Patents

Literature

793 results about "Spodumene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spodumene is a pyroxene mineral consisting of lithium aluminium inosilicate, LiAl(SiO₃)₂, and is a source of lithium. It occurs as colorless to yellowish, purplish, or lilac kunzite (see below), yellowish-green or emerald-green hiddenite, prismatic crystals, often of great size. Single crystals of 14.3 m (47 ft) in size are reported from the Black Hills of South Dakota, United States.

Glass-ceramic materials, precursor glass thereof and process-for making the same

The present invention relates to: novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and ithium alumino-silicate glasses, which are precursors of said novel glass-ceramics; methods of preparing said novel glass-ceramics and articles made from said novel glass-ceramics. The present invention relates to the use of SnO2 and of Br, as an agent for fining the glass-ceramic glass precursor.

Owner:EUROKERA SOC & NOM COLLECTIF

Glass-ceramic materials, precursor glass thereof and process for making the same

The invention relates to: a method of preparing glass-ceramics of β-quartz and / or of β-spodumene; a method of preparing articles made from said glass-ceramics; novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and lithium aluminosilicate glasses, which are precursors of such novel glass-ceramics. The present invention relates to the use, as agent for fining the glass-ceramic glass precursor, of fluorine and at least one oxide of a multivalent element.

Owner:EUROKERA SOC & NOM COLLECTIF

Beta-spodumene glass-ceramic materials and process for making the same

InactiveUS7476633B2Increase brightnessReduce the temperatureGlass tempering apparatusSolid solutionGlass-ceramic

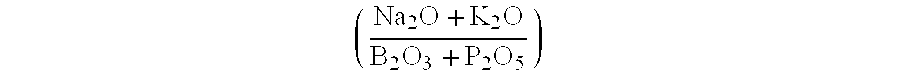

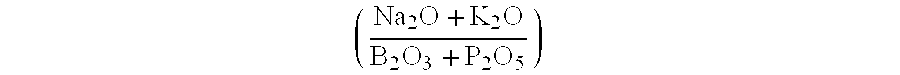

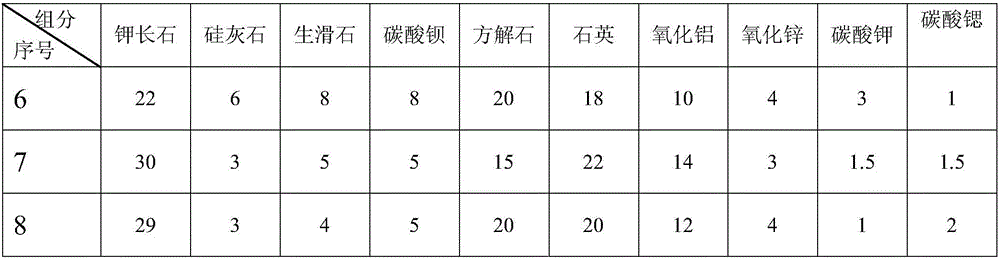

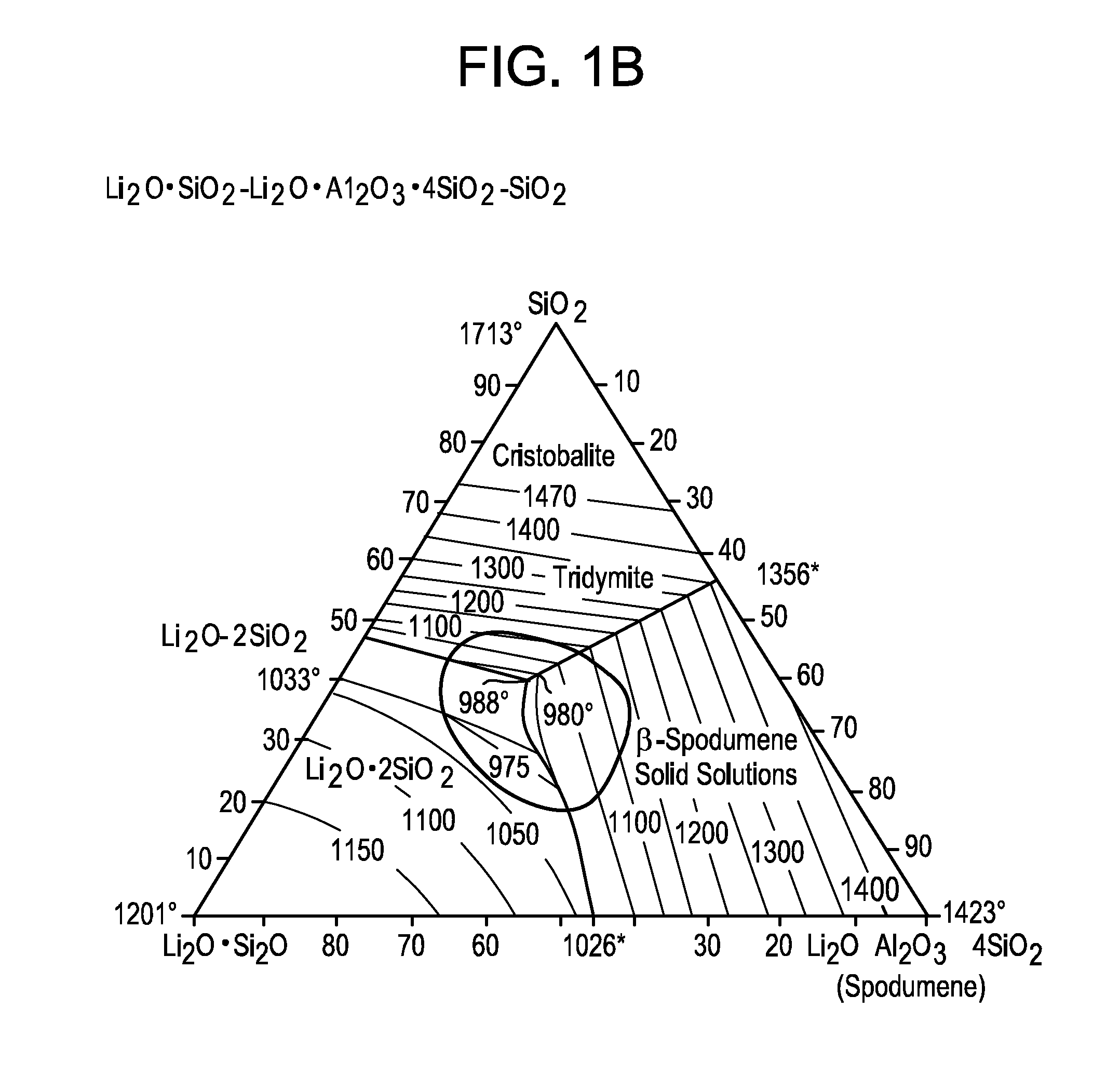

The present invention relates to glass-ceramic materials, processes for making the same and articles comprising the same. The glass-ceramic material has a composition, by weight of the total composition, comprising 55-68% SiO2; 18-24% Al2O3; 3.3-4.1% Li2O; 1.5-4.0% ZnO; 1.5-5.0% MgO; 2-5% TiO2; 0-2% ZrO2; 0-5% B2O3; 0-8% P2O5; 0-2% Na2O, 0-2% K2O; and at least one component resulting from an effective amount of at least one fining agent; wherein: the total of B2O3 and P2O5 is at least 1.5% by weight, the total of MgO and ZnO is at least about 3.5% by weight, the total of Na2O and K2O is less than about 3.0% by weight, the total of P2O5, B2O3, Na2O and K2O is less than about 11% by weight, the weight ratio of the sum total of Na2O+K2O to the sum total of P2O5+B2O3 (Na2O+K2OB2O3+P2O5)is less than about 0.5; advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 9% by weight and the total of Na2O ad K2O is less than about 2% by weight; and more advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 7% by weight and the total of Na2O ad K2O is less than about 1% by weight. The glass-ceramic material comprises β-spodumene solid solution as the predominant crystalline phase.

Owner:EUROKERA SOC & NOM COLLECTIF

B-spodumene glass-ceramic materials and process for making the same

InactiveUS20070213192A1Reduce the temperatureShort durationGlass tempering apparatusSolid solutionGlass-ceramic

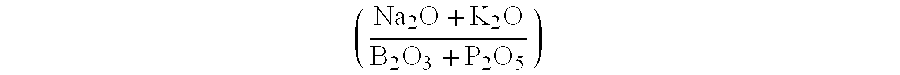

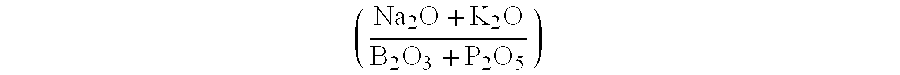

The present invention relates to glass-ceramic materials, processes for making the same and articles comprising the same. The glass-ceramic material has a composition, by weight of the total composition, comprising 55-68% SiO2; 18-24% Al2O3; 3.3-4.1% Li2O; 1.5-4.0% ZnO; 1.5-5.0% MgO; 2-5% TiO2; 0-2% ZrO2; 0-5% B2O3; 0-8% P2O5; 0-2% Na2O, 0-2% K2O; and at least one component resulting from an effective amount of at least one fining agent; wherein: the total of B2O3 and P2O5 is at least 1.5% by weight, the total of MgO and ZnO is at least about 3.5% by weight, the total of Na2O and K2O is less than about 3.0% by weight, the total of P2O5, B2O3, Na2O and K2O is less than about 11% by weight, the weight ratio of the sum total of Na2O+K2O to the sum total of P2O5+B2O3 (Na2O+K2OB2O3+P2O5)is less than about 0.5; advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 9% by weight and the total of Na2O ad K2O is less than about 2% by weight; and more advantageously the total of P2O5, B2O3, Na2O and K2O is less than about 7% by weight and the total of Na2O ad K2O is less than about 1% by weight. The glass-ceramic material comprises β-spodumene solid solution as the predominant crystalline phase.

