Patents

Literature

4651 results about "Hydraulic press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydraulic press is a machine press using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever, and was also known as a Bramah press after the inventor, Joseph Bramah, of England. He invented and was issued a patent on this press in 1795. As Bramah (who is also known for his development of the flush toilet) installed toilets, he studied the existing literature on the motion of fluids and put this knowledge into the development of the press.

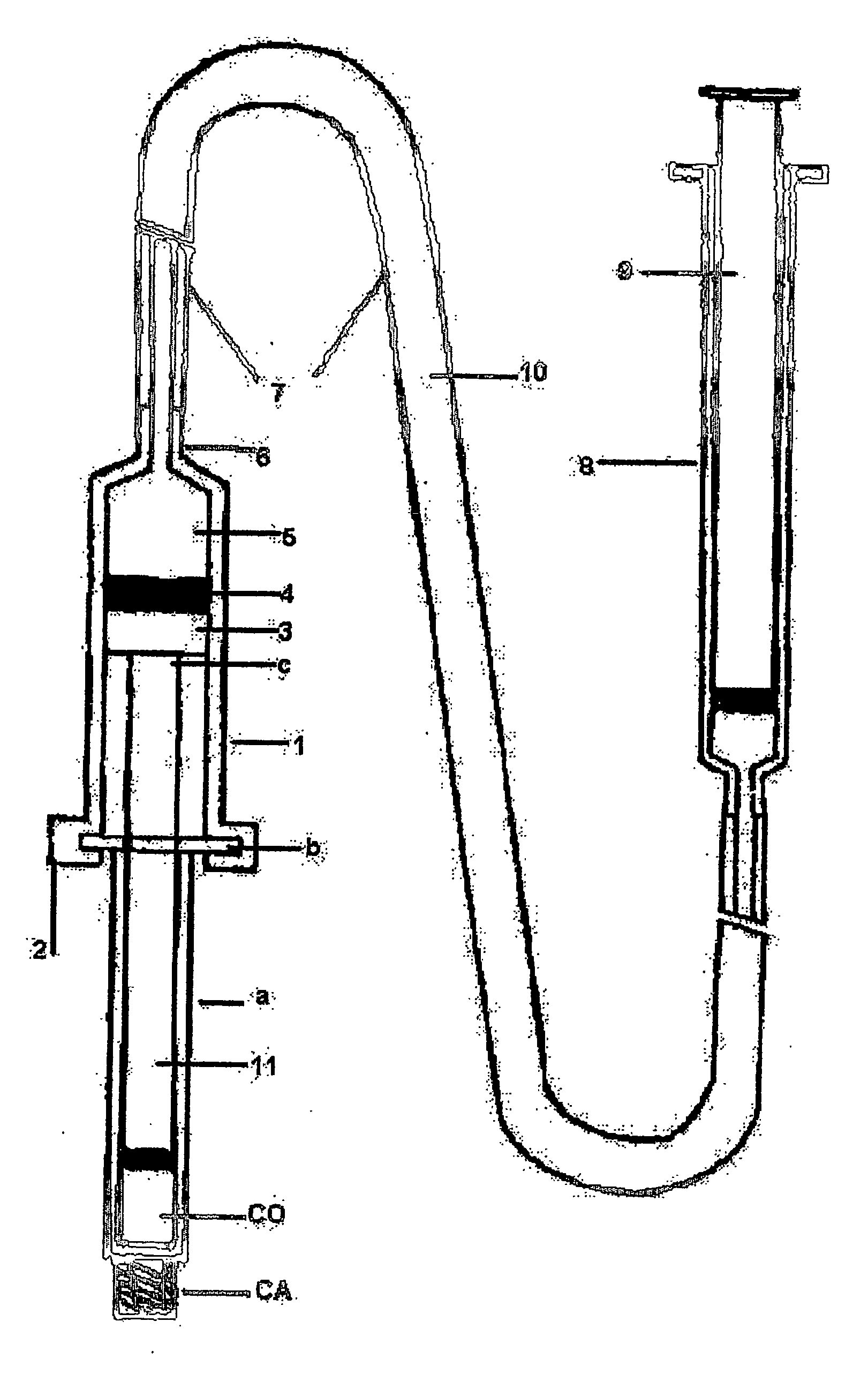

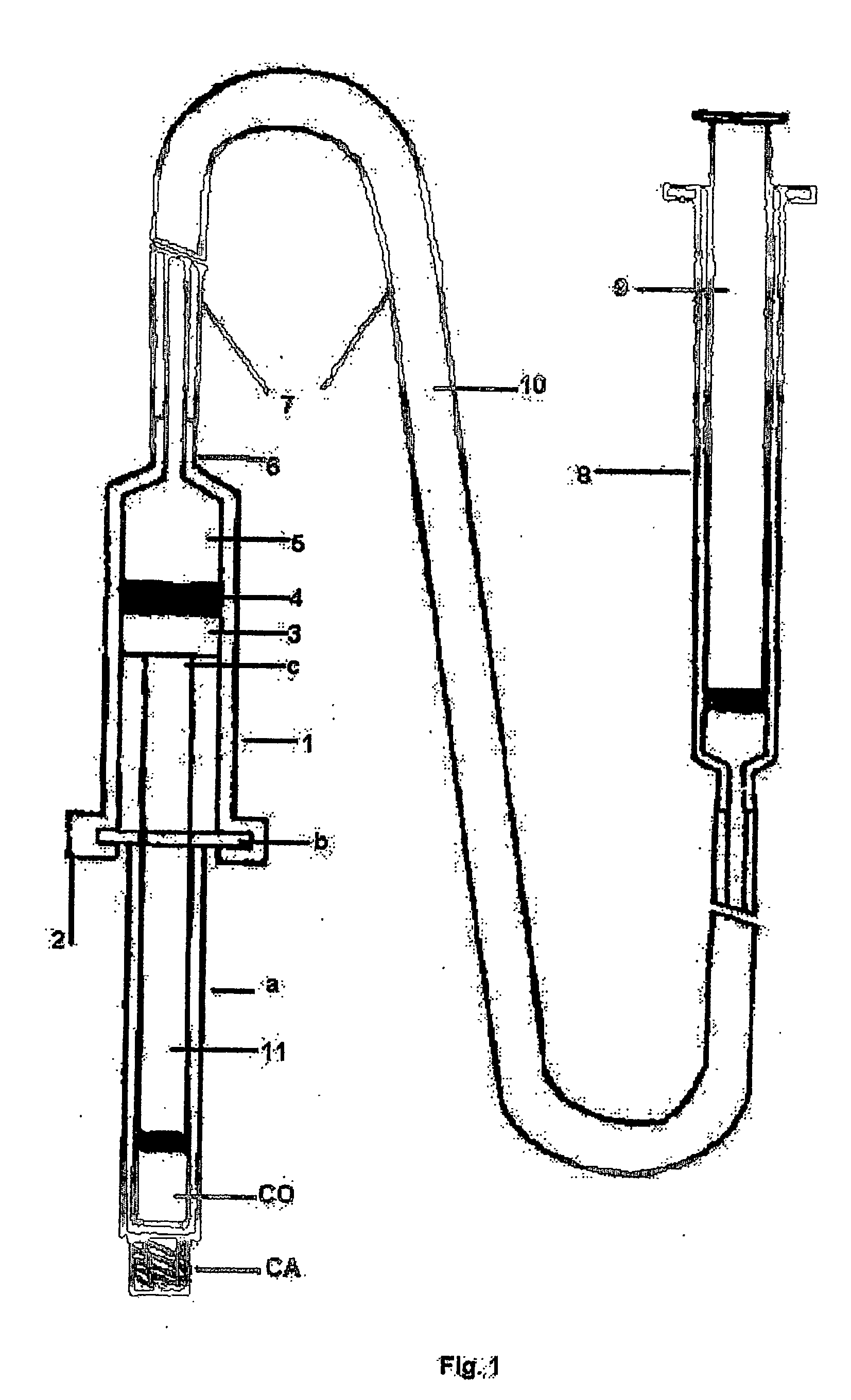

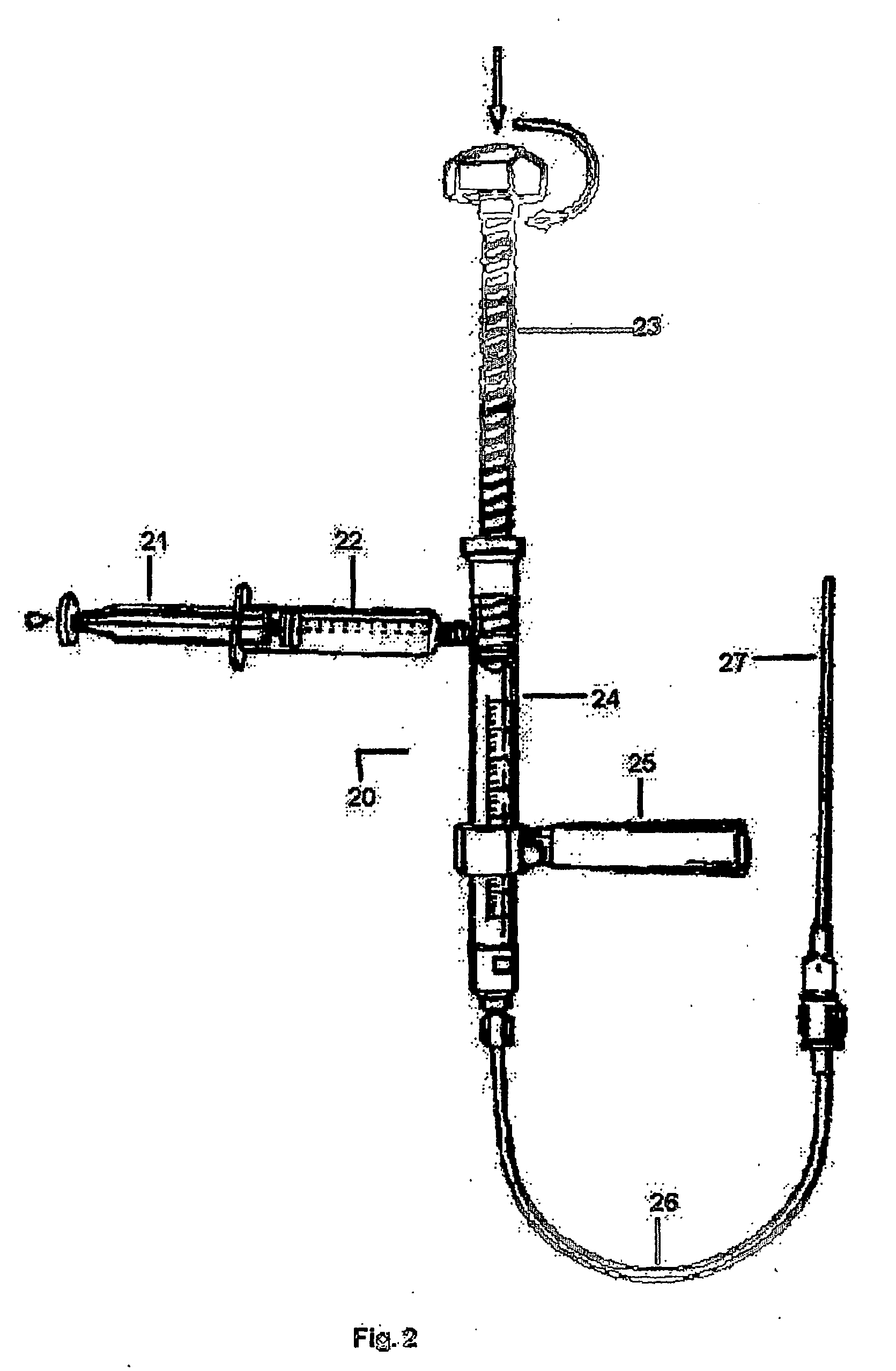

Hydraulic device for the injection of bone cement in percutaneous vertebroplasty

InactiveUS20060264967A1Reduce radiationReduce overexposureJoint implantsIntravenous devicesFluid controlPressure transmission

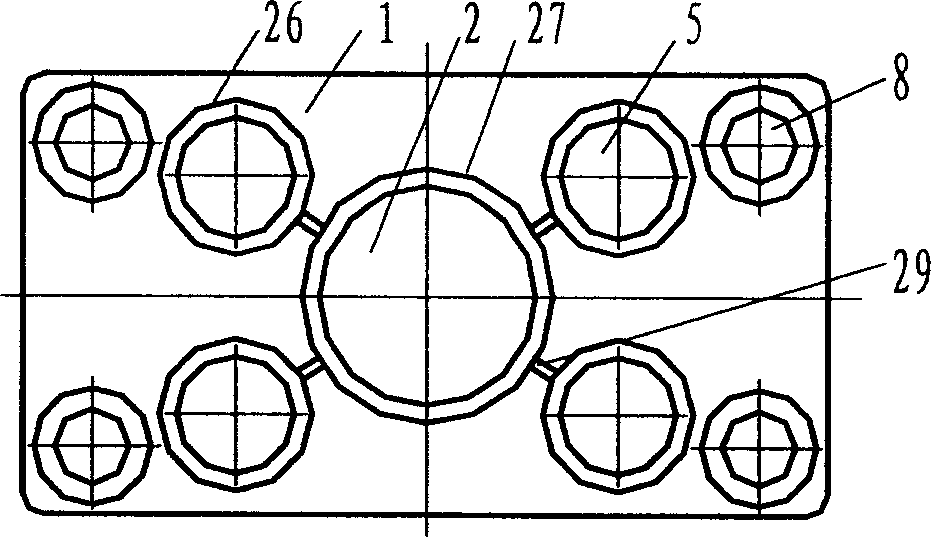

The present invention relates to the medical field, in particular relates to the practice of percutaneous vertebroplasty where a pair of syringes in the distal extreme of a lengthened hydraulic device, are united by a camera of intermediate connection of larger diameter (pressure exerting body) or modified inverted syringe tube with a bolster, a hydraulic connecting tube of flexible material that transmits the pressure of the smaller diameter manual or impulsion syringe in the proximal extreme of the device toward the intermediate cylindrical larger diameter camera (pressure exerting body), this camera is in an inverted position with regard to the first syringe (fluid control), this intermediate camera has a moving piston longitudinal to the axis of the cylinder that is controlled with the first syringe (manual) and in cooperation with the atmospheric pressure. The injecting syringe loaded with bone cement is coupled with the bolster of the body of pressure, and to the needle that drives the cement toward the interior of the bone. The intermediate camera (pressure exerting body) together with the hydraulic tube and the manual syringe form a hydraulic press system (F / A=f / a) that allows to increase in a potential way the pressure exerted in the first syringe and to make the injection of polymethylmethacrylate (PMMA) at an approximate distance of 1.0 m to 1.5 m.

Owner:DEPUY SYNTHES PROD INC

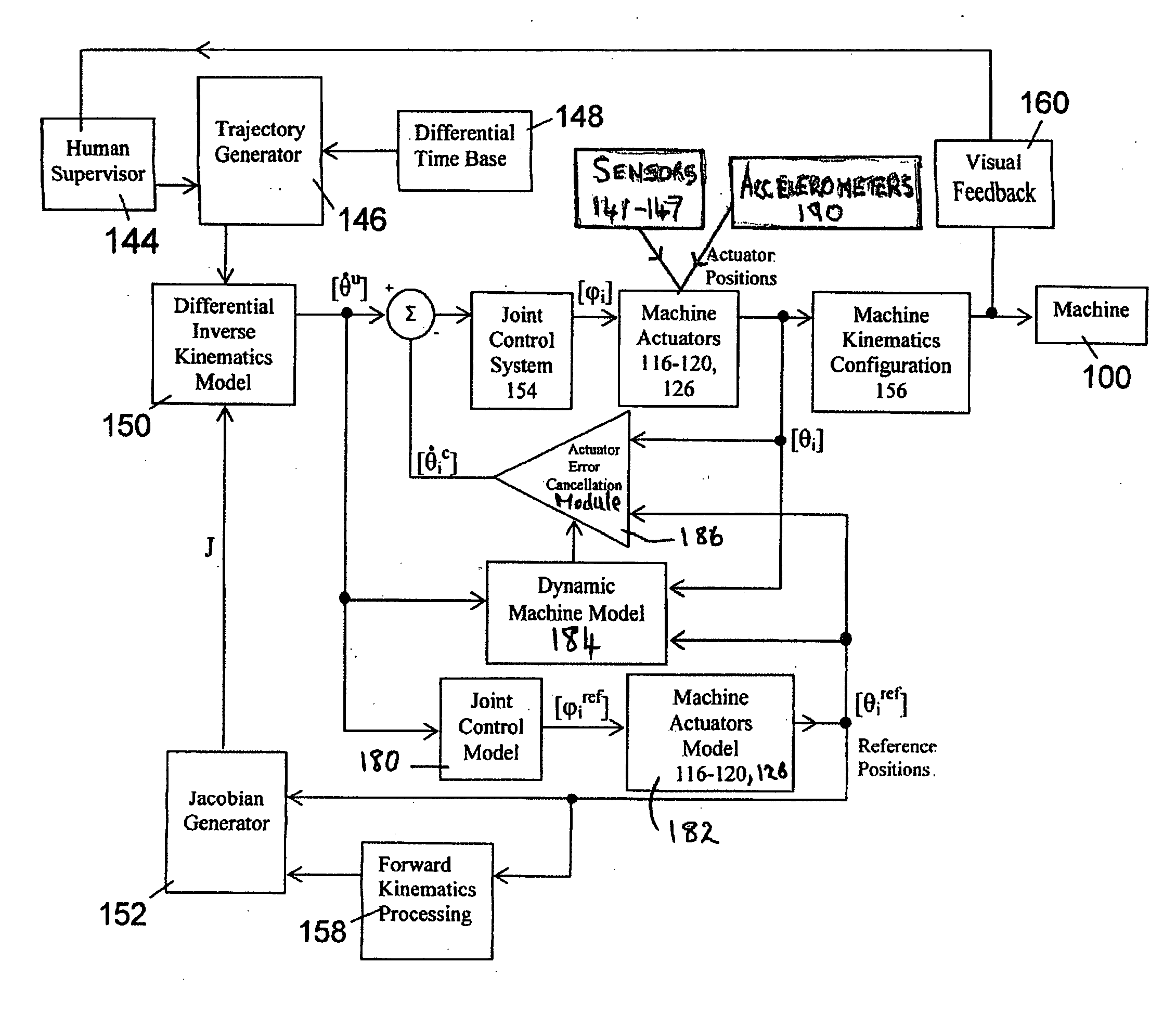

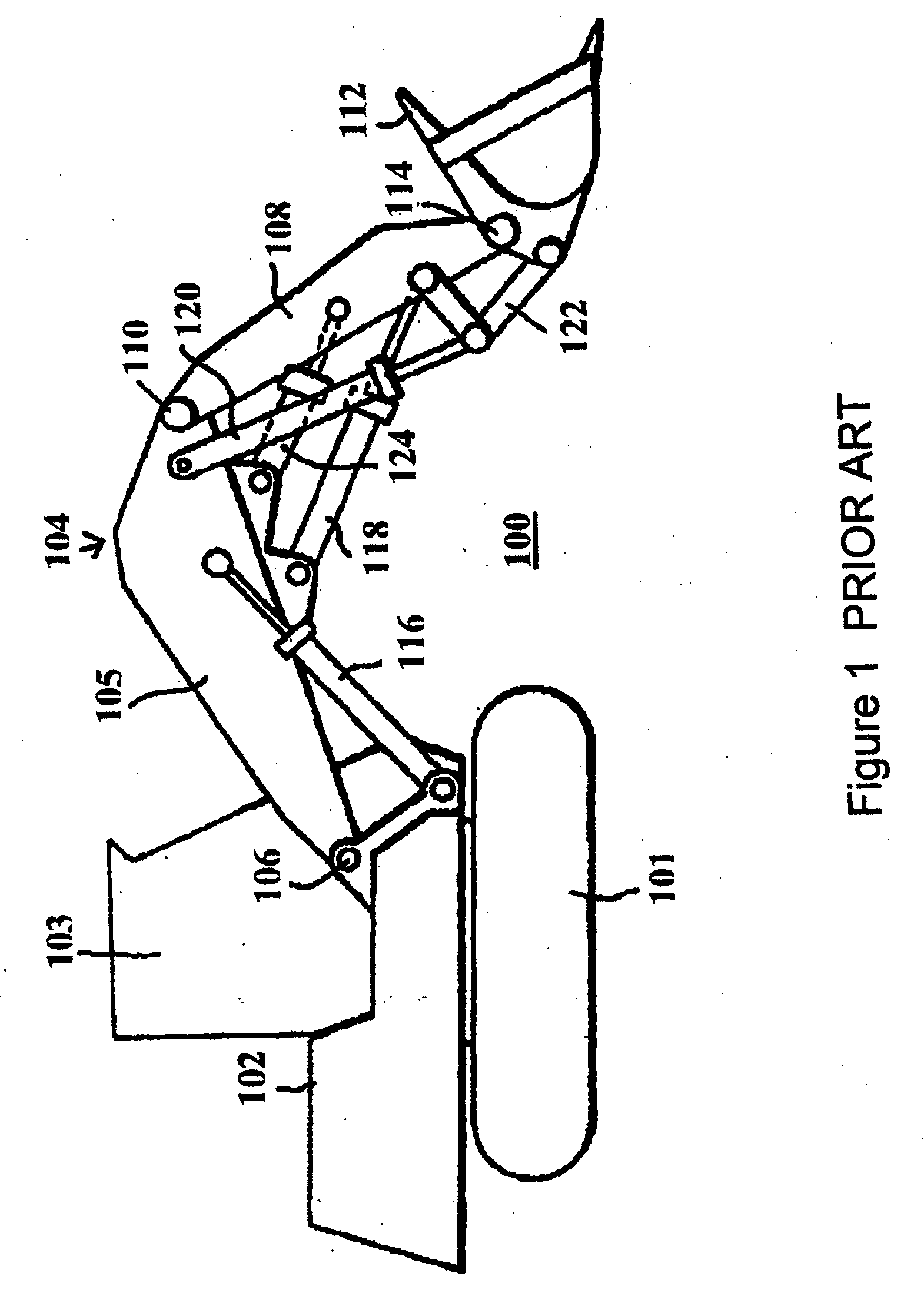

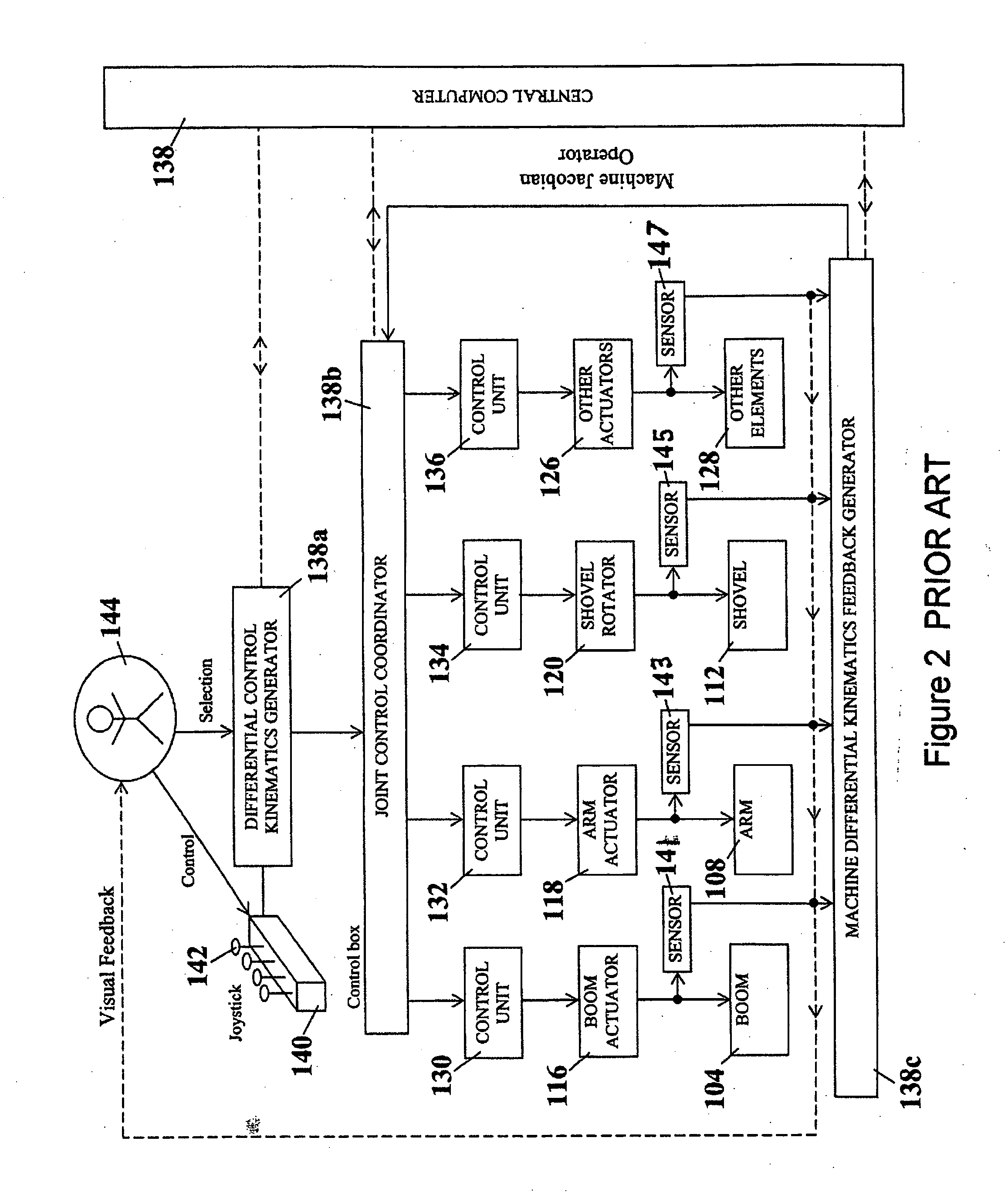

Coordinated joint motion control system with position error correction

InactiveUS20070168100A1Considerable precisionConsiderable repeatabilityAnalogue computers for vehiclesProgramme-controlled manipulatorJoystickControl system

Disclosed are an articulated hydraulic machine supporting, control system and control method for same. The articulated hydraulic machine has an end effector for performing useful work. The control system is capable of controlling the end effector for automated movement along a preselected trajectory. The control system has a position error correction system to correct discrepancies between an actual end effector trajectory and a desired end effector trajectory. The correction system can employ one or more absolute position signals provided by one or more acceleration sensors supported by one or more movable machine elements. Good trajectory positioning and repeatability can be obtained. A two-joystick controller system is enabled, which can in some cases facilitate the operator's task and enhance their work quality and productivity.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

