Patents

Literature

60 results about "Laser milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

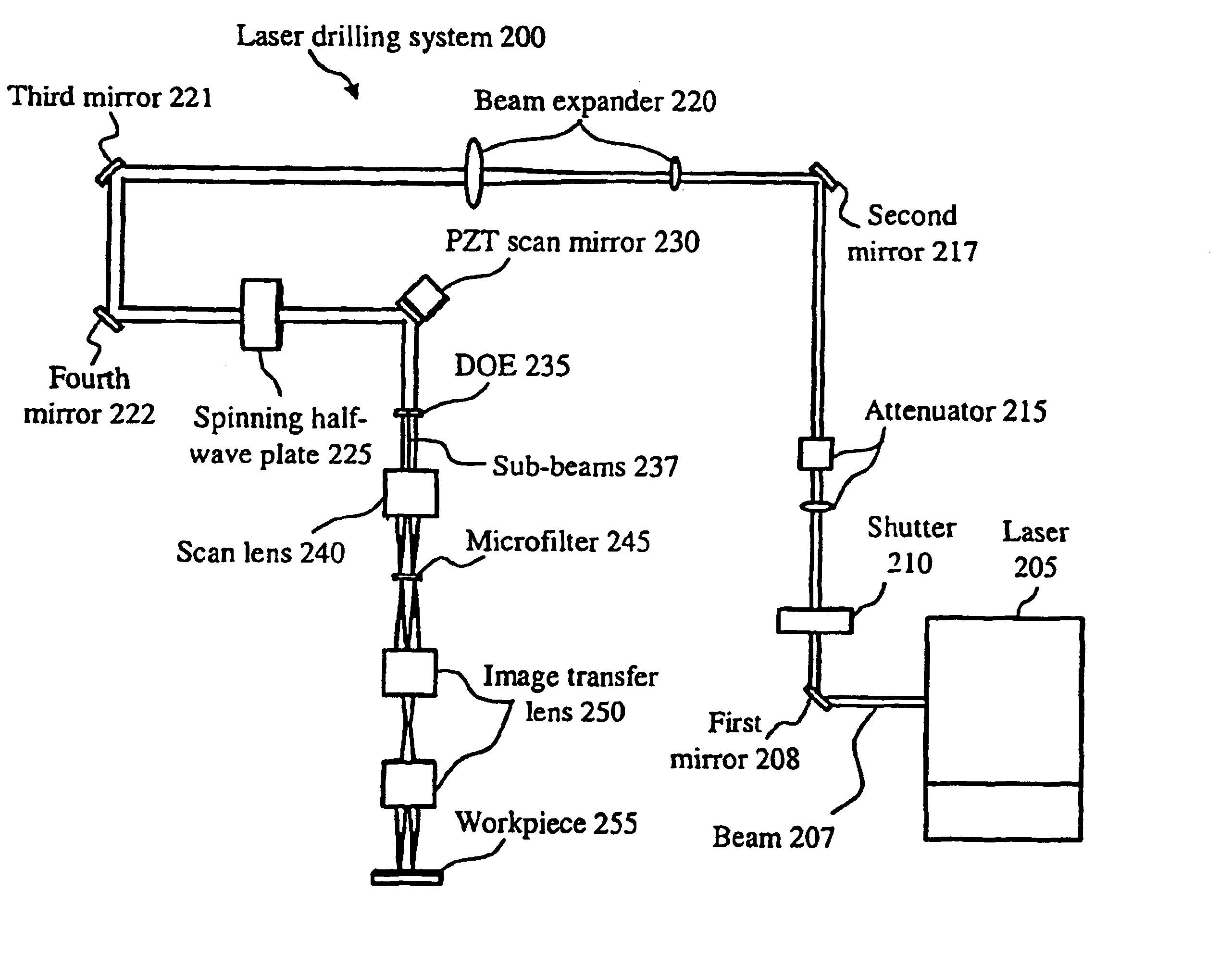

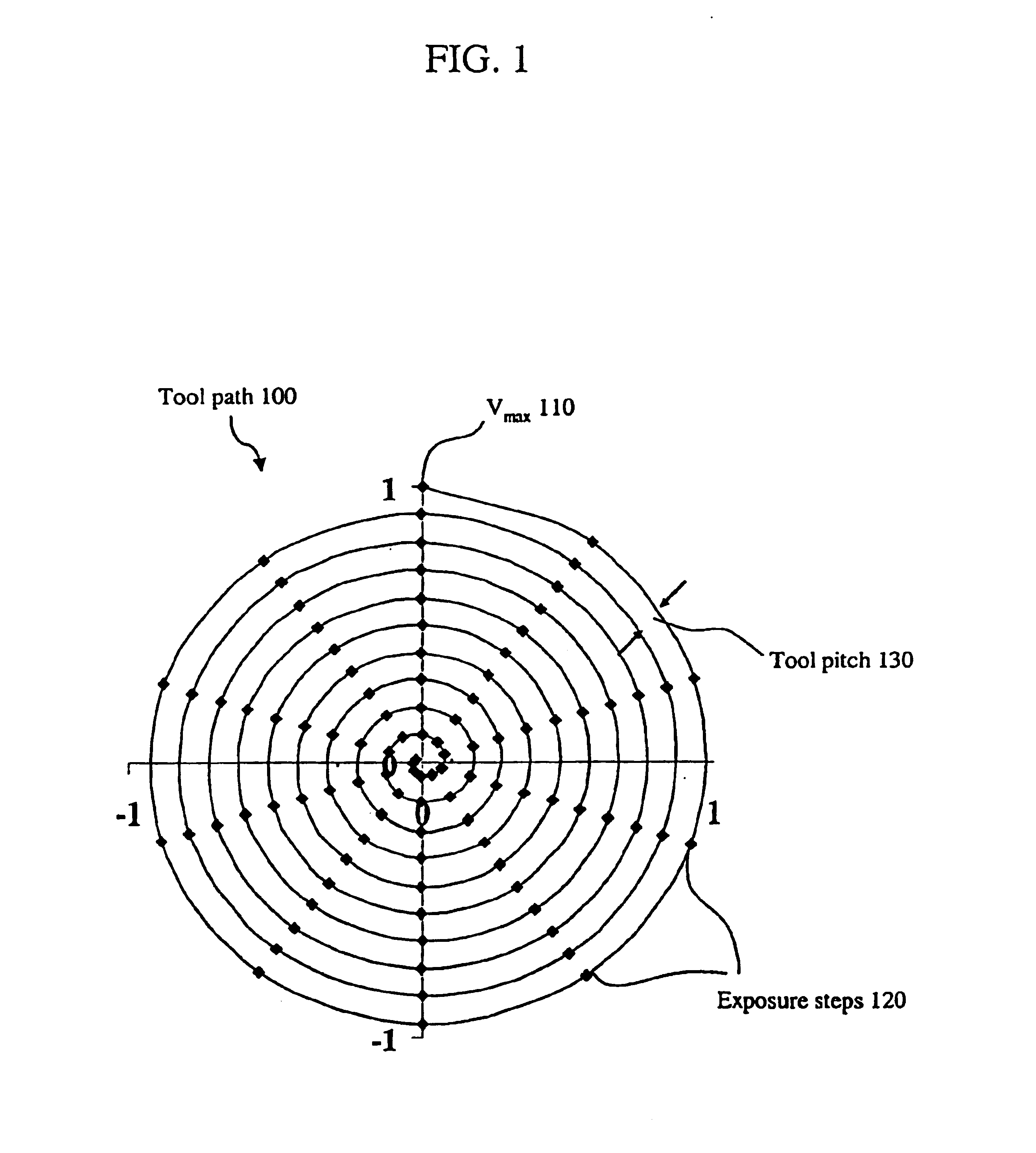

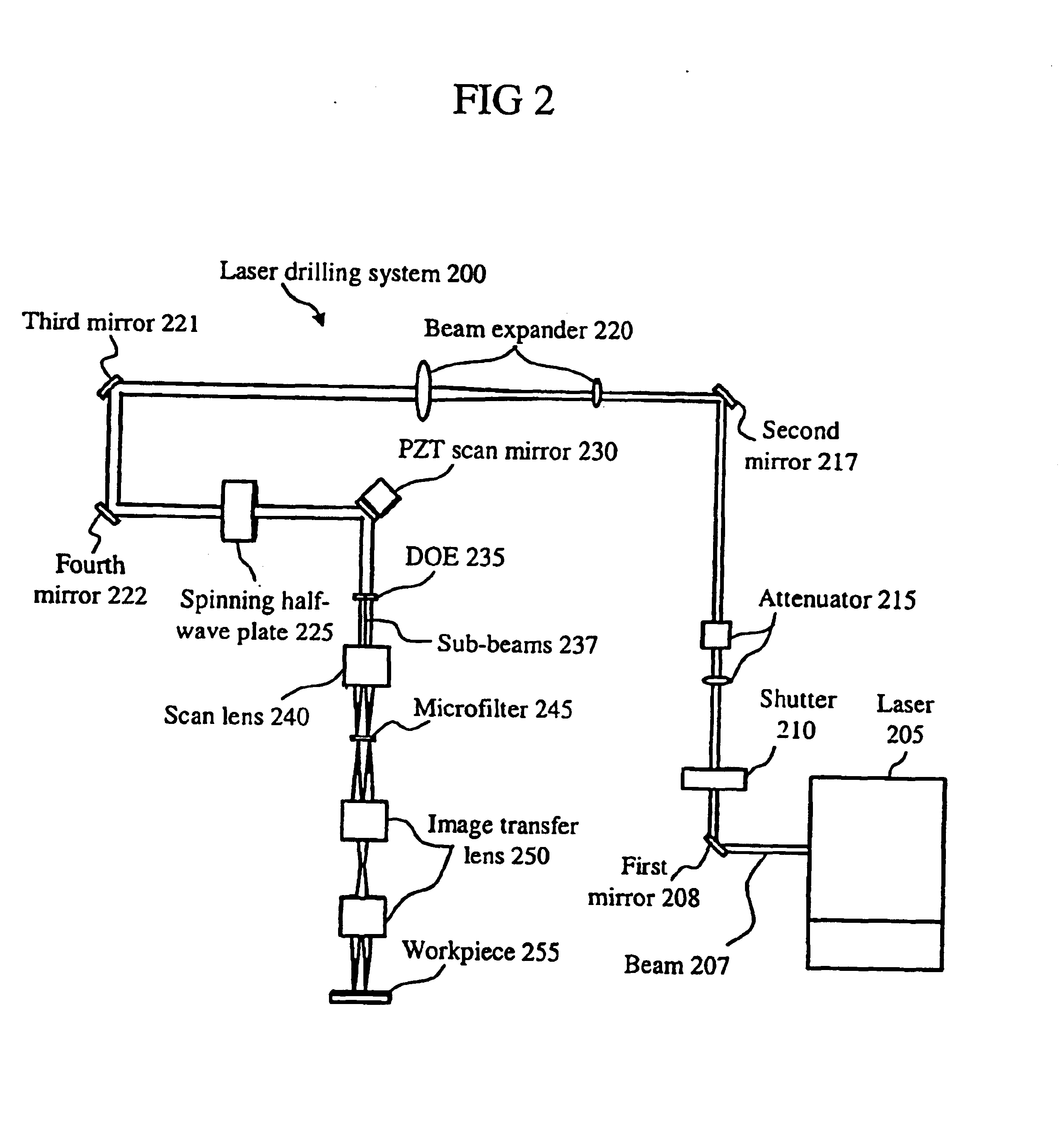

Method of laser milling using constant tool path algorithm

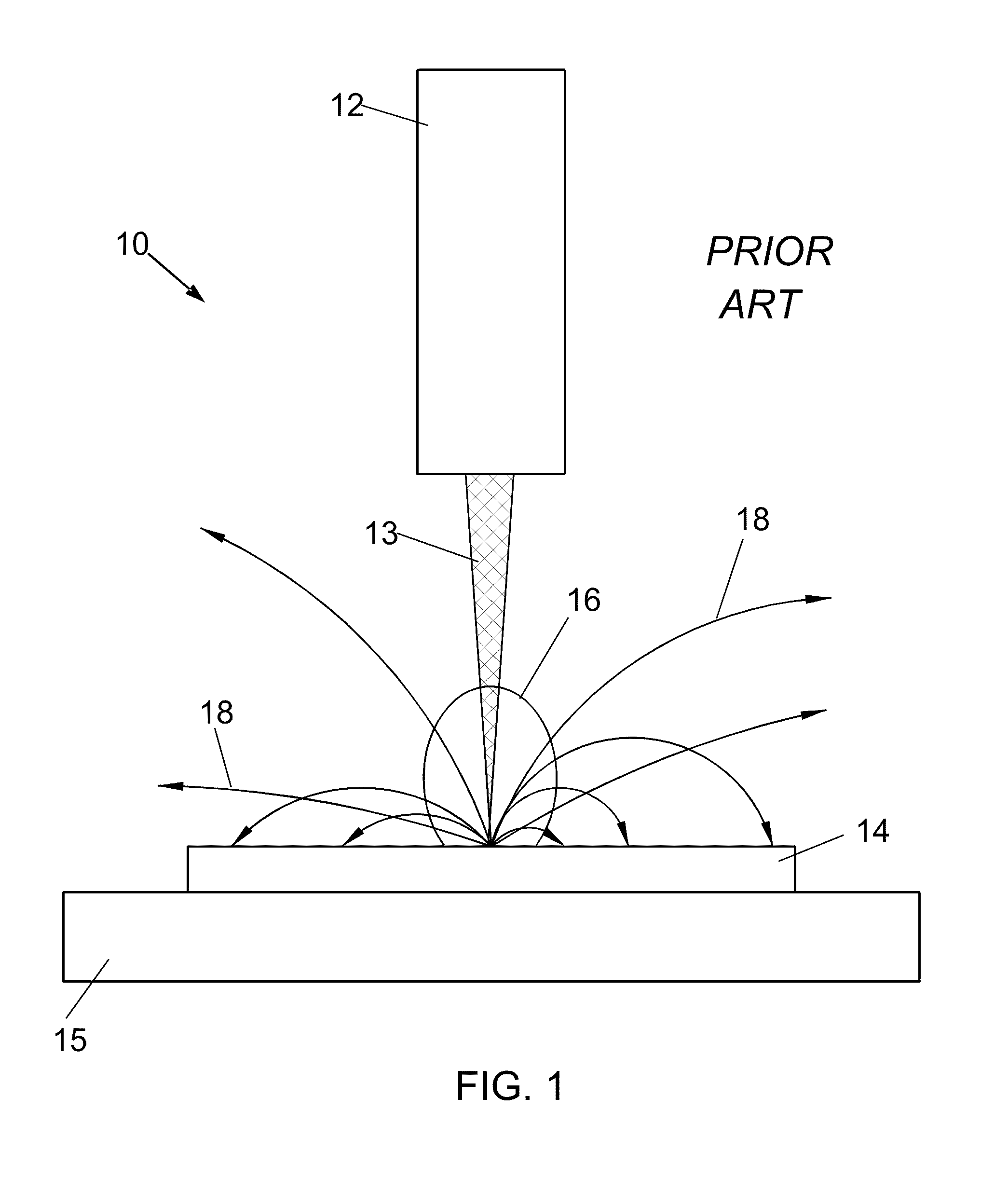

InactiveUS6897405B2Quality improvementGood repeatabilityPrinted circuit manufacturePrintingPicosecond laserLight energy

A method of creating a milled structure in a fixed material using a moving laser beam is disclosed, where a picosecond laser provides short pulses of light energy to produce required exposure steps, where a variable rate of laser beam movement conducts the milling upon the material, where the laser beam tool path directs the milling process to produce a milled hole of high quality and repeatability, and where the knowledge of how to measure these 3 quantities is returned as feedback into the laser system. The present invention is further embodied as a spiral milled tool path structured to achieve the customer specified tapered hole shape. The constant arc speed tool path is required to produce tapered holes to customer specification.