Owner:EUROKERA SOC & NOM COLLECTIF

Method for extracting lithium salt from spodumene

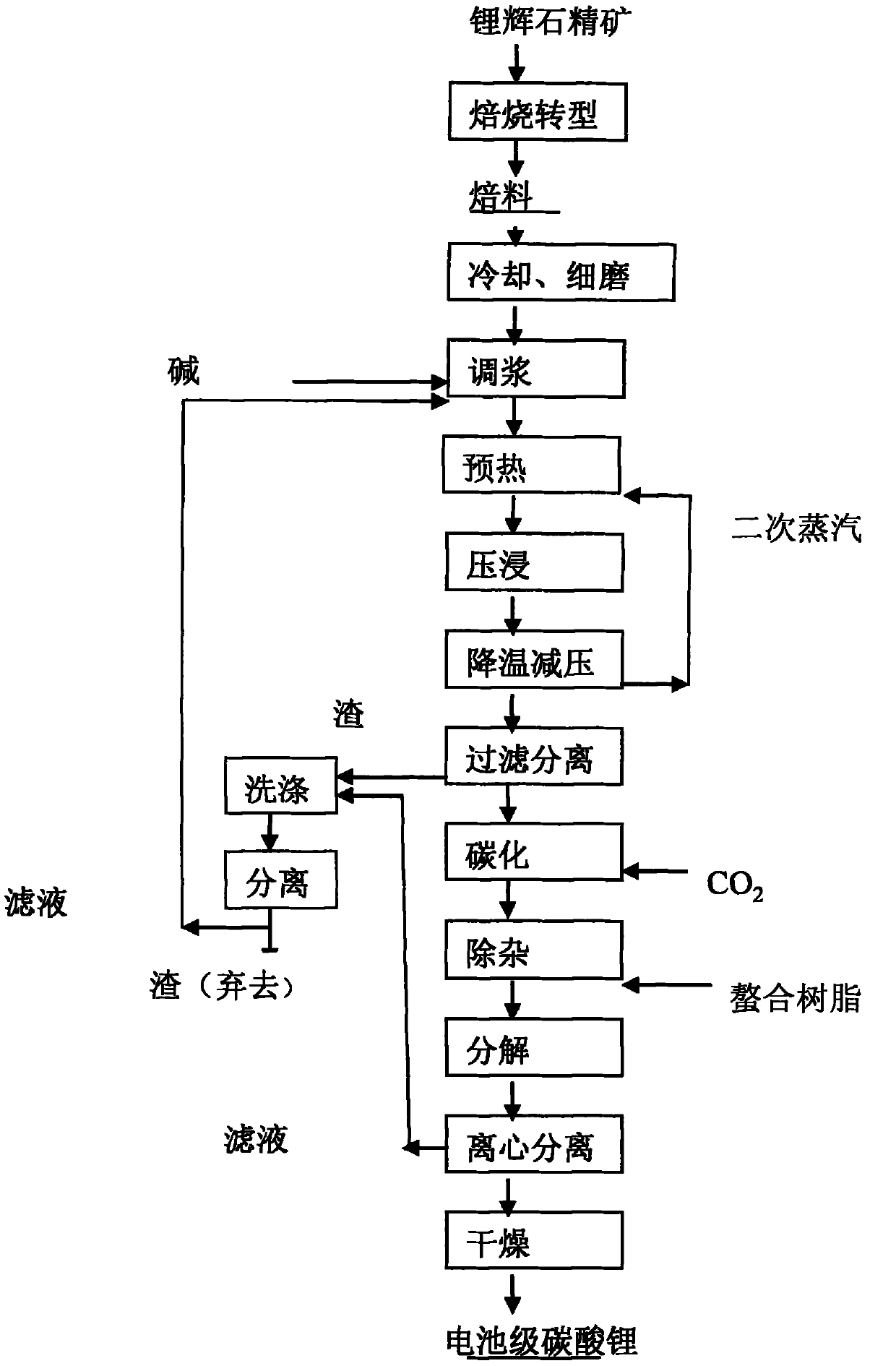

ActiveCN101948124ASimple processReduce manufacturing costProcess efficiency improvementLithium carbonates/bicarbonatesSocial benefitsResource utilization

Owner:GANFENG LITHIUM CO LTD

Coating for lost foam cast iron

InactiveCN101569918AStrong ability to absorb EPSExempt from cleanupFoundry mouldsFoundry coresSodium BentoniteHigh surface

The invention belongs to the technical field of coatings for lost foam, in particular to a coating for lost foam cast iron. The invention provides the coating for the lost foam cast iron, which comprises the following components (calculated as the weight): 70 portions of bauxite, 30 portions of quartz powder, 2 to 5 portions of bentonite, 0.5 to 2 portions of white latex, 0.5 to 1.0 portion of sodium carboxymethyl cellulose, 2 to 3 portions of water soluble phenolic resin, 0.5 to 2 portions of attapulgite, 2 to 5 portions of spodumene powder, 0.01 to 0.03 portion of surfactant, and 0.01 to 0.02 portion of defoaming agent. The coating has thin and even coatings and good air permeability; the surfaces of castings are smooth, clean, and level and easy to peel off, and black defects are eliminated; and the castings have level surfaces and high surface quality.

Owner:山东醴泉机械科技有限公司

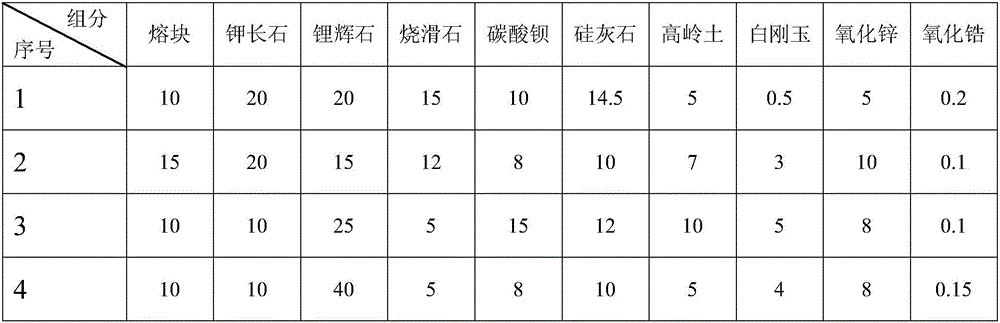

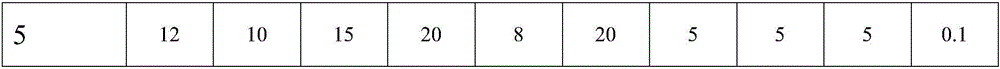

Wear-resistant transparent glaze and method for preparing glazed tile by utilizing same

The invention provides a wear-resistant transparent glaze and a method for preparing a glazed tile by utilizing the same. According to the components of the wear-resistant transparent glaze, spodumene, frit, potash feldspar, calcinedtalc, barium carbonate and zinc oxide are adopted as a fluxing agent, and the Si / Al ratio is adopted by utilizing wollastonite and kaolin. Meanwhile, the wear-resistant performance of the glaze is improved by adopting white corundum and zirconium oxide as a wear-resistant agent. The weight percentage of zirconia relative to the total weight of the raw materials of the wear-resistant transparent glaze is smaller than or equal to 0.2%. The above wear-resistant transparent glaze is applied onto the surface of a green body, and then the green body is polished after being sintered in a furnace to obtain a glazed tile product. Compared with the prior art, the wear-resistant transparent glaze is excellent in wear resistance, and can be used for preparing ceramic tiles with thin glaze layers. The decorative properties and the anti-pollution characteristics of obtained products are greatly improved. Meanwhile, the manufacturing cost of products is lower.

Owner:FOSHAN DONGPENG CERAMIC +3

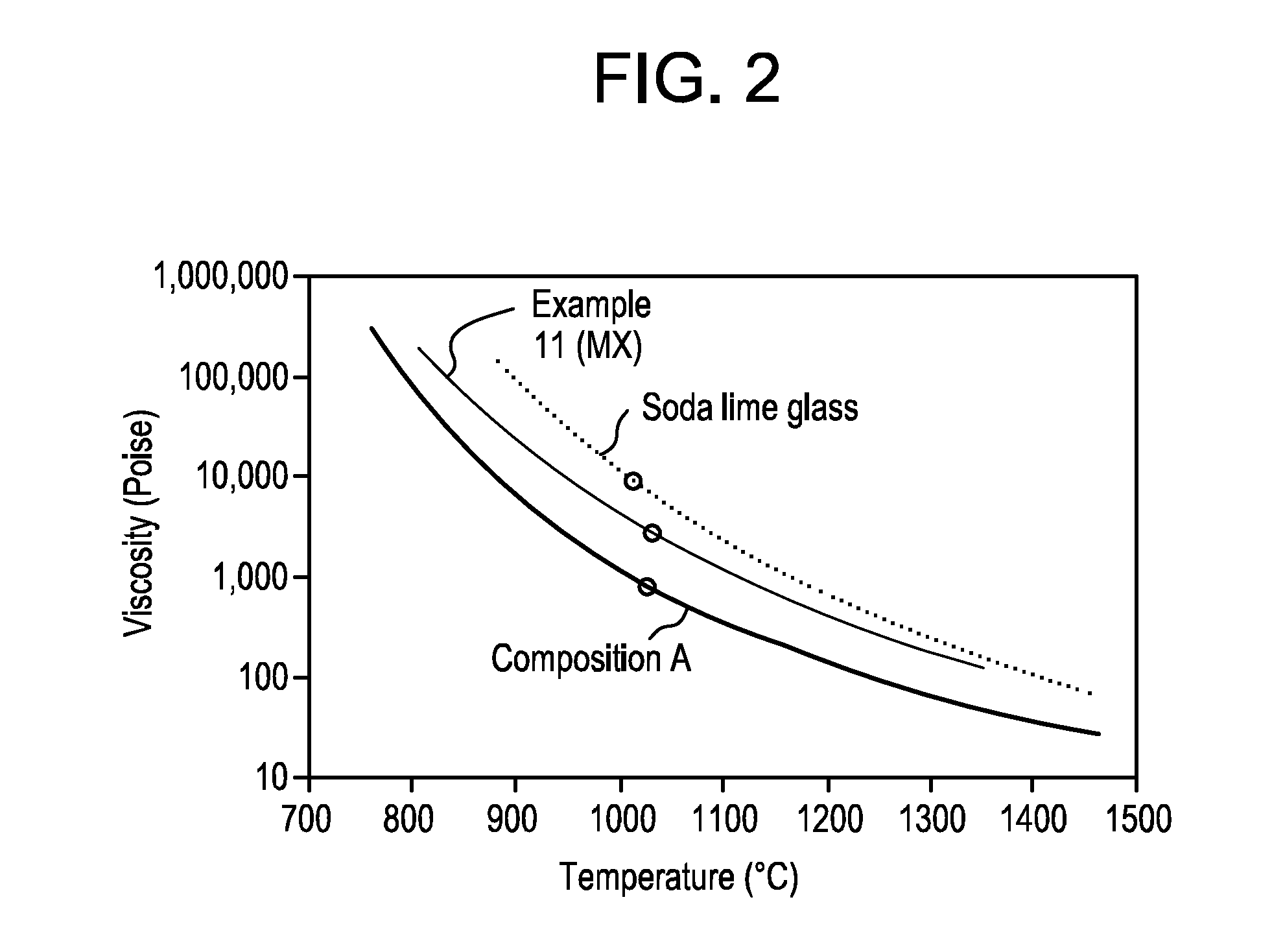

High strength glass-ceramics having lithium disilicate and beta-spodumene structures

Glass and glass ceramic compositions having a combination of lithium disilicate and -spodumene crystalline phases along with methods of making the glass and glass ceramic compositions are described. The compositions are compatible with conventional rolling and float processes and have high mechanical strength and fracture resistance. Further, the compositions are able to be chemically tempered to even higher strength glass ceramics that are useful as large substrates in multiple applications.

