Patents

Literature

427results about How to "Reduce bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

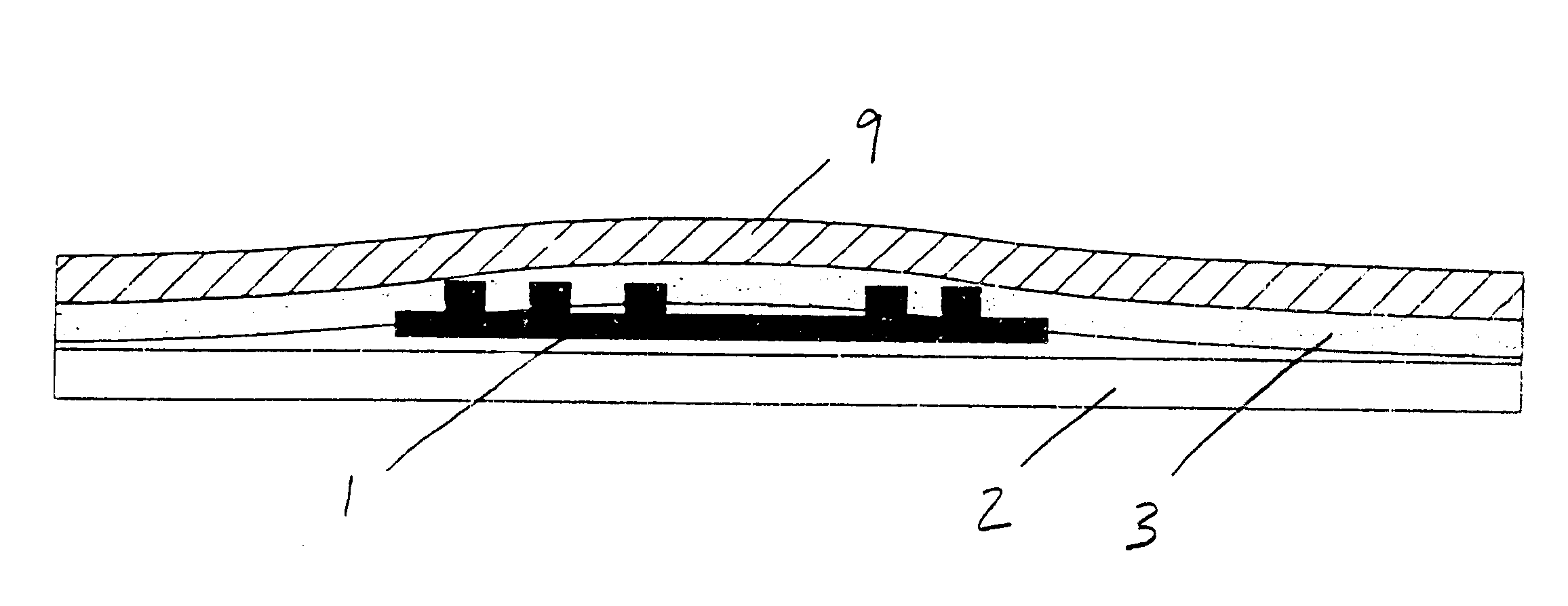

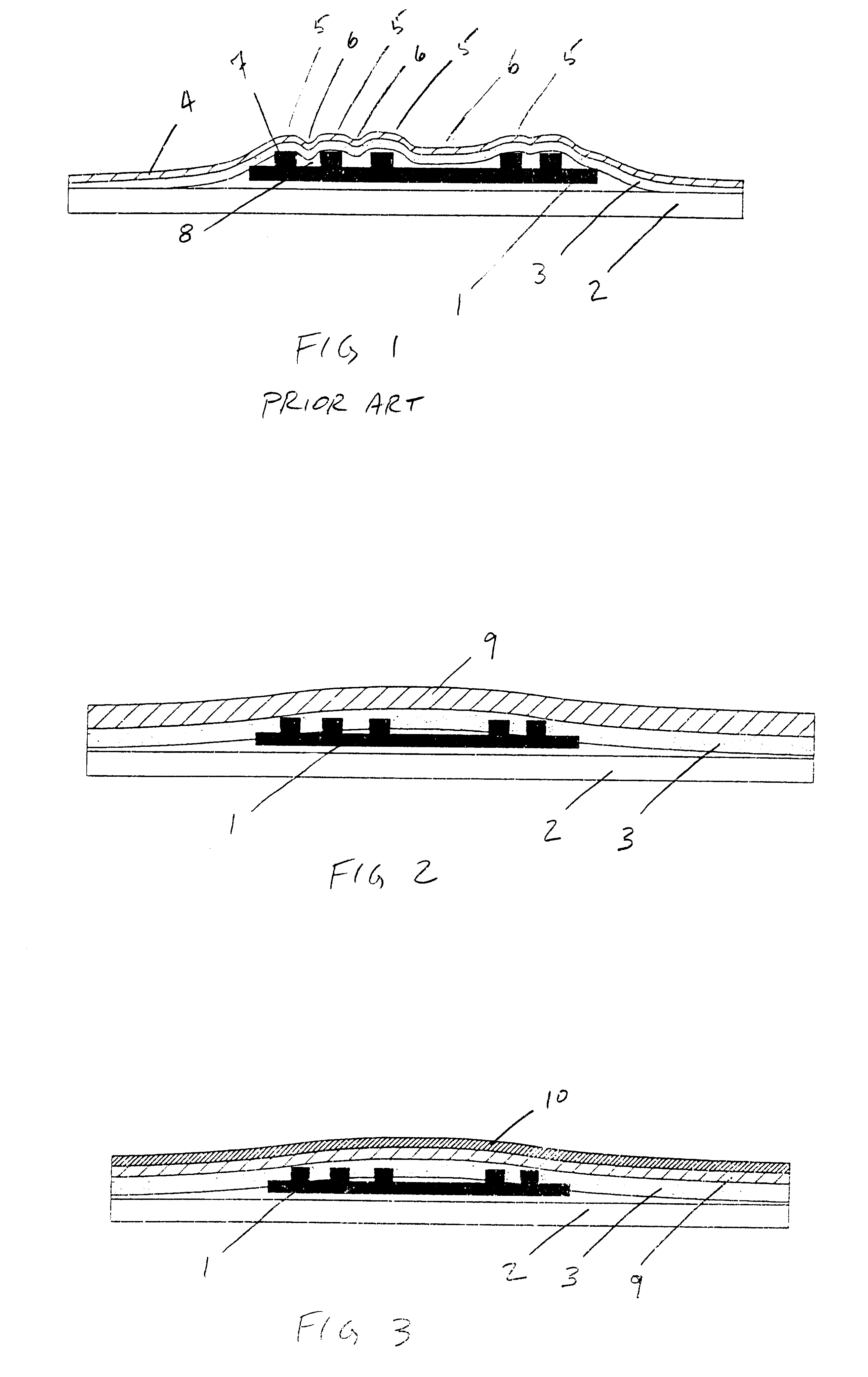

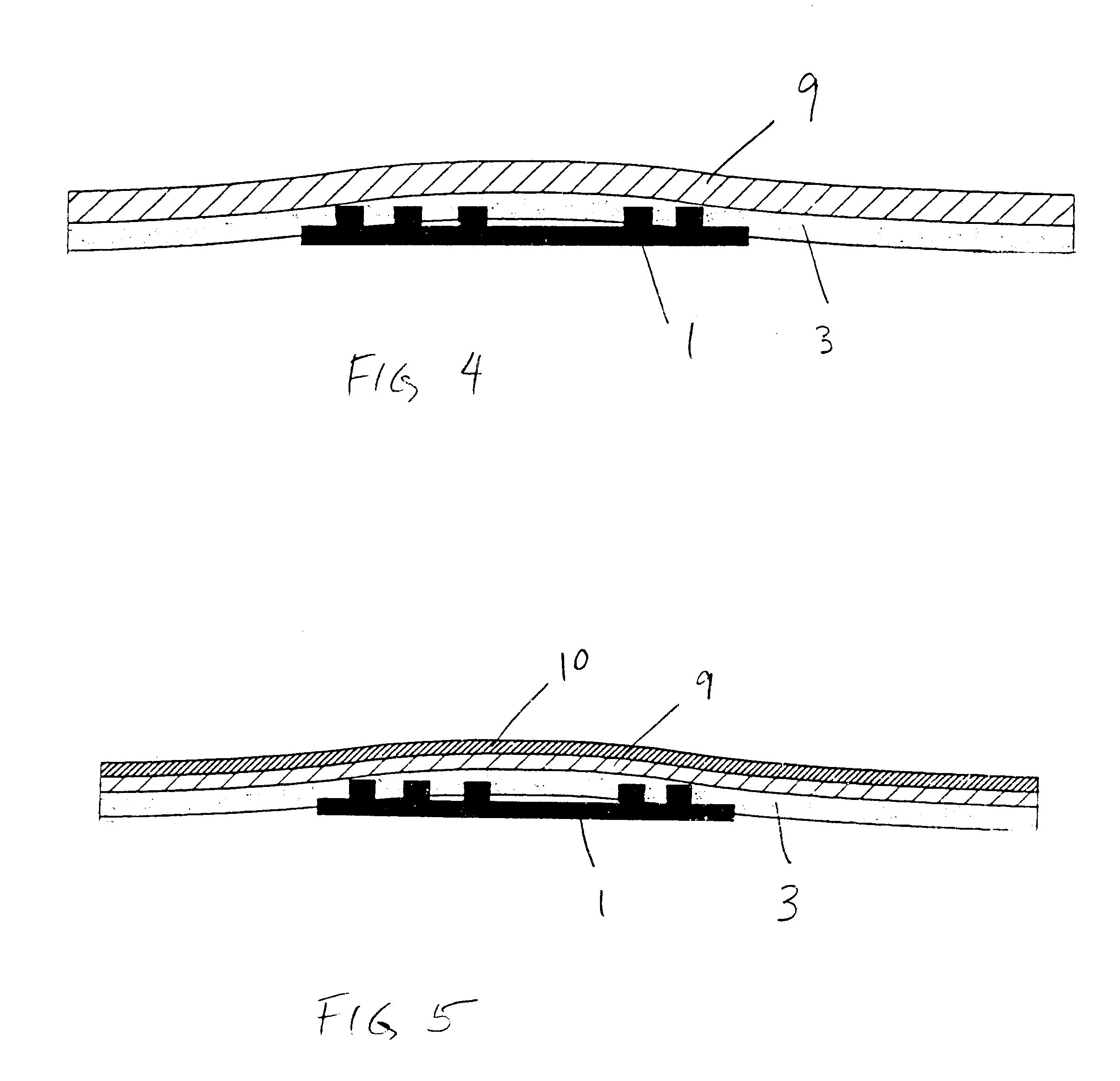

Profile corrected label with RFID transponder and method for making same

InactiveUS6369711B1Reduce deformationReduce bendingConcealed burglar systemsRecord carriers used with machinesEngineeringFace sheet

The present invention sets out a label containing an RFID transponder having a uniform printable surface. The present invention presents a face sheet having an increased rigidity and / or thickness which does not readily conform to the profile of an RFID transponder contained beneath the face sheet. This results in a label having a more readily printable surface, and also presents a label having higher security as a result of the masking of the profile of the contained RFID responder.

Owner:INTERMEC IP

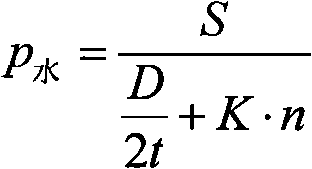

Method for detecting hydrostatic pressure of thin-wall steel pipe under end face seal condition

InactiveCN102042935AEasy to calculateCalculations are reliableMaterial strength using tensile/compressive forcesPore water pressureInlet valve

The invention relates to a method for detecting the hydrostatic pressure of a thin-wall steel pipe under the end face seal condition. Used equipment is an end face seal steel pipe hydrostatic pressure testing machine which comprises a testing machine body, a hydraulic system, a water pressure system and an electric control system. The method for detecting the hydrostatic pressure of the thin-wall steel pipe under the end face seal condition comprises the following steps of: 1) feeding the pipe and pre-clamping, namely respectively sealing the two pipe orifices of the pressure test thin-wall steel pipe by using two seal flat gaskets on a main pressure test head body and an auxiliary pressure test head body; 2) filling water, namely filling low-pressure water into the pressure test thin-wall steel pipe, exhausting, and closing a low-pressure water inlet valve, an exhaust port and a pressure relief port; 3) pressurizing, namely supplementing the water to the pressure test thin-wall steel pipe for pressurizing, pressurizing a main hydraulic cylinder synchronously, and determining a test pressure value according to a calculation formula; 4) stabilizing pressure, namely after the pressure of the water in the pressure test thin-wall steel pipe reaches a specified test pressure value, stabilizing the pressure until time specified by the test is up; and 5) relieving the pressure and discharging the water and the pipe. The detection method overcomes the defects of the conventional pipe making specifications, and the calculation process is simple, convenient and reliable.

Owner:马利芳

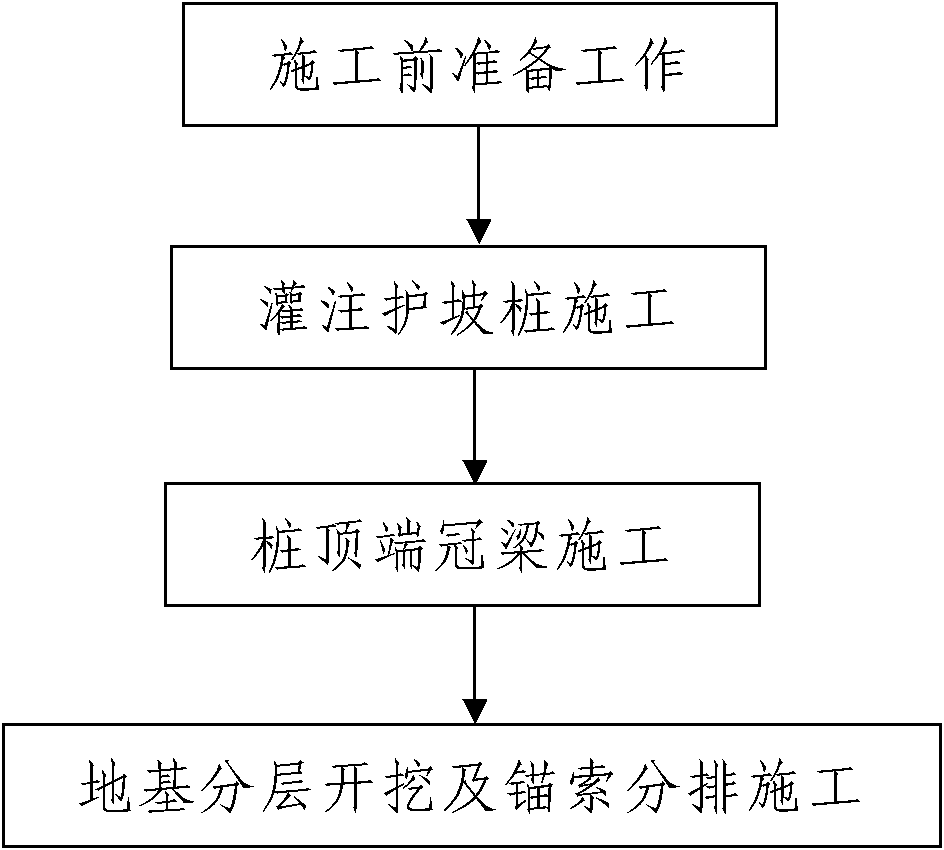

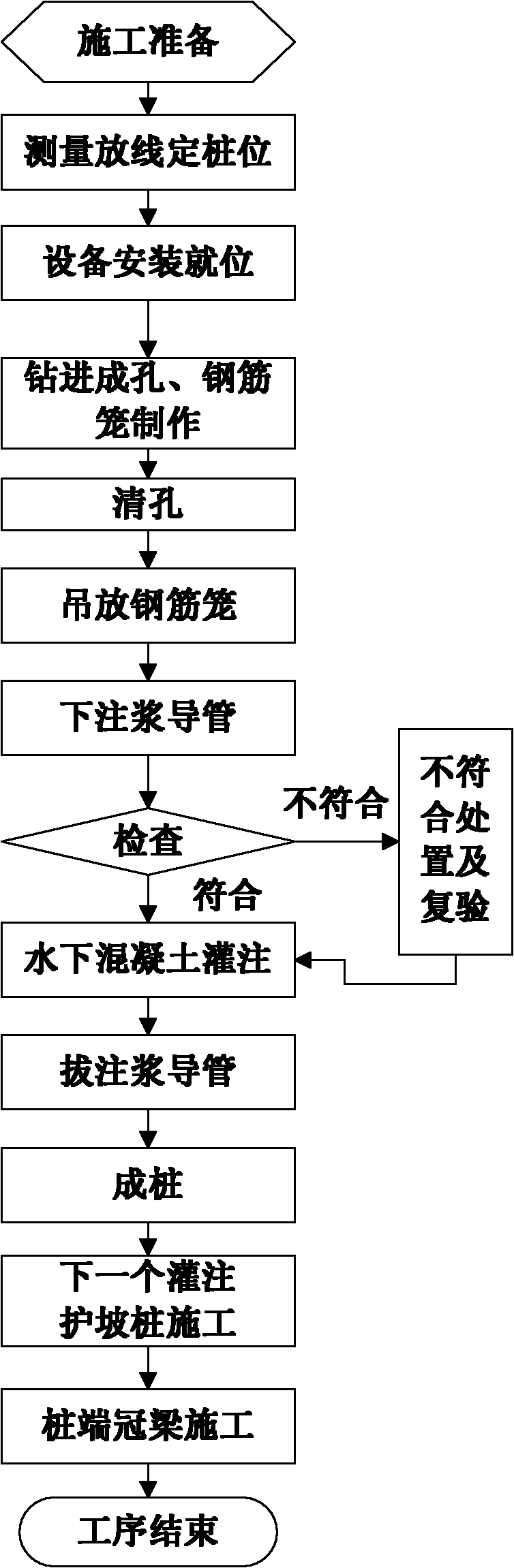

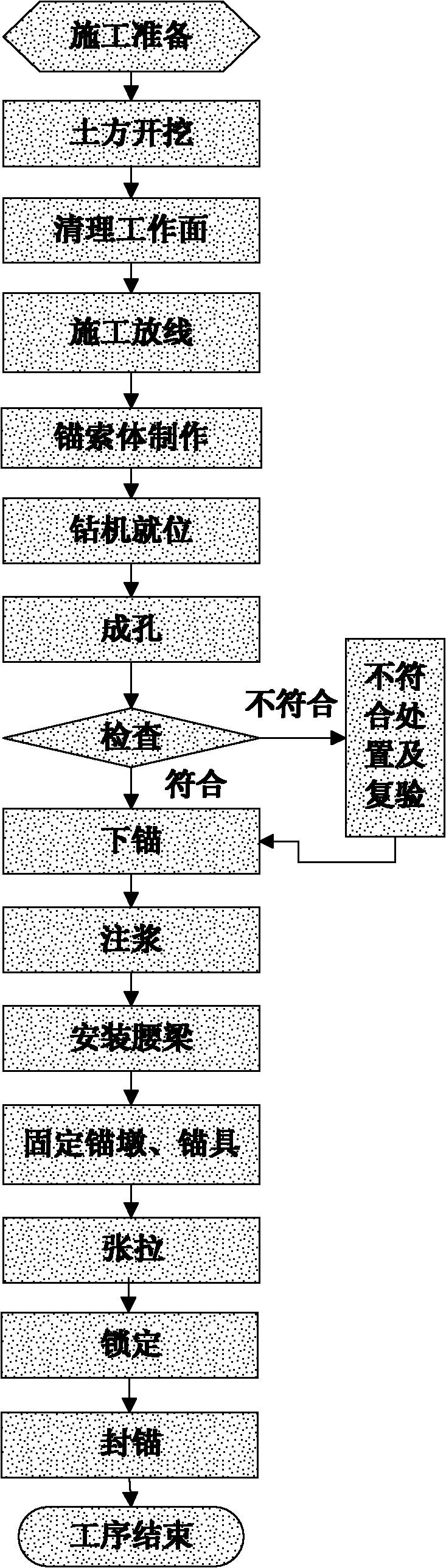

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784ASimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

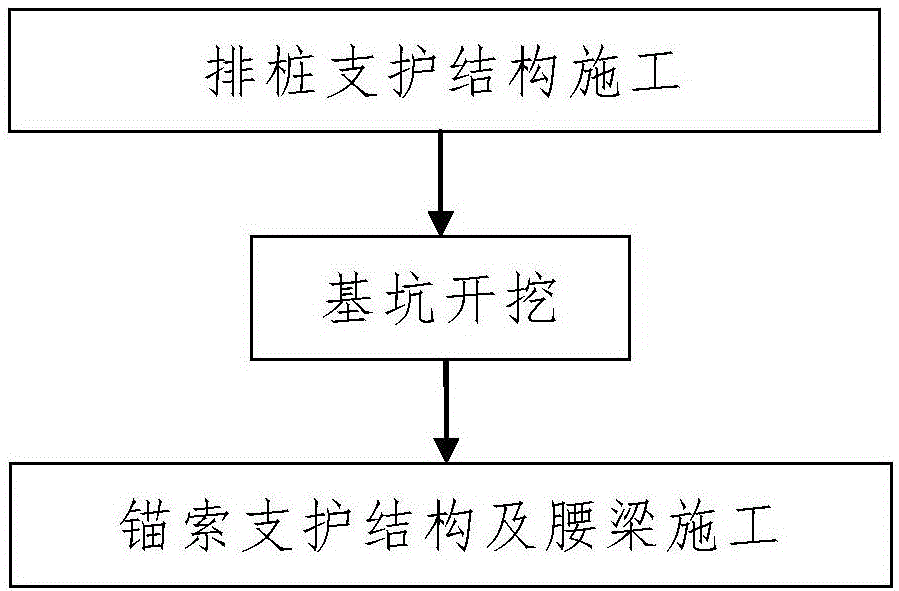

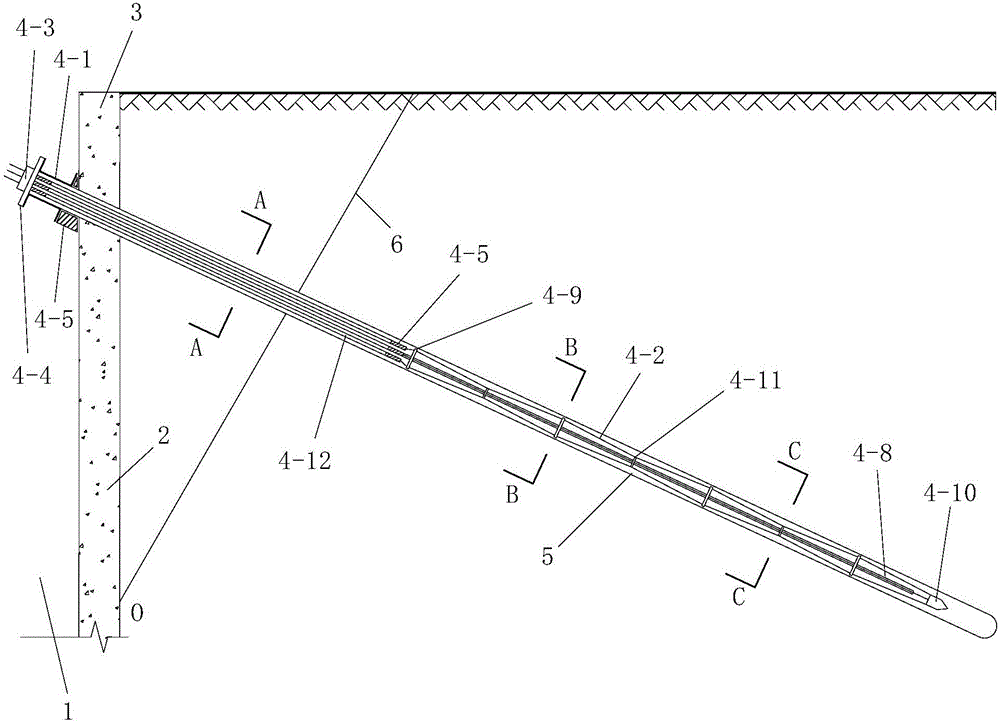

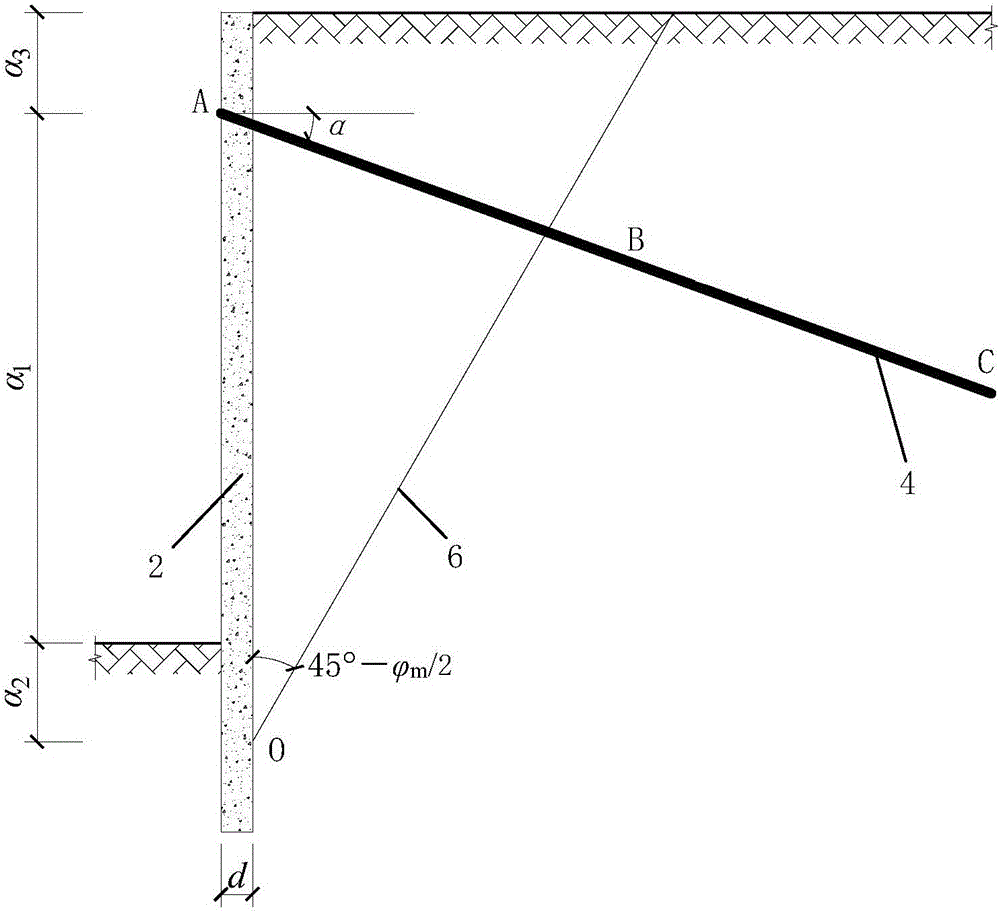

Construction method for supporting deep foundation pit through grouting after pile arrangement and anchor cable mounting

ActiveCN106320346AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressEngineering

The invention discloses a construction method for supporting a deep foundation pit through grouting after pile arrangement and anchor cable mounting. The construction method comprises the steps that firstly, pile arrangement supporting structure construction is performed, wherein a pile arrangement supporting structure comprises multiple slope protection piles which are arranged along the peripheral edge line of the constructed foundation pit from front to rear and a crown beam connected to the upper portions of the slope protection piles; secondly, foundation pit excavation is performed, wherein the constructed foundation pit is excavated from top to bottom; and thirdly, anchor cable supporting structure and waist beam construction is performed, wherein during excavation of the constructed foundation pit, the constructed foundation pit is excavated to the anchoring position of an anchor cable supporting structure, and the anchor cable supporting structure is constructed; and the anchor cable supporting structure comprises multiple prestress anchor cables, each prestress anchor cable comprises an anchor cable body, a primary grouting pipe and a secondary grouting pipe, and each anchor cable body comprises multiple steel strands. The method has the beneficial effects that the steps are simple, the design is reasonable, construction is easy and convenient, the use effect is good, the deep foundation pit supporting construction process can be completely easily, conveniently and quickly, the cost of the adopted prestress anchor cables is low, the anchoring force is high, and the deep foundation pit can be supported effectively.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

Formula of ceramic for insulator ceramic body and preparation method of the insulator ceramic body

InactiveCN102241506AHigh mechanical strengthImprove electrical performanceCeramicsPotassium dioxideMullite

The invention discloses a formula of a ceramic for an insulator ceramic body and a preparation method of the insulator ceramic body. Beneficial effects of a technical scheme of the invention comprise that the formula contains specific proportions of silicon oxide and alumina and the silicon oxide and the alumina are sintered into mullite to improve a mechanical strength and a hot and cold performance of a ceramic material, and silica can reduce a dry degree, a firing shrinkage degree and a bending deflection degree of a ceramic blank, play a supportive role in a ceramic blank and improve a mechanical strength of a ceramic blank; alumina can improve greatly a mechanical strength of ceramic blank; added potassium dioxide can reduce a sintering temperature, fill gaps of a ceramic blank and improve a compactness of a ceramic material, and a mechanical strength and an electrical performance of a ceramic blank; and through a cooperation with a preparation method, an insulator ceramic body obtains improved greatly hydrophobic properties, anti-fouling properties, insulating properties and mechanical properties.

