Patents

Literature

619 results about "End point detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Endpoint detection and response is an emerging technology that addresses the need for continuous monitoring and response to advanced threats. One could even make the argument that endpoint detection and response is a form of advanced threat protection.

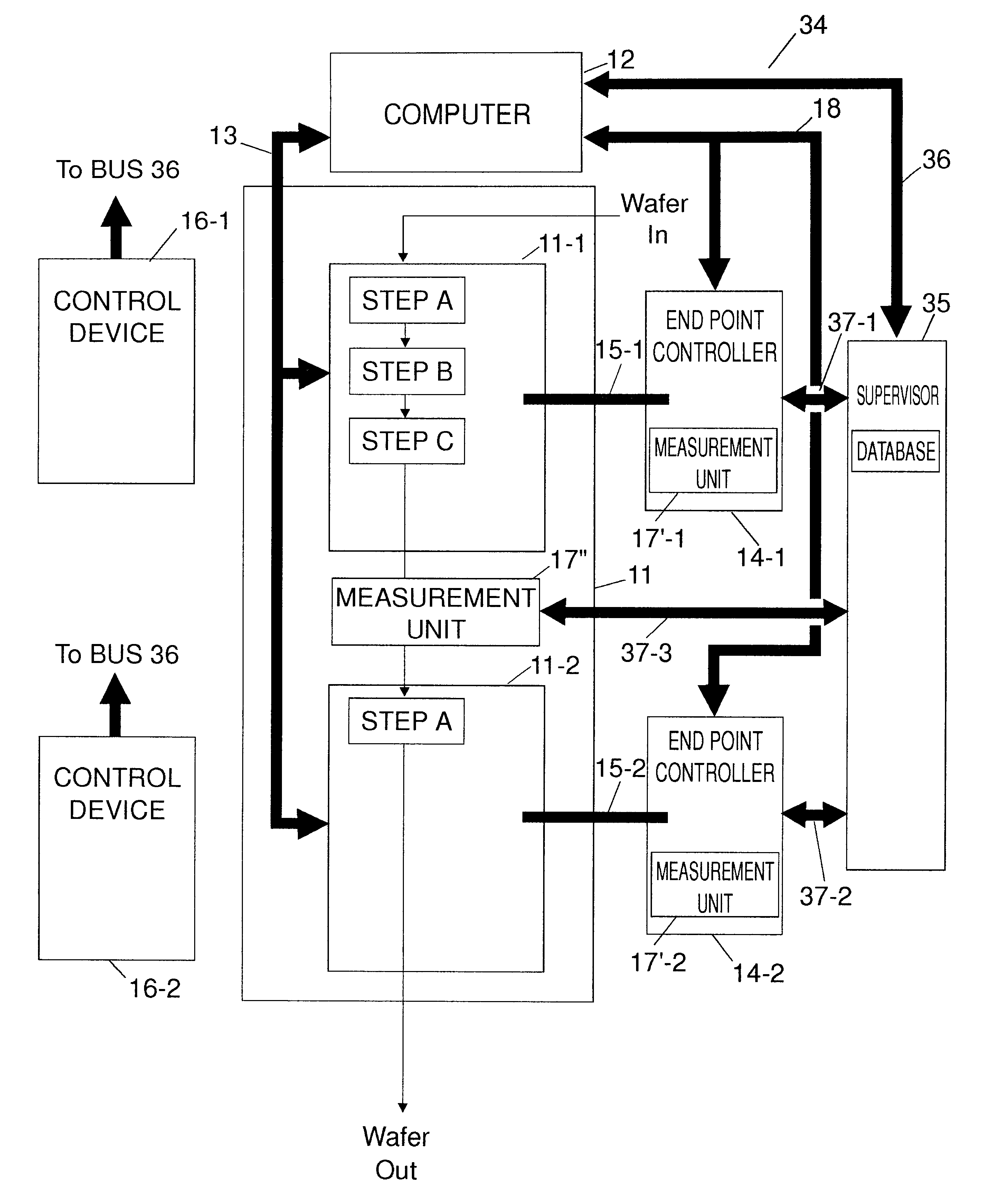

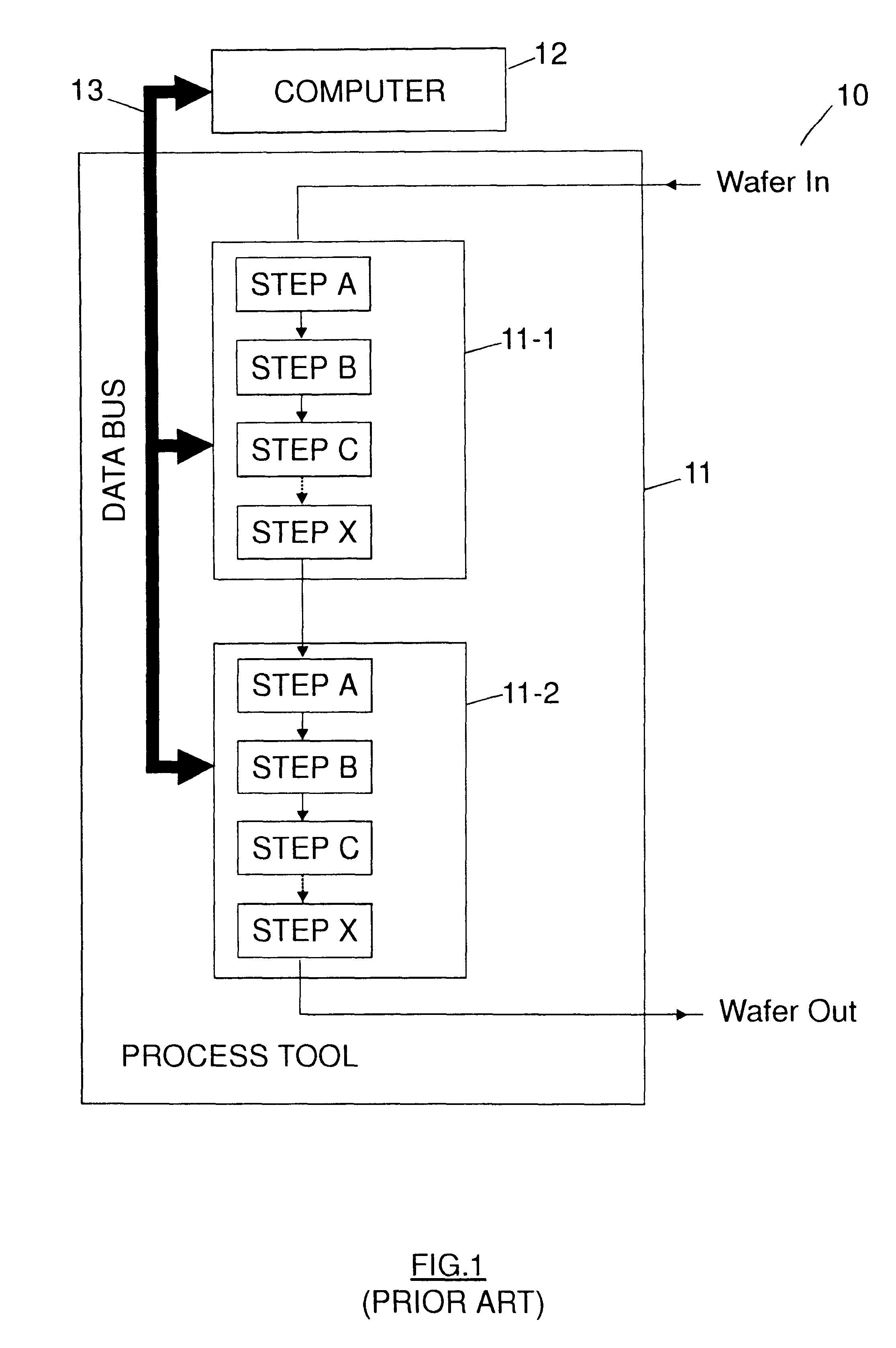

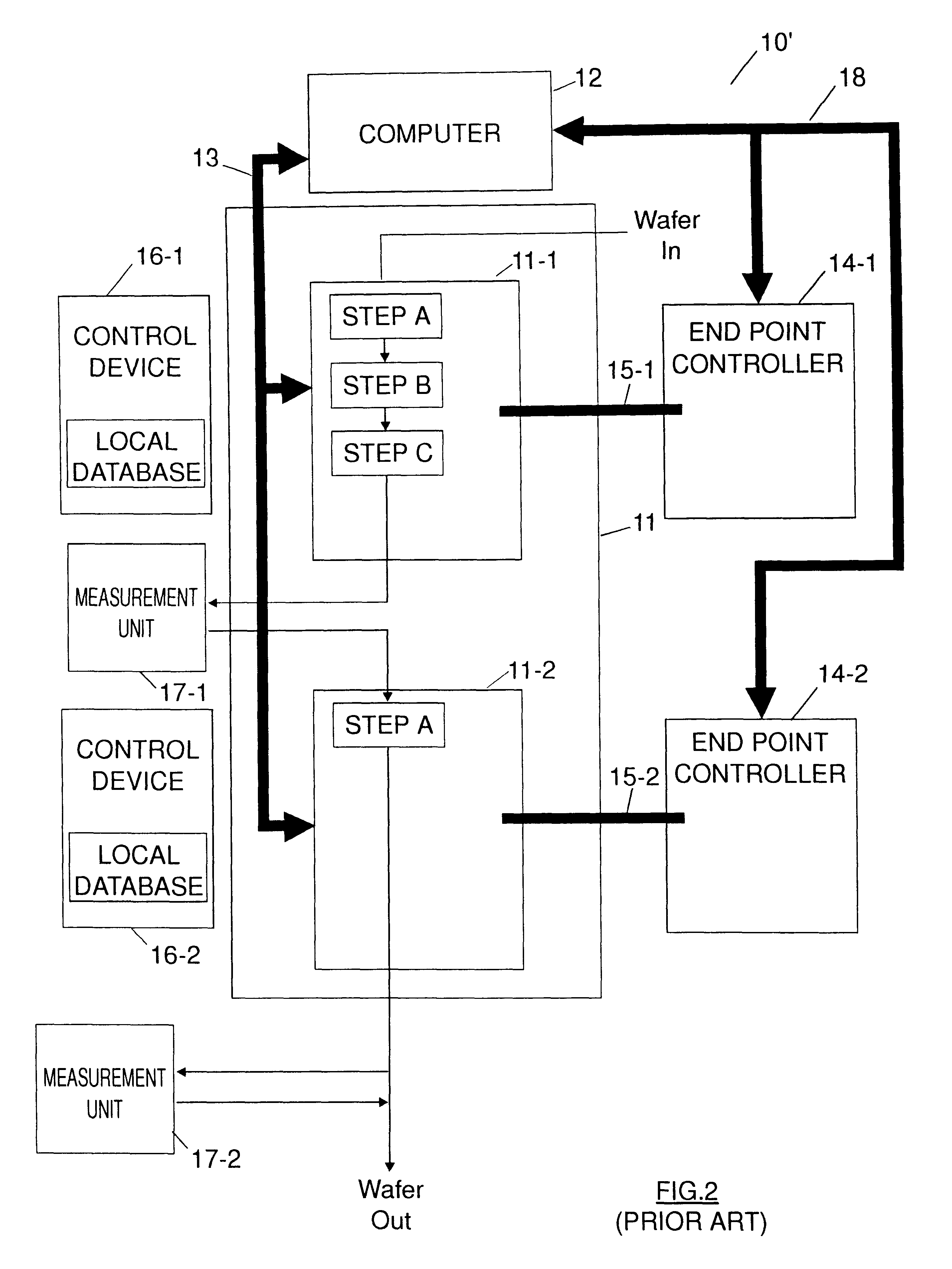

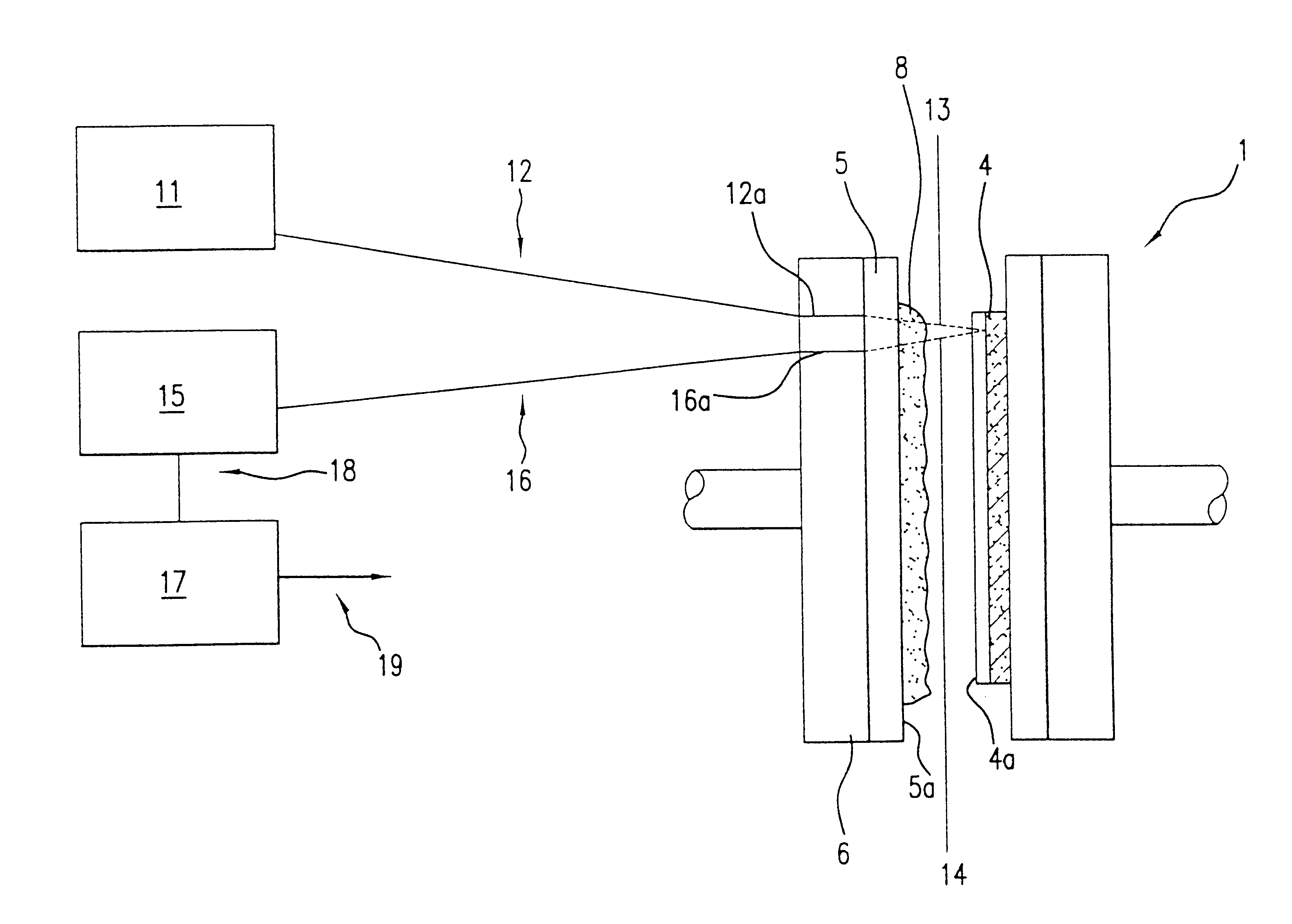

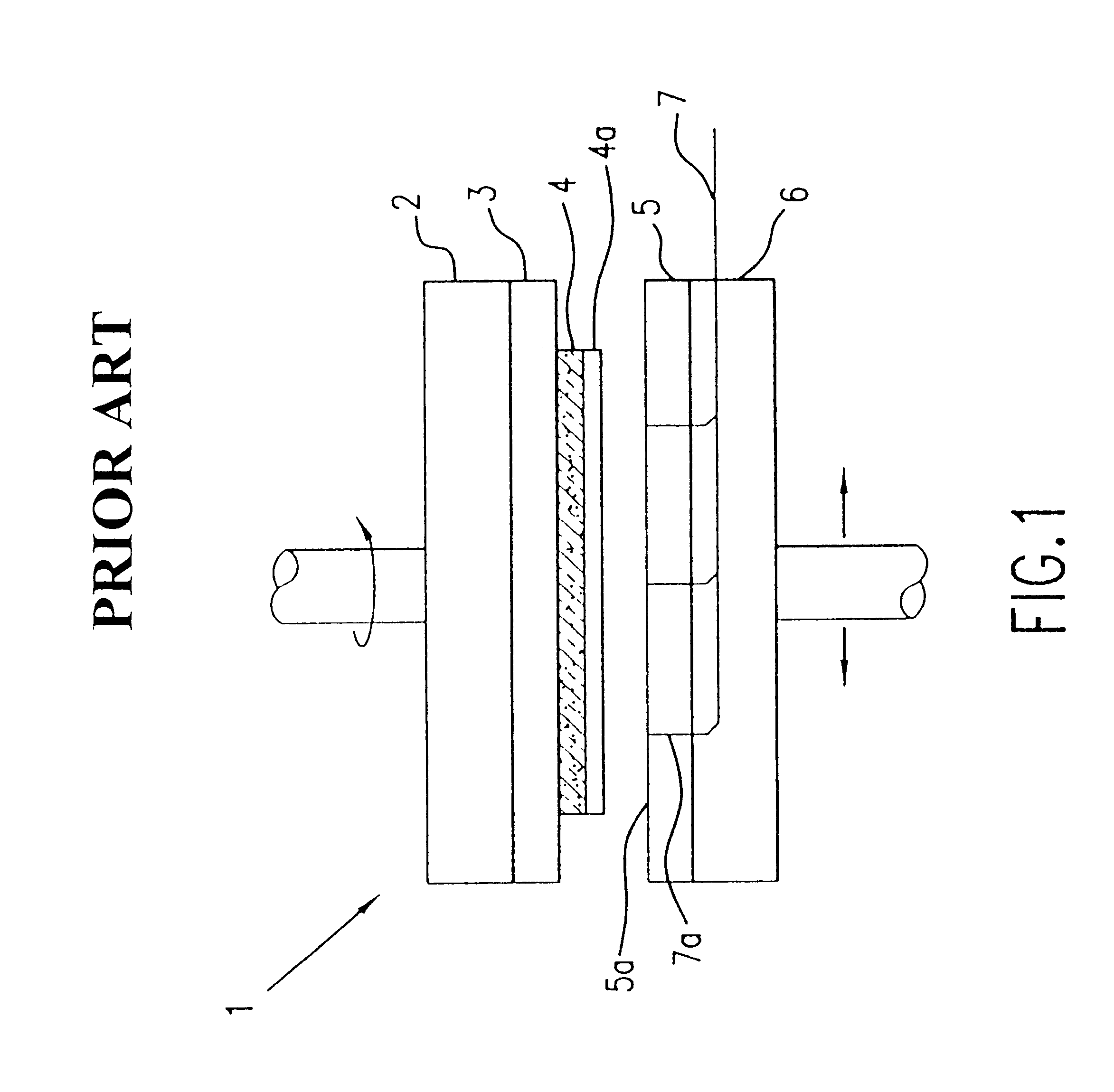

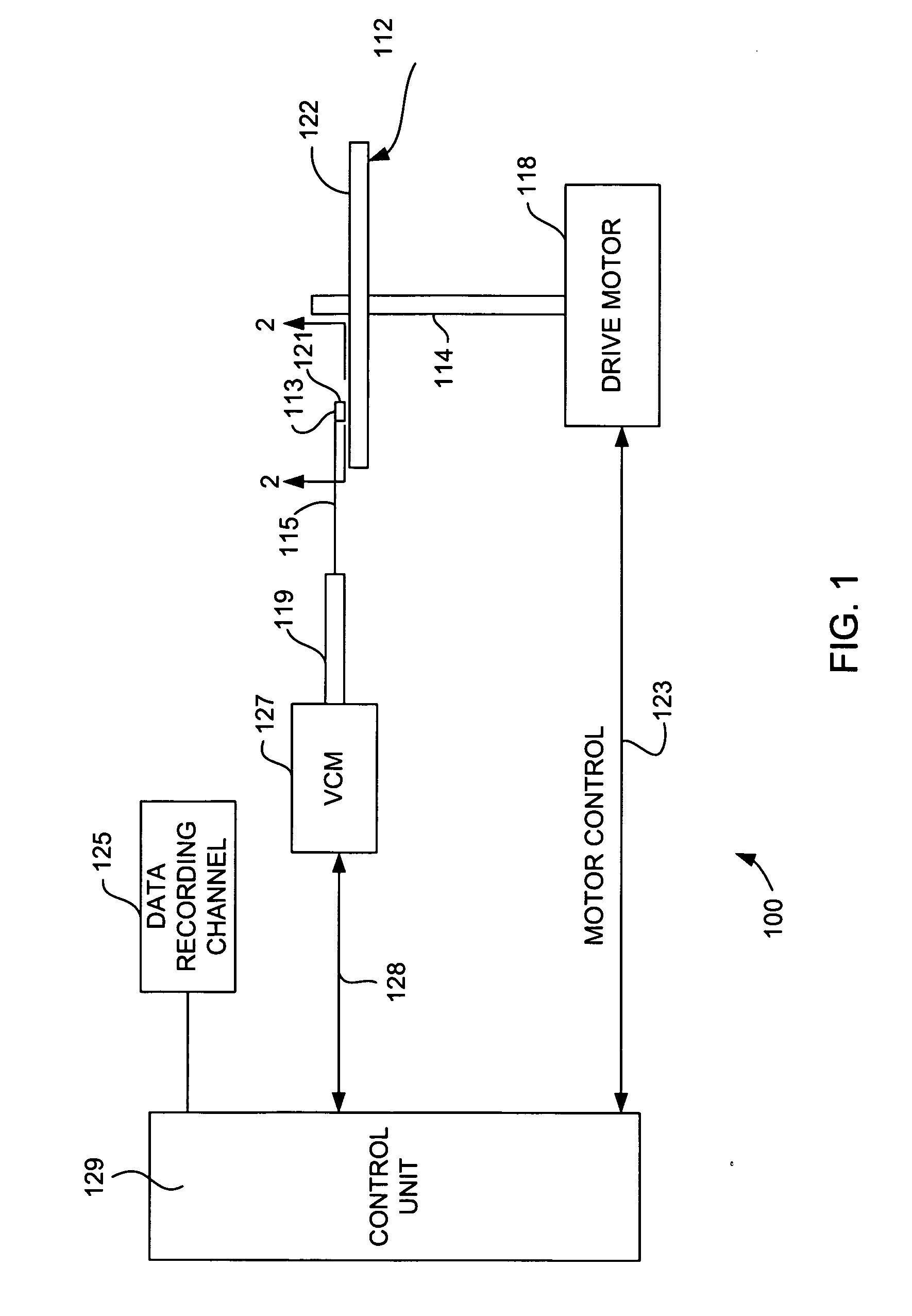

Method and system for semiconductor wafer fabrication process real-time in-situ interactive supervision

InactiveUS6363294B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingWafer fabricationEngineering

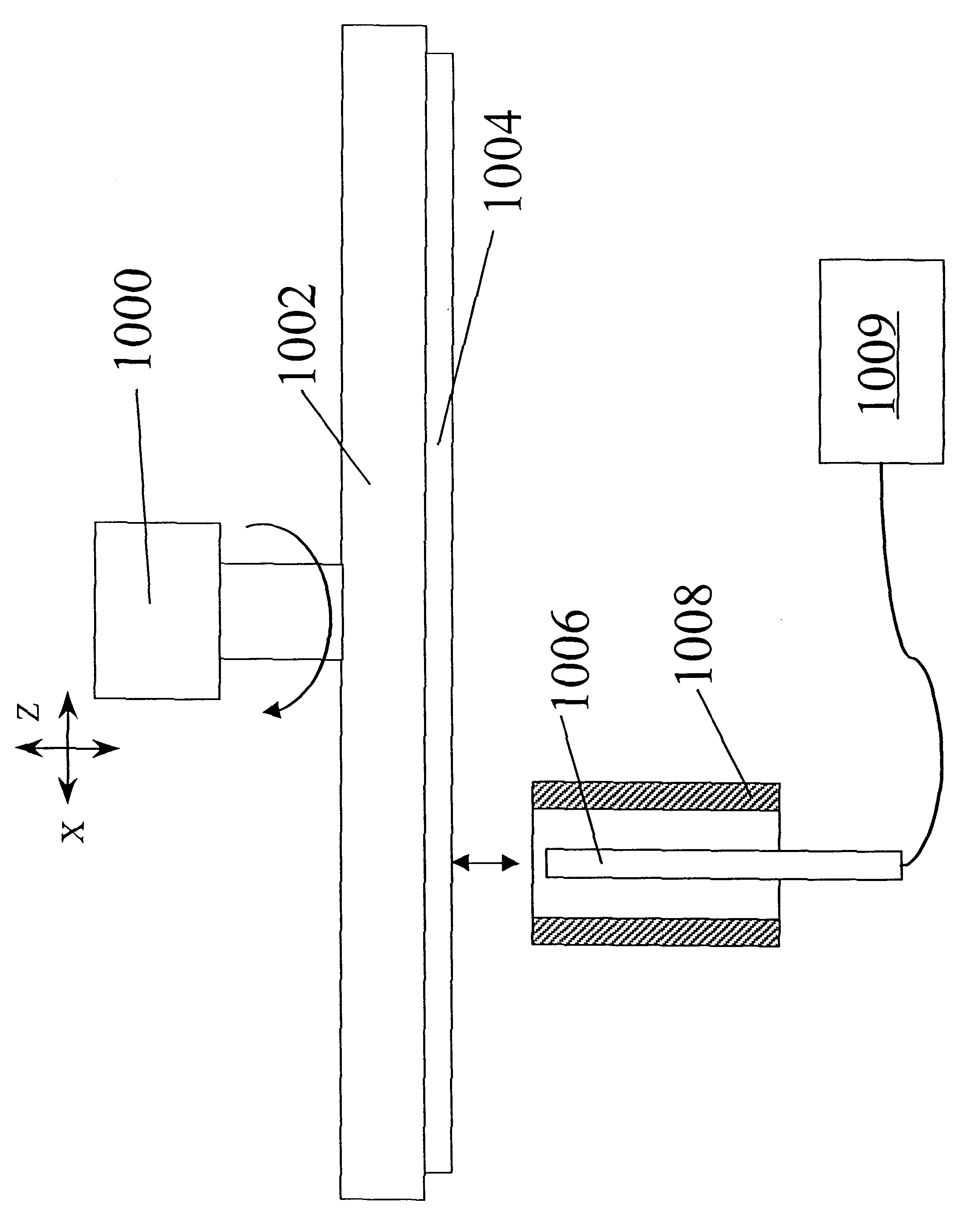

Method and system for real-time in-situ interactive supervision of a step performed in a tool during semiconductor wafer fabrication process. The system includes a tool and the computer attached thereto, an end point detection controller, a database and a supervisor to supervise the whole wafer processing for that step. The controller is used to monitor a key process parameter of the step and is adapted to perform in-situ measurements. The database contains the evolution of said process parameter in normal operating conditions and in all the identified deviations. It further contains the history of the wafer until this step and a reference to the batch and process names for this step and the wafer identification number. At the end of the step, the important process parameters and any alert code are stored in the database to up-date the wafer history. This technique allows a total clusterized wafer fabrication process and prevents wafer rejection.

Owner:IBM CORP

Methods of end point detection for substrate fabrication processes

InactiveUS20130193108A1Liquid surface applicatorsVacuum gauge using ionisation effectsEngineeringThroughput

Methods and substrate processing systems for analyzing an end point of a process are provided. By-products of the process are detected and monitored to determine the completion of various types of reaction processes within a substrate processing chamber. The methods provide real time process monitoring, thereby reducing the need to rigidly constrain other substrate processing parameters, increasing chamber cleaning efficiency, and / or increasing substrate processing throughput.

Owner:APPLIED MATERIALS INC

Rapid and accurate end point detection in a noisy environment

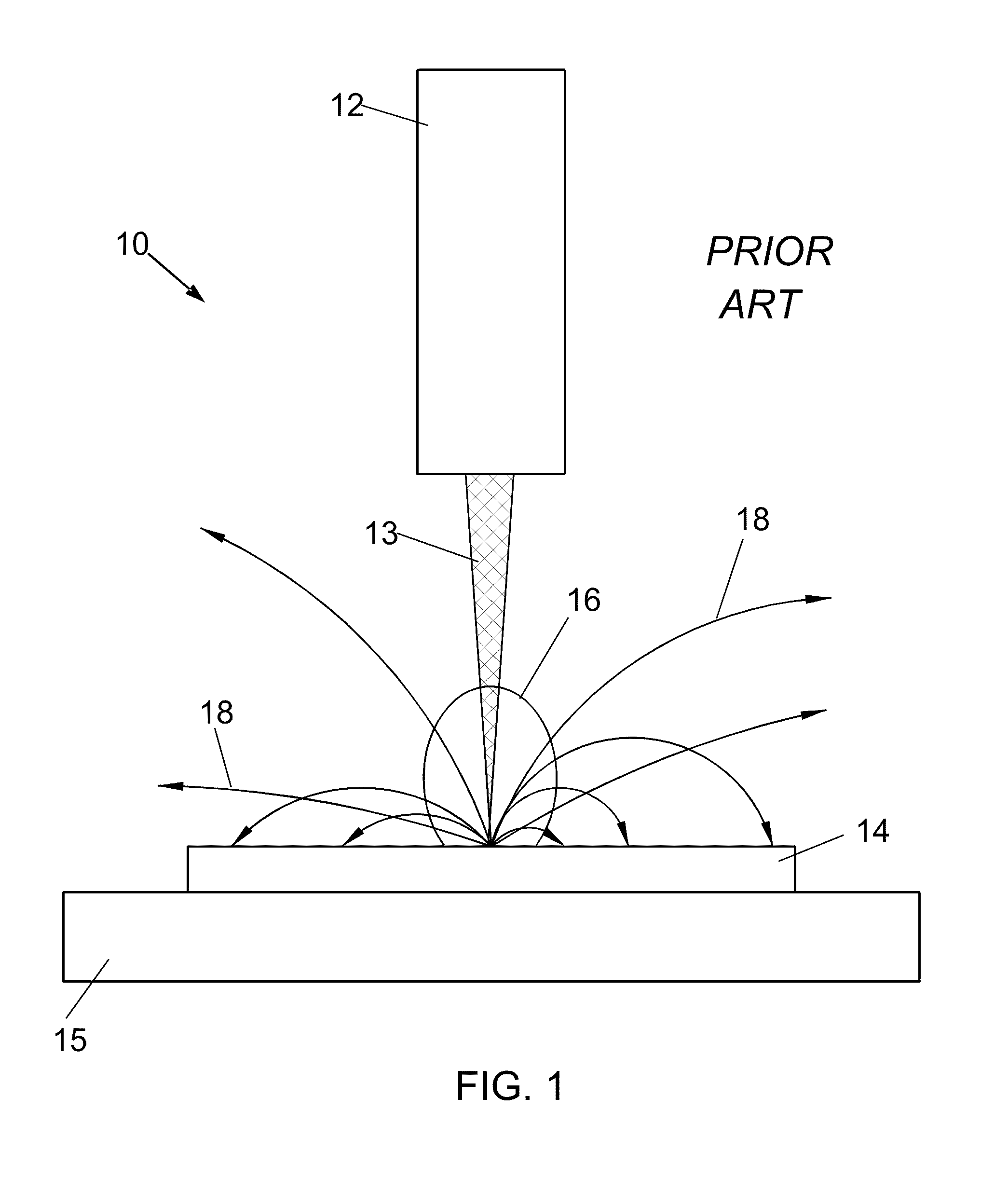

Methods and apparatus for film measurement and endpoint detection in a noisy environment, such as CMP processing of semiconductor wafers, are disclosed, characterized by the use of spectral analysis of intensity data derived from light reflected off the sample to estimate film thickness or detect an endpoint condition.

