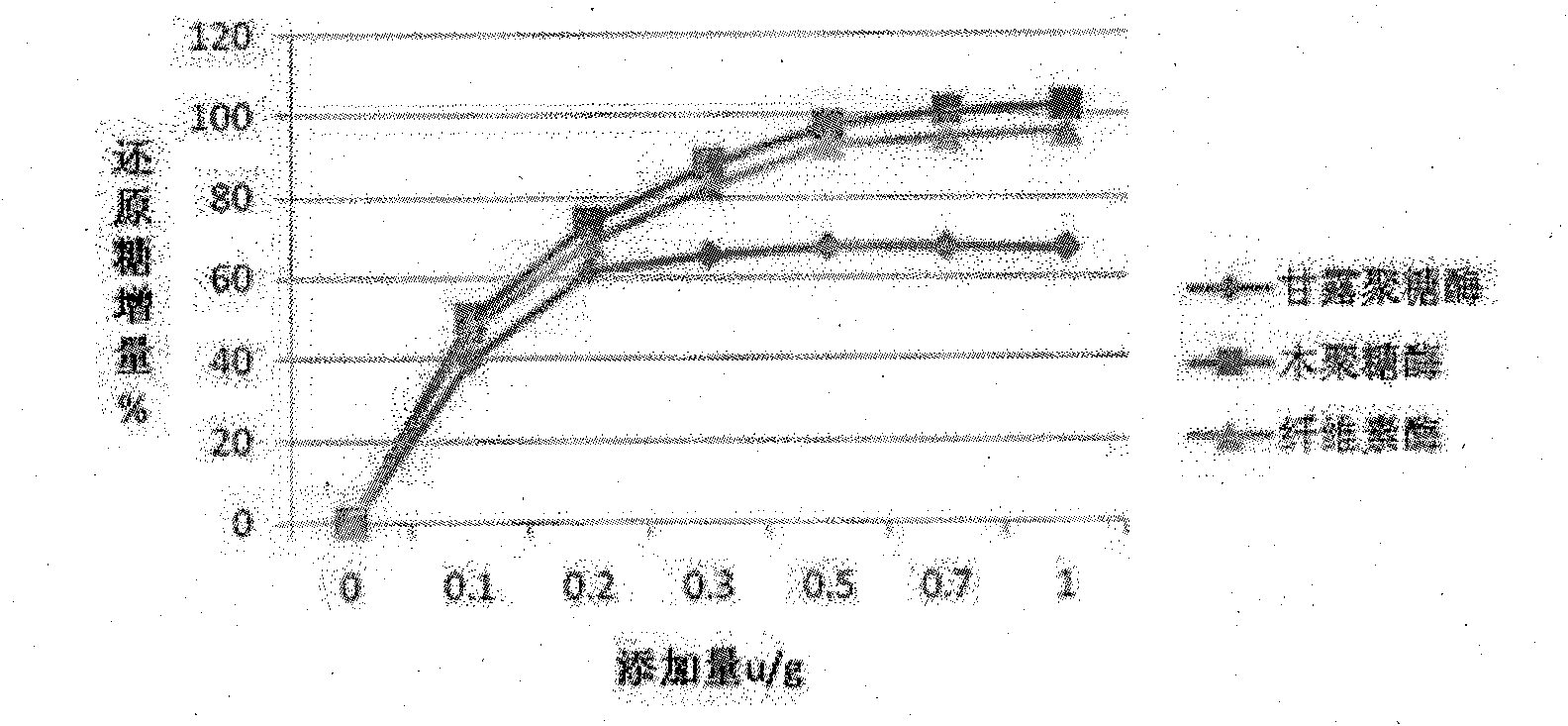

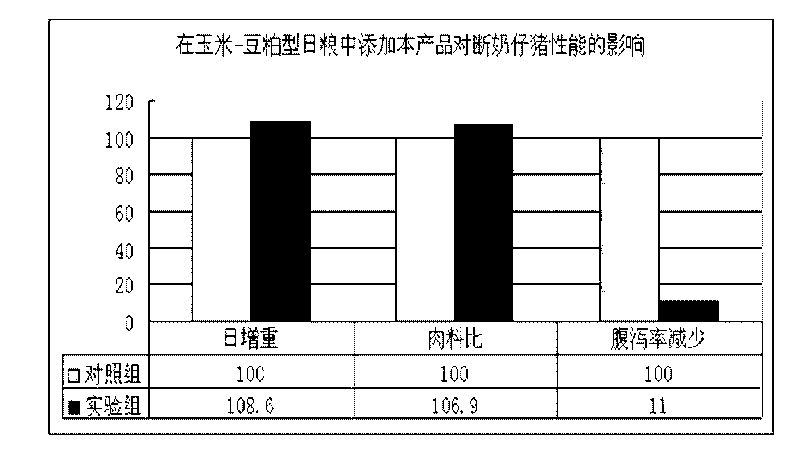

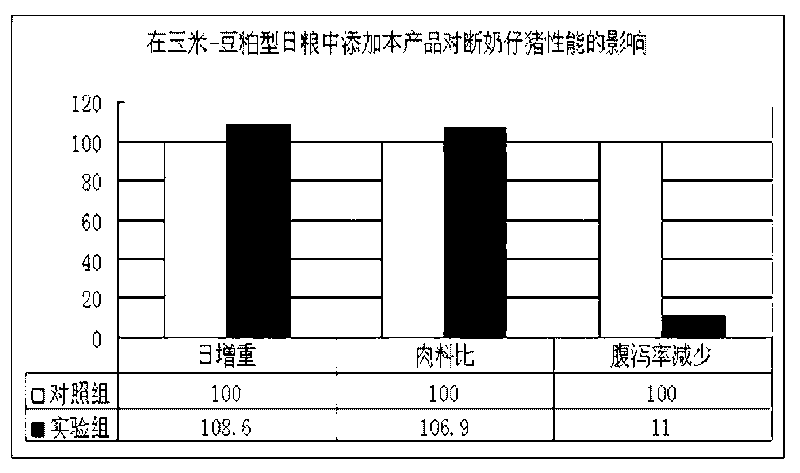

Complex enzyme preparation for feeding piglets

InactiveCN102119768AImprove metabolic energyReduce chyme viscosityAnimal feeding stuffAccessory food factorsPectinaseDisease

The invention discloses a complex enzyme preparation for feeding piglets. The complex enzyme preparation for feeding piglets comprises the following seven enzymes: acid protease, amylase, xylanase, beta-glucanase, cellulase, pectinase and phytase; and the enzymatic activity ratio of the seven enzymes is 1: 1: (8-10): (3.3-4): 1: (0.5-0.55): (0-0.02). By applying the complex enzyme preparation disclosed by the invention, various anti-nutritional factors in feed can be degraded, the viscosity of chyme in an intestinal tract can be reduced, and the metabolic energy of the feed can be improved; the protein and starch digestibility of the piglets can be improved; excessive reproduction of harmful microorganisms in the intestinal tract can be reduced, damage to the intestinal wall can be reduced, and the microecological balance of the intestinal tract can be regulated; the survival rate and disease resistance of the piglets can be improved, the diarrhea rate can be reduced, and the overall uniformity is improved; and the weight gaining of the piglets can be promoted, and the cultivation cost is reduced.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

Complex enzyme for feed

InactiveCN101874547AIncrease profitSolve the problem of uncertain addition amountAnimal feeding stuffCellulosePectinase

The invention belongs to the technical field of feed additives, and in particular relates to complex enzyme for a feed. The complex enzyme comprises 7,500 to 15,000U / g of xylanase, 1,000 to 3,000U / g of mannose, 50 to 80U / g of galactosidase, 200 to 700U / g of cellulose, 500 to 1,500U / g of beta-glucanase, 150 to 1,000U / g of alpha-amylase, 2,000 to 10,000U / g of protease and 100 to 200U / g of pectinase. By adding corresponding enzyme preparations, the anti-nutrition function of the complex enzyme is reduced, the feed utilization is improved, and the animal production efficiency is improved, so the problems that the utilization rate of animal feed raw materials is low and the animal production performance is inhibited are effectively solved; meanwhile, the complex enzyme has the advantages of reasonable raw material mixing, good effect, and low overall cost.