Owner:PANASONIC CORP

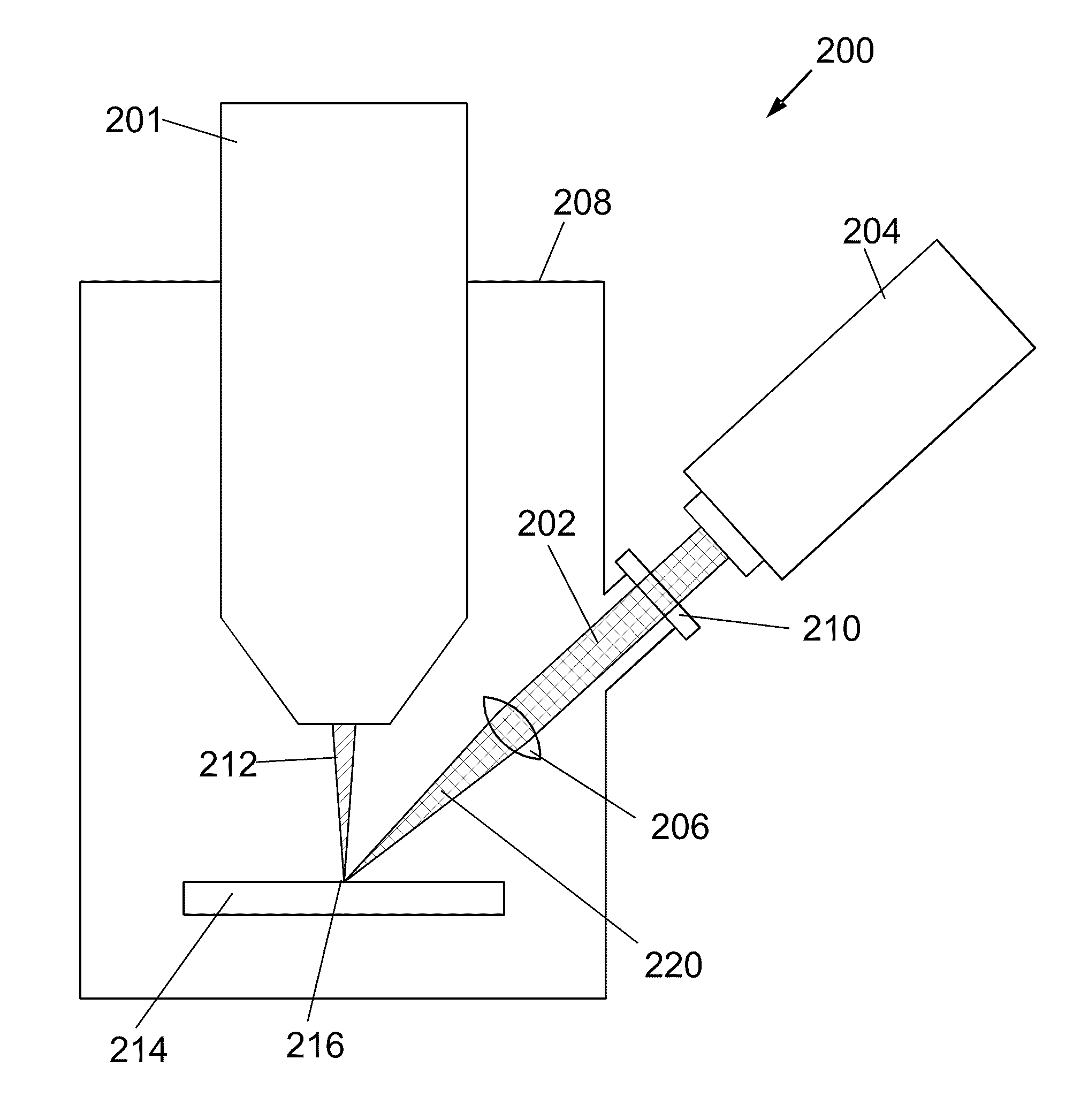

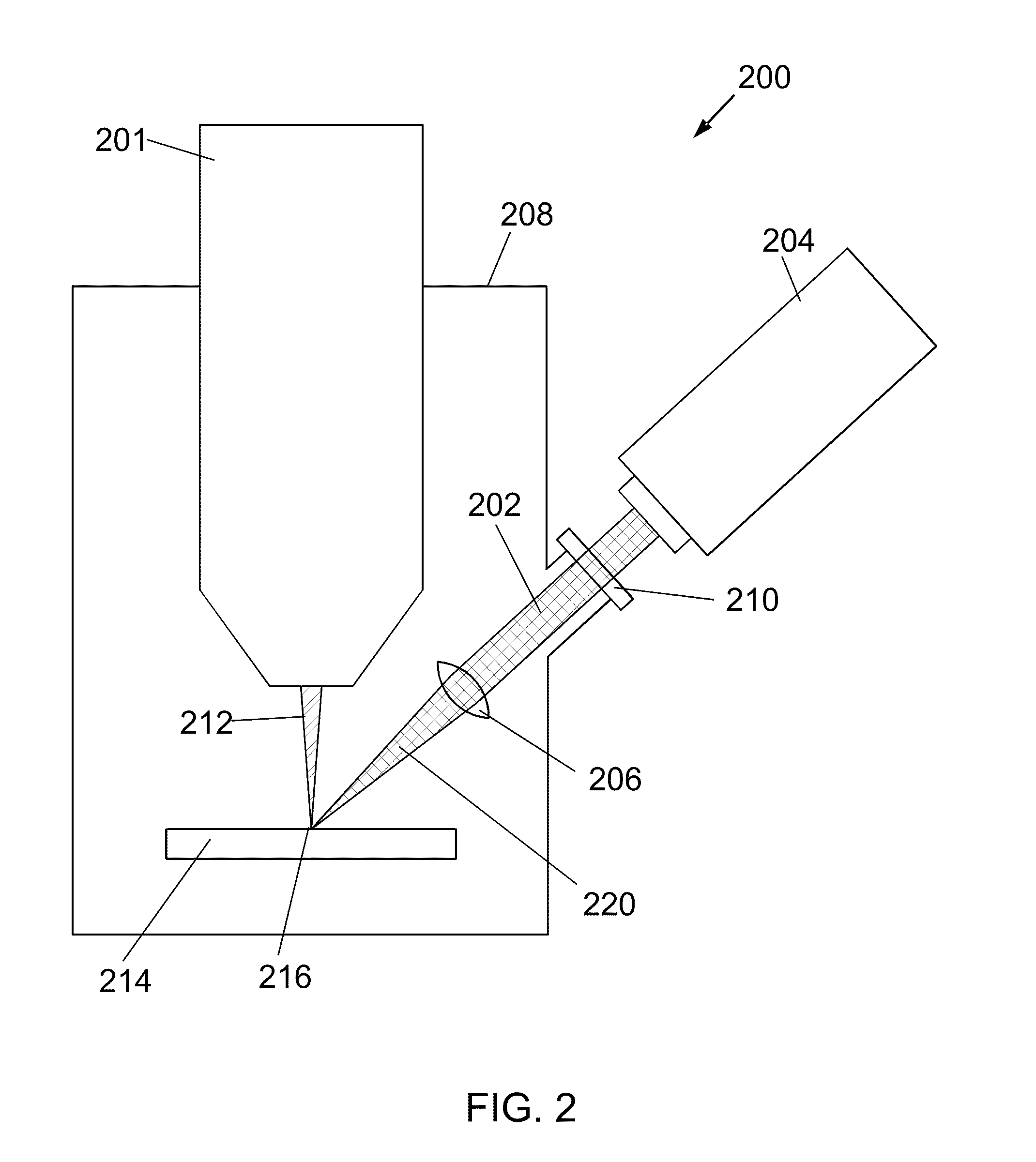

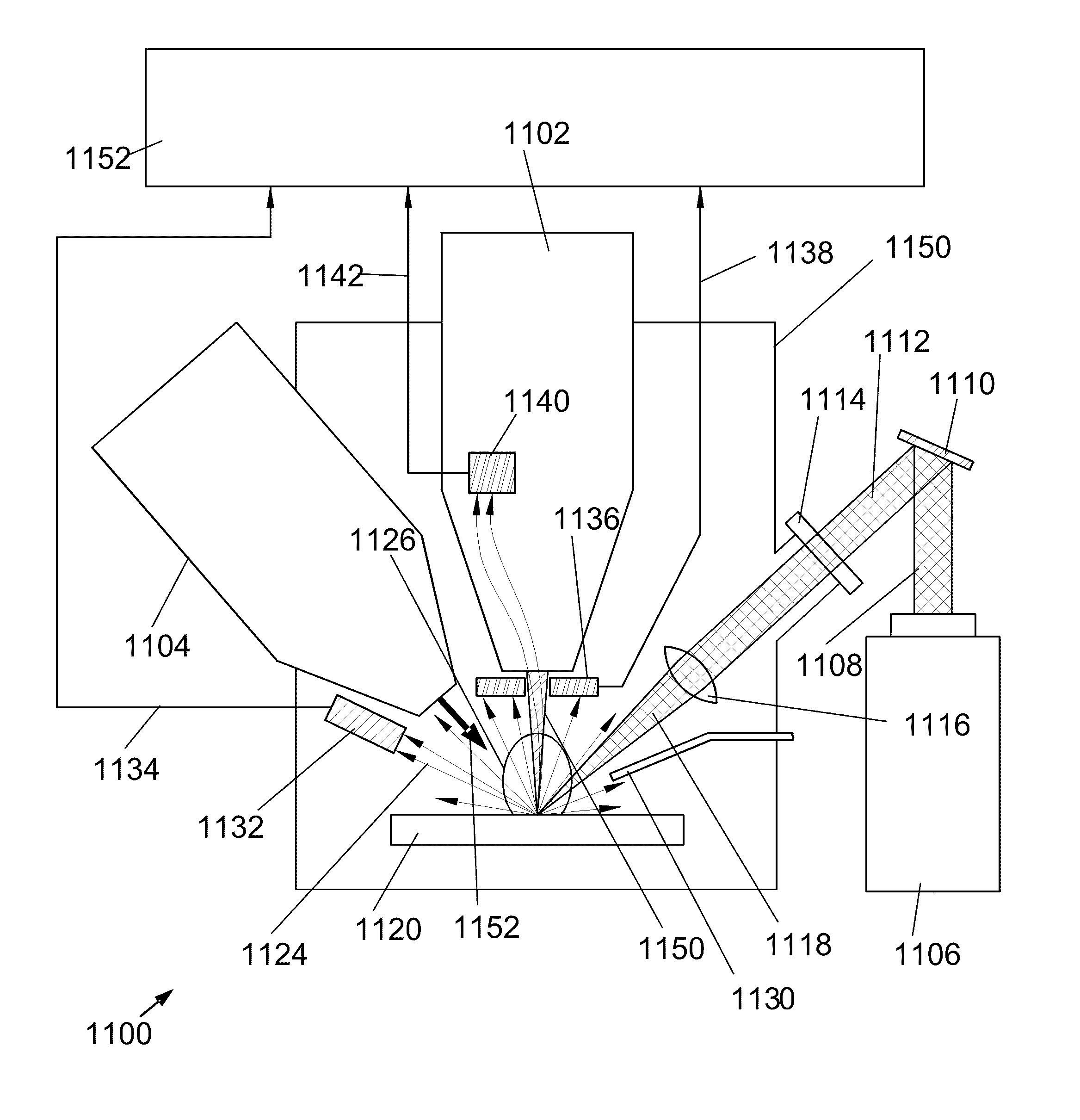

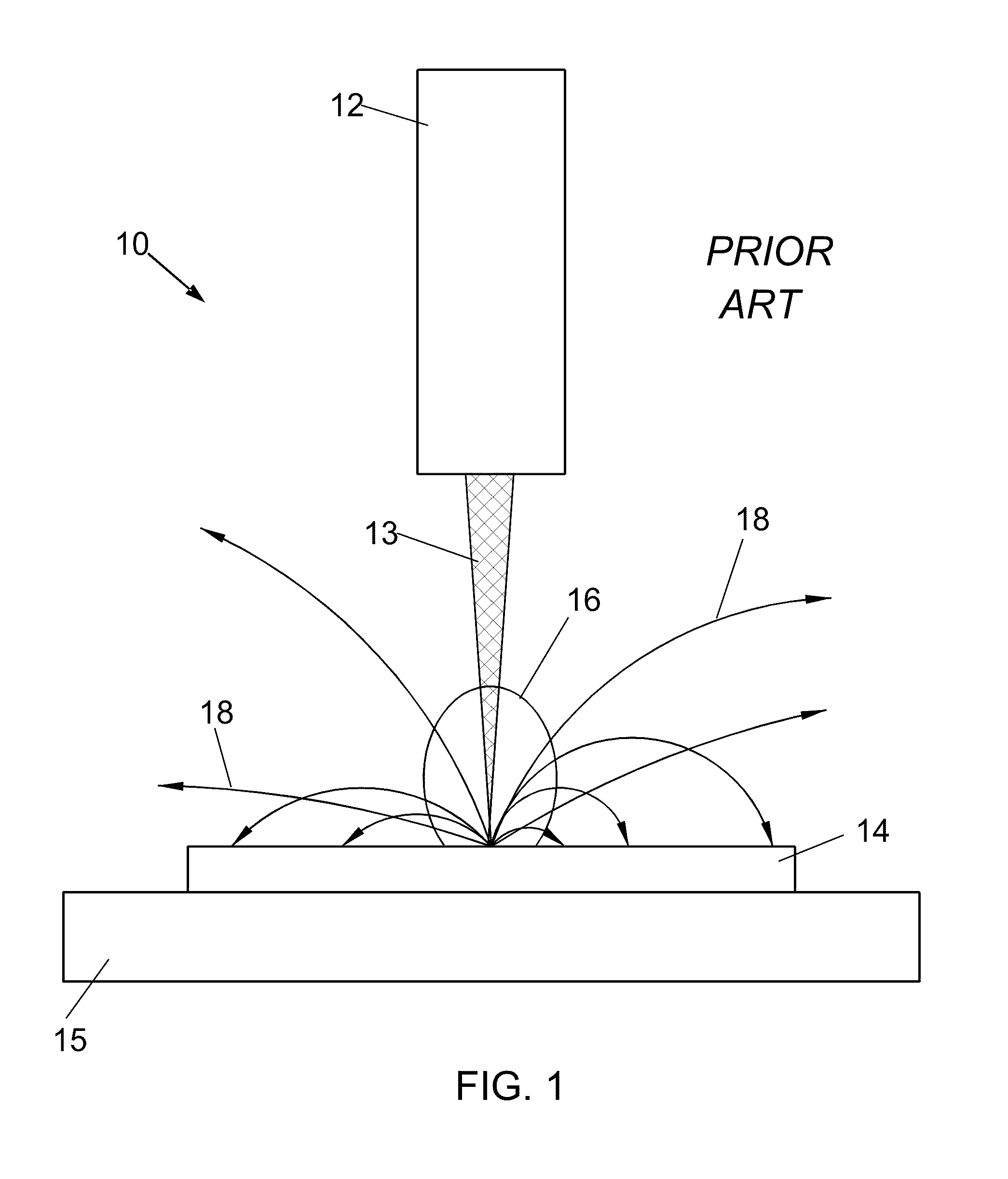

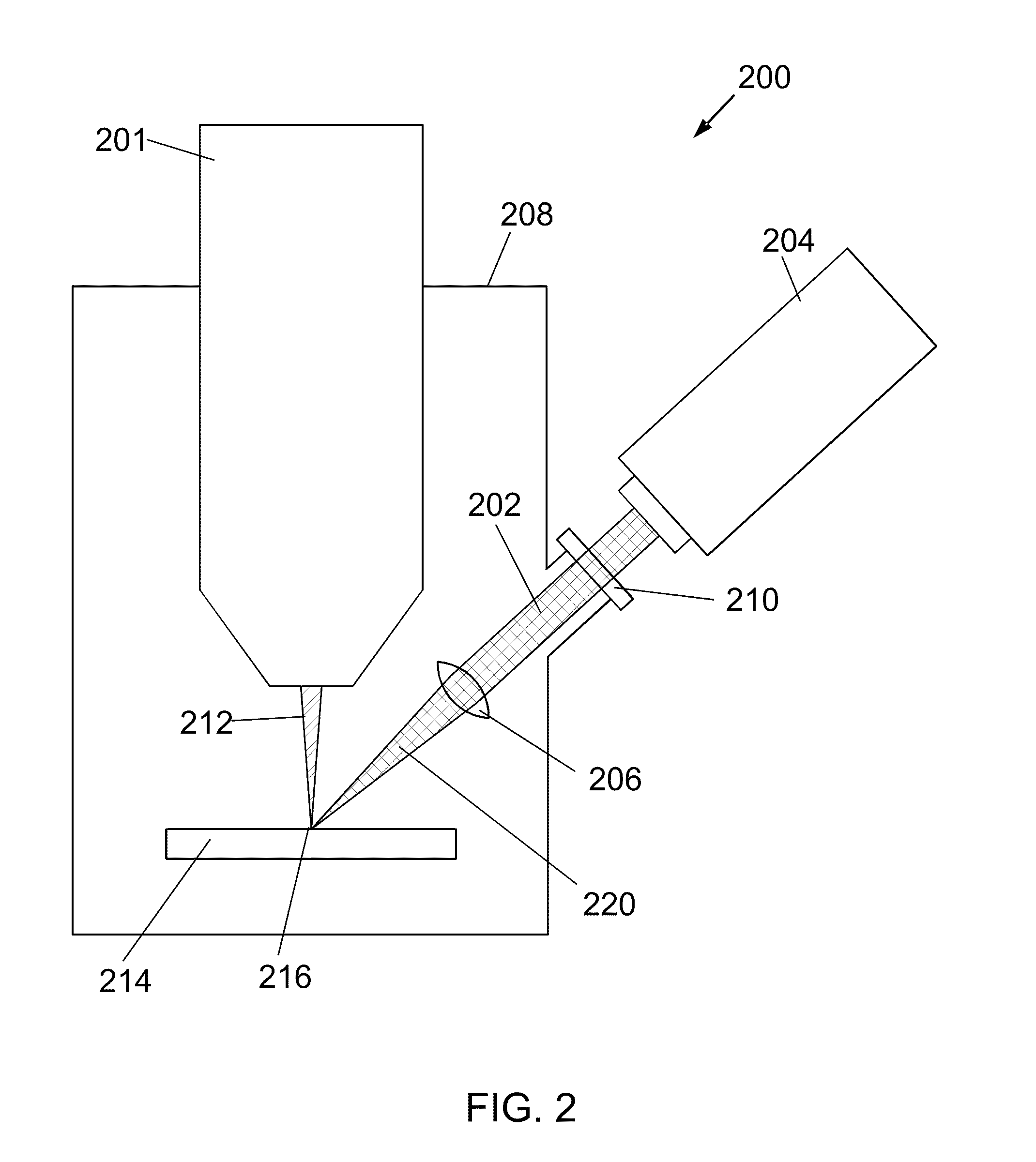

Combination Laser and Charged Particle Beam System

ActiveUS20110248164A1Avoid saturationThermometer detailsStability-of-path spectrometersHigh resolution imagingMaterial removal

A combined laser and charged particle beam system. A pulsed laser enables milling of a sample at material removal rates several orders of magnitude larger than possible for a focused ion beam. In some embodiments, a scanning electron microscope enables high resolution imaging of the sample during laser processing. In some embodiments, a focused ion beam enables more precise milling of the sample. A method and structure for deactivating the imaging detectors during laser milling enables the removal of imaging artifacts arising from saturation of the detector due to a plasma plume generated by the laser beam. In some embodiments, two types of detectors are employed: type-1 detectors provide high gain imaging during scanning of the sample with an electron or ion beam, while type-2 detectors enable lower gain imaging and endpoint detection during laser milling.

Owner:FEI CO

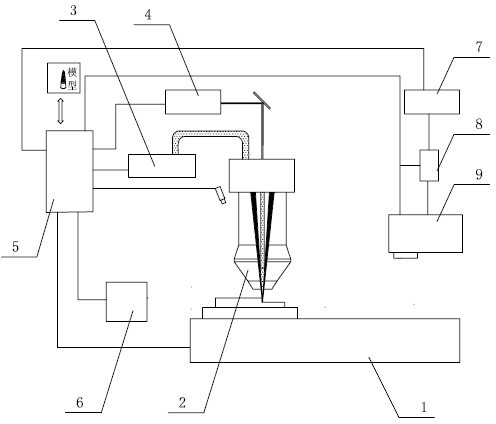

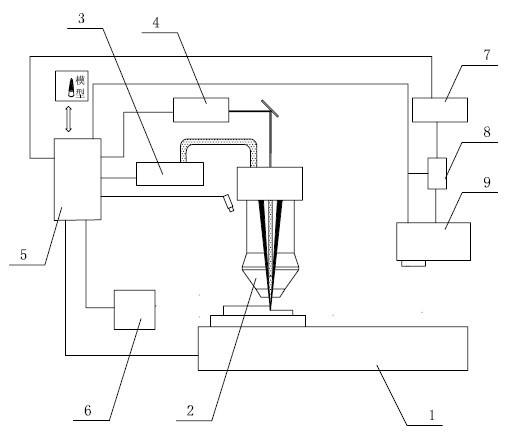

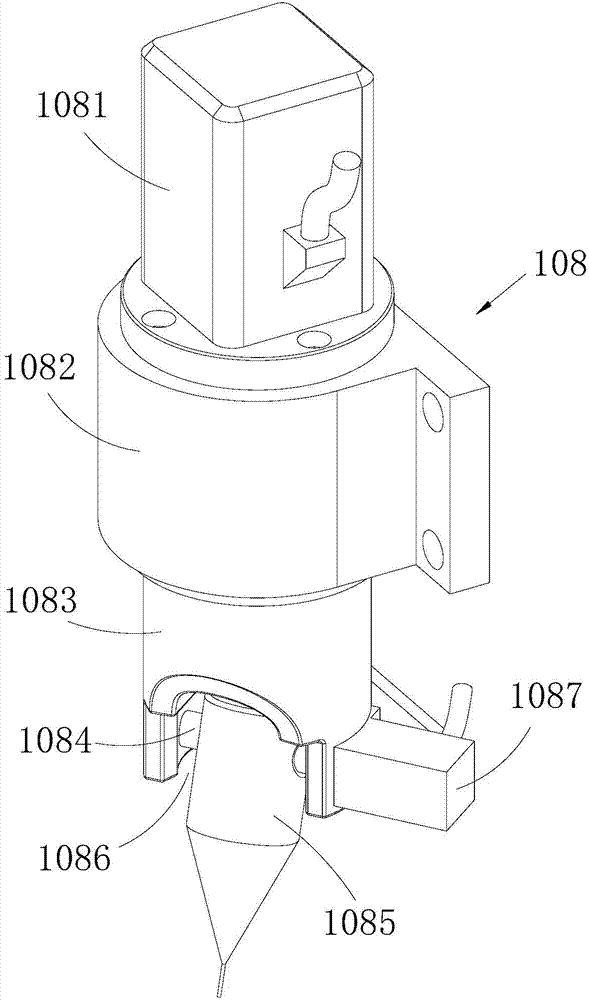

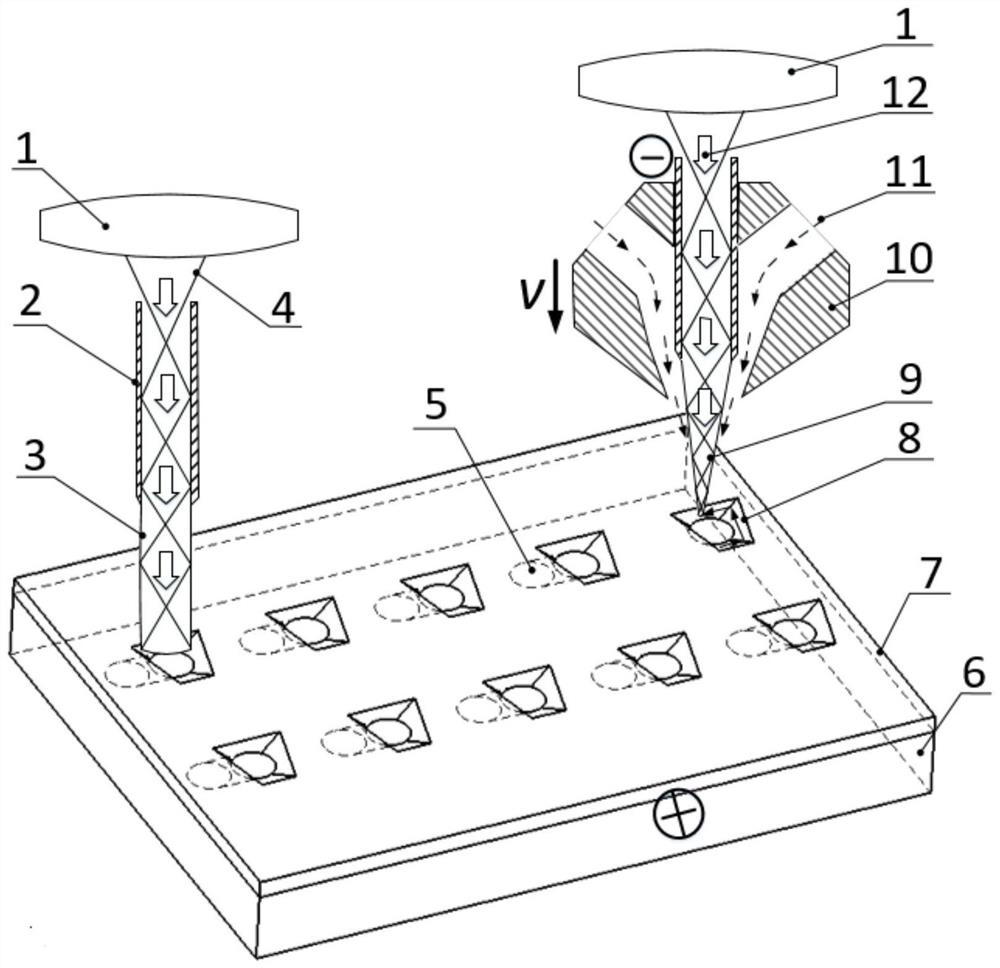

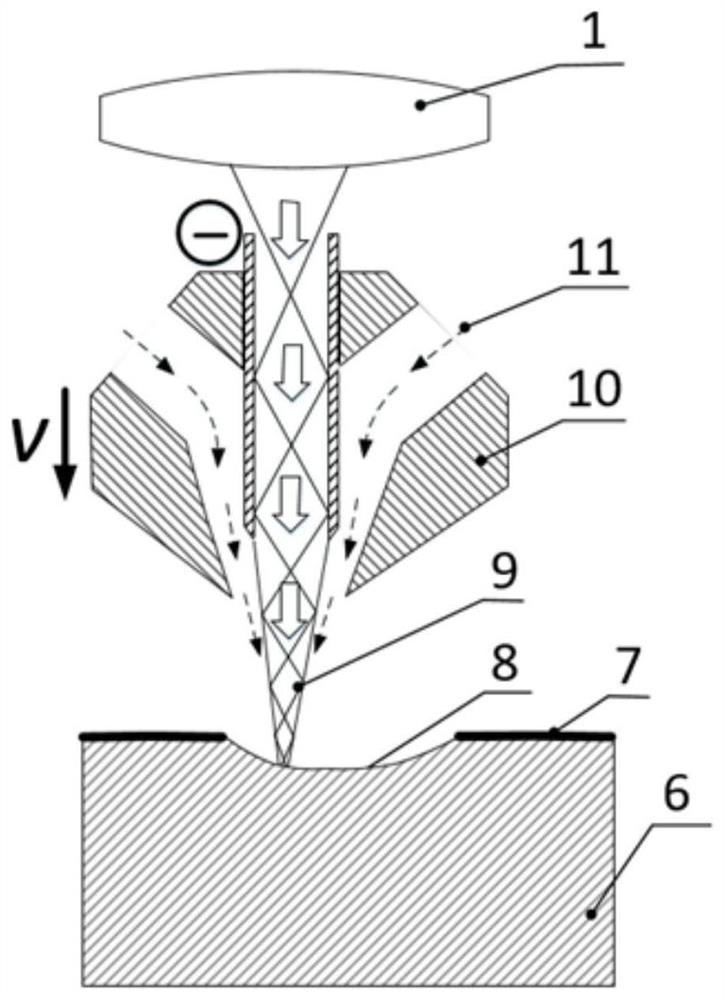

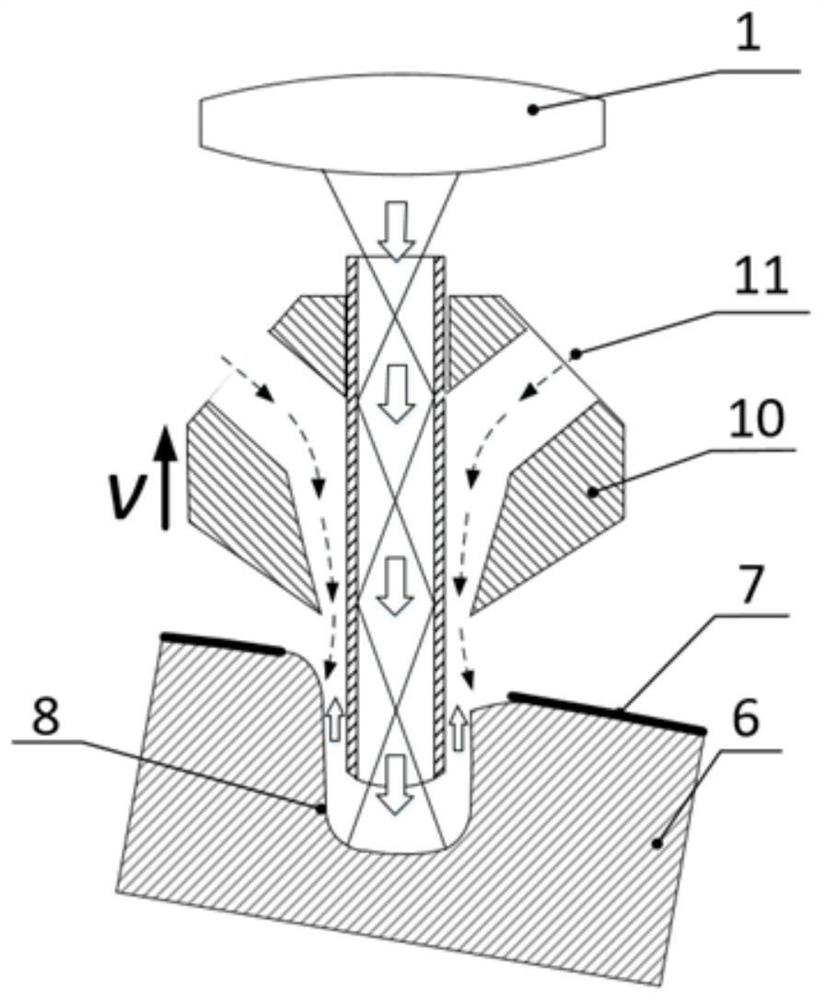

Laser cladding quick precision manufacturing method and device based on laser milling

InactiveCN102304712AHigh speedReduce production processMetallic material coating processesLaser beam welding apparatusLight beamOptoelectronics

The invention discloses a laser cladding quick precision manufacturing method and device based on laser milling. The method is characterized by comprising the following steps: (1) a 3D part model is made, a control computer performs pretreatment to obtain the geometrical information of each section of the part; (2) a light beam and a powder beam are sprayed to the surface of a base material through an internal laser coaxial powder-feeding nozzle to form a cladding layer, and laser cladding is performed; (3) a charge-coupled-device (CCD) collects a digital image in a processing area, and the digital image is transmitted to a part appearance detection system of the control computer so as to measure the height and section size of the part in real time; and (4) the part appearance detection system compares the collected information with the pretreated information; and if the size of the cladding layer exceeds the expectation, the laser and powder-feeding device are closed, the control computer controls a laser milling mechanism to mill the excess part of the cladding layer and finish quick manufacturing of laser cladding. By adopting the method, the manufacturing speed of laser cladding can be increased, the manufacturing flow can be shortened and the manufacturing accuracy is relatively high.

Owner:SUZHOU UNIV

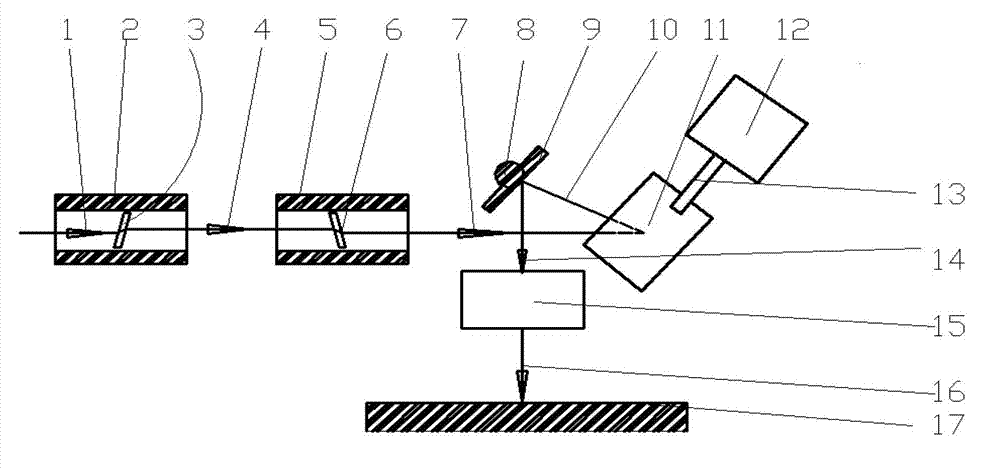

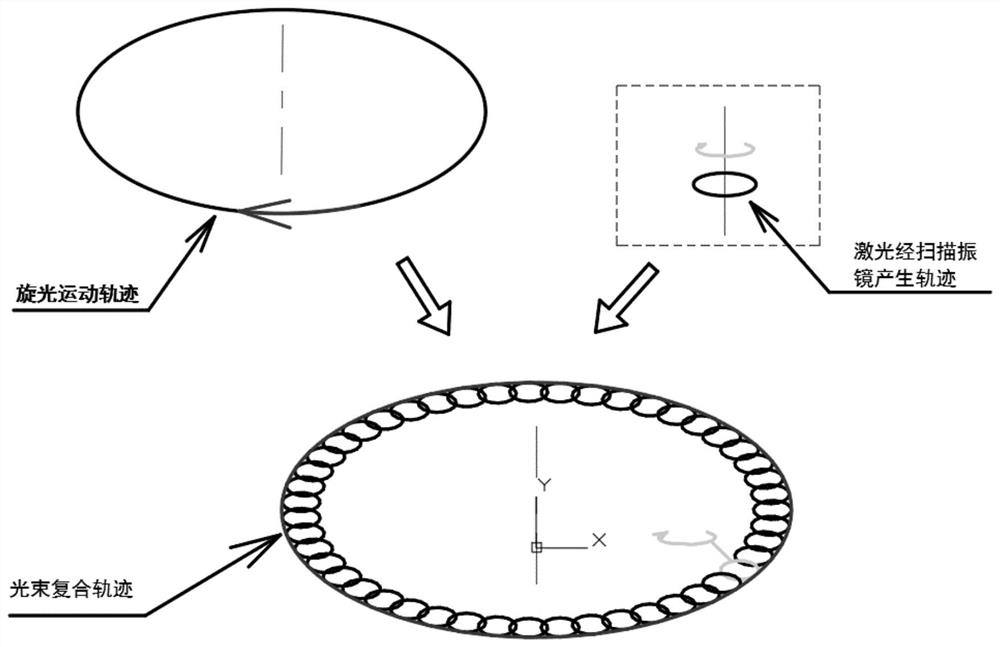

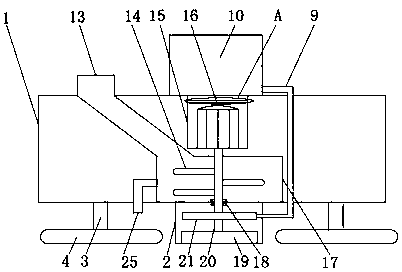

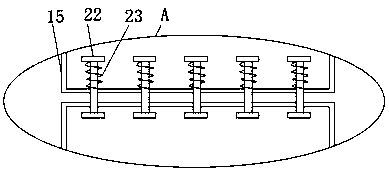

Control system of laser moving track of rotating beam module group

ActiveCN102773605ARealize filling processingEasy to sprayLaser beam welding apparatusLaser processingSlag

The invention belongs to the laser processing field, and discloses a control system of a laser moving track of a rotating beam module group. The control system includes that two or more than two rotating beam modules are connected in series, a last output beam completes revolution along the ray axis of a last rotating module incident light and performs rotation along the revolution track, and obtaining a focused beam through an optical focusing system, if a cross section of a fill movement track of a focusing point is a solid circle, flat top laser processing effects can be achieved by using Gaussian lasers, and laser processing characteristics of deep Gaussian laser telephoto and high Gaussian distribution light are provided; and if the cross section of the fill movement track of the focusing point is a ring, because the laser etched seam is wide, the spraying of material slag is facilitated, the processing efficiency and the processing quality are improved greatly, and the system is suitable for laser drilling and laser milling of certain crisp and hard materials; and if a rotating beam modules are locked, the laser recover narrow line wide leaser micromachining, and the application range of laser equipment is increased.

Owner:张立国

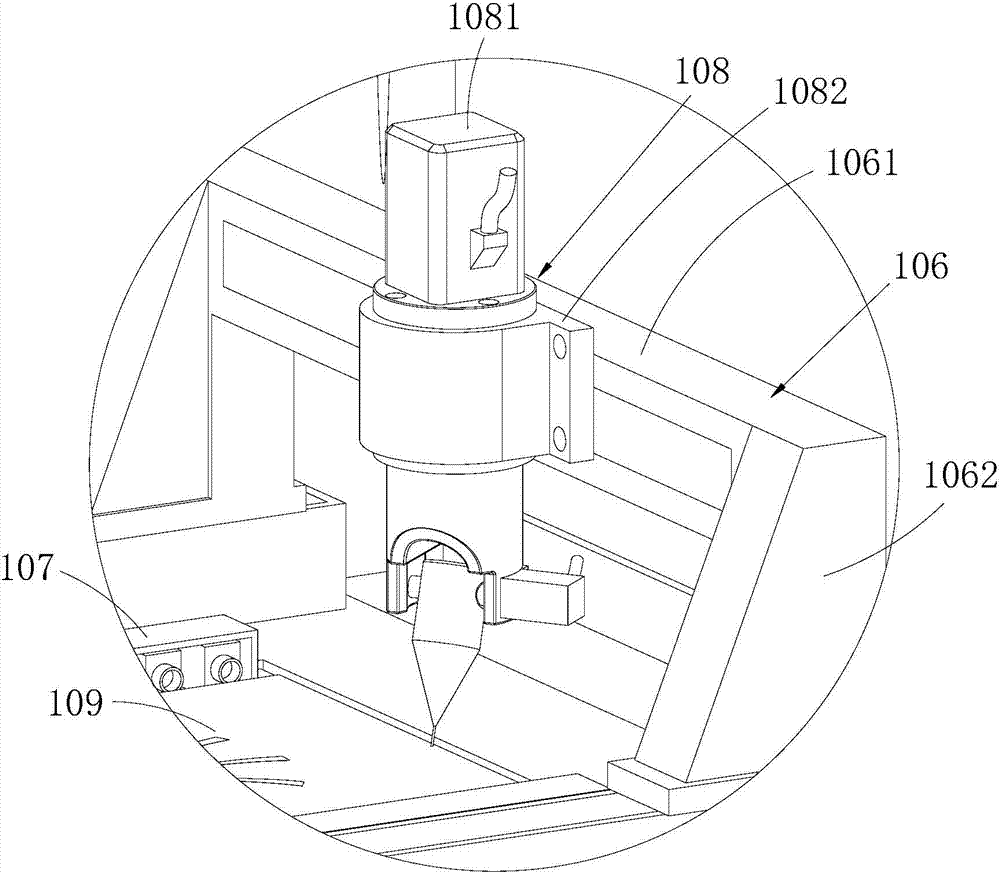

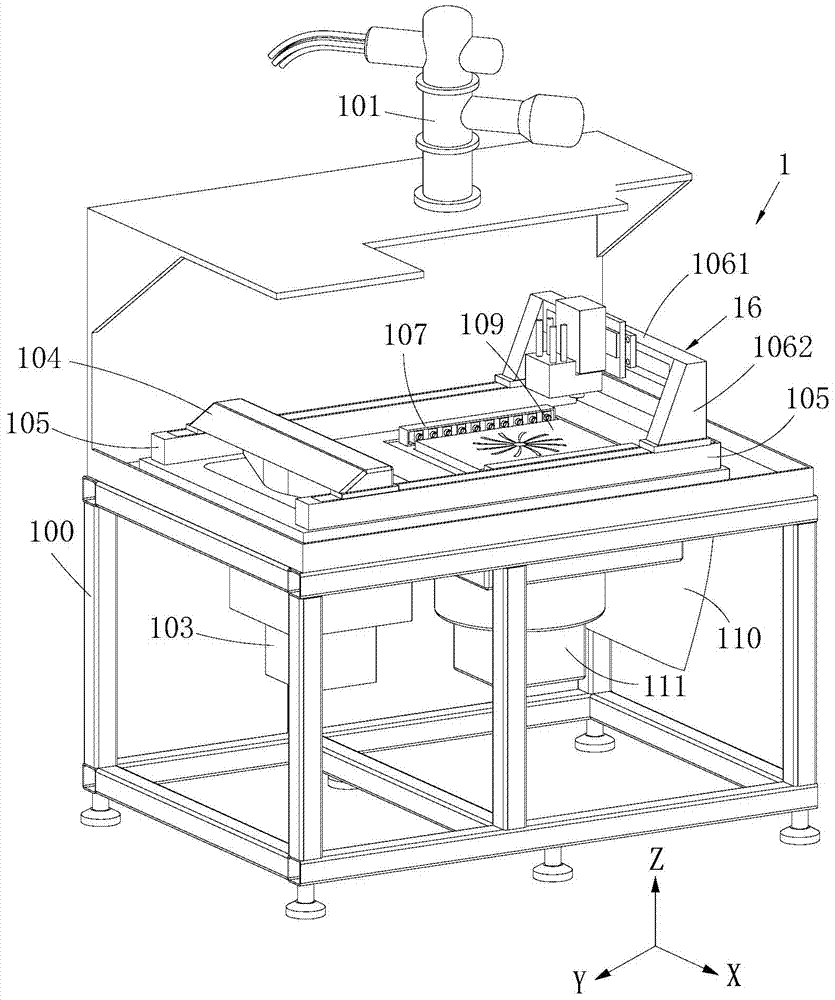

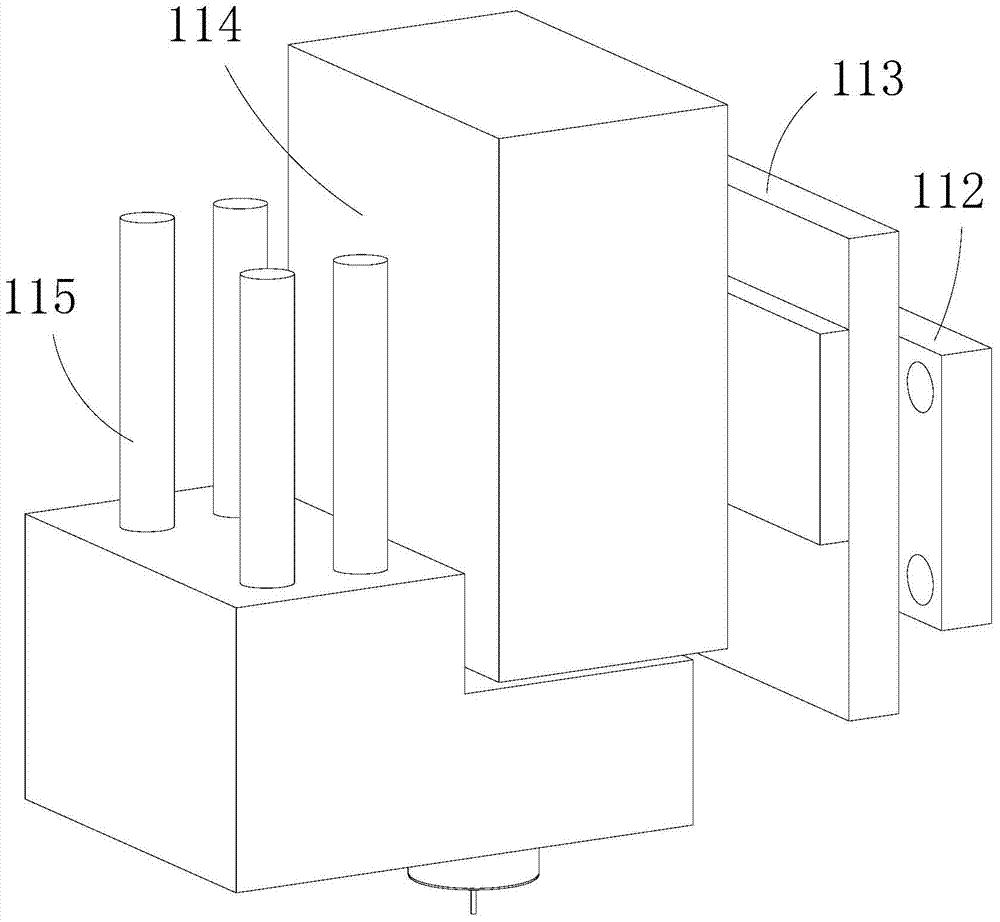

Multi-axis milling and laser melting composite 3D printing apparatus

ActiveCN104493493AAvoid deformationReduce processing stepsAdditive manufacturing apparatusIncreasing energy efficiencyThree-dimensional spaceMulti axis

