Patents

Literature

612results about How to "High desulfurization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrogenation method for producing diesel oil in low sulphur

ActiveCN101092573AHigh activityLow operating pressureRefining to eliminate hetero atomsLiquid productHydrogen

This invention discloses a hydrogenation method for producing low-sulfur diesel oil. The method comprises: mixing base oil with hydrogen, introducing into a hydrogenation reactor to orderly contact hydrogenation protecting agent, hydrorefining catalyst I, hydrorefining catalyst II and freely selected hydrorefining catalyst III for reactions, cooling the effluent, and separating to obtain hydrogen-rich gas and liquid product. With the synergism of the catalysts, the whole catalyst activity is improved. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and low-sulfur diesel oil that can meet Europe III standard and Europe IV standard can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

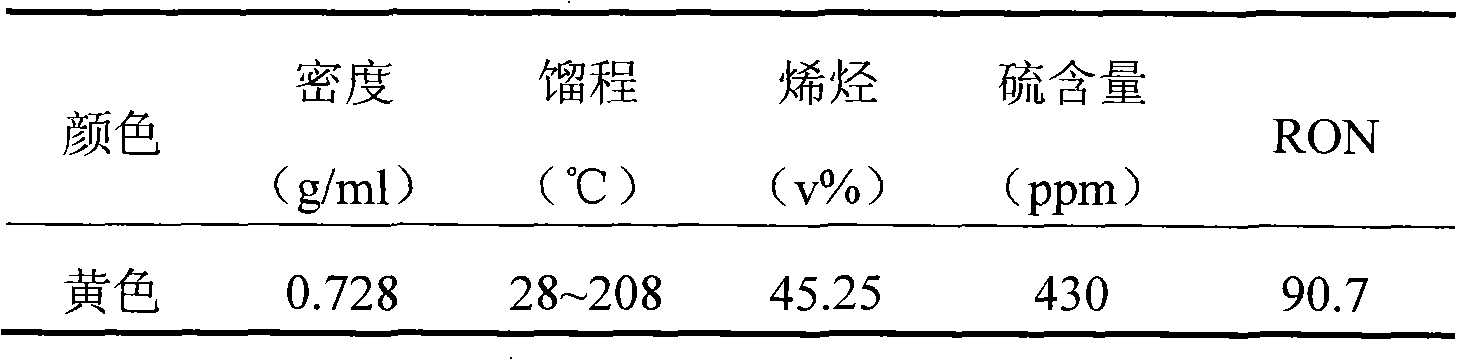

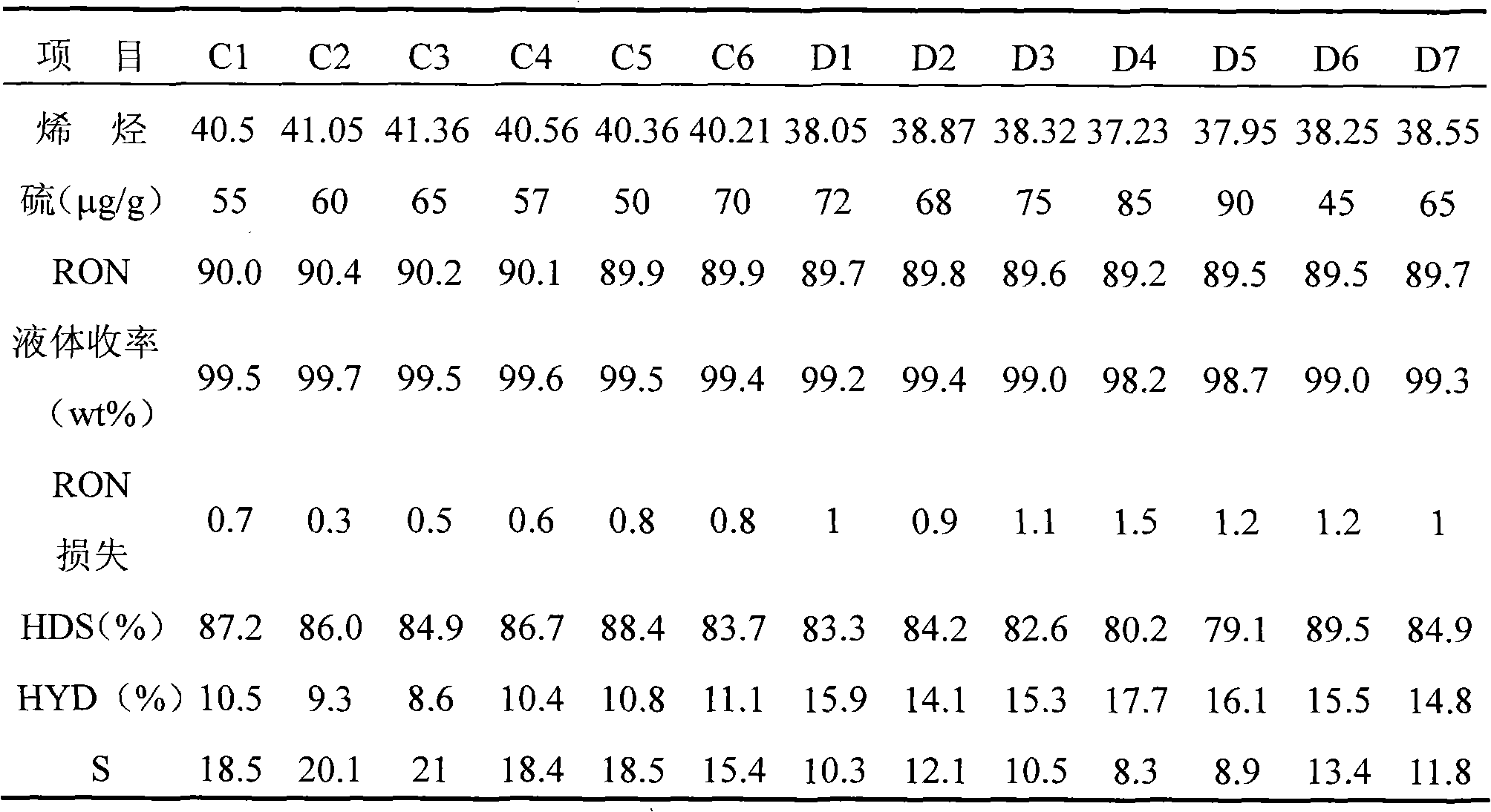

Process for hydrogenating modifying faulty gasoline

ActiveCN1597865ASimple processEasy to operateTreatment with hydrotreatment processesOrganic sulfide compoundIsomerization

The invention provides a process method for making hydrodesulfation and alkene reduction on the bad gasoline, like all-fractional FCC gasoline, etc. Under the conditions of hydrogen gas existence and temperature gradually rising, to contact with three catalysts forms three reaction regions. The first reaction region has lower temperature and uses hydrofining catalyst and mainly eliminates di-alkene in the gasoline; the second reaction region has higher temperature and uses selective hydrodesulfation catalyst and mainly eliminates organic sulfide and some alkenes; the third reaction region has the highest temperature, uses gasoline modifying catalyst and makes the modifying reactions including aromatization, isomerization and benzene alkylation, increasing octane number of gasoline and improving product quality. It has the advantages of simple flow, being easy to operate, fully using reaction heat, prolonging the operating cycle of catalyst, high liquid yield, low hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

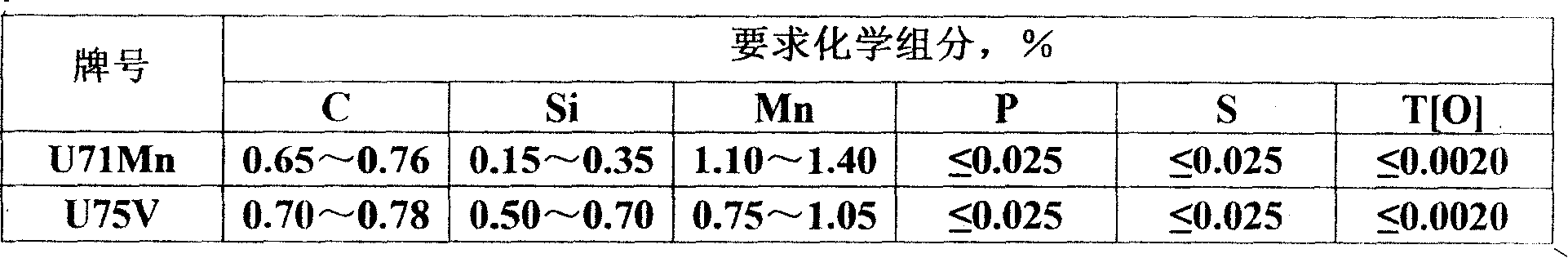

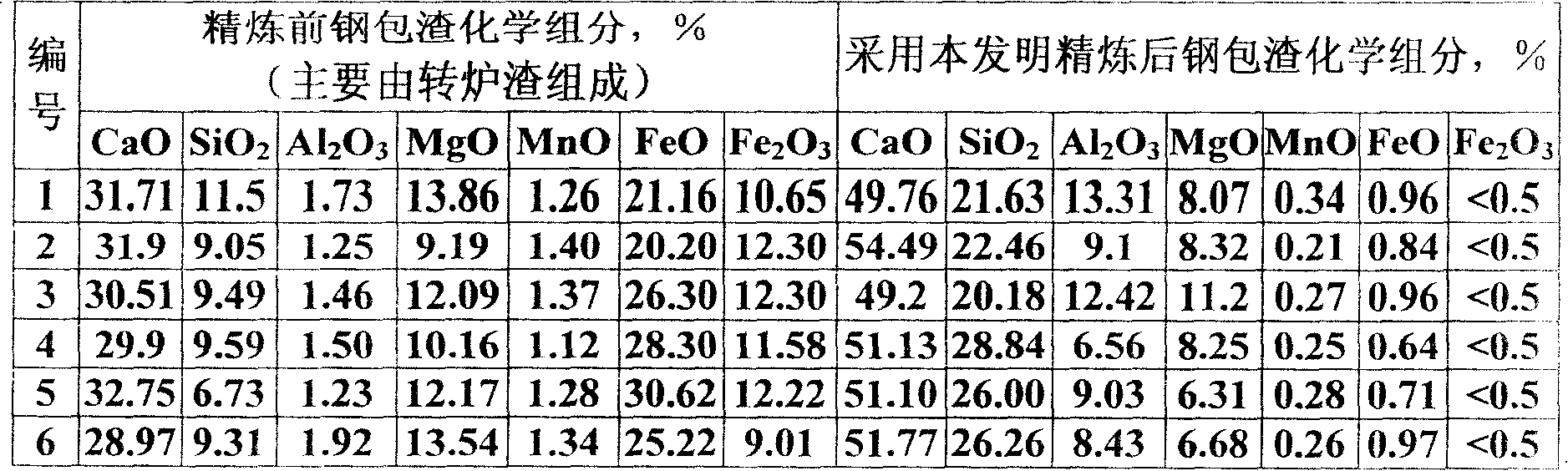

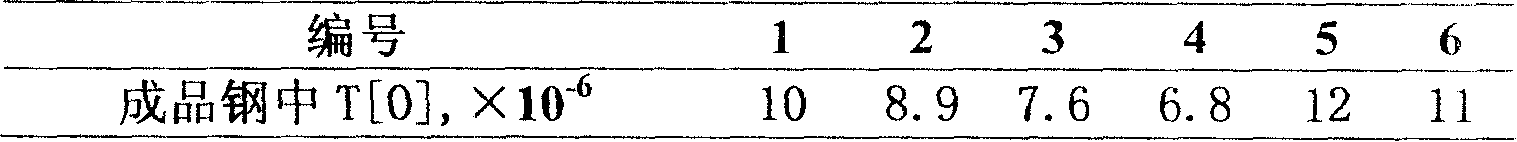

Multifunctional composite refining agent for steel-smelting

The invention provides a multi-functional refining agent which can effectively control inclusion in steel. The refining agent consists of CaO, CaC2, SiC, Na2CO3, C, CaF2 and BaCaSi alloy, wherein the weight percentage of the refining agent is: 30-60 percent of the CaO: 5-15 percent of the CaC2: 5-15 percent of the SiC: 5-15 percent of the Na2CO3: 5-15 percent of the CaCO3: 5-15 percent of the CaF2: 2-10 percent of the BaCaSi: 2-10 percent of the C; the melting point is less than or equal to 1400 DEG C. The refining agent has the functions of wiping off the inclusion in the steel, expanding foam for submerged arc and removing sulfur. After being matched with the complex refining agent, the T(O) in finished steel is declined to the range of 5 multiplied by 10<-6> to 15 multiplied by 10<-6>, and the evaluation grade of the inclusion of B, C and D class is less than 1.0 grade with good sulfur removal effect as well.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

