Patents

Literature

1170 results about "Biomass carbon" patented technology

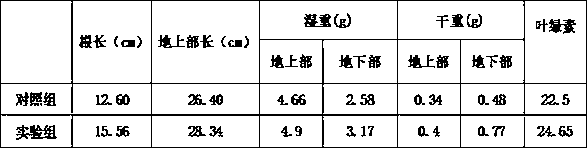

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass carbon includes carbon stored in above- and below-ground live plant components (such as leaf, branch, stem and root) as well as in standing and down dead woody debris, and fine litter.

Method for preparing fewer-layer graphene on basis of biomass waste

ActiveCN105060289AReduce pollutionAbundant and easy-to-obtain raw materialsCarbon layerArgon atmosphere

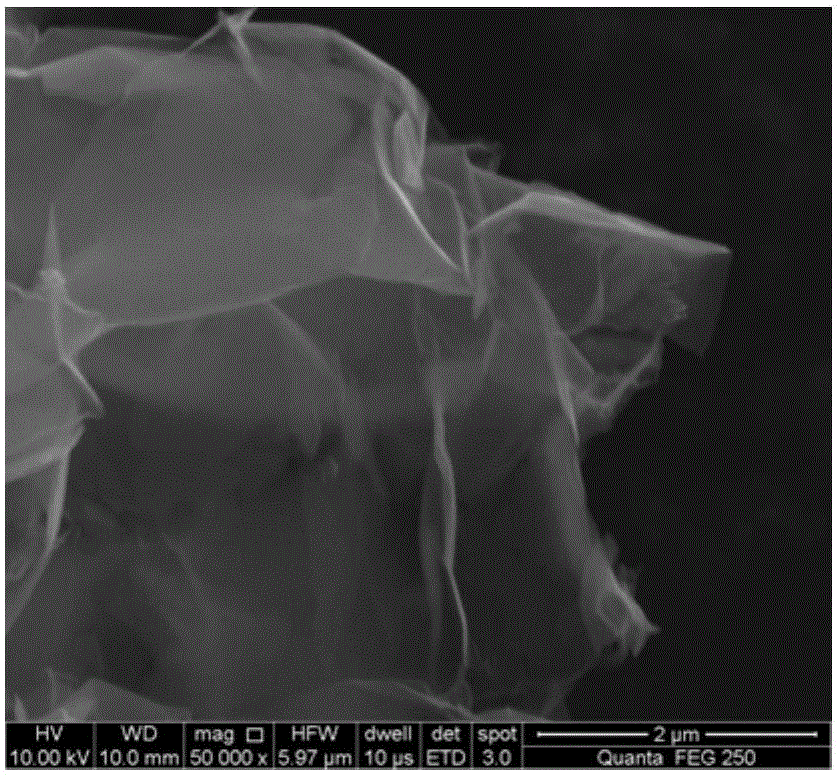

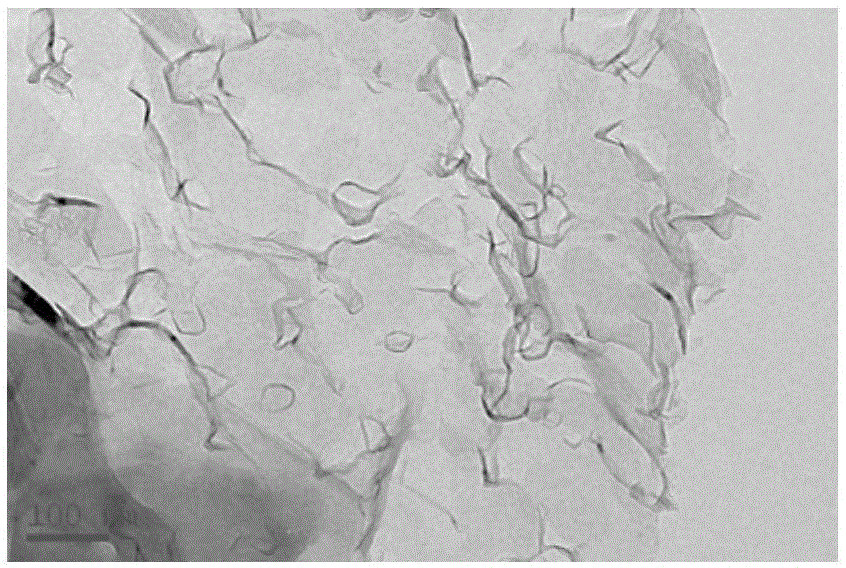

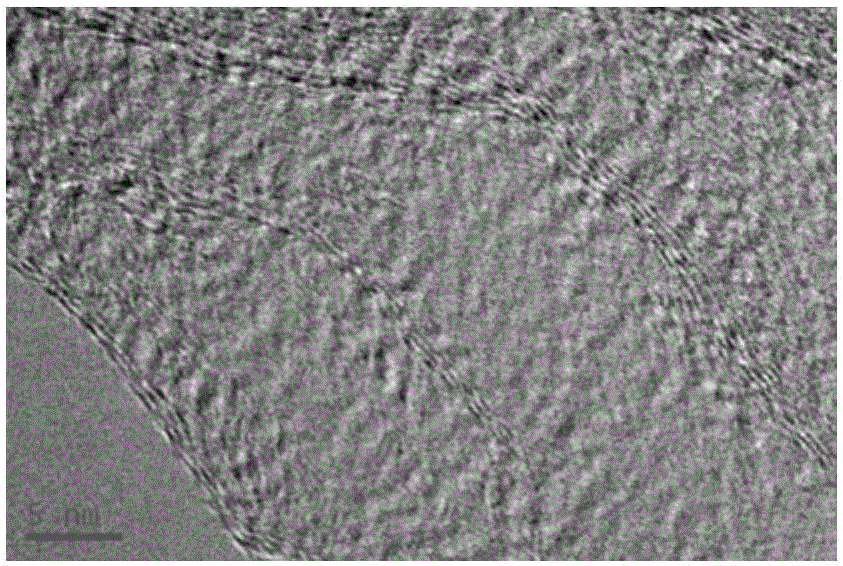

The invention discloses a method for preparing fewer-layer graphene on the basis of biomass waste, which comprises the following steps: carrying out hydrothermal treatment on the biomass waste, and carrying out carbonization by heating and calcination, thereby obtaining a carbonization material; immersing the carbonization material in an acid solution to remove impurities, thereby obtaining biomass carbon; and quickly heating the biomass carbon in an argon atmosphere, and carrying out high-temperature graphitization to obtain the biomass fewer-layer graphene. The hydrothermal process is combined with the high-temperature graphitization to directly strip the biomass waste, and the carbonization and high-temperature graphitization are carried out. Thus, the prepared biomass fewer-layer graphene has the advantages of fewer layers (2-10 layers), fewer defects, fewer oxy groups, high electric conductivity and small carbon layer interval. The method is simple to operate, has the advantages of low cost and high graphene yield, and can easily implement industrialized large-scale production. The prepared biomass fewer-layer graphene can be used in the fields of lithium ion batteries, supercapacitors and the like, is beneficial to green production of battery industry, and has important practical value and favorable application prospects.

Owner:湖南宸宇富基新能源科技有限公司

Preparation method of functional organic fertilizer for soil restoration

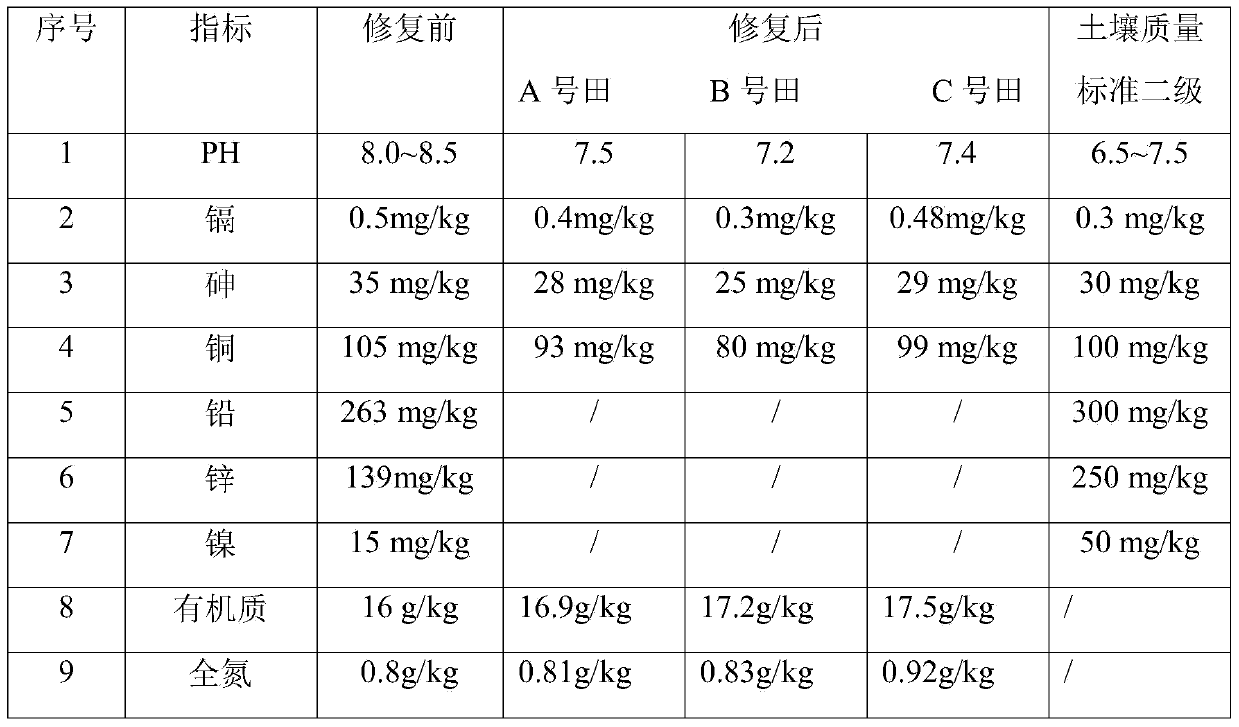

The invention discloses a preparation method of a functional organic fertilizer for soil restoration. The method comprises the following steps: mixing crushed straws with blue-green algae according to the mass ratio of (1-5):10 to obtain a mixture, and then adding a biomass-transformed complex microbial inoculant and a biomass-transformed inductive material to the mixture; evenly mixing and then carrying out conventional stacking fermentation for 5-15 days, so as to obtain a semi-solid organic fertilizer; and mixing and pelletizing the semi-solid organic fertilizer, clay, biomass carbon ash and a heavy metal ion chelating agent according to the ratio of 1000:(50-200):(50-150):(1-5), so as to obtain the functional organic fertilizer for soil restoration. The organic fertilizer disclosed by the invention has a persistent slow-release fertilizer effect, and can adsorb, chelate and immobilize the heavy metal ions in a deactivation manner, soil fleeciness is facilitated, the moisture retention and the breathability are improved, rooting of plants is facilitated, formation of beneficial components of soil microelements and the like is optimized, the heavy metal-polluted soil is effectively restored, and secondary pollution of the soil is not caused.

Owner:合肥市东方美捷分子材料技术有限公司

Method for preparing biomass carbon by utilizing agricultural and forestry waste

InactiveCN102583311AImprove protectionRaw materials are easy to getSolid waste disposalCarbon preparation/purificationBiomass carbonSorbent

The invention relates to a method for preparing biomass carbon by utilizing agricultural and forestry waste, belonging to the technical fields of preparation of carbon materials and utilization of biomass resources. The method comprises the following steps of: adopting agricultural and forestry waste as raw materials; under the condition of subcritical water, fully mixing dried biomass materials and deionized water according to the proportion of 1:(10-30); under the protection of inert atmosphere, carbonizing for 2-6 hours at the temperature of 220-250 DEG C; and then carrying out vacuum filtration and hot-water cleaning, and drying to obtain the biomass carbon. The biomass carbon prepared by the invention is coaly carbon material with an aromatic-ring structure, is high in carbon content and calorific value and large in specific surface area, and can be used as a soil conditioner or an absorbent. The method has the advantages that the materials are low in cost and easy to obtain, the process is simple, the operation is convenient, the manufacturing cost is low, the industrial promotion is convenient, and the application range and the application value of biomass resources are further expanded in the aspect of carbon materials.

Owner:BEIJING FORESTRY UNIVERSITY

Biochar base soil modifier and preparation method thereof

ActiveCN102660291AReduce leaching wasteGood sustained release effectAgriculture tools and machinesOrganic fertilisersDecompositionCarbonization

The invention discloses a biochar base soil modifier and a preparation method thereof. The biochar base soil modifier comprises the following components in percentage by weight: 95.5-98.5% of biomass carbon black and 1.5-4.5% of probiotics agent. Agricultural waste serves as a biomass raw material to carry out low-temperature carbonization to form the porous biomass carbon black; beneficial microorganism is enlarged and cultivated and is fermented into probiotics liquid; after mixing, solid and liquid separation, flash evaporation and drying are carried out to obtain the probiotics agent; the beneficial microorganism is selected from one or more of paenibacillus polymyxa, trichoderma strains, nitrogen-fixing bacteria, rhizobium, phosphate solubilizing bacteria, potassium bacteria, cellulose decomposition bacteria, antibiotic generation bacteria and photosynthetic bacteria. The biochar base soil modifier disclosed by the invention adopts the microporous biomass carbon which has strong adsorption capability and good light absorption and temperature-increasing effect. The probiotics agent has a high survival rate and can be stored for a long time at the normal temperature, the fertilizer synergy action is obvious, and the soil borne disease can be effectively prevented and cured.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Carbon-based fertilizer potentiating agent and application thereof

InactiveCN102675001ASimple production processRaw materials are easy to getClimate change adaptationFertilising methodsNitrification inhibitorsPollution

Owner:SHENYANG AGRI UNIV

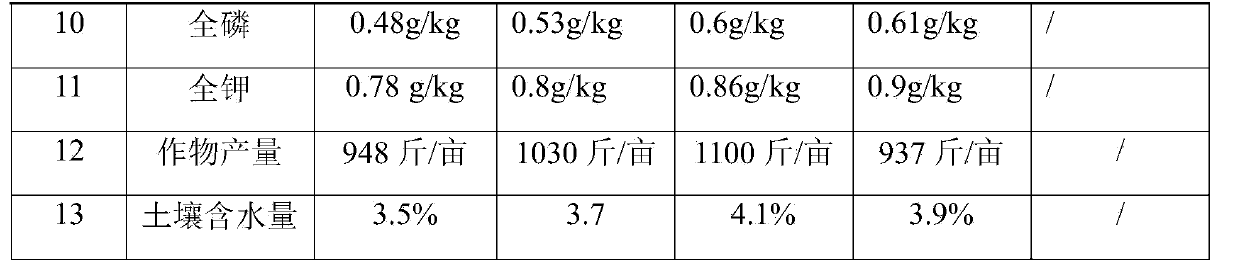

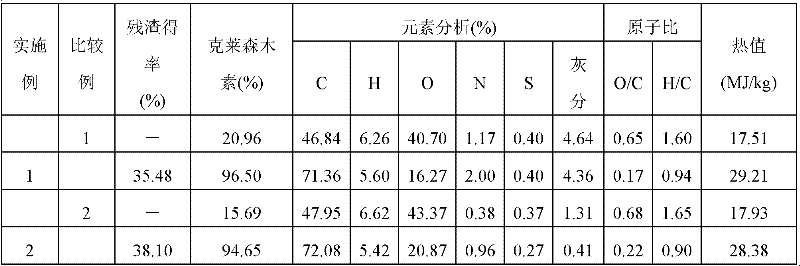

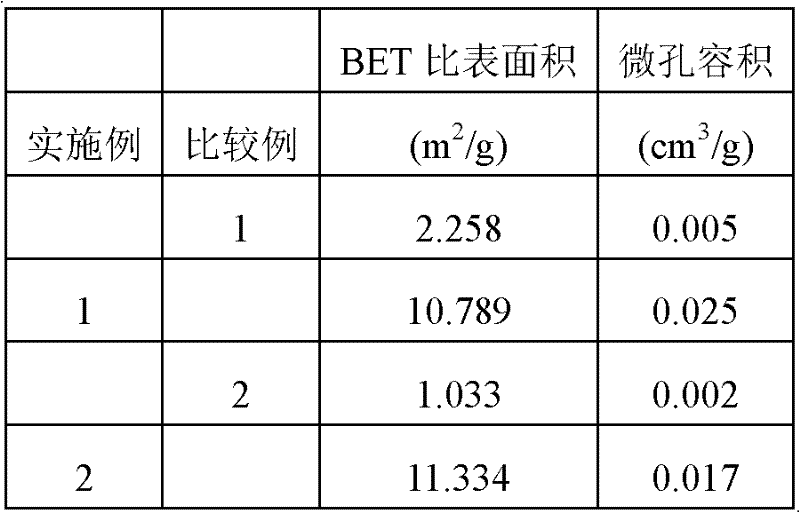

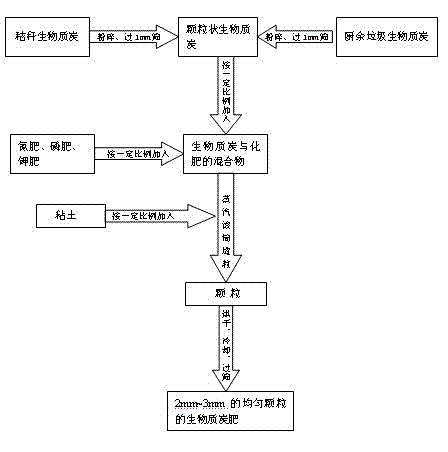

Multi-functional biomass carbon fertilizer produced by using biomass carbon from straws and kitchen waste

