Six-degree-of-freedom parallel micro platform

A micro-platform, degree of freedom technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large weight size, few degrees of freedom, poor stiffness, etc., to reduce bending deformation, reduce weight, reduce The effect of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

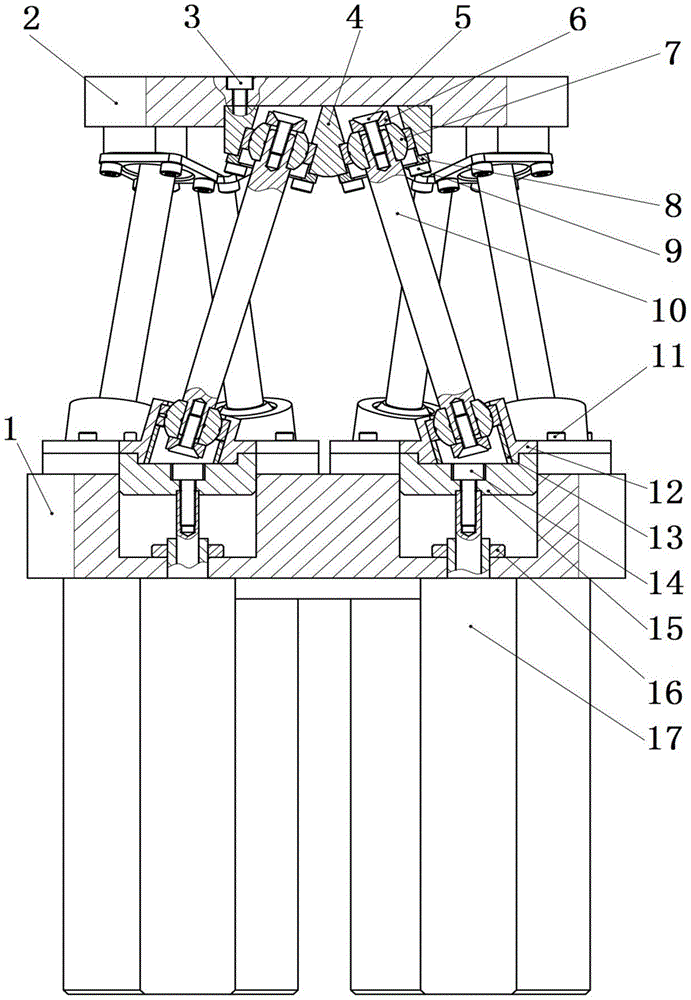

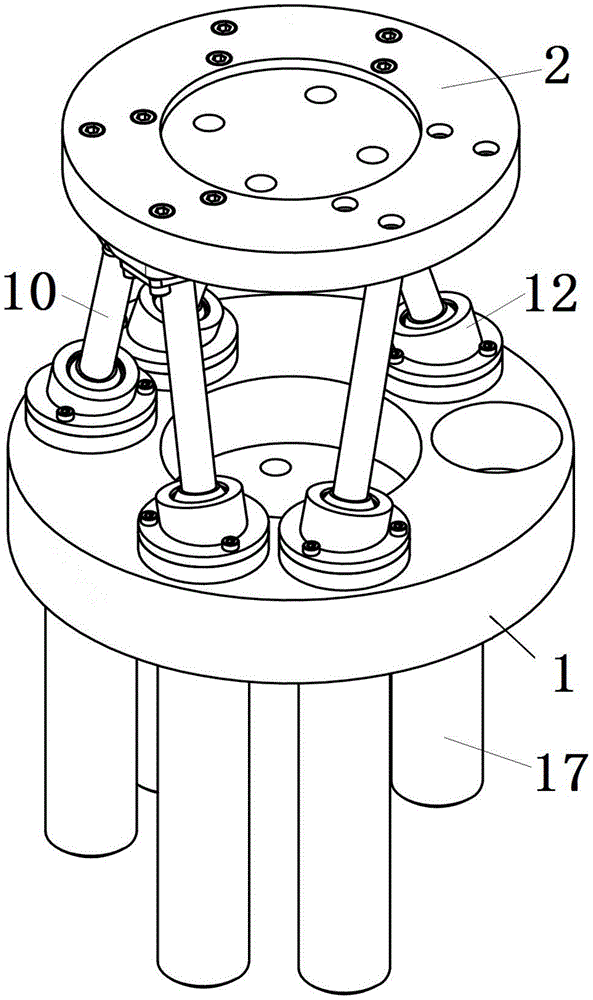

[0026] refer to figure 1 with figure 2 , the structure of the six-degree-of-freedom parallel micro-platform of the present invention is to include a static platform 1 and a dynamic platform 2, and three groups of fixed bearing seats are evenly installed on the