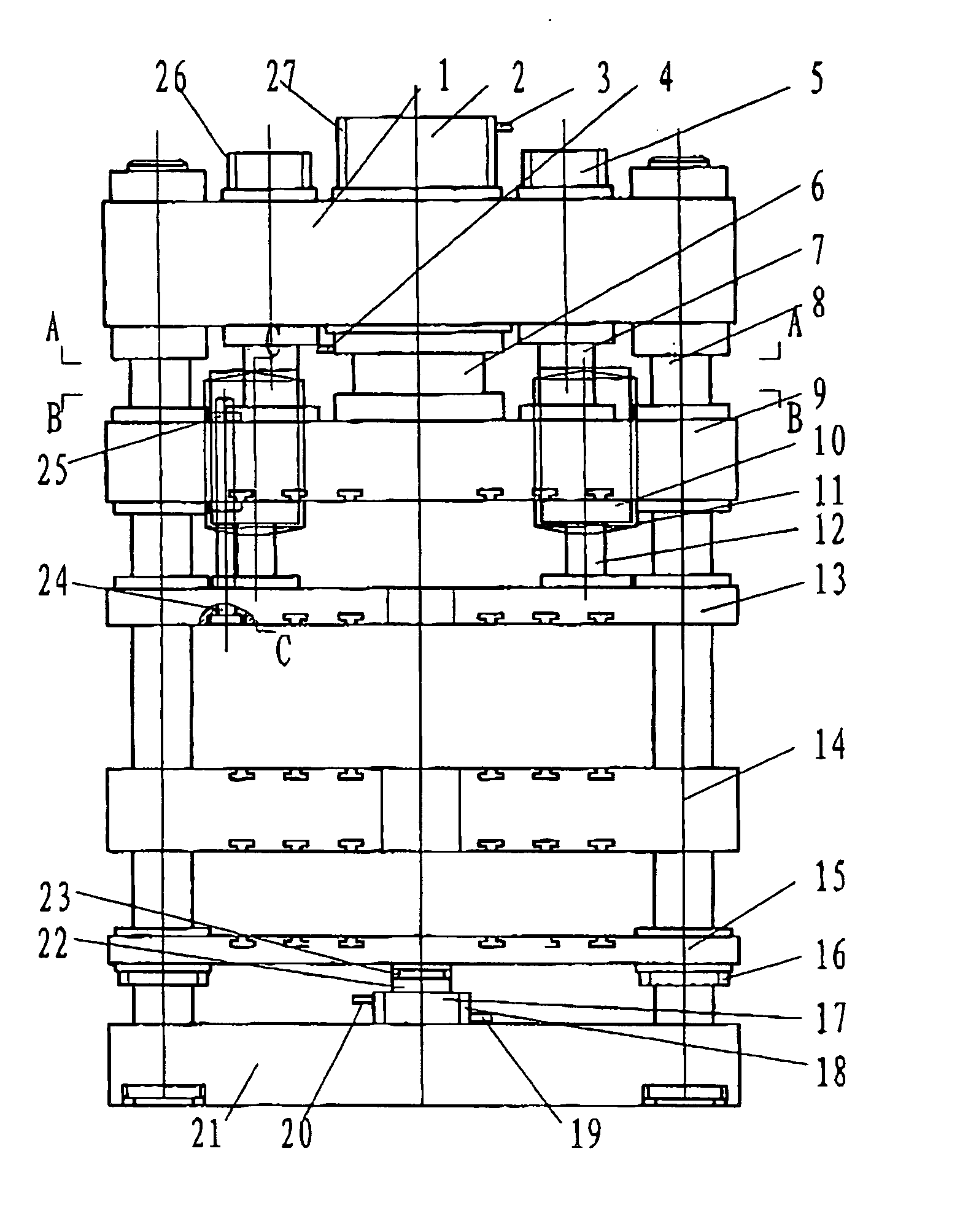

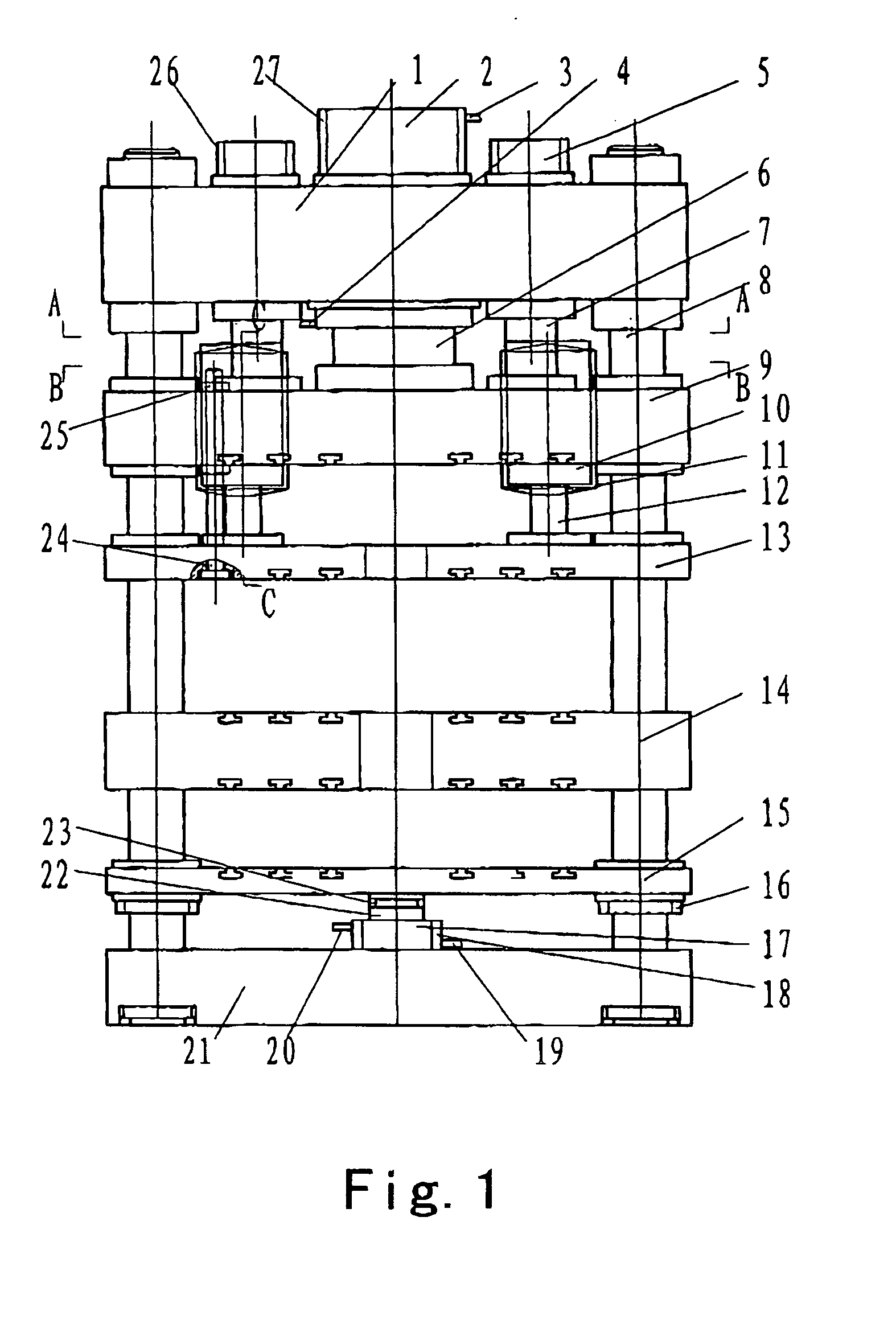

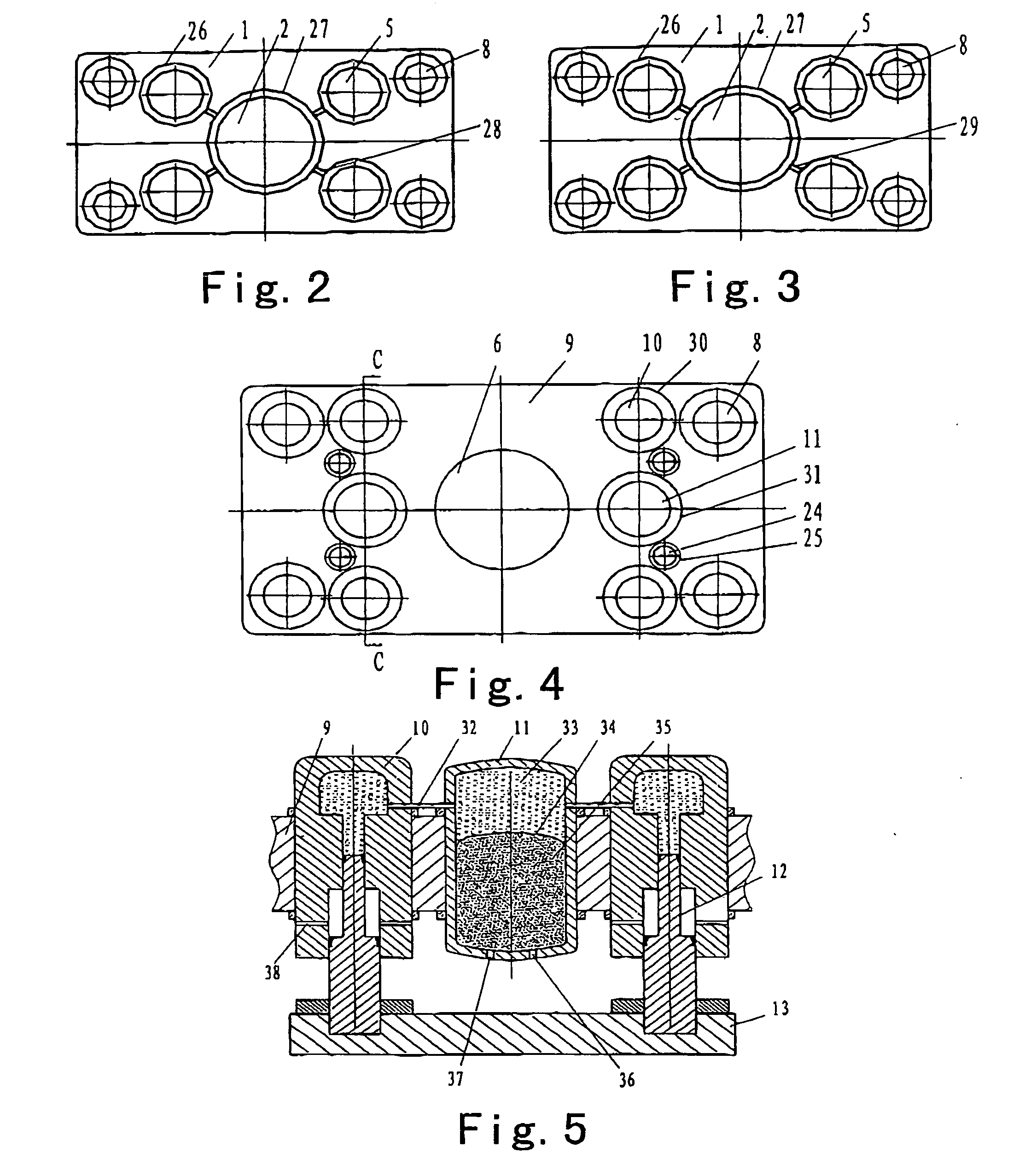

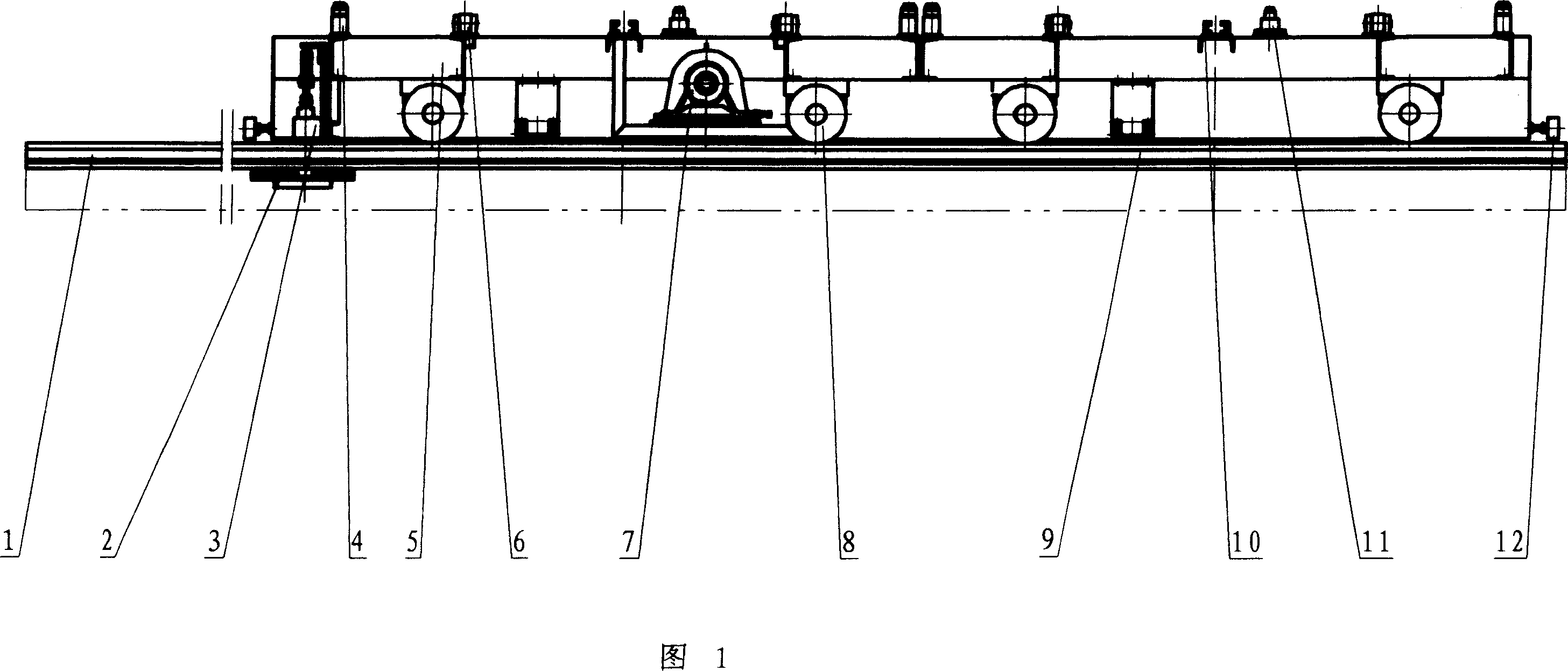

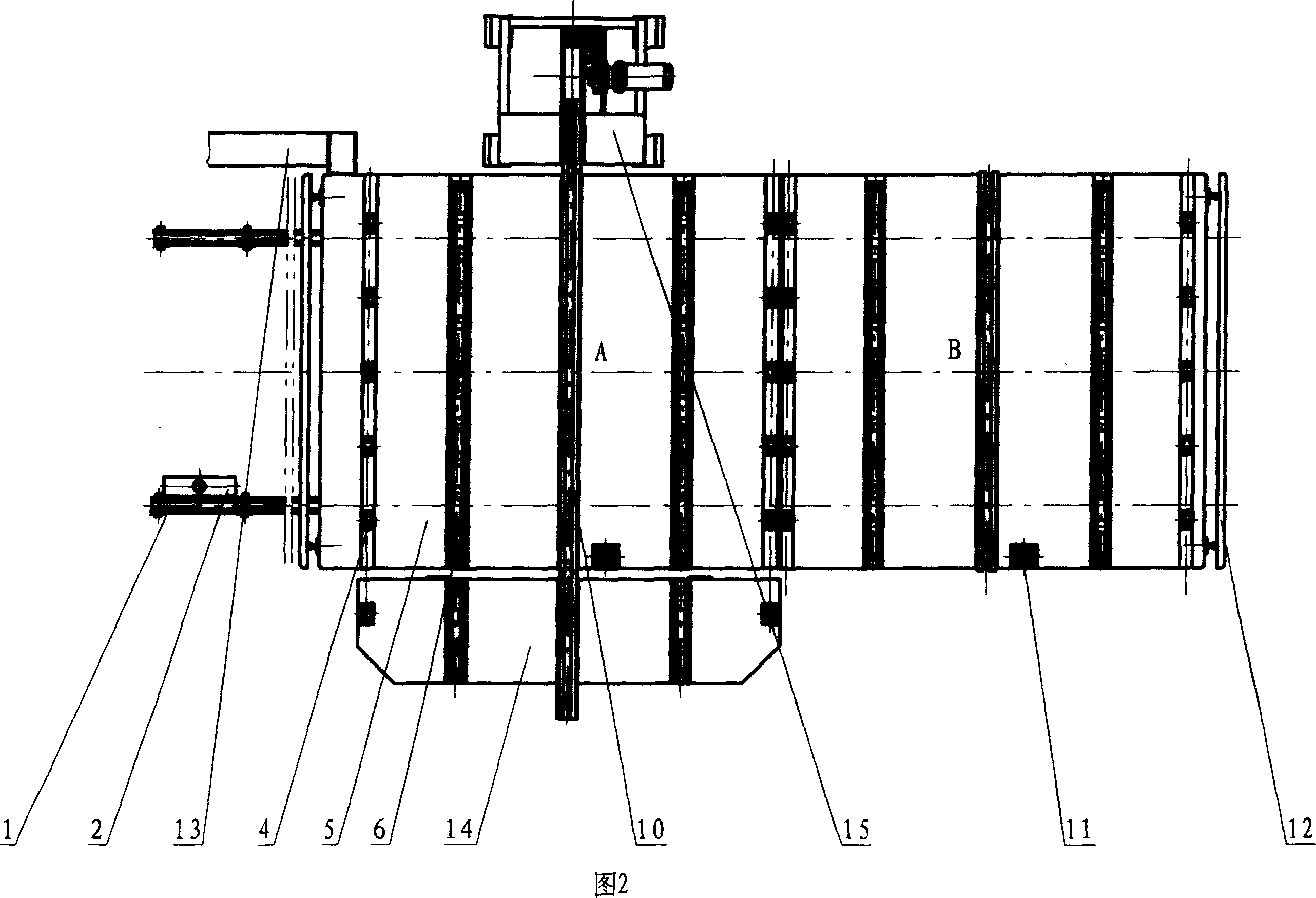

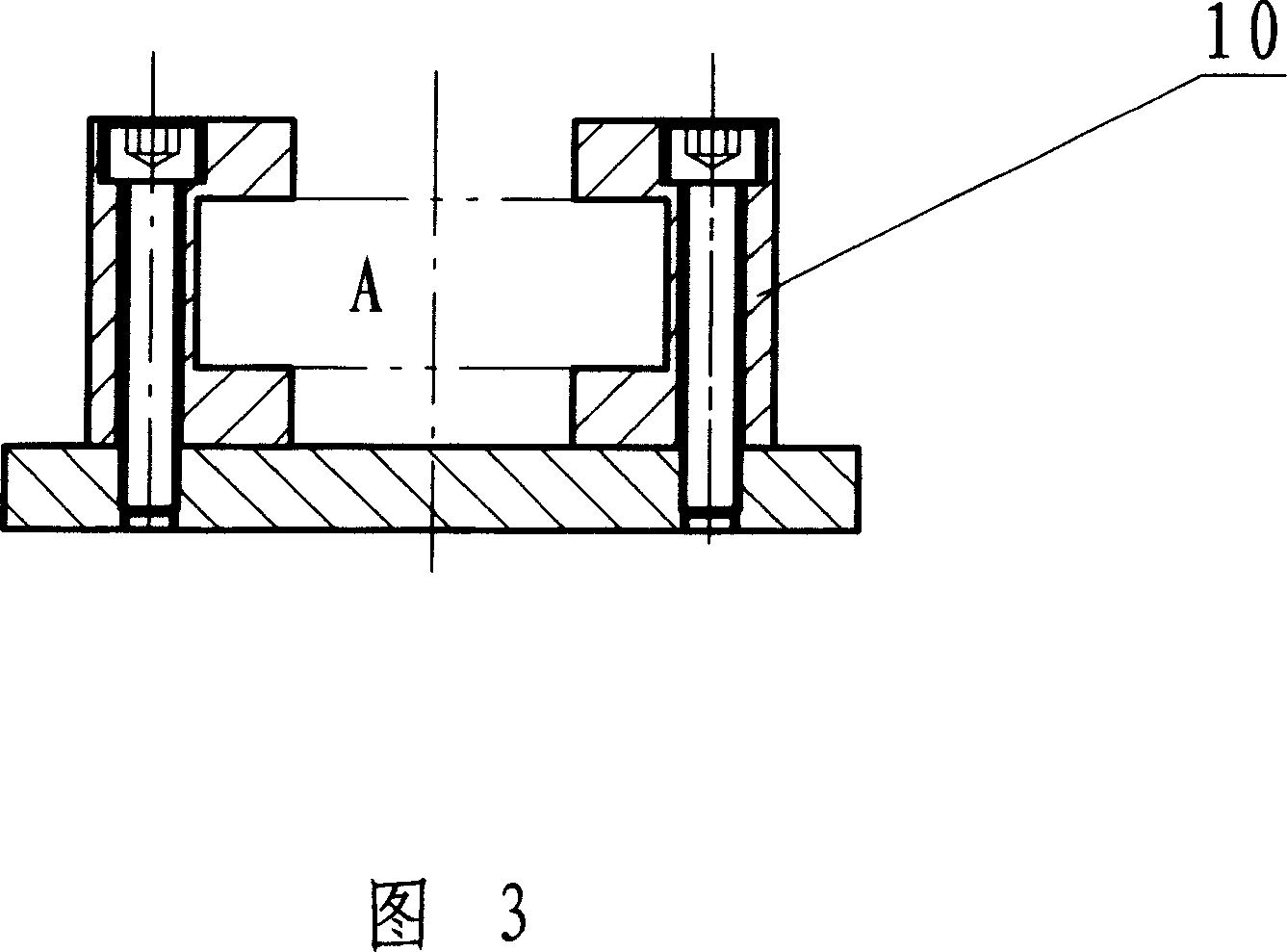

Regulatable hydraulic machine with up and down both double moving

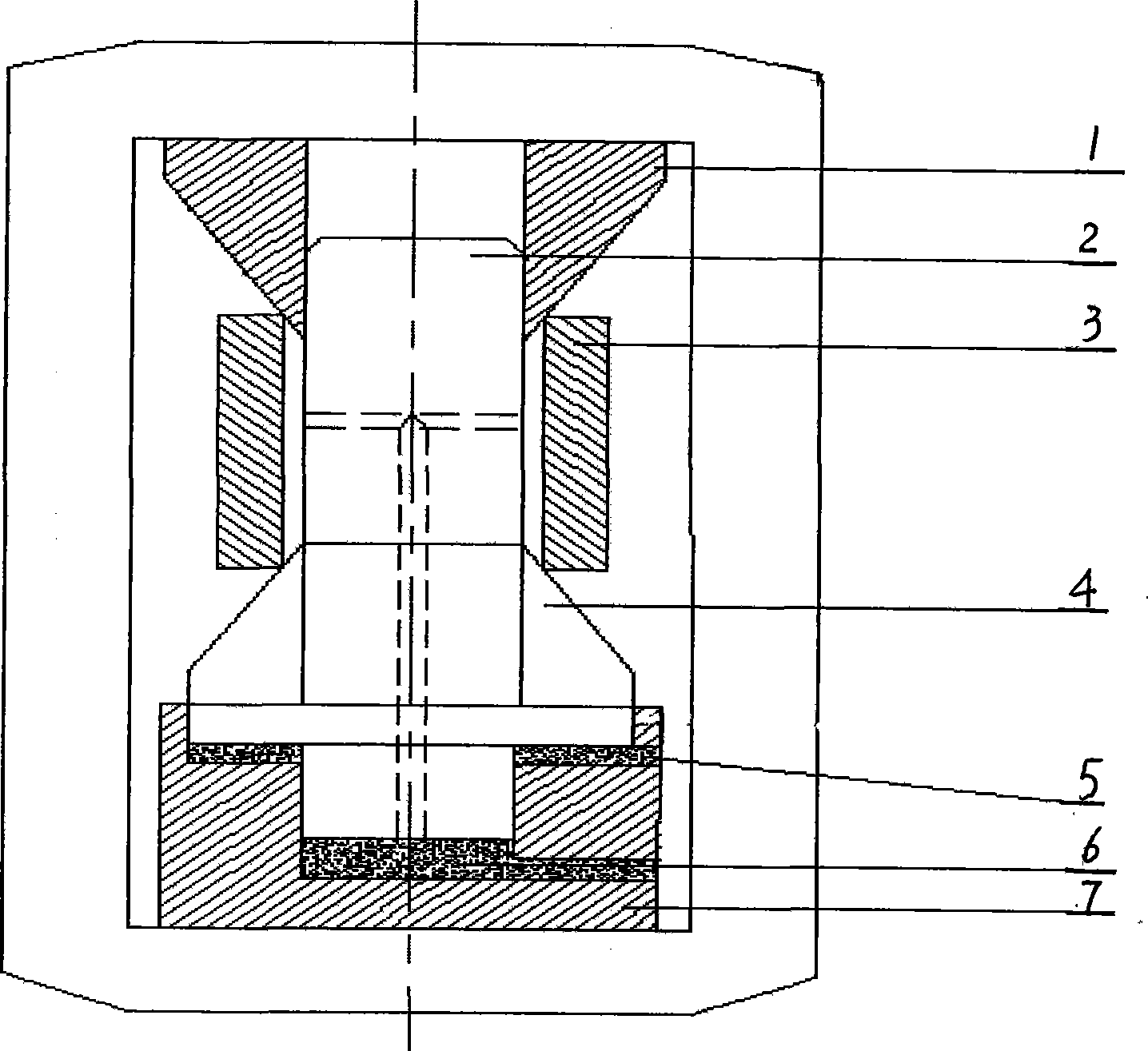

InactiveCN1559792AInnovative designSimple structureForging press drivesPress ramMarine engineeringMaster cylinder

An adjustable hydraulic press with movable upper and lower units is composed of vertical columns, upper transverse beam, primary slide block, the slide block for pressing edge, bench, floating bench, lower transverse beam, the primary and secondary cylinders fixed to upper transverse beam, and a push-up cylinder fixed to lower transverse beam for driving said floating bench.

Owner:JILIN UNIV

Method for the operation of a motor-driven hand-held pressing apparatus, and hand-held pressing apparatus

ActiveUS8056473B2Achieving Reliability RequirementsReliable maintenanceLine/current collector detailsForging press detailsReflux valveMotor drive

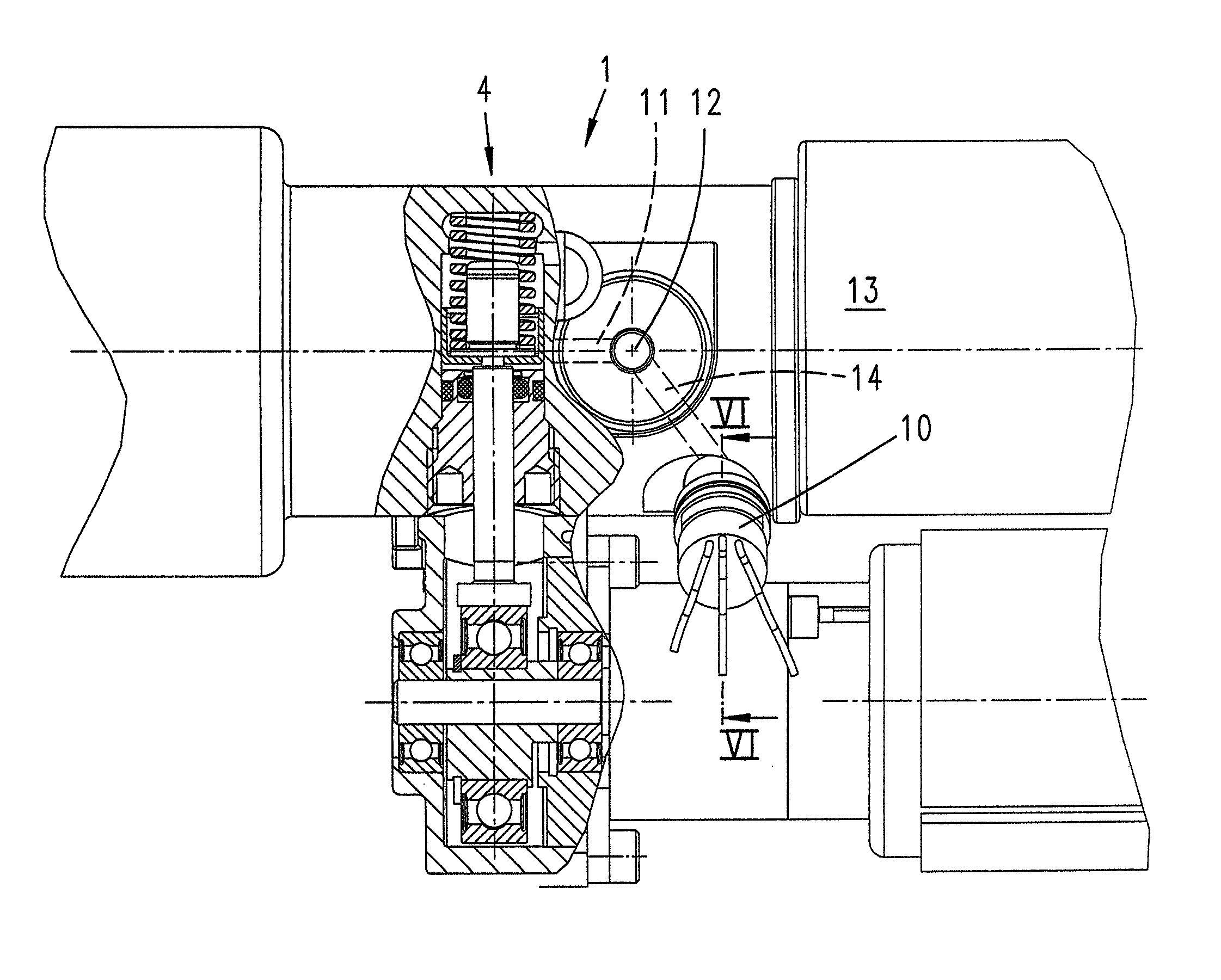

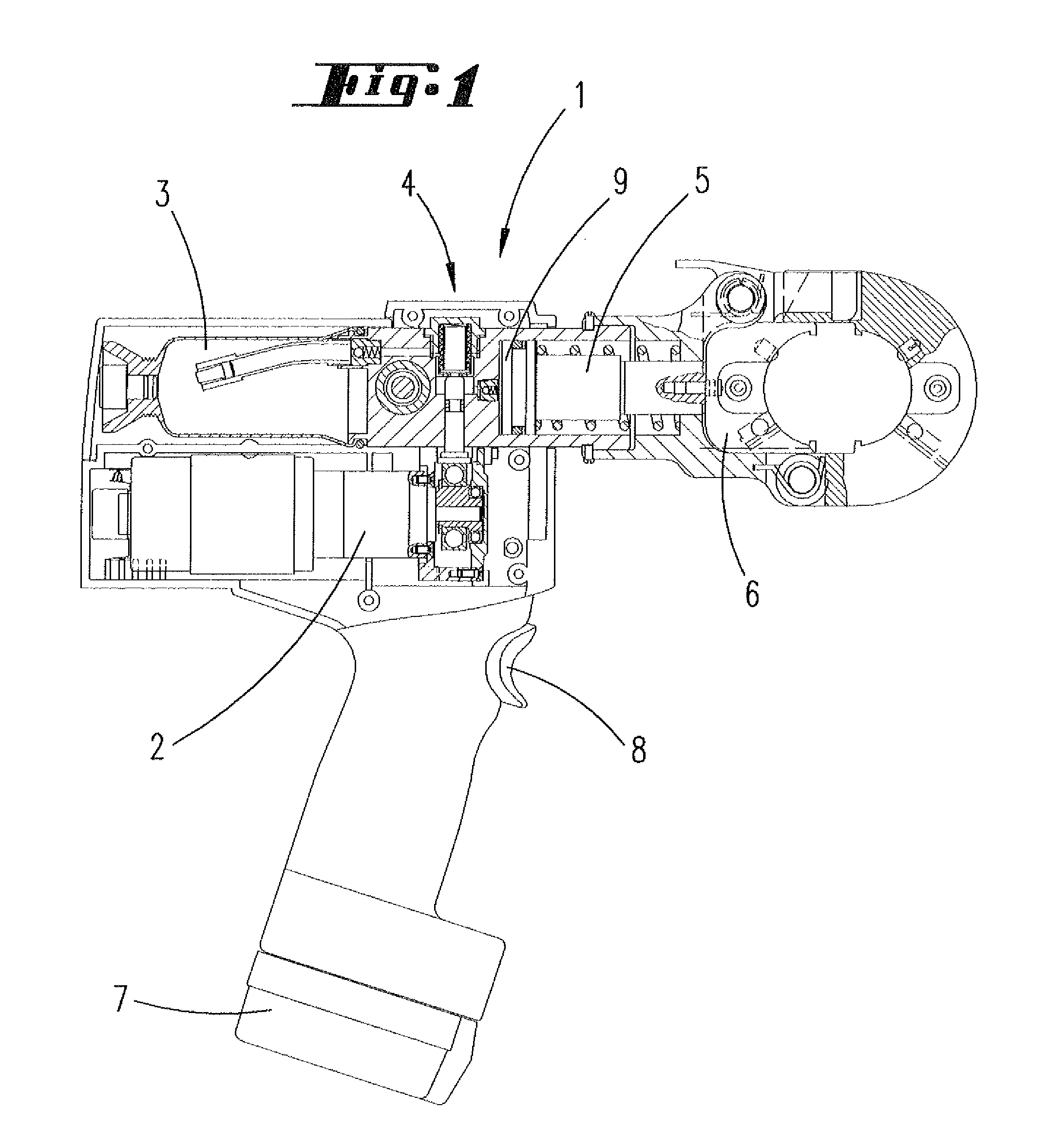

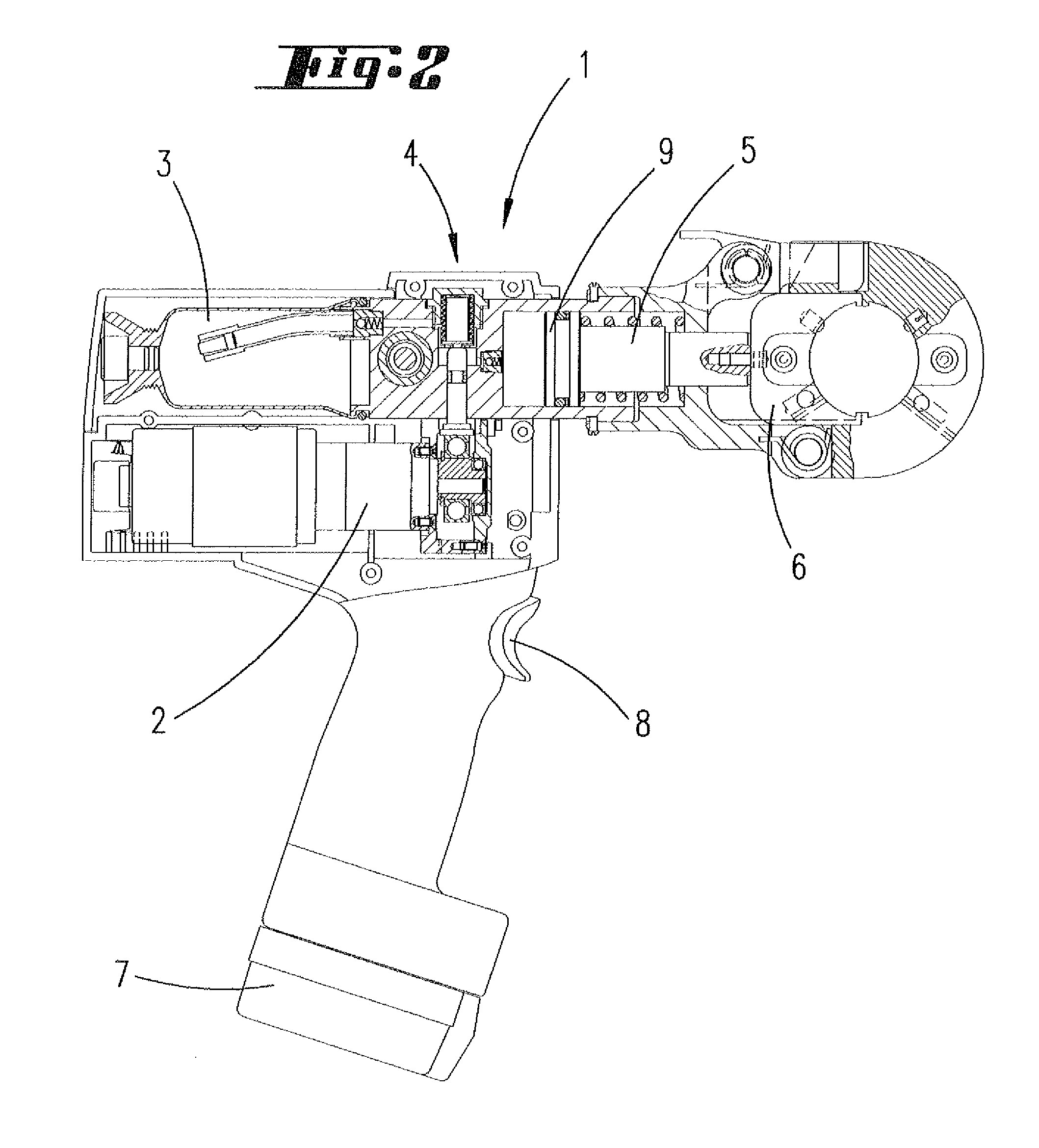

A hydraulic pressing unit includes a hydraulic pump, supply and hydraulic chambers, moving and stationary parts, a restoring spring, and a return valve provided within or attached to a housing. The moving part is displaced from a starting position into a pressing position as a result of filling the hydraulic chamber with a hydraulic medium from the supply chamber by using the hydraulic pump. The return valve is automatically displaced into an open position as a result of a hydraulic pressure corresponding to the pressing position, and the restoring spring moves the moving part. A piston acts on the flow of the hydraulic medium and lowers the pressure such that the return valve is displaced into the closed position.