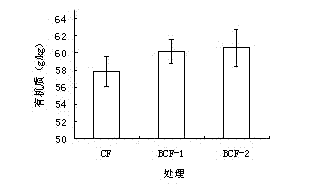

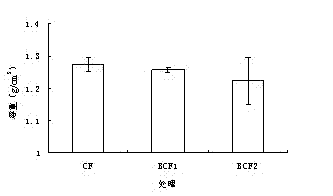

The present invention relates to multi-functional biomass carbon fertilizer produced by using biomass carbon from straws and kitchen waste, and belongs to the technical field of organic and inorganic compound fertilizer. The fertilizer mainly comprises the following components, by weight, 15-30% of biomass carbon, 25-35% of nitrogen fertilizer, 15-25% of phosphorus fertilizer, 15-25% of potassium fertilizer and 2-4% of clay, wherein the total nutrient weight percentage of the prepared fertilizer is 35-42%, the organic matter content is 15-20%. The preparation method comprises the following steps: crushing the biomass carbon; screening the crushed biomass carbon by using a 1 mm sieve; uniformly mixing the screened biomass carbon, the nitrogen fertilizer, the phosphorus fertilizer and the potassium fertilizer; then mixing the clay to the resulting mixture; carrying out pelletizing by a steam drum, drying and screening to prepare uniform particles with the particle sizes of 2-3 mm. According to the present invention, the resource utilization of the waste can be effectively realized; the discharge of nitrous oxide of the soil can be significantly reduced; the fixed carbon content in the soil can be improved; the soil bulk density can be regulated; the nitrogen utilization efficiency of the crop can be increased; the yield and the quality of the crop can be substantially improved.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

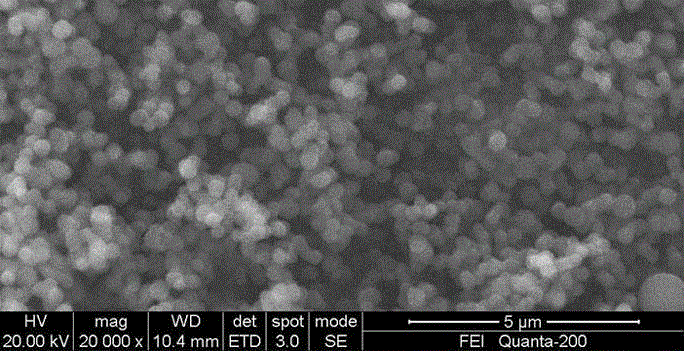

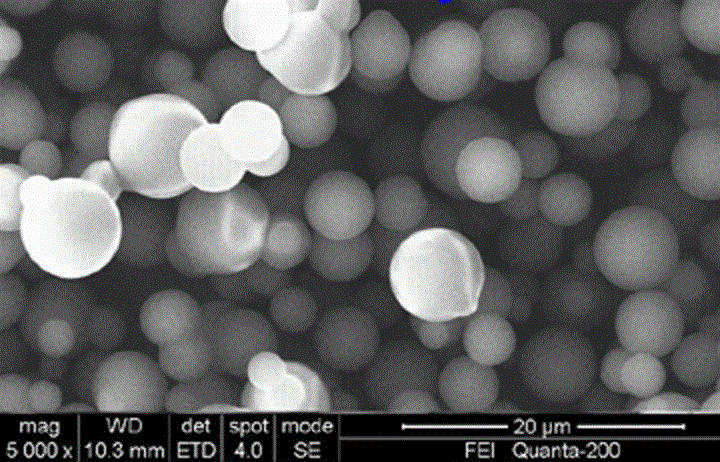

Low temperature hydrothermal preparation method of biomass carbon microsphere / nanosphere

InactiveCN104649246ALow hydrothermal carbonization temperatureImprove securityMaterial nanotechnologyBiomass carbonPtru catalyst

The invention discloses a low temperature hydrothermal preparation method of alkali catalysis or Lewis acid / proton acid catalysis biomass. The method is as below: adding a certain amount of biomass, deionized water and a proper amount of alkali or Lewis acid / protonic acid into carbide carbon of biomass to a teflon inner liner, stirring to dissolve soluble biomass, filling into a stainless steel reaction kettle, and placing in an oven and reacting for a while at preset temperature, and reacting insoluble biomass in a device equipped with a heating sleeve and a thermostat magnetic stirrer under the preset temperature, wherein the reaction conditions are as below: temperature of 110-160 DEG C (preferably 120-140 DEG C) and reaction time of 6-72 h (preferably 12-36 h); naturally cooling to room temperature, conducting high speed centrifugal separation, and re-dispersing and repeatedly washing the obtained solid with deionized water and 95% ethanol to obtain a colorless supernatant, and drying to obtain carbon microsphere / nanosphere. The method provided by the invention has the advantages of low hydrothermal carbonation temperature and high carbon production rate of the biomass, and is applicable to large-scale industrial production; and the product can be used as a catalyst carrier or adsorbent.

