Patents

Literature

612results about How to "Increase oxidation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engine exhaust catalysts containing palladium-gold

ActiveUS7709414B2High activityEmission reductionCombination devicesInternal combustion piston enginesPalladium catalystPt element

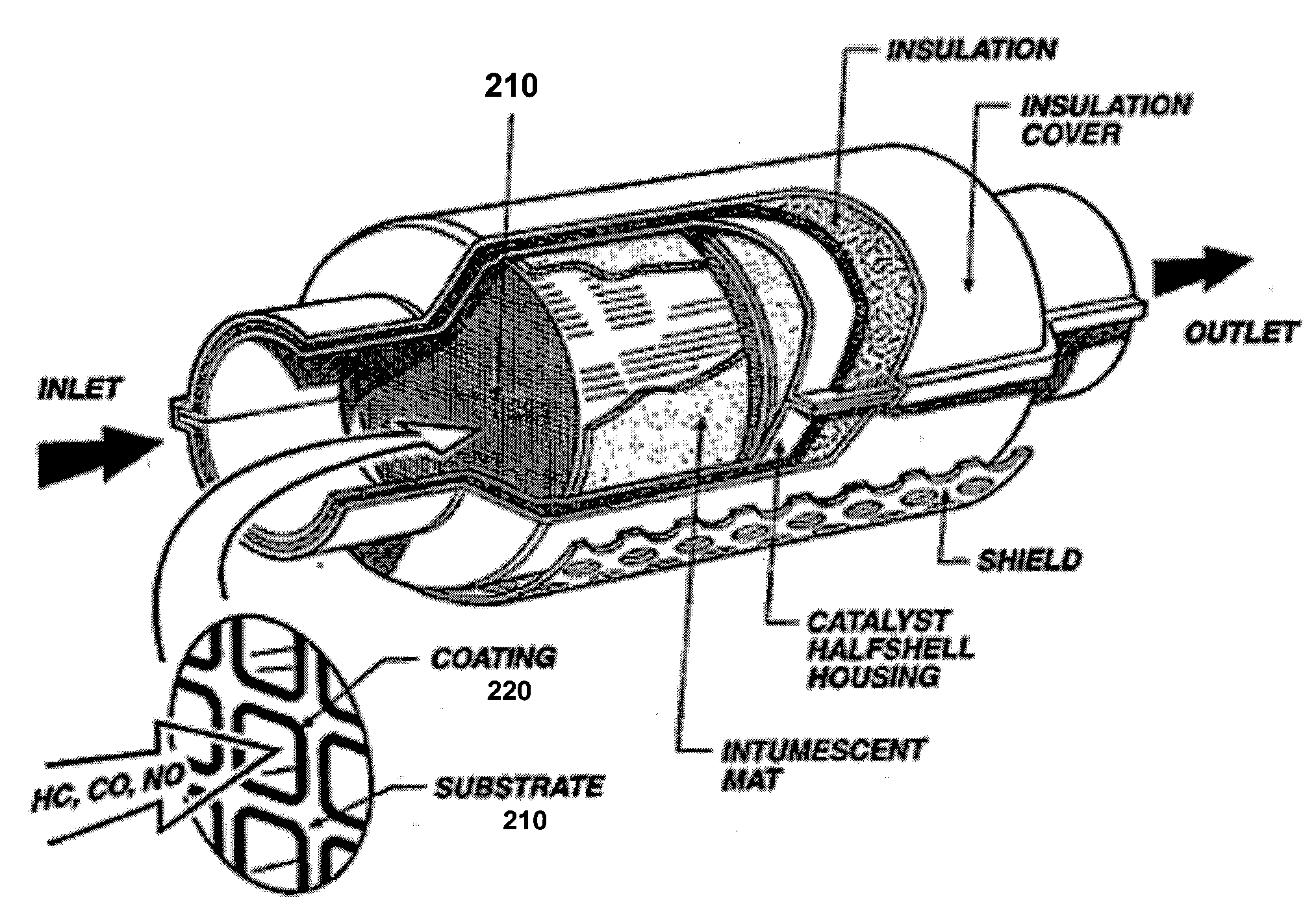

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum—palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGC HLDG LTD

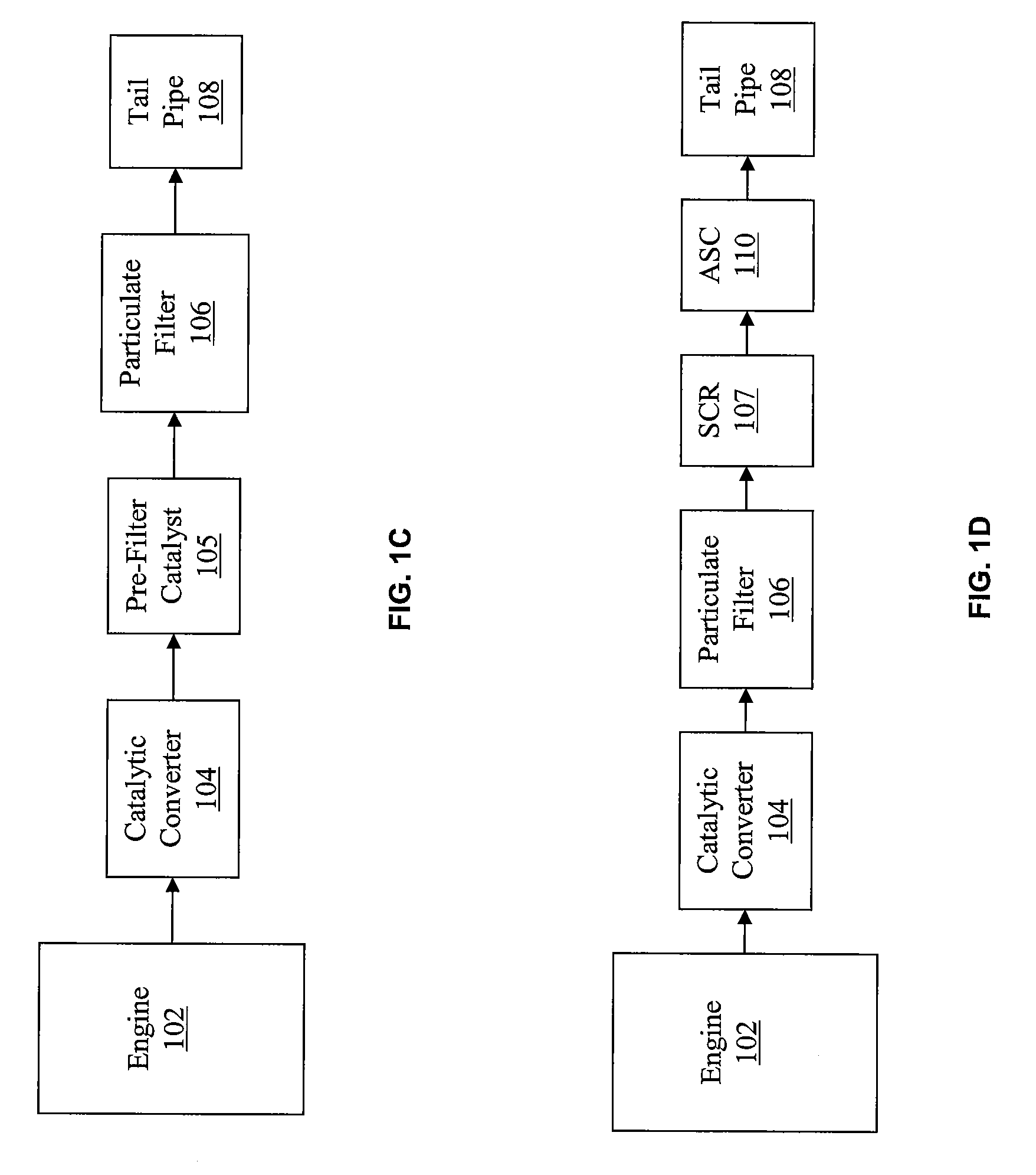

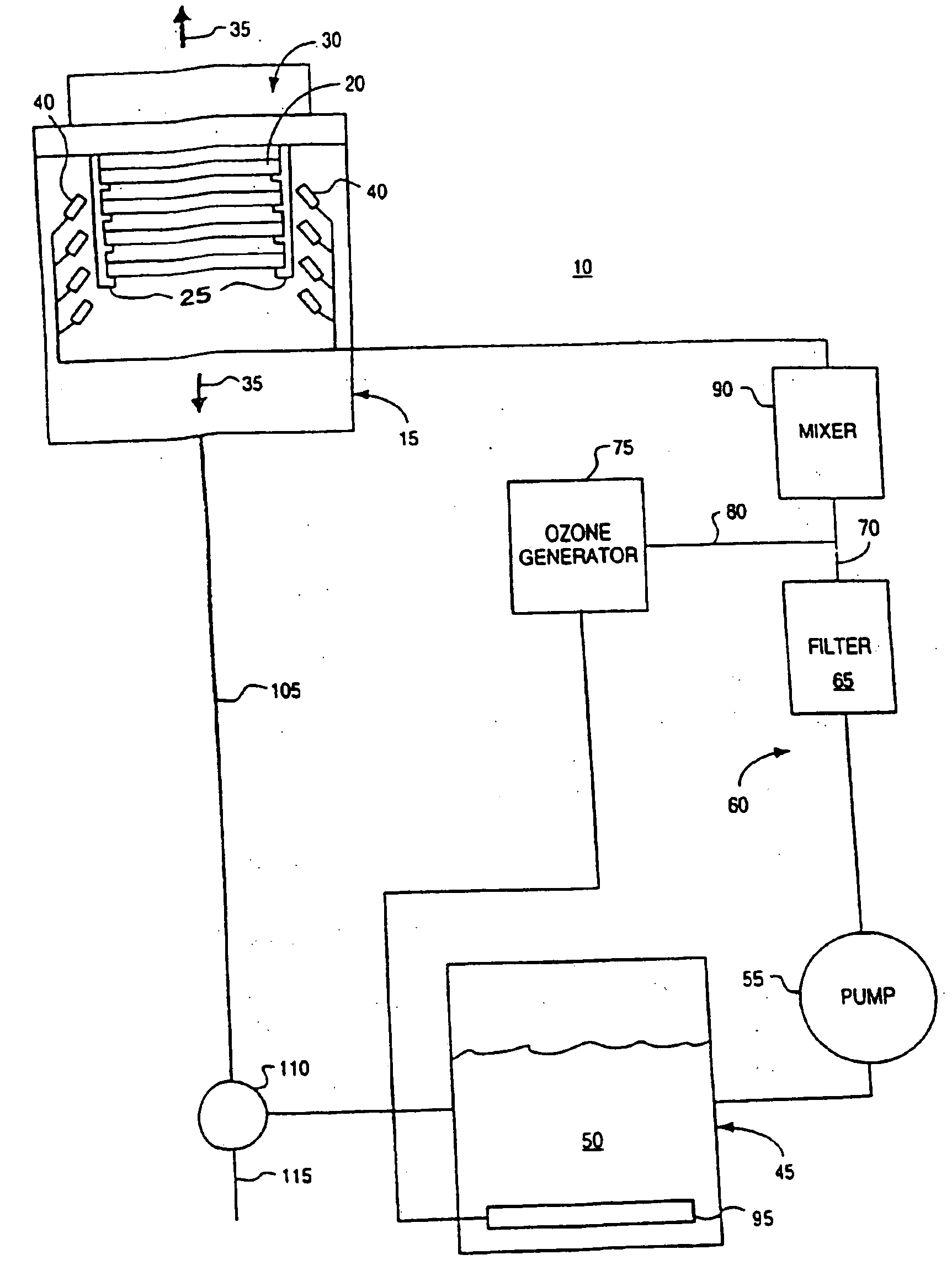

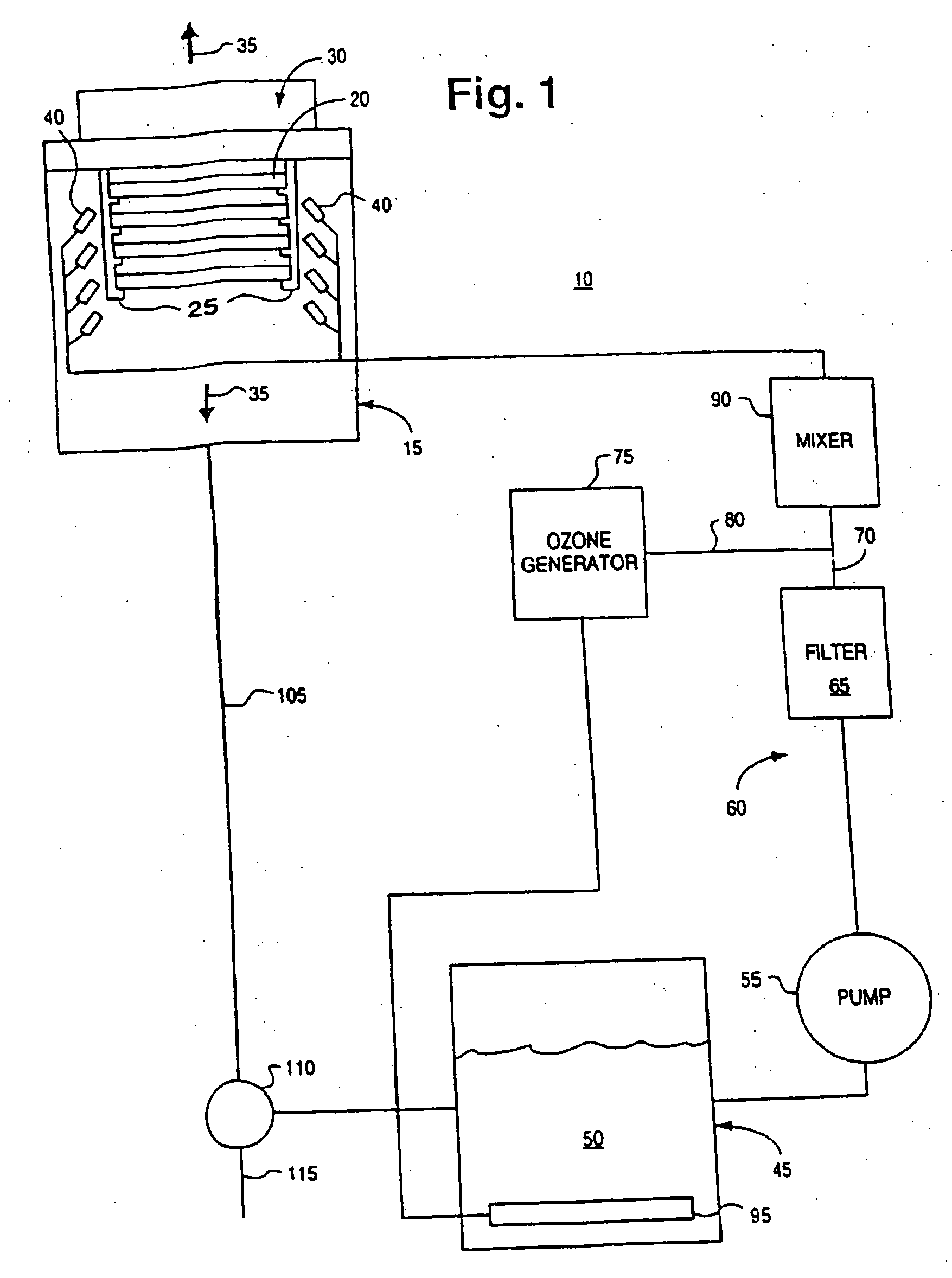

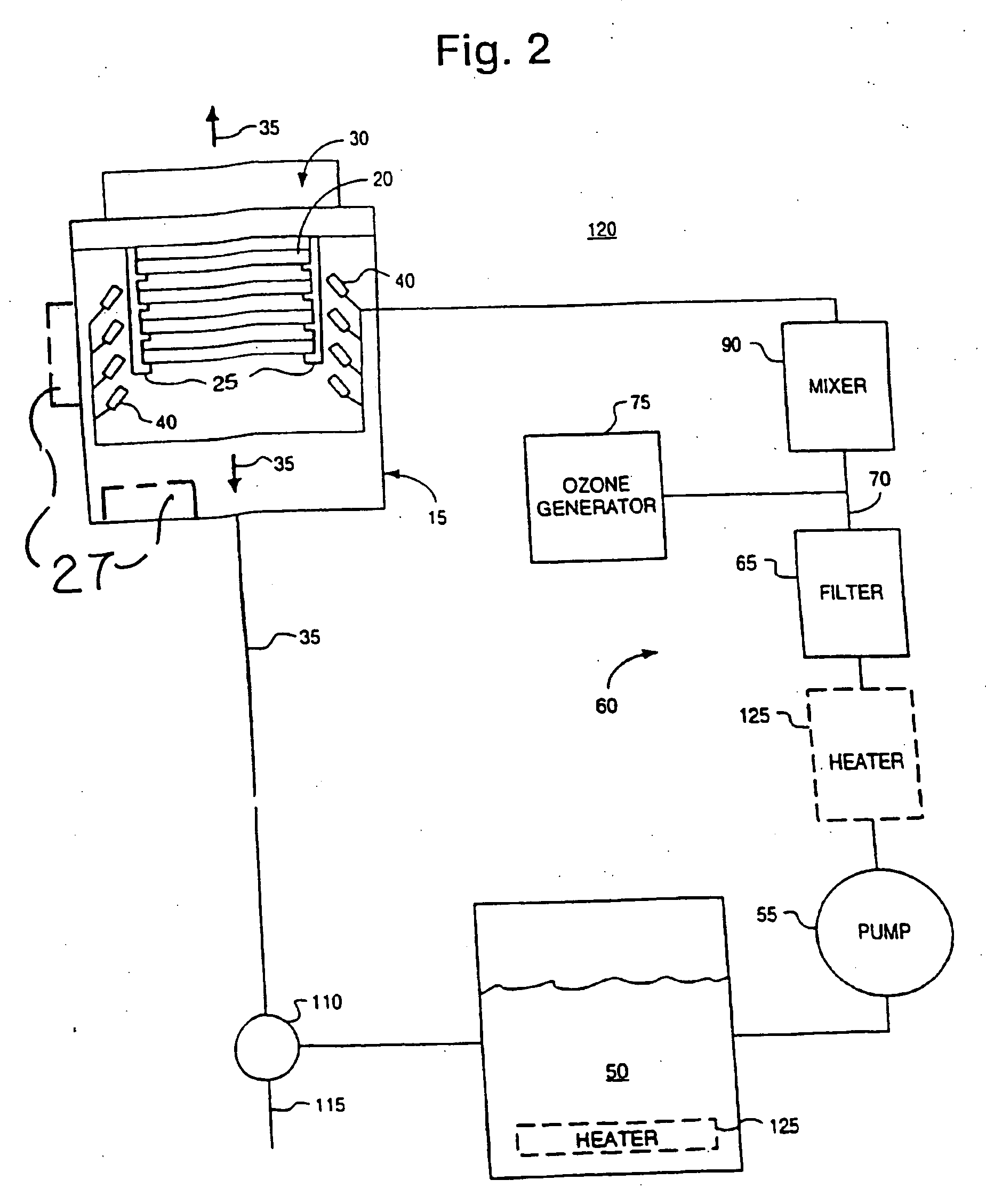

Method and apparatus for treating a substrate with an ozone-solvent solution

InactiveUS6982006B1Increase safetyIncrease oxidation rateLighting and heating apparatusHollow article cleaningSolventAqueous solution

A general method and apparatus for treating materials at high speed comprises the steps of dissolving a relatively high concentration ozone gas in a solvent at a relatively low predetermined temperature T1 to form an ozone-solvent solution with a relatively high dissolved ozone concentration, and heating either the ozone-water solution or the material to be treated or both, the ozone-solvent solution and the material to be oxidized with a point-of-use heater to quickly increase the temperature to a predetermined higher temperature T2>T1, and applying the ozone-solvent solution to said material(s) whereby the heated ozone-water solution will have a much higher dissolved ozone concentration at said higher temperature, than could be achieved if the ozone gas was initially dissolved in water at said higher temperature.

