Patents

Literature

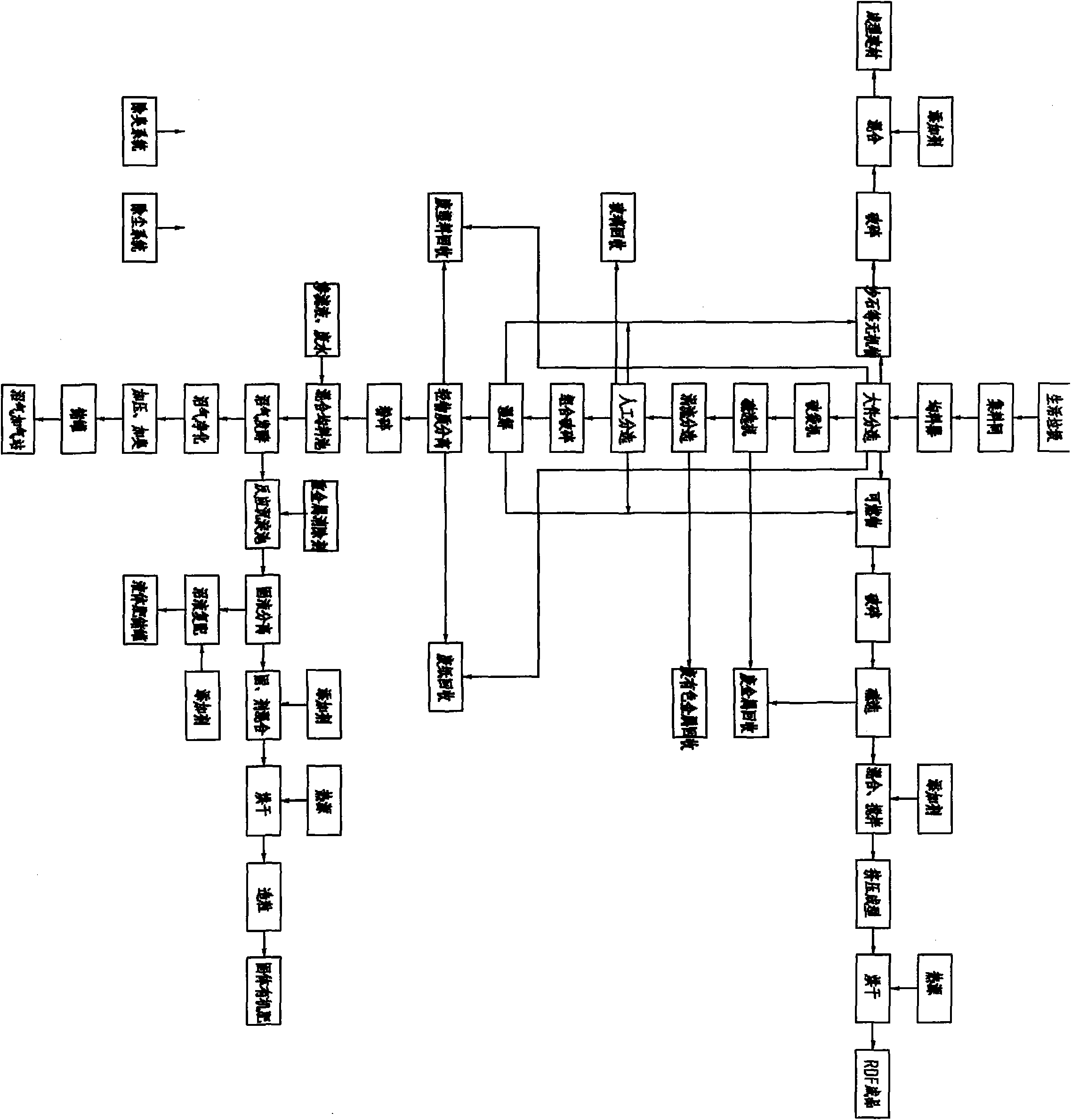

3187 results about "Nonferrous metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-ferrous metals are those which do not contain iron as main constituent or base metal. Non-ferrous metals have industrial applications because of their case of fabrication (like rolling, forging, casting, welding, and machining), electrical and thermal conductivity, resistance to corrosion, light-weight, etc.

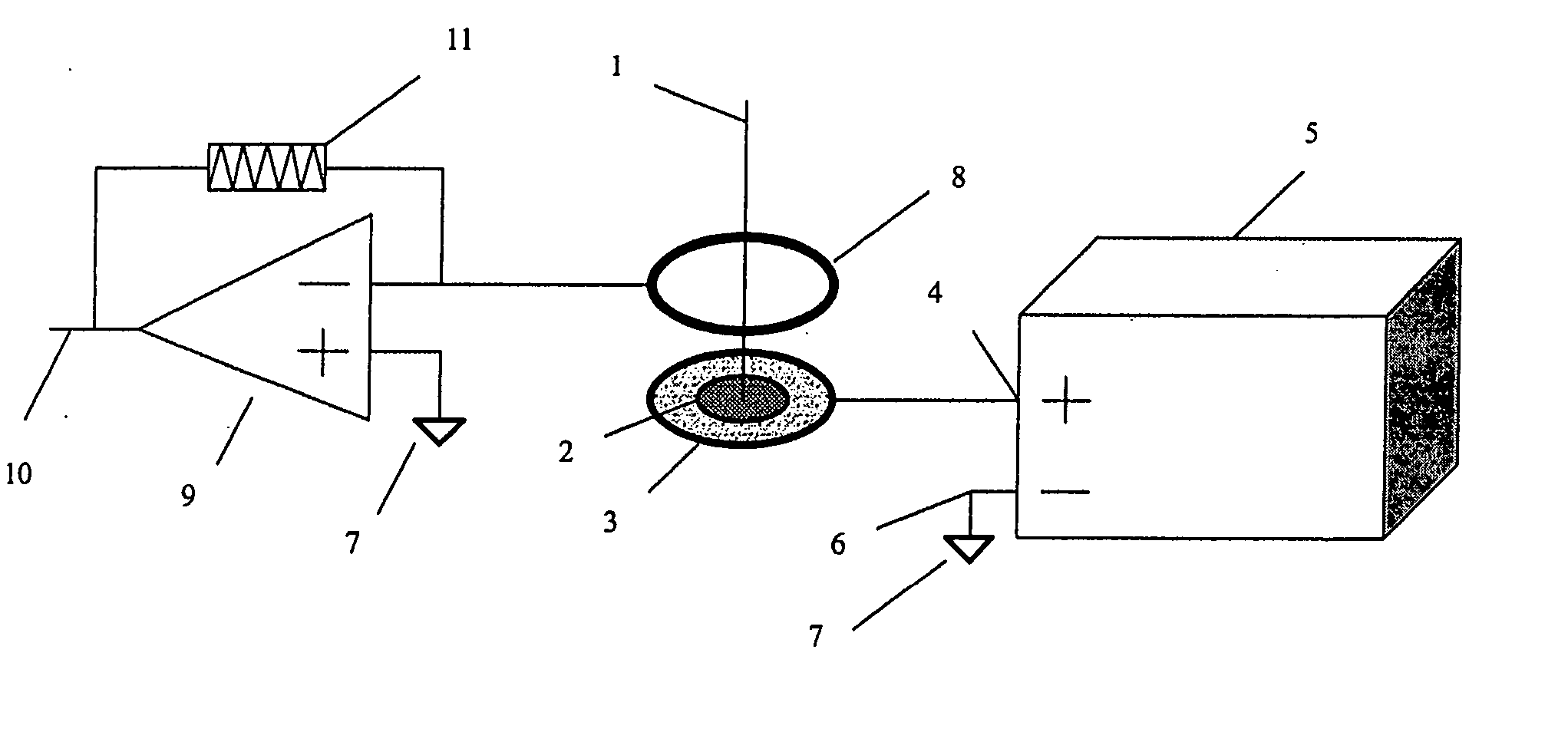

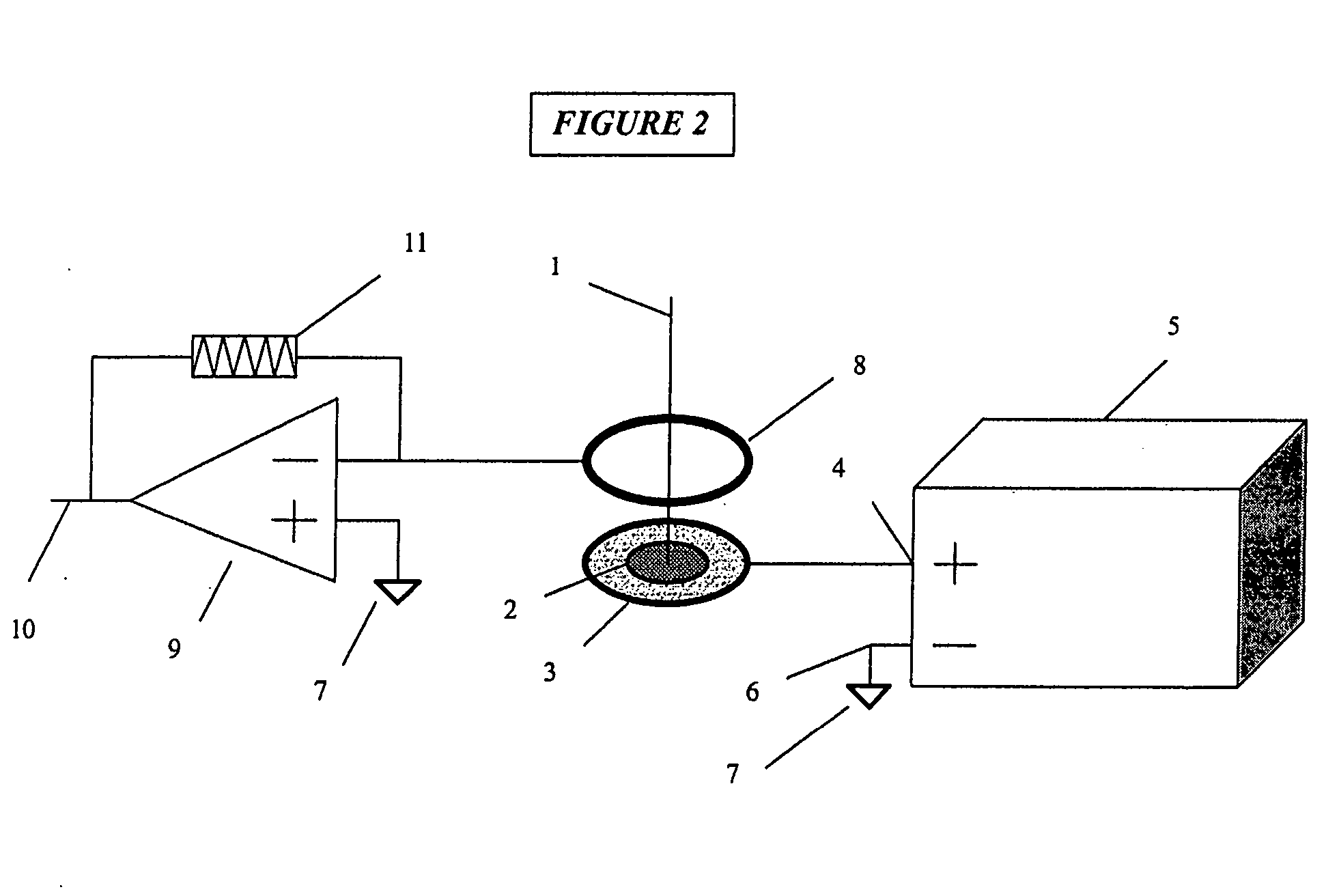

Laser ablation feedback spectroscopy

InactiveUS20050061779A1Precise depth controlReduce the amount requiredWelding/soldering/cutting articlesMetal working apparatusMass spectrometryAblation plasma

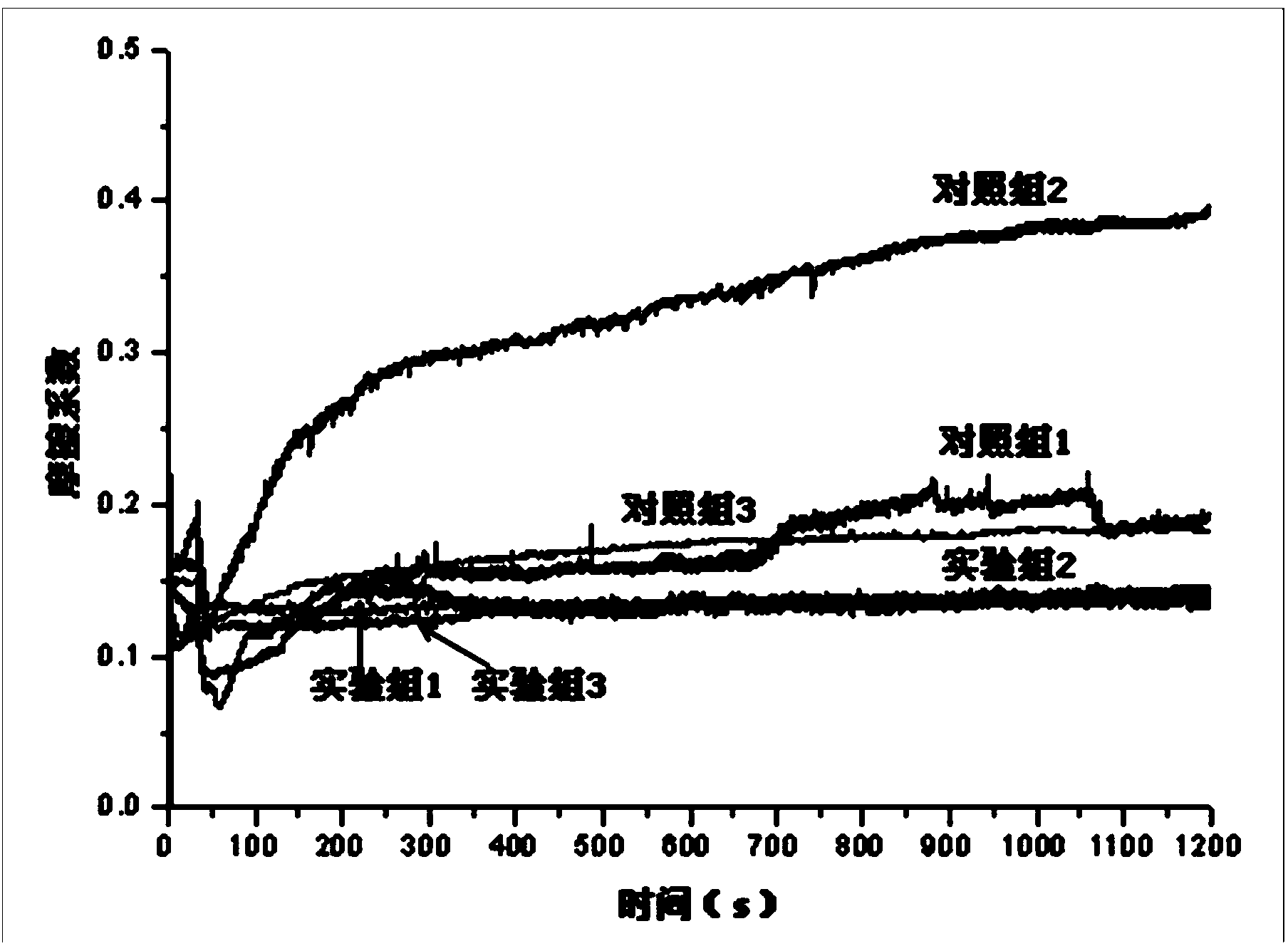

Methods, for use with a laser ablation or drilling process, which achieve depth-controlled removal of composite-layered work-piece material by real-time feedback of ablation plasma spectral features. The methods employ the use of electric, magnetic or combined fields in the region of the laser ablation plume to direct the ablated material. Specifically, the electric, magnetic or combined fields cause the ablated material to be widely dispersed, concentrated in a target region, or accelerated along a selected axis for optical or physical sampling, analysis and laser feedback control. The methods may be used with any laser drilling, welding or marking process and are particularly applicable to laser micro-machining. The described methods may be effectively used with ferrous and non-ferrous metals and non-metallic work-pieces. The two primary benefits of these methods are the ability to drill or ablate to a controlled depth, and to provide controlled removal of ablation debris from the ablation site. An ancillary benefit of the described methods is that they facilitate ablated materials analysis and characterization by optical and / or mass spectroscopy.