Owner:HUNAN NORMAL UNIVERSITY

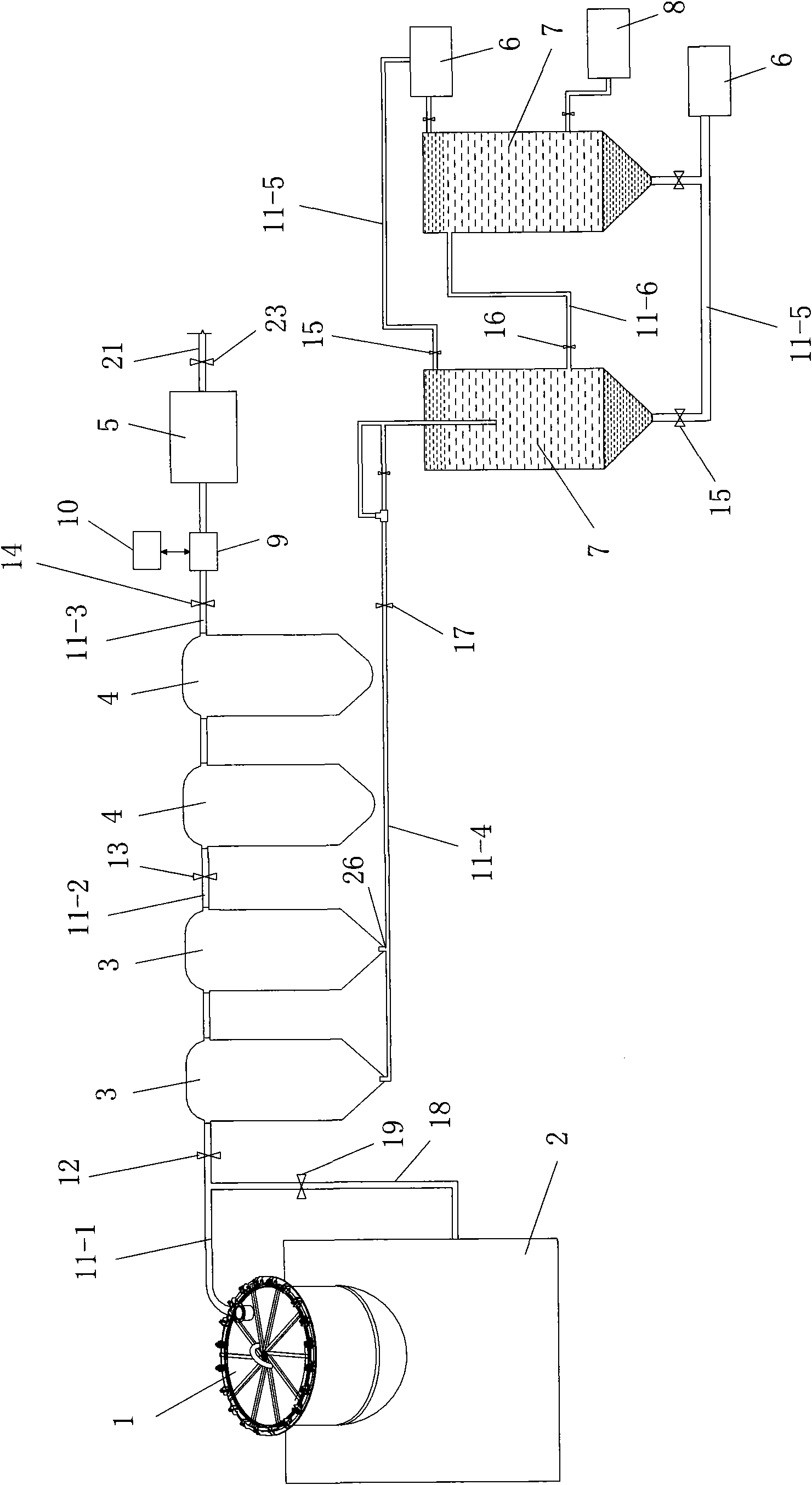

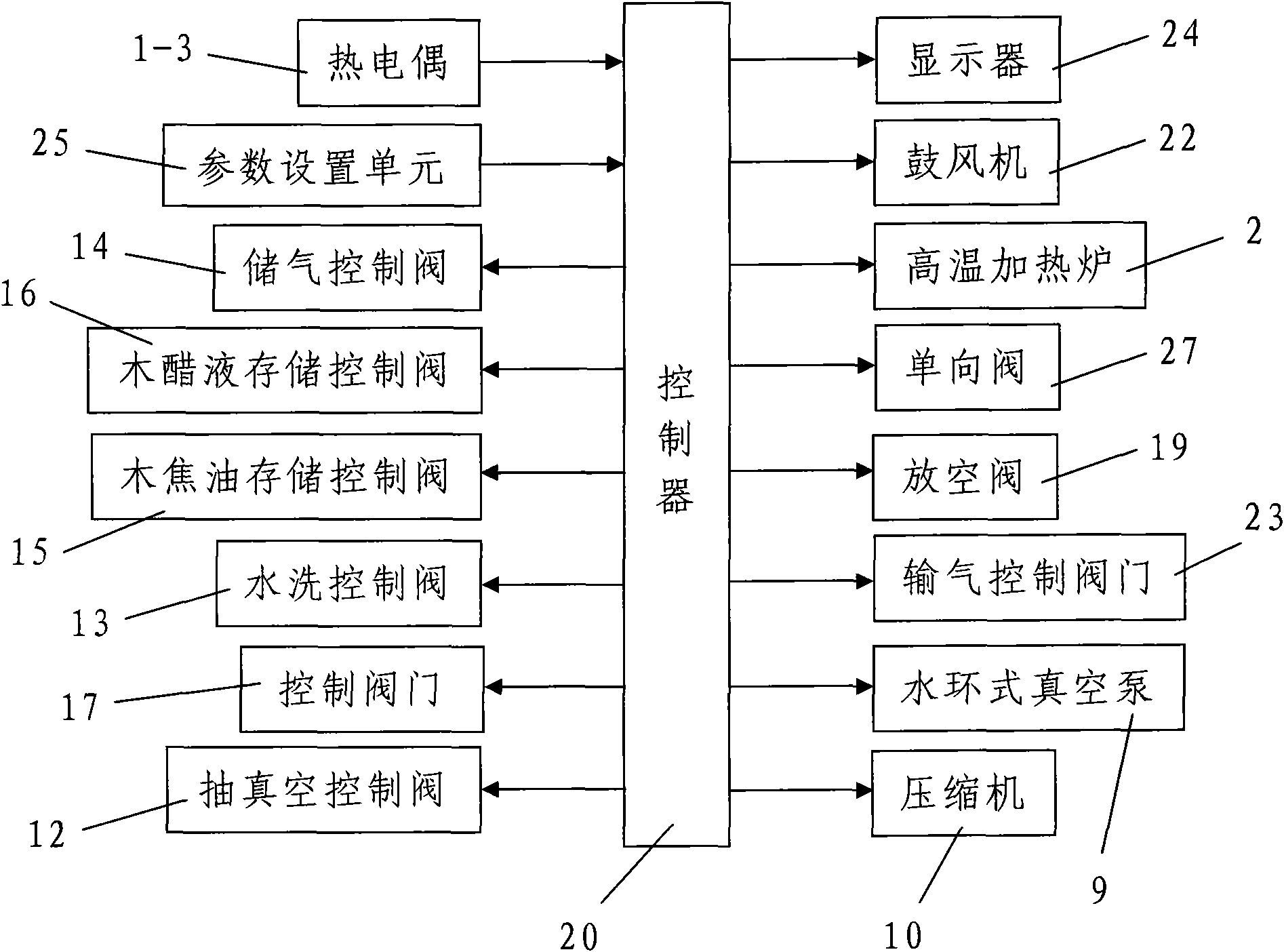

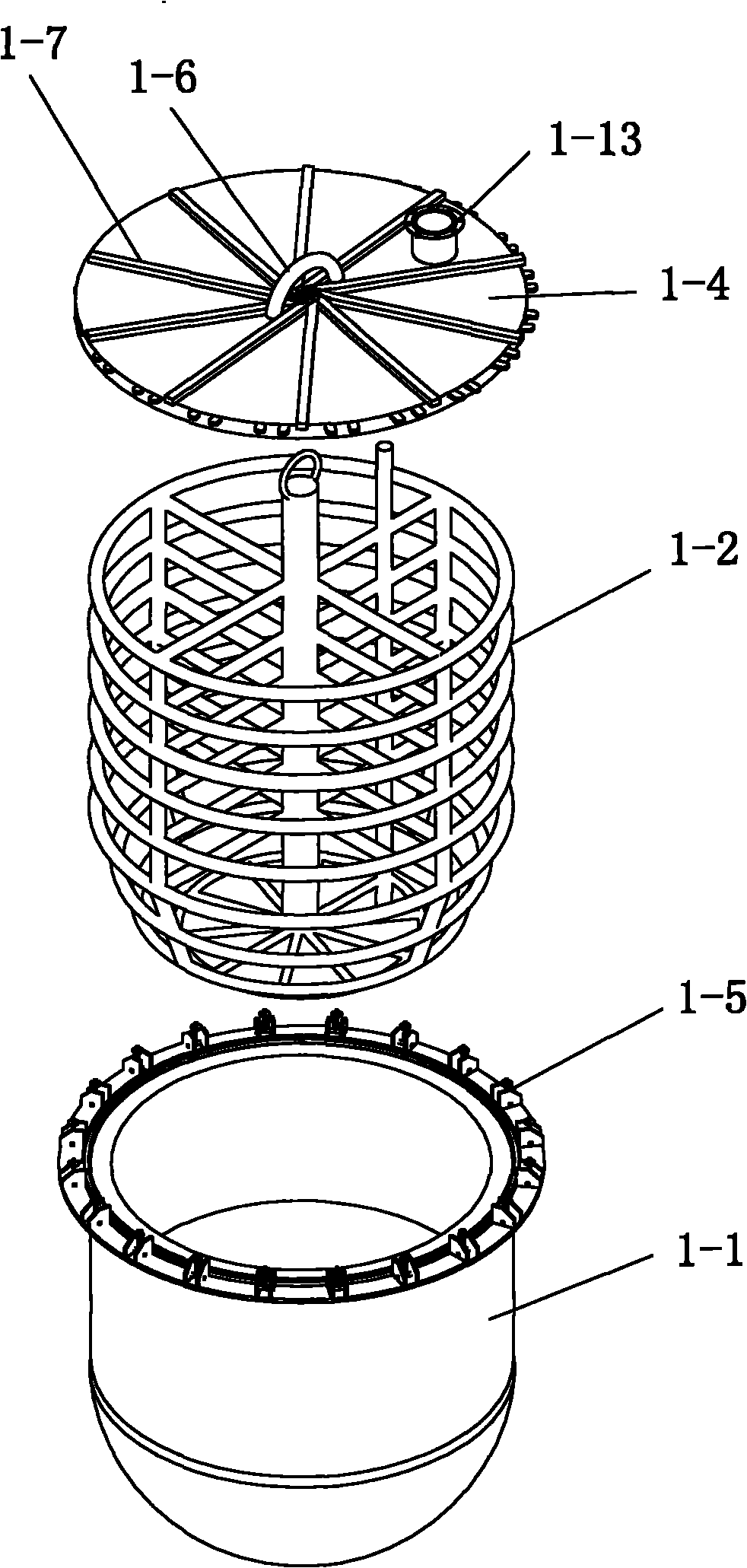

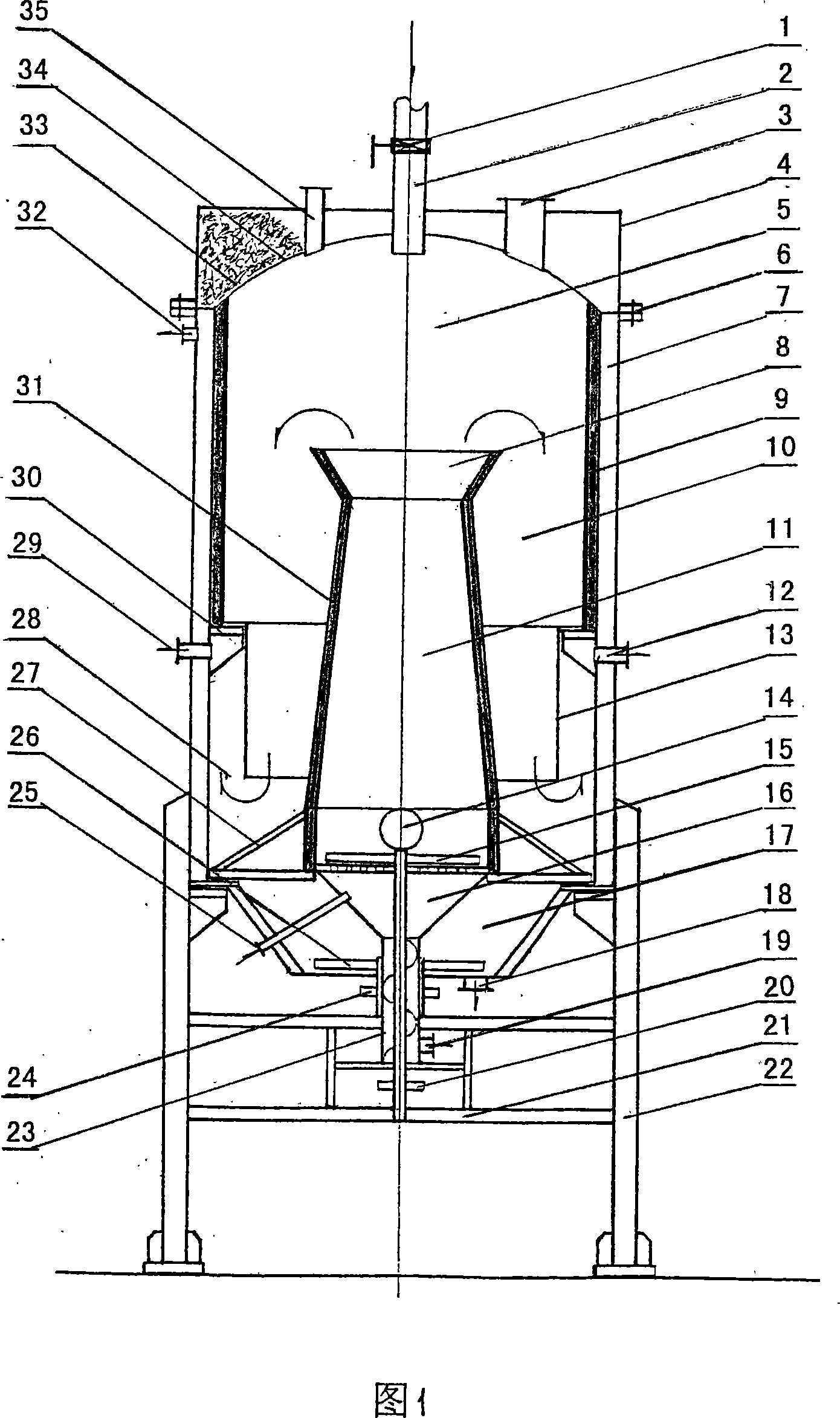

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780AFirmly connectedReasonable designBiofuelsPyroligneous acid productionSocial benefitsBiomass carbon

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

Crop seed coating agent prepared from novel biomass carbon of agricultural wastes and preparation method of coating agent

Owner:NANJING AGRICULTURAL UNIVERSITY

Carbon-based ginseng soil conditioner and preparation method thereof

ActiveCN102604645ASimple production processSimple production equipmentOrganic fertilisersSoil-working methodsEcological environmentPhosphate

The invention relates to the field of agricultural chemistry, in particular relates to a carbon-based ginseng soil conditioner and a preparation method thereof. The carbon-based ginseng soil conditioner comprises biomass particle carbon, wood vinegar and an adhesion agent, and further comprises other fertilizers, such as urea, monoammonium phosphate powder, potassium chloride, zinc sulfate, boric fertilizer, manganese sulfate, ammonium molybdate, ferrous sulfate and copper sulfate. The biomass particle carbon is black carbon powder particles (biomass carbon) generated by incompletely combusting biomasses under a low-oxygen condition and has the advantages of stable property, strong adsorptive capacity and good moisture and fertility preservation effects. The soil conditioner prepared from the biomass particle carbon and the wood vinegar can improve the structure of the soil, optimize a soil ecological environment and improve the utilization efficiency of the fertilizer; when production increasing and synergism of ginsengs can be accelerated, the carbon is effectively stored in the soil, so as to realize agricultural emission reduction; and therefore an application prospect is wide.

Owner:SHENYANG AGRI UNIV

Preparation method of biomass carbon composite material for removing phosphorus in wastewater

ActiveCN103721677AAchieve recyclingMild reaction conditionsOther chemical processesWater/sewage treatment by sorptionBiomass carbonAlcohol

The invention provides a preparation method of a biomass carbon composite material for removing phosphorus in wastewater. The preparation method comprises the steps of adding waste biomass into a metal salt solution to stir and mix evenly, then adding an alkali solution to continuously stir for 30-120 minutes, then performing hydrothermal carbonization, cooling a product to room temperature after reaction is ended, filtering, washing unreacted substances on the surface by using water and / or ethyl alcohol, then drying to constant weight at a temperature of 60-120 DEG C and sieving through a sieve with 40-180 meshes to obtain the biomass carbon composite material. According to the preparation method, the waste biomass serves as the raw material, so that the preparation method is low in cost; due to the adoption of hydrothermal carbonization, the preparation method is warm in reaction condition and simple in whole preparation process; and the prepared biomass carbon composite material is good in stability and efficient in phosphorus removal effect.

