Patents

Literature

210results about How to "Improve accuracy and precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

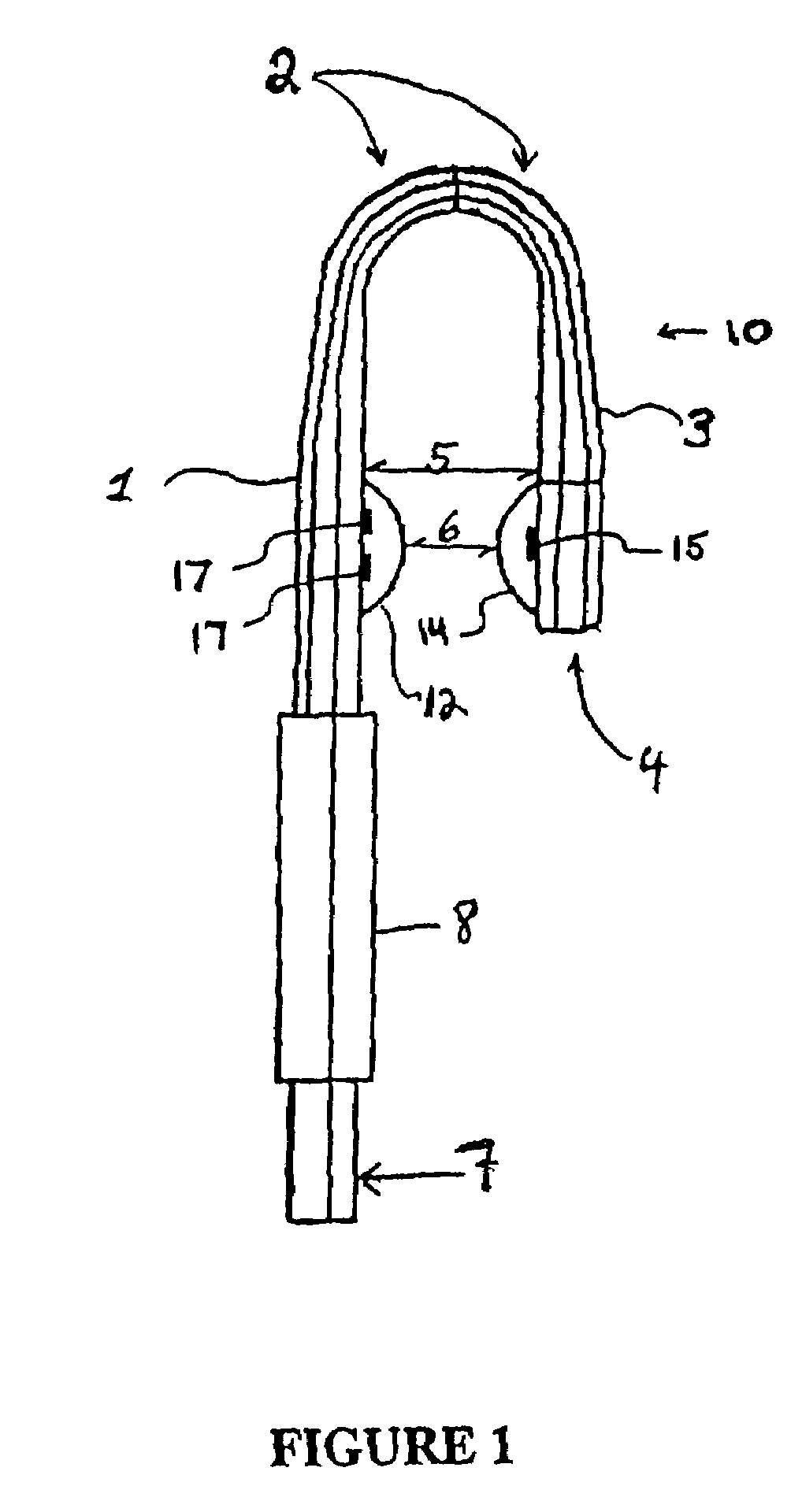

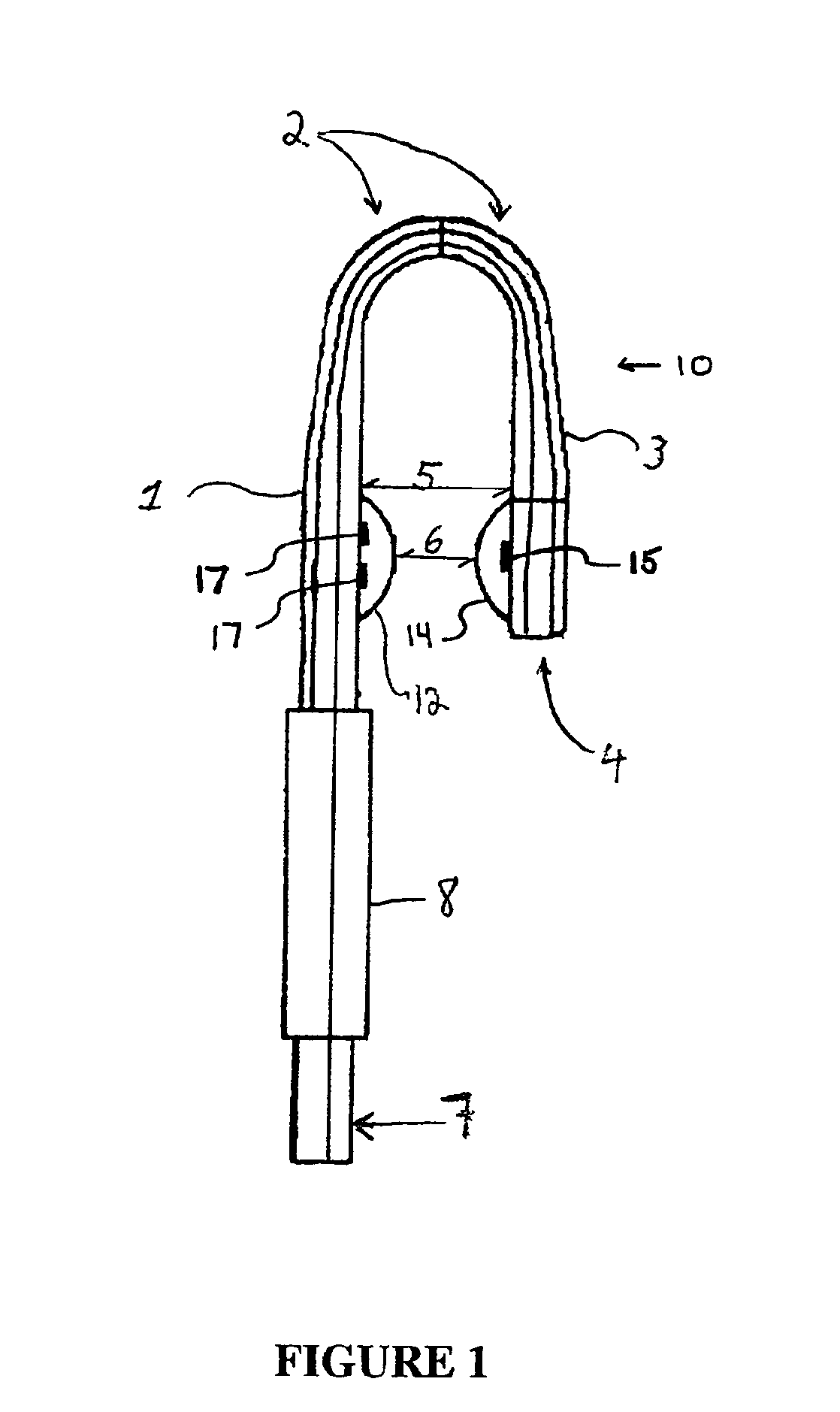

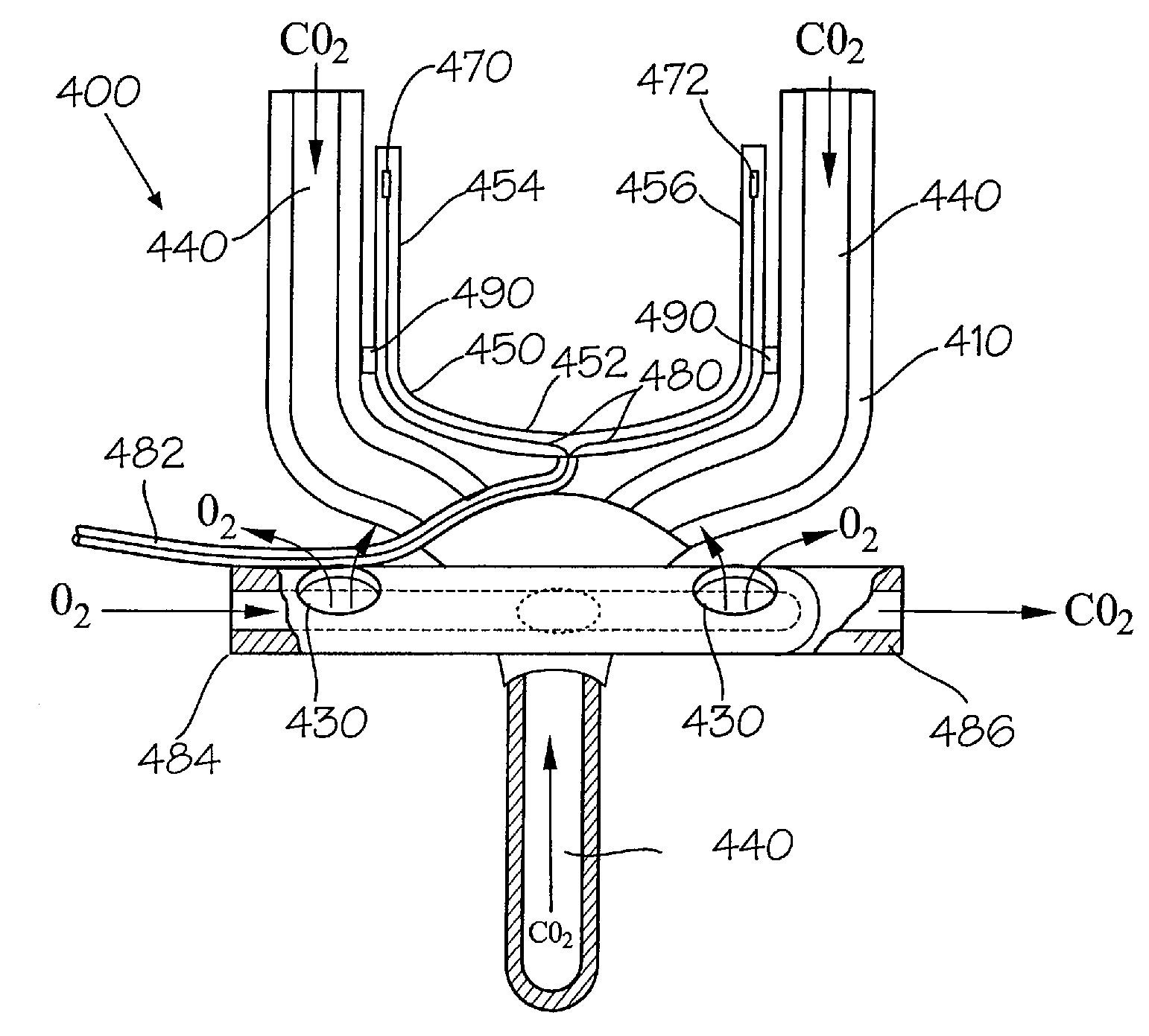

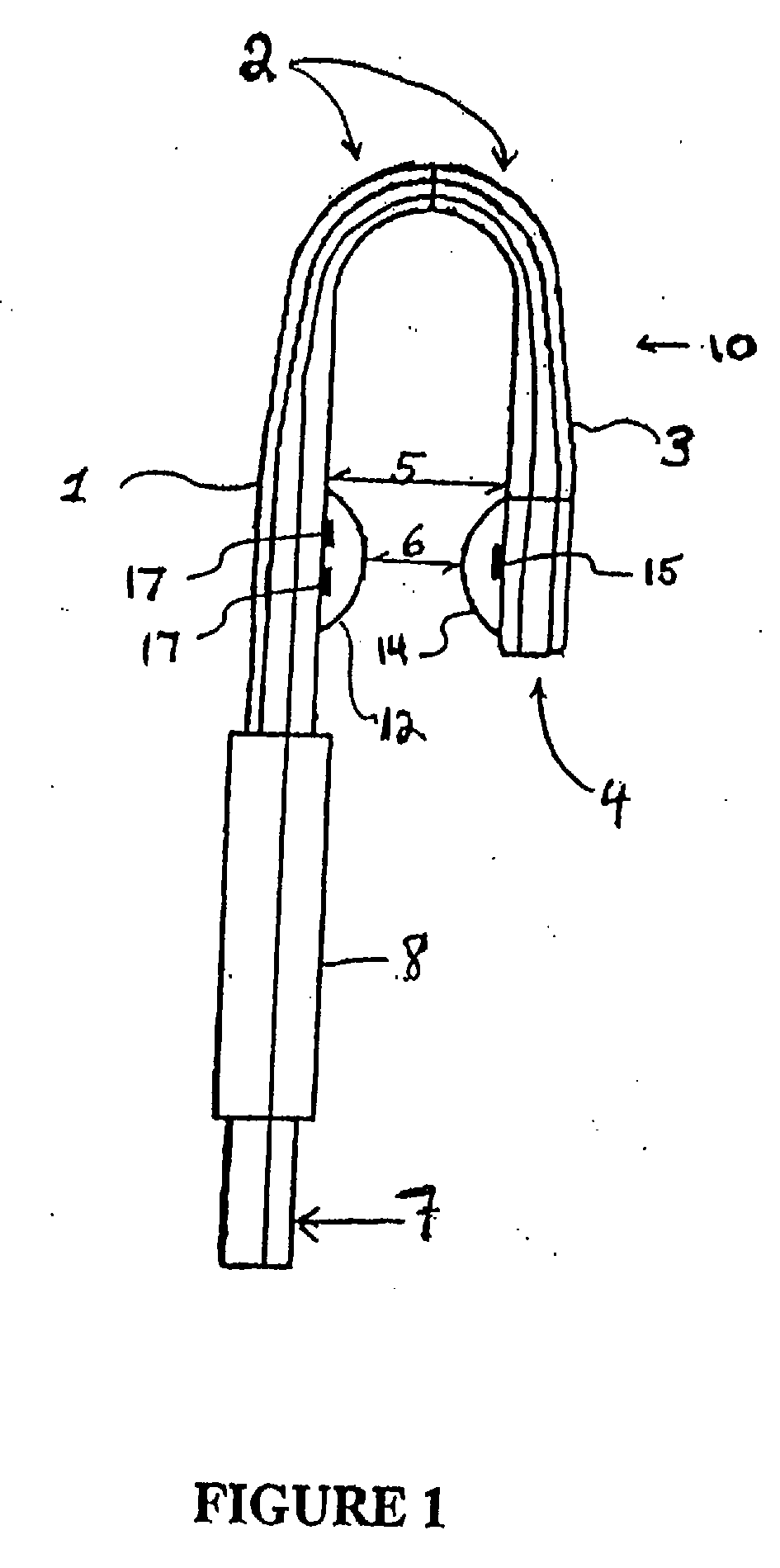

Specially configured nasal pulse oximeter/photoplethysmography probes, and combined nasal probe/cannula, selectively with sampler for capnography, and covering sleeves for same

InactiveUS7024235B2Easy to makeLow costRespiratorsOperating means/releasing devices for valvesPulse oximetersNose

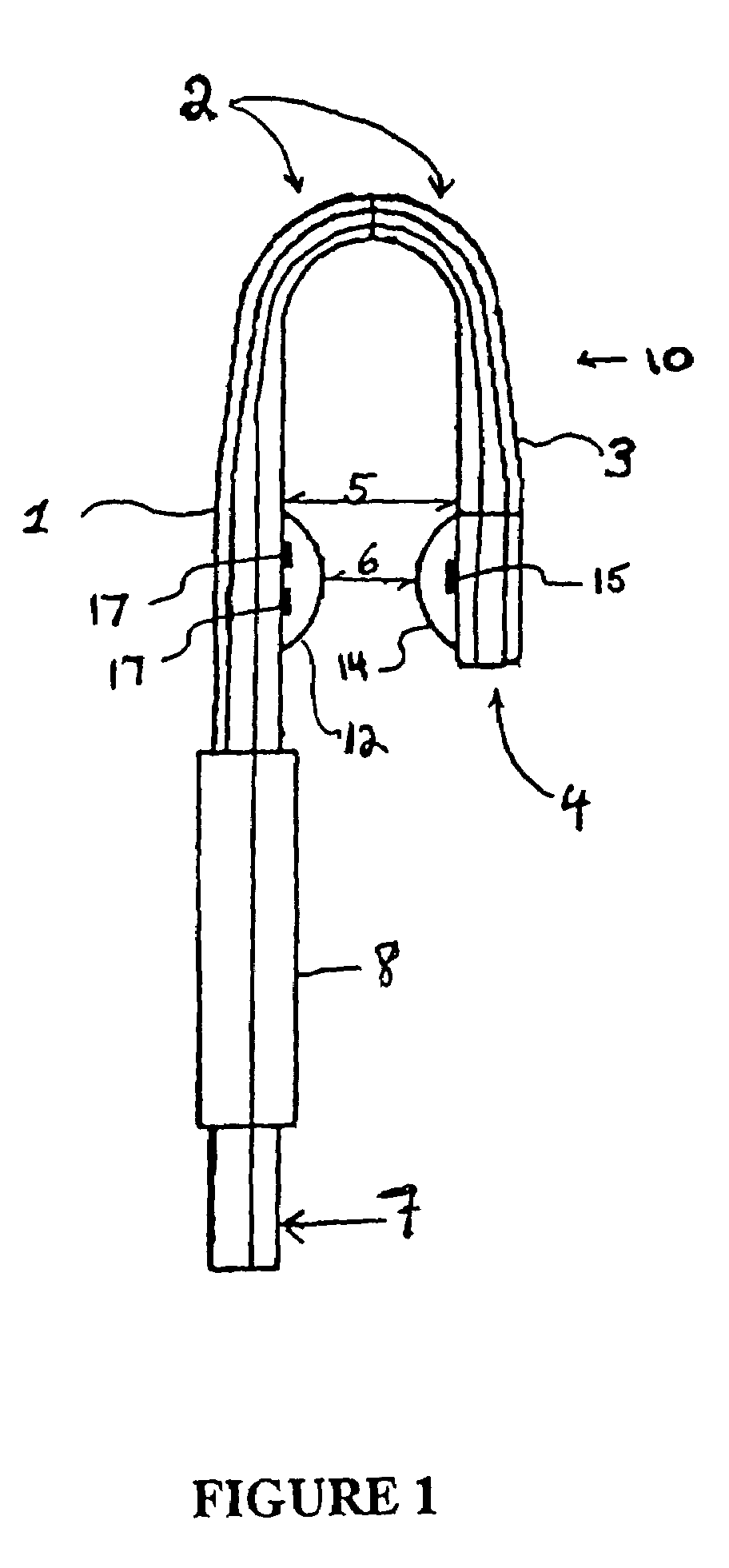

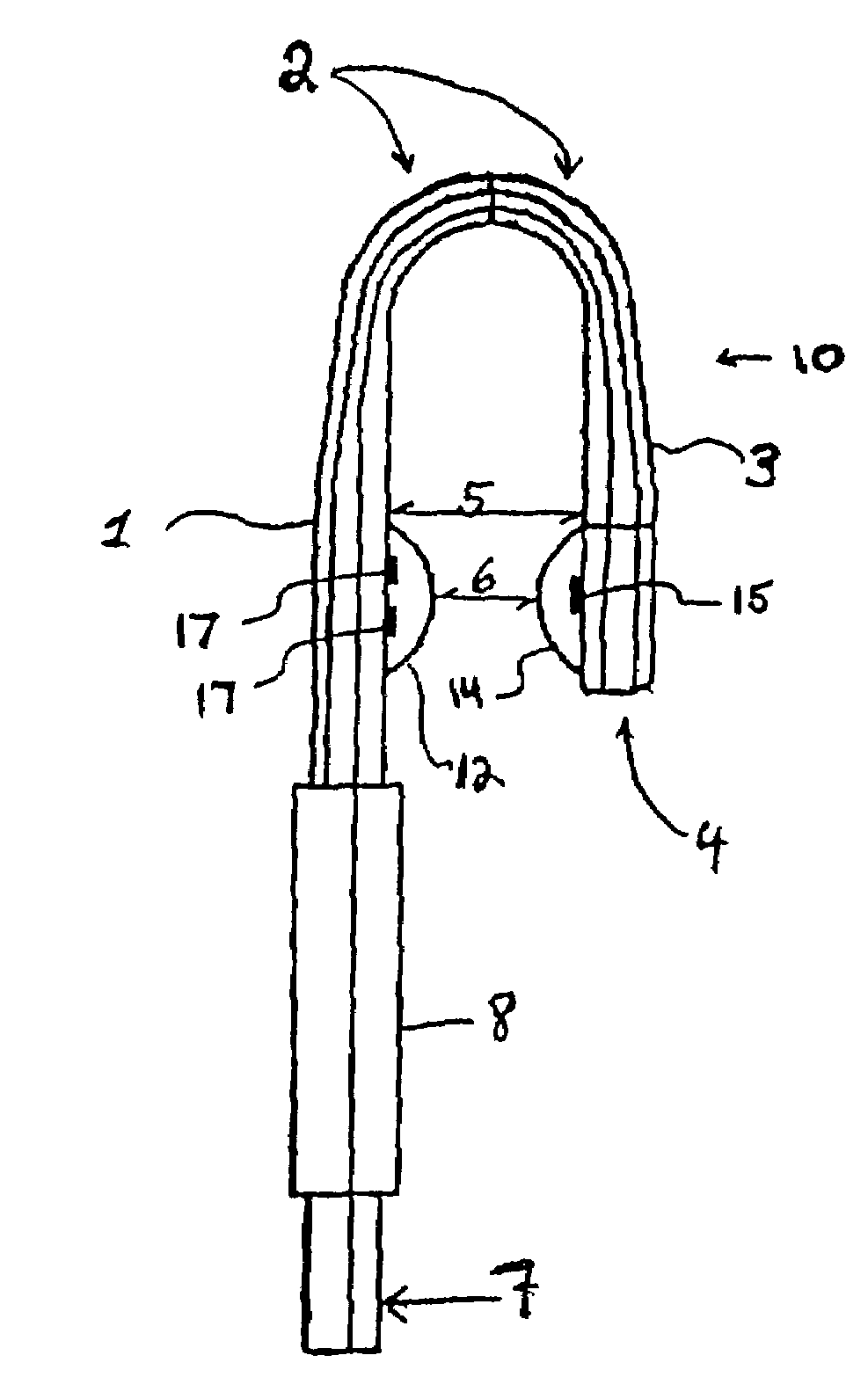

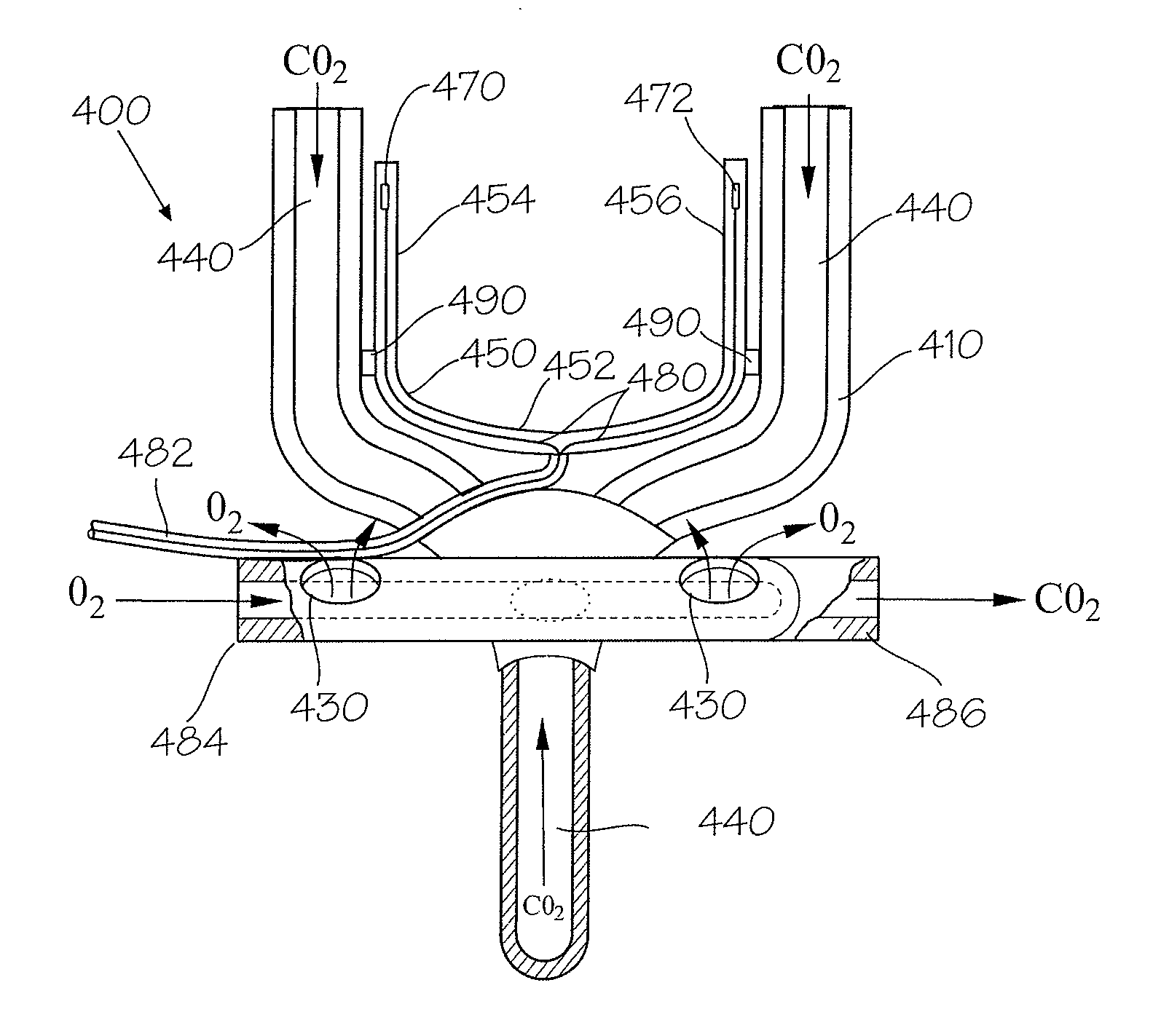

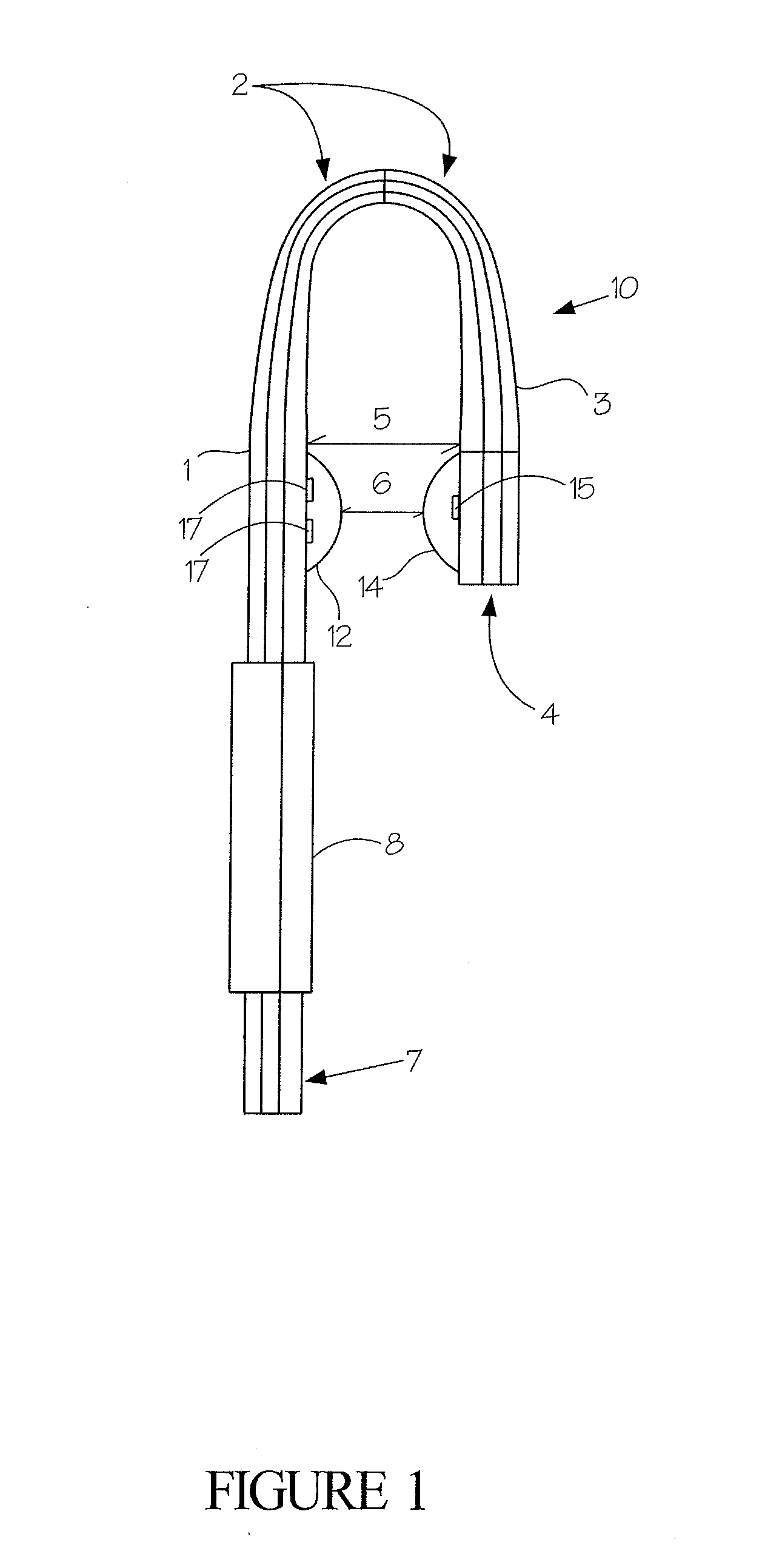

The present invention relates to novel nasal pulse oximeter probes that are configured to be placed across the septum of the nose. These probes are fabricated to provide signals to obtain arterial oxygen saturation and other photoplethysmographic data. The present invention also relates to a combined nasal pulse oximeter probe / nasal cannula. The present invention also relates to other devices that combine a pulse oximeter probe with a device supplying oxygen or other oxygen-containing gas to a person in need thereof, and to sampling means for exhaled carbon dioxide in combination with the novel nasal probe. In certain embodiments, an additional limitation of a control means to adjust the flow rate of such gas is provided, where such control is directed by the blood oxygen saturation data obtained from the pulse oximeter probe.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

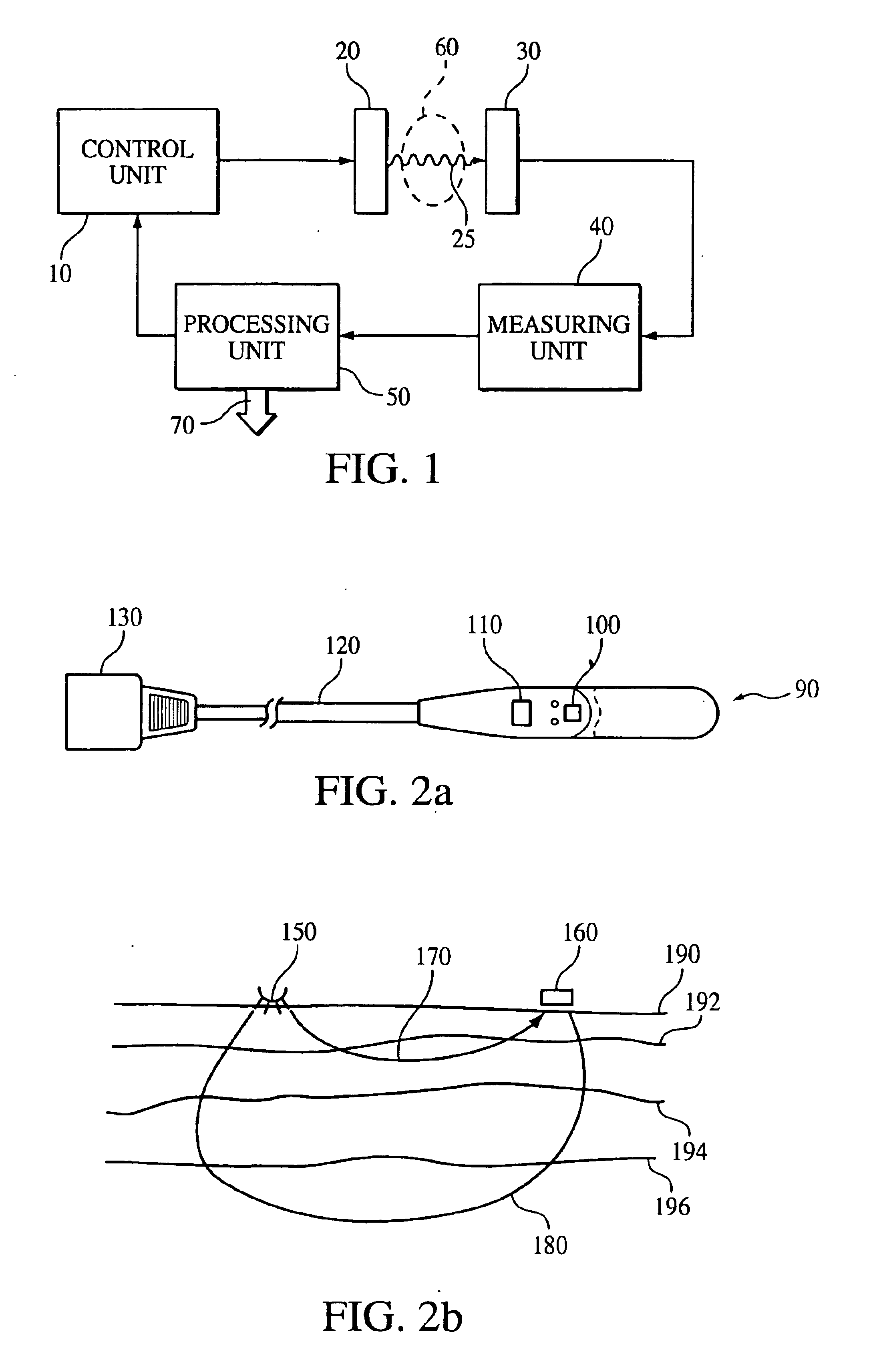

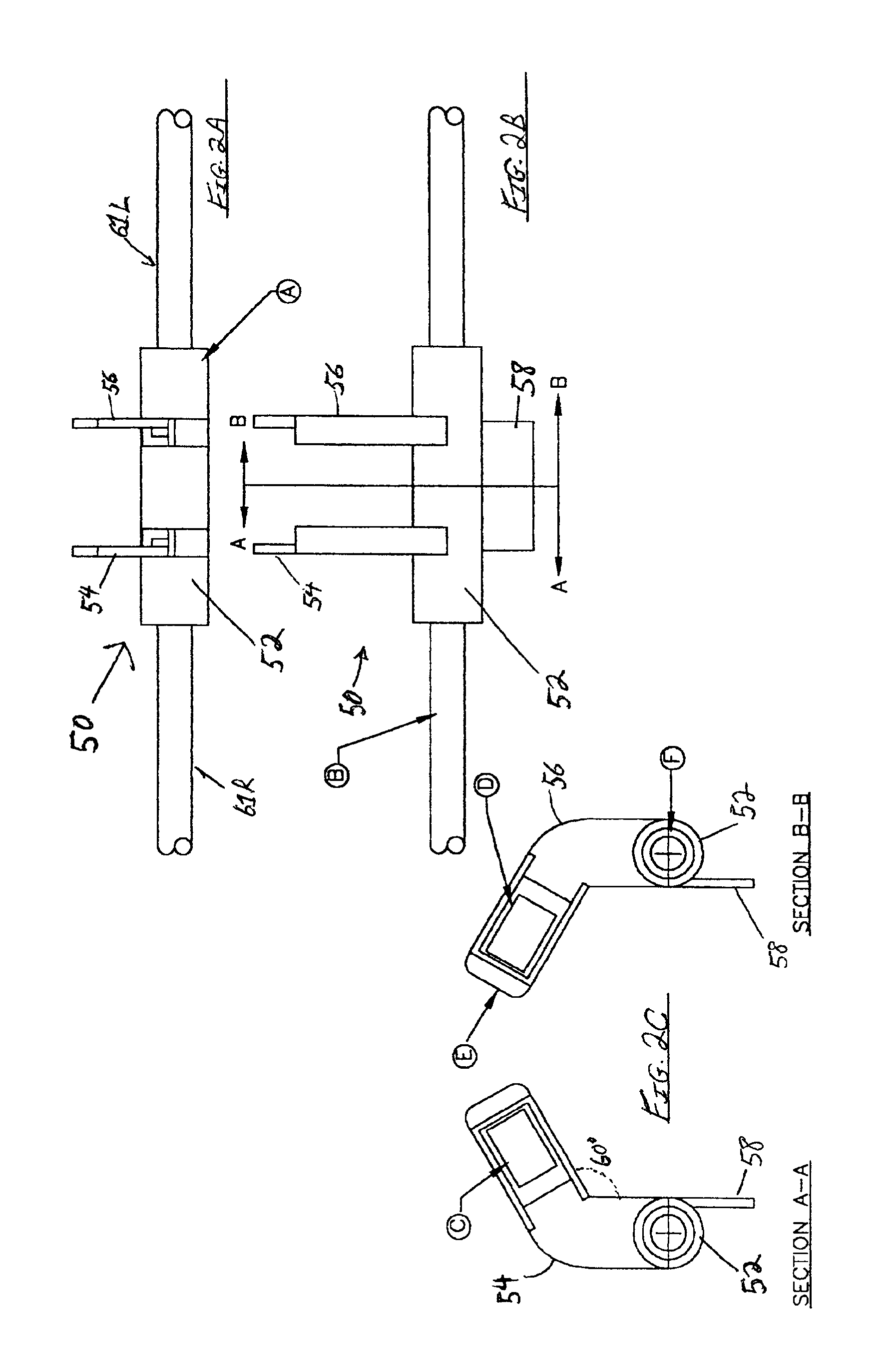

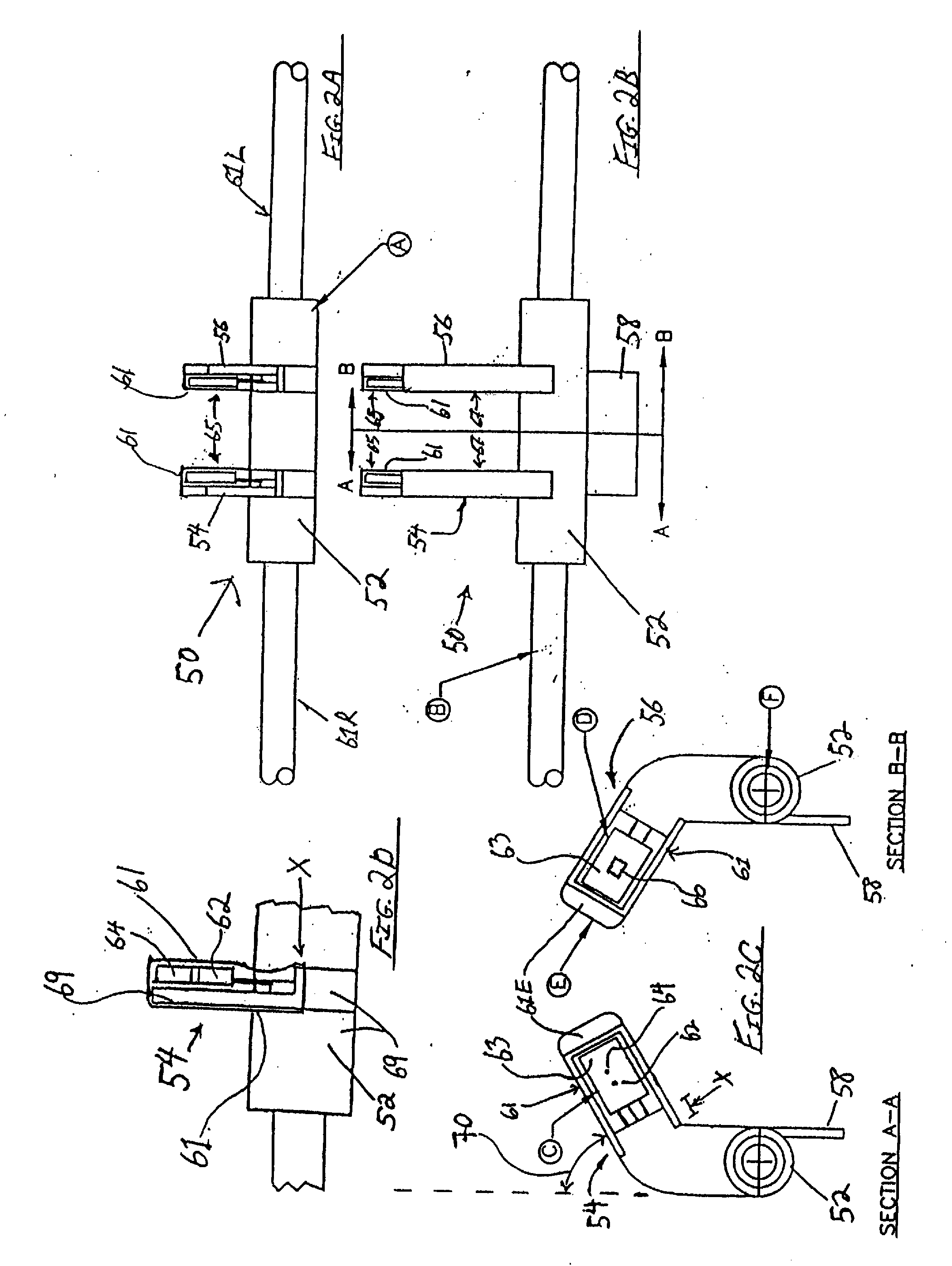

Specially configured lip/cheek pulse oximeter/photoplethysmography probes, selectively with sampler for capnography, and covering sleeves for same

InactiveUS7127278B2Improve accuracy and precisionReliable receptionRespiratorsElectrocardiographyMedicinePulse oximeters

The present invention relates to novel lip / cheek probes for detection of pulse-based differences in light absorbence across the vascularized tissue of a lip or cheek of a patient. These probes are fabricated to provide signals to estimate arterial oxygen saturation, and / or to obtain other photoplethysmographic data. The present invention also relates to a combined probe / cannula. The present invention also relates to other devices that combine a pulse oximeter probe with a device supplying oxygen or other oxygen-containing gas to a person in need thereof, and to sampling means for exhaled carbon dioxide in combination with the novel lip / cheek probes. In certain embodiments, an additional limitation of a control means to adjust the flow rate of such gas is provided, where such control is directed by the blood oxygen saturation data obtained from the pulse oximeter probe.

