Patents

Literature

525results about How to "Strong covering power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Odorless anti-formaldehyde environment-friendly internal wall latex paint and preparation method thereof

ActiveCN103059679AStrong absorption capacityStrong sustainable degradation abilityEmulsion paintsEmulsionSlurry

The invention discloses an odorless anti-formaldehyde environment-friendly internal wall latex paint and a preparation method thereof. The odorless anti-formaldehyde environment-friendly internal wall latex paint is prepared from the following components in percentage by weight: 1-15% of visible light induced nano titanium dioxide photocatalyst slurry, 15-35% of odorless emulsion, 1-15% of formaldehyde absorbent, 0.5-2% of dispersing agent, 0.2-3% of thickening agent, 0.2-1% of wetting agent, 0.1-1% of defoaming agent, 0.5-5% of film-forming assistant, 0.2-3% of anti-freeze agent, 20-40% of pigment and filler, 0.1-1% of pH regulator, 0.01-0.1% of anticorrosive bactericide and 15-40% of deionized water. The invention adopts an IPS+odorless technique, and the visible light induced nano titanium dioxide photocatalyst and the formaldehyde absorbent are added, thereby achieving the optimal effect of removing formaldehyde and other harmful substances through physical adsorption and chemical decomposition. The invention can be widely used for decorative spraying of various internal walls and other constructions.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Method for preparing extra-coarse grained carbide alloy

The invention discloses a method for preparing an extra-coarse grained carbide alloy. The method is characterized by comprising the following steps of: pre-mixing extra-coarse tungsten carbide powder having a grinding Fisher particle size of over 6 mu m and cobalt powder; adding molding agents and pressing the mixture to form lumps; pre-sintering the lumps in a degumming furnace having ammonia decomposition gas therein; placing the obtained product, the tungsten carbide powder and the cobalt powder into a ball mill for smashing and wet grinding to prepare a mixture containing 6 to 13 percent cobalt; adding molding agents into the mixture, and pressing to obtain the finished product; after degumming the finished product, sintering the finished product at the high temperature by using a pressurized sintering furnace; and thermally treating the sintered product by using a double-chamber high-pressure gas cooling vacuum furnace, wherein 87 to 94 parts of tungsten carbide, 6 to 13 parts of carbide powder and 0.5 to 2.5 parts of molding agent are pre-mixed. The method avoids the dispersing or grading sieving, and cobalt coating of the tungsten carbide; moreover, the prepared carbide alloy has good compactness, high strength and impact resistance, simple production process and no environment pollution.