Owner:JINAN TIANTIANXIANG

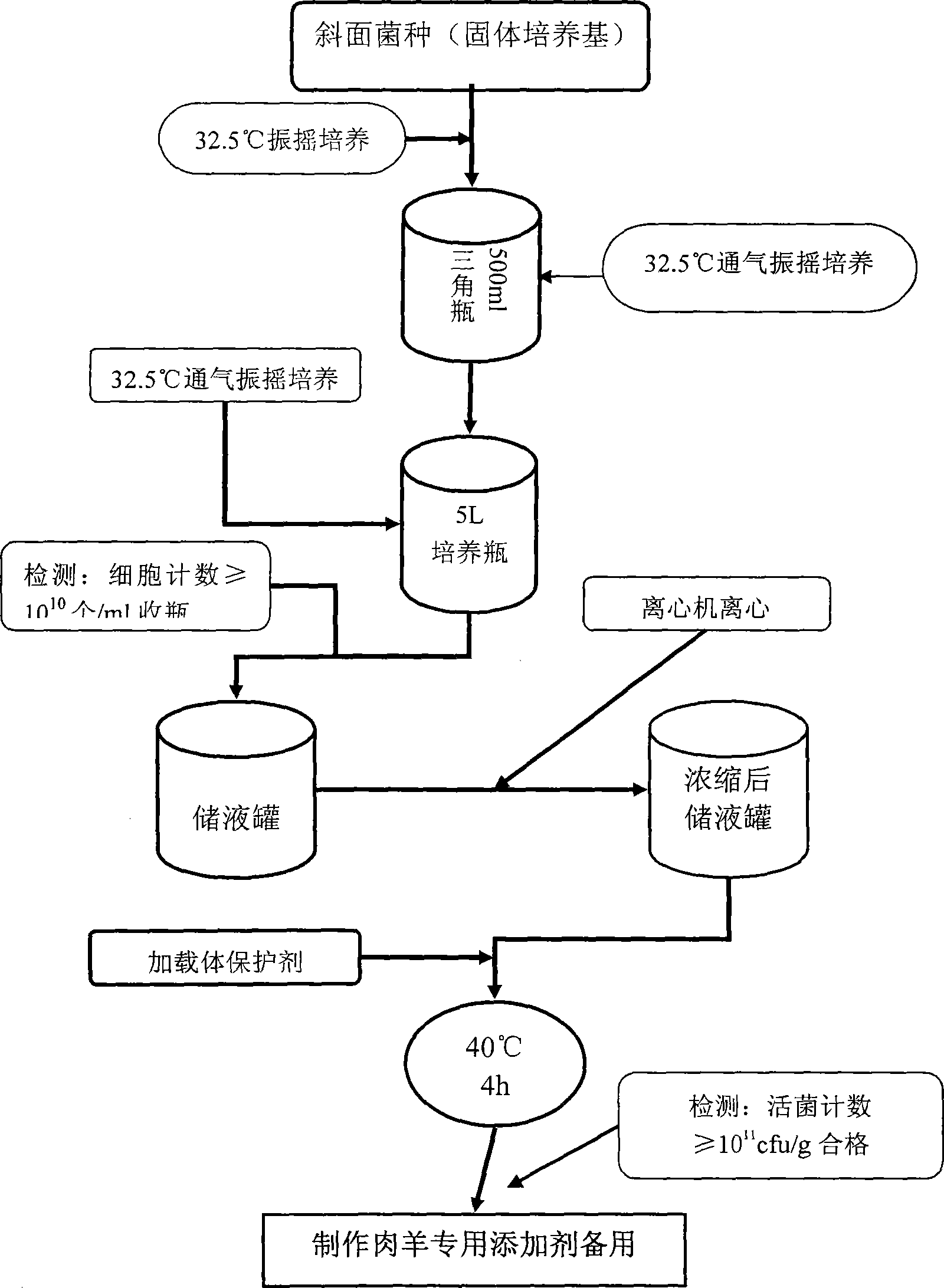

Method for producing complex micro-ecological preparation with microbial agents and enzyme

InactiveCN101690545ALess chance of growthGrow fastAnimal feeding stuffAccessory food factorsMicrobial agentAdditive ingredient

The invention discloses a method for producing a complex micro-ecological preparation with microbial agents and enzyme. According to the action principles and characteristics of every microbial strain, the method adopts scientific combination and adds enzyme preparations and acidifier to enable microorganisms in the product to grow rapidly and take dominance in fermented feed and animal bodies so as to reduce the growth opportunity of miscellaneous bacteria. The preparation comprises the following components: bacillus subtilis, lactobacillus plantarum, candida utilis yeast, lactobacillus acidophilus, protease, amylase, cellulase, xylanase, mannanase, galactosidase, pectinase and citric acid. As all strains of the product adopt liquid deep fermentation culture, the non-polluting property of the product is guaranteed. Liquid microbial agents ensure that the number of bacterial colonies of the product is more than 100 million and the product is free from the pollution of other miscellaneous bacteria, while solid microbial agents ensure that the number of bacterial colonies of the product is more than 1 billion and the proportion of miscellaneous bacteria to effective bacteria is not more than 0.0001. The preparation contains bacillus, lactic acid bacteria and yeast, can apply to the processes of making green-yellow storage feed, fermenting feed, soaking feed, and the like, can be directly added to feed for feeding, and can improve the growth performance of ruminant animals, poultry, pigs, aquatic products and special animals.

Owner:ZHAODONG SUN SHINE ENZYME

Highland barley noodle

ActiveCN1969666AHigh nutritional valueImprove immunityDough treatmentMetabolism disorderManihotCholesterol

The invention discloses a barley noodle, which comprises the following parts: one or more component from barley noodle, wheat flour, maize starch, manihot starch, sweet potato starch, potato starch and glutelin powder, one or more of glutamine transaminase, xylanase and cellulose enzyme, one or more of guar gum, xanthan gum, sodium polyacrylate, sodium alginate and konjaku flour, one or more of monosodium calcium lactate stearate, diacetyl tartaric acid monoester, soya phosphatide and monoaliphatic acid glyceride, water, salt and egg.

Owner:青海大垚生态农业科技发展有限公司

Composite plant enzyme containing probiotics and application of composite plant enzyme

ActiveCN103876155APromote body metabolismWide range of conditionsFood ingredient functionsFood preparationBiotechnologyLactase

The invention discloses a composite plant enzyme containing probiotics and an application of the composite plant enzyme. The composite plant enzyme comprises amylase, lipase, protease, cellulase, beta-dextranase, xylanase and lactase. The composite plant enzyme is obtained by discontinuously feeding materials and fermenting for a plurality of periods, selecting a plurality of types of fruits and vegetables, and edible and medical plants as fermentation substrates and taking a plurality of types of probiotics / yeasts as fermentation inoculation substances through a plurality of grades of deep fermentation. The composite plant enzyme contains seven enzymes needed by a human body at the same time so that the plant enzyme has the synergistic effects of promoting in-vivo metabolism and decomposing toxic substances; the plant enzyme contains a high-activity compound enzyme and has a wide acting condition, good adaptability, and good stability, acid-base resistance and high-temperature resistance; the plant enzyme can effectively and rapidly improve the biochemical reaction speed and can be used as a raw material to be applied to foods and chemicals for daily use.

Owner:田雷

Compound enzyme preparation for fermentation of pu'er tea and application

InactiveCN102492665APromote decompositionImprove the unique quality of connotationHydrolasesPre-extraction tea treatmentBiotechnologyPhytase

The invention relates to a compound enzyme preparation for fermentation of pu'er tea, which is formed by compounding 10% to 20% of cellulase, 10% to 20% of pectinase, 5% to 15% of polyphenol oxidase, 5% to 10% of glucose oxidase, 5% to 10% glucoamylase, 5% to 10% xylanase, 5% to 10% of beta-glucanase, 5% to 10% of beta-mannase, 5% to 10% of tannase, 5% to 10% of acidic protease, 5% to 10% of lipase, 1% to 5% of alpha-amylase and 1% to 5% of phytase. By the aid of coordination of the enzyme system, polysaccharide and other substances in tea including cellulose and hemicellulose can be effectively decomposed, so that various physiochemical substances in cells can be dissolved. Meanwhile, oxidation and condensation of tea polyphenol, decomposition of protein, amino acid and carbonhydrate, a series of reactions of various products including polymerization and condensation and the like are accelerated and promoted.