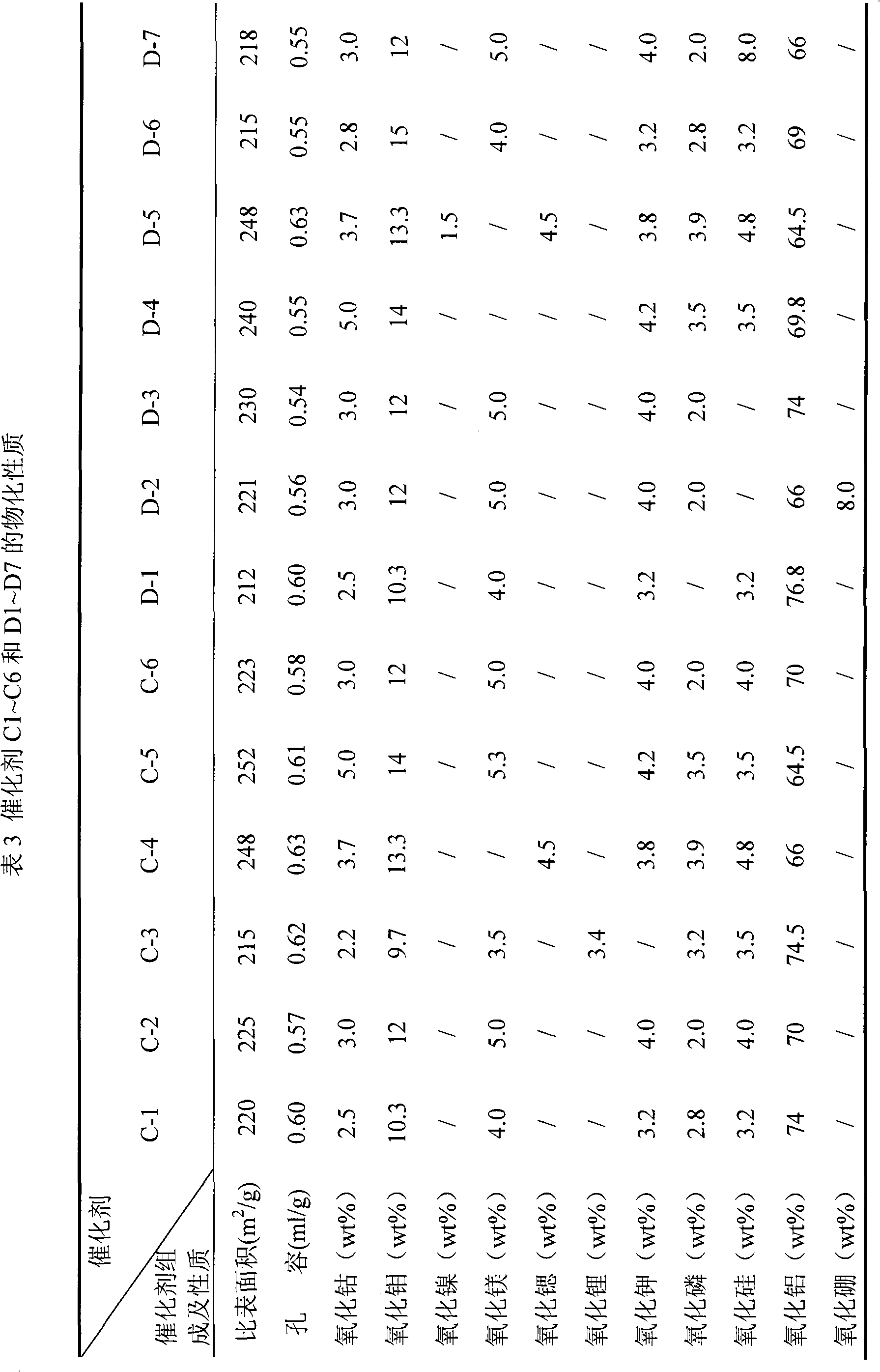

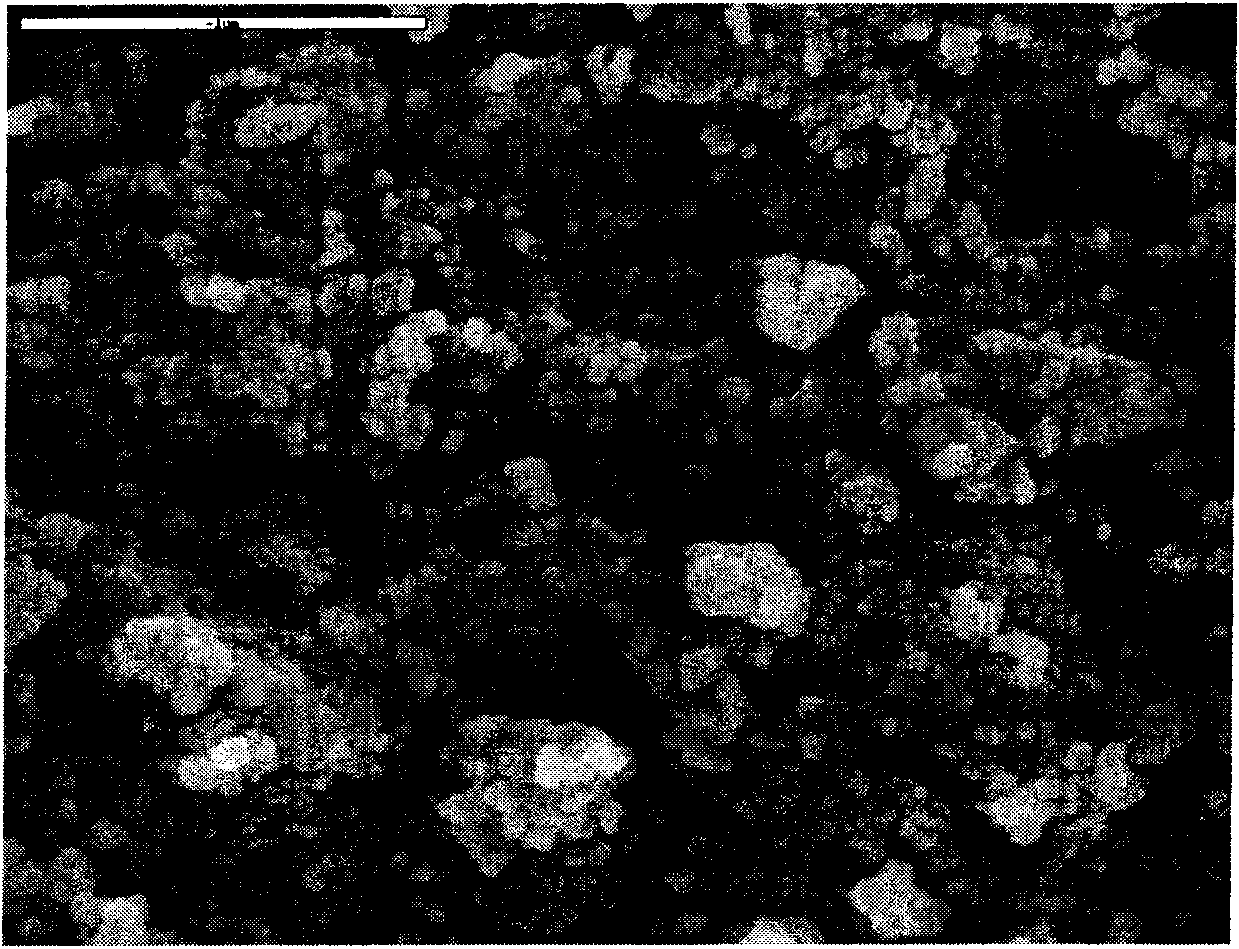

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Smoke desulphurization agent and smoke desulphurization method

ActiveCN101721884AHigh desulfurization rateReduce absorptionDispersed particle separationAbsorption capacityDesorption

The invention provides a smoke desulphurization agent. The desulphurization agent is aqueous solution containing a main absorption component, an activating agent, an anti-oxidation component and acid, wherein the main absorption component is one or more of alkyl piperazine, hydroxyalkyl piperazine and hydroxyalkyl piperazine ketone; the activating agent comprises piperazine and diazabicyclo; and the anti-oxidation component is at least one of 4-tert-butyl catechol, 2,6-di-tert-butyl-p-phenylcresol, acetone oxime and N,N-bi (2-ethoxy) glycine. The smoke desulphurization agent provided by the invention can remove and reclaim sulfur dioxide in the smoke, and has higher desulphurization rate; moreover, even if the smoke desulphurization agent is strongly oxidized and then is recycled, the absorption capacity for the sulfur dioxide is still stable; and in addition, the rich liquor formed by desulphurization after adopting the desulphurization agent has better desorption performance such as high desorption rate.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

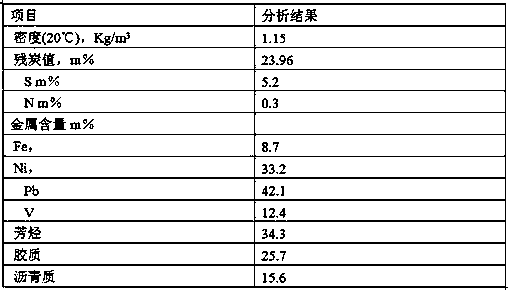

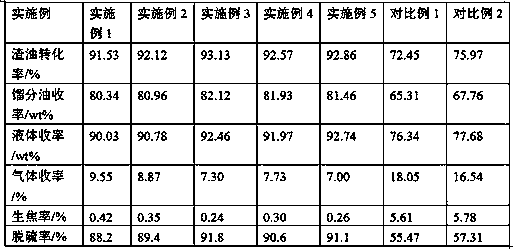

Suspended bed hydrocracking catalyst and preparation method

ActiveCN107754818AStrong focusing abilityHigh yieldPhysical/chemical process catalystsHydrocarbon oil crackingSulfurNitrogen

The invention discloses a suspended bed hydrocracking catalyst and a preparation method thereof. The suspended bed hydrocracking catalyst comprises a sulfurized bauxite and zinc oxide, wherein the content of the zinc oxide is 1.0-50.0wt%; the suspended bed hydrocracking catalyst can be prepared by dryly mixing the sulfurized bauxite and the zinc oxide. The suspended bed hydrocracking catalyst is high in conversion rate, low in coking rate, high in desulfurization rate and strong in capability of resisting sulfur, metal, nitrogen, residual charcoal and other impurities, and is applied to a suspension bed hydrocracking reaction of poor-quality heavy oil.

Owner:FUZHOU UNIV

Heavy oil suspended bed hydro-cracking catalyst and preparation method thereof

ActiveCN107754820AStrong focusing abilityHigh yieldPhysical/chemical process catalystsHydrocarbon oil crackingSulfurFuel oil

The invention discloses a heavy oil suspended bed hydro-cracking catalyst. The catalyst comprises 15.0-55.0 percent by weight of vulcanized kaolin powder, 10.0-65.0 percent by weight of zinc oxide powder and 1.0-25.0 percent by weight of vulcanized molybdenum-containing compound powder; and the catalyst can be prepared by dry-blending the vulcanized kaolin powder, the vulcanized molybdenum-containing compound powder and the zinc oxide powder. In addition, the catalyst disclosed by the invention can also comprise vulcanized lanthanum ferrite. The prepared catalyst is used for the suspended bedhydro-cracking reaction of inferior heavy oil, is low in coke yield, high in liquid yield and desulfurization rate and strong in resistance to sulfur, colloids and other impurities.

Owner:FUZHOU UNIV

Hydrodesulfurization method of gasoline

InactiveCN106867576AAdaptableHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrodesulfurization

The invention discloses a hydrodesulfurization method of gasoline. The method adopts a fixed bed reactor. The catalyst is a loaded cobalt molybdenum catalyst, the hydrodesulfurization process conditions are: a reaction temperature of 190-310DEG C, a reaction pressure of 1.3-2.6MPa, a volume space velocity of 1.3-3.5h<-1>, and a hydrogen-to-oil volume ratio of 180-400:1. The hydrodesulfurization method provided by the invention has the advantages of mild process conditions, strong adaptability to different raw materials, low octane value and high desulfurization rate.

Owner:QINZHOU UNIV

Heavy oil hydrogenation processing catalyst and method for preparing same

ActiveCN101618326AHigh desulfurization rateImprove carbon removal rateMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsFuel oilPore diameter

