Method for preparing high-strength heat-resistant ferro-aluminium alloy parts

A technology of aluminum-iron alloy and heat-resistant aluminum, which is applied in the field of preparation of non-ferrous metal materials, can solve the problems of limited product size, non-compact product structure, low comprehensive performance, etc., achieve high strength and heat resistance, reduce harmful effects, and high The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

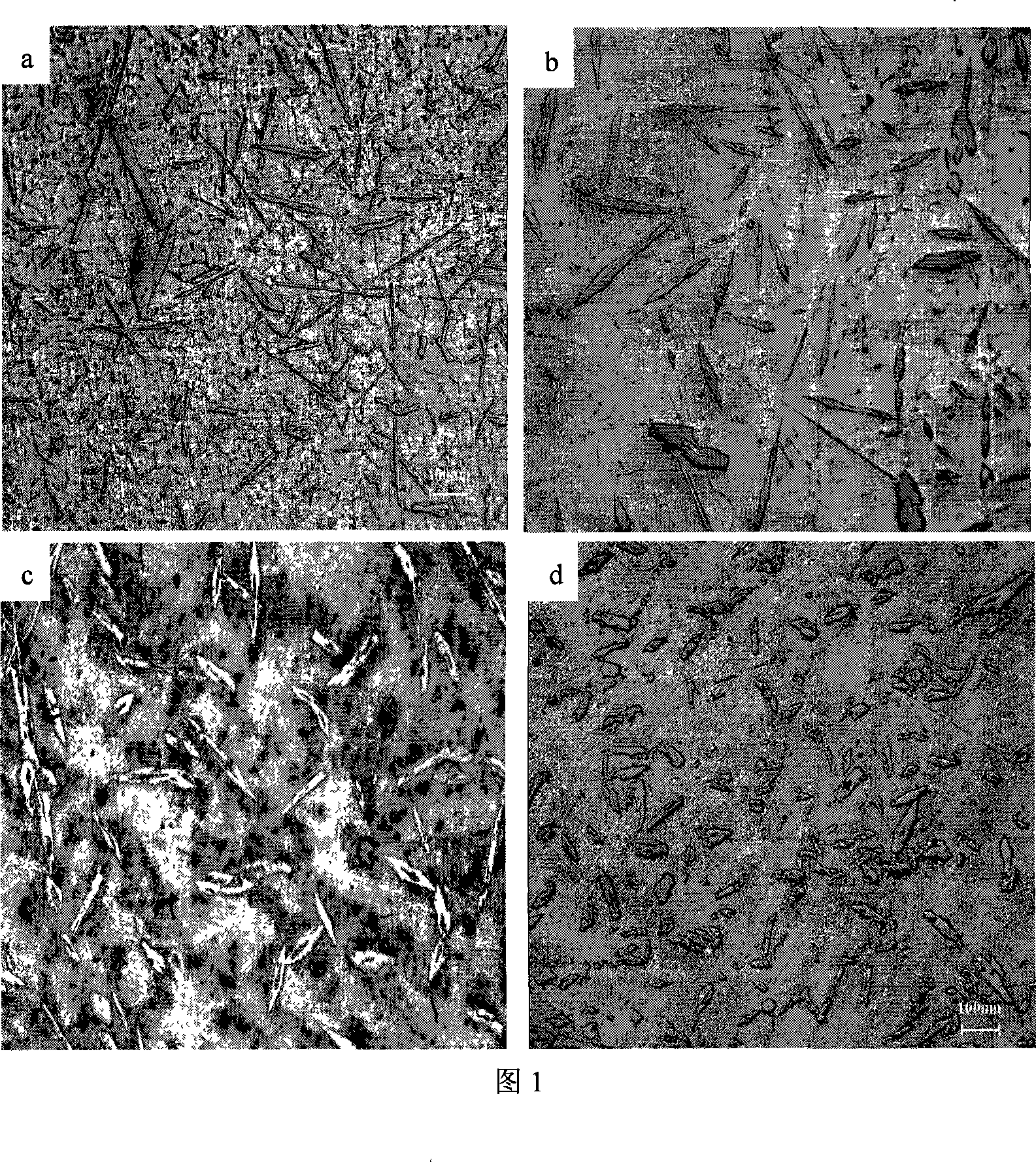

Image

Examples

Embodiment 1

[0015] First carry out alloy composition matching, its alloy chemical composition (wt%)

[0016] Fe, Cu, Zn, Mg, Mn, Ti, B, impurities, Al

[0017] 4.1, 4.25, 2, 0.3, 0.5, 0.15, 0.006 1.2, Margin

[0018] Pure iron, copper, manganese, zinc, and magnesium are formulated into master alloy ingots in an intermediate frequency furnace, and then melted in a resistance crucible furnace. 0.7% to 1.2% wt of the liquid is modified, and then solidified into an ingot under the condition of electromagnetic stirring, and the stirring voltage is 150V.

[0019] According to the requirements of the extrusion die, the ingot is processed to the required size. The processed ingot is reheated at a temperature of 640° C. and kept for 30 minutes, so that the liquid phase component of the ingot reaches 30 Vol%. Put the semi-solid ingot into the mold and extrude it. The extrusion pressure is 20Mpa. The alloy properties of the final test are shown in Table 1.

[0020] Table 1 Mechanical propertie...

Embodiment 2

[0023] First carry out alloy composition matching, its alloy chemical composition (wt%)

[0024] Fe, Cu, Zn, Mg, Mn, impurities, Al

[0025] 5.5, 4, 2, 0.4, 0.5, 1.1, margin

[0026] Pure iron, copper, manganese and aluminum are formulated into master alloys of Fe20Al80, Cu50Al50 and Mn10Al90 respectively. When smelting, put AlFe, AlMn master alloy and pure aluminum into a resistance crucible furnace to melt, add AlCu master alloy, Zn and Mg after the alloy is melted, melt and stir for refining, then keep it at 680°C for 25 minutes, and cast it into an ingot. The ingot is processed into an ingot of the desired size.

[0027] The processed billet is reheated at a heating temperature of 630° C., and when the liquid phase component in the billet reaches 50 Vol%, it is put into a mold for extrusion molding. The extrusion pressure is 30Mpa. The alloy properties of the final test are shown in Table 2.

[0028] Table 2 Mechanical properties of Al-5.5Fe-4Cu-2Zn-0.5Mn-0.4Mg

[00...

Embodiment 3

[0031] First carry out alloy composition matching, its alloy chemical composition (wt%)

[0032] Fe, Cu, Zn, Mg, Mn, impurities, Al

[0033] 5, 3, 4, 0.25, 0.7, 1.1, margin

[0034] Master alloys of Fe20Al80, Cu50Al50, Mn10Al90 and Mg20Al80 are used. When smelting, put pure aluminum and AlFe, AlMn intermediate alloys into a resistance crucible furnace to melt, add AlCu, AlMg intermediate alloys and pure Zn after the alloy is melted, heat-retain and stir for refining, and then solidify into ingots under electromagnetic stirring conditions, stirring voltage 200V. The ingot is processed into an ingot of the desired size.

[0035] Carry out secondary heating to the processed ingot, the heating temperature is 620°C, when the liquid phase component in the ingot reaches 35Vol%, put it into the mold for extrusion molding. The extrusion pressure is 100Mpa. The properties of the alloy at this time are shown in Table 3.

[0036] Table 3 Mechanical properties of Al-5Fe-3Cu-4Zn-0.7Mn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com