The invention relates to the technical field of 3D printing apparatuses and discloses a multi-axis milling and laser melting composite 3D printing apparatus. The multi-axis milling and laser melting composite 3D printing apparatus comprises a base on which a machining platform is arranged; a powder spreading structure for spreading a metal powder on the machining platform is arranged on the base; an electron beam emitting structure for melting the metal powder layer to form a single-layer or multi-layer approximate body and a milling head capable of moving in the three-dimensional space are arranged above the machining platform; the milling head is provided with a milling tool capable of rotating and swinging. The 3D printing apparatus is integrated with the traditional removal type precision machining taking laser milling as the principal method and the incremental laminating manufacturing process with electron beam melting 3D printing as the principal method, and therefore, the defects of the 3D printing technology in the aspects such as size and shape are overcome, the restriction of cutting to the complexity of parts and the like is overcome, the machined parts do not need to be machined secondarily, and the problems of difficult clamping, large machining error, part deformation during machining and difficult machining are avoided.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

Combination laser and charged particle beam system

ActiveUS8314410B2Avoid saturationThermometer detailsMaterial analysis using wave/particle radiationHigh resolution imagingMaterial removal

A combined laser and charged particle beam system. A pulsed laser enables milling of a sample at material removal rates several orders of magnitude larger than possible for a focused ion beam. In some embodiments, a scanning electron microscope enables high resolution imaging of the sample during laser processing. In some embodiments, a focused ion beam enables more precise milling of the sample. A method and structure for deactivating the imaging detectors during laser milling enables the removal of imaging artifacts arising from saturation of the detector due to a plasma plume generated by the laser beam. In some embodiments, two types of detectors are employed: type-1 detectors provide high gain imaging during scanning of the sample with an electron or ion beam, while type-2 detectors enable lower gain imaging and endpoint detection during laser milling.

Owner:FEI CO

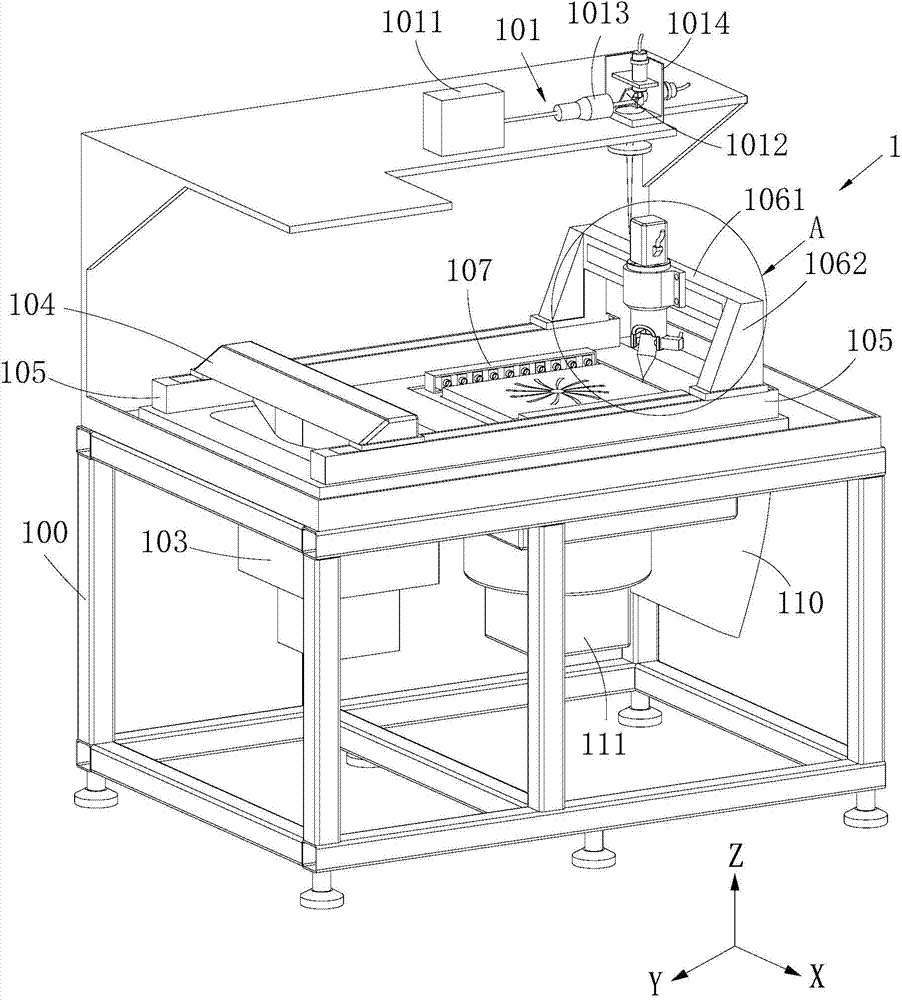

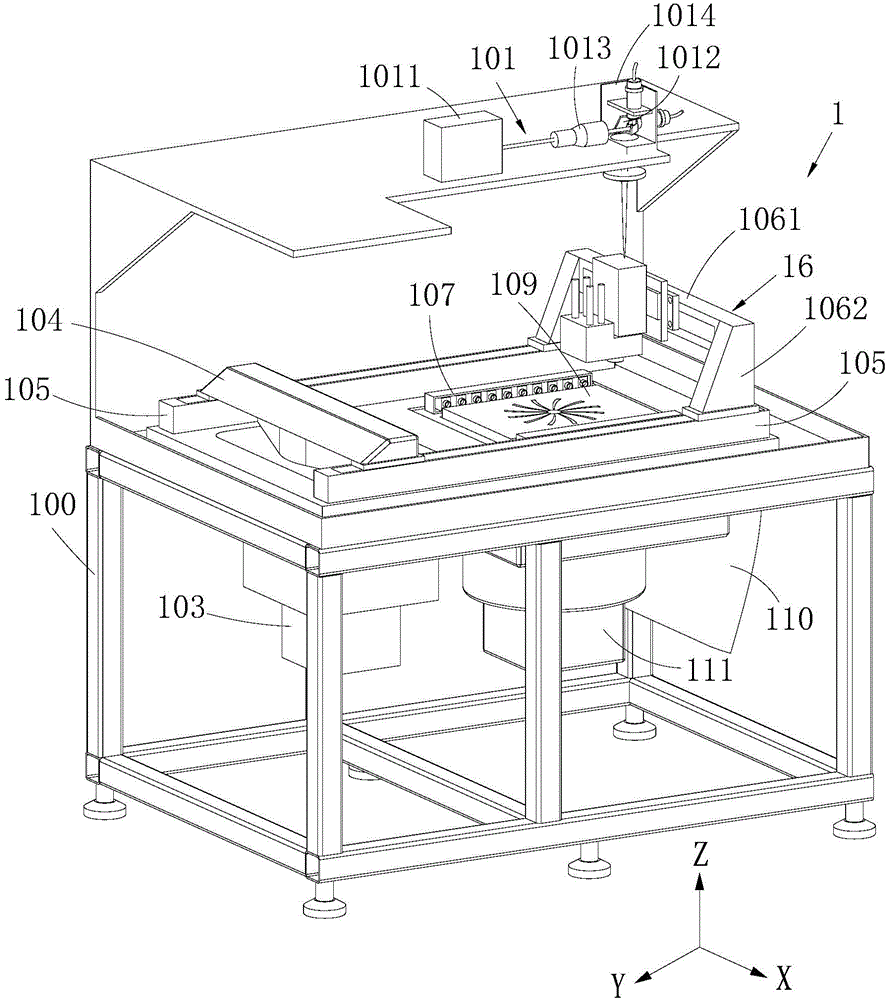

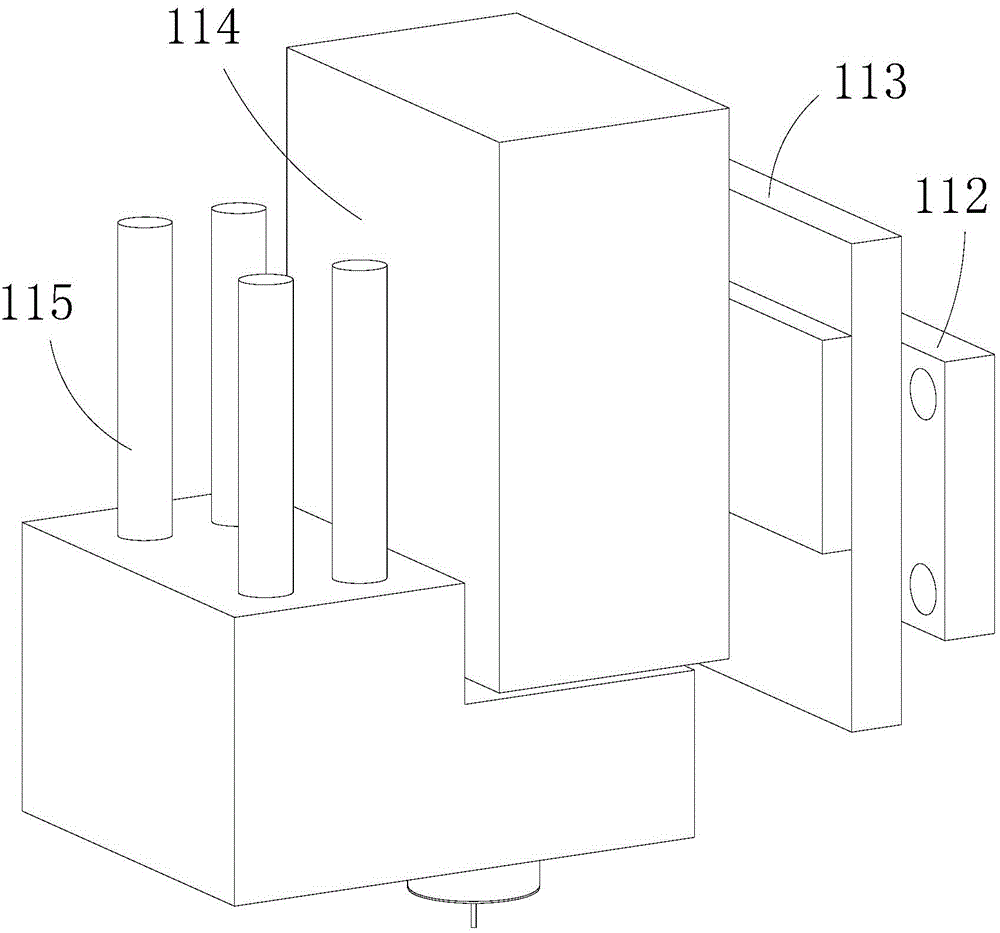

Electron beam melting and laser milling composite 3D printing apparatus

InactiveCN104493165AAvoid deformationReduce processing stepsIncreasing energy efficiencyLaser beam welding apparatusMetal powderLaser beams

The invention relates to the technical field of 3D printing apparatus and discloses an electron beam melting and laser milling composite 3D printing apparatus. The3D printing apparatus comprises a base on which a machining platform is arranged; a powder spreading structure for spreading a metal powder on the machining platform is arranged on the base; an electron beam emitting structure and a laser milling head are arranged above the machining platform, respectively; the electron beam emitting structure emits an electron beam to melt the metal powder layer so as to form a single-layer or multi-layer approximate body; the laser milling head emits a laser beam to perform milling machining on the single-layer or multi-layer approximate body. The 3D printing apparatus is integrated with the removal machining taking laser milling as the principal method and the incremental laminating manufacturing process with electron beam melting 3D printing as the principal method, and therefore, the defects of the 3D printing technology in the aspects such as size and shape are overcome, the restriction of cutting to the complexity of parts and the like is overcome, the machined parts do not need to be machined secondarily, and the problems of difficult clamping, large machining error, part deformation during machining and difficult machining are avoided.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

Combined laser melting and laser milling 3D (three-Dimensional) printing equipment

InactiveCN104476196AOvercoming constraints such as complexityAvoid deformationAdditive manufacturing apparatusIncreasing energy efficiencyMachine partsLight beam

The invention relates to the technical field of 3D (three-Dimensional) printing equipment, and discloses combined laser melting and laser milling 3D printing equipment, which comprises a pedestal with a machining platform, wherein a powder laying structure is arranged on the pedestal; a laser emission structure and a laser milling head are arranged above the machining platform; a laser beam is emitted by the laser emission structure to melt a metal powder layer on the machining platform to form a single-layer or multilayer approximate body; a laser beam is emitted by the laser milling head to mill the formed single-layer or multilayer approximate body. According to the 3D printing equipment, a conventional milling-based removal precision machining process is integrated with a conventional laser beam melting 3D printing-based incremental stacking manufacturing process, so that shortcomings in aspects of dimensional and shape precision and the like of a conventional 3D printing technology are overcome, the restrictions of cutting machining to the complexity and the like of a part are broken, a machined part is not required to be secondarily machined, and the problems of difficulty in clamping, great machining errors and deformation and machining difficulty of the part during machining are solved.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

Electron beam melting and laser milling composite 3D printing apparatus

InactiveUS20160325383A1Large machining errorBroad application spaceAdditive manufacturing apparatusWelding/cutting auxillary devicesOptoelectronicsMetal powder

The present application relates to the technical field of 3D printing apparatus, and discloses an electron beam melting and laser milling composite 3D printing apparatus which comprises a base, in which a powder spreading structure configured for spreading metal powders onto the machining platform is arranged on the base, an electron beam emitting structure and a laser milling head are arranged above the machining platform, the electron beam emitting structure is configured for emitting an electron beam to melt the metal powder layer to form a single-layer or multi-layer approximate body, and the laser milling head is configured for emitting a laser beam to mill the single-layer or multi-layer approximate body.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

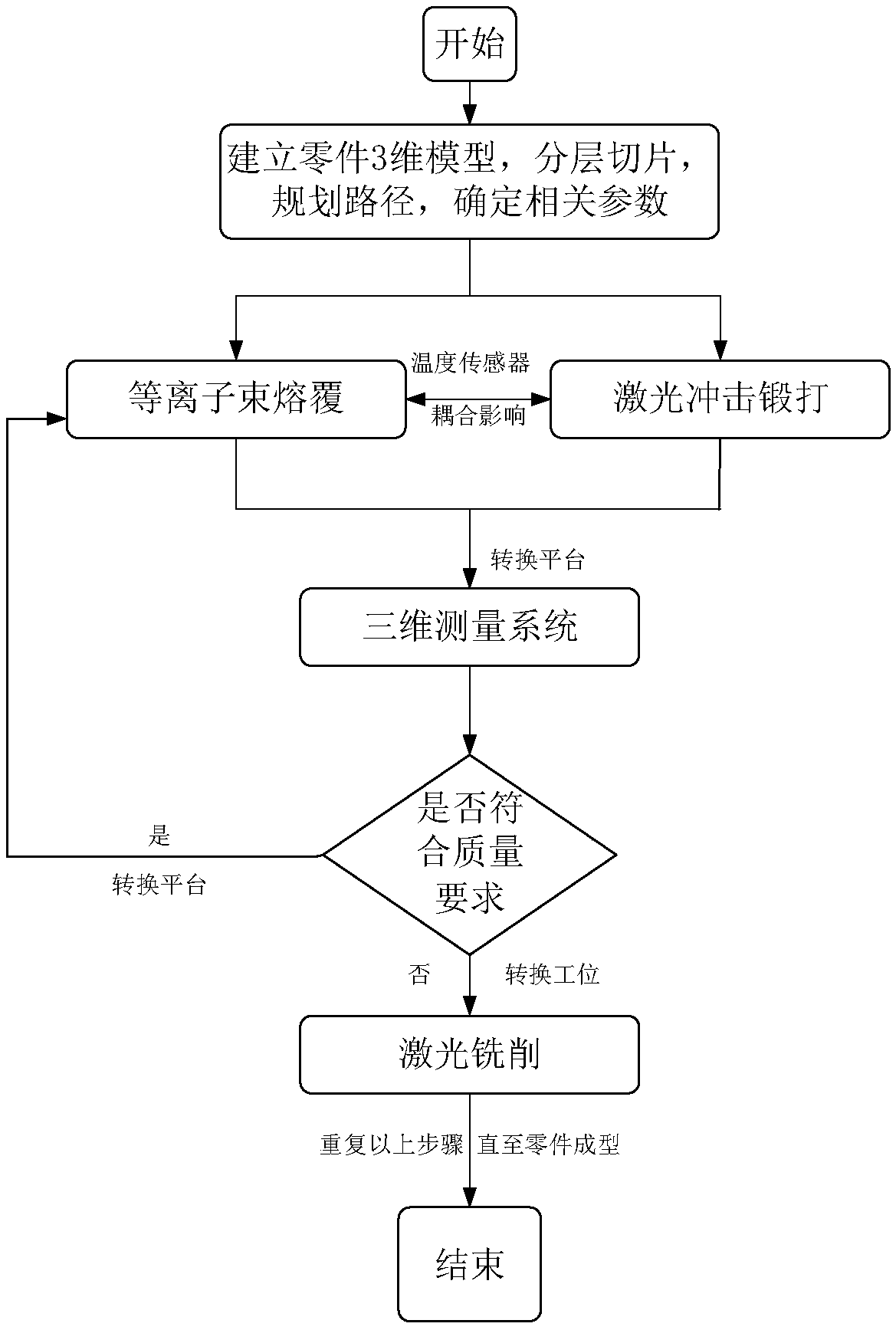

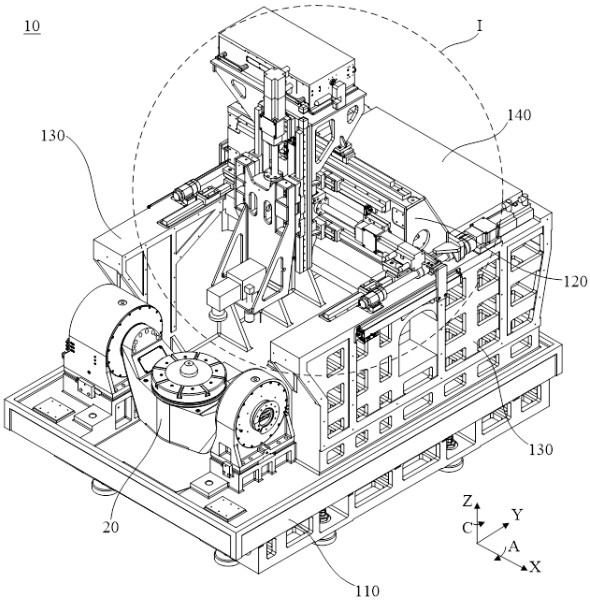

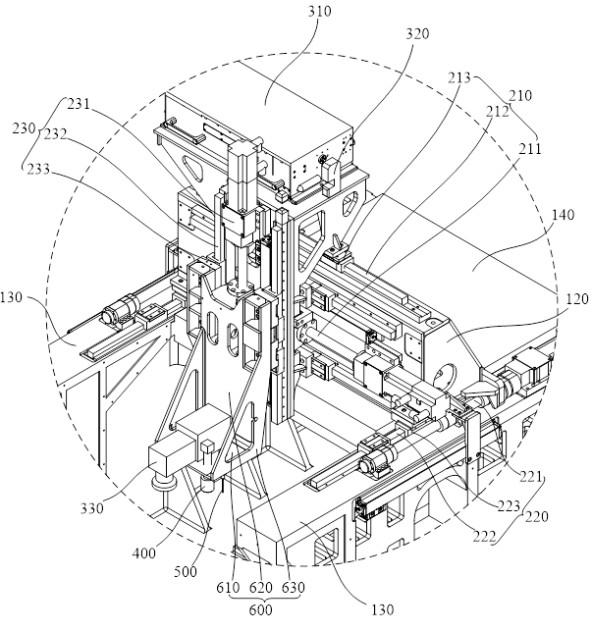

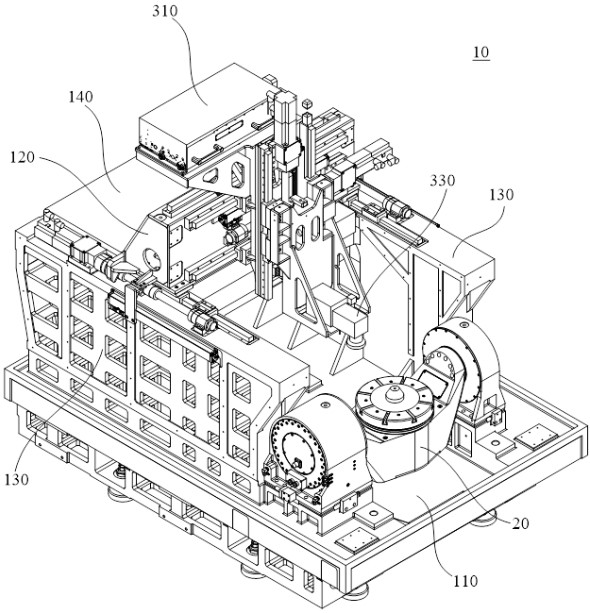

Plasma cladding and laser forging composite additive and subtractive manufacturing method and device

InactiveCN109434110AShort duration of actionImprove securityAdditive manufacturing apparatusIncreasing energy efficiencySlagMetallic materials

The invention designs a plasma cladding and laser forging composite additive and subtractive manufacturing method and device, and belongs to the field of metal material increasing and additive and subtractive manufacturing. The method is based on integration of three technologies of a plasma beam cladding technology, a laser impact forging technology and a laser cutting technology, the three technologies are coupled with and affect each other, a formed area is subjected to laser impact forging through short-pulse laser while plasma beam cladding is conducted, internal residual tensile stress is removed, and the cracking and deformation problems of the formed area are solved; the formed area is subjected to laser milling after three or more layers are formed, and based on the characteristics of non-contact cutting force, slight heat influence and special surface processing of laser processing, the problems that the formed area has adhering slag and is high in roughness are solved, meanwhile, through the method, a workpiece does not need to be moved frequently, and the problem of errors and deformation caused by mechanical milling and clamping are solved. The method integrates the advantages that heat is concentrated of plasma beam cladding, the heat influence is slight, the vacuum environment is not needed, residual compressive stress in materials can be increased through laserimpact forging, inside pores and defects of parts are eliminated, grain structures are refined, no cutting force exists during laser cutting, and the heat influence is slight, complementation is achieved, and the mechanical properties and surface quality of the parts obtained through additive manufacturing are improved.

Owner:合肥华脉激光科技有限公司

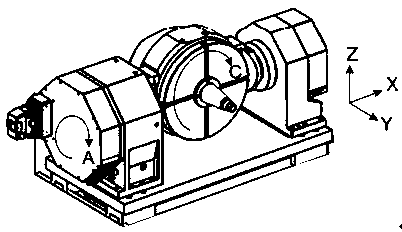

Five-axis laser milling machine tool

PendingCN112207430ASolve processing and manufacturing problemsSmooth machining processLaser beam welding apparatusLinear motionLaser processing

The invention relates to a five-axis laser milling machine tool. The five-axis laser milling machine tool comprises a rack, a mechanical motion assembly and a laser machining assembly; the rack comprises a base, an X-axis mounting frame and two Y-axis mounting frames; the mechanical motion assembly comprises an X-axis motion assembly, a Y-axis motion assembly and a Z-axis motion assembly; the laser machining assembly comprises a laser device, a light path system and a three-dimensional scanning galvanometer module; the X-axis motion assembly, the Y-axis motion assembly and the Z-axis motion assembly are used for carrying the laser machining assembly to conduct linear motion in the X-axis direction, the Y-axis direction and the Z-axis direction correspondingly; the X-axis motion assembly, the Z-axis motion assembly and the Y-axis motion assembly are installed on the Y-axis mounting frames to form a portal frame structure machine body, and stability is achieved in the machining motion process to improve machining precision; the X-axis motion assembly, the Y-axis motion assembly, the Z-axis motion assembly, an AC-axis rotary table and a three-dimensional scanning galvanometer are adopted for conducting linkage motion control over the laser machining assembly, the machined tool and the laser beams correspondingly, one-time laser machining forming of the tool is achieved, the machining efficiency and the machining quality are effectively improved, and the machining and manufacturing problems of high-end tools can be solved.