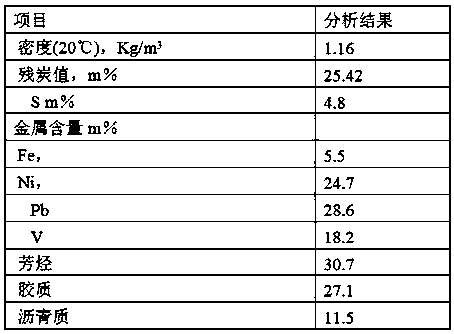

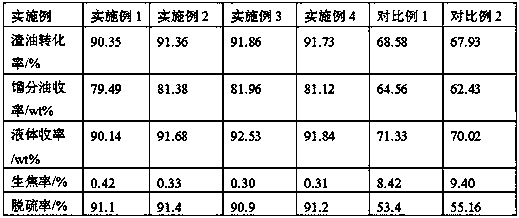

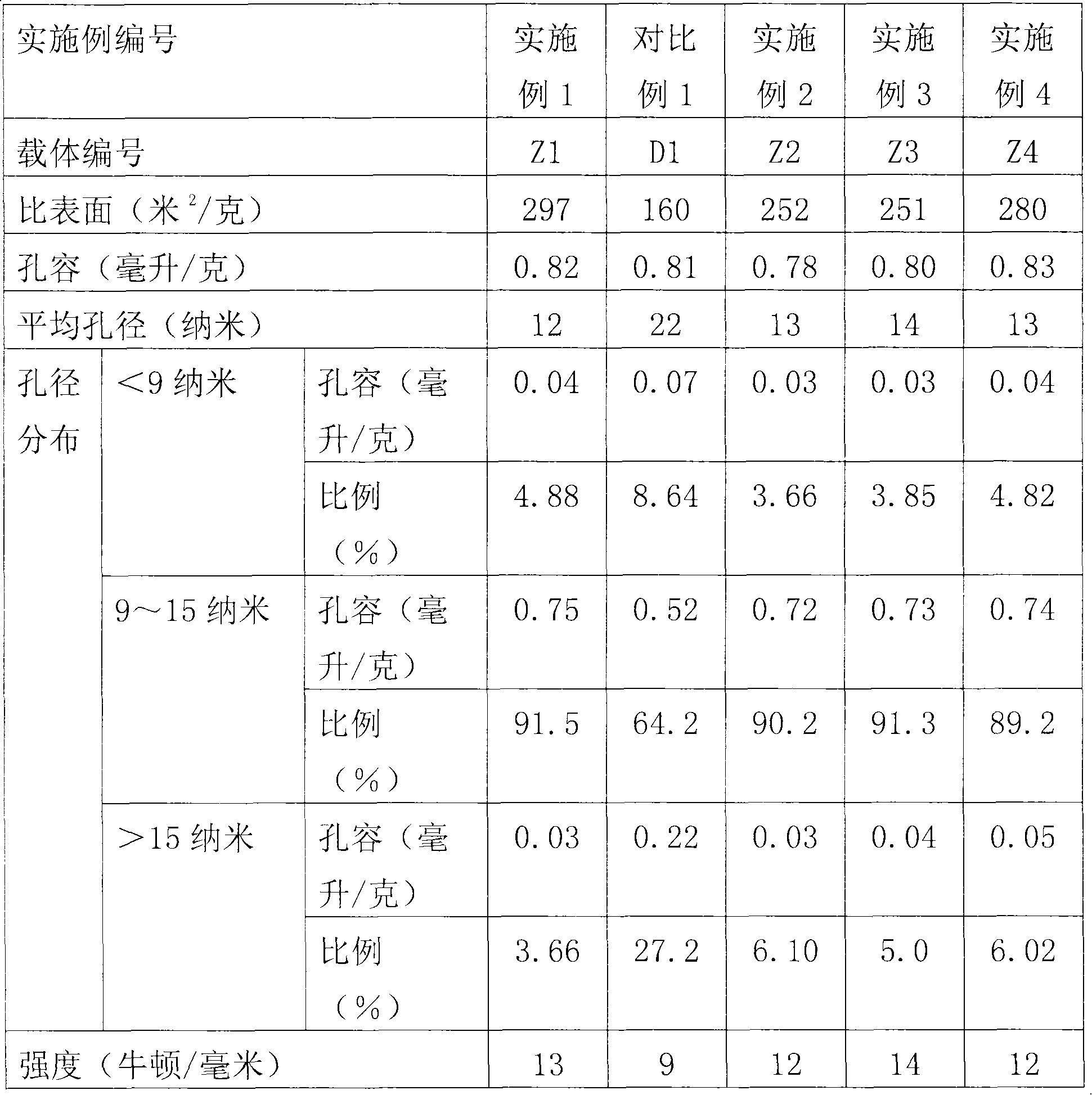

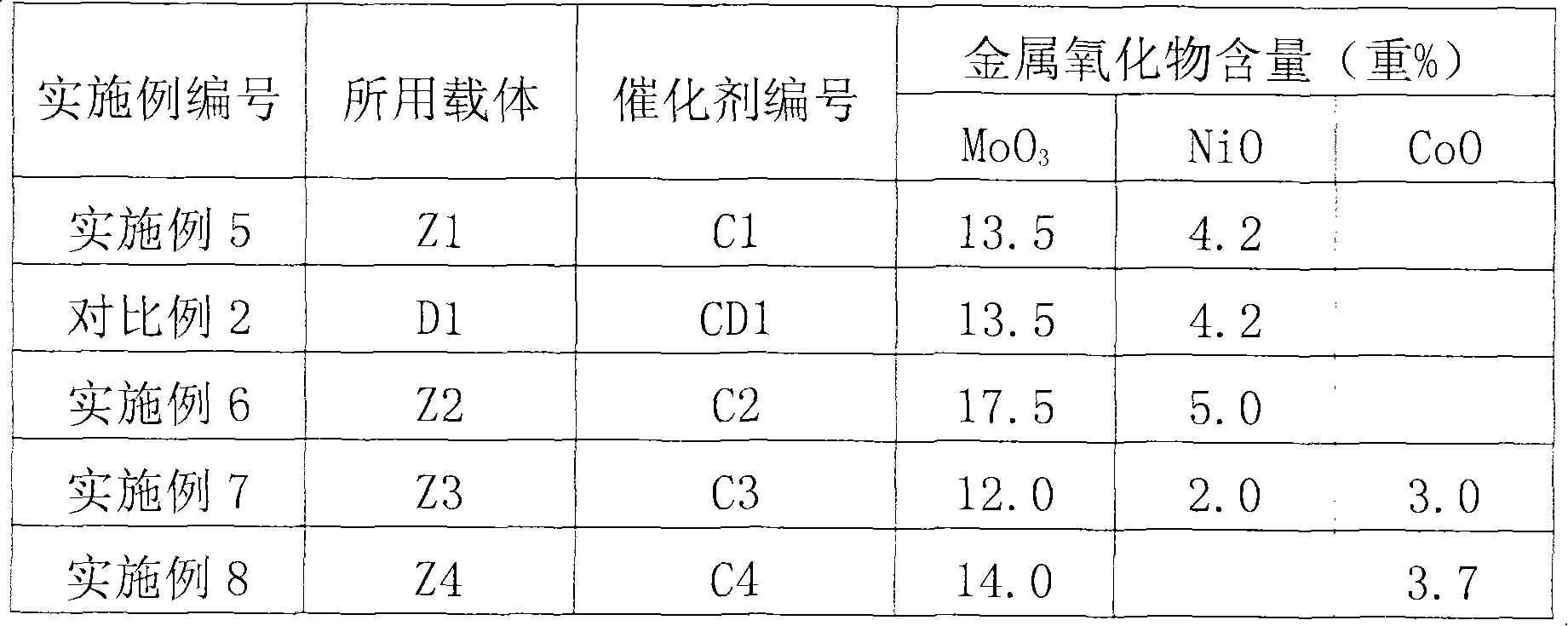

The invention provides a heavy oil hydrogenation processing catalyst and a method for preparing the same. The catalyst comprises a carrier, at least one metal component selected from the VIII group and at least one metal component selected from the VIB group. The catalyst is characterized in that: the pore volume of the carrier is between 0.6 and 1.2ml / g, the specific surface of the carrier is between 200 and 380m<2> / g, the average pore diameter of the carrier is between 11 and 14nm, and the pore volume of the pores of which the pore diameter is between 9 and 15nm is 80 to 95 percent of the total pore volume. The method for preparing the carrier comprises the step of forming, drying and baking a precursor of aluminum oxide, wherein the baking conditions comprise that the precursor is baked for 0.5 to 2 hours at a temperature of between 350 and 400 DEG C, and for 1 to 6 hours at a temperature of between 600 and 800 DEG C. Compared with the catalyst provided by the prior art, the catalyst of the invention has high demetalization activity as well as excellent desulfuration and carbon residue removal properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