Owner:YUNNAN NORMAL UNIV

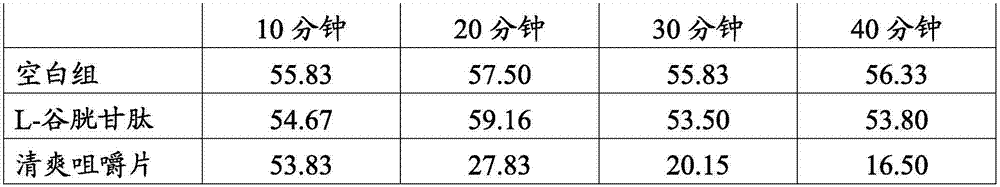

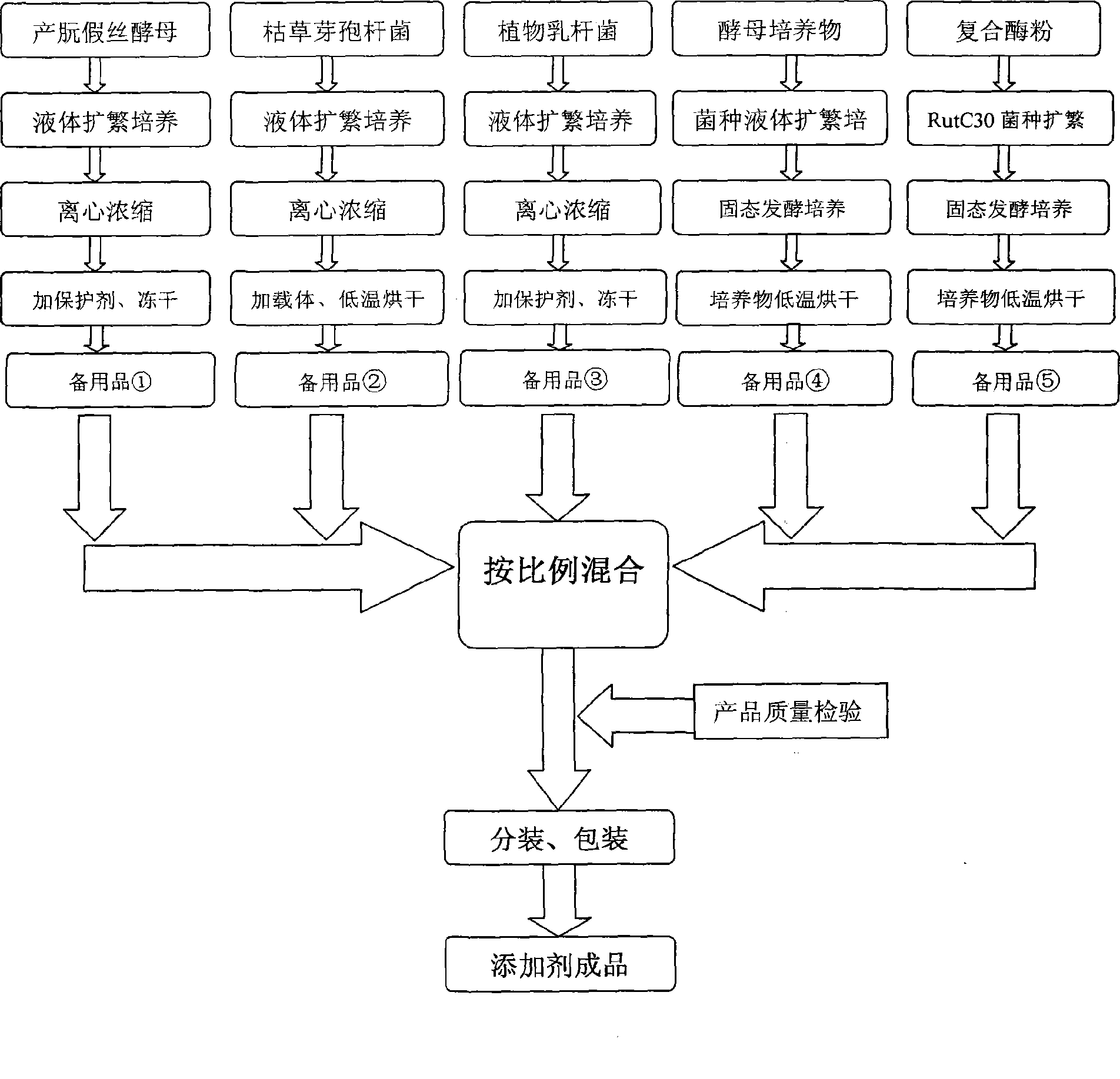

Composite biological feed additive agent for fattening early weaning mutton sheep

InactiveCN101485402AImprove developmentIncrease weightAnimal feeding stuffEcological environmentMicrobial agent

The invention relates to an early weaning meat sheep fattening compound biological feed additive, which belongs to the technical field of animals feeding by feed. The feed additive comprises prebiotics consisting of candida utilis, bacillus subtilis and a lactobacillus plantarum microbial agent, non-starch polysaccharide enzyme containing cellulase, xylanase, beta-dextranase, beta-mannase and pectinase and a yeast culture formed by using saccharomyces cerevisiae to completely ferment bean pulp. The additive is specially used for fattening period ration of the early weaning(the weaning lunar age is less than or equal to 2 ages of the moon) meat sheep, and the adding percentage for the full-mixing ration of the fast-fattening meat sheep in 3 to 5 ages of the moon is 1 percent. The additive can provide functional nutrients such as digestive enzyme, B group vitamins and growth promoting factors, and the like which are inadequately produced and insufficient for the early weaning baby sheep and simultaneously contains probiotics for adjusting the micro-ecological environment in intestinal canals, thereby improving the immunity and the healthy level of the baby meat sheep; and after weaning, the daily gaining in weight is more than 10 percent in the prior period and later period of fattening, and the economic benefits are obviously improved.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Construction of highly efficient cellulase compositions for enzymatic hydrolysis of cellulose

InactiveUS7883872B2High activityPronounced synergismBryophytesSugar derivativesCellulose bindingEnzymatic hydrolysis

This invention provides novel enzyme compositions using newly identified and isolated C. lucknowense enzymes, including CBH Ib CBH IIb, EG II, EG VI, β-glucosidase, and xylanase II in conjunction with previously identified enzymes CBH Ia, CBH IIa (previously described as Endo 43), and EG V. These enzyme compositions demonstrate an extremely high ability to convert lignocellulosic biomass (e.g., Avicel, cotton, Douglas fir wood pretreated by organosolv) to glucose. CBH Ia and IIb, which both have a cellulose-binding module (CBM) displayed a pronounced synergism with three major endoglucanases (EG II, EG V, EG VI) from the same fungus in hydrolysis of cotton as well as a strong synergy with each other. The enzyme compositions are effective in hydrolysis of the lignocellulosic biomass.

Owner:DANISCO US INC

Antibiotic-free piglet conservation material and preparation method thereof

InactiveCN102987153AComprehensive and balanced nutritionIncrease production capacityAnimal feeding stuffPhytaseThreonine

The invention relates to an antibiotic-free piglet conservation material and a preparation method thereof. The conservation material comprises the following raw materials of puffed corn, wheat, a base material, efficient cream, soybean meal, fermentation soybean meal, whey powder, composite yeast, rice protein powder, stone powder, calcium hydrogen phosphate, lysine, methionine, threonine, choline chloride, liquid phytase, liquid xylanase, a acidifying agent, sodium butyrate and a premix compound. The antibiotic-free piglet conservation material can increase immunity of the piglet, prevents the piglet from generating drug resistance and appearing drug residue problems, maintains stability of intestinal flora, and improves digestion and absorption for forage of the piglet.

