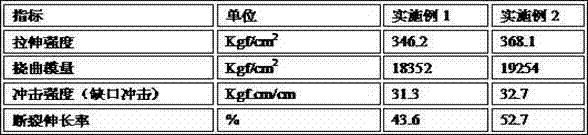

Patents

Literature

118 results about "Cellulose acetate propionate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The family of cellulosics includes cellulose acetate, cellulose acetate butyrate, cellulose propionate, and ethyl cellulose. There are other cellulosics, but these are the most widely used. Cellulosics are characterized by good strength, toughness, and transparency and high surface gloss.

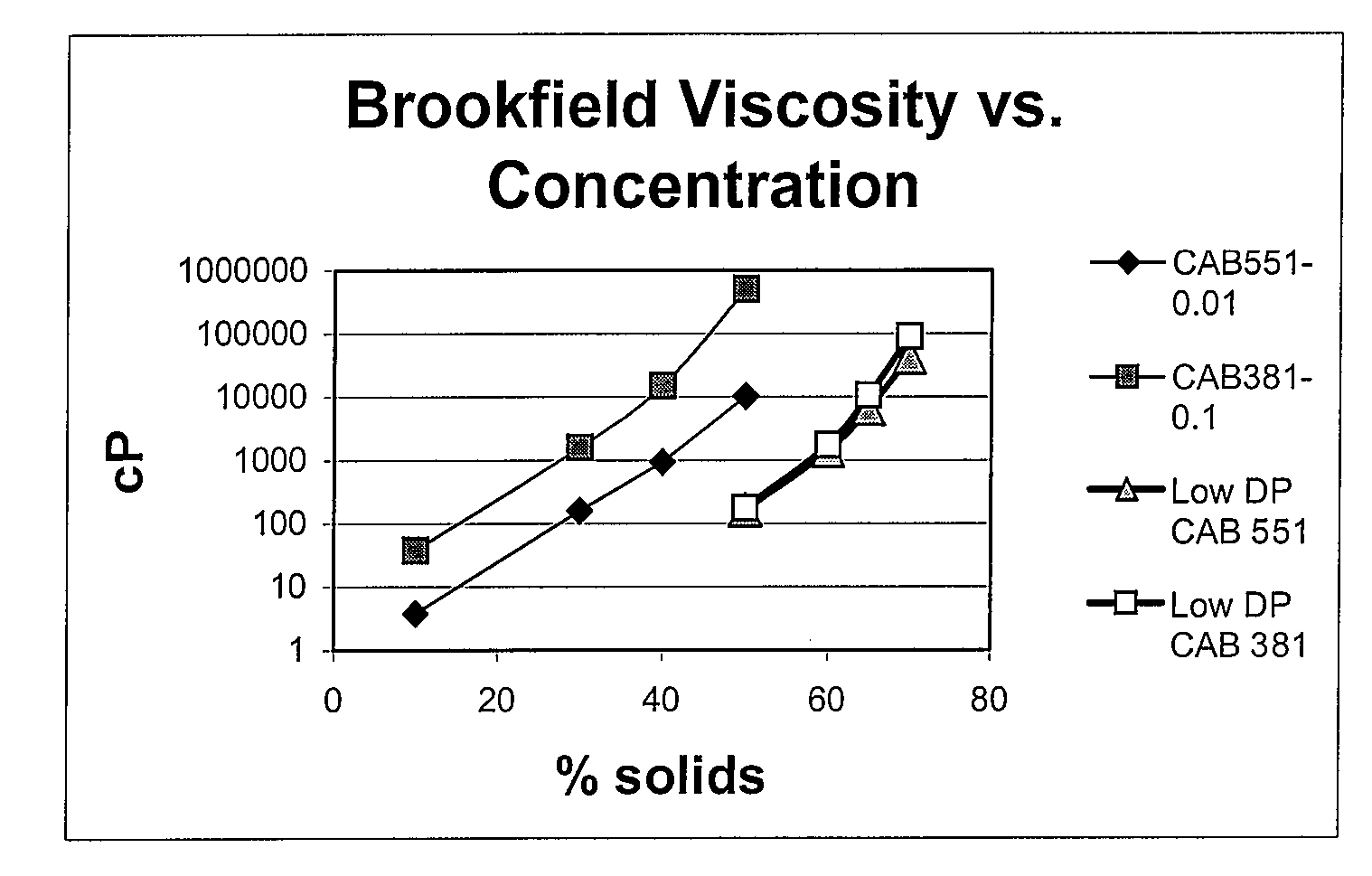

Low molecular weight cellulose mixed esters and their use as low viscosity binders and modifiers in coating compositions

ActiveUS7585905B2Reduce molecular weightHigh maximum degree of substitutionInksPolyurea/polyurethane coatingsSolubilityCellulose