Owner:GUSTAV KLAUKE GMBH

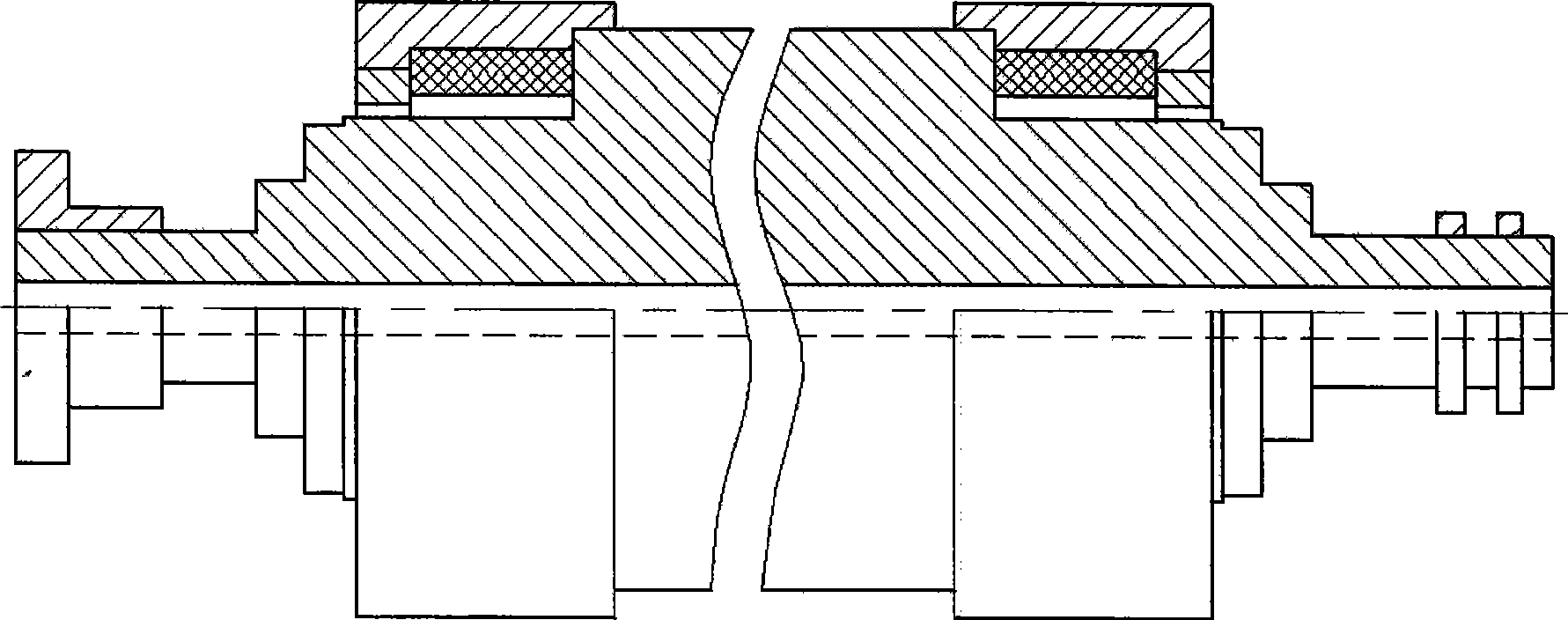

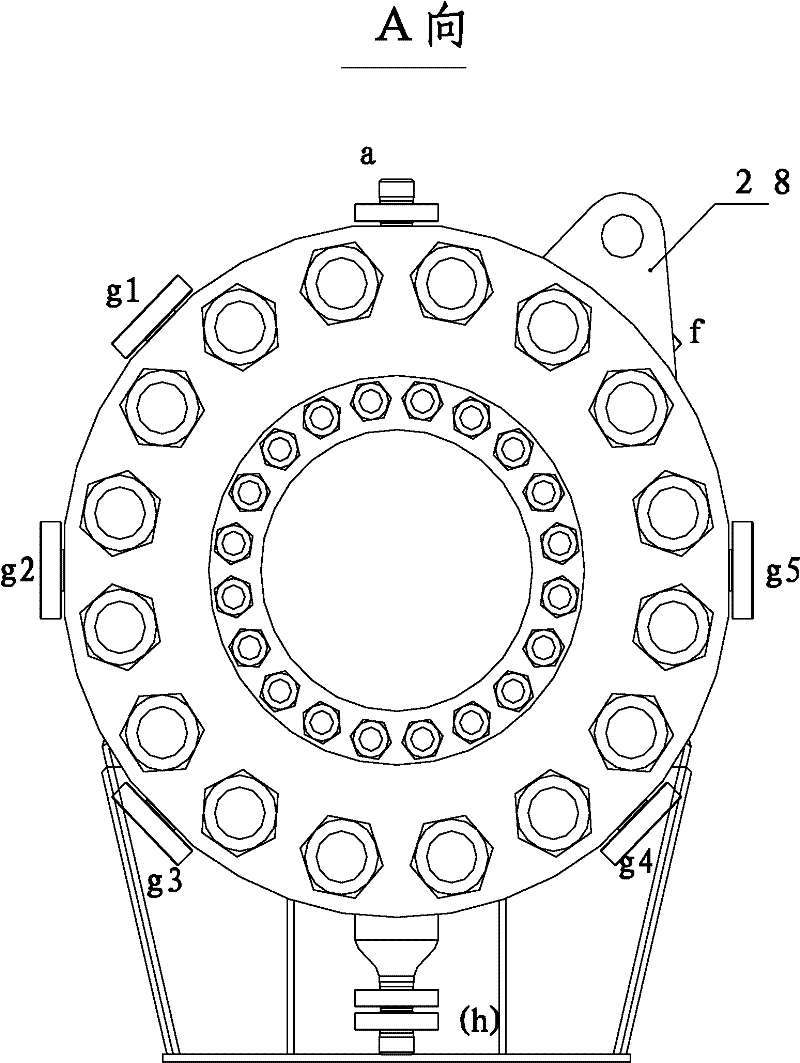

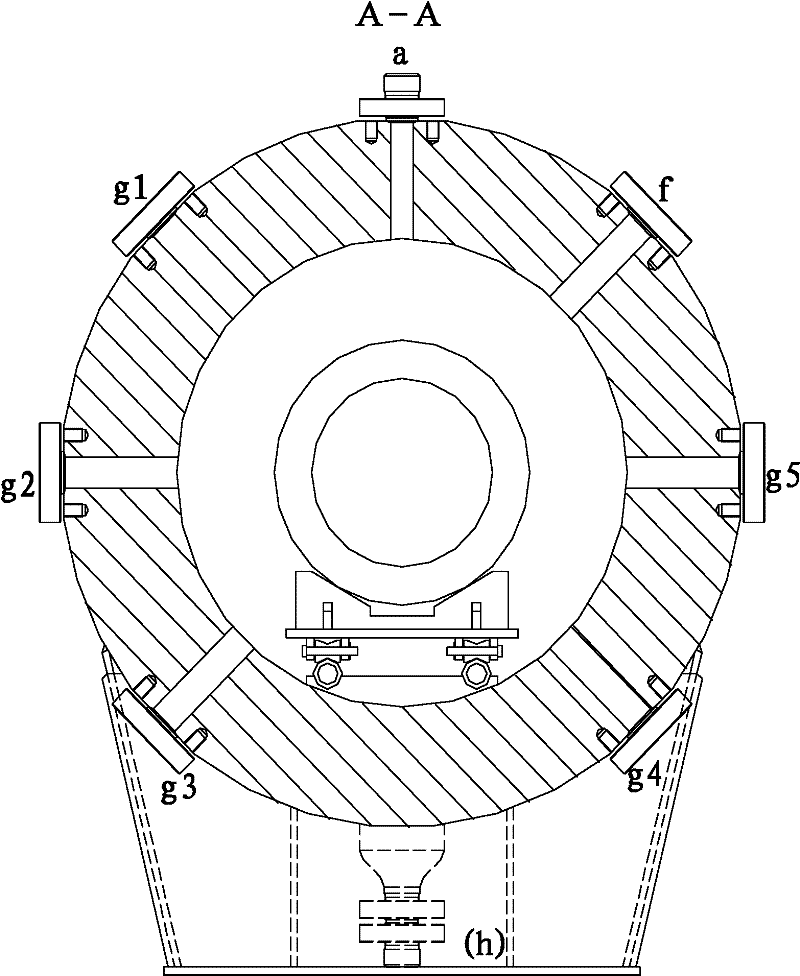

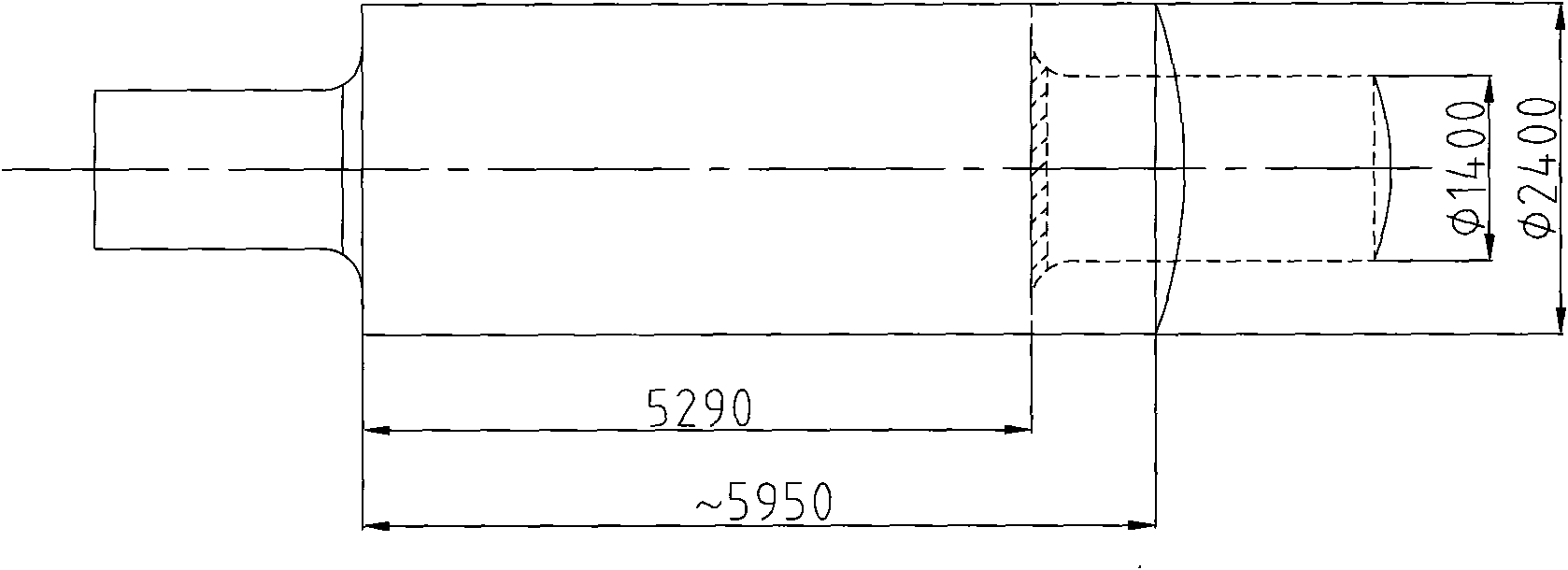

Shroud ring external fluid infusion hydraulic pressure expanding and reinforcing process for turbine generator

InactiveCN101367104AHigh forming precisionImprove general performanceMetal-working apparatusFluid infusionEngineering

The invention relates to a process for strengthening the bulging of external fluid replenishing hydraulic of a protective ring of a turbine generator, which is applied to the turbine generator field. High-pressure liquid produced by an external high-pressure pump passes through a passage of a high-pressure cylinder and is injected into a closed space formed by a upper fixed cone mould, a lower movable cone mould and the protective ring by a passage in a force-reduction column of a mould part in order that the protective ring generates plastic deformation under the action of hydraulic pressure, thereby achieving the aim of strengthening the protective ring; through adjusting low pressure of liquid in a low-pressure cylinder, the stress size of a contact part between the protective ring and the mould is adjusted so as to achieve the aim of sealing and adjusting the shape and the size of the protective ring; and a displacement sensor is used to monitor the bulging size of the protective ring. The process no longer occupies large-scale hydraulic press equipment, uses a load-bearing frame with a simple structure and small dimension and an external liquid replenishing cylinder to replace a hydraulic press for strengthening the protective ring; the bulging process can substantially reduce force, is easy to control the forming process, can repeatedly bulge, greatly improve the forming precision of the protective ring and reduce the machining allowance by 1 / 3 than the routine common hydraulic bulging; and the mould has a simple structure, convenient mounting and detachment, strong universality and low production cost and can achieve higher economical benefit.

Owner:SHENYANG HEAVY MACHINERY GROUP

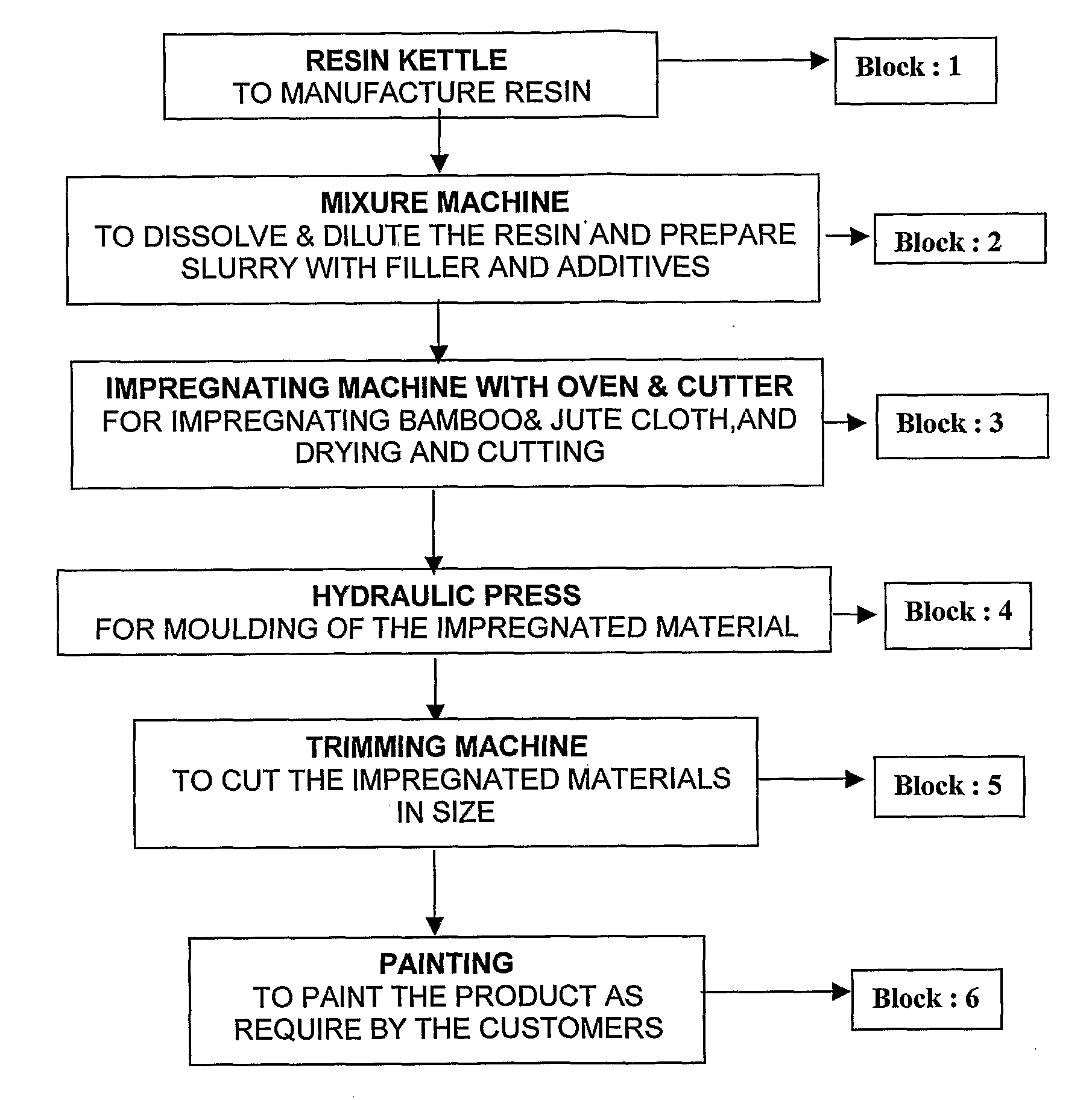

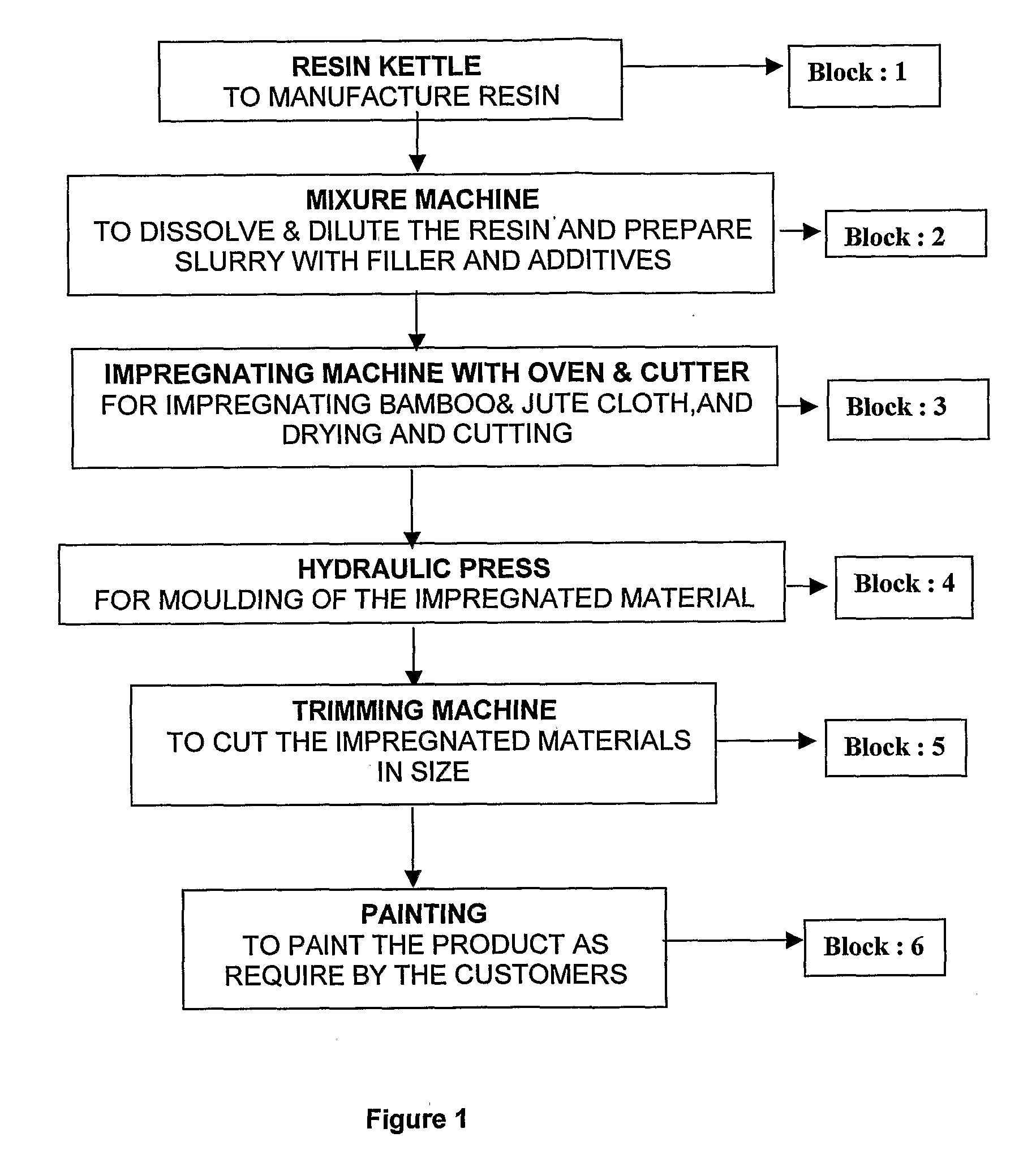

Natural Fibre Thermoset Composite Product and Method For Manufacturing the Same

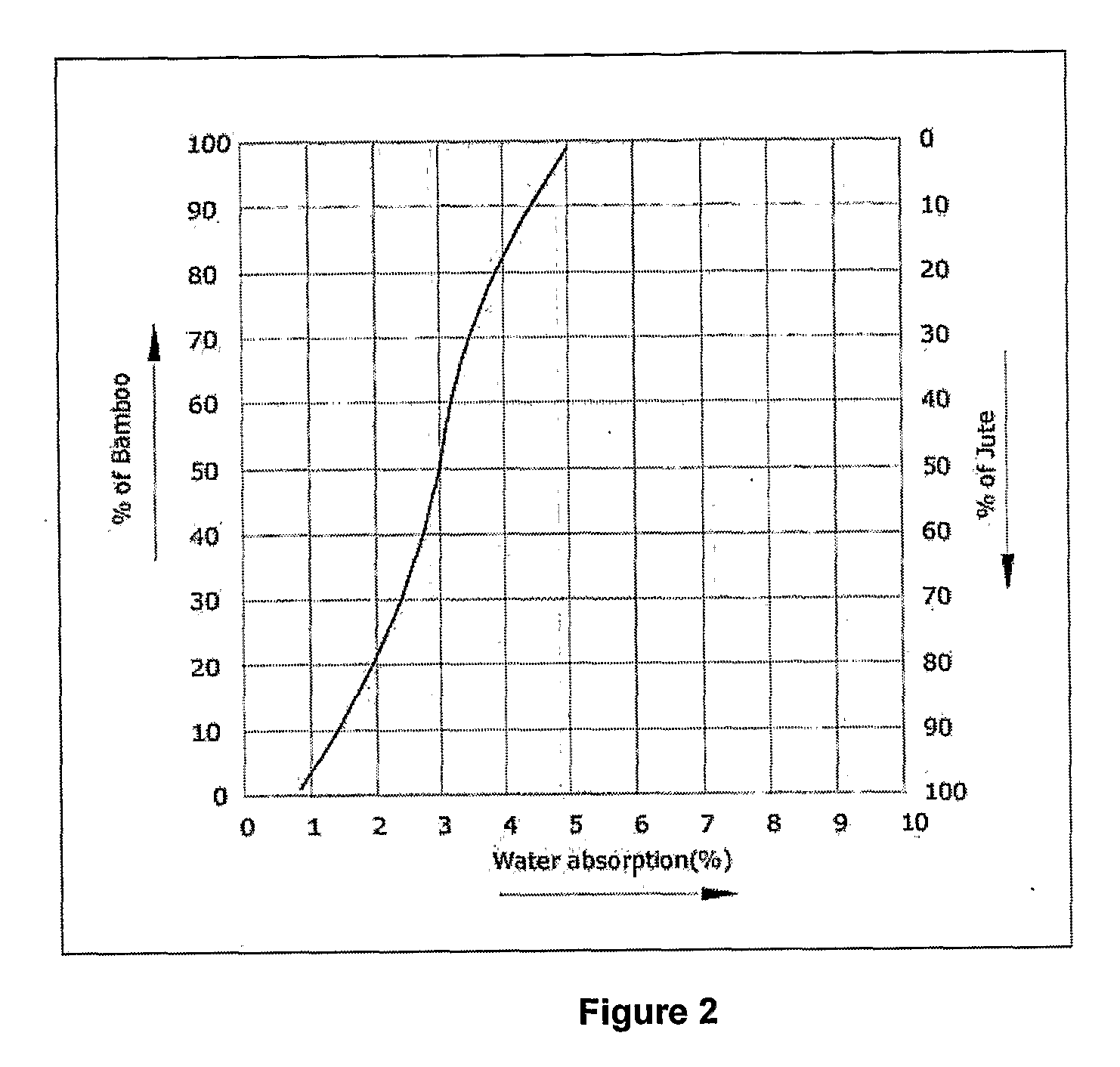

InactiveUS20090130377A1High tensile strengthLow water absorptionLamination ancillary operationsLaminationDefinite periodSlurry

Owner:A B COMPOSITES PRIVATE

Non ionic/electrolyte, liquid/gaseous, mechanically refined/nanoparticle dispersion Building Materials/High Wear-Heat Resistant Part Brushes, Windings, Battery Cells, Brake Pads, Die Cast Molding, Refrigeration, Polarized/Integrated Optical, Spectrometric Processors, Central Processor Unit Processors, Electronic Storage Media, Analogous Series/Parallel Circuit Generators/Transceivers, Particulate Matter PM Carbonaceous-Polyamide, Crystalline Silica, and Cellulosic Filament Extraction/Miners Suit

InactiveUS20140178513A1High wear-heat resistant partAuxillary shaping apparatusShaping pressTransceiverTransformer

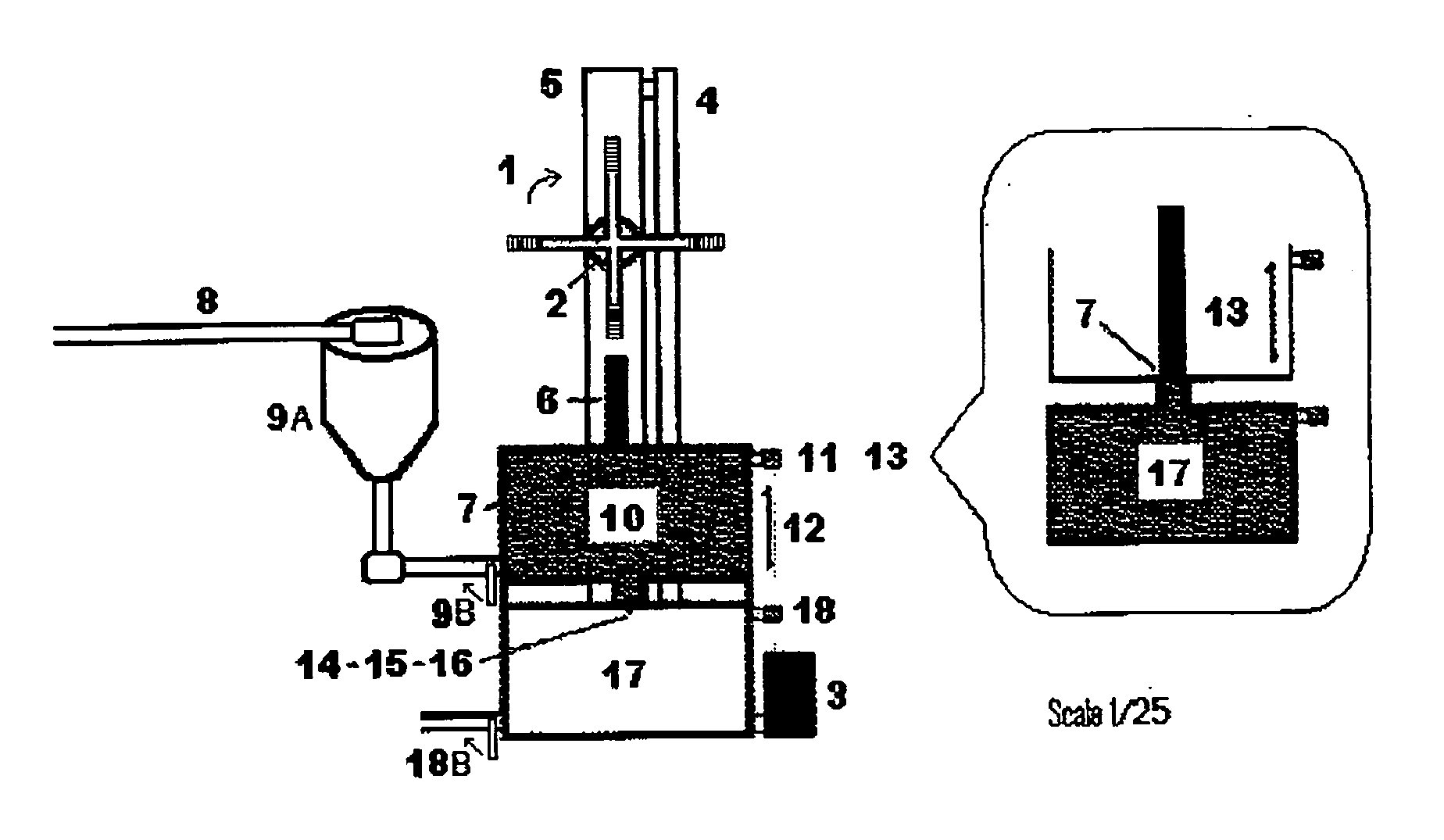

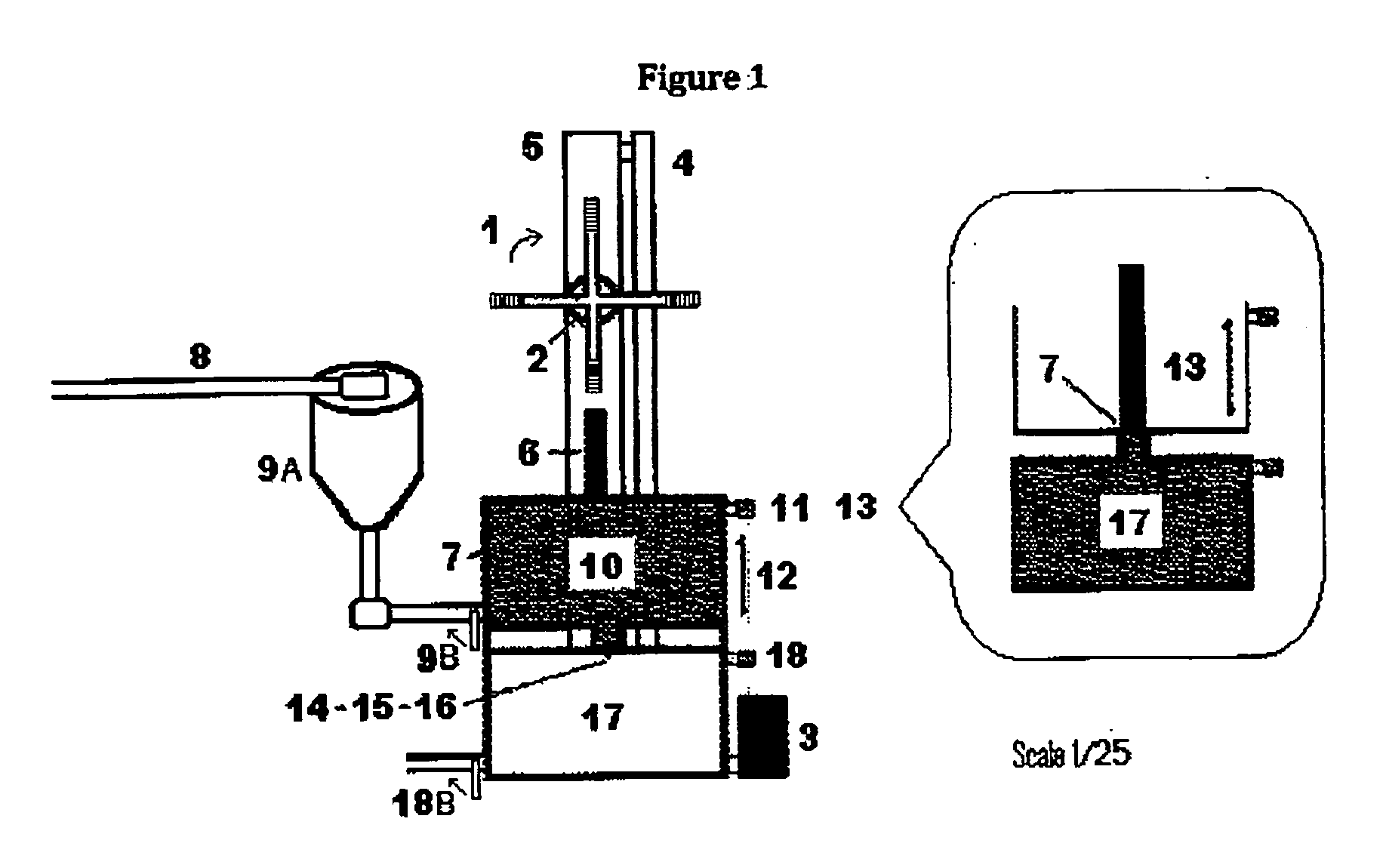

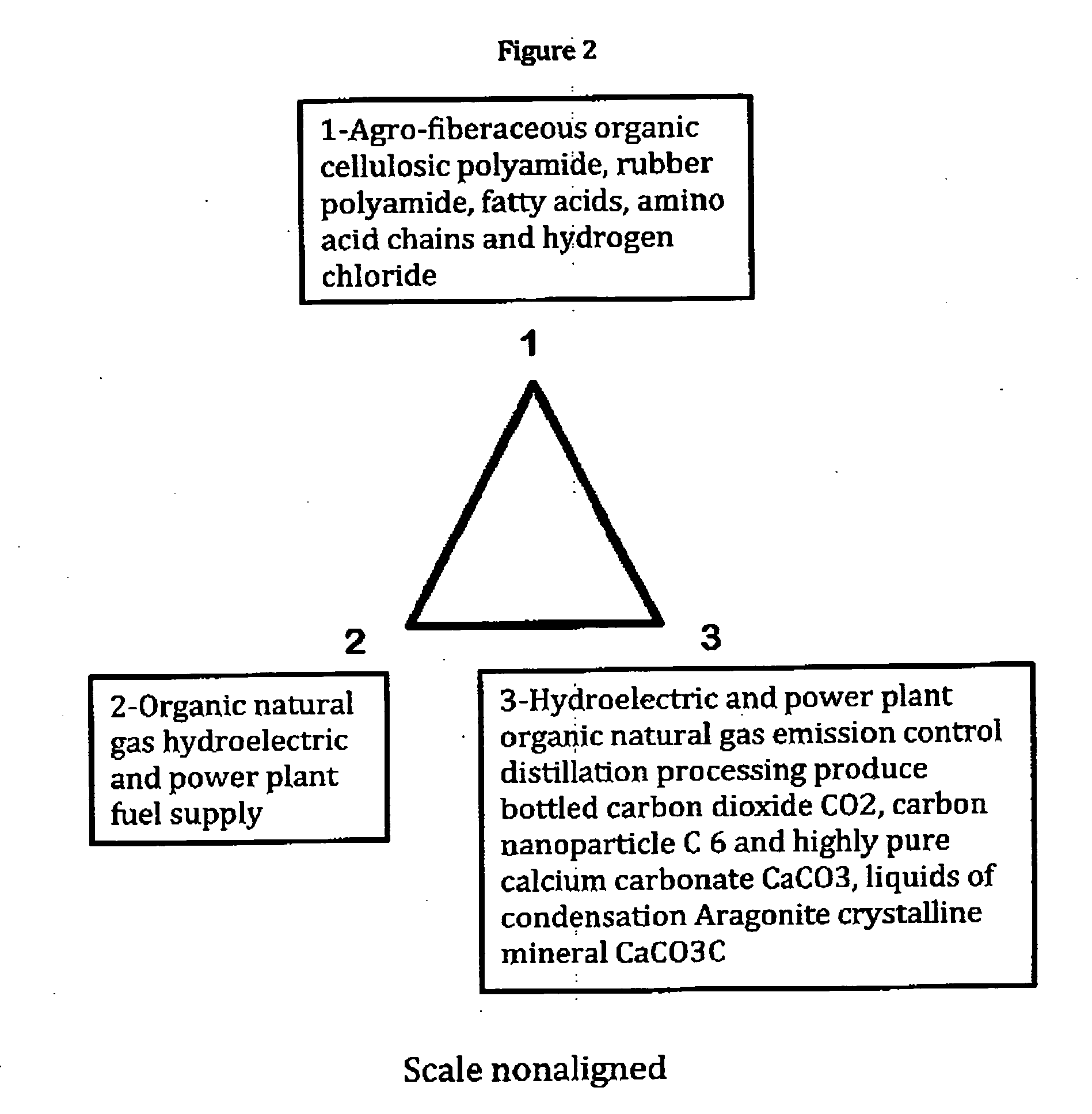

The variable hydraulic press and distillation reservoir process scientific formula non ionic or electrolyte mechanically refined and nanoparticle dispersion preform slurry extrusion with or without ionic suspension Preform slurry high wear-heat resistant parts electronic composite coils, windings, annealing, drawn, spun, coils, windings, wire, woven textile mesh, shielding, parts brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension enhanced composite coils, composite windings, spun wound coils and windings beryllium Be4, magnesium Mg12, copper Cu29 and carbon nanofoam C6, electronic parts capacitors, ionic suspension circuit battery cells, electronic parts rheostats, resistors, transformers, transducers, rectifiers, power supplies, or heat sinks Preform slurry high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, and bushings Preform slurry non ionic or electrolyte mechanically refined and nanoparticle high wear-heat resistant parts precision casting molds 2.5 phase die cast molding Building Materials fine concrete, mortar, brick, and tiles.

Owner:MATTHEWS ROBERT RICHARD

Method for preparing carbon molecular sieve adsorbent

InactiveCN101596445ALow costReduce pollutionOther chemical processesAdsorption purification/separationPolymer scienceSorbent

The invention discloses a method for preparing a carbon molecular sieve adsorbent. The steps are as follows: (1) solidification: polymer is used as a raw material and is arranged in a thermostatic drying oven to be solidified; (2) dry distillation: the solidified macromoleclar polymer is pulverized by a pulverizer and then is processed by dry distillation; (3) fine pulverization: the macromoleclar polymer which is pulverized and processed by dry distillation is further processed by fine pulverization in the premise that the particle diameter of the macromoleclar polymer does not meet the requirement, and ball milling or gas milling is used for preparing micro-particles; (4) molding: the macromoleclar polymer which is processed by fine pulverization is mixed and uniformly stirred with agglomerant by mass ratio, and the mixture obtained is pressed and molded by an oil hydraulic press and then is dried; (5) carbonization and activation: under the state of N2 protection, temperature is raised for carbonization so as to increase the CMS surface area; and (6) carbon precipitation and hole adjustment: the hole adjustment agent is decomposed in the carbon molecular sieve for carbon deposition, the particle diameter is shortened and is enabled to be uniform, and the carbon molecular sieve product can be obtained after cooling. The carbon molecular sieve has the advantages of high CH4 adsorbing capacity, high selectivity factor of adsorption, favorable strength, low cost and no pollution, and the performance achieves or surpasses the standard of a sample of Japan carbon molecular sieve.

Owner:ANHUI UNIV OF SCI & TECH

Water-control fracturing yield increasing method for oil gas well

The invention relates to a method for increasing the yield of an oil gas well by controlling water pressing crack, in particular to water control pressing crack technology which takes a jelly glue system capable of automatically reducing the viscosity when encountering bottom water as a pressing crack liquid and wax-coated sand as partial supporting agent. At present, when hydraulic pressing construction is performed on low permeating bottom water oil pool, because the stress difference between layers is small or no interlayer forms the stress difference between the layers, the extending of cracks in the vertical direction can be effectively prevented, cracks formed by the hydraulic pressing crack extend and enter a water layer on the bottom in the vertical direction and jump to flow into a shaft along the cracks, and violent flooding of an oil well is generated. When pressing crack construction is carried out, the method adopts a coated supporting agent formed by mixing a thickening agent and a cross-linking agent carrying wax and quartz sand to undergo chemical degradation to coat and block so as to form a blocking layer. The method effectively solves the problems that the prior manual shielding layer cannot effectively prevent the oil well from being flooded by water, and a pressing crack liquid carrying a diversion agent or a temporary plugging agent cannot reduce viscosity basically when encountering the water and has slower settling.

