Laser processing device with controllable light beam incident angle and laser processing method

A technology of laser processing and incident angle, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of expensive device, small diameter, less than 2 mm, etc., and achieve simple device structure and simple control algorithm. , to achieve the effect of laser processing with a wide range of inclination angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

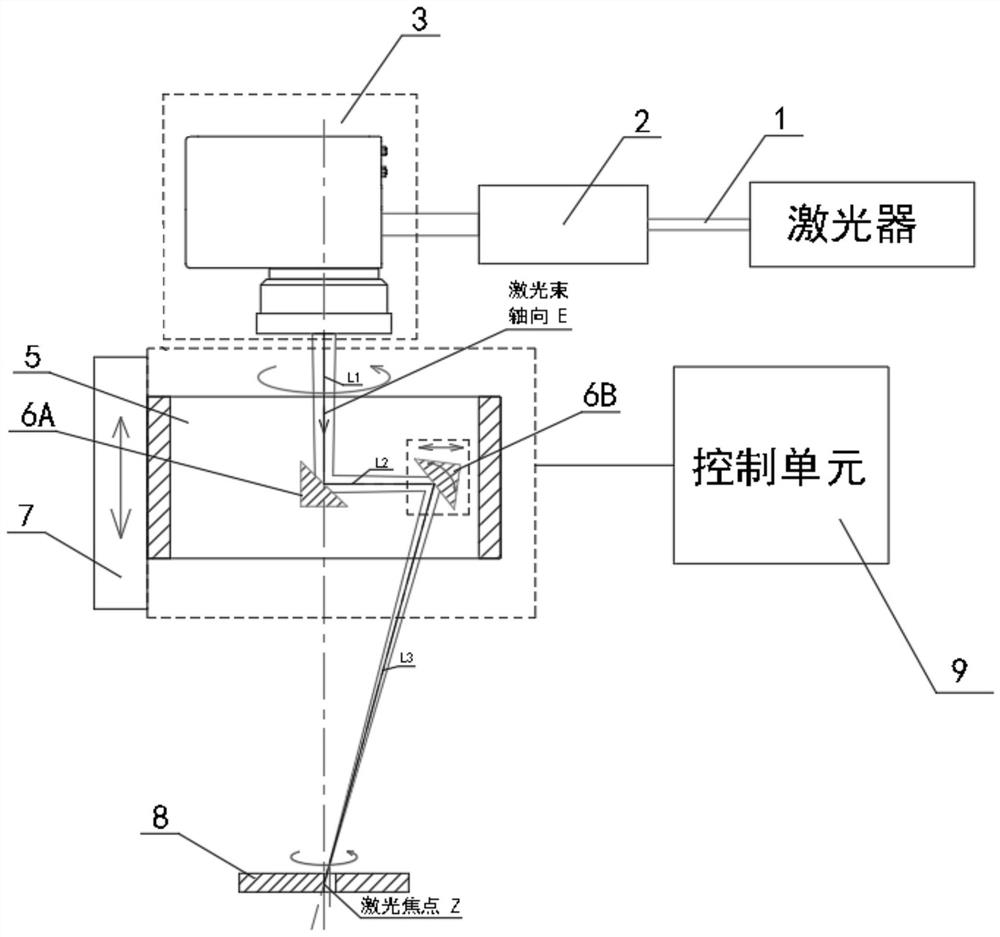

[0054] Laser processing equipment such as image 3 As shown, it includes a laser generating unit and a hollow unit 5 , and the laser generating unit includes a laser 1 , an optical modulator 2 and a focusing device 3 . The beam emitted by the laser 1 is coupled into the focusing unit 3 through the optical modulator 2. After focusing, it emits a beam with a focal length F. The direction of the central axis of the beam is the axis E. The beam is incident on the surface of the workpiece 8 after passing through the hollow unit.

[0055] The hollow unit 5 is provided with a first reflector 6A and a second reflector 6B. The light beam emitted by the laser generating unit is irradiated on the first reflector, reflected by the first reflector and then irradiated on the second reflector, and reflected by the second reflector. Irradiate on the workpiece 8 surface.