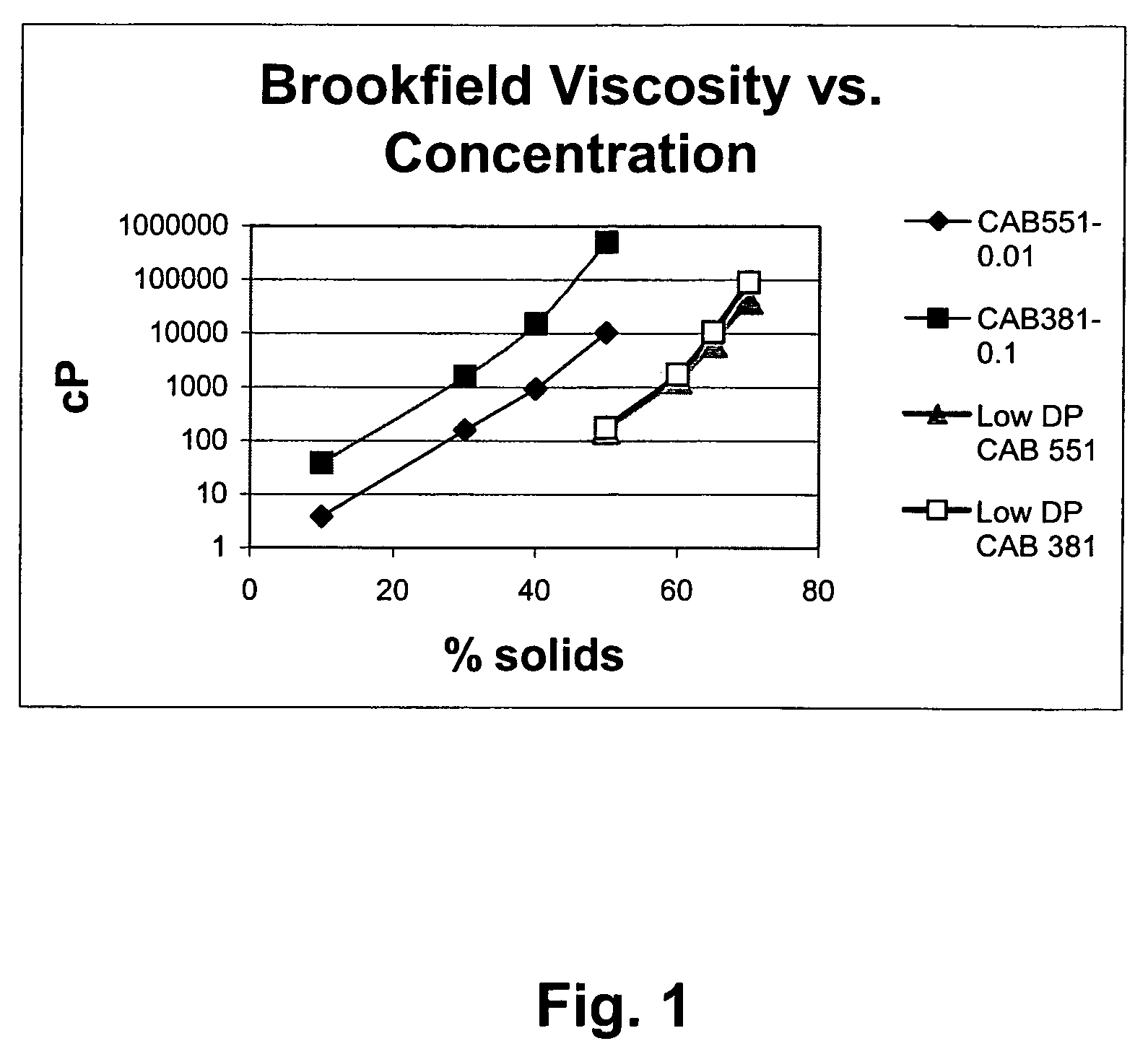

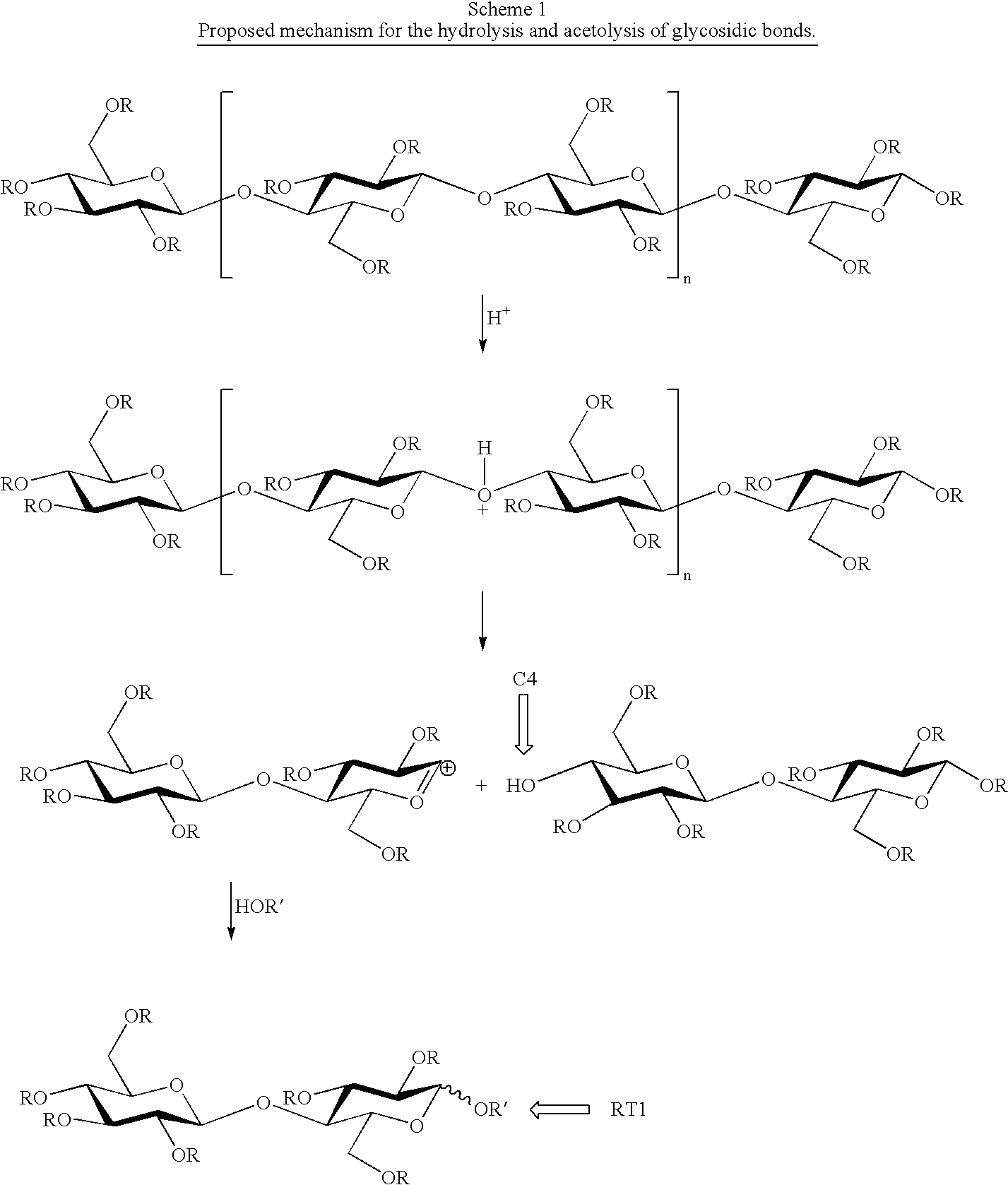

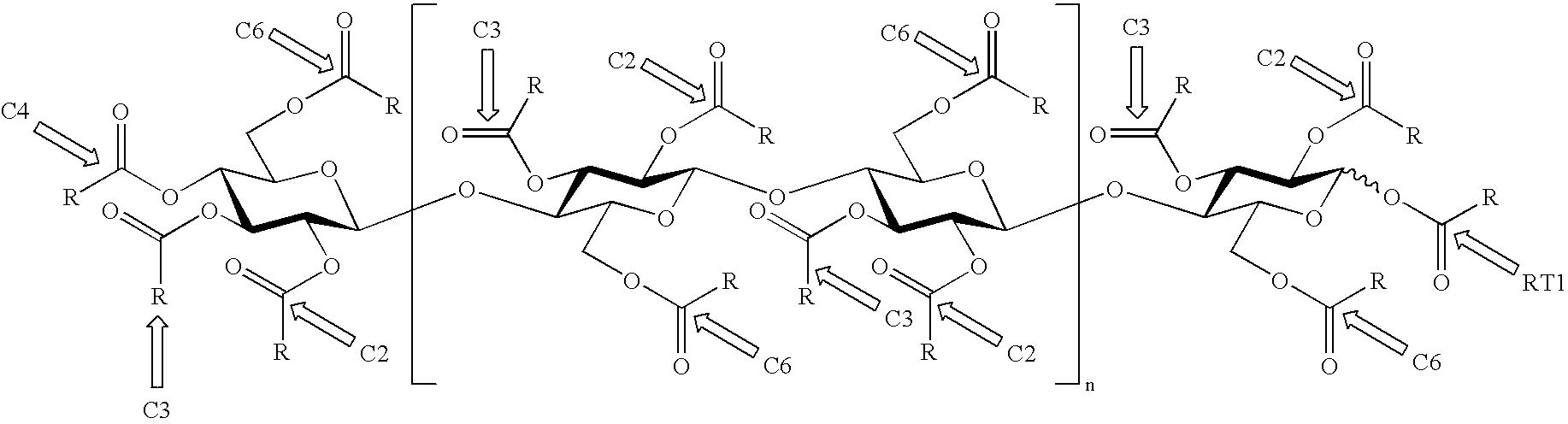

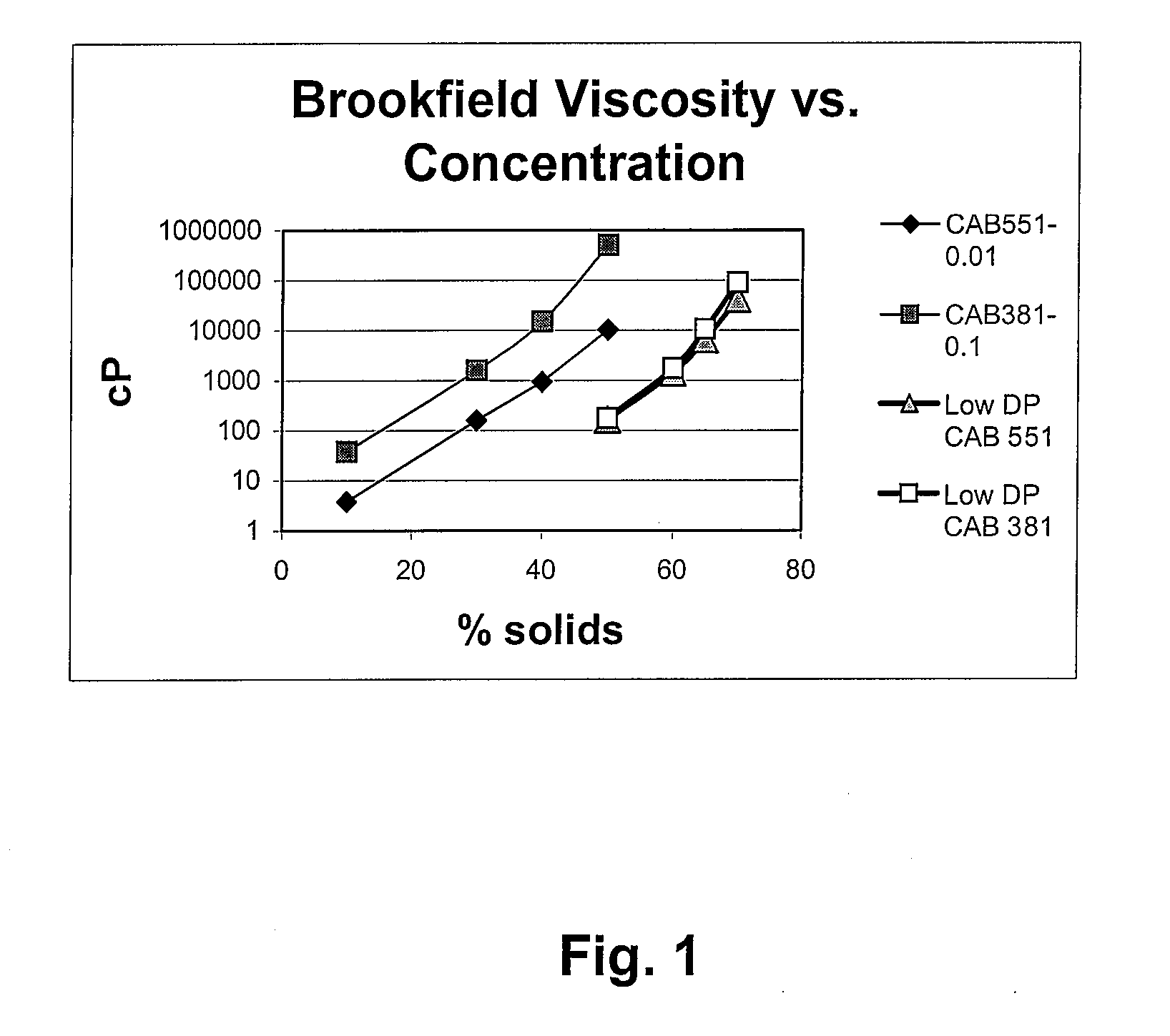

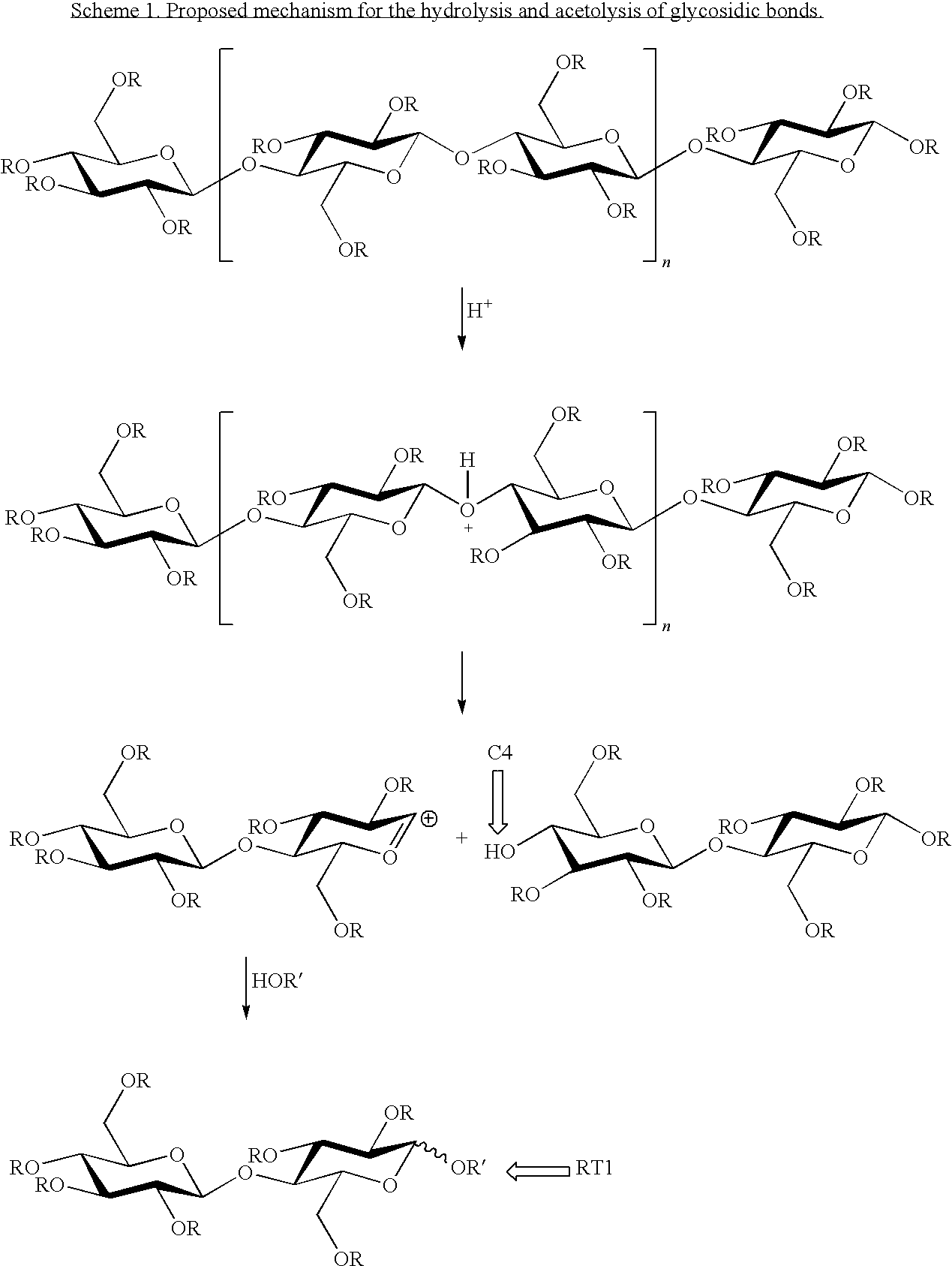

Cellulose mixed esters are disclosed having low molecular weights and low degrees of polymerization. These new cellulose mixed esters include cellulose acetate propionate and cellulose acetate butyrate. The esters exhibit solubility in a wide range of organic solvents with minimal viscosity increase, are compatible with a wide variety of resins, and are useful in coatings and inks compositions as binder resins and rheology modifiers.

Owner:EASTMAN CHEM CO

Method for preparing cellulose acetate propionate or cellulose acetate butyrate

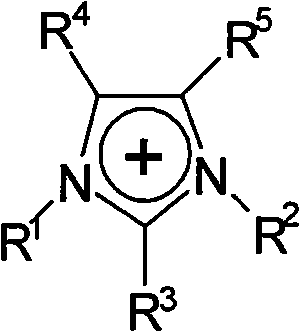

The invention provides a method for preparing cellulose acetate propionate or cellulose acetate butyrate. The method comprises the following steps: a. mixing fibrin and ionic liquid capable of dissolving the fibrin to obtain an ionic liquid solution containing the fibrin; b. adding acetylate and propionyl reagent (1) or acetylate and reagent (2) into the ionic liquid solution containing the fibrin, reacting for 1-24h at 40-120 DEG C, preferably 1-12h, and obtaining reaction mixture; c. adding lower fatty alcohol from C1 to C3 into the reaction mixture and filtering the reaction mixture containing the lower fatty alcohol; and d. drying a solid obtained by filtering to obtain the cellulose acetate propionate or cellulose acetate butyrate. The invention utilizes the ionic liquid as a solvent without any catalyst and has the advantages of simple process and no pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for preparing organic cellulose acid ester by solid acid catalysts

The invention discloses a method for preparing organic cellulose acid ester by solid acid catalysts, relating to the technical field for preparing organic cellulose acid ester. In the invention, the organic cellulose acid ester refers to cellulose formic acid, cellulose acetate, cellulose propionate, cellulose acetate butyrate, cellulose acetate propionate, cellulose acetate butyrate and cellulose acetate propionate butyrate. Three solid acids, namely, SO42- / MxOy solid acid, biomass carbon-based solid acid, phosphorus-aluminum molecular sieve solid acid; the organic acid is used as solvent and the organic acid anhydride is used as esterifying agent; the using amount of the catalyst is 0.01-5% of the reaction liquid; the organic cellulose acid ester is prepared under the conditions that the reaction temperature is 15-90 DEG C and the reaction time is 0.5-72 h. The method adopts the novel environment-friendly solid acid catalyst; the obtained product has good quality; the catalyst is easy to separate, recover and recycle; no device corrosion exists and the environment is protected.

Owner:CHANGMAO BIOCHEMICAL ENG CO LTD +1

Preparation method of cellulose acetate propionate

ActiveCN102127169AThe broken crystal zone works wellHigh Molecular Weight DistributionCellulosePropanoic acid

The invention relates to a preparation method of cellulose acetate propionate, belonging to technical field of cellulose modification. The preparation method of cellulose acetate propionate comprises the following steps of: taking cellulose as a raw material, activating by a mixed solution of acetic anhydride and propionic anhydride, adding acetic acid and propionic acid solvents and a solid super acidic catalyst for esterification, after esterification, filtering to remove the catalyst, adding waste acid water for hydrolyzing, settling out by waste acid water, and finally obtaining the cellulose acetate propionate by steps of filtering, washing, drying and the like. The production process is simple to operate, the solid super acidic catalyst substitutes the concentrated sulfuric acid catalyst and can be cyclically used for many times, thus alleviating the problem of serious corrosion of the original process equipment. The waste acid water generated in the reaction process only contains acetic acid and propionic acid without sulfuric acid and can be fully recovered and cyclically used, thus decreasing the tension in environmental protection, realizing zero discharge and greatly reducing the production cost. The cellulose acetate propionate prepared by the method has fine toughness, heat stability and compatibility, thus being extensively used.

Owner:CHANGMAO BIOCHEMICAL ENG CO LTD +1

Mechanical activation and enhancement method for preparing cellulose acetate-butyrate or cellulose acetate-propionate

The invention relates to the field of cellulose processing, and in particularly relates to a mechanical activation and enhancement method for preparing cellulose acetate-butyrate or cellulose acetate-propionate. The method comprises the following steps: weighing reactants including cellulose, butyric acid, acetic anhydride and a catalyst in a ratio of 10g:(30-100g):(10-30g):(0.1-0.5g), putting all the reactants into a ball mill, controlling the ratio of the reactants to pellets at 100g:(100-300ml), controlling the temperature of a circulating water bath at 50-80 DEG C, stirring at a low speed to perform an acylation reaction for 1-4 hours to obtain a crude product, separating the crude product and the pellets, standing the crude product in 50% ethanol water to separate out a solid, separating the separated solid, and washing the separated solid with deionized water until the solid is neutral, thereby obtaining a cellulose acetate-butyrate or cellulose acetate-propionate product. Compared with the existing method for producing cellulose acetate-butyrate or cellulose acetate-propionate, the method disclosed by the invention has the characteristics of simple process, high efficiency, no pollution, high product quality and the like.

Owner:福建鸿燕化工有限公司

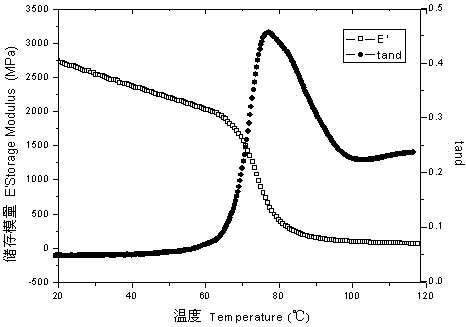

Cellulose acetate propionate film, process for producing cellulose acetate propionate film, optical compensation sheet, polarizing plate and liquid crystal display device

InactiveUS20080227881A1High elastic modulusHigh mechanical strengthNon-linear opticsOptical elementsCrystallographyDynamic viscoelasticity

A cellulose acetate propionate film has a density νe of entanglement points of a polymer chain of cellulose acetate propionate represented by the following expression (A) of from 0.3 to 2.0 moles / dm3:νe=ER′ / 3RTR (A)wherein R represents a gas constant; ER′ represents a storage elastic modulus in a rubbery state plateau upon measurement of a dynamic viscoelasticity; and TR represents a temperature in the rubbery state plateau.

Owner:FUJIFILM CORP

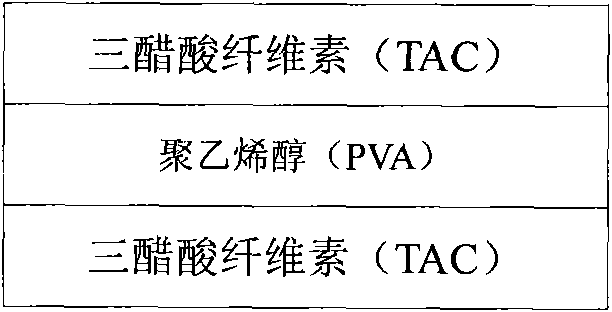

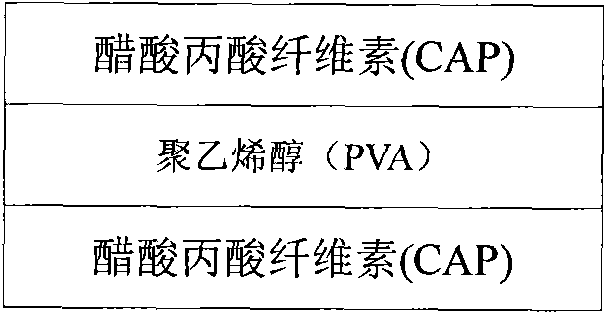

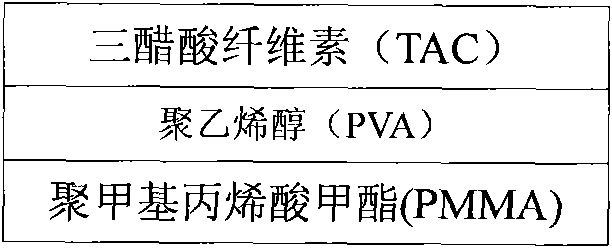

Polarized lens and method for manufacturing same

InactiveCN101726764AImprove impact performanceWiden perspectiveSynthetic resin layered productsLaminationForeign matterPolymethyl methacrylate

The invention discloses a polarized lens and a method for manufacturing the same. In the process of manufacturing the polarized lens of the invention, a poly vinyl alcohol (PVA) membrane is inserted between a tri acetyl cellulose (TAC) membrane and a cellulose acetate propionate (CAP) membrane or between the tri acetyl cellulose (TAC) membrane and a polymethyl methacrylate (PMMA); or materials with different chemical properties and physical properties are attached to two sides of the poly vinyl alcohol (PVA) membrane, and then the polarized lens is manufactured. The polarized lens is used for preventing foreign matters from hurting eyes or dazzling caused by light rays, and has excellent transparency.