Owner:QINGYANG CHANGQING DOWN HOLE OILFIELD AUXILIARIESCO

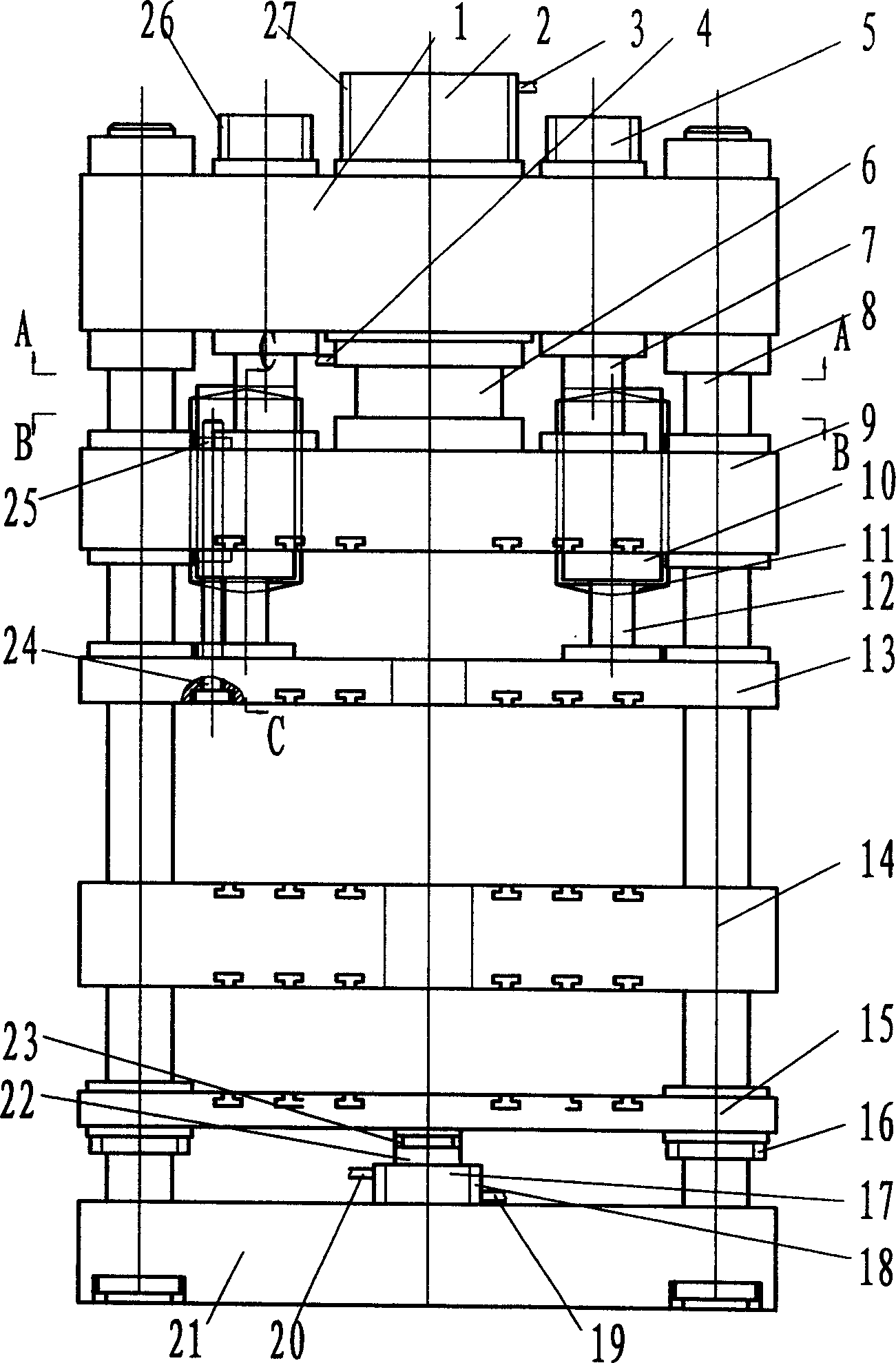

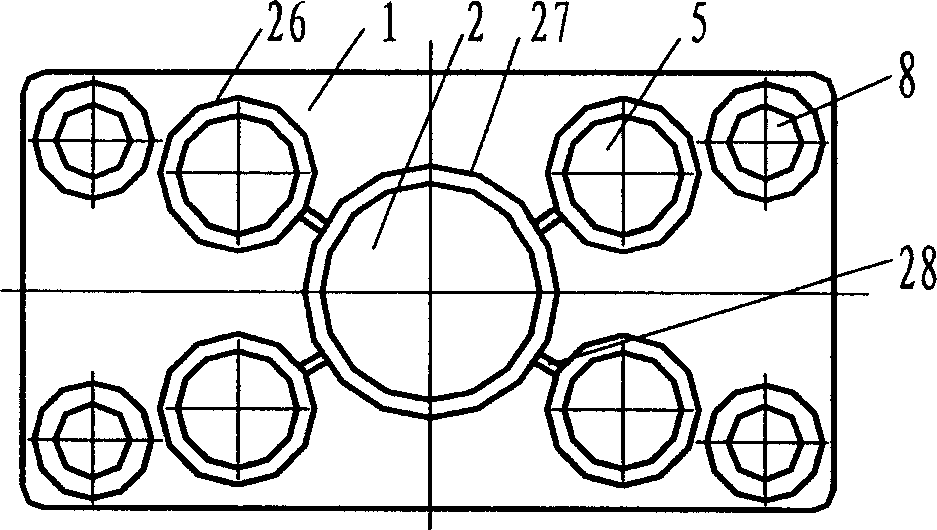

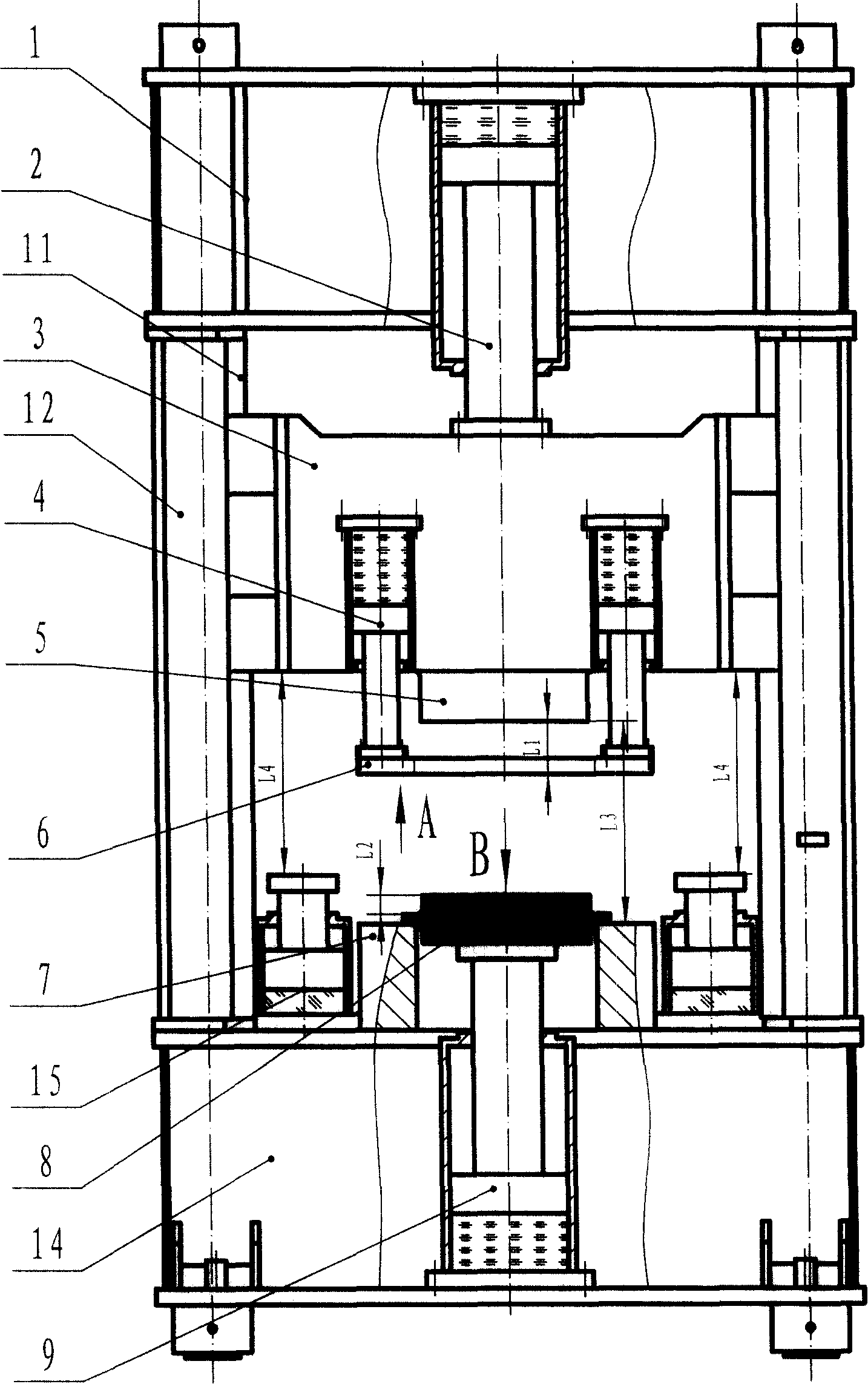

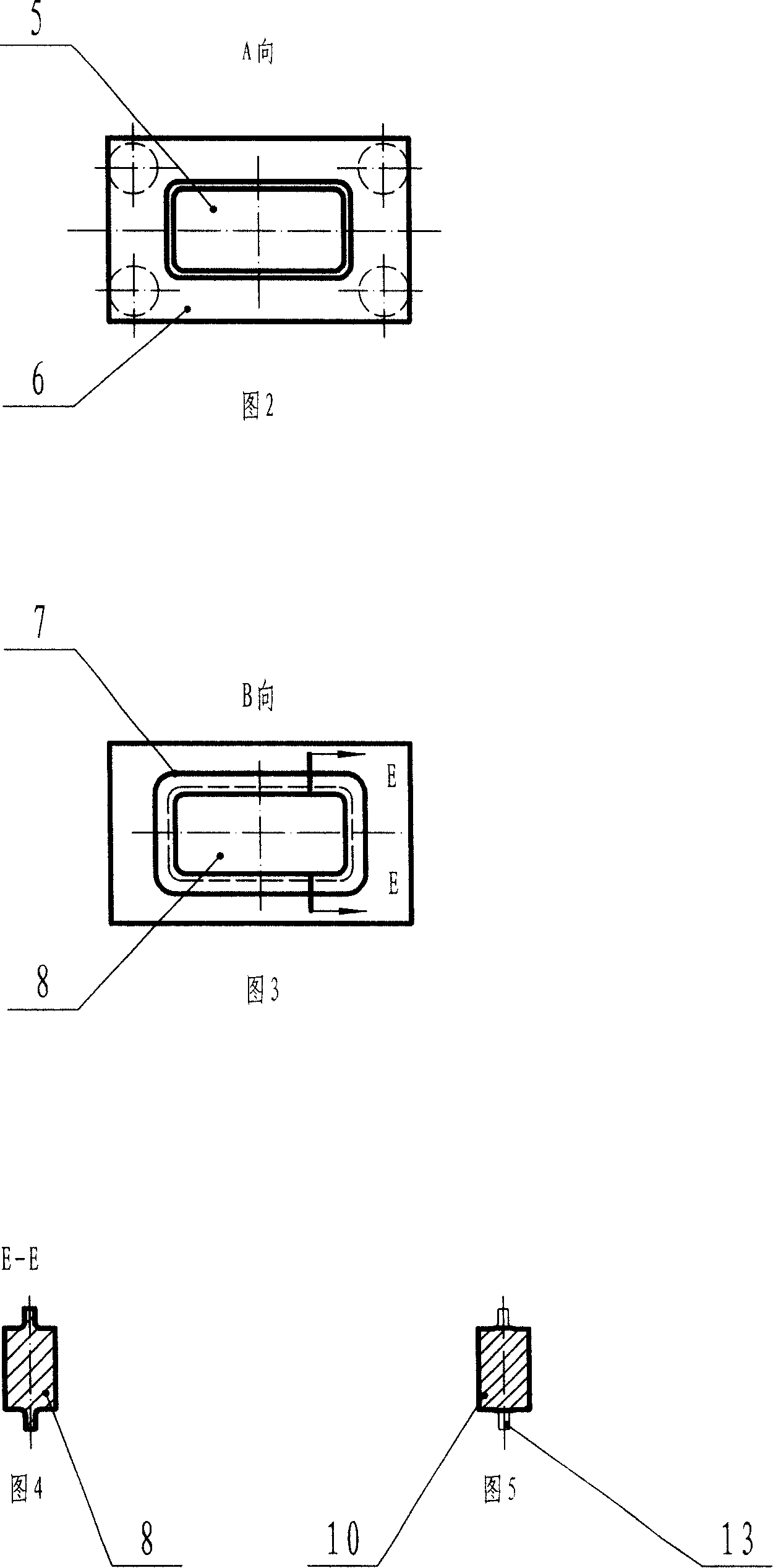

Adjustable Hydraulic Press With Both Upper And Lower Double Action

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

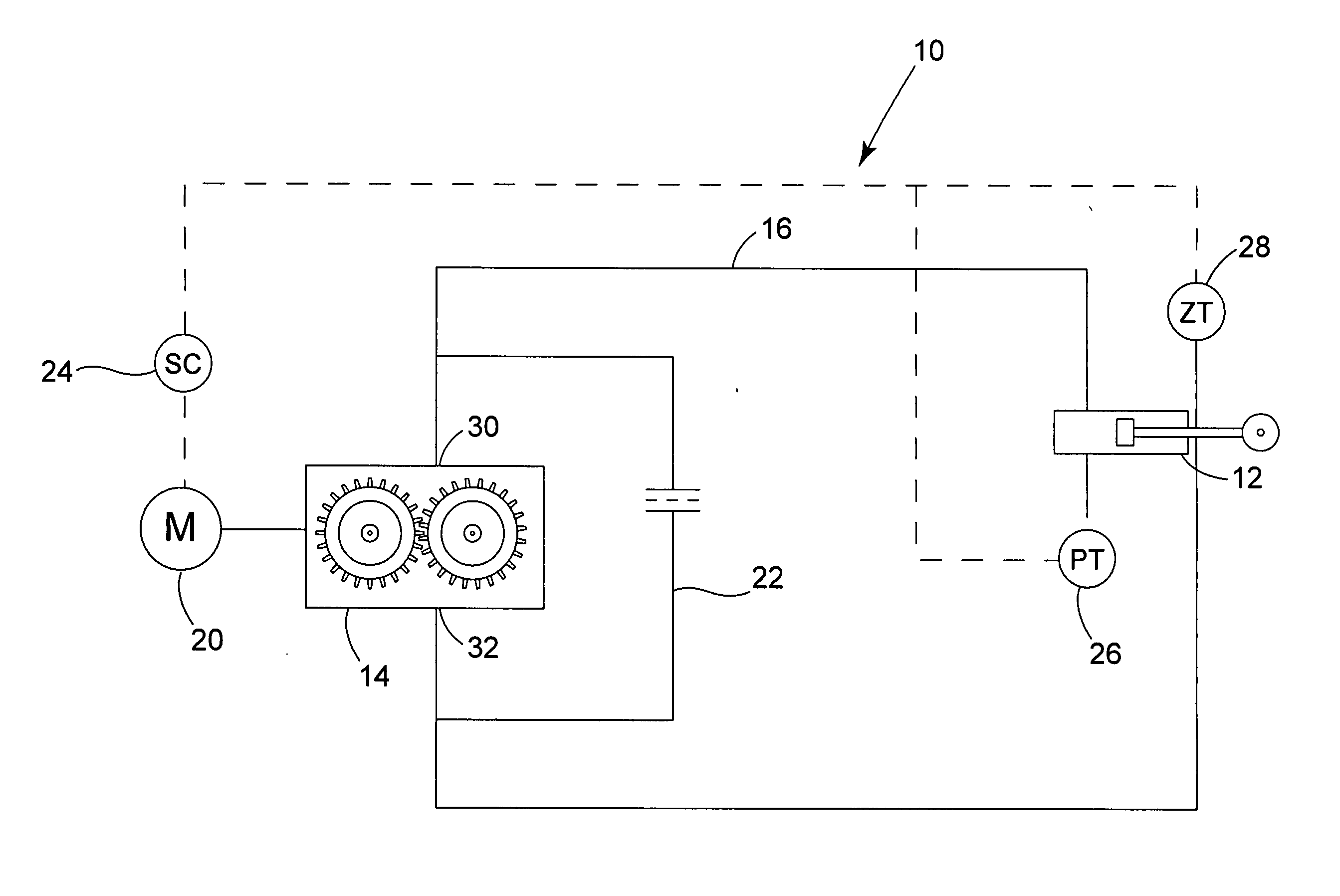

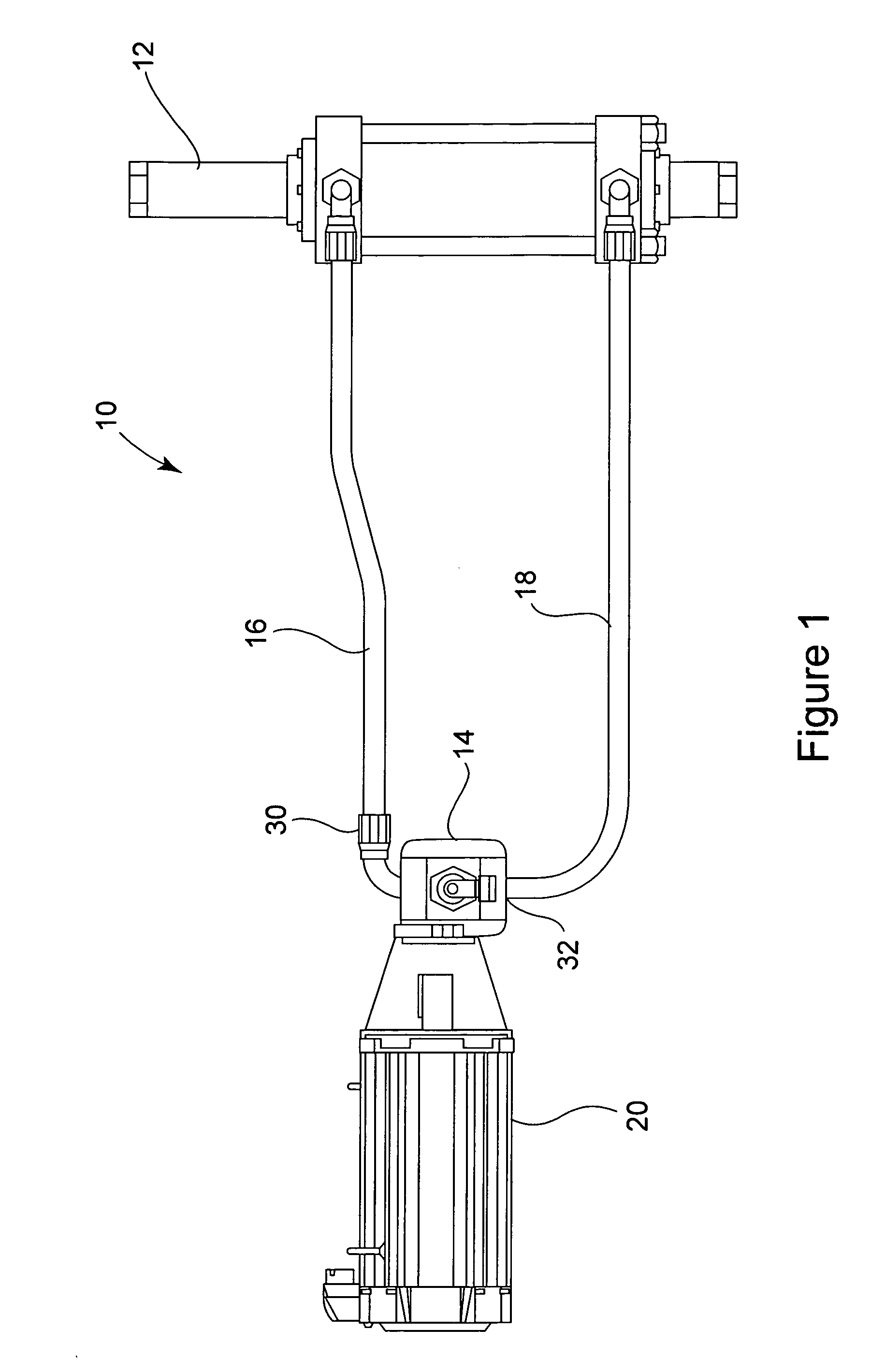

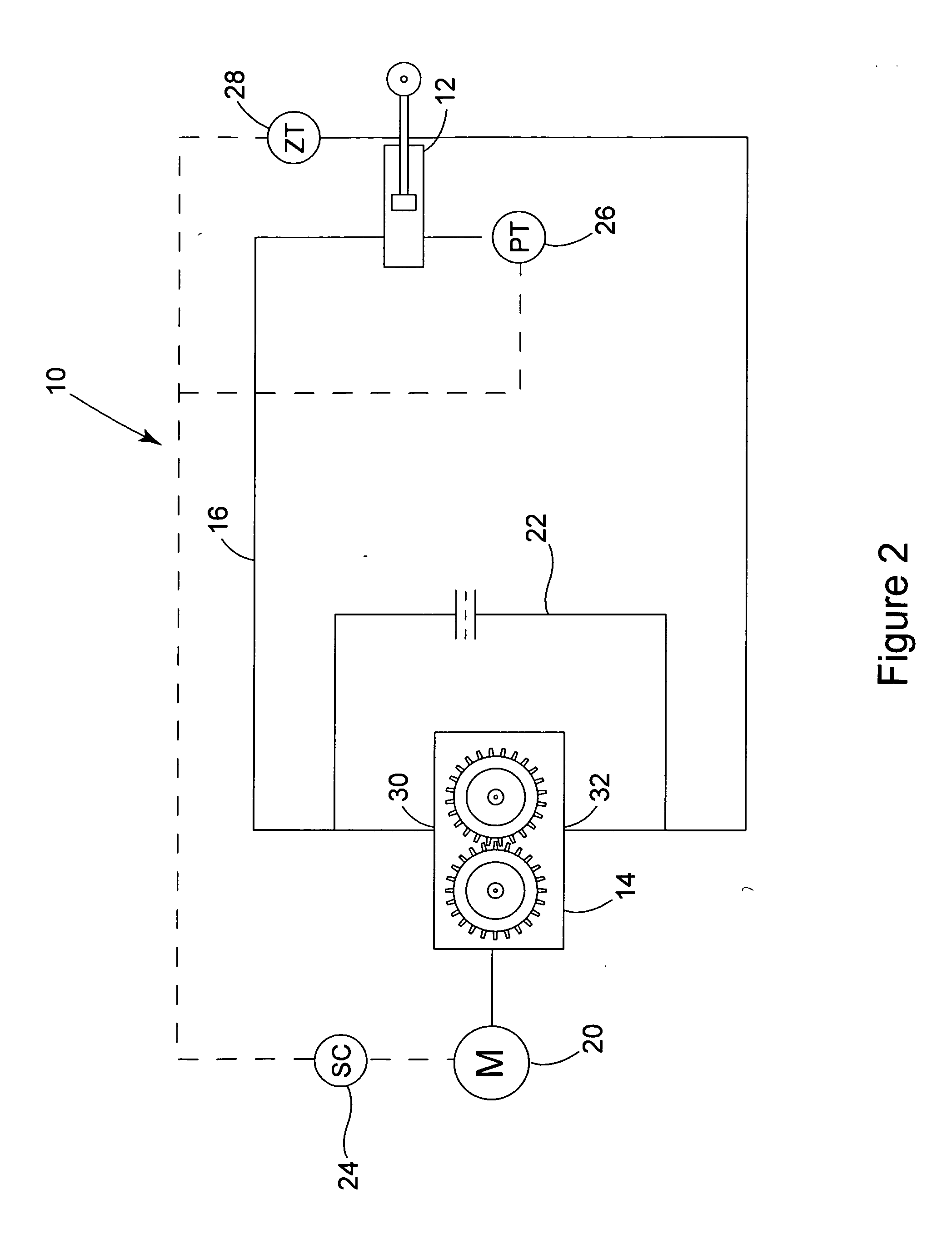

Servo-motor controlled hydraulic press, hydraulic actuator, and methods of positioning various devices

A hydraulic system that includes an actuator, a pump, a servo-motor, and (optionally) an actuator position sensor, an actuator hydraulic pressure sensor, a comparator, a servo-valve, and a hydraulic fluid filter. The pump communicates with the actuator and provides hydraulic fluid to the actuator to control it. Also, the pump includes a hydraulic fluid inlet, outlet, and a bypass path from the outlet to the inlet. The bypass path allows a portion of the hydraulic fluid to bypass the pump. In response to a signal to control the actuator, the servo-motor (which is operatively coupled to the pump) drives the pump. As a result of the bypass path, the servo-motor is able to run continuously thereby avoiding the on / off hysteresis of the pump. Methods of positioning hydraulic actuators are also provided.

Owner:THE BECKWOOD CORP

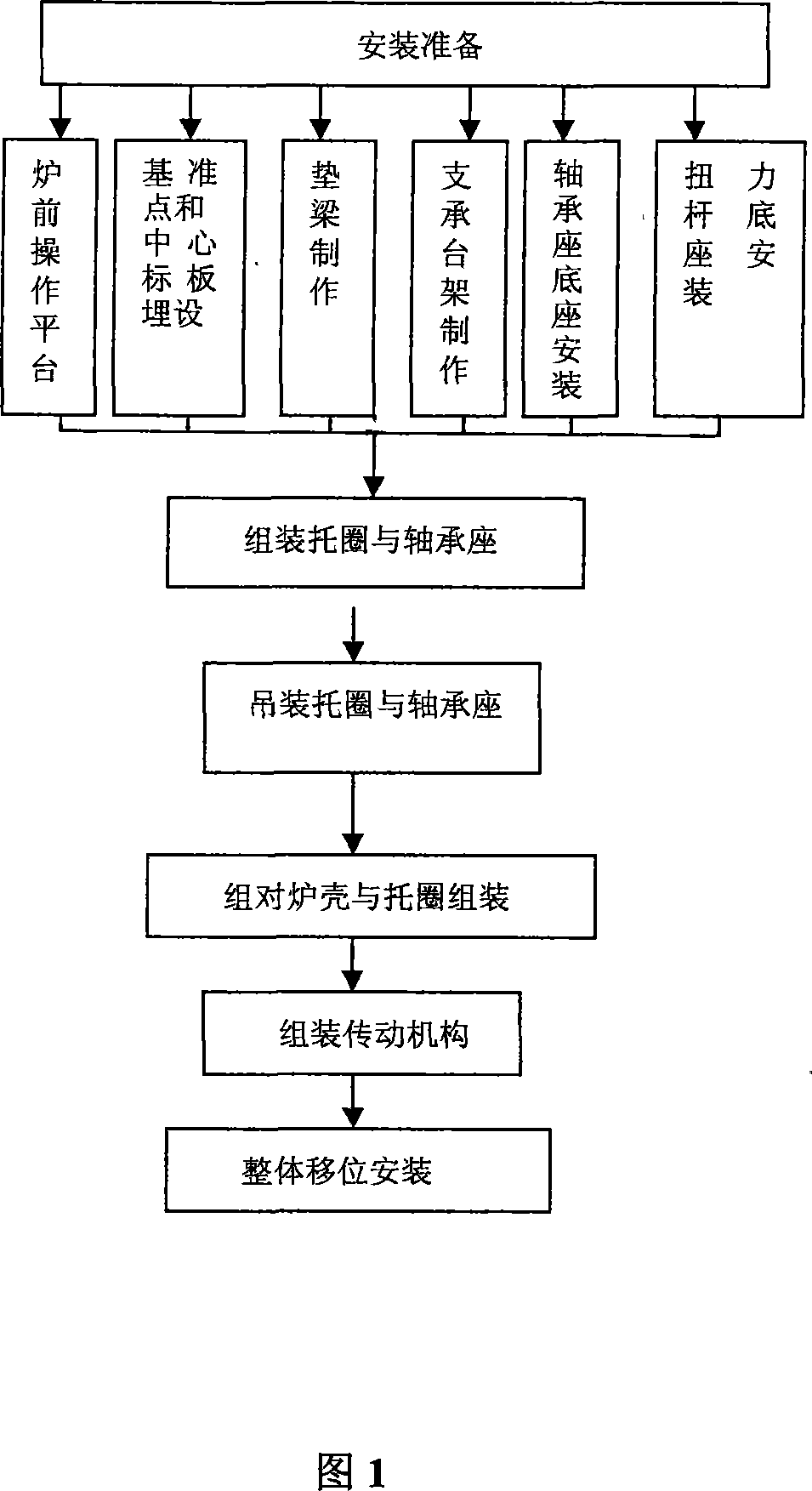

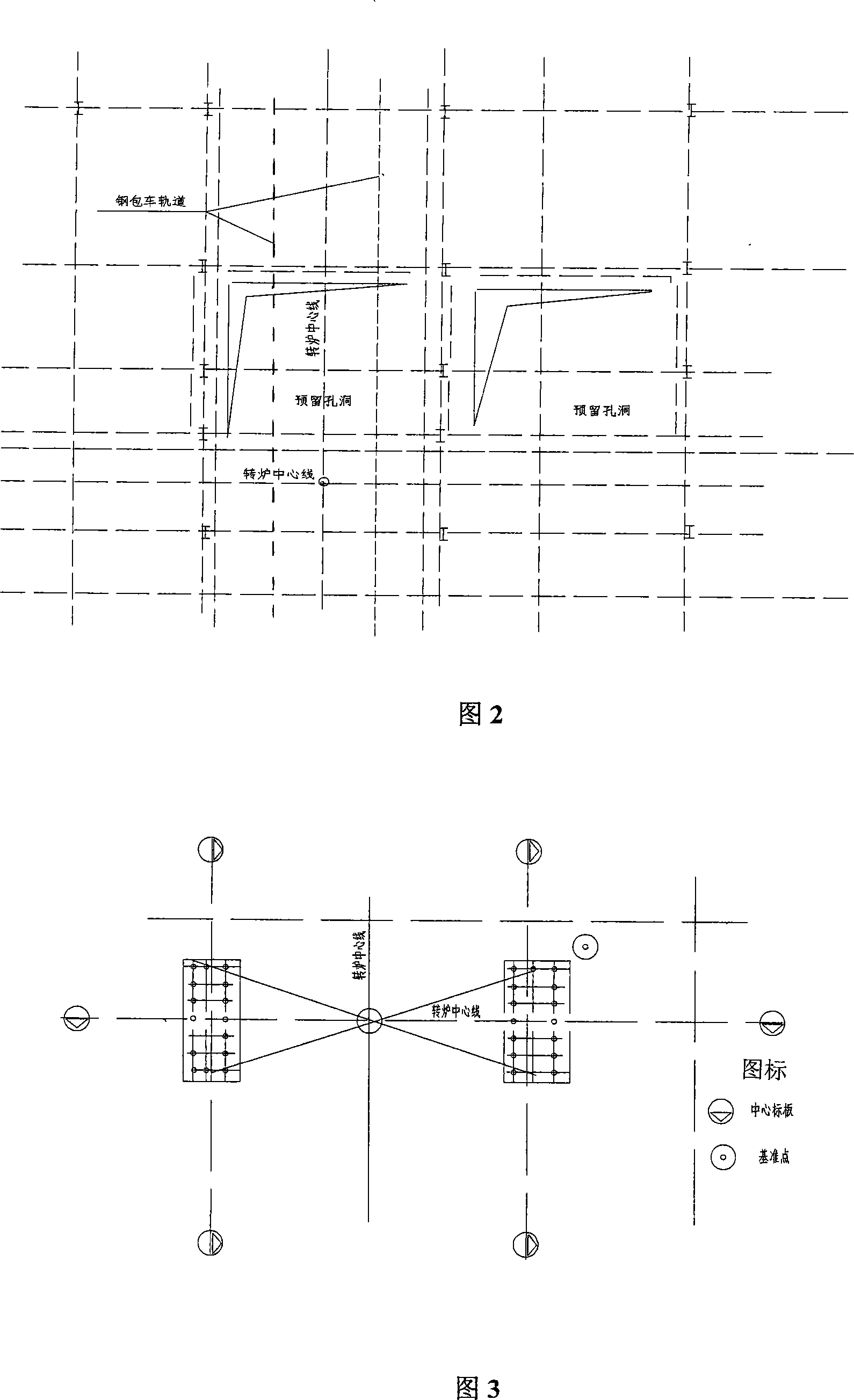

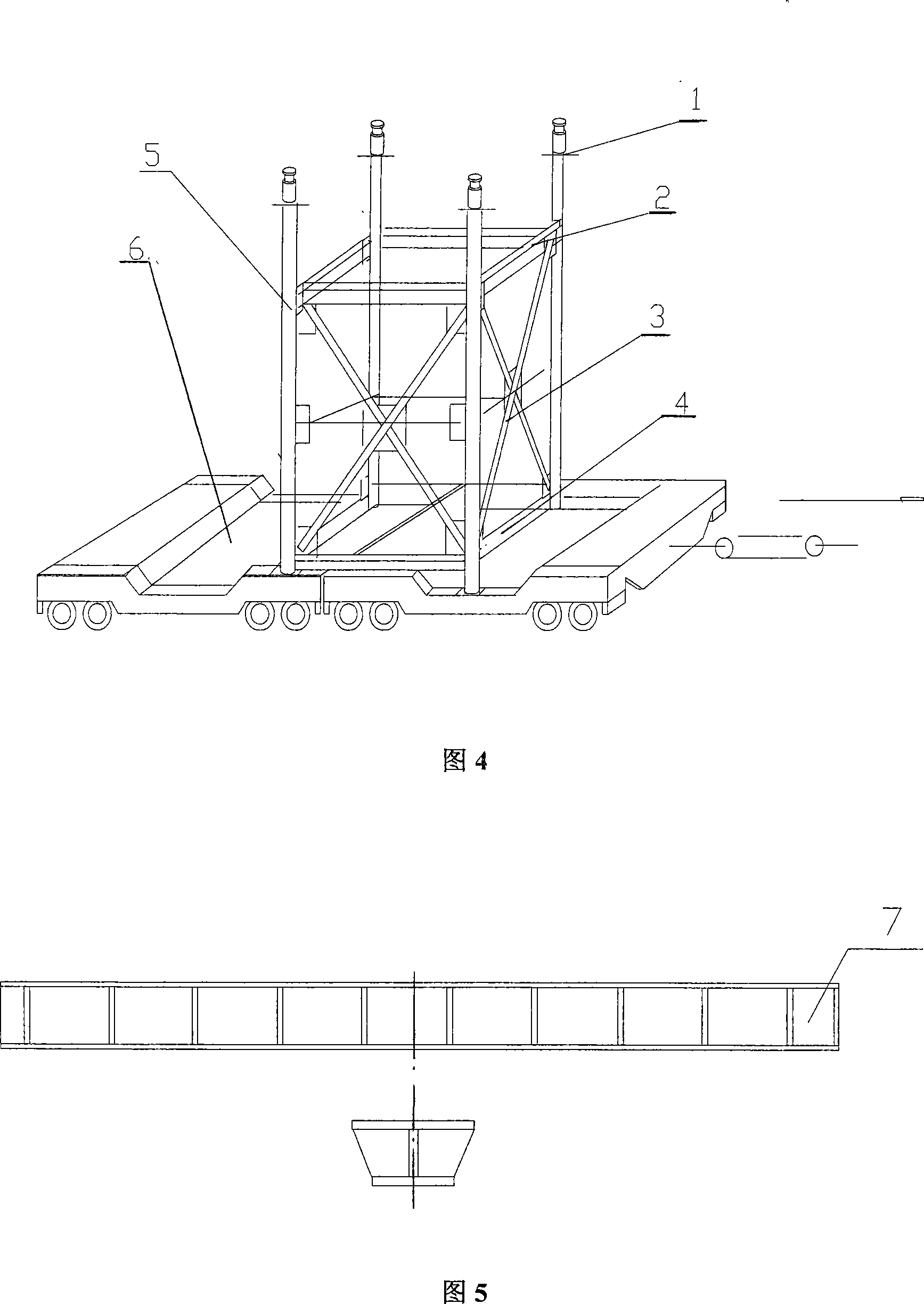

Combination method mounting technique for ultra-large type steel converter

ActiveCN101215615ASolve the installationEasy to operateAssembly machinesManufacturing convertersOperabilityEngineering

The invention relates to a combination method installation technology for an ultra large steel-smelting converter, belonging to the installation of steel-smelting devices, which is characterized in that respectively installing hydraulic presses and cylindrical safety cushion blocks on the upper portions of four vertical props of a supporting platform relatively to the chassis portions of bearing bases on the driving side and non driving side of the converter, installing pad beams which are respectively indentified with height marks of the chassis of the bearing bases and are integrated together on steel pillars or steel beams of the operational platform on the front of the converter, assembling three components of the converter on charging bays, suspending the three components on the hydraulic presses on the supporting platform and the pad beams which are provided with rolling rods and assembling integrally, regulating the hydraulic presses to make each supporting point with balance force, installing a winding engine and a main pulley block on the advancing end of a ladle car to drag the ladle car and the supporting platform, arranging a single-sheaved block on the driving lateral bearing base which is dragged by a line hook of a steel-melting bay, correcting directions by regulating the rolling rods, and slowly dragging the whole converter to the installation position of the steel-melting bay, which is safe and reliable, and has high effect and strong operability.