Owner:BIOGAS SCI RES INST MIN OF AGRI

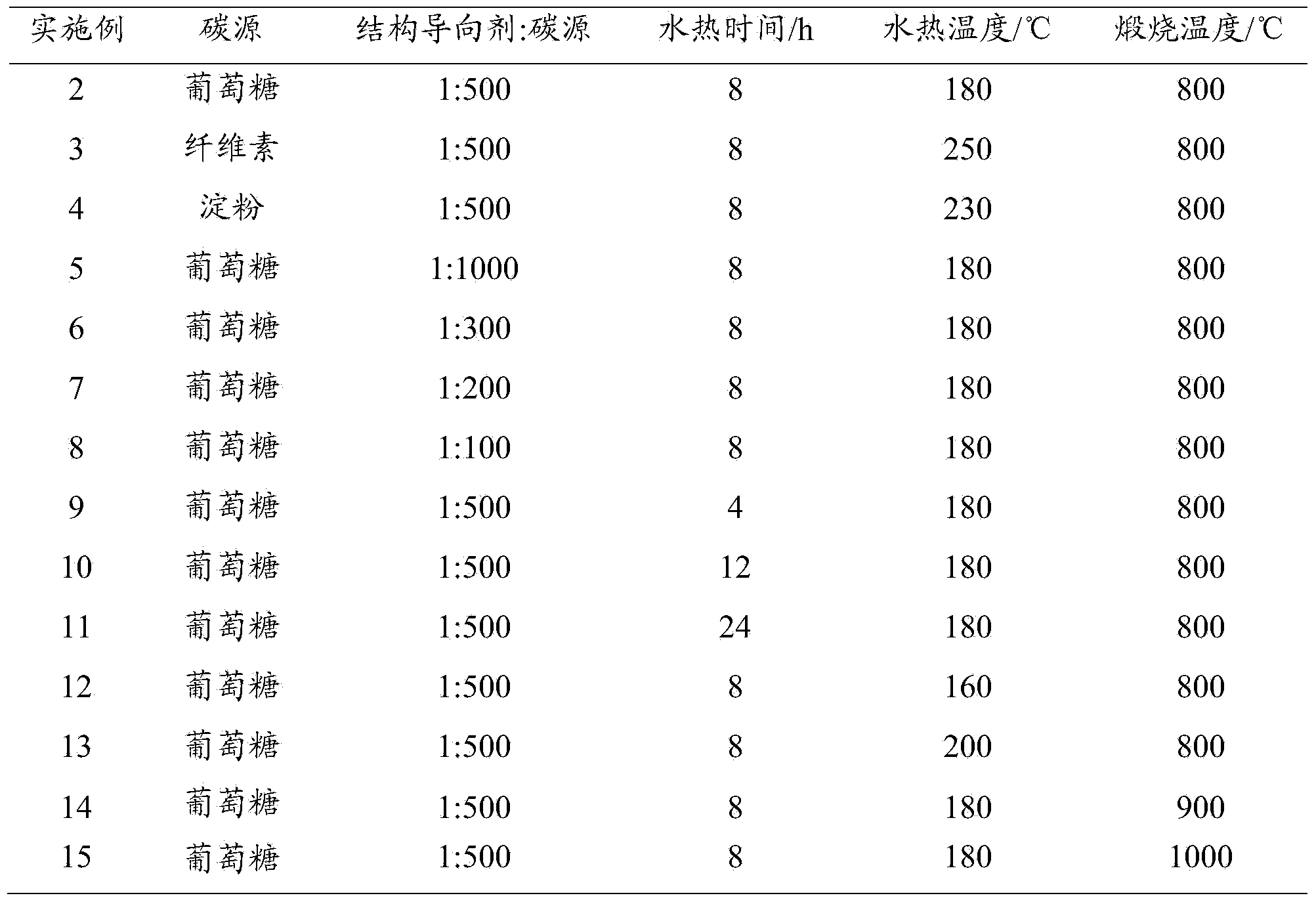

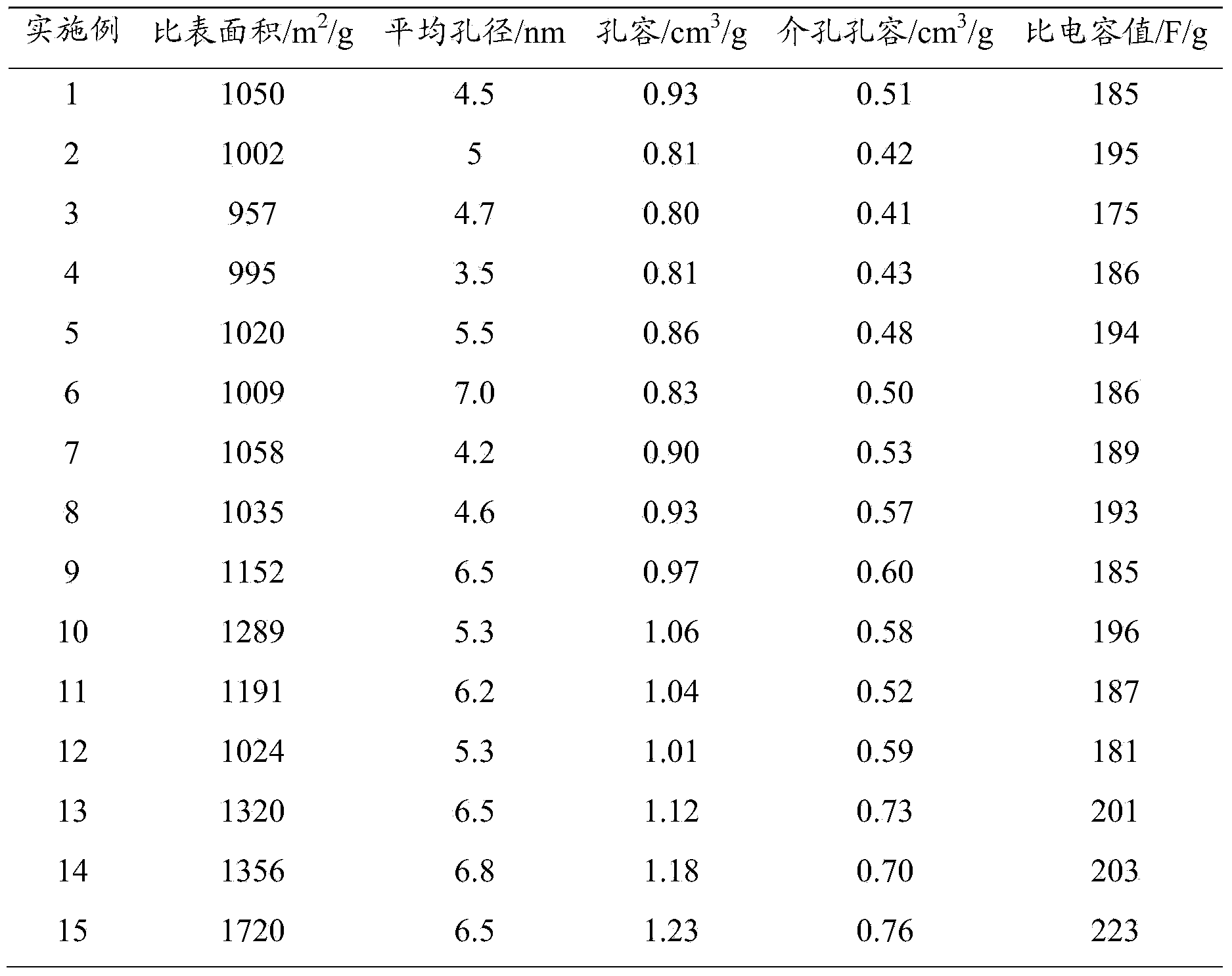

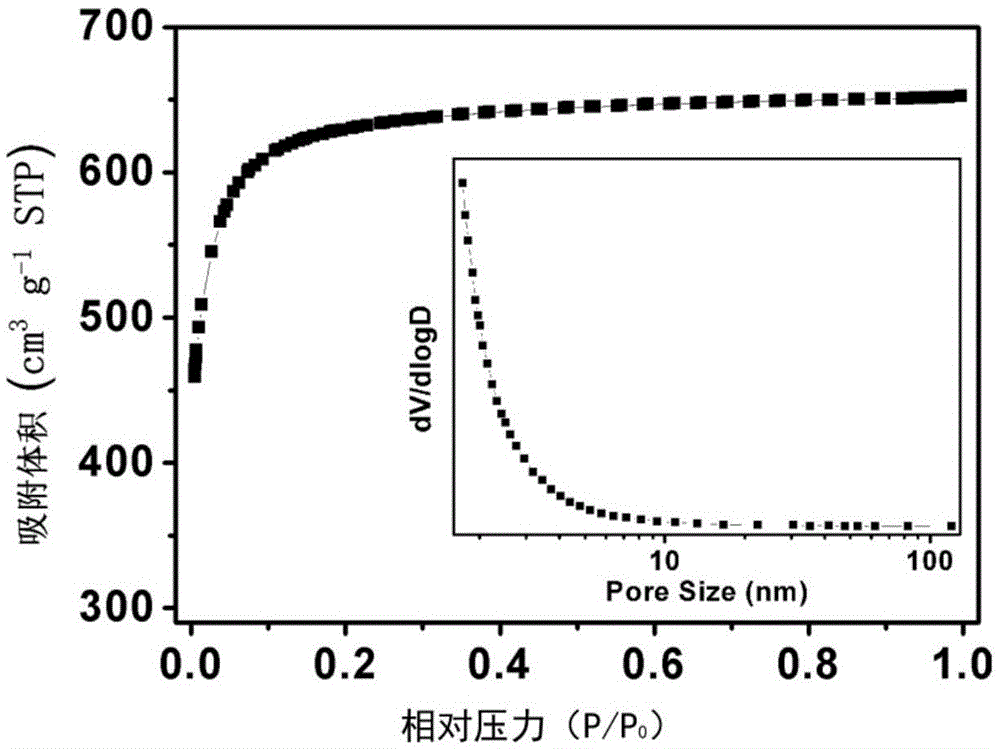

Preparation method of porous carbon and product thereof

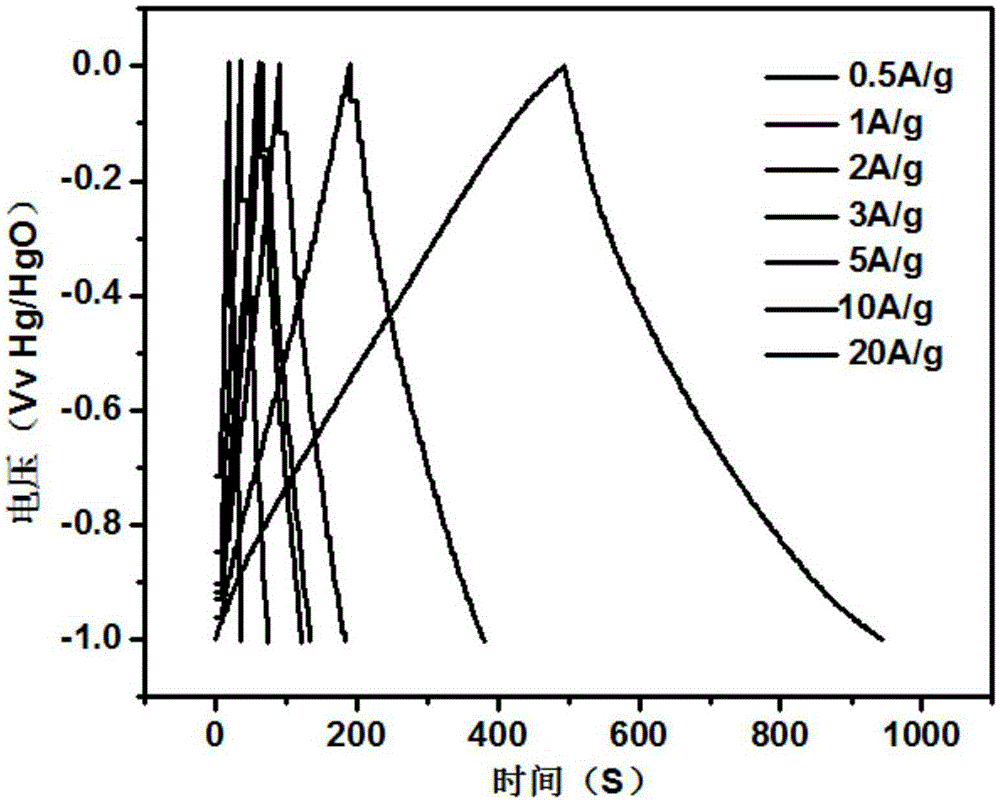

ActiveCN103803527AWide variety of sourcesNo toxicityHybrid capacitor electrodesNano-carbonCapacitanceMass ratio

The invention discloses a preparation method of porous carbon and a product thereof. The preparation process of the method comprises the following steps: uniformly mixing a biomass carbon source, a structure-directing agent and water to obtain mixed liquor; carrying out a hydrothermal reaction; cooling, washing, drying and calcining to obtain the porous carbon, wherein the mass ratio of the structure-directing agent to the biomass carbon source is 1:5000-1:50; the structural guiding agent is ionic polyelectrolyte. The invention further discloses porous carbon prepared by using the method. The particle diameter of the porous carbon is 50-100 nanometers, the BET specific surface area is 1000-2000m<2> / g, the BJH beverage aperture is 2-10 nanometers, the pore volume is 0.8-1.2cm<3> / g, and meso pores account for 50-70 percent of the total pore volume. A super capacitor manufactured by taking the porous carbon as an electrode material has the advantages of high activity, low resistance and large specific capacitance, and the maximum specific capacitance value can be up to 223F / g.

Owner:ZHEJIANG UNIV

Biomass charcoal based probiotic preparation and preparation method thereof

InactiveCN102701834AReduce leaching wasteGood sustained release effectClimate change adaptationAgriculture gas emission reductionAbsorption capacityDecomposition

The invention discloses a biomass charcoal based probiotic preparation, which is composed of biomass carbon black and concentrated probiotic preparation based on a weight ratio of (8.85-9.15): (0.85-1.15). The preparation is prepared by using agricultural wastes as biomass raw materials, conducting low-temperature carbonization to form porous biomass carbon black; conducting amplification culture to beneficial microorganism, and fermenting to produce probiotic solution; mixing above materials and separating solid from liquid; and drying by flash evaporation to obtain concentrated probiotic preparation, wherein the beneficial microorganism is one or more of paenibacillus polymyxa, trichoderma, nitrogen-fixing bacteria, rhizobium, phosphate dissolving bacteria, potassium dissolving bacteria, cellulose decomposition bacteria, antibiotic producing bacteria, and photosynthetic bacteria. In addition, the invention also discloses a preparation method for the biomass charcoal based probiotic preparation. The biomass charcoal based probiotic preparation provided by the invention uses microporous biomass charcoal, which has very strong absorption capacity and very good light absorption and warming effect. The probiotic preparation is high in survival rate of live bacteria, can be preserved for a long time at normal temperature and has evident synegistic effect for fertilizer.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

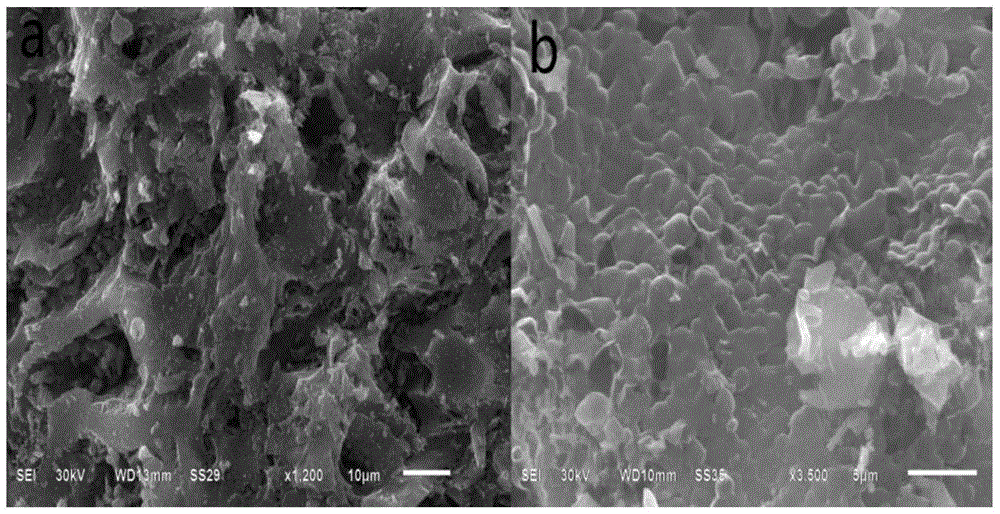

Biomass carbon catalyst and preparation method and application thereof

The invention discloses a biomass carbon catalyst and a preparation method and application thereof. The precursor of the catalyst comprises biomass and metal salts, wherein the biomass includes one or more of maize straw, corncob, rice straw, cotton straw, peanut straw, peanut shell, wheat hull, rice hull, wood, sawdust, bamboo wood and weed. Through controlling addition of metal salts in different amounts, adjusting impregnation concentration of the precursor and reaction ambient and carbonization and nitriding treatment temperatures, the biomass carbon catalyst with controllable and adjustable pore structure and specific surface area can be prepared. When used as a fuel battery cathode catalyst, the biomass carbon catalyst shows excellent oxygen reduction reaction activity and stability. The preparation process is simple in flow, short in period and free of environment, provides a novel high-value-added resource recycling way for waste biomass and has dual effects of biomass disposal and energy and power generation.

Owner:SHENYANG AGRI UNIV

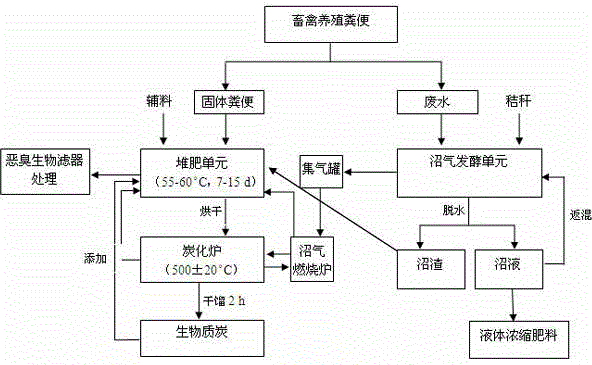

Resource utilization method of livestock and poultry breeding wastes

ActiveCN104150987AHigh calorific valueReduce moisture contentBio-organic fraction processingClimate change adaptationFecesResource utilization

The invention discloses a resource utilization method of livestock and poultry breeding wastes. The method comprises the following steps of carrying out solid-liquid separation on livestock and poultry breeding wastes to obtain solid manures and breeding wastewater, composting solid manures at a high temperature and carbonizing to prepare biomass carbon and carrying out biogas fermentation on the breeding wastewater and concentrating to obtain a liquid fertilizer. By adopting the method disclosed by the invention, livestock and poultry breeding wastes are subjected to optimal utilization in form of material and energy to obtain biomass carbon and the concentrated liquid fertilizer capable of being applied to the agricultural production and thus the resource utilization of wastes is achieved, and the recycling of resources can be realized inside a livestock and poultry breeding wastes treatment region to achieve the purposes of reducing energy consumption and pollutant emission.

Owner:ZHEJIANG UNIV

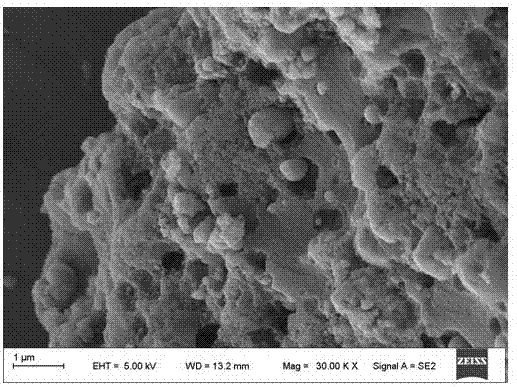

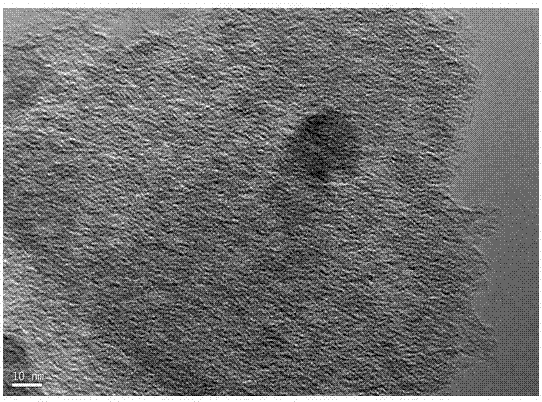

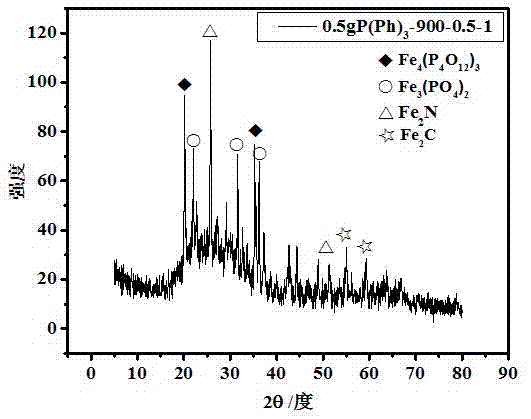

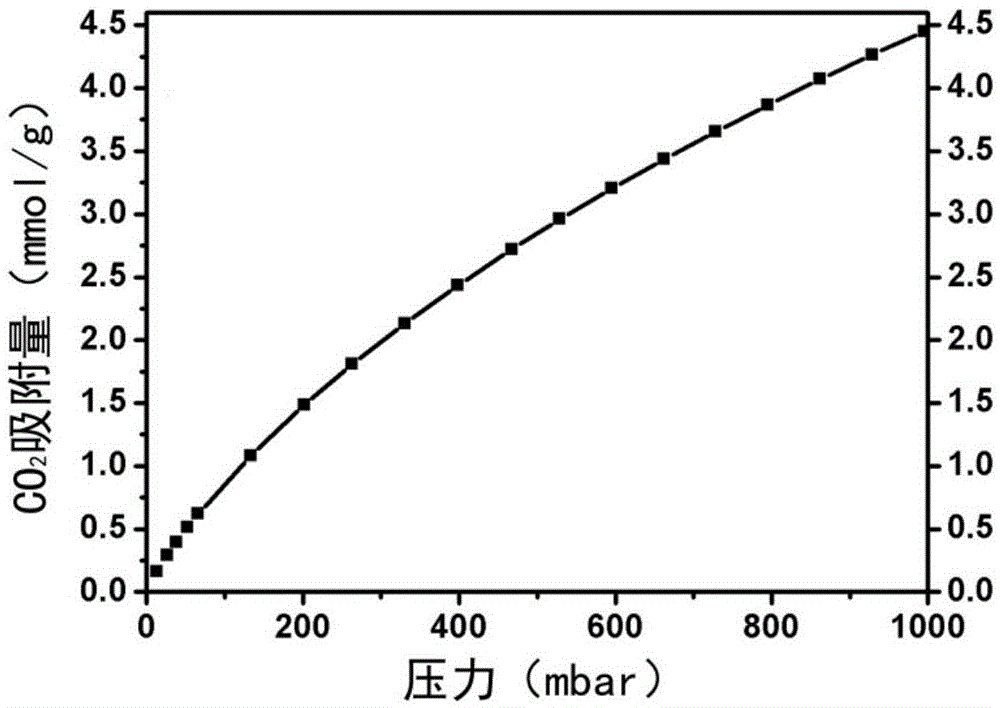

Preparation method of N-P-codoping porous biomass carbon catalyst

ActiveCN106881138ALarge specific surface areaRich microporous structurePhysical/chemical process catalystsCell electrodesMolecular levelNitrogen gas

The invention provides a preparation method of N-P-codoping porous biomass carbon catalyst. Cheap and easy-to-get biomass chitosan is taken as carbon source and nitrogen source (as nitrogen-containing ligand at the same time), organic phosphorus compound triphenylphosphine is taken as phosphorus-containing ligand, the nitrogen-containing ligand and the phosphorus-containing ligand form a coordination compound together with metal ions in metallic salt solution, ZnCl2 is taken as activating agent, the coordination compound is subjected to high-temperature pyrolysis in a nitrogen atmosphere to form holes, and finally diluted hydrochloric acid is used to remove metals for secondary hole formation, so as to prepare the N-P-codoping porous biomass carbon catalyst with rich micropores and a mesopores structure as well as a high specific surface area. The N-P-codoping porous biomass carbon catalyst is comparable to commercial Pt / C (20%) in catalytic performance in an alkaline environment, has good methanol poisoning resistance and stability, and can regulate components and performance of catalyst in molecular level. The N-P-codoping porous biomass carbon catalyst disclosed by the invention is expected to replace cathode oxygen reduction catalyst of the commercial Pt / C, and has a very good industrial application prospect.

