Patents

Literature

7631 results about "Sulfur dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

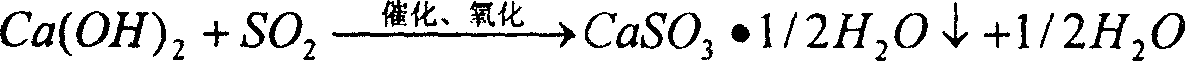

Sulfur dioxide (also sulphur dioxide in British English) is the chemical compound with the formula SO₂. It is a toxic gas responsible for the smell of burnt matches. It is released naturally by volcanic activity and is produced as a by-product of copper extraction and the burning of fossil fuels contaminated with sulfur compounds.

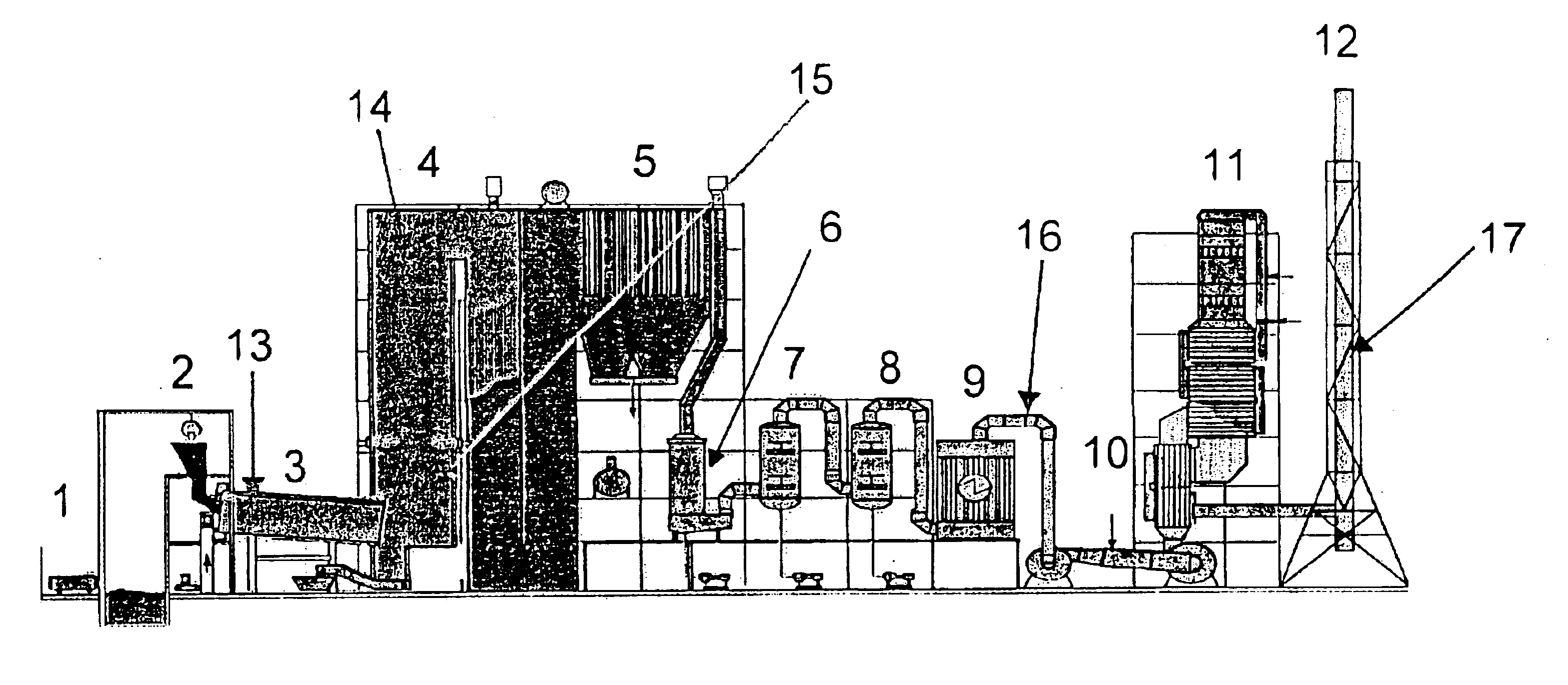

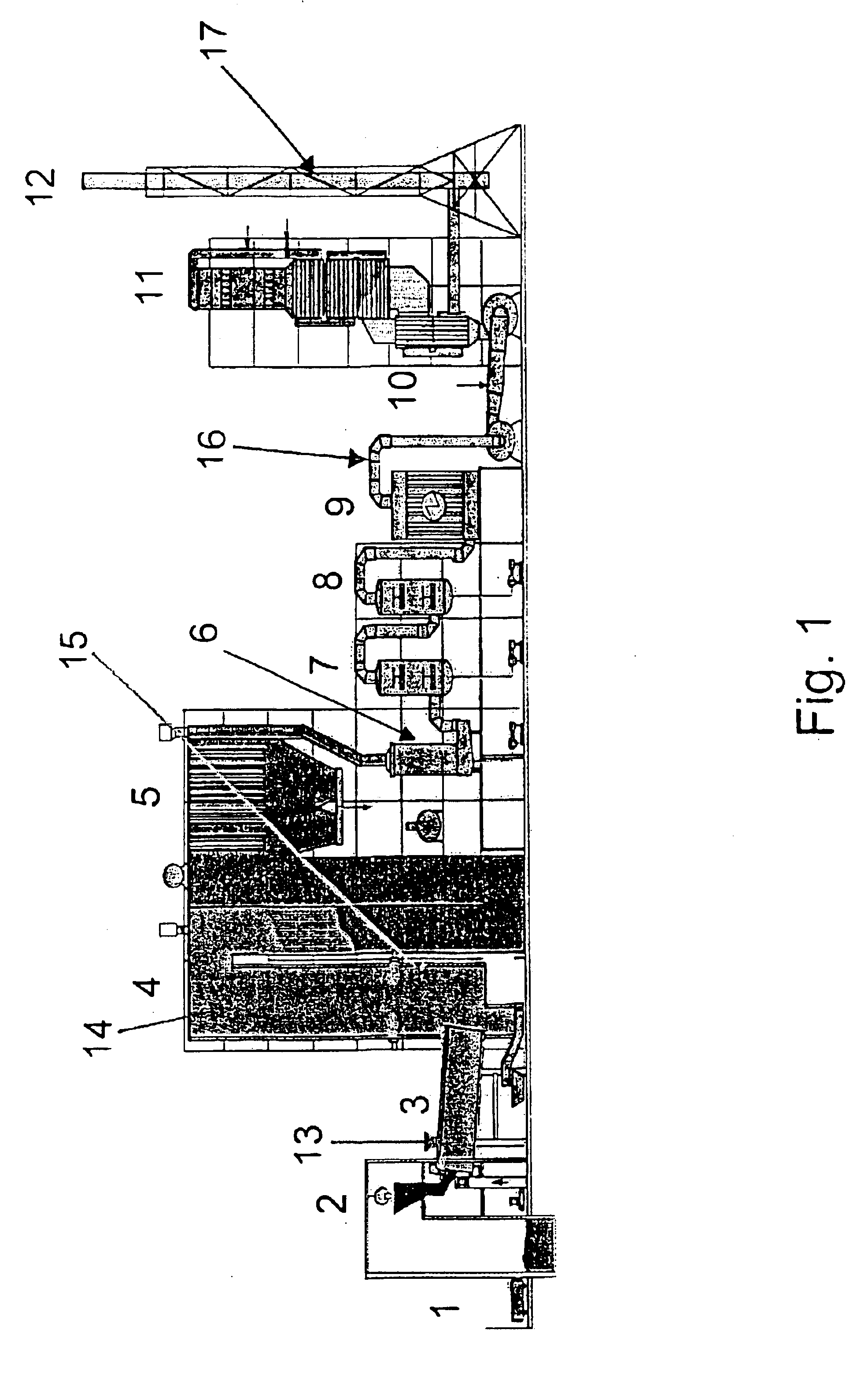

Process for removing mercury from flue gases

InactiveUS6878358B2Reduce operating costsSmall amountUsing liquid separation agentChemical/physical processesPower stationCombustion

Process for removing mercury from flue gases of high-temperature plants, in particular power stations and waste incineration plants in which a bromine compound is fed to the multistage furnace and / or the flue gas in a plant section downstream of the furnace, the temperature during contact of the bromine compound with the flue gas being at least 500° C., preferably at least 800° C. The combustion is carried out in the presence of a sulphur compound, in particular sulphur dioxide. Subsequently to the furnace, the flue gas is subjected to an optional multistage cleanup for removing mercury from the flue gas, which cleanup comprises a wet scrubber and / or a dry cleanup.

Owner:BROMERC

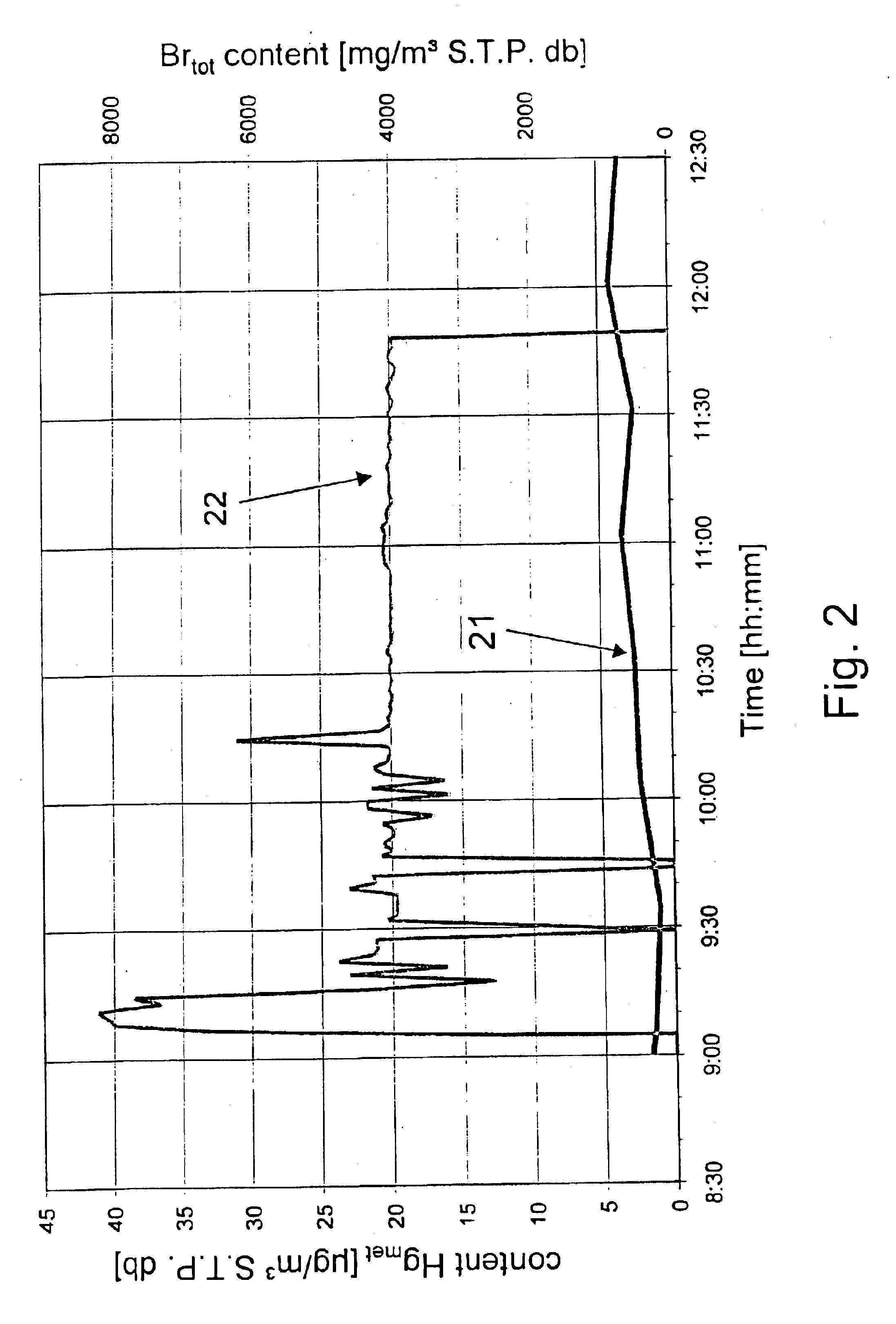

Apparatus and method for generating nitrogen oxides

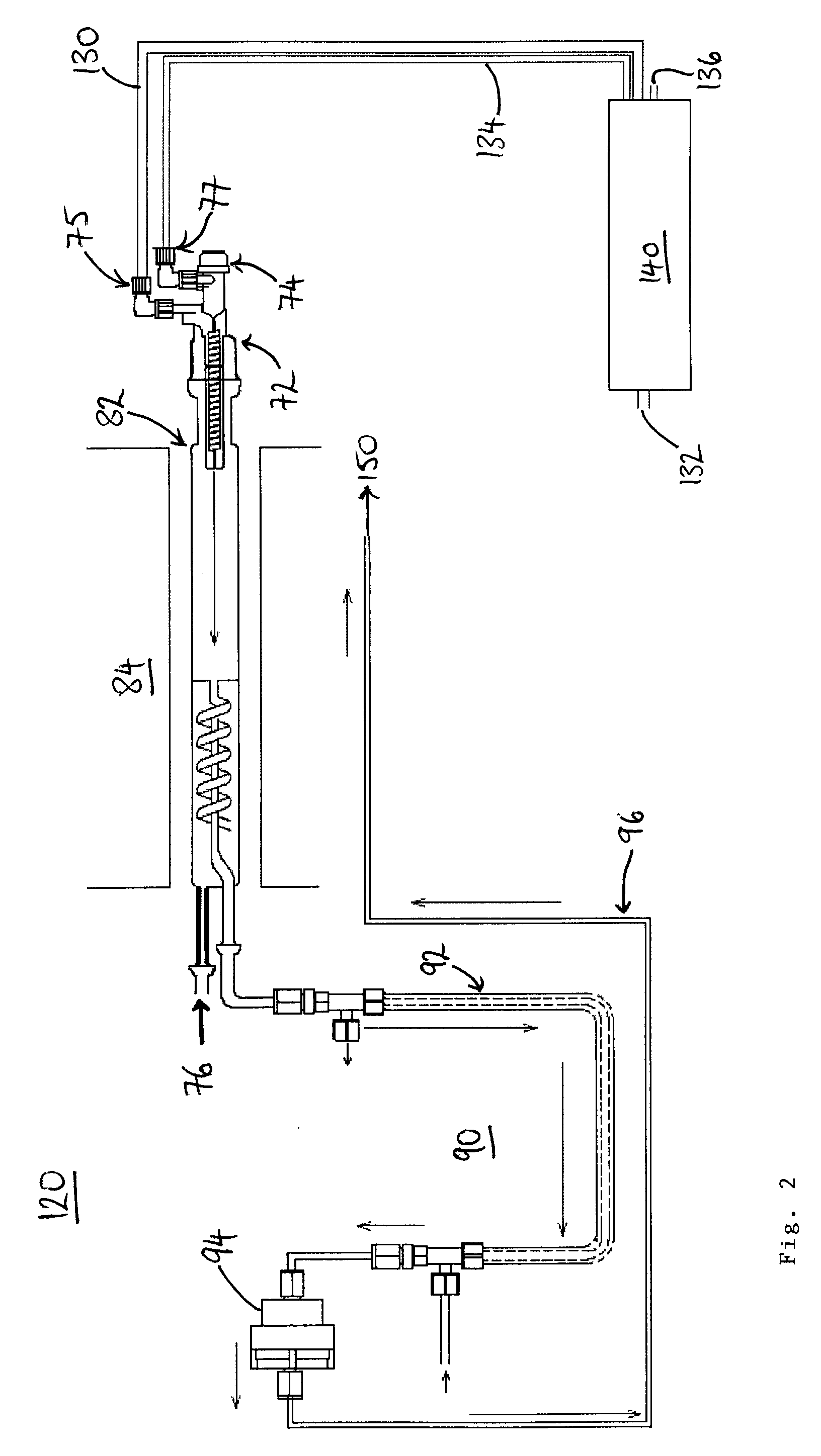

InactiveUS20080176335A1Possible to useIncrease productionChemical analysis using combustionNitrogen compoundsCombustion chamberWorking temperature

A combustion analyzer apparatus and method for combustion analysing a sample, the analyzer comprising a combustion chamber (82) for receiving a sample for combustion therein to form combustion products, and a fluid supply apparatus for supplying fluid(s) into the chamber. The fluid supply apparatus (130-140) comprises a nitrogen oxides (NOx) generating apparatus (140,190,210,240) and is arranged to supply NOx into the combustion chamber. A yield of sulphur dioxide in the combustion products may thereby be improved. The NOx generating apparatus may be operated at a raised working temperature. The NOx generating apparatus may be provided by an ozonator with a supply of nitrogen and oxygen. A Venturi tube arrangement (246) may draw the generated NOx into a (carrier or oxygen) gas line to the combustion chamber. Ozone may be supplied to the combustion products to convert nitrogen monoxide therein to nitrogen dioxide. The NOx and ozone may be supplied by a single device (210,240).

Owner:THERMO ELECTRON MFG

Process for sequestering carbon dioxide and sulfur dioxide

A process for sequestering carbon dioxide, which includes reacting a silicate based material with an acid to form a suspension, and combining the suspension with carbon dioxide to create active carbonation of the silicate-based material, and thereafter producing a metal salt, silica and regenerating the acid in the liquid phase of the suspension.

Owner:PENN STATE RES FOUND

Method for preparing lithium cobaltate by directly using invalid lithium ion battery

InactiveCN102030375AReduce dispersionHigh purityCell electrodesCobalt compoundsElectrical batteryPotassium hydroxide

The invention provides a method for preparing lithium cobaltate by directly using an invalid lithium ion battery. The method comprises the following steps: crushing the invalid lithium ion battery or scraps generated when a lithium cobaltate battery is produced by a mechanical crusher at normal temperature; adding water and one or more of acetic acid, sulfuric acid, hydrochloric acid or nitric acid to produce mixed aqueous solution of the battery scraps and acid; filling the mixed aqueous solution into a hermetic pressure reactor, and controlling the temperature in the reactor to be between 50 and 150 DEG C; introducing or adding one leaching additive of sulfur dioxide or hydrogen, or adding hydrazine hydrate; stirring and leaching, cooling, and filtering; adding one precipitator of sodium carbonate, potassium carbonate and ammonium carbonate, or adding composite precipitator consisting of one of the sodium carbonate, the potassium carbonate and the ammonium carbonate and one of sodium hydroxide and potassium hydroxide to obtain mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide; drying and calcining at high temperature to produce a lithium cobaltate product. The method is particularly suitable for the treatment scale of medium-sized and small enterprises, and is an effective method for directly materializing cobalt secondary resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

