Method for preparing wax emulsion from branched polyethylene wax through direct emulsification

A technology of branched polyethylene and wax emulsion, which is applied in coating, textiles, papermaking, fiber treatment, etc. It can solve the problems of difficult emulsification of branched polyethylene wax, and achieve the goal of not easy to break emulsion, no discharge of three wastes, and simplified emulsification The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) the trade mark that U.S. BakerHughes company produces is that vybar103 branched polyethylene wax and white oil are fully mixed to obtain mixture by the mass ratio of 100:5;

[0029] 2) Mix the mixture with the emulsifier sodium lauryl sulfate at a mass ratio of 100:10, then heat and melt at 70-95°C, slowly add hot water at 95°C, homogenize and emulsify until the emulsion is uniform to obtain an emulsion ;

[0030] 3) Cool the emulsion to 60° C., add water to adjust the solid content to 30% to obtain a wax emulsion.

Embodiment 2

[0032] 1) the trade mark that U.S. BakerHughes company produces is that vybar260 branched polyethylene wax and liquid paraffin are fully mixed to obtain mixture by the mass ratio of 100:8;

[0033] 2) Mix the mixture with the emulsifier sodium dodecylsulfonate at a mass ratio of 100:14, then heat and melt at 70-95°C, slowly add hot water at 93°C, homogenize and emulsify until the emulsion is uniform lotion;

[0034] 3) Cool the emulsion to 40° C., add water to adjust the solid content to 50% to obtain a wax emulsion.

Embodiment 3

[0036] 1) the trade mark that U.S. BakerHughes company produces is that vybar103 branched polyethylene wax and turpentine are fully mixed to obtain mixture by the mass ratio of 100:10;

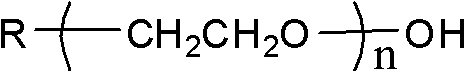

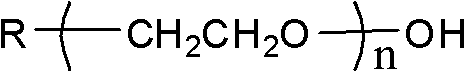

[0037] 2) Mix the mixture with the emulsifier fatty alcohol polyoxyethylene ether sodium sulfate at a mass ratio of 100:18, then heat and melt at 70-95°C, slowly add hot water at 90°C, homogenize and emulsify until the emulsion is uniform get lotion;

[0038] 3) Cool the emulsion to 50° C., add water to adjust the solid content to 10% to obtain a wax emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com