Owner:CORNING INC

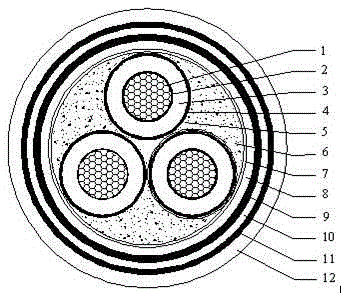

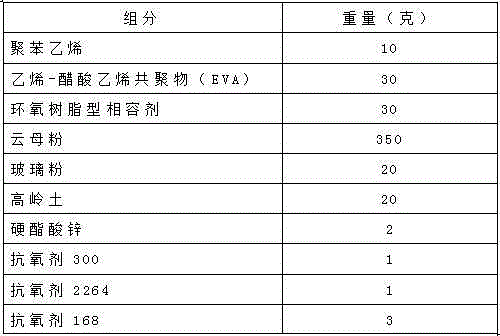

Ceramifying polyolefin fireproof cable material

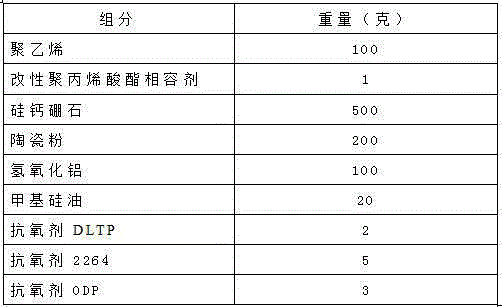

InactiveCN105348627ALow priceSimple processing technologyPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention provides a ceramifying polyolefin fireproof cable material. The material is prepared by the following components in parts by weight: 40-100 parts of polyolefin; 1-30 parts of a compatilizer; 350-450 parts of ceramifying powder; 20-200 parts of a flux; 20-90 parts of a fire retardant; 2-20 parts of a lubricant; and 1-10 parts of an anti-oxidant. Polyolefin is selected from one or more of an ethane-vinyl acetate copolymer, polypropylene, polystyrene, polyethylene and a polyolefin elastomer. The ceramifying powder is selected from one or more of pottery clay, powdered steatile, mica powder, pyrophillite, ascharite, datolite, calcite, limestone, spodumene and clay. The ceramifying polyolefin fireproof cable material has the advantages of good fireproof performance, environmental protection, low cost, easy processing and good application prospect.

Owner:SUZHOU CPLUS NEW MATERIAL

Roasting sagger for circulating type lithium battery anode material and preparation method thereof

ActiveCN103311498AGood chemical inertnessStrong alkali corrosion resistanceElectrode manufacturing processesCharge supportsMulliteCordierites

The invention discloses and provides a roasting sagger for a circulating type lithium battery anode material, which is simple in manufacturing process and structure, does not easily react with a lithium battery material, can avoid polluting the lithium battery material, does not pollute the environment and can be recycled, and a preparation method thereof. The preparation method of the roasting sagger for the circulating type lithium battery anode material comprises the following steps of: (1) uniformly mixing mullite, cordierite, aluminum oxide, corundum, kaolin, active magnesium oxide, spodumene and a bonding agent; adding the materials into a metal mould according to the weight; and pressing and molding a blank by pressing and molding equipment; (2) uniformly mixing zirconium oxide, the spodumene, cerium oxide, the corundum and the bonding agent; uniformly distributing the materials on the surface of the blank by a material distribution machine or manpower and pressing again by the pressing and molding equipment to obtain a semi-finished sagger product; and (3) drying the sagger semi-finished product and sintering. The roasting sagger disclosed by the invention can be widely applied to the field of the sagger for the lithium battery anode material.