Owner:CONPROFE TECH GRP CO LTD +2

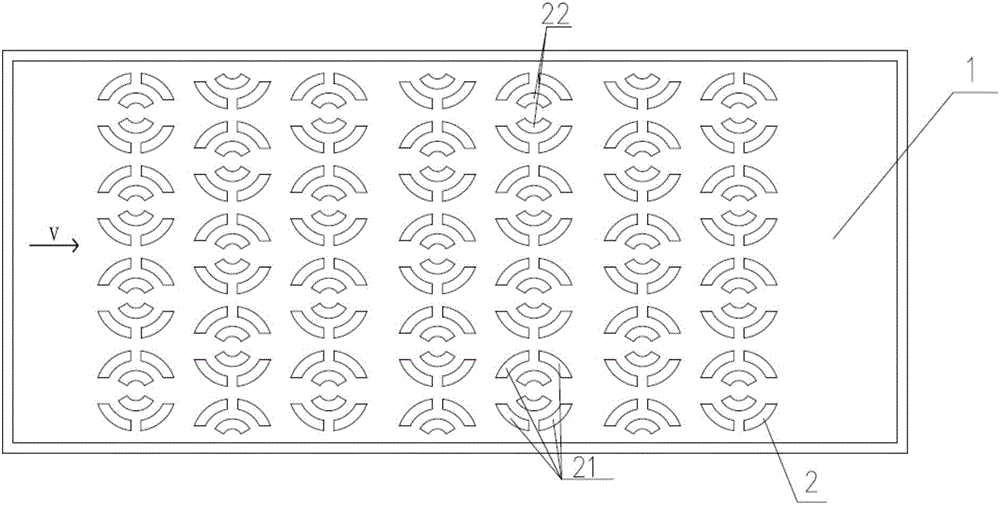

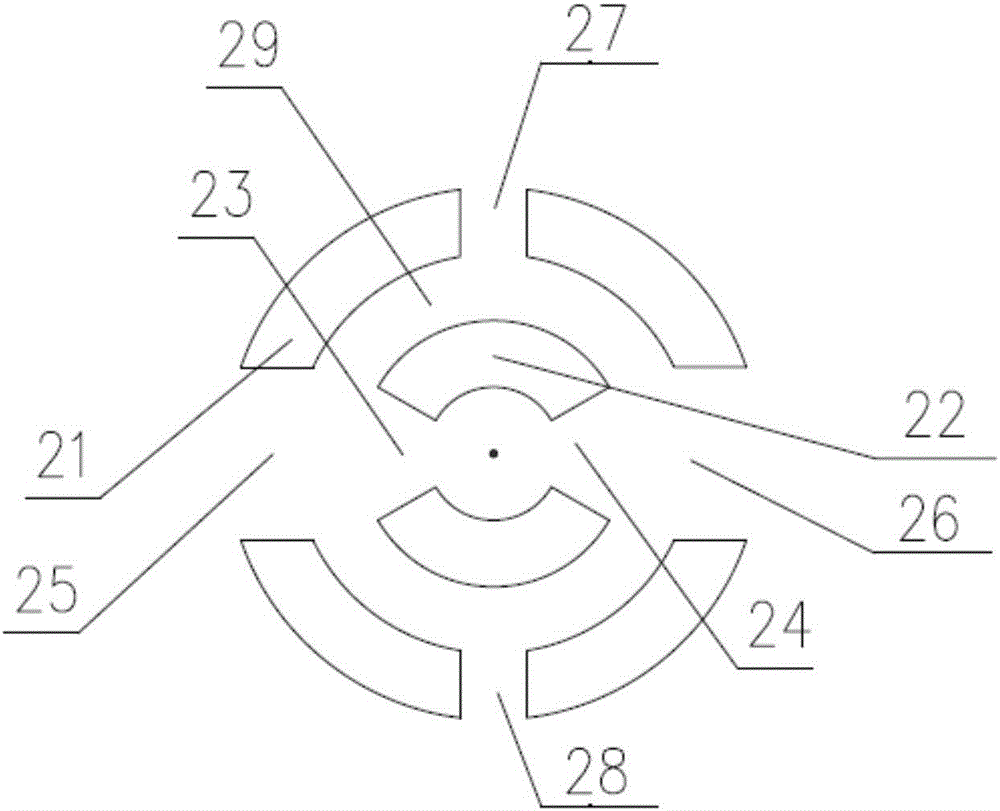

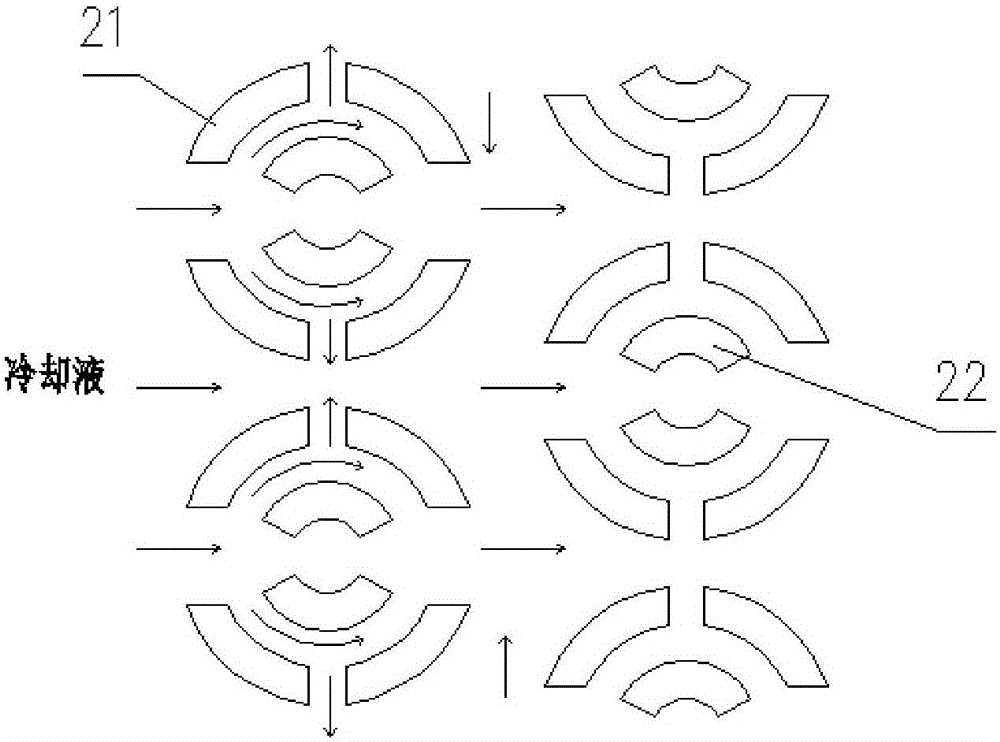

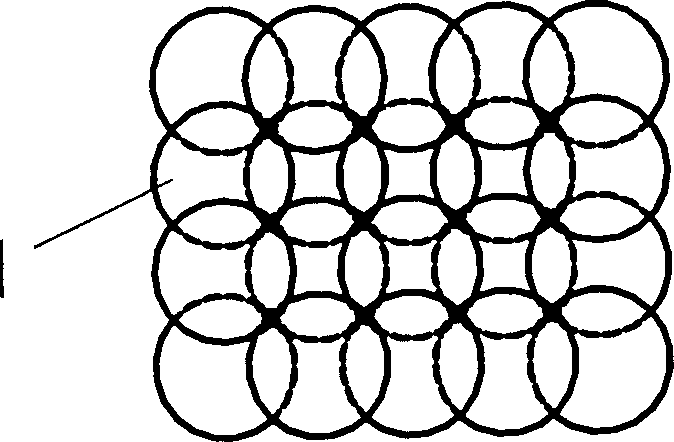

Micro-channel heat exchanger with multiple flow path interconnection structures and method for manufacturing micro-channel heat exchanger

ActiveCN106705713AChange normal flowIncrease contact areaHeat exchanger casingsLaminated elementsPlate heat exchangerEngineering

The invention provides a micro-channel heat exchanger with multiple flow path interconnection structures and a method for manufacturing the micro-channel heat exchanger. The micro-channel heat exchanger comprises a metal micro-channel substrate. The substrate is provided with a plurality of open circular ring structures which are parallelly arranged along the flow direction of cooling liquid and are distributed to form arrays, each open circular ring structure comprises four outer first arc-shaped fins and two inner second arc-shaped fins, the four first arc-shaped fins of each open circular ring structure are circumferentially uniformly arranged at intervals, and the two second arc-shaped fins of each open circular ring structure are symmetrically arranged, so that large open circular rings and small open circular rings which are nested in the large open circular rings can be formed. A front slit, a rear slit, an upper slit and a lower slit are respectively formed by each large open circular ring in the directions parallel and perpendicular to the flow direction of the cooling liquid, a front slit and a rear slit are formed by each small circular ring in the directions parallel to the flow direction of the cooling liquid, and multiple flow path interconnection channels are formed by the slits. The method includes processing multiple flow path interconnection micro-channel structures by the aid of laser milling technologies; packaging upper cover plates by the aid of heat-resistant glass to obtain the micro-channel heat exchanger. The micro-channel heat exchanger and the method have the advantages that processes for manufacturing the micro-channel heat exchanger are simple, the micro-channel heat exchanger and the method are low in cost, and boundary layers can be destructed, so that micro-channel heat exchange can be enhanced.

Owner:XIAMEN UNIV +1

Laser milling method for hard brittle material

InactiveCN1730227AAchieve the purpose of formingSimple methodLaser beam welding apparatusHigh power densityLaser milling

The laser milling method for hard fragile material uses solid pulse laser for manufacture. Compared with common methods, this invention needs not to prepare electrode and mould, easy to manufacture for single piece and small scale; the laser device has simple structure and well reliable to spread in industry, which has high power density and fit to material of high melting point, such as high alloy steel, semiconductor silicon slice, engineering ceramics, and diamond.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

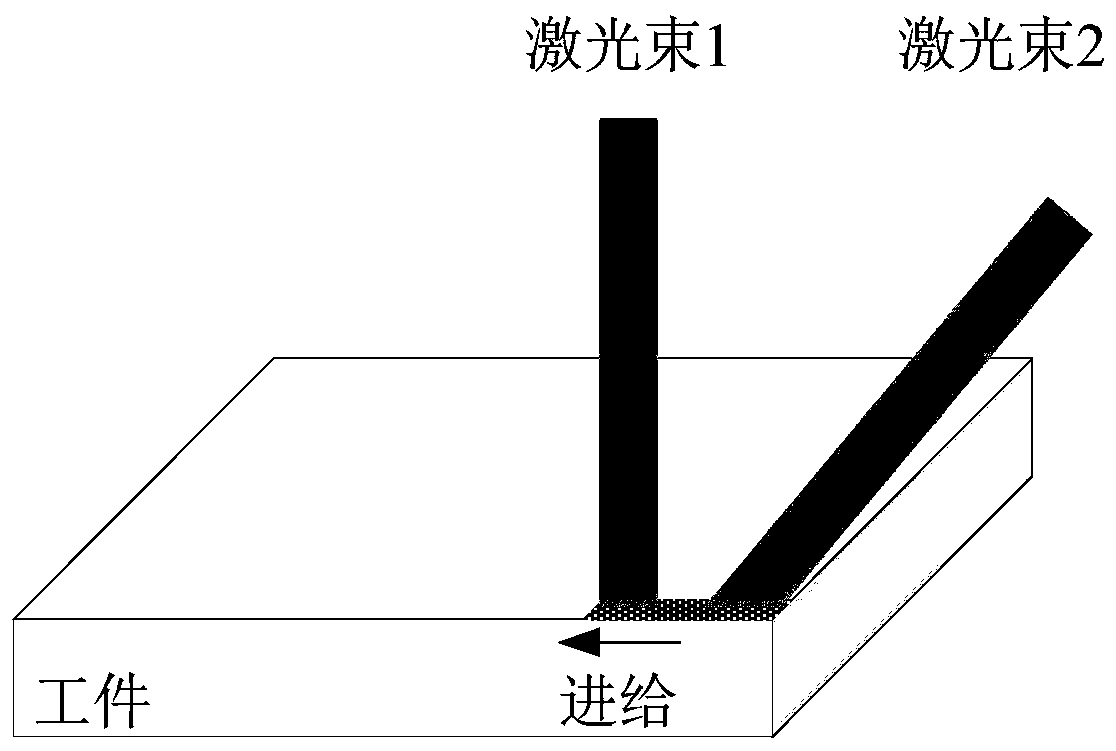

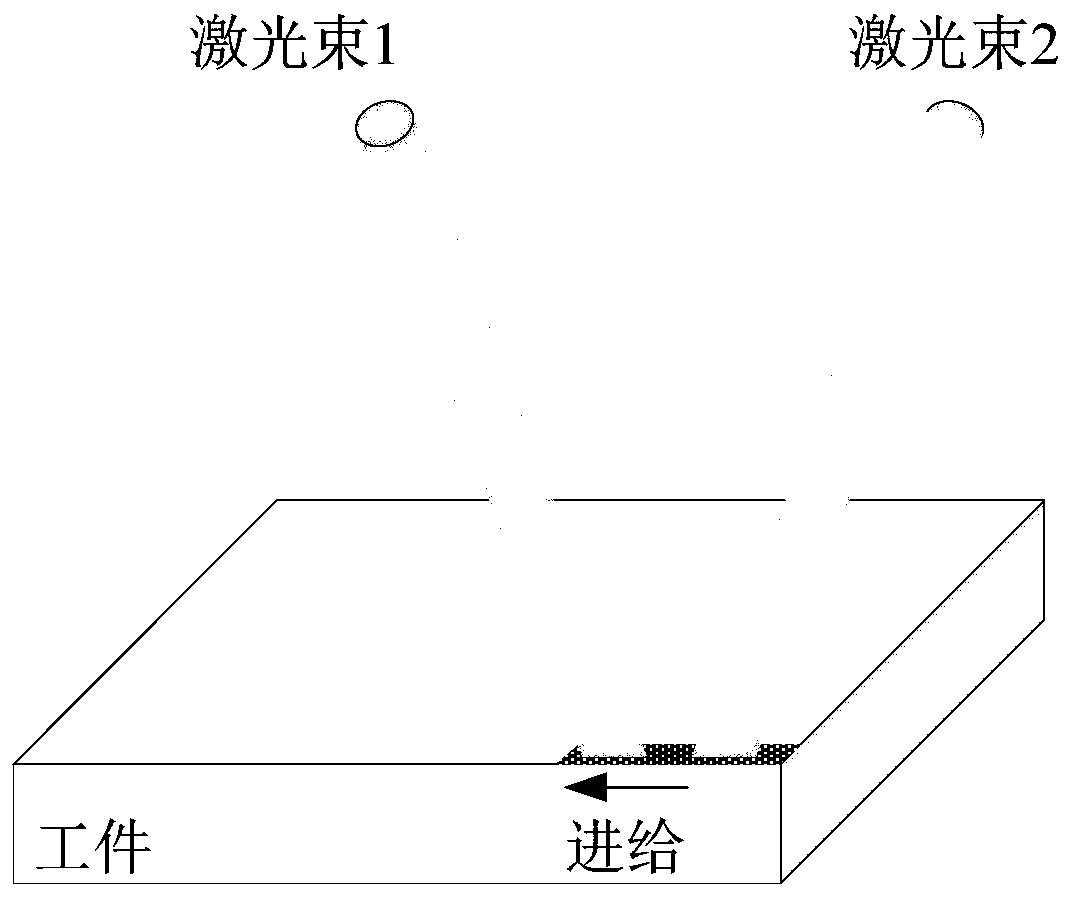

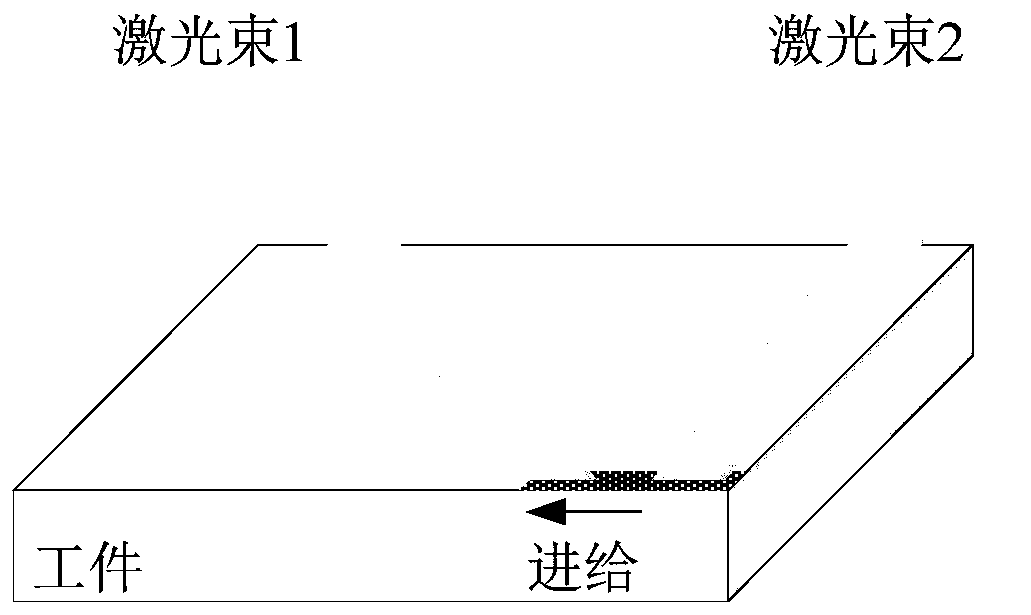

Attitude-controllable laser milling composite polishing synchronous machining method

The invention discloses an attitude-controllable laser milling composite polishing synchronous machining method. The method comprises the following steps that an area to be machined on the surface ofa workpiece is milled by using a first laser beam, and a second laser beam is adopted to carry out polishing treatment on the milled area on the surface of the workpiece, wherein the fusion depth of milling treatment by the first laser beam on the workpiece is larger than the fusion depth of polishing treatment by the second laser beam on the workpiece. According to the method, by means of high-speed laser milling and vector controllable laser polishing composite synchronous machining, high-integrity surface machining with coordinated efficiency and quality is realized, the laser milled surface is rapidly leveled, and the features present different structures and properties at different space positions, region selection planning is carried out, different process strategies are adopted in different regions, multi-axis laser polishing machining is carried out by regulating and controlling space vectors, and application of fixed-axis or variable-axis laser milling composite fine polishingsynchronous machining is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

