Ammonia process flue gas treatment method for acidic tail gas and device

A sour tail gas and flue gas technology, applied in the fields of environmental protection, electric power, and chemical industry, can solve the problems of limited market capacity of by-product desulfurized gypsum, high operating costs, and consumption of sodium and alkali resources, so as to facilitate operation management, reduce investment costs, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

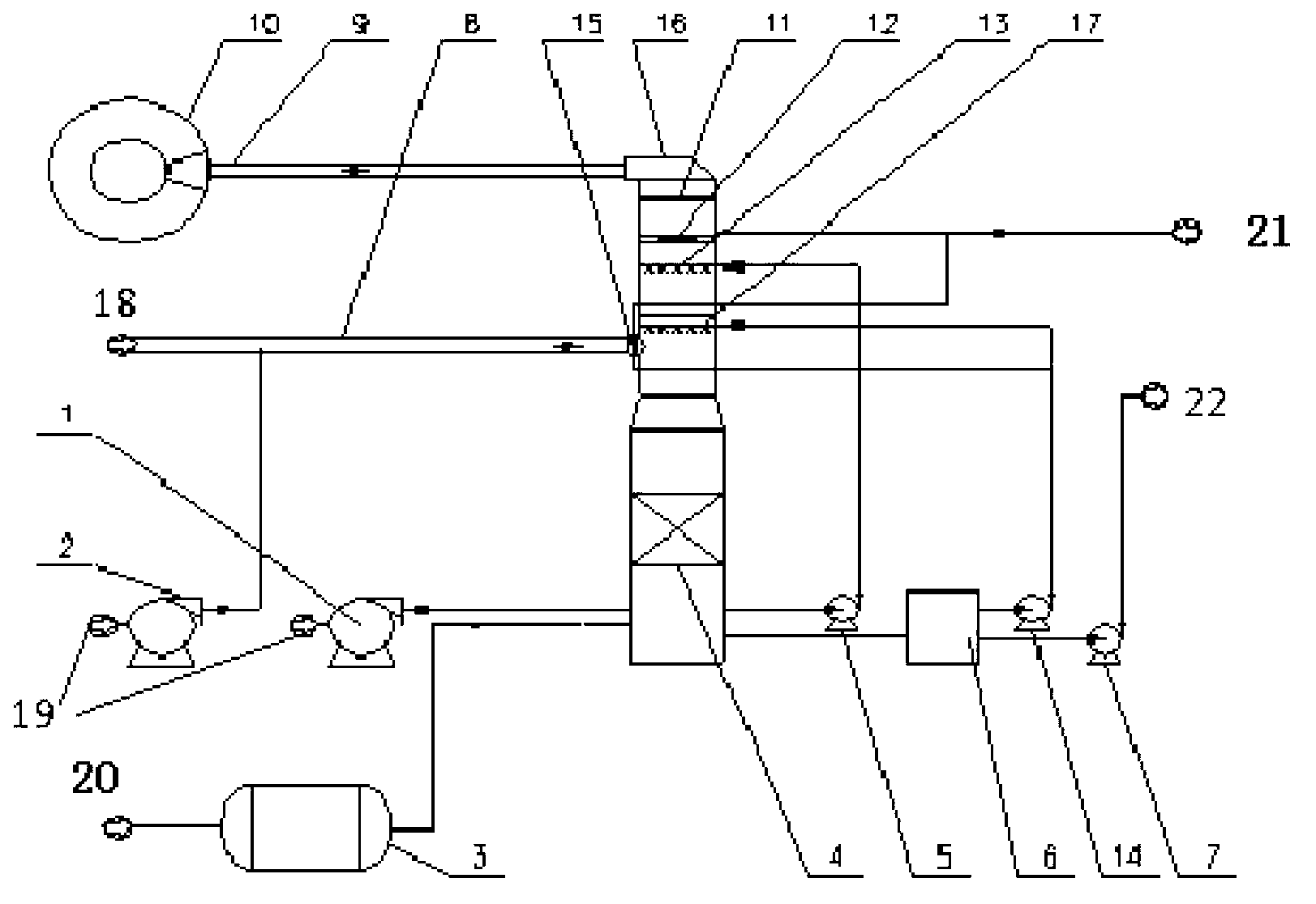

[0065] Example 2: figure 2 Sour tail gas ammonia desulfurization device in a natural gas plant

[0066] Total acid gas flue gas: 13375Nm 3 / h, flue gas temperature: 152°C, flue gas sulfur content 31443mg / Nm 3 , pressure 100000Pa. The reactant is ammonia water with a concentration of 15%.

[0067] Technological process and device: See the appendix for the technological process and device figure 2 . After the original flue gas is supplemented with normal temperature air through the blower 2, the sulfur dioxide content is reduced to 22000mg / Nm 3 , the temperature dropped to 115°C. The original flue gas is sprayed with process water and ammonium sulfate solution at the entrance of the absorption tower 15 (process water 0.2m 3 / h, ammonium sulfate solution 20m 3 / h) After the washing temperature drops to 70°C, it enters the absorption tower 16 to spray the absorption liquid. After entering the absorption tower 16, the flue gas is washed by three absorption liquid spray l...