Owner:BETA BIOMED SERVICES +1

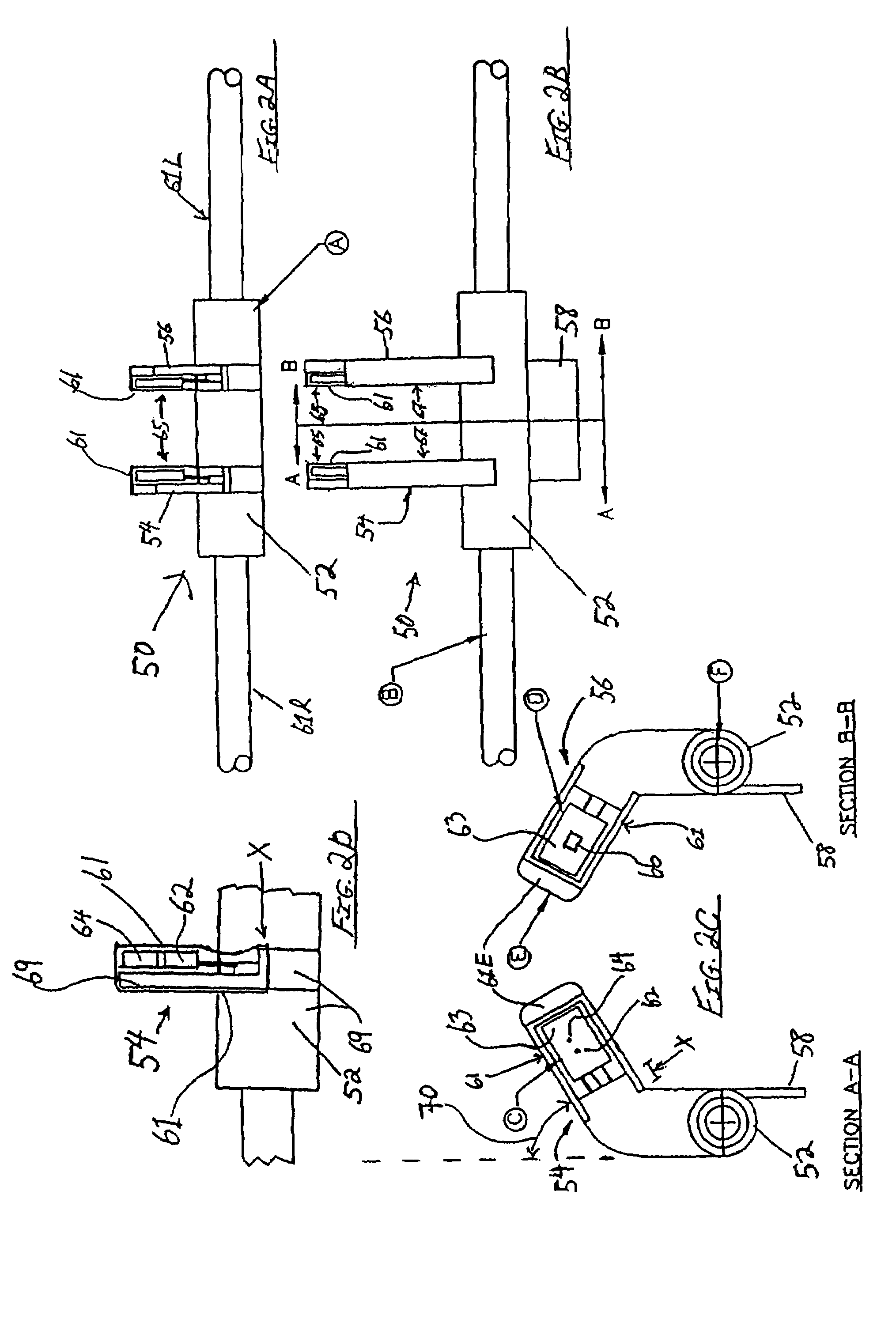

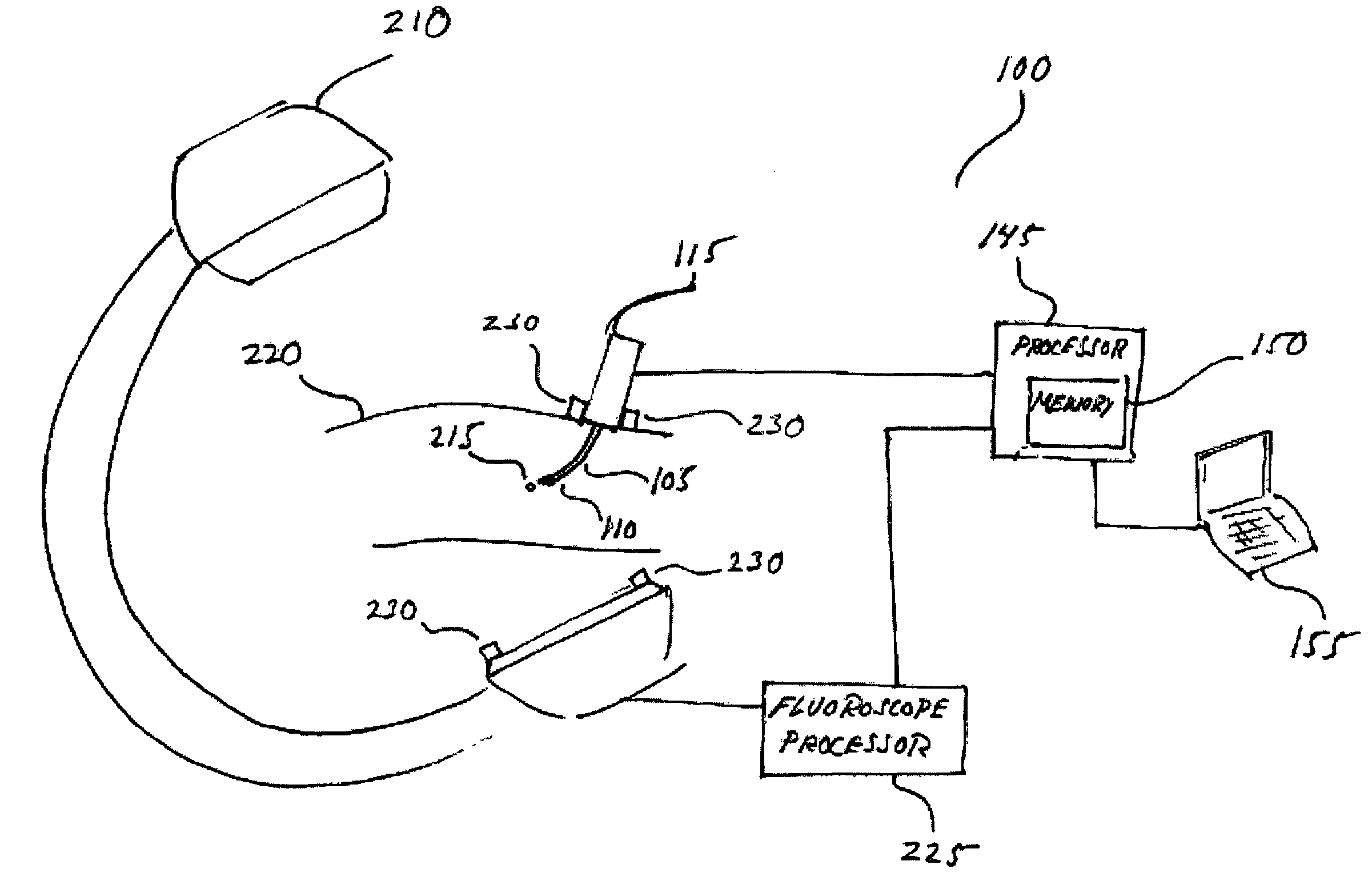

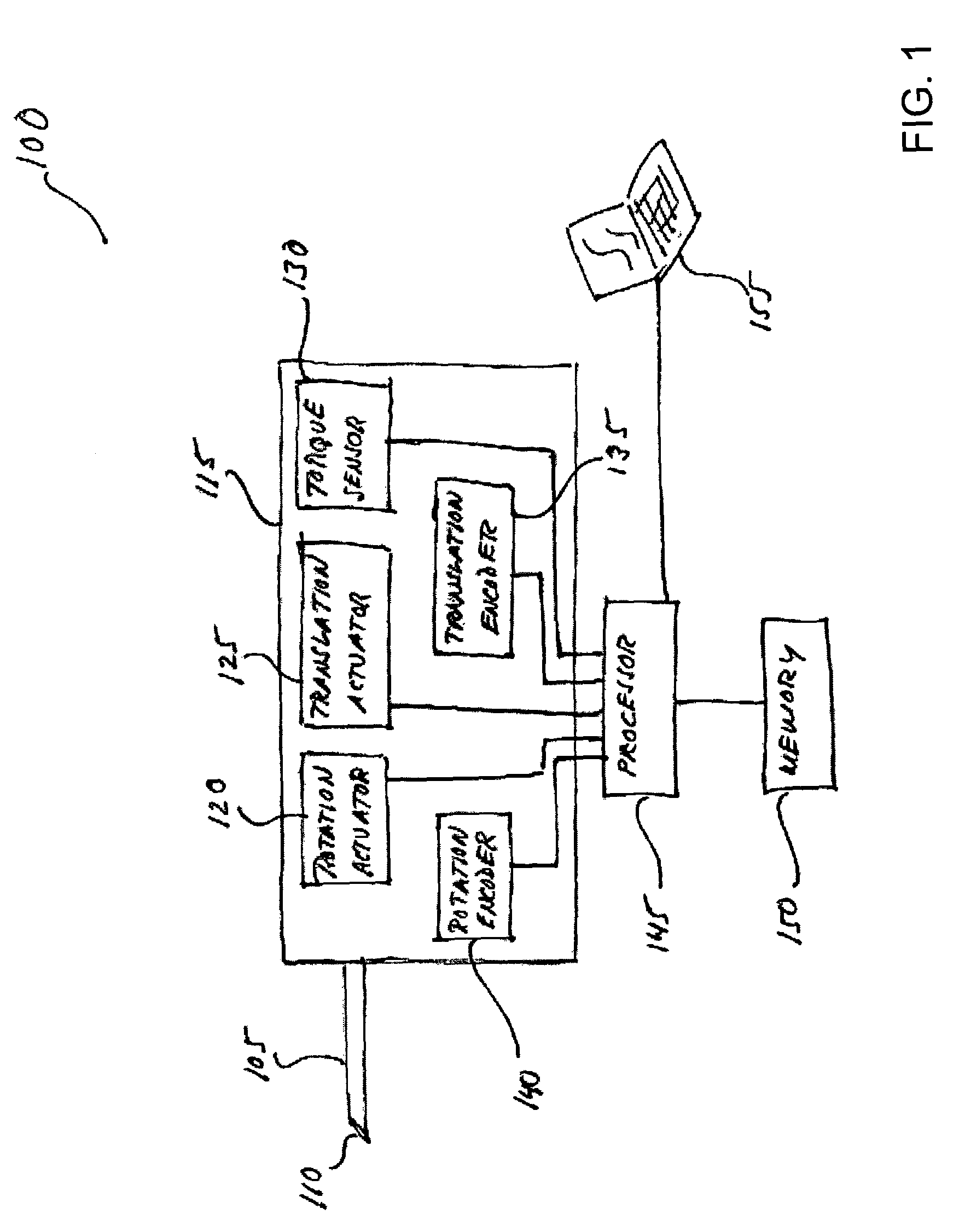

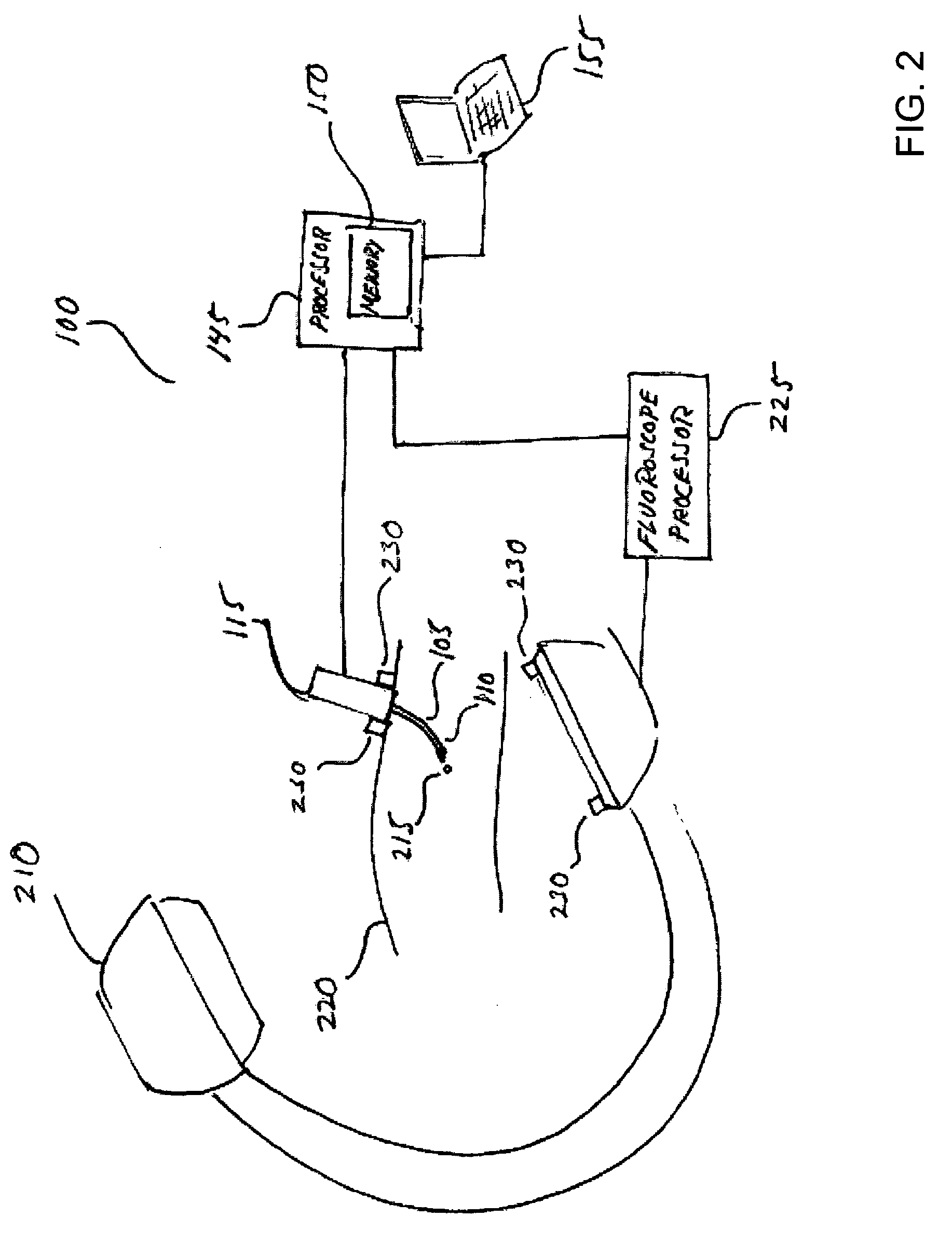

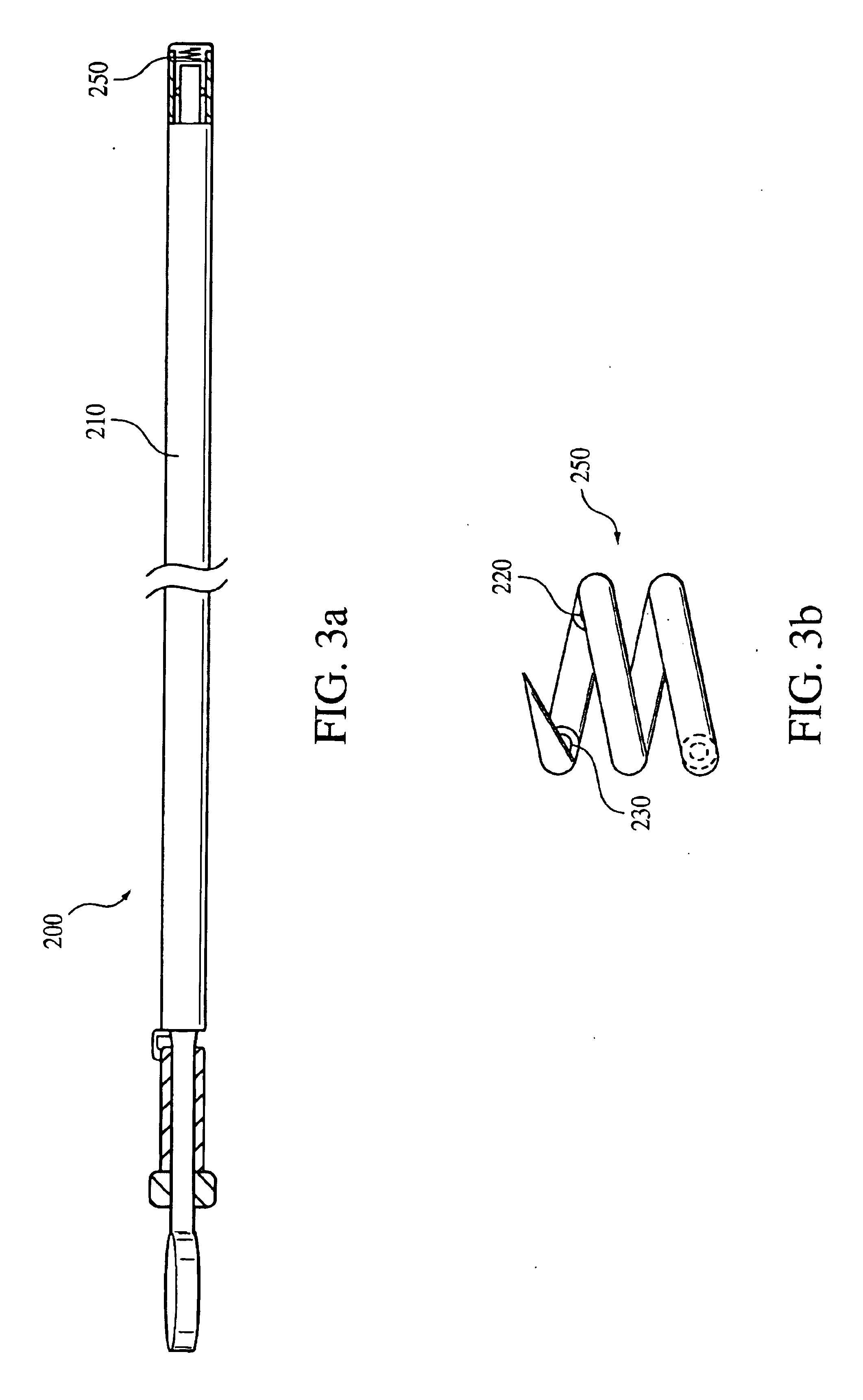

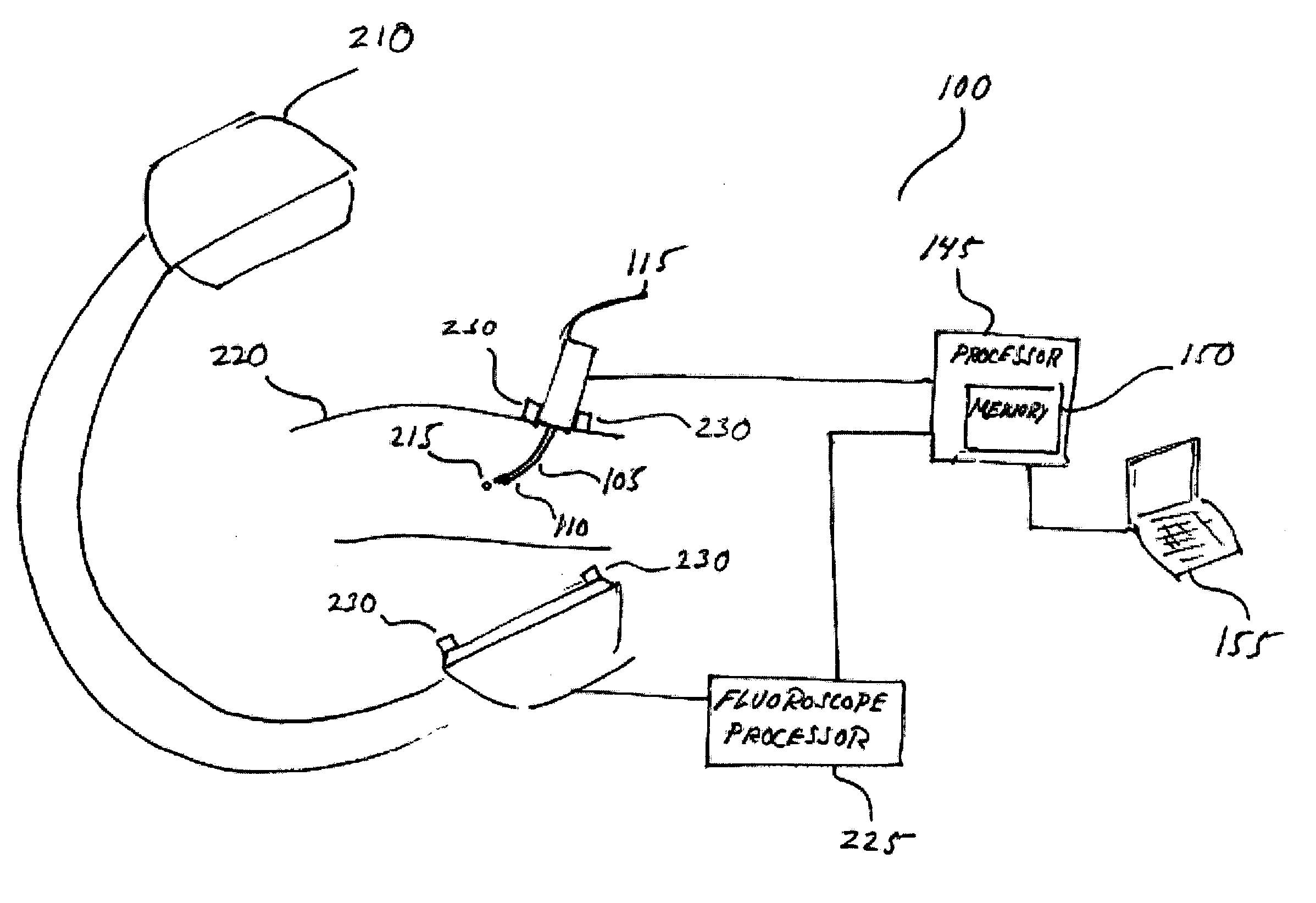

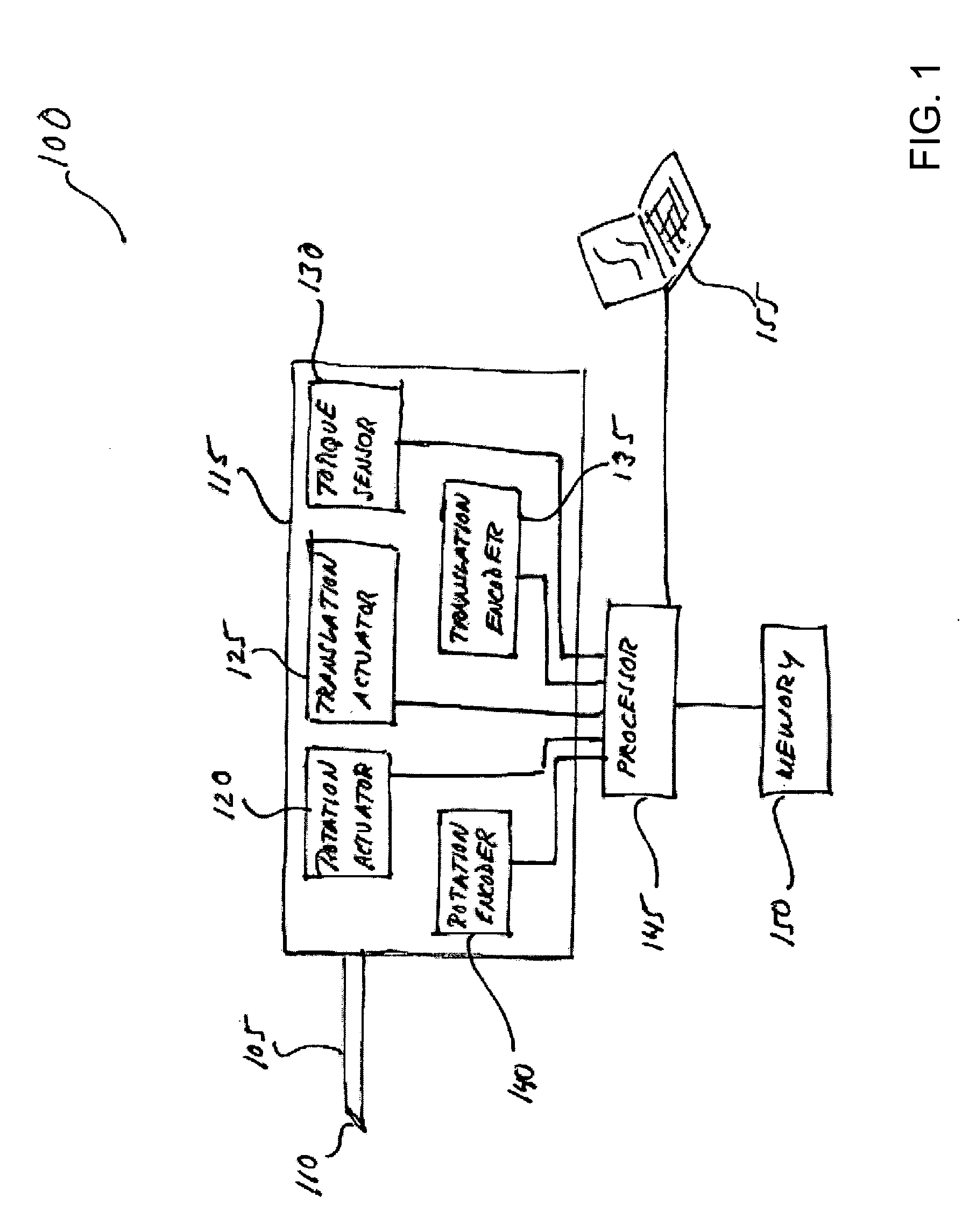

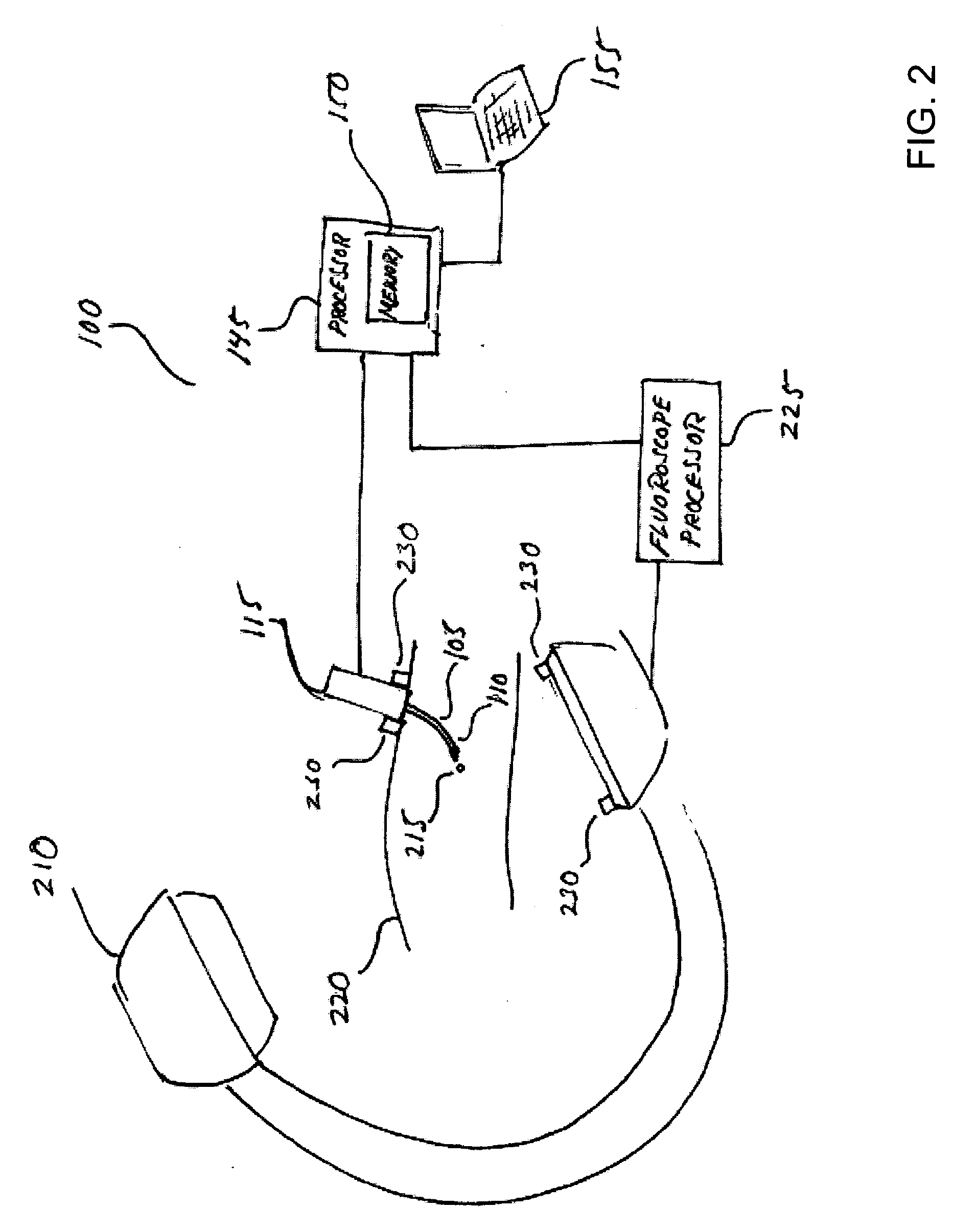

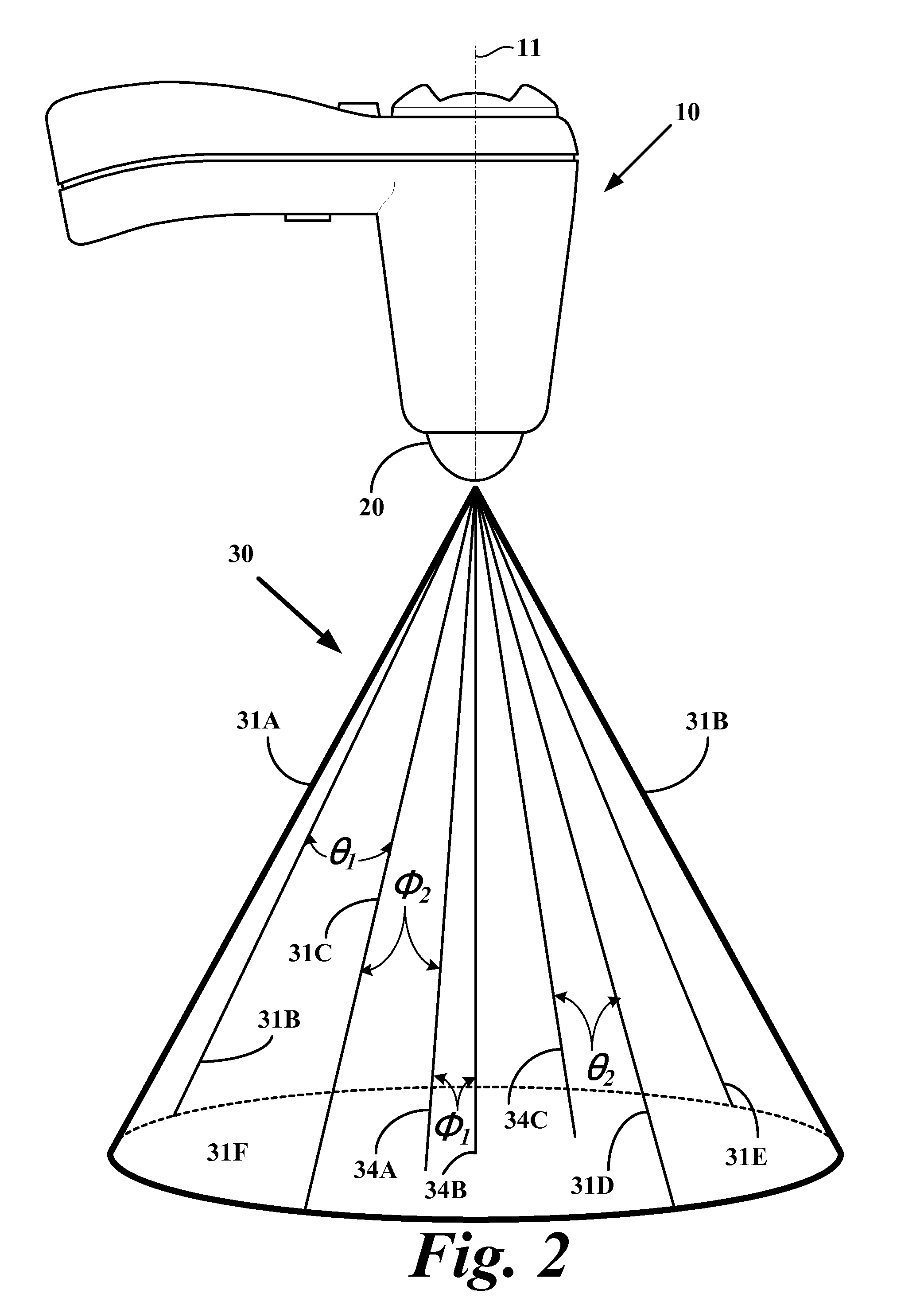

Distal bevel-tip needle control device and algorithm

ActiveUS7822458B2Improve accuracy and precisionReduce complicationsUltrasonic/sonic/infrasonic diagnosticsSurgical needlesNeedle steeringMechanical property

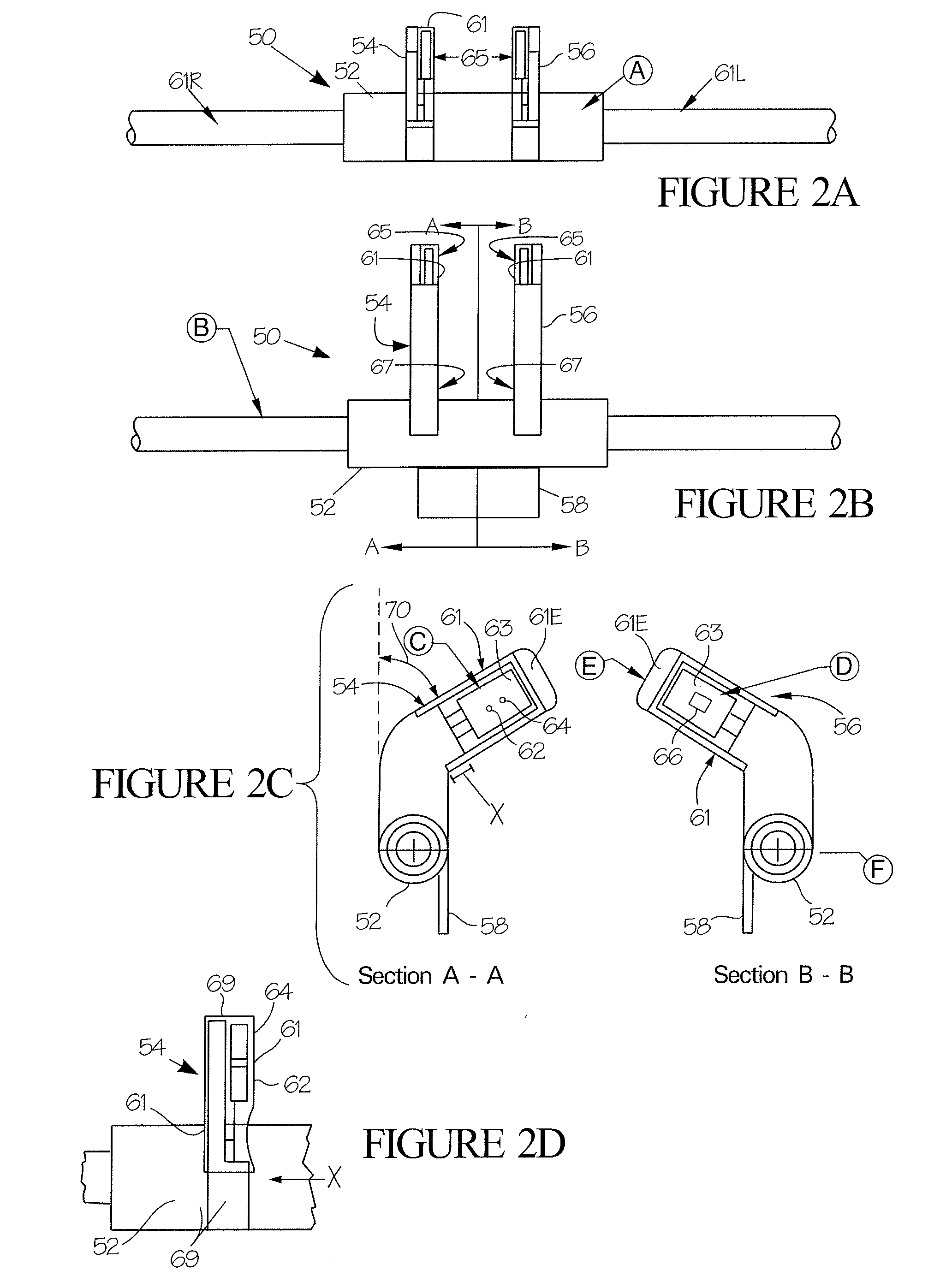

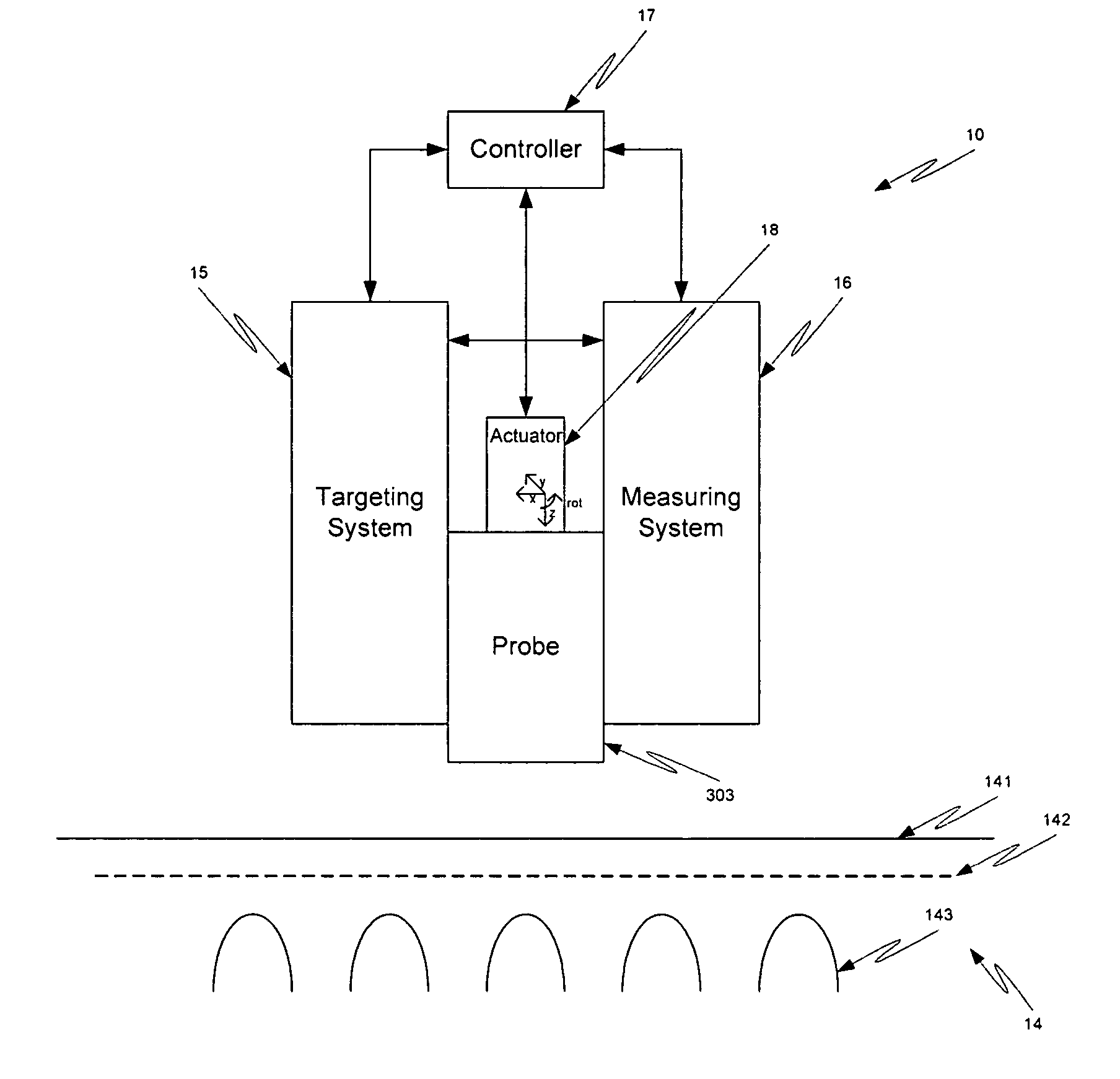

Disclosed is a system for percutaneously steering a surgical needle. Needle steering is accomplished by taking advantage of a deflection force imparted on the bevel tip of the needle by the tissue medium as the needle is pushed through the tissue. By controlling the translation speed and rotation angle of the bevel, a flexible needle may be steered substantially without deflecting or distorting the tissue. The control inputs (translation speed and rotation angle) are computed based on a “bicycle” non-holonomic kinematic model that is a function of mechanical properties of the tissue medium. The system may be used with image-based feedback, which may provide for feedback-based refinement of the model as the needle propagates through the tissue.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

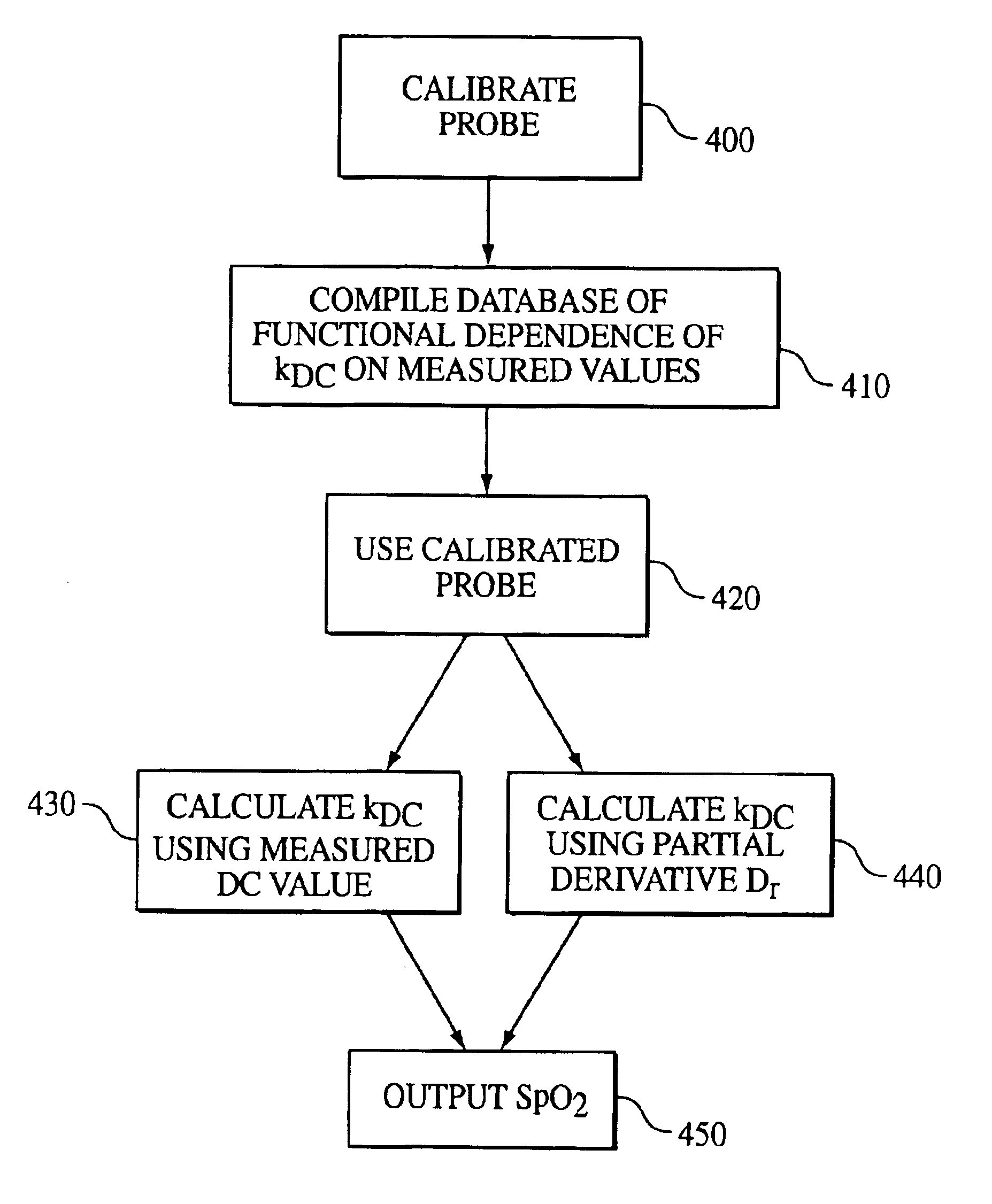

Adaptive calibration for pulse oximetry

InactiveUS6839580B2Improve accuracy and precisionDiagnostic recording/measuringSensorsPulse oximetryLength wave

A method for calibrating a pulse oximeter device and an apparatus incorporating the method and a system for utilizing the method. The method is based on modeling light propagation in tissue at two wavelengths, typically, one in the red and one in the infrared range of the spectrum. A formula is derived relating the arterial oxygen saturation to a ratio R commonly measured by standard pulse oximeters. A specific parameter is identified and utilized in the calibration of the oximeter. This parameter is formulated in terms of the DC signals measured by the pulse oximeter at the two wavelengths. An empirical method for estimating this parameter based on experimental data is also described.