Owner:金泰德

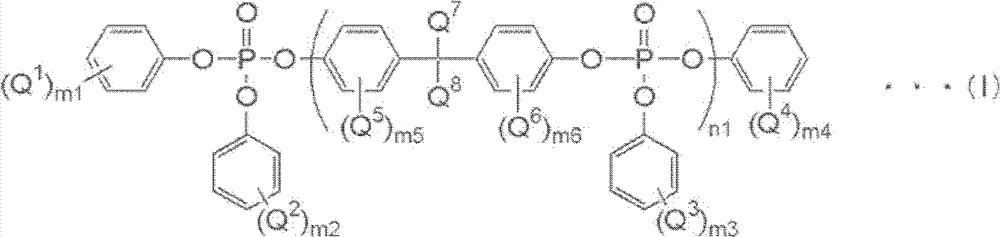

Resin composition and resin-molded product

Provided are a resin composition and a resin-molded product. The resin composition includes cellulose acetate propionate; from about 5 phr to about 30 phr of at least one of plasticizer selected from an adipate-based plasticizer and a polyester-based plasticizer; and from about 5 phr to about 50 phr of a condensed phosphoric acid ester compound.

Owner:FUJIFILM BUSINESS INNOVATION CORP

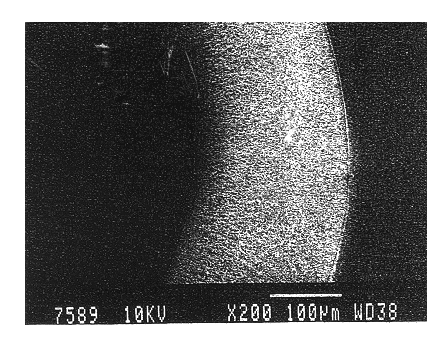

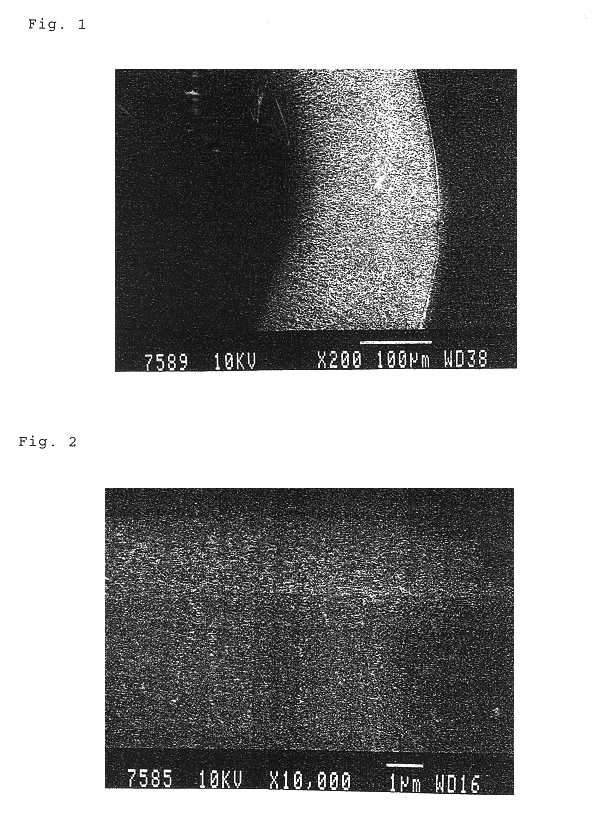

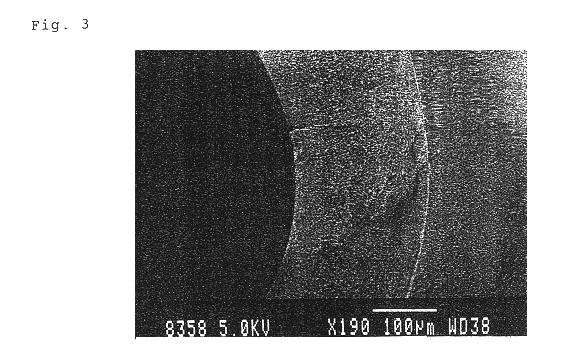

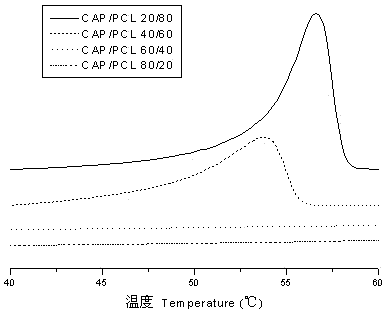

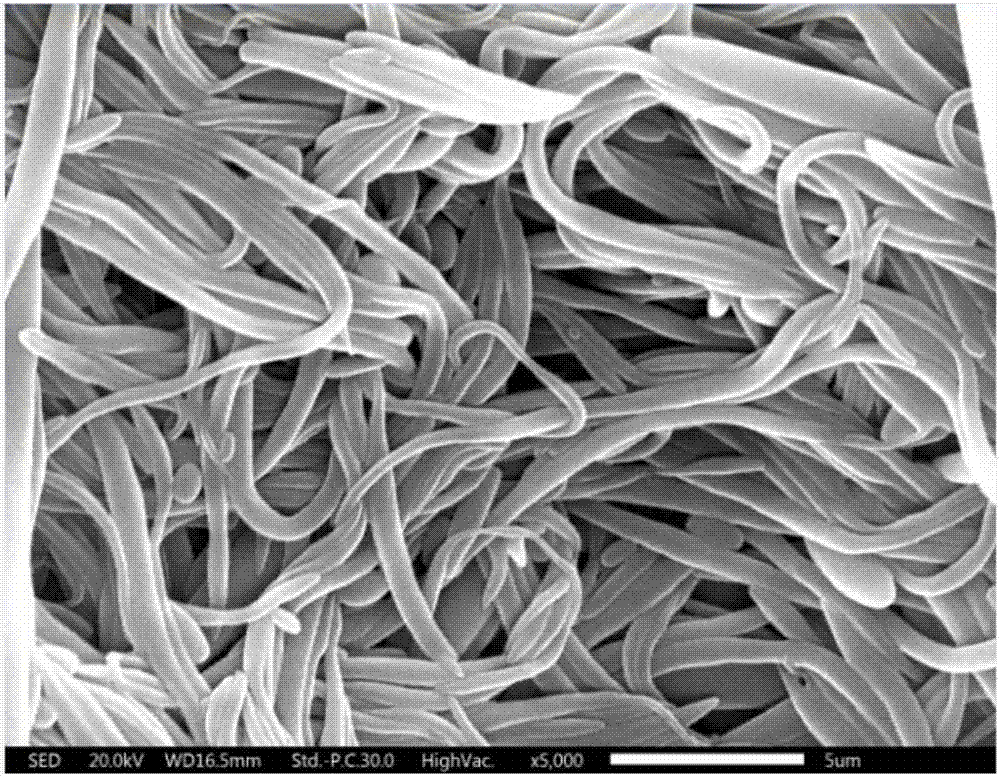

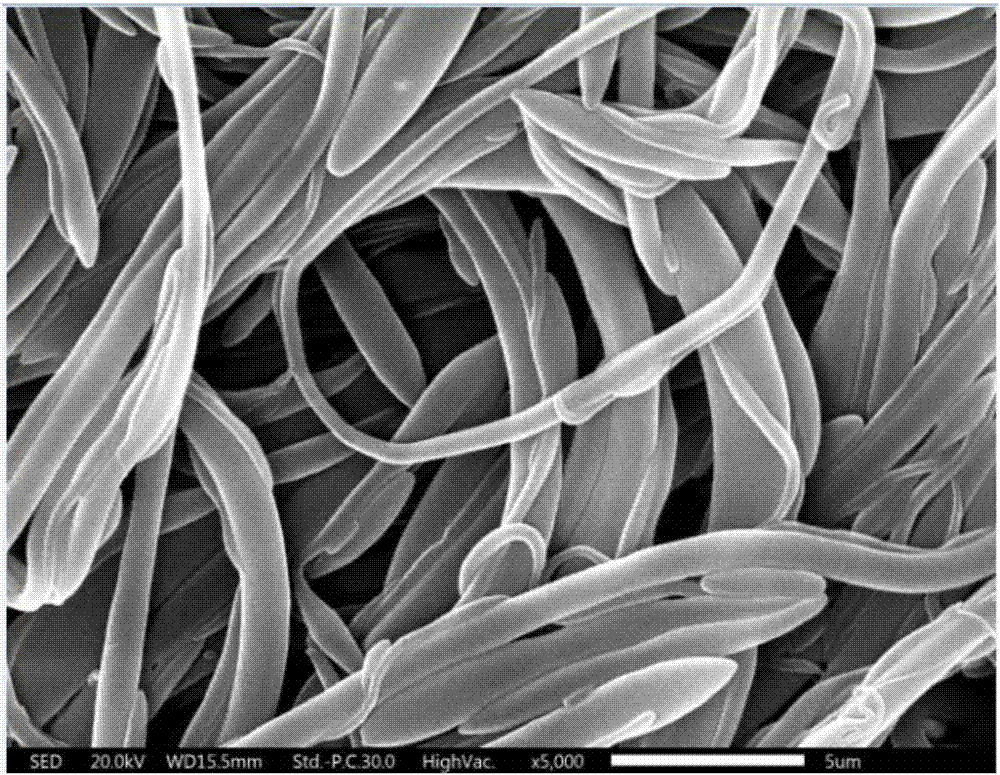

Cellulose compound hollow fiber membrane

InactiveUS6632366B1Improve balanceGood water permeabilitySemi-permeable membranesMembranesAcetic acidHollow fibre membrane

The present invention relates to a cellulose compound hollow fiber membrane having high mechanical strength and is hardly degraded by microorganisms, wherein a cellulose compound is comprised as a membrane material, the thickness of the membrane is 50 to 500 mum, a dense membrane surface having an average pore diameter of 0.001 to 0.05 mum exists on the internal and / or external surface thereof, the inside of the membrane is composed of a three-dimensional network-like porous structure having voids with an average pore diameter of 0.05 to 2 mum, and 70% by weight or more of the membrane material is cellulose acetate propionate or cellulose acetate butyrate.< / PTEXT>

Owner:DAICEL CHEM IND LTD

Biodegradable polymer material compatibilized and blended by lignocellulose and preparation method thereof

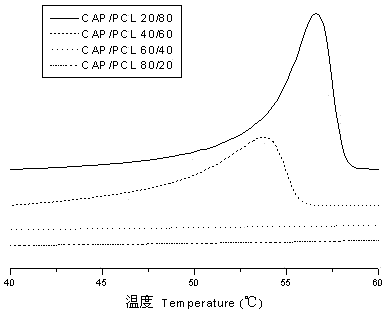

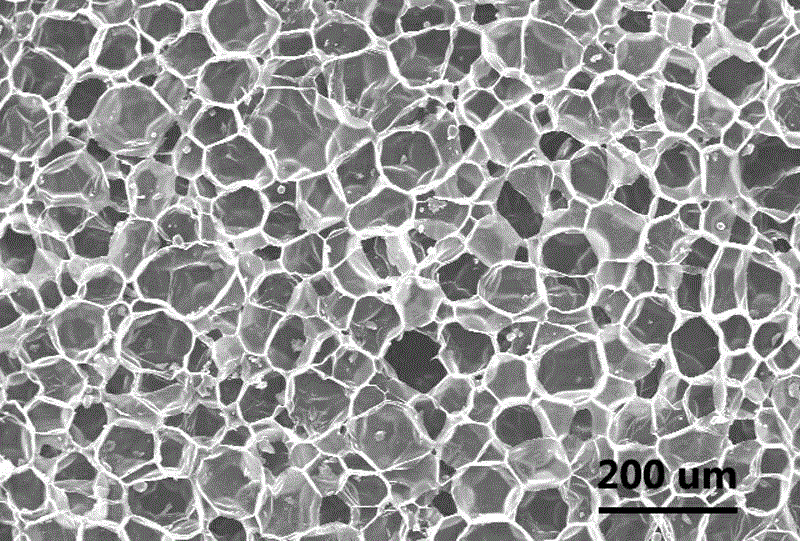

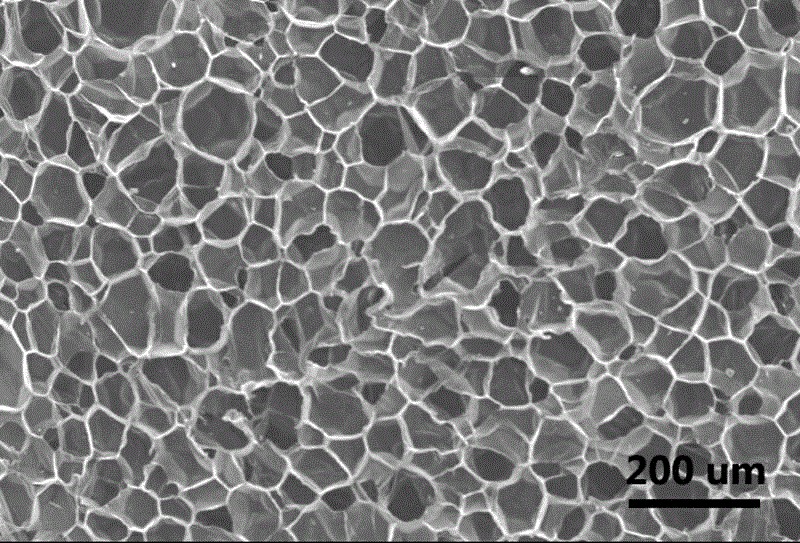

The invention discloses a biodegradable polymer material compatibilized and blended by lignocellulose and a preparation method thereof. The biodegradable polymer material is composed of a resin mixture and a compatibilizer. The resin mixture is composed of resin and cellulose acetate or cellulose acetate propionate which is prepared from cellulose of poplar wood pulp. The resin is selected from any one of polycaprolactone, polylactic acid and polyhydroxybutyrate. The compatibilizer is a block copolymer of polycaprolactone-acid anhydride compound and the use amount of the compatibilizer is 2-30% of the total mass of the resin mixture. The preparation method provided by the invention comprises the following steps of: mixing celluosic resins to obtain the resin mixture; then compulsively feeding after adding the resin mixture and the compatibilizer into a feed bin of a double-screw extruder; cooling the extrudate by air and then dicing the extrudate into particles to obtain resin particles. The biodegradable polymer material and the preparation method provided by the invention have advantages of environmental friendliness, low cost, good combination property, stable product performance and higher promotion value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of uniform-cell and high-buffer polylactic acid foamed material

The invention relates to a preparation method of a uniform-cell and high-buffer polylactic acid foamed material. The foamed material comprises a main material and an auxiliary material, and the main material comprises polylactic acid, EVA elastomer, cellulose acetate propionate, esterification modified nano-cellulose, polylactic acid grafted maleic anhydride and gelatin; and the auxiliary material comprises an antioxidant, a plasticiser and an ultraviolet resisting agent. The main material comprises, by mass, 100 parts of polylactic acid, 20-35 parts of the EVA elastomer, 8-15 parts of cellulose acetate propionate, 3-6 parts of esterification modified nano-cellulose, 4-8 parts of polylactic acid grafted maleic anhydride and 3-6 parts of gelatin. The auxiliary material comprises 2-4 parts of the antioxidant, 2-4 parts of the plasticiser and 2-4 parts of the ultraviolet resisting agent. The foamed material is prepared through a premixing, autoclave foaming and liquid nitrogen cooling technology, has the advantages of effective guaranteeing of cell uniformity, high foaming rate and good buffering performance, and can be used in the field of packaging buffering.