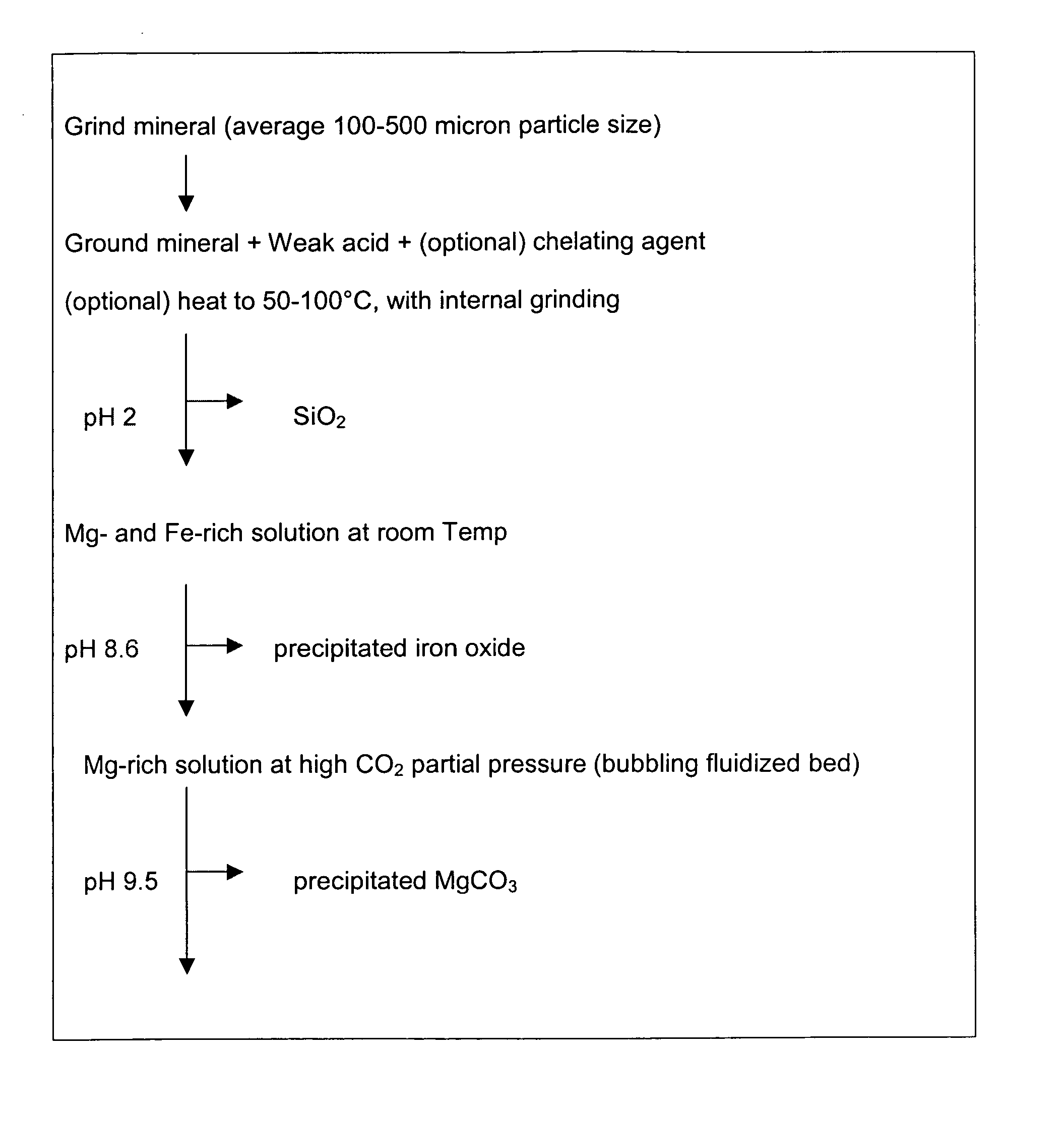

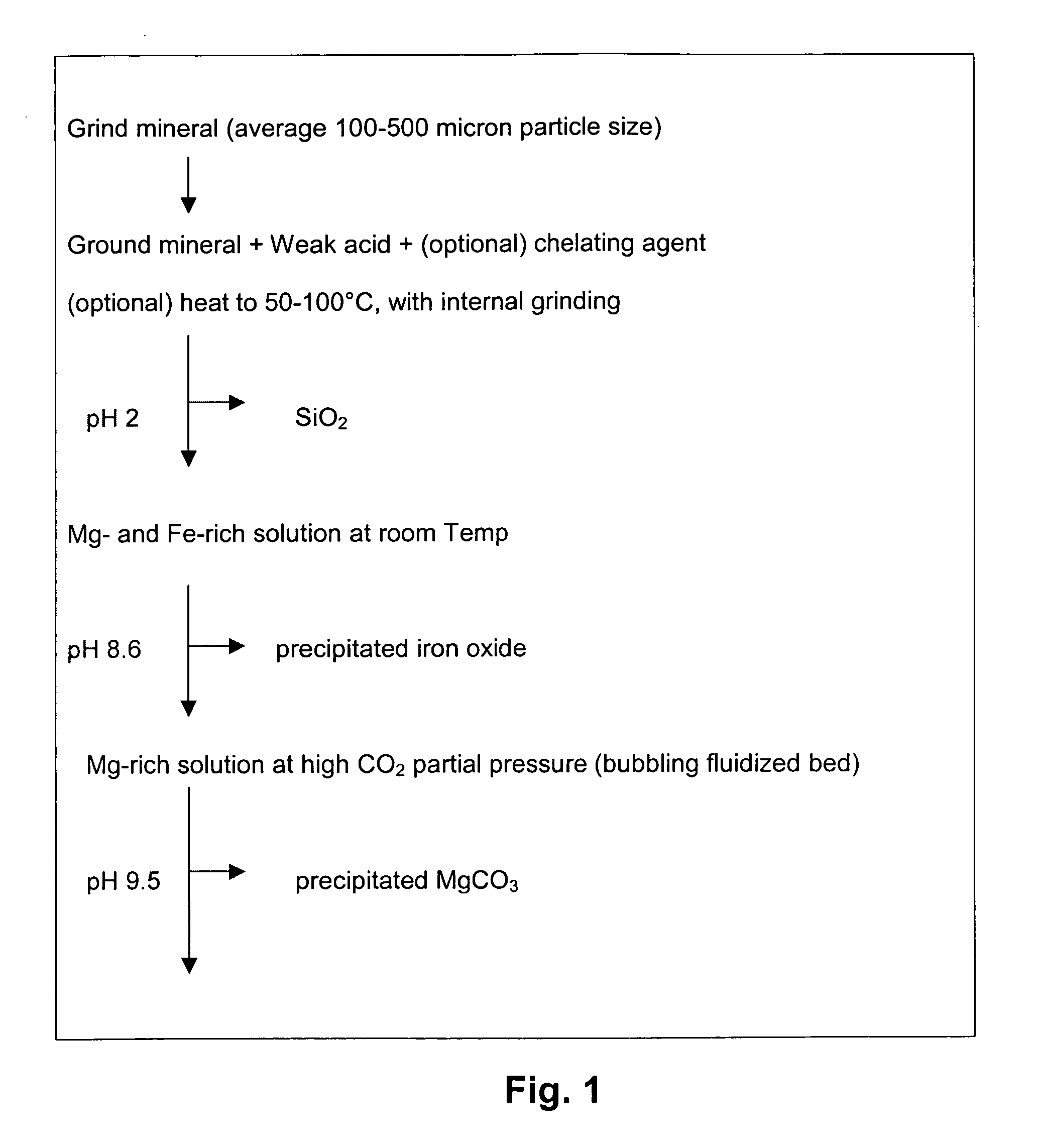

Carbon dioxide sequestration using alkaline earth metal-bearing minerals

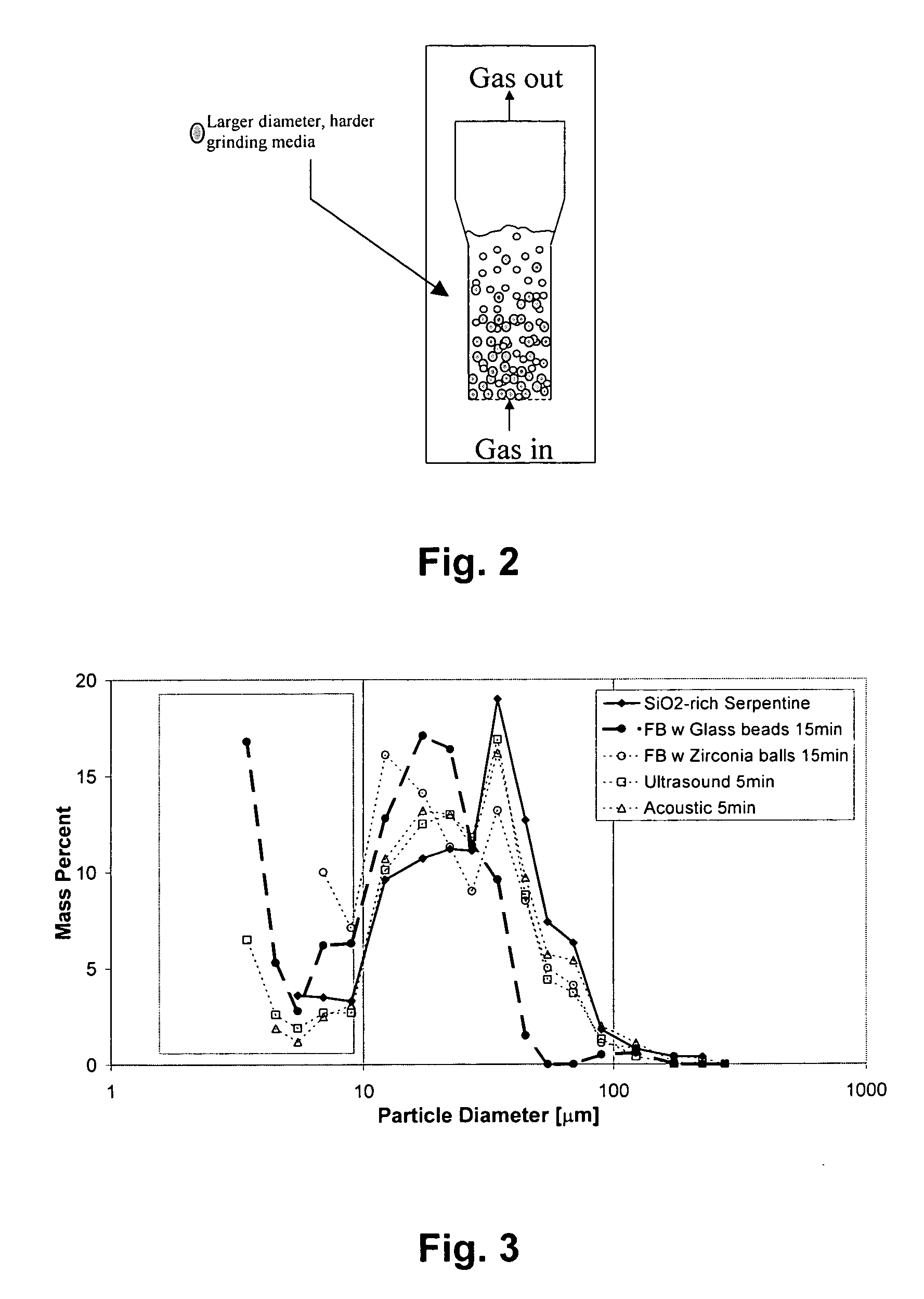

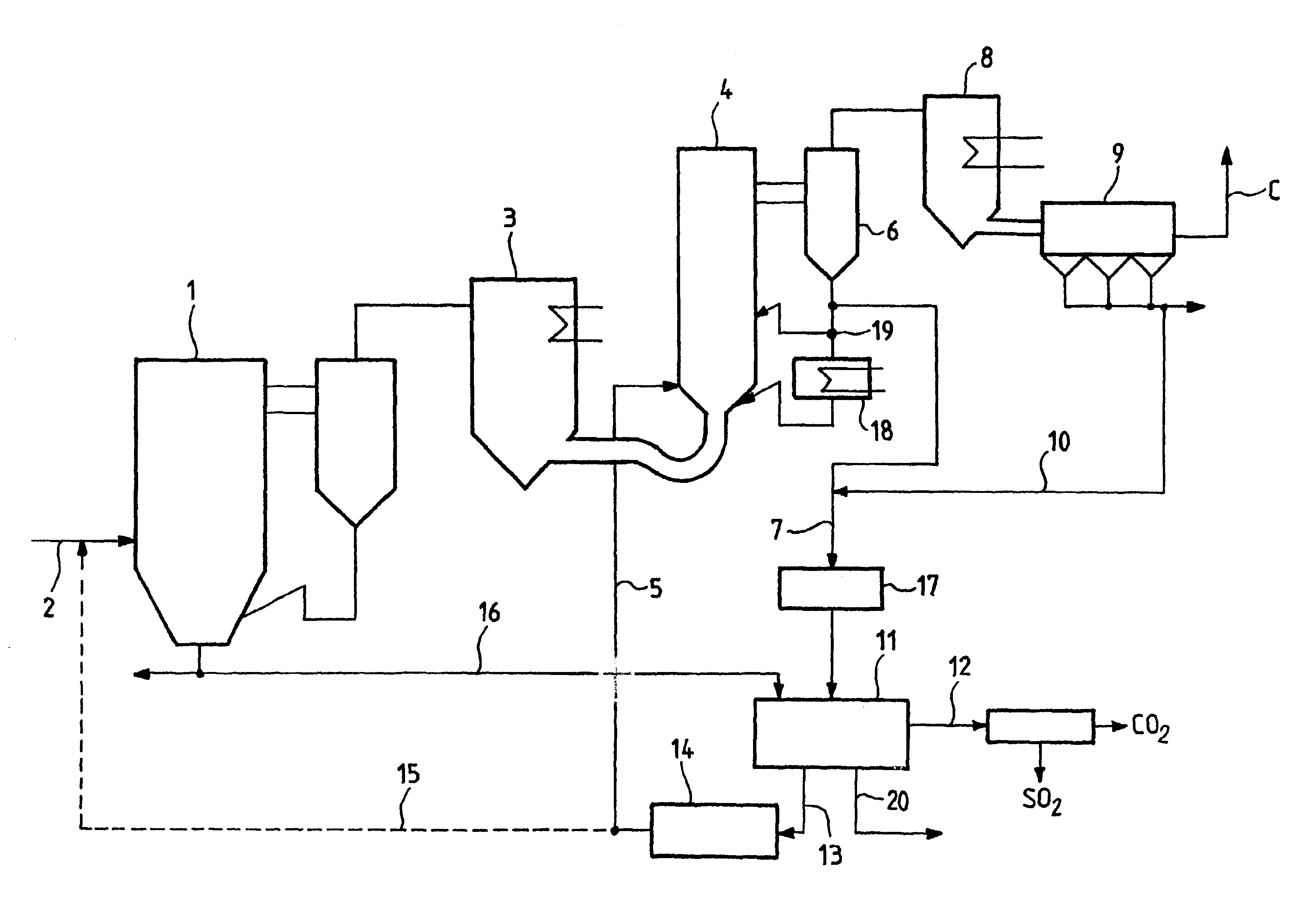

ActiveUS20050180910A1High dissolution rateEfficient removalCalcium/strontium/barium carbonatesProductsParticulatesAlkaline earth metal

A method for mineral sequestration of pollutant gases resulting from the combustion of carbon-based fuels such as carbon and sulfur dioxides is provided and includes, providing a particulate magnesium-containing mineral and exposing the magnesium-containing mineral to a weak acid to dissolve magnesium from the mineral and form a magnesium-containing solution. The surface of the particulate magnesium-containing mineral is physically activated to expose and dissolve additional magnesium into the solution. Pollutant gases such as carbon dioxide are mixed with the magnesium-containing solution. When the pH of the magnesium-containing solution is increased, solid magnesium carbonate is formed.

Owner:THE OHIO STATES UNIV

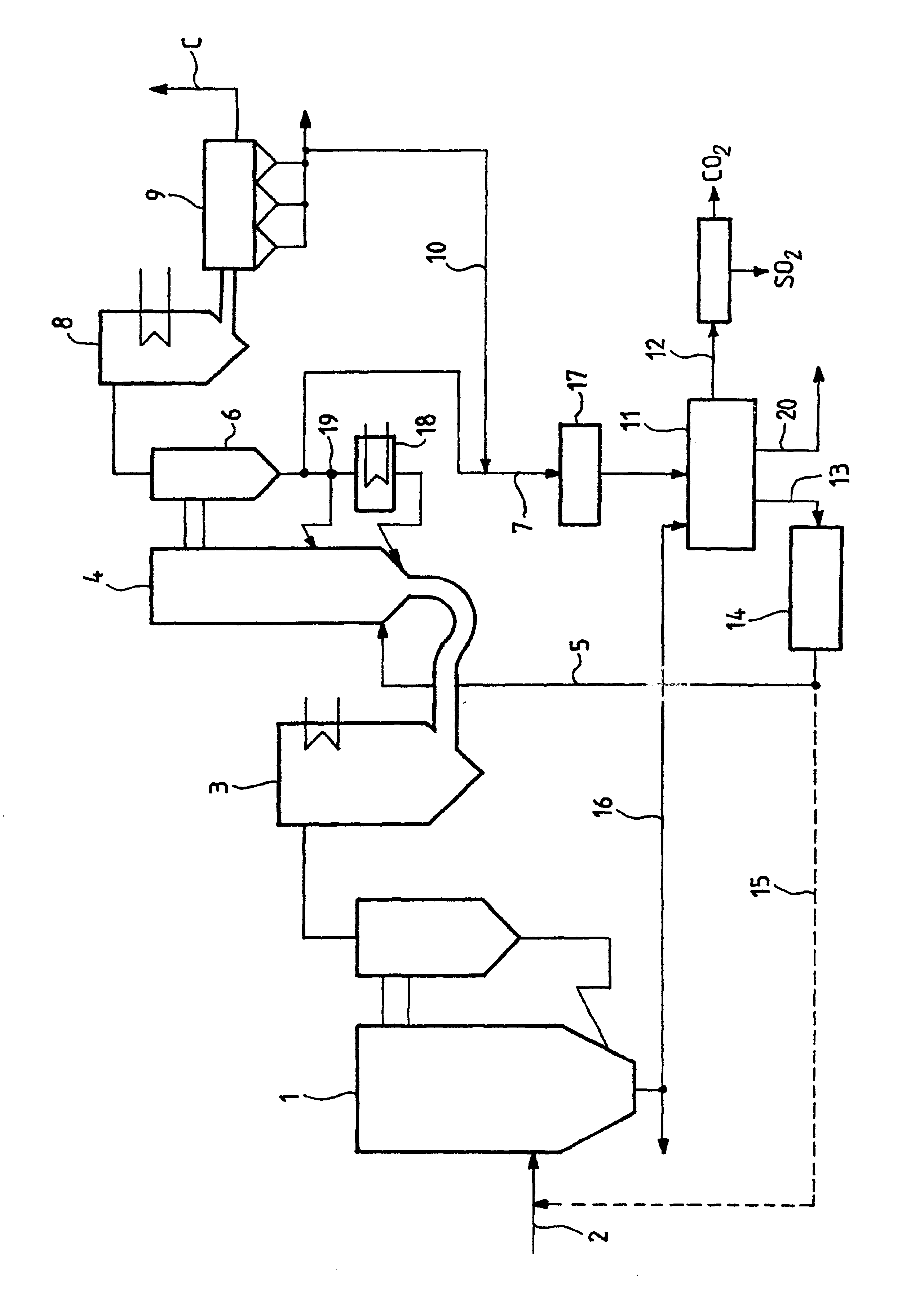

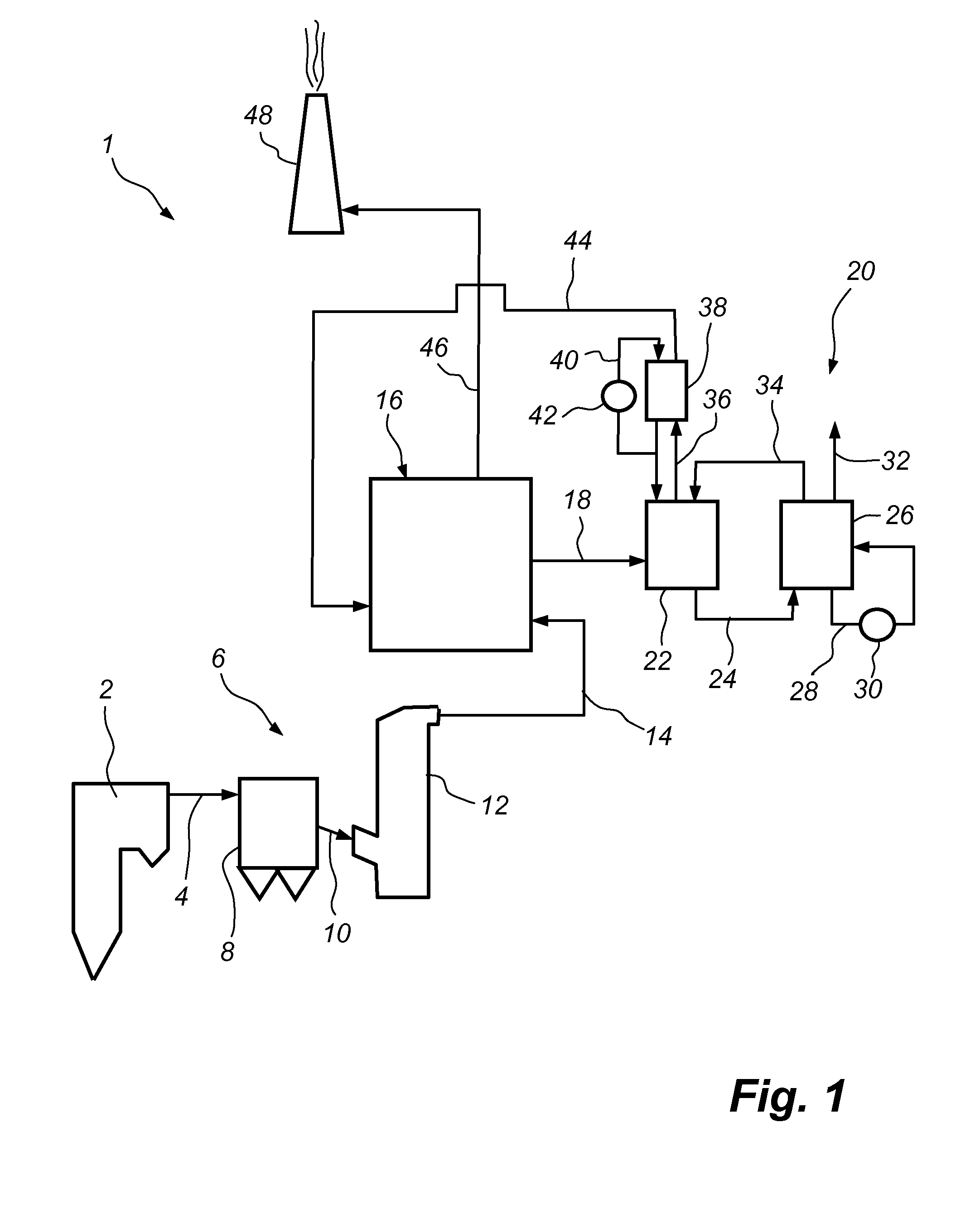

Method of simultaneously reducing CO2 and SO2 emissions in a combustion installation

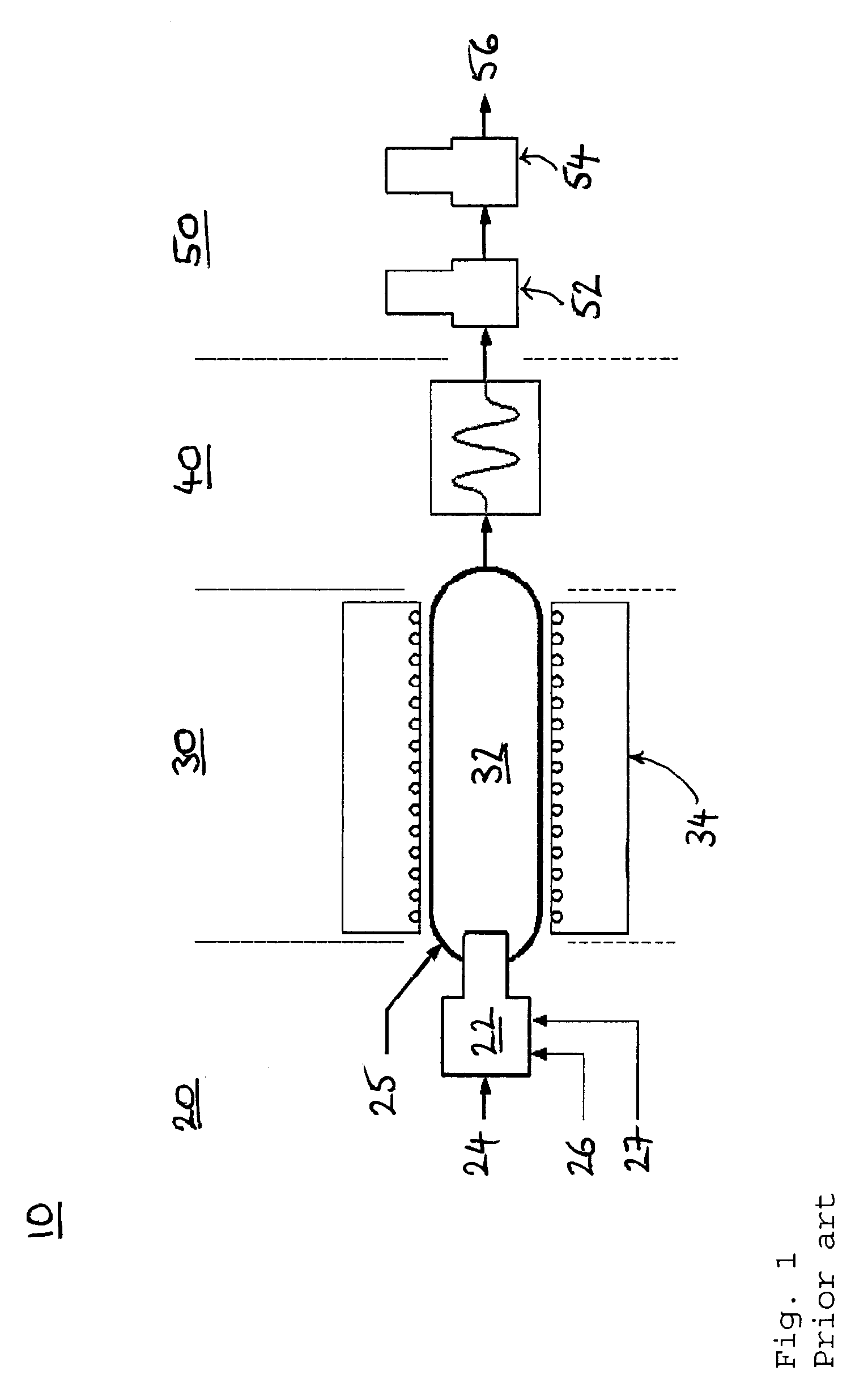

InactiveUS6737031B2Reduce carbon dioxide emissionsFluidized bed combustionGas treatmentCombustionFlue gas

The method of simultaneously reducing carbon dioxide (CO2) emissions and sulfur dioxide (SO2) emissions produced by the combustion of carbon-containing matter in a hearth consists in injecting into the hearth a calcium-based agent, a fraction of which absorbs SO2 after decarbonization, and then, after the flue gases have been subjected to intermediate cooling, in causing them to transit via a first reactor and in putting them in contact therein with the other fraction of the absorbant that has not reacted with SO2 so as to capture CO2 from the flue gases by carbonization, then, in a separator, in extracting the solids contained in the flue gases output from the first reactor so as to subject them to heat treatment in a second reactor in order to extract CO2 therefrom by decarbonization and in order to recycle the resulting regenerated CO2 absorbant to the first reactor.

Owner:GENERAL ELECTRIC TECH GMBH

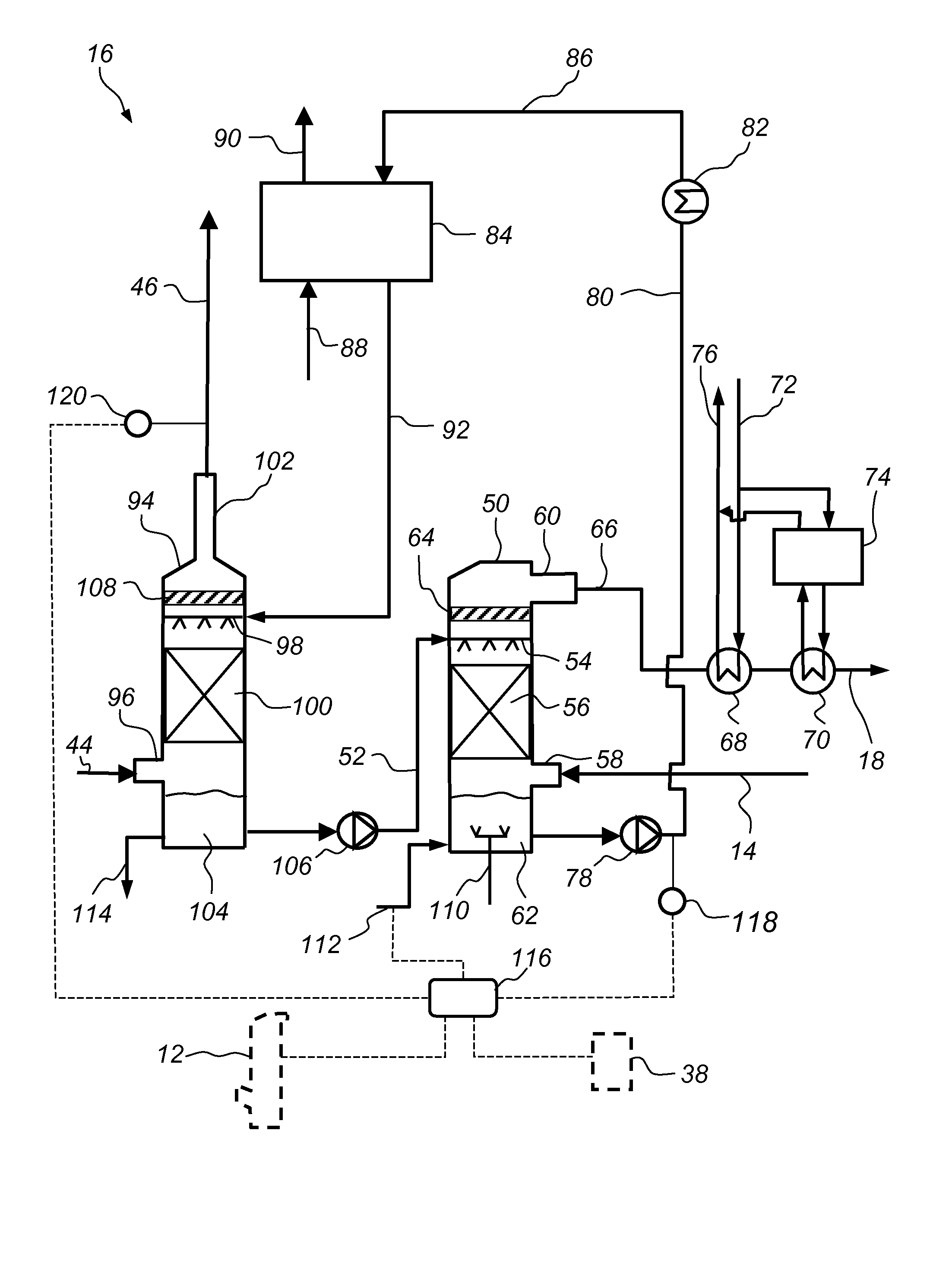

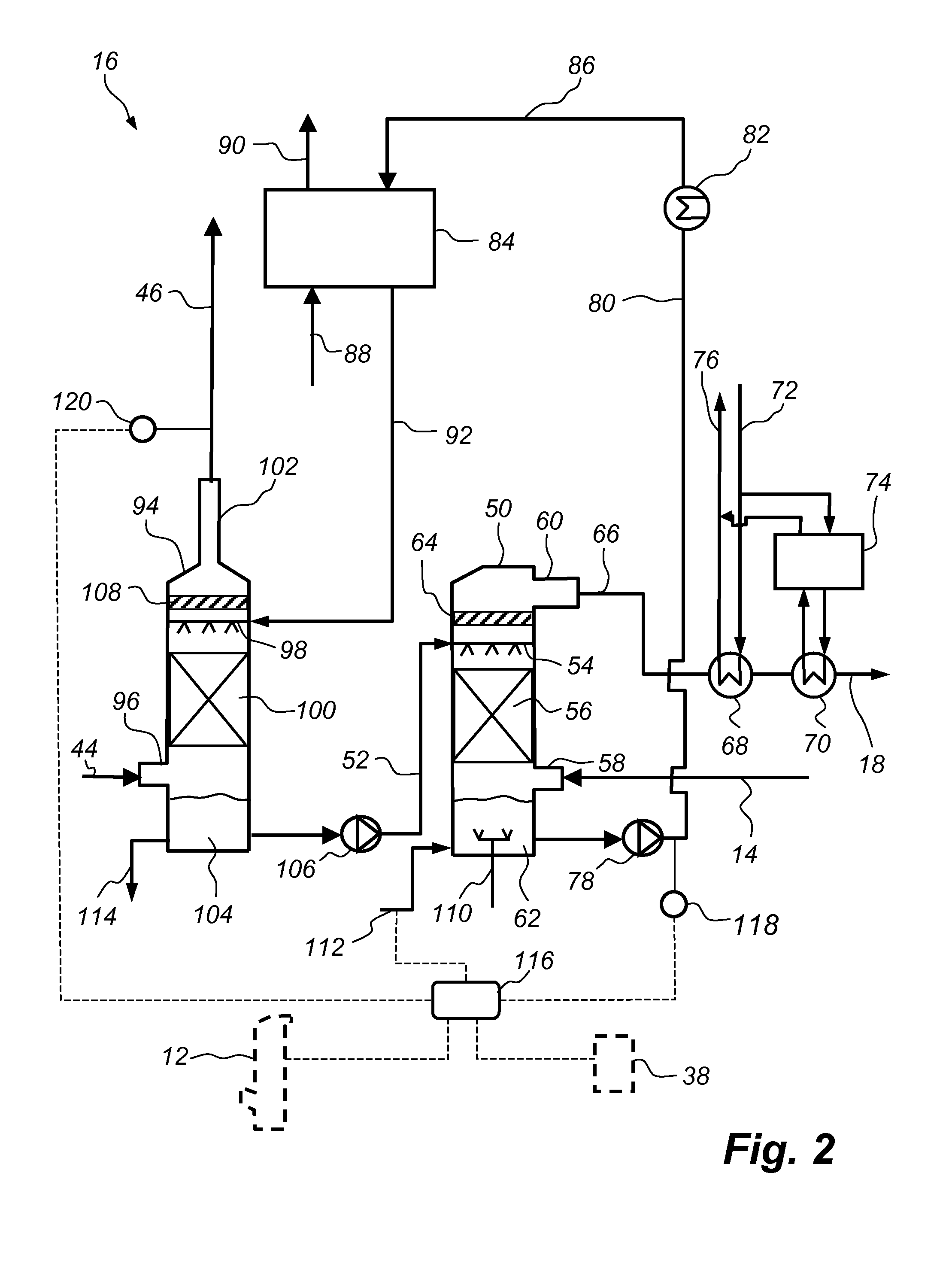

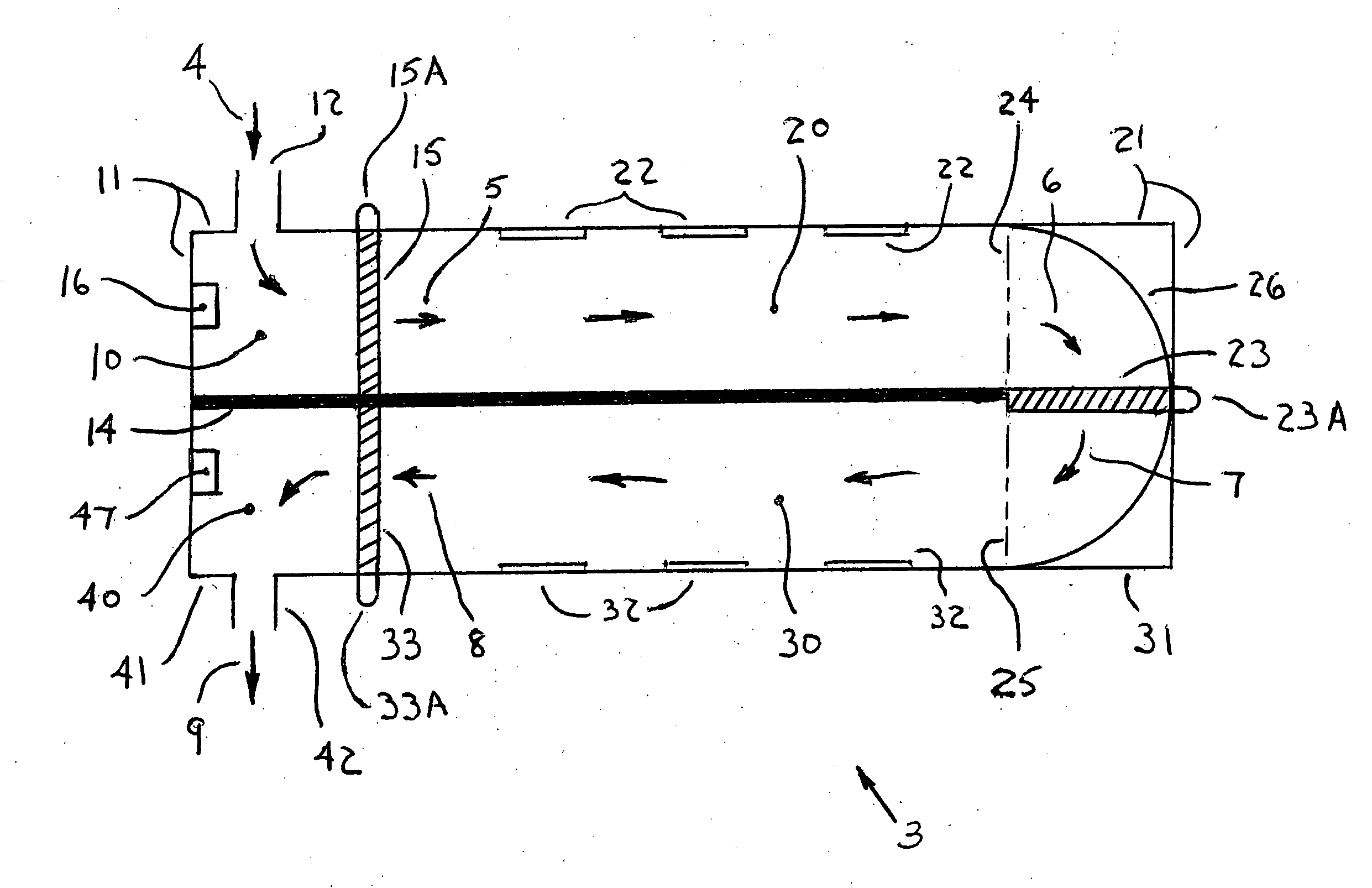

Use of so2 from flue gas for acid wash of ammonia

ActiveUS20080178733A1Efficient and environmentally acceptableGas treatmentDispersed particle filtrationSulfateFlue gas

A gas cleaning system, which is operative for cleaning a process gas containing carbon dioxide and sulphur dioxide, comprises a combined cooling and cleaning system (16), and a CO2-absorber. The combined cooling and cleaning system (16) comprises a first gas-liquid contacting device (50) located upstream of the CO2-absorber and operative for cooling the process gas by means of a cooling liquid, and for absorbing into the cooling liquid sulphur dioxide of the process gas, such that a cooling liquid containing sulphate is obtained. The combined cooling and cleaning system (16) further comprises a second gas-liquid contacting device (94) located downstream of the CO2-absorber and operative for removing ammonia from the process gas, which has been treated in the CO2-absorber, by means of bringing the process gas containing ammonia into contact with the cooling liquid containing sulphate.

