Patents

Literature

871 results about "Mirror reflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

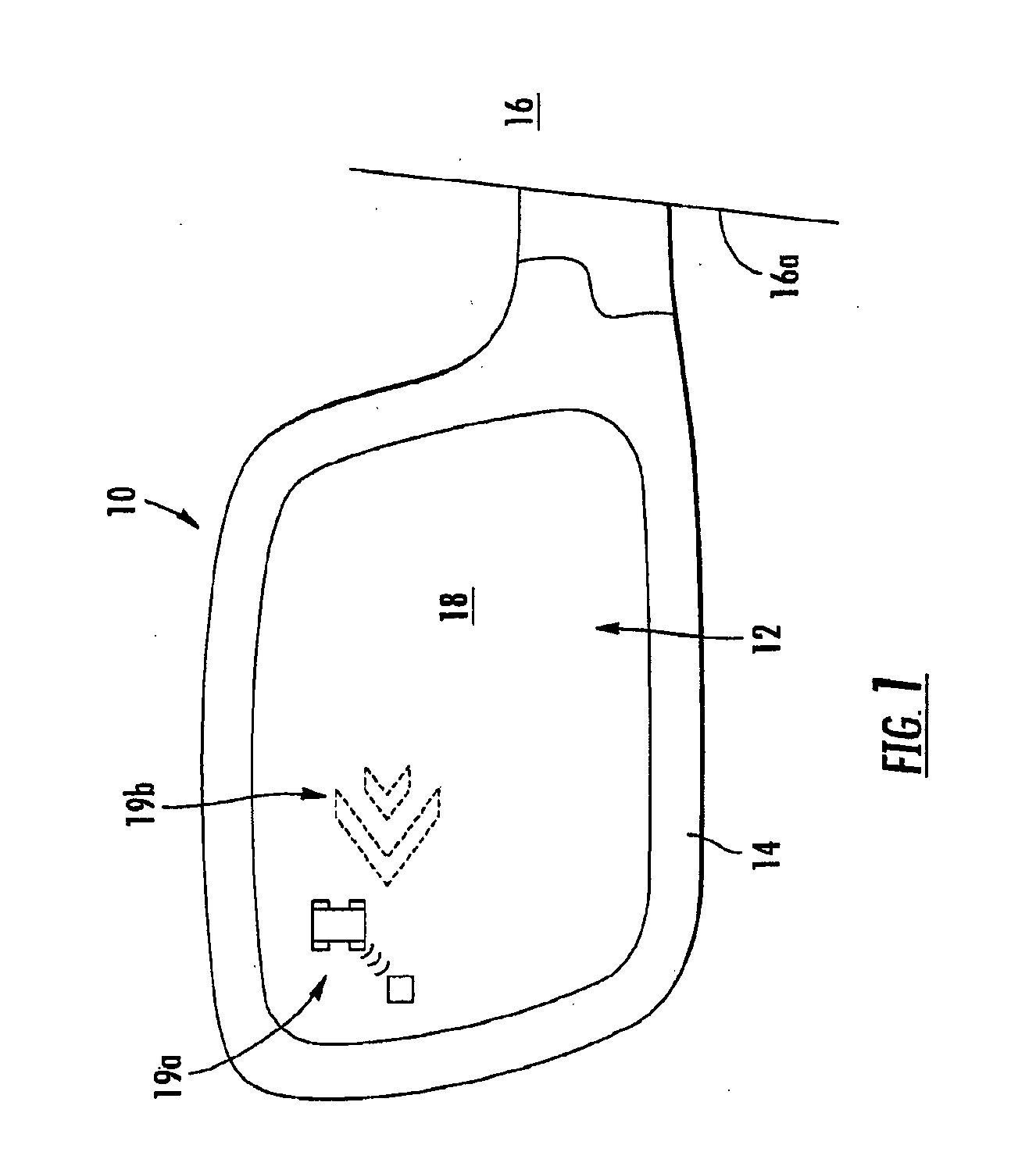

Vehicle control system and method

InactiveUS6302545B1Improve reliabilityAccurately determinedImage enhancementTelevision system detailsMirror reflectionControl signal

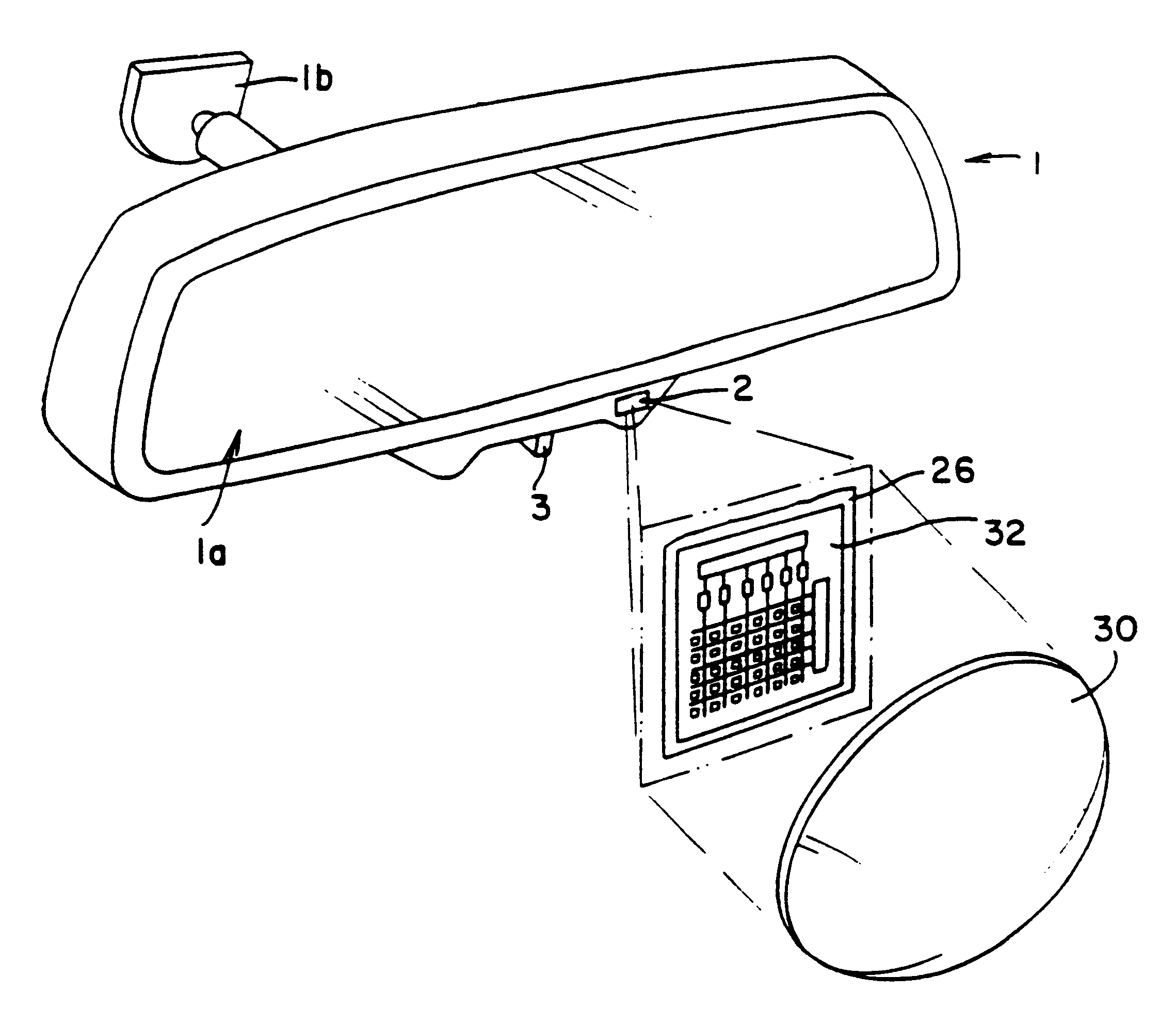

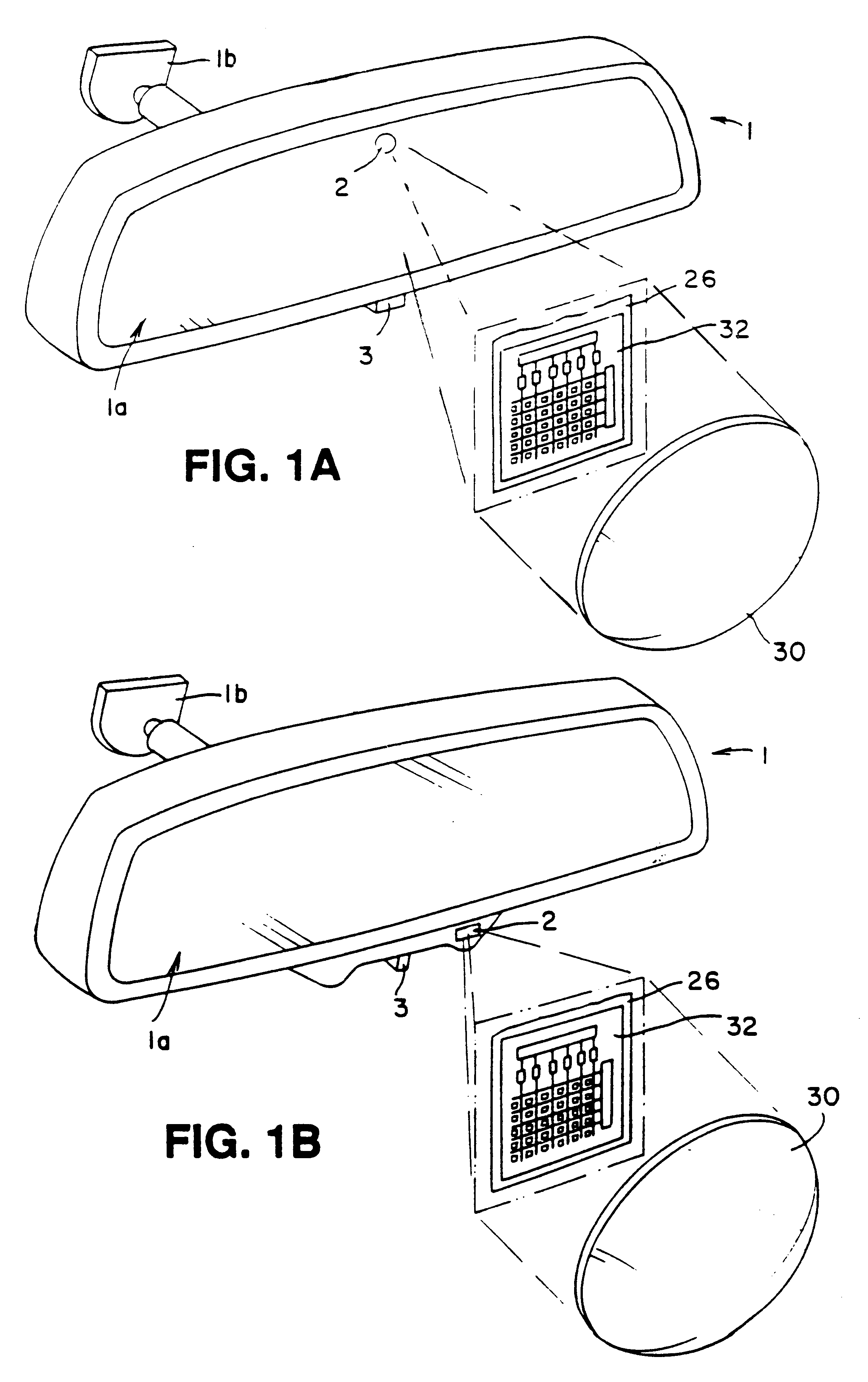

A vehicle control system and method includes structure and steps for capturing an image of a front seat of the vehicle and outputting image data corresponding thereto. A processor is provided which receives the image data output form the imaging device, compares the received image data with stored image data, and outputs a vehicle equipment control signal based on the comparison. Preferably, the vehicle equipment control signal controls one or more of airbag activation, mirror reflectance, vehicle lights activation, and vehicle intruder alarms. Preferably, the imaging device comprises a single chip camera disposed adjacent the vehicle rearview mirror.

Owner:DONNELLY CORP

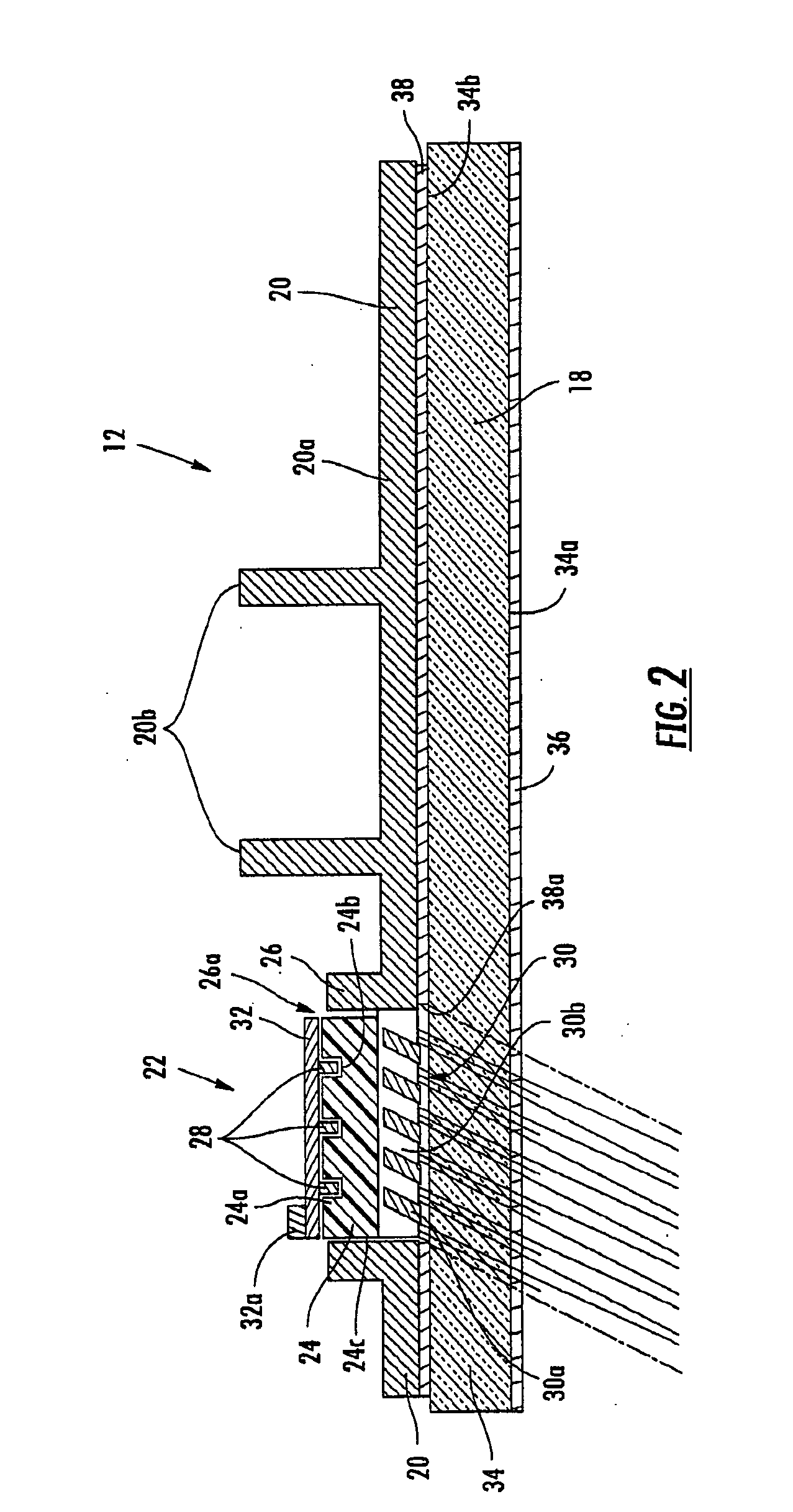

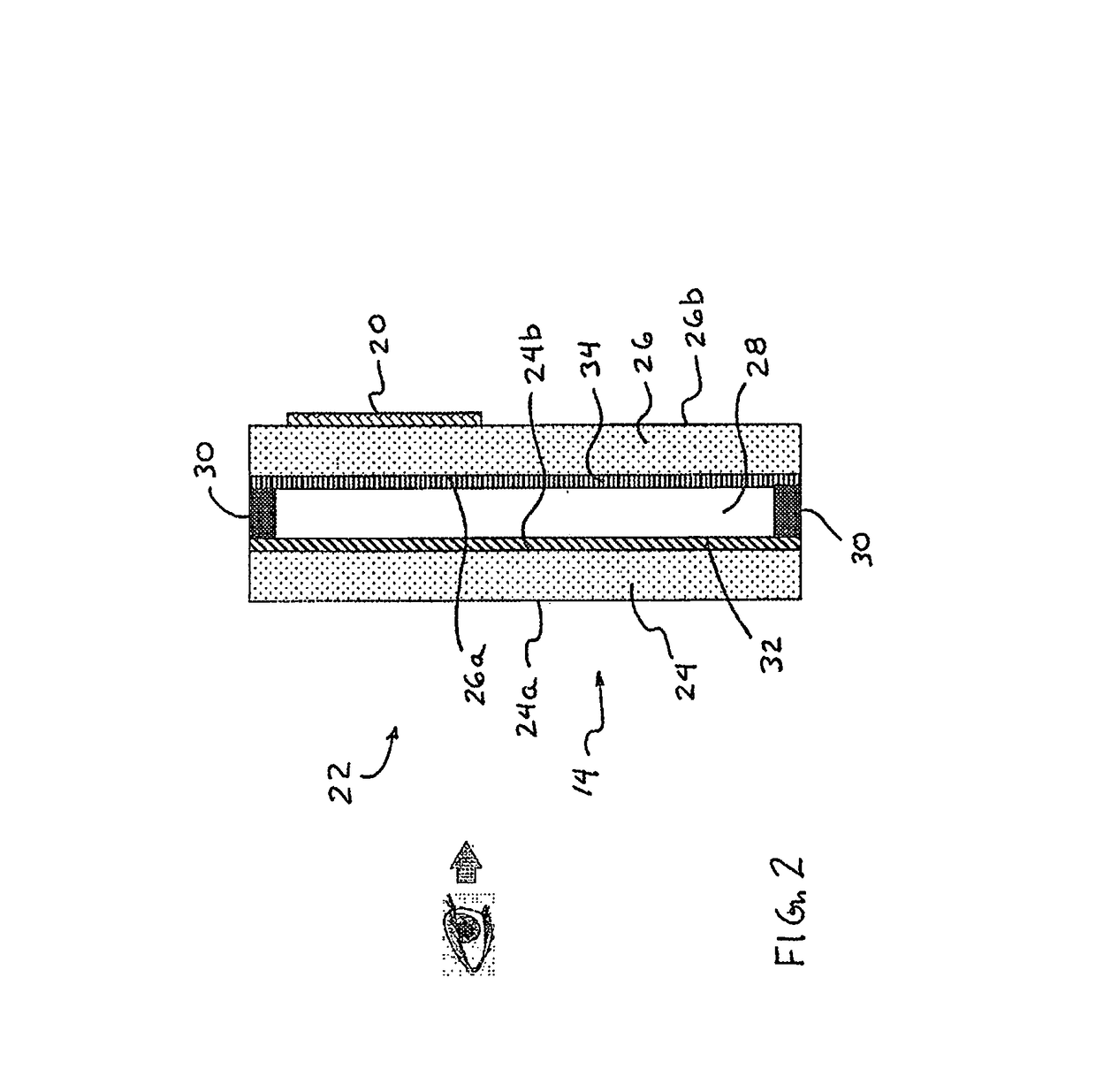

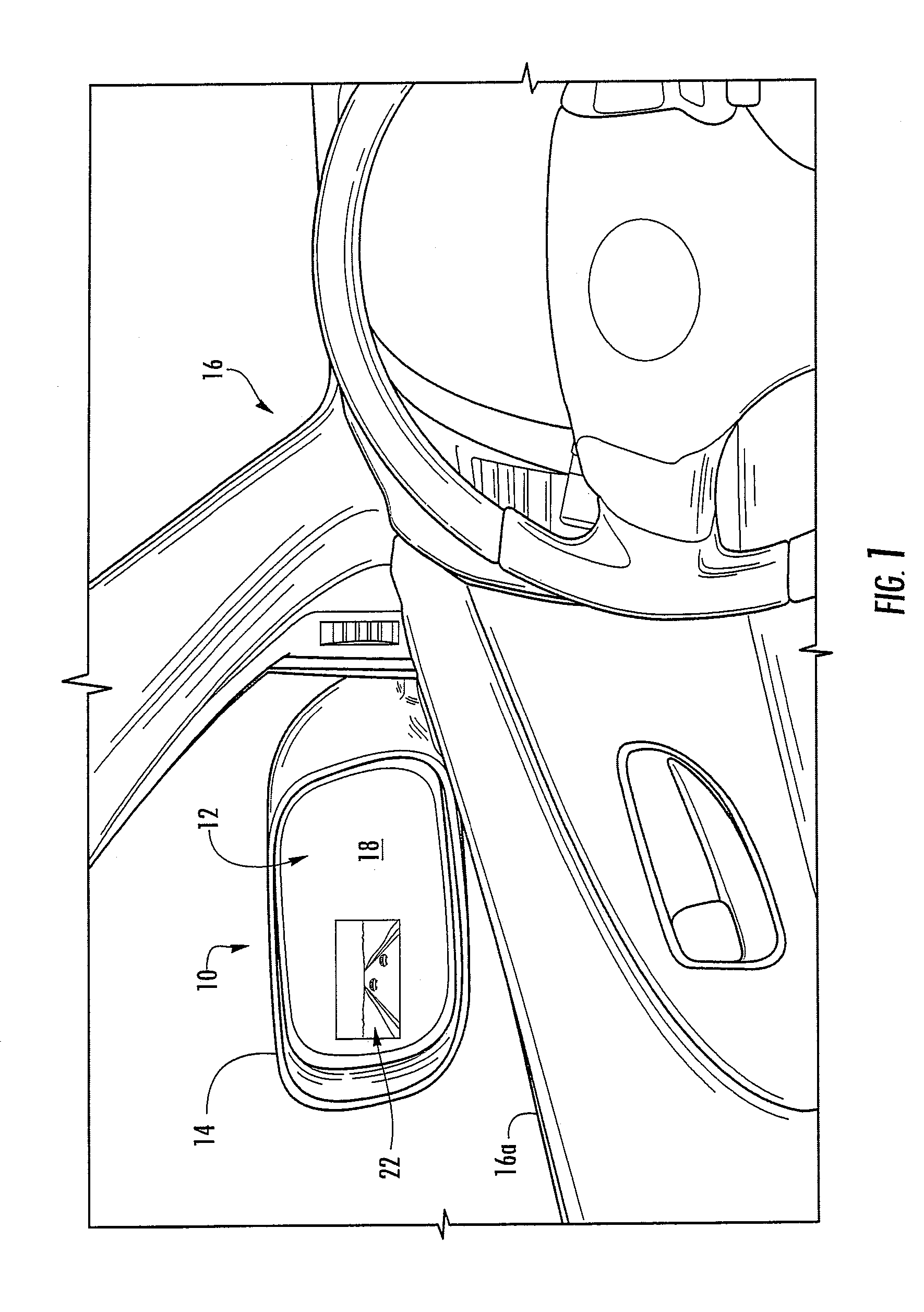

Display device for exterior mirror

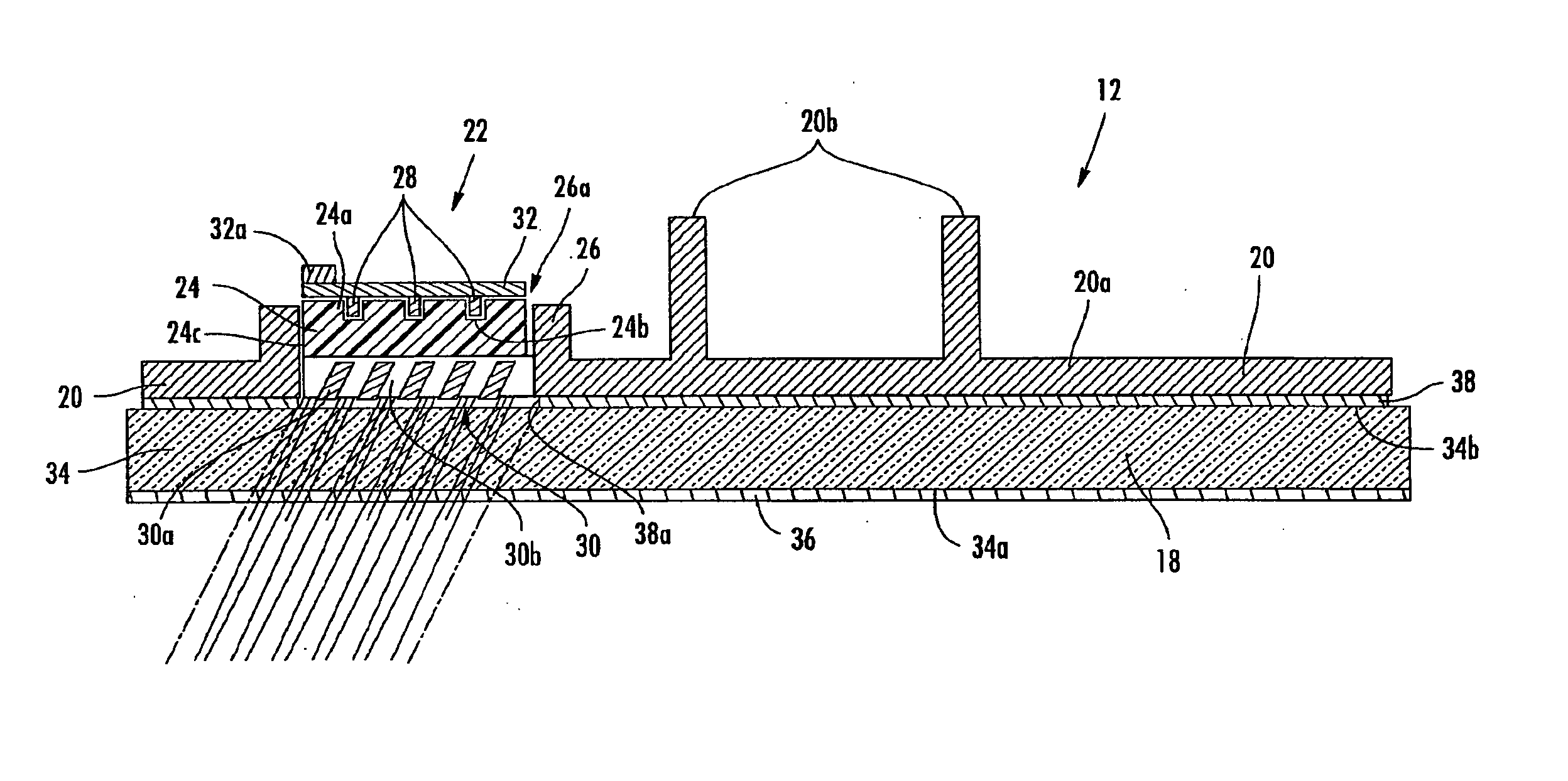

ActiveUS20100182143A1Easy to assembleGood adhesionOptical signallingOptical viewingDisplay deviceOptoelectronics

A mirror reflective element sub-assembly includes a mirror back plate having a display receiving portion established thereat and being molded to have an integral light baffle at the display receiving portion. A display element attached to the display receiving portion of the mirror back plate and a light source is activatable to emit light through the display receiving portion and through the light baffle. The light baffle is configured to allow light emanating from the display element to pass through the light baffle at a predetermined angle so that light exiting the mirror reflective element when the light source is activated is viewable from one direction, while the light baffle substantially shields the light emanating from the display element so that the light is substantially non-viewable from another direction.

Owner:MAGNA MIRRORS OF AMERICA INC

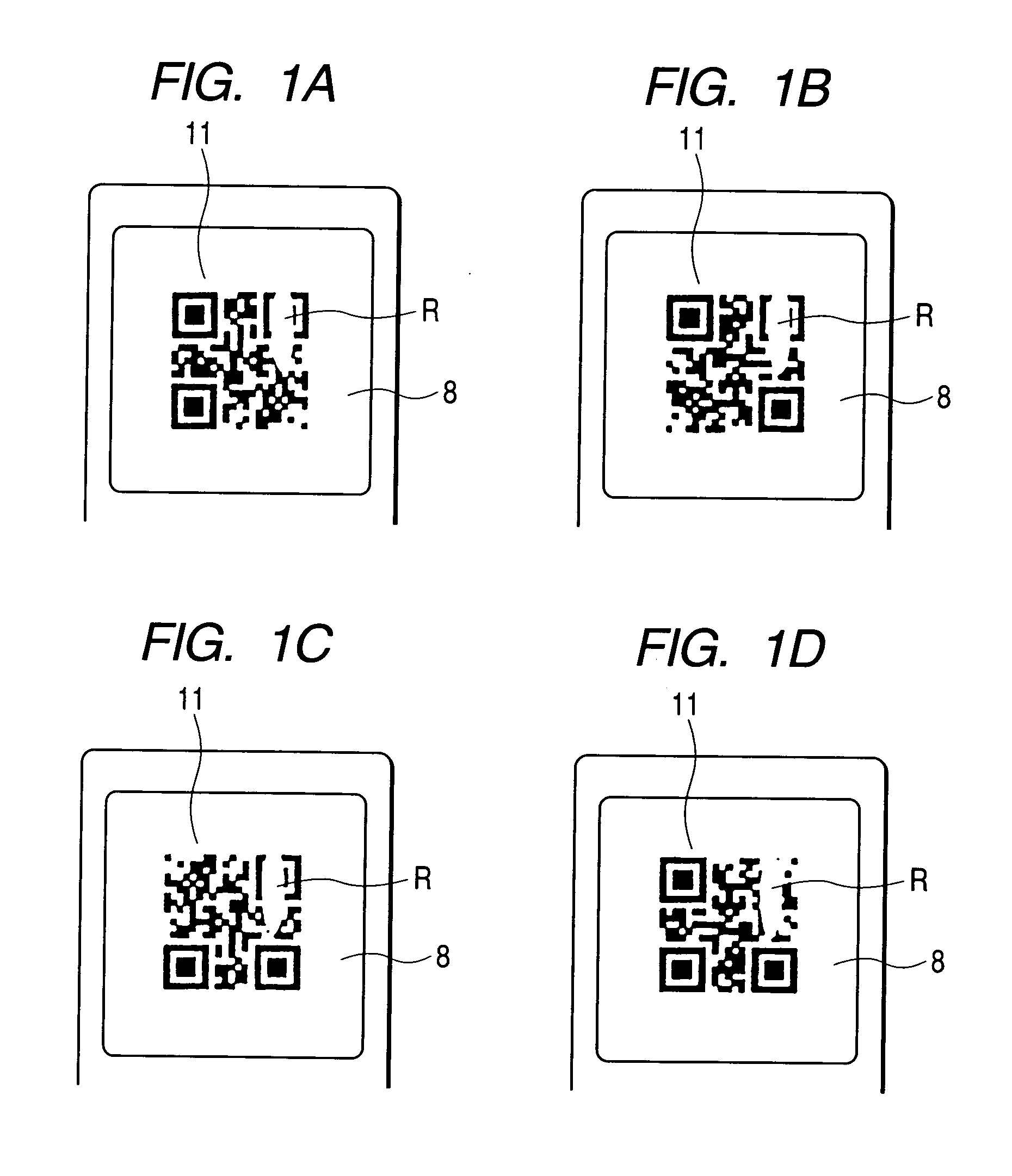

Method for displaying and reading information code for commercial transaction

ActiveUS20040012569A1Easy to combineInput/output for user-computer interactionCharacter and pattern recognitionMirror reflectionDisplay device