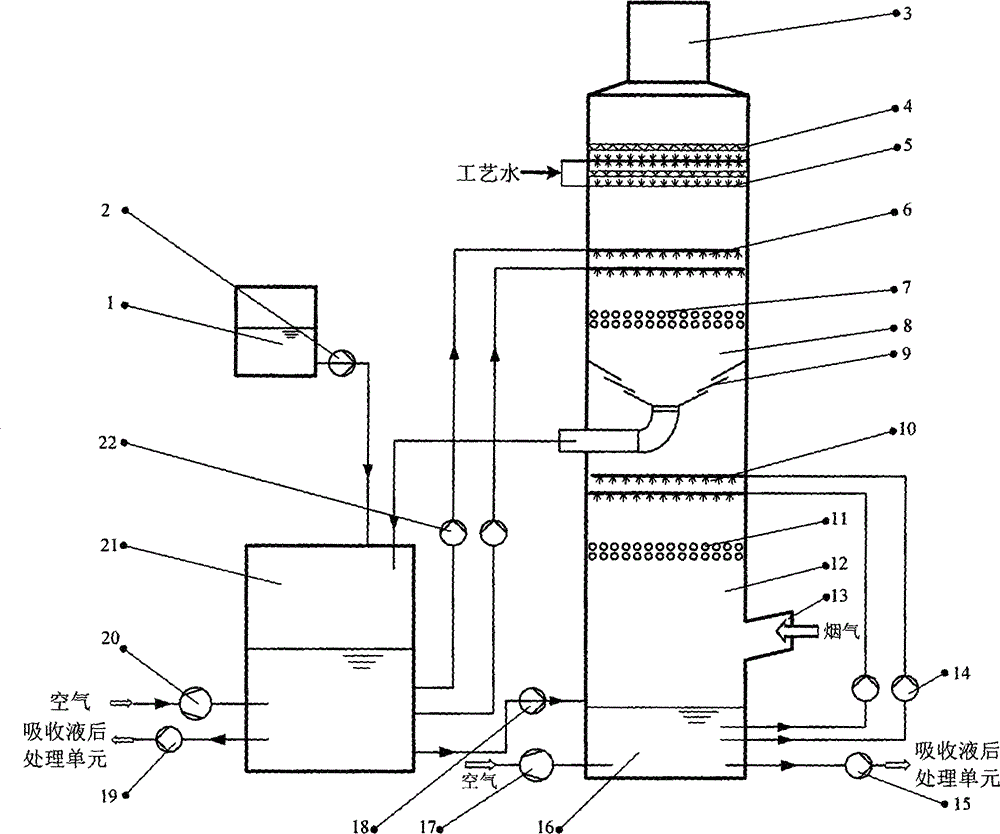

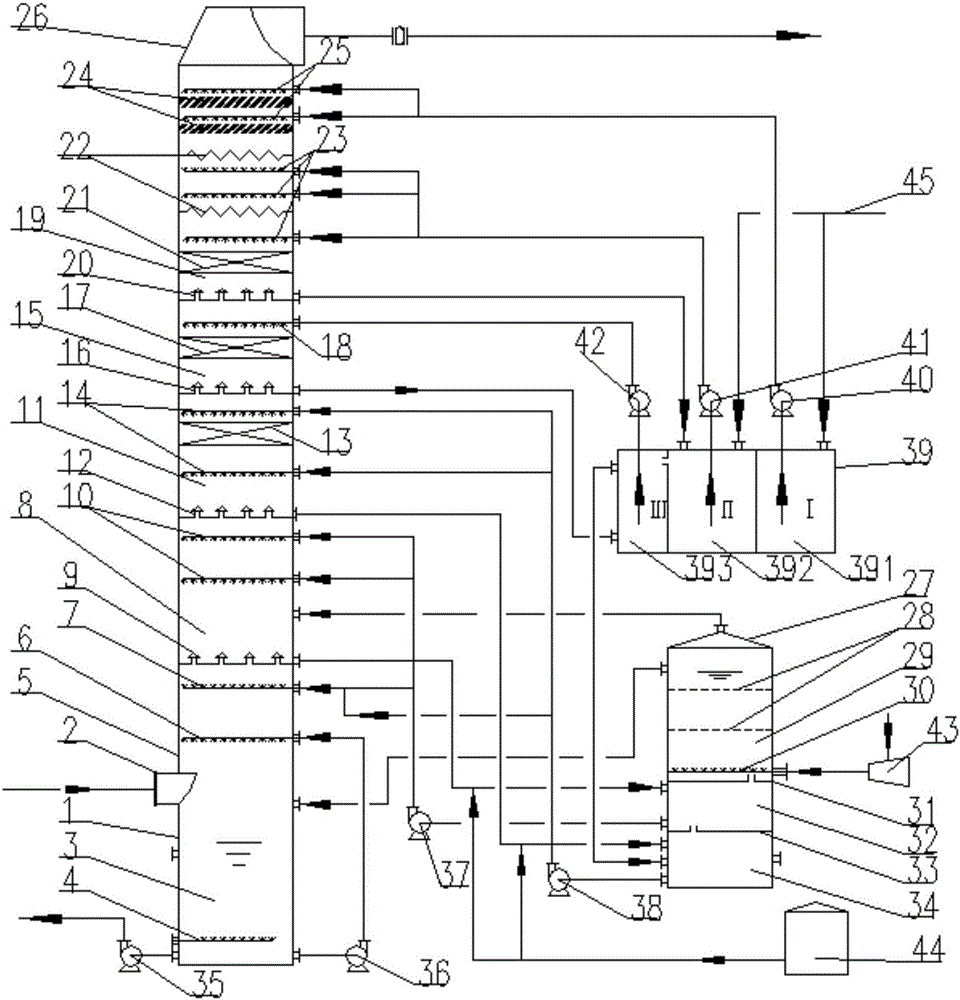

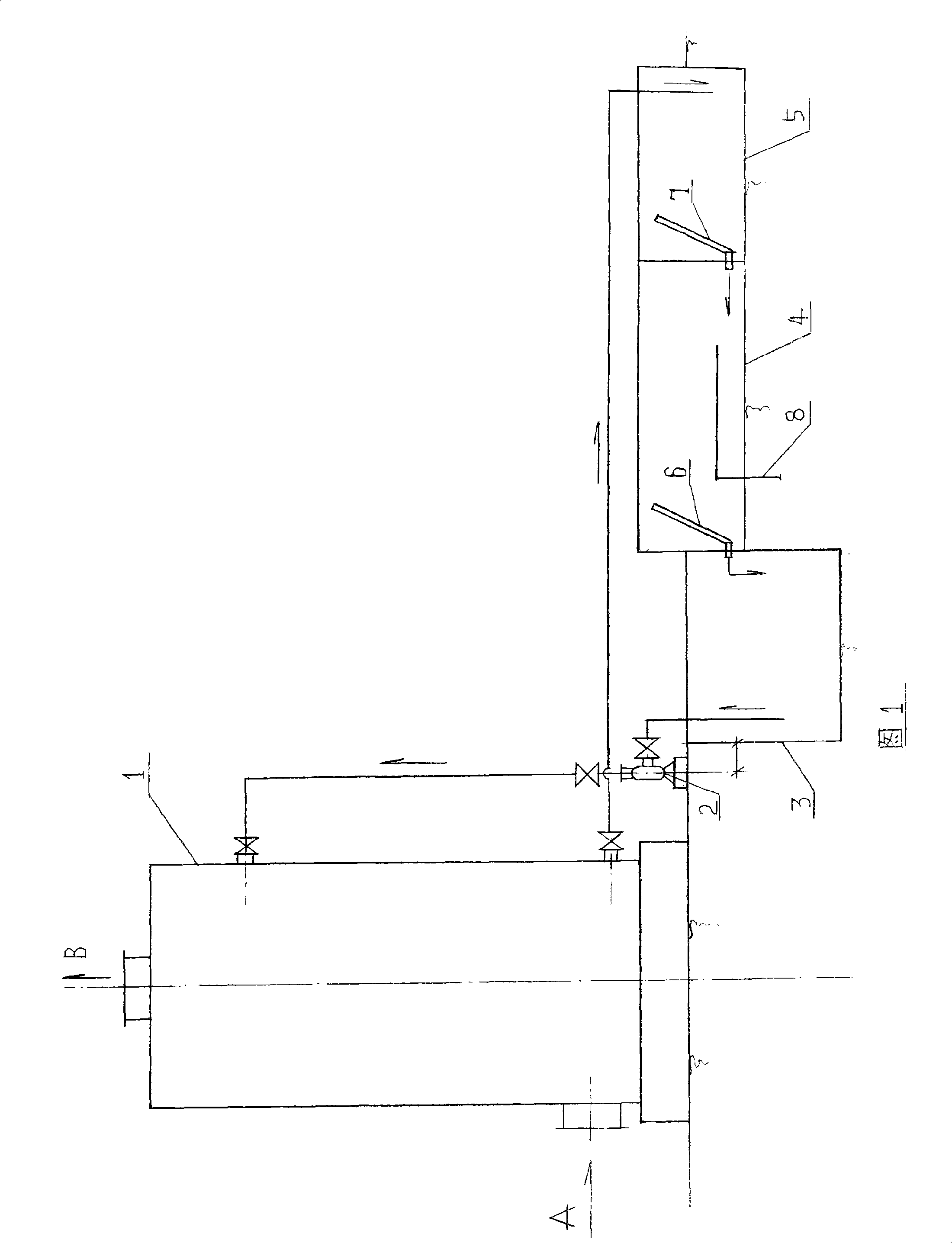

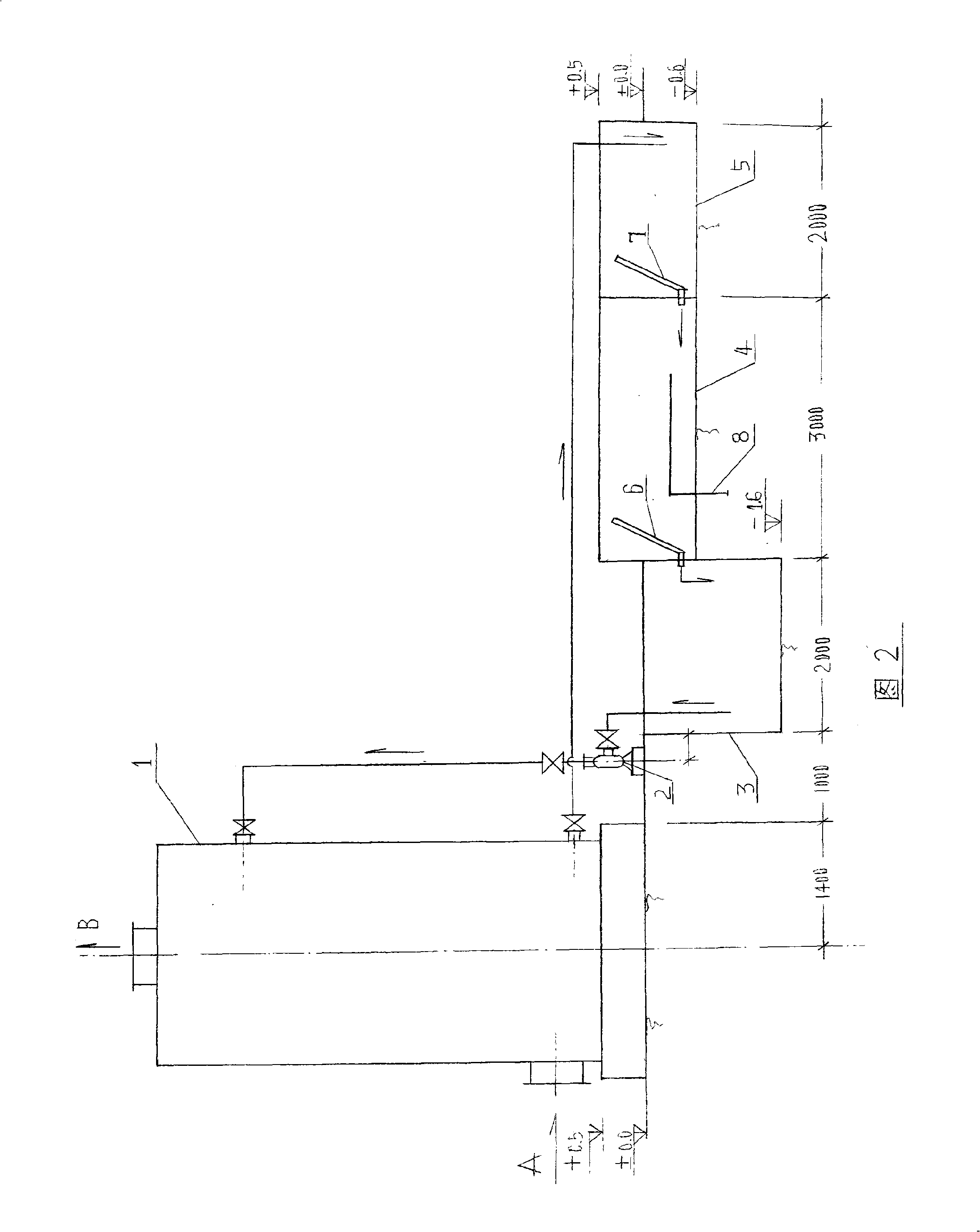

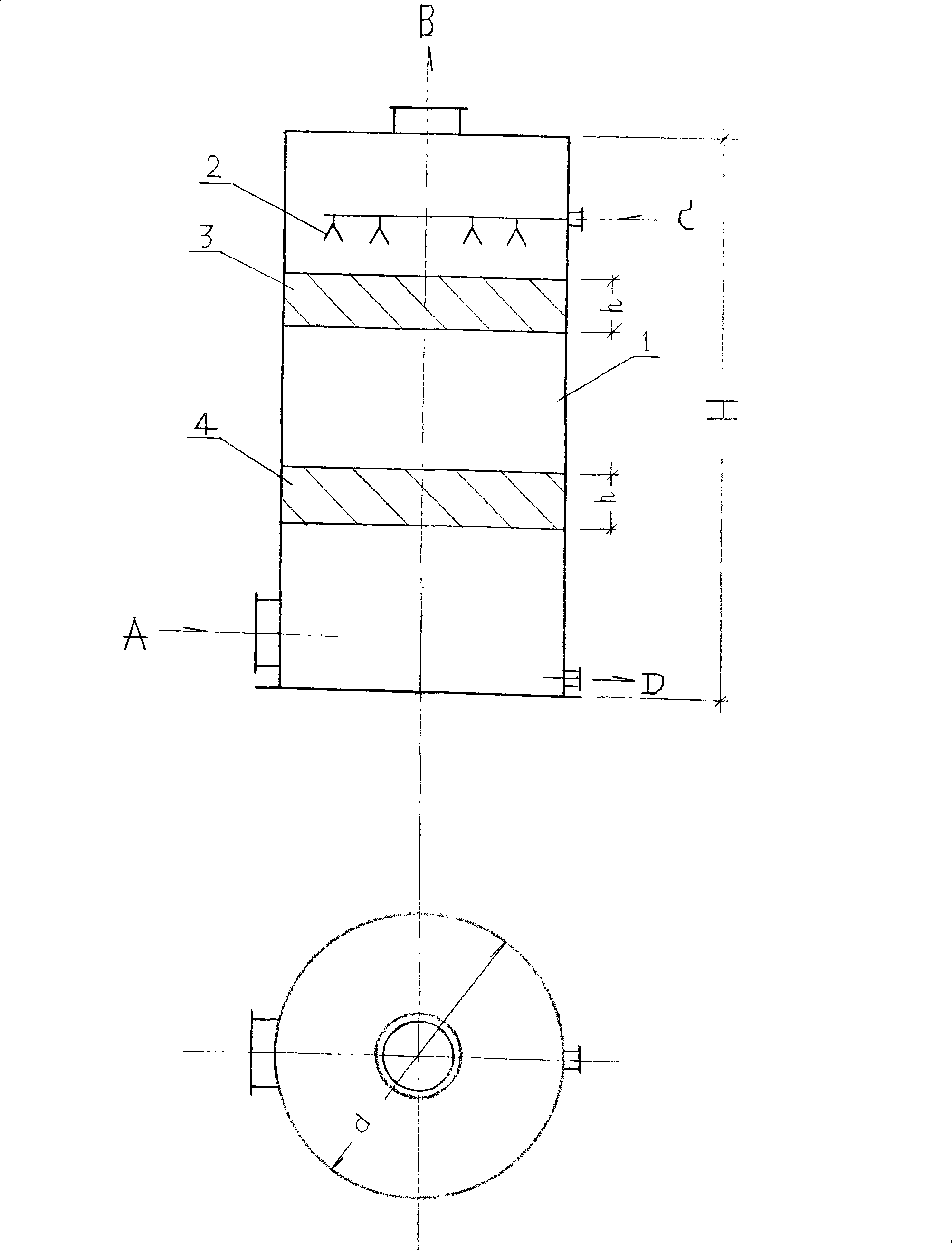

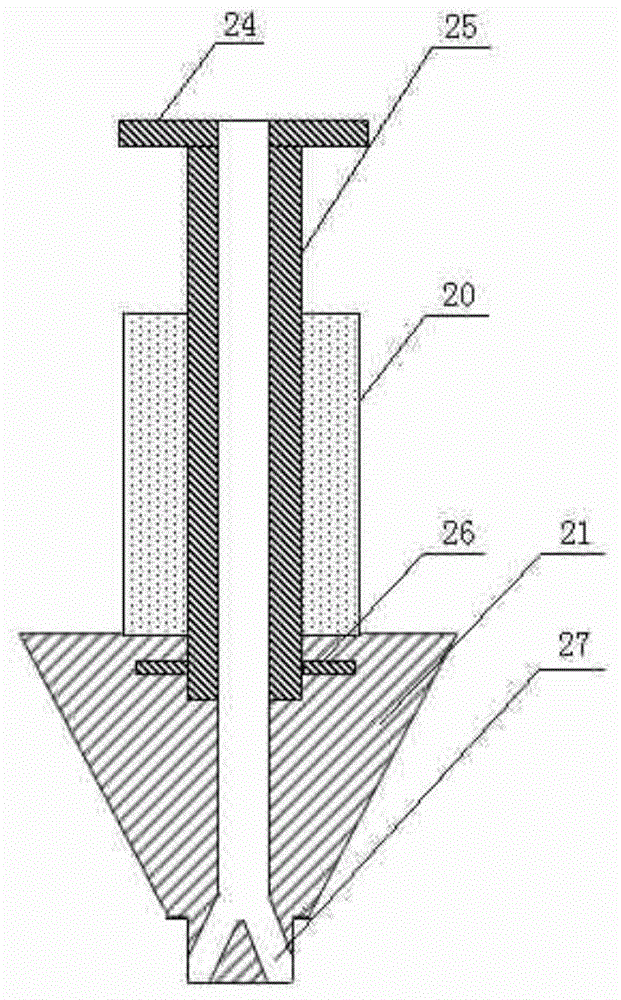

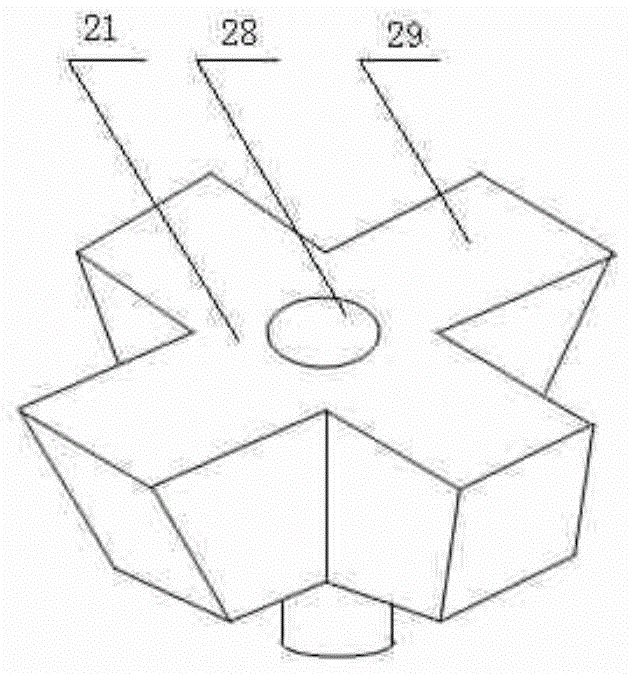

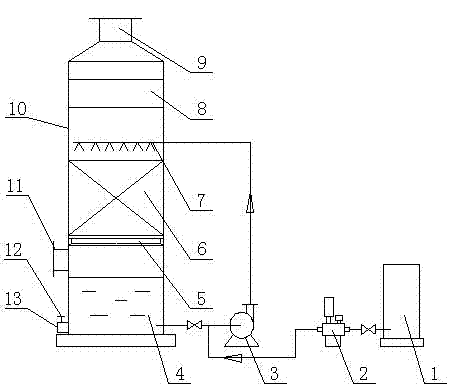

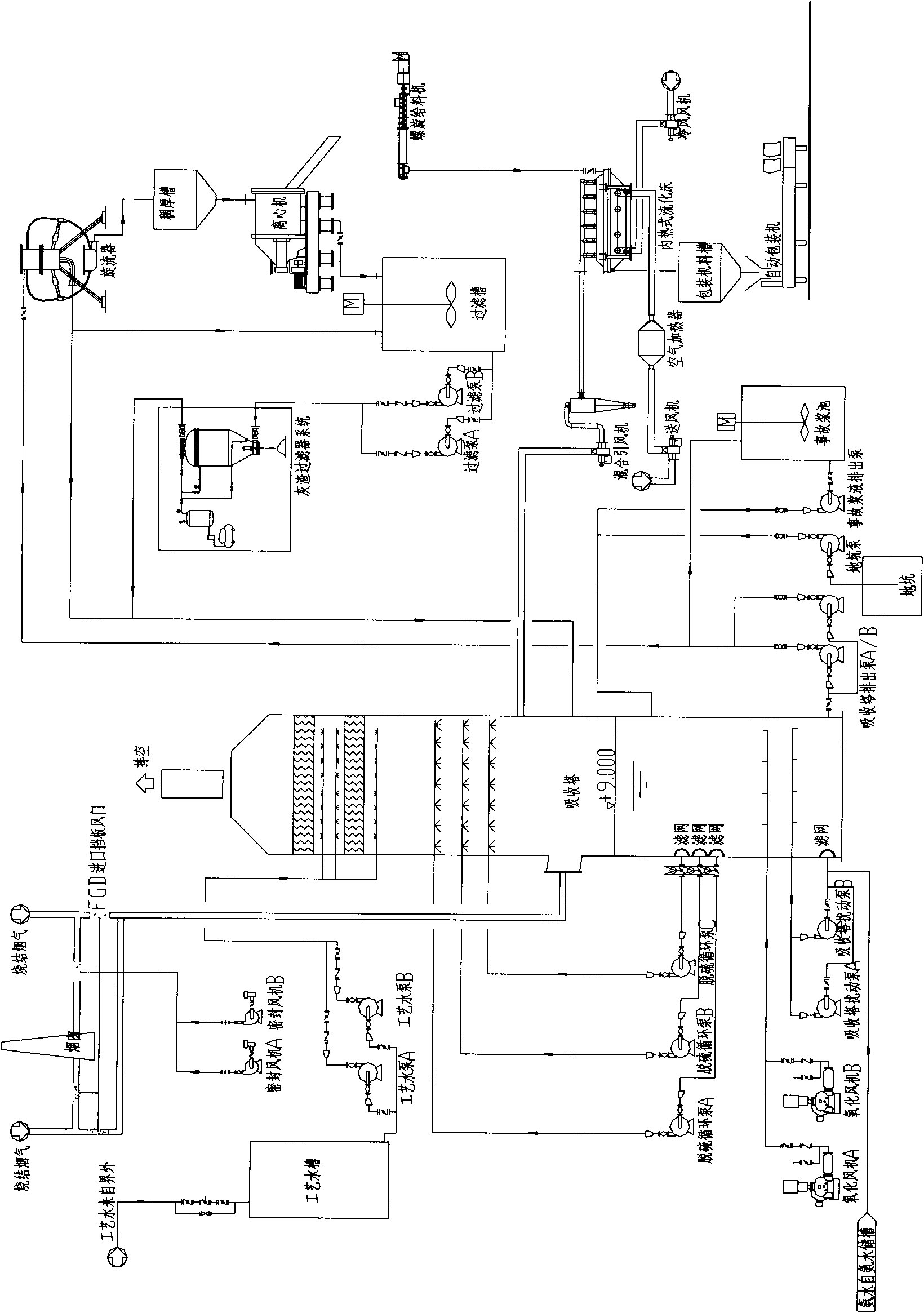

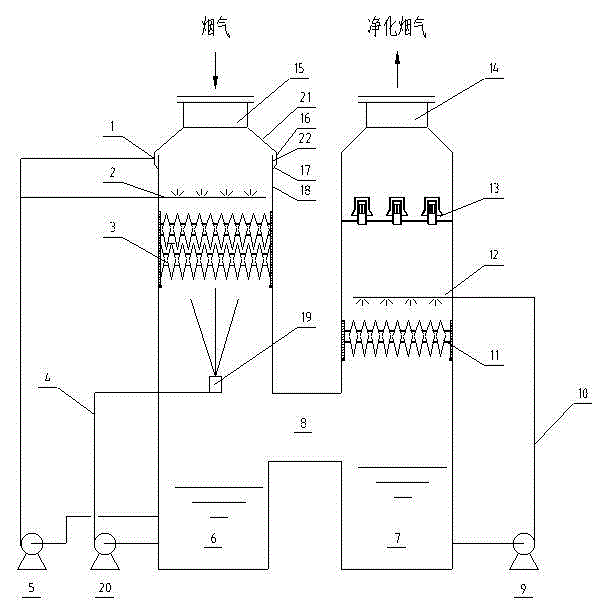

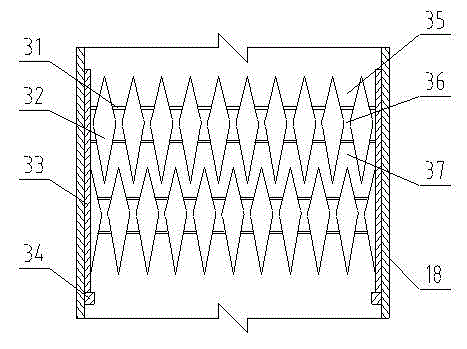

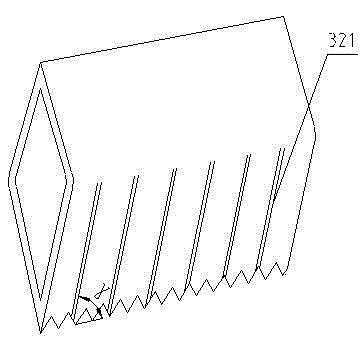

Flue gas dust removal desulphurization system of double-circulation Venturi rod tower