Embodiment 3

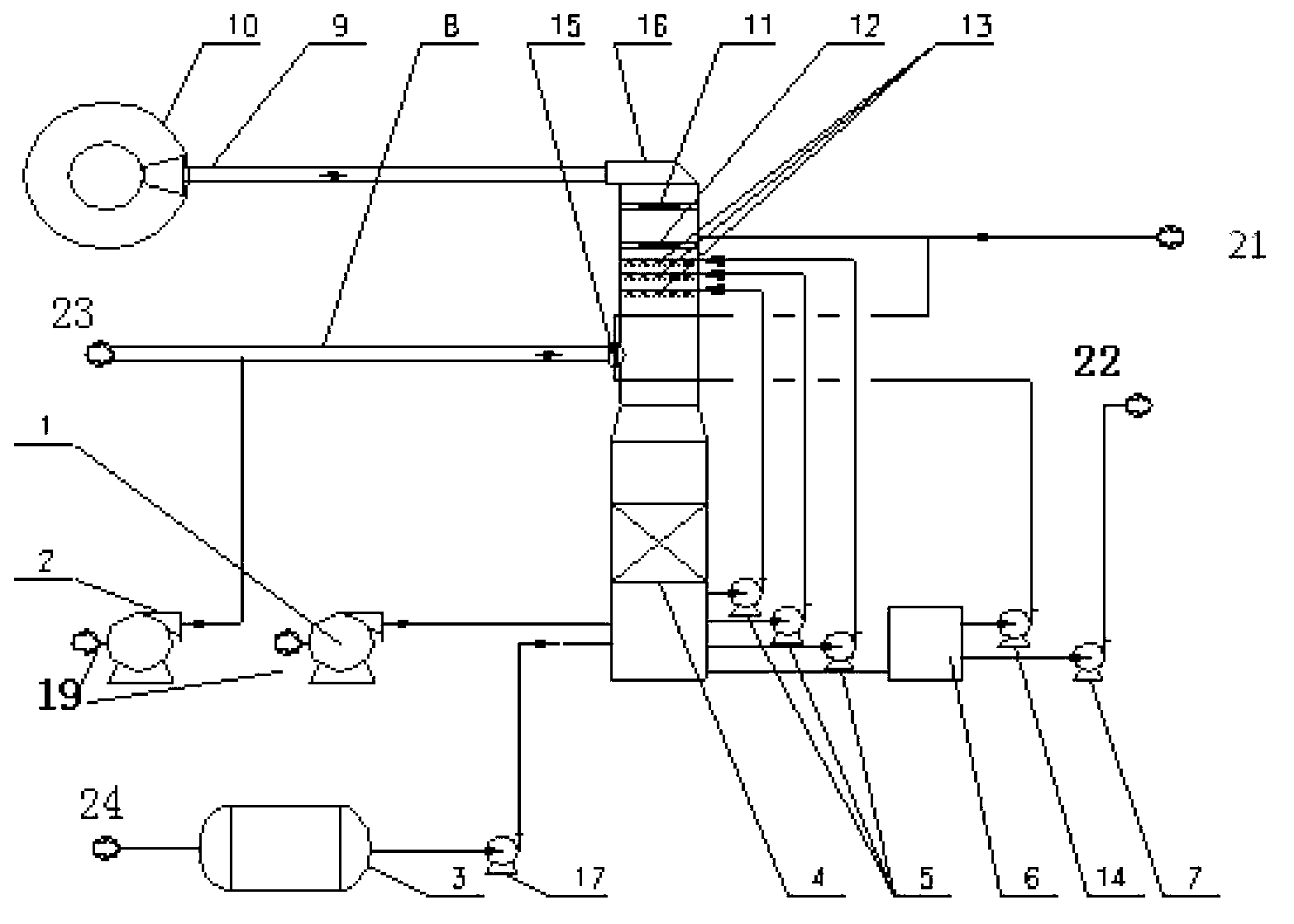

[0079] Example 3: A ammonia-based desulfurization device for Claus sulfur recovery tail gas in a coal chemical industry

[0080] The acid gas comes from the Claus sulfur recovery section of the coal chemical plant. It is produced by hydrogen sulfide gas after two-stage Claus sulfur recovery and then through the tail gas incinerator and waste heat boiler. The total amount of flue gas: 59912Nm 3 / h, flue gas temperature: 165°C, flue gas SO 2 Content 12600mg / Nm 3 , O 2 Content 2%, pressure 0.02MPa. The reactant is 99.6% liquid ammonia.

[0081] Process: See the attached flow chart of the device image 3 . The original flue gas is sprayed by process water at the entrance of the absorption tower 15 (process water 1m 3 / h) After the washing temperature drops to about 100°C, it enters the absorption tower 16. After entering the absorption tower 16, the flue gas is washed by the washing and cooling spray layer 2 in the absorption tower (ammonium sulfate solution 120m 3 / h), the ...