Owner:RIC INVESTMENTS LLC

Apparatus and methods for examining, visualizing, diagnosing, manipulating, treating and recording of abnormalities within interior regions of body cavities

InactiveUS20070213590A1Improve accuracy and precisionImprove accuracySurgeryEndoscopesImage sensorLight source

A portable multi-functional endoscopic device and method for use in the examination of tissue within a corporeal orifice to permit diagnostic, therapeutic or anatomical assessment data to be transmitted, recorded, or analyzed. The device includes a base unit sized and configured to be held in a human hand to permit functional and directional control of the device, an interchangeable head assembly sized and configured to be inserted into the orifice being removably connectable to the base unit, and an inflatable tissue stabilizer disposed external to a distal end of the device. In preferred aspects, the endoscopic device has an image sensor, light source, lens, air pump, and working tools.

Owner:GYNTEC MEDICAL

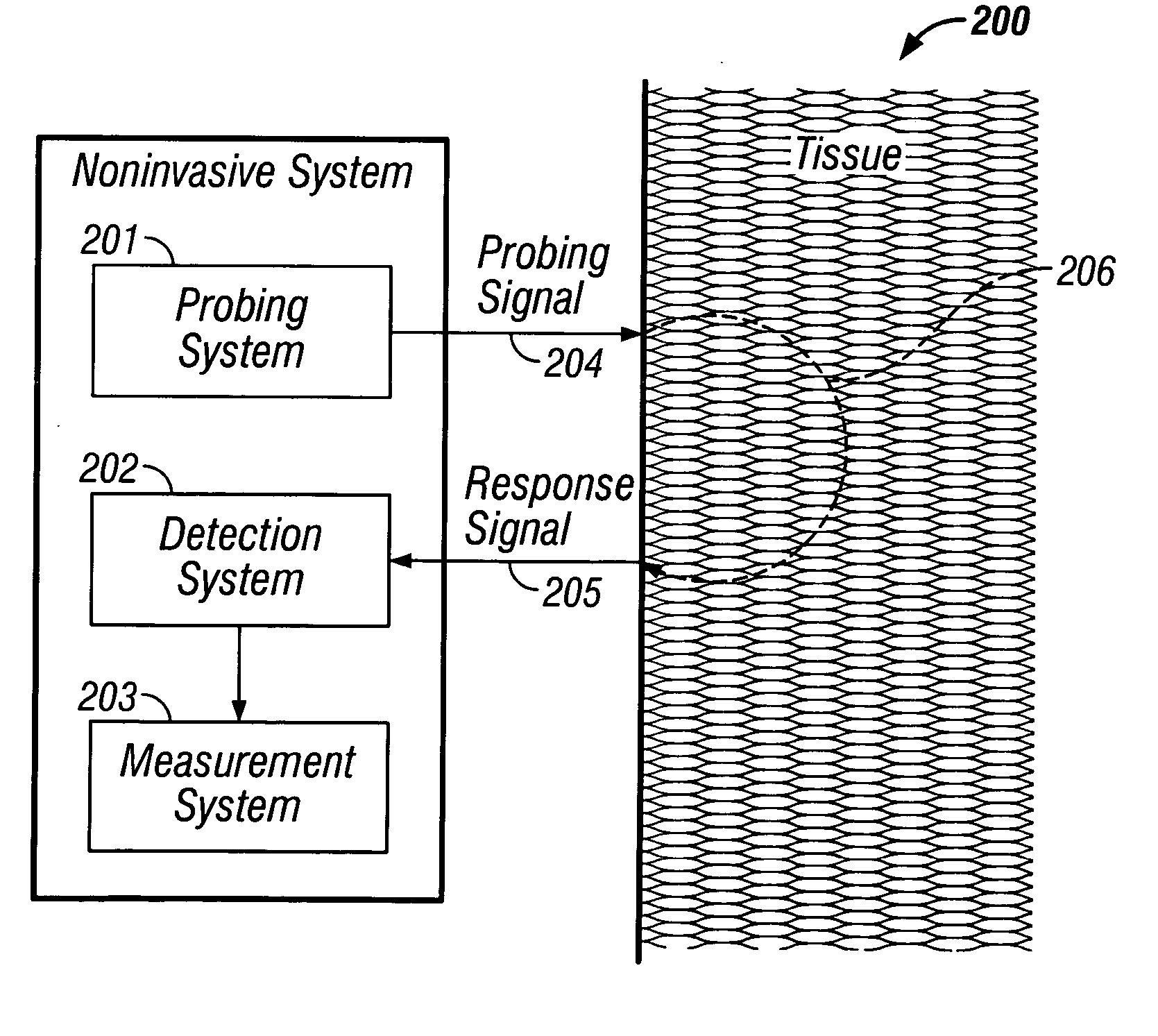

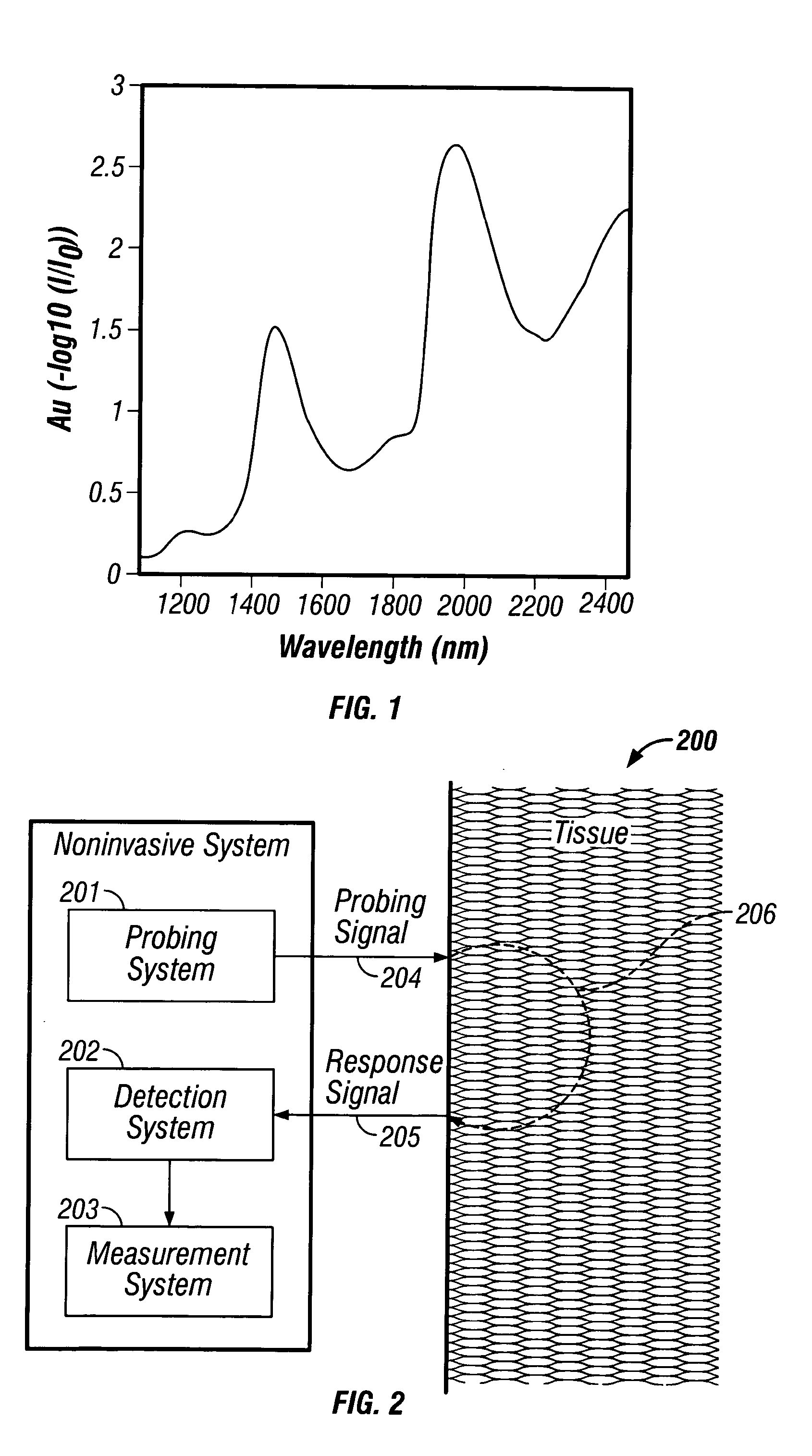

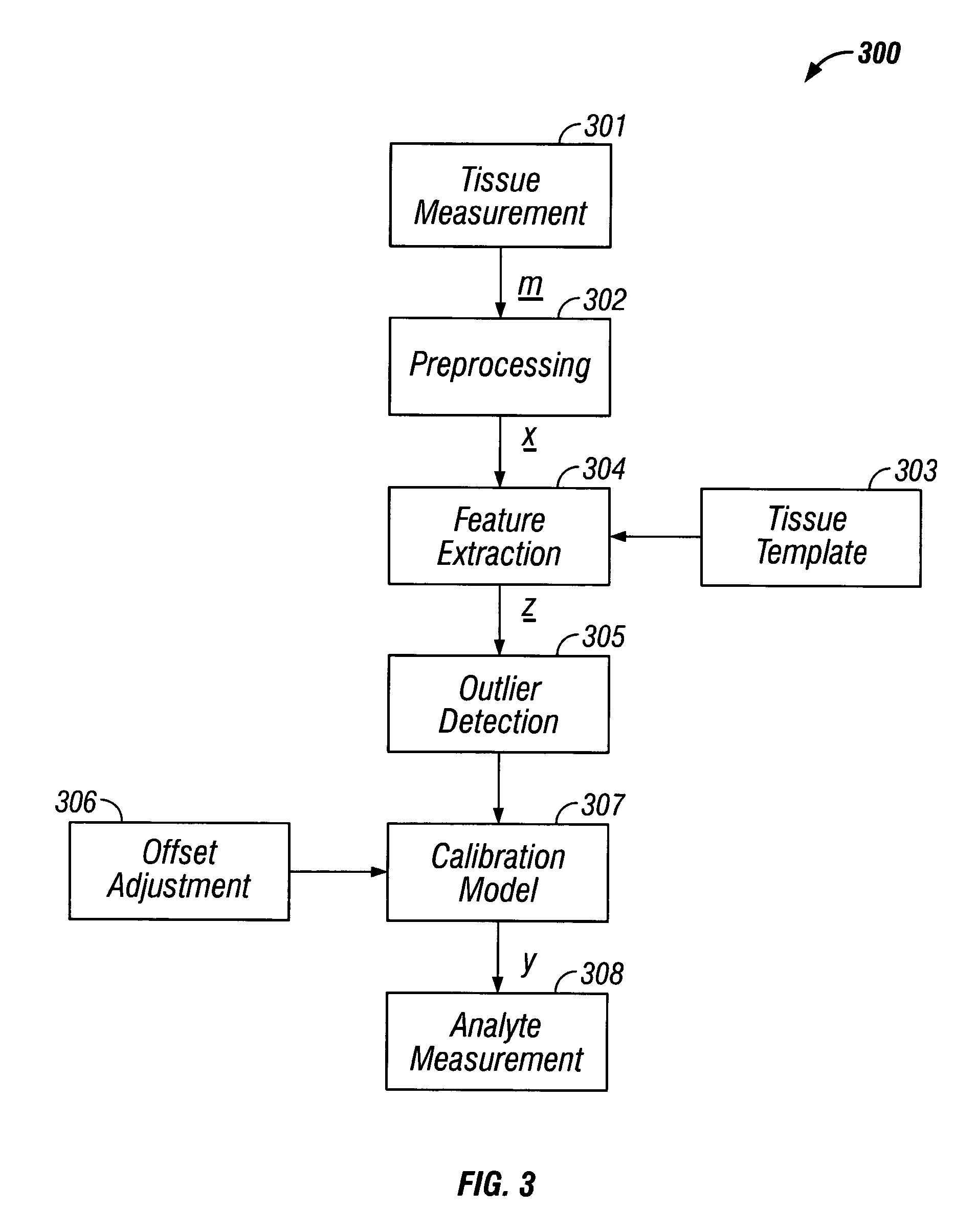

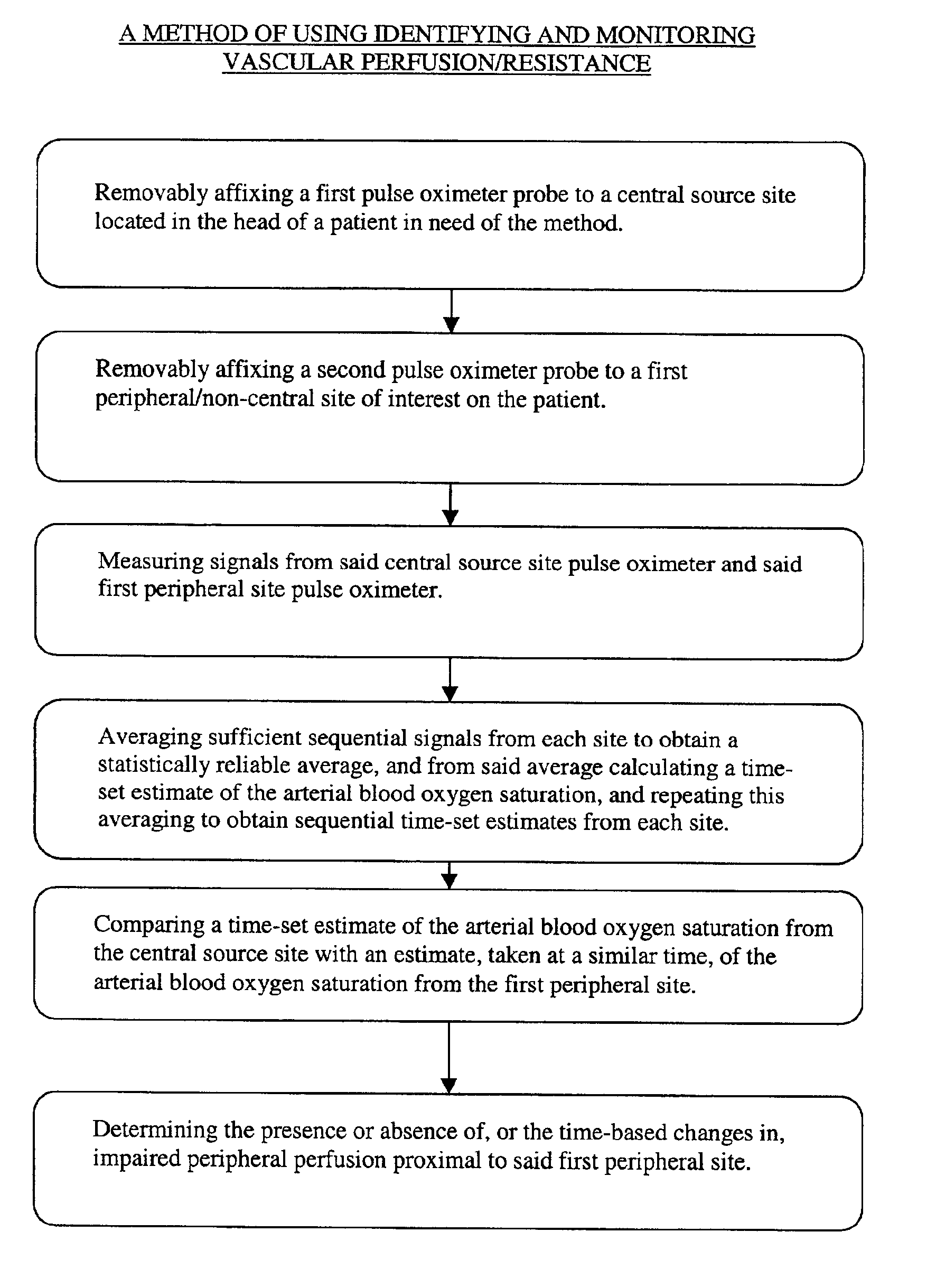

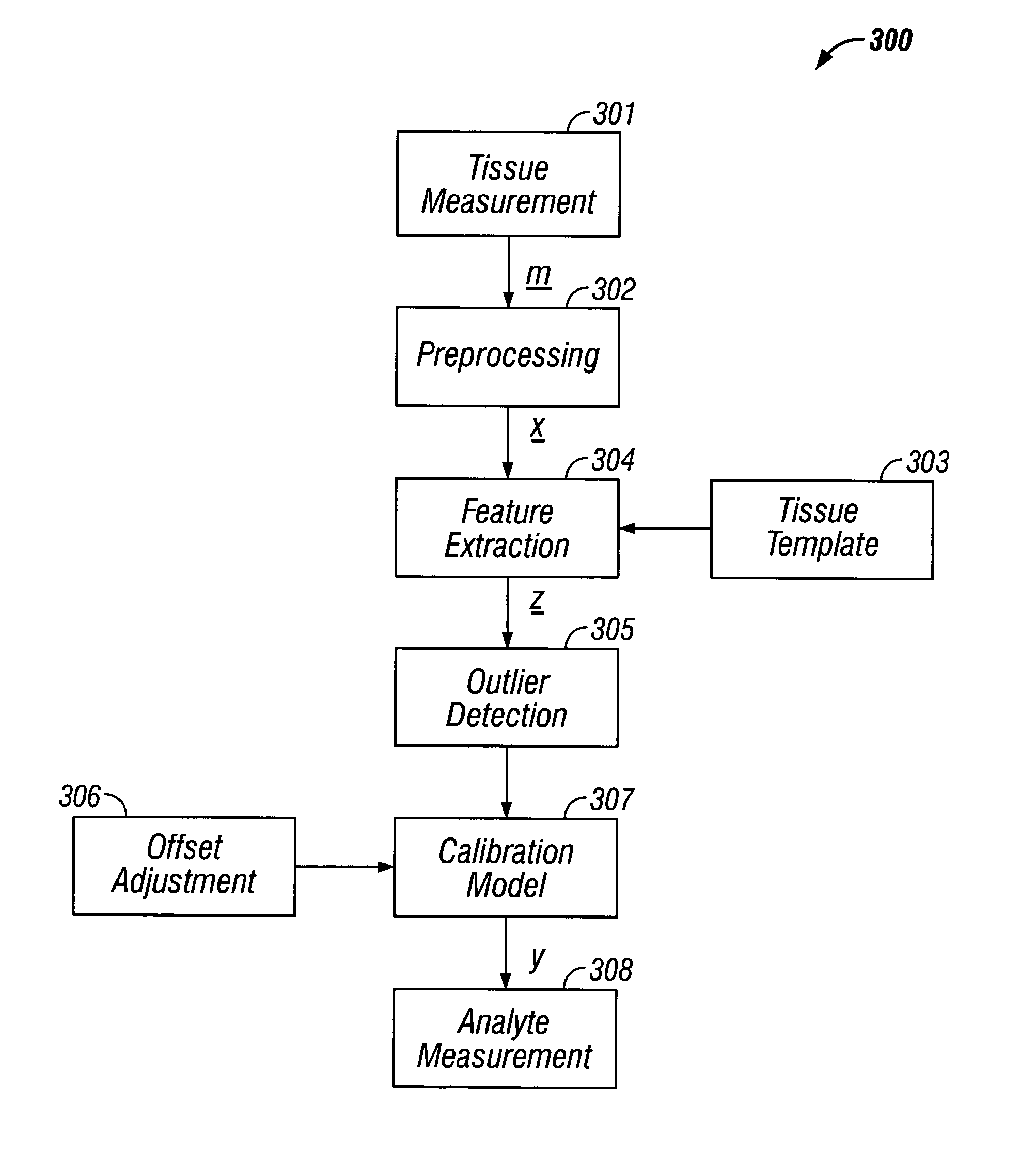

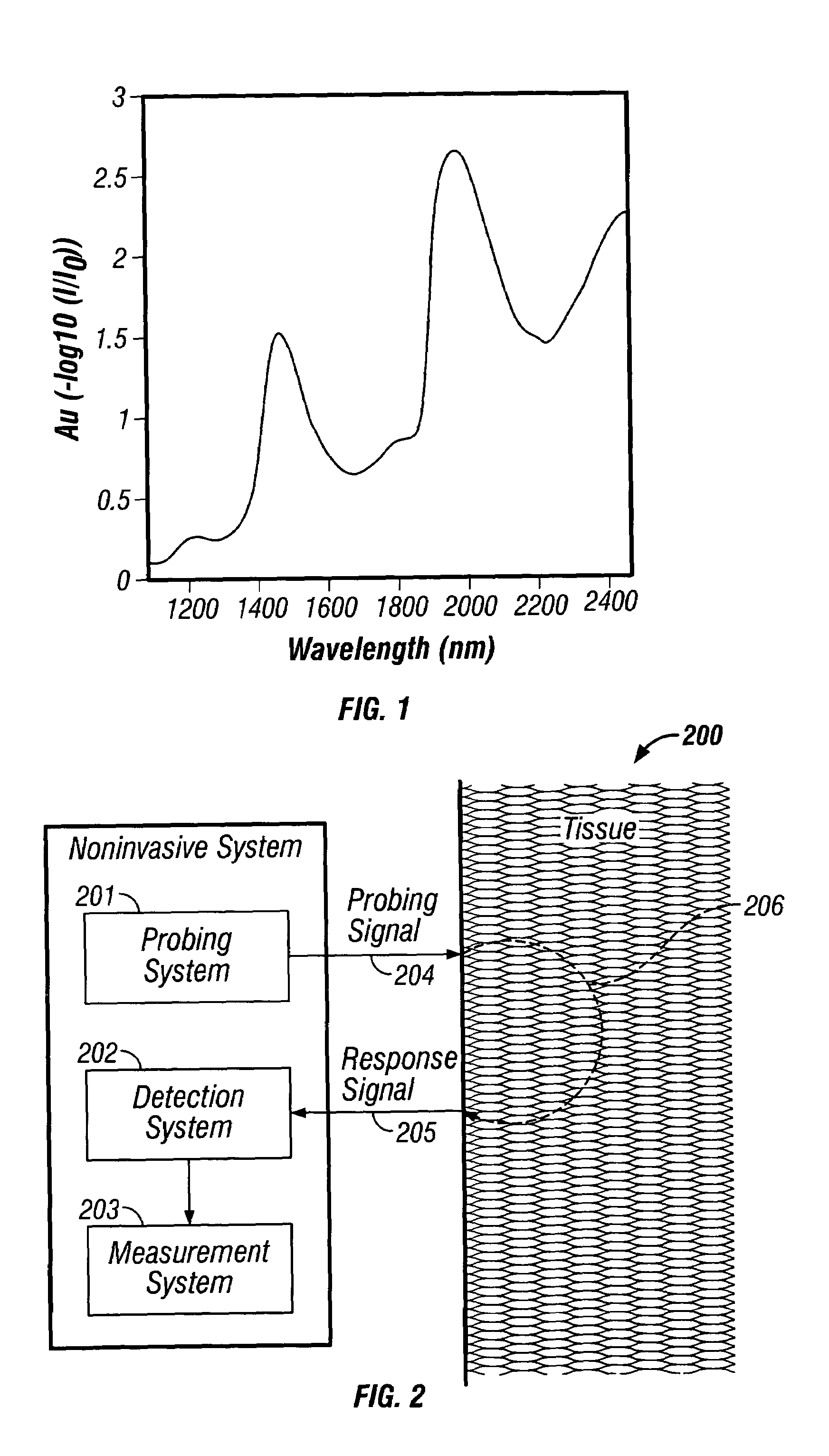

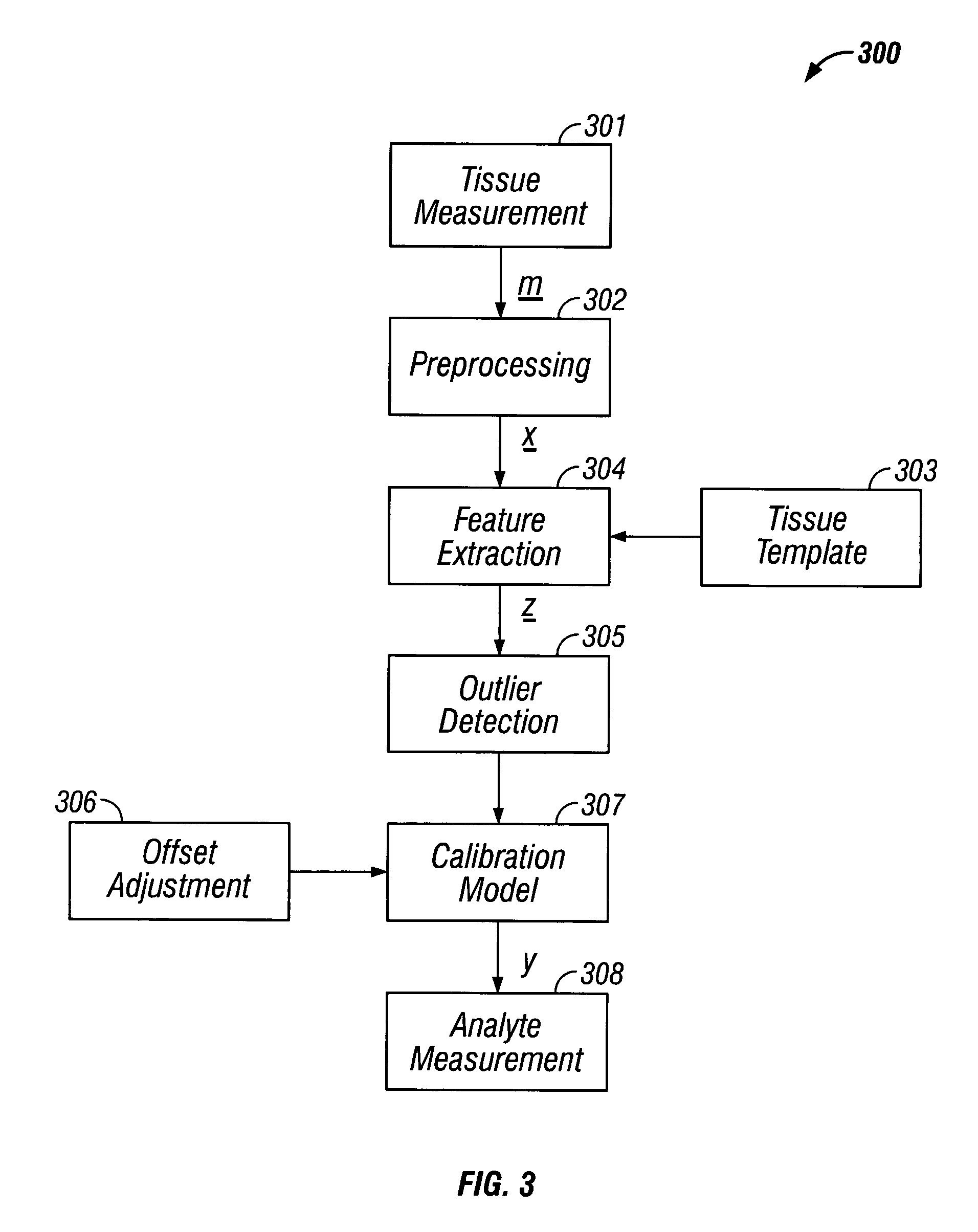

Indirect measurement of tissue analytes through tissue properties

InactiveUS20040127777A1Improve accuracy and precisionLimited stateDiagnostics using spectroscopyRaman scatteringAnalyteMedicine

Methods and system for noninvasive determination of tissue analytes utilize tissue properties as reflected in key features of an analytical signal to improve measurement accuracy and precision. Physiological conditions such as changes in water distribution among tissue compartments lead to complex alterations in the measured analytical signal of skin, leading to a biased noninvasive analyte measurement. Changes in the tissue properties are detected by identifying key features in the analytical signal responsive to physiological variations. Conditions not conducive to the noninvasive measurement are detected. Noninvasive measurements that are biased by physiological changes in tissue are compensated. In an alternate embodiment, the analyte is measured indirectly based on natural physiological response of tissue to changes in analyte concentration. A system capable of such measurements is provided.

Owner:GLT ACQUISITION +1

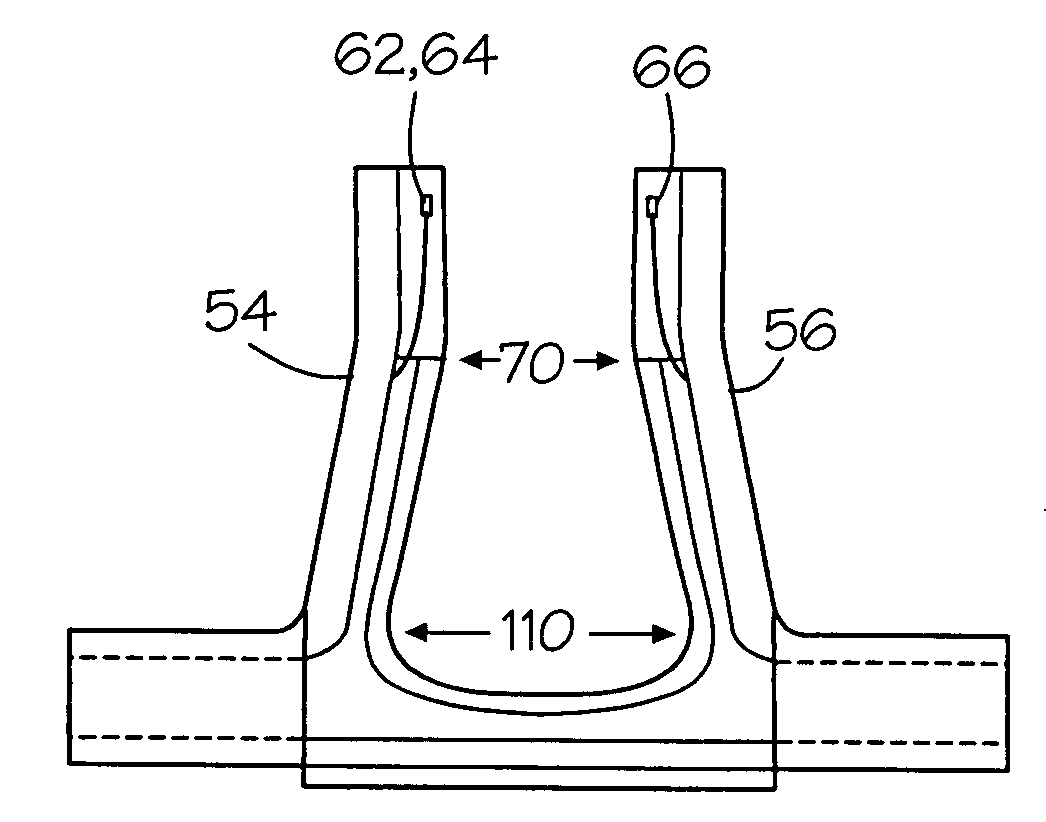

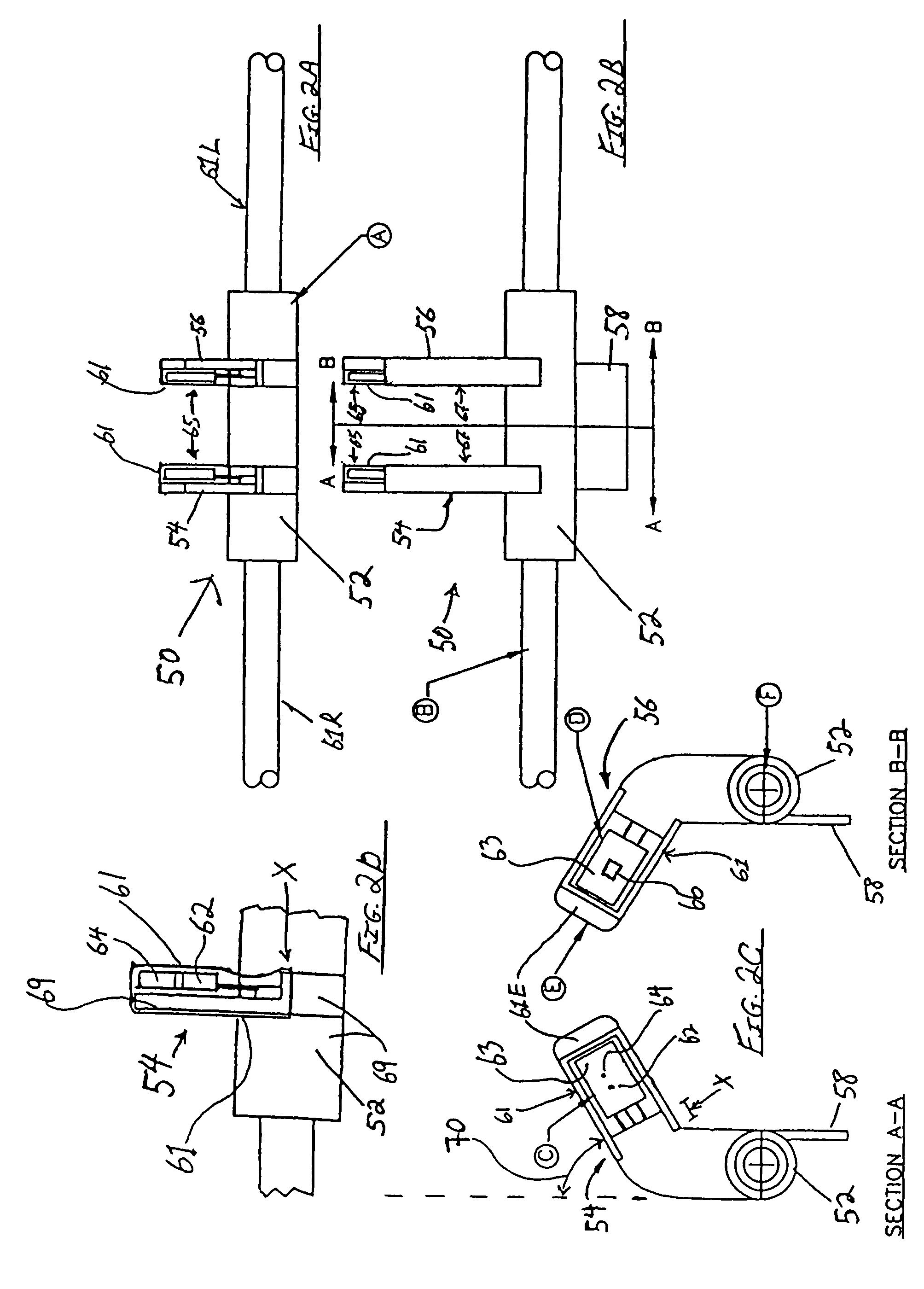

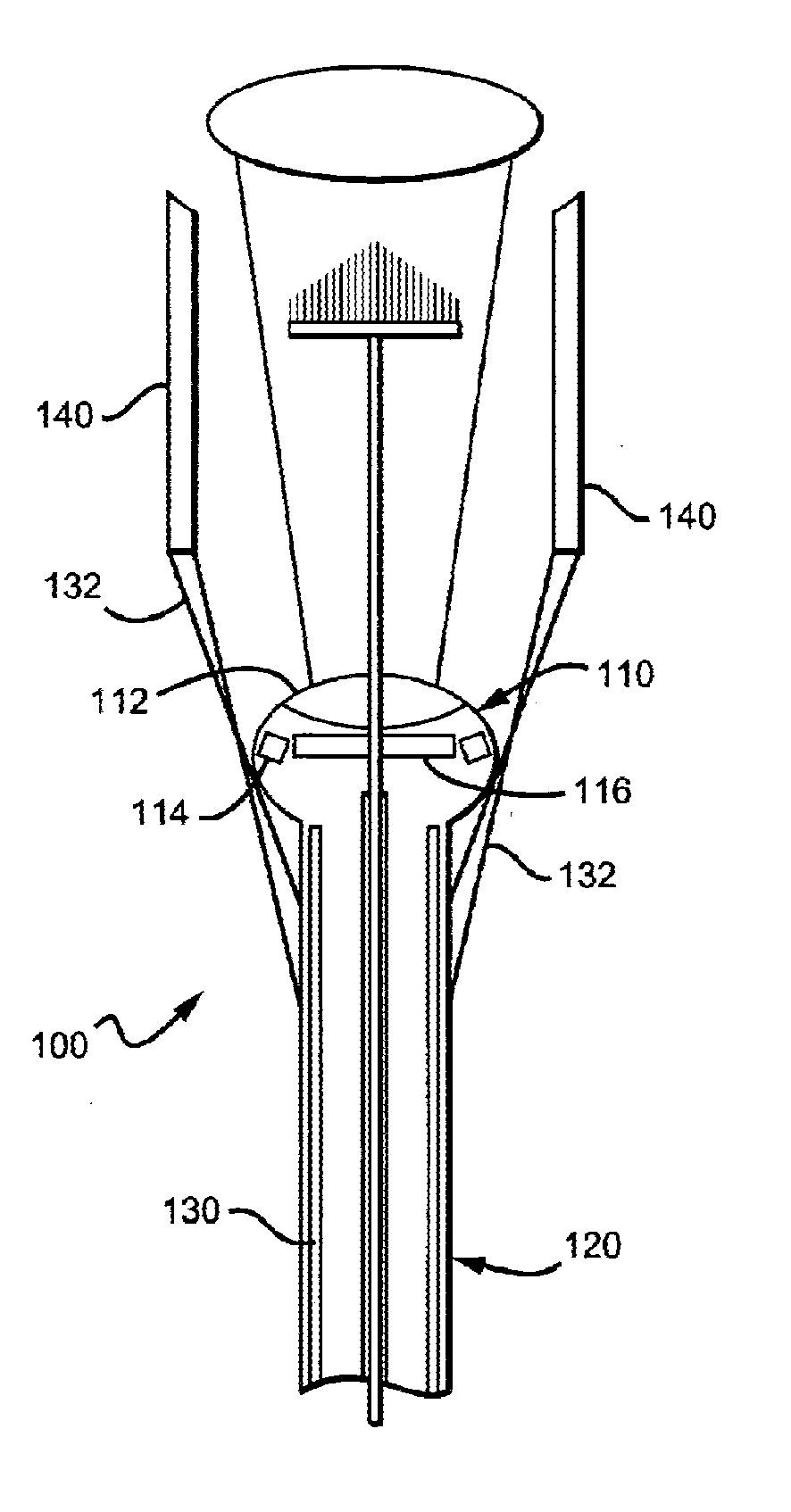

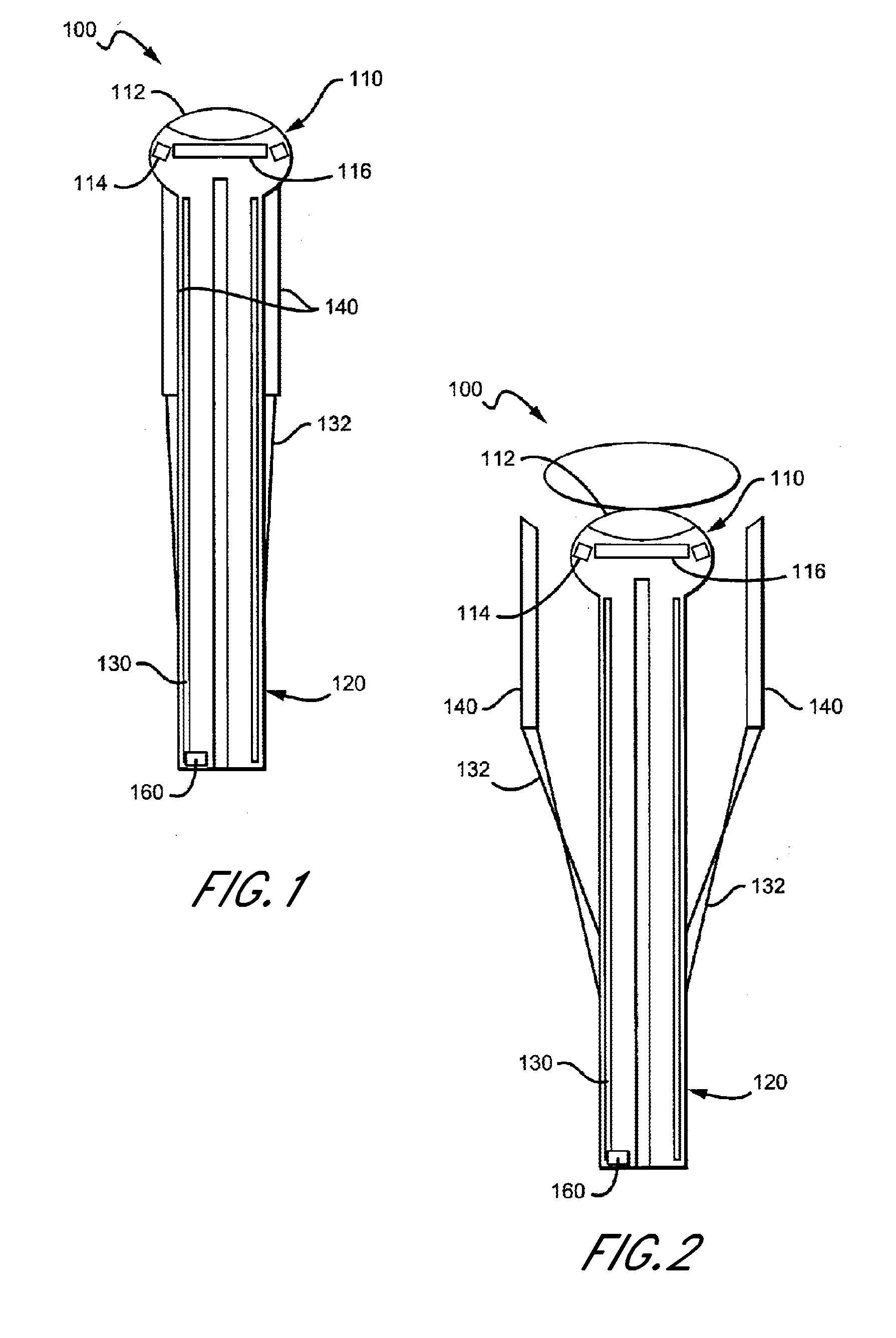

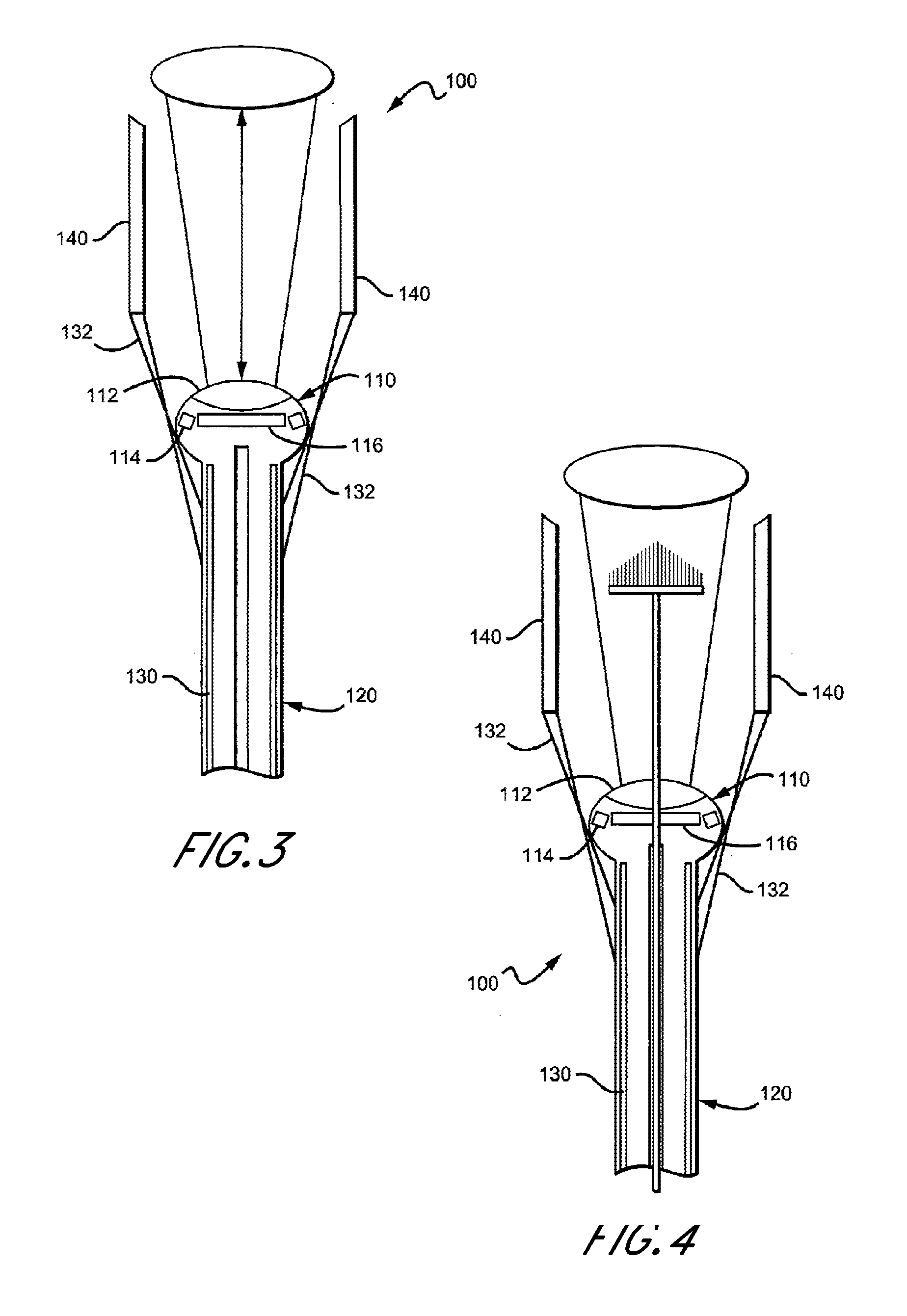

Non-invasive perfusion monitor and system, specially configured oximeter probes, methods of using same, and covers for probes

The present invention relates to a novel non-invasive perfusion / resistance status monitor system and methods of using the same, and more specifically, a vascular perfusion status monitor system receiving and processing signals from at least two pulse oximeter probes, where each of the at least two pulse oximeter probes are situated at advantageously different locations in a patient. Novel pulse oximeter probes are configured to be placed, respectively, across the lip or cheek, across the septum or nares of the nose, and on the tongue. These probes are fabricated to provide signals to estimate arterial oxygen saturation. Conventional oximeter probes also can be configured to function according to the novel methods of determining differences in peripheral blood flow and / or resistance described herein.