Owner:BLUMENFELD WALTER +2

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

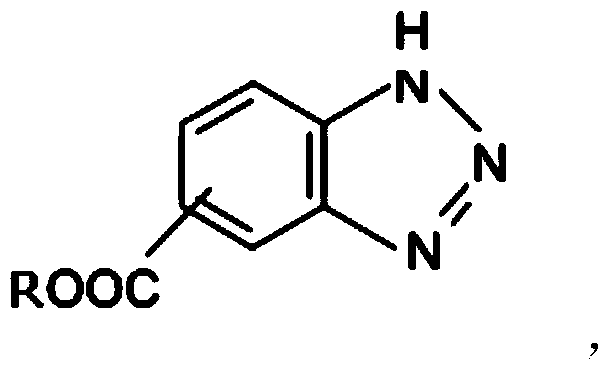

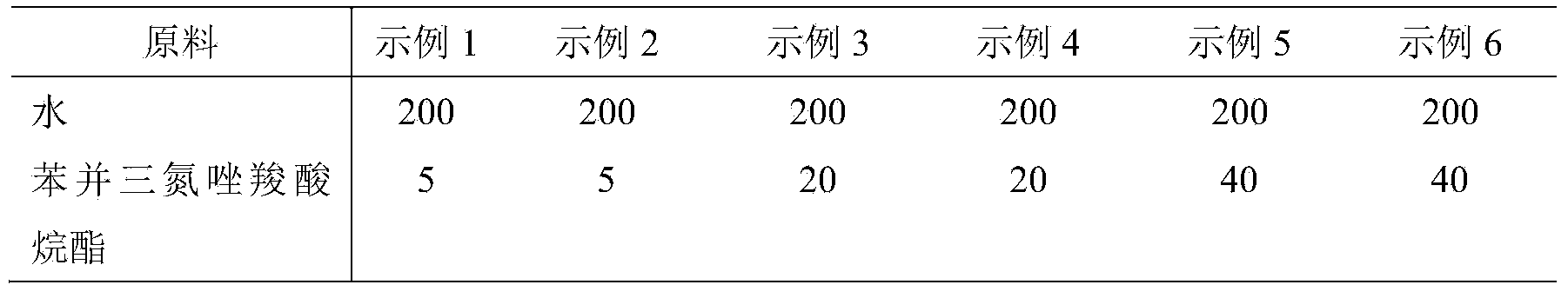

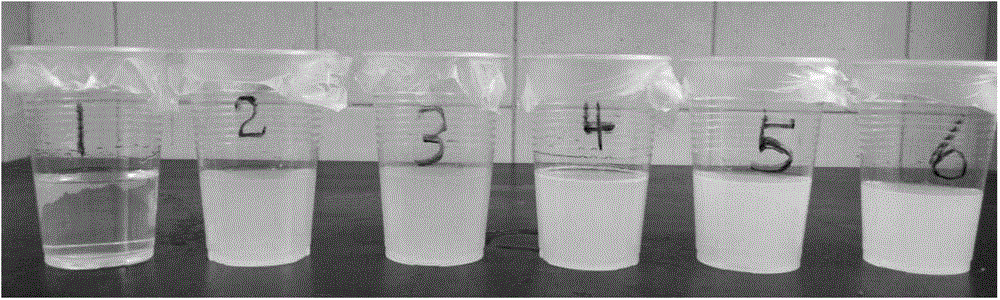

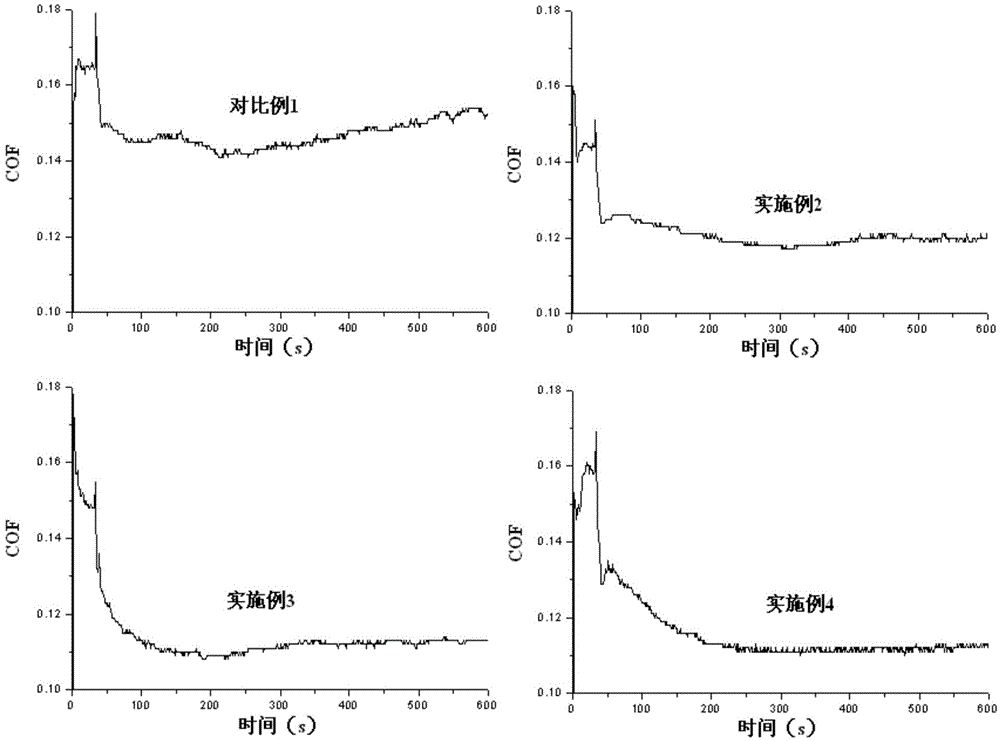

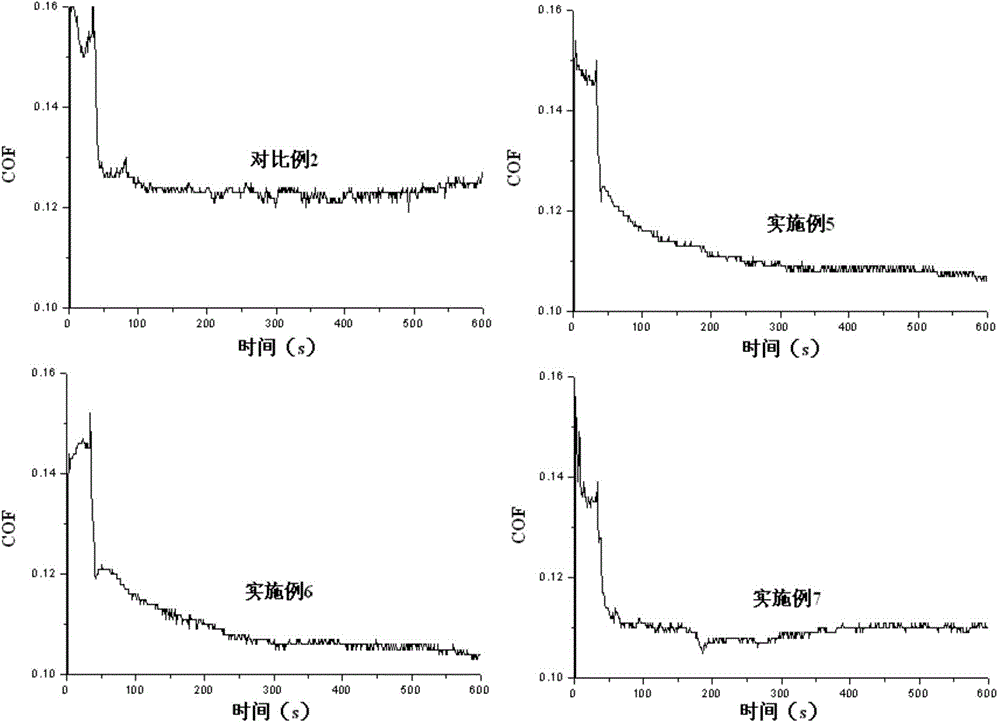

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

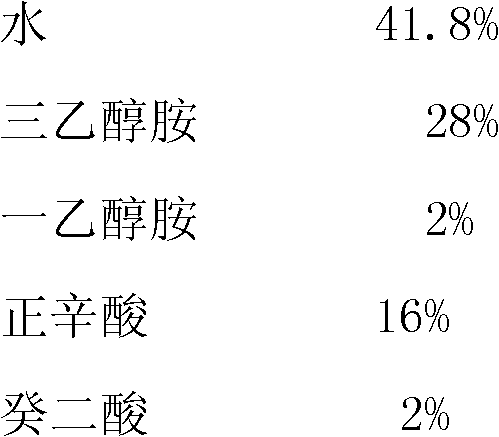

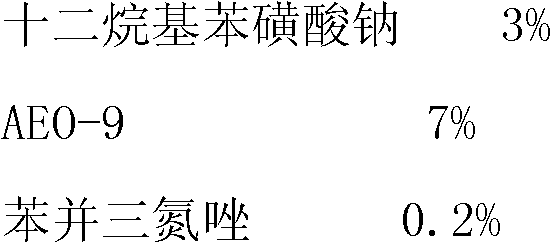

Microemulsion metal cutting fluid

ActiveCN104164283AMeet cutting processing requirementsHigh thermodynamic stabilityLubricant compositionEmulsionNonferrous metal

The invention discloses a microemulsion metal cutting fluid which contains 1-20 wt% of fatty oil, 1-40 wt% of emulsifier, 5-40 wt% of co-emulsion, 5-30 wt% of wear and rust inhibitor, 1-20 wt% of penetrant, 5-30 wt% of pH regulator, 0.5-5 wt% of defoaming agent and 0.1-5 wt% anticorrosive bactericide. The microemulsion metal cutting fluid has excellent lubricating, antiwear, antirust, cleaning and cooling properties, and can be widely used in precise cutting work of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

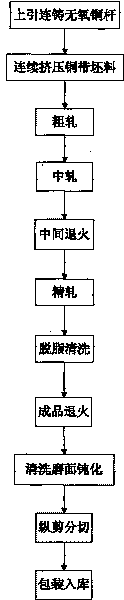

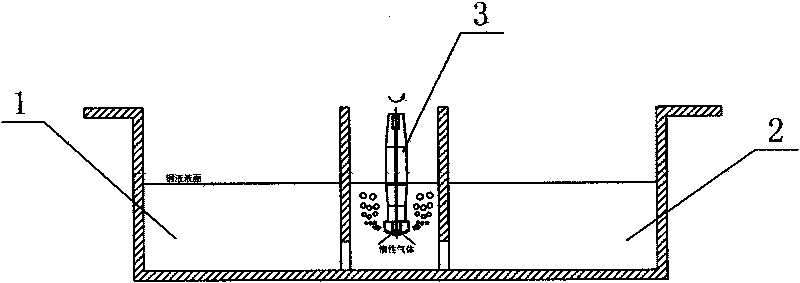

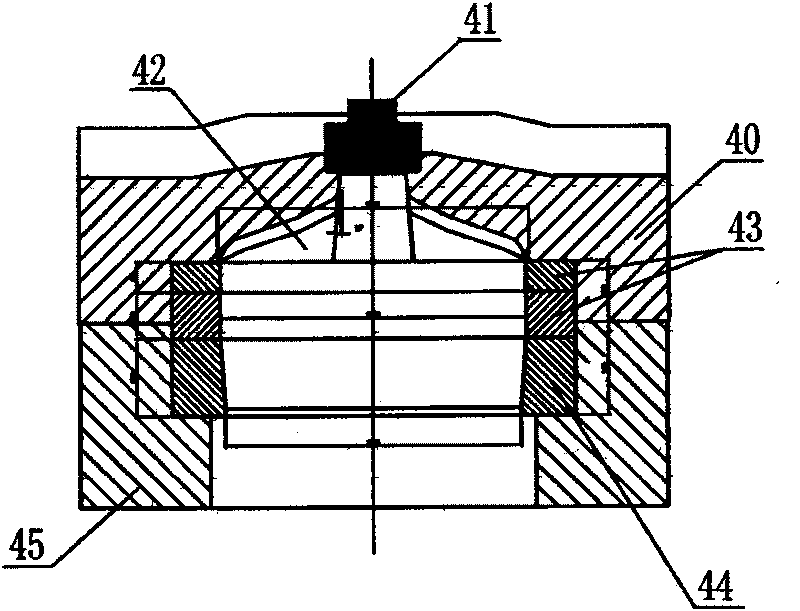

Production technique of copper strips for solar modules

InactiveCN101719527AHigh purityImprove conductivityFinal product manufactureSemiconductor devicesElectrolysisLiquid surfaces

The invention discloses a production technique of copper strips for solar modules, which belongs to the technical field of nonferrous metal processing and comprises the following steps: drawing-up of continuous-casting oxygen-free copper bar: using high-quality electrolytic copper as the raw material, melting at 1150+ / -10 DEG C, keeping the temperature, covering the copper liquid surface with charcoal and graphite scales to ensure the vacuum state during melting, degassing on line, deoxidizing, stirring, and drawing up the copper bar with a tractor set in an on-off vacuum way; continuous extrusion of copper strip blanks: using oxygen-free copper rods as the raw material, producing copper strip blanks by using a continuous extruder set, cooling the extruded copper strip blanks through a vacuum oxidation-resisting pipe and a water tank, drying and coiling; and rough-rolling the copper strip blanks, medium-rolling, interstage annealing, finish rolling, degreasing, washing, annealing the finished product, washing, grinding the surface to passivate, and longitudinally cutting to obtain the finished product. The product of the invention has the advantages of high purity, low oxygen content and high electrical conductivity.

