Patents

Literature

43results about How to "Avoid high temperature and pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for saccharification of lignocellulose by ultrasonic synergistic catalysis of modified cellulose

InactiveCN1970781AIncrease concentrationImprove adaptabilityEnzymesFermentationMonomethoxypolyethylene glycolBeta-Glucosidases

The invention discloses a saccharifying method of xylon cellulose through ultrasonic coordinated modified cellulose enzyme, which comprises the following steps: grinding and predisposoing xylon in the raw material through alkaline; reacting activated methoxy carbowax and cellulose enzyme in the citrate-sodium citrate buffer solution to obtain modified cellulose enzyme; blending modified cellulose enzyme, beta-glucosidase, amylase and pectase to obtain composite liquid; adding composite enzyme into predisposed raw material according to corresponding proportion; proceeding enzyme catalytic reaction through ultrasound; filtering; decompressing; evaporating; obtaining condensed sugar liquid.

Owner:TIANJIN UNIV

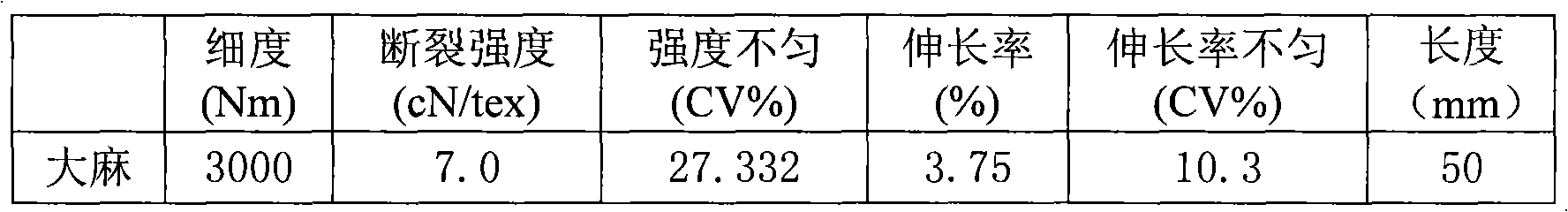

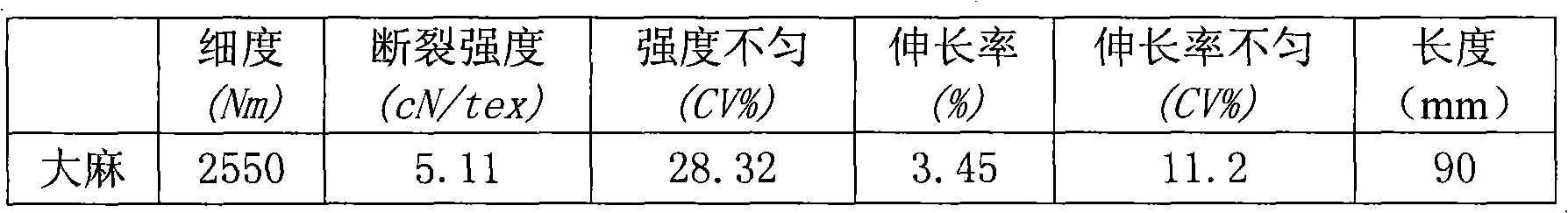

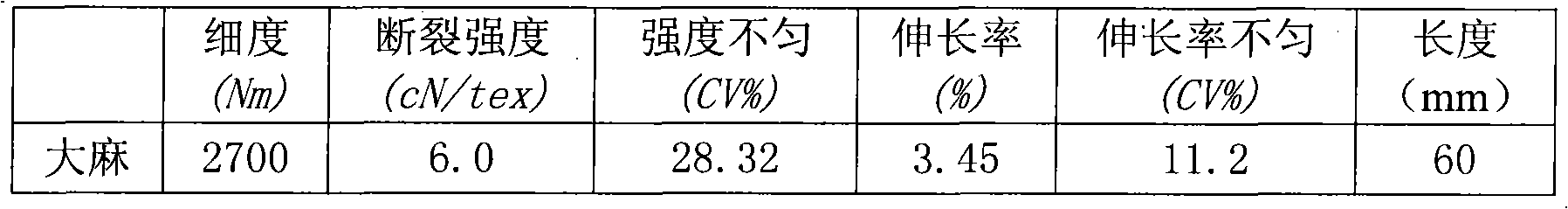

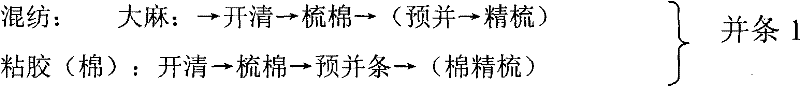

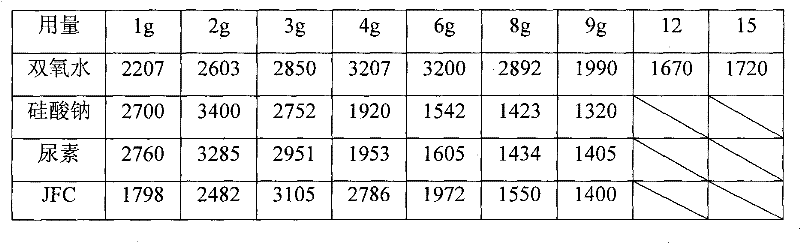

Hemp fiber and preparation method thereof

ActiveCN101831715AShorten the timeReduce processFibre cleaning/openingCarding machinesHempcreteSoftening

The invention provides a hemp fiber with a fineness of 1,500-4,000 Nm and the strength of 4-10cN / dtex. The hemp fiber has higher fineness and strength and can be used for spinning by using a dry method and preparing various grades of textile products by blending with other fibers. The invention also provides a preparation method of the hemp fiber, comprising the following steps of: chemical degumming, aftertreatment, stamping, oil feeding, softening, oil feeding and humidification, stowing and mechanical opening, wherein the step of chemical degumming specifically comprises the following steps of: adding hydrogen peroxide, alkali metal silicates, urea and a penetrating agent to water and uniformly stirring; then adding hemp peels; heating up, preserving heat and washing by using clear water; adding alkali, the alkali metal silicates, urea and the penetrating agent to water and uniformly stirring; adding oxidized hemps; and heating up, preserving heat and washing by using clear water. The method can prepare hemp fibers with an extremely high fineness and has low environmental pollution.