Owner:HUNAN UNIV OF TECH

Low molecular weight cellulose mixed esters and their use as low viscosity binders and modifiers in coating compositions

ActiveUS20090286095A1Reduce molecular weightHigh maximum degree of substitutionImpression capsNon-macromolecular adhesive additivesPolymer sciencePropanoic acid

Cellulose mixed esters are disclosed having low molecular weights and low degrees of polymerization. These new cellulose mixed esters include cellulose acetate propionate and cellulose acetate butyrate. The esters exhibit solubility in a wide range of organic solvents with minimal viscosity increase, are compatible with a wide variety of resins, and are useful in coatings and inks compositions as binder resins and rheology modifiers.

Owner:EASTMAN CHEM CO

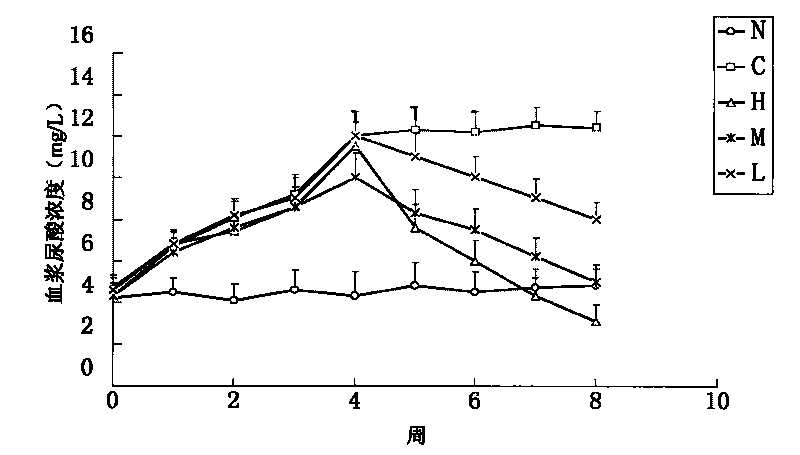

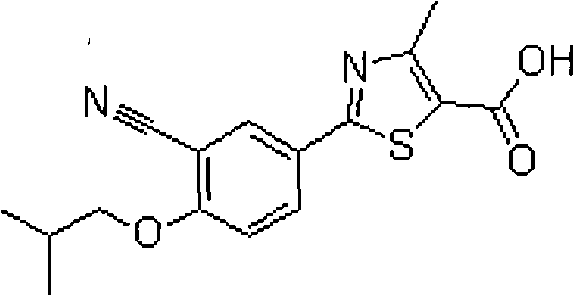

Febuxostat enteric preparation

ActiveCN101716132ADissolves and absorbs quicklyImprove bioavailabilityOrganic active ingredientsSkeletal disorderPylorusHypromellose phthalate

The invention provides a Febuxostat enteric preparation comprising a medicament inner core, an isolated layer and a casing layer. The Febuxostat enteric preparation adopts hypromellose phthalate ester to wrap an isolated coat and selects cellulose acetate propionate (CAP) and polyvinylacetate phthalate of an enteric-coated material dissolvable in a pH value range of 5-6.8 to wrap an enteric coat. The enteric preparation does not leak after being orally taken into the stomach of a human being, is rapidly dissolved and disintegrated after entering the pylorus with a pH value larger than 5 and releases the Febuxostat medicament for the ntestinal tract to rapidly absorb so as to achieve the aim of improving the bioavailability and the healing effect. Compared with a common Febuxostat tablet or capsule, the invention has the advantages of stability in gastric juice, rapid dissolution and absorption in the ntestinal tract and high bioavailability, is prepared by general process and is easy to realize the industrialized production.

Owner:BEIJING KONRUNS PHARMA TECH CO LTD

Cellulose acetate propionate microspheres and preparation method thereof

The invention relates to a preparation method of cellulose acetate propionate microspheres by an ionic liquid as a solvent. The preparation method utilizes a homogeneous esterification method to realize cellulose acetate propionate synthesis and realizes cellulose acetate propionate regeneration thereby producing the cellulose acetate propionate microspheres. The preparation method comprises the following steps of dissolving cellulose in an ionic liquid to obtain a cellulose solution, carrying out a process of a reaction of a propionic anhydride-acetic anhydride mixed solution and the cellulose solution, dispersing the above mixed solution into an oil phase, coagulating the cellulose solution by reversed phase suspension and programmed freezing to obtain cellulose solution drops, adding a curing agent into the cellulose solution drops for curing the cellulose solution drops so that cellulose microspheres are formed, after the reaction, carrying out solid-liquid phase centrifugation to obtain the cellulose acetate propionate microspheres and recovering the ionic liquid. The cellulose acetate propionate microspheres have regular spherical shapes, an acetyl substitution degree of cellulose acetate propionate is in a range of 0.02-0.5 and a propionyl substitution degree is in a range of 0.03-0.4, good mechanical properties, good thermostability and acid and alkali resistance are obtained, and the cellulose acetate propionate microspheres can be used for separation purification of biomacromolecule proteins and can also be used as a carrier of an enzyme or other biomaterials.

Owner:广西弘耀祥科技有限公司 +1

Drawing decorative film with frosting effect

ActiveCN103625202AImprove heat resistanceGuaranteed MatteOrnamental structuresSpecial ornamental structuresCellulosePolymer science

The invention relates to a drawing decorative film with the frosting effect. The decorative film is composed of a substrate, a release layer, a protective layer, a decorative layer and a bonding layer which are sequentially overlapped together. The release layer is formed by applying a coating liquid on the surface of the substrate through curing and drawing, wherein the coating liquid is prepared from the following materials in parts by weight: 20-30 parts of hex-methoxymethyl melamine resin, 5-10 parts of cellulose acetate propionate resin, 5-8 parts of organic silicon resin, 5-10 parts of an acid catalyst, 8-12 parts of silica powder, 2-4 parts of high-white aluminum silicate, 0.2-2 parts of a dispersing agent, 0.2-0.5 part of a flatting agent and 30-60 parts of a solvent. The frosting drawing texture of the decorative film is real, and the decorative film can be widely applied to surface decoration of high-grade plastic parts.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

Polylactic acid composite material

The present invention relates to a polylactic acid composite material. The composite material is compounded and prepared by using polylactic acid, polylactic acid grafted glycidyl methacrylate, starch grafted polylactic acid, acetate esterified nano cellulose, acetate propionate cellulose and an antioxidant through melting extrusion in two steps. According to the composite material disclosed by the present invention, the preparation process is simple, the composite material has excellent strength and toughness due to excellent compatibility between each component, so that the composite material can be widely used in the environment protection packaging and industrial fields with the requirements of high strength and high toughness.

Owner:HUNAN UNIV OF TECH

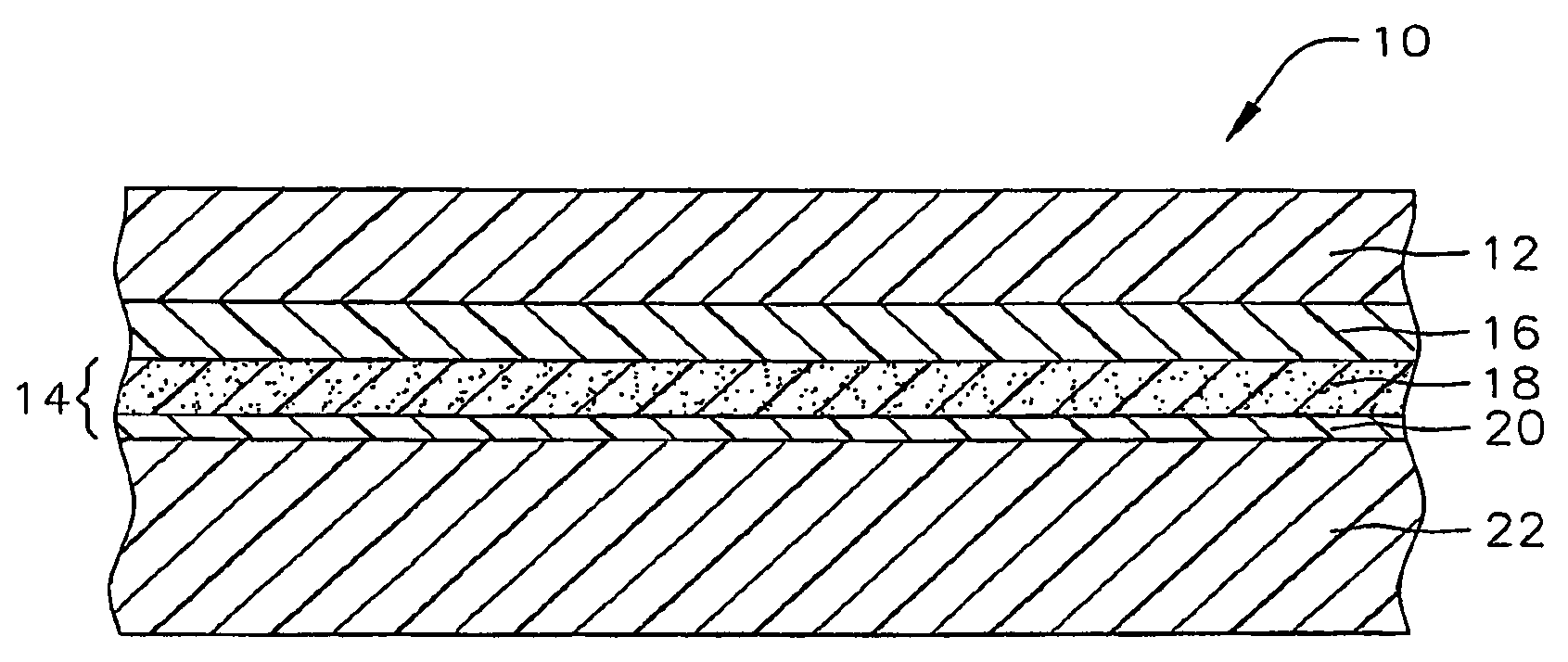

Cellulosic films incorporating a pharmaceutically acceptable plasticizer with enhanced wettability

An enteric coating for a solid pharmaceutical carrier or substrate wherein the enteric coating includes a cellulosic polymeric material selected from selected from the group consisting of hydroxypropyl cellulose, hydroxyethyl cellulose, hydroxypropyl methyl cellulose, methyl cellulose, ethyl cellulose, cellulose acetate, cellulose acetate butyrate, cellulose acetate phthalate, cellulose acetate succinate, cellulose acetate propionate, cellulose acetate trimellitate, hydroxypropylmethyl cellulose phthalate, hydroxypropylmethyl cellulose succinate, hydroxypropylmethyl cellulose acetate succinate, cellulose acetate succinate butyrate, cellulose acetate succinate propionate, carboxymethylcellulose sodium, cellulose butyrate, and mixtures thereof and a plasticizer selected from a water-soluble preparation of a fat-soluble vitamin. A preferred plasticizer is Vitamin E polyethylene glycol 1000 succinate.

Owner:EASTMAN CHEM CO

Cellulosic films incorporating a pharmaceutically acceptable plasticizer with enhanced wettability

An enteric coating for a solid pharmaceutical carrier or substrate wherein the enteric coating includes a cellulosic polymeric material selected from selected from the group consisting of hydroxypropyl cellulose, hydroxyethyl cellulose, hydroxypropyl methyl cellulose, methyl cellulose, ethyl cellulose, cellulose acetate, cellulose acetate butyrate, cellulose acetate phthalate, cellulose acetate succinate, cellulose acetate propionate, cellulose acetate trimellitate, hydroxypropylmethyl cellulose phthalate, hydroxypropylmethyl cellulose succinate, hydroxypropylmethyl cellulose acetate succinate, cellulose acetate succinate butyrate, cellulose acetate succinate propionate, carboxymethylcellulose sodium, cellulose butyrate, and mixtures thereof and a plasticizer selected from a water-soluble preparation of a fat-soluble vitamin. A preferred plasticizer is Vitamin E polyethylene glycol 1000 succinate.