Owner:浙江力博实业股份有限公司

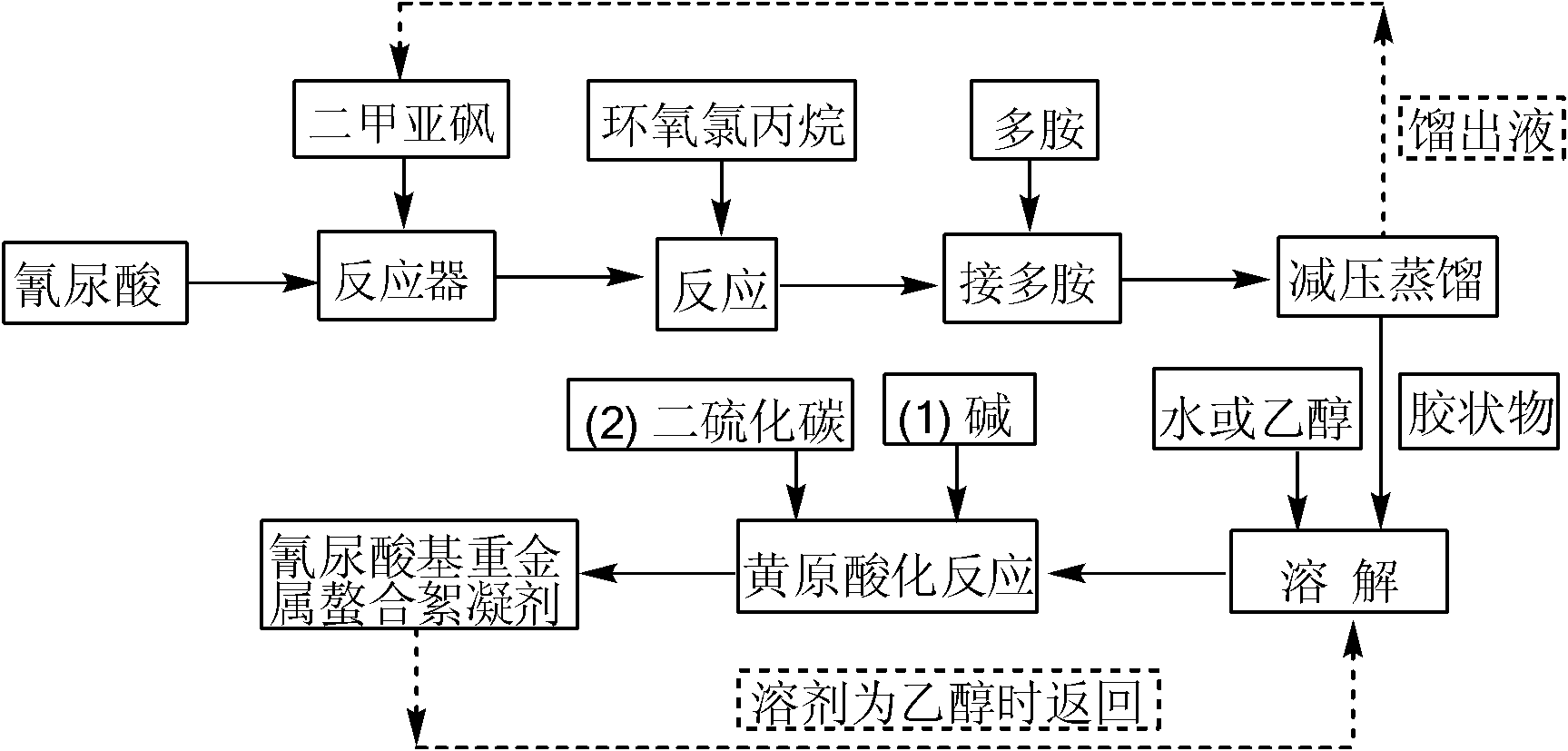

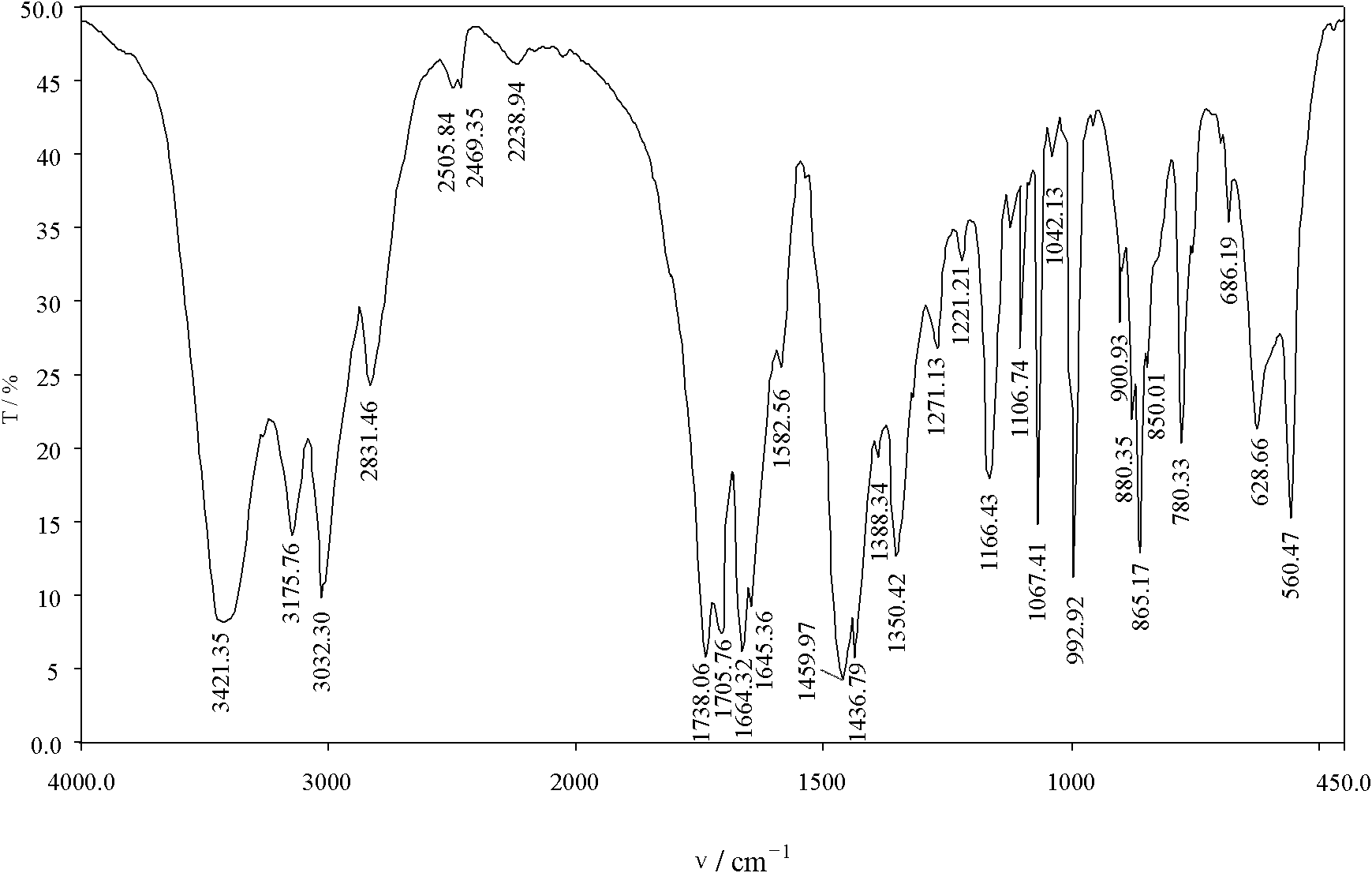

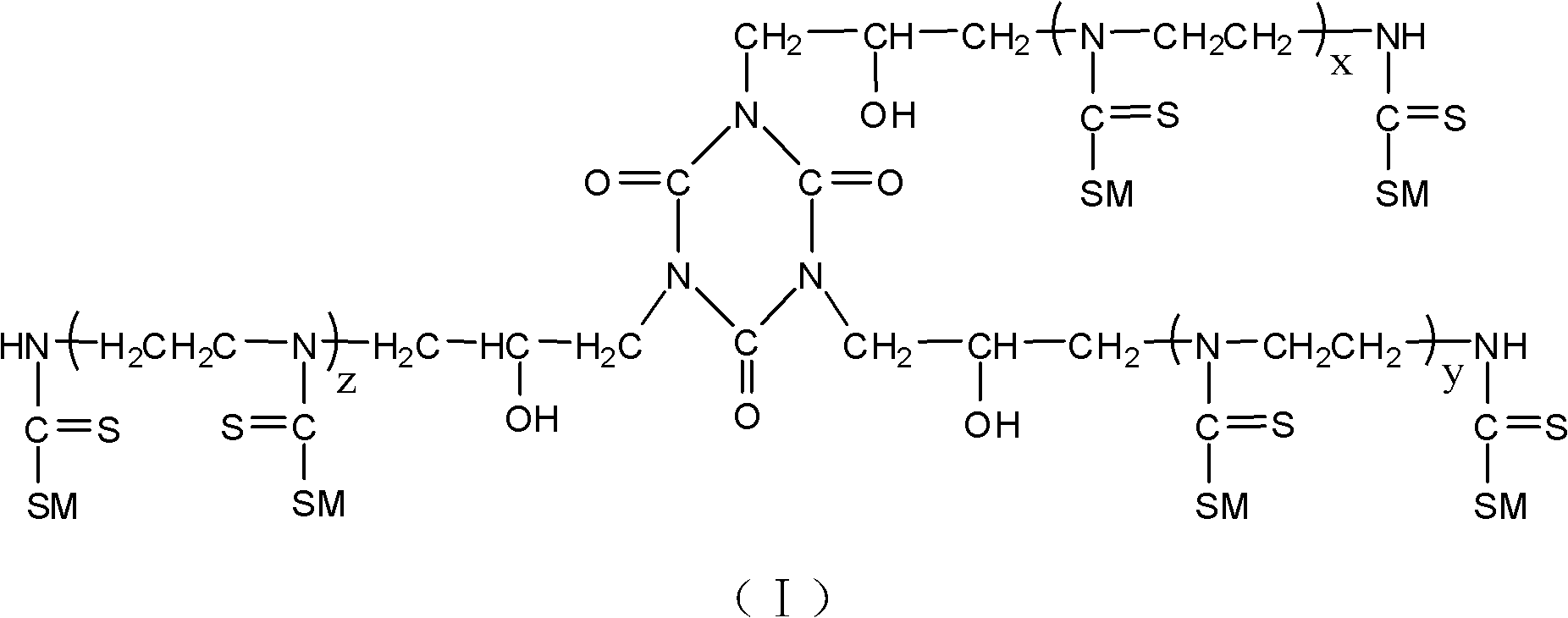

Cyanuric acid-based heavy metal chelating flocculant and preparation method thereof

InactiveCN101863544AOvercome the defect that the ion concentration is difficult to reach the standardIncrease steric hindranceWater/sewage treatment by flocculation/precipitationEpoxyHeavy metal chelation

The invention belongs to the technical field of heavy metal wastewater treatment, and in particular relates to cyanuric acid-based heavy metal chelating flocculant and a preparation method thereof. In the method, cyanuric acid is adopted as a basic framework; and polyamine is connected to a molecule through epoxy chloropropane, and reacts with carbon disulfide in an alkaline condition to prepare the heavy metal chelating flocculant of which the molecule contains a plurality of branches and a plurality of dithio formate functional groups. The method overcomes the defects that the conventional monofunctional flocculant has small flocculating body, and poor precipitation performance, and when polymeric chelant chelates heavy metals, steric clash is great, and the residual heavy metal ion concentration is difficult to meet the standard and the like. The flocculant has the advantages of simple preparation process, mild condition, easy operation and control, high yield, high raw material utilization, less three waste discharge and environmental protection of technical process, convenient popularization and industrialization realization and suitability for treatment of various types of heavy metal wastewater, such as smelting wastewater, electroplating wastewater, nonferrous metals processing wastewater, mining and beneficiating wastewater, printed circuit board wastewater, battery plants and the like.

Owner:HUNAN UNIV OF SCI & TECH

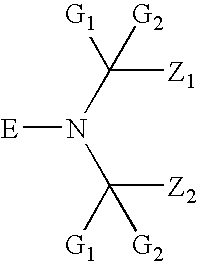

Flame retardant coatings

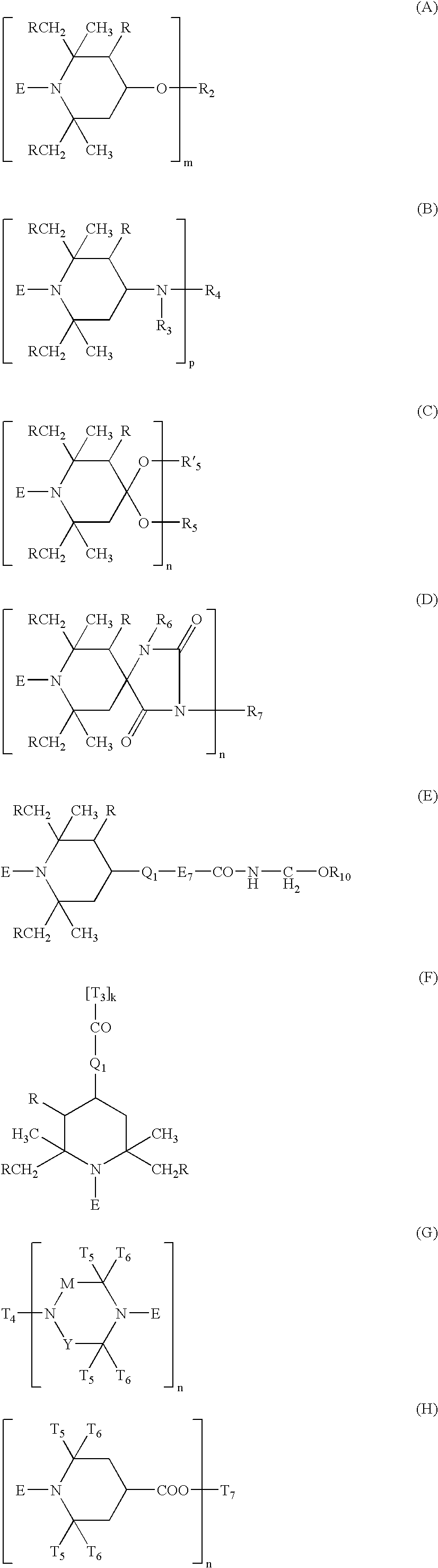

Provided are flame retardant coating compositions and articles coated therewith, which compositions comprise (A) a coating and (B) an effective flame retarding amount of a mixture of (i) at least one compound selected from the group consisting of the (a) sterically hindered nitroxyl stabilizers, (b) sterically hindered hydroxylamine stabilizers and (c) sterically hindered alkoxyamine stabilizers and (ii) at least one conventional flame retardant selected from the group consisting of (d) organohalogen flame retardants, (e) organophosphorus flame retardants, (f) isocyanurate flame retardants and (g) melamine based flame retardants. The coated articles are for example iron, steel, stainless steel, aluminum and other non-ferrous metals, wood, plywood, paper, cardboard, chip board, particle board, plastics, thermoplastics, epoxies, neoprene, rubber, composites, fiberglass reinforced composites, polyesters, polymeric foam, masonry, fabric or textiles, wire and cable constructions and circuit boards.

