Patents

Literature

783results about How to "No waste discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lithiumion cell positive material Iron-lithium phosphate

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

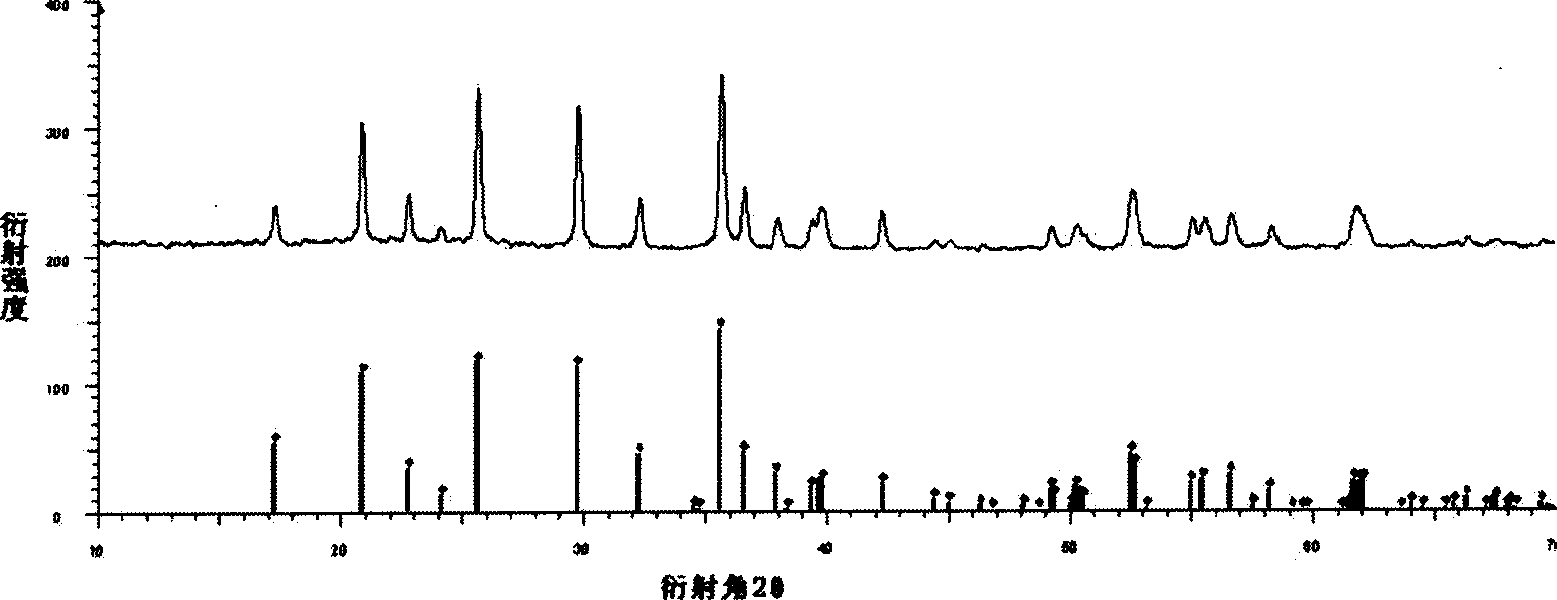

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

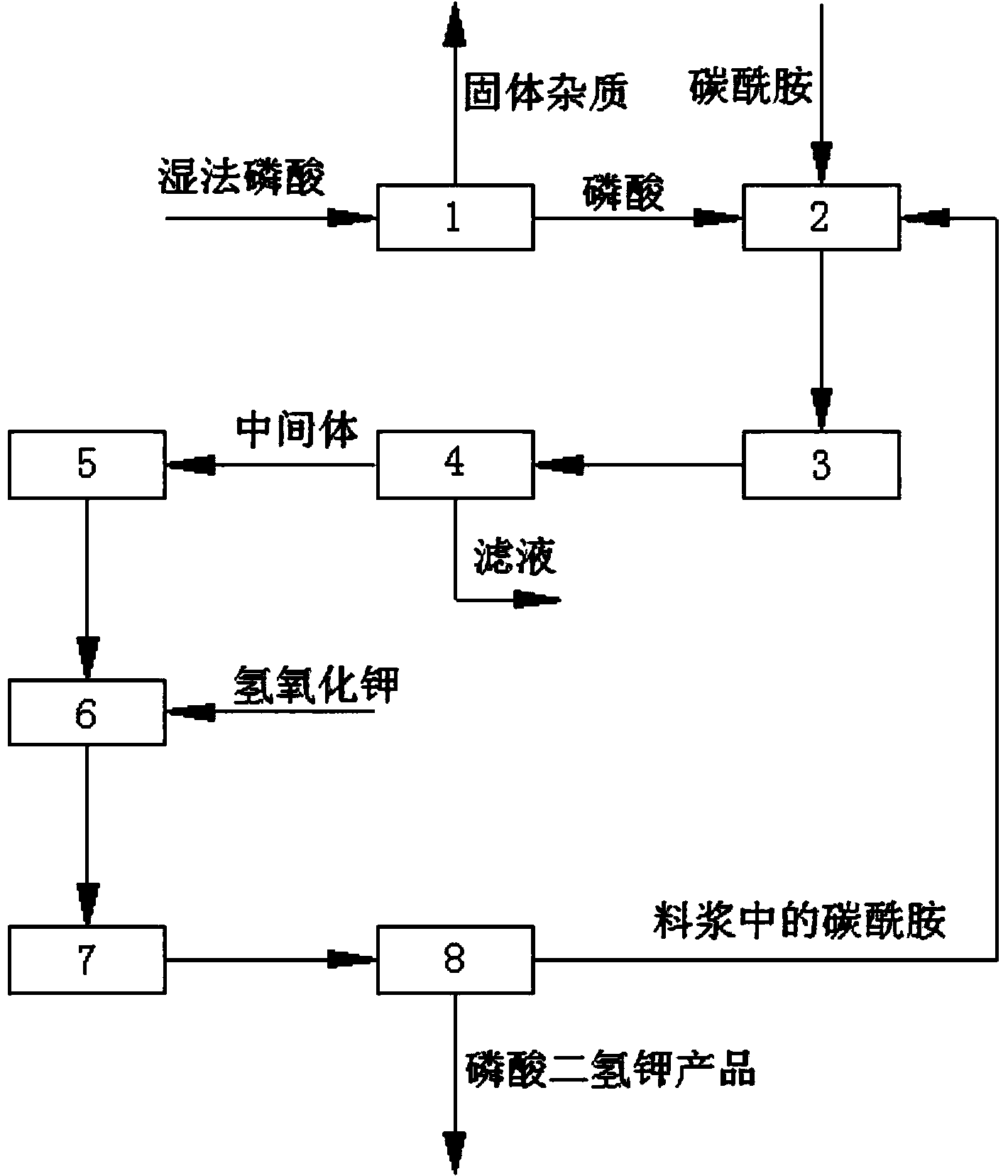

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

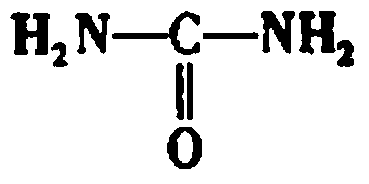

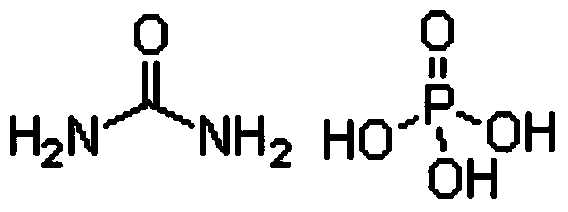

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Production method for producing vacuum-insulation wall insulation board by utilizing expanded and vitrified small balls

InactiveCN102720277ASimple processNo waste dischargeClimate change adaptationInsulation improvementGlass fiberCooking & baking

The invention relates to a production method for an insulation board. The method comprises the following steps of: a, adding 50-70 parts by weight of expanded and vitrified small balls, 5-10 parts by weight of fibre glass, 5-20 parts by weight of silicon ash, 5-10 parts by weight of bentonite and 1-5 parts by weight of getter into a stirring kettle, then adding 2-5 parts by weight of wetting agent and 15-20 parts by weight of binding agent, and stirring the ingredients to obtain a pasty material; b, spreading out the well stirred pasty material on a microwave baking line, baking the pasty material until the water content of the board is less than 1% and then cutting the board into blocks; c, vacuumizing the board which is cut into blocks, wherein the degree of vacuum is below 200Pa; and d, cutting and packing the obtained insulation board. By utilizing the production method provided by the invention to produce the insulation board, the process is simple, no three wastes are discharged, and the produced insulation board can well achieve the effects of heat preservation and heat insulation, and has the combustion performance of grade A and the insulation thickness of 10-15mm; and the produced insulation board is light in weight and long in weather-proof time and has service life of more than 30 years.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Continuously-produced full-degradable starch-based plastic alloy and preparation method thereof

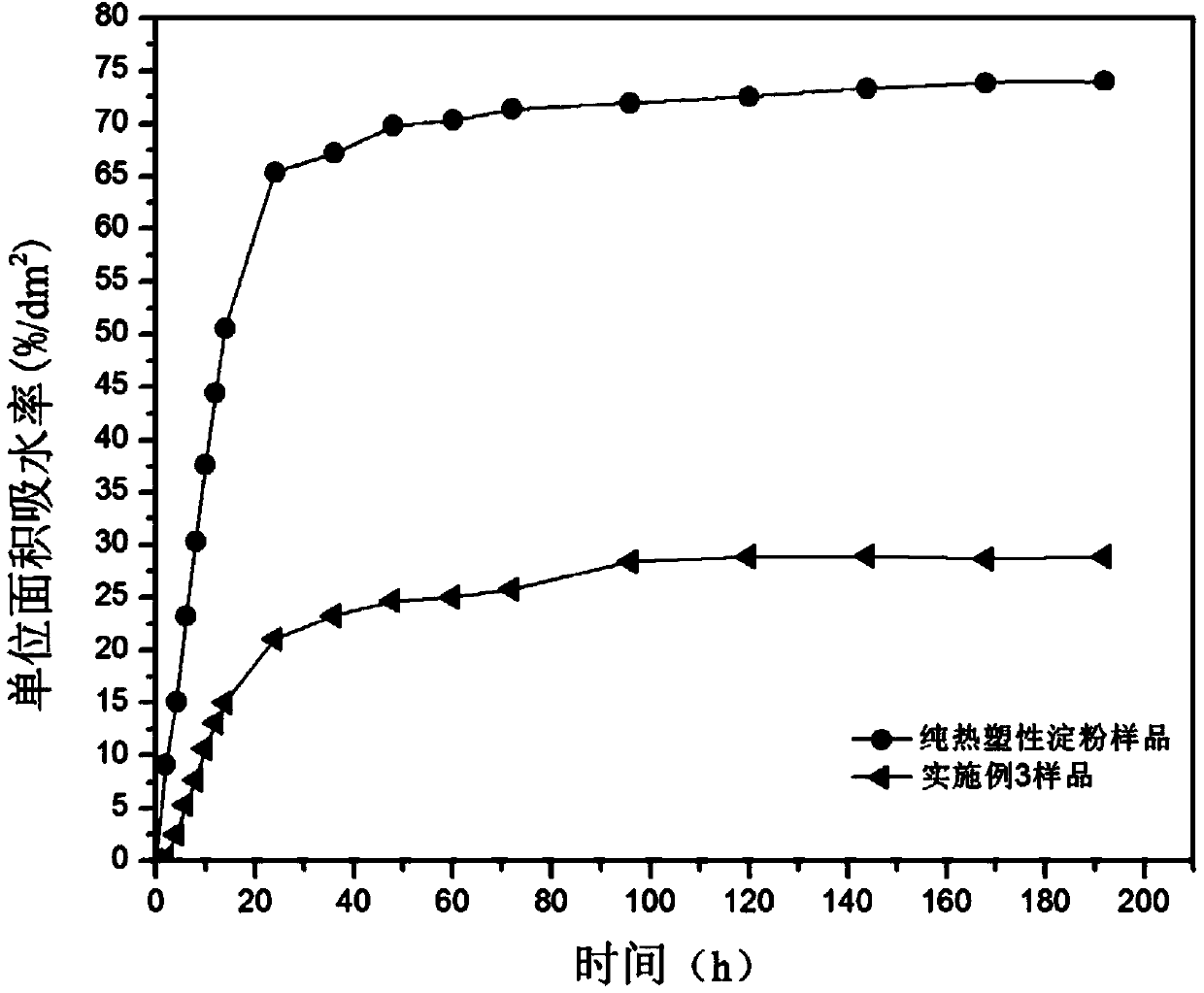

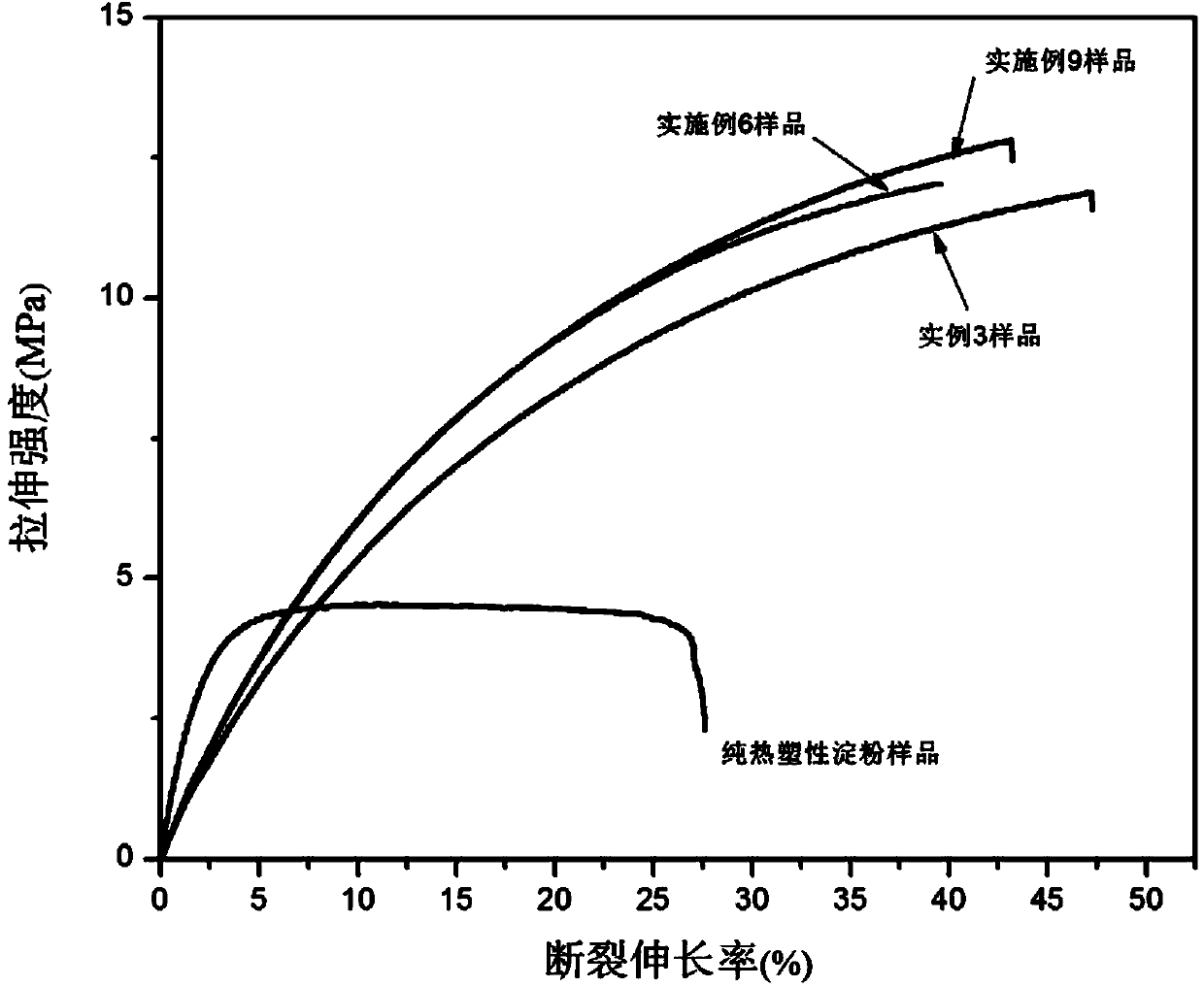

The invention discloses a continuously-produced full-degradable starch-based plastic alloy and a preparation method thereof. The starch-based plastic alloy contains the following components in parts by weight: 40-90 parts of starch, 5-60 parts of poly(butylene succinate), 5-60 parts of polylactic acid, 10-40 parts of plasticizer, 0.1-10 parts of compatibilizer and 1-10 parts of processing acid. The preparation method comprises the steps of mixing starch, plasticizer and part of processing aid, and extruding to obtain thermoplastic starch particles; then, mixing the thermoplastic starch particles with poly(butylene succinate), polylactic acid, compatibilizer and the residual processing aid, and extruding to obtain the starch-based plastic alloy. The starch-based plastic alloy disclosed by the invention is favorable in hydrophobicity and strength, good in component compatibility, favorable in thermoplastic processability, capable of realizing continuous production and processing as well as simple and feasible in technical process.

