Integrated apparatus for removing pollutants from a fluid stream in a lean-burn environment with heat recovery

a technology of fluid stream and integrated apparatus, which is applied in mechanical apparatus, machines/engines, separation processes, etc., can solve the problems of pm/nox trade-off, complex diesel emissions, and remained problematic in the diesel engine industry, and achieve excellent noise absorption qualities and compact size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

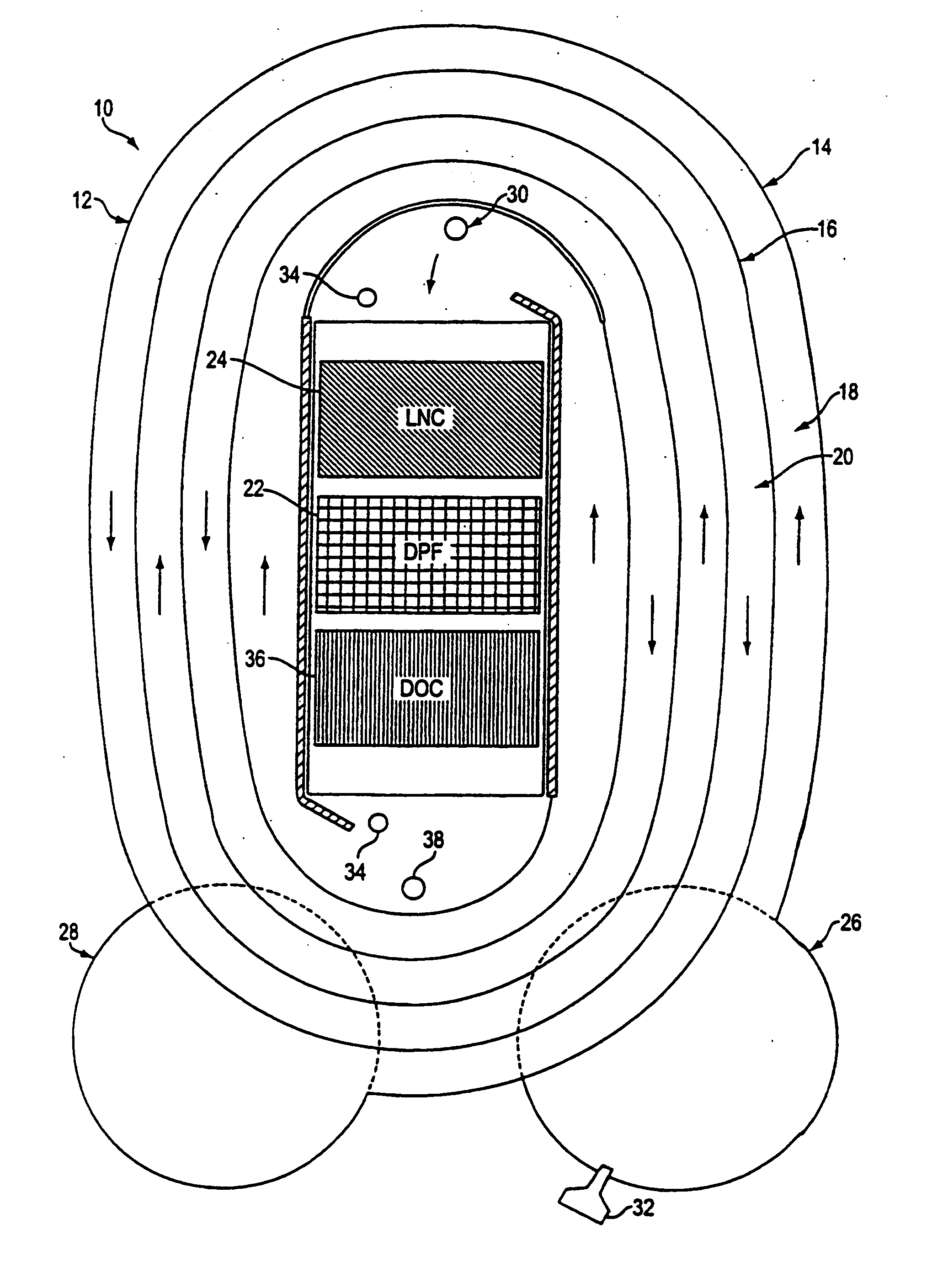