Owner:GENERAL ELECTRIC TECH GMBH

Amino acid ion liquid for acidic gas absorption

The present invention relates to amino acid ion liquid for absorbing acidic gas. The anion of ion liquid is amino acid, amino acid ramification, similar to amino acid ion, imidazole cation, phosphoric cation, amine cation, ammoniumate cation and etc. After dipping craft, all ions can adhere to poriferous solid to absorb acidic gas such as carbon dioxide, sulfur dioxide emitted by flue and motor vehicles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

Method and apparatus for removing sulfur, nitrate and mercury simultaneously from boiler flue gas

InactiveCN1962034AExtended stayIncrease profitDispersed particle separationOxygenCalcium hypochlorite

The invention relates to a method for realizing desulfuration, denitration and demercuration of boiler smoke synchronously, wherein it comprises feeding smoke into cycle fluidize bed reactor, and injecting oxygen-enriched active absorber; said absorber is formed by coal ash at 20-70, lime hydrate at 27-80, additive at 0.5- 3 as kalii permangana KMnO4, sodium chlorite NaClO2, natrii chloridum NaCl, calcium hypochlorite Ca(ClO)2 or acetic hyctro peroxide CH3COOH. The invention's desulfuration efficiency can reach 90%, the denitration efficiency can reach 60%, and the demercuration can reach 50%, with low cost and non pollution.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

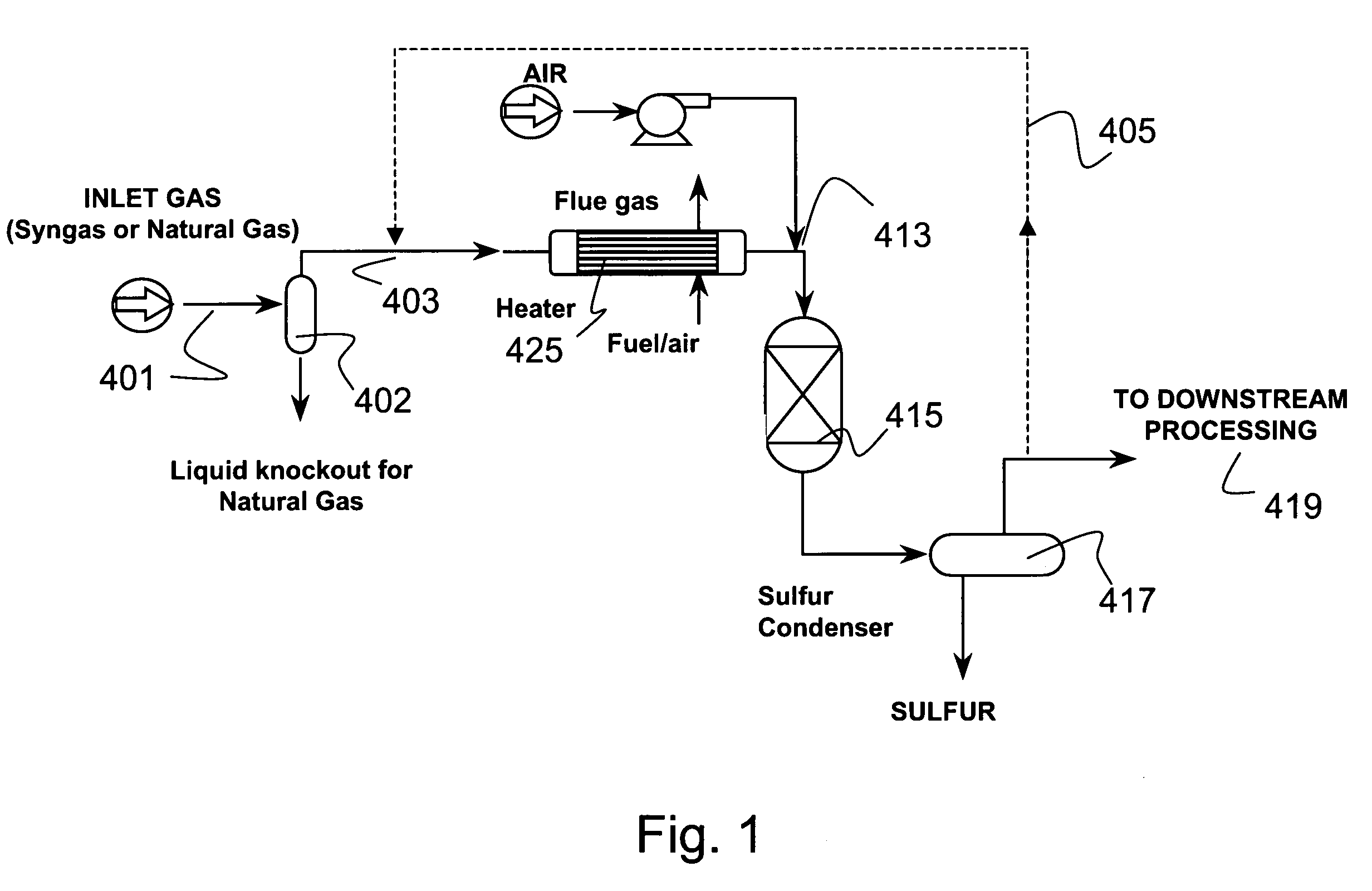

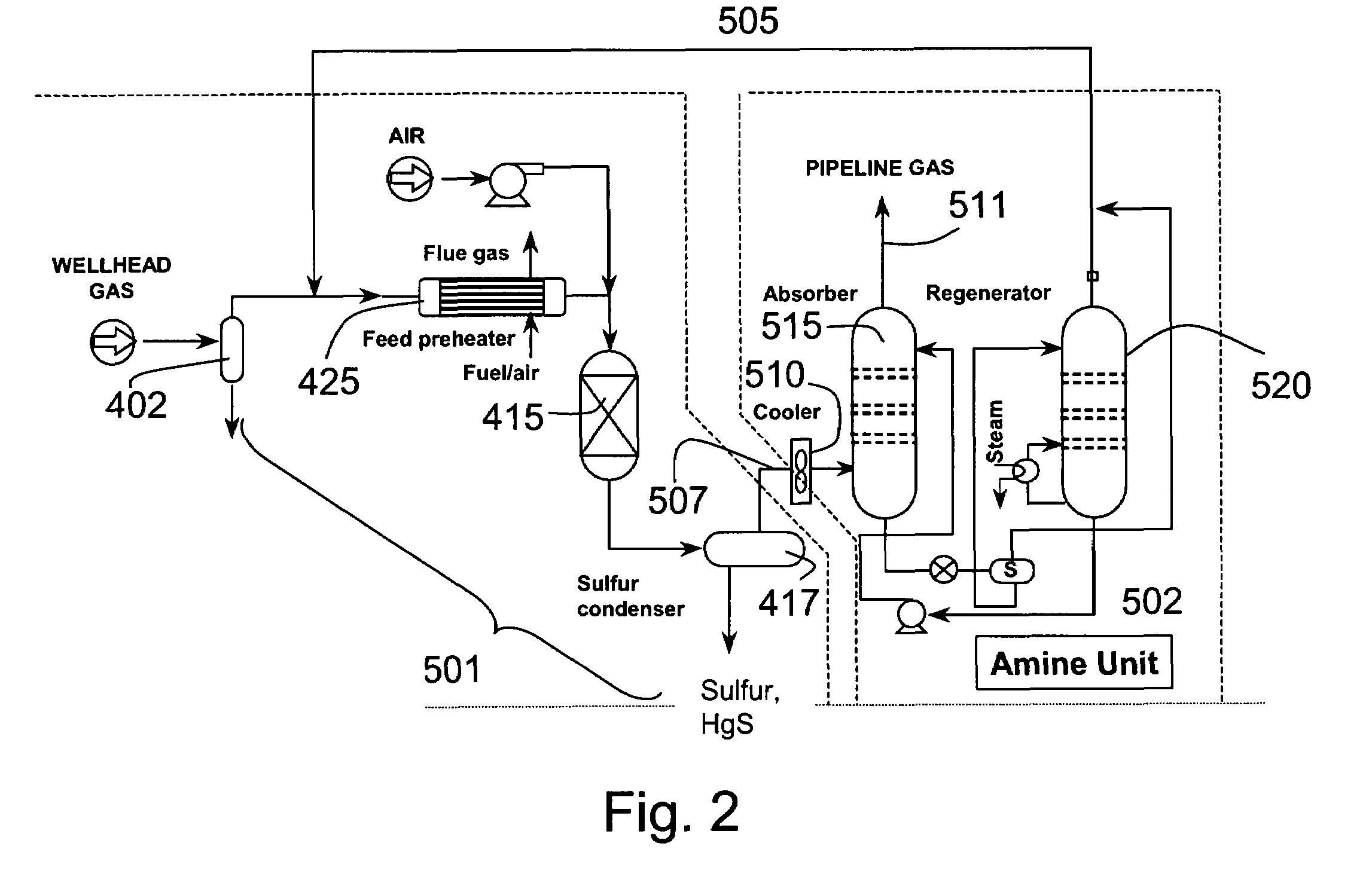

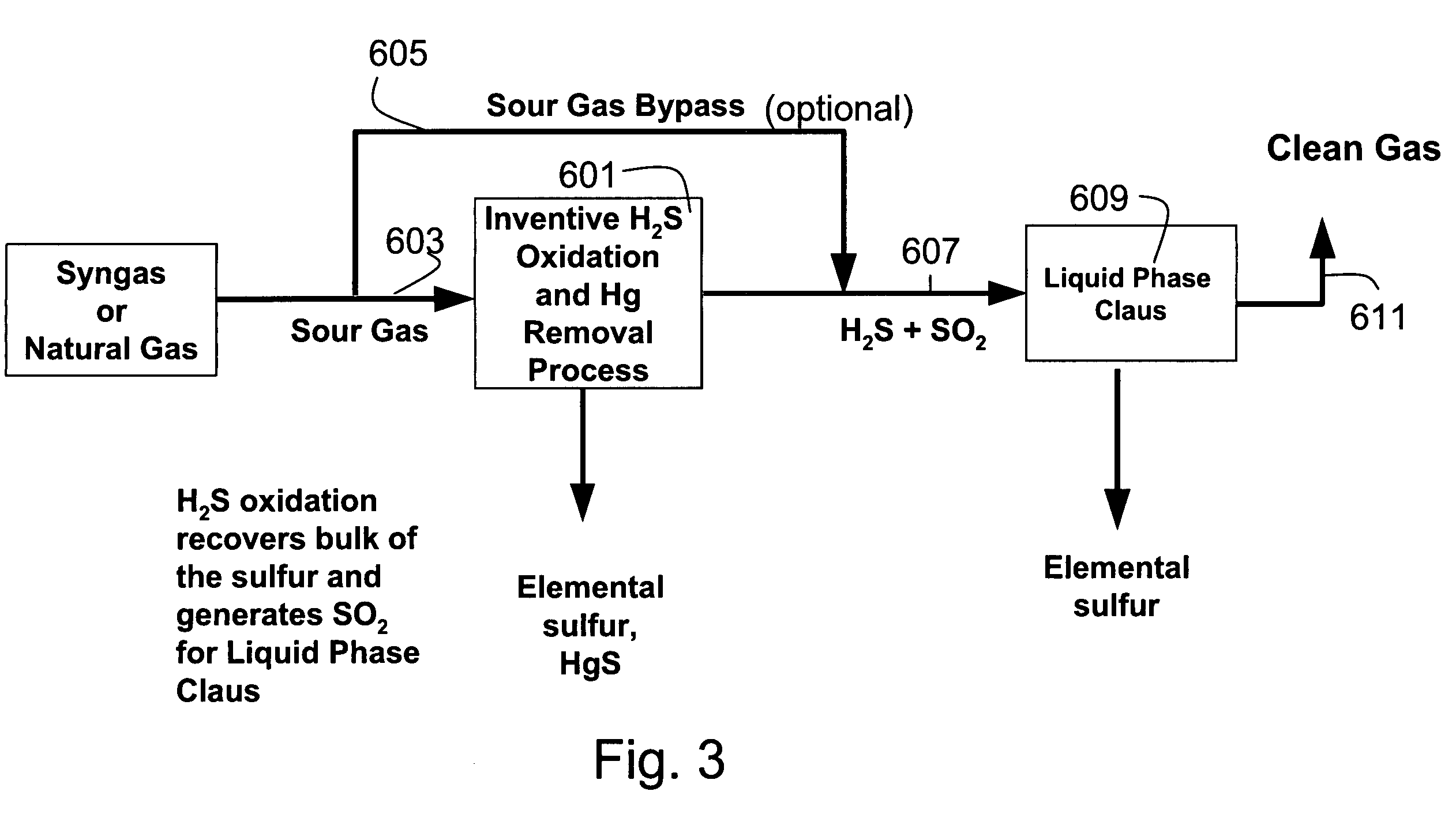

Process for the simultaneous removal of sulfur and mercury

InactiveUS7060233B1Lower capitalReduce operating costsGas treatmentUsing liquid separation agentSulfur containingInorganic sulfide

A process for removing hydrogen sulfide, other sulfur-containing compounds and / or sulfur and mercury from a gas stream contaminated with mercury, hydrogen sulfide or both. The method comprises the step of selective oxidation of hydrogen sulfide (H2S) in a gas stream containing one or more oxidizable components other than H2S to generate elemental sulfur (S) or a mixture of sulfur and sulfur dioxide (SO2). The sulfur generated in the gas stream reacts with mercury in the gas stream to generate mercuric sulfide and sulfur and mercuric sulfide are removed from the gas stream by co-condensation.