Owner:李艳晖

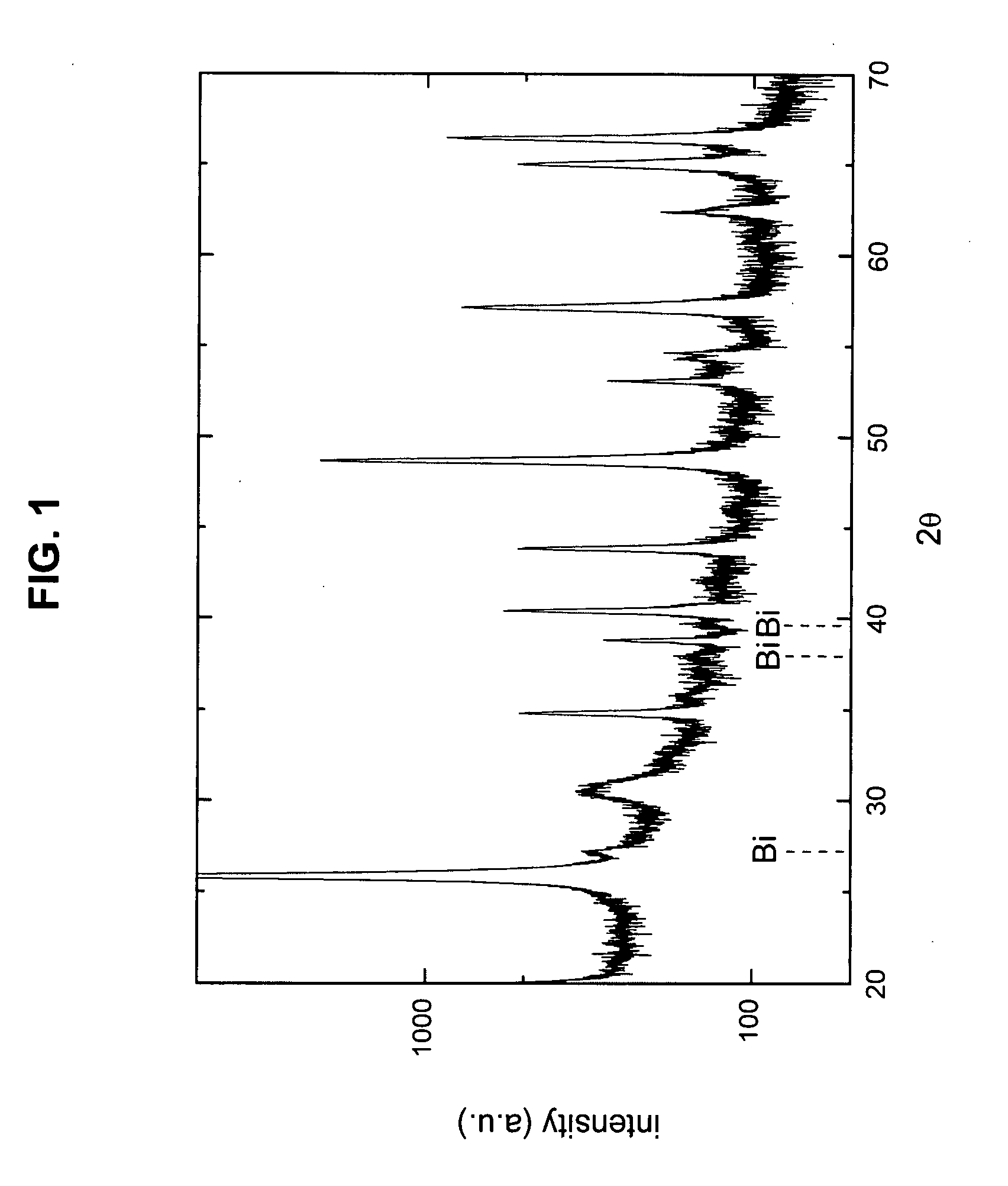

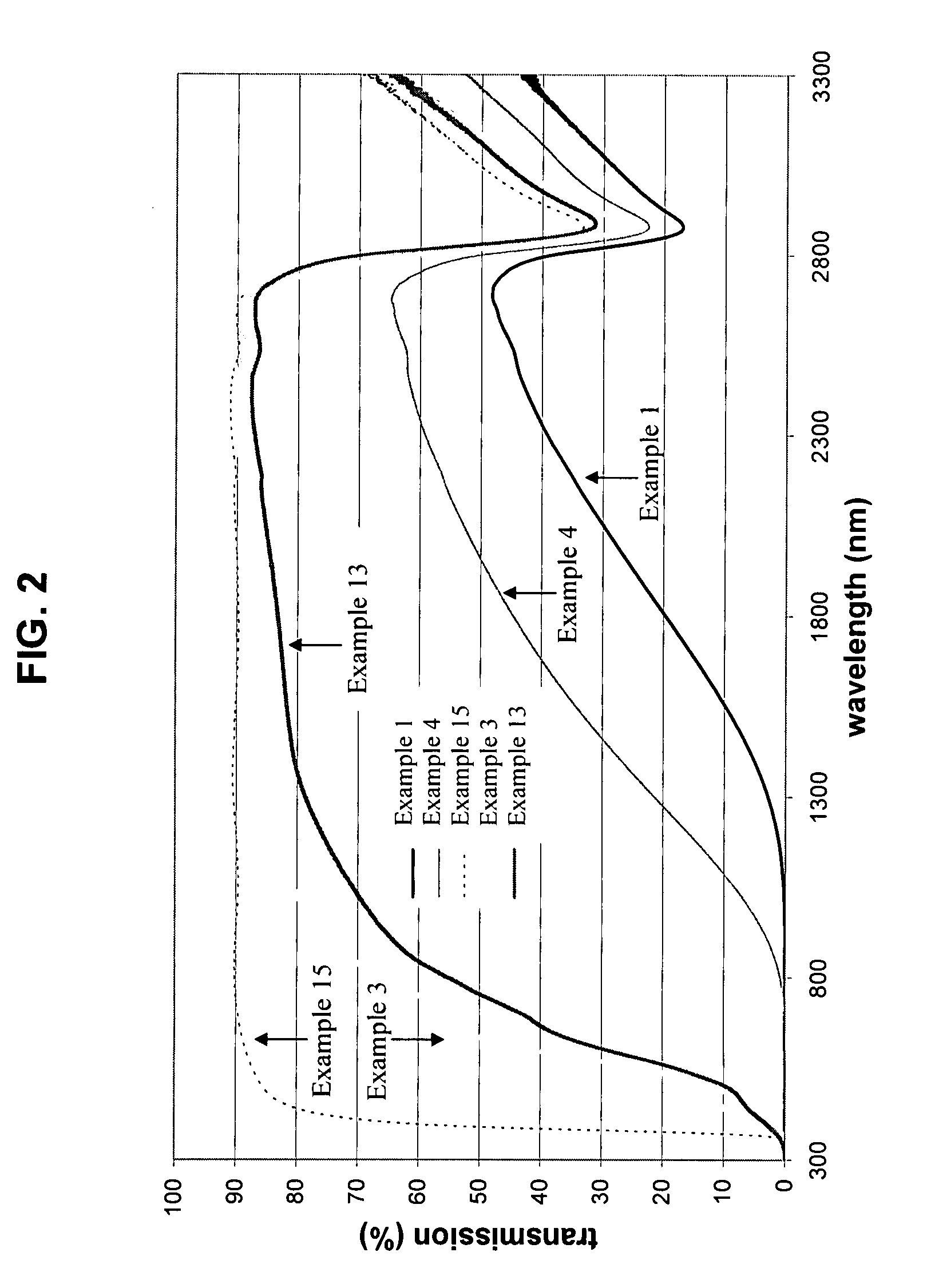

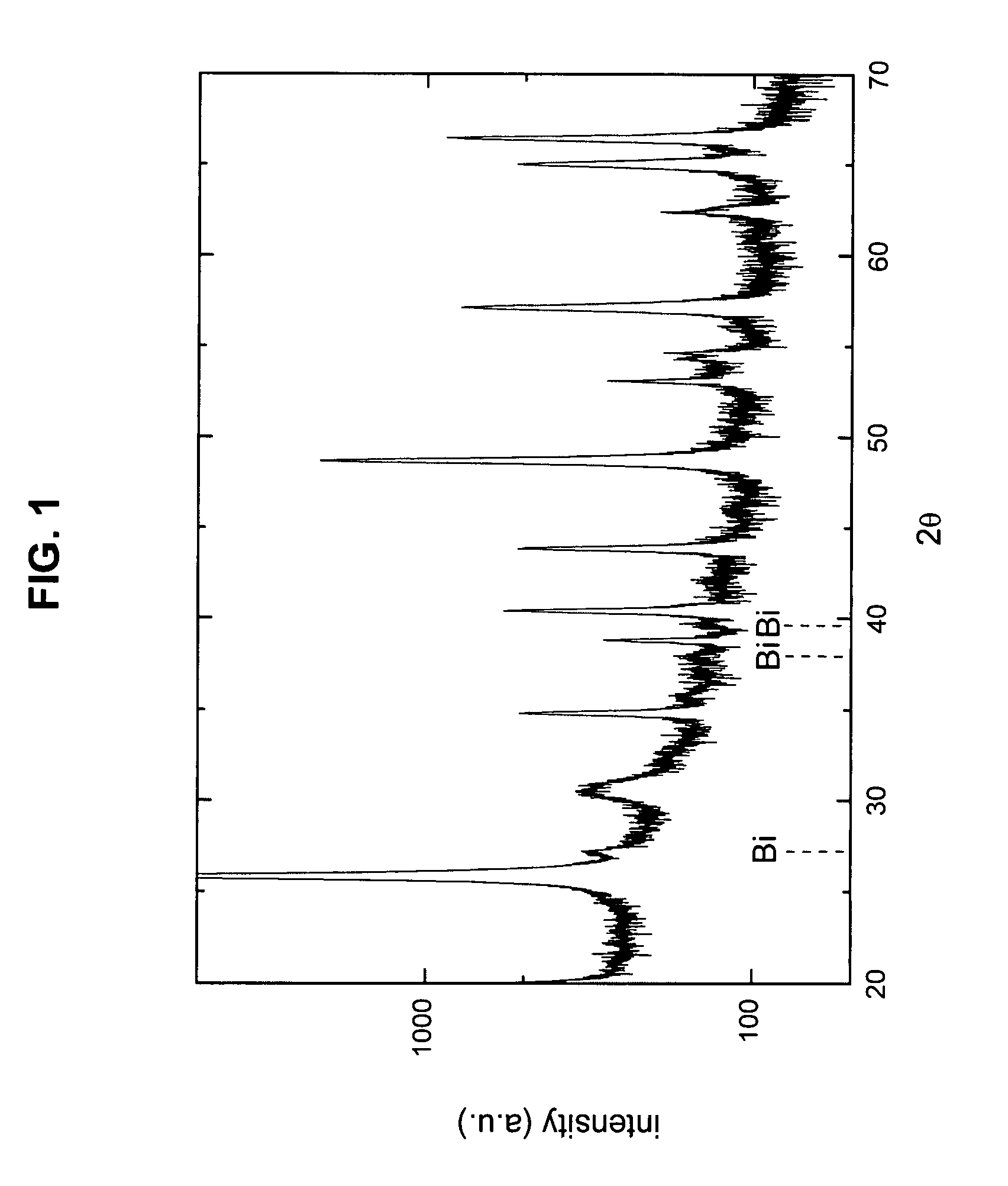

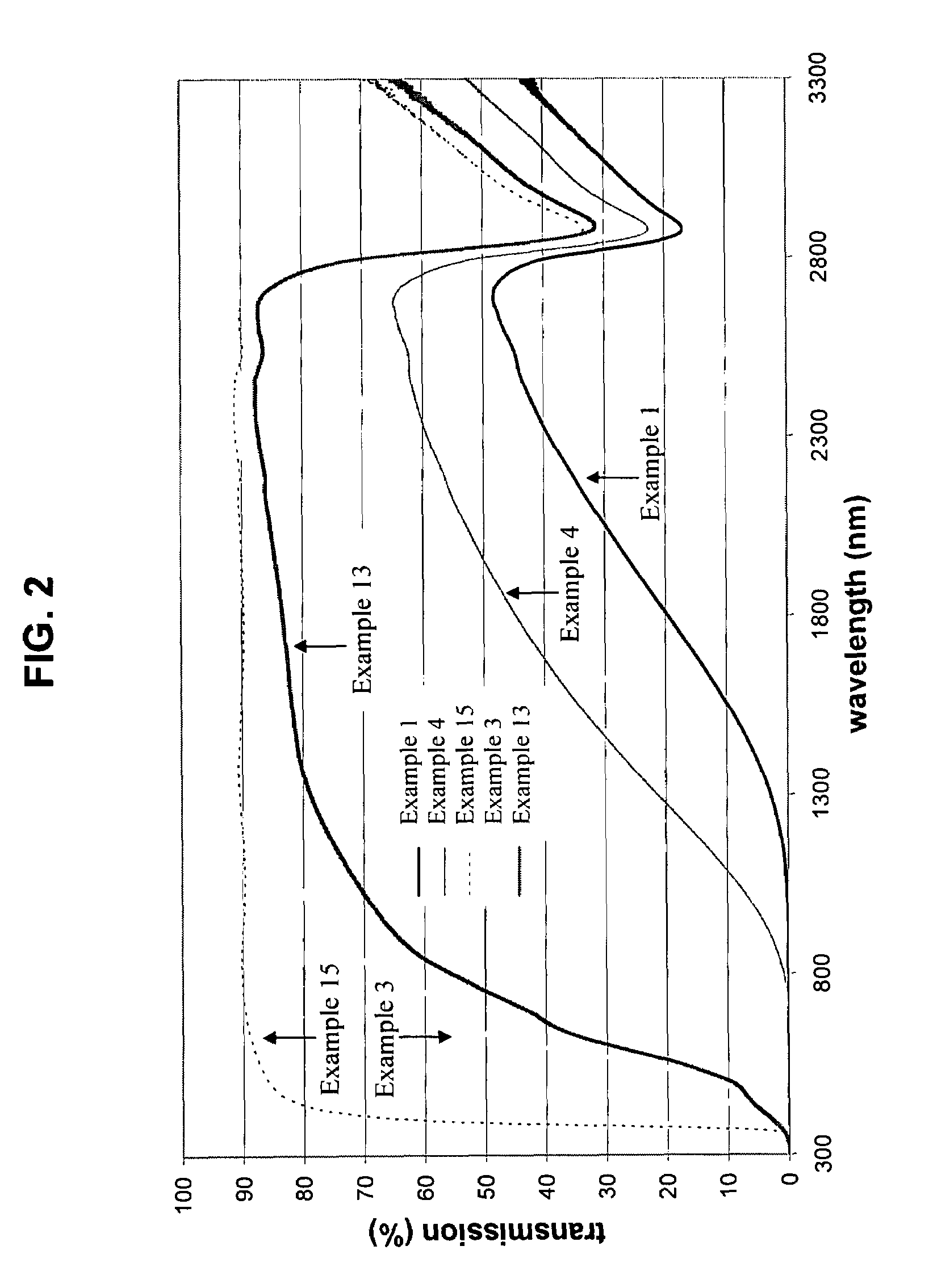

Bismuth-containing glass, glass-ceramic, articles and fabrication process

InactiveUS20080207424A1Low costLow glass viscosityElectric heatingGlass tempering apparatusManufacturing technologyDark color

Bi-containing glass-ceramic material, especially those containing β-quartz and / or β-spodumene solid solutions as the predominant crystalline phase, and the precursor glass material as well as process of making such glass-ceramic material and articles. The glass-ceramic can be made to have a dark color, and essentially to be free of V2O5, As2O3 and Sb2O3.

Owner:EUROKERA SOC & NOM COLLECTIF

Glass-ceramic materials, precursor glass thereof and process for making the same

The invention relates to: a method of preparing glass-ceramics of β-quartz and / or of β-spodumene; a method of preparing articles made from said glass-ceramics; novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and lithium aluminosilicate glasses, which are precursors of such novel glass-ceramics. The present invention relates to the use, as agent for fining the glass-ceramic glass precursor, of fluorine and at least one oxide of a multivalent element.

Owner:EUROKERA SOC & NOM COLLECTIF

Process for preparing super-low expansion ceramic material

The invention provides a process for preparing a super-low expansion ceramic material, which is characterized in that lithium-contained mineral (such as spodumene, eucryptite, and the like), lithium carbonates, zinc oxide, barium carbonate, titanium dioxide, talcum, and the like. are mixed in advance, melted as a glass frit at the temperature of about 1450 DEG C and taken as material A; subsequently, raw materials such as kaolin, quartz, and the like are mixed and taken as material B; the material A, the material B and the calcined spodumene are mixed by a certain proportion; and the steps of ball-milling, forming and baking are carried out to prepare the super-low expansion ceramic material with the thermal expansion coefficient of 0.6-1.0*10[-6] / DEG C (at the normal temperature of about 800 DEG C). The ceramic material can be widely applied to kilns, high-temperature clamps, high-temperature radiation baffles, induction cooker panels, microwave oven liner, household heat-resistance dishware, thermocouple protection tubes, and the like.