Owner:EASTMAN CHEM CO

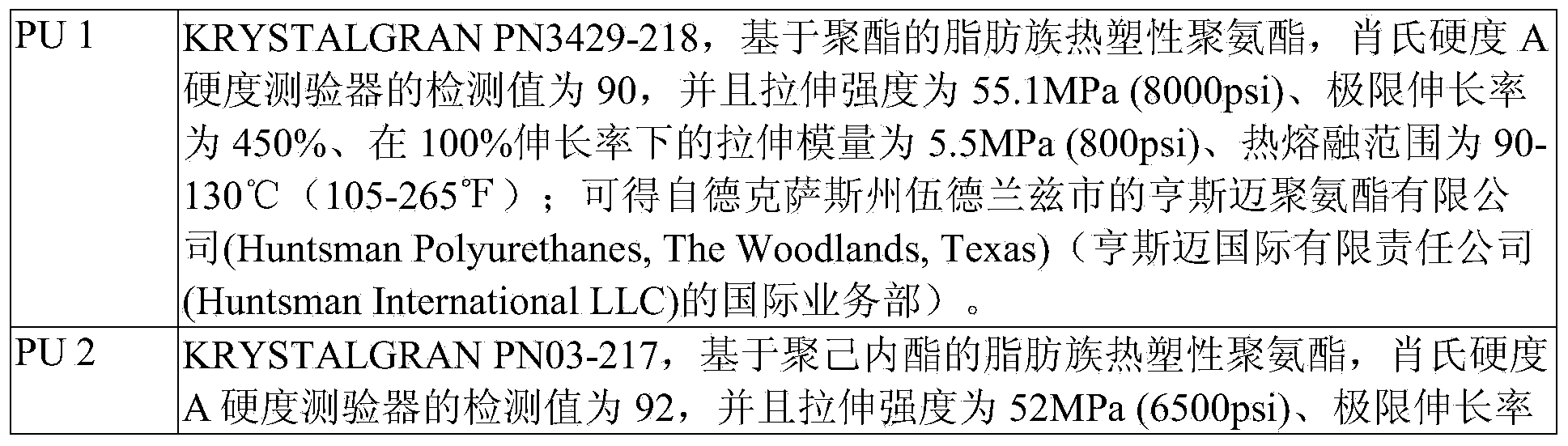

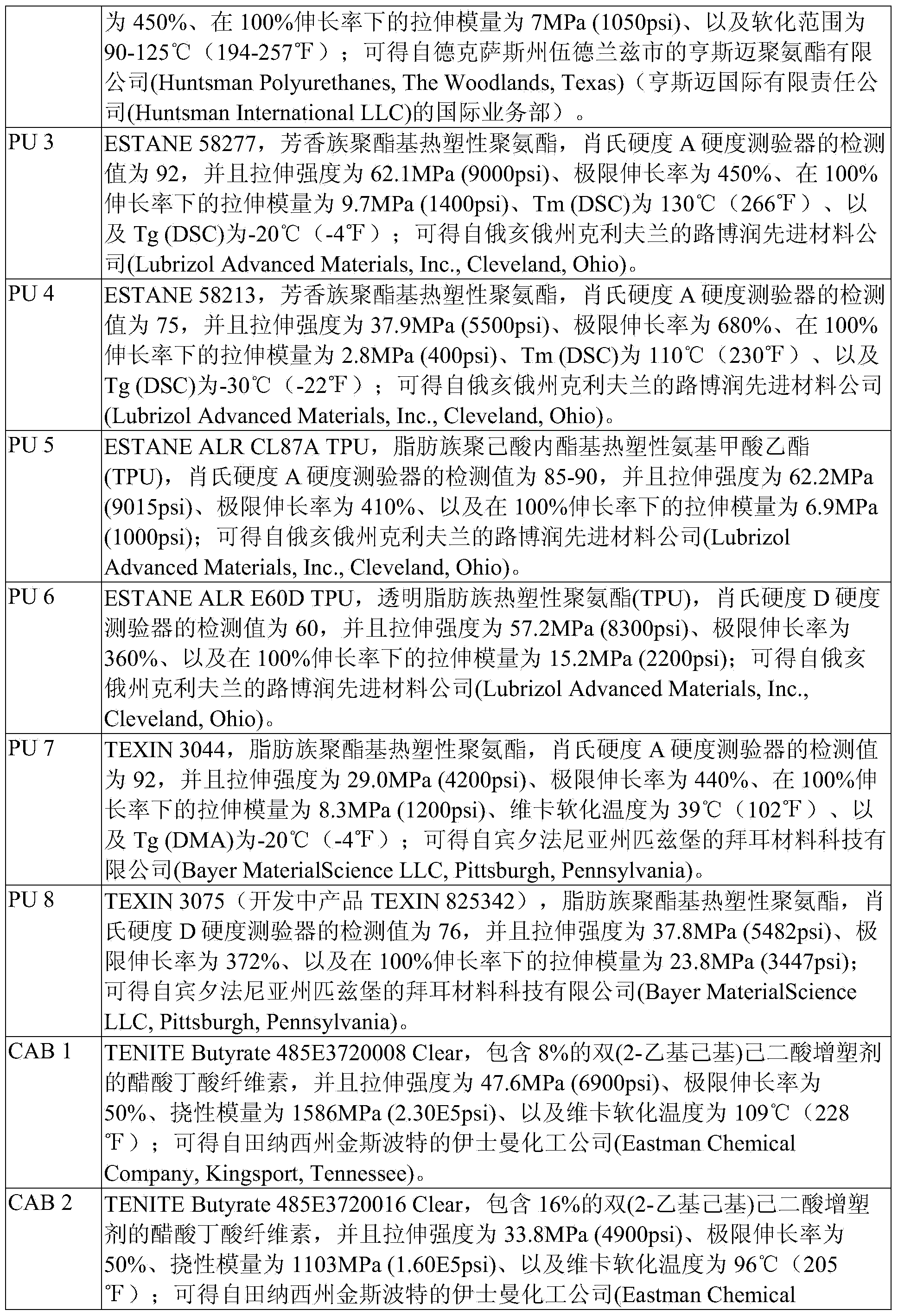

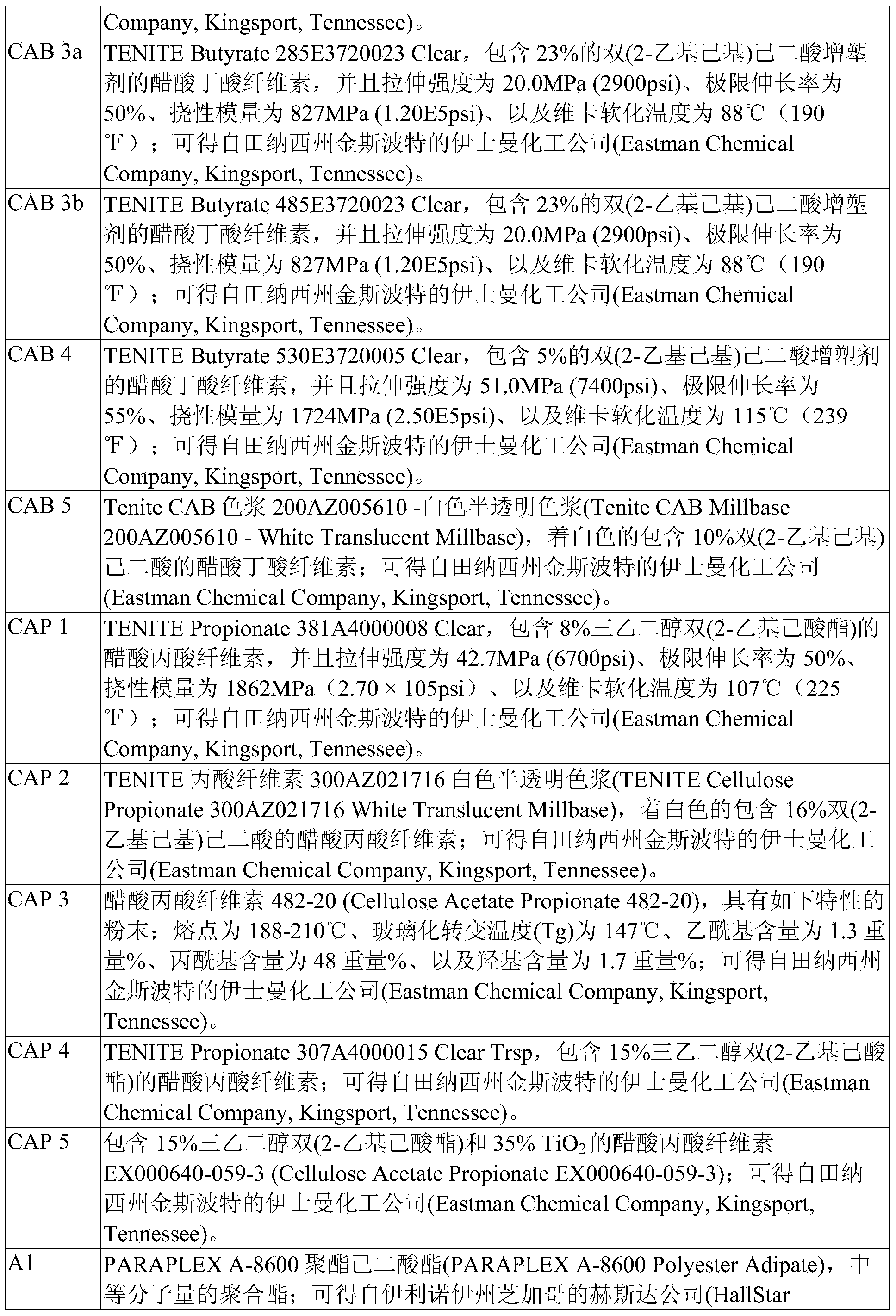

Graphic article

The present application is directed to articles useful as graphic films. Specifically, the present application is directed to an article comprising a film layer, the film layer comprising a polymer blend comprising a thermoplastic polyurethane and a cellulose ester, and an ink layer adjacent to at least one surface of the film. In some embodiments, the cellulose ester is a cellulose acetate butyrate. In some embodiments, the cellulose ester is a cellulose acetate propionate.

Owner:3M INNOVATIVE PROPERTIES CO

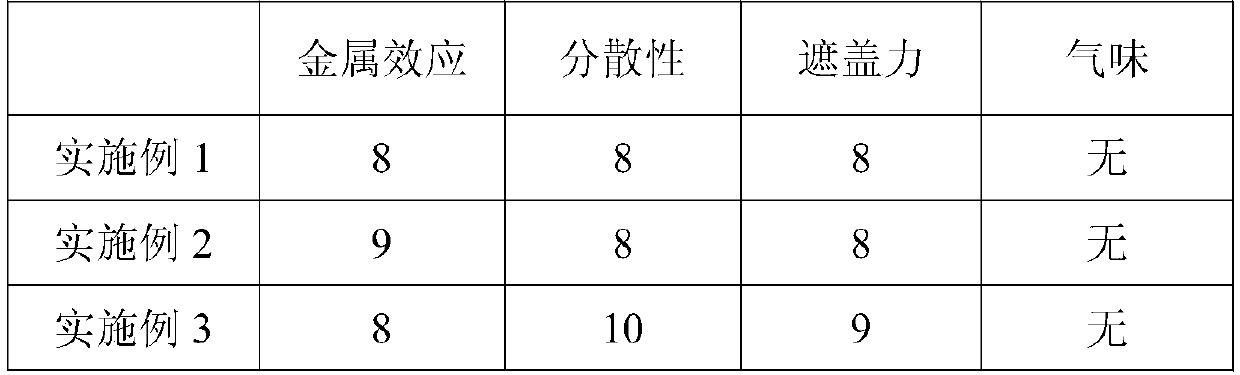

Aluminum strip for cigarette package ink and preparation method of aluminum strip

The invention provides an aluminum strip for cigarette package ink. A preparation process is as the follows: under a heating condition, carrying out functionalization modification on a surface of an aluminum sheet by cooperation of partial free acrylic acid and / or acrylic acid ester in a solution and cellulose functional molecules, carrying out a free radical polymerization reaction on residual acrylic acid and / or acrylic acid ester on the surface of the aluminum sheet to form a polymer serving as molded resin, and carrying out pressure filtration, hydraulic extrusion molding and vacuum staticbaking on the materials to obtain the aluminum strip. The preparation raw materials comprise a solvent, an initiator, aluminum paste, a component A and a component B, wherein the component A comprises at least one selected from hydroxypropyl methacrylate, methyl methacrylate, hydroxyethyl acrylate, isobornyl acrylate, butyl acrylate and methacrylic acid, and the component B comprises at least oneselected from cellulose acetate butyrate, cellulose acetate propionate and cellulose nitrate. According to the invention, functionalization of the surface of the aluminum sheet and one-step generation of the molded resin are realized, and the aluminum strip product has excellent metal effect, striping property and printing adaptability.