Owner:CHINA GARMENT BUYITIANXIA BEIJING TRADING

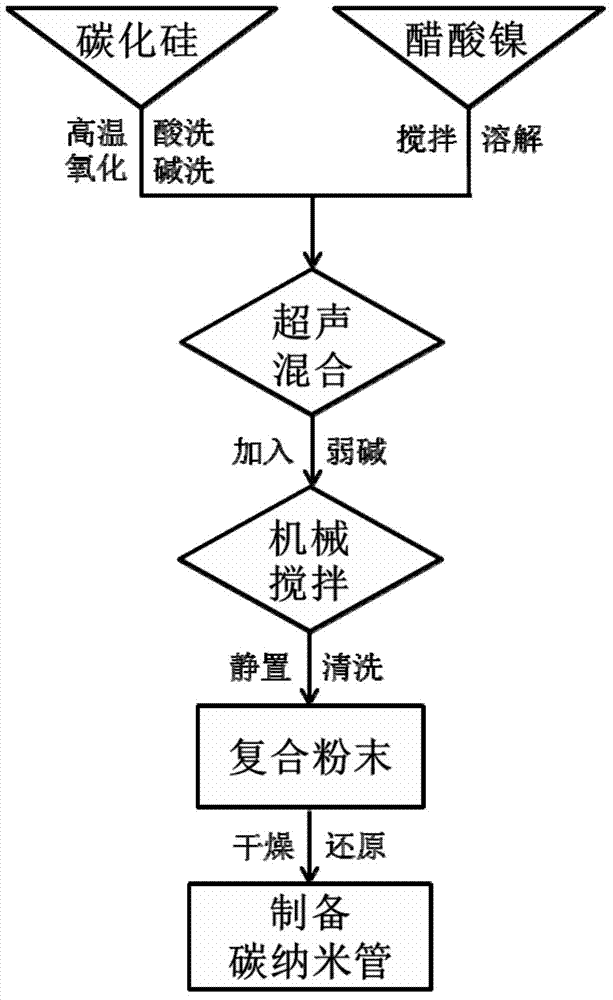

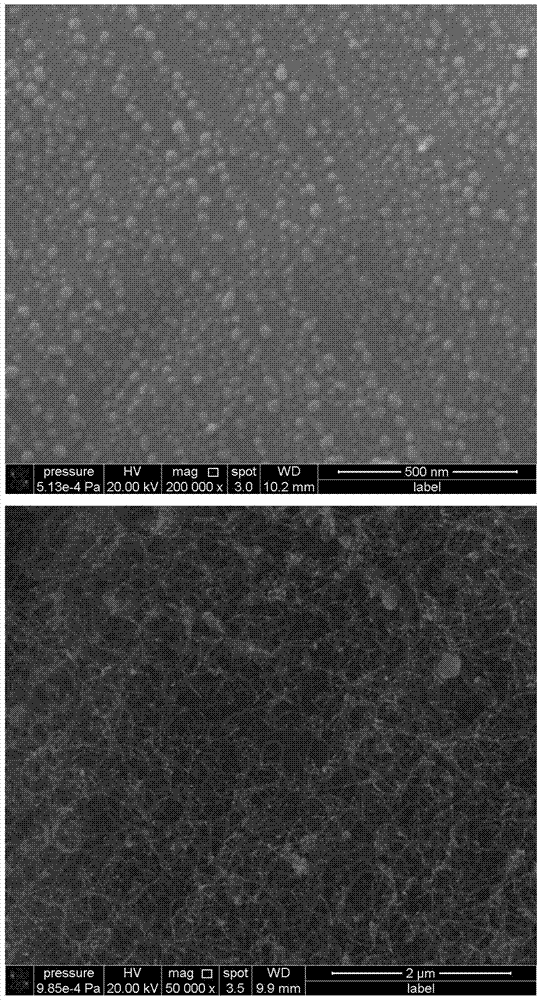

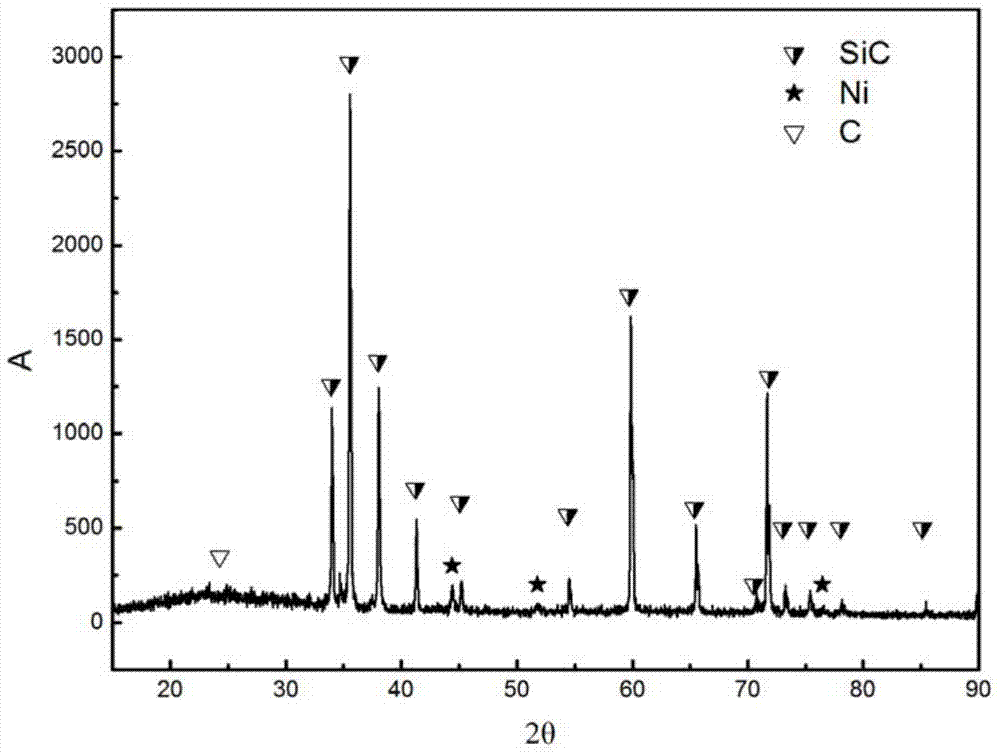

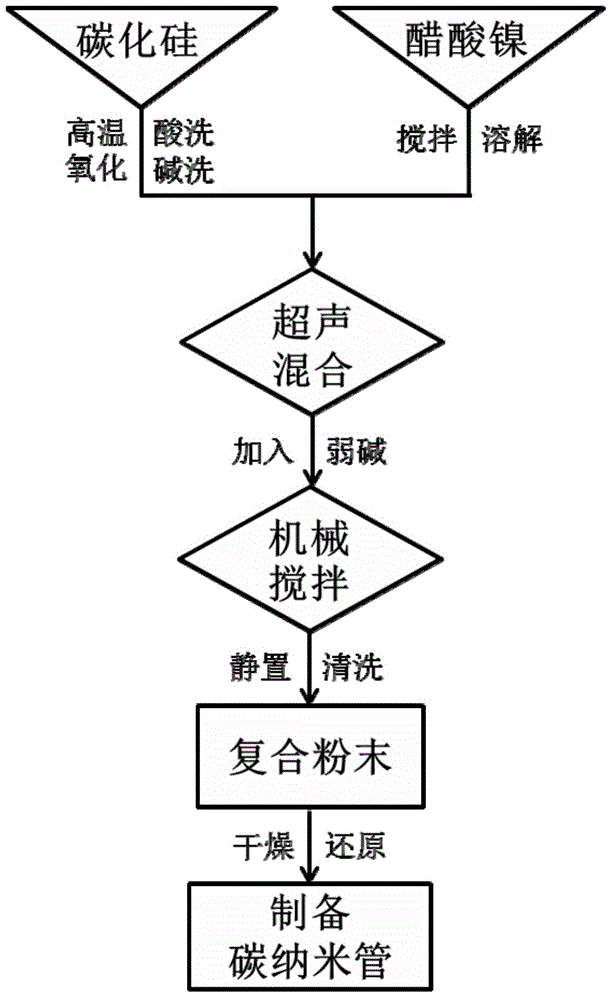

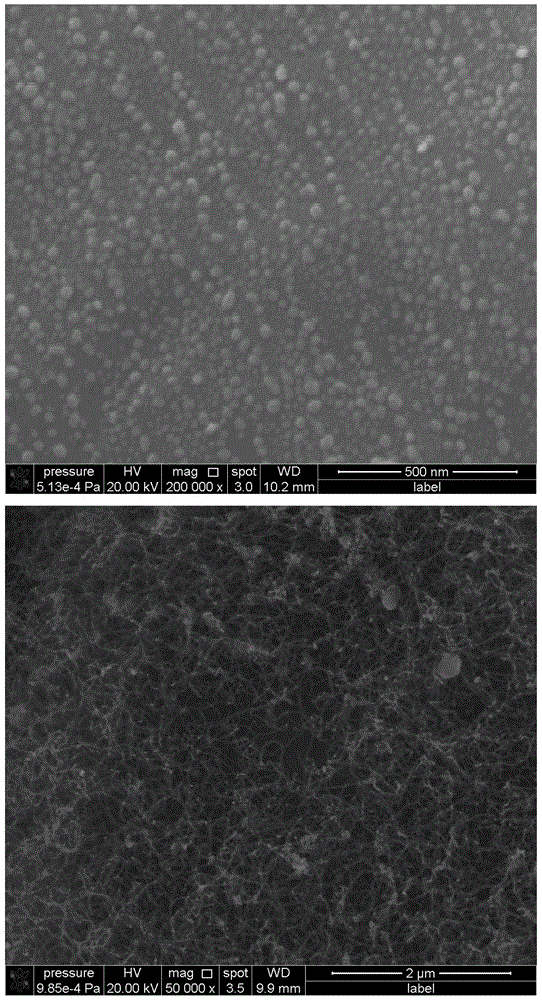

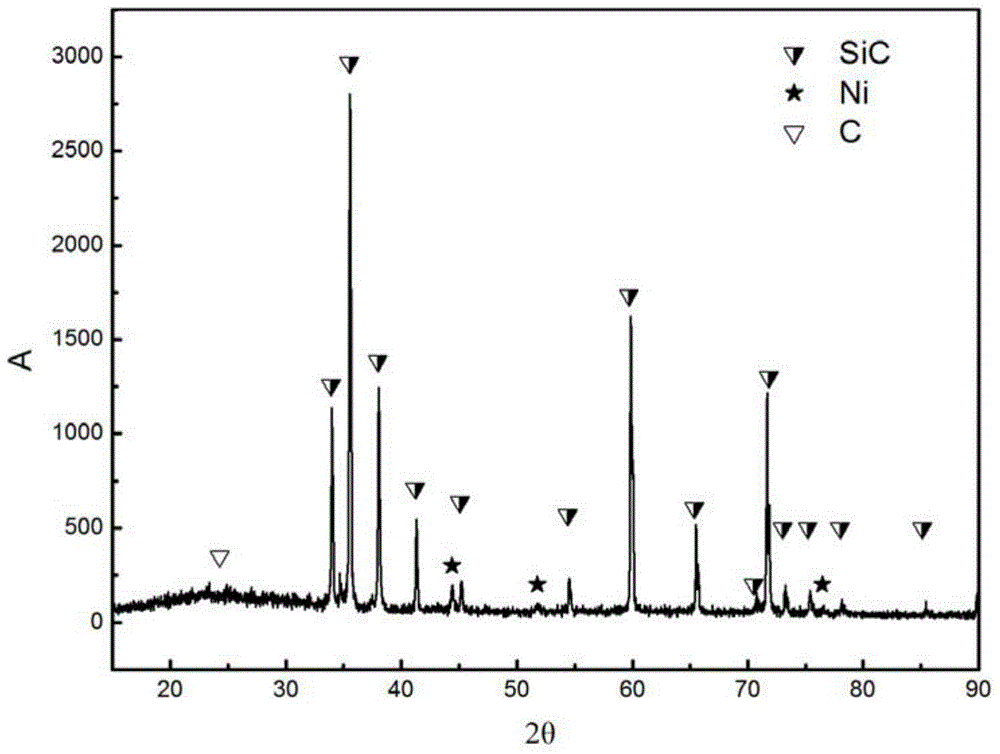

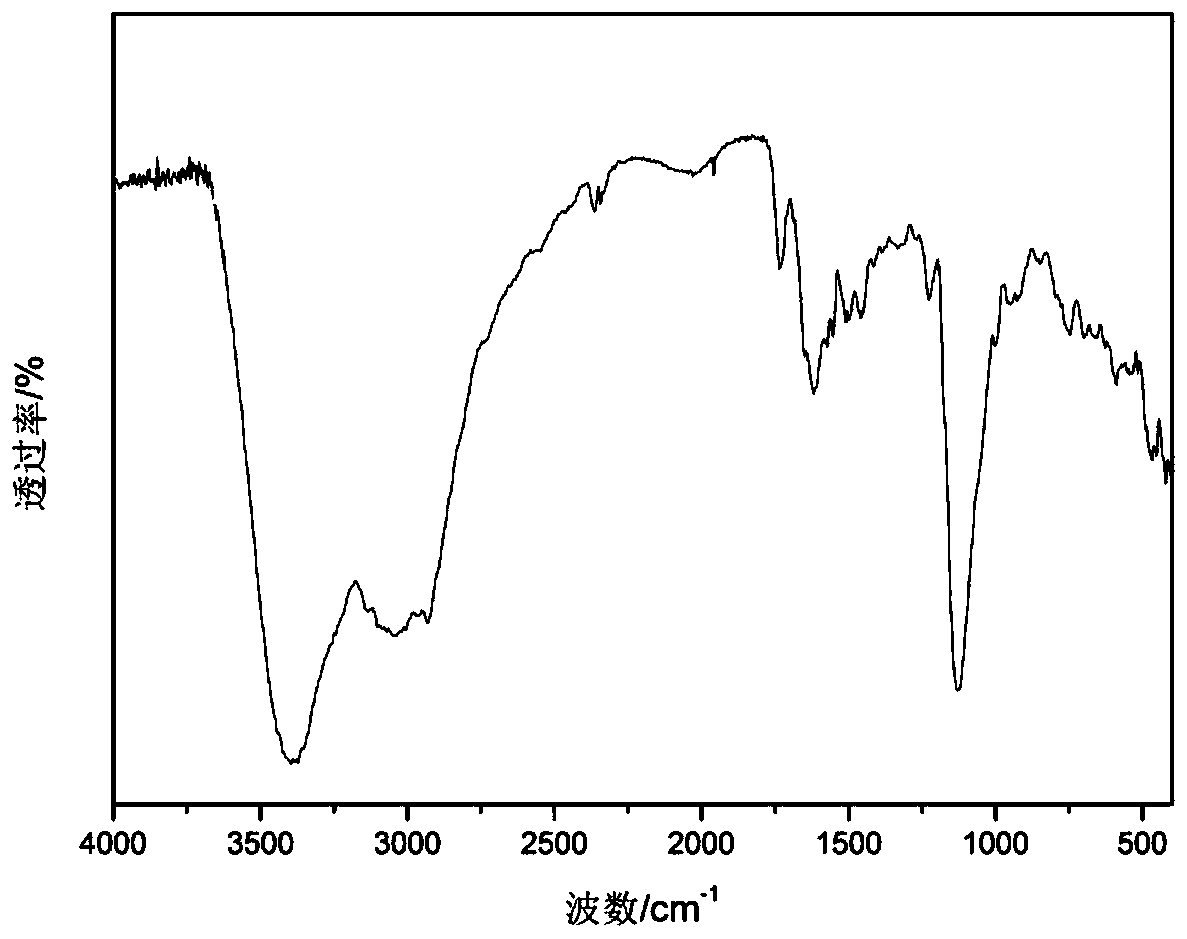

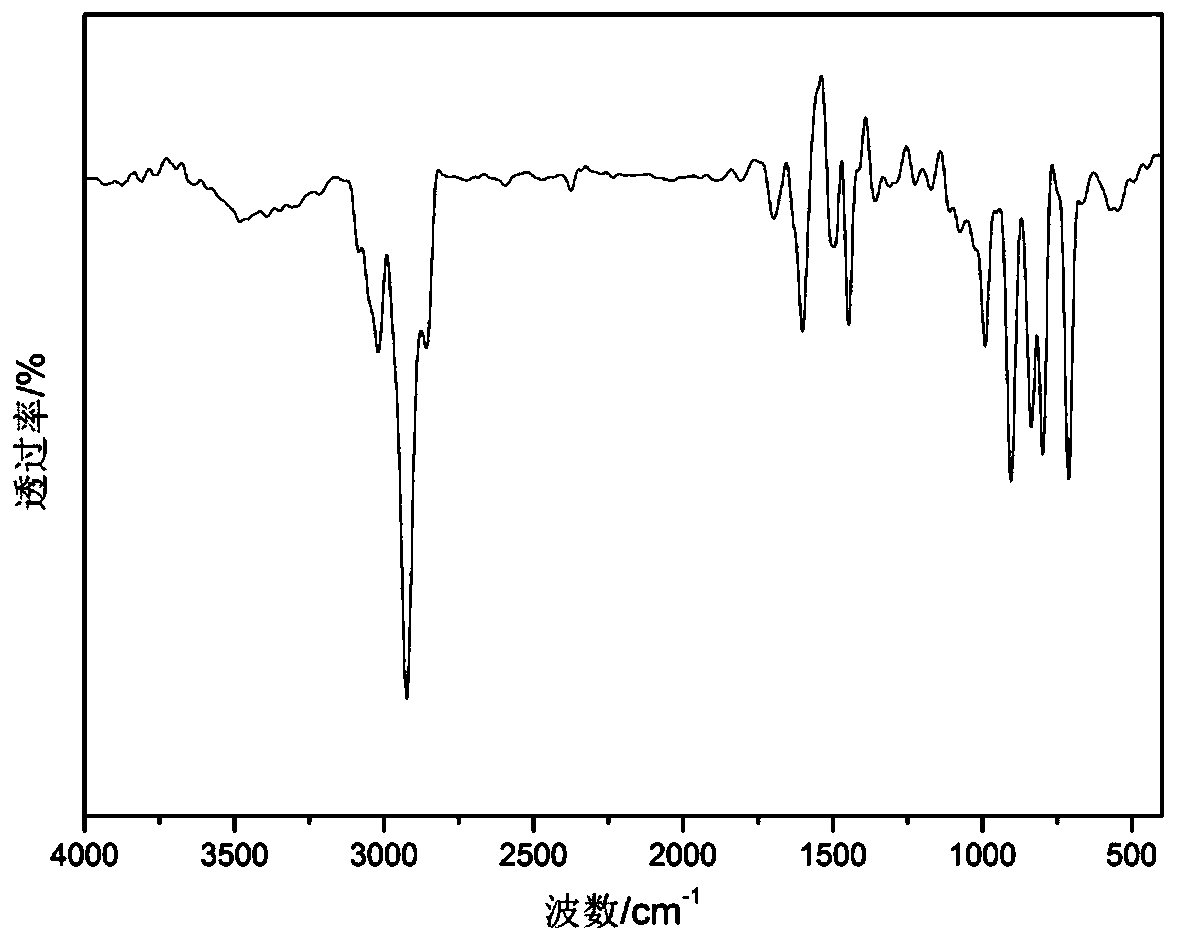

Method for preparing carbon nano tubes on surfaces of silicon carbide particles through in-situ synthesis

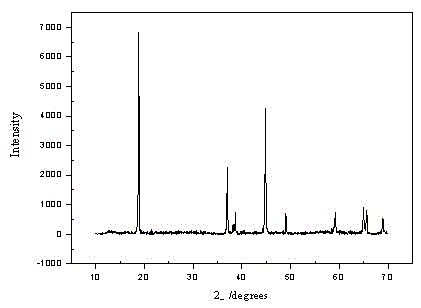

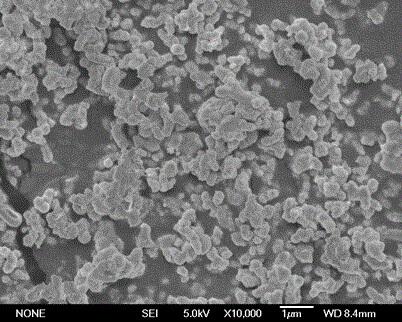

ActiveCN103754878AImprove adsorption capacityCalcination temperature is lowMaterial nanotechnologySilicon carbideNano catalystGas phase

The invention provides a method for growing multi-walled carbon nano tubes on the surface of micron silicon carbide powder in situ. The method comprises the steps of firstly oxidizing, acid-washing and alkali-washing the surface of the silicon carbide powder to remove silicon oxide and other impurities on the surface; secondly wrapping the surface of silicon carbide with a layer of uniformly distributed nano-catalyst particles by adopting the method of chemical codeposition, then putting the powder into a quartz tube furnace, and preparing the carbon nano tubes on the surface of silicon carbide in situ through catalytic cracking by utilizing the method of chemical vapor deposition. By adopting the method, uniform distribution of the carbon nano tubes on the surface of micron silicon carbide can be achieved, the difficulty that the carbon nano tubes are easy to agglomerate is solved, and a basis is provided for preparing high-performance multi-scale composite materials. The method is simple and has high feasibility. The prepared carbon nano tubes are uniformly dispersed on the surface of silicon carbide and are controllable in quantity.

Owner:深圳优越科技新材料有限公司

Preparation processes of bambuterol hydrochloride and intermediate thereof

InactiveCN102617404ALow priceImprove responseCarbamic acid derivatives preparationOrganic compound preparationBambuterol hydrochlorideBiochemical engineering

The invention relates to preparation processes of bambuterol hydrochloride and an intermediate thereof. The bambuterol hydrochloride is synthesized by taking 3,5-dihydroxyacetophenone as a starting raw material and undergoing esterifying, brominating, reducing, condensing and salting reactions. Compared with other processes, the process has the advantages that: the technical problems of industrial production are solved, each step of reaction is simple, and conditions are mild; and the process is a preparation process with the lowest cost at present, and is successfully applied to industrial production.