Owner:TDA RES

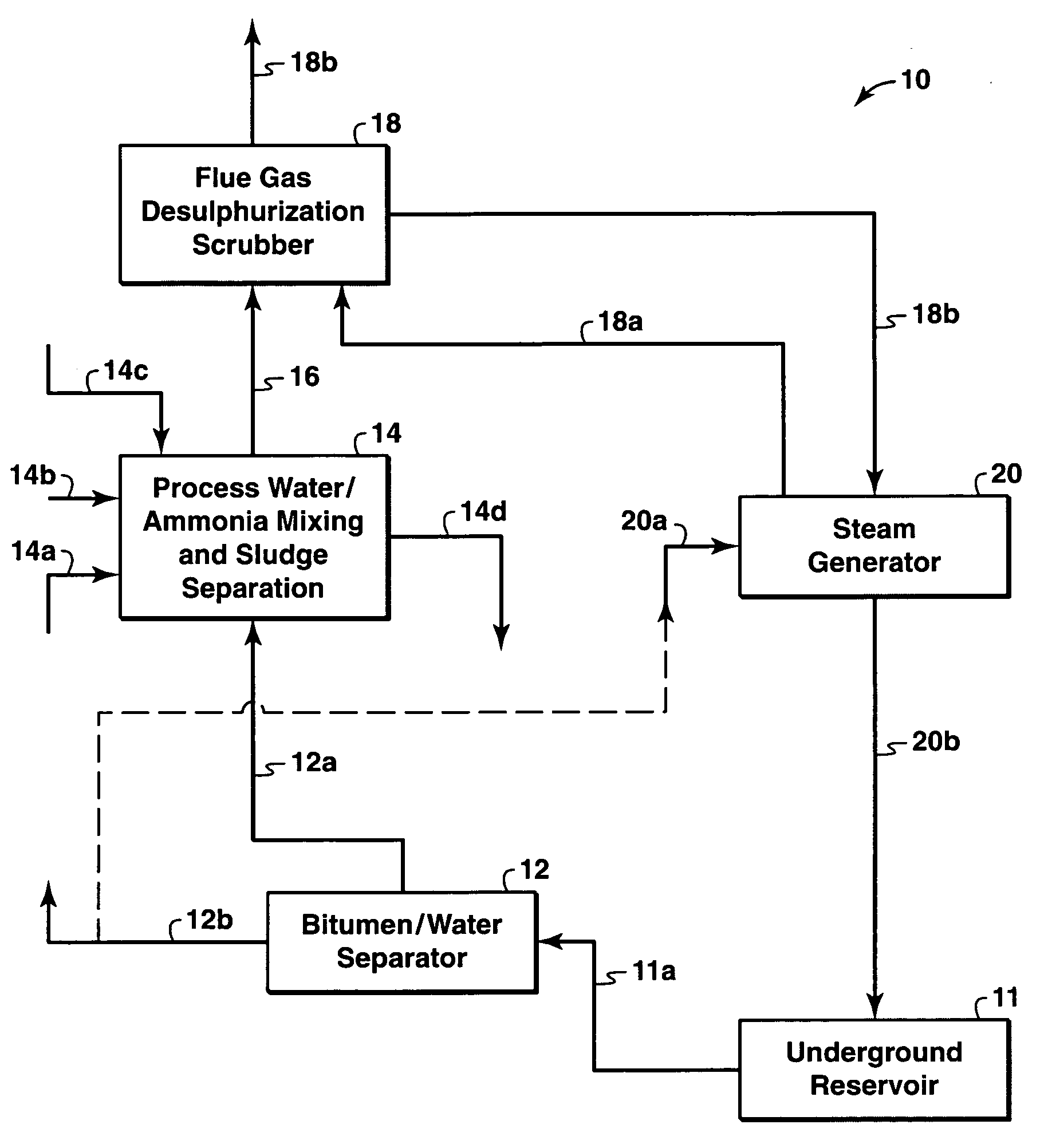

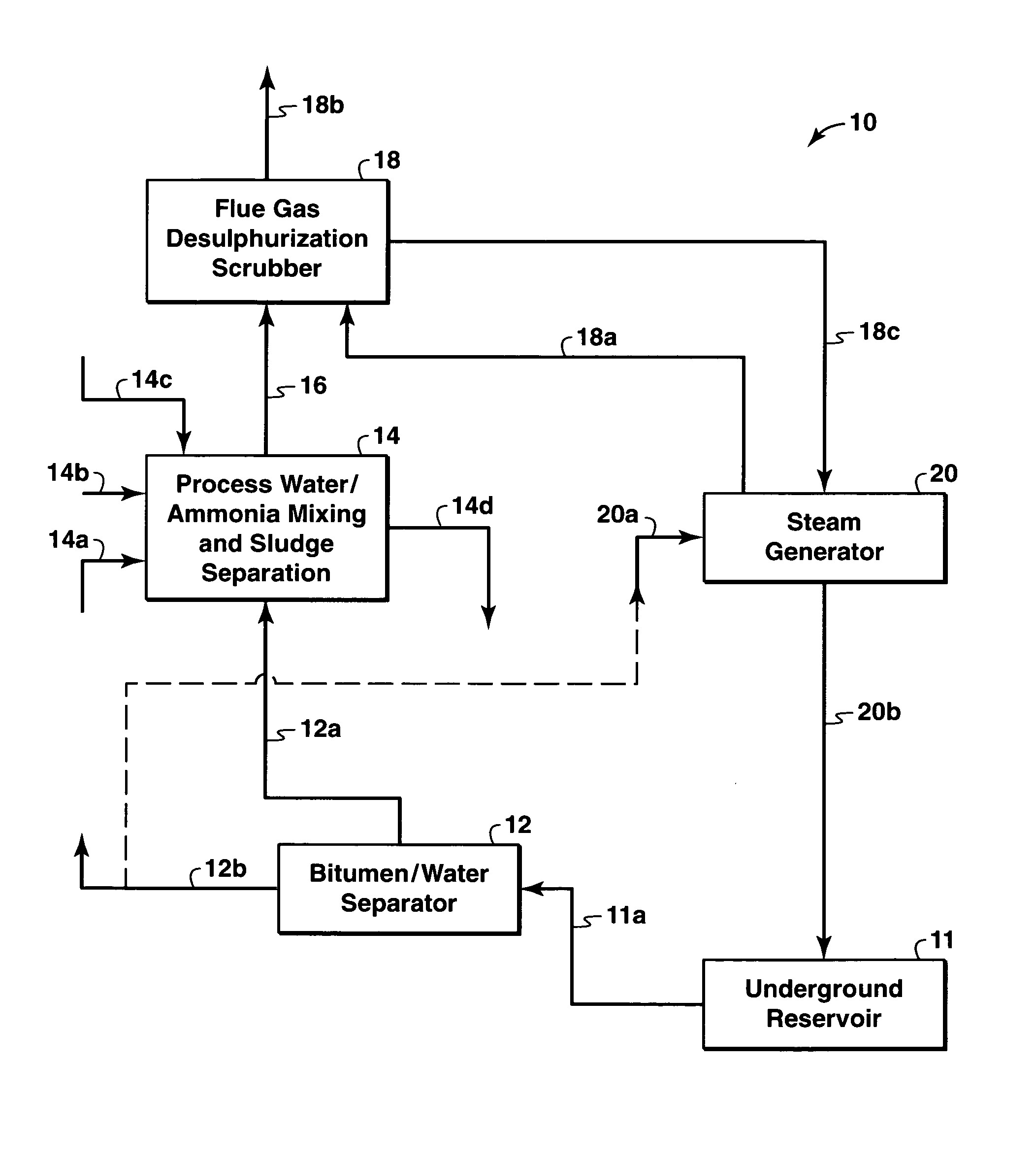

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

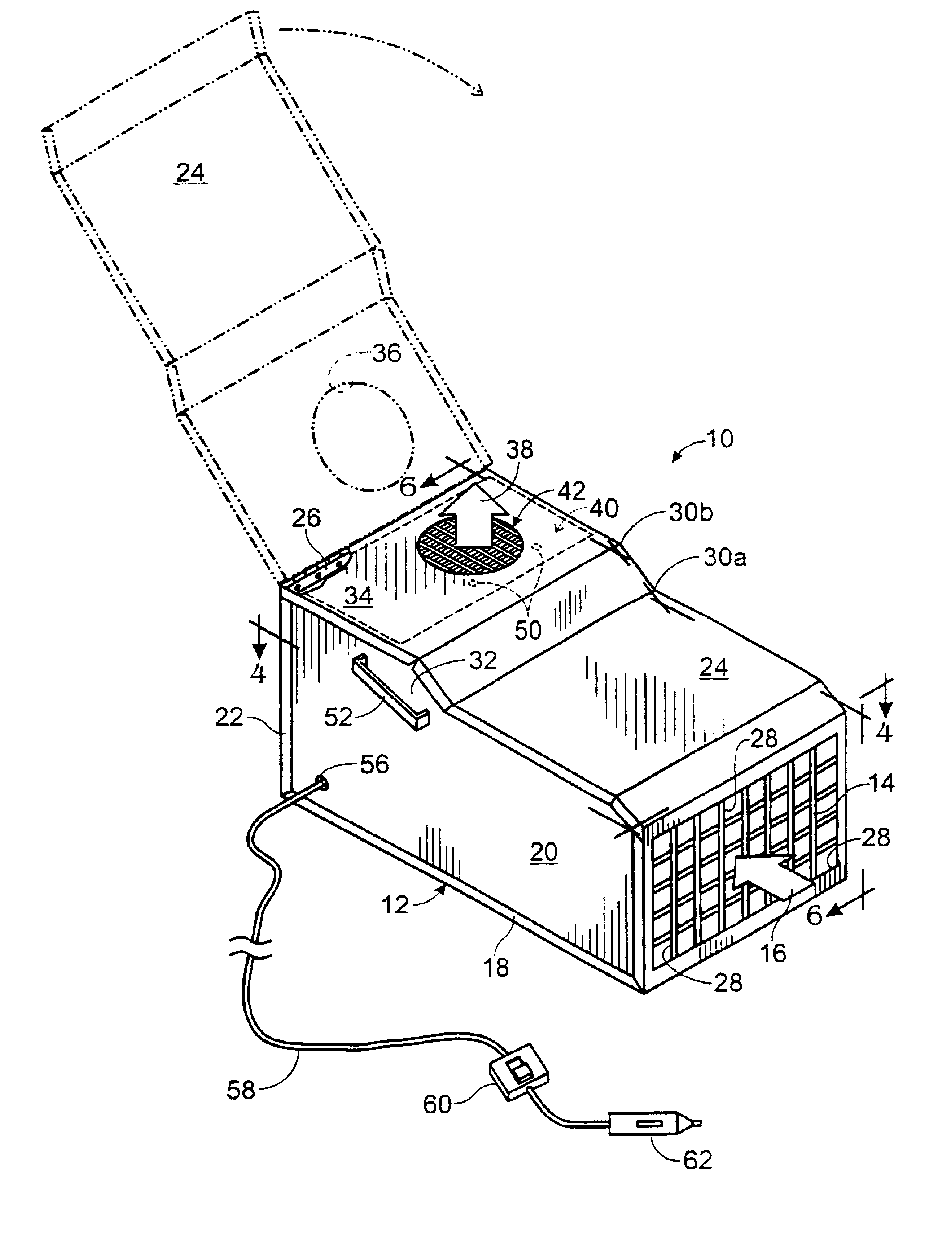

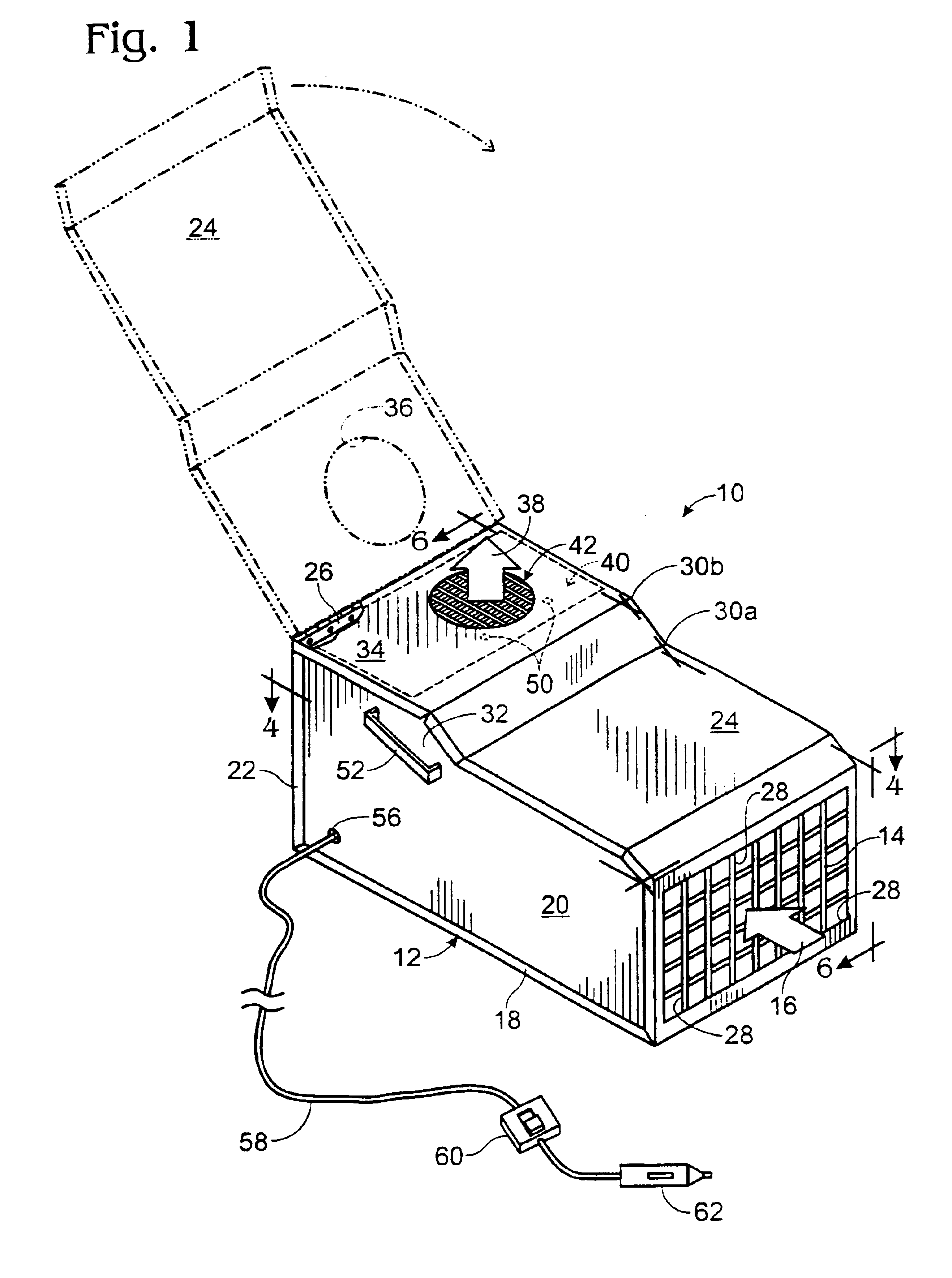

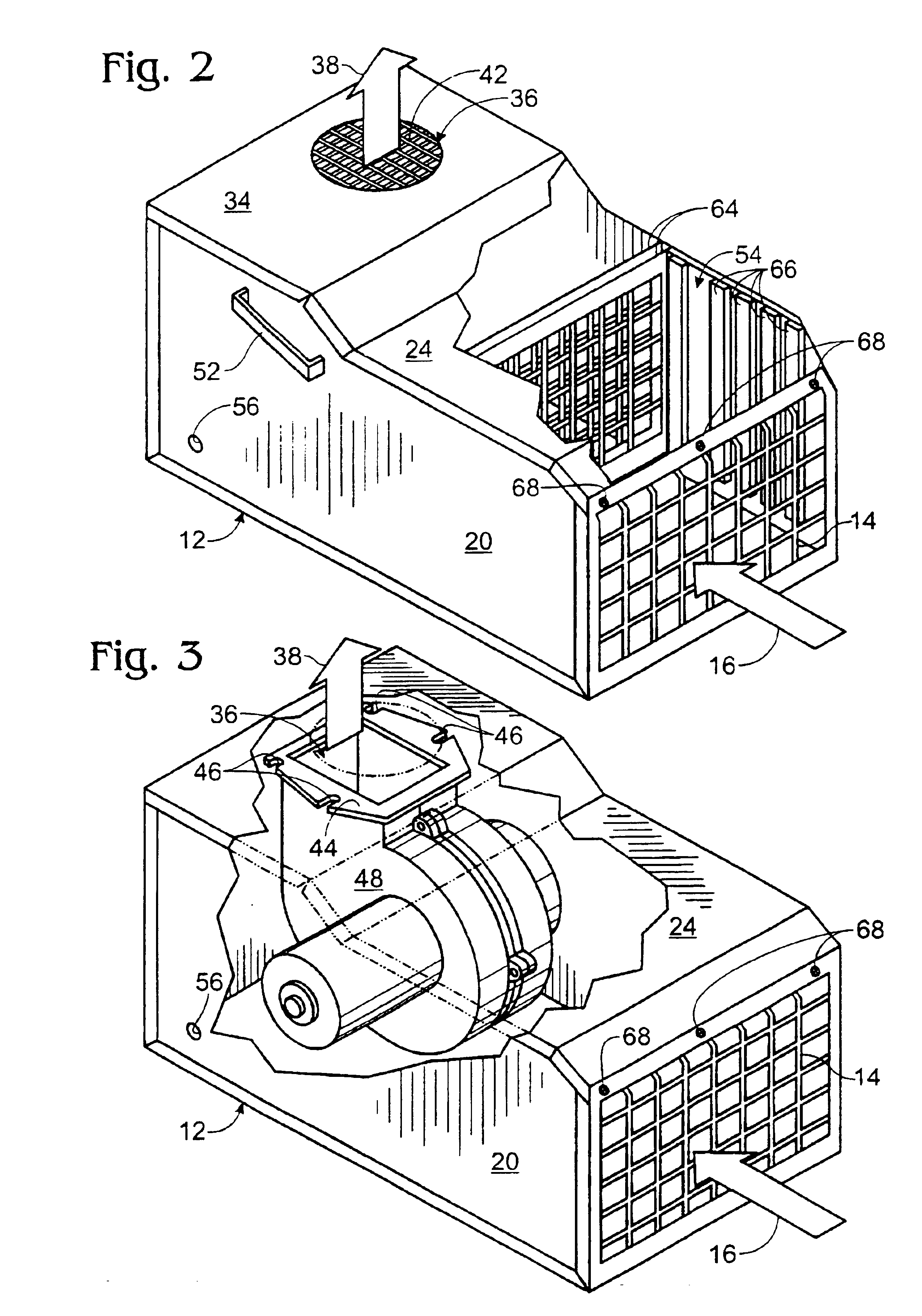

Portable motor vehicle cabin air purifier

InactiveUS6773477B2Improve comfortEasy to moveHuman health protectionCombination devicesHEPAAir cycle

A portable air purifier for reducing pollutants in the passenger cabin of a vehicle to concentrations at least as low as the US-EPA National Ambient Air Quality Standards for: carbon monoxide, ozone, nitrogen dioxide, sulfur dioxide, lead, and particulate matter; plus benzene to a European ambient air standard. The purifier includes an air inlet and air outlet in communication with the vehicle cabin, with air circulation provided by a DC electric motor / blower attachable to a vehicle power plug. The filter assembly includes a specified series of filter media packets and a HEPA filter. The machine's preferred location is in the center of a rear seat where it can serve as an armrest / console and be secured by a seat belt.

Owner:ZELLER MARIE DEHARPPORT

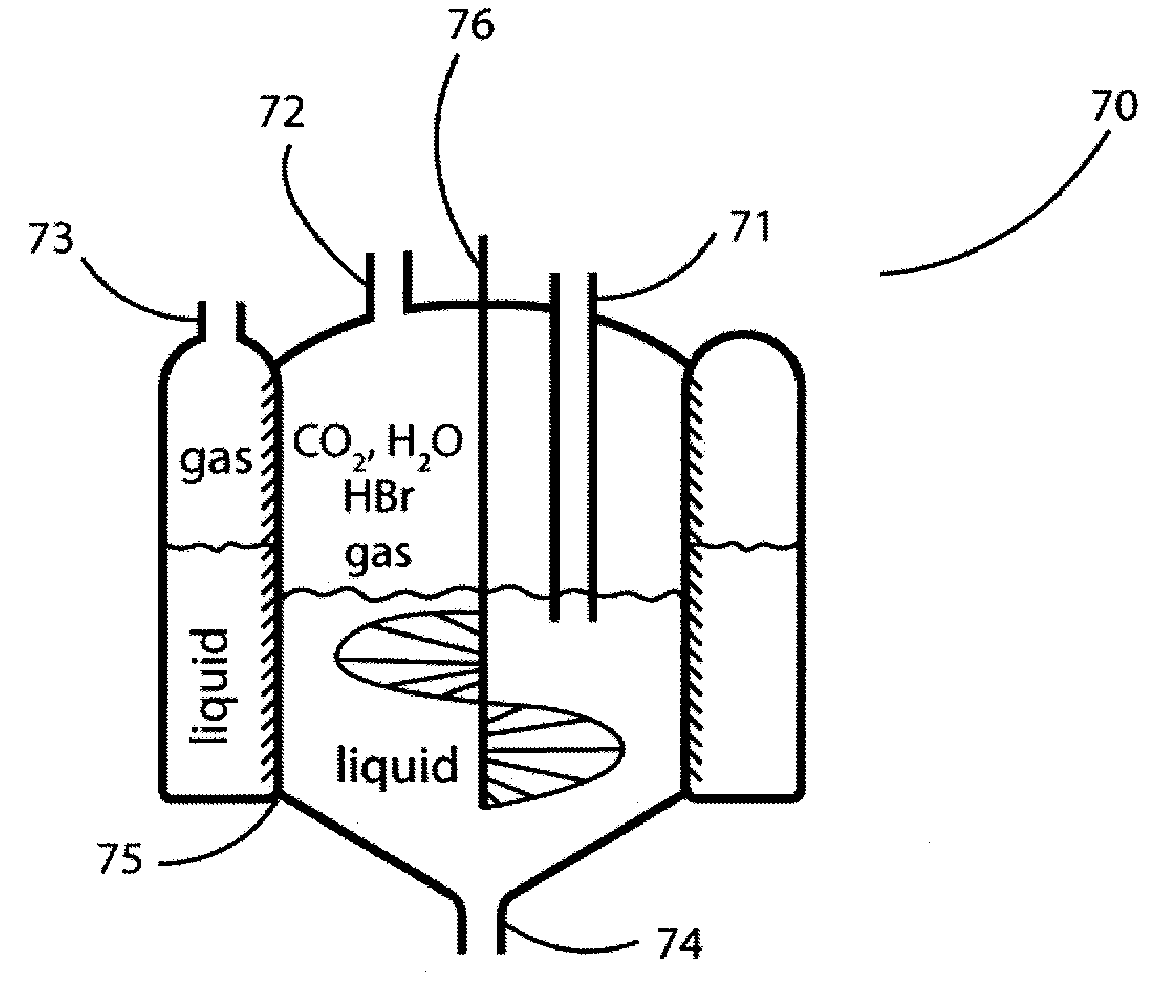

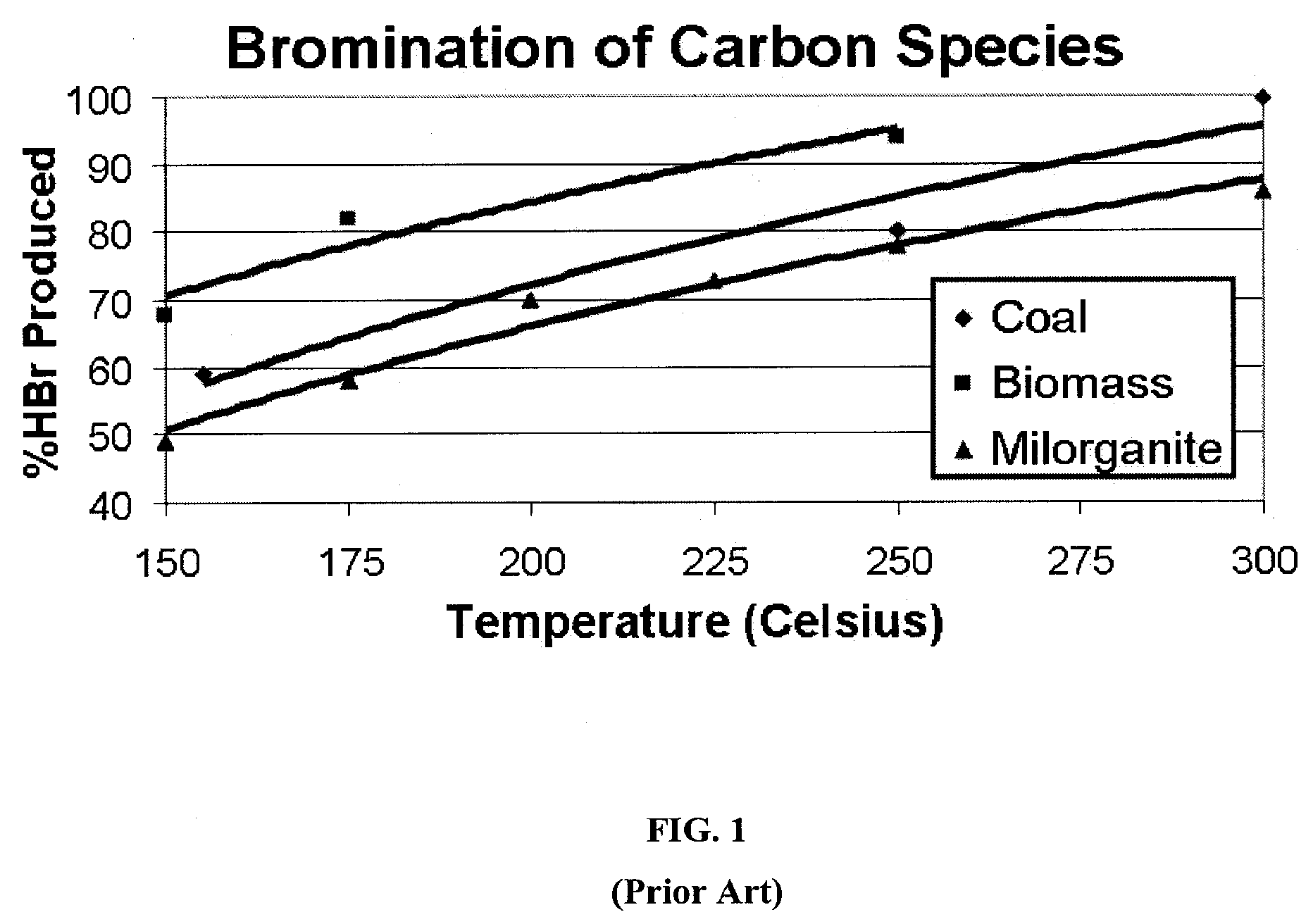

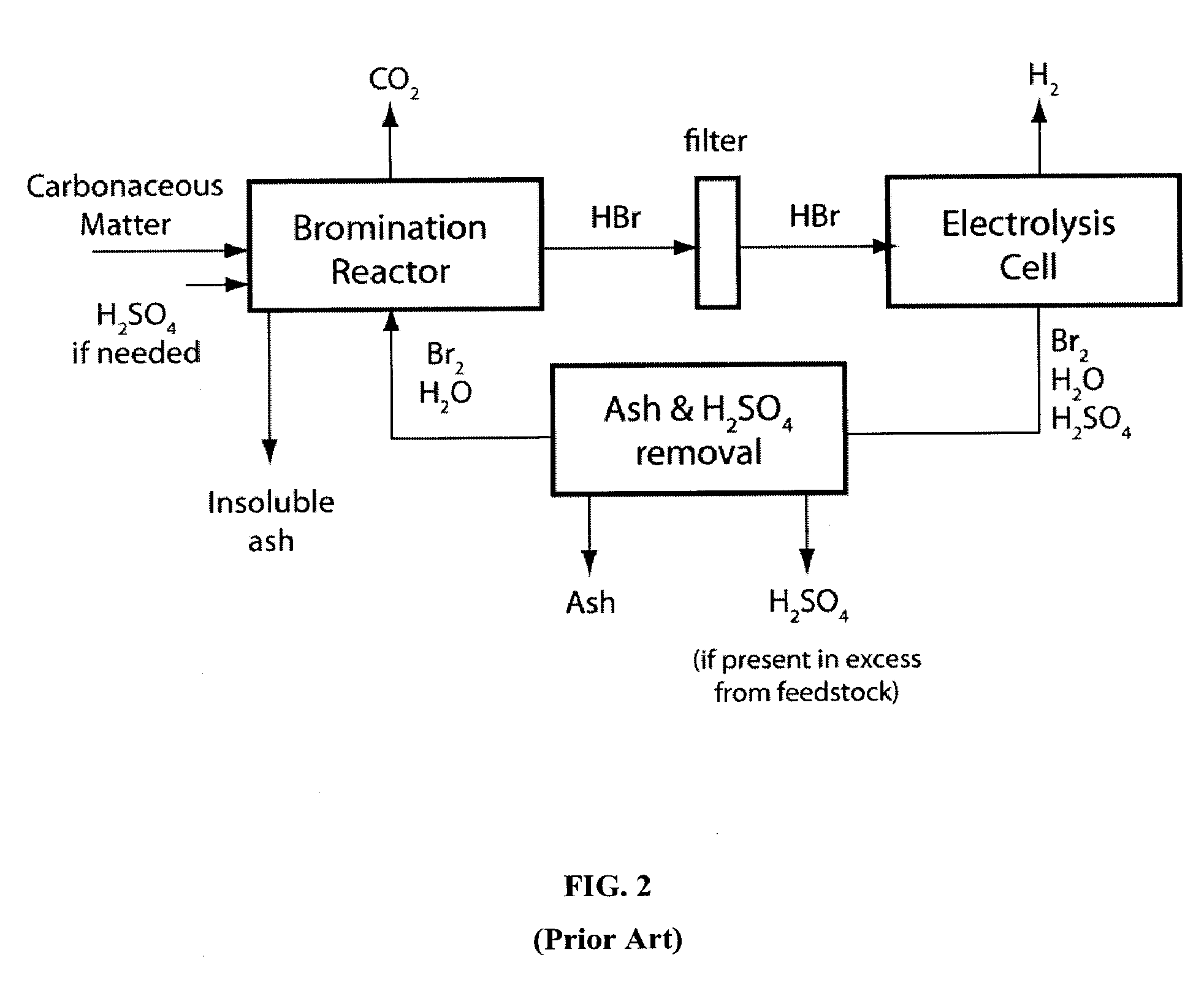

Waste Treatment and Energy Production Utilizing Halogenation Processes

InactiveUS20090028767A1Reduce needEfficient processingPhotography auxillary processesElectrolysis componentsCelluloseEngineering

A method for generating energy and / or fuel from the halogenation of a carbon-containing material and / or a sulfur-containing chemical comprises supplying the carbon-containing material (e.g., coal, lignite, biomass, cellulose, milorganite, methane, sewage, animal manure, municipal solid waste, pulp, paper products, food waste) and / or the sulfur-containing chemical (e.g., H2S, SO2, SO3, elemental sulfur) and a first halogen-containing chemical to a reactor. The carbon-containing material and / or the sulfur-containing chemical and the halogen-containing chemical are reacted in the reactor to form a second halogen-containing chemical and carbon dioxide, sulfur and / or sulfuric acid. The second halogen-containing chemical is dissociated (e.g., electrolyzed) to form the first halogen-containing chemical and hydrogen gas (H2). The first halogen-containing chemical can be Br2 and the second halogen-containing chemical can be HBr. Any carbon dioxide formed during reaction can be directed to a prime mover (e.g., turbine) to generate electricity. Any ash and / or sulfur formed can be removed. In some cases a sulfur-containing chemical can be supplied to the reactor with the carbon-containing material.

Owner:SRT GROUP

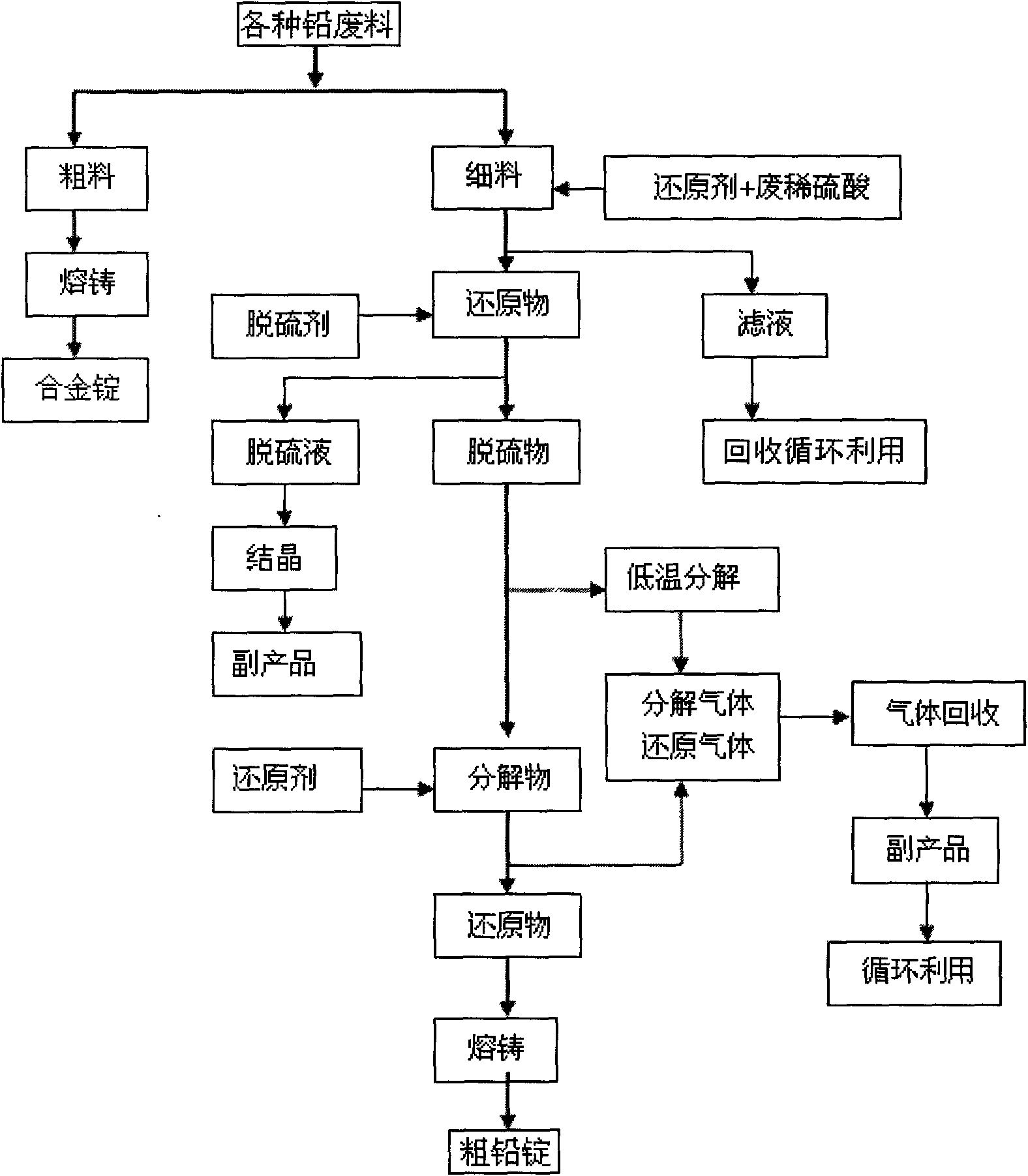

Waste lead recovering method for lead-acid storage batteries

InactiveCN101608264AAvoid harmLower decomposition temperaturePhotography auxillary processesProcess efficiency improvementLead dioxideEngineering

The invention discloses a waste lead recovering method for lead-acid storage batteries. The method comprises the following steps: fine stuff such as diachylon and the like are added in a reaction kettle with a stirring device; reducing agent (FeSO4) and dilute sulfuric acid are simultaneously added; stirring reaction is carried out at the temperature of 50-60 DEG C for 50-70 minutes so as to reduce lead dioxide into lead sulfate; the lead sulfate is added into the reaction kettle with the stirring device; water is simultaneously added into the reaction kettle for size mixing; then sodium carbonate is added; desulfuration is carried out at the temperature of 50-60 DEG C so as to obtain solid lead carbonate; the lead carbonate is put into a smelting furnace and then decomposed at the temperature of 320-350 DEG C so as to obtain lead oxide; and reducing agent (carbon) is added into the smelting furnace to reduce the lead oxide into metal lead at the temperature of 700-800 DEG C. The method recovers the lead by means of the combination of the wet and the dry processes, thereby avoiding the harm to the environment caused by lead dust, lead vapor, lead skim, sulfur dioxide gas, and the like by adopting fire smelting. The method has the advantages of high lead recovery rate, low energy consumption and no environment pollution.