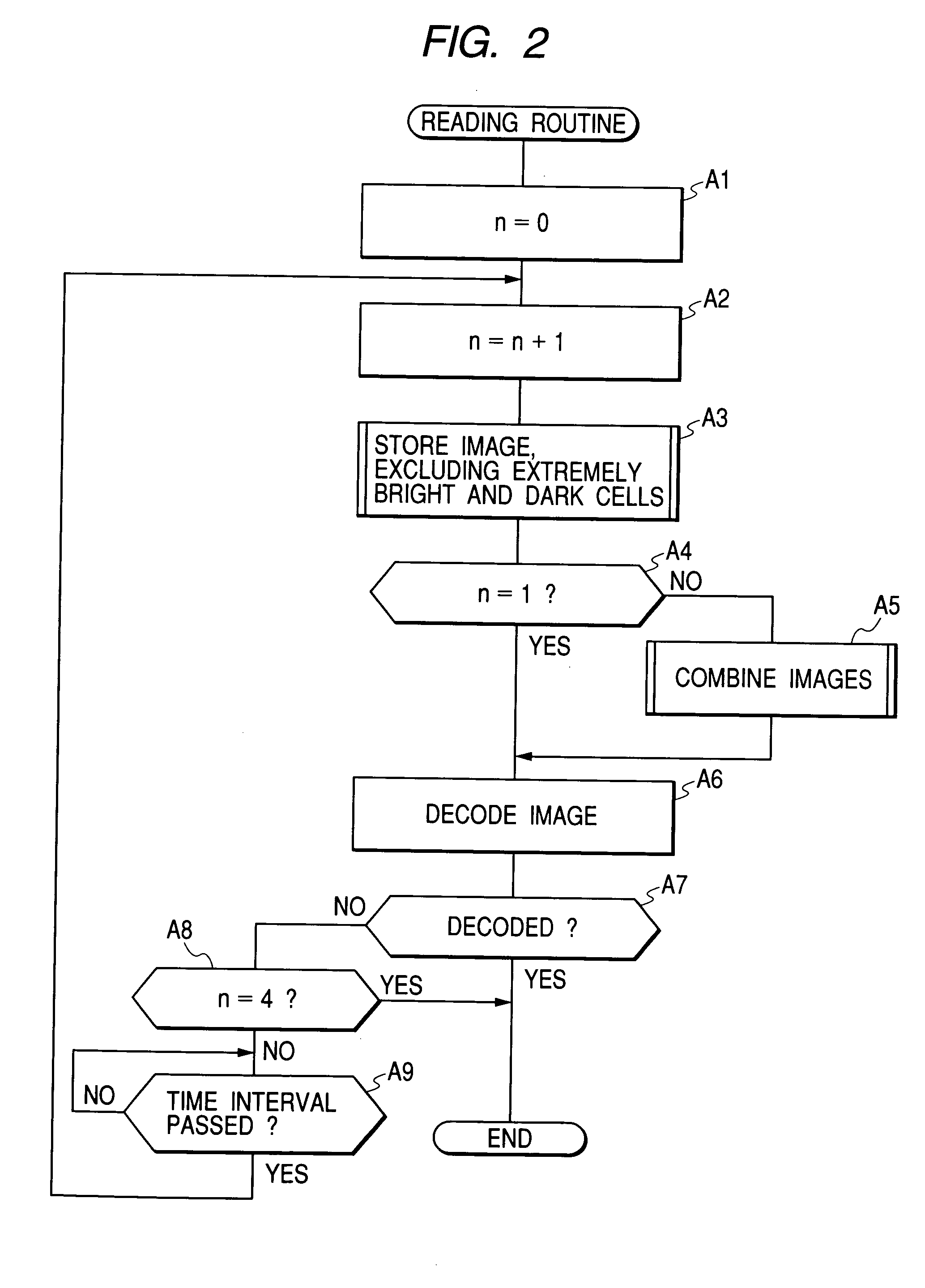

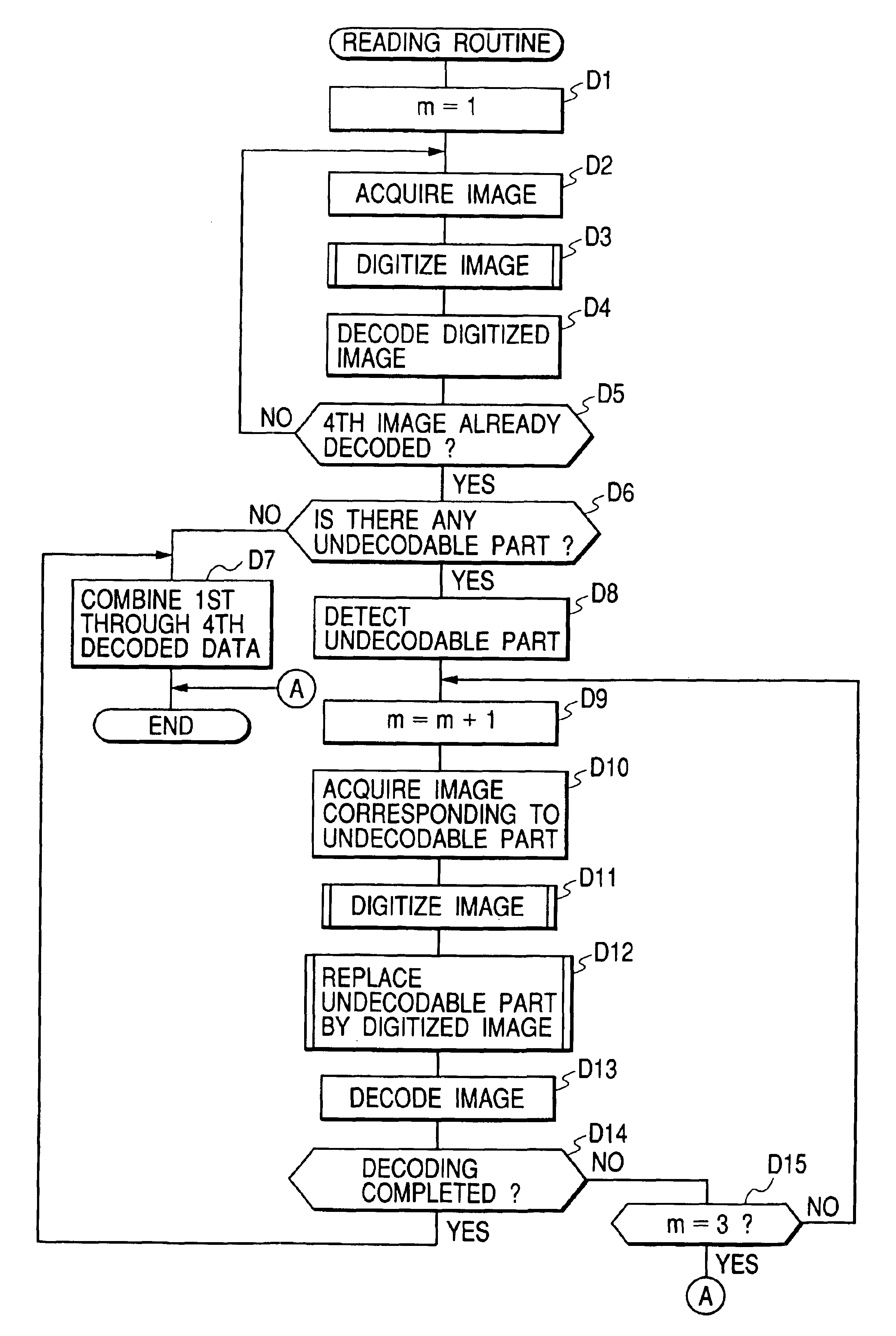

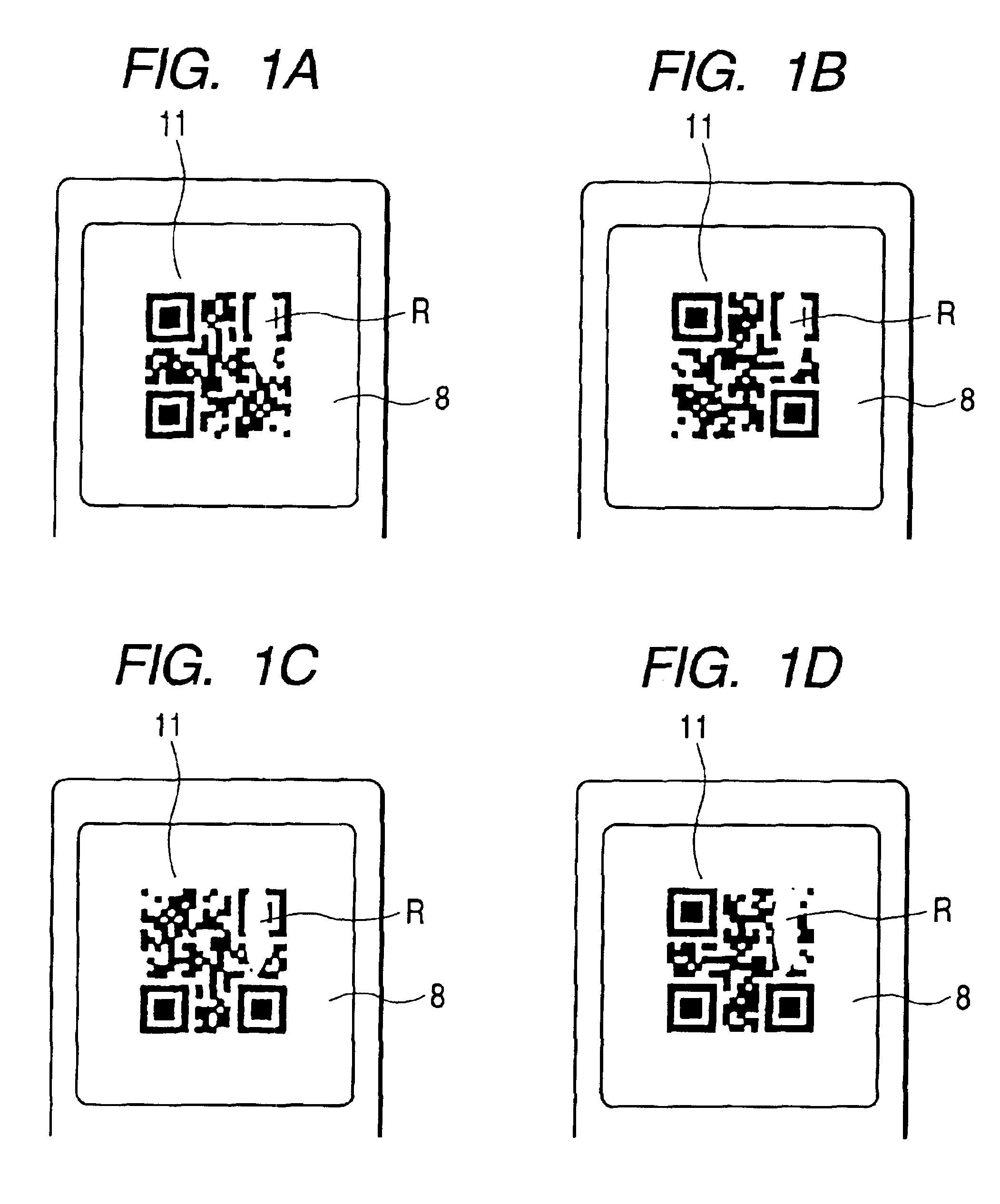

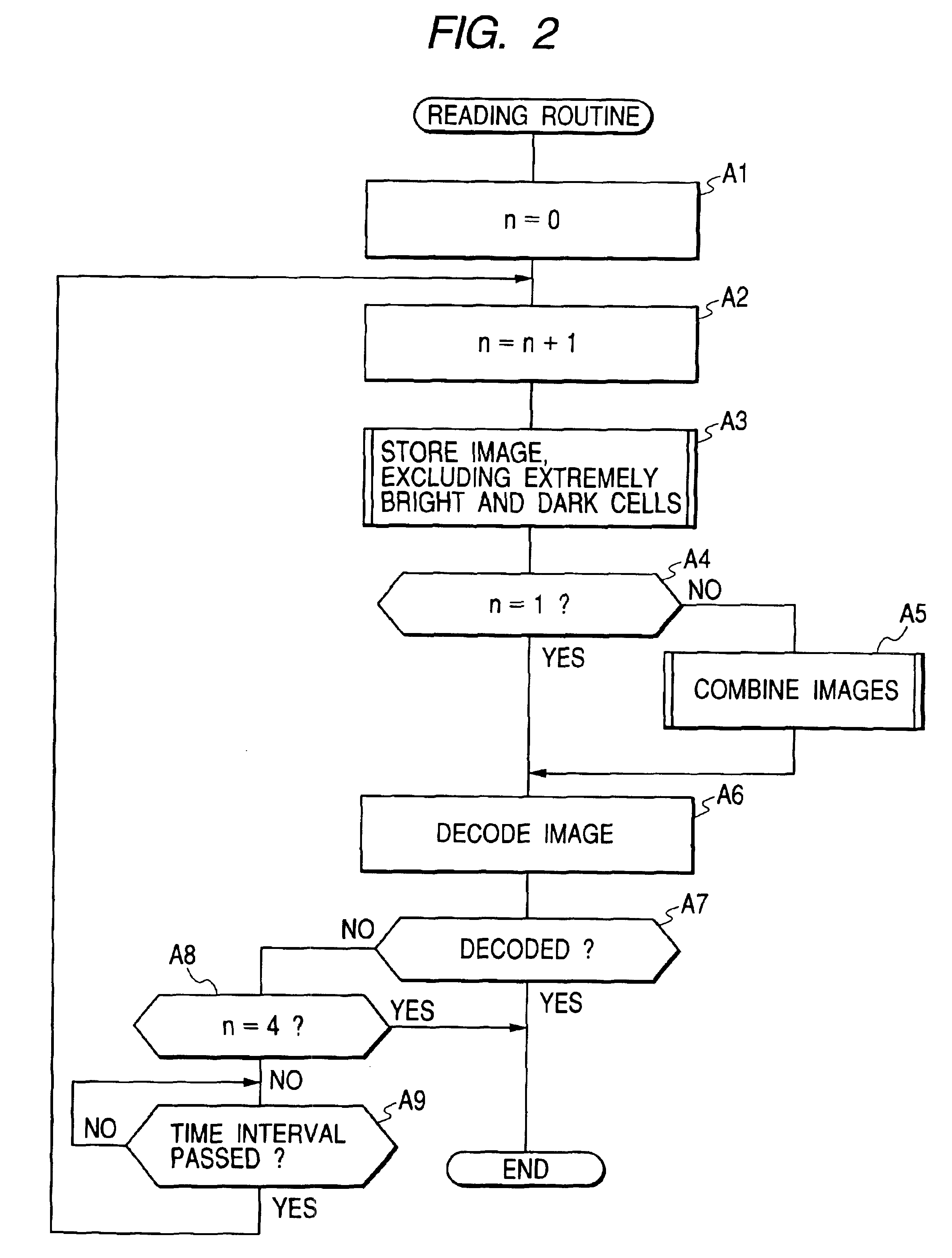

An object of the present invention is for an optical information reader for settling a commercial transaction to read and decode with certainty a quick response (QR) code displayed on a buyer's mobile telephone display. A QR code 11 is displayed on the display a plurality of times at a prescribed time interval. The QR code is rotated by 90□ every time. Therefore, a part of the QR code which could not have been decoded due to a mirror reflection, stains or scratches on the display can be decoded at the second, third or fourth display, because the QR code 11 is displayed four times at different angles.

Owner:DENSO WAVE INC

Method for displaying and reading information code for commercial transaction

ActiveUS6997384B2PickedEasy to combineInput/output for user-computer interactionCharacter and pattern recognitionMirror reflectionDisplay device

An optical information reader for settling a commercial transaction reads and decodes with certainty a quick response (QR) code displayed on a buyer's mobile telephone display. A QR code 11 is displayed on the display a plurality of times at a prescribed time interval. The QR code is rotated by 90° every time. Therefore, a part of the QR code which could not have been decoded due to a mirror reflection, stains or scratches on the display can be decoded at the second, third or fourth display, because the QR code 11 is displayed four times at different angles.

Owner:DENSO WAVE INC

Interior rearview mirror assembly

ActiveUS9598016B2Image can be preventedMirrorsOptical viewingDriver/operatorComputer graphics (images)

Owner:MAGNA MIRRORS OF AMERICA INC

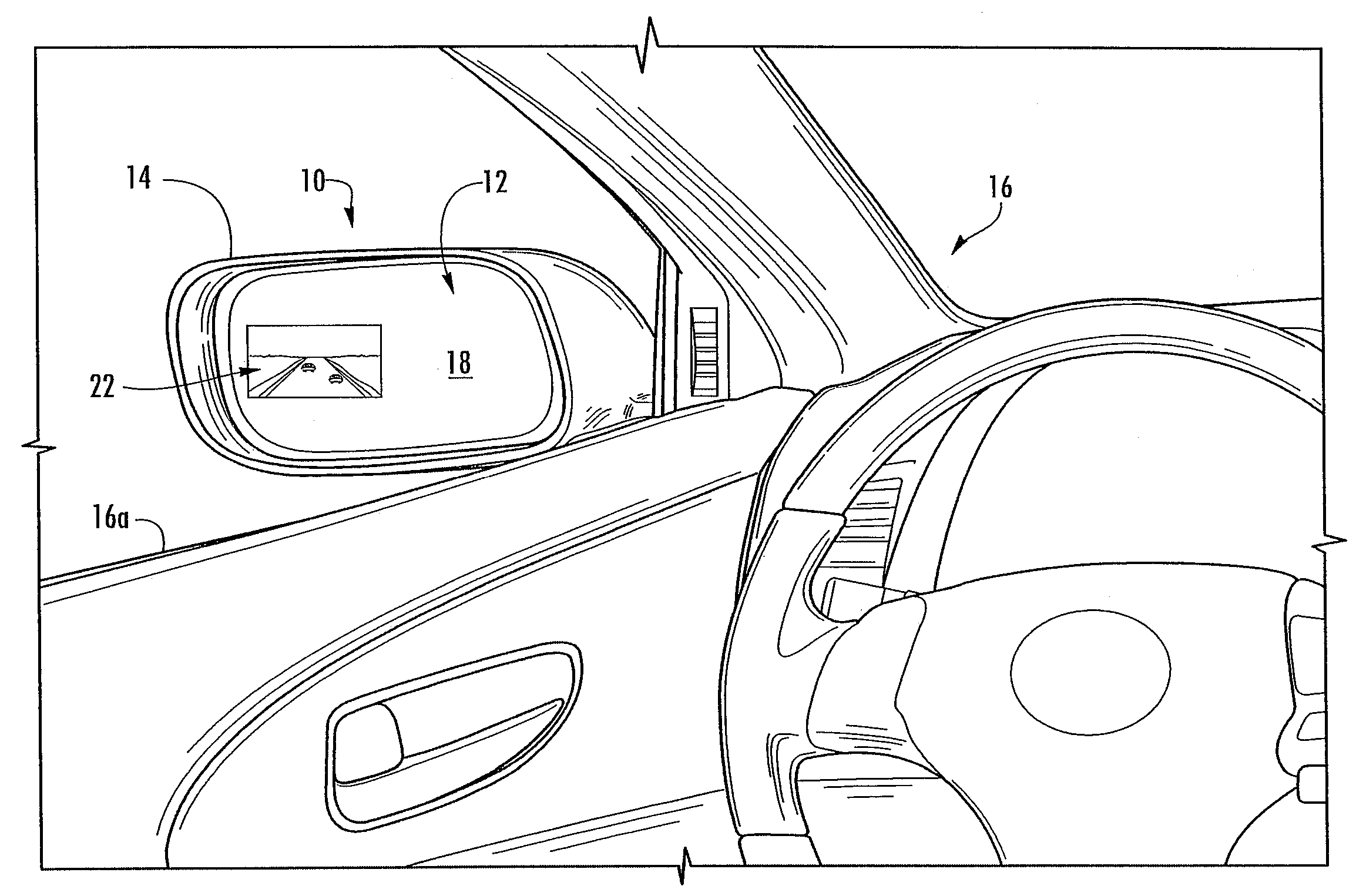

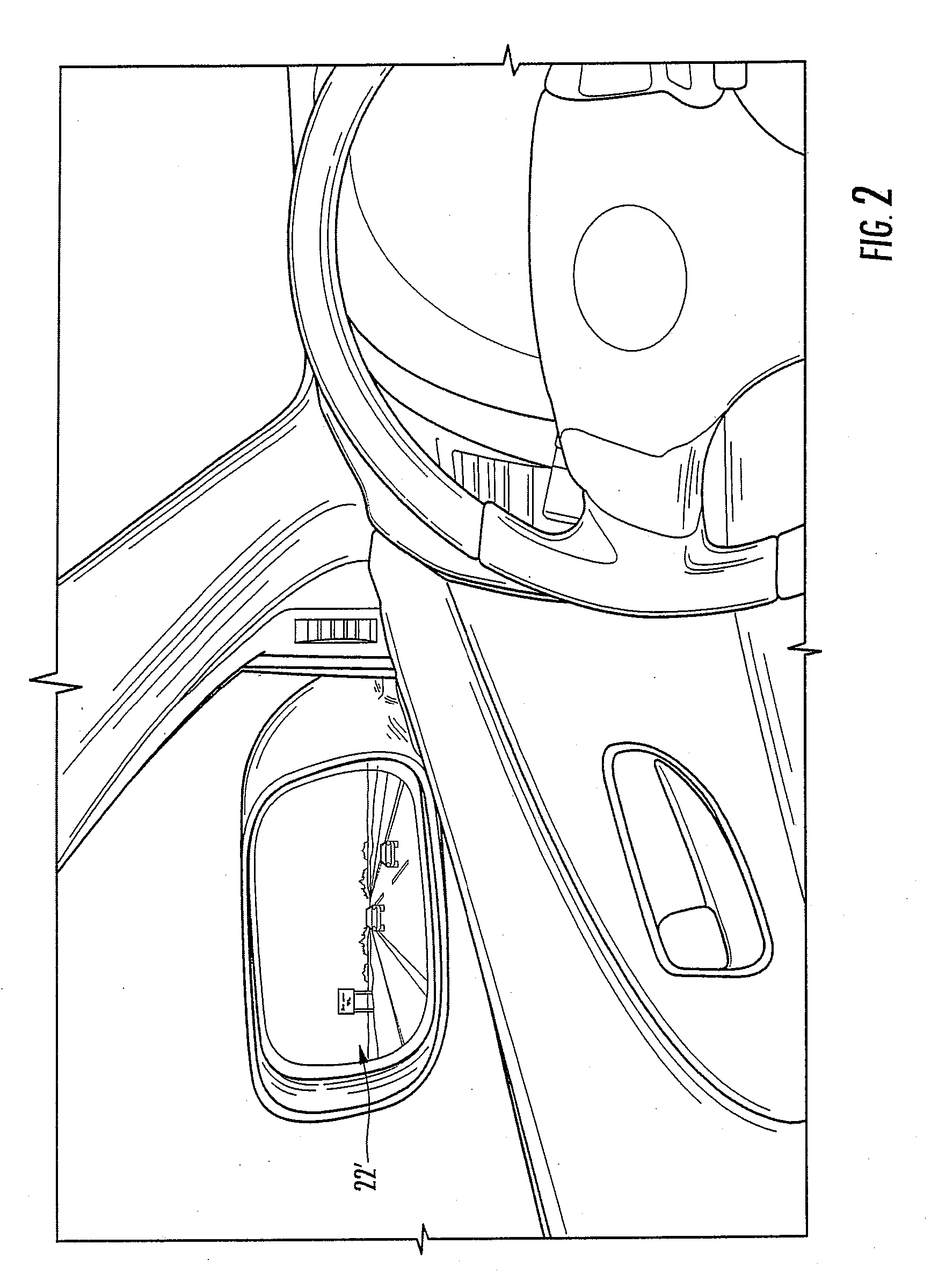

Display device for exterior rearview mirror

InactiveUS20080106389A1Easy to viewLighting elementsOptical signallingDriver/operatorComputer graphics (images)

A mirror reflective element sub-assembly for an exterior rearview mirror assembly of a vehicle includes a mirror reflective element and a video display element. The video display element is disposed behind the mirror reflective element so that images displayed by the video display element are viewable through the mirror reflective element when the video display element is activated. The video display element is configured to display images that are readily viewable by the driver of the host vehicle and not readily viewable by drivers of other vehicles in the lane adjacent to the host vehicle.

Owner:DONNELLY CORP

Method and apparatus for obtaining geometrical data relating to a canal

InactiveUS7110124B2Accurate modelingAccurate dataOtoscopesPerson identificationDistal portionWavelength range

The invention uses light to determine the distance from the tip of a probe to the internal wall of the canal, and based on the position of the probe, this information is used to generate information about the shape of the canal. Light with a first and a second wavelength range is directed onto a semi-transparent mirror surface at the distal portion of the probe. Light in the first wavelength range is reflected from the mirror surface to illuminate a circumferential area of the internal surface of the canal, and light in the second wavelength range is transmitted through the mirror surface to illuminate an area in front of the distal portion of the probe. The received light is analyzed in the first wavelength range to determine the distance from the probe to the internal surface of the canal at points of the circumference, and analyzed in the second wavelength range to determine the distance from the probe to an object in front of the probe. Thereby it is ensured, that the bottom surface of the canal is not touched or injured while the internal surface of the canal is measured.

Owner:OTICON

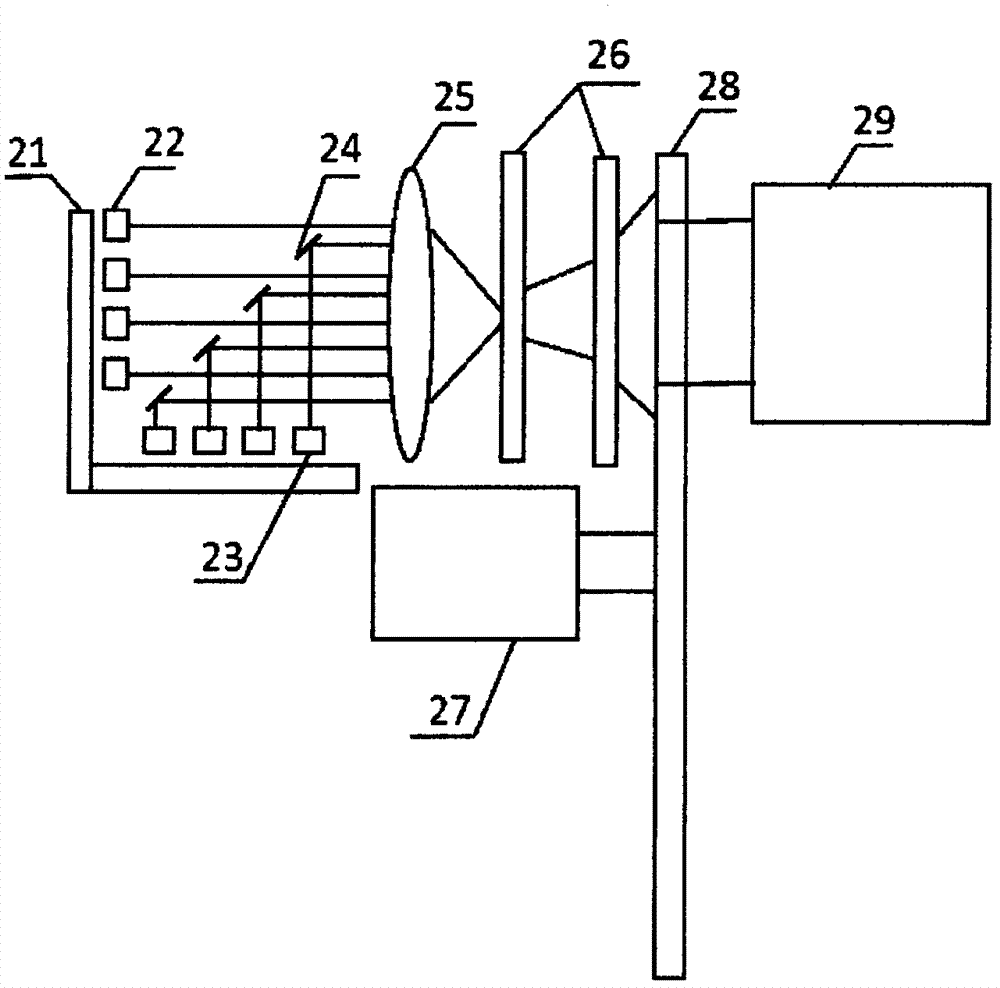

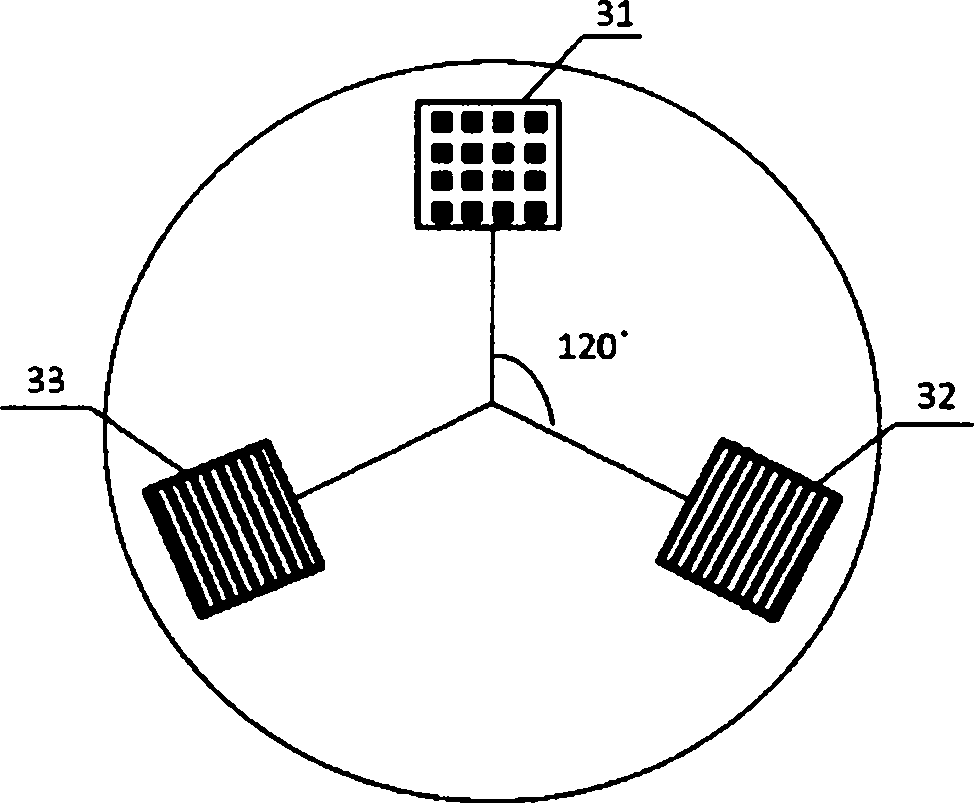

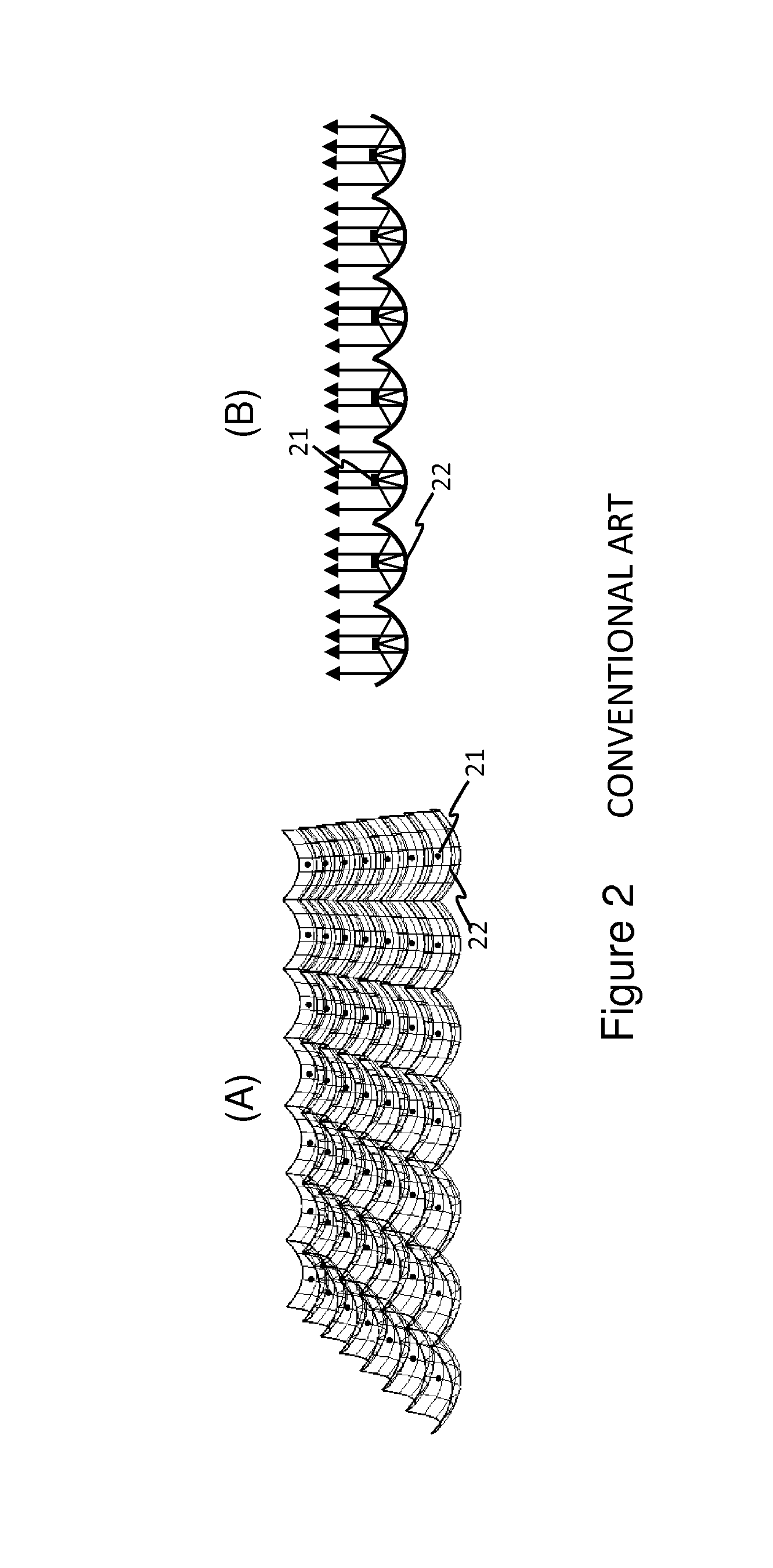

Systematic geometric demarcation method for reflection three-dimensional measurement of stripe

The invention discloses a systematic geometric demarcation method for reflection three-dimensional measurement of a stripe, and relates to systematic geometric demarcation during the three-dimensional appearance measurement of an object with a mirror reflection characteristic. As a stripe display device appears in a viewing field range of a video camera indirectly, the conventional systematic geometric demarcation process is fulfilled by adopting a method of sticking a marking point on a plane mirror. However, the physical coordinates of the marking point are required to be pre-measured through other precision measurement means. To solve the problem, the systematic geometric demarcation method adopts the scheme that the operation of sticking the marking point on the plane mirror is eliminated, the stripe on the stripe display device is reflected three times by the plane mirror, and analysis and linear calculation are conducted on the coordinates of the characteristic point and the imaging point of the stripe, so that the original value evaluation of the systematic geometric demarcation process is fulfilled; and then the evaluation result is optimized by adopting bundle adjustment, so as to obtain the final systematic geometric demarcation result. The systematic geometric demarcation method has the advantages of simplicity and flexibility; and only a plane mirror with a proper size is required for fulfilling the systematic geometric demarcation of the reflection three-dimensional measurement of the stripe. The systematic geometric demarcation method provides an efficient systematic demarcation way for phase position measurement deflection methods, stripe reflection photogrammetric survey and like which are based on stripe reflection three-dimensional measuring methods, thereby having a wide application prospect.