Owner:EAST CHINA UNIV OF SCI & TECH

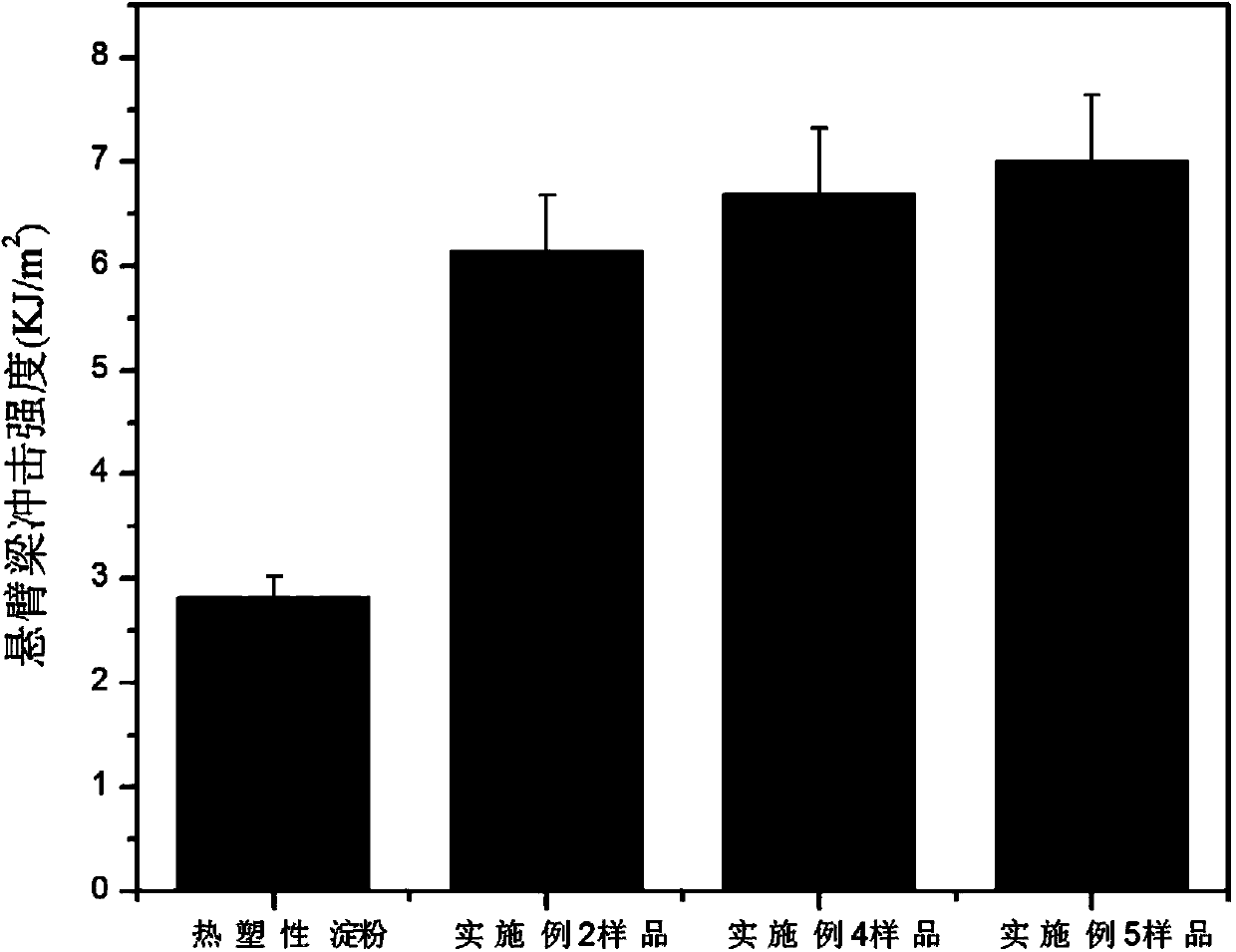

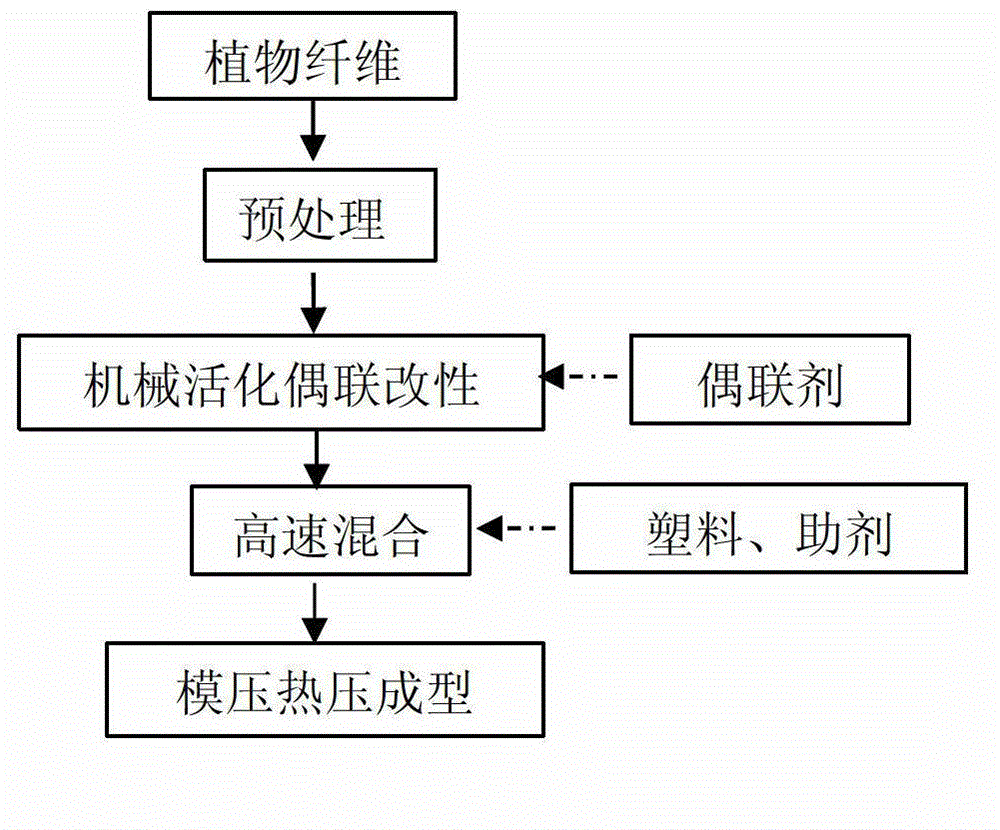

Plant fiber wood-plastic composite material and preparation method thereof

InactiveCN102942797ATake advantage ofImprove responseRaw material divisionPlant fibreCompatibilization

The invention relates to a plant fiber wood-plastic composite material and a preparation method thereof. The wood-plastic composite material includes compositions by mass: 40-60% of plant fibers, 0.6-3% of a coupling agent, and 30-55% of plastic. The additive comprises: 0.5-5% of a lubricating additive, 0.5-3% of a dispersing additive, 0.5-2% of a thermal stability additive, and 1-2% of a plasticizing additive. The modified plant fibers are obtained through synchronous activation and modification of plant fiber and a coupling agent by using the mechanical activation technology. Then the modified plant fibers, the plastic and the additive are high-speed mixed and finally molded to form the wood-plastic composite. The material utilizes the waste plant fibers in the light industry and agriculture, and has significant ecological environmental benefits. The method realizes simultaneous activation and modification for plant fibers, simplifies the preparation process, is pollution-free and has no three waste discharging in the process. The coupling agent-modified plant fibers is improved in compatibility with a thermoplastic material, and the quality of the wood-plastic composite material is enhanced.

Owner:GUANGXI UNIV +1

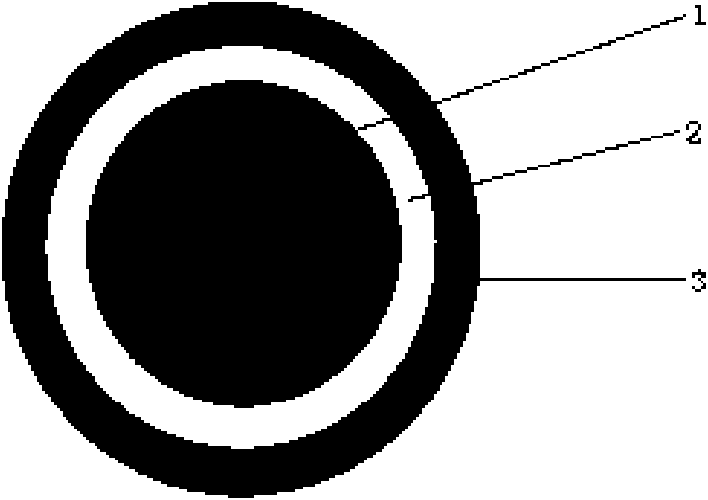

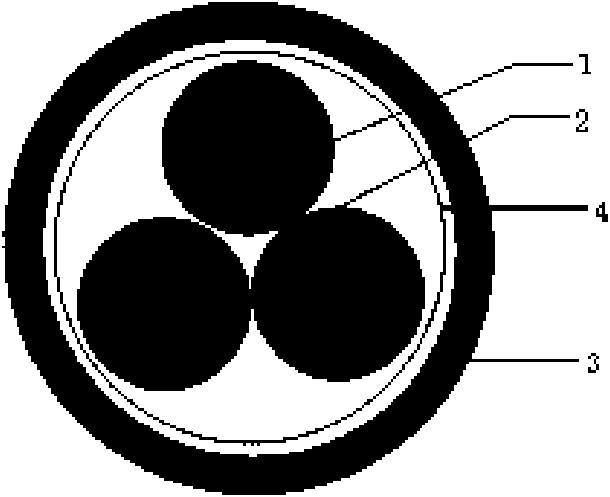

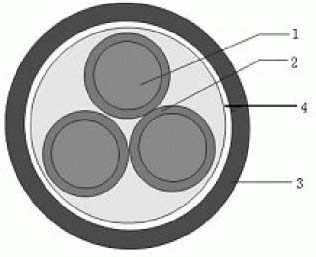

Fire-resistant silicon rubber and preparation method thereof and cable

ActiveCN101781463AStable fire resistanceImprove insulation performanceRubber insulatorsInsulated cablesMaterials sciencePlatinum Compound

The invention discloses a fire-resistant silicon rubber, which is prepared by the following raw materials by weight: 100 parts of silicon rubber, 0.1 to 3 parts of hydrogen-containing silicone oil, 2 to 15 parts of hydroxy silicone oil, 10 to 30 parts of pyrogenic silica, 10 to 30 parts of silicon epitaxy material, 20 to 50 parts of nanomontmorillonite, 10 to 30 parts of silicon carbide, 1 part of vulcanizing agent and less than 50 ppm of platinum compound calculating at the platinum quantity compared with the silicon rubber. The invention also provides a preparation method of the silicon rubber and a fire-resistant cable prepared with the silicon rubber. The fire-resistant silicon rubber has the performances such as stable fire resistance and good insulation performance, and has simple preparation method. The cable which is prepared with the fire-resistant silicon rubber has simple structure and convenient process. Particularly the reliability of the fire-resistant cable can be greatly improved.

Owner:浙江元通线缆制造有限公司

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

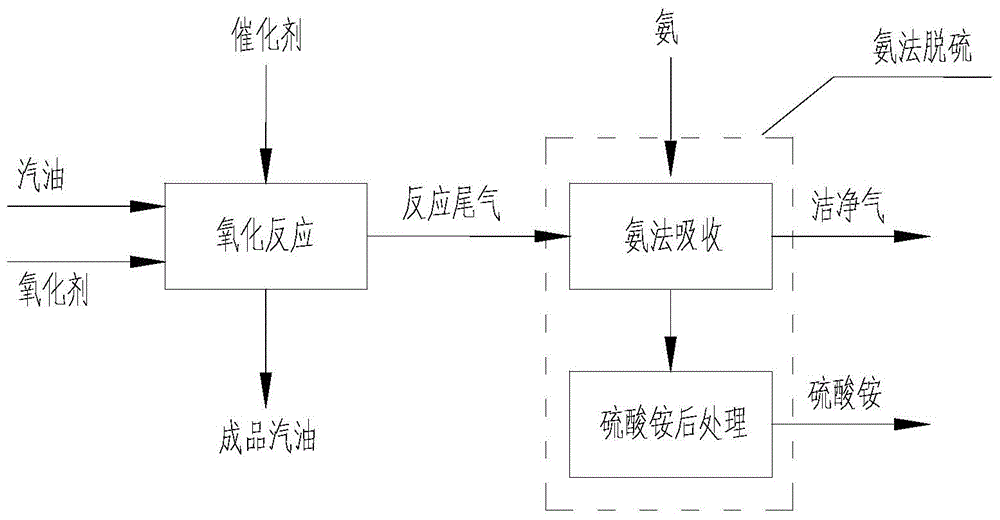

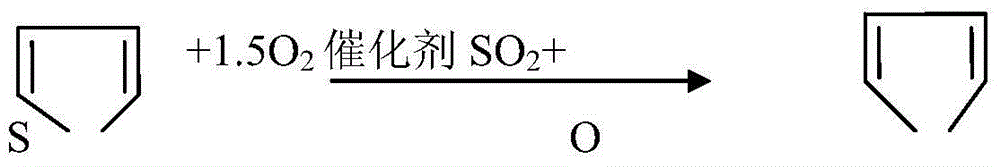

Gasoline-oxidation ammonia-process desulfurization method

InactiveCN104946296ARealize recycling of resourcesImprove desulfurization efficiencyRefining with oxygen compoundsDispersed particle separationGasolineComponents of crude oil