The invention belongs to the field of environment protection, and discloses a wet-method flue gas dust removal desulphurization system of a double-circulation Venturi rod tower. The system comprises an adsorption-liquid supplying unit, a flue-gas purification unit and an adsorption-liquid postprocessing unit. The flue-gas purification unit comprises an upper Venturi rod tower section, a lower Venturi rod tower section, a shutter-type separation cone separating the upper Venturi rod tower section and the lower Venturi rod tower section, an upper circulation liquid pool, a lower circulation liquid pool, upper circulation-liquid sprayers, lower circulation-liquid sprayers, and demisters. Flue gas in the upper tower section and flue gas in the lower tower section are in series connection. A circulation-liquid spraying system is operated independently. Dust removal and desulphurization are separately optimized and performed. The "homogenization" gas flow distribution, "gas in liquid" efficient mass transfer, highly-turbulent "self-cleaning", and other effects of Venturi rod layers are fully utilized by the system so as to perform efficient cooling, dust removal desulphurization of the flue gas. The system is advantages by high dust removal desulphurization efficiency, low operation liquid gas ratio, small resistance, less scale, small occupation area, low investment, low operation energy consumption, less discharge of high-salt water, and the like, and is suitable for dust removal and desulphurization for various kinds of flue gas, particularly suitable for processing of high-temperature high-dust high-sulfur flue gas such as regenerated flue gas of a petroleum catalytic cracking device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydrogenation method for producing clean diesel oil

The present invention relates to a hydrogenation method for producing clean diesel oil, after the raw material oil is mixed with circulating hydrogen, the mixture enters into a second hydrogenating reactor area, under the action of hydrogenation refining catalyst, the reaction is performed, after the reaction effusion is cooled, separated and fractionated, naphtha distillate, light diesel oil distillate and heavy diesel oil distillate are got, after a part or whole heavy diesel oil distillate is mixed with new hydrogen, the mixture enters into a first hydrogenating reactor area, and contacts with the hydrogenating reforming catalyst to perform reaction, the reactant enters into the second hydrogenating reactor area directly without separation, the left heavy diesel oil distillate and the light diesel oil distillate are mixed to get the diesel oil product. The adoption method of the present invention can treat high sulpher, high nitrogen and high drying point diesel oil distillate, under the relaxer operation condition, 2 type and 3 type of standard clean diesel oil which meet the requirement of the World Fuel Oil Code can be got. The present invention has simple flow and low operation pressure, the investment for equipments and the operation cost are all comparatively lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

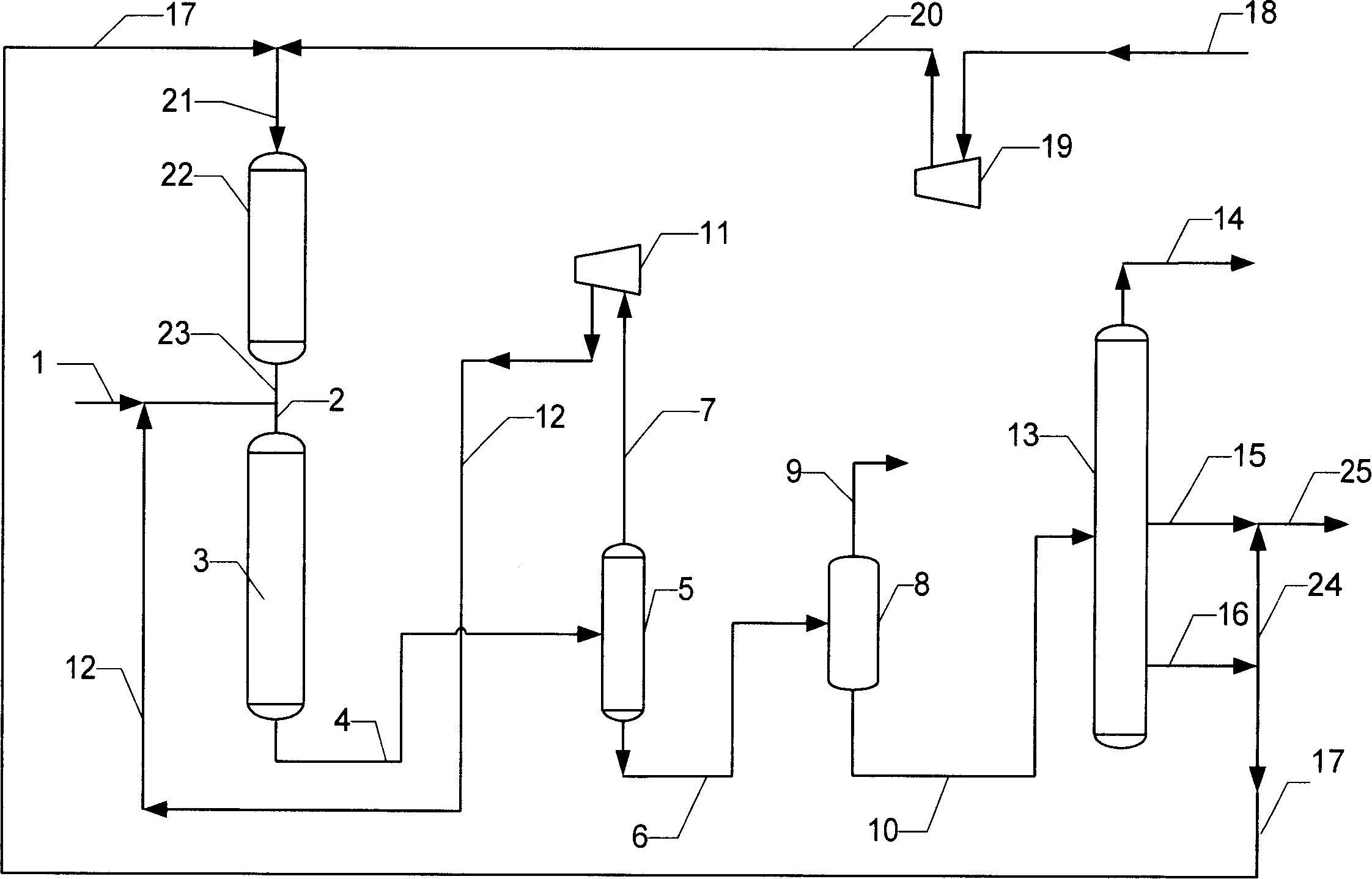

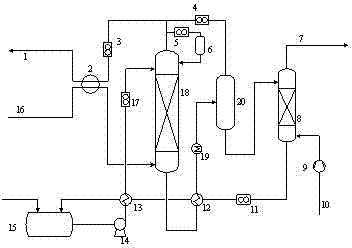

Method and device for removing organic sulfur in methyl tertiary butyl ether (MTBE)

InactiveCN102381945AHigh yieldHigh desulfurization rateEther separation/purificationTowerMethyl tert-butyl ether

The invention relates to a method and a device for removing organic sulfur in methyl tertiary butyl ether (MTBE). The method and the device are utilized for high-sulfur content MTBE refinement. The method and the device realize normal-pressure low-temperature extraction rectification desulphurization of a high-sulfur content MTBE product. A technical scheme of the invention comprises the following steps that 1, a sulfur-containing MTBE product is heated by a heat exchanger and then is fed into a rectifying tower from a lower part of the rectifying tower; 2, an extractant is fed into the heat exchanger, is heated and then is fed into the rectifying tower from an upper part of the rectifying tower, wherein a rectifying tower temperature is in a range of 70 to 80 DEG C and the heated sulfur-containing MTBE product and the heated extractant countercurrently contact with each other so that countercurrent contact extraction desulphurization is realized; 3, the desulfurated MTBE product is output from the top of the rectifying tower, is subjected to cooling condensation to form liquid in the heat exchanger and then is output; and 4, the sulfur-containing extractant obtained by the step 2is output from the bottom of the rectifying tower, is heated by the heat exchanger, is fed into a flash tank, is distilled at a temperature of 80 to 85 DEG C so that the residual desulfurated MTBE product is distilled off, then is fed into an actifier column, and countercurrently contacts with dry air in the actifier column so that countercurrent contact gas stripping regeneration is realized. Through the method and the device, good desulphurization effects are realized; a high product yield is obtained; and an extractant can be regenerated for recycle. The method is convenient for operation,has low costs and low energy consumption, and can be utilized for high-sulfur content MTBE product refinement.

Owner:SOUTHWEST PETROLEUM UNIV

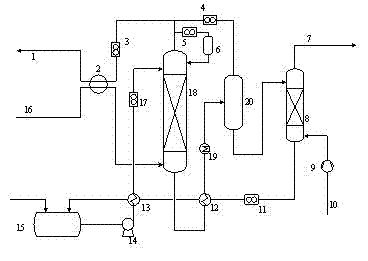

Ultralow emission method and device for split-type flue gas desulfurization and dust removal

InactiveCN105727699ALower the altitudeHigh desulfurization rateGas treatmentUsing liquid separation agentModel selectionFlue gas

The invention discloses an ultralow emission method and device for split-type flue gas desulfurization and dust removal.The device comprises a desulfurization tower and an oxidization circulation tank arranged outside the desulfurization tower.The desulfurization tower and the oxidization circulation tank are connected through a pipeline.A hydromechanical combined super demister is arranged at the top of the desulfurization tower.The ultralow emission method and device for split-type flue gas desulfurization and dust removal have the advantages that the desulfurization efficiency is high (>=99%), and the adaptability to coal types and boiler load changes is high; each stage of absorption and circulation are relatively independent, the density and pH value of absorption liquid are controlled in a partitioned mode, the output of aerosol is controlled in the process, the system ammonia escape is low (<2.5 mg / Nm<3>), and the concentration of emitted particles is low (<5 mg / Nm<3>); the specific humidity electrostatic-demisting energy consumption is low, and sewage treatment is omitted; the desulfurization tower and the oxidization circulation tank are separately arranged, and thus the tower height can be reduced; the system resistance of the device is small (<2000 Pa), reasonable equipment model selection can be carried out according to different conditions of flue gas, and thus investment and energy consumption are reduced.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

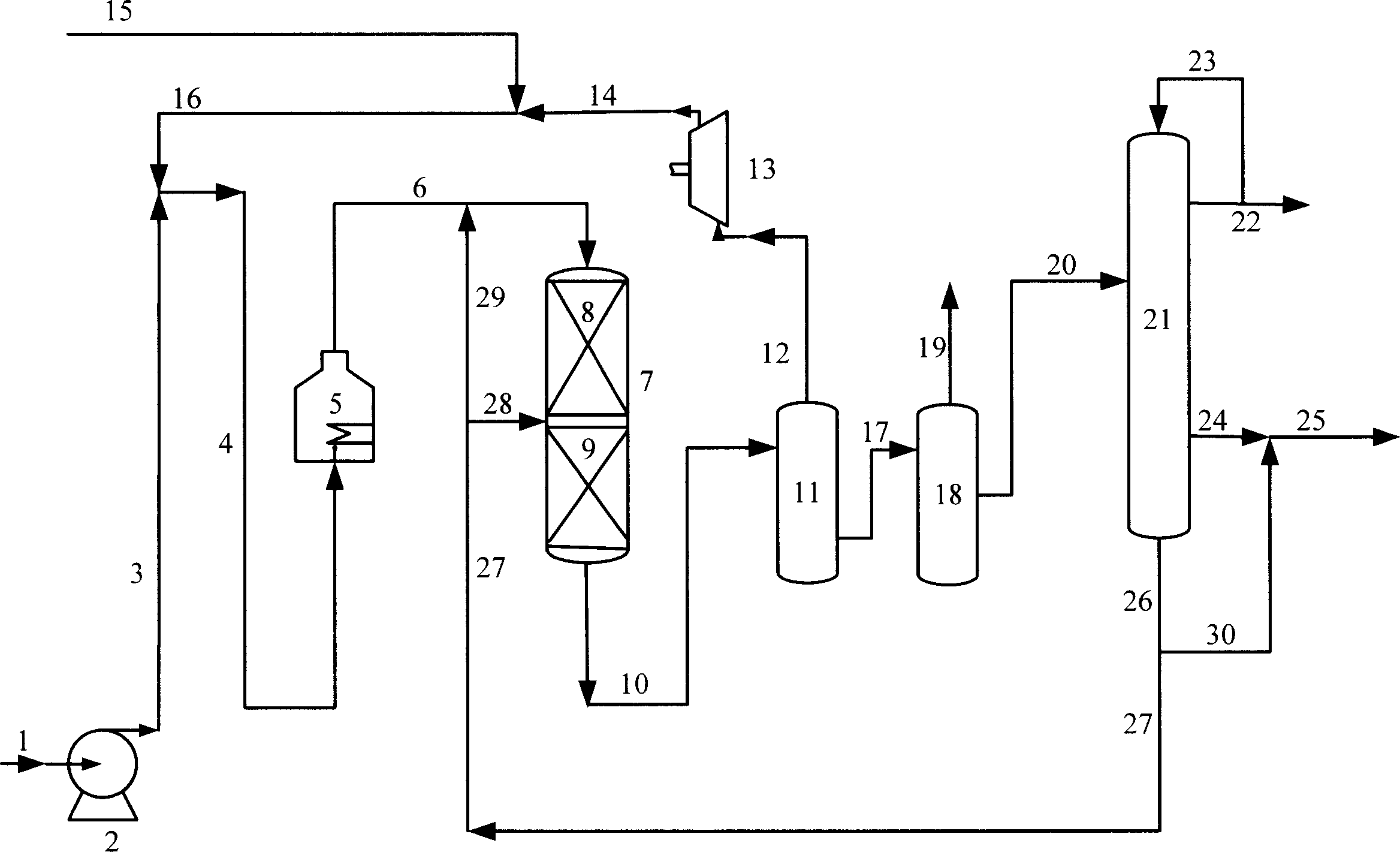

Method for producing diesel oil with low sulphur and low arene

ActiveCN101092575ASimple processLow operating pressureTreatment with hydrotreatment processesHydrogenGasoline

This invention discloses a method for producing low-sulfur low-arene diesel oil. The method comprises: mixing base oil and hydrogen, introducing into a hydrogenation reactor, reacting in the first hydrogenation region by contacting hydrorefining catalyst I, directly introducing the reaction product into the second hydrogenation region without separation, reacting by contacting hydrorefining catalyst II, cooling and separating the reaction product to obtain hydrogen-rich gas and liquid substance, circulating the hydrogen-rich gas for repeated use, introducing the liquid substance into a fractionating system, fractionating to obtain crude gasoline fraction, light diesel oil fraction and heavy diesel oil fraction, introducing part or all of the heavy diesel oil fraction bake to the hydrogenation reactor. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and clean diesel oil (with low sulfur content and low arene content) can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst and application thereof in residue fixed-bed hydrogenation method