Owner:SICHUAN UNIV

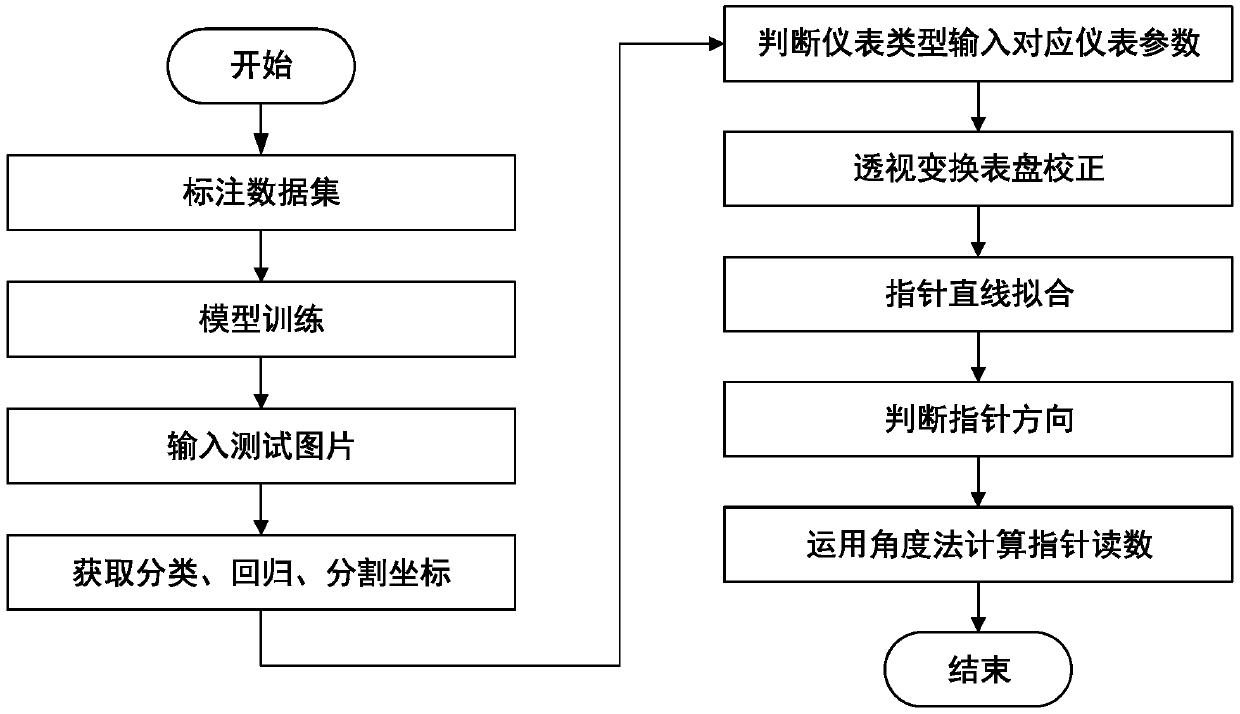

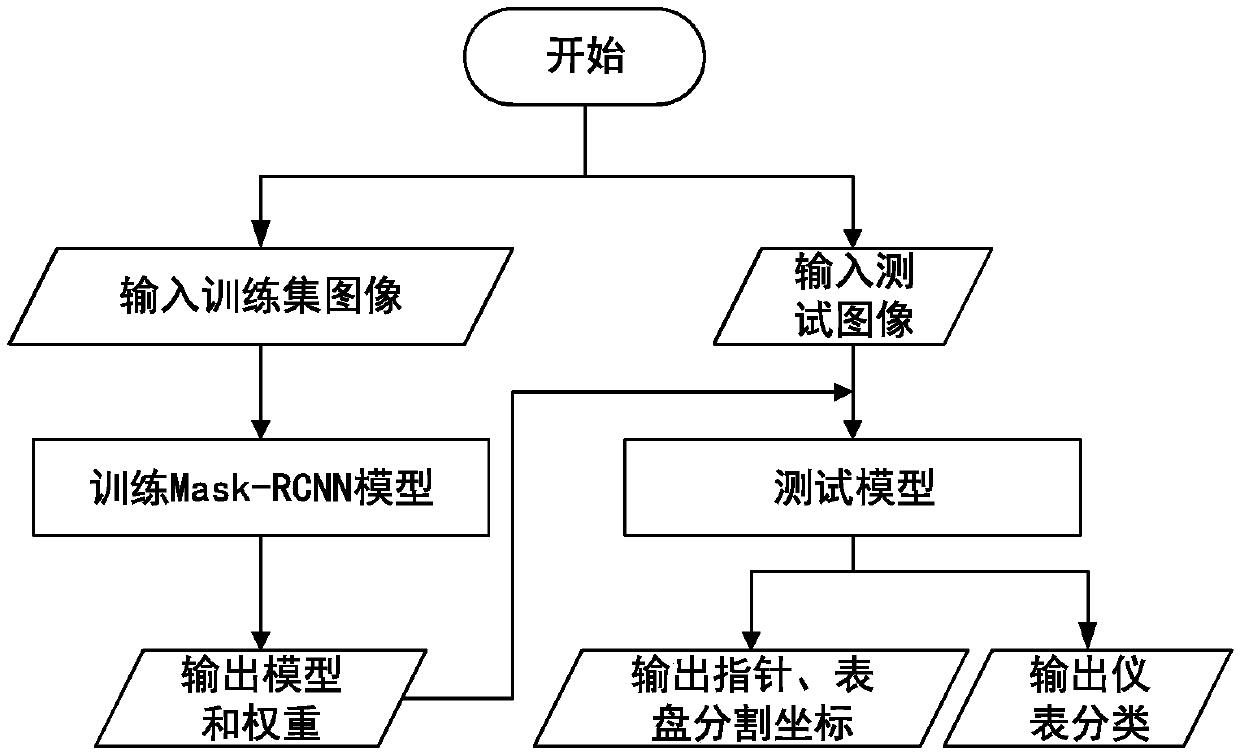

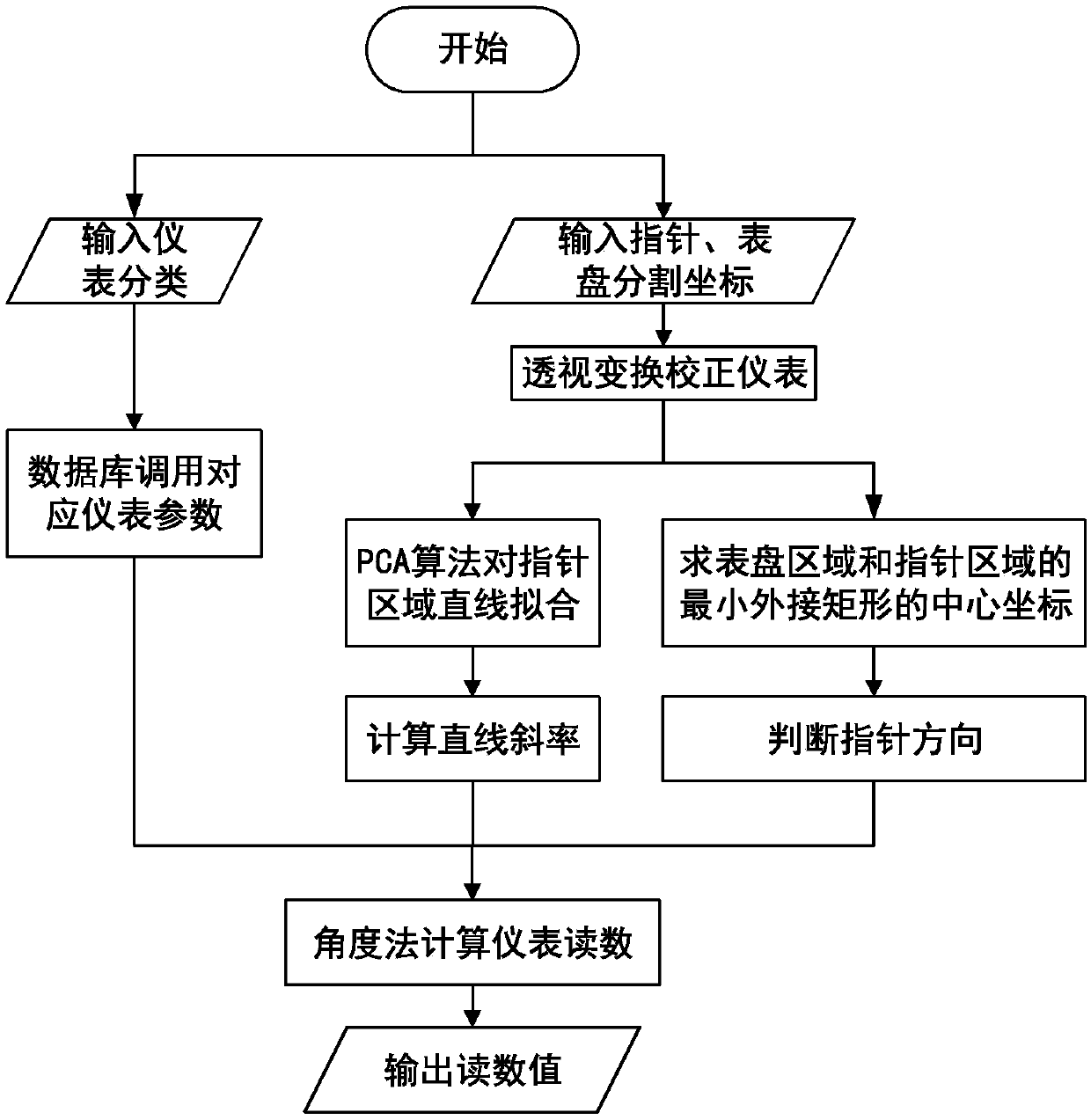

A reading method of a pointer type meter based on depth learning

InactiveCN109543682AImprove reading efficiencySolve the problem of low recognition accuracyCharacter and pattern recognitionMirror reflectionPrincipal component analysis

The invention discloses a reading method of a pointer type meter based on depth learning, belonging to the field of depth learning and computer vision. The method of the invention utilizes Mask- RCNNobject detection and instance segmentation algorithm to divide the dial and pointer images firstly, then correcting the dial by perspective transformation, Then using PCA (Principal Component Analysis) algorithm to fit the segmented instrument pointer, Then judging the direction of the pointer according to the center coordinate of the smallest oblique circumscribed rectangle of the pointer and thecenter coordinate of the dial; Finally, calculating the pointer reading according to the slope and direction of the pointer by using the angle method. As that method of the invention can accurately classify the type of the instrument, high precision pixel level segmentation of the pointer and dial, under non-uniform illumination conditions, different scales still have good robustness, to solve the traditional pointer instrument recognition field of the dial and pointer positioning difficulties, uneven light, mirror reflection, blurred pictures caused by low recognition accuracy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

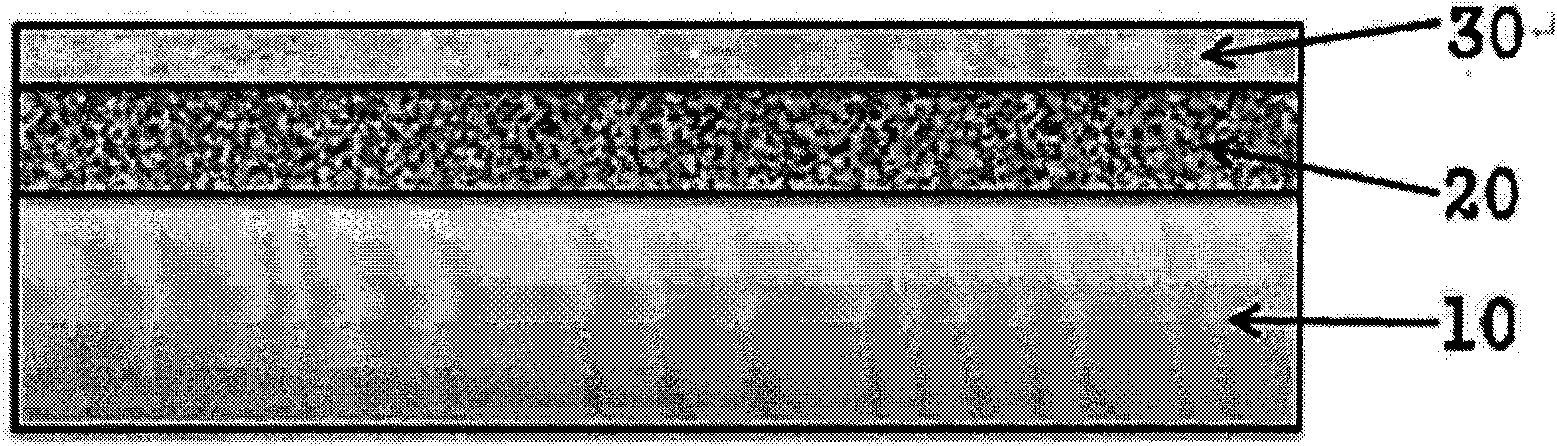

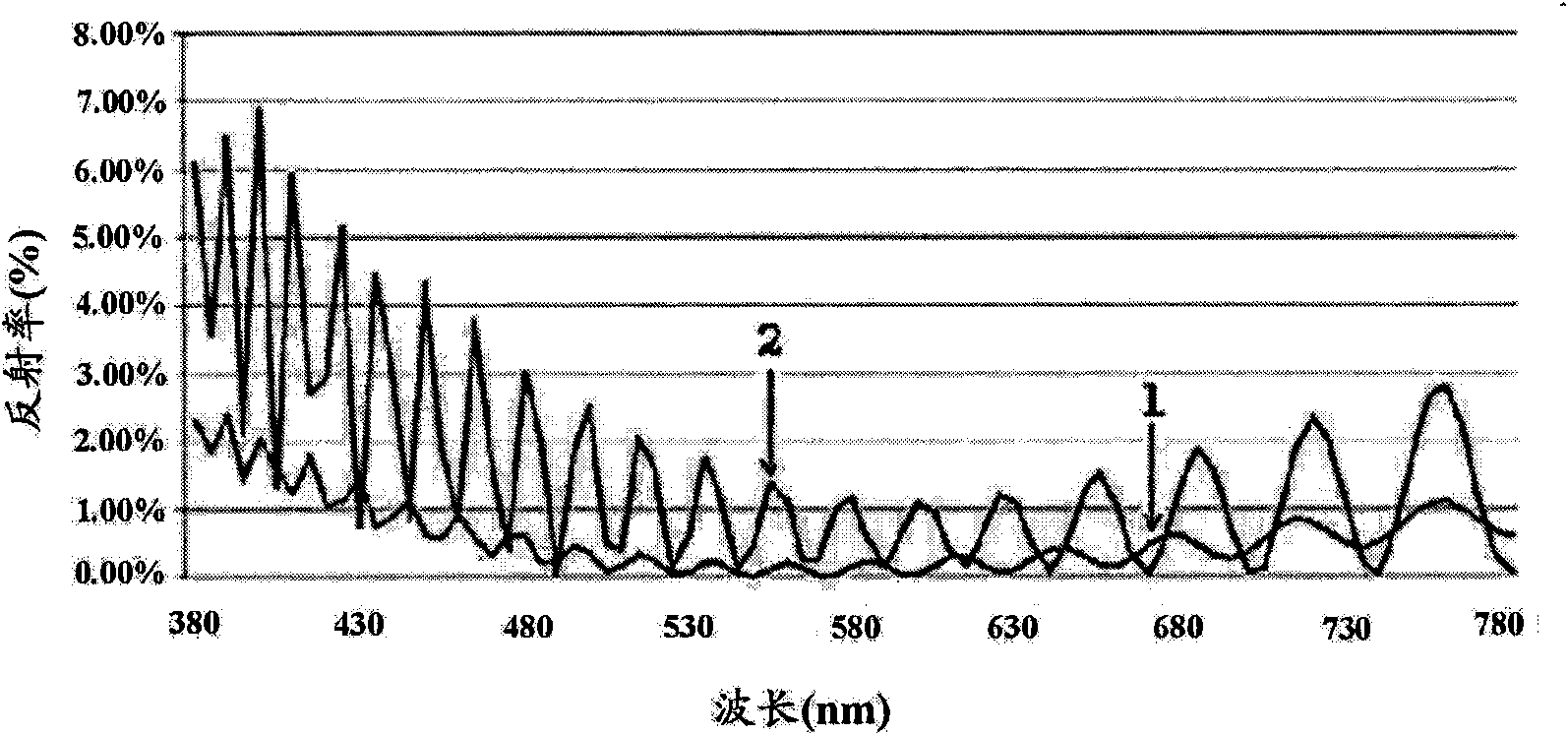

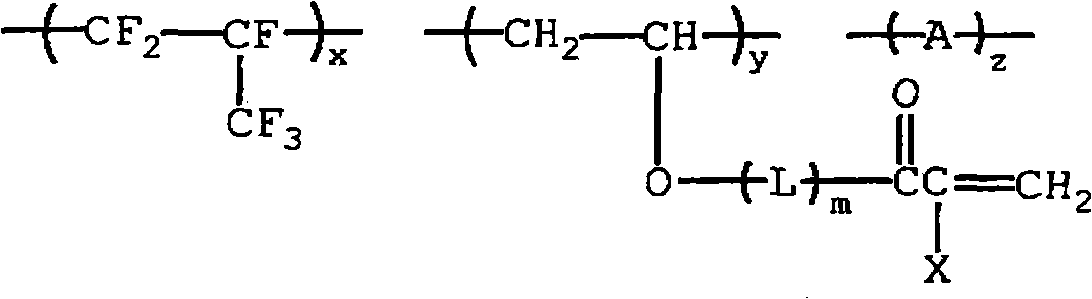

Anti-reflection film and polarization plate containing the same

InactiveCN101900841AExcellent rainbow effectReduce reflectivityCellulosic plastic layered productsPolarising elementsAngle of incidencePolyvinyl alcohol

The present invention generally relate to an anti-reflection film and a polarization plate containing the same, particularly relate to the anti-reflection film having an excellent rainbow effect and low reflectivity by reducing amplitude of reflection spectrum, and the polarization plate containing the anti-reflection film. The anti-reflection film includes a cellulose triacetate (TAC) transparent base for protecting a polyvinyl alcohol (PVA) polaroid sheet; a high-hardness layer coated on the transparent base and having a high refractivity of 1.50-1.60 as well as antistatic function; and a low refractivity layer coated on the high-hardness layer by a wet method and having a refractivity of 1.31-1.40, wherein the anti-reflection film has an average specular reflectance of 0.1-1.40% in a wavelength range from 480-680nm at an incidence angle of 5 DEG.

Owner:TORAY ADVANCED MATERIALS KOREA

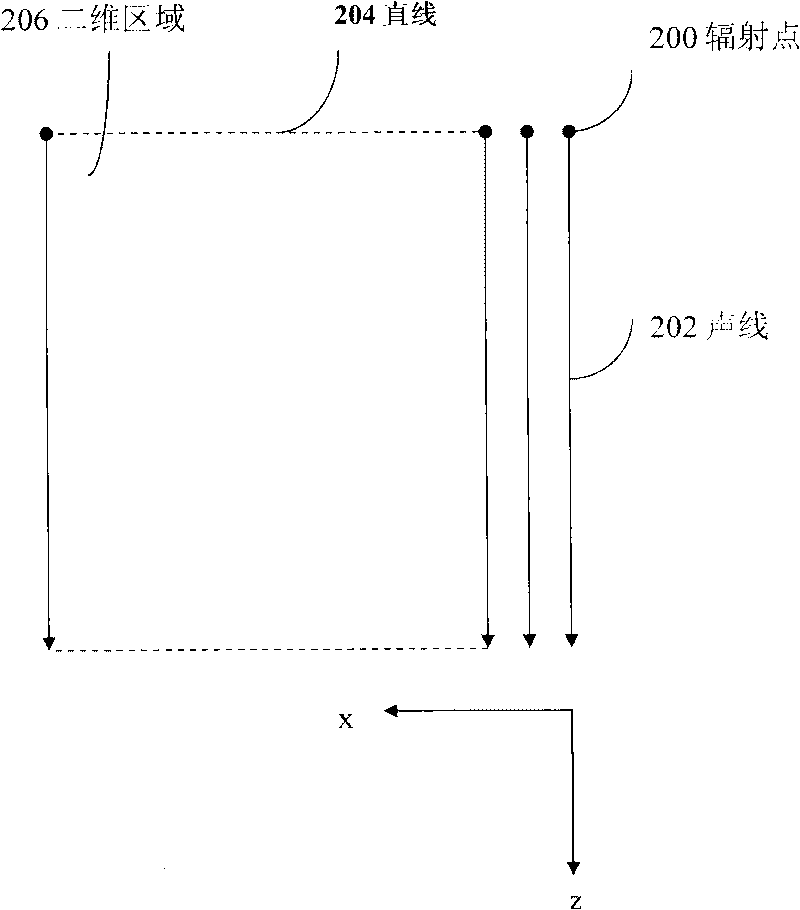

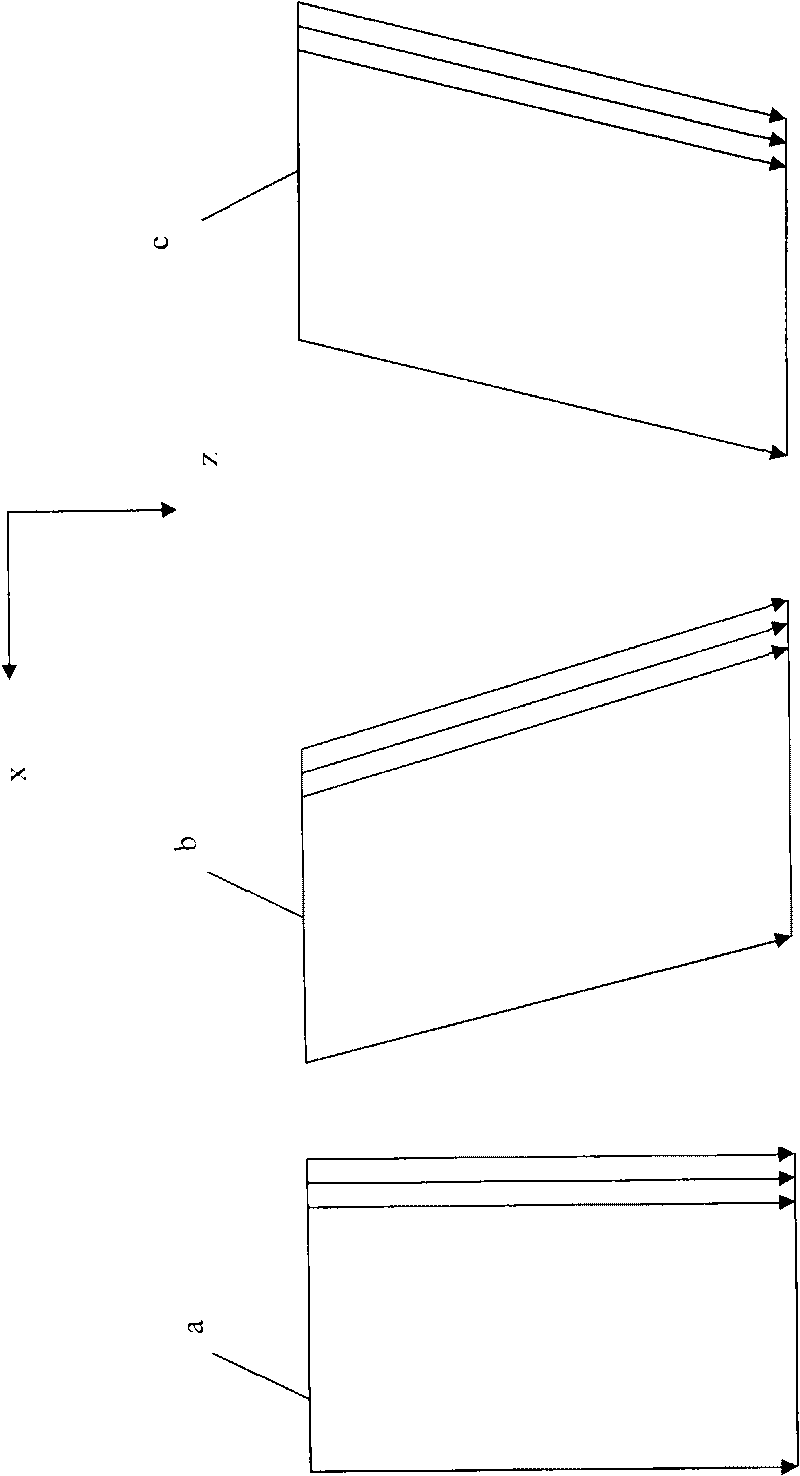

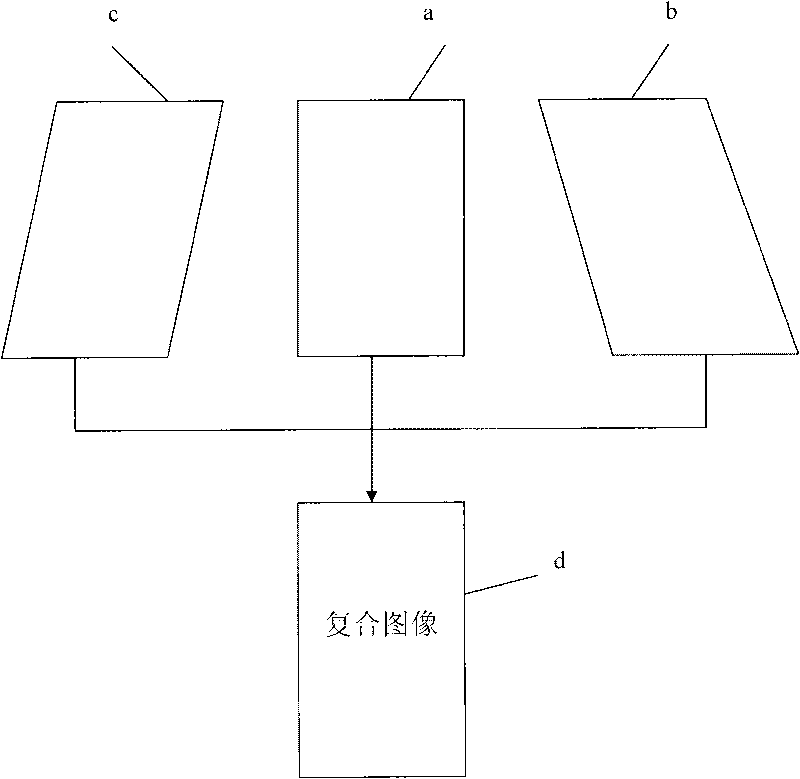

Ultrasonic imaging method and device

InactiveCN101744639AHigh resolutionGood mirror reflection profileUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsMirror reflectionSignal-to-quantization-noise ratio

The invention relates to ultrasonic imaging method and device, in particular to ultrasonic imaging method and device for acquiring a composite ultrasonic image by using a space and frequency composite technology. By using the space and frequency composite technology, frames observable from a plurality of angles are acquired by a Tx / Rx frequency and beam deflection angles which can be configured by a user and the frames are compounded to form a composite image with high resolution and favorable mirror reflection contour. Because the frequency in the invention can be flexibly configured along with the deflection angles, the invention can further widen the allowable range of the beam deflection angles and lower less resolution to a certain extent to restrict the side lobes and the grating lobes of the deflection frames and weaken spot noise and clutter, thereby improving the visibility, the signal-to-noise ratios of the tested tissue and needle and the texture appearance and smoothening the edges.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

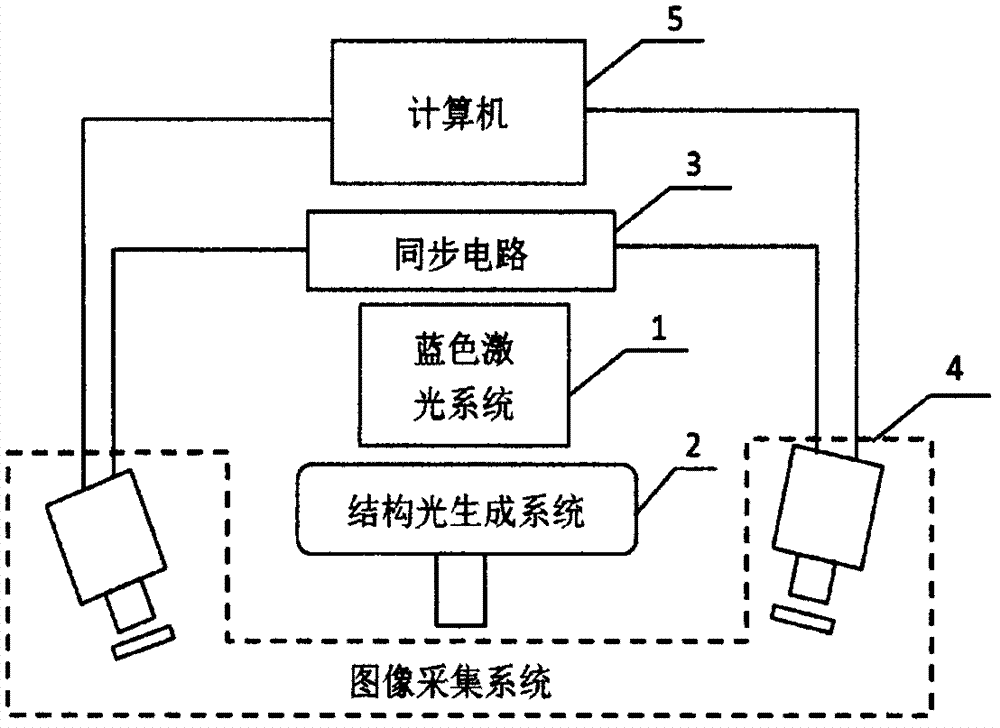

Planar structured light three dimension measuring device and method for high-reflectivity part

ActiveCN103868472ARealize measurementThere is no gamma nonlinearityUsing optical meansMeasurement deviceCollection system

A planar structured light three dimension measuring device and method for a high-reflectivity part relate to the field of three dimension optical measurement and aim to solve the problems of large size and slow measuring speed due to the complex structure of the existing device. The planar structured light three dimension measuring device comprises a blue laser source system, a structured light pattern generation system, a synchronous control circuit, an image collection system and a computer. The device has the advantages of small size, light weight, fast projecting speed and the like. The phenomena of local mirror reflection, mutual reflection and direction reflection and the like at the part surface are effectively inhibited by the projecting random or pseudo random coding patterns and two groups of periodically, forwardly and reversely changed black and white strip patterns, the sub pixel point match of two images shot by left and right cameras are fast realized, and the efficient measurement of the high-reflectivity part is finished. The planar structured light three dimension measuring device and method for the high-reflectivity part is suitable for the planar structured light three dimension measurement of the high-reflectivity part.