Owner:SHANDONG CEMENTED CARBIDE

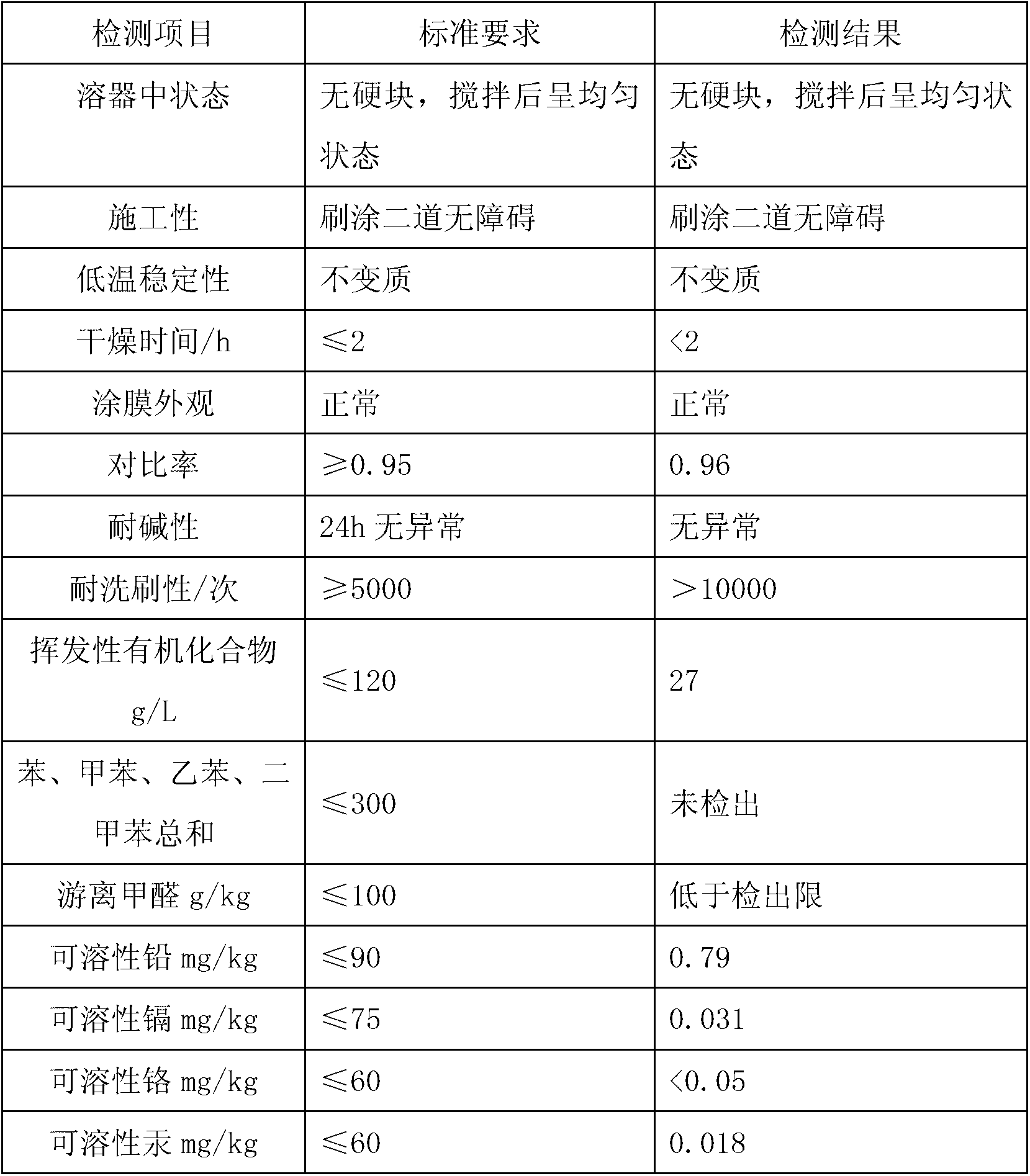

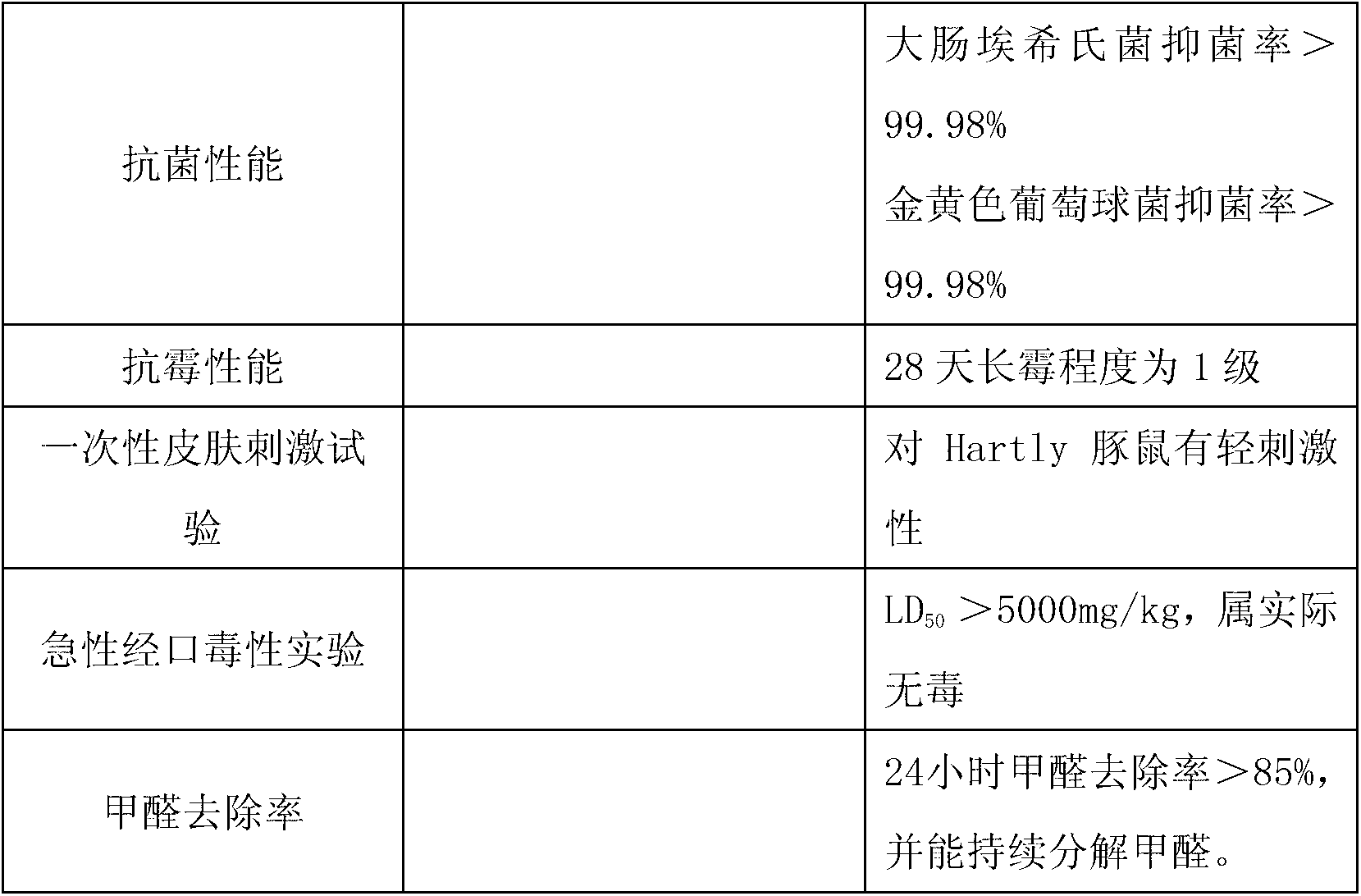

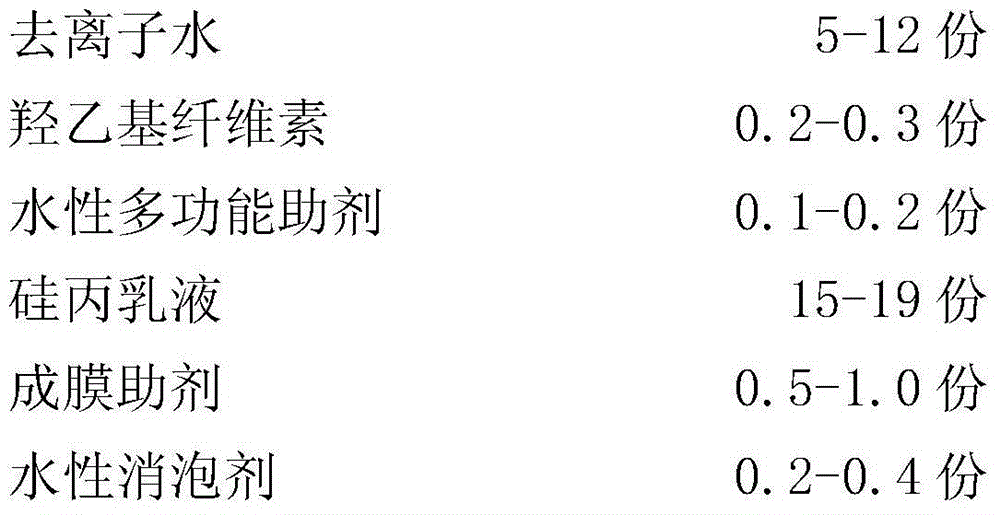

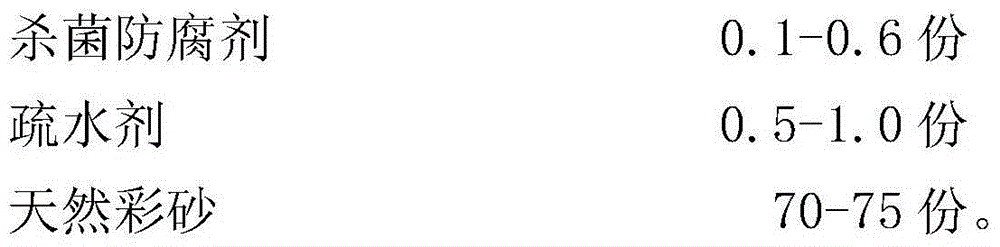

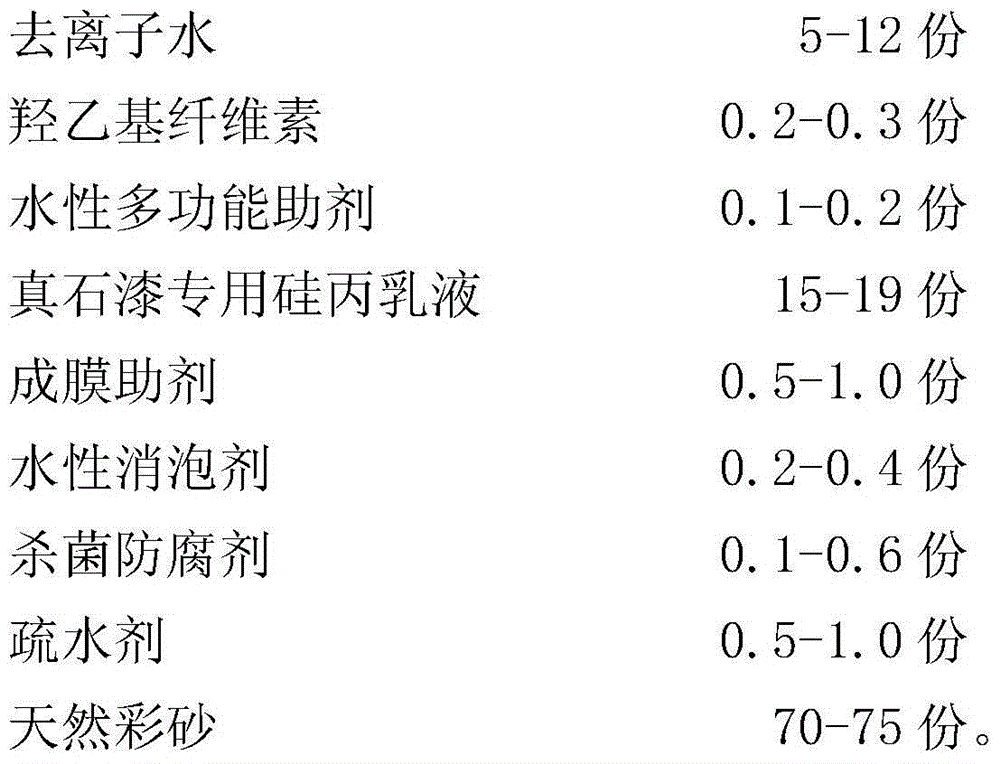

Functional real stone paint building exterior wall coating material and preparation method thereof

The invention relates to a functional real stone paint building exterior wall coating material and a preparation method thereof. The functional real stone paint building exterior wall coating material is composed of the following components in parts by weight: deionized water, hydroxyethyl cellulose, an aqueous multifunctional addition agent, a real stone paint special silicone acrylic emulsion, a coalescing agent, an aqueous defoamer, a sterilizing corrosion remover, a hydrophobing agent and natural colored sand. The functional real stone paint building exterior wall coating material prepared by the invention is formed with one construction process and strong in covering power with surface covering-free performance, simultaneously is excellent in water resistance, stain resistance and weather resistance performance.

Owner:SKSHU PAINT

High performance outer wall paint and its prepn

ActiveCN101067062AReduced light level cleavageLight level cleavage meetsEmulsion paintsPermeationNanometre

The present invention relates to outer wall paint, and is especially one kind of high performance nanometer outer wall paint and its preparation process. The nanometer outer wall paint has introduced organosilicon and fluoro resin to result in watertight coating with high permeation resistance and breathing function, water-thinned resin, nanometer titania particle, dispersing assistant and other assistants to make the paint possess well dispersed nanometer titania particle and excellent photocatalytic self-cleaning function.