Owner:BETA BIOMED SERVICES +2

Optimized gas supply using photoplethysmography

InactiveUS20070027375A1Improve accuracy and precisionReliable receptionRespiratorsOperating means/releasing devices for valvesMedicinePulse oximeters

The present invention relates to optimized gas supply utilizing photoplethysmography. Flow rate, pressure or amount of gas is adjusted as a function of blood oxygen saturation data, photoplethysmography signals, or both, obtained from the pulse oximeter probe.

Owner:BETA BIOMED SERVICES +1

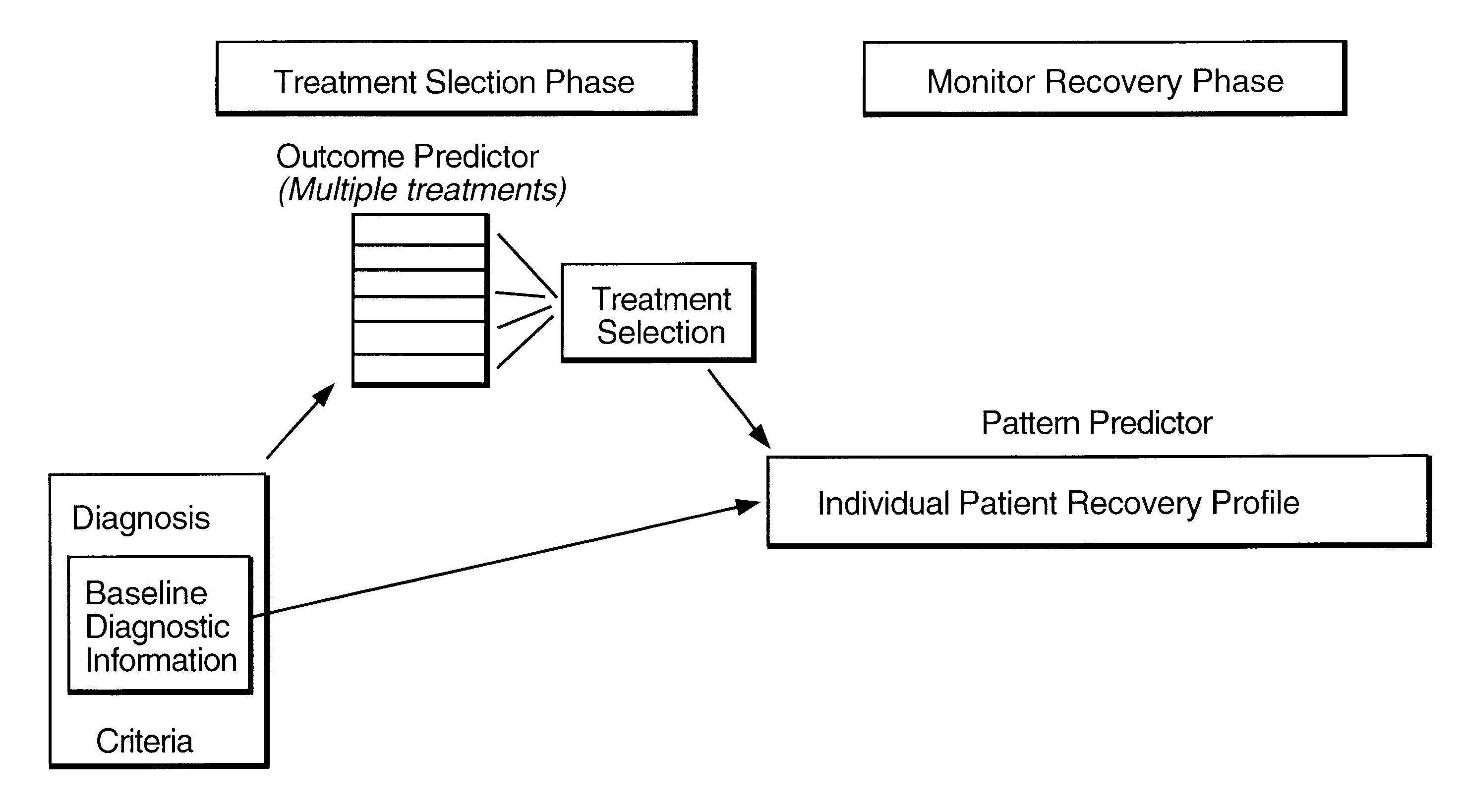

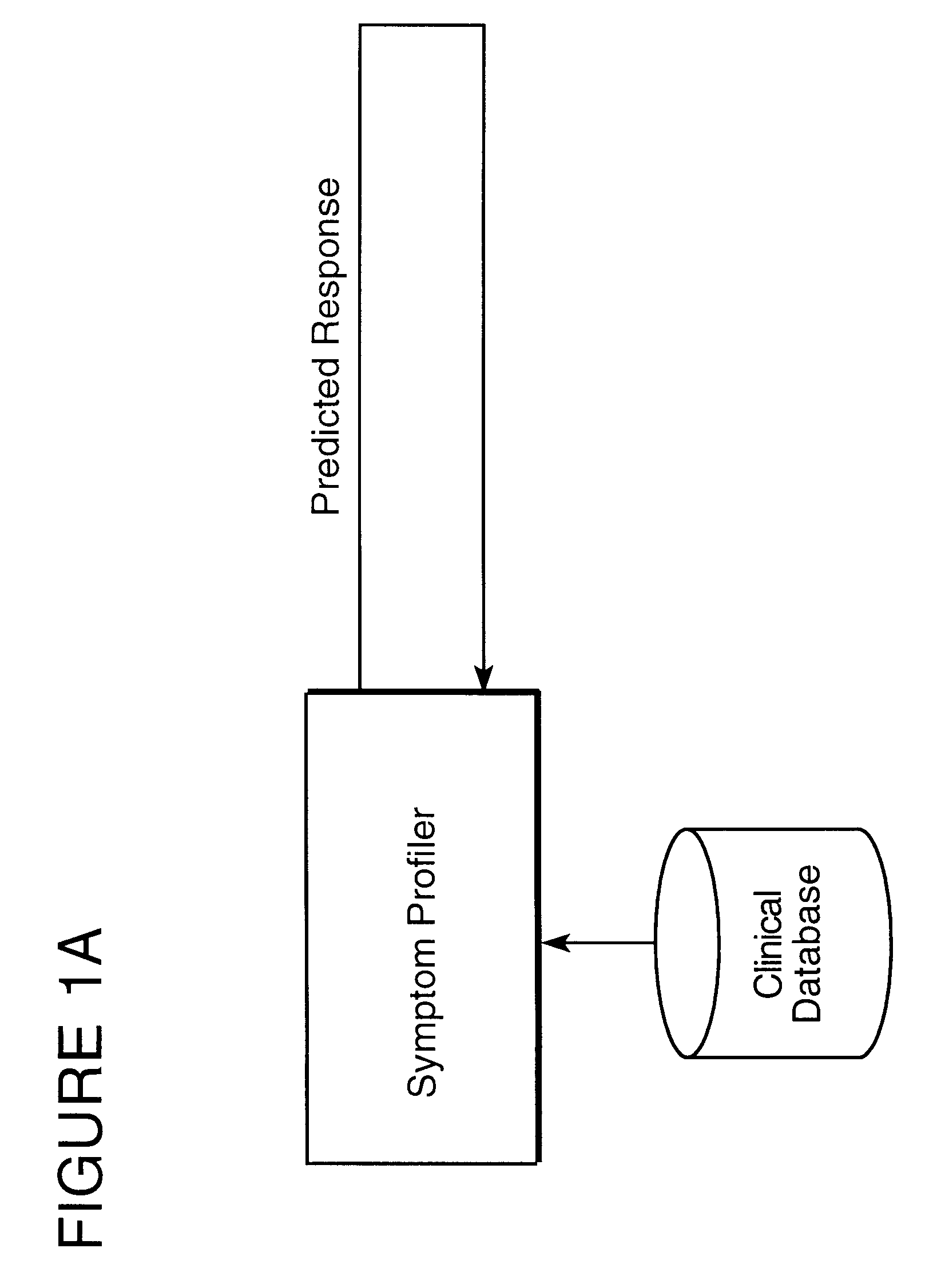

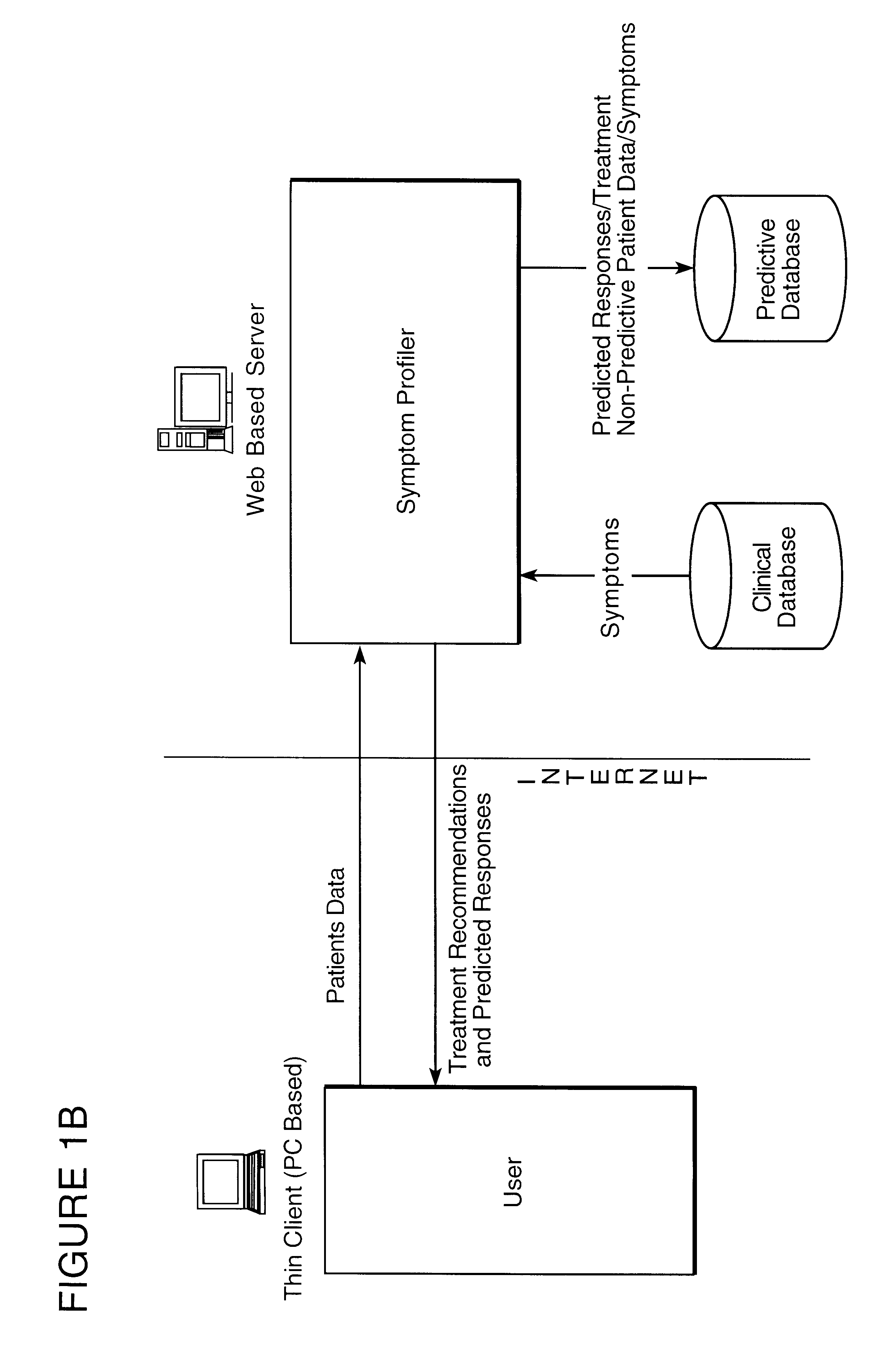

Method for predicting the therapeutic outcome of a treatment

InactiveUS6317731B1Improve accuracy and precisionHigh precisionBiological neural network modelsComputer-assisted medical data acquisitionDiseaseNerve network

A method useful for facilitating choosing a treatment or treatment regime and for predicting the outcome of a treatment for a disorder which is diagnosed and monitored by a physician or other appropriately trained and licensed professional, such as for example, a psychologist, based upon the symptoms experienced by a patient. Unipolar depression is an example of such a disorder, however the model may find use with other disorders and conditions wherein the patient response to treatment is variable. In the preferred embodiment, the method for predicting patient response includes the steps of performing at least one measurement of a symptom on a patient and measuring that symptom so as to derive a baseline patient profile, such as for example, determining the symptom profile with time; defining a set of a plurality of predictor variables which define the data of the baseline patient profile, wherein the set of predictor variables includes predictive symptoms and a set of treatment options; deriving a model that represents the relationship between patient response and the set of predictor variables; and utilizing the model to predict the response of said patient to a treatment. A neural net architecture is utilized to define a non-linear, second order model which is utilized to analyze the patient data and generate the predictive database from entered patient data.

Owner:ADVANCED BIOLOGICAL LAB

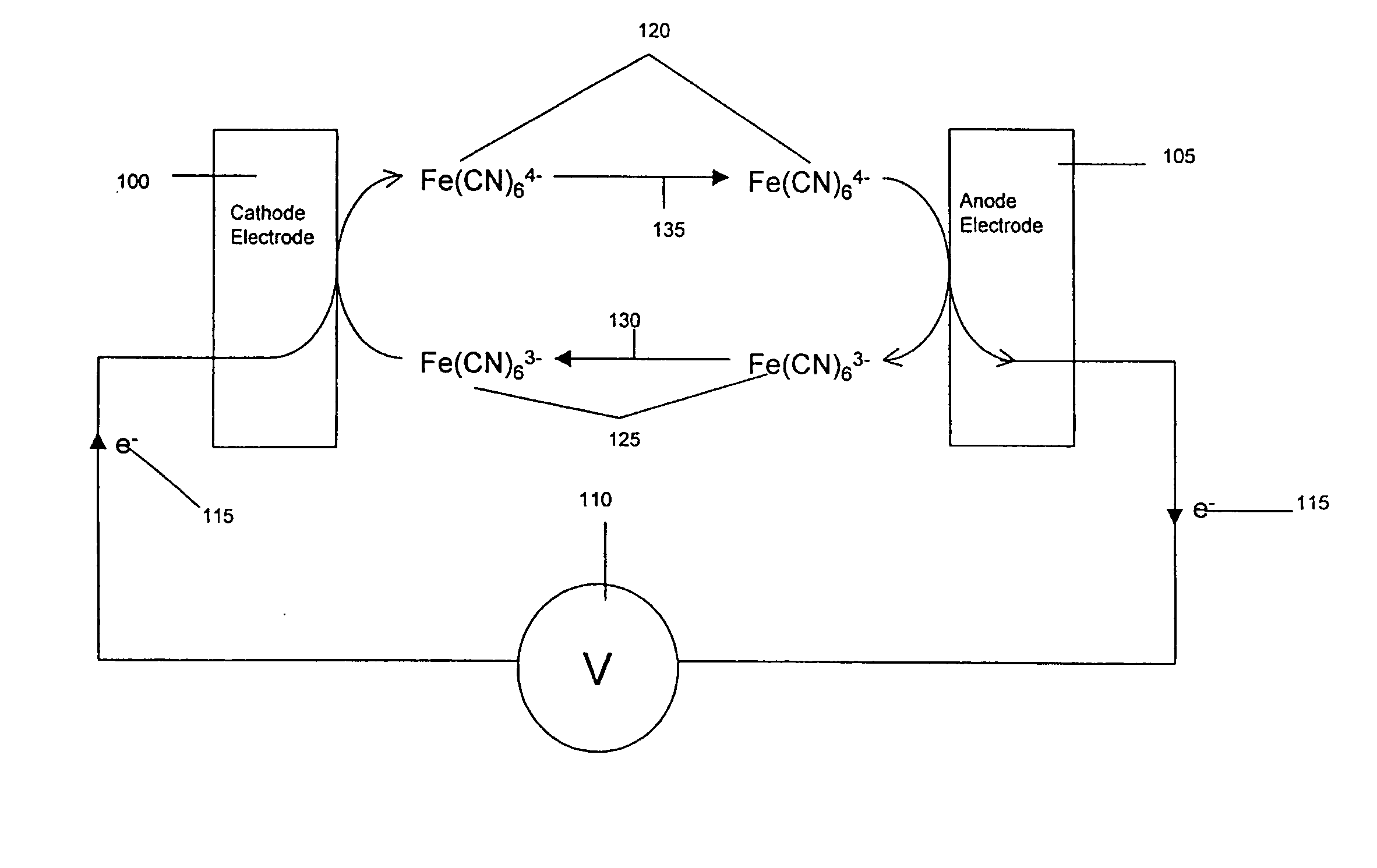

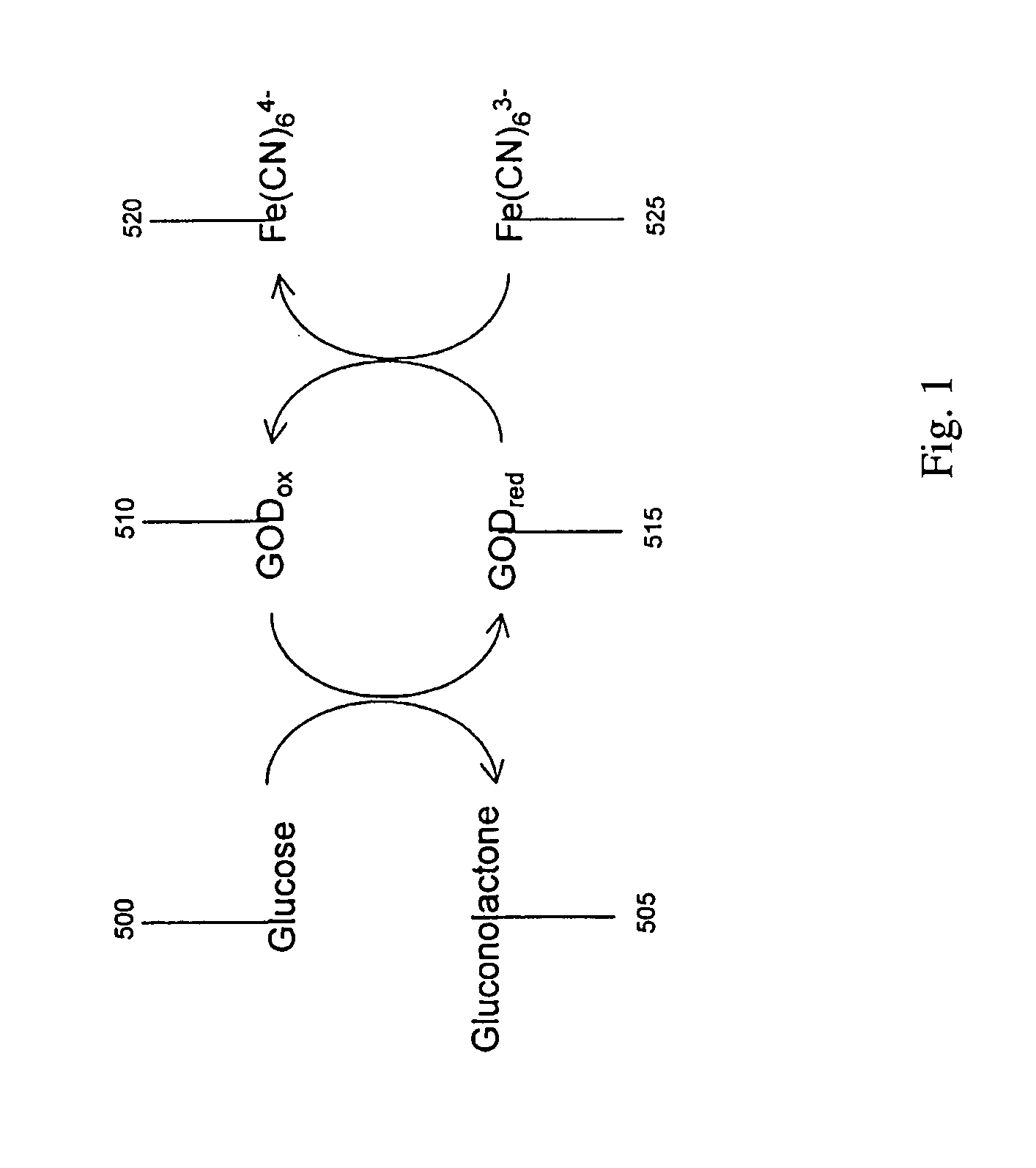

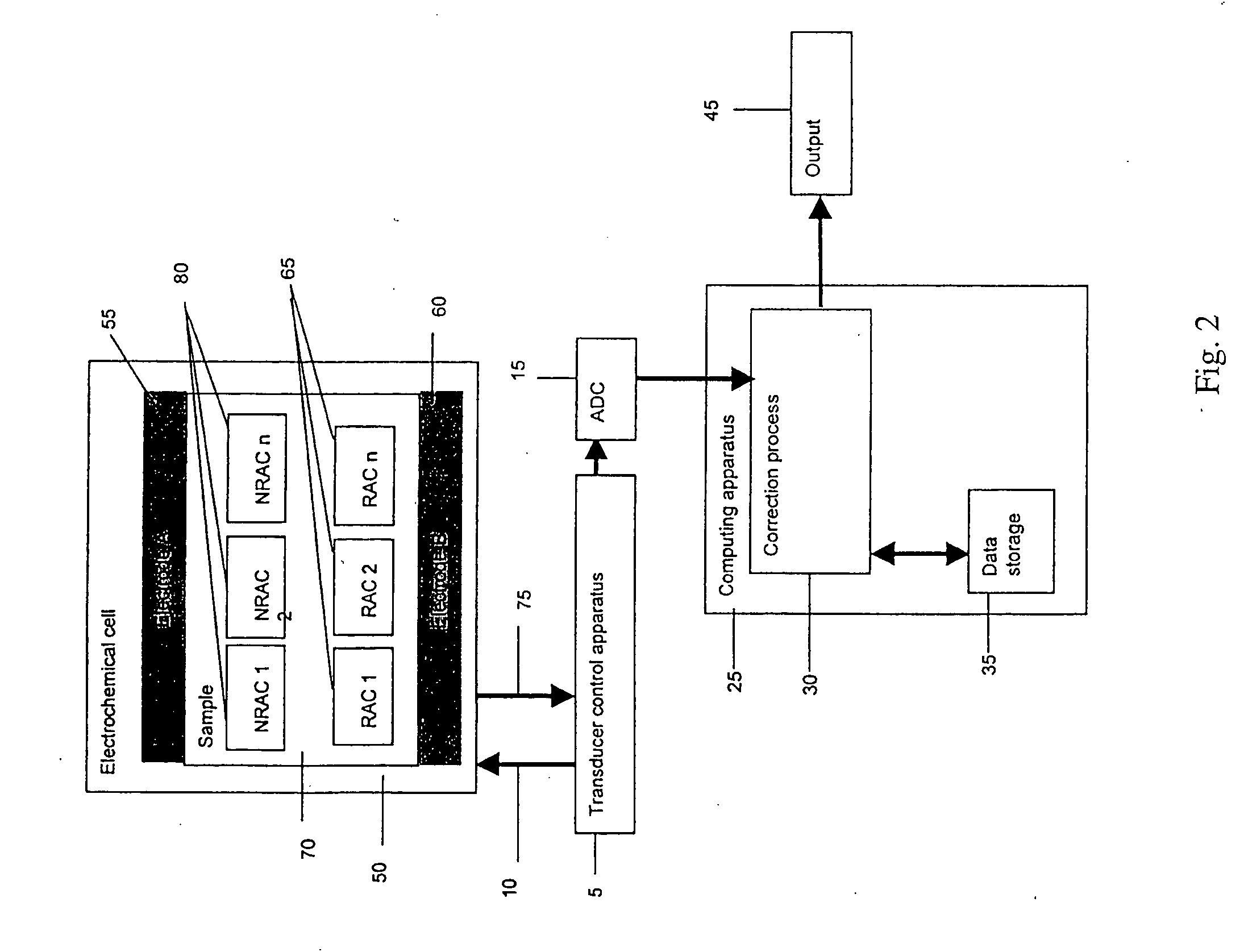

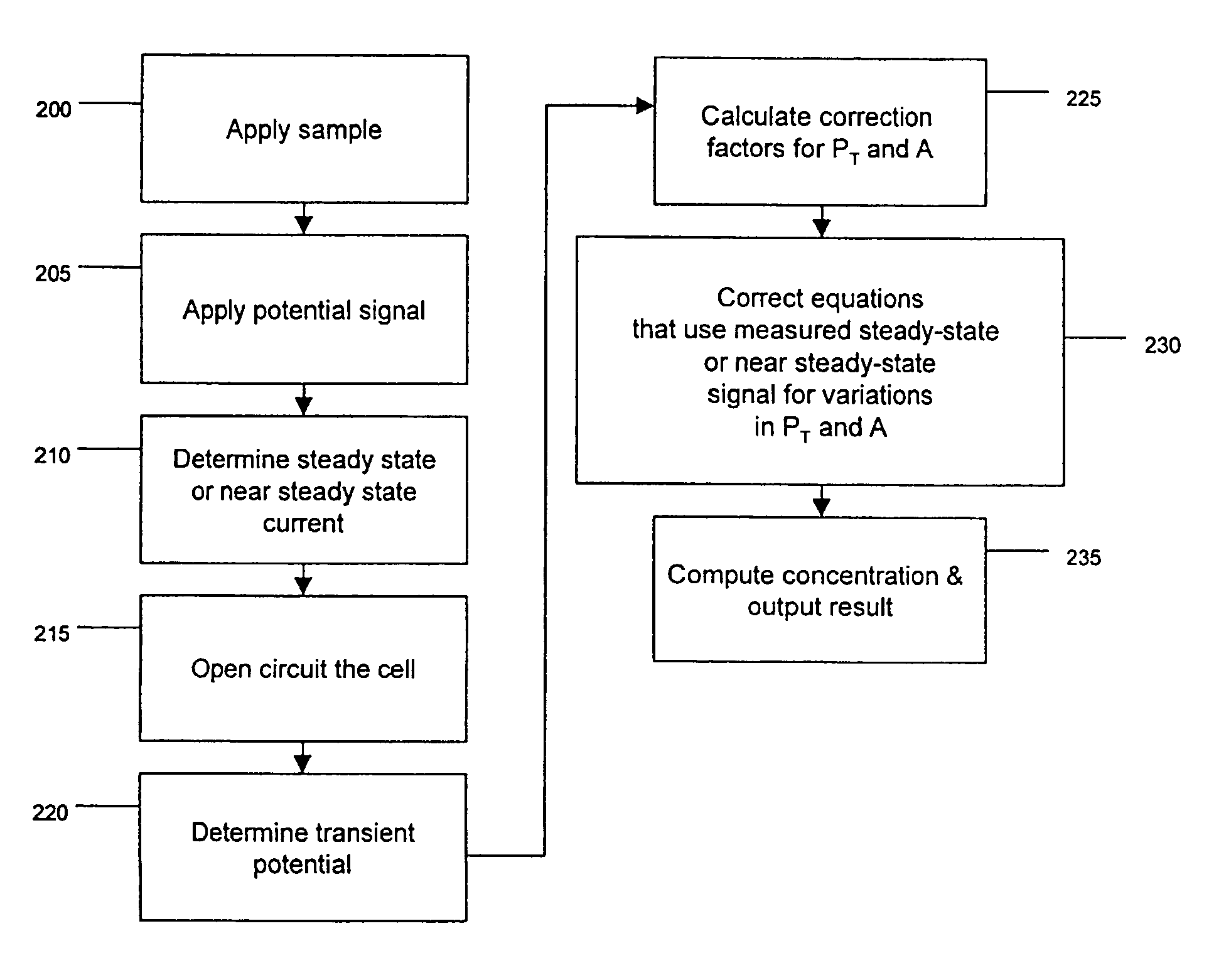

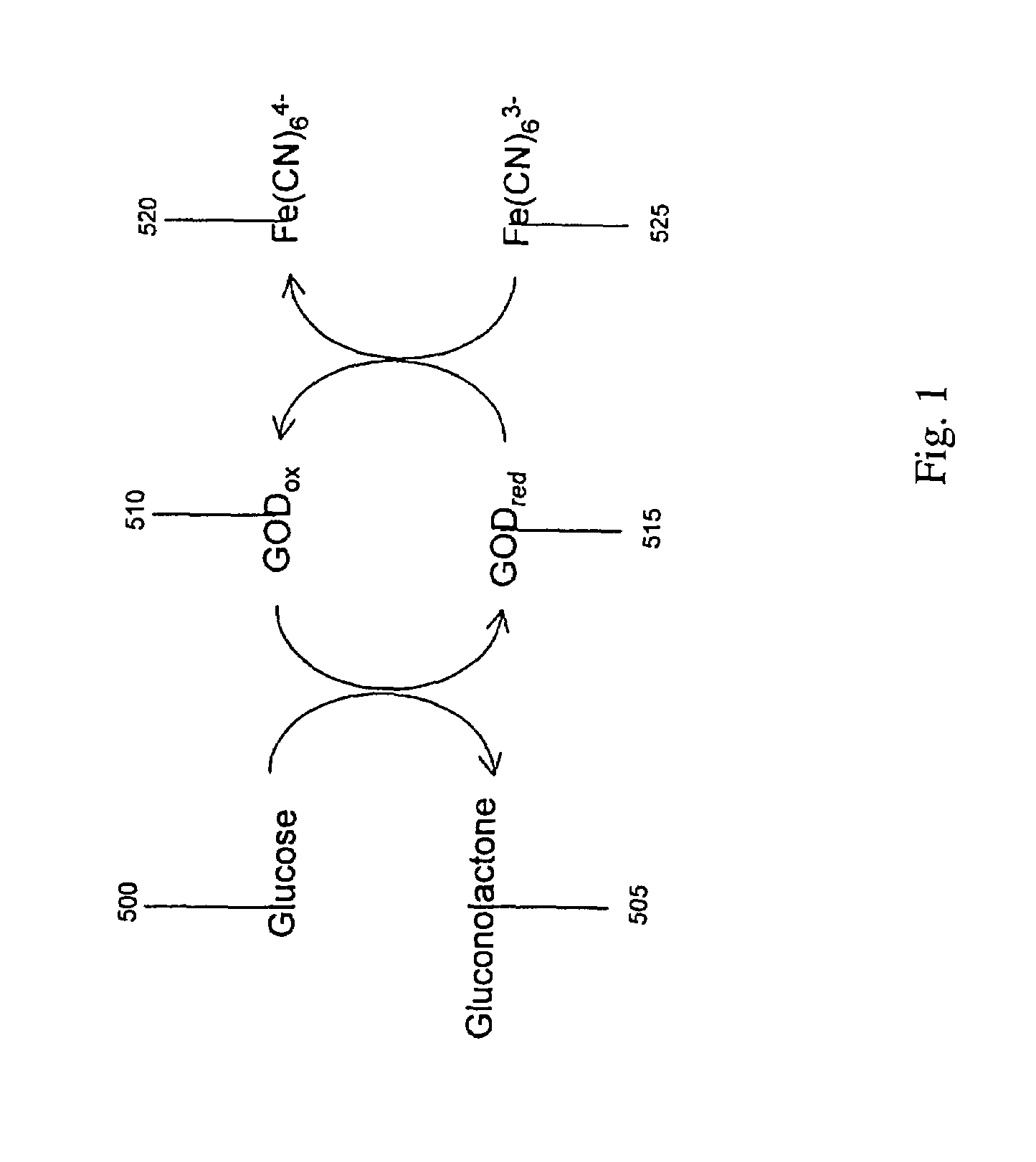

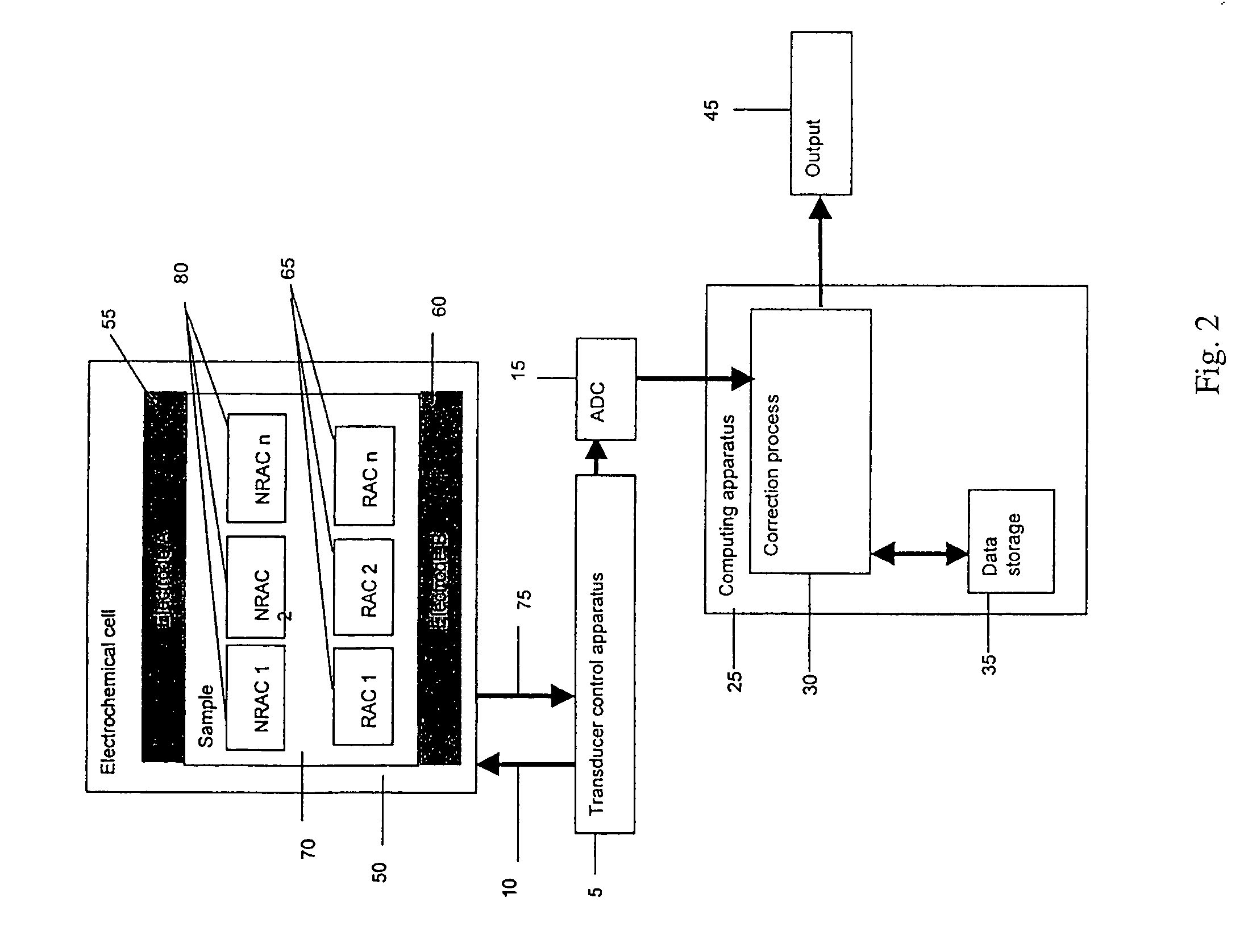

Method and apparatus for assay of electrochemical properties

ActiveUS20050109637A1Easy to measureImprove accuracyWeather/light/corrosion resistanceMicrobiological testing/measurementHand heldApplied potential

The presence of a select analyte in the sample is evaluated in an an electrochemical system using a conduction cell-type apparatus. A potential or current is generated between the two electrodes of the cell sufficient to bring about oxidation or reduction of the analyte or of a mediator in an analyte-detection redox system, thereby forming a chemical potential gradient of the analyte or mediator between the two electrodes After the gradient is established, the applied potential or current is discontinued and an analyte-independent signal is obtained from the relaxation of the chemical potential gradient. The analyte-independent signal is used to correct the analyte-dependent signal obtained during application of the potential or current. This correction allows an improved measurement of analyte concentration because it corrects for device-specific and test specific factors such as transport (mobility) of analyte and / or mediator, effective electrode area, and electrode spacing (and as a result, sample volume), without need for separate calibration values. The analysis can be performed using disposable test strips in a hand held meter, for example for glucose testing.

Owner:AGAMATRIX INC

Indirect measurement of tissue analytes through tissue properties

InactiveUS7039446B2Improve accuracy and precisionLimited stateDiagnostics using spectroscopyRaman scatteringAnalyteMedicine

Owner:GLT ACQUISITION +1

Method and apparatus for assay of electrochemical properties

ActiveUS7501052B2Easy to measureImprove accuracy and precisionImmobilised enzymesBioreactor/fermenter combinationsHand heldApplied potential

The presence of a select analyte in the sample is evaluated in an an electrochemical system using a conduction cell-type apparatus. A potential or current is generated between the two electrodes of the cell sufficient to bring about oxidation or reduction of the analyte or of a mediator in an analyte-detection redox system, thereby forming a chemical potential gradient of the analyte or mediator between the two electrodes After the gradient is established, the applied potential or current is discontinued and an analyte-independent signal is obtained from the relaxation of the chemical potential gradient. The analyte-independent signal is used to correct the analyte-dependent signal obtained during application of the potential or current. This correction allows an improved measurement of analyte concentration because it corrects for device-specific and test specific factors such as transport (mobility) of analyte and / or mediator, effective electrode area, and electrode spacing (and as a result, sample volume), without need for separate calibration values. The analysis can be performed using disposable test strips in a hand held meter, for example for glucose testing.