Owner:TROUTMAN MALISA +3

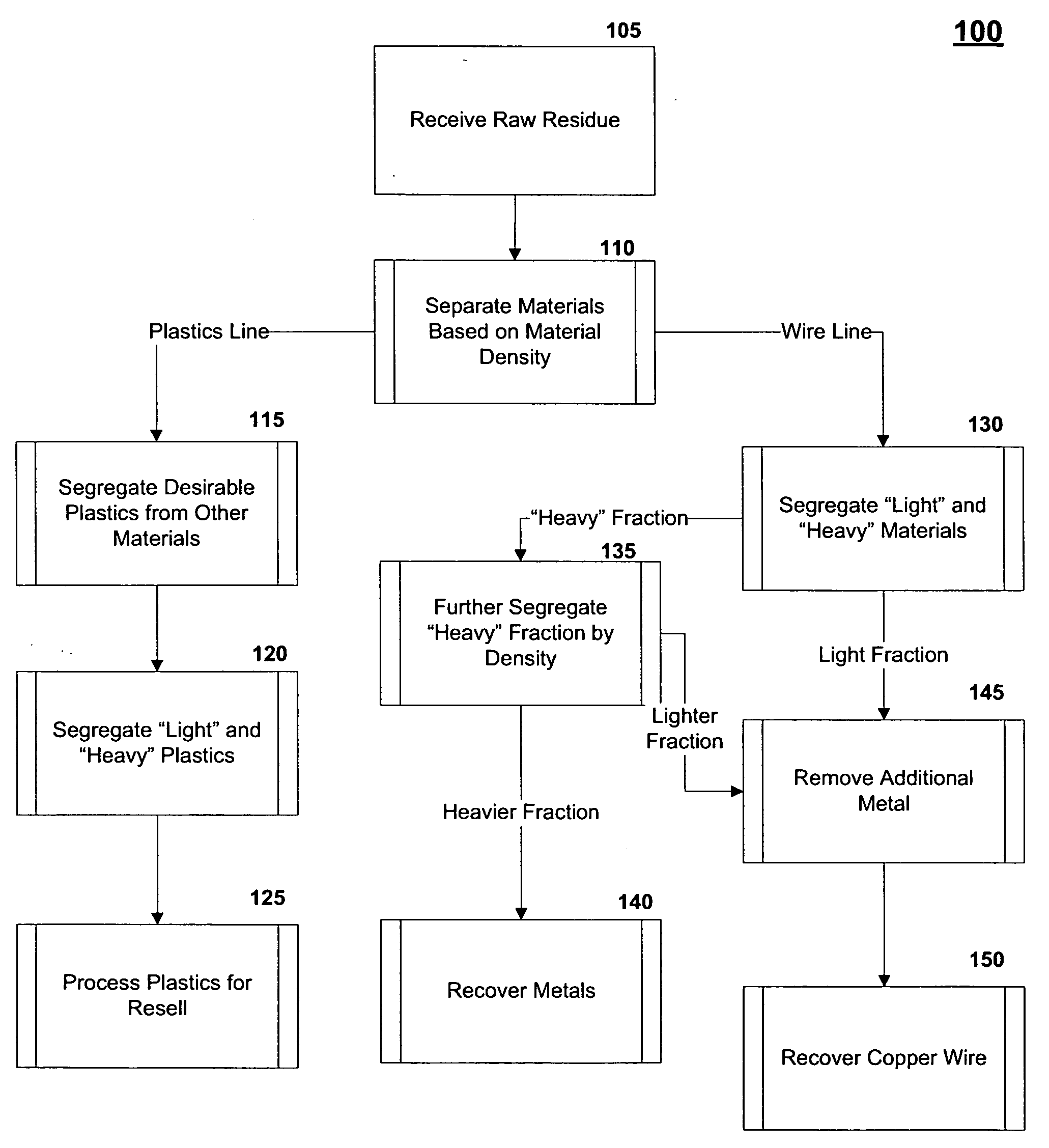

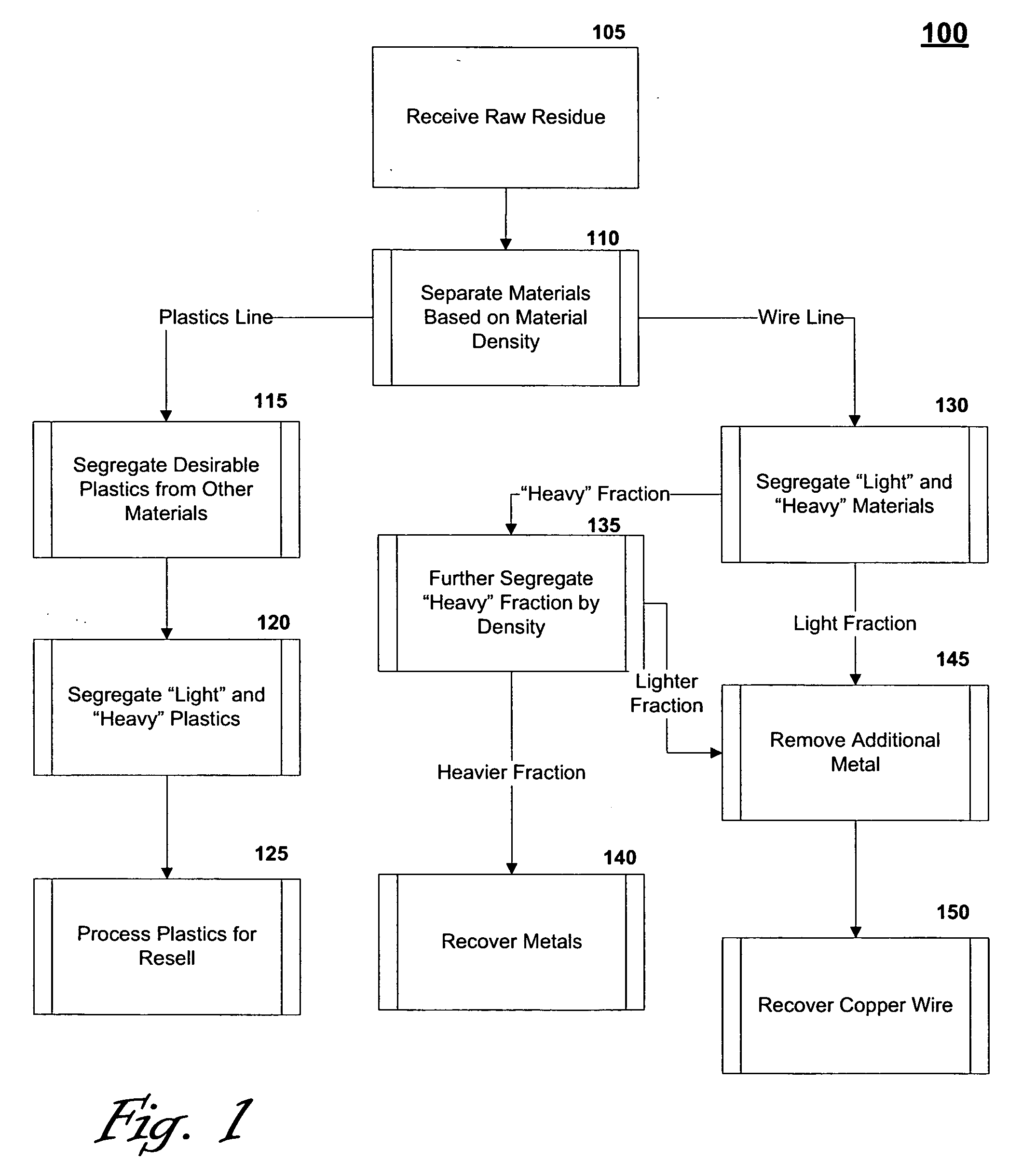

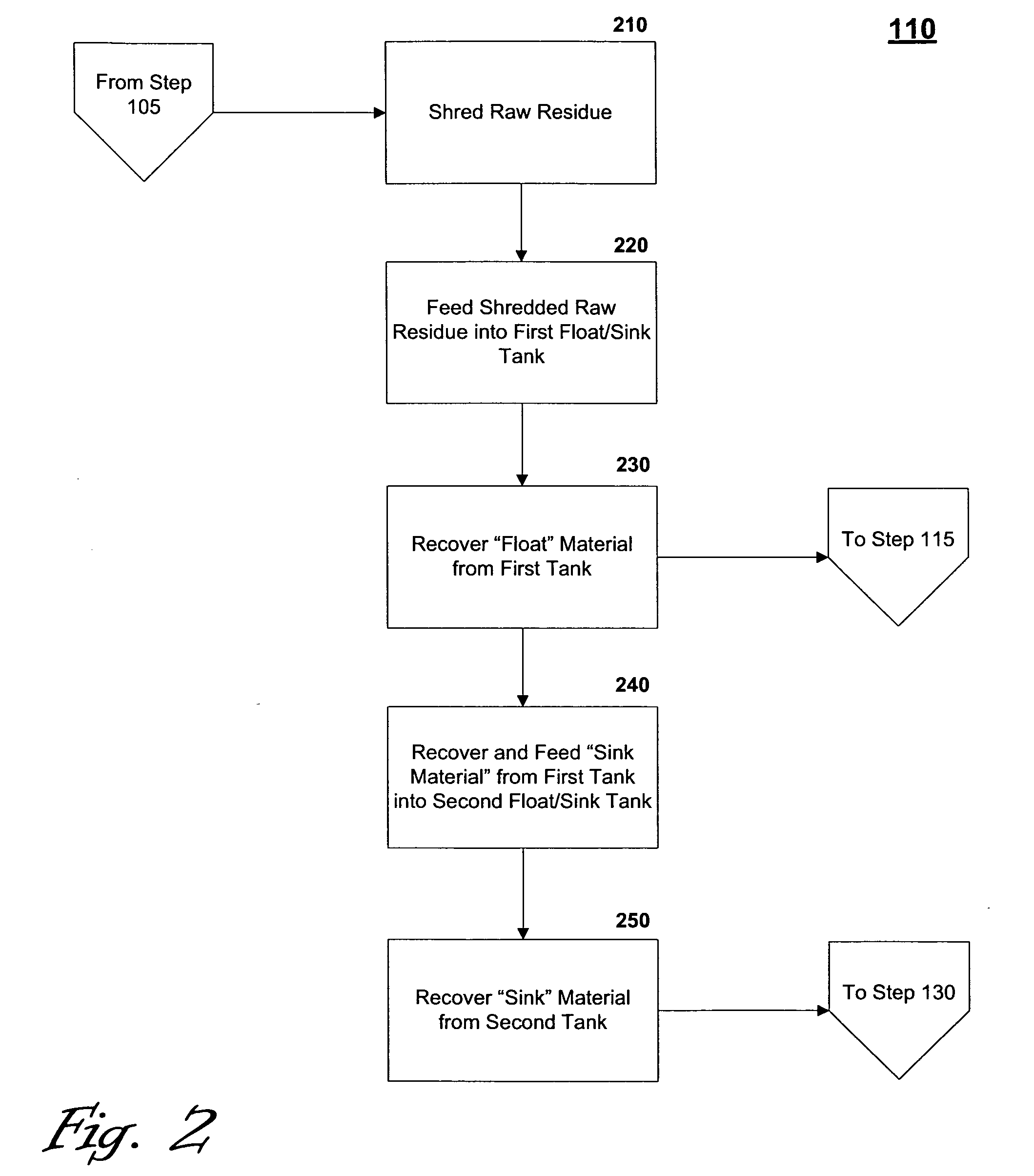

Method and system for sorting and processing recycled materials

InactiveUS20080257794A1Small sizePlastic recyclingAuxillary shaping apparatusCopper wireNonferrous metal

Processing recycled materials to recover plastics, copper wire, and other non-ferrous metals. Aspects of the invention employ density separation to separate plastic-bearing materials from copper-bearing materials. Plastic-bearing materials are further separated to separate light plastics from heavy plastics. Plastics are concentrated, extruded, and palletized. Copper and other valuable metals are recovered from copper-bearing materials using a water separation table.

Owner:VALERIO THOMAS A

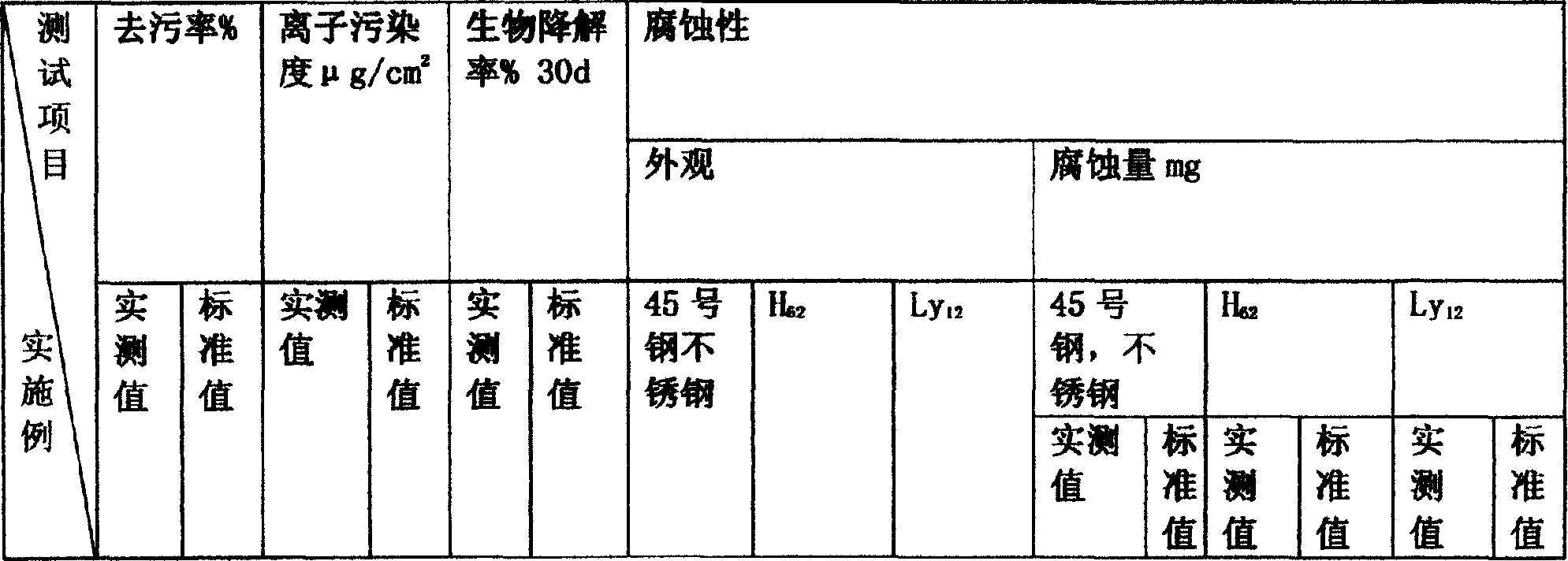

Phosphorus-free water-based metal cleaning agent

The invention relates to a phosphorus-free metal cleaning agent comprising the components of, by weight, 2-20% of a cleaning aid, 1-20% of a surfactant, 1-10% of a chelating agent, 1-20% of an emulsifier, 1-10% of an antirust agent, 0.2-4% of a copper alloy corrosion inhibitor, 1-10% of a penetration agent, 1-6% of a solubilizing agent, 0.1-0.6% of a defoaming agent, and balance of water. The cleaning agent provided by the invention has excellent cleaning capacity, long rust proof period, low foam, long service life, and the like. The cleaning agent is suitable for ferrous metal and non-ferrous metal processing industries. The agent has the advantages of no volatilization, no irritation, no toxic or harmful substance such as nitrite, no damage to health, and no environment pollution.

Owner:SHENYANG PARKERIZING

Deep purifying method for manganese sulfate solution

InactiveCN1502710AMeet production requirementsReduce consumptionPhotography auxillary processesSulfateNonferrous metal

The present invention belongs to extraction of nonferrous metal, and it is a method for deep removing impurities of elements of K, Mo, Fe, Co, Ni and Cu, etc. from manganese sulfate solution. It is characterized by that the precipitant or reagent can be added into the manganese sulfate solution to form precipitating agent in the solution to remove the impurities from solution. The EMD extracted by said method not only can meet the requirements for producing functional cell, but also its process is simple and cost is low.

Owner:CENT SOUTH UNIV

Regenerating method and process for recycling rare precious metals from electronic wastes

ActiveCN103397186AAdvanced technologyLow costProcess efficiency improvementMagnetic separationTelevision setHigh voltage

The invention discloses a regenerating method and process for recycling rare precious metals from electronic and electric wastes, and particularly discloses a process for recycling non-ferrous and rare precious metals such as copper, tin, gold, silver, platinum, palladium, rhodium and the like from electronic wastes. The regenerating method comprises the following steps of: smashing circuit boards and elements dismounted from waste electronic and electric appliances such as waste computers, waste mobile phones, waste televisions and the like to 40-200 meshes; dissolving a binder by using an organic solvent; then, separating metals and nonmetals by using a high voltage electrostatic method; next, leaching the precious metals by using sulfuric acid and aqua regia; extracting silver, gold, platinum, palladium and rhodium step by step by using a liquid membrane; and finally, carrying out purification treatment to obtain nonferrous metals such as copper and tin and the rare precious metals such as gold, silver, platinum, palladium, rhodium and the like, so that the waste secondary resource is regenerated and recycled. The regenerating method has the advantages of simplicity and convenience in process, high comprehensive metal recycle ratio, few three wastes, easiness for treatment and low cost, is a favorable technical approach for efficient utilization of mineral resources of cities, and not only has an environment-friendly benefit, but also has favorable economic and social benefits.