Owner:广东拓扑中润科技发展有限公司

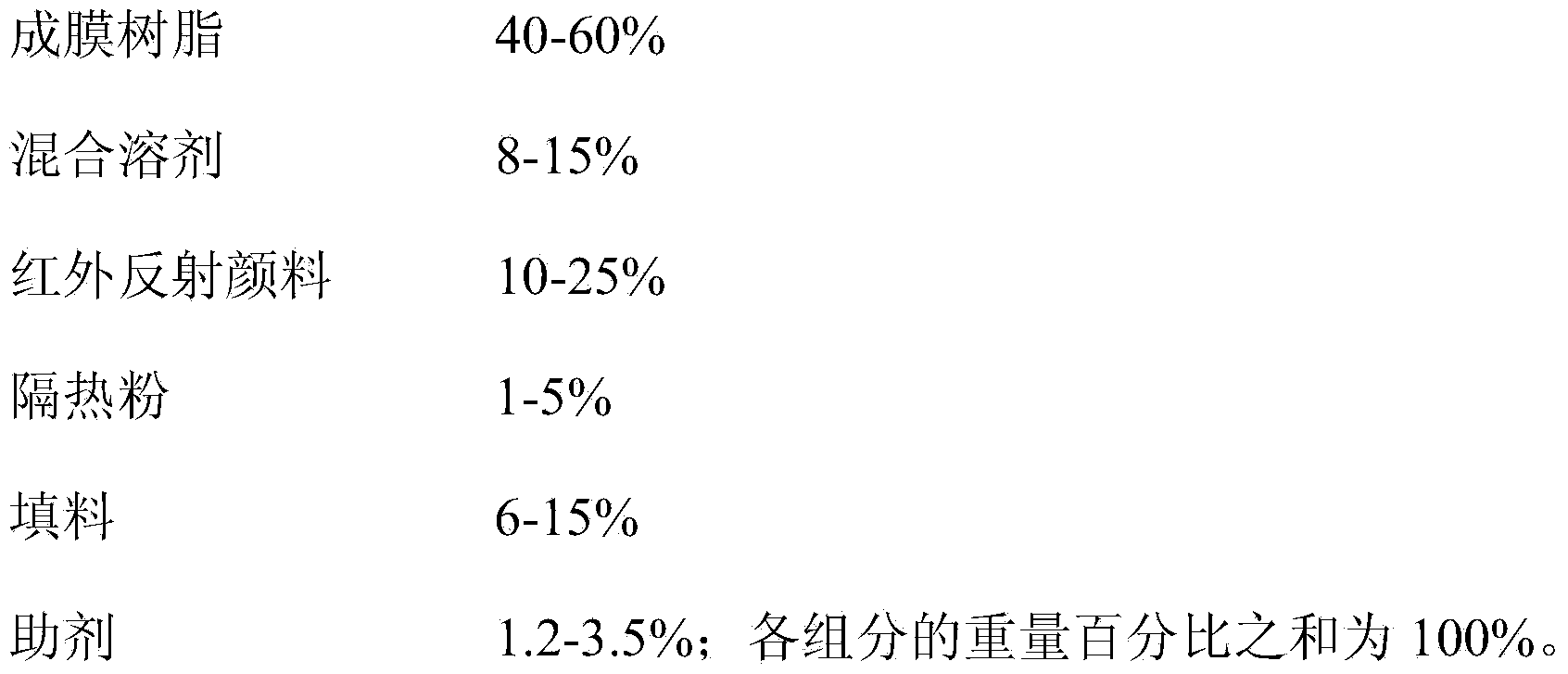

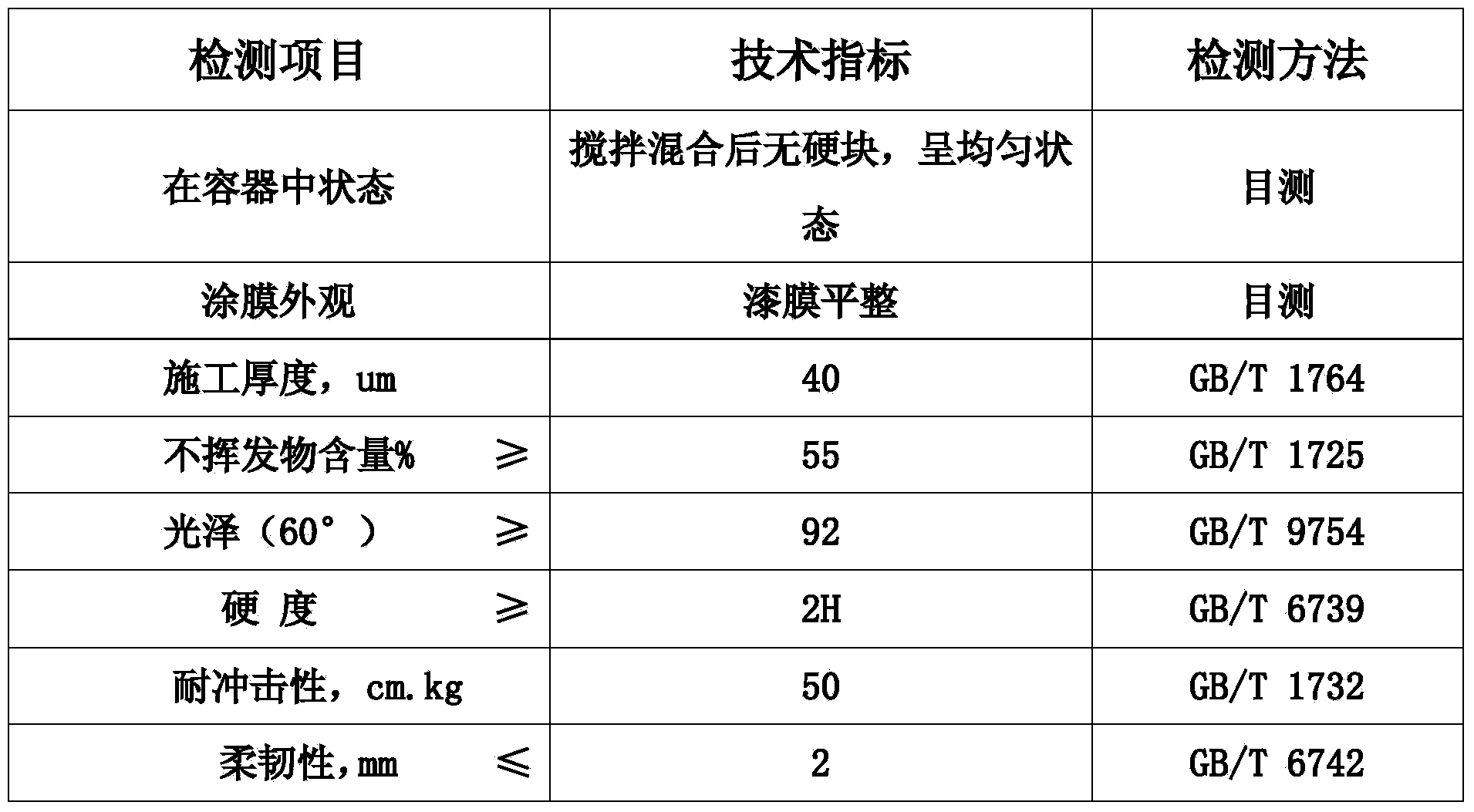

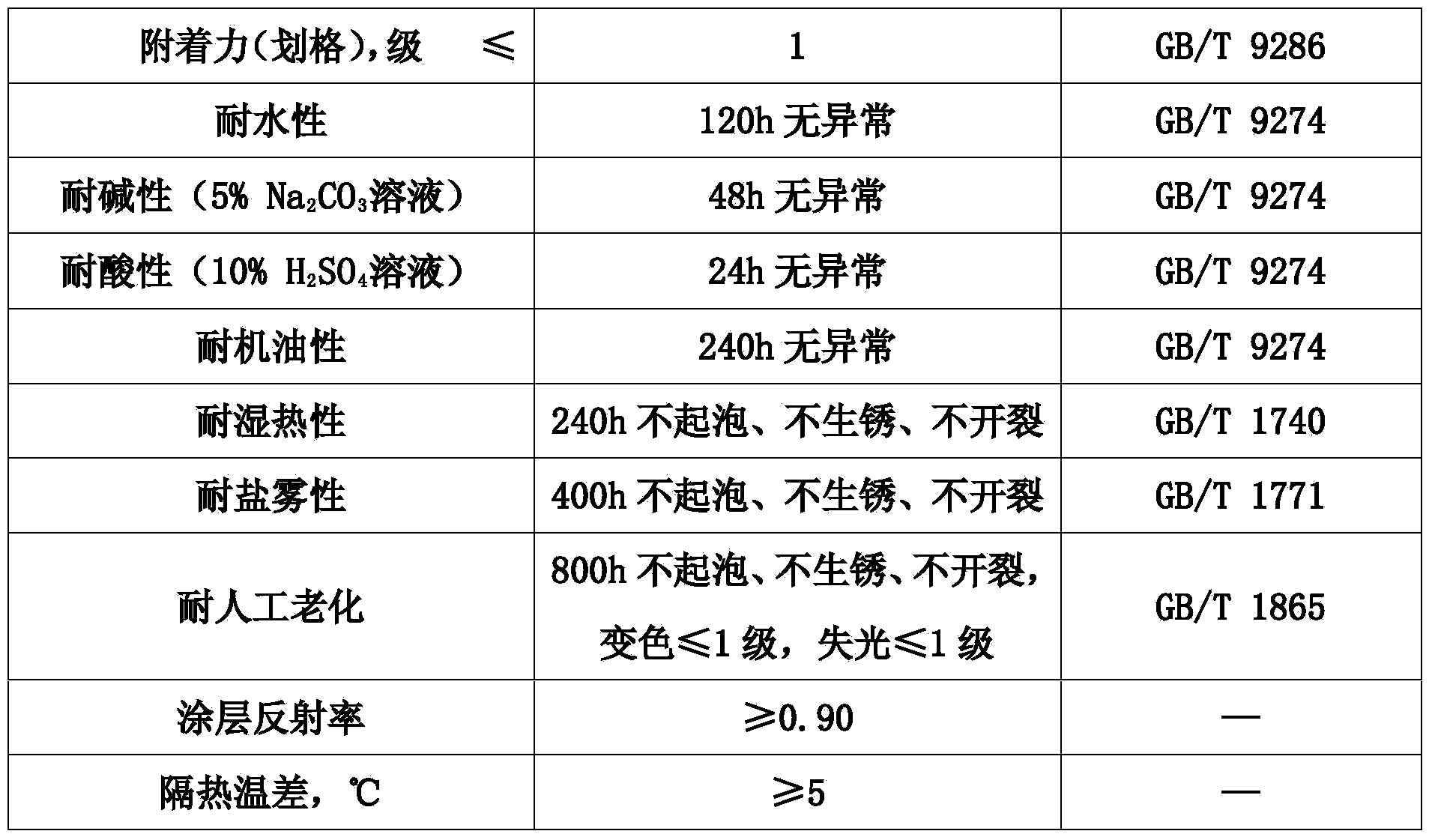

Heat reflective insulating stoving varnish coating and preparation method thereof

ActiveCN104109438AHigh strengthImprove impact resistancePolyester coatingsReflecting/signal paintsAcrylic resinSolvent

The invention discloses a heat reflective insulating stoving varnish coating and a preparation method thereof. The stoving varnish coating comprises the following components in percentage by weight: 40-60% of a film-forming resin, 8-15% of a mixed solvent, 10-25% of an infrared reflective pigment, 1-5% of insulating powder, 6-15% of filler and 1.2-3.5% of an auxiliary, totaling 100%, wherein the film-forming resin comprises a mixture of thermosetting acrylic resin, acrylic resin and amino resin. As the film-forming resin contains the above three main resins, the stoving varnish coating has good weather ability, mechanical property and chemical resistance. As the infrared reflective pigment and heat insulating powder are added into the raw material, the coating is high in reflection efficiency of sunlight and good in insulating effect.