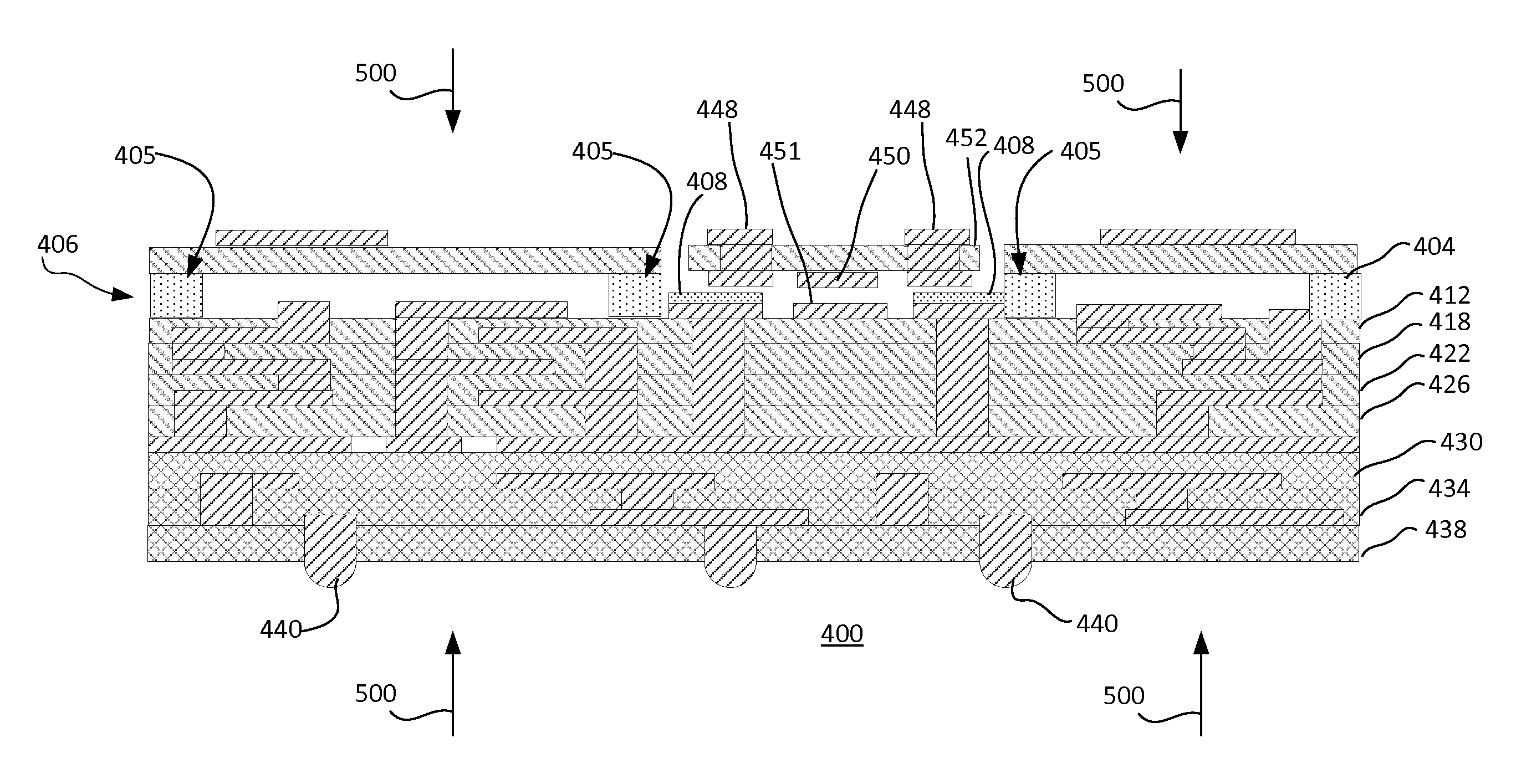

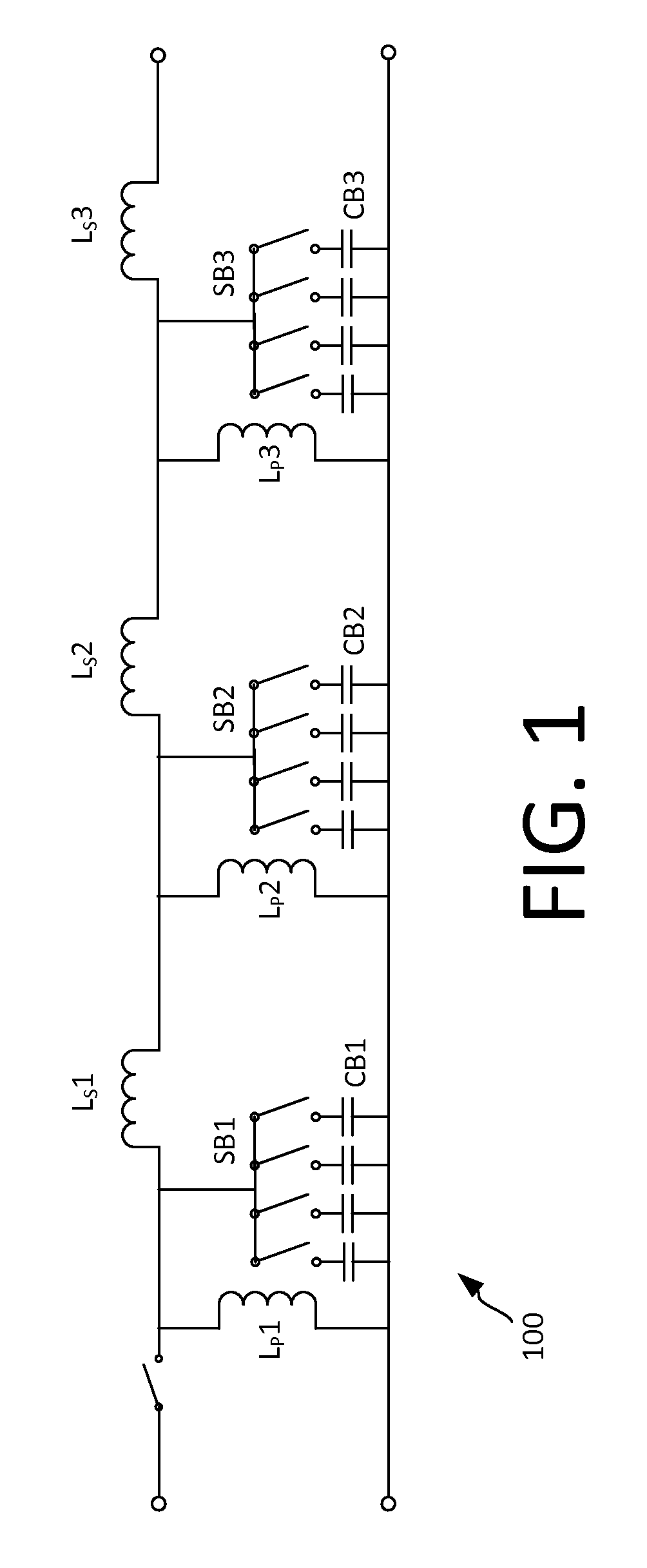

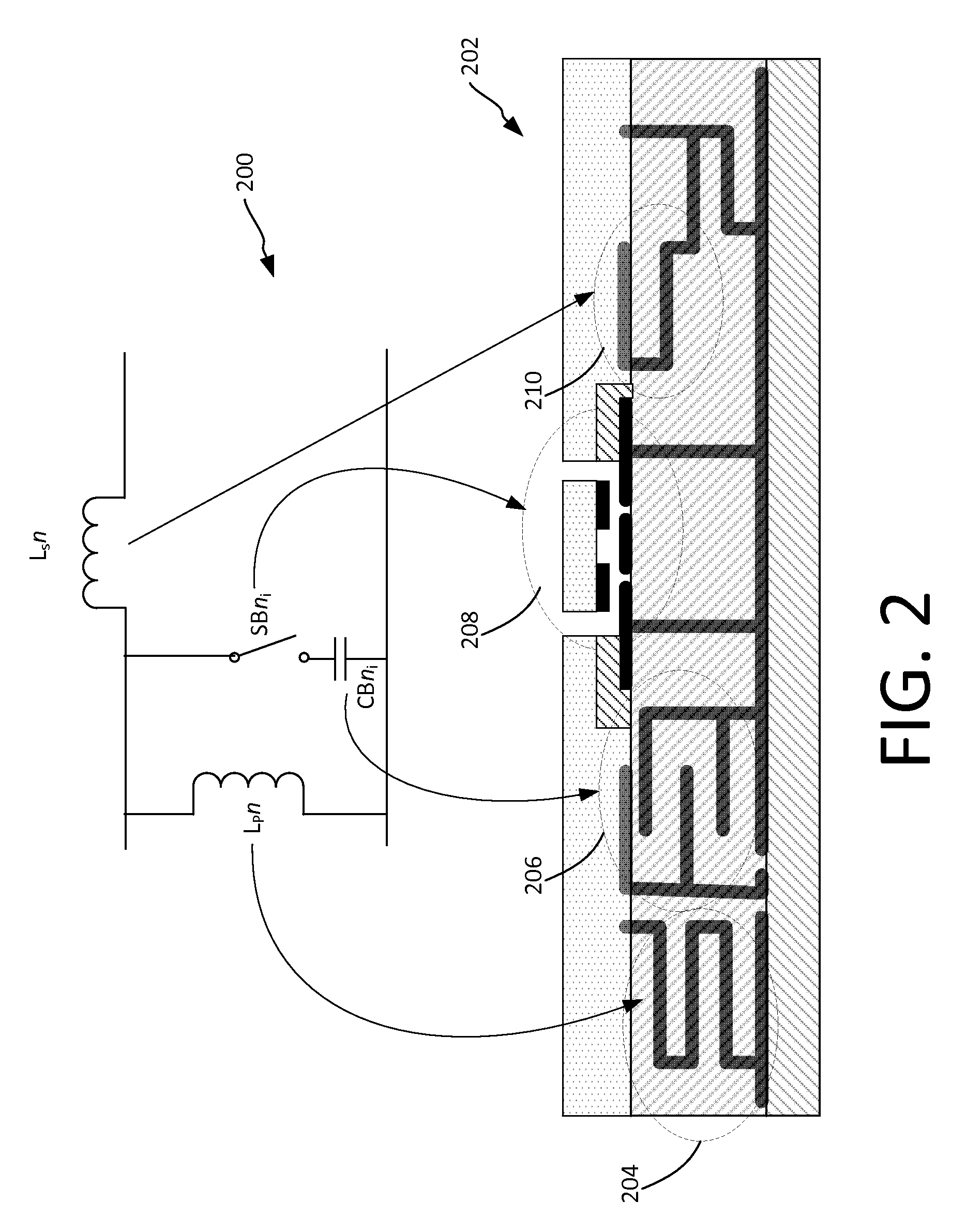

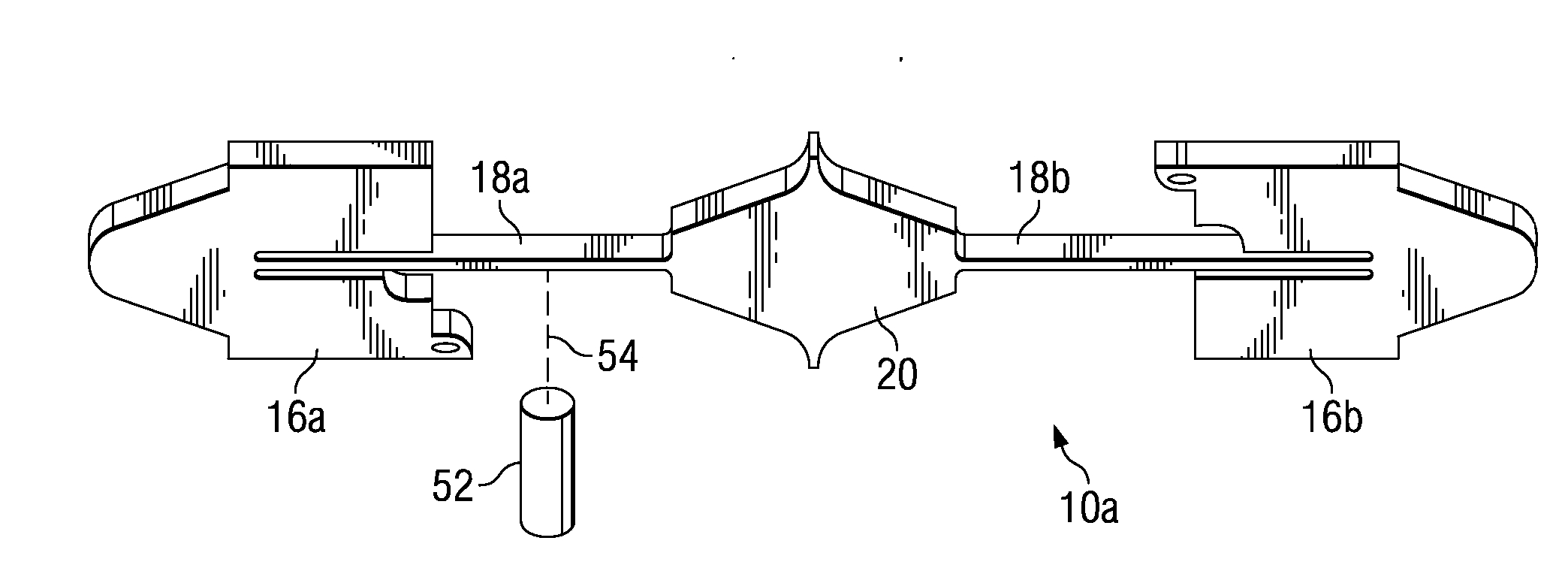

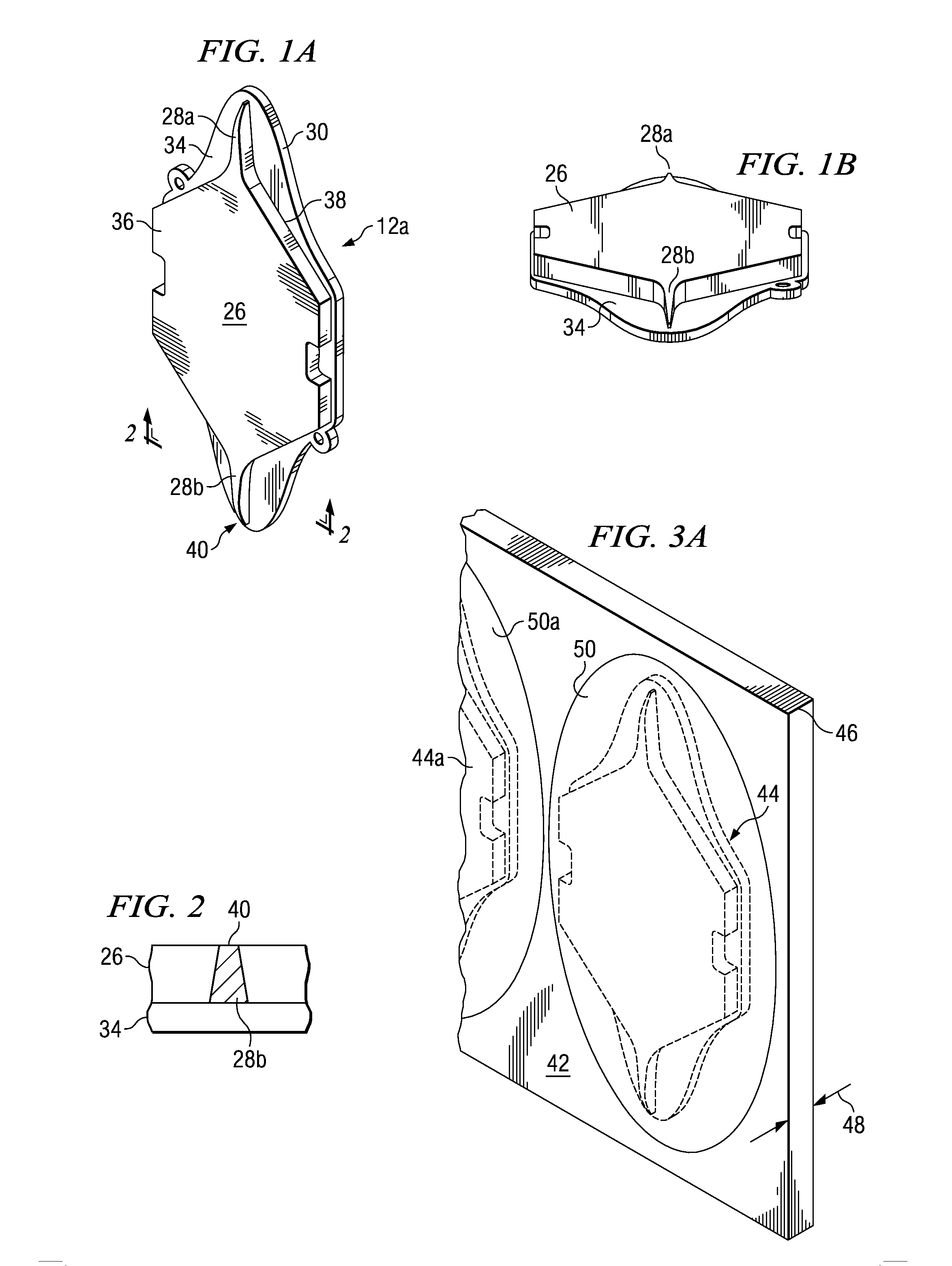

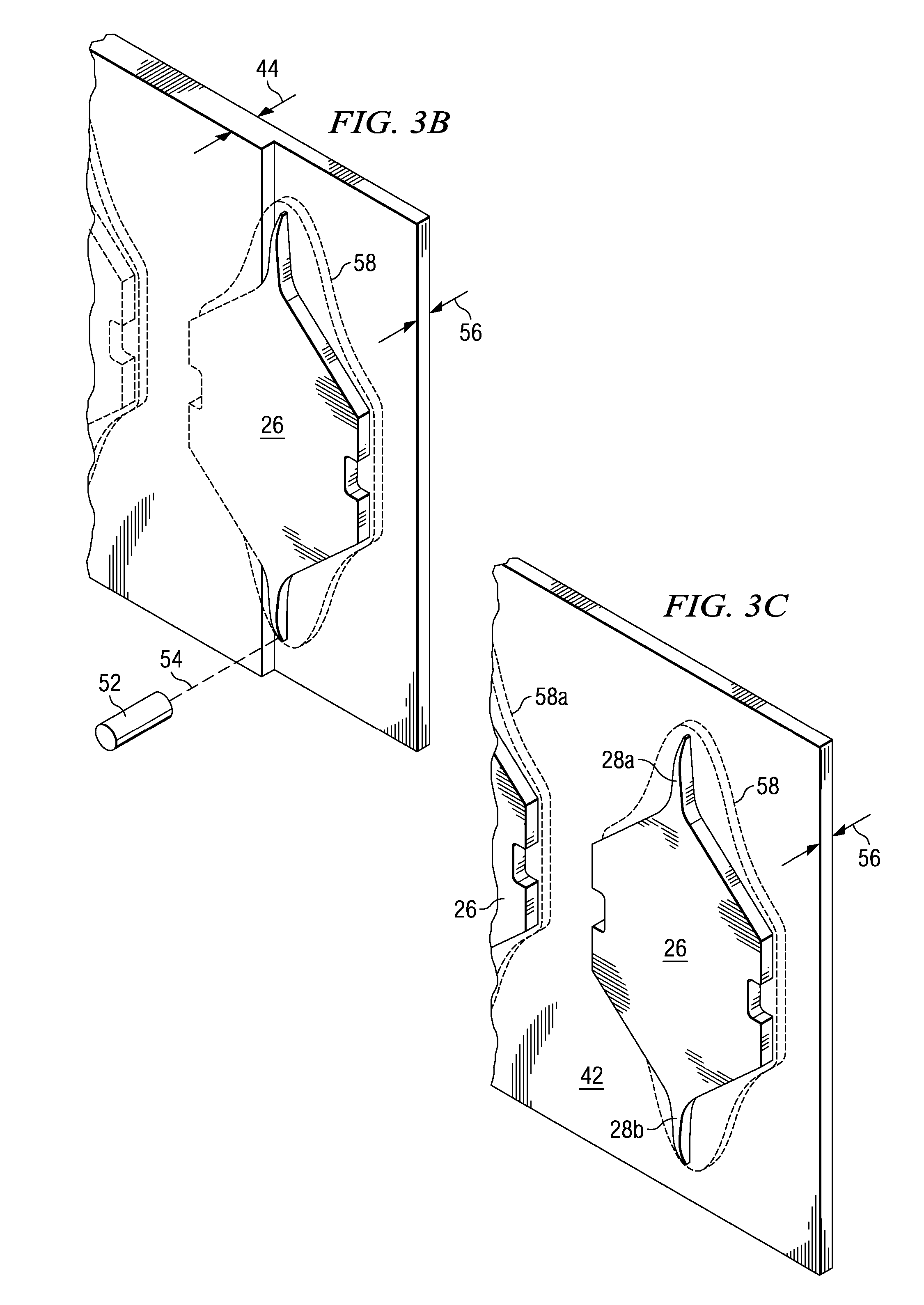

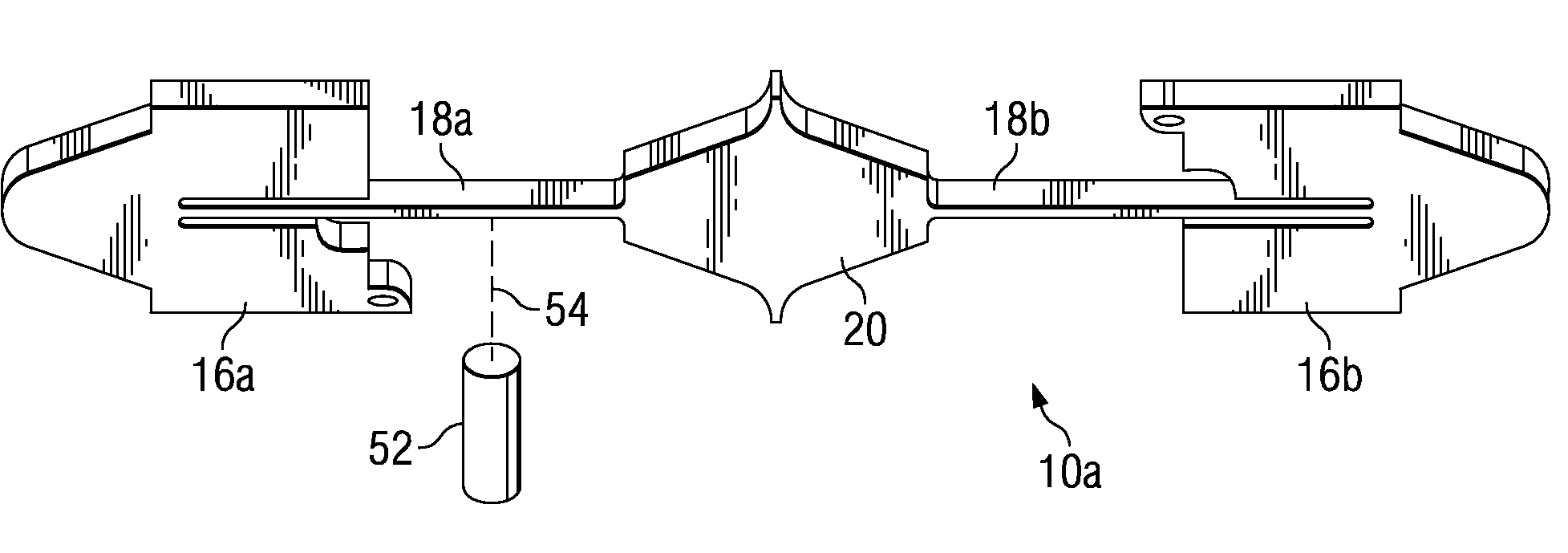

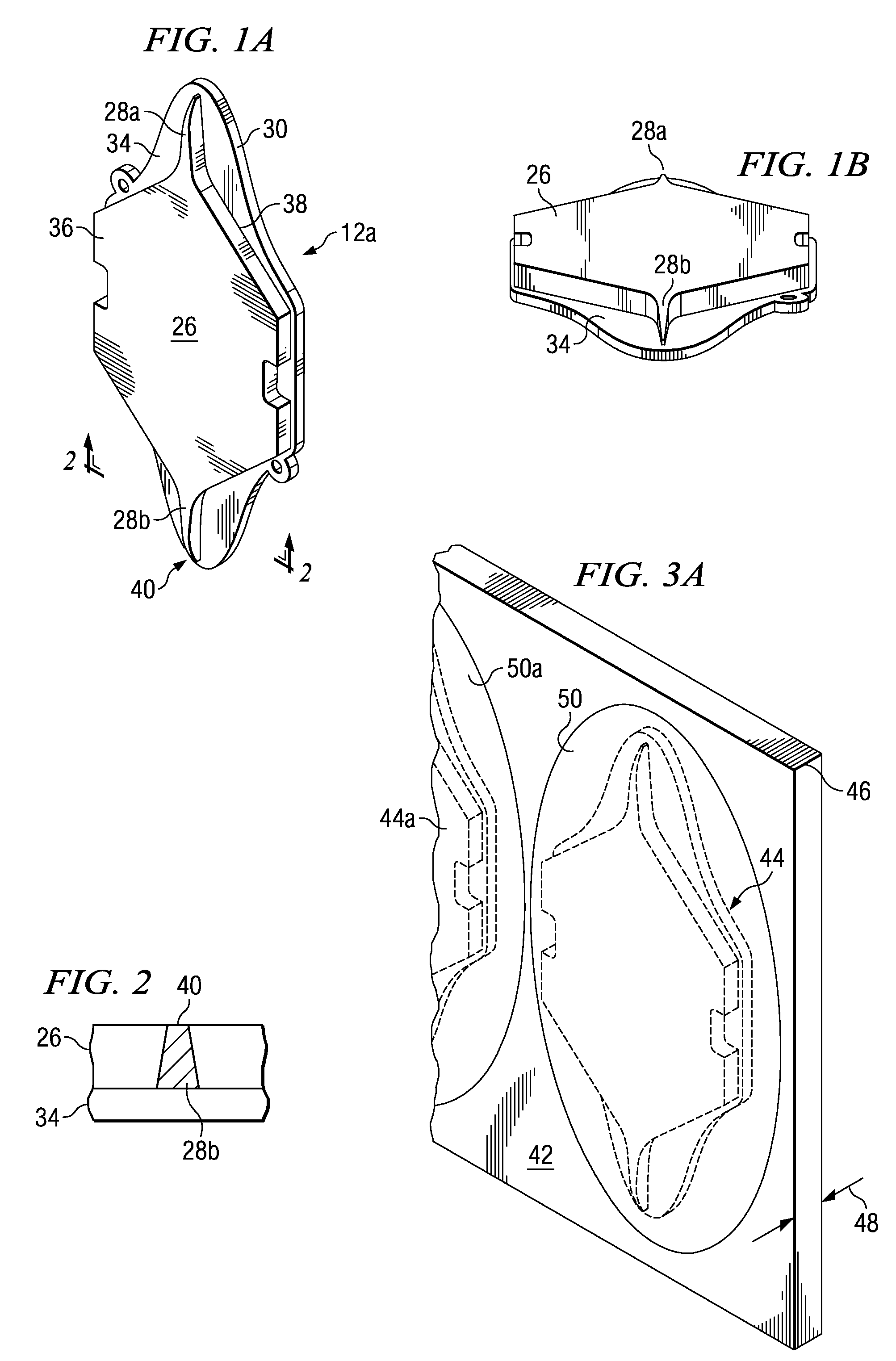

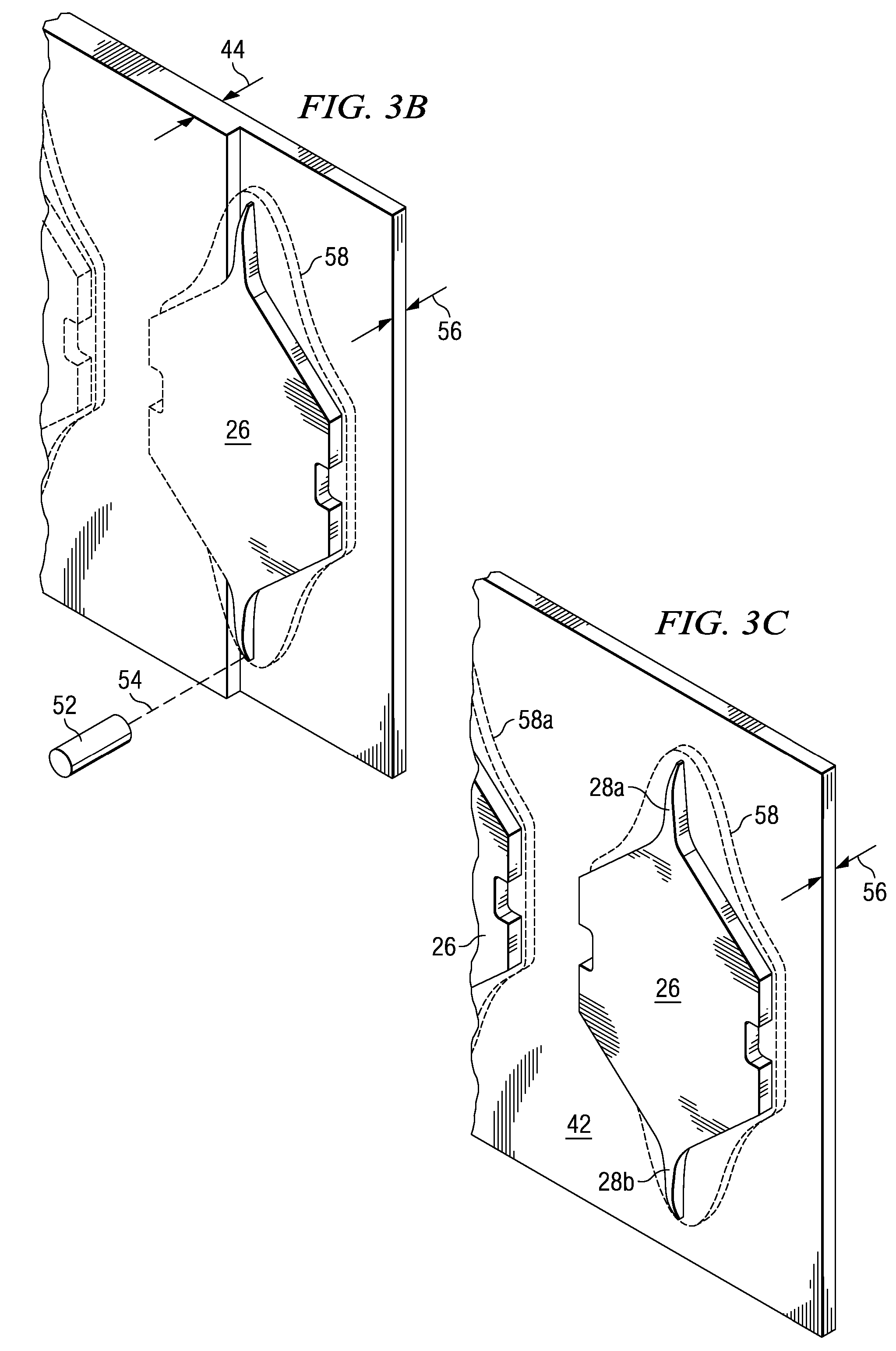

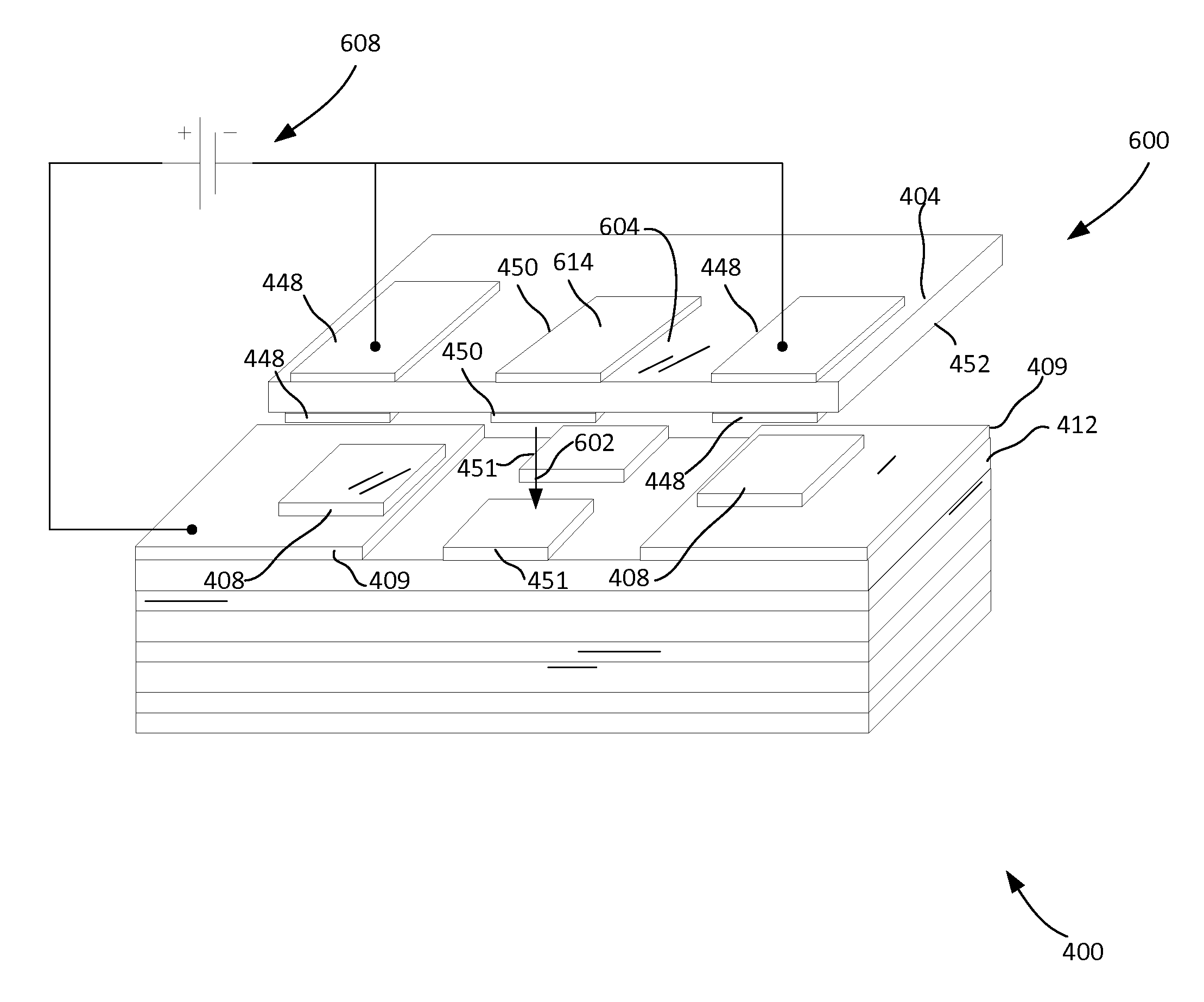

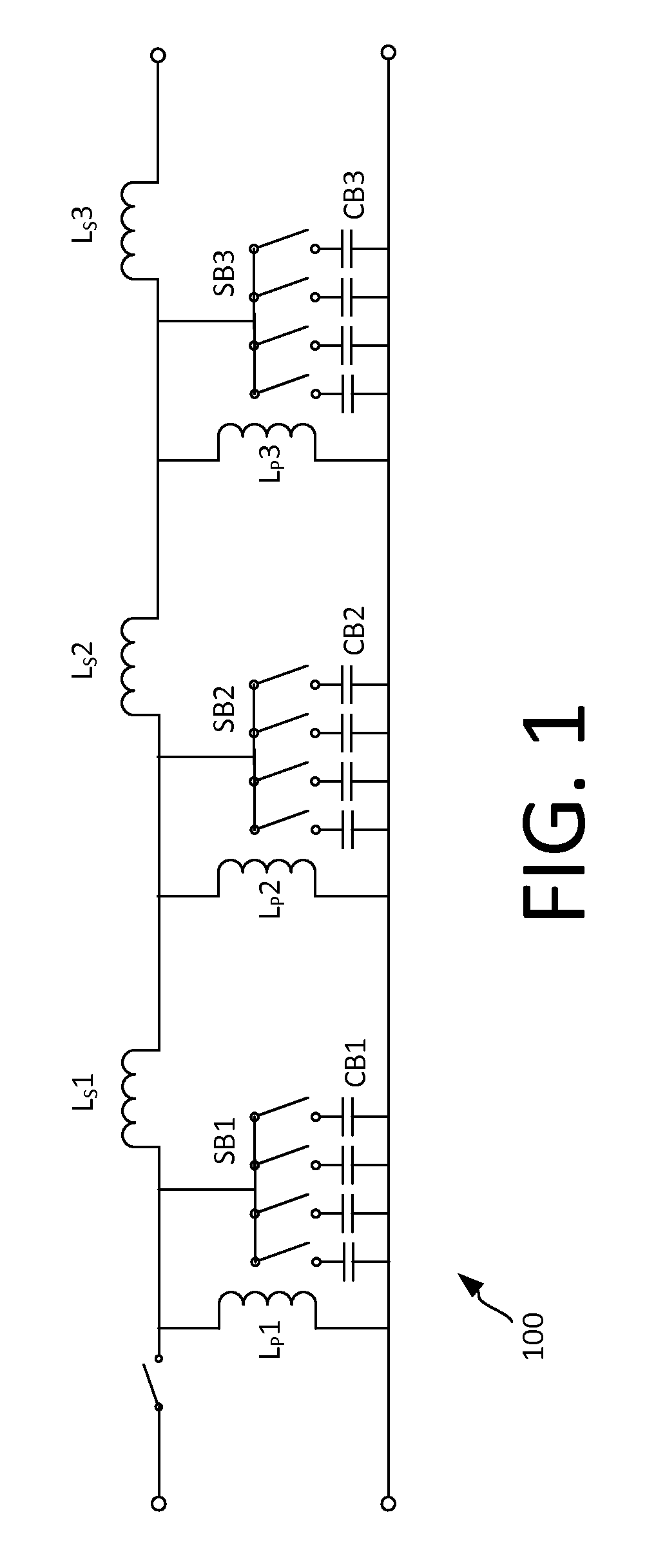

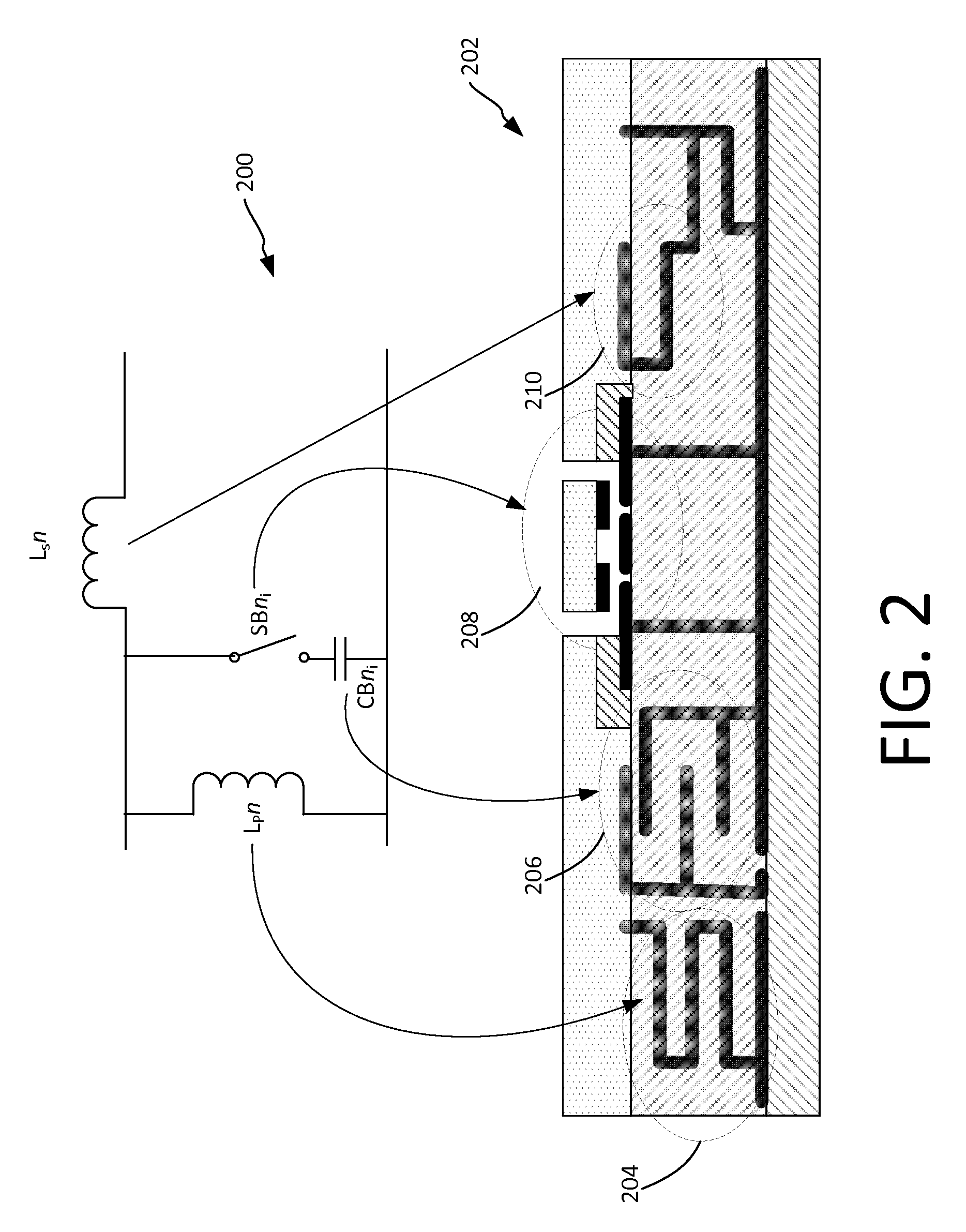

Method of manufacturing a switch system

A method for manufacturing a micro electro-mechanical system (MEMS) switch system (600, 700) includes etching each of a plurality of base circuit layers (425) and a plurality of passive component substrate layers (412, 418, 42, 426). The method continues with laser milling of a first dielectric film (406) to create a spacer layer (405). A metal cladding (402, 403) formed on a flexible dielectric film layer 404 is etched so as to form a plurality of switch component features. Further laser milling is performed with respect to the flexible dielectric film layer to form at least one switch structure (448, 450). Thereafter, a stack (400) is assembled which is comprised of the spacer layer disposed between the flexible dielectric film layer and the plurality of base circuit layers. Additional layers can also be included in the stack. When the stack is completed, heat and pressure are applied to join the various layers forming the stack.

