Detection method and device of trace hydrogen chloride in hydrogenation device gaseous phase

A hydrogen chloride, trace technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as large errors, achieve high detection limits, be beneficial to environmental protection, and reduce harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

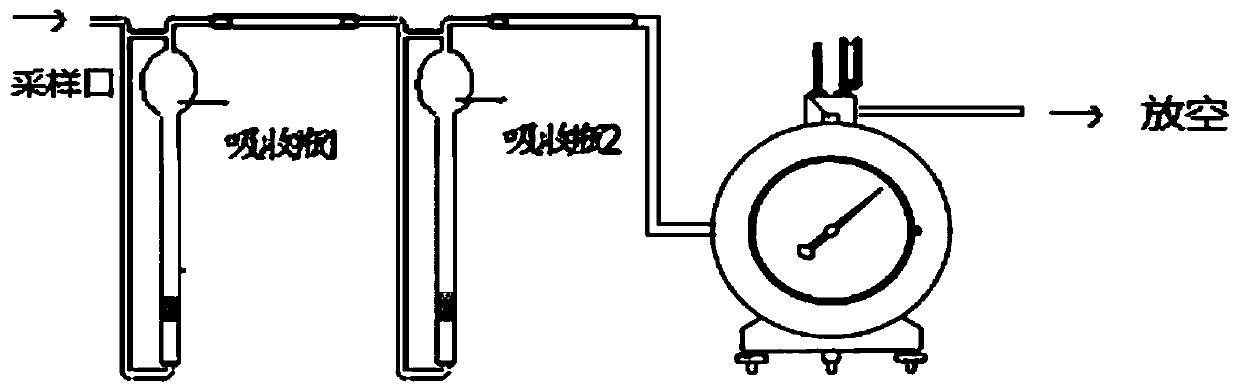

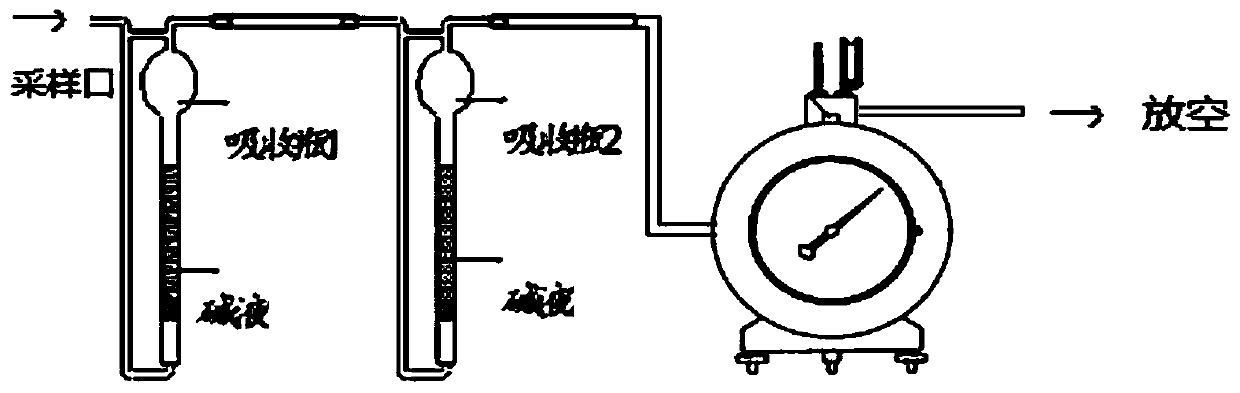

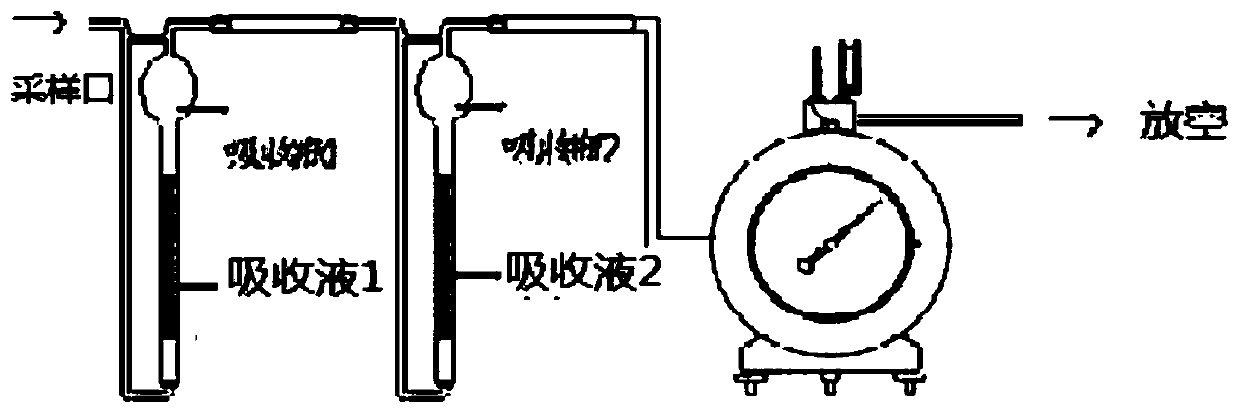

Image

Examples

example 1

[0041] Taking the hydrogen after the dechlorination tank in the reforming unit as the collection object, the concentration of hydrogen sulfide is less than 50ul / L, prepare a sodium hydroxide solution with a molar mass fraction of 0.001mol / L, add 1 drop of phenolphthalein indicator solution, and pipette Pipet 10ml of sodium hydroxide solution into a 10ml porous glass plate absorption bottle. Connect the sampler to the flowmeter, adjust the valve, control the gas volume flow rate to 0.8L / min, remove the flowmeter and directly connect the sampling port with a silicone tube, and connect two porous glass absorption bottles and a wet flowmeter in series to collect the gas The time was 40 minutes, and the content of chloride ions was measured by ion chromatography. After calculation, the content of trace hydrogen chloride in hydrogen gas was 0.378uL / L, and the repeatability was 0.988 after three parallel measurements.

example 2