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

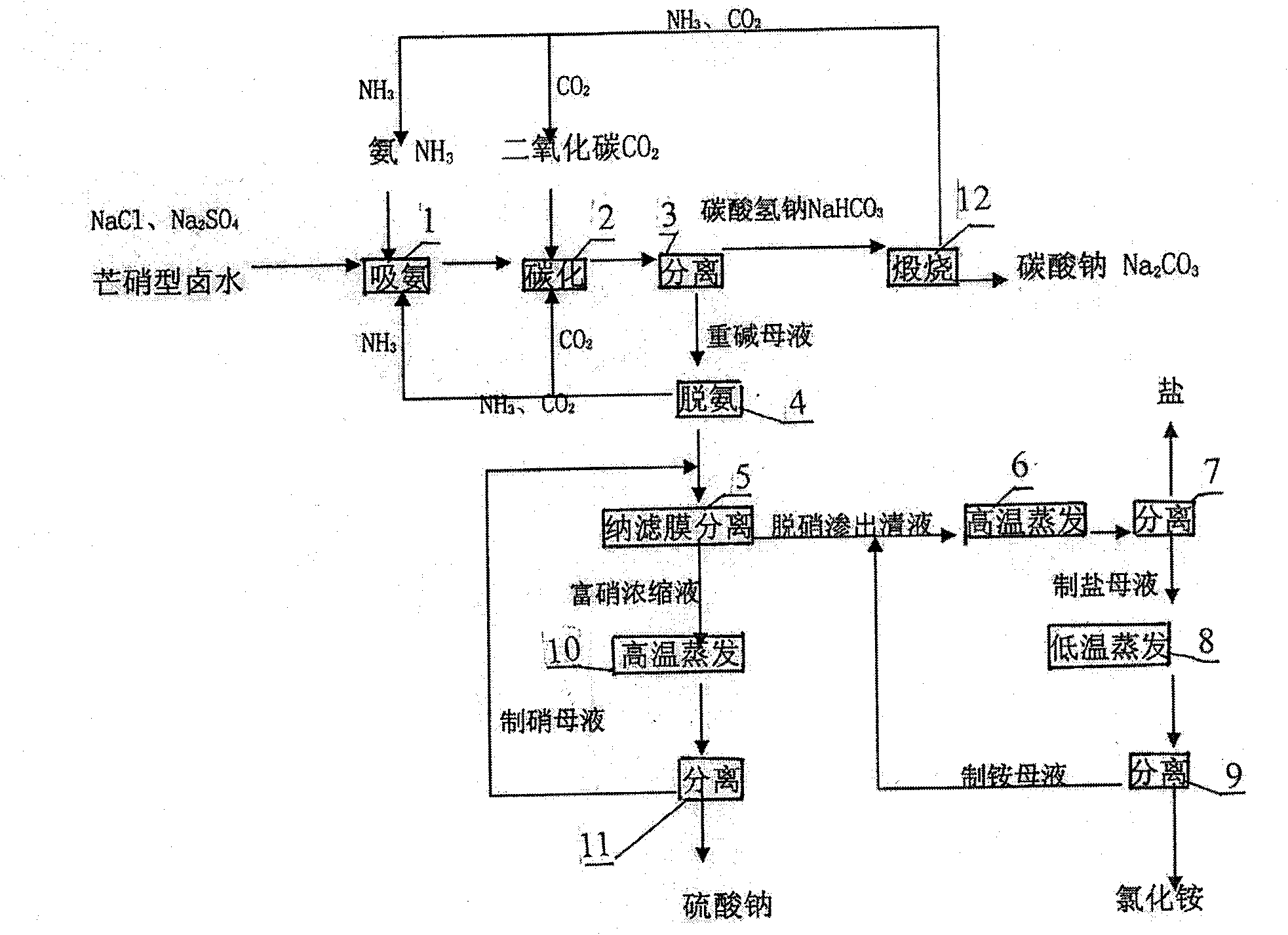

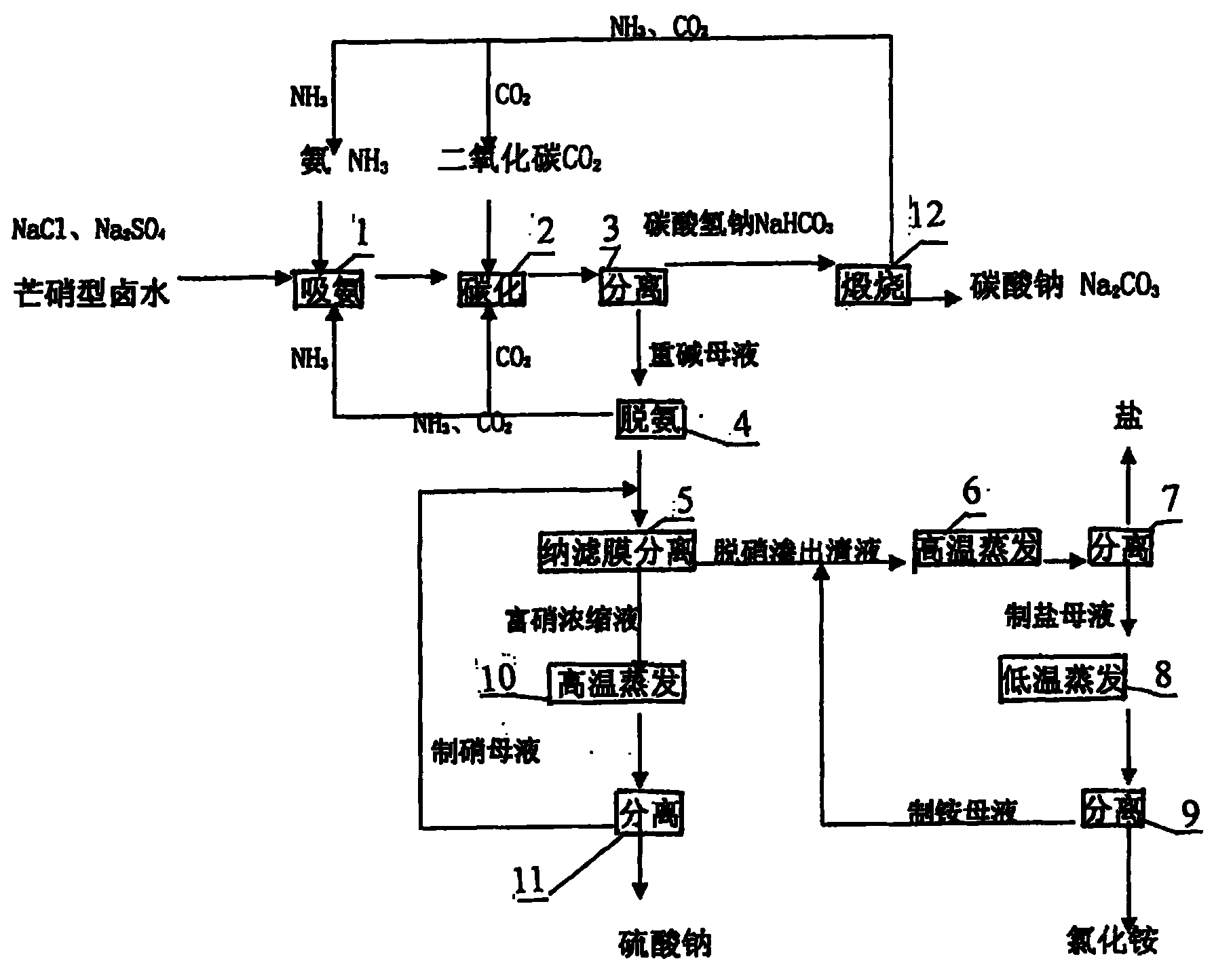

Process for producing mirabilite type bittern, sodium carbonate, sodium chloride, sodium sulfate and ammonium chloride

ActiveCN102153113AHigh quality main and by-productsStrong raw material adaptabilityAmmonium halidesAlkali metal chloridesDecompositionChemistry

The invention provides a process for producing mirabilite type bittern, sodium carbonate, sodium chloride, sodium sulfate and ammonium chloride. The process comprises the following steps of: performing double decomposition reaction by using mirabilite type bittern, ammonia and carbon dioxide as raw materials, and then separating the reaction products to obtain sodium bicarbonate and sodium bicarbonate mother solution; performing preheating and high-temperature ammonia removal on the sodium bicarbonate mother solution to obtain ammonia removed mother solution; separating the ammonia removed mother solution through a nano-filtration membrane to obtain denitration seeped clear solution and mirabilite rich concentrated solution; performing high-temperature evaporation and separation on the mirabilite rich concentrated solution to obtain solid sodium sulfate and mirabilite preparation mother solution, and circularly mixing the mirabilite preparation mother solution and the ammonia removed mother solution to perform the nano-filtration membrane separation process; performing high-temperature evaporation and separation on the denitration seeped clear solution and the circular ammonium preparation mother solution to obtain solid sodium chloride and salt preparation mother solution; performing low-temperature evaporation and separation on the salt preparation mother solution to obtain solid ammonium chloride and ammonium preparation mother solution; and mixing the ammonium preparation mother solution and the denitration seeped clear solution, and performing circular evaporation and separation to obtain solid sodium chloride and salt preparation mother solution. The process has the characteristics of high main product and byproduct quality, low steam energy consumption and production cost, no three-waste discharge in closed cycle and the like.

Owner:CHINA LIGHT IND INT ENG CO LTD

Environment-friendly separation and recovery method of fluorine in fluorine-containing waste liquid

InactiveCN105948083AAchieve separationAchieve recyclingMagnesium fluoridesHydrogen fluorideRecovery methodEnvironmental resistance

The invention discloses an environment-friendly separation and recovery method of fluorine in a fluorine-containing waste liquid. According to the invention, a magnesium-containing compound is added into the fluorine-containing waste liquid as a precipitation agent, such that fluorine in the waste liquid is selectively precipitated; filtering is carried out, and fluorine-removed liquid and magnesium fluoride precipitate are obtained; the fluorine-removed liquid is used in waste water recycling; the magnesium fluoride precipitate is decomposed with sulfuric acid, such that a series of compounds of fluorine are obtained; decomposition residue is subjected to a dissolution-crystallization treatment, such that magnesium sulfate crystals are obtained; the obtained magnesium sulfate crystals are returned and recycled in the fluorine selective precipitation process; the crystallization mother liquor of magnesium sulfate is returned to the dissolution-crystallization process or the magnesium fluoride precipitation decomposition process. The method has the advantages of simple process, simple operation, low production cost, and good fluorine-removing effect. With the method, fluorine resource utilization is realized. The method also has the advantages of no fluorine-containing waste production and no three-waste emission.

Owner:CENT SOUTH UNIV

Method and device for removing organic sulfur in methyl tertiary butyl ether (MTBE)

InactiveCN102381945AHigh yieldHigh desulfurization rateEther separation/purificationTowerMethyl tert-butyl ether

The invention relates to a method and a device for removing organic sulfur in methyl tertiary butyl ether (MTBE). The method and the device are utilized for high-sulfur content MTBE refinement. The method and the device realize normal-pressure low-temperature extraction rectification desulphurization of a high-sulfur content MTBE product. A technical scheme of the invention comprises the following steps that 1, a sulfur-containing MTBE product is heated by a heat exchanger and then is fed into a rectifying tower from a lower part of the rectifying tower; 2, an extractant is fed into the heat exchanger, is heated and then is fed into the rectifying tower from an upper part of the rectifying tower, wherein a rectifying tower temperature is in a range of 70 to 80 DEG C and the heated sulfur-containing MTBE product and the heated extractant countercurrently contact with each other so that countercurrent contact extraction desulphurization is realized; 3, the desulfurated MTBE product is output from the top of the rectifying tower, is subjected to cooling condensation to form liquid in the heat exchanger and then is output; and 4, the sulfur-containing extractant obtained by the step 2is output from the bottom of the rectifying tower, is heated by the heat exchanger, is fed into a flash tank, is distilled at a temperature of 80 to 85 DEG C so that the residual desulfurated MTBE product is distilled off, then is fed into an actifier column, and countercurrently contacts with dry air in the actifier column so that countercurrent contact gas stripping regeneration is realized. Through the method and the device, good desulphurization effects are realized; a high product yield is obtained; and an extractant can be regenerated for recycle. The method is convenient for operation,has low costs and low energy consumption, and can be utilized for high-sulfur content MTBE product refinement.