Owner:HUNAN TONGLI ELECTRONICS WASTE RECOVERING DISSEMBLING & UTILIZATION

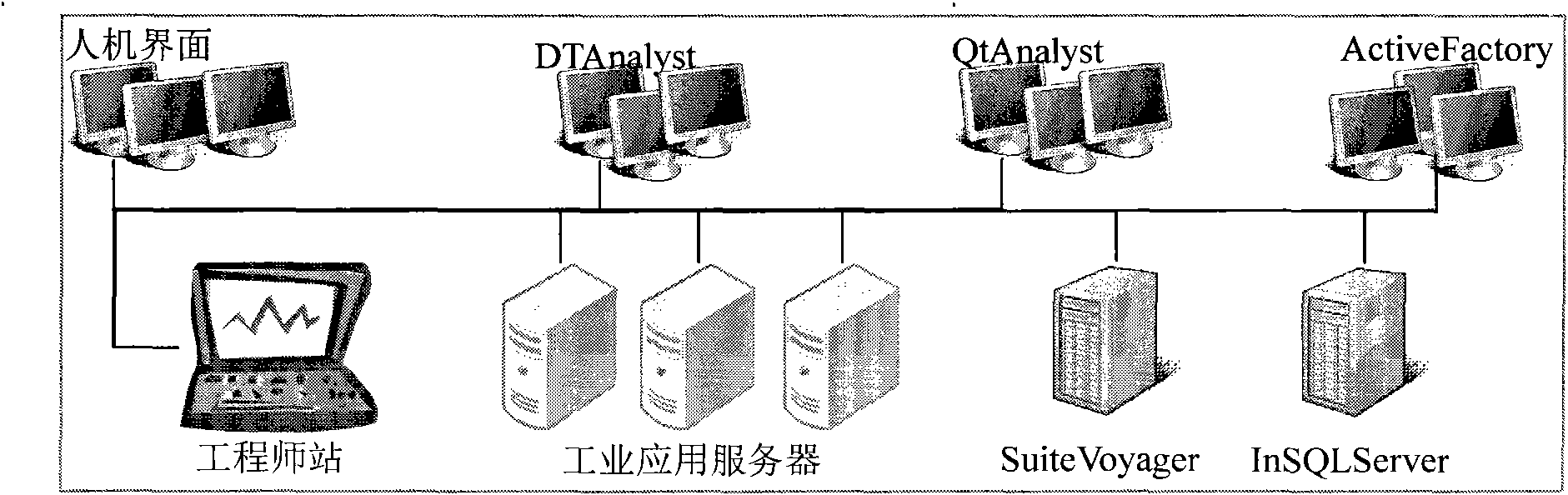

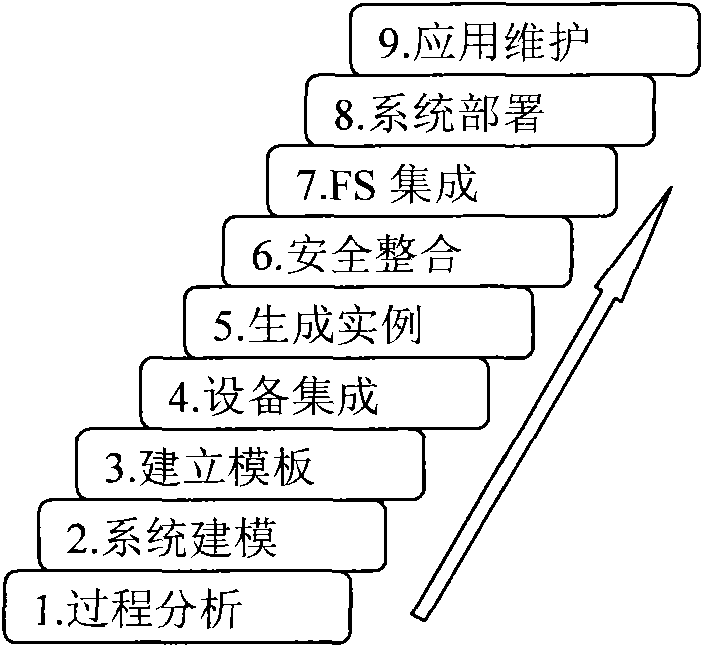

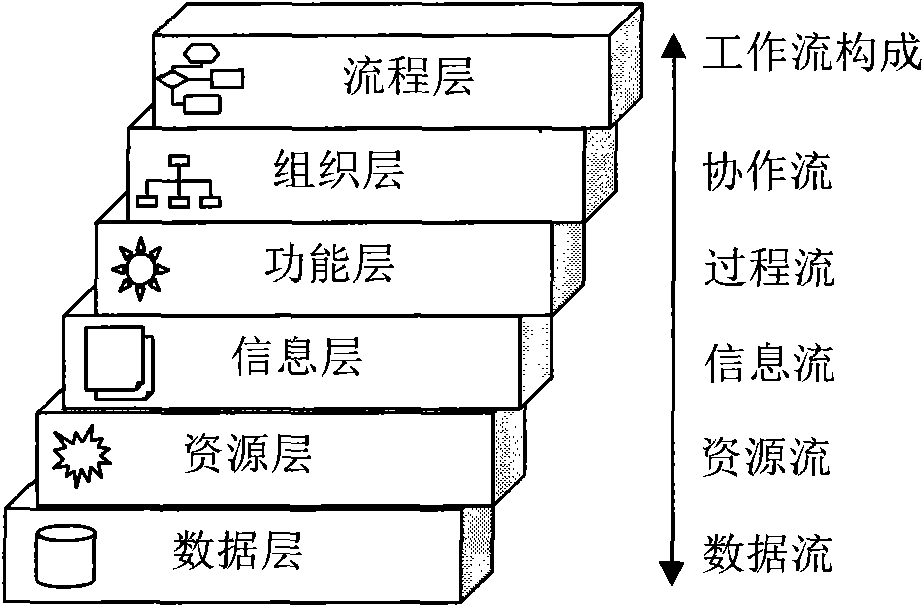

Production information system based on factory management infrastructure platform

InactiveCN101964081AReduce development and maintenance costsReduce development costsResourcesCommunication interfaceReal-time data

The invention provides a factory management infrastructure platform and an application system thereof. The platform comprises a plurality of communication interfaces, an I / O acquisition server, an IAS (Industrial Application Server) application server, an IAS IDE (Integrated Development Environment), a monitoring picture designer, a process statistic analysis system, a production data base, a business model base, a business server, a business IDE, a production technology monitoring system, a real-time data analysis and query system, an equipment operation management system, a quality inspection management system, an energy source metering management system, a production statement management system, a production data statistical management system and a production machine account management system. The platform has the characteristics of strong application system functions and representativeness in the nonferrous metal smelting industry.

Owner:CHINA ENFI ENGINEERING CORPORATION

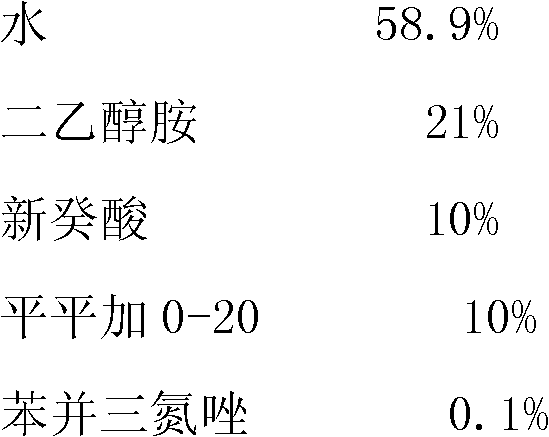

Environment-friendly water-based cleaning agent

The invention discloses an environment-friendly water-based cleaning agent which is characterized by comprising the following components in percentage by weight: 15-60% of antirust agent, 5-20% of surfactant, 0.1-0.5% of nonferrous metal corrosion inhibitor, 0-0.5% of bactericide and the balance of water. The environment-friendly water-based cleaning agent disclosed by the invention has the beneficial effects of no toxicity or phosphorus, excellent antirust performance, favorable inter-process antirust effect, wide application range, suitability for cleaning various metals including black metal, aluminum alloy and copper alloy, no corrosion to nonferrous metal, excellent cleaning capability for oil stain with higher viscosity, long service cycle and effective range, simplicity and practicability in use and maintenance, multiple functions for efficiently removing oil, preventing rusting and the like, no harm to body health and no adverse effect on the environment.

Owner:LOCKS LUBE SHANGHAI

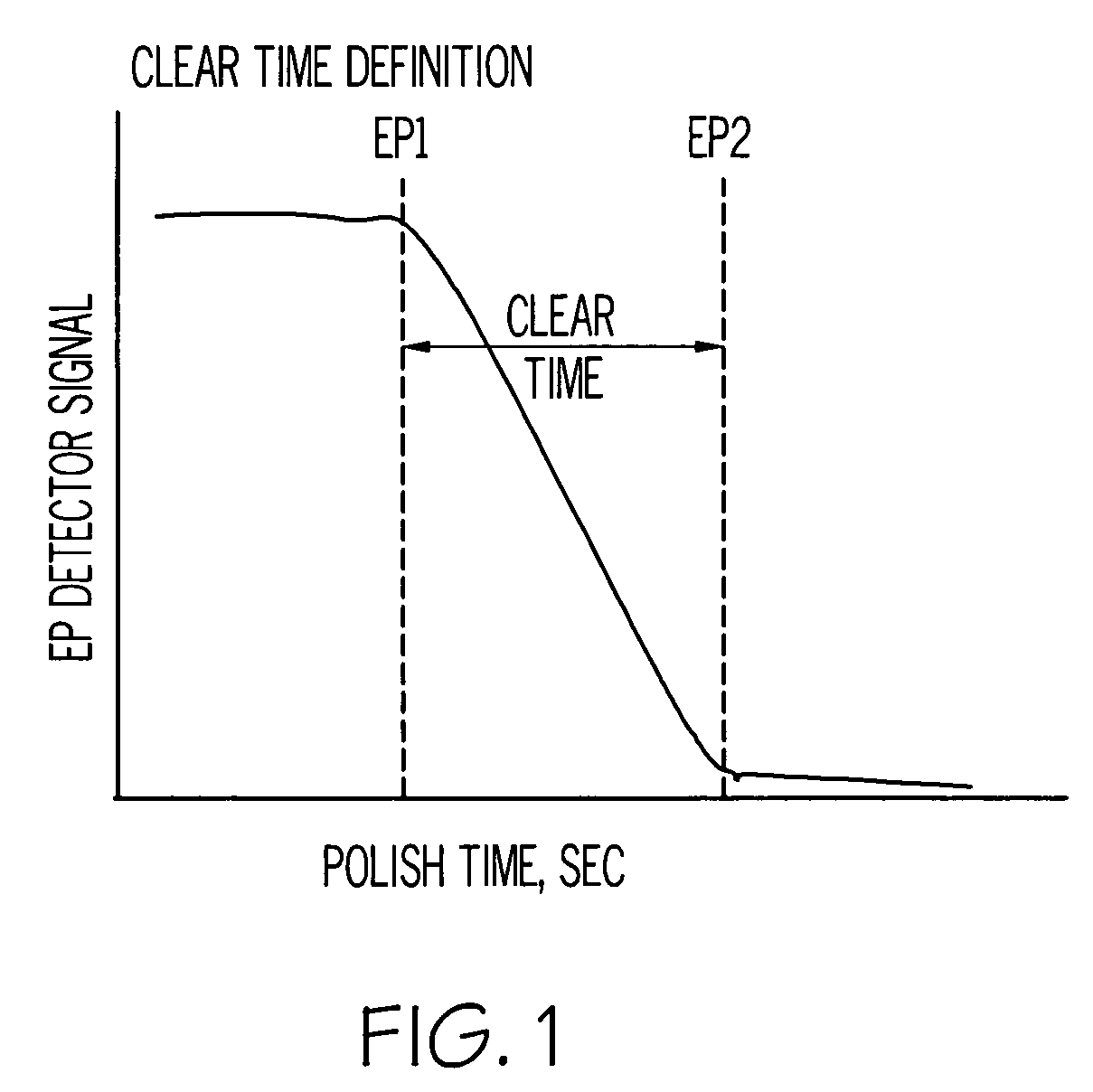

Chemical mechanical polishing compositions and methods relating thereto

ActiveUS20060000151A1Inorganic/elemental detergent compounding agentsPigmenting treatmentNonferrous metalCompound (substance)

The present invention provides an aqueous composition useful for CMP of a semiconductor wafer containing a metal comprising oxidizer, inhibitor for a nonferrous metal, complexing agent for the nonferrous metal, modified cellulose, 0.001 to 10% by weight copolymer blends of a first copolymer and a second copolymer and balance water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Green multifunctional detergent and its prepn process

InactiveCN1847381AHigh decontamination efficiencyOperational securityOrganic detergent compounding agentsSurface-active detergent compositionsSemiconductor materialsLiquid-crystal display

The present invention discloses one kind of green multifunctional detergent comprising surfactants, detergency promoter, permeating agent, chelating agent, defoaming agent and water in certain weight proportion. The green multifunctional detergent is used in cleaning ferrous metals, non-ferrous metals and stainless steel, as well as semiconductor material and device, LCD glass plate, coated glass, LCD box and electronic circuit board. The present invention has the advantages of compounding and use at normal temperature, powerful detergency, high cleaning efficiency, no ODS matter contained, no phosphate contained, no inflammability, no explosion, no pollution, and direct exhaust and reuse of used waste liquid.

Owner:BEIJING XINLI MACHINERY

Cellulose-containing polishing compositions and methods relating thereto

An aqueous composition is useful for chemical mechanical polishing of a patterned semiconductor wafer containing a nonferrous metal. The composition comprises an oxidizer, an inhibitor for the nonferrous metal, 0.001 to 15 weight percent of a water soluble modified cellulose, non-saccaride water soluble polymer, 0 to 15 weight percent phosphorus compound, 0.005 to 10 weight percent of a water miscible organic solvent, and water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

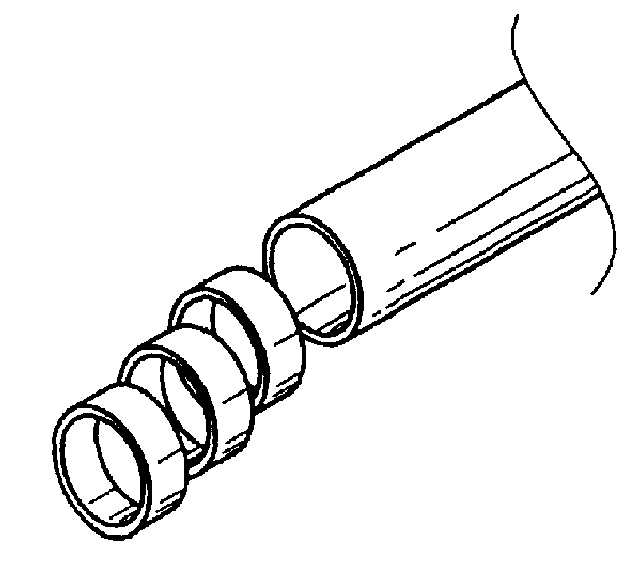

Seamless, ring-shaped brazing material and method for producing same

InactiveUS6164517AReduce necessityWelding/cutting auxillary devicesAuxillary welding devicesNonferrous metalMetal powder

The seamless, ring-shaped brazing material comprises a brazing metal and a flux uniformly dispersed in the brazing metal for brazing nonferrous metal members and has a relative density of 0.90 or more. The seamless, ring-shaped brazing material is produced by (a) mixing brazing metal powder and flux powder uniformly; (b) pressing the resultant mixture to a powder compact billet; (c) forming the billet into a pipe by hot extrusion; and (d) slicing the pipe into rings.

Owner:SUN KWANG BRAZING FILLER METAL +2

Multielement catalysis iron-carbon micro-electrolysis filler and preparation method thereof

InactiveCN102951708AReduce contact resistanceReduce the highest potential differenceWater/sewage treatmentElectrolysisSludge

The invention discloses multielement catalysis iron-carbon micro-electrolysis filler and a preparation method thereof. The multielement catalysis iron-carbon micro-electrolysis filler mainly comprises 55-75 parts of iron powder, 10-30 parts of active carbon powder, 5-20 parts of nonferrous metal powder catalyst A, 5-10 parts of nonferrous metal powder catalyst B and 5-10 parts of inorganic catalyst C. The preparation method comprises the steps of weighing, extruding, primary moulding and high-temperature sintering. The invention has the advantages that the multielement catalysis iron-carbon micro-electrolysis filler disclosed by the invention overcomes the defects that the traditional scrap iron is hardened easily and generated sludge is tripled or quadrupled after reaction because reaction speed cannot be controlled when micro cell reactions are excessive, iron-carbon micro cell potential difference is enlarged, reaction speed is higher, reaction ratio can be controlled, contact ratio of pollutant to a micro cell is tripled, sewage oxidation treatment efficiency is doubled or tripled, no hardening is caused as iron atoms are not in direct contact, and the filler does not need to be replaced or regenerated.