Owner:SUZHOU AIJIAN ELECTRICAL PORCELAIN

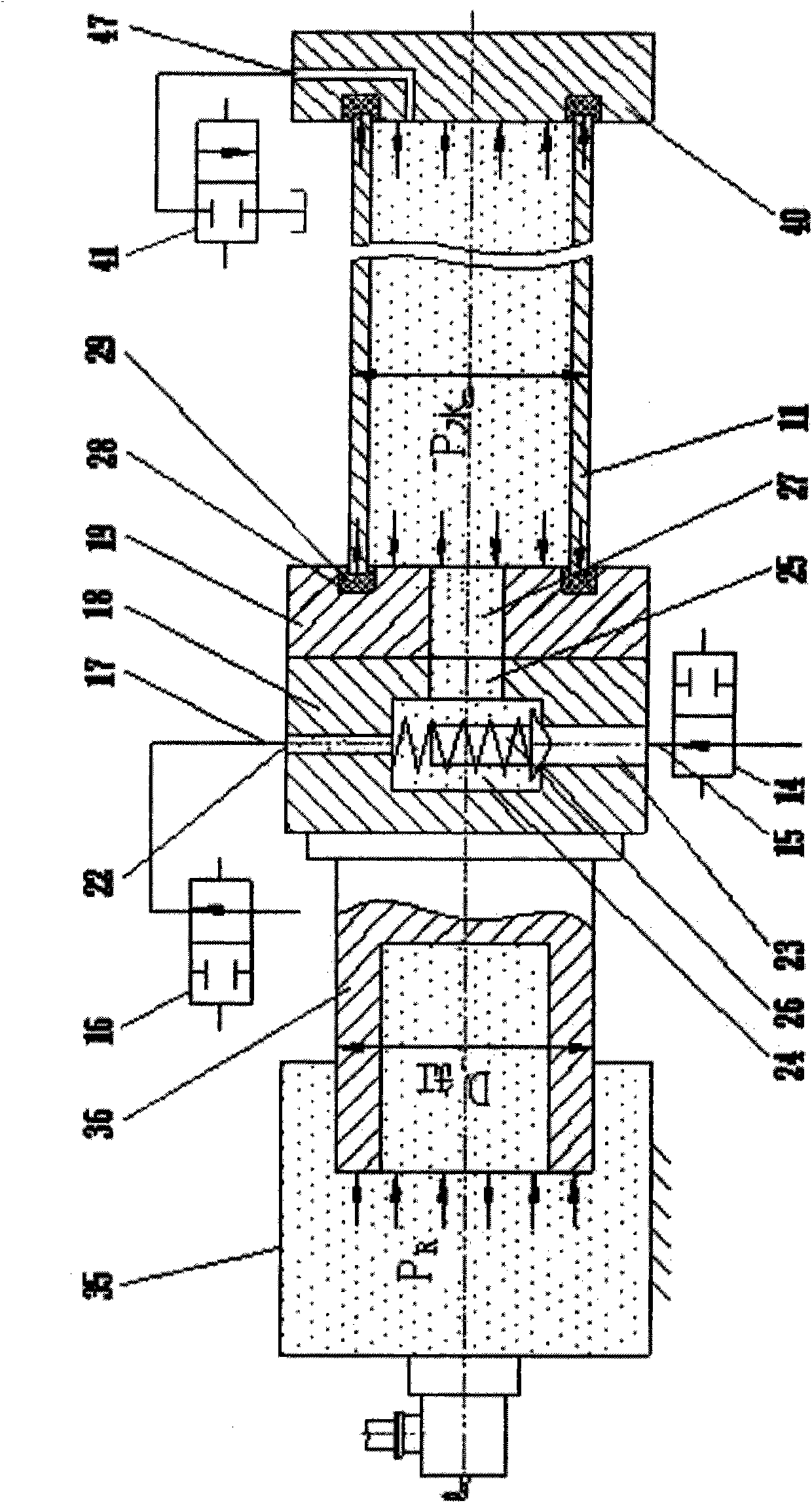

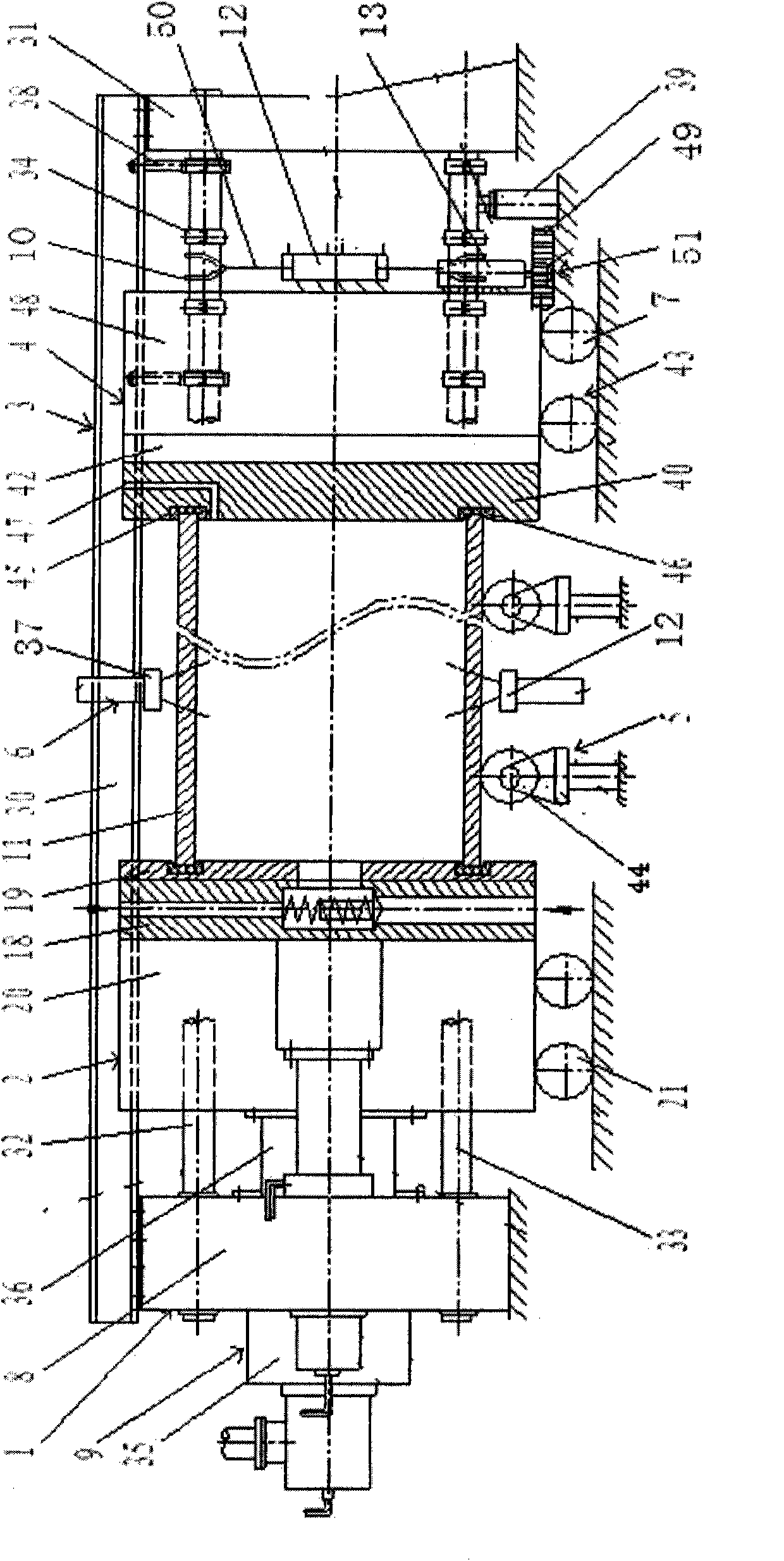

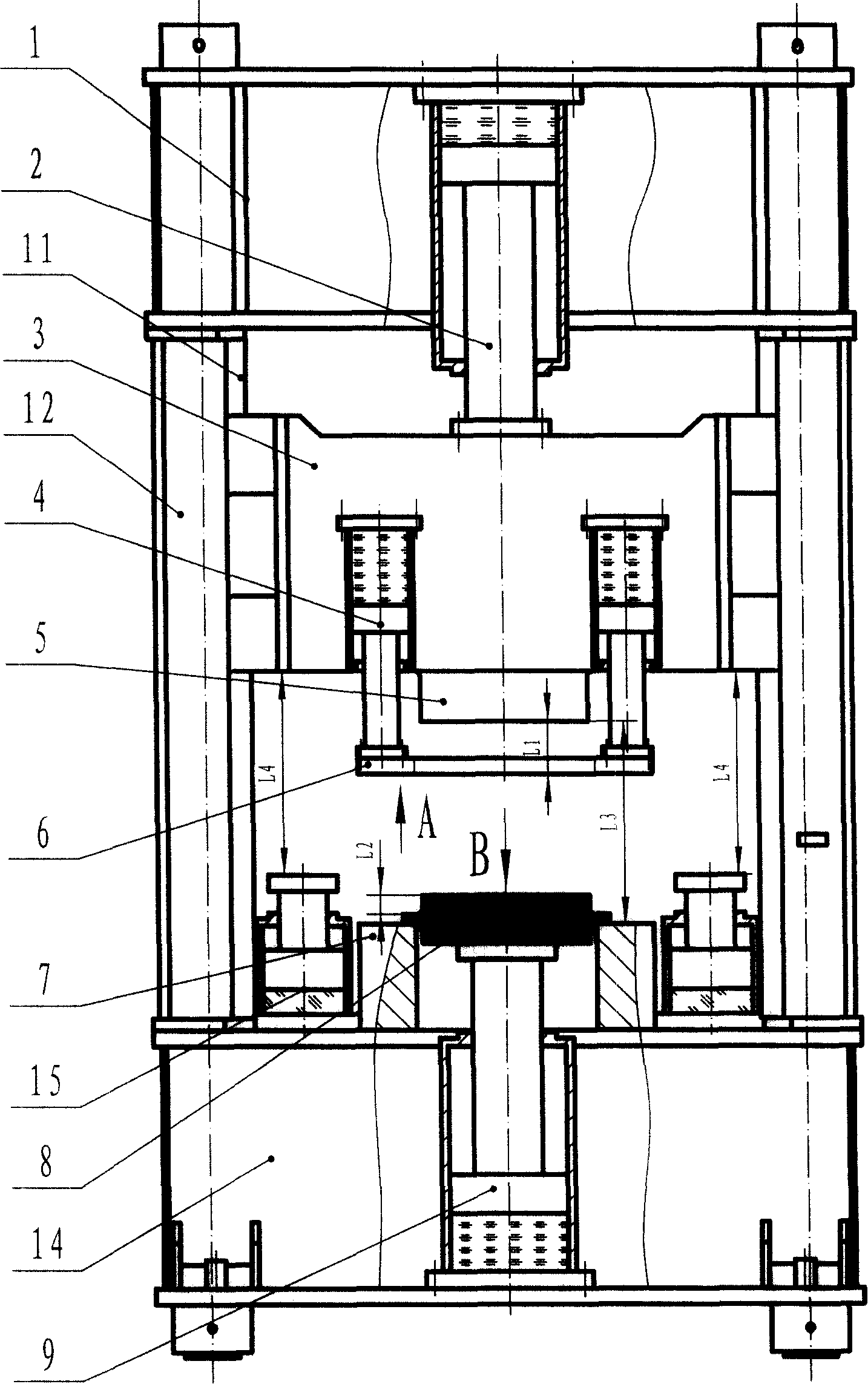

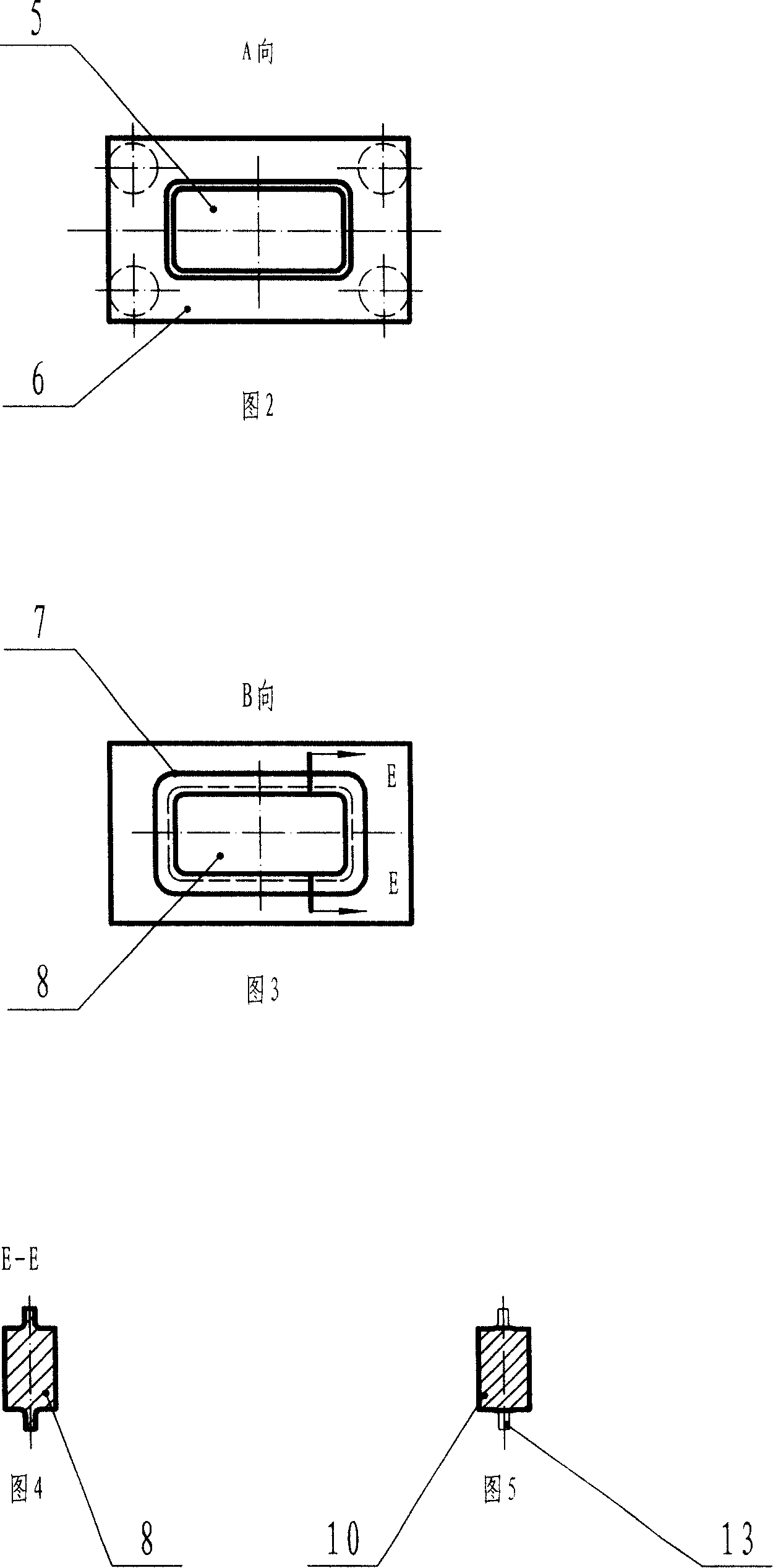

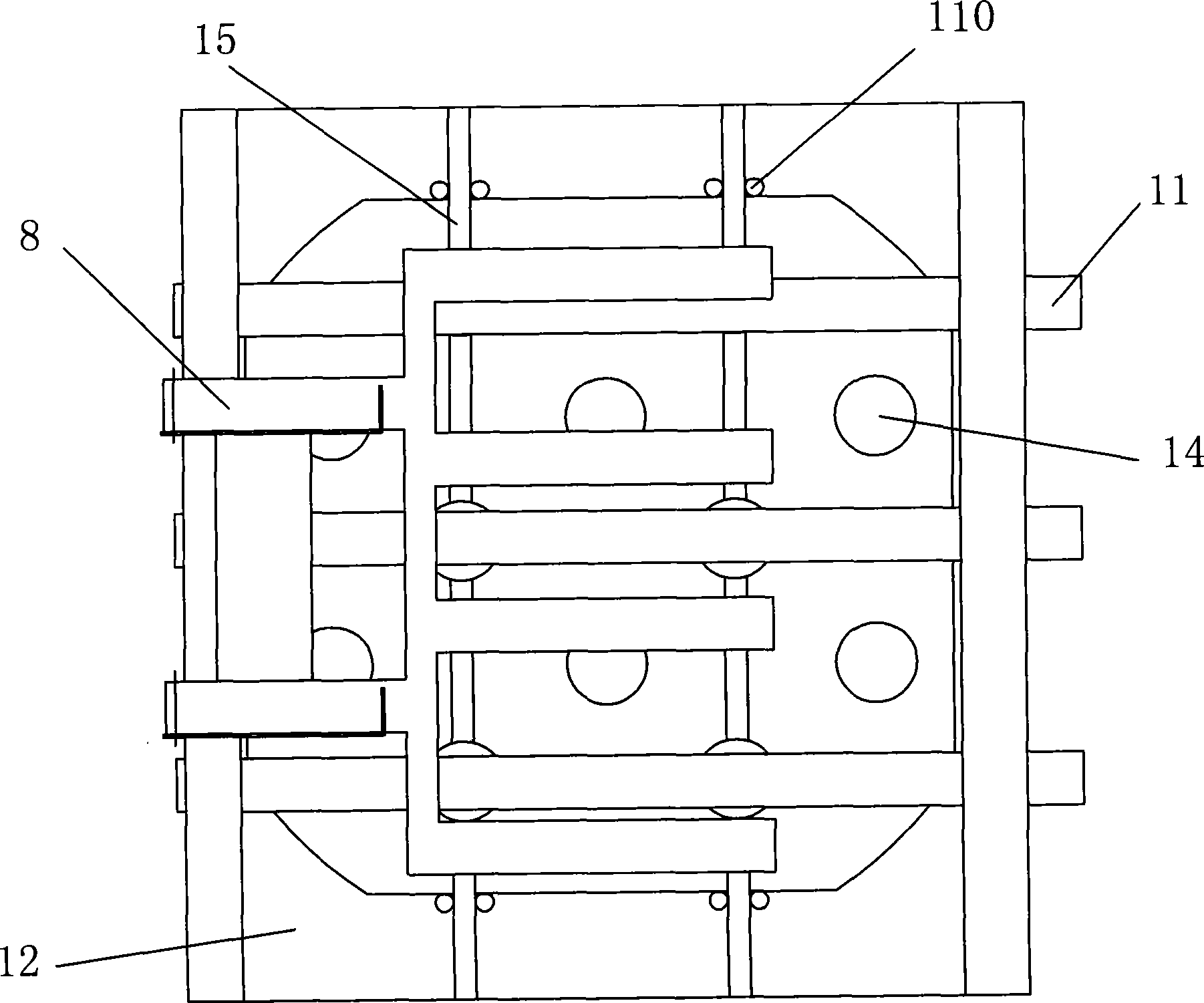

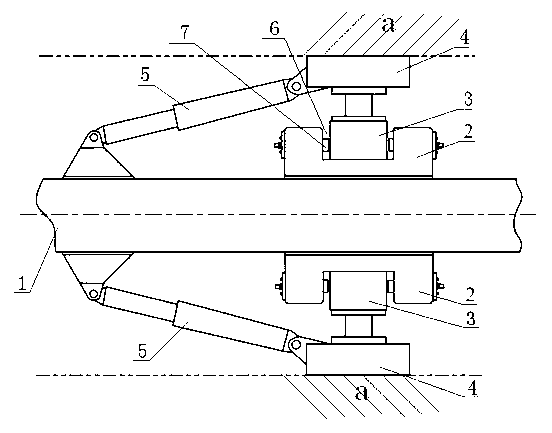

Flashing precise planning and cutting hydropress

The invention relates to a flash precise slicing hydraulic press used for the punching shear of a forging flash. The equipment combines a linear driving mechanism, a blank holding mechanism, a back pressure mechanism and a buffer device into novel special punching shear equipment. By adopting the linear unidirectional driving type of the equipment, a workpiece is only subject to a vertical unidirectional punching shear force, but not subject to a lateral force or an additional torsion in the punching-shear process; owning to the blank holding mechanism, the flash can not be warped in the punching-shear process as the flap edge is subject to a compulsive restraining force; owning to the back pressure mechanism, the forging is supported by a back pressure cylinder in the punching-shear process, and the flexible deformation of the forging is reduced; owning to the buffer device, the impact to the hydraulic system is avoided. The slicing hydraulic press which is provided by the invention can be used for the normal punching shear of the flash of the forging, and is especially suitable for the precise punching shear of the flap edge of the forging; the incision of the forging after punching shear has high precision and good quality. The invention can be suitable for all the enterprises which produce forgings.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

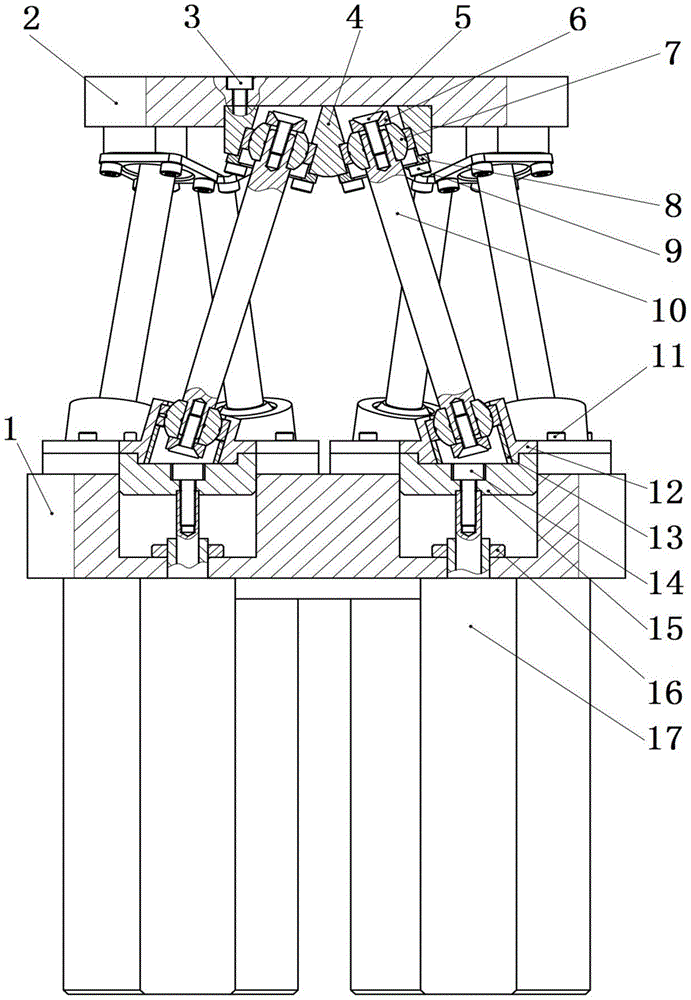

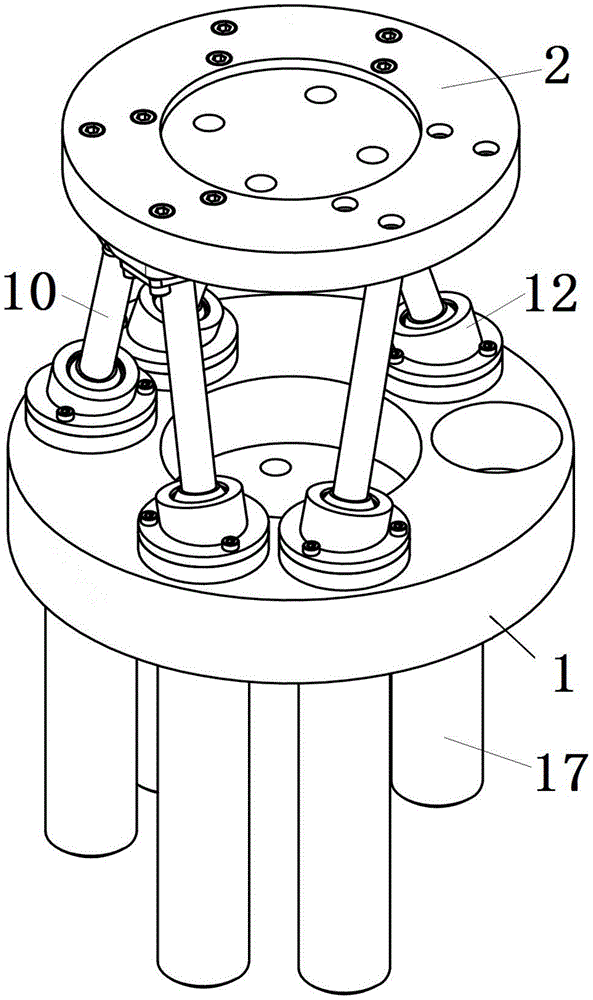

Six-degree-of-freedom parallel micro platform

InactiveCN104002299ASolve sizeSolve the accuracy problemProgramme-controlled manipulatorFixed bearingActuator

The invention discloses a six-degree-of-freedom parallel micro platform which comprises a fixed platform body and a movable platform body. The lower surface of the movable platform body is evenly provided with three sets of fixing bearing bases, and each fixing bearing base is connected with the fixed platform body downwards in a transmission mode through two branch chains, namely, the three sets of the bearing bases and six branch chains are arranged between the fixed platform body and the movable platform body. According to the six-degree-of-freedom parallel micro platform, the fixed platform body is fixed to the installation end face at the tail end of a macro robot through a micro platform installation hole, a tail end actuator is fixed to the movable platform body through a gripper installation hole in the movable platform body, the size is small, the weight is low, rigidity and precision are high, six-degree-of-freedom precise trimming of space postures of a workpiece in the assembly process is achieved, and the aim of precise assembly is achieved.