Owner:SOUTHWEST PETROLEUM UNIV

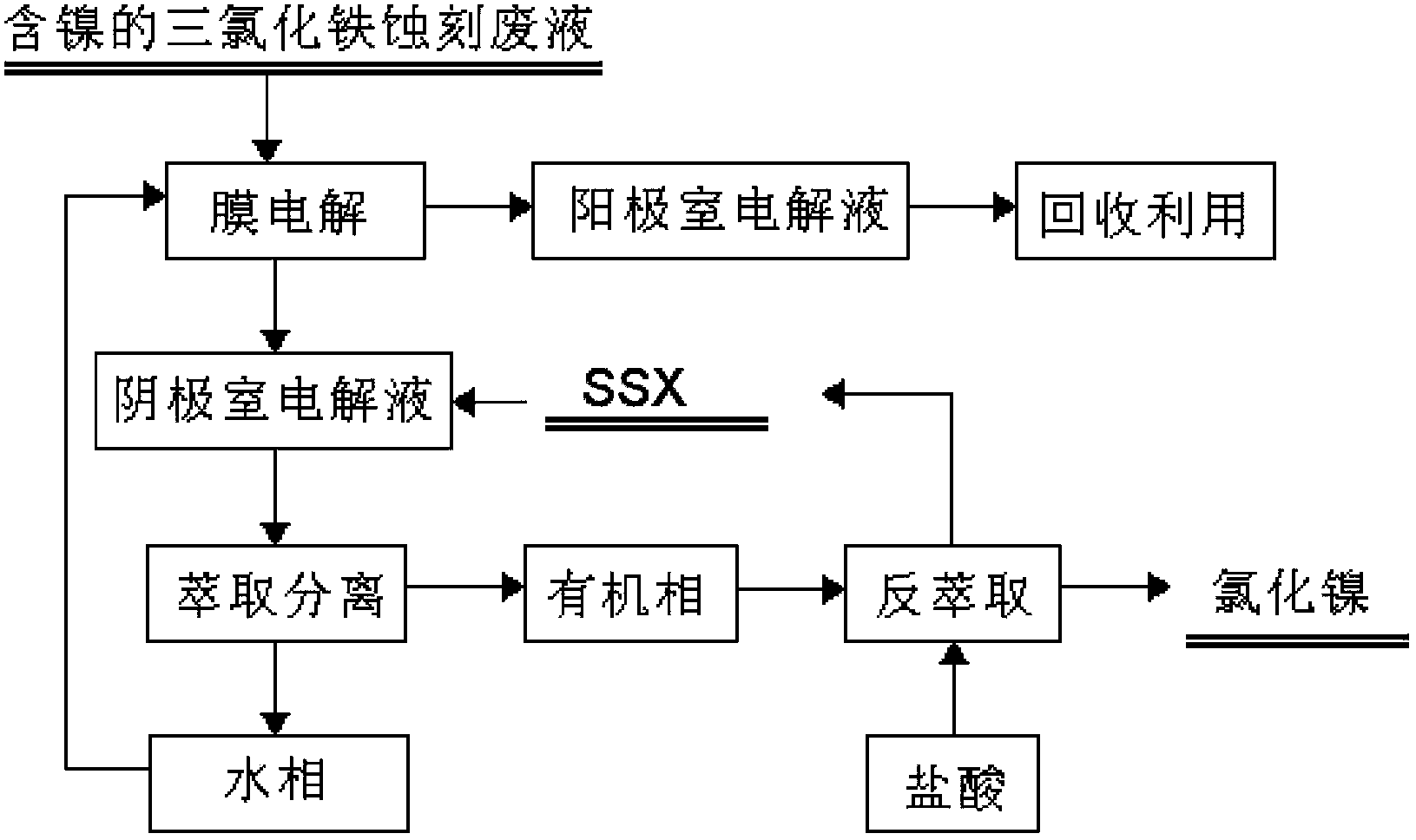

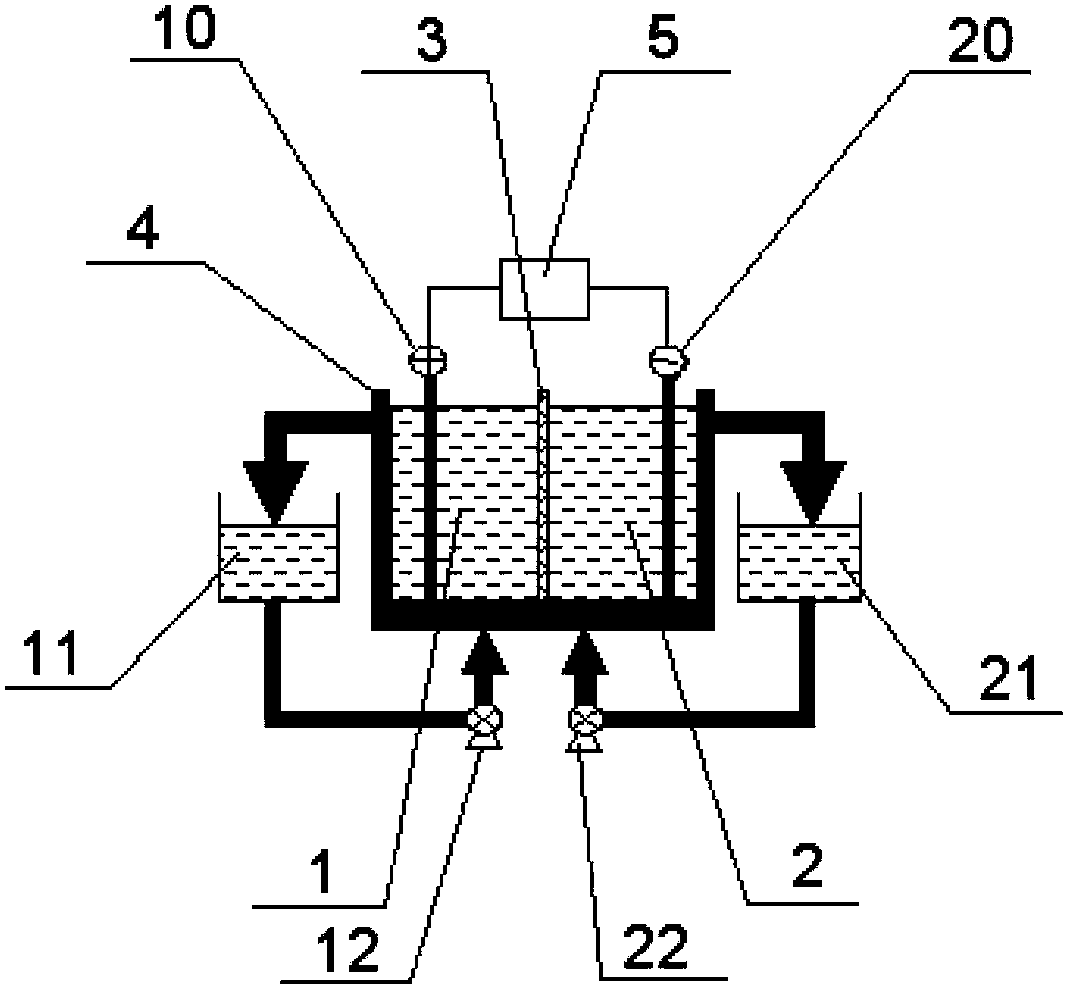

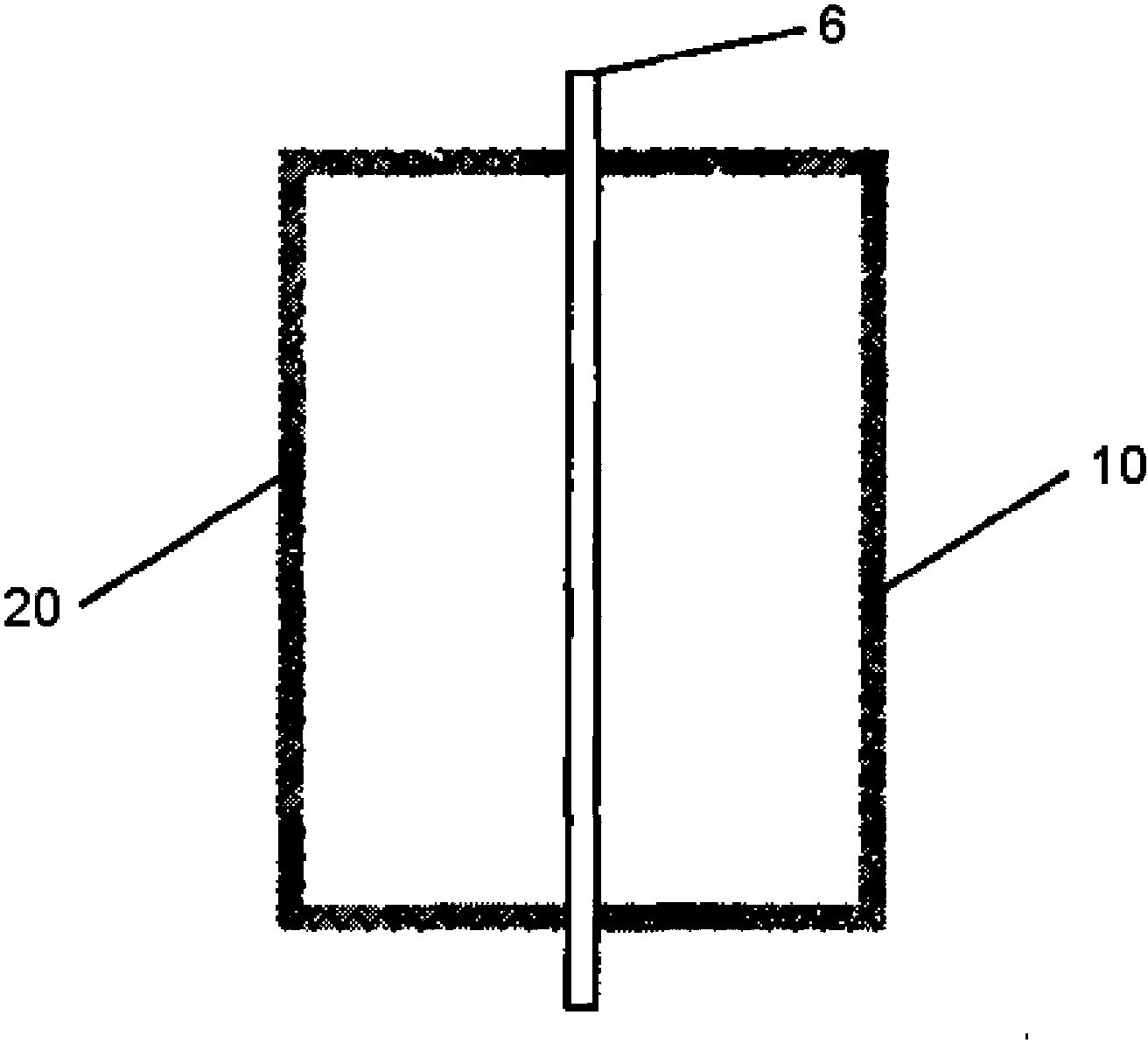

Recovery method for waste ferric trichloride etching liquid

ActiveCN104131285AImprove qualityLow operating costWater contaminantsWaste water treatment from metallurgical processElectrolysisIon-exchange membranes

The invention provides a recovery method for a waste ferric trichloride etching liquid. The method adopts integrated membrane electrolysis and extraction technology and comprises the following steps: providing an electrolytic tank, wherein an ion exchange membrane is arranged in the electrolytic tank to divide the electrolytic tank into an anode chamber and a cathode chamber, and a cathode and an anode are respectively positioned in the cathode chamber and the anode chamber located at two sides of the ion exchange membrane; adding the waste ferric trichloride etching liquid into the cathode chamber and carrying out membrane electrolysis so as to reduce Fe3+ ions into Fe2+ ions; carrying out extraction on a solution obtained after electrolysis in the cathode chamber to remove impurity metals so as to obtain an extract phase solution and a metal impurity-removed phase solution and delivering the metal impurity-removed phase solution to the anode chamber for membrane electrolysis so as to oxidize Fe2+ ions into Fe3+ ions; and recovering a solution obtained after electrolysis in the anode chamber. Compared with conventional processing technology for the waste ferric trichloride etching liquid, the recovery method provided by the invention has the advantages of short and simple process flow, no generation of secondary pollution, no discharge of waste gas, waste water and industrial residue, low production cost, applicability to large-scale treatment, treating capacity of more than ten thousands every year and good environmental and economic benefits.

Owner:宁波东顺电子科技有限公司

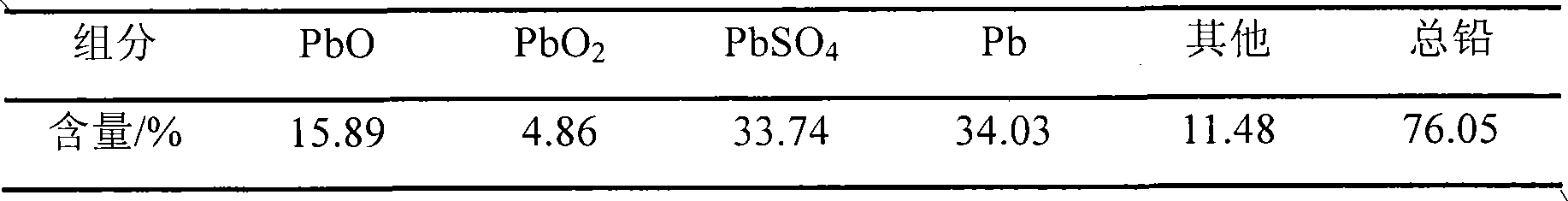

Method for preparing lead nitrate and lead oxide by using lead plaster of waste lead accumulator

InactiveCN101857919ASimple processNo waste dischargeProcess efficiency improvementGranularityLead nitrate

The invention discloses a method for preparing lead nitrate and lead oxide by using lead plaster of a waste lead accumulator, which comprises the following steps of: mixing the lead plaster with the granularity of less than 100 microns and 4.5 to 6.5 percent ammonium carbonate solution in a weight ratio of 1: 10-12, then reacting the mixture for 2 to 3 hours at the temperature of between 60 and 100 DEG C with stirring, separating and washing the reaction product, and collecting filter cakes; then mixing the filter cakes, 6 to 12 percent diluted nitric acid and 28 to 30 percent hydrogen peroxide in turn in a weight ratio of 1: 8-10 and 1: 0.05-0.2 respectively, reacting the mixture for 1 to 1.5 hours at the temperature of between 40 and 60 DEG C with stirring, separating and washing the reaction product, and collecting filtrate; concentrating the filtrate till the density of the solution is 1.30 to 1.45 g / cm<3>, adding 65 to 70 percent nitric acid into the solution in a volume ratio of 1: 8-10 and mixing the solution, reacting the solution for 1 to 2 hours with stirring, separating and washing the reaction product, and drying and dehydrating the filter cakes to obtain a lead nitrate product; and performing reaction conversion on the lead nitrate and sodium hydroxide solution, and calcining the reaction product to obtain a lead oxide product. The purities of both the lead nitrate and the lead oxide are more than or equal to 99 percent. The process adopts closed cycle and has no three-waste emission.