Owner:AGAMATRIX INC

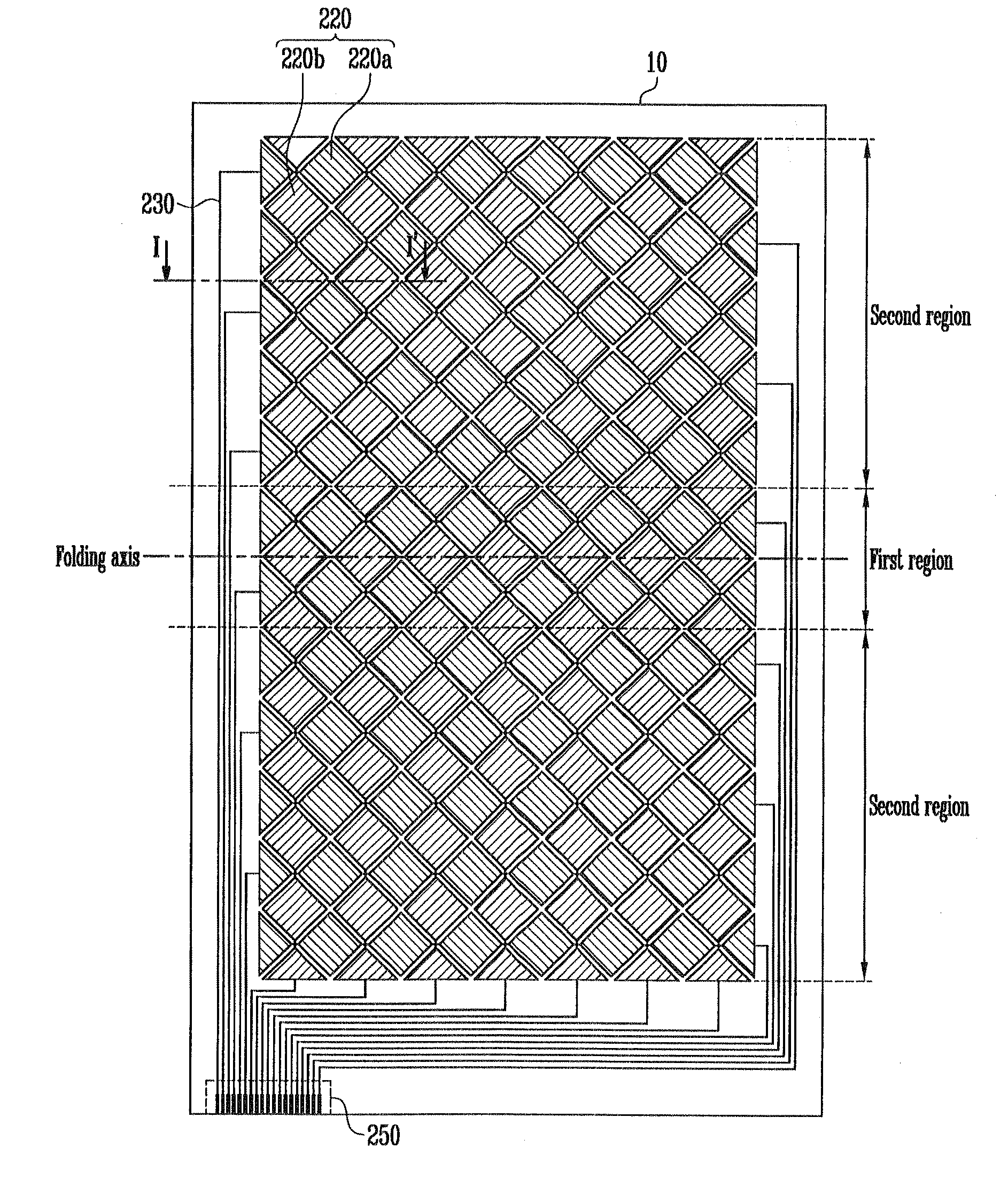

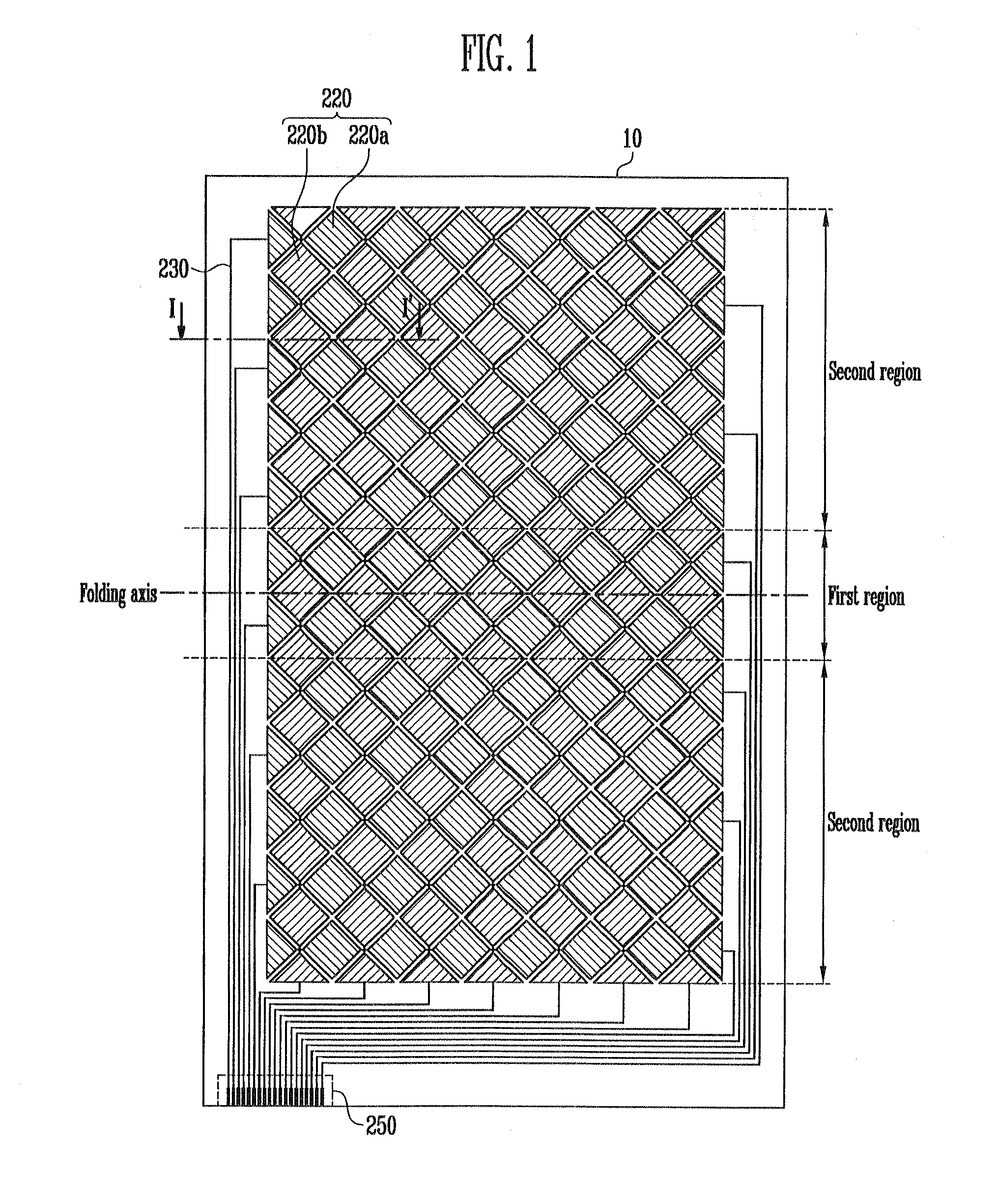

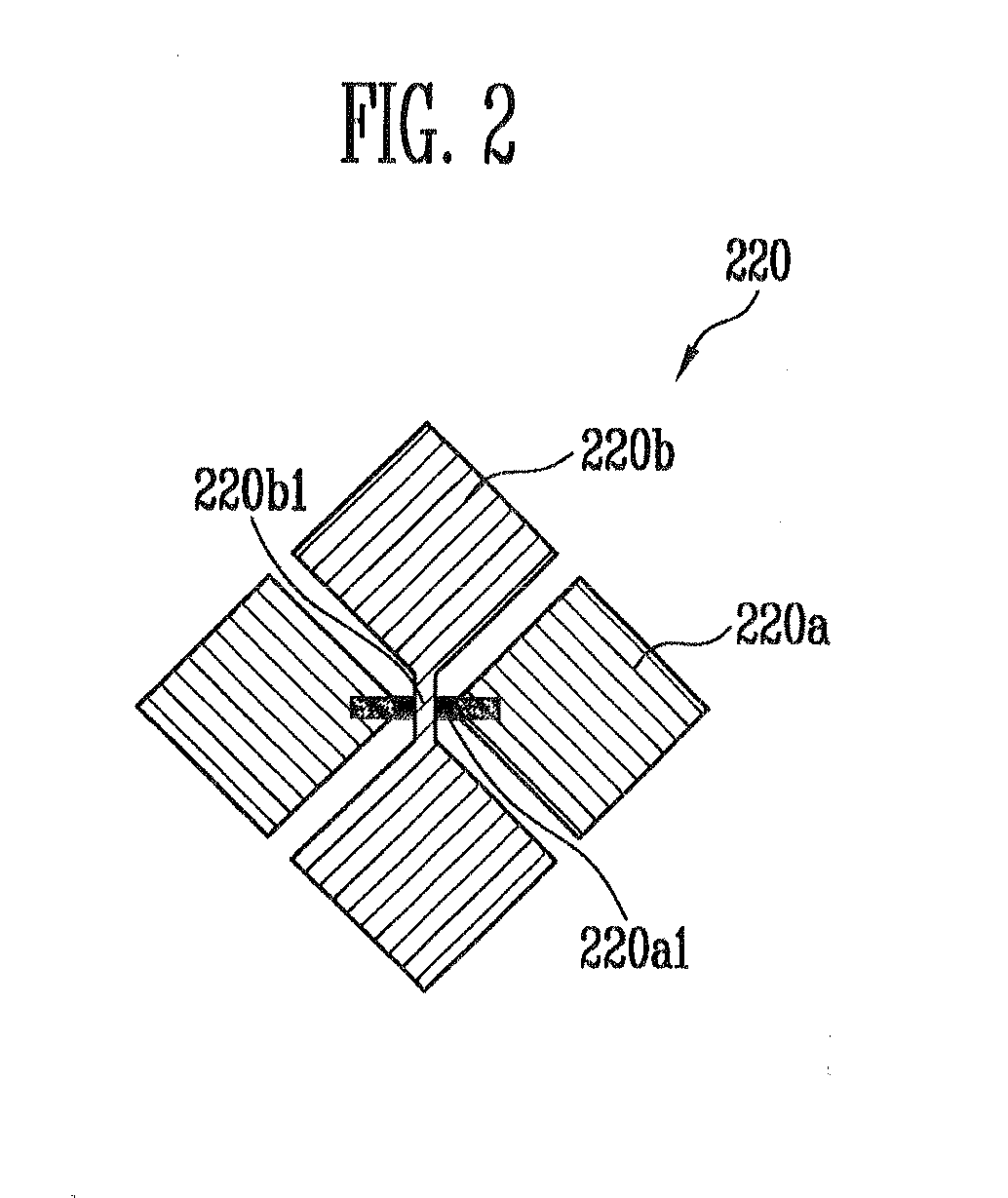

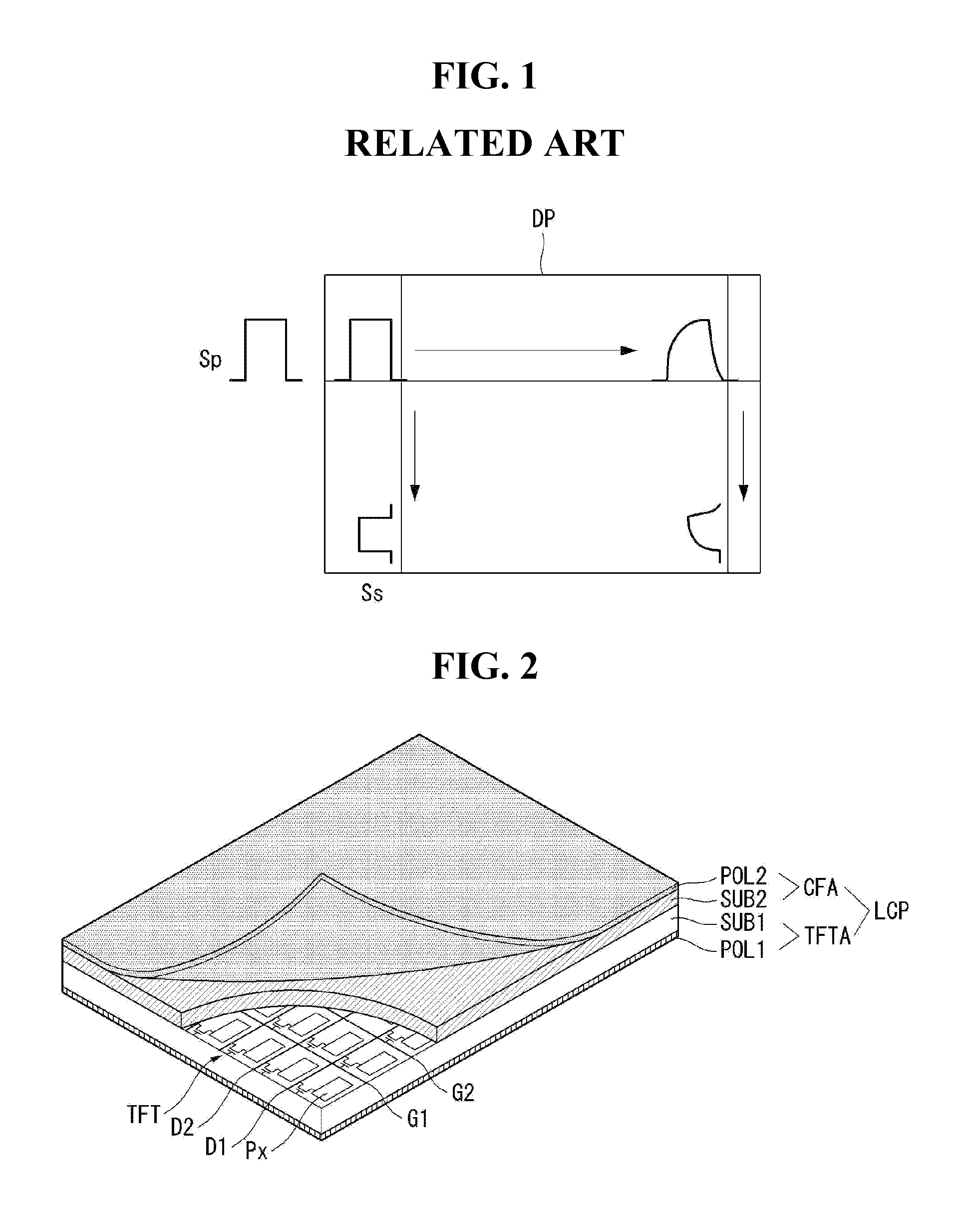

Flexible touch screen panel and flexible display device with the same

InactiveUS20140132553A1Minimize the differenceImprove accuracyInput/output processes for data processingTouchscreenFlexible display

Owner:SAMSUNG DISPLAY CO LTD

Distal bevel-tip needle control device and algorithm

ActiveUS20070016067A1Improve accuracyImprove precisionUltrasonic/sonic/infrasonic diagnosticsSurgical needlesKinematicsNeedle steering

Disclosed is a system for percutaneously steering a surgical needle. Needle steering is accomplished by taking advantage of a deflection force imparted on the bevel tip of the needle by the tissue medium as the needle is pushed through the tissue. By controlling the translation speed and rotation angle of the bevel, a flexible needle may be steered substantially without deflecting or distorting the tissue. The control inputs (translation speed and rotation angle) are computed based on a “bicycle” non-holonomic kinematic model that is a function of mechanical properties of the tissue medium. The system may be used with image-based feedback, which may provide for feedback-based refinement of the model as the needle propagates through the tissue.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

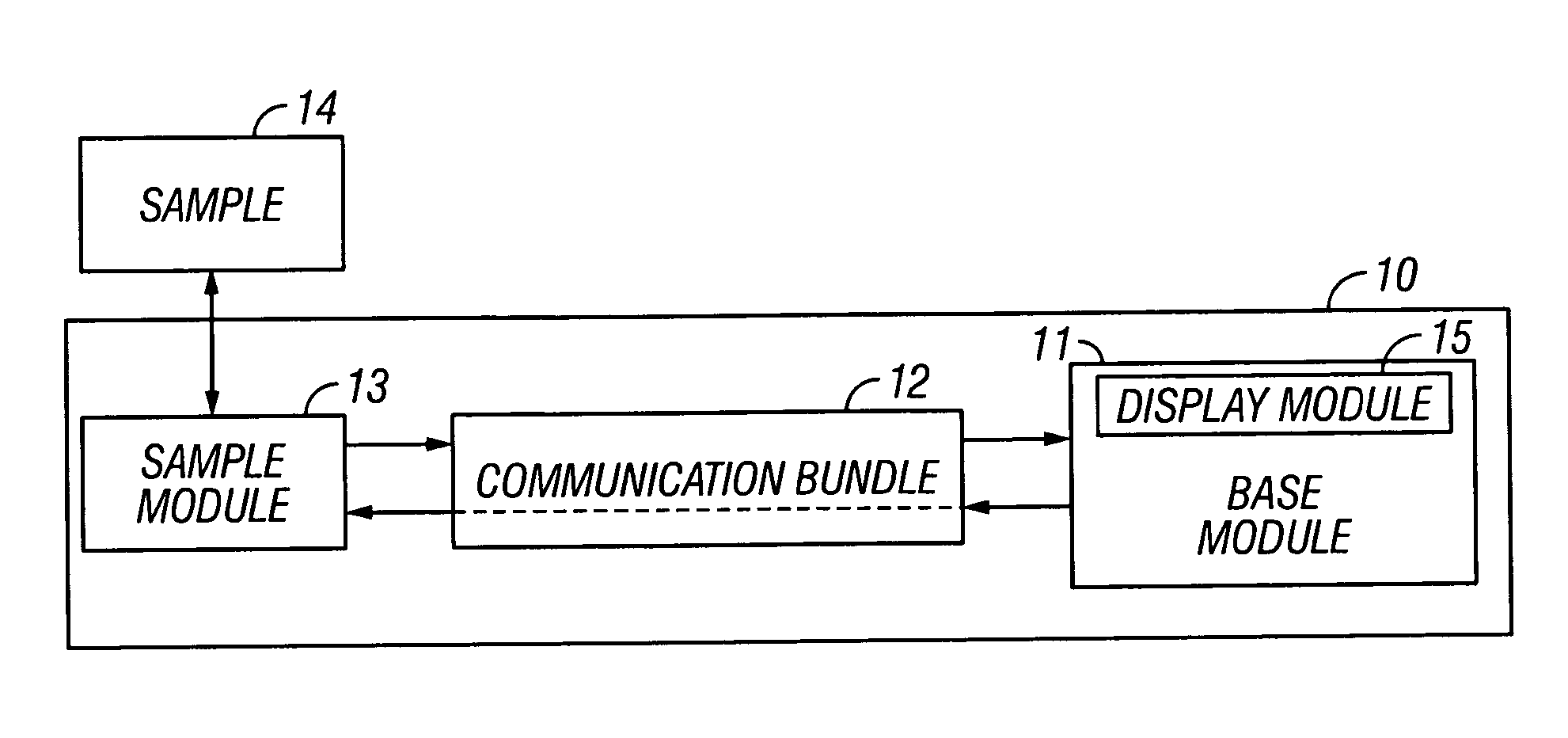

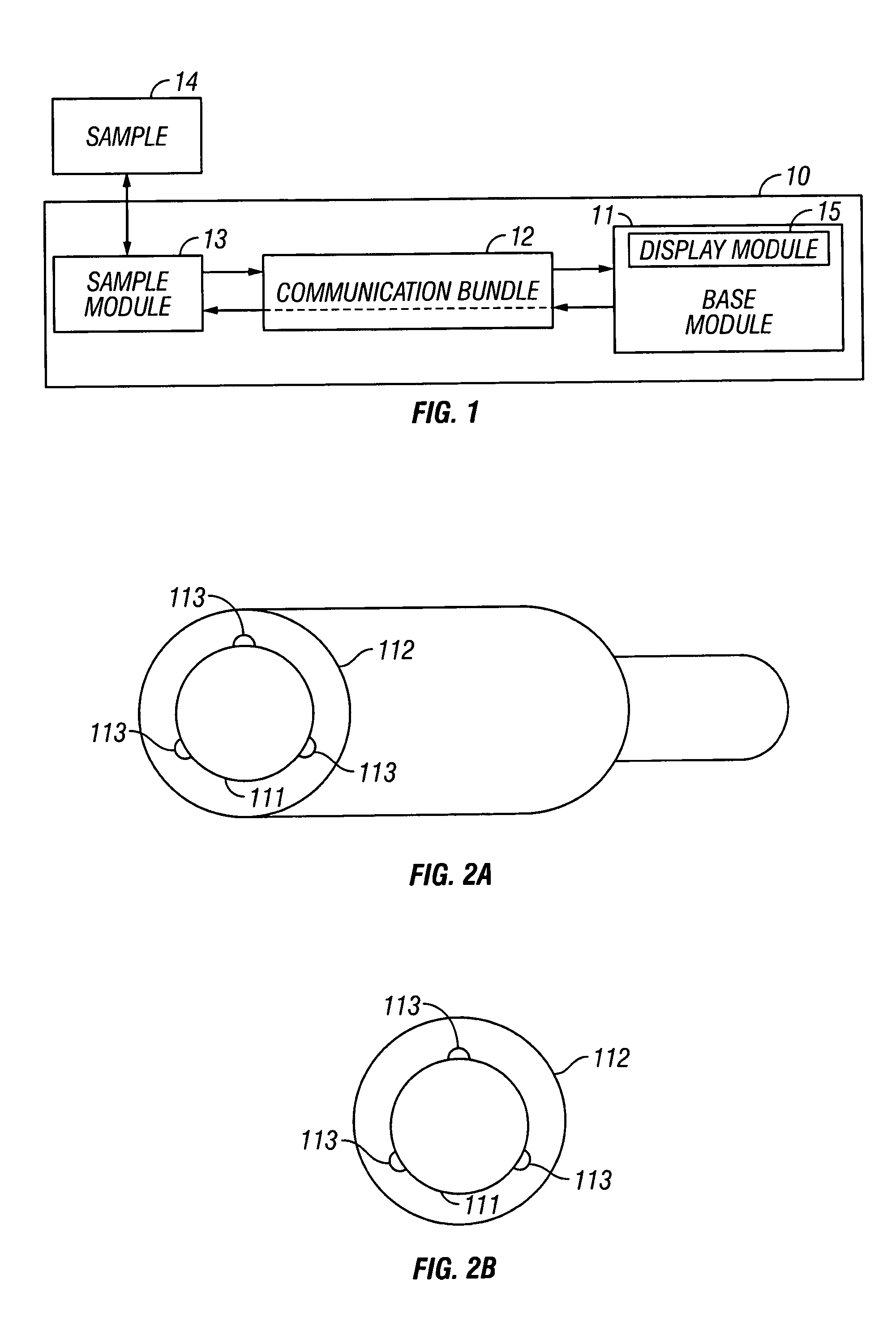

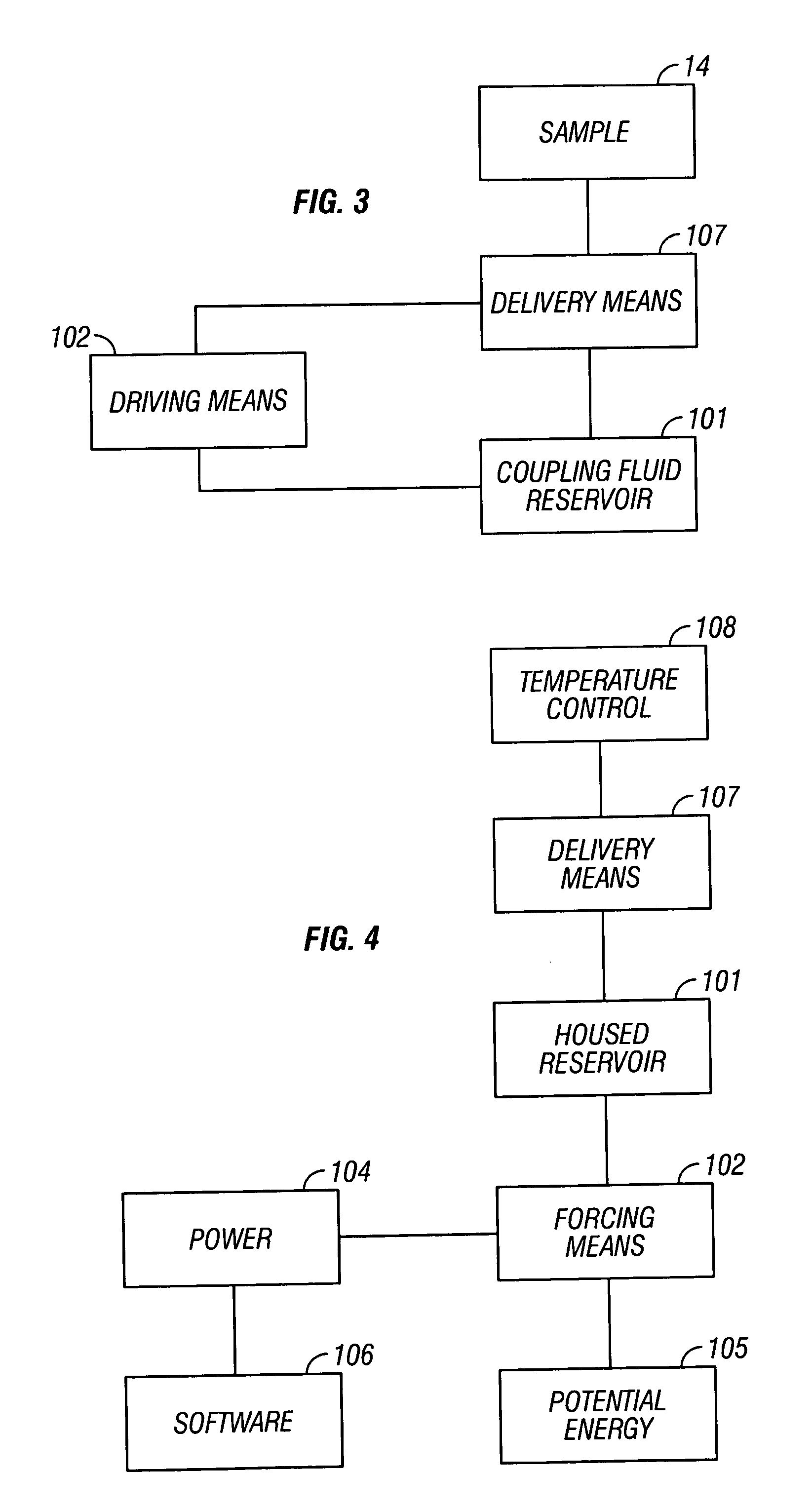

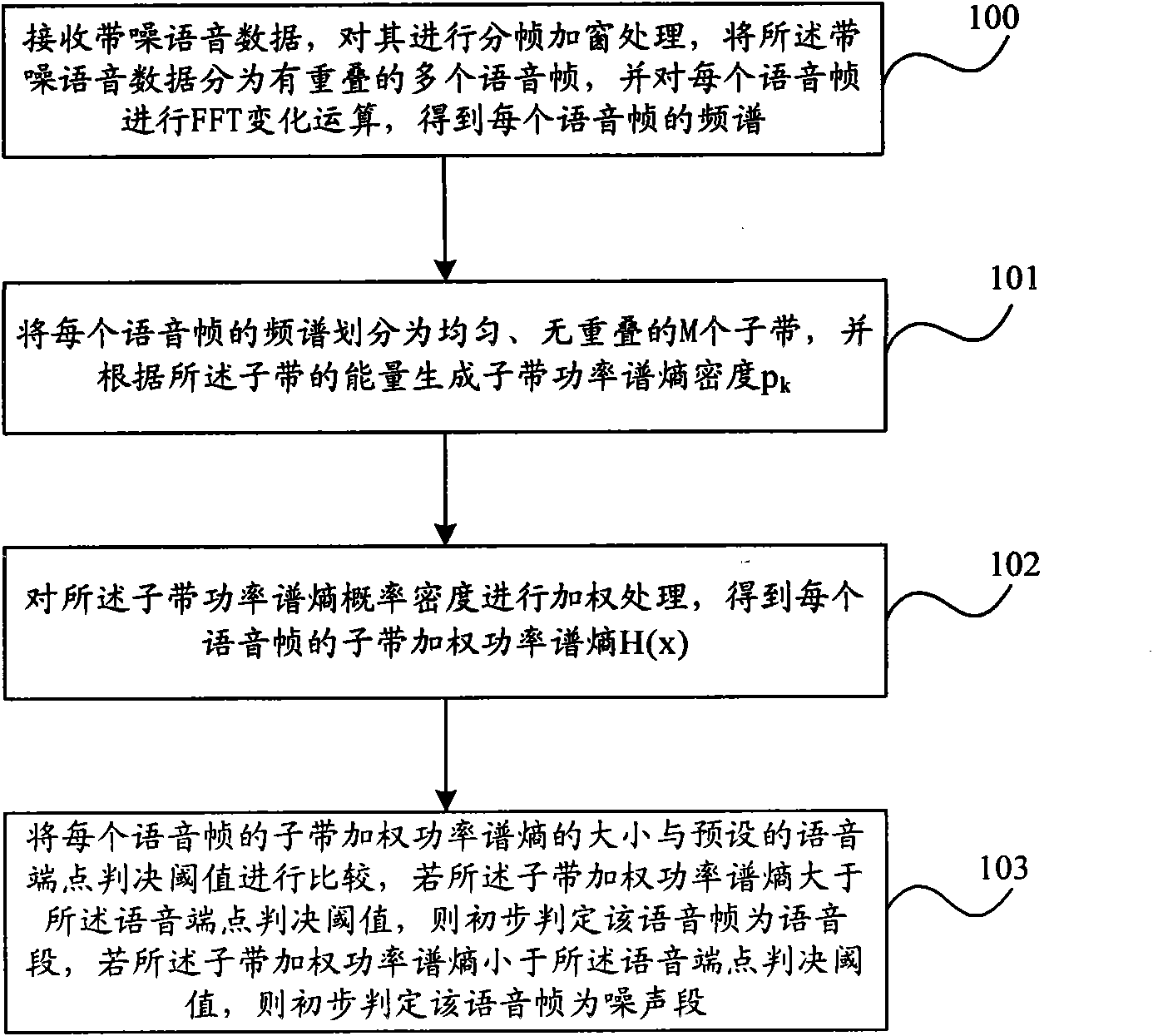

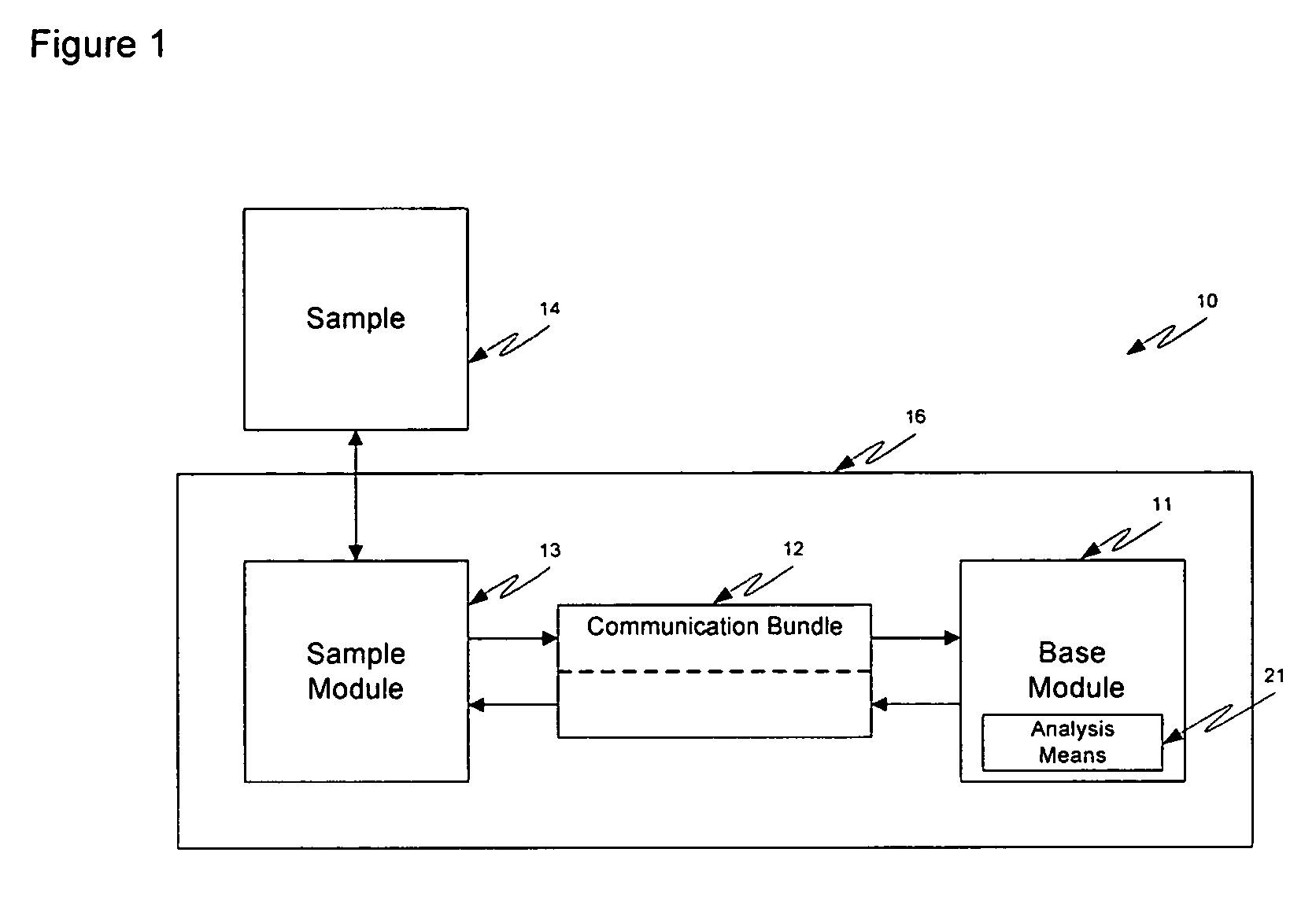

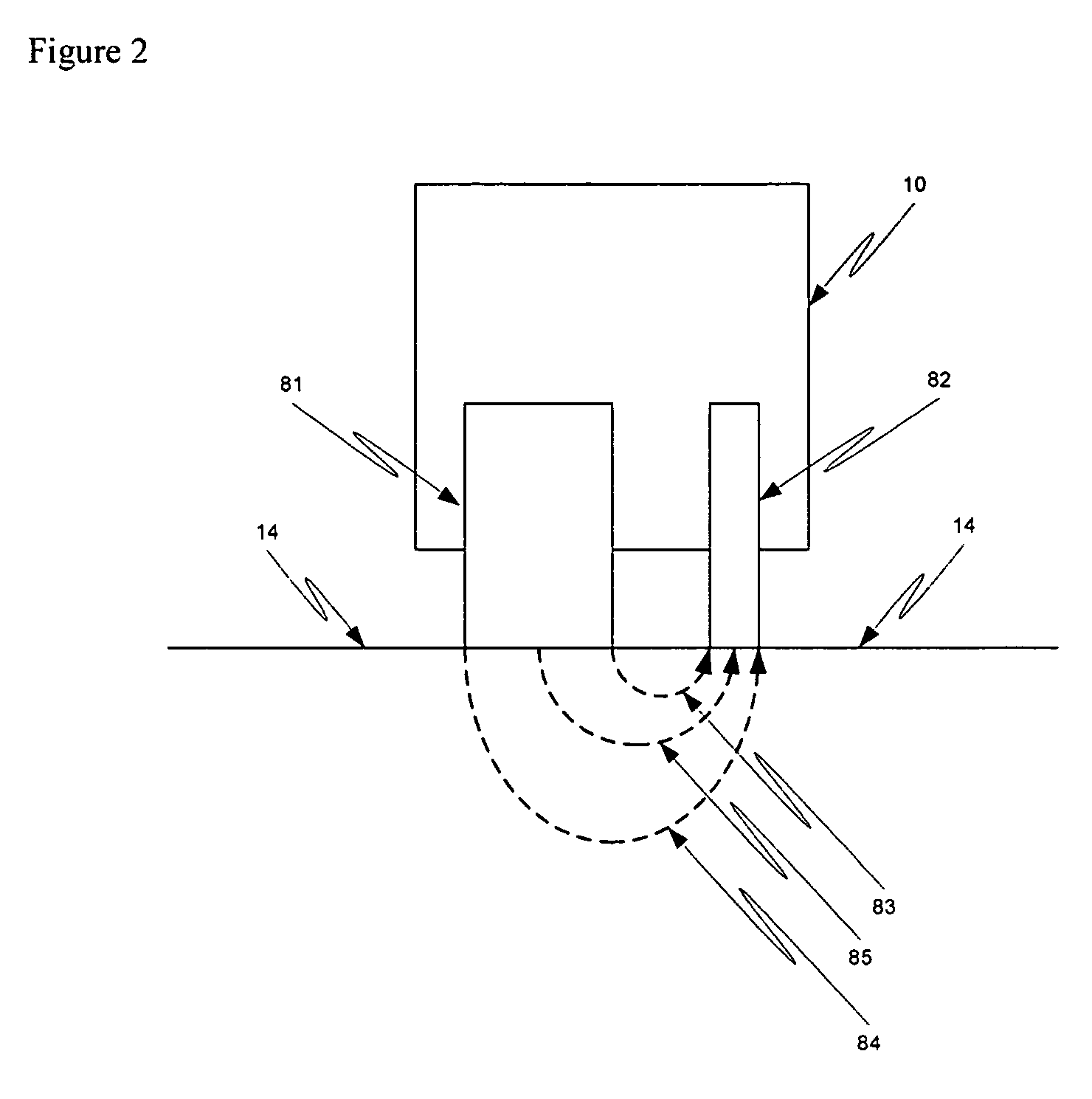

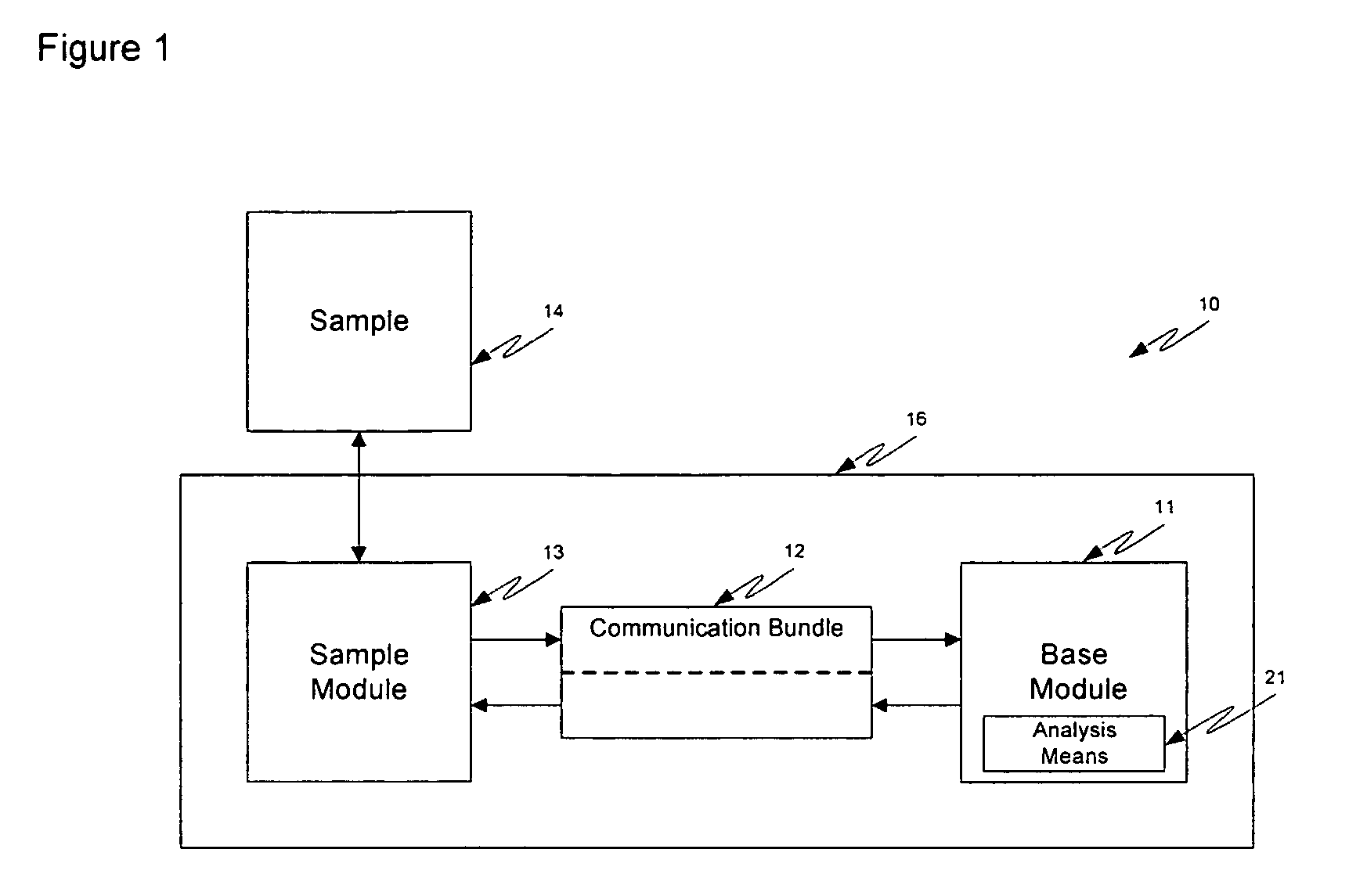

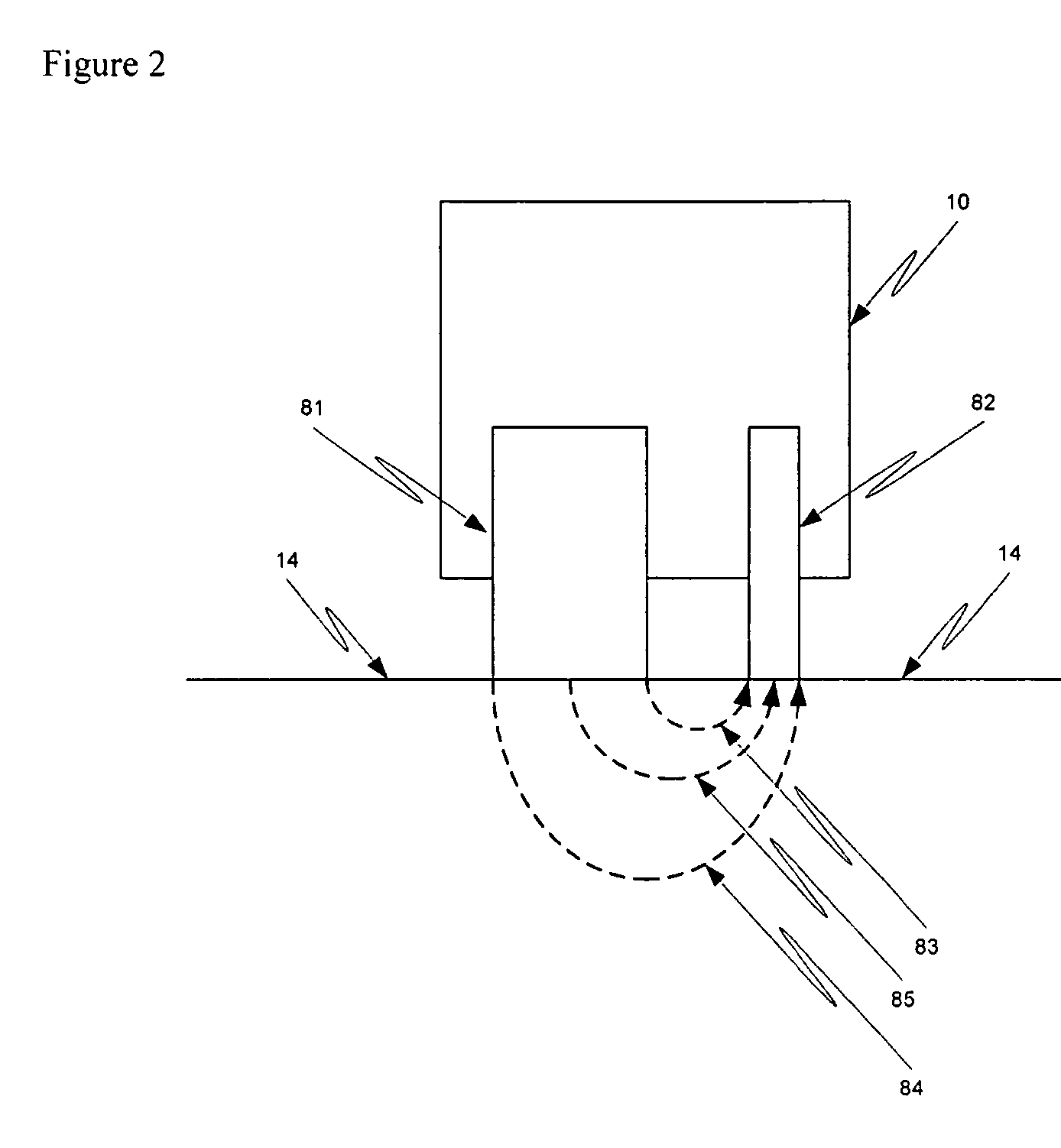

Sampling interface system for in-vivo estimation of tissue analyte concentration

InactiveUS20050187439A1Good optical performanceMinimizing sampling errorDiagnostics using spectroscopyColor/spectral properties measurementsAnalyteCoupling

Sampling is controlled to enhance analyte concentration estimation derived from noninvasive sampling. Means of assuring that the same tissue sample volume is repeatably sampled are presented, thus minimizing sampling errors due to mechanical tissue distortion, specular reflectance, and probe placement. In a first embodiment of the invention, sampling is controlled using automated delivery of a coupling fluid to a region between a tip of a sample probe and a tissue measurement site in a manner requiring minimal user interaction. In a second embodiment of the invention, sampling is controlled by controlling temperature variations, preferably with a coupling fluid, at a region about the tip of a sample probe and a sample site. In a third embodiment, sampling is procedurally controlled via timing and location of coupling fluid delivery to a sample site.