Owner:FILMETRICS

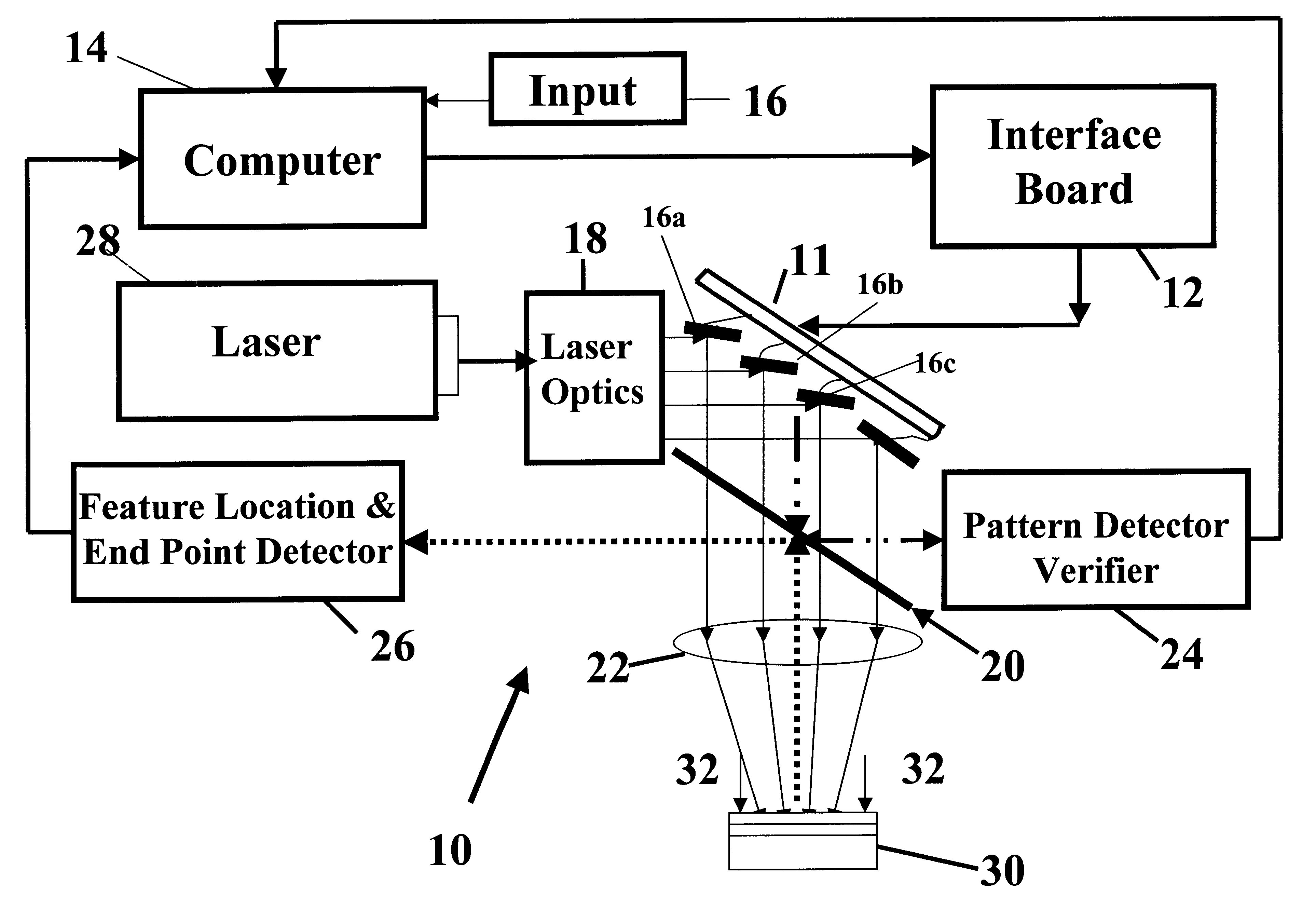

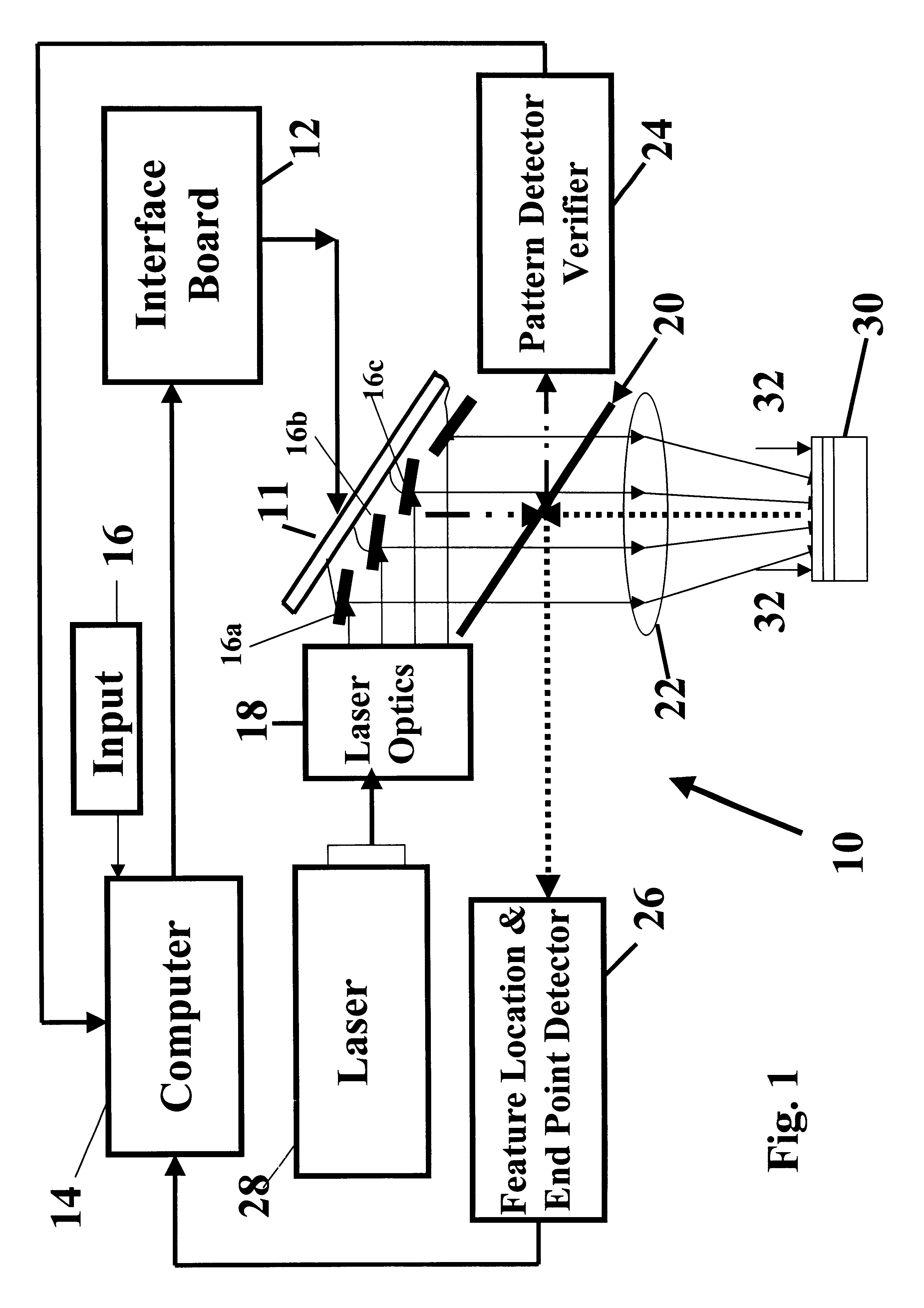

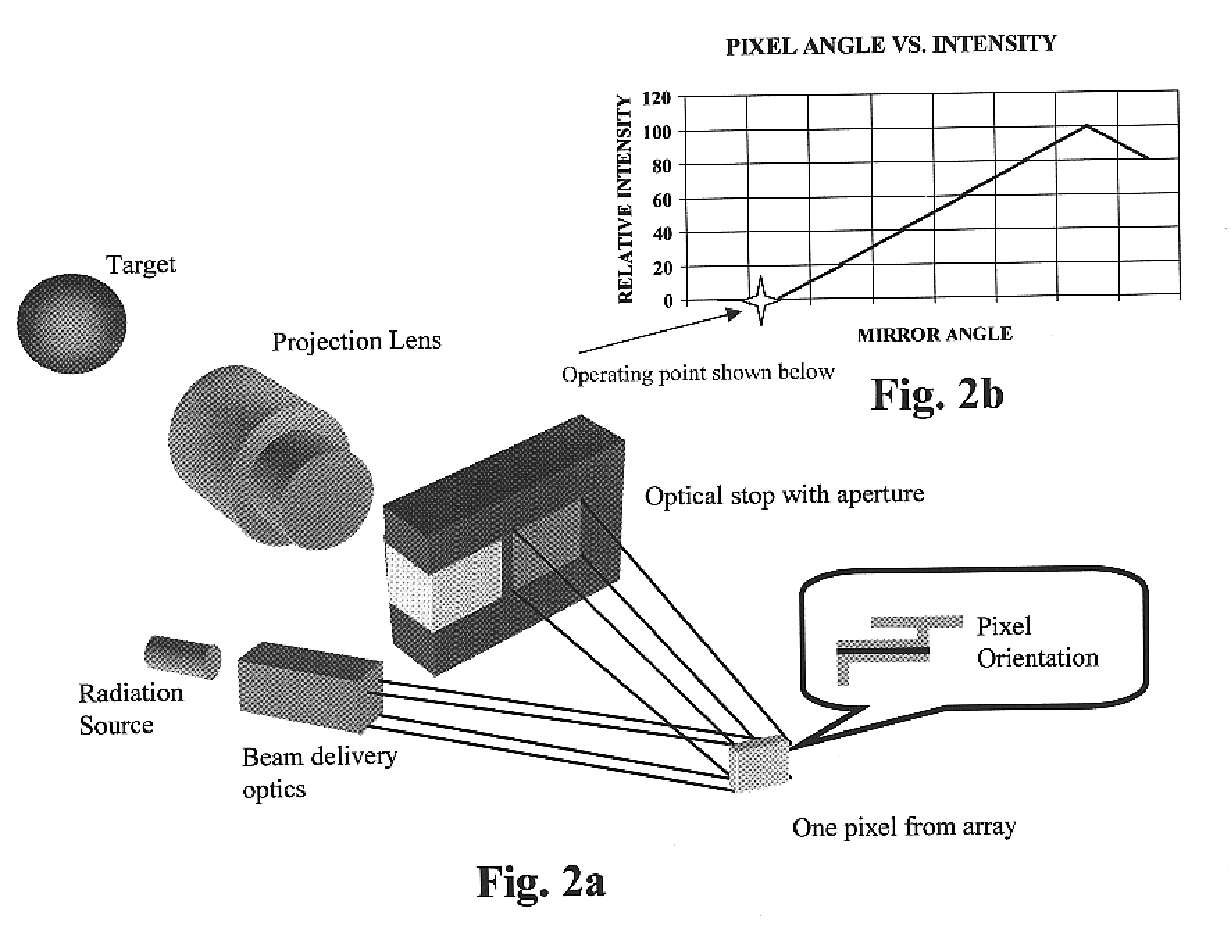

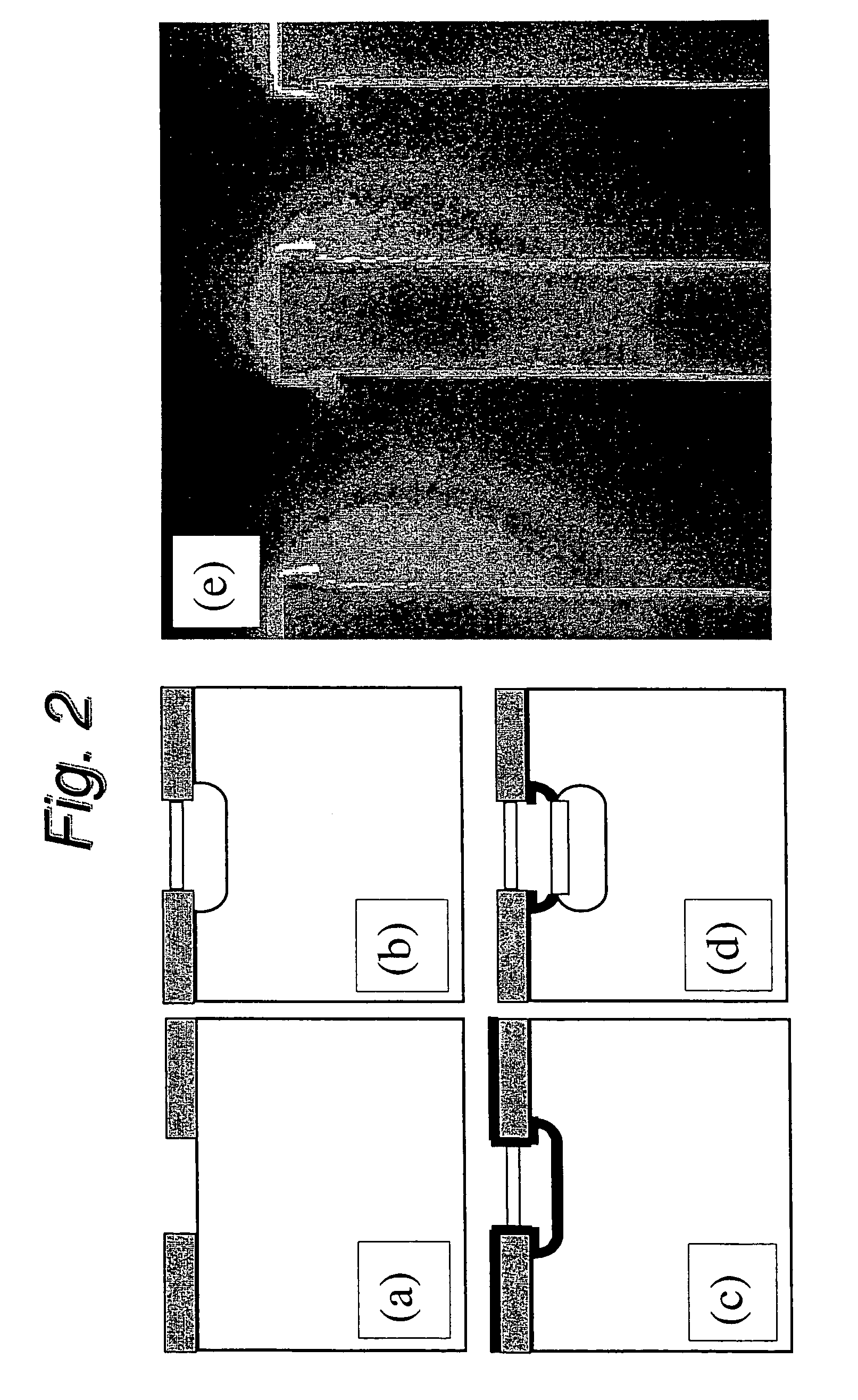

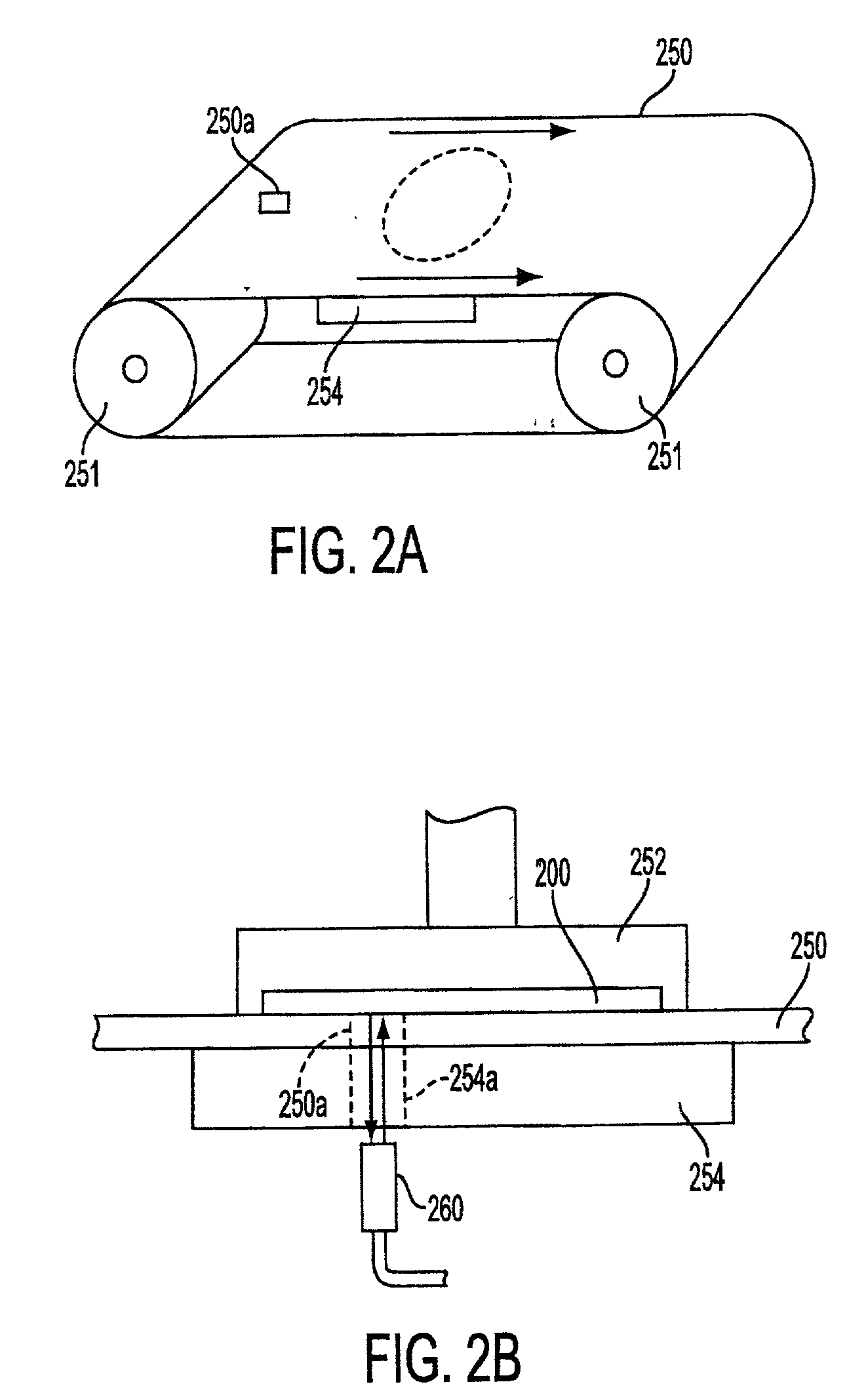

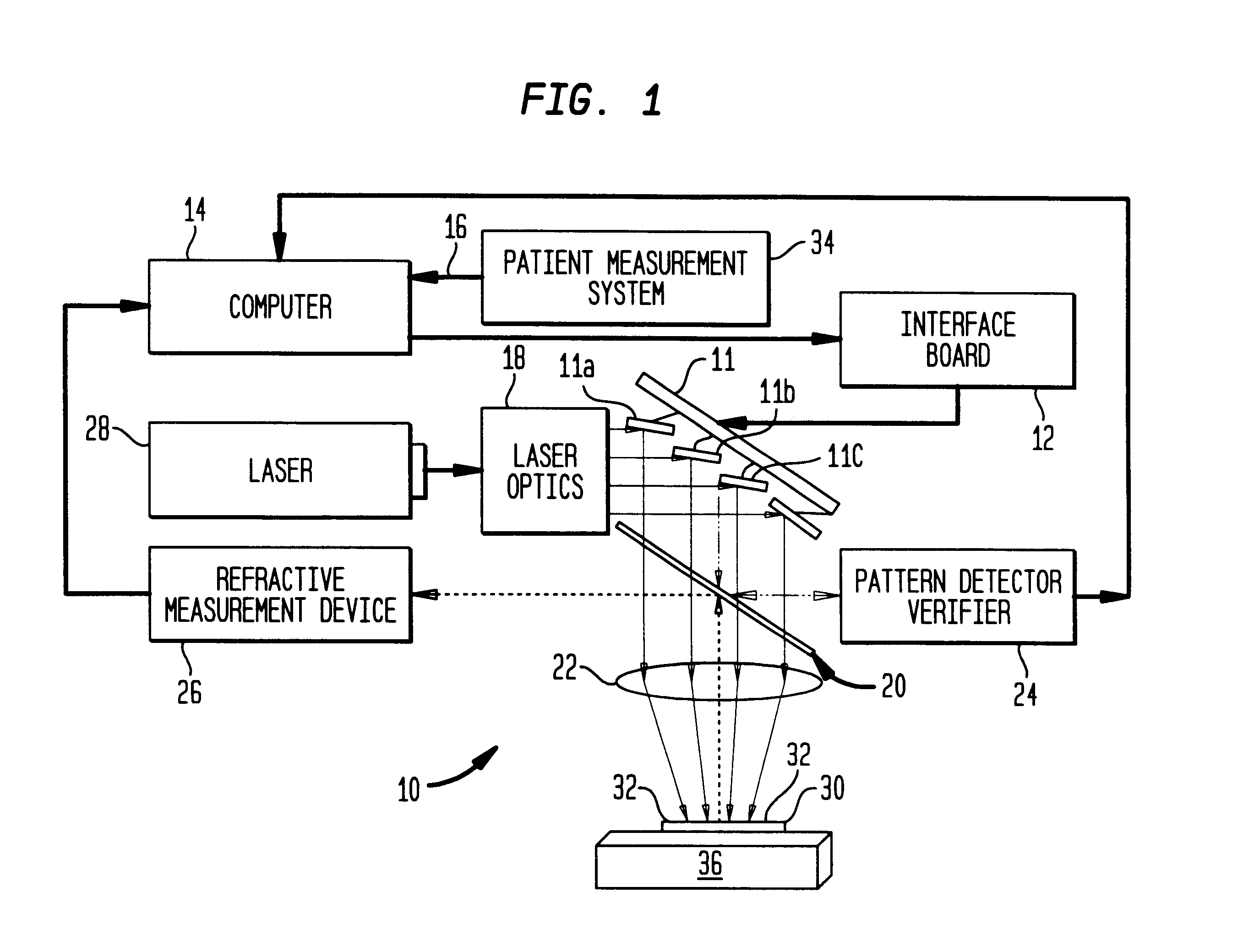

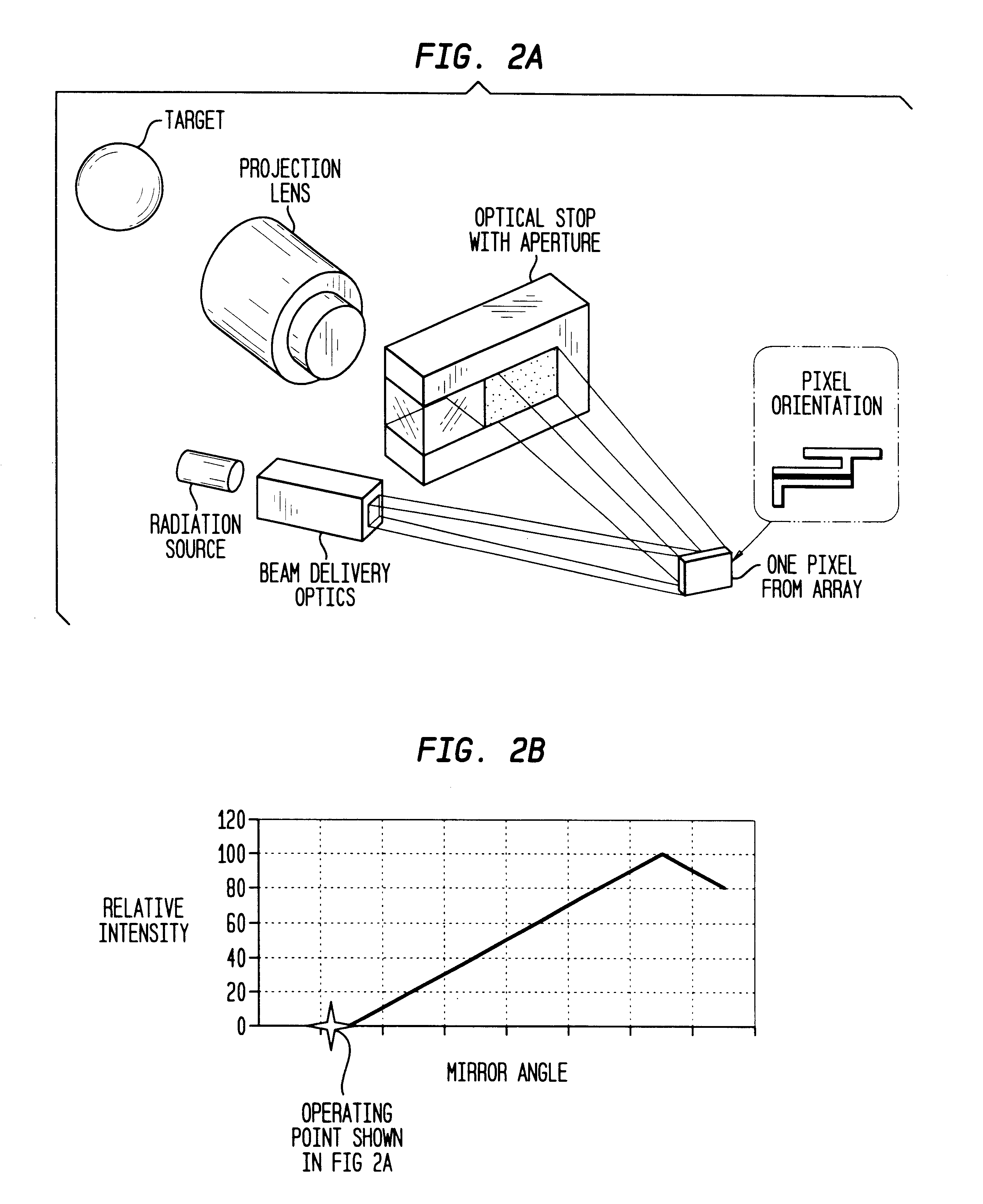

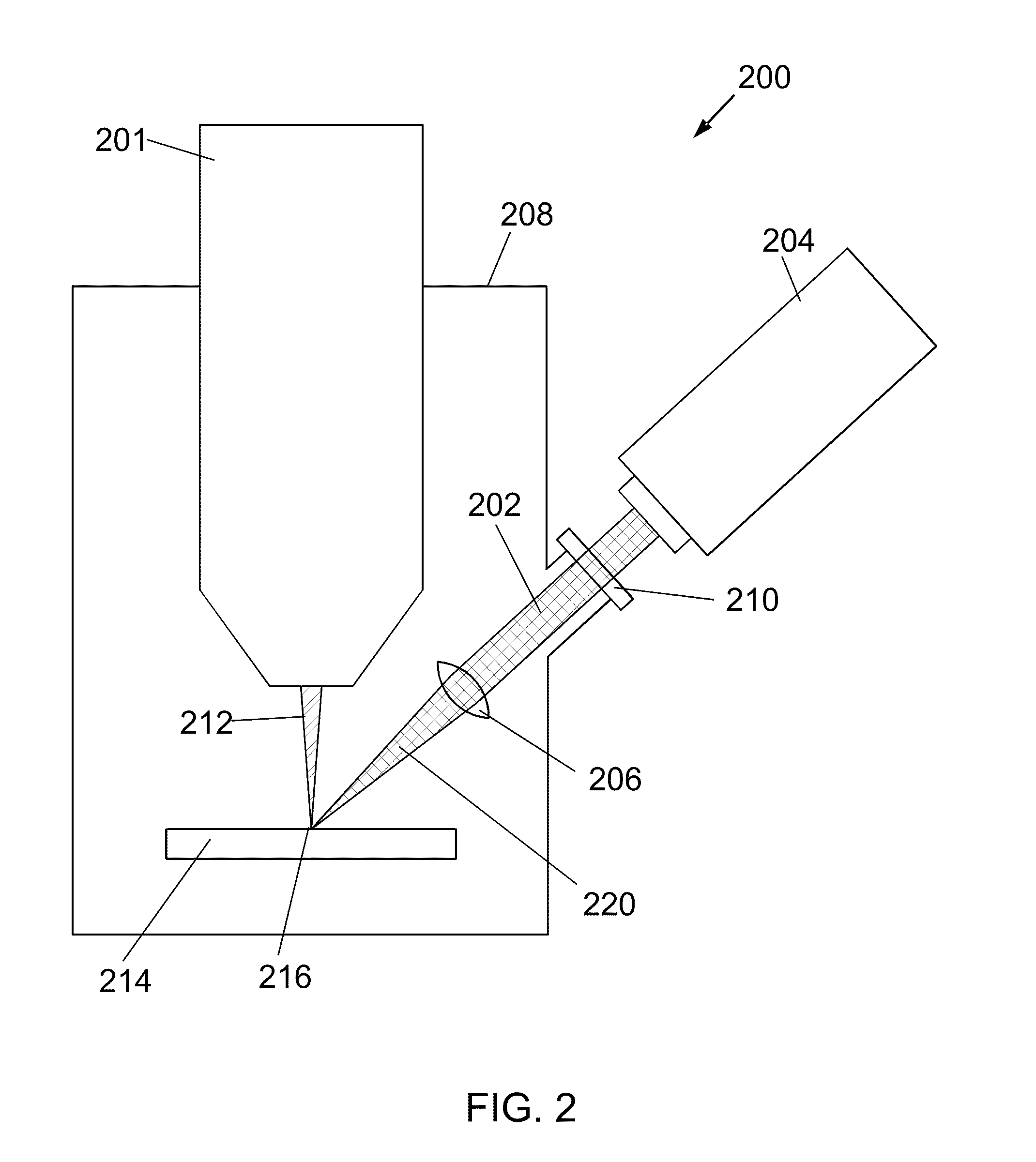

Maskless laser beam patterning ablation of multilayered structures with continuous monitoring of ablation

A maskless patterning apparatus allows for laser beam ablation of one or more layers of material while not etching an underlying different material layer. A micromirror array produces the desired complex pattern on the workpiece and a continuous feature and end point detection system provides location and material parameter changes to accurately control the pattern position and depth of etching. End point detection includes monitoring energy reflected from a specially prepared replica of the material to be ablated, whose thickness and consistency match the active workpiece area. The process terminates when the proper amount of material is removed.

Owner:WESTAR PHOTONICS

Methods and apparatus for end-point detection

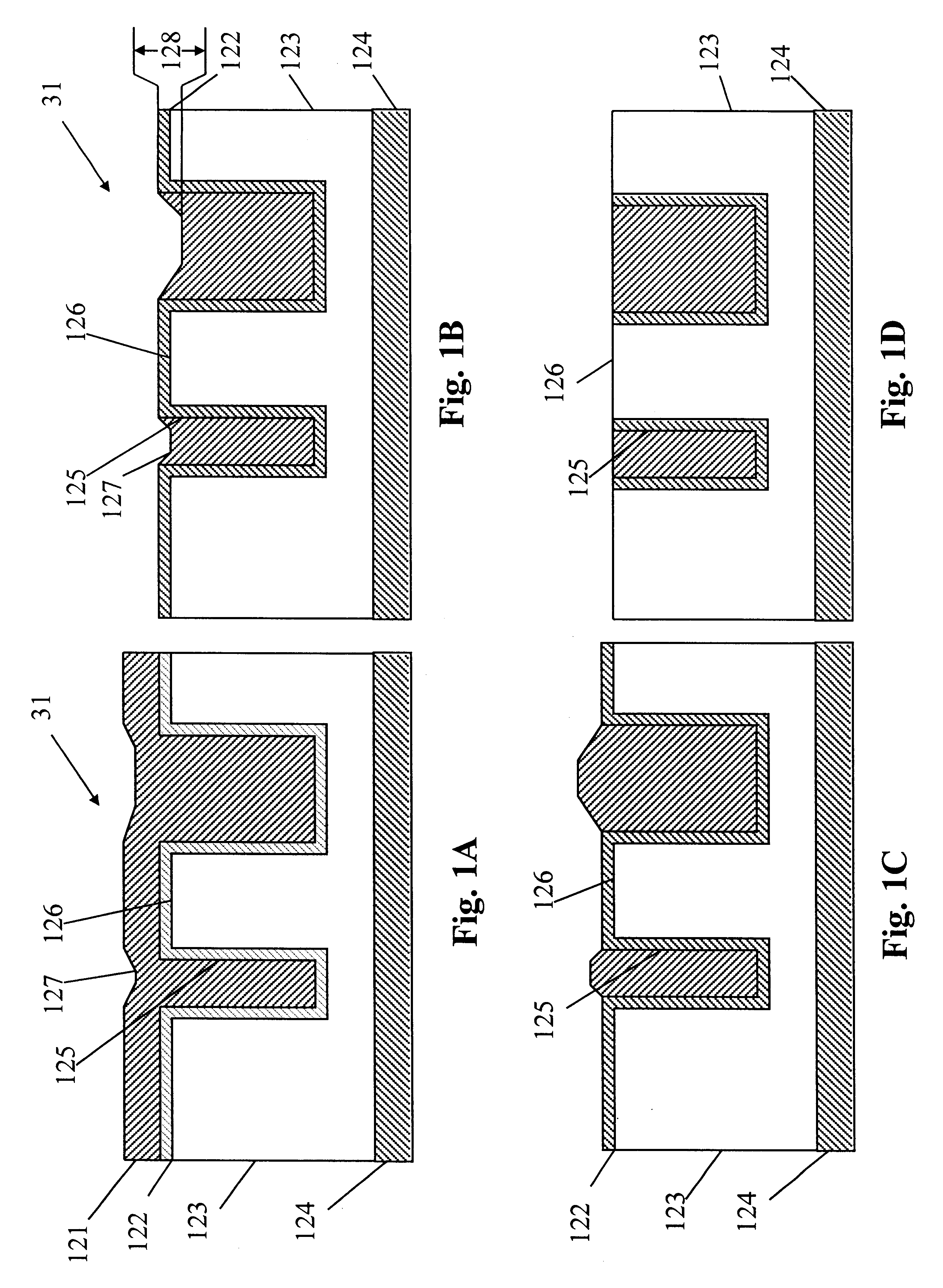

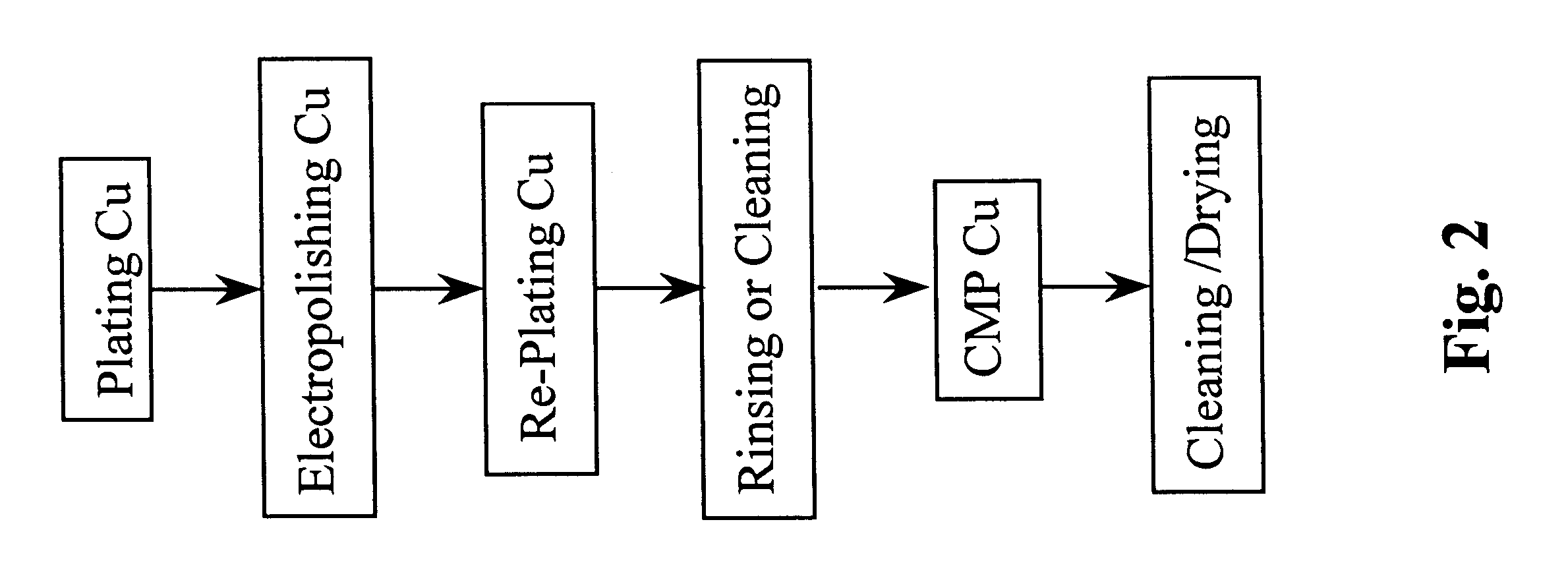

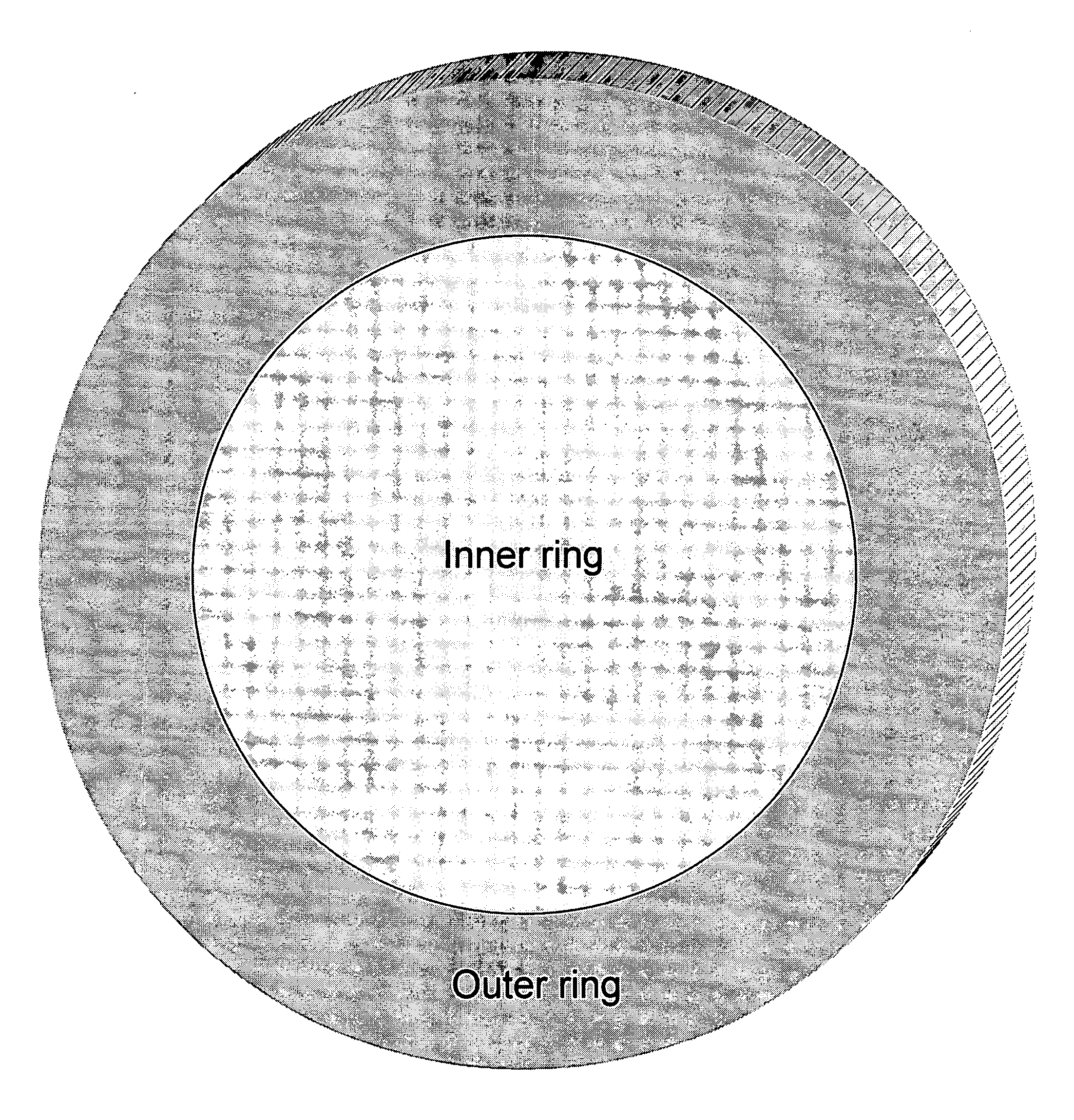

An apparatus for detecting the end-point of an electropolishing process of a metal layer formed on a wafer includes an end-point detector. The end-point detector is disposed adjacent the nozzle used to electropolish the wafer. In one embodiment, the end-point detector is configured to measure the optical reflectivity of the portion of the wafer being electropolished.