Owner:JINGDEZHEN CERAMIC INSTITUTE

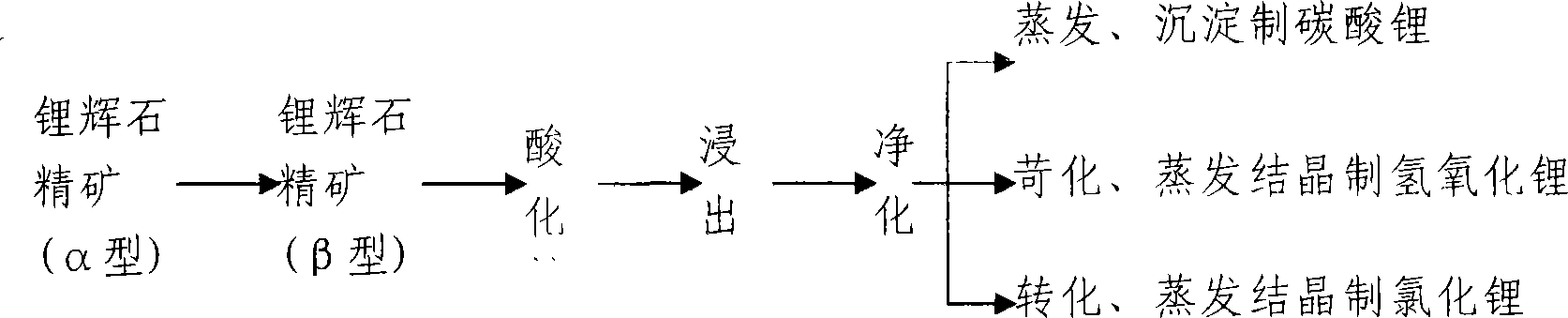

Novel method for producing lithium carbonate and lithium hydroxide

InactiveCN102115101ASimple production processLow costLithium oxides/hydroxidesLithium carbonates/bicarbonatesLithium sulphateCalcium hydroxide

The invention relates to a novel method for producing lithium carbonate and lithium hydroxide, which belongs to the technical field of production of lithium salts. The method comprises the following steps of: baking spodumene concentrate; preparing a lithium sulfate solution; preparing lithium carbonate mother liquor; and preparing lithium hydroxide, wherein the lithium hydroxide can also be obtained by adding barium hydroxide into the lithium carbonate mother liquor. The method has the advantages that: lime is added into a lithium carbonate sinker mother liquor to produce the lithium hydroxide by causticizing and transforming, and the production of lithium carbonate is combined with the production of the lithium hydroxide, so that a process flow is simplified, investment and production costs are lowered, a production process is more flexible to regulate and control, and the quality of a lithium carbonate product is more stable. By adopting the method, the mother liquor of lithium carbonate is easier to treat, impurities in the lithium hydroxide mother liquor are easy to treat, and the product quality is not influenced.

Owner:屈俊鸿

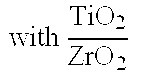

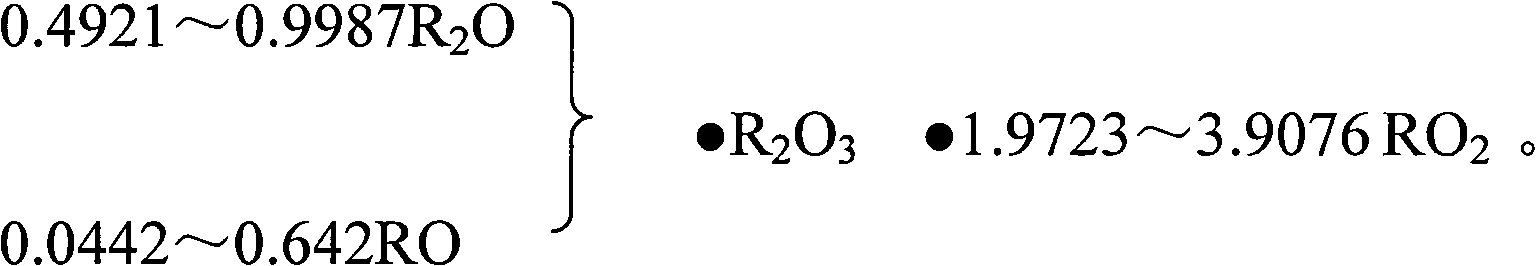

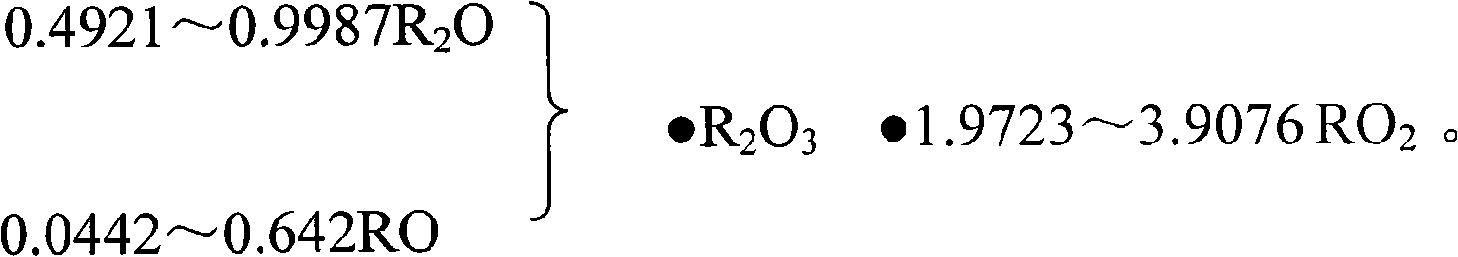

Furnace transmutation decoration glazed brick and production technology

The invention relates to a furnace transmutation decoration glazed brick and a production technique thereof. The furnace transmutation decoration glazed brick is prepared from the following componentsin percentage by weight: 10-30% of albite, 3-10% of spodumene, 5-10% of kaoline Al2O3.2SiO2.2H2O, 8-30% of zinc oxide ZnO, 3-10% of talc 3MgO.4SiO2.H2O, 0-20% of titanium TiO2, 3-10% of zirconite ZrSiO, and 1-10% of coloring metallic oxide MnO2, V2O5, Fe2O3 and CoO2. The production technique of the furnace transmutation decoration glazed brick comprises the following steps: (1) shaping the substrate of the furnace transmutation decoration glazed wall and floor bricks; (2) decorating the wall and floor brick substrate surface or anti-abrasion transparent glaze layers and drying; and (3) sintering the furnace transmutation decoration glazed wall and floor bricks once in a high-temperature roller kiln.

