Water purifier for treating production wastewater of rubber accelerator NOBS and wastewater treatment method

A technology of rubber accelerator and waste water production, which is applied in biological water/sewage treatment, water/sewage treatment, natural water treatment, etc. It can solve the pollution hazards of sewage water, trouble enterprises, and the impact of biochemical treatment equipment, etc. Produce secondary pollution, wide range of use, fast water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

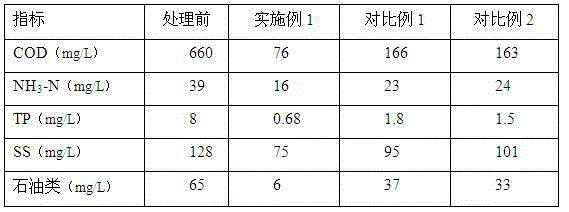

Embodiment 1

[0035] The rubber accelerator NOBS produces the method for treating waste water with water purifying agent for waste water treatment, and the method comprises the following steps:

[0036] First add flocculation water purifier and activated carbon into the sewage, stir evenly at a speed of 15 rpm, stir for 0.6 hours, and let it stand for 4 hours; the flocculation water purifier is: polyaluminum ferric chloride 15, polyacrylamide 10, Ferrous sulfate 10, aluminum sulfate 10; activated carbon accounts for 5% of the waste water;

[0037]Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 15 rpm, stir for 0.5 hours, and let stand for 4 hours; the microbial water purifiers are: nitrifying bacteria Bacteria powder 1.2, denitrifying paracoccus bacteria powder 0.9, sulfur bacteria powder 0.5, aniline degrading bacteria powder 0.9, flocculation bac...

Embodiment 2

[0047] The rubber accelerator NOBS produces the method for treating waste water with water purifying agent for waste water treatment, and the method comprises the following steps:

[0048] First add flocculation water purifier and activated carbon into the sewage, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 2 hours; Ferrous sulfate 5, aluminum sulfate 5; activated carbon accounts for 3% of the wastewater;

[0049] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 2 hours; microbial water purifiers are: nitrifying bacteria Bacteria powder 0.5, denitrification paracoccus bacteria powder 0.5, sulfur bacteria powder 0.2, aniline degrading bacteria powder 0.3, flocculation bacteria powder 0.5, silicate bacteria powder 0.3, Bacillus subtilis powder 0.4;

[0050] Then a...

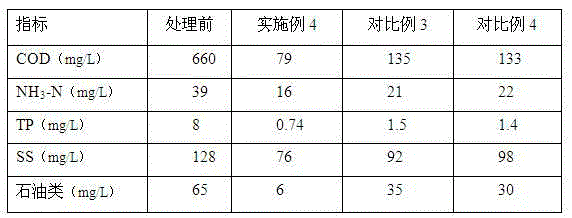

Embodiment 3

[0052] The rubber accelerator NOBS produces the method for treating waste water with water purifying agent for waste water treatment, and the method comprises the following steps:

[0053] First add flocculation water purifier and activated carbon into the sewage, stir evenly at a speed of 20 rpm, stir for 1 hour, and let stand for 5 hours; Ferrous sulfate 15, aluminum sulfate 15; activated carbon accounts for 8% of the wastewater;

[0054] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 20 rpm, stir for 1 hour, and let stand for 6 hours; the microbial water purifiers are: nitrifying bacteria Bacteria powder 2.0, denitrifying paracoccus bacteria powder 1.5, sulfur bacteria powder 0.8, aniline degrading bacteria powder 1.2, flocculation bacteria powder 1.5, silicate bacteria powder 1.0, Bacillus subtilis powder 1.2;

[0055] Then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com