Owner:南京禺疆电子技术有限公司

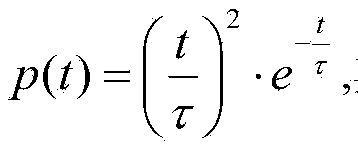

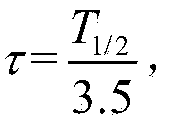

Lidar three-dimensional imaging system based on virtual instrument

ActiveCN104049259AAchieve seamless integrationShorten the development cycleElectromagnetic wave reradiationMirror reflectionFull waveform

A lidar three-dimensional imaging system based on a virtual instrument comprises a three-dimensional scene modeling module, a lidar testing system simulation environment modeling module, a full-waveform signal processing module and a three-dimensional reconstruction module. The three-dimensional scene modeling module comprises a three-dimensional model loading element used for setting background colors, visual angle control, illumination, a projection mode, a display model and other basic scene projects. The lidar testing system simulation environment modeling module comprises four modeling sub-modules which are a laser pulse model, an atmospheric transmission model, an object interaction model and a receiving unit model. The laser pulse model is used for simulating a laser source according to the wavelength, pulse width, energy and other characteristics of a laser. The atmospheric transmission model is used for simulating a tested atmospheric environment, so that a noise model is generated for acting on the laser. The object interaction model is used for simulating effects of the laser and a detected object, and the effects comprise mirror reflection, diffuse reflection, surface reflection and speckles. The receiving unit model is used for simulating detector noise and amplifier noise which are generated after sensing.

Owner:NANJING UNIV

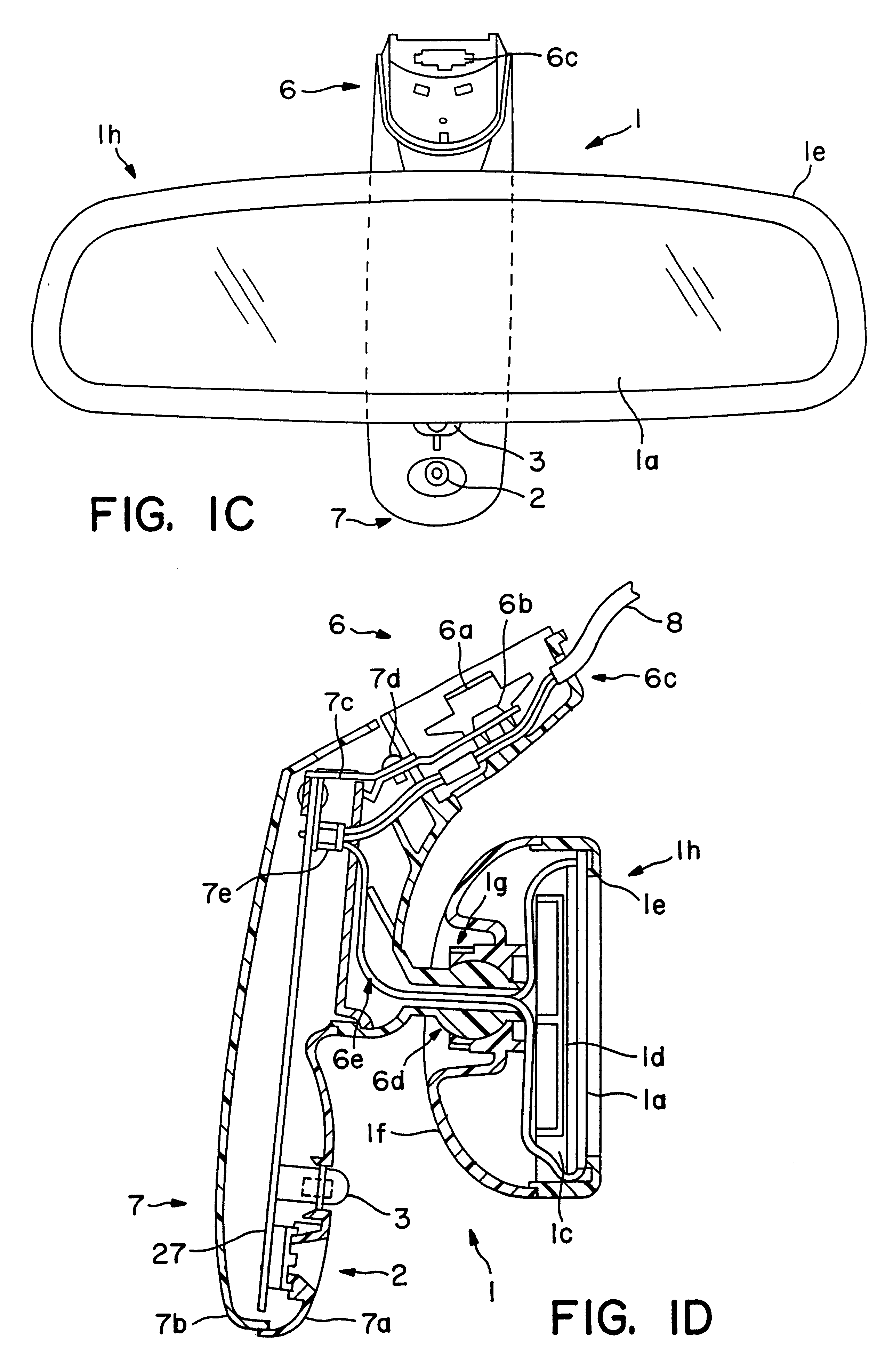

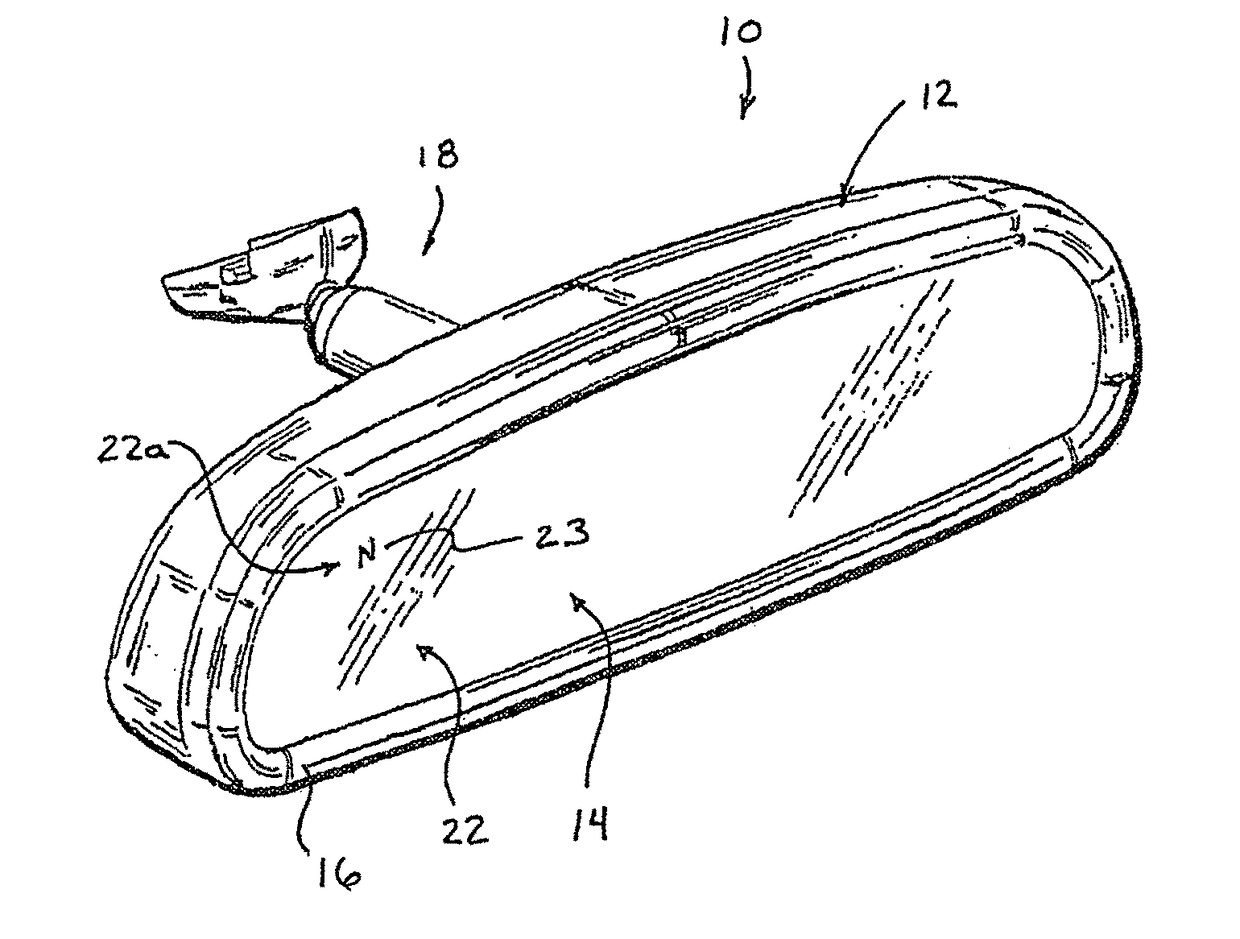

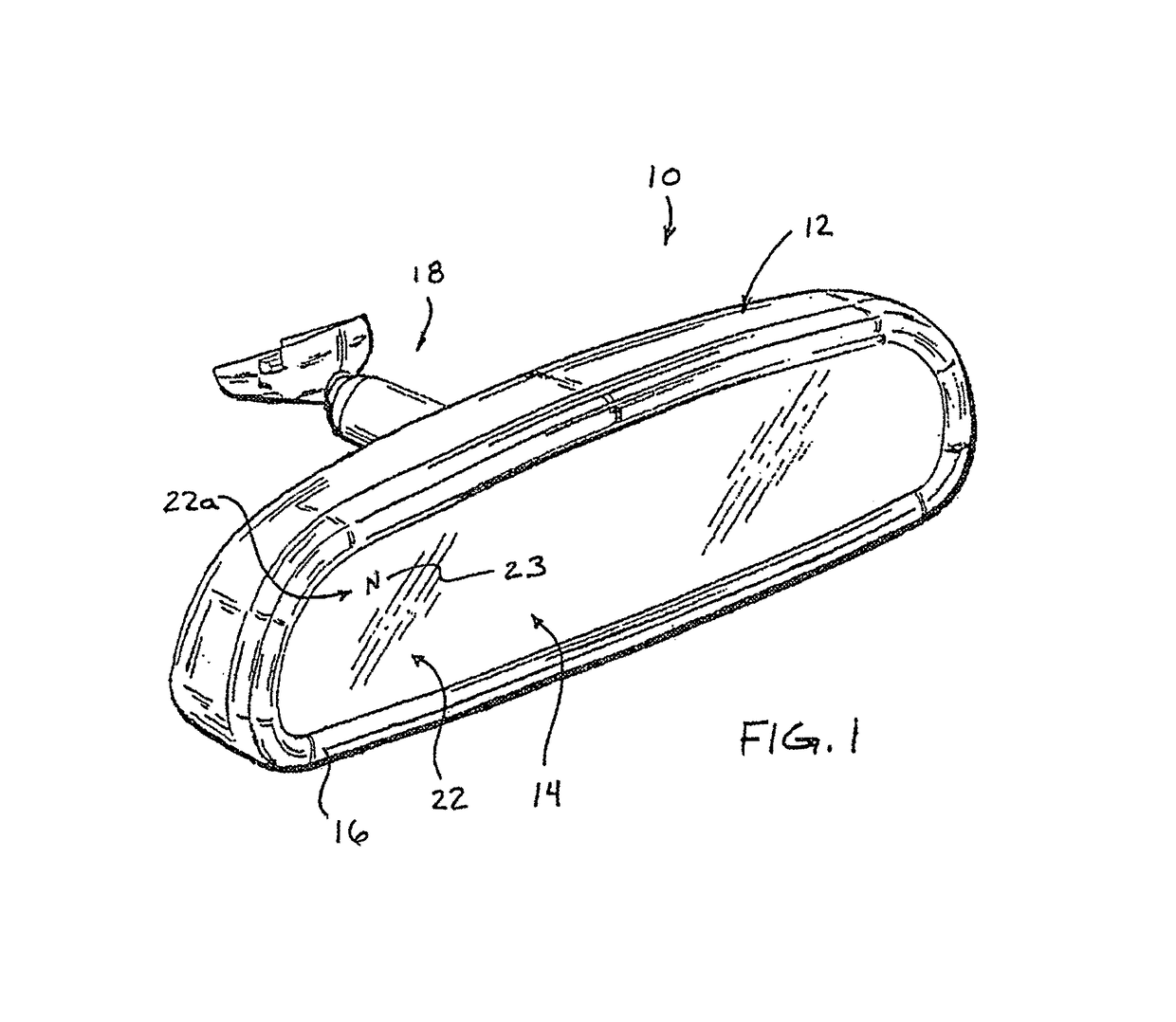

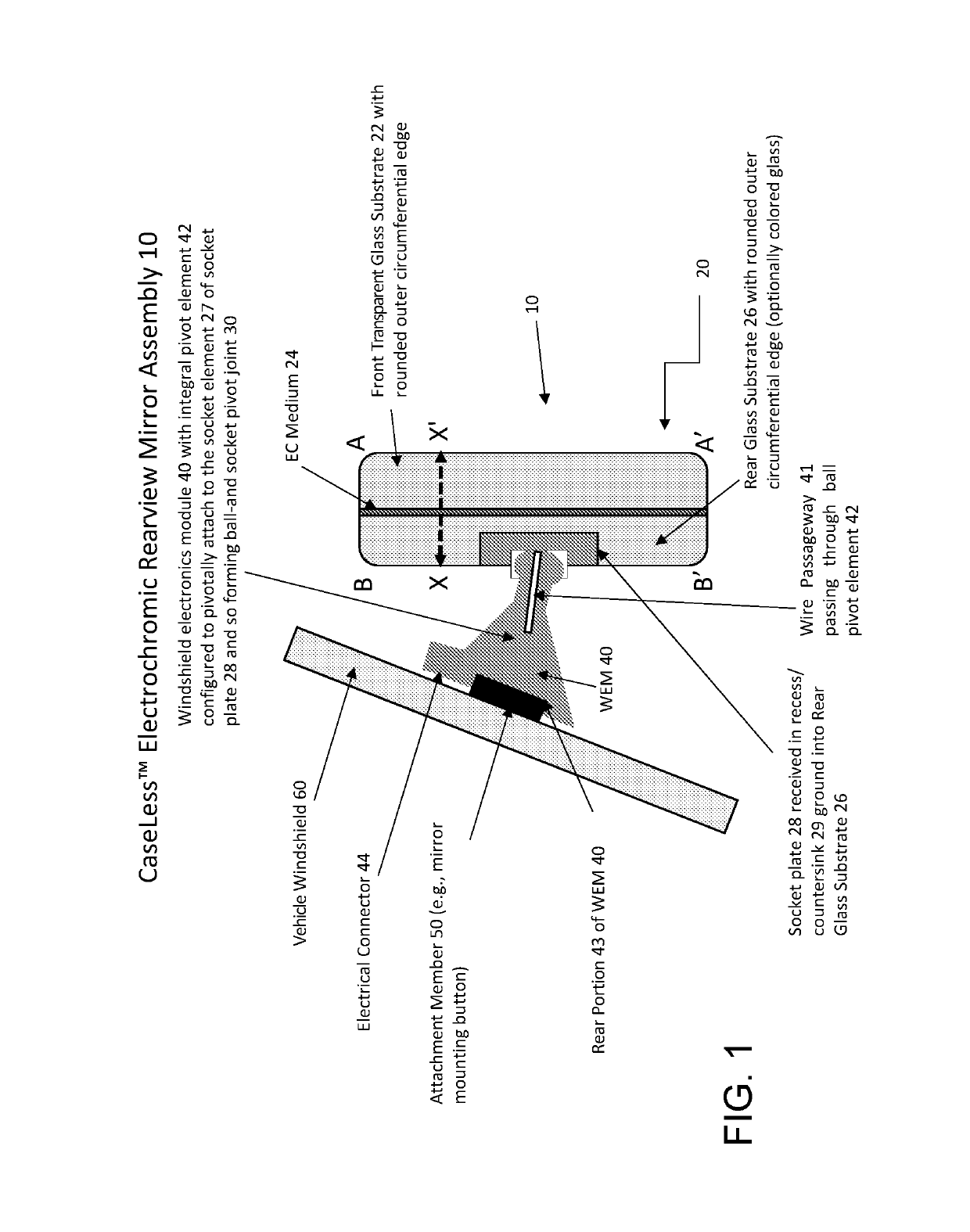

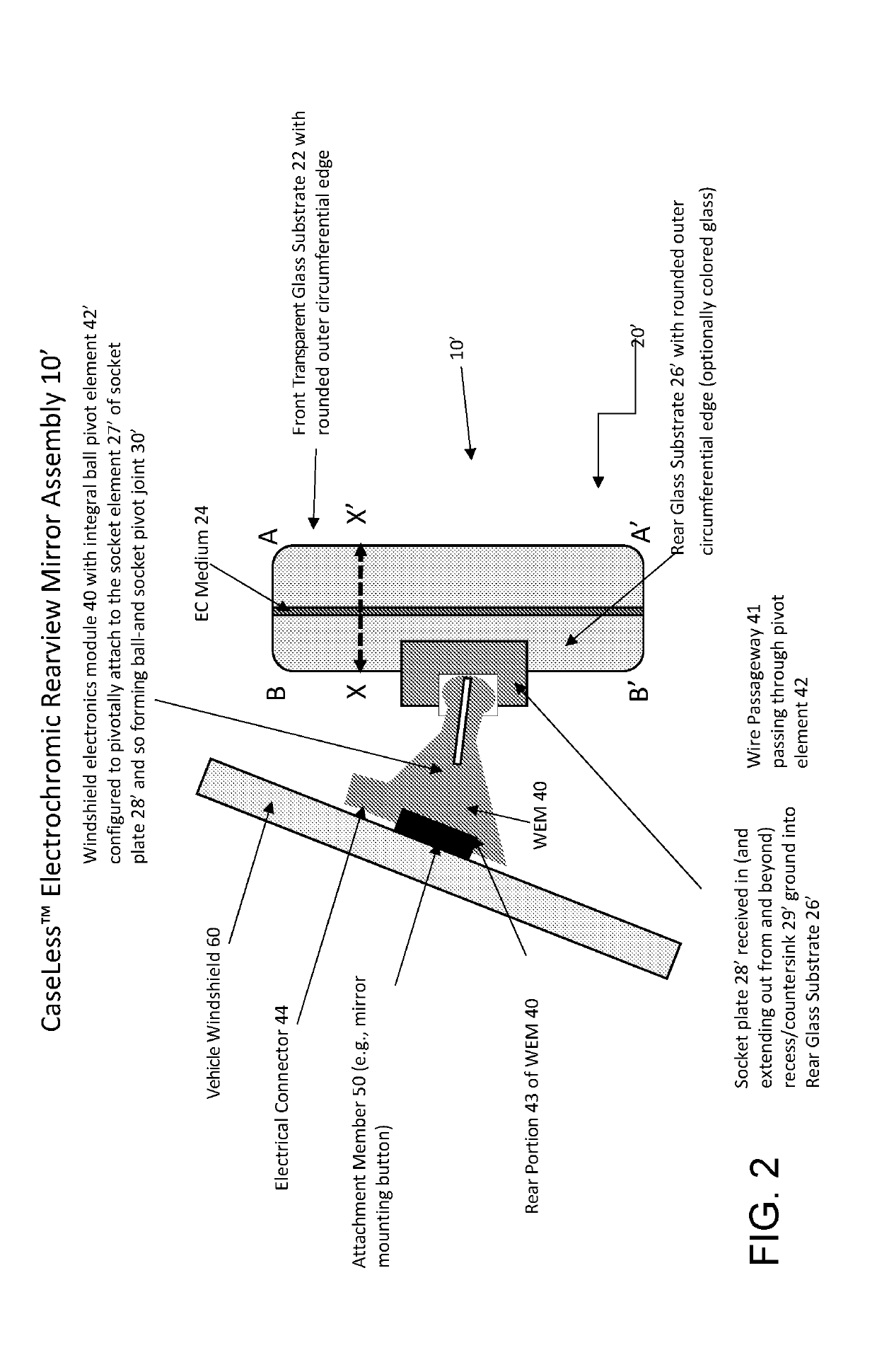

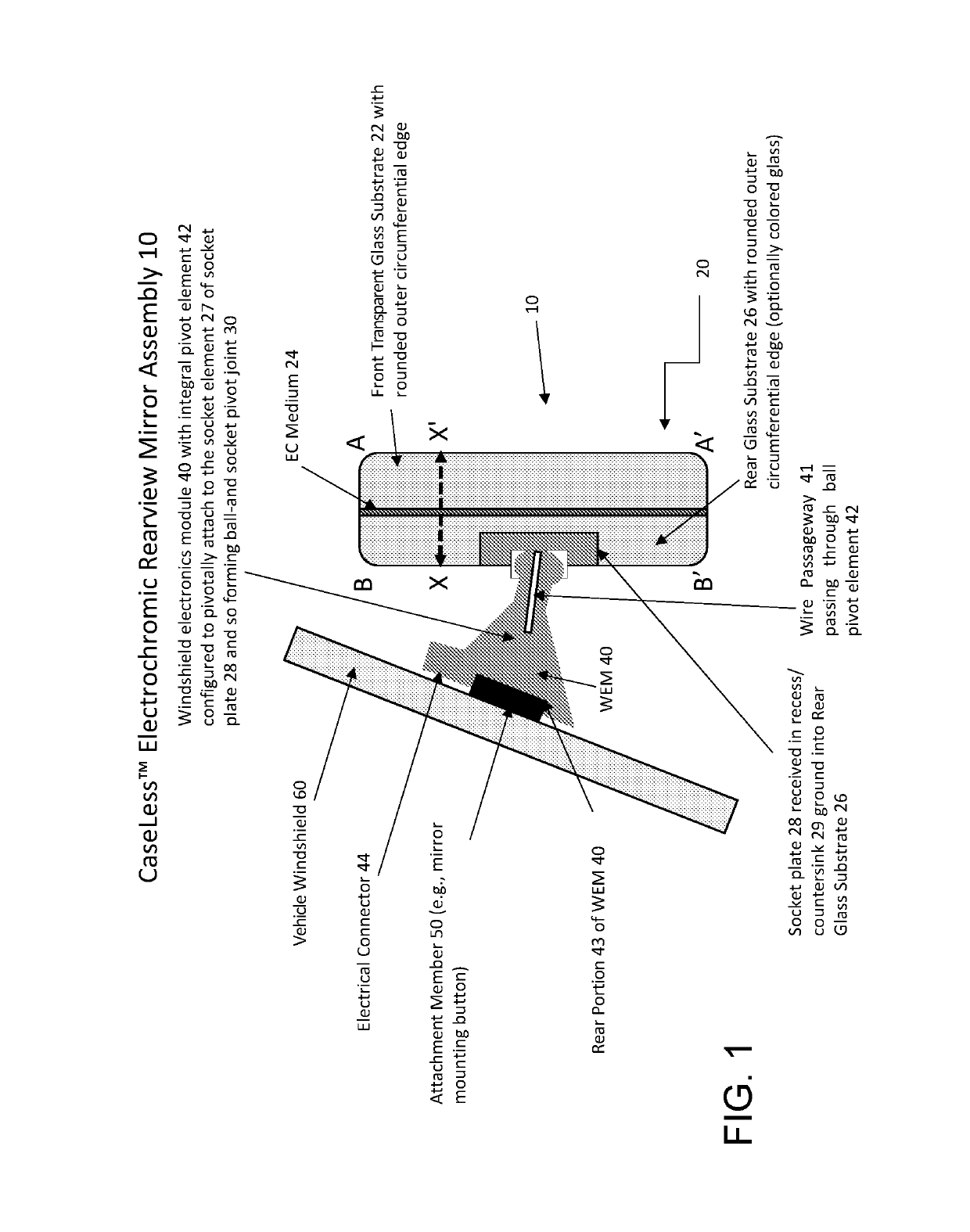

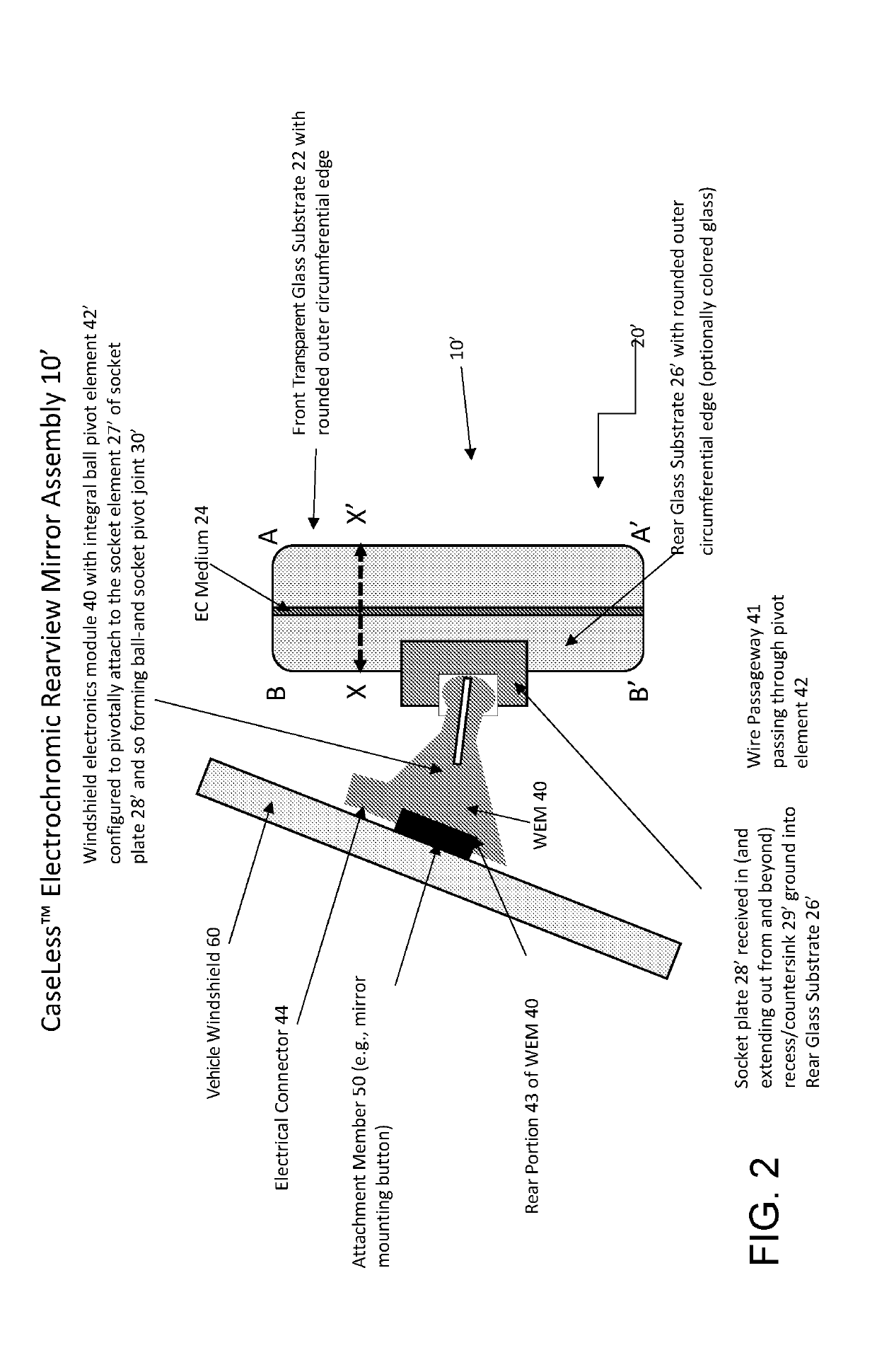

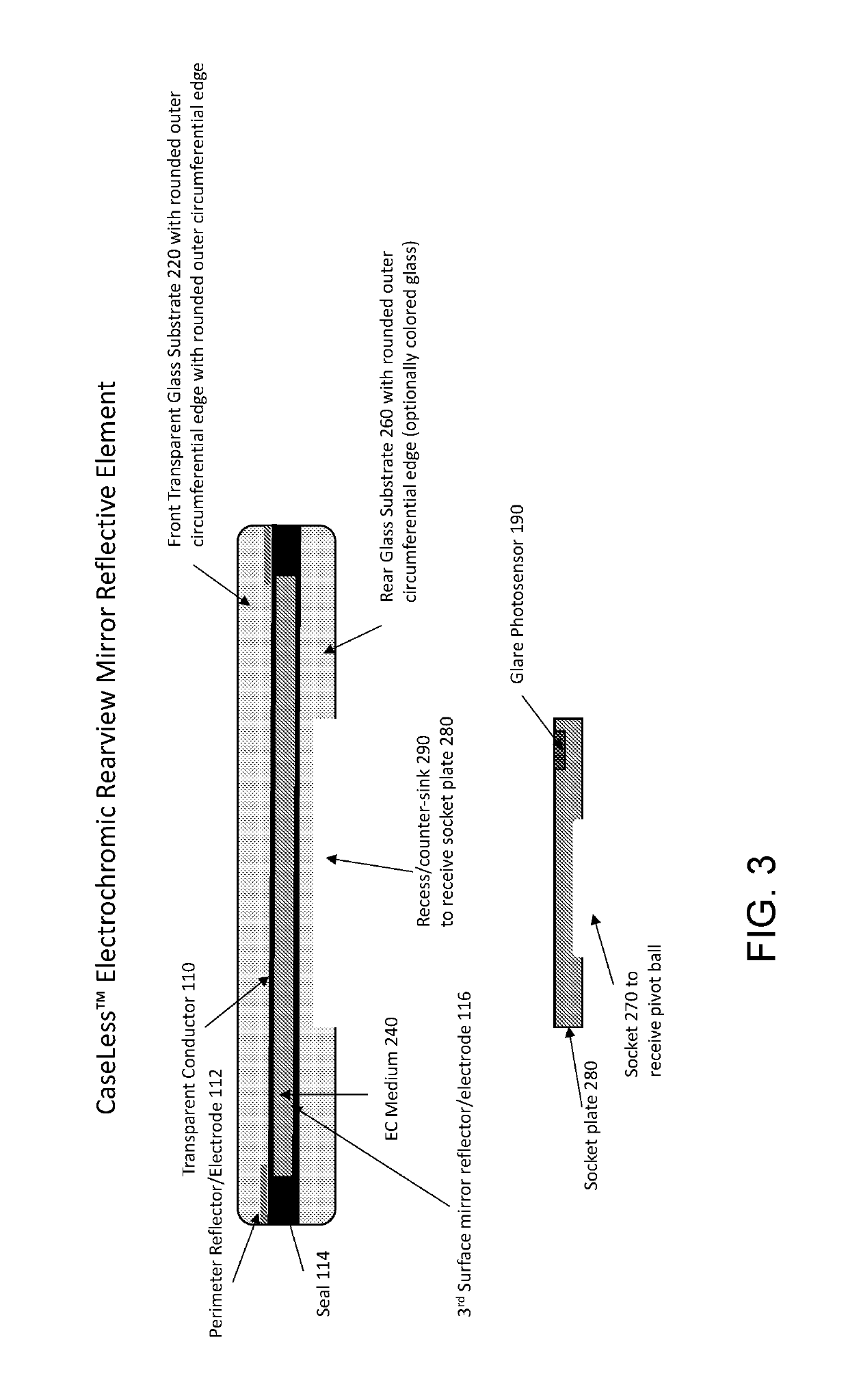

Caseless rearview mirror assembly

An electro-optic rearview mirror assembly for a vehicle includes a caseless electro-optic rearview mirror reflective element and a plate attached at the rear of the reflective element. The mirror reflective element connected to and pivotal about a windshield electronics module via a ball and socket pivot joint. Control circuitry may be disposed in a windshield electronics module for automatically controlling dimming of the electro-optic medium or alternatively, dimming of the electro-optic medium is automatically controlled via a multifunctional rear backup camera system of the equipped vehicle. Optionally, the control circuitry controls dimming of the electro-optic medium of the mirror reflective element via wiring that passes through the ball and socket pivot joint. Optionally, image data captured by the multifunctional rear backup camera may be used for ambient light determination and to provide video image display at the interior rearview mirror assembly.