Owner:张天任

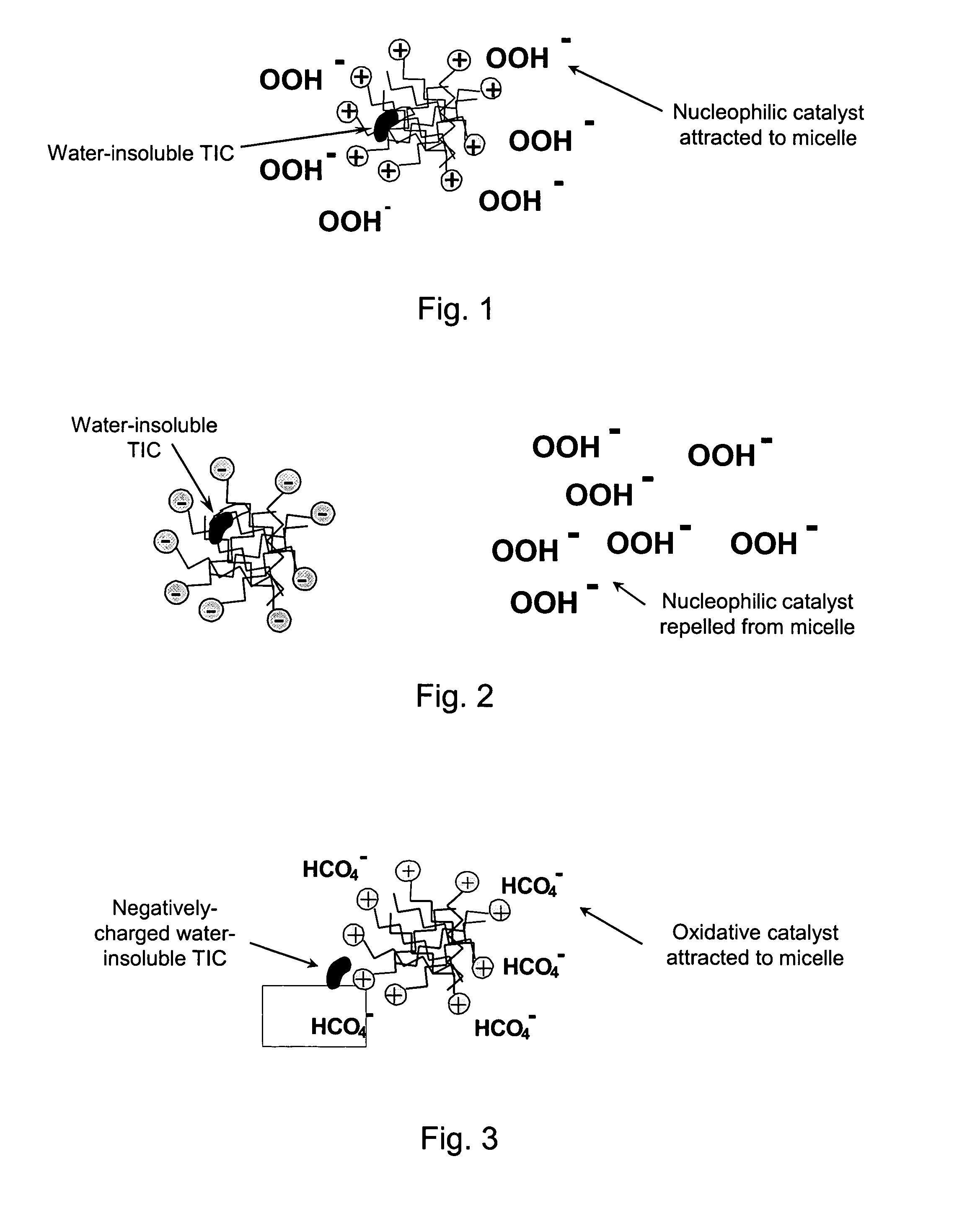

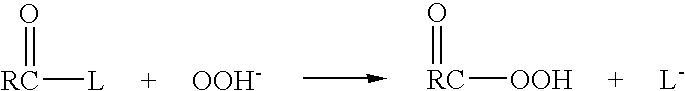

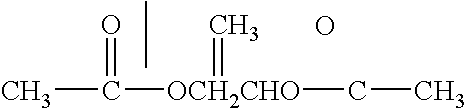

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

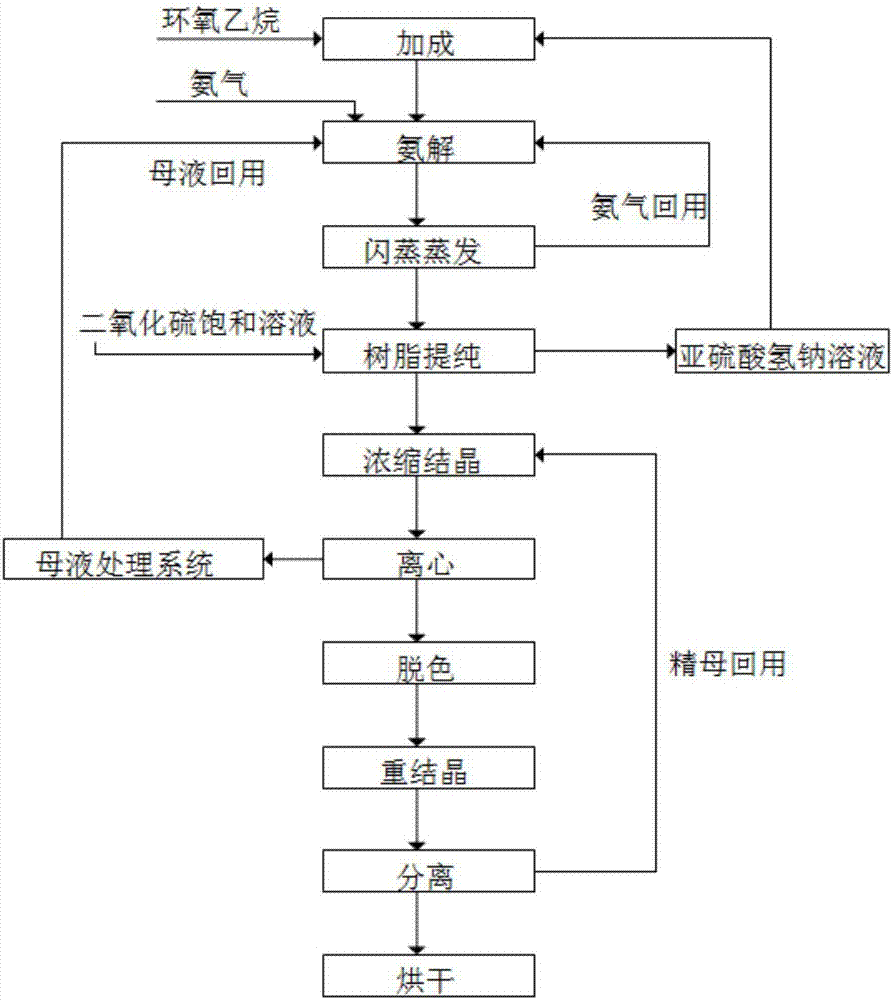

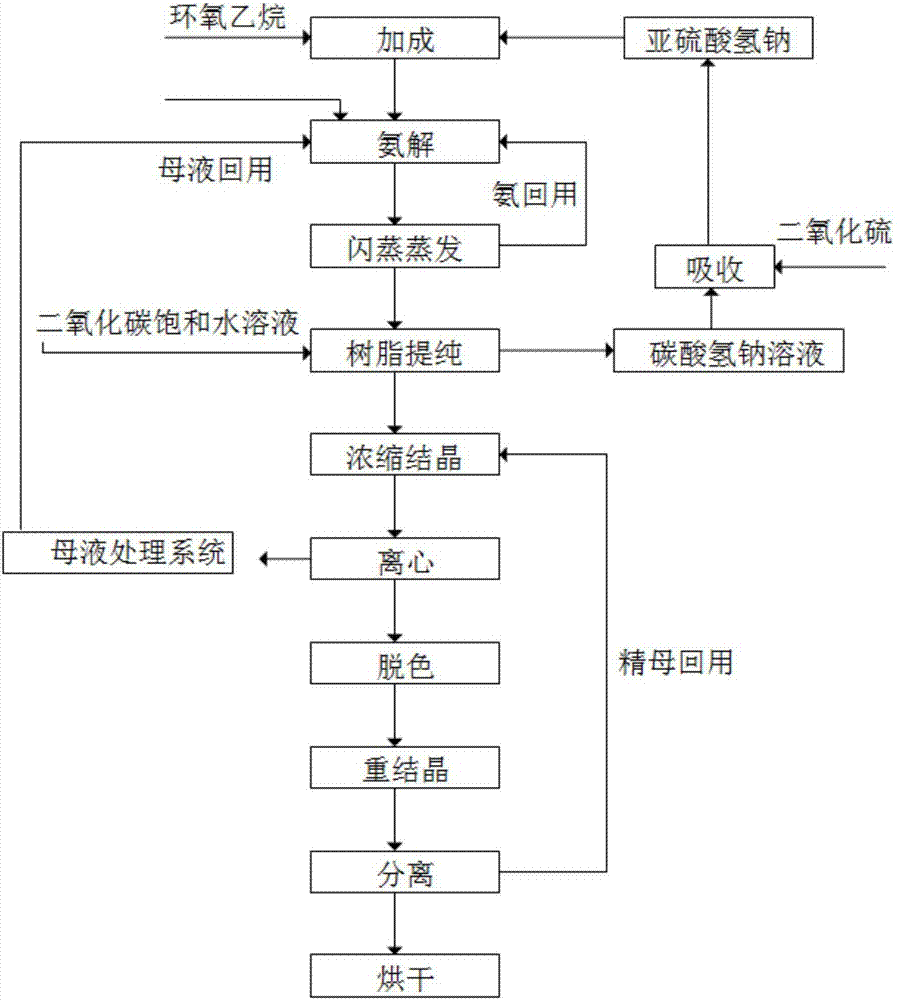

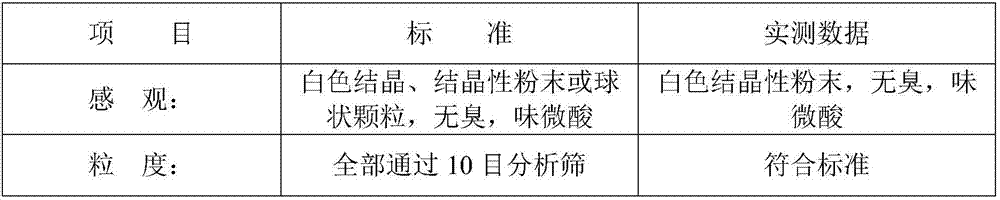

Method for cyclically producing taurine at high yield

ActiveCN107056659AReduce productionEfficient recyclingPhysical/chemical process catalystsOrganic compound preparationAfter treatmentHydrogen

The invention relates to a method for cyclically producing taurine at a high yield. The method includes the following steps that S1, ethylene oxide reacts with a sodium hydrogen sulfite solution to generate sodium hydroxyethyl sulfonate; S2, sodium hydroxyethyl sulfonate obtained in S1 is subjected to an ammonolysis reaction in ammonium hydroxide, flashing is carried out after the reaction is completed, and ammonia gas is recycled; S3, taurine-containing feed liquid of reaction liquid obtained after flashing in S2 is collected through an acid cation exchange resin column, the resin column is regenerated with a sulfur dioxide or carbon dioxide water solution after being inactivated, and eluant obtained during regeneration can be directly reused or reused after being treated with sulfur dioxide; S4, the feed liquid collected in S3 is subjected to after-treatment, and taurine is obtained. The method has the advantages that the generation amount of waste liquid in the whole process is small, part of substances are effectively and cyclically utilized in the process, the cost is reduced, the yield of taurine can reach 90% or above, meanwhile, the production process is relatively simple, and large-scale production is easy.

Owner:QIANGJIANG YONGAN PHARMA

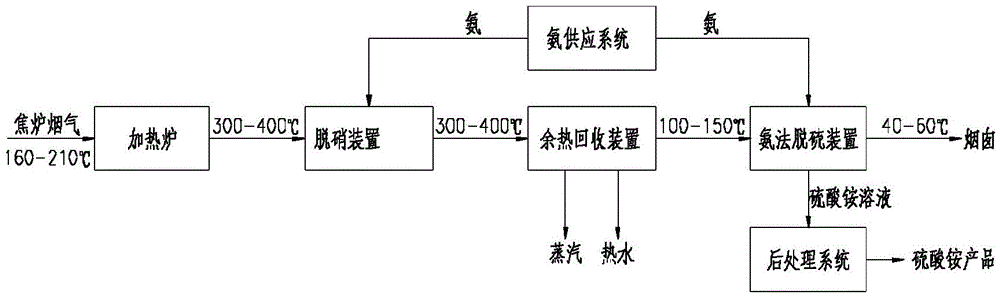

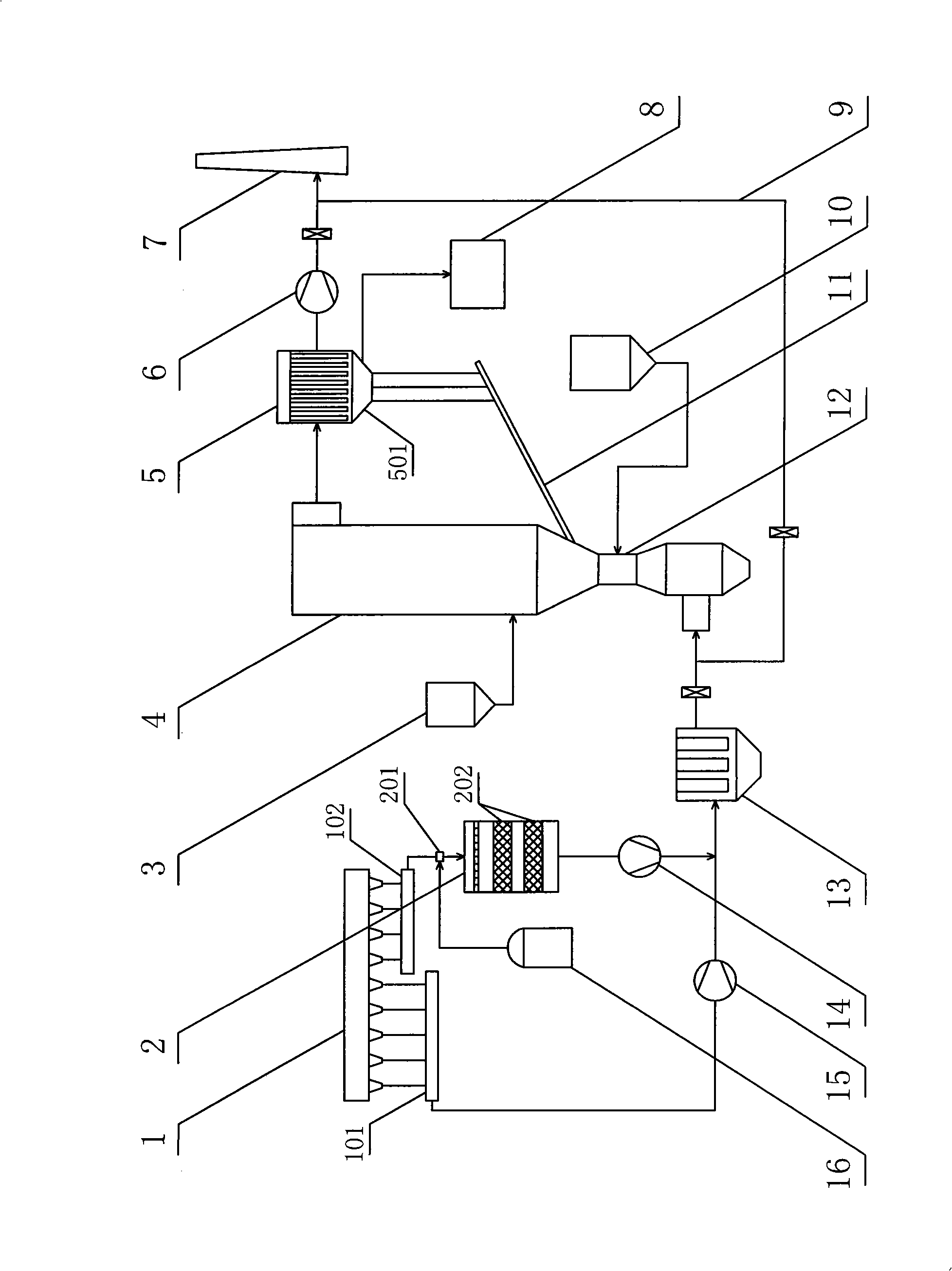

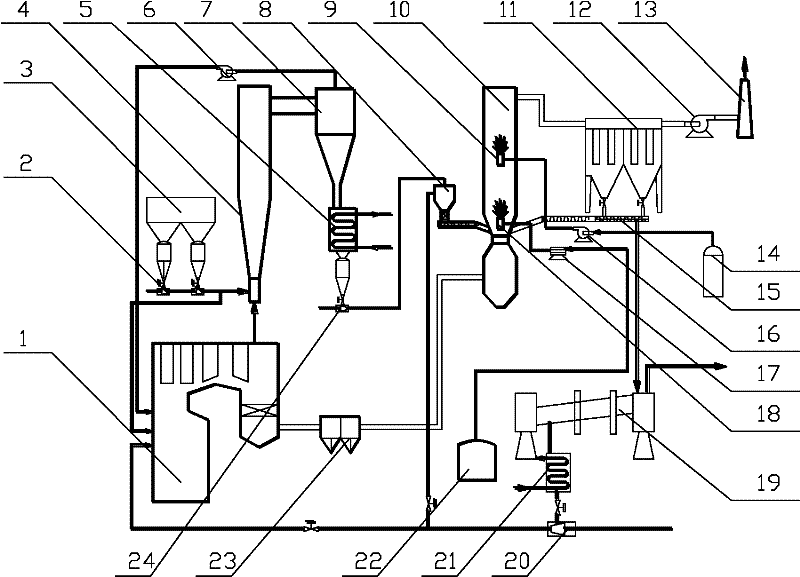

Coke oven flue gas desulfurization, denitration and waste heat recovery integrated method

InactiveCN104923046ASimple processWork lessDispersed particle separationEnergy inputFlue gasReaction temperature

The invention relates to a coke oven flue gas desulfurization, denitration and waste heat recovery integrated method. Flue gas from a coke oven firstly enters a heating furnace to be heated to 300 to 400 DEG C, and then the flue gas enters a denitration device for removing nitrogen oxide in the flue gas through a denitration reducer and a denitration catalyst, wherein the denitration reducer is ammonia; and the flue gas discharged from the denitration device is subjected to heat recovery through a waste heat recovery device and cooled to 100 to 150 DEG C, and then the flue gas enters an ammonia desulfurization device for removing sulfur dioxide in the flue gas. Both a desulfurization absorbent and the denitration reducer in the method are ammonia, and public ammonia is supplied to a system, so that operation and maintenance work is reduced. The heating furnace for heating and the waste heat recovery device are arranged, so that the flue gas temperature reaches the optimal denitration and desulfurization reaction temperatures respectively, relatively high denitration and desulfurization efficiency can be achieved, and flue gas waste heat can be recycled for greatly reducing the operation cost of coke oven flue gas treatment.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

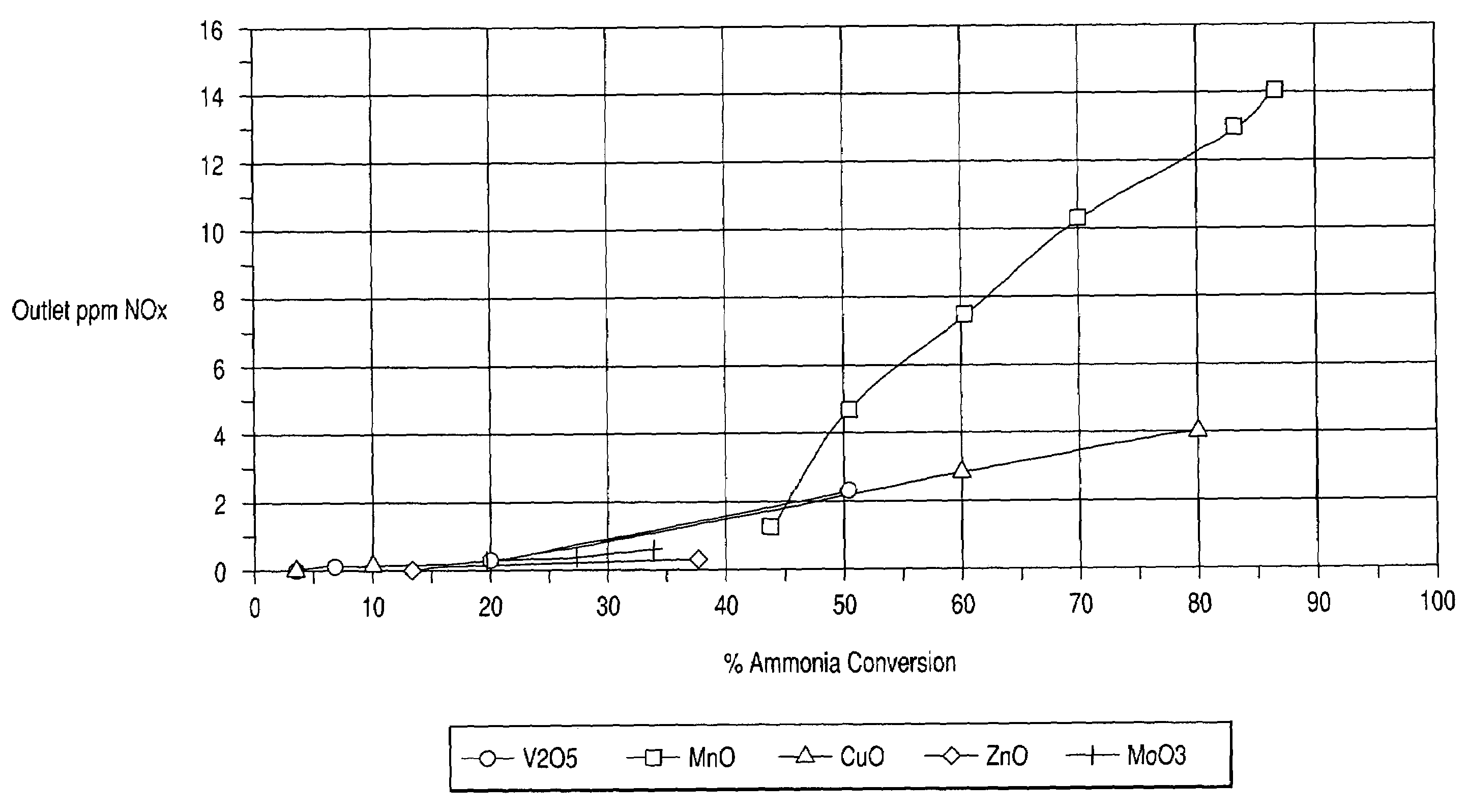

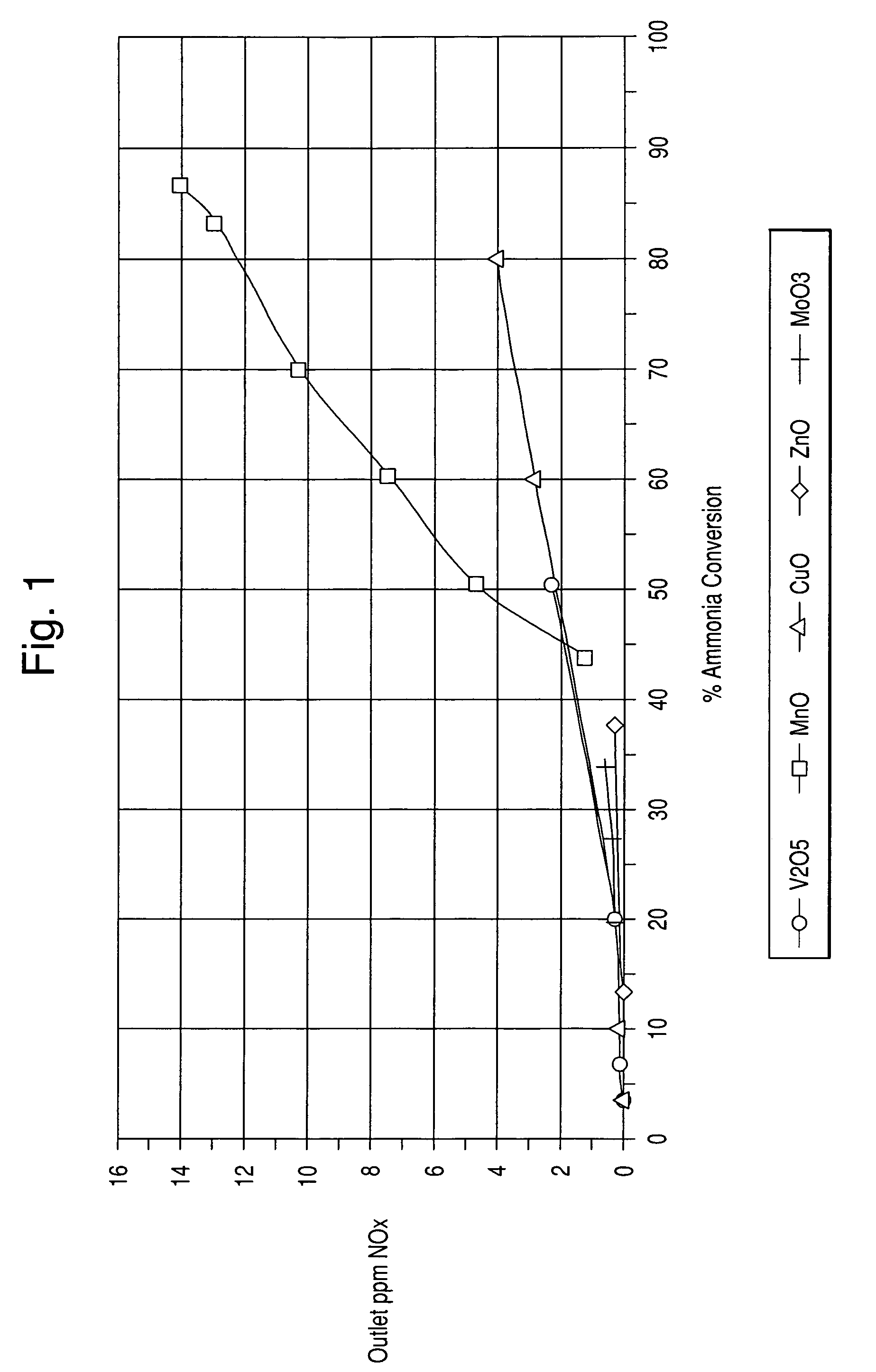

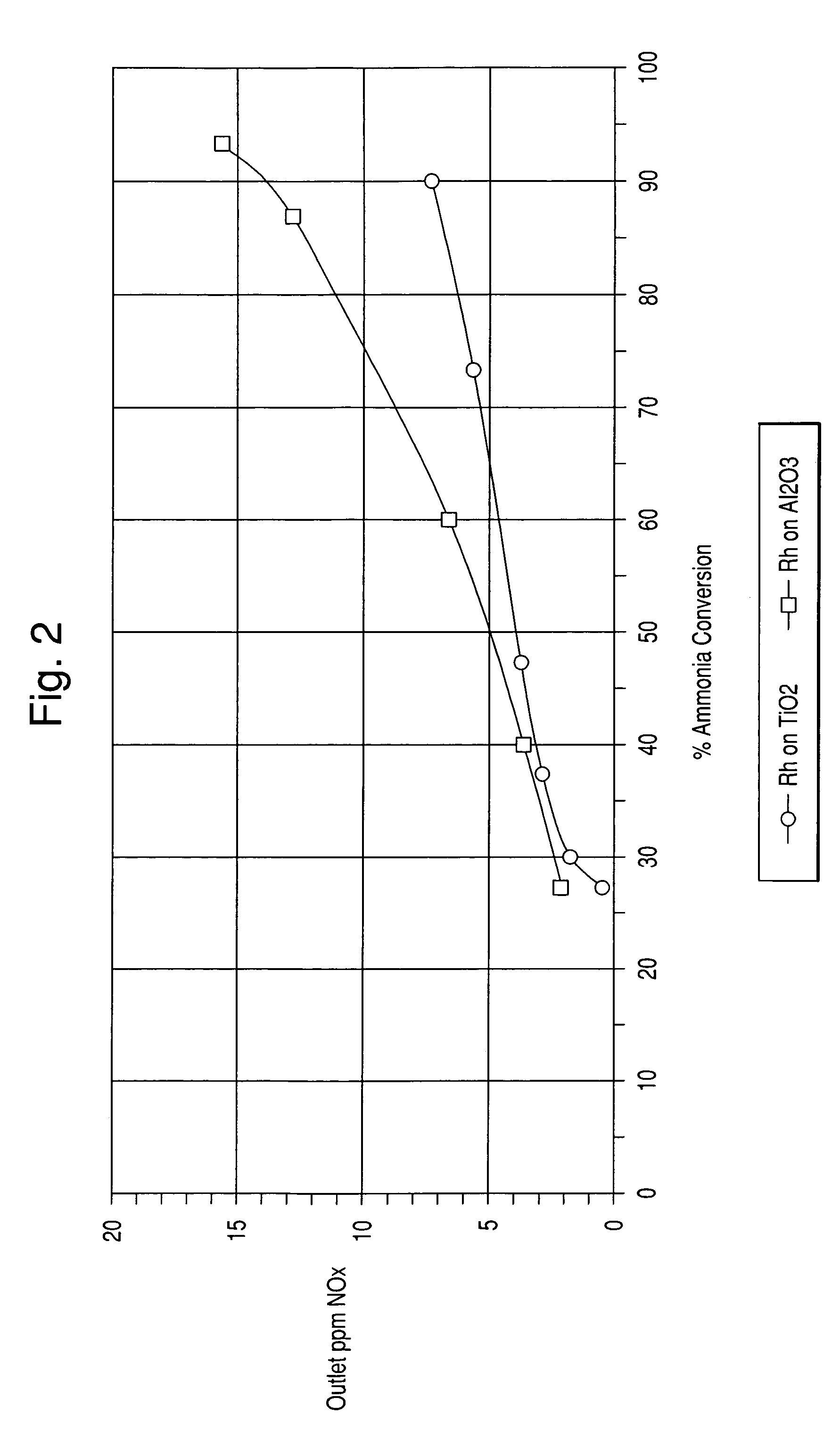

Ammonia oxidation catalyst for the coal fired utilities

InactiveUS7393511B2Undesirable emission levelNo sulfurCyanogen compoundsNitrogen compoundsSulfur dioxideCarbon monoxide

A process is described that removes by oxidation the excess ammonia (NH3) gas from flue gases that have been subjected to selective catalytic reduction (SCR) of oxides of nitrogen (NOx) by ammonia injection. The inventive process incorporates a secondary catalyst of precious metal and vanadia on a metal oxide such as titania to catalyze the oxidation of both ammonia and carbon monoxide (CO) while maintaining sulfur dioxide (SO2) levels.