Owner:河南商都生物技术股份有限公司

Feed additive containing compound enzyme

InactiveCN102771627AImprove digestibilityIncrease production capacityAnimal feeding stuffBacillus licheniformisBiotechnology

The invention relates to an animal feed additive containing compound enzyme. The additive is a microecological compound enzyme preparation mainly composed of xylanase, mannanase, beta-glucanase, cellulase, acid protease, alpha-amylase, phytase, Bacillus subtilis, Bacillus licheniformis and the like. The product of the additive containing compound enzyme in the invention can be used as a novel feed additive, has no drug residue, no pollution and no generation of drug resistance, drug residues and drug-resistant strains, can be extensively applied to livestock feeds and ruminant feeds and has effects on improving the digestion and utilization rate of feeds, enhancing production performance of animals, strengthening immunity of animals, etc.

Owner:北京奕农生物技术有限公司

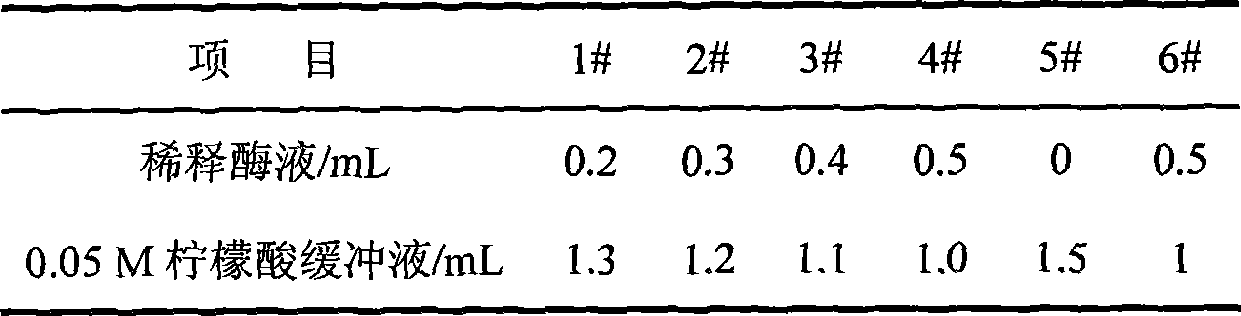

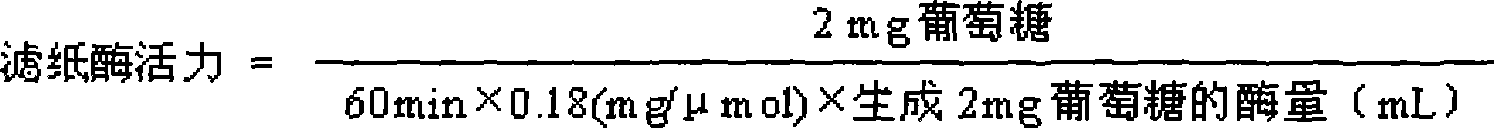

Method of preparing heat-proof xylanase, heat-proof beta-xylosidase or heat-proof beta-glucosidase

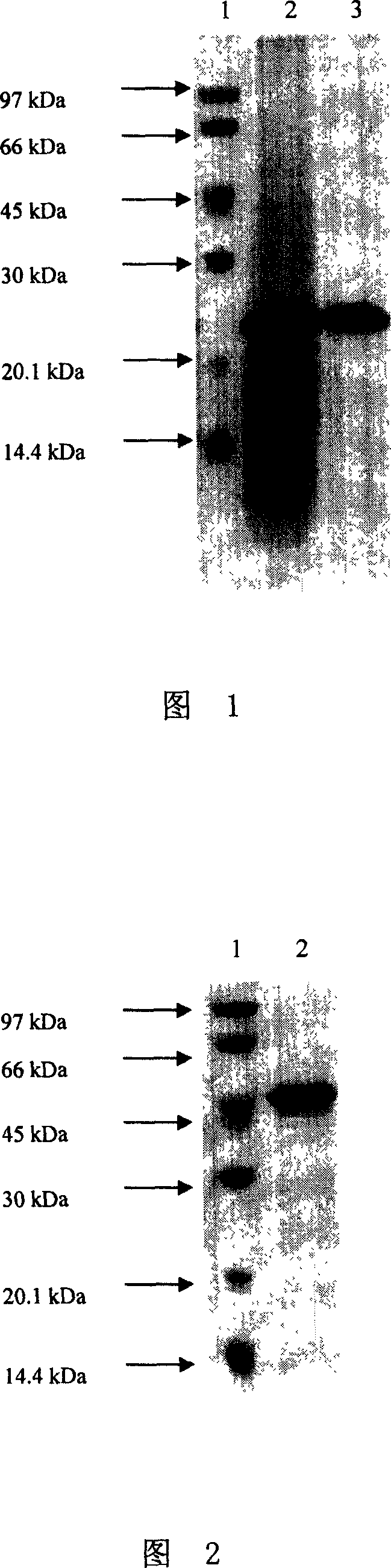

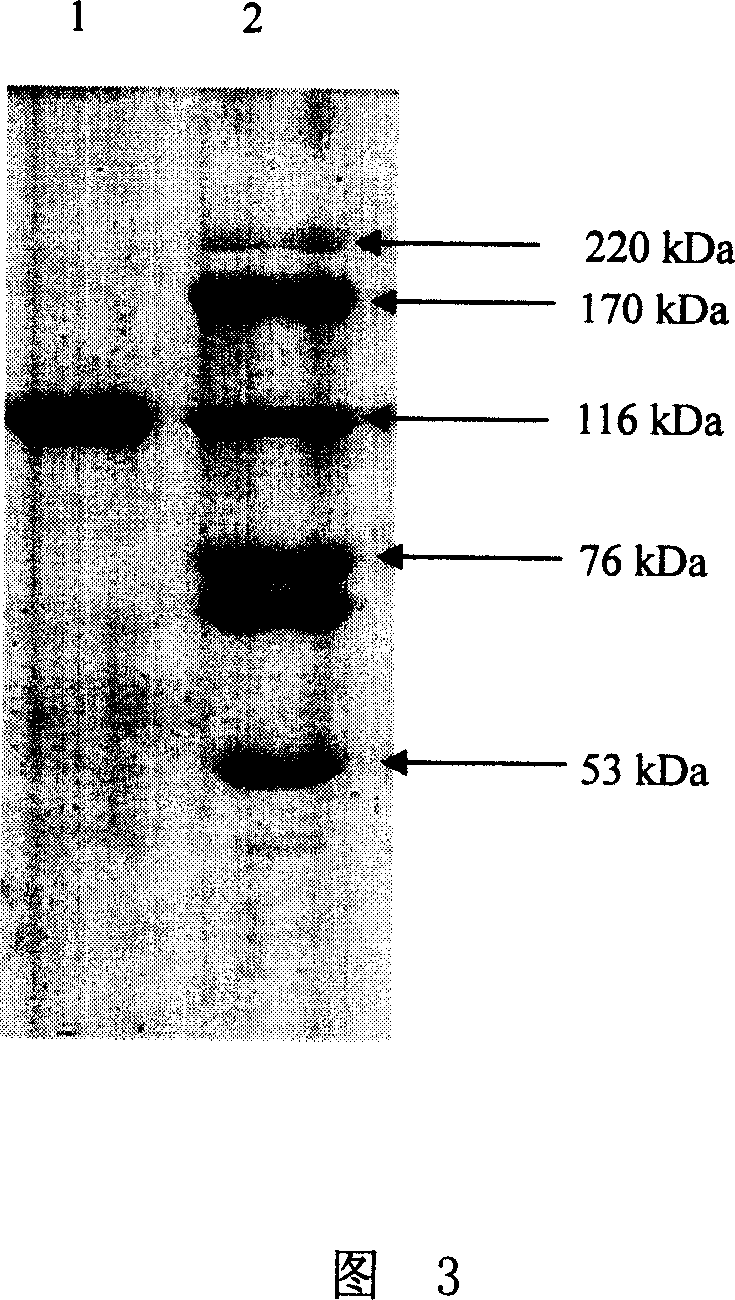

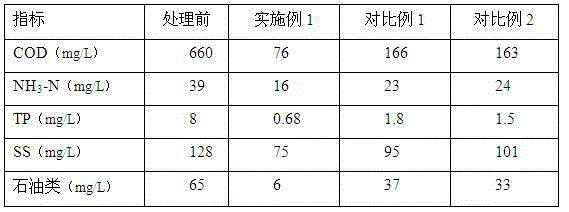

The invention discloses a making method of heat-proof xylanase, heat-proof beta-xylosidase or heat-proof beta-glucosidase, which comprises the following steps: adopting agricultural waste as carbon source; fermenting Paecilomyces thermophila J18 at 40-60 deg.c to obtain the ferment liquid with heat-proof xylanase, heat-proof beta-xylosidase or heat-proof beta-glucosidase; purifying; obtaining electrophoretic grade product.