Owner:长沙族兴新材料股份有限公司

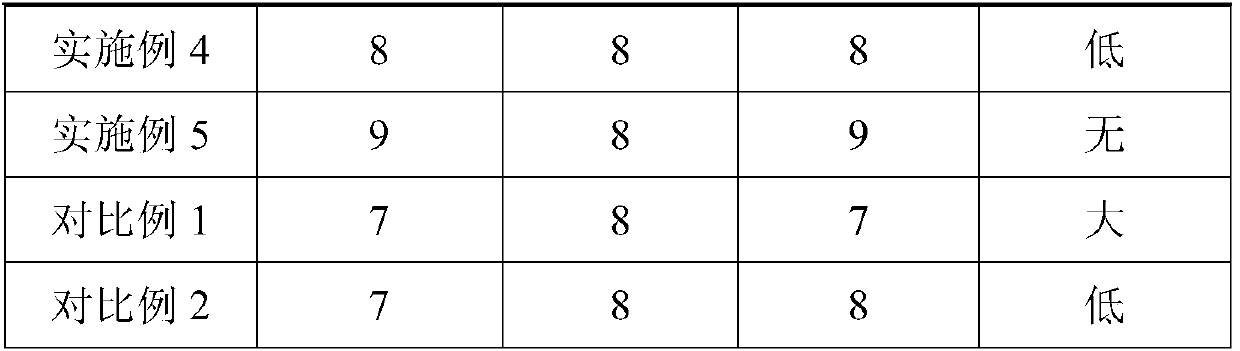

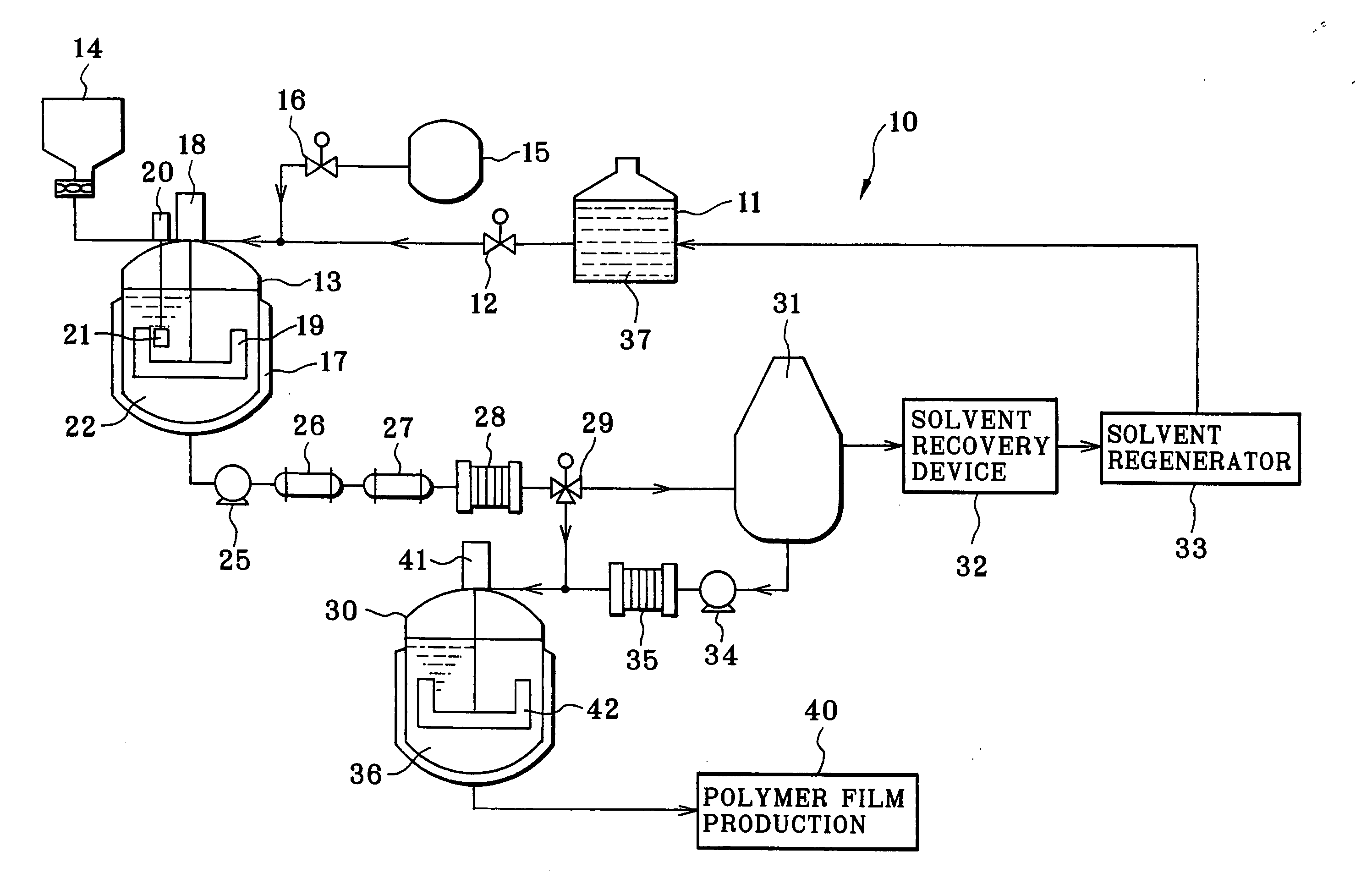

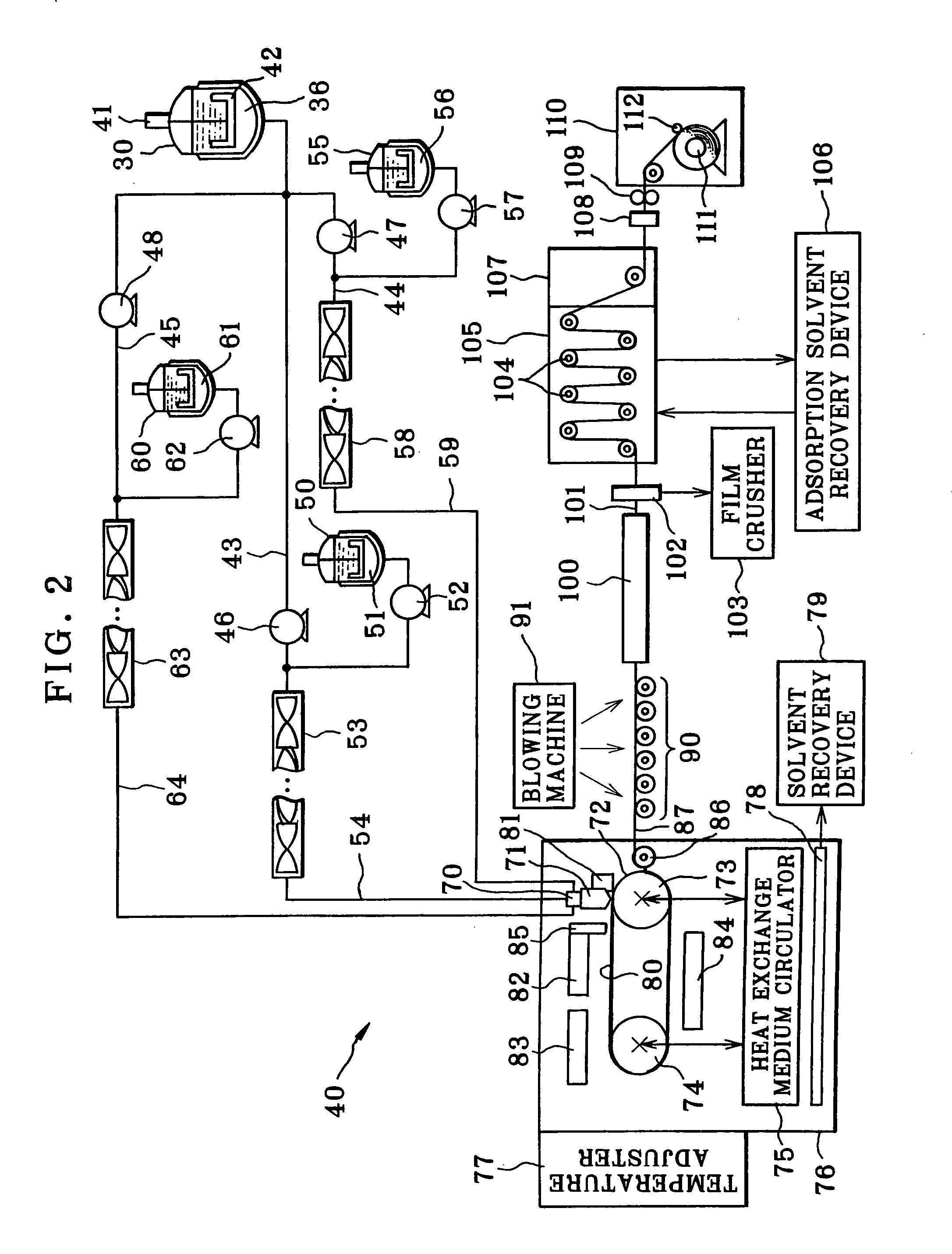

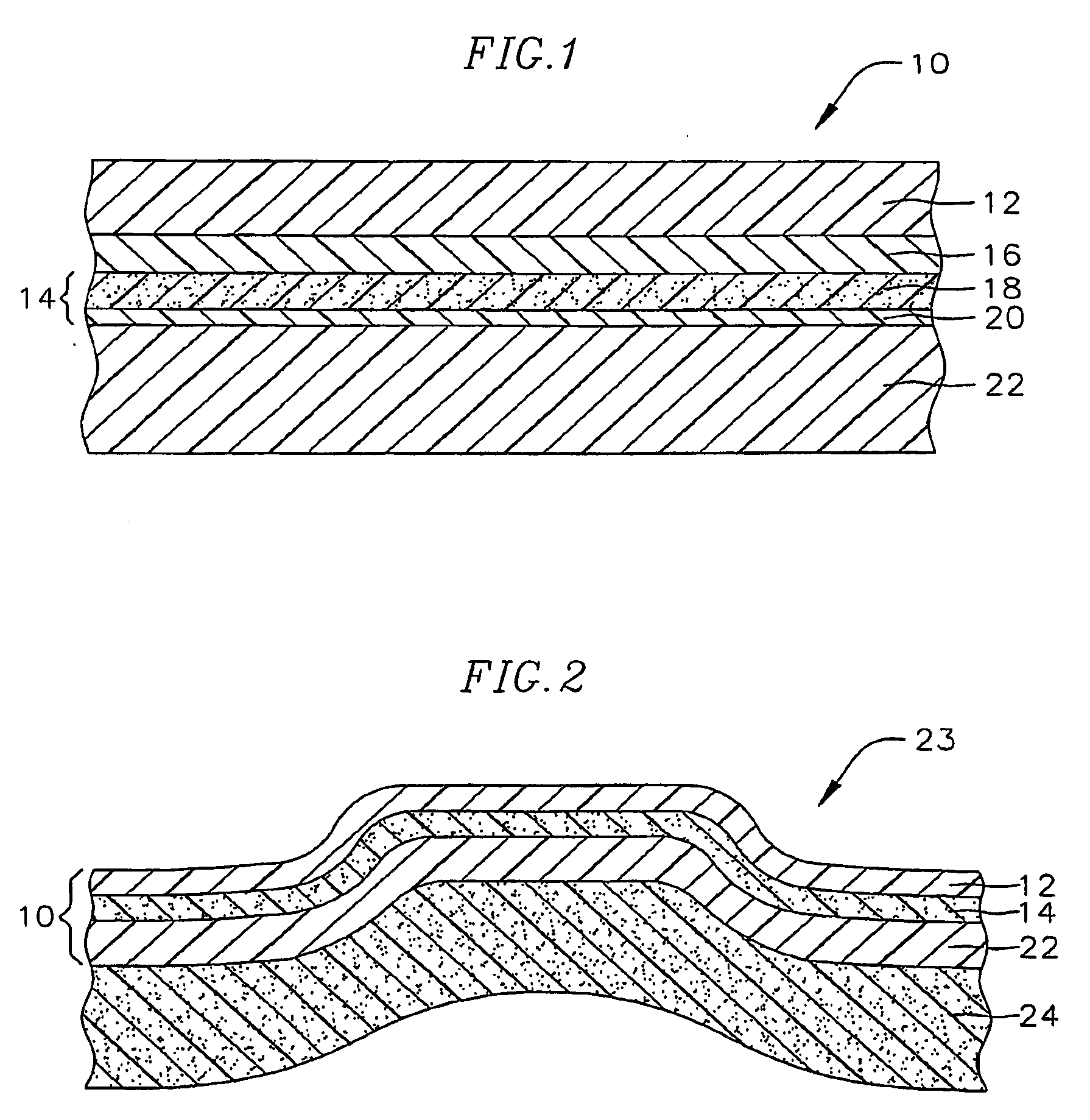

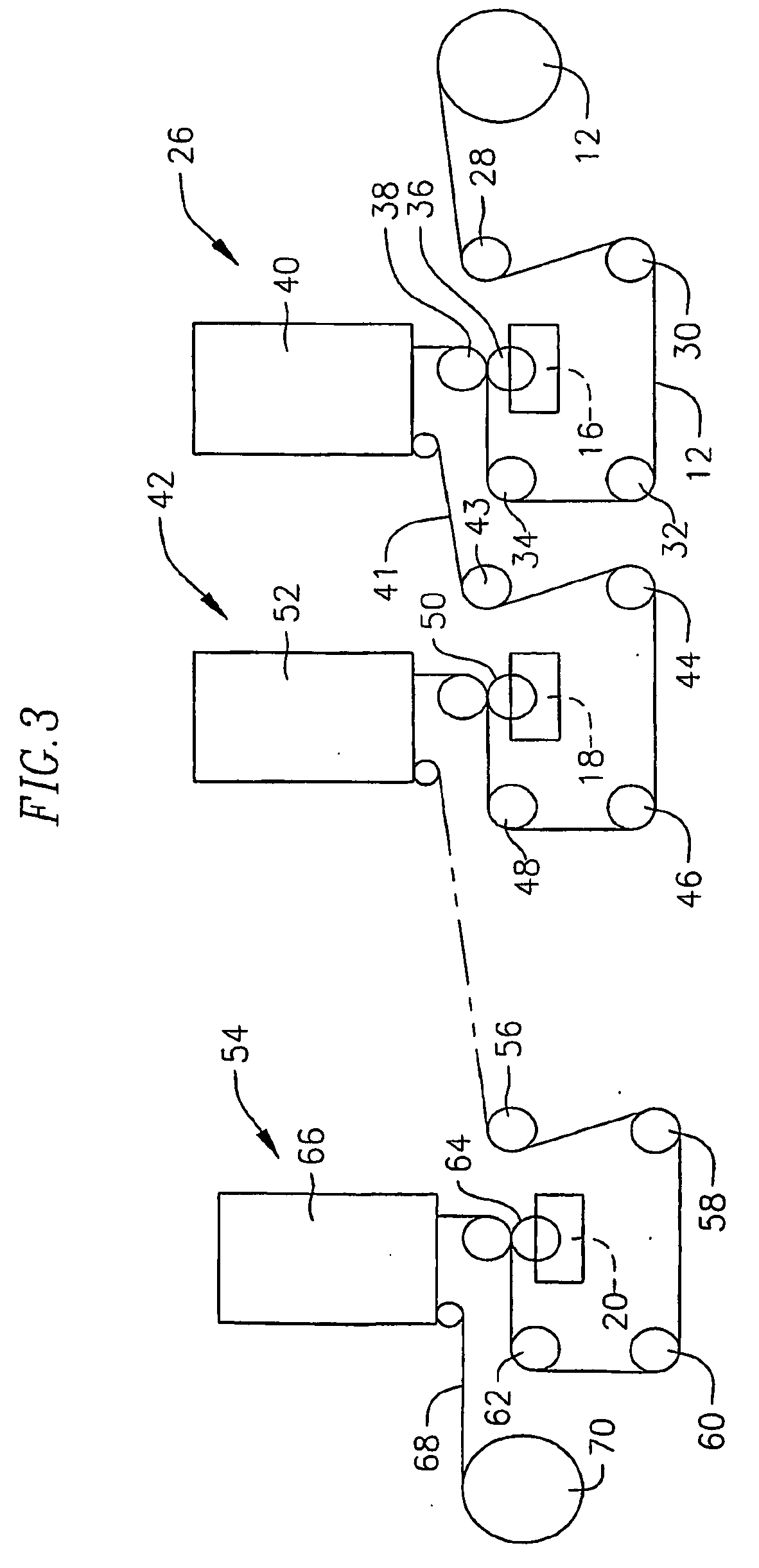

Solution casting process and cellulose ester film

In solution casting, dope containing a polymer and a solvent is cast on to a support to form a cast film. The cast film is stripped from the support to obtain a polymer film of cellulose ester, for example, cellulose acetate propionate (CAP). The polymer film is stretched. While the polymer film is stretched, tension of 80 N / m or more is applied thereto in a stretching direction. Polymer film surface temperature thereof is set equal to or more than a glass transition temperature Tg thereof. Furthermore, before stretching the polymer film, the polymer film stripped from the support is dried. After stretching the polymer film, the polymer film is dried. Also, the solution casting process is according to multi casting of plural dopes at one time together for plural cast films in the polymer film.