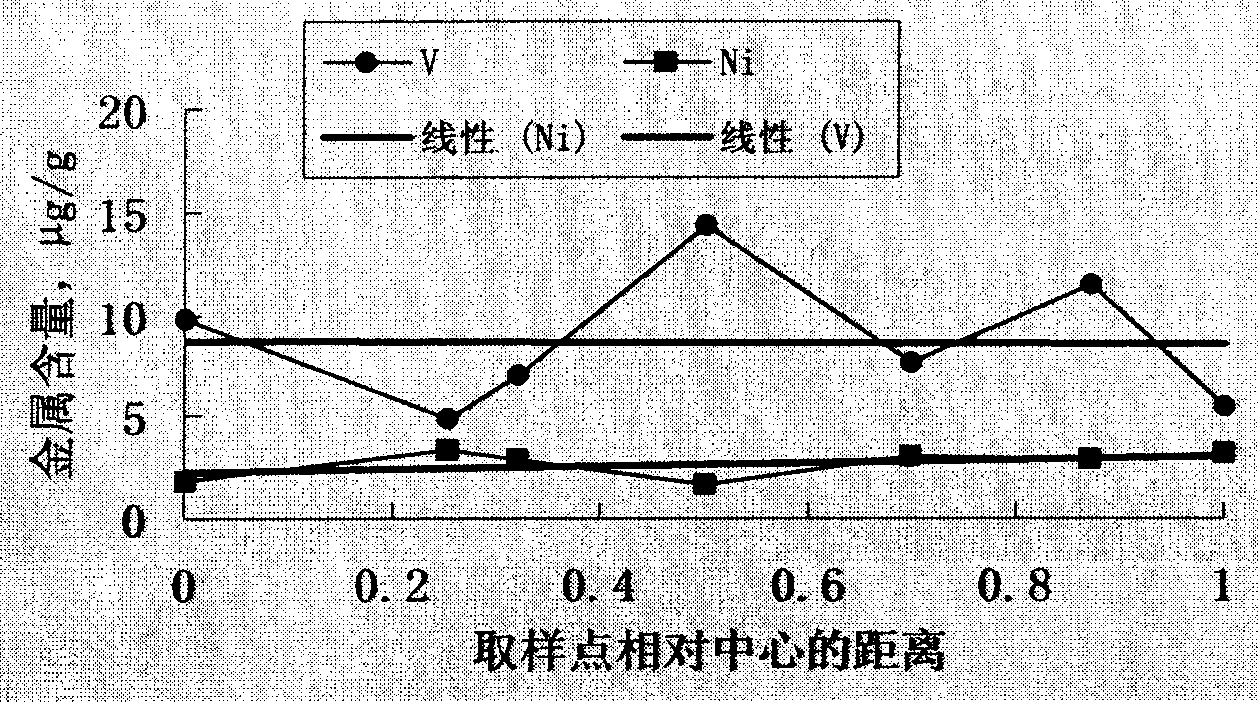

ActiveCN101890378AExtended operating cycleIncrease depositionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPorosityFixed bed

The invention discloses a hydrogenation catalyst and the application thereof in a residue fixed-bed hydrogenation method. The catalyst comprises rod-like nano oxide which is stacked in a framework structure in a disordered way. The catalyst has the advantages of large pore volume, large aperture, high porosity, large outer surface orifice and high duct penetrability. Particularly, when used in the residue fixed-bed hydrogenation method, the catalyst can make reduced metal uniformly deposit on an entire catalyst bed and keep a long-period operation and has a very high desulfurization rate and a very high denitrogenation rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

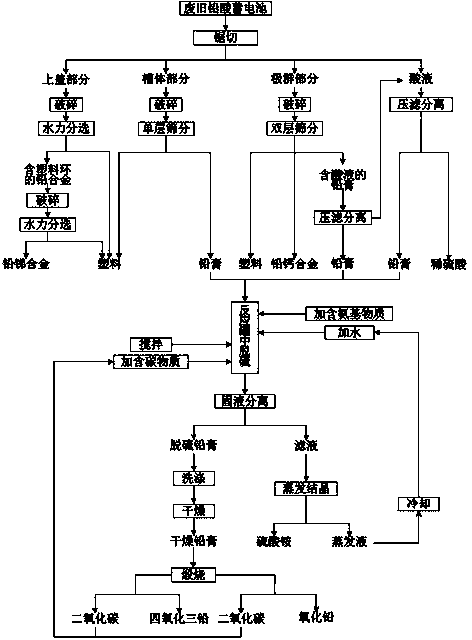

Method for recycling used lead-acid batteries in full circulation mode

InactiveCN103794834AAchieve separationGuaranteed normal processingMetal sawing devicesWaste accumulators reclaimingLEAD TETROXIDELead oxide

The invention relates to a method for recycling used lead-acid batteries in a full circulation mode. According to the technical scheme, a band sawing machine for cutting the used lead-acid batteries is used for sawing and cutting a used lead-acid battery into an upper cover, a groove body, an electrode set and acid liquid, and the upper cover, the groove body, the electrode set and the acid liquid are respectively processed to obtain lead-antimony alloy, plastic, lead plaster, lead-calcium alloy and dilute sulphuric acid. Then, the lead plaster is added into a reaction tank, amidogen-contained substances are added to the lead plaster, stirring is conducted, desulfurization is conducted after carbon-contained substances are added, solid-liquid separation is conducted, and therefore desulfurated lead plaster and filter liquid are obtained. Then, the filter liquid is evaporated and crystallized to obtain ammonium sulfate, and liquid evaporated in the evaporation and crystallization process is cooled to the room temperature and recycled. The washed desulfurated lead plaster is dried, and the dried desulfurated lead plaster is roasted at the temperature larger than 400 DEG C and smaller than or equal to 500 DEG C or at the temperature larger than 500 DEG C and smaller than or equal to 650 DEG C to obtain lead tetroxide or lead oxide. The method has the advantages of being simple in process, low in recycling cost, high in recycling rate, high in product purity and environmentally friendly.

Owner:襄阳远锐资源工程技术有限公司 +1

Converter steelmaking process

InactiveCN1470653AImprove efficiencySave operating timeManufacturing convertersSteelmakingLate stage

The convertor steel-smelting method adopts the top and bottom combined converting process, uses molten iron and solid iron material as raw material, their weight percentage are, molten iron 85%-95% and solid iron material 5-15%. The pretreatment of desilication, dephosphorization and decarbonization of molten iron and decarbonizing refining process are implemented in same convertor, i.e. front stage is pretreatment of molten iron, and late stage is decarbonizing refining stage, in the pretreatment stage the dephosphorization agent can be added, the top-bottom combined converting process can be adopted, top converting adopts flow rate changed oxygen supply, and its medium and late stage adopts weak oxygen supply, and the decarbonizing refining stage adds lime, makes secondary slag formation and adopts large quantity of oxygen to make top and bottom combined converting process.

Owner:CENT IRON & STEEL RES INST

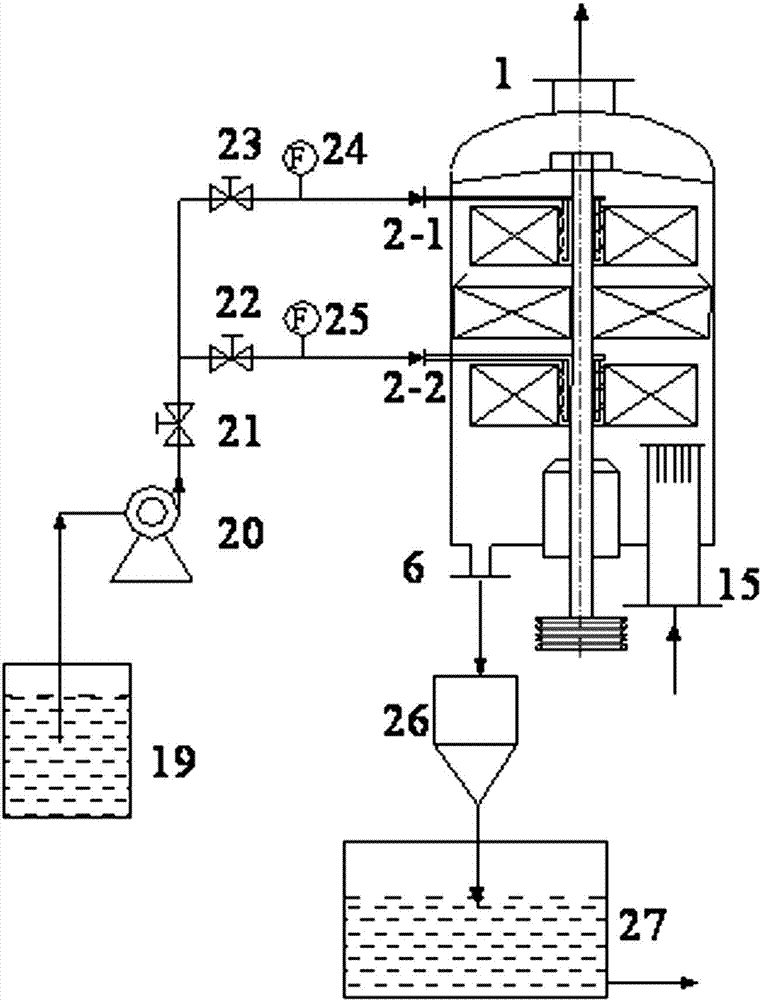

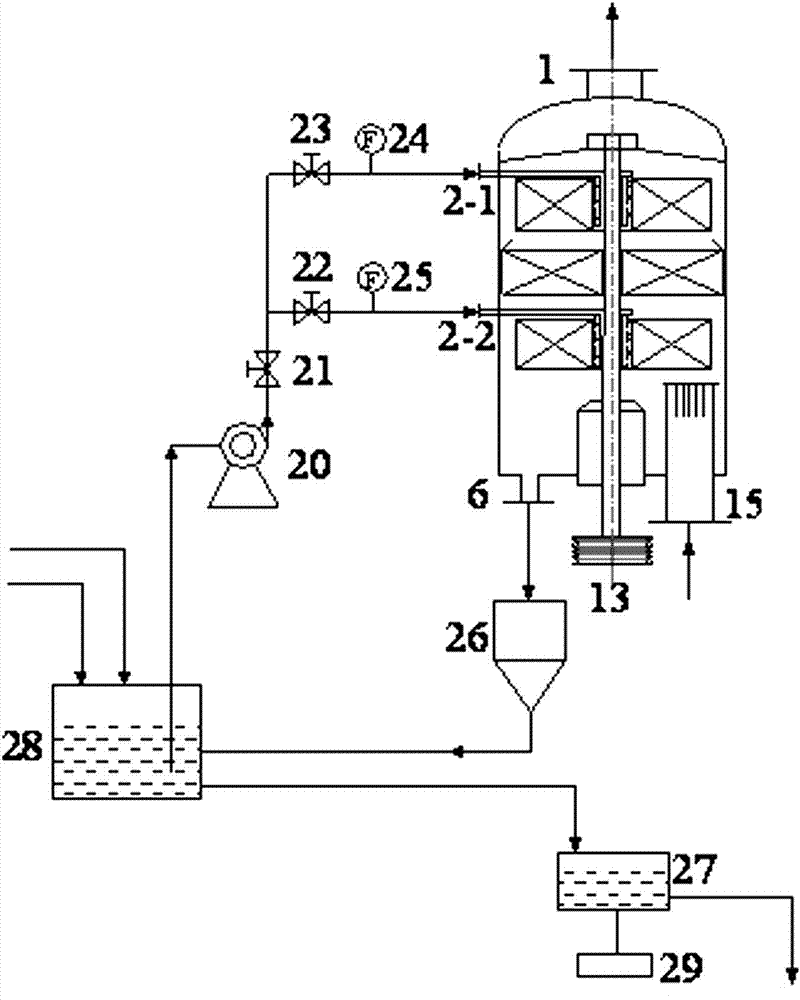

Flue gas desulfurization and dust removal technology and integrated apparatus applicable to ship

ActiveCN104492210AEnhanced mass transferIncrease capture rateCombination devicesGas treatmentFlue gasDust control

The invention belongs to the technology of flue gas desulfurization and dust removal, and in particular relates to a flue gas desulfurization and dust removal technology and an integrated device applicable to ships, and solves the problems in the flue gas desulphurization technology and equipment for ships of the prior art. The flue gas desulfurization and dust removal apparatus includes a multi-stage cross flow rotating packed bed, a barren liquor tank, a barren liquor circulating pump and an aeration tank. The flue gas desulfurization process includes an open seawater method flue gas desulphurization technology and a enclosed alkali method flue gas desulfurization technology. Two technologies can be combined with the rotating packed bed, and the invention has the advantages of high desulfurization efficiency, low energy consumption, simple process, low investment and operation cost, stable operation, convenient startup and shutdown, and integrated desulphurization and dust removal.

Owner:ZHONGBEI UNIV

Desulfurizing method using soda waste liquid and calcium carbide waste residue

InactiveCN101306304AHigh desulfurization rateQuick responseDispersed particle separationLiquid wasteSlag

The invention discloses a method for removing SO2 by utilizing soda ash waste liquid and carbide waste slag. CaCl2 in the soda ash waste liquid is utilized to react with the SO2 in flue gas, white CaSO3 settlement is generated, HCl is released and dissolved in water to form hydrochloric acid with very low concentration; Ca(OH)2 in the carbide waste slag is used for neutralizing HCl and generating CaCl2 and water, and CaCl2 is recycled. The desulphurization process mainly consumes Ca(OH)2 in the carbide waste slag. If no local soda ash waste liquid, calcium chloride dehydrate (CaCl2*2HO) produced by the soda ash waste liquid can be purchased for preparing CaCl2 solution. The carbide waste slag can be replaced by lime. The process is characterized by one high, two low and three points of environmental protection. The process firstly has high desulphurization rate, secondly has low fixed-asset investment and low running costs and thirdly utilizes the waste liquid and the waste slag to reduce the environmental pollution. Compared with all prior desulphurization processes, the process has great advantages.