Owner:CHINA AGRI UNIV

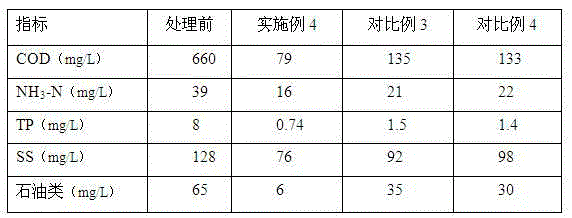

Water purifier for treating production wastewater of rubber accelerator NOBS and wastewater treatment method

ActiveCN104529062AHigh transparencyImprove water purification effectMultistage water/sewage treatmentNature of treatment waterPectinaseDesorption

The invention belongs to the technical field of environmentally water treatment and particularly relates to a water purifier for treating production wastewater of a rubber accelerator NOBS and a wastewater treatment method. The water purifier comprises a flocculating water purifier, a microbial water purifier and an enzyme preparation, wherein the flocculating water purifier consists of polyaluminum ferric chloride, polyacrylamide, ferrous sulfate and aluminum sulfate; the microbial water purifier consists of nitrobacteria powder, paracoccus denitrificans powder, thiobacteria powder, aniline degradation bacteria powder, flocculating bacteria powder, bacillus siliceous powder and bacillus subtilis powder; the enzyme preparation consists of pectinase, cellulose, oxidordeuctase, xylanase, alkaline protease and monoamine oxidase. The water purifier for treating sewage provided by the invention is good in water purification effect, quick in water purification speed, high in safety and free of secondary pollution. By using a material with a desorption capacity as a raw material, sewage is treated by being assisted by microorganisms, so that the water purifier is wide in application range, and the treated water is extremely high in transparency and can be recycled.

Owner:安徽优盾信息科技有限公司

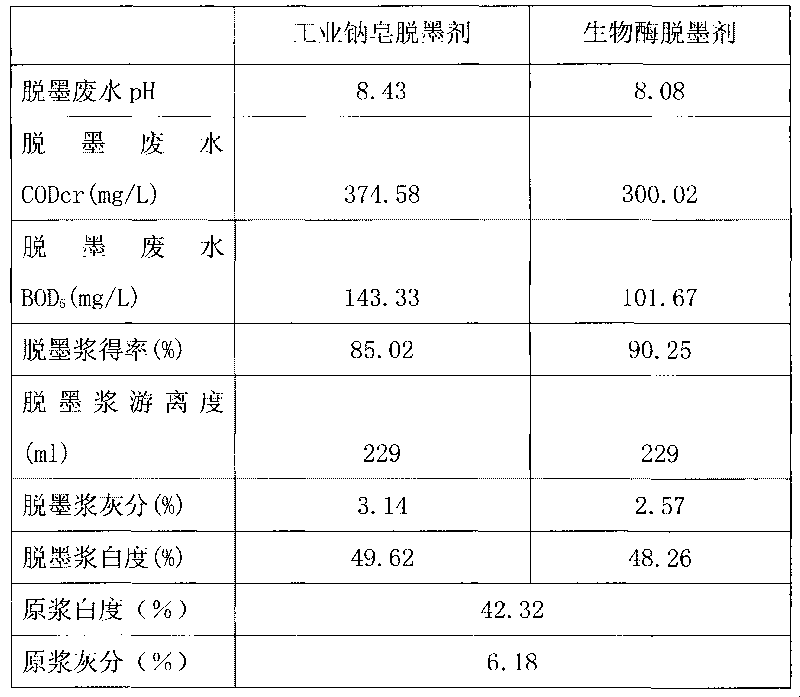

Process for de-inking waste newspaper by biologic enzyme

InactiveCN101718050AReduce usageImprove water filtration performancePaper recyclingWaste paper working-upHigh concentrationPrinting ink

The invention provides a process for de-inking waste newspaper by a biologic enzyme, which relates to the process of the pulping of waste paper. The process is characterized by comprising the following technological procedures of: (1) preparing a de-inking agent: adding one or several of alkali lipase, amylase and xylanase into cellulase to prepare a composite enzyme and then adding 0.05-0.15 kilogram of surfactant into the composite enzyme with the weight to form the de-inking agent, wherein the composite enzyme comprises the following components in proportion: 2000-10000U of cellulase, 10000-100000U of alkali lipase, 1000-5000U of xylanase and 8000-15000U of amylase; (2) pulping by using a high-concentration pulper: adding 40-60 DEG C water into the high-concentration pulper, counting by 100 kilograms of absolutely dry paper, putting 10-150 grams of de-inking agent and 0.2-0.4 kilogram of sodium metassilicate nonahydrate into waste newspaper and journal paper and stopping after starting the pulper for 10-30 minutes; and (3) carrying out the procedures of floatation and printing ink separation to obtain the de-inked pulp. The invention has the advantages that sodium hydroxide and hydrogen peroxide are not used, and the production cost and the wastewater pollution are lowered.

Owner:FUJIAN JIAFENG BIOCHEM

Pulping and papermaking process through multiple-composition biological enzyme method

InactiveCN102345244AReduce consumptionImprove product qualityNon-fibrous pulp additionPaper/cardboardBlack liquorWastewater

The invention discloses a pulping and papermaking process through a multiple-composition biological enzyme method. The method is a biopulping method, which adopts a production process for preparing paper pulp through pulping and fermenting by using a multiple-composition biological enzyme method (phanerochaete, phanerochaete chrysosporium, xylanase, glucoamylase, yeast), adopts agricultural straws, rice and wheat straws, cotton stalks, rape stalks, reeds, bamboo, wood and the like as main raw materials, and comprises treatments of glass cutting, impurity removing, puffing, fermenting through multiple-composition biological enzyme, pulp washing, pulp selecting, defibrination and separation to form the pulp. According to the present invention, no black liquid is generated during the pulping process, the water from fermenting and pulping is recycled so as to achieve zero discharge of wastewater.