Embodiment 4

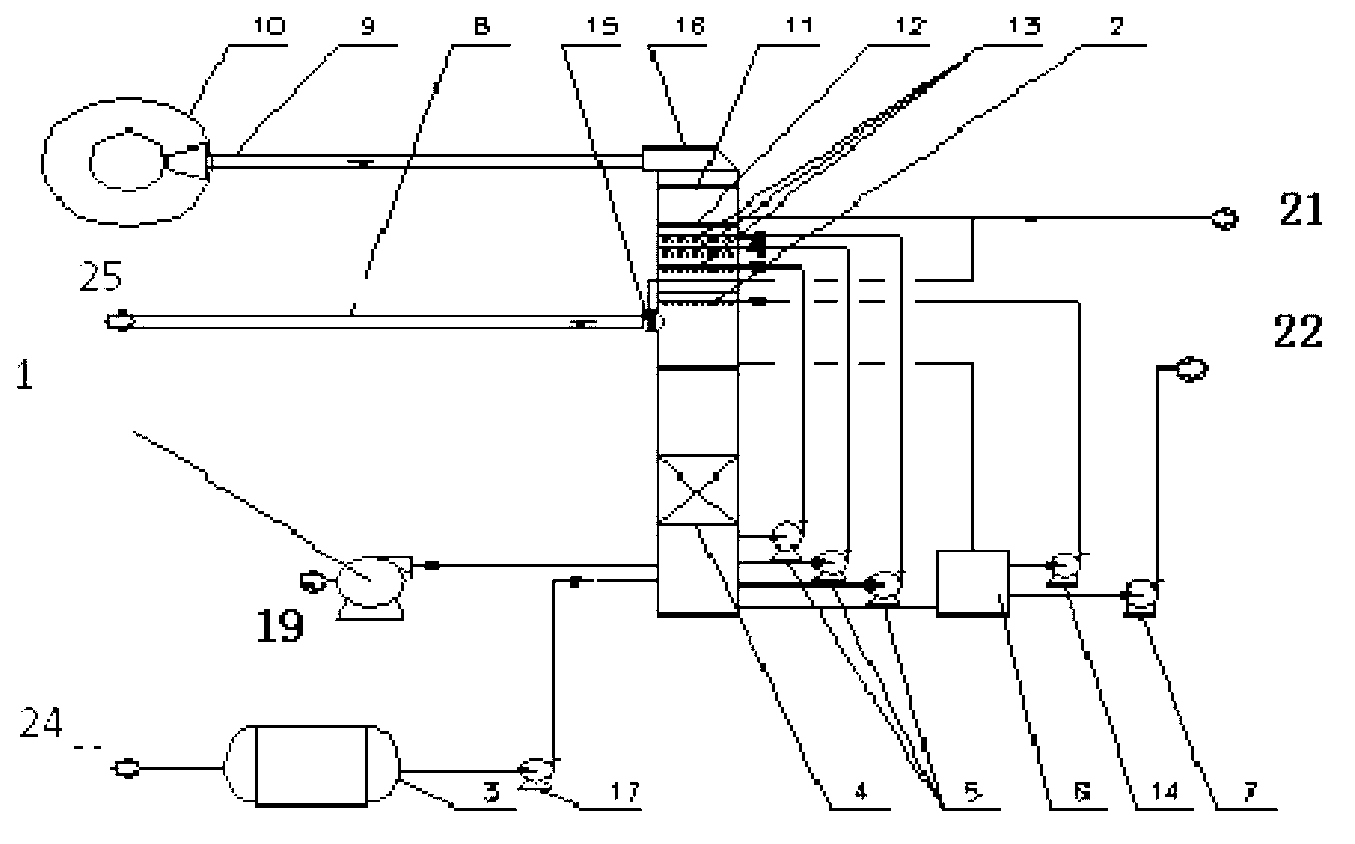

[0097] Example 4, a chemical acid tail gas ammonia desulfurization device

[0098] A chemical project produces sulfur-containing acid gas and organic waste liquid, which are burned in the incinerator, and the heat is recovered by the waste heat boiler to produce steam, which generates SO-containing 2 acidic exhaust. The total amount of flue gas of this acid gas: 11018Nm 3 / h, flue gas temperature: 350°C, flue gas SO 2 Content 2.57%, O 2 Content 6.22%, pressure 5000Pa.

[0099] The reactant is 99.6% liquid ammonia.

[0100] Process: See the attached flow chart of the device Figure 4 . After the original flue gas is supplemented with normal temperature air through the blower 10, the sulfur dioxide content is reduced to 6680mg / Nm 3 , the temperature dropped to 60°C. The original flue gas is sprayed by the process water layer 15 at the entrance of the absorption tower (process water 0.5m 3 / h) Washing temperature. And after entering the absorption tower 16, the flue gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Tower diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com