Owner:BOYERS DAVID G +1

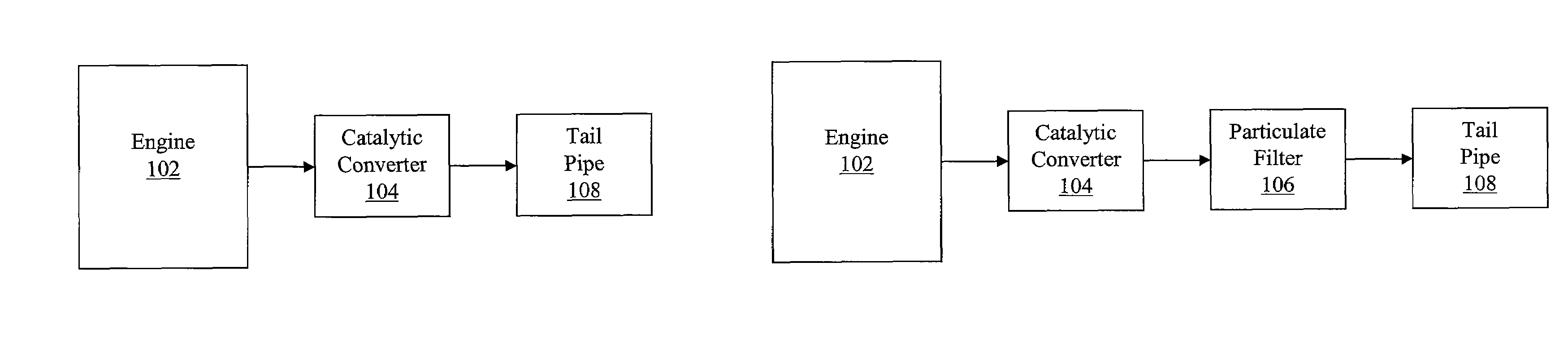

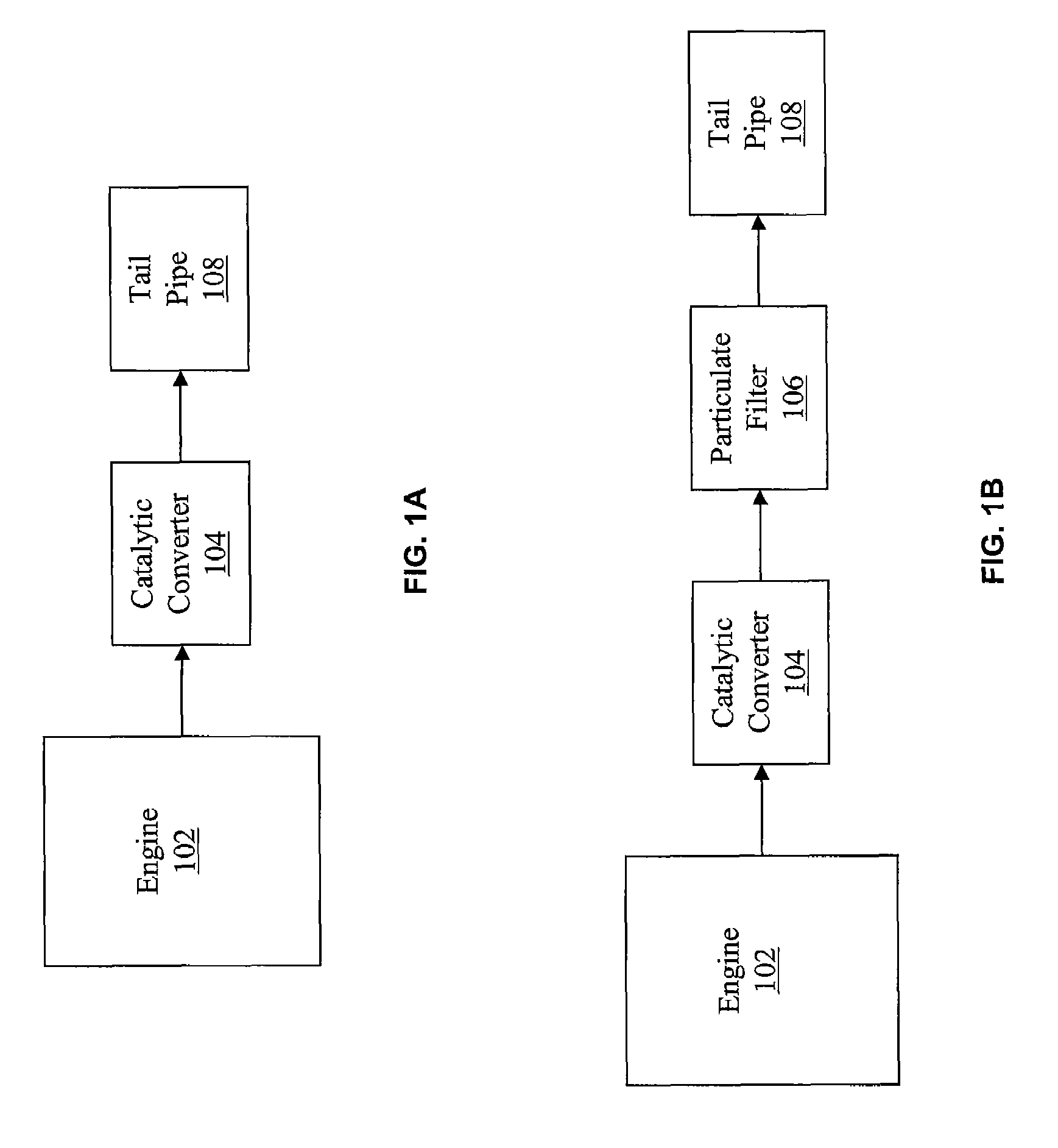

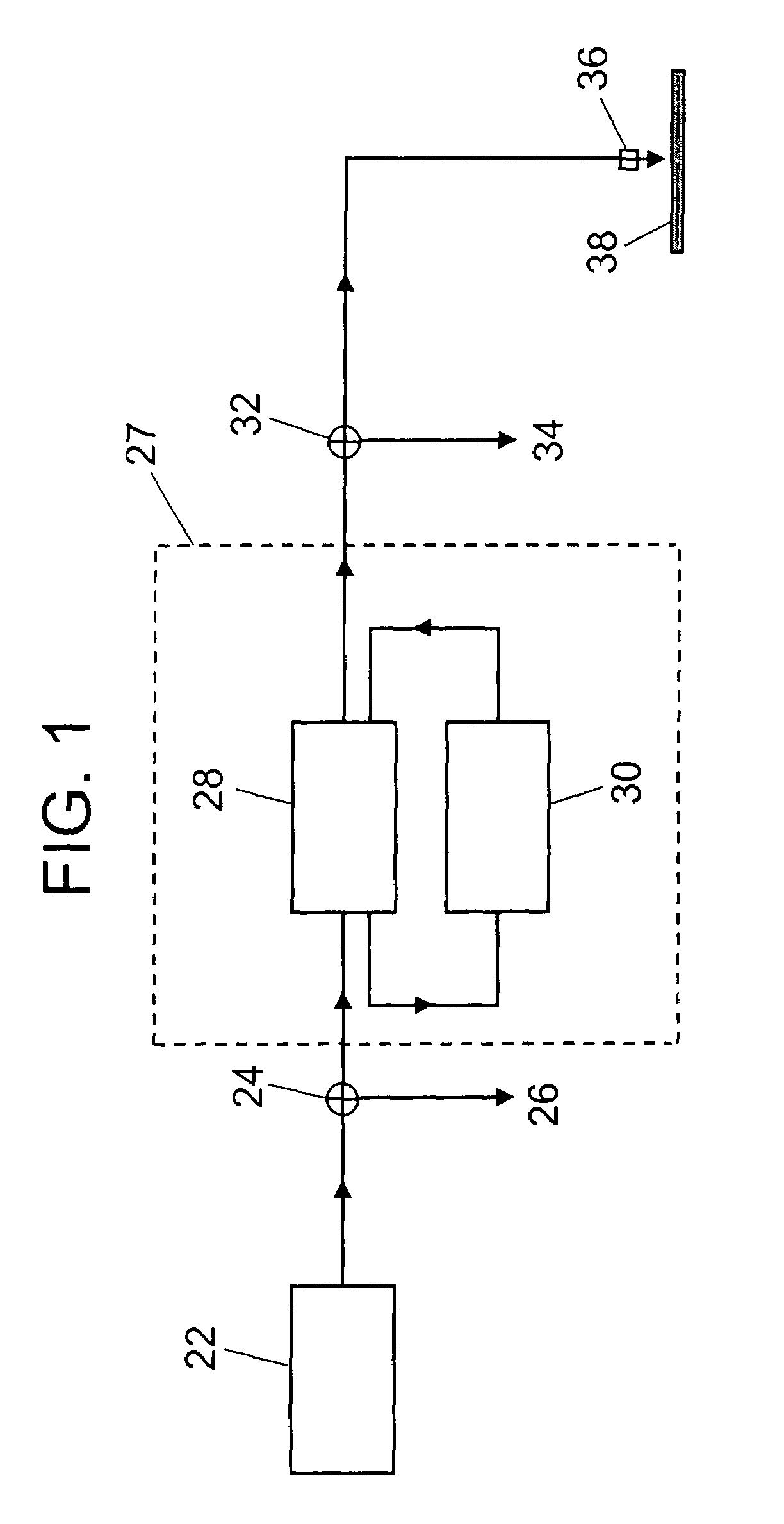

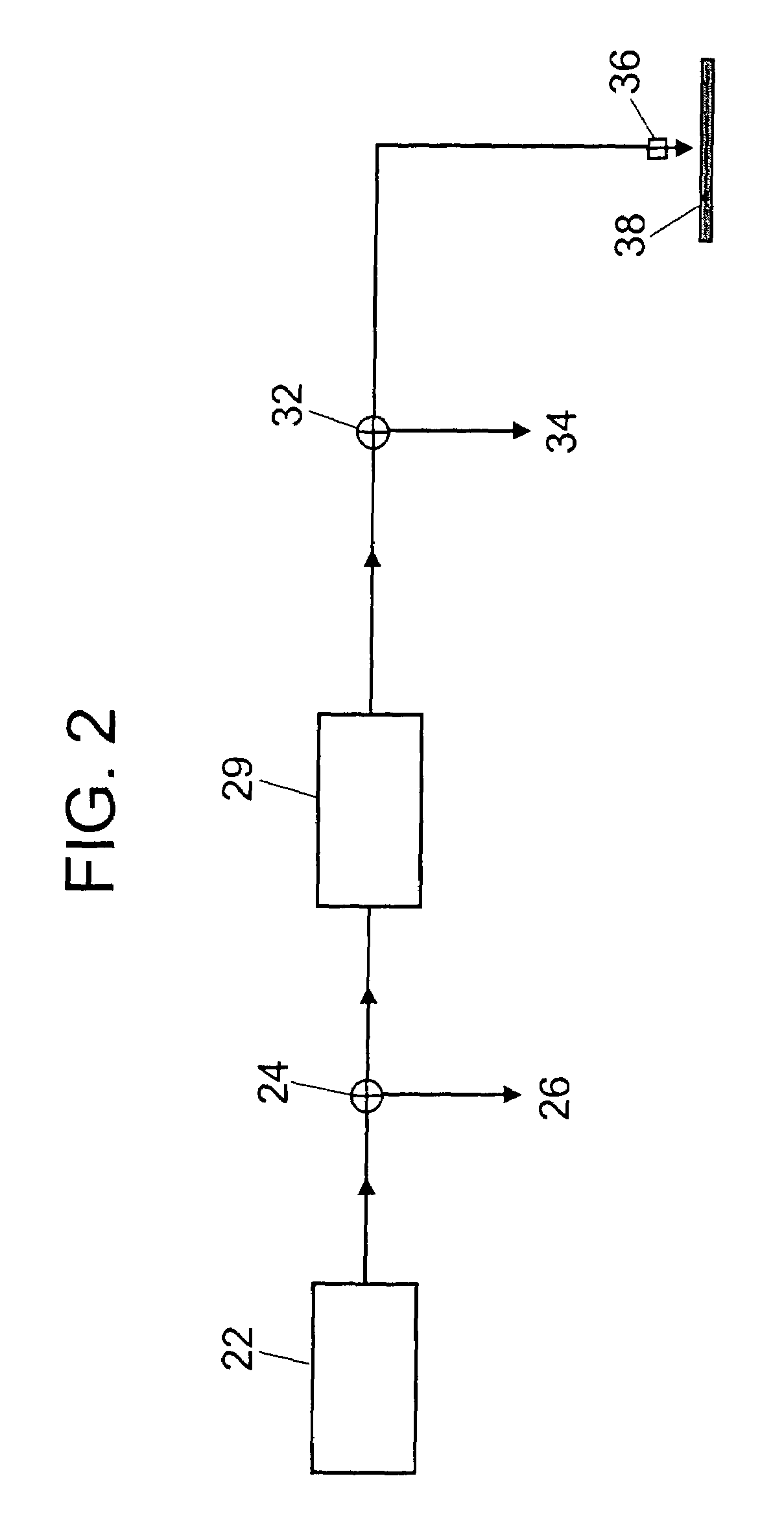

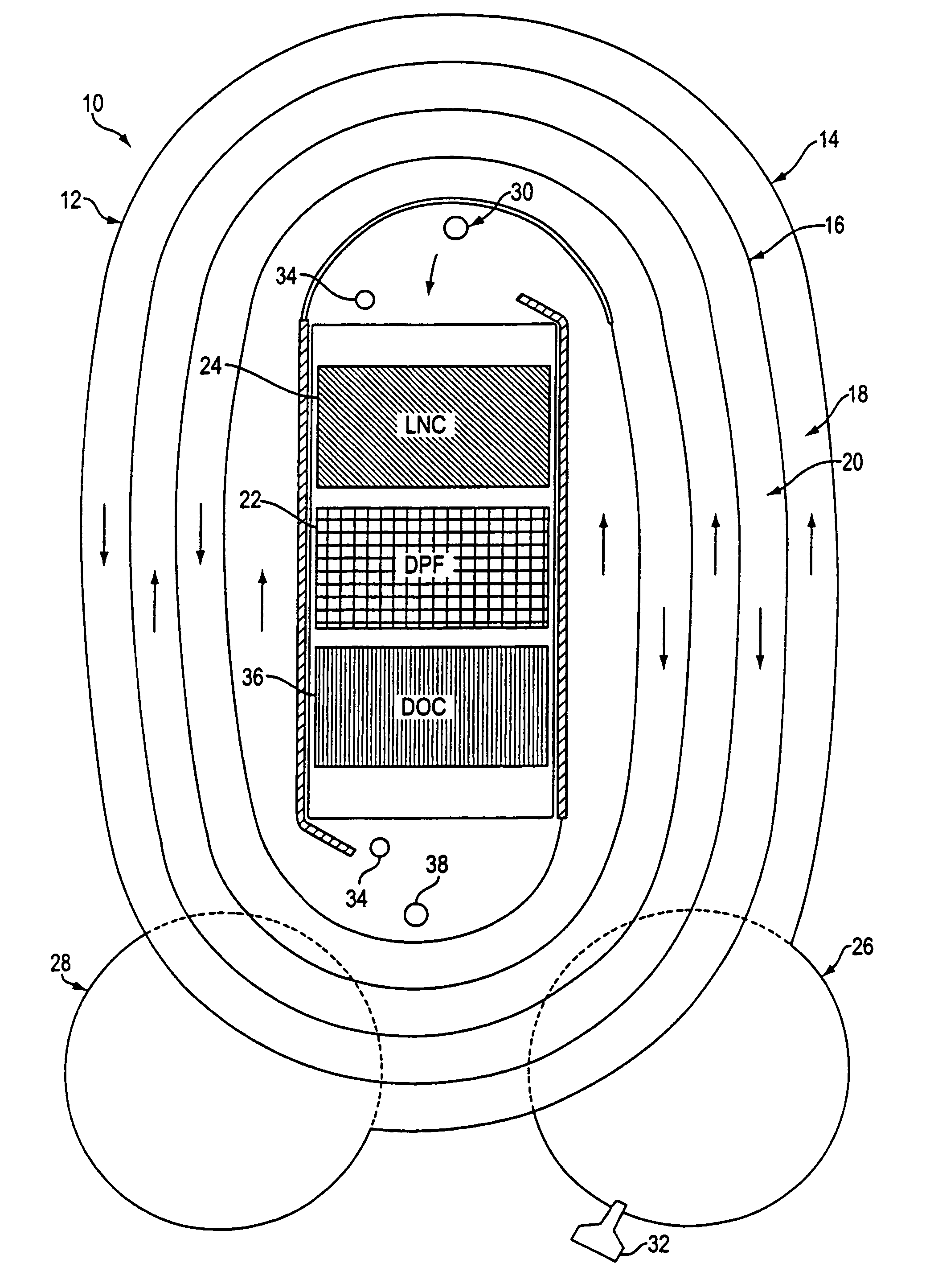

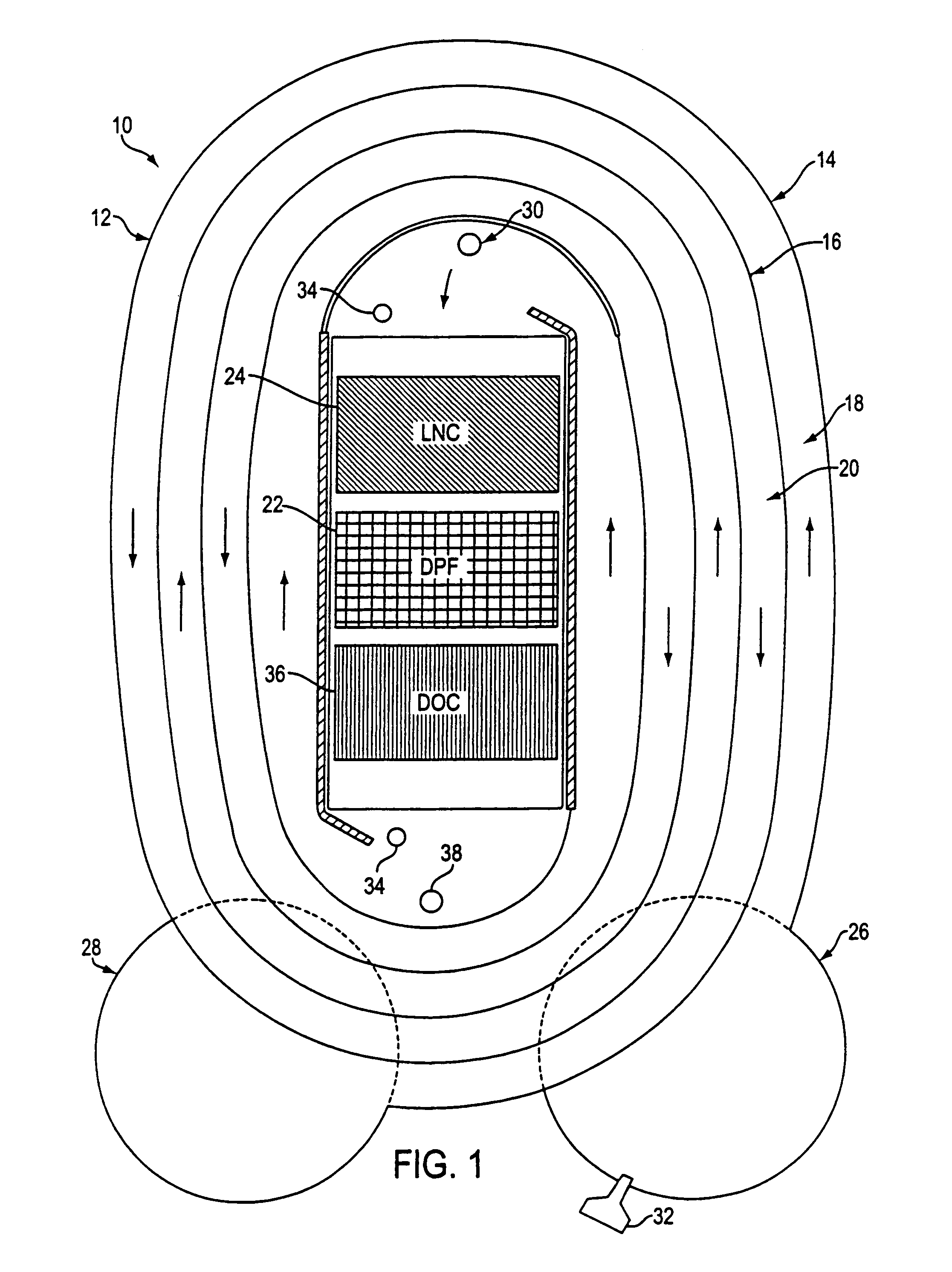

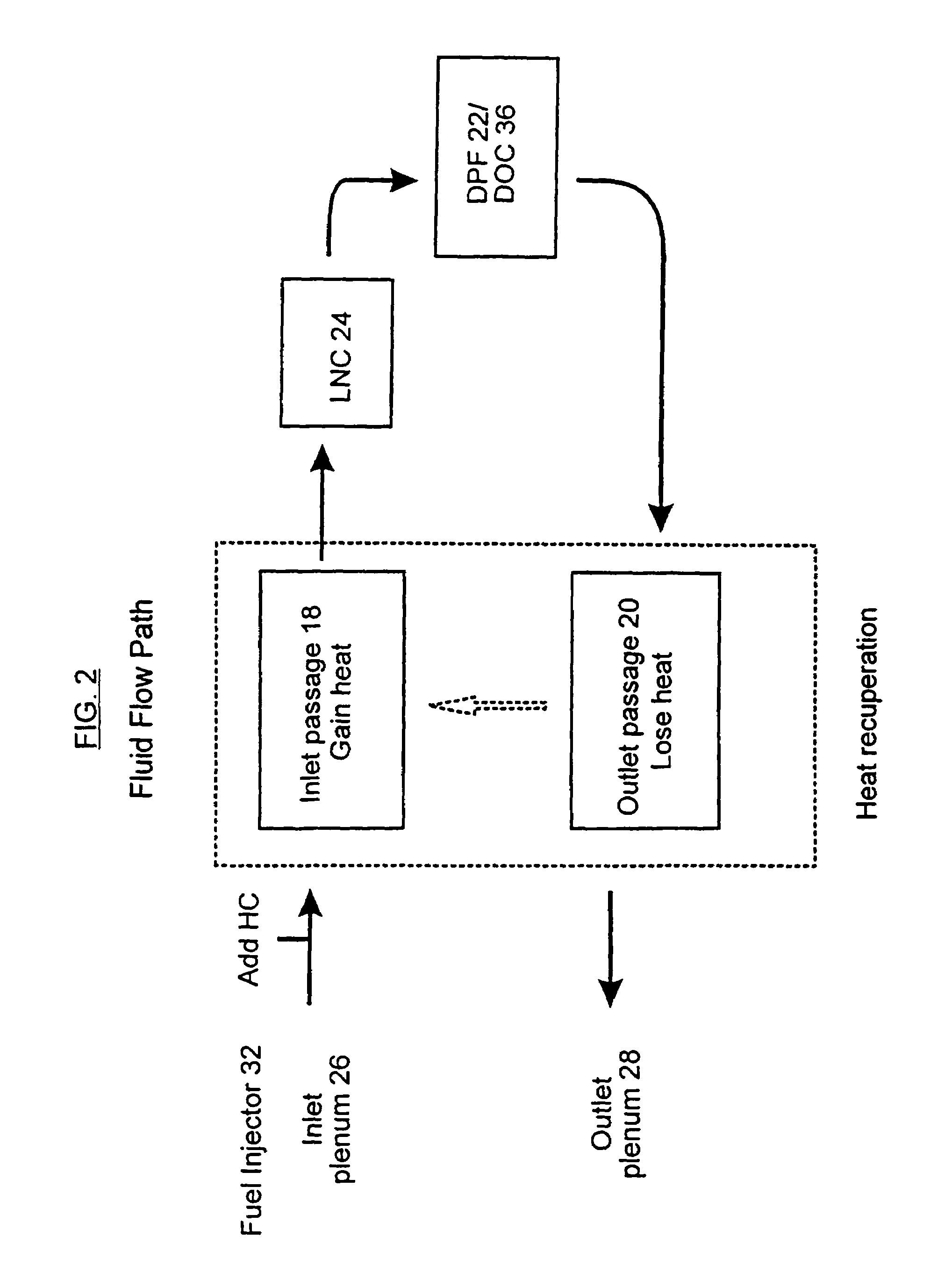

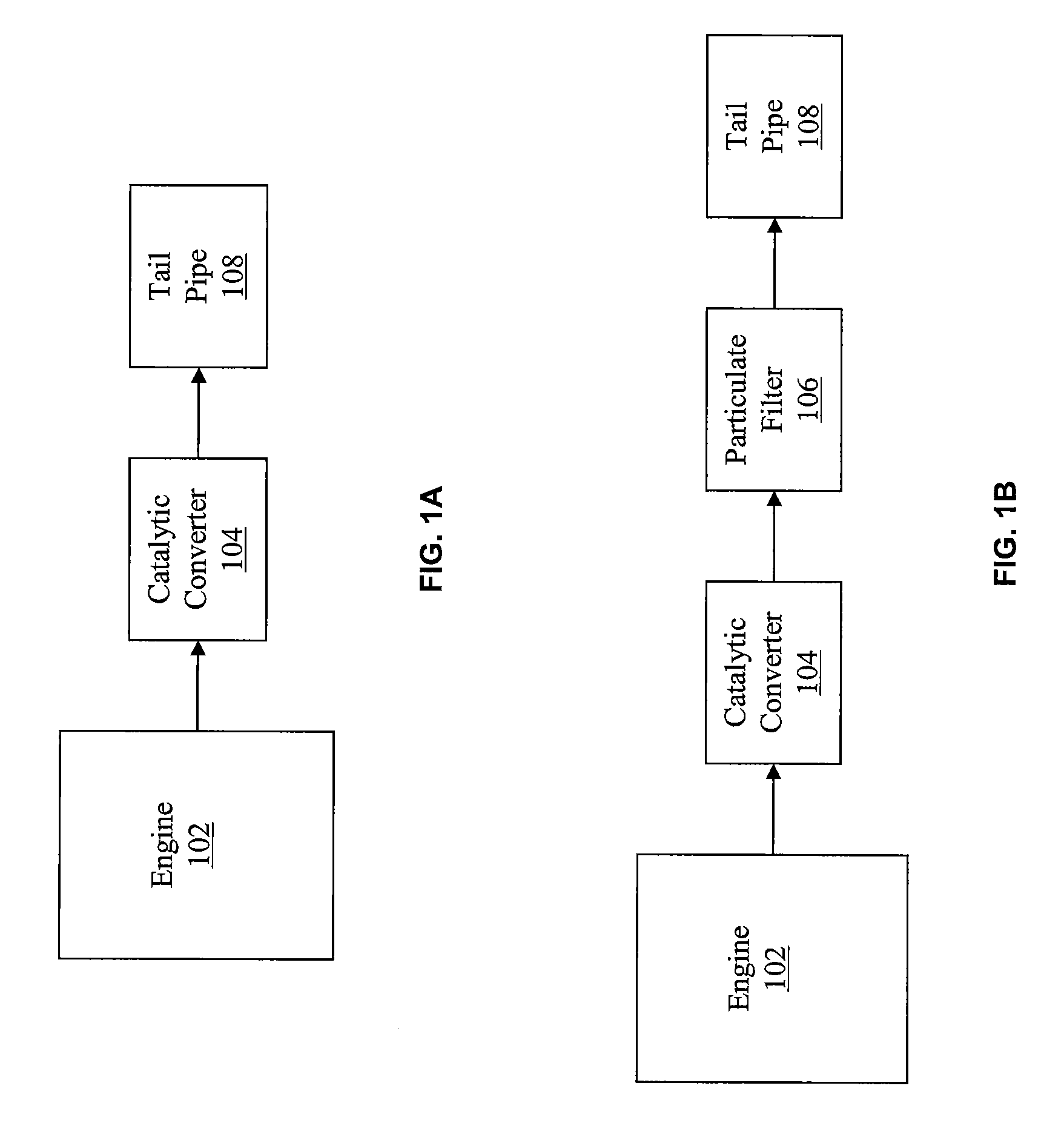

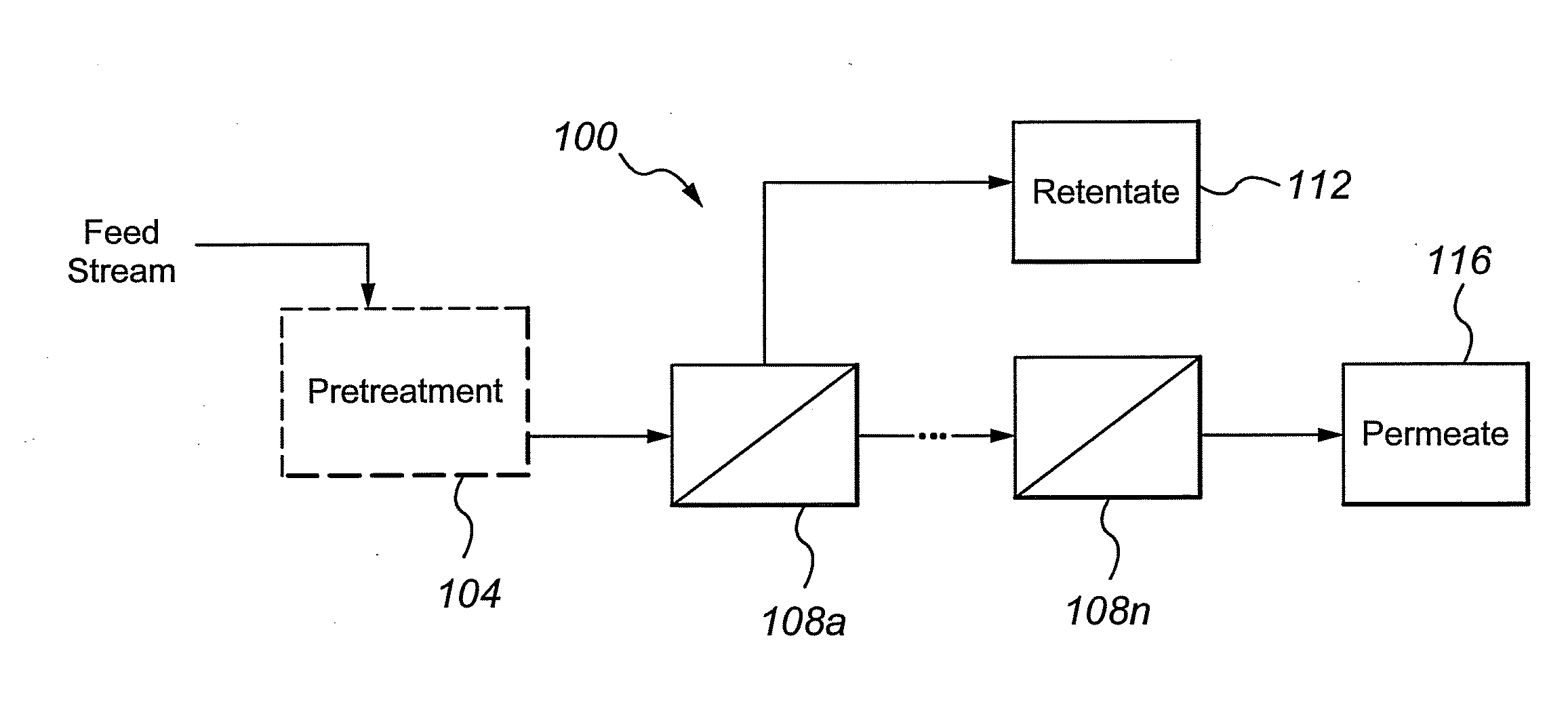

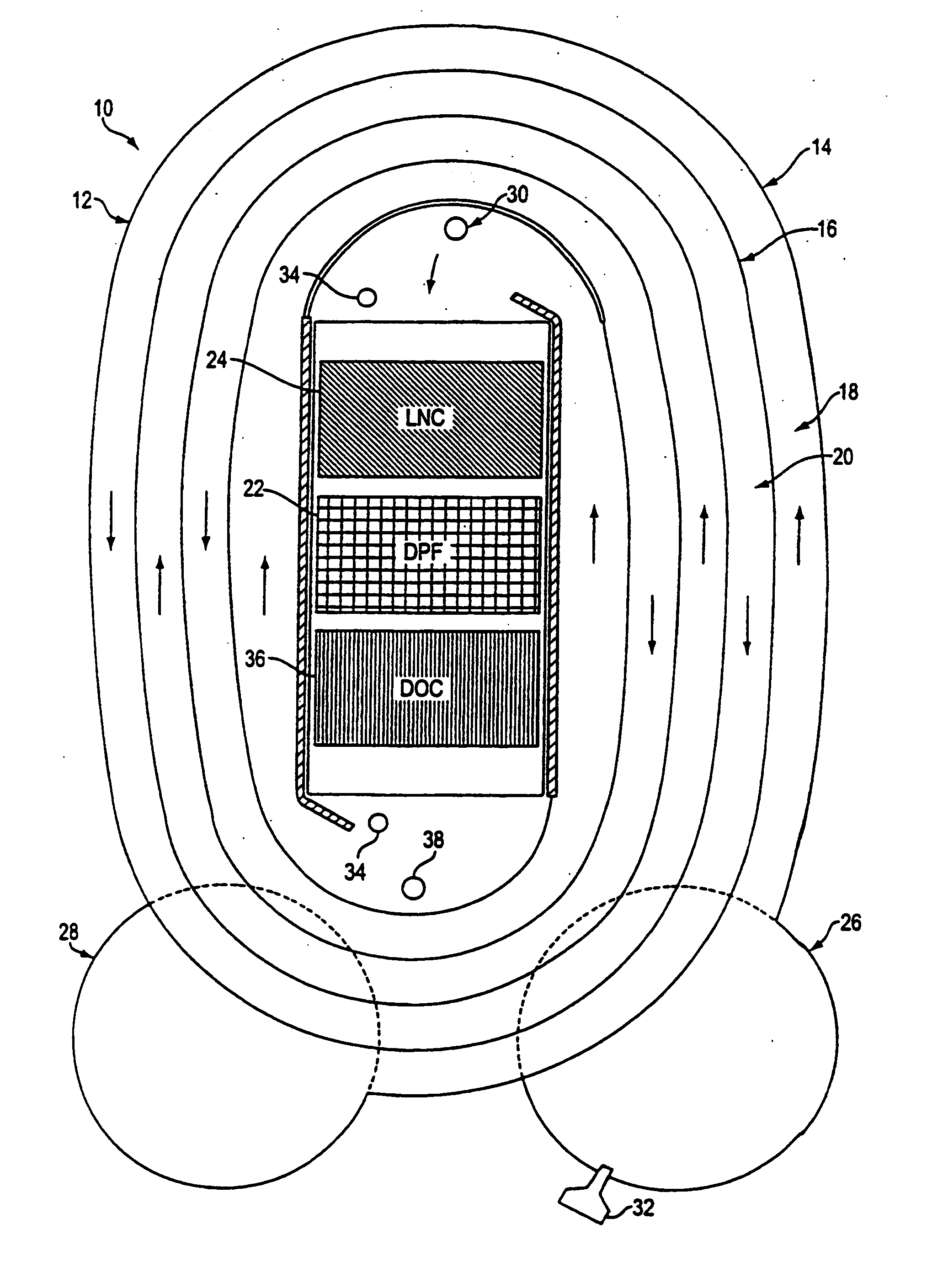

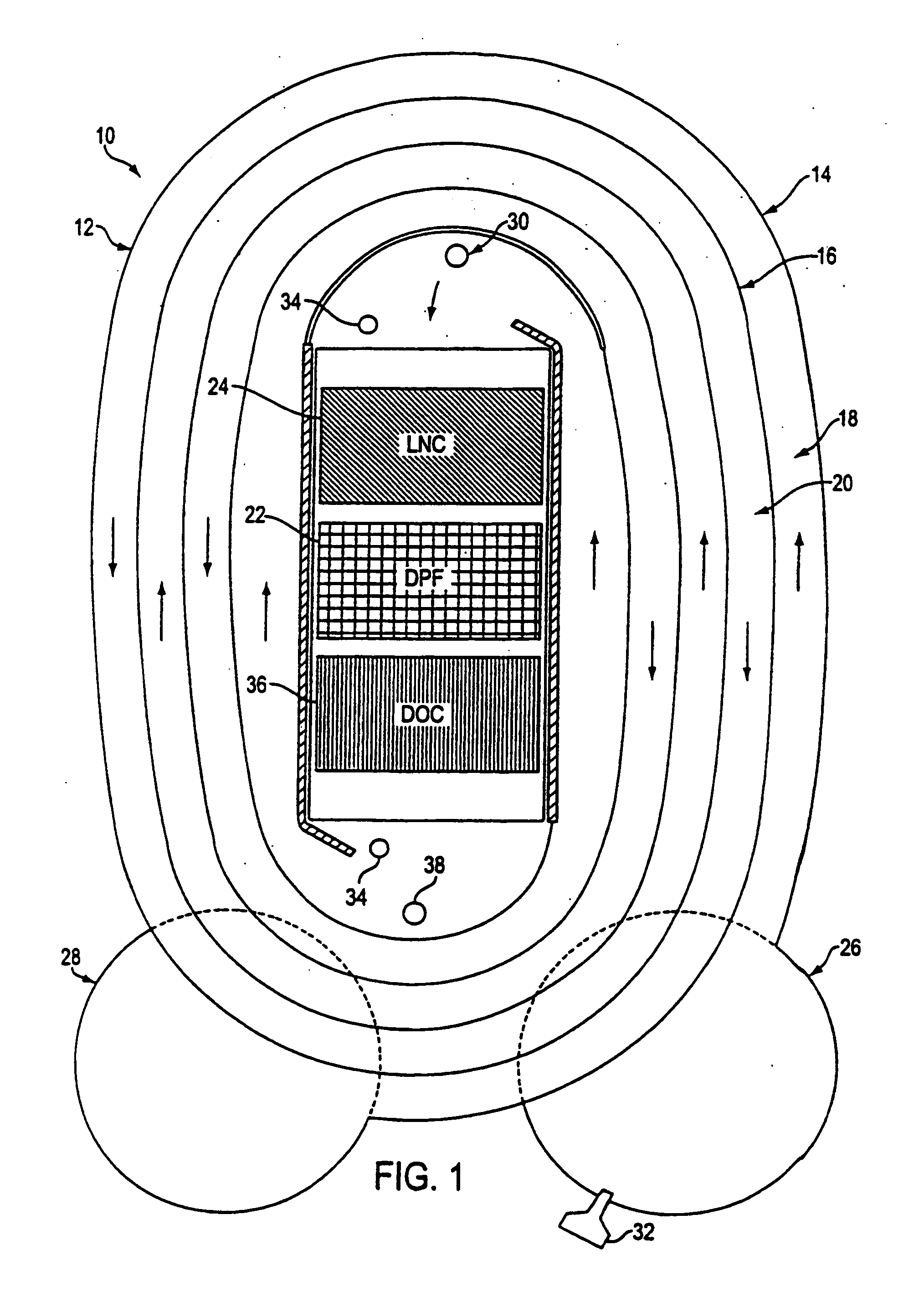

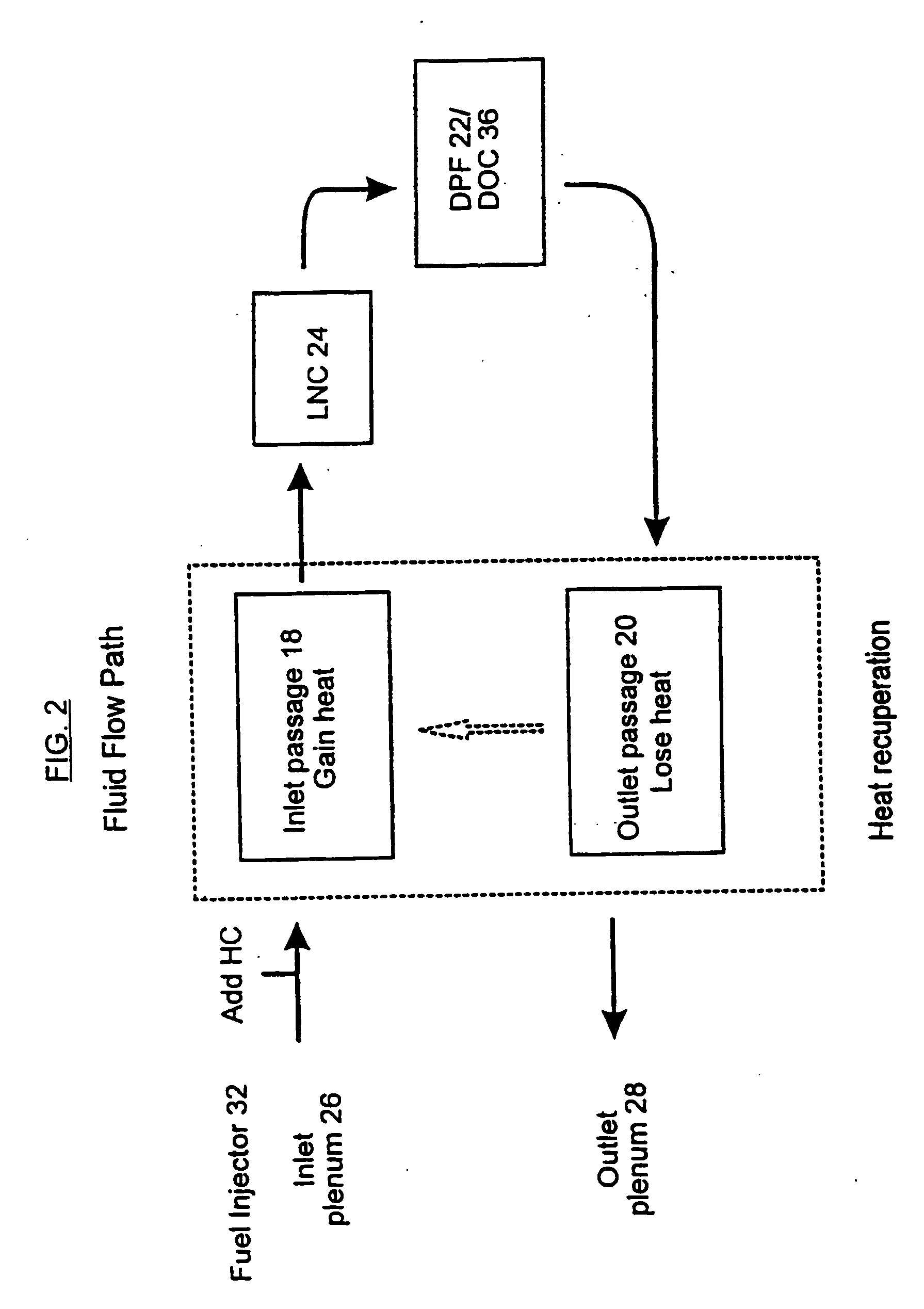

Integrated apparatus for removing pollutants from a fluid stream in a lean-burn environment with heat recovery

InactiveUS6935105B1Increase oxidation rateSmall sizeGas treatmentInternal combustion piston enginesParticulatesNitrogen

An apparatus and method to treat fluid streams, and in particular emissions from lean-burn engines such as diesel engines, are disclosed, which use multiple catalysts chosen to remove hydrocarbons, carbon monoxide, particulate matter, and oxides of nitrogen. The apparatus and method also provide for heat exchange between the inlet and outlet exhaust streams to sustain the catalyzed reactions, by placing the catalysts in the temperature zones where their operation is enhanced, and they also allow for regeneration of a filter used to trap particulate matter in the streams.