Owner:BASF CATALYSTS LLC

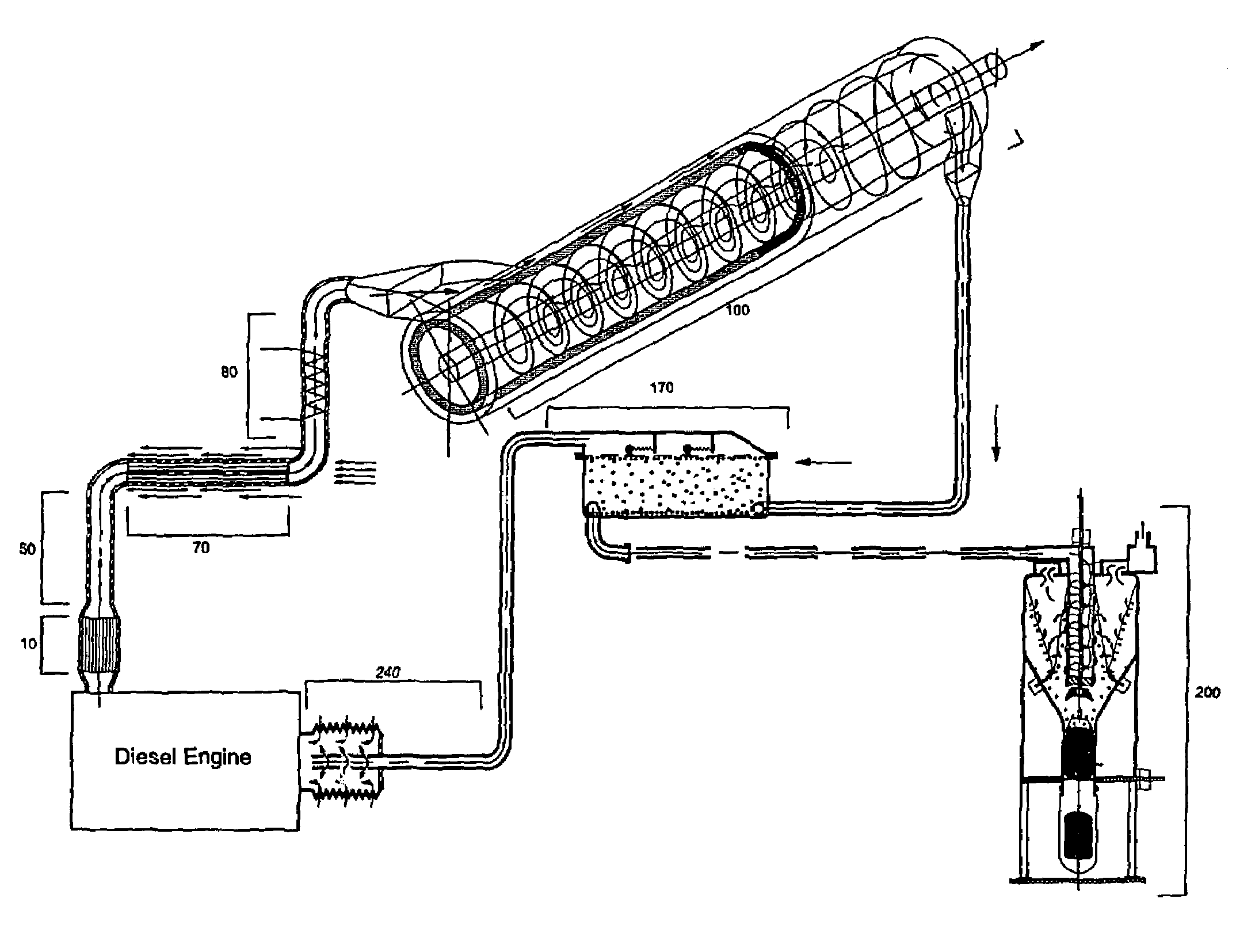

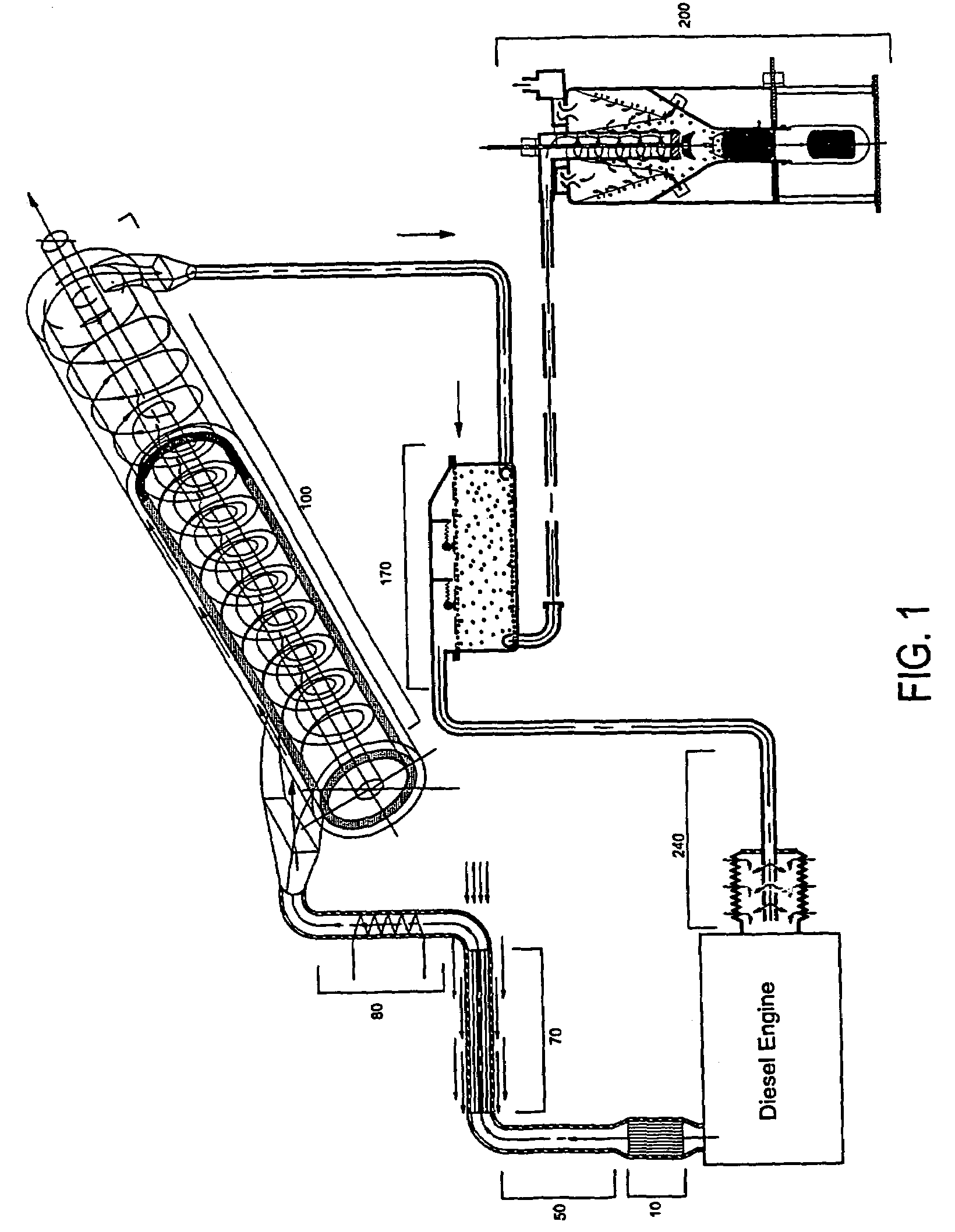

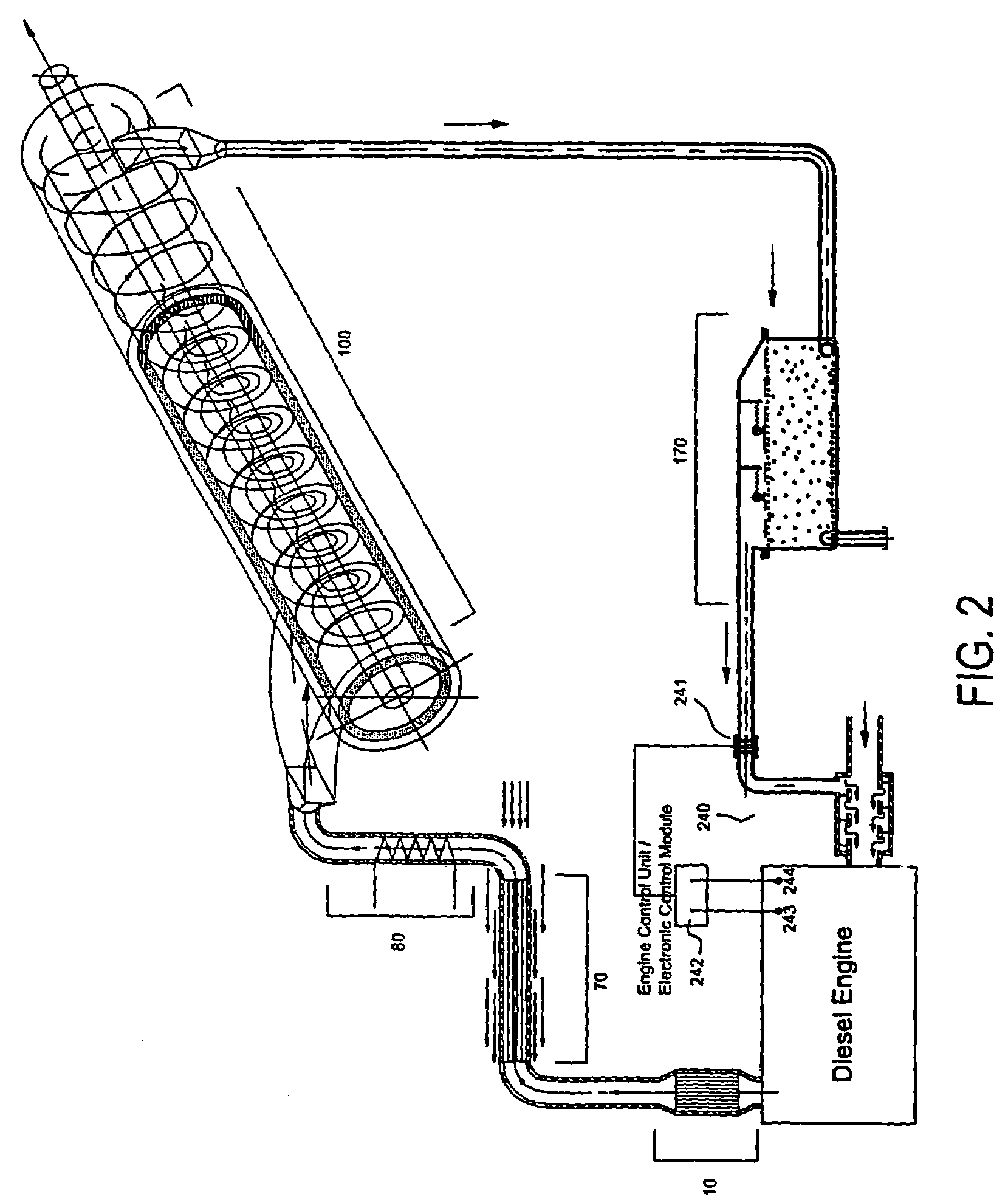

Exhaust after-treatment system for the reduction of pollutants from diesel engine exhaust and related method

InactiveUS7266943B2Easy to separateLower overall pressure dropCombination devicesInternal combustion piston enginesParticulatesAfter treatment

Exhaust after-treatment system for the reduction of particulate, NOx, HC, CO, VOCs, nano-particle count and sulfur dioxide from diesel exhaust. System employs diesel oxidation catalyst, exhaust cooling system, particulate converter, soot collection chamber, soot processing drum, EGR and water scrubber.

Owner:KAMMEL REFAAT

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

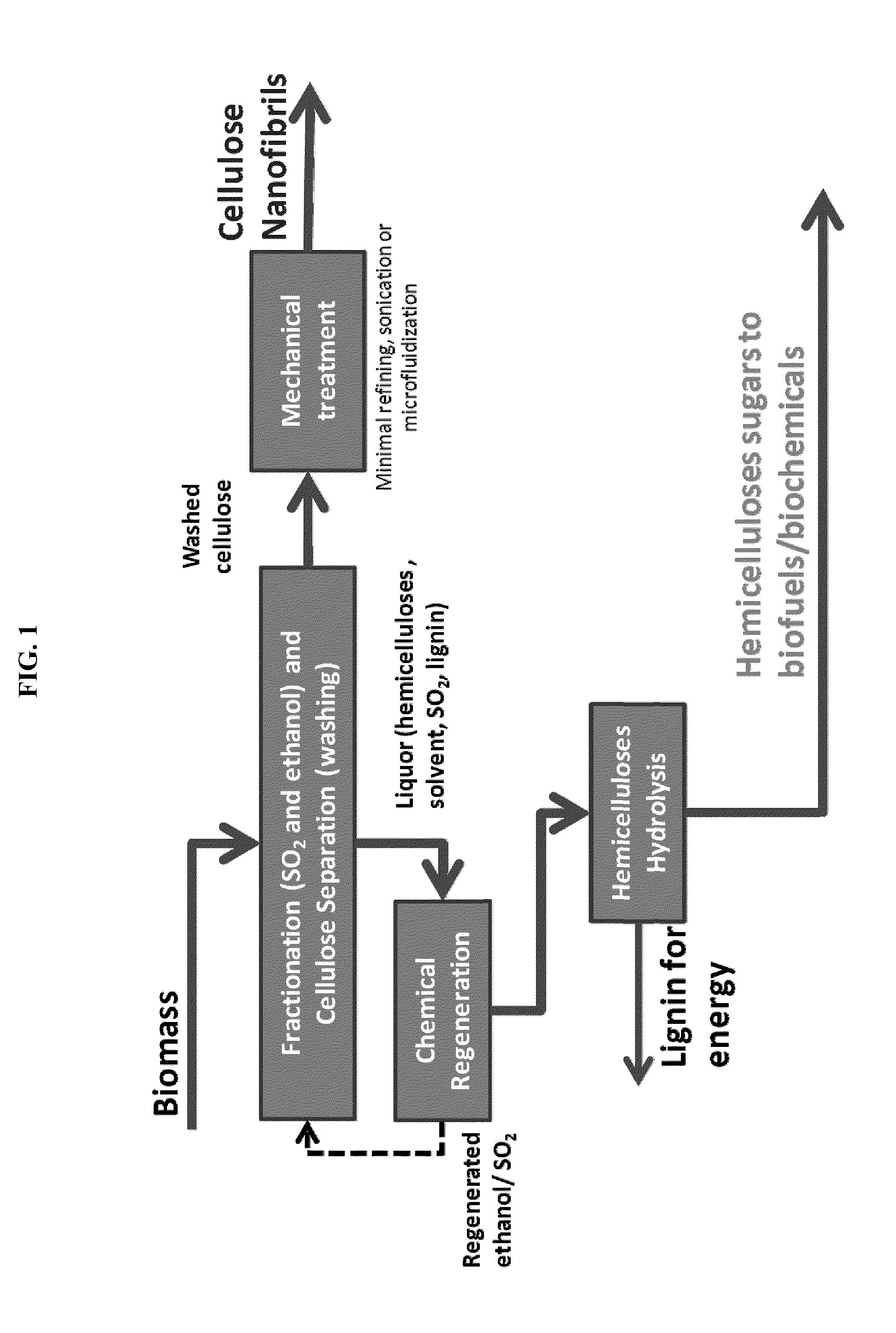

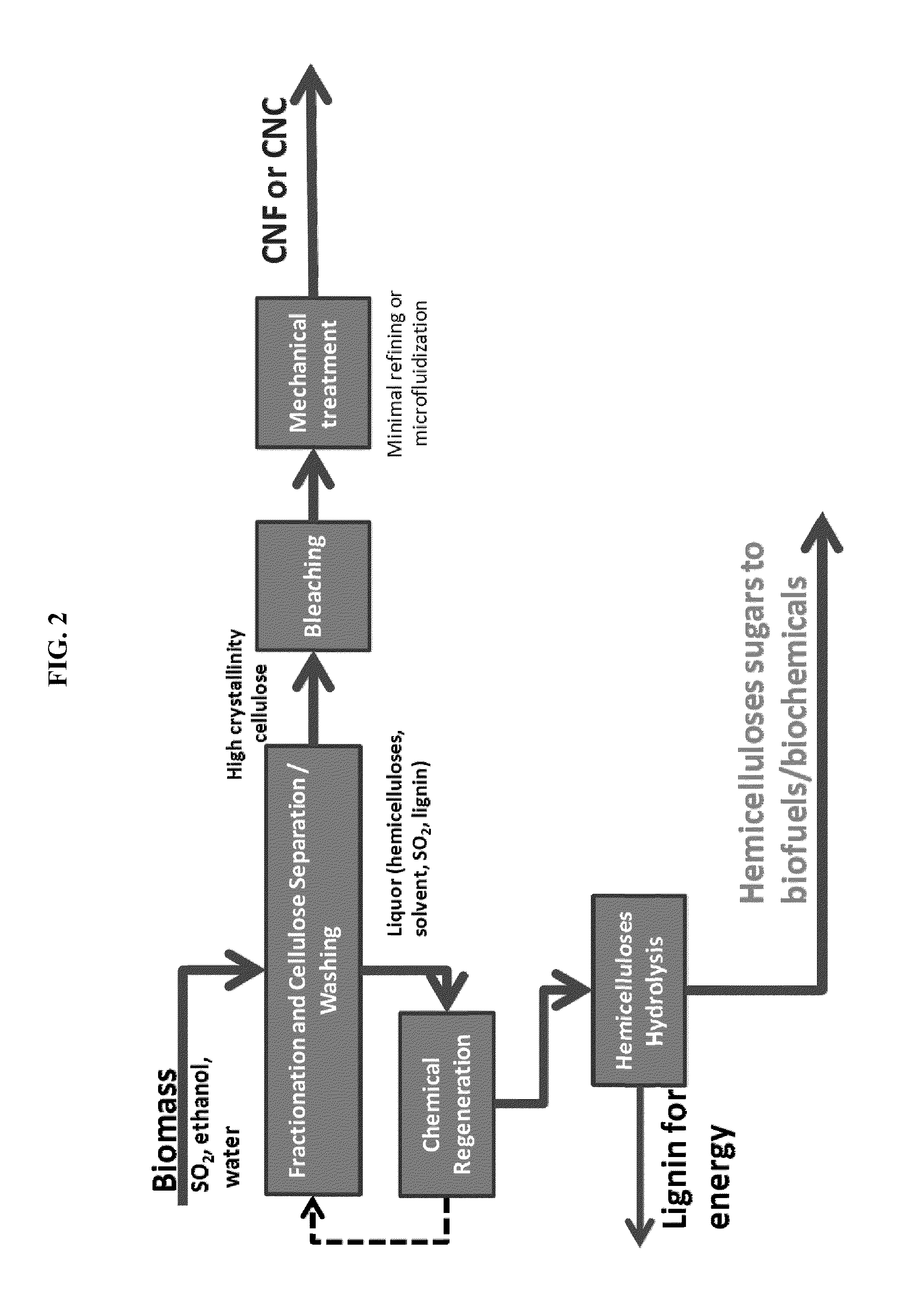

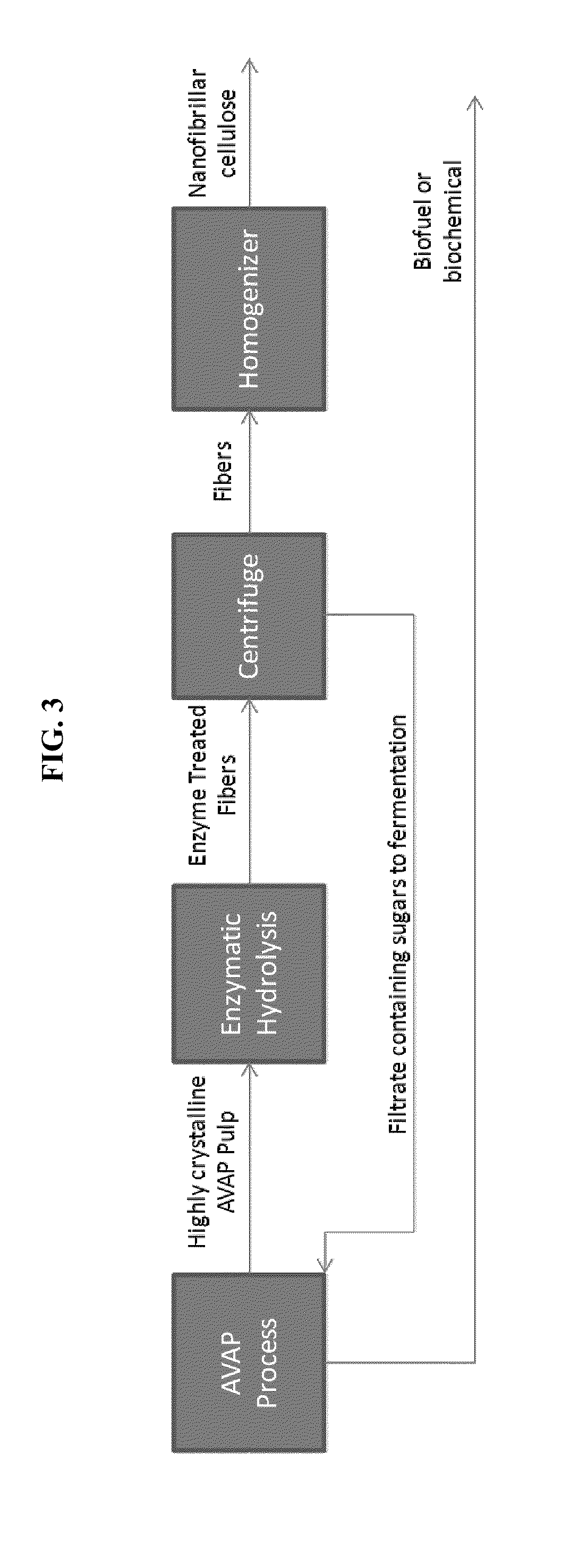

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Catalyst for denitration of power plant soot fume SCR and preparation method thereof

InactiveCN101422728AImprove wear resistanceStrong anti-poison abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporWorking temperature

The invention relates to a catalyst carrier, an SCR denitrifying catalyst of electric plant flue gas that is prepared by the catalyst carrier and a preparation method of the SCR denitrifying catalyst. The invention adopts purple mud clay and anatase TiO2 to form the carrier; by weight, the content of the TiO2 is 50 to 99 percent and the content of the purple mud clay is 1 to 50 percent. The catalyst carrier can further contain active carbon, CaSO4 and ammonia-typed Y molecular sieve, which respectively account for 0 to 20 percent of the weight of the catalyst carrier. The active ingredients of the catalyst comprise V2O5 accounting for 1.0 to 6.0 percent of the weight of the catalyst, WO3 accounting for 4.0 to 10.0 percent of the weight of the catalyst, MoO3 accounting for 0 to 9.0 percent of the weight of the catalyst, and CeO2 accounting for 0 to 2.0 percent of the weight of the catalyst. The working temperature of the catalyst is 200 to 500 DEG C, has high catalytic activity, large specific surface and strong toxin immunity, hardly has inactivation phenomenon in long-time running, and is insensitive to vapor and sulfur dioxide.