Owner:HEFEI UNIV OF TECH +1

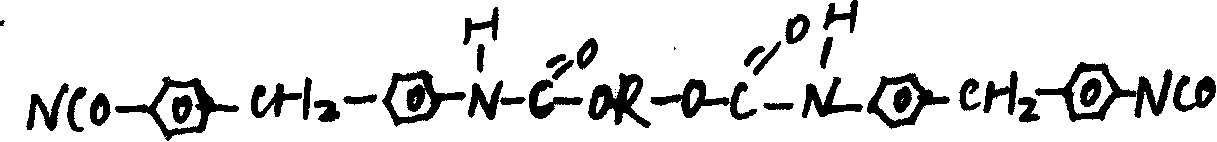

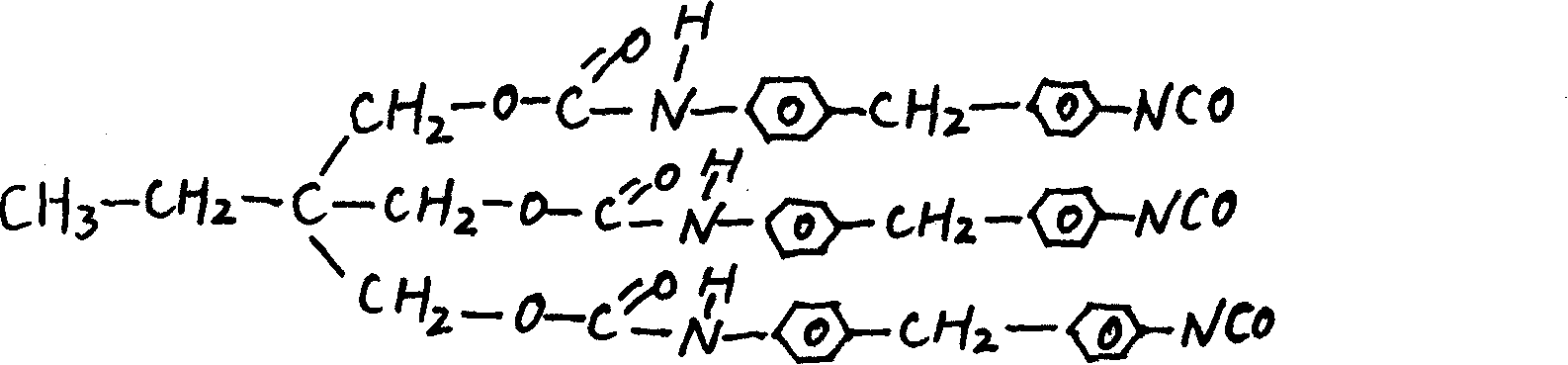

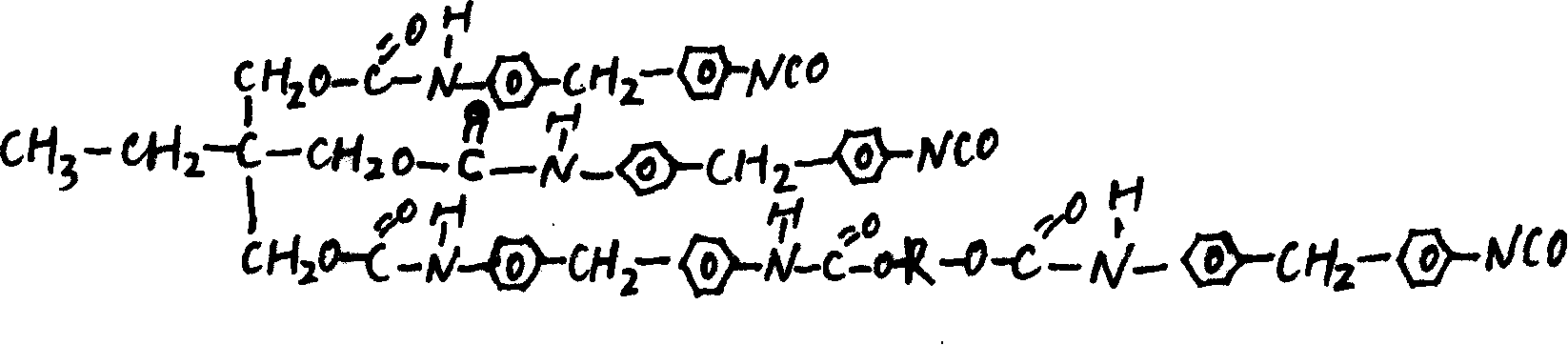

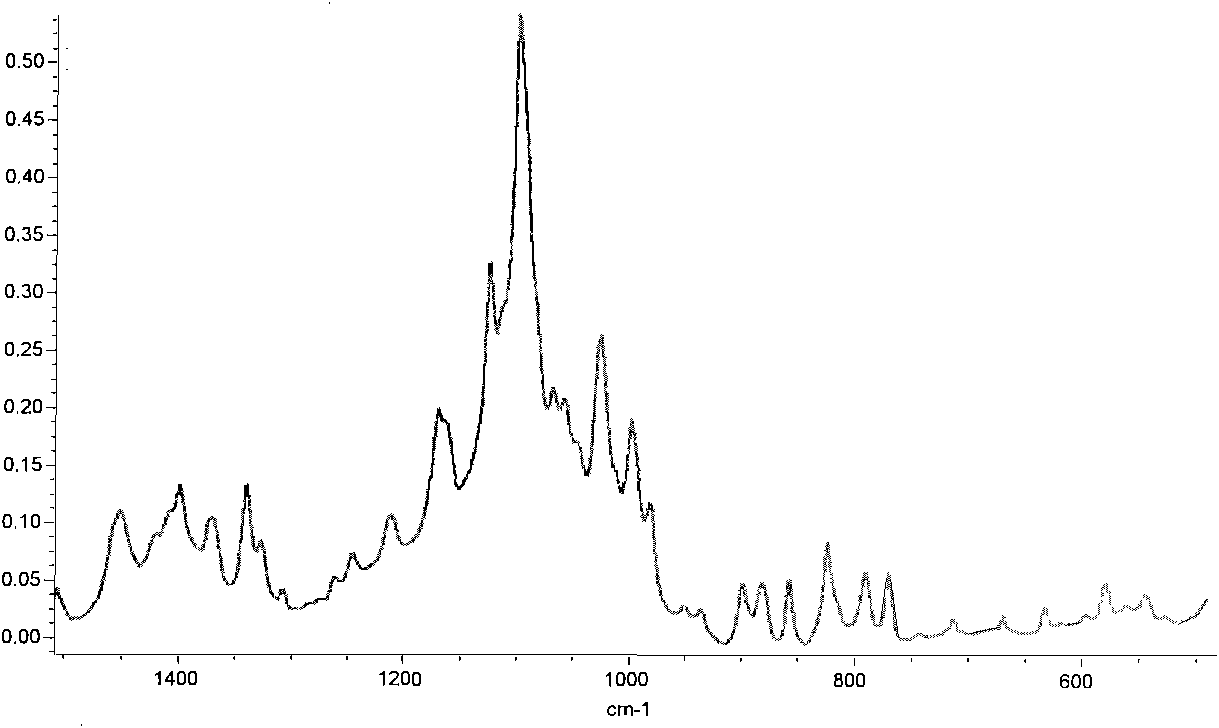

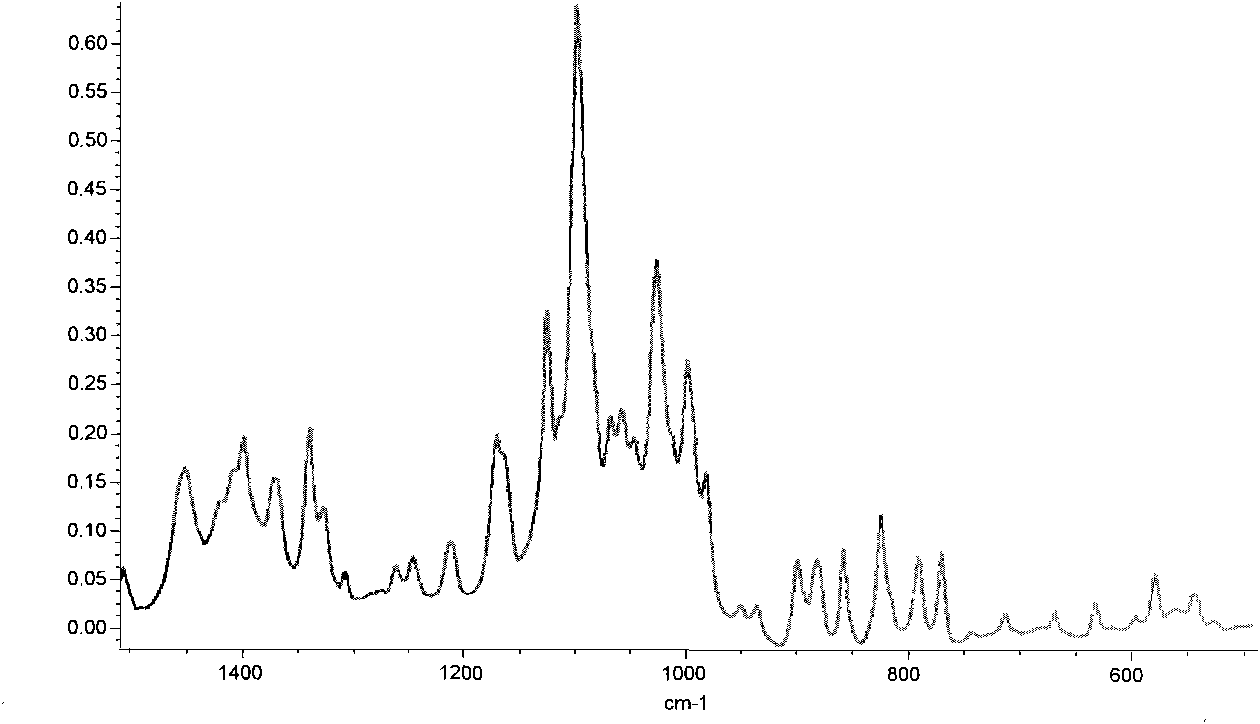

Curing agent 4,4'-biphenyl methane diisocyanate prepolymer and preparation method thereof

The invention relates to a curing agent, namely, 4, 4 (1)-diphenylmethane diisocyanate prepolymer and a preparation method thereof. The method comprises the steps that molten 4, 4(1)-MDI and an organic solvent are added into a reaction vessel, and stirred uniformly, the temperature is raised to 65 DEG C, polyhydric alcohol dehydrated through evacuation is added, to react for 2 to 4 hours at 60 to 100 DEG C, and then an MDI modifier is produced; when being stirred, the mixed liquor of trimethylol propane and the organic solvent is titrated into the reaction vessel for 1 to 4 hour(s), the titration temperature is 60 to 100 DEG C, heat preservation and reaction are performed for 1 to 3 hour(s), then the temperature is raised to 90 to 100 DEG C and the heat preservation and the reaction are performed again for 1 to 4 hour(s), the temperature is reduced, and the organic solvent is added for dilution to appropriate viscosity. The curing agent has the advantages that the application scope is broad, the molecular structure of the polyhydric alcohol can be adjusted according to the requirements of users to produce the prepolymer of polyurethane coating, adhesive, and the curing agent, the storage stability is good, the curing speed is quick, the toxicity is low, the price is low, products with high solid content can be obtained, etc.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

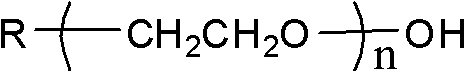

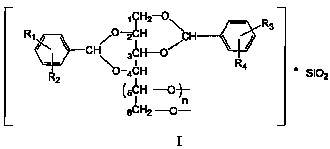

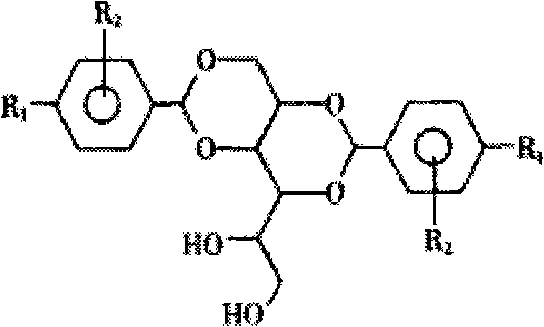

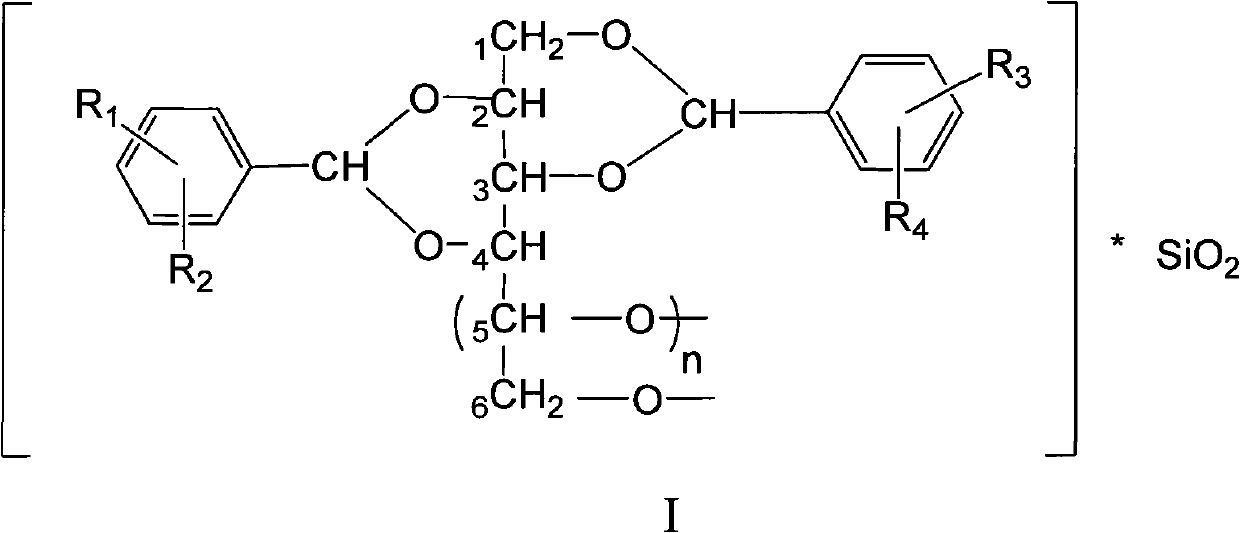

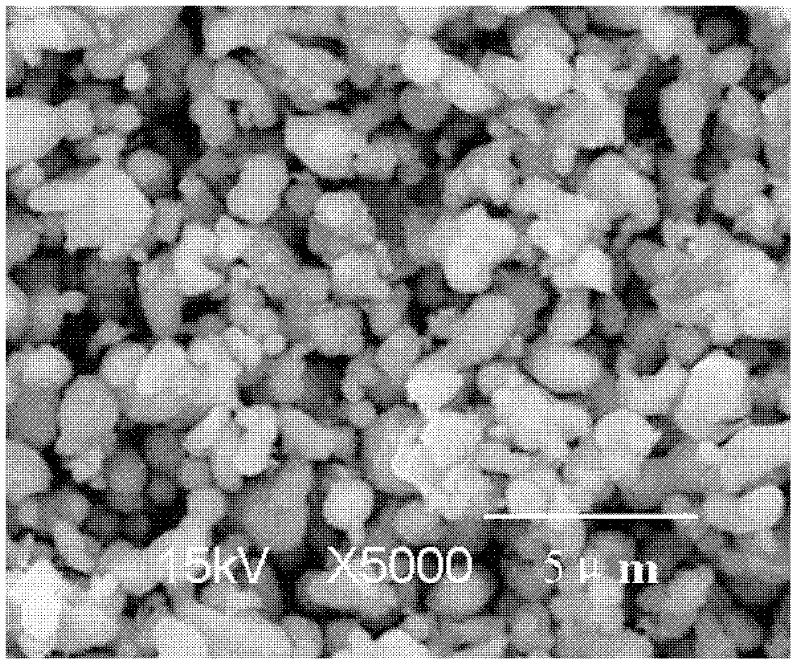

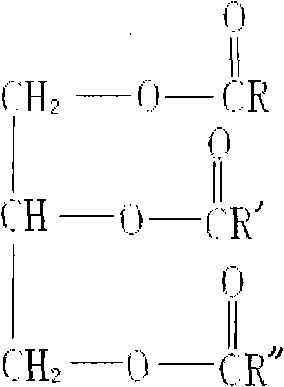

Polyolefin resin nucleating agent and preparation method thereof

The invention discloses a polyolefin resin nucleating agent and a preparation method thereof. The nucleating agent is polyol acetal-silica gel graft copolymer shown as a right general formula (I); the nucleating agent improves the stability of organic acetal and environment-friendly performance, reduces the production cost and remarkably improves the mechanical performance and thermal performance of polyolefin resin in particular.

Owner:CHINA PETROLEUM & CHEM CORP

Aqueous hammer paint

The present invention relates to a paint material, in particular to a waterborne hammer paint. The present invention is characterized by comprising water, waterborne aluminum silver paste, film forming additive, antifreeze, anti-corrosion fungicide, defoaming agent, dispersant, regulator, waterborne bi-crosslinking acrylic emulsion, epoxy acrylic emulsion, paint sizing agent, thickening agent, flow agent, hammer tone agent, antitarnish agent and hardening agent. After being evenly stirred, the mixture is emulsified mechanically, the speed is reduced to between 400 and 600 rounds per minute; the waterborne bi-crosslinking acrylic emulsion is added and thickened after PH valve is adjusted between 8 and 9 with the regulator; after viscosity reaches between 80 and 160 seconds (T-4 / 23 DEG C) the waterborne hammer tone agent, antitarnish agent and hardening agent are added, and the paint sizing agent is added according to requirements, stirred evenly, filtered by a filter and then discharged to be packed into products. The present invention has the advantages of smooth appearance of paint film, vivid flower pattern and excellent antifouling, water and chemical resistant performances. The product can be widely applied to motors, machine tools, machinery, household electrical appliances and inside and outside building decoration. Compared with unctuous paint, the product has long life-span and durability and meets requirements of various environmental protection indexes. The product is nontoxic, harmless, noncombustible, nonexplosive and safe and reliable in storage and transportation.

Owner:王敏吉

Preparation method of suspended nano-calcium carbonate for food

InactiveCN101880051ANo pollutionSimple production processCalcium/strontium/barium carbonatesCarbonizationImpurity

The invention discloses a preparation method of suspended nano-calcium carbonate for food. The method comprises the steps of high-temperature calcining limestone, taking out optimum quicklime, digesting, sieving and removing impurities, introducing CO2 gas, and adding a crystal form control agent for carbonization reaction under stirring; and then press filtering, washing, drying, crushing and classifying, and preparing the suspended nano-calcium carbonate for food. The method for producing the suspended nano-calcium carbonate for food has high efficiency, no environment pollution and good quality.

Owner:HENAN KELI NEW MATERIALS

Method for preparing wax emulsion from branched polyethylene wax through direct emulsification

The invention discloses a method for preparing wax emulsion from branched polyethylene wax through direct emulsification, which comprises the following steps of: mixing the branched polyethylene wax and a cosolvent, adding an emulsifier and heating and emulsifying; adding water and dispersing and emulsifying by a phase transfer method; and shearing, emulsifying and dispersing to prepare milky branched polyethylene wax emulsion. In the emulsification method, the cosolvent is added into the branched polyethylene wax for direct emulsifying, and the process for production of the emulsion is greatly simplified. The branched polyethylene wax emulsion can be applied in the fields of leather finish, fur finishing, textile finishing, automobile polishing, shoe cream and the like, the coating has smooth handfeel, natural color, high hardness and high scratch resistance, and the wax emulsion is a high-grade wax emulsion product. The emulsification process can greatly expand the use of the branched polyethylene wax and reduce the application of solvent products, and is an environmentally-friendly emulsification process.