Owner:王凤忠

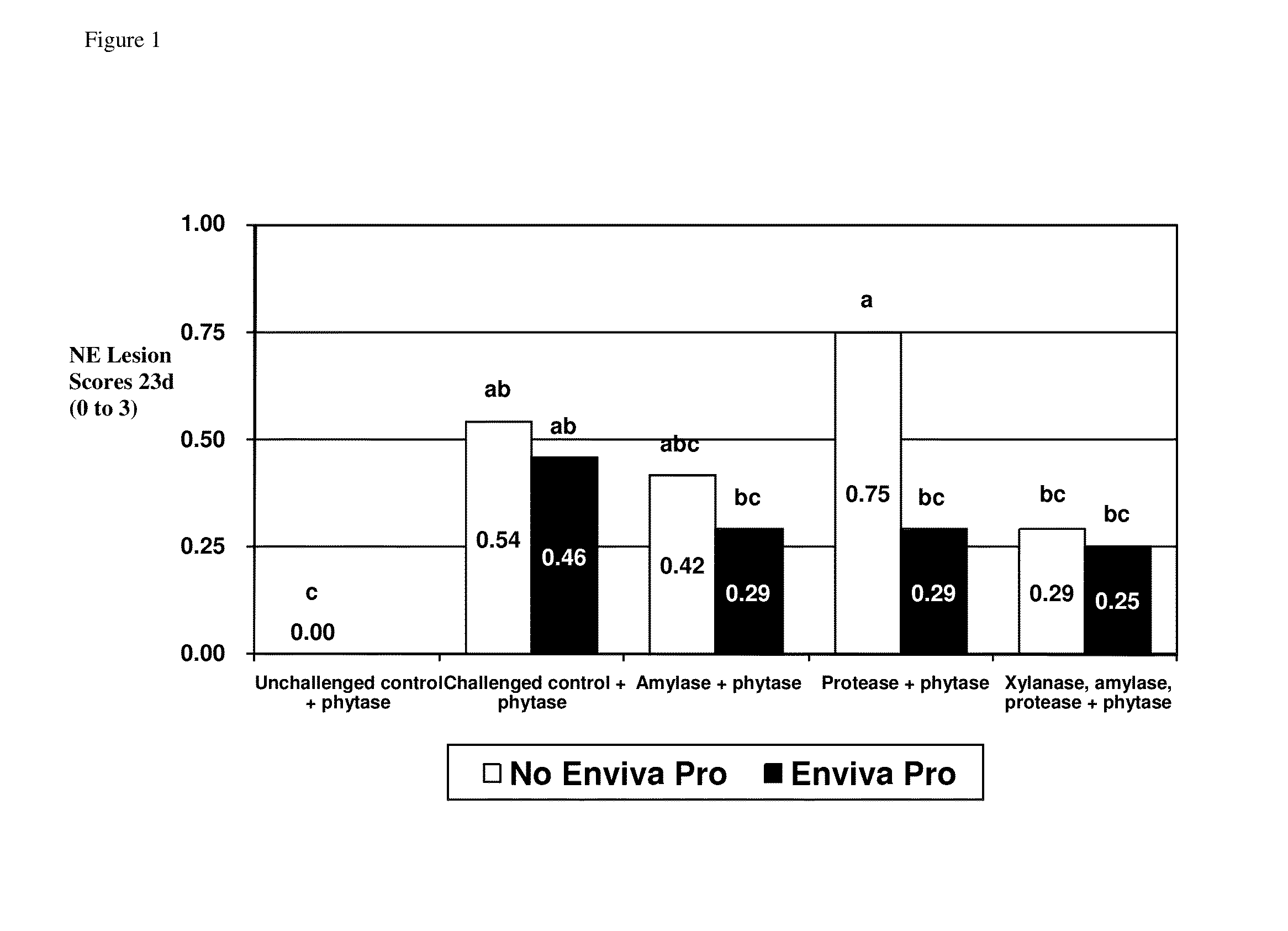

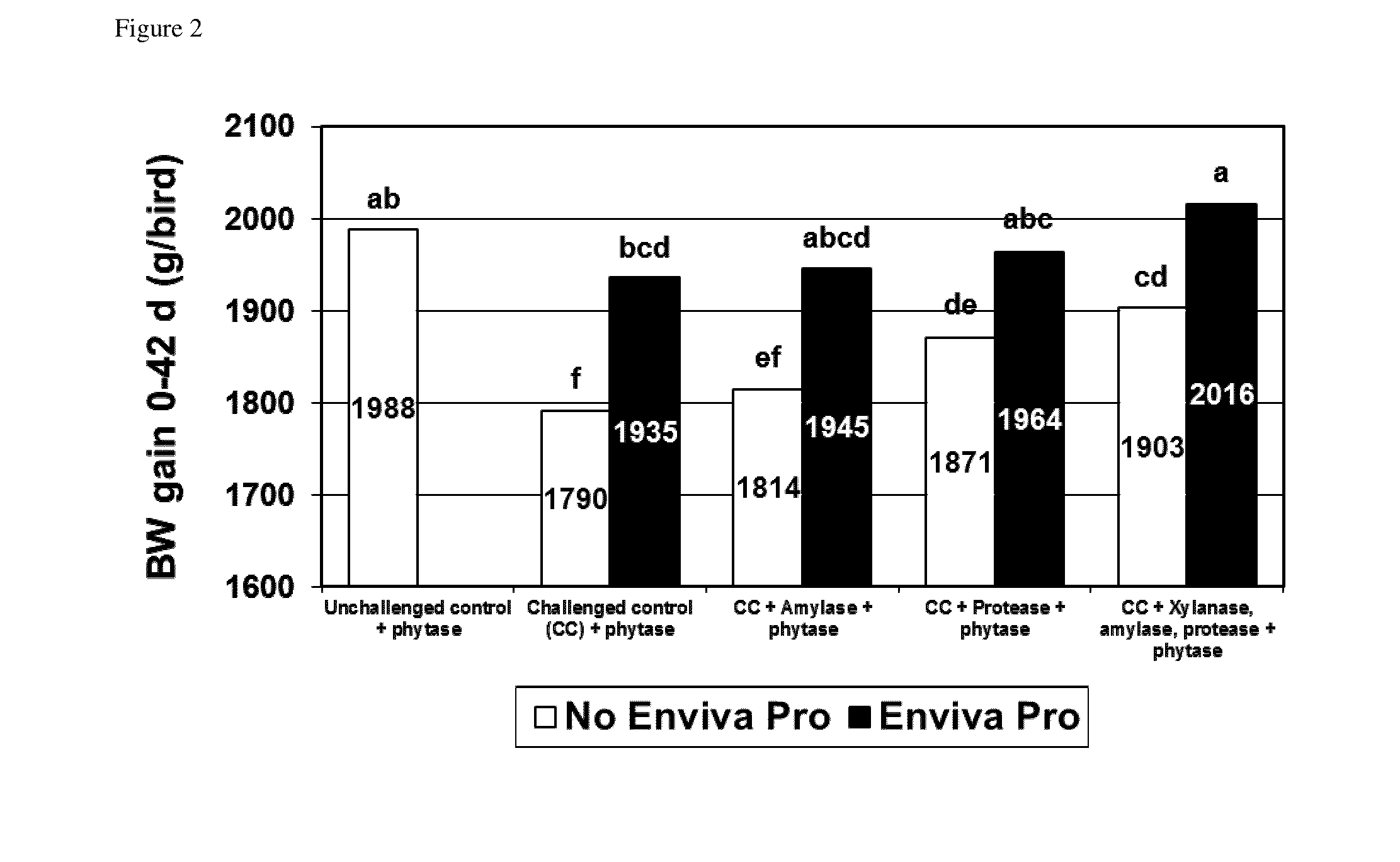

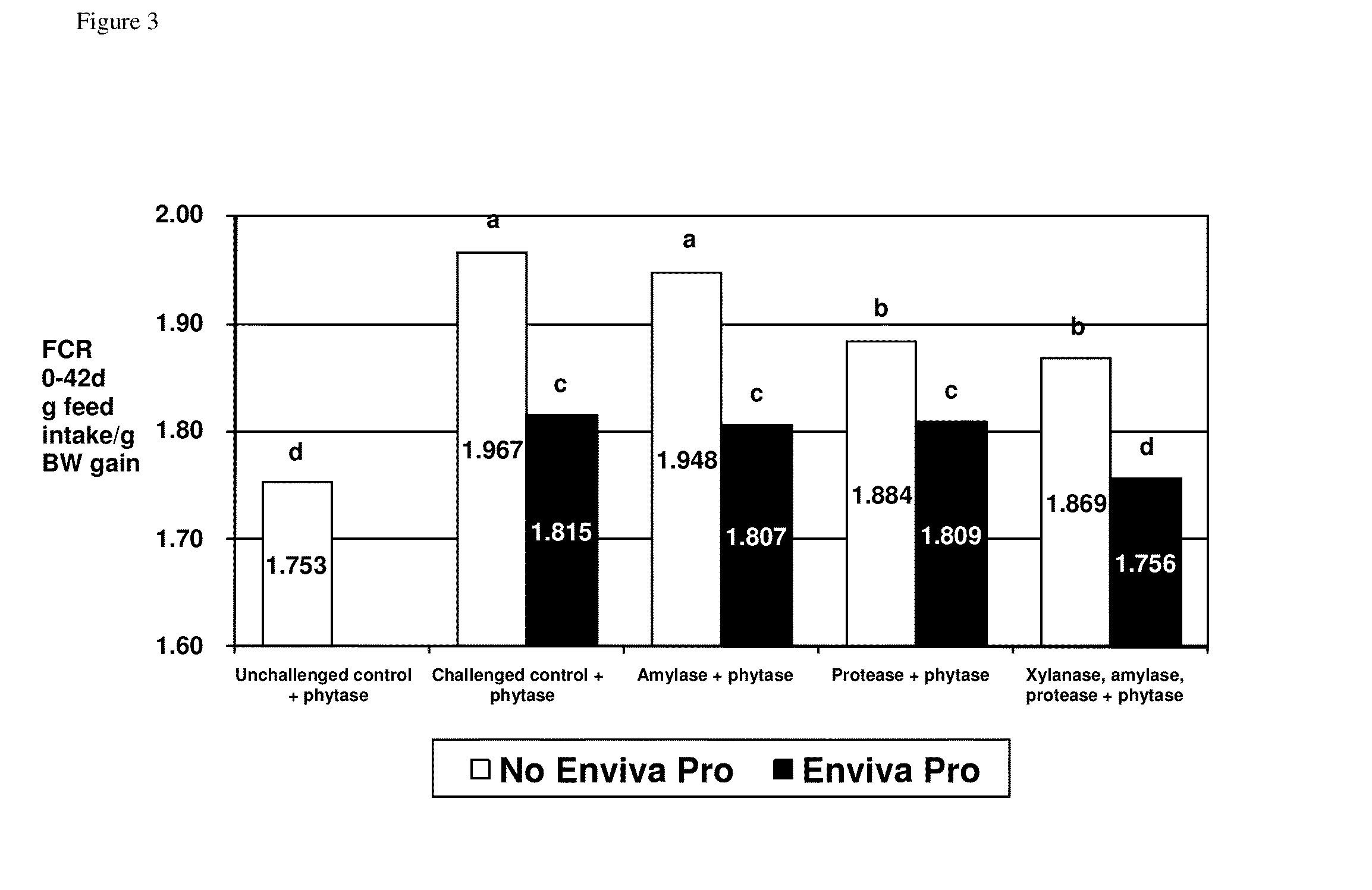

Feed additive composition

A feed additive composition comprising a direct fed microbial in combination with a protease, a xylanase, an amylase and a phytase, and a method for improving the performance of a subject or for improving digestibility of a raw material in a feed (e.g. nutrient digestibility, such as amino acid digestibility), or for improving nitrogen retention, or for avoiding the negative effects of necrotic enteritis or for improving feed conversion ratio (FCR) or for improving weight gain in a subject or for improving feed efficiency in a subject or for modulating (e.g. improving) the immune response of the subject or for promoting the growth of beneficial bacteria in the gastrointestinal tract of a subject, which method comprising administering to a subject a direct fed microbial in combination with a protease, a xylanase, an amylase and a phytase.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Process for the fractionation of cereal brans

InactiveUS7709033B2Improve efficiencyEasy to separateTea extractionProtein composition from vegetable seedsUltrafiltrationFractionation

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

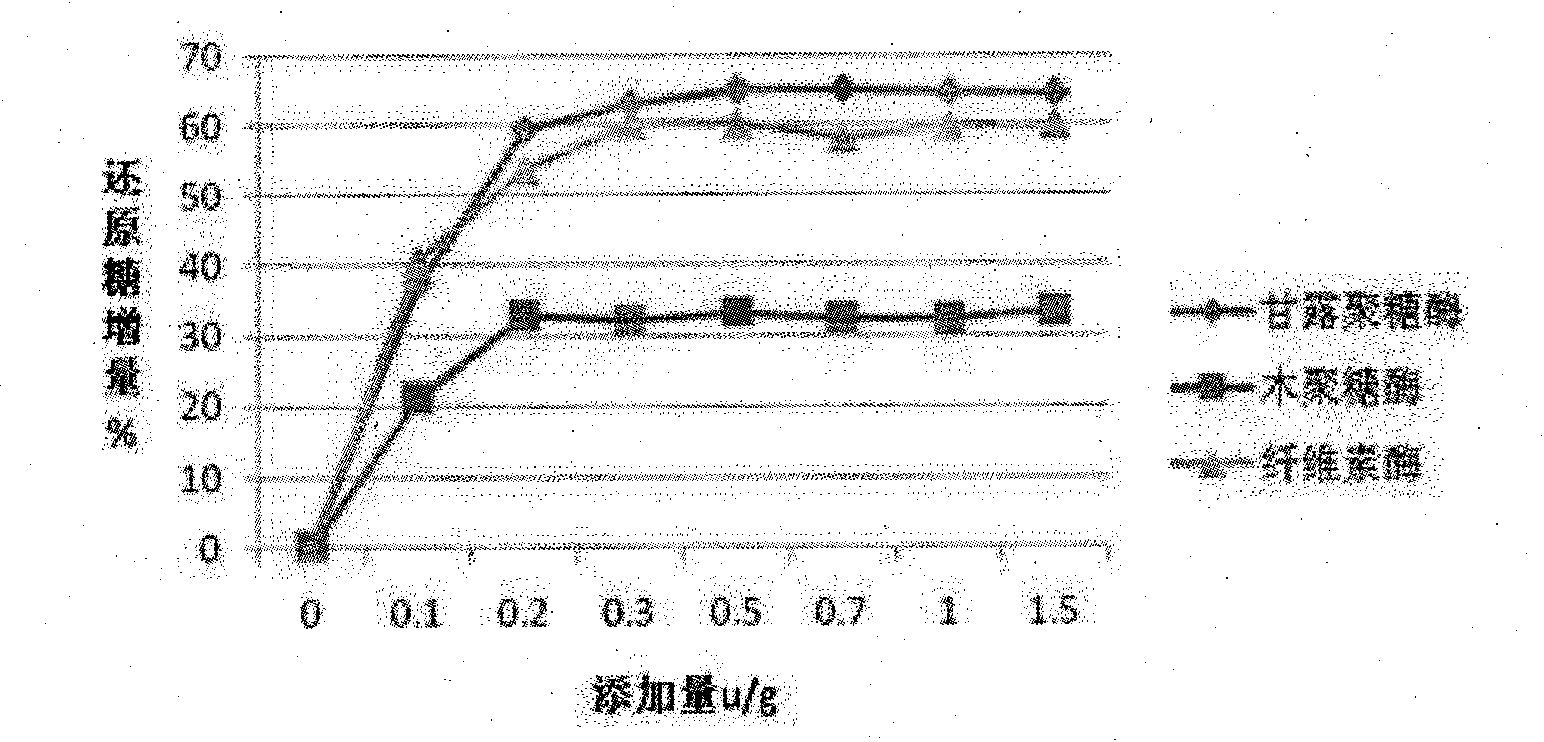

Complex enzyme preparation for growing and fattening pig feed

InactiveCN102106477AImprove metabolic energyReduce chyme viscosityAnimal feeding stuffAccessory food factorsPectinaseAnimal science

The invention discloses a complex enzyme preparation for a growing and fattening pig feed. The complex enzyme preparation for the growing and fattening pig feed comprises the following eight enzymes: acid protease, amylase, beta-mannase, xylanase, beta-dextranase, cellulase, pectinase and phytase; and the enzyme activity ratio of the eight enzymes is sequentially 1: (0.8-14.5): (0.19-0.3): (33.7-35): (25-30): (3.2-3.5): (0.19-2.0): (0-0.025). The complex