Owner:NORTHWEST NORMAL UNIVERSITY

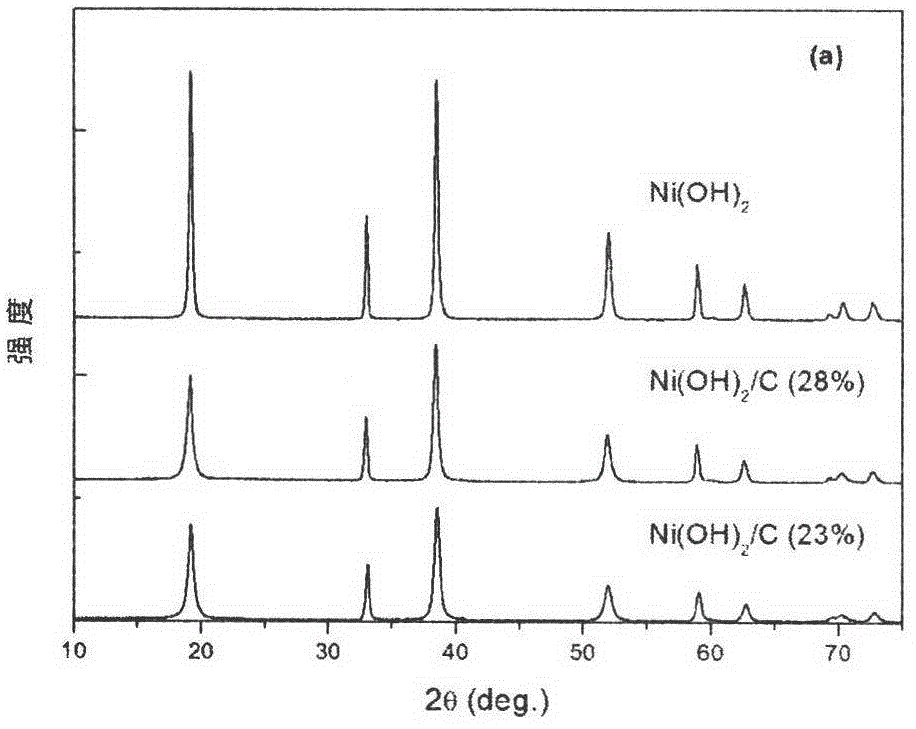

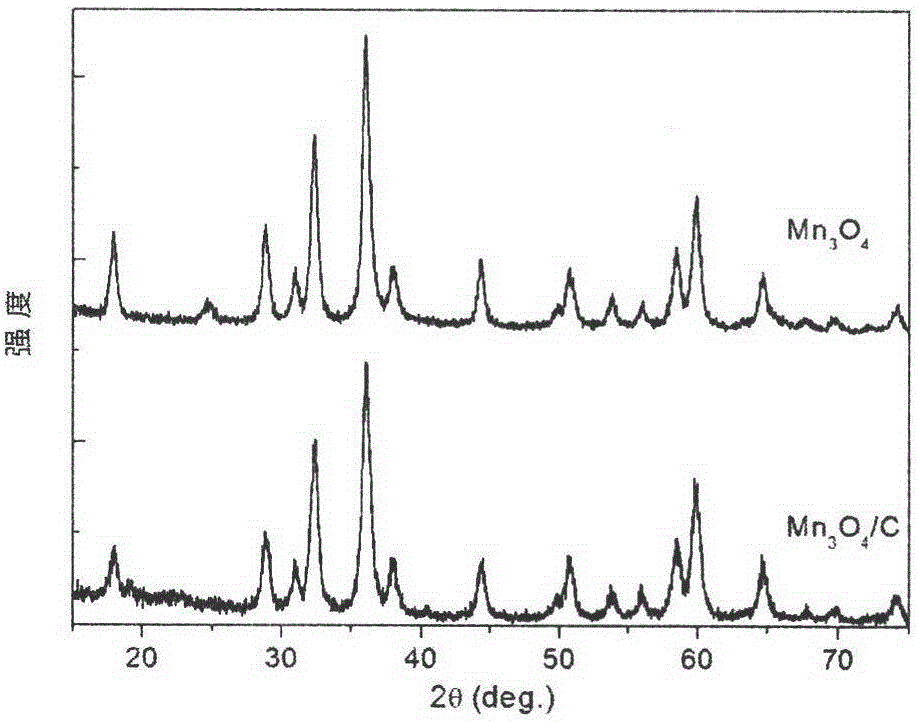

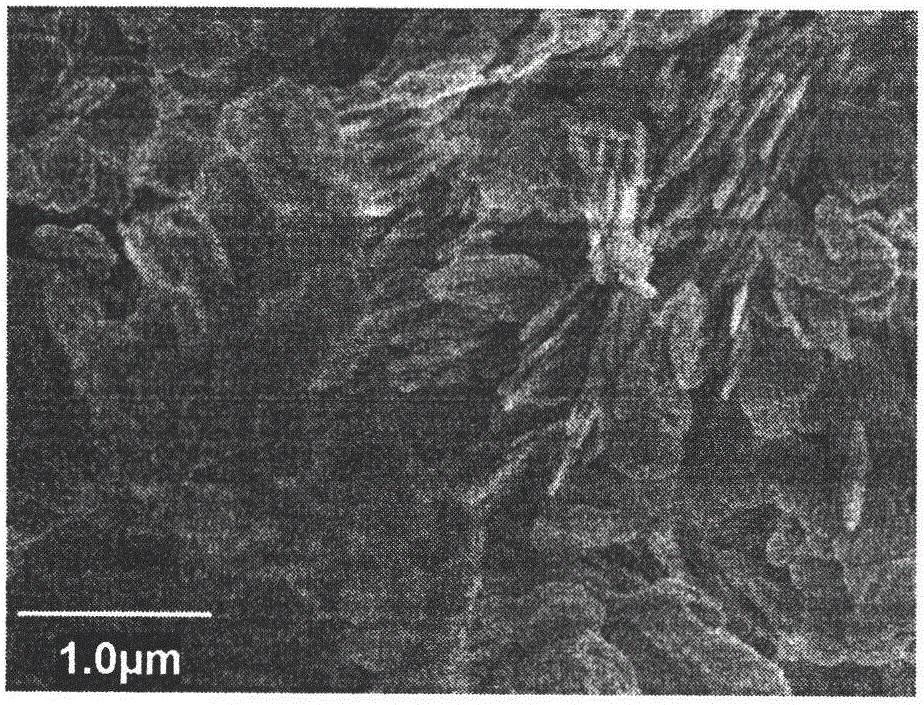

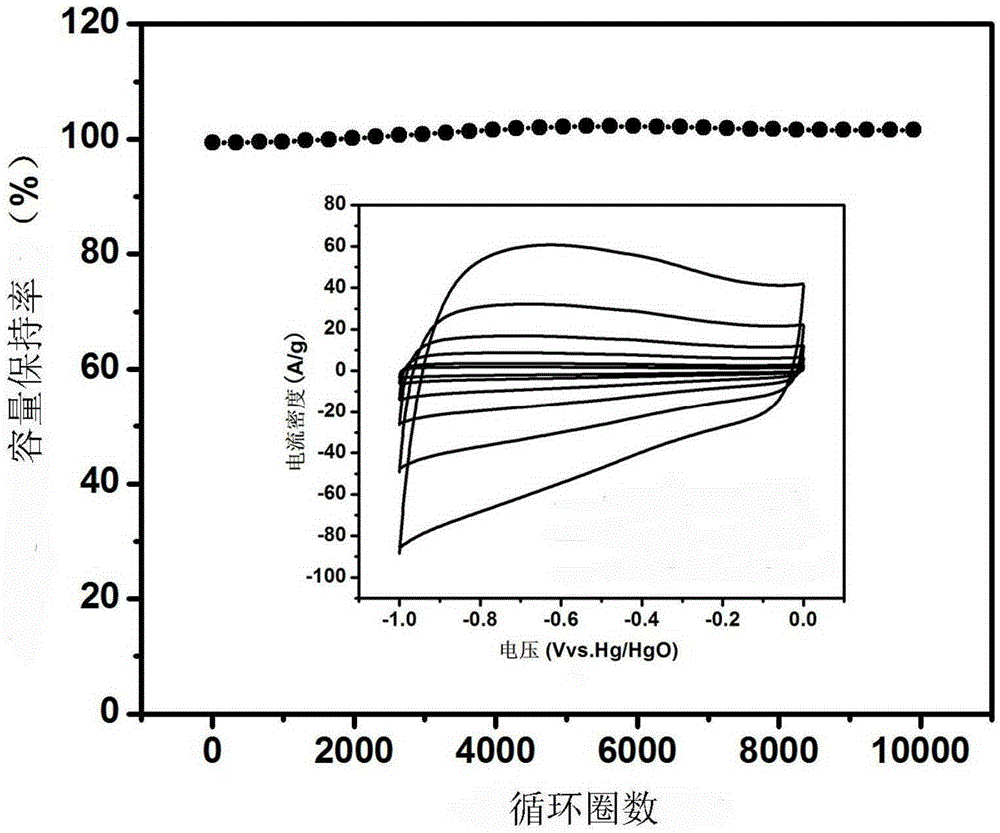

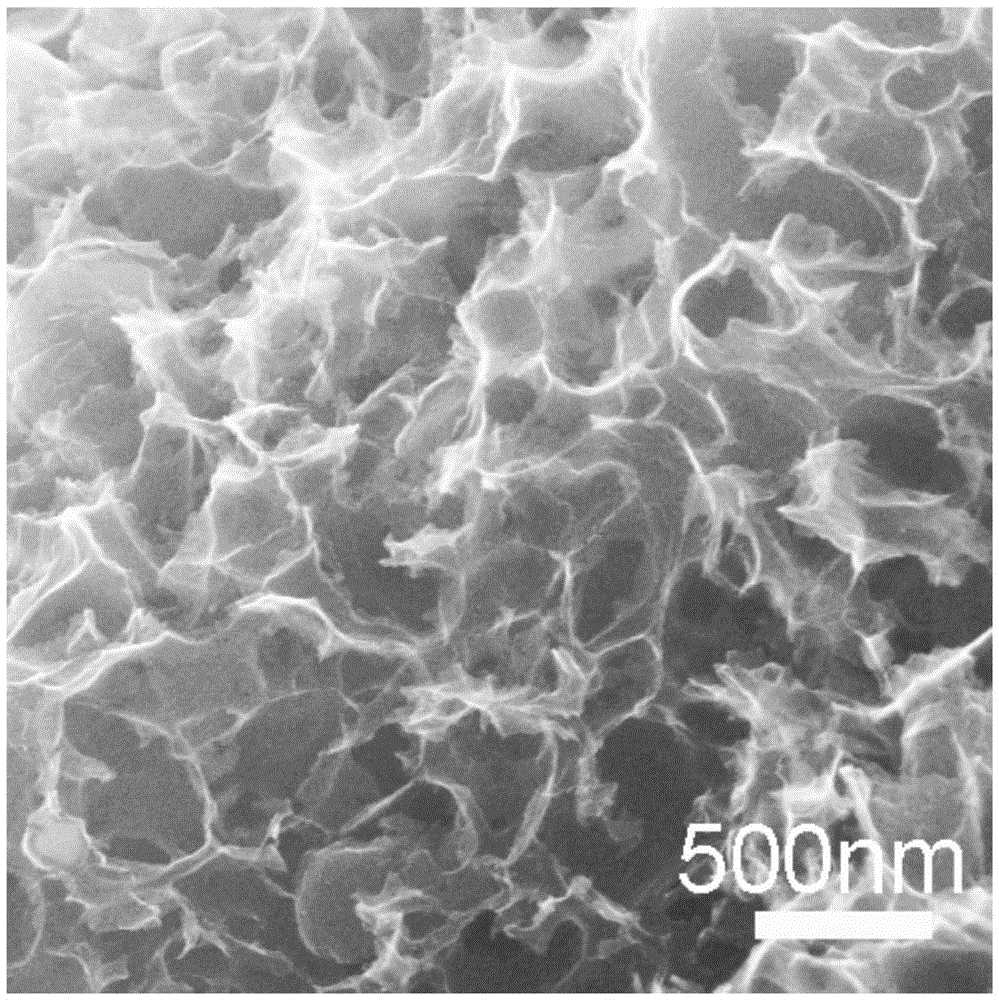

Method for preparing biomass carbon-based composite energy storage material by utilizing plant fiber

The invention discloses a method for preparing a biomass carbon-based composite energy storage material by utilizing plant fiber. Natural plant fiber such as straws, sawdust and cotton is subjected to mechanical pulverization and ultrasonication, and then conducts hydrothermal reaction with metal salt at 150-350 DEG C for 10-72 hours under an alkaline condition to synthesize in one step; or the plant fiber is subjected to hydrothermal carbonization in advance; then biomass carbon reacts with the corresponding metal salt, including the hydrothermal reaction; and the biomass carbon-based metal oxide and hydroxide composite material is synthesized in two steps. The electrochemical energy storage performance of the biomass carbon-based composite material prepared by the method is significantly improved compared with corresponding pure metal oxide and hydroxide.

Owner:TIANJIN POLYTECHNIC UNIV

Method for directly preparing co-doping three-dimensional graphene electrode material through biomass carbon sources

The invention discloses a method for directly preparing a co-doping three-dimensional graphene electrode material through biomass carbon sources. The method mainly includes the steps that biomass such as eggshells of artemia cysts, bean pulp and shrimp shells are used as the carbon sources, red phosphorus or boric acid is added to serve as a stripping agent, metal nickel salt is added to serve as a catalyst, and oxygen-nitrogen-phosphor multi-atom co-doping three-dimensional porous graphene is synthesized in a roasted mode at the temperature of 700 DEG C to 900 DEG C under argon atmosphere; the obtained graphene is ground into powder, the graphene, acetylene black and PTFE are ultrasonically dispersed into absolute ethyl alcohol in the mass ratio of 85:10:5, the mixture is dried at the temperature of 80 DEG C to be pasty, 0.5 mg to 5 mg of the mixture is taken and evenly smeared on 1*1-cm foam nickel, vacuum drying is carried out at the temperature of 120 DEG C for 12 h, plate pressing is carried out at the pressure of 12 MPa, and an electrode plate is obtained. According to the method, the source of the required raw materials is wide, the price is low, devices are simple, repeatability is good, and low-cost large-scale industrial production can be achieved easily; the prepared graphene electrode material has the advantages of being good in electrochemical activity, large in specific area, not prone to repeated accumulation and the like; the broad application prospects are achieved in the aspects such as electrode materials and catalyst carriers of supercapacitors and lithium ion batteries.