Owner:SENSYS MEDICAL

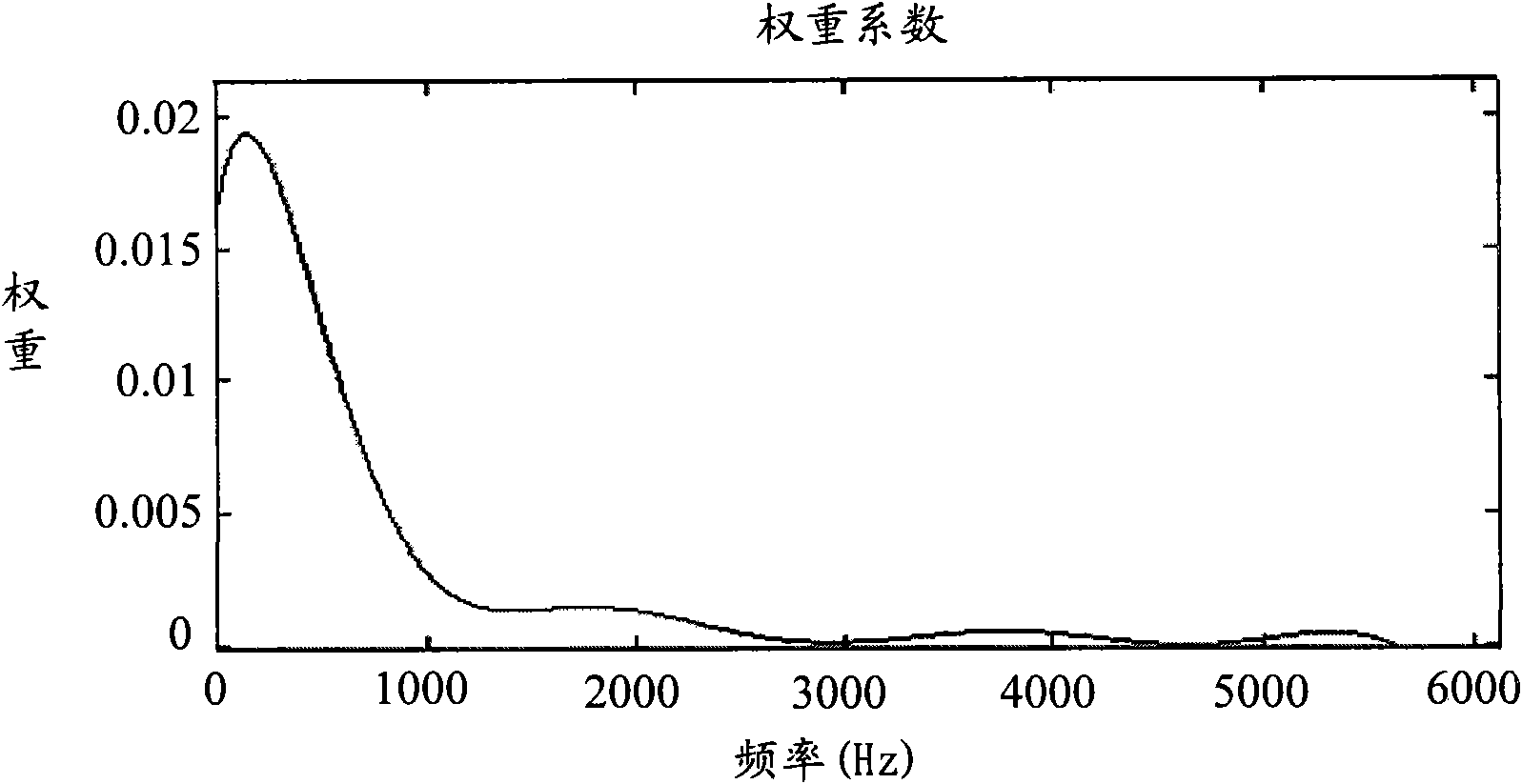

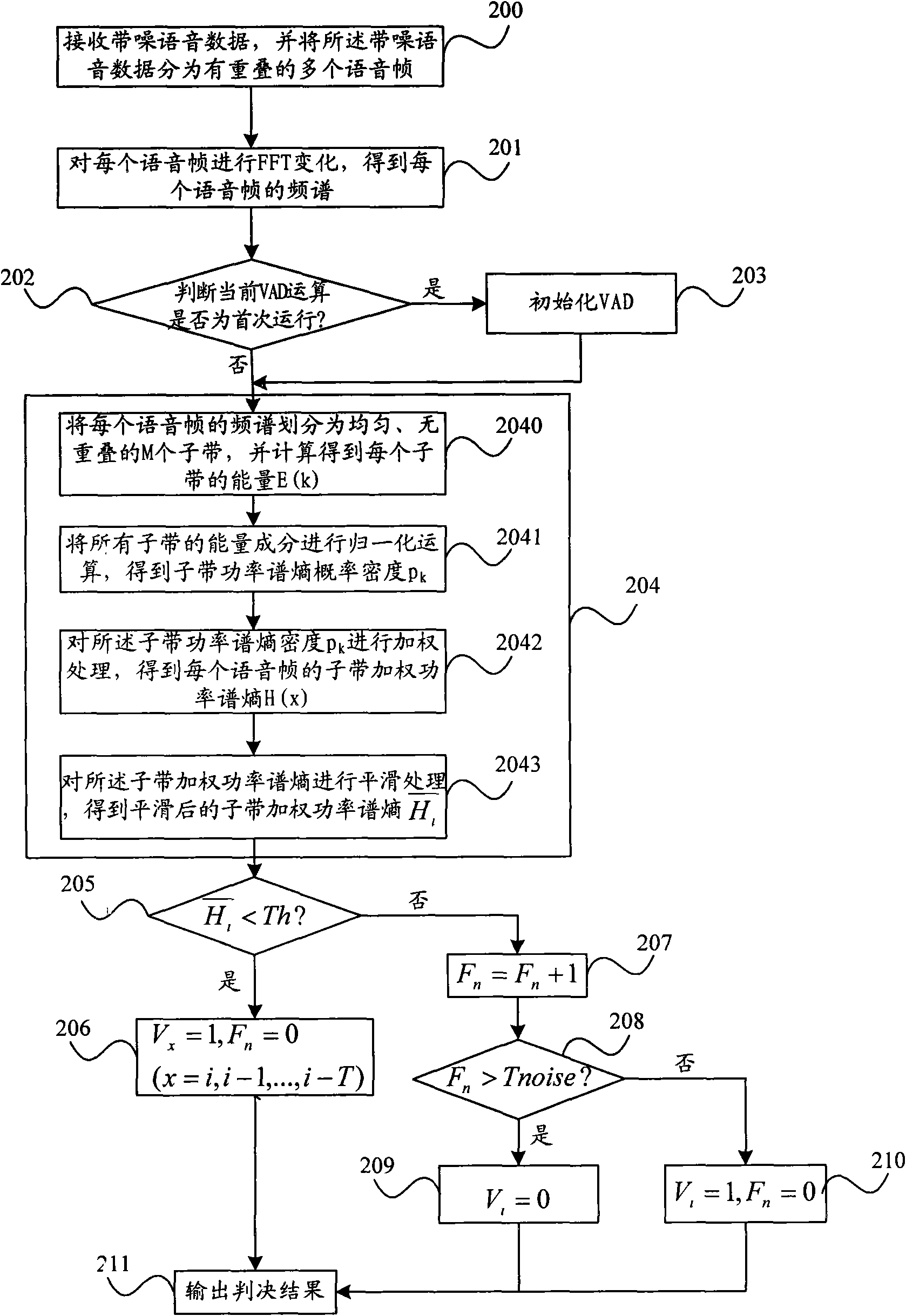

Phonetic end point detection method and device therefor

InactiveCN101599269AImprove accuracy and precisionImprove communication signal-to-noise ratioSpeech analysisSignal-to-noise ratio (imaging)Voice data

The invention provides a phonetic end point detection method and a device therefor. The phonetic end point detection method comprises: receiving phonetic data with noise, dividing the phonetic data with noise into plural overlapped phonetic frames, carrying out rapid Fourier variation calculation to obtain the frequency spectrum of each phonetic frame; dividing the frequency spectrum of each phonetic frame into plural sub-bands uniformly, and generating sub-band power spectral entropy density according to sub-band energy; weighing the sub-band power spectral entropy density to obtain sub-band weight power spectral entropy of each phonetic frame; judging the current phonetic frame as a noise section or phonetic section according to preset phonetic end point judgment threshold and sub-band weight power spectral entropy. The invention adopts sub-band power spectral entropy as phonetic eigenvalue of VAD judgment, and adaptively selects sub-band number and weight factor according to actual application environment, thus improving accuracy and preciseness of phonetic detection and obviously enhancing signal-to-noise ratio of communication.

Owner:CHINA AGRI UNIV +1

Blood Flow Monitoring

InactiveUS20120078069A1Improve accuracy and precisionReliable receptionRespiratorsElectrocardiographySystems designMedicine

The present invention relates to a method of utilizing photoplethysmography obtained from a central site and a non-central site to detect a low blood flow or low blood volume condition. Also disclosed are apparatuses and systems designed to acquire and process physiological information based on photoplethysmograpy signal information from dual sites.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

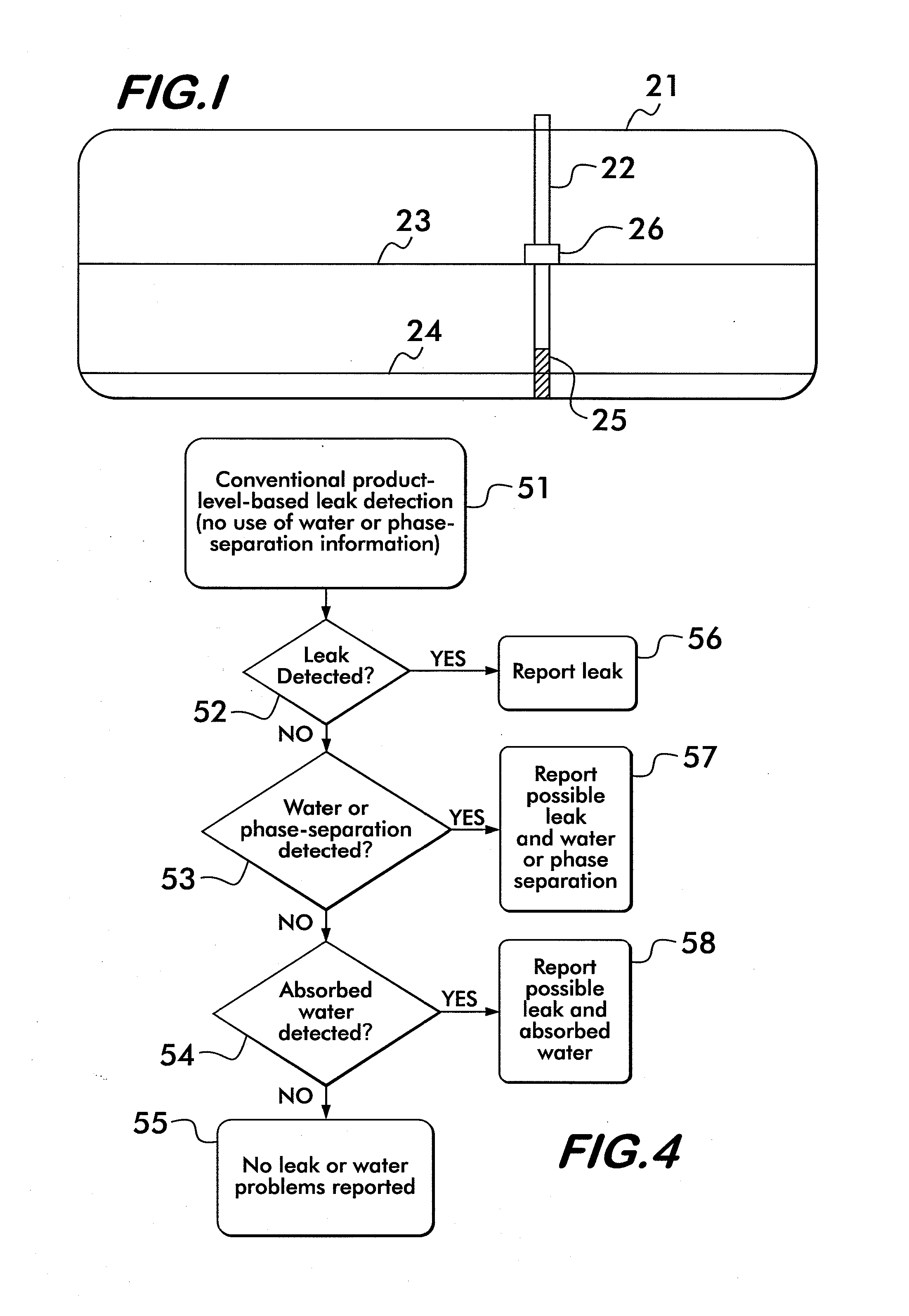

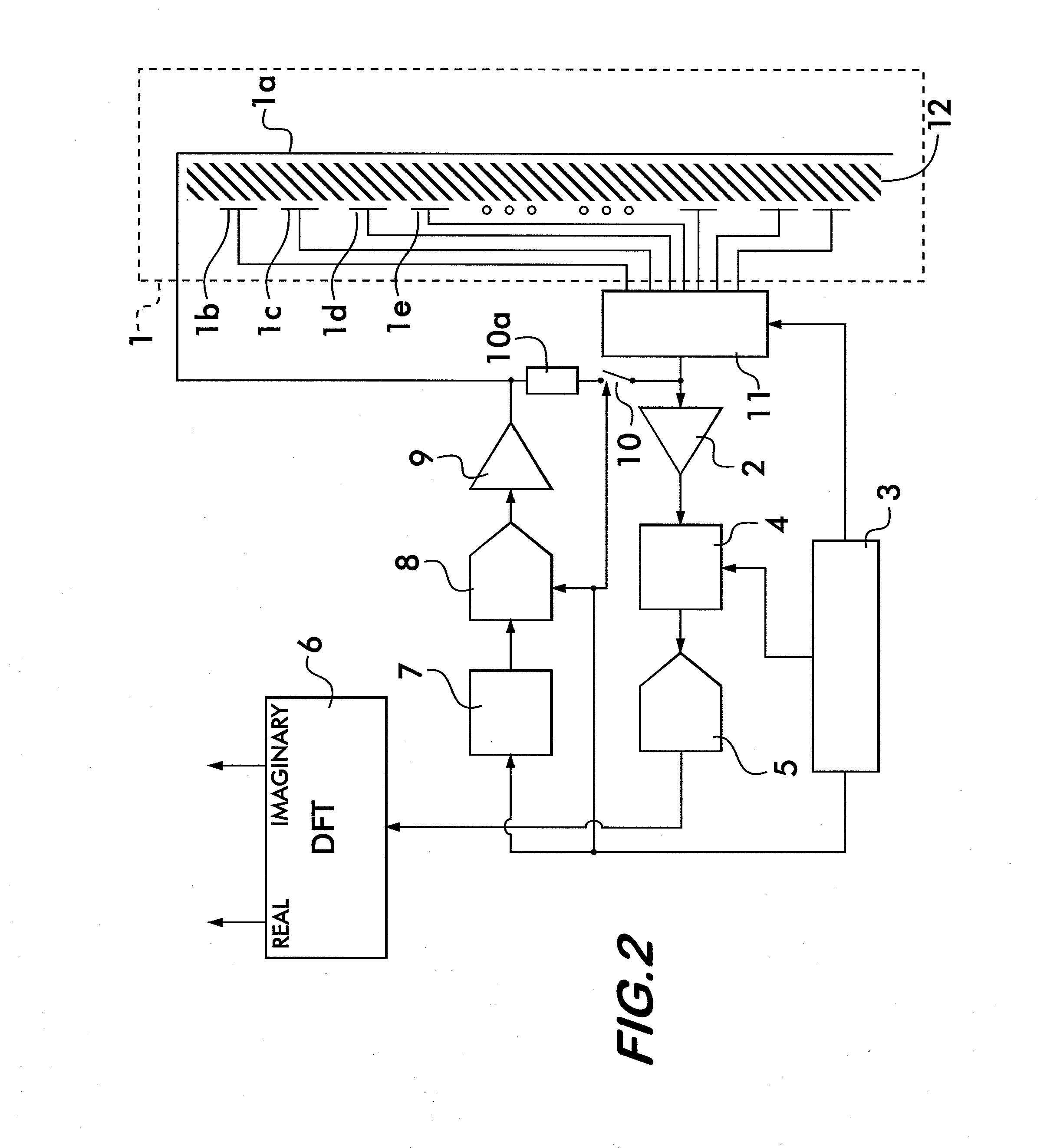

Automated phase separation and fuel quality sensor

InactiveUS20100295565A1Not easy to make mistakesMinimize attractionVolume measurement apparatus/methodsResistance/reactance/impedenceFuel qualityEngineering

A fluid characterization sensor comprising a plurality of sensor segments is disclosed. Each segment comprises two electrodes, spaced apart so the fluid in the corresponding interval of depth for that segment is positioned between them. Complex current or impedance is measured by exciting one electrode with an AC signal, and measuring the amplitude and phase of the current in the other electrode. After automatically measuring and accounting for pre-determined gain, offset, temperature, and other parasitic influences on the raw sensor signal, the complex electrical impedance of the fluid between the electrodes is calculated from the measured phase / amplitude and / or real / imaginary components of the received electrical current signal and / or the variation of the measured response with variation in excitation frequency. Comparison of measured results with results taken using known fluids identifies fluid properties. Alternatively, measured results are compared to predicted results using forward models describing expected results for different fluids or contaminants.

Owner:DIRACTION

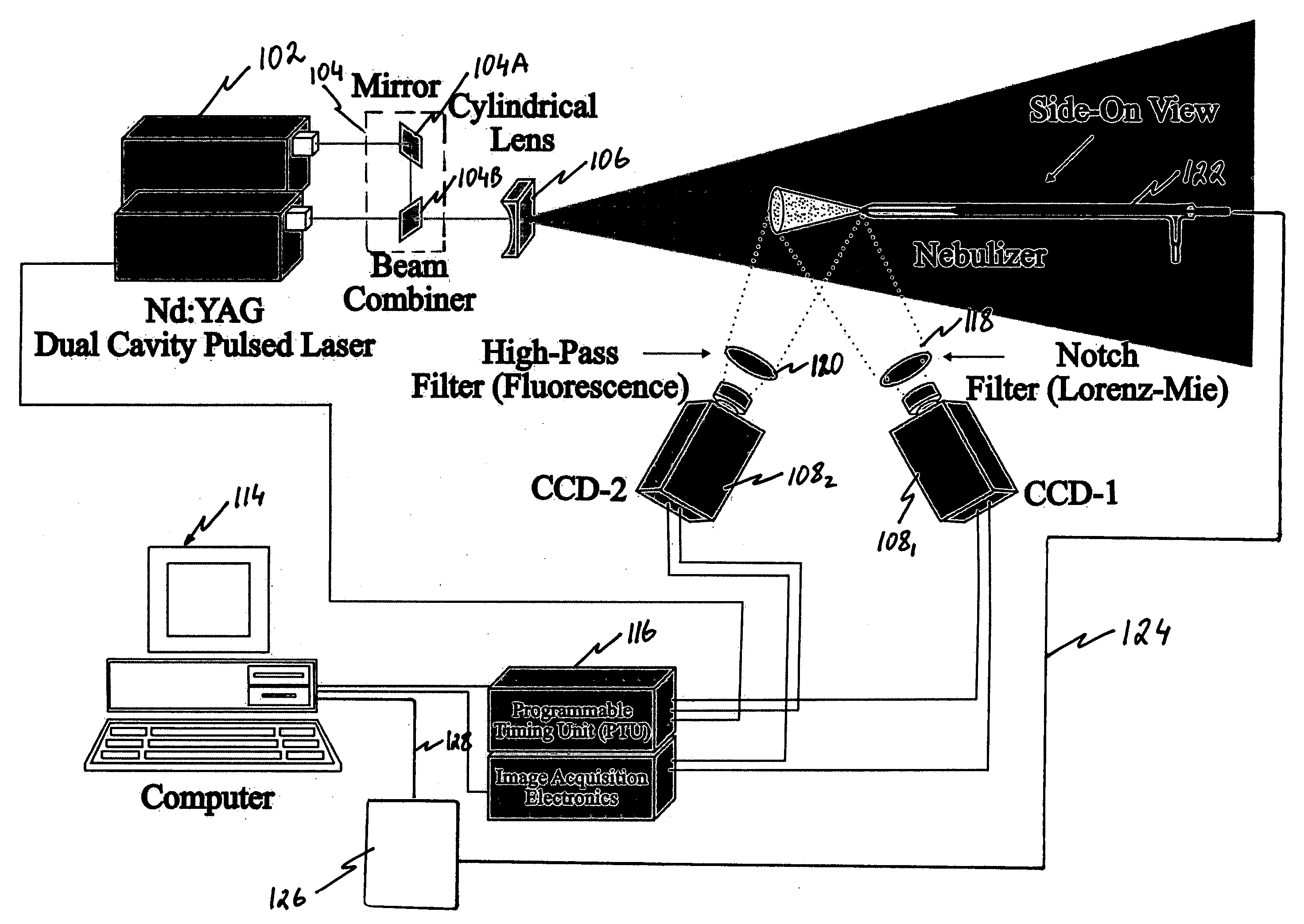

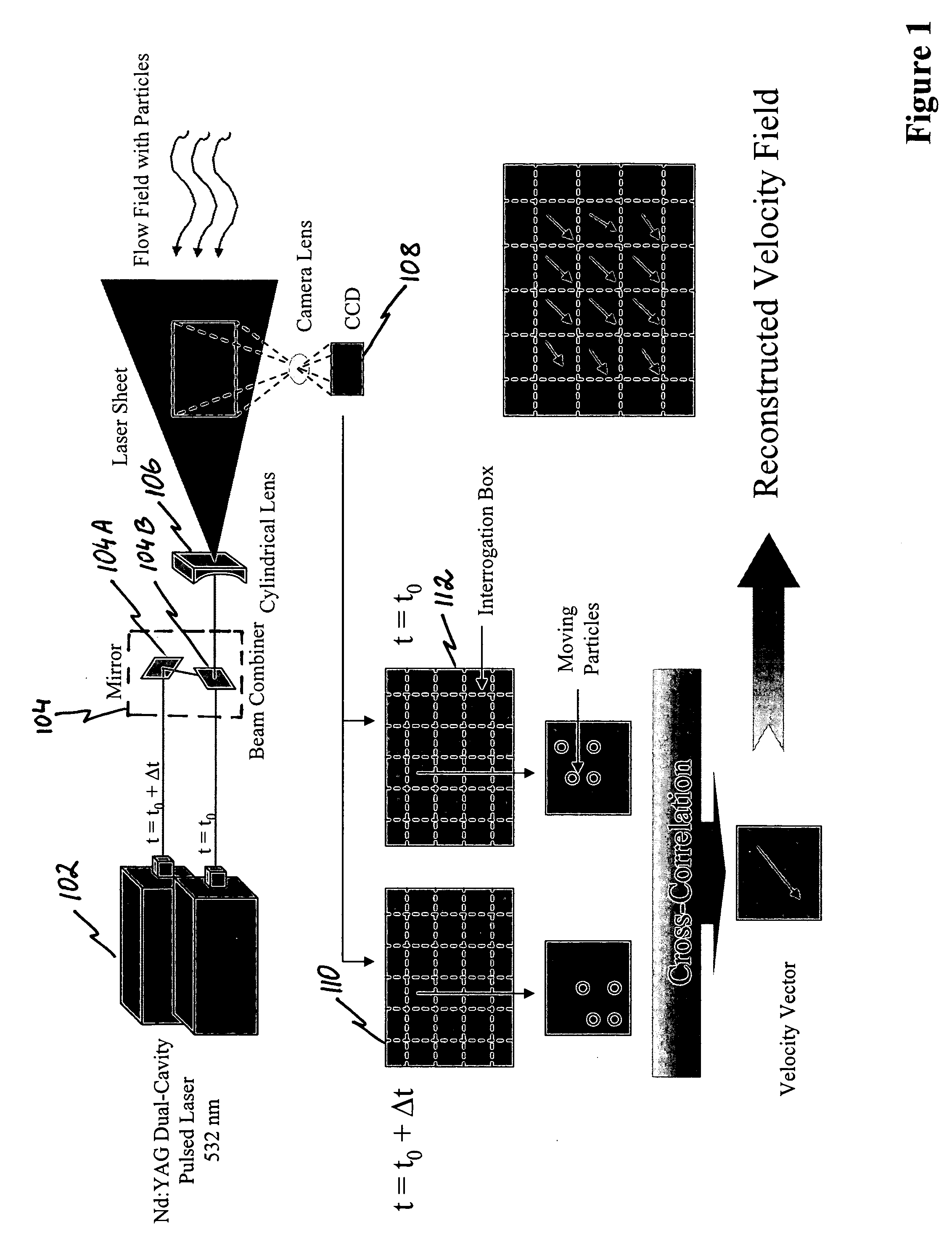

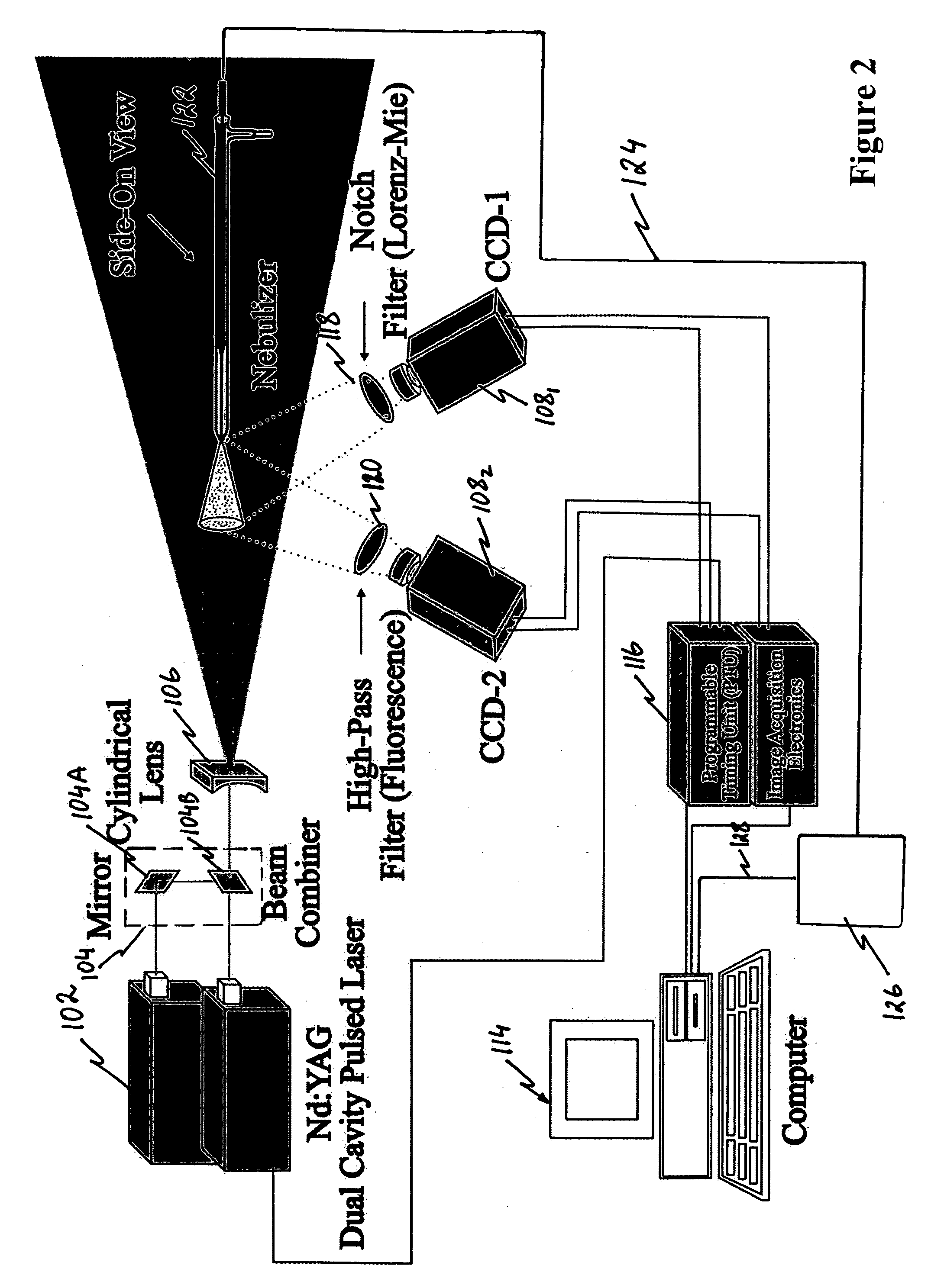

Feedback mechanism for smart nozzles and nebulizers

ActiveUS20070299561A1Reduce the amount requiredImprove performanceSelf-acting watering devicesWatering devicesFluorescenceLaser light

Nozzles and nebulizers that can be adjusted to produce an aerosol with optimum and reproducible quality based on the feedback information obtained using laser imaging techniques are provides. Two laser-based imaging techniques based on particle image velocimetry (PIV) and optical patternation are provided to map and contrast the size and velocity distributions for indirect and direct pneumatic nebulizations in plasma spectrometry. The flow field of droplets is illuminated by two pulses from a thin laser sheet with a known time difference. The scattering of the laser light from droplets is captured by a charge coupled device (CCD), providing two instantaneous images of the particles. Pointwise cross-correlation of the corresponding images yields a two-dimensional (2-D) velocity map of the aerosol velocity field. For droplet size distribution studies, the solution is doped with a fluorescent dye and both laser induced florescence (LIF) and Mie scattering images are captured simultaneously by two CCDs with the same field of view. The ratio of the LIF / Mie images provides relative droplet size information, which is then scaled by a point calibration method via a phase Doppler particle analyzer (PDPA). Two major outcomes are realized for three nebulization systems: 1) a direct injection high efficiency nebulizer (DIHEN); 2) a large-bore DIHEN (LB-DIHEN); and 3) a PFA microflow nebulizer with a PFA Scott-type spray chamber. First, the central region of the aerosol cone from the direct injection nebulizers and the nebulizer-spray chamber arrangement comprise fast (>13 m / s and >8 m / s, respectively) and fine (<10 μm and <5 μm, respectively) droplets as compared to slow (<4 m / s) and large (>25 μm) droplets in the fringes. Second, the spray chamber acts as a momentum separator, rather than a droplet size selector, as it removes droplets having larger sizes or velocities. Smart-tunable nebulizers may utilize the measured momentum as a feedback control for adjusting certain operation properties of the nebulizer, such as operating conditions and / or critical dimensions.

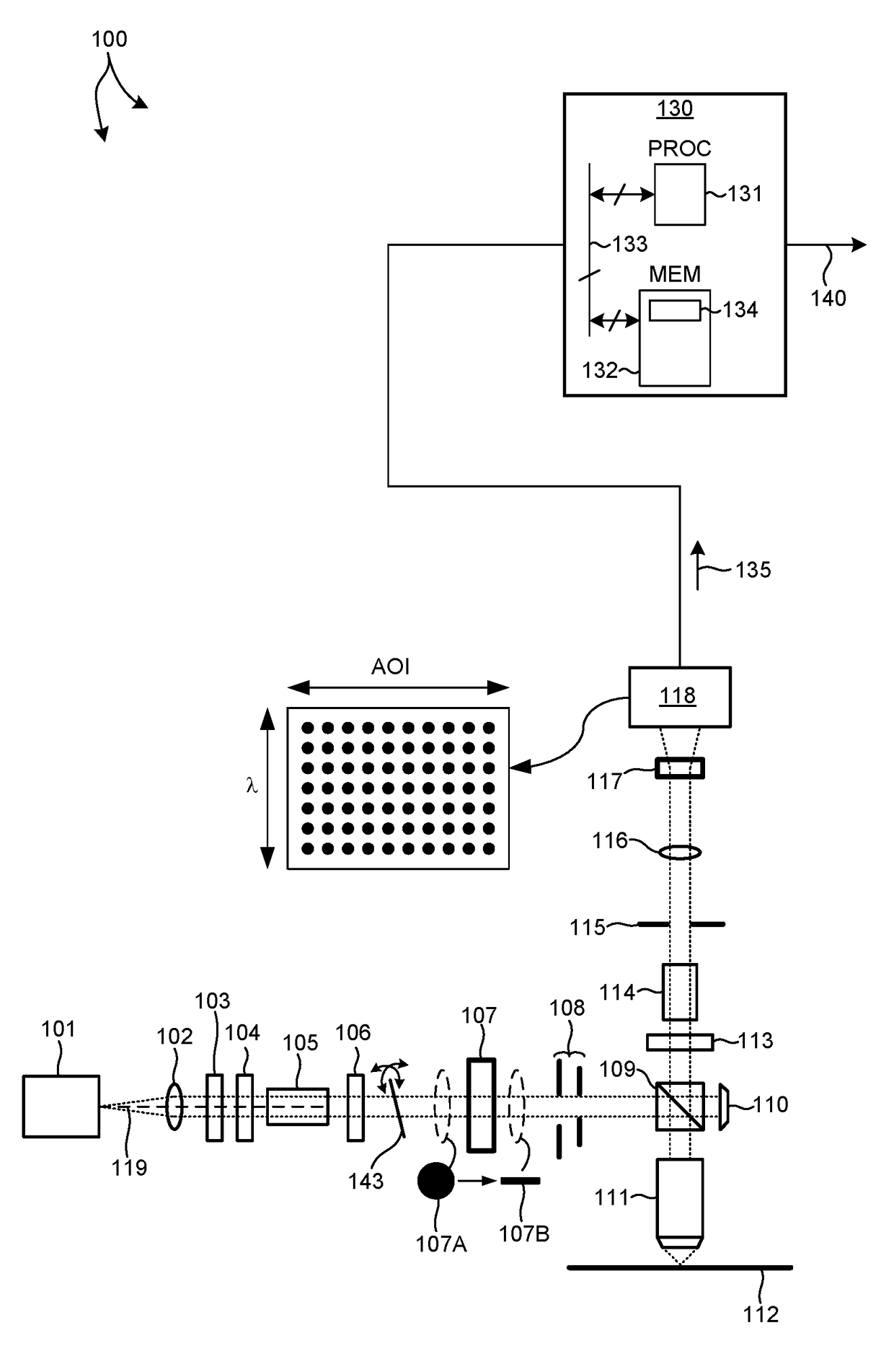

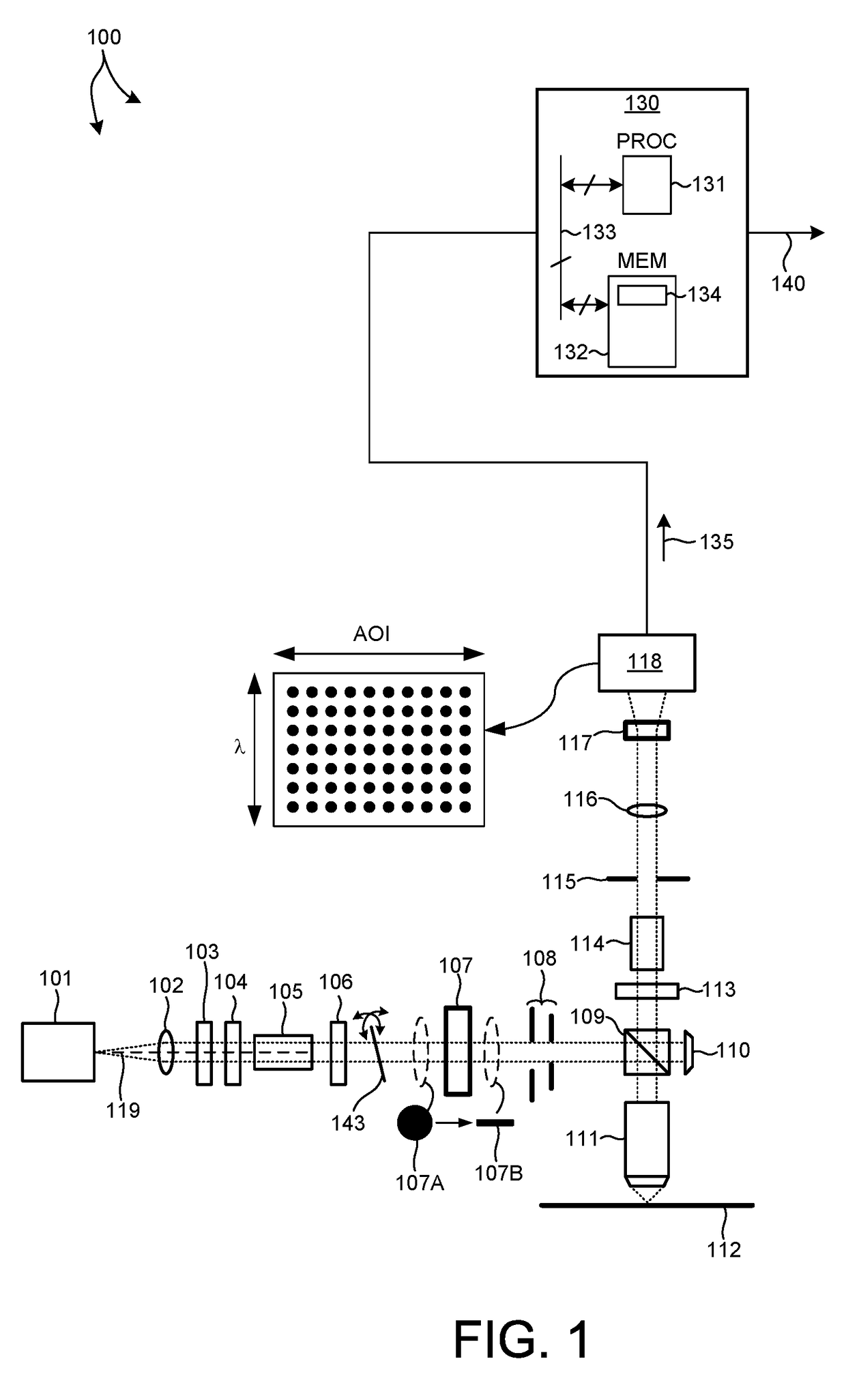

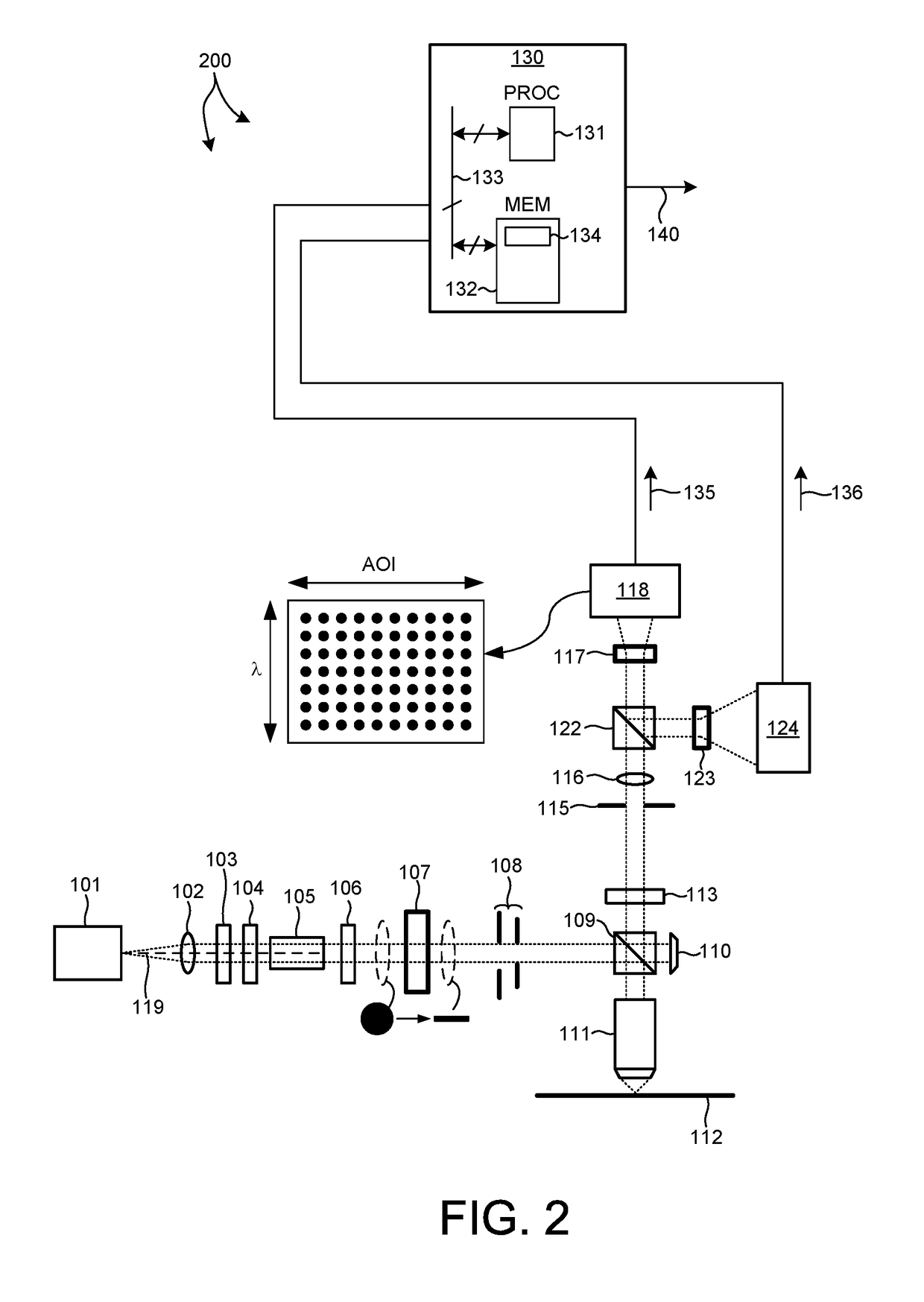

Spectroscopic Beam Profile Overlay Metrology

ActiveUS20170082932A1Improve accuracyImprove precisionSemiconductor/solid-state device testing/measurementPhotomechanical apparatusMetrologyShaped beam

A spectroscopic beam profile metrology system simultaneously detects measurement signals over a large wavelength range and a large range of angles of incidence (AOI). In one aspect, a multiple wavelength illumination beam is reshaped to a narrow line shaped beam of light that is projected onto an overlay metrology target such that the direction of the line shaped beam is aligned with the direction of extent of a grating structure of the overlay metrology target. Collected light is dispersed across a detector according to AOI in one direction and according to wavelength in another direction. The measured signal at each detector pixel is associated with a particular AOI and wavelength. The collected light includes first order diffracted light, zero order diffracted light, or a combination thereof. In some embodiments, first order diffracted light and zero order diffracted light are detected over separate areas of the detector.