Owner:FUJIFILM CORP +1

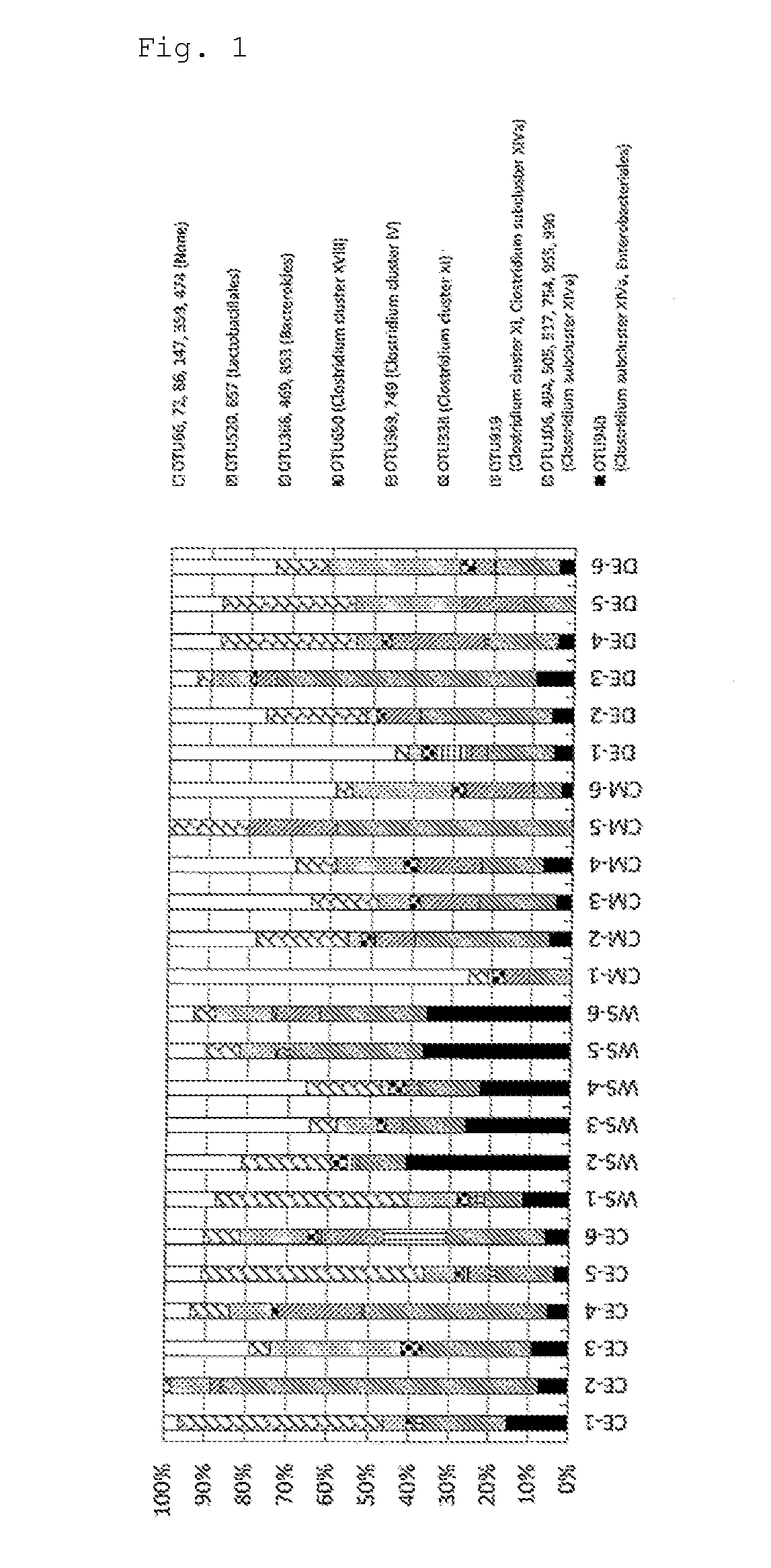

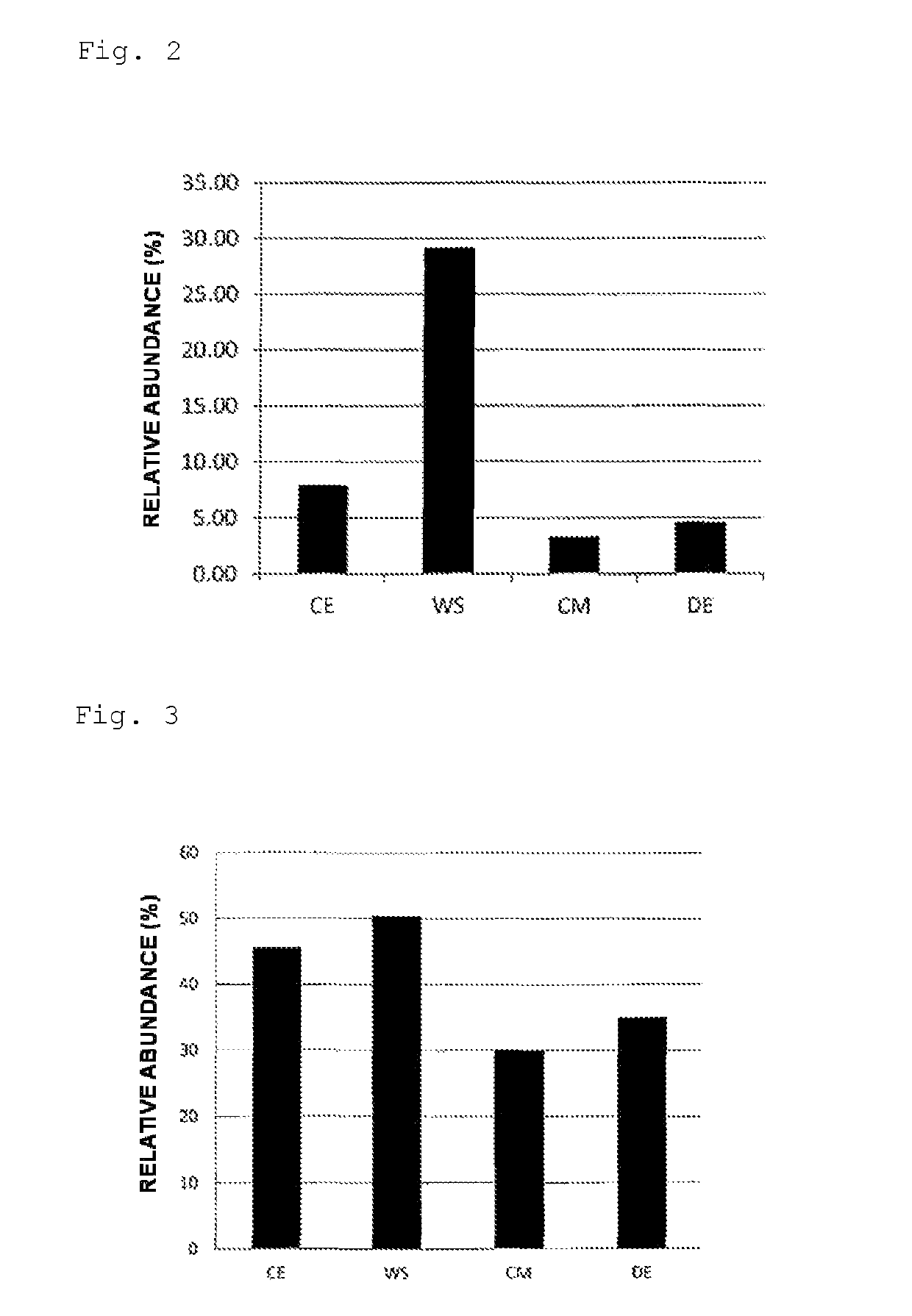

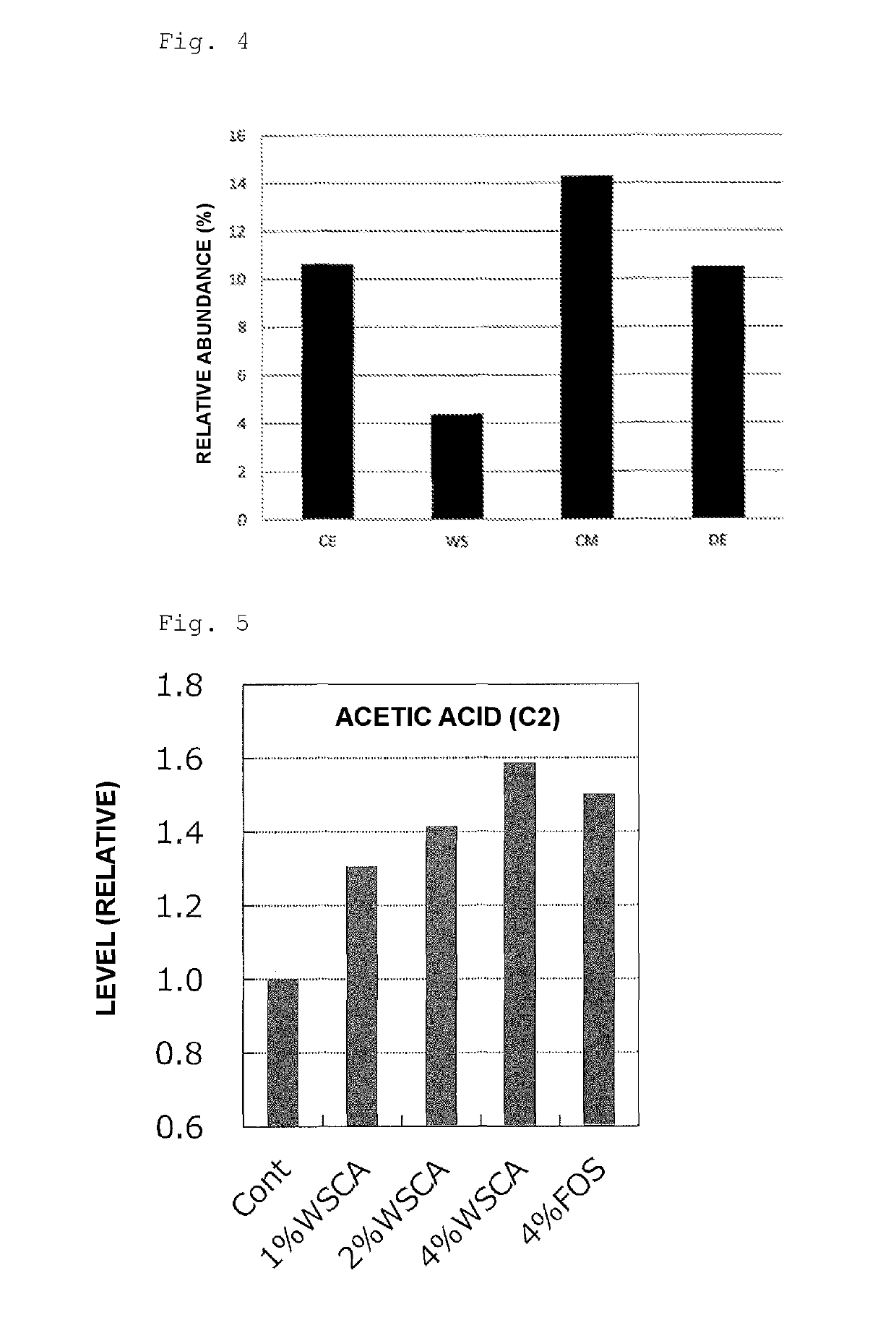

Nutritional composition

ActiveUS10300085B2Low degreeImprove hydrophilicityOrganic active ingredientsMetabolism disorderCellulose acetate propionateNutrient

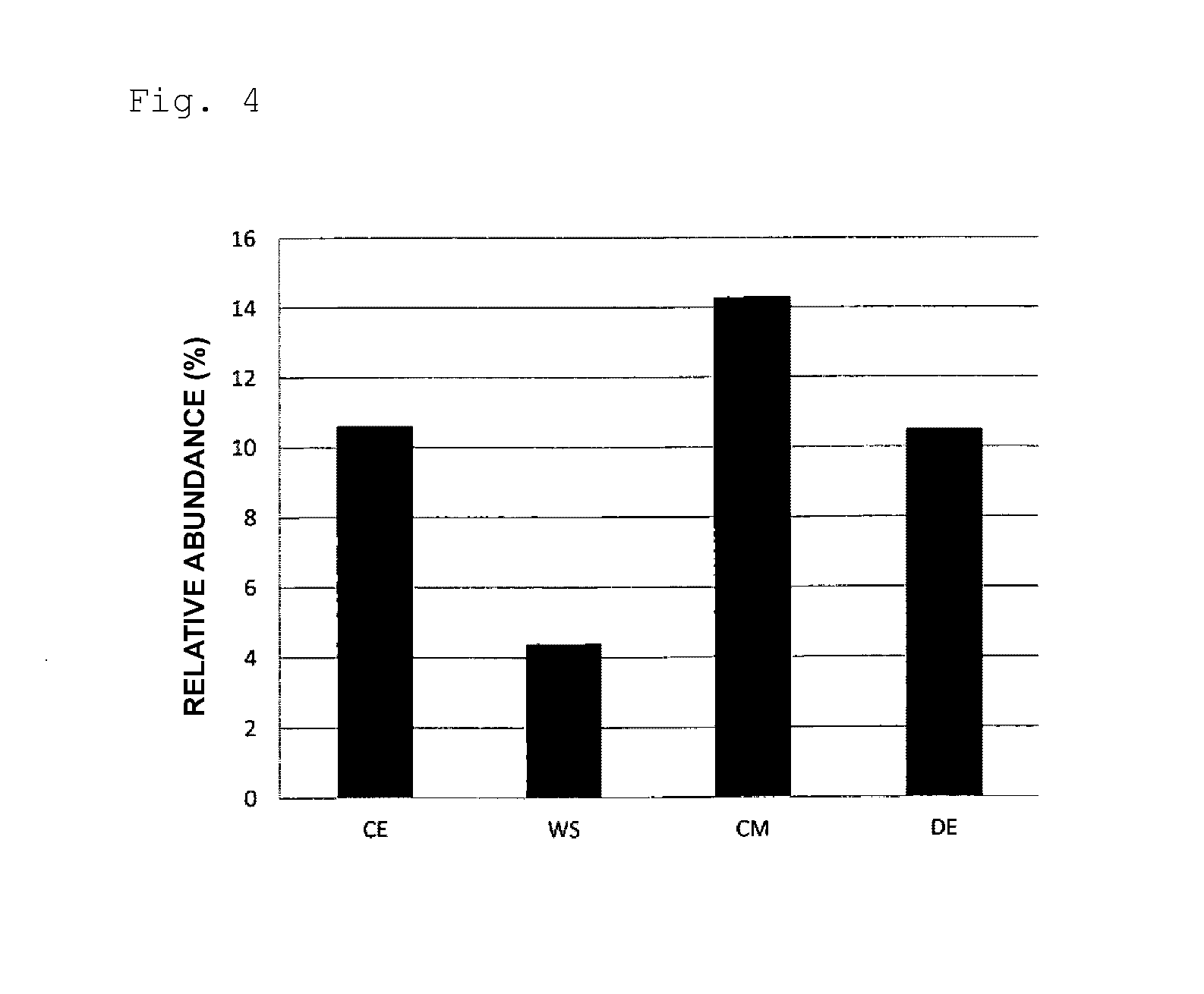

A nutrient composition, a lipid metabolism-improving agent, and prophylactic and / or therapeutic agents typically for inflammatory bowel diseases, immune disorders, cancers, non-alcoholic steatohepatitis, obesity, diabetes, and hypercholesterolemia each contain a cellulose acetate having a total degree of acetyl substitution of 0.4 to 1.1. The cellulose acetate may be one having a compositional distribution index (CDI) of 2.0 or less, where the CDI is defined by the formula:CDI=(Measured value of half height width of chemical composition) / (Theoretical value of half height width of chemical composition)where the measured value of half height width of chemical composition represents a half height width of chemical composition determined by HPLC analysis of a cellulose acetate propionate prepared by propionylating all residual hydroxy groups of the cellulose acetate (sample), andthe theoretical value of half height width of chemical composition =2.35482√{square root over (3*DPw*(DS / 3)*(1−DS / 3))} / DPw [Math. 1]where DS is the total degree of acetyl substitution; and DPw is a weight-average degree of polymerization determined by a GPC-light scattering method using a cellulose acetate propionate prepared by propionylating all residual hydroxy groups of the cellulose acetate (sample).

Owner:DAICEL CHEM IND LTD

High Gloss Laminates for Decorative Automotive Parts

InactiveUS20090274922A1Improve performanceHigh glossVehicle componentsCoatingsCellulosePolymer science

A thermoformable decorative automotive laminate includes a flexible free film comprising a transparent UV light-stabilized cellulosic outer film, an optional primer, ink layers, and an opaque layer. The cellulosic outer film may include cellulose acetate butyrate and / or cellulose acetate propionate. The cellulosic film may he laminated to a polymeric sheet or film and thermo-formed to a three dimensional shape while maintaining a high gloss and DOI along with durability properties suitable for interior or exterior automotive use.