Owner:ZHANG ZHOU SAN PAINTS

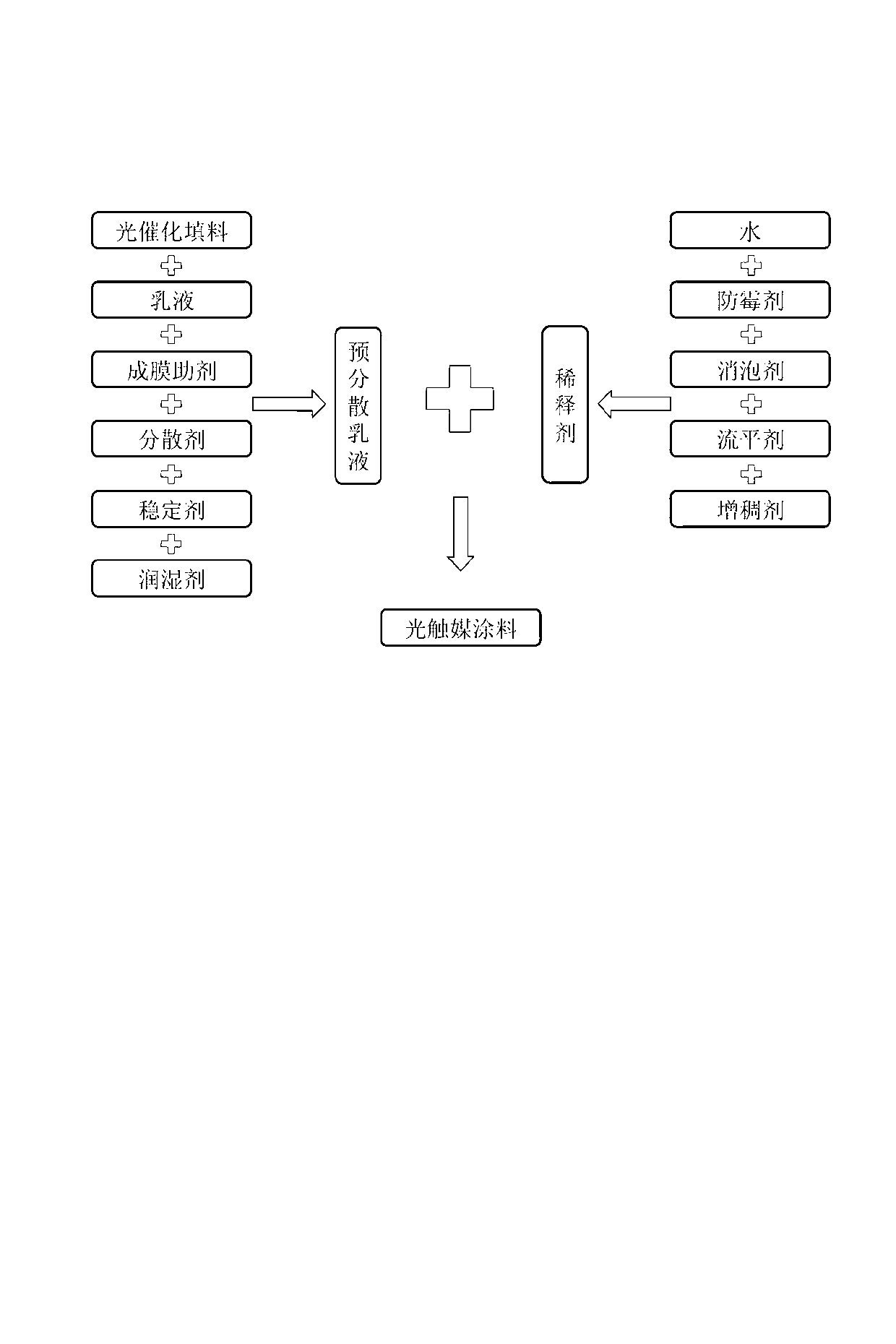

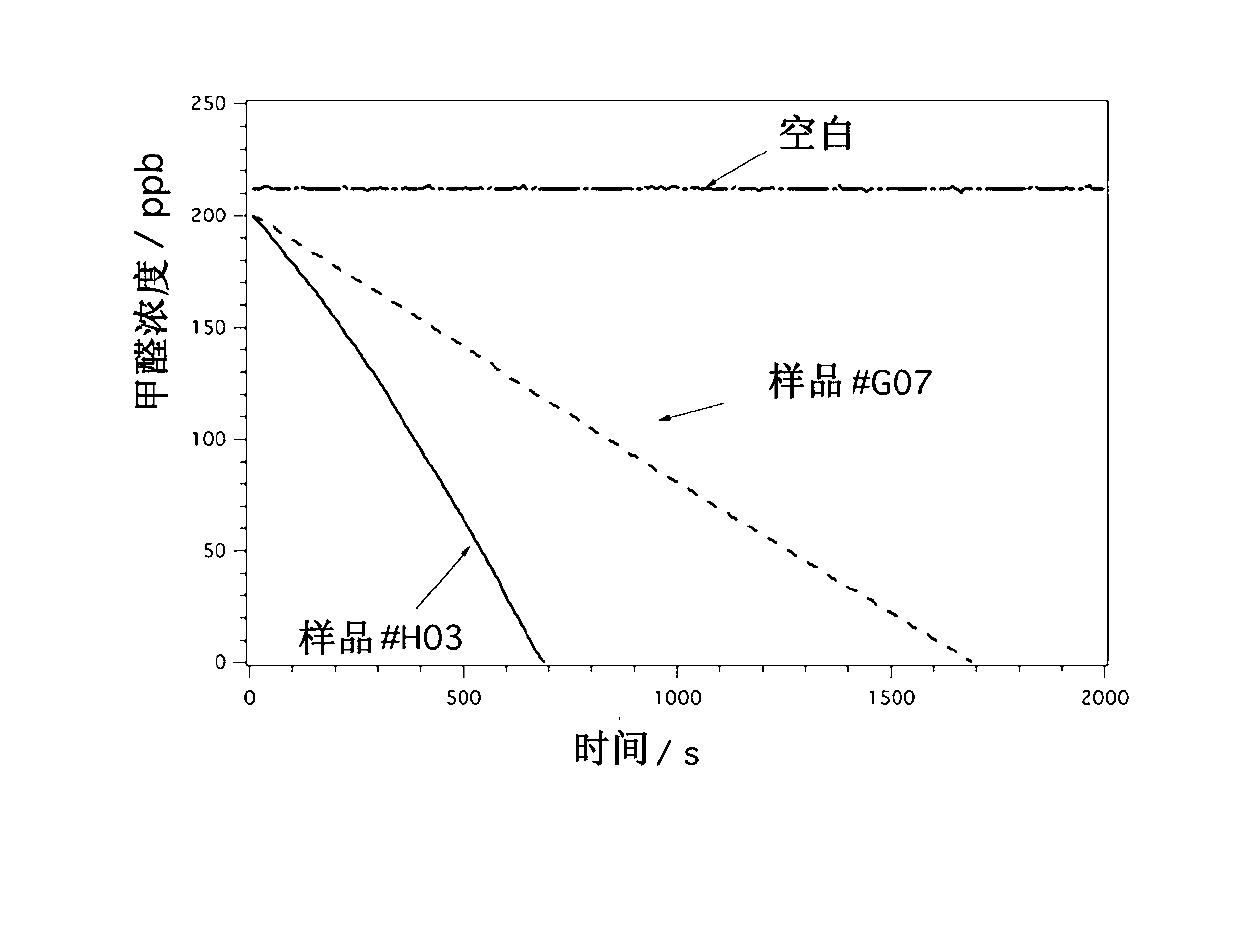

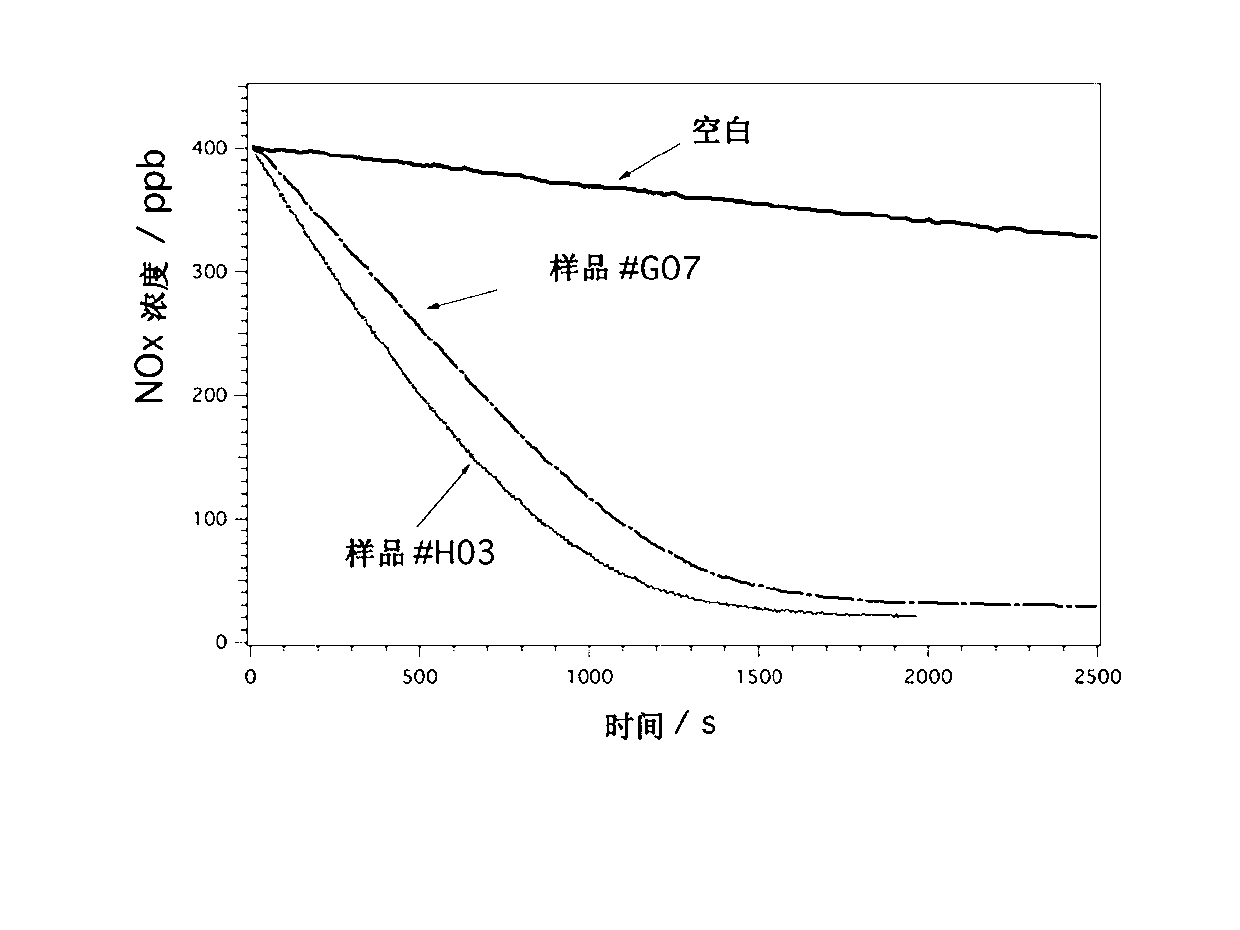

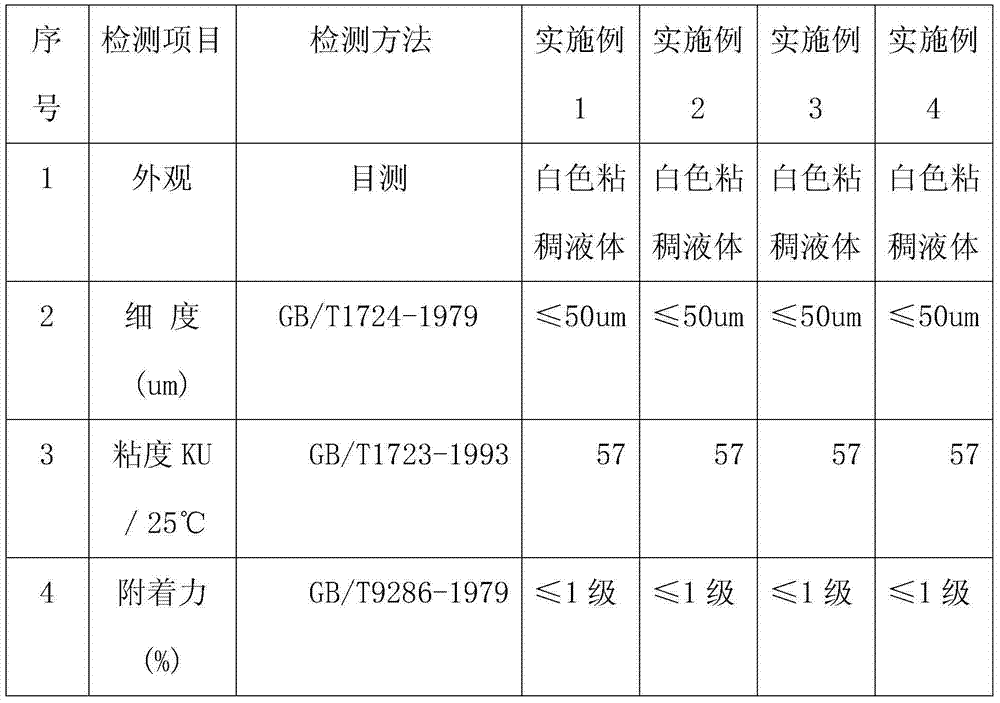

Compound type photocatalyst air purification waterborne interior wall coating and preparation method thereof

ActiveCN103131313ABroaden the photoresponse wavelengthImprove photocatalytic abilityAntifouling/underwater paintsPaints with biocidesChemistryPhoto catalysis

Provided are a compound type photocatalyst air purification waterborne interior wall coating and a preparation method thereof. The compound type photocatalyst air purification waterborne interior wall coating comprises, by weight, the following materials of 5.5-22.3% of photocatalysis packing, 25-65% of polyurethane emulsion, 1-6% of propylene glycol phenylate, 2-6% of dispersing agents, 2-4% of stabilizing agents, 1-2% of wetting agents, 20-60% of water, 1.5-4% of mildewproof agents, 1-2% of antifoaming agents, 0.5-2% of flatting agents, and 0.5-1% of thickening agents. The photocatalysis packing is formed by complexation of nanoanatase type titanium dioxide and nano-zinc oxide or nano stannic oxide according to a weight ratio of 5-9:1-5. The coating has good air purifying capacity, and can effectively degrade harmful gases in the air and kill bacterial viruses under excitation of ultraviolet light. As an interior decorative material, the coating has good covering power and adhesive power and excellent stability. The coating and the production method are simple in production process, suitable for various coating methods, and easy to popularize and apply.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