Owner:黄建平

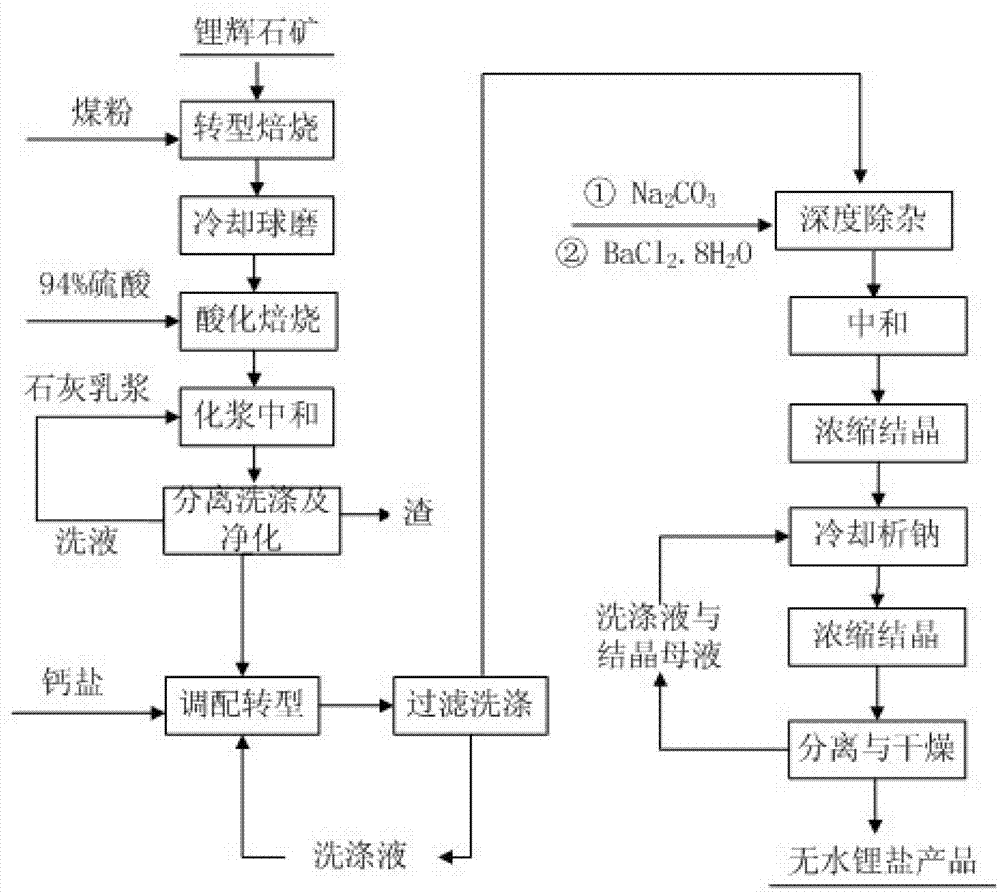

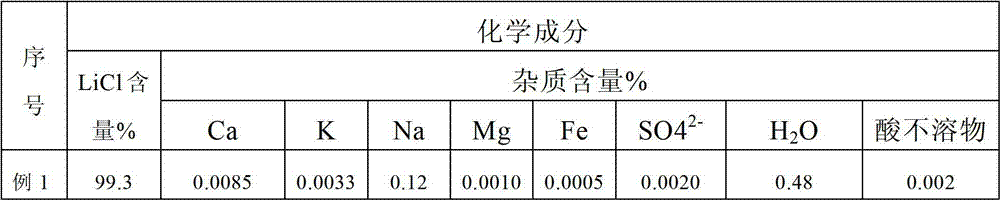

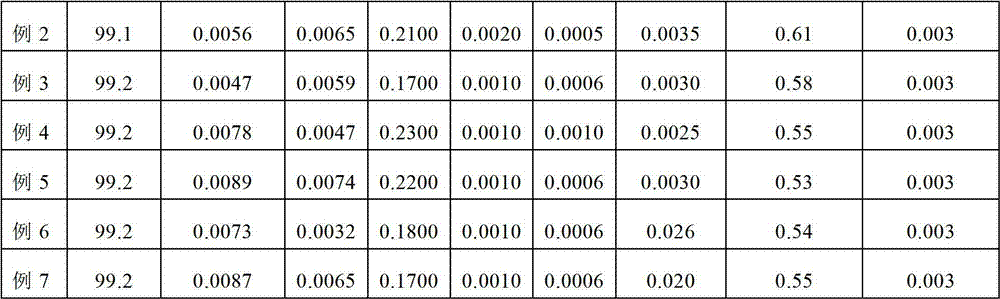

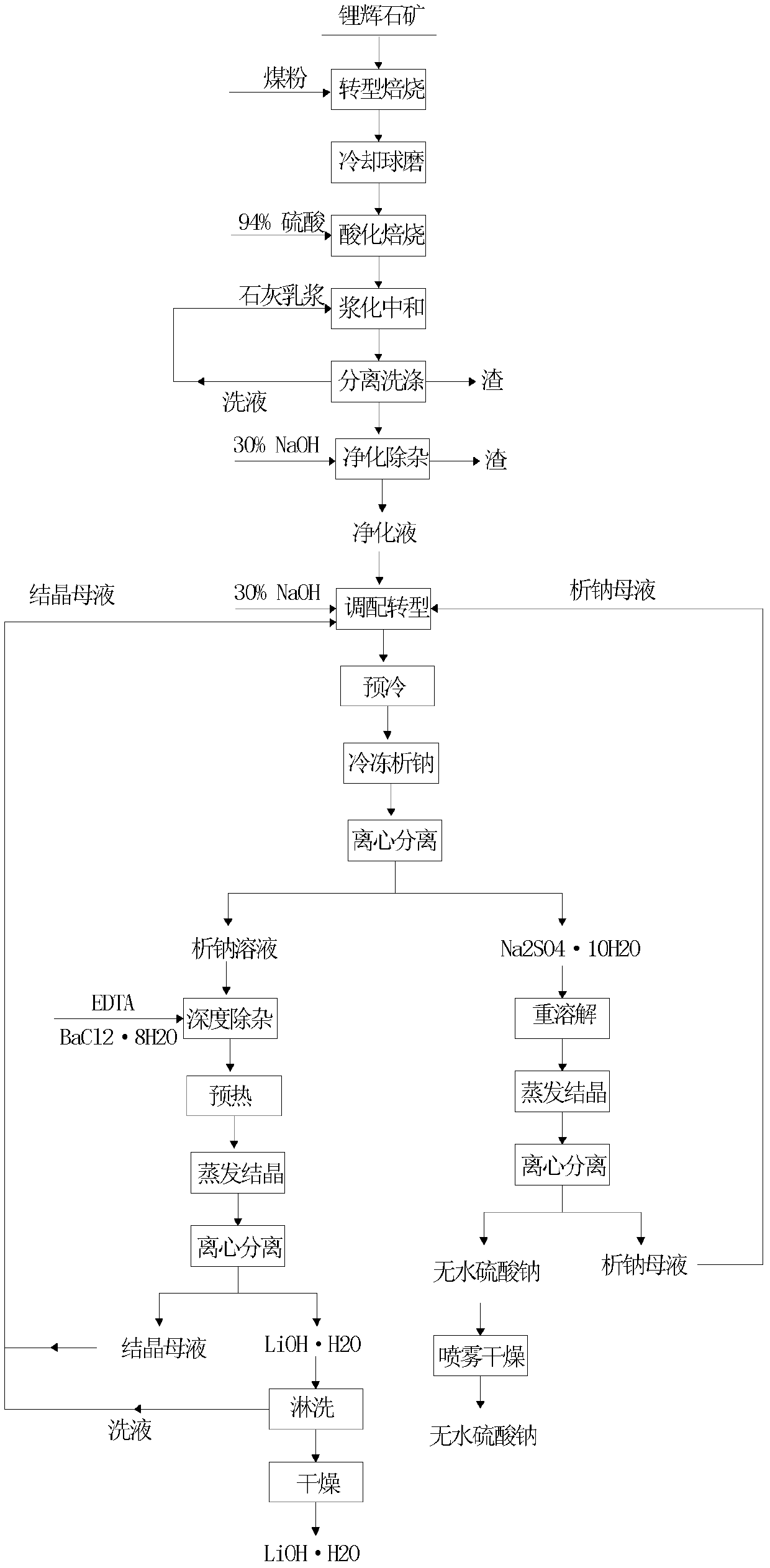

Method for preparing lithium salts from lithium extracted from spodumene

InactiveCN102765734AShort processEasy to operateLithium halidesLithium nitratesResource utilizationImpurity

The invention discloses a method for preparing lithium salts from lithium extracted from spodumene, which comprises the following steps: a. transforming and roasting; b. cooling and ball milling; c. acidifying and roasting; d. slurrying and neutralizing; e. separating, washing and purifying; f. blending and transforming; g. filtering and washing; h. deep impurity removing; i. neutralizing; j. concentrating and crystallizing; k. cooling to precipitate sodium; l. concentrating and crystallizing; and m. separating and drying. The method disclosed by the invention has the advantages of short technical process, low energy consumption, simple operation steps, low production cost and high resource utilization ratio.

Owner:GANFENG LITHIUM CO LTD

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

Glass-ceramic materials, precursor glass thereof and process-for making the same

The present invention relates to: novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and ithium alumino-silicate glasses, which are precursors of said novel glass-ceramics; methods of preparing said novel glass-ceramics and articles made from said novel glass-ceramics. The present invention relates to the use of SnO2 and of Br, as an agent for fining the glass-ceramic glass precursor.

Owner:EUROKERA SOC & NOM COLLECTIF

Glass-ceramic, articles and fabrication process

InactiveUS7507681B2Low costLow viscosityElectric heatingGlass tempering apparatusManufacturing technologyDark color

Bi-containing glass-ceramic material, especially those containing β-quartz and / or β-spodumene solid solutions as the predominant crystalline phase, and the precursor glass material as well as process of making such glass-ceramic material and articles. The glass-ceramic can be made to have a dark color, and essentially to be free of V2O5, As2O3 and Sb2O3.