Owner:XIAN UNIV OF TECH

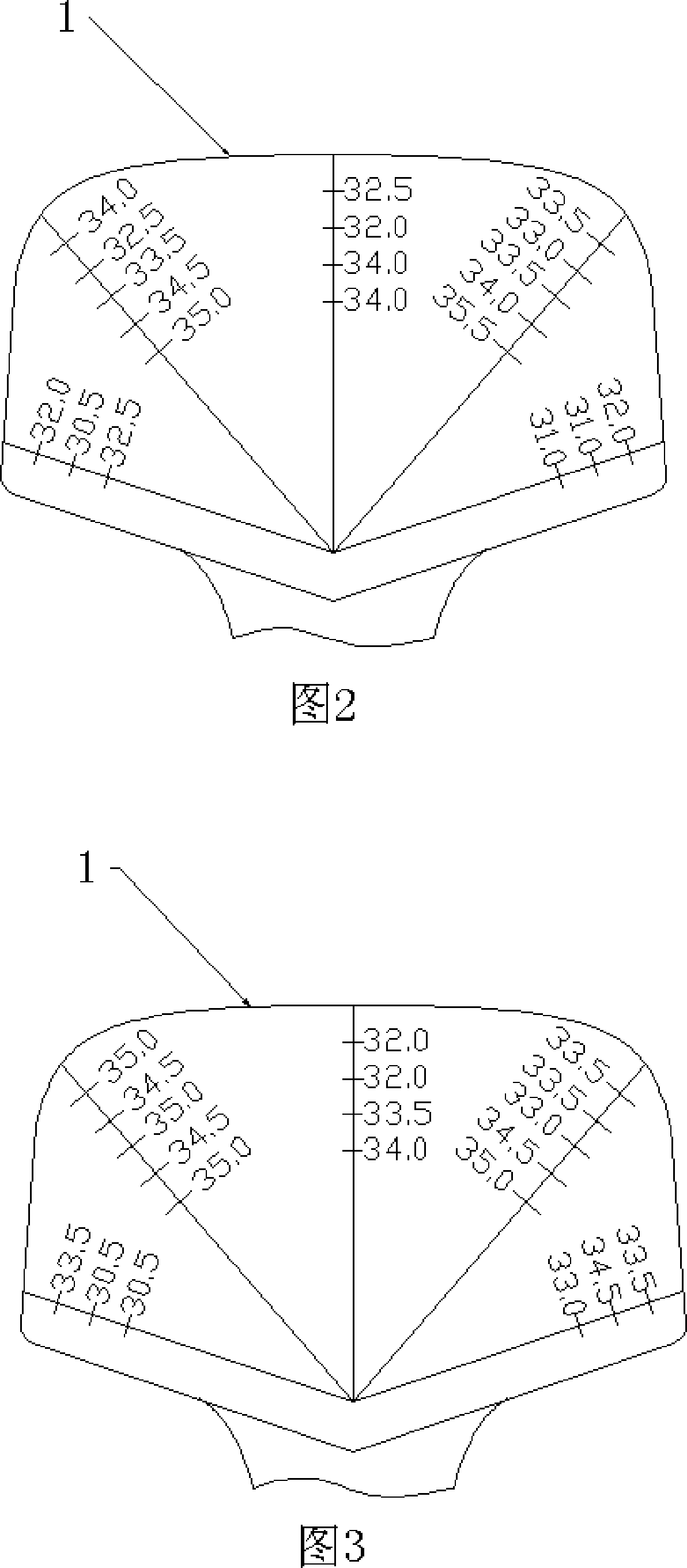

Steel rail and producing method thereof

InactiveCN101148736AReduce rateNo contact fatigue cracksFurnace typesHeat treatment process controlChemical compositionTrace element

The present invention relates to metallurgy technology, and is especially one kind of steel rail with high contact fatigue resistance and its production process. The steel rail has the chemical composition comprising C 0.61-0.73 %, Si 0.20-0.50 %, Mn 0.80-1.30 %, and Fe and other trace elements for the rest. It has tensile strength Rm over 1080 MPa, fracture toughness KIC over 45 MPa.m1 / 2, excellent contact fatigue resistance and high comprehensive use effect. Its production process includes the on-line treatment of rolled steel rail, including simultaneous quenching and cooling to the rail head, the rail web and the rail base.

Owner:PANZHIHUA IRON AND STEEL

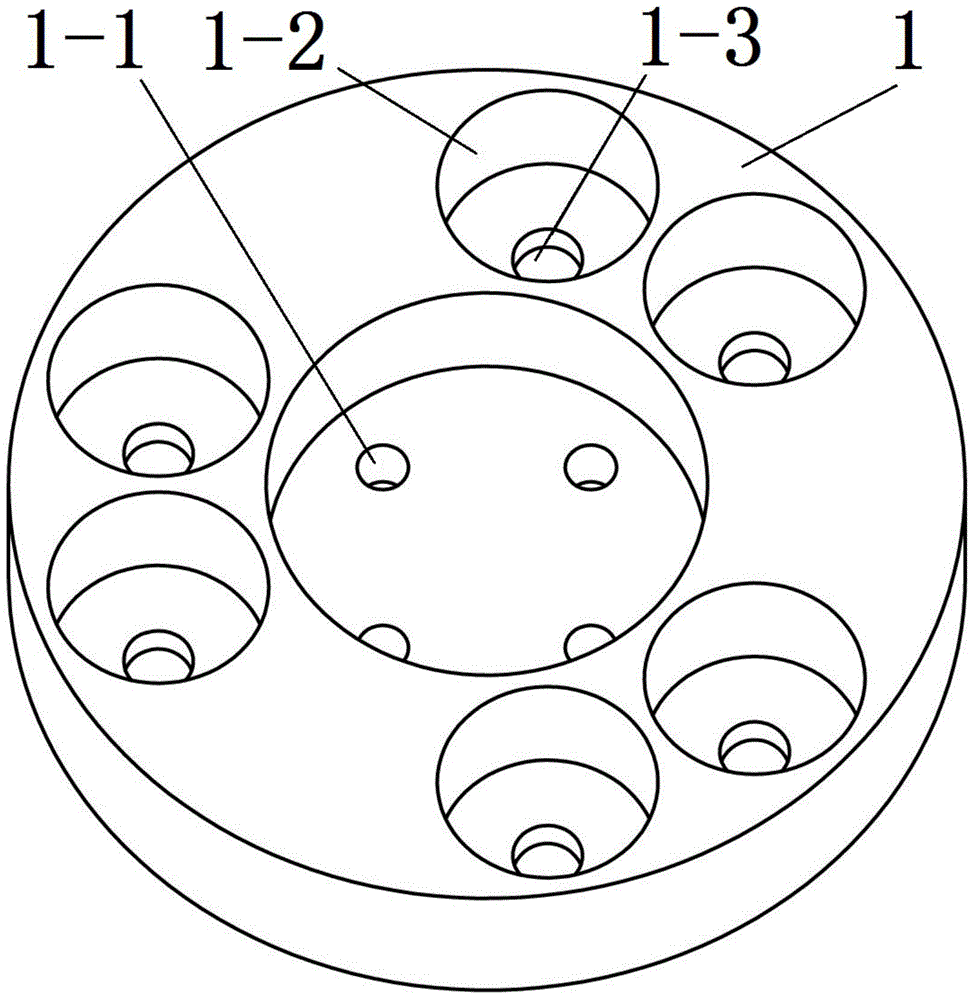

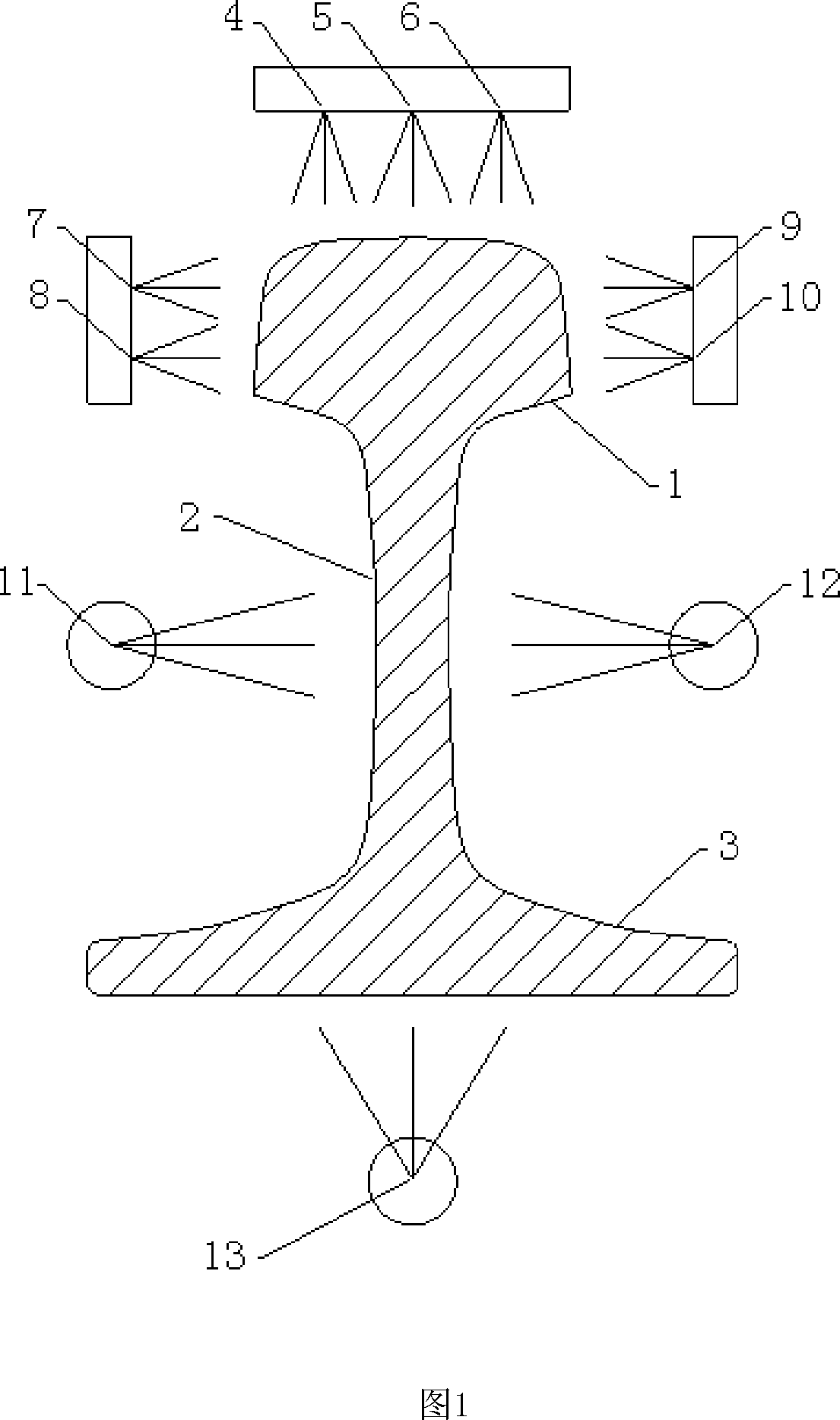

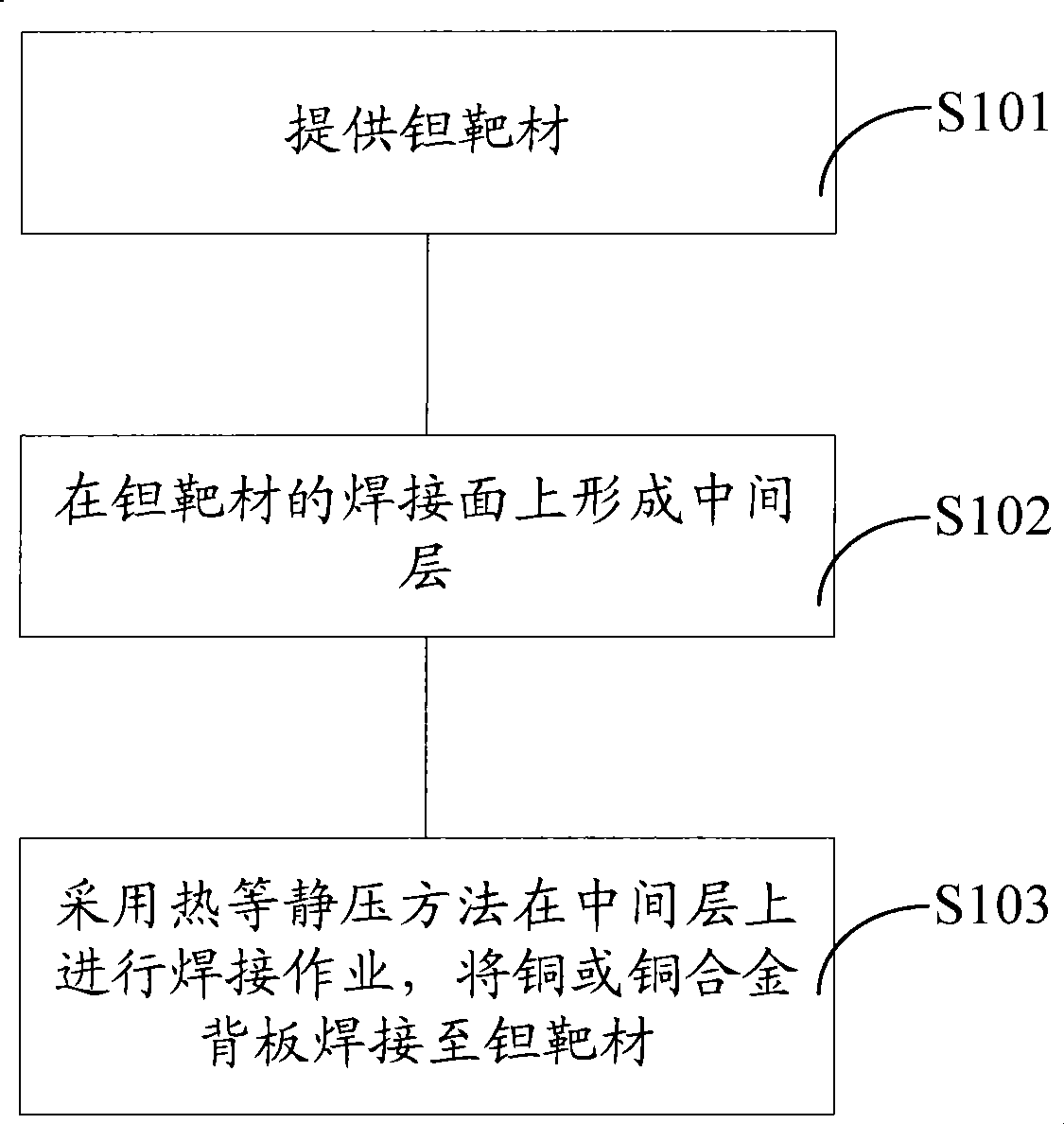

Structure and method for welding target material and backboard

ActiveCN101518851APrevent metals from being oxidizedHigh bonding strengthVacuum evaporation coatingSputtering coatingHot isostatic pressingBackplane

The invention relates to a structure and a method for welding a target material and a backboard, wherein the method for welding the target material and the backboard comprises the following steps: providing a tantalum target material; forming an intermediate layer on the welding surface of the tantalum target material; and performing welding operations on the intermediate layer through a hot isostatic pressing method so as to weld a copper or copper alloy backboard to the tantalum target material. The method can perform extensive welding to effectively prevent metals form being oxidized and improve the bonding strength between the tantalum target material and the copper or the copper alloy backboard, thus the tantalum target material cannot break away in the sputtering process so as to perform sputter coating normally.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