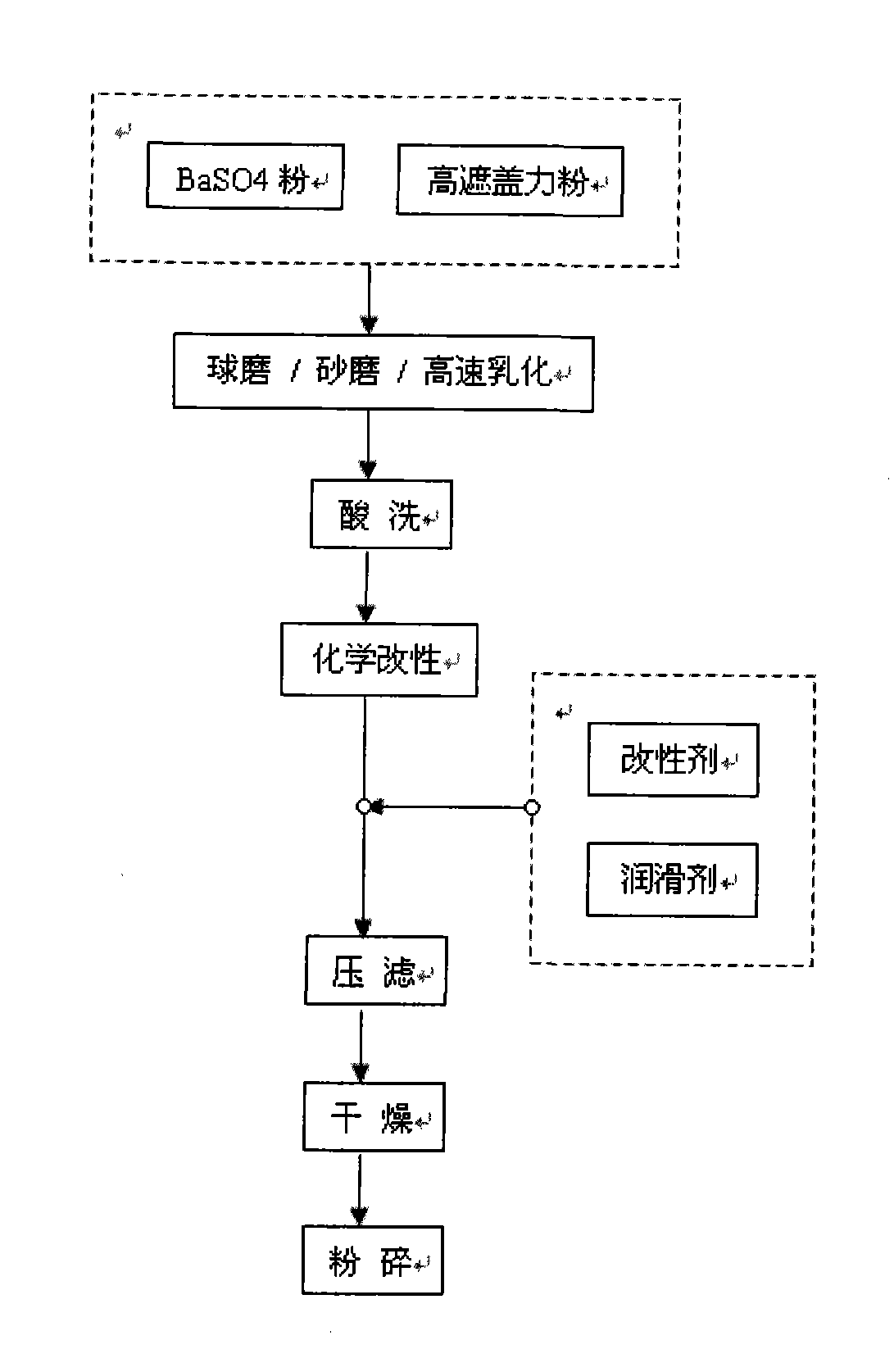

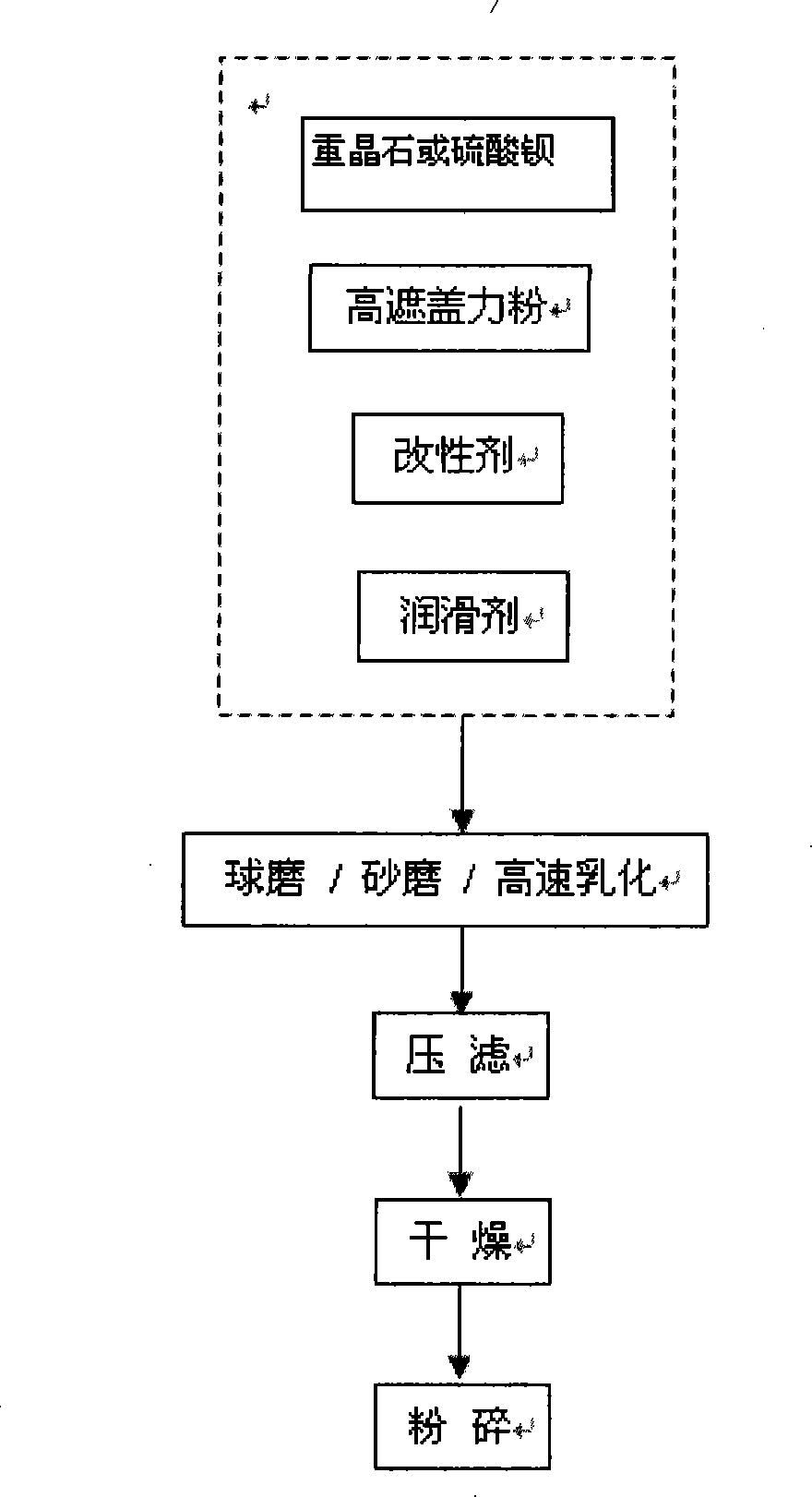

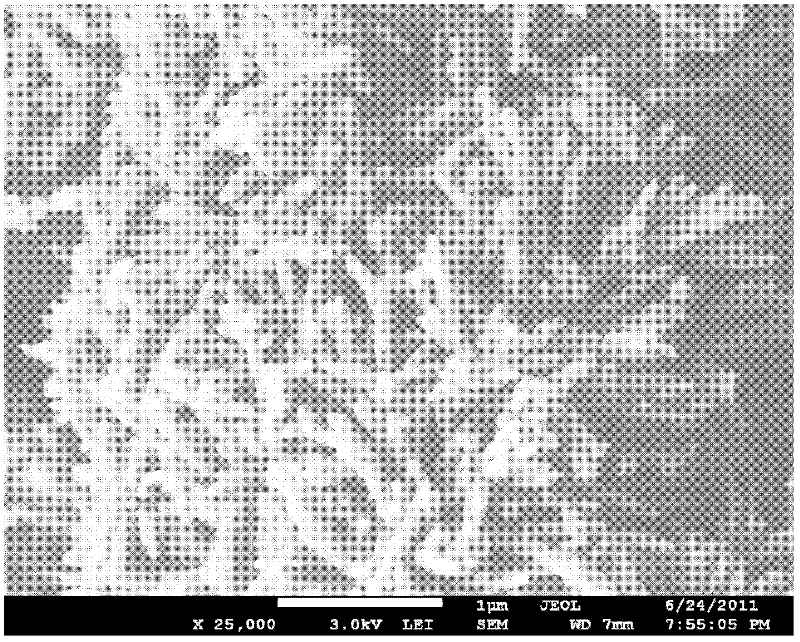

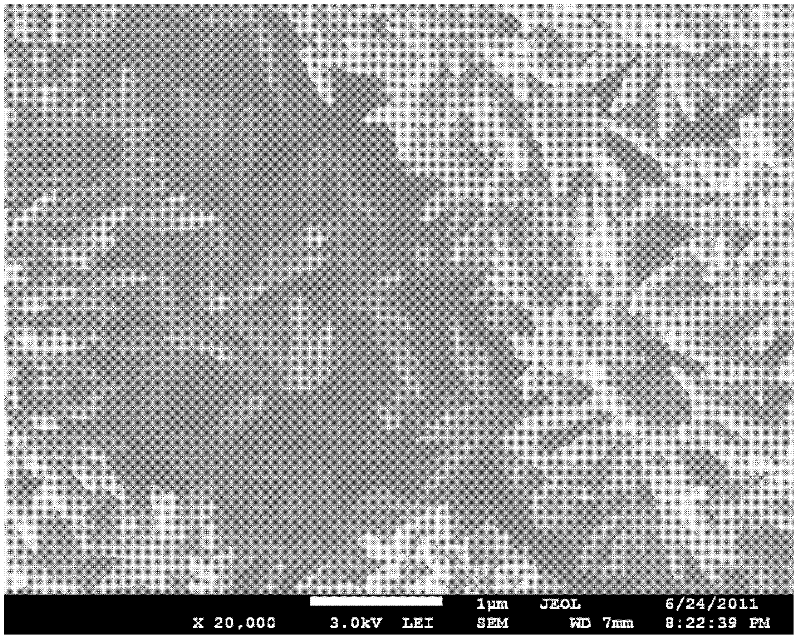

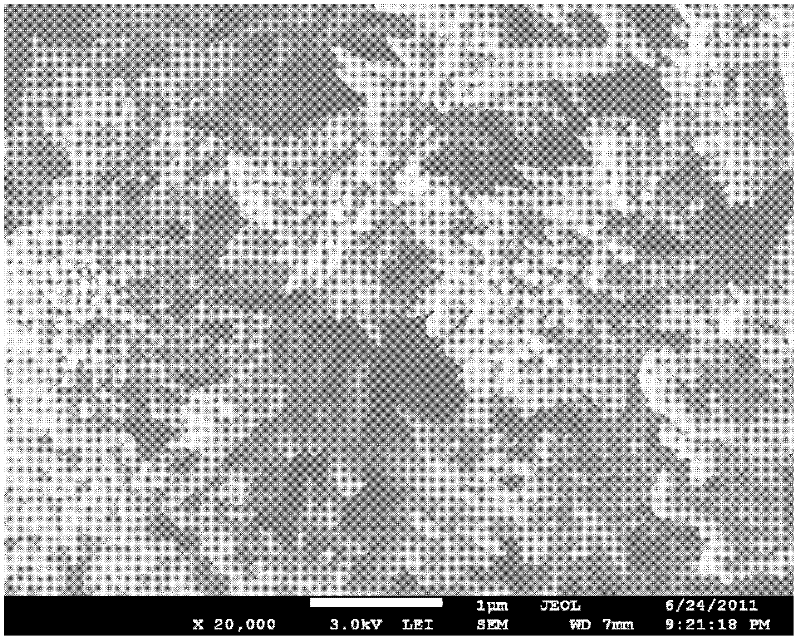

Barium sulfate based polybasic composite white pigments and method for preparing same

InactiveCN101250336AFine and uniform particle sizeHigh whitenessInorganic pigment treatmentBarium sulfatePigment

The invention discloses barium sulfate group multi-composite white pigment, which is characterized in that the invention comprises components with parts by weight: 100 parts of powder with barium sulfate, 0.1-10 parts of dispersant, 0.1-90 parts of powder with high covering power, 0.1-10 parts of modifier and 0.01-20 parts of lubricating agent. The barium sulfate group multi-composite white pigment has fine and even particle diameter, high whiteness, excellent dispersing ability, strong covering powder and wonderful weather-ability, and has the advantages of low production cost, simple technique and suitable industrial production.

Owner:FOSHAN ONMILLION NANO MATERIALS

Luminant white paint and preparation method thereof

ActiveCN102533070AHigh hiding powerGood filling effectPolyester coatingsKetone solventsToluene diisocyanate

The invention discloses a luminant white paint. The luminant white paint is obtained by mixing a main paint, a curing agent and a diluent according to a mass ratio, wherein the main paint comprises the following components in parts by weight: 35-40 parts of alkyd resin, 3-5 parts of dispersing agent, 30-40 parts of titanium white powder, 10-20 parts of extender pigment, 0.2-0.5 parts of anti-setting agent, 0.2-0.4 parts of leveling agent, 0.2-0.5 parts of antifoaming agent, 0.5-1.0 parts of anti-yellowing agent and 20-25 parts of main paint solvent; the curing agent comprises the following components in parts by weight: 10-20 parts of curing agent solvent, 0.1-0.2 parts of dehydrating agent, 60-70 parts of HDI (Hexamethylene Diisocyanate) type curing agent and 30-40 parts of TDI (Toluene Diisocyanate) type curing agent; and the diluent comprises the following components in parts by weight: 60-70 parts of ester solvent and 30-40 parts of ketone solvent. The luminant white paint disclosed by the invention has the advantages of rapidness for leveling after being sprayed, full paint film, rockiness and scratch resistance. Meanwhile, the invention also discloses a preparation method of the luminant white paint.

Owner:NIPPON PAINT GUANGZHOU

Environment-friendly polyurethane coating layer for synthetic court and preparation method thereof

InactiveCN101993652AImprove wear resistanceIncrease coveragePolyurea/polyurethane coatingsEnvironmental resistanceAdditive ingredient

The invention relates to an environment-friendly polyurethane coating layer for a synthetic court, which consists of an ingredient A and an ingredient B, wherein the ingredient A consists of polyether polyol, crosslinking chain extendors, catalysts, filling materials, pigment and plasticizers, and the ingredient B consists of performed polymers made from polyether polyol, isocyanate, chemical inhibitors and ultraviolet ray absorbing agents. When the environment-friendly polyurethane coating layer is used, the ingredient A and the ingredient B can be mixed to obtain the polyurethane coating layer for the synthetic court in a weight ratio A:B=100:50-75. The invention successfully applies the polyurethane coating layer which has the advantages of high intensity, high wear resistance, strong shielding power and no solvent and is convenient for repairing to the synthetic court, solves the problem that the synthetic court usually has color difference and surface abrasion, and lays a solid foundation for prolonging the service life of the synthetic court. Meanwhile, the polyurethane coating layer does not contain toxic or harmful catalysts and belongs to the environment-friendly polyurethane coating layer products.

Owner:SHANDONG INOV POLYURETHANE

PVC (polyvinyl chloride) foam material for sole and preparation method of PVC foam material

InactiveCN105440505AImprove temperature resistanceGood weather resistanceSolesWeather resistanceFoaming agent

The invention relates to the technical field of PVC materials, in particular to a PVC (polyvinyl chloride) foam material for a sole and a preparation method of the PVC foam material. The PVC foam material for the sole comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 20-30 parts of a filling agent, 6-10 parts of a wear-resistant modifier, 4-8 parts of a thermal stabilizer, 2-4 parts of a foaming agent, 0.8-1.2 parts of a lubricant and 1-2 parts of a processing aid. The raw materials are adopted for preparation of the PVC foam material for the sole, the weight proportion of the raw materials is controlled strictly, the performance of the prepared PVC foam material for the sole exceeds the national standards, and the PVC foam material is environment-friendly and has good temperature resistance and weather resistance, high strength, excellent anti-impact performance, good flame-retardant effect, good processing performance and excellent comprehensive performance.