Owner:EUROKERA SOC & NOM COLLECTIF

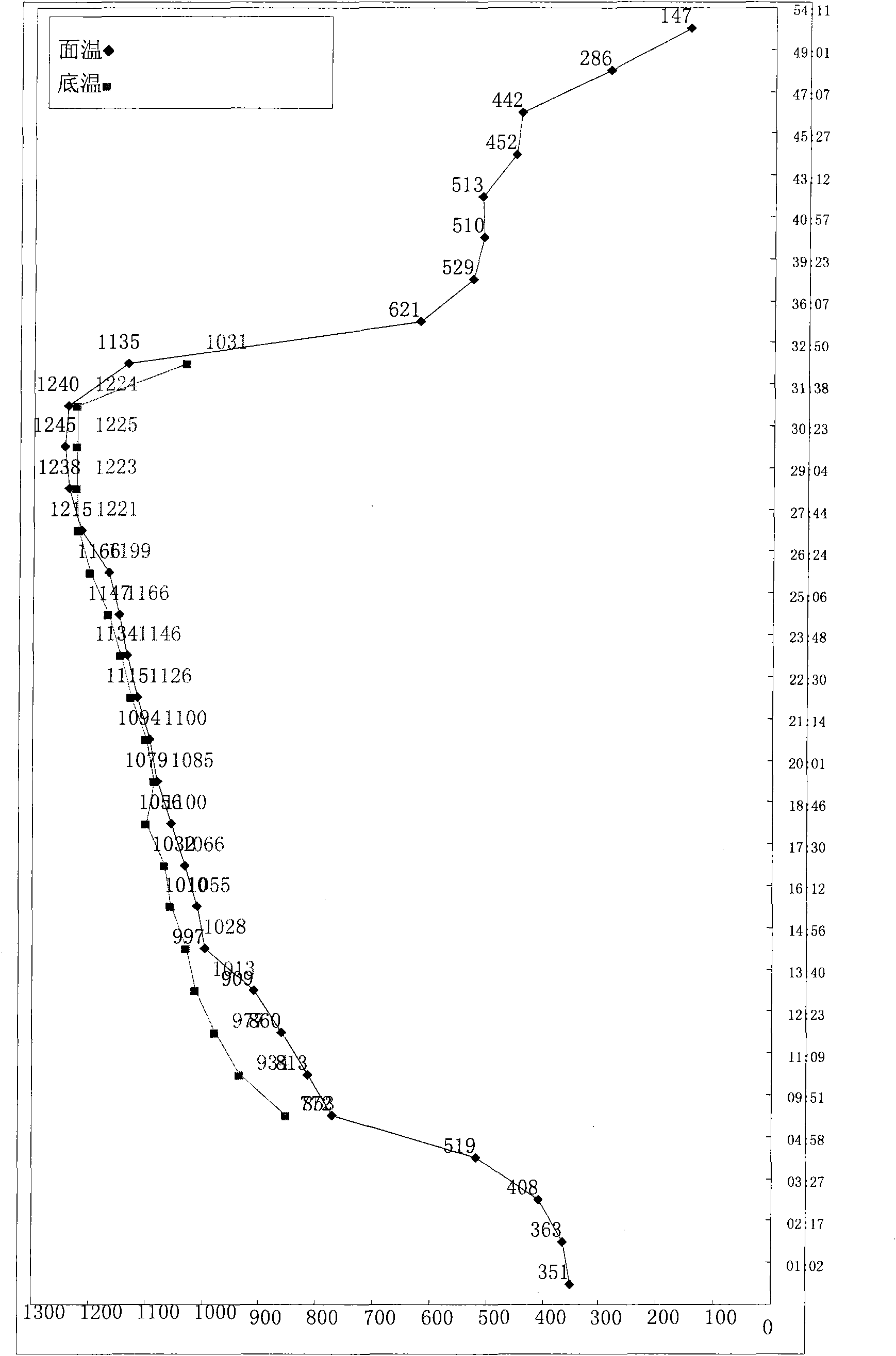

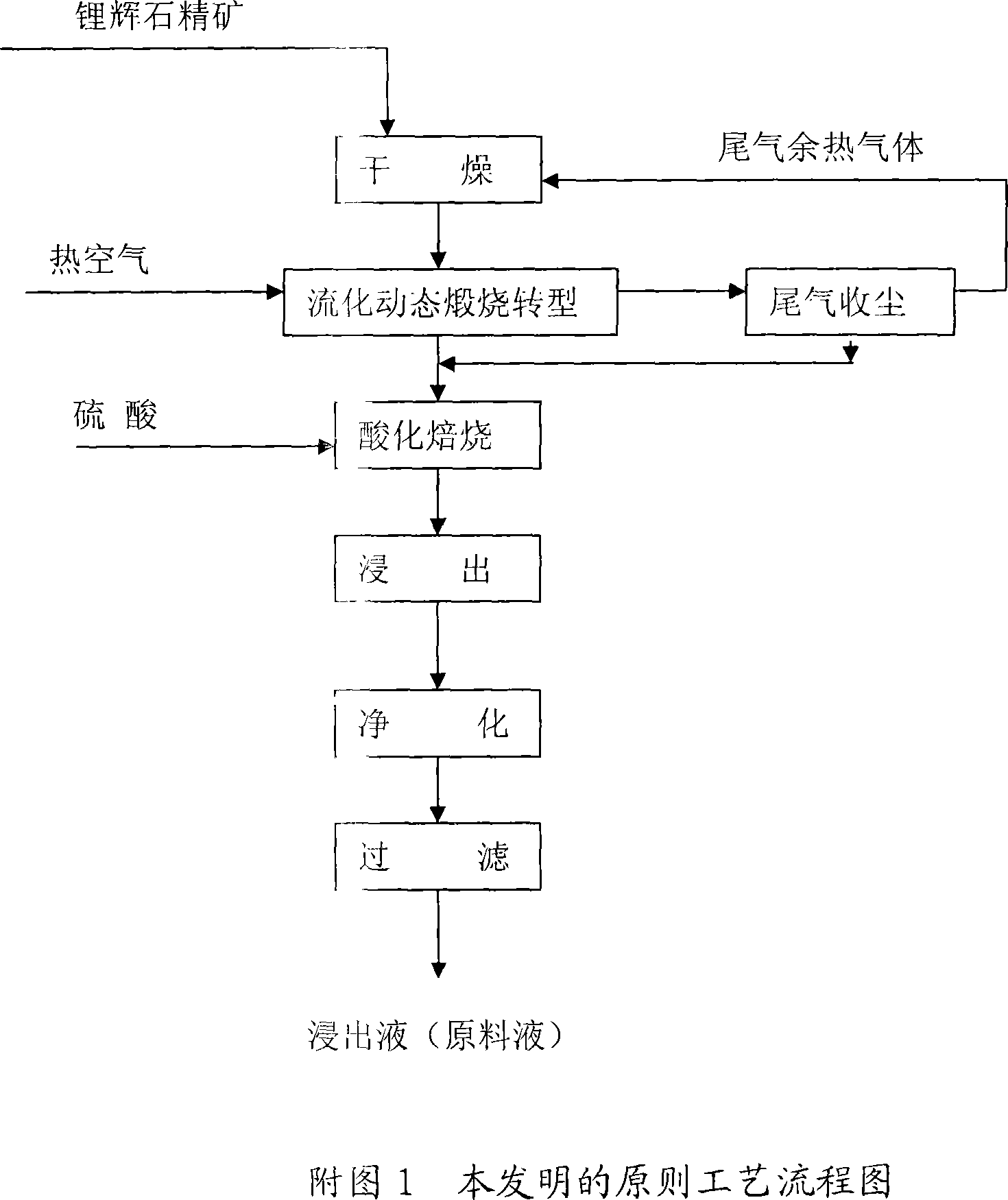

Novel method for spodumene calcining transformation

InactiveCN101224900AEvenly heatedFast heat transferChemical industryLithium halidesLithium chlorideLithium hydroxide

The invention relates to a method for producing lithium carbonate, lithium hydroxide and lithium chloride with spodumene. Aiming at the defect of the calcination transformation technology of the spodumene concentrate, the invention provides a new method of the fluidization and dynamic calcination transformation of the spodumene concentrate: the spodumene concentrate from a concentration plant is dried and milled to granules with the granularity of minus 250 meshes to minus 350 meshes; then a fluidization dynamic calcinator is adopted to carry out high temperature calcination transformation to the concentrate, the material temperature is controlled between 900 and 1200 DEG C; because the material in the furnace is fluidized and transfers heat and is delivered in the form of air delivery with hot air, the process is rapid in heat transfer rate, high in efficiency and short in calcination time, which overcomes the technical defect of the existing calcination technology that the material is easy to be agglomerated and avoids cooling and ball-milling procedures. When the calcined material is treated by the procedures of leaching, purging, filtering, etc., the obtained filtrate (raw material liquid) can be utilized for producing products such as lithium carbonate, lithium hydroxide, lithium chloride and so on by adopting existing different technologies.

Owner:钟辉

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

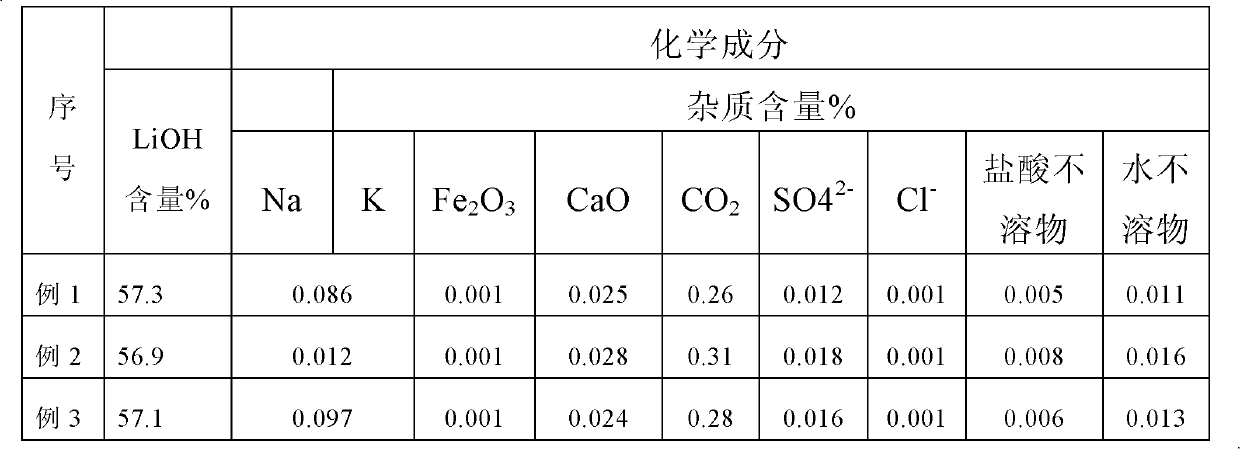

Method for preparing lithium hydroxide monohydrate by extracting lithium from spodumene

ActiveCN102701239AAchieve coolingAchieve evaporative crystallizationLithium oxides/hydroxidesResource utilizationPhysical chemistry

The invention discloses a method for preparing lithium hydroxide monohydrate by extracting lithium from spodumene. The method includes steps of transformation roasting, cooling, ball milling, acidification roasting, pulping, neutralizing, separation washing, purifying, blending for transformation, freezing for sodium precipitation, deep decontaminating, evaporative crystallization, centrifugal separation, drip washing and drying. By means of a DTB (draft tube baffle) type crystallizer, an FC (forced circulation) crystallizer or an OSLO crystallizer, continuous cooling crystallization and evaporative crystallization are realized, equipment yield is increased by more than 50%, and equipment utilization rate is increased. Therefore, the method is simple and practical in process, high in equipment yield, low in production cost, high in resource utilization rate, low in energy loss and low in three wastes (waste gas, waste water and waste residues).

Owner:GANFENG LITHIUM CO LTD

Crystal glaze and its preparation method and use method

ActiveCN102659453AShorten the firing cycleTo achieve the purpose of industrialized mass productionBrickComposite ceramic

The invention discloses a crystal glaze and its preparation method and use method. The crystal glaze is prepared by uniformly mixing a basic crystal glaze and one or more coloring agents, wherein the weight of the one or more coloring agents is 0 to 10% of the total weight of the basic crystal glaze and the one or more coloring agents; and the basic crystal glaze mainly comprises 2 to 40 parts of spodumene, 5 to 20 parts of quartz, 5 to 25 parts of calcite, 5 to 25 parts of talcum, 5 to 20 parts of alumina, 1 to 5 parts of zinc oxide, 1 to 3 parts of sodium nitrate, 5 to 15 parts of zircon powder, 1 to 5 parts of bone ash, 1 to 5 parts of lithium carbonate and 5 to 15 parts of boric acid. In melting of the basic crystal glaze of the crystal glaze, the one or more coloring agents are used and thus a composite ceramic tile adopting the crystal glaze has a bright color and strong stereoscopic impression and produces crystal patterns having diameters of 3 to 4 centimeters. The preparation method greatly reduces a firing period of the traditional crystal glaze and realizes industrial production. An experiment proves that a crystal glaze surface with large crystal patterns can be obtained in a firing period of only 75 minutes.

Owner:JIANGSU BAIFU TECH CO LTD

Full polish ceramic product and preparation method thereof

The invention relates to a full polish ceramic product and a preparation method thereof. The full polish ceramic product comprises a ceramic green body and a full polish layer outside the ceramic green body, wherein the full polish layer mainly comprises powder which comprises following components by weight percent: 42-62% of albite, 2-7% of potash feldspar, 0-4% of dolomite, 4-8% of calcite, 0-2% of barium carbonate, 6-8% of aluminum oxide, 3-5% of fired talc, 2-4.6% of zinc oxide, 3-9% of quartz powder, 0.5-2.5% of soochow kaolin, 1-6% of calcined kaolin, 5-10% of aedelforsite, 0.1-3.0% of spodumene, and 0.1-2.8% of borocalcite. The full polish slurry is prepared by burdening and ball milling once. As the full polish slurry contains less wearproof materials like aluminum oxide, the ball milling time is short, and the production efficiency is higher; due to the addition of little amount of spodumene and borocalcite, the abrasion performance and hardness of the fired full polish ceramic product can be improved.

Owner:JIANGSU BAIFU TECH CO LTD +1

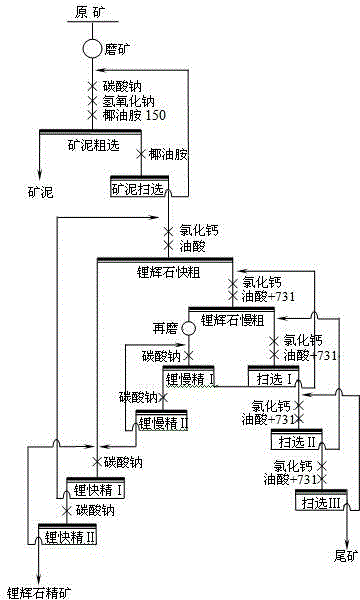

Ore dressing method of spodumene quarry

ActiveCN102909136AImprove sorting effectExtended flotation timeFlotationControllabilityMaterials science

The invention discloses an ore dressing method of a spodumene quarry, which comprises the following steps: raw ore grinding, slime floating, spodumene fast roughing, spodumene fast selecting, spodumene slow roughing, spodumene slow selecting and other steps, and a spodumene concentrate is finally obtained. The spodumene quarry separated by adopting the ore dressing method has good separation index, and the grade and the recovery rate of the spodumene concentrate are high. The ore dressing method is a new spodumene flotation process with the advantages of economy, applicability, simplicity, cleanness, strong controllability and good separation effect and is suitable for popularization and application.