Owner:HARRIS CORP

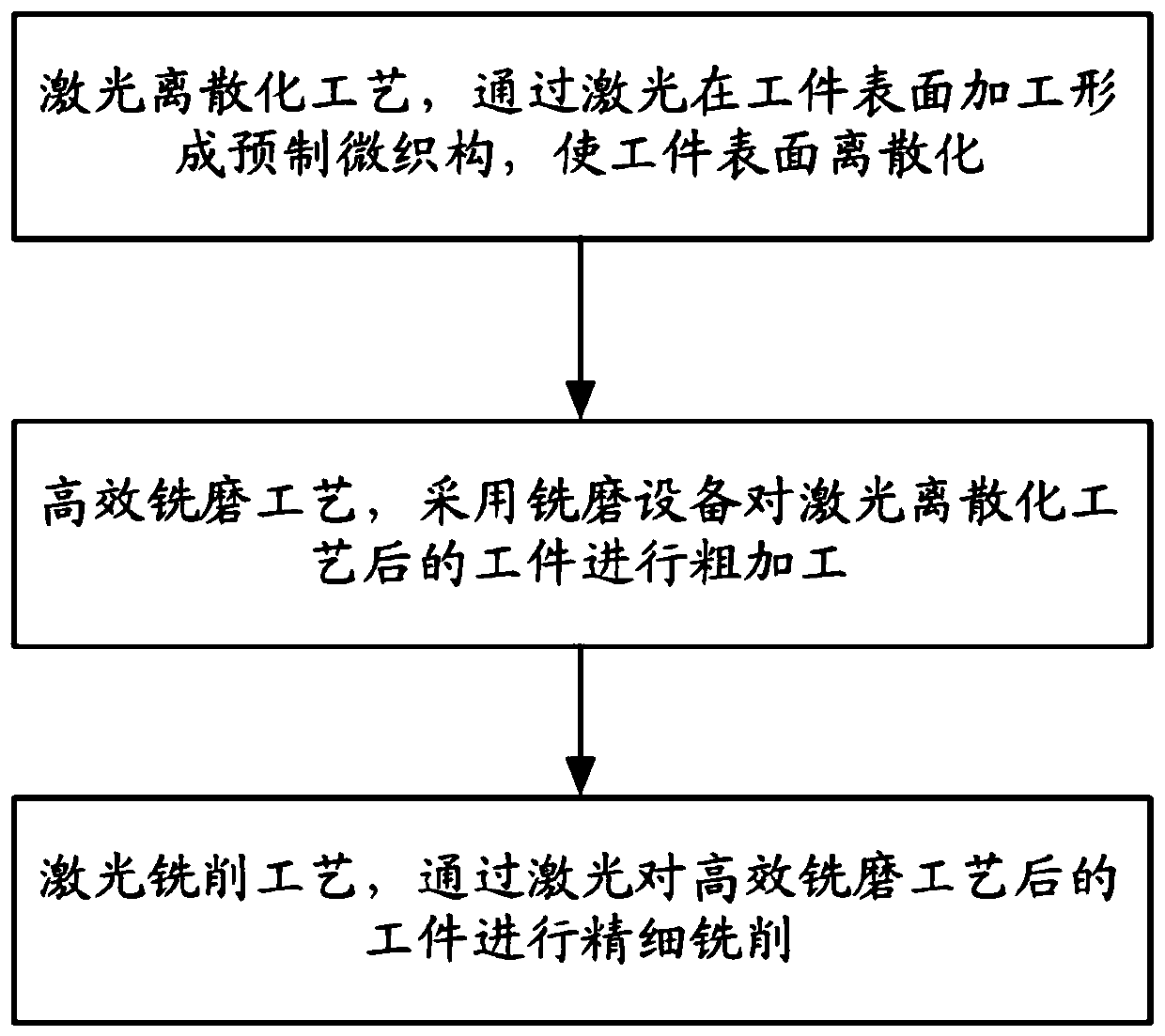

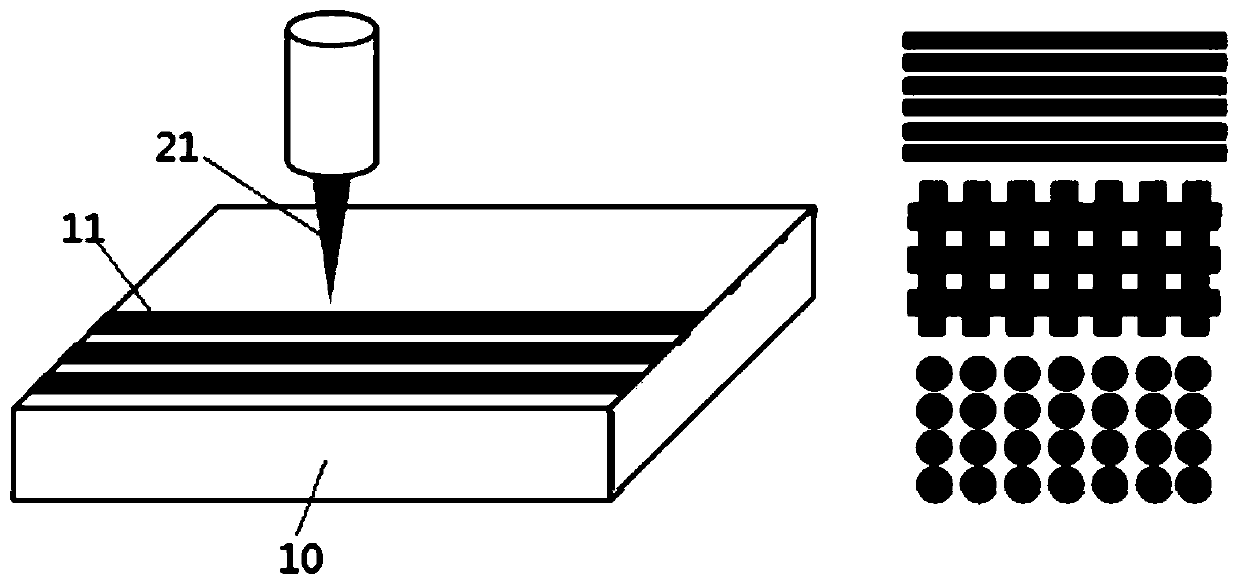

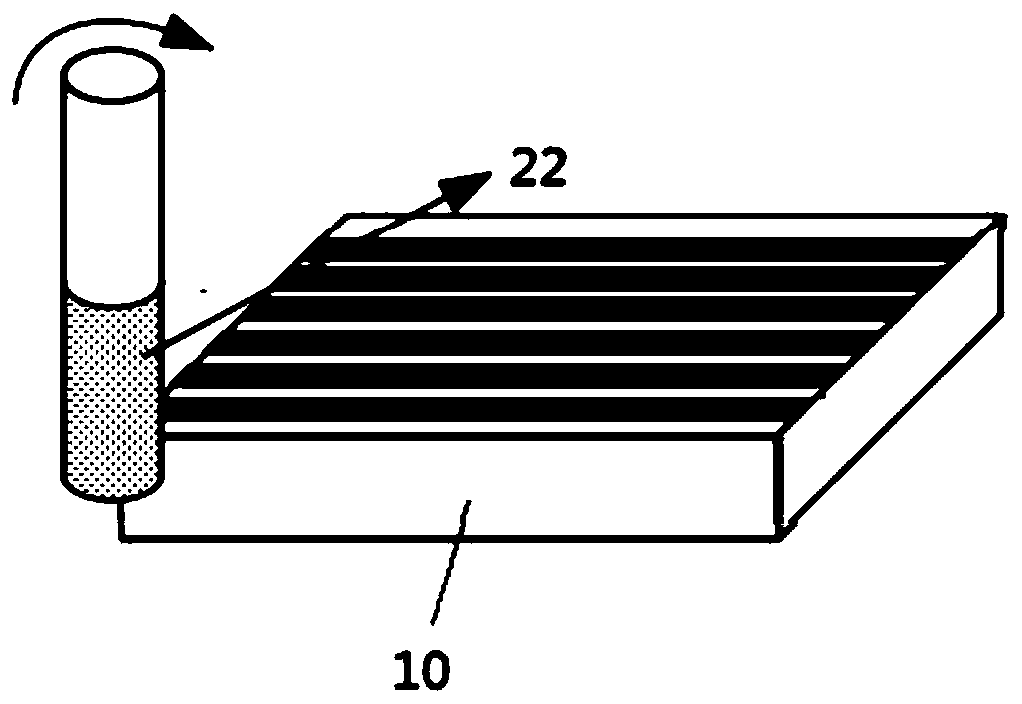

Composite machining method based on laser discretization, efficient milling and grinding and laser milling

ActiveCN110091054AImprove machinabilityGood surface roughnessLaser beam welding apparatusMachined surfaceEngineering

The invention discloses a composite machining method based on laser discretization, efficient milling and grinding and laser milling. The method includes the steps that a laser discretization technology is adopted, machining is conducted on the surface of a workpiece through lasers, a prefabricated microtexture is formed, and workpiece surface discretization is achieved; an efficient milling and grinding technology is adopted, and milling and grinding equipment is adopted for conducting rough machining on the workpiece obtained after the laser discretization technology; and a laser milling technology is adopted, and fine milling is conducted on the workpiece obtained after the efficient milling and grinding technology through lasers. By means of the composite machining method, the laser discretization technology, the efficient milling and grinding technology and the laser milling technology are combined, machinability of hardly-machined materials can be improved, efficient large-removing-rate machining is achieved, the roughness of a machined surface is improved, and regional machining can be conducted according to workpiece features. Due to multi-technology composite machining, the machining efficiency, the machining precision and the machining quality are greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

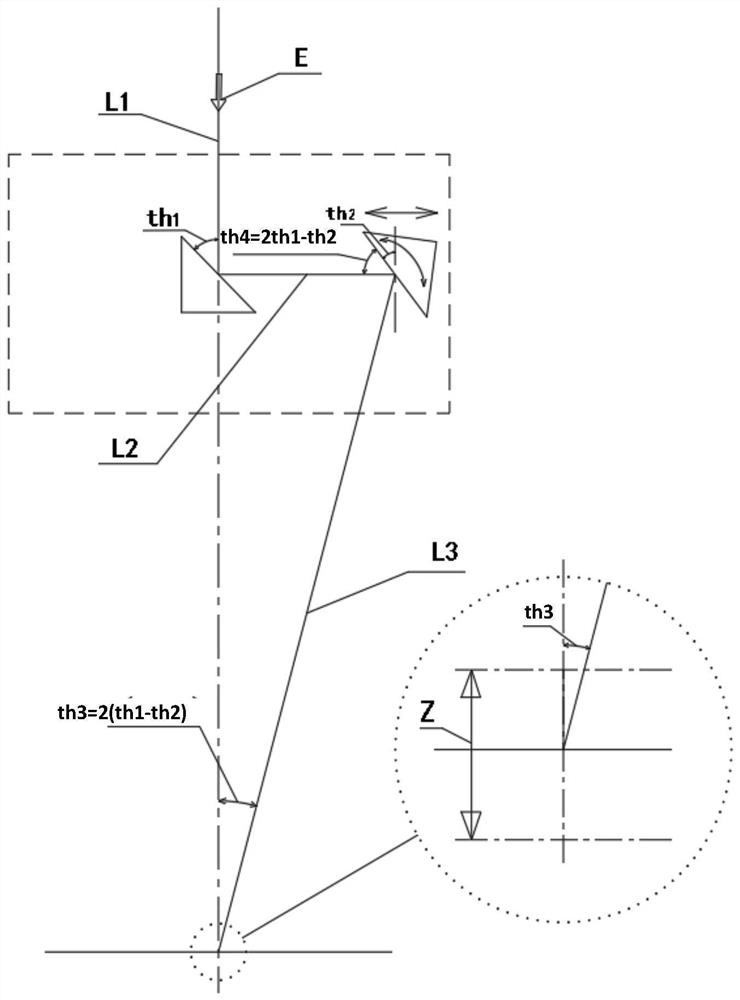

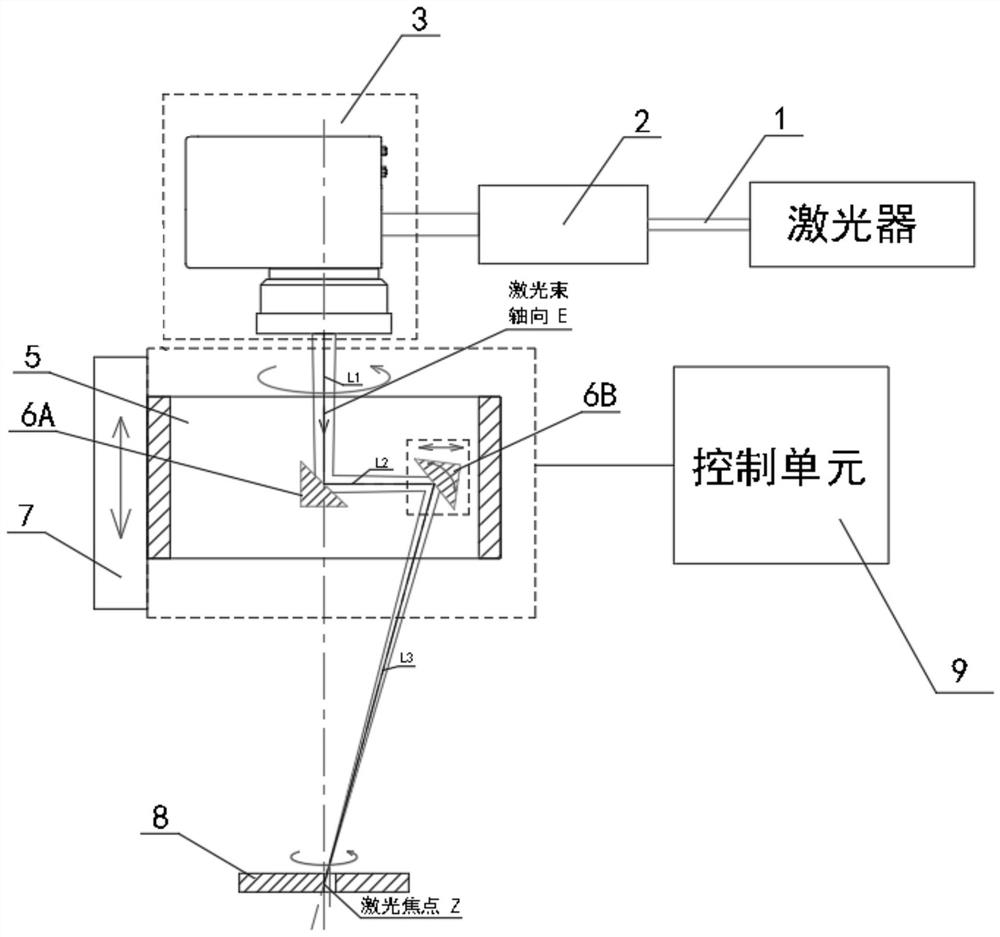

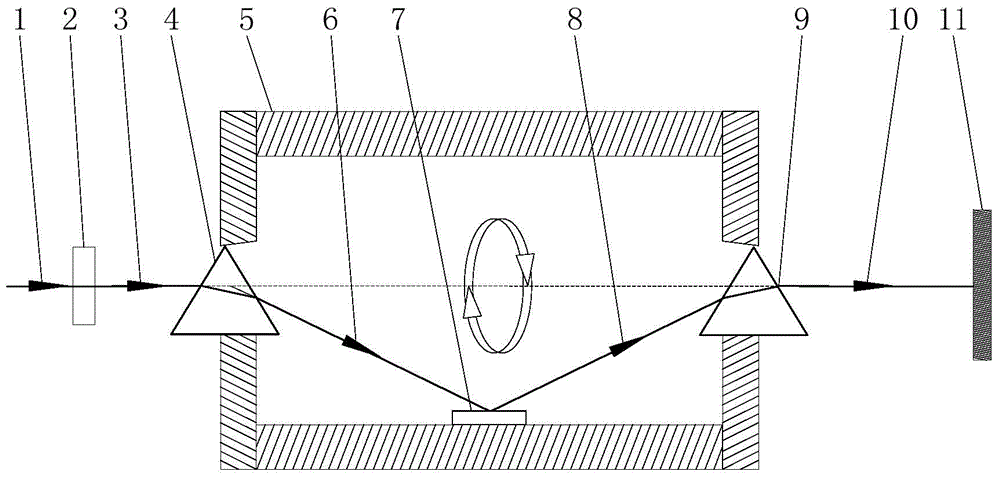

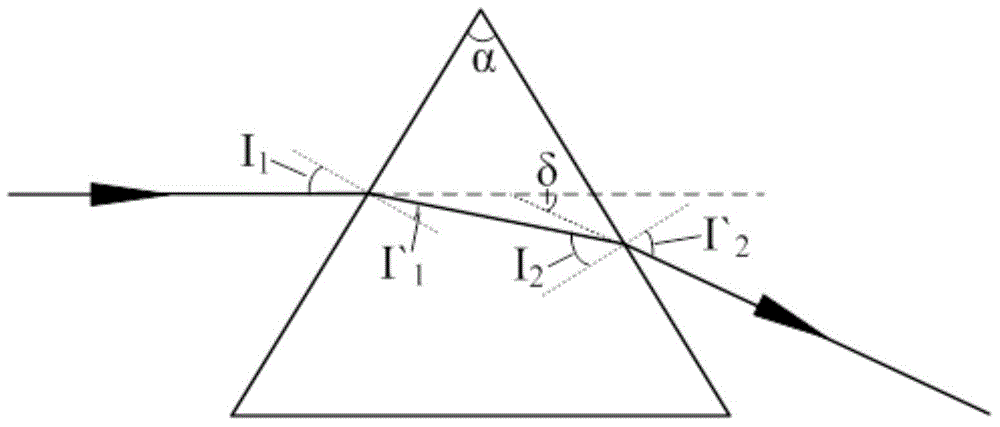

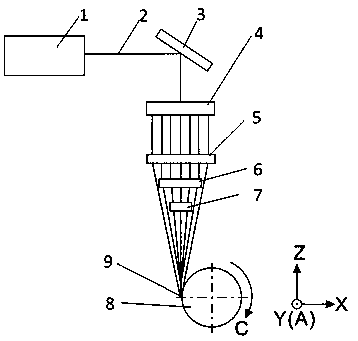

Laser processing device with controllable light beam incident angle and laser processing method

PendingCN111872548APrecise control of machining radiusRealize controllable taper machiningLaser beam welding apparatusAngle of incidenceLaser processing

The invention provides a laser processing device with a controllable light beam incident angle and a laser processing method. The laser processing device comprises a laser generating unit and a hollowunit, the laser generating unit emits a light beam with a focal length F and an axial direction E, and the light beam is incident on the surface of a workpiece after passing through the hollow unit;the hollow unit is provided with a first reflecting mirror and a second reflecting mirror, and the light beam emitted by the laser generating unit irradiates a first reflecting mirror surface, irradiates a second reflecting mirror surface after being reflected by the first reflecting mirror surface and irradiates the surface of the workpiece after being reflected by the second reflecting mirror surface; and by adjusting the inclination angle of the first reflecting mirror surface and / or the inclination angle of the second reflecting mirror surface, the light beam incident angle can be adjustedand controlled, so that laser processing of any light beam incident angle can be realized, particularly large-angle light beam incidence can be obtained, taper-controllable laser rotary processing can be obtained when the hollow unit rotates, and the device and the method have the good application prospects in processing of laser drilling, laser milling, laser polishing, laser cutting, laser welding and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

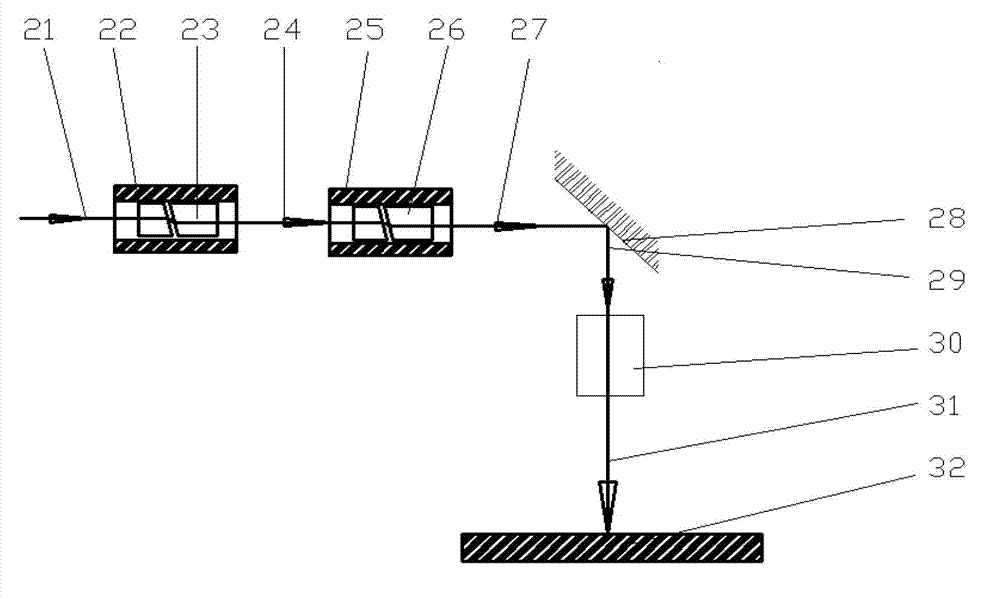

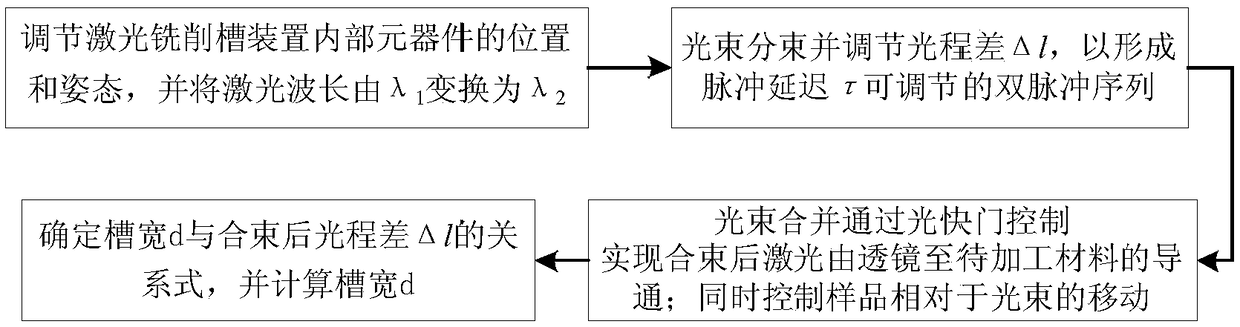

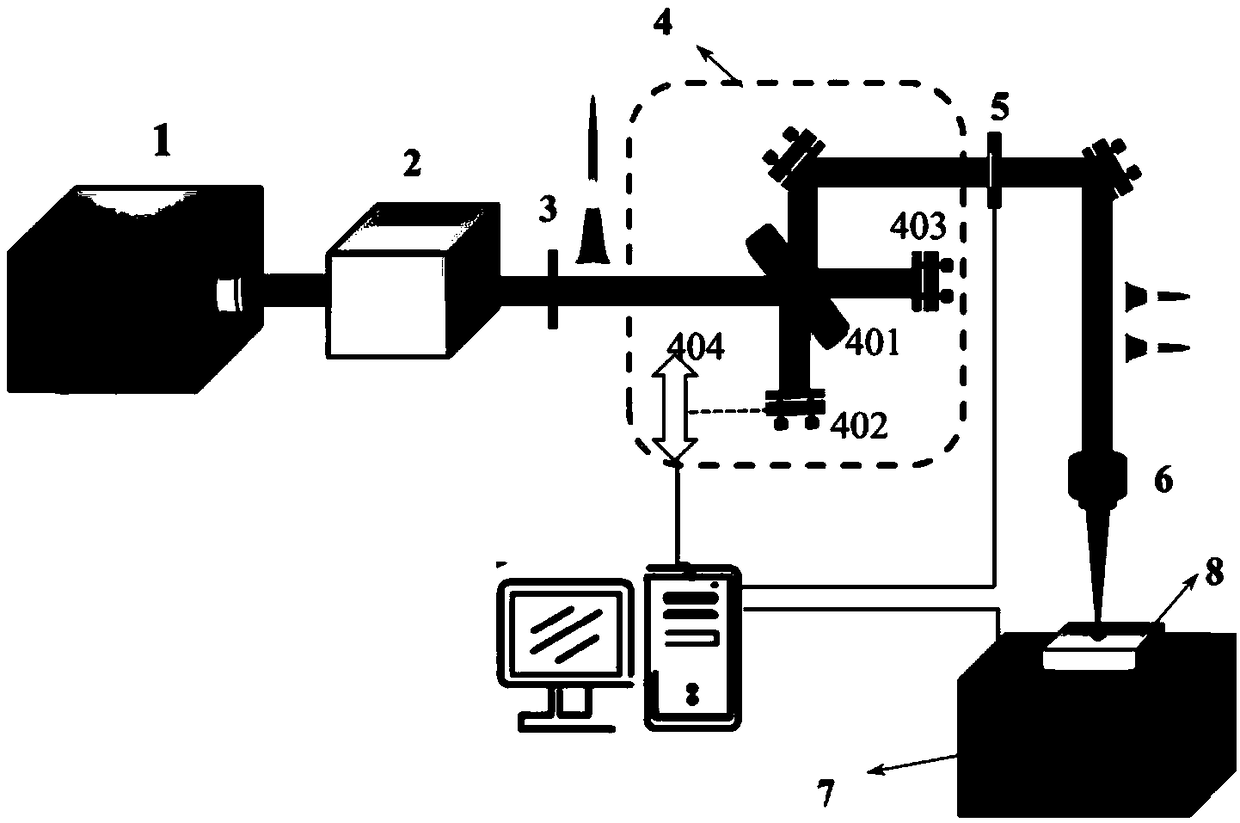

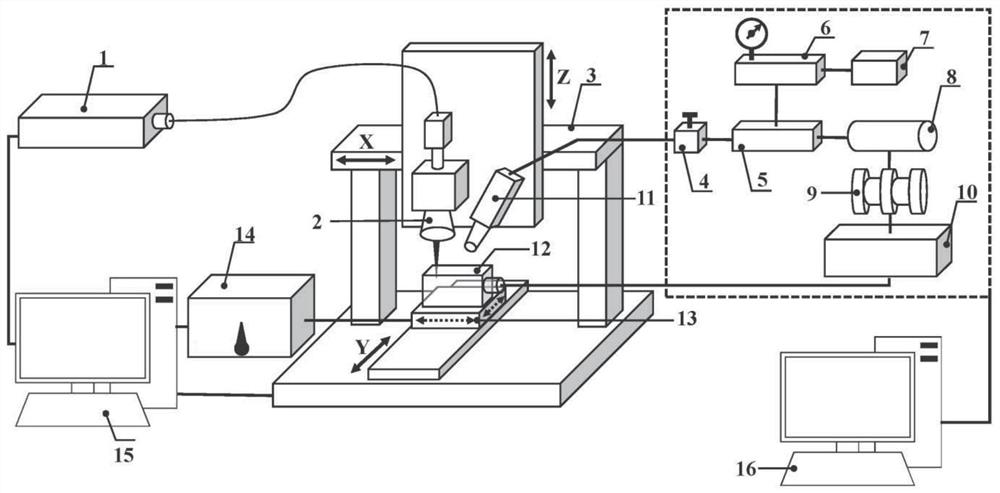

Method for performing milling microgroove machining by utilizing ultrafast laser

ActiveCN108637489AReduce deposition rateReduce widthLaser beam welding apparatusTime delaysOptoelectronics

Provided is a method for performing milling microgroove machining by utilizing ultrafast laser. By utilizing a laser milling groove system comprising a Michelson interferometer, single pulse sequencelaser is changed into double pulse sequence laser; by increasing an optical path difference of two interference arms of the Michelson interferometer, pulse delay of the double pulse sequence laser isindirectly increased; time delay of the laser is increased, and the optical path difference of the double pulse laser is indirectly increased; the purpose of reducing the width of a milling groove isachieved; and meanwhile, an accurate width value of the milling groove is acquired due to calculation, and the groove milling precision is high.