Owner:中国冶金科工股份有限公司

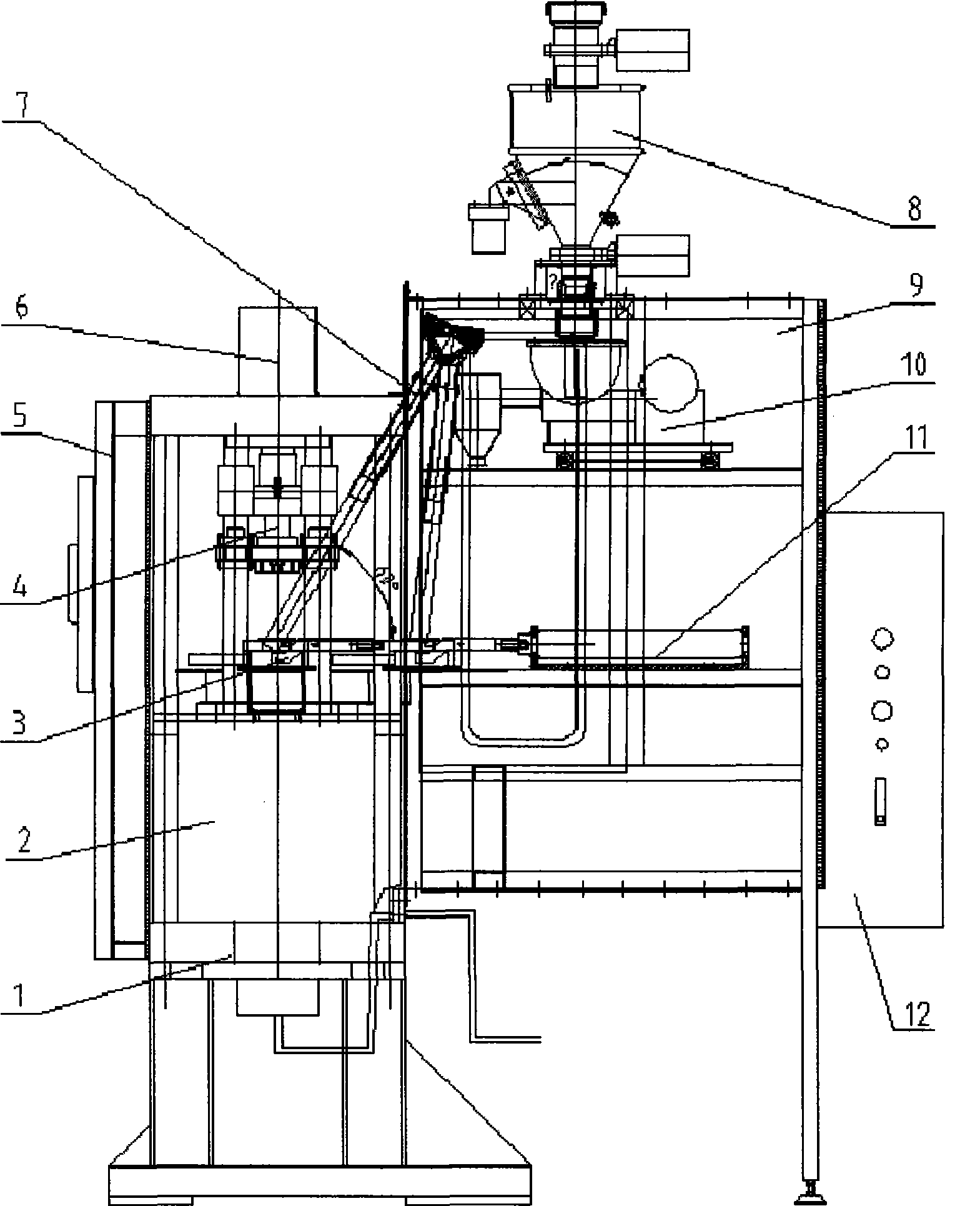

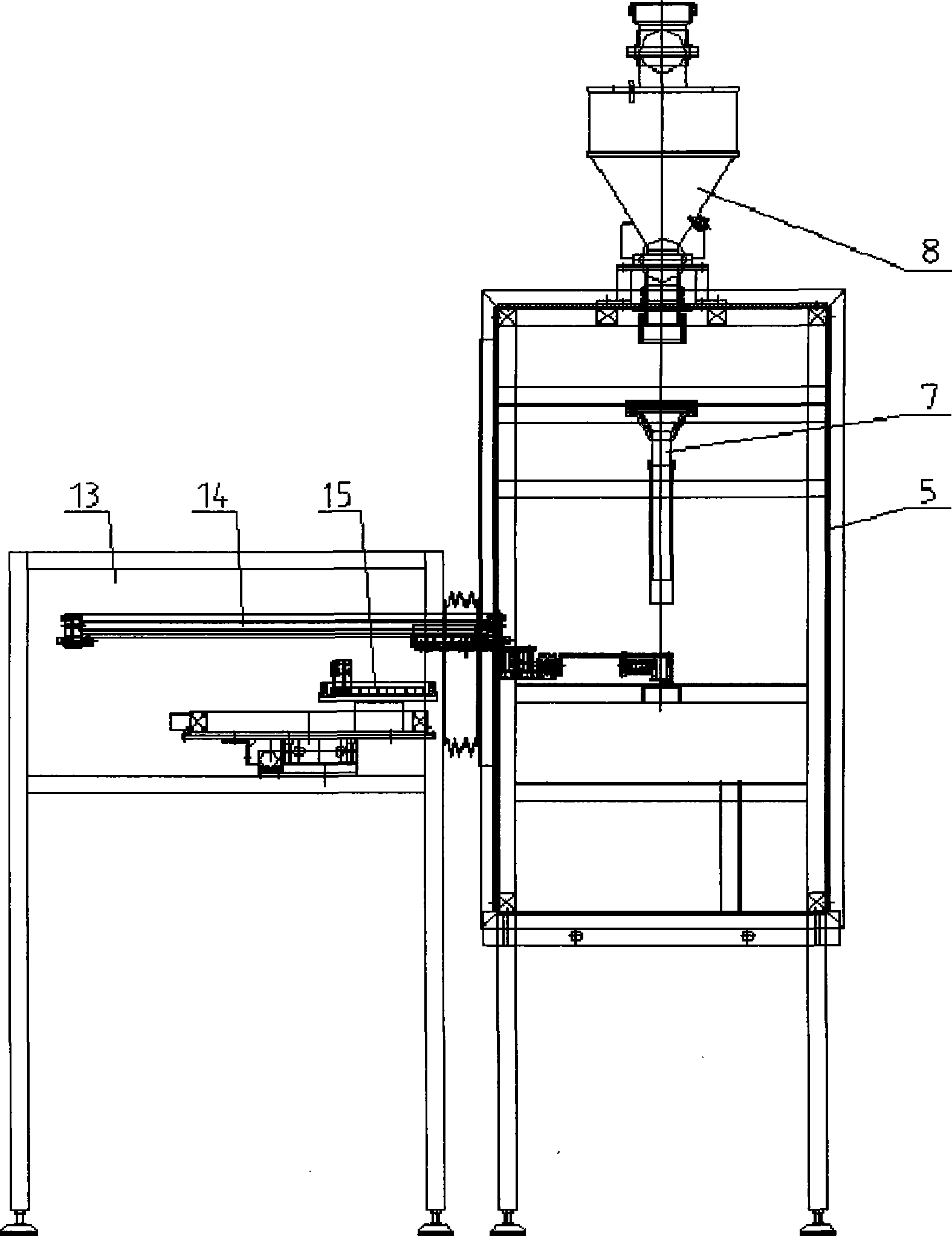

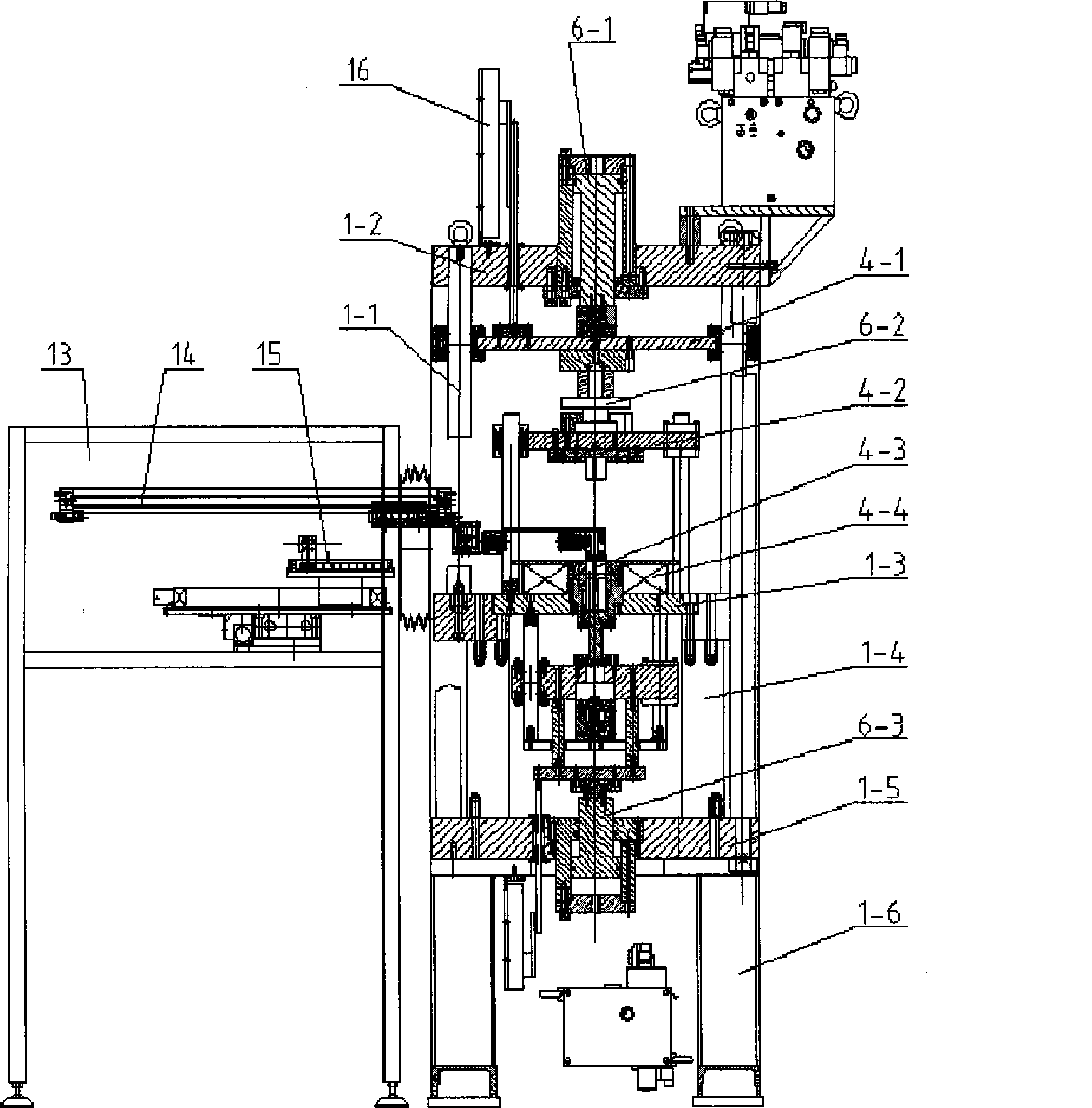

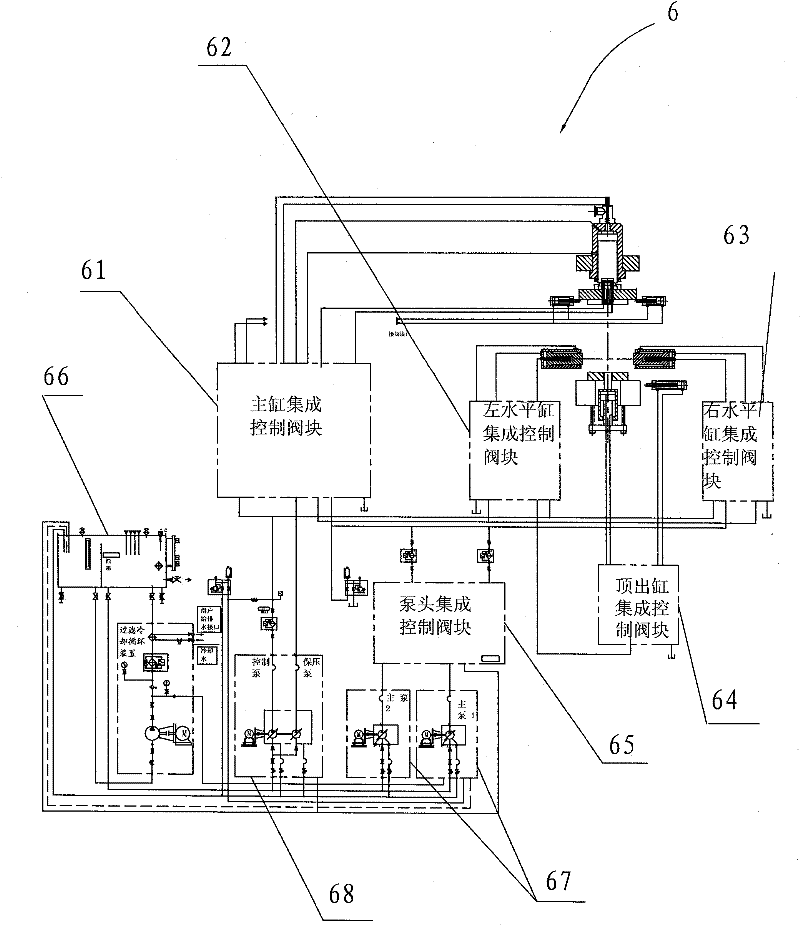

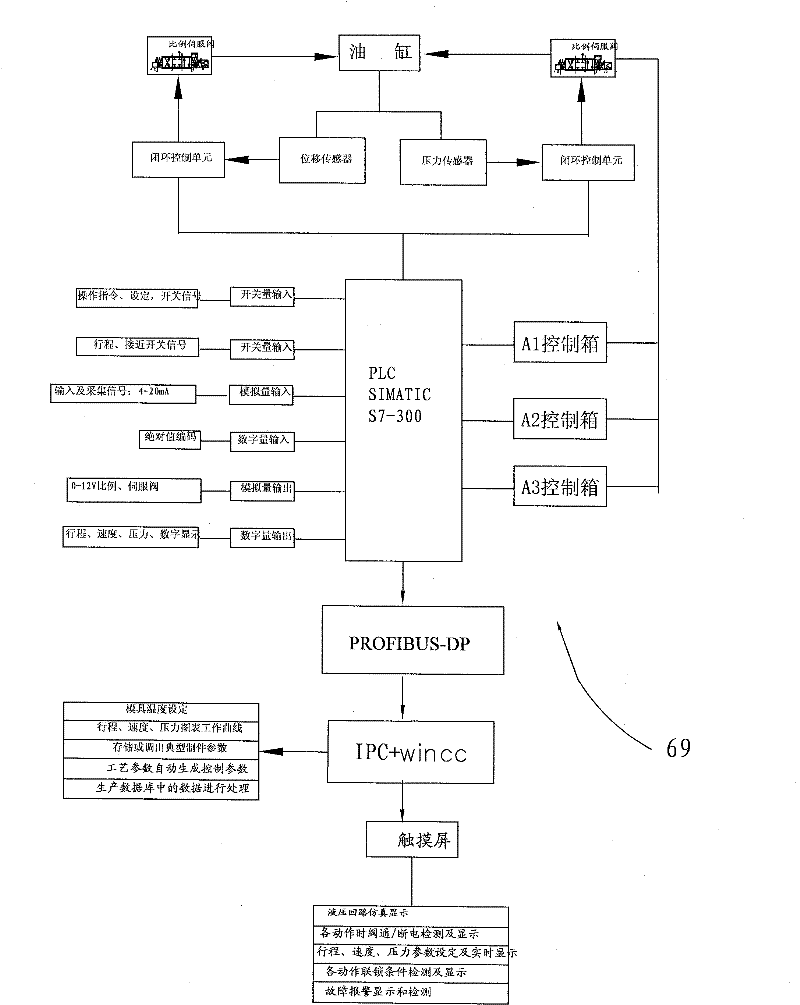

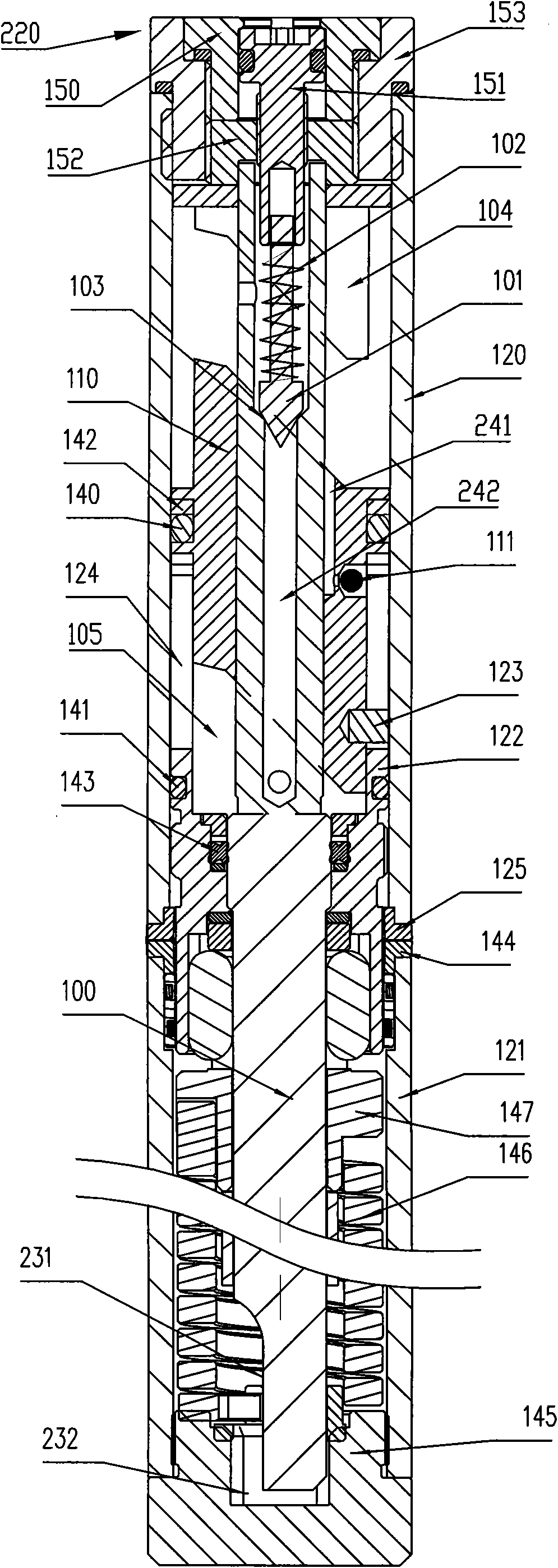

Oil press for automatically moulding rare-earth magnetic powder

The invention relates to an automatic forming oil-hydraulic press for rare earth magnetic powder, and belongs to the technical field of high-quality rare earth permanent magnet mechatronic processing equipment. The automatic forming oil-hydraulic press for the rare earth magnetic powder consists of a feeding system, a forming and pressing system, a material taking system and an electrical control system, wherein body frames of the feeding system, the forming and pressing system and the material taking system are connected with each other in the shape of Chinese character 'pin'; a shell of the automatic forming oil-hydraulic press is sealed by transparent organic glass materials; and the inside of the automatic forming oil-hydraulic press is mutually communicated and provided with an oxygen content detector, so that the processing operation process of the rare earth magnetic powder can be performed in a completely hermetic inert protective gas environment. The automatic forming oil-hydraulic press has the advantages of automatic powder supply of the feeding system, a magnetic (field) oriental coil in a die component of the forming and pressing system, automatic die lubrication, leftover removal and a completely automatic PLC control system with a low oxygen concentration, and guarantees uniaxial orientation of the height of a magnetic axis of the rare earth magnetic powder and full automation, high accuracy, high reliability and high product quality in the whole pressing production process.

Owner:QIANDONG RARE EARTH GRP

Die forging method of high-temperature alloy

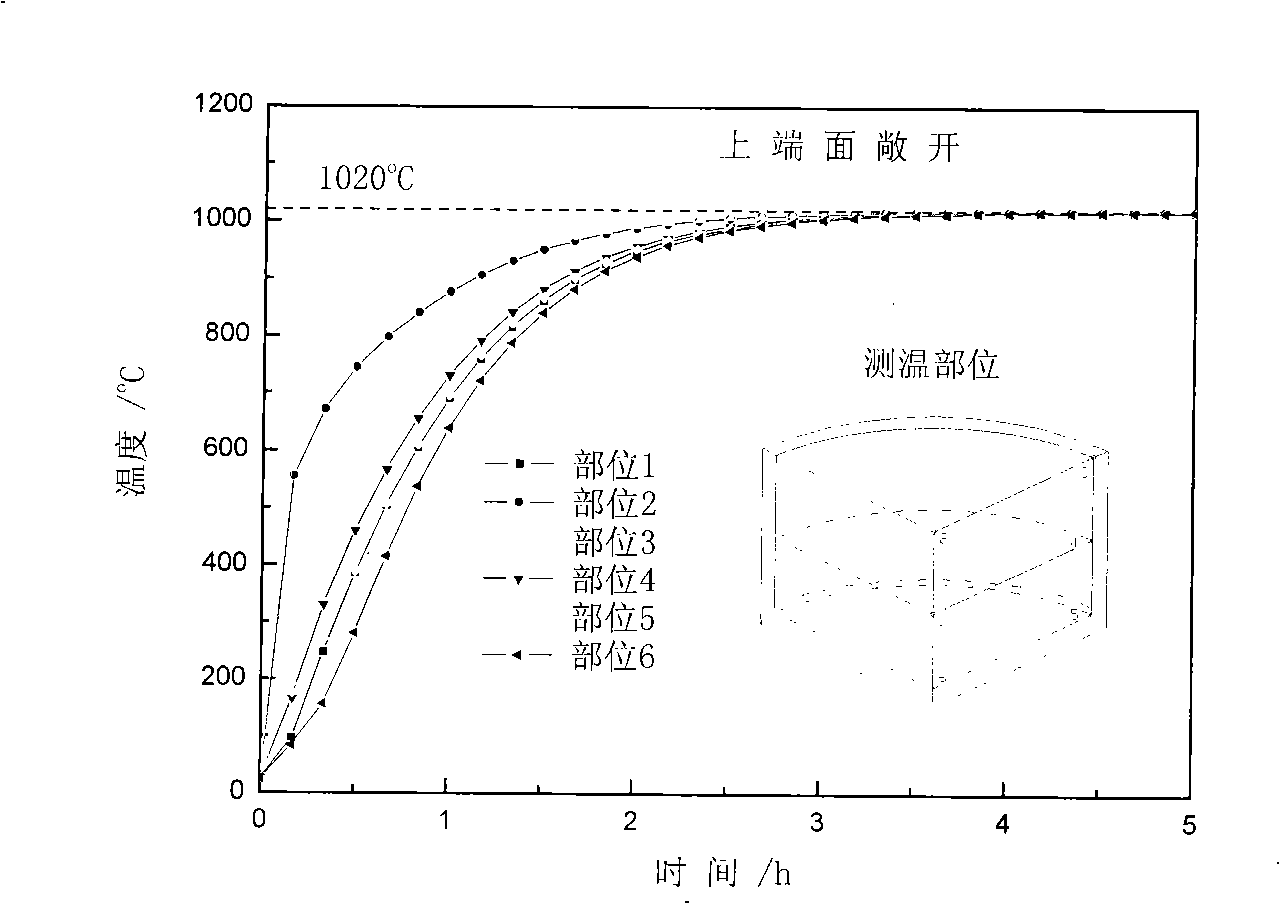

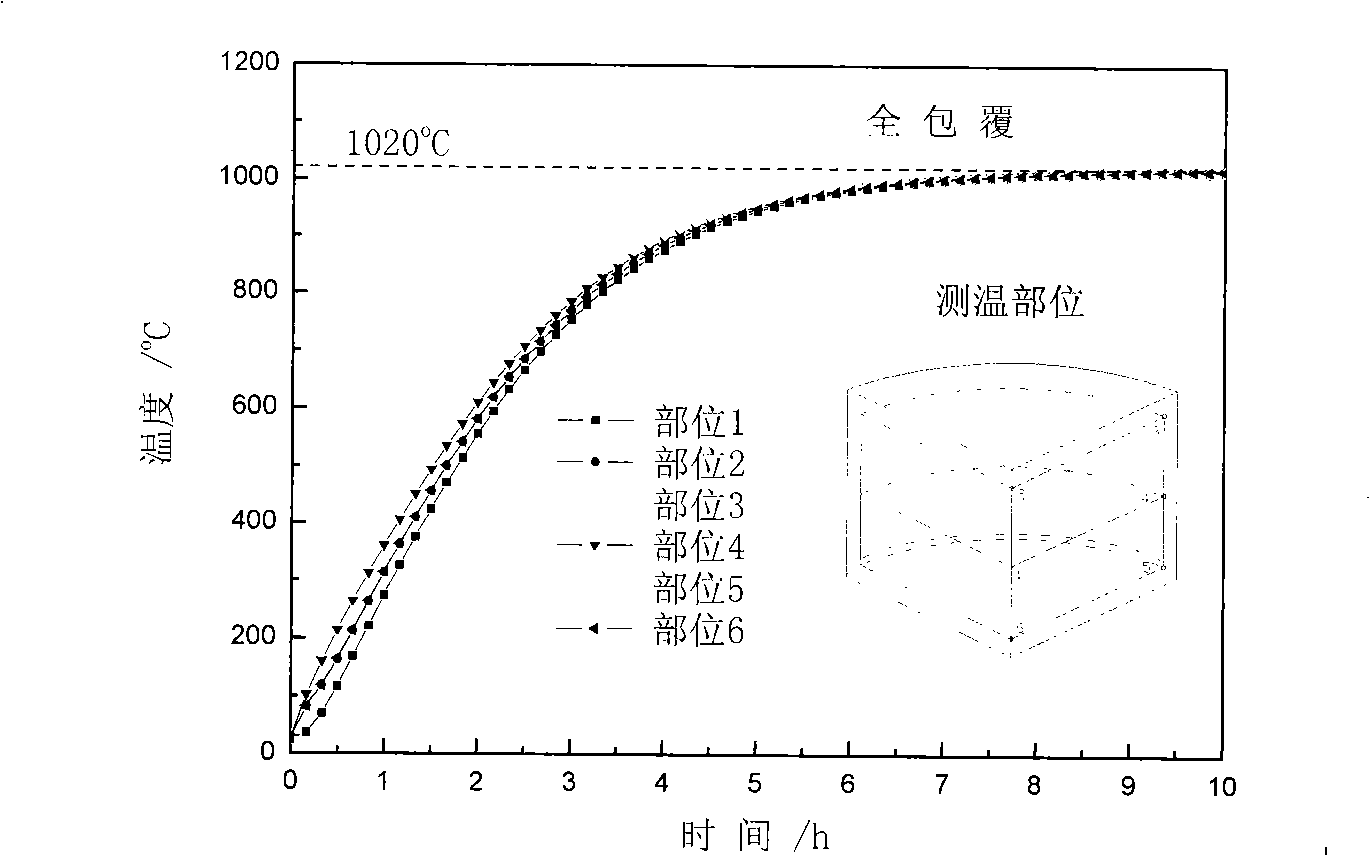

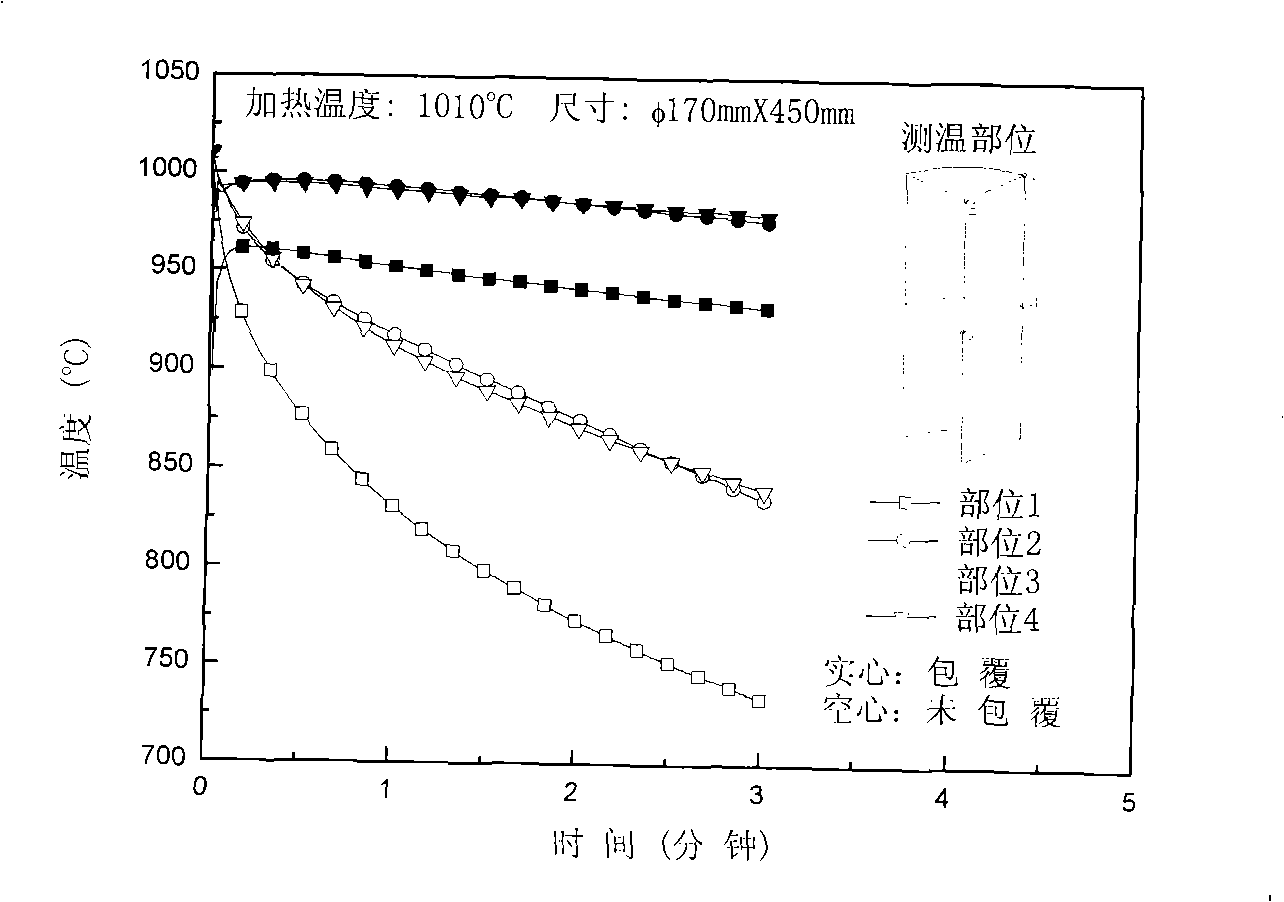

ActiveCN101332484ASolve the shortcomings of slow heatingImprove insulation effectForging/hammering/pressing machinesThermal insulationWorking temperature

The invention discloses a die forging method of a high-temperature alloy; the method comprises the following steps: a) die forging stock is in thermal insulation and heat preservation, and clad with thermal insulation cotton; b) heating of the die forging stock: the die forging stock clad with the thermal insulation cotton is heated in a heating furnace and preserved at a temperature, the heating temperature is 900-1200 DEG C, and the heat preservation time is not less than 30 minutes; c) heating of a die: the die is put into a press, and heated to the working temperature of 600-650 DEG C in the heating furnace of the press; d) die forging: the die forging stock is taken out of the heating furnace and sent to an oil press or a hydraulic press for die forging, the amount of deformation is 40-80%, and the die forging speed is 1-5mm / s. The die forging method of the invention solves the problem of slow heating-up of the die forging stock in the heating furnace resulting from the existing 'compound jacketing' mode, improves the heat preservation effect of workpiece, and lower the cost for the application of heat insulating materials; the die forging method adopts a lower die temperature, which sufficiently eliminates the problems of short service life of the hot press forging die and great production difficulty, and facilitates producing the alloy forged pieces conforming to finecrystalline requirements.

Owner:宝武特种冶金有限公司

Air brick for magnesia carbon ladle and method for producing the same

The invention discloses an air brick used for a magnesium and carbon ladle, and a producing method thereof, aiming at producing high-quality air bricks used for the ladles. The mass percentage of the chemical compositions of the air brick is: 55 to 99 percent of MgO, 0 to 20 percent of C, 0 to 20 percent of AI2O3, 0 to 5 percent of ZrO2, 0 to 5 percent of AI, 0 to 5 percent of AI-Mg alloy, 0 to 5 percent of CaB6, and 0 to 2 percent of B4; the physical property indexes are: volume density (g / cm<3>): 3.00 to 3.15, apparent porosity (%): 1.5 to 5.0, cold compressive strength (MPa): 40 to 65, and distortion resistance at high temperature (MPa): 14.0 to 25.0. Raw materials adopted by the invention comprise fused magnesite, magnesite clinker, crystalline flake graphite, corundum, zirconia and oxidation inhibitor. The raw materials are added into a pug mill and externally added with a bonding agent for mulling. Mulled pug is added into a mould, and molded by utilizing isopressing equipment or a friction brick press or a hydraulic press. The invention obviously reduces the apparent porosity of the air brick, not only can improve the basic slag corrosion resistant capability of the air brick, but also can reduce the cost of the raw materials by more than two thirds.