Owner:MAGNA MIRRORS OF AMERICA INC

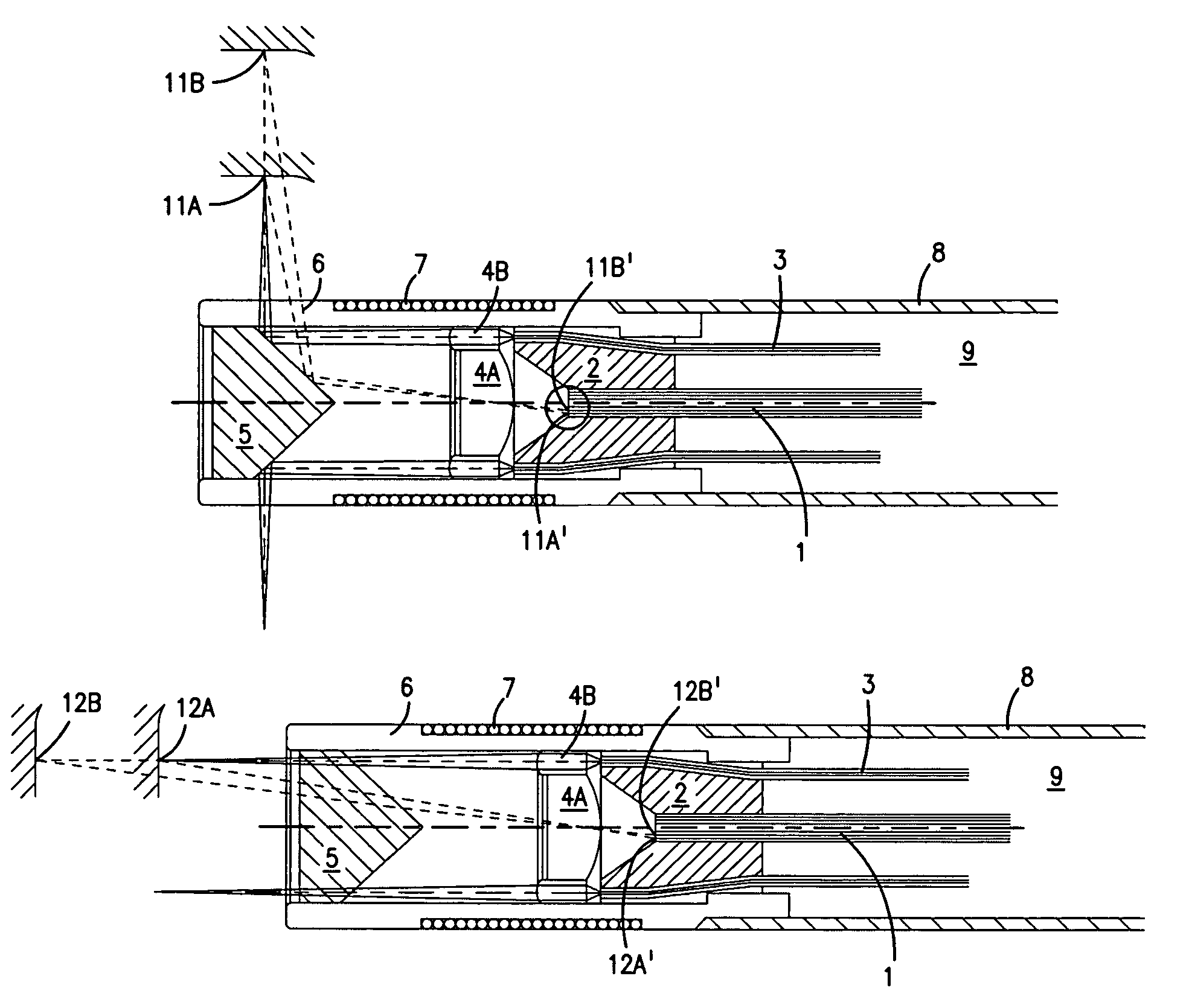

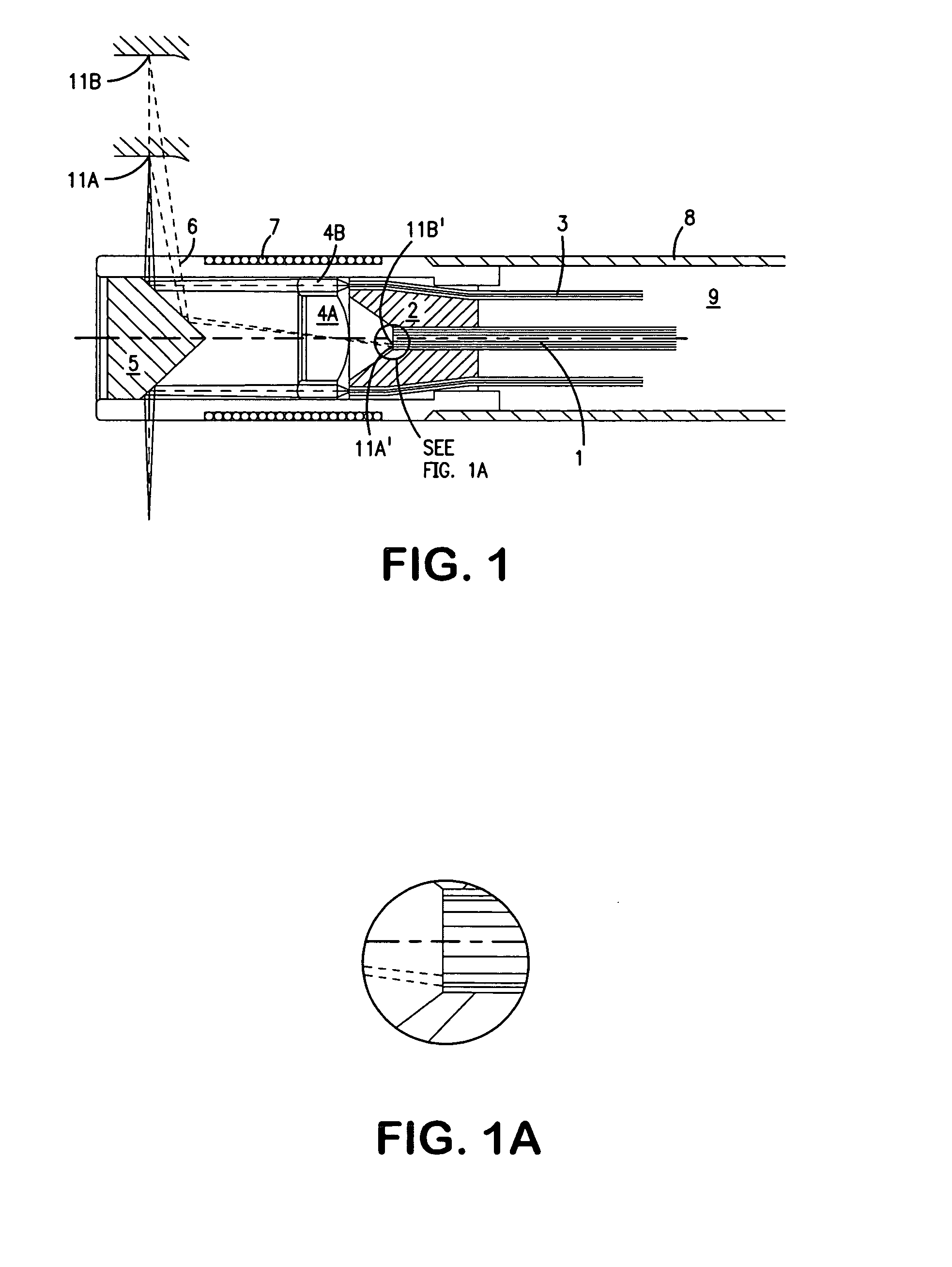

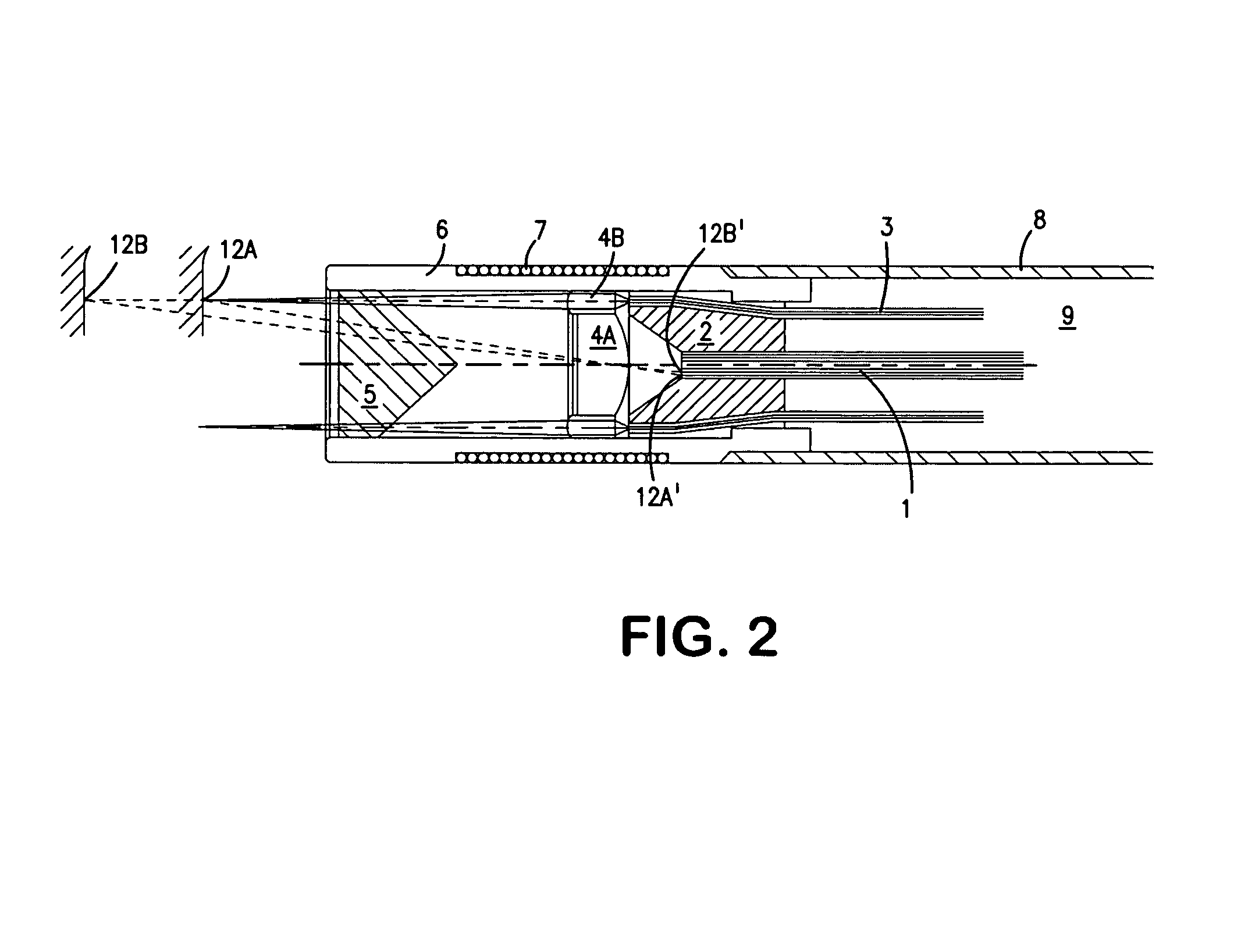

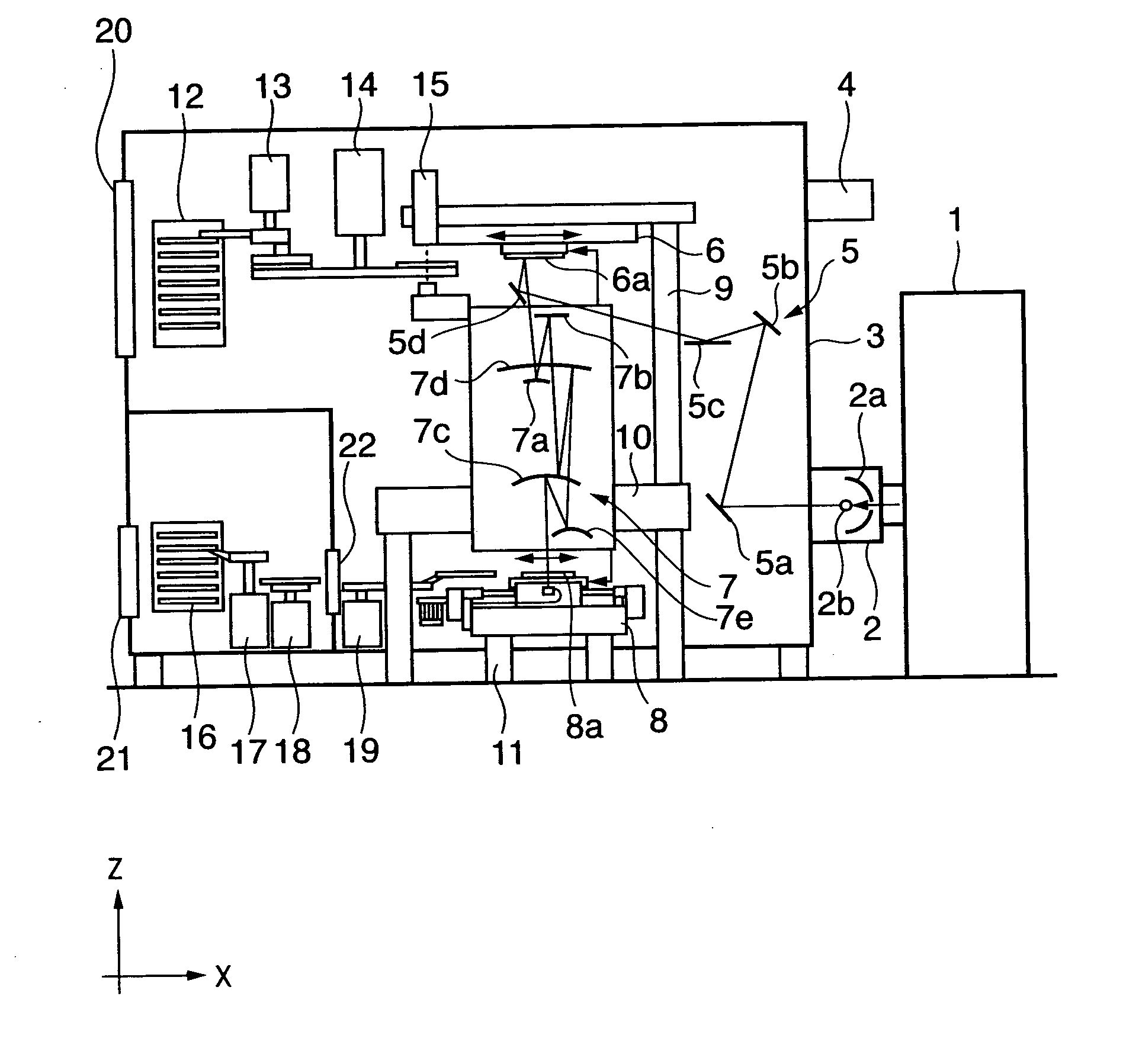

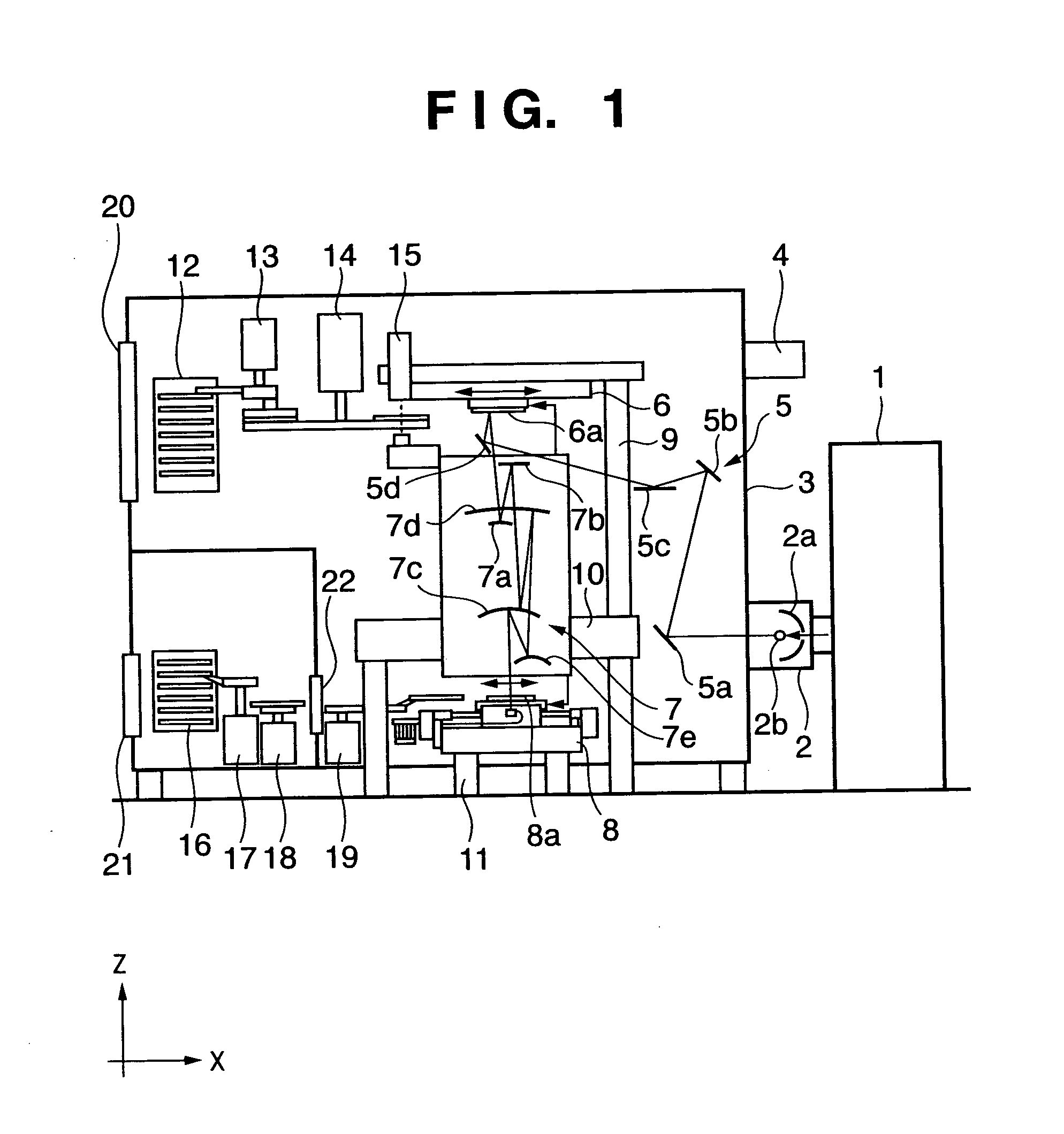

Reflection mirror apparatus, exposure apparatus and device manufacturing method

InactiveUS20050073663A1MirrorsHandling using diffraction/refraction/reflectionTemperature controlMirror reflection

A reflection mirror apparatus, used in a reflection optical system of an exposure apparatus which performs exposure processing by guiding exposure light by reflection, has a mirror having a reflection surface to reflect the exposure light, and radiation plates for radiation-cooling provided in positions away from an outer surface of the mirror. The radiation plates are provided so as to ensure a passage area for the exposure light incident on and reflected from the reflection surface of the mirror. Further, the respective radiation plates are temperature-controlled by cooling liquid flowing through cooling pipes. Thus the temperature rise of the mirror used in the reflection optical system of the exposure apparatus can be suppressed, and the accuracy of surface form of the mirror reflection surface can be maintained.

Owner:CANON KK

Polarization control coding method coder and quantum key distributing system

InactiveCN1651947ALower requirementReduce speed requirementsKey distribution for secure communicationCoupling light guidesMirror reflectionQuantum channel

Owner:UNIV OF SCI & TECH OF CHINA

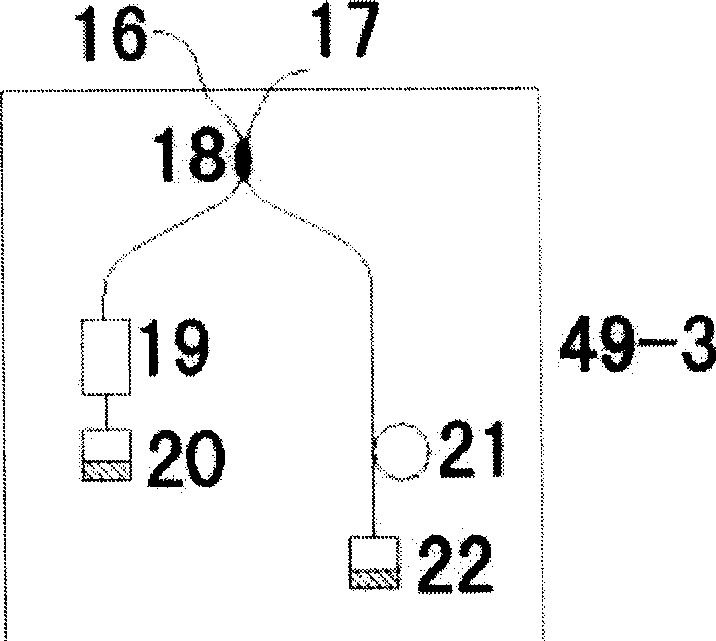

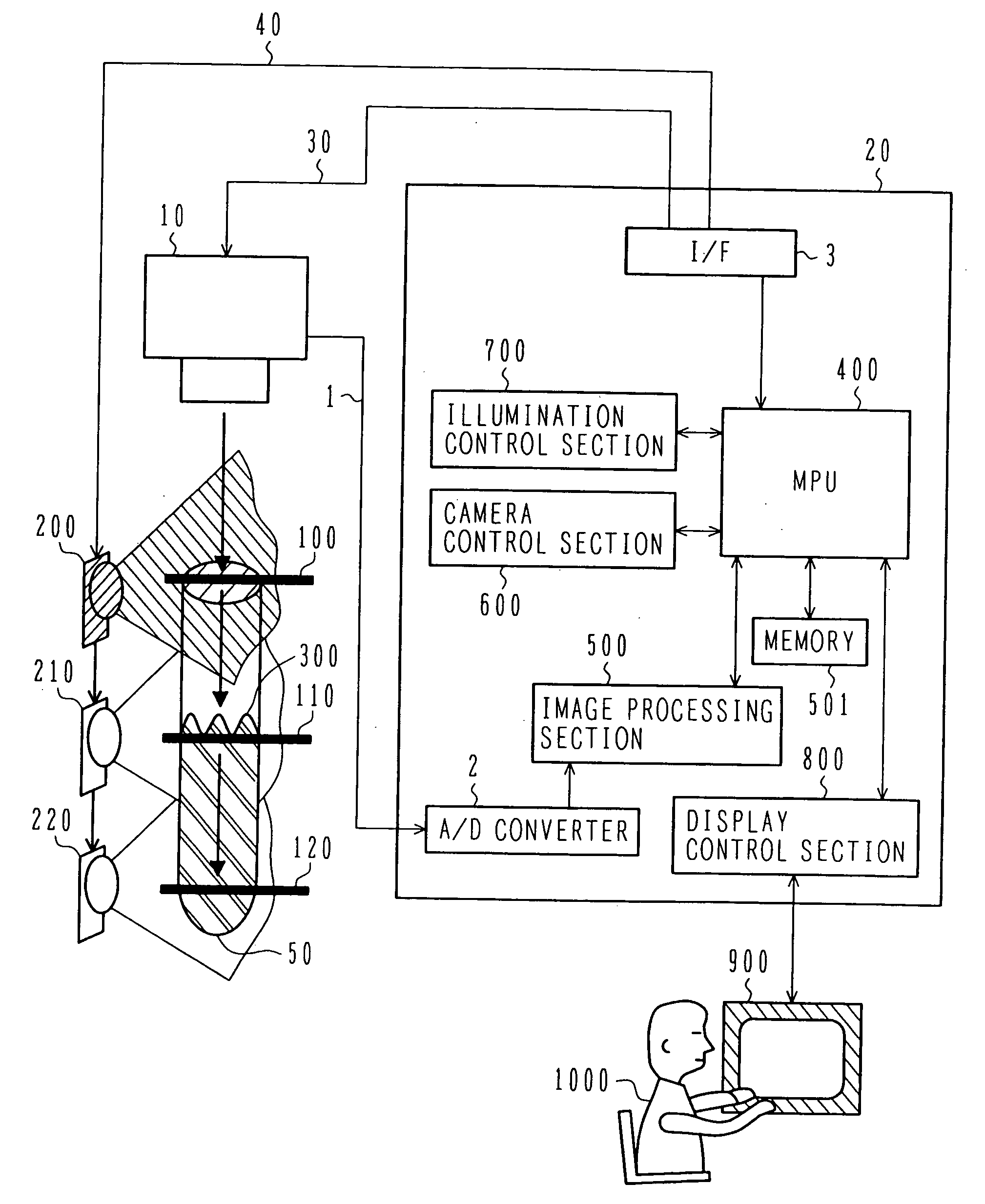

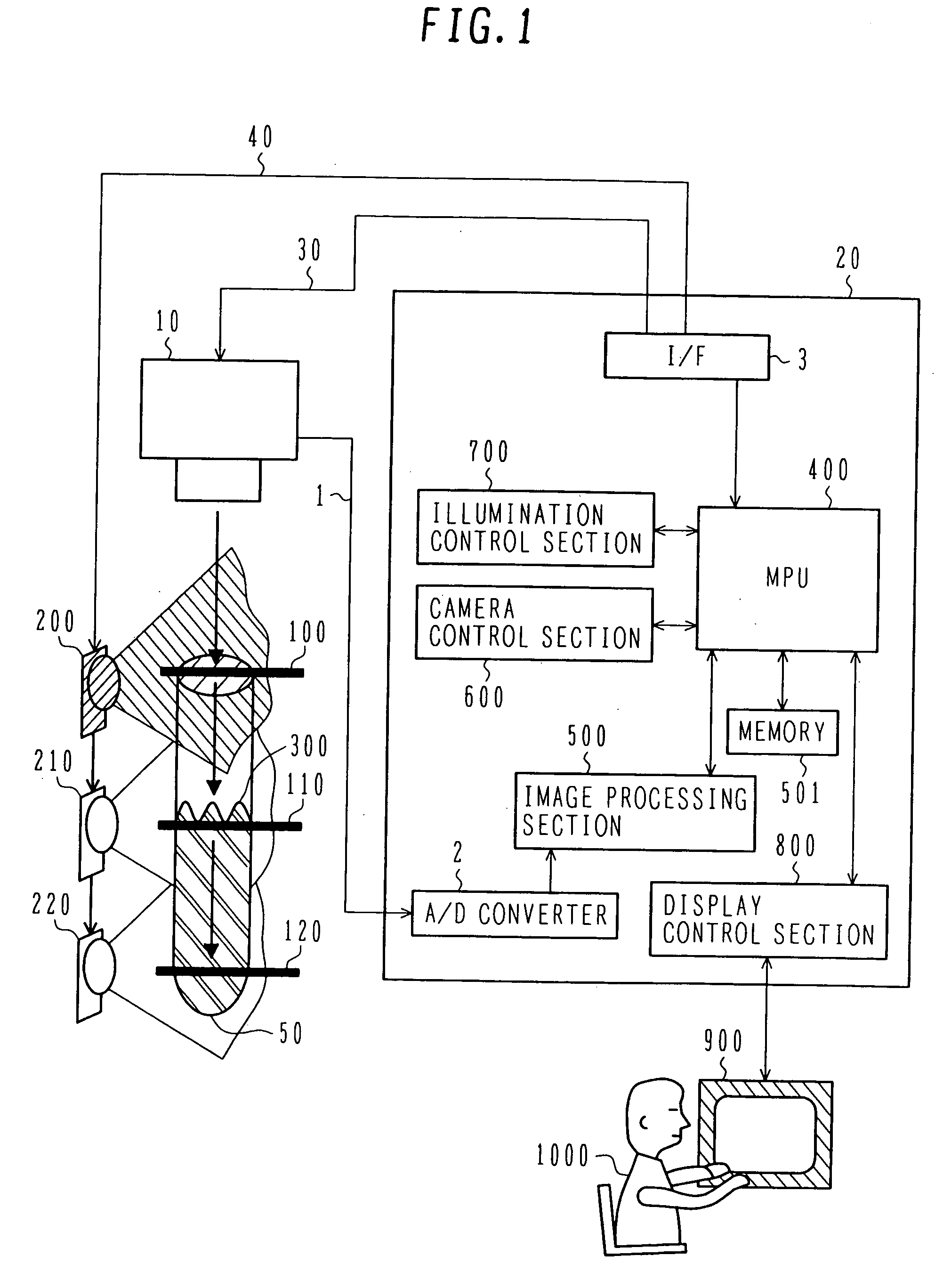

Foreign matter detecting system

InactiveUS20050219523A1Improve accuracyClear imagingOptically investigating flaws/contaminationUsing optical meansForeign matterImaging processing

A foreign matter detecting system which can acquire a clear image and detect a foreign matter with high accuracy based on the acquired image regardless of whether a subject is located far or near from an image capturing device in spite of a depth variation or a level difference. An image capturing unit having an externally controllable focus position is disposed above or below a liquid surface, and a ray of light from an LED is illuminated toward the liquid surface from above or the side at least at a focus position of the image capturing unit so that a foreign matter on the liquid surface causes mirror reflection. The focus position of the image capturing unit is changed over the range from the top of a container containing a liquid to the bottom thereof. At each focus position, an input image from the image capturing unit is taken into an image input unit of an image processing section. An image selecting unit of the image processing section selects an image focused on the liquid surface or a clearest image of the liquid surface from among the input images. An image detecting unit of the image processing section checks the presence and position of the mirror reflection, thereby detecting the foreign matter.