Owner:HARBIN INST OF TECH

Supported type active carbon and its preparation method

The invention relates to a loading activated carbon and ití»s preparing method. The invention uses activated carbon as carrier and the additive components are loaded on the activated carrier via immersion method, while the additive components is distributed over most surfaces of pore passages of said activated carbon, and the additive components is 0.01-50% of absorbent. The invention is prepared via the immersion method which is processed in the temperature higher than room temperature. The invention can overcome the defect of present technique by which additive components can not be distributed over most pore passages; therefore, it can improve the availability ratio of activated carbon and the application property. In addition, according to the difference of said additive components and their contents, the invention can apply the processes of gas desulfurization, flue gas desulfurization, and exhaust gas purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

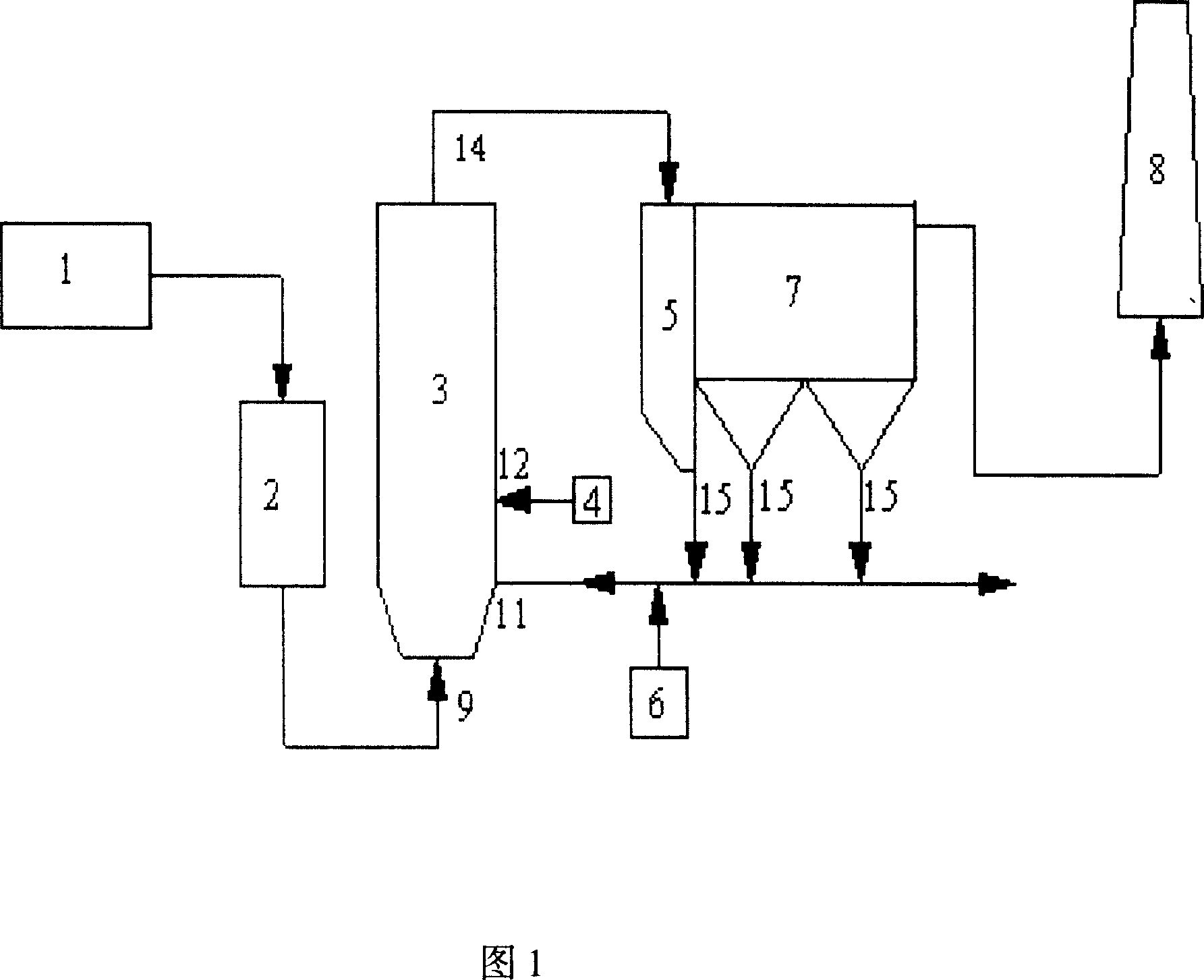

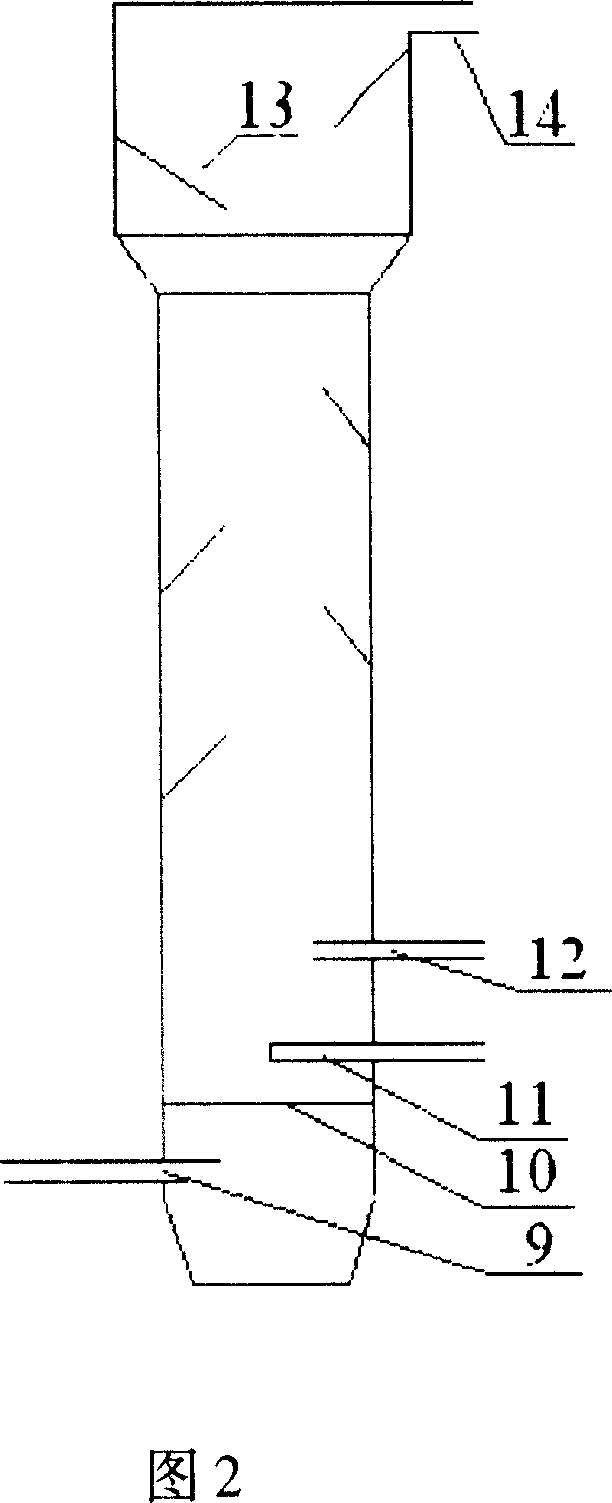

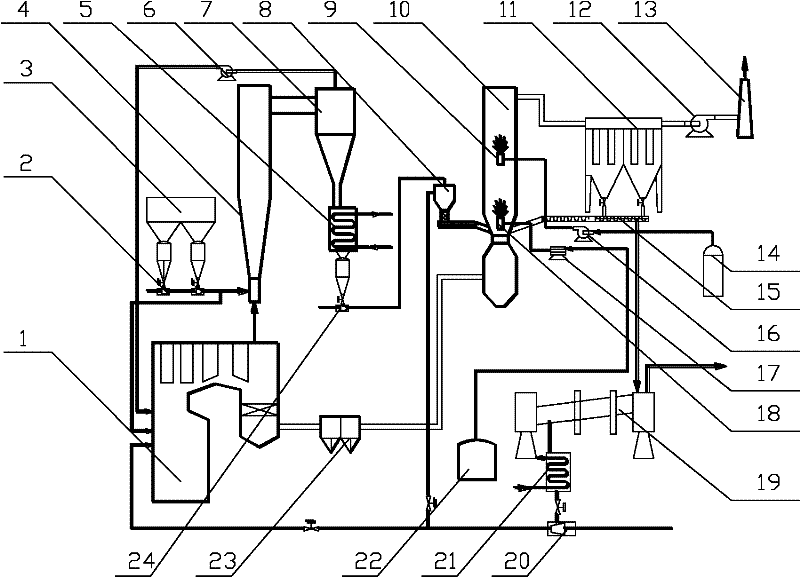

Sintering device flue gas multiple pollutant removing process and system thereof

ActiveCN101254394ALow flow resistanceReduce investmentDispersed particle filtrationElectrostatic separationFluidized bedMulti pollutant

The invention provides a process used for removing multiple contaminants in the off-gas of a sintering machine, as well as the system thereof. The process has the following steps: firstly, the machine tail off-gas undergoes SCR denitrification treatment; then, primary dedusting treatment is carried out to the denitrated machine tail off-gas and un-denitrated machine head off-gas at the same time, so as to remove the dust and ash particles in the off-gas; and then, circulating fluidized bed desulfurization treatment is carried out to the off-gas; finally, secondary dedusting treatment is carried out to the off-gas, so as to remove the resultant particles in the off-gas, the resultant particles are used for recycling, and the purified gas is separated out. The system thereof is mainly composed of a machine head off-gas header and a machine tail off-gas header which are used for collecting the machine head off-gas and the machine tail off-gas of the sintering machine, a SCR denitrification reactor which is used for removing the multiple contaminants in the off-gas, a primary dust remover, a circulating fluidized bed desulfurization reactor and a secondary dust remover. The process can carry out the classification integrated processing as well as the high efficient and synchronous removing to the sulfur dioxide, the nitrogen oxides and the dust in the sintering off-gas. The system has the characteristics of simple and compact whole design, low investment and running cost, and stable and reliable working.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

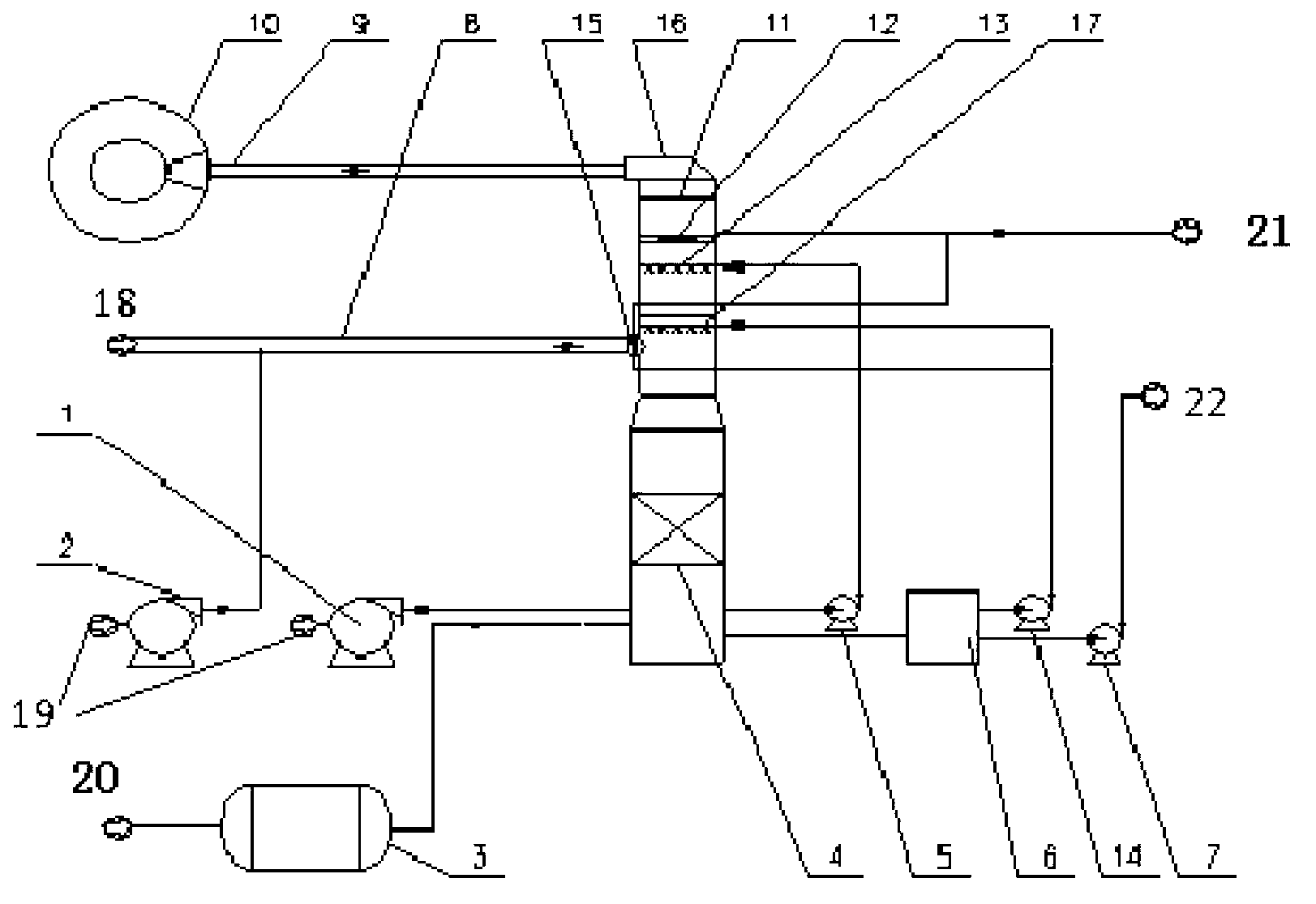

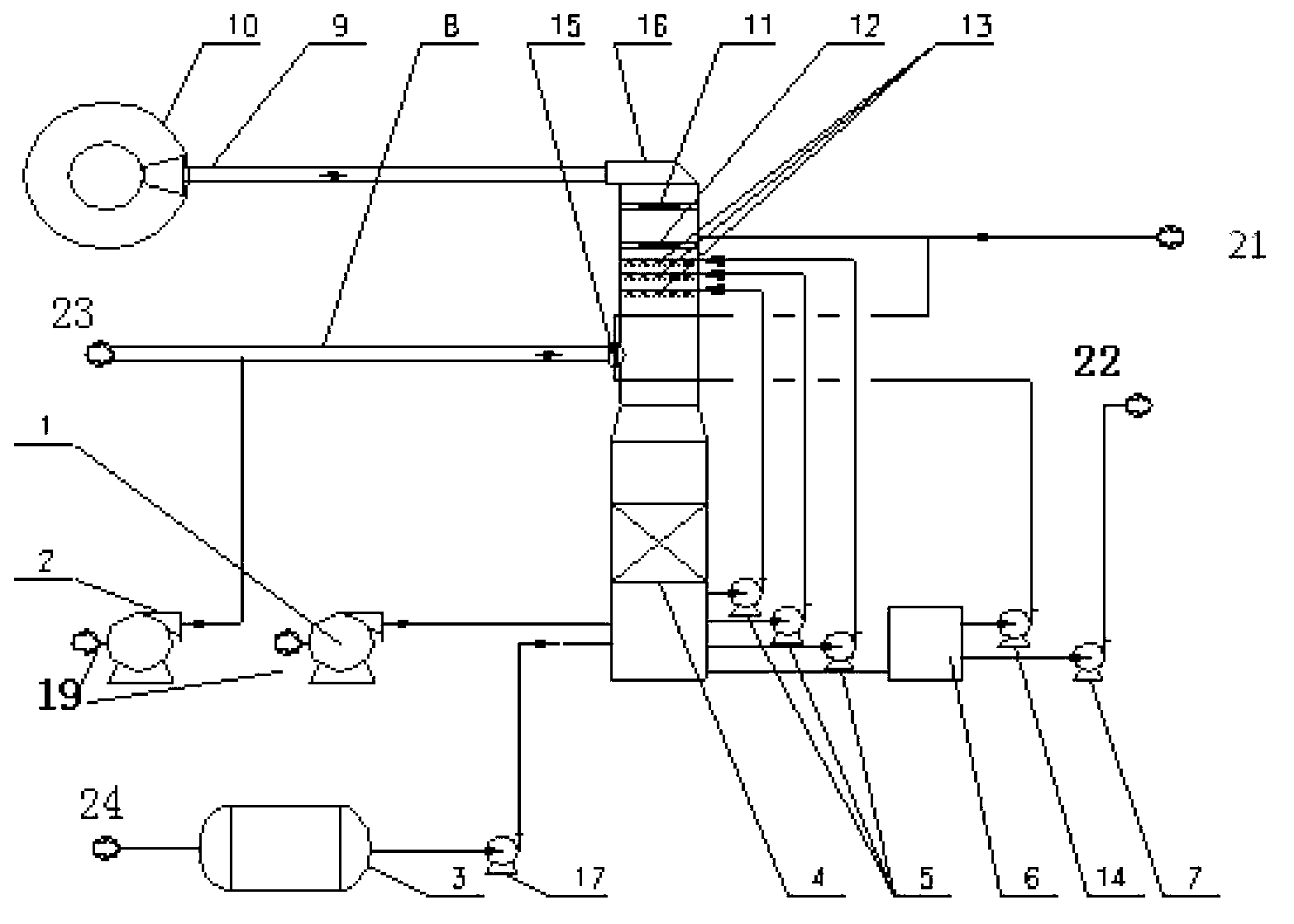

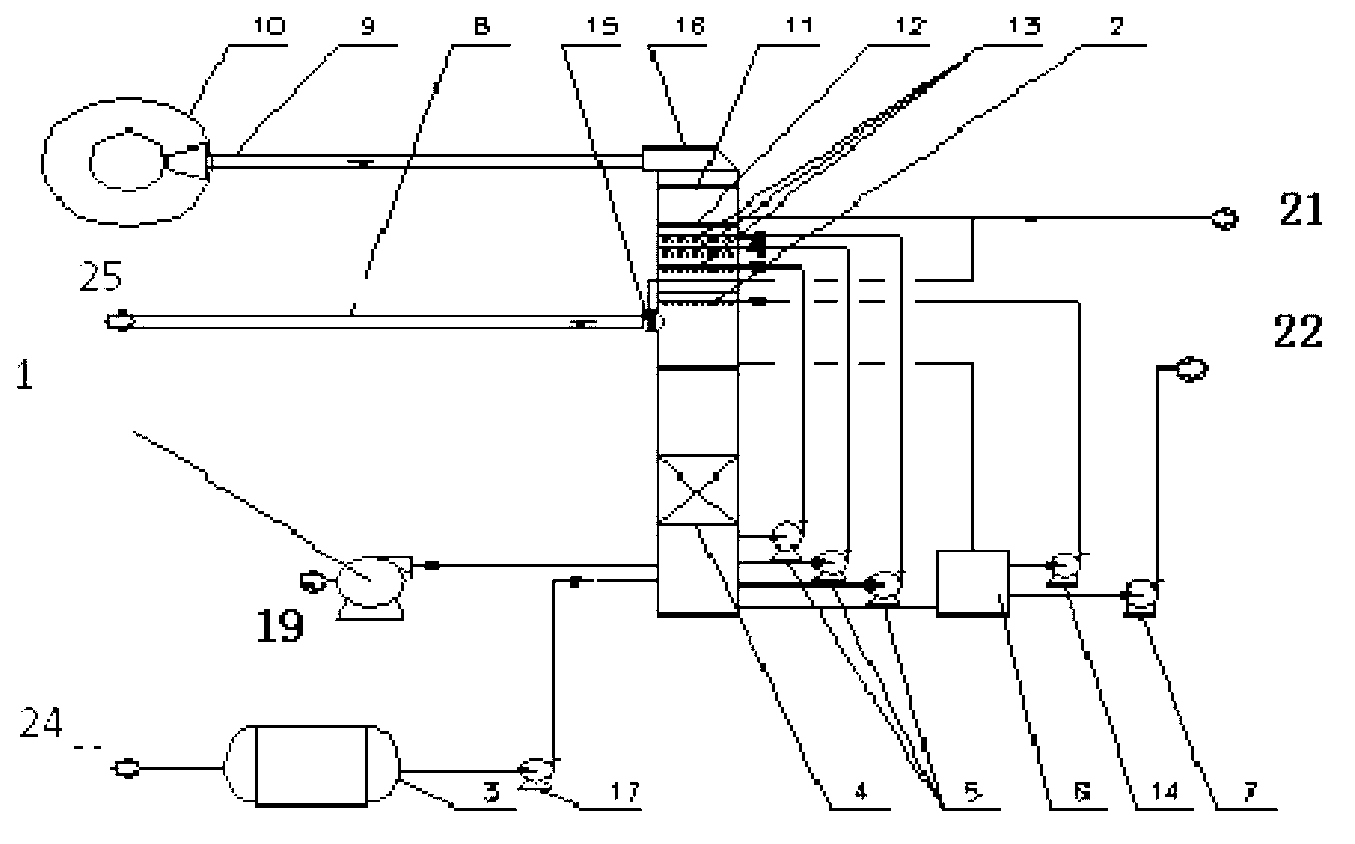

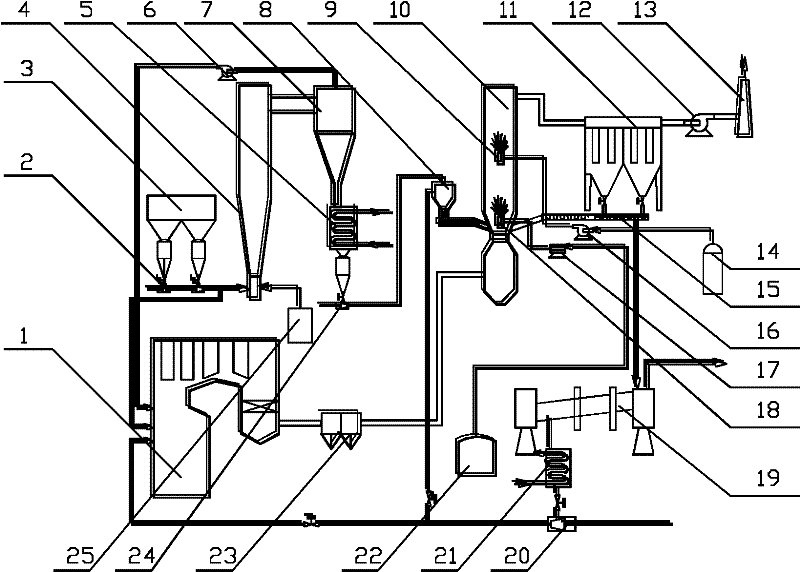

Ammonia desulfurizing process and apparatus with crystallization inside tower

The present invention belongs to the field of environment protection apparatus, and is especially crystallizing ammonia type desulfurizing process and apparatus for removing and recovering SO2 from fume. The apparatus includes one desulfurizing tower, one absorbing and circulating tank outside the tower, one concentrating and circulating tank, one ammonium sulfate thickener, one centrifuger and one drier. It features the crystallizing section and oxidizing section set below the fume inlet inside the desulfurizing tower, the connection of the crystallizing section with the concentrating and circulating tank, the connection of the oxidizing section outlet with the absorbing and circulating tank, and the successive connection of the other parts. The present invention has low cost and convenient apparatus maintenance and operation.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