Owner:RODNEY ELLIOTT +1

Engine Exhaust Catalysts Containing Palladium-Gold

InactiveUS20080125313A1Reduce inhibitionEmission reductionGas treatmentInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum-palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGCH TECH LIMITED WORLD GOLD COUNCIL

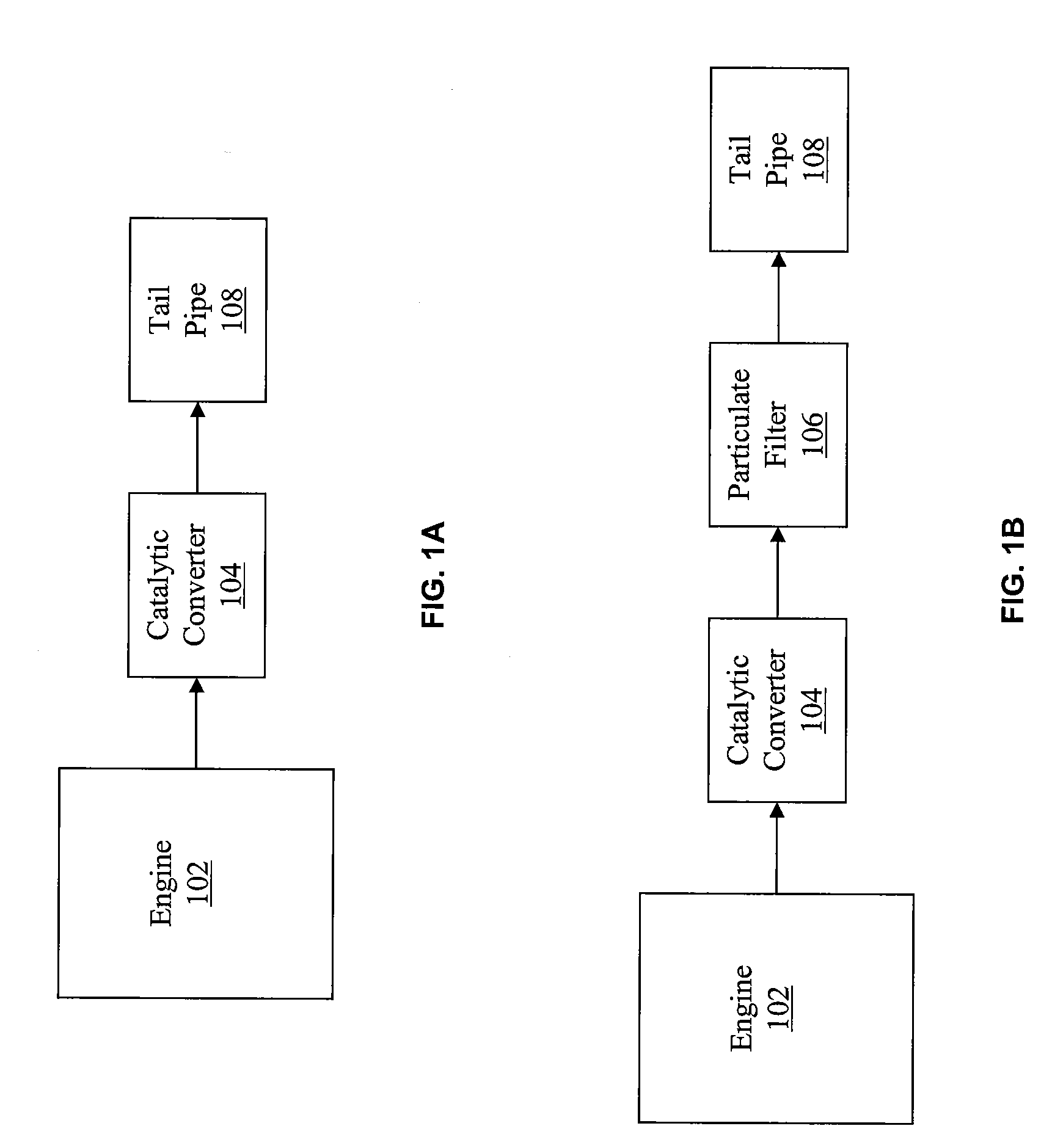

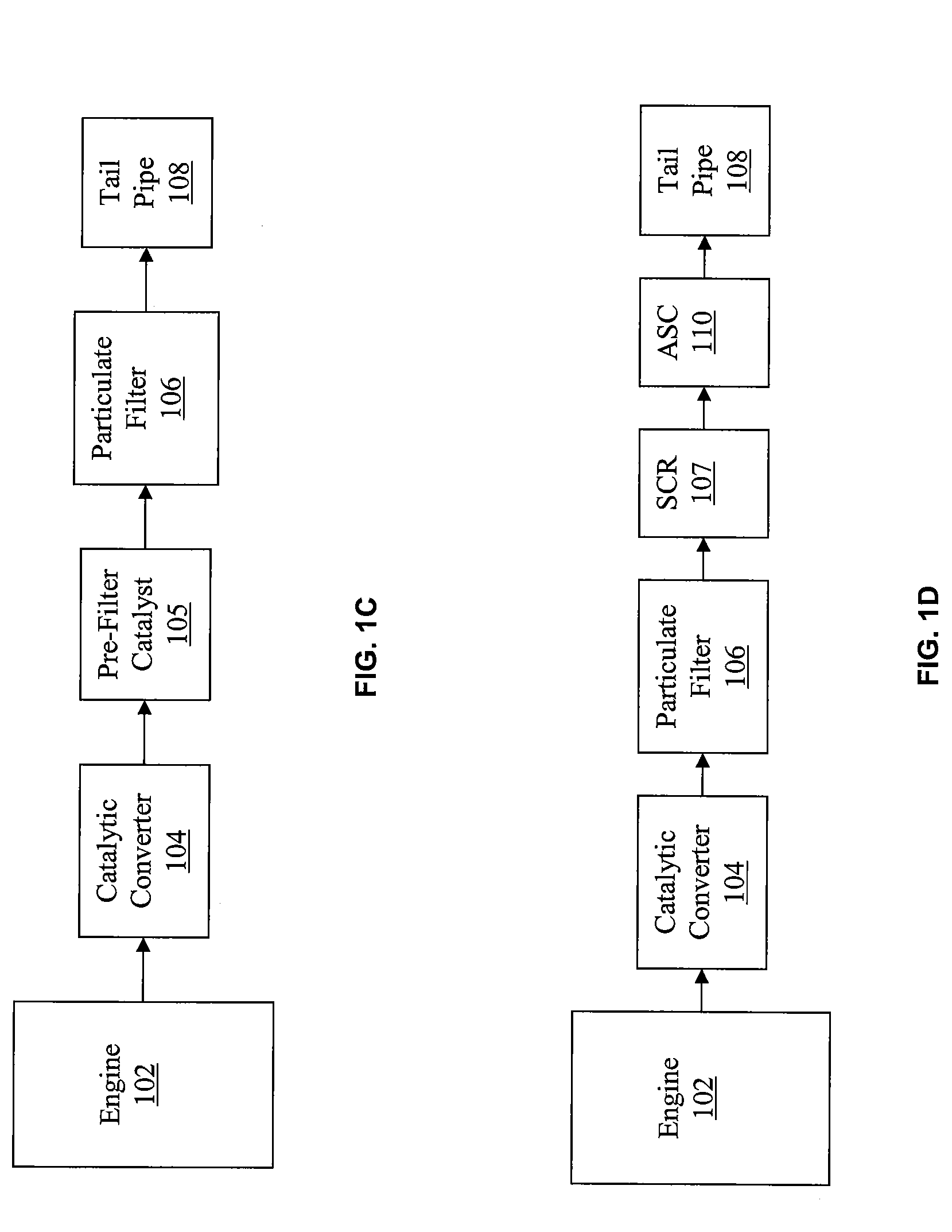

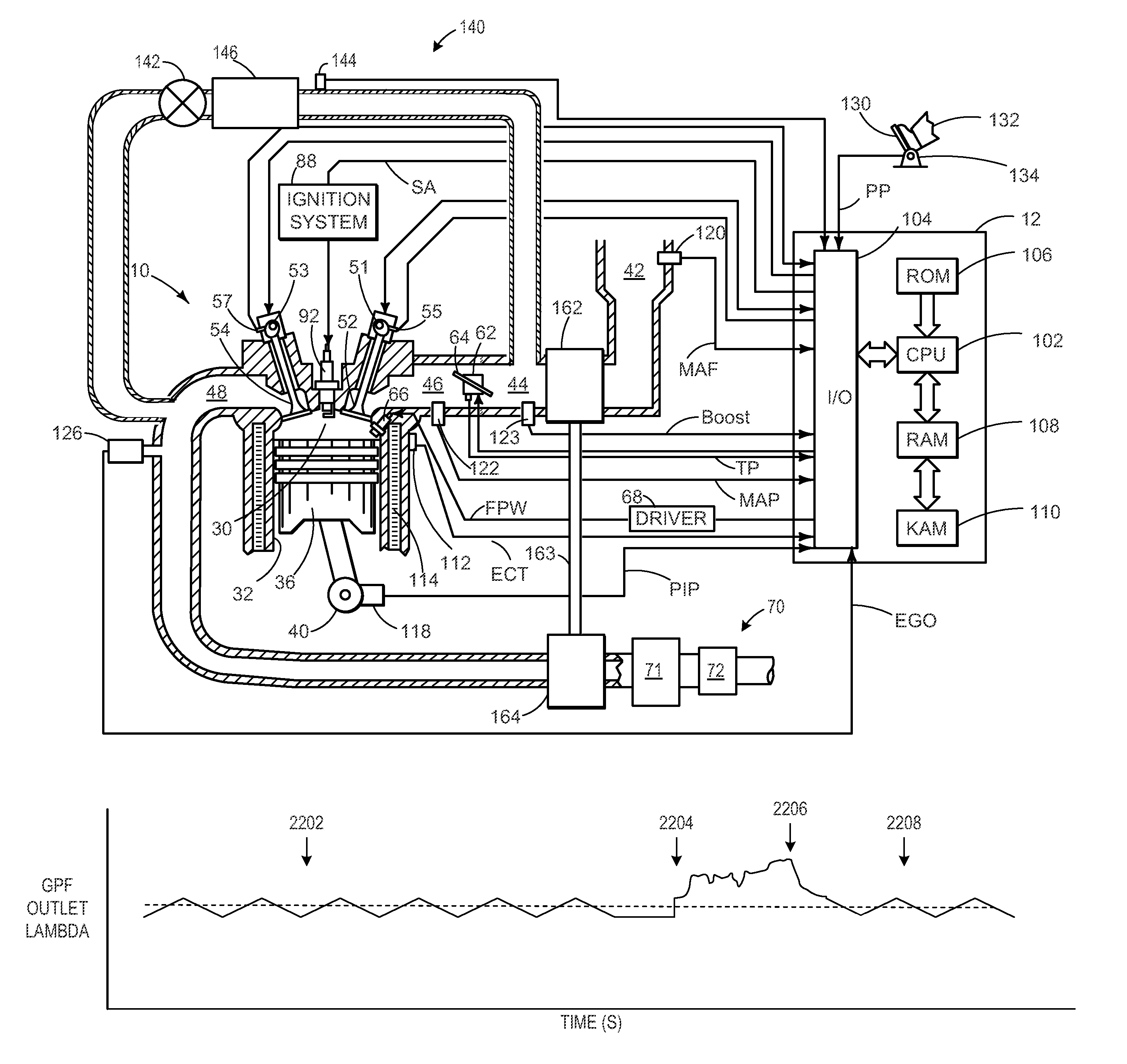

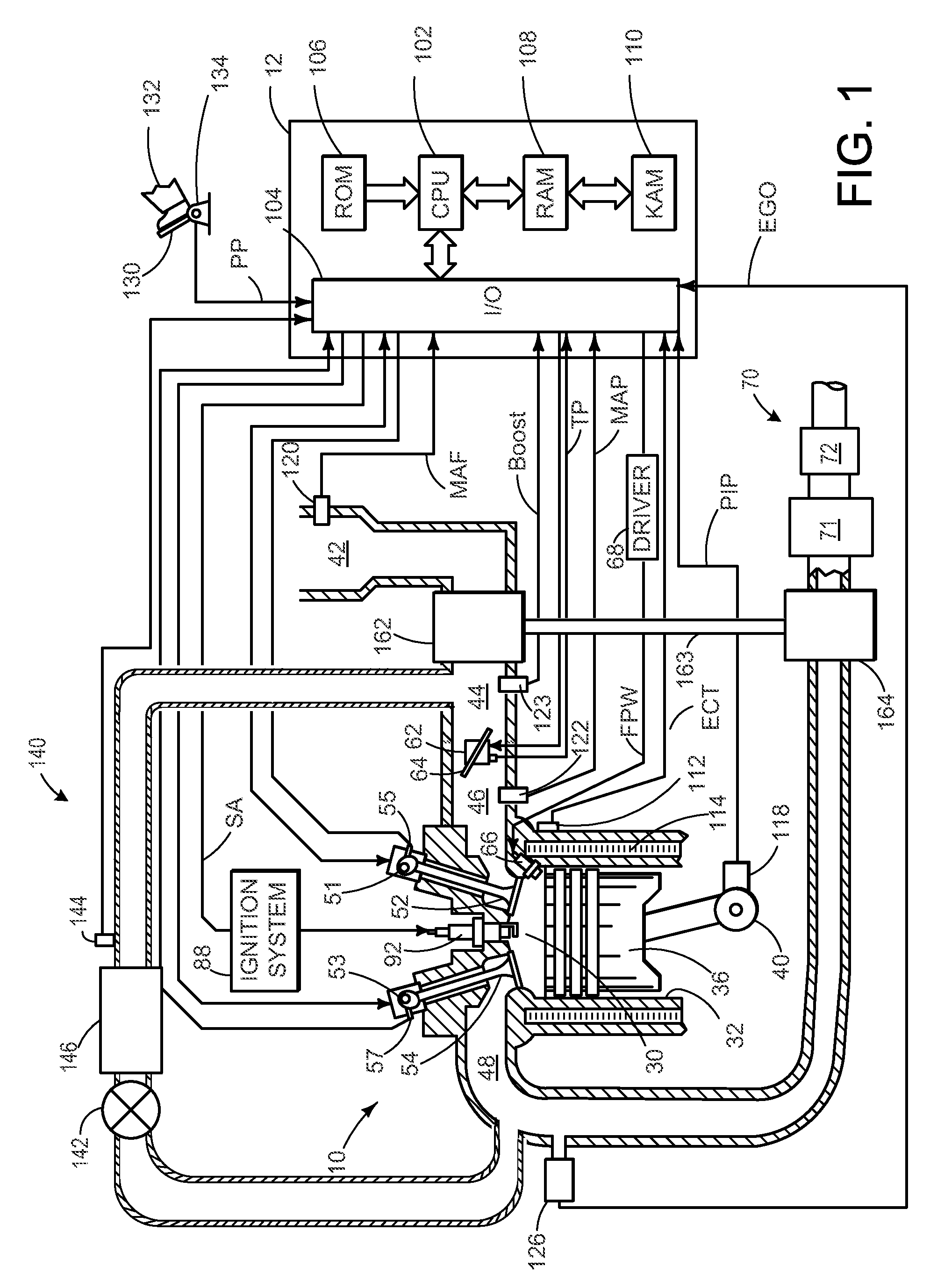

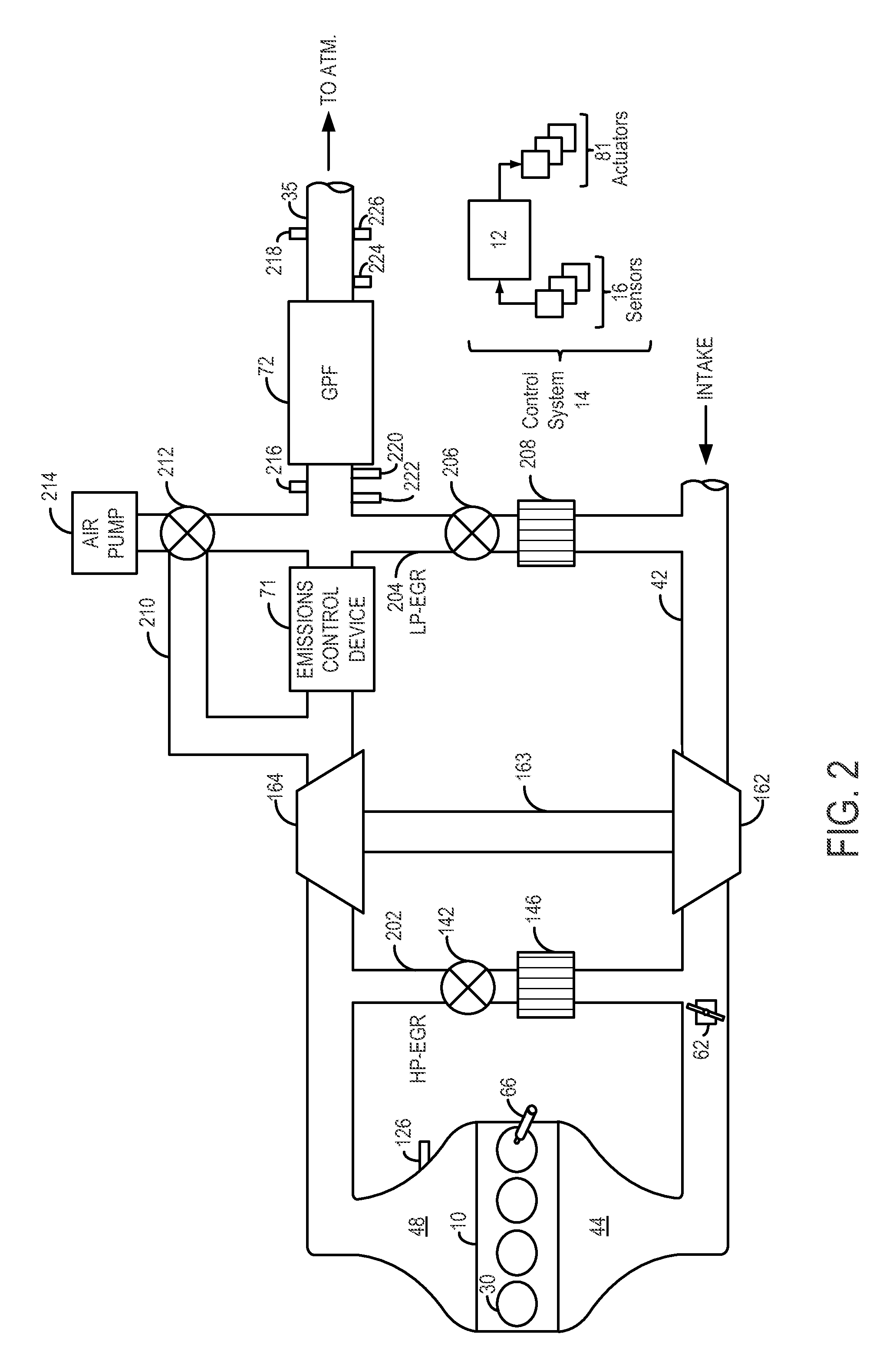

Gasoline particulate filter regeneration and diagnostics

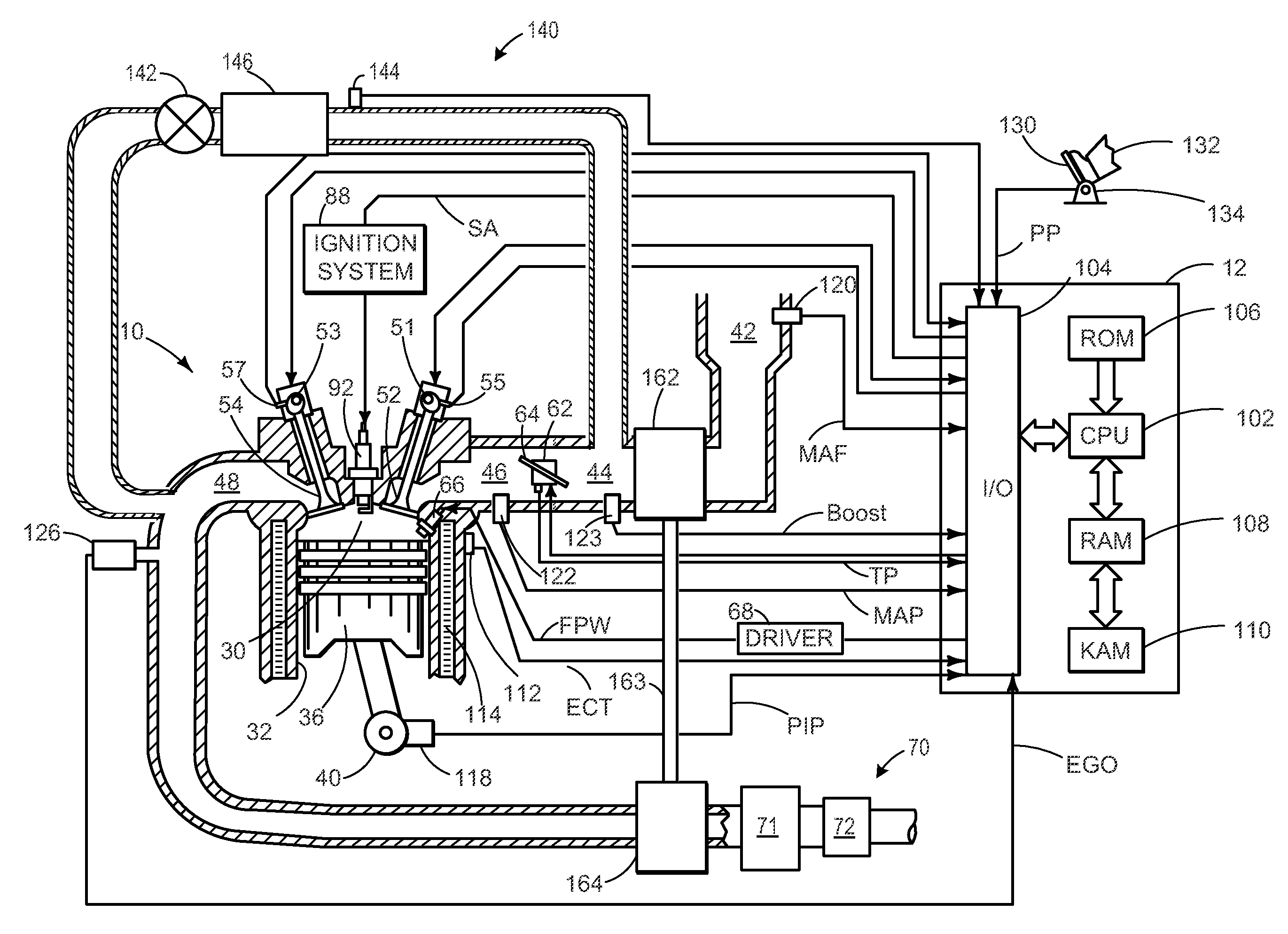

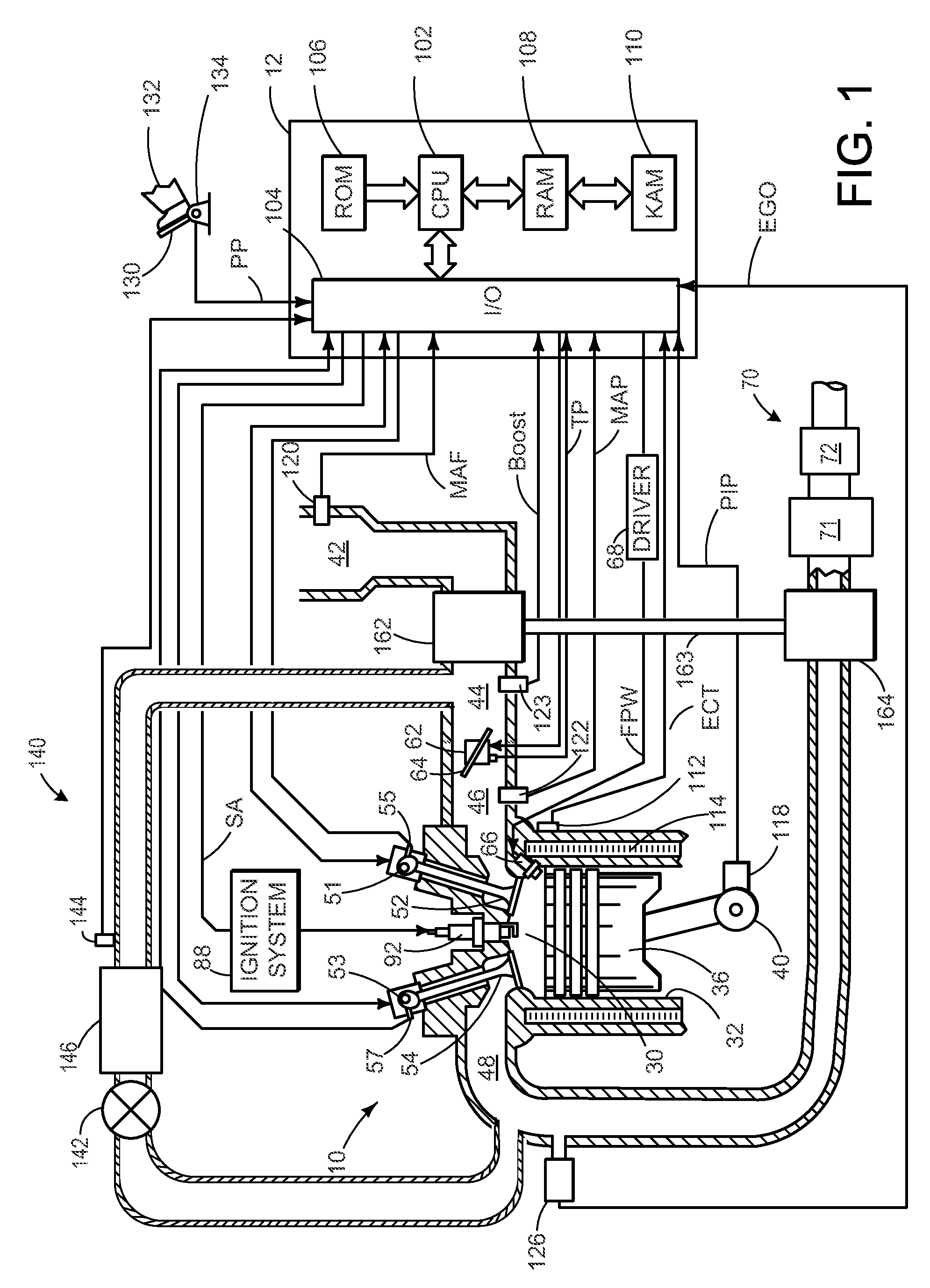

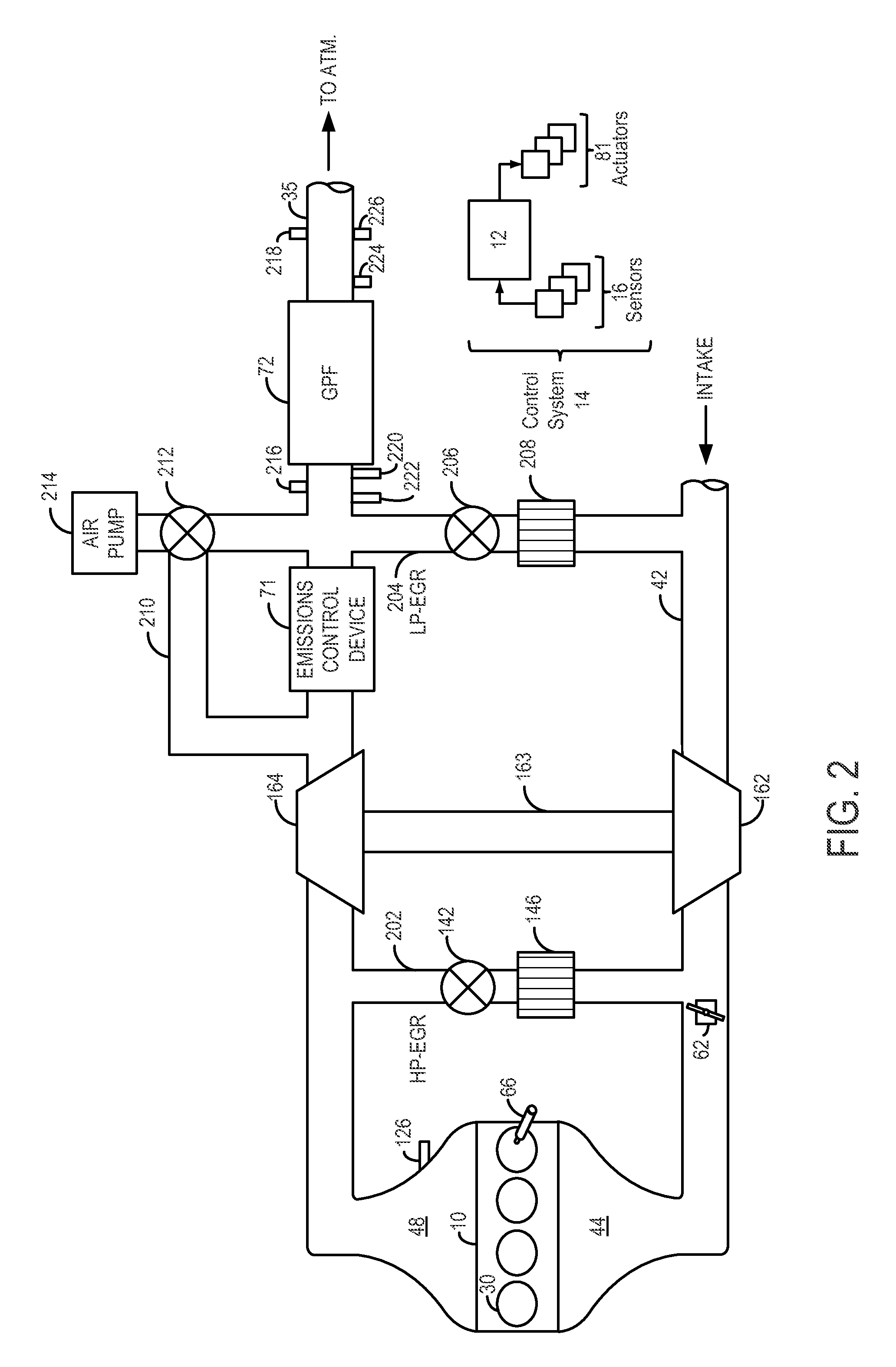

ActiveUS20110072788A1Improve engine performanceReduce transient air-fuel disturbanceElectrical controlNon-fuel substance addition to fuelParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

Engine Exhaust Catalysts Containing Palladium-Gold

ActiveUS20080124514A1Reduce inhibitionEmission reductionCombination devicesInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum-palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGC HLDG LTD

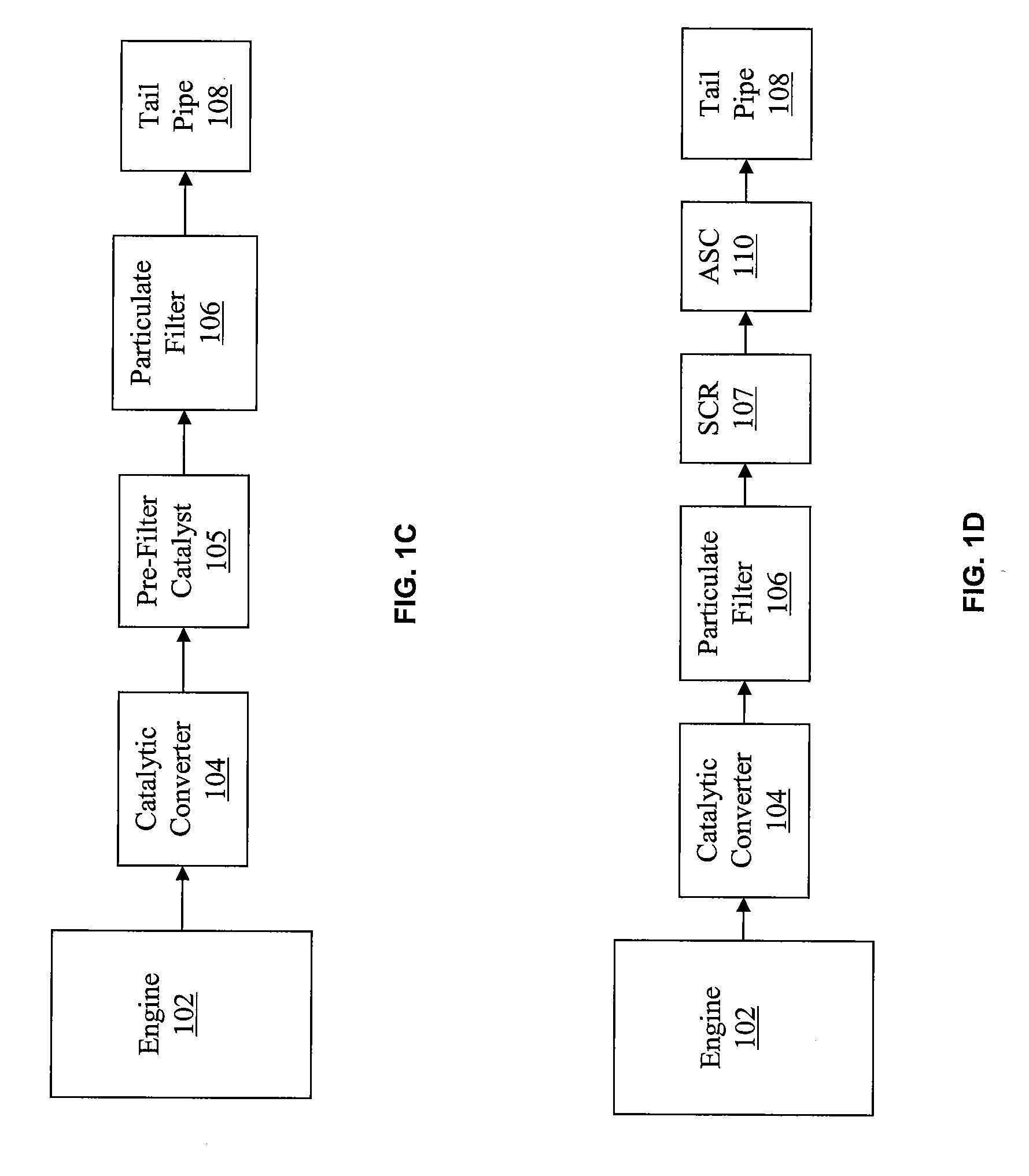

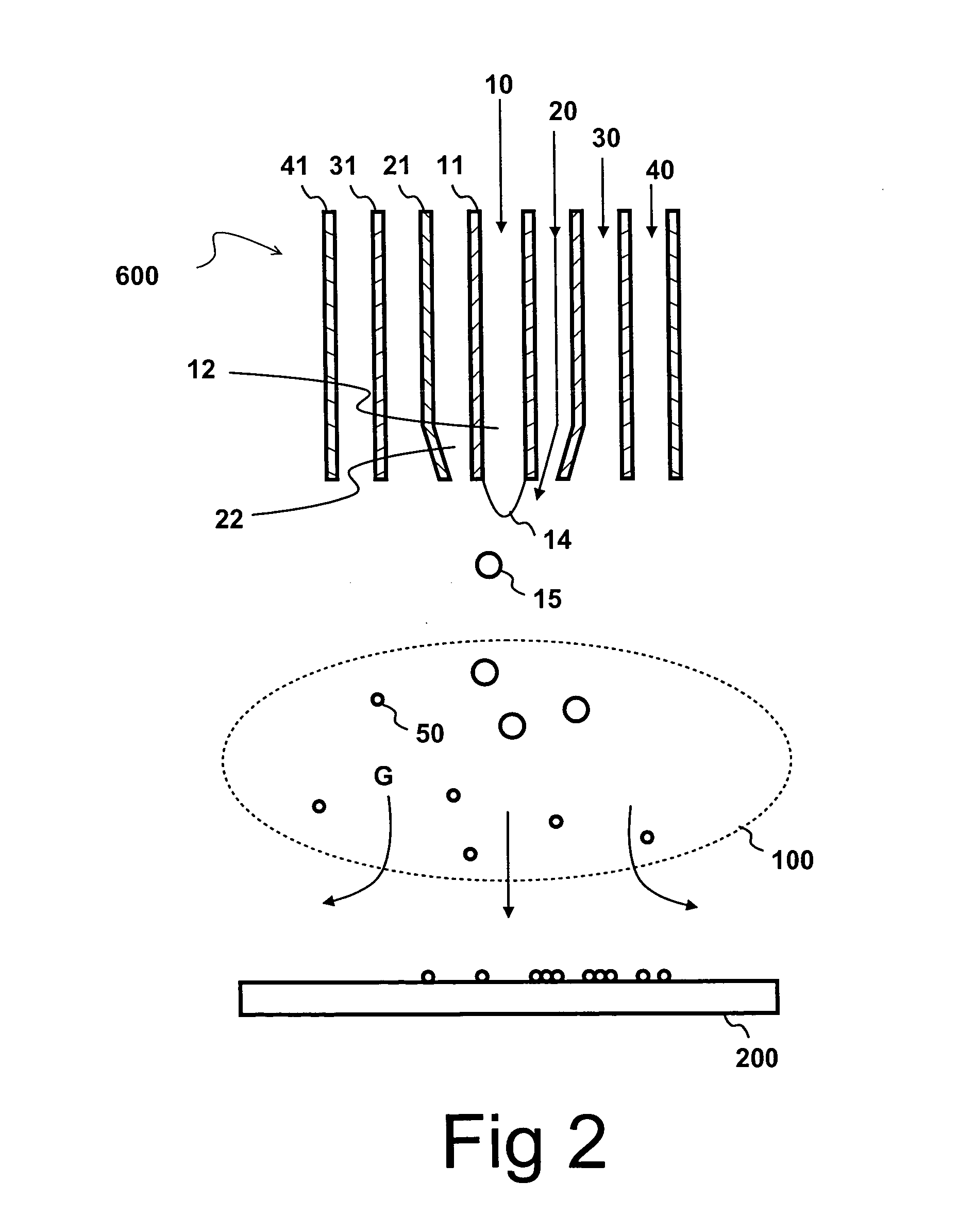

A device for remediation of organic contaminated soil by using thermal desorption combined with an oxidant and a remediation method

ActiveCN103230933AReduce moistureIncrease temperatureContaminated soil reclamationSoil propertiesInsulation layer

The invention belongs to the technical field of environmental protection, and in particular relates to a device for remediation of organic contaminated soil by using thermal desorption combined with an oxidant and a remediation method. The device of the invention is composed of an air heater, an air compressor, an air valve, a dosing valve, a dosing tank, a vacuum suction pump, a delivery pump, an electric power control unit, an insulation layer, lateral pipes, injection syringes, injection wells, a gas collection well and vacuum suction pipelines. According to the invention, through a treatment method of in situ thermal desorption and adding the oxidant, volatile organic compound contaminated soil is effectively treated. The technique of the invention is applicable to a relatively broad scope, can be used to perform in situ pollution remediation of volatile organic compounds under different climatic conditions, geological conditions, soil properties, and earth surface conditions. The heater of the present invention can infuse more produced heat into the soil, thus saving fuel and combustion time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