Owner:HITACHI LTD

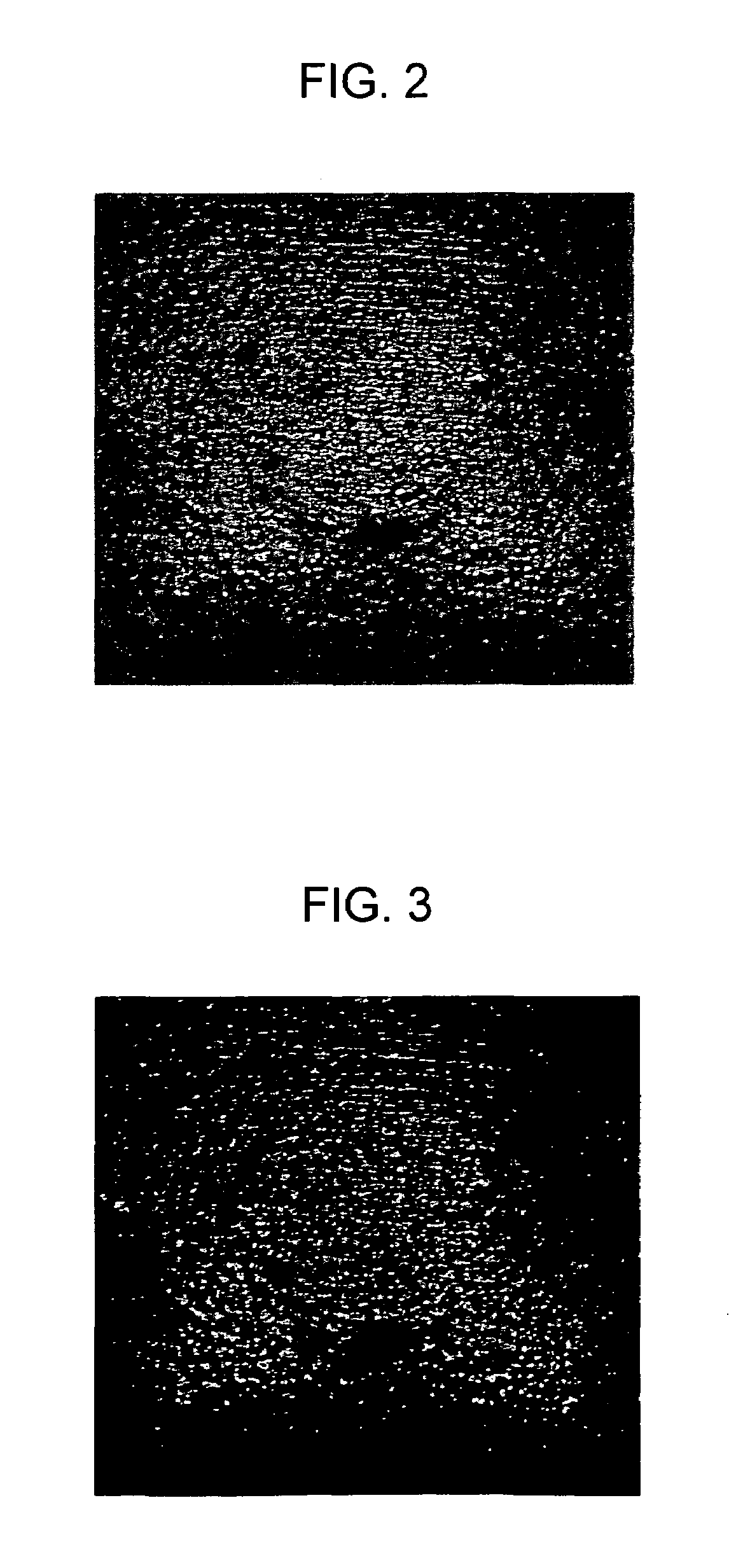

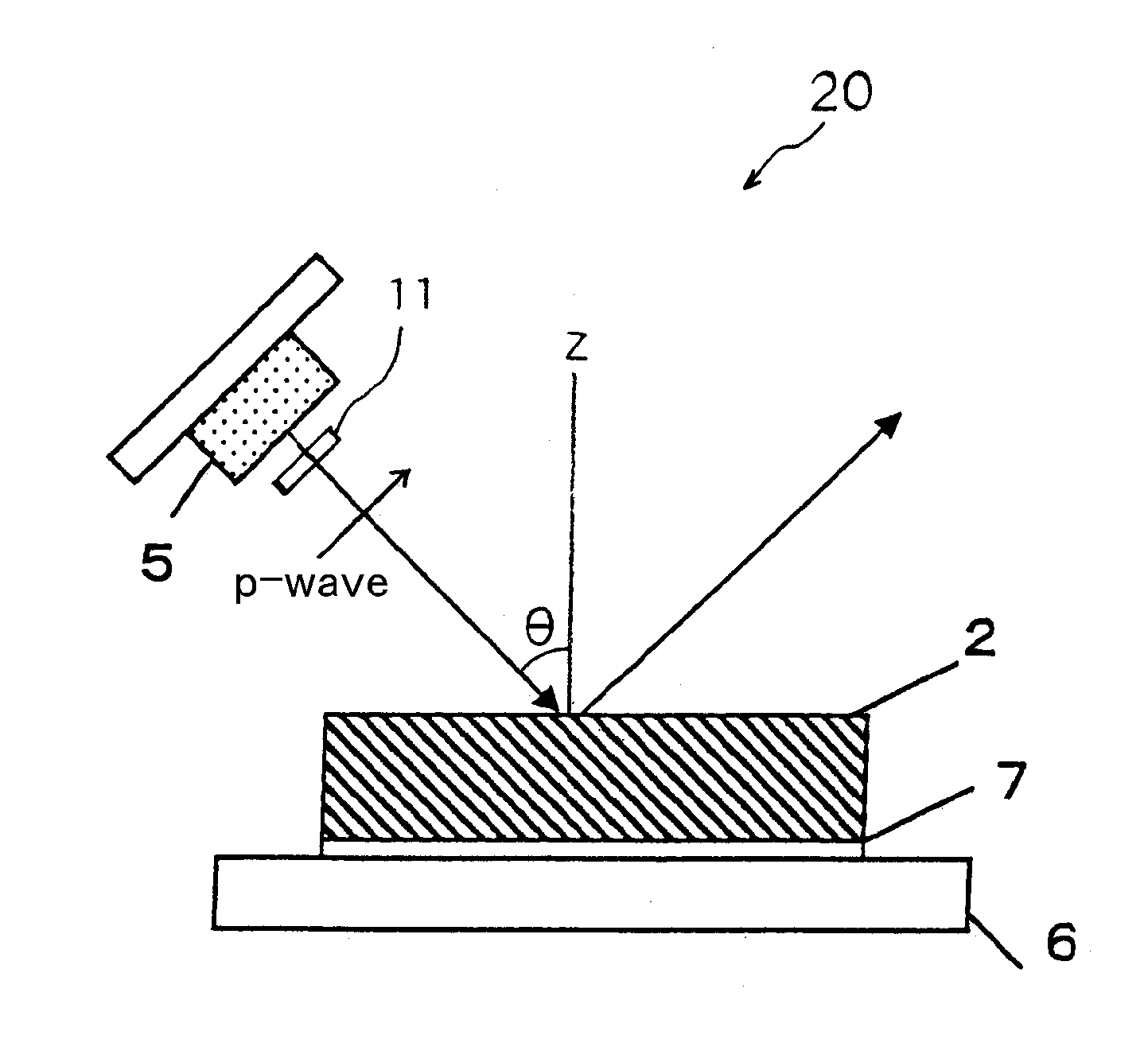

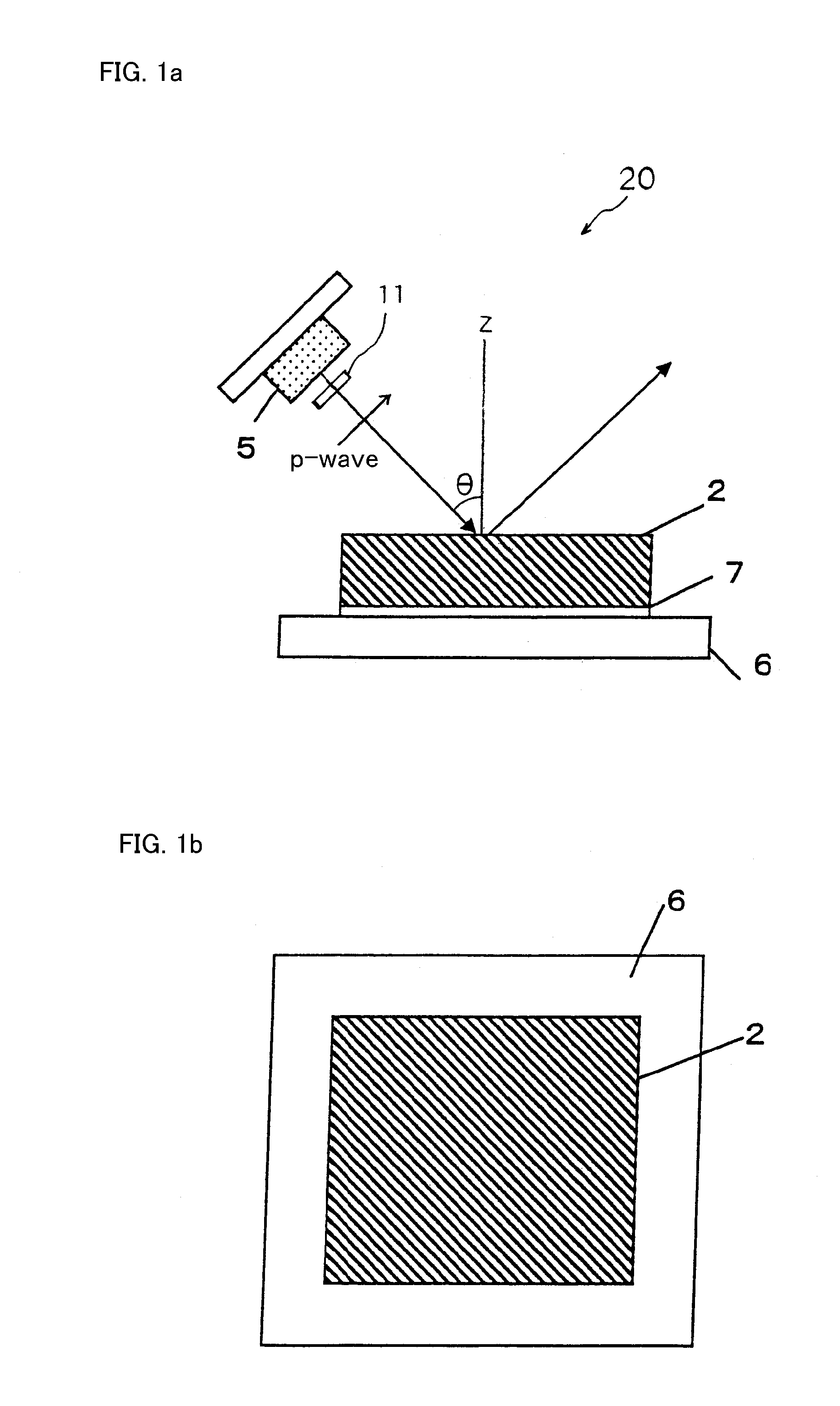

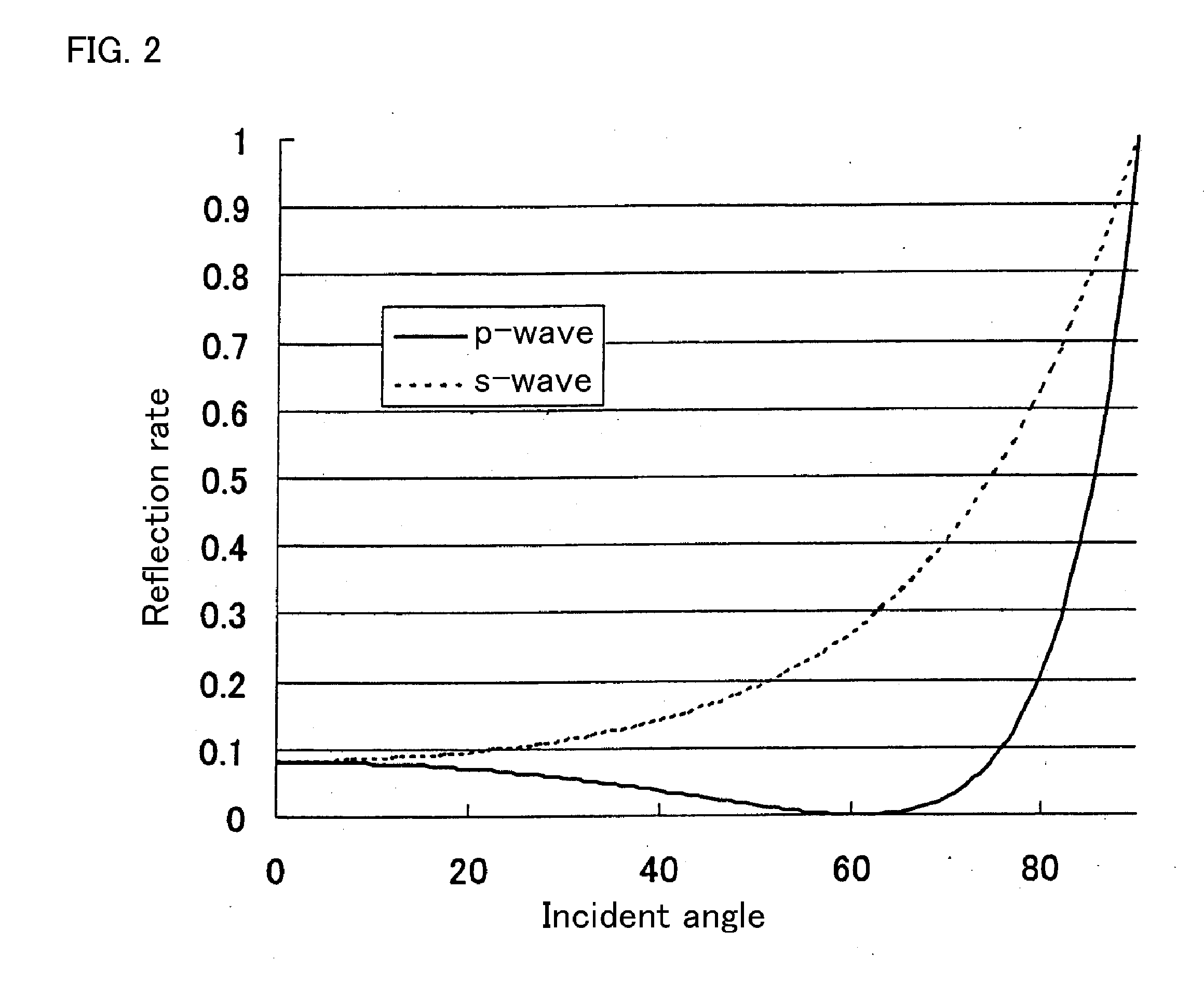

Skin evaluation method and image simulation method

InactiveUS7336810B2Beauty can be objectivelyDiagnostics using lightScattering properties measurementsMirror reflectionDigital image data

A skin beauty evaluation method for imaging an object such as human face to obtain digital image data, extracting data on a mirror reflection light component of each pixel from the digital image data and evaluating the skin sheen and skin beauty by using this. A simulation image obtaining method is also disclosed.By using these methods, it is possible to objectively evaluate the skin sheen and beauty which have been conventionally evaluated only subjectively. Thus, the methods are useful for development of a new skin cosmetic material.Moreover, by using a polarized light source, a digital camera to which polarization filter can be attached and a computer having a predetermined calculation or analysis equation, it is possible to easily evaluate the customer skin sheen and beauty and perform simulation of the face state of a test subject after improvement of the skin state or makeup. Accordingly, the methods are also hopeful for promoting sale of cosmetics at the cosmetic counter of a department store, or at a cosmetic store or a drug store.

Owner:KOBAYASHI KOSE CO LTD

Semiconductor light source apparatus and lighting unit

ActiveUS20120230007A1Efficient entryEfficiently wavelength-convertedLighting applicationsMechanical apparatusPhosphorMirror reflection

A semiconductor light source apparatus can emit various color lights having a substantially uniform color tone and high brightness. The semiconductor light source apparatus can include a radiating substrate, at least one phosphor layer disposed on the radiating substrate and a semiconductor light source emitting blue light. The at least one phosphor layer can be composed of at least one of a glass phosphor and a phosphor ceramic. The light source can be located adjacent the phosphor layer so that the blue light having high brightness can be efficiently reflected on the radiating substrate via the phosphor layer while preventing the blue light from a mirror reflection on the phosphor layer. Thus, the disclosed subject matter can provide a semiconductor light source apparatus that can emit various uniform color lights having high brightness and a lighting unit using the light source apparatus, which can be used for general lighting, vehicle lighting etc.

Owner:STANLEY ELECTRIC CO LTD

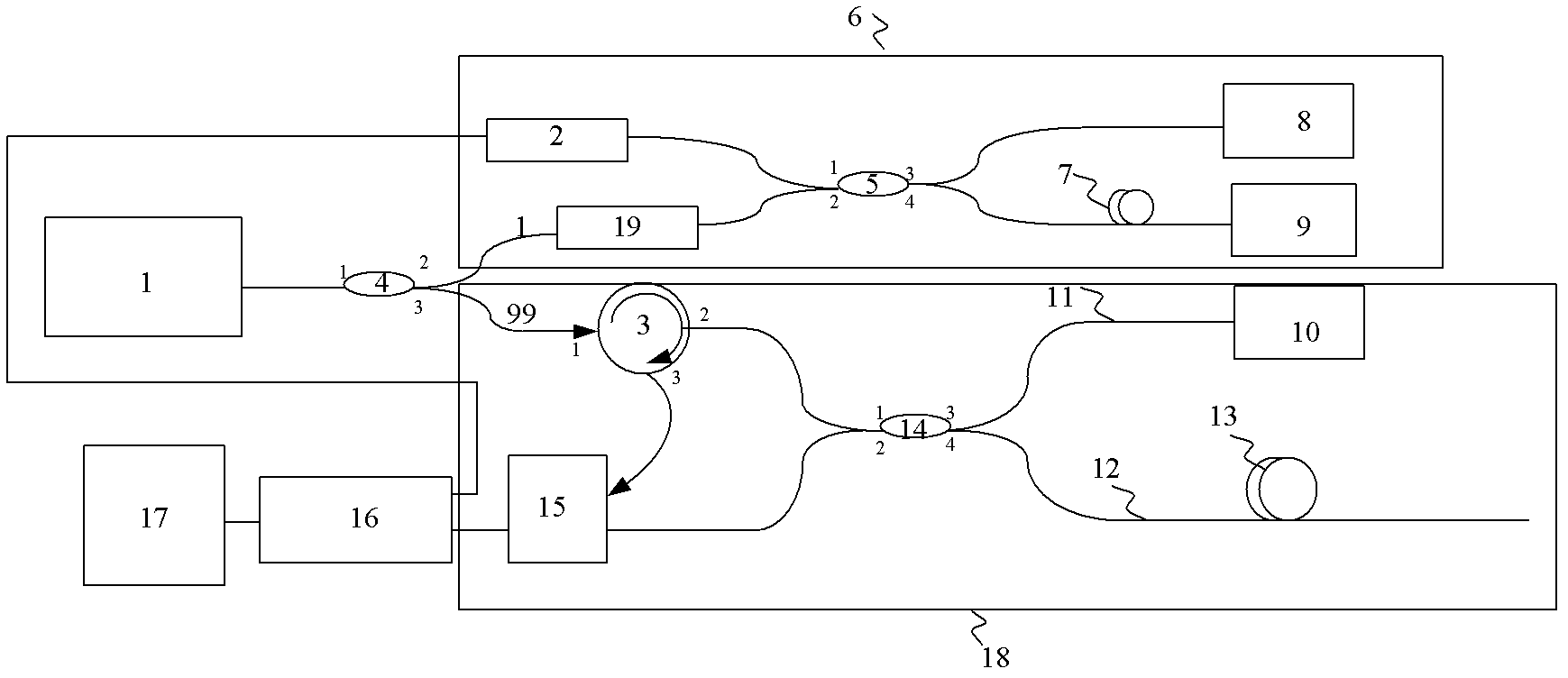

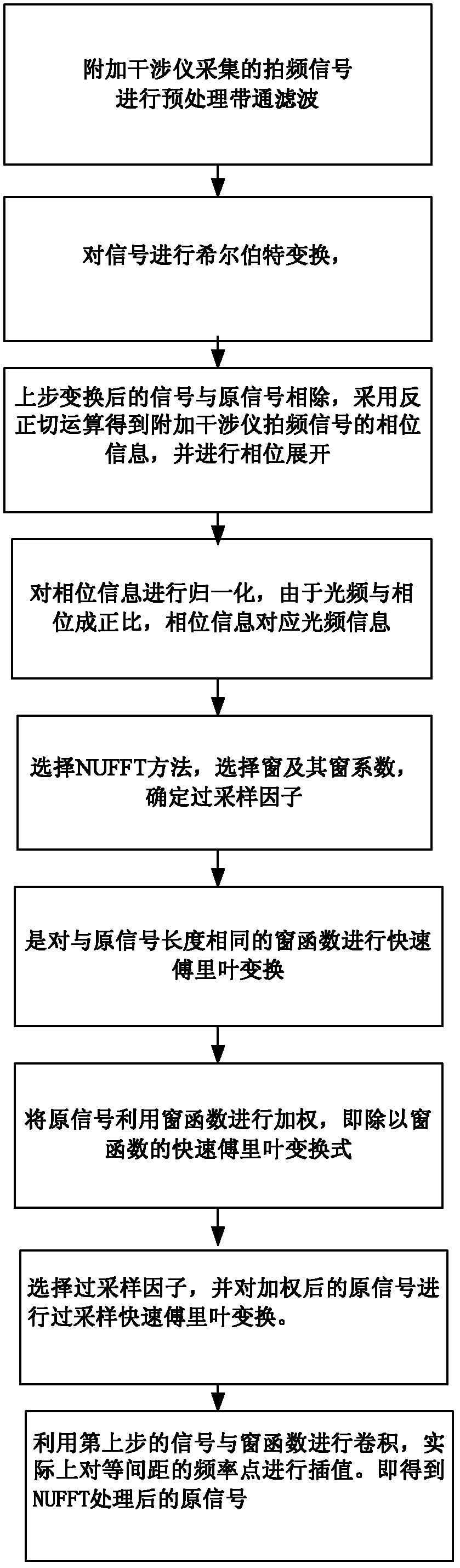

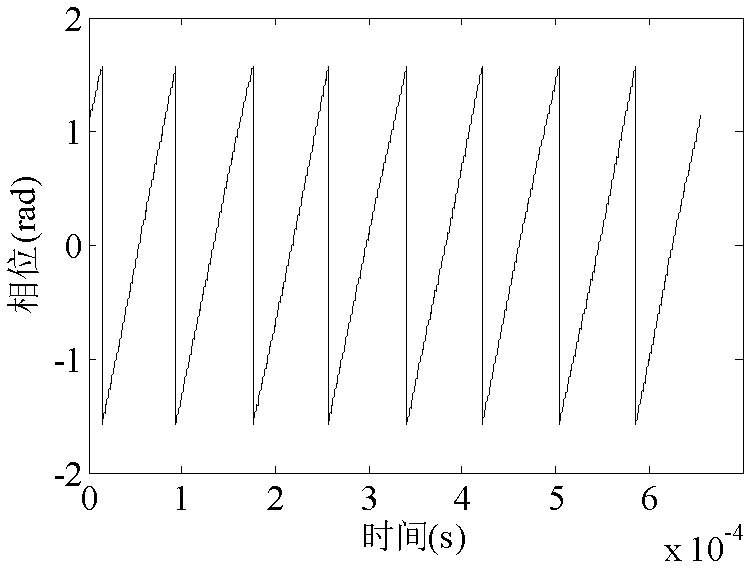

Device and method for inhibiting nonlinear scanning of laser of optical frequency domain reflectometer

ActiveCN102420650AImprove spatial resolutionLower requirementElectromagnetic transmissionFast Fourier transformSignal-to-noise ratio (imaging)

The invention relates to a device and a method for inhibiting the nonlinear scanning of a laser of an optical frequency domain reflectometer. The device mainly comprises a main interferometer and an additional interferometer, wherein the additional interferometer adopts dual-Faraday rotation mirror reflection for inhibiting the polarization fading phenomenon in the interferometers. A balanced detection technology is adopted in the main interferometer for inhibiting the common-mode noise of a system, and the signal-to-noise ratio of the system is improved by above 3dB. In the method, a Hilbert algorithm is adopted for beat frequency interference signals of the additional interferometer so as to extract optical frequency information, and a non-uniform fast Fourier transform (NUFFT) technology is further utilized for processing beat frequency information of the main interferometer so as to achieve the effect of inhibiting the optical frequency non-linear scanning, reduce the reflection peak by above 300 times and improve the spatial resolution of the optical frequency domain reflectometer.

Owner:TIANJIN UNIV

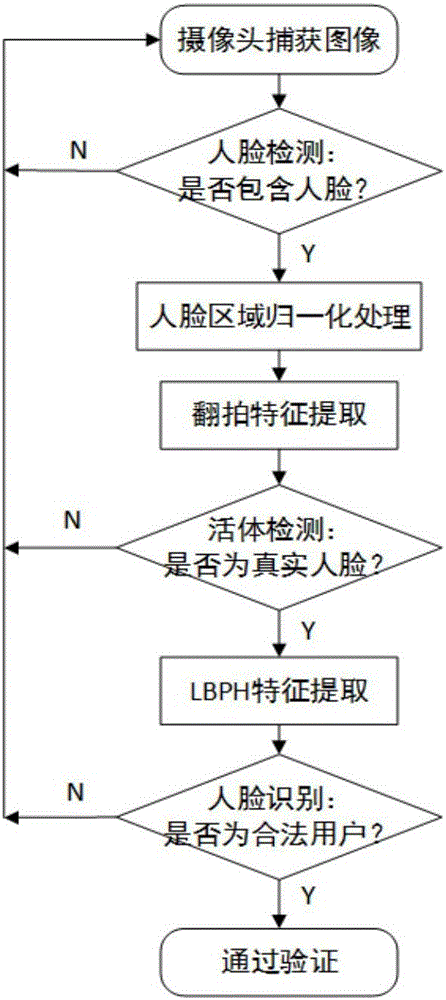

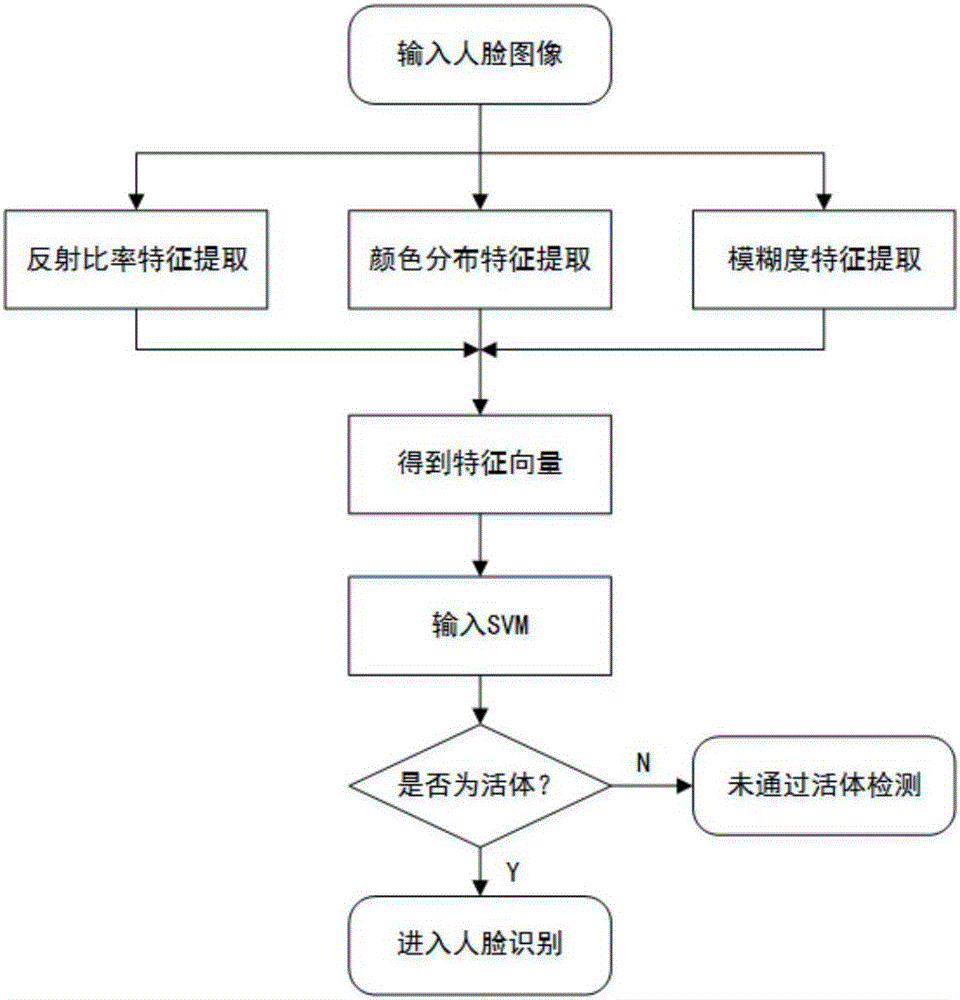

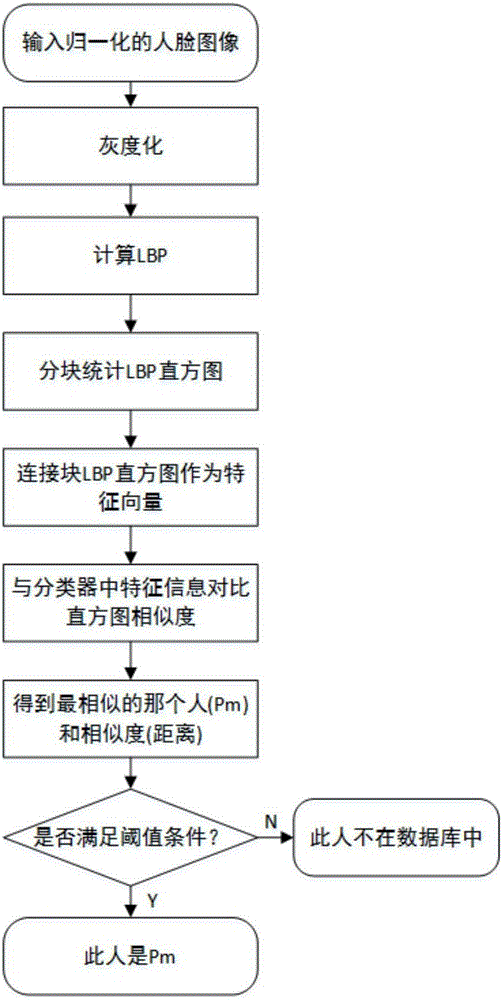

Face recognition method for identifying counterfeit photo deception

InactiveCN106650669ANot vulnerable to targeted attacksImprove robustnessSpoof detectionColor imageMirror reflection

