Method for determining content of magnesia in phosphorus ore

A technology of phosphate rock and magnesium oxide, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem that magnesium hydroxide cannot be completely washed down, and the accuracy of magnesium oxide is Low, high allowable error, to achieve the effect of small analysis error, easy operation and high analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

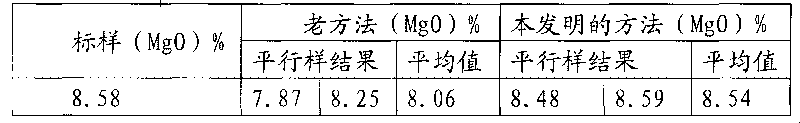

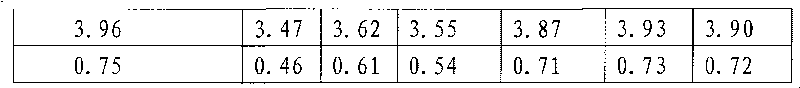

Examples

Embodiment Construction

[0008] The content of the present invention is described in detail below.

[0009] Weigh 1.0013g of the sample phosphate rock sample (MgO%=1.03) and place it in a 300mL beaker, add 40ml of aqua regia to dissolve the phosphate rock sample, filter after constant volume of 250mL with distilled water, accurately pipette 25mL of the filtrate, add 12mL of EGTA solution and 30mL of triethanolamine, stir for a while, add 2 drops of malachite green indicator, neutralize with sodium hydroxide solution until the solution is colorless, then add 3mL; heat to about 80°C, keep warm for 30min, at this time, the precipitate condenses into a block , filter while hot with filter paper with a small amount of absorbent cotton, wash the beaker and the precipitate with 40°C sodium hydroxide solution for 3 to 4 times, put the filter paper and the precipitate directly into the beaker, and dissolve the precipitate with 20 mL of 40°C hydrochloric acid solution; Dilute to 150mL with distilled water at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com