Owner:SHAANXI UNIV OF SCI & TECH

Ammonia nitrogen-free leather-making deliming agent and preparation method thereof

InactiveCN102010917AEasy to processReduce energy consumptionPre-tanning chemical treatmentInorganic saltsLiquid waste

The invention discloses an ammonia nitrogen-free leather-making deliming agent and a preparation method thereof. The method comprises the following steps of: mixing 60 to 80 mass parts of organic acid A, 15 to 30 mass parts of organic acid B and 5 to 30 mass parts of inorganic salt; and mechanically crushing until the granularity is 80 to 100 meshes, adding 1 to 10 mass parts of aids and uniformly mixing to obtain the ammonia nitrogen-free leather-making deliming agent. The deliming agent does not contain ammonia nitrogen materials, the ammonia nitrogen content of the waste liquid and chemical oxygen demand (COD) content after deliming are respectively reduced by over 80 percent and 20 percent compared with those of the conventional process, no irritant gas is generated in the deliming process, safety production of an operator is facilitated, and the deliming agent is a clean leather-making aid, and has great popularization and application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

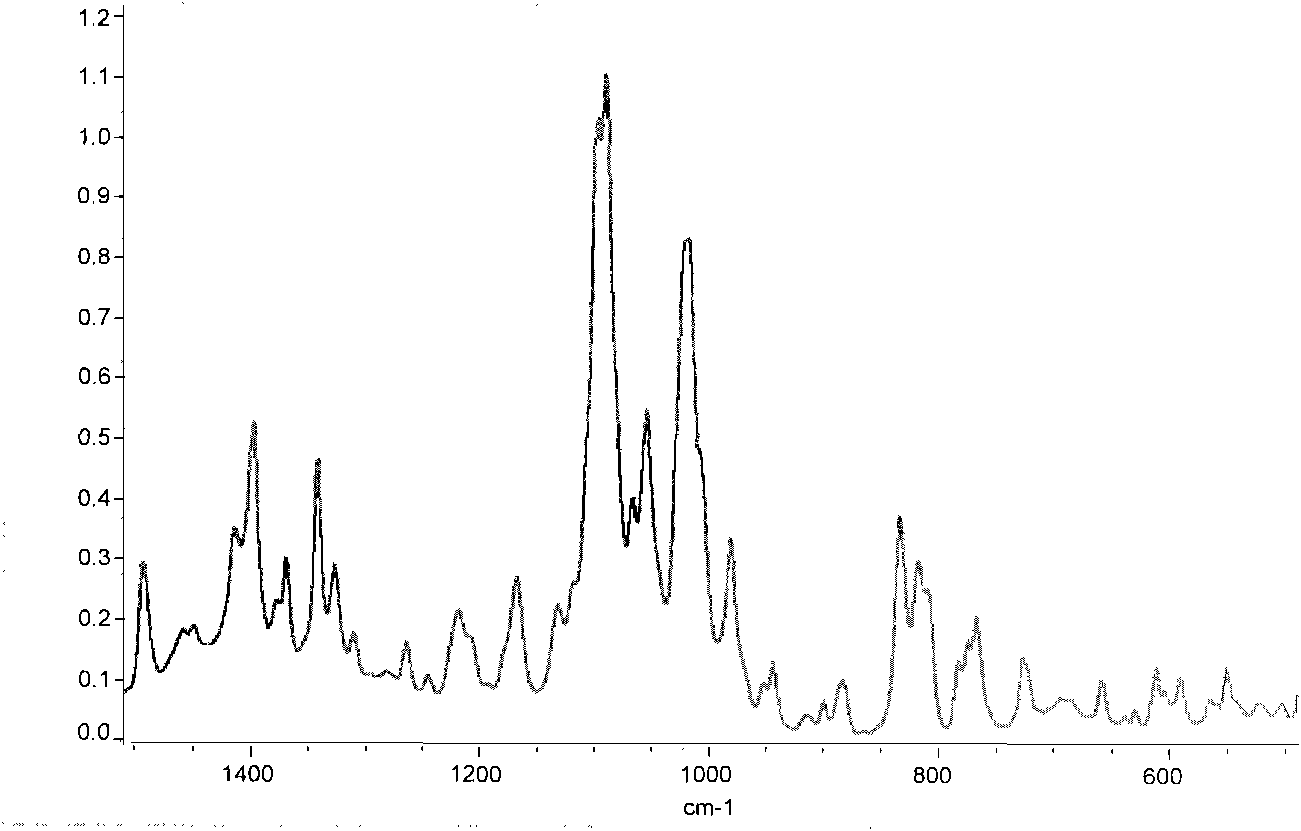

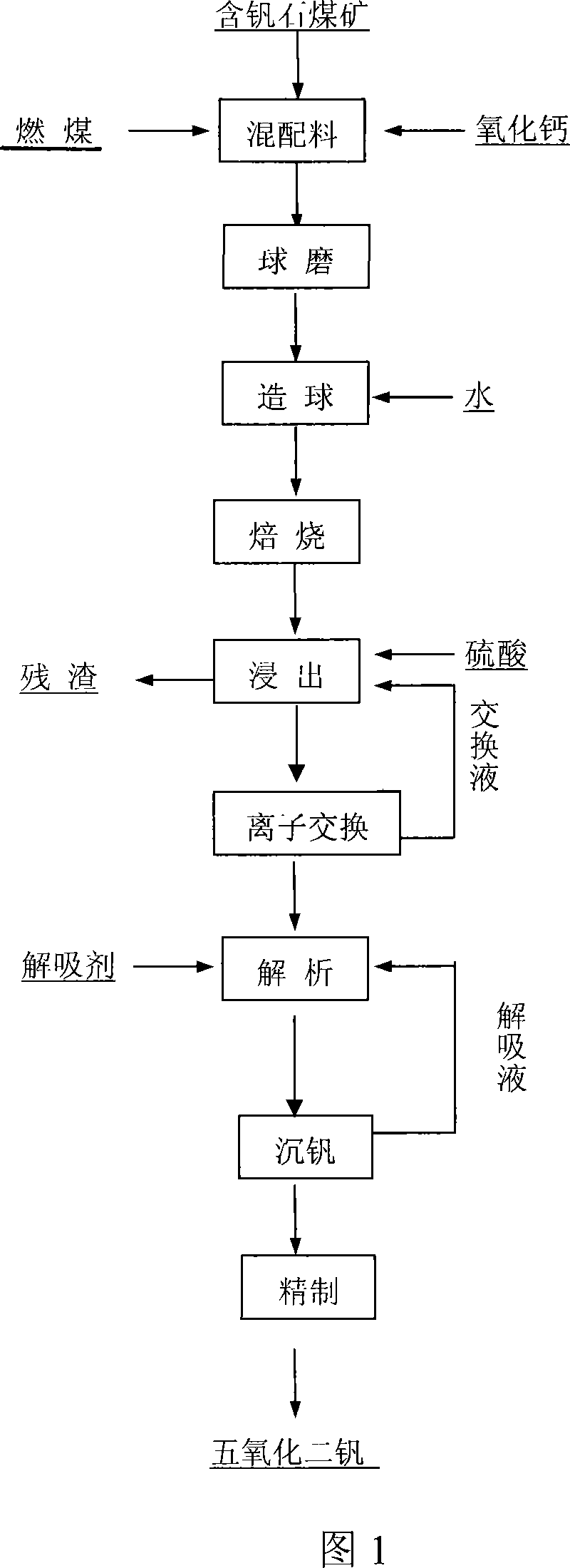

Process of extracting vanadium pentoxide from coal gangue

The present invention relates to process of extracting vanadium pentoxide. The process includes the following five steps of: calcifying roasting, acid leaching, ion exchanging, depositing vanadium pentoxide, and roasting to eliminate ammonia. The process has the available of short production period, simple operation, high vanadium pentoxide product purity up to 99.0 % and low production cost, and is suitable for industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Polyolefin resin and nucleating agent-containing composition

ActiveCN101987891AImprove environmental performanceSmall smellPigment treatment with non-polymer organic compoundsPolymer sciencePolyolefin

The invention discloses a polyolefin resin and nucleating agent-containing composition. The composition is characterized in that: a nucleating agent is a polyalcohol diacetal-silica gel graft with a general formula (I). The polyolefin resin and nucleating agent-containing composition of the invention improves the stability of organic acetals, is highly environmentally-friendly, reduces the production cost, and particularly has remarkably improved mechanical properties and thermal properties.

Owner:CHINA PETROLEUM & CHEM CORP

Composite solid acid catalyst

ActiveCN102114432AImprove anti-aging effectGood anti-aging performanceOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAntioxidantSolid acid

The invention discloses a composite solid acid catalyst for antioxidant RD preparation. The composite solid acid catalyst is characterized in that D002-type strong acid cation exchange resin is compounded with arylsulfonate substances to prepare the solid acid catalyst; in the presence of the composite solid acid catalyst, aniline reacts with acetone to generate an antioxidant RD monomer with high aniline conversion rate and high chemical yield; and then the antioxidant RD monomer is polymerized, distilled and granulated to prepare the antioxidant RD finished product. The composite solid acidcatalyst has the advantages that the continuous environment-friendly process with simple process, high product chemical yield, high content of dimer of the product antioxidant RD, excellent antioxidant effect of the finished product, no three-waste emission and low production cost is suitable for industrial production.

Owner:JIANGSU SINORGCHEM TECH CO LTD

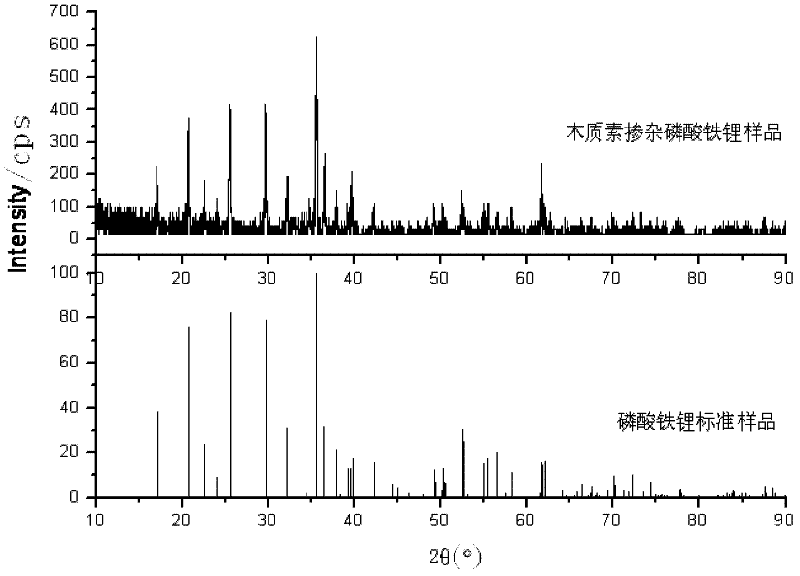

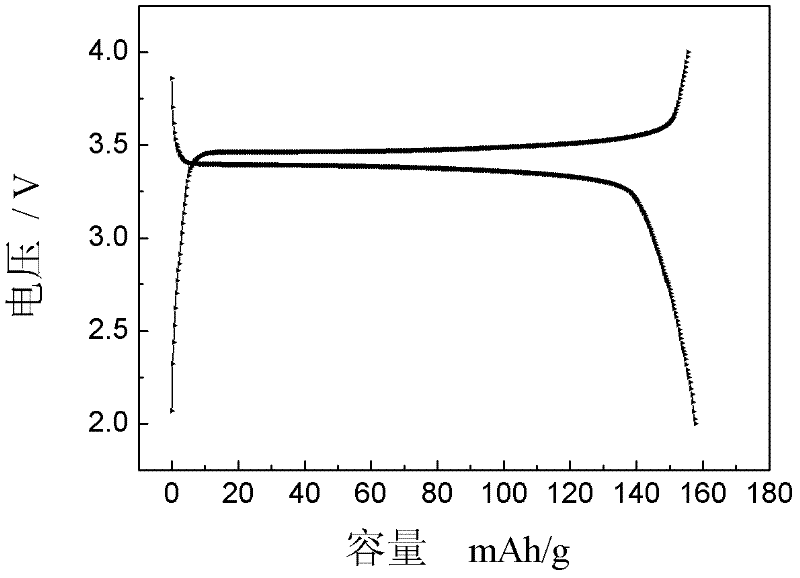

Preparation method for modified LiFePO4 lithium ion battery anode material

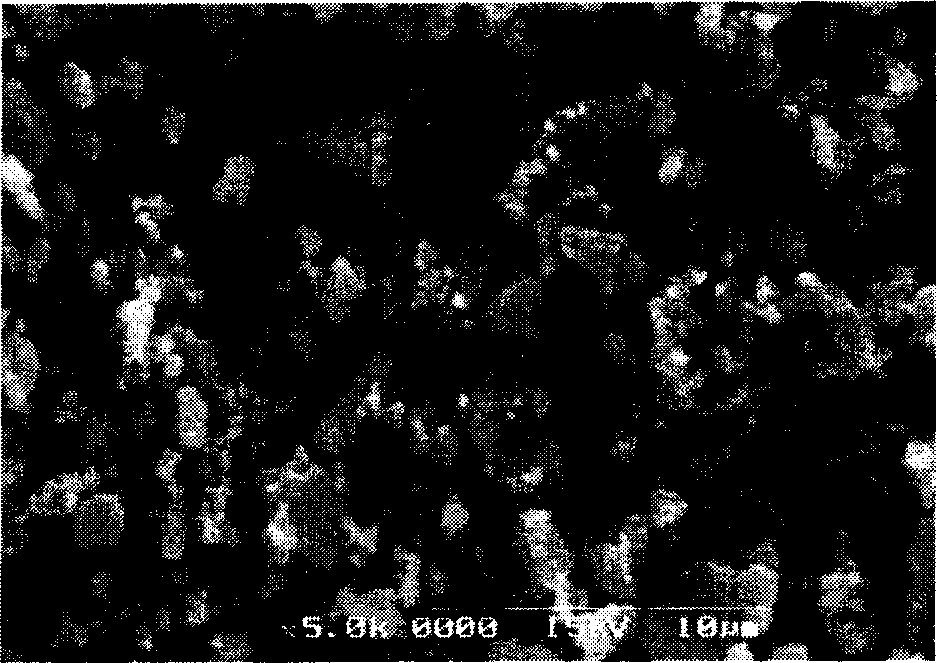

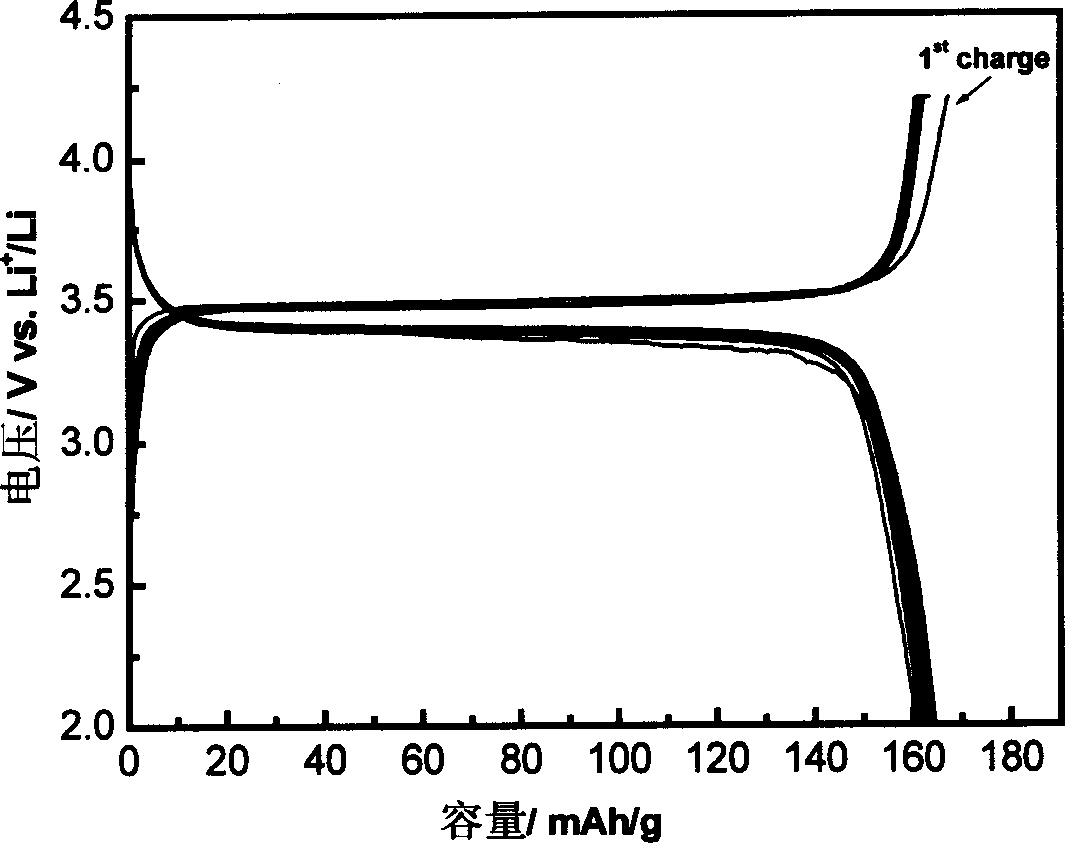

InactiveCN102361071ARich sourcesImprove electrochemical performanceCell electrodesCharge dischargeCellulose fiber

The invention relates to a preparation method for a modified LiFePO4 lithium ion battery anode material, which belongs to the field of lithium ion battery materials. In the process of preparing a LiFePO4 lithium ion battery cathode material, a modifier is added, and the modifier is cellulose fiber, a lignin salt or a mixture of the two. According to the invention, cheap lignin, a renewable natural high-molecular material, is used as a carbon source precursor for the LiFePO4 lithium ion battery anode material, and lignin is widely available and easy to well mix with lithium source compounds, iron source compounds and phosphor source compounds once and for all; the prepared LiFePO4 lithium ion battery anode material has high purity and good electrochemical performance; a process for the anode material is simple and is easy to control; low production cost is obtained; a lithium ion battery made of the cathode material has a stable quality and 0.2C charge-discharge reversible specific capacity higher than 157 mAh / g, and battery capacity of the prepared lithium ion battery does not attenuate after 50 times of cycle; the method is applicable to large scale industrial production.