Owner:康仁

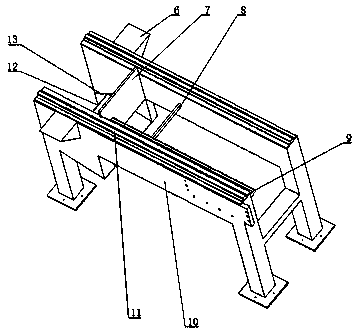

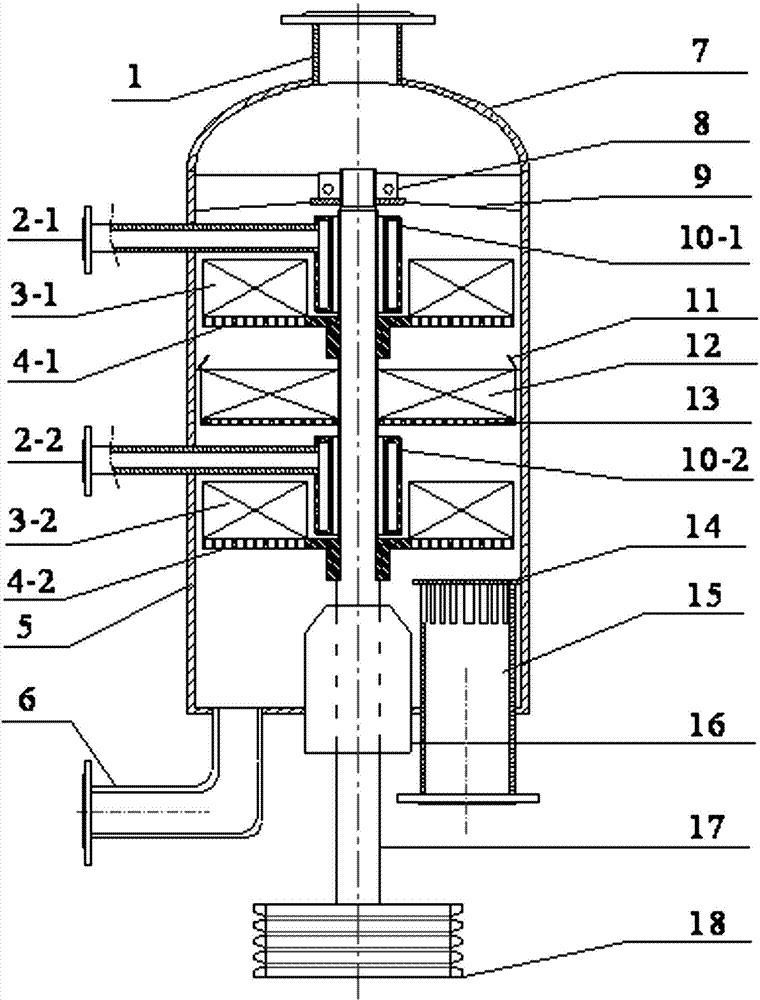

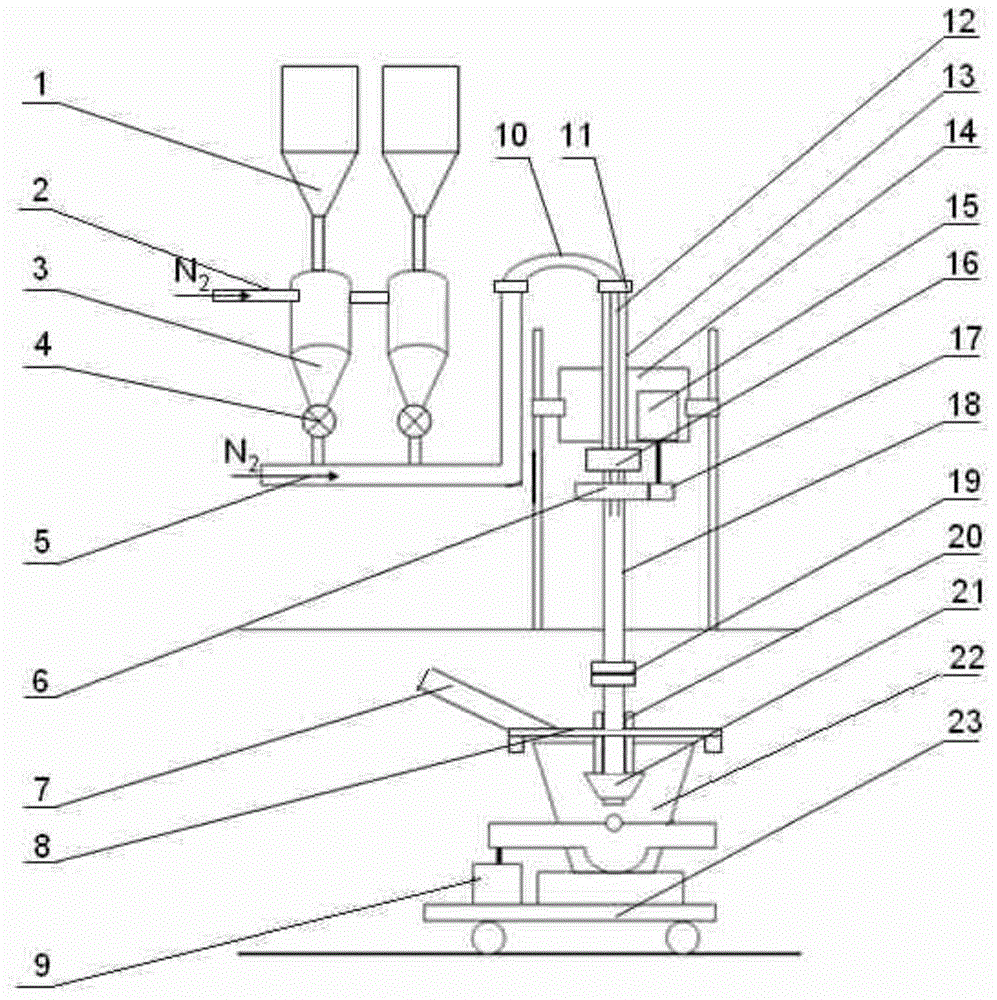

Blowing and stirring integrated type molten iron pretreatment desulphurization device and method

The invention discloses a blowing and stirring integrated type molten iron pretreatment desulphurization device and method. A powder-gas conveying pipe at the lower ends of weighing hoppers is in flexible connection with a powder spraying gun. The lower end of a fixed sleeve which is arranged outside the powder spraying gun in a sleeving mode is connected with a hollow transmission shaft through a bearing sleeve. A driven gear in which the bearing sleeve is embedded is engaged with a driving gear connected with a motor. A powder spraying pipe located at the lower end of the transmission shaft is buried in a stirring blade provided with a powder spraying channel. The stirring blade is inserted into a molten iron ladle cover. The method comprises the steps that the molten iron ladle cover is descended to the position above the edge of a molten iron ladle, the stirring blade enters the ladle cover to start a blowing system, and after the stirring blade conducts blowing in molten iron for 10-20 s, a stirring system is started for desulphurization; blowing and stirring are conducted for 8-20 min, and if the sulphur content in the molten iron reaches the standard, slagging-off operation is conducted; otherwise, desulphurization continues to be conducted till converting requirements are met; and the motor stops operating after the desulphurization, the blowing system is ascended, and blowing is stopped when the lower end of the stirring blade is flush with the edge of the molten iron ladle. According to the device and method, compared with a blowing method, the desulfurization rate is increased, and the consumption amount per ton of desulfurizing agents is reduced; compared with a KR stirring method, the temperature drop of the molten iron is reduced, and the service life of a stirring head is prolonged.

Owner:ANGANG STEEL CO LTD

Method and apparatus for removing sulfur dioxide from sulfuric acid industrial tail gas, and for recovering sulfuric acid

InactiveCN102228776AReduce manufacturing costImprove removal effectSulfur compoundsDispersed particle separationSulfurProduct gas

The invention relates to the methods and apparatuses for treating sulfuric acid industrial tail gas, and discloses a method and an apparatus for removing sulfur dioxide from sulfuric acid industrial tail gas, and for recovering sulfuric acid. The method comprises the steps that: sulfur dioxide in flowing sulfuric acid industrial tail gas is removed in an absorption tower by using a hydrogen peroxide solution, and sulfuric acid is recovered. The apparatus comprises an absorption tower, a spraying apparatus and a demister. The spraying apparatus comprises a circulating pump, a metering pump, a hydrogen peroxide storing tank and a sprayer. The absorption tower is provided with a gas inlet and a gas outlet. The following components are sequentially arranged in the absorption tower from bottom to top: a collecting tank, a gas distributing plate, a diluted-acid-resisting filling material, the sprayer, and the demister. A circulating port and a liquid discharging port are arranged on the bottom of the collecting tank. The circulating port communicates with the sprayer through the circulating pump. A valve is arranged on the liquid discharging port. The hydrogen peroxide storing tank communicates with a liquid inlet port of the circulating pump through the metering pump. According to the invention, effect for removing sulfur dioxide from sulfuric acid industrial tail gas is good, sulfur can be recovered and reused, production cost of sulfuric acid is reduced, and secondary pollution is avoided. The apparatus has advantages of simple structure, easy operation, low investment and low operation cost.

Owner:威海恒邦化工有限公司

Pre-molten low-melting point composite calcium aluminate desulfurizer and its prepn.

The invention discloses a kind of premelt-type, low-melting point, calcium aluminate complex desulfurizing agent and its preparation method, which is prepared according to the below components and proportion (weight): aluminum alum earth (calculated according to the Al2O3 content) 30-60%, and calcium oxide 40-70%. In advance perform passivating treatment on calcium oxide, then mix all the components according to the required proportion, then smelt them in the electric stove or the reflecting stove, then cool them, and by crashing, prepare the particle-shape or powder-shape desulfurizing agent. By the premelting treatment, the melting point of desulfurizing agent lowers to 1250-1400 centigrade, which obviously raises its desulfurizing rate in the molten iron molten steel and shortens the reactive time and production cycle.

Owner:盛富春

Desulfurization method for gasoline

ActiveCN101314727APromote regenerationLarge adsorption capacityHydrocarbon oils refiningMolecular sieveOil processing

The invention belongs to the field of petroleum processing technology and discloses a gasoline desulfurization method. The method can achieve gasoline desulfurization by absorption method, which comprises the step of contacting sulfur-containing gasoline with an absorbent selected from a MCM-48 mesoporous molecular sieve doped by copper element or cerium element. The method has good desulfurization effect, and particularly has large absorption capacity to thiophene and derivatives thereof to achieve high desulfurization rate. The absorption operation can be carried out at normal temperature and under normal pressure to reduce the operation cost, and the absorbent can be easily regenerated to maintain better desulfurization effect.

Owner:NANJING UNIV OF TECH

Flue gas desulfurization process suitable for sintering machine of steel mill

InactiveCN101862583AHigh desulfurization rateLow running costDispersed particle separationProcess engineeringSteel mill

The invention discloses process technology suitable for removing a sulfur dioxide byproduct, namely, ammonium sulfate chemical fertilizer in flue gas produced by a sintering machine of a steel mill and suitable for the characteristics of large sintering flue gas amount, large flue temperature fluctuation, high moisture content, high dust content and the like. The process comprises the following steps of: allowing sintering flue gas to enter from the middle of an absorption tower, wherein the flue gas is reversely contacted with absorption liquid; removing sulfur dioxide from the flue gas in a contacting process; exhausting the flue gas through a chimney on the top of the tower after the flue gas flows through a demister on the top of the tower; introducing compressed air and ammonia water into the absorption liquid, wherein ammonium sulfate in solution is saturated and 5 percent of crystal is separated out along with continuous absorbing and oxidizing processes; and rotating, filtering and drying ammonium sulfate crystal-containing suspension to obtain a finished product. Since the absorption, oxidation and condensation of the sintering flue gas are completed in the absorption tower at the same time, the process has the characteristics of refined flow, high desulfurization efficiency and high byproduct quality.

Owner:高翀

H-shaped flue gas dust removal desulfurization tower and flue gas desulfurization method

ActiveCN104607017AImprove cooling effectEasy to handleUsing liquid separation agentFlue gasProcess engineering

The present invention discloses an H-shaped flue gas dust removal desulfurization reactor and a flue gas desulfurization method. The desulfurization tower of the present invention comprises a pre-treatment unit and a deep treatment unit, wherein the two units form an H-shaped double-tower structure, the pre-treatment unit comprises a flue gas inlet, a water membrane assembly, a first-stage spraying system, a common jujube seed-shaped regular packing assembly, a turbulent scrubber and a first-stage liquid holding tank from top to bottom, the deep treatment unit comprises a second-stage liquid holding tank, a packing assembly, a demister and a purified flue gas outlet from bottom to top, and the pre-treatment unit and the deep treatment unit are communicated through the flue gas channel on the middle portion. According to the desulfurization tower of the present invention, the common jujube seed-shaped regular packing assembly and the high level potential energy of the turbulent scrubber absorbing liquid can be utilized to concurrently pre-treat the flue gas, and the desulfurization tower has advantages of high contaminant removal rate, low energy consumption and the like, and is especially for the dust removal desulfurization process of high dust content flue gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