Owner:潍坊海洁环保设备有限公司

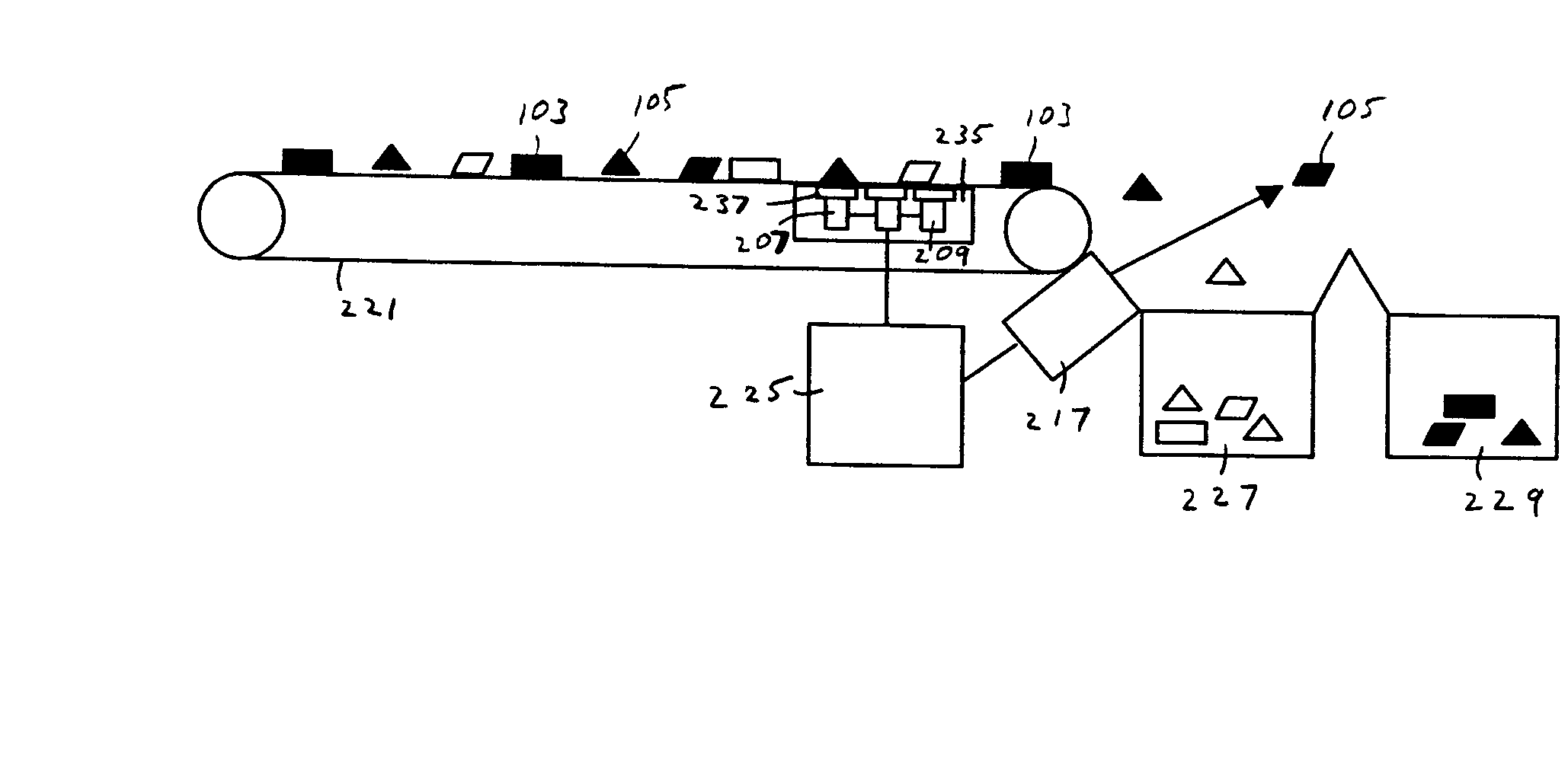

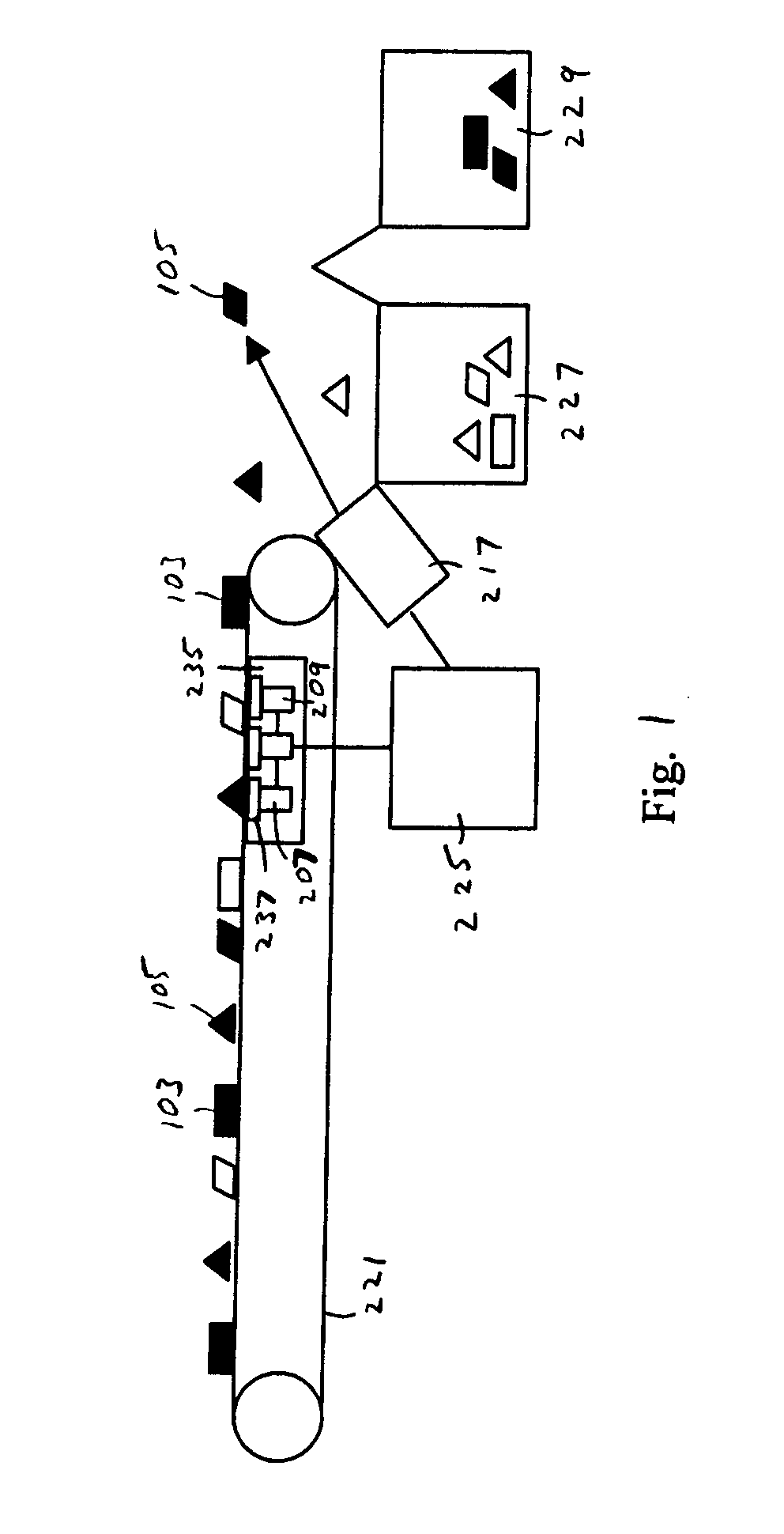

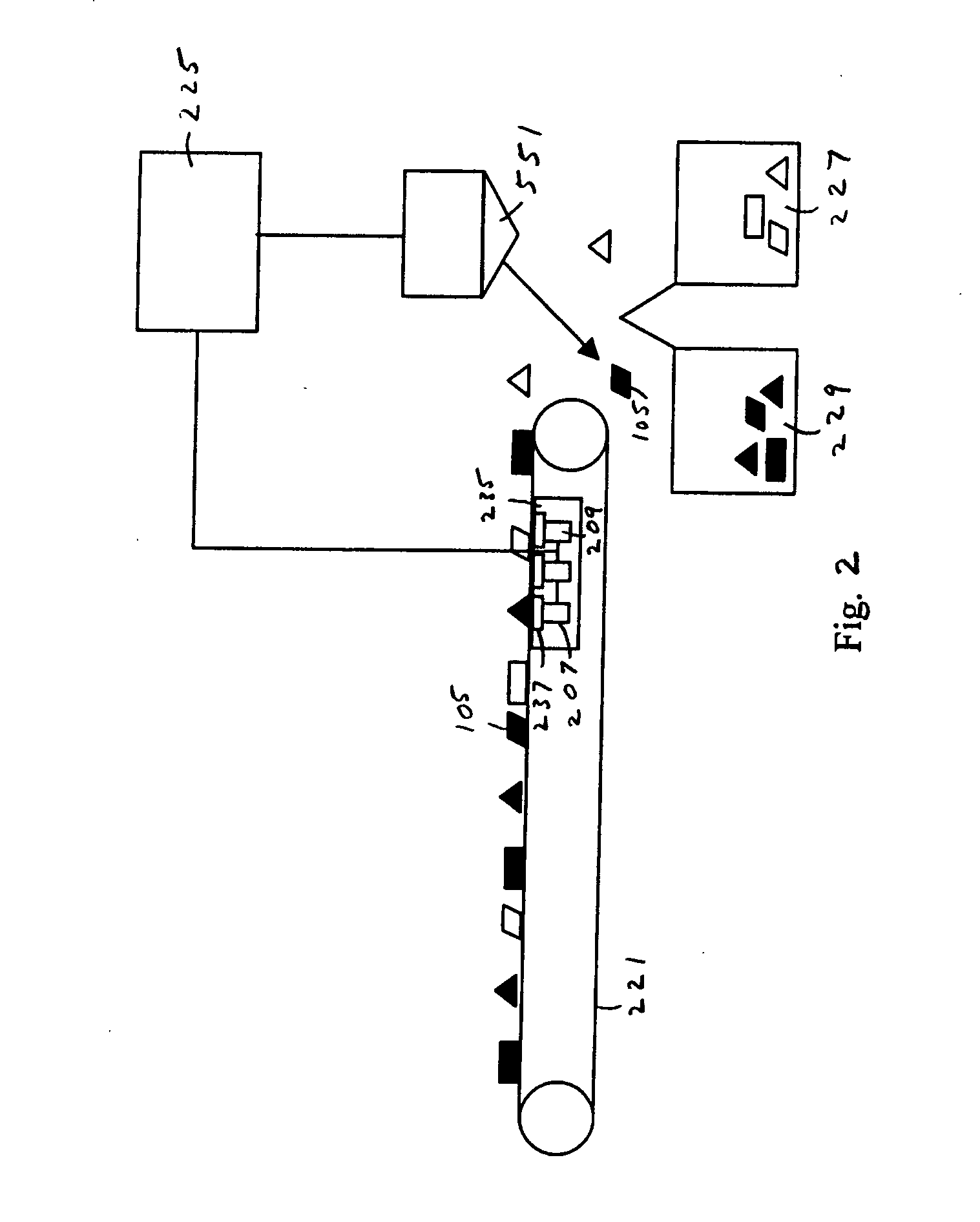

Method and apparatus for sorting fine nonferrous metals and insulated wire pieces

InactiveUS20070262000A1Accurate materialsEfficient recyclingMagnetic property measurementsUsing electrical meansNonferrous metalCopper wire

A system for sorting fine nonferrous metals and insulated copper wire from a batch of mixed fine nonferrous metals and insulated wire includes an array of inductive proximity detectors, a processing computer and a sorting mechanism. The inductive proximity detectors identify the location of the fine nonferrous metals and insulated copper wire. The processing computer instructs the sorting mechanism to place the fine nonferrous metals and insulated copper wire into a separate container than the non-metallic pieces.

Owner:VALERIO THOMAS A

Technology for full classification recycling treatment on household waste

InactiveCN102728601ASolve problems in the treatment processRealize recycling of resourcesBio-organic fraction processingSolid waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a technology for full classification recycling treatment on household waste and relates to the field of recycling integrated utilization of household waste. A main process route of the technology comprises that household waste is homogenized by a homogenizer, is subjected to large object sorting (wherein large objects comprise large combustibles and inorganic matters), is treated by a bag breaking device (for scratching a plastic packaging bag), is treated by a magnetic separator (for separating out magnetic materials), is treated by an eddy sorting machine (for separating out nonferrous metals), is subjected to artificial sorting, then is broken, is fed into a hydrothermal degradation tank, is treated by a light material separator (for separating out papers and plastics), and then is crushed; then mixed organic matters and percolate are mixed and then are subjected to methane fermentation so that methane is produced; and methane residues and a methane liquid are prepared into an organic fertilizer and inorganic matters are prepared into a building material and the combustibles are prepared into a refuse derived fuel (RDF). The technology really realizes reduction, harmlessness and recycling of waste.

Owner:张希曾 +1

Tantalum barrier removal solution

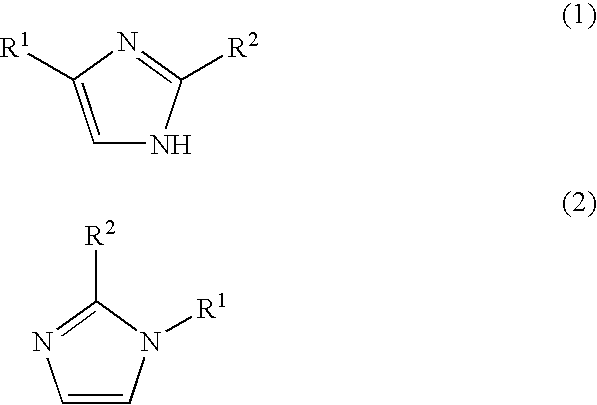

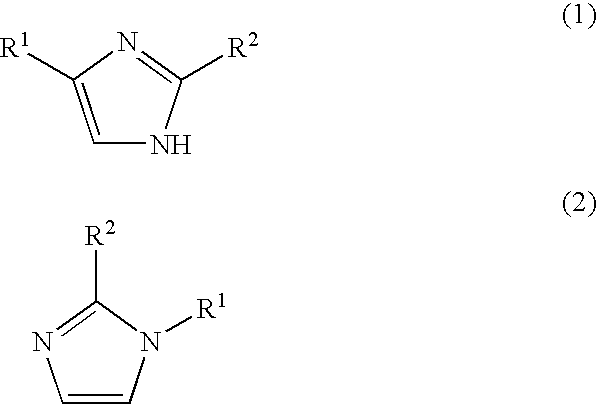

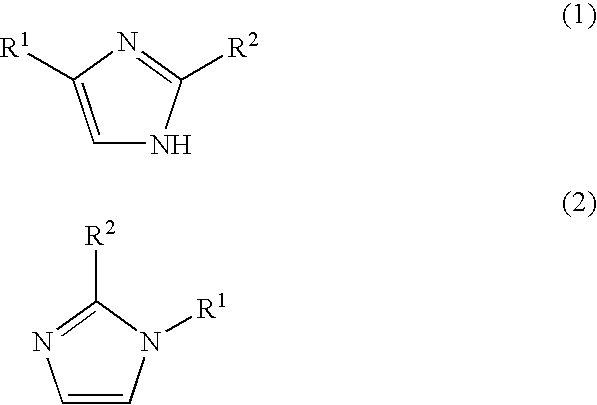

InactiveUS20030181345A1Reduce erosionMaterial removalPigmenting treatmentSoap detergents with inorganic compounding agentsGuanidine derivativesTantalum nitride

A chemical mechanical planarization solution is useful for removing tantalum barrier materials. The solution includes by weight percent 0 to 25 oxidizer, 0 to 15 inhibitor for a nonferrous metal and 0 to 20 complexing agent for the nonferrous metal, 0.01 to 12 tantalum removal agent selected from the group consisting of formamidine, formamidine salts, formamidine derivatives, guanidine derivatives, guanidine salts and mixtures thereof, 0 to 5 abrasive, 0 to 15 total particles selected from the group consisting of polymeric particles and polymer-coated coated particles and balance water. The solution has a tantalum nitride to TEOS selectivity of at least 3 to 1 as measured with a microporous polyurethane polishing pad pressure measure normal to a wafer less than 20.7 kPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Compositions and methods for controlled polishing of copper

InactiveUS20050136670A1Good removal effectAvoid corrosionOther chemical processesAbrasion apparatusNonferrous metalCopper