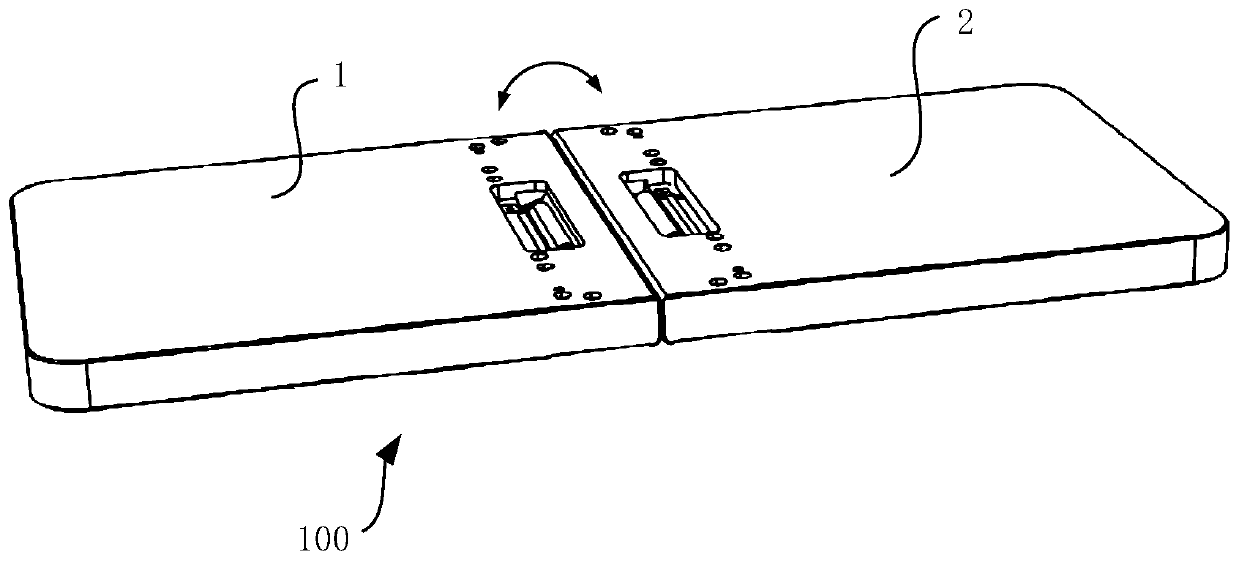

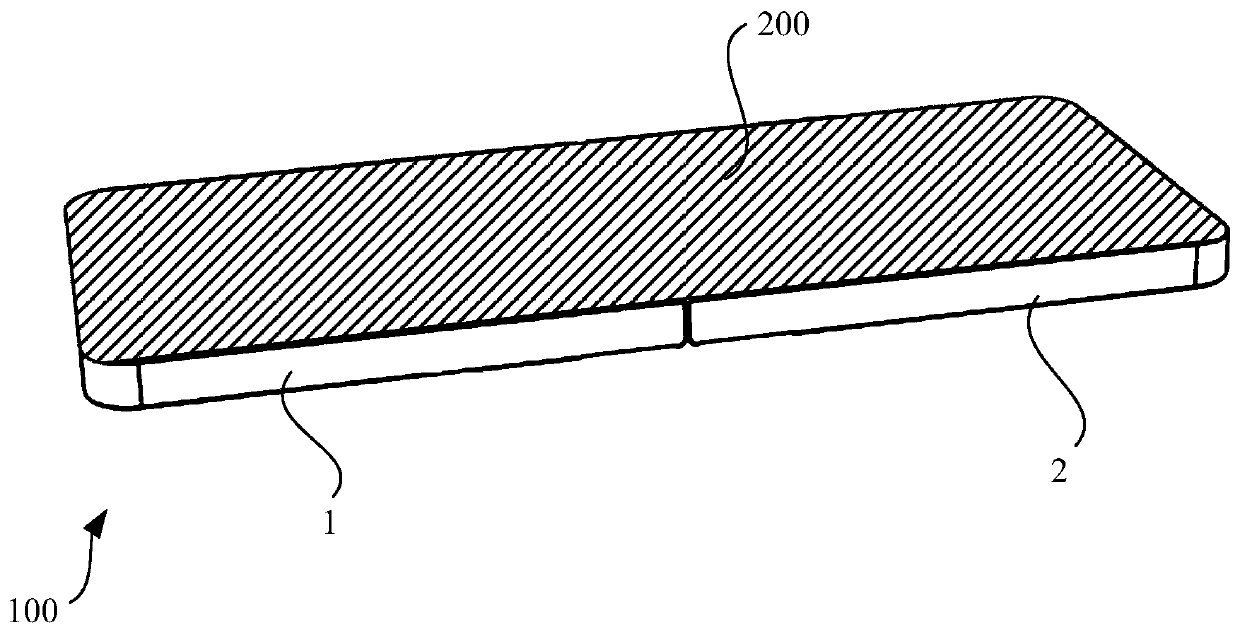

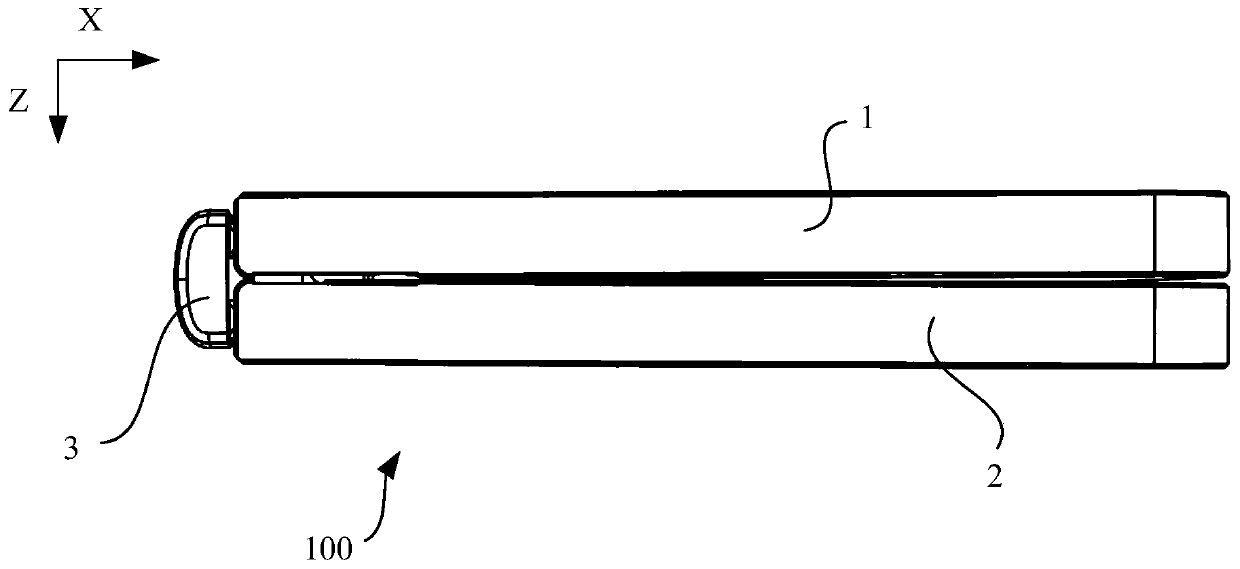

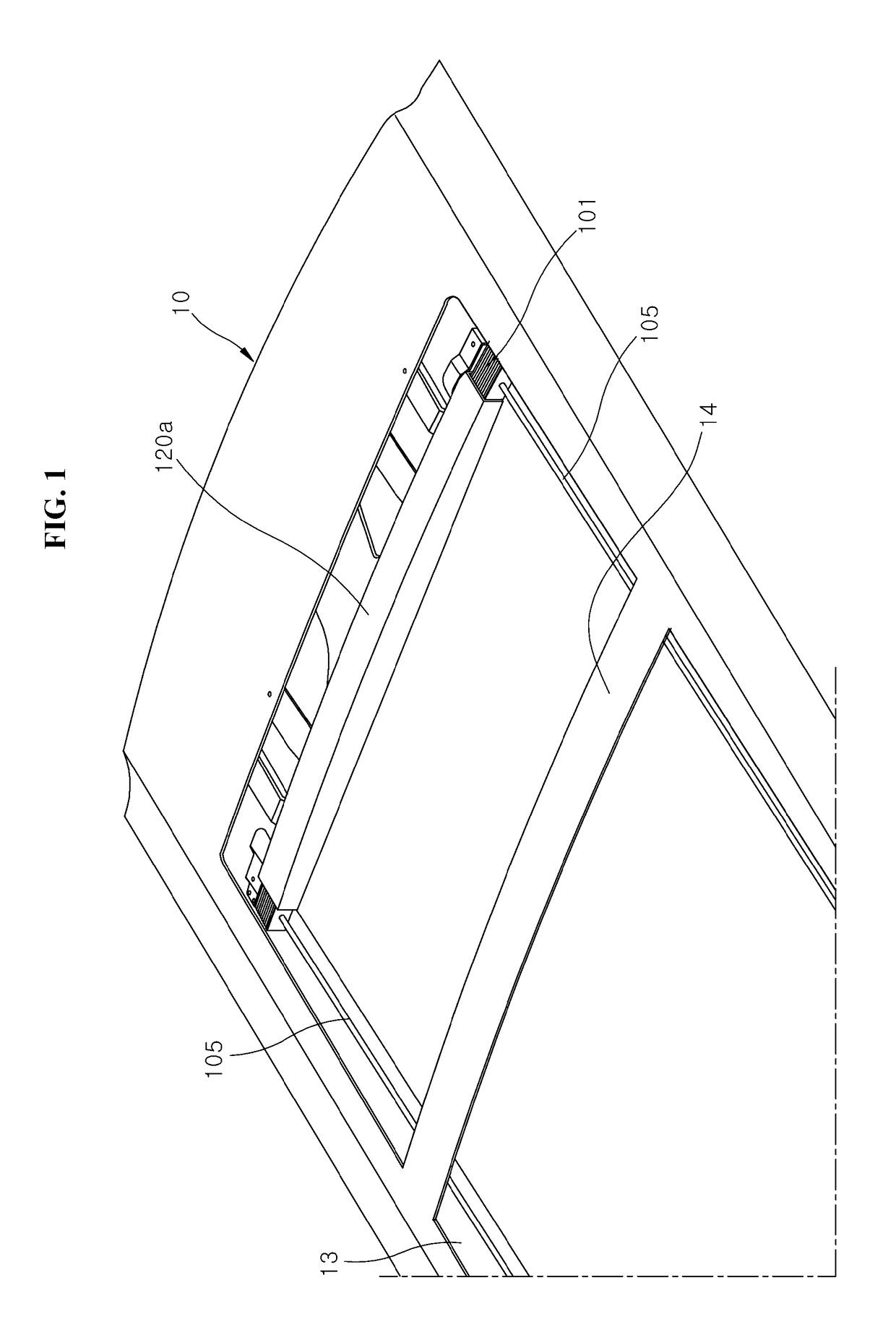

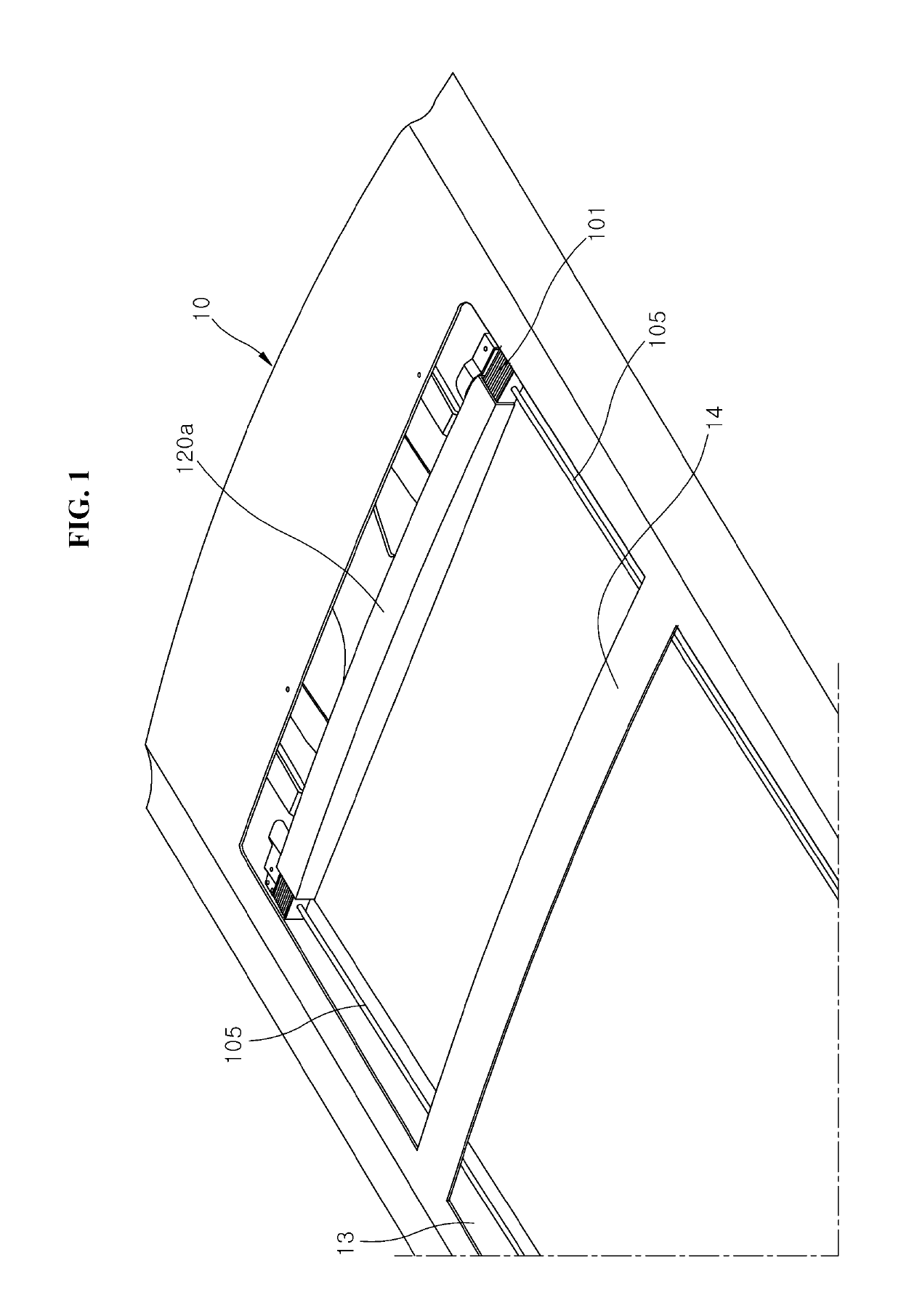

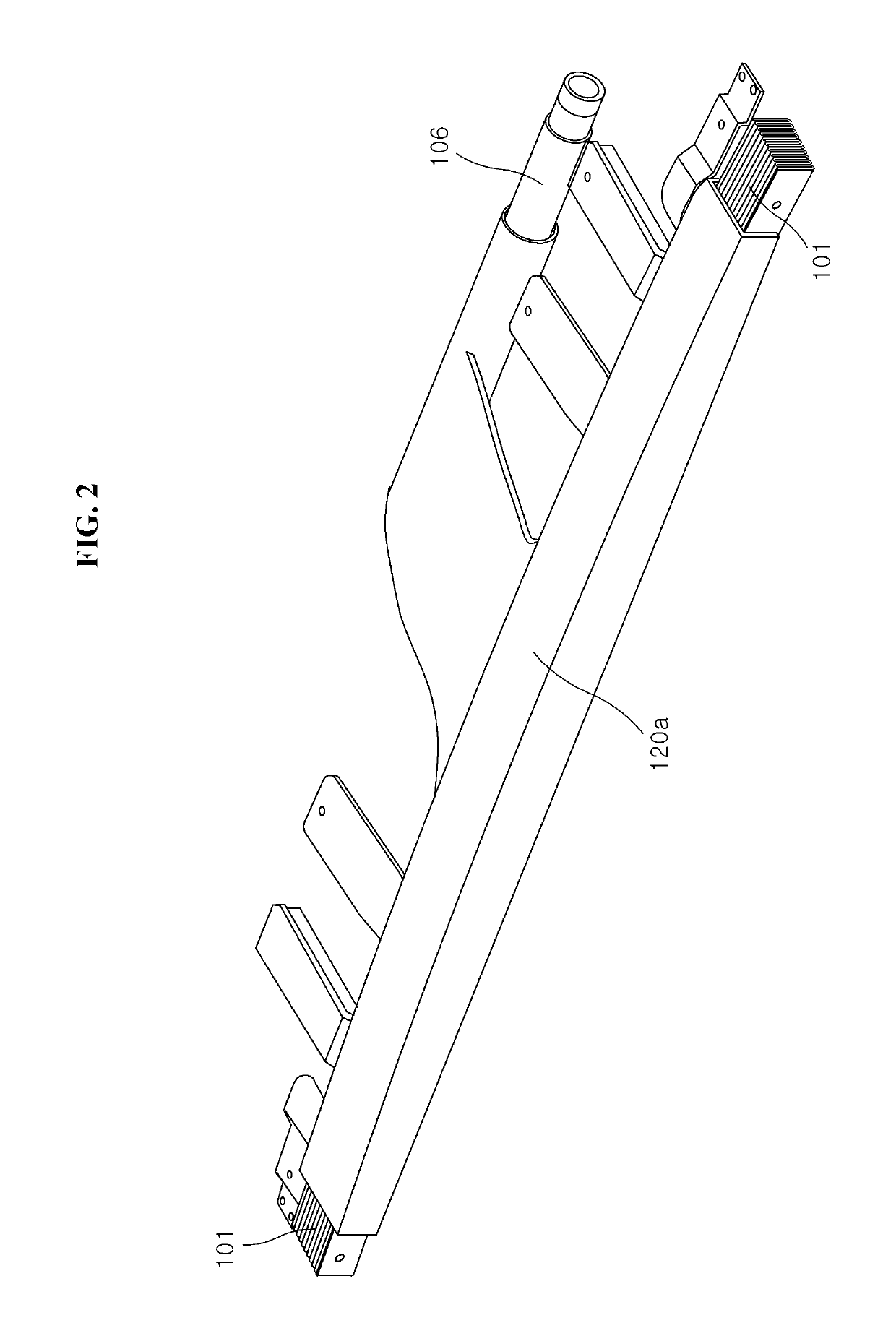

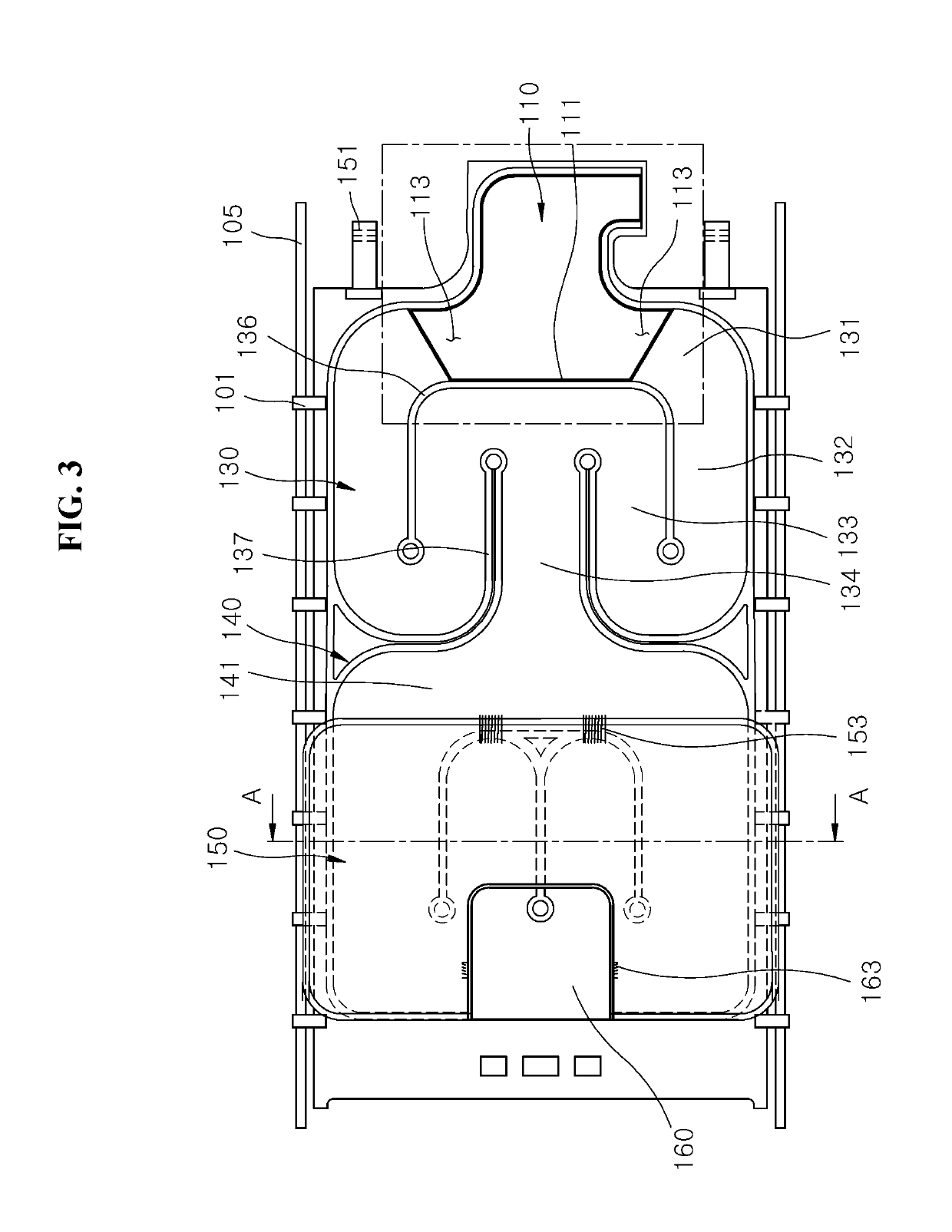

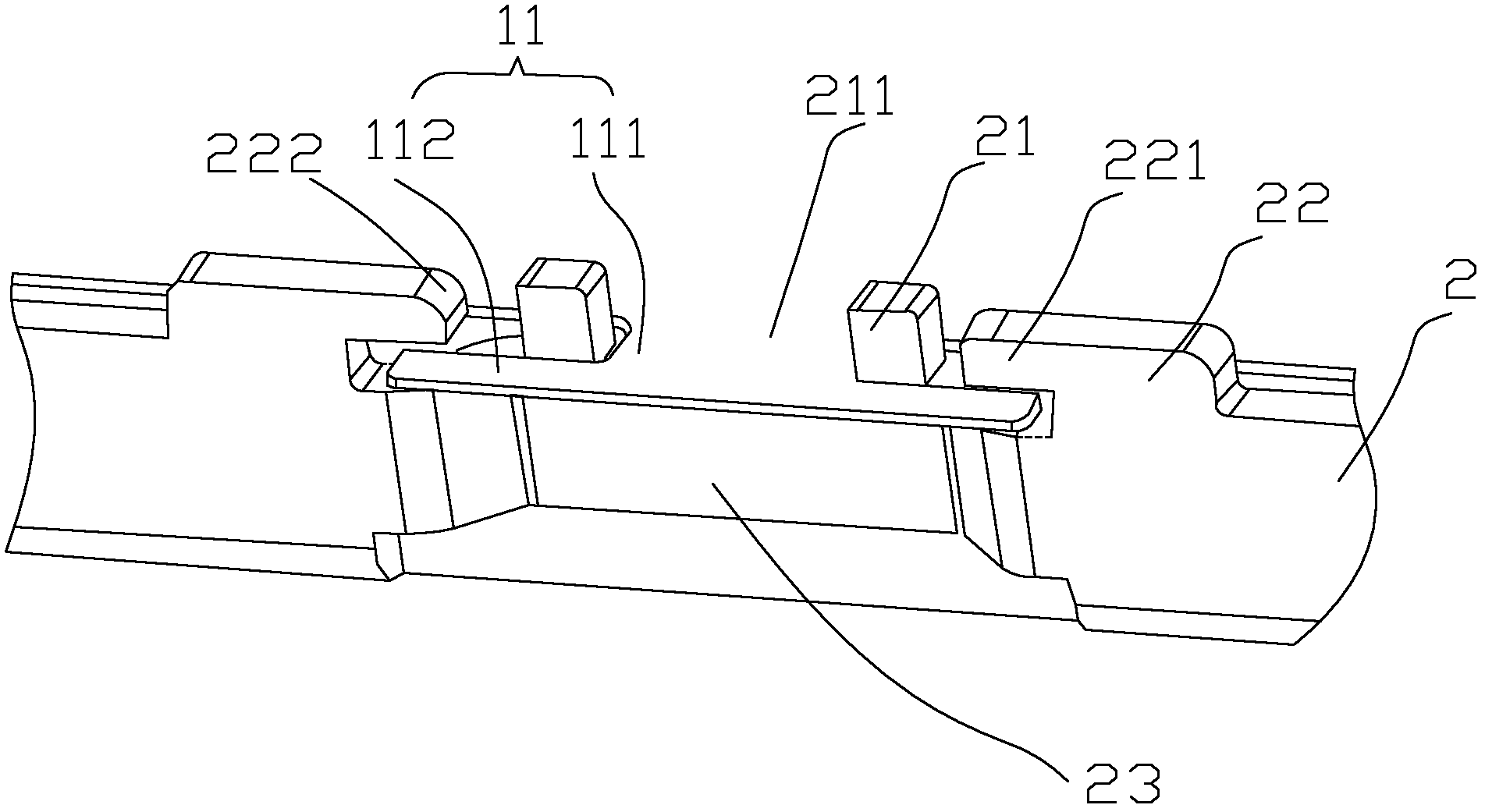

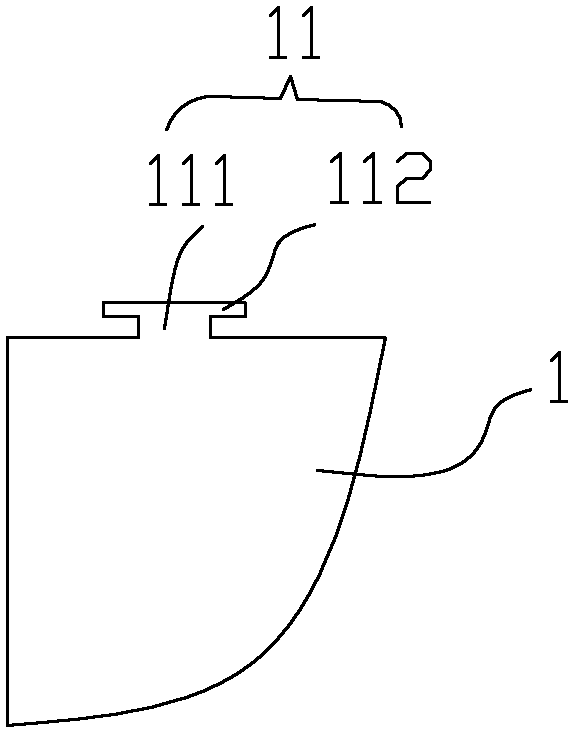

Folding screen device

ActiveCN111147630AReduce bending deformationBending deformation is reducedDigital data processing detailsPrinted circuit aspectsElectrical connectionEngineering

The invention provides a folding screen device. The folding screen device comprises two frame bodies which are jointly hinged to a rotating shaft assembly, and the two frame bodies can rotate around arotating shaft of the rotating shaft assembly so as to be closed or opened; the rotating shaft assembly comprises a connecting structure and a hinge, the connecting structure is provided with a channel penetrating through the two opposite sides of the rotating shaft assembly, an electric connecting wire of the folding screen device can be arranged in the channel in a penetrating mode, the two ends of the electric connecting wire are connected with the two frame bodies respectively, and the hinge and the channel are located at different positions of the rotating shaft assembly in the axial direction. Therefore, the bending deformation of the electric connecting wire is small when the folding screen equipment is folded, and the electric connecting wire has high connection reliability.

Owner:HUAWEI TECH CO LTD

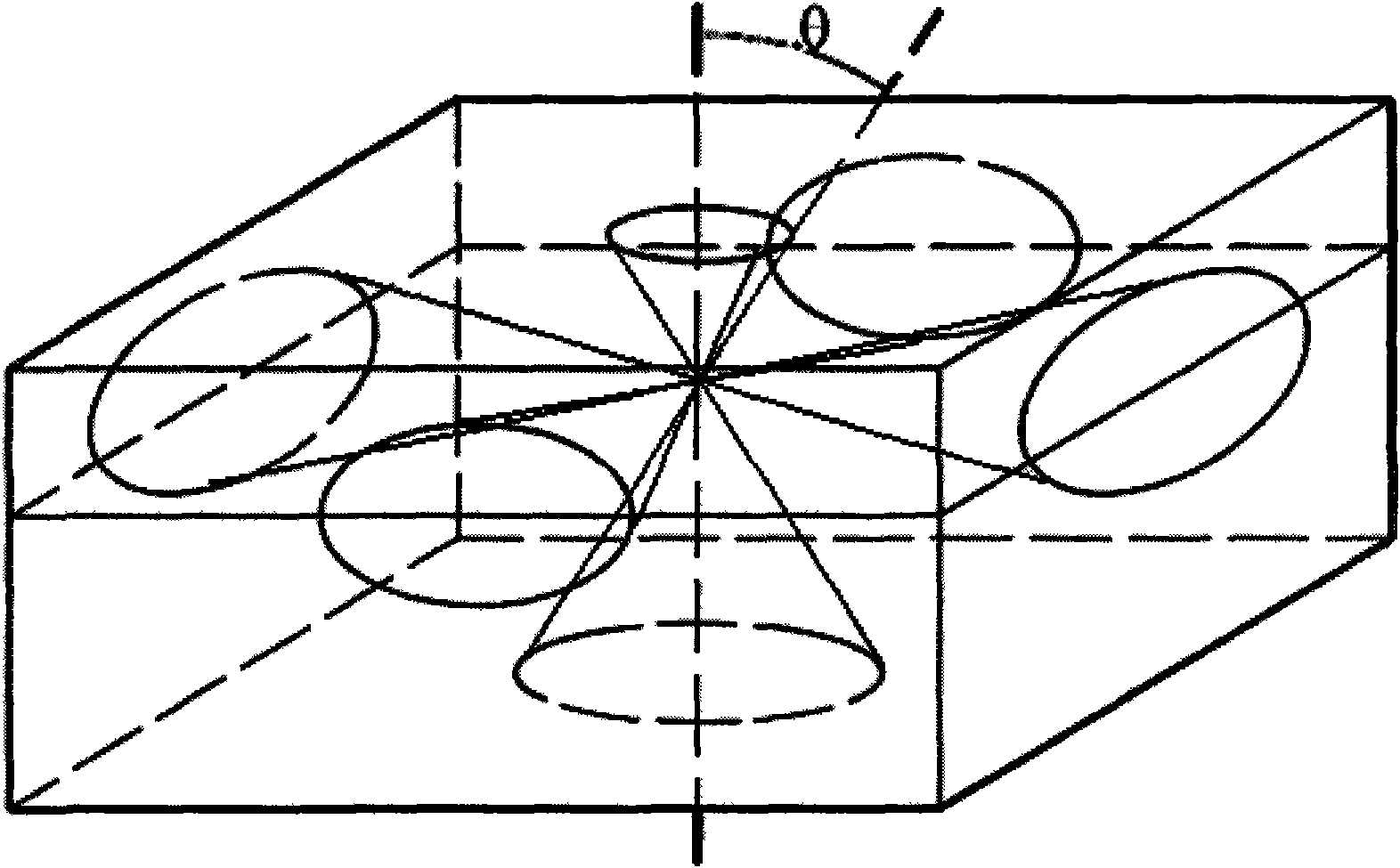

Laterally inclined LED chip and preparation method thereof

InactiveCN101604718AExtended range of available beam anglesExpand the light emitting area of the spaceSemiconductor devicesEvaporationThinning

The invention provides a laterally inclined LED chip and a preparation method thereof. The lateral face of the epitaxial layer of the chip is of a certain angle of inclination, thus the efficiency of light emission of the LED chip can be improved; the preparation method is as follows: firstly, an epitaxial layer grows on a substrate, wherein the epitaxial layer includes a buffer layer, an N-shaped layer, an multiple quantum well(MQW) layer and a P-shaped layer; an N-shaped layer region is formed by etching, a transparent conductive layer is plated on the P-shaped region, metal electrodes are respectively plated on the N-shaped region and the P-shaped region by evaporation, and a passivation layer is prepared on the entire chip; under the protection of the passivation layer, the epitaxial part is etched, and the speed of etching towards both sides is controlled so as to form an etched lateral face which is inclined in a certain angle; and the chip is thinned, scraped, cracked, tested and separated. The invention has the advantages of simple process and lower cost; meanwhile, the processing of the epitaxial layer in the invention contributes to the reduction of the inner stress of the chip as well as the bending deformation of the chip during processing, and also contributes to the improvement of effect of thinning, scraping and cracking the chip.

Owner:HC SEMITEK CORP

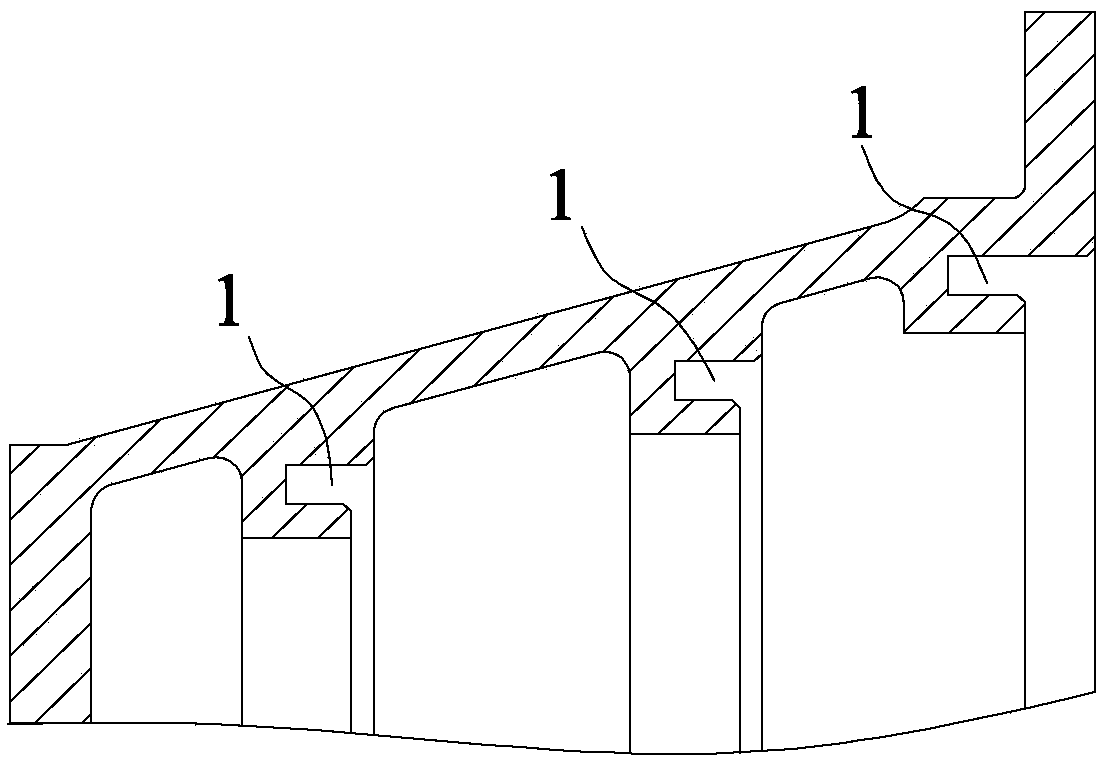

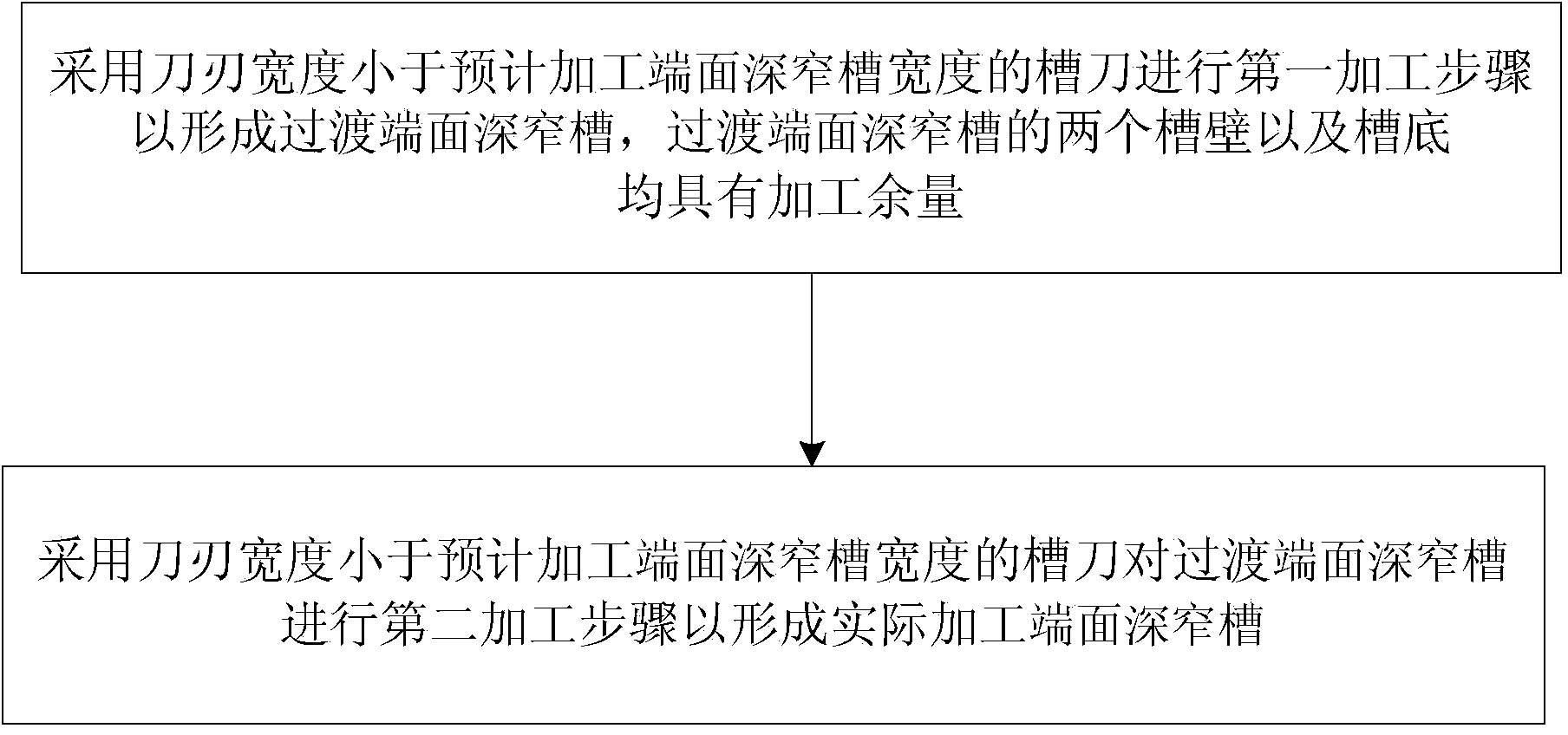

Lathe machining method for end face deep narrow groove in aerial engine crankcase

InactiveCN104028782AReduce offsetSmall thermal deformation and bending deformationEngineeringAviation

The invention provides a lathe machining method for an end face deep narrow groove in an aerial engine crankcase. The method comprises the following machining steps: 1, using a groove cutter to carry out the first machining step to form a transition end face deep narrow groove, wherein the width of a blade of the groove cutter is less than that of the end face deep narrow groove to be machined, and at least two opposite groove walls of the transition end face deep narrow groove have machining allowances; 2, removing the machining allowances of the transition end face deep narrow groove to form the actually machined end face deep narrow groove. According to the lathe machining method, the machined end face deep narrow groove is higher in machining precision.