Owner:CCL LABEL INC

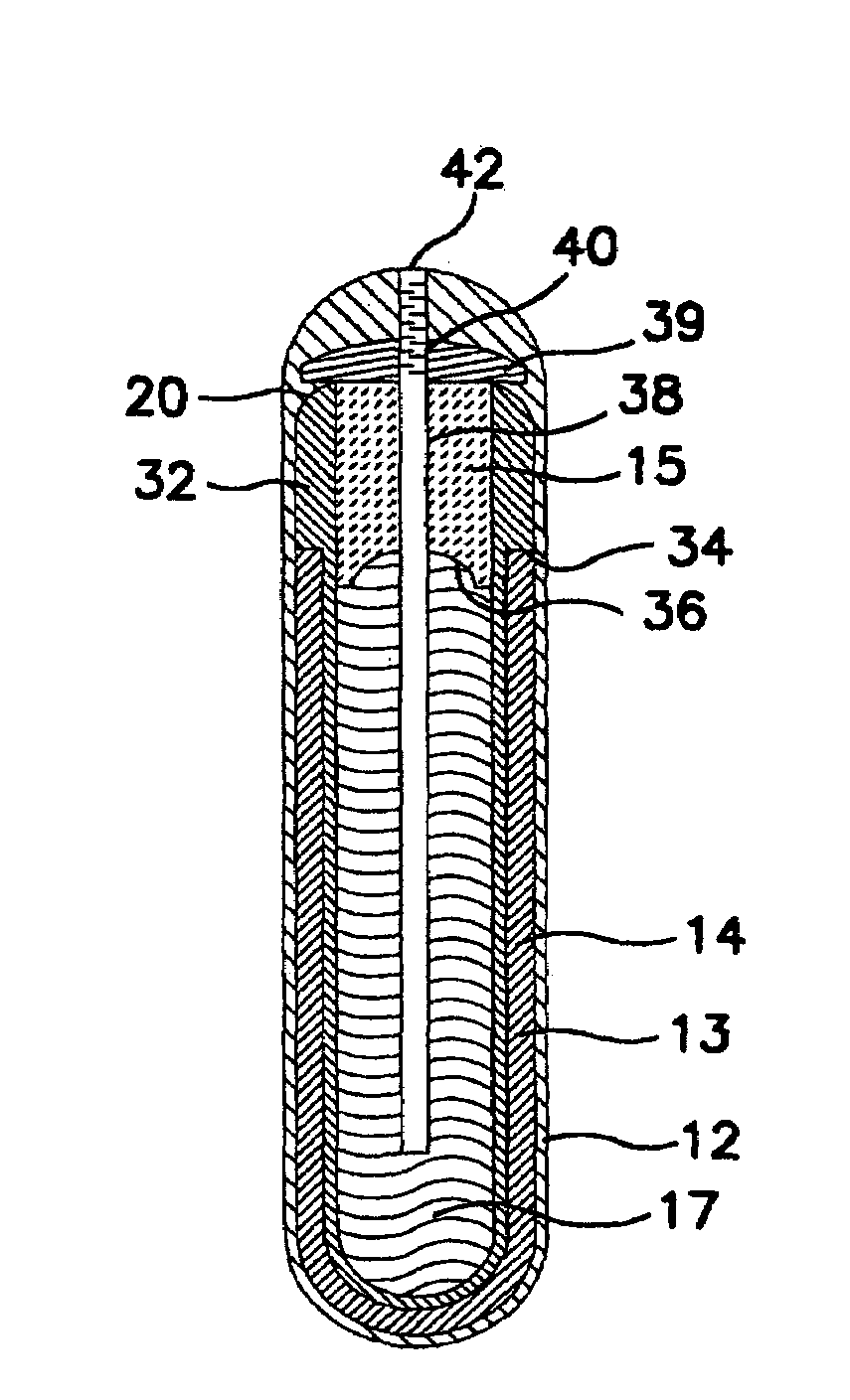

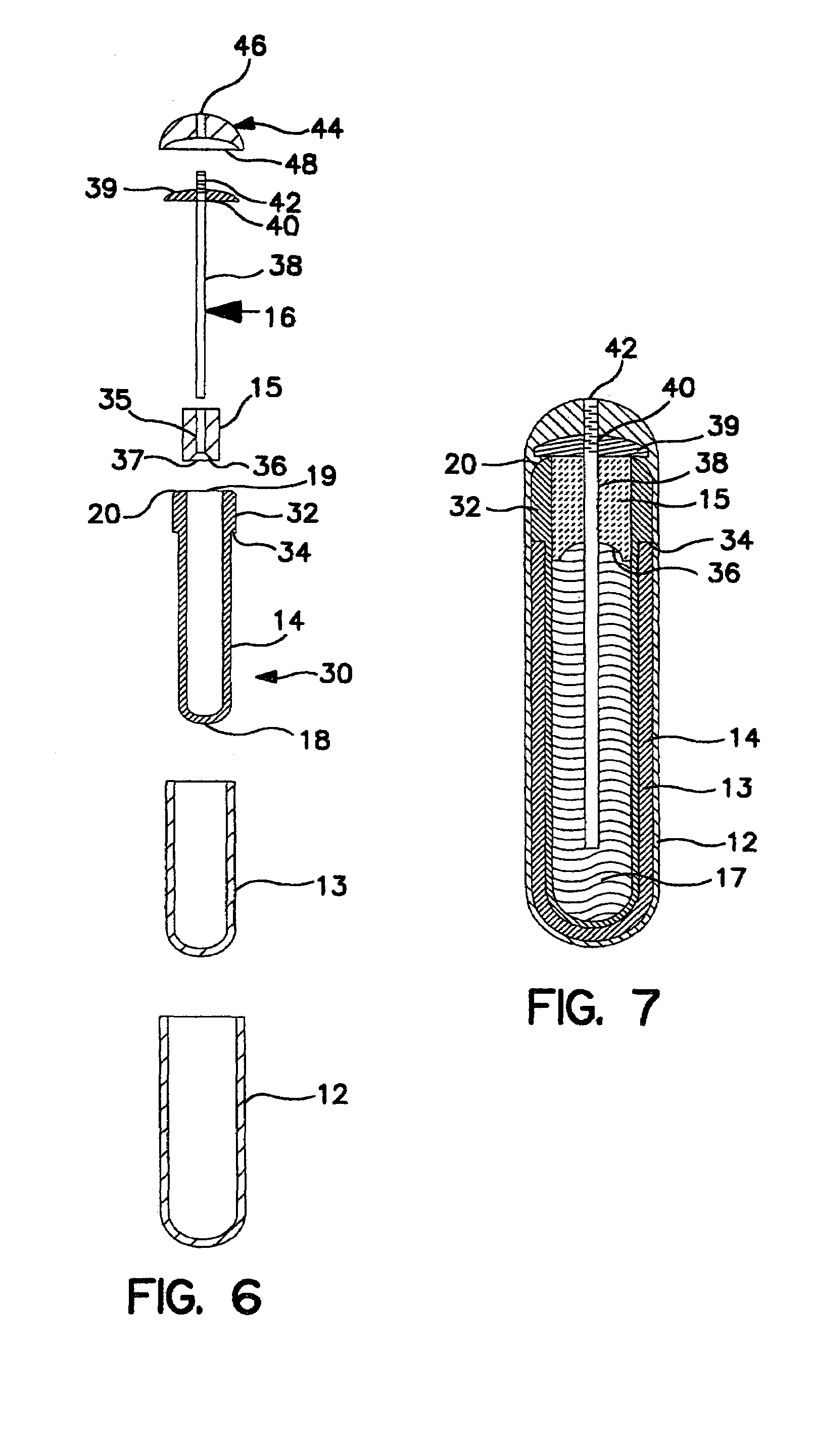

Osmotically-driven fluid dispenser

Improvements in a mini-osmotic pump and coating compositions are described. The dispensing pump includes an inner fluid-filled bag encased by an osmotic layer and outer, semi-permeable membrane. The inner bag is formed with an arcuate edge at the open end of the bag to inhibit formation of fissures in the outer membrane in this edge region. The coating compositions include cellulose acetate butyrate, cellulose acetate propionate, and polymethylmethacrylate polymers, optionally mixed with ethyl cellulose in acetone based solvent systems.

Owner:DURECT CORP

Nutrient composition having lipid metabolism-improving action

ActiveUS20160317568A1Low degreeImprove hydrophilicityOrganic active ingredientsMetabolism disorderChemical compositionNutrition

A nutrient composition contains a cellulose acetate having a total degree of acetyl substitution of 0.4 to 1.1. The cellulose acetate may have a compositional distribution index (CDI) of 2.0 or less, where the CDI is specified by the formula:CDI=(Measured value of half height width of chemical composition) / (Theoretical value of half height width of chemical composition)where the measured value of half height width of chemical composition represents the half height width of chemical composition determined by HPLC analysis of a cellulose acetate propionate prepared by propionylating all residual hydroxy groups of the cellulose acetate (sample); andthe theoretical value of half height width of chemical composition=2.35482√{square root over (3*DPw*(DS / 3)*(1−DS / 3))} / DPw [Math. 1]where DS is the total degree of acetyl substitution; and DPw is a weight-average degree of polymerization determined by a GPC-light scattering method using a cellulose acetate propionate prepared by propionylating all residual hydroxy groups of the cellulose acetate (sample).

Owner:DAICEL CHEM IND LTD

Preparation method of low-propionyl-content cellulose acetate propionate mixed ester

The invention relates to a preparation method of low-propionyl-content cellulose acetate propionate mixed ester. Cellulose is prepared from, by weight, 650 g of wood pulp, 296 g of propionic acid, 2250 g of acetic acid, 118 g of acetic anhydride, 2070 g of propionic anhydride and 19.5-52 g of catalysts. The ratio of liquid acid catalysts to heteropolyacid catalyst is between 4 to 6 and 6 to 4. The preparation method includes the steps of conducting activating, the esterification reaction, mixing, magnesium acetate solution adding, hydrolysis and chromatography, sequentially conducting conventional filtering, washing and drying, and obtaining the finished product. The method has the advantages that the propionyl content of the obtained cellulose acetate propionate finished product is 15-20%, and the acetyl content is smaller than 22-30%; the mixture of liquid acid and heteropolyacid is selected for the catalysts, and therefore the sulfuric acid consumption is lowered, the corrosion to a technological device and the pollution to the environment can be reduced, and technological safety is improved; meanwhile, by adding heteropolyacid, the esterification reaction is accelerated, and the hydrolysis reaction is more precise and controllable.

Owner:JIANGSU RUICHEN CHEM +1

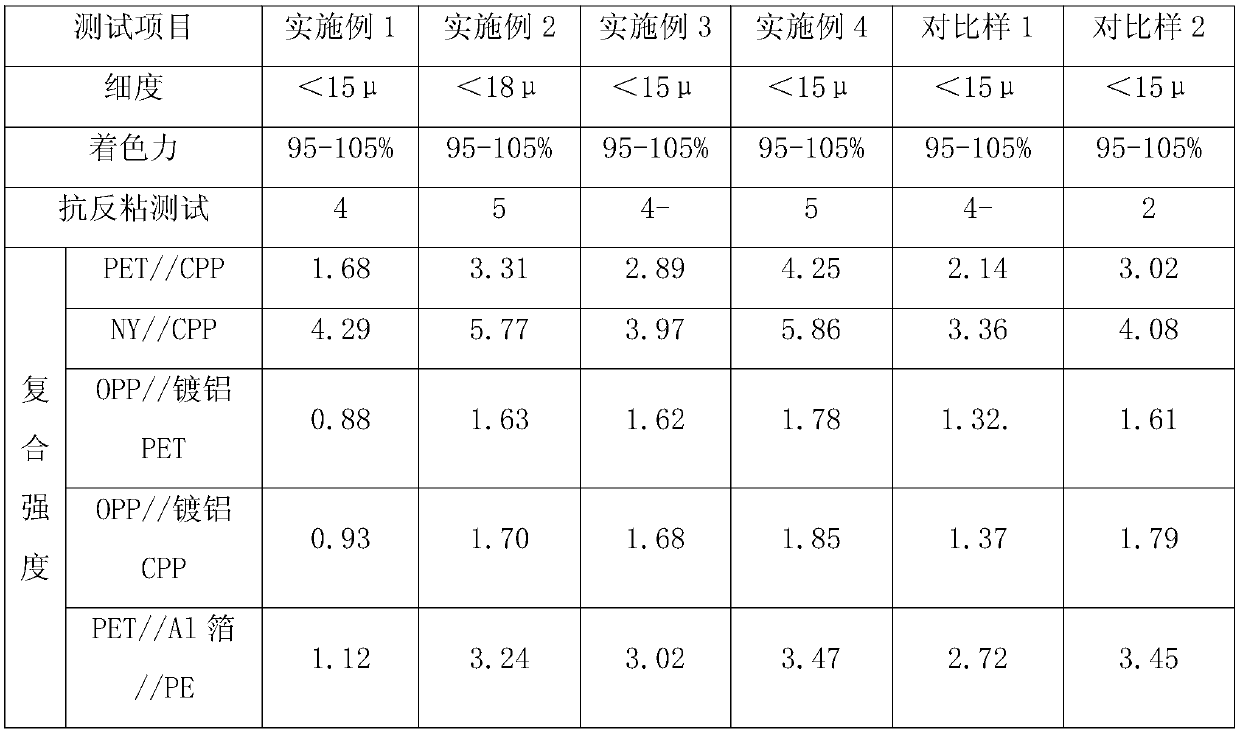

Environmentally-friendly polyurethane composite ink composition capable of adapting to ultra-high-speed printing and manufacturing method of composition

The invention discloses an environmentally-friendly polyurethane composite ink composition capable of adapting to ultra-high-speed printing. The composition comprises the following raw materials: 25-32 parts of amide modified polyurethane resin, 5-15 parts of a vinyl chloride-acetate copolymer liquid, 3-8 parts of a cellulose acetate propionate resin liquid, 8-33 parts of a pigment, 34-60 parts ofan environmentally-friendly mixed solvent, 1-2.5 parts of an auxiliary agent, 0.2-0.5 part of matt powder, and 0.2-1 part of wax powder. According to the invention, the environmentally-friendly polyurethane composite ink composition capable of adapting to ultra-high-speed printing has the advantages of good tinting strength, a vivid color and high transparency; the printing adaptability is strong, and the composition can be widely applied to printing of plastic flexible packaging composite materials such as PET, NY and BOPP; and in particular, the composition can be applied to ultra-high-speed printing with a printing speed higher than 350m / min, can effectively solve the problems that the composite strength of a printing film is not high, solvent residues easily exceed a standard, and a back adhesion phenomenon exists.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

Preparation method for spontaneously-heating elastic nanofiber

ActiveCN106939442AHas elastic propertiesImprove heating effectMonocomponent polyolefin artificial filamentArtifical filament manufactureElastomerFiber

The invention relates to the field of preparation of nanofibers, especially to a preparation method for a spontaneously-heating elastic nanofiber. The preparation method comprises the following steps: subjecting thermoplastic elastomer and cellulose acetate butyrate to blending and drawing for fiber formation so as to obtain an elastic fiber; then removing cellulose acetate butyrate in the elastic fiber through extraction so as to obtain an elastomer nanofiber; then uniformly dispersing the elastomer nanofiber and inorganic heating powder in an organic solvent so as to obtain blended liquid; adding acetone into the blended liquid to allow a polymer to be precipitated; and subjecting the polymer and cellulose acetate butyrate to blending, extrusion and drawing for fiber formation and removing cellulose acetate butyrate through extraction so as to obtain the spontaneously-heating elastic nanofiber. The spontaneously-heating elastic nanofiber prepared by using the method has good elasticity and spontaneous heating performance.

Owner:WUHAN TEXTILE UNIV

Preparation method for water-soluble cellulose acetate propionate mould-pressing and aluminium-plating emulsion

The invention discloses a preparation method for water-soluble cellulose acetate propionate mould-pressing and aluminium-plating emulsion. The preparation method comprises a step of weighing the substances of cellulose acetate propionate, methyl methacrylate, butyl methacrylate, ethyl acrylate, dicyclopentadienyl acrylate, acrylic acid and N-hydroxyethyl acrylamide in a weight ratio, a step of preparing a pre-mixing solution, namely, performing mixed reaction on cellulose acetate propionate, an organic solvent, an initiator and a part of monomers, and a step of preparing pre-emulsion, namely, mixing a non-ionic emulsifier with an anionic emulsifier at first, and then adding the remainder substances to prepare the pre-emulsion, adding the pre-emulsion in a reaction kettle to react after the initiator is completely dissolved, dropwise adding ammonia water to neutralize, and finally diluting until the solid content is 35%, and then cooling and discharging. With the adoption of the preparation method disclosed by the invention, the problem of discharge for volatile organic compounds is solved; and the obtained product is good in water resistance after being dried, and improved in hardness, glossiness and plasticity after film-forming.

Owner:上海百道成新材料科技有限公司

Polylactic acid composite material formula and preparation method thereof

InactiveCN107118416AImprove toughnessImprove antioxidant capacityEnvironmental resistanceAntioxidant

The invention discloses a polylactic acid composite material formula, which is composed of the following raw materials in parts by weight: 10-40 parts of polylactic acid, 5-35 parts of polybutylene succinate, and 4-16 parts of expandable graphite 8-24 parts of nano ferrite, 10-50 parts of polyethylene, 3-21 parts of maleic anhydride, 5-35 parts of polyvinyl acetate resin, 6-24 parts of cellulose acetate propionate, modified carbon nano Tube conductive powder 6-18 parts, antioxidant 2-18 parts, lubricant 1-11 parts, coupling agent 3-21 parts, filler 4-16 parts, toughening agent 6-14 parts, impact modifier 2‑12 servings. The invention has the advantages of stable performance, self-degradability, good environmental performance and the like.

Owner:安徽省卓煜新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com