Owner:广东祺龙科技有限公司

Method for preparing special titanium dioxide pigment for plastic sectional materials by chlorination method

ActiveCN102070921APrevent chalkingGood weather resistancePigment treatment with organosilicon compoundsPigment physical treatmentPhosphateSlurry

The invention provides a method for preparing special titanium dioxide pigment for plastic sectional materials by a chlorination method, which comprises the following steps that: the chlorination method is adopted for preparing titanium dioxide primary products into slurry, and the pH value of the slurry is regulated to 4.0 to 5.0; phosphate dispersing agents are added; grinding treatment is carried out, then, grinding media is removed, and the temperature is raised; water-soluble silicate solution is added, the pH value of the slurry is maintained between 3.5 and 4.5, amorphous silicon oxide is formed, curing is carried out, and a first covering layer is formed; the pH value of the slurry is regulated to 6.0 to 7.0, curing is carried out, and a second covering layer is formed; aluminum salt solution is added, the pH value is controlled between 7.0 and 9.0, curing is carried out, a third covering layer is formed, the pH value of the slurry is regulated to 6.0 to 7.0, and curing is carried out; the slurry is washed by de-ionized water until the conductivity of filter cake is higher than 15000 ohm*cm, and then, drying and air powder treatment are carried out; modified polysiloxane is added in the air powder process, and a fourth organic covering layer is formed; and materials are recovered through a bag filter. The titanium dioxide pigment prepared by the method provided by the invention has the advantages of high weatherability, high shielding capability, high non-transparency and excellent processing performance in the field of plastic sectional materials.

Owner:中信钛业股份有限公司

High-concentration white polyolefine agglomerate and its prepn process

InactiveCN1487012ADoes not affect mechanicsDoes not affect printing performanceParaffin waxHigh concentration

The high-concentration white polyolefin agglomerate consists of pigment, plastic assistants and carrier resin, nd the plstic assistants include polyvinyl wax, zinc stearate, bright lubricant, compatibilizer-bulking material, crosslinking agent and liquid paraffin. The preparation process includes mixing via high speed stirring, extruding the mixture in a double-screw extruder, cooling, stoving, and pelletizing. The present invention has the features of high whiteness, low consumption, high dispersivity, etc., and is suitable for plastic product with polyethylene, polypropylene or their copolymer as basic material and suitable for injection molding, blowing to film, hollow forming and extruding to produce sheet, flat belt, wire and pipe.

Owner:山东色母料厂

UV (Ultraviolet) curing white primer for laser roller painting of woodware and preparation and application methods thereof

InactiveCN103694862AReduce lossReduce usagePretreated surfacesPolyurea/polyurethane coatingsPolyesterUltraviolet

The invention discloses a UV (ultraviolet) curing white primer for laser roller painting of woodware, which has high coating quantity and flat and bright coated surface. The UV curing white primer comprises 15-25 percent of bisphenol A epoxy acrylate, 15-25 percent of polyester acrylate, 1-10 percent of polyurethane acrylate, 8-15 percent of tripropylene glycol diacrylate, 3-8 percent of reagent type hydroxyethyl acrylate, 10-25 percent of trimethylolpropane triacrylate, 5-8 percent of photoinitiator, 0.2-0.4 percent of wetting dispersant, 0.2-0.4 percent of anti-settling agent, 8-15 percent of talcum powder and 10-20 percent of titanium dioxide. The UV curing white primer has the characteristics that after laser roller painting construction is ended, the coating amount is capable of reaching 35-45g / m<2>, the coated surface is flat and bright, the covering power is stronger than that of a common roller painting UV white primer, and the semi-curing repainting between paint films is not required to be ground, and the like. When being used for performing coating, the UV curing white primer has the advantages of time and labor saving, high fullness of products, and less loss of a machine.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Preparation method of high-light-resistant titanium dioxide pigment for laminated paper

ActiveCN109705630AImprove retentionGood dispersant effectInorganic compound additionPigment treatment with non-polymer organic compoundsALUMINUM PHOSPHATESlurry

The invention provides a preparation method of a high-light-resistant titanium dioxide pigment for laminated paper. The method comprises the following steps: preparing titanium dioxide slurry from a rutile-type titanium dioxide initial product prepared by adopting a chlorination process method, and adjusting the pH value to 8.5-10.5; adding a citric acid radical-containing organic substance as a dispersing agent, and performing grinding treatment; performing heating to 55-65 DEG C for coating treatment, performing coating by using a dense aluminum phosphate coating layer, performing coating byusing a loose silicon aluminum compound coating layer, and performing coating by using a loose boehmite-type hydrated aluminum oxide coating layer; performing washing by using deionized water until conductivity of a filter cake is greater than 15000 omega*cm, and performing drying; and adding amino-containing organic matter in the steaming powder process, and performing organic coating treatmentto obtain the titanium dioxide pigment for the decorative laminated paper. The method provided by the invention has the advantages that the titanium dioxide pigment prepared by the method has the characteristics of high light performance, good whiteness and a high retention rate in the laminated decorative paper, and the prepared titanium dioxide pigment has a medium color bottom phase and the advantage of easy color matching, and can be widely used in the field of the high-end laminated decorative paper.

Owner:中信钛业股份有限公司

Method for preparing rose calcium carbonate from low-grade limestone

InactiveCN102502749AFull flowImprove mass transfer efficiencyCalcium/strontium/barium carbonatesChemical industryPorosityHigh surface

The invention discloses a method for preparing rose calcium carbonate from low-grade limestone, which comprises the following steps: 1) proportionally calcining low-grade limestone and blind coal to prepare calcium oxide; 2) screening under vibrations to remove coal ash and lime powder, thereby obtaining lumpy lime; 3) adding water to slake the lumpy lime, removing impurities by hydrocyclone and vibration screening to obtain fine emulsion slurry, adding a whitener, and aging to obtain the Ca(OH)2 prime slurry; 4) after regulating the temperature and concentration of the Ca(OH)2 prime slurry, adding a crystal form control agent, carrying out bubbling carbonation reaction, and adding a dispersant; when the pH value of the slurry is lower than or equal to 7, stopping carbonation to obtain a cured slurry; and 5) after the cured slurry is thickened, dehydrating to obtain the rose calcium carbonate. Compared with common light calcium carbonate, the rose calcium carbonate disclosed by the invention has the advantages of higher crystal completeness, high surface porosity, high light scattering coefficient and stronger covering power; and the invention is applicable to the industries of paper making, rubber, plastics and paint.

Owner:福建省万旗非金属材料有限公司

Coating process applying water-based paint to metal parts of construction machinery

InactiveCN102974520AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringMechanic - metal

The invention discloses a coating process applying water-based paint to metal parts of construction machinery. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the construction machinery. The coating process applying the water-based paint to the metal parts of the construction machinery enables the water-based paint to be correctly used for the coating of the metal parts of the construction machinery, not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Marine organism shell powder paint

ActiveCN102167936AImprove finenessHigh whitenessAlginic acid coatingsHyaluronic acid coatingsCitric Acid MonohydrateCitric acid

The invention provides a type of marine organism shell powder paint, mainly comprising biosynthesis adhesive, sodium hexametaphosphate, shell powder, emulsifier, and citric acid mono. The marine organism shell powder paint is purely natural, environment-friendly, of simple preparation and of low manufacturing cost, and has no toxic effects on human body.

Owner:青岛万源生物科技有限公司

Coating process applying water-based paint to cast iron parts

InactiveCN102974518AMeet the use requirementsGood lookingPretreated surfacesAnti-corrosive paintsCast ironCoating

The invention discloses a coating process applying water-based paint to cast iron parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the cast iron parts of machinery. The coating process applying the water-based paint to the cast iron parts enables the water-based paint to be correctly used the coating of the cast iron parts of the machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

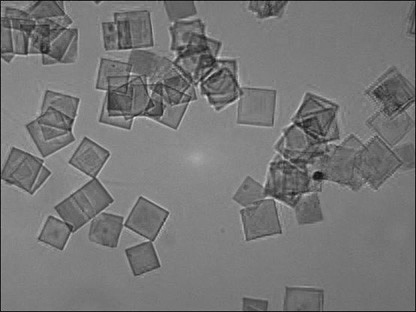

Plate-type bismuth oxychloride crystal with controllable shape and preparation method thereof

ActiveCN101935022AIncrease brightnessIncrease coveragePigment pastesHalogen oxides/oxyacidsBismuth oxychlorideSURFACTANT BLEND

The invention provides a bismuth oxychloride crystal and a preparation method thereof. The bismuth oxychloride crystal is a square and regular octagonal thin-plate bismuth oxychloride crystal with a regular shape. In the preparation process, different selected surfactants are covered on the surface of the bismuth oxychloride seed crystal, so that the bismuth oxychloride crystal can directionally grow in different acidic mediums. The bismuth oxychloride crystal has better brightness, effulgent effect and covering capability, compared with irregular bismuth oxychloride crystal.

Owner:FUJIAN KUNCAI MATERIAL TECH

Method for preparing wax emulsion from branched polyethylene wax through direct emulsification

The invention discloses a method for preparing wax emulsion from branched polyethylene wax through direct emulsification, which comprises the following steps of: mixing the branched polyethylene wax and a cosolvent, adding an emulsifier and heating and emulsifying; adding water and dispersing and emulsifying by a phase transfer method; and shearing, emulsifying and dispersing to prepare milky branched polyethylene wax emulsion. In the emulsification method, the cosolvent is added into the branched polyethylene wax for direct emulsifying, and the process for production of the emulsion is greatly simplified. The branched polyethylene wax emulsion can be applied in the fields of leather finish, fur finishing, textile finishing, automobile polishing, shoe cream and the like, the coating has smooth handfeel, natural color, high hardness and high scratch resistance, and the wax emulsion is a high-grade wax emulsion product. The emulsification process can greatly expand the use of the branched polyethylene wax and reduce the application of solvent products, and is an environmentally-friendly emulsification process.

Owner:SHAANXI UNIV OF SCI & TECH

Sound-absorbing radiation protective paint and preparation method thereof

ActiveCN101831211AImprove sound absorptionGood radiation protectionRadiation-absorbing paintsLow speedHydroxyethyl cellulose

The invention relates to a sound-absorbing radiation protective paint, which comprises the following components in percentage by weight: 30 to 38 percent of porous modified starch, 5.0 to 9.5 percent of styrene-acrylic latex emulsion, 33 to 41 percent of barite, 0.5 to 1 percent of iron oxide, 0.25 to 1 percent of sodium polycarboxylate dispersant, 0.01 to 1 percent of brightening agent, 1.0 to 6 percent of titanium white, 0.5 to 1 percent of defoamer, 0.01 to 1 percent of mildew preventive, 13 to 18 percent of water, 0.4 to 1 percent of ethylene glycol, 0.3 to 1 percent of film-forming auxiliary agent, 0.005 to 1 percent of anti-freeze agent, 0.5 to 1 percent of graphite, 1 to 3 percent of hydroxyethyl cellulose and 0.20 to 1 percent of thickening agent. A preparation method of the sound-absorbing radiation protective paint comprises the steps of: (a) premixing, namely stirring 1 / 2 water, the sodium polycarboxylate dispersant, 1 / 2 defoamer, the mildew preventive, the thickening agent, the hydroxyethyl cellulose and the brightening agent at low speed to form colloidal solution; (b) dispersing and grinding, namely adding the titanium white, the barite, the graphite and the iron oxide into the colloidal solution and stirring the solution at high speed to prepare uniform sizing agent; (c) paint mixing, namely adding crylic acid emulsion, the film-forming auxiliary agent and the anti-freeze agent into the sizing agent, uniformly stirring the sizing agent, then dividing the porous modified starch into 1 to 5 parts, and adding the porous modified starch by 1 to 5 times into the mixture for low-speed and uniformly stirring the mixture; and (d) packaging the resulting product.

