Process for preparing super-low expansion ceramic material

A technology of ceramic materials and preparation process, which is applied in the field of preparation of ultra-low expansion ceramic materials, can solve problems such as difficult control of the green body, and achieve the effect of eliminating the difficult control of molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

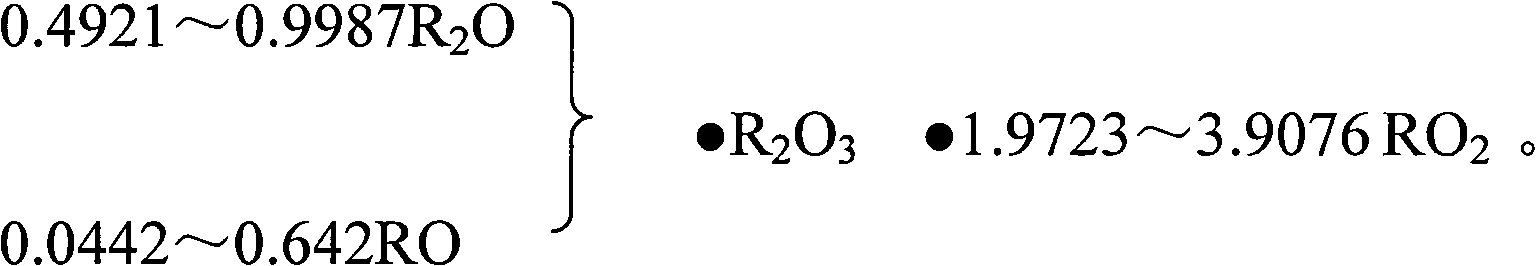

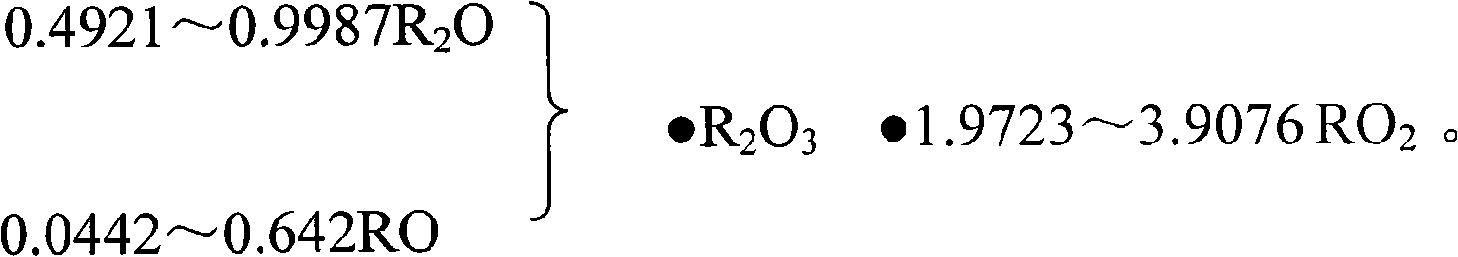

Method used

Image

Examples

Embodiment 1

[0012] The weight ratio of material A is: 75% of natural spodumene, 20% of industrial lithium carbonate, 1% of zinc oxide, 2% of titanium dioxide, and 2% of magnesium oxide. The frit is pulverized for later use; the weight ratio of material B is: 15% of quartz, 80% of kaolin, and 5% of calcined talc, and these three raw materials are mixed for later use. Then get A material 45% by weight, B material 55% accurate batching, according to material: ball: water=1: 2: 0.8, the residue of slurry crossing 250 mesh sieves is less than 0.1%, slurry dehydration becomes plastic mud material, After shaping, drying, and glazing, it is fired at a firing temperature of 1310°C and kept for 30 minutes. The expansion coefficient of the ceramic product is measured, and its thermal expansion coefficient is a (常温~800℃) is 0.73×10 -6 / ℃, measuring its thermal stability, it can resist rapid cooling and rapid heating 650 ℃ ~ 20 ℃ once without cracking.

Embodiment 2

[0014] The weight ratio of material A is: 75% of natural spodumene, 20% of industrial lithium carbonate, 1% of zinc oxide, 2% of titanium dioxide, and 2% of magnesium oxide. The frit is pulverized for later use; the weight ratio of material B is: 15% of quartz, 80% of kaolin, and 5% of calcined talc, and these three raw materials are mixed for later use. Then get A material 50% by weight, B material 50% accurate batching, according to material: ball: water=1: 2: 0.8, slurry is crossed 250 mesh sieves and remains less than 0.1%, and slurry dehydration becomes plastic mud material, After shaping, drying, and glazing, it is fired at a firing temperature of 1300°C and kept for 30 minutes. The expansion coefficient of the ceramic product is measured, and its thermal expansion coefficient is a (常温~800℃) is 0.66×10 -6 / ℃, measuring its thermal stability, it can resist rapid cooling and rapid heating 650 ℃ ~ 20 ℃ once without cracking.

Embodiment 3

[0016] The weight ratio of material A is: 75% of natural spodumene, 20% of industrial lithium carbonate, 1% of zinc oxide, 2% of titanium dioxide, and 2% of magnesium oxide. The frit is pulverized for later use; the weight ratio of material B is: 15% of quartz, 80% of kaolin, and 5% of calcined talc, and these three materials are mixed for later use. Then get A material 55% by weight, B material 45% accurate batching, according to material: ball: water=1: 2: 0.8, the residue of slurry crossing 250 mesh sieves is less than 0.1%, and slurry dehydration becomes plastic mud material, After shaping, drying, and glazing, it is fired at a firing temperature of 1290°C and kept for 30 minutes. The expansion coefficient of the ceramic product is measured, and its thermal expansion coefficient is a (常温~800℃) 0.60×10 -6 / °C, measuring its thermal stability, it can resist rapid cooling and rapid heating at 650°C to 20°C without cracking once.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com