Owner:UNIV OF SCI & TECH LIAONING

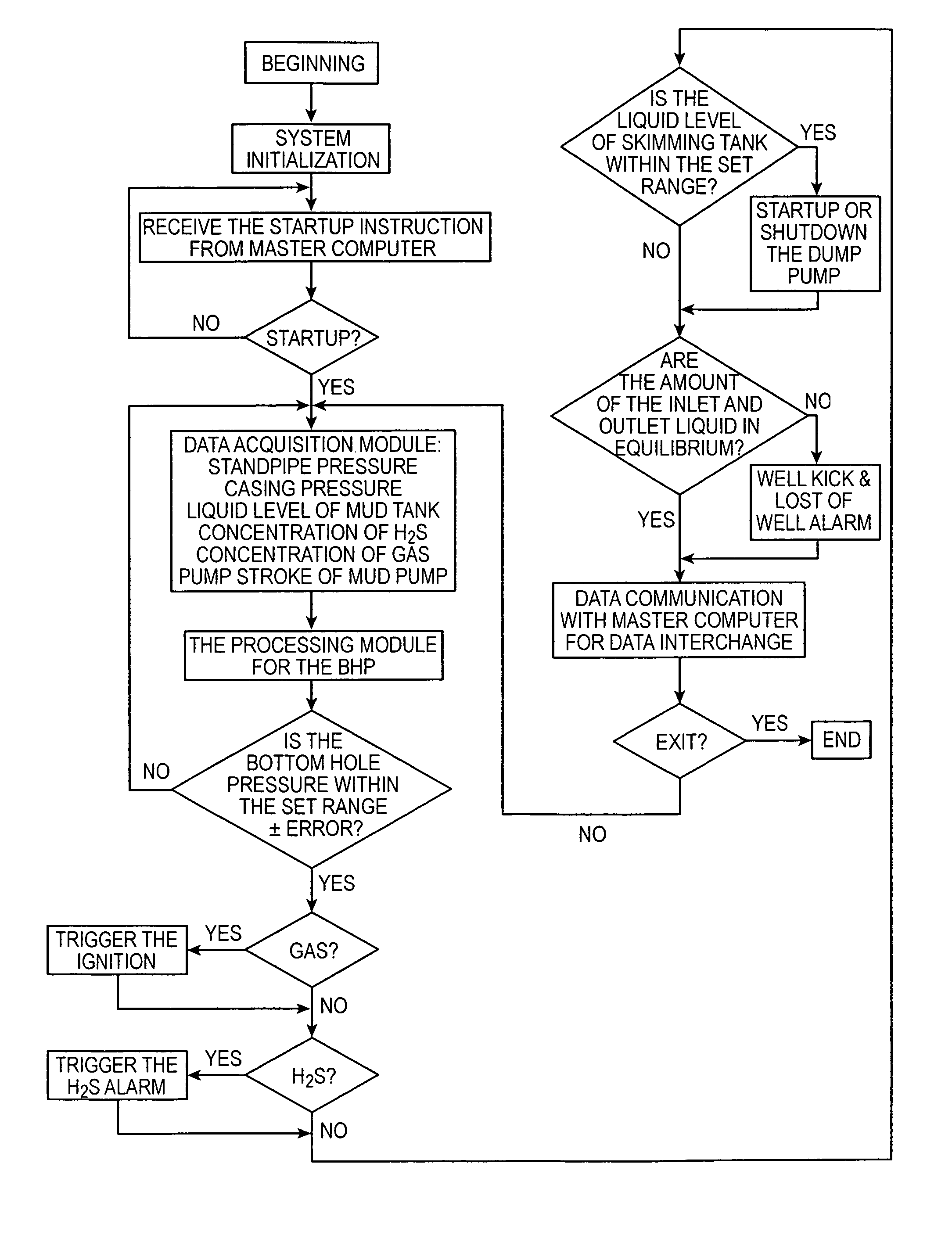

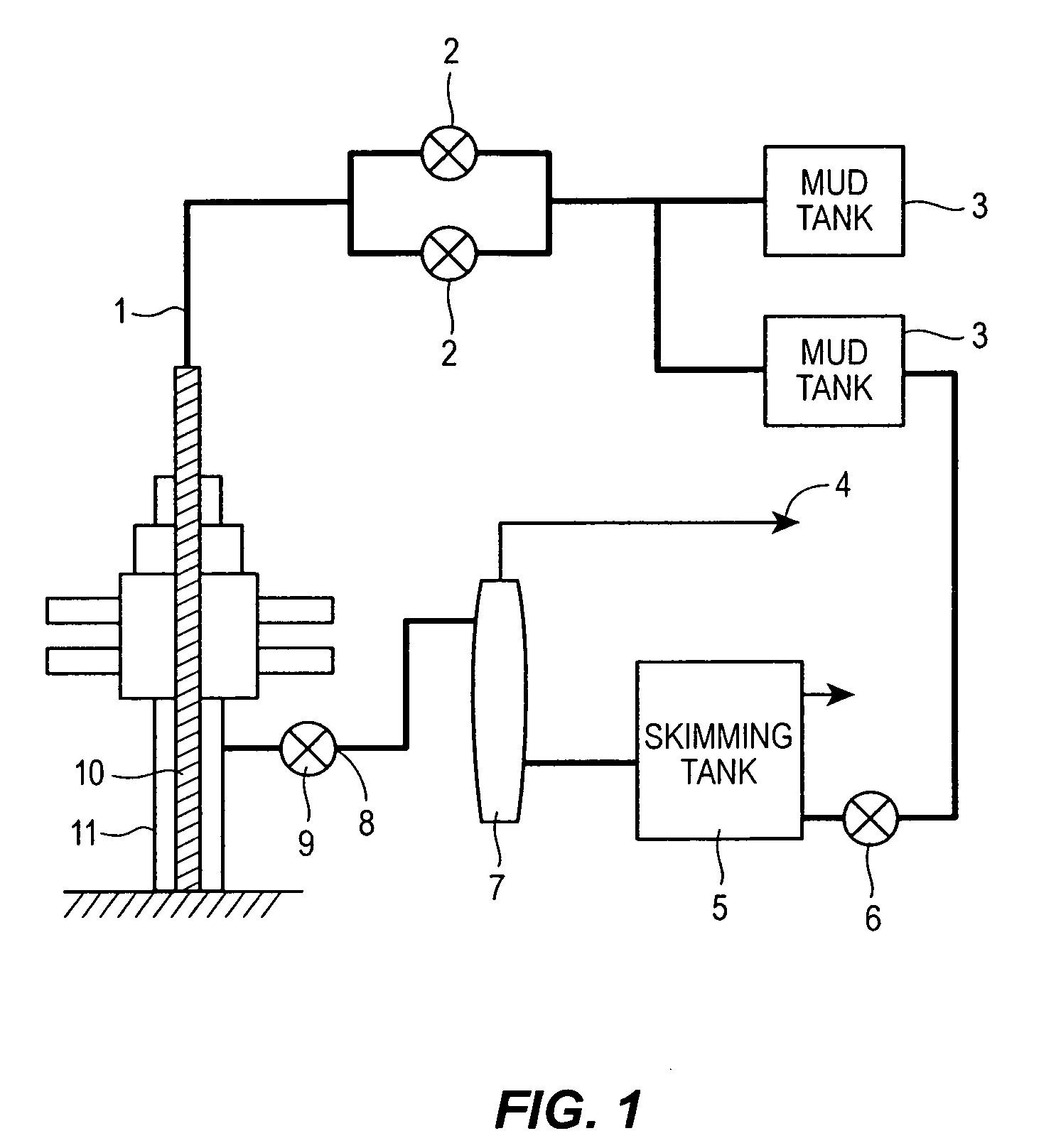

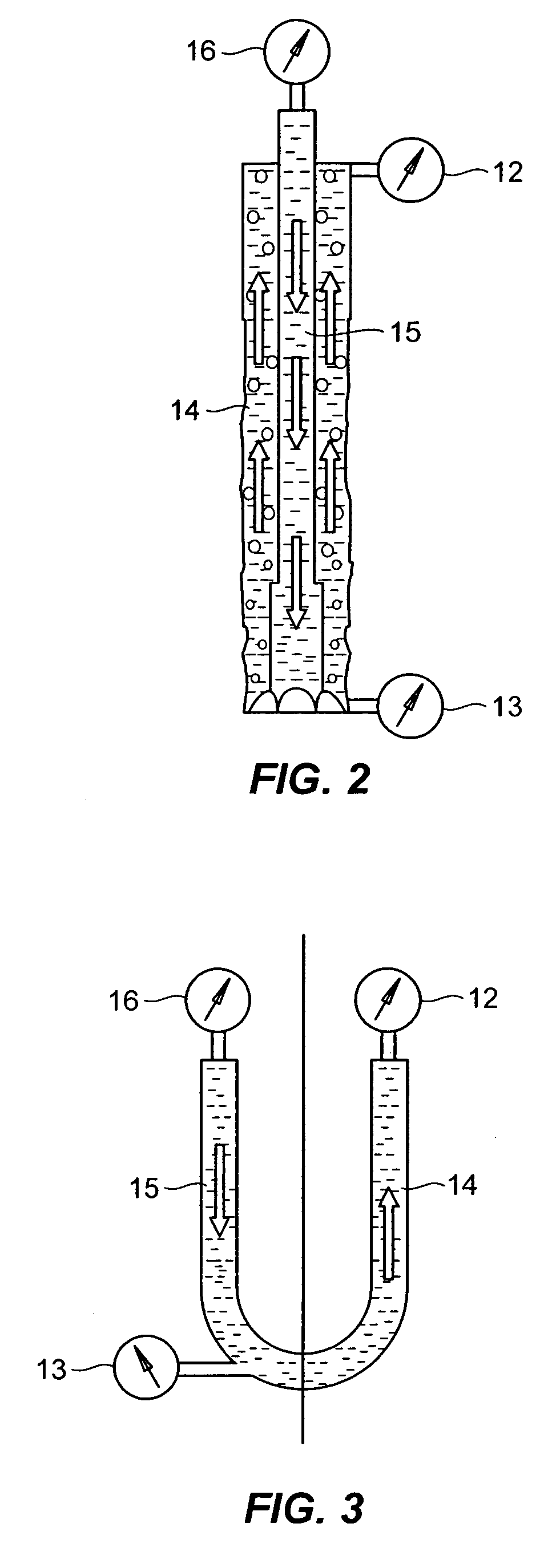

Automatic control system and method for bottom hole pressure in the underbalance drilling

ActiveUS7158886B2Accurate calculationRelatively small errorElectric/magnetic detection for well-loggingConstructionsAutomatic controlAutomated control system

This invention provides an automatic control system and method for bottom hole pressure (BHP) in the underbalanced drilling. It relates to a computer automatic control technology. The automatic control system according to the invention includes a processing module for the BHP based on the mechanisms of hydraulics. The BHP in the underbalanced drilling is calculated from the acquired standpipe pressure (SPP), the calculated circulating pressure loss in the drilling tools, drill bit pressure drop and the fluid colunm pressure in the drill string. The resulting BHP is then compared with the set pressure value of the system. In case that the BHP is higher or lower than the set pressure, an instruction to regulate throttle valve opening will be issued in order to bring the BHP back to the set pressure range and complete BHP monitoring and control.

Owner:CHINA PETROCHEMICAL CORP +1

Process for forming medium-strength heat-resistant magnesium alloy thick plate

The invention discloses a process for forming a medium-strength heat-resistant magnesium alloy thick plate with the thickness of 50-80mm. The process route comprises the following steps: big furnace smelting, semi-continuous casting, homogenizing annealing, variable temperature multi-directional forging, extrusion forming and aging treatment, wherein the step of variable temperature multi-directional forging is performed on a hydraulic machine, the temperature of the ingot blank is kept at 380-410 DEG C for 3-5 hours before forging, and the pressing speed is 200-400mm / minute; the step of extrusion forming is performed on a horizontal extruder, the temperature of the ingot blank is kept at 340-350 DEG C for 3-5 hours before extrusion, and the thickness plate with the extrusion ratio of 13-15, the extruded thickness of 50-80mm, the width of 130-200mm and the length of more than or equal to 1000mm is extruded. After the aging treatment, the room-temperature yield strength of the thick plate along the extrusion direction is more than or equal to 260MPa, the tensile strength is more than or equal to 370MPa, and the elongation is more than or equal to 9 percent. The process is high in forming efficiency, and large-scale industrial production can be realized.

Owner:CENT SOUTH UNIV +1

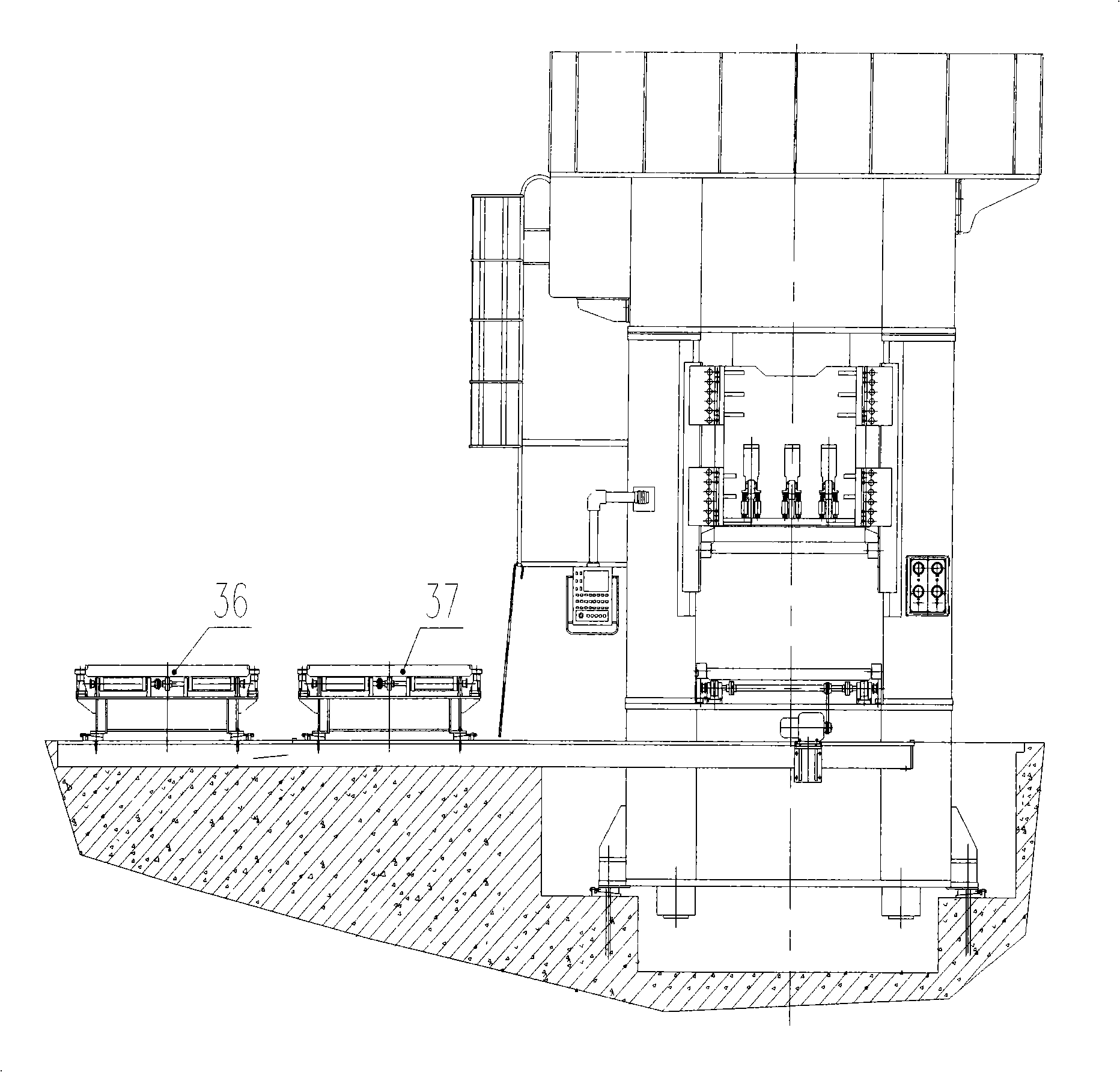

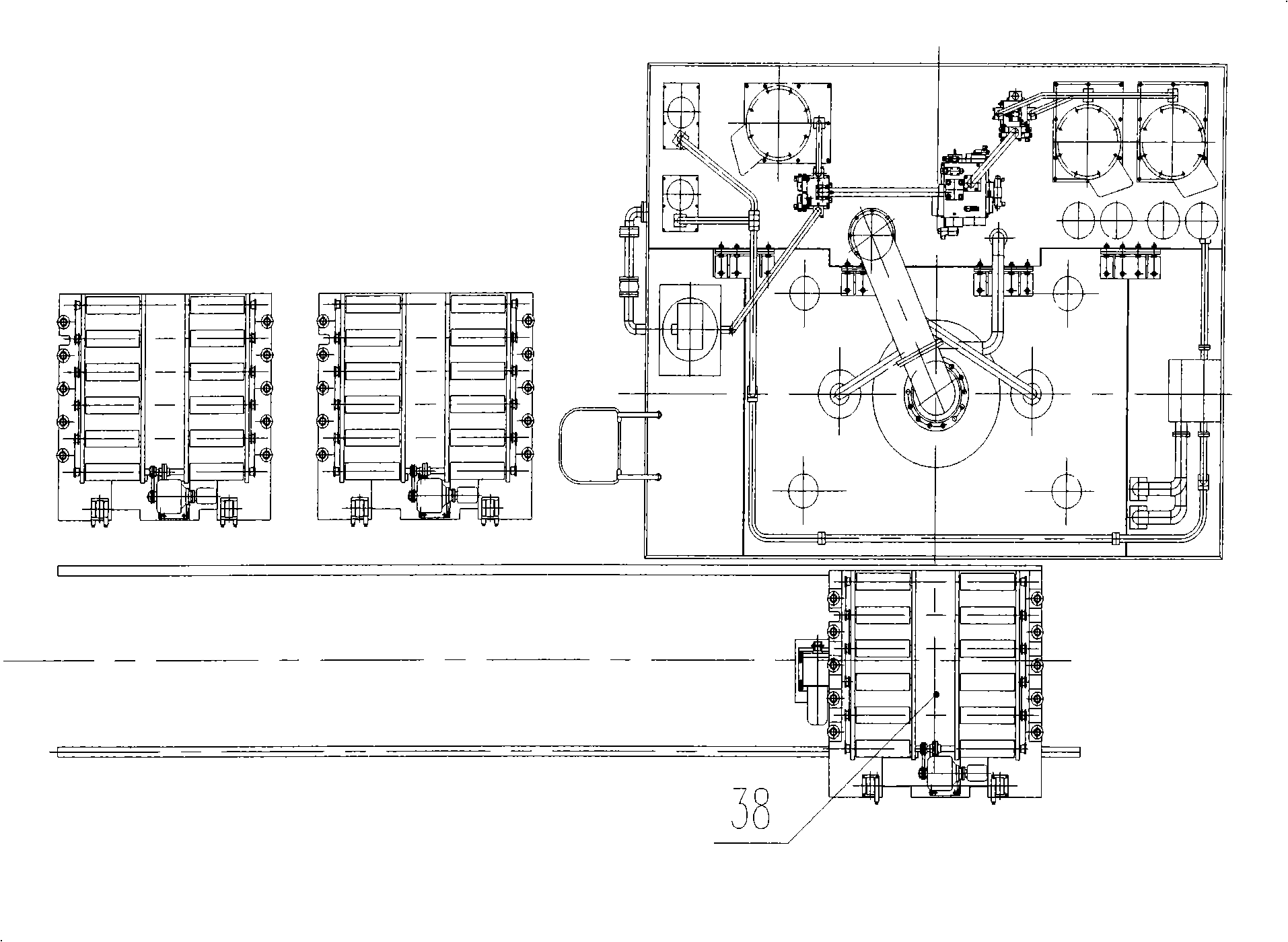

Double-mold hydraulic press capable of quick changing mold

The invention relates to a hydraulic machine which is provided with a dual-formwork typed quick die replacing function and is characterized in that two sets of upper / lower die alternative changing installation dies, two sets of die storage platform and a die changing trolley are arranged in the hydraulic machine equipment of the continuous production line; when the first set of dies are arranged on the first set of formworks, the upper / lower formworks are closely locked on an upper fixed cushion plate and a lower fixed cushion plate by ten hydraulic locking cylinders. The hydraulic machine provides two sets of upper / lower formworks, alternatively replaces and installs the dies outside the host machine, subsequently uses the functional parts such as a hydraulic floating roller, two sets of die storage platforms, a die replacing trolley and a die automatic clamping part, and the like, conveniently and quickly replaces the dies, changes the traditional type in which the dies are replaced inside the host machine, improves the exactness and coordination of the process operation, greatly shortens the die-replacing auxiliary time, thus meeting the high requirements on the functions such as installation, transport, storage, etc. of quick replacement in the pipelining of online equipment.

Owner:HEFEI METALFORMING MACHINE TOOL

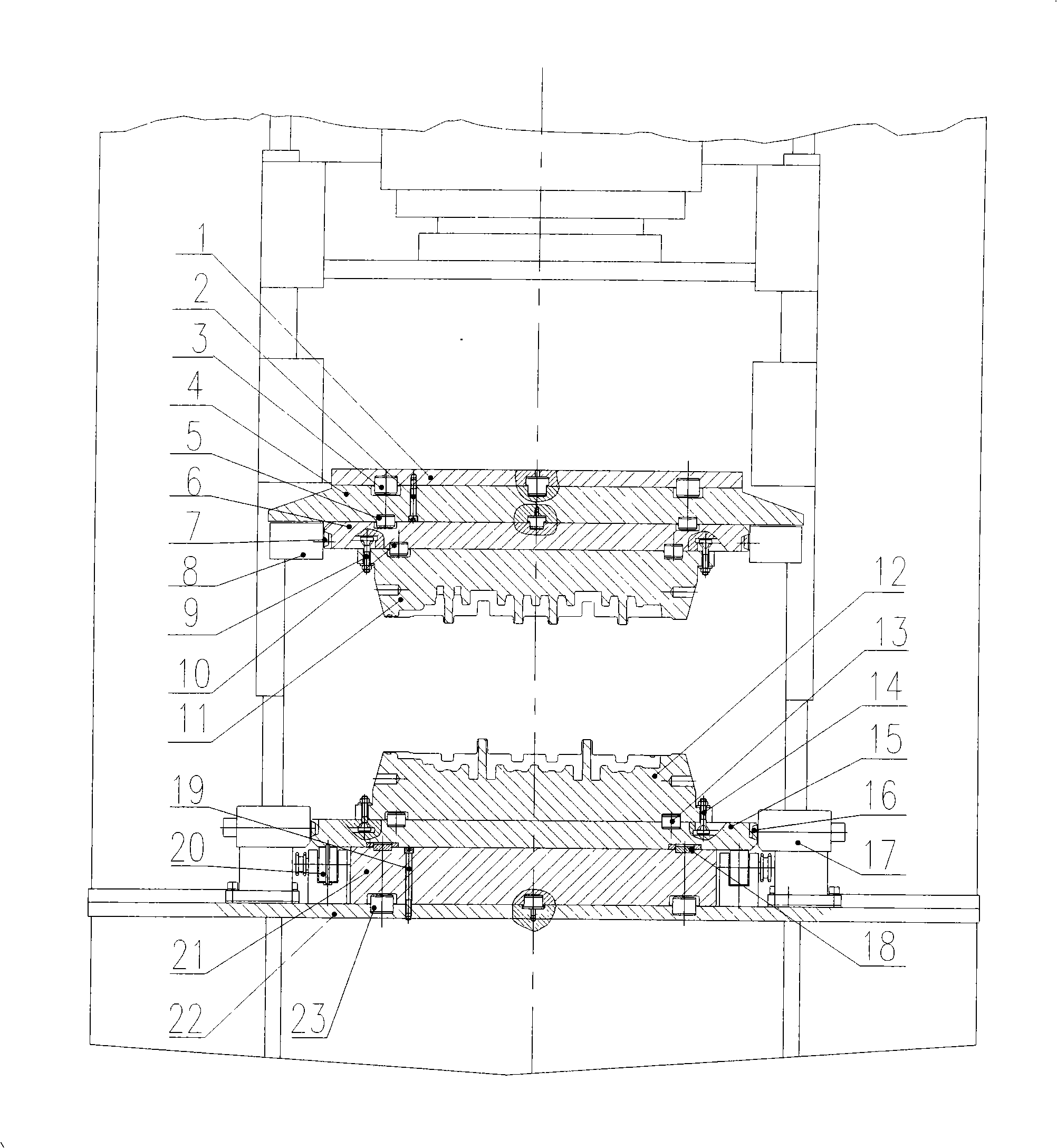

Multidirectional numerical control hydraulic press for metal plasticity forming

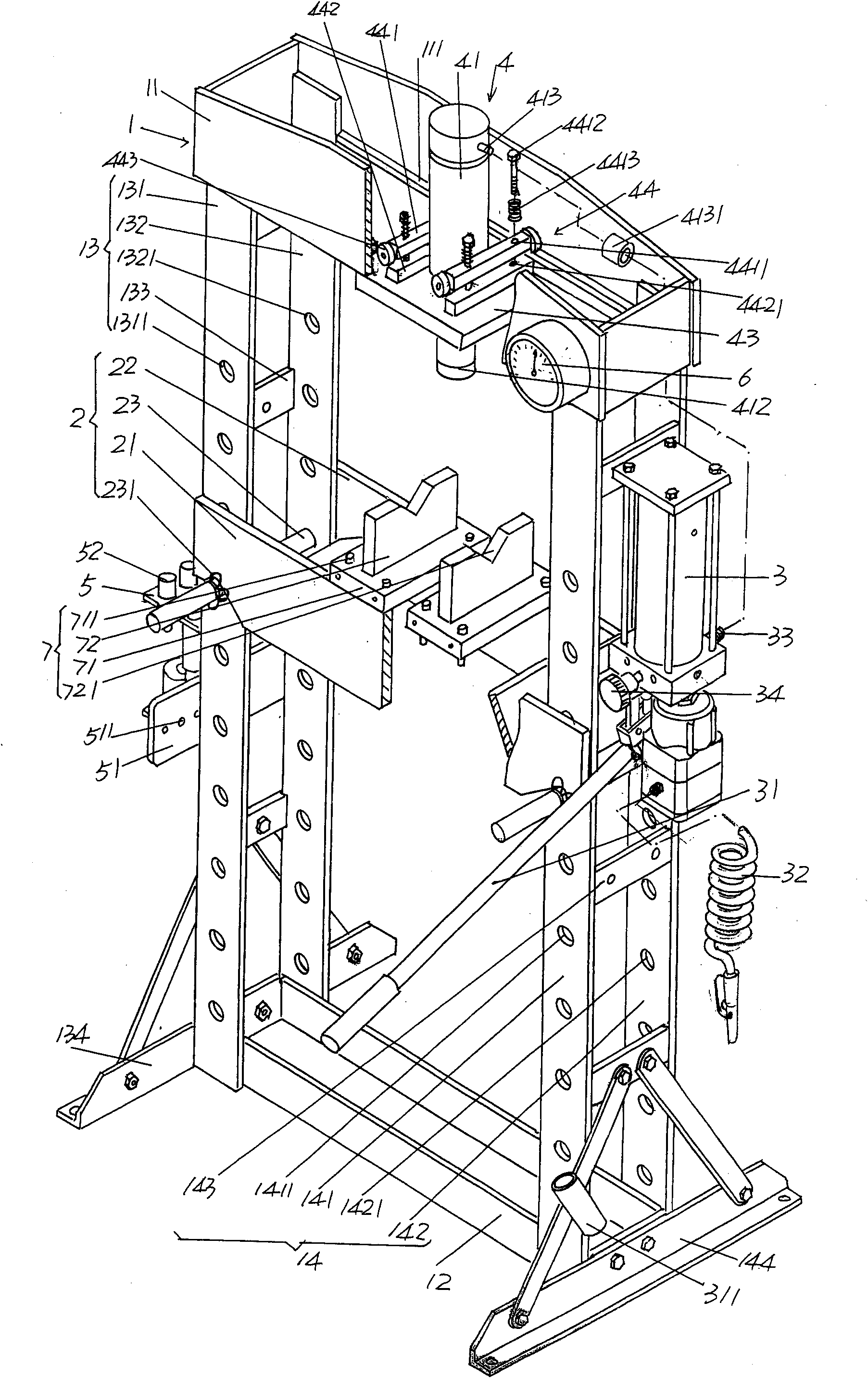

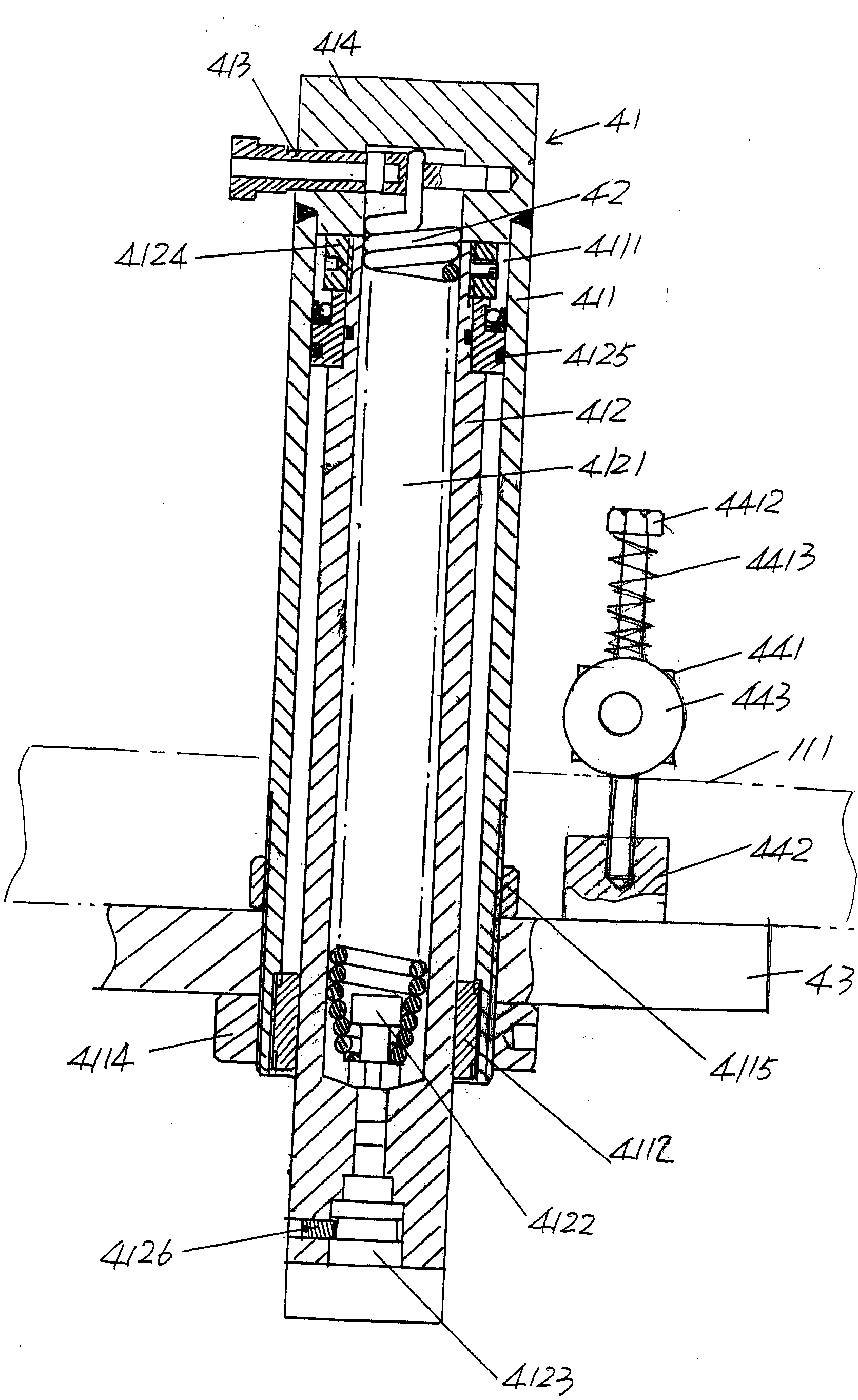

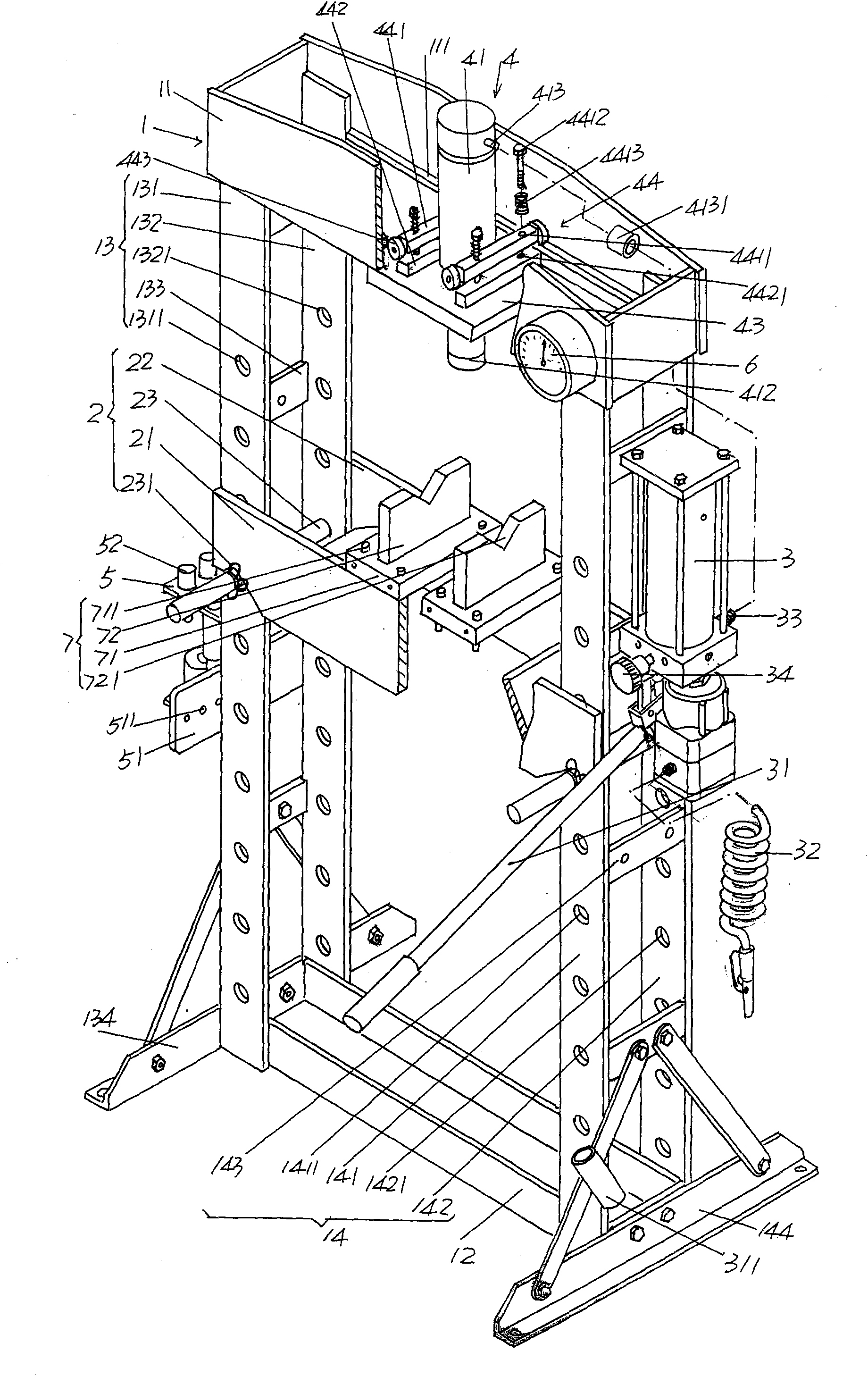

ActiveCN102049461AOvercoming single axisOvercoming processabilityForging press drivesNumerical controlPunching

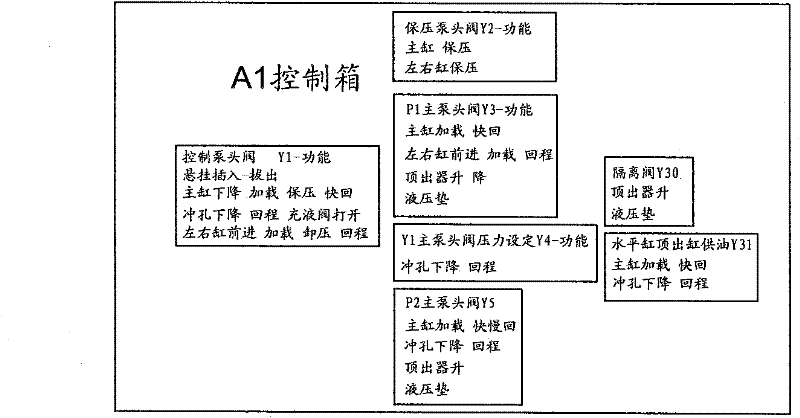

The invention mainly discloses a multidirectional numerical control hydraulic press for metal plasticity forming. A vertical main working cylinder, two horizontal cylinders and a push-out cylinder are mounted on a stress frame; a punching cylinder is combined inside the vertical main working cylinder stroking downwards, the two horizontal cylinders are a left horizontal cylinder and a right horizontal cylinder both of which stroke in the opposite directions, and each horizontal cylinder is combined with a quick-speed cylinder; the push-out cylinder is positioned below the vertical main working cylinder and adopts an inverted cylinder acting structure; and all cylinder bodies are controlled by a hydraulic control system. In the invention, an oil pump is used for direct driving, numerical control closed loop servo control is achieved, and meanwhile, axial loading and transverse loading are performed at the same time, so as to form high-precision parts with branch shaped or cavity-like complex structures in different directions.