Owner:张长利

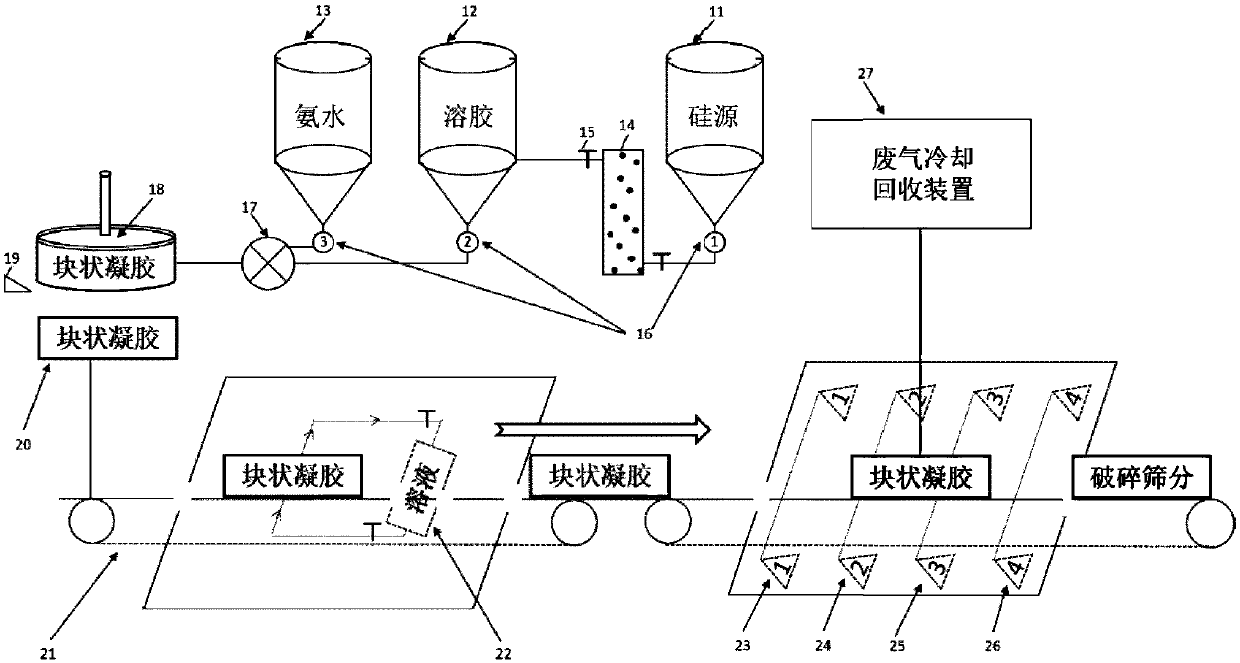

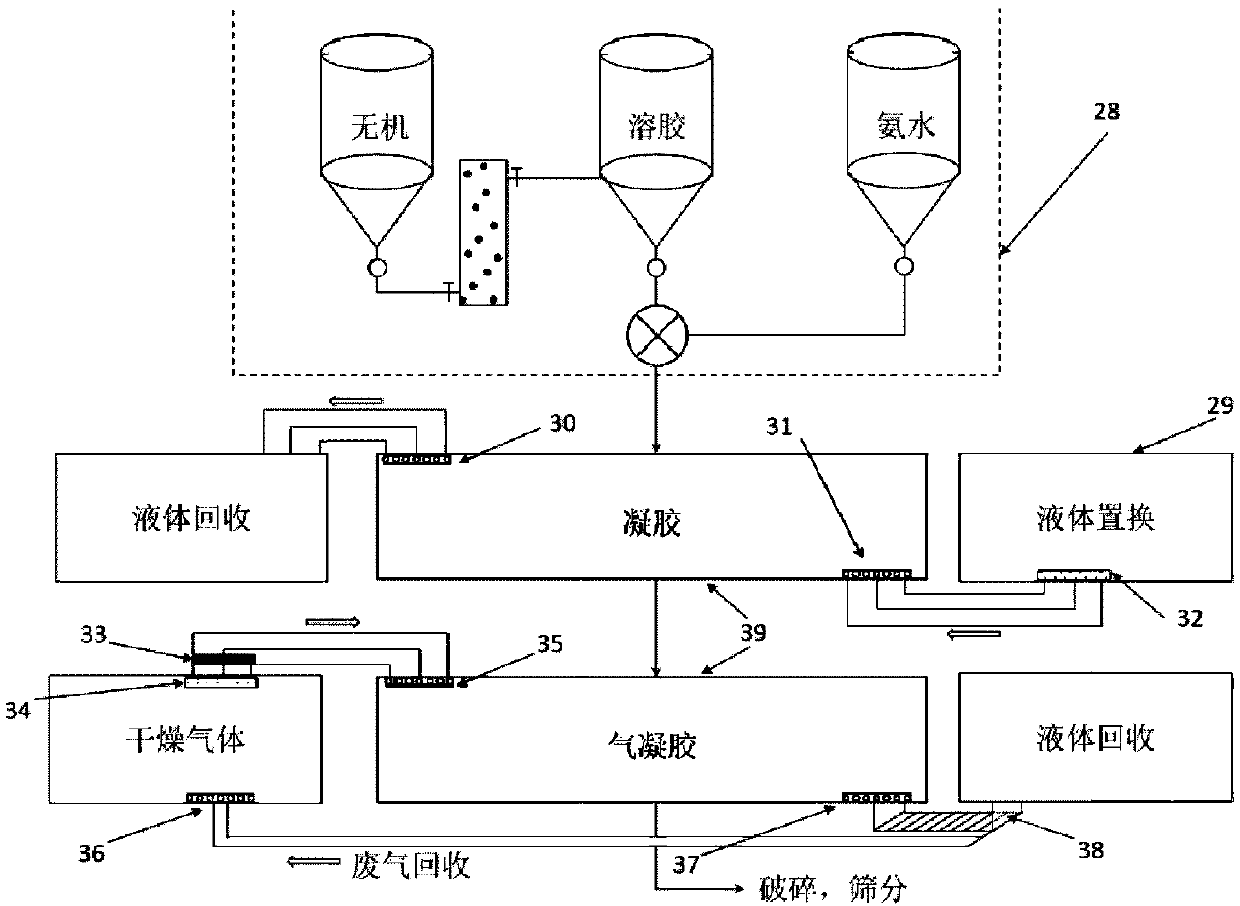

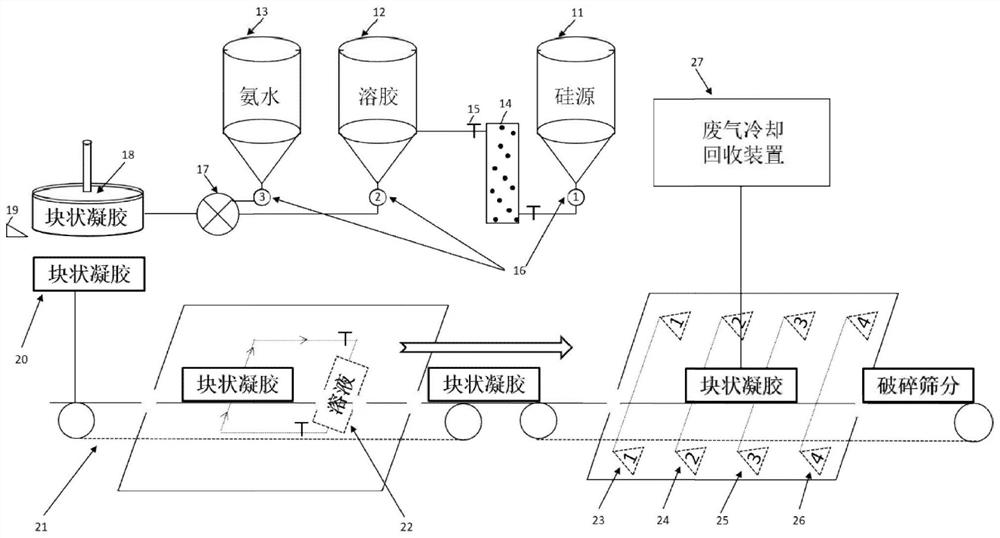

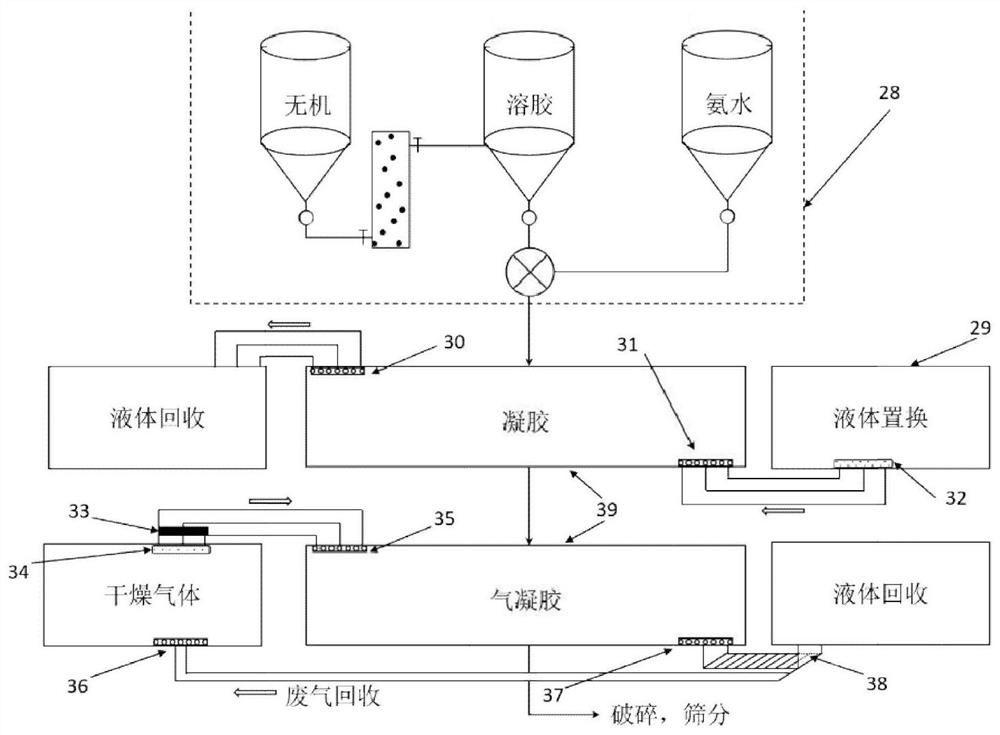

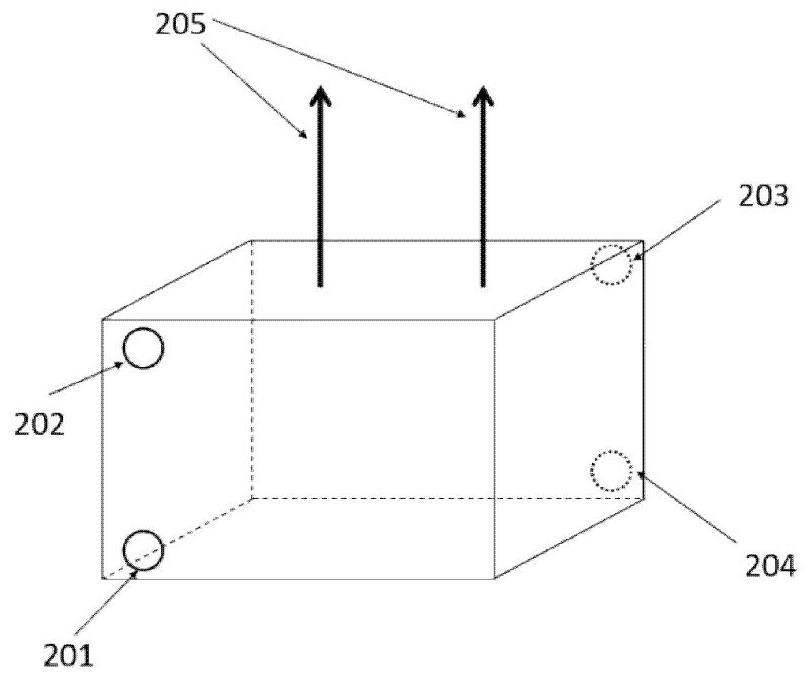

Method for continuously preparing boron-doped SiO2 aerogel

InactiveCN107662923APrecise thickness controlAccurate control of aging timeSilicon compoundsTransmittanceSmall footprint

The invention discloses a method for continuously preparing boron-doped SiO2 aerogel, belonging to the preparation field of novel porous materials. According to the method, by setting a preparation system with the functions of raw material feeding, sol preparation, gel preparation, solvent replacement, gel drying and waste material recycling, a large number of boron-doped SiO2 aerogel can be continuously produced. The method has the advantages that the occupied area of equipment is small, the preparation process is continuous and controllable, the production energy consumption is reduced, theequipment cost is lowered, and the labor cost is lowered. The prepared boron-doped SiO2 aerogel has good mechanical property, light transmittance performance and high-temperature stability.

Owner:CANEW TECH SHENZHEN CO LTD

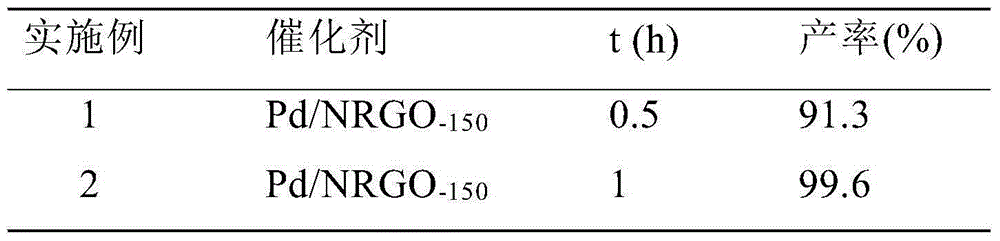

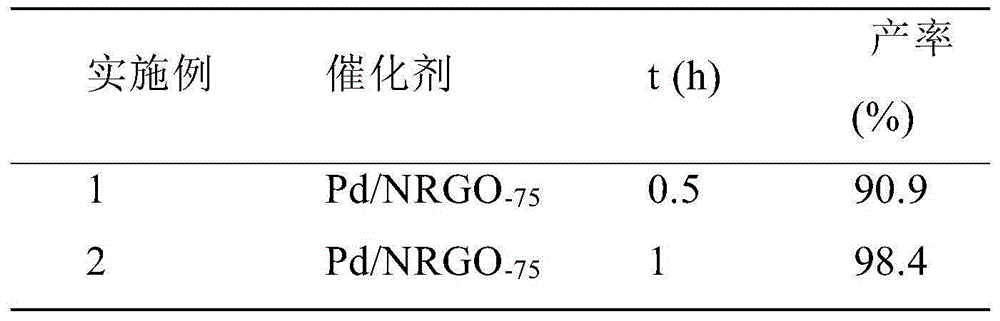

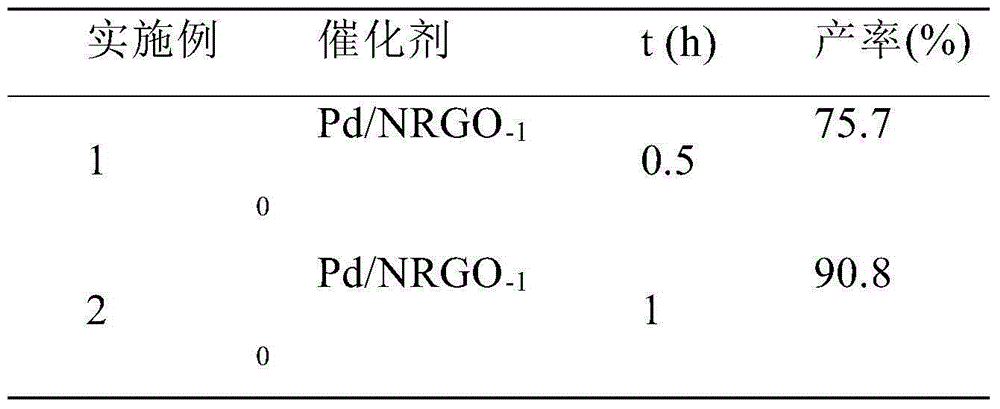

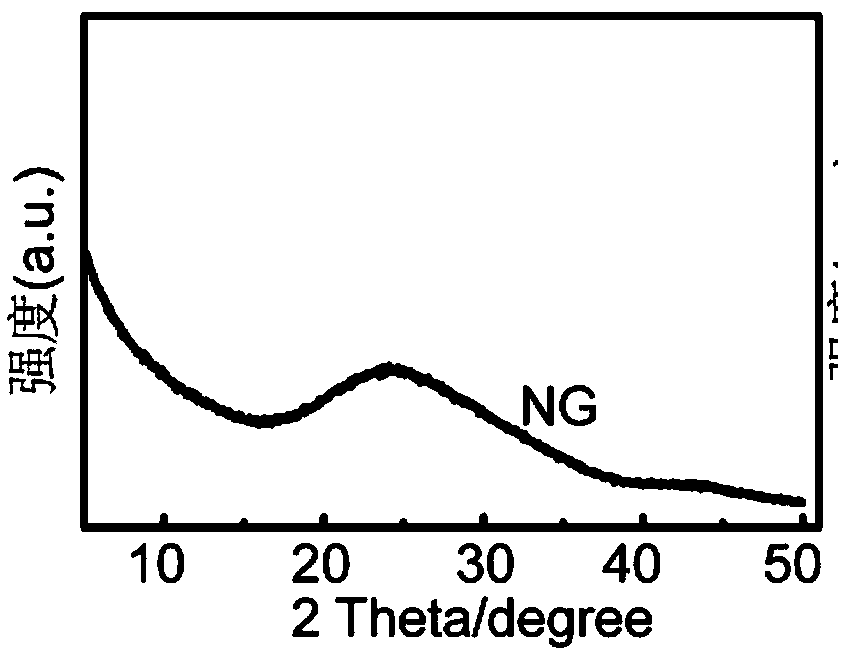

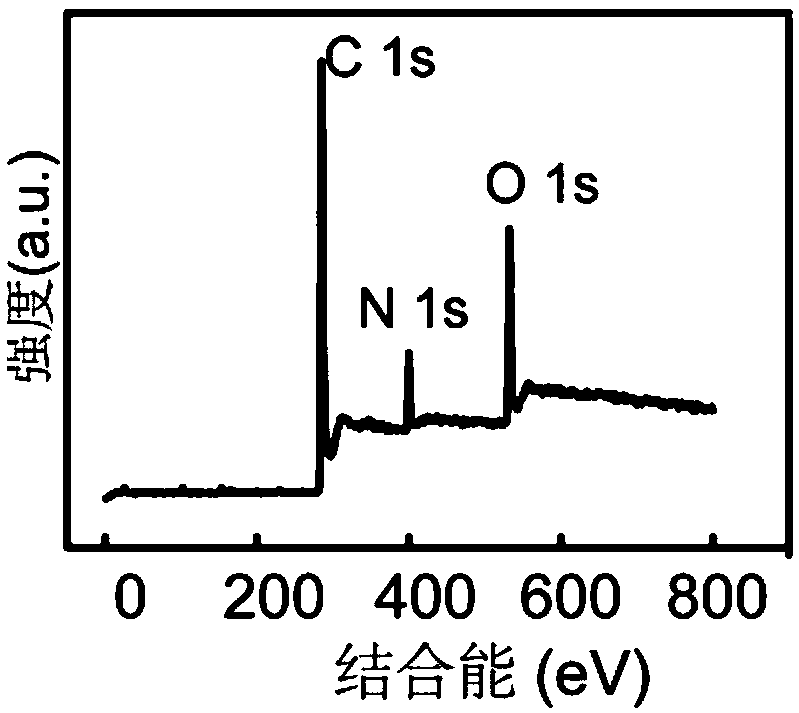

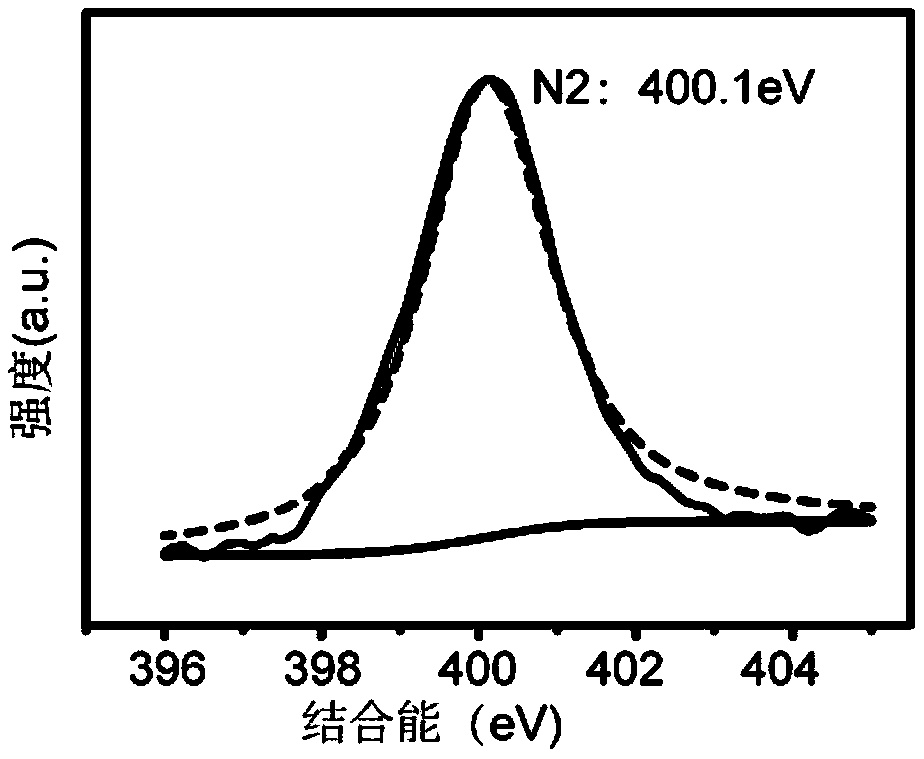

Nitrogen-doped graphene, Pd-loaded nitrogen-doped graphene catalyst and preparation method and application thereof

InactiveCN104998631AIncrease exposureAvoid high temperature and pressureOrganic chemistry methodsHydrocarbonsFiltrationNitrogen

The invention provides nitrogen-doped graphene, a Pd-loaded nitrogen-doped graphene catalyst and its preparation method and application. The preparation method of the Pd-loaded nitrogen-doped graphene catalyst comprises the following steps: mixing graphene oxide, urea and water, and conducting ultrasonic treatment for 3h; transferring the mixture into a reaction vessel and stirring at 180 DEG C to react for 10 h; conducting suction filtration, washing and drying to obtain NRGO-x; mixing NRGO-x, a palladium chloride solution and water, and conducting ultrasonic treatment for 1 h; pouring the mixture into a reaction vessel, heating to 40 DEG C, and stirring at 2MPaH2 to react for 8 h; and conducting suction filtration after the reaction, washing, and conducting vacuum drying at 60 DEG C for 12 h, so as to obtain Pd / NRGO-x. In comparison with a traditional carbon material-loaded Pd catalyst, the nitrogen-doped graphene-loaded Pd catalyst has higher catalytic activity and stability. High temperature and high pressure are avoided by a method for preparing the nitrogen-doped graphene, and content of nitrogen is easy to adjust.