The present invention provides an aqueous composition useful for polishing copper on a semiconductor wafer comprising by weight percent 0.001 to 6 inhibitor for a nonferrous metal, 0.05 to 10 complexing agent for the metal, 0.01 to 25 copper removal agent for accelerating the removal of the copper, 0.5 to 40 abrasive, 0 to 10 selected from the group comprising, polyvinylpyrrolidone, thermoplastic polymer and mixtures thereof, wherein the copper removal agent is imidazole.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Fast-drying hard film rust preventive oil and preparation method thereof

ActiveCN103087808AReduce adhesionImprove applicabilityLubricant compositionAntioxidantNonferrous metal

Owner:布兰诺工业包装材料(上海)有限公司

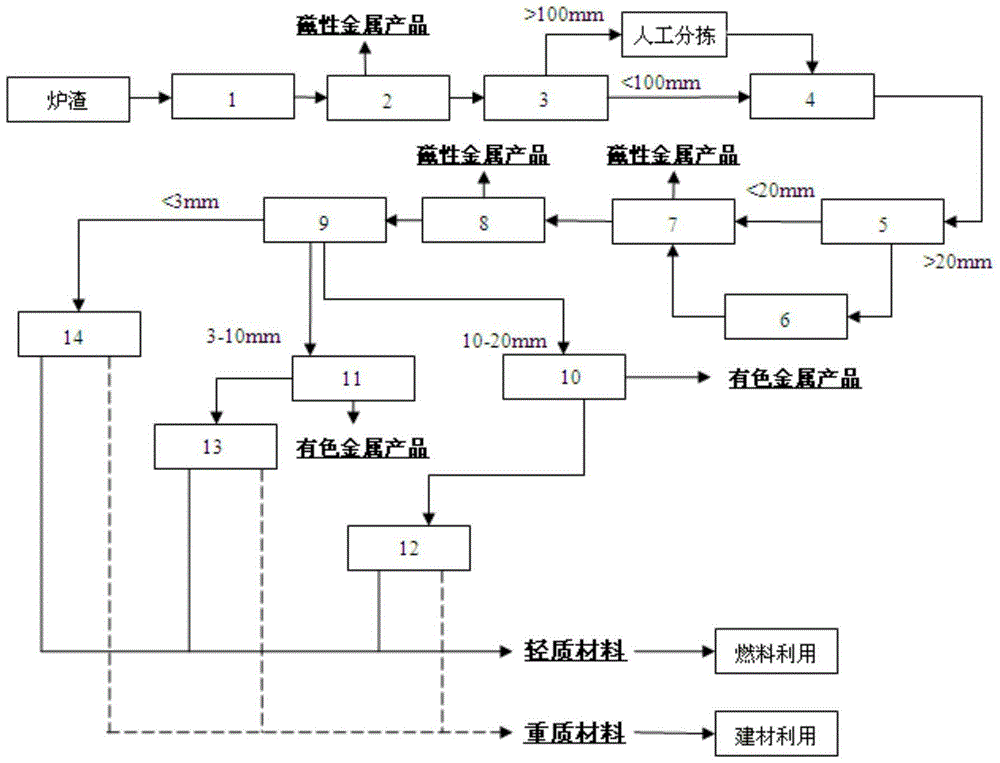

Method for recycling metal and combustibles from domestic waste incineration slag

The invention relates to a method for recycling metal and combustibles from domestic waste incineration slag, and belongs to the field of the solid waste harmless and recycling technology. By means of multi-stage gradient magnetic separation, separation of magnetic metal in the slag is achieved. By means of two-stage eddy current, nonferrous metal in the slag is separated and recycled. According to the grain size distribution and chemical morphological characteristics of the metal in the slag, the metal is crushed and screened in multiple steps so that separated slag particles can be uniform, the recycling rate of magnetic separation and eddy current separation is effectively increased, and finally, according to the density difference of materials, air separation is used for recycling the combustibles in the slag. Finally, the magnetic separation recycling rate of iron in the technological process is 60-80%, the recycling rate of the nonferrous metal aluminum is 60-70%, the recycling rate of the nonferrous metal copper is 40-50%, and separation of the metal in the slag and slag particles can be effectively achieved. The separated metal products can be directly sold or sold after refining, the combustibles can serve as waste incinerator fuel, and the remaining slag can be used as building materials.

Owner:TONGJI UNIV

Regenerated acidic etching solution, copper recycling method and special device thereof

InactiveCN101768742ARealize recyclingEmission reductionPhotography auxillary processesProcess efficiency improvementAlloyElectrochemistry

The invention discloses regenerated acidic etching solution, a copper recycling method and a special device thereof, belonging to the field of electrochemically recycling waste solution and nonferrous metal. An electrolytic tank in electrochemical treatment is divided into an anode chamber, an intermediate chamber and a cathode chamber. Dilute sulfuric acid solution is contained in the anode chamber, and a lead-tin-calcium alloy plate is adopted as an anode electrolytic plate. Waste acidic etching solution is contained in the intermediate chamber. Copper sulfate solution is contained in the cathode chamber, and a stainless steel plate is adopted as a cathode electrolytic plate. Under the function of an electric field, copper is dissolved out from a copper sulfate system. Water in the anode chamber is oxidized to generate oxygen gas and hydrogen ions. When the concentration of the copper ions is reduced to 1g or lower than 1g, the etching solution can be used anew. The method greatly reduces the production cost and causes no atmospheric pollution at the same time as realizing the recycling.

Owner:青海复绿生态科技有限公司

Tantalum barrier removal solution

InactiveUS7491252B2Pigmenting treatmentSoap detergents with inorganic compounding agentsGuanidine derivativesNonferrous metal

A chemical mechanical planarization solution is useful for removing tantalum barrier materials. The solution includes by weight percent 0 to 25 oxidizer, 0 to 15 inhibitor for a nonferrous metal and 0 to 20 complexing agent for the nonferrous metal, 0.01 to 12 tantalum removal agent selected from the group consisting of formamidine, formamidine salts, formamidine derivatives, guanidine derivatives, guanidine salts and mixtures thereof, 0 to 5 abrasive, 0 to 15 total particles selected from the group consisting of polymeric particles and polymer-coated coated particles and balance water. The solution has a tantalum nitride to TEOS selectivity of at least 3 to 1 as measured with a microporous polyurethane polishing pad pressure measure normal to a wafer less than 20.7 kPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Selective slurry for chemical mechanical polishing

ActiveUS20060131275A1Decorative surface effectsSemiconductor/solid-state device manufacturingNonferrous metalCompound (substance)

An aqueous solution is useful for selective removal in the presence of a low-k dielectric. The aqueous solution comprises by weight percent 0 to 25 oxidizer; 0.00002 to 5 multi-component surfactant, the multi-component surfactant having a hydrophobic tail, a nonionic hydrophilic portion and an anionic hydrophilic portion, the hydrophobic tail having 6 to 30 carbon atoms and the nonionic hydrophilic portion having 10 to 300 carbon atoms; 0 to 15 inhibitor for a nonferrous metal; 0 to 50 abrasive; 0 to 20 complexing agent for a nonferrous metal; and water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

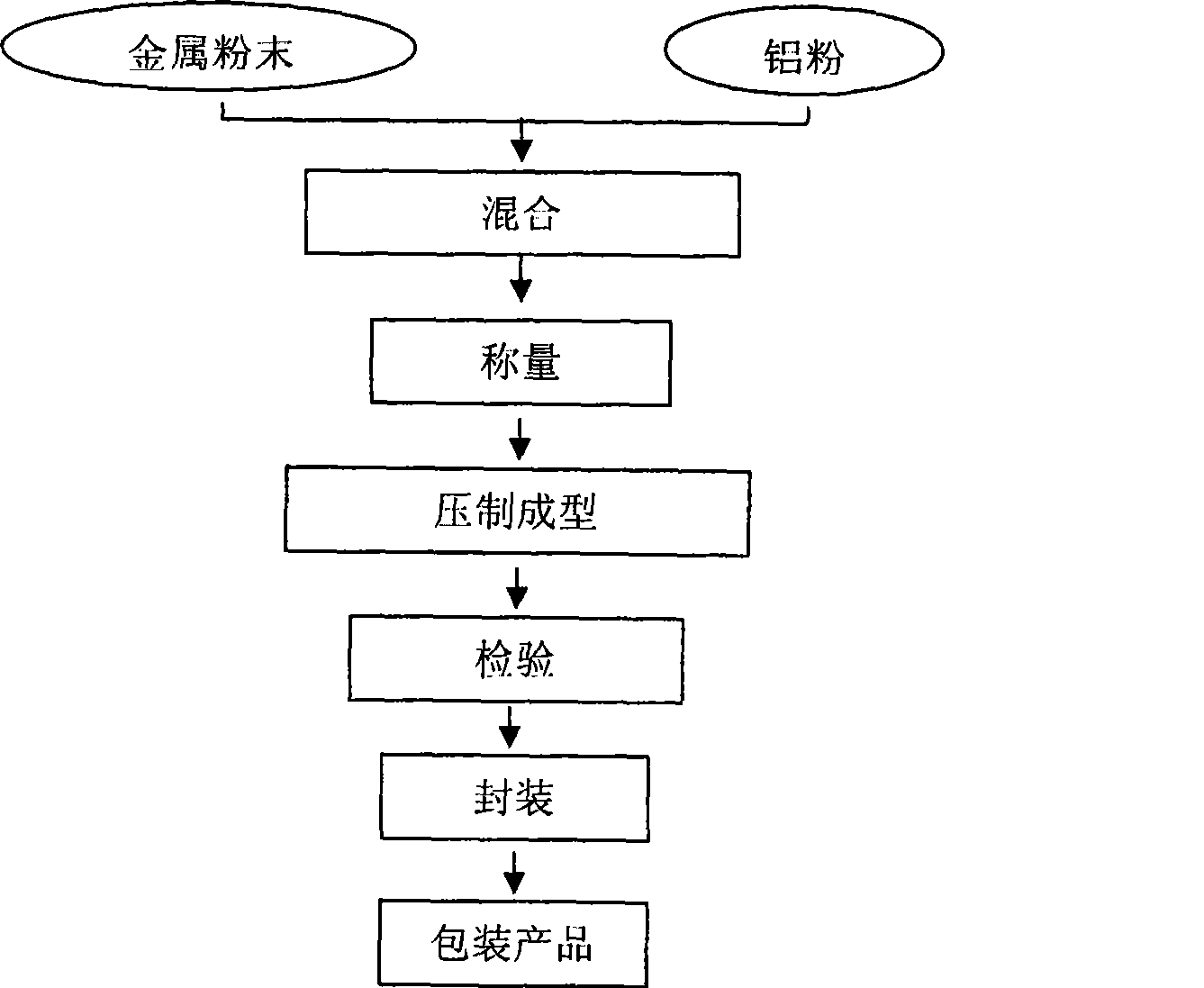

Flux-free aluminium alloy additive agent and preparation method

The invention belongs to the field of nonferrous metal aluminum alloy processing and relates to a flux-free aluminum alloy additive and a preparation method thereof. The additive is formed by pressing metal powder and aluminum powder, and the compositions in weight percentage of the additive are 70 to 95 percent of the metal powder and 5 to 30 percent of the aluminum powder, wherein the metal powder in the additive is one type or a plurality of types among iron, manganese, copper, titanium, chromium and nickel. The performance of the metal powder and the aluminum powder meets the demands that: firstly, the purity of the metal powder is not less than 98 percent, and the average mean diameter of the powder is between 0.01 and 0.5 millimeter; and secondly, the purity of the aluminum powder is not less than 95 percent, and the average mean diameter of the powder is between 0.01 and 0.5 millimeter. The preparation method is to uniformly mix the metal powder and the aluminum powder, to press the mixture into blocks by a press machine, and to perform hermetical package. The preparation method has the advantages of simple addition means, quick melting under the condition of normal aluminum alloy casting temperature, high extraction yield, stable content, easy control, no flux contained, incapability of exhausting fluorine-containing pollutant, and improvement of the purity of fused masses.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

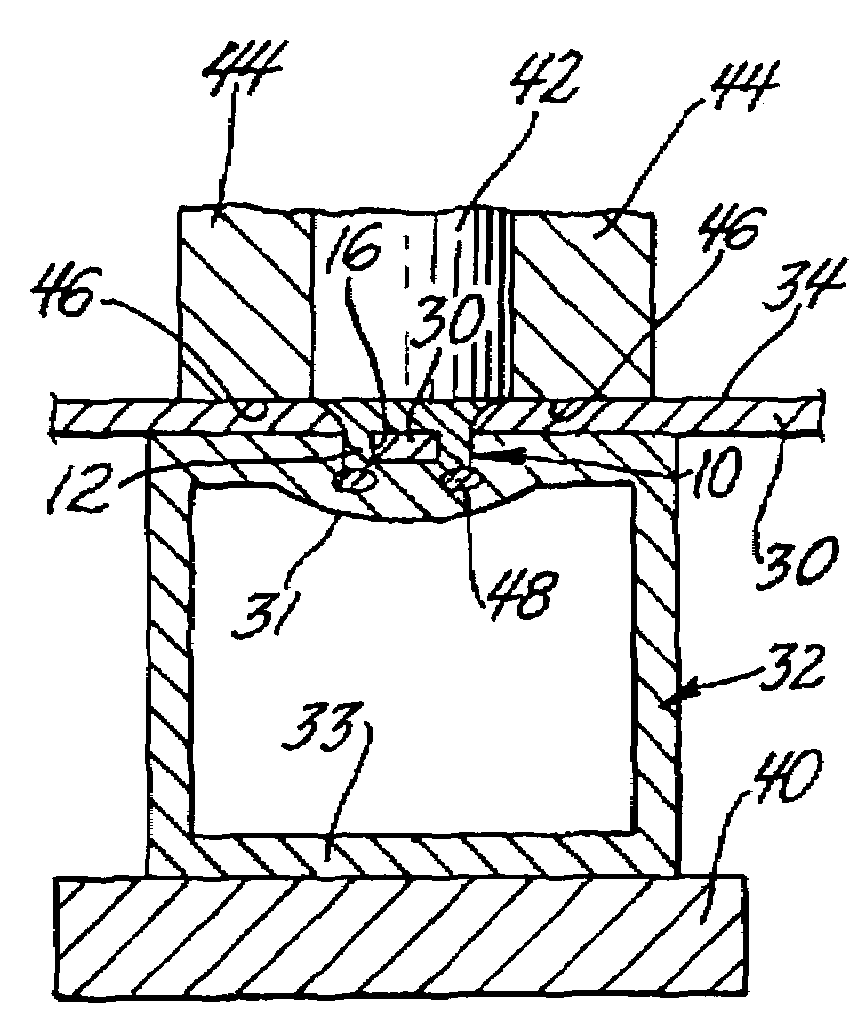

Lost foam casting vibration clotting method

The invention relates to a vibration solidification method of lost mold casting, pertaining to the precision casting field, which aims at fining the organization of castings of the lost mold casting, reducing the cost and enhancing the performance of castings. The invention comprises three steps of: production of foamy mold, imbedding the foamy mold into a casting box for filling and compacting sand as well as casting of molten metal; the invention is characterized in that: before and during the period of casting molten metal, during the solidification period, or the solidification period after the period of casting molten metal, casting box filled with foamy mold and scattered sand is vibrated at the frequency ranging from 10 to 100Hz and the amplitude ranging from 0.1 to 3.0mm, and rotation speed of a vibration motor that drives the vibration is 750 to 3000 rpm, and the vibration is stopped after the solidification of casting is completed. The invention has the advantages of low cost, easy operation and control, obvious fining effect of casting organizations, greatly improving performance and no environmental pollution, which is both suitable for the casting of the lost molds of nonferrous metals components, such as aluminum alloy, magnesium alloy, copper alloy, etc., and is also suitable for the casting of the lost mold of ferrous metal components, such as cast iron, cast steel and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of joining dissimilar materials

The present invention provides a method of joining dissimilar materials, particularly a non-ferrous component to a ferrous component to form an assembly. In an overlapping configuration, the parts are held together under a clamping force while a self-piercing rivet is driven through the assembly by a welding electrode. The rivet pierces and passes through the non-ferrous component and then at least into contact with the ferrous component to thereby form a mechanical interlock. An electrical current is then applied to this mechanical retention to melt a portion of the rivet as well as a portion of the ferrous metal in the joining region. The flow of electrical current is then stopped after several welding cycles where the now melted material is allowed to solidify upon cooling, thereby forming a weld.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