Owner:ZHONGBEI UNIV

Jack hydraulic press

The invention discloses a jack hydraulic press, which belongs to the technical field of presses, and comprises a machine frame comprised of an upper beam, a lower beam, first and second trailing arms which are connected between the upper beam and the lower beam and longitudinally parallel to each other, a work rest arranged at the first trailing arm and the second trailing arm and corresponding to the space between the upper beam and the lower beam, a jack body arranged on the outer side of the first trailing arm or the second trailing arm, and an under-thrust device arranged at the upper beam and connected with a hydraulic circuit of the jack body. The jack hydraulic press is characterized in that: the upper beam is in a square structure which is closed on four sides and hollow along the up-and-down direction, the inner walls of a pair of wall bodies along the length direction of the upper beam are fixedly provided with a guide rail respectively, two guide rails are parallel to each other, and the under-thrust device is slipperily arranged on the guide rails. The jack hydraulic press has the advantages of saving operational labor, achieving high adaptability and reducing the labor intensity of the operator.

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

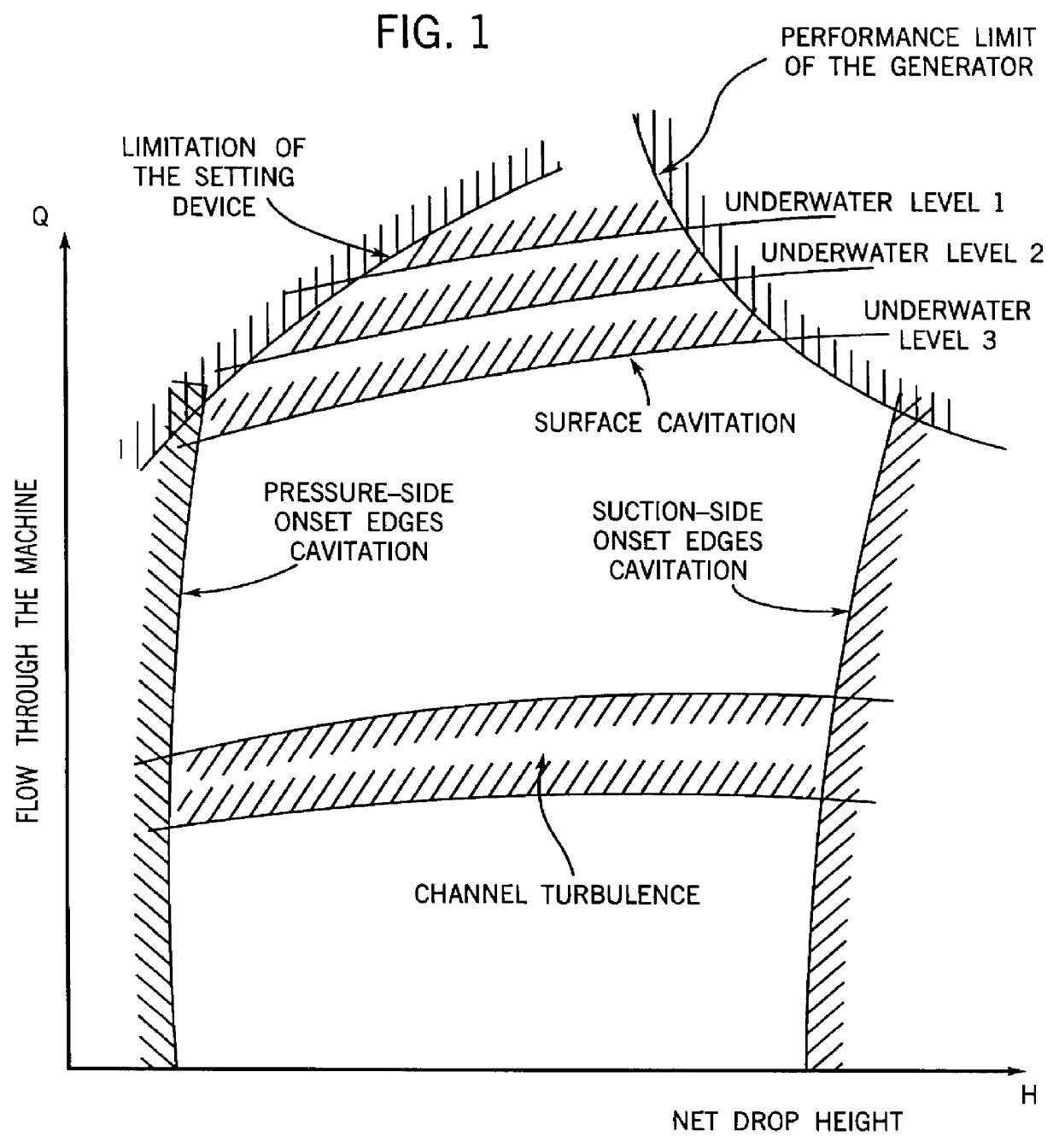

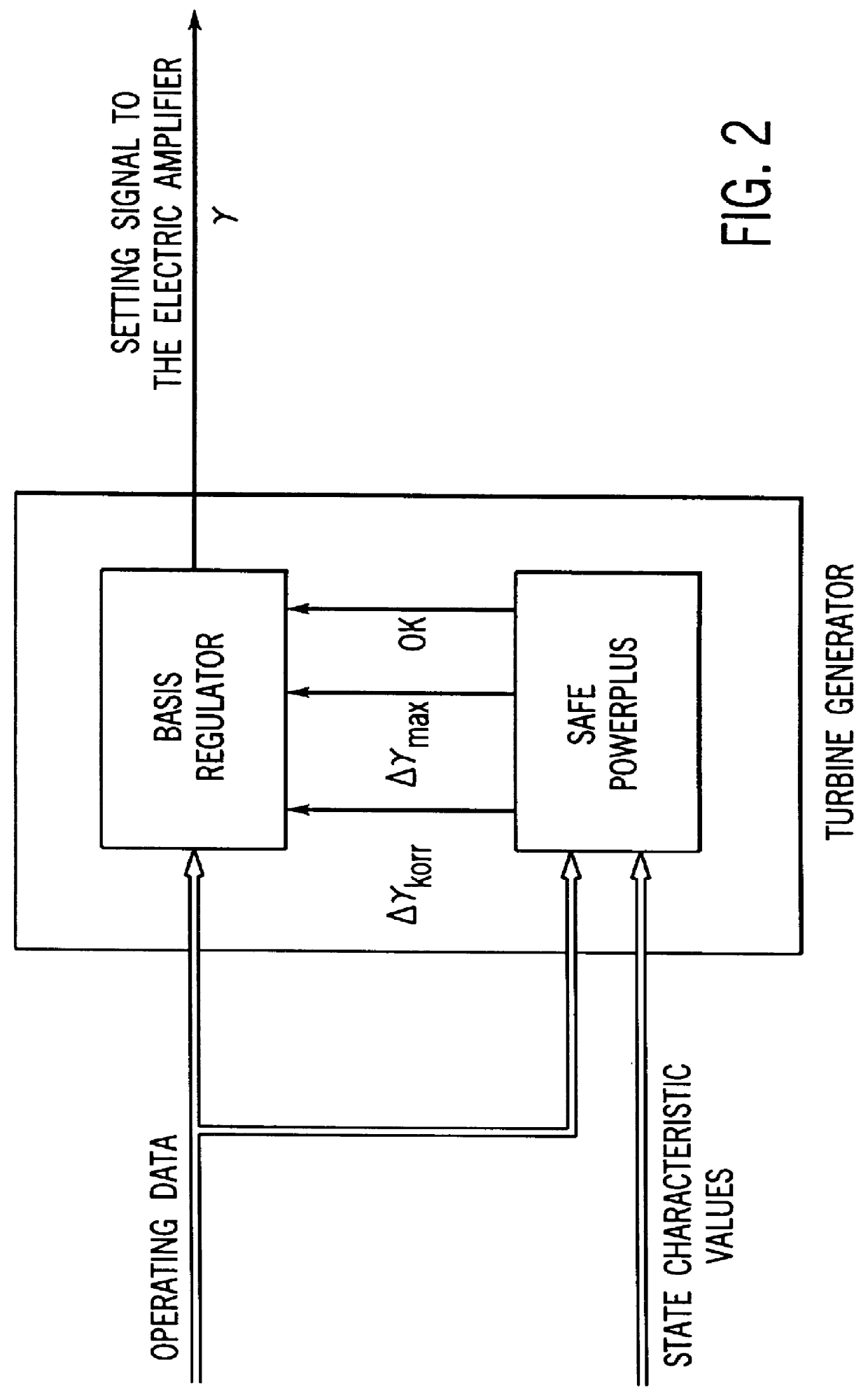

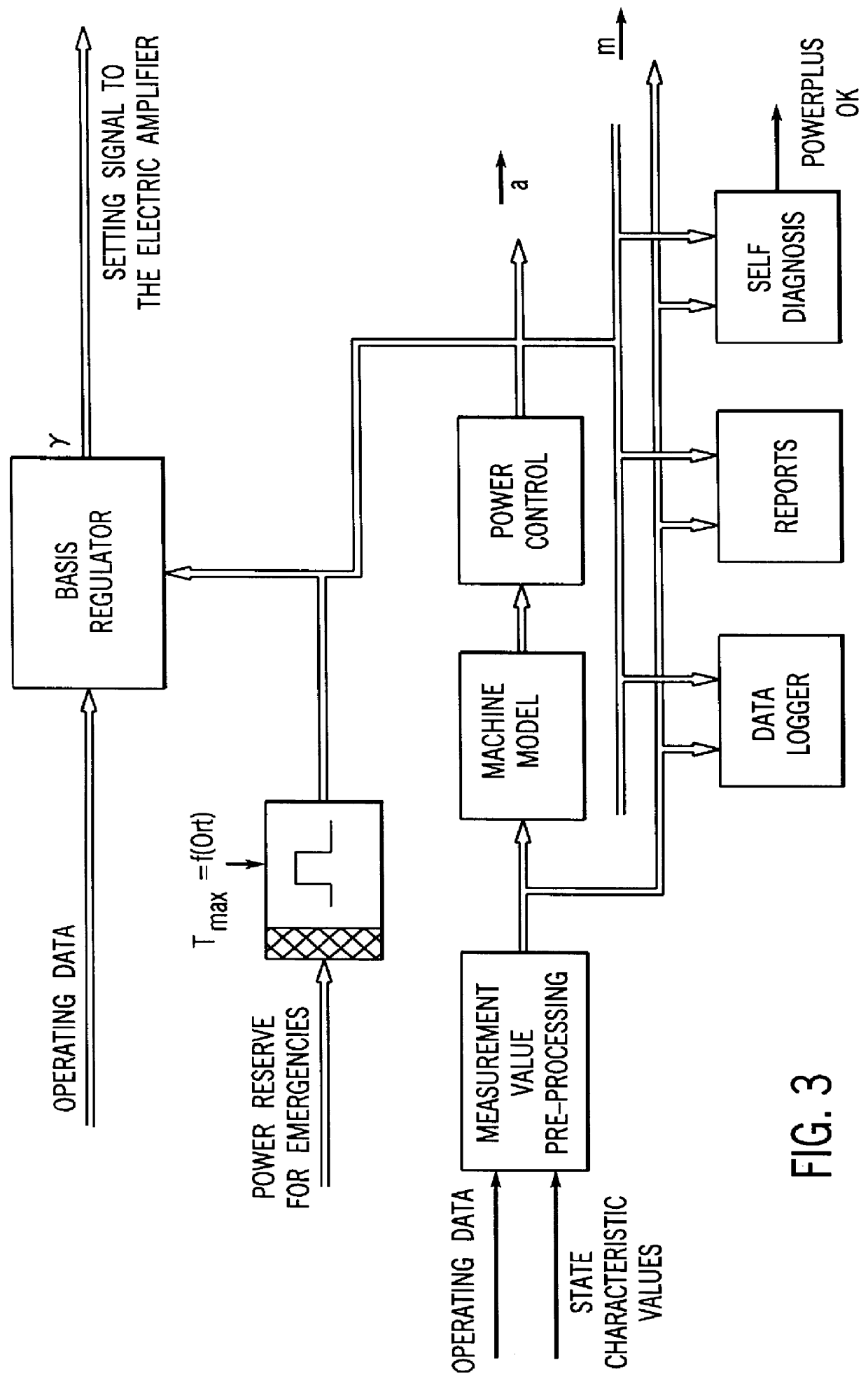

Method for operation of hydraulic turbine

InactiveUS6152684ASignificant utilityCavitation safety is givenWind motor controlHydro energy generationOperating pointCavitation

A process for operating a hydraulic machine, especially a hydro-turbine, includes the step of detecting an actual machine state during operation of the machine by ascertaining operating data. The ascertained operating data includes flow through the turbine (if present), effective and reactive power fed into the electric mains, guide vane opening, pressure before the machine and at the suction pipe exit, headwater level, and tailwater level. The method further includes the step of processing at least one state characteristic values of a first cavitation characteristic value (indicative of cavitation intensity), a second cavitation characteristic value (indicative of an abrupt rise in cavitation manifestations), vibration characteristic values, suction pipe pressure, sand concentration, air pressure, water temperature, and generator temperature (for example winding temperature). The method also includes the step of altering an operating point of the machine based on the at least one processed characteristic value to reduce cavitation and / or quiet running.

Owner:VOITH HYDRO

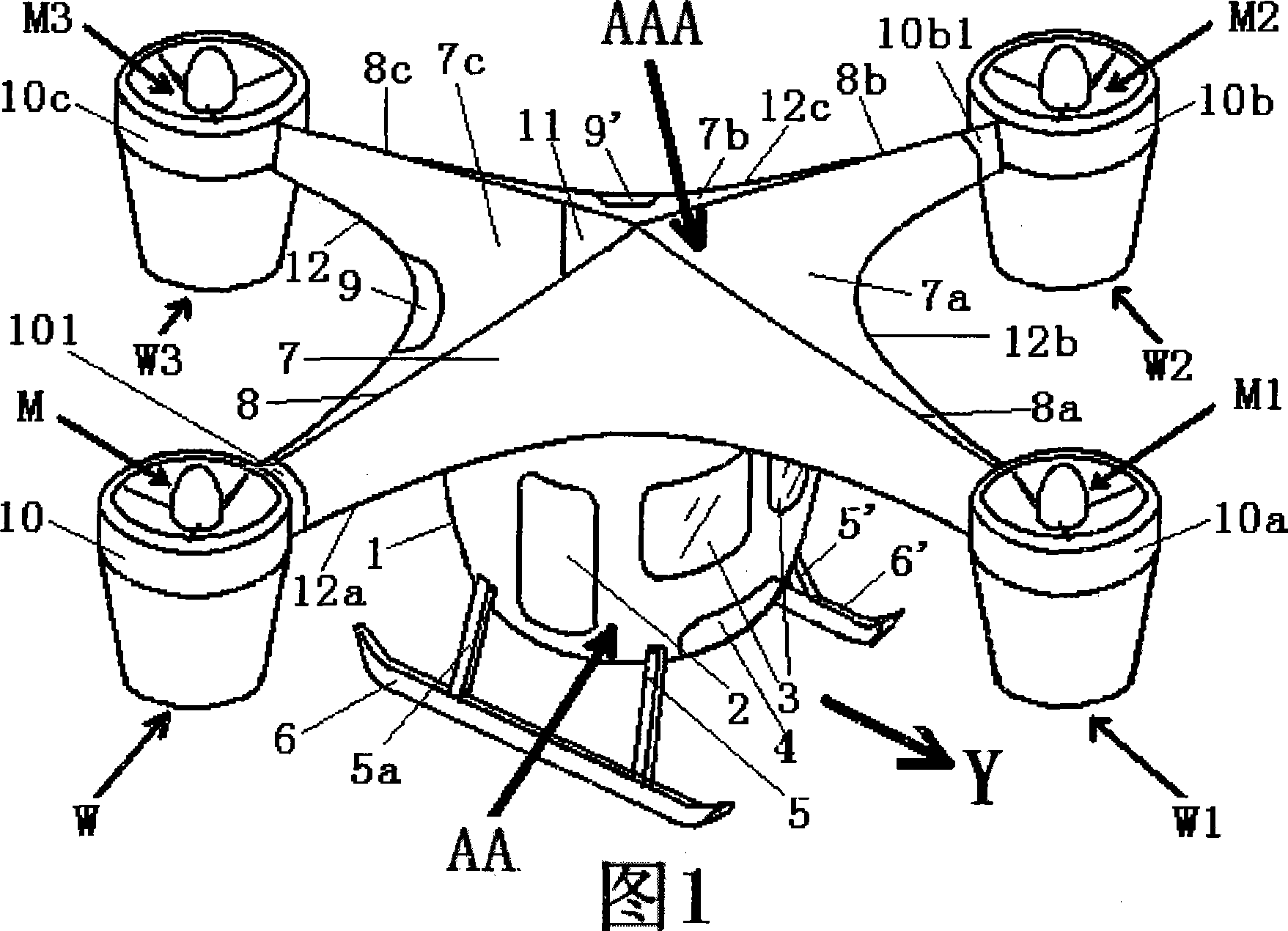

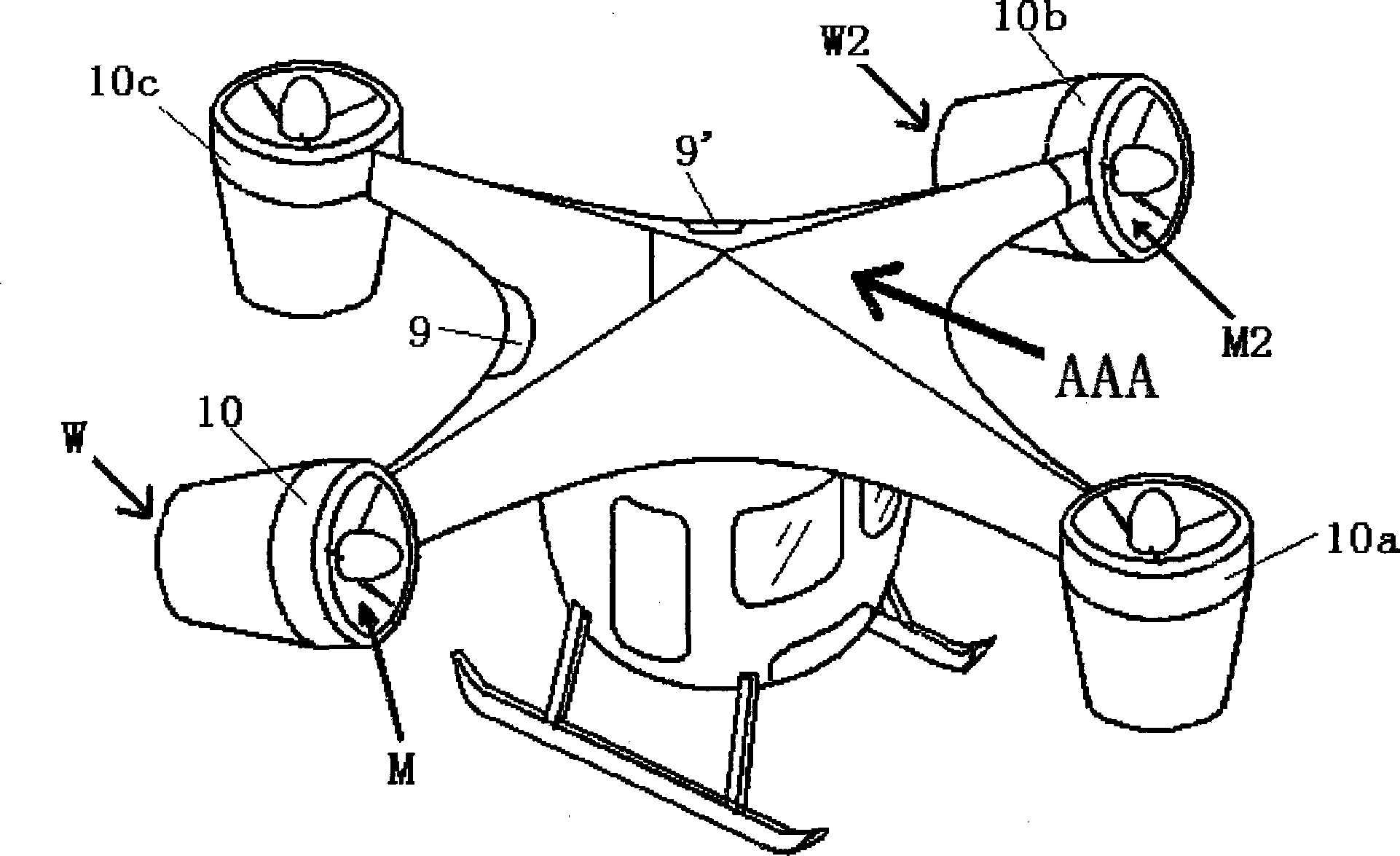

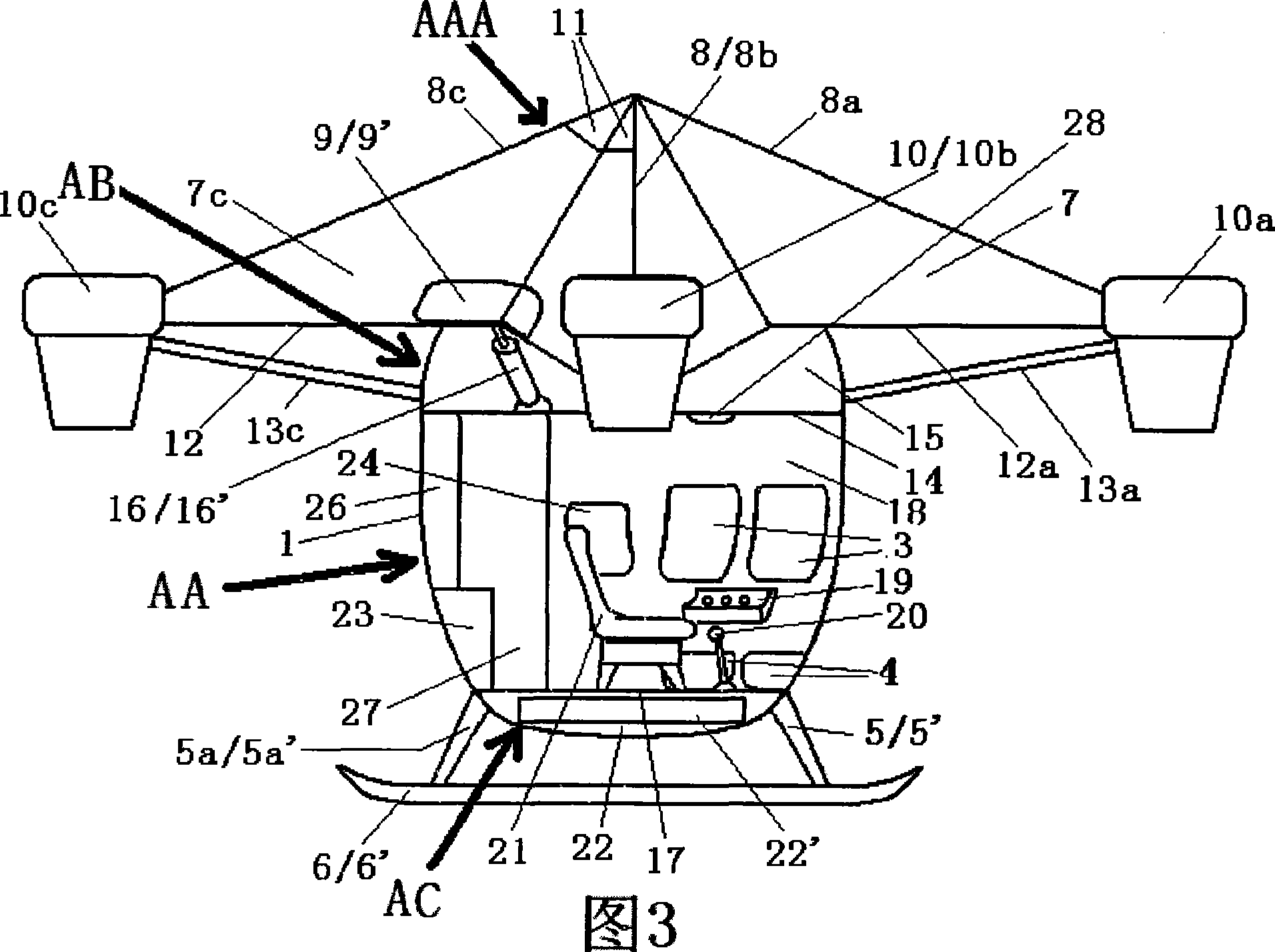

Novel air injection aerial vehicle

The invention relates to a novel jet aircraft, in particular to a novel vertical-elevating or bevel multilateral-elevating jet aircraft which not only can fly, but also can slide and stop in the sky steadily. The jet aircraft comprises eight parts: a chamber body, an awl-top crisscross parasol wing, a parasol metal support, a jet motor cantilever, a jet motor, a turning axis of a jet motor and an operation device of the turning axis, a hydraulic press and an aircraft tail. The jet aircraft is characterized in that the unique awl-top crisscross parasol wing, four jet motors or four jet turbine ducted fans are provided, wherein, the angles of two motors or tow fans can be changed; the crisscross parasol wing is provided with two balancing wings and a parachute cover of a launching parachute; the launching parachute and the device thereof are arranged in the parachute cover; the bottom of the parachute is fixedly connected with the top end of the parasol metal support; the chamber body with a three-layer structure is also provided, the bottom of which is provided with an elevating foot and an oil tank or a cargo chamber which can be abandoned; the middle part of the chamber body is provided with a spare oil tank and a spare water tank which can be abandoned; under emergency, a double parachute insurance can protect the aircraft and the safe landing of people. The novel jet aircraft can fly all-weather, can be used for civilian and military, can be applied to short, middle and long travels or to the rescue mission in the steep mountain, the cliff and precipice and the flood and fire disaster; moreover, the novel jet aircraft does not have high requirement to the elevating place and the elevating space. Thus, the invention is a novel aircraft with higher safety insurance parameter, more flexible flying and more practical performance in the history.

Owner:GUANGZHOU WEITAO ELECTRONICS TECH +1

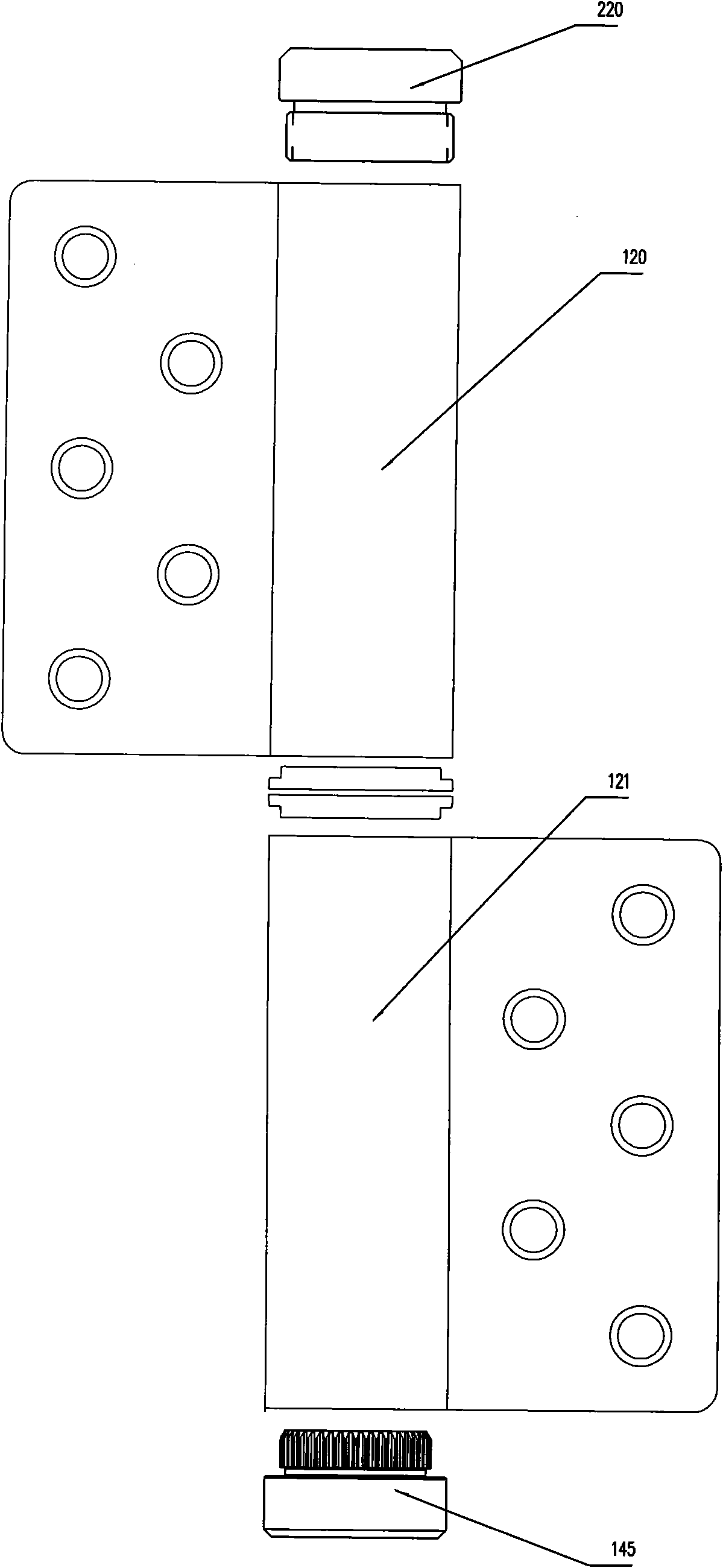

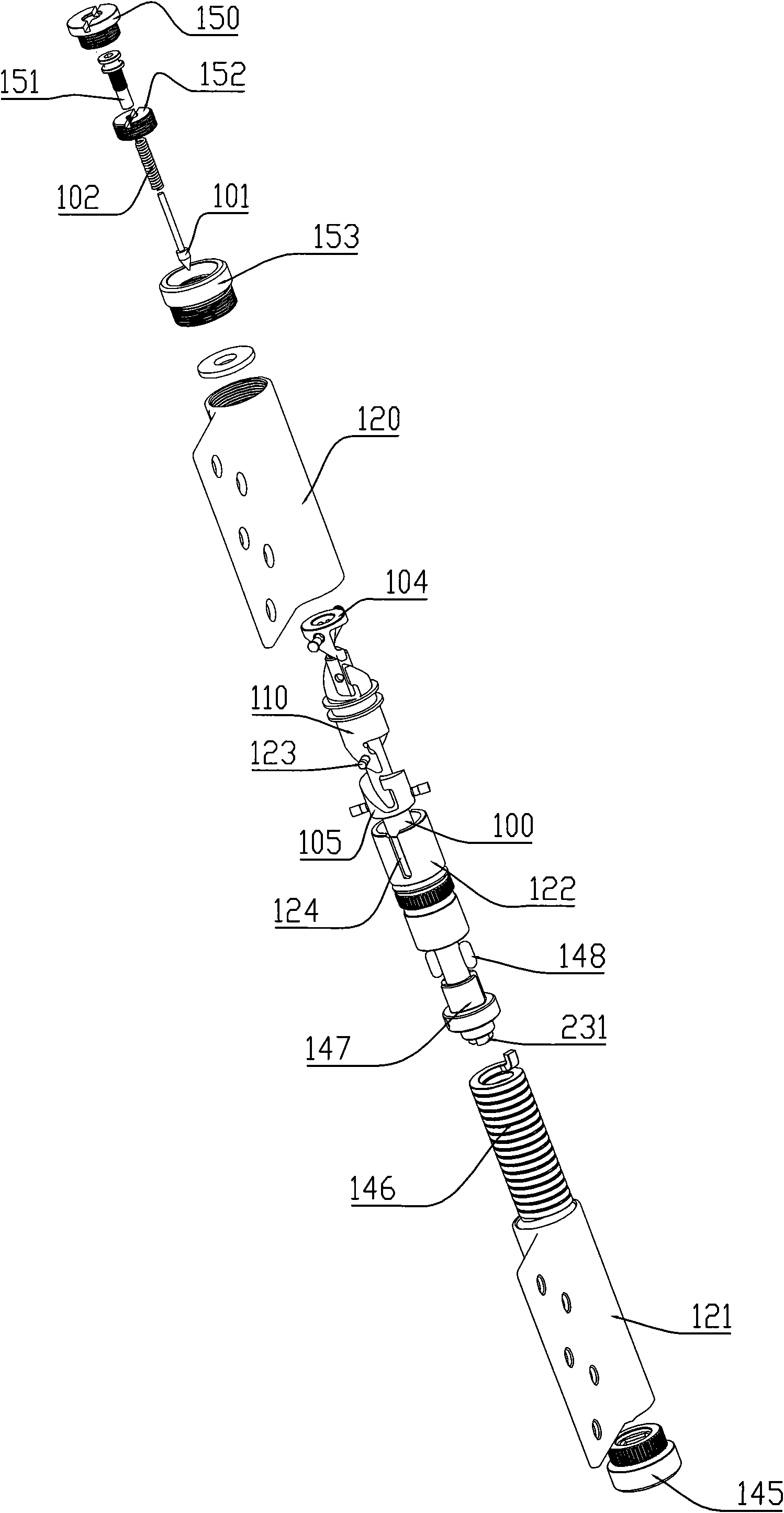

Hinge device

ActiveCN101787830AReduce the impactExtended service lifeBuilding braking devicesPin hingesCushioningEngineering

The invention discloses a hinge device which has the functions of door stop, automatic door closing, cushioning for door closing and the like. A cam piston, which divides the space in an upper shell into an upper independent compartment and a lower independent compartment, is arranged in the upper shell of the hinge device; and the cam piston moves up and down when the door sheet is opened and closed, thereby driving hydraulic oil in the upper compartment and the lower compartment to flow back and forth in the two compartments. When the door is automatically closed, the cam piston moves down,the hydraulic oil should flow into the upper compartment from the lower compartment via a cushion valve; the action of the resistance of the cushion valve has the cushioning effect on closing door, thereby avoiding overhigh closing speed, lightening the violent impact between a door sheet and a door frame while closing the door, reducing the noise while closing the door, and prolonging the service lives of the door sheet and the door frame. In addition, a hydraulic mechanism does not abrade a mechanical cushioning mechanism, thus the invention has the advantages of stable cushioning effect and long service life.