Owner:KLA TENCOR TECH CORP

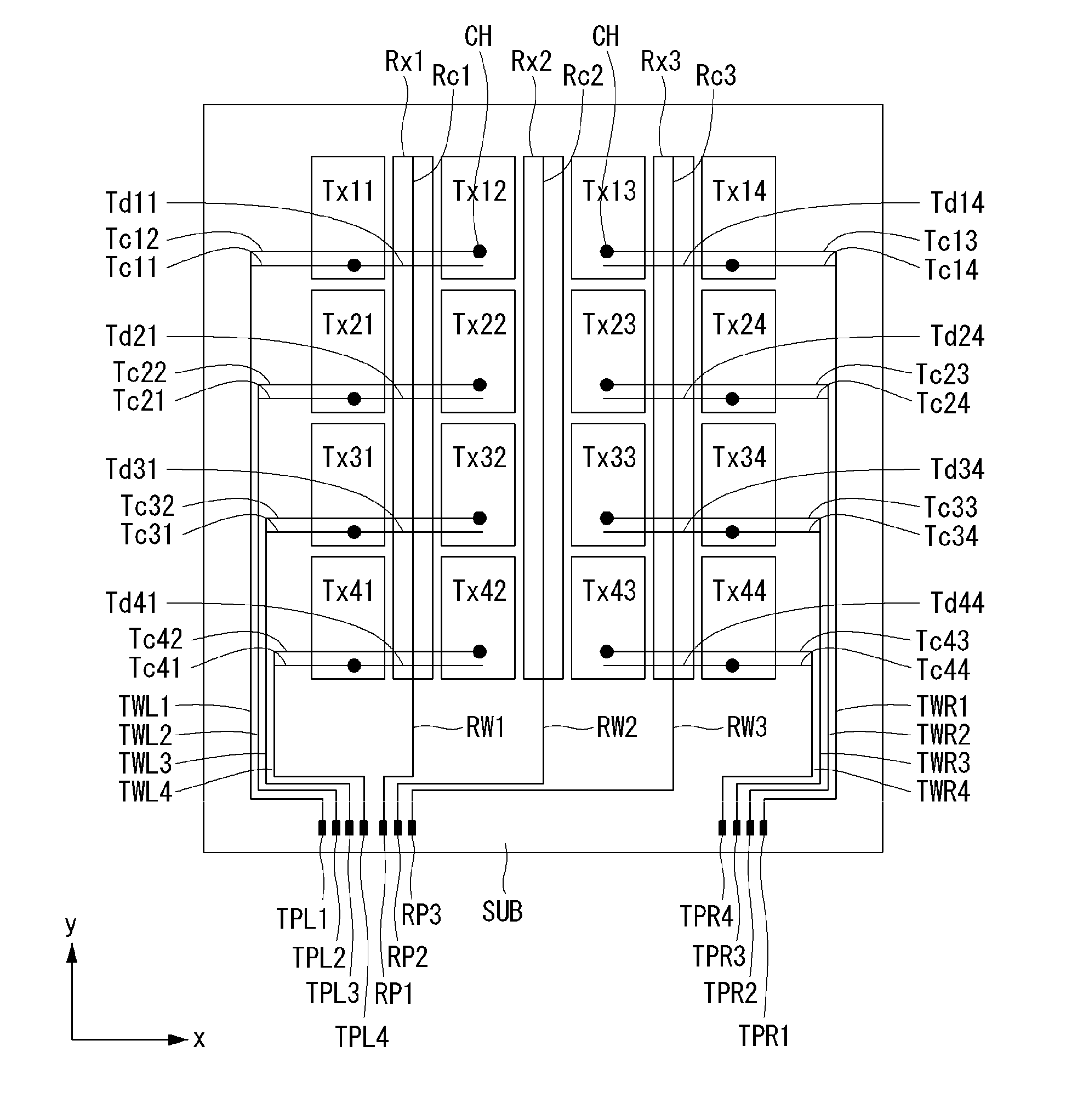

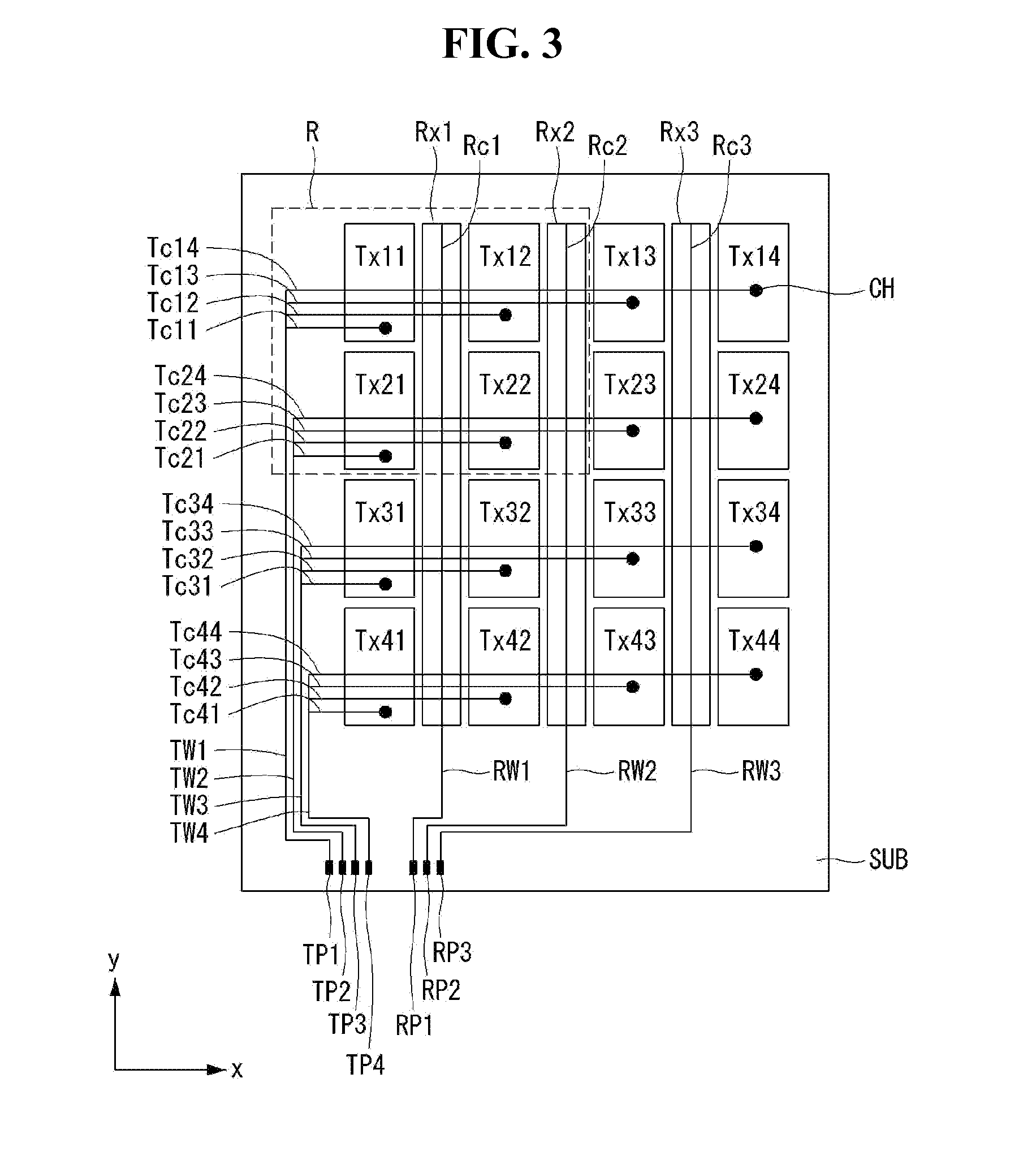

Touch sensor integrated type display device

ActiveUS20150145821A1Touch sensing electrodes easy and efficientImprove accuracy and precisionInput/output processes for data processingDisplay deviceEngineering

A touch sensor integrated type display device is disclosed. The device includes gate lines and data lines crossing the gate lines. It also includes pixel electrodes disposed in regions defined by crossings of the gate lines and the data lines. Further, the device includes common electrodes overlapping the pixel electrodes. The common electrodes include a group of first electrodes arranged in a first direction, and second electrodes disposed between the first electrodes and extending in a second direction substantially perpendicular to the first direction. The display device additionally includes first electrode connecting wires, each extending in the first direction and connected to a respective one of the first electrodes.

Owner:LG DISPLAY CO LTD

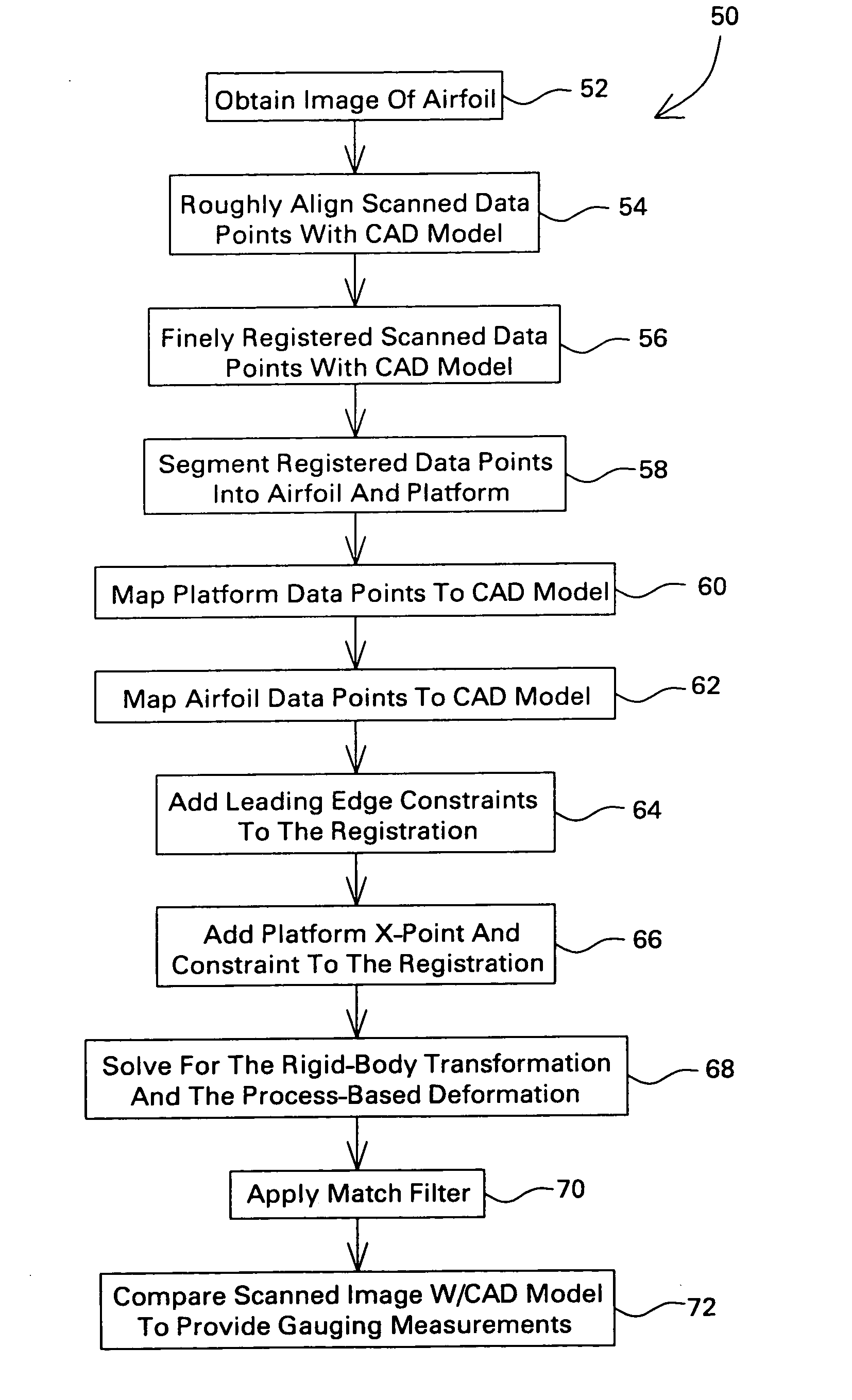

Non-contact measurement method and apparatus

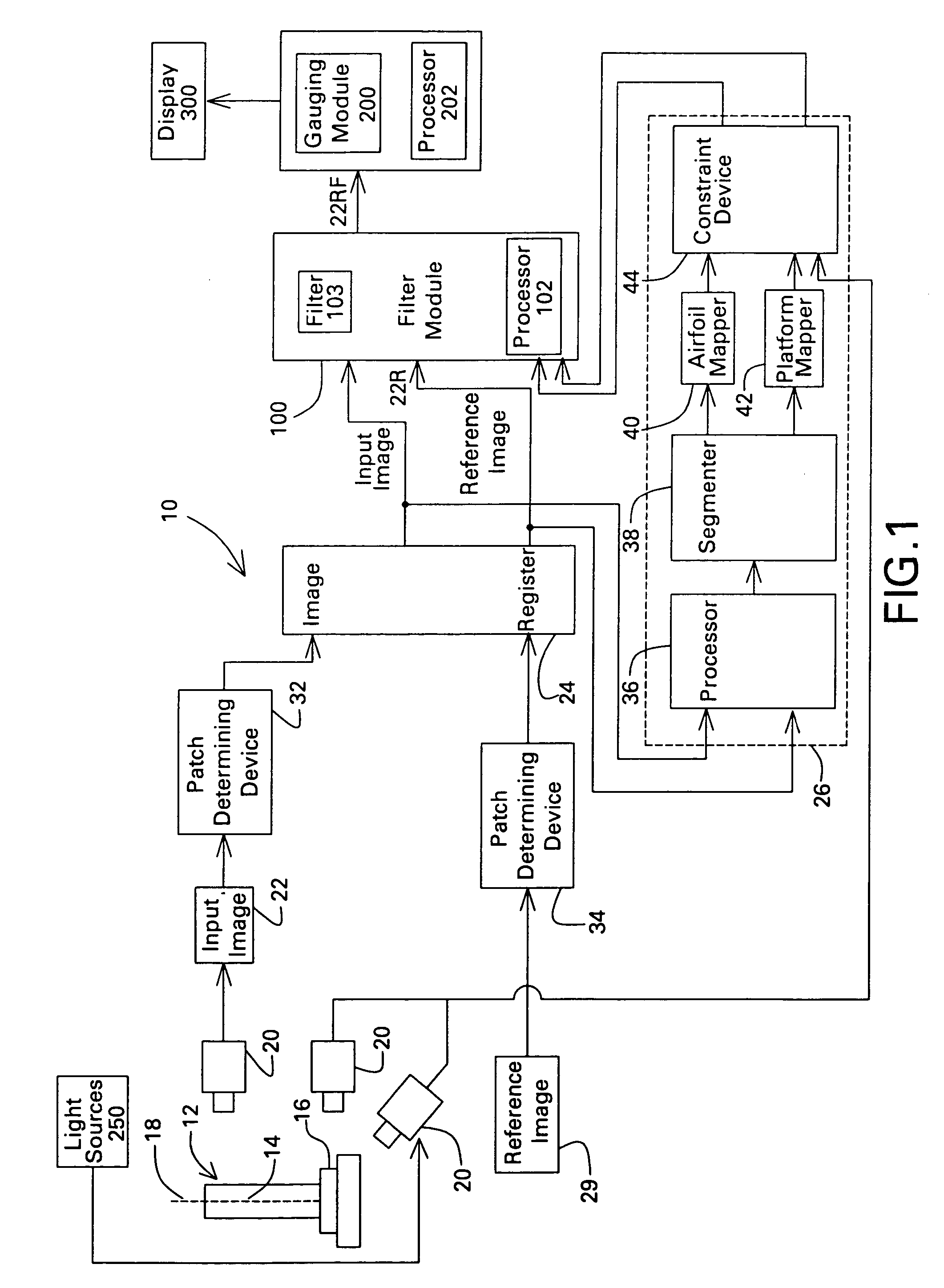

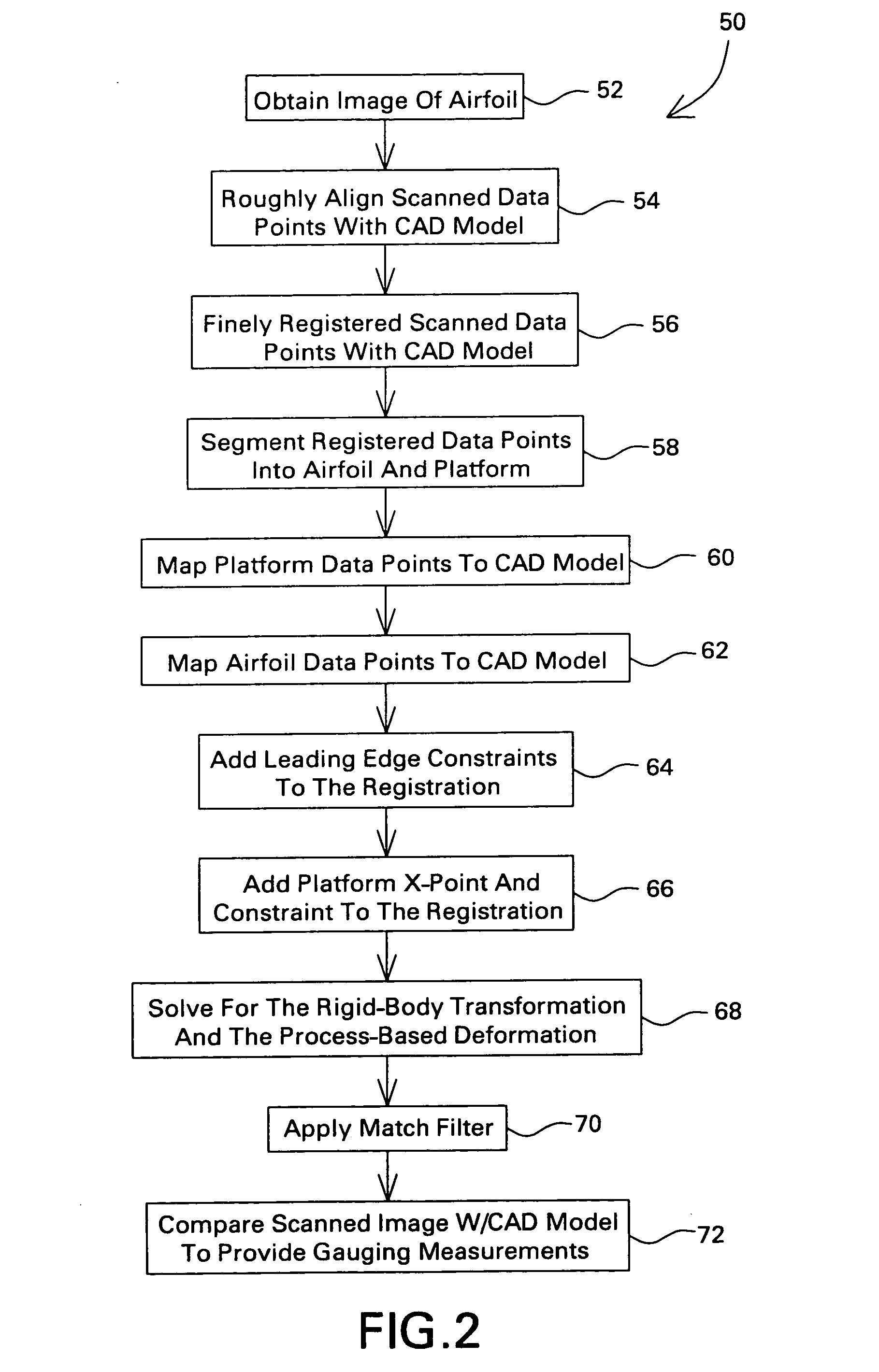

InactiveUS20050201611A1Reduce noiseImprove accuracyImage enhancementBlade accessoriesPrior informationReference image

A non-contact imaging apparatus for examining an object having complex surfaces or shape deformations. The imaging apparatus includes at least one imaging device for obtaining a scanned image of the exterior surfaces of the object being examined. A predetermined reference image) of an ideal model for the object is stored in a memory. An image register is coupled to the imaging device and to the memory containing the reference image of the ideal model for the object. A transformation estimator compares the scanned image to the reference image and provides a transform which maps the scanned image to the reference image and provides a set of registered object data points. One or more filter modules process the registered object data points with a priori information to reduce noise and to further enhance the accuracy and precision of the registration. A gauge estimator is coupled to the filter module. The gauge estimator utilizes the processed and registered object data to determine deformation parameters of the object, which are then displayed to an operator as gauging information.

Owner:GENERAL ELECTRIC CO

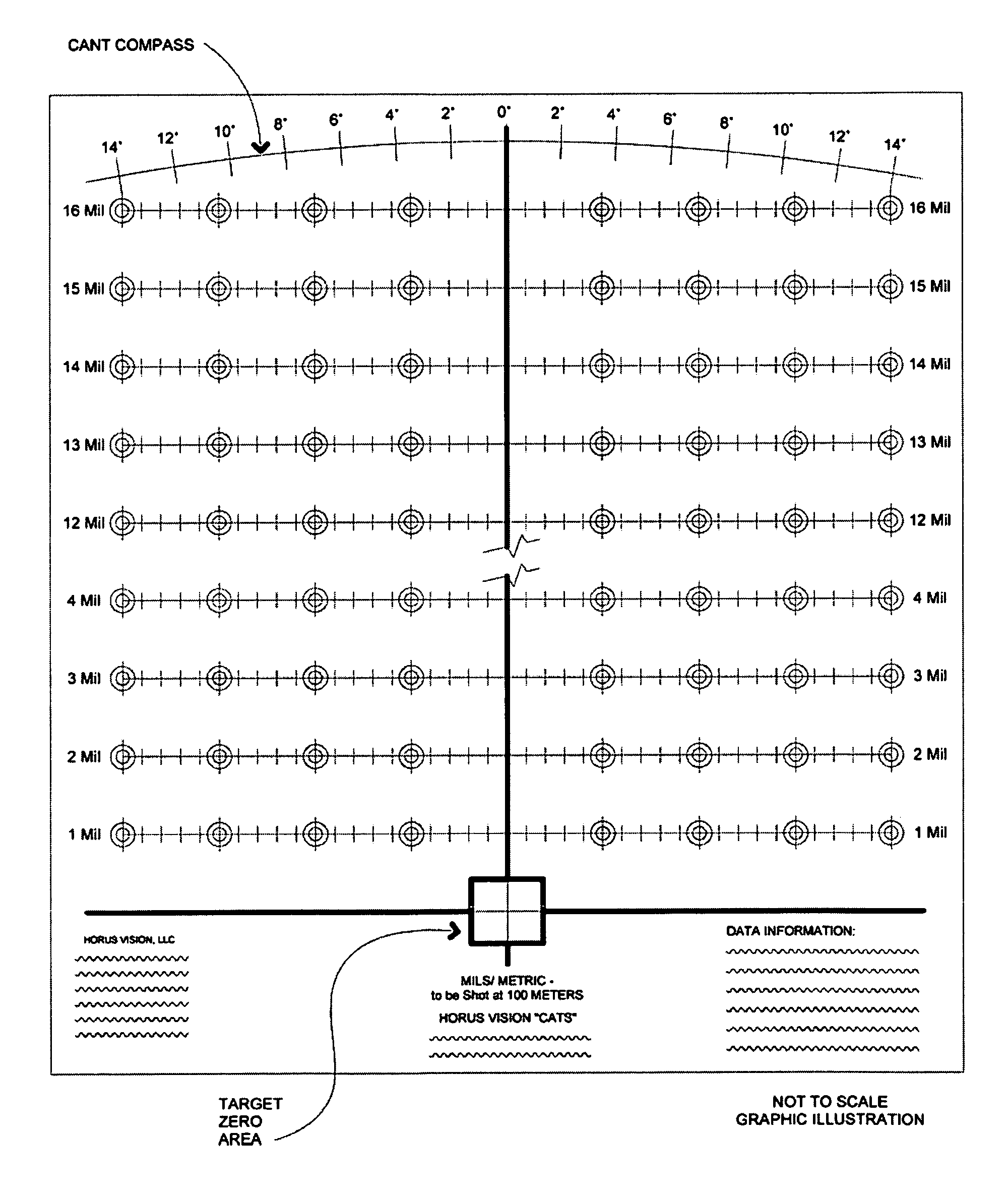

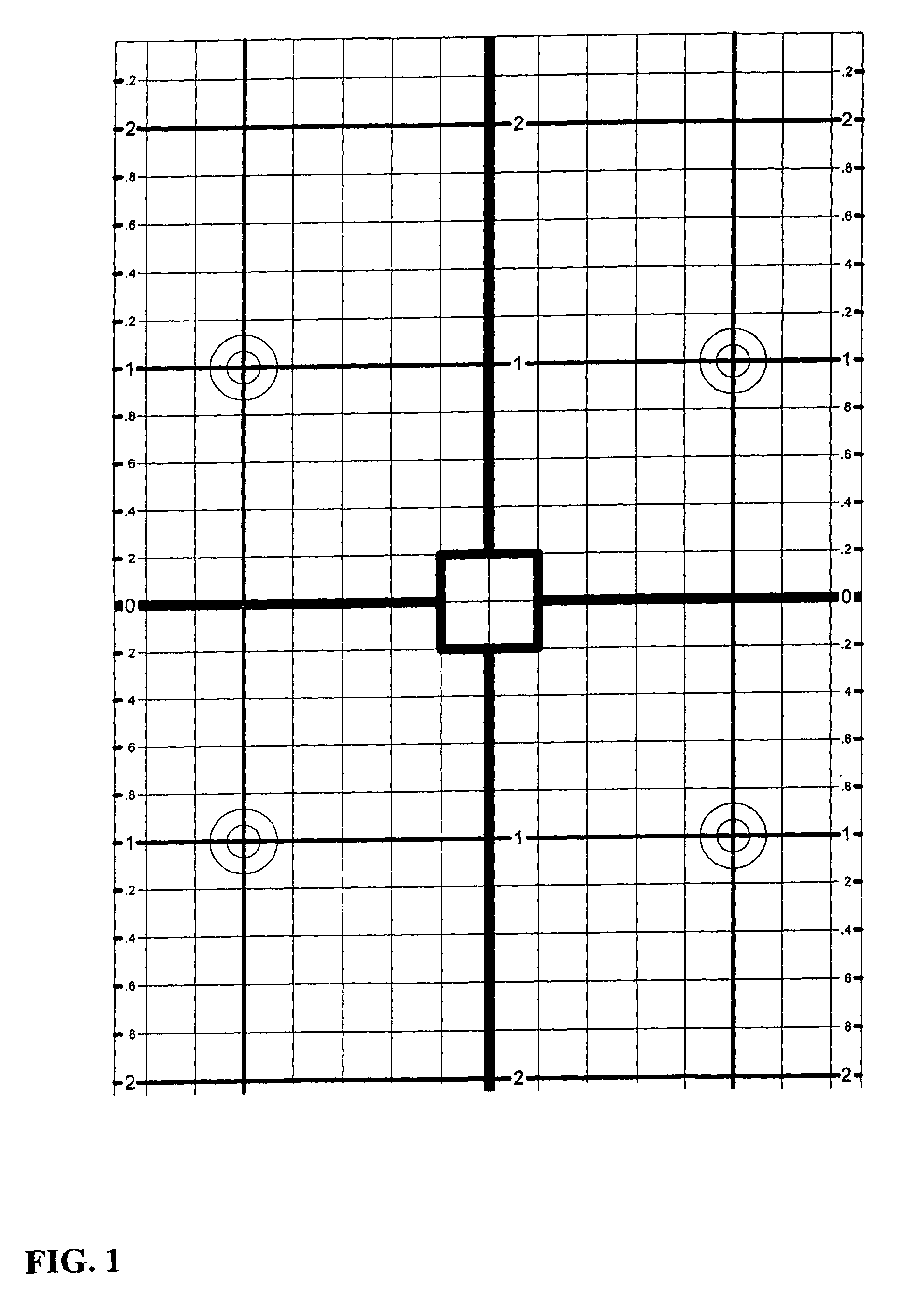

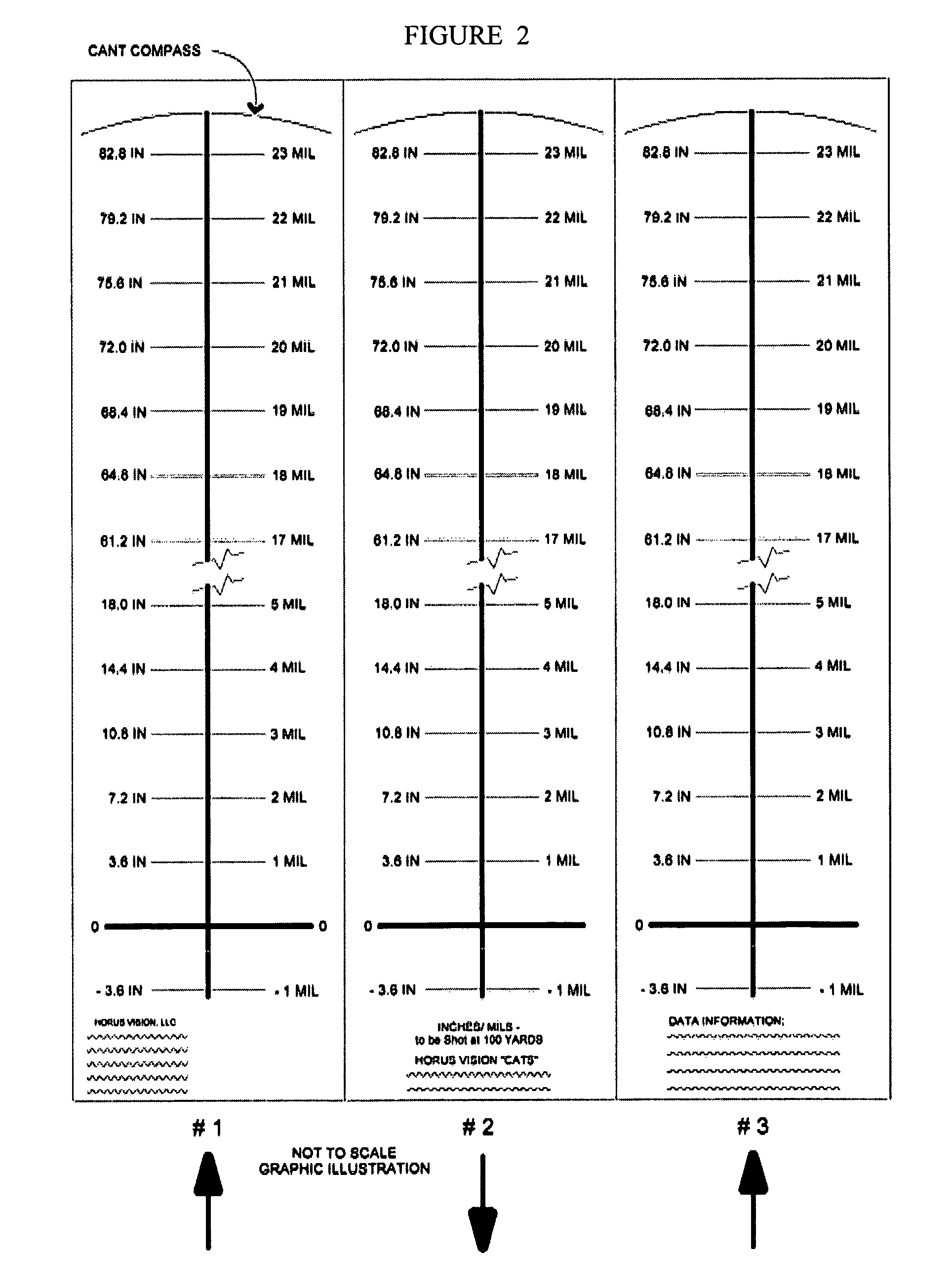

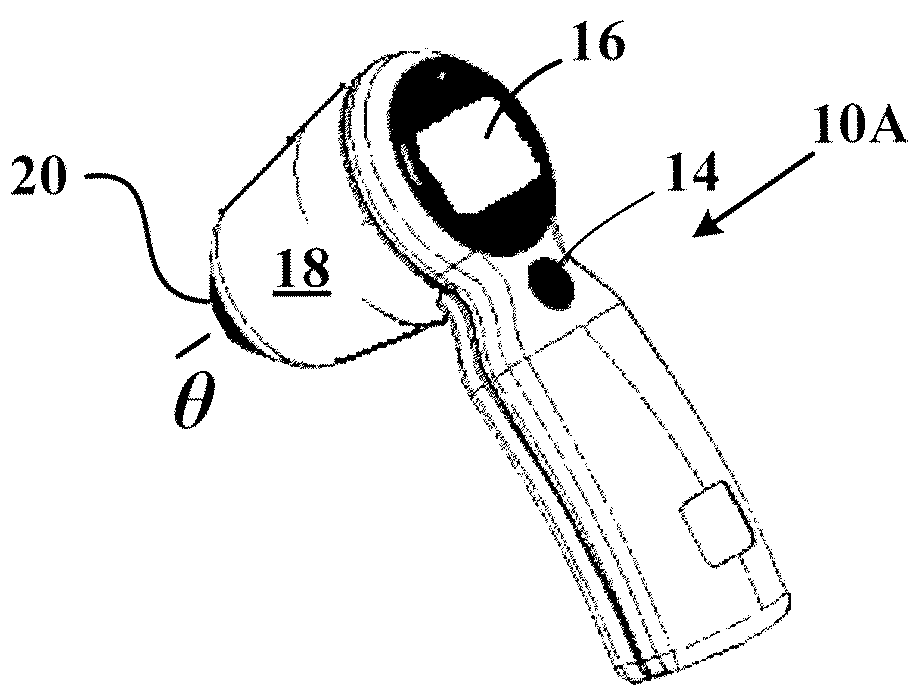

Shooting calibration systems and methods

InactiveUS7712225B2Improve shooting accuracyImprove accuracy and precisionSighting devicesAiming meansMedium rangeTarget acquisition

The present invention relates to target acquisition and related systems and devices, and more particularly to telescopic gunsights and associated equipment used to achieve shooting accuracy at, for example, close ranges, medium ranges and extreme ranges. The present invention also provides targets and methods of using the systems to achieve enhanced shooting accuracy.

Owner:HVRT CORP

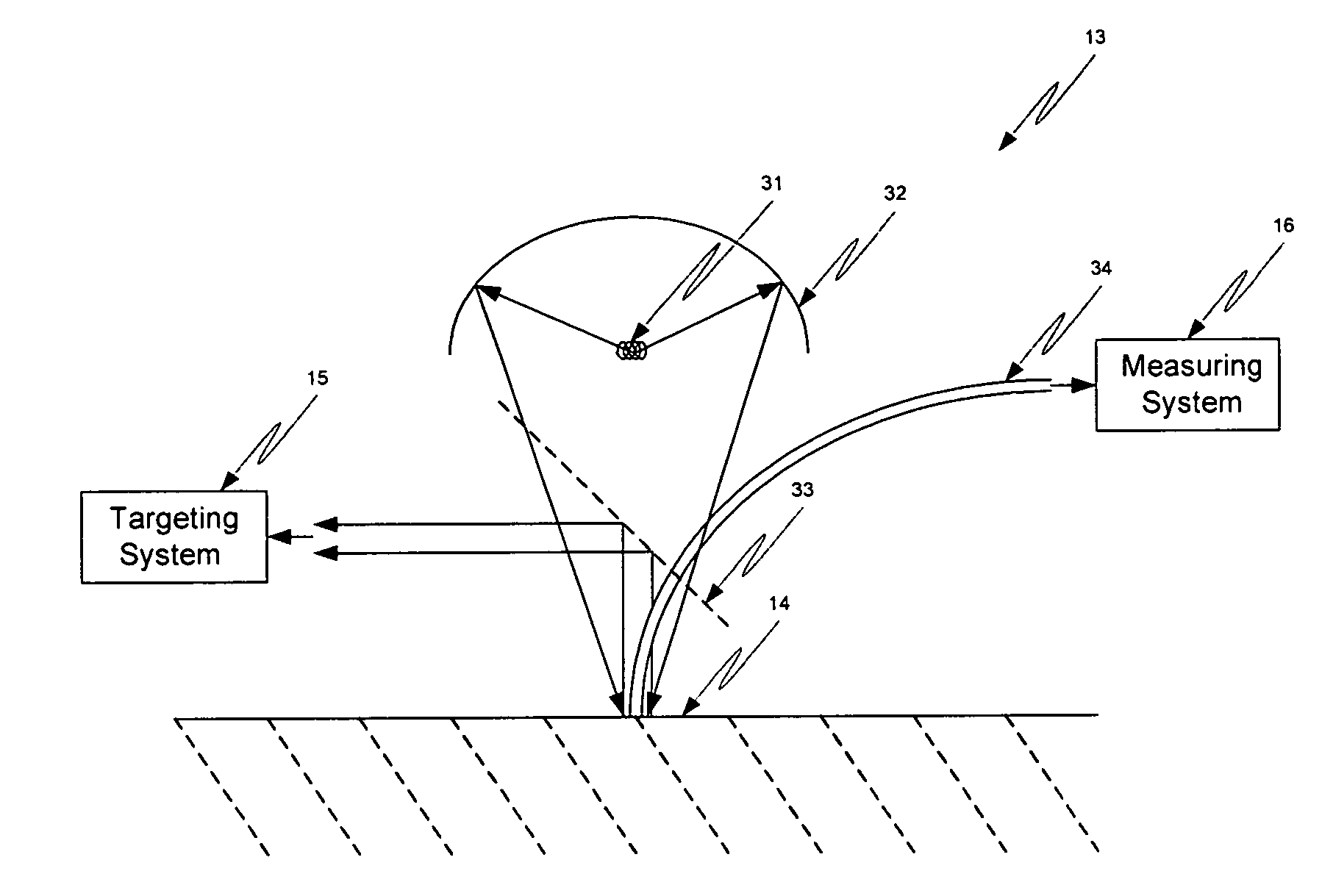

Method and apparatus for noninvasive targeting

InactiveUS20060206018A1Enhanced signalImprove precisionDiagnostic recording/measuringOptical sensorsNoninvasive samplingSpectral variation

The invention relates to noninvasive sampling. In one embodiment, the invention relates to a sample probe interface method and apparatus for targeting a tissue depth and / or pathlength that is used in conjunction with a noninvasive analyzer to control spectral variation. In a second embodiment, a signal from a sample or target probe of a tissue feature or volume is used in positioning a portion of a measuring system relative to the sample. The system is optionally used in conjunction with a targeting system used to control the sampling location of the measuring system.

Owner:SENSYS MEDICAL

Method and apparatus for noninvasive targeting

InactiveUS20060217602A1Enhanced signalIncrease precision and accuracyDiagnostic recording/measuringOptical sensorsNoninvasive samplingSpectral variation

The invention relates to noninvasive sampling. In one embodiment, the invention relates to a sample probe interface method and apparatus for targeting a tissue depth and / or pathlength that is used in conjunction with a noninvasive analyzer to control spectral variation. In a second embodiment, a signal from a sample or target probe of a tissue feature or volume is used in positioning a portion of a measuring system relative to the sample. The system is optionally used in conjunction with a targeting system used to control the sampling location of the measuring system.