Owner:HUBEI UNIV

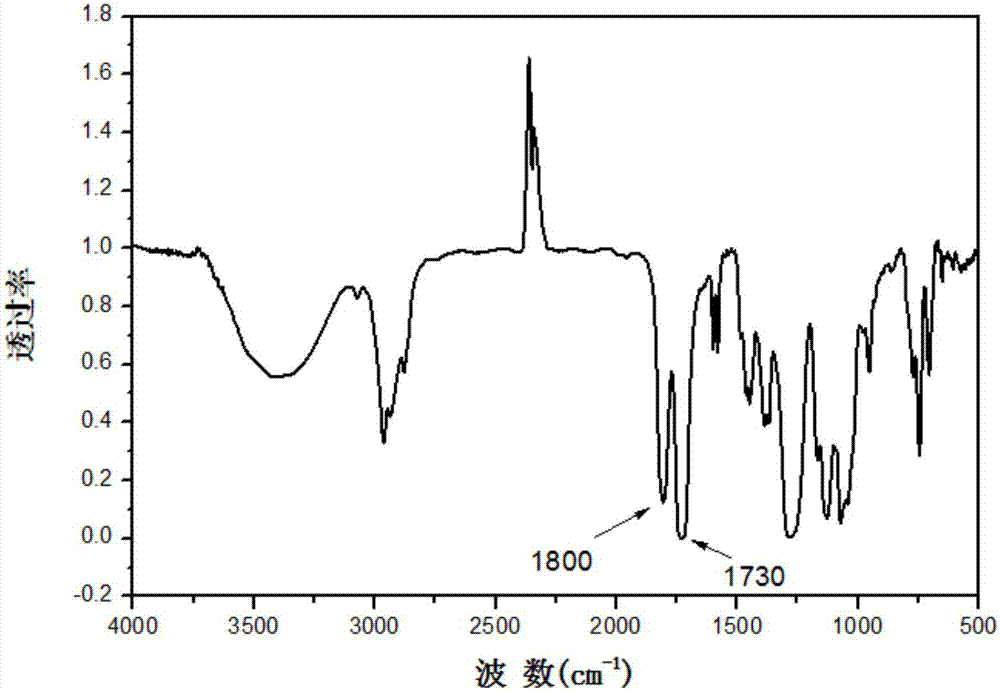

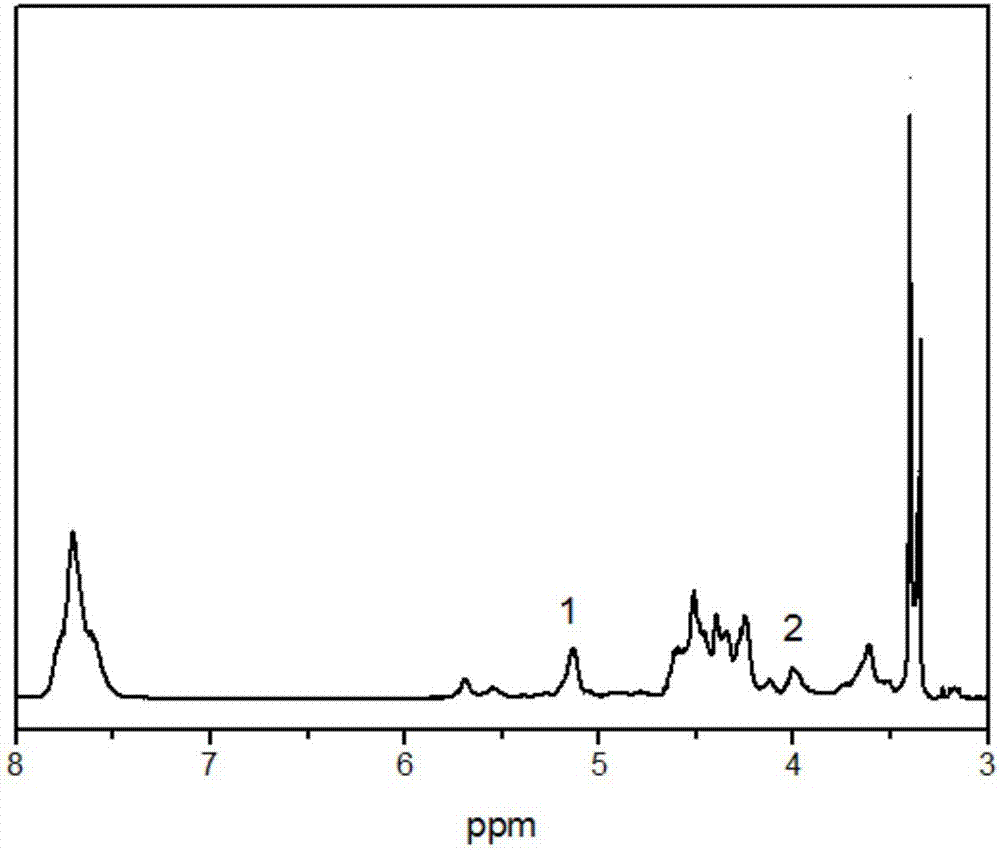

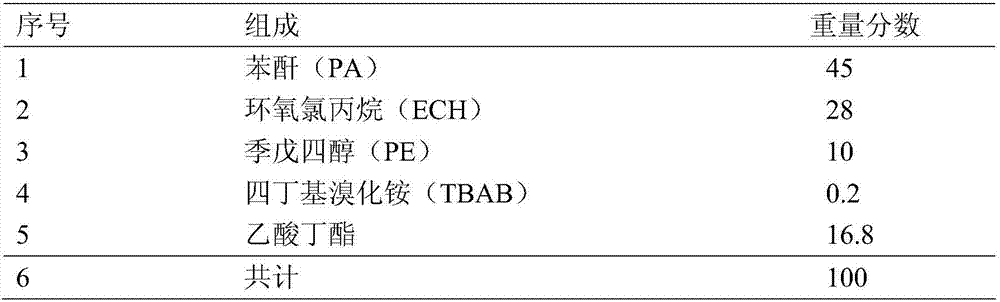

Polycyclic carbonate resin, preparation method thereof at normal pressure and application thereof

ActiveCN107189053AAvoid high temperature and pressureLow equipment requirementsPolyurea/polyurethane coatingsPolyolHydrogen

The invention discloses polycyclic carbonate resin, a preparation method thereof at normal pressure and application thereof. The preparation method includes: using anhydride, polyol and epichlorohydrin as raw materials to synthesize chlorohydrin resin; further enabling the chlorohydrin resin and hydrogen carbonate to synthesize the polycyclic carbonate resin in an atmosphere with a catalyst and CO2. High temperature and high pressure are not needed for preparation of the polycyclic carbonate resin, and reaction can be realized at the normal pressure, so that process and equipment are simple, reaction time is short, and the raw materials are easy to get. The polycyclic carbonate resin prepared by the method is low in volatility and basically nontoxic and has high biodegradability. Mechanical performance and chemical medium resistance of non-isocyanate polyurethane synthesized by the polycyclic carbonate resin and polyamine are improved greatly, and medium permeability resistance is lowered greatly; the synthesis process is unaffected by moisture, and the polycyclic carbonate resin is expected to become a good-performance environment-friendly material to replace conventional polyurethane.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for wall breaking of oil-containing microalgae and assistant assisted extraction of oil

ActiveCN105176671AHigh extraction rateReduce dosageFatty-oils/fats productionOil and greaseScenedesmus

The invention discloses a method for wall breaking of oil-containing microalgae and assistant assisted extraction of oil. The method comprises the following steps: 1, adjusting the pH value of a suspension of the oil-containing microalgae to 7.5-14, and carrying out hydrothermal treatment; 2, carrying out an enzymatic hydrolysis reaction in the presence of an enzyme; 3, adding an assistant for promoting precipitation of oil in the oil-containing microalgae, and reacting; and 4, adding an organic solvent to extract, and separating the oil. The method has the advantages of high oil extraction rate, mild operation conditions, effective maintenance of nutrition components of the microalgae, small dosage of the organic solvent, environmental protection and low energy consumption, is suitable for Nannochloropsis oceanica, chlorella, diatom, scenedesmus, Monoraphidium sp. and other microalgae, and has a wide application range.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing different types of nitrogen-doped graphene with low-temperature plasma

InactiveCN109368618AAvoid the synthetic processLow requirementsGrapheneCvd grapheneNitrogen doped graphene

The invention discloses a method for preparing different types of nitrogen-doped graphene with low-temperature plasma. The method comprises the steps that a nitrogen-containing compound is added intoan oxidized graphene solution with the concentration of 0.5-50 mg / ml to obtain a mixed solution, wherein the mass ratio of the nitrogen-containing compound to the oxidized graphene solution is 1:1-1:10; the mixed solution is subjected to ultrasound dispersion for 15-60 minutes to obtain a dispersion solution; the dispersion solution is subjected to centrifugal separation, a separated precipitate compound is subjected to freeze drying to obtain powder of the nitrogen-containing compound and the oxidized graphene; the powder is subjected to low-temperature plasma discharge in the atmosphere of reducible and / or inert gas to obtain different types of nitrogen-doped graphene. Compared with the prior art, the method is simpler, low in condition requirement and suitable for large-scale production, improves the benefits and reduces the cost.

Owner:CAS HEFEI INST OF TECH INNOVATION

Wall-breaking and surfactant-assisted method used for extracting grease from microalgae containing oil

ActiveCN105273831AHelps to separate outReduce dosageFatty-oils/fats productionOil and greaseScenedesmus

The invention discloses a wall-breaking and surfactant-assisted method used for extracting grease from microalgae containing oil. The wall-breaking and surfactant-assisted method comprises following steps: (1) pH value of a suspension liquid of microalgae containing oil is adjusted to be 7.5 to 14, and is subjected to hydro-thermal treatment; (2) after hydro-thermal treatment, enzymatic hydrolysis is carried out in the presence of enzymes; and (3) after enzymatic hydrolysis, a surfactant is added for reaction, and an organic solvent is added for extraction and separation of grease. Grease extraction rate of the wall-breaking and surfactant-assisted method is high; operation conditions are mild; nutritional ingredients of microalgae can be maintained effectively; using amount of the organic solvent is small; the wall-breaking and surfactant-assisted method is friendly to the environment, is low in energy consumption, and is suitable for nannochloropsis oculata, chlorella, diatom, scenedesmus, and monoraphidium komarkova-legnerova; and application range is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hemp fiber and preparation method thereof

ActiveCN101831715BShorten the timeReduce processFibre cleaning/openingCarding machinesHemp fiberHydrogen peroxide

The invention provides a hemp fiber with a fineness of 1,500-4,000 Nm and the strength of 4-10cN / dtex. The hemp fiber has higher fineness and strength and can be used for spinning by using a dry method and preparing various grades of textile products by blending with other fibers. The invention also provides a preparation method of the hemp fiber, comprising the following steps of: chemical degumming, aftertreatment, stamping, oil feeding, softening, oil feeding and humidification, stowing and mechanical opening, wherein the step of chemical degumming specifically comprises the following steps of: adding hydrogen peroxide, alkali metal silicates, urea and a penetrating agent to water and uniformly stirring; then adding hemp peels; heating up, preserving heat and washing by using clear water; adding alkali, the alkali metal silicates, urea and the penetrating agent to water and uniformly stirring; adding oxidized hemps; and heating up, preserving heat and washing by using clear water. The method can prepare hemp fibers with an extremely high fineness and has low environmental pollution.

Owner:CHINA GARMENT BUYITIANXIA BEIJING TRADING

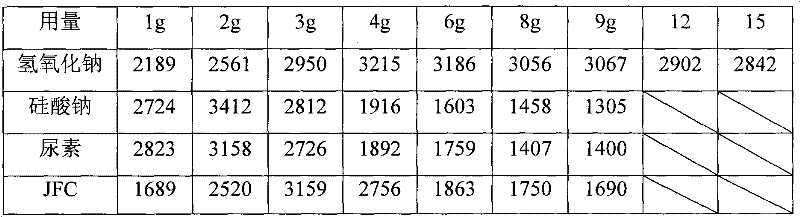

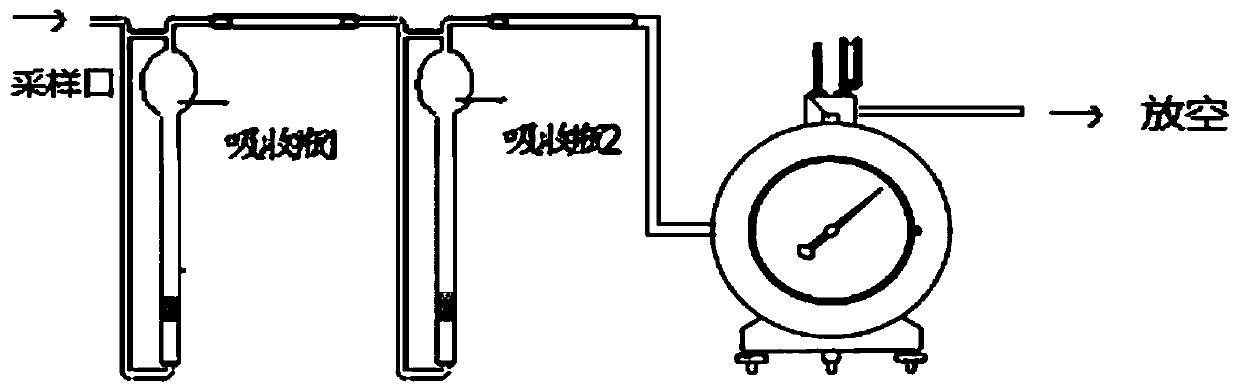

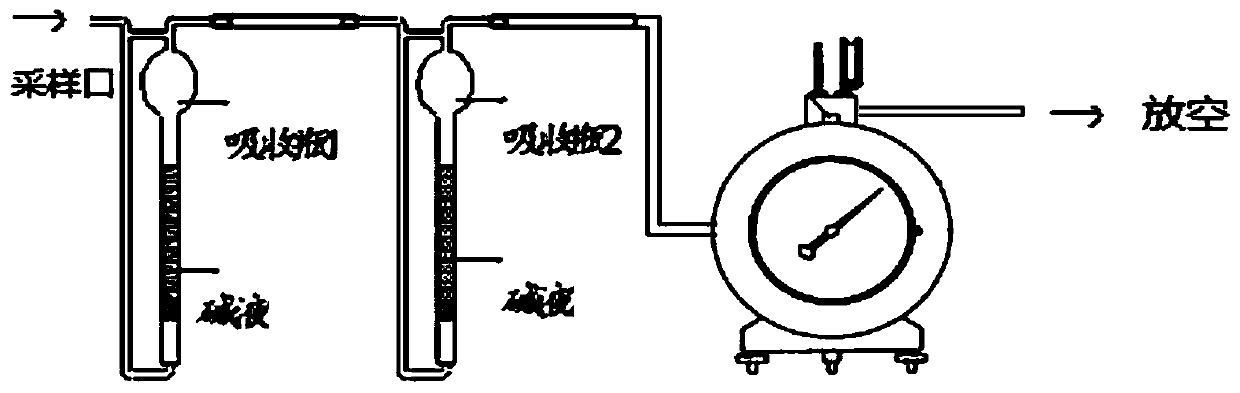

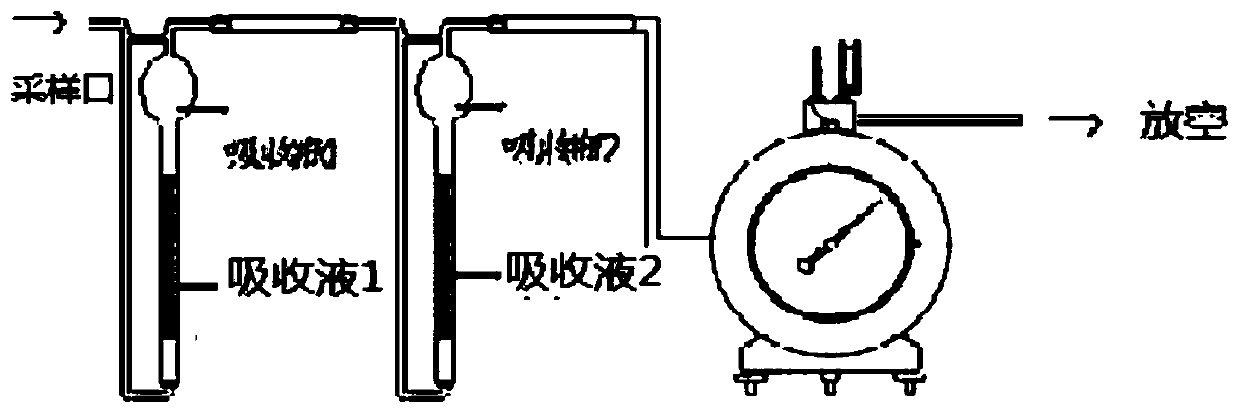

Detection method and device of trace hydrogen chloride in hydrogenation device gaseous phase

InactiveCN110441412AReduce analysis errorAvoid high temperature and pressureComponent separationSolventIon content

The invention relates to a detection method and device of trace hydrogen chloride in hydrogenation device gaseous phase. The method comprises the following steps: analyzing content of acid gas H2S ina sample point material; preparing a sodium hydroxide solution according to the concentration of the acid gas H2S, wherein the mole mass fraction is 0.01-1.0mol / L; transferring the configured sodium hydroxide solutions into two porous glass board absorption bottles by utilizing transfer pipettes, connecting a sampling port through a silicon tube, regulating the gas volume flow as 0.1-3.0L / min, andthe gas collection time is 10-70min; taking out the absorption liquid in two porous glass board absorption bottles, and determining the chloride ion content in the absorption liquid by utilizing ionchromatography, and computing the trace hydrogen chloride content in the hydrogen. High-temperature, high-pressure and high H2S dangerous sampling conditions of the hydrogenation device can be avoided, the dangerous gas in the sample is absorbed, the damage on the personnel is reduced, the determination result is more accurate, the solvent is treated in a centralized manner, and the detection limit is comparatively high.

Owner:CHINA PETROLEUM & CHEM CORP

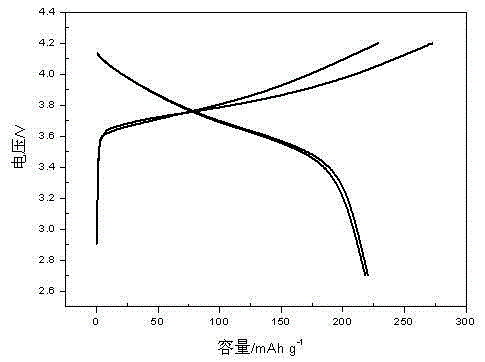

Layered ternary cathode material of lithium ion battery and microwave preparation method of layered ternary cathode material

InactiveCN105098175ASmall particle sizeSimple processCell electrodesSecondary cellsNickel saltLithium-ion battery

The invention discloses a layered ternary cathode material of a lithium ion battery and a microwave preparation method of the layered ternary cathode material. The chemical formula of the layered ternary cathode material of the lithium ion battery is Li<x>Ni<y>Co<z>Ti<1-y-z>O<2>, wherein x is more than or equal to 1.0 and less than or equal to 1.2, y is more than 0 and less than or equal to 0.6, z is more than 0 and less than or equal to 0.4, and (1-y-z) is more than 0. The microwave preparation of the layered ternary cathode material comprises the following steps of firstly, sequentially weighing a lithium salt, a divalent nickel salt, a trivalent cobalt salt and a tetravalent titanium salt according to a mole rate and placing the above salts into a mortar; secondly, adding an appropriate amount of a chelating agent and a grinding agent and grinding to prepare a mixture solution; and finally, placing the mixture solution in a crucible, placing the crucible in a microwave oven and heating for 10 to 40 minutes, naturally cooling, taking out and grinding, thereby obtaining the layered ternary cathode material. The layered ternary cathode material is high in product capacity retention ratio and high in cyclic stability; and the method has the advantages of simplicity and feasibility in process, availability in raw material, high response, low requirement for a device and low pollution, and the process parameter in the reaction process is simple and controllable.

Owner:HUBEI NORMAL UNIV

A method for in-situ self-growth of carbon nanotubes on the surface of silicon carbide particles

ActiveCN103754878BOvercoming Nanoscale EffectsPlay a reinforcing roleMaterial nanotechnologySilicon carbideNano catalystGas phase

The invention provides a method for growing multi-walled carbon nano tubes on the surface of micron silicon carbide powder in situ. The method comprises the steps of firstly oxidizing, acid-washing and alkali-washing the surface of the silicon carbide powder to remove silicon oxide and other impurities on the surface; secondly wrapping the surface of silicon carbide with a layer of uniformly distributed nano-catalyst particles by adopting the method of chemical codeposition, then putting the powder into a quartz tube furnace, and preparing the carbon nano tubes on the surface of silicon carbide in situ through catalytic cracking by utilizing the method of chemical vapor deposition. By adopting the method, uniform distribution of the carbon nano tubes on the surface of micron silicon carbide can be achieved, the difficulty that the carbon nano tubes are easy to agglomerate is solved, and a basis is provided for preparing high-performance multi-scale composite materials. The method is simple and has high feasibility. The prepared carbon nano tubes are uniformly dispersed on the surface of silicon carbide and are controllable in quantity.