enzyme preparation can degrade various anti-nutritional factors in the feed, reduce the chime viscosity of the intestinal tract, improve the metabolic energy of the feed, improve the digestion rate of growing and fattening pigs on protein and starch, reduce the nutrient content of the chime entering the intestinal tract, effectively inhibit the reproduction of harmful microbes in the intestinal tract, reconcile the micro-ecological balance of the intestinal tract, promote the health of the pigs, improve the average daily gain of the growing and fattening pigs, reduce the feed-meat ratio, shorten the maintenance period and improve the economic benefit.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

Preparation method of yak bone collagen peptide

InactiveCN103783254AEasy extractionShort manufacturing timeAnimal proteins working-upPectinaseEnzymatic hydrolysis

The invention discloses a preparation method of yak bone collagen peptide. The method is characterized by comprising the following technological processes: pretreatment of raw materials, gelatin extraction, separation of a collagen extracting solution, composite enzymatic hydrolysis, enzyme deactivation and sterilization, separation of a peptide solution, decoloring and deodorizing, concentrating and drying. The compound enzyme for composite enzymatic hydrolysis is prepared from protease, amylase, pectinase, cellulose and xylanase. The method has the advantages that the gelatin extraction process is simple, oil and gelatin are completely separated by using flow of a mixed solution, the enzymatic hydrolysis temperature is 48-52 DEG C, the time is 4-6 hours, the temperature is reduced in comparison with common enzymatic hydrolysis temperature, the preparation time of the product is shortened, and the method comprises enzyme deactivation and sterilization procedures, and decoloring and deodorizing procedures, so that the product is good in taste, and applicable to preparation of the yak bone collagen peptide.