Owner:SENSYS MEDICAL

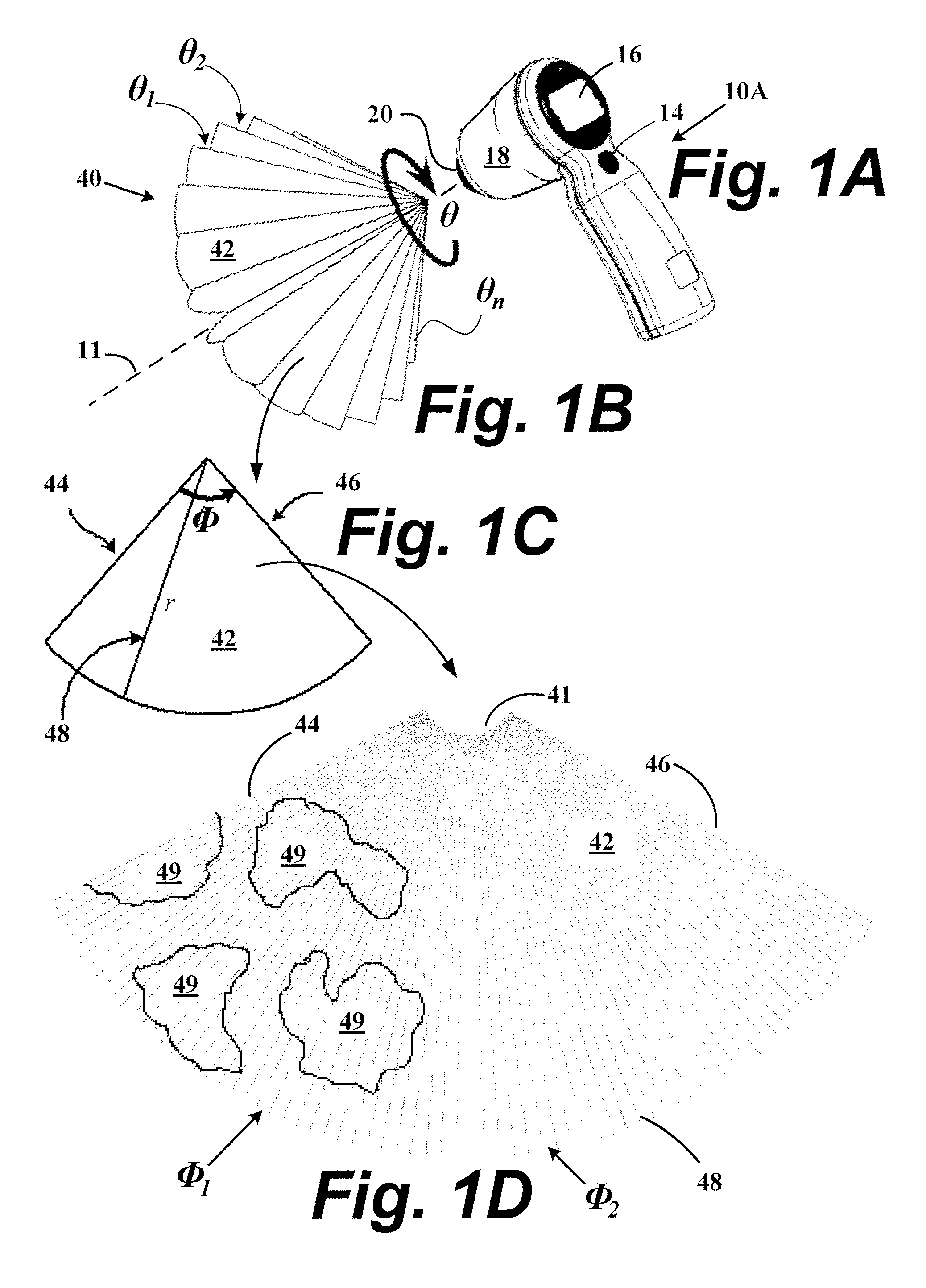

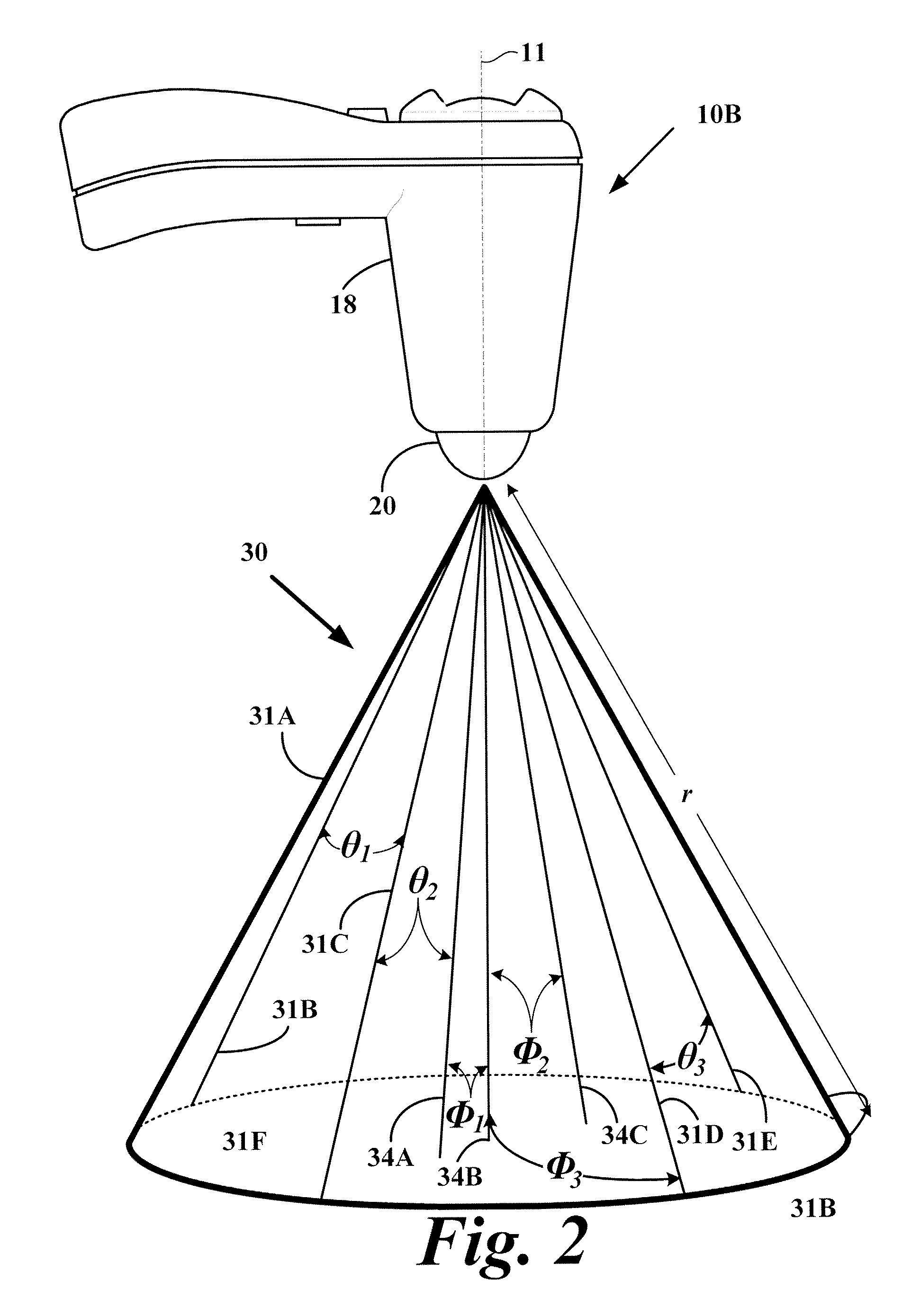

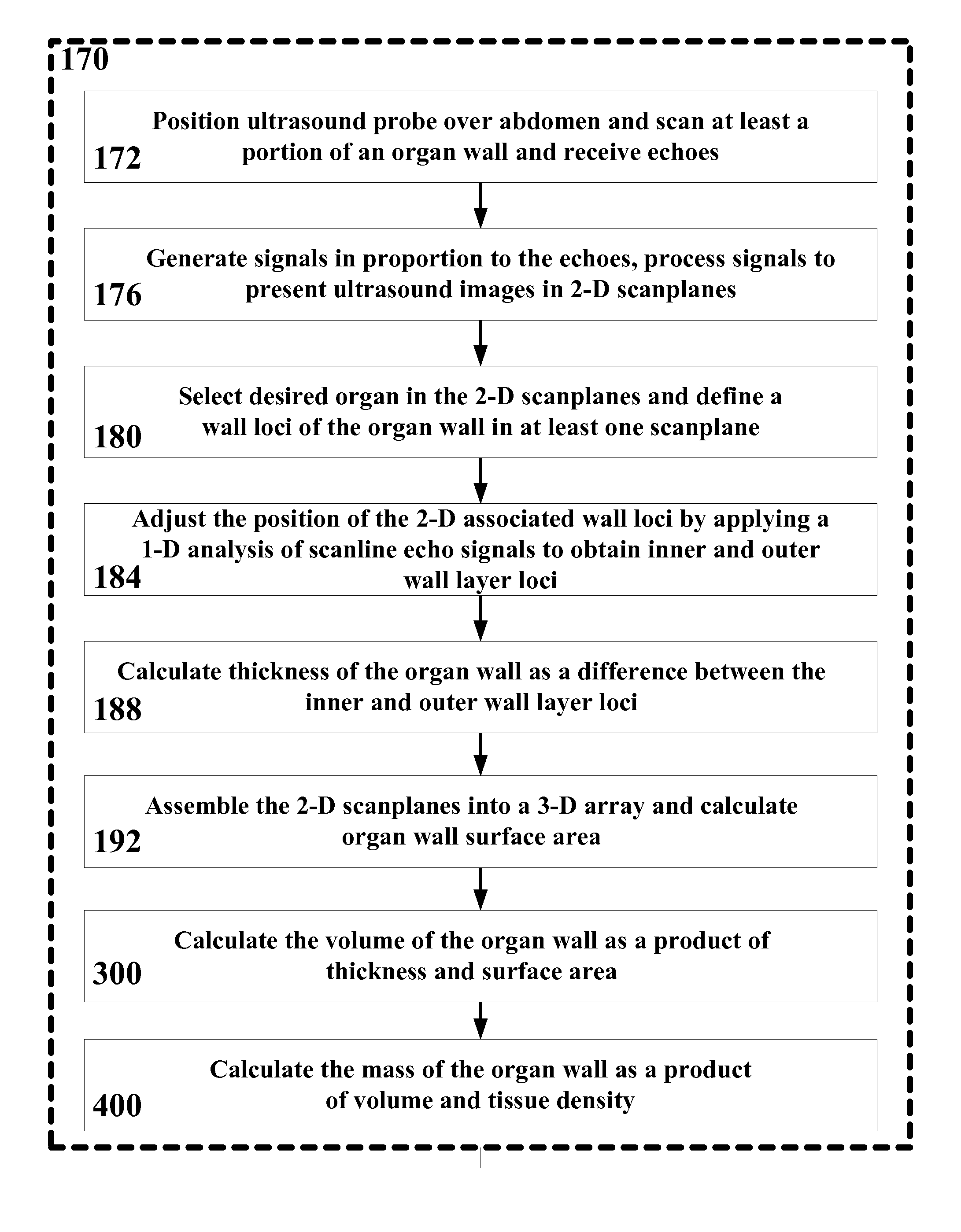

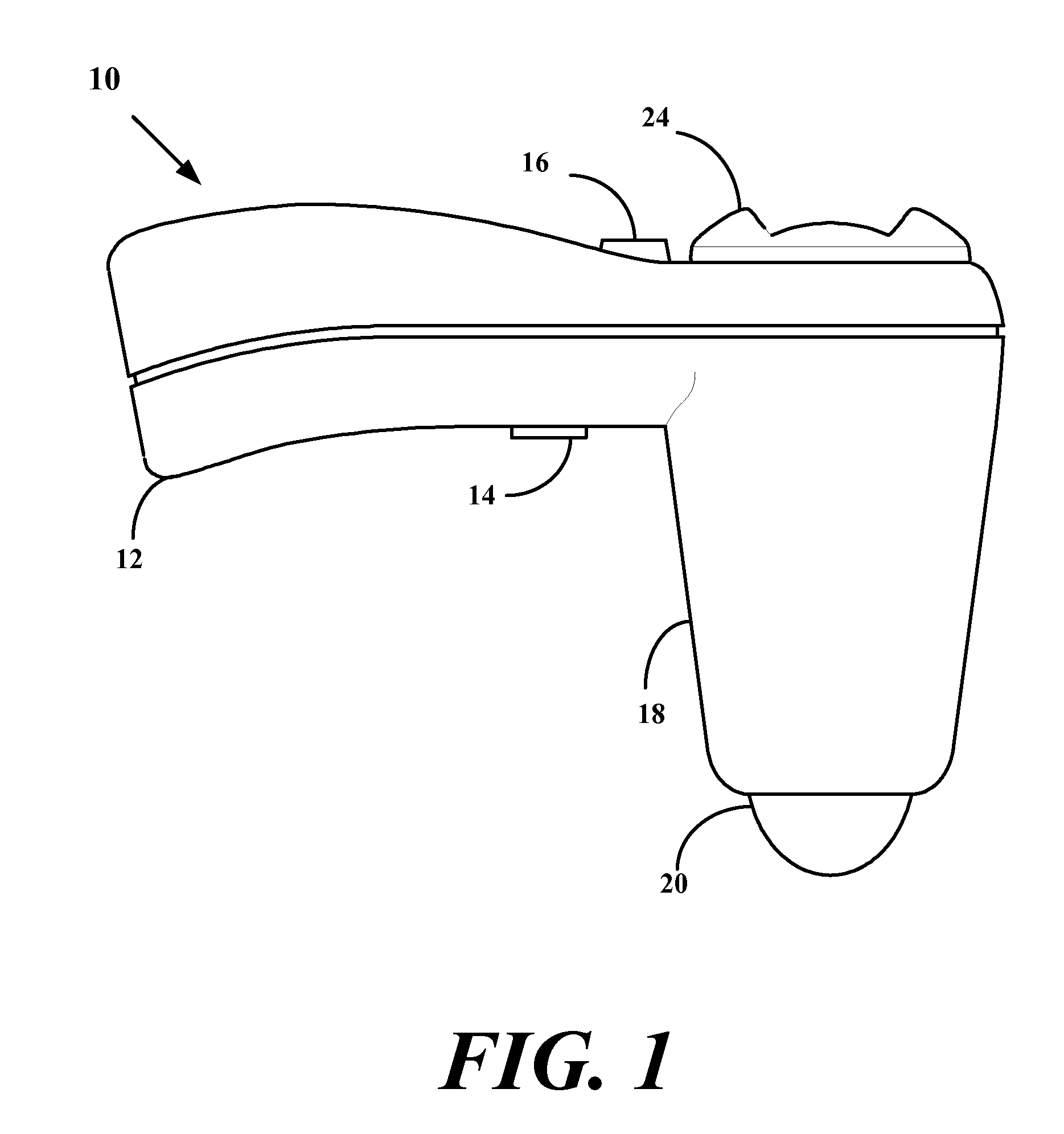

System and method for measuring bladder wall thickness and presenting a bladder virtual image

InactiveUS20090112089A1Improve accuracyImprove precisionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsTransceiverBladder walls

An ultrasound transceiver scans a bladder in a three dimensional array to measure the thickness and surface area of the bladder to determine bladder mass. The bladder wall thickness and masses may be determined for anterior, posterior, and lateral locations of the bladder.

Owner:BARNARD BILL +4

Ultrasound system and method for measuring bladder wall thickness and mass

An ultrasound transceiver scans an organ and processes the echogenic signals to produce three-dimensional, two-dimensional, and one-dimensional information of the organ. The 3-D, 2-D, and 1-D information is utilized to determine the thickness, surface area, volume, and mass of the organ wall.

Owner:VERATHON

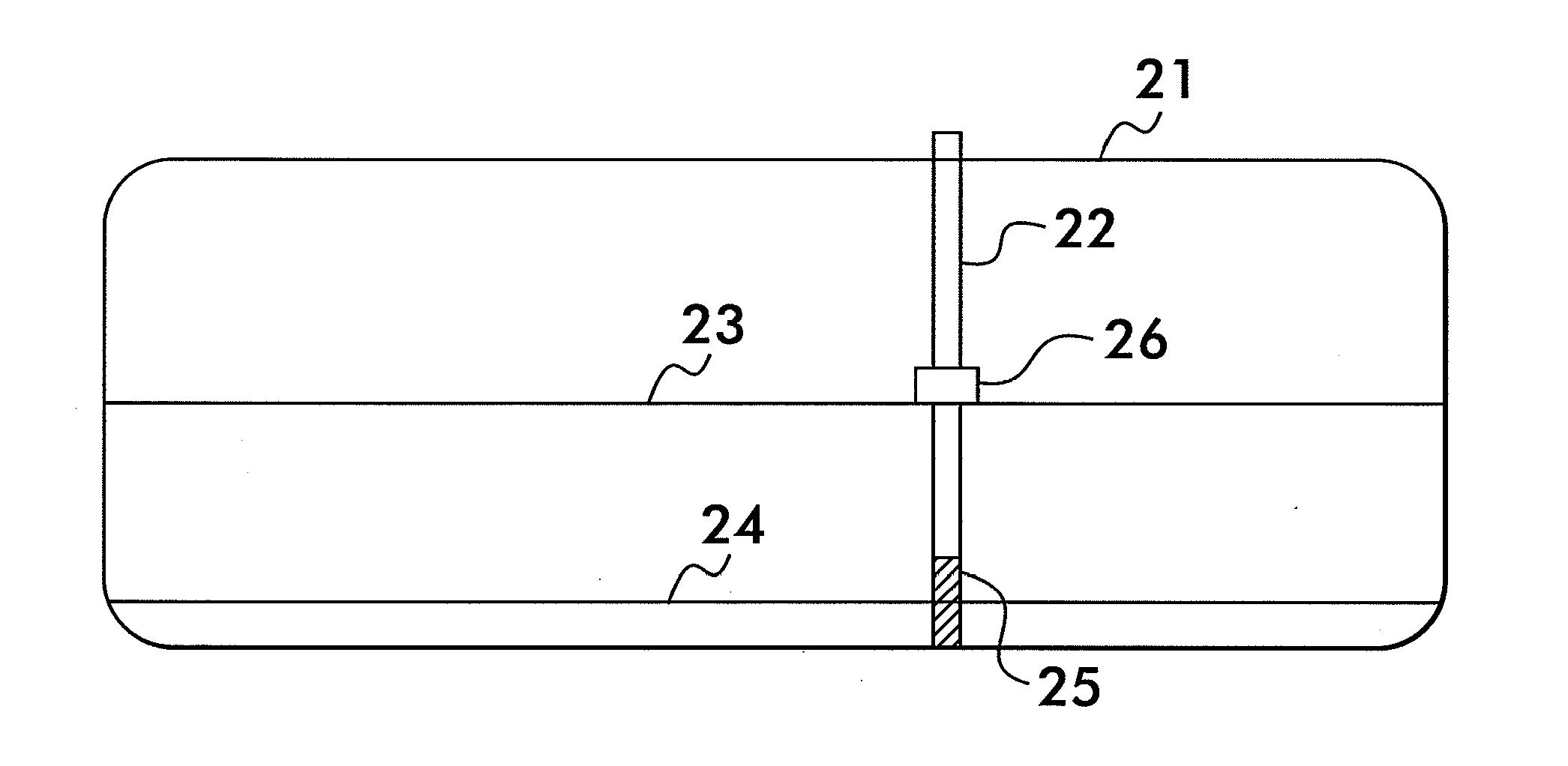

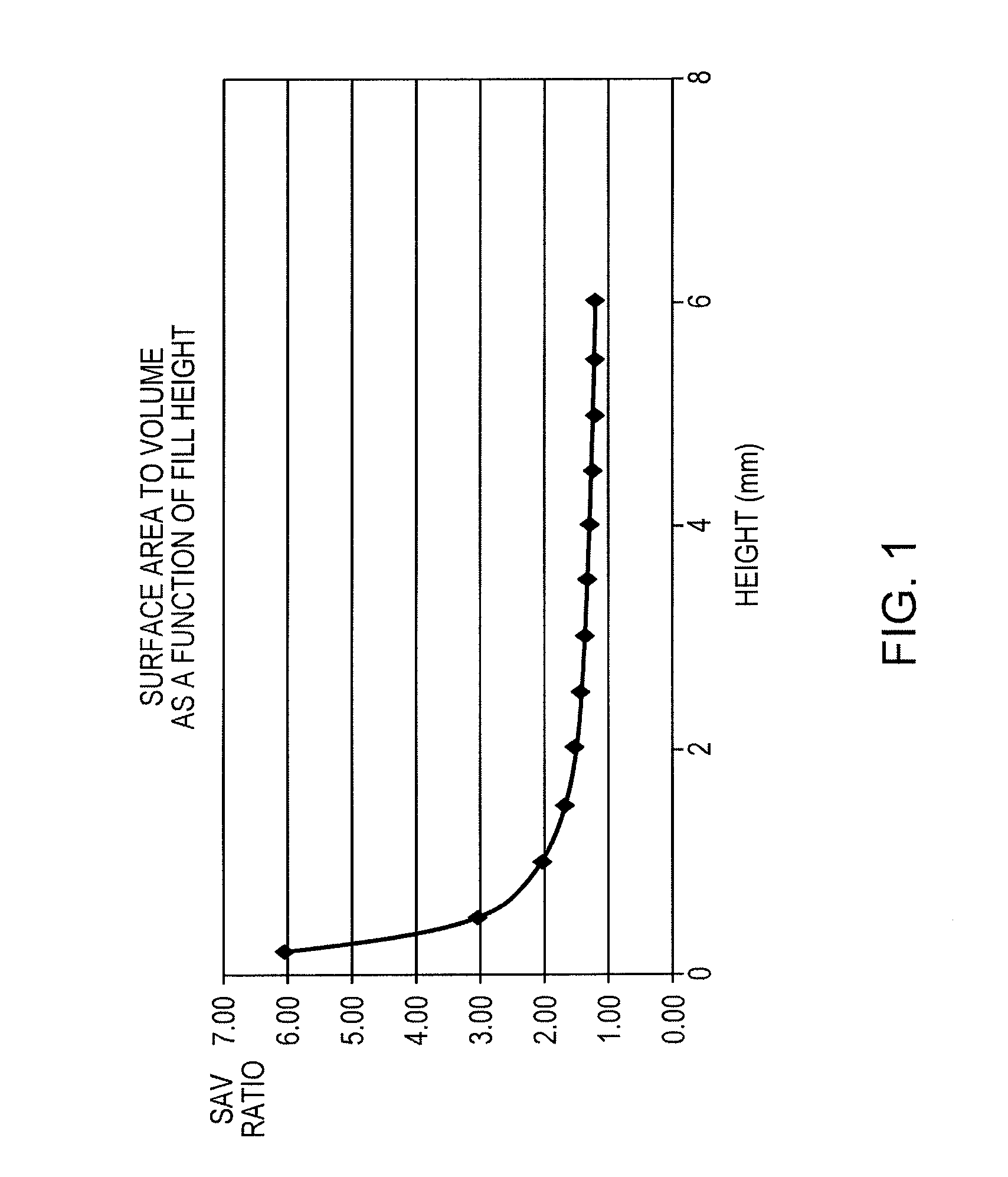

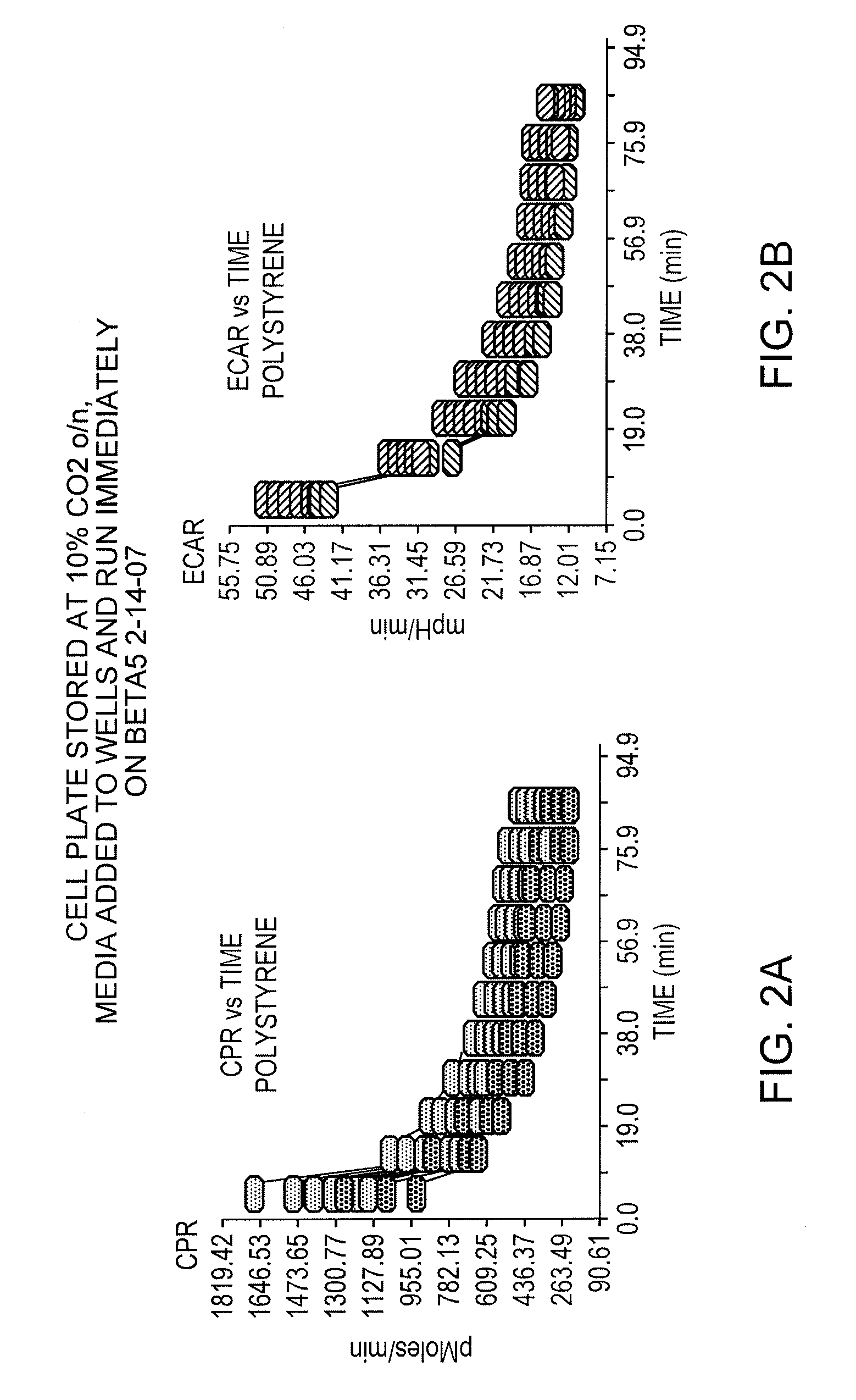

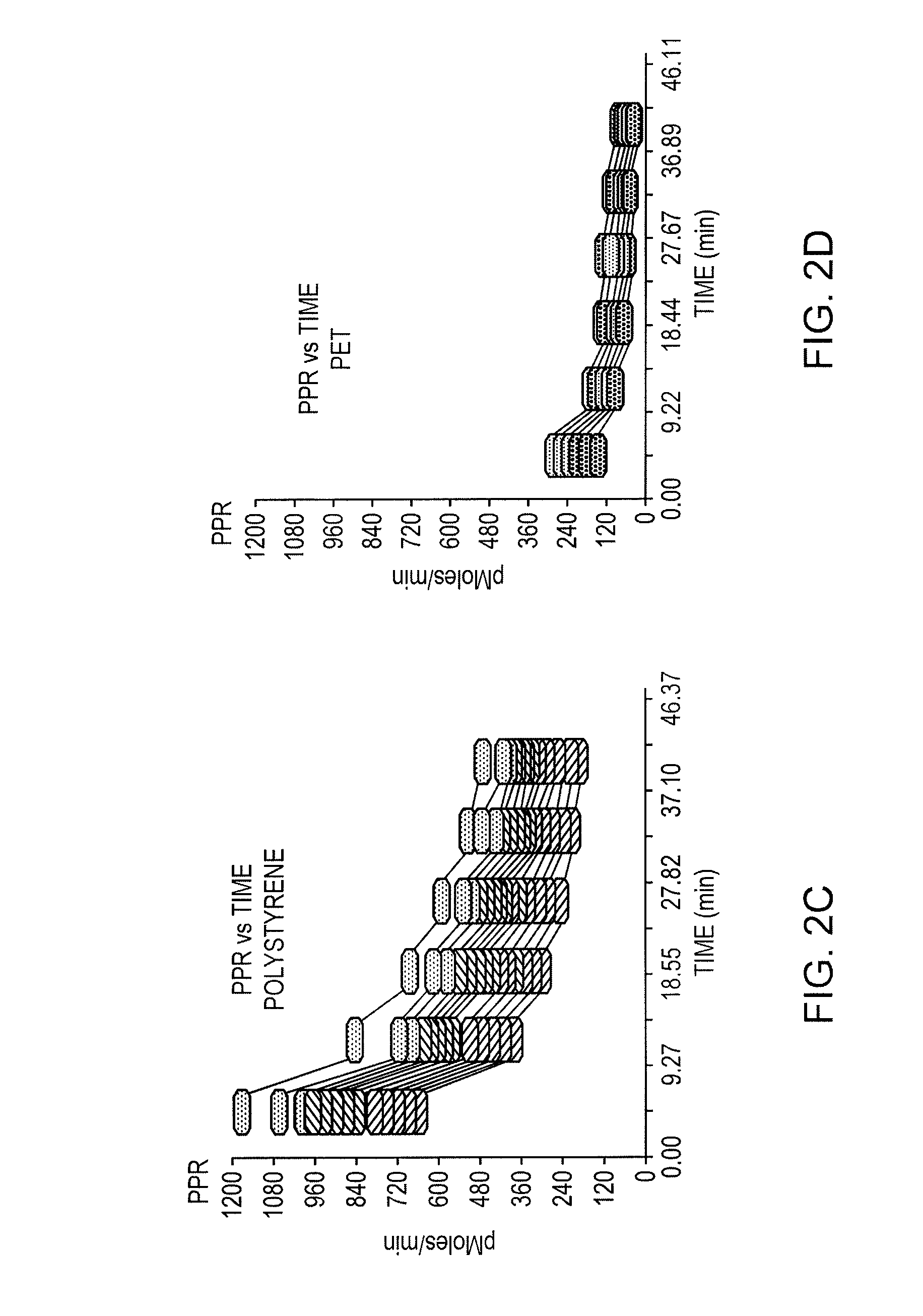

Method and device for measuring extracellular acidification and oxygen consumption rate with higher precision

ActiveUS8202702B2Avoid measuringImprove accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsCell culture mediaExtracellular acidification

The accuracy and / or precision of measurements of extracellular acidification rate or CO2 evolution in cell culture medium may be improved by using materials with low CO2 permeability for medium-containing vessels.

Owner:AGILENT TECH INC

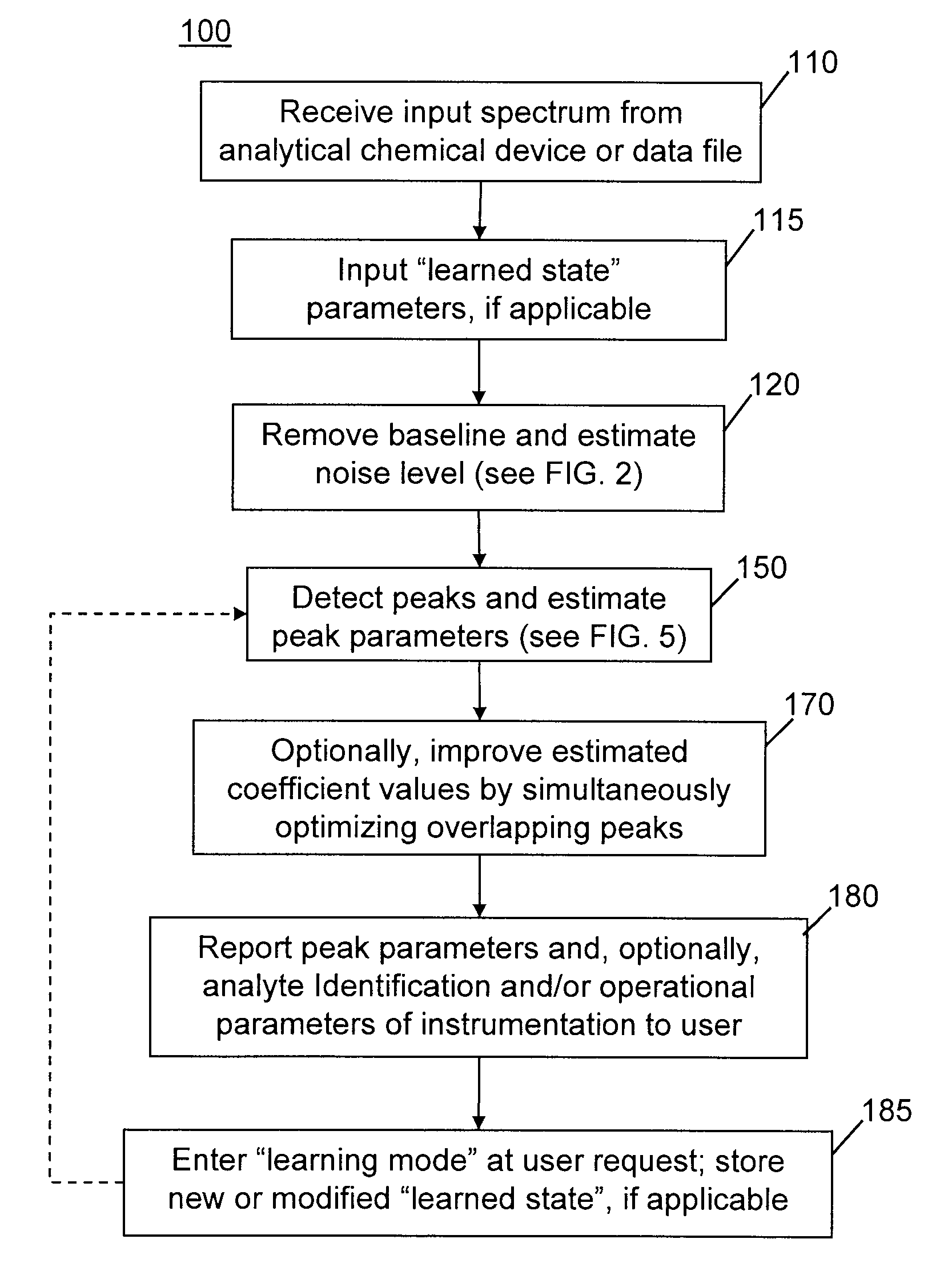

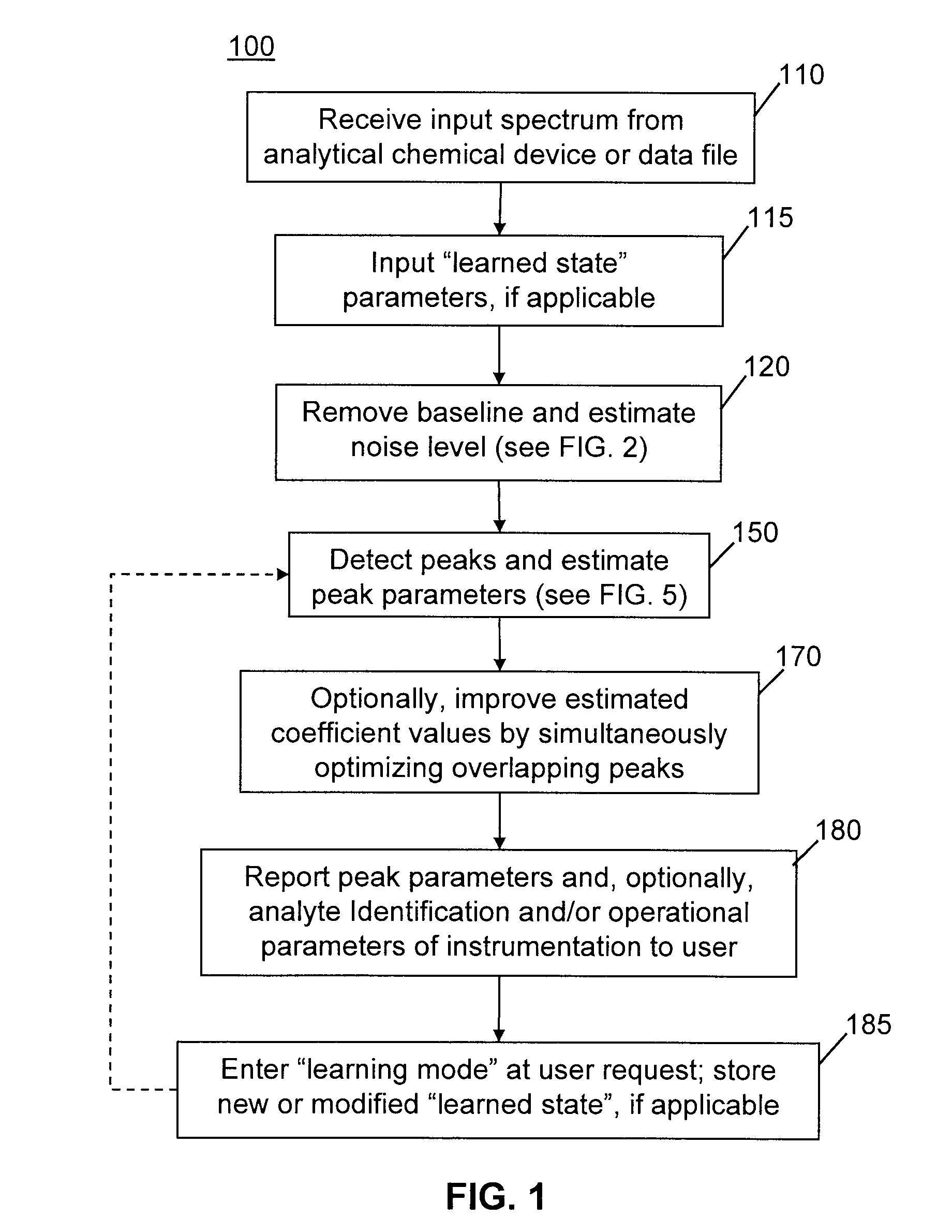

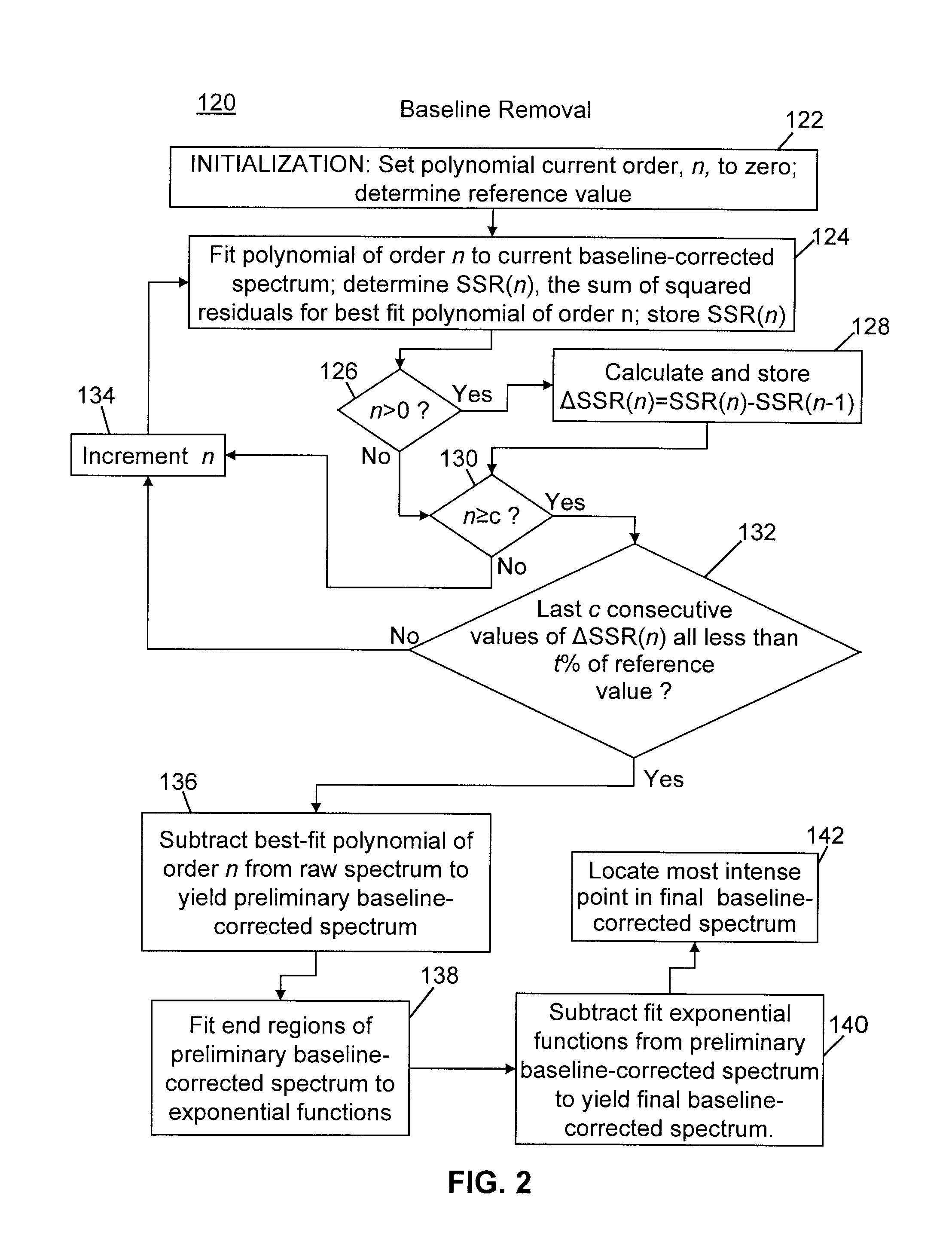

Methods of automated spectral peak detection and quantification having learning mode

InactiveUS8428889B2Easy to handleImprove accuracyMolecular entity identificationParticle separator tubesFrequency spectrumPeak value

There is provided a method of automatically identifying and characterizing spectral peaks of a spectrum generated by an analytical apparatus comprising the steps of: receiving the spectrum generated by the analytical apparatus; automatically subtracting a baseline from the spectrum so as to generate a baseline-corrected spectrum; automatically detecting and characterizing the spectral peaks in the baseline-corrected spectrum; reporting the detected and characterized spectral peaks to a user; receiving a list of adjustments to be made to the detecting and characterizing step from the user; and adjusting exit values used in the detecting and characterizing step, based on the list of adjustments.

Owner:THERMO FINNIGAN

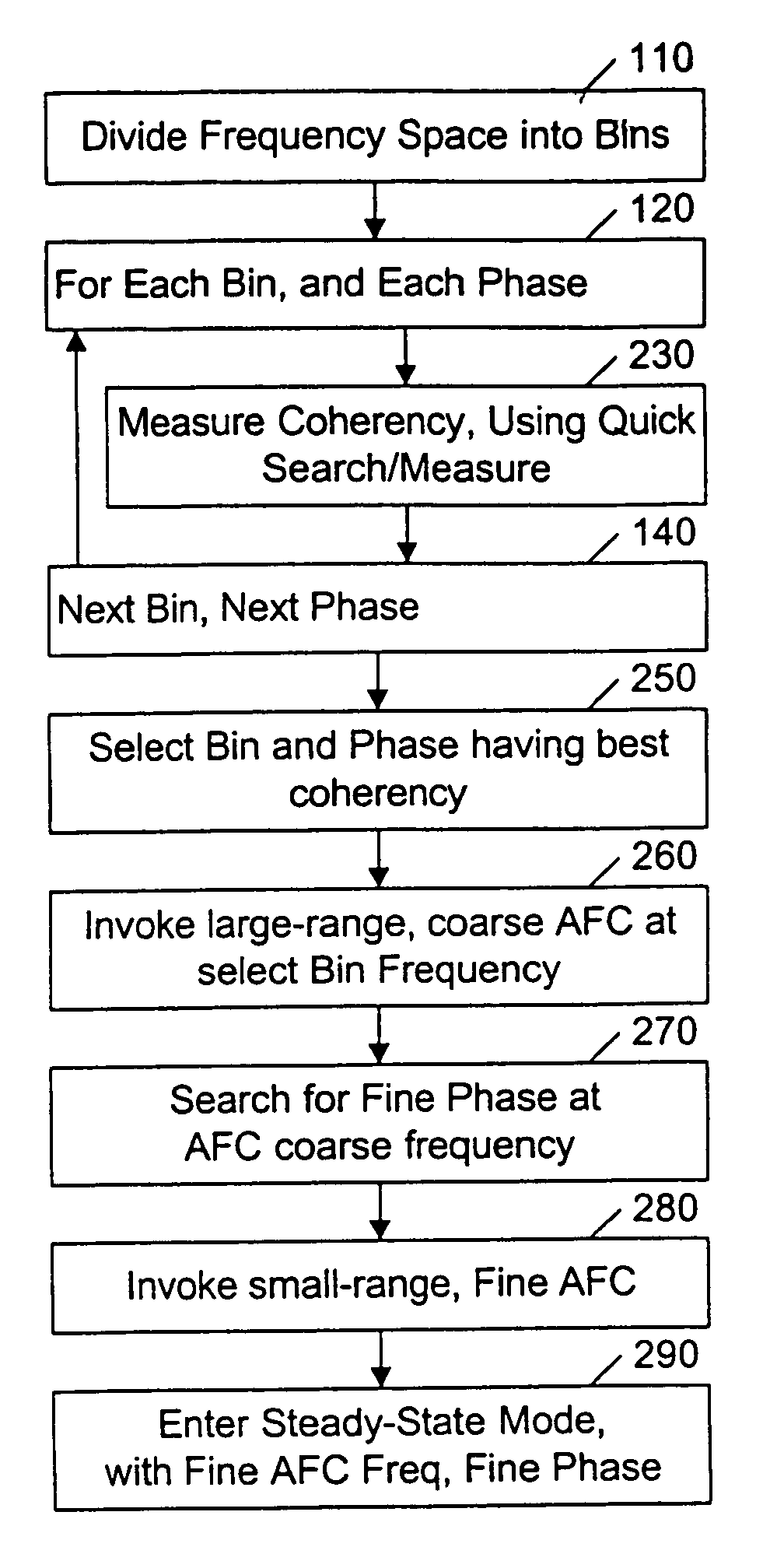

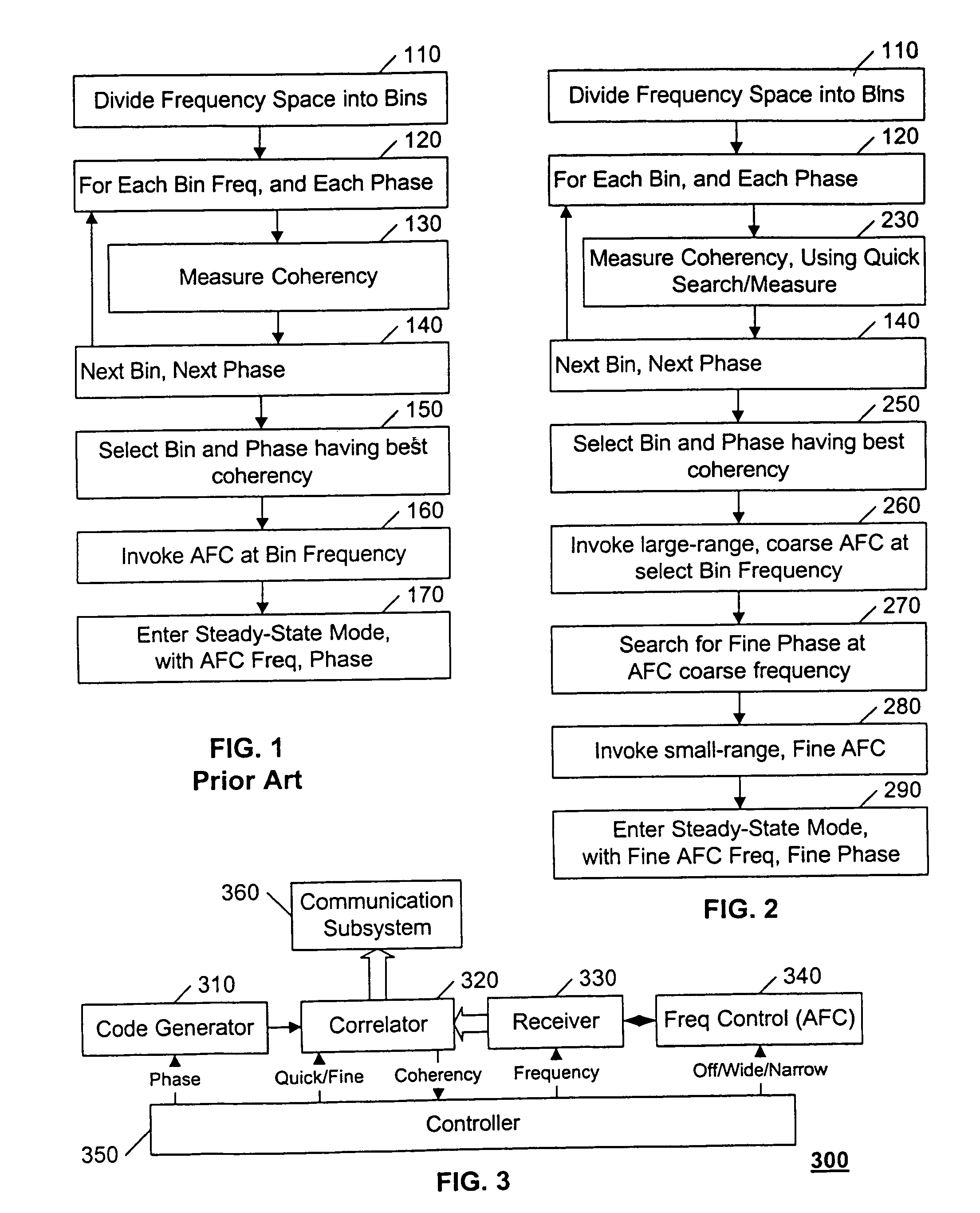

Iterative CDMA phase and frequency acquisition

InactiveUS7050485B2Improve acquisitionHigh frequency accuracyTransmissionFrequency determinationEngineering

A system and method is provided that searches for the frequency and phase of a CDMA transmission in an iterative manner. With its automatic frequency control (AFC) disabled, the receiving system performs a coarse search for the transmitter's CDMA phase at a nominal receiving frequency. When the coarse phase is obtained, the AFC is invoked with a large-range pull-in, to obtain an initial, coarse frequency that is likely to be closer to the transmitter's frequency than the initial nominal frequency. At this coarse frequency, the receiving system repeats its search for the transmitter's CDMA phase, starting at the previously determined coarse phase. Because this second phase determination is conducted in the presence of less frequency error, it provides for a more accurate phase determination. The AFC is again invoked, but with a small-range pull-in, to obtain a finer frequency determination. Because the finer frequency determination is conducted in the presence of less phase error, a substantial improvement in the accuracy and precision of the frequency determination can be achieved. To achieve this more accurate phase and frequency determination within the same time duration as a conventional acquisition process, the initial coarse phase determination is conducted using a rapid, albeit less accurate, process than the conventional phase determination.

Owner:NXP BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com