Owner:深圳优越科技新材料有限公司

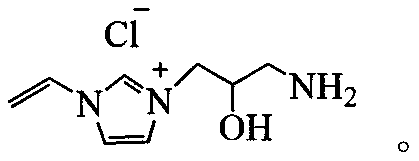

Imidazole ionic liquid, polyionic liquid and preparation methods and applications of the imidazole ionic liquid and the polyionic liquid

PendingCN110483404AEasy to separateConducive to industrial production operationsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methods1-Amino-2-propanol

The invention relates to an imidazole ionic liquid, a polyionic liquid, and preparation methods and applications of the imidazole ionic liquid and the polyionic liquid. The structural formula of the polyionic liquid is shown in the specification, wherein a is equal to 100-1000, b is equal to 100-1000, and the number-average molecular weight of the polymer ranges from 10,000 to 700,000. According to the preparation method which is a two-step synthesis method, (S)-1-amino-3-chloro-2-propanol hydrochloride is bonded to 1-vinylimidazole through a halogenation reaction by virtue of a two-step synthesis method; and in the second step, radical polymerization is performed on the chlorinated 1-vinyl-3-(1-amino-2-propanol) imidazole to generate a new substance that is the polyionic liquid. The imidazole ionic liquid and the polyionic liquid can be used as catalysts for preparing propylene carbonate, and the conversion rate and the selectivity can be improved.

Owner:HEBEI UNIV OF TECH

Preparation method of foam carbon based on hydrophobic component in coal

InactiveCN104310374AReduce energy consumptionAvoid pointless consumptionApparent densityCarbonization

The invention discloses a preparation method of foam carbon based on a hydrophobic component in coal, belonging to the preparation method of foam carbon. The preparation method comprises the following steps: (1) taking the hydrophobic component separated from a coal component as a raw material; (2) putting the raw material into a solvent A for extraction, and regulating molecular components; (3) washing the hydrophobic component obtained by extracting by use of a solvent B at the room temperature; (4) drying the hydrophobic component in an air medium with a certain temperature, relative humidity and flow velocity, so that a foam structure with a film foam wall is further formed in the hydrophobic component; (5) grinding the dried hydrophobic component, and pressing to form a tablet; (6), putting the sample subjected to the tabletting into a high-temperature carbonization furnace for heating in an inert atmosphere to obtain semi-foam carbon, and performing carbonation and heating, naturally cooling in the presence of inert gas, and cooling to the room temperature to obtain the foam carbon. The preparation method has the advantages that the raw material source is simple and low in cost, the method is simple and does not need sealed pressuring equipment, the foam carbon is rich in cellular structure, and very low in volume density and apparent density.

Owner:CHINA UNIV OF MINING & TECH

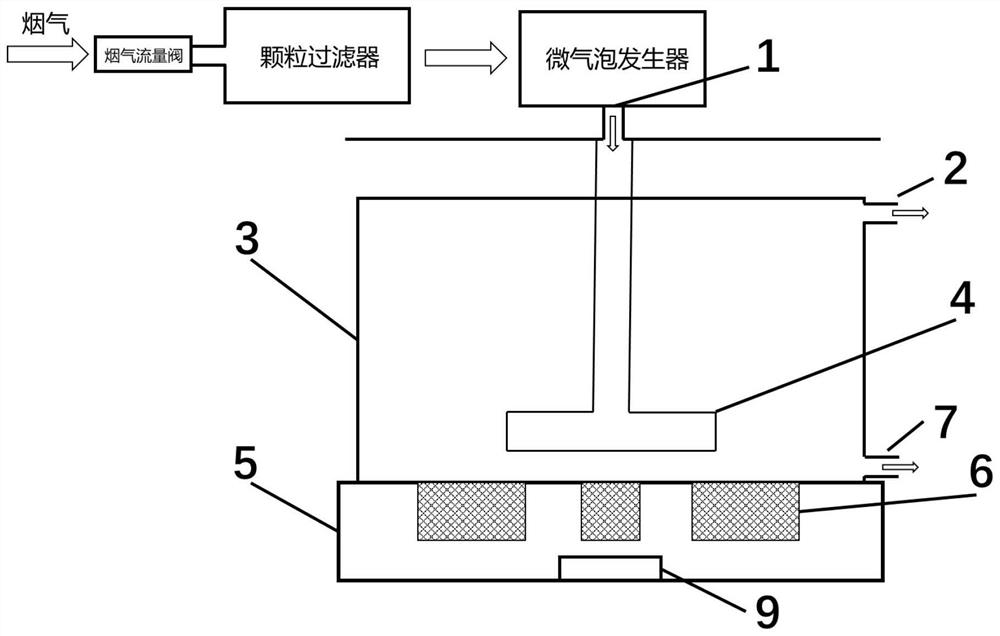

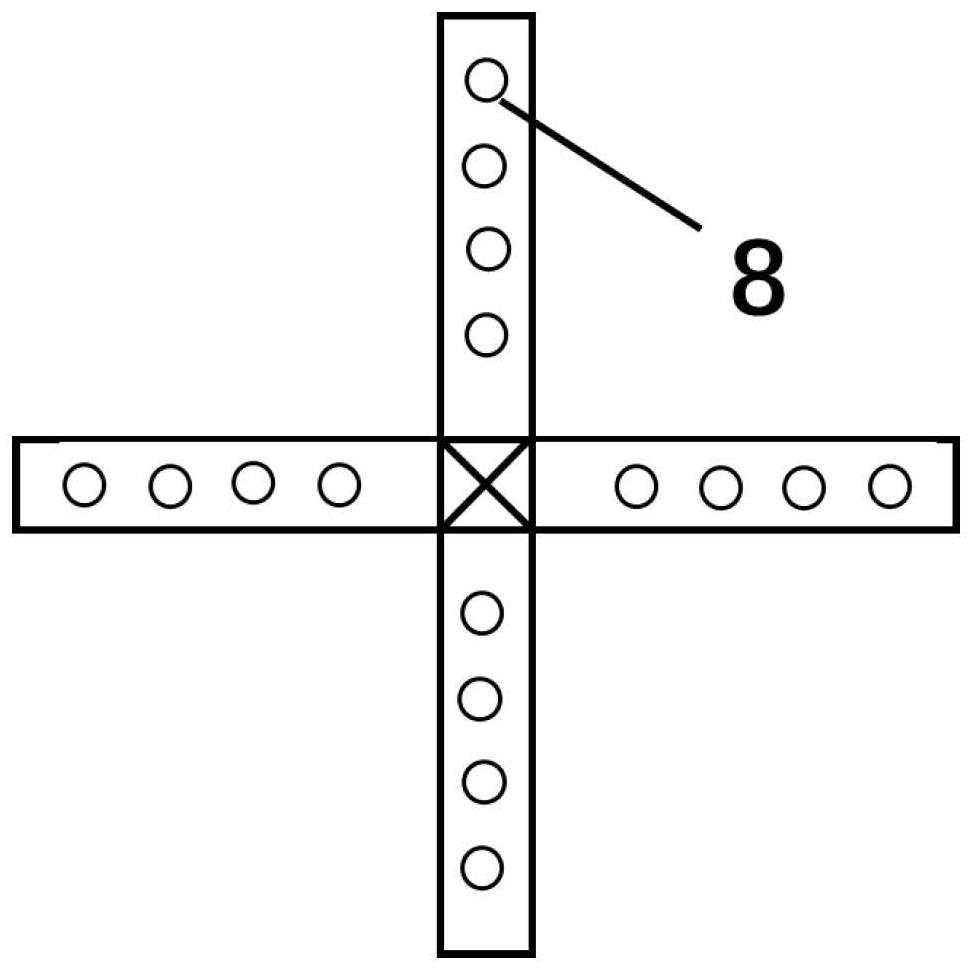

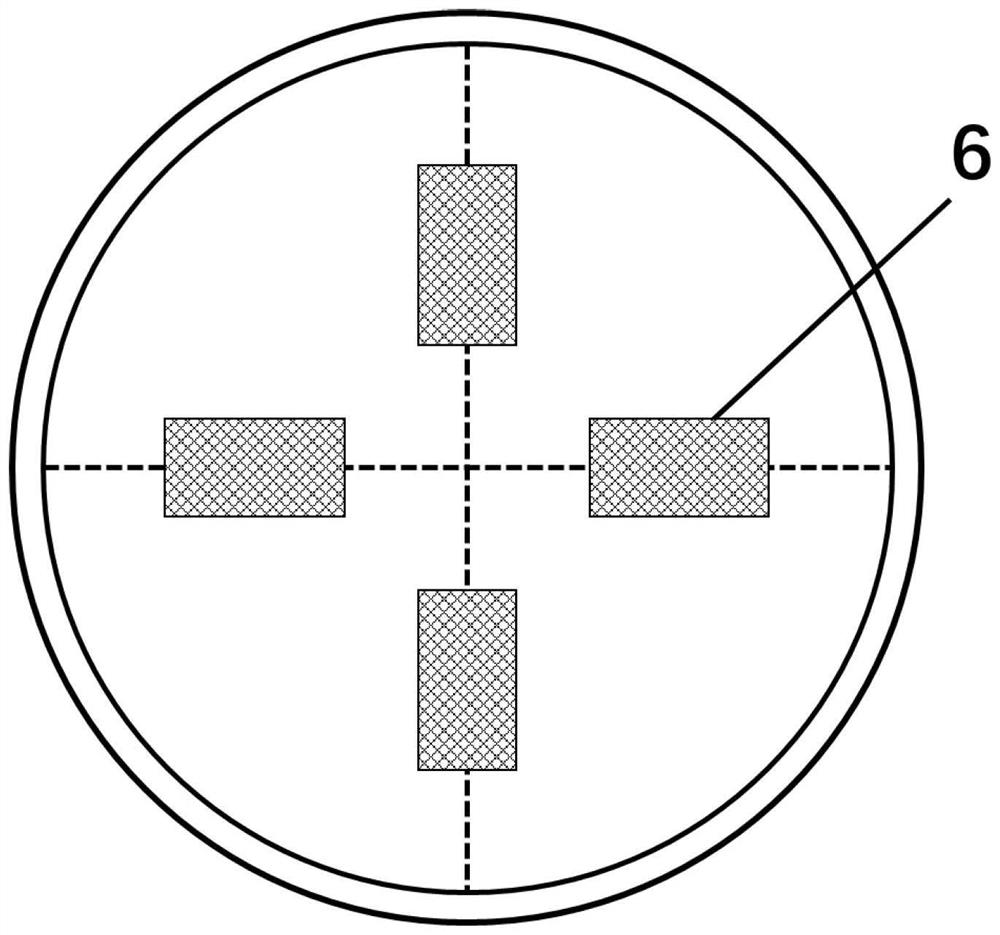

Method for efficient carbonation and harmless treatment of waste incineration fly ash

ActiveCN114453402AReduce disposal costsEasy to operateTransportation and packagingSolid waste disposalMicrobubblesFlue gas

The invention relates to a waste gas treatment technology, and aims to provide a method for efficient carbonation and harmless treatment of waste incineration fly ash. Comprising the following steps: uniformly mixing the waste incineration fly ash with water, feeding flue gas containing carbon dioxide into a particle filter, and then feeding filtered gas into a microbubble generator; the method comprises the following steps: feeding microbubbles containing carbon dioxide into a reactor, and carrying out a fly ash carbonation reaction under stirring and ultrasonic conditions to obtain carbonated wet fly ash; and after standing, carrying out drying treatment to obtain blocky carbonated fly ash. The method disclosed by the invention is low in treatment cost and does not need to add any additive; operation is simple and convenient, maintenance cost is low, operation is safe, and high temperature and high pressure are avoided; according to the method, the waste incineration fly ash is subjected to harmless treatment while carbon dioxide is captured, heavy metal is solidified, the alkalinity of the fly ash is reduced, the pH value of a reacted aqueous solution tends to be neutral, and the concentration of the heavy metal reaches the underground water discharge standard.

Owner:ZHEJIANG UNIV

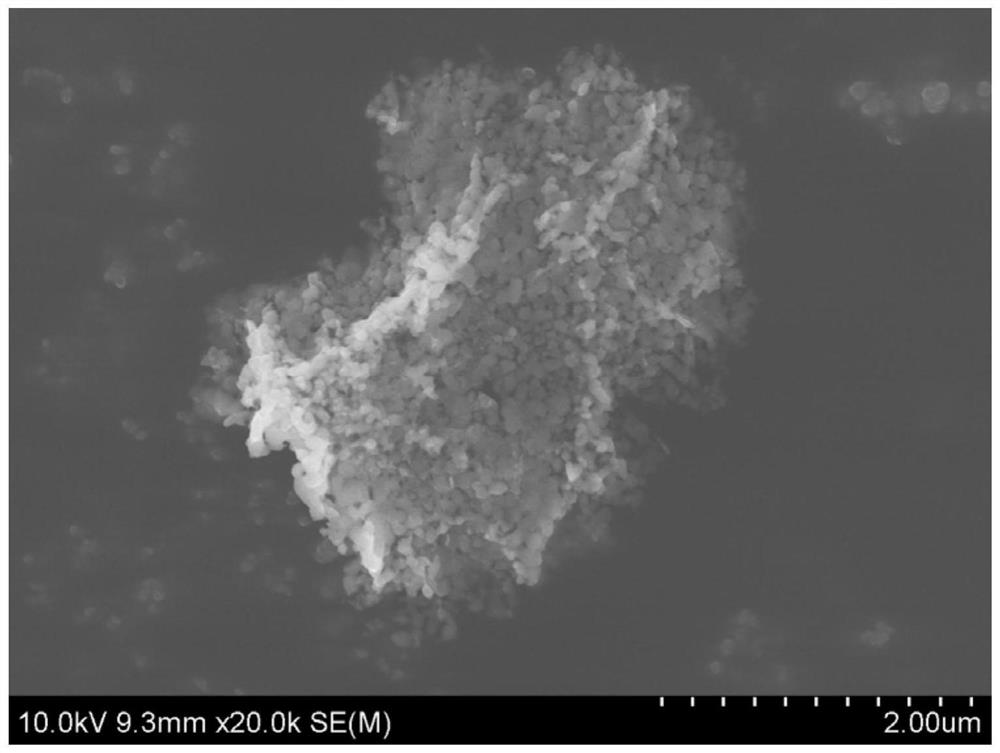

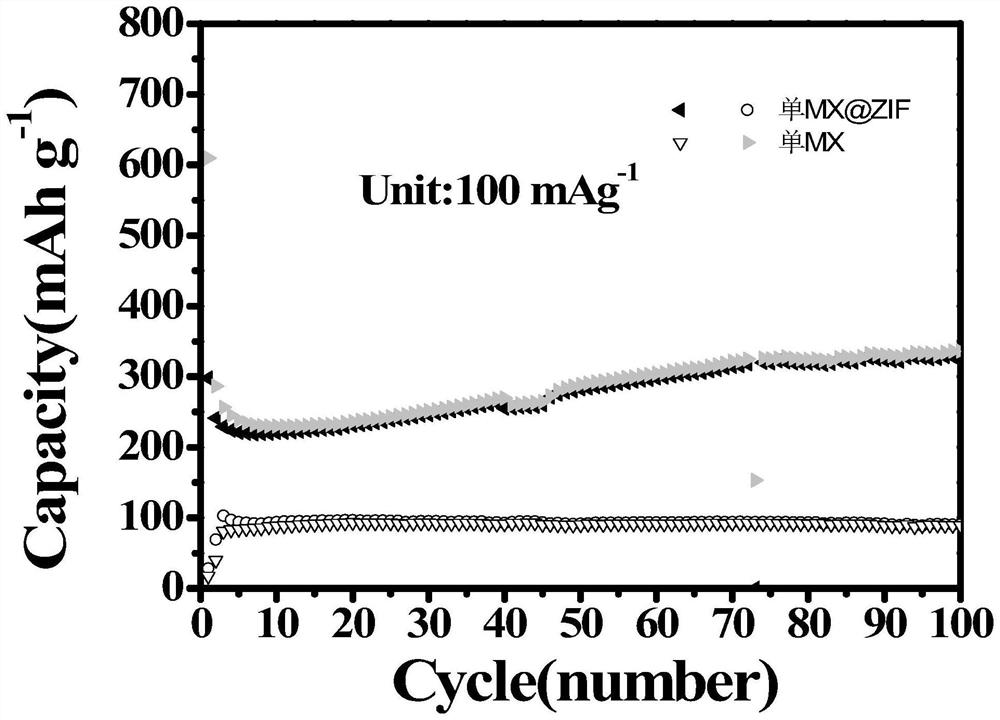

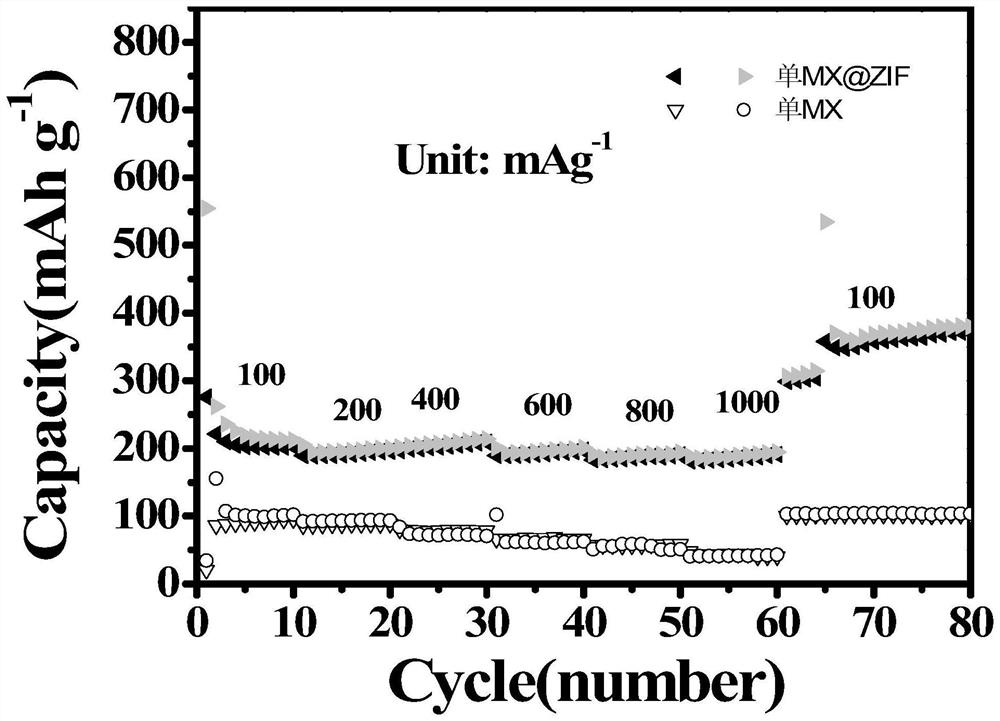

Preparation method of single-layer MXene nanosheet/ZIF-67 composite material

PendingCN114854030ASimple methodAvoid high temperature and pressureCell electrodesTitanium carbidePhysical chemistryCarbide

The invention relates to a preparation method of a single-layer MXene nanosheet / ZIF-67 composite material, which comprises the following steps: (1) stirring and dissolving a hydrochloric acid solution and lithium fluoride in a container to form hydrofluoric acid, slowly adding titanium aluminum carbide into the solution, and etching and stripping an aluminum layer; (2) centrifuging and drying the reaction liquid to obtain MXene; (3) dispersing Ti < 3 > C < 2 > MXene in deionized water, and performing ultrasonic treatment for a period of time at low temperature to obtain a single-layer Ti < 3 > C < 2 > MXene solution; and (4) growing ZIF-67 on MXene through an in-situ growth method, and sequentially centrifuging and calcining the composite material precursor. Compared with the prior art, the preparation method is environment-friendly, the preparation process is simple and easy to operate, industrial production is facilitated, and the preparation method has a wide application prospect in the field of lithium batteries.