Owner:ACM RES

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

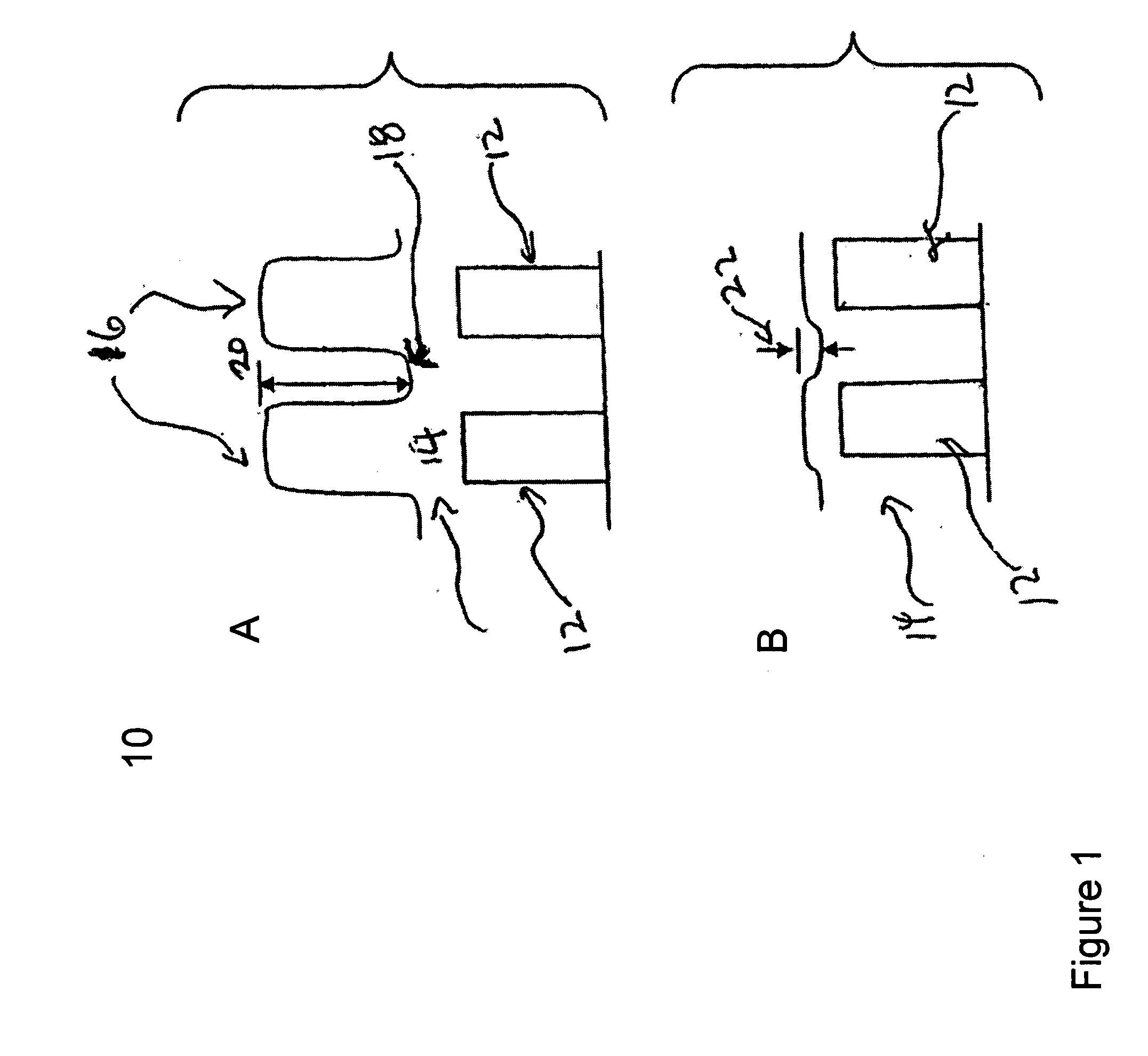

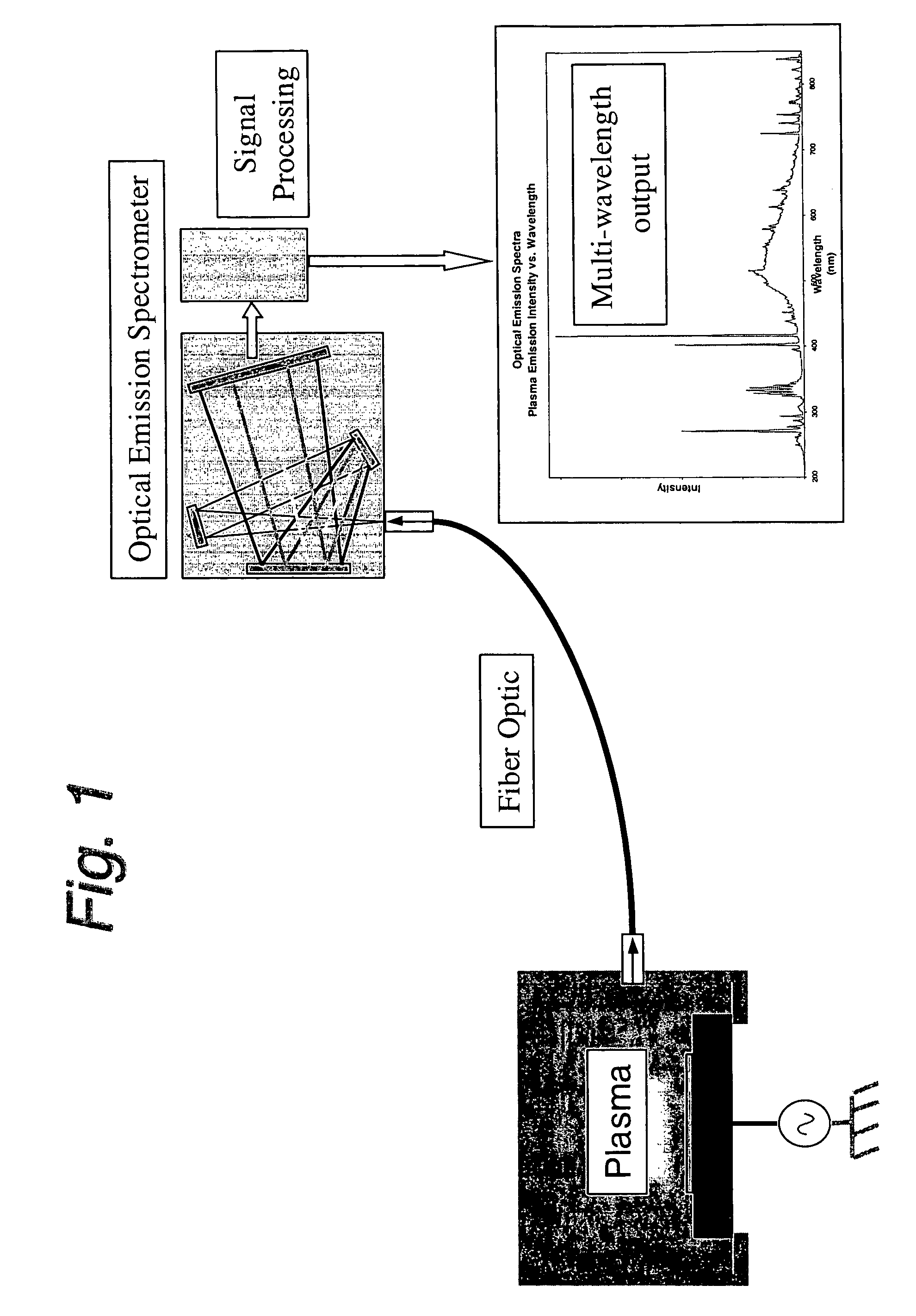

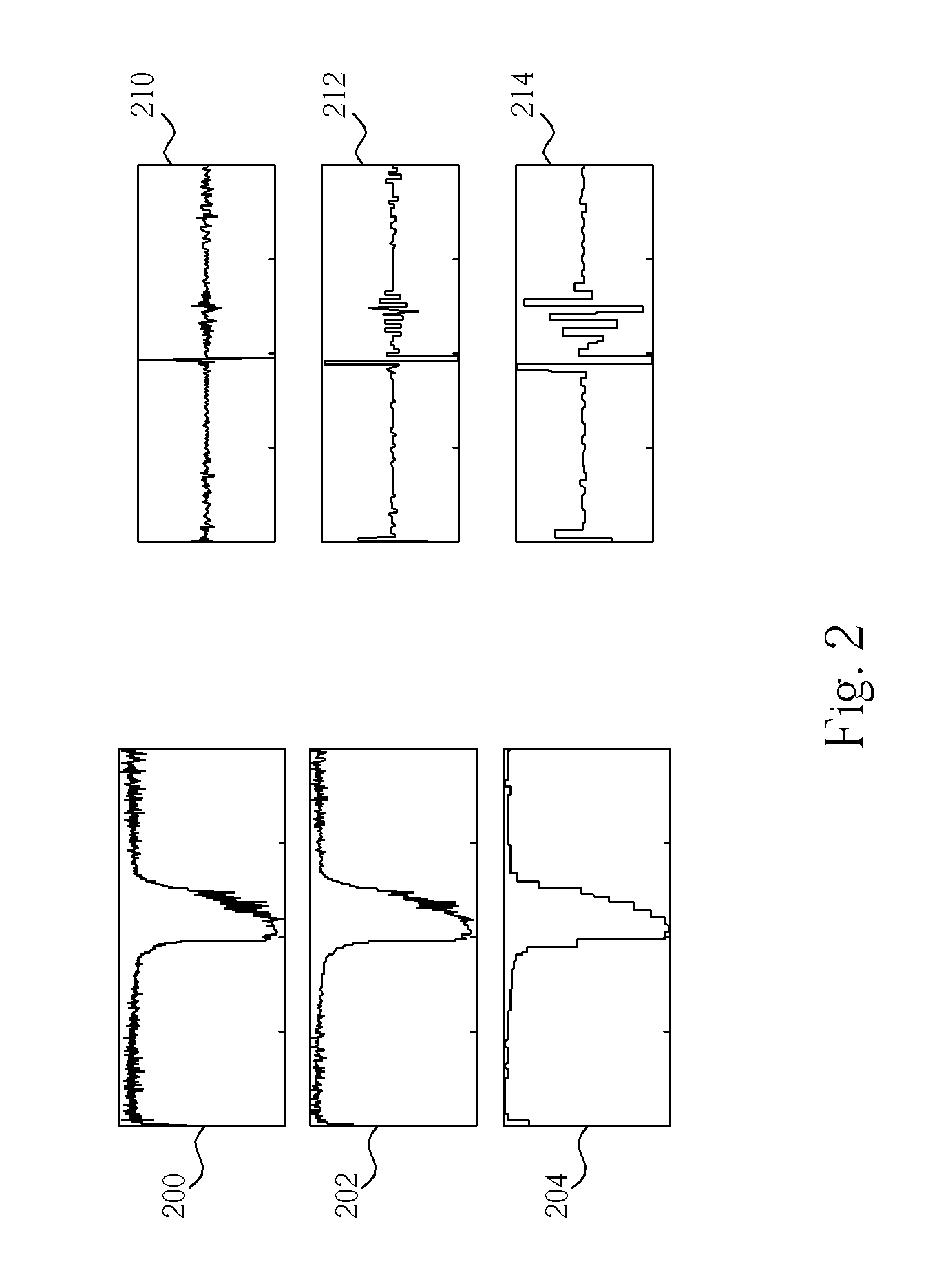

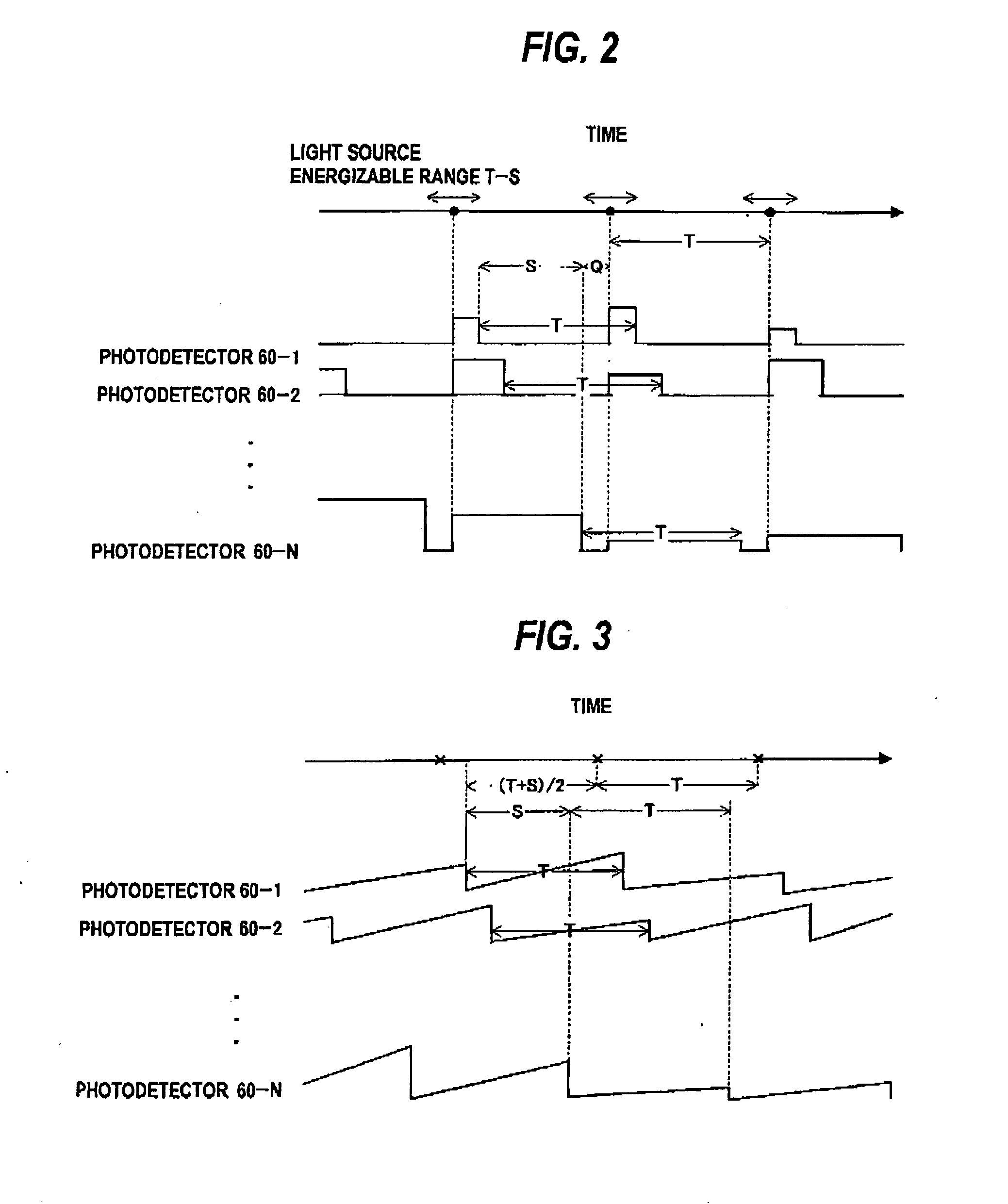

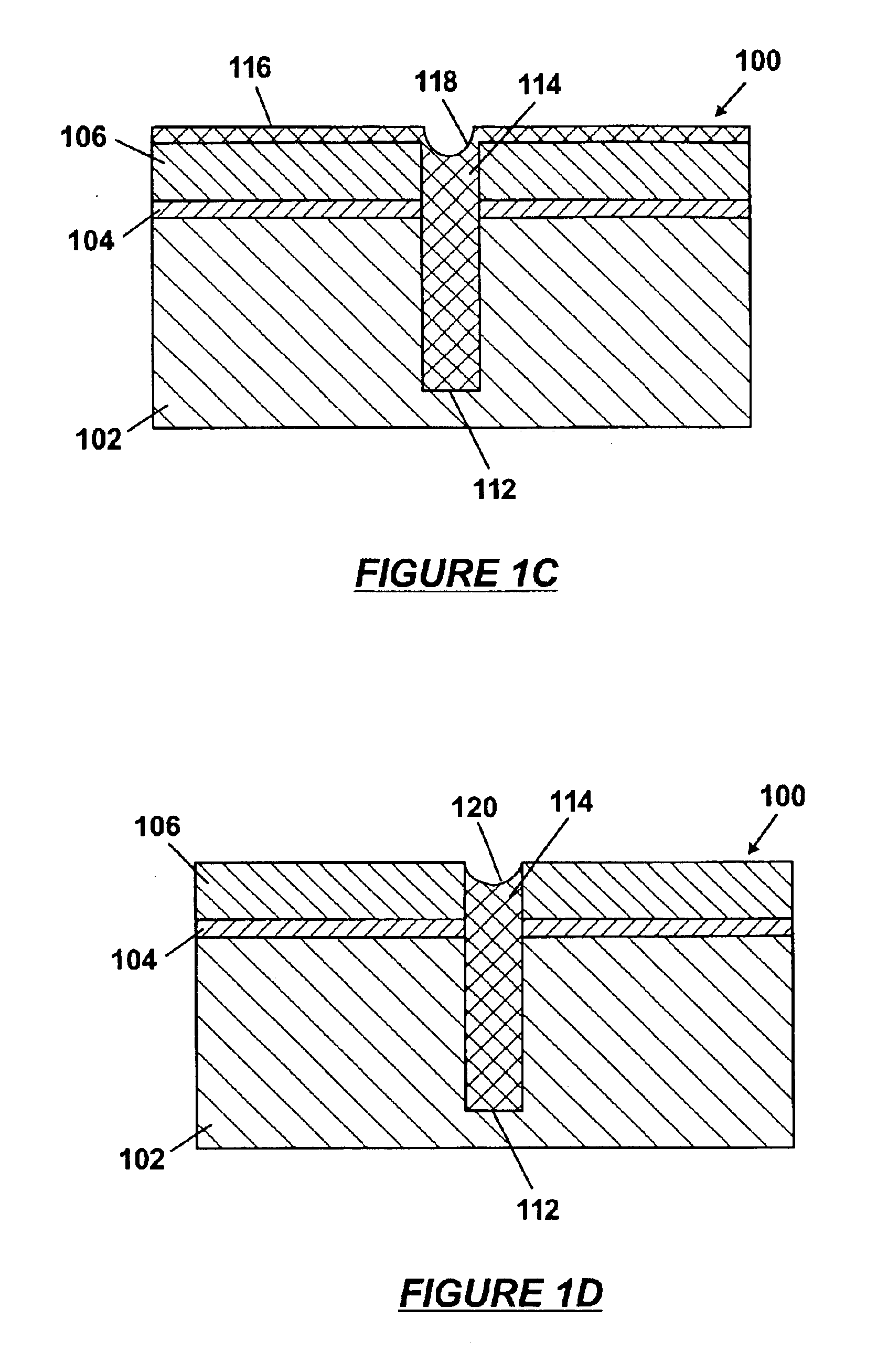

Envelope follower end point detection in time division multiplexed processes

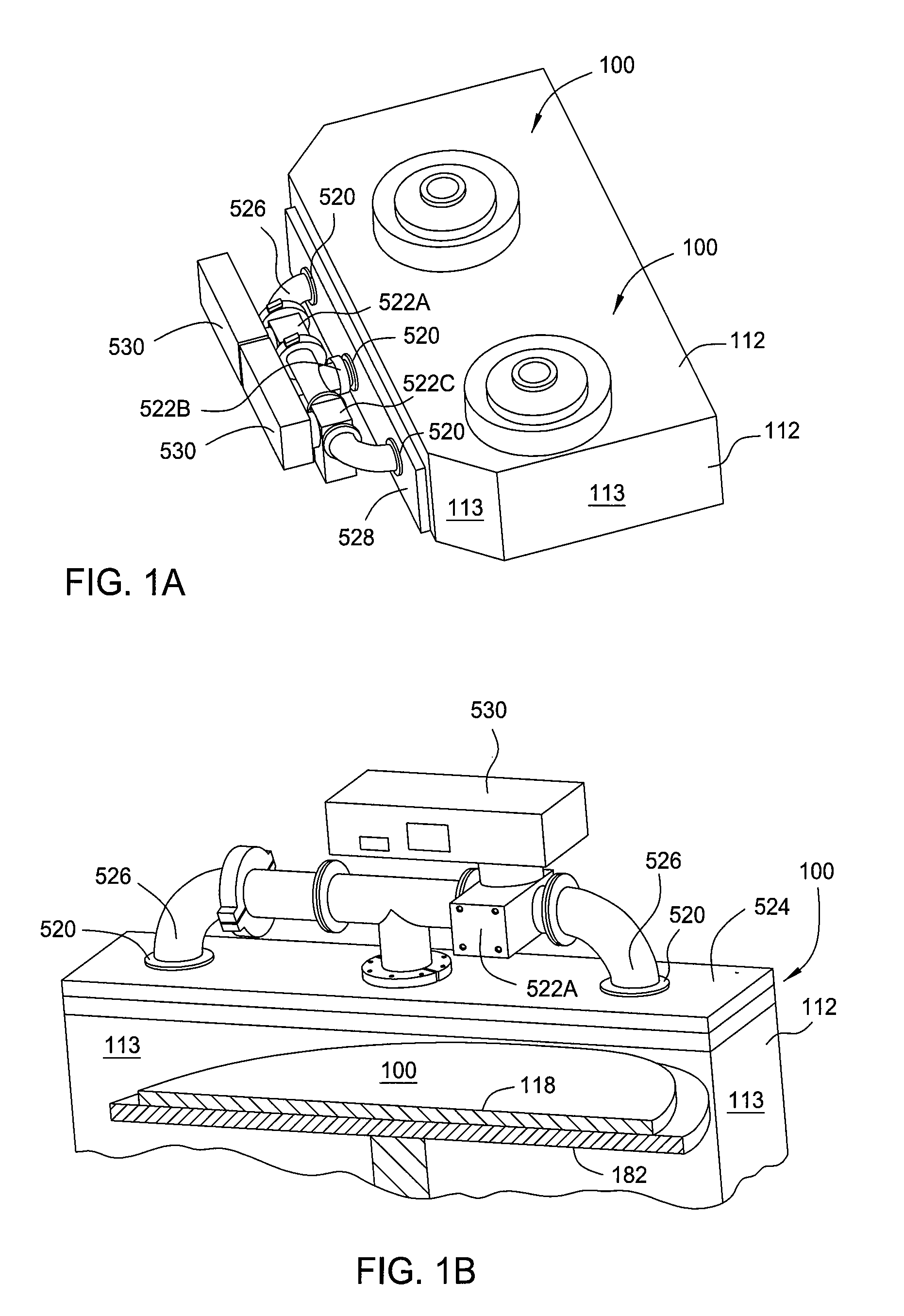

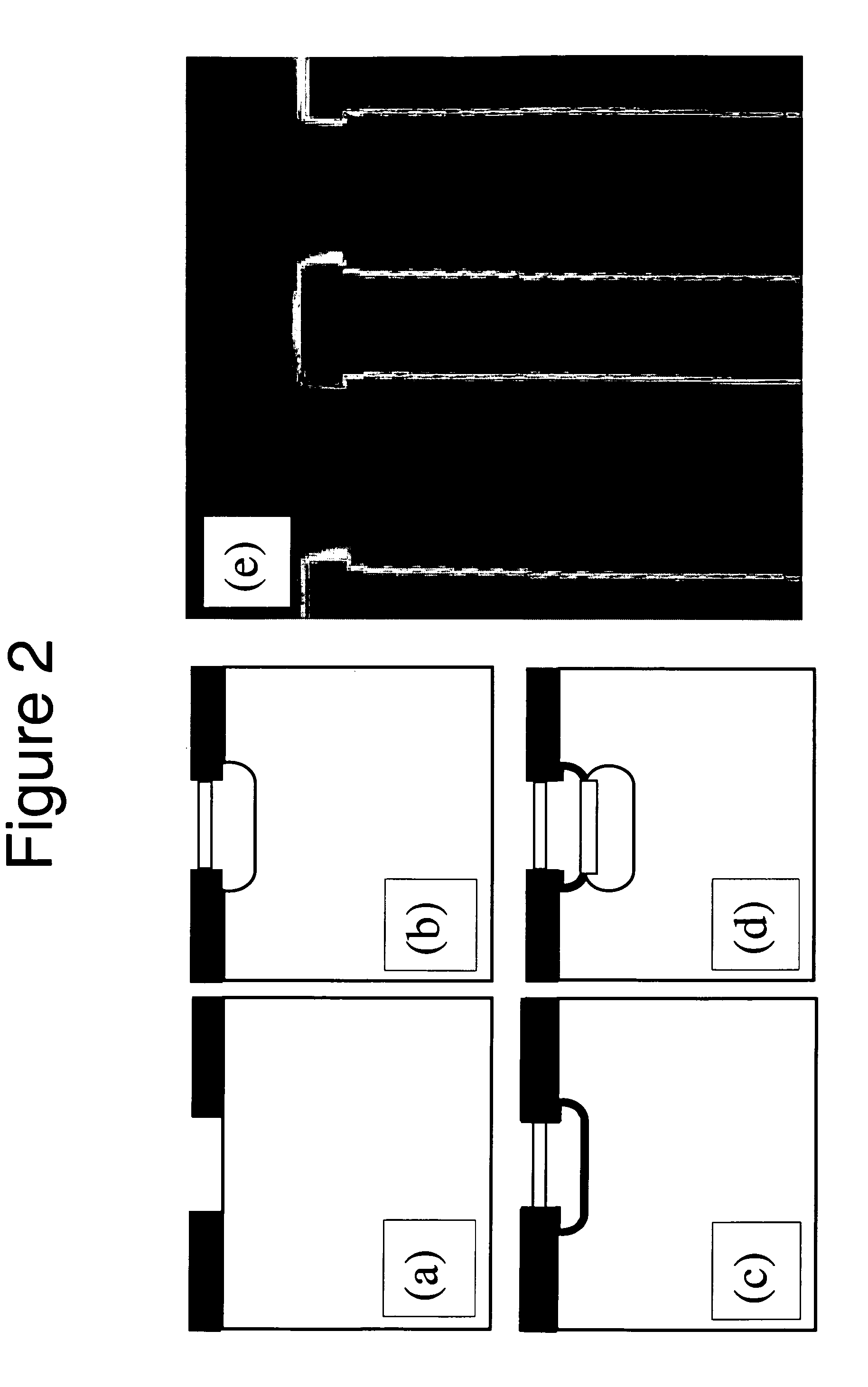

ActiveUS7101805B2Semiconductor/solid-state device testing/measurementElectric discharge tubesOptical emission spectrometryPlasma chamber

The present invention provides a method and an apparatus for establishing endpoint during an alternating cyclical etch process or time division multiplexed process. A substrate is placed within a plasma chamber and subjected to an alternating cyclical process having an etching step and a deposition step. A variation in plasma emission intensity is monitored using known optical emission spectrometry techniques. An amplitude information is extracted from a complex waveform of the plasma emission intensity using an envelope follower algorithm. The alternating cyclical process is discontinued when endpoint is reached at a time that is based on the monitoring step.

Owner:PLASMA THERM

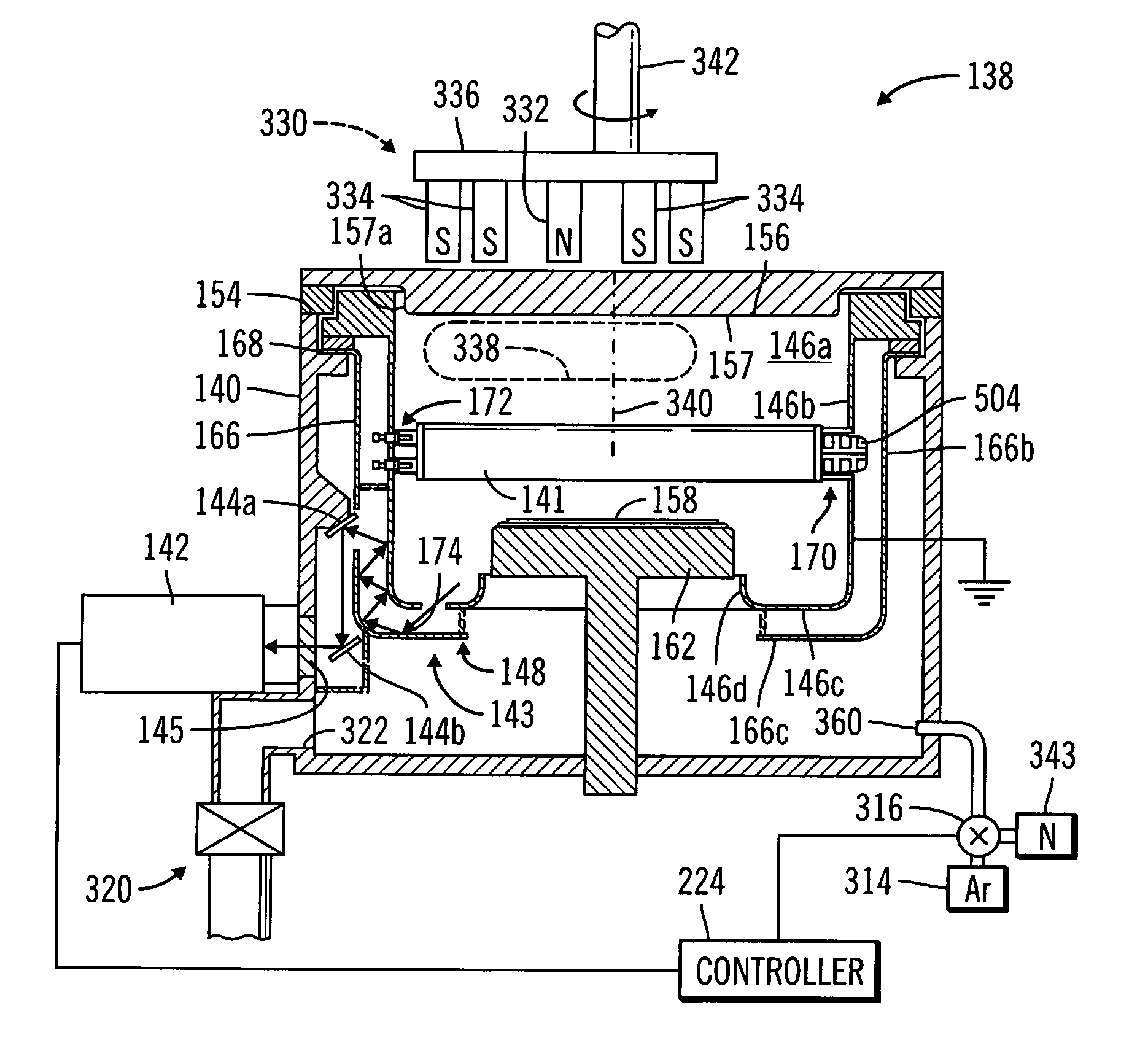

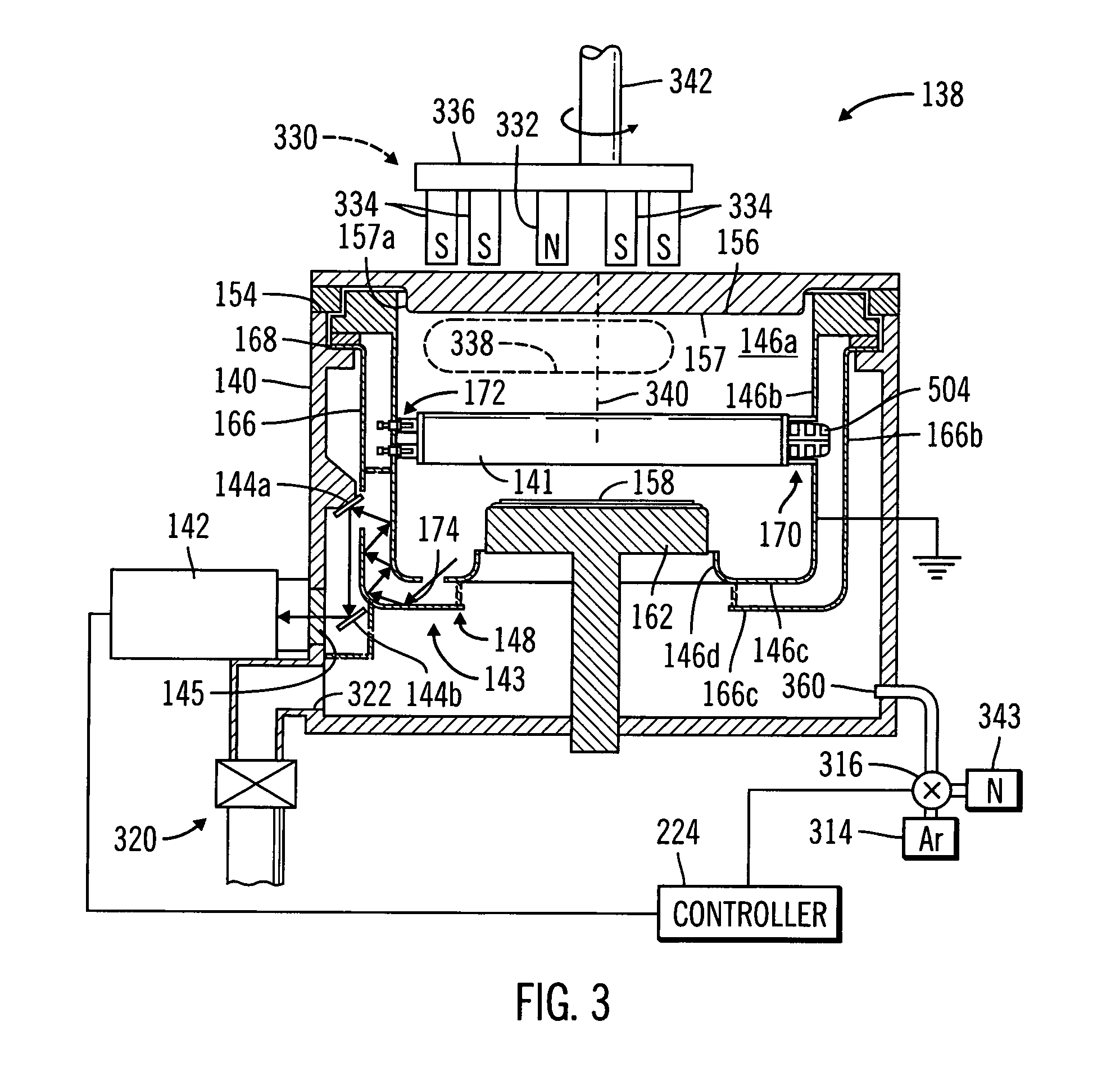

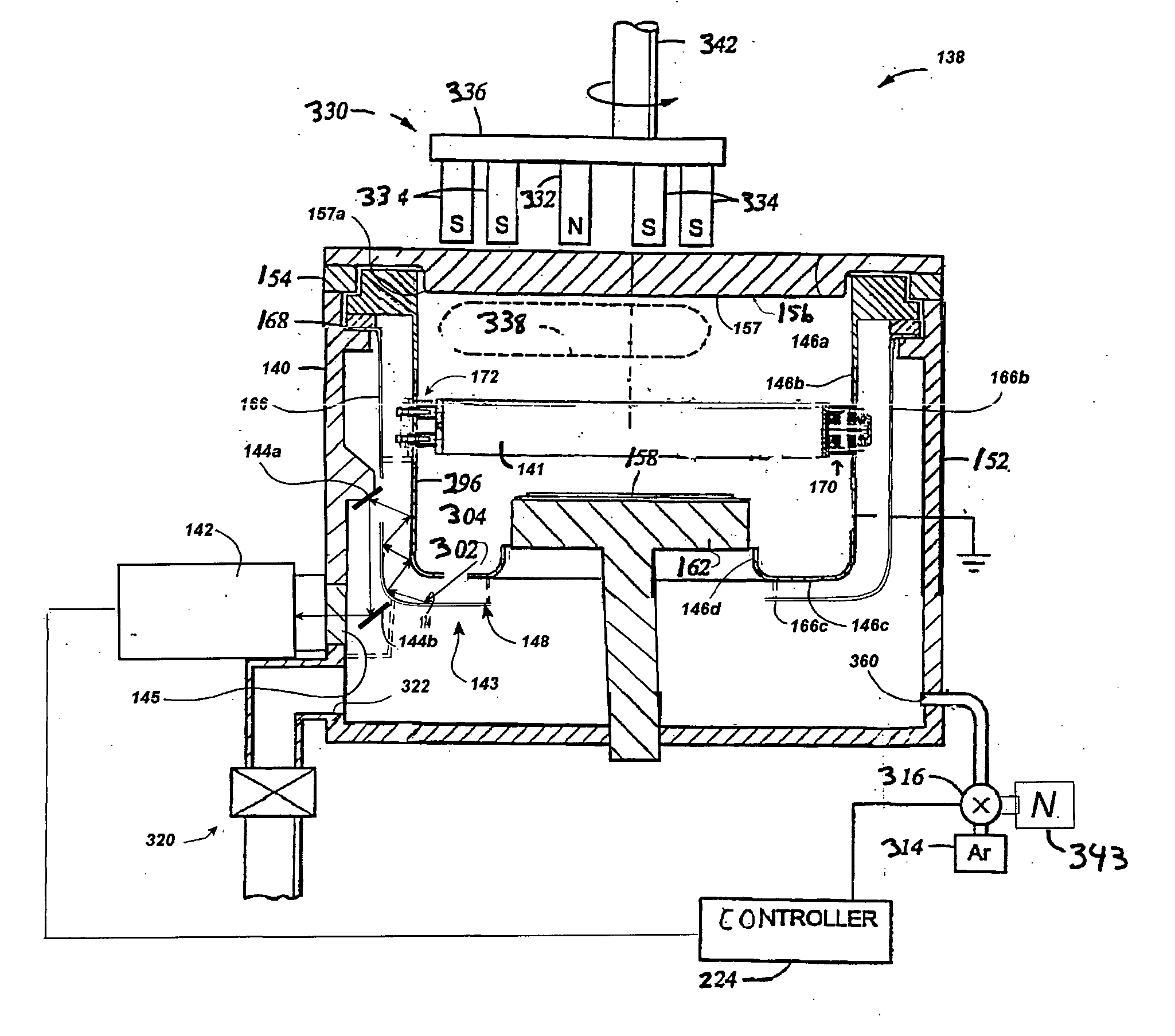

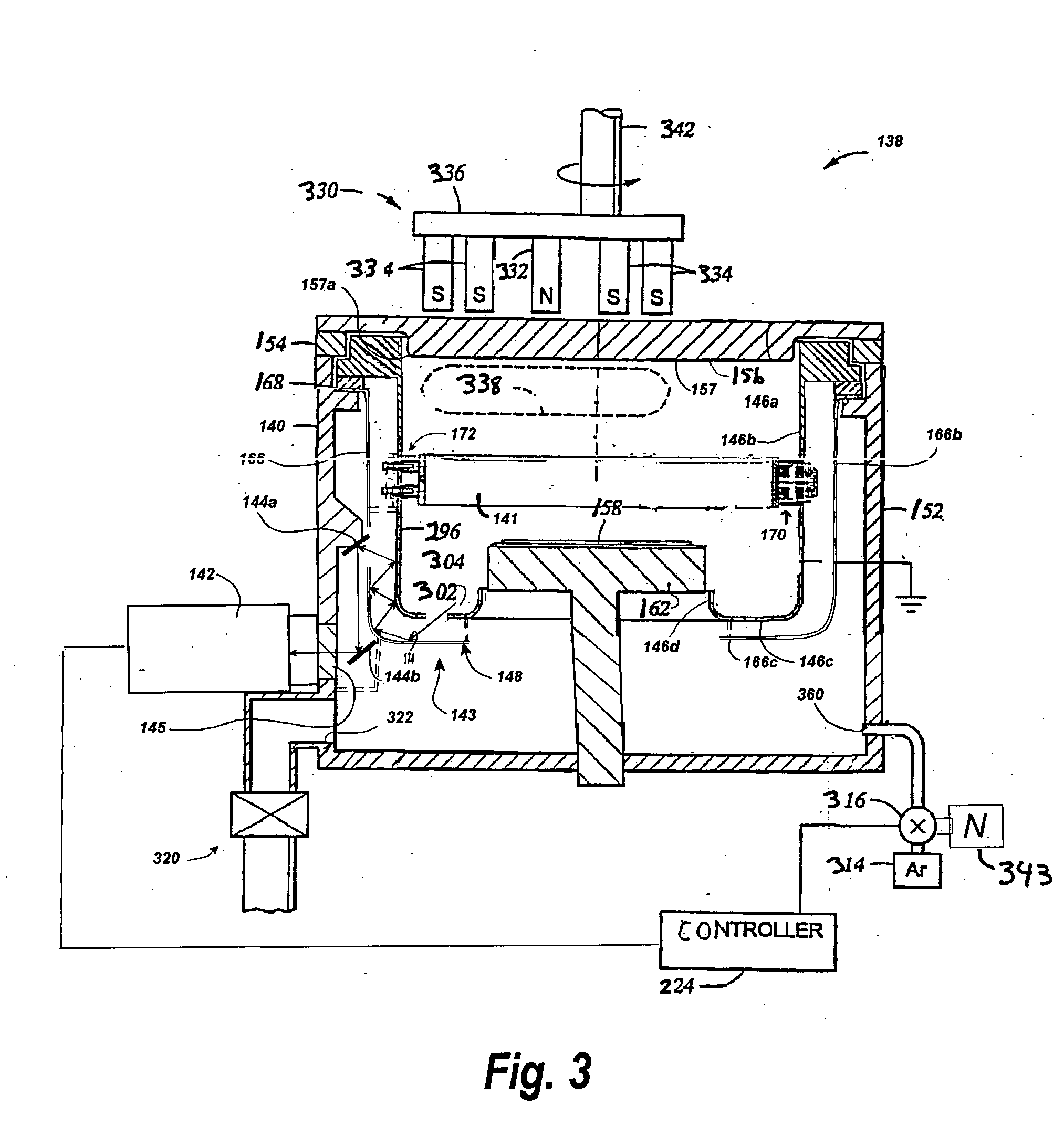

End point detection for sputtering and resputtering

InactiveUS7048837B2Avoid depositionRaise the ratioCellsSemiconductor/solid-state device testing/measurementReactor systemElectrical conductor

Plasma etching or resputtering of a layer of sputtered materials including opaque metal conductor materials may be controlled in a sputter reactor system. In one embodiment, resputtering of a sputter deposited layer is performed after material has been sputtered deposited and while additional material is being sputter deposited onto a substrate. A path positioned within a chamber of the system directs light or other radiation emitted by the plasma to a chamber window or other optical view-port which is protected by a shield against deposition by the conductor material. In one embodiment, the radiation path is folded to reflect plasma light around the chamber shield and through the window to a detector positioned outside the chamber window. Although deposition material may be deposited onto portions of the folded radiation path, in many applications, the deposition material will be sufficiently reflective to permit the emission spectra to be detected by a spectrometer or other suitable detector without significant signal loss. The etching or resputtering may be terminated when the detector detects that an underlying layer has been reached or when some other suitable process point has been reached.

Owner:APPLIED MATERIALS INC

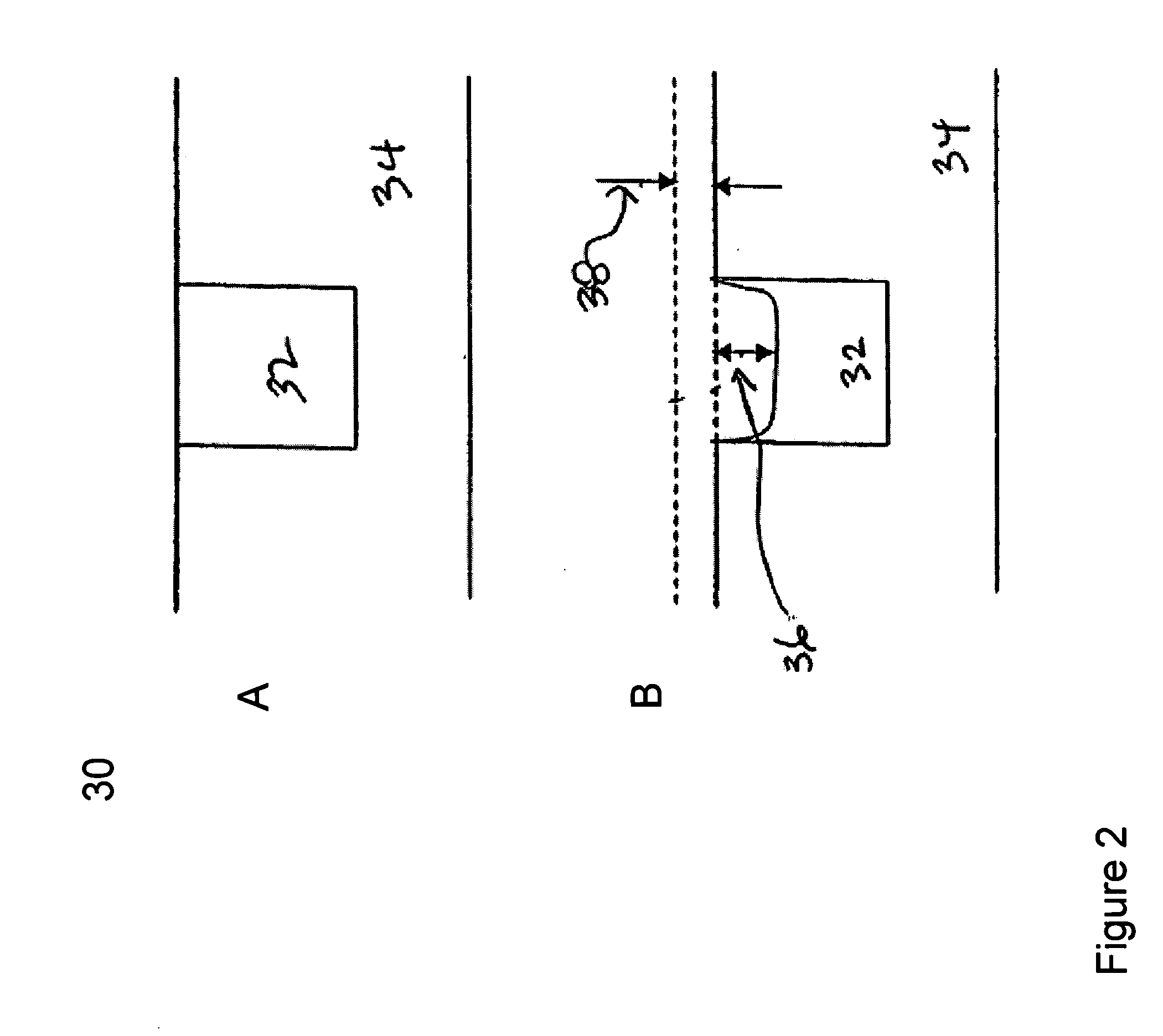

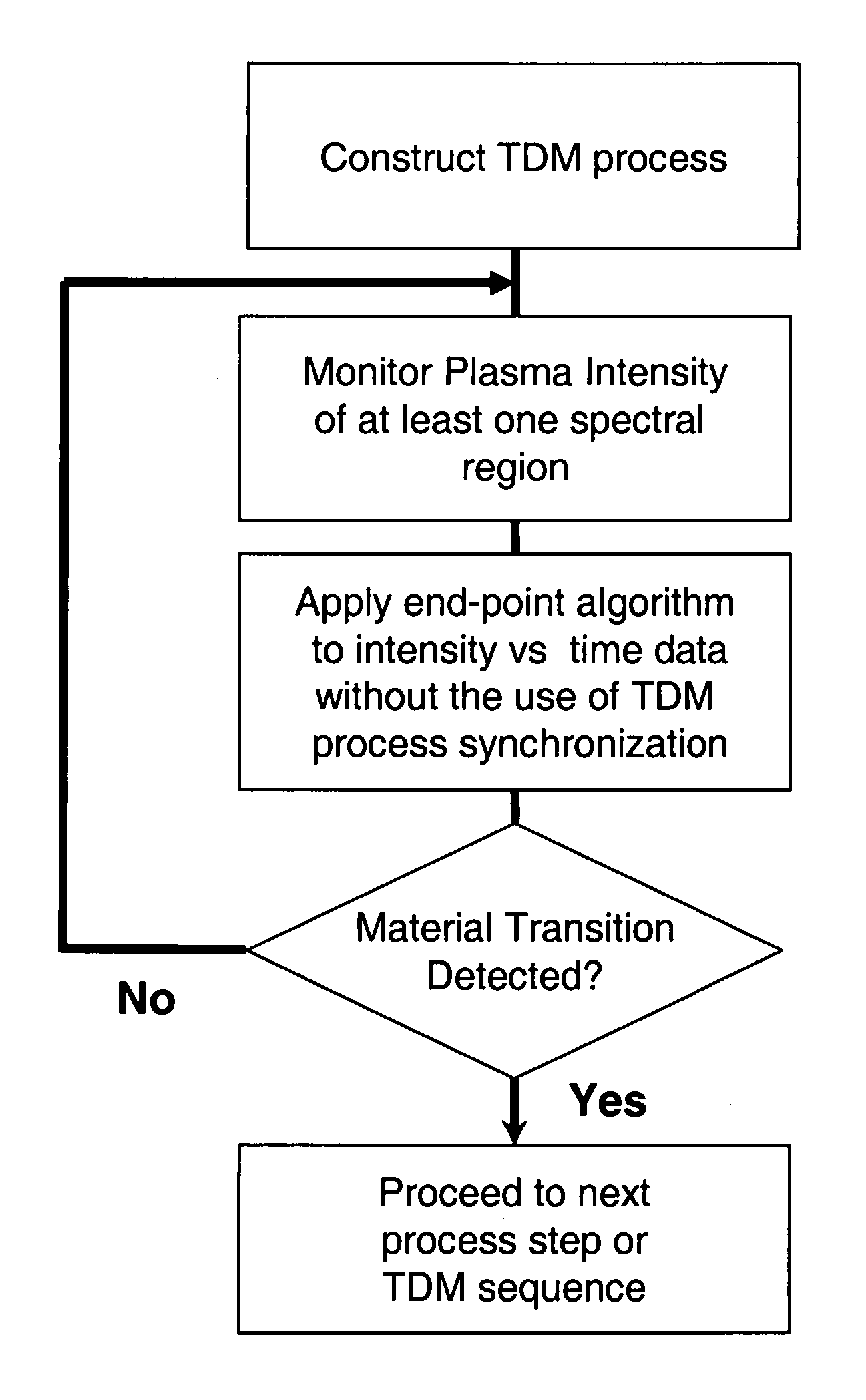

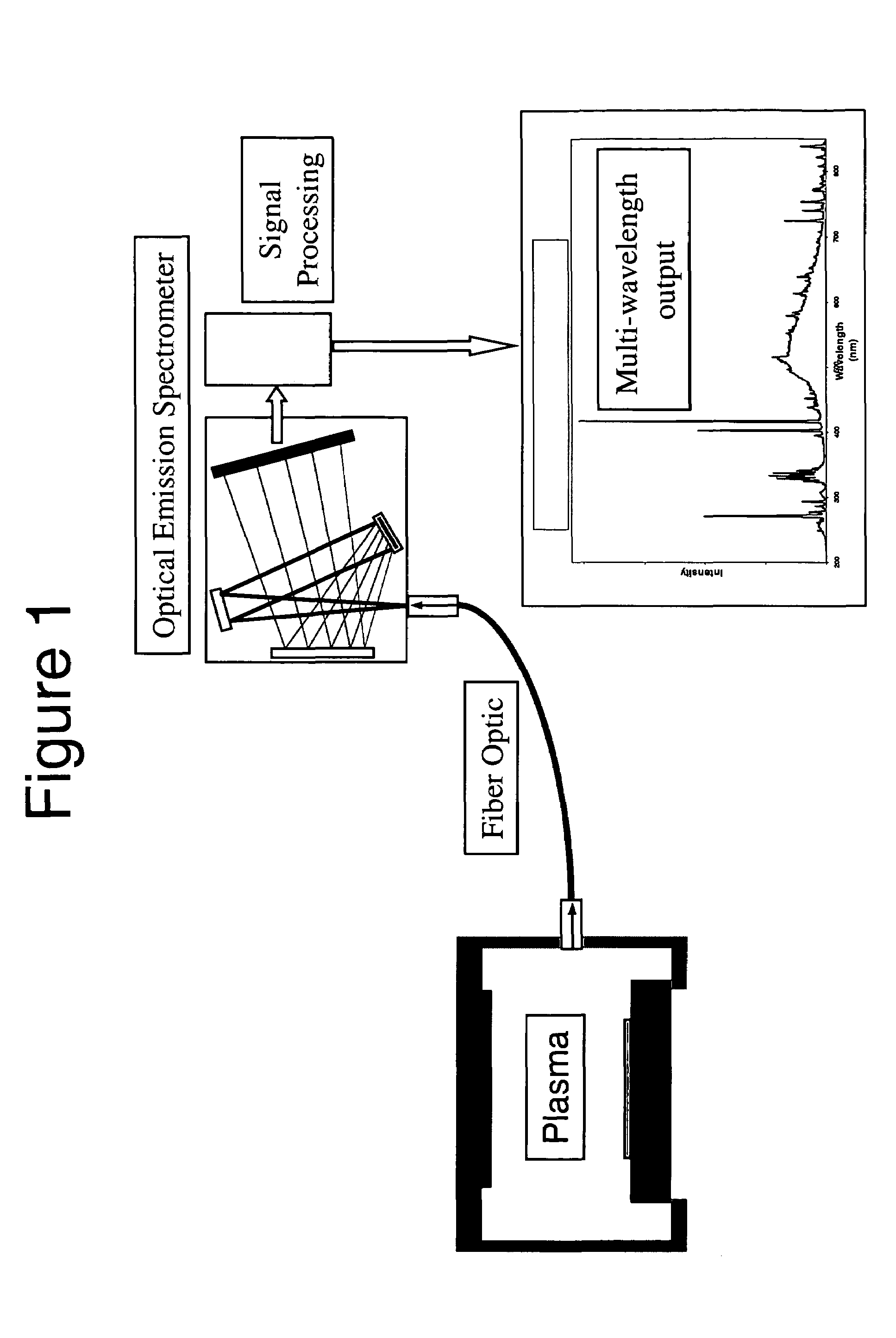

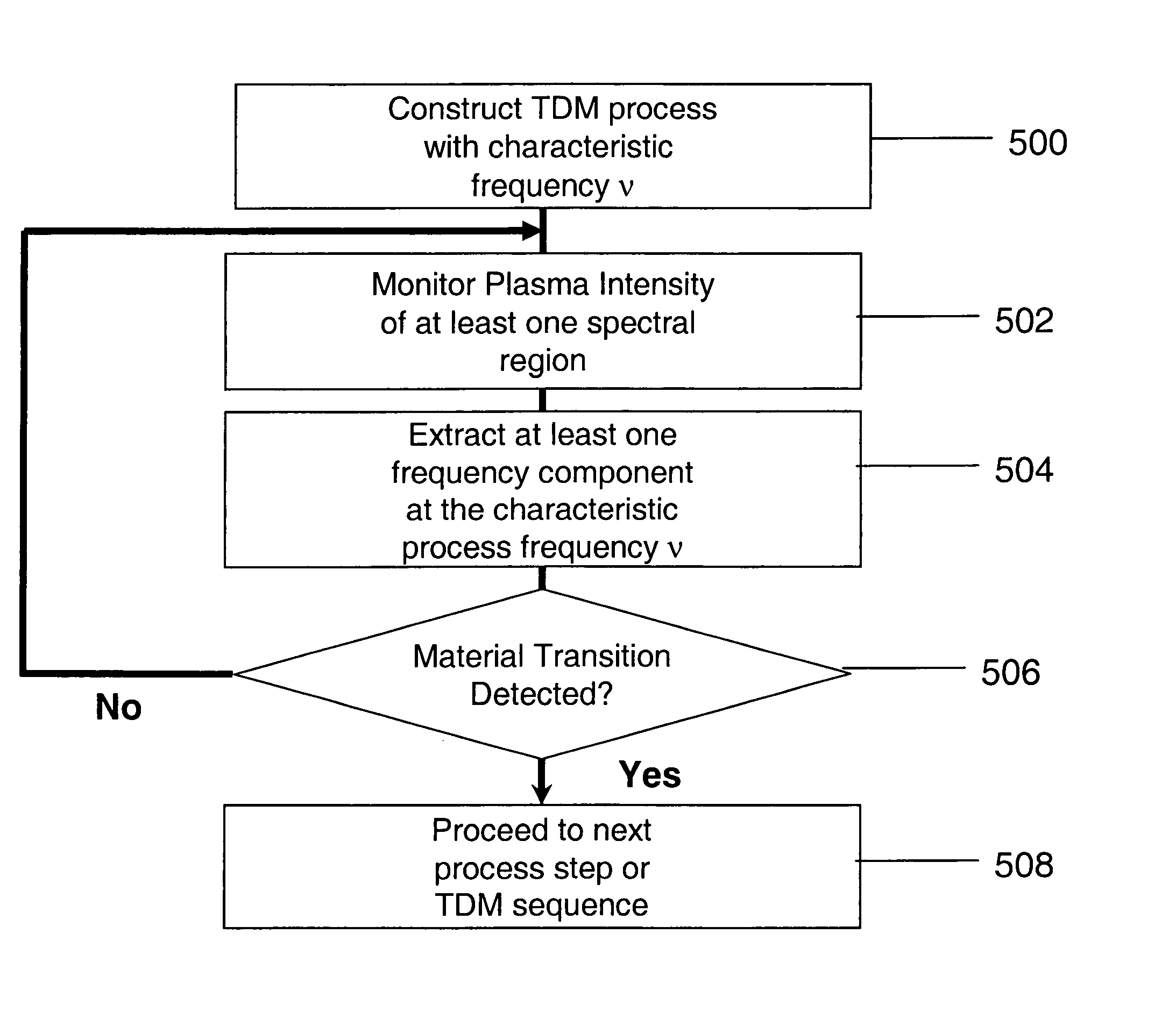

End point detection in time division multiplexed etch processes

ActiveUS6982175B2Material removalSemiconductor/solid-state device testing/measurementElectric discharge tubesSpectral emissionFrequency spectrum