Owner:吴长海

Pre-treatment of cotton fabrics by rolling and piling up of enzyme

The invention provided a fore treatment process of the enzyme rolling pile for the fabric which belongs to the fore treatment process of the dyeing and finishing field. The process is: first to impregnate the fabric into the mixture of the alkali pectinase liquid, neutral proteinase liquid and xylanase liquid, then to keep the temperature, next to wash with the hot water (killing the enzyme) and the cool water last to blanch with the H2O2. The pectinase is produced by the Bacillus subtilis WSHB04-03. The process has many merits such as high efficiency, low work output and the energy conservation and so on.

Owner:JIANGNAN UNIV

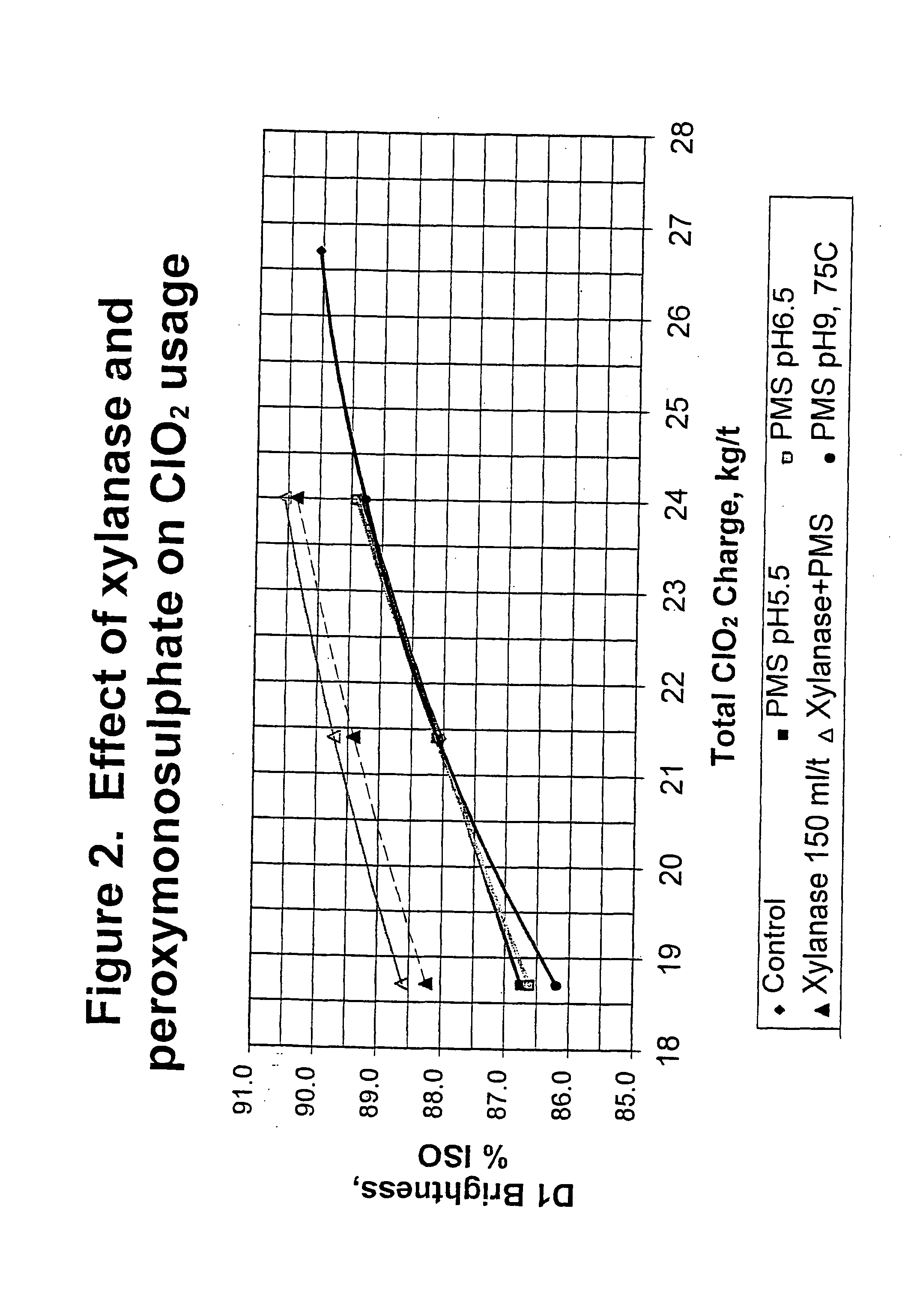

Xylanase treatment of chemical pulp

InactiveUS20050150619A1Reduce usageHigh strengthPulp bleachingPulping with organic solventsChlorine dioxidePulp mill

The present invention discloses methods of bleaching chemical pulp that use xylanase enzymes after chemical bleaching. The method comprises the steps of carrying out a chlorine dioxide stage to produce a partially bleached pulp, treating the partially bleached pulp with a xylanase enzyme, optionally in the presence of oxygen and hydrogen peroxide, in a mild extraction stage, then bleaching the pulp with a second chlorine dioxide stage. The method allows the mill to decrease the usage of sodium hydroxide or other alkali, while decreasing the use of chlorine dioxide, and possibly improving the yield and strength of the pulp, while maintaining a similar level of bleached brightness of the pulp. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:NOVOZYMES AS

Method for preparing dietary fiber from bean dregs serving as raw material by combining steam explosion and enzymolysis

The invention discloses a method for preparing dietary fiber from bean dregs serving as a raw material by combining steam explosion and enzymolysis. In the method, a pure natural and fully water-soluble dietary fiber product is obtained through pretreatment of the bean dregs, steam explosion, ultrafine grinding, enzymolysis and drying of enzymolysis slurry. In the method, conversion rate of the soluble dietary fiber can be quickly and effectively increased by performing the steam explosion before the enzymolysis. Other chemical substances are not required to be added due to the adoption of the steam explosion, and the product is the pure natural dietary fiber. Cellulase, pectinase or xylanase can be separately used as an enzyme used in the method. Compared with a method for producing the fully water-soluble dietary fiber, the method for producing the mixed dietary fiber with high water-soluble dietary fiber content has the advantages of reduced investment, low production cost and capability of solving the problem of pollution of three wastes (waste water, waste gas and industrial residues).

Owner:GUANGXI UNIV

Novel method for saccharification of ligno-cellulose

InactiveCN101434976AAvoid high temperature and pressureSave operating timeBiofuelsFermentationCellulaseXylanase

The invention relates to a new method for processing lignocellulose by saccharification, comprising dilute acid pretreatment, milling and crushing, cellulase compounding and enzymolysis saccharification process. The detail method thereof comprises the following steps: the crushed lignocellulose raw materials are pretreated with dilute acid with the H <+> concentration of 0.01mol / L-0.1mol / L and later milled and crushed, and then acidolysis sugar solution is obtained; at least two types of cellulase are mixed with xylanase for obtaining compound cellulase, and then further enzymolysis saccharification treatment is carried out to the rest solid after enzymolysis and milling for obtaining enzymolysis sugar solution. By using the process that the milling of dilute acid is combined with the one-step enzymolysis of compound enzyme, the hydrolysis sugar yield of the lignocellulose raw materials can be up to more than 90 percent. The method has the advantages of mild reaction condition, simple operation, and high enzymolysis efficiency; moreover, the obtained sugar solution after being processed produces no inhibition to the follow-up fermentation, can be comprehensively utilized, and causes no environmental pollution, etc.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com