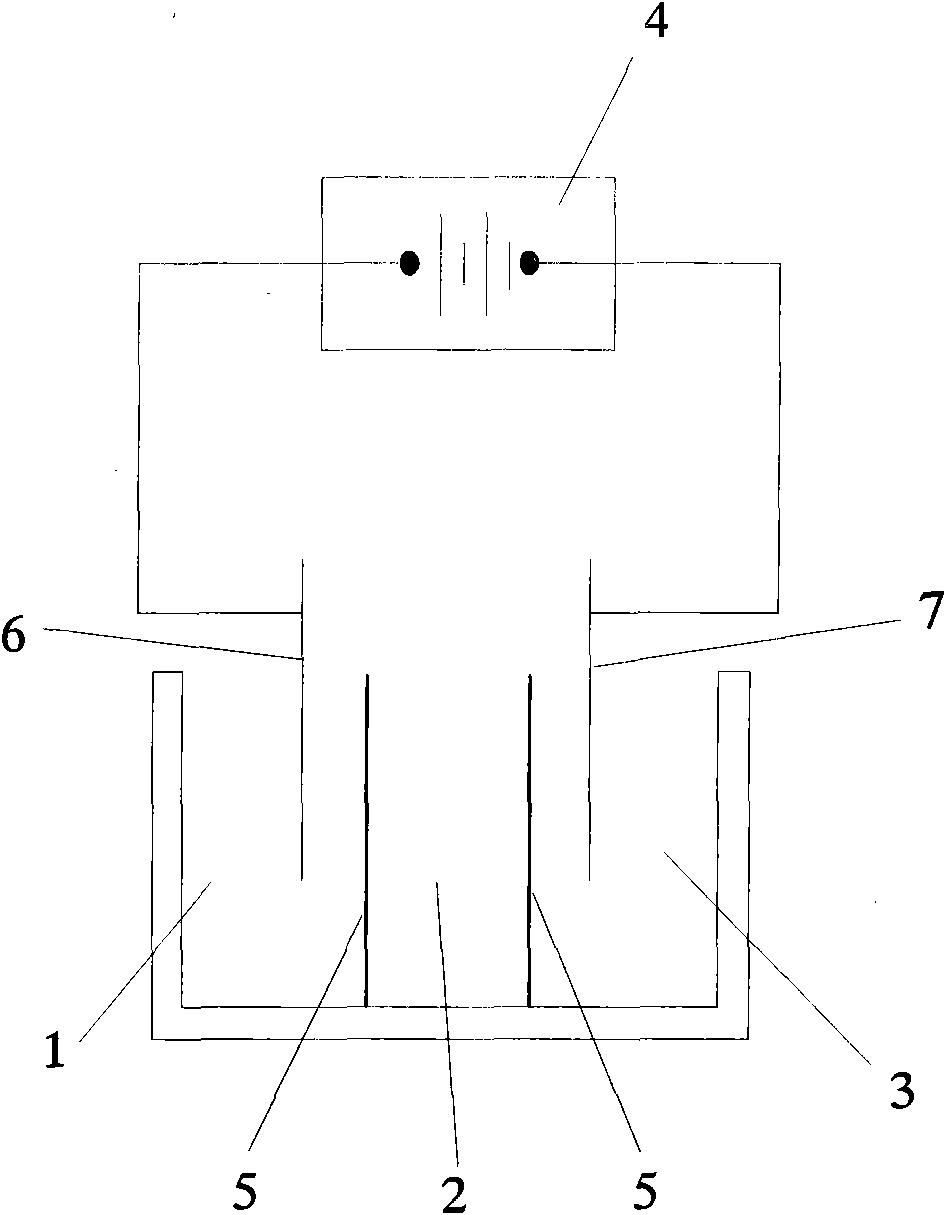

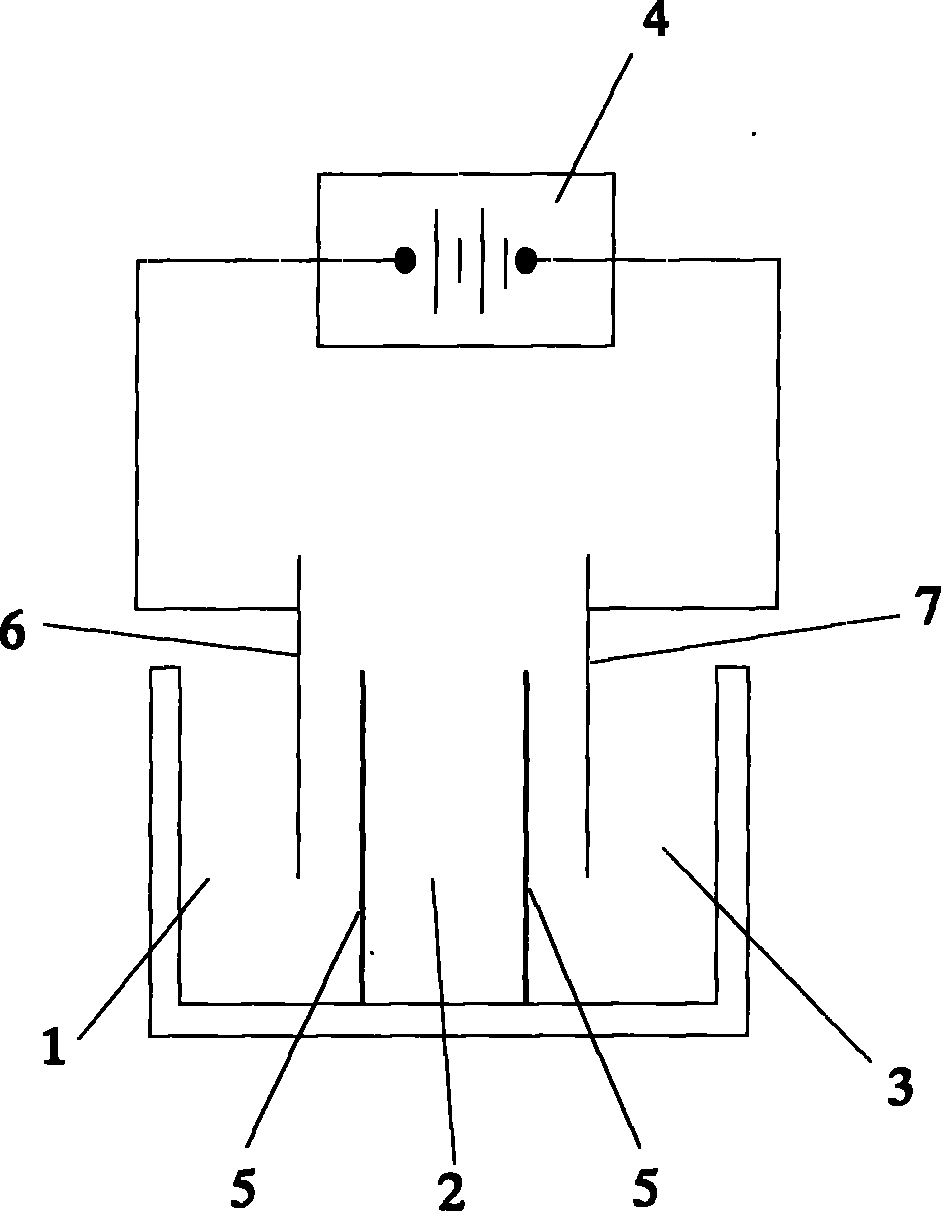

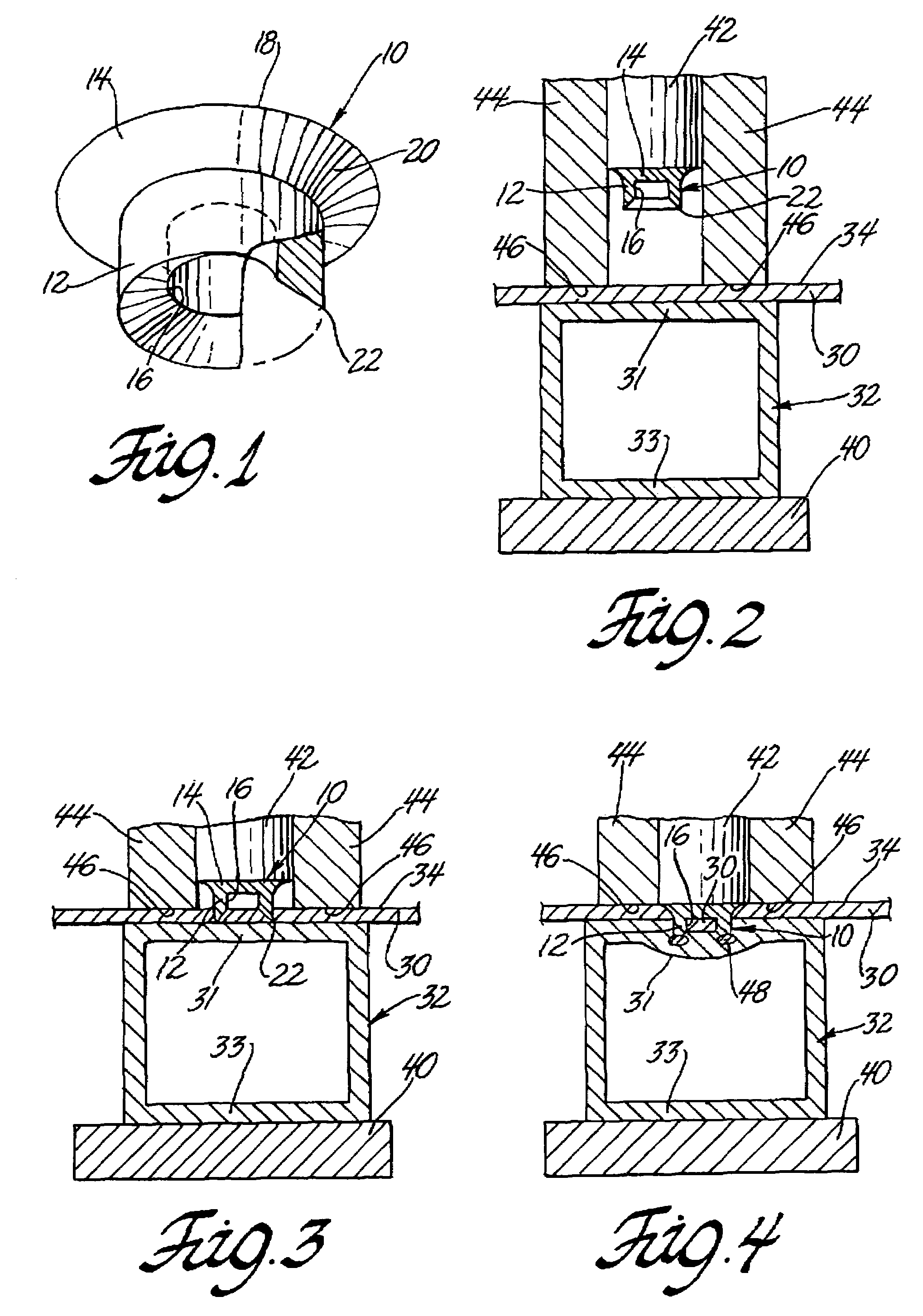

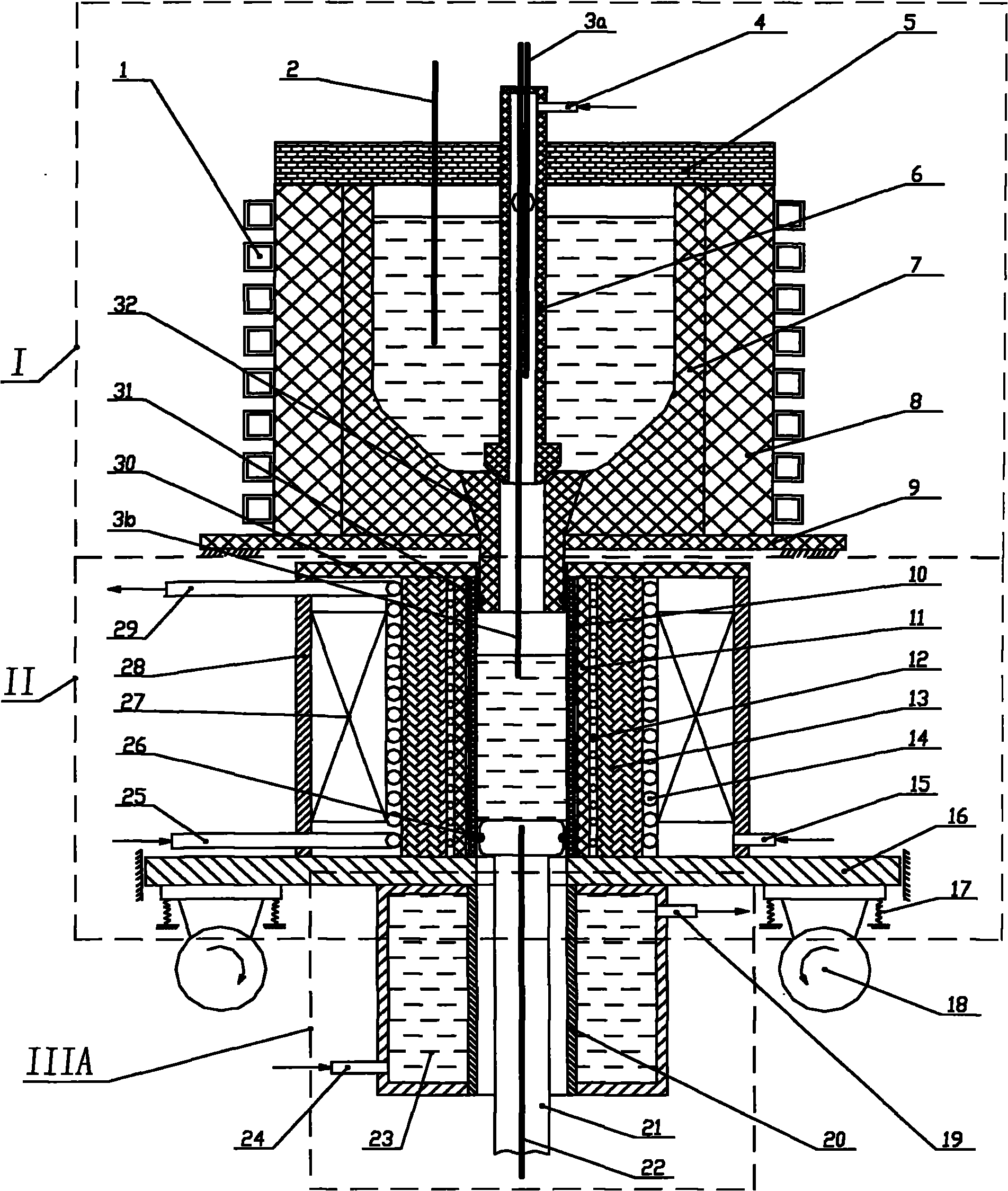

Electromagnetic stirring and vibration combined device for preparing semi-solid slurry of black metal

The invention relates to an electromagnetic stirring and vibration combined device for preparing semi-solid slurry of a black metal. The device comprises three main sections: a melting furnace, a stirring chamber, and a crystallizer or a rheologic conveyor, wherein the melting furnace is arranged at the upper part of the stirring chamber, and the crystallizer or the rheologic conveyor is arranged at the lower part of the stirring chamber. When molten metal is poured into the melting furnace, a medium-frequency induction heater is used for maintaining temperature and uniformly heating; when the temperature of the molten metal is within the liquidus temperature range, the molten metal is poured into a stirring crucible in a quantitative amount, and a non-dendritic fine equiaxial spherical or nearly spherical microstructure is obtained by electromagnetically stirring and mechanically vibrating the molten metal; and the prepared fine nearly spherical semi-solid slurry is poured into the crystallizer, then cooled and solidified into a blank, or the slurry is poured into the rheologic conveyor and then is rapidly conveyed to a forming mold for rheoforming. The device can be used for preparing semi-solid slurry of a black metal and nonferrous metal, which improves the efficiency and the quality for preparing metal semi-solid slurry and shortens the preparation time. The device is especially suitable for rheoforming.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com