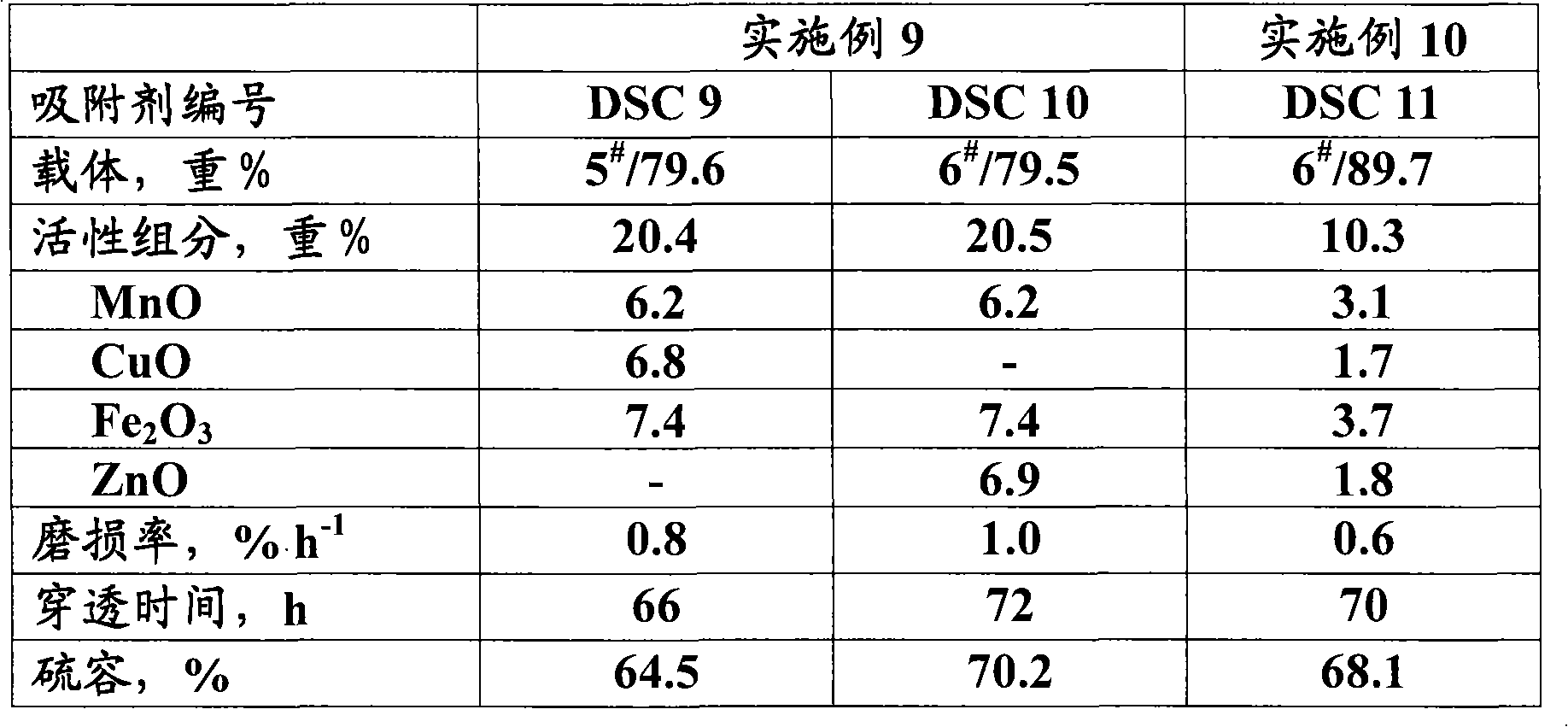

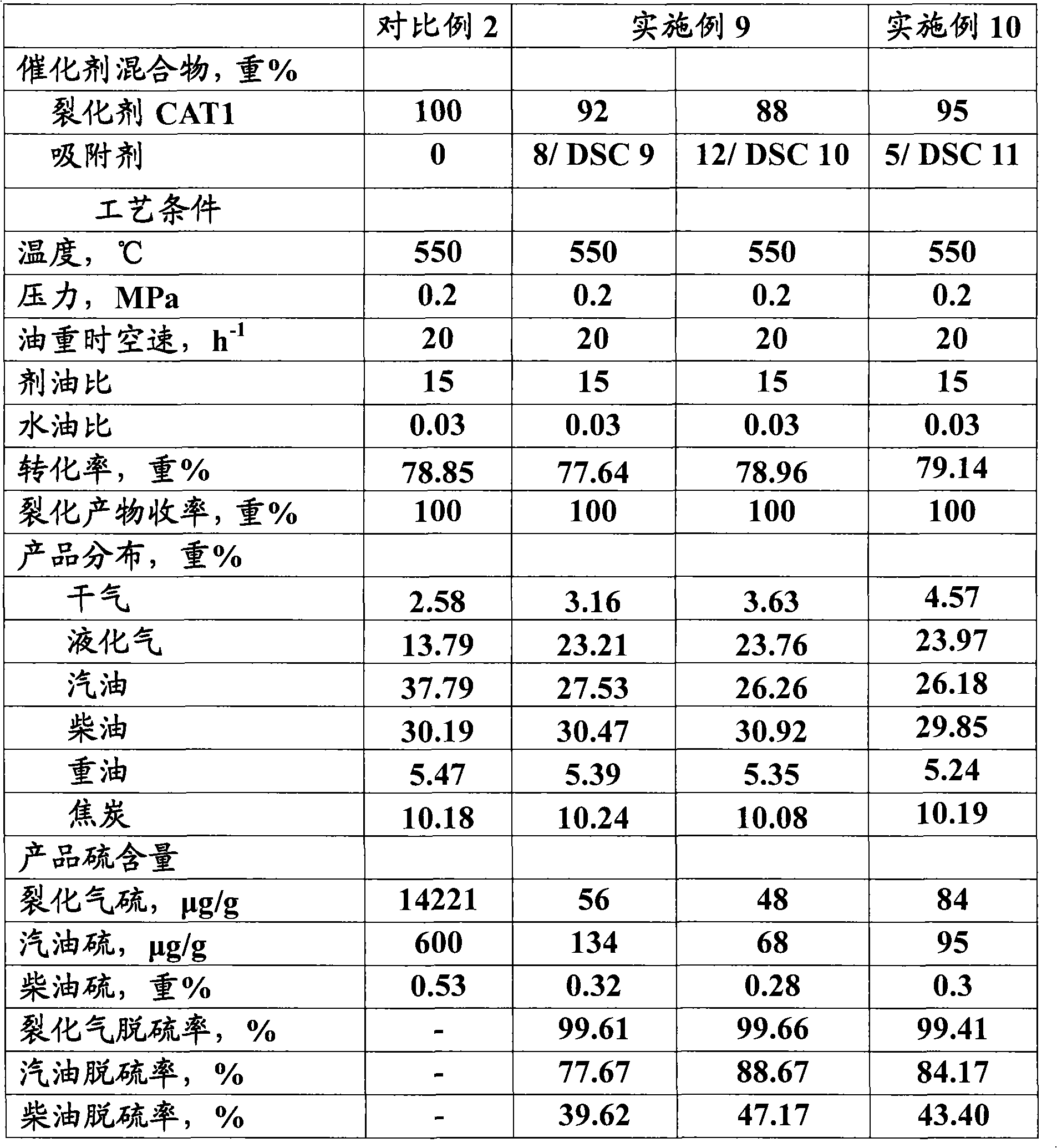

Adsorption agent for reducing sulphur content of catalytic cracking production

ActiveCN101314726AReduce sulfur contentHigh desulfurization rateHydrocarbon oils refiningMolecular sieveChemistry

An absorbent for reducing sulfur content of catalytic cracking product comprises an active component accounting for, calculated by oxide, 5 to 50wt percent of the total amount of the absorbent, and carrier in balance, wherein the active component is active metal oxide; the active metal is selected from one or more of Mn, Fe, Cu, and Zn; and the carrier is selected from one or more of silicon oxide, aluminum oxide, zirconium oxide, titanium oxide, amorphous silica-alumina, natural porous carrier material and molecular sieve. During processing petroleum material, the absorbent and the method can achieve higher desulfurization capacity while maintaining the prior catalysis activity and selectivity of the catalytic cracking catalyst in comparison with catalytic cracking method without absorbent, so that the catalytic cracking product has lower sulfur content. The catalytic cracking system with the absorbent can improve the desulfurization rate of gasoline above 70 percent, the desulfurization rate of cracking up to 90 percent and the desulfurization rate of diesel above 30 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep desulfurizer for refining ultra-low-carbon steel and manufacturing method thereof

The invention discloses an ultralow carbon steel refining deep-desulfurizer and making method, which comprises the following parts: 60%-69% CaO, 11%-20% Al, 5%-10% MgO, 5%-10% SiO2, 1%-5% Al2O3, 0.5%-1.2% Fe2O3, 1%-3% CaF2, 1%-3% B2O3, 1%-3% BaO and impurity. The making technique comprises the following steps: blending; grinding the material with grain size not more than 1mm; inactivating the material; drying; draining the trace element of water; packing.

Owner:ANGANG STEEL CO LTD

Titanium dioxide production process calcining tail gas processing method

ActiveCN105561721AHigh utilization rate of waste heat recoveryReduce consumptionCombination devicesGas treatmentProduction lineUtilization rate

The present invention discloses a titanium dioxide production process calcining tail gas processing method comprising the following steps: 1) dust removal; 2) preliminary heat exchange, to be more specific, calcining tail gas after the dust removal is discharged into a waste heat boiler system for heat exchange with process water, and the calcining tail gas is preliminarily calcined; 3) further heat exchange, to be more specific, the preliminarily-calcined calcining tail gas enters a venturi system and further cooled by spraying with spent sulfuric acid; and 4) desulfurization. According to the titanium dioxide production process calcining tail gas processing method, waste heat boiler system with high heat recovery utilization rate is used, and by step-by-step heat exchange, heat can be efficiently recovered from the calcining tail gas, and can be used for other processes in a titanium dioxide production line, energy and water consumption can be greatly saved, and by the desulfurization, desulfurization rate of the calcining tail gas is significantly increased.

Owner:SHANGHAI TITANOS IND

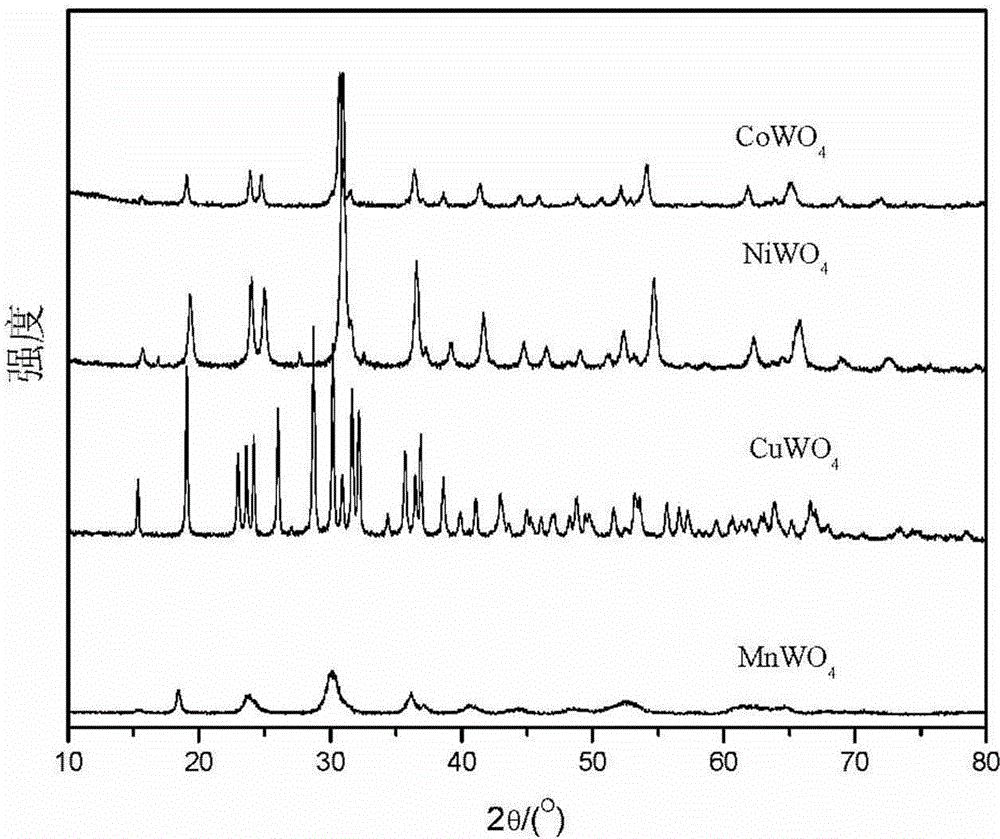

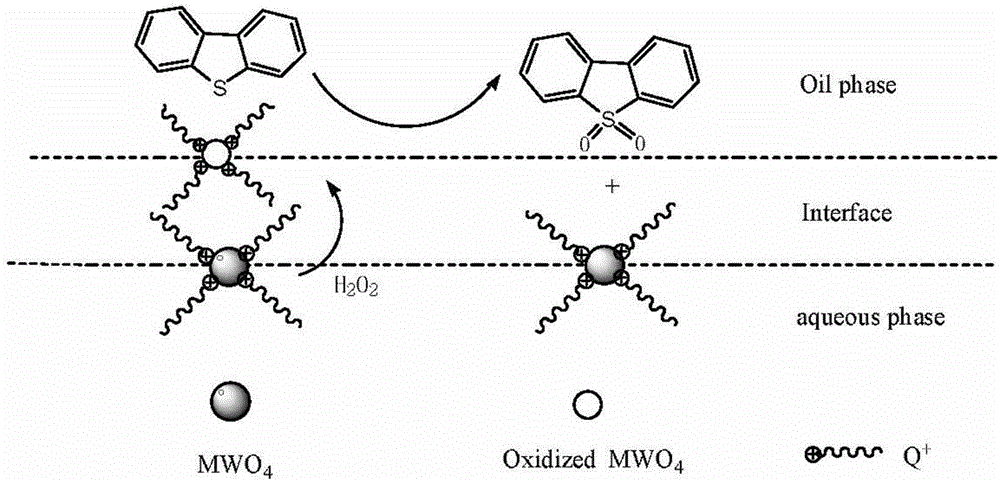

Method for removing sulfide in simulated oil through oxidation by using transition metal tungstate as catalyst

InactiveCN103333711ASimple processLow costRefining with oxygen compoundsTungstateCatalytic oxidation

The invention belongs to the field of vehicle fuel desulfurization realized through catalytic oxidation and particularly relates to a method for removing a sulfide in simulated oil through oxidation by using transition metal tungstate as a catalyst. The method can be implemented according to the following steps of: (1) weighting the transition metal tungstate, adding water to dissolve the transition metal tungstate, adding sodium tungstate and stirring at room temperature; collecting a product, drying the product after the product is washed, and then, calcining the product to obtain the transition metal tungstate; (2) adding the tungstate into the simulated oil, adding an oxidizing agent and cetyltrimethylammonium bromide, cooling a reaction mixture to the room temperature, and separating out an oil phase, wherein the tungstate is synthesized in the step (1), further adding N-N-dimethyl formamide and stirring, separating out the oil phase, measuring the sulphur content and calculating the desulfurization degree; and (3) recovering a tungstate catalyst, drying and washing to remove the surface sulfide, and drying the tungstate catalyst for repeated use. The method is simple in process, low in cost and high in desulfurization degree; the transition metal tungstate is easy to recover after reaction and can be repeatedly used after regeneration.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

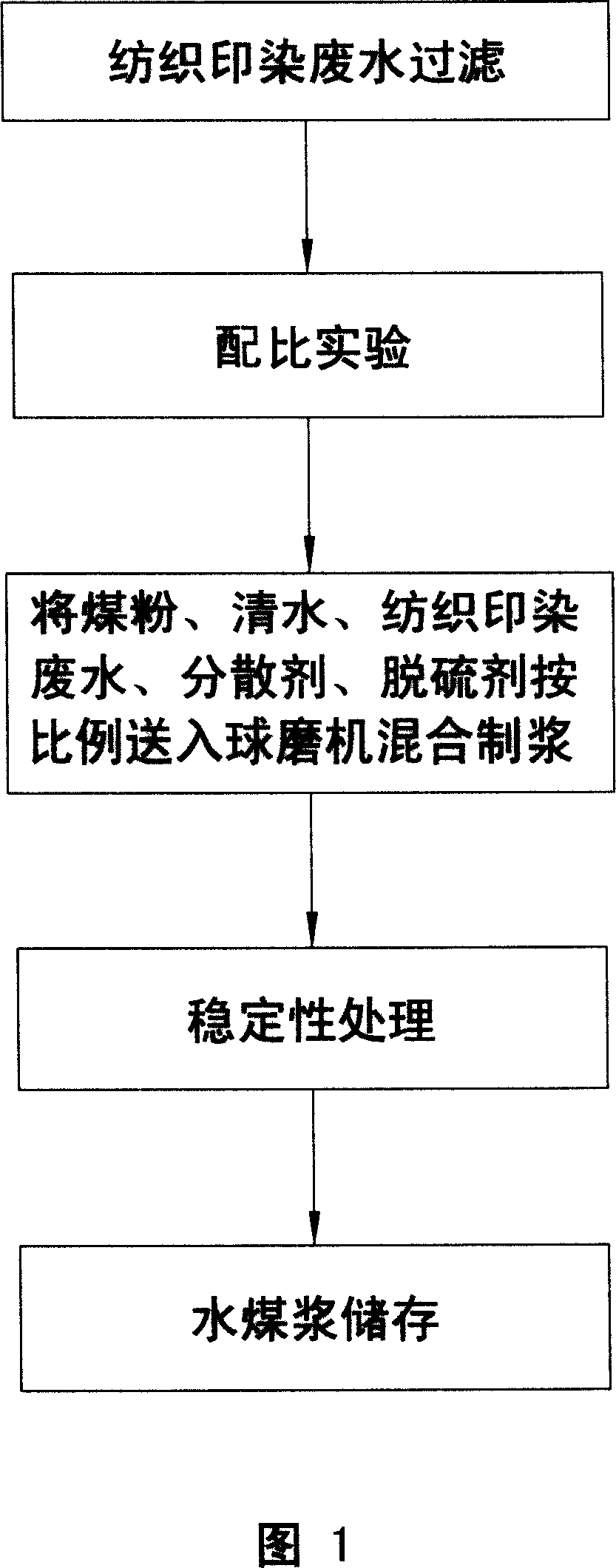

Method of treating weave printing and dyeing wastewater by slurries production technology

InactiveCN101033103AReduce pollutionReduce dosageMultistage water/sewage treatmentWater/sewage treatment by neutralisationCoal waterDyeing wastewater

This invention discloses a method for processing spinning, printing and dyeing waste water by a coal-water slurry production technology including a step of filtering spinning, printing and dyeing waste water, a step of determining the mixture ratio among desulfurizer, dispersant, clean water and waste water, a step of mixing slurrying, a step of stabilizing the slurry and a step of aging and storing coal-water slurries.

Owner:珠海市金火炬清洁能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com