Owner:YANSHAN UNIV

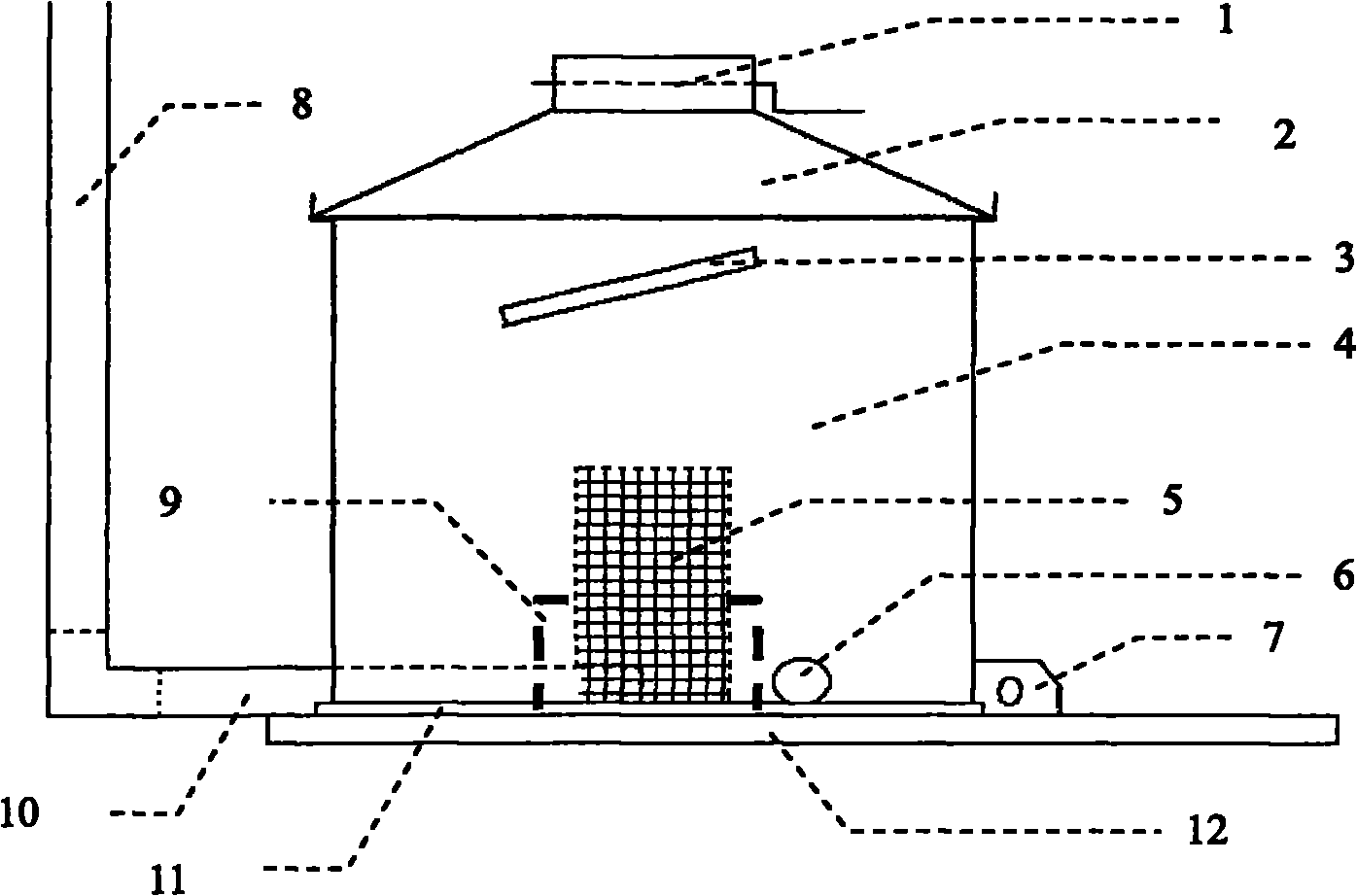

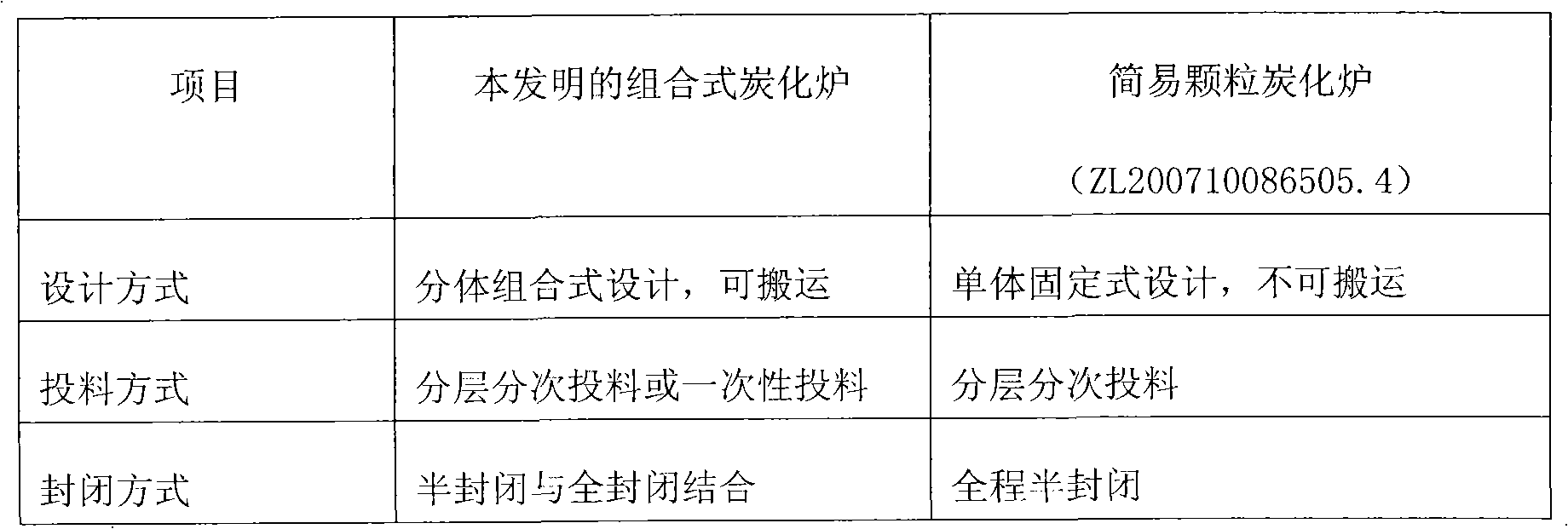

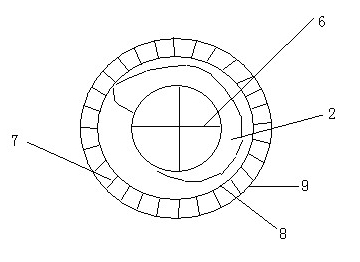

Combined biomass particle carbonization furnace and carbonizing method thereof

The invention relates to the field of agricultural machinery, in particular to a combined carbonization furnace which utilizes agricultural and forestry residue biomass particles to produce biomass carbon particles, and a carbonizing method thereof. The carbonization furnace contains a furnace body, a top cover, a burner, a swing door, a transverse exhaust pipe and a longitudinal exhaust pipe, wherein each component adopts the split-type design and the components are combined for use. The invention also provides a method which uses agricultural and forestry residue biomass as raw material and adopts the carbonization furnace to prepare biochar. The method comprises the following steps: selecting materials, processing the materials, assembling the furnace body, igniting the materials, filling the materials in the furnace, closing the cover, banking, etc. The agricultural and forestry residue biomass refers to corn stalks, corn cobs, peanut hulls, rice hulls, straws, waste edible mushroom medium for production or other wastes.

Owner:沈阳隆泰生物工程有限公司

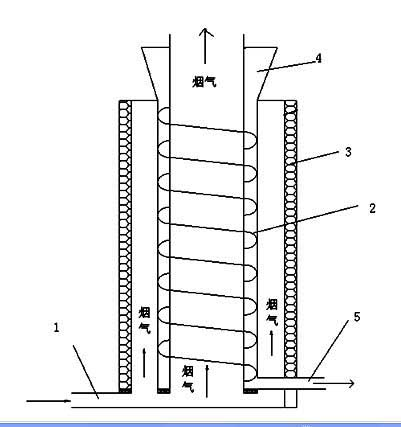

Method for producing biomass carbonization carbon and biomass gas, and rapid thermal decomposition coke oven

InactiveCN101195757AHigh calorific valueImprove surface propertiesBiofuelsSpecial form destructive distillationElectric generatorMethane

The invention relates to a method for producing biomass dry distillation carbon and biomass fuel gas and a rapid pyrolysis carbonized oven, materials of biomass straw, and tree branches, etc. are utilized to be added into the oven through a material filling pipe mouth, after the over is filled with the materials, an air inlet pipe mouth arranged at the bottom part of a gasification reaction chamber in the oven is opened, a negative pressure Roots blower fan arranged outside the oven is started, a oven door arranged at the lower part of the gasification reaction chamber is opened, the oven door is closed after gasification materials filled at the lower part of the gasification reaction chamber are ignited, generated combustible gas in the gasification reaction chamber is sucked to be diffused in a dry distillation carbonized chamber arranged on the periphery of the gasification reaction chamber through a fuel gas diffusing opening arranged at the upper part of a gasification chamber, thus carbonized materials are retorted into biomass carbon, simultaneously after methane, carbon monoxide, hydrogen, and hydrocarbon ChHmm in volatile component are released to be mixed with the flue gas generated in the gasification reaction chamber, the heat value of the flue gas is as high as about 6000 kJ / m3, after the purification and the treatment, the flue gas is the clean, inexpensive, and good quality biomass flue gas used for a flue gas electric generator group to generate power or provided for the burning of town dweller.

Owner:韩璋鑫

Process using date pits to prepare nitrogen-doped porous carbon material and preparation method of super-capacitor electrode

ActiveCN105645408AHigh cycle efficiency ratioImprove electrochemical performanceCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention belongs to the field of biomass carbon material preparation and particularly discloses a process using date pits to prepare nitrogen-doped porous carbon material and a preparation method of a super-capacitor electrode. The process includes the steps of firstly, preprocessing the date pits; secondly, preparing nitrogen-doped carbon material; thirdly, preparing the nitrogen-doped porous carbon material. The process is characterized in that the date pits are used as the carbon source and mixed with ammonia gas and steam in inert protecting gas, the nitrogen doping reaction is performed during the carbonization process, activated perforation is performed under the effect of activating agent, and the nitrogen-doped porous carbon material with high specific surface area and pore volume is prepared. The preparation method is simple, low in cost, high in preparation efficiency and energy saving. Experiments show that the super-capacitor electrode prepared by the nitrogen-doped porous carbon material has high specific capacitance, ideal pseudo-capacitance and high circulation stability, the performance of the super-capacitor electrode is better than the performance of commercial activated-carbon super-capacitors, and the performance of the nitrogen-doped porous carbon material is better than that of most nitrogen-doped porous carbon materials.

Owner:XIANGTAN UNIV

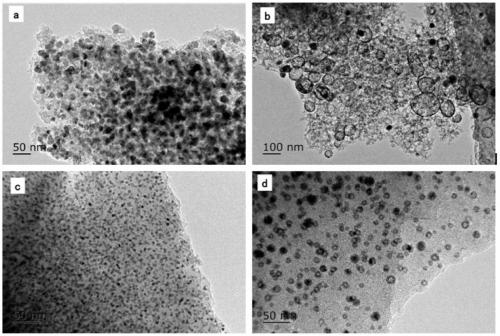

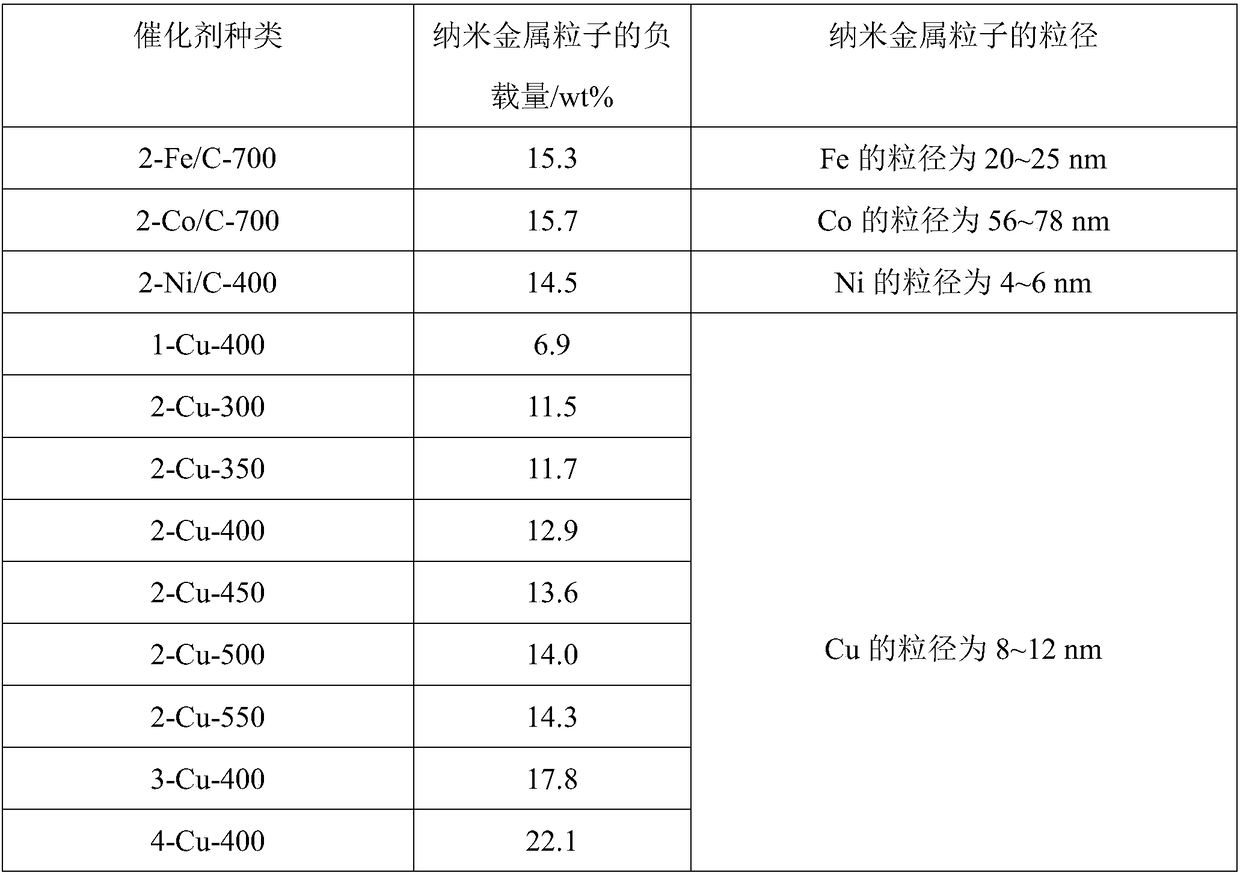

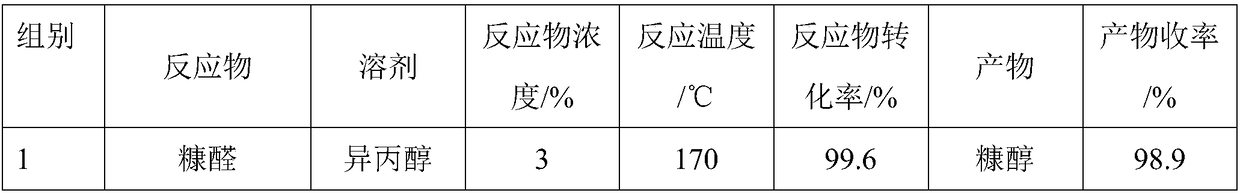

Biomass carbon-base material high-load nano-metal catalyst, as well as preparation method and application thereof

ActiveCN109364922ARaw greenEasy to makeMaterial nanotechnologyCatalyst carriersSimple componentCopper nitrate

The invention discloses a biomass carbon-based material high-load nano-metal catalyst, as well as a preparation method and application thereof. The catalyst is prepared by soaking shaddock peel powderin a nitrate solution having a certain concentration, drying and calcining, metal simple component serves as the active component, and organic carbon serves as the carrier; the nitrate is ferric nitrate, cobalt nitrate, nickel nitrate or copper nitrate; and the metal simple component is iron, cobalt, nickel or copper. The catalyst has the characteristics of environment-friendly raw materials, simple preparation process and high hydrogenation selectivity, has a good effect when being applied to a hydrogenation reaction of biomass derivatives, for instance, the furfuryl alcohol yield at a relatively low temperature of 170 DEG C can be 98,9 percent when the furfuryl alcohol is prepared by a furfuryl alcohol selective hydrogenation reaction.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