Owner:SHANGHAI INST OF TECH

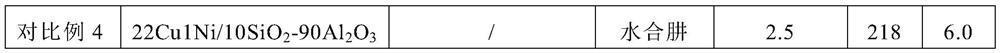

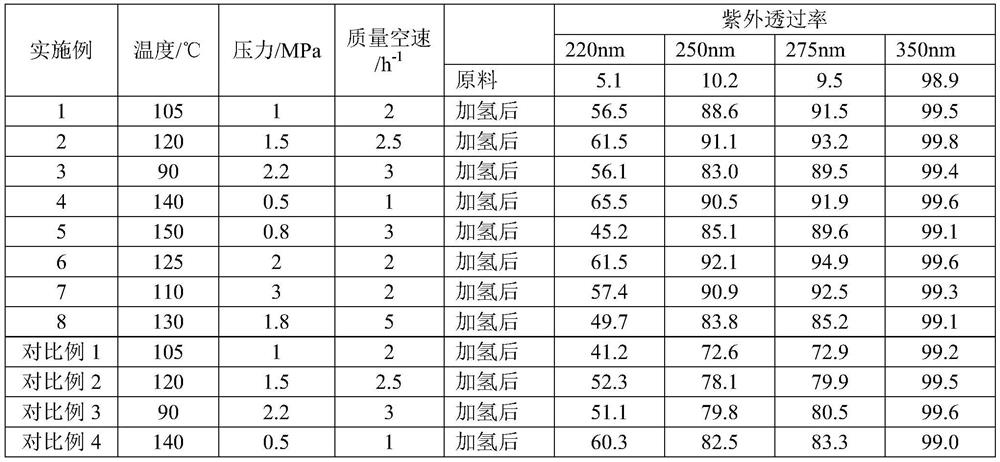

Catalyst for liquid phase hydrogenation, and preparation method and application thereof

PendingCN111644172ASimple preparation processImprove uniformityOrganic compound preparationHydroxy compound preparationPtru catalystSilicon oxide

The invention relates to a catalyst for liquid phase hydrogenation, and a preparation method and application thereof. The catalyst comprises a catalyst carrier and an active component loaded on the catalyst carrier, the active component is selected from one or more of copper, iron and nickel, the loading capacity of the active component on the catalyst carrier is 10-40 wt%, the catalyst carrier isan alumina carrier, a silicon oxide carrier or a silicon-aluminum composite carrier, and the catalyst is prepared by a sol-gel method. The catalyst is applied to a liquid-phase online reduction reaction, the reduction condition is mild, the reaction condition is mild, and the ultraviolet transmittance of ethylene glycol can be greatly improved.

Owner:PUJING CHEM IND SHA

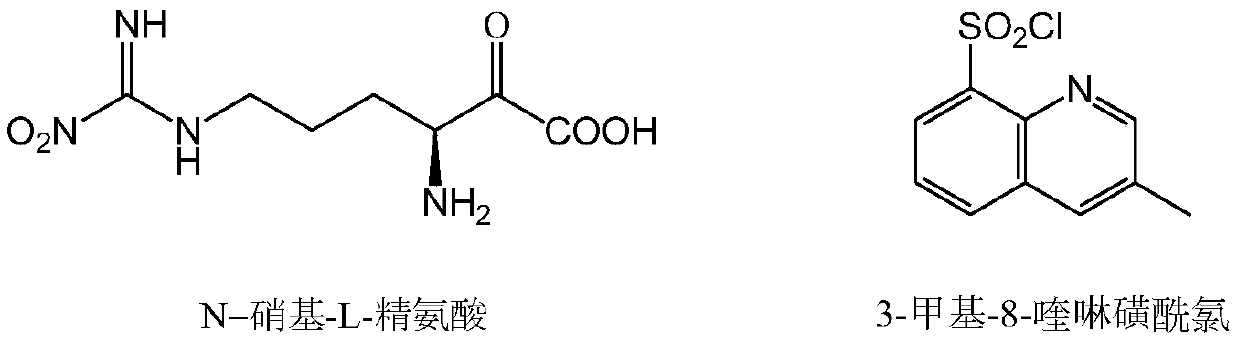

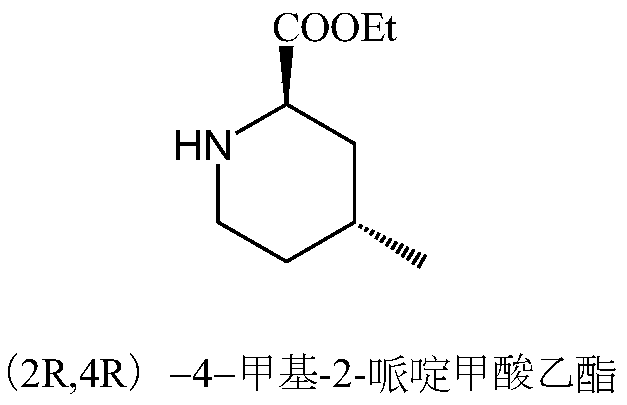

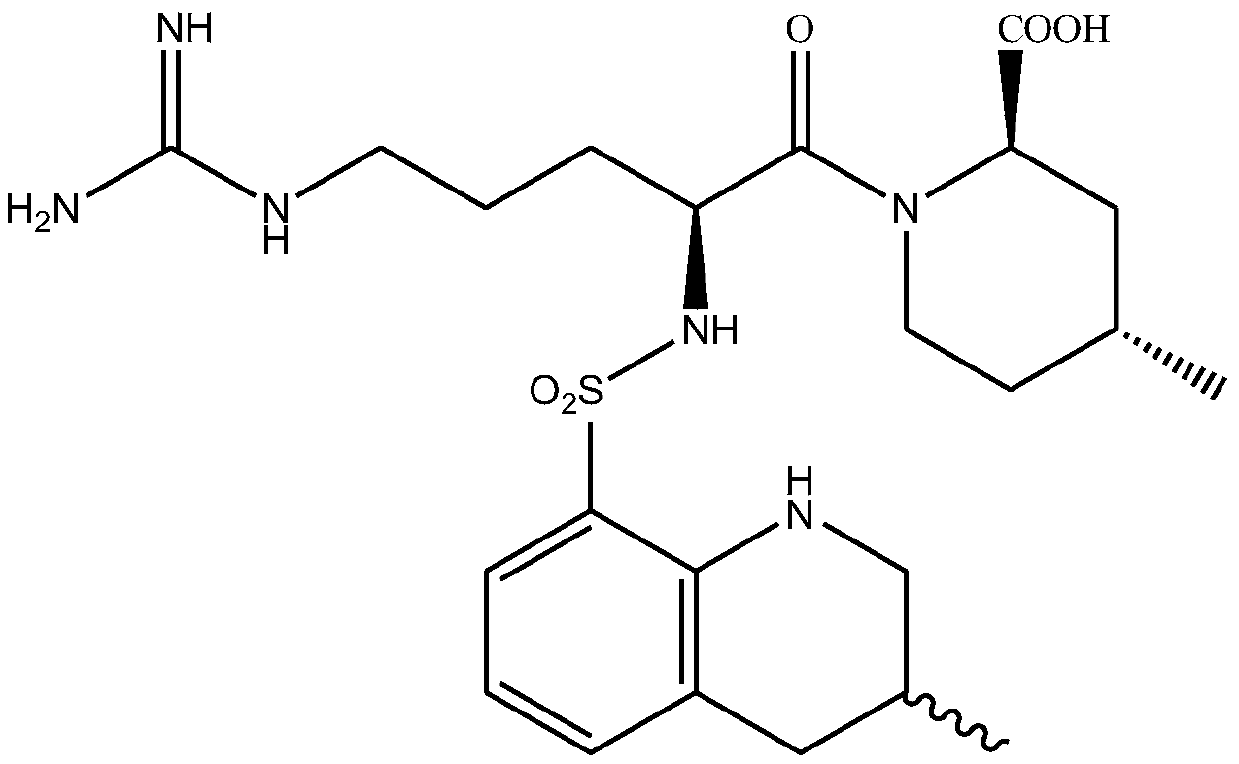

Method for continuously preparing argatroban

PendingCN111471085AReduced handling and purification stepsAchieving Continuous ResponsePeptide preparation methodsPtru catalystArginine

The invention belongs to the technical field of medicines and relates to a method for continuously preparing argatroban. The method comprises the specific processes of achieving N-nitro-L-arginine sulfonylation reaction through a phase transfer catalyst in two phases of water and a solvent; after reaction is completed, directly carrying out condensation on an organic phase without concentration treatment and ethyl (2R,4R)-4-methyl-2-piperidinecarboxylate; after reaction is completed, carrying out hydrolysis reaction on a water phase in an alkaline condition; carrying out hydrogenation reduction by using a microreactor; and finally carrying out refining to obtain argatroban. According to the method, tedious treatment and purification steps of various intermediates are reduced, and continuous reaction is achieved, so that the production efficiency is improved. Meanwhile, almost the same solvent is adopted by a plurality of steps in the reaction process, solvent recovery is facilitated, and the target of waste liquid reduction is achieved. In addition, the microreactor is adopted by the method for carrying out palladium carbon hydrogenation reduction, so that high temperature, high pressure, long reaction time and other problems in the hydrogenation process are avoided to ensure the safety in the production process.

Owner:江巨东

Method for breaking walls of oily microalgae and extracting grease in assisted manner by virtue of saponification reaction

ActiveCN105219515ALow costImprove the breaking effectFatty-oils/fats productionChemistryEnzymatic hydrolysis

The invention discloses a method for breaking walls of oily microalgae and extracting grease in an assisted manner by virtue of saponification reaction. The method comprises the following steps: (1) adjusting the pH value of a suspension of oily microalgae to 7.5-14 and carrying out hydro-thermal treatment on the oily microalgae; (2) after hydro-thermal treatment, carrying out enzymatic hydrolysis on the oily microalgae in the presence of an enzyme; (3) adjusting the pH value of the oily microalgae to be alkaline for reaction and then adjusting the pH value of the oily microalgae to be acidic for reaction; and (4) adding an organic solvent into the oily microalgae for extracting and separating grease. The method disclosed by the invention is high in grease extraction rate and mild in operating condition, can effectively maintain nutritional components of microalgae, is small in dosage of the organic solvent, environmentally-friendly and low in energy consumption, can be suitable for various microalgae such as nannochloropsis oculata, chlorella, diatom, scenedesmus, single needle algae and the like, and is wide in application range.

Owner:CHINA PETROLEUM & CHEM CORP +1

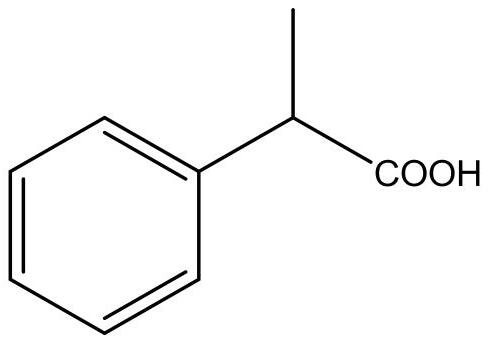

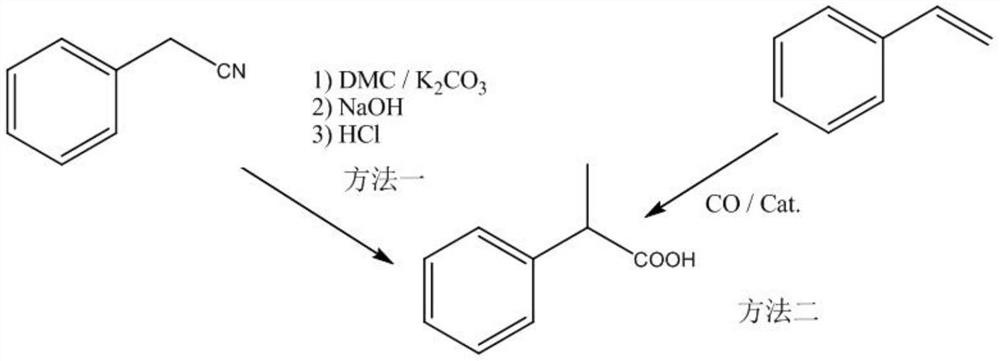

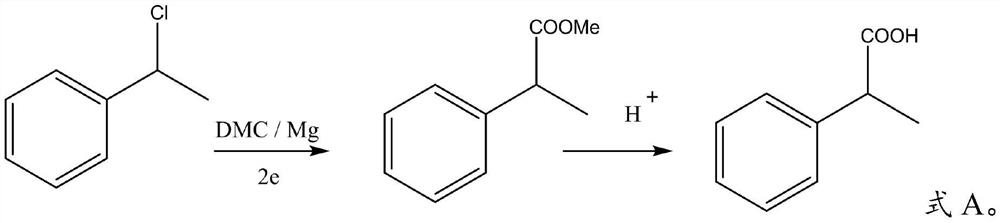

Method for electrochemically preparing 2-phenylpropionic acid

ActiveCN113979854ALow toxicityReduce usageElectrolysis componentsOrganic-compounds/hydrides/coordination-complexes catalystsElectrochemical responseOrganic synthesis

The invention provides a method for electrochemically preparing 2-phenylpropionic acid, and belongs to the technical field of organic synthesis. The method comprises the following steps: (1) in the presence of a phase transfer catalyst, carrying out electrochemical reaction by taking 1-phenyl chloroethane and dimethyl carbonate as reaction raw materials and magnesium as a consumable electrode to obtain 2-phenyl methyl propionate; and (2) mixing the 2-phenyl methyl propionate with inorganic acid, and carrying out hydrolysis reaction to obtain 2-phenylpropionic acid. According to the invention, 1-phenyl chloroethane and dimethyl carbonate are taken as reaction raw materials, the toxicity is extremely low, and dimethyl carbonate is taken as a reaction raw material and a reaction solvent, so that the use of other organic solvents can be avoided, and the method is more environment-friendly; an electrochemical reaction mode is adopted, so that reaction conditions are mild, high-temperature and high-pressure reaction conditions are avoided, and the method has very high industrial application value; and the 2-phenylpropionic acid obtained by the method provided by the invention has relatively high yield and purity.

