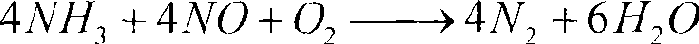

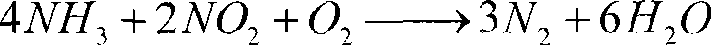

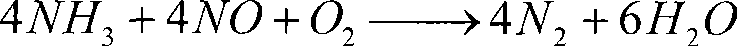

Catalyst for denitration of power plant soot fume SCR and preparation method thereof

A coal-fired flue gas and catalyst technology, applied in the field of preparing the catalyst, to achieve uniform pore distribution, improved catalyst performance, and outstanding wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Measure absolute ethanol, tetrabutyl titanate, and nitric acid with a concentration of 0.6mol / L at a molar ratio of 10:5:4, first add tetrabutyl titanate to absolute ethanol, and stir fully to form a dilute Then add the solution dropwise to the above-mentioned nitric acid solution, stir vigorously to form a transparent solution, then use a NaOH solution with a concentration of 0.5mol / L to adjust the pH value to 2, and stir fully at the same time until a transparent solution is obtained. solution, ready to use. Take the purple clay pottery clay, pulverize it and filter it with a 60-mesh sieve, take the filtered purple clay pottery clay, the amount is the same as that of tetrabutyl titanate, and at the same time fully infiltrate and beat with water, then add the oxalic acid solution containing ammonium metavanadate, and then Stir for 1 hour to make it evenly mixed (the oxalic acid solution of ammonium metavanadate is obtained by dissolving 8 g of ammonium metavanadate per...

Embodiment 2

[0040] Measure absolute ethanol, tetrabutyl titanate, and nitric acid with a concentration of 0.8mol / L at a molar ratio of 12:6:7, first add tetrabutyl titanate to absolute ethanol, and stir fully to form a dilute Then add the solution dropwise to the above-mentioned nitric acid solution, stir vigorously to form a transparent solution, then use a NaOH solution with a concentration of 0.5mol / L to adjust the pH value to 2, and stir fully at the same time until a transparent solution is obtained. solution, ready to use. Take purple clay pottery clay, crush it and filter it with a 60-mesh sieve, take the filtered purple clay pottery clay, its amount is 0.8 times that of tetrabutyl titanate, and add a certain amount of activated carbon at the same time, the amount of activated carbon is three times the amount of purple clay pottery clay. At the same time, fully infiltrate and beat with water, then add the oxalic acid solution containing ammonium metavanadate, and stir for another 2...

Embodiment 3

[0043] Measure absolute ethanol, tetrabutyl titanate, and nitric acid with a concentration of 0.8mol / L at a molar ratio of 18:6:15, first add tetrabutyl titanate to absolute ethanol, and stir fully to form a dilute Then add the solution dropwise to the above-mentioned nitric acid solution, stir vigorously to form a transparent solution, then use a NaOH solution with a concentration of 0.5mol / L to adjust the pH value to 2, and stir fully at the same time until a transparent solution is obtained. solution, ready to use. Take the purple clay pottery clay, pulverize it and filter it with a 60-mesh sieve, take the filtered purple clay pottery clay, the amount is 1 times that of tetrabutyl titanate, and at the same time add a certain amount of activated carbon, the amount of activated carbon is three times the amount of the purple clay pottery clay. At the same time, fully infiltrate and beat with water, then add the oxalic acid solution containing ammonium metavanadate, and stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com