Owner:CHONGQING UNIV OF POSTS & TELECOMM

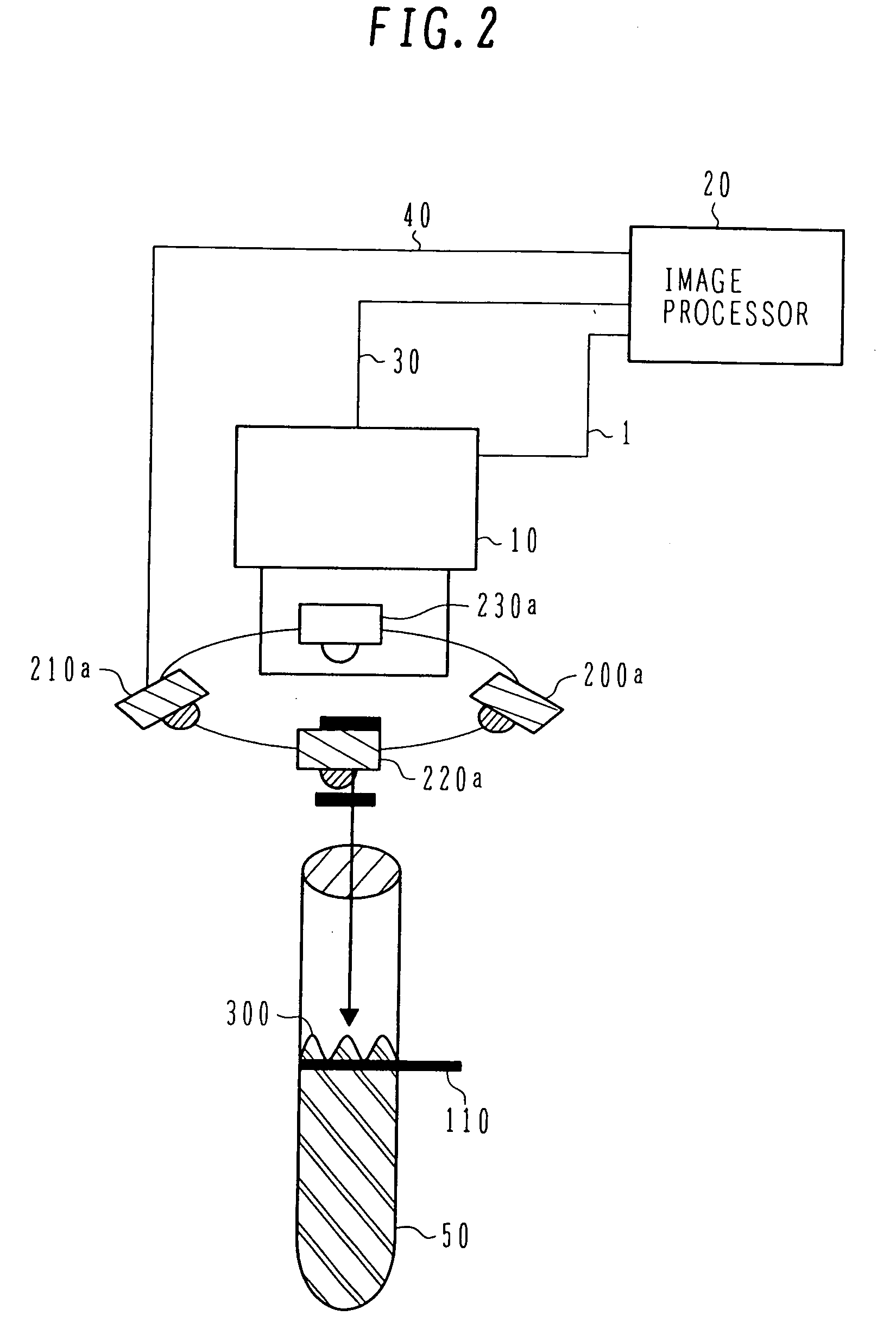

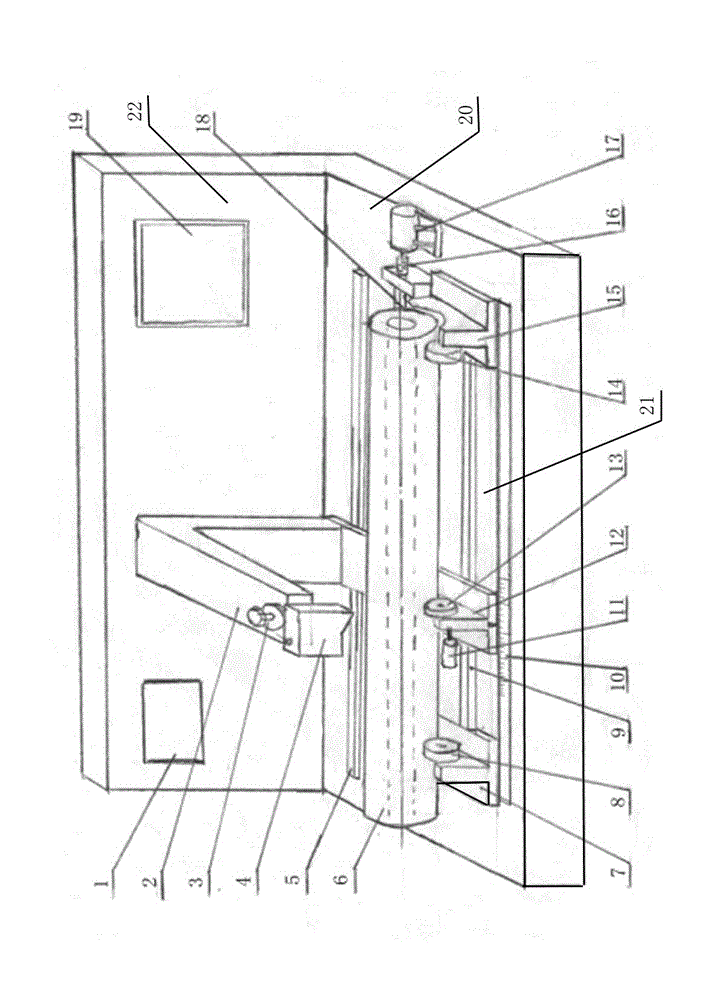

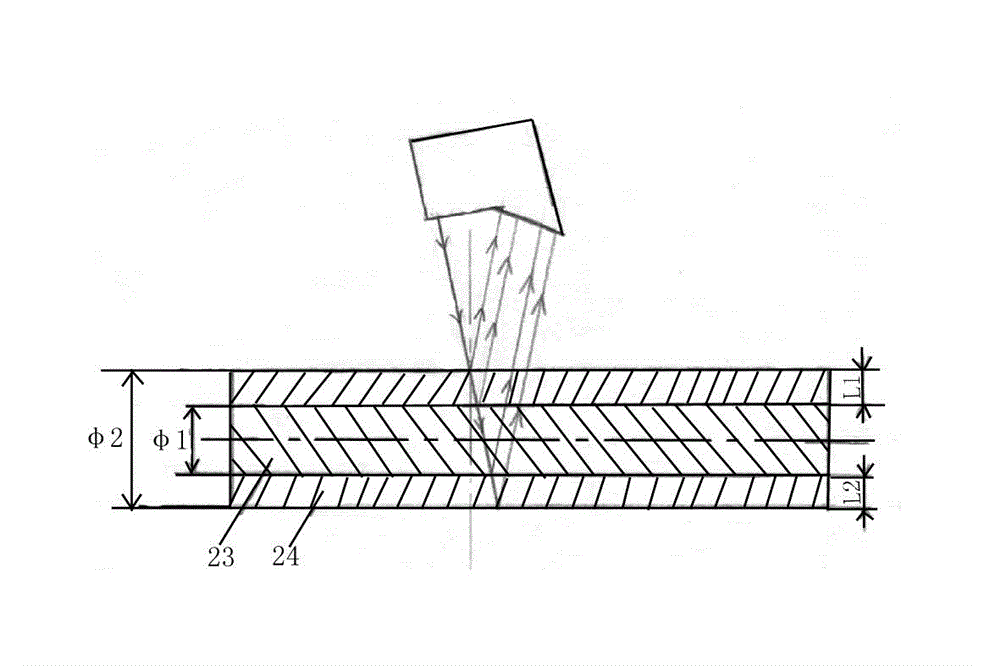

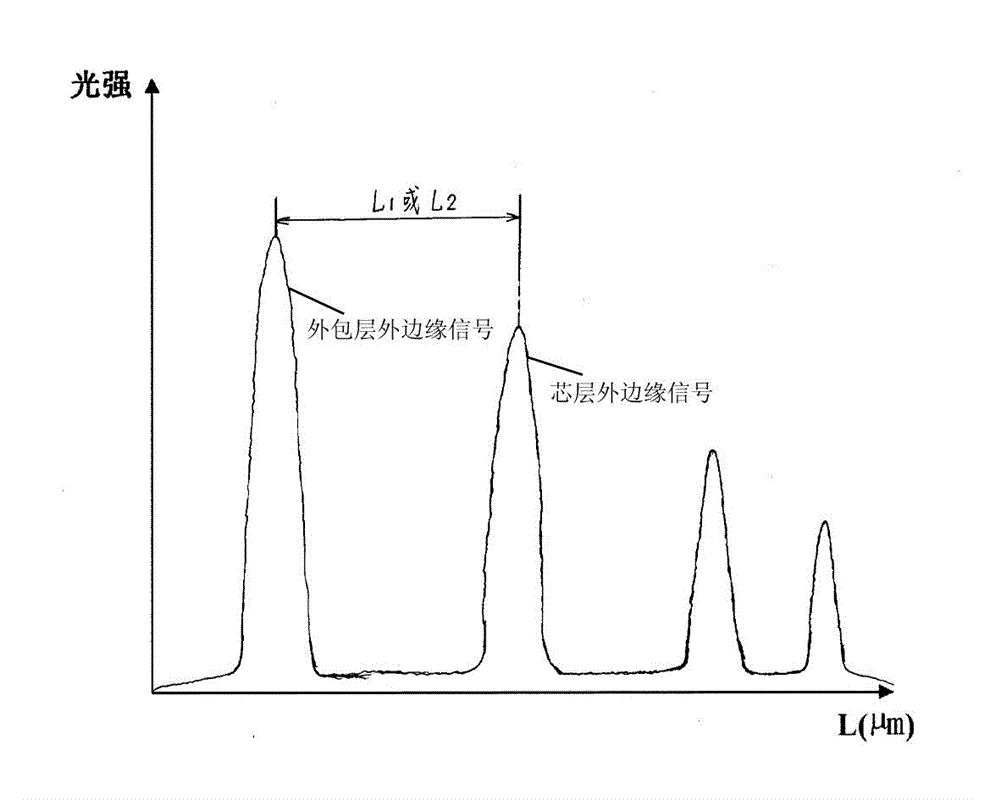

Measuring equipment and measuring method for eccentricity ratios of large-diameter preform

ActiveCN102878955AStrong adaptability to specification changesSimple structureUsing optical meansData displayMirror reflection

The invention discloses measuring equipment and a measuring method for eccentricity ratios of a large-diameter preform, belongs to the field of manufacture of optical fiber preforms, and relates to equipment and methods for measuring eccentricity ratios of preforms by mirror reflection measurement. The measuring equipment comprises a measuring table, a sliding table, a measuring table back plate, a detected data display screen, a data output display screen, a laser transmitting and receiving instrument support, an adjusting knob, a laser transmitting and receiving instrument, a rear linear guide rail, a left fixed roller bracket, a left support roller, a front linear guide rail, a graduated scale, a rotating motor, a moving bracket, a preform supporting rotating roller, a right fixed roller bracket, a right support roller, a left-right moving motor and a left-right moving lead screw. The measuring method includes steps of placing the preform on the left support roller and the right support roller on the left fixed roller bracket and the right fixed roller bracket, testing the surface of a body of the preform by the laser transmitting and receiving instrument in real time, recording data, collecting data of eccentricity ratios of various circumferential points around a first measuring point, computing an eccentricity ratio of the first measuring point by an eccentricity ratio computational formula; and measuring eccentricity ratio of a second measuring point.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

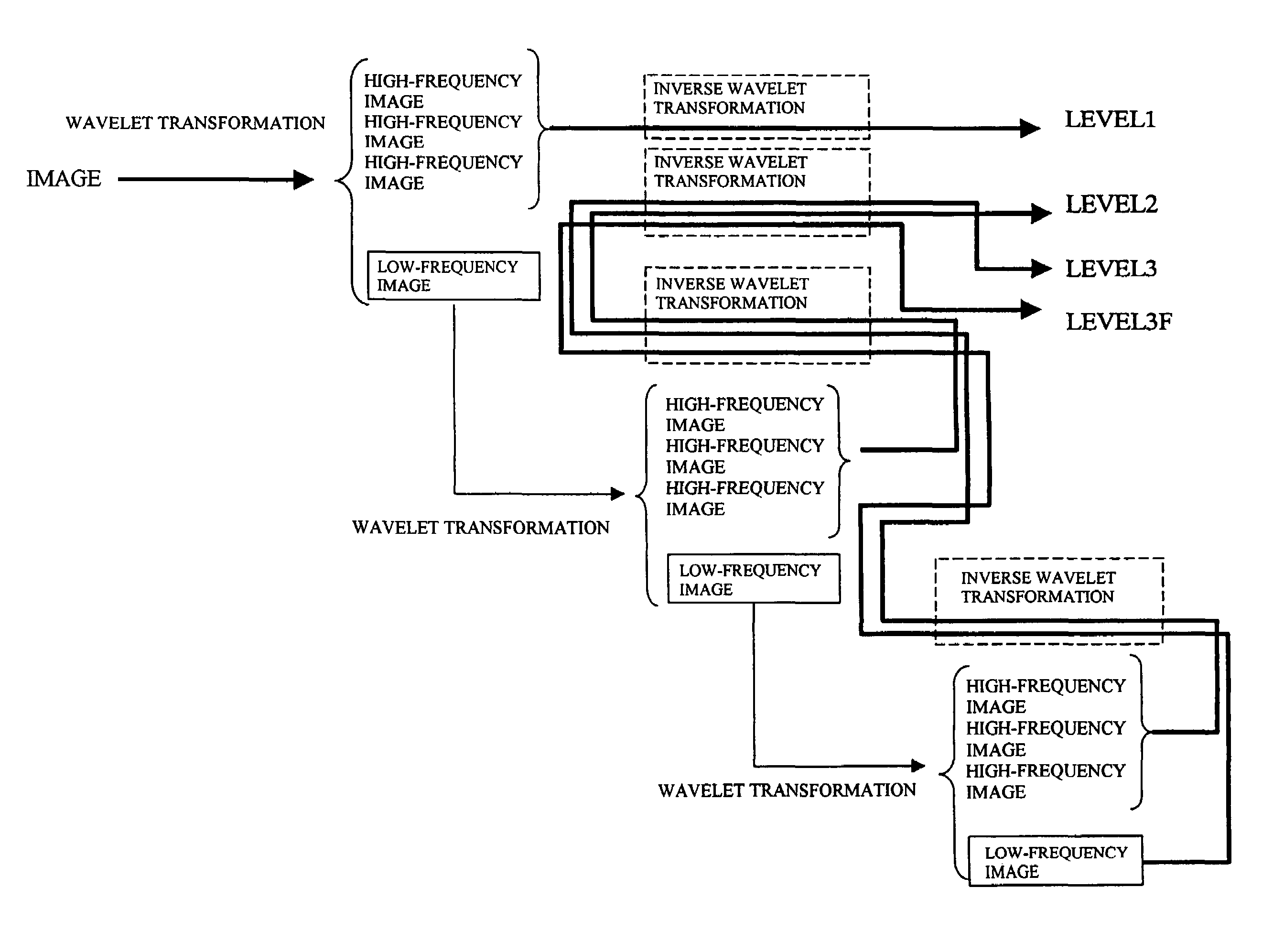

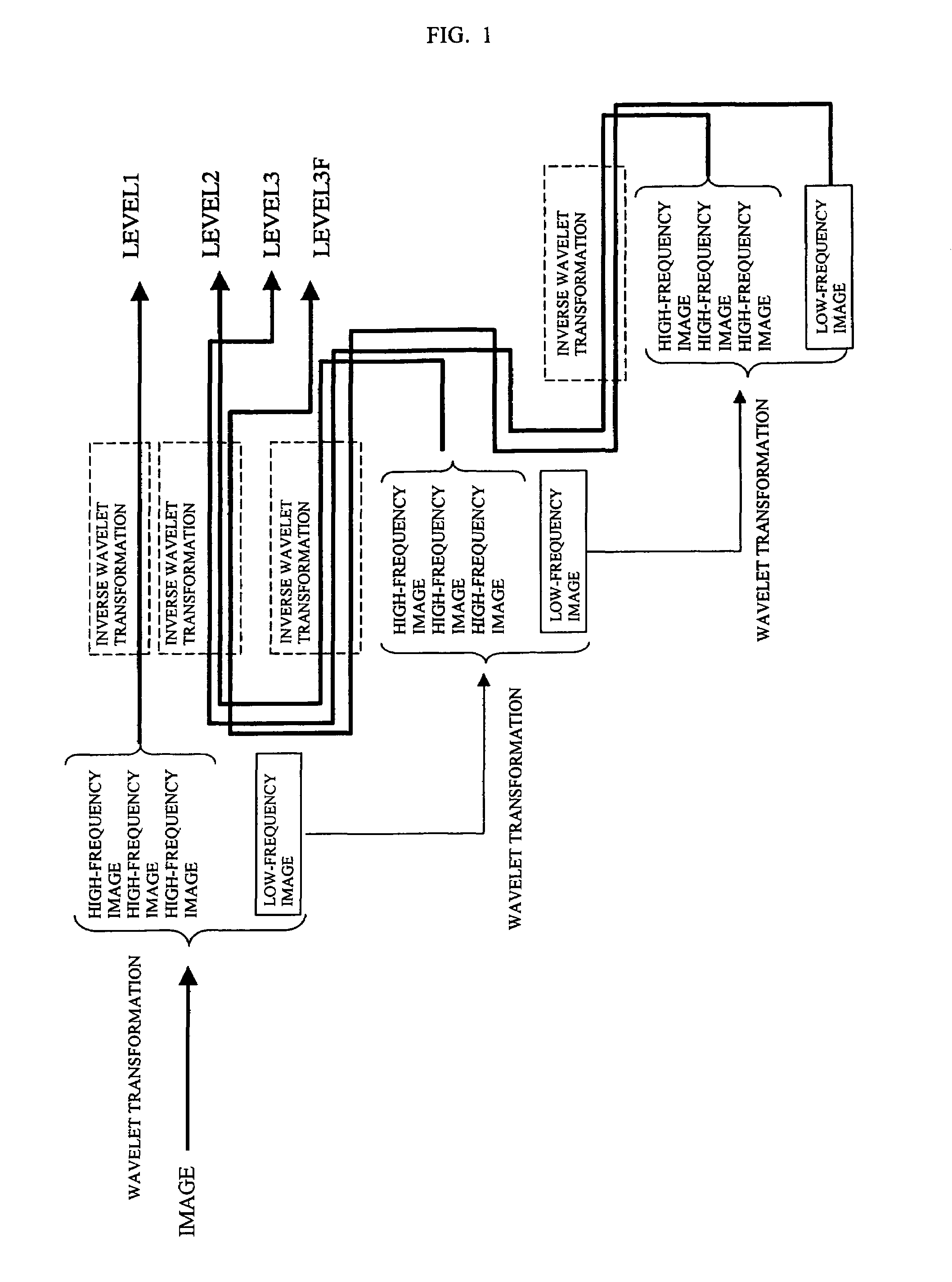

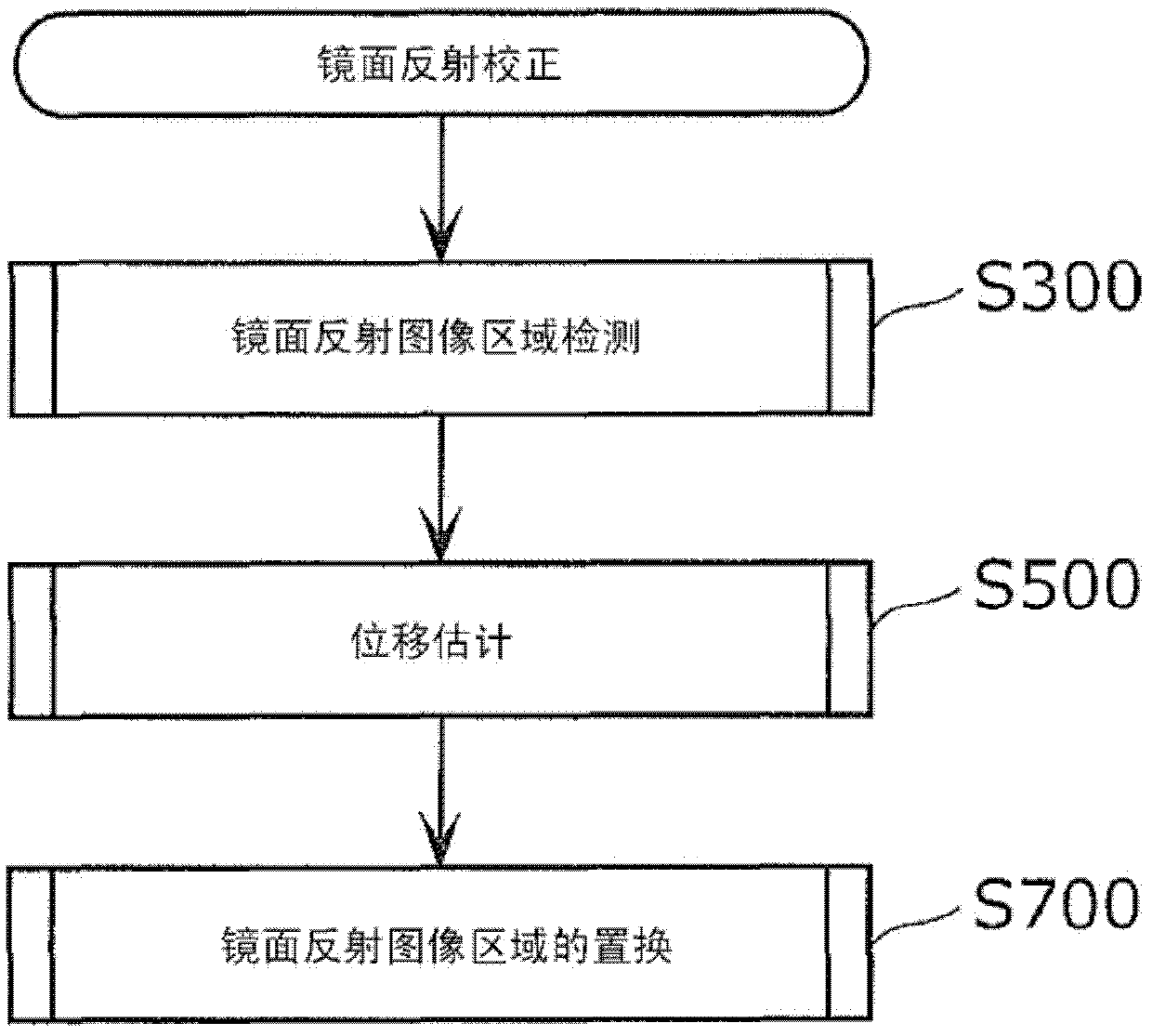

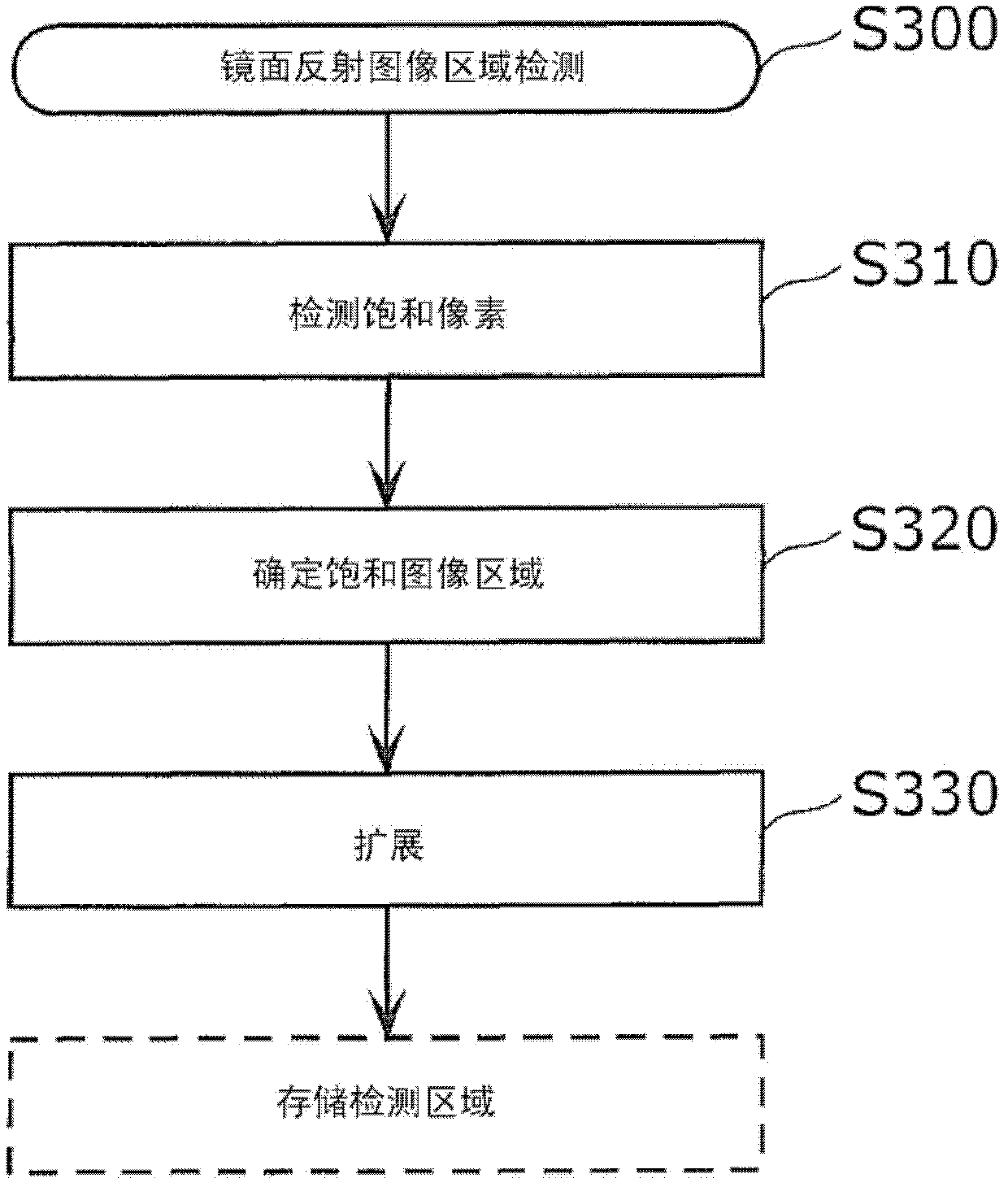

Image processing method and image processing device

An image processing method and an image processing device. The image processing device includes: a specular reflection detector (1110) for detecting, in the first image, an enlarged area including a saturated area and an adjacent area, where the saturated area is a pixel area with a pixel value equal to or greater than a predetermined threshold, and the adjacent area is at least partially an area surrounding the saturated area; and a replacement unit (1130) for using the enlargement in the second image for pixel values of pixels included in at least an adjacent area of the enlarged area detected by the specular reflection detector (1110) The pixel value of the pixel at the corresponding position of the region or the pixel value of the adjacent pixel at the corresponding position is replaced.

Owner:PANASONIC CORP

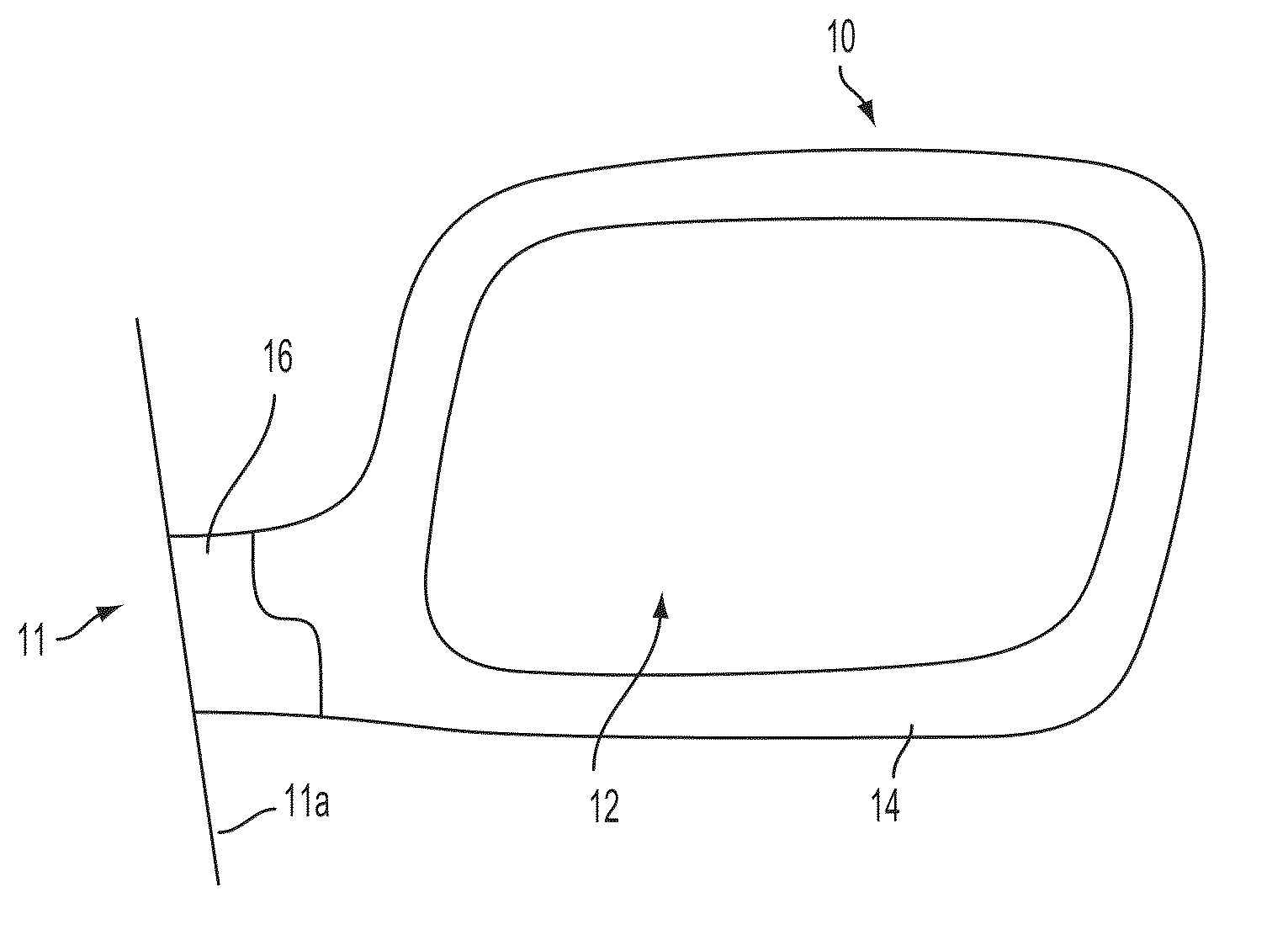

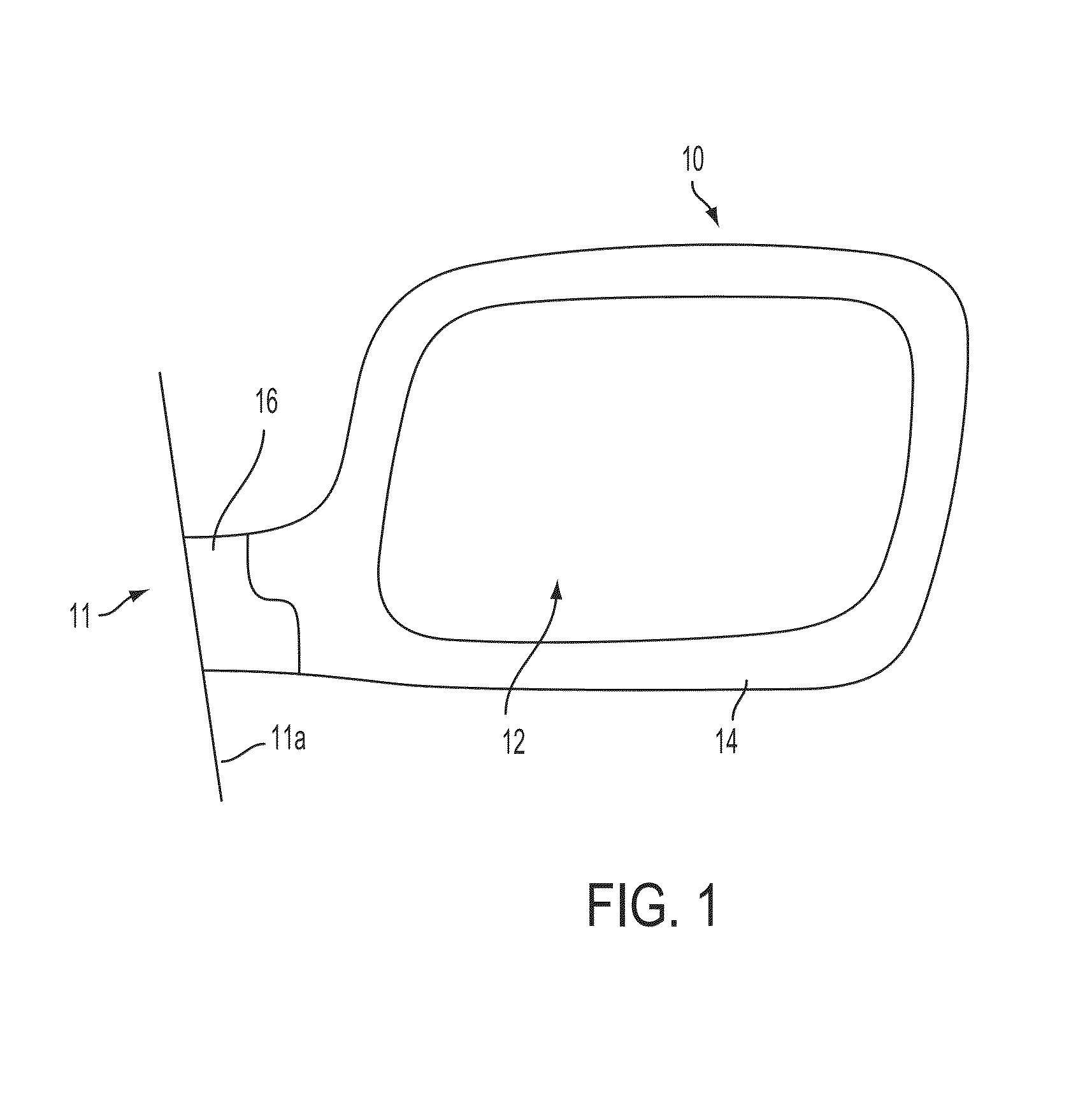

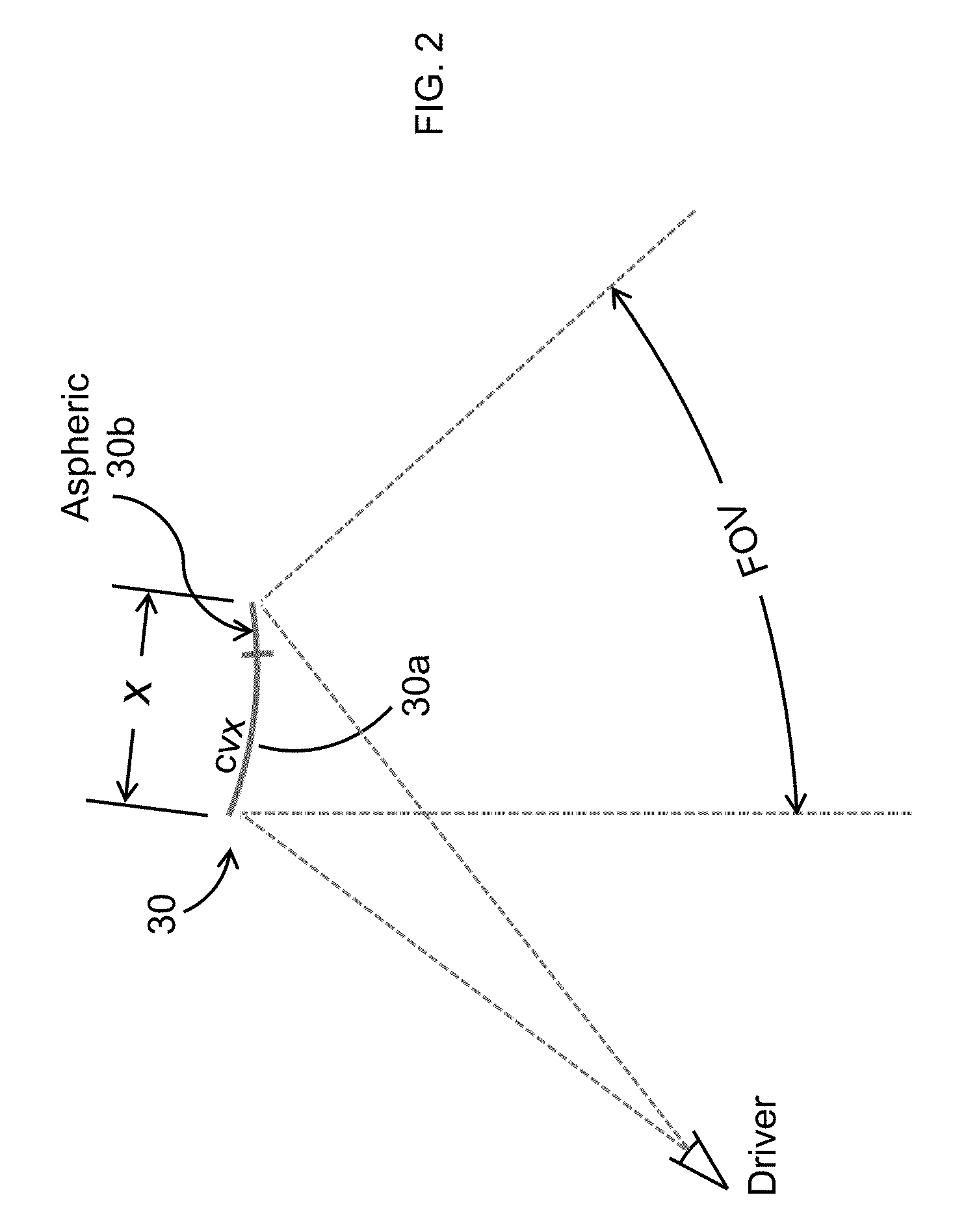

Mirror assembly with formed reflective element substrate

An exterior rearview mirror assembly for a vehicle includes a mirror head portion and a reflective element accommodated by the mirror head portion. The reflective element includes a glass substrate and a mirror reflector coated at a surface of the glass substrate. The reflective element is configured to provide a field of view of at least about 15 degrees at the side of the vehicle and provides a substantially undistorted reflected image as viewed by the driver of the vehicle. The reflective element may have a width dimension of less than about 15 cm and a height dimension of less than about 9 cm. The mirror substrate is curved or formed via a hydro-bending process utilizing at least one bending element, which may be CNC formed in accordance with a free form pattern of curvatures.

