Proportional direct driving system in hydraulic machine for warm cold extrusion

A technology of extruding hydraulic presses and proportions, which is applied in the field of hydraulic machinery, can solve the problems of high cost and complex structure of hydraulic presses, and achieve the effects of improving efficiency, beautiful lines, and reducing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

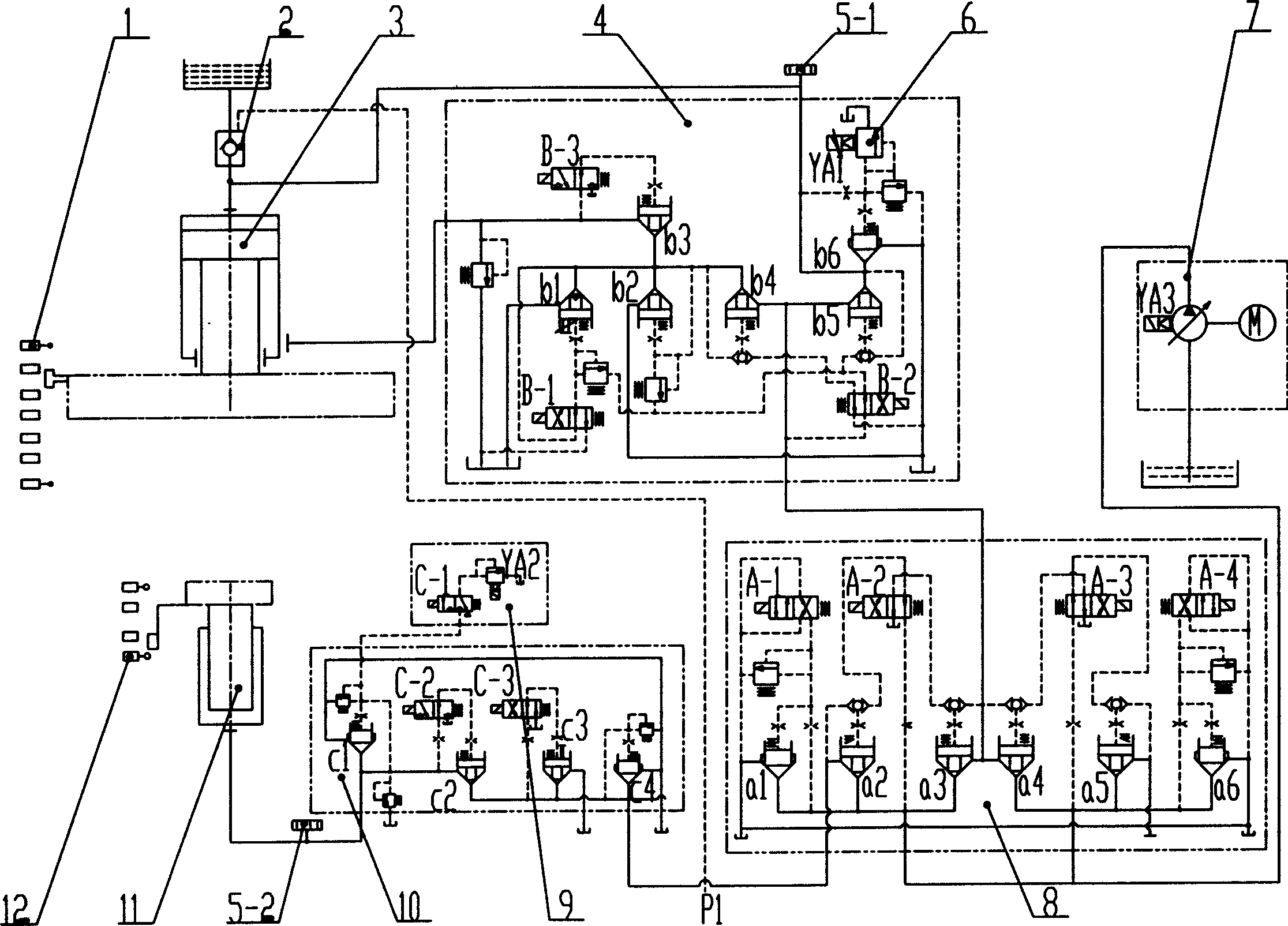

[0035] see figure 1 .

[0036] The proportional direct drive system of the warm and cold extrusion hydraulic press is composed of the self-weight fast lower block 4, the ejector valve block 10, the pump outlet valve block 8 and the proportional pump group 7. Self-weight fast lower block 4 is connected with master cylinder 3 and pump outlet valve block 8, ejector valve block 10 is connected with ejector cylinder 11 and pump outlet valve block 8, pump outlet valve block 8 is connected with proportional pump group 7.

[0037] 1. Self-weight quick lower block 4: Self-weight quick lower block 4 is composed of 6 plug-ins, 2 two-position four-way electromagnetic slide valves and 1 ball valve. The 6 plug-ins are respectively connected with the sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com