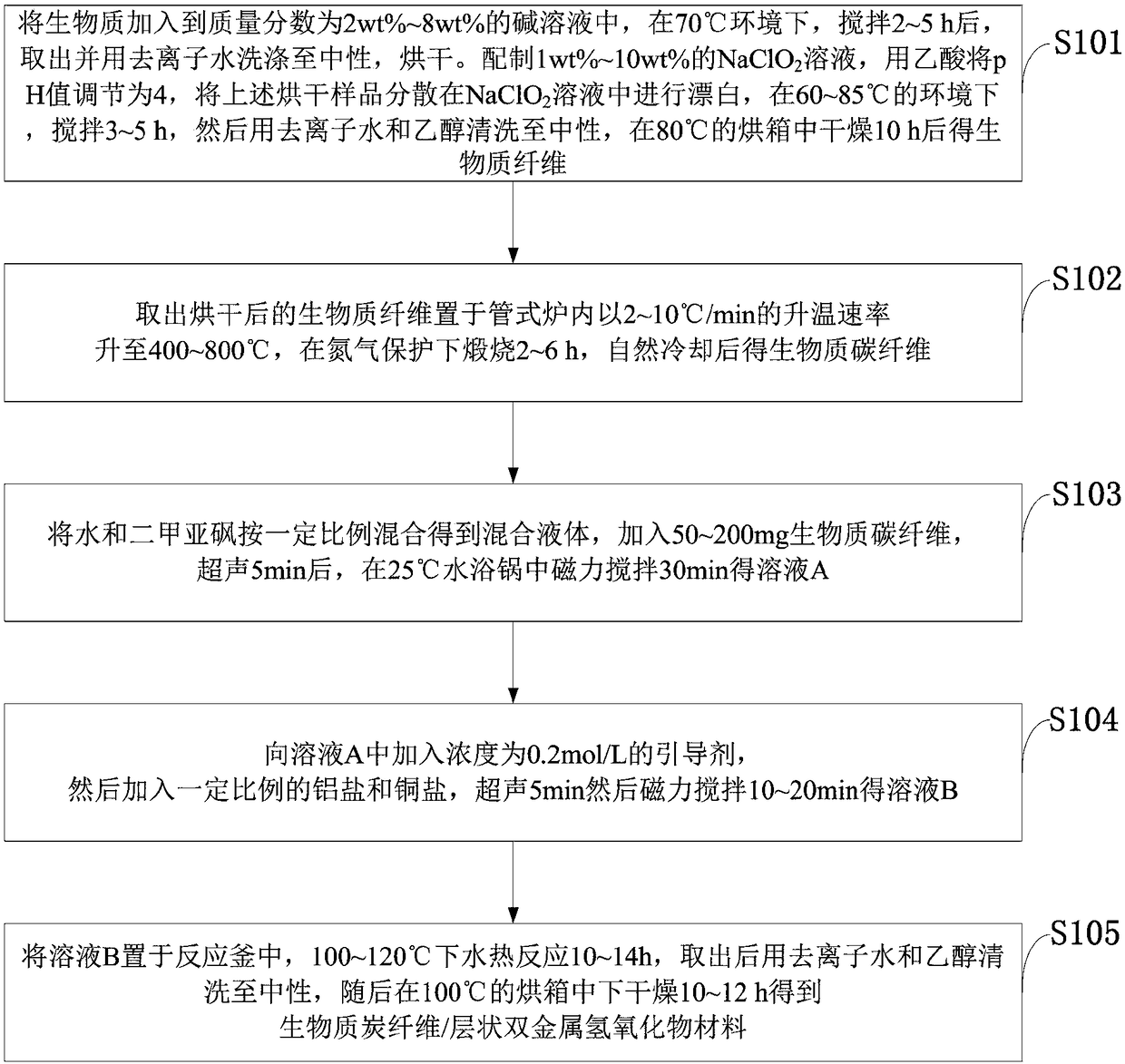

Biomass carbon fiber/layered double metal hydroxide adsorption material for phosphorus removal

ActiveCN108525638AThe preparation process is simple and controllableEfficient removalOther chemical processesWater contaminantsFiberCellulose

The invention belongs to the technical field of preparation, regeneration or reactivation, and discloses a biomass carbon fiber / layered double metal hydroxide adsorption material for phosphorus removal. The material is composed of biomass carbon fiber and layered double metal hydroxide, the layered double metal hydroxide grows on the surface of the biomass carbon fiber in a crescent sheet shape, and the biomass carbon fiber is prepared by using the steps of: extracting cellulose from biomass, and then performing carbonization, wherein the biomass carbon fiber has a length of 50-1500 mum and adiameter of 5-20 mum, and the layered double metal hydroxide is two-dimensional sheet-shaped copper-aluminum bimetallic hydrotalcite hydroxide which has a sheet thickness of 100 nm-1 mum and a copper-aluminum molar ratio of (2:1)-(4:1). The material has a simple and controllable preparation process, and the adsorption performance is improved through a double adsorption effect of the biomass carbonfiber / LDH, so that the purpose of efficient and rapid removal is achieved, the removal rate is up to 99.5%; therefore, reliable theory and actual support are provided for practical application.

Owner:EAST CHINA JIAOTONG UNIVERSITY

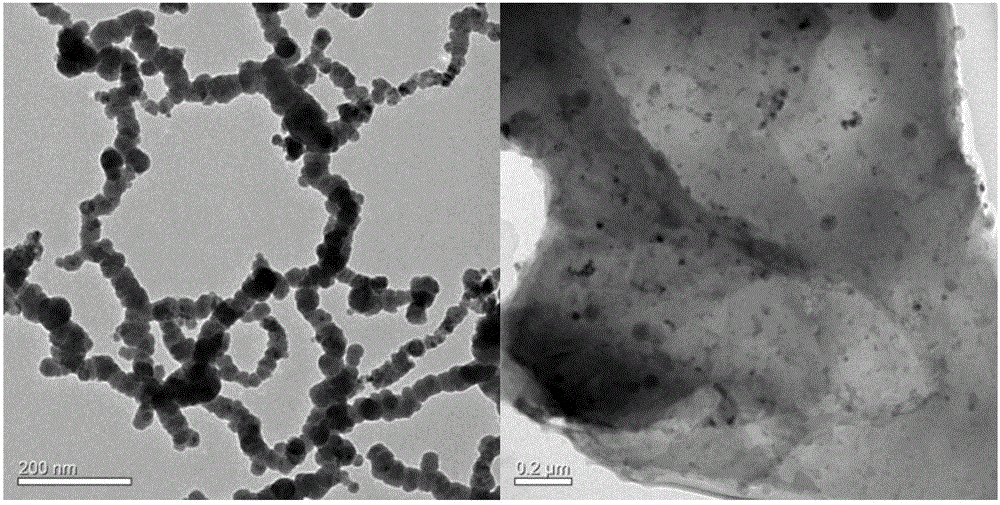

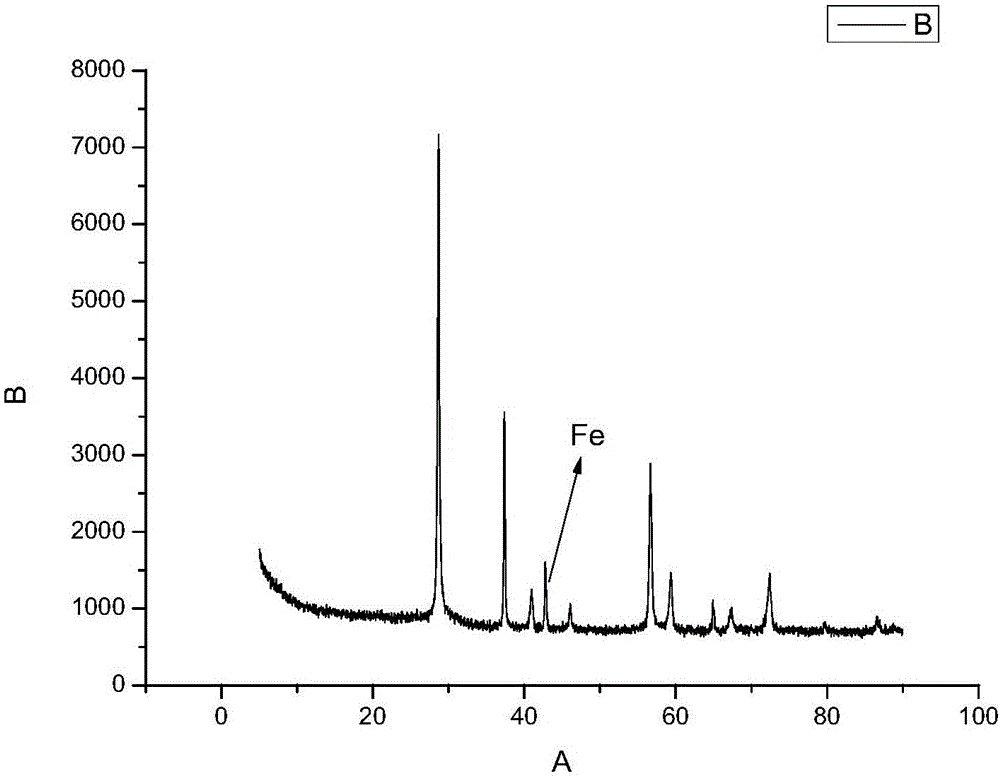

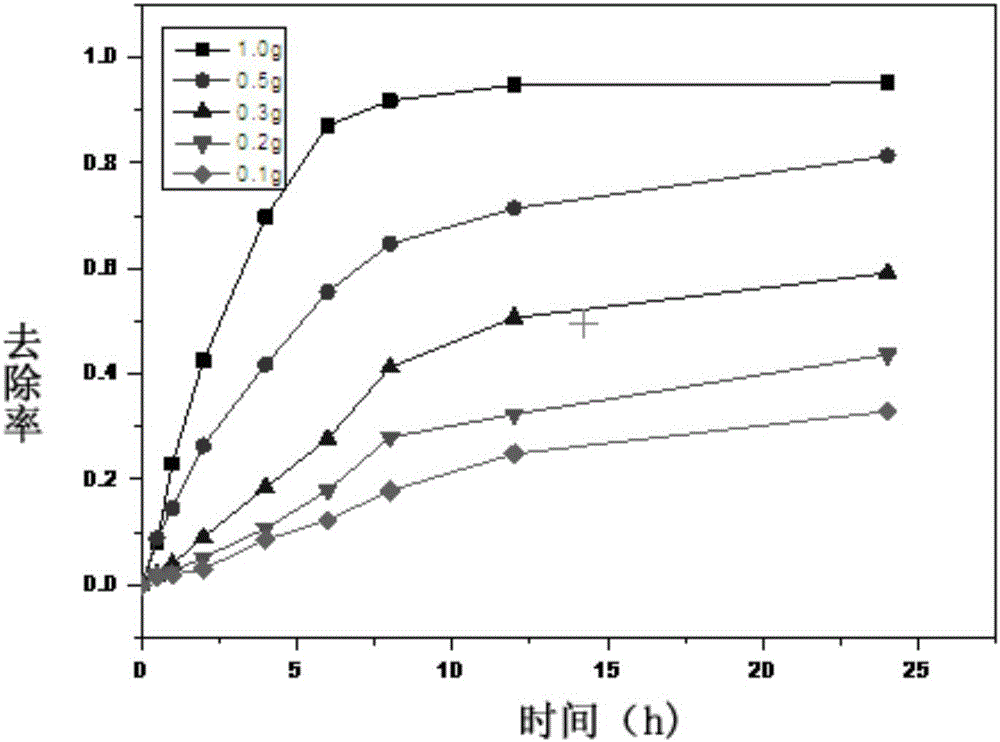

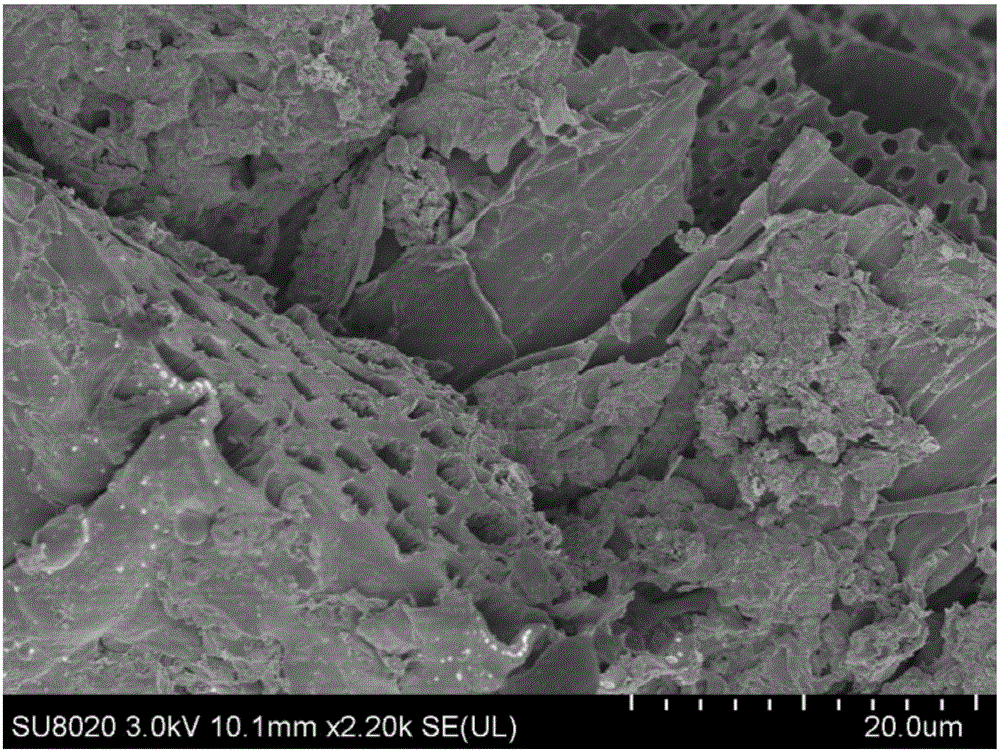

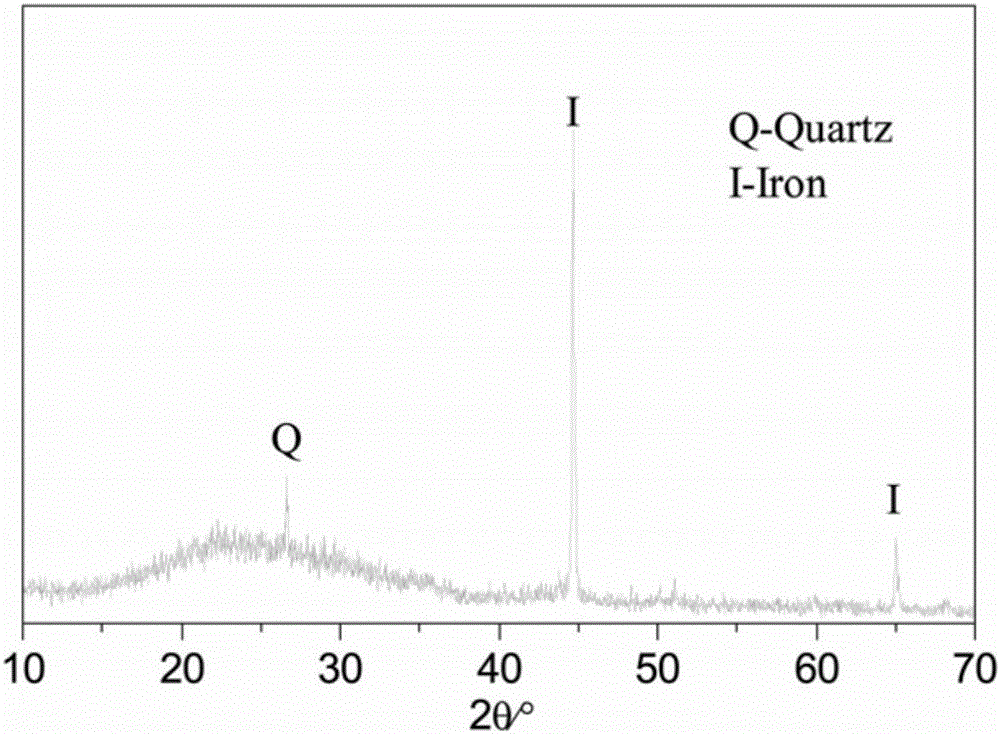

Biomass carbon-loaded nano zero-valent iron material as well as preparation method and application thereof

InactiveCN105903436AEasy to preparePreparation materials are cheap and readily availableOther chemical processesWater contaminantsBiomass carbonFiltration

The invention discloses a biomass carbon-loaded nano zero-valent iron material as well as a preparation method and application thereof. The method concretely comprises the following steps: adding walnut shell biomass carbon into an FeCl3.6H2O solution, mixing for 20-30 hours at the room temperature, then dropwise adding an NaBH4 solution into the mixture under the protection of inert atmosphere, and continuously stirring for 0.5-1 hour after adding; finally, carrying out suction filtration, taking filter residue, washing and drying to obtain the biomass carbon-loaded nano zero-valent iron material. The preparation method is simple; in the material obtained by the method, zero-valent iron particles are small in particle sizes, even in distribution and can not easily agglomerate, so that the biomass carbon-loaded nano zero-valent iron material can be applied to repairing pollutants such as organic matters and heavy metal in underground water and soil.