Owner:CHONGQING WERLCHEM FINE CHEM

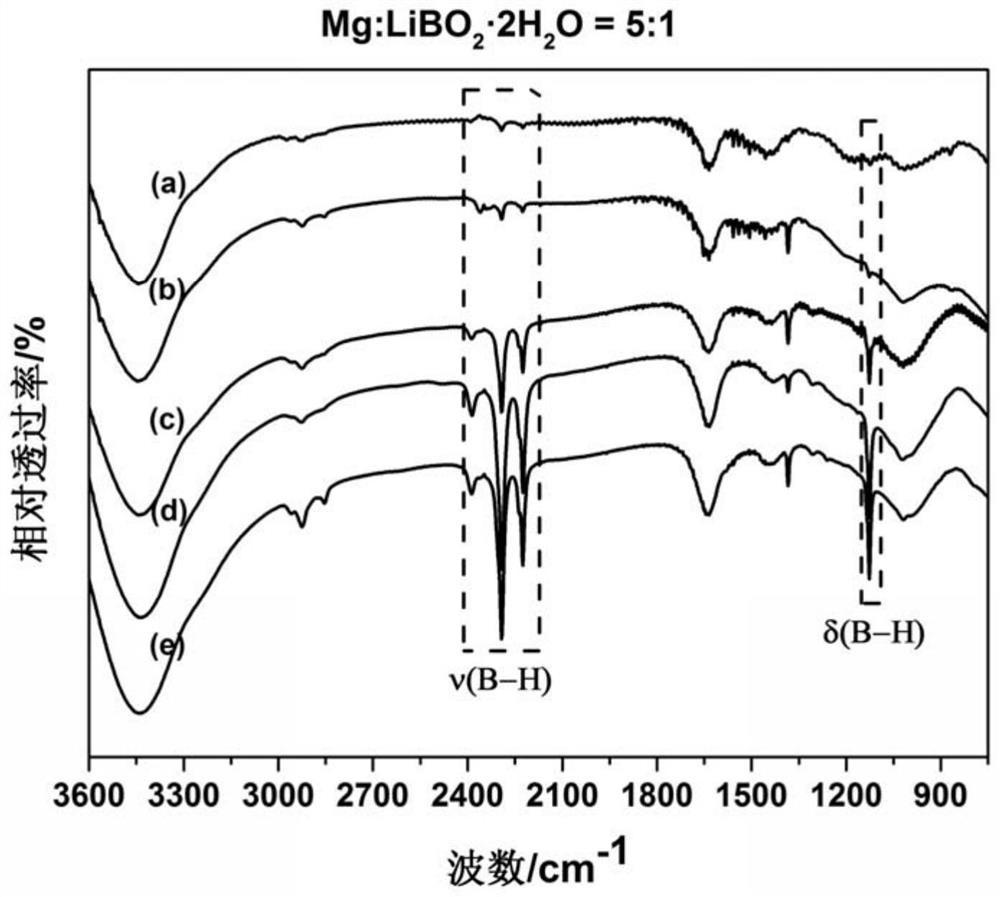

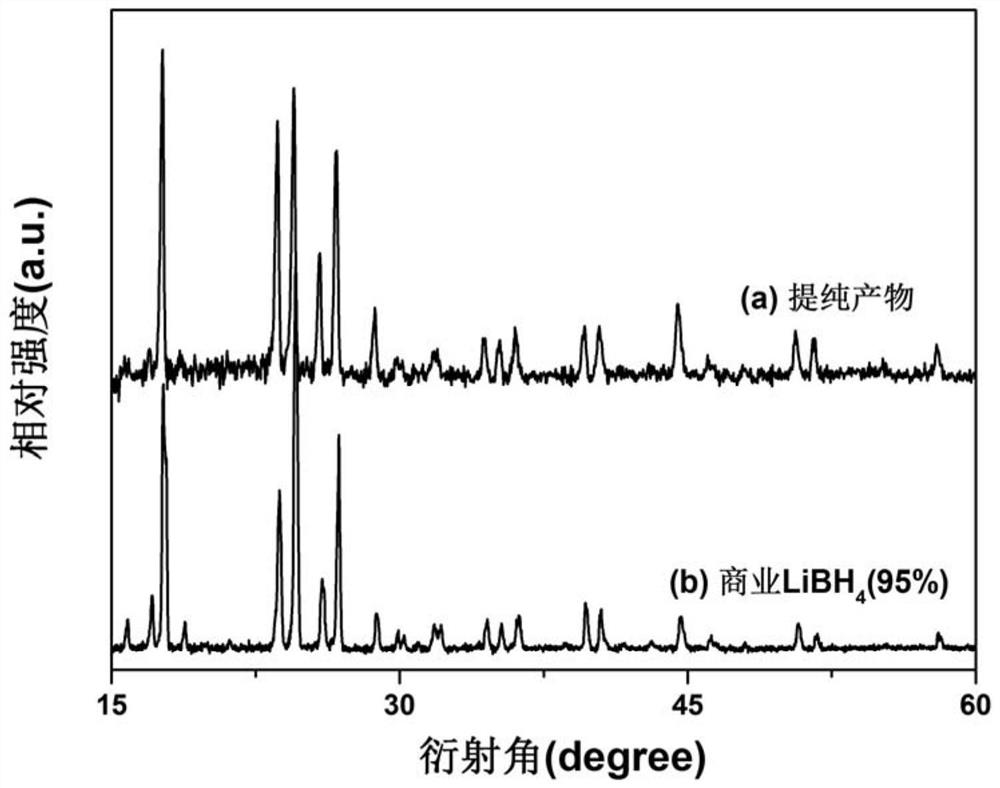

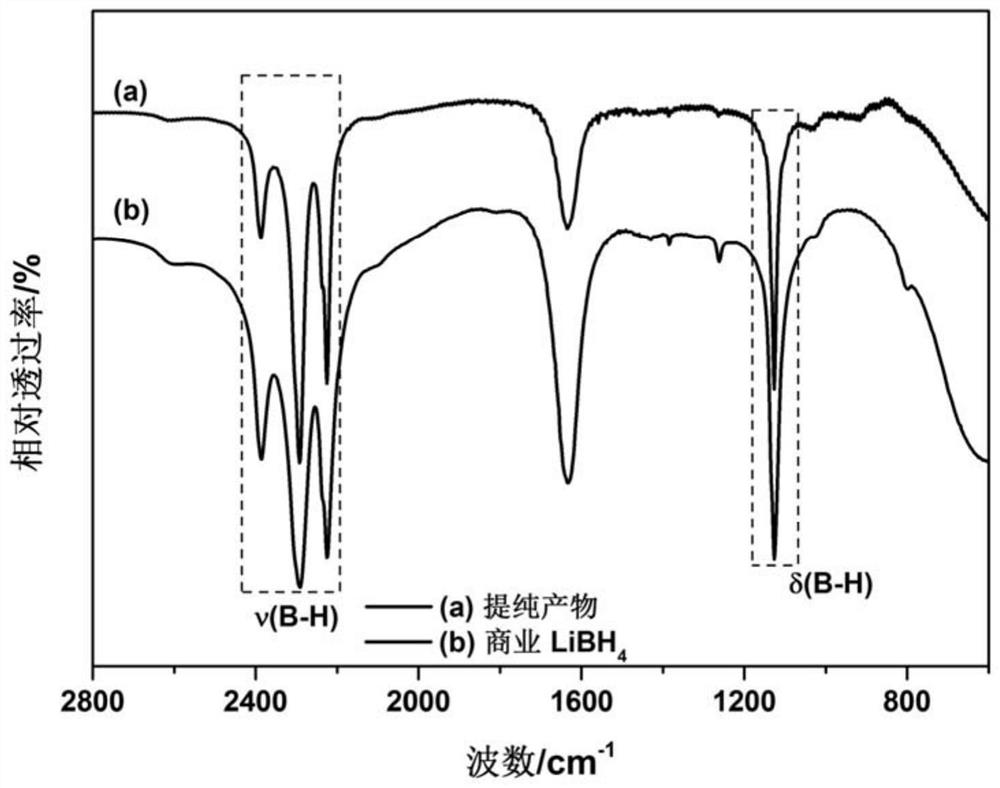

A kind of method for preparing lithium borohydride by solid phase ball milling at room temperature

ActiveCN108285131BAvoid high temperature and pressureImprove securityReversible hydrogen uptakeMonoborane/diborane hydridesLithium metaborateNon oxidative

The invention discloses a method for preparing lithium borohydride by solid phase ball milling at room temperature. The method comprises the following steps: uniformly mixing a reducing agent containing magnesium and a reducing material containing lithium metaborate under a non-oxidizing atmosphere at room temperature, performing solid-phase ball milling, separating and purifying to obtain lithium borohydride. The preparation method of the present invention has the advantages of simple process, controllable and adjustable reaction process, mild reaction conditions, low energy consumption, low cost, high output, no pollution, good safety, and can realize the recycling of boron resources, and has important practical significance.

Owner:SOUTH CHINA UNIV OF TECH

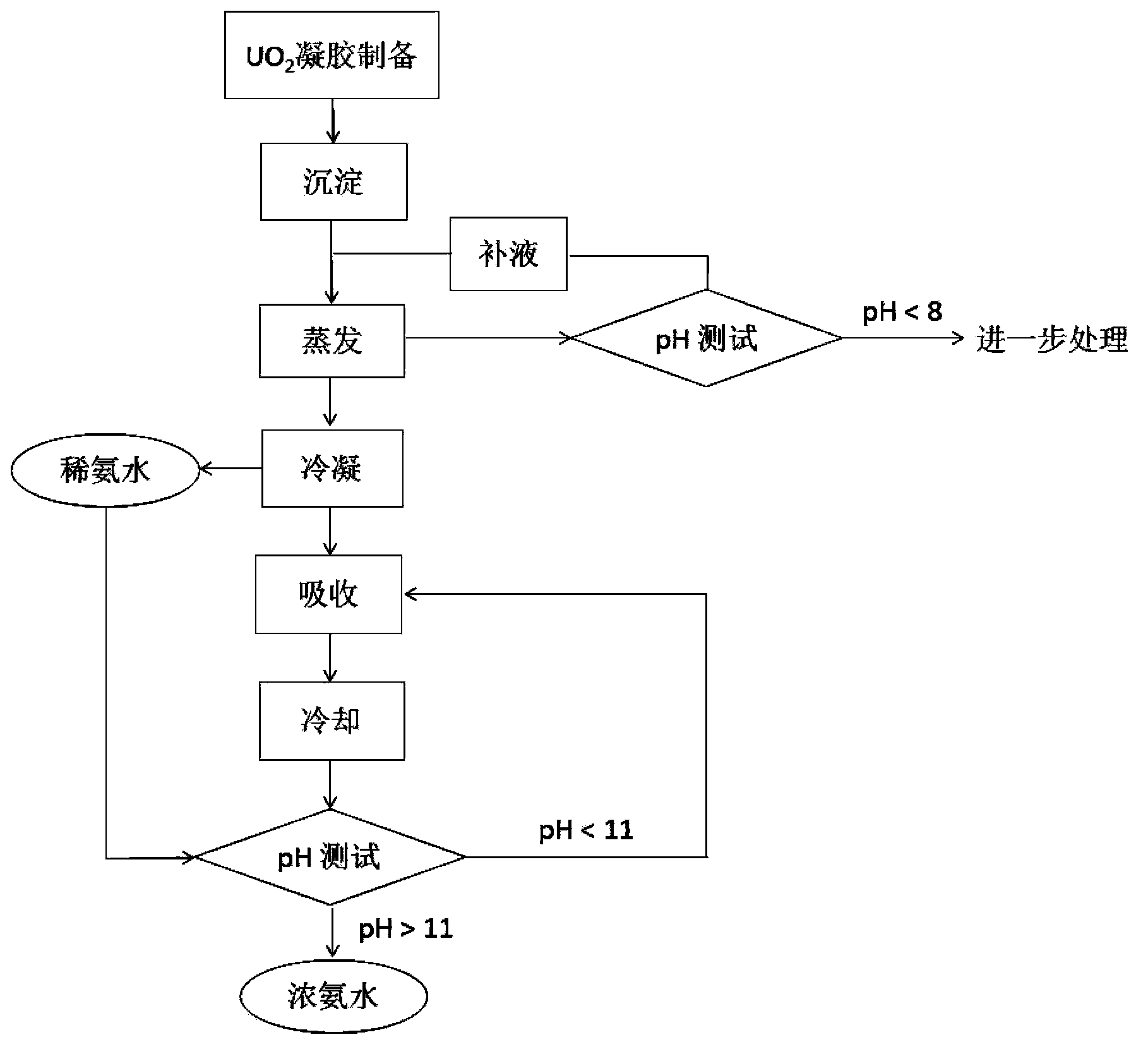

Method for recycling NH3-N from ammoninted waste liquid

ActiveCN103214047BIncreased concentration of ammoniaMeet reuse requirementsWater contaminantsWater/sewage treatment by heatingHigh concentrationAmmoniacal nitrogen

Owner:TSINGHUA UNIV

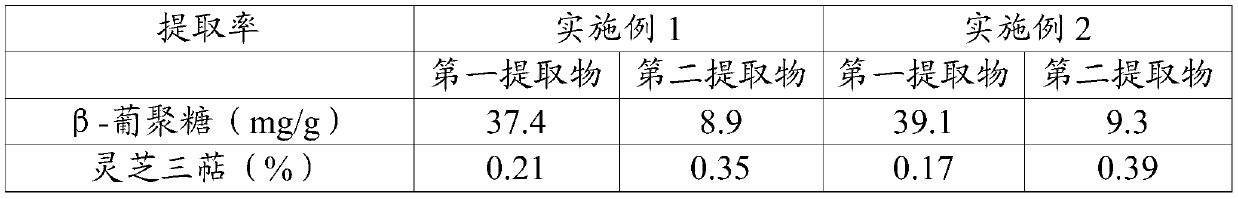

Preparation method and application of ganoderma amboinense extract

InactiveCN110742911AThe extraction process is simple and easy to operateHigh extraction rateUnknown materialsPlant ingredientsBeta-glucanEngineering

The present invention belongs to the technical field of traditional Chinese medicinal material extraction and particularly relates to a preparation method and an application of a ganoderma amboinenseextract. The preparation method comprises the following steps of processing raw materials, obtaining a first extract and obtaining a second extract. The present invention also provides a nutritional product. The nutritional product comprises a first extract and / or a second extract. In a provided technical scheme, two different extraction methods and extraction solvents are used to realize relatively higher extraction rates of ganoderma triterpene and beta glucan in ganoderma amboinense and at the same time roughly separate the two components, which is convenient to adjust addition amount of the two components according to requirements in a later period, besides, a high-temperature and high-pressure extraction method is avoided in an extraction process, the used solvents are also safe and environment-friendly, the extraction process is simple and easy to operate, and the feasible method is provided for effective and efficient utilization of the ganoderma amboinense.

Owner:SHENZHEN HUACHUANG BIO PHARM TECH CO LTD

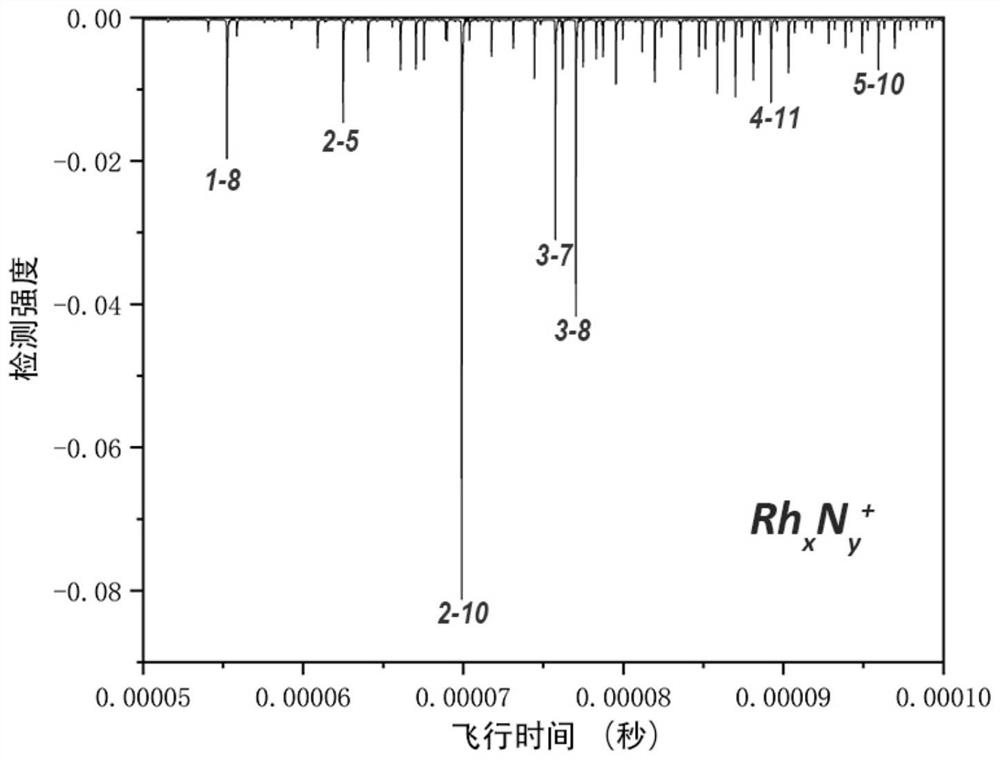

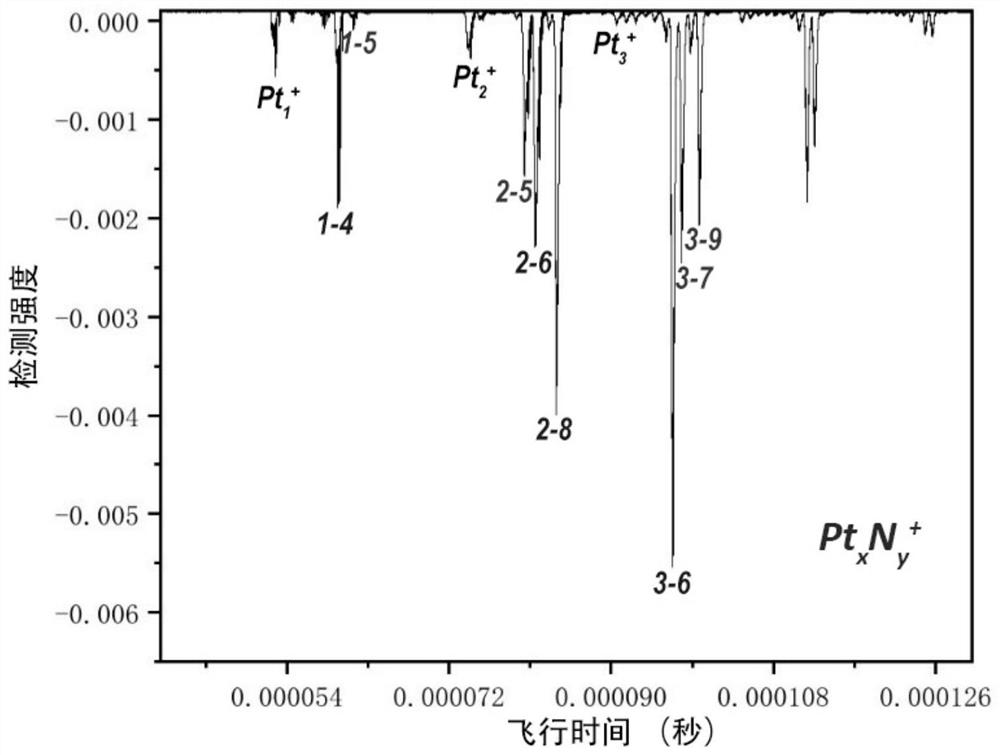

Plasma-assisted method for catalyzing nitrogen activation dissociation by metal cluster

InactiveCN112114026AAchieve dissociationAvoid high temperature and pressureNitrogen-metal/silicon/boron binary compoundsMaterial analysis by electric/magnetic meansMetal clustersNitrogen gas