Owner:BEIJING SATELLITE MFG FACTORY

Manufacturing a mirror plate or other operational structure having superior flatness by laser milling for use with torsional hinged devices

Owner:TEXAS INSTR INC

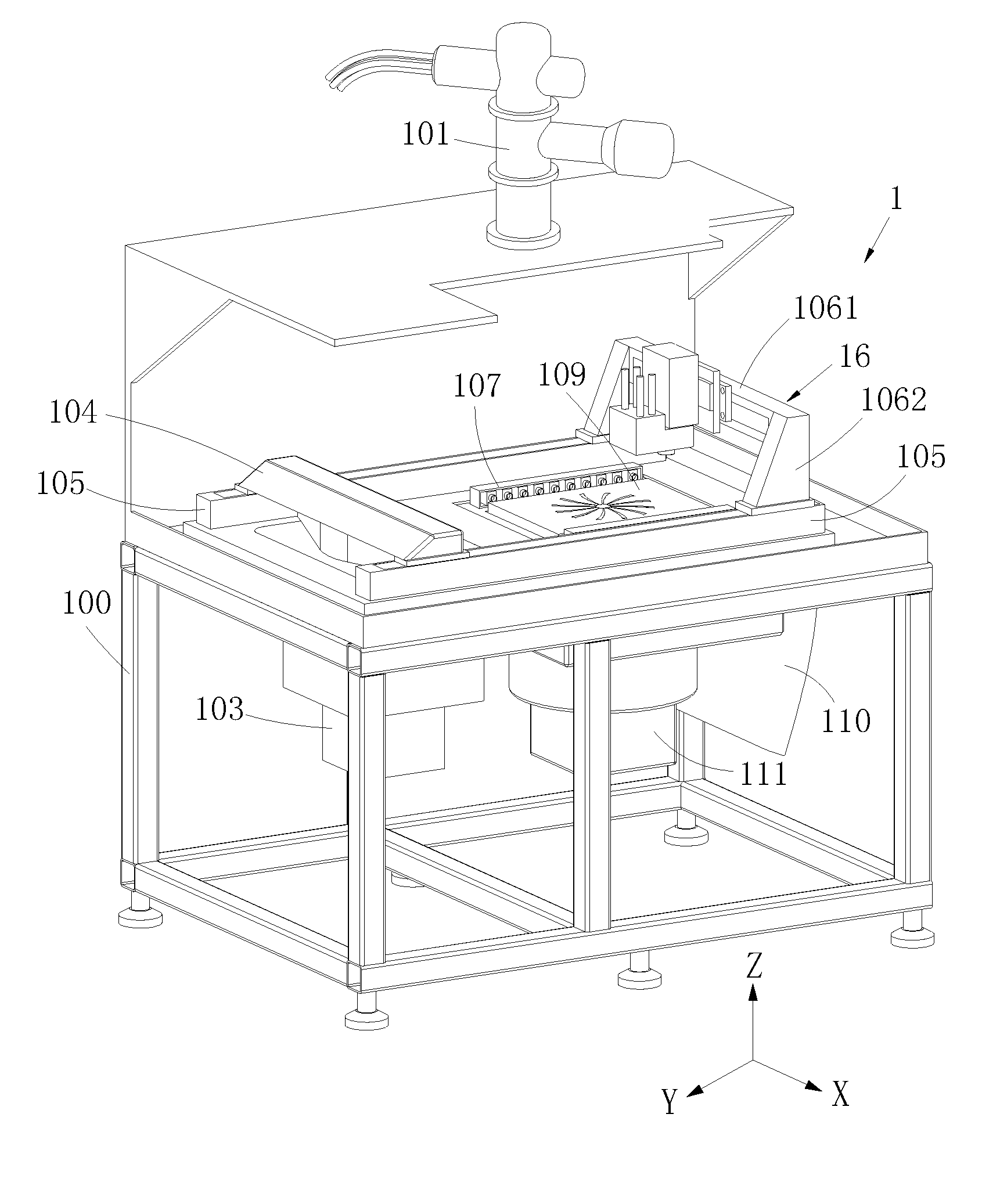

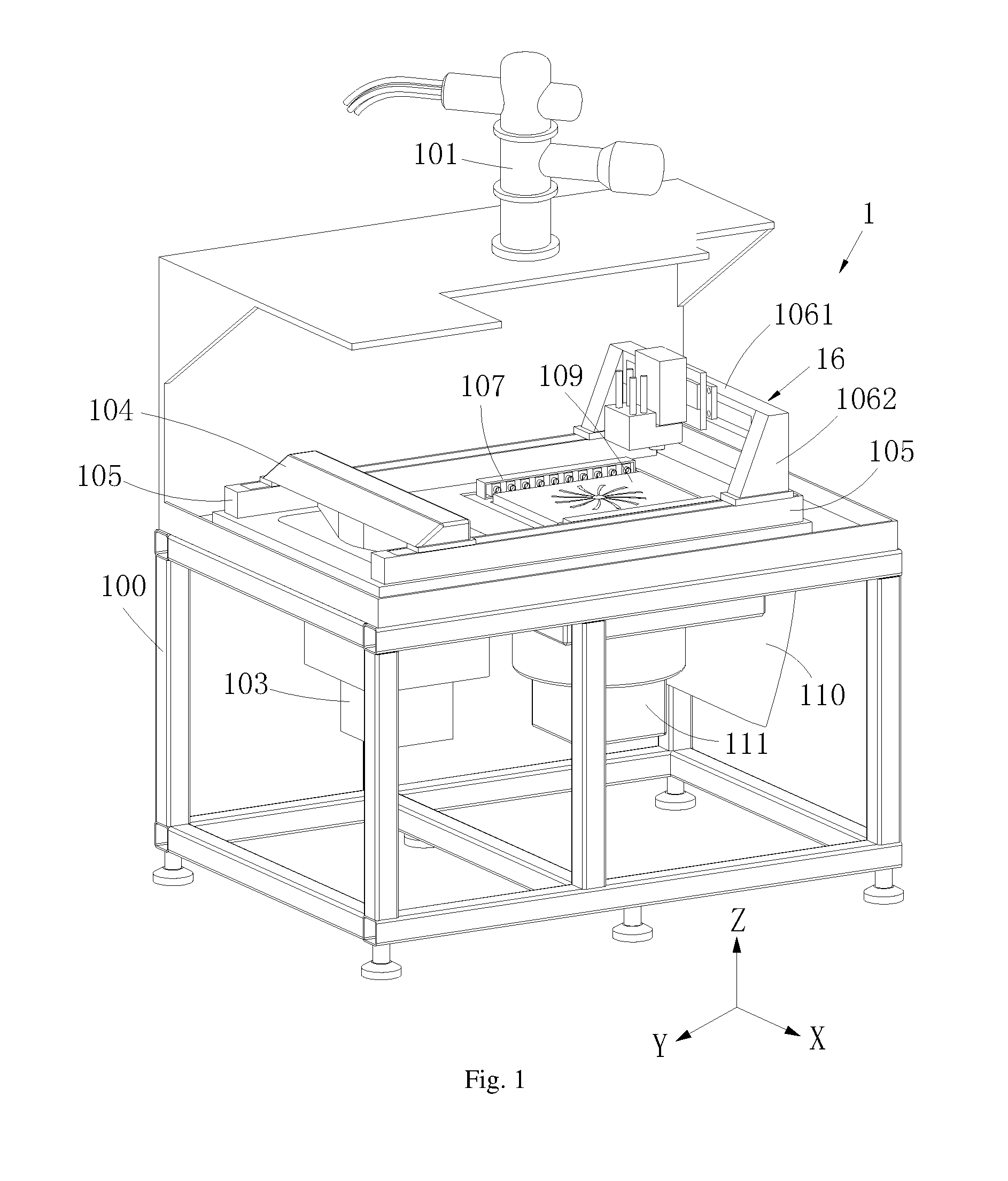

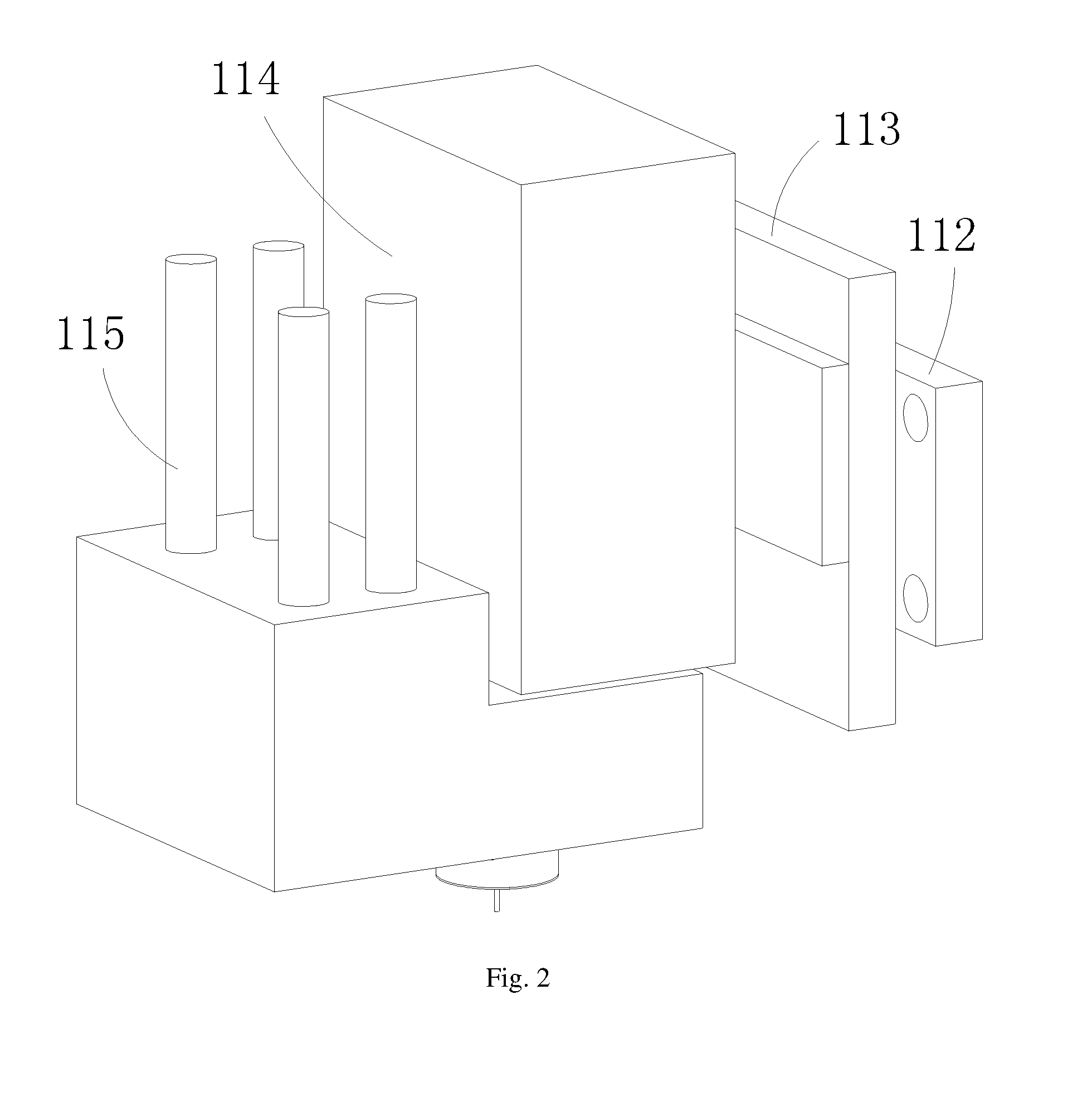

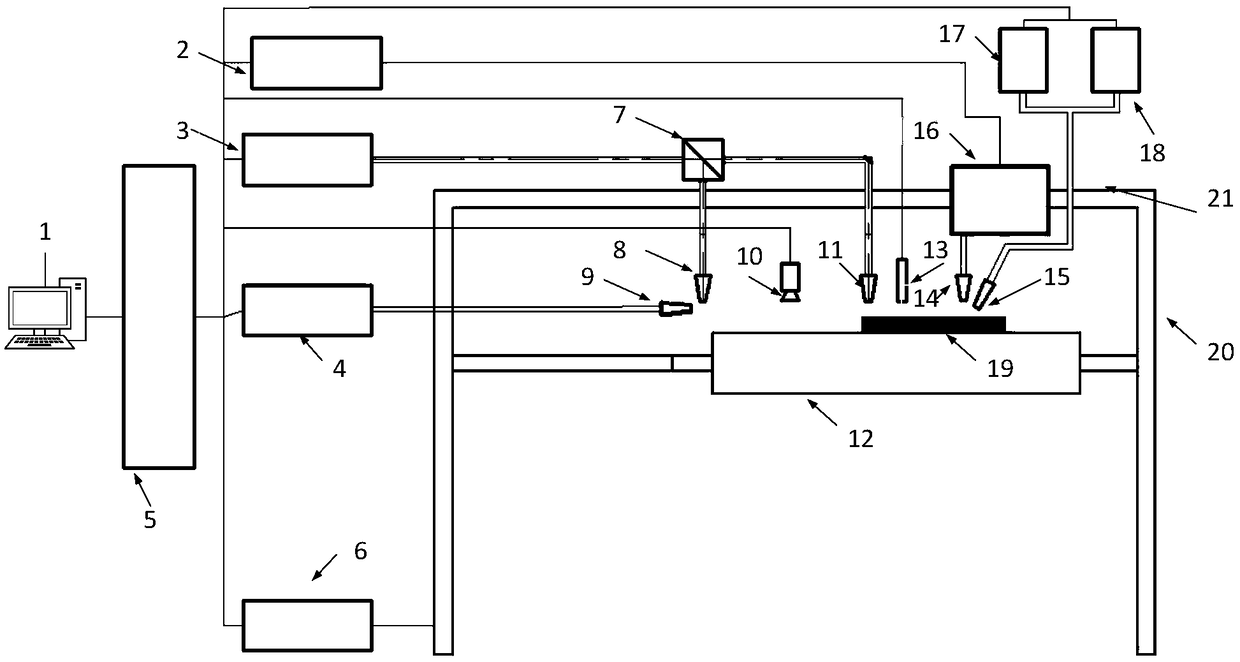

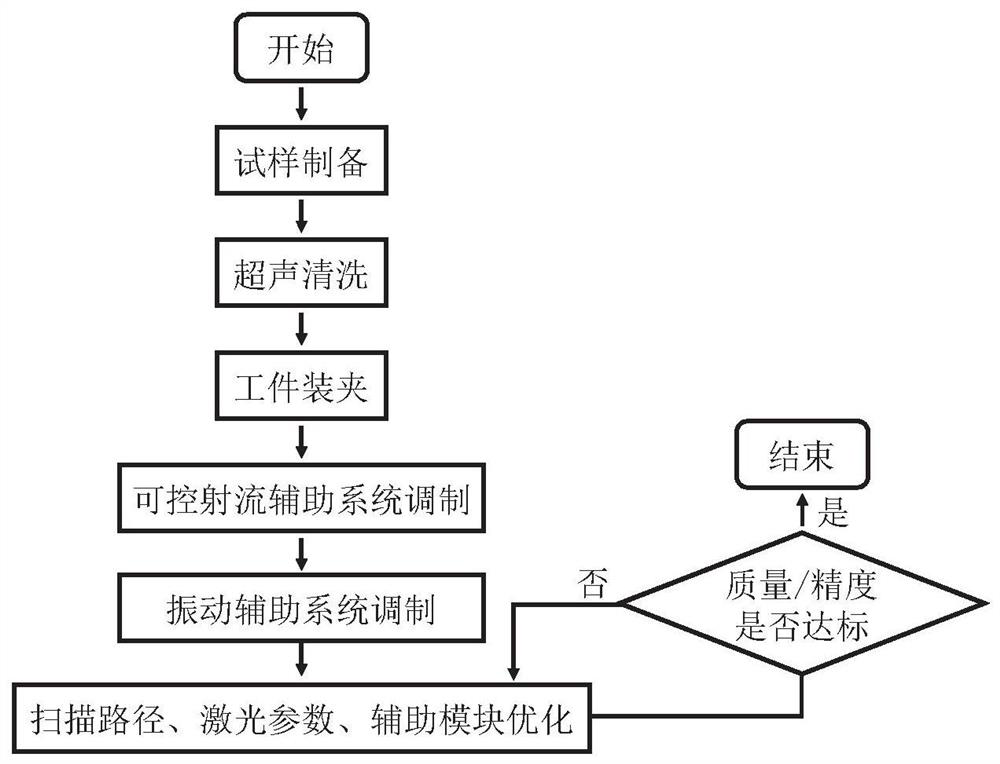

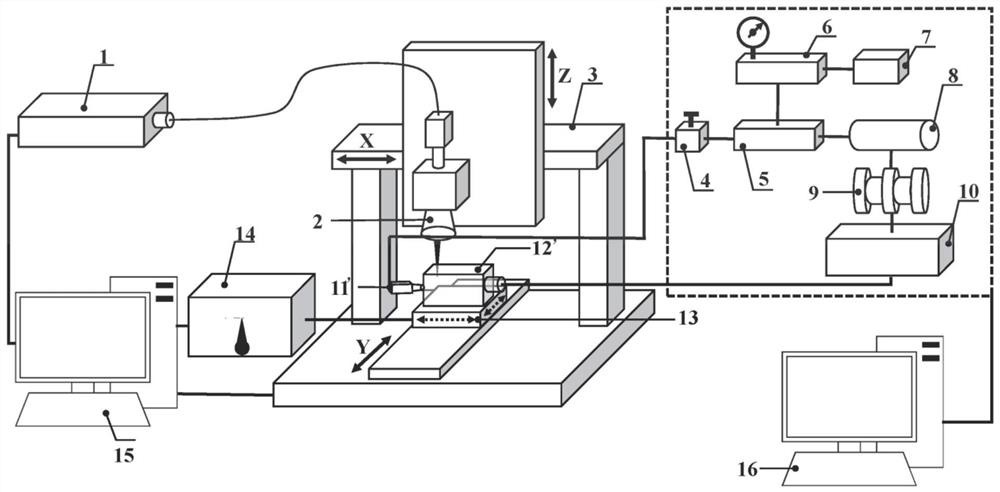

Controllable liquid flow-vibration coupling auxiliary laser milling and polishing machining method and system

ActiveCN113732515AImprove removal efficiencyOptimize energy distributionLaser beam welding apparatusMachining vibrationsLaser processing

The invention discloses a controllable liquid flow-vibration coupling auxiliary laser milling and polishing machining method and system. The machining system comprises a laser machining unit used for conducting laser machining on a workpiece; a liquid flow auxiliary unit used for providing liquid flow to be in contact with the workpiece; a vibration auxiliary unit used for applying vibration to the workpiece; and a control unit used for regulating and controlling the working states of the laser machining unit, the liquid flow auxiliary unit and the vibration auxiliary unit so as to realize controllable coupling of laser machining, vibration and liquid flow. By controllable coupling of laser, vibration, liquid flow and the like, superiority of each process / energy field can be exerted, coupling complementation is realized, macro-micro-scale energy distribution characteristics of a machining area are effectively regulated and controlled, heat influence is reduced, micro-cracks are avoided, laser milling and polishing chip removal characteristics and machining quality are remarkably improved, workpiece quality is greatly improved, and the material removal efficiency is effectively improved. The machining system of the invention is particularly suitable for precision machining of metal materials, hard and brittle materials and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

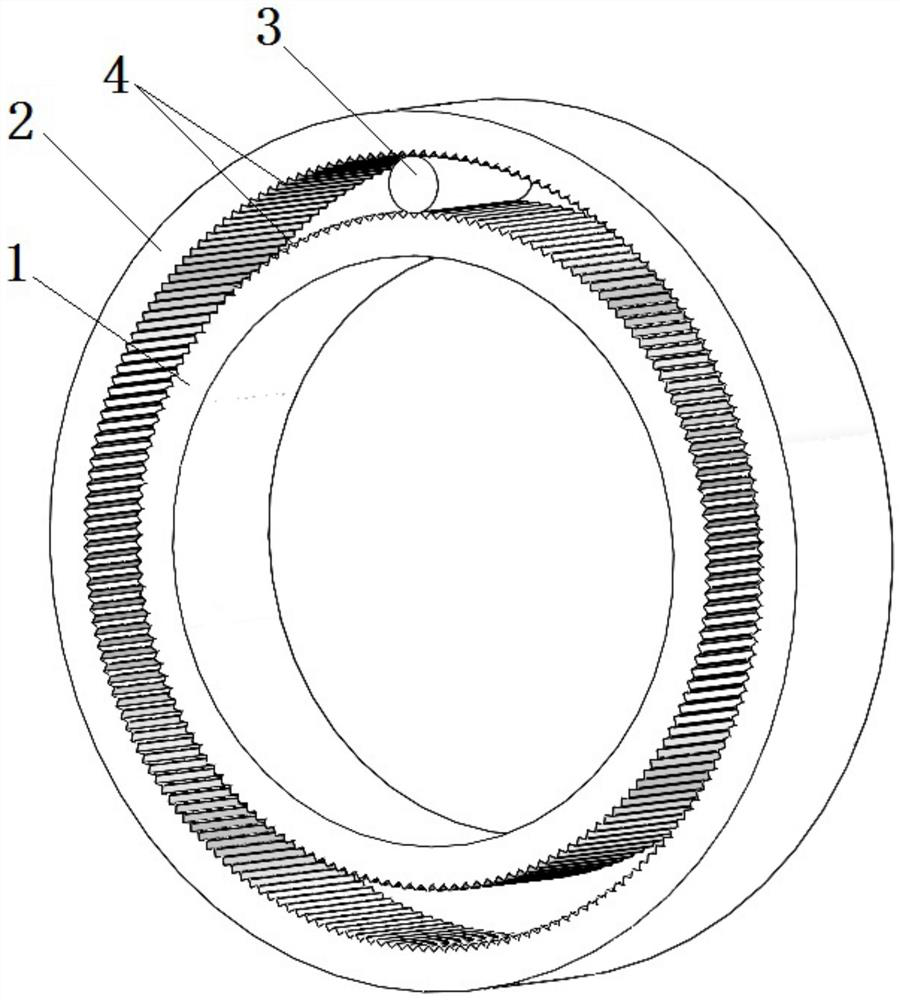

Micro milling control system based on rotating laser beam mechanism

InactiveCN104625421ATo achieve the purpose of millingLaser beam welding apparatusPlane mirrorControl system

The invention discloses a micro milling control system based on a rotating laser beam mechanism. The micro milling control system comprises a horizontal laser beam, a focusing module and a rotating beam module. An optical element of an optical rotating beam module mechanism comprises two triple prisms with the deflection angle of 60 degrees, a plane mirror and a rotating barrel. The two triple prisms are symmetrically fixed to the two ends of a center shaft of the rotating barrel. The plane mirror is fixed to the middle of the inner wall of the rotating barrel. Horizontal light irradiates in the center shaft direction of the rotating barrel and reaches the plane mirror after being deflected by the first triple prism. The light is emitted through the second triple prism after being reflected by the plane mirror. In the acting process unit time, light spots acting on the fixed unit area are distributed more evenly through the rotating of the light spots, the laser milling removing rate is increased, and a better surface machining quality is obtained. Meanwhile, a mask in a certain shape can be machined on the rotating beam, the shape of a cutter is simulated, rotating is carried out along with the beam, and the milling purpose is achieved.