Owner:JIANGXI UNIV OF SCI & TECH

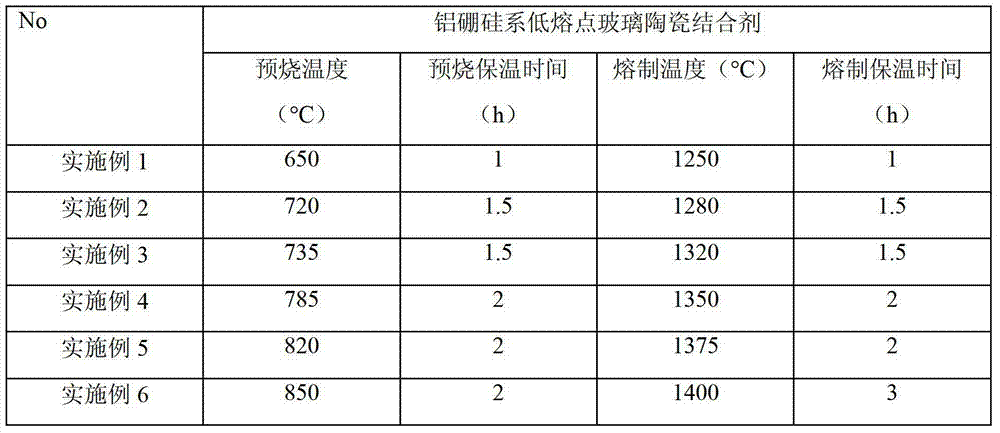

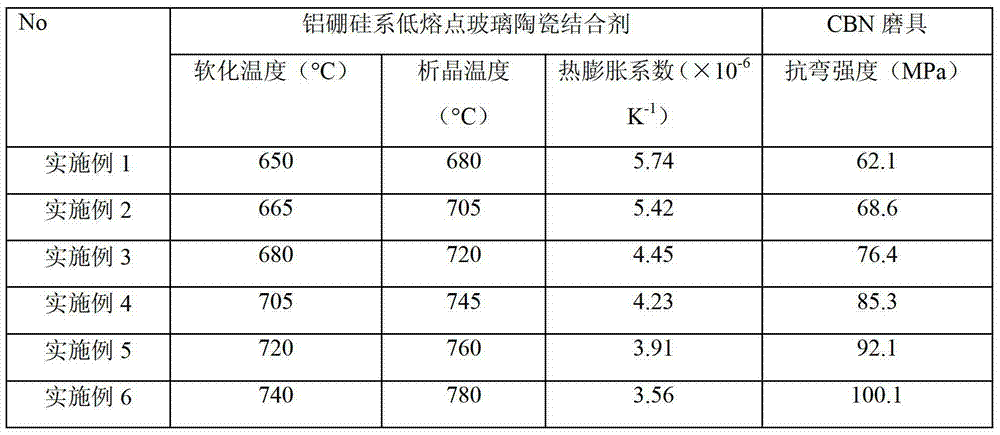

Preparation method of low melting point aluminum-boron-silicon glass ceramic bond for CBN (Cubic Boron Nitride) grinding tool

InactiveCN103395996AHigh strengthMeet low temperature sintering requirementsLithium oxideBoron nitride

The invention provides a preparation method of a low melting point aluminum-boron-silicon glass ceramic bond for a CBN (Cubic Boron Nitride) grinding tool. The glass ceramic bond with uniform components can be obtained by taking oxides such as 55-70% of SiO2, 5-20% of Al2O3, 5-15% of B2O3, 3-7.5% of Na2O, 0.1-2% of K2O, 1-6% of Li2O, 1-3% of ZnO, 0.5-2% of CaO, 0.5-2% of MgO and the like as raw materials for melting the glass ceramic bond and using a high temperature melting and water quenching method. Boron oxide and sodium oxide are added into the raw materials to reduce the softening temperature of the bond, and meanwhile, a proper amount of lithium oxide is added to ensure that low-expansion spodumene crystals are separated out in the bond sintering process, so that the thermal expansion coefficient of the glass ceramic bond is reduced, and the mechanical strength and chemical stability of the glass ceramic bond are improved. Compared with the traditional glass ceramic bond for the grinding tool, the bond provided by the invention has the advantages of low melting and softening temperatures and convenience in crystallization control; and the prepared glass ceramic bond has a lower thermal expansion coefficient and higher chemical stability and mechanical strength.

Owner:XI AN JIAOTONG UNIV

Anti-vein precoated sand and preparation method thereof

InactiveCN103567357AAnti-sticking sand strengthStrong anti-veining abilityFoundry mouldsFoundry coresSesbania gumPhenol

The invention discloses anti-vein precoated sand and a preparation method thereof. The anti-vein precoated sand is prepared from the following raw materials in parts by weight: 80-90 parts of quartz sand, 15-25 parts of menaccanite, 10-15 parts of spodumene, 2-3 parts of boric acid, 2-3 parts of thermoplastic phenolic resin, 0.5-1 part of thermosetting phenol resin, 5-10 parts of cement clinker, 4-7 parts of sulphite liquor, 3-5 parts of corn flour, 2-3 parts of sesbania gum, 1-2 parts of ammonium benzoate, 0.5-0.8 part of gamma-aminopropyl triethoxy silicane, 3-6 parts of dioctyl phthalate, 7-11 parts of urotropine, 2-4 parts of calcium stearate and 3-5 parts of composite powder. The anti-vein precoated sand has strong anti-sand burning and anti-vein capacities, also has the characteristics of high strength, good liquidity, low gas evolution, good heat resistance, good gas permeability and the like, can obviously reduce or eliminate defects of vein, sand burning, pores and the like, effectively improves quality of the inner surface and the outer surface of a casting and is applicable to production of a gray iron bulb iron steel casting.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Granular double-layer reaction glaze and preparation method

The invention belongs to the technical field of ceramic glazes and particularly relates to a granular double-layer reaction glaze and a preparation method. The granular double-layer reaction glaze comprises the following ingredients in parts by weight: a ground glaze: 30-40 parts of soda feldspar, 5-15 parts of quartz, 5-15 parts of wollastonite, 2-6 parts of calcined alumina, 25-35 parts of kaolin and 15-25 parts of toner; and an overglaze: 35-45 parts of high-boron clinker, 15-25 parts of quartz, 5-10 parts of wollastonite, 5-15 parts of spodumene, 10-20 parts of calcined zinc oxide, 5-15 parts of kaolin, 5-10 parts of calcined talcum, 5-10 parts of titanium dioxide powder and 5-15 parts of zirconium silicate. The granular double-layer reaction glaze is short in firing time and has relatively high thermal shock resistance and glazed surface hardness.

Owner:HUNAN HUALIAN CHINA IND

Refractory material for steel tapping hole of converter and preparation method for refractory material

The invention relates to a refractory material for a steel tapping hole of a converter and a preparation method for the refractory material. The technical scheme of the invention is as follows: the preparation method comprises the steps of spraying the surface of a magnesia-carbon brick body with a glaze slip coating with the thickness of 1mm to 2mm, carrying out drying, and carrying out heat preservation, thereby preparing the refractory material for the steel tapping hole of the converter. A preparation method for the magnesia-carbon brick body comprises the steps: mulling magnesia fines, flake graphite fines, expandable graphite, aluminum powder and silicon powder in a high-speed mulling machine, so as to prepare mixed fine powder; and then, mulling fused magnesia granules and artificial graphite granules, adding phenol-formaldehyde resin into the mixture, carrying out mulling, then, adding granulated graphite and the mixed fine powder into the mulled mixture, carrying out mulling, carrying out aging, carrying out shaping, and carrying out standing, thereby preparing the magnesia-carbon brick body. A preparation method for glaze slip comprises the steps of adding water into glass powder, spodumene, potassium feldspar, silicon micropowder, potassium carbonate, SiC fines, chrome green and aluminum dihydrogen phosphate, which serve as raw materials of the glaze slip, and carrying out grinding, thereby preparing the glaze slip. The refractory material for the steel tapping hole of the converter, prepared by the preparation method, has the characteristics that the thermal shock stability is good, the integrity is good, the oxidation resistance is good, the erosion resistance is good, and the life is long.

Owner:WUHAN UNIV OF SCI & TECH

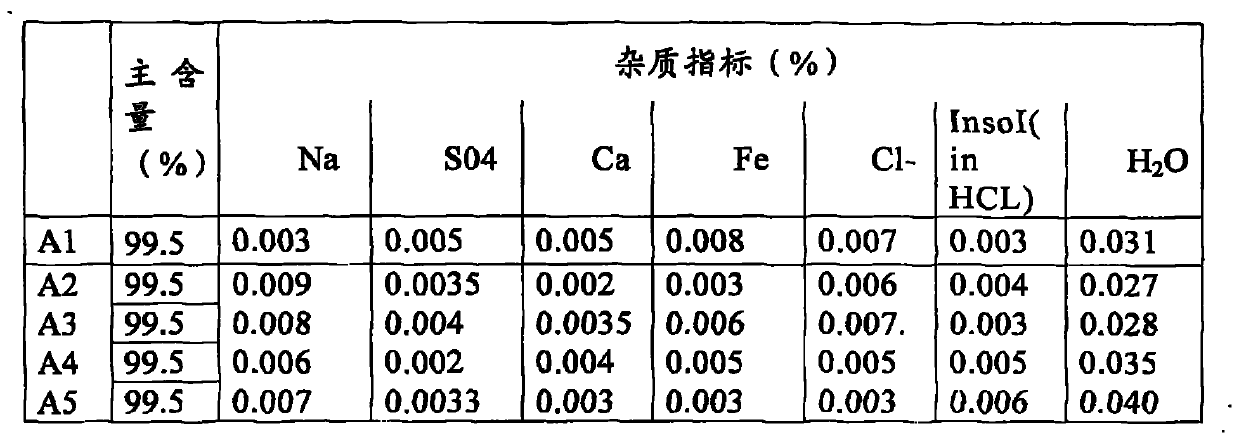

Process for extracting lithium salt from spodumene by adopting sulfuric acid pressure boiling method

ActiveCN104071811AFully recycleShort process routeLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention discloses a process for extracting lithium salt from spodumene by adopting a sulfuric acid pressure boiling method. The process comprises the following steps: transforming the spodumene at high temperature, and adding sulfuric acid for pressure boiling to obtain soluble lithium sulfate and insoluble high-silicon residues, and separating lithium from lithium concentrate to further prepare lithium carbonate and obtain a byproduct-high-silicon soil; adding lime for purifying leachate liquid containing a small quantity of aluminum, iron and other alkali metal sulfate, removing impurities in a multi-step way to obtain a high-purity lithium sulfate solution, and carbonizing to generate a lithium carbonate product and a sodium sulfate byproduct. According to the process, the yield is high, the wastewater discharge quantity is low, mother liquor can be recycled, and the cost is low.

Owner:江西雅保锂业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com