Owner:MAGNA MIRRORS OF AMERICA INC

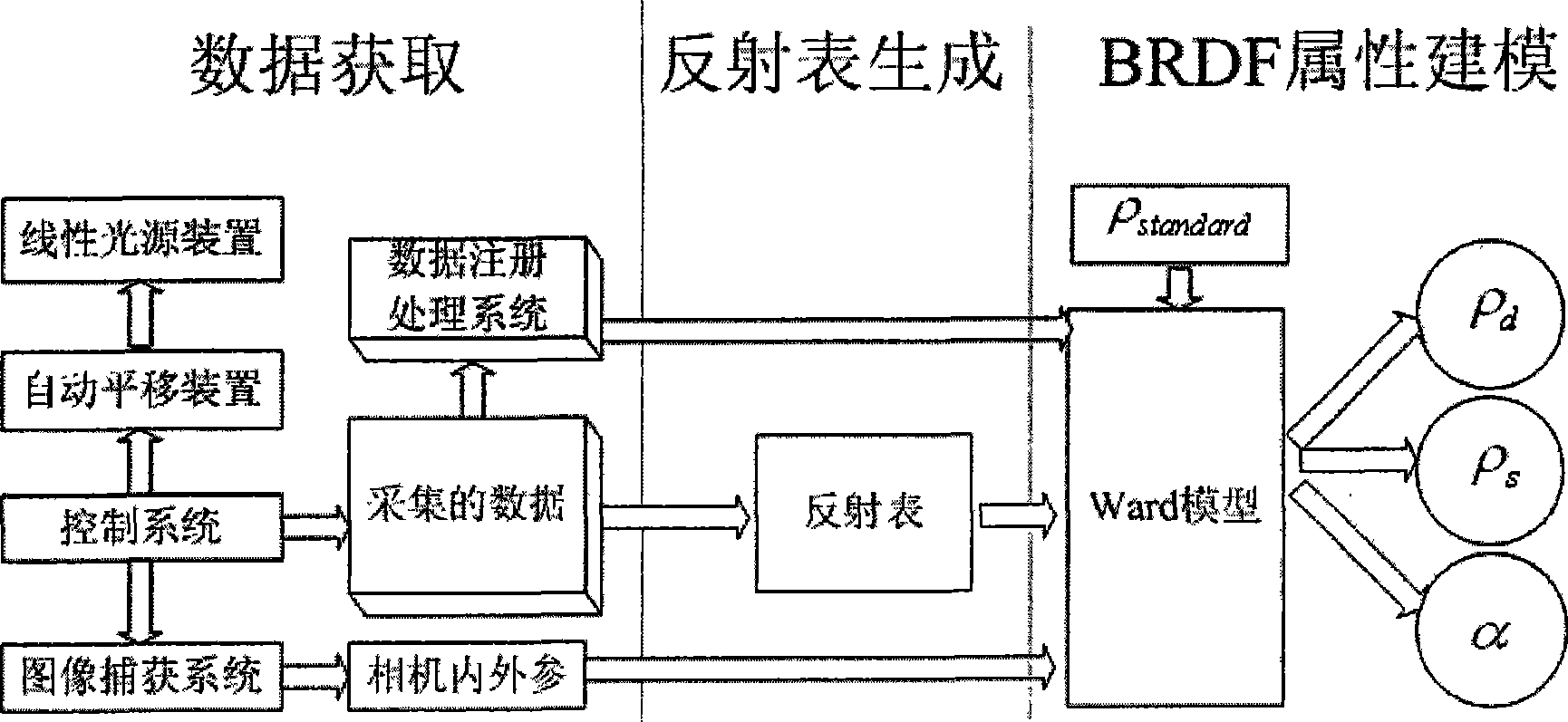

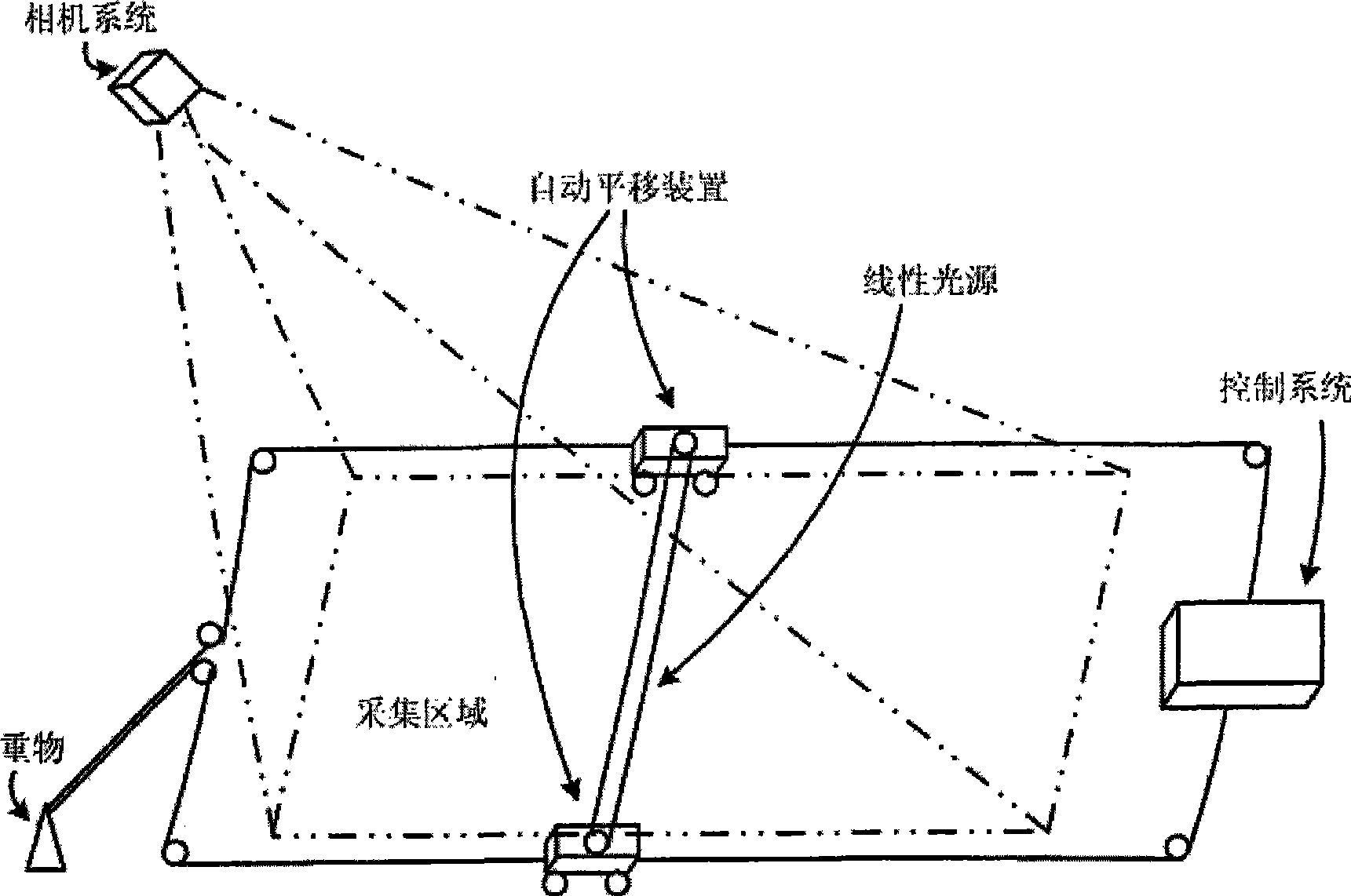

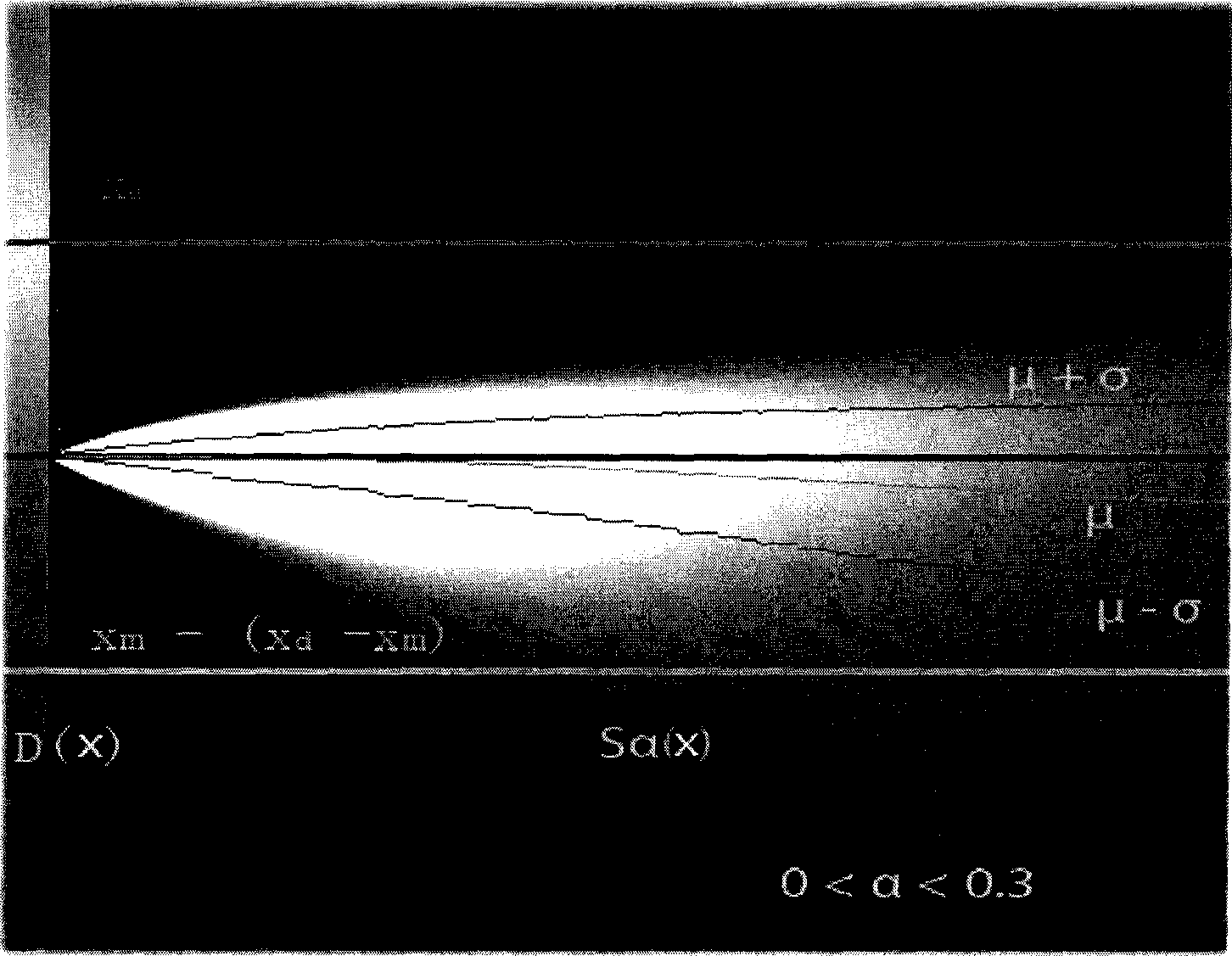

True object material quality reflecting attribute modeling approach based on linear light

A method for modeling a reflection attribute of a real object material based on a linear light source comprises the following steps: (1) a data collection device based on the linear light source collects and process data; the linear light source is taken as a light source system of the data collection device; the linear light emitted by the linear light source shines a collected plane object, a control system drives an automatic translation system to move forwards; meanwhile, an industrial camera collects images of the collected plane object, a computer performs subsequent processing of the collected image data to obtain a trajectory curve of pixel values and store the trajectory curve; (2) a reflection table is generated; (3) BRDF attribute is modeled to obtain rhod of a Ward illumination model, and then obtain alpha, and finally obtain rhos according to the trajectory curve of the pixel values obtained in the step (1) and the reflection generated in the step (2), wherein, the rhod is a diffuse reflection parameter, the rhos is a mirror reflection parameter and the alpha is a material roughness coefficient. The method can efficiently collect data and quickly solve the parameters of the BRDF model, and is easy to be realized.

Owner:BEIHANG UNIV

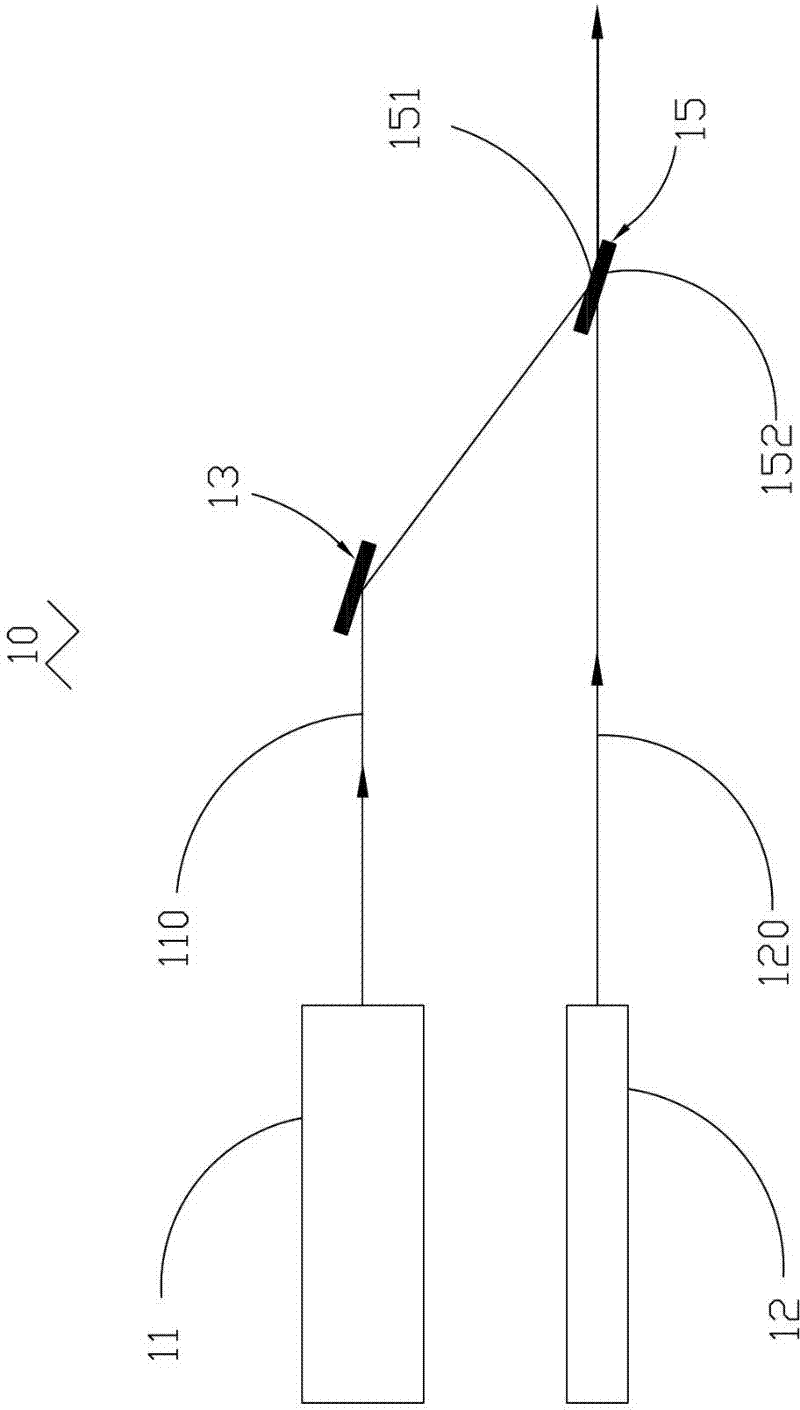

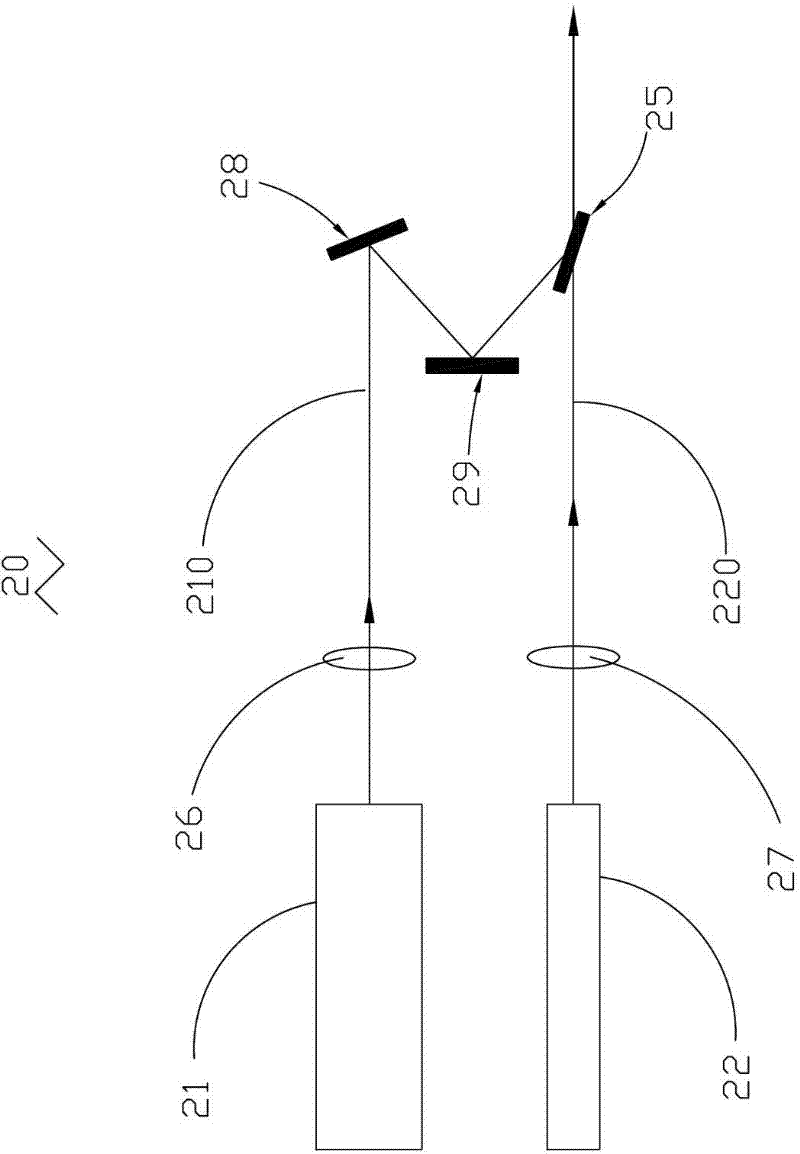

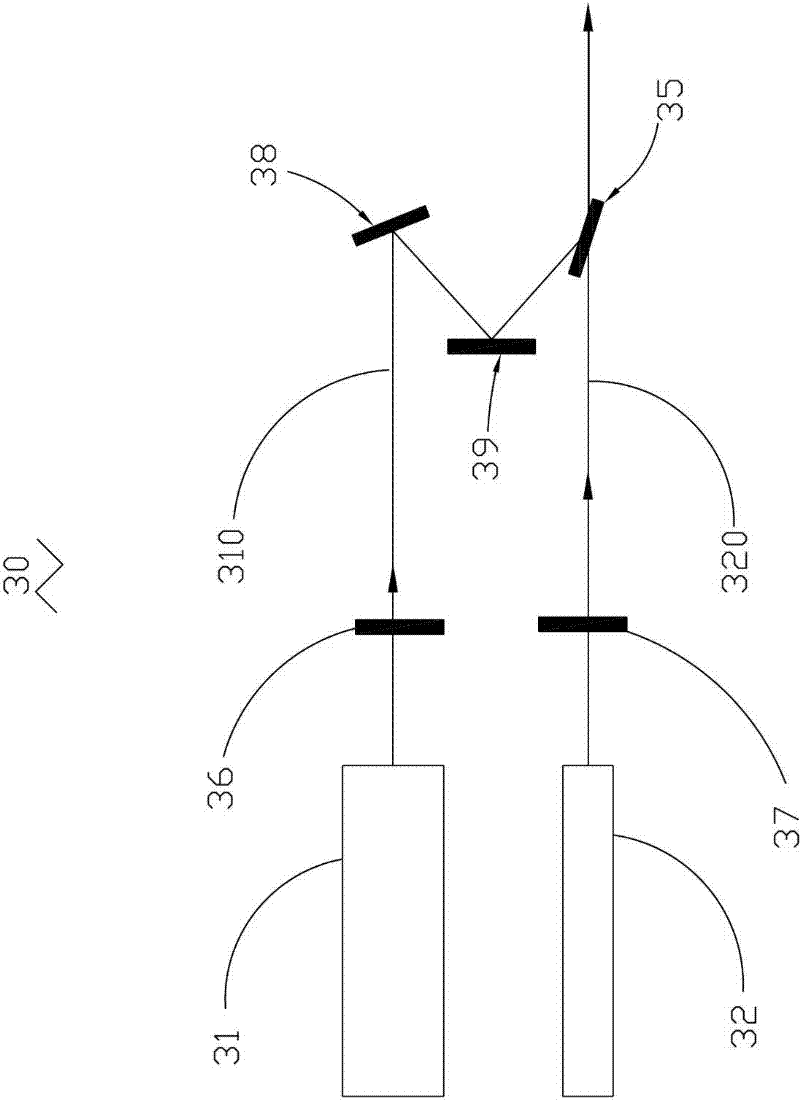

A laser beam combining system and a laser beam combining method

InactiveCN102289078AStable jobMeets high laser power requirementsOptical elementsLight beamOptoelectronics

The present invention provides a laser beam combining system, comprising a first laser, a second laser, a reflecting mirror, and a beam combining mirror, wherein the beam combining mirror is a thin film polarizer, the beam combining mirror includes a first mirror surface and a second mirror surface, and the first laser outputs A reflector is arranged on the center line of the optical path. After being reflected by the reflector, the laser beam output by the first laser is incident on the first mirror surface of the beam combiner and reflected by the mirror surface. The laser beam emitted by the second laser is at the Brewster angle. Incident to the beam combiner, after the laser beam emitted by the second laser is transmitted through the beam combiner, it overlaps with the laser beam reflected by the first mirror surface of the beam combiner to form a beam. The invention also discloses a laser beam combining method. The laser beam combining system of the present invention can combine laser beams emitted by lasers of the same type. The power of the combined output laser beam is twice that of the single beam laser power, which can meet the requirements of high laser power for processing and use under the premise of ensuring the stable operation of the laser.

Owner:HANS LASER TECH IND GRP CO LTD

Caseless rearview mirror assembly

An electro-optic rearview mirror assembly for a vehicle includes a caseless electro-optic rearview mirror reflective element and a plate attached at the rear of the reflective element. The mirror reflective element connected to and pivotal about a windshield electronics module via a ball and socket pivot joint. Control circuitry may be disposed in a windshield electronics module for automatically controlling dimming of the electro-optic medium or alternatively, dimming of the electro-optic medium is automatically controlled via a multifunctional rear backup camera system of the equipped vehicle. Optionally, the control circuitry controls dimming of the electro-optic medium of the mirror reflective element via wiring that passes through the ball and socket pivot joint. Optionally, image data captured by the multifunctional rear backup camera may be used for ambient light determination and to provide video image display at the interior rearview mirror assembly.

Owner:MAGNA MIRRORS OF AMERICA INC

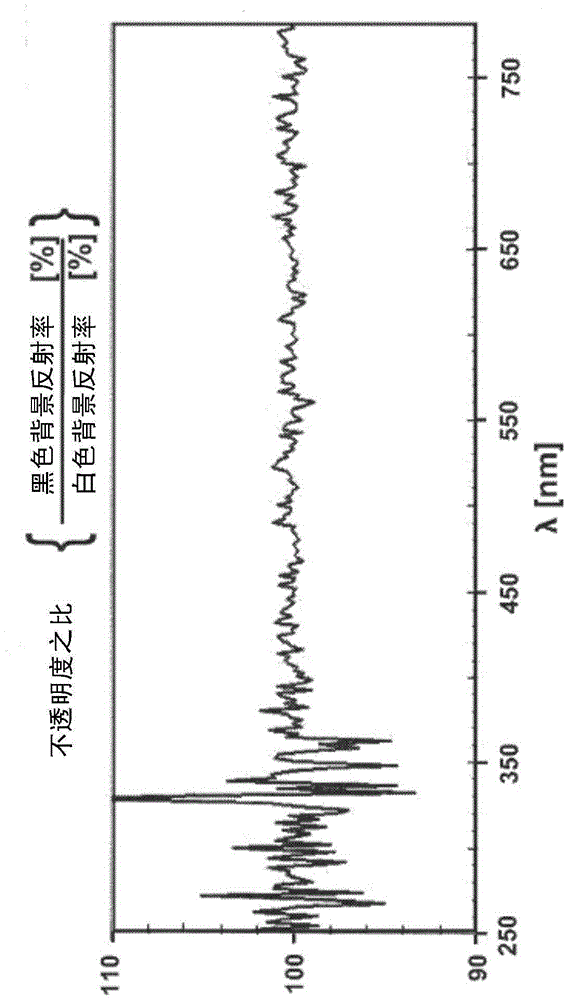

White, opaque, beta-spodumene/rutile glass-ceramics,articles comprising the same,and methods for making the same

Crystallizable glasses, glass-ceramics, IXable glass-ceramics, and IX glass-ceramics are disclosed. The glass-ceramics exhibit beta-spodumene ss as the predominant crystalline phase. These glasses and glass-ceramics, in mole %, include: 62-75 SiO2; 10.5-17 Al2O3; 5-13 Li3O; 0-4 ZnO; 0-8 MgO; 2-5 TiO2; 0-4 B2O3; 0-5 Na2O; 0-4 K2O; 0-2 ZrO2; 0-7 P2O5; 0-0.3 Fe2O3; 0-2 MnOx; and 0.05-0.2 SnO2. Additionally, these glasses and glass-ceramics exhibit the following criteria: a. a ratio: [ Li 2 O + Na 2 O + K 2 O + MgO + ZnO _ ] [ Al 2 O 3 + B 2 O 3 ] between 0.7 to 1.5; b. a ratio: [ TiO 2 + SnO 2 _ ] [ SiO 2 + B 2 O 3 ] greater than 0.04. Furthermore, the glass-ceramics exhibit an opacity >=about 85% over the wavelength range of 400-700 nm for an about 0.8 mm thickness and colors an observer angle of 10° and a CIE illuminant F02 determined with specular reflectance included of a* between -3 and +3, b* between -6 and +6, and L* between 88 and 97.

Owner:CORNING INC

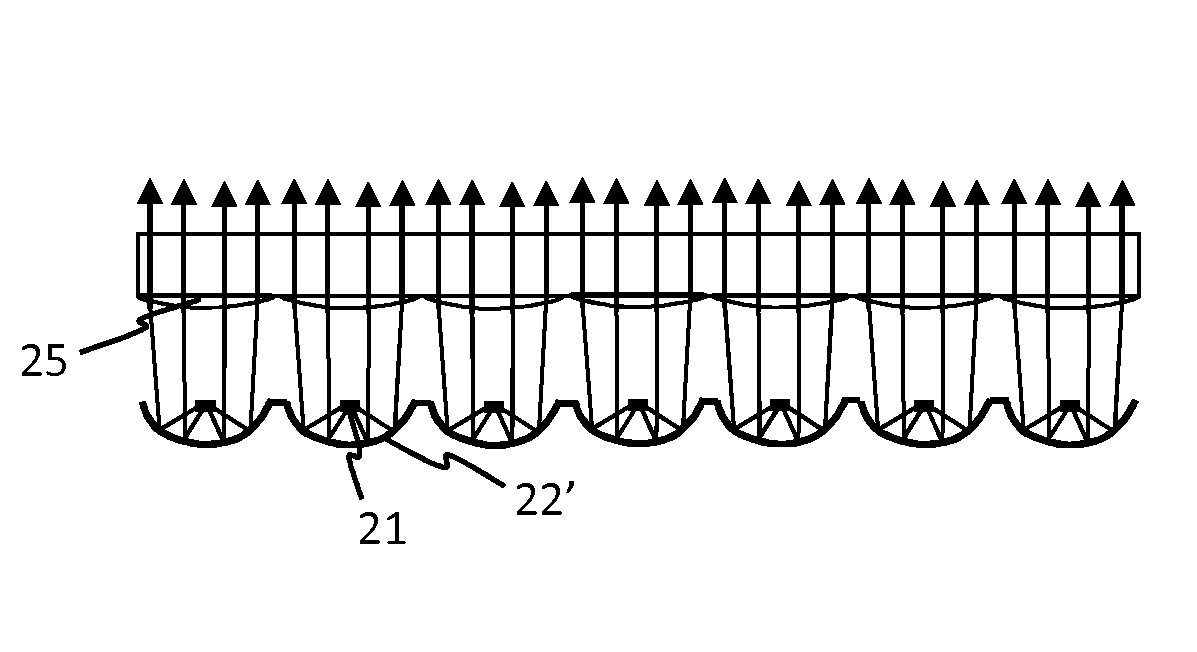

Backlight

A backlight is provided for an at least partially transmissive display or another lighting application. The backlight comprises an array of primary light sources that emit downwards towards an arrangement of curved mirror surfaces. The light reflected by the mirror surfaces is collimated by an arrangement of lenses. The mirror surface shape, lens shape, primary light source positions and the separation between the lens and mirror surfaces are chosen to ensure a high degree of spatial uniformity as well as collimation.

Owner:SHARP KK

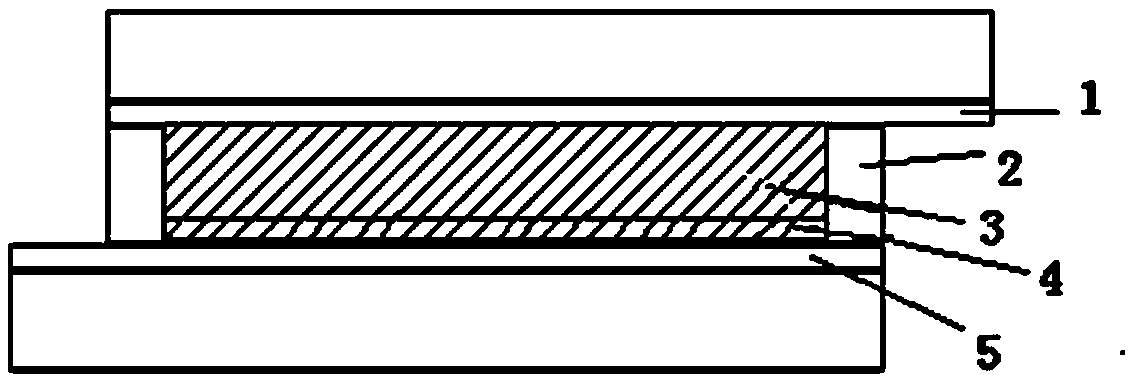

Mirror reflection type electrochromic device and preparation method thereof

InactiveCN103744246ASurface Roughness AdjustmentSurface Roughness ControlNon-linear opticsMirror reflectionSilver ion

The invention discloses a mirror reflection type electrochromic device and a preparation method thereof. The electrochromic device comprises transparent conducting glass, an insulating spacer, gel electrolyte, zinc oxide (ZnO) nanocrystallines and aluminum zinc oxide (AZO) transparent conducting glass. The preparation method comprises the following specific steps: directly growing the ZnO nanocrystallines on an AZO transparent glass electrode to form a coarse surface; uniformly mixing silver ion inorganic salt, bromide or iodide salt, auxiliary conducting ion inorganic salt and high-molecular polymer in organic solvent to from the transparent, stable and uniform gel electrolyte; using an encapsulating material to encapsulate the gel electrolyte between the transparent conducting glass with smooth surface and the AZO transparent conducting glass with coarse surface. The mirror reflection type electrochromic device has the advantages of simple technology and low cost, and large-area dimming devices with high reflectance, high transmittance and quick response capacity can be assembled.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com