Owner:HUNAN ZHONGTIAN NEW ENERGY

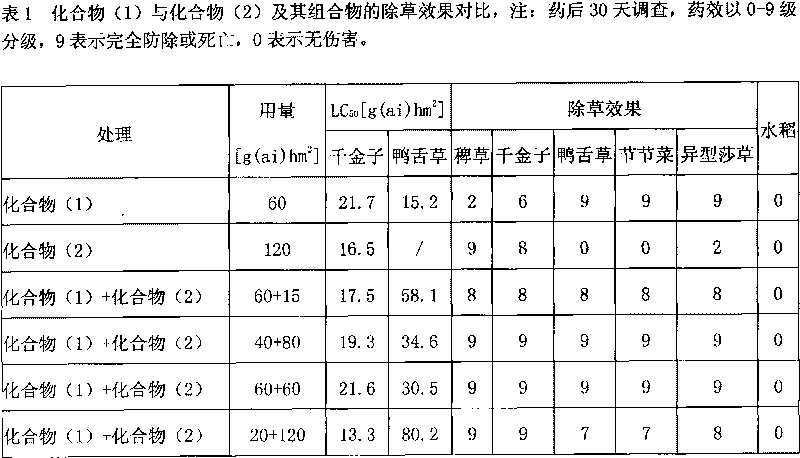

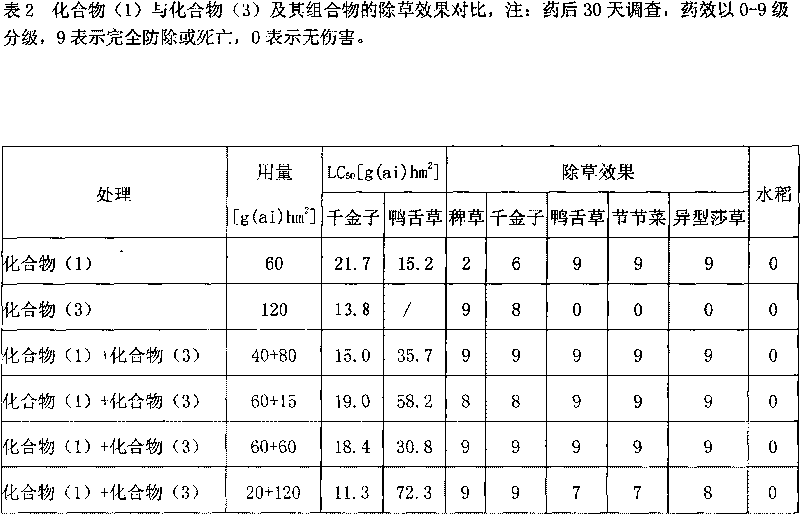

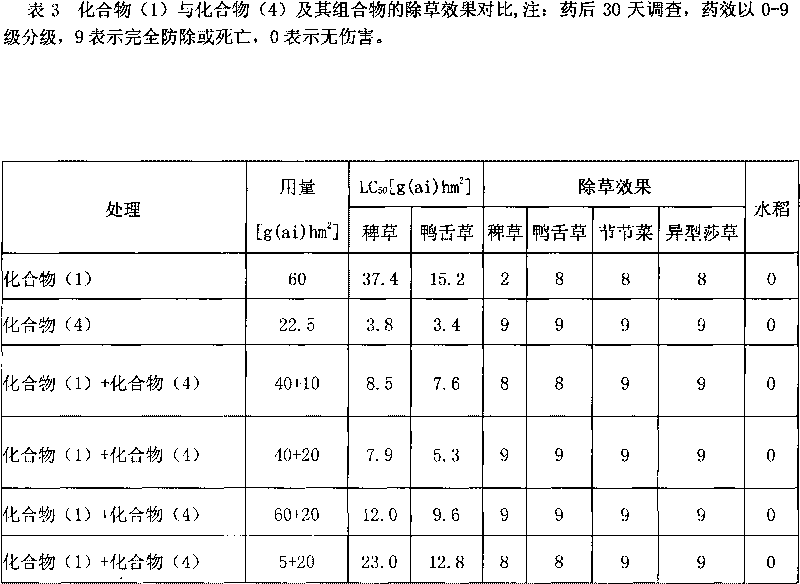

Weed control foliar herbicide compositions in paddy field

The invention relates to weed control foliar herbicide compositions in a paddy field, which are three foliar herbicide compositions for eliminating weeds in the paddy field. The three foliar herbicide compositions are the composition of mesotrione and metamifop, the composition of mesotrione and cyhalofop-butyl and the composition of mesotrione and penoxsulam respectively. The single use of the existing herbicide in the paddy field has the limited weed-killing spectrum and can not control all the weeds in the paddy field, and a complex product has poor safety or a narrow using cycle or resistance to the weeds in a water field, thereby limiting the popularization and the applications of the complex product. The three herbicide compositions provided by the invention can overcome the defects and control all the weeds in the paddy field; furthermore, the three herbicide compositions have broader using cycle, no resistance to the weeds in the water field and good safety to paddy rice and succeeding crops.

Owner:刘雪源

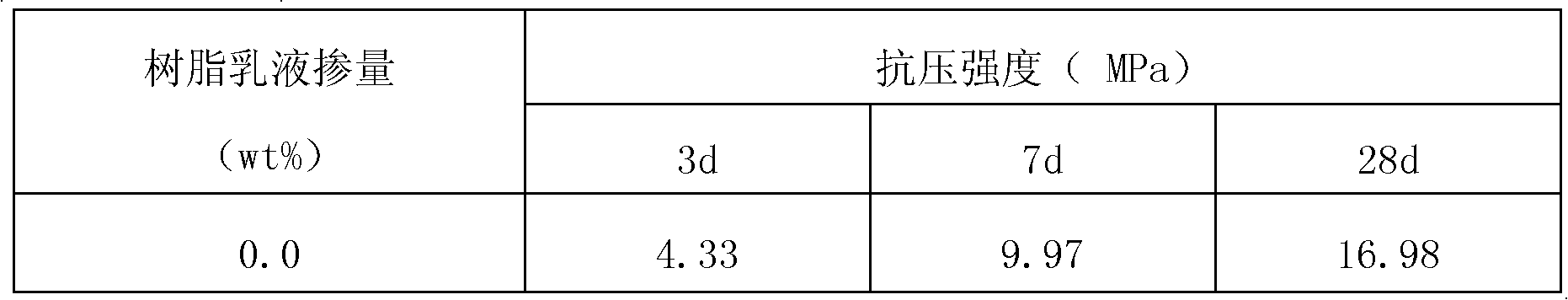

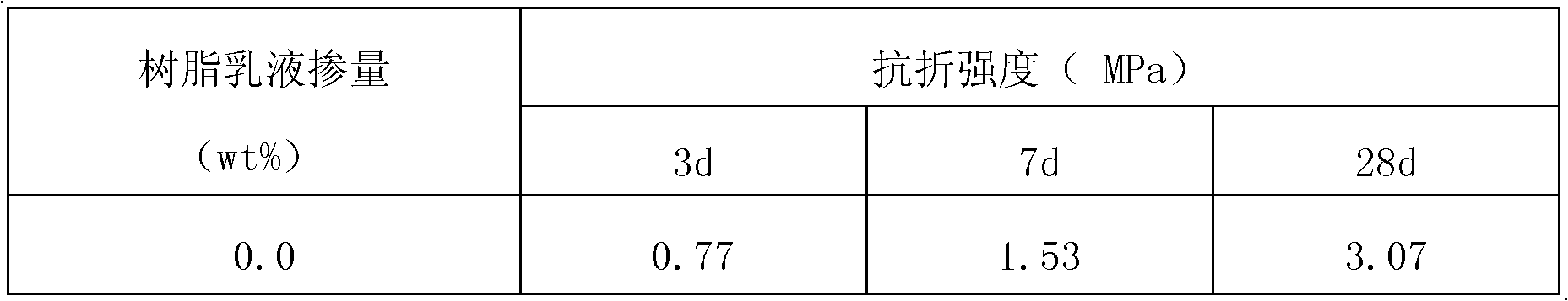

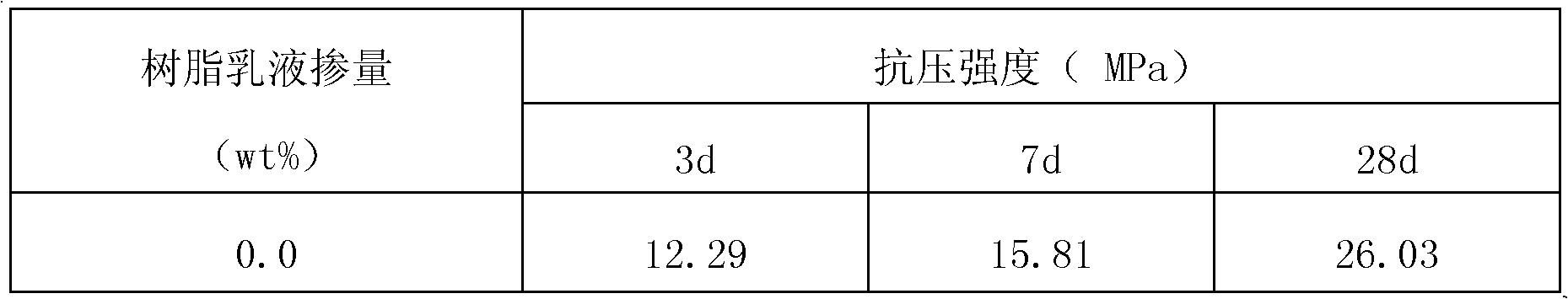

Fly ash-based inorganic polymer composite cementitious material and preparation method thereof

InactiveCN101792275AEfficient circular economyNo waste dischargeSolid waste managementCement productionAcrylic resinFlexural strength

The invention relates to a fly ash-based inorganic polymer composite cementitious material and a preparation method thereof, and the fly ash-based inorganic polymer composite cementitious material comprises the following raw materials: 1350g of fly ash, 150g of silicon powder, 225 or 300g of sodium silicate and 307 or 264g of water (water + crystal water in Na2SiO29H2O: fly ash and silicon powder is equal to 0.29), wherein the doping amount of butyl acrylate-acrylic resin emulsion is 0.5%-3% of the weight of the fly ash and the silicon powder. The fly ash-based inorganic polymer composite cementitious material is prepared by using the sodium silicate for exciting the binary complex fly ash and the silicon powder at room temperature or doping the butyl acrylate-acrylic resin emulsion into the binary complex fly ash and the silicon powder excited by the sodium silicate at the room temperature. The optimal compressive strength at the age of 28 days is improved by 10.43MPa in comparison with a binary complex fly ash-based inorganic polymer, and the flexural strength at the age of 28 days is improved by 2.52MPa. The doping of the butyl acrylate-acrylic resin emulsion can significantly improve the compressive strength and the flexural strength of the fly ash-based inorganic polymer composite cementitious material; and the preparation process is carried out under normal temperature and normal pressure and has the advantages of zero emission, greenness and environmental protection.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

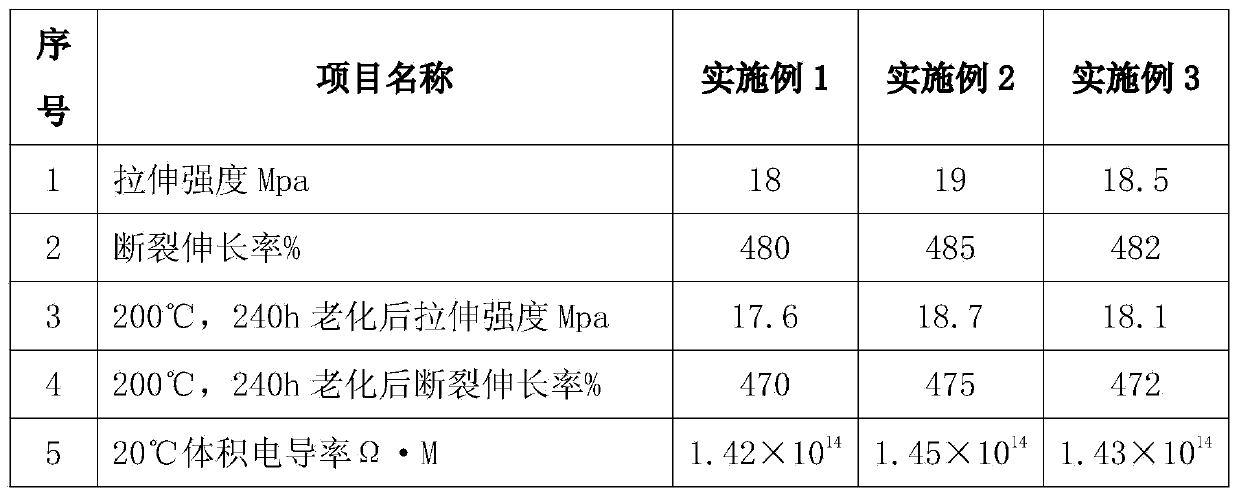

Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

The invention relates to a fluorosilicone rubber cable material for a coal mine cable and a preparation method of the cable material. The cable material comprises the following raw materials: fluorosilicone rubber, methyl vinyl silicone rubber, precipitation-method white carbon black, light calcium carbonate, zinc oxide, magnesium oxide, stearic acid, an accelerator N, N-tetramethylthiuram disulfide, an antiager-2-mercapto benzimidazole, a vulcanizer-2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, a flame retardant-ammonium polyphosphate, diphenyl silanediol, talcum powder and vaseline. According to the cable material, the advantages of the fluorosilicone rubber and the methyl vinyl silicone rubber as raw materials are combined, the performance of a conventional fluorosilicone rubber cable material is improved, the cable material has excellent performances such as friction and collision resistance, high and low temperature resistance, medium resistance, ageing resistance, flame retardance, waterproof and moistureproof properties, long service life and the like, the requirement of safety use in a coal mine in a special environment is met, and the preparation method of the cable material is simple in process and free of environmental pollution and three-waste emission.

