Recovery and processing technique for waste lead acid accumulator

A lead-acid battery, recycling technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of animal and human harm, difficult to remove, insufficient combustion, etc., to achieve significant economic benefits and social Benefit, perfect treatment process, long flow time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

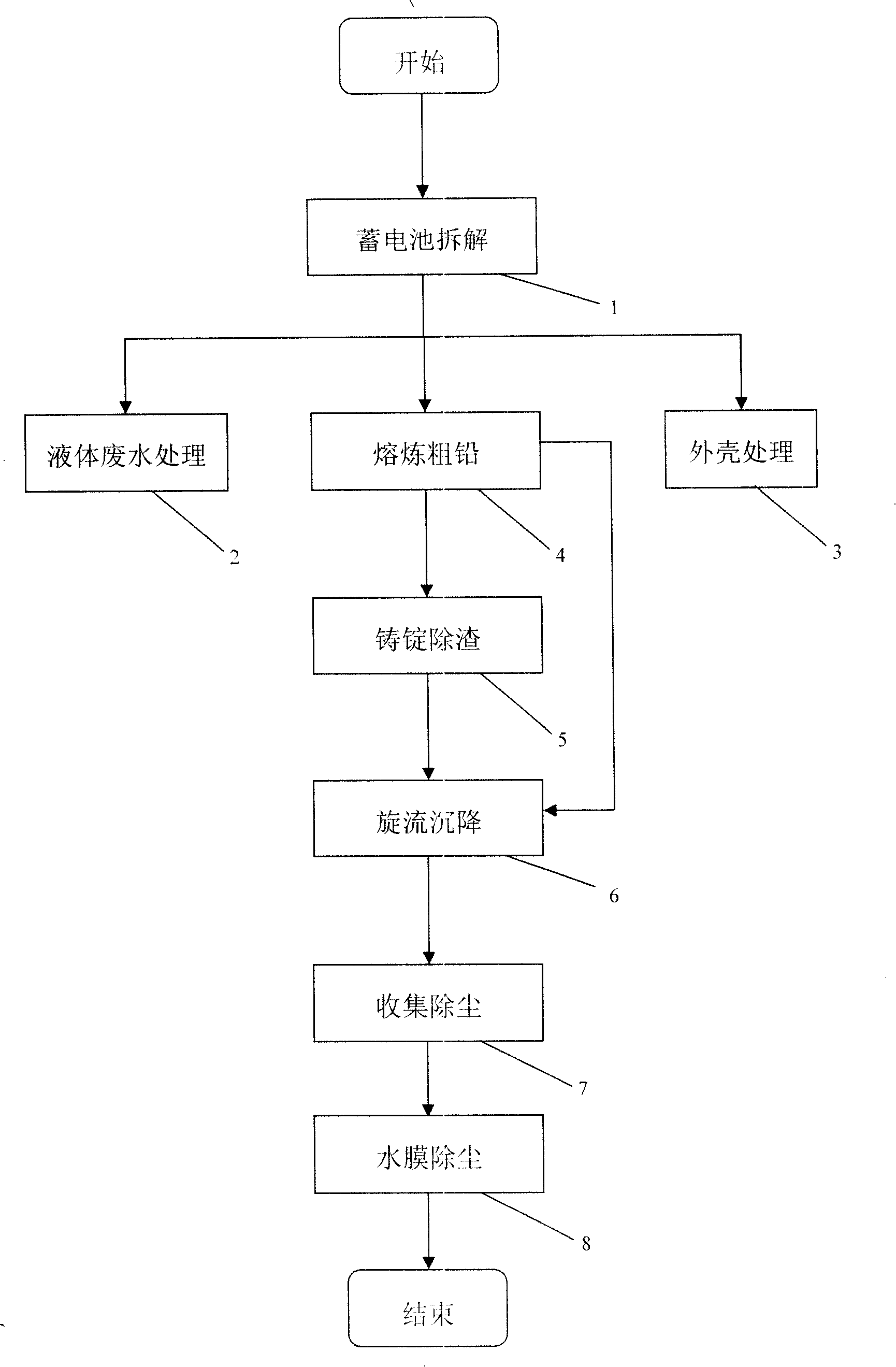

[0029] figure 1 It is a process flow chart of the waste lead-acid storage battery recycling process of the present invention. Including the following steps:

[0030] Battery dismantling 1: Disassemble the waste lead-acid battery and divide it into three categories: waste water, shell and lead-containing solid waste. The waste water is put into the acid-proof and anti-leakage sewage pool, the shell enters the shell treatment workshop, and the lead-containing solid waste enters the reverberatory furnace; The anti-acid and anti-leakage sewage pool is preferably made of marble, which has good anti-acid and anti-leakage performance, so that the acid will not enter the soil and cause pollution.

[0031] Liquid wastewater treatment 2: import the wastewater in the sewage tank into the ordinary wastewater treatment system for wastewater treatment;

[0032] Shell treatment 3: wash the shell, the water after rinsing is introduced into the sewage pool, and the shell after rinsing is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com