An improved method for determining endpoint of a time division multiplexed process by monitoring an identified region of a spectral emission of the process at a characteristic process frequency. The region is identified based upon the expected emission spectra of materials used during the time division multiplexed process. The characteristic process frequency is determined based upon the duration of the steps in the time division multiplexed process. Changes in the magnitude of the monitored spectra indicate the endpoint of processes in the time division multiplexed process and transitions between layers of materials.

Owner:PLASMA THERM

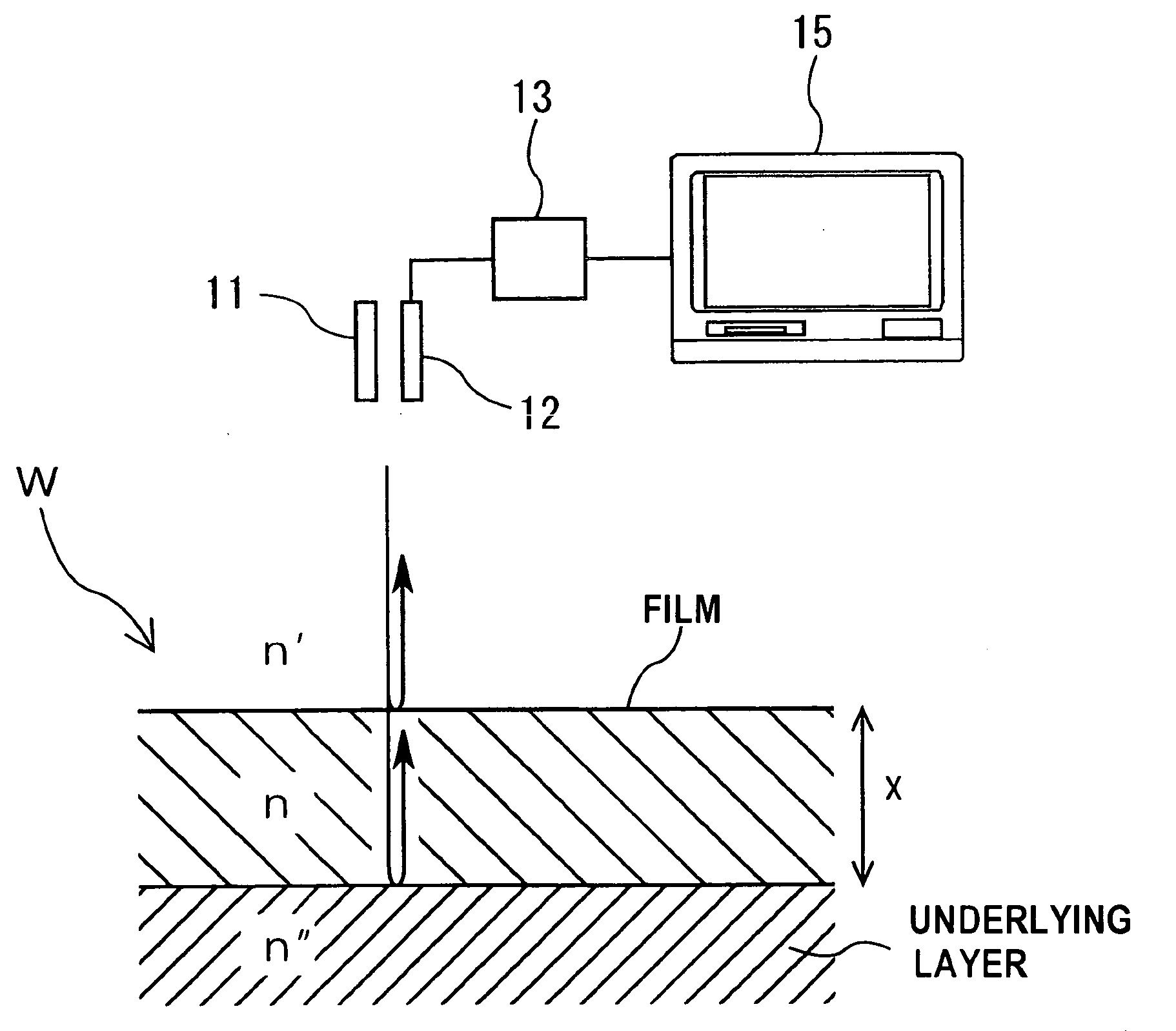

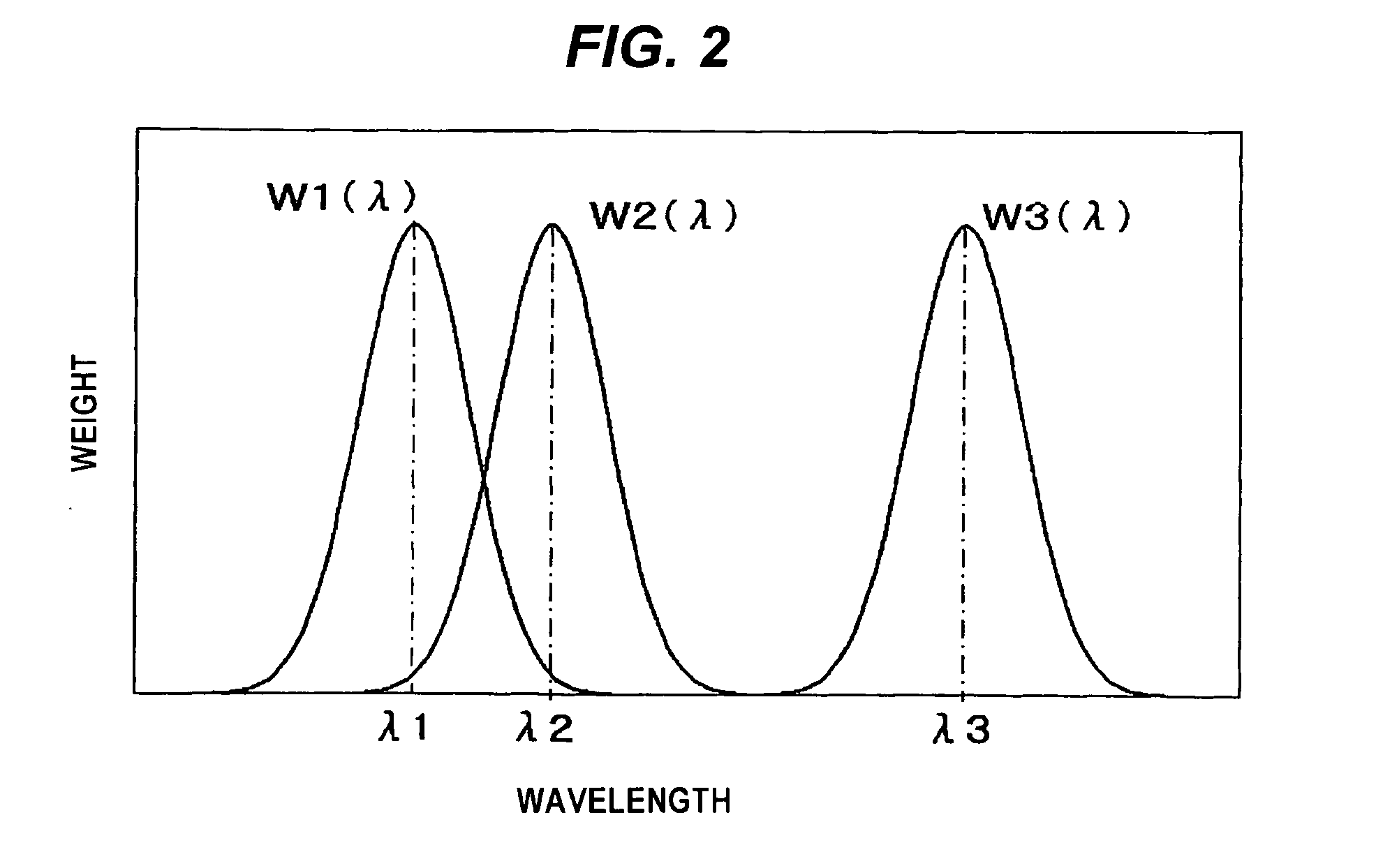

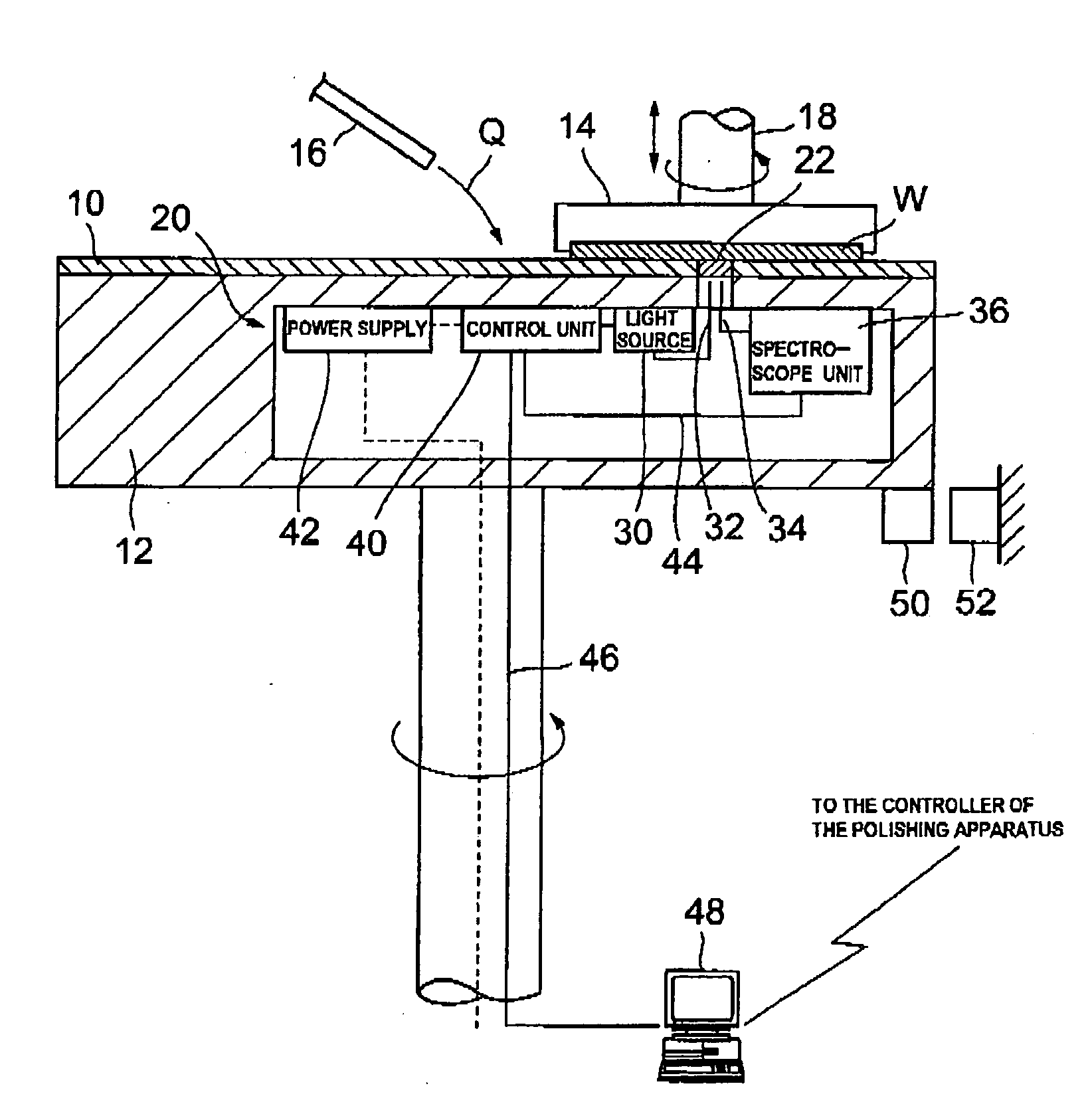

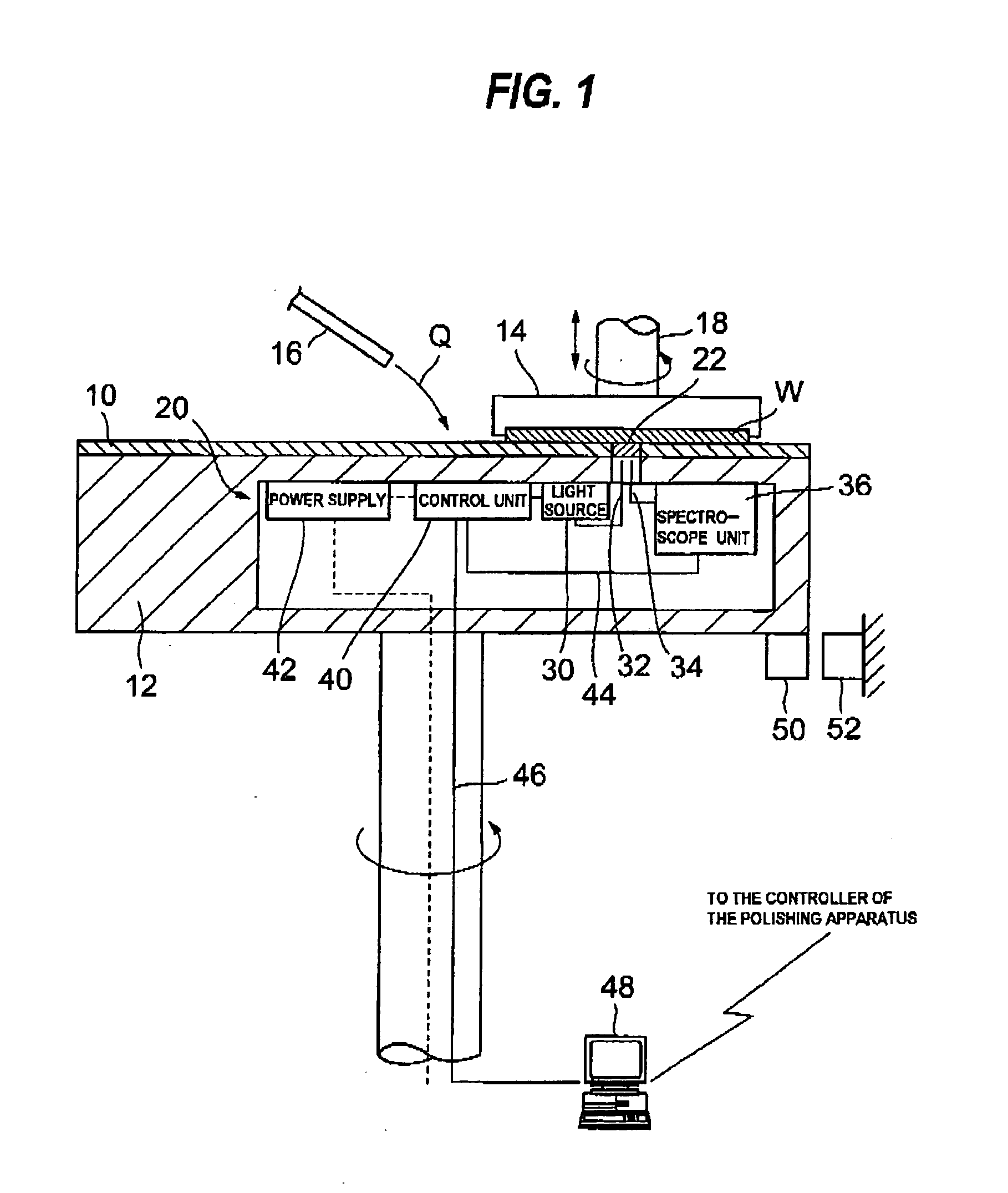

Method of making diagram for use in selection of wavelength of light for polishing endpoint detection, method and apparatus for selecting wavelength of light for polishing endpoint detection, polishing endpoint detection method, polishing endpoint detection apparatus, and polishing monitoring method

ActiveUS20100093260A1Valid choiceAccurate detectionLapping machinesGrinding feed controlLength waveWavelength

A method of producing a diagram for use in selecting wavelengths of light in optical polishing end point detection is provided. The method includes polishing a surface of a substrate having a film by a polishing pad; applying light to the surface of the substrate and receiving reflected light from the substrate during the polishing of the substrate; calculating relative reflectances of the reflected light at respective wavelengths; determining wavelengths of the reflected light which indicate a local maximum point and a local minimum point of the relative reflectances which vary with a polishing time; identifying a point of time when the wavelengths, indicating the local maximum point and the local minimum point, are determined; and plotting coordinates, specified by the wavelengths and the point of time corresponding to the wavelengths, onto a coordinate system having coordinate axes indicating wavelength of the light and polishing time.

Owner:EBARA CORP

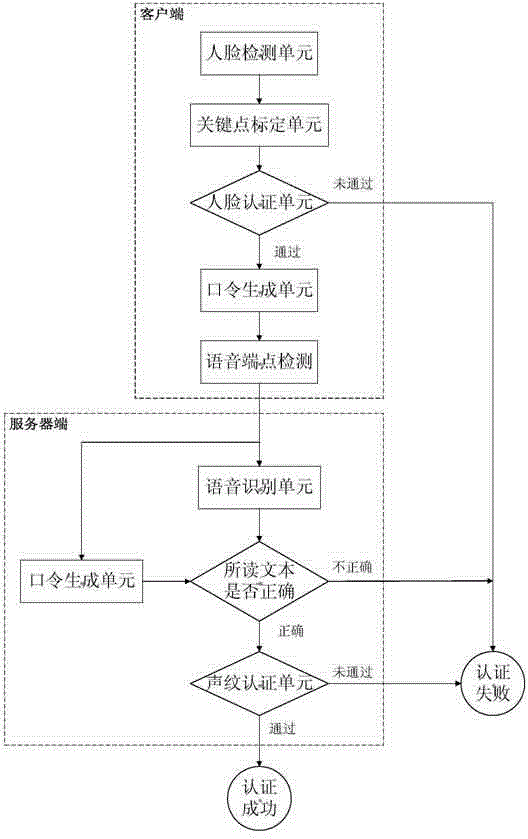

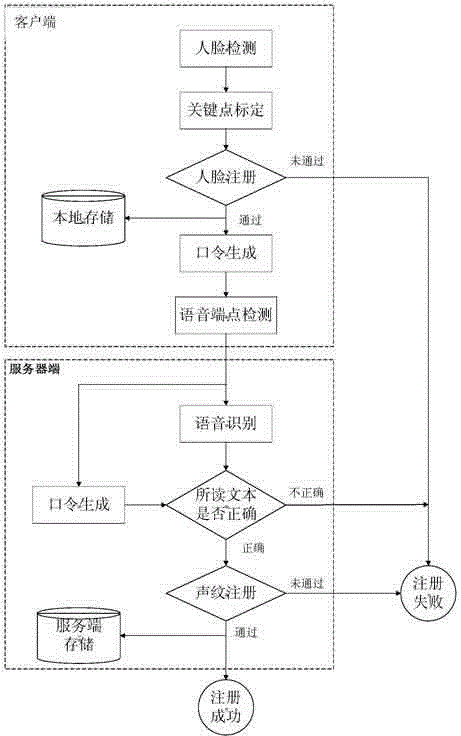

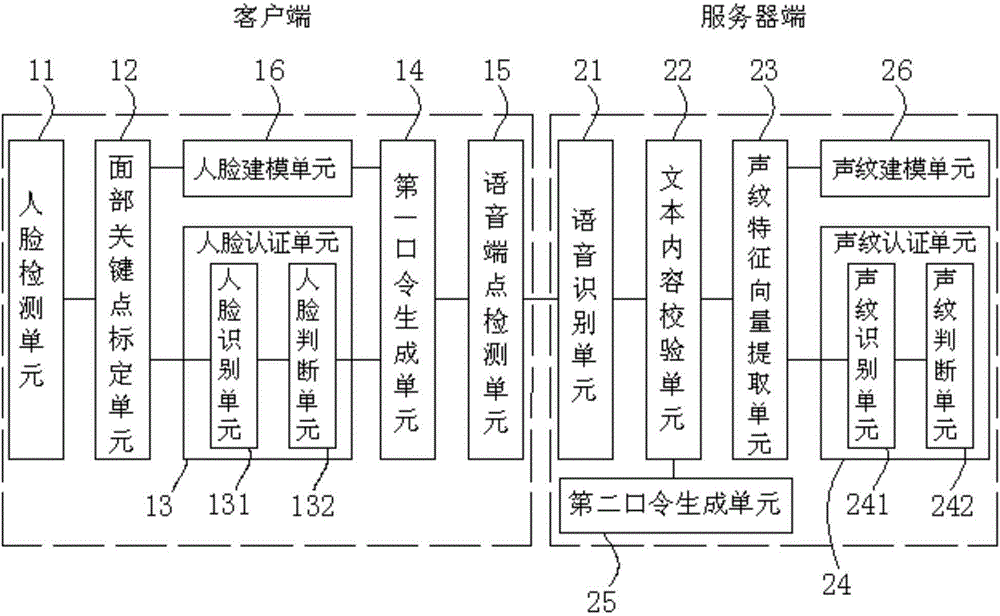

Dual-factor identity authentication method and system based on voiceprint recognition and face recognition

ActiveCN104834849AImprove securityImprove reliabilitySpeech analysisCharacter and pattern recognitionFace detectionUser identifier

Owner:TIMESAFER BEIJING TECH

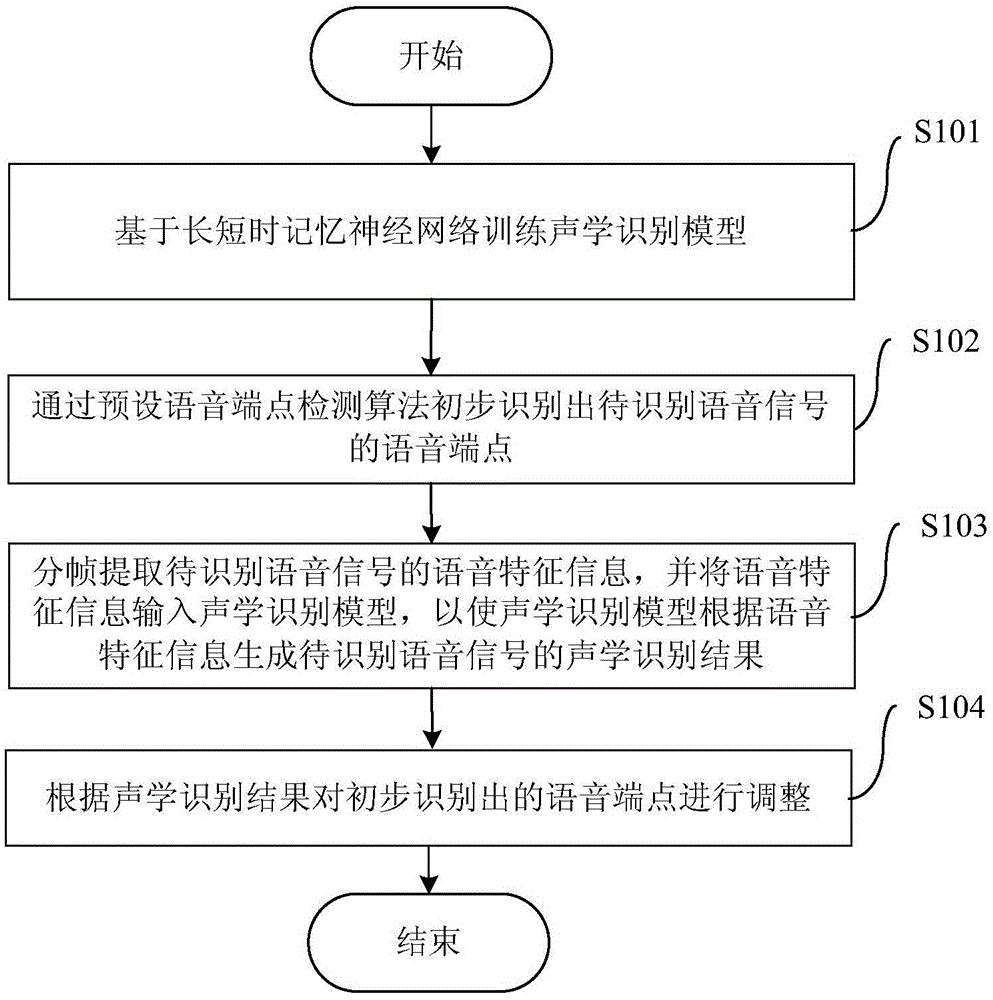

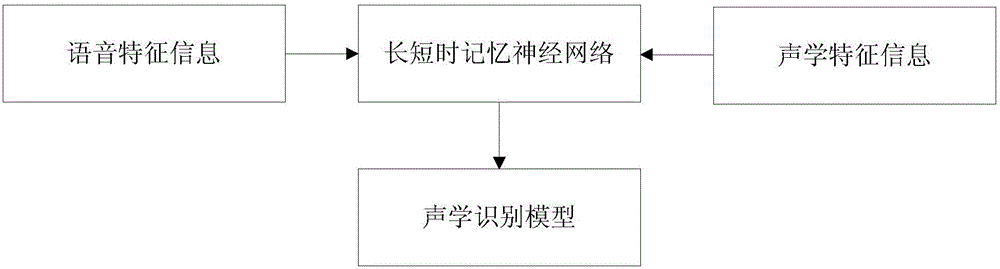

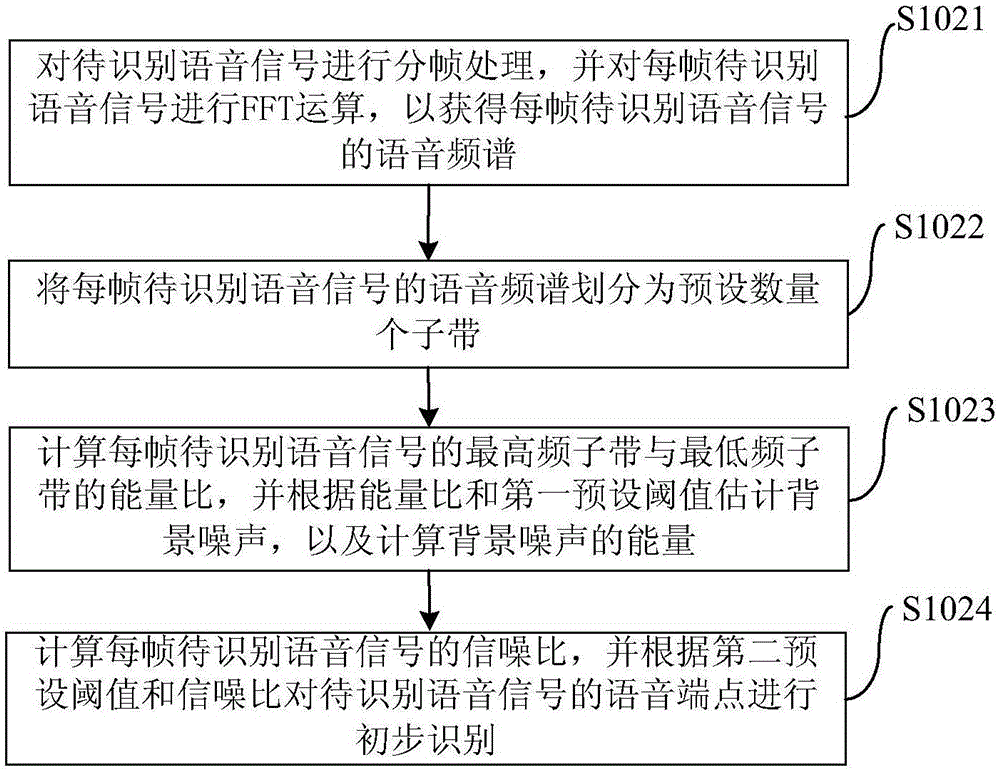

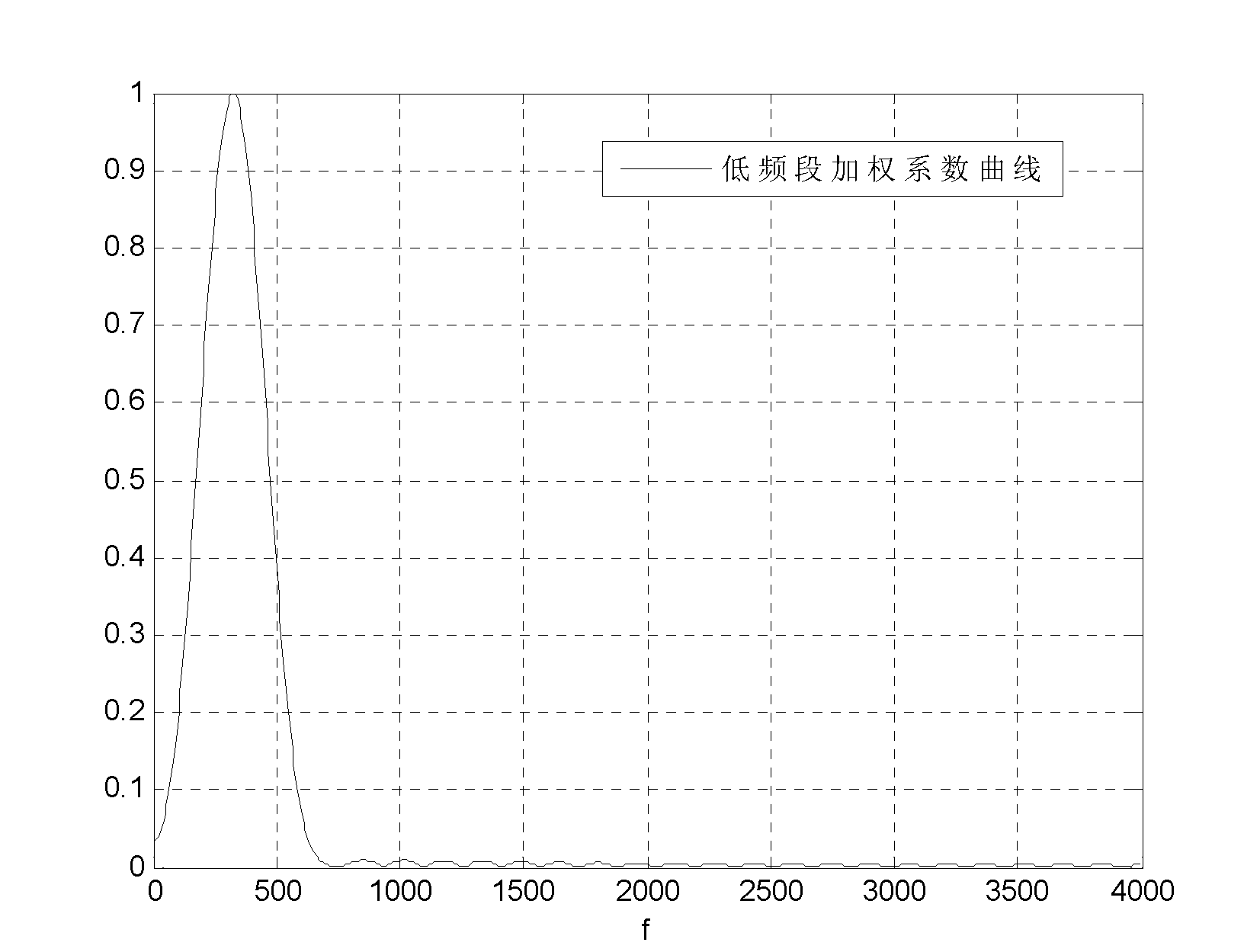

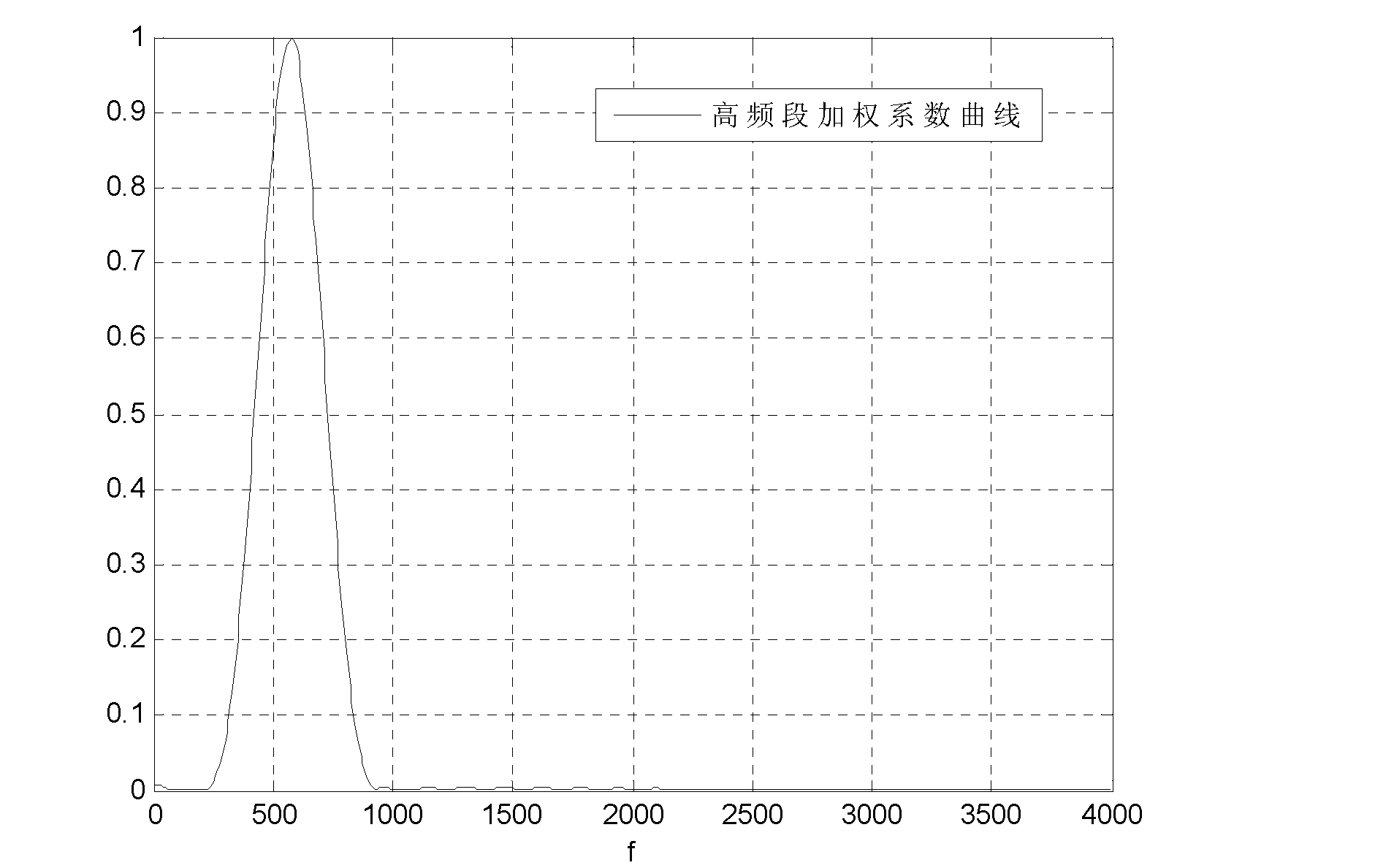

End point detection method and system of voice identification system

ActiveCN105118502AImprove accuracyImprove performanceSpeech recognitionShort-term memorySpeech identification