Owner:CHINA HANGFA SOUTH IND CO LTD

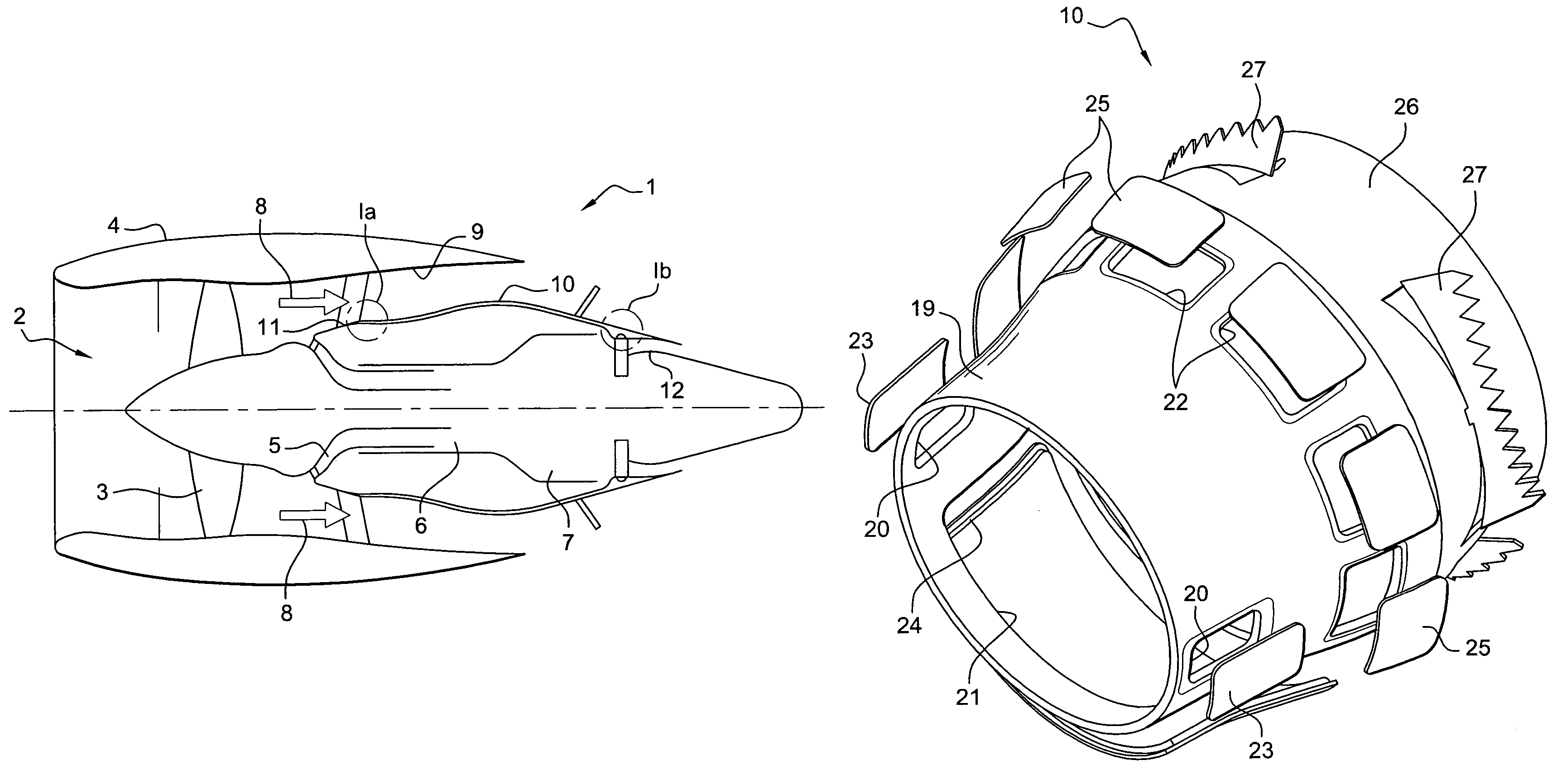

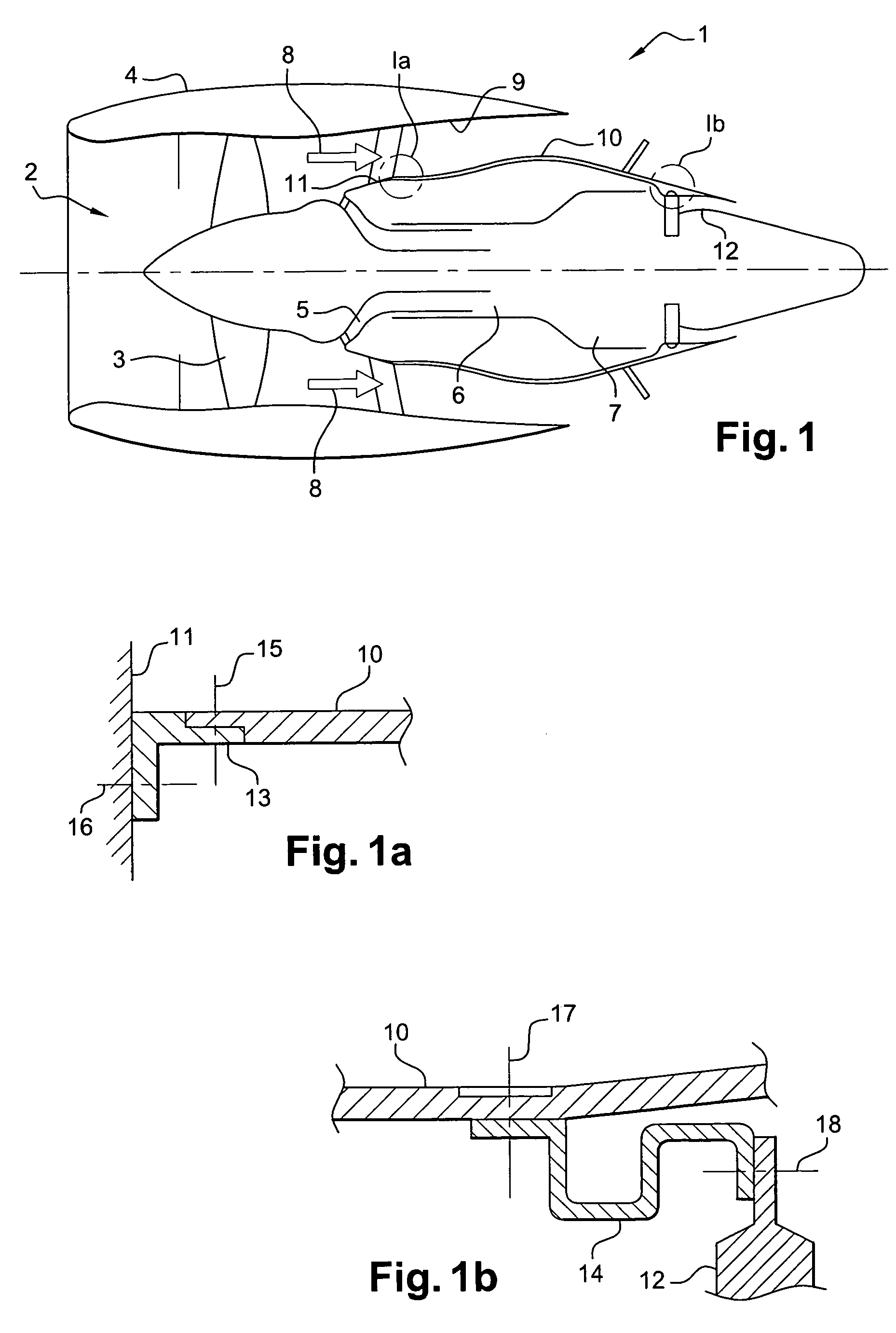

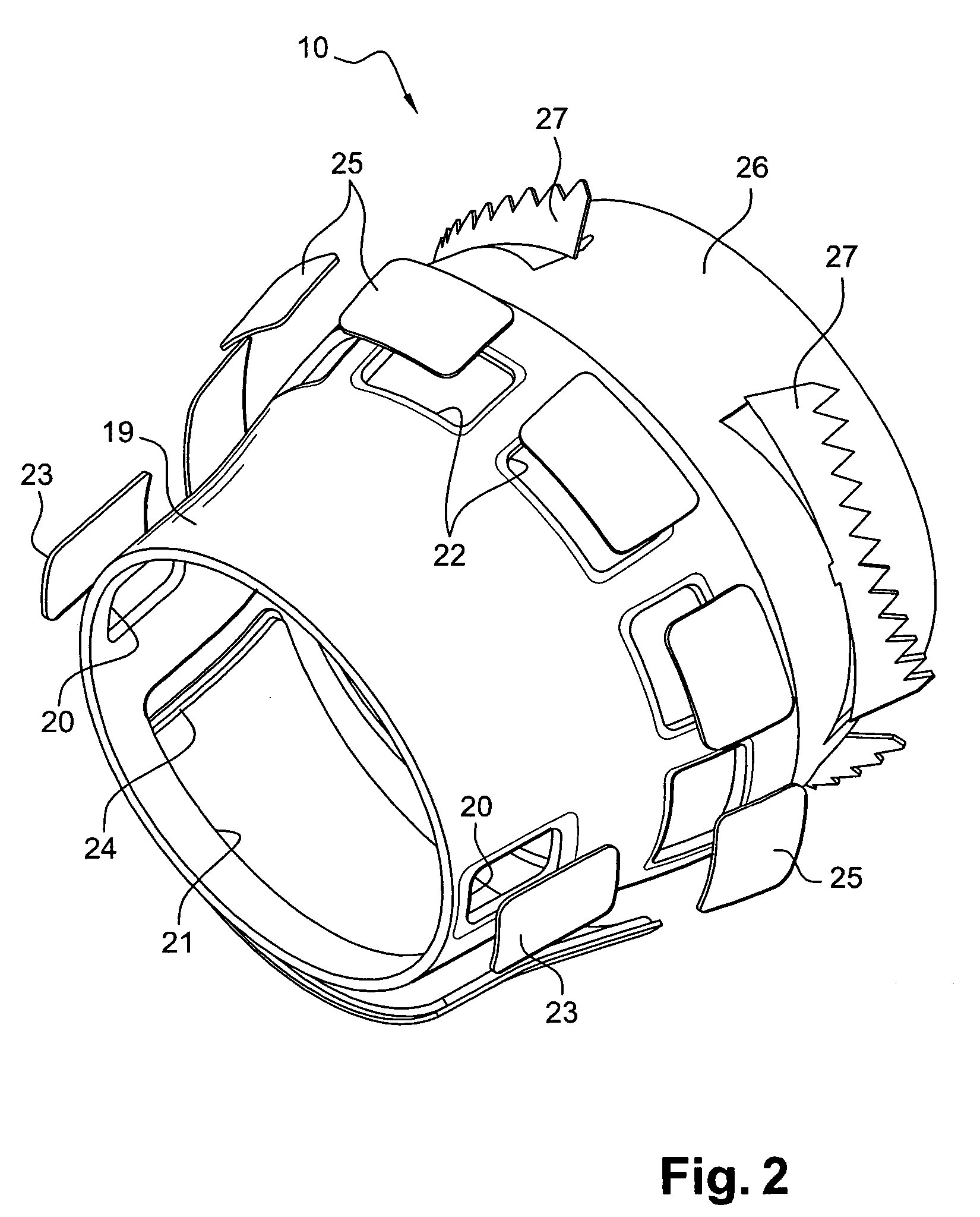

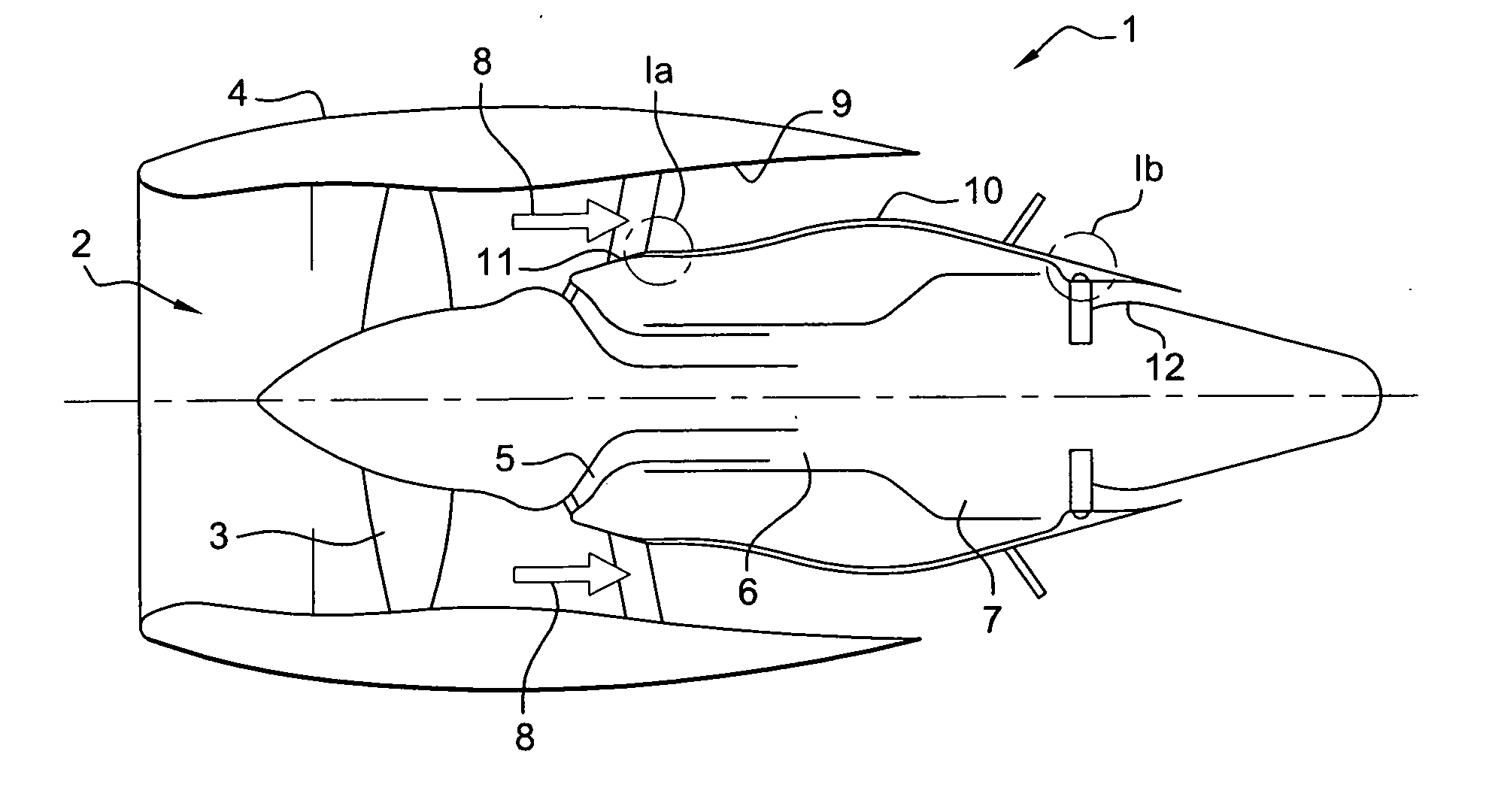

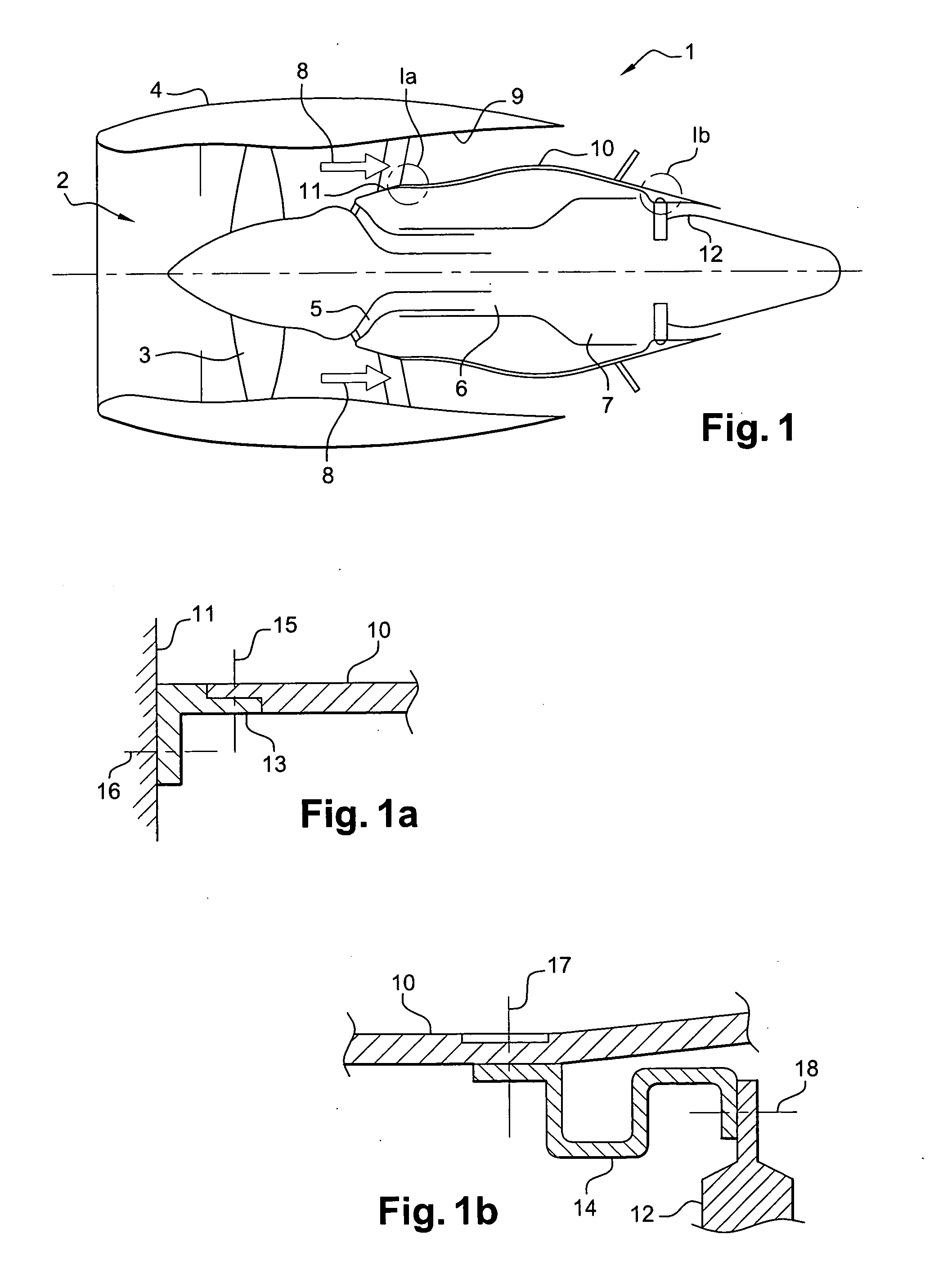

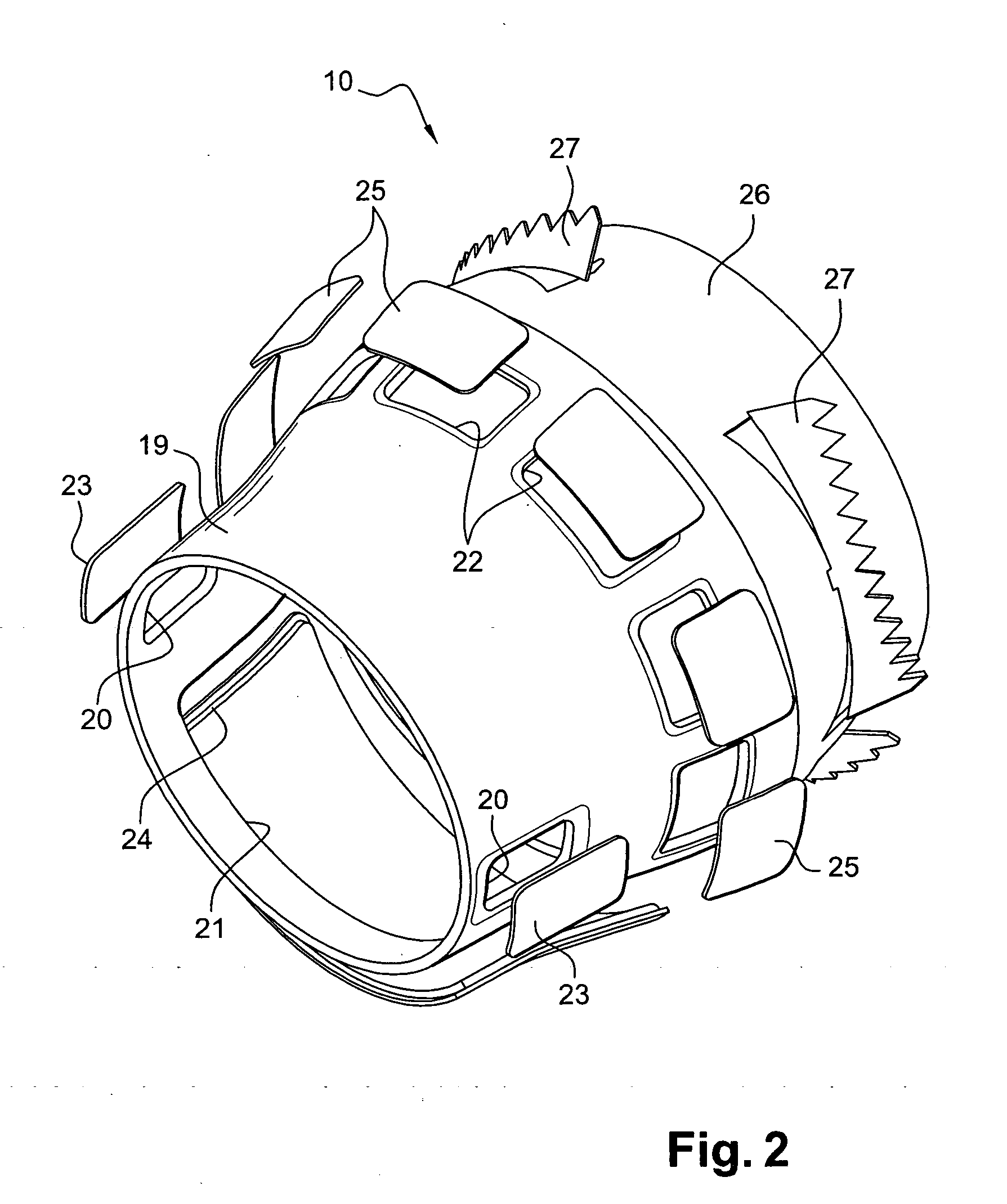

Turbojet having a large bypass ratio

ActiveUS7430852B2Simple and effective and inexpensiveBig ratioSpraying apparatusBlade accessoriesCombustion chamberBypass ratio

A turbojet comprises at least a fan, a compressor, a combustion chamber, a turbine, and a rigid substantially-cylindrical jacket fastened at its upstream end to an intermediate casing and at its downstream end to an exhaust casing, the jacket serving to transmit forces between the intermediate casing and the exhaust casing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Roof airbag apparatus

ActiveUS20180312130A1Reduce bending deformationPedestrian/occupant safety arrangementMarine engineeringAirbag

A roof airbag apparatus including: a leading deployment part connected to a diffuser; a trailing deployment part connected to the leading deployment part, and deployed with a time difference from the deployment of the leading deployment part; and an overlap deployment part connected to the trailing deployment part, overlapped by the trailing deployment part, and deployed with a time difference form the deployment of the trailing deployment part.

Owner:HYUNDAI MOBIS CO LTD

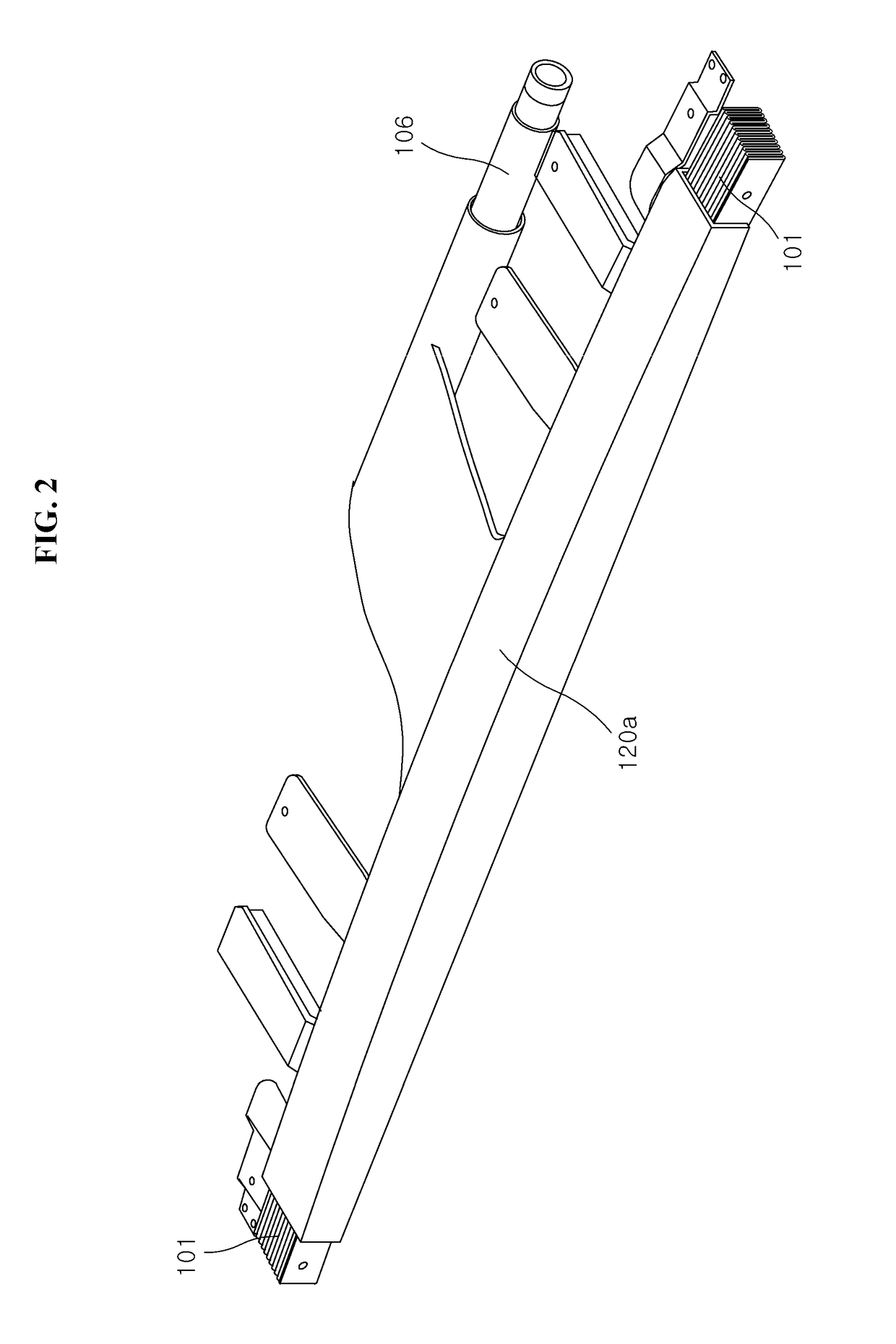

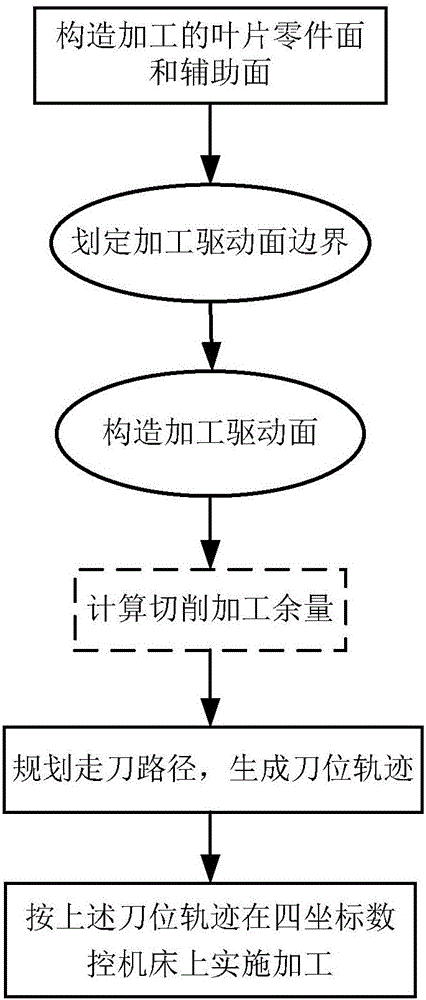

Two-way allowance-variable milling method for blade

ActiveCN103990840AHigh precisionImprove positionMilling equipment detailsEngineeringDimensional modeling

The invention discloses a two-way allowance-variable milling method for a blade. The method is used for solving the technical problem that an existing allowance-variable milling method for the blade is low in accuracy. According to the technical scheme, firstly, a three-dimensional blade model is established in three-dimensional modeling software UG; both the two end faces of the blade are made deflect towards a blade body in the three-dimensional blade model, so that two deflection faces, namely, the blade root edge interface and the blade tip edge interface, are obtained; a driving face is determined by means of a section line lofting method; then, machining routes on the driving face are determined; allowance of each machining route is determined by means of a lever allowance fine tuning method; finally, circulation machining is conducted on the blade according to the set allowance, so that machining accuracy is improved for the blade. According to the method, when the blade with the length which is about 70 mm is machined, the surface tolerance of the blade can be controlled within the range of 0.06 mm to 0.1 mm.