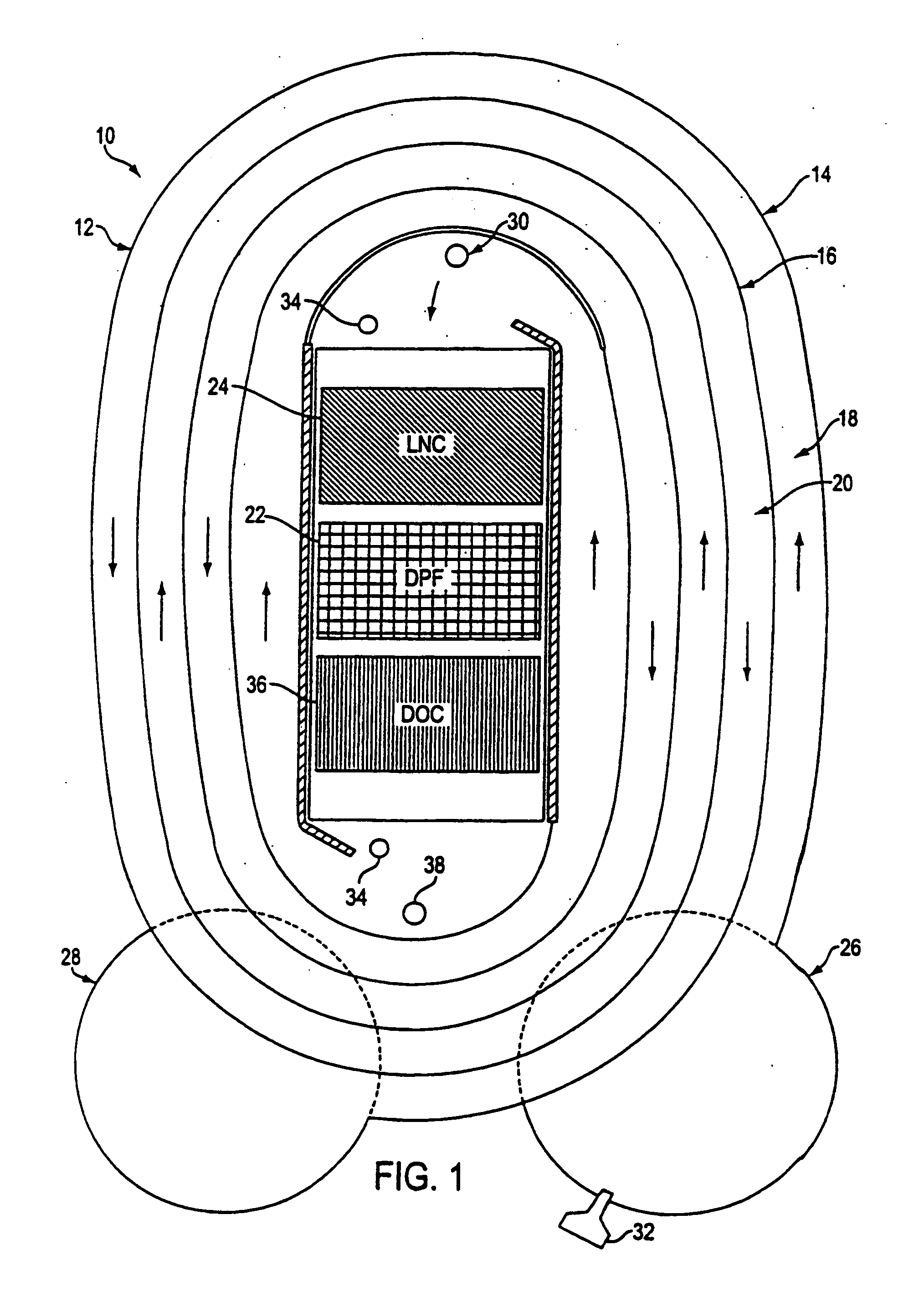

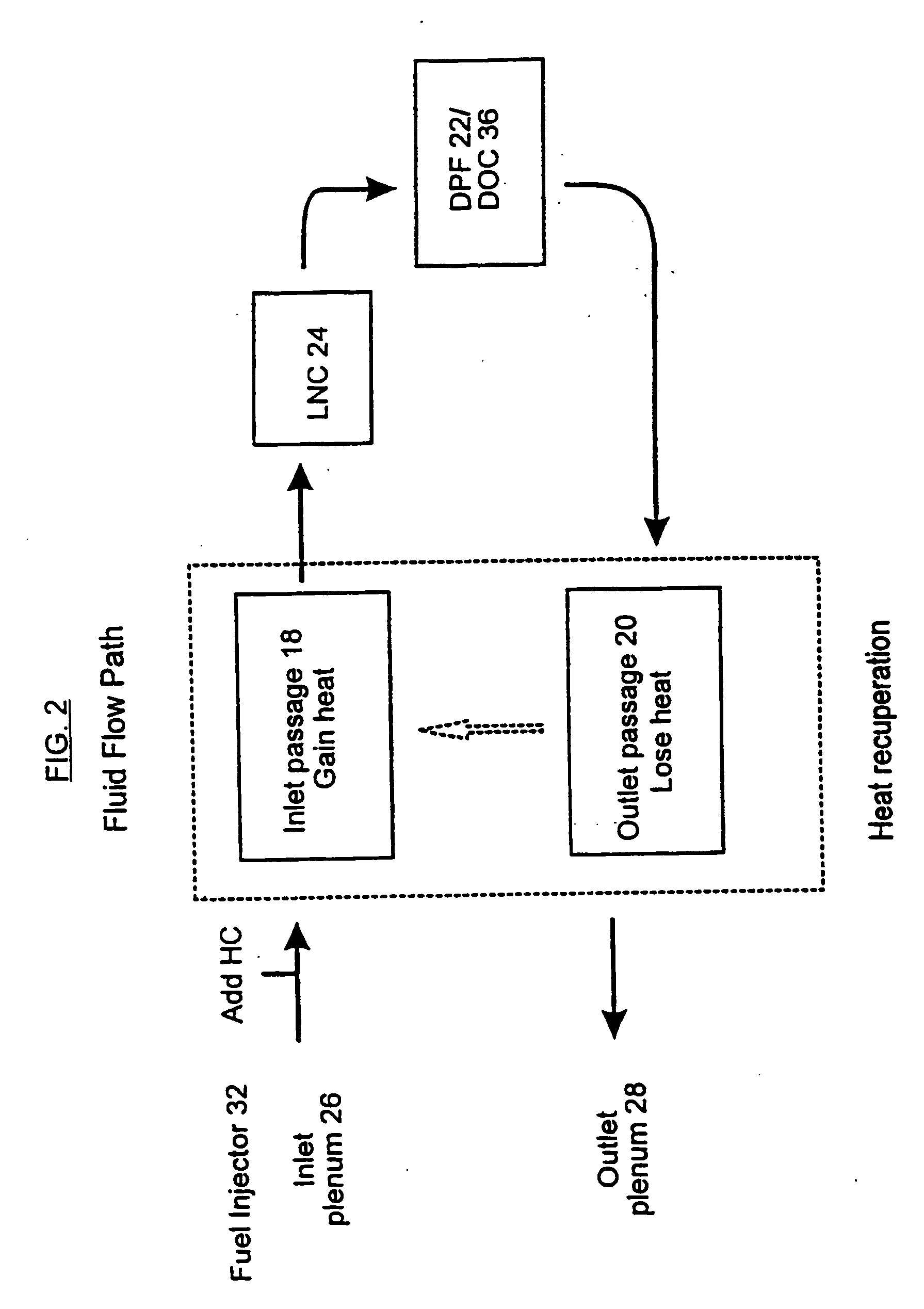

[0028] With reference now to the illustrative drawings, and particularly to FIG. 1, there is shown an apparatus 10 for treating fluid streams, such as emissions from lean-burn engines, for hydrocarbon (HC), particulate matter (PM), carbon monoxide (CO) and nitrogen oxides (NOx) in an integrated system. The apparatus can be positioned downstream of a turbocharger in the exhaust duct of an engine or other emissions source.

[0029] The outer surface of the apparatus forms a heat exchanger shell 12.

[0030] Within the shell are two exchanger walls 14 and 16 that form an inlet passage 18 and an outlet passage 20 for heat exchange between the entering and exiting fluid stream. The exchanger walls allow heat transfer across their surfaces, and can receive normal lean-burn exhaust flows without excess corrosion. The exchanger walls form a spiral structure, in which heat exchanges between the pre-and post-treatment streams in an inward spiral flow path and an outward spiral flow path. The exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com