Method and device for removing organic sulfur in methyl tertiary butyl ether (MTBE)

A technology of methyl tertiary butyl ether and thiomethyl tertiary butyl ether, which is applied in the field of methyl tertiary butyl ether desulfurization, can solve the problem of high energy consumption in the production process, high operating temperature and reduced yield of desulfurized MTBE products and other problems, to achieve the effects of no three waste discharge, high yield, and safe and easy-to-control production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

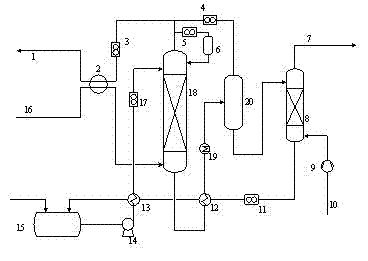

[0016] The sulfur content of the MTBE raw material is 125 μg / g, liquid paraffin is used as the extractant, and the feed volume space velocity is 0.5h -1 , the temperature at the bottom of the tower is 70°C, the temperature at the top of the tower is 65°C, the operating pressure of the extractive distillation tower 18 is 0.12MPa, the reflux ratio of the extractive distillation tower 18 is 0.5, the temperature of the flash tank 20 is 80°C, the residence time of the flash tank 20 is 30min, and the regeneration tower 8 temperature is 80°C, the operating pressure of regeneration tower 8 is 0.08MPa, and the air volume space velocity of regeneration tower 8 is 250h -1 Under the conditions of desulfurization, the desulfurization operation is carried out in the device shown in the attached figure. The sulfur content of the refined MTBE reaches 2μg / g, the desulfurization rate is 98.40%, and the mass yield is 99.97%.

example 2

[0018] The sulfur content of the MTBE raw material is 149μg / g, liquid paraffin is used as the extractant, and the feed volume space velocity is 0.5h -1 , the temperature at the bottom of the tower is 80°C, the temperature at the top of the tower is 73°C, the operating pressure of the extractive distillation tower 18 is 0.13MPa, the reflux ratio of the extractive distillation tower 18 is 1.0, the temperature of the flash tank 20 is 80°C, the residence time of the flash tank 20 is 40min, and the regeneration tower 8 temperature is 80°C, operating pressure of regeneration tower 8 is 0.08MPa, air volume space velocity of regeneration tower 8 is 280h -1 Under the conditions of desulfurization, the desulfurization operation is carried out in the device shown in the attached figure, the sulfur content of the refined MTBE reaches 7μg / g, the desulfurization rate is 95.30%, and the mass yield is 99.98%.

example 3

[0020] The sulfur content of the MTBE raw material is 197μg / g, the extraction agent is sulfolane, and the feed volume space velocity is 0.8h -1 , the temperature at the bottom of the tower is 80°C, the temperature at the top of the tower is 70°C, the operating pressure of the extractive distillation tower 18 is 0.13MPa, the reflux ratio of the extractive distillation tower 18 is 1.5, the temperature of the flash tank 20 is 85°C, the residence time of the flash tank 20 is 30min, and the regeneration tower 8 temperature 85°C, operating pressure of regeneration tower 8 0.09MPa, air volume space velocity of regeneration tower 8 250h -1 Under the conditions of desulfurization, the desulfurization operation is carried out in the device shown in the attached figure. The sulfur content of the refined MTBE reaches 4 μg / g, the desulfurization rate is 97.97%, and the mass yield is 99.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com