Owner:WUXI HUAMEI CABLE

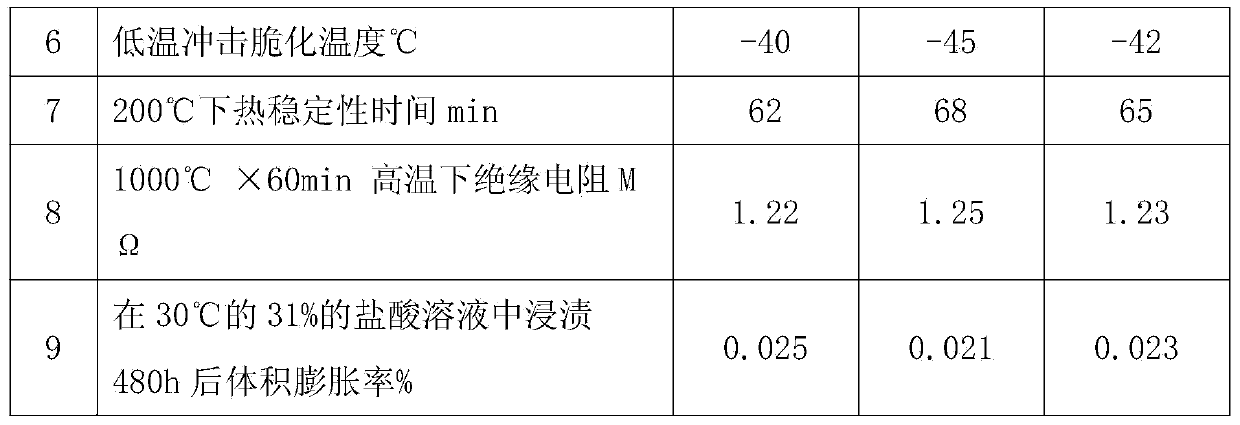

Method for continuously effectively circularly extracting taraxacum rubber and synanthrin from dandelion taraxacumkok-saghyz

ActiveCN103435720AImprove resource utilization efficiencyLow energy and material consumptionResidual biomassPolymer science

The invention relates to a method for continuously effectively circularly extracting taraxacum rubber and synanthrin from dandelion taraxacumkok-saghyz. Taraxacum rubber belongs to a nonpolar substance, synanthrin belongs to a polar substance, and taraxacum rubber and synanthrin are obtained by extraction based on the water-oil separation principle employed by the method of the invention. The extract liquor of taraxacum rubber is subjected to steam distillation for separation of taraxacum rubber, and recycling and reusing of the solvent are realized. The extract liquor of synanthrin is subjected to a spray drying technology for obtaining of refined synanthrin. The final residual biomass residue is subjected to composting and is returned to the field, so that solid pollution is avoided and effective utilization of waste is realized. The method is characterized in that only one organic solvent is employed, and two products of taraxacum rubber and synanthrin are obtained during production. Taraxacum rubber and synanthrin split the cost mutually, and the product price is effectively reduced. The final composting and field returning of the residue help to realize resource utilization maximization. The whole technological process is circulatory, the extraction solvents are utilized circularly, energy consumption and material consumption are substantially decreased, and there are basically no discharged ''three wastes (waste gas, waste water and industrial residue)''.

Owner:BEIJING UNIV OF CHEM TECH +2

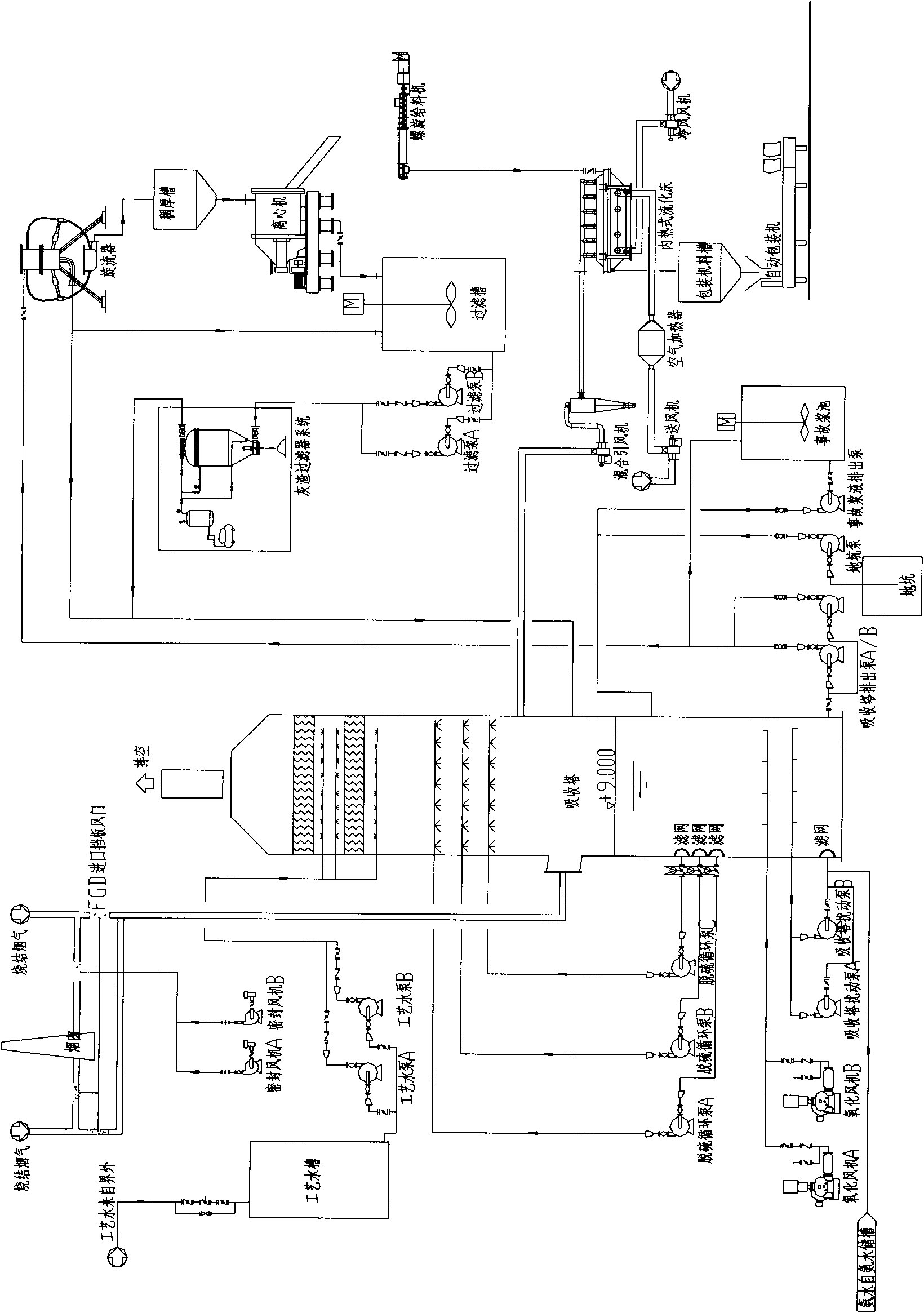

Flue gas desulfurization process suitable for sintering machine of steel mill

InactiveCN101862583AHigh desulfurization rateLow running costDispersed particle separationProcess engineeringSteel mill

The invention discloses process technology suitable for removing a sulfur dioxide byproduct, namely, ammonium sulfate chemical fertilizer in flue gas produced by a sintering machine of a steel mill and suitable for the characteristics of large sintering flue gas amount, large flue temperature fluctuation, high moisture content, high dust content and the like. The process comprises the following steps of: allowing sintering flue gas to enter from the middle of an absorption tower, wherein the flue gas is reversely contacted with absorption liquid; removing sulfur dioxide from the flue gas in a contacting process; exhausting the flue gas through a chimney on the top of the tower after the flue gas flows through a demister on the top of the tower; introducing compressed air and ammonia water into the absorption liquid, wherein ammonium sulfate in solution is saturated and 5 percent of crystal is separated out along with continuous absorbing and oxidizing processes; and rotating, filtering and drying ammonium sulfate crystal-containing suspension to obtain a finished product. Since the absorption, oxidation and condensation of the sintering flue gas are completed in the absorption tower at the same time, the process has the characteristics of refined flow, high desulfurization efficiency and high byproduct quality.

Owner:高翀

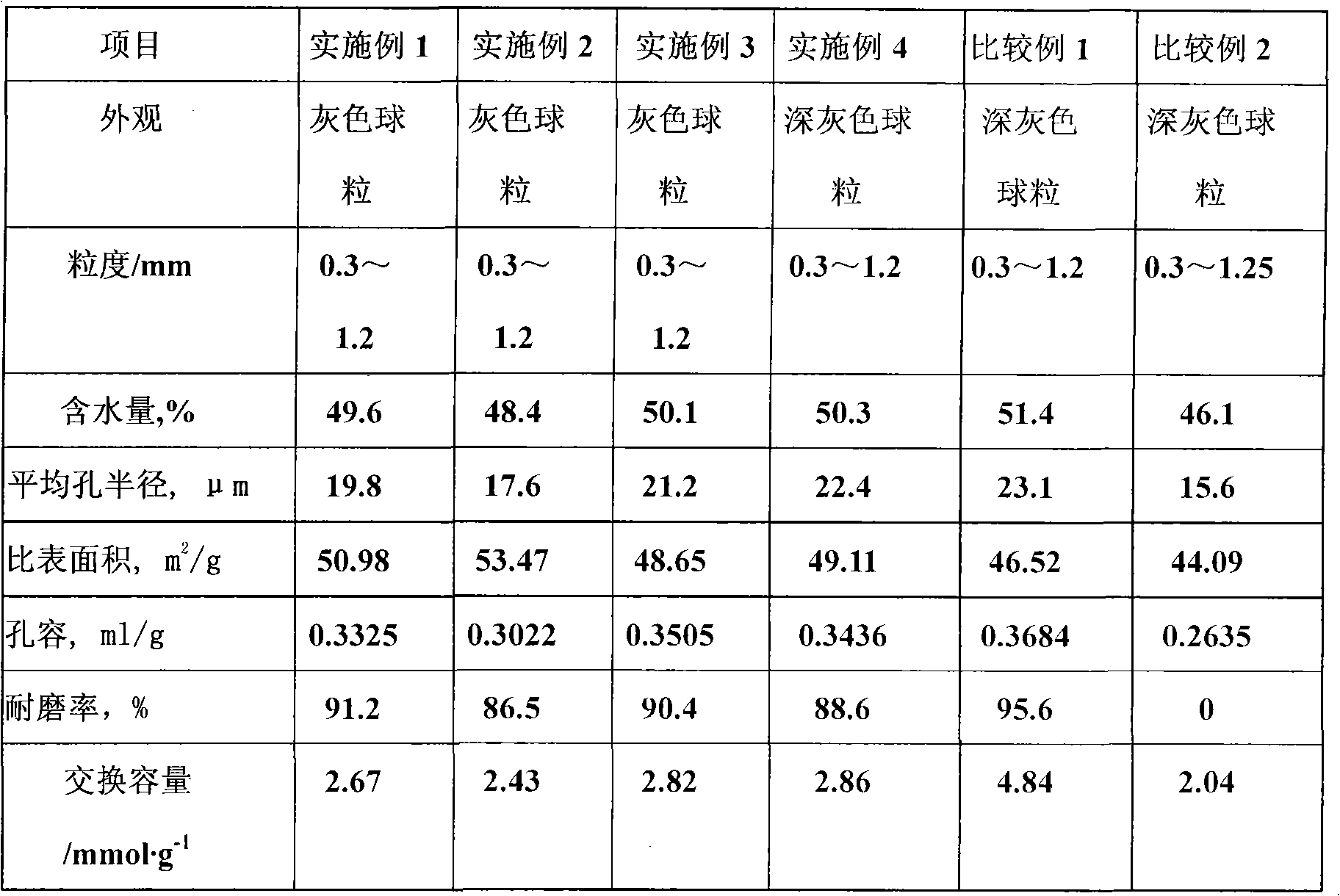

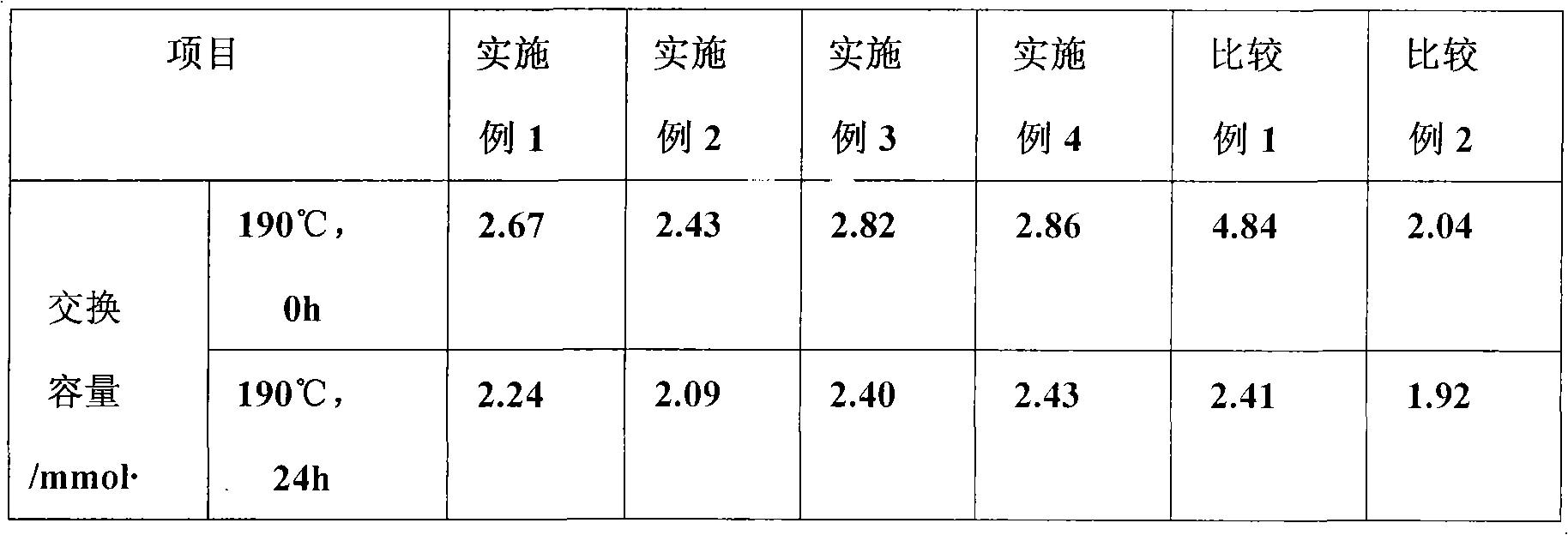

Preparation method for high temperature resistant macroporous cation exchange resin catalyst

ActiveCN102371181AHigh viscosityImprove dispersion stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationDivinylbenzenePorous channel

The present invention provides a preparation method for a high temperature resistant macroporous cation exchange resin catalyst. According to the preparation method, a linear chain saturated acid with carbon atoms of 4-25, any one component selected from a unsaturatcd fatty acid glyceride, or a mixture is adopted as a pore-foaming agent to prepare styrene-divinylbenzene copolymer containing the pore-foaming agent, wherein the mixture comprises two or more components selected from the unsaturatcd fatty acid glyceride; an organic solvent is adopted to extract the pore-foaming agent and low molecular weight impurities in the copolymer; the macroporous polymer is subjected to a halogenating reaction in the presence of a catalyst; the resulting halogenated product is subjected to a sulfonationreaction. According to the present invention, the polarity of the used pore-foaming agent by the preparation method of the present invention is similar to the polarity of the monomer, such that uniform porous channels can be formed during the polymerization process; the used materials by the preparation method of the present invention have characteristics of environmental protection, no toxicity,cheap price and easy availability; during the preparation process of the present invention, only a hydrocarbon solvent with low boiling point and low toxicity is adopted to clean the pore structure, such that the operation is simple and three wastes are not discharged; the pore structure-cleaned styrene-divinylbenzene copolymer is subjected to the halogenation and the sulfonation to obtain the resin catalyst with uniform pore structure, good high temperature resistance and high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of undecylene amido propyl betaine modified diatomite

InactiveCN105642237AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionAlcoholBetaine

The invention discloses a preparation method of undecylene amido propyl betaine modified diatomite. The method is characterized in that after diatomite is treated with 2 mol / L HCL, pretreated diatomite is obtained; the pretreated diatomite is subjected to organic modification by using absolute ethyl alcohol and (3-chloropropyl)trimethoxysilane; then 45%-55% of deionized water and 8%-18% of undecylene amido propyl betaine are added to a reactor in percentage by mass, the mixture is stirred for dissolution, then 28%-38% of organic diatomite is added, the mixture is evenly mixed, 5%-8% of hydrogen peroxide with the mass percentage concentration of 30% is added, the sum of percentages of all components is 100%, the mixture is stirred at the constant temperature of 65 plus / minus 2 DEG C for a reflux reaction for 4-6 h, solid-liquid separation is performed after cooling, separated solids are washed with deionized water until the filtrate is neutral, filtration and drying are performed, and the undecylene amido propyl betaine modified diatomite is obtained. The adsorbent has very high adsorption capacity for oil, has excellent physical and mechanical properties and high regeneration capacity, and capable of being reused, low in cost and environment-friendly.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com