Owner:BEIJING UNIV OF TECH

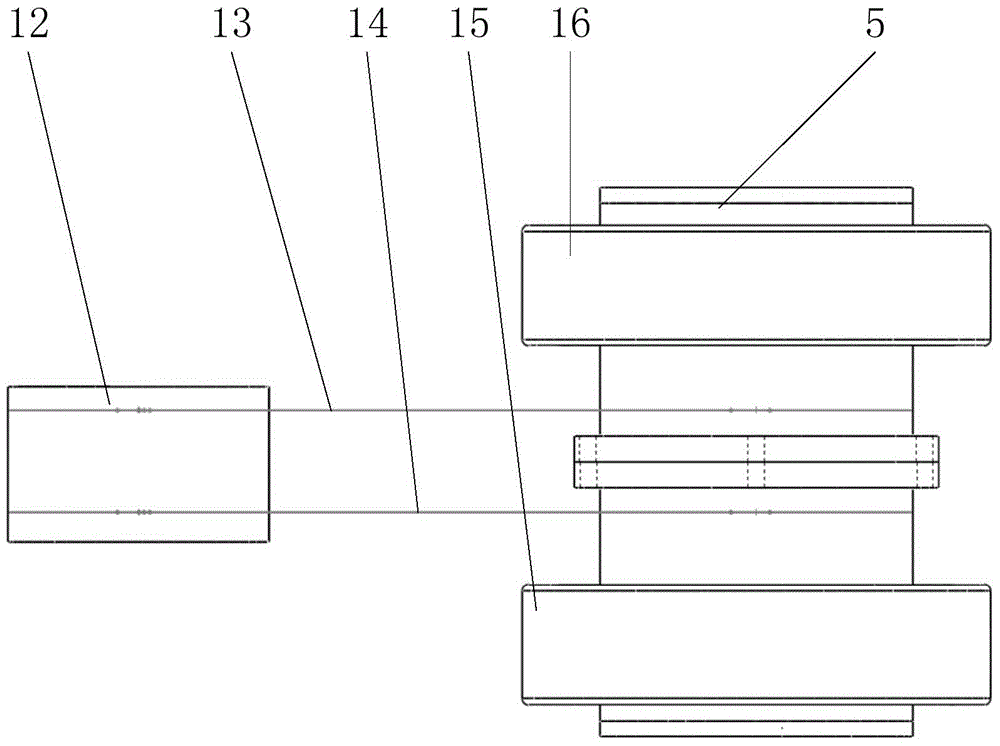

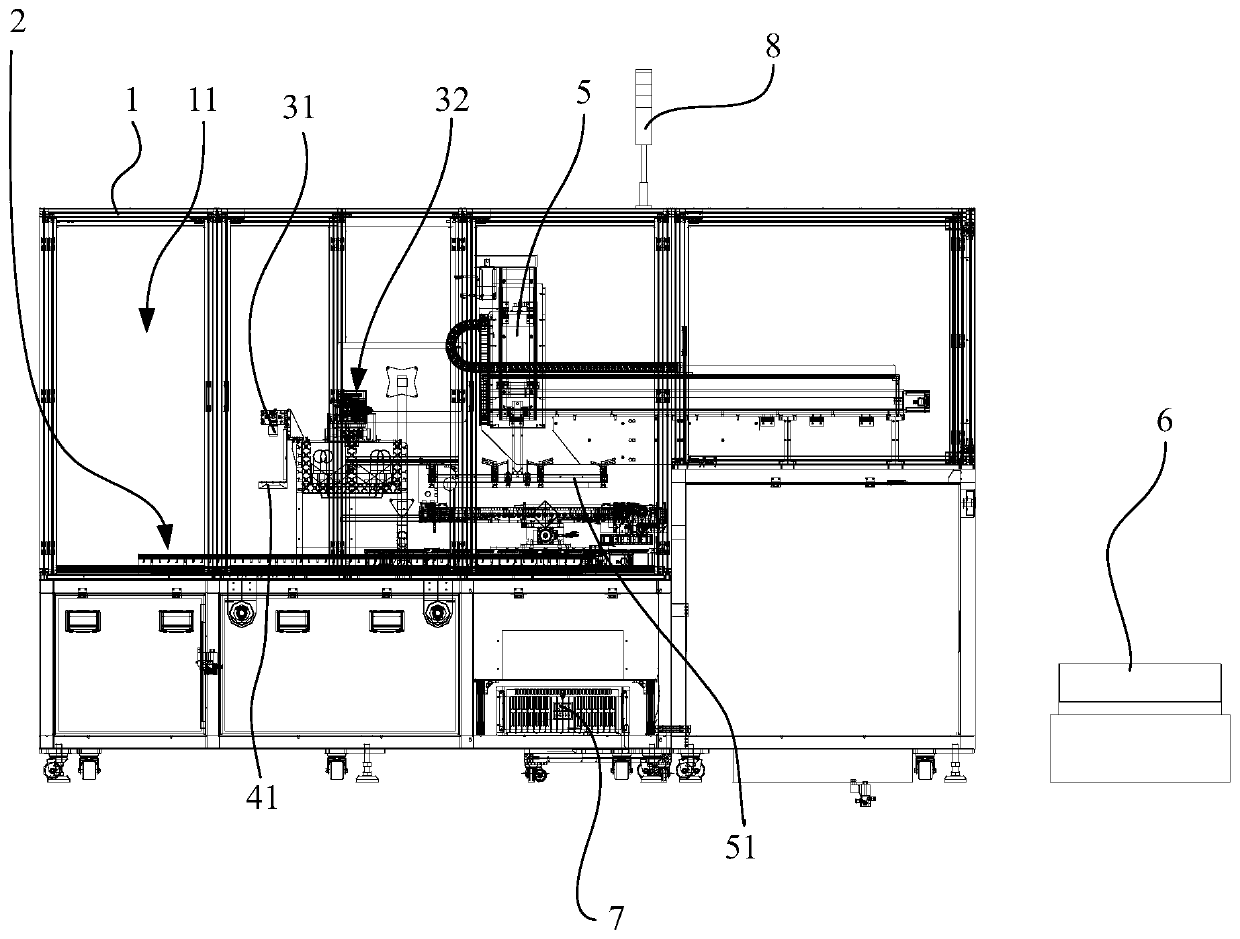

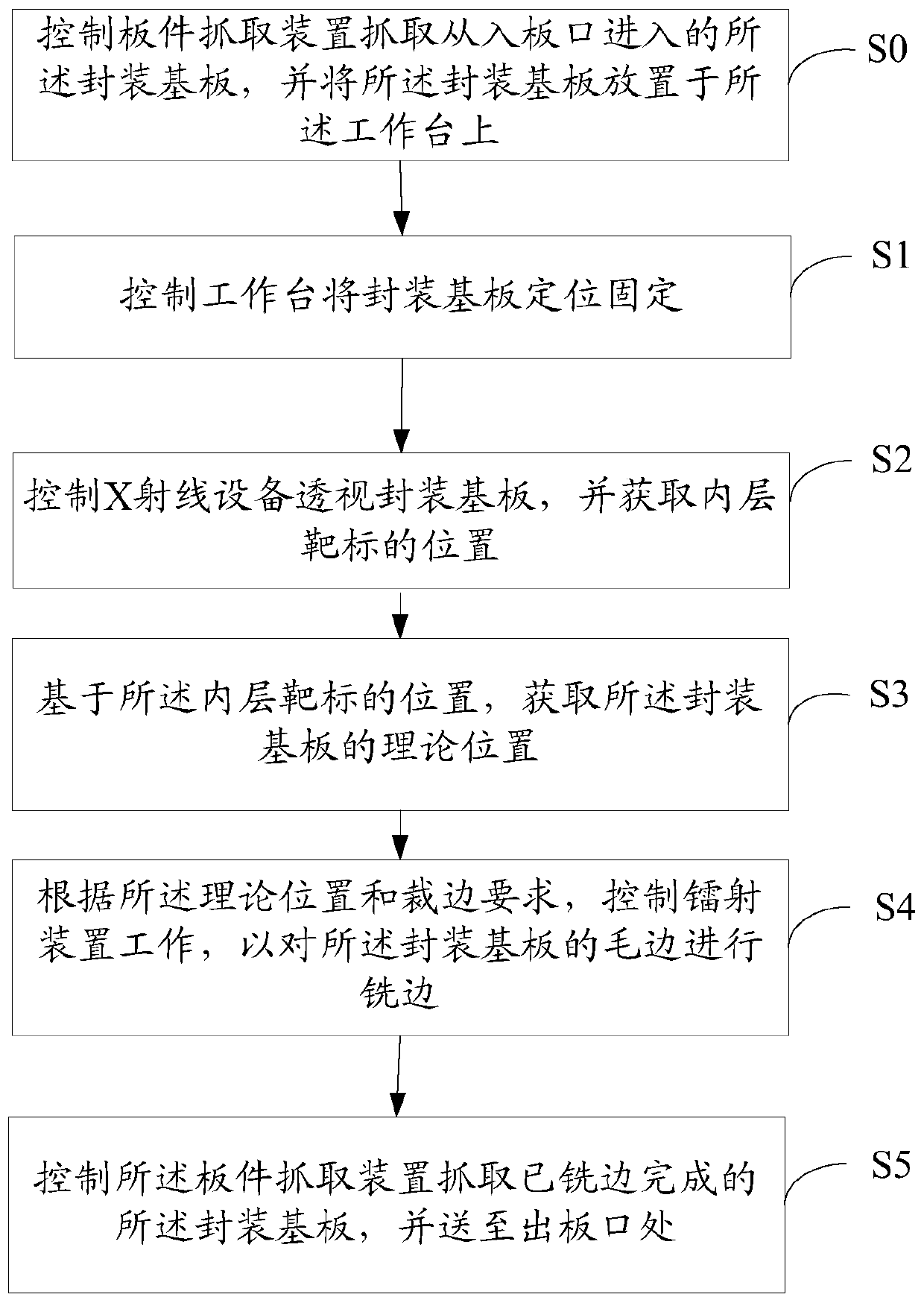

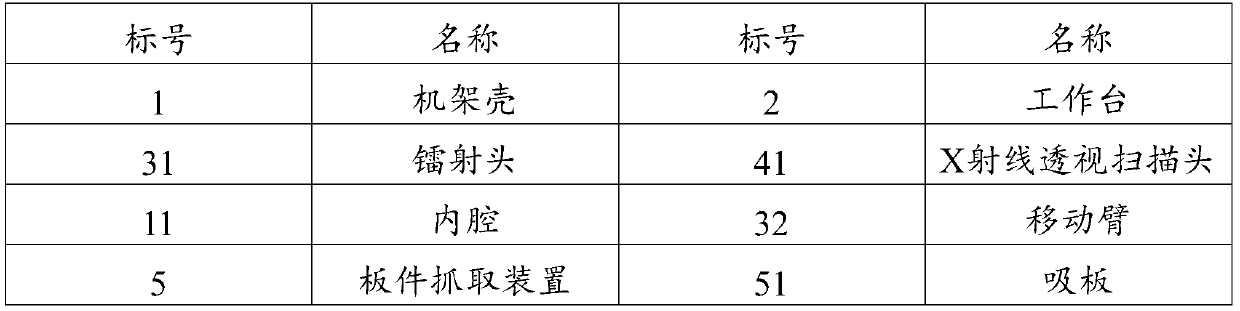

Laser edge milling device and method for packaging substrate

InactiveCN109848567AEasy job removalOne less transferPrinted circuit manufactureLaser beam welding apparatusX-rayEngineering

The invention discloses a laser edge milling device and method for a packaging substrate. The laser edge milling device comprises a rack shell, a workbench, a laser device, an X-ray device and a mainmachine, wherein the rack shell is provided with a hollow inner cavity and an inlet plate port communicating with the inner cavity; and the workbench, the laser device and the X-ray device are all arranged in the inner cavity, the main machine is connected with the workbench, the X-ray device and the laser device, the main machine is used for controlling the workbench to place and transfer the packaging substrate, a theoretical position of the packaging substrate is obtained by controlling the X-ray device, and the laser device is controlled to carry out laser milling on the packaging substrate according to the theoretical position. According to the technical scheme, the cost problem and quality in the production process of the packaging substrate can be reduced and improved.

Owner:WUXI SHENNAN CIRCUITS CO LTD

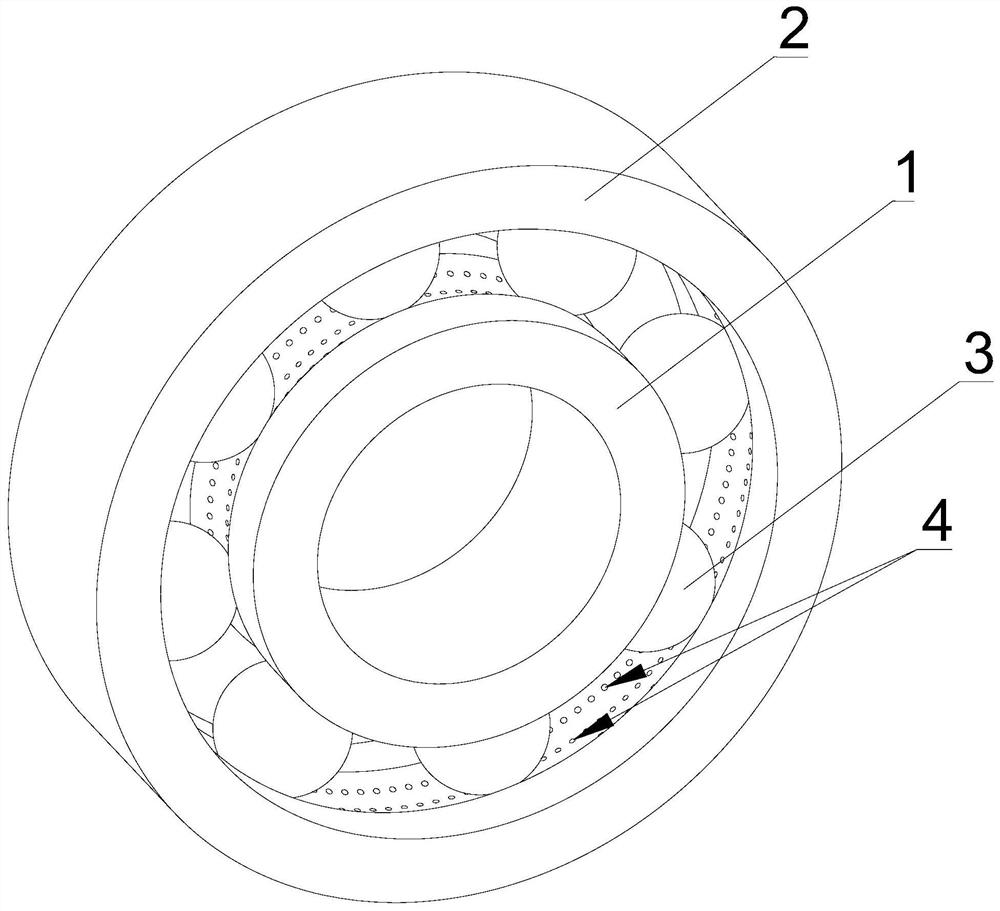

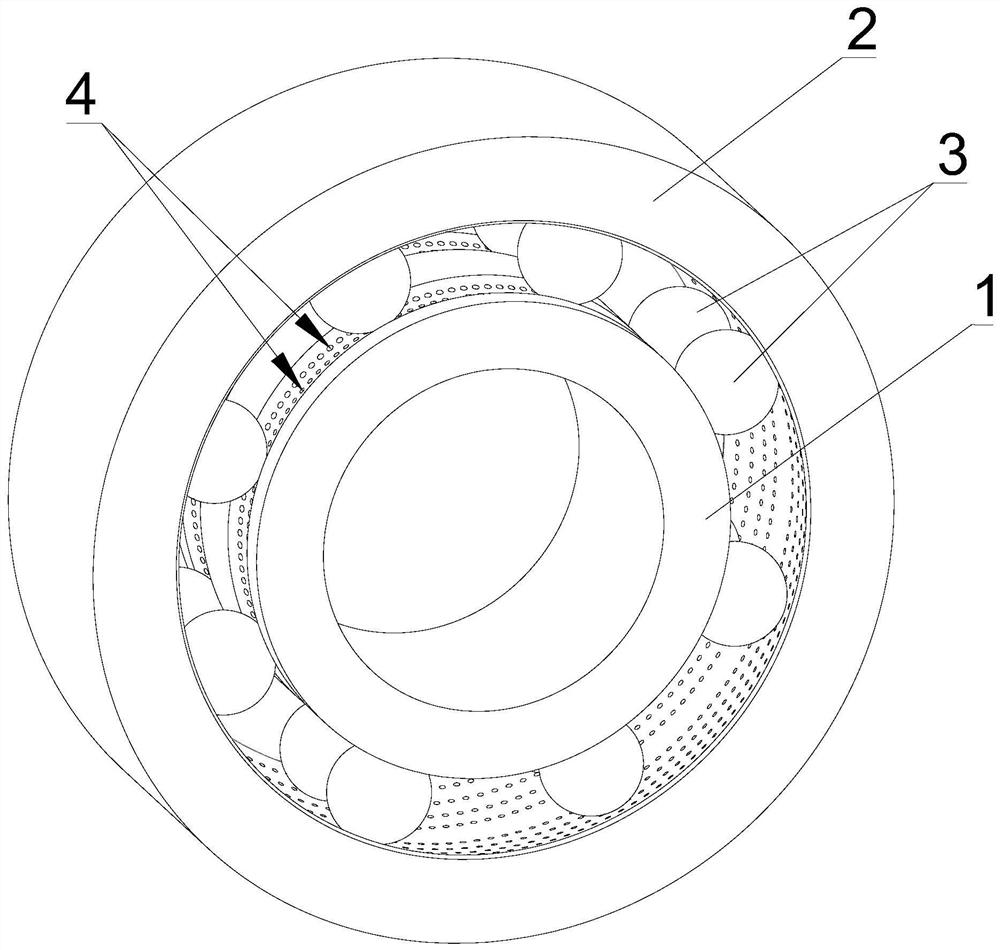

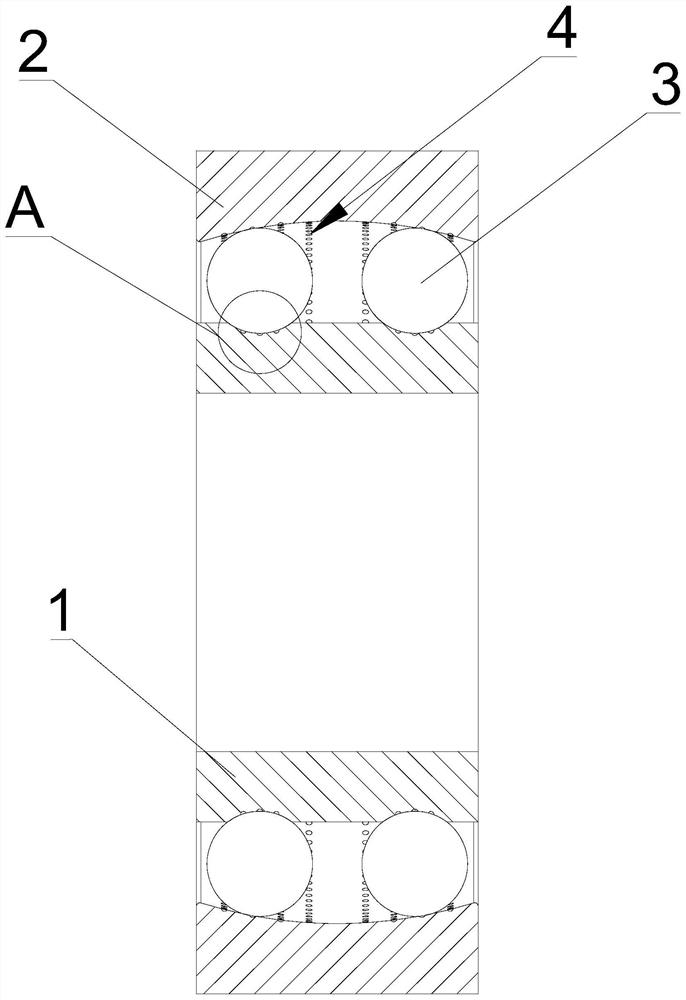

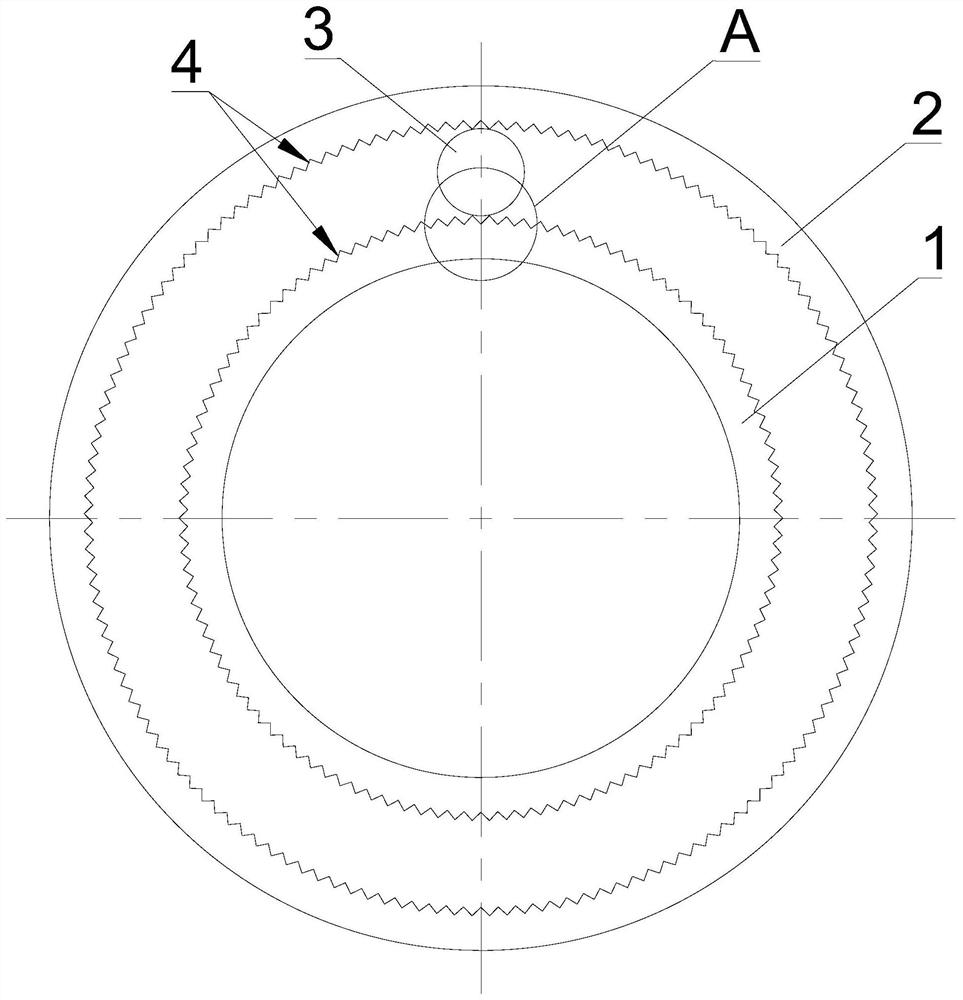

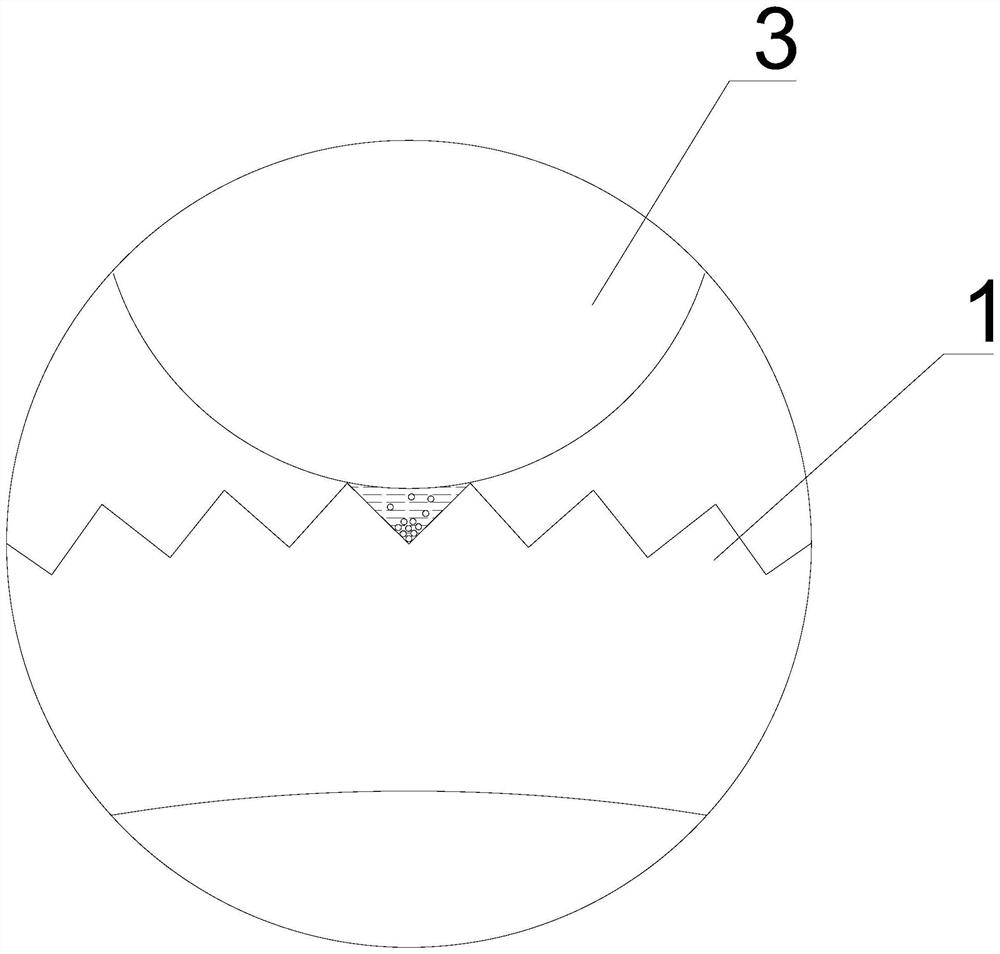

Ball bearing with micro-texture on raceway surfaces of inner ring and outer ring and processing method thereof

PendingCN112797074AReduce wear debrisImprove physical performancePolishing machinesOther chemical processesBall bearingLaser processing

The invention discloses a ball bearing with micro-texture on raceway surfaces of an inner ring and an outer ring and a processing method thereof. The ball bearing comprises a bearing inner ring, a bearing outer ring and a rolling body, and the raceway surface of the bearing inner ring and the raceway surface of the bearing outer ring are both provided with reinforced grinding layers; One or more groups of micro-texture structures which are arranged along the axial direction of the bearing are arranged on the surface of the reinforced grinding layer, each group of micro-texture structure comprises a plurality of pits which are uniformly arranged along the circumferential direction, the pits are locally spherical, and openings of the pits face a tangent line which is vertical to the surface of a raceway. The method comprises the following steps that the bearing inner ring and the bearing outer ring are processed according to the design size of the ball bearing; reinforced grinding processing is carried out, and then cleaning is carried out; a multi-axis linkage laser machining system is used for conducting rapid laser milling machining, one or more groups of micro-texture structures arranged in the axial direction of the bearing are prepared, and each group of micro-texture structure comprises the multiple pits evenly arranged in the circumferential direction; ultrasonic cleaning is carried out and then polishing is carried out.

Owner:GUANGZHOU UNIVERSITY

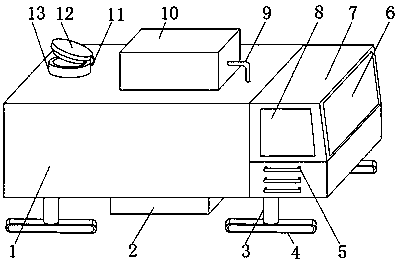

Adjustable concrete laser milling machine

InactiveCN108487022ASimple structureEasy to operateRoads maintainenceCement mixing apparatusEngineeringRoad surface

The invention discloses an adjustable concrete laser milling machine. The adjustable concrete laser milling machine comprises a vehicle body and a vehicle head, wherein a vehicle window is fixedly mounted on the outer surface of the other side of the vehicle head; a vehicle door is movably mounted on the outer surface of the front end of the vehicle head; a handle is welded below the vehicle door;a connecting support is fixedly mounted on the outer surface of the lower end of the vehicle body; a crawler wheel is movably mounted on the outer surface of the lower end of the connecting support;a feeding opening is formed in the outer surface of the upper end of the vehicle body; a connecting belt is fixedly connected with the outer surface of one side of the feeding opening; a feeding opening plug plate is fixedly connected with one end, far away from the feeding opening, of the outer surface of one end of the connecting belt. The adjustable concrete laser milling machine disclosed by the invention is provided with a motor mounting frame, a water spraying mechanism and a stirring mechanism, so that concrete can be stirred when milling work is carried out on a road surface; in a working process, the cooling efficiency of a milling rotor is higher and the vibration generated in a working process of the motor can be reduced, so that a better application prospect is brought.

Owner:JIANGSU KERUIXIN MACHINERY

Manufacturing a mirror plate or other operational structure having superior flatness by laser milling for use with torsional hinged devices

Owner:TEXAS INSTR INC

Method of manufacturing a switch system

A method for manufacturing a micro electro-mechanical system (MEMS) switch system (600, 700) includes etching each of a plurality of base circuit layers (425) and a plurality of passive component substrate layers (412, 418, 42, 426). The method continues with laser milling of a first dielectric film (406) to create a spacer layer (405). A metal cladding (402, 403) formed on a flexible dielectric film layer 404 is etched so as to form a plurality of switch component features. Further laser milling is performed with respect to the flexible dielectric film layer to form at least one switch structure (448, 450). Thereafter, a stack (400) is assembled which is comprised of the spacer layer disposed between the flexible dielectric film layer and the plurality of base circuit layers. Additional layers can also be included in the stack. When the stack is completed, heat and pressure are applied to join the various layers forming the stack.

Owner:HARRIS CORP

Manufacturing method for pattern in stepped groove

InactiveCN106686893AIntegrity guaranteedThe production process is simplePrinted circuit manufactureState of artEtching

The invention relates to a manufacturing method for a pattern in a stepped groove. By processing the pattern in the groove through laser milling and cutting, the completeness of the pattern in the groove is ensured; the manufacturing method specifically comprises the following steps of 1) pressing an inner layer pattern; 2) drilling holes; 3) performing reverse groove milling to expose the inner layer pattern; 4) performing pore formation; 5) cutting the pattern by laser; 6) performing tin plating; 7) etching and 8) performing tin removal. Compared with the prior art, the manufacturing method provided by the invention has the advantages of simplifying the manufacturing flow, ensuring the completeness of the pattern in the groove, effectively improving the percent of pass and punctual delivery ratio of products, and the like.

Owner:SHANGHAI FAST PCB CIRCUIT TECH CORP LTD

Method for realizing integrated machining of special-shaped deep small hole with thermal barrier coating by restraining liquid light transmission through dry ice

ActiveCN114505551AHigh-resolutionAvoid layeringEfficient propulsion technologiesLaser beam welding apparatusElectrolytic agentMachined surface

The invention discloses a method for achieving integrated machining of a special-shaped deep small hole with a thermal barrier coating by restraining liquid light transmission through dry ice, and relates to the field of combined machining in the non-traditional machining technology, and the method comprises a special-shaped hole machining stage and a deep small hole machining stage. Wherein the laser beam is totally reflected by the inner tube of the hollow tube electrode to obtain a plurality of laser beams, and the electrolyte flows through the hollow tube electrode; the metal substrate is connected with a positive electrode of the pulse power supply; a small deep hole is machined on the basis of machining of the special-shaped hole; in the special-shaped hole machining stage, laser machining is used as a main part, and water jet is used as an auxiliary part to remove materials; and in the deep small hole machining stage, materials are removed through the combined action of laser, electrolysis and water jet. According to the method, the diameter of a jet electrolyte water column is compressed through the dry ice fluid, the resolution ratio of the special-shaped hole machined through laser milling is remarkably improved, the machined surface is cooled, material layering is avoided, and integrated machining of the special-shaped hole and the small deep hole is achieved at the same station through one machining tool.

Owner:JIANGSU UNIV

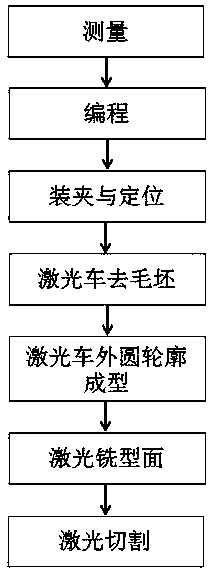

Method for laser turn-milling compound machining of tool

The invention provides a method for laser turn-milling compound machining of a tool. The method for laser turn-milling compound machining of the tool includes the following steps of S1, measurement, S2, programming, S3, clamping, S4, laser turning for removing blanks, S5, laser turning of outer circle contour for molding, S6, laser milling of a profile, and S7, laser cutting. According to the method for laser turn-milling compound machining the tool, laser turning machining of the tool contour and milling machining of the tool profile are realized through one clamping, a traditional machiningtechnological process of the tool is subverted, and the problems of low machining efficiency, high machining cost and affecting machining precision and quality caused by requiring multiple processes for multiple clamping in the traditional machining process of the tool are solved.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com