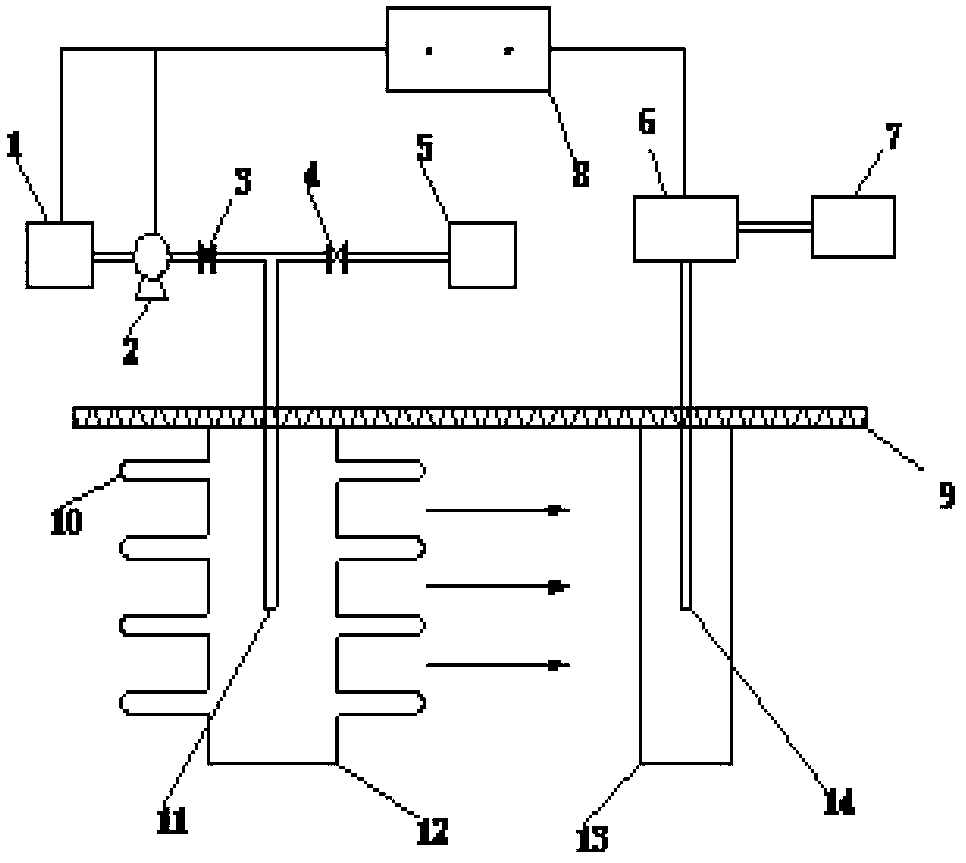

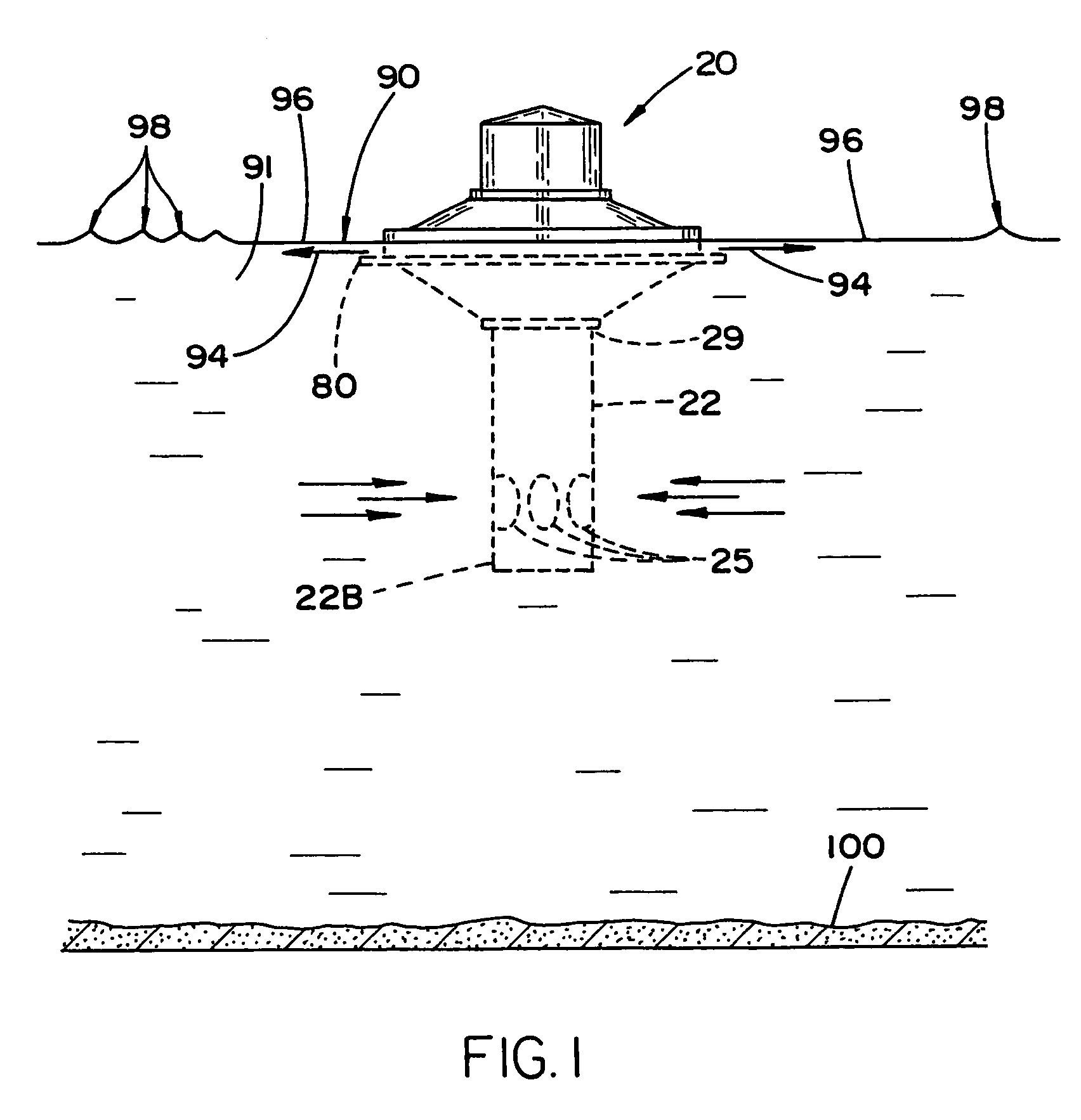

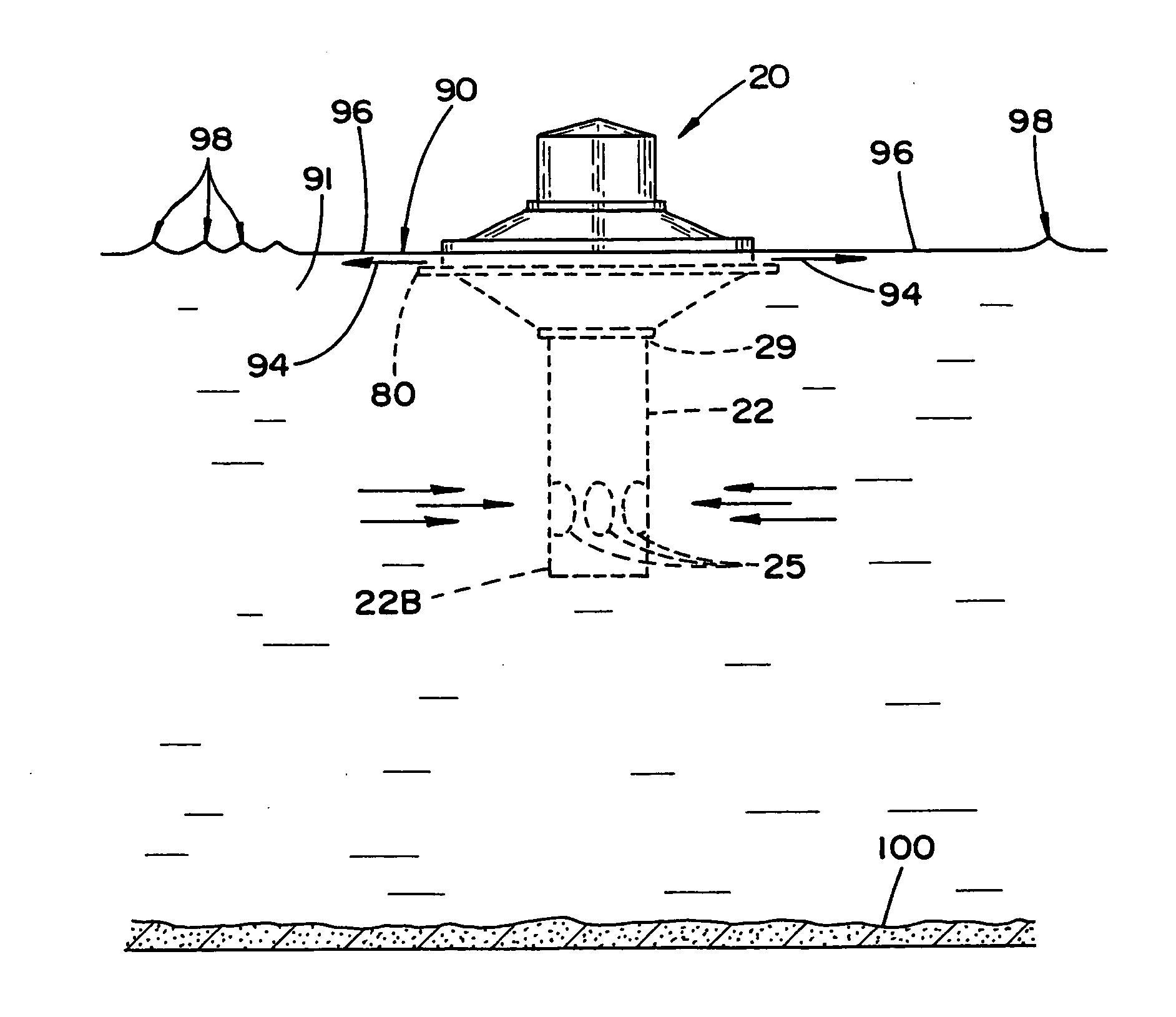

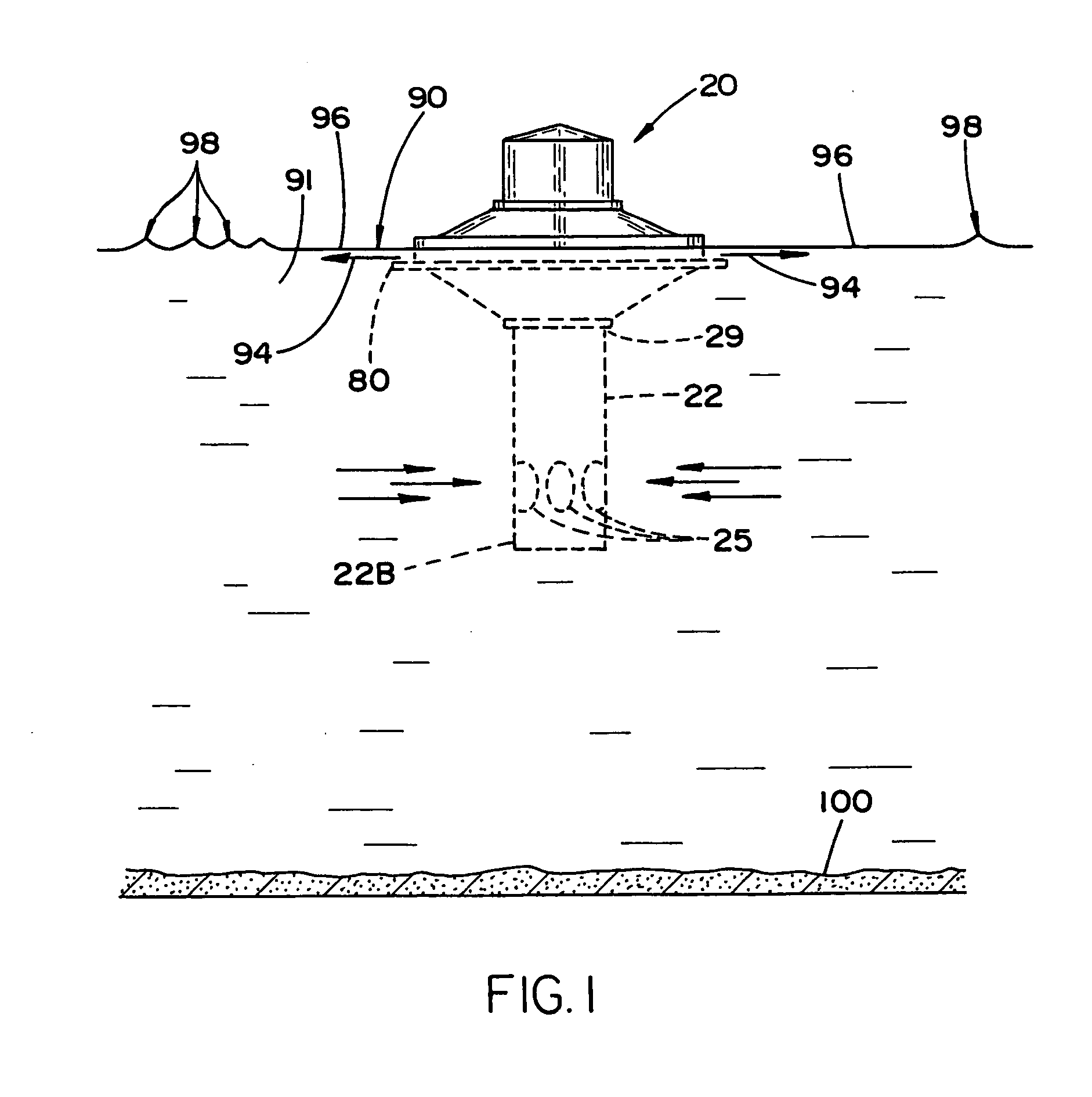

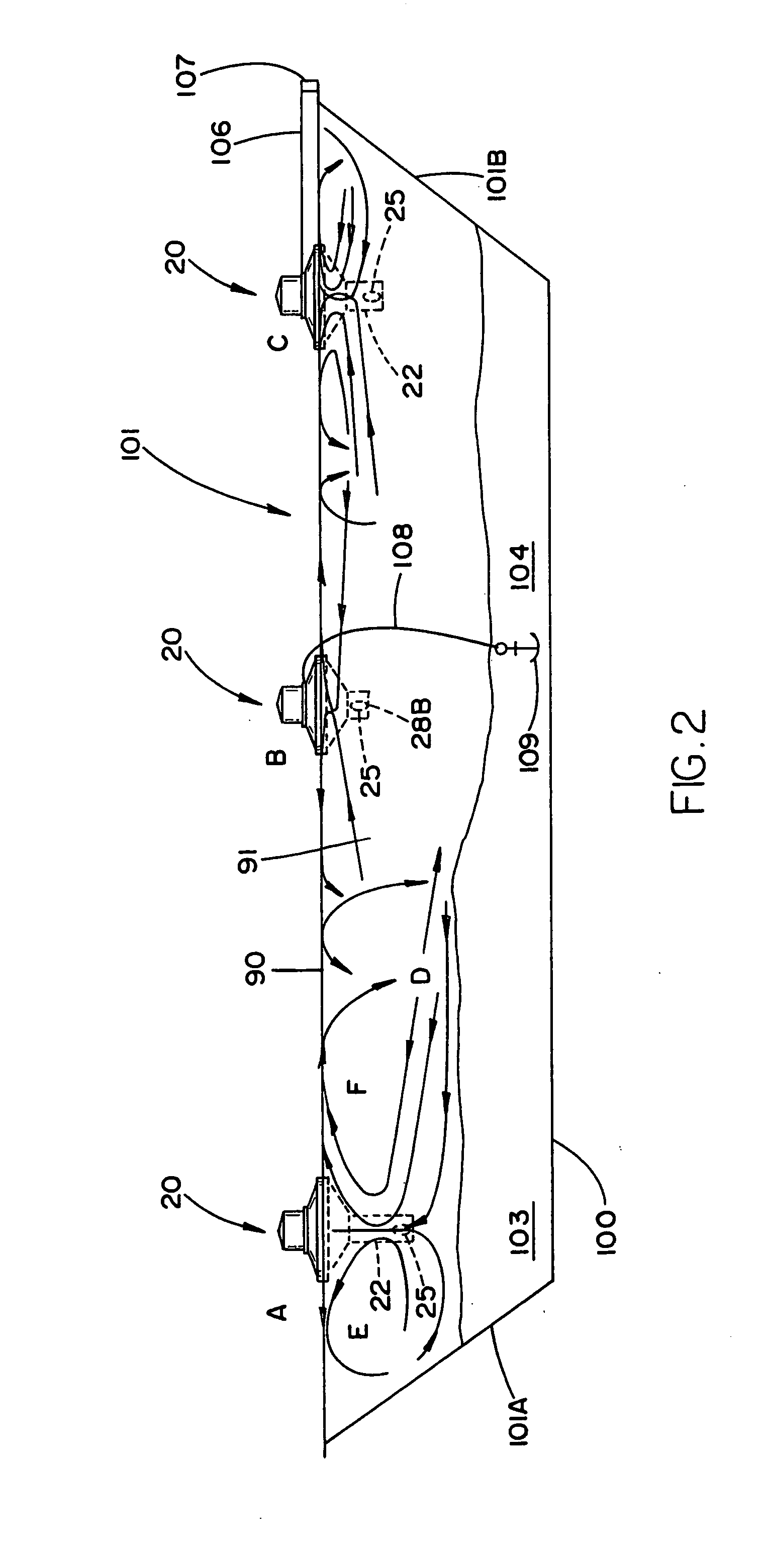

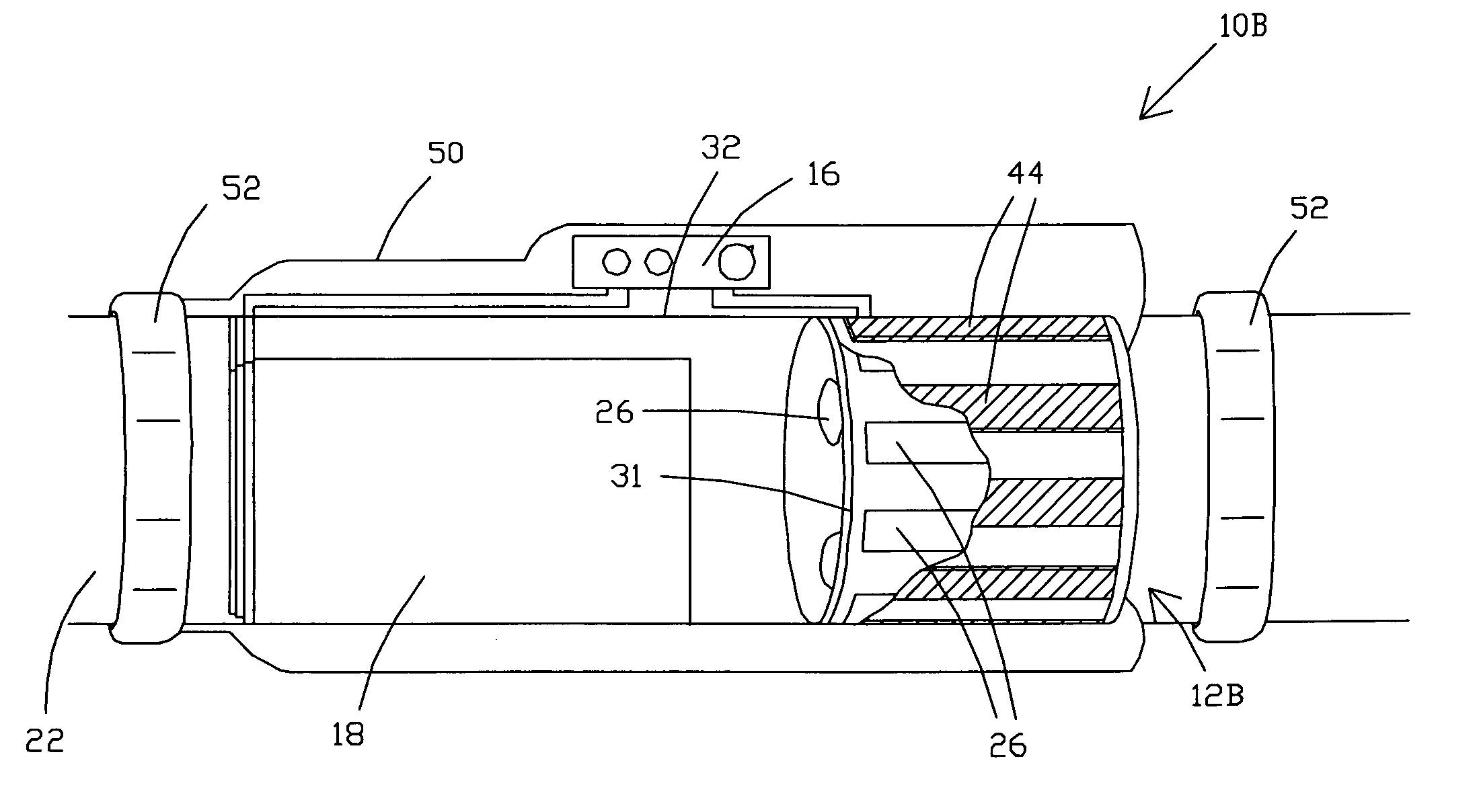

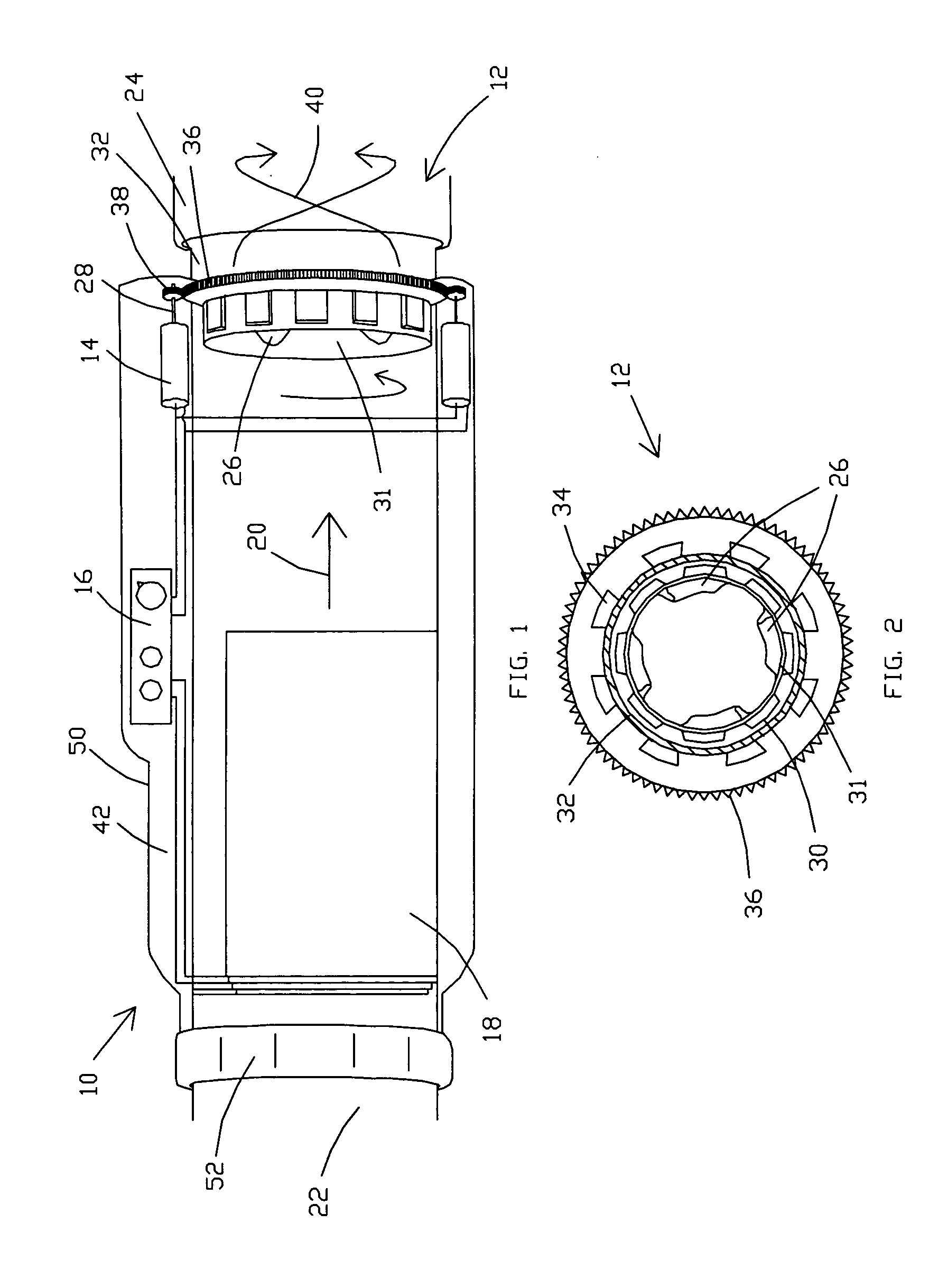

Process and apparatus for increasing biological activity in waste treatment in bodies of water

ActiveUS7329351B2Improve biological activityIncrease oxygenTreatment using aerobic processesLighting and heating apparatusImpellerMotor drive

A process and apparatus for increasing biological activity in waste treatment ponds and lagoons. In this process a floating fluid circulator having an annular space between nested frusto-conical surfaces is operated in a pond or lagoon. An aerator within the scope of the floating fluid circulator is provided. That aerator includes an upper float chassis having a frusto-conical configuration, a sectional diverter arranged in a lower portion of the upper float chassis, the sectional aerator having a lower diverter portion and motor driven means mounted on the upper float chassis connected to a rotatable impeller.

Owner:ABSOLUTE AERATION

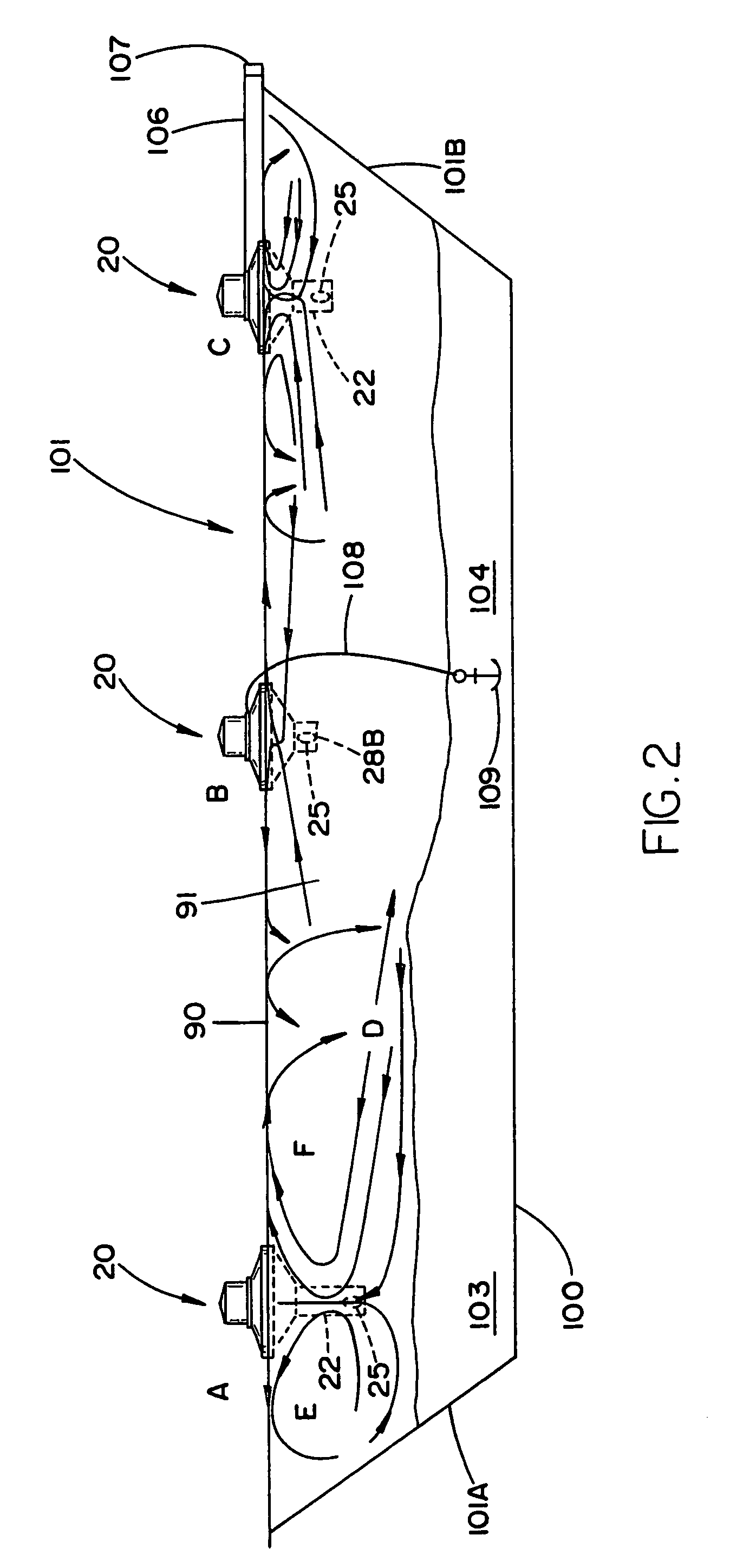

Biocatalytic oxidation process with alkl gene product

ActiveUS20130052700A1Increase synthesisHigh expressionBacteriaUnicellular algaeSimple Organic CompoundsMicroorganism

The invention provides a biocatalytic process for oxidation of organic compounds with the aid of an alkL gene product, and microorganisms used in this process.

Owner:EVONIK OPERATIONS GMBH

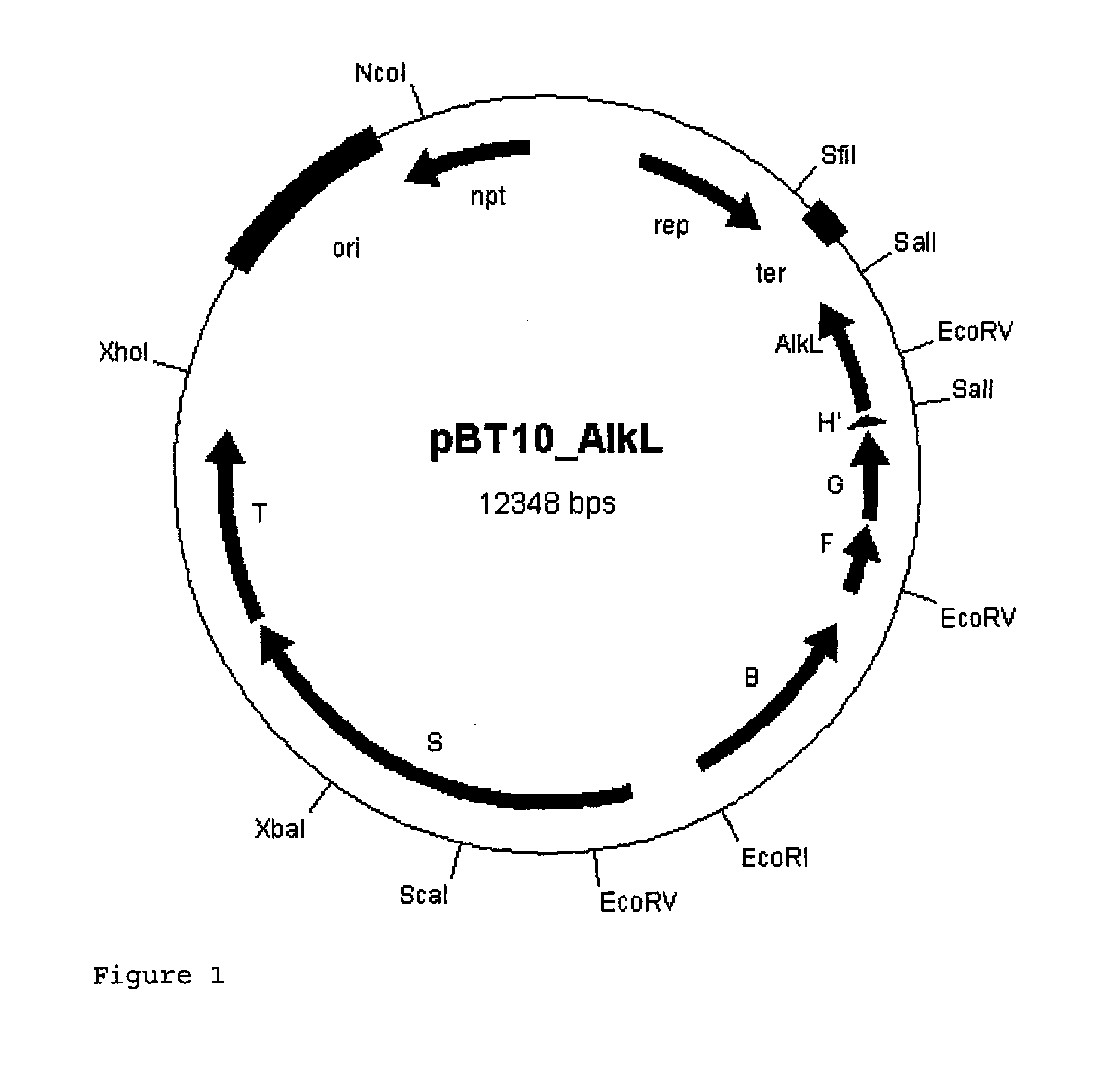

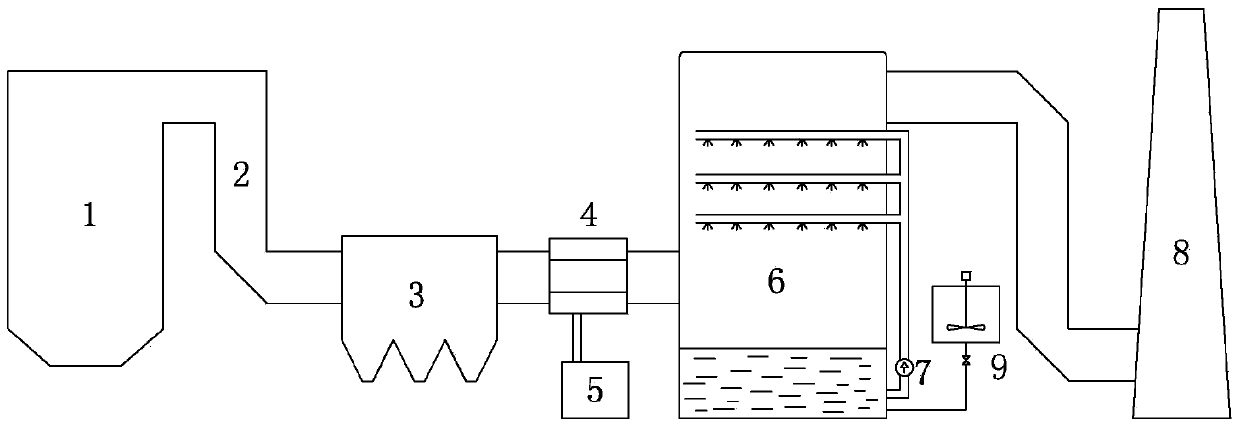

Smoke desulfurization and denitrification integration method and special device thereof

InactiveCN103212281AIncrease the amount of dissolutionIncrease oxidation rateDispersed particle separationAir quality improvementLiquid wasteNitric oxide

The invention discloses a smoke desulfurization and denitrification integration method and a special device thereof. The method is characterized in that a wet-method process is used in one technological system to simultaneously remove sulfur dioxide and nitrogen oxide in the smoke; an ammonium method is used for desulfurization, ammonia water is also used as a desulfurizer of the sulfur dioxide and a neutralizing agent for byproduct nitric acid produced in the denitrification process; an oxidization reduction method is used for the denitrification, a desulfurization byproduct ammonium sulfite or ammonium bisulfite is used as a reducing agent, urea is used as a reducing agent, a quinine-contained hydroxyl compound is used as a catalyst, air is blown into the denitrification circulating liquid so as to provide the dissolving oxygen and the oxidant for the oxidization reaction of the nitrogen oxide; a byproduct ammonium nitrate of the denitrification reaction is placed into the desulfurization liquid so as to recycle the nitrogen ammonium; and ammonia nitrogen chemical fertilizer ammonium sulfate and ammonium nitrate are recycled, and the entire technological flow is free from discharging sulfur-contained or ammonia nitrogen-contained waste liquid out of the system. Due to the adoption of the method, the integration of the desulfurization and the denitrification can be realized, the device is miniaturized, and no waste liquid is discharged in the technological process.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

Process and apparatus for increasing biological activity in waste treatment in bodies of water

ActiveUS20070039878A1Improve biological activityIncrease oxygenTransportation and packagingWater aerationImpellerMotor drive

A process and apparatus for increasing biological activity in waste treatment ponds and lagoons. In this process a floating fluid circulator having an annular space between nested frusto-conical surfaces is operated in a pond or lagoon. An aerator within the scope of the floating fluid circulator is provided. That aerator includes an upper float chassis having a frusto-conical configuration, a sectional diverter arranged in a lower portion of the upper float chassis, the sectional aerator having a lower diverter portion and motor driven means mounted on the upper float chassis connected to a rotatable impeller.

Owner:ABSOLUTE AERATION

Method for catalytic oxidation of calcium sulfite in desulphurization ash by dry method and semi-dry method

InactiveCN101734875ASimple methodLow implementation costSolid waste managementCalcium sulfiteInstability

The invention relates to a method for the catalytic oxidation of calcium sulfite in desulphurization ash by a dry method and a semi-dry method, which is carried out according to the following steps: (a) preparing a manganese salt solution with the concentration of 0.2-4%; (b) adding the manganese salt solution into desulphurization ash proportionally; (c) taking a hydrogen peroxide solution with the concentration of 1-10% and adding into the mixture of the manganese salt solution and the desulphurization ash proportionally; and (d) keeping the temperature of the mixture of the desulphurization ash, the manganese salt solution and the hydrogen peroxide solution and digesting for 0.5-2 hours. The invention uses manganese salt and hydrogen peroxide as a catalyst and an oxidant to oxidize the calcium sulfite in the desulphurization ash and has simple method, low implementation cost and easy realization. The invention can enhance the oxidation speed and limit of the calcium sulfite, solves the adverse effect of the instability caused by the slow oxidation of the calcium sulfite in air on the quality of an autoclaved brick and provides an approach which is easy to realize for the mass utilization of the desulphurization ash.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Water treatment turbine apparatus and method

InactiveUS20060226060A1Consume energyConstant energy consumptionLiquid separation by electricityGeneral water supply conservationElectric powerElectric generator

The present invention provides an improved water purifier and method. In one possible embodiment, the present invention provides a turbine mounted in or to piping of a pool or spa filtering system. The turbine comprises one or more rotatable elements such as fins, paddles, blades, propellers, or the like which are responsive to water flow through the piping to produce rotation. The rotatable element may comprise magnets which rotate along with the rotatable element to produce a rotating magnetic field. The rotating magnetic field may be utilized for generating electricity utilizing various types of electric power generators. Electricity so produced may be utilized to power a water purification unit such as a chlorine generator, UV generator, or an ozone generator. In one embodiment, the output of the water purification unit is directed into turbulence, such as turbulence produced by the rotatable element, so that the purification efficiency is enhanced.