Owner:谢绍何

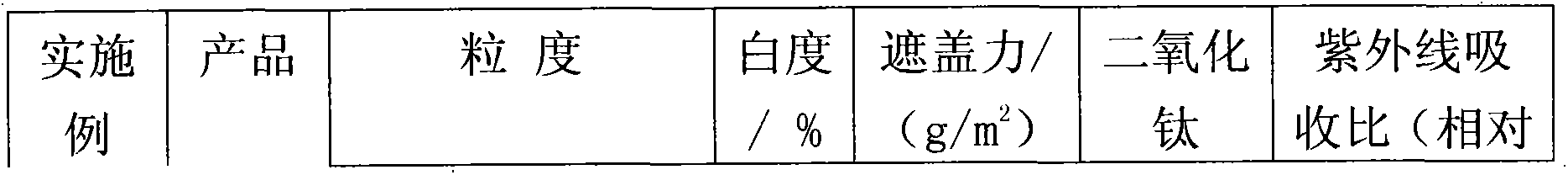

Preparation method for inorganic composite white pigment capable of replacing titanium dioxide at high proportion

InactiveCN104119701AReduce the dosage ratioNo emissionsPigment treatment with macromolecular organic compoundsPigment physical treatmentCalciteSODIUM SILICATE SOLN

The invention provides a preparation method for an inorganic composite white pigment capable of replacing titanium dioxide at a high proportion. The method employs calcite, barite or white carbon black as an inorganic white powder with the granularity less than 45 mu m, employs rutile type titanium dioxide or anatase type titanium dioxide as pigment-grade titanium dioxide, employs sodium polyacrylate with the concentration of 25% or a sodium silicate solution with the concentration of 15% as a surfactant, and employs diluted sulfuric acid as a pH regulator. The inorganic composite white pigment capable of replacing titanium dioxide at a high proportion is prepared by respectively pulping the white mineral powder and the pigment-grade titanium dioxide with water, employing an organic modifier to perform surface modification, regulating pH value, then uniformly mixing the prepared pulps, and performing intense agitation, press filtering and drying processing. Specifically, in the compositions, the inorganic white powder accounts for 55%-76% by weight and the pigment-grade titanium dioxide accounts for 24%-45%.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

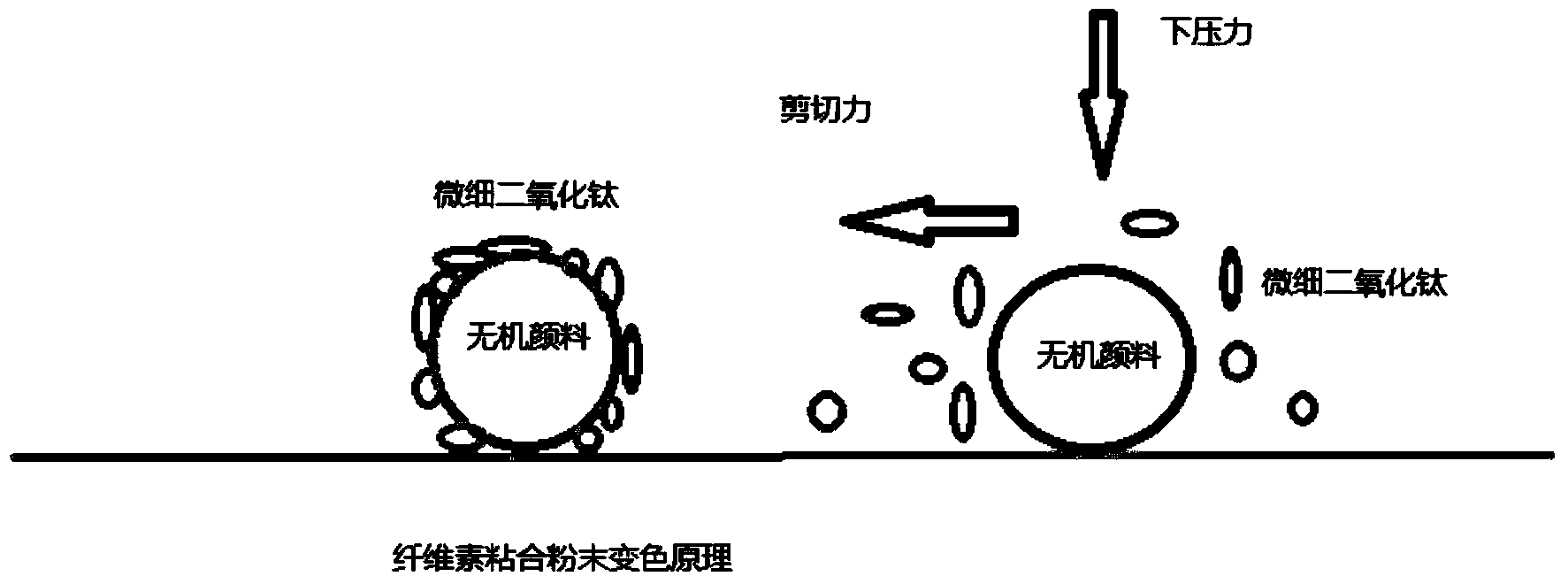

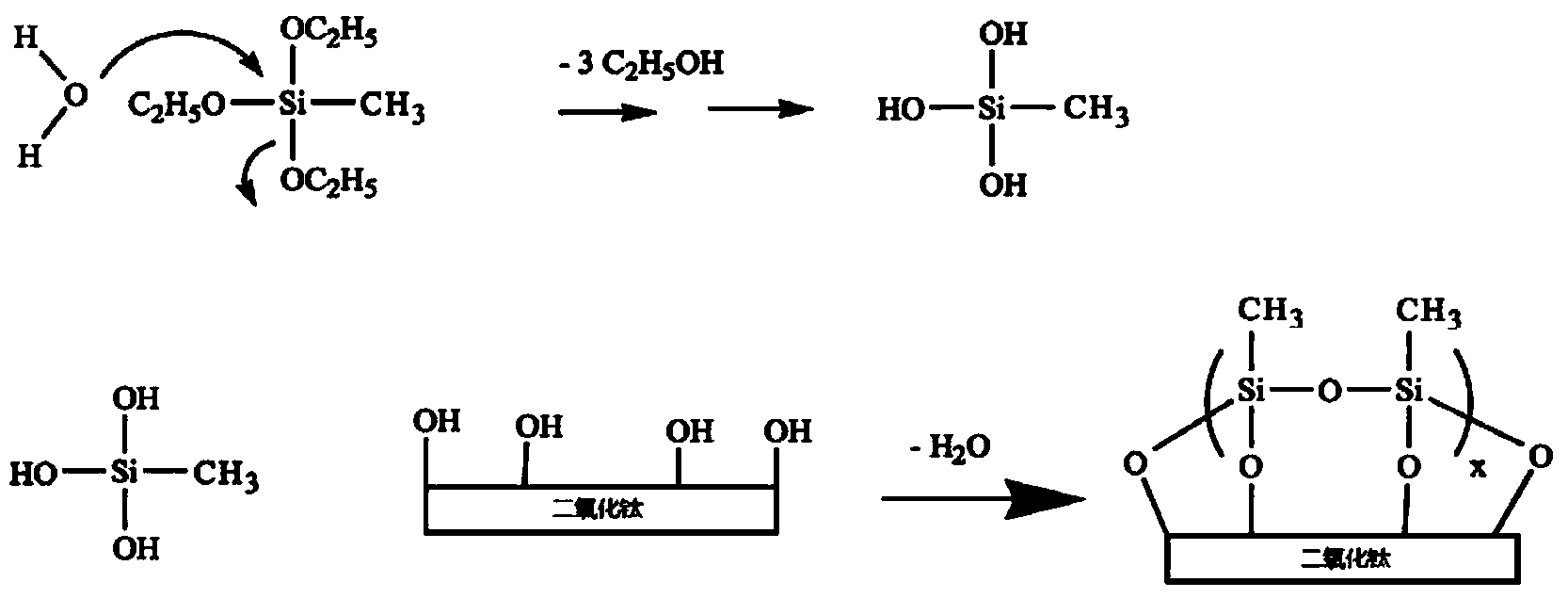

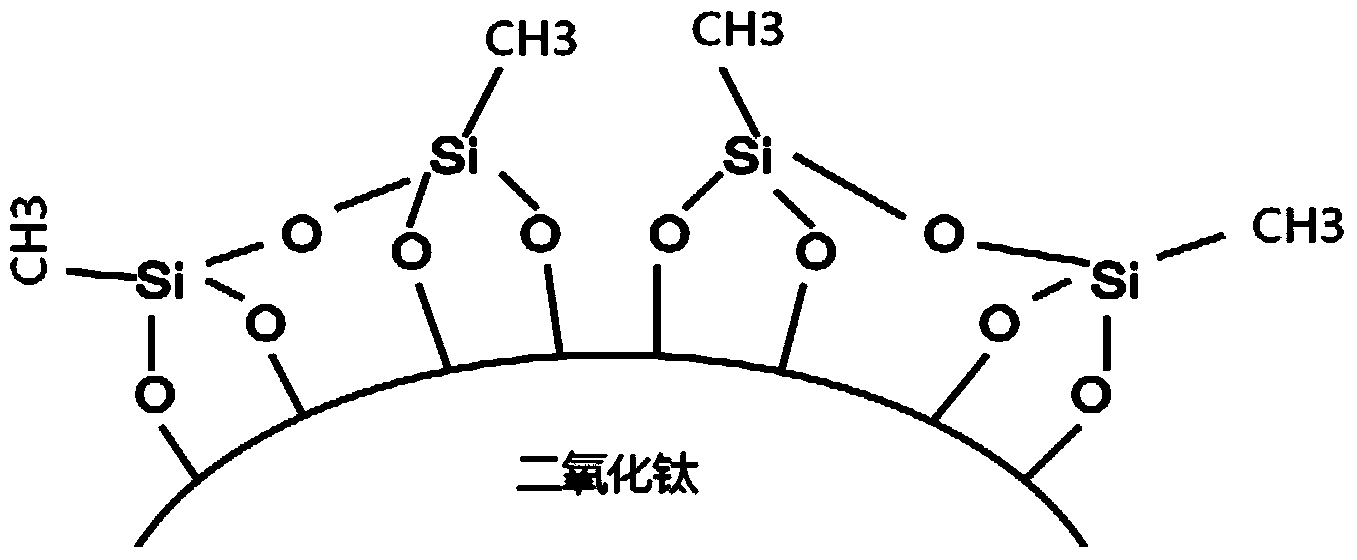

Controllable discolouring foundation cream/liquid foundation

ActiveCN104069014AFast discolorationWith discoloration effectCosmetic preparationsBody powdersSilylationIron oxide

The invention relates to controllable discolouring foundation cream / liquid foundation and a preparation method thereof. The preparation method of the controllable discolouring foundation cream / liquid foundation comprises the following steps: providing a powder premix compound containing titanium dioxide and inorganic pigment, for the coloured foundation cream / liquid foundation, wherein the titanium dioxide is subjected to triethoxy methyl silylation surface treatment, and the inorganic pigment is subjected to triethoxy octyl silylation surface treatment. The controllable discolouring foundation cream / liquid foundation has the advantages that completely different surface treatment methods are adopted for the titanium dioxide and inorganic pigment (ferric oxide) in the foundation cream / liquid foundation, so that surface properties of the two powders are obviously different;the discolouring foundation cream / liquid foundation prepared by utilizing the titanium dioxide and inorganic pigment is controllable and quick in discolouring effect; covering power is high; colours are diverse; the discolouring foundation cream / liquid foundation is safe and harmless; a production process is simple.

Owner:SHANGHAI CO FUN BIOTECH

Environmental protection water mica coating

The invention relates to a environment- friendly water- borne paint. The comprised components and their weight proportion are as follows: mica pigment 40 -50%, water 7- 30%, synthetic resin 25- 60%, emulsifying agent 0.05- 0.1%, wetting agent 0.05- 0.1%, defoaming agent 0.1- 0.2%, pH modifying agent 0.05- 0.1%, film adjuvant 1- 2%, thickening agent 0.5- 1%, dispersing agent 0.1- 0.2%, conservative 0.05- 0.2%. It is characterized by strong properties of wearing resistance, covering power, antiweatherability, age resistance, thermal insulating and heat insulating property, non toxic, non smell and no pollution.