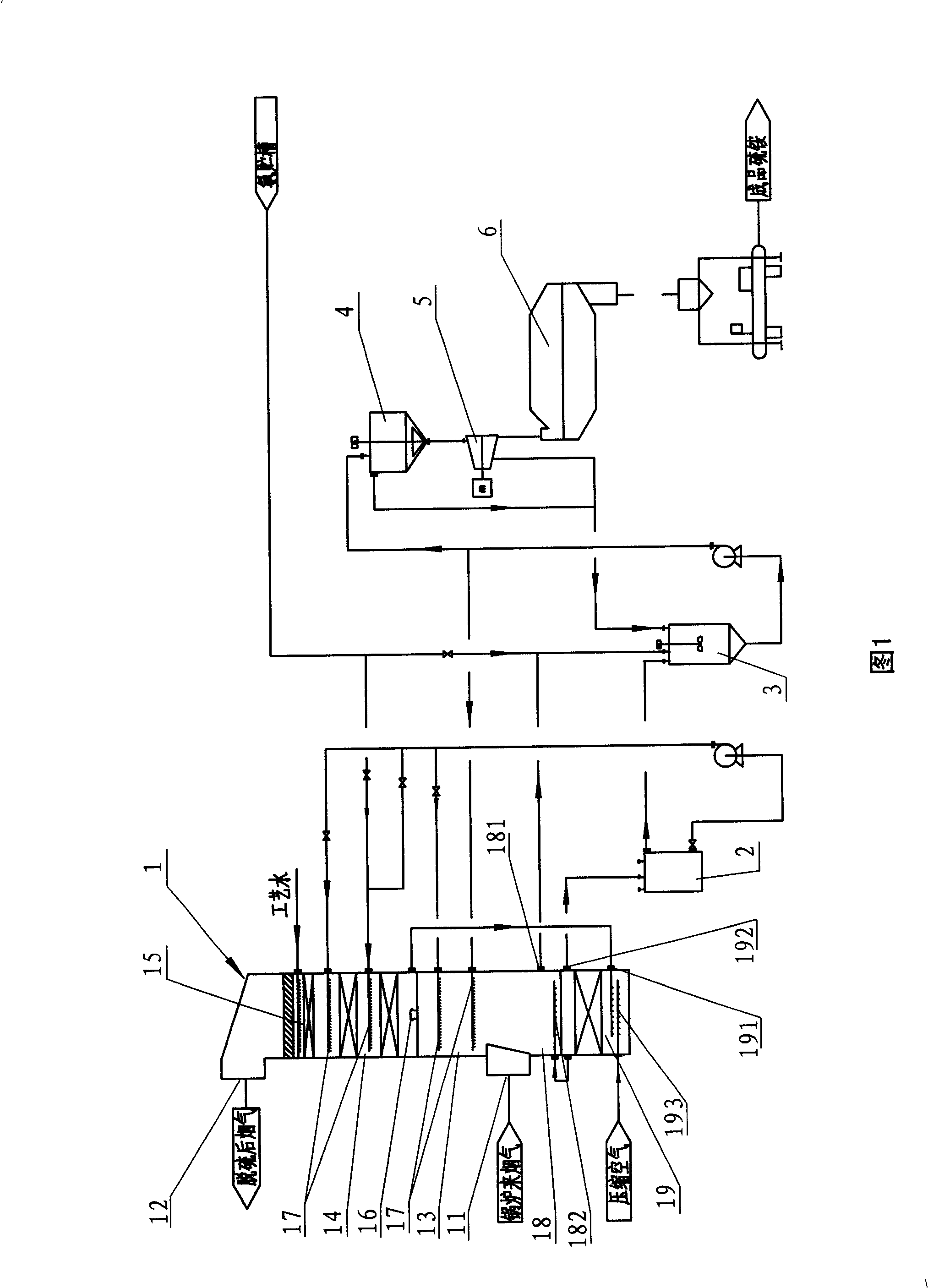

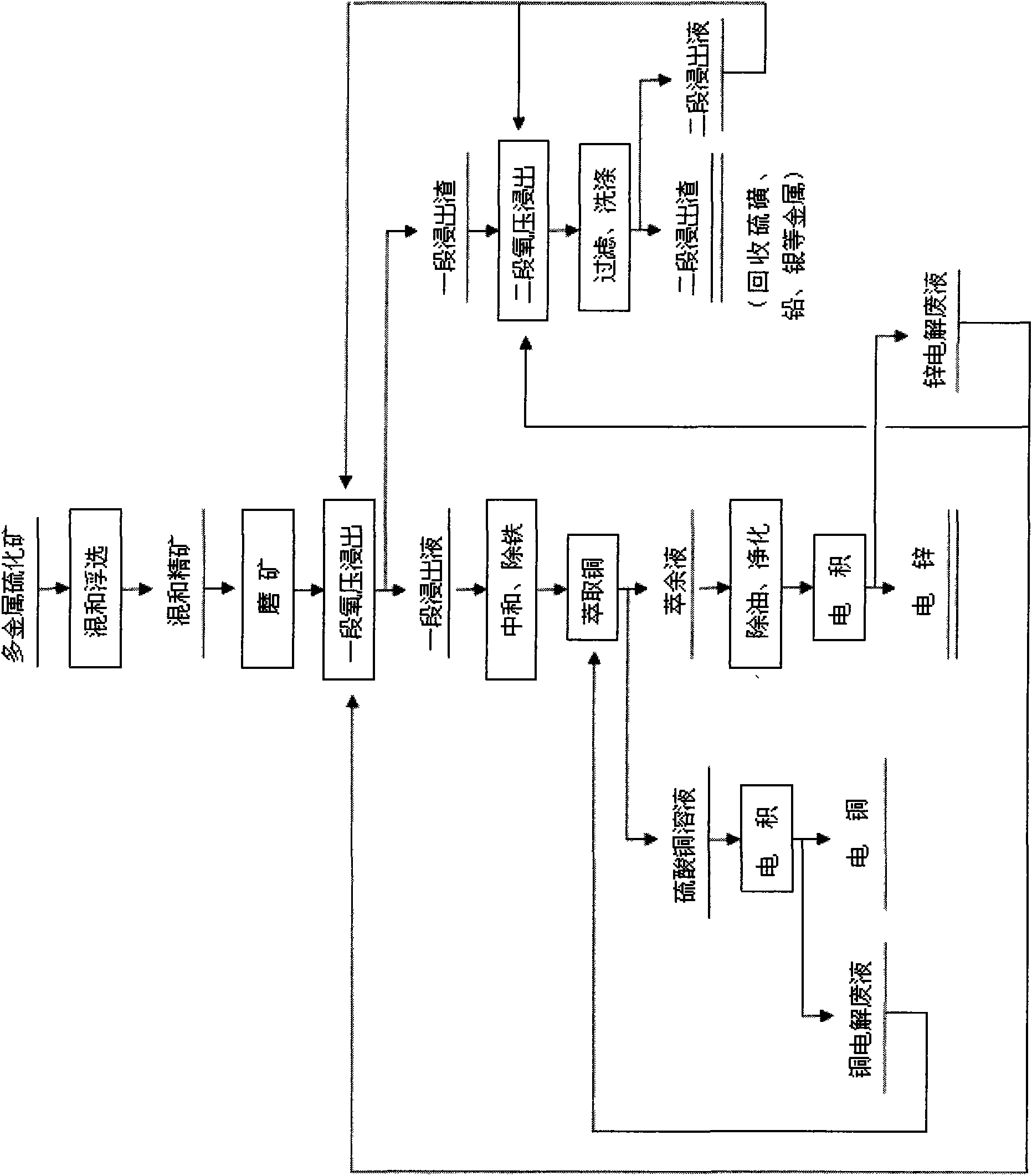

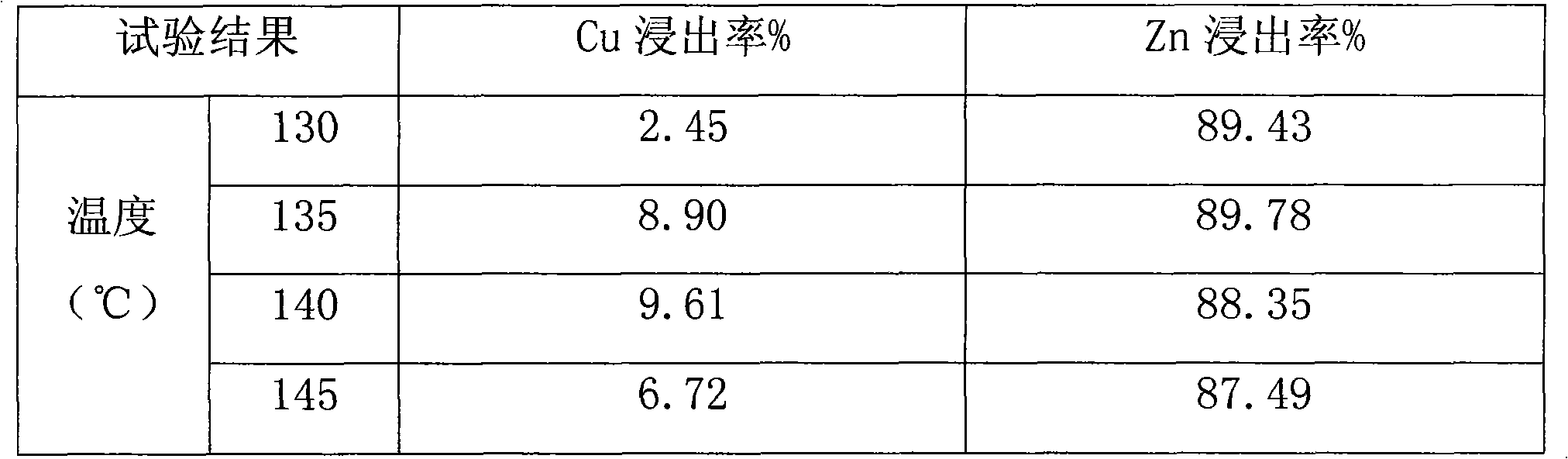

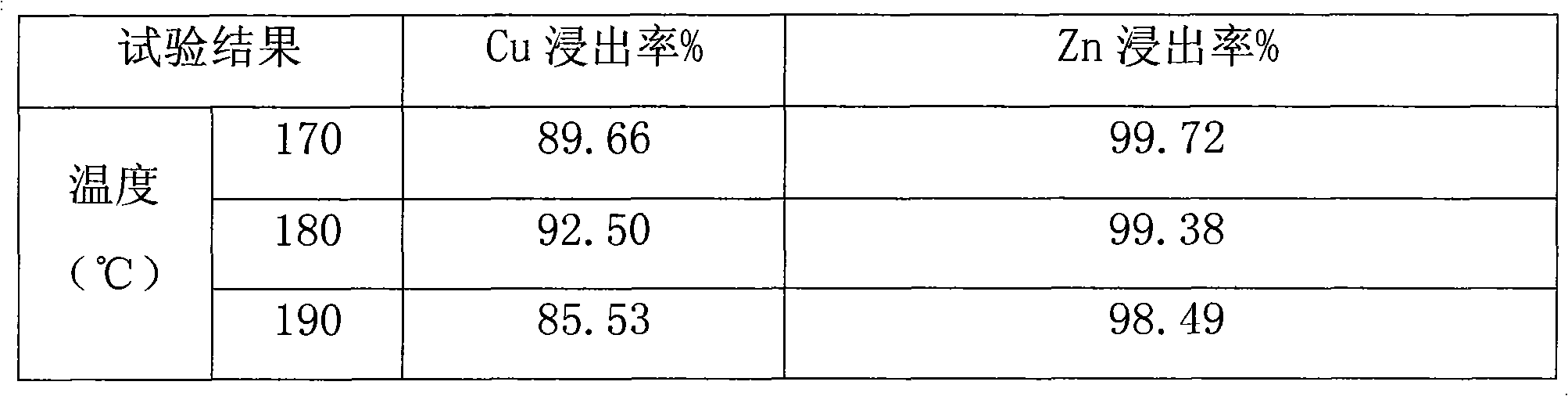

Comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc

InactiveCN101643857AHigh recovery rateSimple processSulfur preparation/purificationFlotationRecovery methodLead smelting

The invention discloses a comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc and adopts dressing-metallurgy combination method and hydrometallurgy-pyrometallurgy combination method to recover metals. The recovery method comprises the following steps: first performing bulk flotation to the complex polymetal sulphide ore, fine grinding the obtained concentrate, leaching by using two-step counter flow oxygen pressure leaching process, extracting and separating copper and zinc from the obtained leachate, electrodepositing the strip liquor of copper-loaded organic phase to obtain cathode copper, cleaning the obtained raffinate and electrodepositing to obtain cathode zinc; pressurizing leaching residue to perform flotation separation and obtain sulfur concentrate and lead silver residue, distilling sulfur concentrate to obtain sulfur; performing lead smelting process to lead silver residue to obtain electrolytic lead product and lead anodic slime; and comprehensively recovering noble metals such as gold, silver and the like from lead anodic slime. The method can greatly improve the metal recovery rate, resource utilization and the economic efficiency of mines and generate a lot of sulfur so as to obviously reduce the sulfur dioxide pollution to the atmosphere.

Owner:WESTERN MINING CO LTD

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

Atmospheric molecular respirator

InactiveUS20100111792A1Purifying substantial volumes of room airRobust methodProductsGas treatmentActivated carbon filtrationAtmospherics

An apparatus for removing contaminants from air, including nitrogen oxides, carbon monoxide, carbon dioxide, and sulphur dioxide. In one of the chambers of a multi-chambered enclosure, polluted inlet air is exposed to one or more first light sources emitting light at wavelengths less than or equal to 242.3 nm to cause dissociation of contaminant molecules, creating ozone plus remaining atoms. The remaining atoms are largely filtered by activated charcoal filters having an appropriate thickness which is sized to achieve suitable dwell times, and which also serves as an oxygen rich medium permitting the ozone generated to undergo atomic rearrangement, whereby ozone molecules (O3) and atomic oxygen atoms (O) form oxygen molecules (O2). In another downstream chamber, the air flow is exposed to one or more second light sources emitting light at wavelengths greater than 242.3 nm but less than 280 nm, causing conversion of remaining ozone into oxygen molecules.

Owner:NELSON EDWARD D

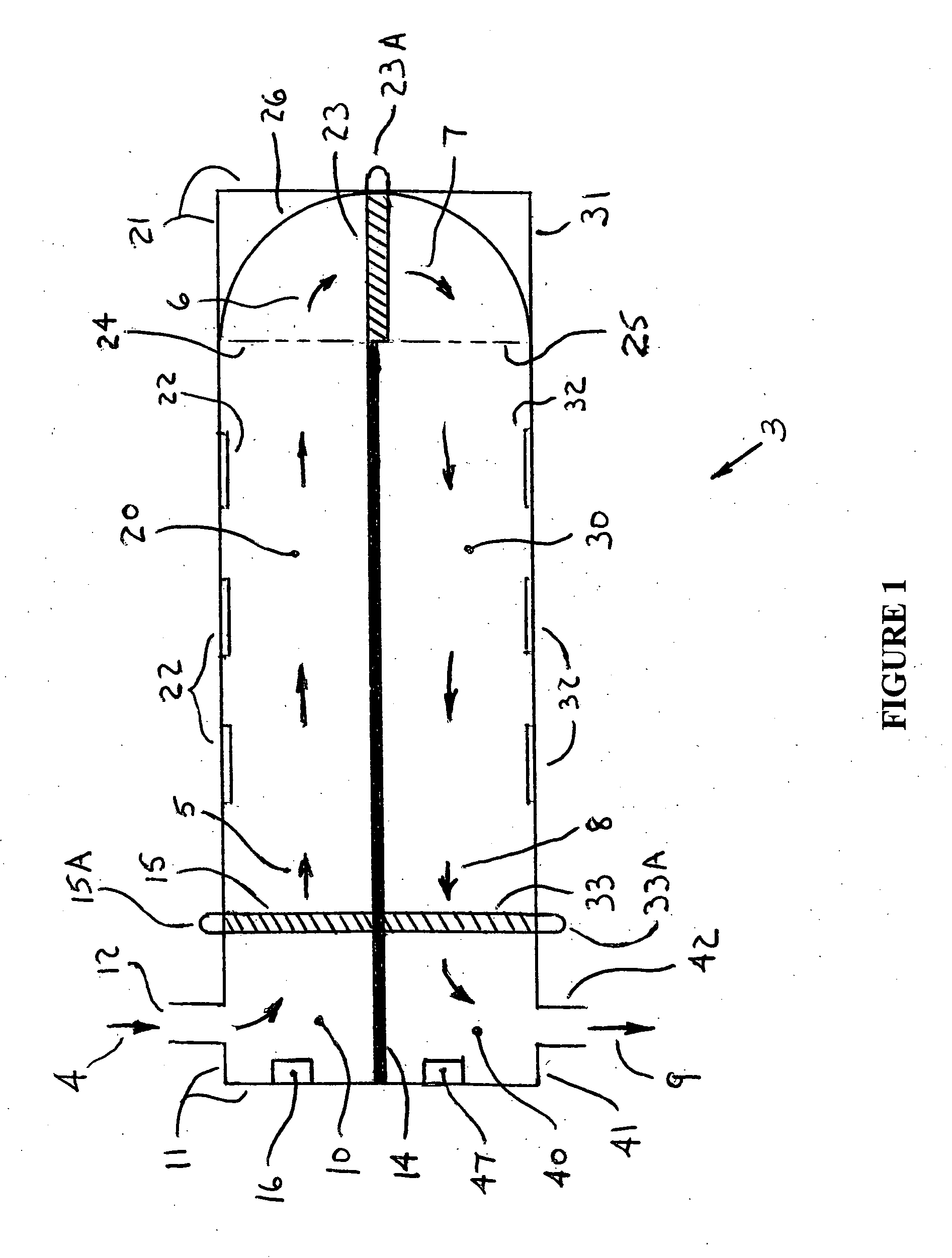

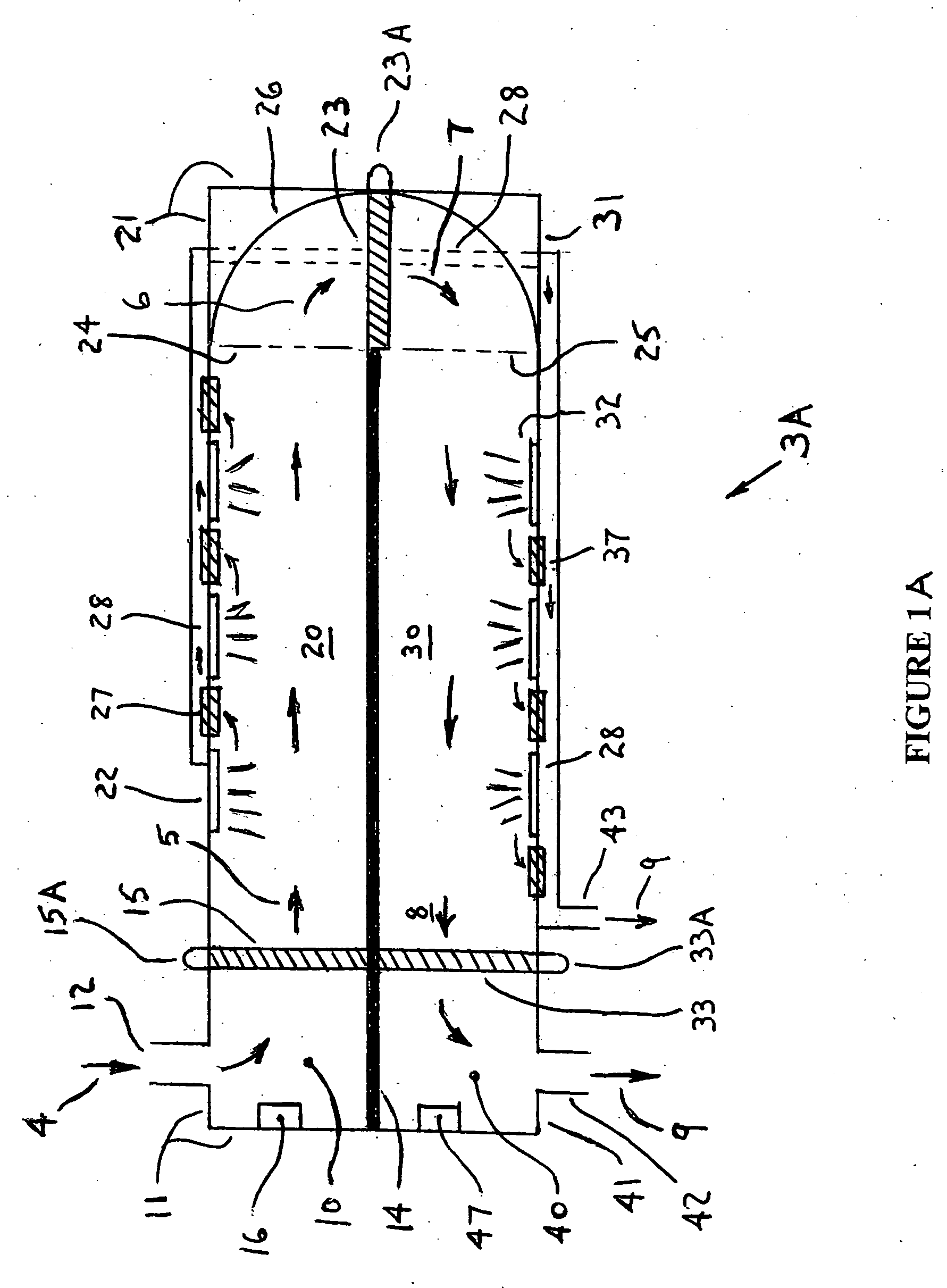

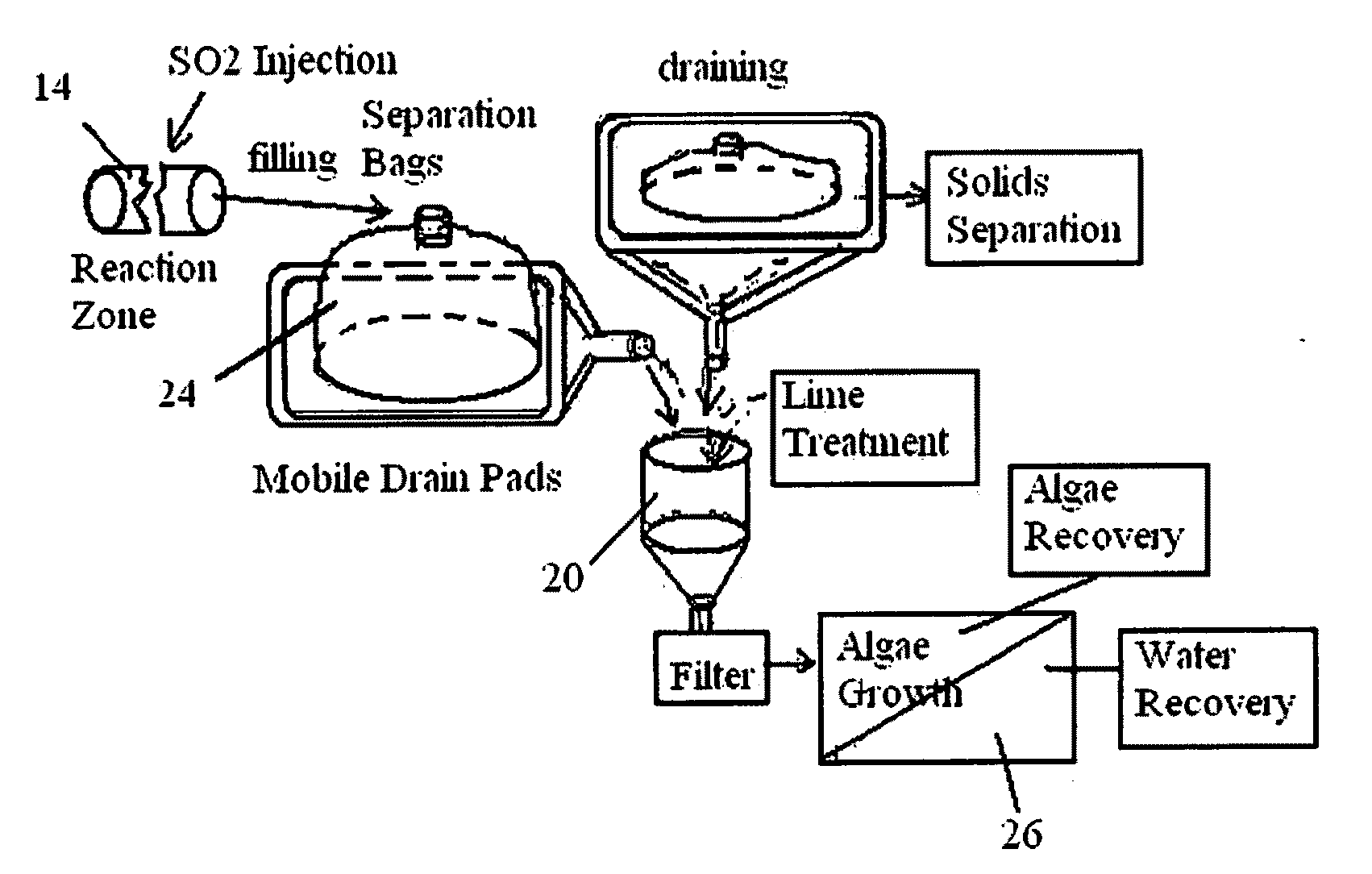

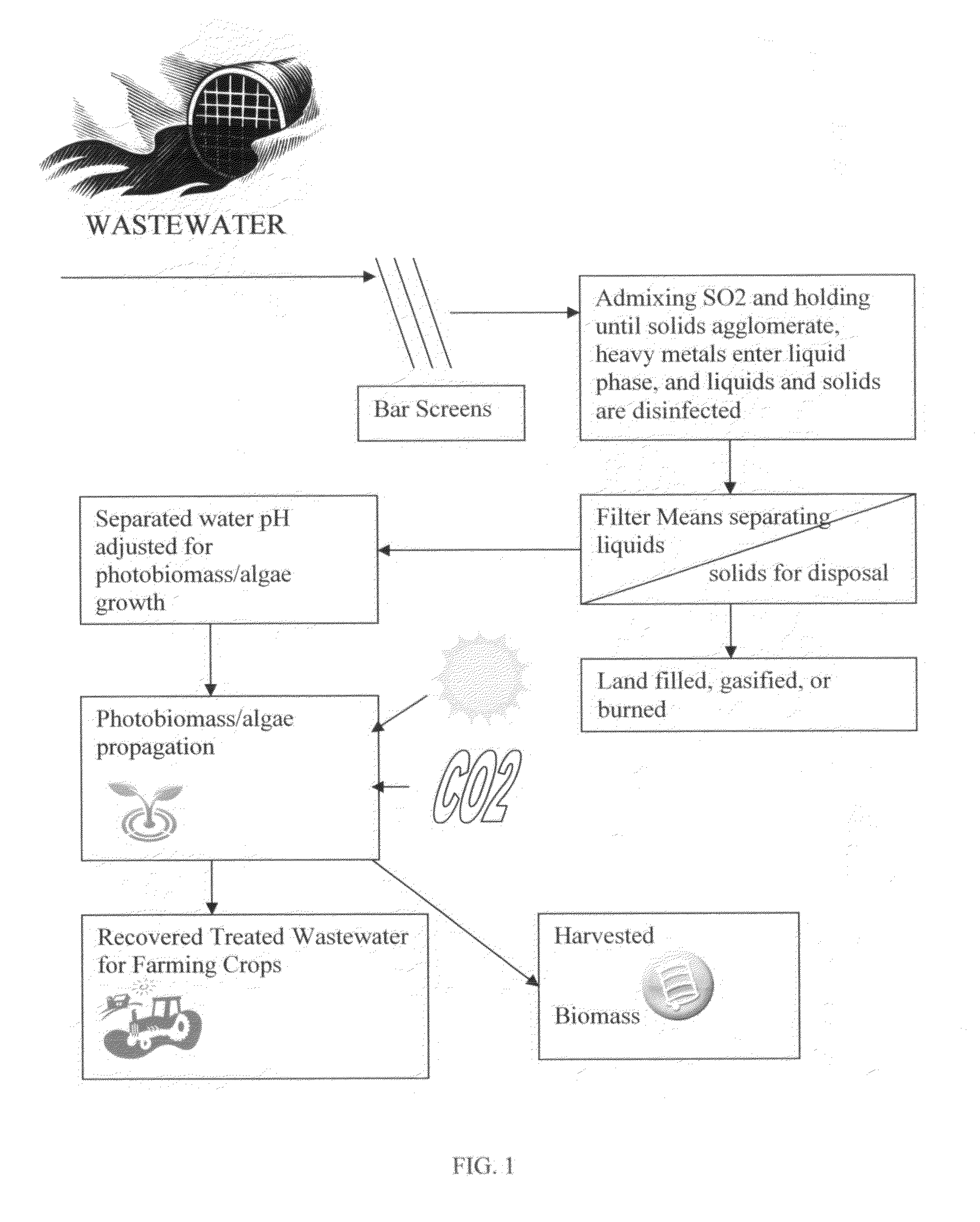

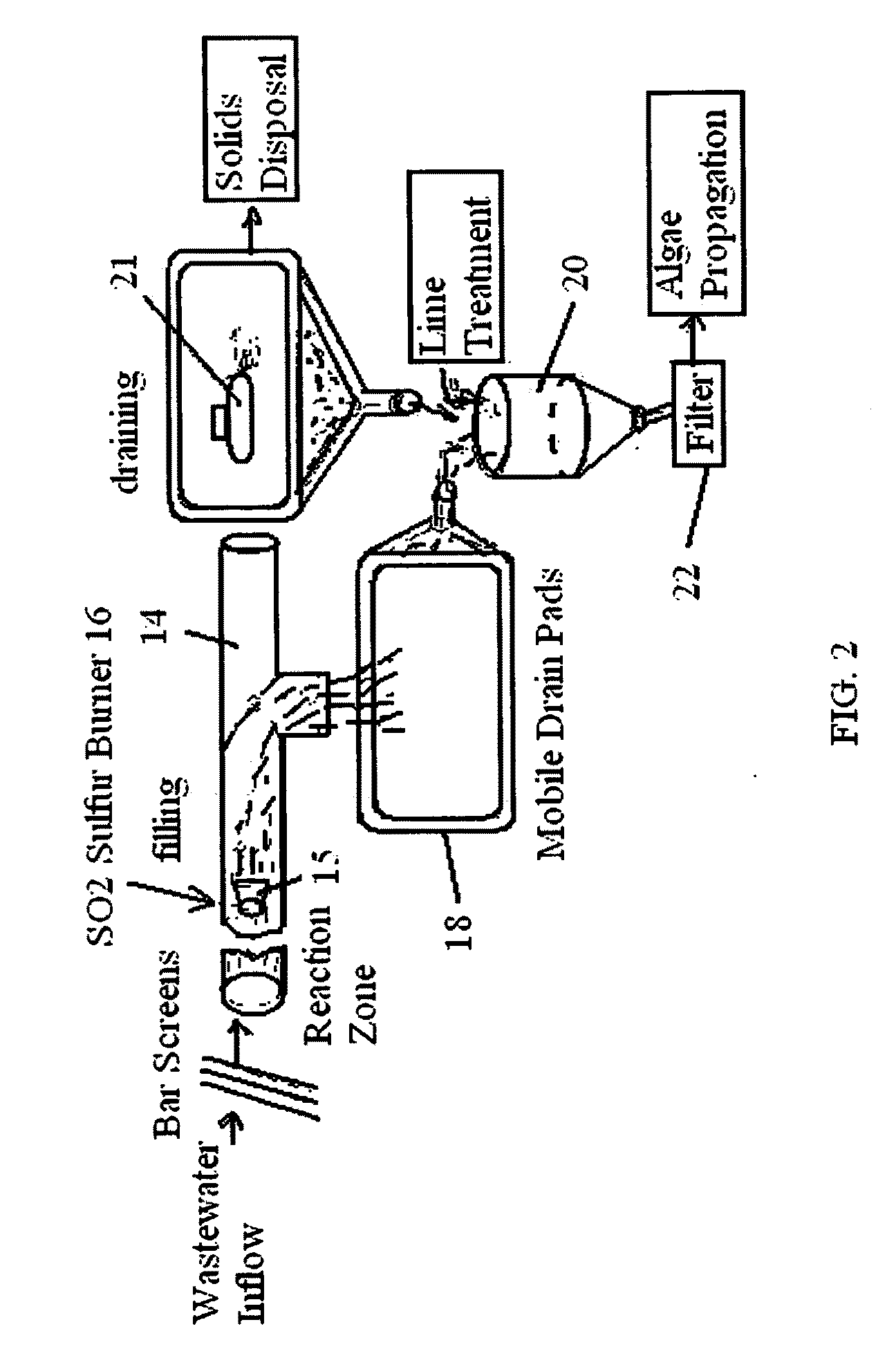

Wastewater photo biomass/algae treatment method

ActiveUS20090294354A1Minimizing stream eutrophicationPrevent eutrophicationUnicellular algaeEnergy based wastewater treatmentCarbon creditBiofuel feedstock

A treatment method for wastewater employing sulfur dioxide and lime chemical dewatering technology in conjunction with an environmental photo biomass / algae biological treatment system growing photo biomass / algae to reduce dissolved solids, heavy metals, and ammonia in the wastewater to produce recovered treated wastewater for vegetation consumption, biofuel feedstock, and biofuel and carbon credits.

Owner:EARTH RENAISSANCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com