Owner:MERCER RICHARD D

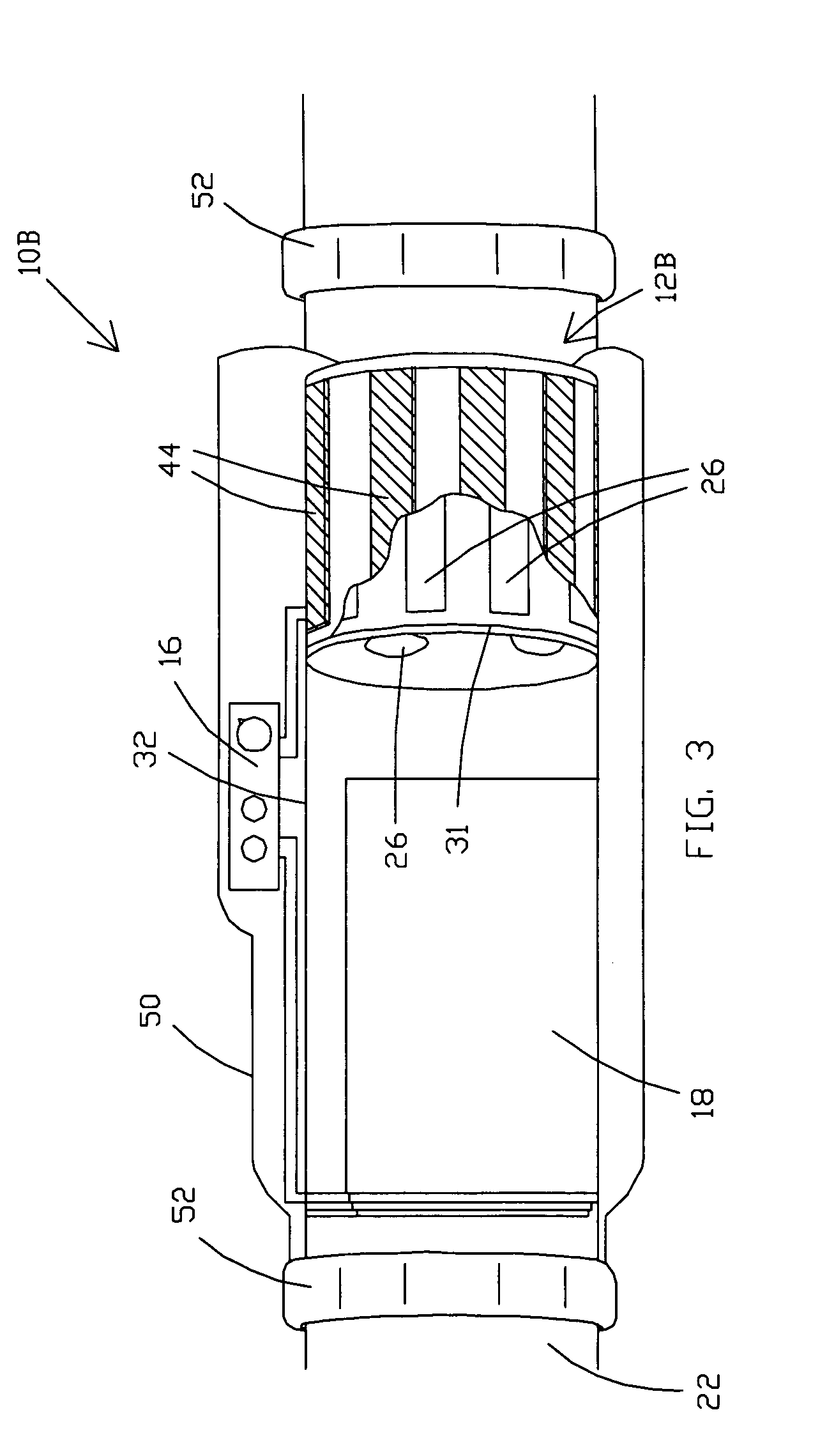

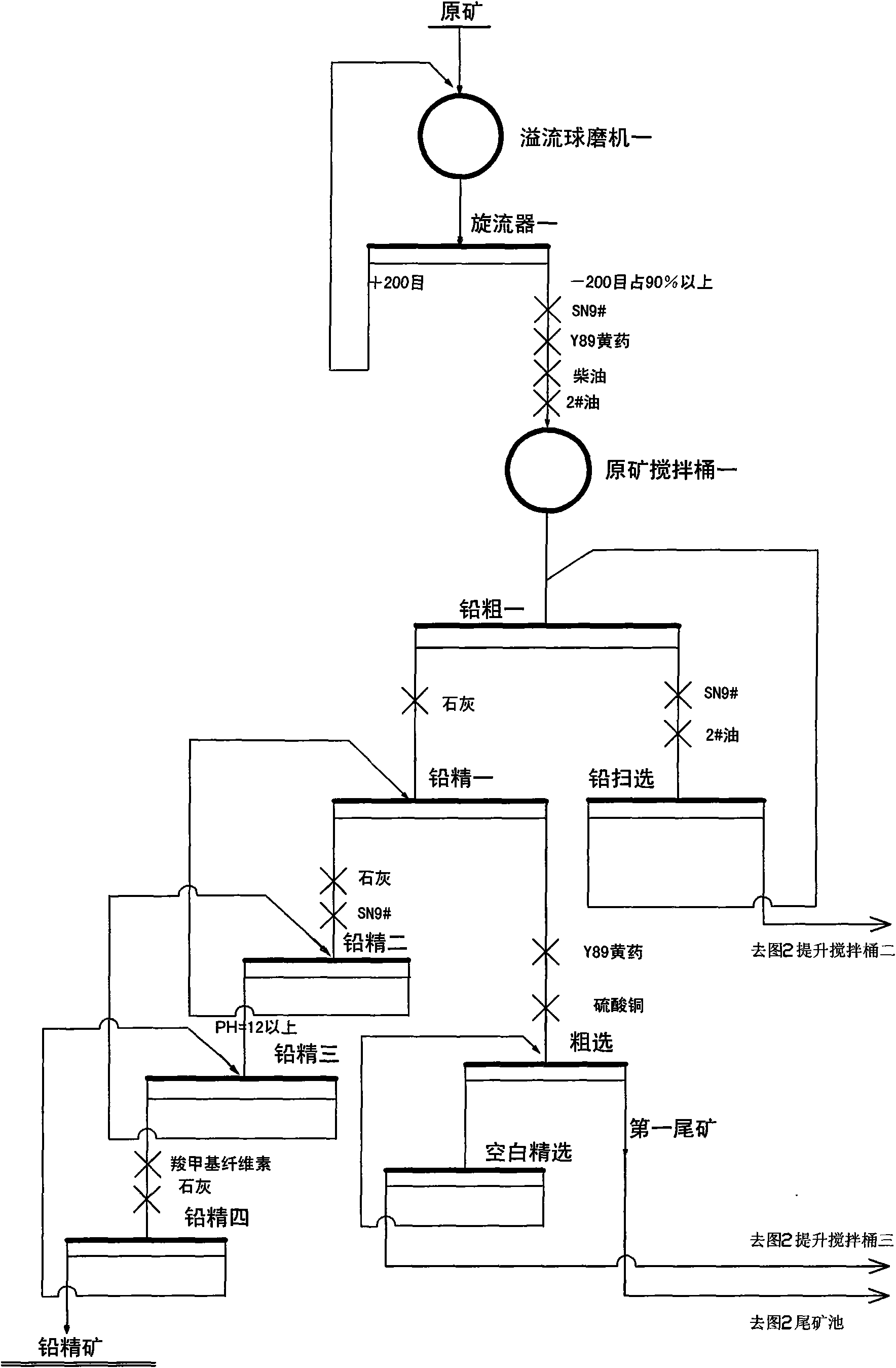

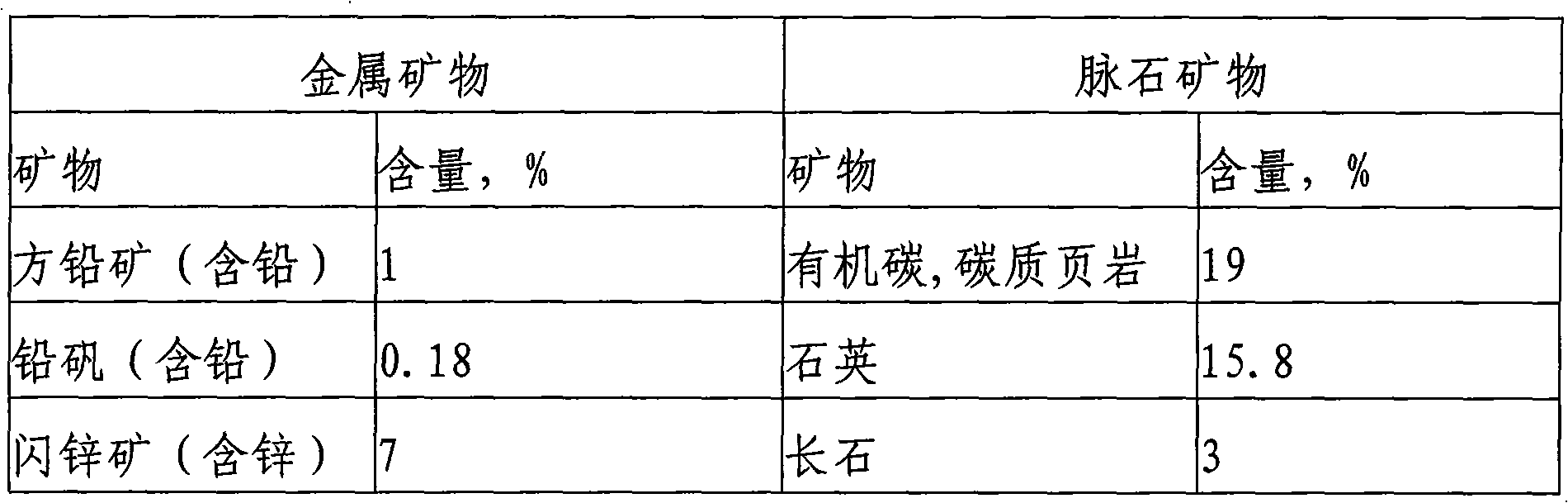

Floatation process of complex lead zinc ores

The invention relates to a floatation process of complex lead zinc ores, which uses the following process flows: ore grinding-floatation of lead in a lead flotation area-floatation of zinc in a zinc / sulfur mixed flotation area-floatation of zinc in a zinc middling re-flotation area; the invention uses floatable process like lead zinc full-opening, effectively removes carbon and iron sulfide with good floatability by means of entire processes of the lead area, reduces influence of carbon and iron sulfide with good floatability on the flotation of zinc, avoids lime from entering rougher flotation and scavenging of primary processes and enables refining of zinc to be blank refining to thereby greatly reduce vicious circle of a large amount of middling, and a collecting agent is not added to the separation of zinc from sulfur in re-flotation of zinc middling.

Owner:何任义 +2

Apparatus for treating a substrate with an ozone-solvent solution

InactiveUS20060107976A1Increase oxidation rateReduce disposal costsSemiconductor/solid-state device manufacturingDisinfectionProcess engineeringSolvent

A system for treating a substrate with an ozone-solvent solution has an ozone-solvent solution supply. The supply has a supply outlet, and the ozone solvent solution supply is capable of delivering at the supply outlet a generally continuous supply of an ozone-solvent solution formed at a first temperature. The system includes a heater having an inlet and heater outlet, with the inlet fluidly coupled to receive the ozone-solvent solution at approximately the first temperature from the supply outlet. The heater is configured to heat the ozone-solvent solution from the first temperature to a second temperature to form a heated ozone-solvent solution such that the heated ozone-solvent solution is supersaturated with ozone. The heater is capable of providing a generally continuous supply of heated, supersaturated, ozone-solvent solution at the heater outlet for use in treating the substrate.

Owner:BOYERS DAVID G +1

Processing a workpiece using water, a base, and ozone

InactiveUS20050133067A1Simple processAccelerating cleaning chemical reactionLighting and heating apparatusHollow article cleaningLiquid layerChemical reaction

Contaminants such as photoresist are quickly removed from a wafer having metal features, using water, ozone and a base such as ammonium hydroxide. Processing is performed at room temperature to avoid metal corrosion. Ozone is delivered into a stream of process liquid or into the process environment or chamber. Steam may alternatively be used. A layer of liquid or vapor forms on the wafer surface. The ozone moves through the liquid layer via diffusion, entrainment, jetting / spraying or bulk transfer, and chemically reacts with the photoresist, to remove it.

Owner:OEM GRP LLC

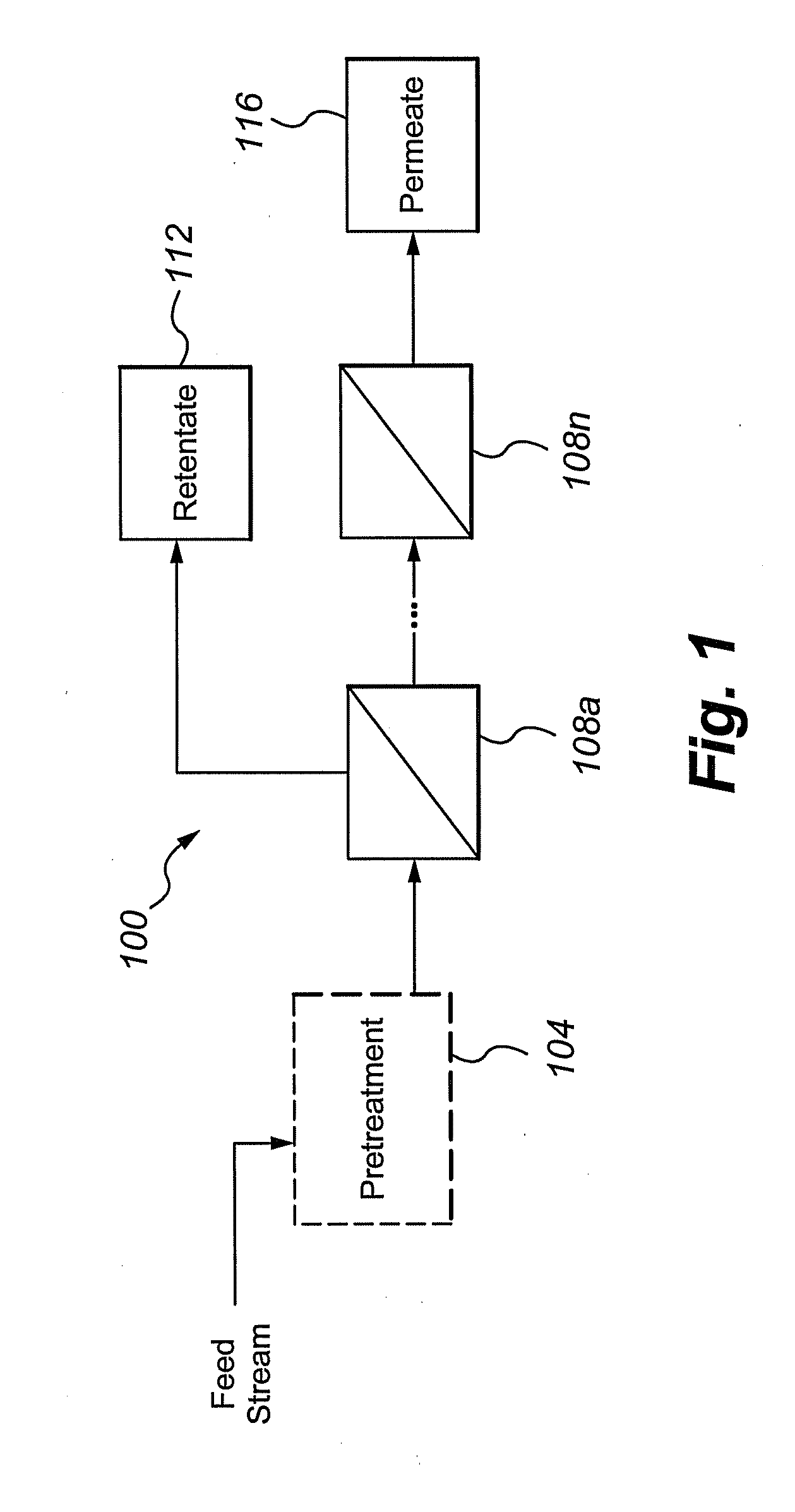

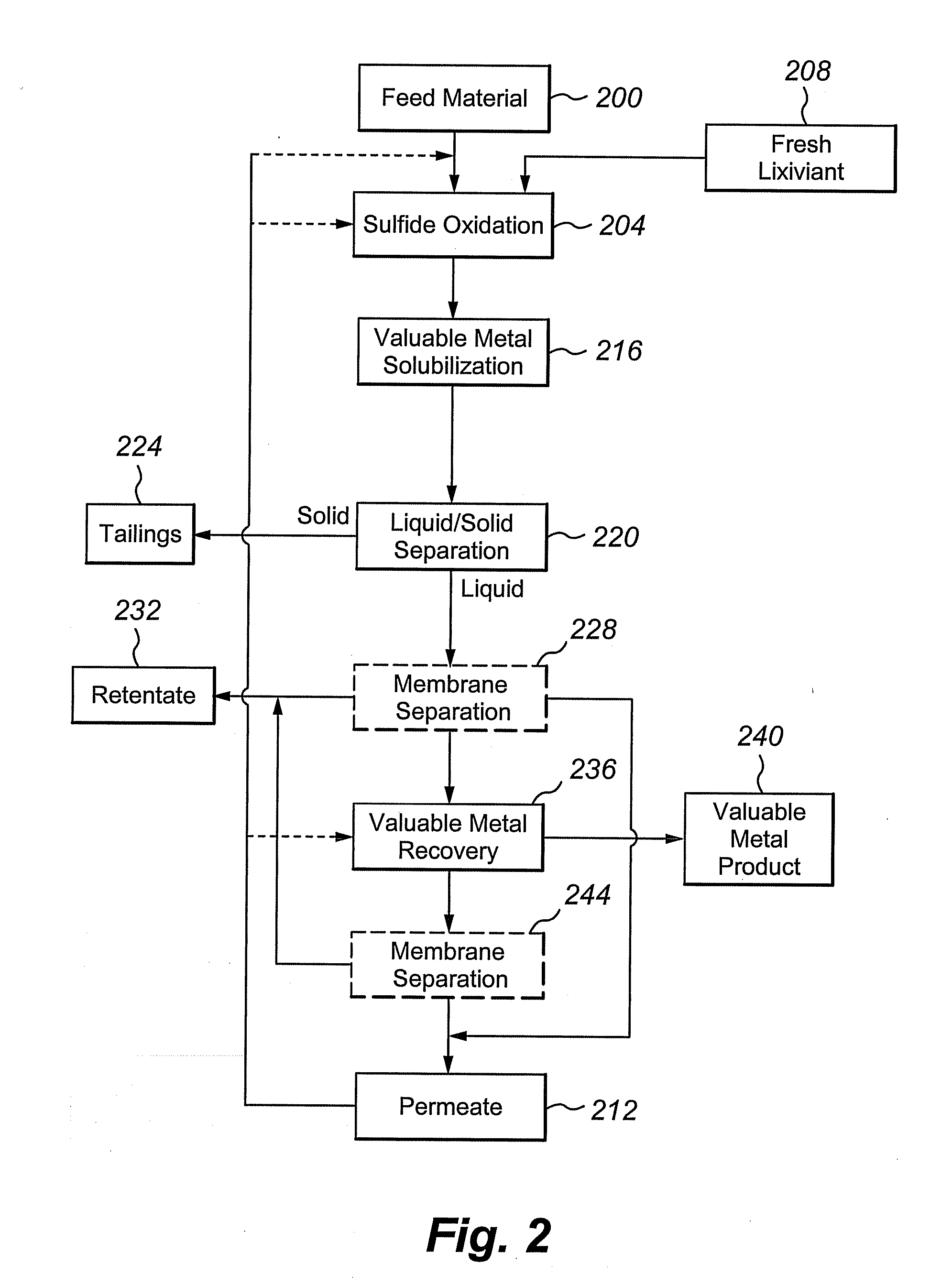

Multivalent iron ion separation in metal recovery circuits

InactiveUS20080069748A1High sulfide sulfur oxidation rateReduce electricity costsSolvent extractionFerrous oxidesPhysical chemistryFerric ion

Owner:HW PROCESS TECH

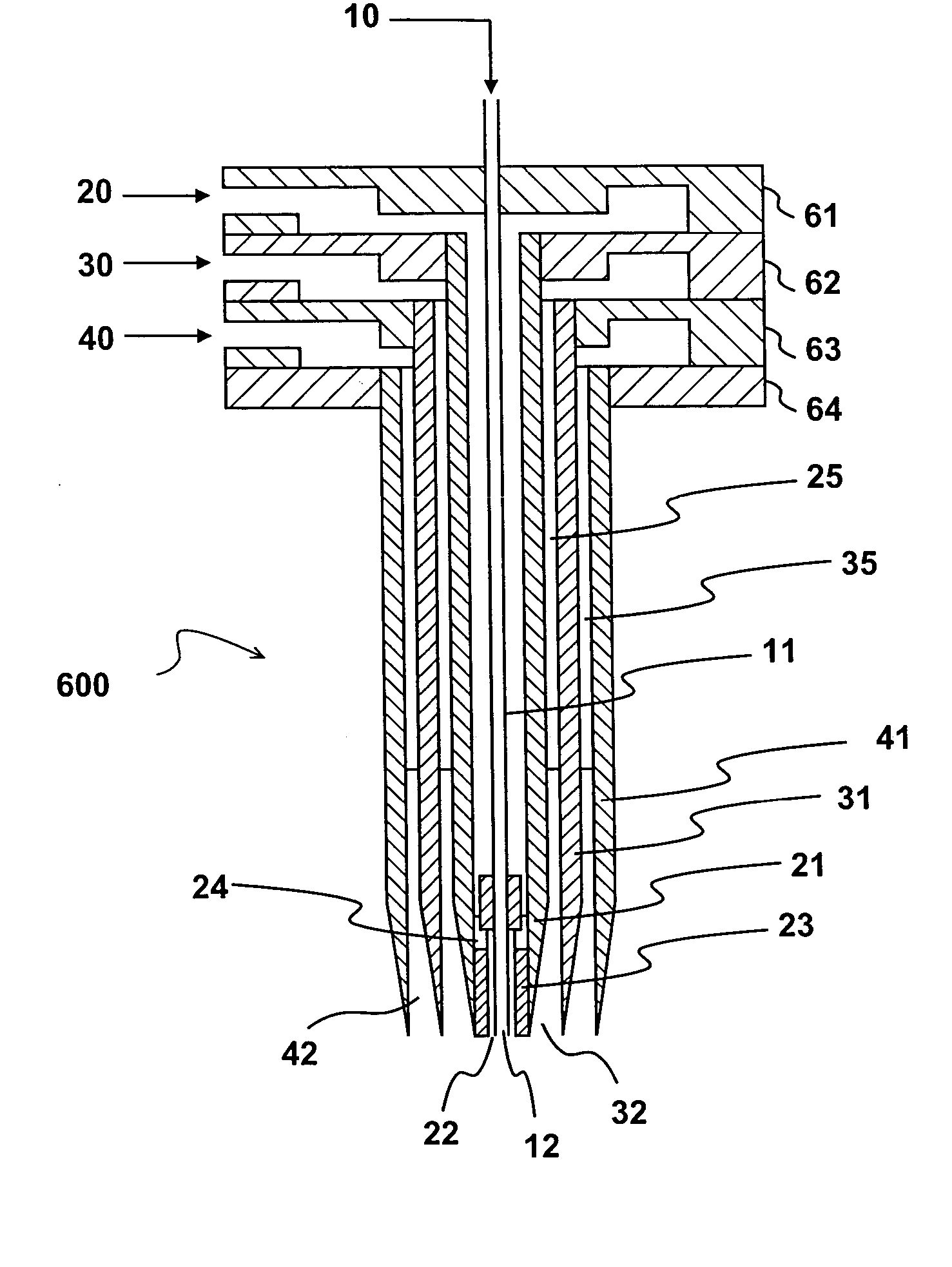

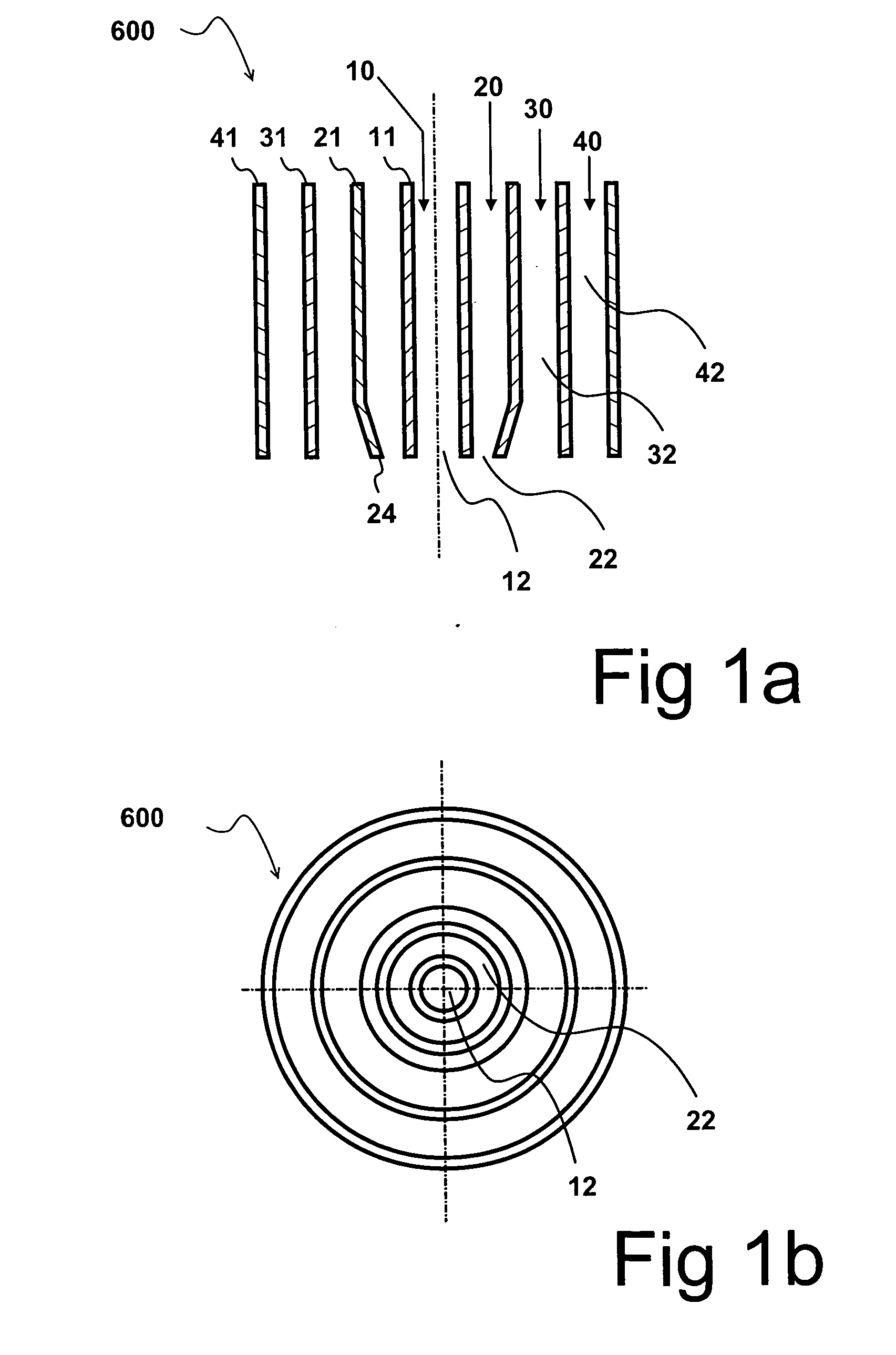

Method and device for producing optical material, and an optical waveguide

InactiveUS20060001952A1Improve abilitiesImprove homogeneityLaser detailsMolten spray coatingReaction rateErbium doping

The invention relates to the production of light-amplifying optical material. Liquid reactant is atomized into droplets using a high velocity gas. The droplets are subsequently introduced into a flame. Reactants are oxidized in the flame and condensed by forming small particles. At least a fraction of said particles is collected and fused to form optical waveguide material, which is subsequently drawn to form an optical waveguide. According to the invention, the velocity of the atomizing gas stream is in the order of the velocity of sound. The high velocity enhances atomization and increases reaction rates in the flame. The residence times are reduced to such a degree that unwanted phase transformations in the produced particles are substantially minimized. Consequently, very homogeneous material is produced. Especially, in the production of erbium-doped silica, low percentage of clustered erbium ions is achieved.

Owner:LIEKKI OY

Process for preparing cerous hydroxide

InactiveCN1635169ACoarse particlesImprove filtering effectRare earth metal compoundsProcess efficiency improvementCeriumRoom temperature

The invention belongs to wet method metallurgy field of rare earth production, especially relates to a preparation method for cerium hydroxide. The method comprises: (1) adding raw cerium material into alkali liquor with stirring for creating precipitate Ce(OH)3 ensuring that the mol ratio of OH ion and cerium ion is 0.5~4:1; (2) adding oxidizing agent with stirring under normal temperature with mol ratio of oxidizing agent and Ce(OH)3 as 0.1~4:1 for creating Ce(OH)4 or Ce(OH)3.OOH; (3) washing the Ce(OH)4 obtained in step (2), separating the solid from liquid, airing, and obtaining the cerium hydroxide product. The invention has a wide range of application. According to different purposes, cerium hydroxide products with different purities (80~99.9999%(CeO2 / ª�RE2O3)) depending to the raw material.