The present invention provides an end point detection method and system of a voice identification system, wherein the method comprises the steps of training an acoustics identification model based on a long / short term memory neural network; primarily identifying a voice end point of a to-be-identified voice signal by a preset voice end point detection algorithm; extracting the voice characteristic information of the to-be-identified voice signal frame by frame, and inputting the voice characteristic information in the acoustics identification model to enable the acoustics identification model to generate an acoustics identification result of the to-be-identified voice signal according to the voice characteristic information; adjusting the primarily identified voice end point according to the acoustics identification result. The end point detection method of the voice identification system of the embodiment of the present invention provides an end point detection mode of adjusting the primarily identified voice end point by the acoustics identification result, thereby positioning the voice end point of the to-be-identified voice signal accurately, improving the voice end point detection accuracy, and further being able to improve the voice identification accuracy, and improving the performance of the voice identification system.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

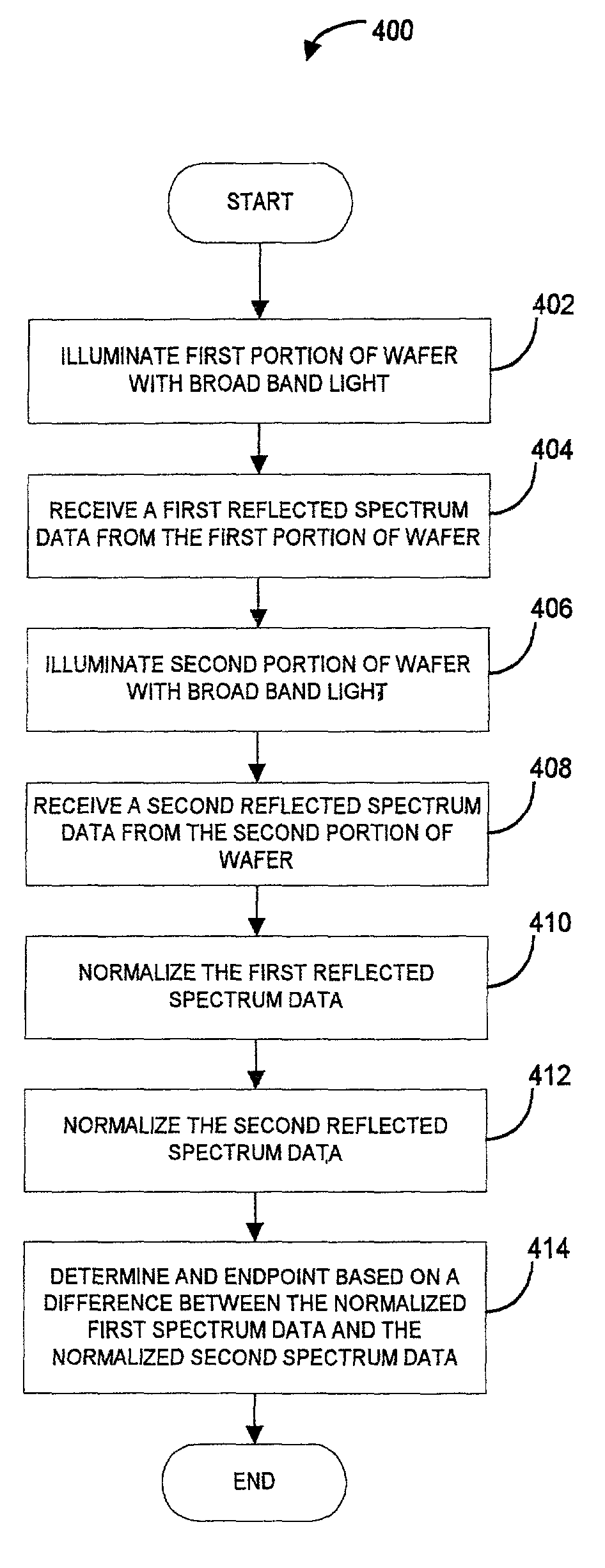

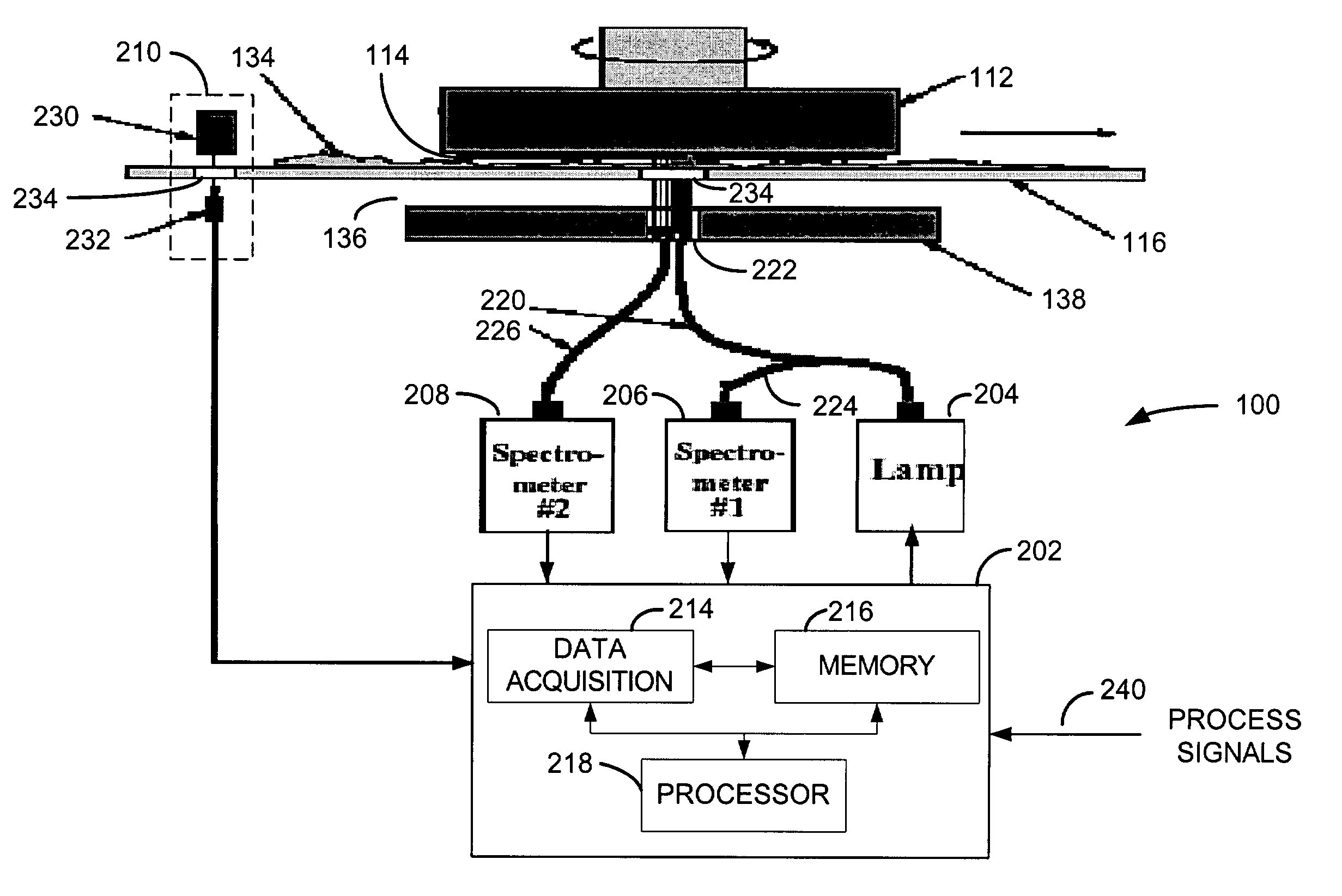

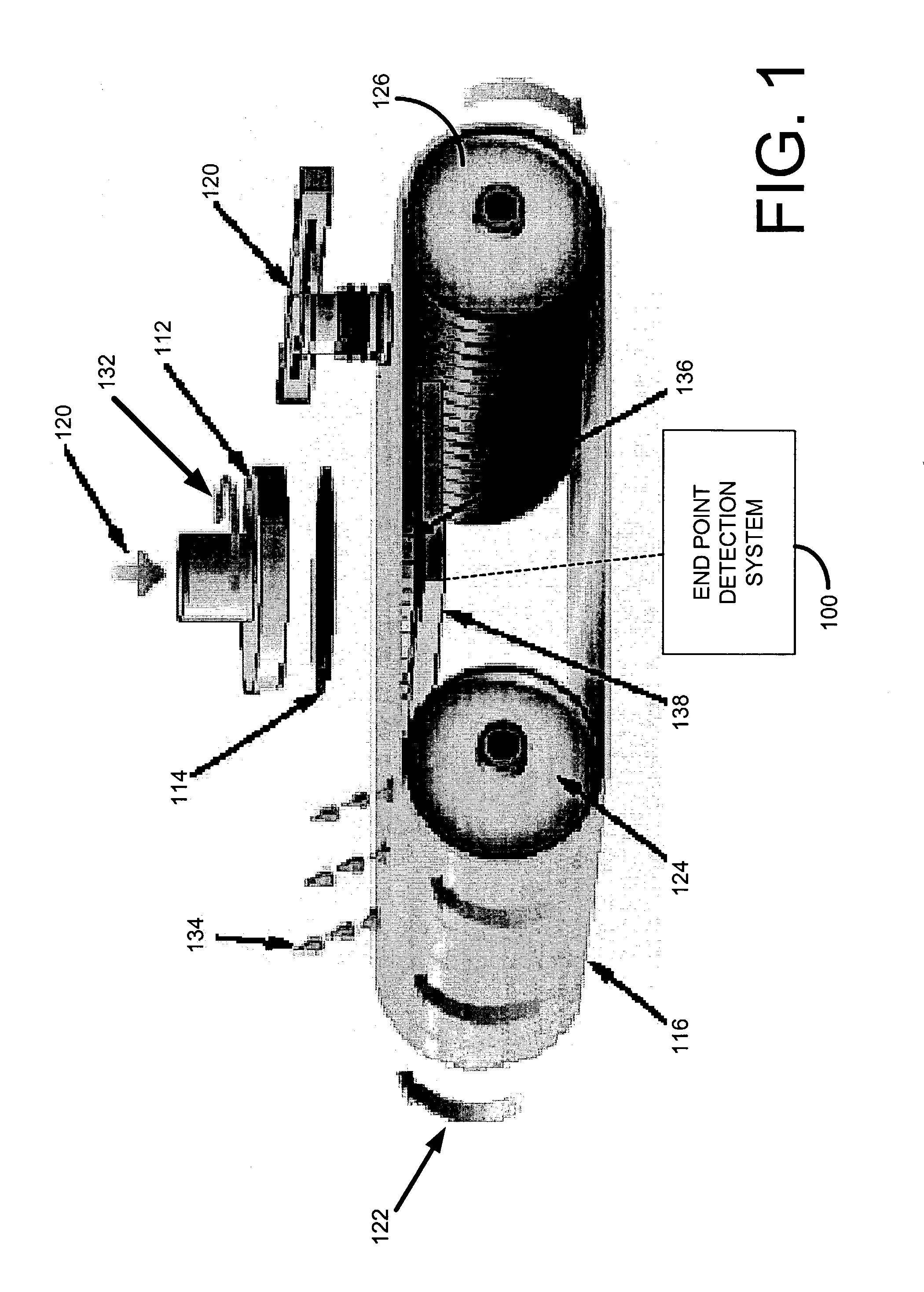

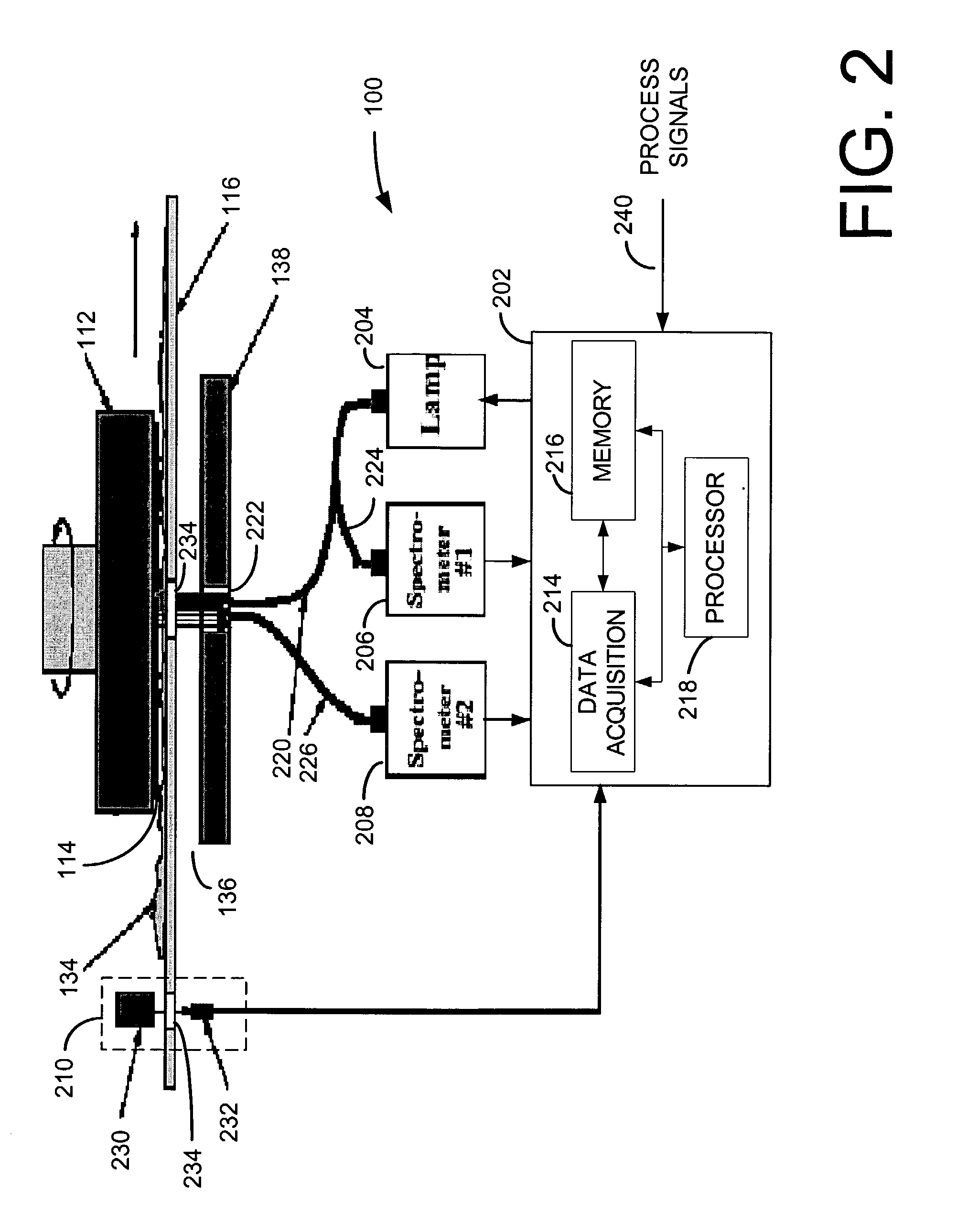

System and method of broad band optical end point detection for film change indication

A system and method for detecting an endpoint during a chemical mechanical polishing process is disclosed that includes illuminating a first portion of a surface of a wafer with a first broad beam of light. A first reflected spectrum data is received. The first reflected spectrum of data corresponds to a first spectra of light reflected from the first illuminated portion of the surface of the wafer. A second portion of the surface of the wafer with a second broad beam of light. A second reflected spectrum data is received. The second reflected spectrum of data corresponds to a second spectra of light reflected from the second illuminated portion of the surface of the wafer. The first reflected spectrum data is normalized and the second reflected spectrum data is normalized. An endpoint is determined based on a difference between the normalized first spectrum data and the normalized second spectrum data.

Owner:APPLIED MATERIALS INC

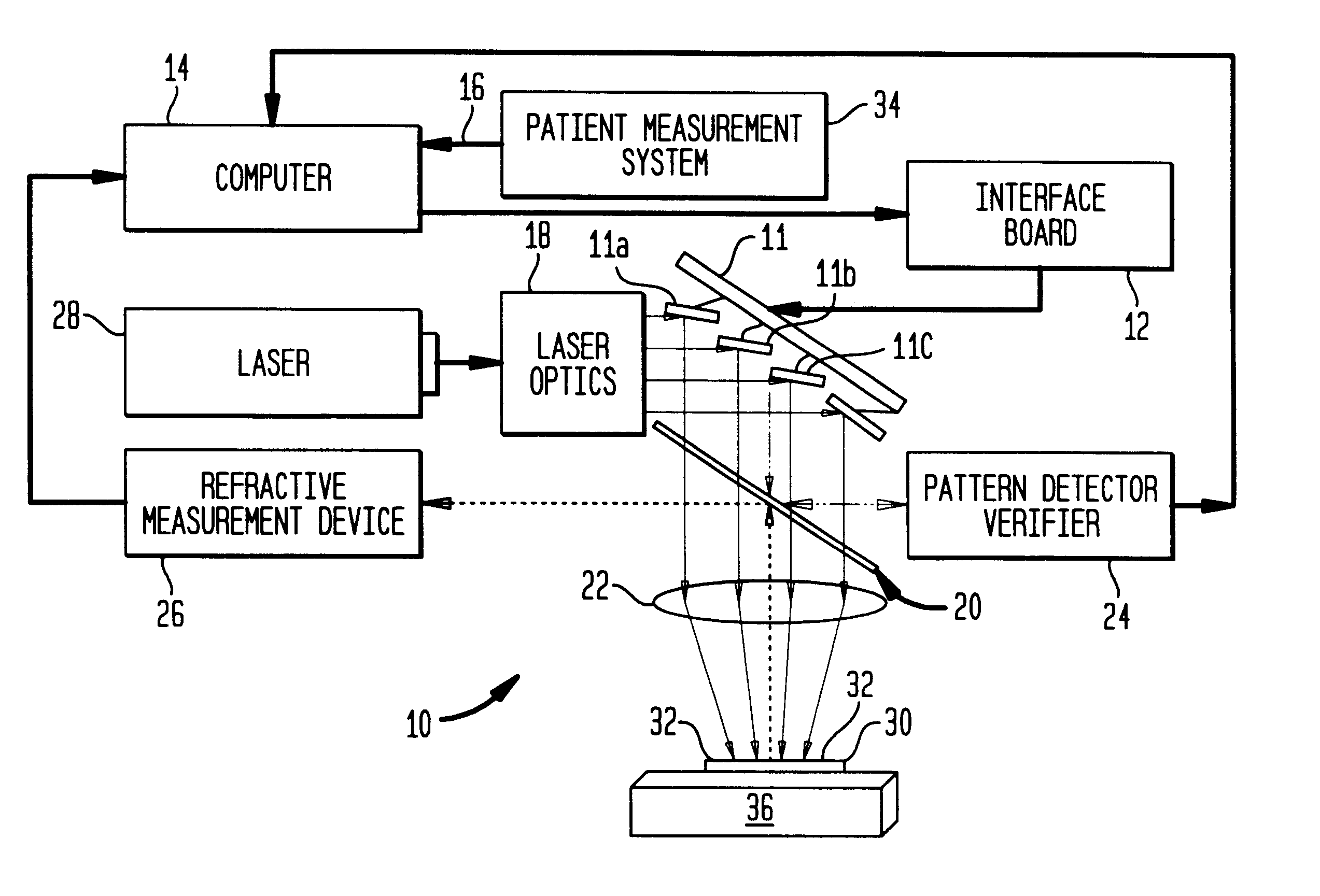

Laser method for shaping of optical lenses

A method for making accurate and precise customized corrections to the surface of an optical lens is described. An electronic correction contour is generated from a measured refractive correction for a patient, and transferred to the surface of the lens by ablation etching with one or more laser pulses. After each of the laser pulses, the refractive properties of the lens are measured and compared to the electronic contour correction derived from a patient's refractive correction. The ablation etching is terminated in localized areas where the refractive properties match the electronic correction contour. End point detection includes monitoring refractive qualities of the lens during the recontouring process, modifying the pattern through changes in the laser pulses.

Owner:WESTAR PHOTONICS

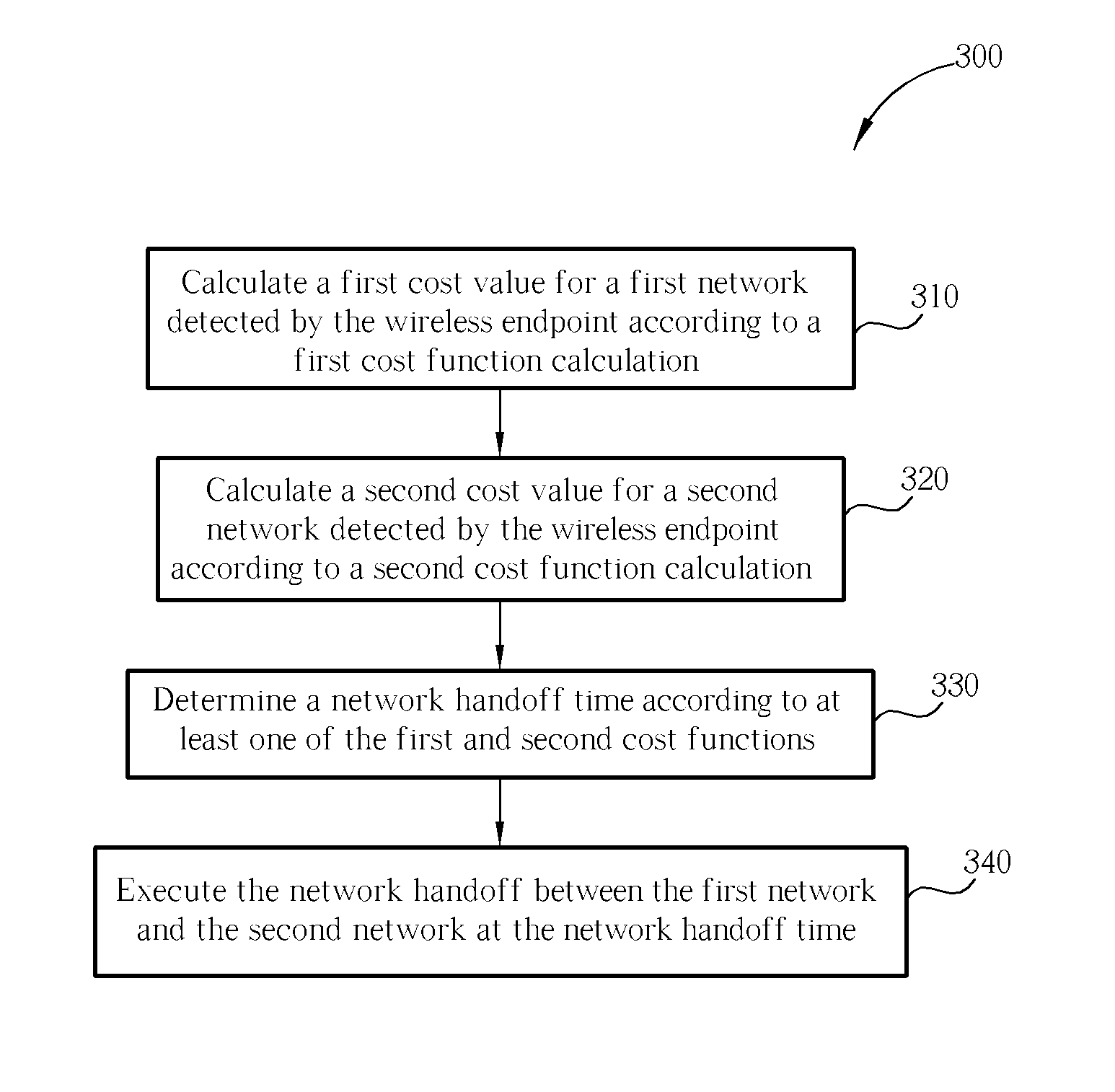

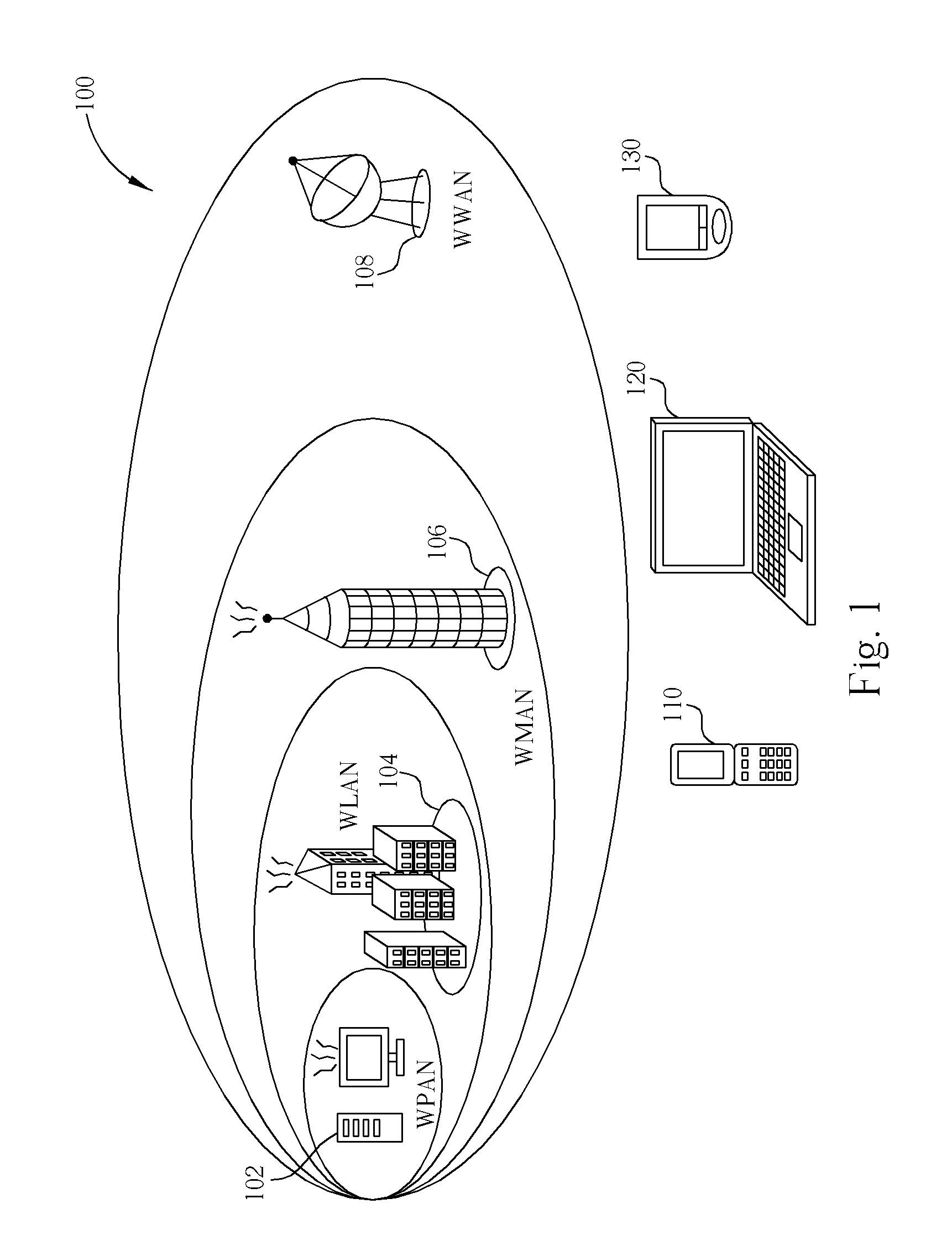

Method and device for cost-function based handoff determination using wavelet prediction in vertical networks

InactiveUS20070160007A1Determine feasibilityMore concise, accurate, and overall qualitativeAssess restrictionTelephonic communicationNetwork communicationDistributed computing

A method for performing a network handoff between different network communication providers for a wireless endpoint includes: calculating a first cost value for a first network detected by the wireless endpoint according to a first cost function calculation, calculating a second cost value for a second network detected by the wireless endpoint according to a second cost function calculation, utilizing a cost function based wavelet predictor to determine a network handoff time according to at least one of the first and second cost functions, and executing the network handoff between the first network and the second network at the network handoff time, wherein the cost function based wavelet predictor is for predicting future trends of various network characteristics.

Owner:ZYXEL

End point detection for sputtering and resputtering

InactiveUS20050173239A1Avoid depositionRaise the ratioCellsSemiconductor/solid-state device testing/measurementElectrical conductorReactor system

Plasma etching or resputtering of a layer of sputtered materials including opaque metal conductor materials may be controlled in a sputter reactor system. In one embodiment, resputtering of a sputter deposited layer is performed after material has been sputtered deposited and while additional material is being sputter deposited onto a substrate. A path positioned within a chamber of the system directs light or other radiation emitted by the plasma to a chamber window or other optical view-port which is protected by a shield against deposition by the conductor material. In one embodiment, the radiation path is folded to reflect plasma light around the chamber shield and through the window to a detector positioned outside the chamber window. Although deposition material may be deposited onto portions of the folded radiation path, in many applications, the deposition material will be sufficiently reflective to permit the emission spectra to be detected by a spectrometer or other suitable detector without significant signal loss. The etching or resputtering may be terminated when the detector detects that an underlying layer has been reached or when some other suitable process point has been reached.

Owner:APPLIED MATERIALS INC

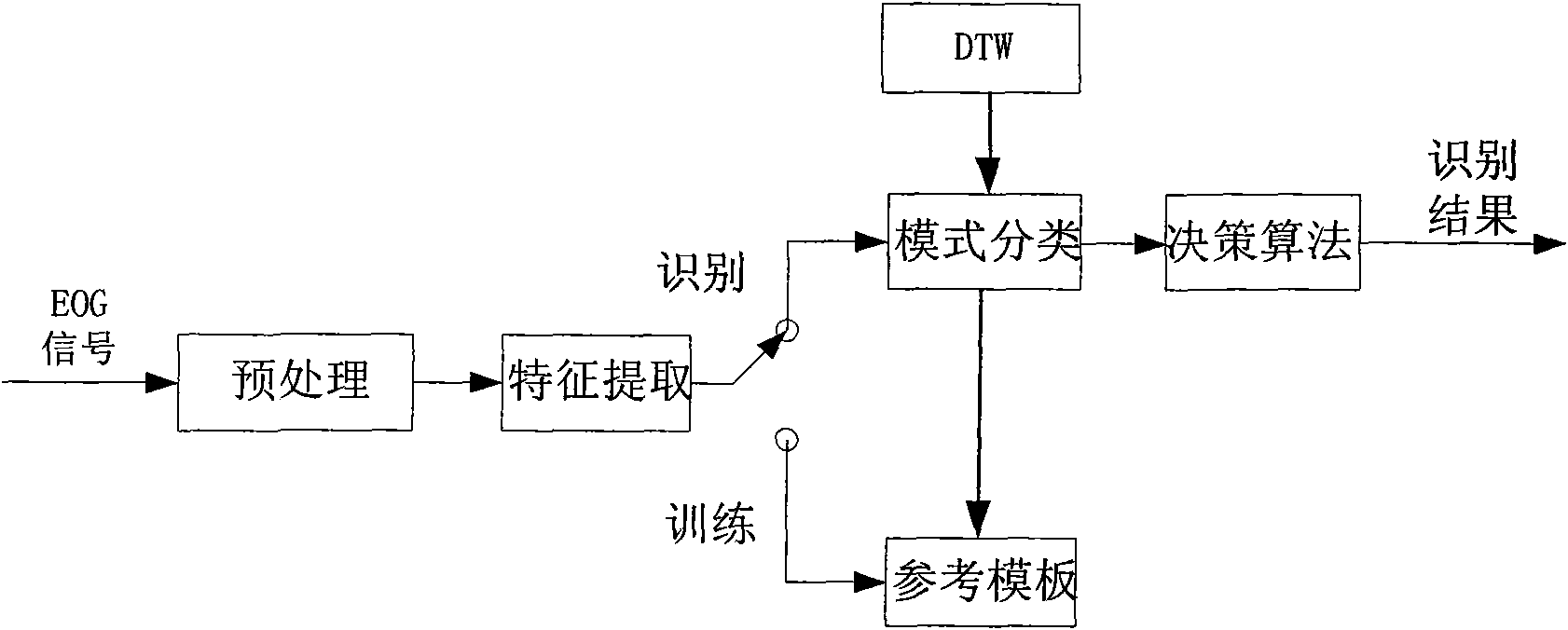

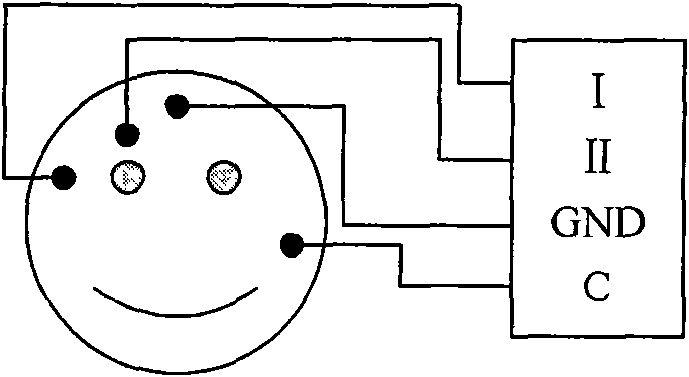

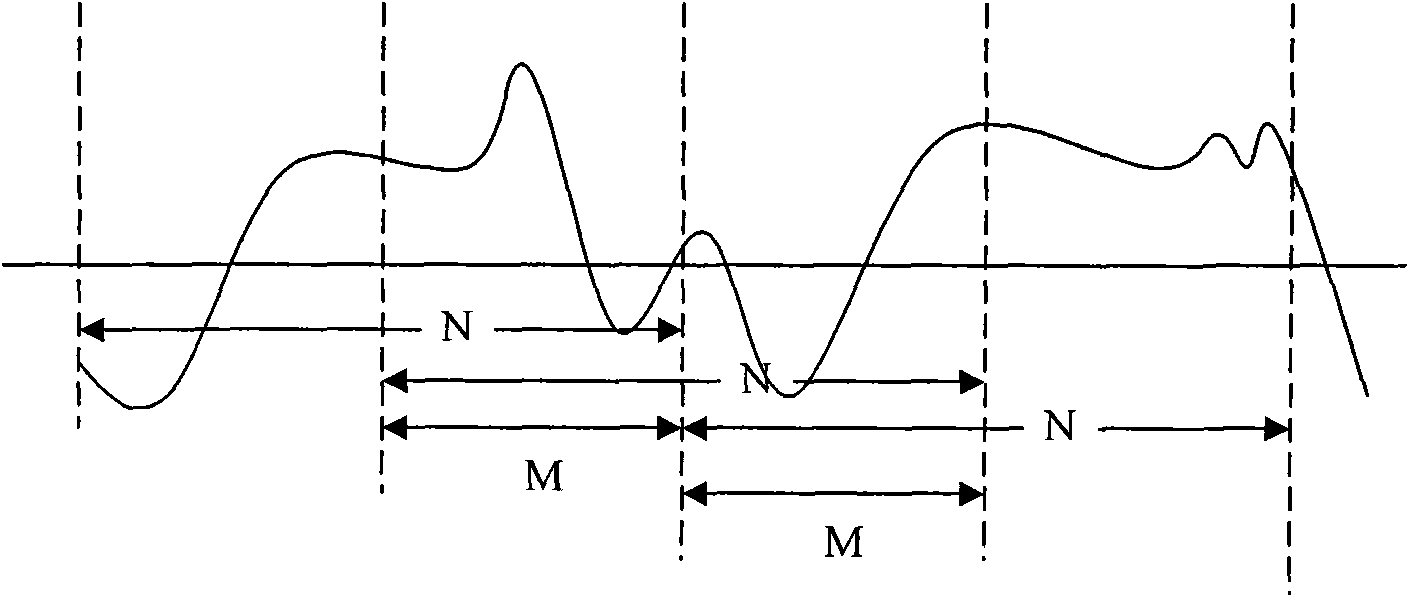

Method for extracting and identifying characteristics of electro-ocular signal

InactiveCN101599127AHigh accuracy of electro-ocular recognitionImprove accuracyInput/output for user-computer interactionCharacter and pattern recognitionBandpass filteringElectricity

The invention relates to a method for extracting and identifying characteristics of an electro-ocular signal, which is characterized by comprising three stages, namely pretreatment of the electro-ocular signal, extraction of characteristic parameters of the electro-ocular signal and mode identification of the electro-ocular signal, wherein in the pretreatment stage, endpoint detection and bandpass filtering on the electro-ocular signal are carried out; in the characteristic parameter extraction stage, frame separation and windowing on the electro-ocular signal are carried out, and an electro-ocular characteristic parameter sequence changed along with time after converting the continuous electro-ocular signal into a plurality of sections of short-time electro-ocular signals is extracted; and in the mode identification stage, similarity comparison between the input electro-ocular characteristic parameter sequence and each template of a template base sequentially through a dynamic time normalization method is carried out so as to judge the corresponding eye movement of the operator. The method has the characteristics of high identification accuracy of the electro-ocular signal, certain antijamming capacity, strong application value and the like.

Owner:ANHUI UNIVERSITY

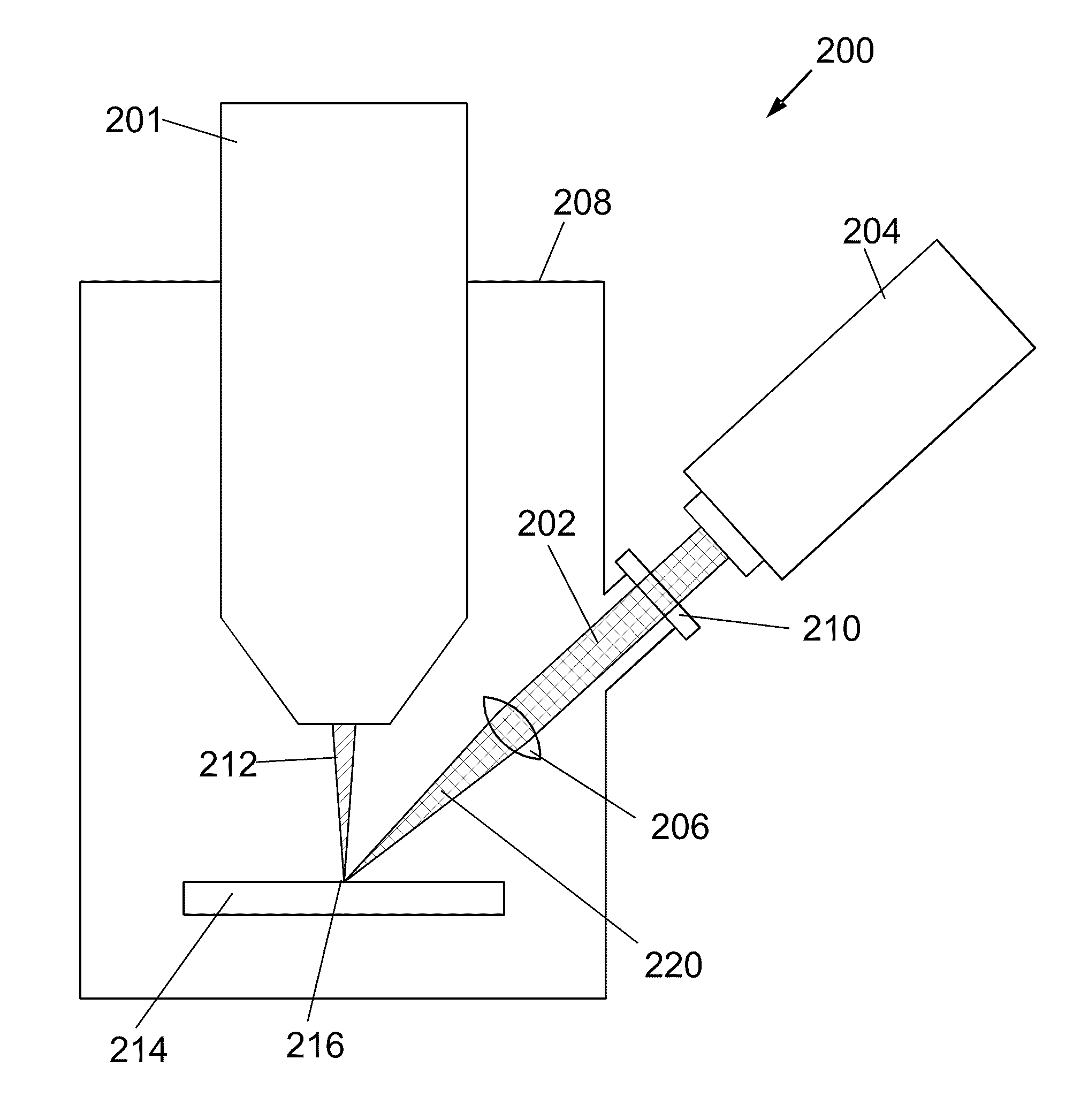

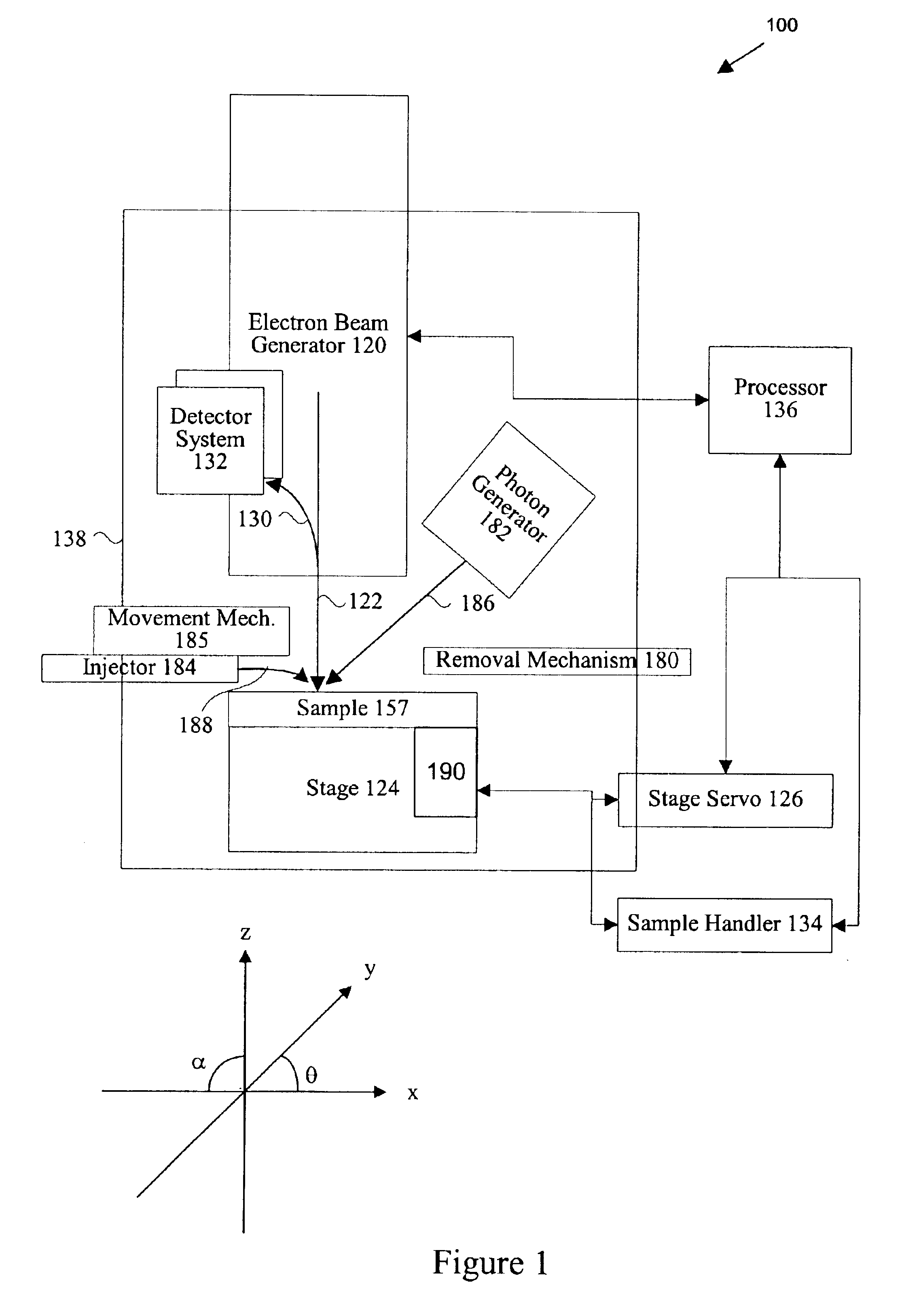

Combination Laser and Charged Particle Beam System

ActiveUS20110248164A1Avoid saturationThermometer detailsStability-of-path spectrometersHigh resolution imagingMaterial removal

A combined laser and charged particle beam system. A pulsed laser enables milling of a sample at material removal rates several orders of magnitude larger than possible for a focused ion beam. In some embodiments, a scanning electron microscope enables high resolution imaging of the sample during laser processing. In some embodiments, a focused ion beam enables more precise milling of the sample. A method and structure for deactivating the imaging detectors during laser milling enables the removal of imaging artifacts arising from saturation of the detector due to a plasma plume generated by the laser beam. In some embodiments, two types of detectors are employed: type-1 detectors provide high gain imaging during scanning of the sample with an electron or ion beam, while type-2 detectors enable lower gain imaging and endpoint detection during laser milling.