[0043] Take the hydrogen after the dechlorination tank in the reforming unit as the collection object, the concentration of hydrogen sulfide is less than 50ul / L, prepare a sodium hydroxide solution with a molar mass fraction of 0.01mol / L, add 1 drop of phenolphthalein indicator solution, and pipette Take 10ml of sodium hydroxide solution in a 10ml porous glass plate absorption bottle, connect the sampler and flowmeter, adjust the valve, control the gas volume flow rate to 0.8L / min, remove the flowmeter and directly connect the sampling port with a silicone tube, and connect them in series Two porous glass plate absorption bottles and wet flowmeters, the time of gas collection is 40min, and the content of chloride ions is determined by ion chromatography. After calculation, the content of trace hydrogen chloride in hydrogen is 0.438uL / L, and the parallel measurement is performed three times. Repeat The sex is 0.991.

example 3

[0045] Taking the hydrogen after the dechlorination tank in the reforming unit as the collection object, the concentration of hydrogen sulfide is less than 50ul / L, prepare a sodium hydroxide solution with a molar mass fraction of 0.1mol / L, add 1 drop of phenolphthalein indicator solution, and pipette Take 10ml of sodium hydroxide solution in a 10ml porous glass plate absorption bottle, connect the sampler and flowmeter, adjust the valve, control the gas volume flow rate to 0.8L / min, remove the flowmeter and directly connect the sampling port with a silicone tube, and connect them in series Two porous glass plate absorption bottles and wet flowmeters, the time of gas collection is 40min, and the content of chloride ions is measured by ion chromatography. After calculation, the content of trace hydrogen chloride in hydrogen is 0.440uL / L, and the parallel measurement is performed three times. Repeat The sex is 0.985.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com