Owner:北京方正稀土科技研究所有限公司

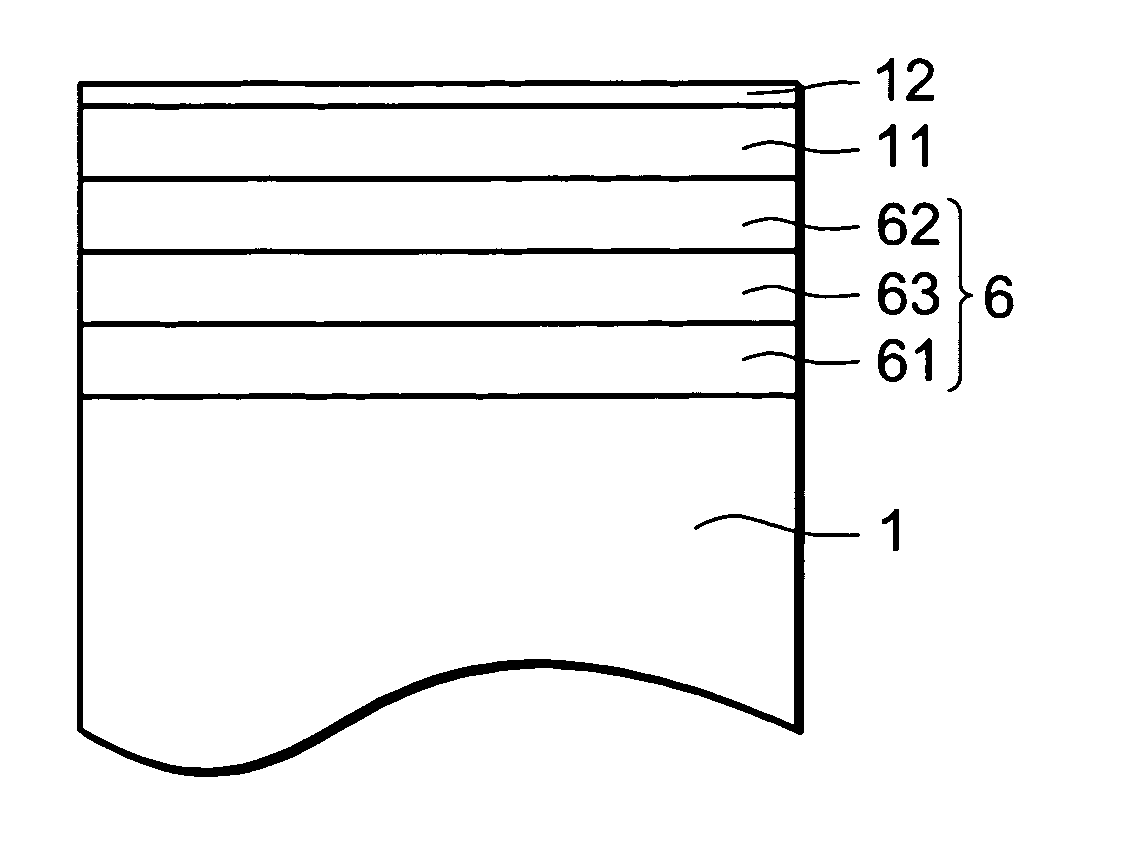

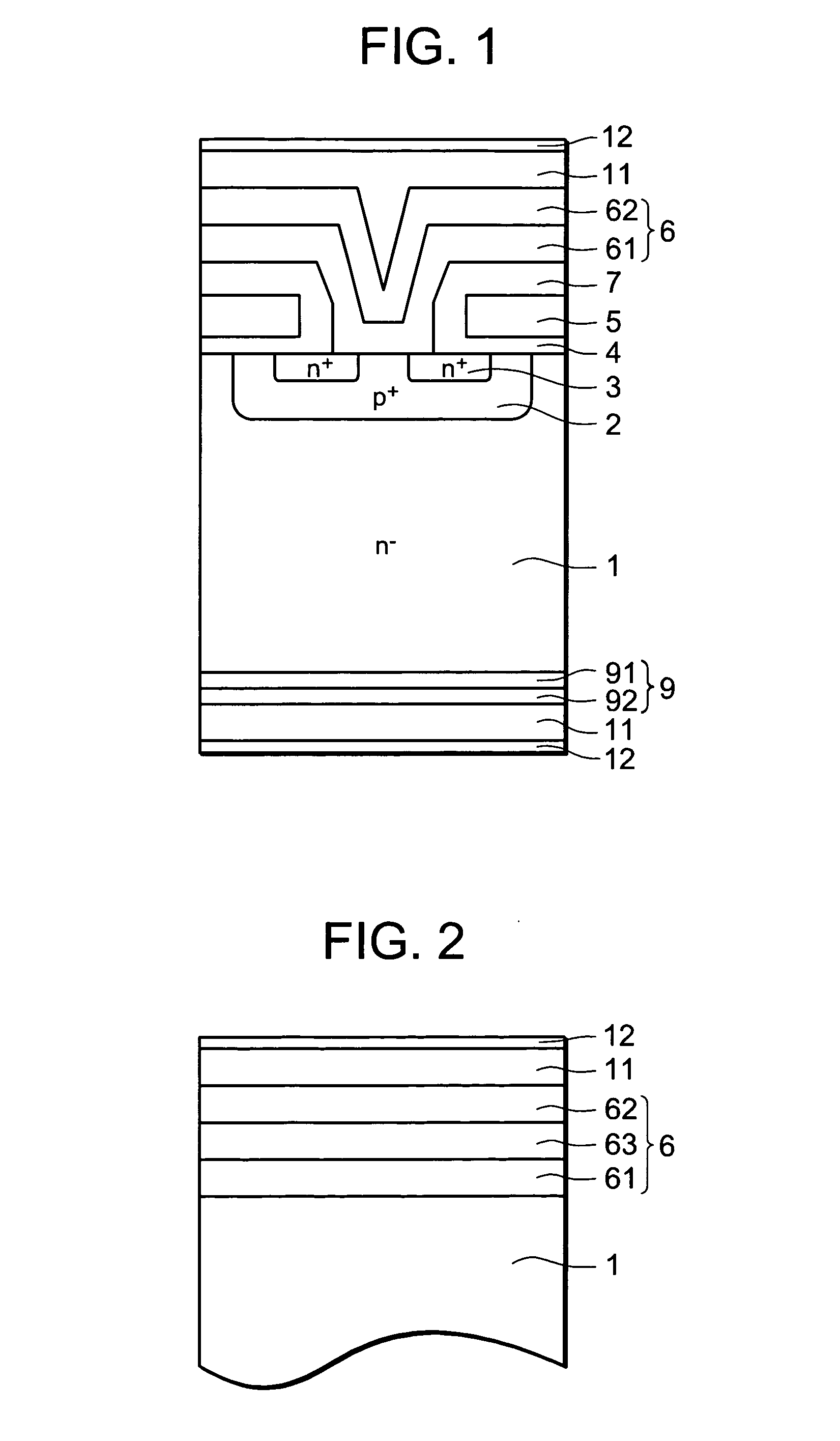

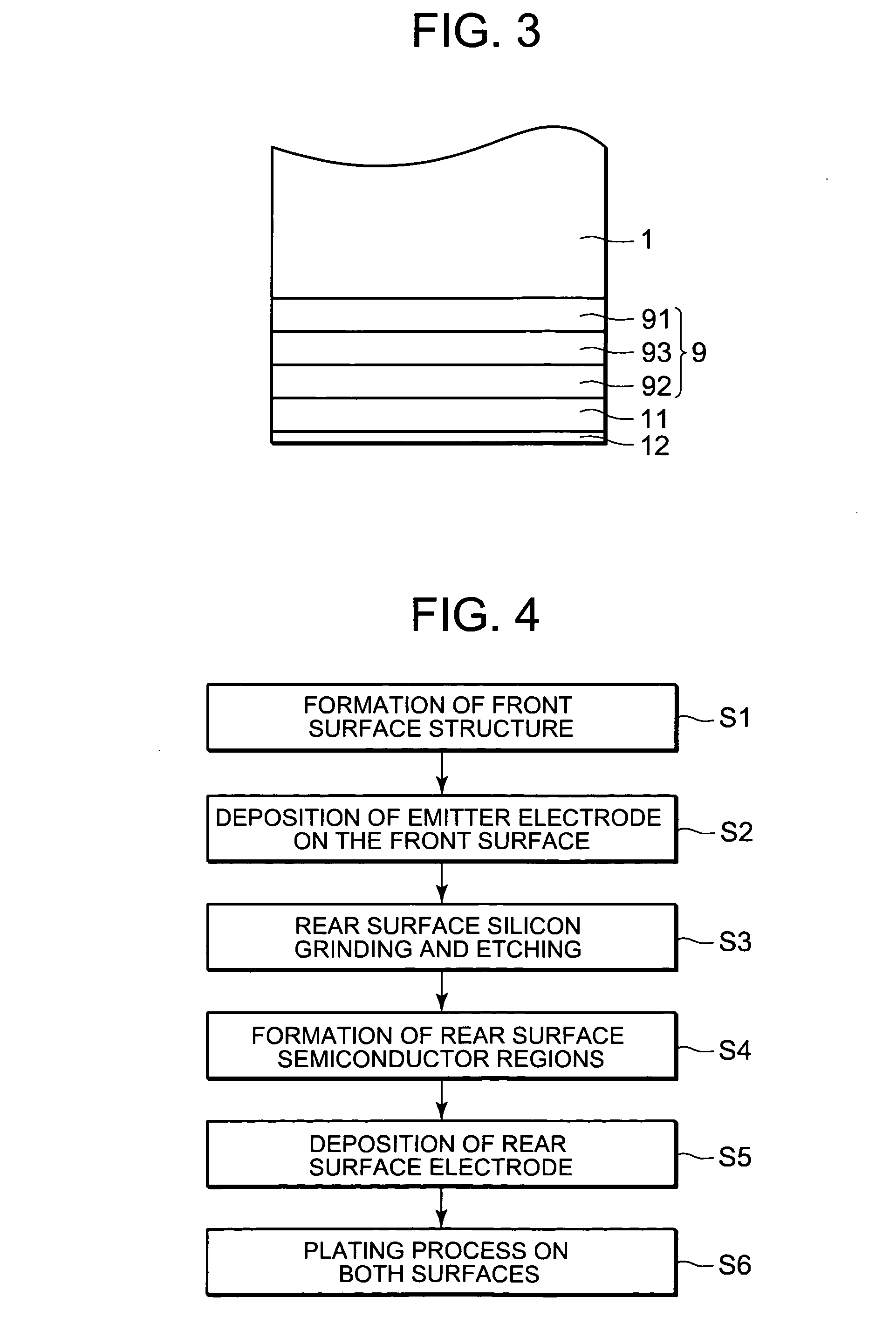

Method of manufacturing a semiconductor device

ActiveUS20100240213A1Increase the speed of oxidation reactionPreventing characteristic variationTransistorSemiconductor/solid-state device manufacturingSemiconductorElectroplating

A method of manufacturing a semiconductor device on a semiconductor substrate, includes the steps of forming a first metal film on a front surface of the semiconductor substrate; forming a second metal film on the surface of the first metal film; activating a surface of the second metal film to provide an activated surface; and forming a plated film on the activated surface by a wet plating method in a plating bath that includes a reducing agent that is oxidized during plating and that has a rate of oxidation, wherein the second metal film is a metal film mainly composed of a first substance that enhances the rate of oxidation of the reducing agent in the plating bath. Wet plating is preferably an electroless process.

Owner:FUJI ELECTRIC CO LTD

Integrated apparatus for removing pollutants from a fluid stream in a lean-burn environment with heat recovery

InactiveUS20050252202A1Effectively and conveniently oxidizing and reducingAvoid pressure dropGas treatmentInternal combustion piston enginesParticulatesHydrocotyle bowlesioides

An apparatus and method to treat fluid streams, and in particular emissions from lean-burn engines such as diesel engines, are disclosed, which use multiple catalysts chosen to remove hydrocarbons, carbon monoxide, particulate matter, and oxides of nitrogen. The apparatus and method also provide for heat exchange between the inlet and outlet exhaust streams to sustain the catalyzed reactions, by placing the catalysts in the temperature zones where their operation is enhanced, and they also allow for regeneration of a filter used to trap particulate matter in the streams.

Owner:PAGE DORRIAH L +2

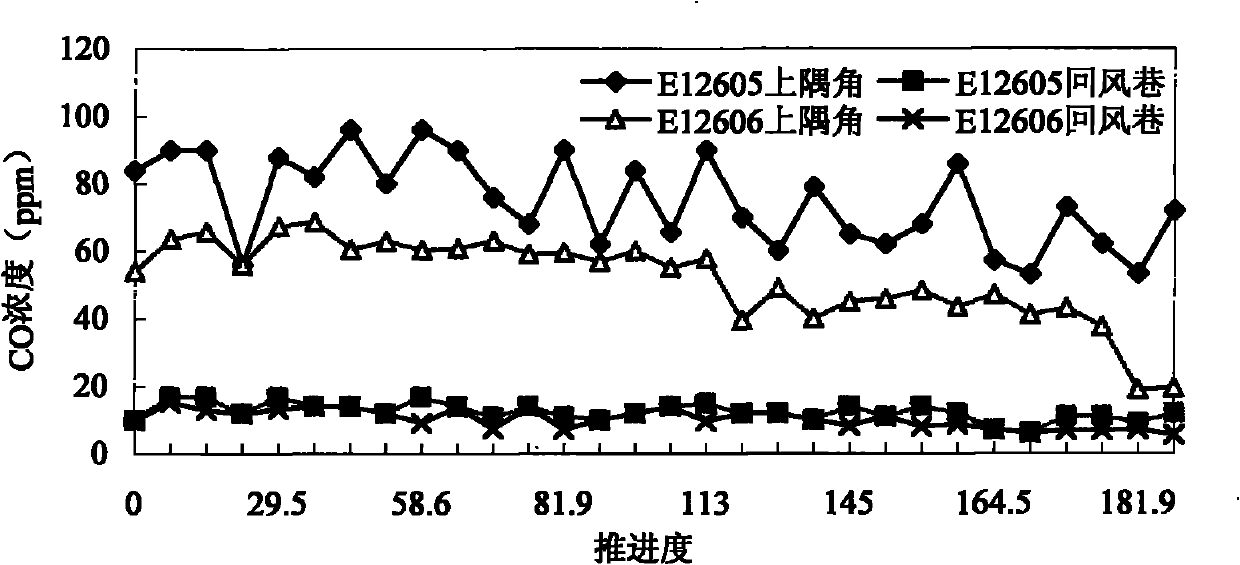

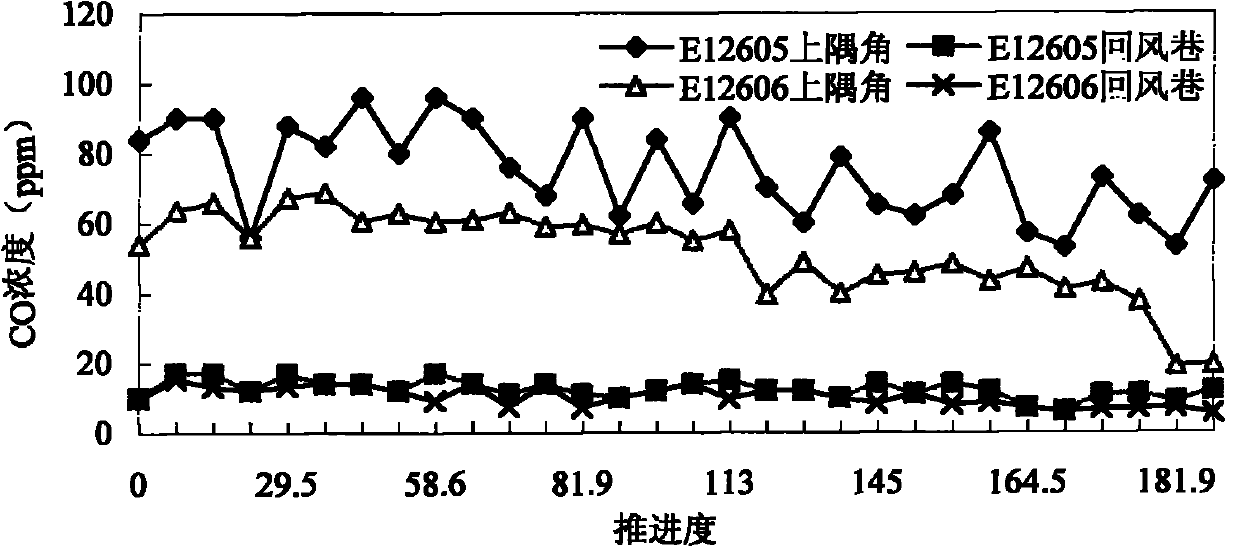

Inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in goaf of coal mine

InactiveCN101766877AAvoid contactStop spontaneous combustionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention discloses an inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in a goaf of a coal mine, which belongs to the field of fire prevention and extinguishment in the goaf of the coal mine. The inorganic salt type inhibitor consists of sodium bicarbonate, calcium bicarbonate, calcium chloride, magnesium chloride, sodium chloride and zinc chloride according to a certain proportion by weight. The average inhibiting rate of the inorganic salt type inhibitor can achieve 85%, and the inhibiting effect is ideal. When in use, the inhibitor is covered on the surface of the residual coal in the goaf, thereby achieving the effects of preventing and controlling the spontaneous combustion of a coal layer in the region for a long time. The dusting method of the inorganic salt type inhibitor for fire prevention and extinguishment is safe and stable, the process flow is simple, the operation is convenient, the initial investment is low, and the using cost is relatively low. The fire prevention and extinguishment technology of the inorganic salt type inhibitor which has thermal instability and can release inert gas carbon dioxide has broad application prospects in the work of preventing and controlling the spontaneous combustion fire disasters of the coal layers. The inorganic salt type inhibitor is applicable to the fire prevention and extinguishment in the goaf of the coal mine.

Owner:UNIV OF SCI & TECH BEIJING

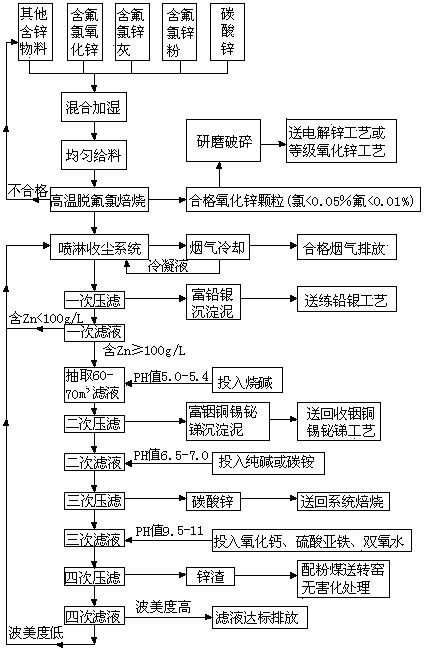

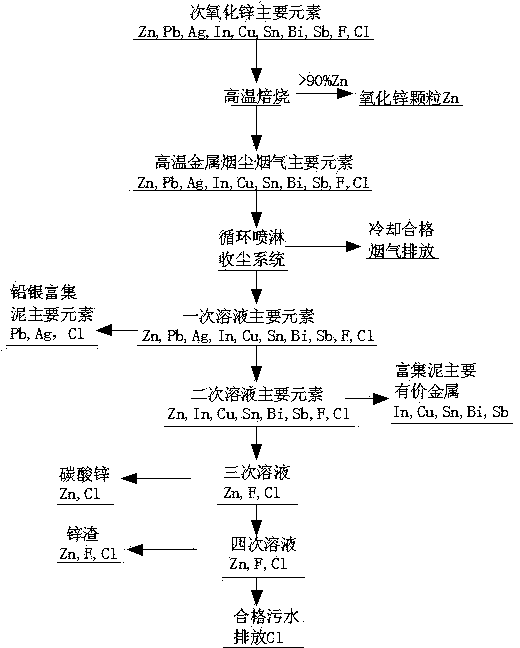

Smelting method for removing fluorine and chlorine out of fluorine-and-chlorine-containing inferior zinc oxide and enriching valuable metals

InactiveCN103924091AReduce water consumptionEasy to handleProcess efficiency improvementHydrometallurgySoot

The invention discloses a smelting method of removing fluorine and chlorine out of fluorine-and-chlorine-containing inferior zinc oxide and enriching valuable metals and relates to the technical field of hydrometallurgy and thermometallurgy of nonferrous metals such as zinc. The method disclosed by the invention comprises the following steps: oxidizing and roasting inferior zinc oxide in a rotary kiln at a high temperature so as to remove fluorine and chlorine and generate high-purity zinc oxide particles; meanwhile, volatilizing valuable metals in form of high-temperature soot and smoke, circularly spraying and washing so that valuable metals enter a spraying solution or precipitate to be enriched; further separating valuable metals in the solution; and finally, treating the sewage containing fluorine and chlorine and discharging the sewage reaching the standard or reusing the sewage by the system. Therefore, the inferior zinc oxide is purified in a primary continuous multi-sectional process to reach the technical index of conventional zinc-making raw materials, and the valuable metals are enriched by 5-20 times. The zinc making enterprises can widely use various types of inferior zinc oxide as the raw material, so that the production process is unified, the production cost is lowered, various valuable metals are comprehensively recovered, and discharge of sewage is reduced.

Owner:何宇波

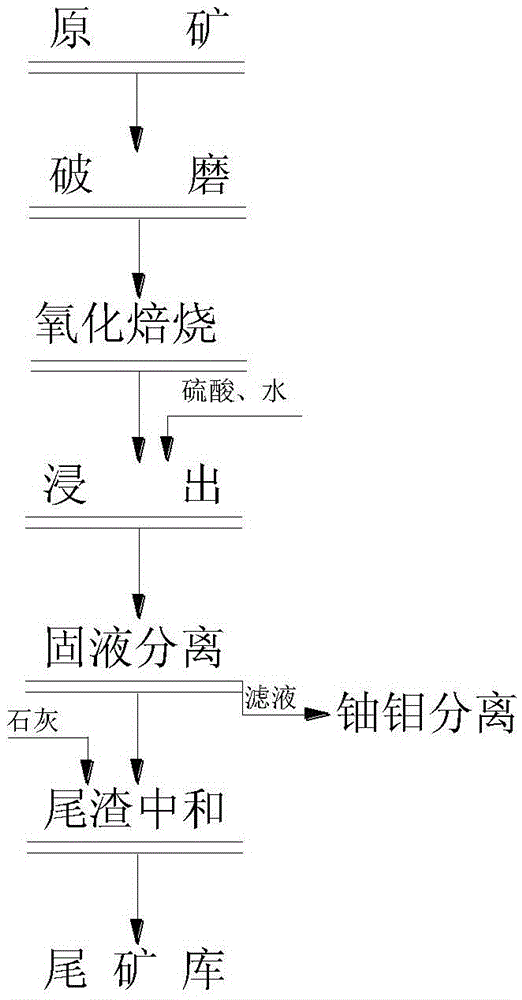

Method for preprocessing wrapped uranium-molybdenum ores through oxidizing roasting

The invention belongs to the technical field of uranium-molybdenum ore processing, specifically relates to a method for preprocessing wrapped uranium-molybdenum ores through oxidizing roasting, aims to overcome the shortages of prior art and further improve the leaching rate of valuable metal such as uranium, molybdenum, and the like, and provides a method for improving the leaching rate of uranium and molybdenum in wrapped uranium-molybdenum ores through an oxidizing roasting pretreatment. Through the oxidizing roasting treatment, the colloidal sulfur-molybdenum ore wrapping is destroyed, thus the oxidation of molybdenum ores in the wrapped uranium-molybdenum ores is promoted, and molybdenum becomes easier for leaching. After oxidizing roasting treatment, uranium and molybdenum can be leached out under a lower acid degree at a lower temperature, the leaching rate of uranium can reach 90% or more, the leaching rate of molybdenum can reach 80% or more, the leaching rates are improved by 5% and 30% respectively compared with the conventional method, moreover, no oxidizing agent is used during the leaching process, and the liquid and solid in leached ore slurry can be separated easily. The method has the advantages of low burning temperature, high oxidation rate of uranium and molybdenum, simple technology, little consumption of reagent, and low production cost.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

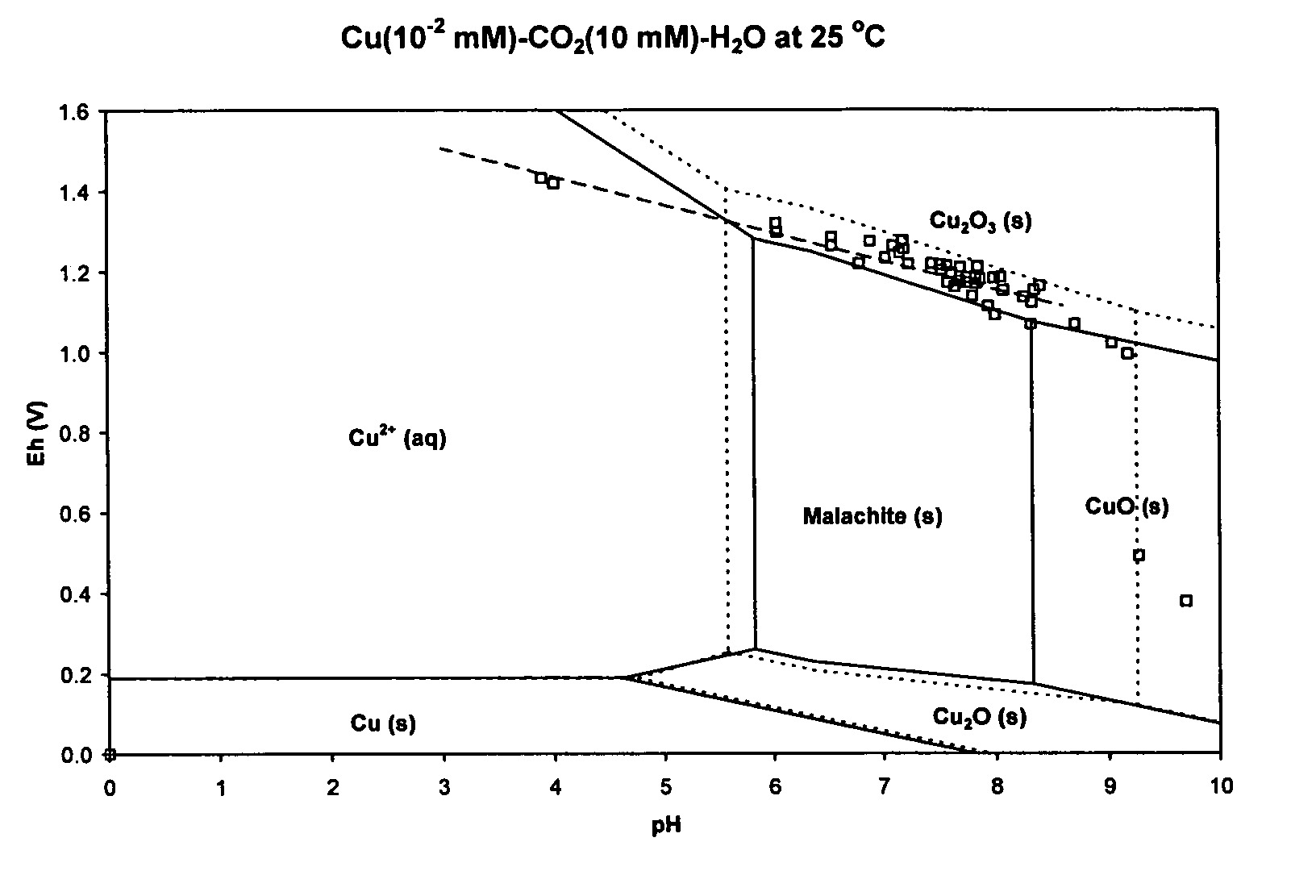

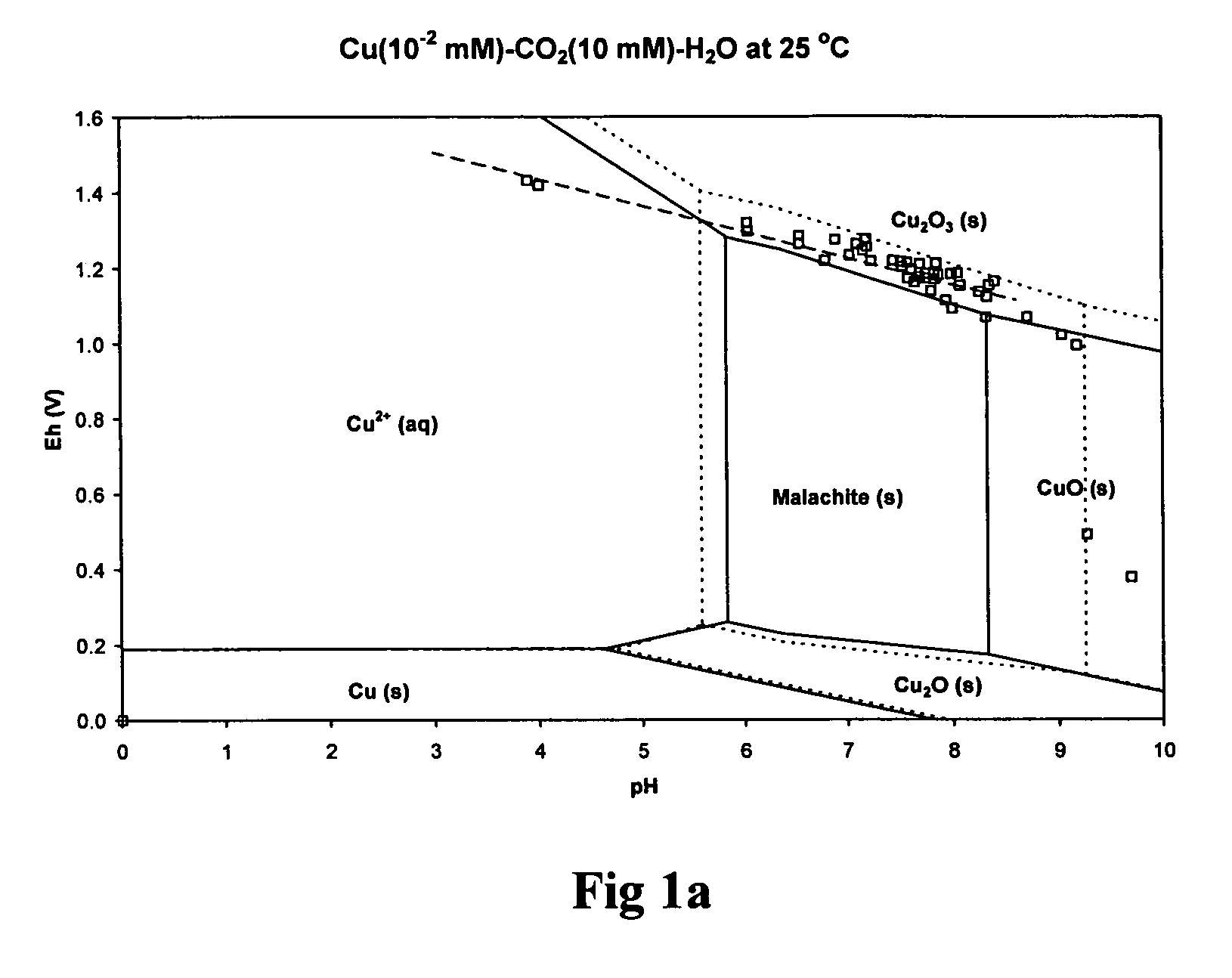

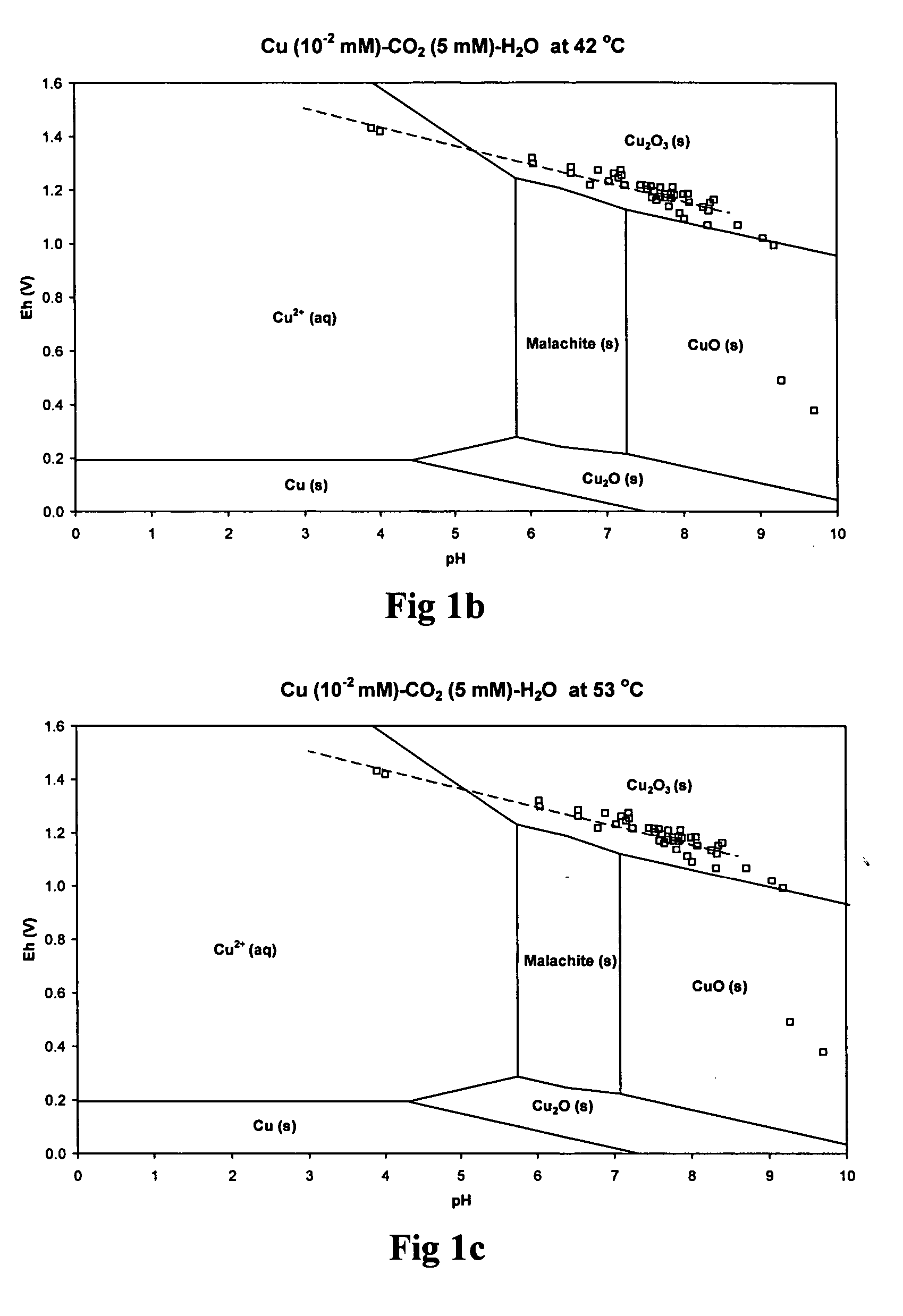

Copper processing using an ozone-solvent solution

InactiveUS20060084260A1Avoid corrosionAccurate removalPhotomechanical apparatusSemiconductor/solid-state device manufacturingDevice materialAlloy

The present invention relates to a method and apparatus for treating materials such as copper or copper based metal alloys, used in fabricating semiconductor devices with an ozone solvent solution and avoiding damage to metals by corrosion. The invention is also applicable to treating of materials such as copper and copper based alloys for the purpose of forming a protective layer on the exposed metal surface for protection of those copper surfaces from damage or corrosion caused by subsequent exposure to other liquid, gas, or plasma environments. This can be achieved by properly selecting the composition of the ozone solvent solution and controlling the pH and ORP of the ozone-solvent solution while avoiding the use of certain chemical constituents in the ozone solvent solution.