Owner:FEI CO

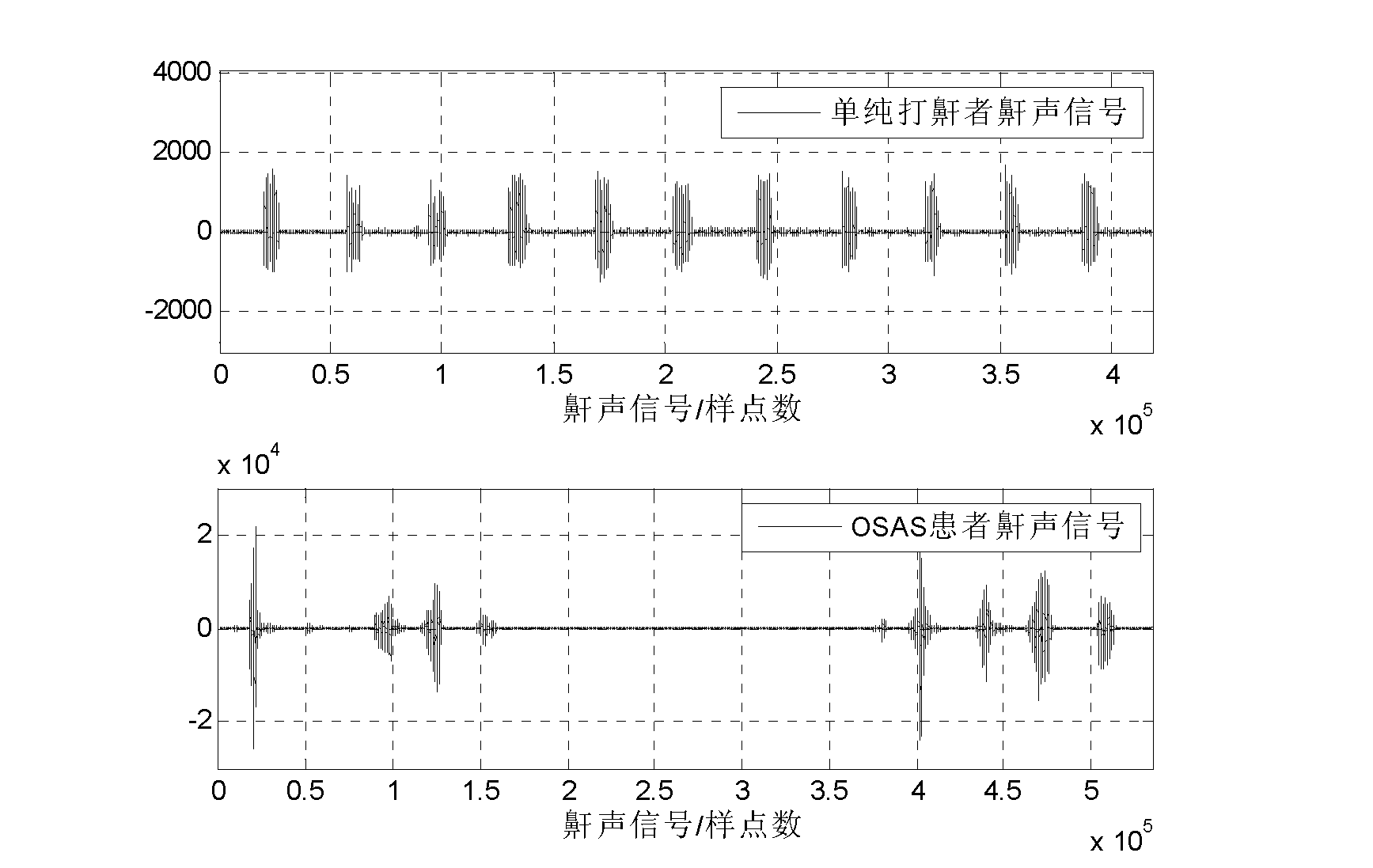

Screening system for sleep apnea syndrome in family environment

The invention discloses a screening system for sleep apnea syndrome in family environment, comprising a snore data obtaining module, a snore processing module and a distinguishing module, wherein the data obtaining module is used for collecting the snore data; the snore signal processing module is used for firstly performing the preprocess of the voice signals such as framing, pre-emphasizing and window adding and then completing the end point detection for the snore by a double-gate detecting method; the first ten frame data of the snore sample is taken as the first measure of the background noise in the process of performing end point detection; and then the data of snore section is transmitted to an energy-ratio solution module. Finally, resolving the features of the energy ratio of the snore section and then transmitting the features of the energy ratio to the distinguishing module. The distinguishing module takes the energy ratio as the categorical data; if the energy ratio of a patient is higher than a certain threshold quantity, then the patient is distinguished as OSAS sufferer; if not, then the patient is the single snorer. The invention provides a system that brings less interference for the sleep of the patient and low cost and can still reach higher screening precision even in family environment.

Owner:DALIAN UNIV OF TECH

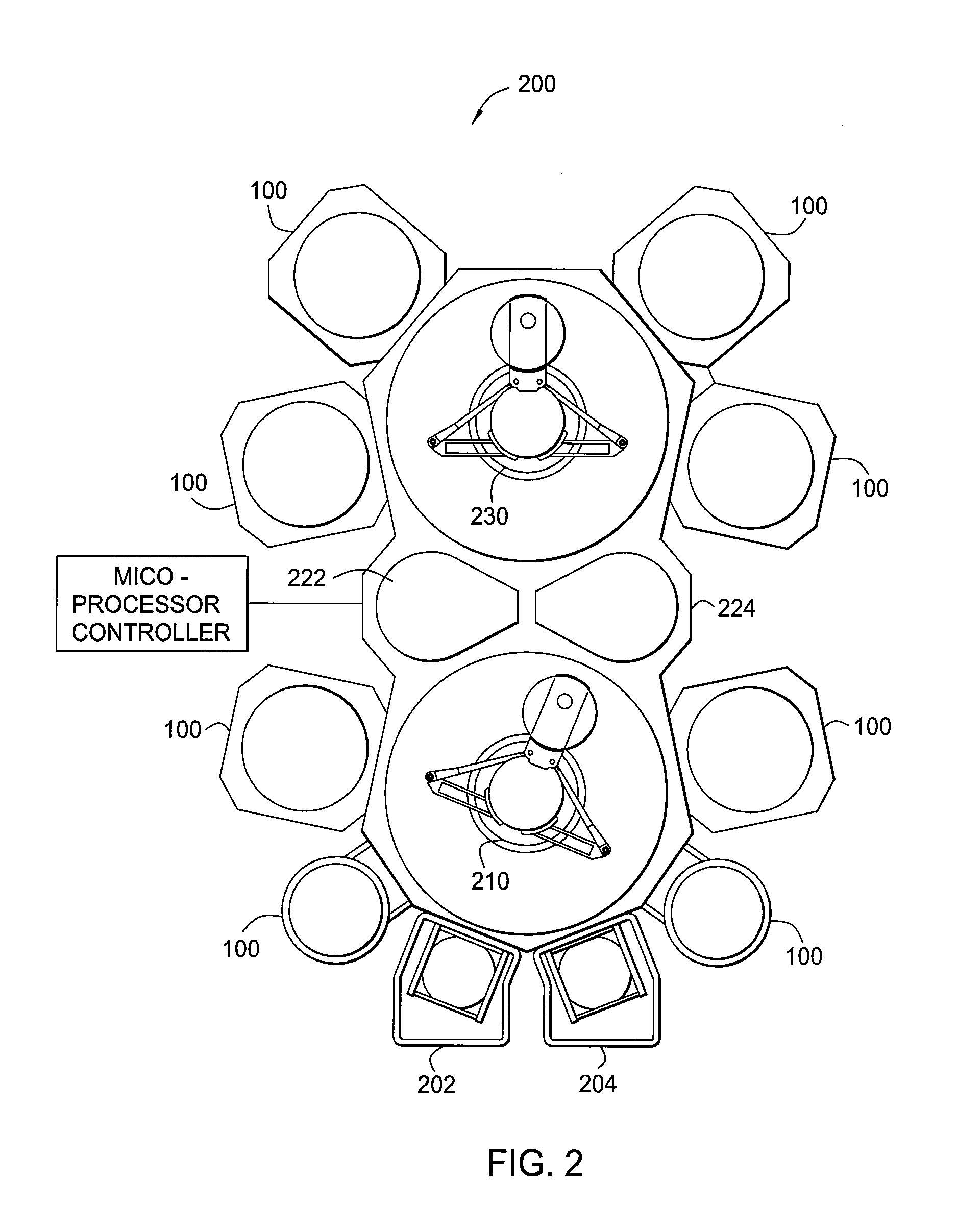

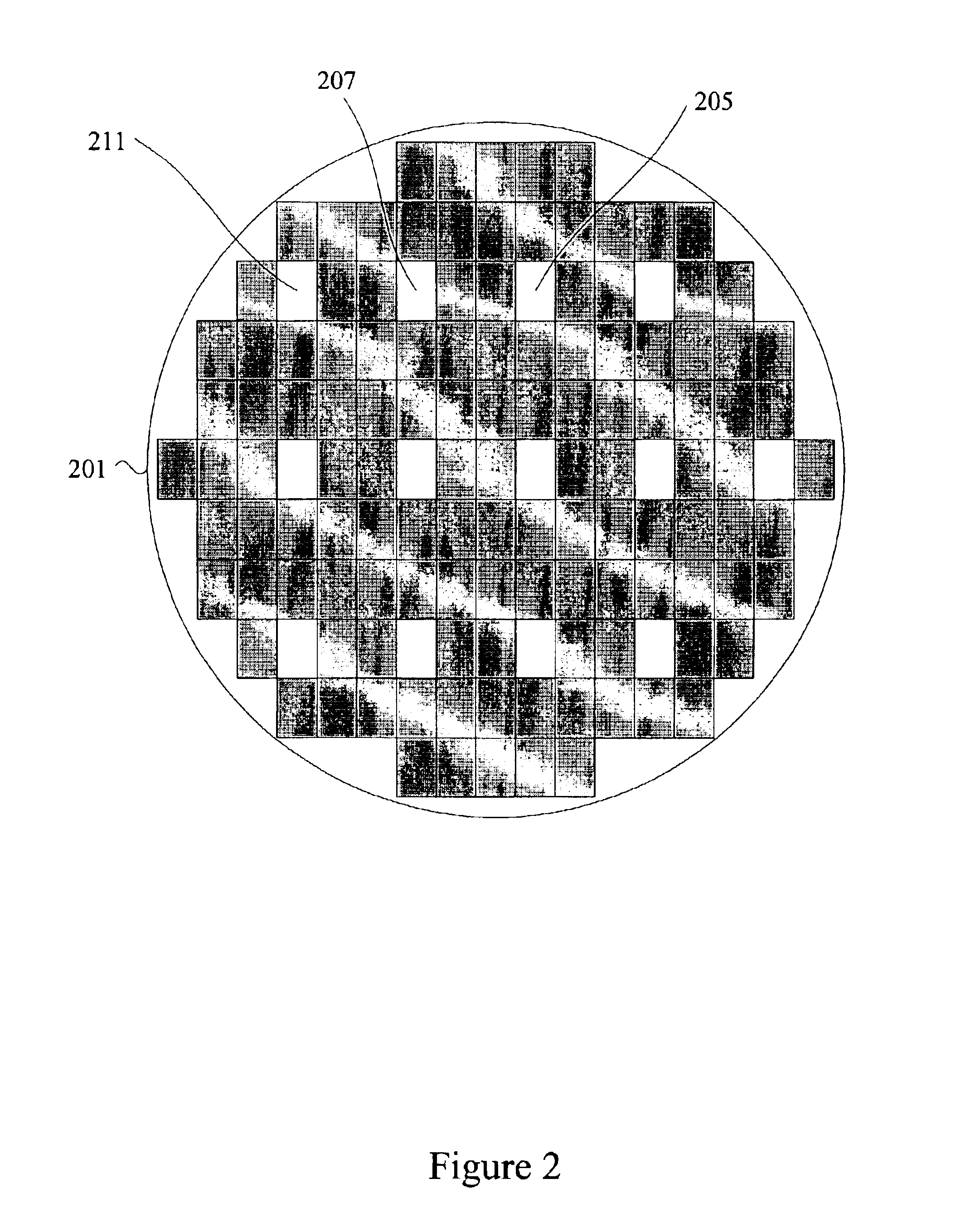

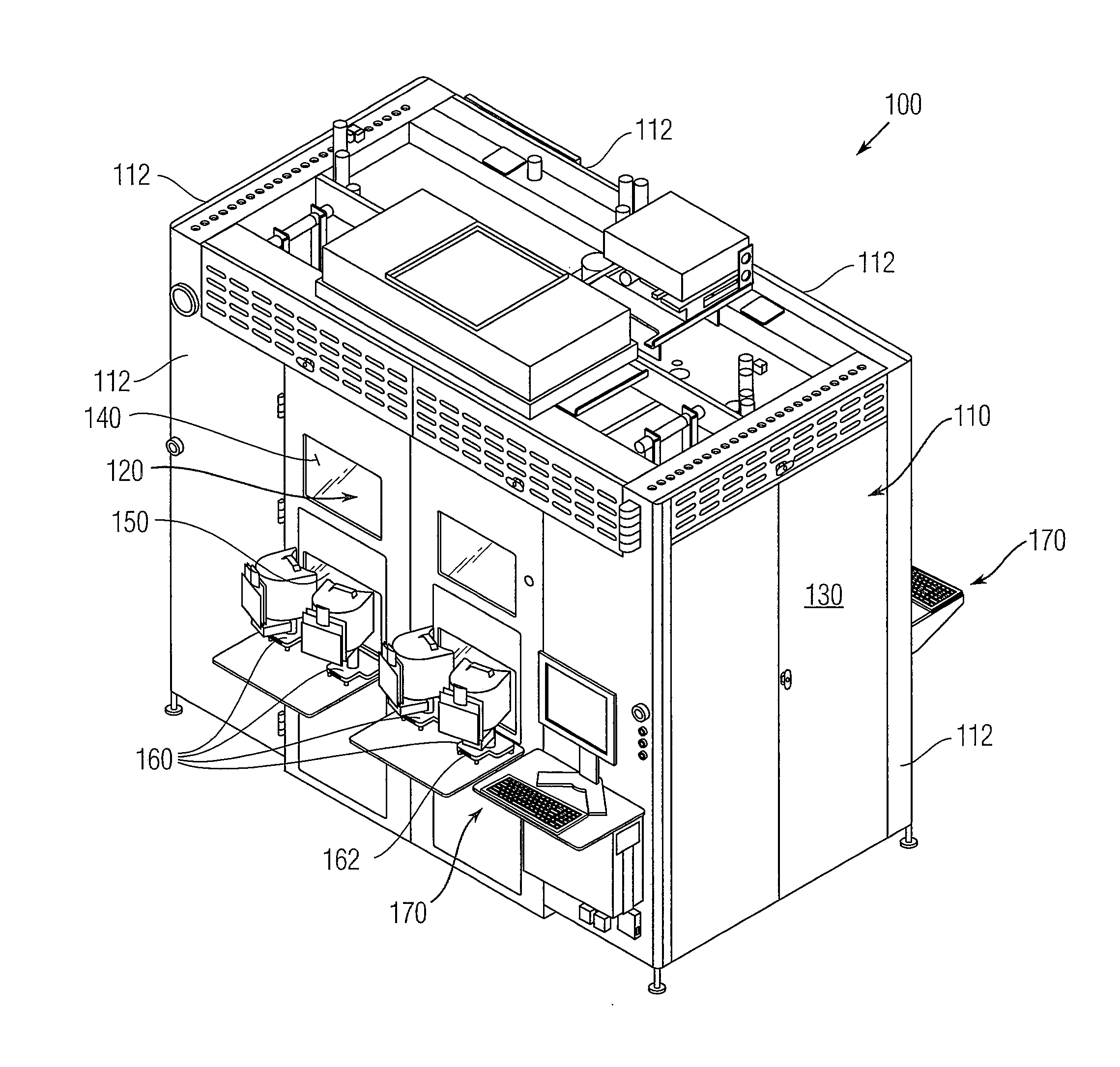

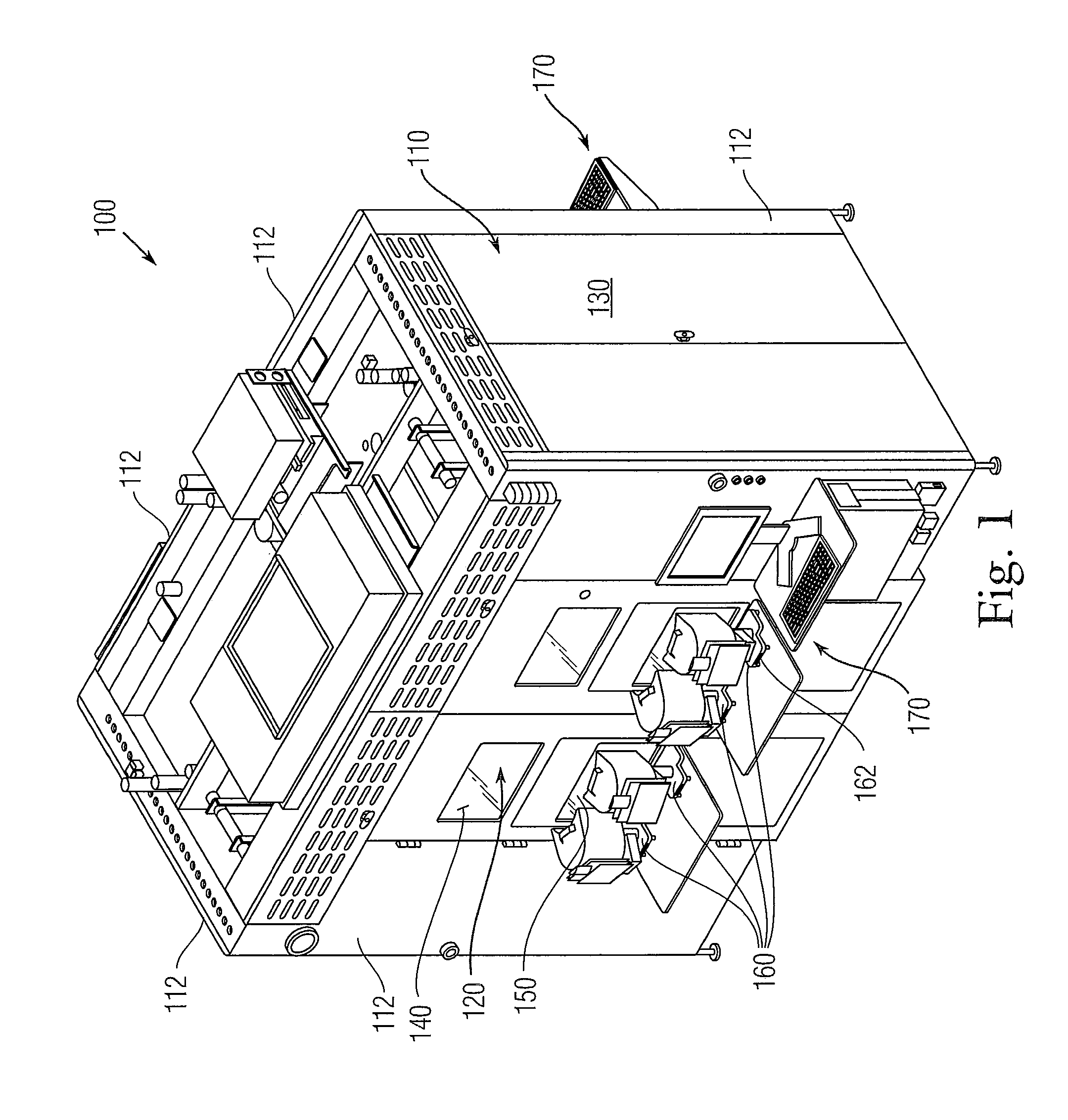

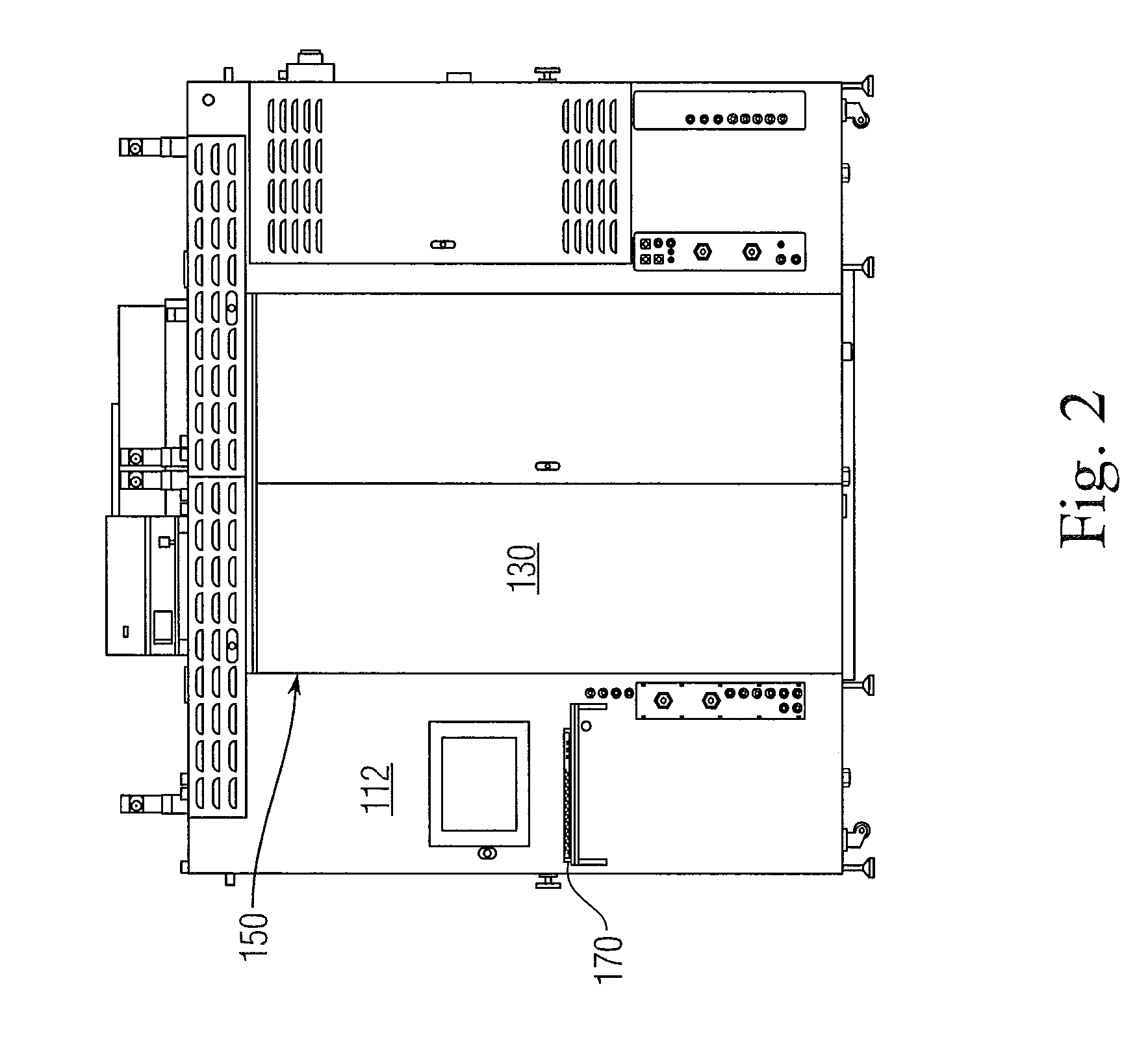

End point detection with imaging matching in semiconductor processing

An end point detection system may compare a production image developed during processing of production semiconductor wafer with a reference image. The reference image is representative of a desired state of processing of the production semiconductor wafer. The reference image is determined by processing a reference semiconductor wafer. The reference semiconductor wafer may be part of a wafer group of similar wafers that includes the production semiconductor wafer. The end point detection system may dynamically develop the production image during processing of the production semiconductor wafer. Indication may be provided by the end point detection system when the reference image and the production image are substantially similar.

Owner:LAM RES CORP

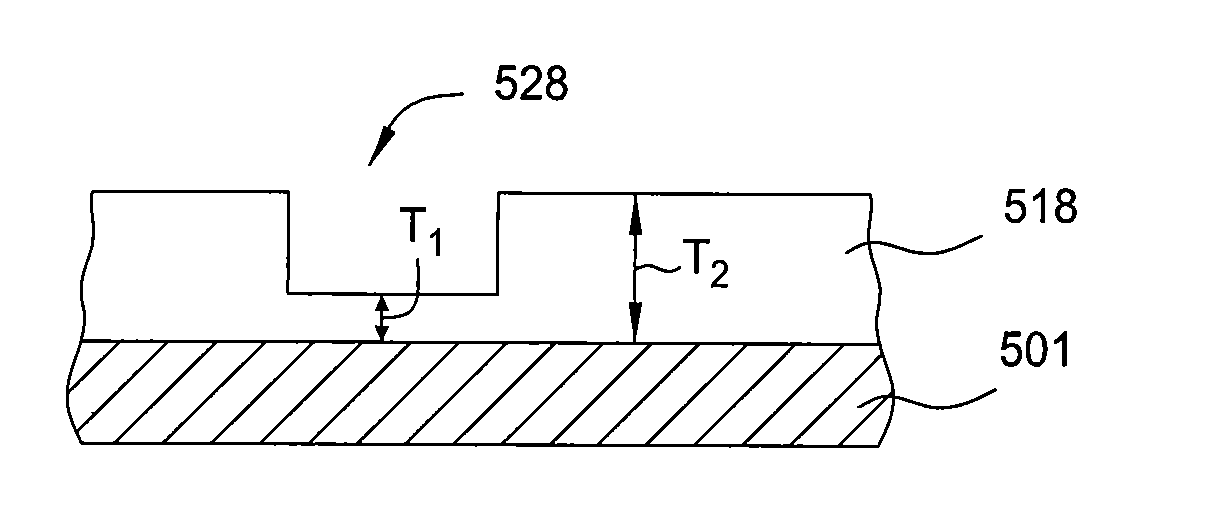

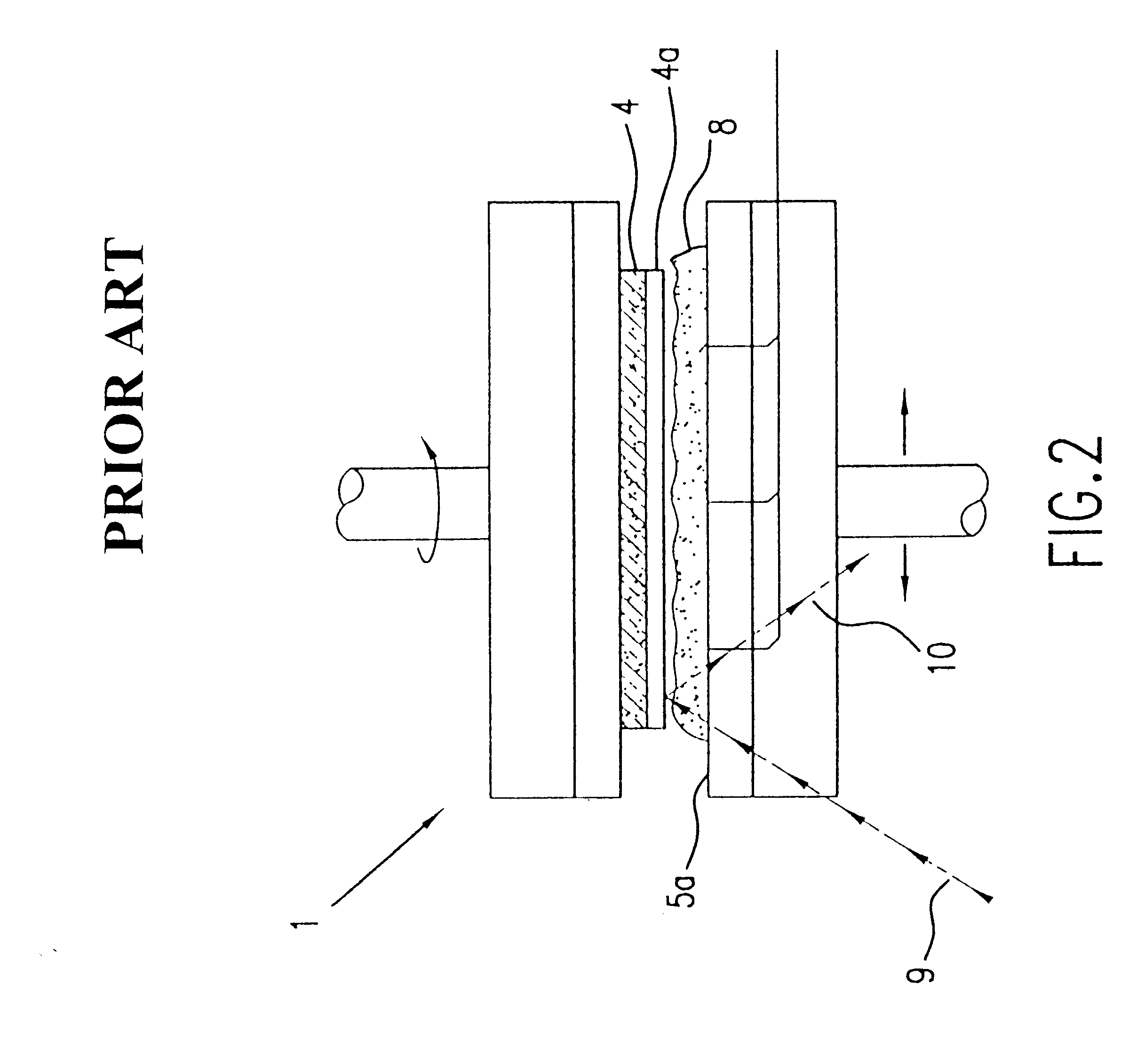

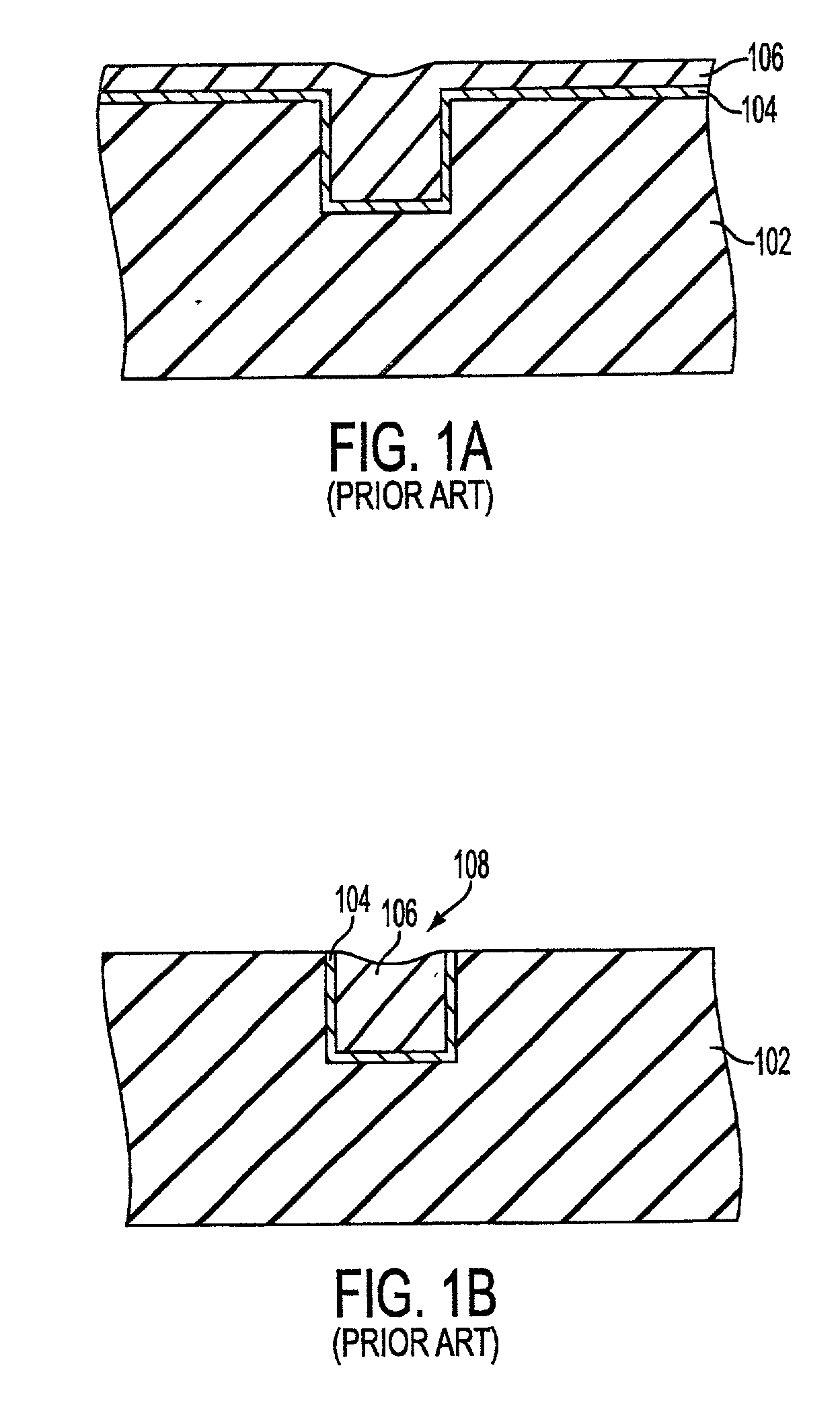

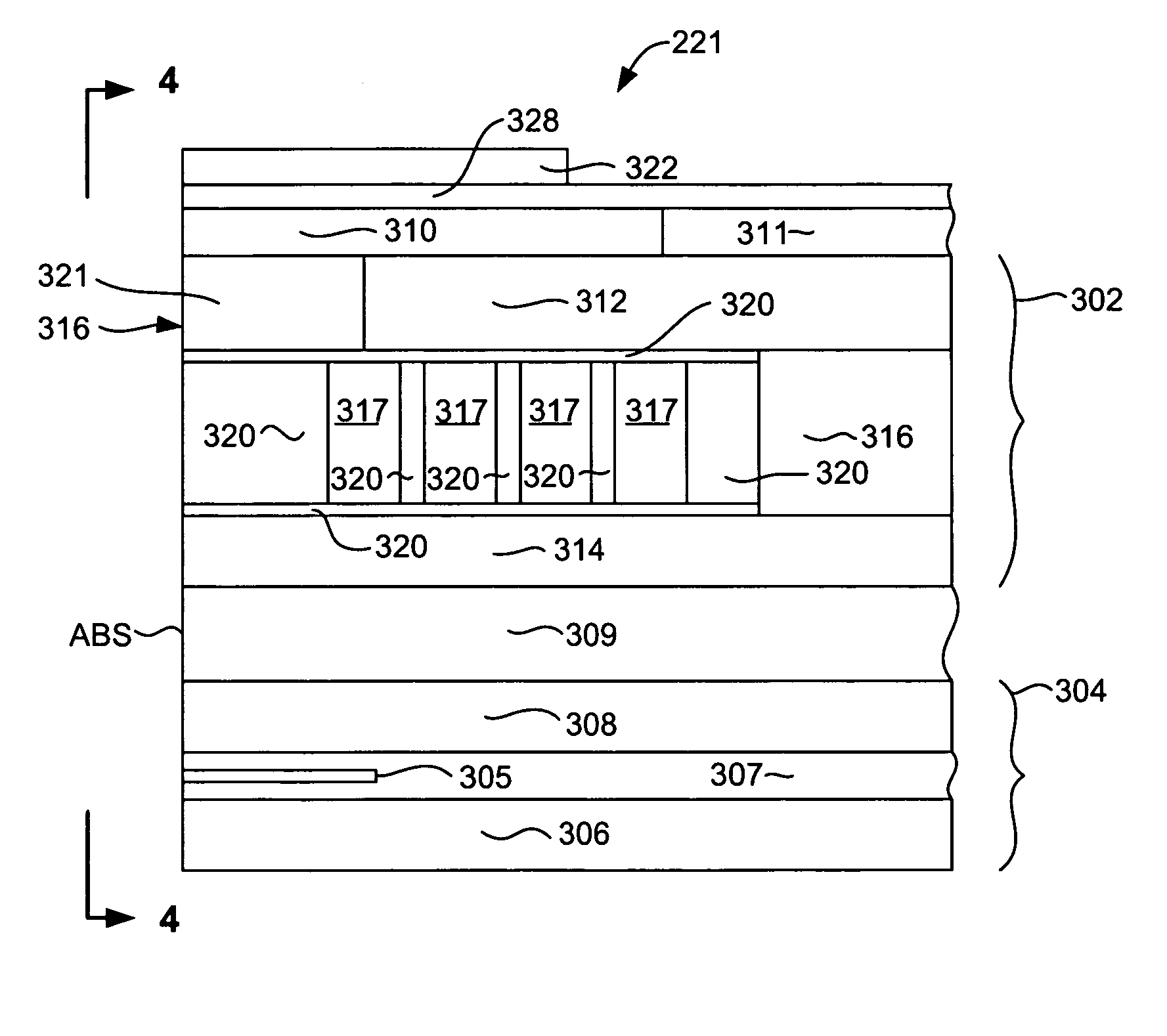

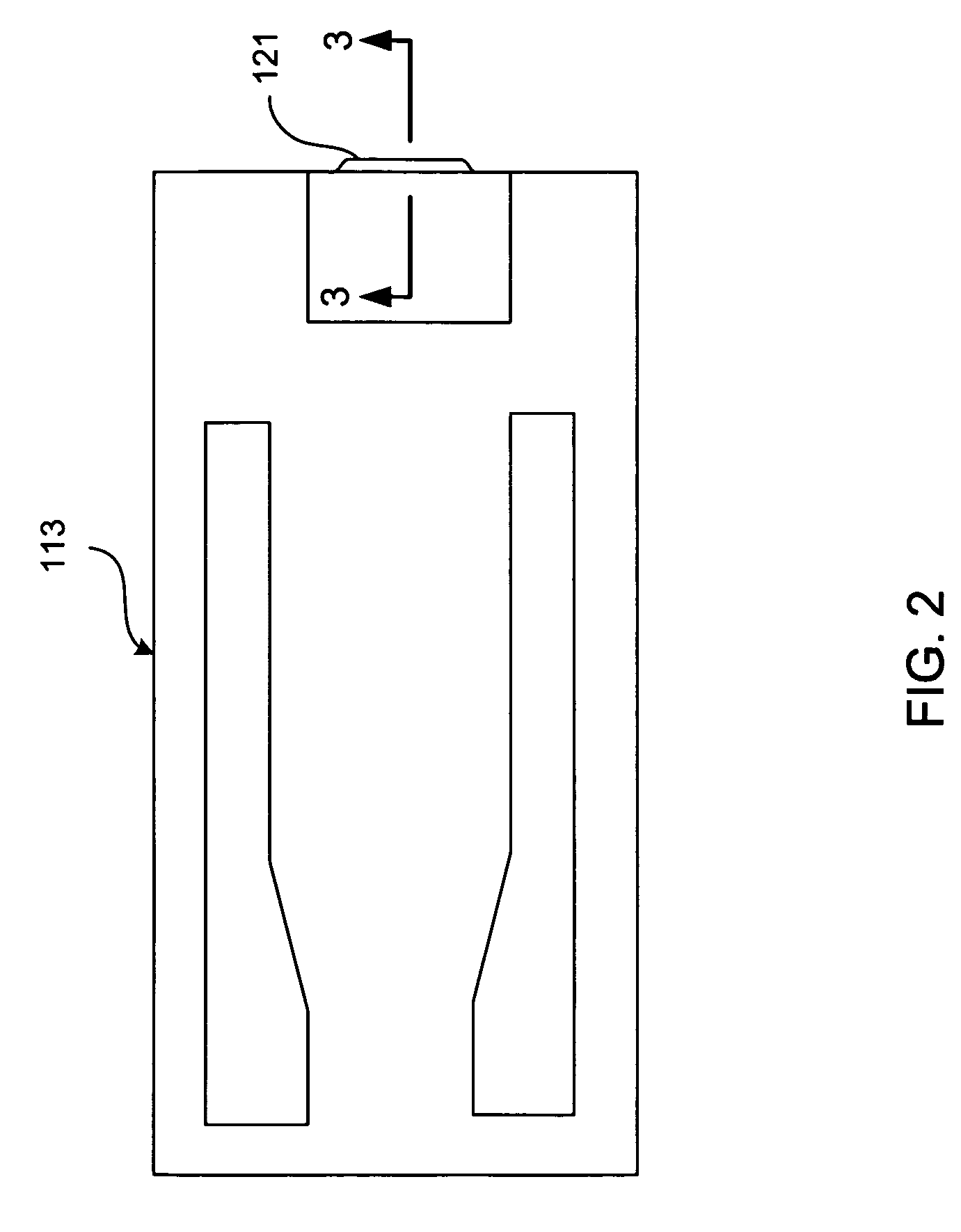

Method of manufacturing a wrap around shield for a perpendicular write pole using a laminated mask

InactiveUS20070245545A1Construction of head windingsManufacture head surfaceTrailing edgeNon magnetic

A method for constructing a magnetic write head for use in perpendicular magnetic recording, the write head having a write pole with a trailing shield that wraps around the write pole. The method allows the trailing shield to be constructed with a very well controlled trailing gap thickness and also allows the write pole to be constructed with a well controlled track width and a straight, flat trailing edge. The method includes depositing a magnetic write pole over a substrate and forming a mask structure over the write pole layer. The mask structure includes an end point detection layer that can be removed by reactive ion etching. An ion mill is performed to form a write pole by removing magnetic write pole material that is not covered by the mask layer. A layer of non-magnetic material such as alumina is deposited and is ion milled to expose the end point detection layer. The end point detection layer is then removed by reactive ion etch and a magnetic wrap around trailing shield is deposited.