Owner:SHANGHAI INST OF TECH

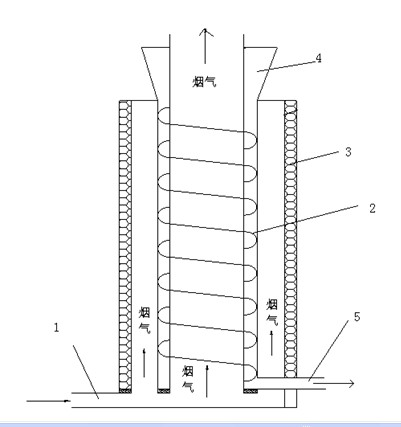

Biomass spiral pyrolytic process and antipyretic device

InactiveCN102010730ALow costImprove heat transfer effectBiofuelsIndirect heating destructive distillationBiomass carbonThermodynamics

Owner:KUNMING UNIV OF SCI & TECH

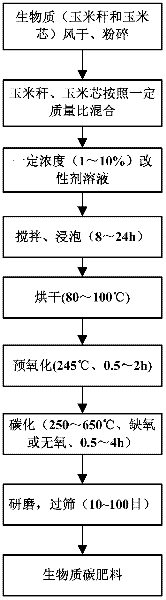

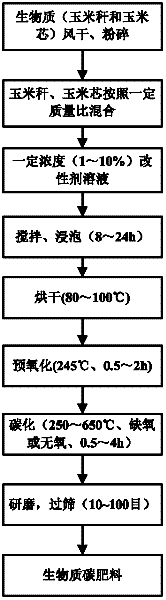

Preparation method and use method of biomass carbon fertilizer

InactiveCN102515914AIncrease productionQuality improvementHorticultureFertilizer mixturesBiomass carbonSurface layer

The invention relates to a preparation method of a biomass carbon fertilizer, which comprises the following three steps of: 1) air-drying and crushing a biomass raw material; 2) putting the biomass raw material obtained in the step 1) into modifier solution with a concentration of 1-10 percent to soak for 8-24 hours, and drying at a temperature of 80-100 DEG C; and 3) pre-oxidizing the biomass raw material dried in the step 2) in a box type furnace for 0.5-2 hours at a temperature of 245 DEG C, then carbonizing for 0.5-4 hours at a temperature of 250-650 DEG C and under the anoxic and anaerobic conditions, grinding and sieving with a 10-100-mesh sieve to prepare the biomass carbon fertilizer. A use method of the biomass carbon fertilizer comprises the following three steps of: 1, applying the prepared biomass carbon fertilizer in farmland soil according to the 100-1000 kilograms / hectare; 2, ploughing 0-30 centimeters of soil on a surface layer in the fertilized farmland soil, so that the biomass carbon fertilizer is uniformly mixed with the soil; and 3, planting crops in the soil applied with the biomass carbon fertilizer to obtain a higher-quality crop product.

Owner:BEIJING NORMAL UNIVERSITY

Multi-amino carbon composite material for selectively fixing mercury, chromium and lead in polluted soil and preparation method

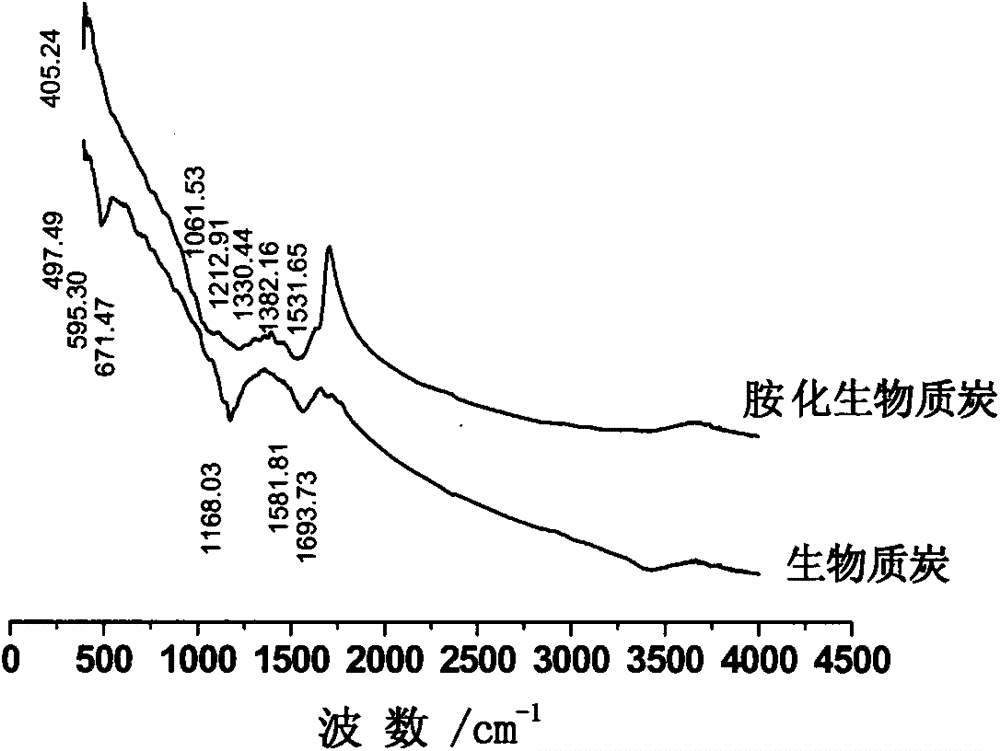

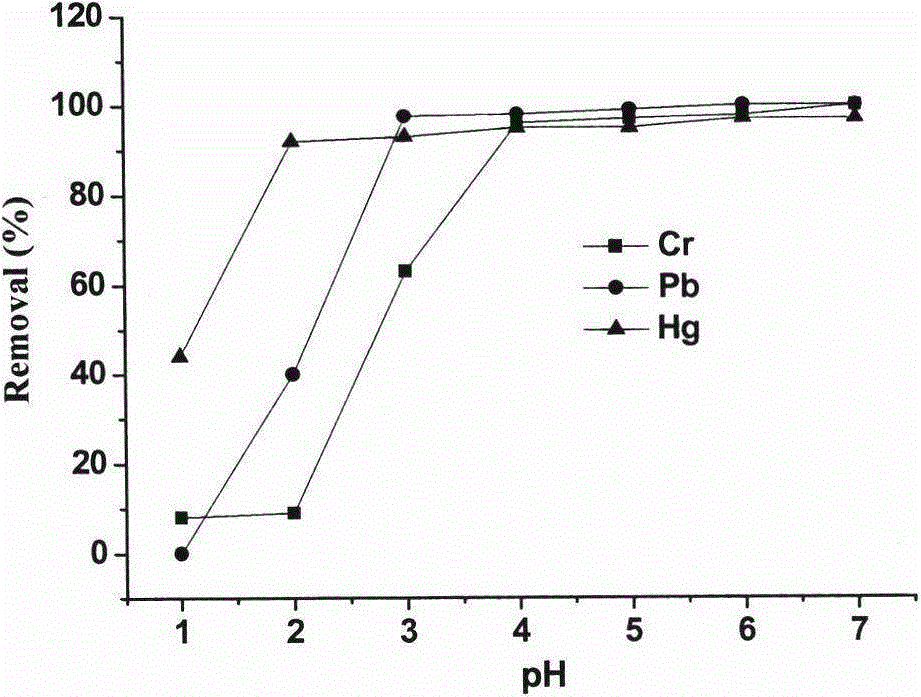

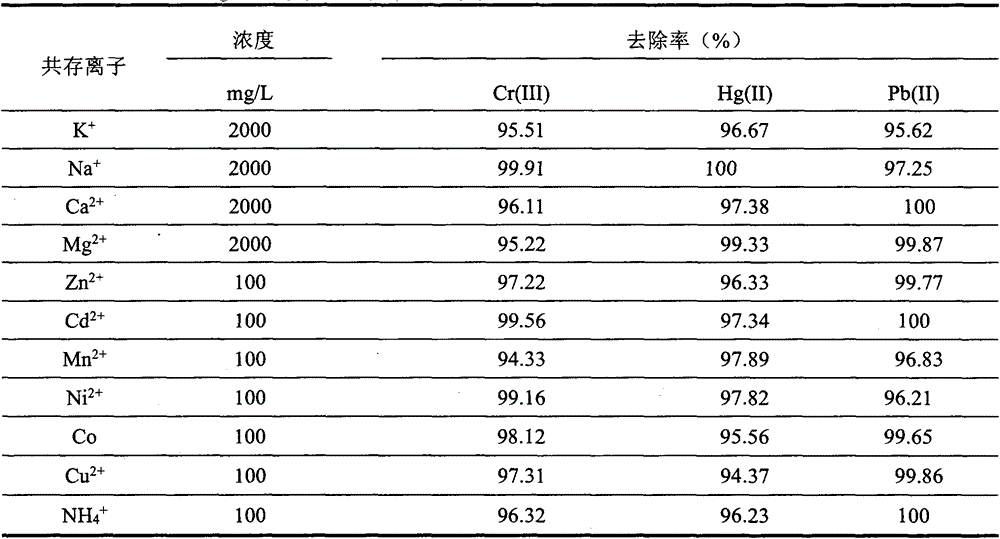

InactiveCN104941575AImplement select fixed fixesLow costOther chemical processesContaminated soil reclamationEthylenediamineCarbon composites

The invention provides a preparation method of an ethylenediamine grafted modified biomass carbon composite material for selectively fixing metal mercury (II), chromium (III) and lead (II) in soil, aiming at solving the actual problems that an existing passivant has small adsorption capacity on heavy metal of the soil, low selectivity and bad safety. The novel multi-amino biomass carbon composite material agent takes common substances including agricultural straw biomass, hydrochloric acid, nitric acid, ethylenediamine and the like as raw materials and is prepared through carbonization, carboxylation and molecule copolycondensation, and has abundant pore channels and abundant content of surface multi-amino groups; and the product has large fixed capacity and good selectivity on mercury (II), chromium (III) and lead (II) in the heavy metal polluted soil, has the advantages of simple process, easiness for implementation and the like, and can be produced in a large batch.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for preparing organic cellulose acid ester by solid acid catalysts

The invention discloses a method for preparing organic cellulose acid ester by solid acid catalysts, relating to the technical field for preparing organic cellulose acid ester. In the invention, the organic cellulose acid ester refers to cellulose formic acid, cellulose acetate, cellulose propionate, cellulose acetate butyrate, cellulose acetate propionate, cellulose acetate butyrate and cellulose acetate propionate butyrate. Three solid acids, namely, SO42- / MxOy solid acid, biomass carbon-based solid acid, phosphorus-aluminum molecular sieve solid acid; the organic acid is used as solvent and the organic acid anhydride is used as esterifying agent; the using amount of the catalyst is 0.01-5% of the reaction liquid; the organic cellulose acid ester is prepared under the conditions that the reaction temperature is 15-90 DEG C and the reaction time is 0.5-72 h. The method adopts the novel environment-friendly solid acid catalyst; the obtained product has good quality; the catalyst is easy to separate, recover and recycle; no device corrosion exists and the environment is protected.

Owner:CHANGMAO BIOCHEMICAL ENG CO LTD +1

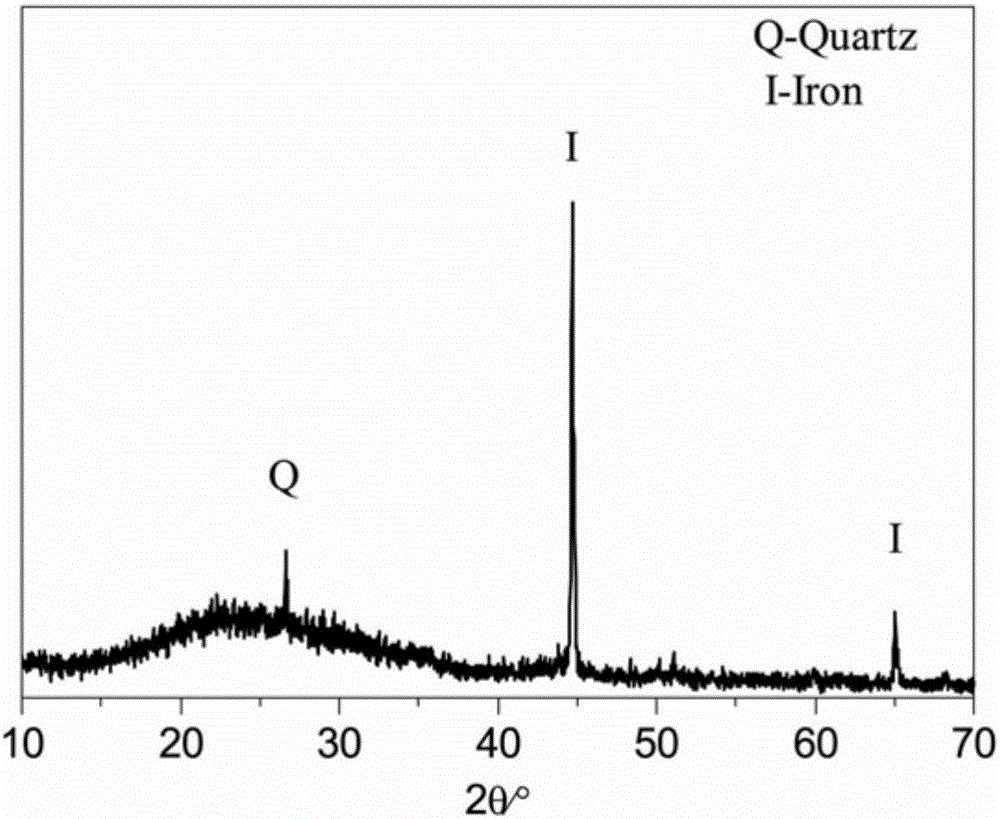

Fe/C composite porous structure material as well as preparation method and application thereof

ActiveCN105776506AHigh particle strengthHas a bonding effectTreatment using aerobic processesContaminated soil reclamationPorosityMagnetic susceptibility

The invention discloses a Fe / C composite porous structure material as well as a preparation method and application thereof. The Fe / C composite porous structure material is characterized by being prepared from low-grade sedimentary iron ore and biomass as raw materials in manners of crushing, mixing, extrusion molding and pyrolysis and reduction reaction in the presence of hydrogen atmosphere at 650-900 DEG C, wherein the main phase composition comprises biomass carbon and zero-valent iron. The Fe / C composite porous structure material disclosed by the invention is high in opening porosity, magnetic susceptibility, adsorbability and biological chemical activity, can be used for treating eutrophicated river water, living sewage and landscape water bodies, or can be used for mediation of underground water pollution and polluted soil.

Owner:HEFEI UNIV OF TECH

Method for preparing biomass carbon based on waste crop straw

InactiveCN101993701ASolve the problem of the large amount of land required for stackingReduce pollutionBiofuelsSpecial form destructive distillationBiomass carbonRoom temperature

The invention relates to a method for preparing biomass carbon based on waste crop straw. The method comprises the following steps of: (1) cutting the crop straw into straw particles, washing and drying; (2) loading the processed straw particles in a quartz tube of a carbonizing furnace and introducing an inert gas; (3) heating to 350 to 550 DE C from room temperature in an environment with inert gas flow rate of 100mL / min at the heating rate of 25 DEG C / min, maintaining for 1 to 3 minutes, stopping heating, and cooling to the room temperature to obtain solid; and (4) washing and drying the solid obtained in the step (3) to obtain the biomass carbon. The device of the invention is simple in operation, the raw material has low cost and is readily available, and the method is suitable for large-scale industrial production; and the biomass carbon prepared by the method has a high specific area, can be used as a soil modifying agent to improve the fertility of the soil and can also be used as a soil repairing agent to repair the polluted soil, and has good application prospect.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com