Owner:BOYERS DAVID G +1

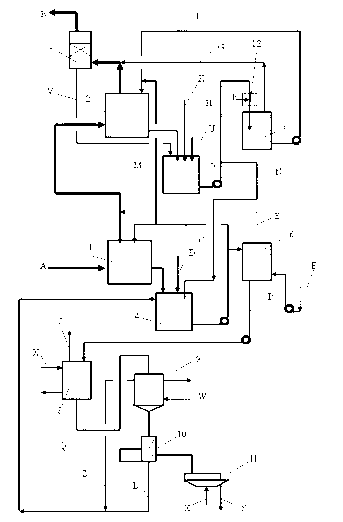

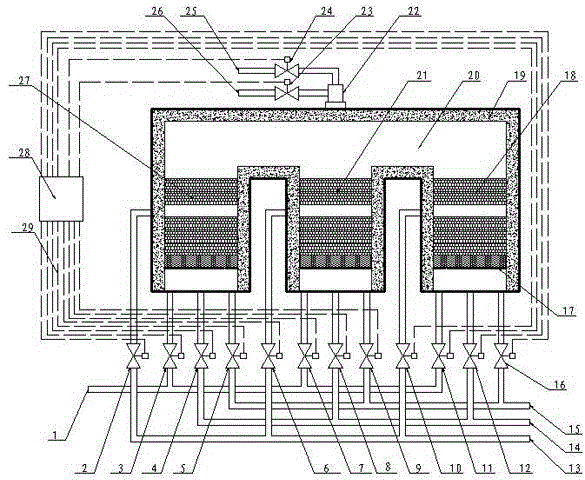

Multi-bed type ventilation air methane regenerative thermal oxidation device

InactiveCN102720527AIncrease oxidation rateImprove running stabilityTunnel/mines ventillationGas removalCounter flowCombustion chamber

The invention discloses a multi-bed type ventilation air methane regenerative thermal oxidation device which is used in a ventilation air methane counter-flow thermal oxidation treatment process during production of coal mines. The device comprise three or more oxidation beds, a combustion chamber, a preheater, a ventilation air inlet pipe, a flue gas outlet pipe, a purging pipeline, a flue gas extraction pipeline, a switching valve and a control unit. Oxidation beds are in a vertical structure, heat-insulating fire-resisting materials are arranged on peripheries of oxidation beds, and in addition to a heat accumulation and heat release circulation, a purging purification process is added, so that unoxidized ventilation air is prevented from being directly exhausted into the air, and the oxidation rate exceeds 99%. Besides, flue gas extraction openings are arranged between high-temperature zones and low-temperature zones of oxidation beds, so that part of high-temperature flue gases can be extracted for waste-heat utilization. The device has the advantages of being high in oxidation rate of methane, convenient for waste-heat utilization, stable to operate and the like.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

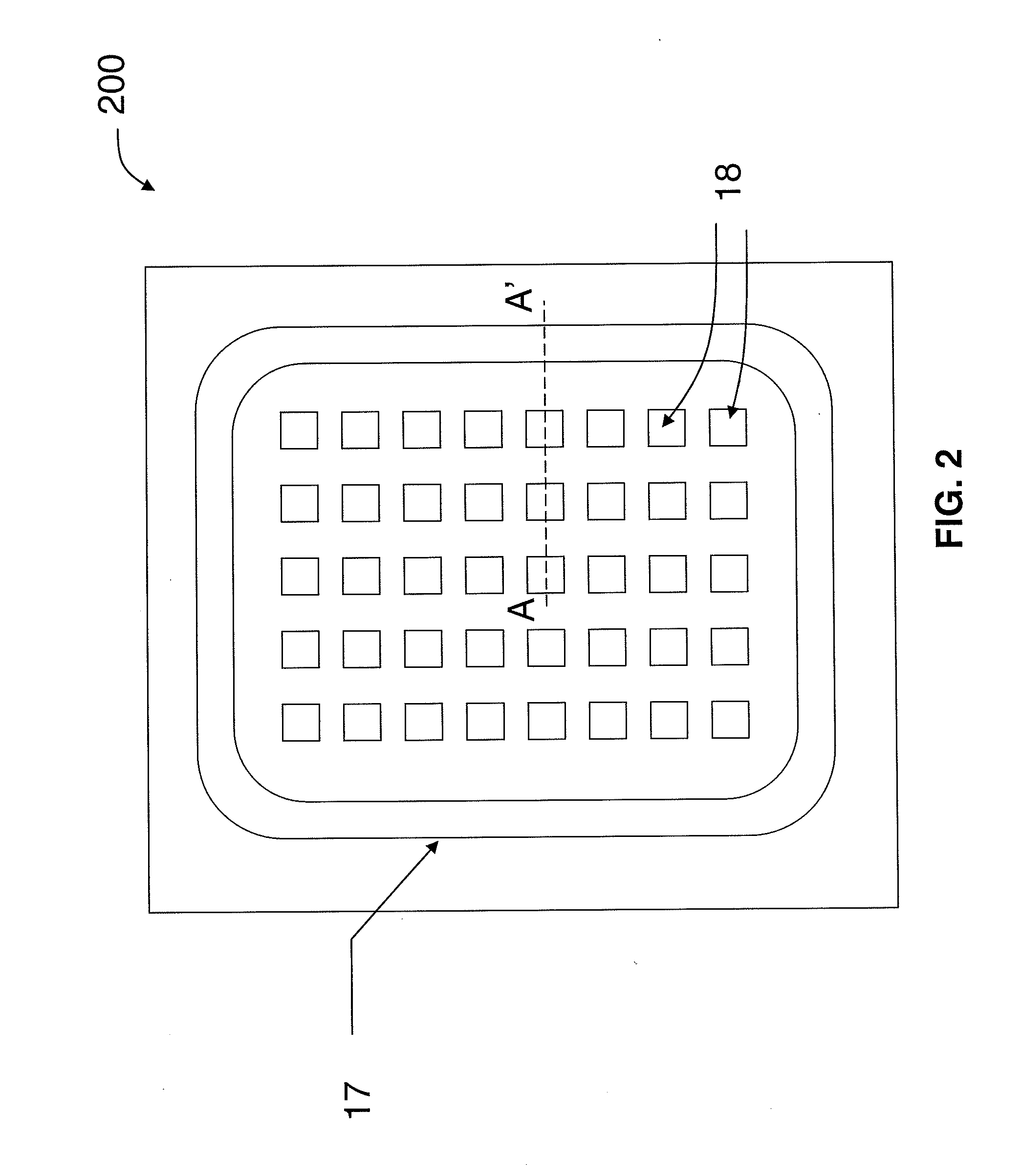

Gap-filling for isolation

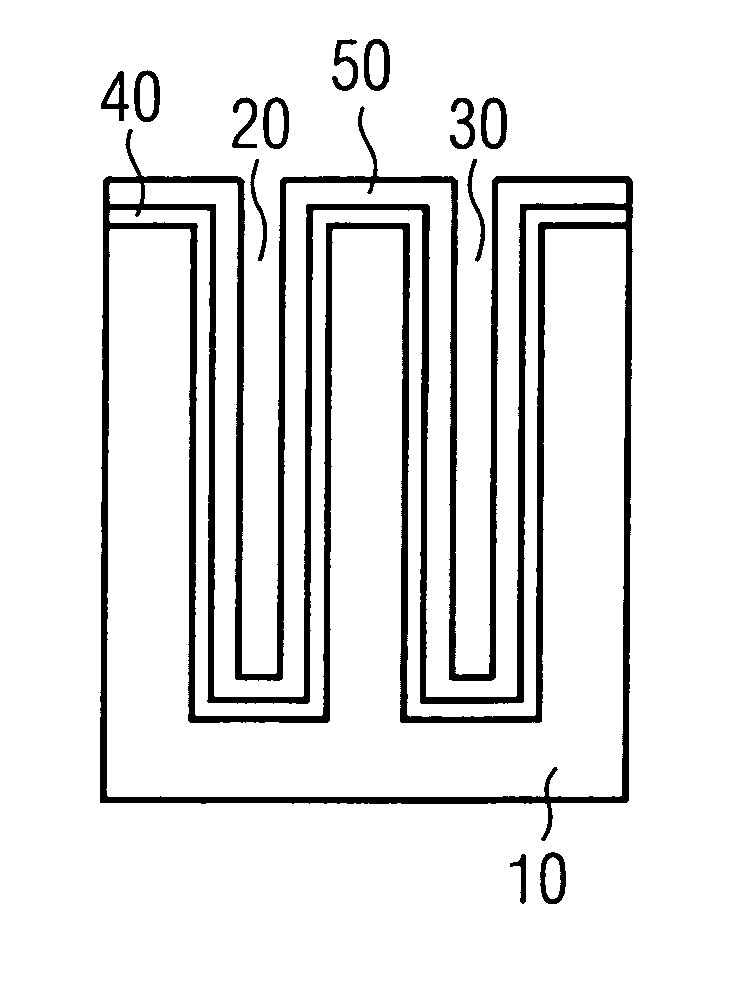

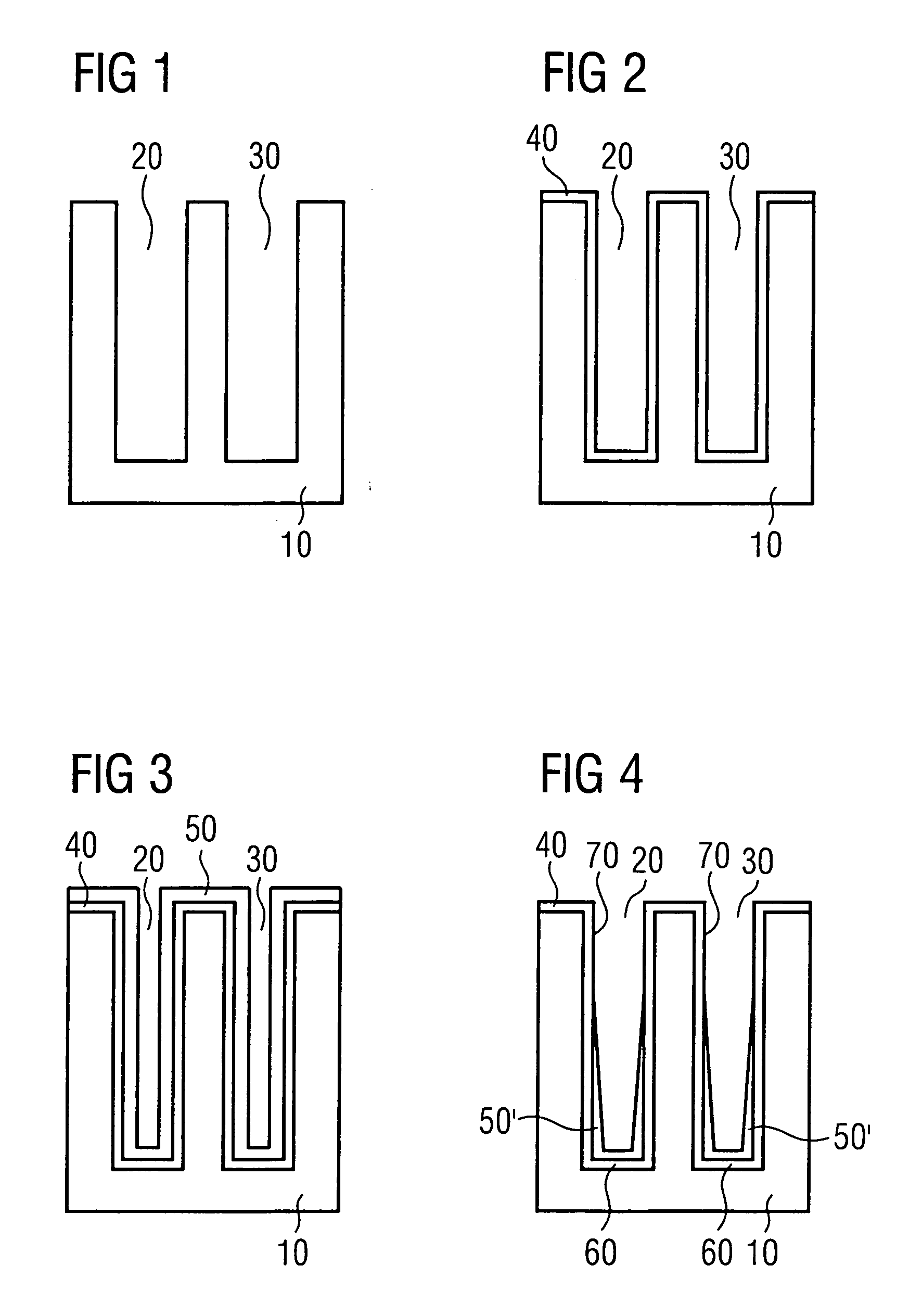

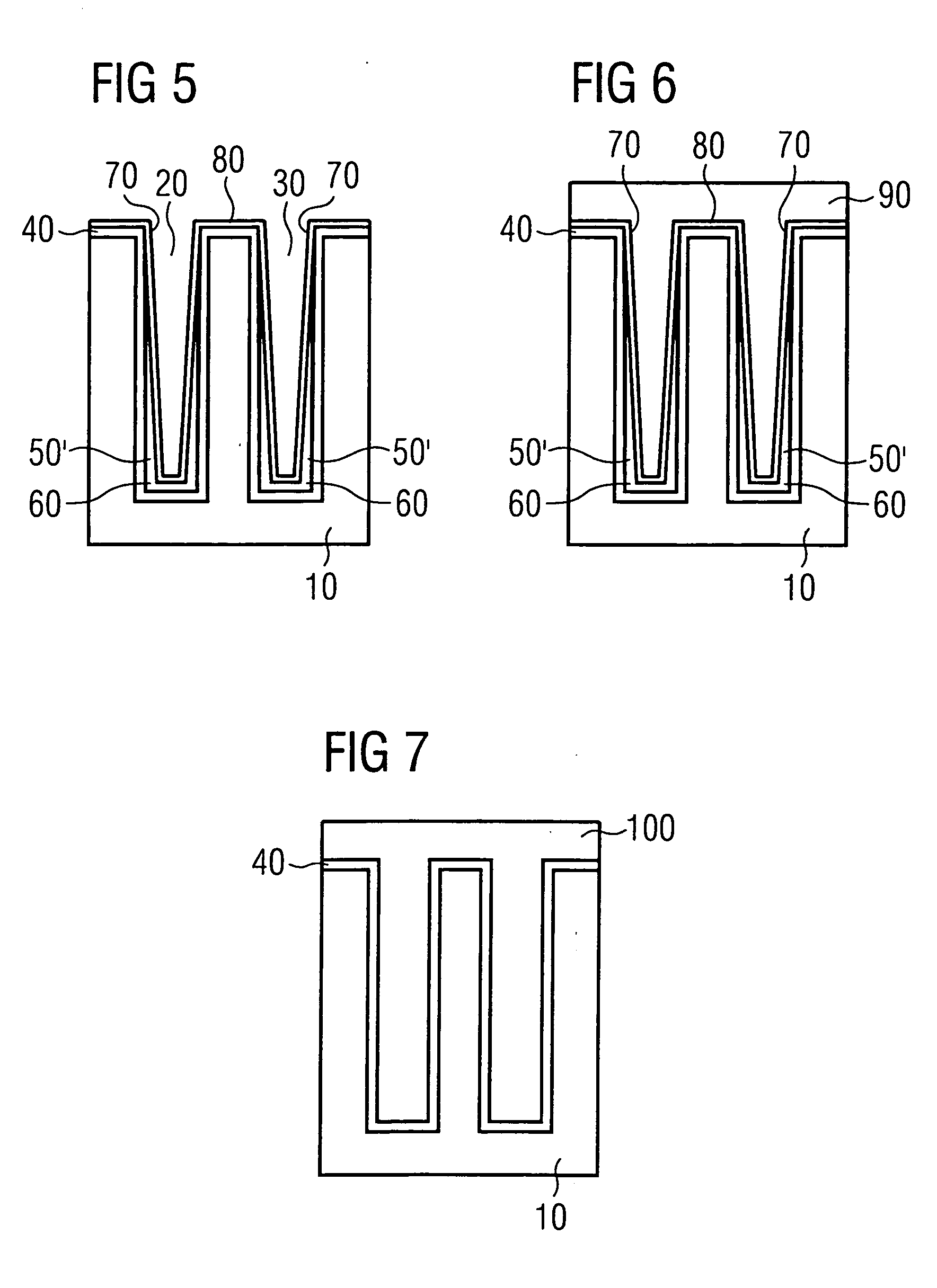

InactiveUS20060003546A1Avoid discontinuitiesIncrease oxidation rateSemiconductor/solid-state device manufacturingOxygenGap filling

A method of filling high ratio trenches on a substrate is described. First, an oxidizable layer is deposited on the substrate. Thereafter, a trench fill oxide is deposited on the substrate and on the oxidizable layer. Afterwards, the resulting structure is annealed using an oxygen containing gas such that the oxidizable layer is oxidized.

Owner:INFINEON TECH AG

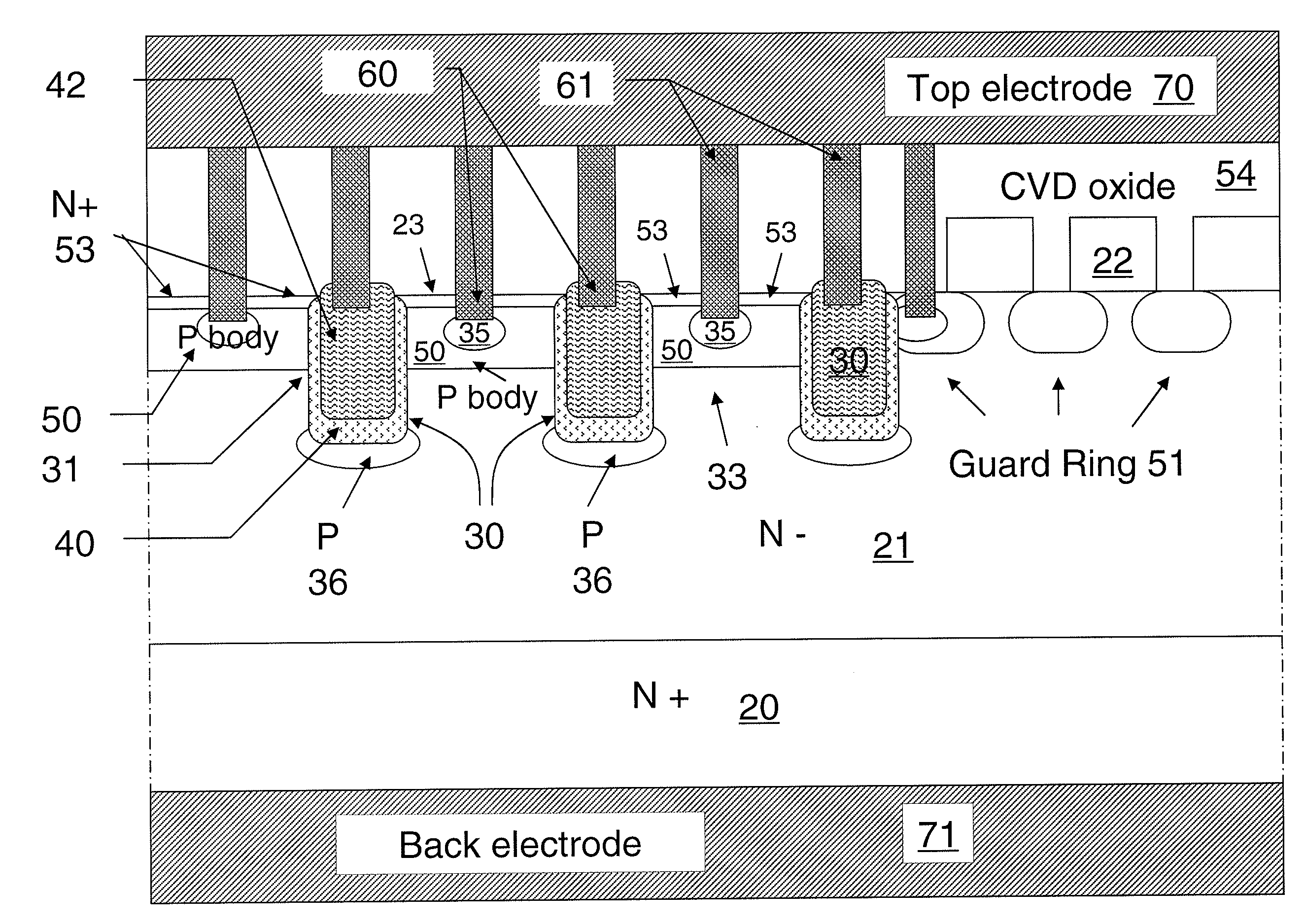

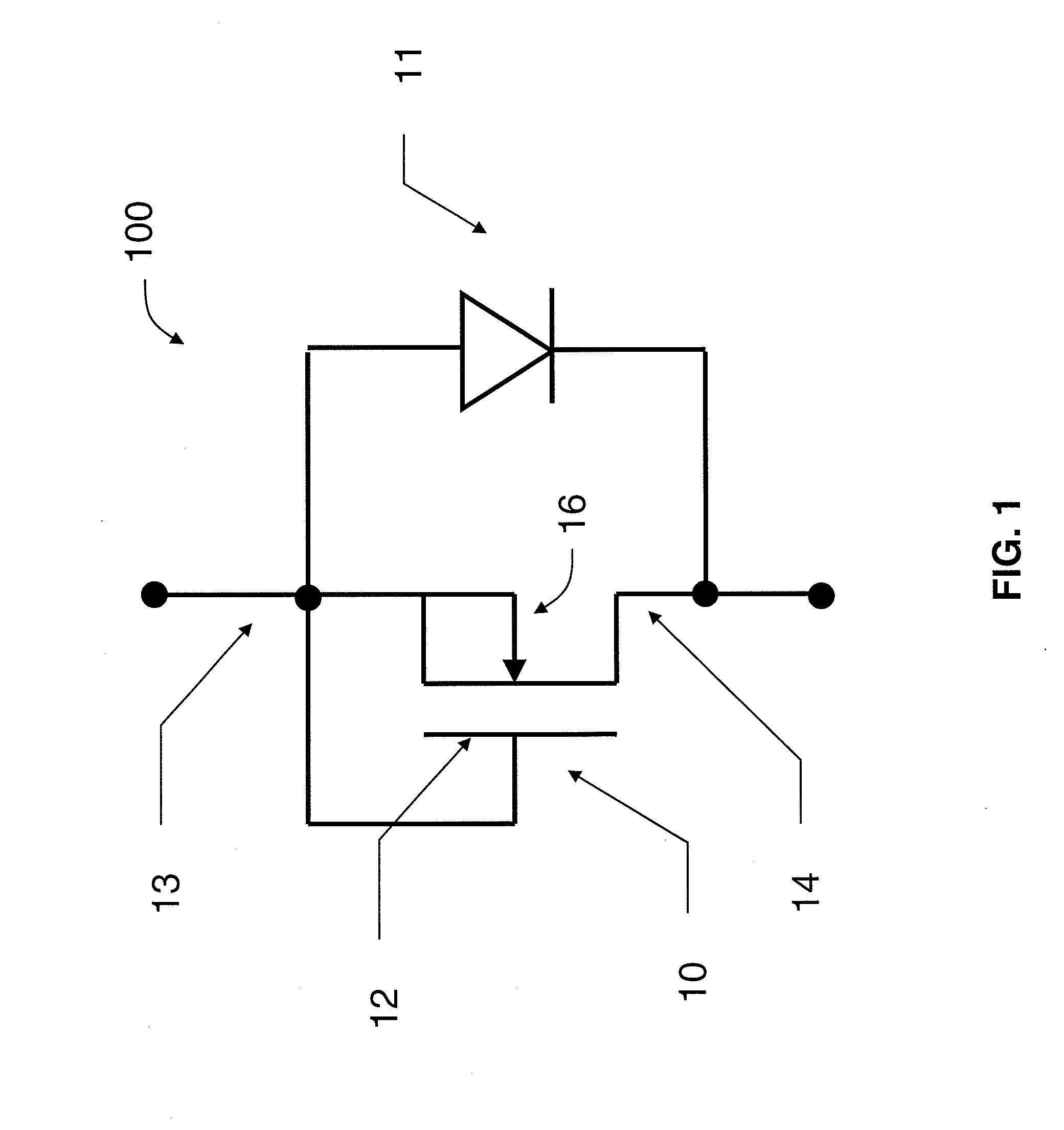

Power trench mosfet rectifier

A trench MOSFET rectifier includes oxide layers having different thicknesses formed in different regions of the devices. The rectifying device also includes a source region of first conductivity type at a surface of each mesa region and a body region of a second conductivity type beneath each source region. The rectifying device also includes a dielectric layer lining the bottom and sidewall surfaces of the trenches, the portion of the dielectric layer on the bottom surface being thicker than the portion on the sidewall surface. A doped region underlies each of the first plurality of trenches. A polycrystalline silicon region filling each of the first plurality of trenches to form a gate region in each trench. A conductive material fills a plurality of contact trenches and forms ohmic contacts with the source region, body region, and gate region.

Owner:BCD SHANGHAI MICRO ELECTRONICS CO LTD

Gasoline particulate filter regeneration and diagnostics

ActiveUS8327628B2Reduce smoke and dust emissionsImprove engine performanceElectrical controlInternal combustion piston enginesParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

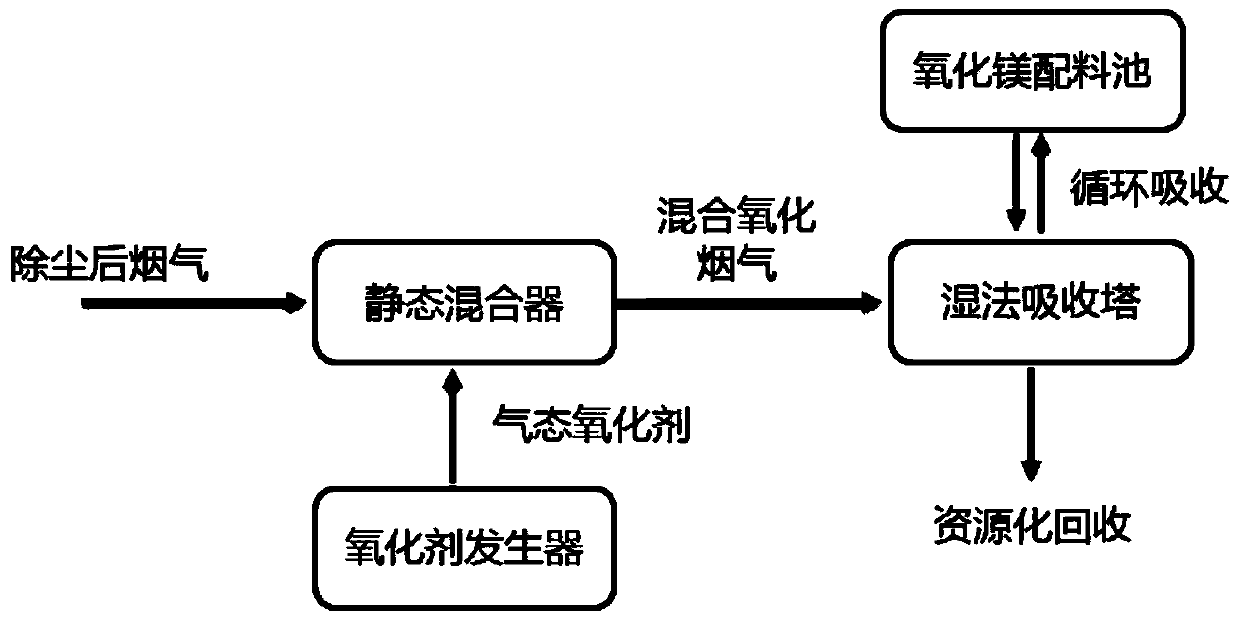

Flue gas treatment method and flue gas treatment device capable of simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide

InactiveCN103736373AFully oxidizedPrevent oxidationDispersed particle separationFlue gasDust control

The invention discloses a flue gas treatment method and a flue gas treatment device for simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide. The flue gas treatment method comprises the following steps: (1) removing dust from boiler flue gas and then transmitting the boiler flue gas into a static mixer, spaying ozone into the static mixer at the same time, mixing and oxidizing the boiler flue gas with the ozone; (2) transmitting the mixed and oxidized mixture gas into an absorbing tower from the bottom part of the absorbing tower, circularly spraying magnesium oxide solution in the absorbing tower; and (3) exhausting the sprayed-absorbed flue gas from the top of the absorbing tower through a chimney. Due to the adoption of combination of oxidization with a gaseous oxidizing agent and absorbing with magnesium oxide solution, the effect of simultaneous desulfurization, de-nitration and mercury removal in one tower is realized, and furthermore, the effects of simultaneous desulfurization, de-nitration and mercury removal are all good.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com