The invention discloses a plasma-assisted method for catalyzing nitrogen activation dissociation by metal cluster, and belongs to the technical field of cluster science. The method comprises the following steps: in a vacuum cavity, nitrogen or mixed gas of nitrogen passes through a metal plasma area, and then activated dissociation of the nitrogen is achieved. According to the method, dissociationof nitrogen molecules can be achieved through a method of generating metal plasmas through laser sputtering under the room temperature condition, and high temperature and high pressure in the nitrogen catalytic reaction process in the prior art are avoided. The method disclosed by the invention is simple and convenient to operate, a used metal target material is selectable, and a reliable methodis provided for nitrogen dissociation and subsequent nitrogen-containing compound generation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

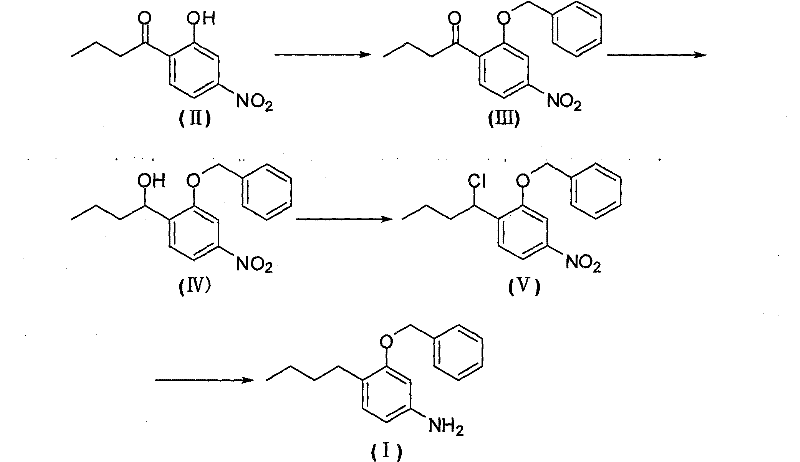

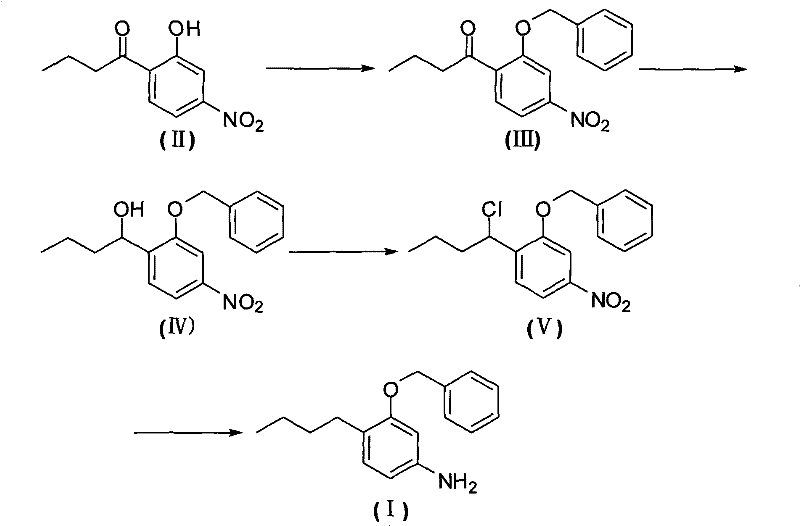

Method for preparing 3-butyl-4-benzyloxy-aniline

InactiveCN101550087BEasy to operateSimple reaction conditionsOrganic compound preparationAmino-hyroxy compound preparationPotassium borohydrideBenzyl chloride

A method for preparing 3-butyl-4-benzyloxy-aniline, relates to a a method for preparing 3-butyl-4-benzyloxy-aniline that is a crucial intermediate of broad-spectrum anticoccidial pesticide nequinate. The method includes following steps in turns: using 2-butyryl-5-nitro-phenol as raw materials, proceeding substitution reaction with benzyl chloride, reduction reaction with sodium borohydride or potassium borohydride, chlorination reaction with thionyl chloride in turns, at last proceeding hydrogenation at presence of catalyst to obtain 3-butyl-4-benzyloxy-aniline. The invention provides a novelsynthetic route, reaction condition of each step is mild, the process is simple and every reaction is common operation, which can avoid strict reaction condition of high-temperature and high-pressureeffectively.

Owner:ZHEJIANG GENEBEST PHARMA

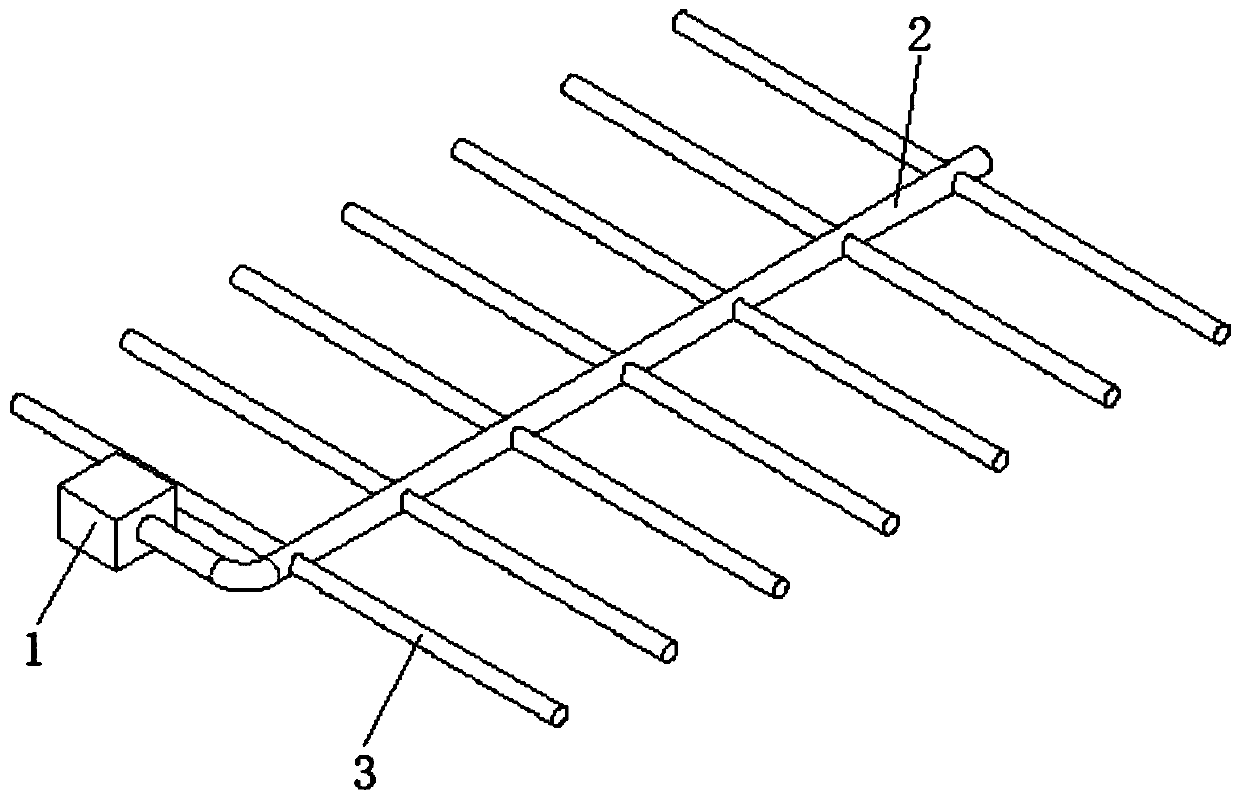

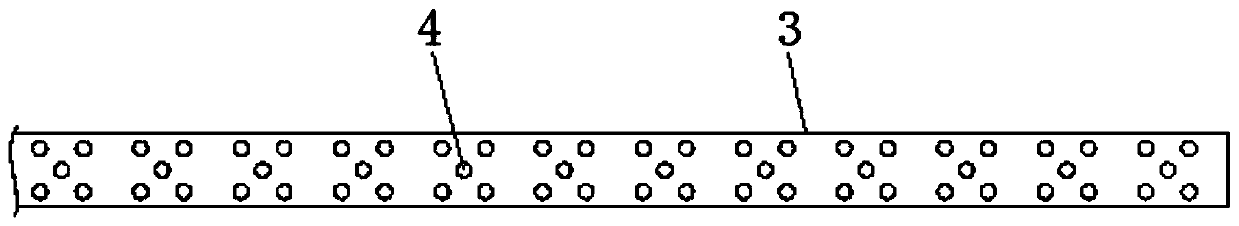

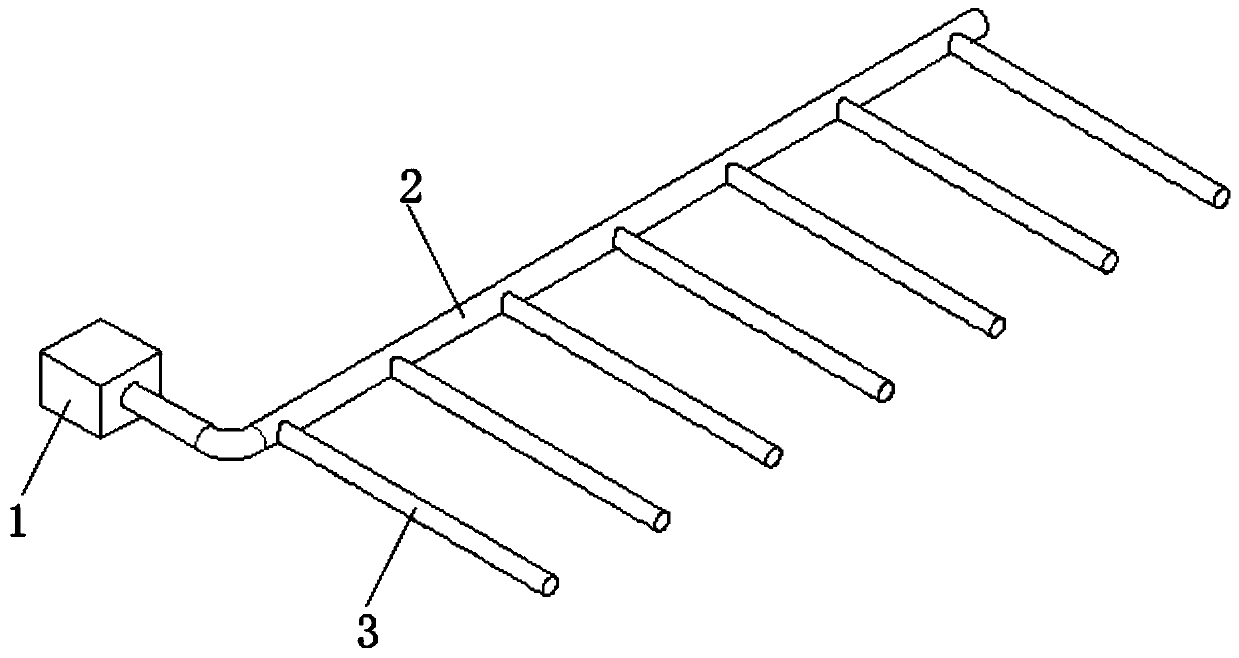

Hot-air temperature increasing and humidity reducing device for greenhouse

InactiveCN110622745AAvoid high temperature and pressureUniform temperature distributionClimate change adaptationGreenhouse cultivationSmall holeHigh pressure

The invention discloses a hot-air temperature increasing and humidity reducing device for a greenhouse, and relates to the technical field of hot-air temperature increasing. The device comprises a fanheater, a main pipeline and a branch pipe, the main pipeline is connected with a fan heater air outlet, the branch pipe is connected with the main pipeline, and lattice exhaust holes are uniformly distributed on the surface of the branch pipe along the axial direction of the branch pipe. According to the device, dense lattice small holes are formed in the branch pipe, high temperature and high pressure at an outlet are sufficiently avoided, so that the temperature is uniformly distributed, air humidity can be uniformly reduced, and death of parts of crops caused by high temperature can be effectively reduced when heat supply of the greenhouse is effectively ensured.

Owner:SHANXI AGRI UNIV

A continuous preparation of boron-doped SiO 2 Airgel method

Owner:CANEW TECH SHENZHEN CO LTD

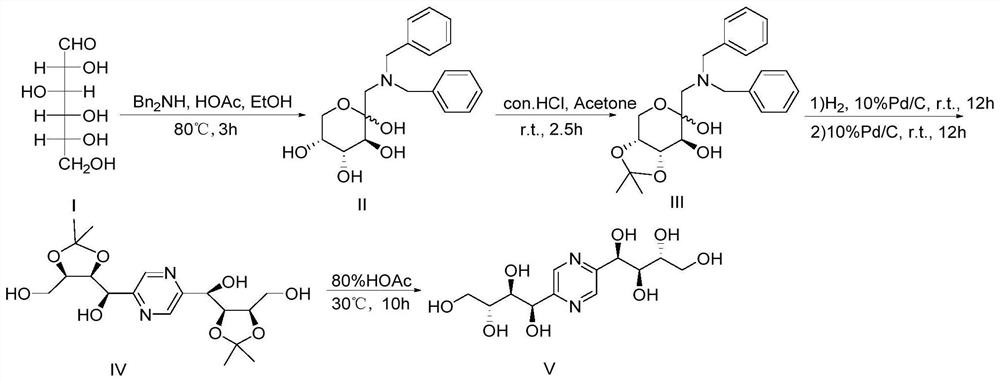

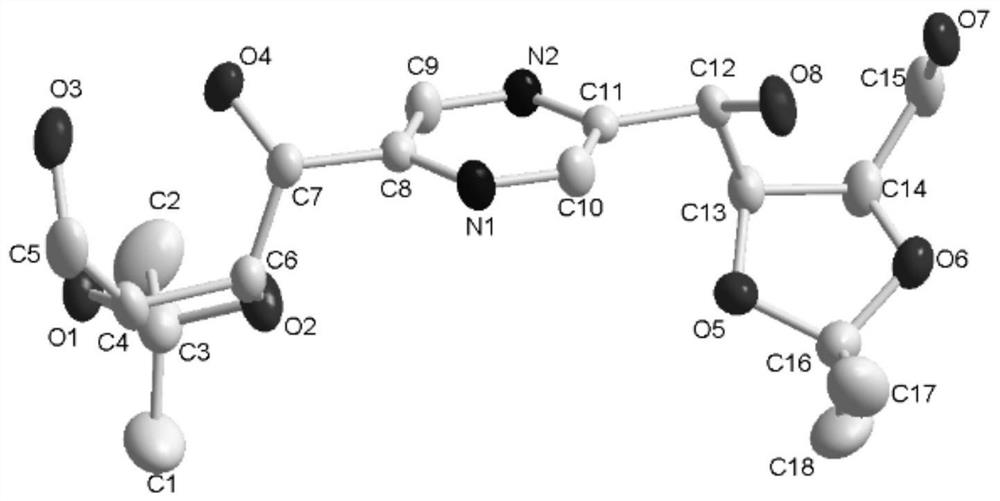

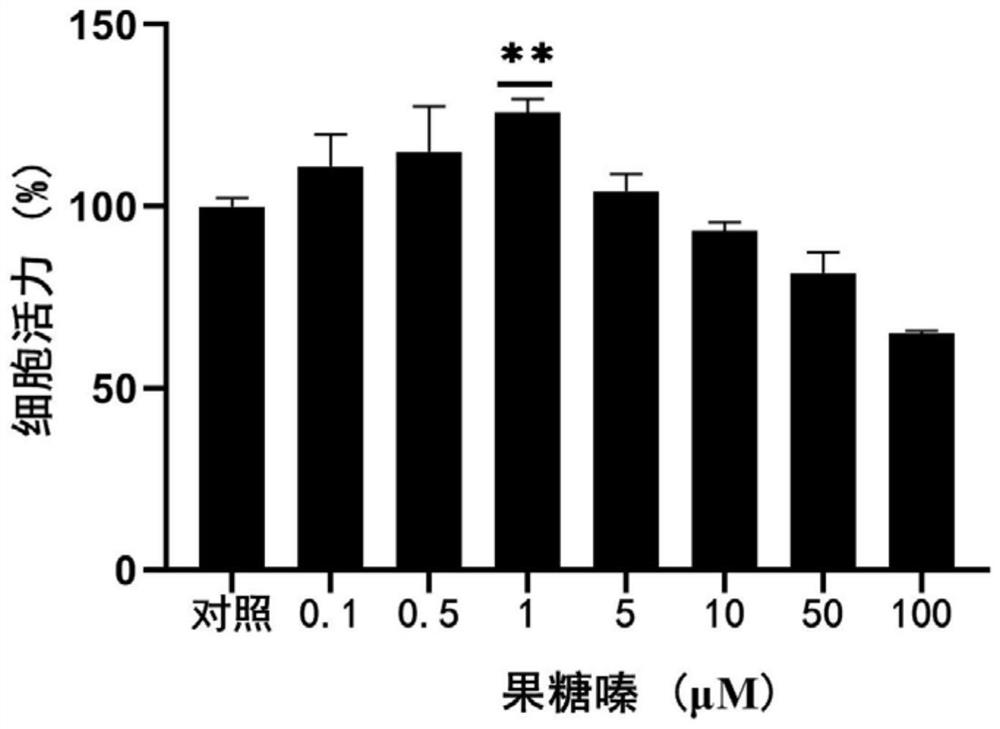

Preparation method and application of fructosazine

ActiveCN112679443ARaw materials are economically availableMild reaction conditionsCosmetic preparationsOrganic chemistryFructosePyrazine

The invention discloses a preparation method and application of fructozine, and the preparation method of the fructozine comprises the steps of synthesis of 1-dibenzylamino -1-deoxidized- D-fructose, preparation of 1-dibenzylamino- 1-deoxidized -4, 5-oxo- isopropylidene- D-fructose, preparation of isopropylidene protected fructozine and synthesis of the fructozine. According to the preparation method of the fructosazine, Pd / C is used for catalyzing amino sugar to be oxidized to form pyrazine rings for the first time. According to the reaction route, raw materials are economical and easy to obtain, reaction conditions are mild, high temperature and high pressure are avoided, the product is single and high in purity, and a complex post-treatment process is avoided. In addition, the invention provides application of the fructosazine in preparation of anti-aging cosmetics.

Owner:DALIAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com