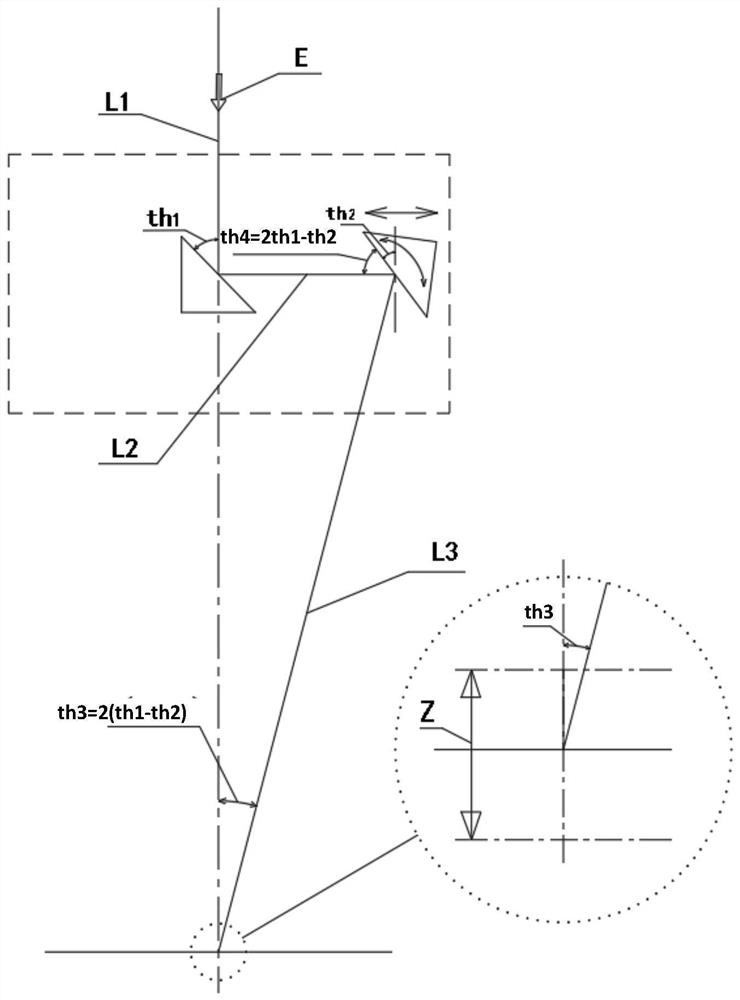

[0056] Such as figure 2 As shown, the included angle th1 between the axis E and the first mirror surface is the inclina...

Embodiment 2

[0076] In this embodiment, the structure of the laser processing device is basically the same as that of Embodiment 1, except that the focusing device is a long focal length lens, and the focal length of the beam after focusing is 1000mm; the hollow rotating head is installed on an electric translation platform, and the hollow unit Connected with the displacement unit, the displacement unit is an electric translation platform, the hollow unit can be displaced in the axial E direction on the electric translation platform, and the displacement stroke is + / -200 mm, so as to adjust L1.

[0077] Table 3 has shown each parameter of this laser processing device when focal length F=1000 millimeters, for example:

[0078] When the inclination angle of the first reflector is 45°, in order to realize the inverse cone processing with an incident angle of 3°, use the difference to adjust the inclination angle of the second reflector to 43.5°;

[0079] When the inclination angle of the firs...

Embodiment 3

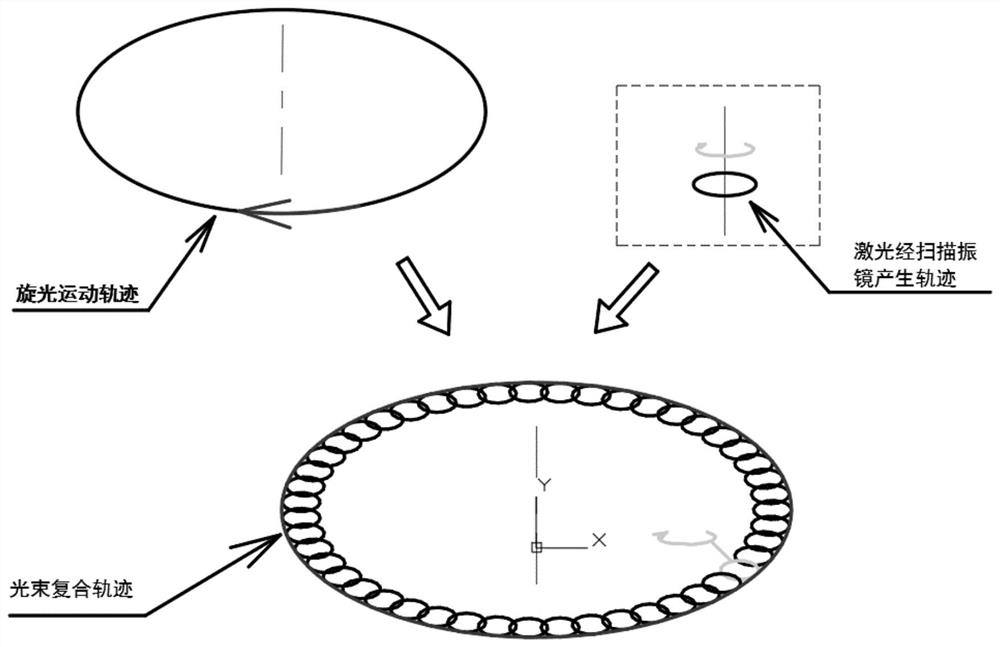

[0088] In this embodiment, the structure of the laser processing device is basically the same as that in Embodiment 2, except that the focusing device is a scanning galvanometer. When the hollow unit is rotated, the fixed-point tilt mode is used, that is, the hollow unit is rotated to a certain position, and the incident angle of the beam is incident by adjusting the difference between the first mirror and the second mirror. Combined with the scanning galvanometer, local complex shapes can be realized. Controlled taper processing.

[0089] For example, if Figure 4 As shown, the hollow unit is rotated to the static position when the system θ=0°, 90°, 180°, and 270° respectively, and the beam incident angle th3 is adjusted to the required processing inclination angle, and the galvanometer system scans to obtain Figure 4 Shown are shapes with certain tapers at θ = 0°, 90°, 180°, 270°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com