Owner:WESTERN DIGITAL TECH INC

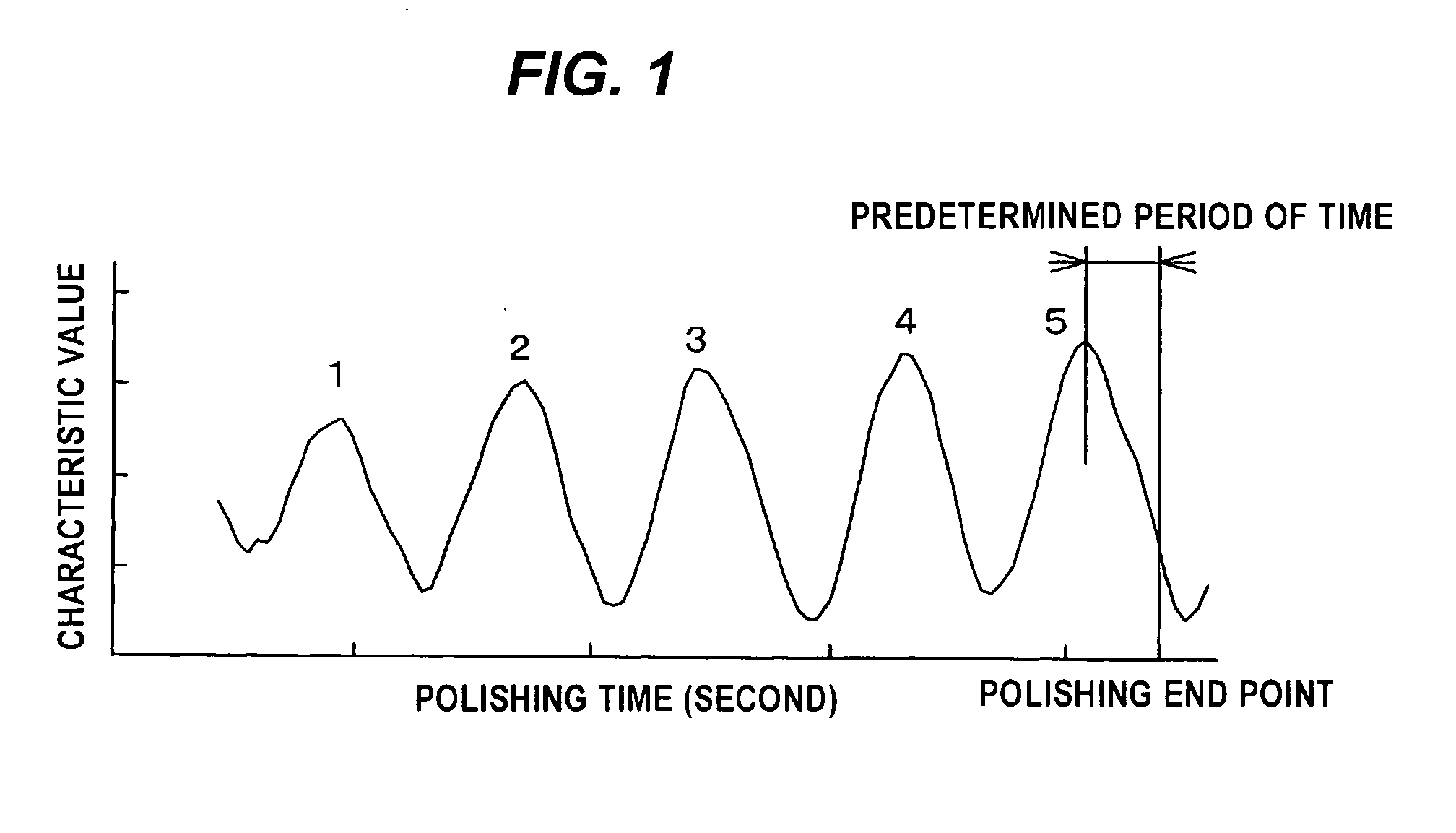

Processing end point detection method, polishing method,and polishing apparatus

ActiveUS20100015889A1Accurate polishing end point detectionUniform film thicknessSemiconductor/solid-state device testing/measurementSolid-state devicesLength waveArtificial intelligence

The present invention relates to a processing end point detection method for detecting a timing of a processing end point (e.g., polishing stop, changing of polishing conditions) by calculating a characteristic value of a surface of a workpiece (an object of polishing) such as a substrate. This method includes producing a spectral waveform indicating a relationship between reflection intensities and wavelengths at a processing end point, with use of a reference workpiece or simulation calculation, based on the spectral waveform, selecting wavelengths of a local maximum value and a local minimum value of the reflection intensities, calculating the characteristic value with respect to a surface, to be processed, from reflection intensities at the selected wavelengths, setting a distinctive point of time variation of the characteristic value at a processing end point of the workpiece as the processing end point, and detecting the processing end point of the workpiece by detecting the distinctive point during processing of the workpiece.

Owner:KIOXIA CORP +1

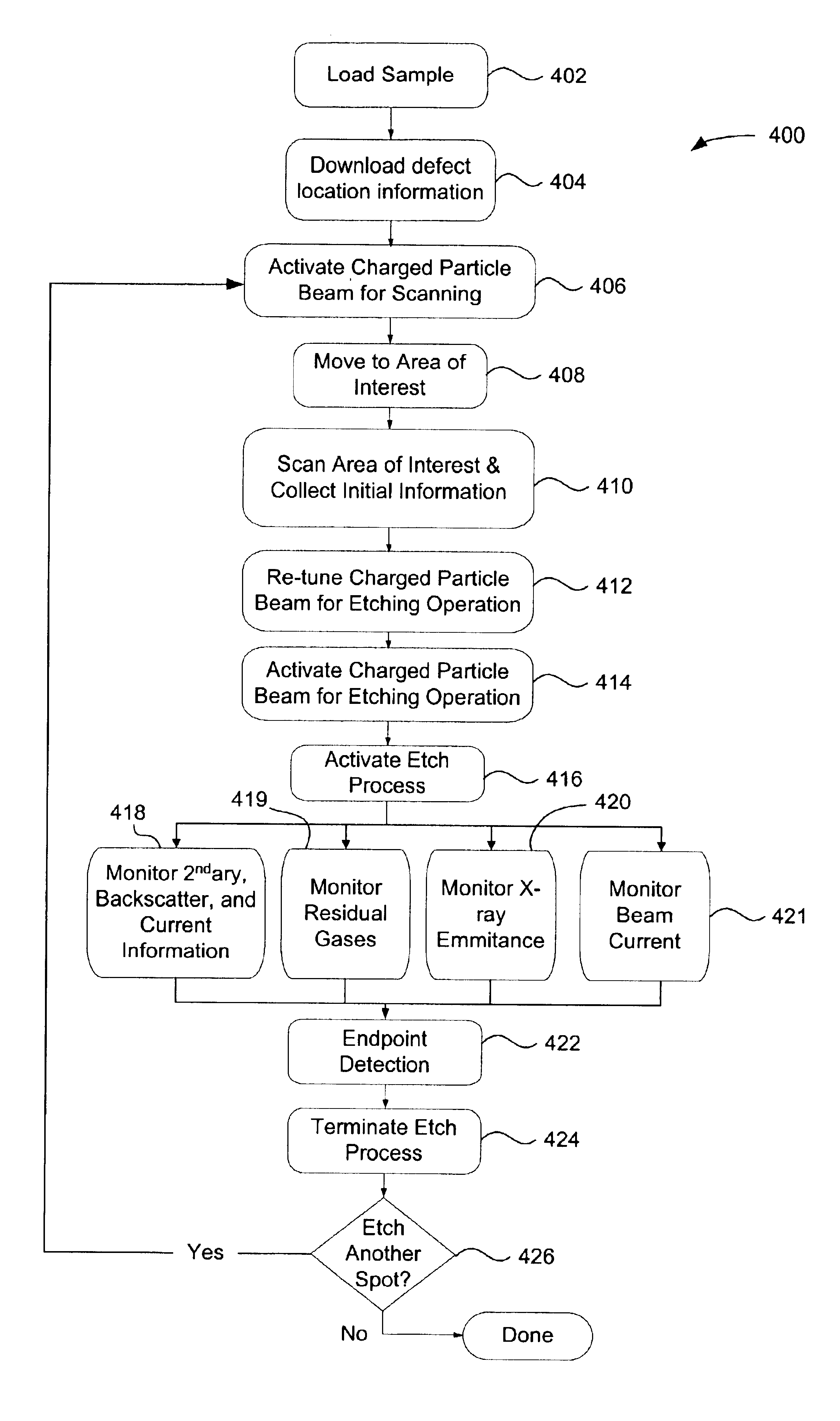

Method and apparatus for endpoint detection in electron beam assisted etching

InactiveUS6843927B2Semiconductor/solid-state device testing/measurementElectric discharge tubesSecondary electronsPhoton beam

Techniques for detecting endpoints during semiconductor dry-etching processes are described. The dry-etching process of the present invention involves using a combination of a reactive material and a charged particle beam, such as an electron beam. In another embodiment, a photon beam is used to facilitate the etching process. The endpoint detection techniques involve monitoring the emission levels of secondary electrons and backscatter electrons together with the current within the sample. Depending upon the weight given to each of these parameters, an endpoint is identified when the values of these parameters change more than a certain percentage, relative to an initial value for these values.

Owner:KLA TENCOR TECH CORP

System and method for performing a wet etching process

ActiveUS20140242731A1Semiconductor/solid-state device testing/measurementSolid-state devicesEtchingEngineering

A system and method for performing a wet etching process is disclosed. The system includes multiple processing stations accessible by a transfer device, including a measuring station to optically measure the thickness of a substrate, a controller to calculate an etch recipe for the substrate, in real time, and cause a single wafer wet etching station to etch the substrate according to the recipe. In addition, the system can measure the after etch thickness and calculate etch recipes, in real time, as a function of the final measurements of a previous substrate. The system can also include an in situ end point detection device for detecting the TSV reveal point while etching TSVs substrates. The system provides an automated solution to adjust etch recipe parameters in real time according to feedback concerning previously etched wafers and precisely control the TSV reveal height and etch duration using end point detection.

Owner:VEECO INSTR

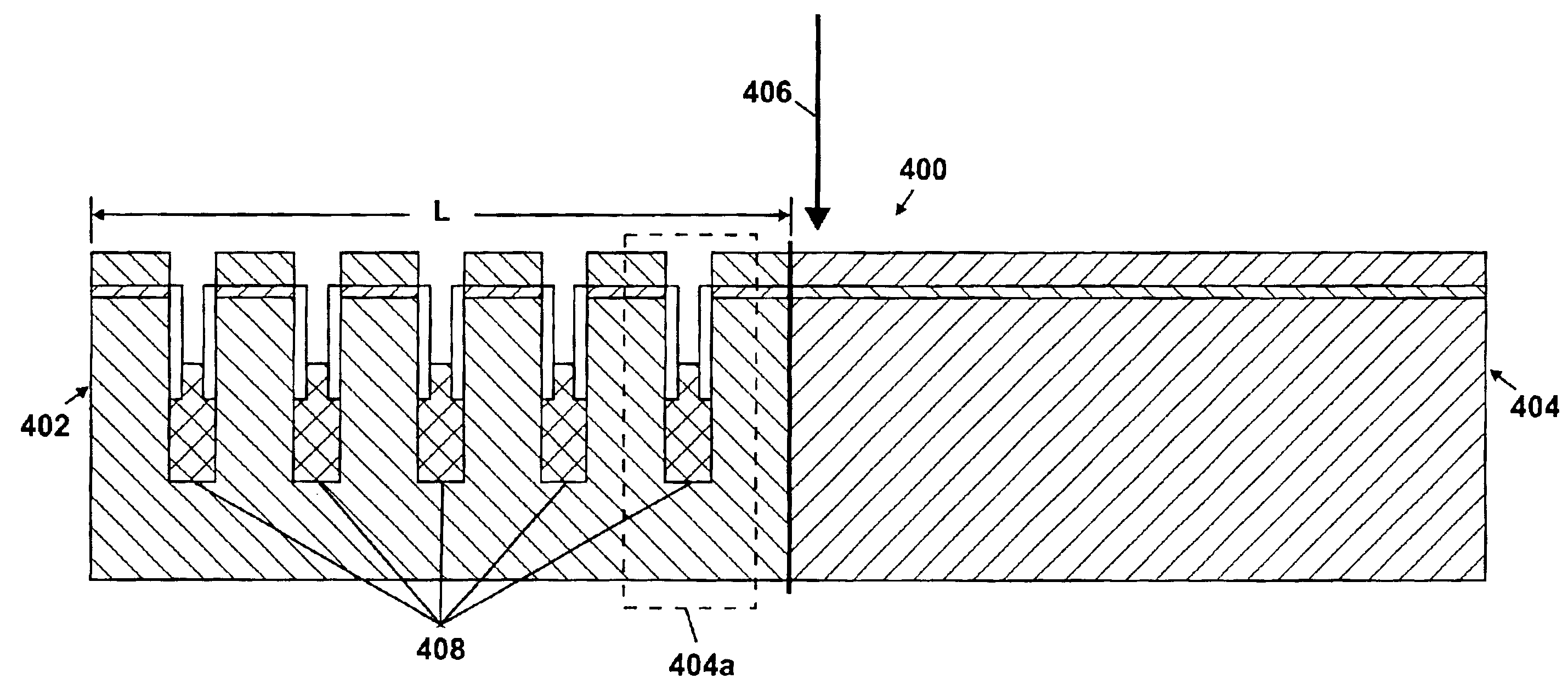

Process endpoint detection method using broadband reflectometry

InactiveUS6979578B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingReflectance spectroscopyLight beam

A method of determining a parameter of interest during processing of a patterned substrate includes obtaining a measured net reflectance spectrum resulting from illuminating at least a portion of the patterned substrate with a light beam having a broadband spectrum, calculating a modeled net reflectance spectrum as a weighted incoherent sum of reflectances from different regions constituting the portion of the patterned substrate, and determining a set of parameters that provides a close match between the measured net reflectance spectrum and the modeled net reflectance spectrum. For wavelengths below a selected transition wavelength, a first optical model is used to calculate the reflectance from each region as a weighted coherent sum of reflected fields from thin film stacks corresponding to laterally distinct areas constituting the region. For wavelengths above the transition wavelength, a second optical model based on effective medium approximation is used to calculate the reflectance from each region.

Owner:LAM RES CORP

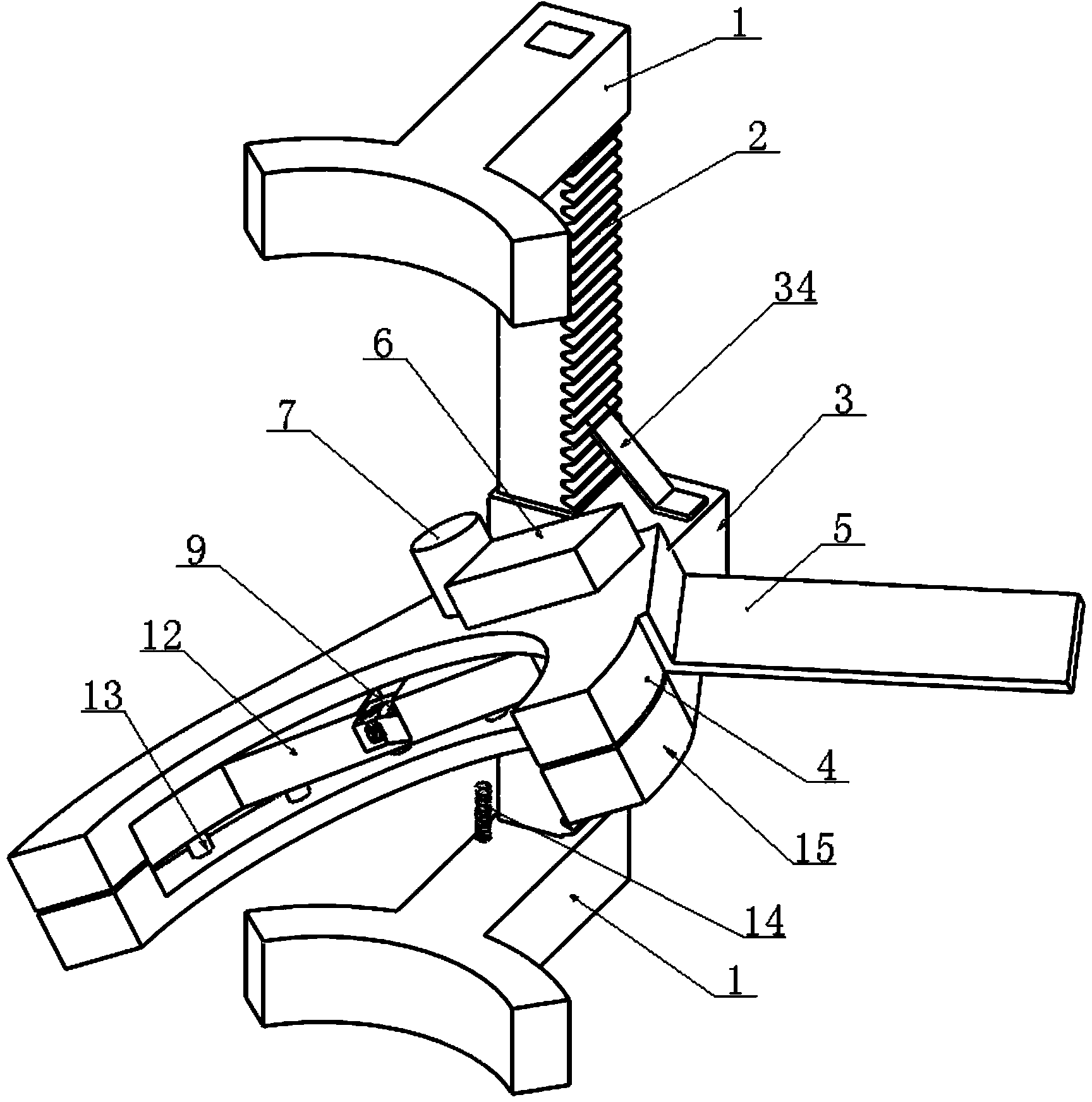

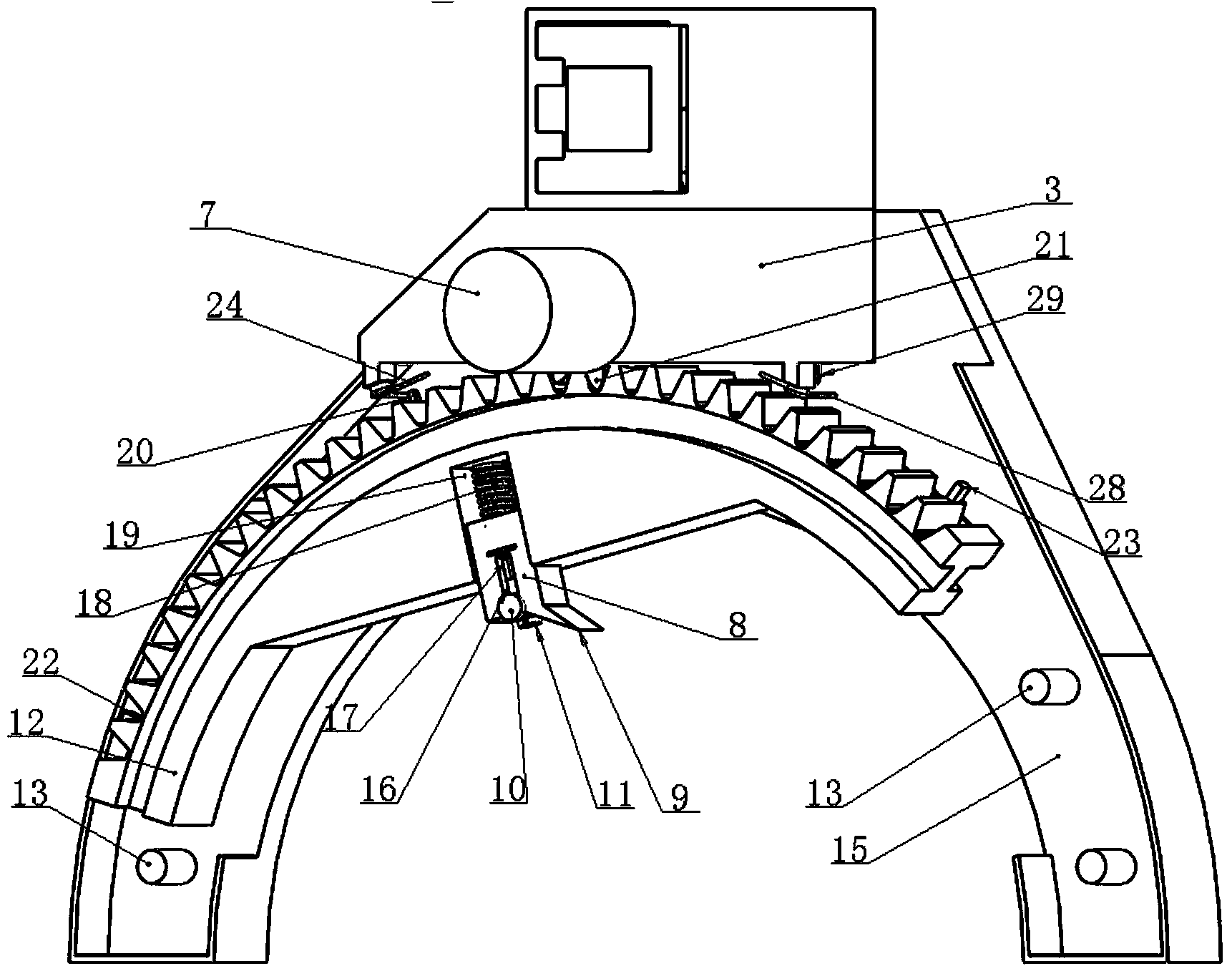

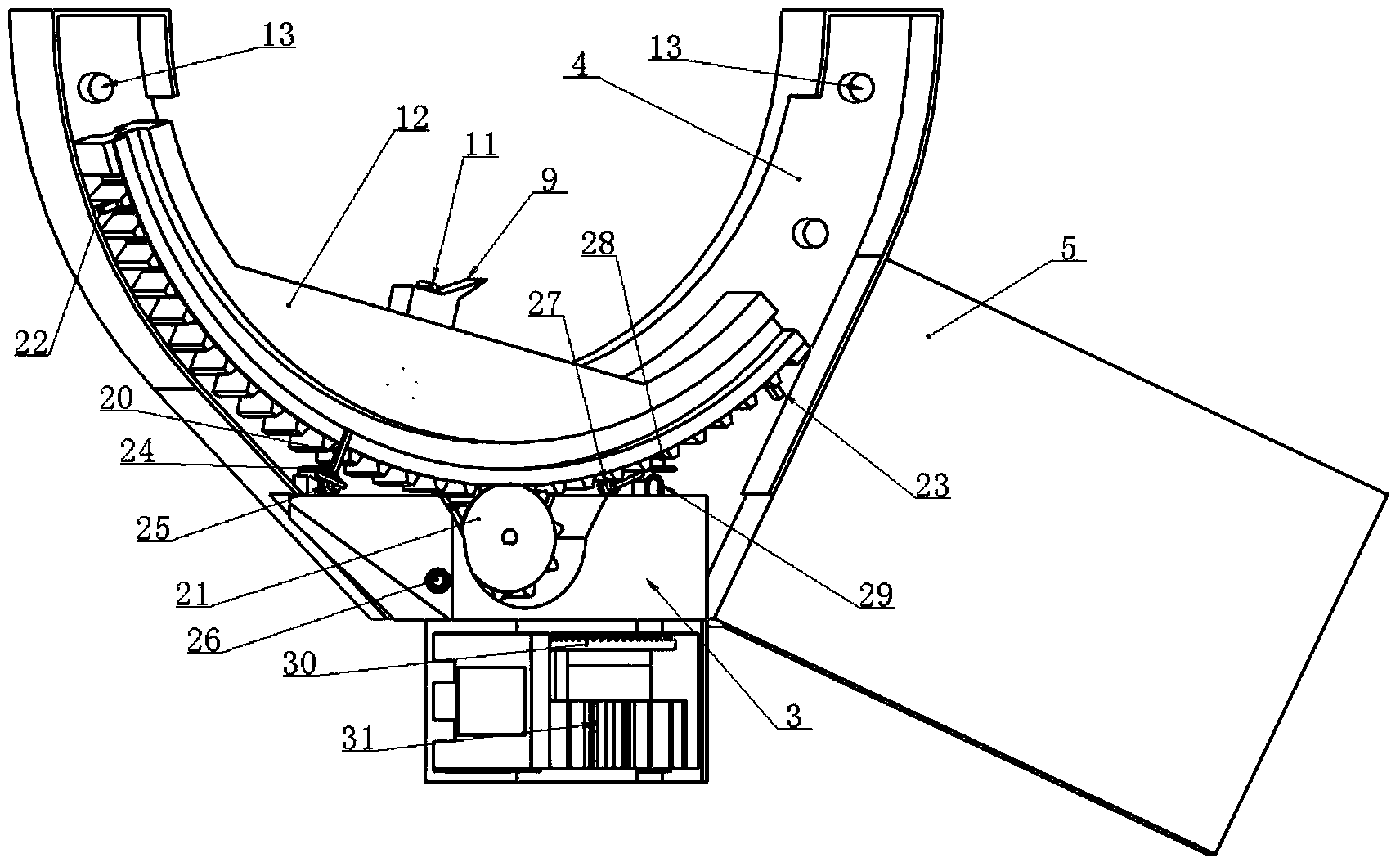

Automatic rubber tapping machine for rubber tree rubber picking

ActiveCN104067904AReduce laborAchieving Micro-Cost RequirementsRenewable energy machinesForestryEngineeringSolar power

The invention relates to an automatic rubber tapping machine for rubber tree rubber picking. The machine comprises a tapping frame and is characterized in that the tapping frame is formed by a support rod and a support arm. A cut depth location structure, a curved cutter moving structure, an automatic line feed location structure, an end point detection structure, a solar power structure and a control structure are arranged on the tapping frame. The end point detection structure is used for detecting the moving track of a cutter in the curved cutter moving structure, and the signal output end of the end point detection structure is connected with the signal input end of the control structure. The control output end of the control structure is connected with the control input ends of the cut depth location structure, the curved cutter moving structure and the automatic line feed location structure through driving mechanisms. The cut depth location structure is provided with a cutter tapping depth adjusting and locating mechanism. The curved cutter moving structure is provided with a mechanism capable of achieving arc movement, lateral movement and vertical movement simultaneously. Therefore, the automatic rubber tapping machine allowing cut depth location, end point detection limiting, automatic line feed location and the arc tapping track is formed. The automatic rubber tapping machine has the advantages of being capable of reducing labor quantity of rubber picking workers and lays a device foundation for large scale rubber automatic production and the like.

Owner:宁国市吉思知识产权运营有限公司

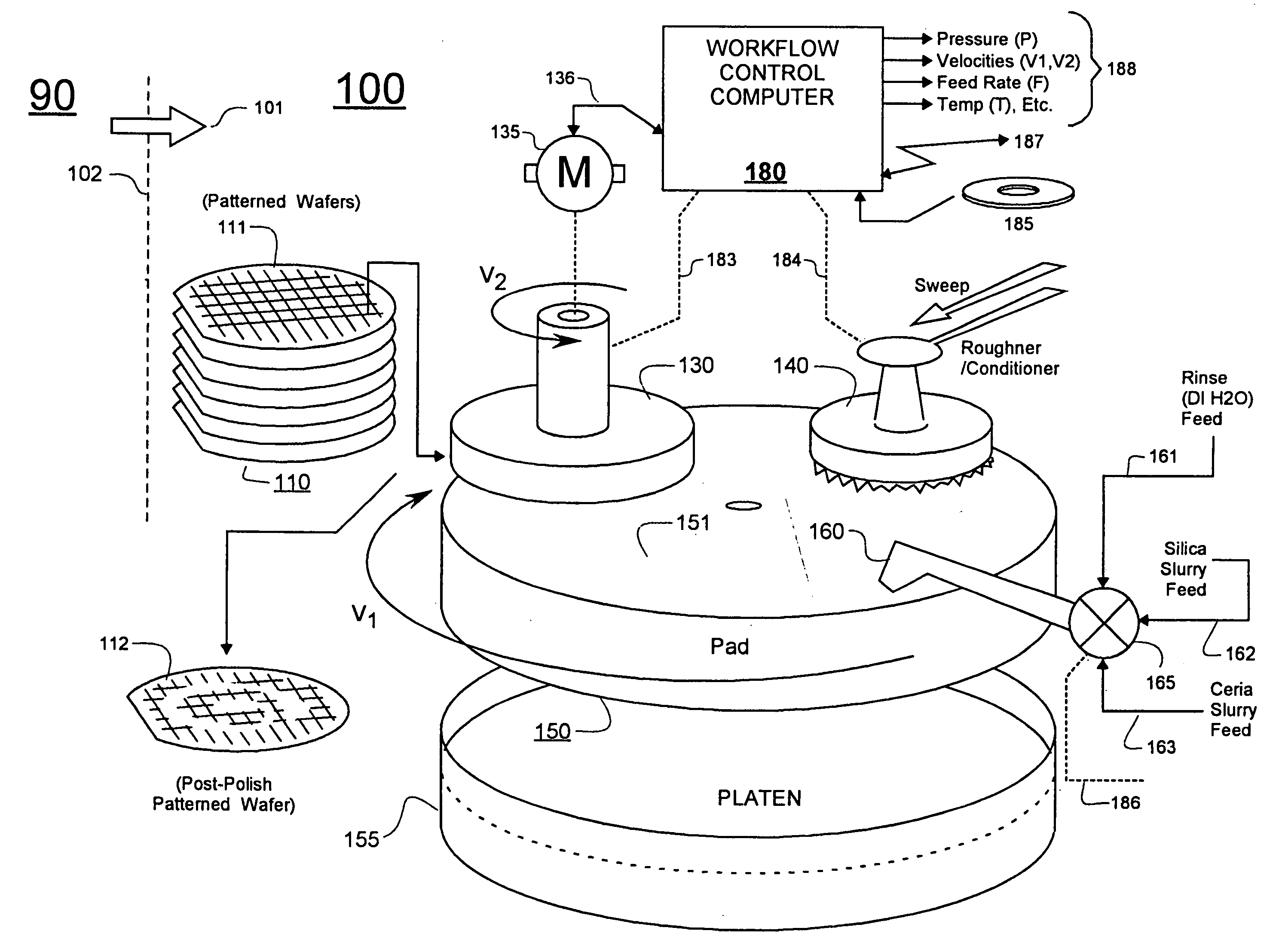

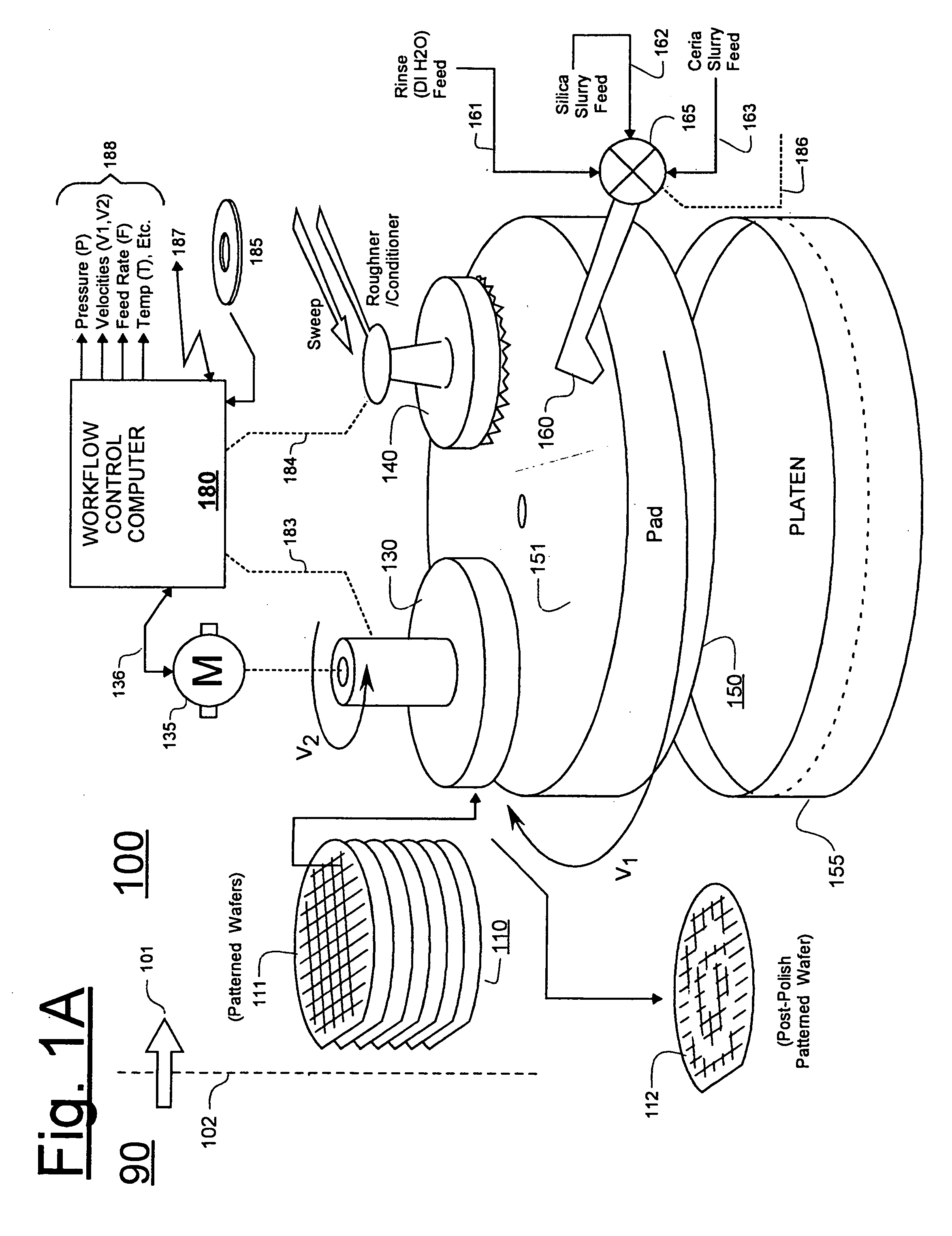

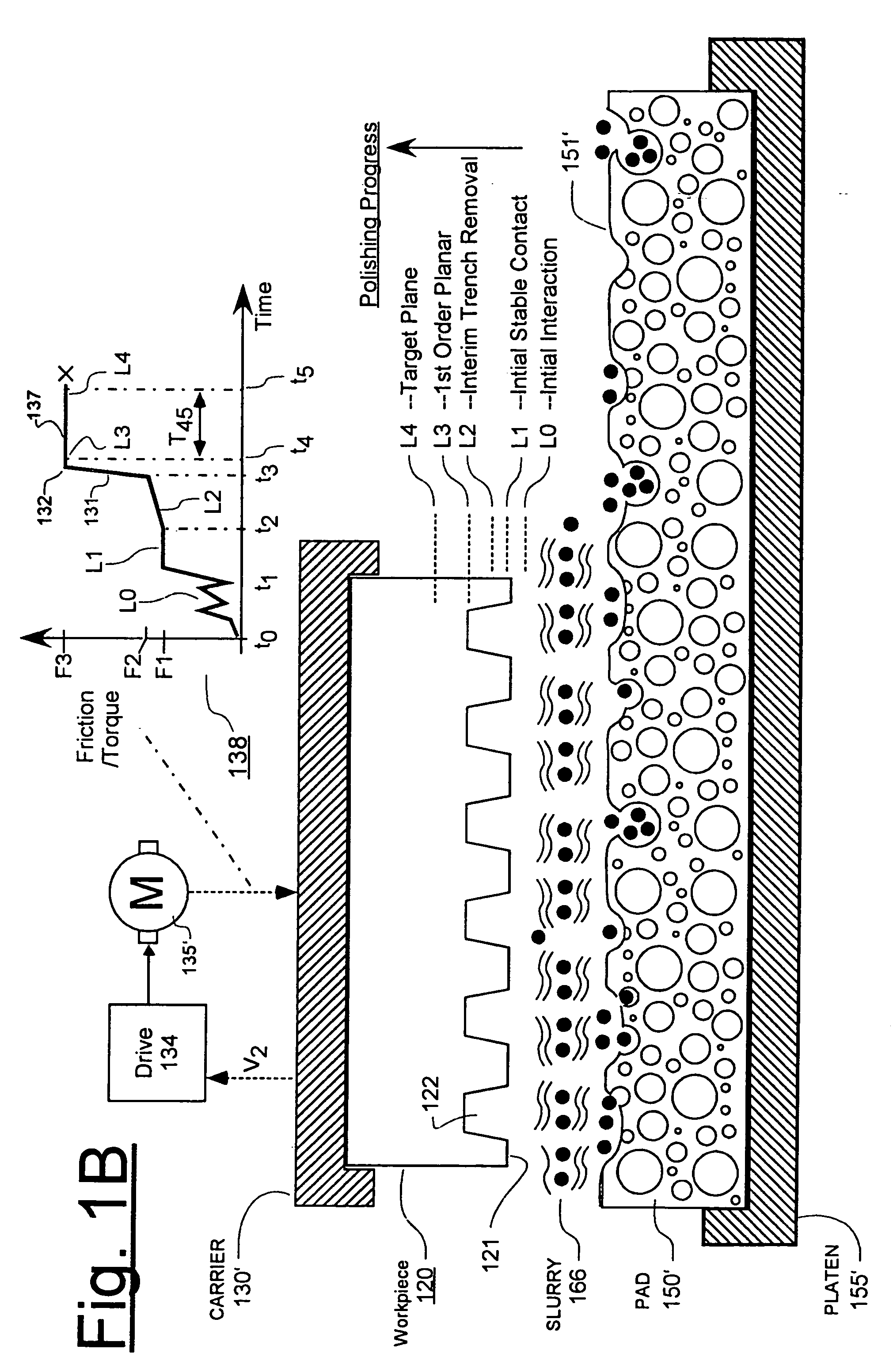

Torque-based end point detection methods for chemical mechanical polishing tool which uses ceria-based CMP slurry to polish to protective pad layer

A chemical mechanical polishing (CMP) method is disclosed in which a torque-based end-point algorithm is used to determine when polishing should be stopped. The end-point algorithm is applicable to situations where a ceria (CeO2) based CMP slurry is used for further polishing, pre-patterned and pre-polished workpieces (e.g., semiconductor wafers) which have a high friction over-layer (e.g., HDP-oxide) and a comparatively, lower friction and underlying layer of sacrificial pads (e.g., silicon nitride pads). A mass production wise, reliable and consistent signature point in the friction versus time waveform of a torque-representing signal is found and used to trigger an empirically specified duration of overpolish. A database may be used to define the overpolish time as a function of one or more relevant parameters.