Owner:SHIJIAZHUANG JINGONG FINE MICA CHEM FACTORY

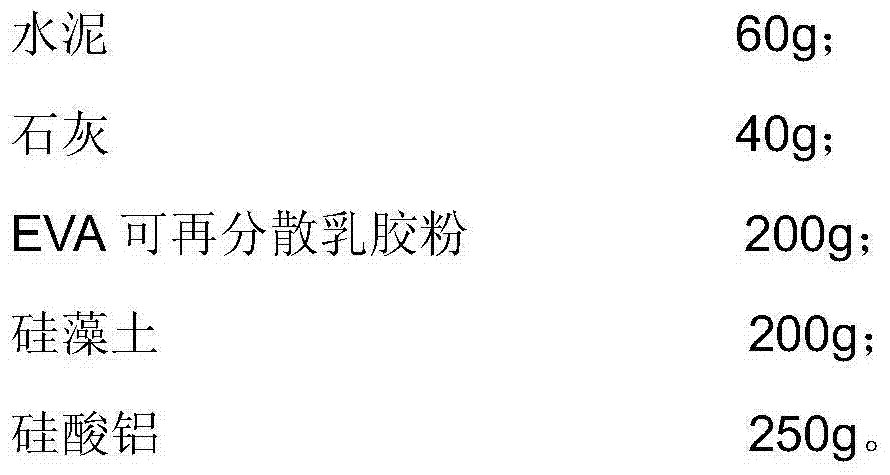

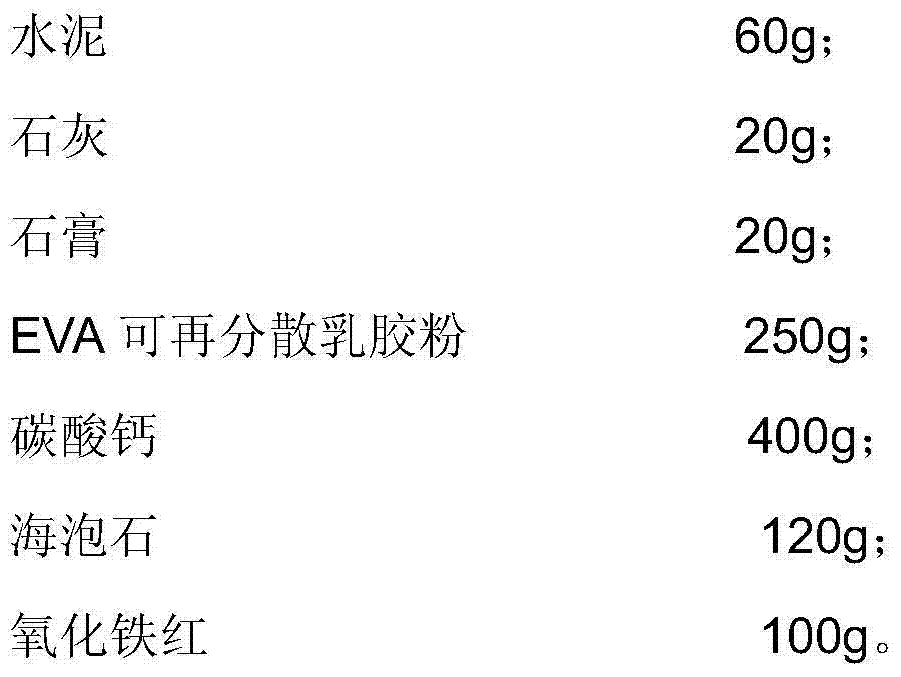

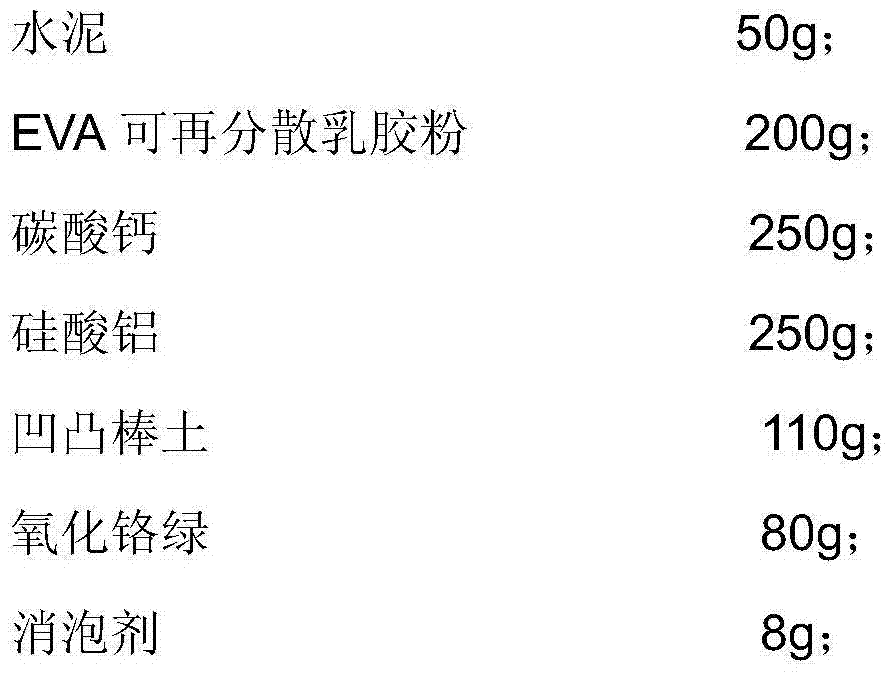

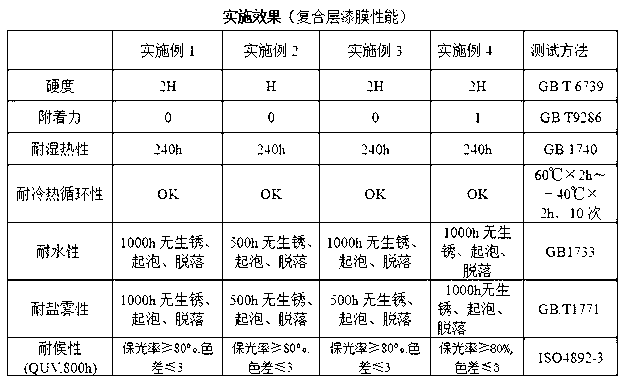

Indoor inorganic dry powder building coating capable of automatically regulating humidity

The invention provides an indoor inorganic dry powder building coating capable of automatically regulating humidity. The components of the coating include inorganic cementing material, dispersible adhesive powder, porous adsorbing functional filler and conventional filler. The indoor inorganic dry powder building coating capable of automatically regulating humidity is dry powder, has excellent moisture absorption and moisture releasing functions, reaches the JC / T2082-2011 standard, has good humidity regulating property reaching I-grade standard requirement, also has excellent covering power, scrub resistance and storage stability, is convenient to transport, does not generate VOC, benzene, formaldehyde, heavy metals and other harmful substances when in use, and is convenient to produce and use and low in cost.

Owner:SHANGHAI GIANT ENERGY SAVING MATERIALS

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Coating process applying water-based paint to metal parts of engineering machinery

InactiveCN102974522AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsMetallurgyEngineering

The invention discloses a coating process applying water-based paint to metal parts of engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery enables the water-based paint to be correctly used for the coating of the metal parts of the engineering machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and physical and chemical performance coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Laser markable high-shading polyester composite material for LED (Light Emitting Diode), and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to a laser markable high-shading polyester composite material for an LED (Light Emitting Diode), and a preparation method thereof. The laser markable high-shading polyester composite material for the LED comprises the following raw materials in parts by weight: 40-60 parts of polyester, 15-20 parts of glass fiber, 15-20 parts of main fire retardant, 3-5 parts of auxiliary fire retardant, 4-8 parts of flexibilizer, 0.1-0.2 part of antioxidant, 10-15 parts of opacifier, 0.3-1.0 part of laser marking powder and 0.5-1.0 part of other accessory ingredients. The laser markable high-shading polyester composite material for the LED has the advantages of good shading effect, good anti-flaming effect, good temperature tolerance and weather fastness, high intensity, excellent shock resistance, good processability and excellent overall performance, can be used for laser marking and can pass a high and low temperature (40DEG C below-120DEG C) impact test.

Owner:东莞市东翔塑胶有限公司

Full effect negative ion interior wall paint

InactiveCN101575471AStrong covering powerEasy constructionAntifouling/underwater paintsPaints with biocidesMaterials scienceDefoamer

The invention discloses a full effect negative ion interior wall paint, comprising the following raw materials according to parts by weight: 100 to 500 parts of water, 0.05 to 25 parts of composite nano sterilizing powder, 1 to 2 parts of preservative, 1.5 to 4.5 parts of droxyethylcellulose, 1 to 2 parts of pH modifier, 2 to 5 parts of dispersant A, 1 to 3 parts of dispersant B, 15 to 35 parts of glycol, 1 to 2 parts of wetting dispersant, 1 to 3 parts of antifoaming agent A, 2 to 3 parts of antifoaming agent B, 40 to 70 parts of French chalk, 30 to 150 parts of heavy calcium carbonate, 2 to 7 parts of film forming agent, 4 to 6 parts of thickening agent A, 40 to 240 parts of titanium dioxide; one or more of light calcium carbonate, acetic acid emulsion, styrene-acrylic emulsion, Lithopone, calcined kaolin, elastic emulsion, rheology modifier are added to the mixture to obtain various full effect negative ion interior wall paint which can be widely applied to interior walls in dwelling houses and hospitals; the full effect negative ion interior wall paint in the invention has no toxicity, no smell, and has strong sterilization and antimeldow effects.

Owner:ZHANG ZHOU SAN PAINTS

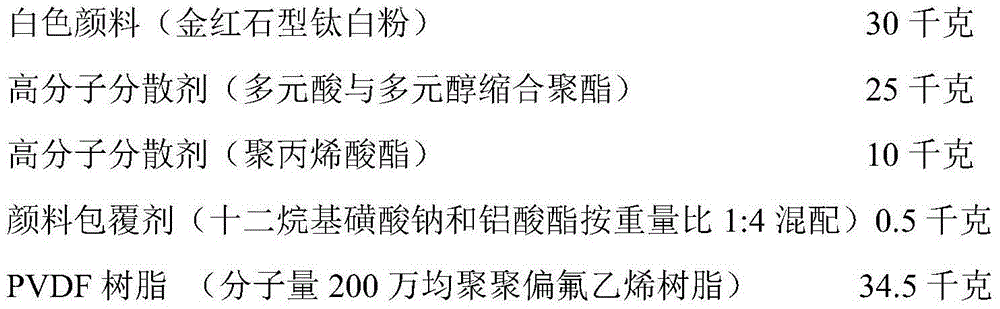

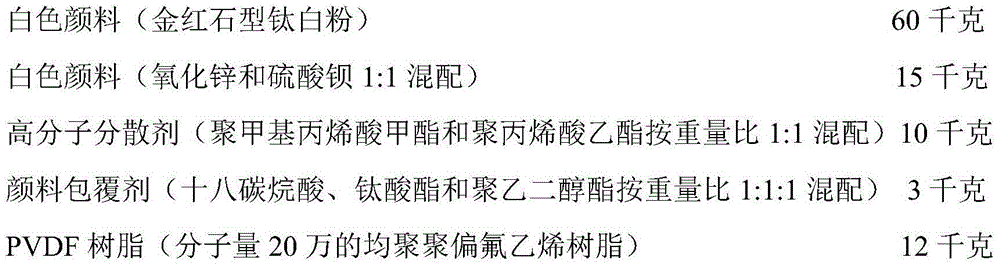

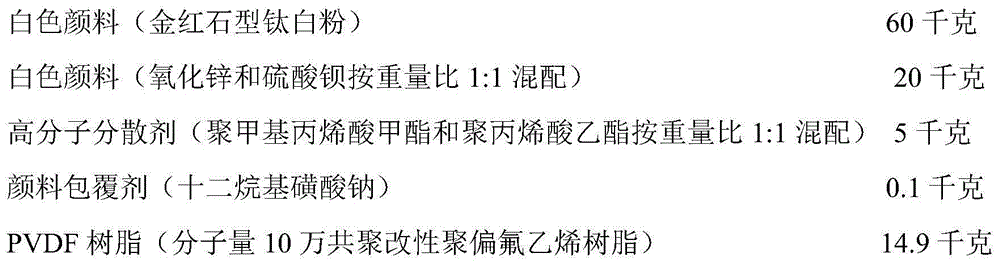

High-concentration white master batch for polyvinylidene fluoride (PVDF) films and production method thereof

The invention relates to a high-concentration white master batch for polyvinylidene fluoride (PVDF) films and a production method thereof, and mainly solves the problems of lower pigment concentration, poor dispersity and lower covering power in the white master batch for PVDF films, and the problems of poor flowability and poor film-forming property under high-concentration pigment proportioning conditions in the prior art. The high-concentration white master batch for PVDF films comprises the following components in percentage by weight: 30-80% of white pigment, 5-35% of dispersing agent, 0.1-5% of pigment organic coating agent and 5-52% of PVDF resin. The technical scheme well solves the problems, and the production method can be used for producing the high-concentration white master batch for PVDF films.

Owner:SHANGHAI HUAYI GRP CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com