Method and apparatus for removing sulfur dioxide from sulfuric acid industrial tail gas, and for recovering sulfuric acid

A technology for industrial tail gas and sulfur dioxide is applied in the field of recovering sulfuric acid and removing sulfur dioxide in sulfuric acid industrial tail gas. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

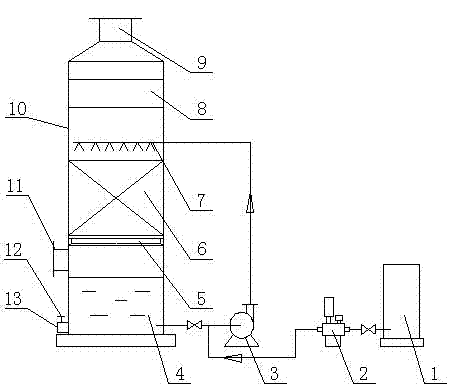

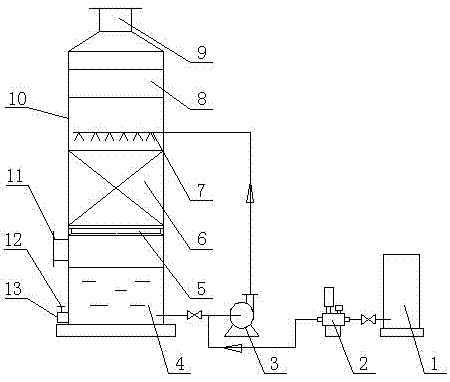

[0013] A method for removing sulfur dioxide in sulfuric acid industrial tail gas and recovering sulfuric acid, using hydrogen peroxide solution in an absorption tower to remove sulfur dioxide in flowing sulfuric acid industrial tail gas and recovering sulfuric acid, the specific steps are as follows:

[0014] a. Input the sulfuric acid industrial tail gas containing sulfur dioxide from the air inlet at the lower part of the absorption tower;

[0015] b. The spraying device is sprayed with hydrogen peroxide solution by a sprayer located on the upper part of the absorption tower. The hydrogen peroxide content of the hydrogen peroxide solution is controlled at 0.1%-5%, and the liquid-gas volume ratio of the sprayed hydrogen peroxide solution and the input sulfuric acid industrial tail gas is controlled At 1:500-1:100, after the tail gas and hydrogen peroxide contact and react in the absorption tower, the mist in the tail gas is removed by the demister above the sprayer, and finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com