Owner:PROMOS TECH INC

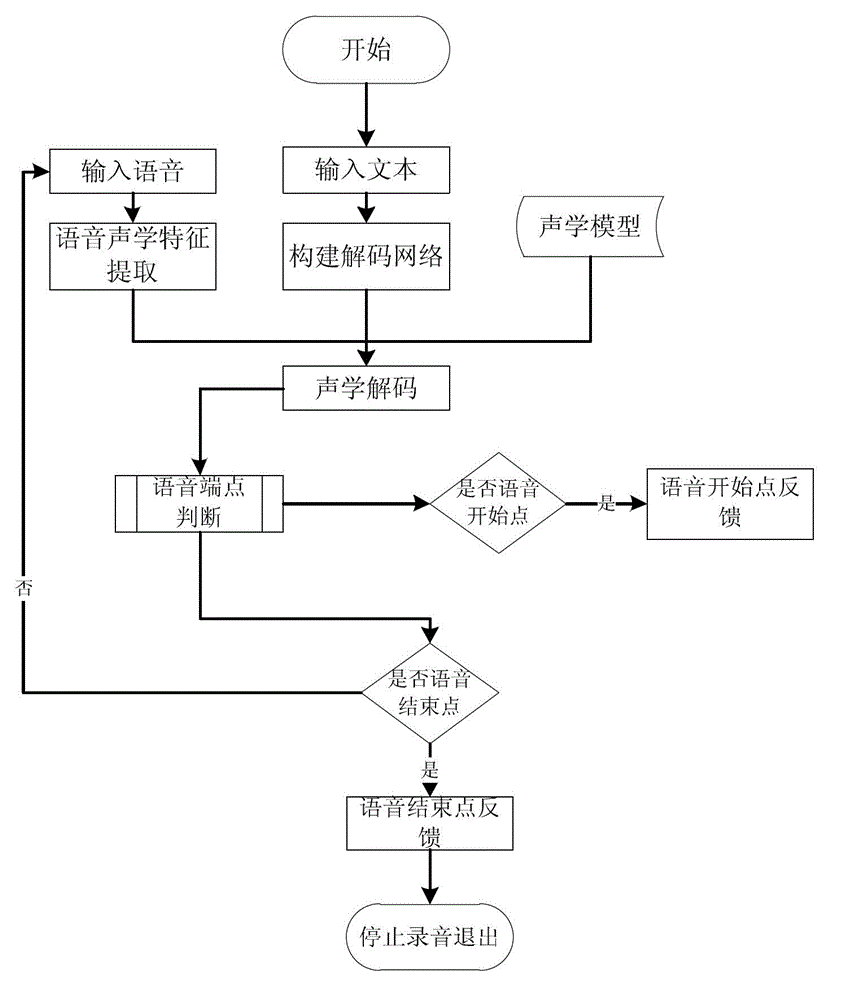

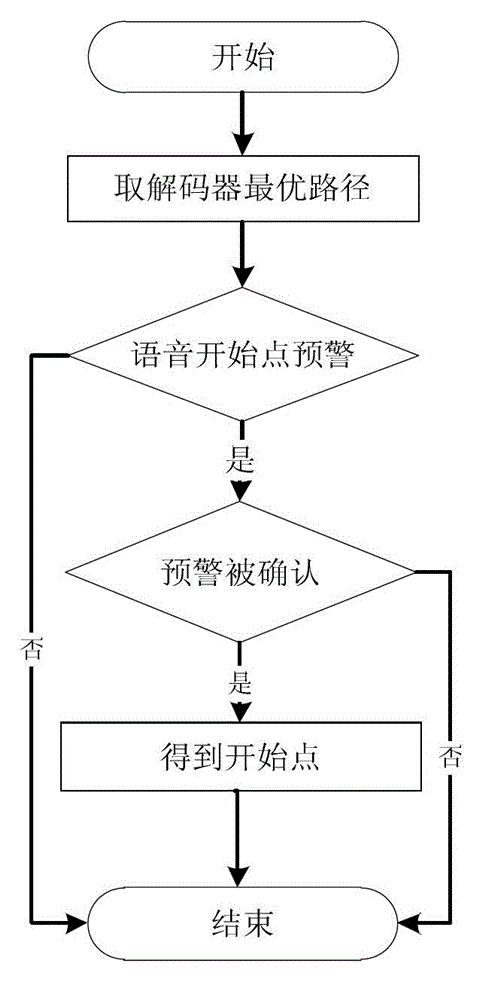

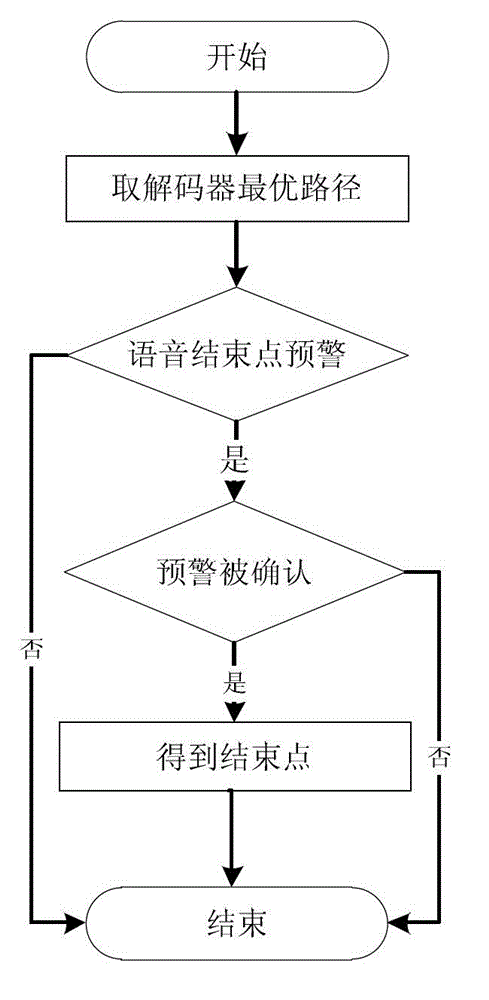

Voice endpoint detection method based on real-time decoding

ActiveCN102982811AShort response timeImprove real-time performanceSpeech recognitionSpeech synthesisExternal applicationSpeech sound

A voice endpoint detection method based on real-time decoding includes the following steps: inputting texts related to voice recognition, analyzing the texts, constructing a decoding network according to text analyzing results, inputting voice, extracting acoustic characteristics in the voice, decoding the acoustic characteristics based on the constructed decoding network to obtain a decoded voice unit sequence, conducting voice endpoint judgment on the decoded voice unit sequence to judge whether voice endpoints exist or not, dividing voice endpoints into voice starting points and voice ending points, feeding voice endpoint information to an external application system on yes judgment and continuing step2 on no judgment. The voice starting point judgment is selectable in the third step, and voice starting point is not judged if the external application system does not care about the voice starting point. The voice endpoint detection method resolves the problem that targeted detection cannot be conducted on voice cared by users due to the fact that real time performance of the traditional endpoint detection technology is not high under the condition that voice recognition texts are not determined.

Owner:ANHUI IFLYREC TECH CO LTD

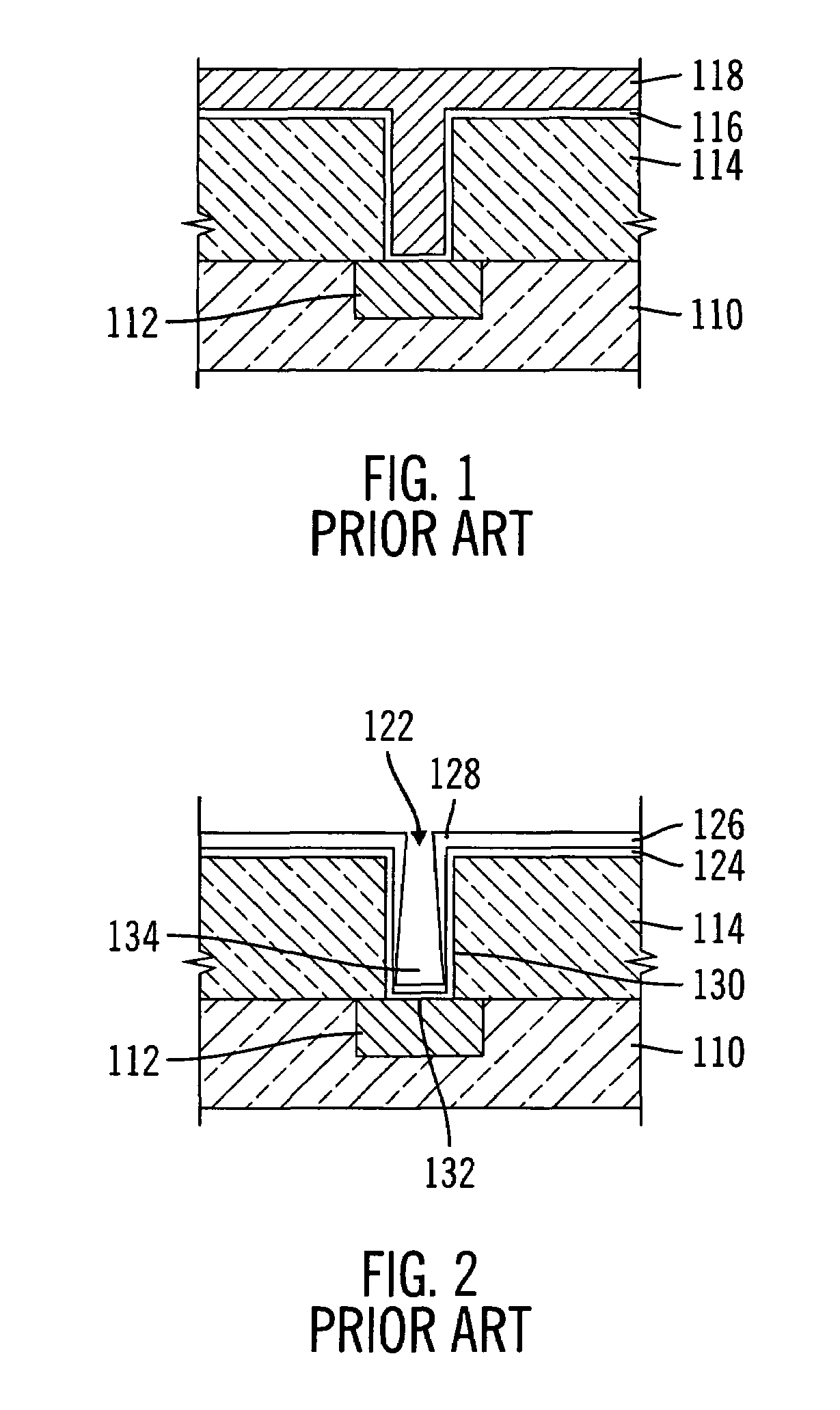

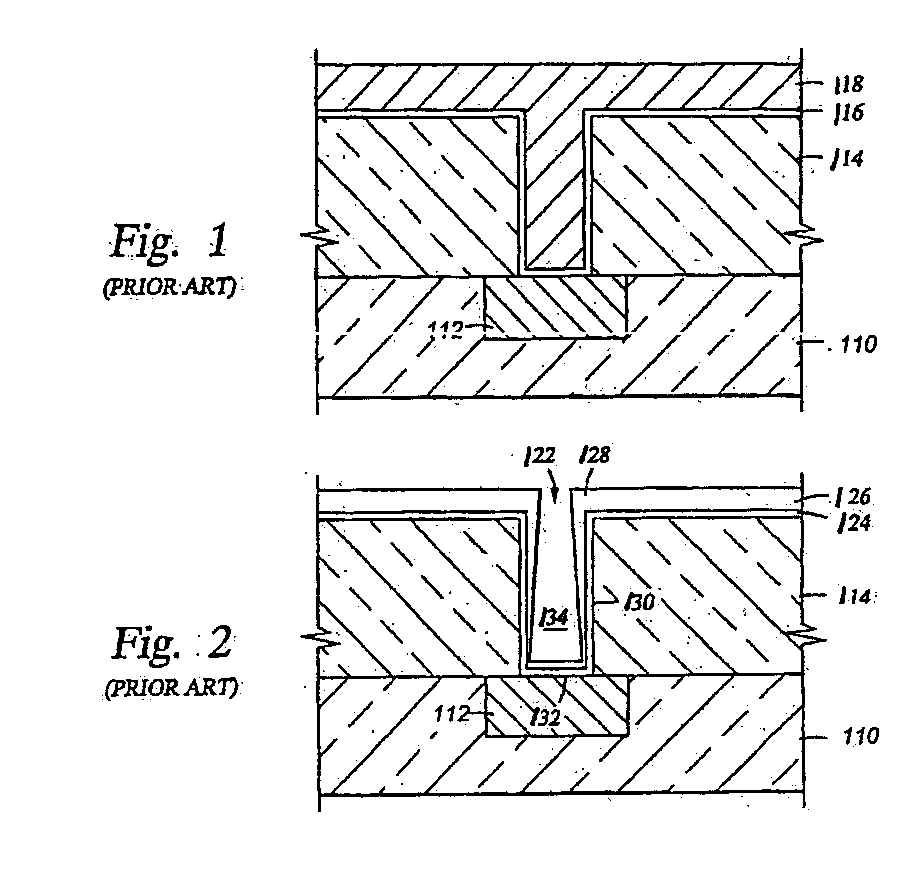

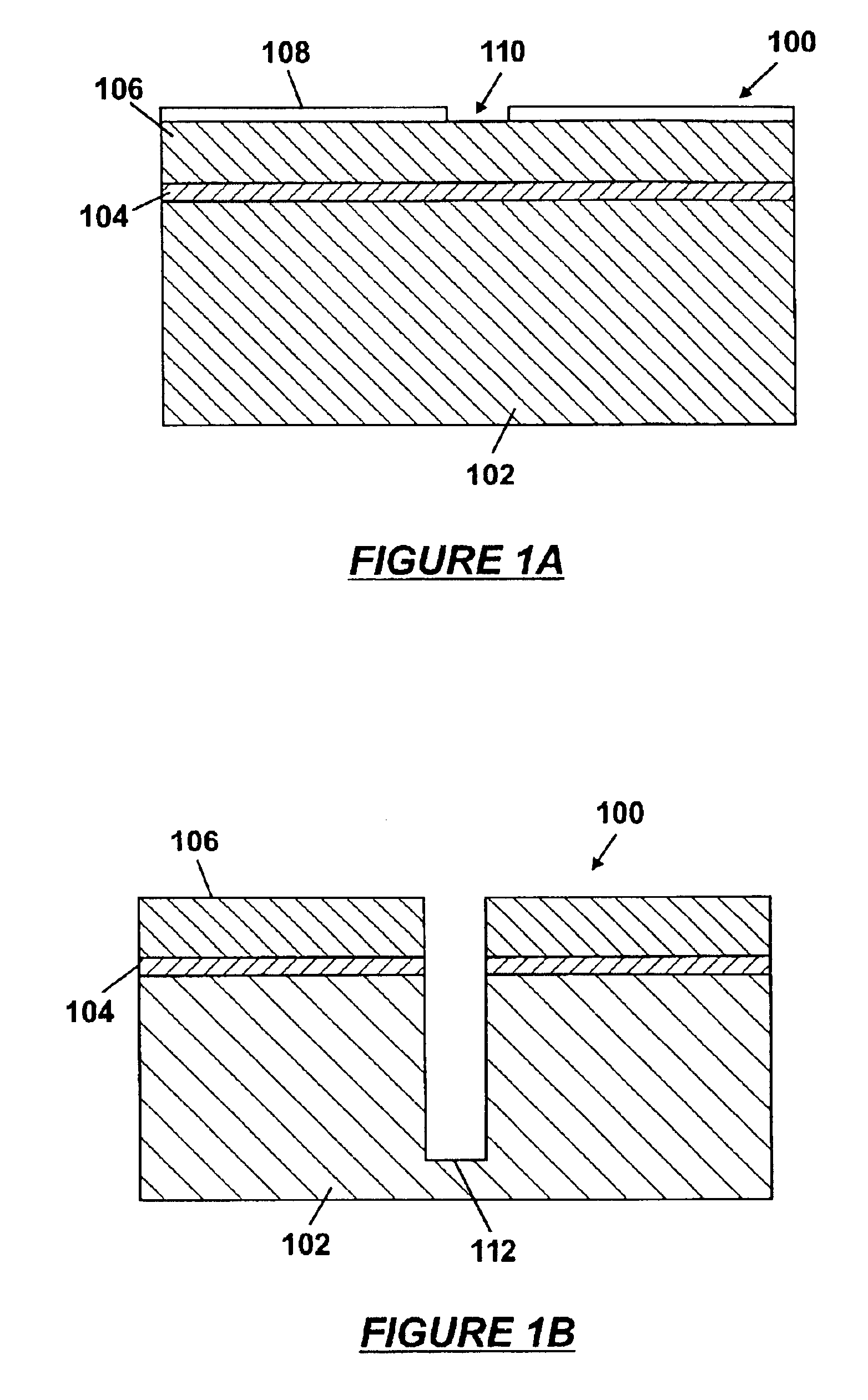

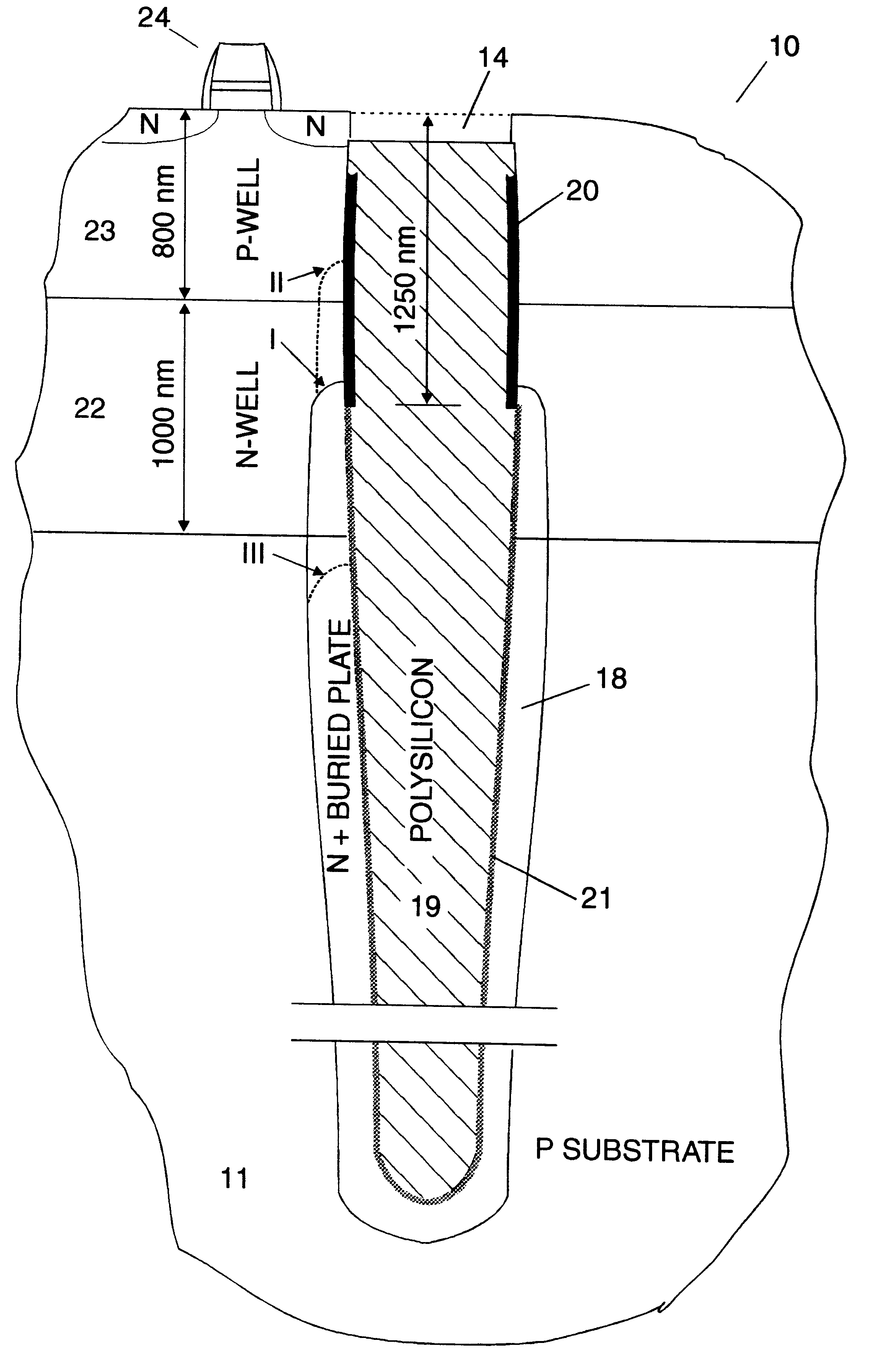

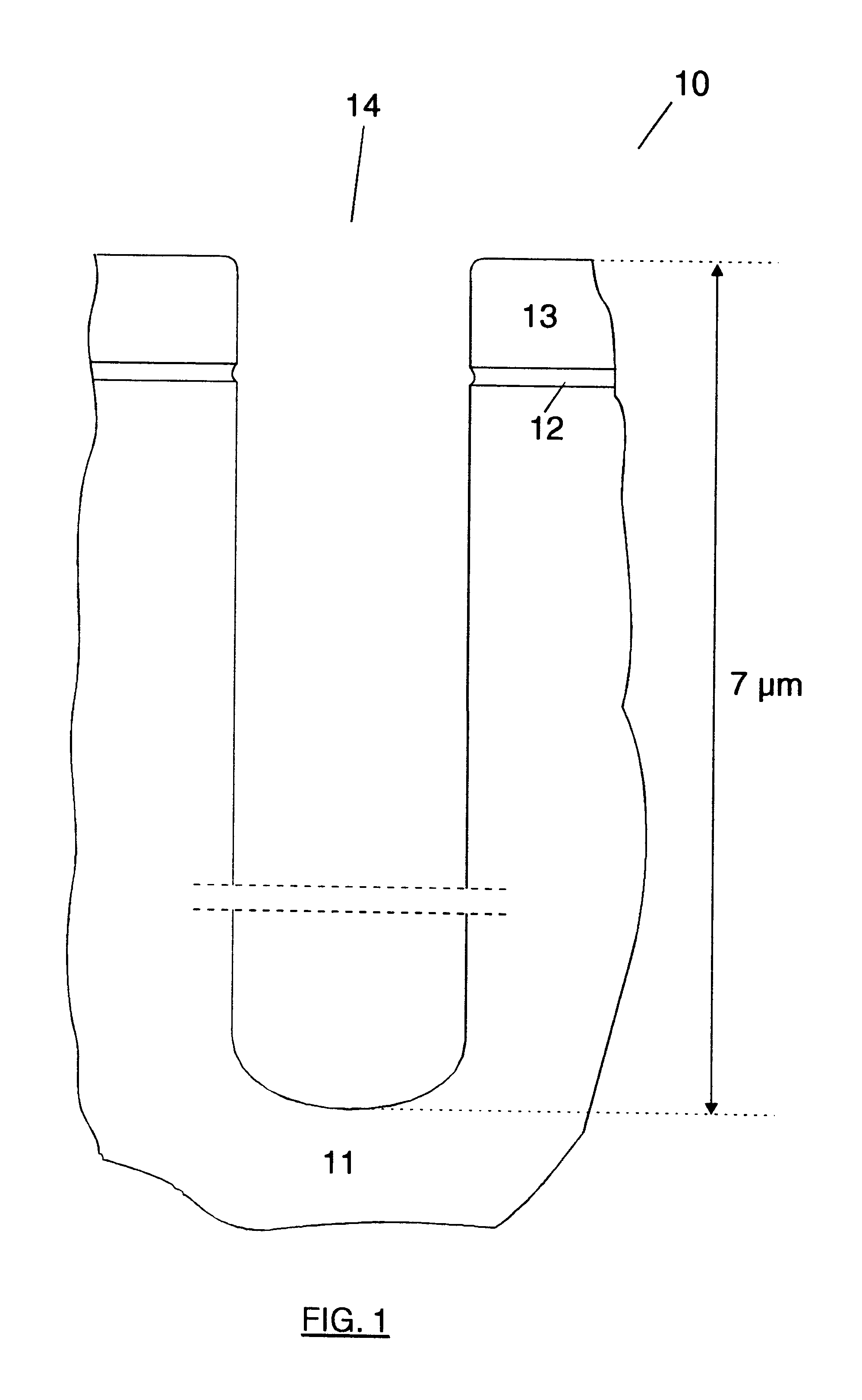

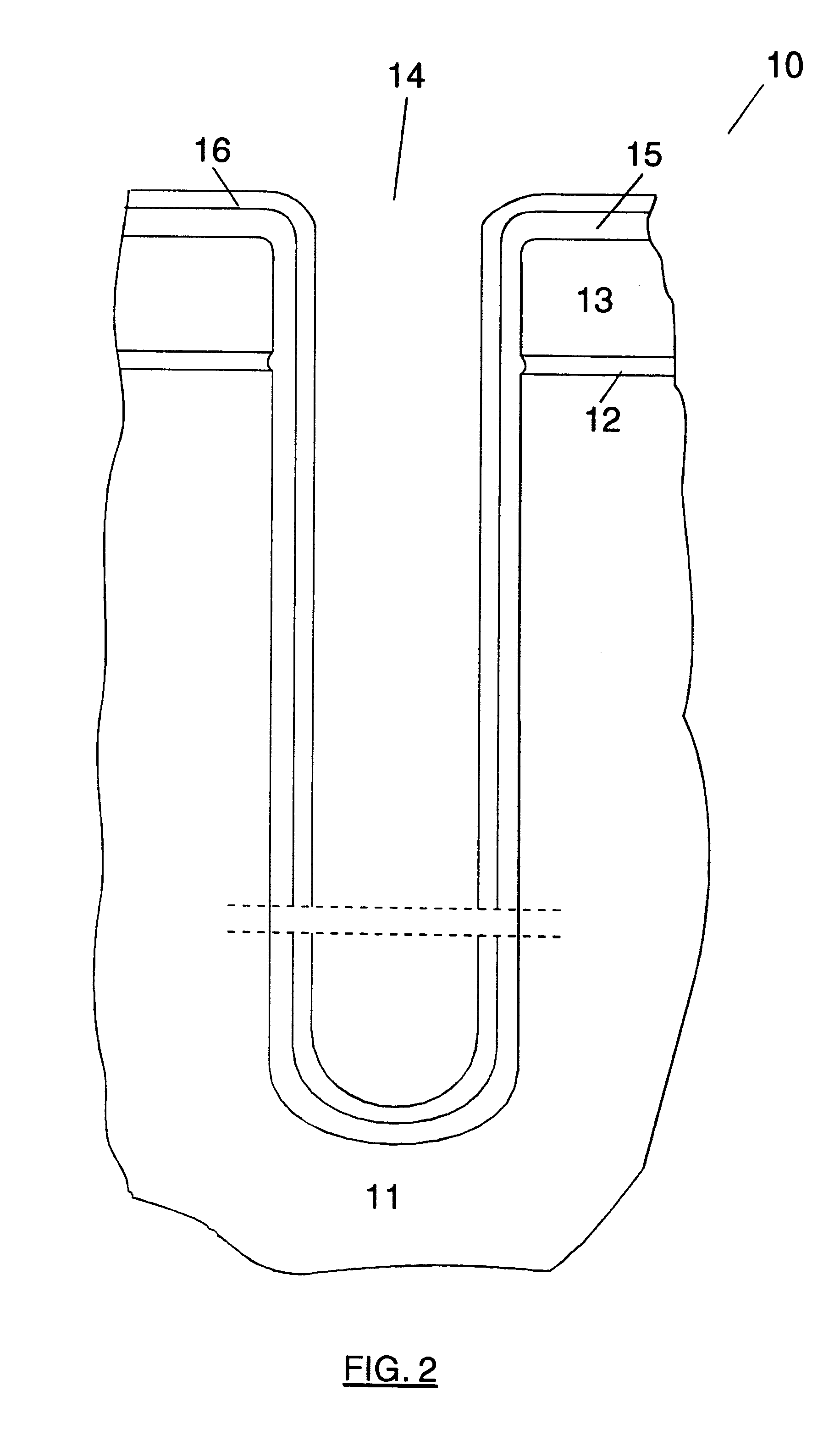

Method for buried plate formation in deep trench capacitors

InactiveUS6281068B1Manufacturing process flow simplificationBig advantageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPolymer

An improved method of forming the buried plate regions in deep trench capacitors used in DRAM memory semiconductor circuits in which the polymer used in the deep trench is etched down to the desired depth in a reactive ion etch tool using an O2 / CF4 chemistry. Since optical / interferometric etch end-point detection system can be used to monitor the etch back step in its totality, the quantity of the polymer remaining in deep trenches can be very accurately controlled, which in turn will produce a well controlled buried plate region during the out-diffusion step of the arsenic dopant contained in the arsenic doped silicon glass layer.

Owner:IBM CORP

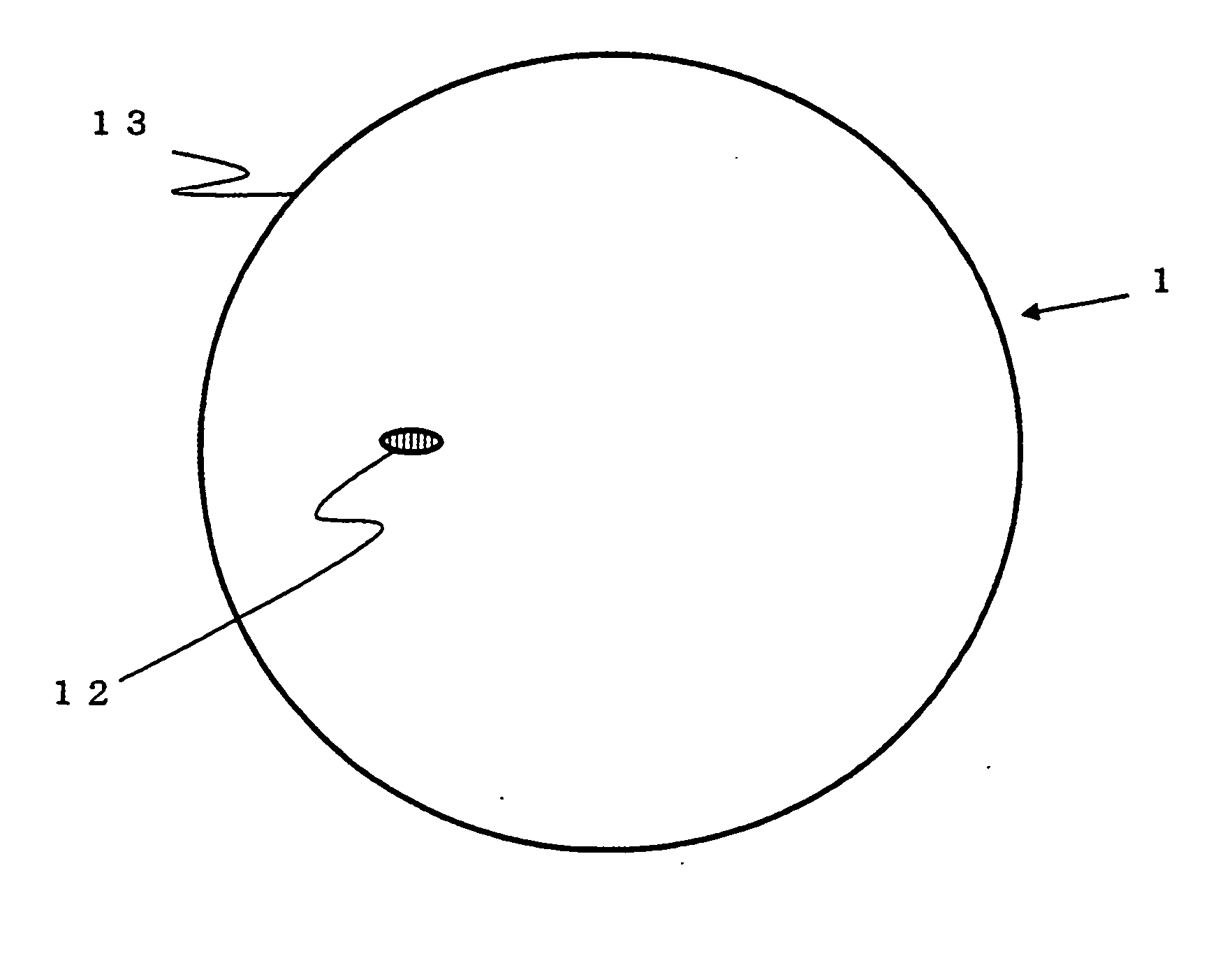

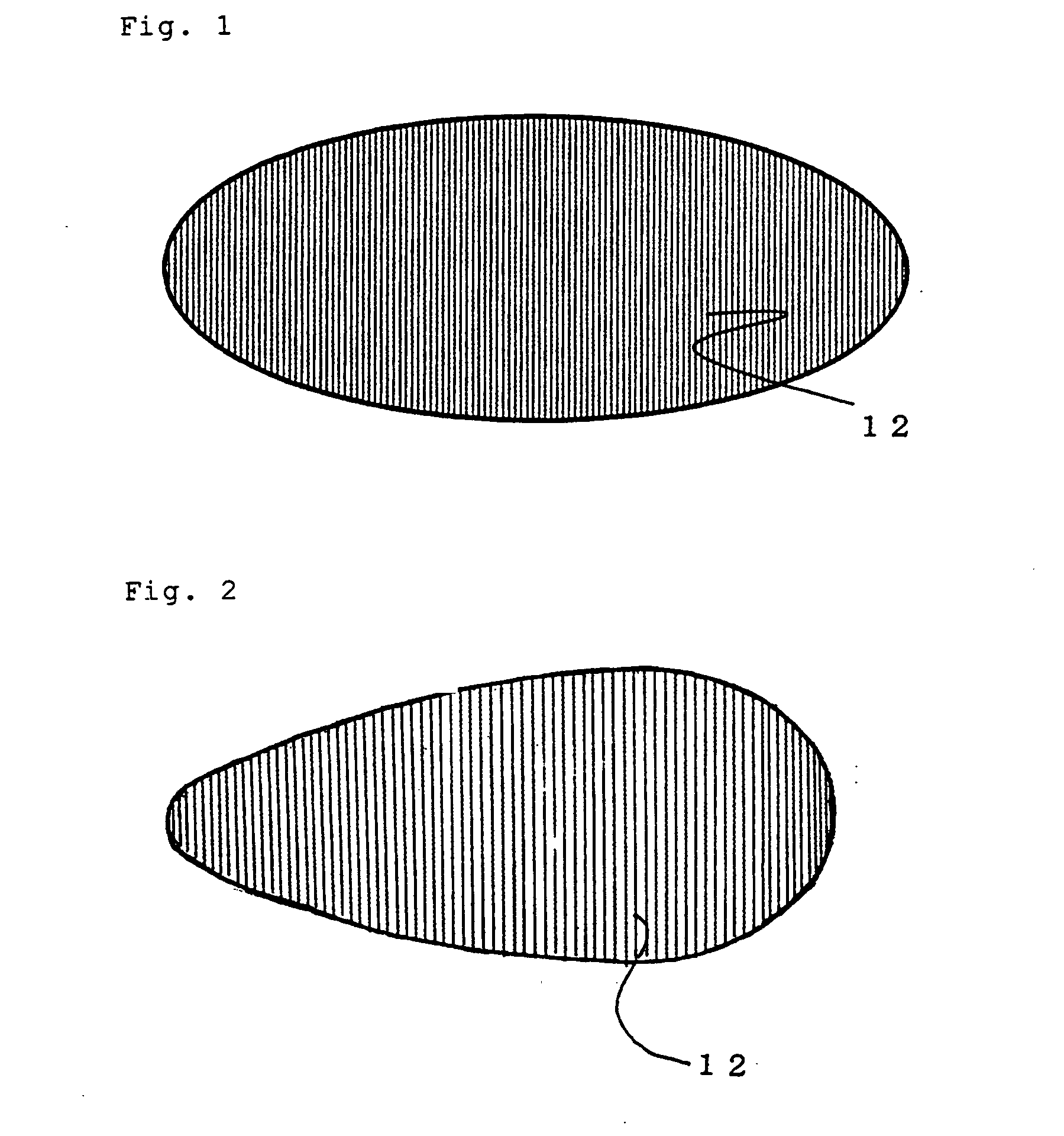

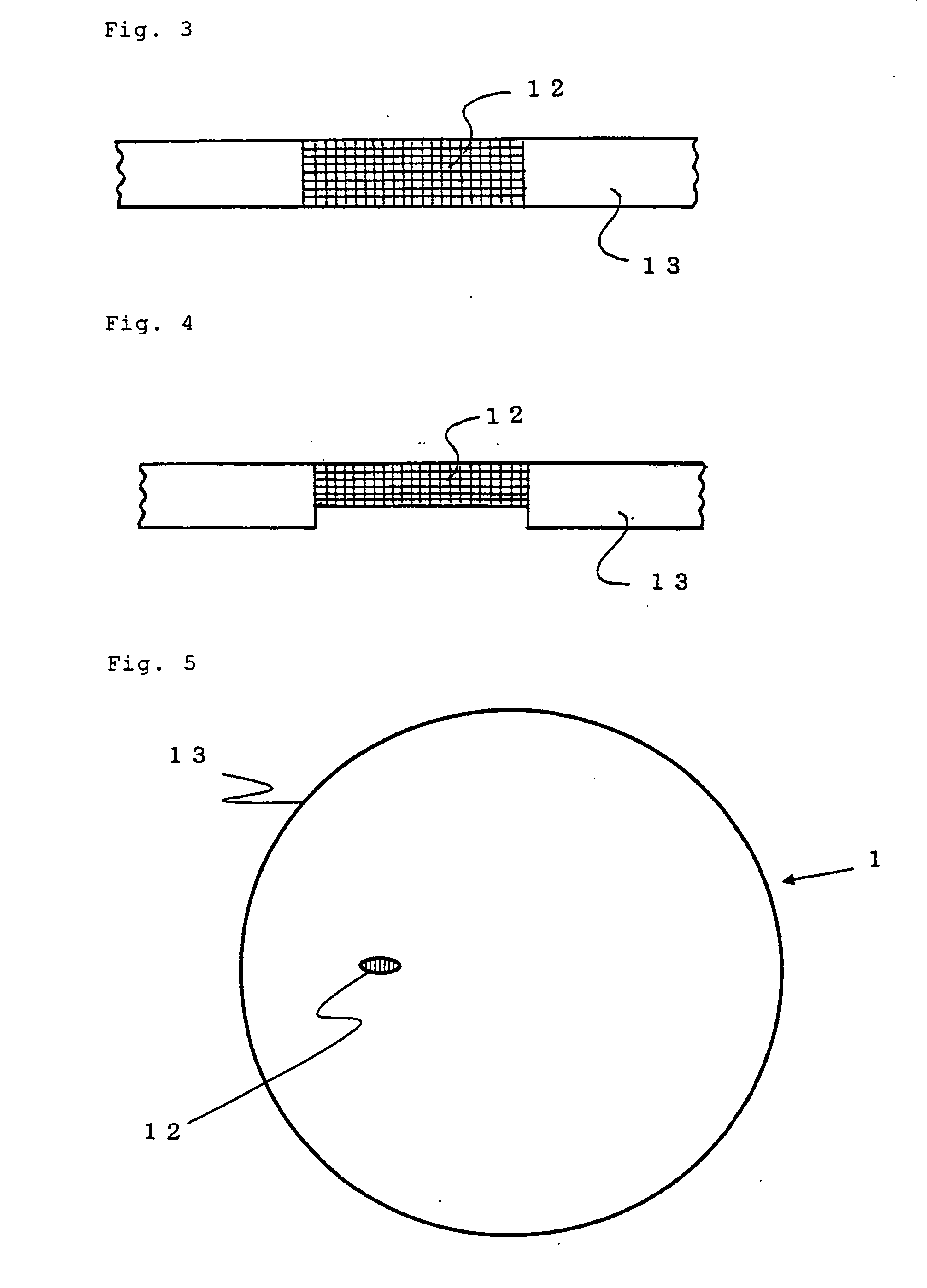

Chemical mechanical polishing pad, manufacturing process thereof and chemical mechanical polishing method for semiconductor wafers

InactiveUS20050245171A1Improve polishing efficiencySemiconductor/solid-state device manufacturingLapping machinesLongest DiameterCompound (substance)

There is provided a chemical mechanical polishing pad containing a polishing substrate having a polishing surface and a light-transmitting member fused to the polishing substrate. The sectional form of the light-transmitting member when it is cut with a plane parallel to the polishing surface is elliptic with a value obtained by dividing its long diameter by its short diameter of more than 1. The pad is capable of transmitting end-point detection light without reducing its polishing efficiency in polishing a semiconductor wafer.

Owner:JSR CORPORATIOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com