Owner:广州市新豪精密科技有限公司

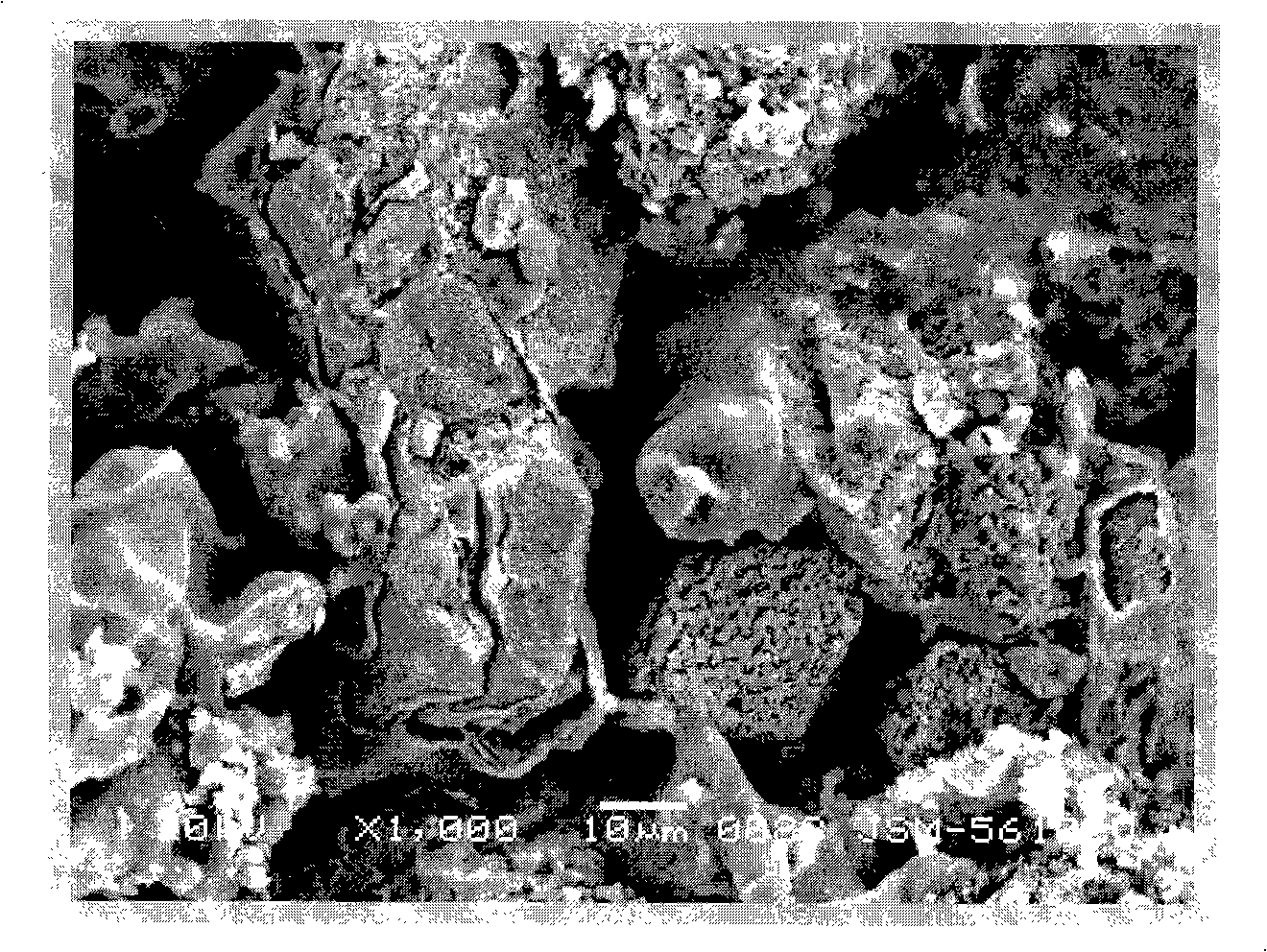

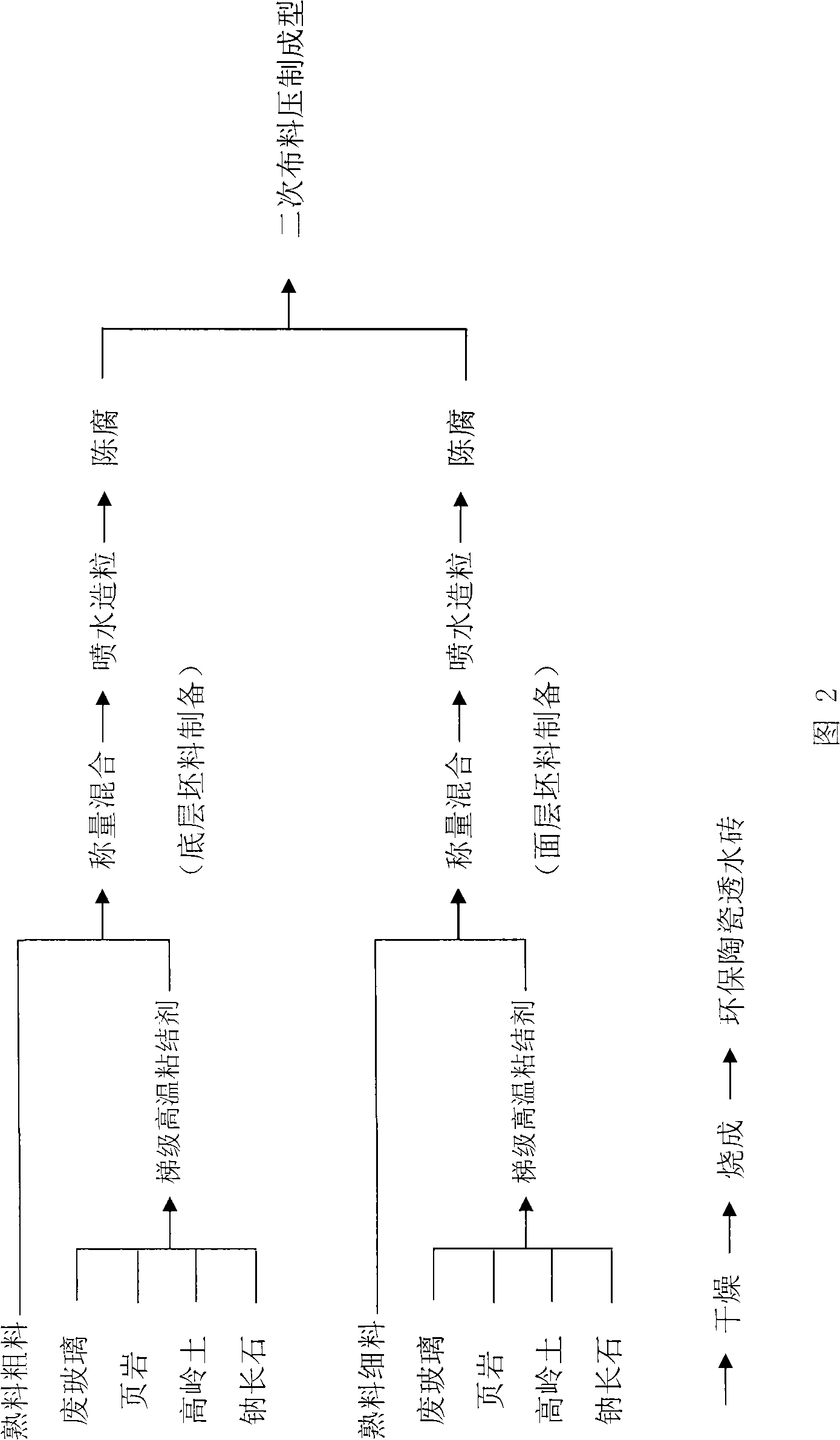

Preparation of enviroment protective ceramic water permeable brick

The invention belongs to the building material technology field, specially relates to a method for preparing a ceramic permeable brick comprising the following steps: 1) preparation of the bottom blank: crushing the solid waste clinkers and screening the same into coarse grains with a grain size of 2-3mm to get coarse grain solid waste clinkers, wherein the weight percentage of each component is as follows: 60-80% of coarse grain solid waste clinkers, 20-40% of cascade high temperature binders which pass through a 100 mesh screen; choosing the coarse grain solid waste clinkers and the cascade high temperature binders which pass through a 100 mesh screen for stand; sealing and staling the mixture by plastic clothing to get the bottom blank; 2) preparation of the surface course blank: crushing the solid waste clinkers, screening the same into fine grains with a grain size less than 2mm and more than or equal to 1mm; 3) moulding by means of hydraulic press machine of brick; 4) drying the permeable brick green body; 5) calcining the dried permeable brick green body by a silicon carbide bar furnace or a fuel gas shuttle kiln at 1100-1200 DEG C to get the environmental ceramic permeable brick products. The ceramic permeable brick has advantages of high intension and low cost.

Owner:WUHAN UNIV OF TECH +1

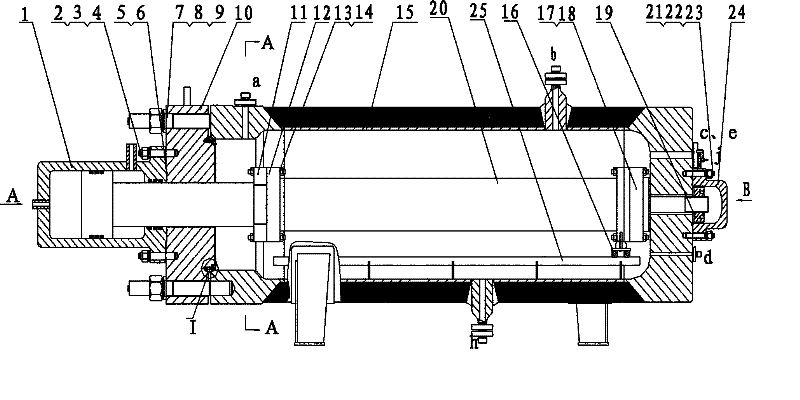

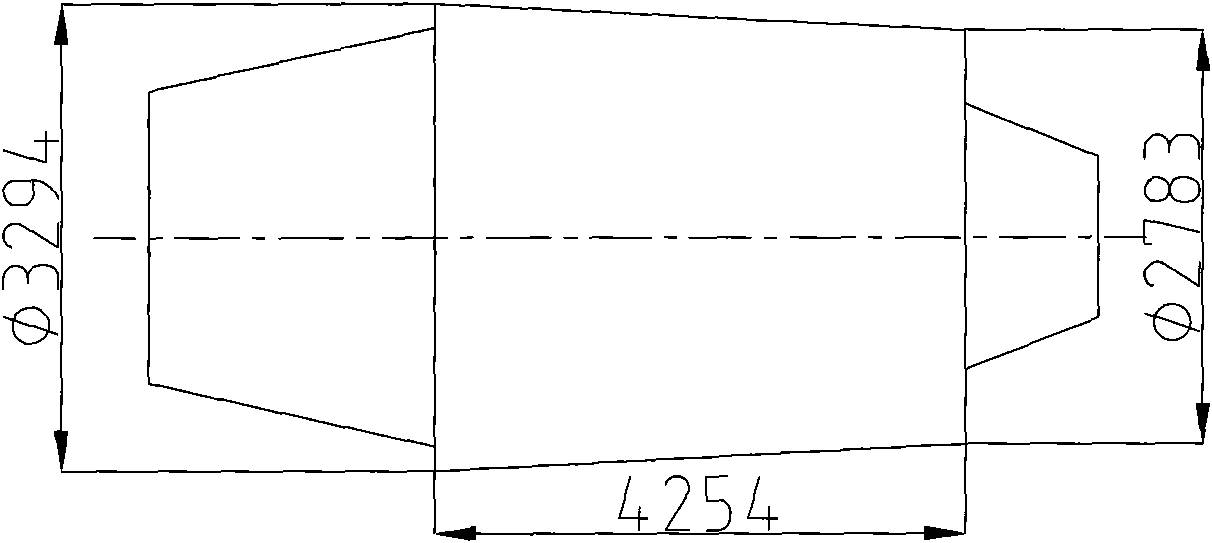

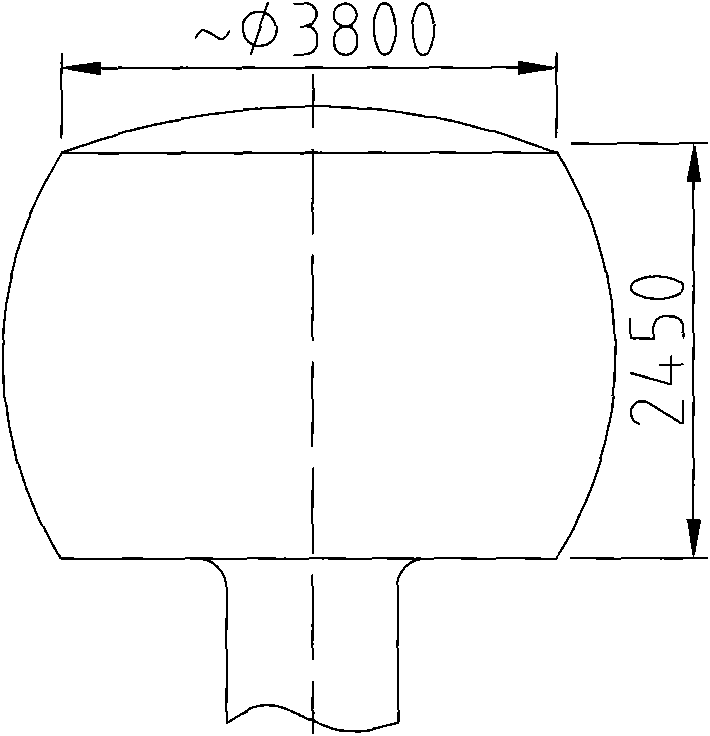

Buckling test device for deepwater submarine conduit

The invention relates to a buckling test device for a deepwater submarine conduit, belonging to the technical field of development, exploration and transportation of deepwater oil. The buckling test device of the deepwater submarine conduit comprises a pressure cabin consisting of a main cabin body, a front-end cabin cover and a tail-end cabin cover of the cabin body, wherein the front-end cabin cover and the tail-end cabin cover are respectively connected to the two ends of the main cabin body; a seal ring is respectively arranged on the inner sides of the front-end cabin cover and the tail-end cabin cover; an oil hydraulic press is fixed on the front-end cabin cover; the piston rod of the oil hydraulic press is extended into the main cabin body through penetrating the front-end cabin cover; the end part of the piston rod is provided with a piston rod flange; the upper surface of the bottom of the main cabin body is provided with guide rails; a tackle for transporting a conduit piece to be tested is placed on the guide rails; the two ends of the conduit piece to be tested are connected with an end flange of the conduit respectively; the piston rod flange is matched with one end flange of the conduit; and the other end flange of the conduit on the other end of the conduit piece to be tested is matched with a top-bottom flange which is fixed on the tail-end cabin cover of the cabin body. Through the buckling test device for deepwater submarine conduit, a deepwater high-pressure environment can be simulated, thus a buckling test for the conduit with various loads can be performed.

Owner:TIANJIN UNIV

Flashing precise planning and cutting hydropress

The invention relates to a flash precise slicing hydraulic press used for the punching shear of a forging flash. The equipment combines a linear driving mechanism, a blank holding mechanism, a back pressure mechanism and a buffer device into novel special punching shear equipment. By adopting the linear unidirectional driving type of the equipment, a workpiece is only subject to a vertical unidirectional punching shear force, but not subject to a lateral force or an additional torsion in the punching-shear process; owning to the blank holding mechanism, the flash can not be warped in the punching-shear process as the flap edge is subject to a compulsive restraining force; owning to the back pressure mechanism, the forging is supported by a back pressure cylinder in the punching-shear process, and the flexible deformation of the forging is reduced; owning to the buffer device, the impact to the hydraulic system is avoided. The slicing hydraulic press which is provided by the invention can be used for the normal punching shear of the flash of the forging, and is especially suitable for the precise punching shear of the flap edge of the forging; the incision of the forging after punching shear has high precision and good quality. The invention can be suitable for all the enterprises which produce forgings.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

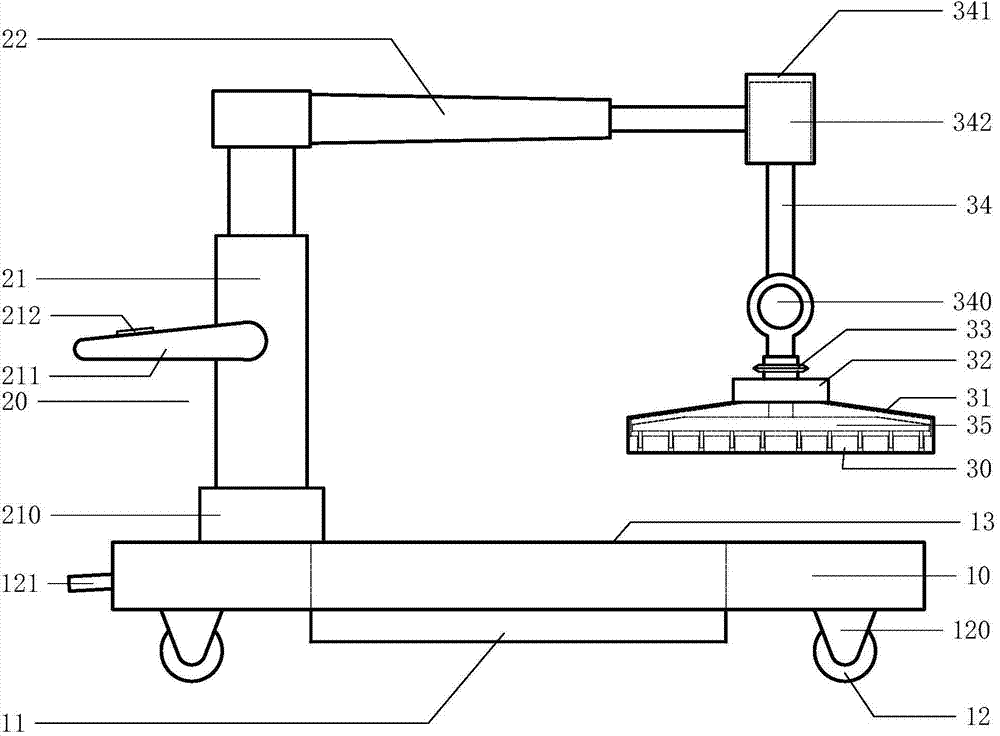

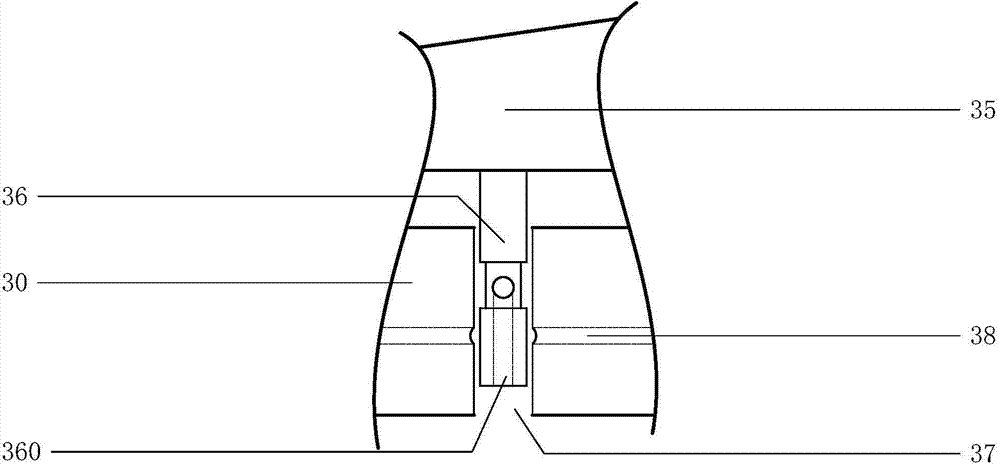

Movable ceramic tile laying machine

ActiveCN104775604AReduce labor intensityEasy to operateBuilding constructionsEngineeringUltimate tensile strength

The invention discloses a movable ceramic tile laying machine which comprises a movable rack, a sucker control frame and a ceramic tile sucker, wherein the movable rack is of a box-type structure and is provided with a multi-port hydraulic press and moving rollers; the sucker control frame is arranged at the tail of the movable rack and structurally comprises a vertical lifting frame and a transverse telescopic arm; the bottom surface of the ceramic tile is flat and smooth; a hood-type casing is arranged at the top of the ceramic tile sucker; a sand dust vibrator, a round ray gun and a suspension hanging rod are arranged at the top of the hood-type casing. According to the embodiment, ceramic tiles are carried by using a negative pressure attraction principle; sand dust on the bottom surfaces of the ceramic tiles is tempered and flattened by the sand dust vibrator; the ceramic tiles are laid to set horizontal positions by the round ray gun; a decoration worker can flatly and firmly lay the ceramic tiles on the ground by gripping a control handle by hand and controlling a keyboard; therefore the movable ceramic tile laying machine is reasonable in structure and convenient for control; the laying time of the ceramic tiles by the decorating workers can be shortened, and the labor intensity of the decorating workers can be reduced.

Owner:NANTONG CHENGSHAN CONSTR ENG

Forging method of tube sheet of nuclear power equipment

The invention discloses a forging method of tube sheets of nuclear power equipment, which forges SA-508 Grade 3 Class 2 dual vacuum steel ingots with the weight of 300+ / -20 tons by using a 165000 ton hydraulic press. The method comprises the following specific steps of step 1, first continuous upsetting, ensuring that the forging rate is 1.85; step 2, first extension by using a wide smashing and strong compressing method; step 3, second continuous upsetting, ensuring that the forging rate is 2.1; step 4, second extension; step 5, third continuous upsetting; step 6, forging and pressing by using a differential temperature compression method; immediately spraying frost to forging parts for cooling or carrying out wind cooling after the third continuous upsetting so that the surface of the forging part is cooled to 700 to 800 DEG C, and then forging by using the differential temperature compression method; and step 7, finally rotating 360 degrees for crossed forging. By carrying out continuous upsetting twice and combining the wide smashing and strong compressing method and the differential temperature compression method, the invention is capable of completely forging the forging part and obtaining uniform deformation of the forging part, and can integrally compress tube sheet forging parts with extremely thick sections from top to bottom so that the tube sheet forging parts havefine and uniform grains, and stable performance can meet requirement of fault detection and further meet various technical conditions of nuclear power tube sheets.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

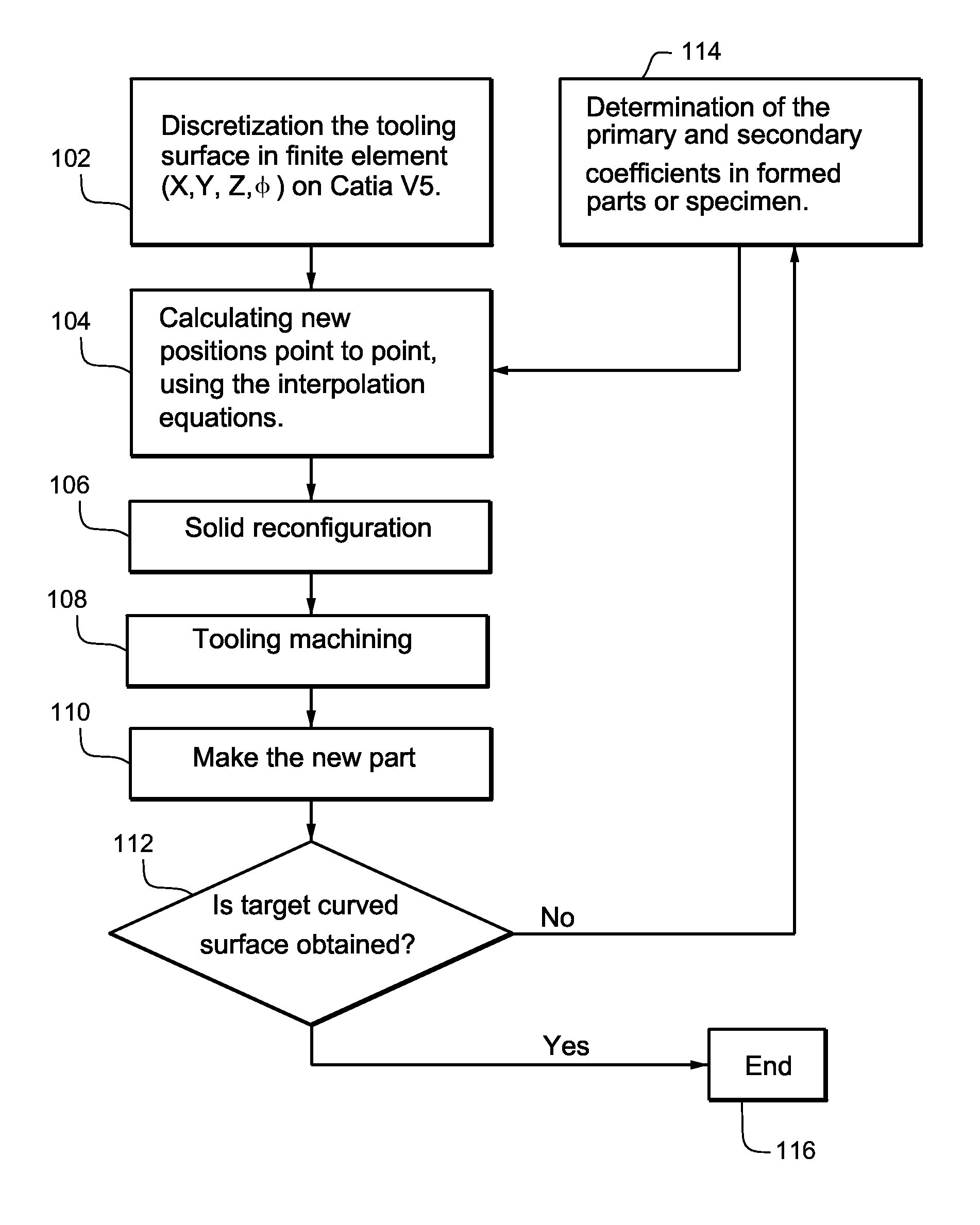

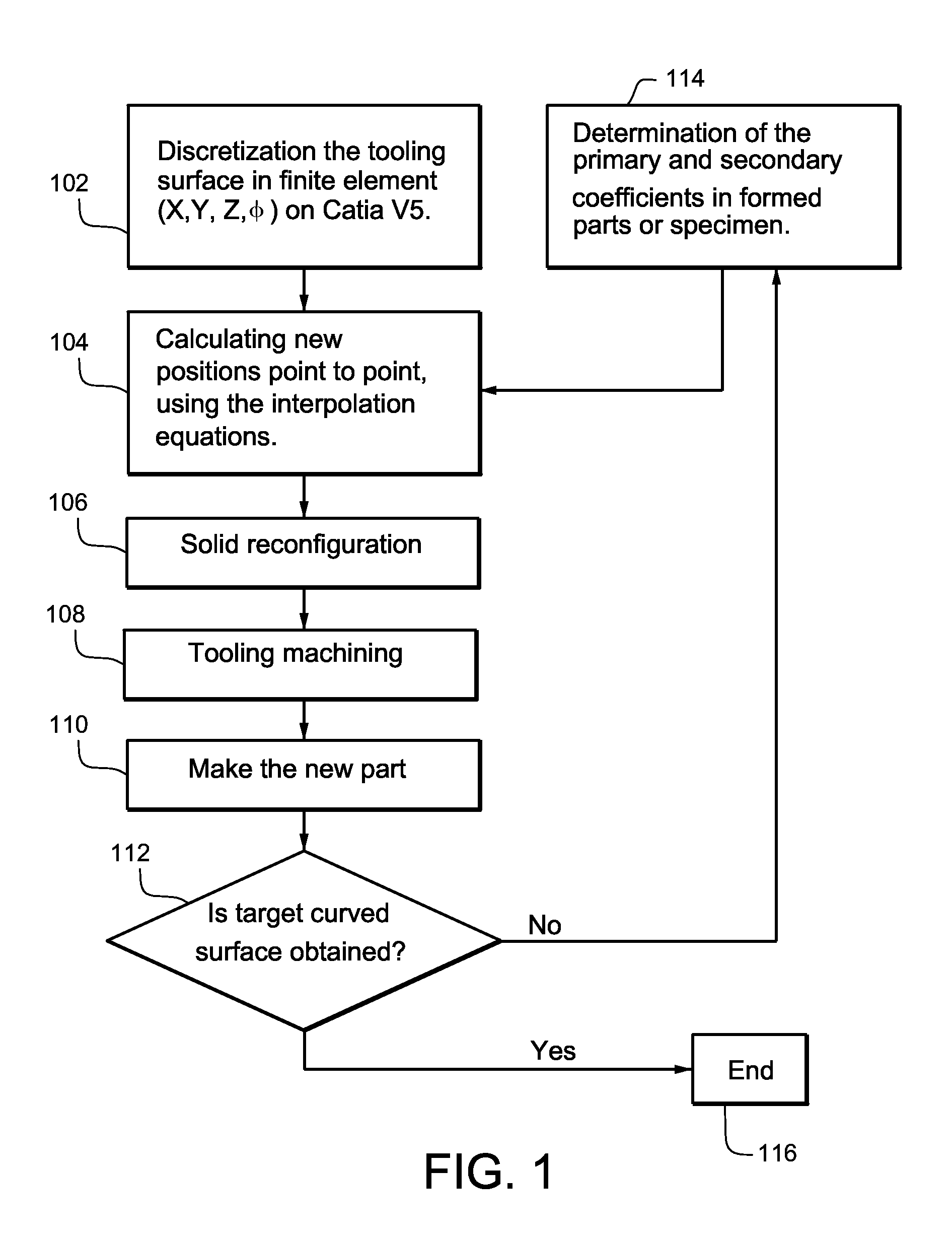

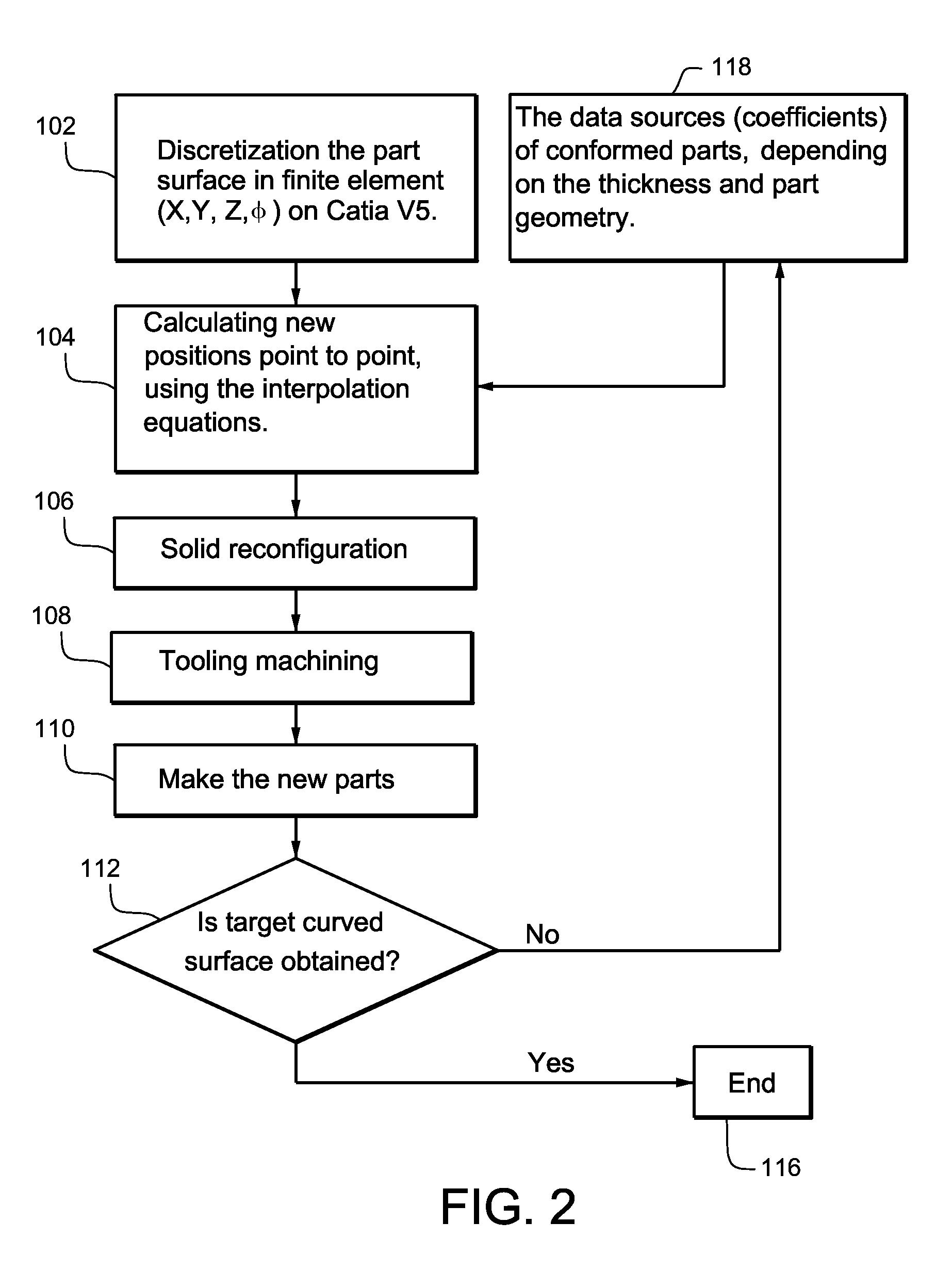

Springback compensation in formed sheet metal parts

ActiveUS20150134093A1Constant adjustability for curvesGeometric CADProgramme controlLeading edgeFinite element method

Finite element methods for compensating for springback in aircraft parts meet the visual appearance and aerodynamics of complex parts including those made of fabricated sheet metal. The methods can be used to make narrow parts (e.g., leading edge and slats) and double negative curvature parts, and do not need to leave marks on the surface of the sheet so that visual aspects are not adversely affected. The compensation technique, point to point uses approach equations with constant adjustable for curves. The constant(s) used depend on geometry and type of forming (e.g., stretch or hydraulic press). This example non-limiting process does not need to use mechanical properties of the material.

Owner:EMBRAER SA

Double-work position automatic die-changing system for hydraulic press

It relates to a hydraulic dual work station automatic mold changing system. It comprises tracks, mold changing cart, electric and pneumatic system, features in two mold work stations on the mod changing cart with each one fixed with chain passing grooves, guide track, guide stopper and spring pin to prevent the jumping of the mold plates, positioning device under the cart, crashproof device at both ends, middle connection platform between the track and the hydraulic machine, chain passing groove, guide track and stopper on the platform, delivery device at the other end of the track opposite to the connection platform, using front end hooking push and pull chains as the extraction tool for mold delivery and exchange. It is independent of the main of the hydraulic machine, reduces its structure, land occupation, auxiliary working period, meeting the need for processing parts of different specifications and kinds.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com