Owner:西安三航动力科技有限公司

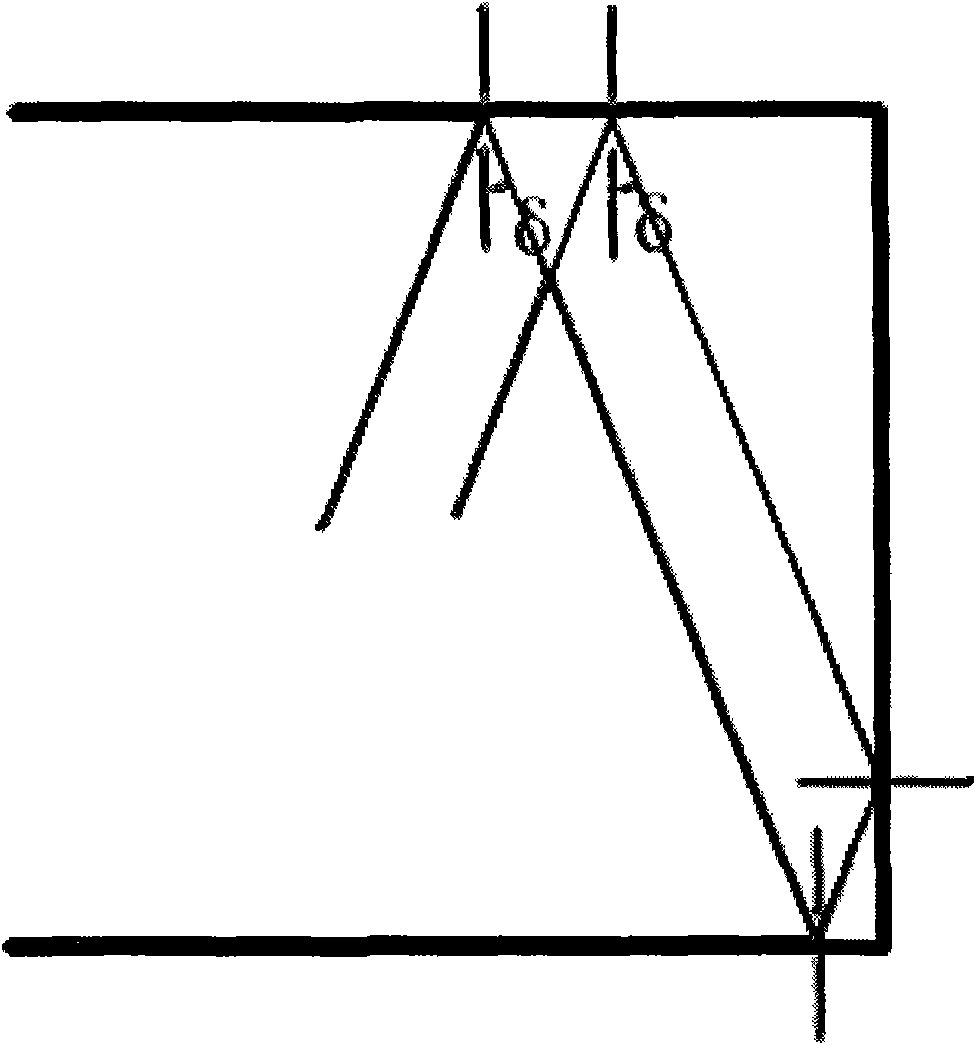

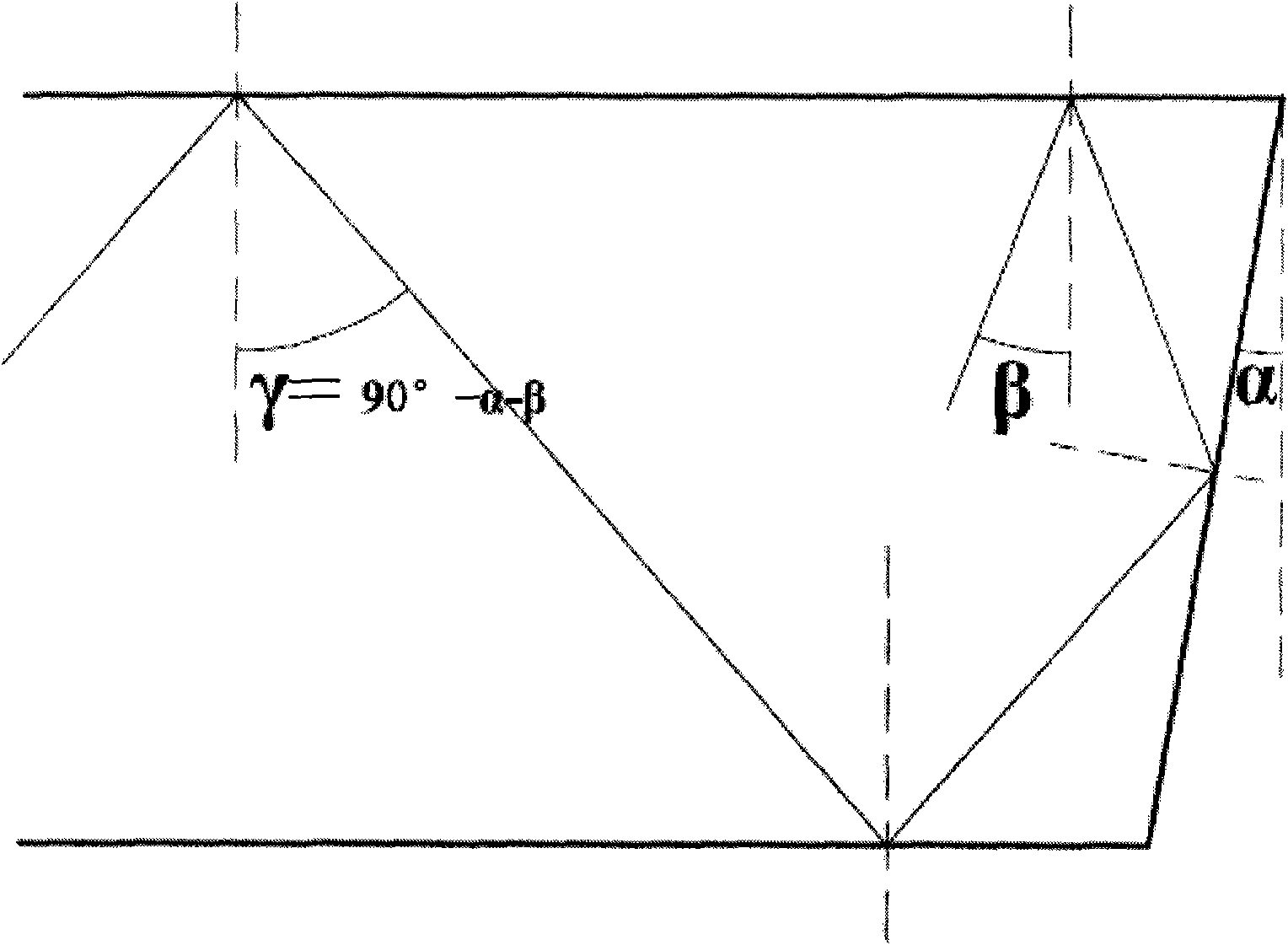

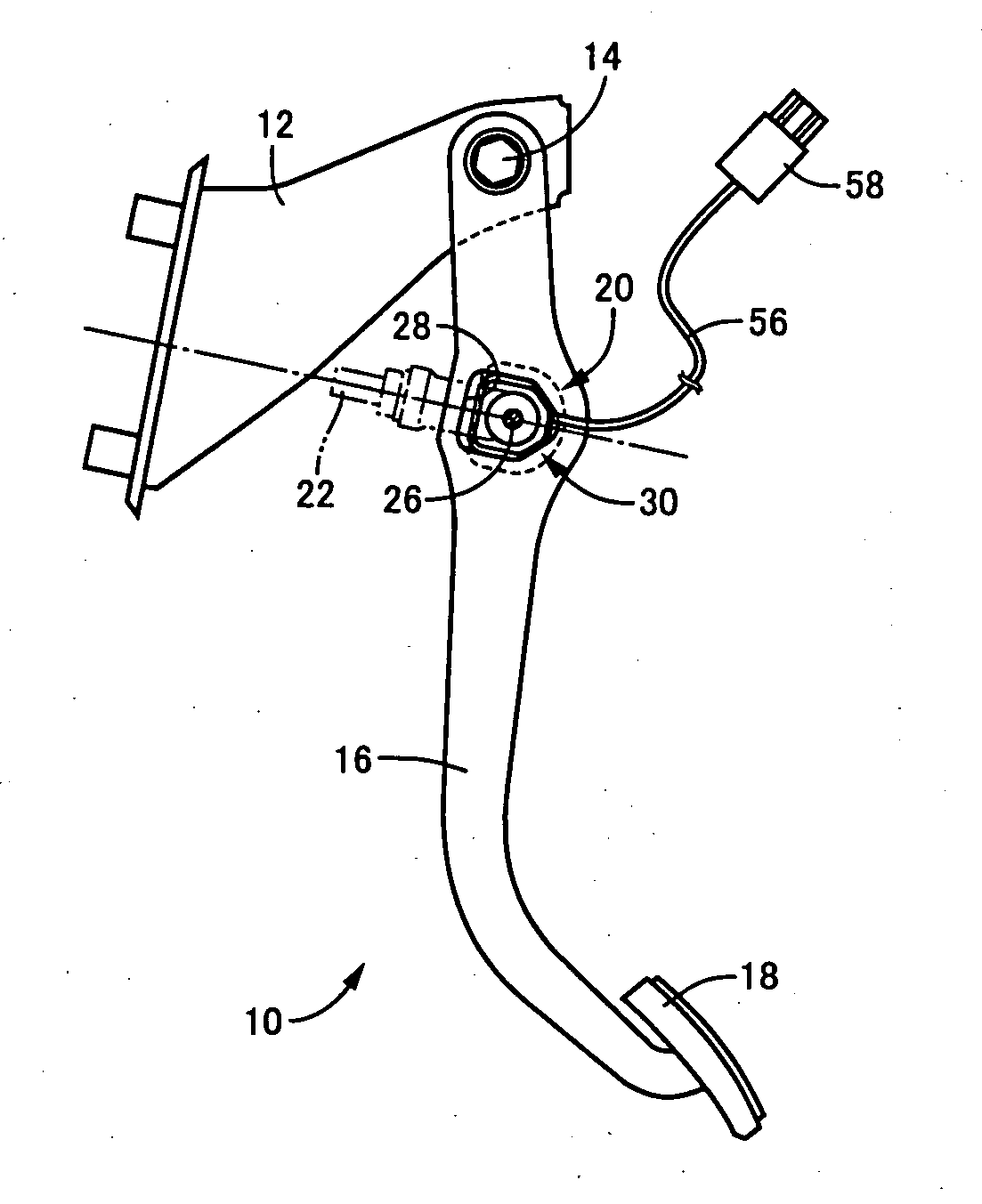

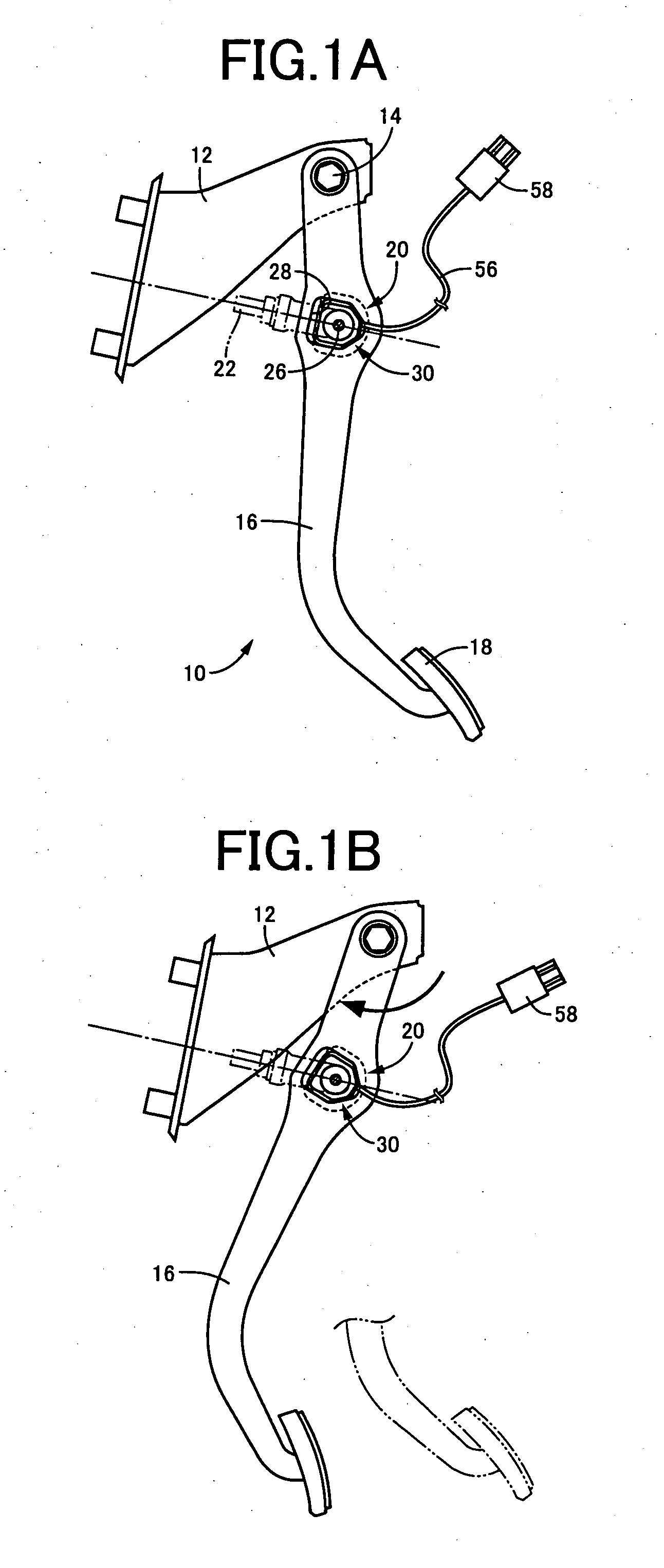

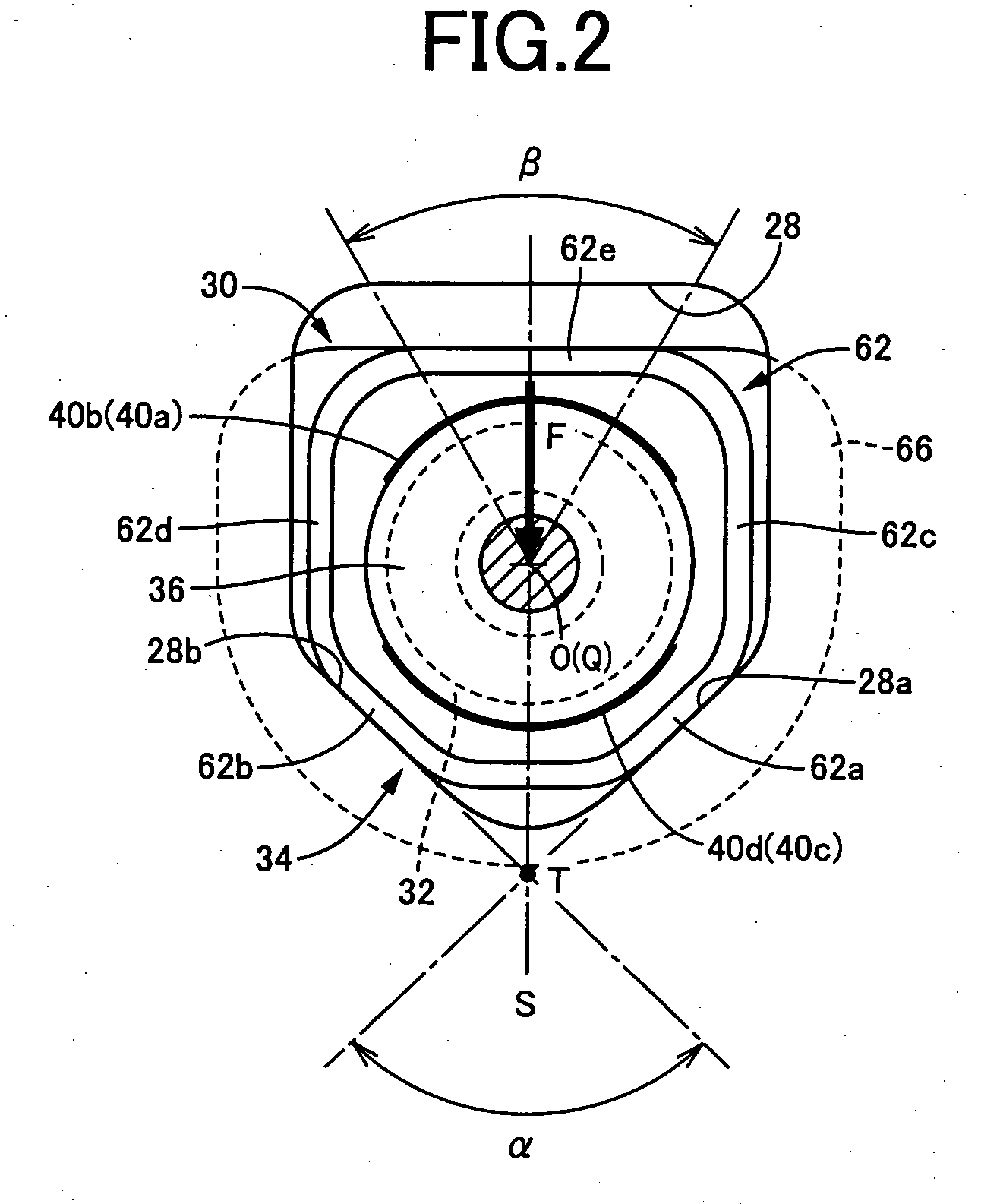

Load-sensor-equipped vehicle operating pedal device and load-sensor-equipped operating device

ActiveUS20080250894A1Minimizes flexure deformationReduce deformationControlling membersMechanical apparatusEngineeringStructural engineering

A load-sensor-equipped vehicle operating pedal device includes a load sensor (30) having a case member (34) formed with a pair of mounting wall portions (62a, 62b) converged in a convex shape at a predetermined apex angle α. The pair of mounting wall portions (62a, 62b) are held in surface contact with a pair of rest surfaces (28a, 28b), formed in a sensor-mounting hole (28) in a fixed and positioned state. Thus, even if a direction of an input load (reactive force), applied to a clevis pin (26) varies with an operating pedal 16 being progressively depressed, the pair of rest surfaces (28a, 28b) always bear the input load via the pair of mounting wall portions (62a, 62b). This suppresses the case member (34) from flexure deforming due to stress concentration. As a result, positional displacement of a sensor is prevented regardless of a variation in the direction of the input load, improving detecting precision.

Owner:TOYODA IRON WORKS CO LTD

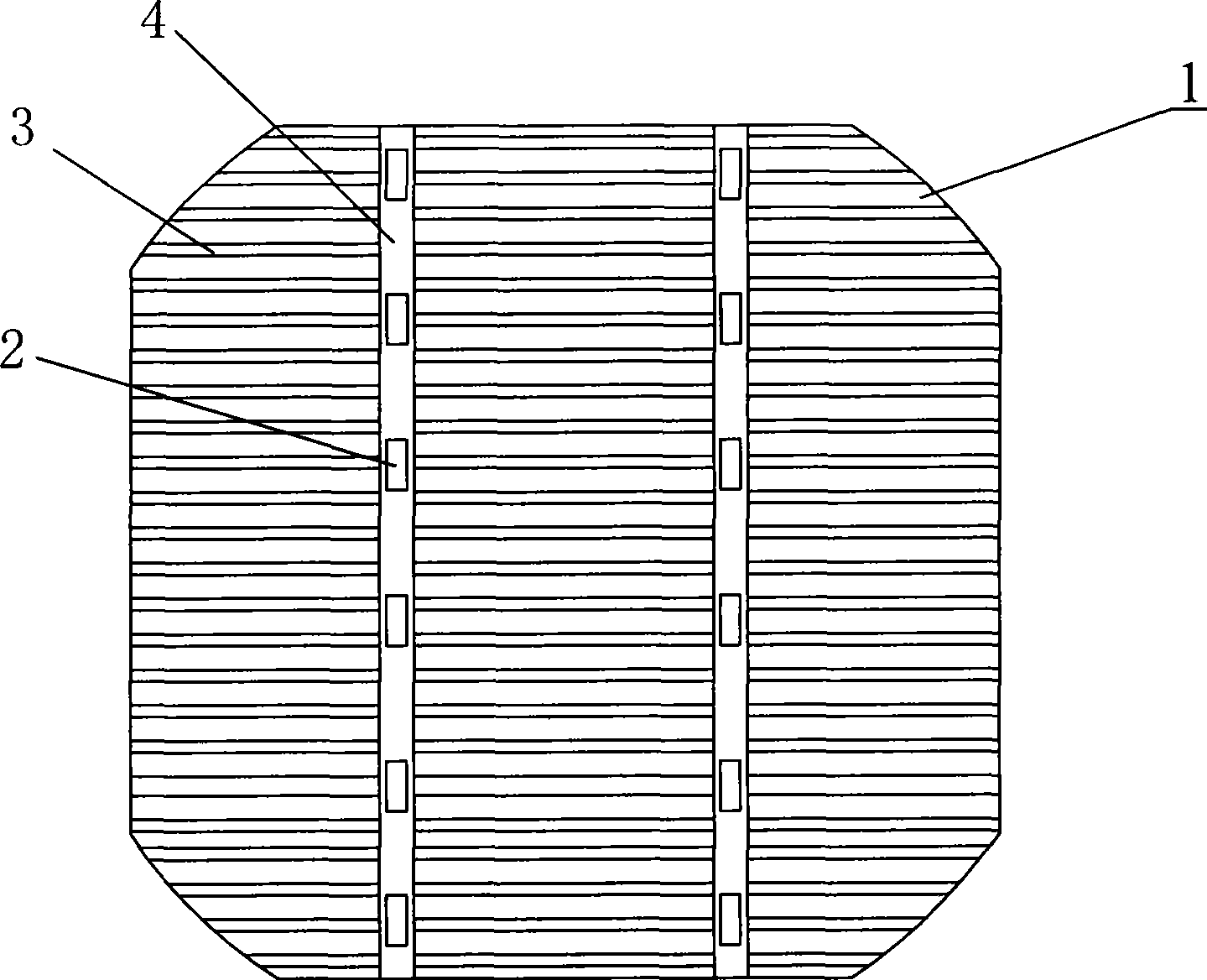

Solar battery welding device and welding process

ActiveCN101502902AAvoid local high temperature thermal shockAvoid damageFinal product manufactureSoldering apparatusHigh volume manufacturingSolar battery

The invention relates to the field of solar battery production, in particular to a solar battery welding device and a welding technology. The welding device consists of a battery patch stationary fixture and a heating welding furnace. At least two positioning grooves in parallel for positioning interconnected strips are arranged on a pedestal of the stationary fixture; a lower press strip is arranged above the positioning grooves of the interconnected strips for positioning a lower interconnected strip; an upper press strip is arranged above the lower press strip for positioning an upper interconnected strip. The invention can increase the welding efficiency of the battery patch, decrease the damage to silicon slices and reduce the waste, which is applicable to batch production of solar battery modules.

Owner:WUXI SUNTECH POWER CO LTD

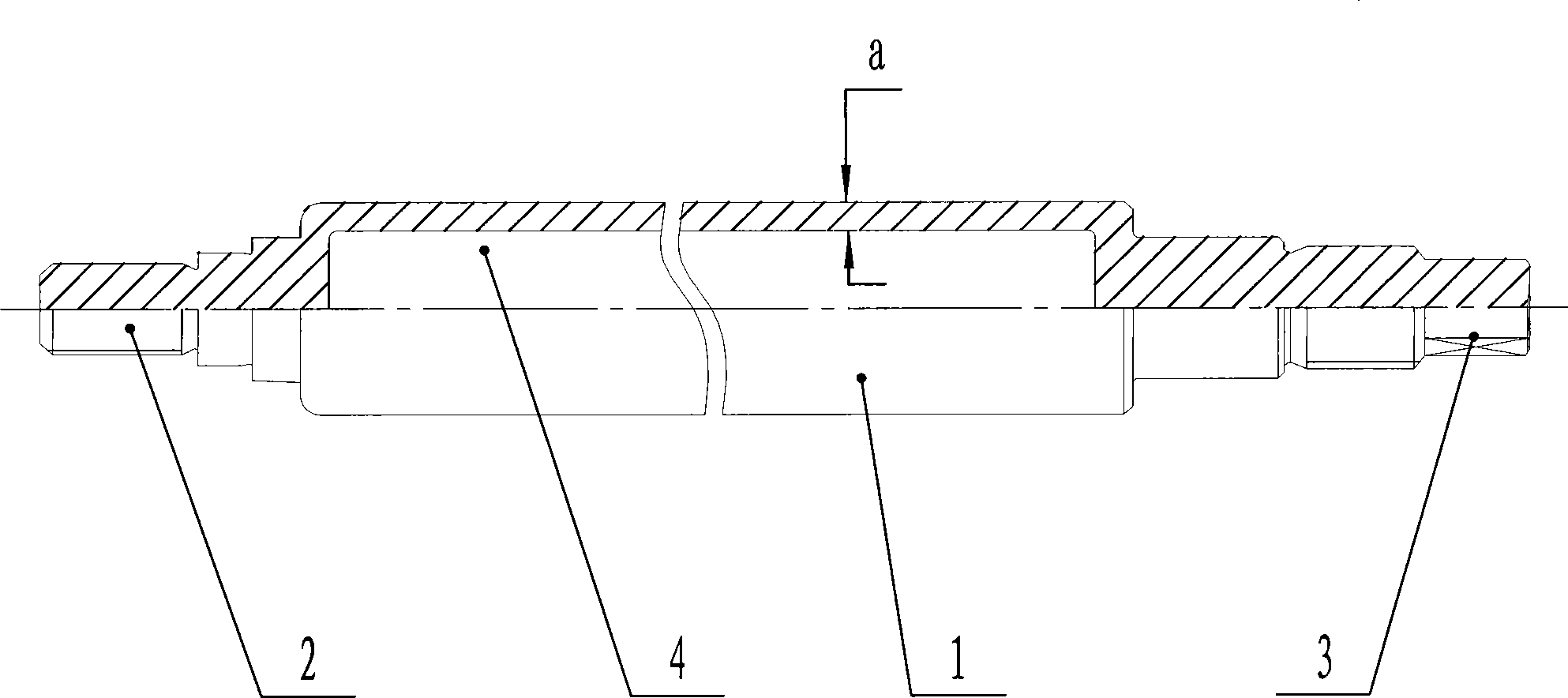

Piston lever of reducer for automobile

InactiveCN101074714AReduce weightSmall inertiaSpringsShock absorbersFriction weldingThermal deformation

The invention discloses a car shock absorber piston rod, which includes heat-treated, cylindrical surface of the piston rod or chrome Ontology (1), as well as connected to the piston rod Ontology (1) Core ends of the piston rod (2) and connectivity Screw (3); described rod Ontology (1) internal (4) For the hollow; referred to the internal (4) For the hollow rod Ontology (1) Thickness (a) 3 mm - 4mm; period Detroit-Core (2) and the piston rod Ontology (1) end of the connectivity options for friction welding pressure; referred to connect Screw (3) and piston rod Ontology (1) the other end of the connectivity options for friction welding pressure. The advantages of this invention are: to maintain the existing strength of the piston rod, manufacture low-cost, long life, light weight, small friction coefficient, thermal deformation fast and small.