lower surface of the dynamic platform 2, and each group of fixed bearing seats passes through two branch chains and the static platform downwards. 1 Transmission connection, that is, there are three sets of fixed bearing seats and six branch chains between the static platform 1 and the dynamic platform 2;

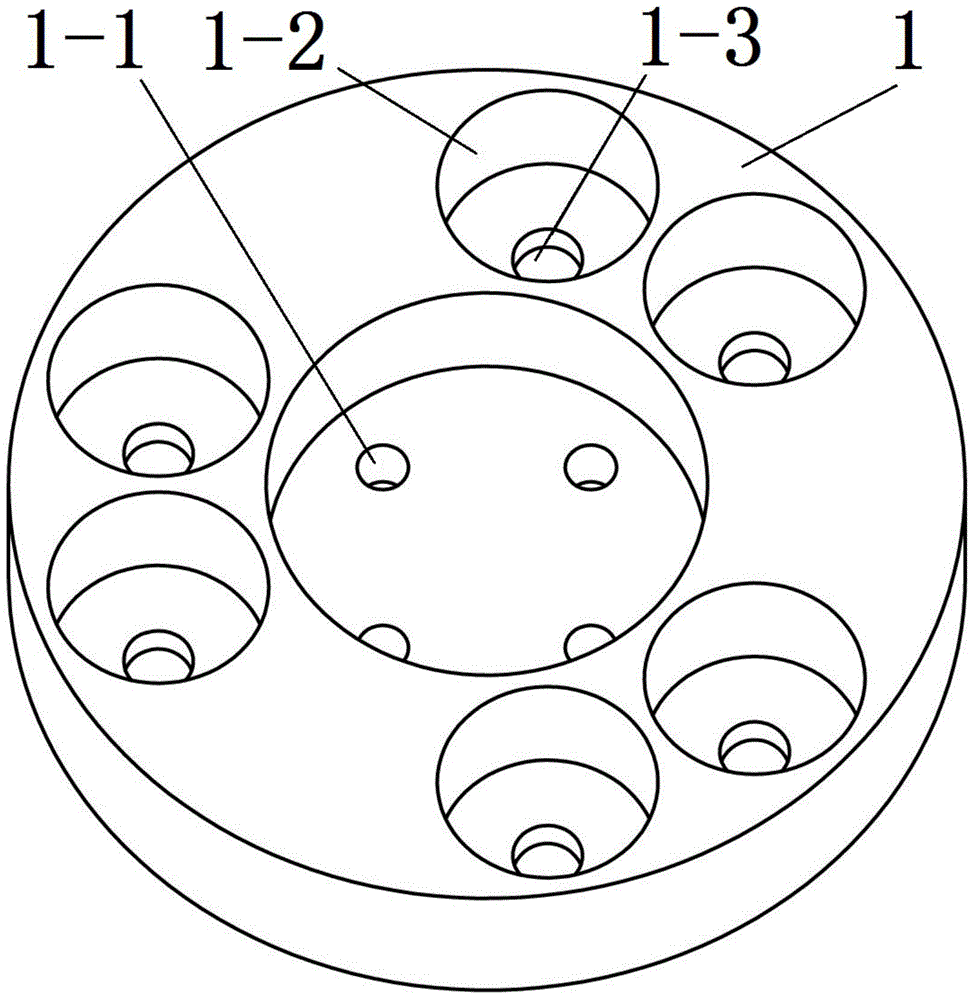

[0027] refer to image 3 , the static platform 1 has a plurality of micro-platform installation holes 1-1 in the groove of the inner ring along the axial direction, and the static platform 1 has a plurality of groove-type slideways 1-2 in the outer ring of the axial direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com