Preparation method and use method of biomass carbon fertilizer

A biomass carbon and biomass technology, applied in botany equipment and methods, fertilizer mixtures, applications, etc., can solve the problems of increasing greenhouse gas emissions, air pollution, soil fertility decline, etc., to reduce emissions, increase organic matter content, The effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

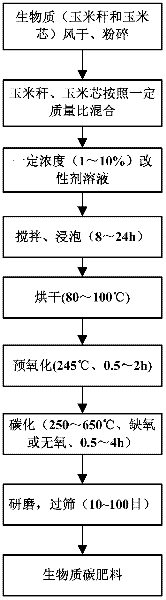

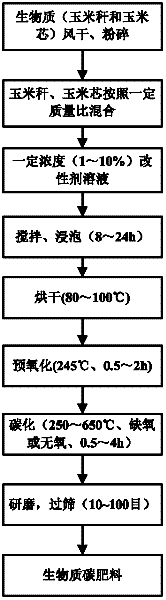

[0025] 1, a kind of preparation method of biomass carbon fertilizer of the present invention, the method concrete steps are as follows:

[0026] Step 1: Dry the biomass—corn stalks and corncobs naturally, and grind them in the FW8 high-speed universal grinder produced by Tianjin Test Instrument Co., Ltd.;

[0027] Step 2: Mix the pulverized corn stalks and corncobs obtained in Step 1 respectively according to the mass ratio of 8:2, and the total mass ratio of the two is 10, and soak them in a 5% ammonium dihydrogen phosphate solution After processing for 8 hours, put it into the DHG-9148A type electric heating constant temperature blast drying oven produced by Shanghai Jinghong Experimental Equipment Co., Ltd. to dry at 80°C;

[0028]Step 3: Put the corn stalks and corn cobs treated in Step 2 into the SX2-4-10 box-type resistance furnace produced by Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd. for pre-oxidation at 245°C for 1 hour, and then at 350°C and Carbonize...

Embodiment 2

[0034] 1, a kind of preparation method of biomass carbon fertilizer of the present invention, the method concrete steps are as follows:

[0035] Step 1: Dry the biomass—corn stalks and corncobs naturally, and grind them in the FW8 high-speed universal grinder produced by Tianjin Test Instrument Co., Ltd.;

[0036] Step 2: Mix the pulverized corn stalks and corn cobs obtained in Step 1 respectively according to the mass ratio of 3:7, and the total mass ratio of the two is 10, and soak them in a 5% diammonium hydrogen phosphate solution After processing for 8 hours, put it into the DHG-9148A type electric heating constant temperature blast drying oven produced by Shanghai Jinghong Experimental Equipment Co., Ltd. to dry at 80°C;

[0037] Step 3: Put the corn stalks and corn cobs treated in Step 2 into the SX2-4-10 box-type resistance furnace produced by Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd. for pre-oxidation at 245°C for 1 hour, and then at 350°C and Carboni...

Embodiment 3

[0043] 1, a kind of preparation method of biomass carbon fertilizer of the present invention, the method concrete steps are as follows:

[0044] Step 1: Dry the biomass—corn stalks and corncobs naturally, and grind them in the FW8 high-speed universal grinder produced by Tianjin Test Instrument Co., Ltd.;

[0045] Step 2: The crushed corn stalks and corncobs obtained in Step 1 are mixed according to the mass ratio of 5:5, and the total mass ratio of the two is 10, and soaked in a 5% potassium dihydrogen phosphate solution After processing for 8 hours, put it into the DHG-9148A type electric heating constant temperature blast drying oven produced by Shanghai Jinghong Experimental Equipment Co., Ltd. to dry at 80°C;

[0046] Step 3: Put the corn stalks and corn cobs treated in Step 2 into the SX2-4-10 box-type resistance furnace produced by Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd. for pre-oxidation at 245°C for 1 hour, and then at 350°C and Carbonize for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com