Owner:宁波培源汽车配件制造有限公司

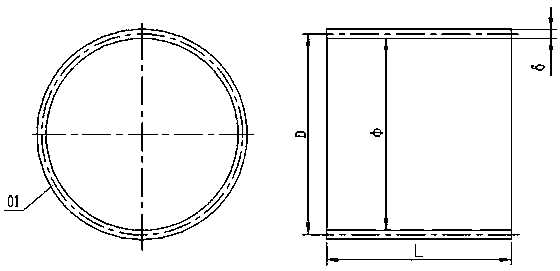

Multi-curvature forming method for stainless steel cylinder

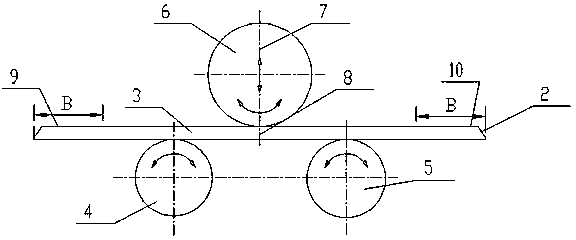

The invention discloses a multi-curvature forming method for a stainless steel cylinder. The method is characterized by comprising the following steps: performing scribing and blanking according to the developed length of the medium diameter of a cylinder to be wound; machining peripheral welding grooves of a plate; rolling-forming a first-curvature circular arc, namely reserving a straight section, not to be wound for the formation of a circular arc, with a width B of 200 to 600 mm at each of the two ends of the cylindrical plate, and bending and winding the middle part of the cylindrical plate into a large circular arc with a curvature radius R of more than or equal to 0.5 Phi to form the first-curvature circular arc of the cylinder; rolling-forming second-curvature circular arcs, namely rolling the parts between the roots of the straight sections with the widths B of 200 to 600 mm and the large circular arc into circular arcs with curvature radiuses r of 0.2 to 0.5 Phi to form second-curvature circular arcs; rolling transition parts between the second-curvature circular arcs and the first-curvature circular arc into smooth transition; performing rolling until the grooves 2 in the two ends of the straight sections get close to each other; performing longitudinal seam assembly and welding on the cylinder, placing the cylindrical body at a horizontal position, and welding longitudinal seams; performing roundness correction on the cylinder after welding.

Owner:SHANGHAI TONGHUA STAINLESS STEEL PRESSURE VESSEL ENG

Nonmagnetic hard alloy and preparation method

The invention discloses a nonmagnetic hard alloy. The nonmagnetic hard alloy comprises the following components in percentage by weight: 6 to 18 percent of nickel, 0.5 to 1.5 percent of chrome carbide and the balance of tungsten carbide. The nonmagnetic hard alloy has the advantages of simple component, high hardness, good abrasion resistance and strong corrosion resistance. A preparation method for the nonmagnetic hard alloy comprises raw material preparation, wet milling, drying, pressing, sintering and the like, wherein the raw material comprises the following components in percentage by weight: 8 to 15 percent of nickel powder, 0.5 to 1.5 percent of chrome carbide powder and the balance of tungsten carbide powder; during material preparation, a forming agent is added; spray drying is performed at the temperature of between 90 and 100 DEG C; and a de-waxing and sintering integrated process is adopted, the furnace temperature is raised to between 450 and 550 DEG C in 25 to 45 hours, the removal of the forming agent is finished, then the furnace temperature is raised in 7 to 9 hours till the product produces a liquid phase, high-purity argon is introduced into the furnace, the furnace temperature is raised to a final sintering temperature of between 1,460 and 1,480 DEG C for 1 to 2 hours, the heat is preserved for 30 to 60 minutes, then the high-purity argon is introduced into the furnace, the heat is continuously preserved for 30 to 60 minutes, and then the product is cooled. The preparation method not only can prepare the nonmagnetic alloy of common specification, but also can meet the preparation and performance requirements of the large-sized nonmagnetic alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Roof airbag apparatus

ActiveUS10471924B2Reduce bending deformationPedestrian/occupant safety arrangementMarine engineeringAirbag

A roof airbag apparatus including: a leading deployment part connected to a diffuser; a trailing deployment part connected to the leading deployment part, and deployed with a time difference from the deployment of the leading deployment part; and an overlap deployment part connected to the trailing deployment part, overlapped by the trailing deployment part, and deployed with a time difference form the deployment of the trailing deployment part.

Owner:HYUNDAI MOBIS CO LTD

Limit protection device for supporting oil cylinder of open type whole-section tunnel rock boring machine

The invention discloses a limit protection device for a supporting oil cylinder of an open type whole-section tunnel rock boring machine. The limit protection device comprises a base frame and a supporting oil cylinder arranged on the base frame, and is characterized in that a groove is arranged on the base frame; one end of the supporting oil cylinder is a restrained end which is movably arranged in the groove of the base frame; the other end of the supporting oil cylinder is a stressed end which is connected with a thrust oil cylinder by a supporting shoe; the groove wall of the base frame is provided with a convex elastic part which corresponds to the side wall of the restrained end of the supporting oil cylinder. The limit protection device has simple structure and low cost; when the supporting oil cylinder bears large lateral pushing force from the thrust oil cylinder through the limit protection device, elastic function of the elastic component in the limit protection device balances the pushing force, so that bending deformation of one end opposite to the other end bearing the lateral force of the supporting oil cylinder is reduced, excessive damages are avoided; when the lateral force is relieved, the supporting oil cylinder can be protected to return a normal working position.

Owner:CHINA RAILWAY CONSTR HEAVY IND

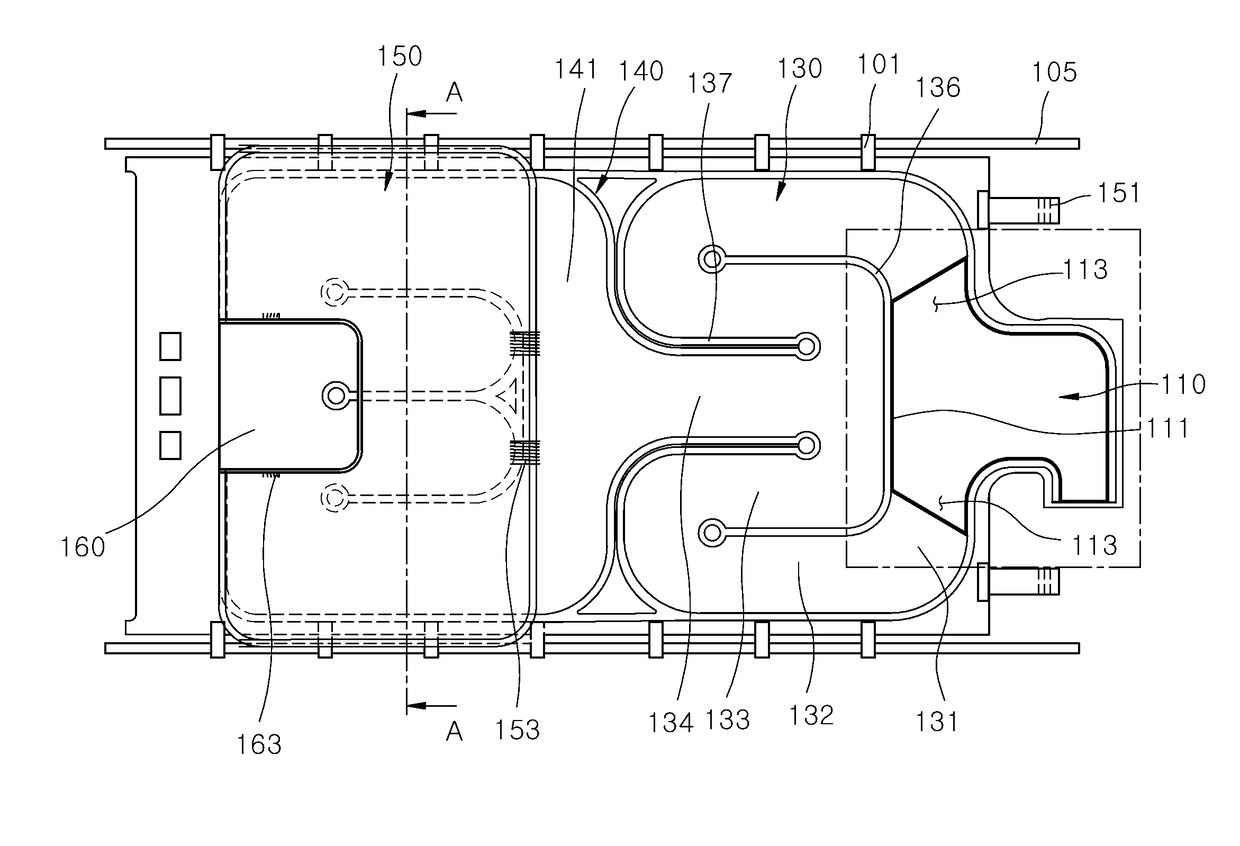

Backlight module and liquid crystal display device using the backlight module

InactiveCN102606954AEasy to installReduce the chance of bending deformationNon-linear opticsLight fasteningsLiquid-crystal displayBackplane

The invention relates to a backlight module and a liquid crystal display device using the backlight module. The backlight module includes a back plate and an optical film arranged on the back plate, wherein a lug for location is arranged on the optical film, and includes a root part and an expansion part extending outwards; the width of the expansion part is larger than that of the root part; a first bump is arranged on the sidewall of the back plate; an opening is formed on the first bump; the root part of the lug of the optical film is accommodated in the opening; a second bump is arranged on the sidewall of the back plate and includes an extension part; and the expansion part of the lug of the optical film is accommodated below the extension part of the second bump. By arranging the second bump on the back plate, the extension part of the second bump can prevent the lug of the optical film from moving in a direction vertical to the plane of the optical film; the second bump can be arranged at a low cost; and the optical film is simple in installation and can save time and effort.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

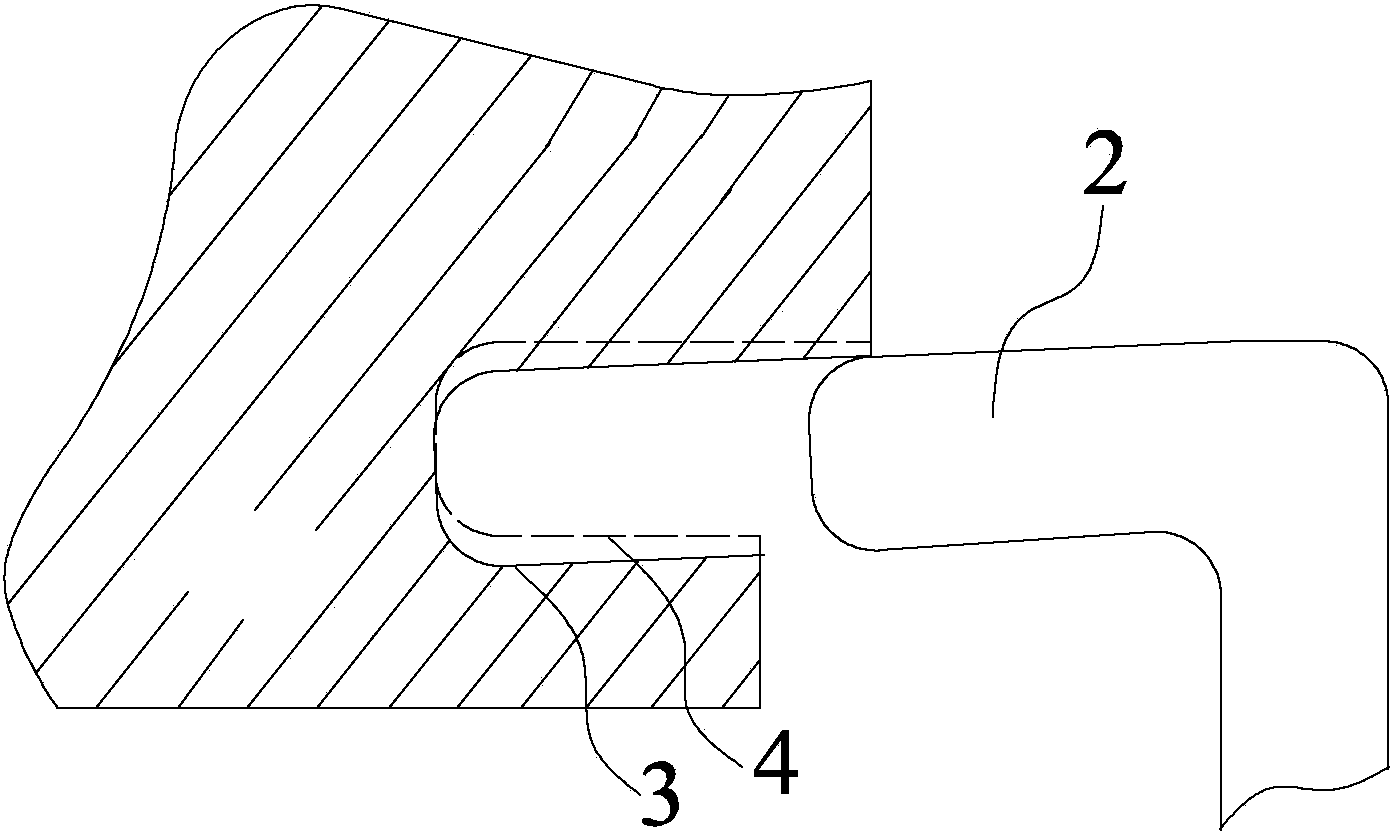

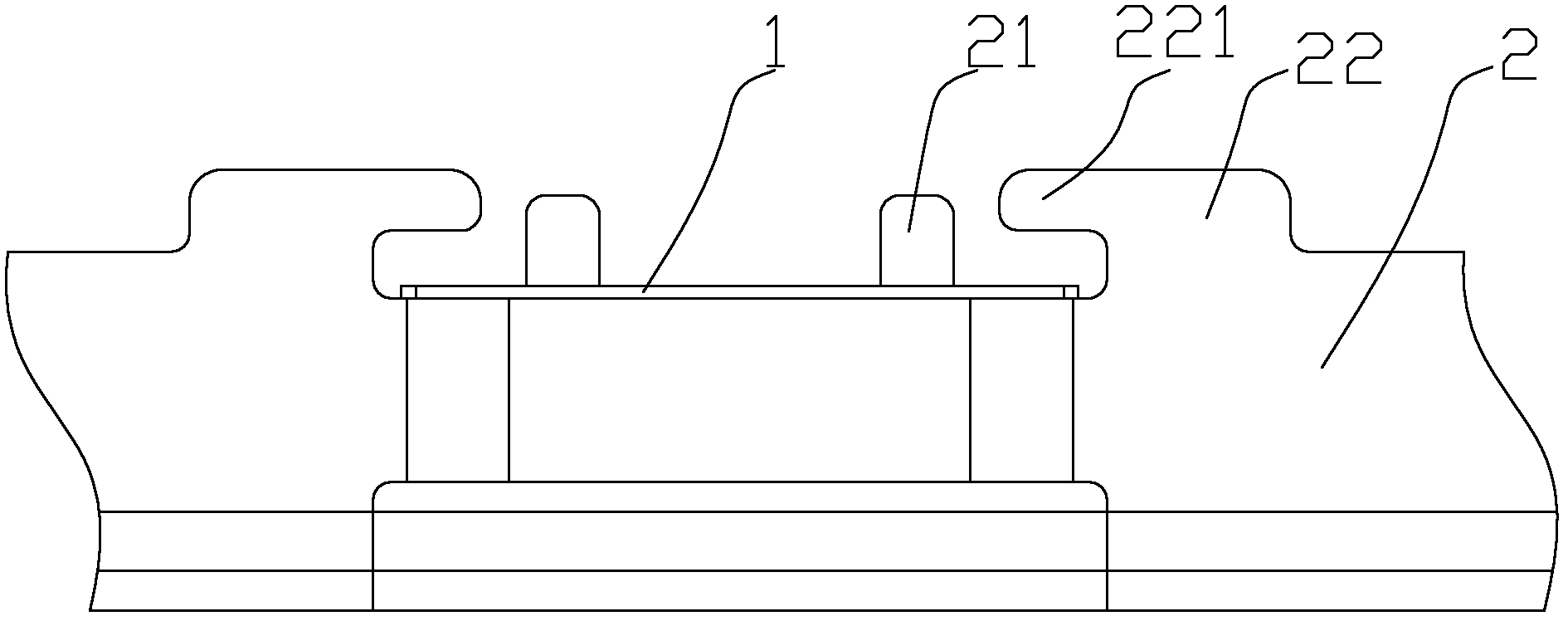

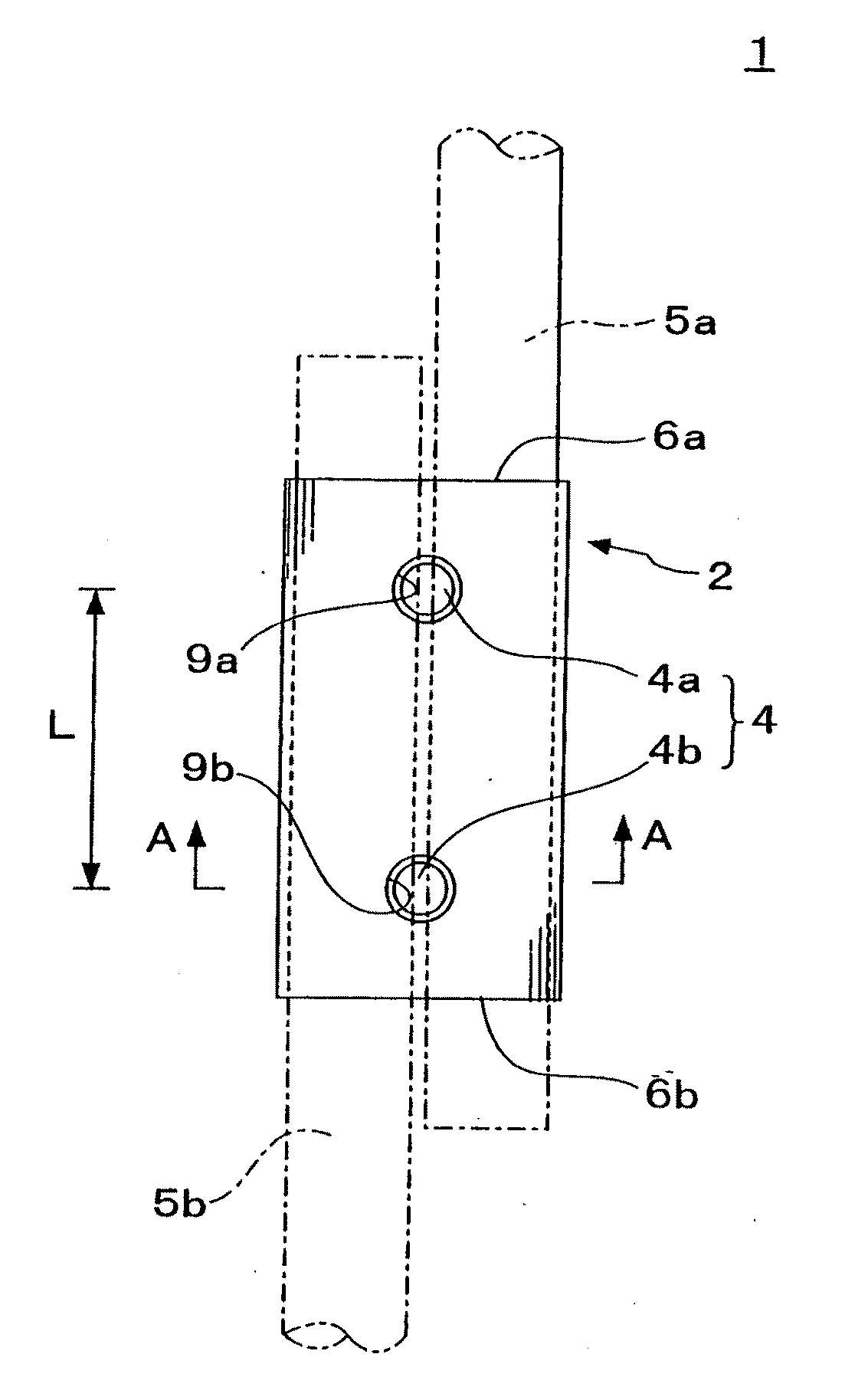

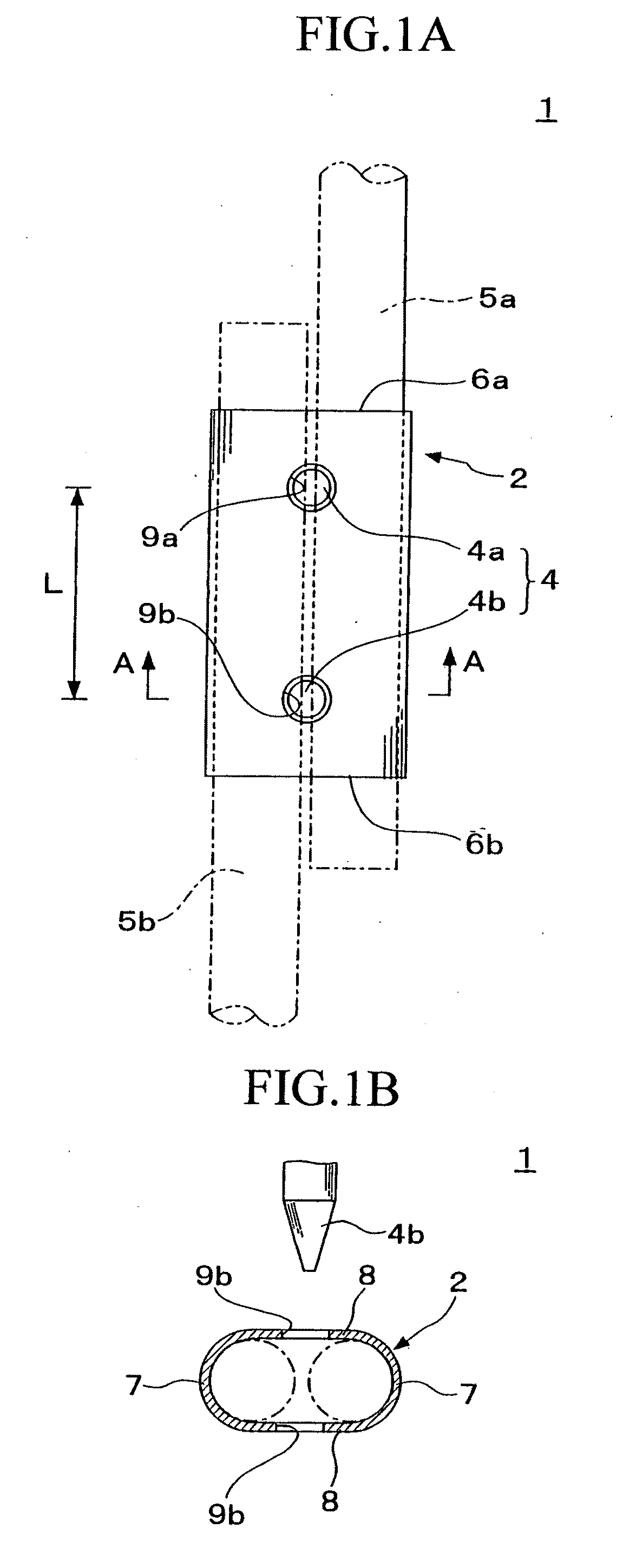

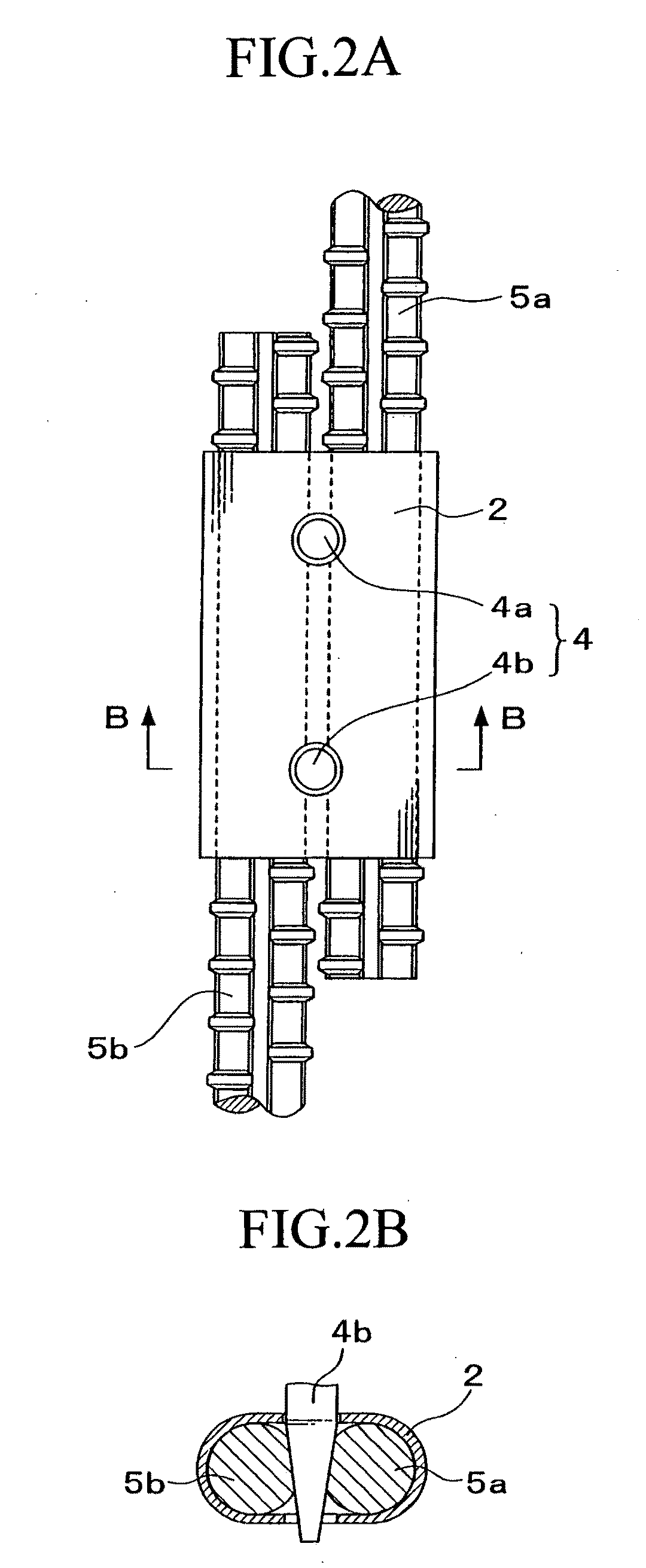

Reinforcing bar joint

InactiveUS20100024344A1DistanceReduce the amount requiredBuilding reinforcementsSteel barMechanical engineering

A reinforcing bar joint 1 includes a sleeve 2 having an elliptic section, and a wedging means 4. The wedging means 4 is composed of wedge members 4a, 4b which are pressed into between reinforcing bars 5a, 5b. The press-in positions of these wedge members 4a, 4b are spaced away from each other so that the reinforcing bars 5a, 5b, the sleeve 2, and the wedge members 4a, 4b are integrated in the area lying between the press-in positions. This can also move the points of action of tensile forces acting on the reinforcing bars outward, thereby increasing the distance between the points of action and reducing the amount of rotation of the sleeve 2.

Owner:OKABE CO LTD

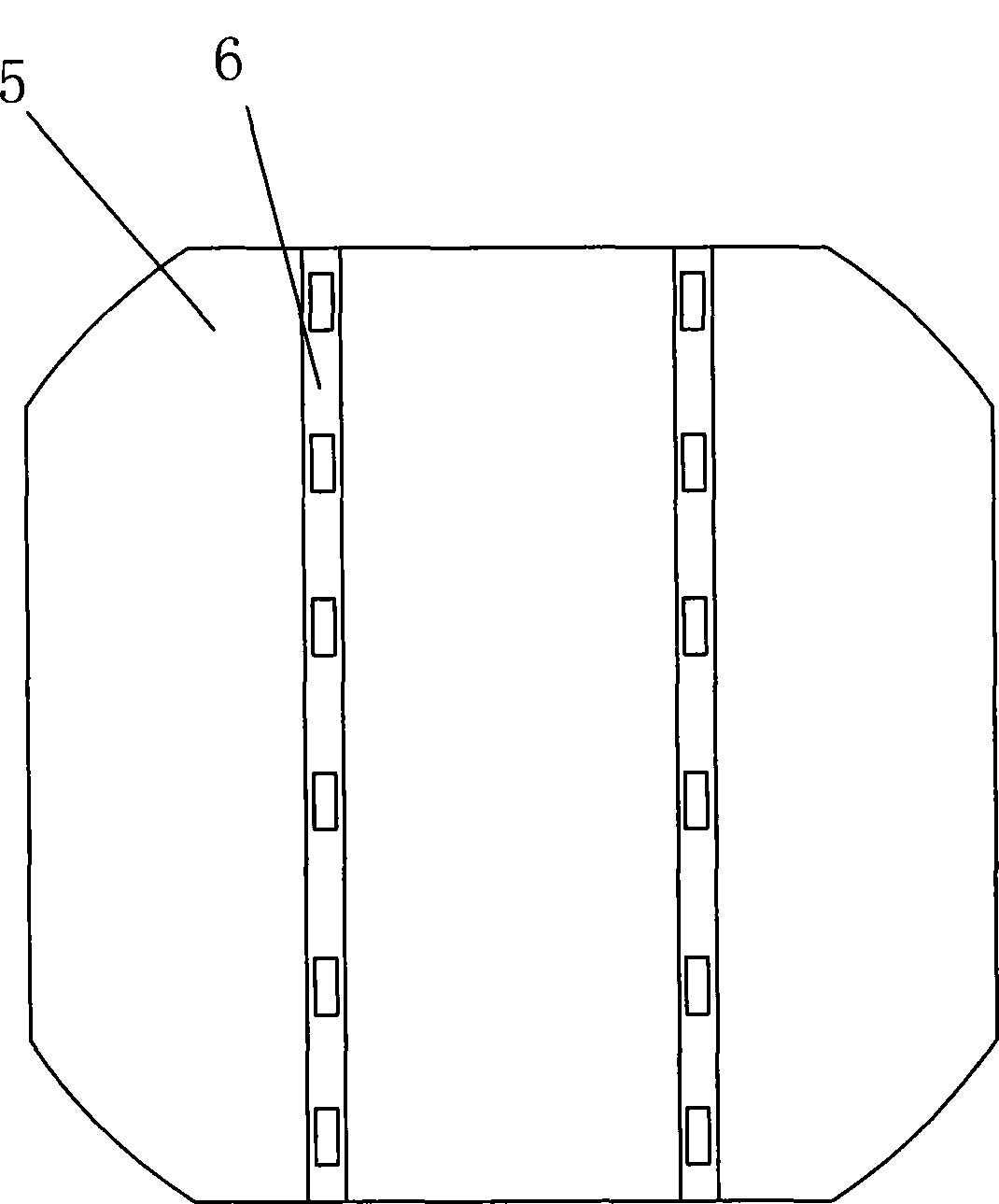

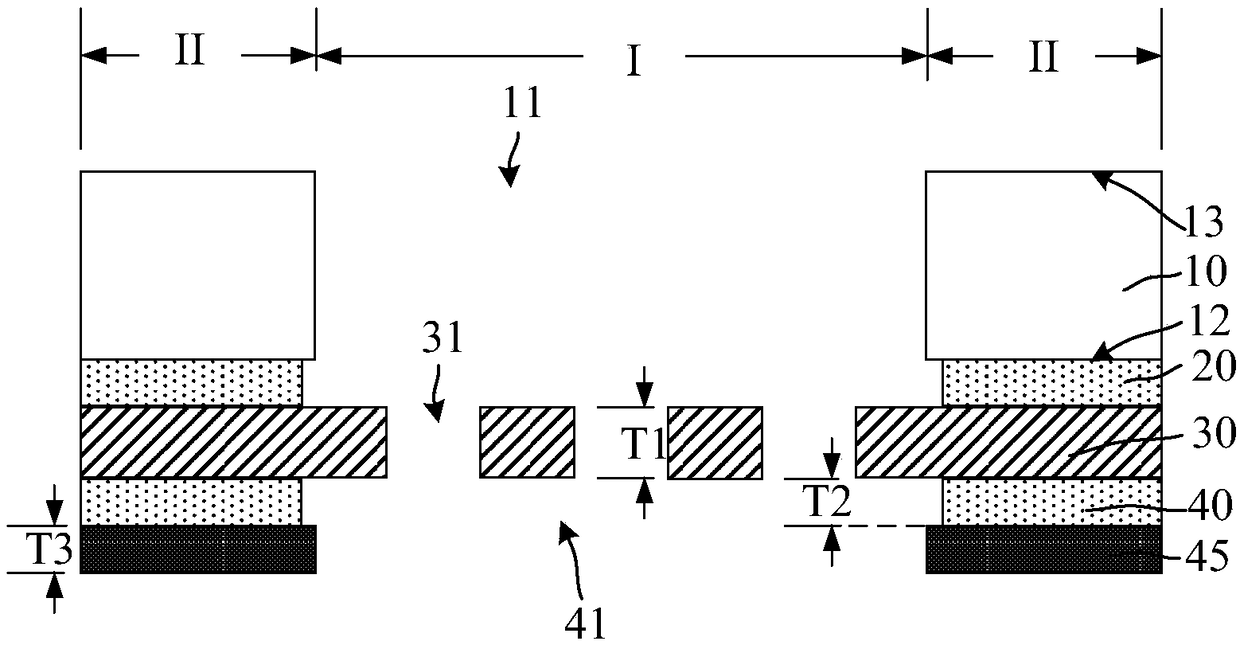

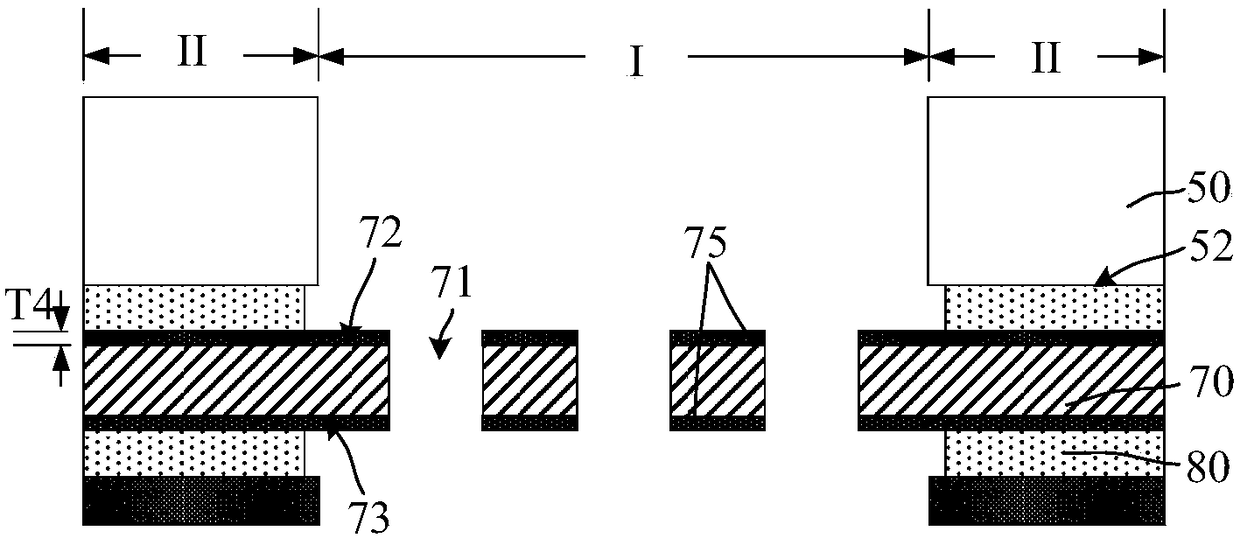

Mask plate and manufacturing method thereof

ActiveCN108546912ASmall sizeReduce thicknessSolid-state devicesVacuum evaporation coatingEngineeringLayer thickness

The invention discloses a mask plate and a manufacturing method of the mask plate. The mask plate comprises a substrate, a mask graph layer, a protection layer and a first sacrificial layer. The substrate comprises a first surface and a second surface reverse to the first surface, multiple openings penetrating the substrate are formed in the substrate, the substrate can use the semiconductor etching process to carry out imaging, the mask graph layer is located on the first surface and comprises a graph area and a shielding area which are adjacent, the graph area is provided with at least one through hole penetrating the mask graph layer, the openings are exposed out of the graph area, each graph area corresponds to the openings, the protection layer is located at the position, on the side,back onto the substrate, of the mask graph layer, of the surface of the shielding area, and the first sacrificial layer is located between the mask graph layer and the protection layer. The mask plate is made through the semiconductor process, compared with a metal mask plate made through the traditional chemical etching manner, the semiconductor process can improve the quality of the mask plateand the through hole precision, the through hole size is reduced, the mask graph layer thickness is reduced, the mask graph layer and the substrate can be prevented from shifting, and the mask plate quality and the precision are higher.

Owner:NINGBO SEMICON INT CORP

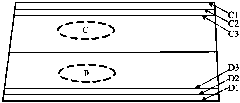

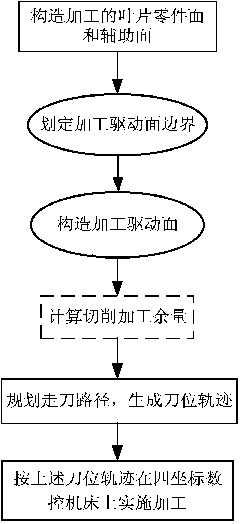

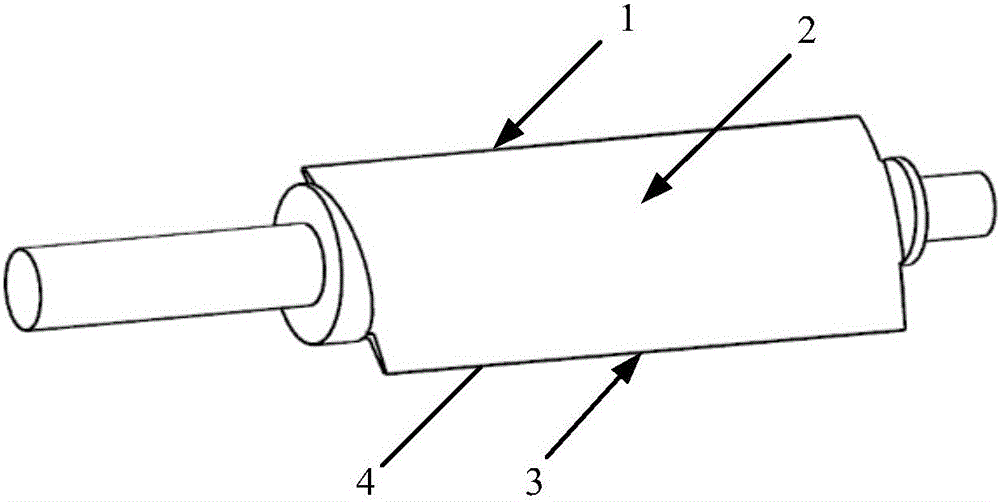

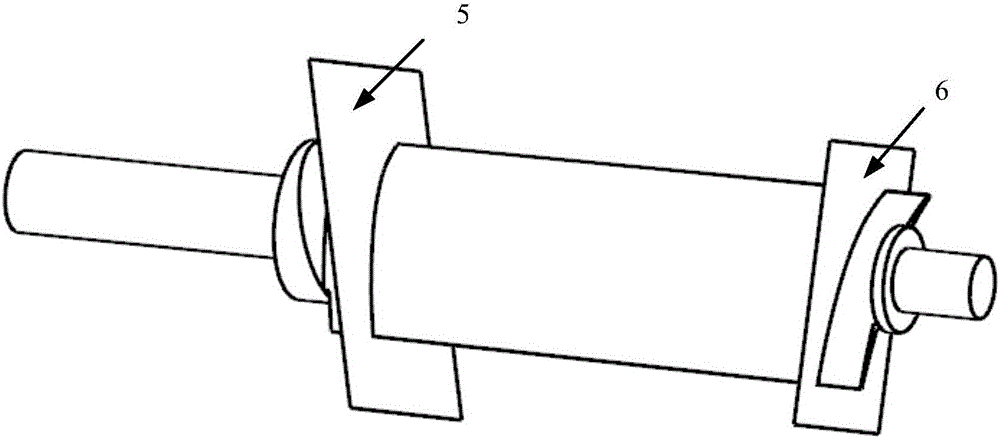

Thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation

ActiveCN106001720AReduce bending deformationReduce torsional deformationWorkpiecesMilling equipment detailsPosition toleranceTorsional deformation

The invention provides a thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation. Modeling is carried out by utilizing a three-dimensional modeling software, and an auxiliary surface and a boundary surface are formed, so that a driving surface is determined by utilizing a section line lofting process. Cutter machining paths are generated according to the driving surface, and the machining allowance of each cutter position point on each machining path is determined by adopting a Newton interpolation method. Finally, vanes are cyclically processed according to symmetrical milling rules. Compared with a traditional longitudinal fixed-allowance cutting and spiral milling method, the thin-walled vane nine-point control variable-allowance milling method has the advantages that technical problems, such as large torsional deformation, low contour precision, poor section position tolerance and difficult error control, in the machining process can be solved; and by adopting a Newton interpolation process allowance fine adjustment method, surface quality can be more comprehensively controlled, and problems, such as large bending deformation, poor section position tolerance and low surface contour precision, in the machining process can be effectively solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

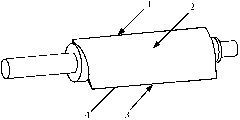

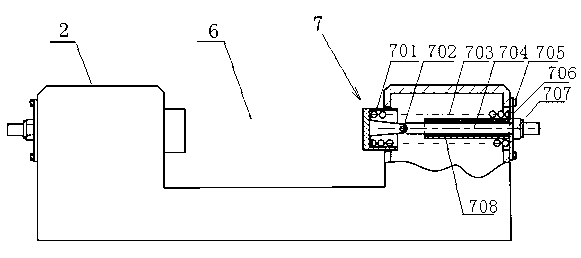

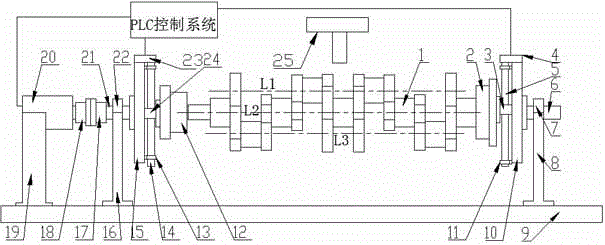

Laser processing device for crankshaft and method for performing laser processing on crankshaft

InactiveCN105689905AReduce bending deformationReduce rotation errorWelding/cutting auxillary devicesAuxillary welding devicesLaser processingControl system

The invention relates to a laser processing device for a crankshaft and a method for performing laser processing on the crankshaft. The laser processing device comprises the crankshaft, a three-claw clamping disk, sliding blocks, a stepping motor, a ball screw, a bearing, a support, a workbench, a guide column, a screw support, a support, a shaft coupler, a motor support, a second stepping motor, a transmission shaft, a second bearing and a laser device. The laser processing device for the crankshaft is used for performing laser processing on the crankshaft, so that the rotating axes of a main shaft neck and a connecting rod shaft neck of the crankshaft can be adjusted more precisely; meanwhile, a PLC control system is adopted to more precisely control the rotating angles of the three stepping motors and the displacements of the two sliding blocks, so that the rotating error can be reduced, and the processing precision is improved; the aim of precise laser processing of the main shaft neck and the connecting rod shaft neck of the crankshaft is fulfilled.

Owner:JIANGSU UNIV

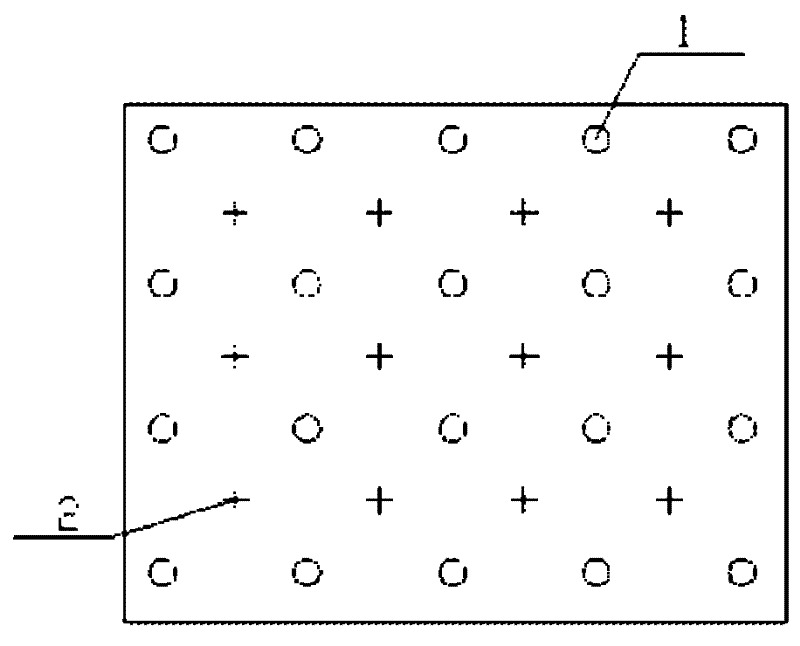

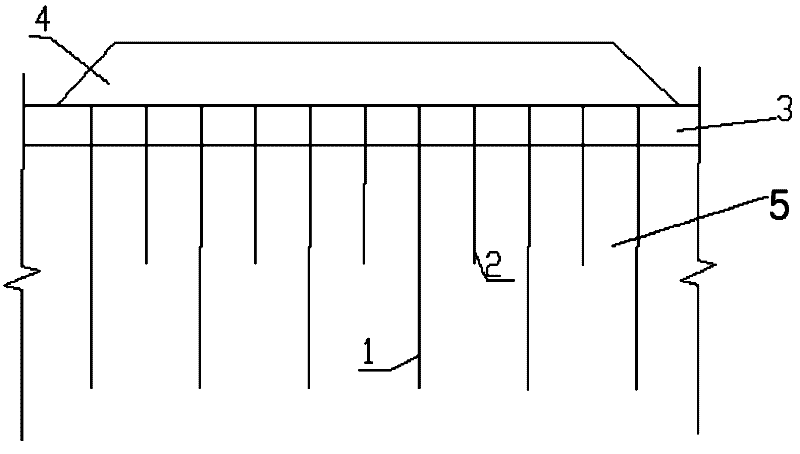

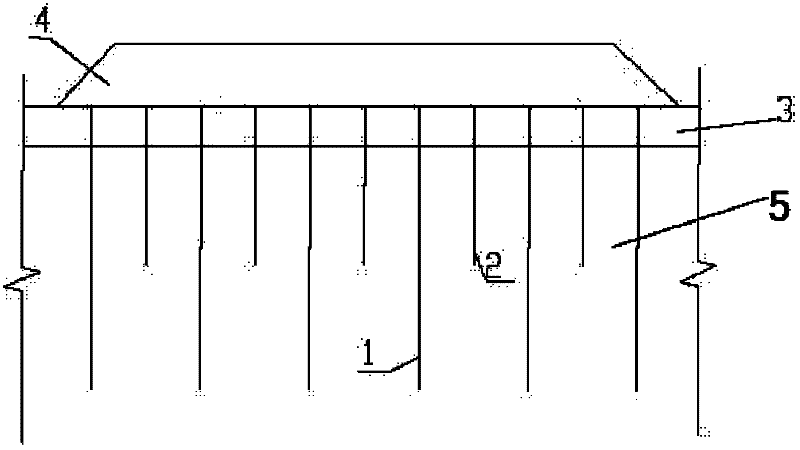

Soft foundation reinforced structure combined by long and short drain boards and construction method thereof

InactiveCN102392448AImprove reinforcement effectIncrease distanceBulkheads/pilesSoil preservationStructure of the EarthEngineering

Owner:SHANGHAI STRONG FOUND ENG

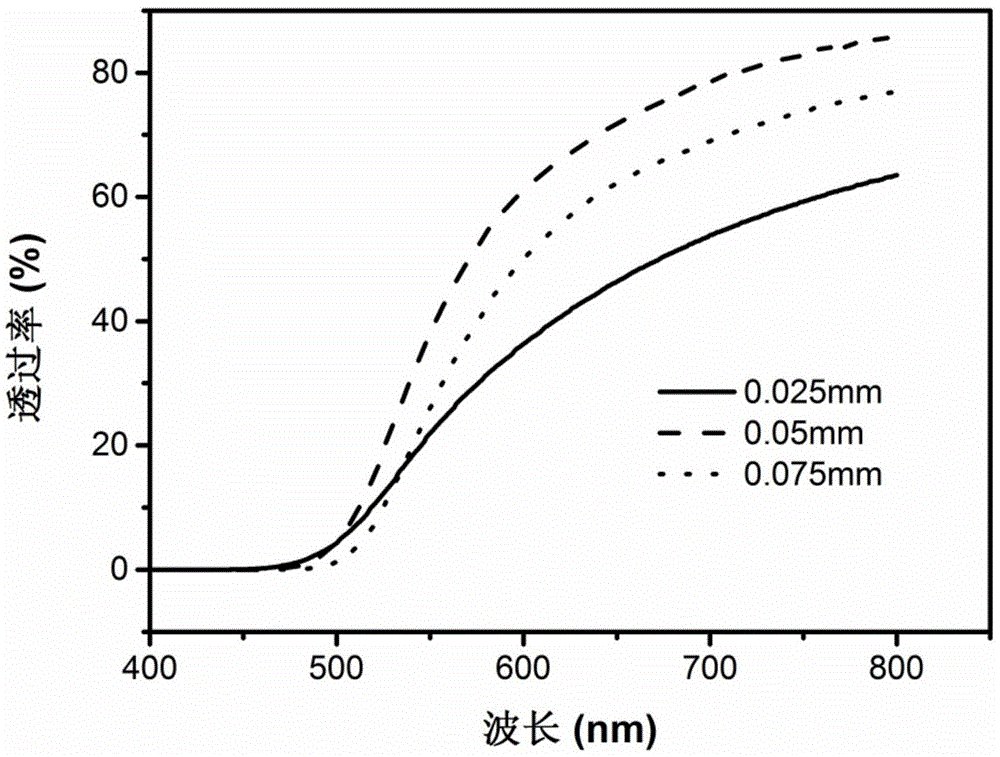

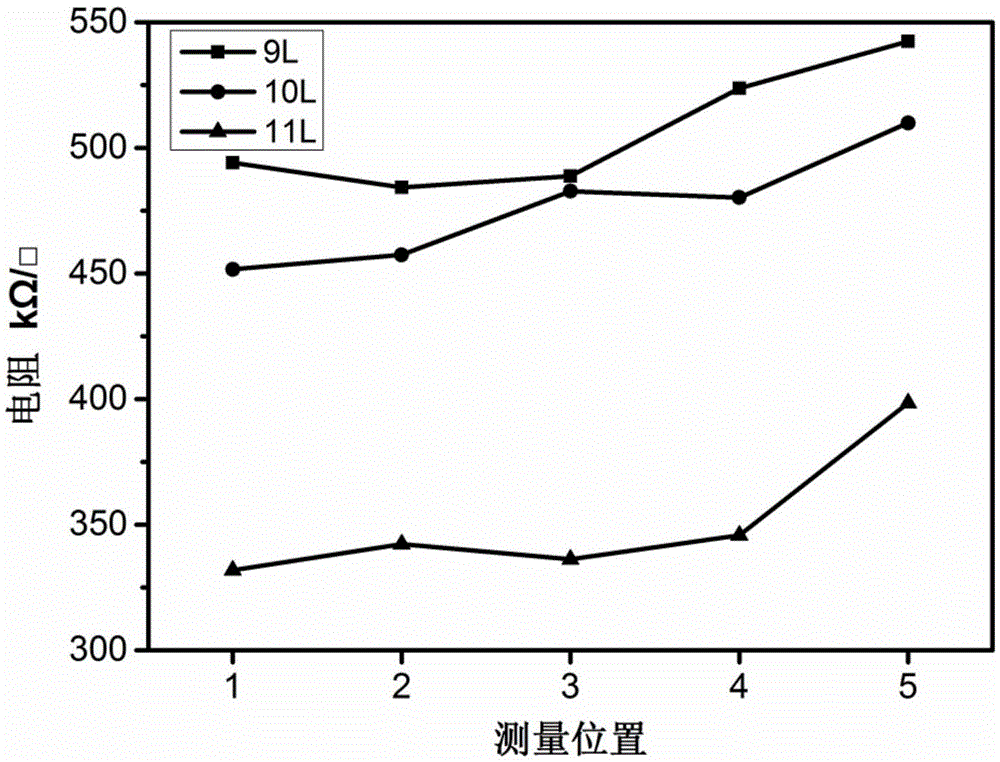

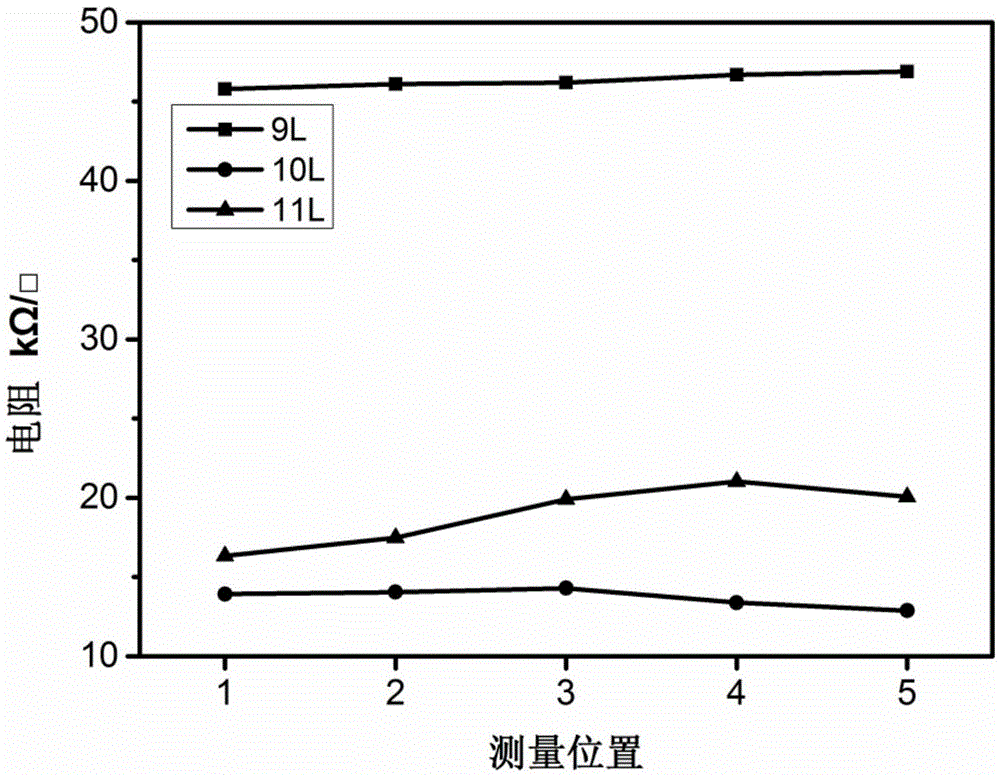

Method of directly preparing flexible and transparent conductive film through sol-gel process

InactiveCN105575551AGuaranteed smoothReduce bending deformationApparatus for heat treatmentAluminum doped zinc oxideHYDROSOL

The invention provides a method of directly preparing a flexible and transparent conductive film through a sol-gel process, mainly relating to the film preparation field. The method employs a sol-gel process to directly prepare an aluminum-doped zinc oxide flexible conductive film, guarantees the transmittance of a flexible transparent conductive film, meanwhile realizes low temperature preparation of the flexible transparent conductive film, and regulates the electrical property of the flexible transparent conductive film through low temperature annealing treatment. The method optimizes the electrical property of the flexible transparent conductive film through selecting different substrate thickness and annealing conditions, realizes the direct preparation of the flexible transparent conductive film with higher transmittance and electrical properties by employing a sol-gel process, effectively optimizes the conductive performance of the film through different annealing treatments, controllably regulates the electrical property of the flexible transparent conductive film, and realizes flexible transparent conductive film production under industrialization and low cost conditions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Turbojet having a large bypass ratio

ActiveUS20050172609A1Increase in-flight idling speedSimple and effective and inexpensiveSpraying apparatusBlade accessoriesCombustion chamberEngineering

A turbojet comprises at least a fan, a compressor, a combustion chamber, a turbine, and a rigid substantially-cylindrical jacket fastened at its upstream end to an intermediate casing and at its downstream end to an exhaust casing, the jacket serving to transmit forces between the intermediate casing and the exhaust casing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com